Page 1

Installation Instruction, Electrical

Installation Instruction, Electrical

Applicable for W760

Contents

General...............................................................................................................2

1

2 Go/No Go Testing.............................................................................................. 2

2.1 Test Set-Up Go/No Go test...................................................................2

2.2 Test Set.................................................................................................3

2.2.1 W760.....................................................................................................3

2.2.2 W760c...................................................................................................3

2.3 RF Connections Antenna Coupler.........................................................3

2.4 RF Connections Probe (optional).......................................................... 3

3 Calibration .........................................................................................................4

3.1 GSM Calibration Test set up – SERP (only authorized centers)...........4

3.2 Test Set.................................................................................................5

3.3 GPIB card and cable.............................................................................5

3.4 Sony Ericsson programming interface – SEPI......................................5

3.5 USB Cable.............................................................................................5

3.6 Phone Power during Calibration............................................................5

3.6.1 Battery...................................................................................................5

3.6.2 Power Supply........................................................................................6

3.6.3 Dummy Battery......................................................................................6

3.7 RF Connection (GSM Calibration only)................................................. 6

3.8 Sony Ericsson programming interface cable (GSM Calibration only) ...6

3.9 Calibration Shield box setup (WCDMA or GSM Calibration)................. 7

4 Software Loading............................................................................................10

4.1 Set up..................................................................................................10

4.2 Computer.............................................................................................11

4.3 USB Activation Dongle........................................................................ 11

4.4 Sony Ericsson programming cable – DCU-65..................................... 11

5 Software........................................................................................................... 11

5.1 Emma.................................................................................................. 11

5.2 SERP Go/No Go Test Script...............................................................12

5.3 SERP Calibration (only authorized centers)........................................12

5.4 Anritsu MT8510B Go/No-Go Test Script (Stand alone) ......................13

6 Lead-Free Electrical Repair............................................................................13

7 Revision History..............................................................................................14

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

Page 2

Installation Instruction, Electrical

1 General

The Electrical Installation Instructions describe the procedures for installing all of the

hardware and software needed to perform testing at an Electrical level for the Sony

Ericsson products specified.

2 Go/No Go Testing

There are two options for performing a Go No/Go test. One is to use an RF Probe and

cable, and the other is to use an antenna coupler together with a shielding box.

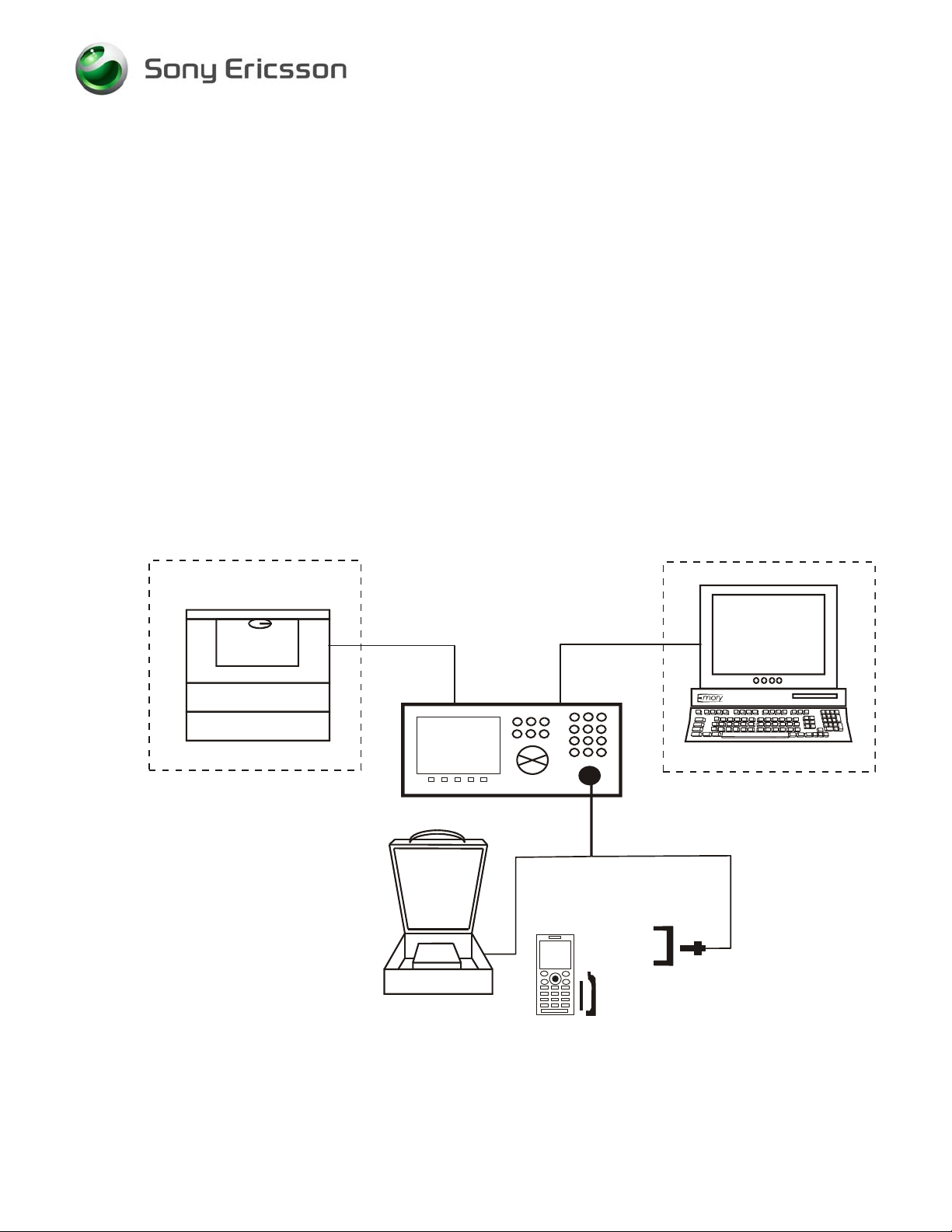

2.1 Test Set-Up Go/No Go test

All test hardware necessary for this test set up is documented in the Mechanical or

Electrical Equipment Lists.

PRINTER

OPTIONAL

Used for

Radiated Signal

to the Unit

TEST SET

RF CABLE

GPIB

CABLE

RF PROBE

HOLDER

RF PROBE

COMPUTER

OPTIONAL

Used for

Conducted Signal

*

to the Unit

The RF Probe Holder and the Battery Cover may not be used for every product.

1211-1559_ 1

See the Installation Instructions and Test Instructions for details.

*

© Sony Ericsson Mobile Communications AB

RF SHIELD

BOX

BATTERY AND

BATTERY COVER

*

2(14)

Page 3

Installation Instruction, Electrical

2.2 Test Set

2.2.1 W760

A Quad Band GSM 850/900/1800/1900 and WCDMA Test Set approved according to

the Electrical Equipment List must be used.

It should be installed according to the Instrument Manufacturer’s Instructions.

2.2.2 W760c

A Quad Band GSM 850/900/1800/1900 Test Set approved according to the Electrical

Equipment List must be used.

It should be installed according to the Instrument Manufacturer’s Instructions.

2.3 RF Connections Antenna Coupler

Connect the RF Cable between the RF-port of the Test set and the RF Shield box. The

Antenna Coupler should be installed into the RF Shield Box according to the

manufacturer’s instructions.

2.4 RF Connections Probe (optional)

Connect the RF-cable between the RF-port of the Test set and the RF Probe. Assemble

the RF Probe to the RF-holder according to the information in the Test Instruction

Electrical.

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

3(14)

Page 4

Installation Instruction, Electrical

3 Calibration

NOTE! W760 requires both GSM and WCDMA Calibration.

W760c requires only GSM Calibration.

There are two types of calibration; GSM and WCDMA. Due to the sensitivity of the

phone from outside interference during WCDMA calibration, a Shield box and Service

Tool Test Interface are required for WCDMA Calibration. These can be also used for

GSM Calibration. Section 3.1 depicts a GSM only setup. For GSM only, follow sections

3.2 thru 3.8. For WCDMA or GSM, follow sections 3.2 thru 3.6 and 3.9.

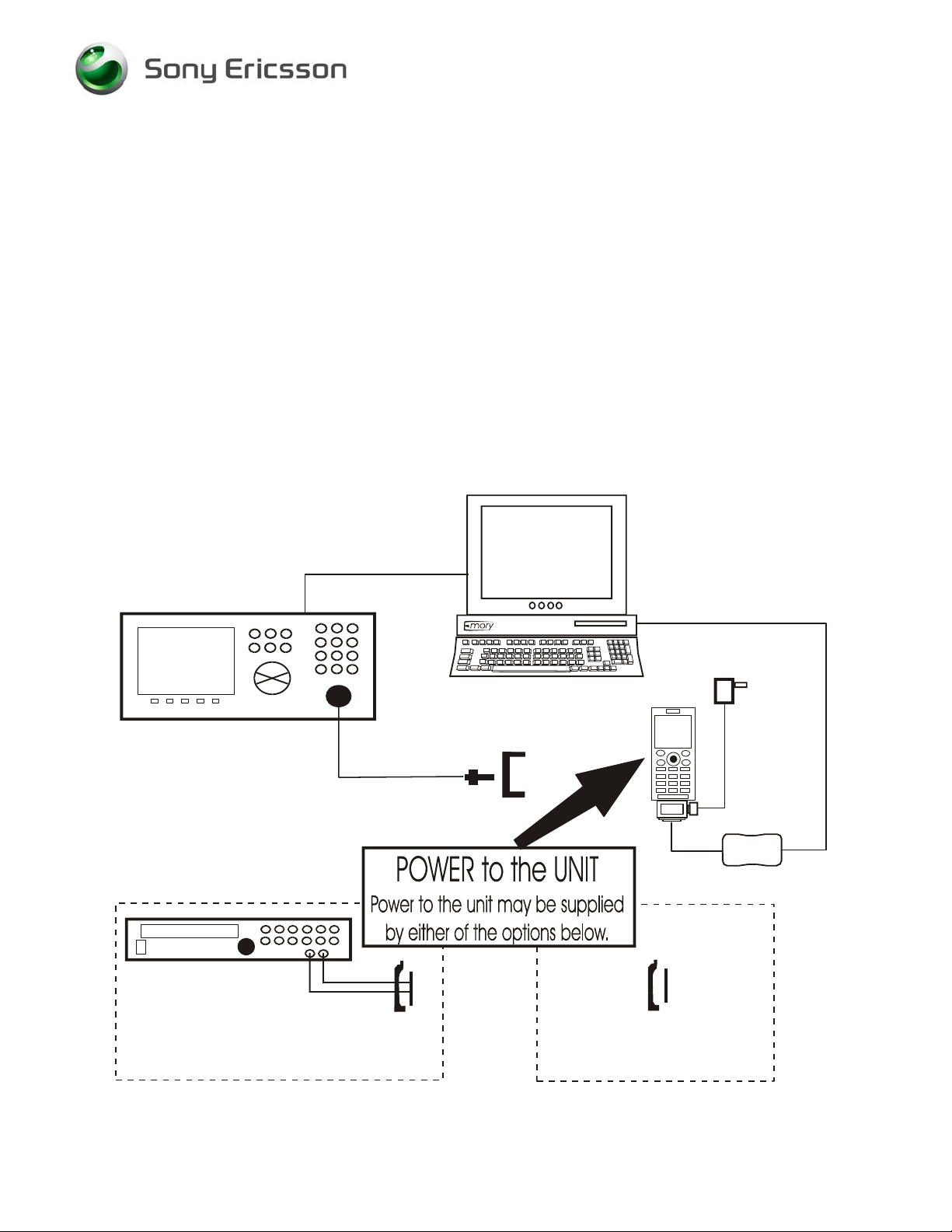

3.1 GSM Calibration Test set up – SERP (only authorized

centers)

COMPUTER

TEST SET

POWER SUPPLY

GPIB

CABLE

RF CABLE

RF PROBE

HOLDER

RF

PROBE

*

SEPI

CABLE

CHARGER

SEPI

USB

CABLE

DUMMY BATTERY

AND MODIFIED

BATTERY COVER

*

The RF Probe Holder, Battery Cover, and Modified Battery Cover may not be used for every product.

See the Installation Instructions and Test Instructions for details.

*

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

FULLY CHARGED BATTERY

AND

BATTERY COVER

*

4(14)

Page 5

Installation Instruction, Electrical

3.2 Test Set

A Test Set approved according to the Electrical Equipment List must be used.

It should be installed according to the instrument Manufacturer’s Instructions.

3.3 GPIB card and cable

Use a GPIB card and cable according to the Electrical Equipment List. Use the GPIB

cable to connect the GPIB card in the computer to the test instrument.

3.4 Sony Ericsson programming interface – SEPI

The USB programming interface is delivered with the necessary software and instruction

for installation. The USB programming interface (SEPI) should be connected to a USBport on the computer.

3.5 USB Cable

The A-B Plug-Plug cable is the interface between the computer and the USB

programming interface (SEPI). Connect the cable between the USB programming

interface and the computer.

3.6 Phone Power during Calibration

There are two options for powering the phone during calibration, a fully charged Battery

or a Power supply with a Dummy Battery, both are acceptable.

3.6.1 Battery

A fully charged Sony Ericsson battery approved for this phone model must be used. The

part number can be found in the Mechanical Equipment List.

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

5(14)

Page 6

Installation Instruction, Electrical

3.6.2 Power Supply

A Power Supply according to Electrical Equipment List must be used.

Set the output of the Power Supply as follows

• Voltage: 3.8Vdc

• Current: 2.0Amps

3.6.3 Dummy Battery

A Dummy Battery is to be used together with a power supply to power the phone.

Connect the cables from the Dummy Battery to the power supply, red cable to positive

output terminal and black cable to negative output terminal. There is a 3-position switch

on the Dummy Battery that should be set to position “B”.

3.7 RF Connection (GSM Calibration only)

Connect the RF-cable between the RF-port of the Test set and the RF Probe. Assemble

the RF Probe to the RF-holder according to the information in the Test Instruction

Electrical.

3.8 Sony Ericsson programming interface cable (GSM

Calibration only)

The cable is the interface between the USB programming interface (SEPI) and the

phone. A standard Sony Ericsson Mobile Communication charger must be connected to

the programming interface cable.

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

6(14)

Page 7

Installation Instruction, Electrical

3.9 Calibration Shield box setup (WCDMA or GSM Calibration)

Due to the sensitivity of the phone from outside interference during WCDMA calibration,

a Shield box and Service Tool Test Interface are required for WCDMA Calibration.

These can be also used for GSM Calibration. A Wiltek 4921 Shield box and Service Tool

Test Interface can be found in the Electrical Equipment list. There are several options

available.

• The Wiltek 4921 Shield Enclosure box along with the Service Tool Test Interface.

• An existing Wiltek Shield box along with the Service Tool Test Interface and modified

rear cover can be used. Remove the coupler, replace the rear cover and follow the

instructions for the Wiltek 4921 Shield Enclosure box. The modified rear cover and N

terminator can be found in the Electrical Equipment list.

• Any Shield box with a RF Isolation factor of >50dbm, has a High density DB-15

connector and an RF-pass thru connection. Attach the Service Tool Test Interface to

the DB-15 connector.

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

7(14)

Page 8

Installation Instruction, Electrical

The following pictures show how to setup a Wiltek 4921 Shield Enclosure box.

1

5

Picture 1

2

6

3

4

1. Connect the RF-cable between the RF-port of the Test set and the RF connector

on the modified Rear Panel.

2. Attach the Outside Service Tool Test Interface to the connector on the modified

Rear Panel.

3. Connect a standard Sony Ericsson Mobile Communication charger to the SEPI

Calibration interface.

4. Connect the Outside Service Tool Test Interface to the SEPI.

5. Attach the N terminator to the Coupler connection.

6. If a Power Supply is used instead of a standard fully charged battery, connect the

output of the Power Supply and the sense lines to the Outside Service Tool Test

Interface.

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

8(14)

Page 9

Installation Instruction, Electrical

1

Picture 2

2

3

4

1. Attach the Inside Service Tool Test Interface to the modified Rear Panel.

2. Attach the RF Cable (Short) to the modified Rear Panel. The other end connects

to the Phone according to the information in the Test Instructions Electrical.

3. Connect the charging cable from the Inside Service Tool Test Interface to the

cable that attaches to the system connector on the phone.

4. If a Power Supply is used instead of a standard fully charged battery, connect the

power cables from the Inside Service Tool Test Interface to the Dummy Battery

black cable to black cable and red cable to red cable.

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

9(14)

Page 10

Installation Instruction, Electrical

4 Software Loading

4.1 Set up

General Test set up to perform SW loading. All necessary hardware for this test set up is

documented in the Mechanical or Electrical Equipment list.

USB

ACTIVATION

DONGLE

DCU-65

CABLE

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

10(14)

Page 11

Installation Instruction, Electrical

4.2 Computer

IBM compatible computer is required. The computer should include at least two USBports. Refer to Equipment List for minimum requirements.

4.3 USB Activation Dongle

A USB Activation Dongle is required for activation in Emma. The USB Activation Dongle

should be connected to a USB-port on the computer. Refer to the Emma Homepage

available from CSPN, for installation instructions.

4.4 Sony Ericsson programming cable – DCU-65

The cable is the interface between the computer and the phone. The DCU-65 cable

should be connected to a USB-port on the computer.

5 Software

5.1 Emma

Emma contains all software required to service the product. Installation and user

manuals are available in the Emma start page.

http://ma3.extranet.sonyericsson.com/ma3/

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

11(14)

Page 12

Installation Instruction, Electrical

5.2 SERP Go/No Go Test Script

SERP stands for “Sony Ericsson Repair Platform”. It is an application used for testing,

calibrating and repairing Sony Ericsson mobile phones.

Download the latest revision of the SERP application from CSPN.

http://cspn.extranet.sonyericsson.com

This application is located in the dropdown menu

Repair Instructions-Electrical/SERP application

1. Unzip the file and open the file “Release Notes and Installation Guide” for installation

instructions.

2. After SERP is installed a file titled “SERPINFO.htm” will be placed on the Windows

Desktop. This file contains numerous documents including:

• SERP Users Manual – This document contains detailed operating and fault

reporting instructions.

• R&S Grid plate for SERP – This document contains an overview and ordering

information for the Rhode & Schwarz Grid Plate used with the Rhode & Schwarz

coupler. Also there is a list of supported SEMC handsets and mounting positions.

• SERP Release Notes and Installation Guide – This document contains system

requirements, release notes and an Installation Guide.

5.3 SERP Calibration (only authorized centers)

Download the latest revision of the SERP application from CSPN.

http://cspn.extranet.sonyericsson.com

This application can be found from the dropdown menu

Repair Instructions-Electrical/SERP application

1. Unzip the file and open the file “Release Notes and Installation Guide” for installation

instructions.

2. Follow the Installation instructions to install SERP.

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

12(14)

Page 13

Installation Instruction, Electrical

5.4 Anritsu MT8510B Go/No-Go Test Script (Stand alone)

The Anritsu MT8510B (SEMC approved) script can be obtained from Anritsu at the

following Website, Registration is required.

https://www1.anritsu.co.jp/Download/MService/Login.asp

Follow the Instructions in the MT8510B Install Procedure for installation of the Test

Parameter files.

The Test Parameter files have attenuation values for the Anritsu MA8120E Shield box.

The Anritsu MA8120E shield box should be used with the Anritsu MT8510B Test

instrument.

6 Lead-Free Electrical Repair

This product is manufactured with lead-free solder and lead-free components. During

electrical repair, it is critical to make sure that no lead is introduced into the product. For

this reason, certain repair materials and equipment must be designated as lead-free and

labelled accordingly. A lead-free work area must be setup that is completely separated

from work areas that are used to make leaded repairs. The lead-free work area must

also be clearly labelled as shown in the figure below. Certain items must be designated

for lead-free work only. Some of the items that need to be clearly labelled in this way

are listed in the table below. Note that any item that contacts the solder must be labelled

and used for lead-free work only.

Soldering Tips Wicking Tape Tip Cleaner (steel wool)

Solder Tip Tinner Soldering Iron

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

13(14)

Page 14

Installation Instruction, Electrical

Because of cost and space limitations, some repair centers may not be able to assign a

full bench to lead-free repairs. In this case, both lead-free and leaded repair setups can

share the same bench, but they must be clearly marked with signs and separated by a

physical divider. In the figure below, the large hot air device functions as the divider.

7 Revision History

Rev. Date Changes / Comments

1 2008-05-28 Initial Release

2 2008-07-16 Updated Stand alone GNG Section 5.4

1211-1559_ 1

© Sony Ericsson Mobile Communications AB

14(14)

Loading...

Loading...