Page 1

Working Instruction /Electrical

Working Instruction, Electrical

Applicable for W760

CONTENTS

1 Read this first!........................................................................................2

2 Lead-free soldering................................................................................3

3 BGA equipment reflow profiles.............................................................5

3.1 General.................................................................................................. 5

3.2 Temperature Measurements ................................................................. 5

3.3 Reflow Profiles ...................................................................................... 6

4 Replacement of components ................................................................7

4.1 D2404: IC IF 3.5X3.5X0.8 ..................................................................... 7

4.2 N1400: Module Bluetooth + FM STLC2592 .......................................... 8

4.3 N1200: RF-Module Thor Pre-bumped................................................... 9

4.4 N1200: RF-Module Thor Pre-bumped Continued ............................. 10

4.5 N1210: RF-Module Mammoth Pre-bumped ........................................11

4.6 N1210: RF-Module Mammoth Pre-bumped Continued..................... 12

4.7 X2200: Battery Connector ................................................................... 13

4.8 X2400: System Connector .................................................................. 14

5 Revision History...................................................................................16

1211-1562 Rev 2 1211-1562

© Sony Ericsson Mobile Communications AB

Page 2

Working Instruction/ Electrical

1 Read this first!

CAUTION

Before you start replacing any components, make sure you have read and fully understood the

contents of section 2 and 3!

Use Electrostatic Discharge (ESD) equipment to avoid damaging the PBA.

Use gloves or finger cots to avoid contaminating the PBA with skin oil.

EQUIPMENT

For equipment information, refer to the Electrical and Mechanical Equipment Lists.

MECHANICAL INSTRUCTIONS

For phone disassembly and reassembly information, refer to the Mechanical Working

Instruction.

1211-1562 Rev 2 2(16)

© Sony Ericsson Mobile Communications AB

Page 3

Working Instruction/ Electrical

2 Lead-free soldering

THIS PRODUCT IS MANUFACTURED WITH LEAD-FREE SOLDER

AND LEAD

During electrical repair, it is critical to make sure that no lead is

introduced.

This symbol indicates that the product is lead- free.

-FREE COMPONENTS!

The lead-free symbol is located on the PCB as shown.

A lead-free work area must be set up completely separated

from work areas that are used to make lead repairs. The leadfree work area must also be clearly labeled with the lead free

symbol as shown in the adjacent picture. The items on this

desk must remain lead-free. They must be adequately labeled

to make their lead-free status clearly and easily recognized.

1211-1562 Rev 2 3(16)

© Sony Ericsson Mobile Communications AB

Page 4

Working Instruction/ Electrical

Lead-free soldering continued

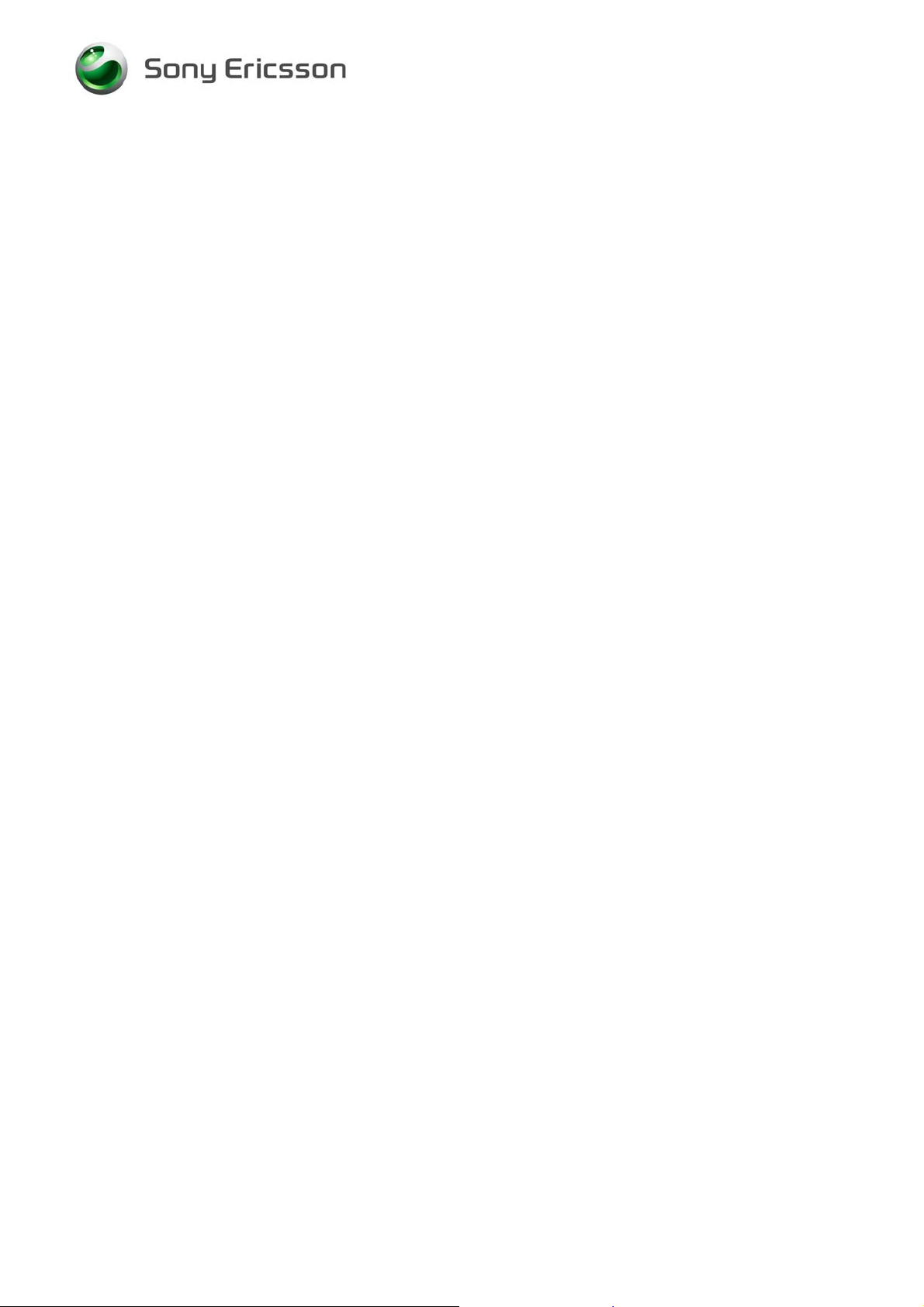

LFS (lead-free solder) characteristics:

• High melting point (typically 217°C)

• Low wetting

• High surface tension

• Difficult to spread

• Recommended tip temperature = 370°C

WHEN SERVICING PBAS THAT HAVE BEEN MANUFACTURED

LFS (LEAD-FREE SOLDER), LFS MUST BE USED!

WITH

F NOT, THERE IS A HIGH RISK OF UNRELIABLE SOLDERING

I

JOINTS

Lead-free solder joints are more difficult to inspect because they

do not have shiny surfaces like leaded solder joints. Also, leadfree solder does not flow as well as leaded solder, so some of

the solder pad areas may remain exposed.

!

1211-1562 Rev 2 4(16)

© Sony Ericsson Mobile Communications AB

Page 5

Working Instruction/ Electrical

3 BGA equipment reflow profiles

3.1 General

This section contains reflow profile recommendations for mobile phones and similar products.

They are just general recommendations and considerations have to be taken for every single product.

The solder is secondary but could also affect the parameters.

In this document one alloy is specified: SnAgCu (Lead free) melting point 217°C

3.2 Temperature Measurements

At least four probes should be used.

They should be placed on components with the highest and lowest thermal mass.

The probes shall be located in the beginning, in the middle, and at the end of the board/panel.

It is recommended that the probes are soldered on the board, but glue and Kapton tape can be used.

At least one probe shall be placed in the air or on top of a component.

These values are strongly dependent on the BGA replacement equipment.

Select a nozzle size that is the same size or slightly larger than the part being replaced.

Make sure the nozzle does not affect any nearby placed components.

T

HESE VALUES ARE RECOMMENDATIONS AND MAY HAVE TO BE CHANGED DEPENDING ON THE TYPE OF

EQUIPMENT

HE MAXIMUM TEMPERATURE FOR ANY COMPONENT MUST NOT EX CEED 260°C!

T

!

1211-1562 Rev 2 5(16)

© Sony Ericsson Mobile Communications AB

Page 6

Working Instruction/ Electrical

3.3 Reflow Profiles

Sn/Ag/Cu (lead-free)

Ramp rate < 4°C/sec

Ramp rate cooling zone < 6°C/sec

Time above liquidus 60-150 sec

Minimum temperature 235°C

Maximum temperature 245°C or 260°C for 10 sec. (the higher

temperature in case the board has

extremely high ΔT)

Bottom heat temperature 125°C-150°C

Total time Approx. 4-7 min

1211-1562 Rev 2 6(16)

© Sony Ericsson Mobile Communications AB

Page 7

Working Instruction/ Electrical

4 Replacement of components

4.1 D2404: IC IF 3.5X3.5X0.8

Locate the small, round, tabs around the perimeter of shield

E1000.

Use a dental pick to pry the lid up at each of the tabs. Be

careful to not damage the lid.

Use clippers to trim the overhang as shown.

Make sure the remaining fence metal does not touch parts

on the board, and make sure the metal does not prevent the

lid from assembling properly.

1211-1562 Rev 2 7(16)

© Sony Ericsson Mobile Communications AB

Page 8

Working Instruction/ Electrical

4.2 N1400: Module Bluetooth + FM STLC2592

After removing the lid of shield E1000 as shown in the

D2404 section, cut the crossbar as shown.

Remove the cut section and discard it.

1211-1562 Rev 2 8(16)

© Sony Ericsson Mobile Communications AB

Page 9

Working Instruction/ Electrical

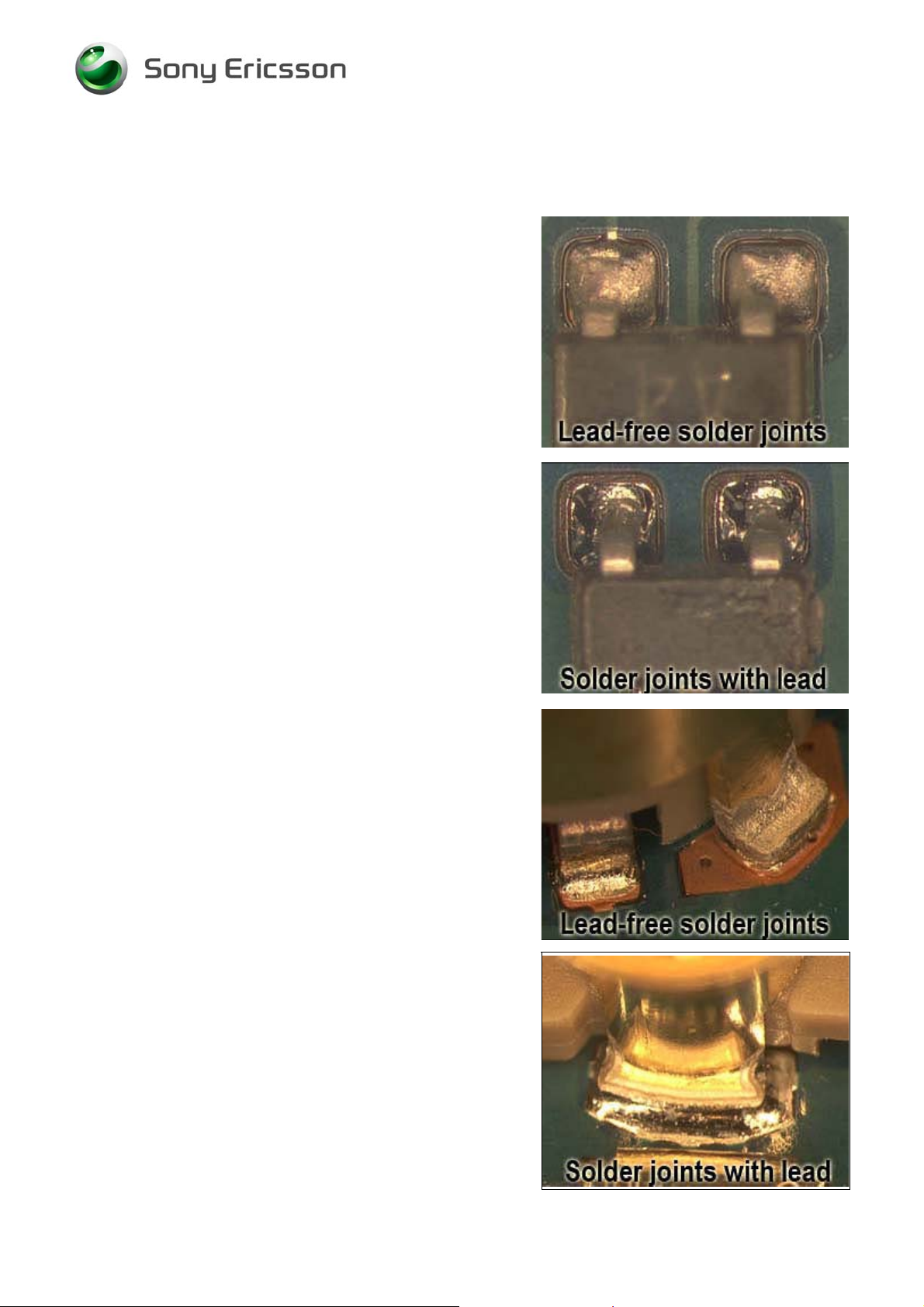

4.3 N1200: RF-Module Thor Pre-bumped

Remove yellow tape from N1200 and N1210.

Apply heat-resistant tape to X4200, X1501, and X2200.

Use a Large Hot Air Device to melt the solder.

Slide the part off the board while the solder is hot.

1211-1562 Rev 2 9(16)

© Sony Ericsson Mobile Communications AB

Page 10

Working Instruction/ Electrical

4.4 N1200: RF-Module Thor Pre-bumped Continued

After installing the new part, apply a new piece of tape to

N1200 and N1210.

1211-1562 Rev 2 10(16)

© Sony Ericsson Mobile Communications AB

Page 11

Working Instruction/ Electrical

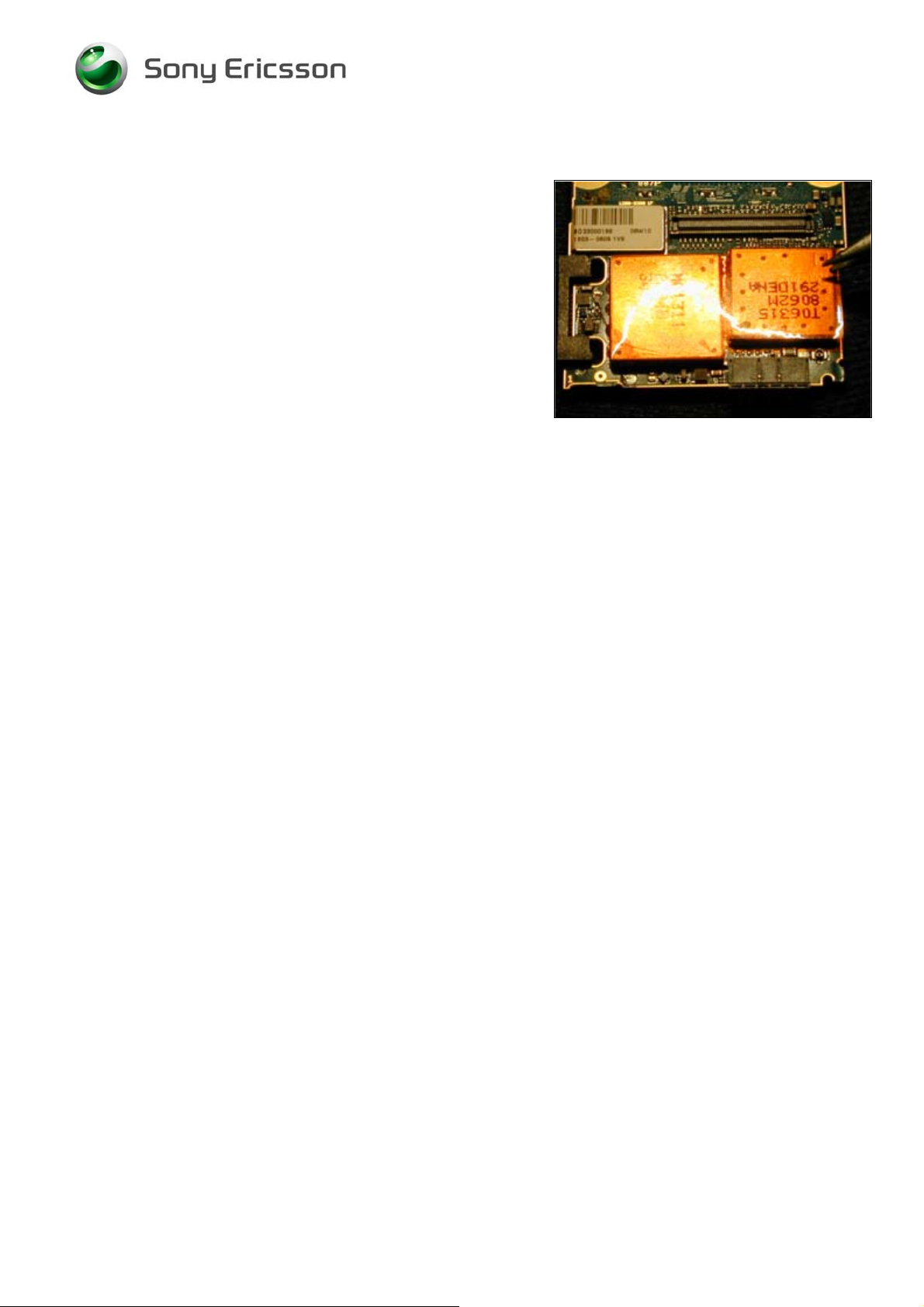

4.5 N1210: RF-Module Mammoth Pre-bumped

Remove yellow tape from N1200 and N1210.

Apply heat-resistant tape to X2200 and X2400.

Use a Large Hot Air Device to melt the solder.

Insert tweezers from the left side of the part. Slide the part

toward N1200 and lift it off the board.

1

1211-1562 Rev 2 11(16)

2

© Sony Ericsson Mobile Communications AB

Page 12

Working Instruction/ Electrical

4.6 N1210: RF-Module Mammoth Pre-bumped Continued

After installing the new part, apply a new piece of tape to

N1200 and N1210.

1211-1562 Rev 2 12(16)

© Sony Ericsson Mobile Communications AB

Page 13

Working Instruction/ Electrical

4.7 X2200: Battery Connector

Use heat-resistant tape to protect X1200.

Use a Large Hot Air Device to melt the solder.

Remove the excess solder from the holes.

Insert a new part and solder the pins in the holes.

1211-1562 Rev 2 13(16)

© Sony Ericsson Mobile Communications AB

Page 14

Working Instruction/ Electrical

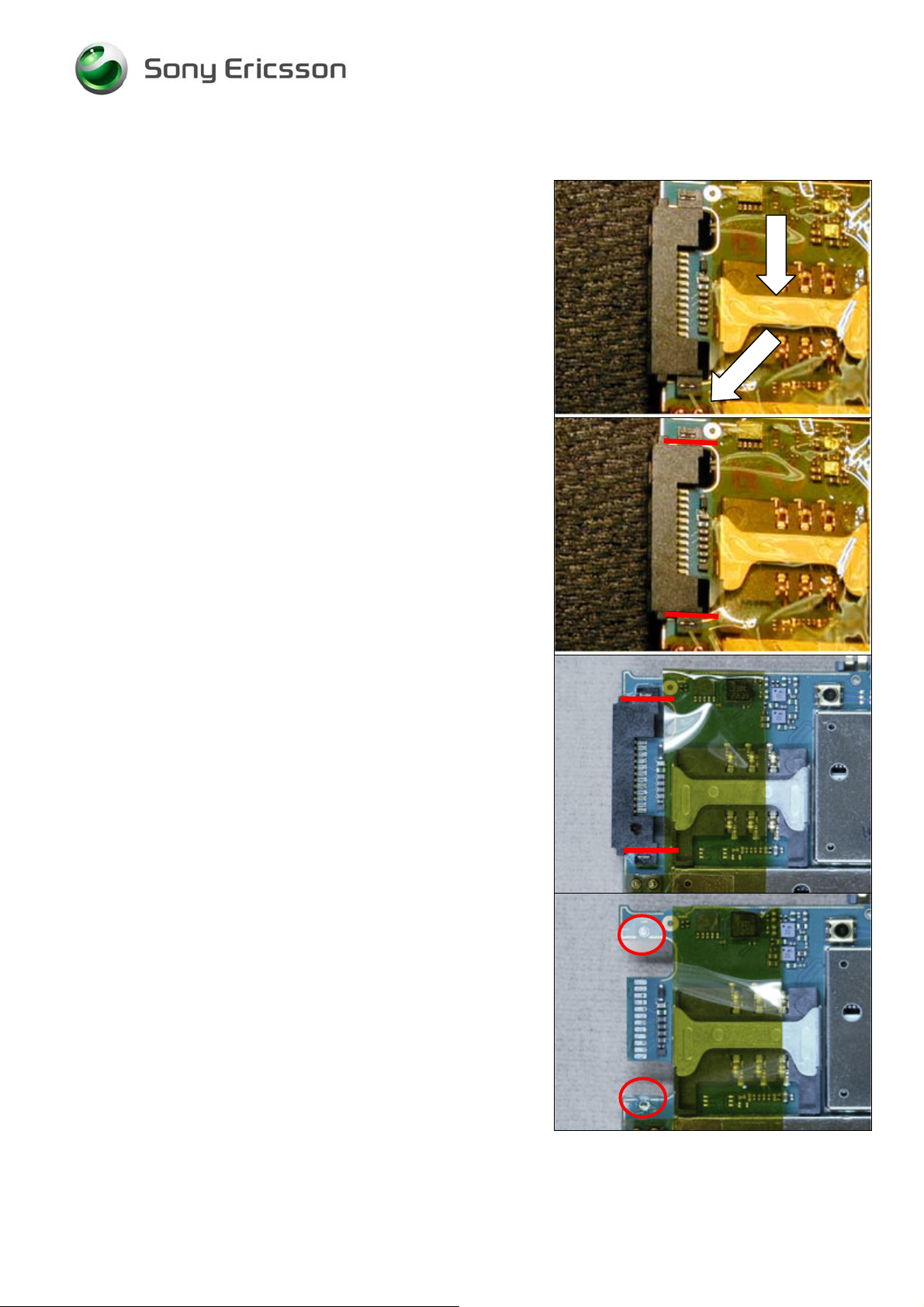

4.8 X2400: System Connector

Apply heat-resistant tape to X2410, X1503, and X4100 (not

shown).

CAREFUL NOT TO DAMAGE THE PCB WHEN CUTTING THE

SYSTEM CONNECTOR

Cut the system connector with a cutting pliers as shown by

red line in picture

Use hot air to remove the connector

NOTE: UNDERFILL IS ADDED ON PHONES PRODUCED AFTER

838

W

Use hot air and a dentist hook to remove the underfill

located as shown in pictures.

1211-1562 Rev 2 14(16)

© Sony Ericsson Mobile Communications AB

Page 15

Working Instruction/ Electrical

X2400: System Connector Continued

Remove excess solder from holes and pads.

Use BGA equipment and soldering paste to mount the new

connector.

1211-1562 Rev 2 15(16)

© Sony Ericsson Mobile Communications AB

Page 16

Working Instruction/ Electrical

5 Revision History

Rev. Date Changes / Comments

1 2008-May-26 Initial Release

2 2008-12-09 X2400 System Connector: Method changed

1211-1562 Rev 2 16(16)

© Sony Ericsson Mobile Communications AB

Loading...

Loading...