SONY XR7040, XR7041, XR7042 Diagram

DCR-DVD106E/DVD108/DVD108E/

DVD109E/DVD608/DVD608E

SERVICE MANUAL

Ver. 1.3 2007.07

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Photo: DCR-DVD108

Link

Link

SPECIFICATIONS

DISASSEMBLY

LEVEL 2

US Model

Canadian Model

AEP Model

UK Model

East European Model

North European Model

E Model

Australian Model

Hong Kong Model

Chinese Model

Argentine Model

Brazilian Model

SCHEMATIC DIAGRAMS

MODEL INFORMATION TABLE

SERVICE NOTE

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

BLOCK DIAGRAMS

FRAME SCHEMATIC DIAGRAM

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

PRINTED WIRING BOARDS

REPAIR PARTS LIST

DIGITAL VIDEO CAMERA RECORDER

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

Sony EMCS Co.

2007G0500-1

© 2007.7

Published by Kohda TEC9-852-173-31

SPECIFICATIONS

System

Video compression format

MPEG2/JPEG (S till images)

Audio compression format

DCR-DVD106E/DVD108E/DVD608E

Dolby Digital 2ch

Dolby Digital Stereo Creator

DCR-DVD109E

Dolby Digital 2/5.1ch

Dolby Digital 5.1 Creator

Video signal

PAL color, CCIR standards

Usable discs

8 cm DVD-RW/D VD+RW/DVD-R/

DVD+R DL

Recording format

Movie

DVD-RW:DVD-VIDEO (VIDEO mode),

DVD+RW: DVD+RW Video

DVD-R/DVD+R DL: DVD-VIDEO

Still image

Exif

DVD-Video Recording

(VR mode)

*

Ver. 2.2

Recording time

DVD-RW/DVD+RW/DVD-R

HQ:Approx. 20 min

SP: Approx. 30 min

LP: Approx. 60 min

DVD+R DL

HQ:Approx. 35 min

SP: Approx. 55 min

LP:Approx. 110 min

Viewfinder

Electric viewfinder (color)

Image device

3 mm (1/6 type) CCD (Charge Coupled Device)

Gross:

Approx. 800 000 pixels

Effective (Movie):

Approx. 400 000 pixels

Effective (Still):

Approx. 400 000 pixels

Lens

Carl Zeiss Vario-Tessar

Optical:40×, Digital:80×, 2 000×

Focal length

F=1.8-4.1

f=1.9 - 76.0mm (3/32 - 3 in.)

When converted to a 35 mm still camera

For movies:

36 - 1 440mm (1 7/16 - 56 3/4 in.)

For still images:

36 - 1 440mm (1 7/16 - 56 3/4 in.)

Color temperature

[AUTO], [ONE PUSH], [INDOOR] (3 200 K),

[OUTDOOR] (5 800 K)

Minimum illumination

3 lx (lux) (AUTO SLW SHUTTR ON, Shutter

speed 1/25 second)

0 lx (lux) (during NightShot plus function)

*“Exif” is a file format for still images, established

by the JEIT A (Japan Electronics and Information

Technology Industries Association). Files in this

format can have additional information such as

your camcorder’s setting information at the time

of recording.

**In 16:9 mode, the focal length figures are actual

figures resulting from wide angle pixel readout.

• Manufactured under license from Dolby

Laboratories.

Input/Output connectors

Audio/Video output

10 pin connector

Video signal: 1 Vp-p, 75 Ω (ohms)

Luminance signal: 1 Vp-p, 75 Ω (ohms)

Chrominance signal: 0.3 Vp-p, 75 Ω (ohms)

Audio signal: 327 mV (at Load impedance

47 kΩ (kilohms)), Output impedance less than

2.2 kΩ (kilohms)

USB jack

mini-B

(DCR-DVD106E/DVD109E: output only)

LCD screen

Picture

6.2 cm (2.5 type)

Total number of pixels

123 200 (560 × 220)

General

Power requirements

6.8 V/7.2 V (battery pack)

8.4 V (AC Adaptor)

Average power consumption

DCR-DVD106E/DVD108E/DVD608E

LCD : 2.9W

Viewfinder : 2.7W

DCR-DVD109E

LCD : 3.0W

Viewfinder : 2.8W

Operating temperature

0°C to +40°C (32°F to 104°F)

Storage temperature

-20°C to +60°C (-4°F to +140°F)

Dimensions (Approx.)

54.5 × 89 × 130.5 mm (2 1/4 × 3 5/8 × 5 1/4

in.) (w × h × d) including the projecting parts

54.5 × 89 × 130.5 mm (2 1/4 × 3 5/8 × 5 1/4

in.) (w × h × d) including the projecting parts

with supplied battery pack NP-FH40 attached

Mass (Approx.)

390 g (13 oz) main unit only

440 g (15 oz) including the NP-FH40

rechargeable battery pack and disc

Supplied accessories

AC Adaptor (1)

Mains lead (1)

A/V connecting cable (1)

USB cable (1)

Rechargeable battery pack NP-FH40 (1)

CD-ROM “Handycam Application Software” (1)

Operating Guide (1)

See page 5-18.

AC Adaptor AC-L200/L200B

Power requirements

AC 100 - 240 V, 50/60 Hz

Current consumption

0.35 - 0.18 A

Power consumption

18W

Output voltage

DC 8.4V*

Operating temperature

0°C to +40°C (32°F to 104°F)

Storage temperature

-20°C to +60°C (-4°F to +140°F)

Dimensions (Approx.)

48 × 29 × 81 (1 15/16 × 1 3/16 × 3 1/4 in.)

(w × h × d) excluding the projecting parts

Mass (Approx.)

170 g (6 oz) excluding the mains lead

* See at the label of AC Adaptor for other

specifications.

Rechargeable battery pack NP-FH40

Maximum output voltage

DC8.4V

Output voltage

DC7.2V

Capacity

4.9 wh (680 mAh)

Dimensions (Approx.)

31.8 × 18.5 × 45.0 mm

(1 5/16 × 3/4 × 1 13/16 in.) (w × h × d)

Mass (Approx.)

45 g (1.6 oz)

Operating temp erature

0°C to +40°C (32°F to 104°F)

Type

Li-ion

Design and specifications are subject to change

without notice.

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

— 2 —

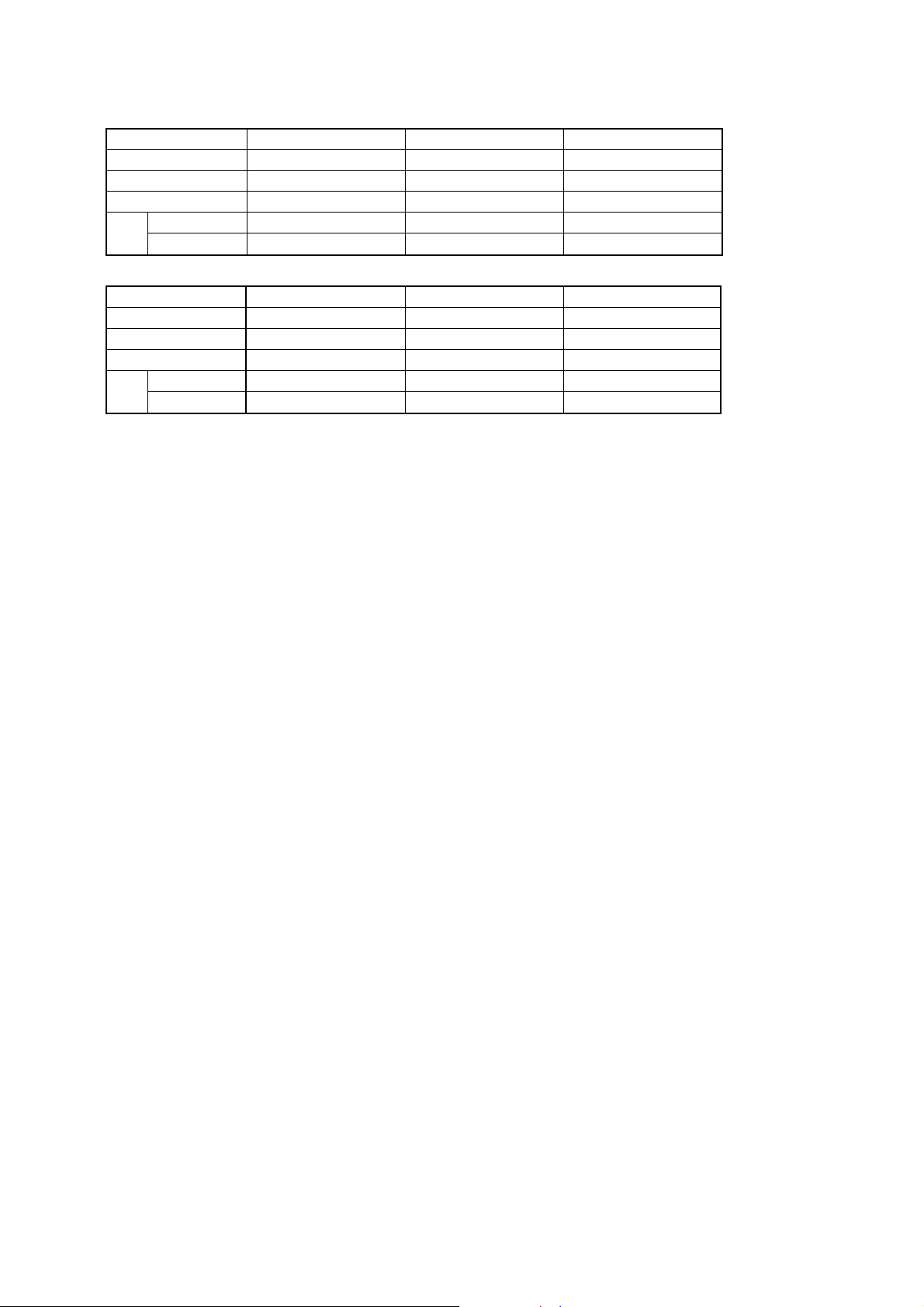

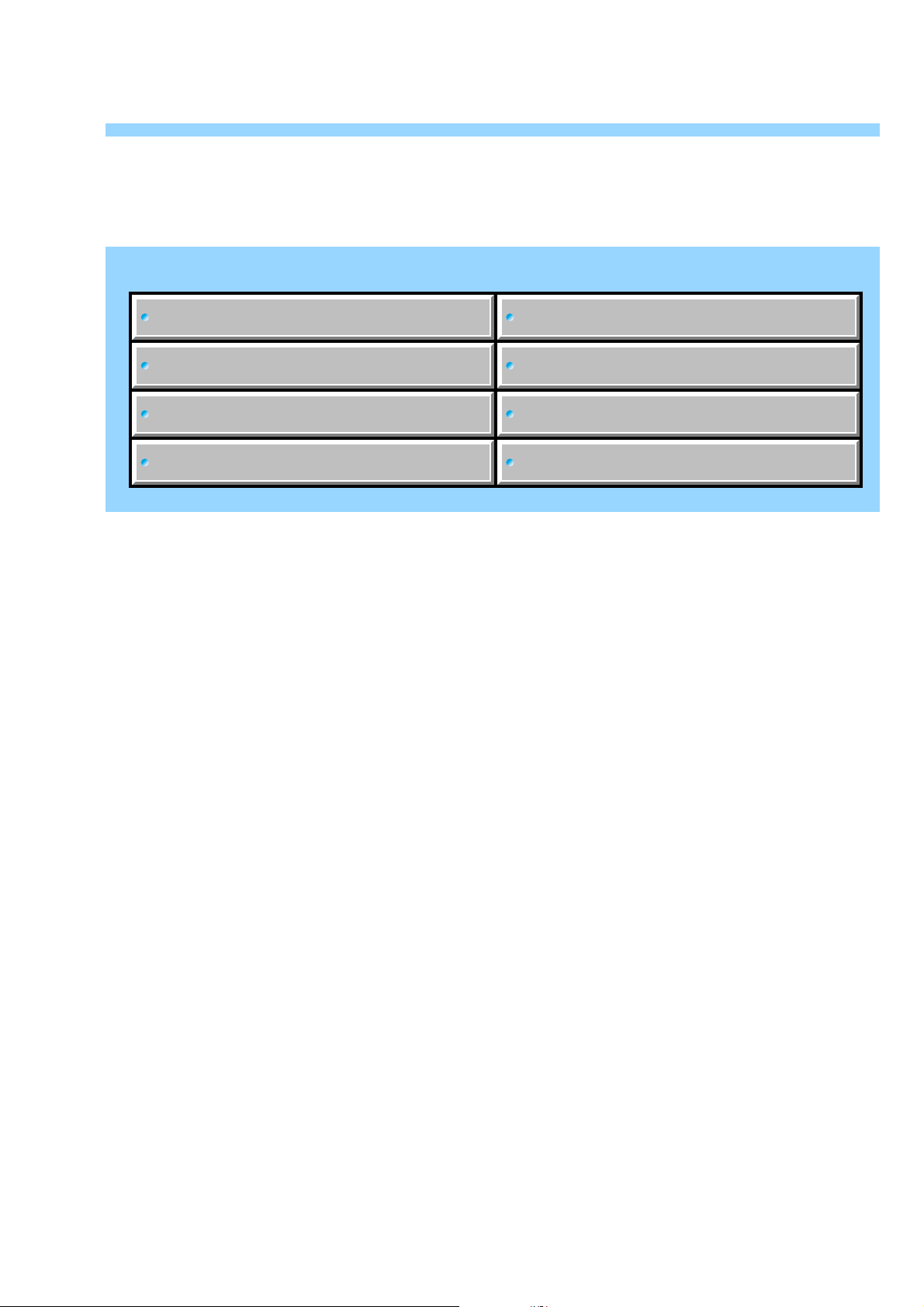

Model information table

Model DCR-DVD106E DCR-DVD108 DCR-DVD108E

Destination AEP, UK, EE, NE US, CND, E, AR, BR NE

Color system PAL NTSC PAL

5.1ch recording ×××

CAM → PC aaa

Data

copy

PC → CAM × aa

Model DCR-DVD109E DCR-DVD608 DCR-DVD608E

Destination AEP, UK, EE, NE E E, HK, AUS, CH

Color system PAL NTSC PAL

5.1ch recording a ××

CAM → PC aaa

Data

copy

PC → CAM × aa

•Abbreviation

AR : Argentine model

AUS: Australian model

BR : Brazilian model

CH : Chinese model

CND: Canadian model

EE : East European model

HK : Hong Kong model

J: Japanese model

JE : Tourist model

KR : Korea model

MX : Mexican model

NE : North European model

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

— 3 —

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

WARNING!!

WHEN SERVICING, DO NOT APPROACH THE LASER

EXIT WITH THE EYE TOO CLOSELY. IN CASE IT IS

NECESSARY TO CONFIRM LASER BEAM EMISSION,

BE SURE T O OBSER VE FR OM A DISTANCE OF MORE

THAN 30 cm FROM THE SURFACE OF THE

OBJECTIVE LENS ON THE OPTICAL PICK-UP BLOCK.

CAUTION:

The use of optical instrument with this product will increase eye

hazard.

CAUTION

Use of controls or adjustments or performance

procedures other than those specified herein may

result in hazardous radiation exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DO TTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQ UES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

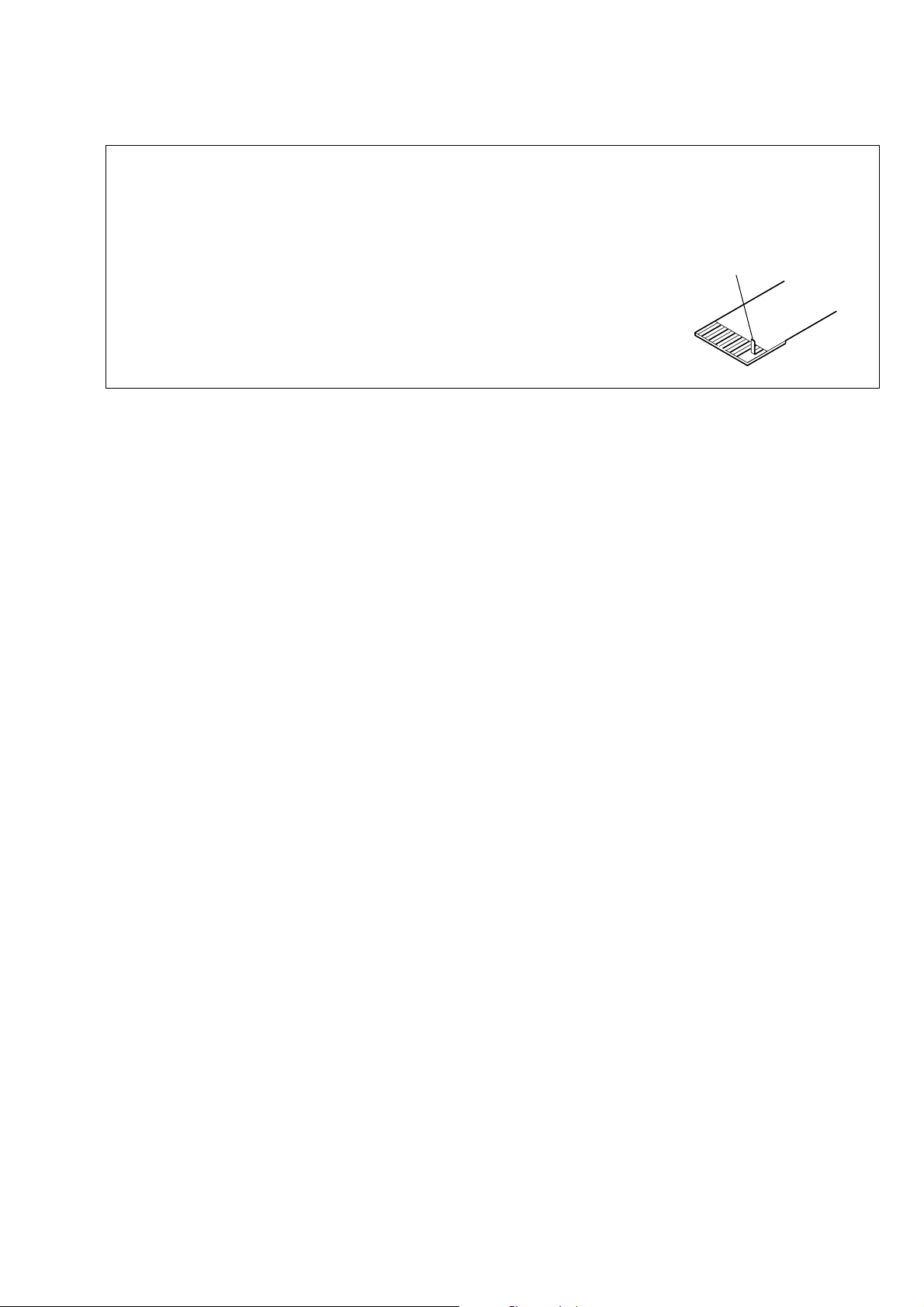

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

•Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

— 4 —

TABLE OF CONTENTS

Section Title Page

1. SERVICE NOTE

1-1. Power Supply During Repairs·········································1-1

1-2. To Take Out a Cassette when not Eject (Force Eject) ·····1-1

1-3. Using Service Jig·····························································1-2

1-4. Self-diagnosis Function ···················································1-2

2. DISASSEMBLY

2-1. Disassembly·····································································2-2

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram (1/5)··········································· 3-1

3-2. Overall Block Diagram (2/5)··········································· 3-2

3-3. Overall Block Diagram (3/5)··········································· 3-3

3-4. Overall Block Diagram (4/5)··········································· 3-4

3-5. Overall Block Diagram (5/5)··········································· 3-5

3-6. Power Block Diagram (1/3)············································· 3-6

3-7. Power Block Diagram (2/3)············································· 3-7

3-8. Power Block Diagram (3/3)············································· 3-8

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagrams·············································4-1

4-2. Schematic Diagrams························································4-3

4-3. Printed Wiring Boards ···················································4-29

4-4. Mounted Parts Location ················································4-43

5. REPAIR PARTS LIST

5-1. Exploded V iews·······························································5-2

5-2. Electrical Parts List ·························································5-9

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

— 5 —

1. SERVICE NOTE

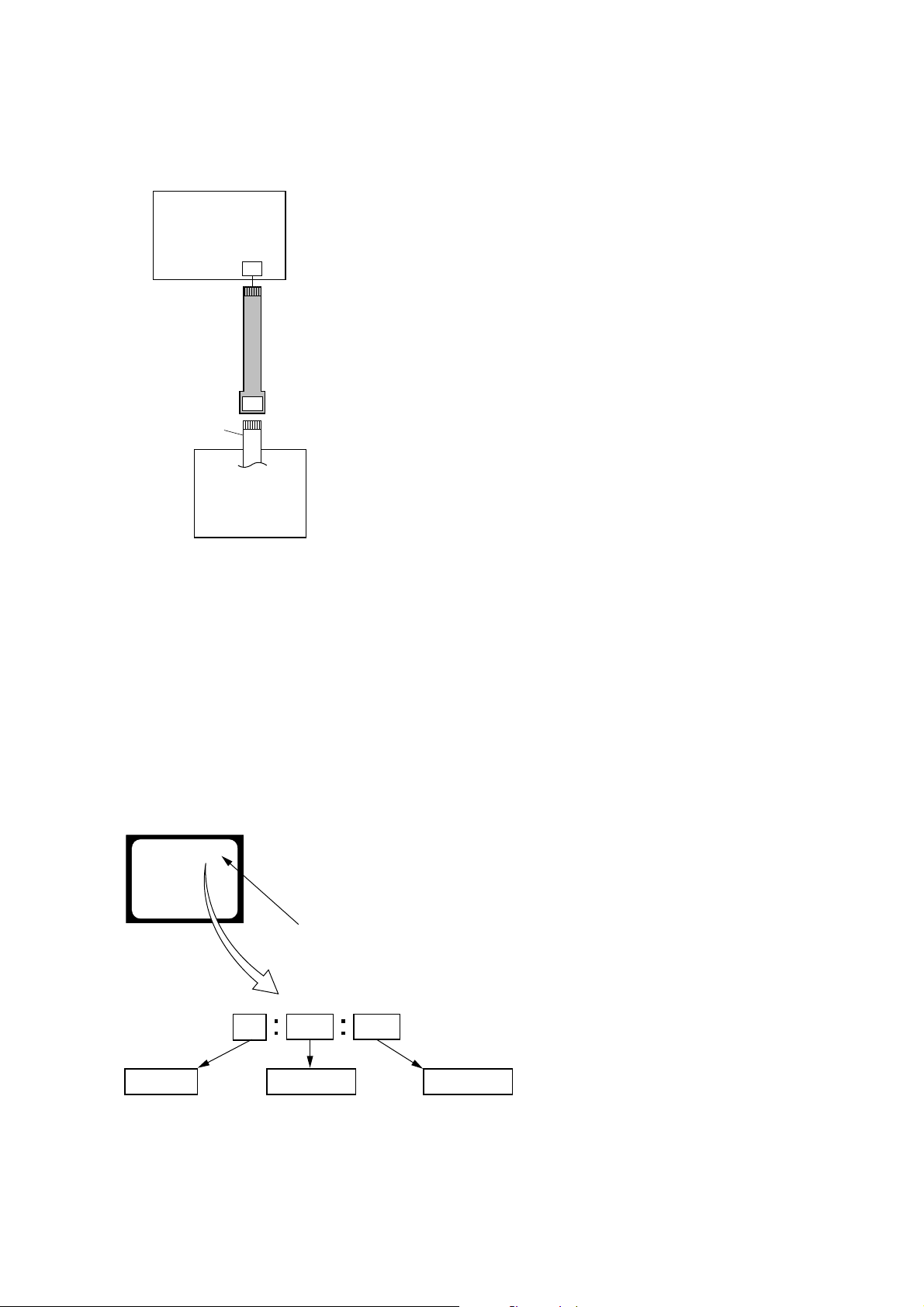

1-1. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated power supply (8.4 V), the power is shut off so

that the unit cannot operate.

These following method is available to prevent this.

Method:

Use the AC power adaptor (AC-L200/L200B).

1-2. TO TAKE OUT A DISC WHEN NOT EJECT (FORCE EJECT)

1 Peel off the jack cover assy and remote control window.

2 Insert the wire etc. in the hole and down the eject slider by it.

Charge

lever

Remote control window

Jack cover assy

Eject slider

Hole

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

1-1

1-3. USING SERVICE JIG

k

Connect the extension cable (J-6082-572-A) between the DVD mechanism deck and CN1008 on the VC-483 board.

VC-483 board (side B)

CN1008

Extension cable (10P)

(J-6082-572-A)

Flexible board (10P)

DVD mechanism dec

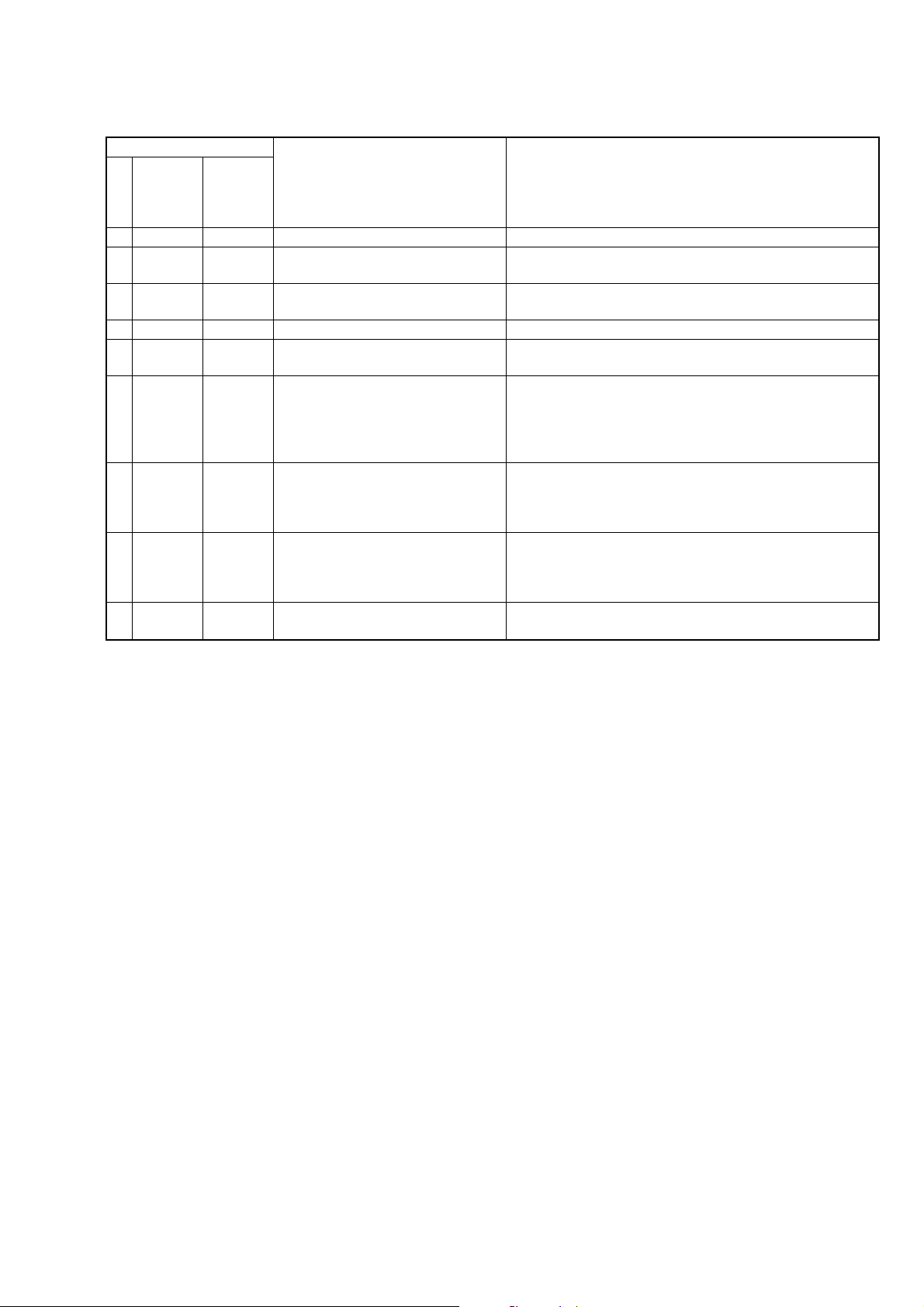

1-4. SELF-DIAGNOSIS FUNCTION

1-4-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder or LCD

screen what to do.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder or LCD screen

C : 3 1 : 1 1

Blinks at 3.2Hz

1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

3 1C

Block

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Tur n o n power again.

1-4-2. Self-diagnosis Display

When problems occur while the unit is operating, the counter of the

viewfinder or LCD screen shows a 4-digit display consisting of an

alphabet and numbers, which blinks at 3.2 Hz. This 5-character

display indicates the “repaired by:”, “block” in which the problem

occurred, and “detailed code” of the problem.

Detailed Code

Refer to “1-4-3. Self-diagnosis Code Table”.

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

1-2

1-4-3. Self-diagnosis Code Table

Self-diagnosis Code

Repaired by:

C

C

C

E

E

E

E

E

E

Block

Function

04

13

13

20

31

61

61

61

94

Detailed

Code

00

01

02

00

00

00

10

11

00

Symptom/State

Non-standard battery is used.

“Memory Stick Duo” is unformatted.

“Memory Stick Duo” is broken.

Disc access error

Flash memory data are rewritten.

Drive fault

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

The abnormalities in initialization of

the focus lens and the abnormalities in

initialization of the zoom lens occurred

simultaneously.

Fault of writing to or erasing the flash

memory

Correction

Use the InfoLITHIUM battery.

Format the “Memory Stick Duo”.

Insert a new “Memory Stick Duo”.

Clean the disc with the supplied cleaning cloth.

Use a compatible disc with the camcorder.

Make flash memory data correct value. (Note)

Inspect or replacement of the mechanism deck, IC (IC4401 on

the VC-483 board) and drive block.

Inspect the lens block focus reset sensor (pin 7 of CN5601 on

the VC-483 board) when focusing is performed when the focus

buttons of the touch panel are pressed in the focus manual mode,

and the focus motor drive circuit (IC5601 on the VC-483 board)

when the focusing is not performed.

Inspect the lens block zoom reset sensor (pin qa of CN5601 on

the VC-483 board) when zooming is performed when the zoom

lever is operated, and the zoom motor drive circuit (IC5601 on

the VC-483 board) when zooming is not performed.

Check whether the flexible board of the lens is broken, and

check whether it is inserted imperfectly. If there is no problem in

the flexible board, inspect the focus/zoom motor drive circuit

(IC5601 on the VC-483 board).

Inspect the flash memory (IC2201 on the VC-483 board). (Note)

Note: Refer to “1-3. DESTINATION DATA WRITE”, ADJ (9-852-173-51).

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

1-3E

NOTE FOR REPAIR

2. DISASSEMBLY

• Make sure that the flat cable and flexible board are not cracked of bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

• When remove a connector, don’t pull at wire of connector. It is possible that a wire is snapped.

• When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

2-1

HELP

EXPLODED VIEW

HELP

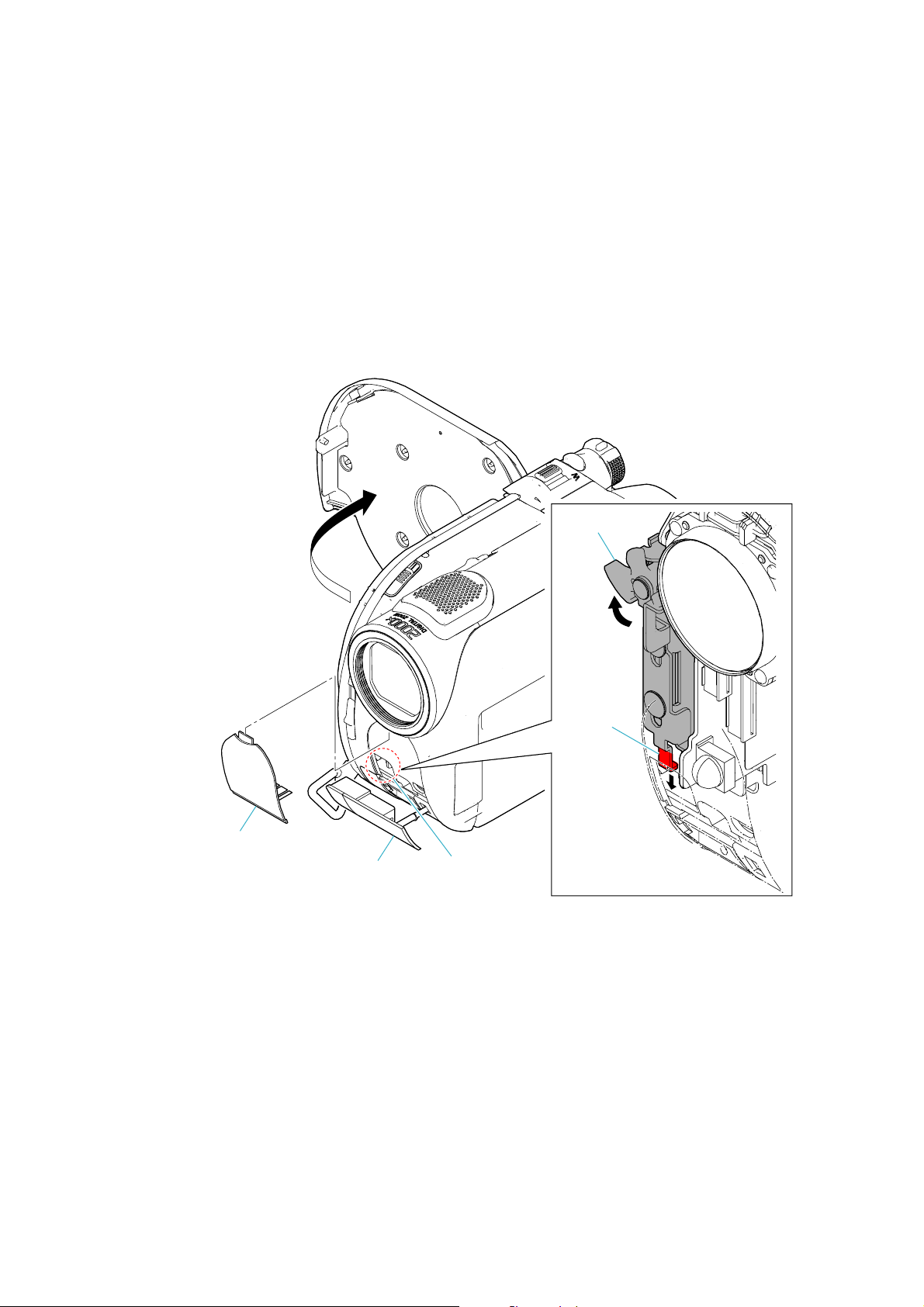

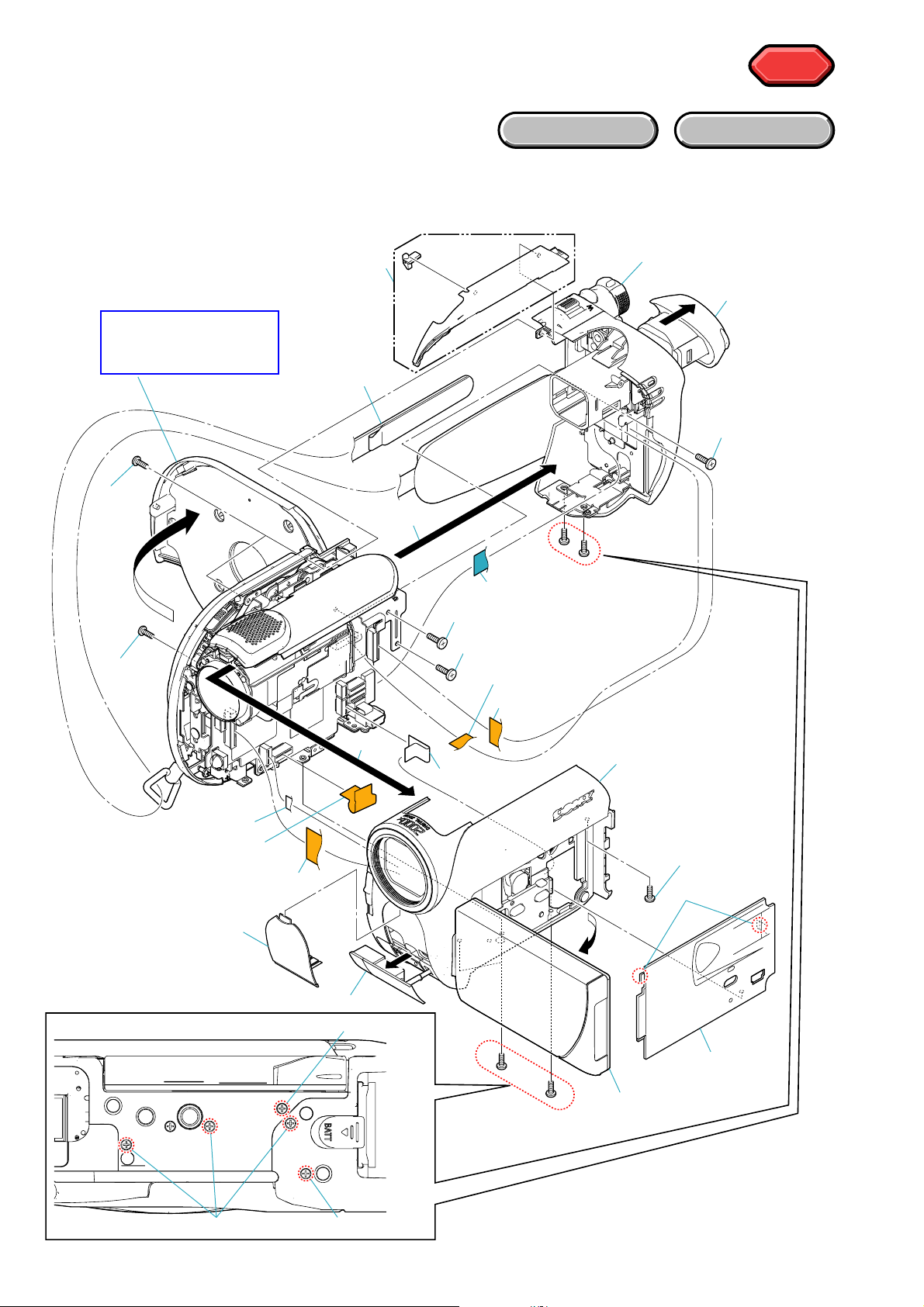

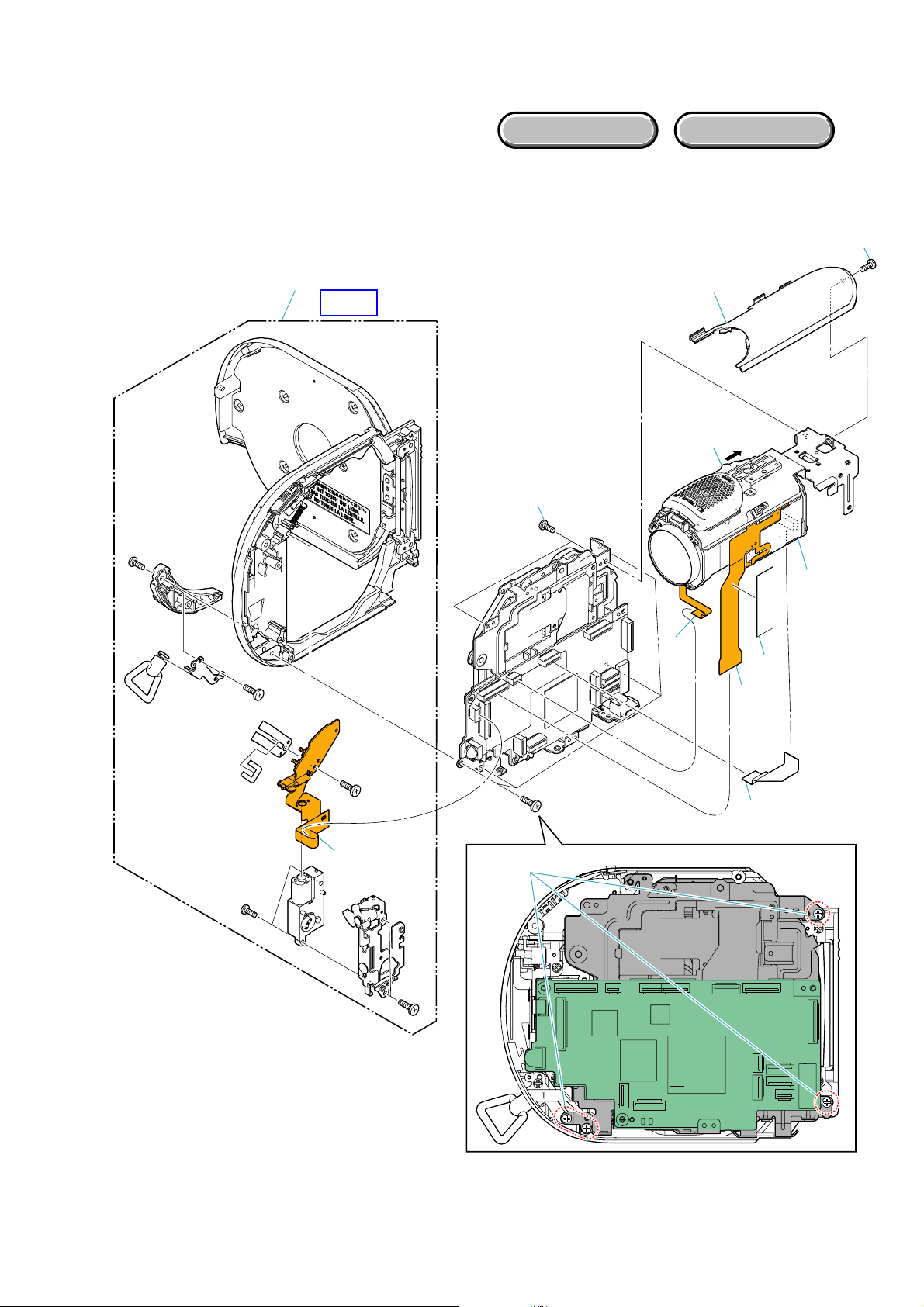

2-1. DISASSEMBLY

2-1-1. OVERALL SECTION

Follow the disassembly in the numerical order given.

1 Cabinet (R) Section (1-1 to 1-17)

2 BT-EVF Block (2-1 to 2-10)

1-10 (Open)

Refer to page 1-1 “1-2.

To take out a disk when

not eject (force eject)”.

1-12

(#11)

2-10

1-1

HARDWARE LIST

2 BT-EVF Block

2-6 (Pull)

2-7 (#2)

2-8

1-11 (#2)

1-14

1-15

1-9

1-17

1-8 (Pull)

1-16

1-3 (#2)

2-4 (#11)

2-5 (#2)

1-13

2-9

2-1

2-2

1 Cabinet (R)

Section

1-7 (#2)

1-4 (Claw)

1-6 (#2)

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

1-5

1-2 (Open)

2-3 (#2)

2-2

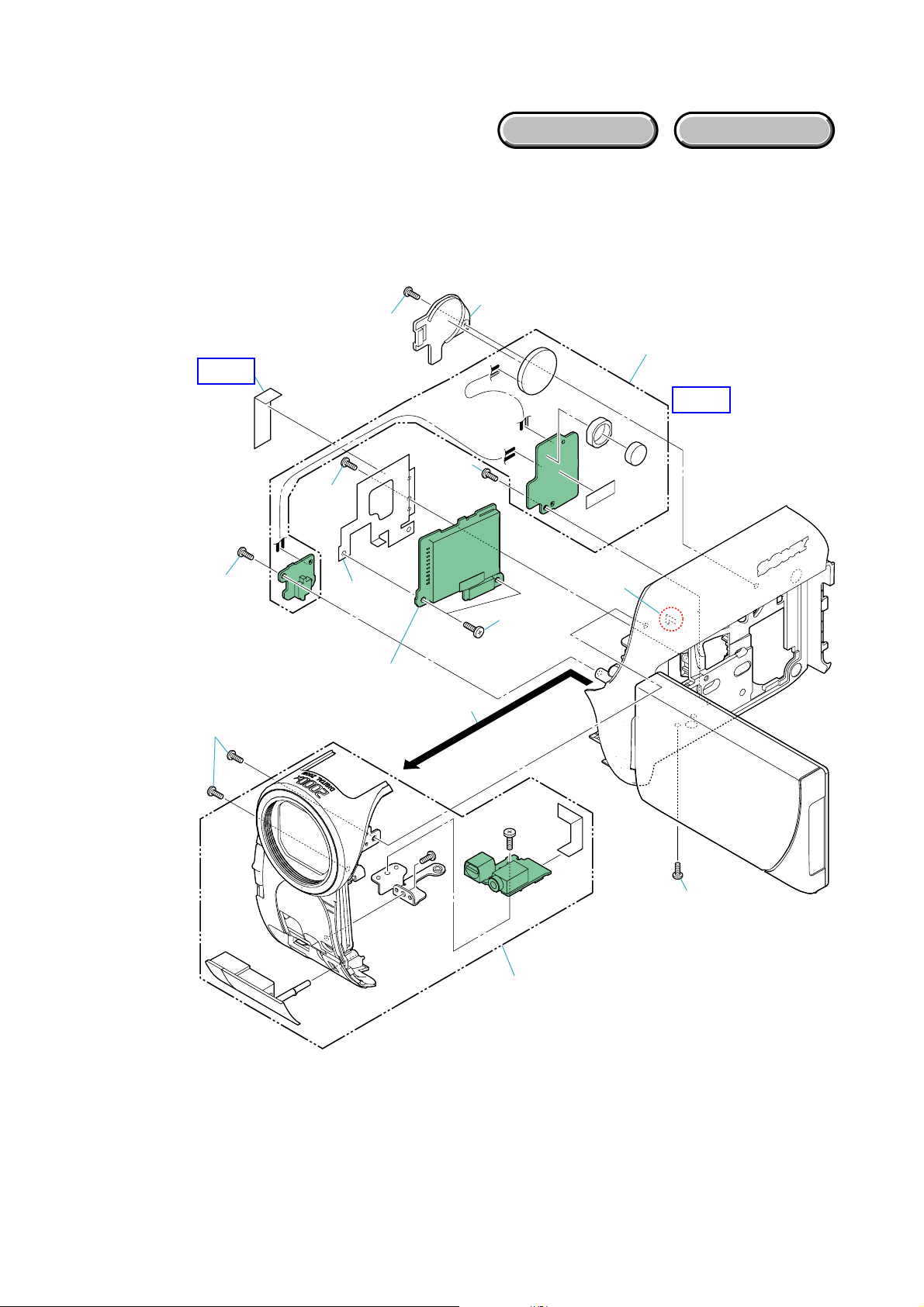

2-1-2. CABINET (L) SECTION

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 Upper Cabinet (1-1 to 1-2)

2 Cabinet L Assy (2-1 to 2-2)

3 Lens Block (3-1 to 3-5)

HARDWARE LIST

1-2 (#1)

2 Cabinet L Assy

HELP

1 Upper Cabinet

1-1

(Pull the Switch)

3-5 (#3)

3 Lens

Block

3-3

3-1

3-2

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

2-1

3-4

2-2 (#11)

2-3

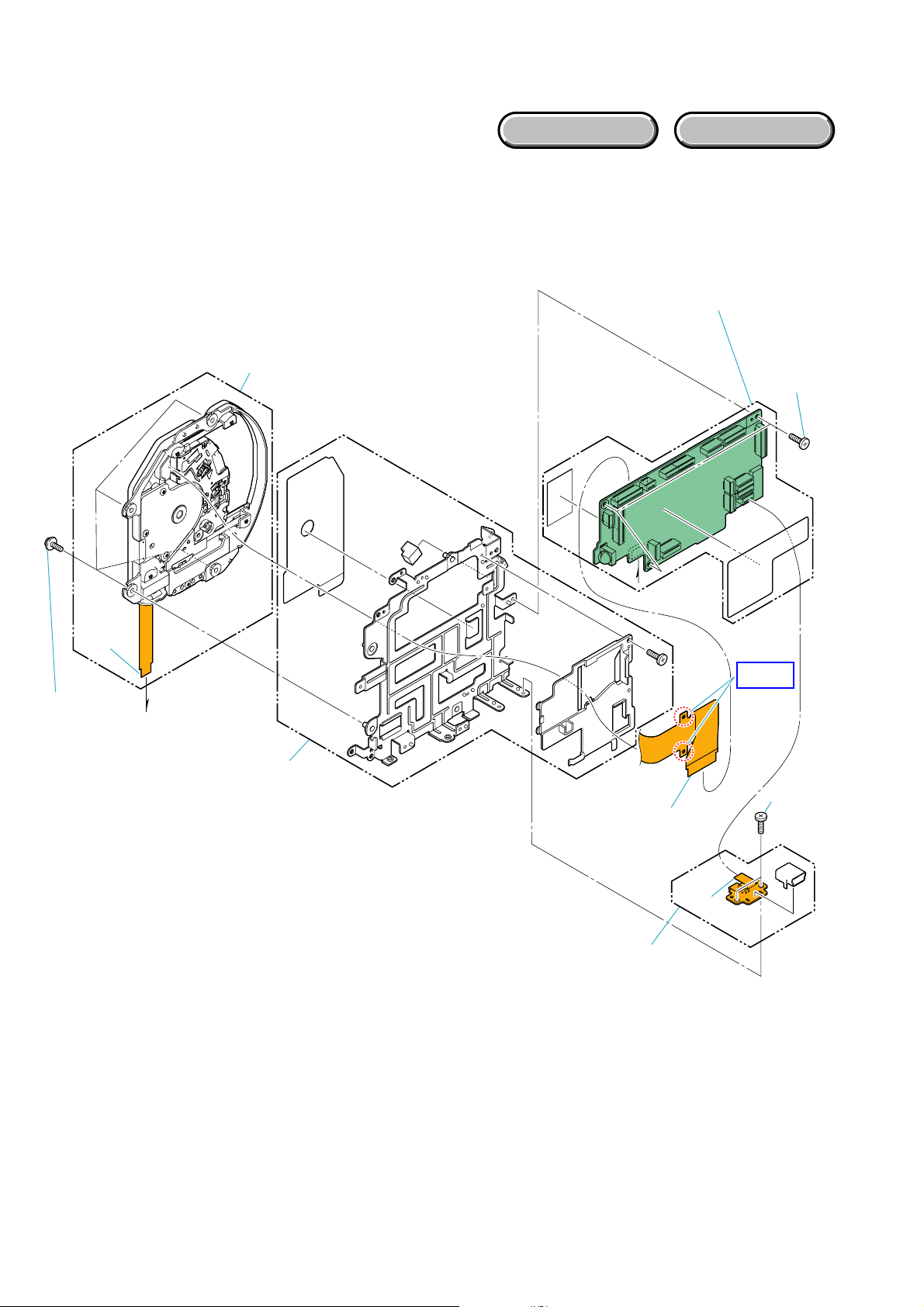

2-1-3. MD BLOCK

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 FP-574 Flexible Board (1-1 to 1-2)

2 VC-483 Board (2-1 to 2-3)

3 Mechanism Deck (3-1 to 3-3)

HARDWARE LIST

2 VC-483 Board

2-3

3-1 (#16)

3 Mechanism Deck

3-3

2-2

2-1

(#3)

VC-483

3-2

HELP

1-1

(#3)

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

1-2

1 FP-574 Flexible Board

2-4

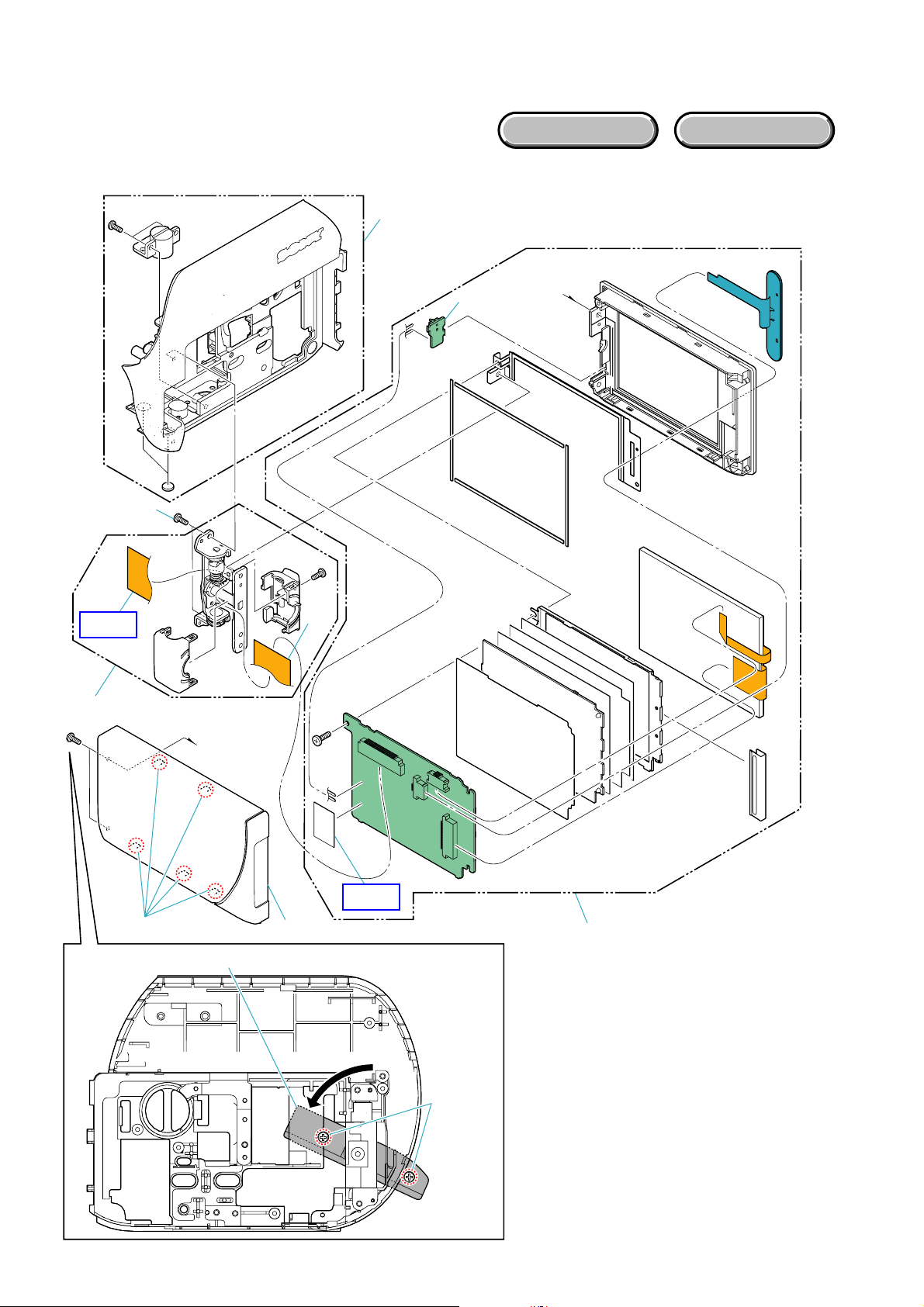

2-1-4. CABINET (R) SECTION

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 Front Panel Block (1-1 to 1-3)

2 MS-358 Board (2-1 to 2-5)

3 OC-001/CK-170 Board (3-1 to 3-4)

3-1 (#11)

HARDWARE LIST

3-2

2-1

HELP

3-4 (#11)

1-2 (#11)

2-2

(#11)

2-5

2 MS-358

Board

3-3

(#11)

MS-358

1-3

3 OC-001/CK-170

Board

HELP

CK170

2-3

(Claw)

2-4

(#3)

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

1-1 (#2)

1 Front Panel Block

2-5

2-1-5. LCD BLOCK

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 LCD Panel Block (1-1 to 1-6)

2 Hinge Assy (2-1 to 2-2)

2-1 (#11)

HARDWARE LIST

2-2

1-6

HELP

2 Hinge Assy

1-3 (Claw)

1-1 (Turn)

1-4

1-5

PD-314

HELP

1 LCD Panel Block

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

1-2 (#2)

2-6E

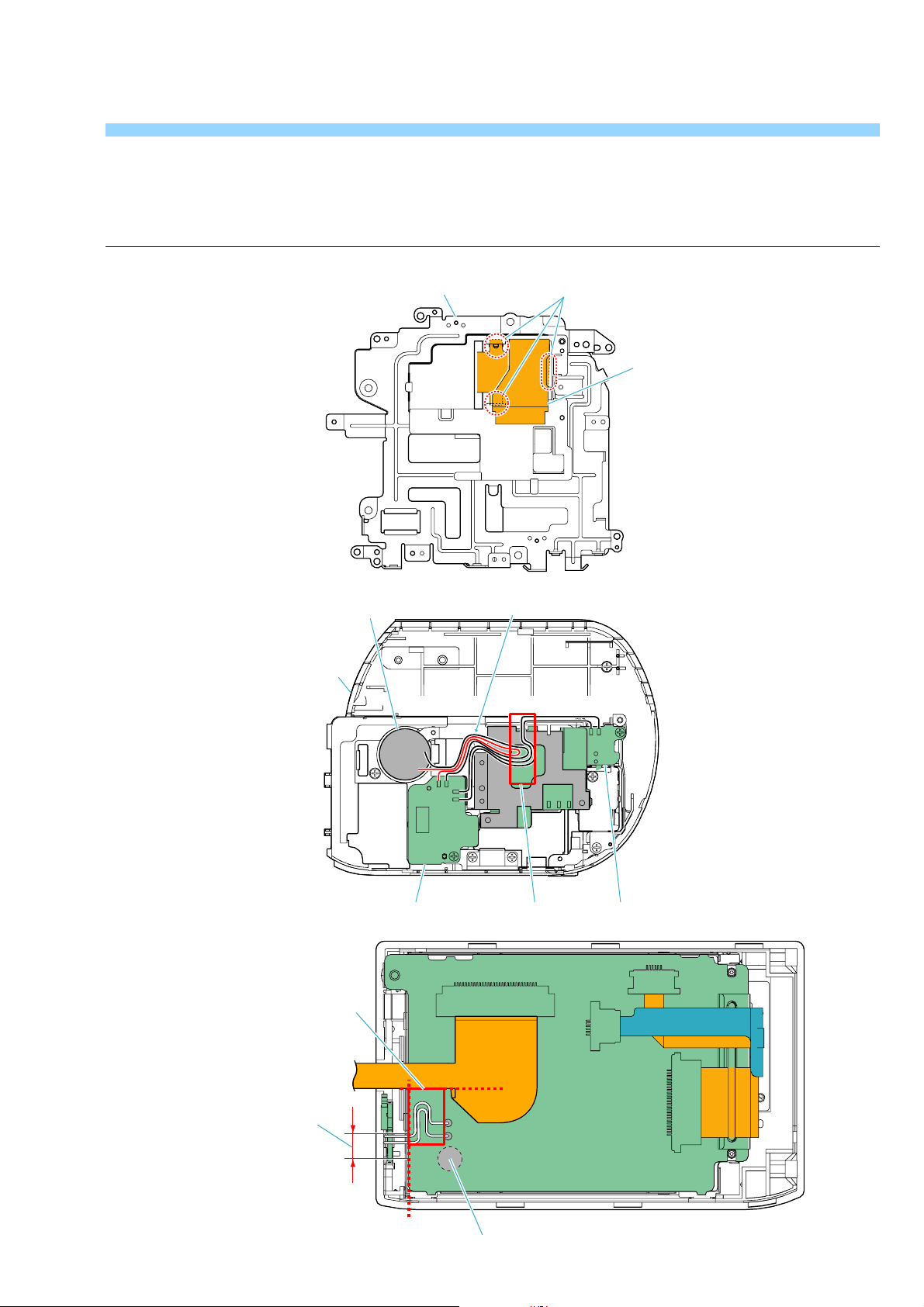

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

Loud speaker

Cabinet (R) section

MD frame assy

Hook

Mechanism deck

flexible board

Harness arrangement

CK-170 board Tape (A) OC-001 board

Tape (P)

Draw around the harness

within this area.

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

PD-314 Board

Put neither the harness nor the tape in this area.

HELP

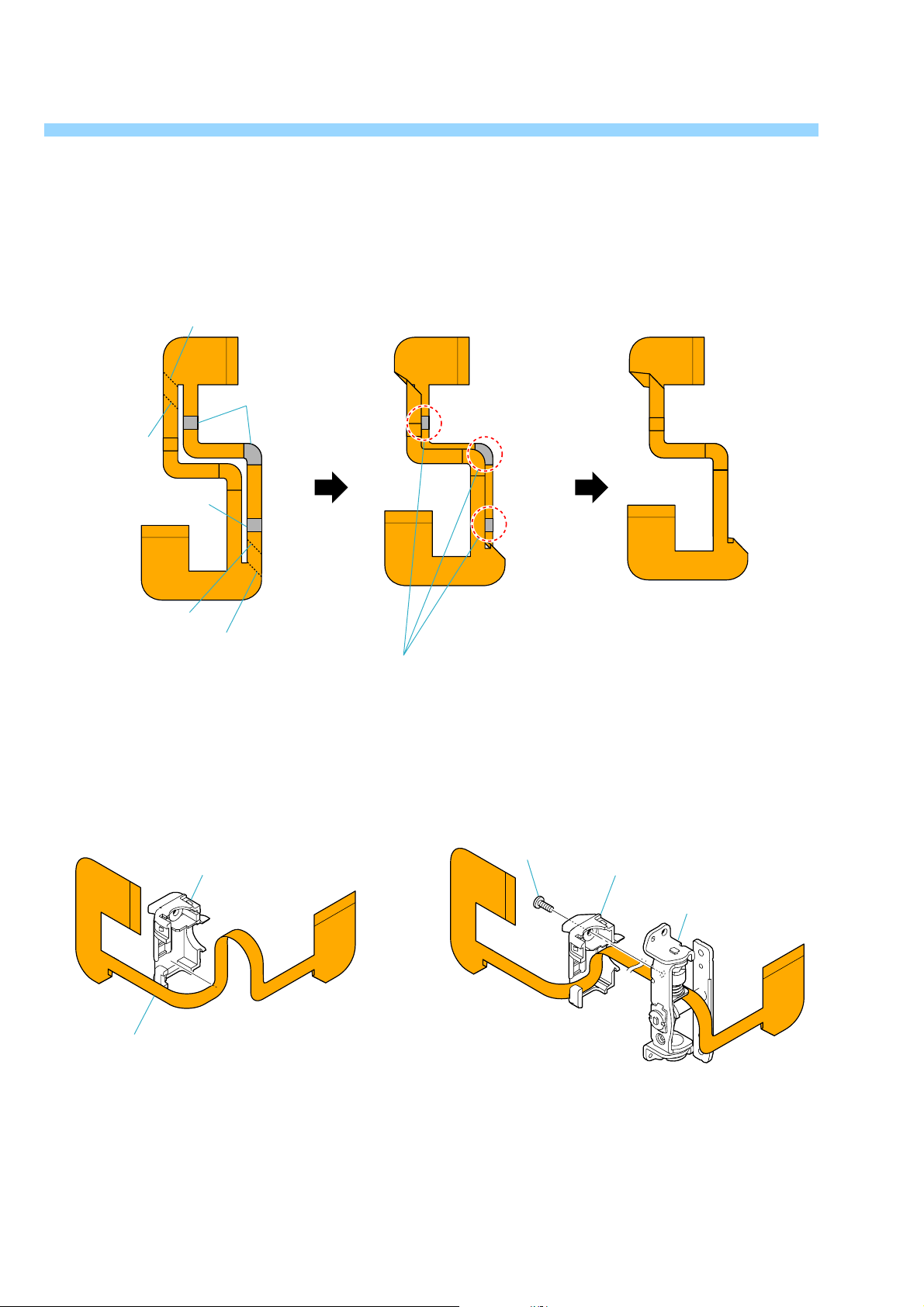

THE METHOD OF ATTACHMENT OF FP-573 FLEXIBLE BOARD

1 Fold dotted line parts of the FP-573 flexible board

as shown in figure.

Valley fold

Adhesive tape

Mountain

fold

Adhesive tape

Valley fold

Mountain fold

Stick it together in the adhesive tape

while bending the FP-573 flexible board.

2 Put the FP-573 flexible board on the

hinge cover (M).

Hinge cover (M)

FP-625 flexible board

3 Fix hinge cover (M) and the panel hinge assy (M)

with the screw.

Screw

Hinge cover (M)

Panel hinge assy (M)

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

HELP

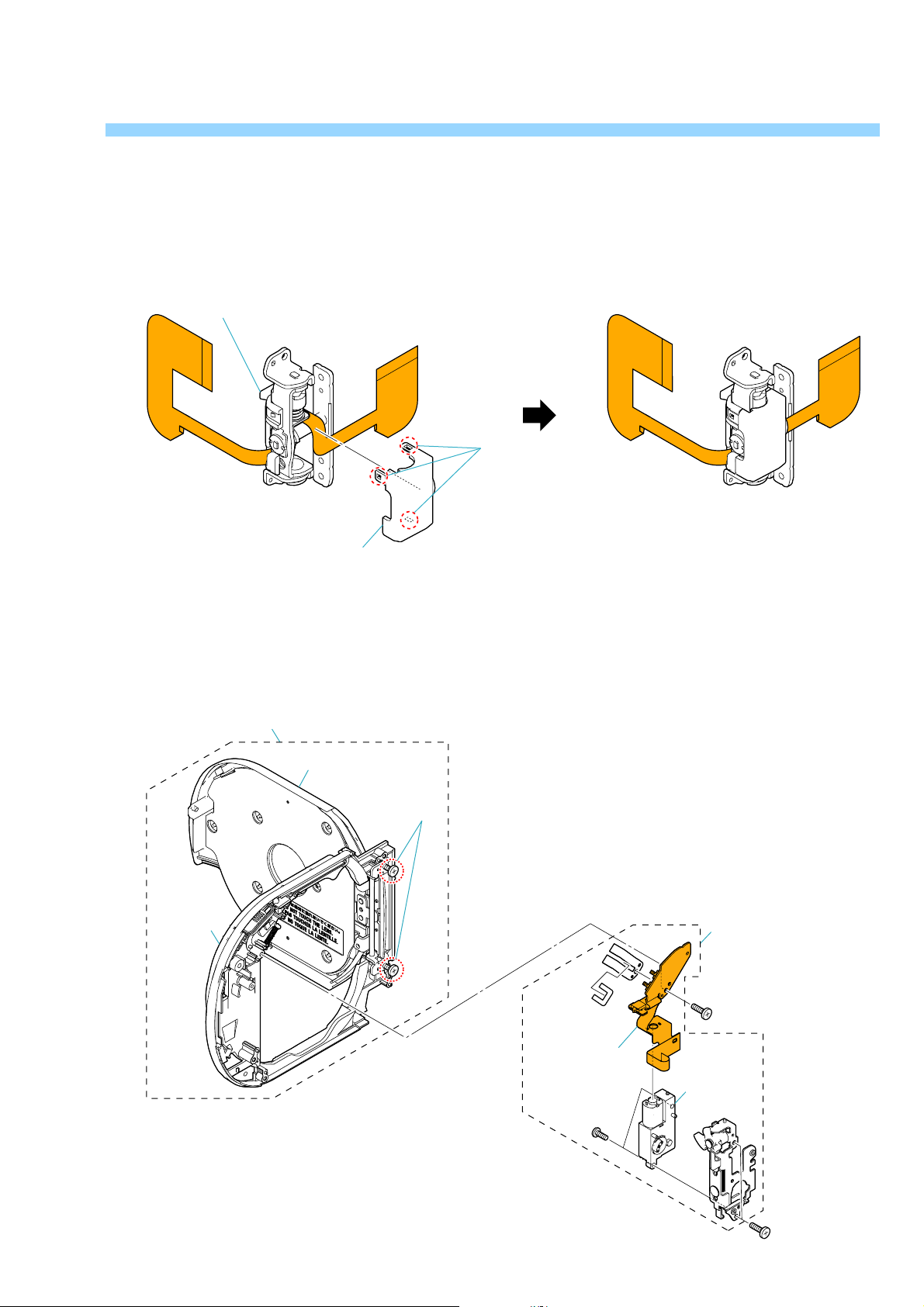

4 Install the hinge cover (C) in the hinge cover (M).

Hinge cover (M)

Claw

Hinge cover (C)

PRECAUTION WHEN INSTALLING THE CABINET L ASSY FOR SERVICE

Cabinet L assy for service

Cabinet D

block

D lid block

Screws

When the eject block is installed on the cabinet L assy

for service, a discrepancy could be made between the

cabinet D block and the D lid block, and as a result,

the D lid may not to be closed.

In case of such discrepancy, loosen the screws on the

hinge to eliminate the discrepancy of the D lid block,

and then retighten the screws.

Eject block

FP-569 flexible

complete board

M903

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

HELP

Link

Link

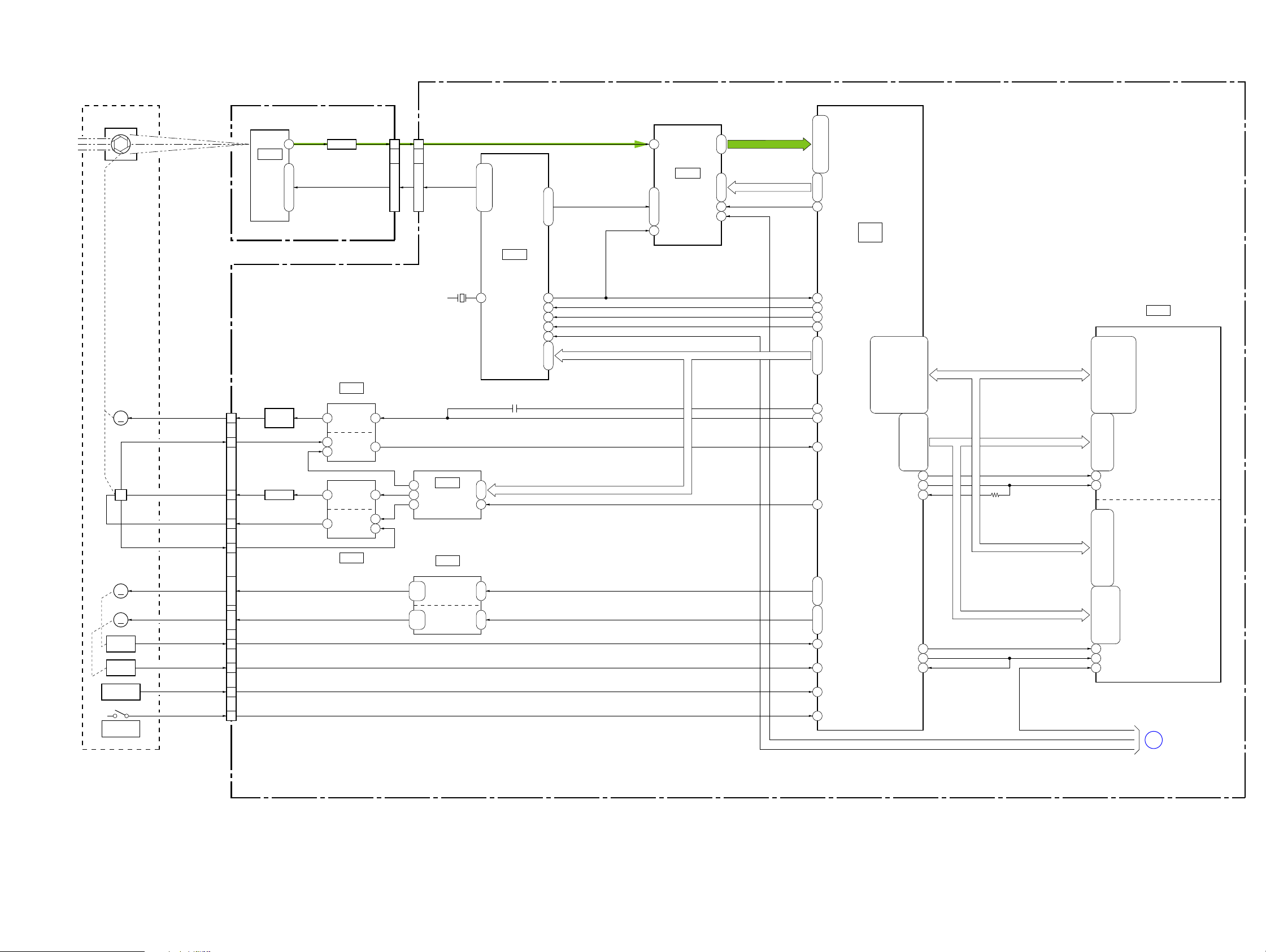

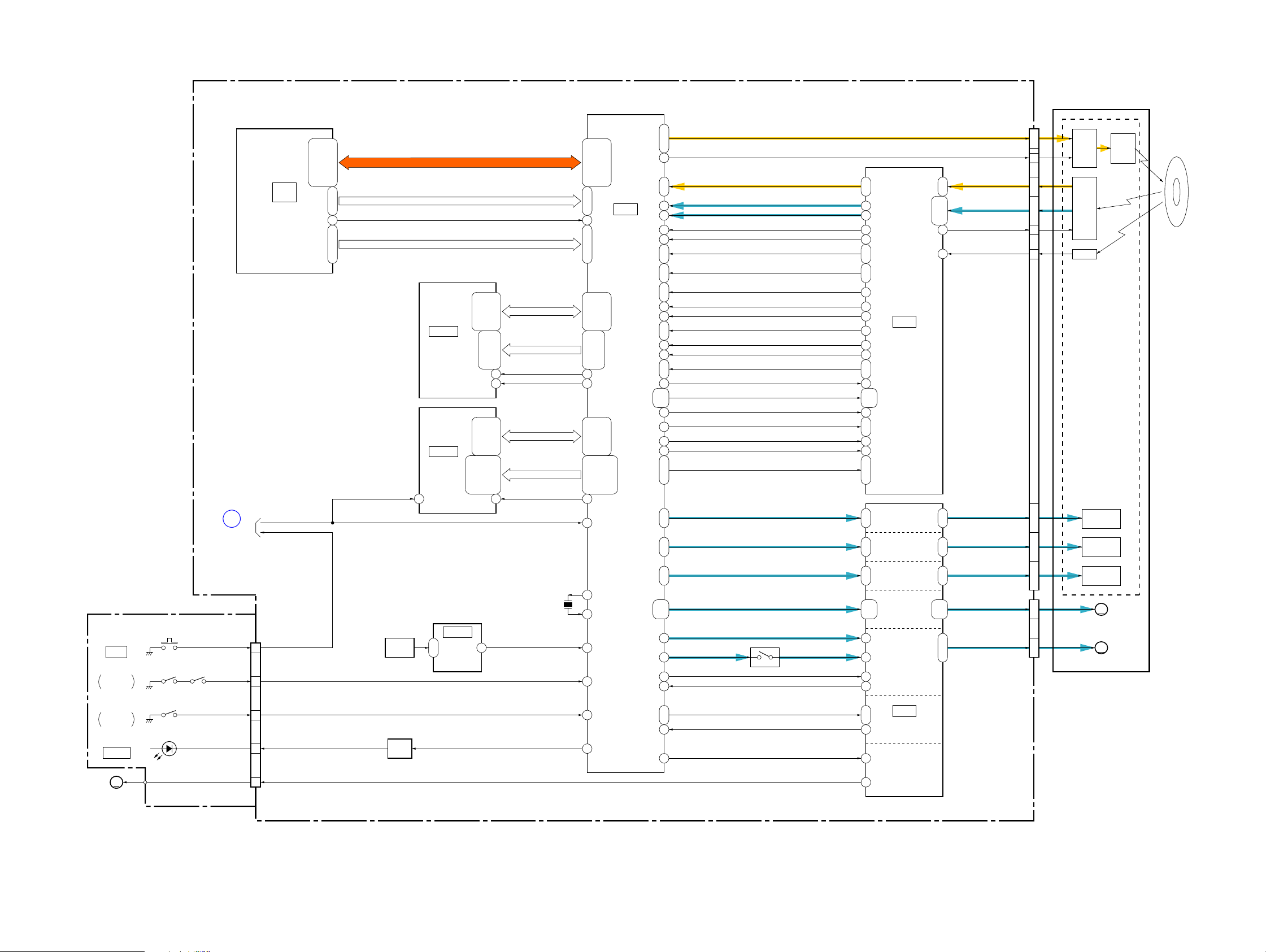

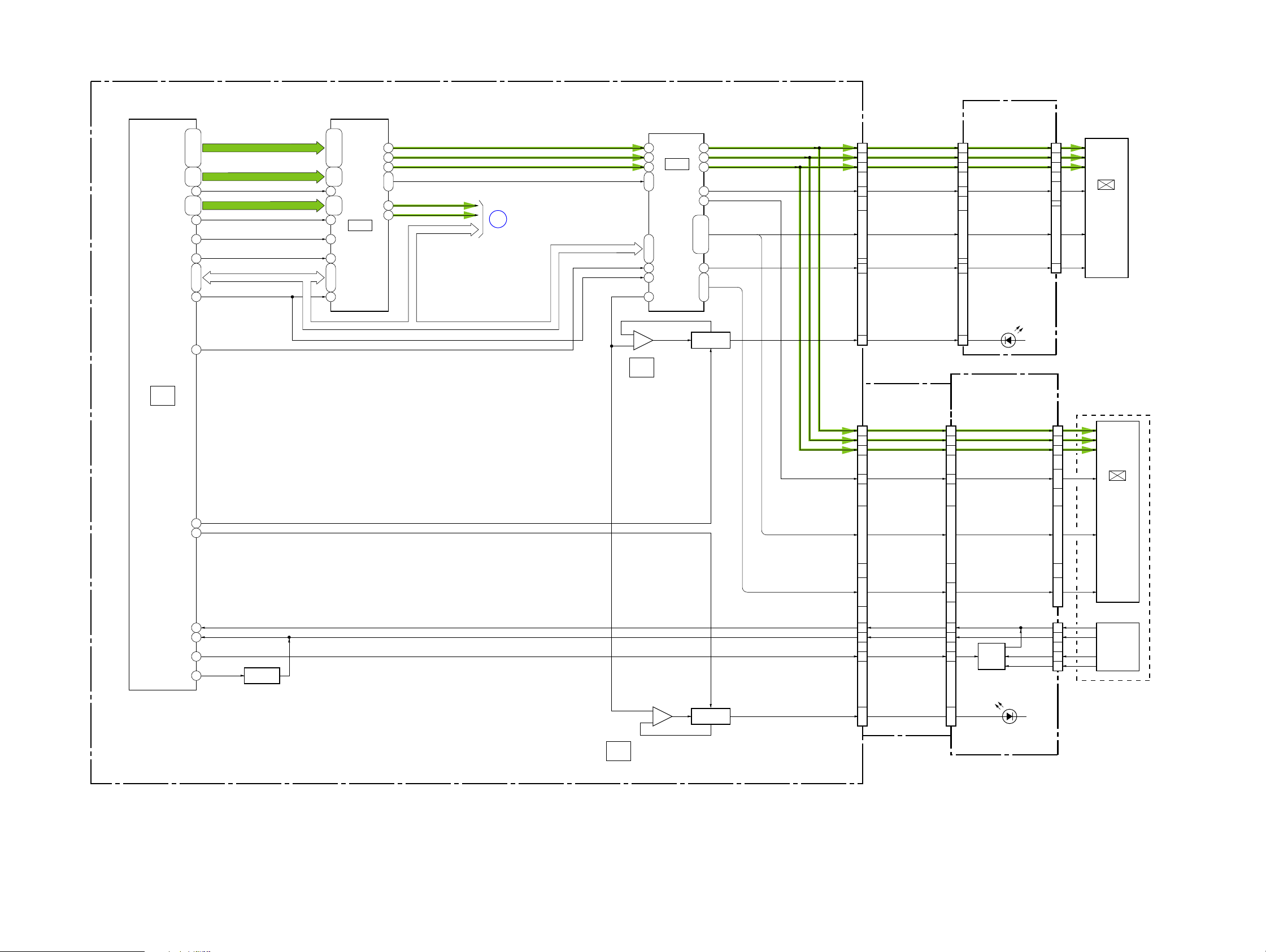

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (1/5)

OVERALL BLOCK DIAGRAM (2/5)

OVERALL BLOCK DIAGRAM (3/5)

OVERALL BLOCK DIAGRAM (4/5)

OVERALL BLOCK DIAGRAM (5/5)

POWER BLOCK DIAGRAM (1/3)

POWER BLOCK DIAGRAM (2/3)

POWER BLOCK DIAGRAM (3/3)

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

3. BLOCK DIAGRAMS

3-1. O VERALL BLOCK DIAGRAM (1/5) ( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

LENS BLOCK

IRIS

(SHUTTER)

IRIS

METER

M

H

FOCUS

MOTOR

M

ZOOM

MOTOR

M

FOCUS

SENSOR

ZOOM

SENSOR

LENS TEMP

SENSOR

NIGHTSHOT

PLUS

I_DRIVE (-)

I_HALL (-)

I_BIAS (-)

I_BIAS (+)

I_HALL (+)

FC_XA, FC_A,

FC_XB, FC_B

ZM_A, ZM_XA,

ZM_XB, ZM_B

FC_SENSE_OUT

ZM_SENSE_OUT

THERMO_OUT

IR_SWITCH_OUT

CD-686 BOARD

IC7101

IMAGER

CN5601

13

18

17

15

16

21 - 241 - 4

7

11

6

19

CCD

Q5601

IRIS

DRIVE

Q5603

AMP

7

4 - 1, 9, 10, 12, 13

BUFFER

V1 - V4, RG, VSHT, H1, H2

5

6

7

1

Q7101

IC5602

(2/17)

IRIS DRIVE

HALL AMP

HALL GAIN

HALL BIAS

IC5603

(2/17)

CN7101

31

7

5

3

2

VC-483 BOARD (1/5)

CN1601

8

7

9 - 12, 2, 1, 4, 5

6 - 3, 13, 14, 11, 10

A_2.8V

1

2

(D/A CONVERTER)

3

21, 4

23, 2,

17, 7

5, 19,

IC5604

EVR

(2/17)

IC5601

(2/17)

FOCUS

MOTOR

DRIVE

ZOOM

MOTOR

DRIVE

X1601

48MHz

9, 45, 12, 13

42, 40, 44, 41,

IC1601

TIMING

GENERATOR

(1/17)

CAM_SO, CAM_SCK

6, 7

DA_STRB

8

13 - 16 9 - 12

CCD_OUT+

PBLK, XSHP, XSHD, CLPDM

21, 16, 17, 22

VCK

2427

TG_HD

33

TG_VD

34

TG_FLD

35

CAM_DD_ON

6

CAM_SI, CAM_CS, CAM_SO, CAM_SCK

47, 3 - 1

DIR0A, DIR0B, EN0

DIR1A, DIR1B, EN01

30

19, 21 - 23

VCK

16

IRIS_COM

IRIS_PWM

I_HALL_AD

FC_RST

ZM_RST

LENS_TEMP_AD

XNS_SW

IC1602

S/H, AGC,

A/D CONVERTER

(1/17)

AD4 - AD13

2 - 11

CH_CS, CH_SO, CH_SCK

46 - 48

CLPOB

20

XSYS_RST

43

CAM_DD_ON

XSYS_RST

B13, C13, D11, B12, B11

D12, A13, D13, C12, A12,

M17, L16, L17

D8

IC2101

(1/5)

CPU

(3/17 - 5/17)

D9

D10

B10

C10

G17, H17, K17, J17

W2

W1

AK34

G10

N7, K8, M7

L9, J8, L8

AE32

A5

AL35

C6

AJ22, AJ25, AH23, AJ26,

AJ23, AF26, AH21, AG25,

AE19, AJ19, AF20, AG18

AE18, AJ20, AF19, AH18,

AE20, AH20, AH19, AF18,

AJ24, AG20, AH25, AD19,

AD18, AJ21, AH26, AG19,

AH24, AG21, AG26, AH22,

Y11, T10, V9, V10,

T11, W11, Y10, Y8

V11, W10, W12, Y9,

AA9, U12, V12, U11,

AF10

W25

W26

AF10

Y25

Y26

EMC_DATA [0] - EMC_DATA [31]

EMC_ADDR [0] - EMC_ADDR [12],

EMC_ADDR [14], EMC_ADDR [15]

EMC_XCS [1]

EMC_CLK0_OUT

EMC_DATA [0] - EMC_DATA [15]

EMC_ADDR [0] - EMC_ADDR [15]

EMC_XCS [0]

EMC_CLK1_OUT

XFLASH_RST

A : VIDEO SIGNAL

G5, G4, F5, G2, G3

P5, N5, N4, J4, H5, H4,

D13, P2, P3, N2, N3, P4,

G11, G10, F11, E13, E12,

M11, L10, L11, H11, H10,

R12, P12, P13, N11, M10,

D4, F4, E4, E3, D3,

R5, R4, T3, R3, E2,

J13

K11

T11, U11, U6, R7, R8,

V5, T6, P8, P9, R9, R10,

F6, C4, D5, C5,

E6, D6, C6, E7,

U3

T4

E8

XFLASH_RST

XSYS_RST

CAM_DD_ON

512M SDRAM

P6, E5, K5, L4, L5

P10, T9, R11, T12, U12,

512M OneNAND FLASH

C11, B11, D11, E9

C10, B10, D10, F8,

IC2201

(6/17)

1

OVERALL (5/5)

(PAGE 3-5)

05

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

3-1

3-2. O VERALL BLOCK DIAGRAM (2/5)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

FP-569 FLEXIBLE BOARD

S5691

OPEN

LID OPEN

DETECT

S5693 S5692

VC-483 BOARD (2/5)

(3/17 - 5/17)

2

OVERALL (5/5)

(PAGE 3-5)

XEJECT_SW

LID_OPEN

5

6

CN1001

IC2101

(2/5)

CPU

XEJECT_SW

AJ8, AJ10, AM12, AJ9

AH11, AJ11, AJ13, AH9,

AJ14, AH8, AH13, AH10,

AH12, AH14, AJ12, AN12,

AM9 - AM11

TXD_TO_IC_4201, RXD_TO_IC_4201, XSCK_IC_4201, XCS_IC_4201

G19, H18, G18, H19

XIC_4201_RESET_FLASH

SE4501

SHOCK

SENSOR

ATA_D0 - ATA_D15

ATA_A0 - ATA_A2

XATA_RESET

IC4303

64M SDRAM

(8/17)

IC4302

16M FLASH

(8/17)

B4

2, 3

IC4501

SHOCK

SENSOR

AMP

(7/17)

50, 51, 53

2, 4, 5, 7, 8,

10, 11, 13, 42,

44, 45, 47, 48,

33, 34, 22, 35

23, 24, 25, 26,

29, 30, 31, 32,

19

38

F4, G5, F5, G6

F2, G2, F3, G3,

E2, H2, E3, H3,

H4, E4, H5, E5,

E6, B2, C3, D4

E1, D1, C1, A1,

B1, D2, C2, A2,

B5, A5, C5, D5,

B6, A6, C6, D6,

F1

10

SDDQ0 - SDDQ15

SDA0 - SDA11

XSDCS

SDCLK

FDQ0 - FDQ15

FEA0 - FEA19

FCE1Z

XIC_4201_RESETXIC_4201_RESET

X4201

33.8688MHz

GSHCK

LID_OPEN

P20, P21, P23, R22,

L22, L20, M22, N21,

R21, P22, N20, N22,

M21, M20, L21, R20

IC4201

H21, J21, H22

R23AL4

DVD DSP,

DVD DRIVE

CONTROL

(7/17)

D13, B13, C13, B14

D20, F21, F22, E23

F20, E20, D23, C23,

C21, A22, B23, C22,

D22, D21, E22, B22,

D17, C18, B17, D18

C17, C16, D15, B15,

A14, C15, B16, D16,

B19

A16

Y21, W20, V20, U22

AA22, Y23, W21, V21,

Y19, Y16, AA20, AB22,

AB19, AB21, AC22, AA21,

U20, U21, T23, T20,

T22, AB20, Y20, Y22

W23, W22, V23, V22,

AA16, Y17, AC18, Y18,

AC19, AC21, AB18, AA19,

AA17

AA13

AC12

AC13

A2

C12

Y5, AB5, AA5

Y12

MPXOUT1, MPXOUT2

N2, P4K2, K3B2, T4

FE

K4

TE

L4

PI

J4

CE

L1

PH1, PH2

J2, P1

BH1, BH2

J3, N3

VC

SWRF

R1

EQRF_S

H1 A8

RECD1

AWBL

U2

DWBL

AB2

LPP, LPP2

AA3, AA8

ATTPLS

AB6

MSPDSH, WFPDSF, ROPCSH, RFPDSH

Y6, AA4,

AB4, AB3

RFMCLK

B1 M4

WLDON

AB8

APCLOAD

Y8 H2

XRST_IC_4101

AC7

SDAT, SCS, SCLK

Y7, AA6, AB7

FFDR, FRDR

C8, D7

TFDR, TRDR

A6, C7

FMPWN_OUT0, FMPWN_OUT1

C4, C3

SLSTFD1, SLSTRD1, SLSTFD2, SLSTRD2

A5, C6

B7, D6,

SP_SPFD

SP_SPRD

SV_FS4SV

FGINI

Q4401

G11, H12

C12

D11

C11

E11

B11, A12

B12, A11

M1

H11

M9

J12

L9

M10, L10

L2

L3, L4,

M2, M3

L11, M11

L8

L6, L7, M6

E5, H6

G6, H7

G7, H8B4, C4

E4, F2,

G1, G2

B5B3

B3D4

A4B6

B7D5

IC4101

RF PROCESS

(9/17)

FOCUS

DRIVE

TRACKING

DRIVE

TILT

DRIVE

SLED

MOTOR

DRIVE

SPINDLE

MOTOR

DRIVE

LDD_W1DIS - LDD_W3DISWP1_OP - WP3_OP

B1, C1

F2, G1, G2, H1

D2, E1, E2, F1,

C2

C7, D5

D6, D7

E7, F6

G5, F5

G4, F4,

C3, D3, E1

CN4101

ENBLLD_EN

RF±

A - H

PDIC_GAIN

FPDIC_OUT

FCS±

TRK±

TLT±

CN1008

SLED1 - SLED4

U, V, W

DVD MECHANISM DECK

(DDX-C2000)

3 - 127, 2625 - 18

12

30

50

37 - 3441 - 3845 - 42

9 - 63 - 5

LD

DRIVE

PD IC

FPD ICA2

SLED MOTOR

SPINDLE MOTOR

FOCUS

COIL

TRACKING

COIL

TILT COIL

M

M

LASER

DIODE

S5694

EJECT

DETECT

D5691

ACCESS

M

M903

MOTOR UNIT

(GEARD MOTOR)

EJECT_DET

EJECT_DRV

8

1

3

05

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

Q1004

LED

DRIVE

EJECT_DET

ACCS_LEDACCS_LED

D12

Y11

3-2

AB11, AA11

C11

B12

XMUTE0, XMUTE1

DRV_SEL

PLG

DVD MECHA DRIVE

B8

H1

F3

IC4401

(10/17)

EJECT

MOTOR

DRIVE

A : VIDEO/AUDIO/SERVO SIGNAL

A : VIDEO/AUDIO SIGNAL

A : SERVO SIGNAL

3-3. O VERALL BLOCK DIAGRAM (3/5)

VC-483 BOARD (3/5)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

BL-006 BOARD

IC2101

(3/5)

CPU

(3/17 - 5/17)

DR_VDATA0 – DR_VDATA7

D32, C34, B33, C33

D35, E34, D33, D34,

DR_GHDATA0 – DR_GHDATA3

E33, F33

E32, G33,

H35 B15

F32, F34

G32, G34,

G35 D12

F35

U27

L18, M19, M18

G20

XCS_LCD

T27

DR_GHPILOT

DR_GSDATA0 – DR_GSDATA3

DR_GSPILOT

DR_VINCK

XCS_IC_2901

BB_SI, BB_SO, XBB_SCK

XBB_RST

E21

H2

J21

A18, B19, A20, B21

B17, A17, D18, B18,

A15, A14

B16, A16,

D13, A13

D14, B14,

IC2901

D/A

CONVERTER

(11/17)

J1, G2, H1

AA2

AA4

AA5

K1, K2

AA9

AA11

IC_2901_Y_OUT

IC_2901_C_OUT

BB_SO, XBB_SCK

3

OVERALL (4/5)

(PAGE 3-4)

PANEL_R

PANEL_G

PANEL_B

PANEL_HD, PANEL_VD

BB_SI, BB_SO, XBB_SCK

XCS_LCD

XBB_RST

EXTDA

34

33

32

42, 45, 44 48, 1

43

3

31

6

–

7

5

+

IC3702

(2/2)

EVF BACKLIGHT

CONTROL

(13/17)

IC3701

LCD/EVF

DRIVE

(13/17)

20

21

22

26

28

6 - 9, 12, 14,

16, 17, 30, 24

10

5, 11, 18

Q3706

BACKLIGHT

DRIVE

CN3701

CN3702

(1/2)

15

14

13

17

7

20

1

2

3

EVF_COM

EVF_HST, EVF_HCK1,

EVF_HCK2, EVF_BLK,

EVF_VCK, EVF_PCG,

EVF_REF, EVF_VST,

EVF_EN, EVF_PSIG

3 - 6, 8 - 12, 16

EVF_STB

FP-573 FLEXIBLE

BOARD (1/2)

PANEL_VR

PANEL_VG

PANEL_VB

EVF_VR

EVF_VG

EVF_VB

LED_K

CN5901

6

7

8

4

14

1

COM, CS

HST, HCK1, HCK2, BLK,

VCK, PCG, REF, VST,

EN, PSIG

18 - 15, 13 - 9, 5

D5902

(BACKLIGHT)

PD-314 BOARD (1/2)

CN6401

(1/2)

30

29

28

VR

VG

VB

STB

CN5902

CN6405

R

G

B

17

18

16

11

LCD902

21, 19

5 - 7, 9, 10, 12 - 15, 20

4

5

3

COLOR

EVF

UNIT

LCD901

30 1

EVF_BL_ON

D26

PANEL_BL_ON

Y4

TP_X

AM35

TP_Y

AN34

TP_SEL1

B29

TP_SEL2

B28

05

Q2101

TP SELECT

SWITCH

IC3702

(1/2)

EVF_BL_ON

PANEL_BL_ON

3

+

2

–

LCD BACKLIGHT

CONTROL

(13/17)

1

BACKLIGHT

DRIVE

Q3710 - Q3713

7, 17, 19 - 24, 28, 29

27 - 25

14

16

15

11 - 9

COM

WIDE, REF, HCK1, HCK2,

HST, PCG, EN, PSIG,

VST, VCK

24, 14, 12 - 7, 3, 2

RGT, DWN, XSTBY RGT, DWN, XSTBY

TP_X

TP_Y

TP_SEL1

BL_H1 - BL_H3

17

15

16

4 - 6

20 - 22

TOUCH

PANEL

I/F

Q6401, Q6402

A : VIDEO SIGNAL

COM, CS

PSIG, HCK1, HCK2,

WIDE, REF, HST,

PCG, EN, VCK, VST

CN6404

TP_TOP

TP_L

TP_R

TP_BOT

D6403 – D6405

(BACKLIGHT)

24, 23

6 - 9, 11 - 13, 20 - 22

2, 19, 14

3

5

2

6

2.5 inch

COLOR

LCD

UNIT

TOUCH

PANEL

DCR-DVD106E/DVD108/DVD108E/DVD109E/DVD608/DVD608E_L2

3-3

Loading...

Loading...