Page 1

WX-C5000

SERVICE MANUAL

Dolby noise reduction manufactured under license from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol ; are trademarks of Dolby

Laboratories Licensing Corporation.

CD

Section

TC

Section

E Model

Model Name Using Similar Mechanism WX-C55

CD Drive Mechanism Type MG-378X-121

Optical Pick-up Name KSS-521A

Model Name Using Similar Mechanism WX-C55

Tape Transport Mechanism Type MG-25E-136

CD player section

Signal-to-noise ratio 94 dB

Frequency response 5 – 20,000 Hz

Wow and flutter Below measurable limit

Cassette player section

Tape track 4-track 2-channel stereo

Wow and flutter 0.08 % (WRMS)

Frequency response 30 – 20,000 Hz

Signal-to-noise ratio

Cassette type Dolby B NR Dolby NR off

TYPE II, IV 67 dB 58 dB

TYPE I 64 dB 55 dB

SPECIFICATIONS

Tuner section

FM

Tuning range FM tuning interval:

50 kHz/200 kHz switchable

87.5 – 108.0 MHz

(at 50 kHz step)

87.5 – 107.9 MHz

(at 200 kHz step)

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz

Usable sensitivity 9 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 65 dB (stereo),

68 dB (mono)

Harmonic distortion at 1 kHz

0.7% (stereo),

0.4% (mono)

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

– Continued on next page –

CHANGER CONTROL AUDIO MASTER

1

Page 2

AM

Tuning range AM tuning interval:

9 kHz/10 kHz switchable

531 - 1,602 kHz

(at 9 kHz step)

530 – 1,710 kHz

(at 10 kHz step)

Aerial terminal External aerial connector

Intermediate frequency 10.71 MHz/450 kHz

Sensitivity 30 µV

Power amplifier section

Outputs Speaker outputs

(sure seal connectors)

Speaker impedance 4 – 8 ohms

Maximum power output 45 W × 4 (at 4 ohms)

SERVICE NOTE

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

General

Outputs Audio outputs (2)

Power aerial relay

control lead

Power amplifier control

lead

Intputs Telephone ATT control

lead

Illumination control lead

Bus audio input connector

Bus control input

Power requirements 12 V DC car battery

(negative ground)

Dimensions Approx. 178 × 100 × 181 mm

(w/h/d)

Mounting dimension Approx. 178 × 100 × 160 mm

(w/h/d)

Mass Approx. 2.2 kg

Supplied accessories Parts for installation and

connections (1 set)

Dummy cover (1)

Design and specifications are subject to change without

notice.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

NOTES ON PICK-UP FLEXIBLE BOARD

The pick-up flexible board in this set is secured to the optical pickup with an adhesive tape. Once the tape is removed, an adhering

force becomes weak, and it cannot be reused.

Therefore, if the optical pick-up is replaced, replace also the pickup flexible board with a new one.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

P ART NUMBERS APPEAR AS SHOWN IN THIS MANU AL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

Page 3

TABLE OF CONTENTS

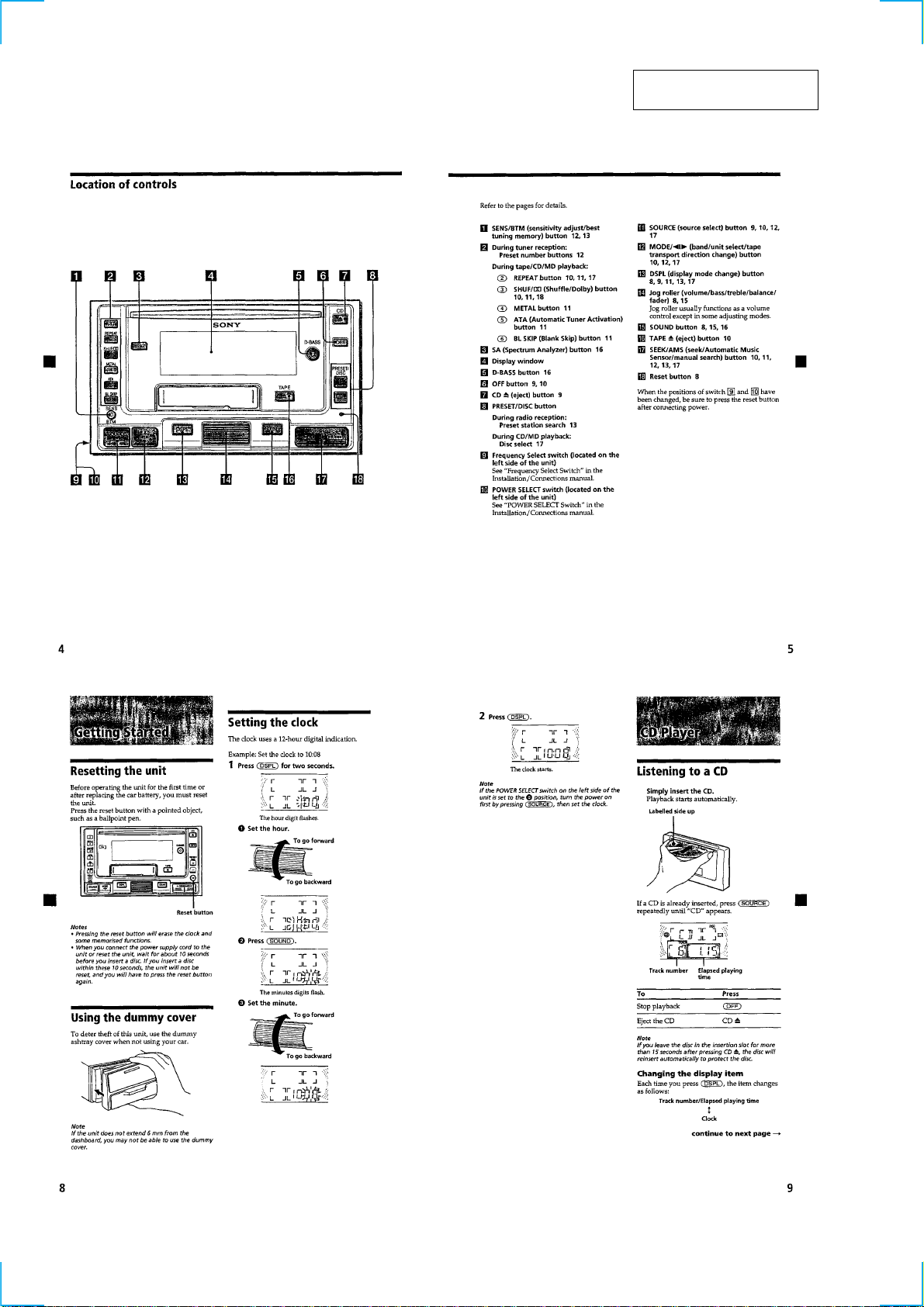

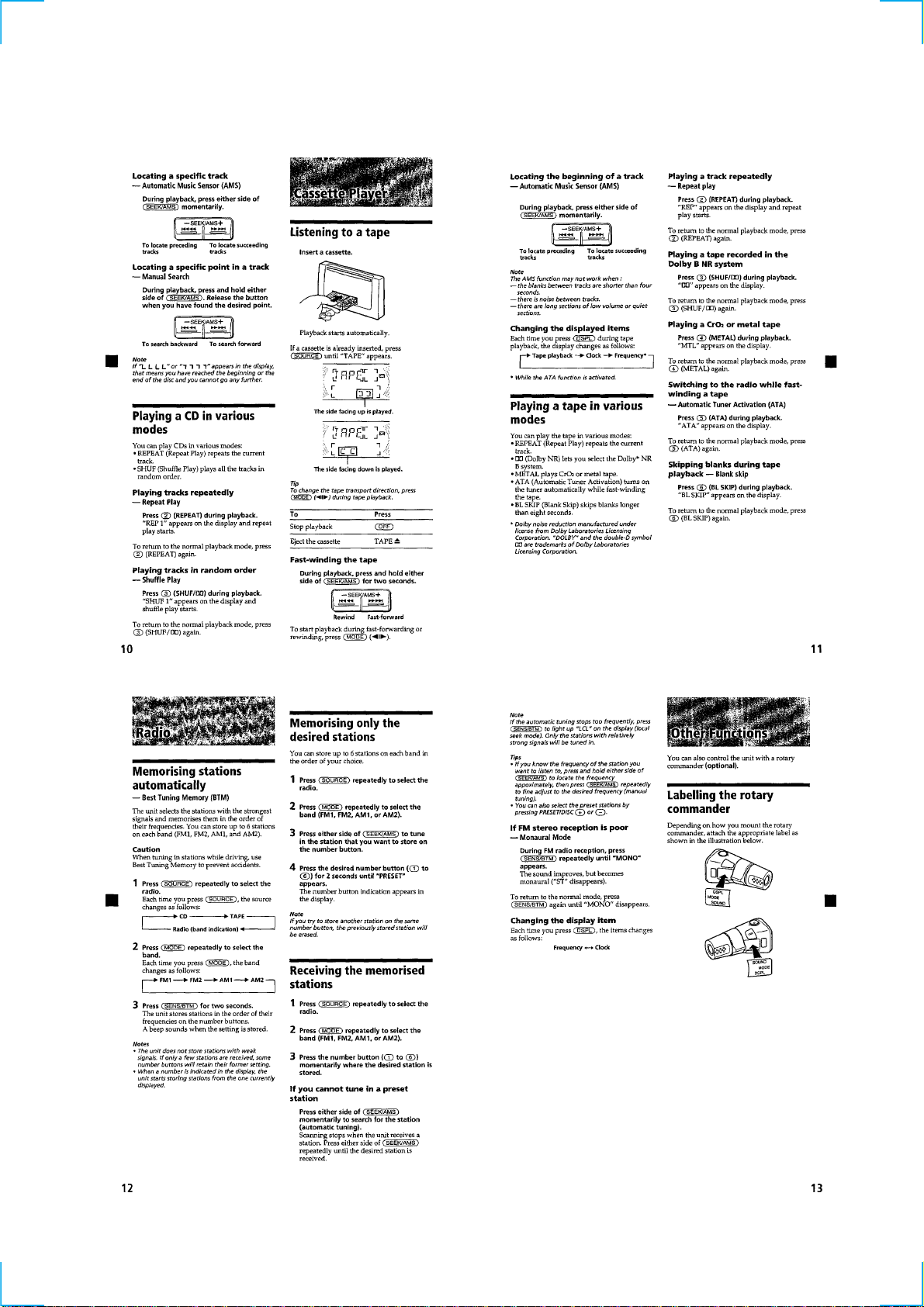

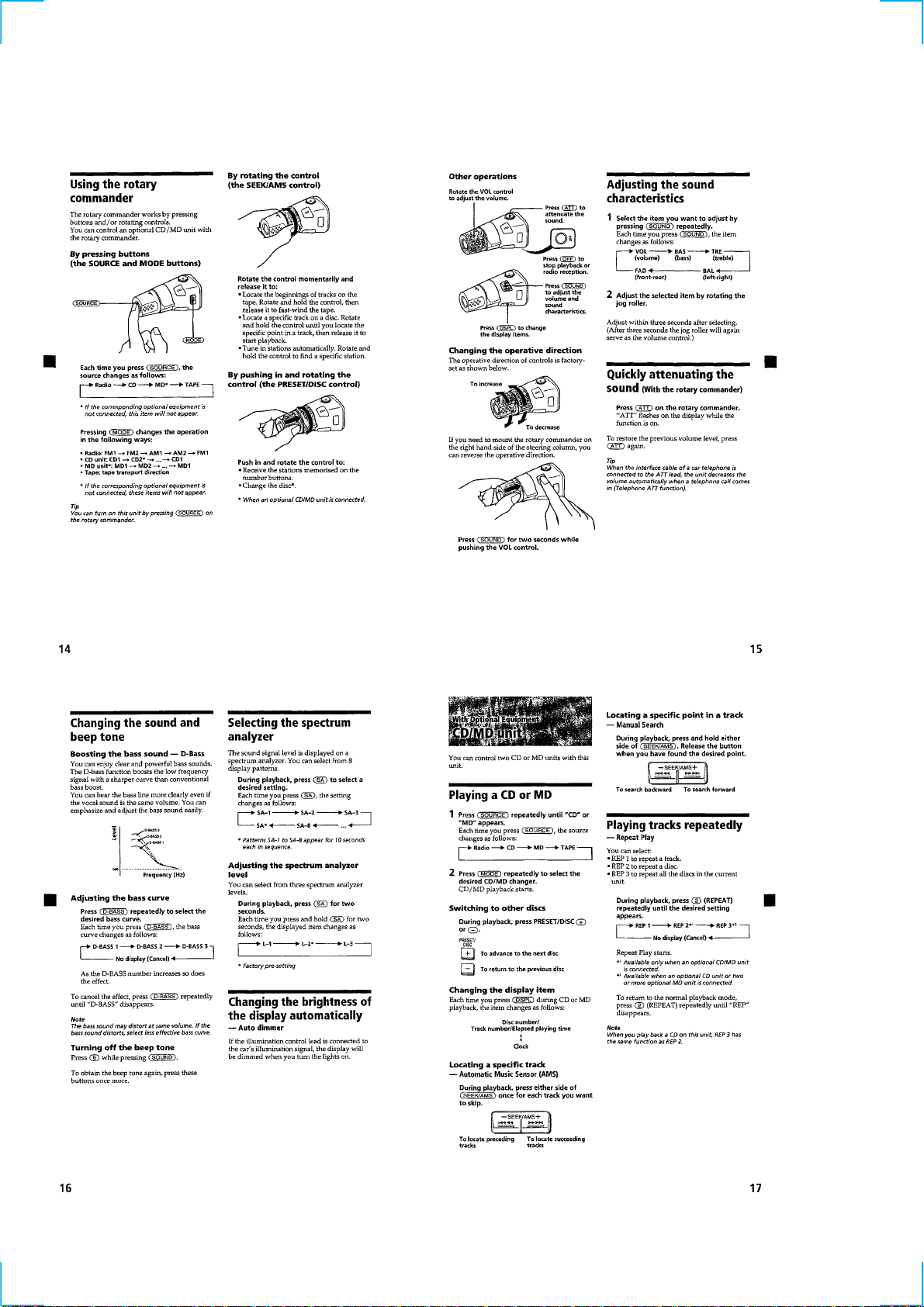

1. GENERAL

Location of Controls............................................................... 4

Getting Started........................................................................ 4

CD Player ............................................................................... 4

Cassette Player ....................................................................... 5

Radio ...................................................................................... 5

Other Functions ...................................................................... 5

CD/MD Unit ........................................................................... 6

Additional Information ........................................................... 7

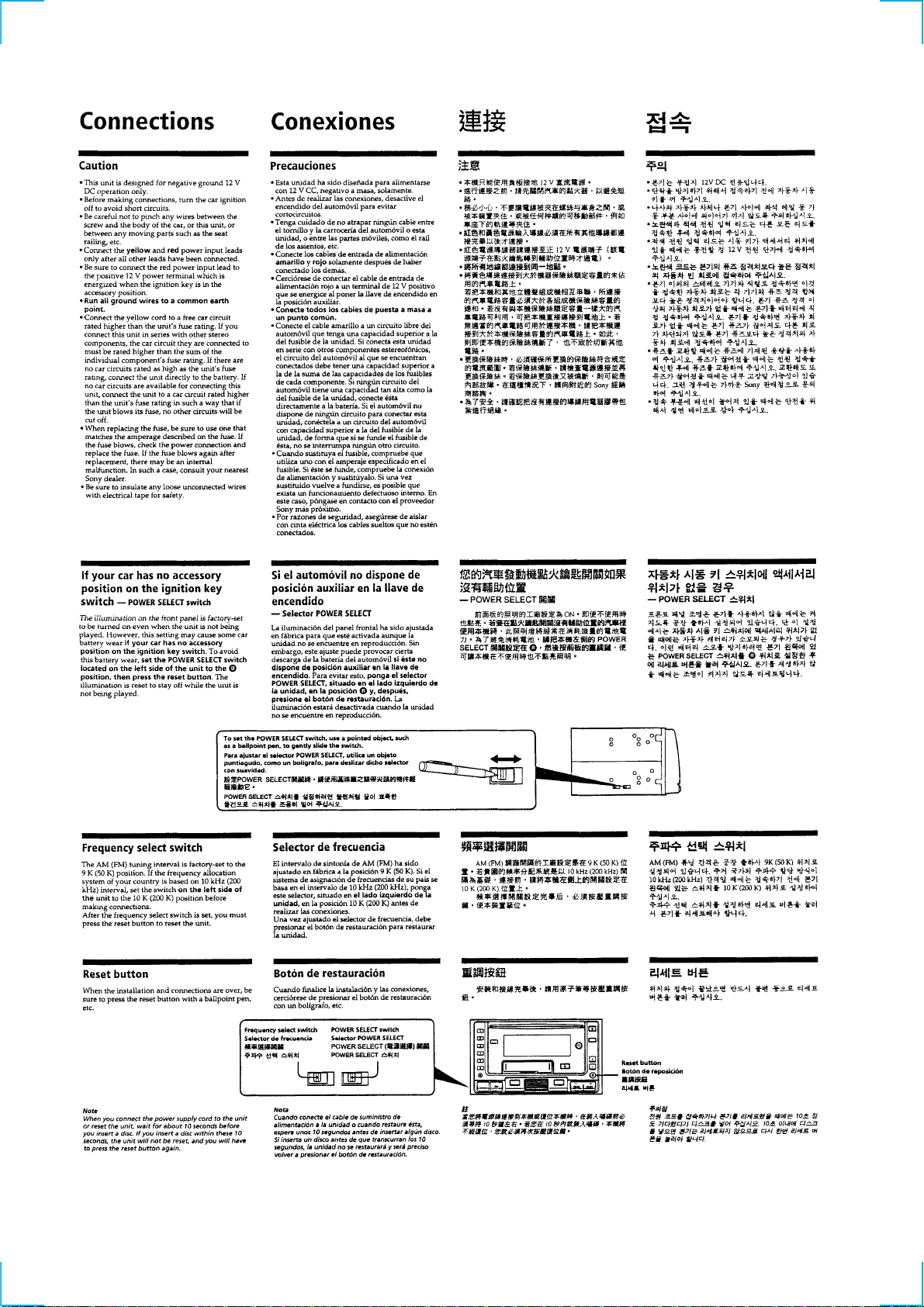

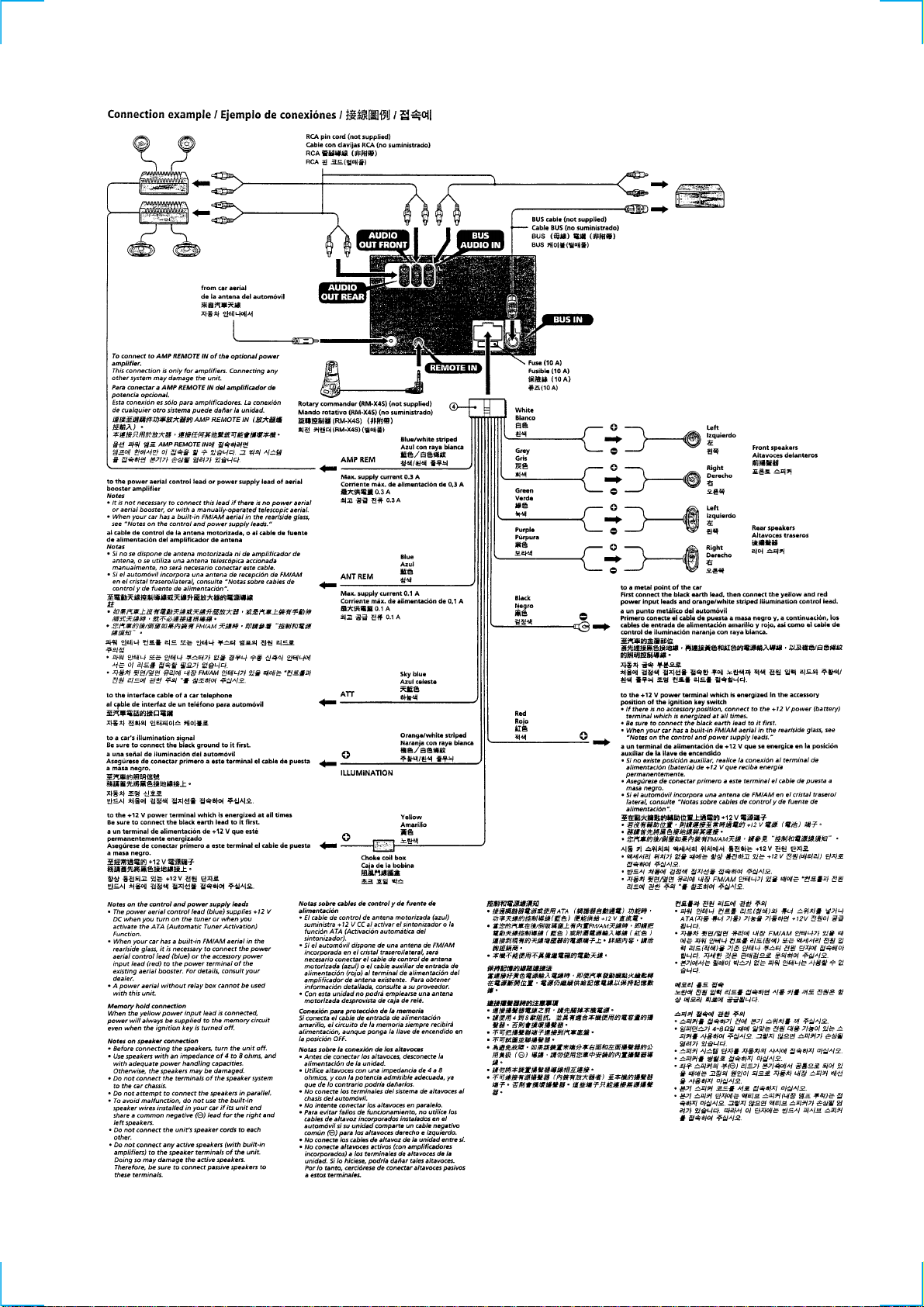

Connections ............................................................................ 8

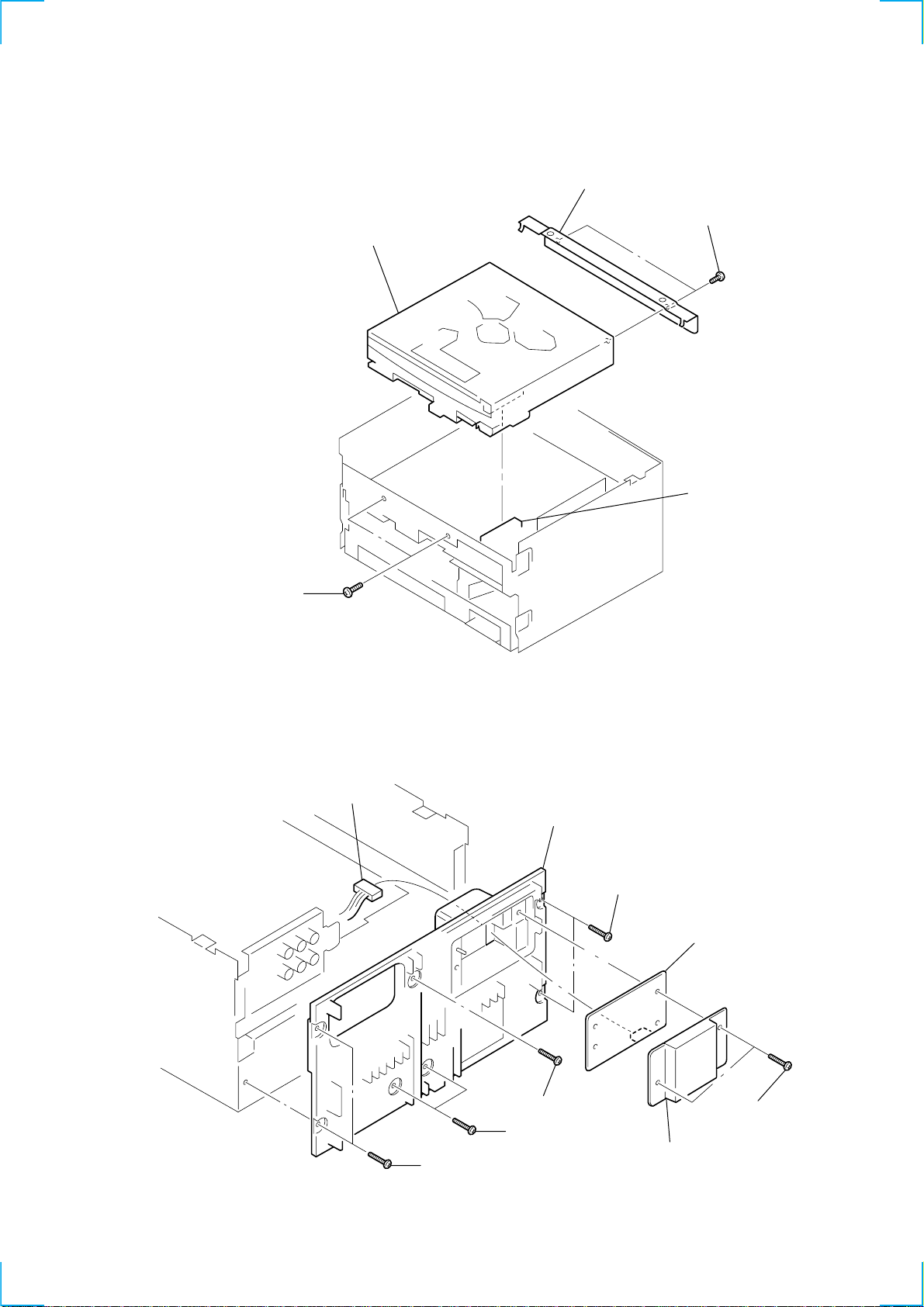

2. DISASSEMBLY

2-1. Cover ................................................................................ 10

2-2. Front Panel Assy .............................................................. 10

2-3. CD Mechanism Block ...................................................... 11

2-4. TR Board, Heat Sink ........................................................ 11

2-5. CD Board ......................................................................... 12

2-6. Chassis (U) ....................................................................... 12

2-7. Tape Mechanism Block .................................................... 13

2-8. Main Board ...................................................................... 13

2-9. Chassis (TM) Assy ........................................................... 14

2-10. Sensor Board .................................................................... 14

2-11. Servo Board...................................................................... 15

2-12. Roller Assy....................................................................... 15

2-13. Chassis (OP) (O/S) Assy .................................................. 16

2-14. Optical Pick-up Block ...................................................... 16

3. ASSEMBLY OF MECHANISM DECK

3-1. Housing ............................................................................ 17

3-2. Arm (Suction)................................................................... 17

3-3. Lever (LDG-A)/(LDG-B) ................................................ 18

3-4. Gear (Loading FT) ........................................................... 18

3-5. Guide (C).......................................................................... 19

3-6. Capstan/Reel Motor (M904) ............................................ 19

4. MECHANICAL ADJUSTMENTS.............................. 20

5. ELECTRICAL ADJUSTMENTS

Tape Section ......................................................................... 21

Tuner Section........................................................................ 21

CD Section ........................................................................... 24

6. DIAGRAMS

6-1. IC Pin Descriptions .......................................................... 25

6-2. Block Diagram –CD Section–.......................................... 29

6-3. Block Diagram –Tape Section– ....................................... 30

6-4. Block Diagram –Main Section–....................................... 31

6-5. Circuit Boards Location ................................................... 32

6-6. Printed Wiring Boards –CD Mechanism Section–........... 33

6-7. Schematic Diagram –CD Mechanism Section (1/2)– ...... 34

6-8. Schematic Diagram –CD Mechanism Section (2/2)– ...... 35

6-9. Printed Wiring Board –TR Section– ................................ 36

6-10. Schematic Diagram –TR Section– ................................... 36

6-11. Printed Wiring Board –CD Section–................................ 36

6-12. Schematic Diagram –CD Section–................................... 37

6-13. Printed Wiring Board –Main Section– ............................. 38

6-14. Schematic Diagram –Main Section (1/4)– ....................... 40

6-15. Schematic Diagram –Main Section (2/4)– ....................... 41

6-16. Schematic Diagram –Main Section (3/4)– ....................... 42

6-17. Schematic Diagram –Main Section (4/4)– ....................... 43

6-18. Printed Wiring Board –Control Section– ......................... 44

6-19. Schematic Diagram –Control Section– ............................ 46

6-20. Printed Wiring Board –Jog Section–................................ 47

6-21. Schematic Diagram –Jog Section–................................... 47

7. EXPLODED VIEWS

7-1. Cover Section ................................................................... 53

7-2. Front Panel Section .......................................................... 54

7-3. Chassis Section ................................................................ 55

7-4. Tape Mechanism Section ................................................. 56

7-5. CD Mechanism Section (1) .............................................. 57

7-6. CD Mechanism Section (2) .............................................. 58

7-7. CD Mechanism Section (3) .............................................. 59

8. ELECTRICAL PARTS LIST ................................... 60

3

Page 4

SECTION 1

GENERAL

This section extracted from

instruction manual.

4

Page 5

56789

Page 6

Page 7

Page 8

Page 9

Page 10

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

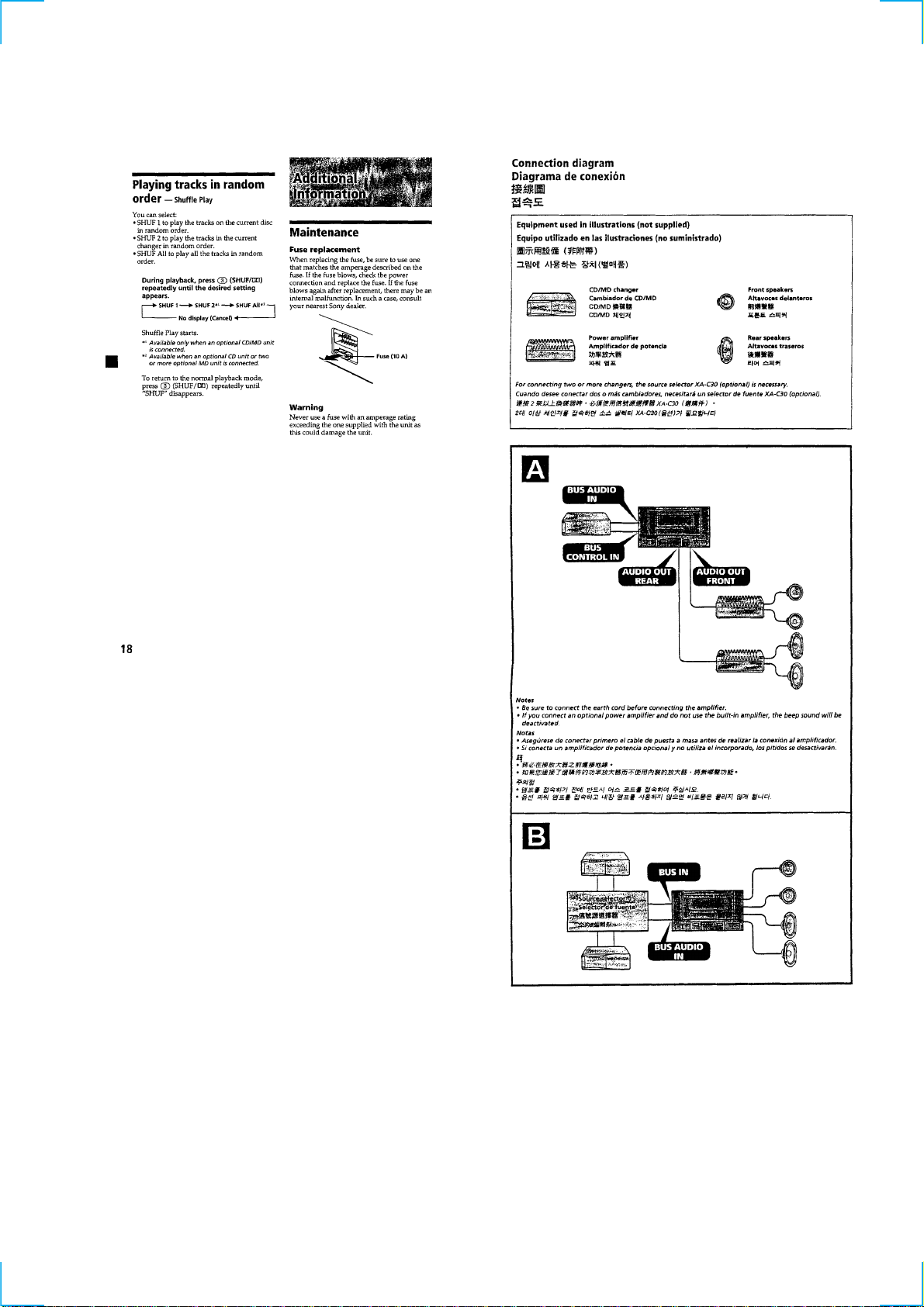

2-1. COVER

2 claws

1 PTT 2.6x5

3 cover

2-2. FRONT PANEL ASSY

1 PTT 2.6x5

3 claw

8 front panel assy

7 CN501

5 CN801

4 claw

6 CN500

2 PTT 2.6x5

10

Page 11

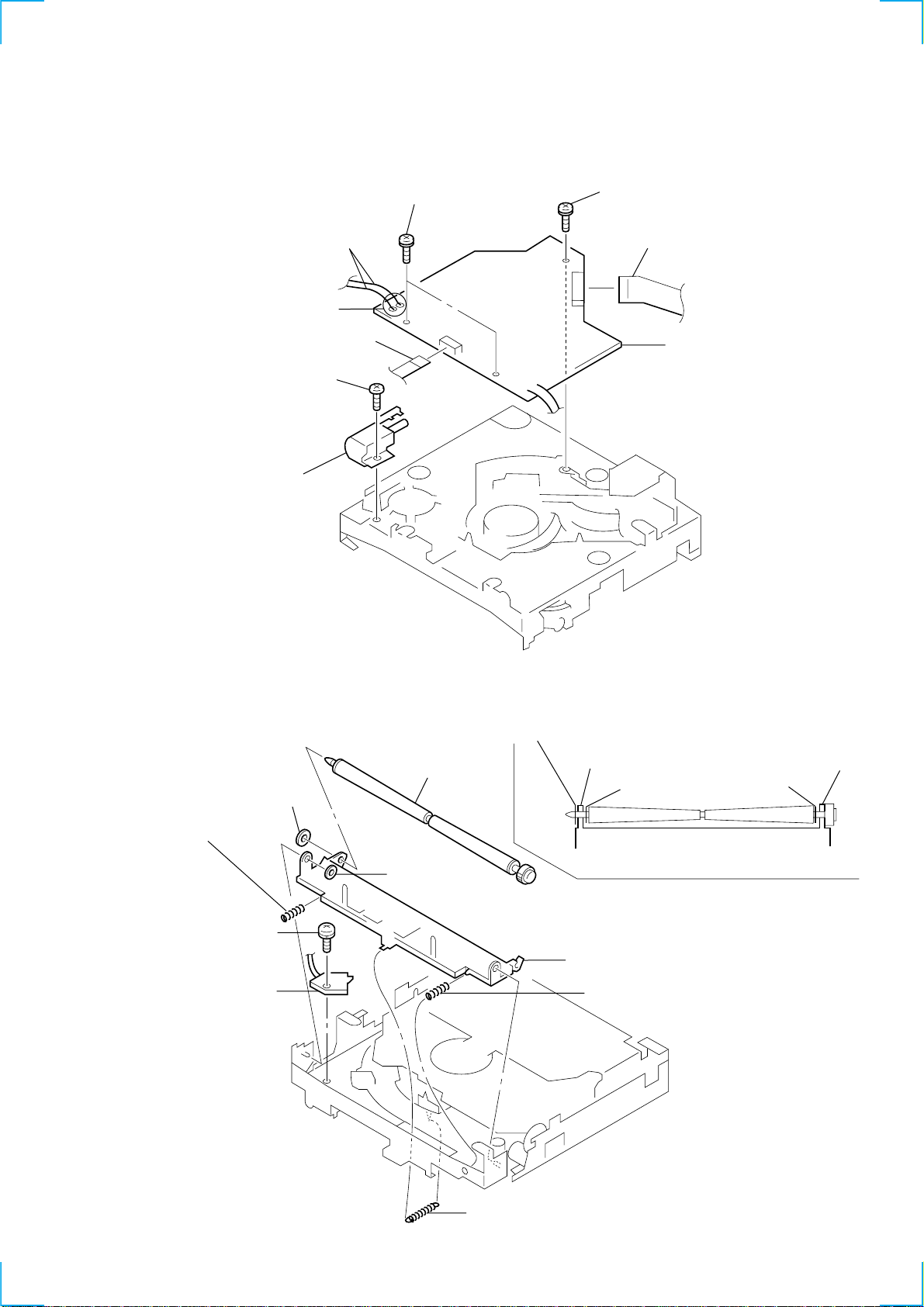

2-3. CD MECHANISM BLOCK

5 bracket (CD)

4 PTT 2.6x5

3 CD mechanism block

2 CN802

1 PTT 2.6x5

2-4. TR BOARD, HEAT SINK

4 CN901

9 heat sink

8 PTT 2.6x12

3 TR board

5 PTT 2.6x12

7 PTT 2.6x12

6 PTT 2.6x12

1 PTT 2.6x10

2 cover (D/D converter)

11

Page 12

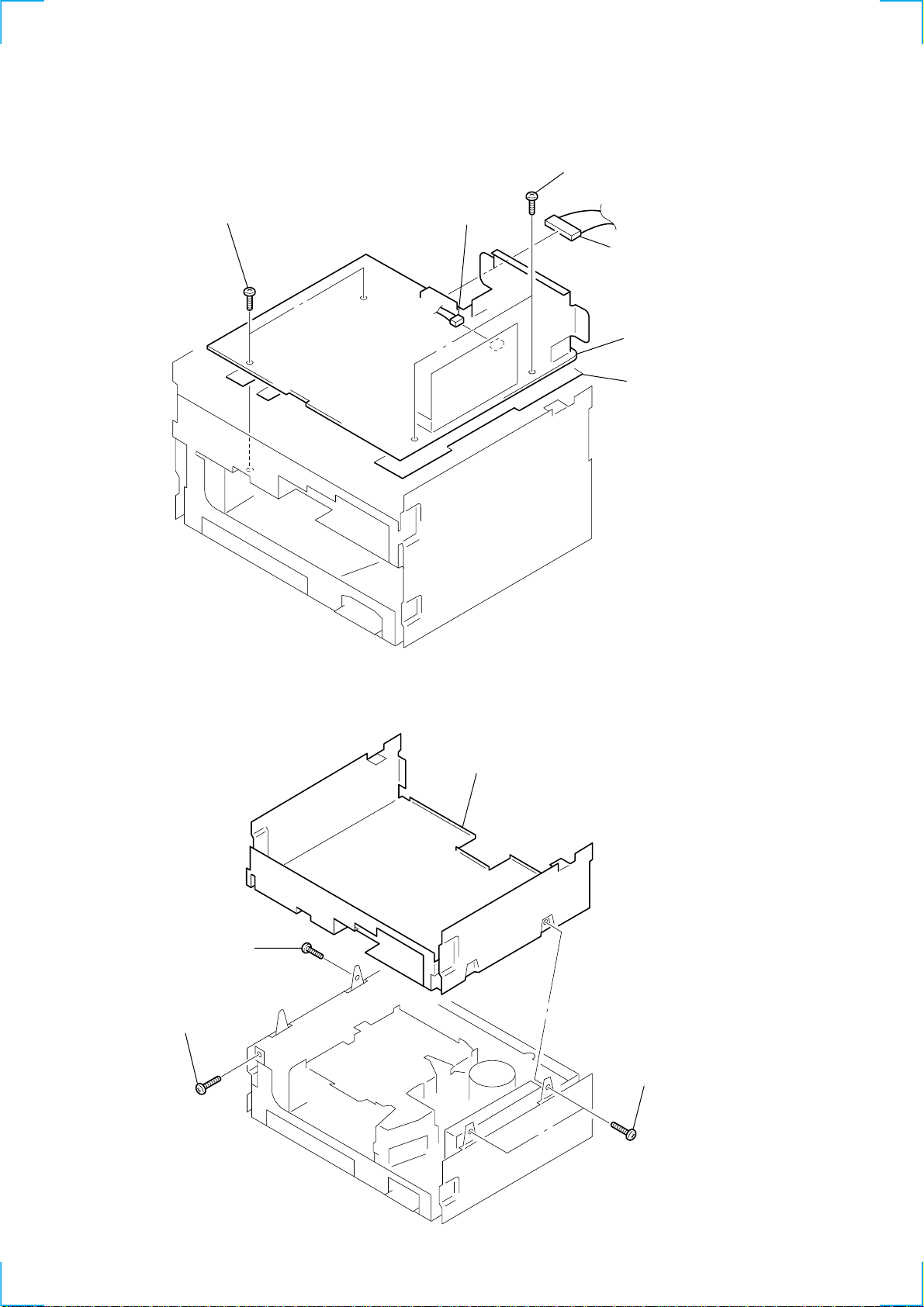

2-5. CD BOARD

ground point screw

4

(PTT2.6x6)

3 ground point screw

(PTT2.6x6)

1 CN803

2 CN402

5 CD board

6 insulating sheet (U)

2-6. CHASSIS (U)

4 chassis (U)

2 PTT 2.6x5

1 PTT 2.6x5

3 PTT 2.6x5

12

Page 13

2-7. TAPE MECHANISM BLOCK

5 tape mechanism block

3 CN600

2 PTT 2.6x5

4 CN300

1 PTT 2.6x5

2-8. MAIN BOARD

ground point screw

1

(PTT2.6x6)

ground point screw

2

(PTT2.6x6)

3 MAIN board

4 insulating sheet (L)

13

Page 14

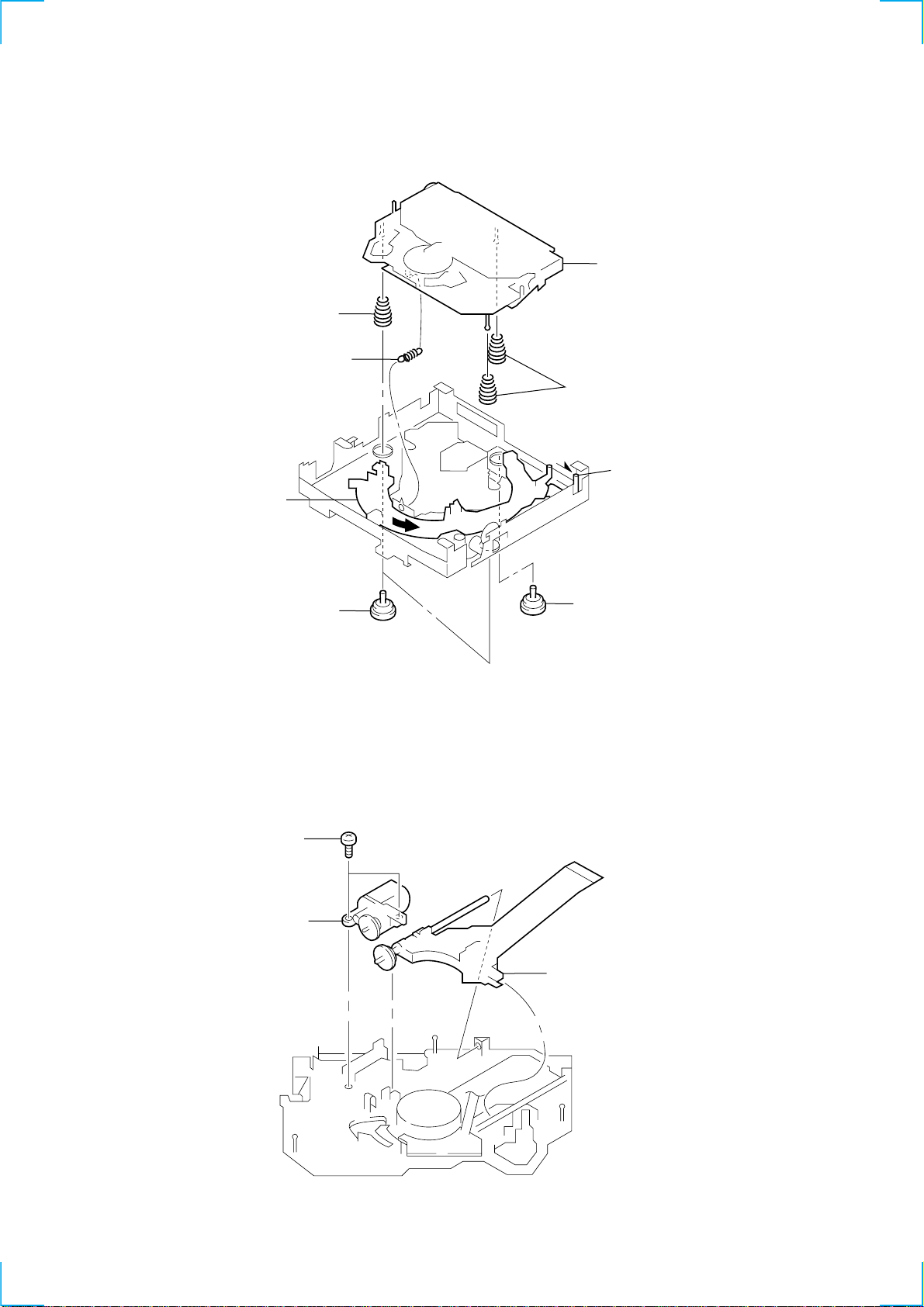

2-9. CHASSIS (TM) ASSY

1 P 2x3

6 chassis (TM) assy

2 P 2x3

3 P 2x3

4 claw

5 CN4

2-10. SENSOR BOARD

1 claw

3 guide (DISC M)

2 claw

4 PS 2x3

5 SENSOR board

14

Page 15

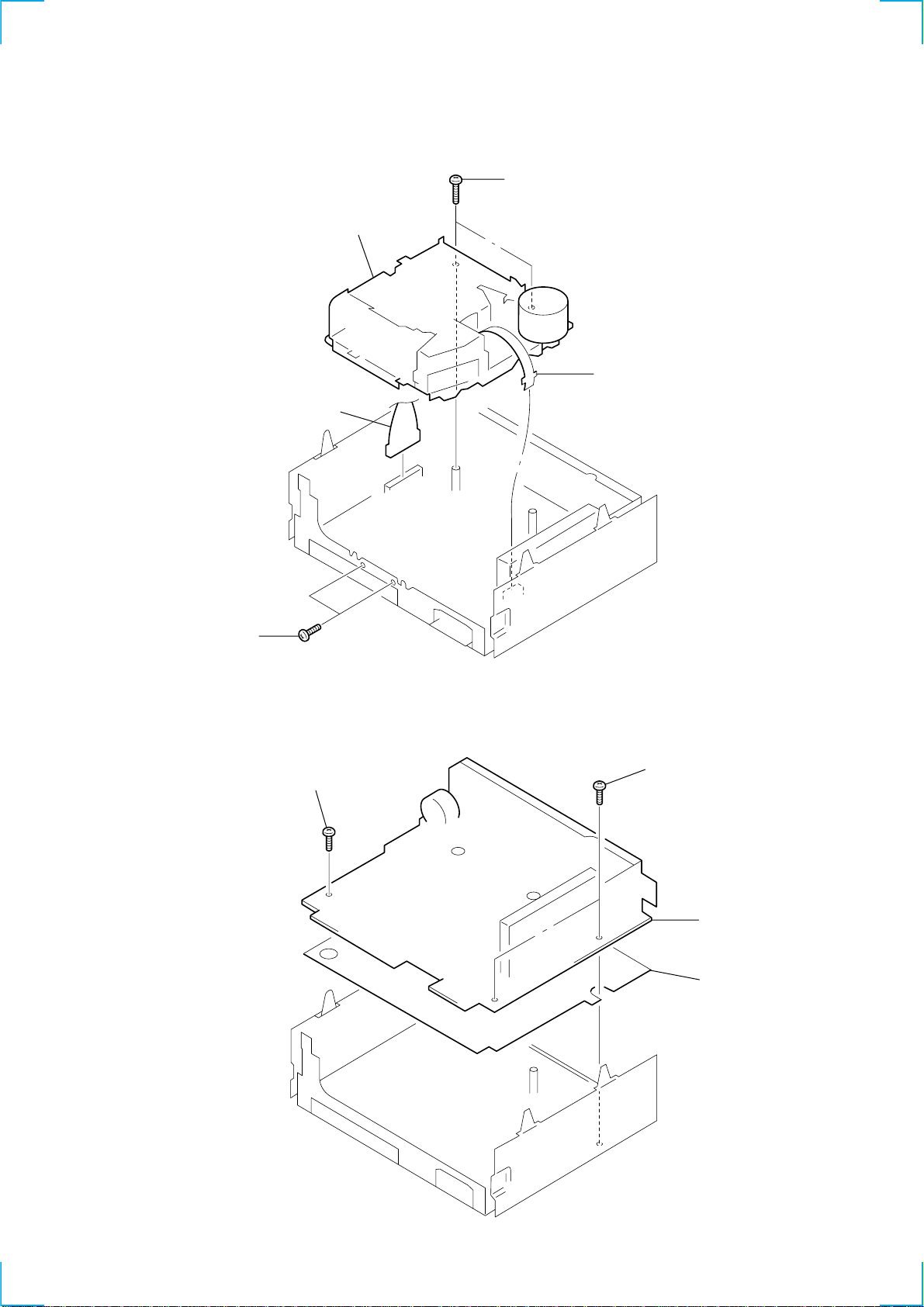

2-11. SERVO BOARD

6

loading motor assy

3

Removal the

two solders.

5

P 2x3

1

4

wires

CN3

7

PS 2x5

8

PS 2x5

2

CN2

9

SERVO board

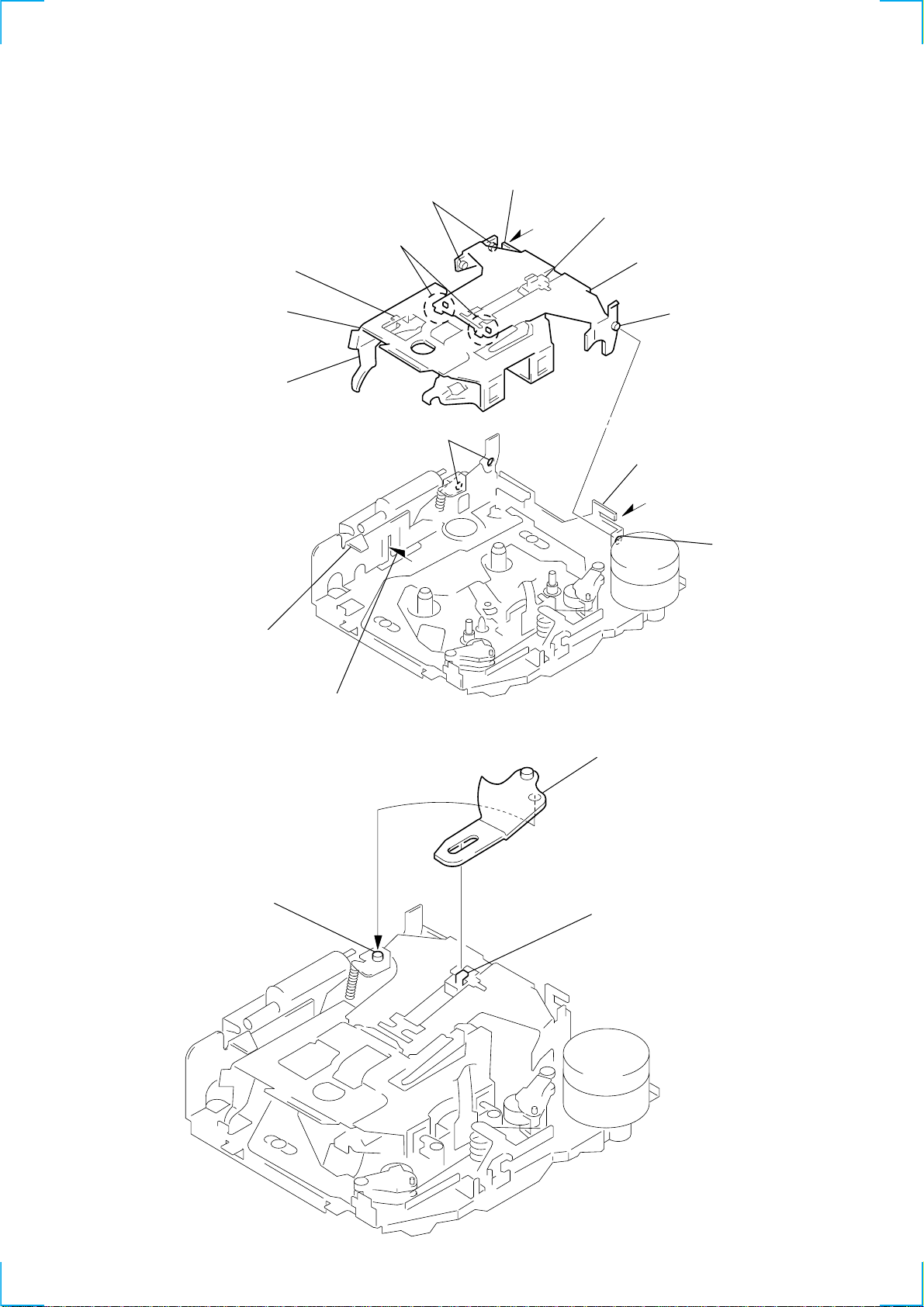

2-12. ROLLER ASSY

• When installing, take note of the positions

arm (roller) and washers. (Fig. 1)

6 retaining ring (roller)

3 compression spring (RA-L)

8 PS 2x3

9 LOAD board

7 roller assy

4 washer

retaining ring (roller)

arm (roller)

5 arm (roller)

2 compression spring (RA-R)

arm (roller)

washer washer

Fig. 1

1 tension spring (RA-E)

15

Page 16

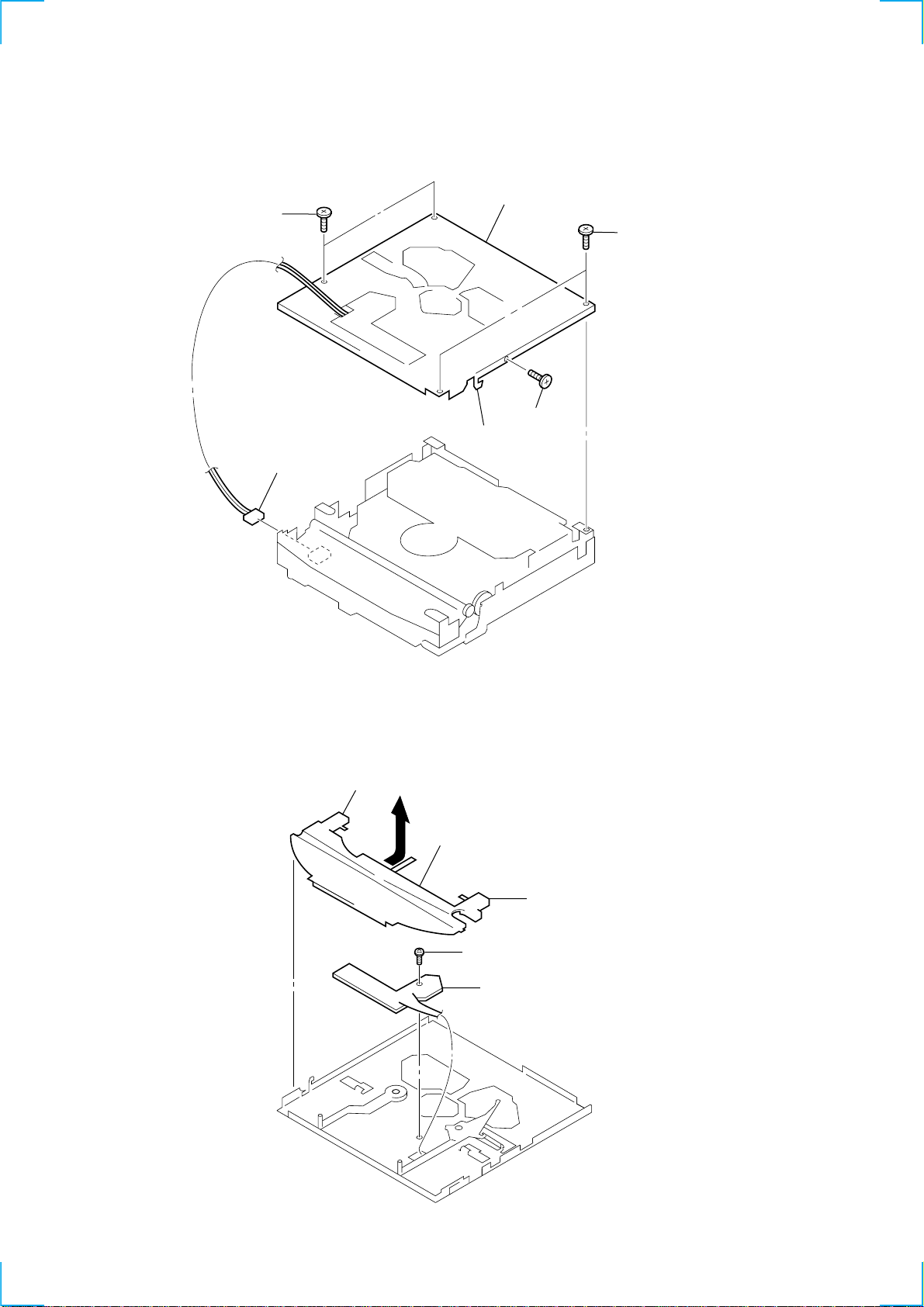

2-13. CHASSIS (OP) (O/S) ASSY

8 compression spring (FL)

1 tension spring (KF8)

5 Turn loading ring in the

direction of the arrow.

6 chassis (OP) (O/S) assy

7 compression spring (FL)

4 Fit lever (D) in the

direction of the arrow.

2 damper (T)

2-14. OPTICAL PICK-UP BLOCK

1 P 2x3

2 sled motor assy

3 damper (T)

3 optical pick-up block

16

Page 17

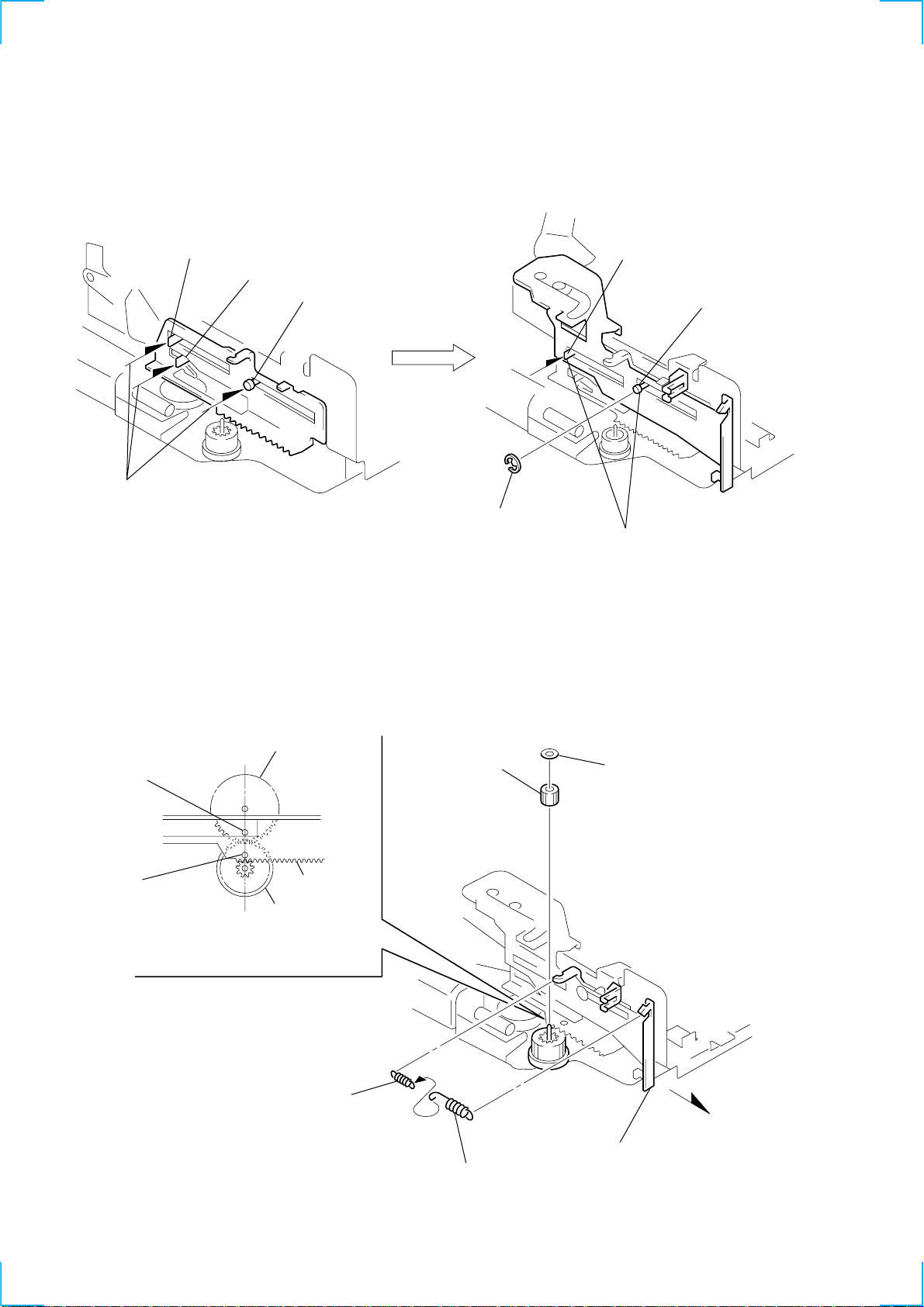

SECTION 3

ASSEMBLY OF MECHANISM DECK

Note : Follow the assembly procedure in the numerical order given.

3-1. HOUSING

4 Fit claw on B part.

3 Put the housing

under A part.

housing

5 Fit projection on C part.

2 Install the hanger onto

two claws of the housing.

7 Holder the hanger by bending the claw.

1 Install the catcher to the hanger.

hanger

6 Fit projection on D part.

C part

8 Hold the hanger by

bending the claw.

D part

3-2. ARM (SUCTION)

projection

A part

B part

2 Move the arm (suction) in the arrow

Direction and fit on projection.

1 Fit the arm (suction) on the shaft.

17

Page 18

3-3. LEVER (LDG-A) / (LDG-B)

shaft A

1 Fit the lever (LDG-A) on

shafts A to C and install it.

3-4. GEAR (LOADING FT)

shaft B

shaft C

shaft A

shaft B

3 type-E stop ring 2.0

2 Fit the lever (LDG-B) on

shafts A and B and install it.

hole

hole

4 Align hole in the gear (LDG-D)

with hole the lever (LDG-A).

2 tension spring (LD-2)

gear (LDG-D)

lever (LDG-A)

gear (LDG-FB)

5 gear (loading FT)

1

2 tension spring (LD-1)

6 polyethylene washer

3 Move the lever (LDG-B)

in the arrow direction.

18

Page 19

3-5. GUIDE (C)

2 guide (C)

1 claws

3-6. CAPSTAN / REEL MOTOR (M904)

3 belt (25)

2 precision screws P 2x3

1 main motor assy

(CAPSTAN/REEL) (M904)

30°

19

Page 20

SECTION 4

MECHANICAL ADJUSTMENTS

SECTION 5

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Wipe the following components with an absorbent cotton cloth

moistened with alcohol before adjustment :

PB head Pinch roller

Idler Rubber belt

Capstan

2. Demagnetize the PB head using a head demagnetizer.

3. Be careful not to use a magnetized screwdriver.

4. After the adjustment is completed, lock the adjustment parts

using screws.

5. Unless otherwise specified, make adjustments at the specified

voltage (14.4 V).

Torque Measurement

Mode Torque Meter Meter Reading

2.95 – 6.37 mN • m

FWD (30 – 65 g • cm)

CQ-102C

FWD

Back T ension

REV (30 – 65 g • cm)

CQ-102RC

REV

Back T ension

FF, REW CQ-201B (60 – 200 g • cm)

(0.42 – 0.90 oz • inch)

0.05 – 0.44 mN • m

(0.5 – 4.5 g • cm)

(0.01 – 0.06 oz • inch)

2.95 – 6.37 mN • m

(0.42 – 0.90 oz • inch)

0.05 – 0.44 mN • m

(0.5 – 4.5 g • cm)

(0.01 – 0.06 oz • inch)

5.89 – 19.61 mN • m

(0.83 – 2.78 oz • inch)

TEST MODE

This set have the test mode function. In the test mode, FM Auto

Scan/Stop Level and AM Auto Scan/Stop Le vel adjustments can be

performed easier than it in ordinary procedure.

<Set the Test Mode>

1. Turn ON the regulated power supply to ACC and BATT

terminals is “OFF” position (display 1:00).

2. Push the preset 4 button.

3. Push the preset 5 button.

4. Press the preset 1 button for more than two seconds.

5. Then the display and LED on the front panel indicates all lights,

the test mode is set.

<Release the Test Mode>

1. Push the OFF button.

T ape T ension Measurement

Mode Tension Meter Meter Reading

FWD CQ-403A

REV CQ-403R

882.60 mN

(more than 90 g)

(more than 3.17 oz)

20

Page 21

See the adjustment location from on page 23 for the

adjustment.

TAPE SECTION

0 dB = 0.775 V

Tape Speed Adjustment

Procedure :

1. Put the set into the FWD PB mode.

test tape

WS-48A

(3 kHz, 0 dB)

set

AUDIO OUT REAR

frequency counter

10 kΩ

TUNER SECTION

0 dB = 1 µV

Cautions during repair

When the tuner unit is defective, replace it by a new one because

its internal block is difficult to repair.

Note on Adjustment

The adjustments of tuner section, should be performed according

to the following sequence.

1. FM Auto Scan/Stop Level Adjustment

2. FM Stereo Separation Adjustment

3. AM Auto Scan/Stop Level Adjustment

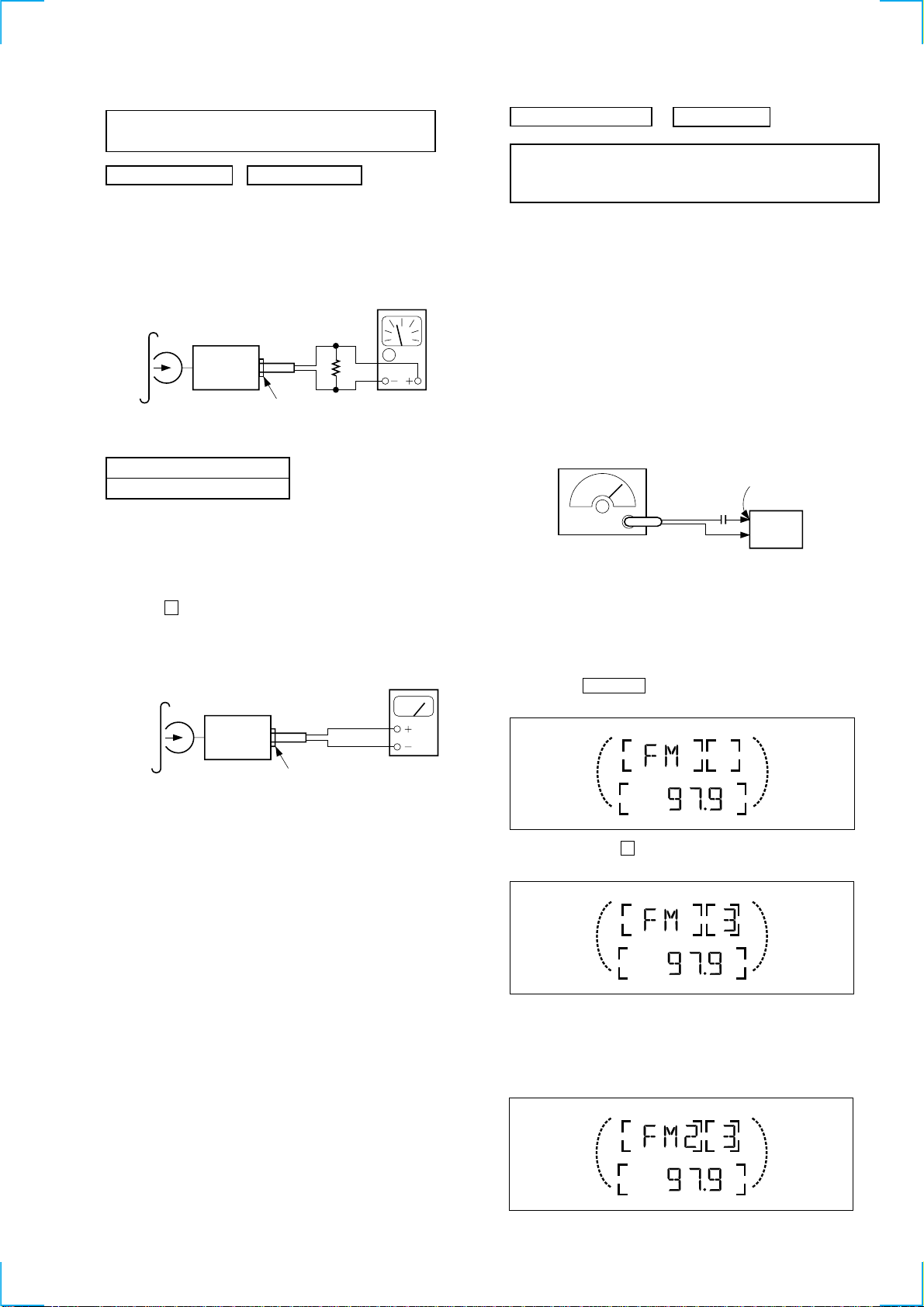

FM Auto Scan/Stop Level Adjustment

Setting :

SOURCE button : FM

FREQUENCY SELECT switch : FM 200k

Specification : Constant speed

Frequency counter

3,010 to 3,030 Hz

Adjustment Location : Capstan motor internal volume

(See page 23)

DOLBY Level Adjustment

Setting :

Preset 3 (SHUF/;) button : Light down mark ;

(DOLBY OFF)

test tape

P-4-D400

(400 Hz, 0 dB)

set

main board

TP-L

TP-R

level meter

Procedure :

1. Put the set into the FWD PB mode.

2. Adjust RV100 (L-CH) and RV200 (R-CH) on main board so

that level meter reading is – 6 ± 0.5 dB (0.37 to 0.41 V).

Adjustment Location : See page 23.

FM RF signal

generator

antenna

0.01 µF

Carrier frequency : 97.9 MHz

Output level : 22 dB (12.6 µV)

Mode : mono

Modulation : 1 kHz, 22.5 kHz deviation (30%)

terminal

Procedure :

1. Set to the test mode.

2. Push the SOURCE button and set to FM.

Display

SHUF1

3. Push the preset 3 button.

Display

PRESET

SHUF1

set

4. Adjust with the volume RV2 on TU1 so that the “FM”

indication turns to “2” indication on the display window.

But, in case of already indicated “2”, turn the RV2 so that put

out light “2” indication and adjustment.

Display

PRESET

SHUF1

Adjustment Location : See page 23.

21

Page 22

FM Stereo Separation Adjustment

Setting :

SOURCE button : FM

FREQUENCY SELECT switch : FM 200k

FM RF signal

generator

0.01 µF

Carrier frequency : 97.9 MHz

Output level : 70 dB (3.2 mV)

Mode : stereo

Modulation : main :1 kHz, 33.75 kHz deviation (45%)

sub :1 kHz, 33.75 kHz deviation (45%)

19 kHz pilot : 7.5 kHz deviation (10%)

antenna

terminal

set

AUDIO OUT REAR

level meter

10 kΩ

AM Auto Scan/Stop Level Adjustment

Note : This adjustment should be performed after the FM Auto

Scan / Stop Level Adjustment is done.

Setting :

SOURCE t MODE button : AM

FREQUENCY SELECT switch : AM 10k

15 pF

30 Ω

65 pF

AM RF signal

generator

AM dummy

antenna (50 Ω)

set

set

Procedure :

FM stereo

signal generator

output channel

Level meter Level meter

connection reading (dB)

L-CH L-CH A

R-CH L-CH Adjust RV4 on TU1 for

maximum reading.

R-CH R-CH C

L-CH R-CH Adjust RV4 on TU1 for

maximum reading.

L-CH stereo separation : A – B

R-CH stereo separation : C – D

The separations of both channels should be equal.

Specification : Separation more than 28 dB

Adjustment Location : See page 23.

B

D

Carrier frequency : 1000 kHz

Output level : 30 dB (44.7 µV)

Mode : mono

Modulation : 1 kHz, 22.5 kHz deviation (30%)

Procedure :

1. Set to the test mode. (See page 20.)

2. Push the SOURCE button.

3. Push the MODE button and set to AM.

Display

SHUF1

4. Push the preset 3 button.

Display

PRESET

SHUF1

antenna

terminal

22

5. Adjust with the volume RV1 on TU1 so that the “AM”

indication turns to “2” indication on the display window. But,

in case of already indicated “2”, turn the RV1 so that put out

light “2” indication and adjustment.

Display

PRESET

SHUF1

Adjustment Location : See page 23.

Page 23

J

Adjustment Location :

– set lower view –

DOLBY

LEVEL

ADJ

RV200

(R-CH)

RV100

(L-CH)

– set upper view –

TP-R

DOLBY LEVEL

TP-L

TAPE SPEED ADJ

TU1

ADJ

RV1 AM AUTO SCAN/STOP LEVEL AD

RV2 FM AUTO SCAN/STOP LEVEL ADJ

RV200 (R-CH) DOLBY LEVEL ADJ

RV4 FM STEREO SEPARATION ADJ

RV100 (L-CH) DOLBY LEVEL ADJ

23

Page 24

CD SECTION

Note :

1. CD Block basically constructed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use the oscilloscope with more than 10 MΩ impedance.

4. Clean an objective lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

Focus Bias Adjustment

Setting :This adjustment is performed with the set placed

horizontally.

oscilloscope

(DC range)

servo board

TP (RF)

TP (RF GND)

Procedure :

1. Connect an oscilloscope between TP (RF) and TP (RF GND)

on the servo board.

2. Connect the power supply.

3. Push the RESET button (SW701) on the control board.

4. Insert the disc (YEDS-18) and playback.

5. Adjust RV1 so tha t the oscilloscope waveform is clear and check

RF signal level is correct or not.

Note : Clear RF signal waveform means that the sharp “ ” can be

clearly distinguished at the center of the waveform.

Focus Gain Adjustment (Coarse adjustment)

This adjustment is not required unless the following parts are

replaced:

• Optical pick-up

•RV4

Procedure :

1. Set RV4 to the standard position. (mechanical center)

2. Check whether operation noise (while noise type) caused by

the 2-axis device (lens section of the optical pick-up) is

abnormally loud.

If the operation noise is too loud, turn RV4 slightly counterclockwise.

• If the gain is too low :

Focus does not function and no music is selected.

• If the gain is too high :

Noise caused by scratches and dust is heard and the operation

becomes unstable.

Adjustment Location : servo board (component side)

FOCUS GAIN ADJ

RV4

IC3

CN2

RF signal waveform

VOLT/DIV : 200 mV

TIME/DIV : 500 nS

RF level :

1.0 – 1.5 Vp-p

• When observing the eye pattern, set the oscilloscope to A C range

and raise the vertical sensitivity so that it may be easily seen.

CN1

IC1

TP

(RF GND)

IC2

TP

(RF)

CN3

RV1

FOCUS BIAS ADJ

24

Page 25

SECTION 6

DIAGRAMS

6-1. IC PIN DESCRIPTIONS

• IC500 µPD78058GC-B51-8BT (SYSTEM CONTROL)

Pin No. Pin Name I/O Pin Description

1 VSM I FM, AM common signal meter A/D conversion input

2 NIL I Not used. (Connect to ground in this set.)

3 SD-IN I Station detecter input (“H” : with SD)

4 AVSS — Analog ground

5 FM-ST I FM stereo input pin (“L” : stereo)

6 AM-ST I AM stereo input pin (“L” : stereo)

7 AVREF — Reference power supply for D/A conversion.

8 PLL-SI I PLL serial data input

9 PLL-SO O PLL serial data output

10 PLL-CKO O PLL serial clock output

11 PLL-CE O PLL serial chip enable output

12 AMS I Music with/without detection input at AMS. (“L” : with music, “H” : without music)

13 PLAY/AMS O Tape AMS control output

14 F/R O FWD/REV detection output (“H” : FWD, “L” : REV)

15 MTL O Metal control output (“H” : metal)

16 BUS-SI I Uni-link serial interface data input

17 BUS-SO O Uni-link serial interface data output

18 BUS-CKI I Uni-link serial interface clock input

19 BUS-CKO O Uni-link serial interface clock output

20 TAPE-MUTE O Tape mute control output

21 DOLON I/O Dolby control input/output

22 EQ-CE O Equalizer serial chip enable output (Not used in this set.)

23 EQ-CLK O Equalizer serial clock output (Not used in this set.)

24 DATA O Serial data output

25 VOL-CLK O Electronic volume serial clock output

26 VOL-CE O Electronic volume serial chip enable output

27 MUT O System mute control output

28 AMP-ON O Power amplifier power supply control output

29 AUX-MUT O AUX mute control output

30 C/B I/O Dolby B/C select control output (Not used in this set.)

31 PWR-SEL I Power select initial setting input

32 TEST I Test mode setting input

33 VSS — Ground

34 NIL I Not used. (Connect to ground in this set.)

35 POWER-ON O System power supply control output

36 TUN-ON O Tuner power supply control output

37 FM-ON O FM power supply control output

38 AM-ON O AM power supply control output (Not used in this set.)

39 NIL I Not used. (Connect to ground in this set.)

40 CM-ON O Capstan motor control output

41 TP-ON O Tape power supply control output

42 LM-EJ O Loading motor control output (Eject direction)

43 LM-LOD O Loading motor control output (Loading direction)

44, 45 POS1, 0 I Position signal detection input 1, 0

46 BEEP O Buzzer control output

47, 48 POS2, 3 I Position signal detection input 2, 3

49 REL I Reel stand rotation detection input

50 RC-IN1 I Rotary commander A/D conversion input 1

51 SUB-CE O Sub serial chip enable output (Not used in this set.)

52 SUB-DATA O Sub serial data output (Not used in this set.)

53 SUB-CLK O Sub serial clock output (Not used in this set.)

25

Page 26

Pin No. Pin Name I/O Pin Description

54 SYS-RST O System reset signal output

55 BUS-ON O Bus ON control output

56, 57 RE1, 0 I Rotary encoder input 1, 0

58 AD-ON O Power supply output for A/D conversion.

59 RAMBU I RAM reset detection input

60 RESET — Reset input

61 SIRCS I Remote control input (Not used in this set.)

62 BU-IN I Backup power detection input

63 NIL — Not used (Connect to ground in this set.)

64 ACC-IN I Accessory power supply detection input

65 DIMMER I Dimmer control input

66 TEL-MUTE I Telephone mute control input

67 KEY-ACK I Key input acknowledge

68 VDD — µ-con power supply

69 X2 O Main ceramic oscillator output (5 MHz)

70 X1 I Main ceramic oscillator input (5 MHz)

71 IC — Connect to ground in this set.

72 XT2 O Sub crystal oscillator output (32.768 kHz)

73 XT1 I Sub crystal oscillator input (32.768 kHz)

74 AVDD — Power supply for A/D conversion.

75 AVREF — Reference power supply for A/D conversion.

76, 77 KEY-IN0, 1 I Key input 0, 1

78 KEY-IN2 I Key input 2 (Not used in this set.)

79 RC-IN0 I Rotary commander A/D conversion input 0

80 DSTSEL I Initial setting input of destination.

26

Page 27

• IC801 µPD78054GC-A32-8BT (CD SYSTEM CONTROL)

Pin No. Pin Name I/O Pin Description

1 LEDCLK — Not used in this set.

2 LEDCKO — Not used in this set.

3 LEDSO — Not used in this set.

4 AVSS — Analog ground

5 FL-CE0 O Display driver chip select output 0

6 FL-CE1 O Display driver chip select output 1 (Not used in this set.)

7 AVREF1 — Reference power supply for D/A conversion.

8 FL-RST O Display driver reset output (Not used in this set.)

9 FL-SO O Display driver data output

10 FL-CKO O Display driver clock output

11 SRDT — Not used in this set.

12 NCO — Not used.

13 SCLK — Not used in this set.

14 FL-BLK O Display driver blank control output

15 NIL — Not used. (Connect to ground in this set.)

16 UNISI I Uni-link serial interface data input

17 UNISO O Uni-link serial interface data output

18 UNICKI I Uni-link serial interface clock input

19 LINKOFF O Link off output

20 ILLON O Illumination power supply control output

21 CMDON O CD mechanism power supply control output

22 CD-ON O CD power supply control output

23 SP-SEL O Signal (L/R channel) select control signal output to spectrum analyzer control IC.

24 SP-C O Frequency select control signal output to spectrum analyzer control IC.

25 SP-B O Frequency select control signal output to spectrum analyzer control IC.

26 SP-A O Frequency select control signal output to spectrum analyzer control IC.

27 CDMUT O CD mute control output

28 EMPH-O O Emphasis control output

29 CD-RST O CD signal process IC reset output

30 XMODE — Not used in this set.

31, 32 NIL — Not used. (Connect to ground in this set.)

33 VSS — Ground

34 TBTGSEL I CD tracking balance, tracking gain auto adjustment select input.

35 – 39 NIL — Not used. (Connect to ground in this set.)

40 GFS I GFS signal detection input

41 SQ-SI I SUB Q data input

42 SQ-CKO O SUB Q clock output

43 NIL — Not used. (Connect to ground in this set.)

44 CD-SO O CD signal process serial data output

45 CD-LAT O CD signal process latch output

46 CD-CKO O CD signal process serial clock output

47 PH2 I 8/12 cm disc detection input

48 F-OK I Focus signal detection input

49 LD-ON O Laser on/off select control output

50 D-SW I Down switch detection input

51 PH1 I Disc insert detection input

52 L-SW I Sled limit switch input

53 LM-LOD O Loading motor control output (Loading direction)

54 LM-EJ O Loading motor control output (Eject direction)

55 PH3 I Disc detect sensor input

56 CTL1 O Driver IC control output

57 NCO — Not used.

27

Page 28

Pin No. Pin Name I/O Pin Description

58 EESIO O Not used in this set.

59 EECKO O Not used in this set.

60 RESET — Reset input

61 SCOR I SCOR signal detection input

62 CNIN I Track jump count input

63 SELF-SW I Disc self store detection input

64 SENS I SENS signal detection input

65 DQSY — Not used in this set.

66 BUIN I Backup power supply detection input

67 BUSON I Bus on control input

68 VDD — µ-con power supply

69 X2 O Main ceramic oscillator output (5 MHz)

70 X1 I Main ceramic oscillator input (5 MHz)

71 IC — Not used. (Not used in this set.)

72 XT2 O Sub crystal oscillator output (Not used in this set.)

73 XT1 I Sub crystal oscillator input (Connect to ground in this set.)

74 AVDD — Power supply for A/D conversion.

75 AVREF — Reference power supply for A/D conversion.

76 NIL — Not used. (Connect to ground in this set.)

77 SP-IN I Spectrum analyzer control signal input from spectrum analyzer control IC.

78 TSTIN0 I LOAD/EJECT prohibition setting input

79 NCO — Not used.

80 LEDOE — Not used in this set.

28

Page 29

WX-C5000

MAIN

1

SECTION

(Page 31)

: CD

Signal path

IC801(1/2)

CD SYSTEM CONTROL

28 EMPHOD

27 CDMUT

DET

DISC IN

51

PH1

Q11,D12

DET

Q12,D11

DISC SIZE

47

PH255PH3

LOADING

COMPLETION

SCOR

GFS

40

61

Q13,D10

BATT

8V REG

Q851,852

MD8V

5V REG

Q853,854

SERVO 5V

Q807

22

CD ON

SQ SI42SQ CKO64SENS44SO

41

21

CMDON

Q803

CD

LAT46CKO

45

SW1

63

SELFSW

CDRST

29

(SELF)

F OK

48

CNIN

62

SW4

50

DSW

LDON

49

(DOWN)

LMLOD

53

LMEJ

54

52

LSW

SW3

(LIMIT)

CTL1

56

Q806

R-CH

9ROUT

12LOUT

IC401

D/A CONVERTER

DATA

CLKO

XTI

1

4 LRCK

5

6 BCK

19

21PCMD

20LRCK

22BCK

34XTAI

IC1

57 XLTO

14 RF

59 CLKO

56 DATO

DIGITAL SIGNAL PROCESSOR

IC2

RF AMP, SERVO CONTROL

50 XRST

31RFO

19CLK

20XLT

21DATA

22XRST

E

PD2

F

39

35 PD1

36

38

SERVO 5V

X401

17

EMPH

16.9MHz

55 CNIN

23

C. OUT

FE BIAS

37

RV1

Q804

18

MUTE

XTO

20

1FOK

3 MDP

54 SEIN

24SENS

25FOK

FEO

1

RV4

FOCUS BIAS

FEI

2

34 PD

FOCUS GAIN

29 29

43

27

GFS

SCOR

6FEO

16SLO

13TAO

LD DRIVE

33 LD

Q1,2

19CH1 IN

22CH2 IN

IC3

DRIVE, MOTOR DRIVE

FOCUS/TRACKING COIL

16 CH2+

15 CH2–

24CH3 IN

18 CH1+

3CH4 IN

17 CH1–

13 CH3+

M902

M

46

SQSO

14 CH3–

(SLED)

47

SQCK

49

51

SENS52DATA

12 CH4+

M

M901

XLAT

11 COM

(SPINDLE)

53

CLOK

M

M903

10 CH5+

(LOADING)

6FWD

4CTL1

7REV

5CTL2

04

I - V

AMP

KSS-521A

OPTICAL PICK-UP

6-2. BLOCK DIAGRAM — CD SECTION —

PD

LD

TRACKING

FOCUS

Page 30

MAIN

SECTION

(Page 31)

IC701

FL DRIVER

CE

98

5

CEO

)

2/2

(

IC801

CD SYSTEM CONTROL

IC802

SA CONTROL

3

SA

)

2/2

(

IC500

SYSTEM CONTROL

F/R

MTL

14

18

19

FWD/REV

MTL/NORMAL

IC300

TAPE EQ/DOLBY NR

32

FL701

FL

DRIVER

Q702-704

2

3

2GB

3GB

CL 1GB

BLK

DATA

99 1

97

100

9

14

SO

BLK

FL FL

SP IN CKO

17 77 10

AIN AOUT

8

DOL ON

211315

MAIN SECTION

TAPE L-CH

24

16

L OUT

NR ON

DOLBY

EQ

R-CH

ABCSEL

2

NR

FL+

11 12 1410

TAPE MUTE

20

(Page 31)

17

MUTE/TAPE

AMS OUT

AUTO

34

23

AMS

12

14

MUSIC

+3V REG

POWER

SP

SENSOR

Q901

Q856

CONTROL

BU5V

A26B25C24SEL

PLAY/AMS

20

AMS/PLAY

R-CH

R-CH

DRIVER +5V

Q701

+5V REG

KEY

76

IN0

27 29

MATRIX

77

IN1

KEY

+10V REG

Q857, 858

BATT

KEY

ACTIVE

58

AD ON

POS0

POS1

45

44

RV100

DOLBY LEVEL

CONTROL

Q859, 860

ILL POWER

Q504, 505

67

KEY ACK

POS2

POS3

47

48

TAPE

MECHANISM

(L-CH)

REF VOLTAGE

REL

49

BLOCK

AVREF

Q805

CONTROL

BU5V

J500

(REMOTE IN)

50

IN179IN0

RC

LM EJ

LM LOD

424340

4

2

DRIVE

MOTOR

LOADING

7

9

BATT

MOTOR DRIVE

CAPSTAN/REEL

M

M904

(CAPSTAN/REEL)

Q802

IC600

Q603, 604

20

ILL ON

UNISI

BUS ON

16

67

55ON16SI17SO18

BUS

CM ON

VR771

TAPE POWER

UNICKI

66

18

19

62

CKI

CKO

BU IN

RE1

RE0

565741

JOG

ENCODER

BATT

CONTROL

Q601, 602

Q600

+8.5V REG

+8.5V

X801

RESET X2X1BU IN

60 69

54

60

RESET

SYS RST

TP ON

5MHz

70

35

POWER ON

RST

IC620

BUS INTERFACE

RST

BATT

Q620

DET

Q620

BATT

IC501

RESET

1

RESET

UNISO

17

LINK OFF

19

SW701

3030

Q801

9

8

11

IN

IN

564

231

OUT

BUS

DATA

6

CN620

(BUS CONTROL IN)

ON

BUS

ON

1 12

Q621

8

CLK

BATT

CHECK

CLK

2 13

3 10

4

D622

7

BATT

6-3. BLOCK DIAGRAM — TAPE SECTION —

WX-C5000

HP901

L

PLAYBACK HEAD

FWD

L

R

R

Signal path

REV

: TAPE (PB)

04

Page 31

WX-C5000

FL+

FL–

RL+

IC331

31

TONE

383635

18

ANT AM L-CH OUT

1

RL–4FR+12FR–3RR+11RR–

2

10

9

7

RL+

RL–

RL IN

11

Q190

(Page 30)

20

RL

OUT

SEL OUT

L

R

SEL OUT

CE

CL

DI

37

TAPE L-CH

2

CD

TAPE

SECTION

(Page 30)

R-CH

16

12

AM DET

R-CH OUT

ANT FM R-CH

2

4 22

STNBY MUTE

TAPE

VC BUFFER

17 16 18 44 34

CD L-CH

1

SECTION

R-CH

3

SECTION

SA

1

IC341

2

3

(Page 29)

FM8V

D1

8

9

+8V TU

+8V FM

D657

Q340

SA MUTE

IC500 (1/2)

SYSTEM CONTROL

VSM DATA

1 24

Q3

S-METER

AM8V

10

19

+8V AM

S-METER

BATT

DET

MUTE

Q651,652

25

26

VOL CE

VOL CLK

FM ST5SD IN

3

20SD22ST13

R654

Q655

MUTE

DRIVE

Q500

MUTE

SWITCH

46

27

MUT

BEEP

X1

1

XI

IC1

PLL

SEEK

7

SEEK

1

9

CN651

AUDIO OUT

REAR

FRONT

L

R CN401(2/2)

L

-3

-6

-5

R-CH

-4

R

POWER AMP

R-CH

5

3

FL+

FL–

IC751

FL IN

12

Q180

21

FL

OUT

IC350

ELECTRONIC VOLUME

R-CH

–2

–1

CN401(1/2)

BUS AUDIO IN

L

R

LPF

TU1

TUNER INIT

D659

BATT

7.2MHz

20

XO

AM IF

13

11

IFC AM

BATT

DET

Q653

28

29

AMP ON

AUX MUT

21

IFC FM

15

TEST

32

TEST

AM OSC15FM OSC SI

6

VCO

D663

8

6

DATA OUT

16

ACC14ILL13ATT16BATT

7

F901

Q654

Q501

ACC DET

Q503

SWITCH

DIMMER

64

65

66

ACC IN

DIMMER

TEL MUTE

PLL

SD

CKO

CE

9

10

11

5

4

2

CE

CLK

DATA IN

LO/DX

PD

9

18

LPF

Q1, 2

4

5

VT

LO/DX

BATT

BATT

IC680

POWER SUPPLY

MODE2 VCC

2 7

36

TUN ON

X269X1

70

X500

5MHz

ANT REM5AMP REM

6

8

ANT+B

AMP+B

BU+B9COM8V

MODE1

3

5

BU5V

PULL-UP+5V

RAM

RESET

1

37

59

FM ON

RAMBU

XT2

XT173PWR SEL

72

X501

32.768KHz

Signal path

: FM

: AM

6

AM8V11FM8V

10

FM8V

AM8V

COM8V

FM200K

IC502

BU.5V

31

B

A

S501

(POWER SELECT)

: TAPE (PB)

: CD

S502

FREQUENCY

( )

AM10K

80

DSTSEL

SELECT

FM50K

AM9K

31 31

J1

6-4. BLOCK DIAGRAM — MAIN SECTION —

(ANTENNA)

04

Page 32

Ref. No. Location

IC1 D-2

Location

(SERVO Board)

• Semiconductor

IC2 D-5

IC3 B-2

Q1 F-4

Q2 F-5

Q11 E-4

Q12 F-3

Q13 F-1

W or less unless otherwise

4

/

1

: Through hole.

: internal component.

f

a

(The other layer’s patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

•

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS

AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is

printed in each block.)

Note on Printed Wiring Boards:

• b : Pattern from the side which enables seeing.

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

•

(Side A) parts face are indicated.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

CD board

LIMIT board

TR board

SUB board

: internal component.

f

specified.

50 WV or less are not indicated except for electrolytics

and tantalums.

• % : indicates tolerance.

•

• All resistors are in Ω and

Replace only with part number specified.

with mark 0 are critical for safety.

Note: The components identified by mark 0 or dotted line

• C : panel designation.

supply from ACC and BATT cords.

• U : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 14.4V and fed with regulated dc power

• Voltage and waveforms are dc with respect to ground

under no-signal conditions.

Voltage variations may be noted due to normal produc-

tion tolerances.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

SERVO board

MAIN board

CONTROL board

Voltage variations may be noted due to normal produc-

tion tolerances.

F : FM

f : AM

E : TAPE (PB)

• Signal path.

J : CD

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

3232

6-5. CIRCUIT BOARDS LOCATION

SENSOR board

LOAD board

JOG board

Page 33

WX-C5000

6-6. PRINTED WIRING BOARDS — CD MECHANISM SECTION —

SW1

PICK-UP

OPTICAL

11

1-659-881-

PICK-UP FLEXIBLE BOARD

JR05

(CHASSIS)

C40

SERVO BOARD

A

D12

SW1

(SELF)

ON:WHEN THE DISC IS

IN/OUT OPERATION

KSS-521A

1

5

1

7

C39

IC3

28 22 2125 15

DISC IN

DETECT

D12

CN2

JR07

CN1

6

BLU

BLU

SW4

(DOWN)

ON:WHEN COMPLETION

SW4

JR58

B C E

Q2

R16

R17

R19

JR53

JR52

L2

TP(RF)

JR30

JR28

JR29

RED

12

(31)

1

1-659-834-

OF THE DISC

CHUKING OPERATION.

7

WHT

WHT

JR59

JR57

JR56

JR55

R7

B C E

Q1

C9

16

JR54

F

M

3

8

JR02JR31

WHT

-

Q12

Q13

9

5

WHT

WHT

CN3

BLK

RED

YEL

M M

WHT

11

6

1

M903

(LOADING)

M901

M902

(31)

11

(11)

1-660-796-

(CHASSIS)

(CHASSIS)

(SPINDLE)

(SLED)

33 33

234 5 6

1

04

11

1-659-880-

BOARD

(31)

C18

353025

Q11

R47

C36

JR39

L1

521

C17

R20

C16

C23

JR40

JR42 JR43

C7

C1

MOTOR FLEXIBLE

SUB BOARD

LOAD BOARD

BLU

BLK

RED

CN4

13

R9 R8

RV1

JR60

R5

JR41

JR25

R21 R10

R11

R14

R15

C10

C13

C15

C14

C12

JR50

JR47

JR49JR48

JR51

JR45 JR46

JR44

JR37

JR36JR34

JR35

JR22

JR15

JR24

JR27

JR26

E

21

(31)

R12

3

1

2

BLU

BLK

RED

1-660-797-

SW3

(LIMIT)

ON:WHEN THE OPTICAL PICK-UP

IS INNER POSITION.

SW3

1-659-835-

12

LIMIT BOARD

R10

D11

D11

DETECT

DISC SIZE

(8CM/12CM)

R11

D10

DETECT

D10

LOADING COMPLETION

SENSOR BOARD

TP

(RF GND)

R30

R31

C20

C22

R34

C24

R36

C26C27

C30

L3

JR16

51

1

0

1 5 7 8 10 14

JR06

JR08

R23

R24

R22

R51

JR09

JR10

B

C11

JR18

JR17

R40

C38

JR11

C31

JR12

C2

R1 R2

R49 R48

R50

JR03

JR13

JR14

C

R32

R33

BL2

RV4

C25 R35

R37

R38

R39

C28

C29

C32

R41

R42

JR19

JR20

C3

JR23

R3 C4

15

202530

30

10

IC1

40

35

20

25

JR21

D

BLU

BLU

R27

R29

R28

BL1

C19

C21

45

40

1510

IC2

15

20

C35

R46

C34

R45

R43

C33

R44

C5

R6 C6

R4

JR38

5

1

6055

45

50

10

CN1

15

1

CD

CN802

BOARD

(Page 36)

Page 34

(Page 35)

: Impossible to measure

∗

under no-signal conditions.

no mark : CD PLAY

Note:

• Voltage and waveforms are dc with respect to ground

34 34

6-7. SCHEMATIC DIAGRAM — CD MECHANISM SECTION (1/2) — • Refer to page 35 for Waveforms and page 48 for IC Block Diagrams.

WX-C5000

Page 35

WX-C5000

(MODE : CD PLAY)

• Waveforms

1

0V

Approx. 620mVp-p

(FEO)

1

IC2

2

1.2Vp-p

(RFO)

ea

IC2

3

0V

(TEO)

Approx. 200mVp-p

rs

IC2

4

2.6Vp-p

7.6µsec

(MDP)

3

IC1

5

5.8Vp-p

22.7µsec

(LRCK)

w;

IC1

6

5.7Vp-p

(BCK)

474nsec

ws

IC1

(Page 37)

7

3.2Vp-p

(XTAI)

ef

16.89MHz

IC1

under no-signal conditions.

no mark : CD PLAY

Note:

• Voltage and waveforms are dc with respect to ground

35 35

6-8. SCHEMATIC DIAGRAM — CD MECHANISM SECTION (2/2) — • Refer to page 48 for IC Block Diagrams.

(Page 34)

Page 36

(Page 38)

(Page 33)

(Page 45)

36 36

6-11. PRINTED WIRING BOARD — CD SECTION —

6-9. PRINTED WIRING BOARD — TR SECTION —

WX-C5000

(Page 39)

6-10. SCHEMATIC DIAGRAM — TR SECTION —

Location (CD board)

• Semiconductor

(Page 37)

Ref. No. Location

D401 F-4

D801 G-8

D802 G-10

D851 H-2

(Page 37)

D852 I-2

D853 E-2

D854 E-2

D855 E-2

D856 F-3

D857 F-3

D858 F-2

D859 K-3

D860 I-11

D862 J-11

D865 K-10

IC401 F-5

IC801 I-7

IC802 F-8

Q801 G-8

Q802 G-9

Q803 G-7

Q804 F-8

Q805 I-9

Q806 H-3

Q807 G-7

Q811 F-10

Q812 E-10

Q851 H-1

Q852 G-3

Q853 I-1

Q854 H-3

Q856 D-4

Q857 G-1

Q858 F-2

Q859 J-2

Q860 K-2

no-signal conditions.

no mark : CD PLAY

Note:

• Voltage is dc with respect to ground under

Page 37

WX-C5000

(Page 41)

(Page 35)

condition.

no mark : CD PLAY

Note:

• Voltage is dc with respect to ground under no-signal

37 37

6-12. SCHEMATIC DIAGRAM — CD SECTION — • Refer to page 51 for IC Block Diagrams.

(Page 41)

(Page 36)

(Page 36)

(Page 46)

Page 38

(Page 36)

6-13. PRINTED WIRING BOARD — MAIN SECTION —

38 38

WX-C5000

D756 C-8

D757 B-7

D758 B-7

IC1 E-11

IC300 H-10

Ref. No. Location

(D1) F-11

(D500) I-2

Ref. No. Location

• Semiconductor Location

IC331 J-11

(D501) I-3

(D502) F-5

(D503) F-5

D504 K-6

D505 H-6

IC341 F-10

D506 B-12

IC350 H-8

D507 B-12

IC500 J-4

D508 K-11

(IC501) J-3

D509 K-11

IC502 I-2

D510 K-11

(IC600) F-2

(D511) L-4

IC620 F-3

(D512) L-5

(IC680) D-6

D513 H-5

(IC751) A-9

(D514) I-3

D600 D-2

(Q1) D-11

D601 G-2

(Q2) D-12

D602 F-2

Q3 H-13

(D603) E-2

(Q4) F-6

D620 E-2

(Q5) E-6

(D621) E-3

Q180 E-8

(D622) E-3

Q190 E-8

D623 B-2

Q280 E-9

D624 D-3

Q290 E-9

D625 B-2

Q340 D-9

(D651) C-3

Q500 G-5

D652 B-6

Q501 G-4

D653 A-6

Q503 G-4

D654 B-6

Q504 K-6

D656 D-3

Q505 K-6

D657 D-7

(Q600) G-2

D659 E-7

Q601 G-2

D660 C-6

Q602 G-2

D661 C-6

(Q603) E-3

D662 D-3

(Q604) E-2

D663 D-4

Q620 E-2

D664 F-5

Q621 E-3

D680 E-8

Q651 B-7

(D681) E-9

Q652 B-7

D751 C-9

Q653 E-7

D752 C-9

Q654 E-4

D753 C-9

(Q655) E-8

D754 C-8

D755 B-8

( ) : SIDE B

Page 39

WX-C5000

(Page 36)

(Page 47)

39 39

(Page 45)

Page 40

(Page 41)

condition.

no mark : FM

(): AM

Note:

• Voltage is dc with respect to ground under no-signal

(Page 42)

40 40

6-14. SCHEMATIC DIAGRAM — MAIN SECTION (1/4) — • Refer to page 50 for IC Block Diagrams.

WX-C5000

Page 41

WX-C5000

(Page 37)

(Page 37)

(detuned) condition.

no mark : FM

Note:

• Voltage is dc with respect to ground under no-signal

(Page 43)

(Page 42)

41 41

6-15. SCHEMATIC DIAGRAM — MAIN SECTION (2/4) —

(Page 40)

Page 42

(Page 41)

(Page 43)

condition.

no mark : FM

( ) : TAPE PLAY

Note:

• Voltage is dc with respect to ground under no-signal

(Page 40)

42 42

6-16. SCHEMATIC DIAGRAM — MAIN SECTION (3/4) — • Refer to page 50 for IC Block Diagrams.

WX-C5000

Page 43

WX-C5000

(Page 41)

(Page 47)

(Page 46)

condition.

no mark : FM

(): AM

Note:

• Voltage is dc with respect to ground under no-signal

43 43

6-17. SCHEMATIC DIAGRAM — MAIN SECTION (4/4) — • Refer to page 50 for IC Block Diagrams.

(Page 42)

Page 44

(IC701) C-7

Ref. No. Location

(Q701) C-9

(Q702) C-10

(Q703) D-10

44 44

(Q704) C-9

6-18. PRINTED WIRING BOARD — CONTROL SECTION —

WX-C5000

(D701) B-8

(D704) C-10

(D705) C-10

(D706) C-9

D730 F-6

D731 A-7

Ref. No. Location

• Semiconductor Location

D732 F-6

D733 B-12

( ) : SIDE B

Page 45

WX-C5000

(Page 36)

45 45

(Page 39)

Page 46

(Page 37)

(Page 43)

(detuned) condition.

no mark : FM

Note:

• Voltage is dc with respect to ground under no-signal

6-19. SCHEMATIC DIAGRAM — CONTROL SECTION —

46 46

WX-C5000

Page 47

6-20. PRINTED WIRING BOARD — JOG SECTION —

WX-C5000

(Page 39)

6-21. SCHEMATIC DIAGRAM — JOG SECTION —

(Page 43)

47

Page 48

• IC Block Diagrams

IC1 CXD2507AQ (SERVO BOARD)

FOK

MON

MDP

MDS

LOCK

TEST

FILO

FILI

PCO

VSS

AVSS

CLTV

AVDD

BIAS

ASYI

ASYO

ASYE

WDCK

XLON

SPOC

SPOD

63

62

64

1

2

3

4

5

6

7

8

9

10

11

12

13

RF

14

15

16

17

18

19

SERVO AUTO

SEQUENCER

CPU

INTERFACE

14

DIGITAL

PLL

ASYMMETRY

CORRECTOR

5

20 21 22 23 24 25 26 27 293031 3228

BCLK

LRCK

PCMD

16K

RAM

GTOP

VDD

CLKO

SPOB

SPOA

58596061

5

SUB CODE

PROCESSOR

EFM

DEMODULATOR

3

ERROR

CORRECTOR

K

S

D

F

C

D

G

P

V

XUGF

X

XLTO

DATO

5657

4

D/A

INTERFACE

3

K

C

F

C2PO

R

CNIN

5455

XROF

SEIN

53

6

MNT3

CLOK

52

MNT1

XLAT

DIGITAL

CLV

DIGITAL

OUT

CLOCK

GENERATOR

51

DATA

50

XRST

49

SENS

48

MUTE

47

SQCK

SQSO

46

45

EXCK

44

SBSO

43

SCOR

42

VSS

41

WFCK

40

EMPH

39

DOUT

C4M

38

37

FSTT

36

XTSL

35

XTAO

34

XTAI

MNTO

33

IC3 BA6796FP-T1

OP IN –

OP IN +

VREF

CH3

28

1

OPOUT

26

27

THERMAL

CTL1 CTL2 FWD REV

23 4

CH4

CH4-IN

CTL1

SHUT

DOWN

CH1

LEVEL

SHIFT

V/I

TRAY

21

VCC

LEVEL

SHIFT

9

VCC

GND

DRIVE

BUFFER

10

CH5 –

CH2

CH3-IN

2425

LEVEL

SHIFT

LOGIC

5

CTL2

23

6

FWD

CH2-IN

22

78

REV

1920

CH1-IN

DRIVE

BUFFER

DRIVE

BUFFER

11

CH1 +

LEVEL

SHIFT

COM

CH1 –

DRIVE

BUFFER

DRIVE

BUFFER

12 13

CH4 +

161718

DRIVE

BUFFER

DRIVE

BUFFER

CH2 +

CH3 +

15

DRIVE

BUFFER

DRIVE

BUFFER

14

CH2 –

CH3 –

48

Page 49

IC2 CXA1782BQ

FE BIAS

PHD 2

36 35 34

37

F

38

E

39

PHD 1

RF IV AMP1

APC

RF IV AMP2

F IV AMP

PHD

33

FE AMP

LD

RF M

32

FOK

RF O

31

LEVEL S

TTL

IIL

FZC COMP

RF I

30 29 28 27 26 25

MIRR

IIL DATA REGISTER

TOG1-3

FS1-4 TG1-2 TM1-7 PS1-4

BAL1-3

CP

DFCT

INPUT SHIFT REGISTER

ADDRESS DECODER

OUTPUT DECODER

CB

CC1

TTL

TTL

FOK

CC2

IIL

IIL

24

SENS

C.OUT

23

XRST

22

21

DATA

20

XLT

19

CLK

VCC

18

VEE

TED

LPFI

TEI

ATSC

TZC

TDFCT

BAL2

TOG1

TOG2

WINDOW COMP

E IV AMP

BAL 3

ATSC

TOG3

TE AMP

TG1

FS1

TRACKING

PHASE

COMPENSATION

987

TGU

SRCH

TG2

TM7

TM6

TM5

TM4

TM3

TA M

ISET

17

SL O

16

SL M

15

SL P

14

13

TA O

ISET

TM2

F SET

11

10

TG2

12

FSET

HPF COMP

TZC COMP

DFCT

TM1

DFCT

FS4

2

1

FEI

FEO

FDFCT

43

FGD

FCS PHASE

COMPENSATION

5

6

FLB

FE O

LPF COMP

FS2

FE M

EI

40

BAL1

41

42

43

44

45

46

47

VC

48

49

Page 50

IC1 BU2624FV-E2 (MAIN BOARD)

XIN

XOUT

20

19

VSS

PHASE

DET

I/O

CTL

REFERENCE

DIVIDER

SHIFT REGISTER LATCH

MAIN

COUNT

PRESCALER

IF COUNT

CTL

20BIT COUNT

1

2

CE

CK

4

DA

5

CD

6

7

P0

9

P1

10

P3

18

PD

17

VDD

FMIN

16

AMIN

15

P2

14

13

IFIN

12

SD

P4

11

IC331, 341 NJM4558M-T1

A OUT

A IN–

A IN+

VEE

1

A

+–

2

3

4

B

+–

8

VCC

7

B OUT

6

B IN–

5

B IN+

IC300 CXA2510AQ-T4

PBEQ1

–

PBFB1

31

32

PBRIN1

PBREF1

PBFIN1

VCT

PBGND

PBFIN2

PBREF2

PBRIN2

PBFB2

33

34

35

36

37

38

39

40

F2

VCT

F1

1

PBEQ2

AUXIN1

TAPEIN1

PBOUT1

GND

282930

27

120µ/

70µ

+

–

+

120µ/

70µ

345 6 7 8 9 10

2

VCC

PBOUT2

X1

+

X1

TAPEIN2

T1

AUXIN2

T2

NR BIAS

TAPE/AUX

TAPE EQ

FWD/RVS

VCC

LPF

+

–

F3

–

+

MSLPF

LINEOUT2

25

DIREF

OFF/B

+

NR

LINEOUT1

24

–

NC

TCH2

NR

OFF/B

PLAY

TCH1

NC

MSSW

21222326

MS

MODE

NR

MODE

DETECT

MS ON/

OFF

20

19

18

17

16

15

14

13

12

11

MSMODE

DRSW

TAPESW

INSW

NRSW

NC

MSOUT

DGND

MSTC

FF

IC620 BA8270F-E2

BUS ON

1

2

RST

BATT

3

4

CLK

5

VREF

6

DATA

GND

7 8

BUS ON

SWITCH

SWITCH

BATTERY

SWITCH

RESET

14

13

12

11

10

9

VCC

RST

BUS ON

CLK IN

BU IN

DATA IN

DATA OUT

50

Page 51

IC350 LC75374E

LVRIN

34

LSELO

35

L4

L3

36

L2

37

L1

38

39

VDD

R1

40

41

R2

R3

42

R4

43

44

RSELO

1

RVRIN

LT3

LT2

+

–

–

+

LT1

–

+

+

–

+

–

DECODER LATCH

+

–

RT1

RT2

RT3

LCOM

+

–

+

–

–

+

–

+

2 345 6 7 8 9

RCOM

LSIN

LTOUT

CONTROL

REGISTER

RSIN

RTOUT

NC

2627282930313233

SHIFT

NC

LSB2

LSB1

NC

2324

25

22

LFIN

+

–

+

+

–

10

11

NC

RSB1

RSB2

–

+

–

–

+

–

+

LFOUT

21

LROUT

20

19

VREF

18

CE

17

DI

16

CL

15

VSS

14

RROUT

RFOUT

13

12

RFIN

IC401 PCM1717E-ST2

1

XTI

2

DGND

3

VDD

4

LRCIN

DIN

BCKIN

ZERO

D/C R

VOUTR

AGND

5

6

7

8

9

10

INTERFACE

5LEVE DAC

LOWPASS FILTER

CMOS

AMP

CONTROL

INPUT

DIGITAL

FILTER

NOISE SHAPER

CLK

5LEVEL DAC

LOWPASS FILTER

CMOS

AMP

MODE

CONT

ROL

20

19

18

17

16

15

14

13

12

11

XTO

CLKO

ML/MUTE

MC/DM1

MD/DM0

RSTB

MODE

D/C L

VOUTL

VCC

IC502 RN5VD23AA-TL

CD

5

RESET

2 3

1

OUT

VDD

IC600 LB1930M-TLM

VCC

1

BUFFER

NC

2

IN1

IN2

S-GND

3

4

BUFFER

5

CONTROL

CIRCUIT

4

NC

GND

MOTOR

DRIVE

CIRCUIT

NC

10

OUT1

9

8

NC

7

OUT2

P-GND

6

51

Page 52

T

IC802 BA3834F

PEAK

HOLD

68Hz

B.P.F.

1

2

BIASC

VREFC

REGISTER

3

4

RREF

REGISTER

PEAK

HOLD

170Hz

B.P.F.

5

NC

IFOUT

IC680 BA3918-V2

18

PEAK

HOLD

420Hz

B.P.F.

DIFFERENTIAL

AMPLIFIER

6

NC

GND

MULTIPLEXER

REGISTER

7

8

CIN

AIN

PEAK

HOLD

1kHz

B.P.F.

AOU

9

VCC

REGISTER

TEST

1617

PEAK

HOLD

2.4kHz

B.P.F.

NC

15

REGISTER

PEAK

HOLD

5.9kHz

B.P.F.

SEL

13

14

DECODER

REGISTER

C

A

B

NC

1011

12

REGISTER

PEAK

HOLD

14.4kHz

B.P.F.

REGULATOR

OVER VOLTAGE

PROTECT

–

+

2 3

4

1

NC

STB

MODE2

MODE1

5 6 7 8 9

ANT

VCC

VDD

AMP

COM

–

+

10

AM

–

+

11

FM

–

+

12

GND

52

Page 53

NOTE:

• The mechanical parts with no reference

number in the exploded views are not supplied.

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

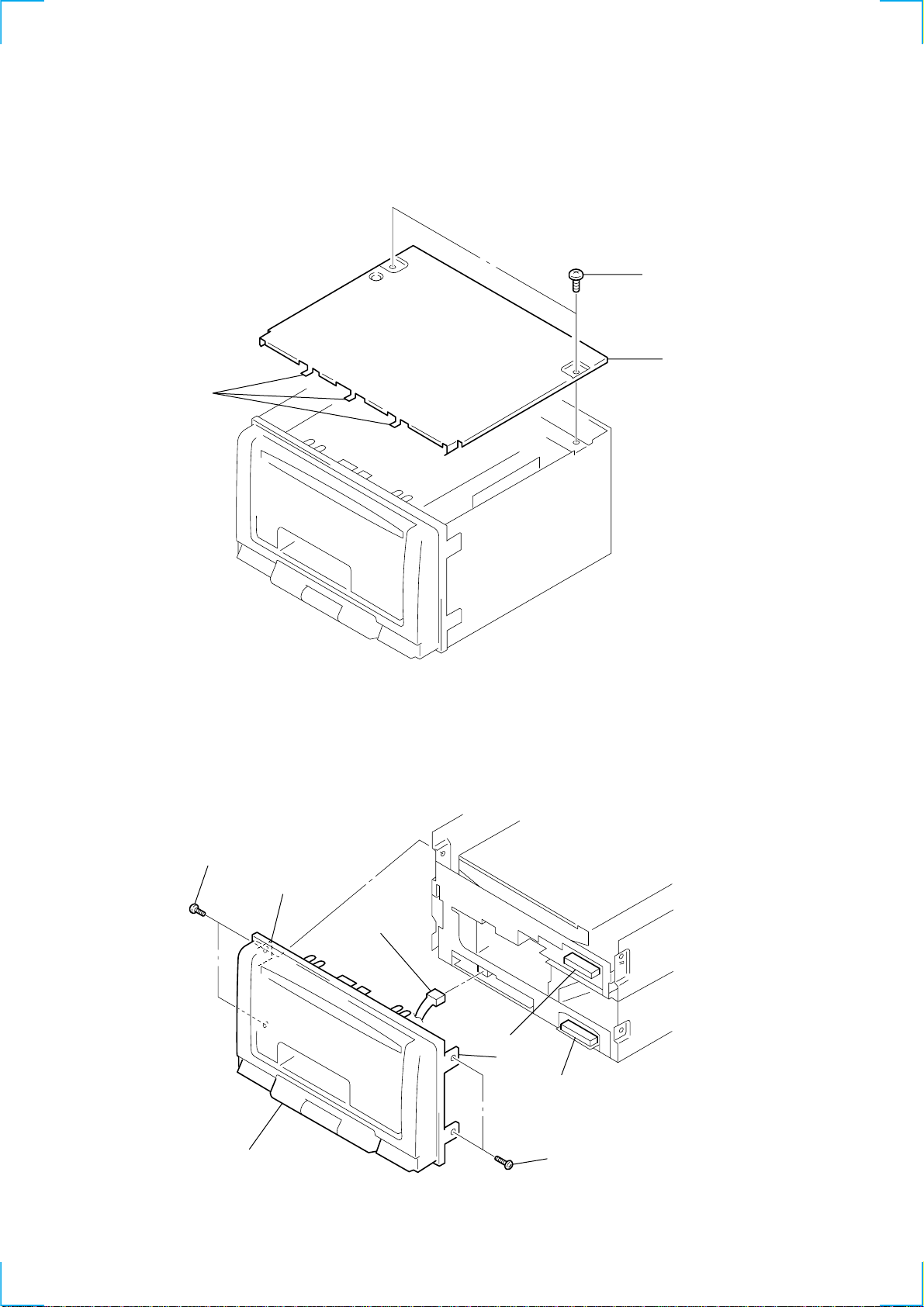

7-1. COVER SECTION

SECTION 7

EXPLODED VIEWS

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• Color Indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ... (RED)

R

Parts Color Cabinet’s Color

#1

• Accessories and packing materials and

hardware (# mark) list are given in

the last of this parts list.

The components identified by

mark 0 or dotted line with mark

R

0 are critical for safety.

Replace only with part number

specified.

#1

2

6

5

4

#2

#11

1

#2

F901

#2

#2

3

#1

Ref. No. Part No. Description Remark

1 1-791-457-11 CORD (WITH CONNECTOR) (POWER)

* 2 3-024-092-21 COVER

* 3 3-024-091-21 HEAT SINK

* 4 1-676-336-11 TR BOARD

Ref. No. Part No. Description Remark

* 5 3-025-964-01 SHEET (TRANSFORMER), INSULATING

* 6 3-025-584-01 COVER (D/D CONVERTER)

F901 1-532-877-11 FUSE (BLADE TYPE) (AUTO FUSE) 10A

53

Page 54

7-2. FRONT PANEL SECTION

56

57

59

53

66

53

53

FL701

53

53

68

67

58

60

54

VR771

53

52

51

51 3-036-193-11 PANEL (VOL)

52 3-036-185-01 PLATE (VOL), LIGHT GUIDE

53 3-029-975-01 SCREW (2X8), +P TITE

* 54 1-673-785-12 JOG BOARD

55 X-3379-666-1 PANEL ASSY, FRONT

61

62

63

65

55

Ref. No. Part No. Description RemarkRef. No. Part No. Description Remark

61 3-036-182-01 DOOR, CASSETTE

62 3-036-183-01 PLATE (CASSETTE), LIGHT GUIDE

63 3-036-186-02 BUTTON (D-BASS)

64 3-036-181-11 BUTTON (OFF)

65 3-036-180-11 BUTTON (S.A.S)

64

56 3-036-178-31 BUTTON (1-6)

* 57 A-3283-037-A CONTROL BOARD, COMPLETE

58 3-036-179-31 BUTTON (M, T)

59 3-036-184-01 PLATE (CD), LIGHT GUIDE

60 3-036-198-01 SPRING (C DOOR), TORSION

54

66 3-036-194-01 SHEET (FL)

67 3-037-479-01 SHEET (LIGHT INTERCEPTION)

68 4-926-578-01 PLATE (P), RUBBER

FL701 1-517-885-11 INDICATOR TUBE, FLUORESCENT

VR771 1-418-378-12 ENCODER, JOG

Page 55

7-3. CHASSIS SECTION

MG-25E-136

102

TU1

#1

#4

MG-378X-121

105

113

102

#4

112

106

102

109

111

101

#1

102

103

#3

104

#4

#1

#1

108

107

#1

#1

#1

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 101 3-024-109-02 BRACKET (CD)

102 3-376-464-11 SCREW (+PTT 2.6X6), GROUND POINT

* 103 3-024-107-11 BRACKET (U)

* 104 3-024-222-01 HEAT SINK (3 TERMINAL)

* 105 A-3283-035-A CD BOARD, COMPLETE

* 106 3-024-113-01 SHEET (U), INSULATING

* 107 3-024-097-12 CHASSIS (U)

110

* 108 3-027-592-01 SHEET (L), INSULATING

* 109 A-3283-034-A MAIN BOARD, COMPLETE

* 110 X-3377-429-1 CHASSIS (L) ASSY

* 111 3-342-925-01 CUSHION, RUBBER

112 3-924-145-01 CUSHION (TU), RUBBER

113 3-563-691-01 CUSHION

TU1 A-3282-029-A TUNER UNIT (TUX-006/2 (E))

55

Page 56

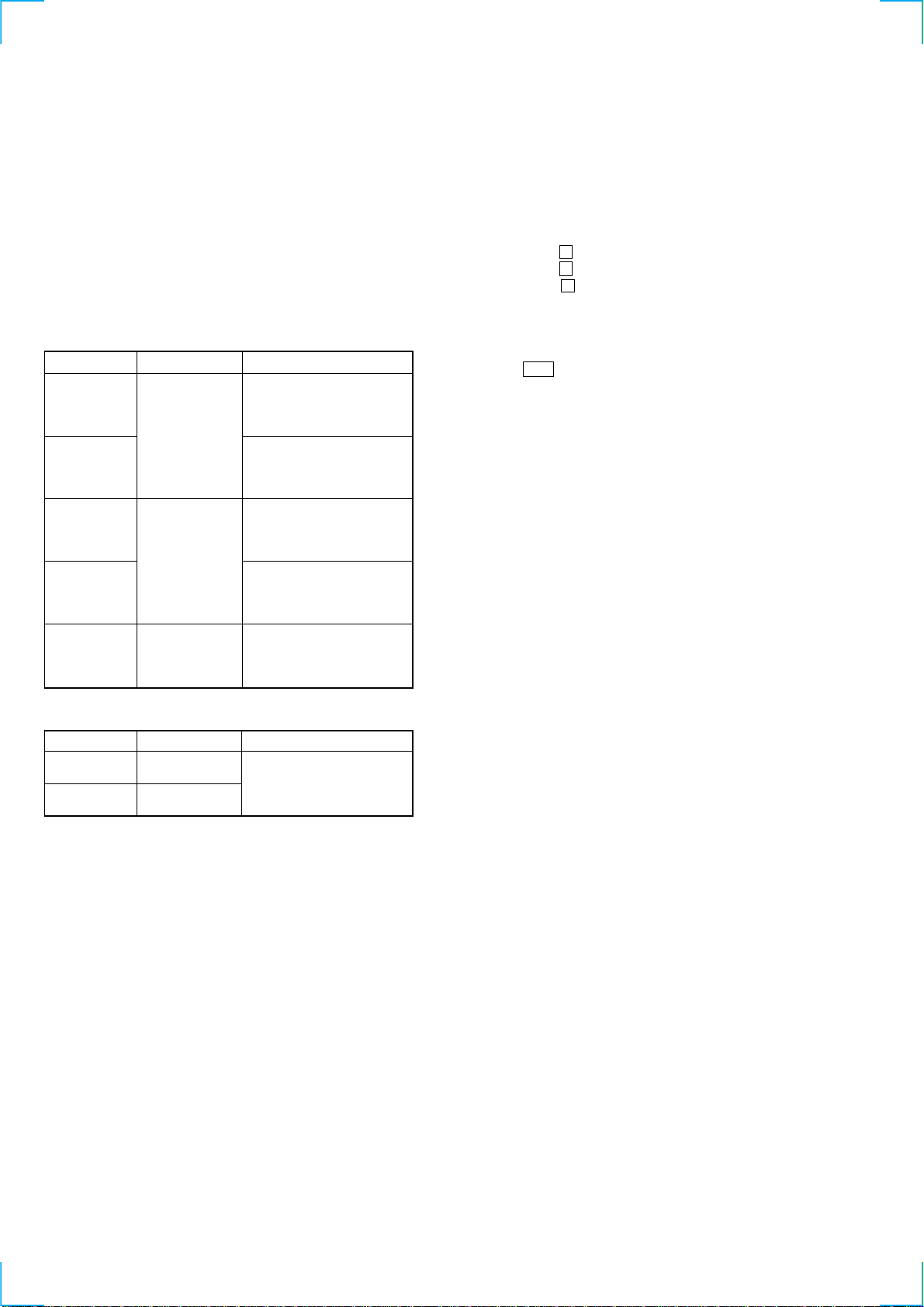

7-4. TAPE MECHANISM SECTION

(MG-25E-136)

165

154

153

#5

155

158

152

157

156

159

160

163

HP901

161

162

M904

164

not supplied

#8

168

168

166

167

151

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

151 A-3291-667-A CLUTCH (FR) ASSY

* 152 3-019-130-01 LEVER (LDG-A)

153 3-019-131-01 LEVER (LDG-B)

154 3-020-539-01 SPRING (LD-1), TENSION

155 3-020-540-01 SPRING (LD-2), TENSION

156 3-020-542-01 GEAR (LOADING FT)

157 3-341-753-11 WASHER, POLYETHYLENE

158 3-020-533-01 HOUSING

* 159 3-020-532-01 ARM (SUCTION)

160 3-020-534-01 HANGER

162 3-933-344-01 GUIDE (C)

163 3-014-798-01 SCREW (HEAD), SPECIAL

164 3-364-151-01 WASHER

165 A-3220-607-A DECK ASSY, MECHANISM

166 3-017-302-01 BELT (25)

167 3-936-853-01 FLYWHEEL (F)

168 3-701-437-21 WASHER

HP901 1-500-157-21 HEAD, MAGNETIC (PLAYBACK)

M904 A-3291-665-A MOTOR ASSY, MAIN (CAPSTAN/REEL)

161 3-933-346-01 CATCHER

56

Page 57

7-5. CD MECHANISM SECTION (1)

(MG-378X-121)

207

206

201

203

204

205

#6

#6

#6

202

204

210

209

215

A

A

208

211

212

#7

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

201 X-3376-767-2 CHASSIS (TM) ASSY

* 202 1-660-797-21 SENSOR BOARD

203 3-032-474-02 GUIDE (DISC M)

204 3-338-737-01 SCREW (2X3), +PS

* 205 1-659-837-11 LOAD BOARD

209 3-321-813-01 WASHER, COTTER POLYETHYLENE

210 3-025-419-01 ARM (ROLLER)

211 3-937-561-01 SPRING (RA-E), TENSION

* 212 A-3313-563-A SERVO BOARD, COMPLETE

* 213 3-007-530-01 BRACKET (MOTOR)

#7

214

#6

M903

#8

213

206 A-3301-204-A ROLLER ASSY

207 3-931-913-11 RING (ROLLER), RETAINING

208 3-040-324-01 SPRING (RA-R), COMPRESSION

* 214 3-939-139-01 SPACER

215 3-040-323-01 SPRING (RA-L), COMPRESSION

M903 A-3291-676-A MOTOR SUB ASSY, LO (LOADING)

57

Page 58

7-6. CD MECHANISM SECTION (2)

(MG-378X-121)

#8

252

253

251

258

256

265

264

260

B

259

257

254

260

261

255

256

269

263

262

B

267

266

268

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

251 X-3372-203-1 ARM ASSY, CHUCKING

252 3-931-894-01 BRACKET (CP)

* 253 3-027-767-01 RETAINER (DISC)

254 3-021-326-01 SPRING (8)

255 3-931-895-11 SPRING (CH), TENSION

256 3-931-898-11 SPRING (FL), COMPRESSION

257 3-023-470-01 SPRING (KF8), TENSION

258 A-3277-813-I CHASSIS (M) COMPLETE ASSY

259 3-931-883-01 SPRING (TR), TENSION

260 3-018-272-01 WASHER

261 3-014-727-01 WHEEL (LW), WORM

262 3-931-881-03 LEVER (LOCK)

263 3-935-828-05 LEVER (D)

264 3-931-882-02 GEAR (MDL)

265 3-007-537-11 WHEEL (U), WORM

266 3-931-897-41 DAMPER (T)

267 3-931-897-31 DAMPER (T)

268 4-926-578-01 PLATE (P), RUBBER

269 3-025-418-11 RING, LOADING

266

58

Page 59

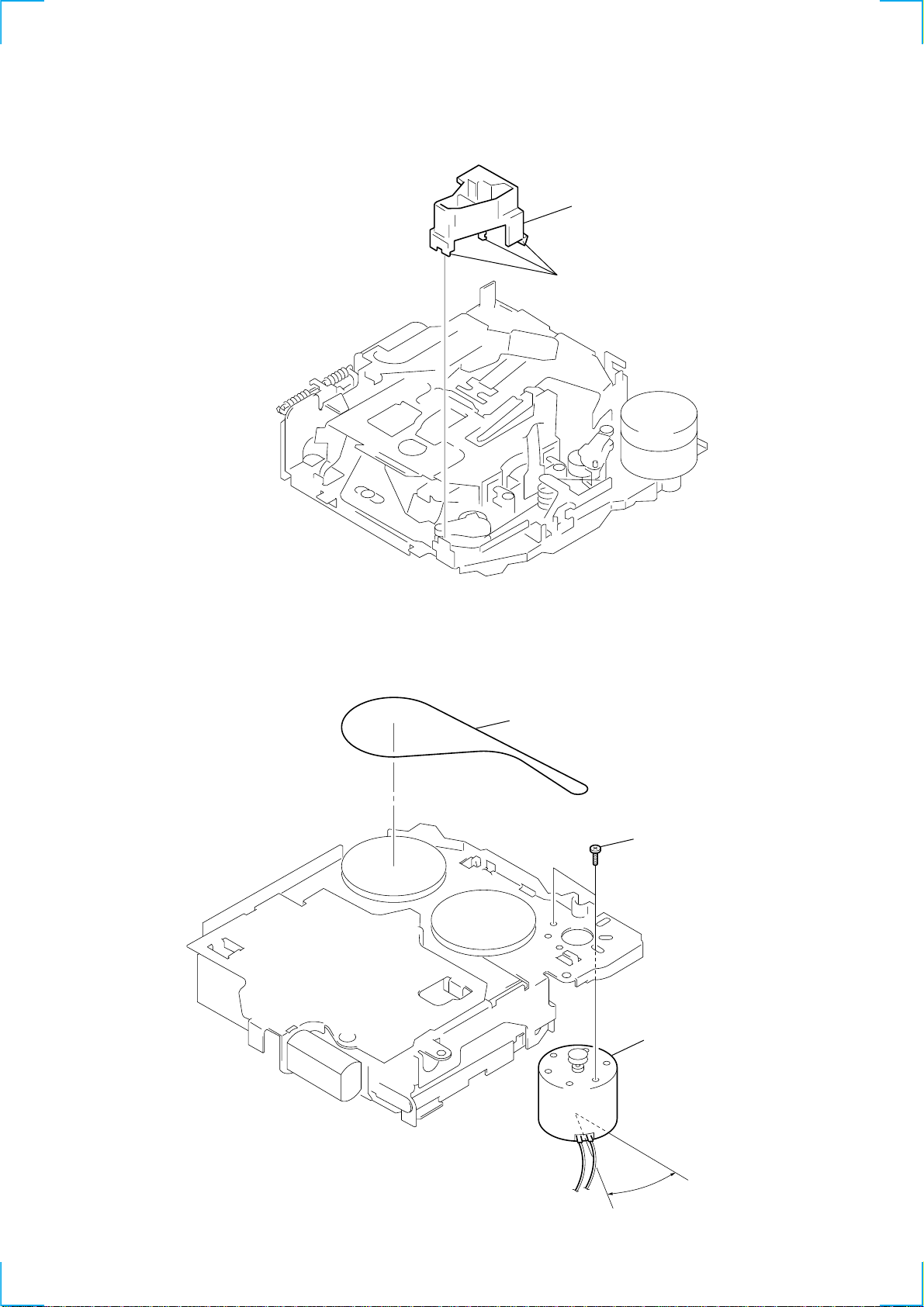

7-7. CD MECHANISM SECTION (3)

(MG-378X-121)

#9

M901

307

301

302

#8

M902

309

308

305

306

310

#6

303

#10

304

313

312

#6

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 301 X-3379-646-1 CHASSIS (OP) (O/S) ASSY

302 3-931-829-01 SPRING (SL), PLATE

303 X-3375-832-1 BASE (DRIVING) ASSY

304 3-931-832-01 GEAR (SL MIDWAY)

* 305 1-659-835-12 LIMIT BOARD

311

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

309 3-909-607-01 SCREW

0310 8-820-010-06 PICK-UP, OPTICAL KSS-521A/K1RP

311 3-025-743-01 SPRING (FEED), LEAF

312 1-659-881-11 PICK-UP FLEXIBLE BOARD

313 A-3291-669-A SHAFT (FEED) ASSY

306 3-338-737-01 SCREW (2X3), +PS

307 1-659-880-11 MOTOR FLEXIBLE BOARD

* 308 1-659-834-11 SUB BOARD

M901 X-3373-664-2 MOTOR ASSY (SPINDLE)

M902 A-3291-674-A MOTOR ASSY, SLED (SLED)

59

Page 60

SECTION 8

CD

NOTE:

• Due to standardization, replacements in

the parts list may be different from the

parts specified in the diagrams or the

components used on the set.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

• RESISTORS

All resistors are in ohms.

METAL:Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F:nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* A-3283-035-A CD BOARD, COMPLETE

*******************

* 3-024-107-11 BRACKET (U)

* 3-024-222-01 HEAT SINK (3 TERMINAL)

7-685-792-09 SCREW +PTT 2.6X6 (S)

7-685-793-09 SCREW +PTT 2.6X8 (S)

< CAPACITOR >

C401 1-124-589-11 ELECT 47uF 20% 16V

C402 1-124-584-00 ELECT 100uF 20% 10V

C403 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C404 1-124-584-00 ELECT 100uF 20% 10V

C405 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C406 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C407 1-163-233-11 CERAMIC CHIP 18PF 5% 50V

C408 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C409 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C410 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C411 1-163-209-00 CERAMIC CHIP 0.0015uF 10% 50V

C412 1-124-234-00 ELECT 22uF 20% 16V

C413 1-126-160-11 ELECT 1uF 20% 50V

C421 1-163-011-11 CERAMIC CHIP 0.0015uF 10% 50V

C422 1-124-234-00 ELECT 22uF 20% 16V

ELECTRICAL PARTS LIST

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• SEMICONDUCTORS

In each case, u : µ, for example:

uA.. : µA.. uPA.. : µPA..

uPB.. : µPB.. uPC.. : µPC.. uPD.. : µPD..

• CAPACITORS

uF : µF

• COILS

uH : µH

C822 1-124-233-11 ELECT 10uF 20% 16V

C823 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C824 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C825 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C826 1-163-077-00 CERAMIC CHIP 0.1uF 10% 25V

C827 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C851 1-126-941-11 ELECT 470uF 20% 25V

C852 1-124-234-00 ELECT 22uF 20% 16V

C853 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C854 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C855 1-124-589-11 ELECT 47uF 20% 16V

C856 1-124-589-11 ELECT 47uF 20% 16V

C857 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

C858 1-124-233-11 ELECT 10uF 20% 16V

C859 1-124-589-11 ELECT 47uF 20% 16V

C860 1-124-589-11 ELECT 47uF 20% 16V

C861 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C862 1-124-233-11 ELECT 10uF 20% 16V

C863 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C864 1-124-234-00 ELECT 22uF 20% 16V

C865 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C866 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C867 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board.

C423 1-126-160-11 ELECT 1uF 20% 50V

C433 1-163-181-00 CERAMIC CHIP 100PF 5% 50V

C434 1-163-181-00 CERAMIC CHIP 100PF 5% 50V

C443 1-163-181-00 CERAMIC CHIP 100PF 5% 50V

C444 1-163-181-00 CERAMIC CHIP 100PF 5% 50V

C451 1-124-257-00 ELECT 2.2uF 20% 50V

C461 1-124-257-00 ELECT 2.2uF 20% 50V

C481 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C482 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C483 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C484 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C485 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C801 1-124-259-11 ELECT 4.7uF 20% 35V

C802 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C803 1-163-077-00 CERAMIC CHIP 0.1uF 10% 25V

C805 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

C807 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C809 1-124-259-11 ELECT 4.7uF 20% 35V

C810 1-128-057-11 ELECT 330uF 20% 6.3V

C813 1-163-287-11 CERAMIC CHIP 10PF 5% 50V

C814 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

60

< JACK >

CN401 1-774-700-11 JACK, PIN 6P (BUS AUDIO IN,

AUDIO OUT FRONT/REAR)

< CONNECTOR >

* CN402 1-564-728-11 PIN, CONNECTOR (SMALL TYPE) 12P

CN801 1-784-988-11 CONNECTOR 20P

CN802 1-764-617-12 PIN, CONNECTOR (PC BOARD) 30P

* CN803 1-506-999-11 PIN, CONNECTOR (PC BOARD) 3P

< DIODE >

D401 8-719-911-19 DIODE 1SS119-25TD

D801 8-719-911-19 DIODE 1SS119-25TD

D802 8-719-911-19 DIODE 1SS119-25TD

D851 8-719-422-97 DIODE MA8091-M-TX

D852 8-719-977-03 DIODE MA8056-M-TX

D853 8-719-035-39 DIODE MA4027-H(TA)

D854 8-719-911-19 DIODE 1SS119-25TD

D855 8-719-200-82 DIODE 11ES2-TA1B

D856 8-719-911-19 DIODE 1SS119-25TD

D857 8-719-911-19 DIODE 1SS119-25TD

Page 61

CD

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

D858 8-719-110-17 DIODE MA4100-L(TA)

D859 8-719-911-19 DIODE 1SS119-25TD

D860 8-719-053-18 DIODE 1SR154-400TE-25

D862 8-719-053-18 DIODE 1SR154-400TE-25

D865 8-719-053-18 DIODE 1SR154-400TE-25

R402 1-216-037-00 METAL CHIP 330 5% 1/10W

R411 1-216-049-11 RES-CHIP 1K 5% 1/10W

R412 1-216-296-91 SHORT 0