Page 1

WX-7700MDX

SERVICE MANUAL

Ver 1.0 2002.06

US and foreign patents licensed from Dolby

Laboratories.

CD

Section

MD

Section

E Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type MG-398D-121

Optical Pick-up Name KSS-720A

Model Name Using Similar Mechanism NEW

MD Mechanism Type MG-164MF-138

Optical Pick-up Name KMS-241C

CD/MD Player section

Signal-to-noise ratio 95 dB

Frequency response 10 – 20,000 Hz

Wow and flutter Below measurable limit

Tuner section

FM

Tuning range FM tuning interval:

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 66 dB (stereo),

Harmonic distortion at 1 kHz

Separation 35 dB at 1 kHz/WIDE

Frequency response 30 – 15,000 Hz

50 kHz/200 kHz switchable

87.5 – 108.0 MHz

(at 50 kHz step)

87.5 – 107.9 MHz

(at 200 kHz step)

74 dB (mono)

0.4 % (stereo),

0.3 % (mono)

SPECIFICATIONS

AM

Tuning range AM tuning interval:

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity 30 µV

Power amplifier section

Outputs Speaker outputs

Speaker impedance 4 – 8 ohms

Maximum power outp ut 52 W × 4 (at 4 ohms)

General

Outputs Audio outputs (front/rear)

Inputs Telephone ATT control

9 kHz/10 kHz switchable

531 – 1,602 kHz

(at 9 kHz step)

530 – 1,710 kHz

(at 10 kHz step)

(sure seal connectors)

Subwoofer output (mono)

Power aerial relay control

terminal

Power amplifier control

terminal

terminal

Illumination control

terminal

BUS control input terminal

BUS audio input terminal

AUX IN terminal

Aerial input terminal

Power requirements 12 V DC car batt ery

Dimensions Approx. 178 × 100 × 194

Mounting dimensions Approx. 178 × 100 × 165

Mass Approx. 3.0 kg

Supplied accessories Parts for installation and

Note

This unit cannot be connected to a digital preamplifier

or an equalizer.

Design and specifications are subject to change

without notice.

(negative earth)

mm (w/h/d)

mm (w/h/d)

connections (1 set)

Card remote commander

RM-X110

9-874-054-01 Sony Corporation

2002F0500-1 e Vehicle Company

C 2002.06 Published by Sony Engineering Corporation

MULTI CONTROL AUDIO MASTER

Page 2

WX-7700MDX

NOTES ON HANDLING THE OPTICAL PICKUP BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

FOR CD

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

FOR MD

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right avove when

checking it for adustment. It is feared that you will lose your sight.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

(KMS-241C)

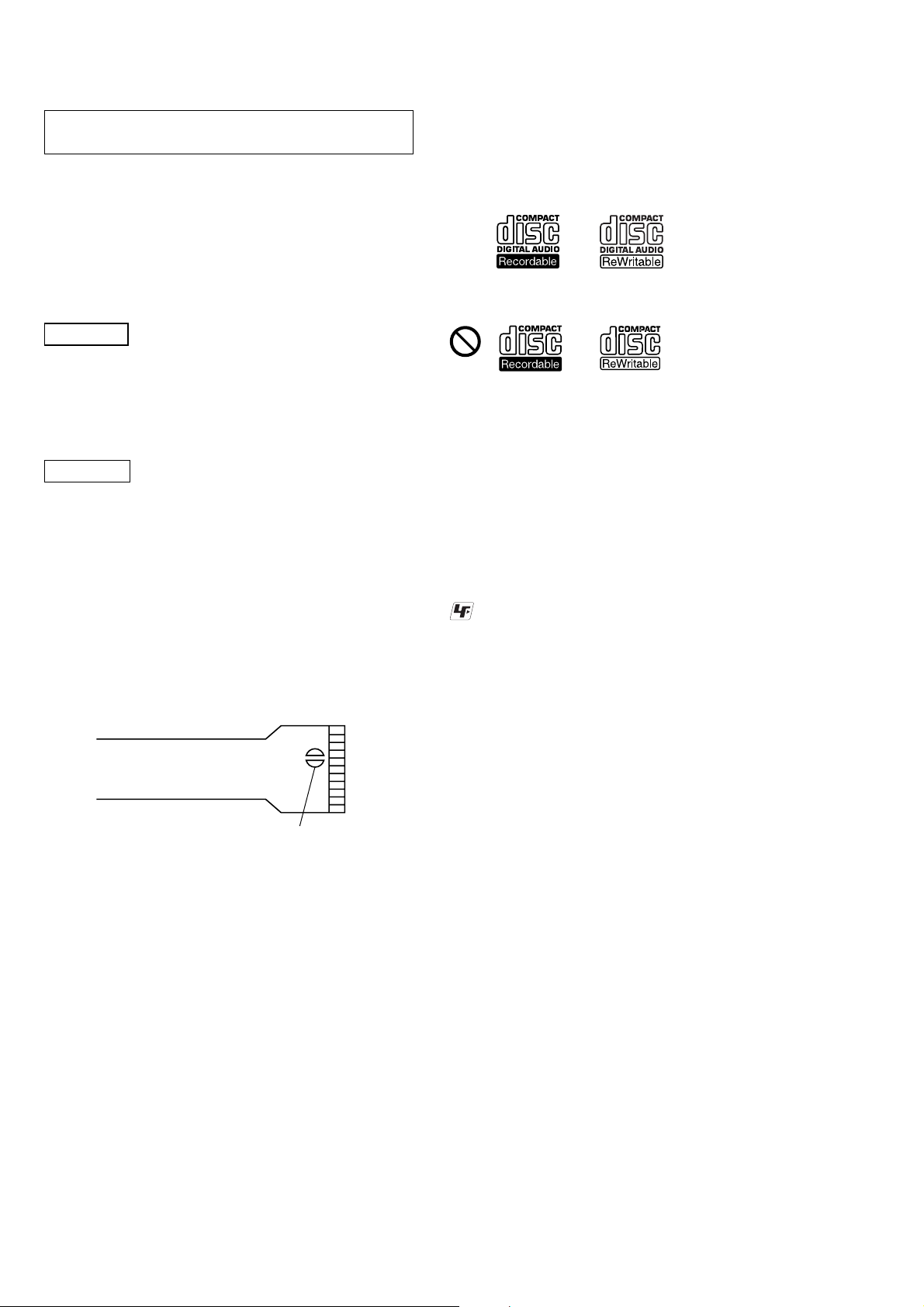

The laser diode in the optical pick-up block may suffer electrostatic break-down easily. When handling it, perform soldering

bridge to the laser-tap on the flexible board. Also perform

m easur es against electrostatic break-down suff iciently before the

operation. The flexible board is easily damaged and should be

handled with care.

laser-tap

OPTICAL PICK-UP FLEXIBLE BOARD

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Notes on CD-R/CD-RW discs

•You can pl ay CD-Rs (recordabl e CD s)/CDRWs (rewritable CDs) designed for audio use

on this unit.

Look for these marks to distinguish CD-Rs/

CD-RWs for audio use.

These marks denote that a disc is not for audi o

use.

•Some CD-Rs/CD-RWs (depending on the

equipment used for its r ecording or the

condition of the disc) m ay not play on this unit.

•You cannot play a CD-R/a CD-RW that is not

finalized*.

*

A process necessary for a recorded CD-R/CD-RW

disc to be played on the audio CD player.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 ˚C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 ˚C .

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less prone to flow) than

ordinary solder so use caution not to let solder bridges occur

such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

2

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Page 3

TABLE OF CONTENTS

WX-7700MDX

1. SERVICING NOTES ................................................ 4

2. GENERAL

Location of Controls ....................................................... 5

3. DISASSEMBLY

3-1. Disassembly Flow........................................................... 10

3-2. Front Panel Section......................................................... 11

3-3. DISPLAY Board ............................................................. 11

3-4. Chassis (T) Section ......................................................... 12

3-5. MD Mechanism Deck (MG-164MF-138)...................... 12

3-6. POWER Board, Chassis (T) Assy .................................. 13

3-7. Heat Sink......................................................................... 13

3-8. SERVO (MD) Board ....................................................... 14

3-9. MD Cover Assy ............................................................... 14

3-10. Float Block ...................................................................... 15

3-11. LO Motor Assy................................................................ 15

3-12. Lever Assy (LE) .............................................................. 16

3-13. Holder Assy..................................................................... 16

3-14. Chucking ARM Assy ...................................................... 17

3-15. Optical Pick-up (KMS-241C)......................................... 17

3-16. SL Motor Assy (SLED) (M902)/

SP Motor Assy (SPINDLE) (M901)............................... 18

3-17. CD Mechanism Deck (MG-398D-121).......................... 18

3-18. Motor Assy (Front Panel Open/Close) (M640).............. 19

3-19. MAIN Board, Chassis (B) Assy ..................................... 19

3-20. Bracket (MAIN) .............................................................. 20

3-21. Chassis (T388) Assy ....................................................... 20

3-22. Sensor (CD) Board.......................................................... 21

3-23. Servo Board, LO Motor SUB Assy (Loading)

(M103)............................................................................. 21

3-24. ARM Roller Assy, LOAD Board.................................... 22

3-25. Floating Block Assy........................................................ 22

3-26. Optical Pick-up (KSS-720A), Sled Motor Assy

(M101)............................................................................. 23

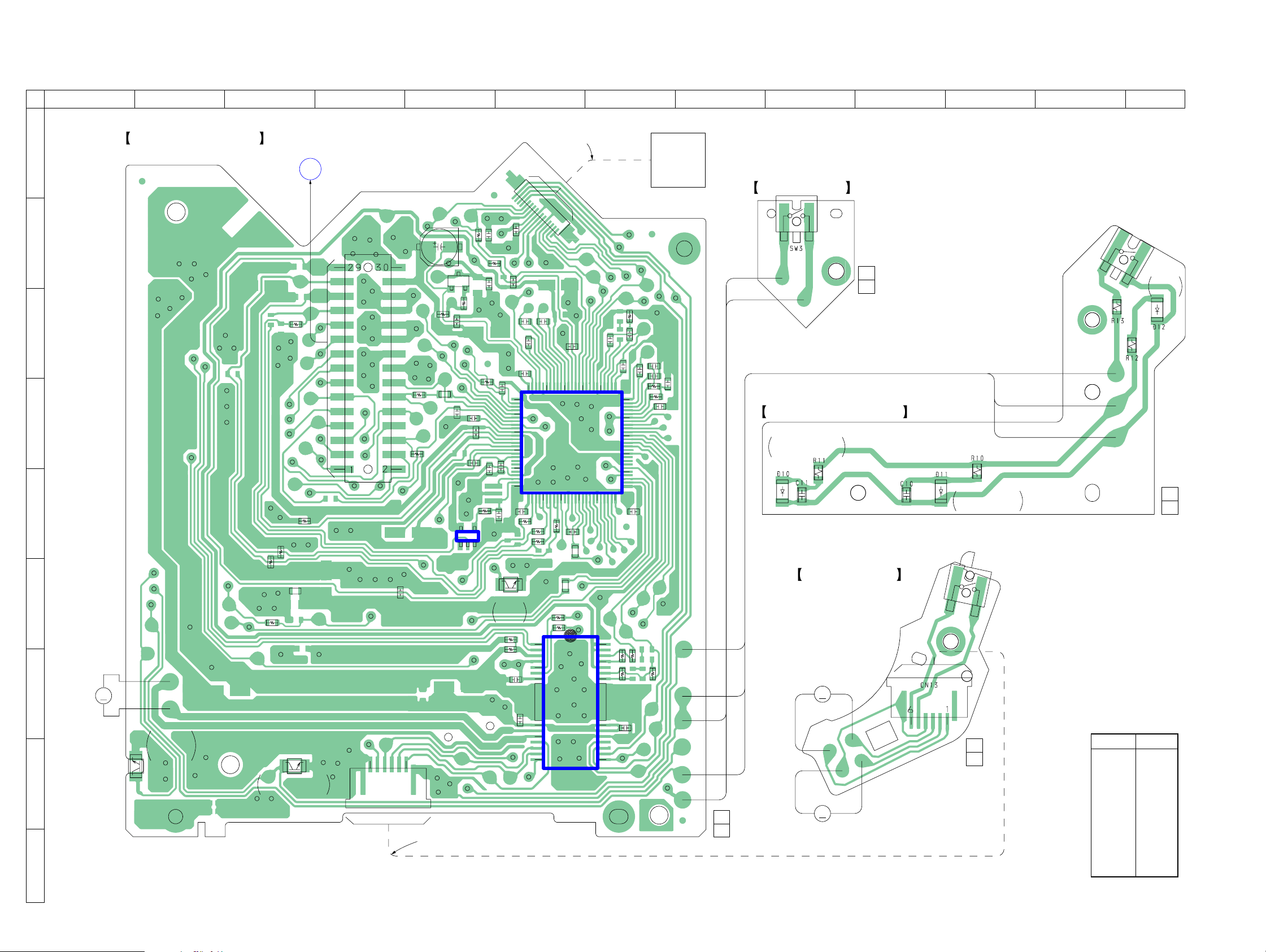

5-20. Printed Wiring Boards

– DISPLAY Board (Conductor Side) – .......................... 43

5-21. Schematic Diagram – DISPLAY Board (1/2) – ............. 44

5-22. Schematic Diagram – DISPLAY Board (2/2) – ............. 45

5-23. Printed Wiring Board

– KEY Board (Component Side) –................................. 46

5-24. Printed Wiring Board

– KEY Board (Conductor Side) –................................... 47

5-25. Schematic Diagram – KEY Board – ............................. 48

5-26. Schematic Diagram – SUB/POWER Boards – ............. 49

5-27. Printed Wiring Board

– POWER Board (Component Side) – ........................... 50

5-28. Printed Wiring Boards – POWER Board

(Conductor Side)/SUB Board – ...................................... 51

5-29. IC Pin Function Description ........................................... 63

6. EXPLODED VIEWS

6-1. MAIN Section ................................................................. 78

6-2. SUB Panel SUB Assy Section ........................................ 79

6-3. Front Panel Section......................................................... 80

6-4. Front Panel SUB Section ................................................ 81

6-5. DISPLAY Board Section ................................................ 82

6-6. Chassis (T) Assy Section ................................................ 83

6-7. Chassis (B) Assy Section-1............................................. 84

6-8. Chassis (B) Assy Section-2............................................. 85

6-9. MD Mechanism Deck Section-1 (MG-164MF-138) ..... 86

6-10. MD Mechanism Deck Section-2 (MG-164MF-138) ..... 87

6-11. MD Mechanism Deck Section-3 (MG-164MF-138) ..... 88

6-12. CD Mechanism Deck Section-1 (MG-398D-121) ......... 89

6-13. CD Mechanism Deck Section-2 (MG-398D-121) ......... 90

6-14. CD Mechanism Deck Section-3 (MG-398D-121) ......... 91

7. ELECTRICAL PARTS LIST ............................... 92

4. ASSEMBLY

4-1. Assembly of ARM (L/R) Assy ....................................... 23

5. DIAGRAMS

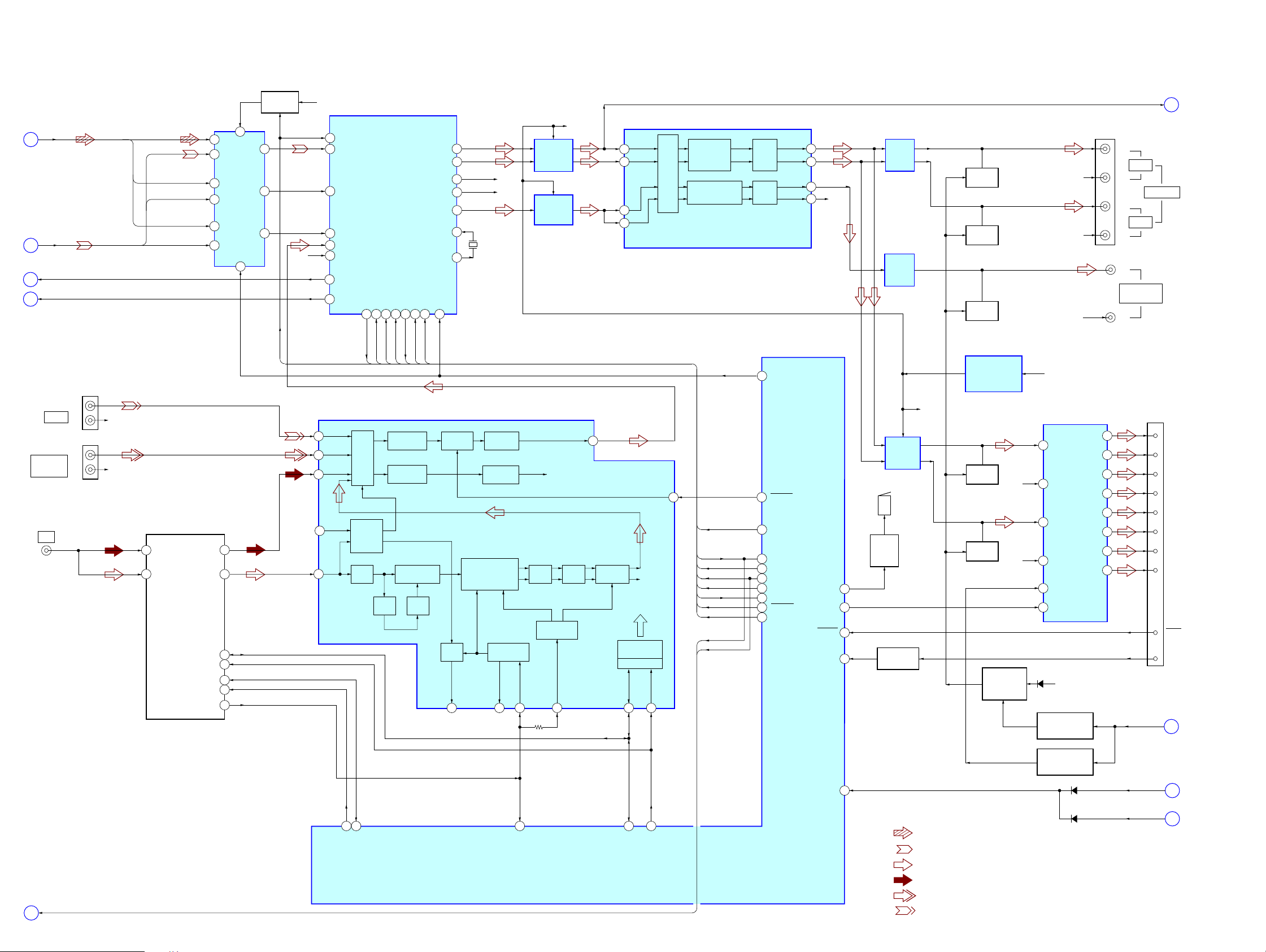

5-1. Block Diagram – CD SERVO Section – ....................... 24

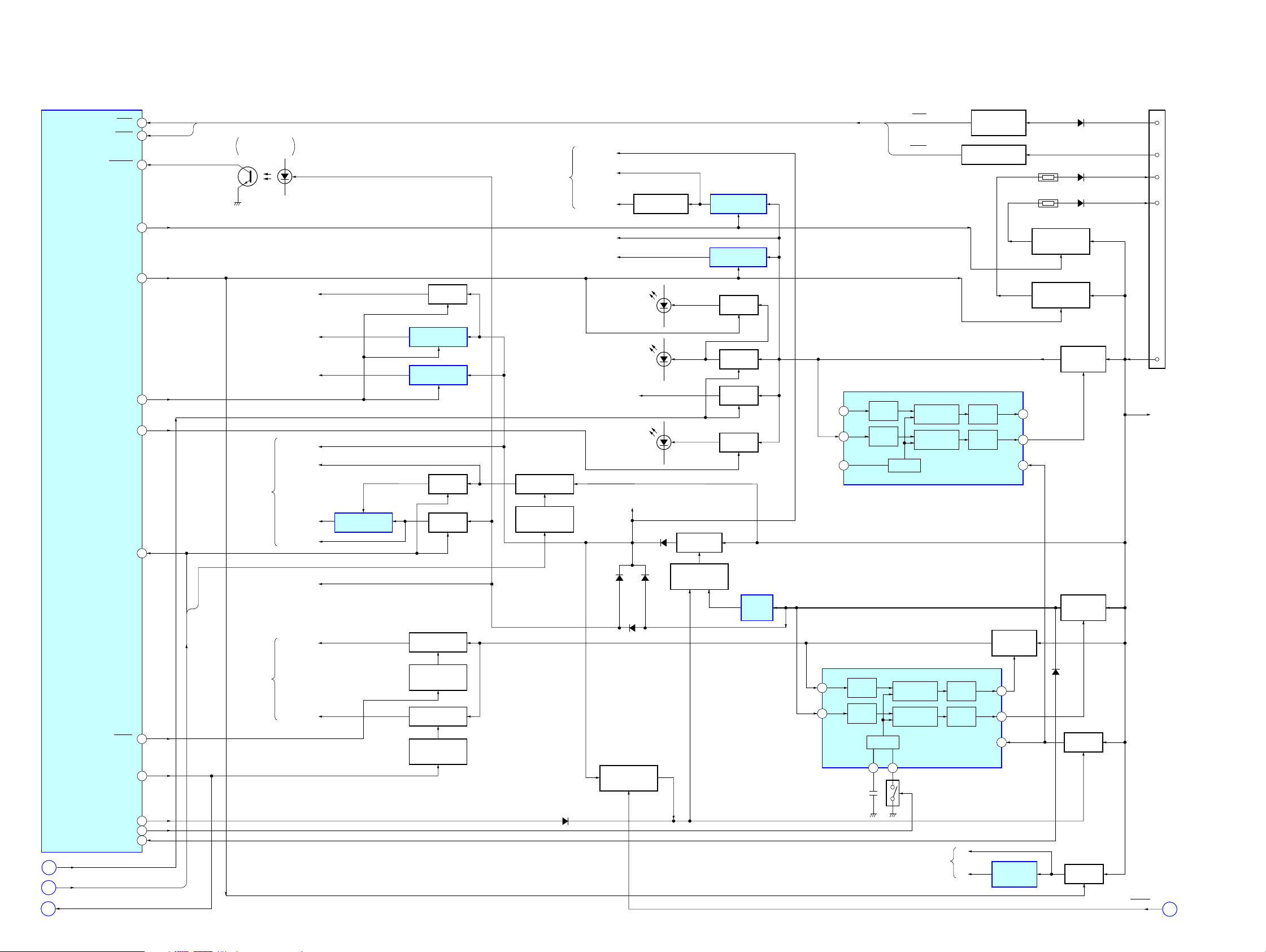

5-2. Block Diagram – MD SERVO Section – ...................... 25

5-3. Block Diagram – MAIN Section –................................ 26

5-4. Block Diagram

– DISPLAY/BUS CONTROL Section – ........................ 27

5-5. Block Diagram – POWER SUPPLY Section – ............. 28

5-6. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 29

5-7. Printed Wiring Boards – CD Section (1/2) – ................ 30

5-8. Printed Wiring Board – CD Section (2/2) – .................. 31

5-9. Schematic Diagram – CD Section –.............................. 32

5-10. Printed Wiring Boards – MD Section –......................... 33

5-11. Schematic Diagram – MD Section (1/2) – .................... 34

5-12. Schematic Diagram – MD Section (2/2) – .................... 35

5-13. Printed Wiring Boards

– MAIN Board (Component Side) – .............................. 36

5-14. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 37

5-15. Schematic Diagram – MAIN Board (1/4) – ................... 38

5-16. Schematic Diagram – MAIN Board (2/4) – ................... 39

5-17. Schematic Diagram – MAIN Board (3/4) – ................... 40

5-18. Schematic Diagram – MAIN Board (4/4) – ................... 41

5-19. Printed Wiring Board

– DISPLAY Board (Component Side) – ........................ 42

3

Page 4

WX-7700MDX

)

SECTION 1

SERVICING NOTES

TEST DISC

This set can playback a CD-R, CD-RW for audio use.

When test this set, use the following test disc.

Test disc for CD-R: TCD-R082LMT (Part No.: J-2502-063-1)

Test disc for CD-RW: TCD-W082L (Part No.: J-2502-063-2)

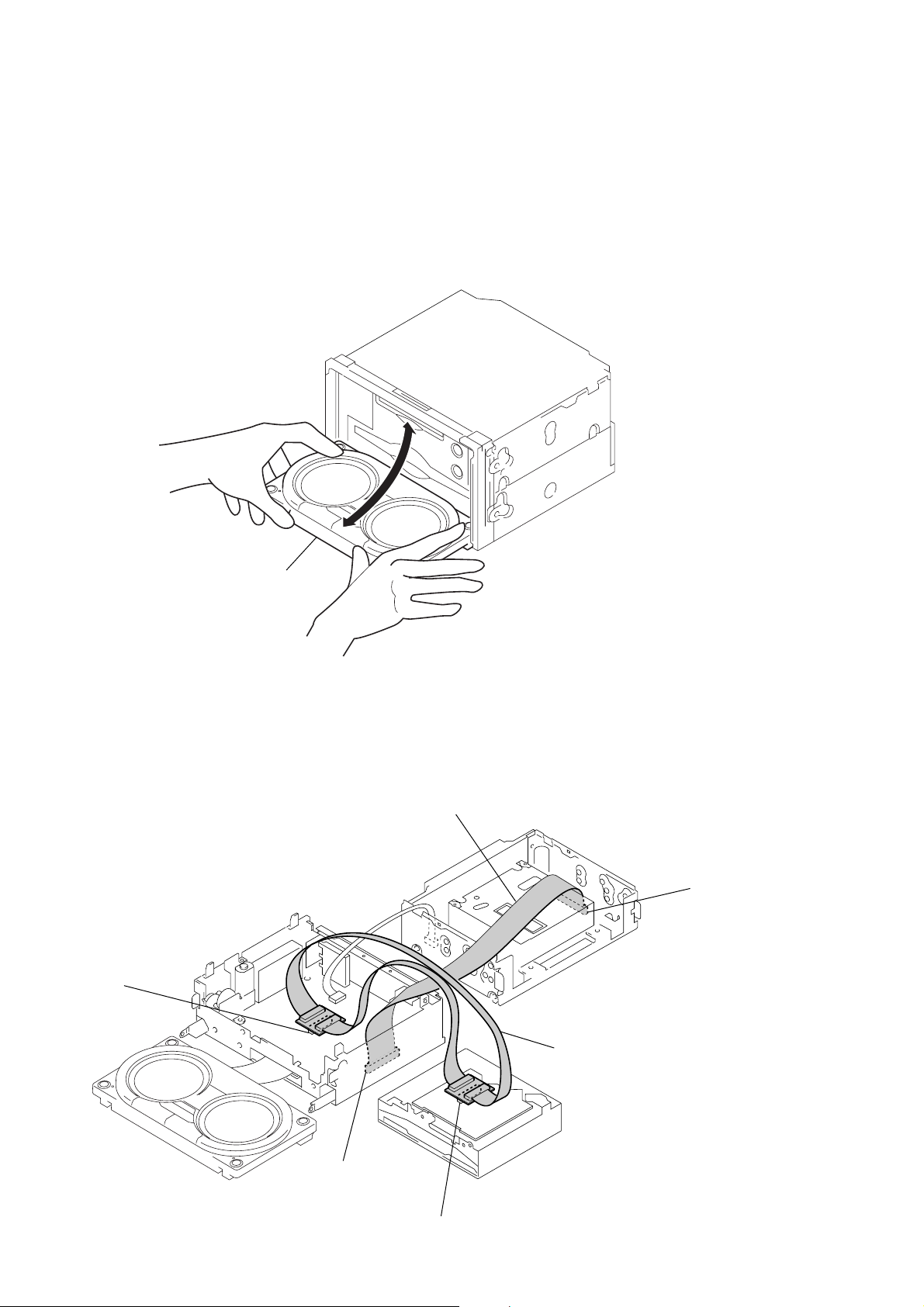

OPENING AND CLOSING OF FRONT PANEL SECTION IN AN ELECTRIC INTERRUPTION STATE

Don't apply impossible power, but open and close slowly with both hands.

front panel section

JIG ON REPAIRING

When repairing this set, etc., connect the extension cable as the figure shown below.

extension cable (main board-power board)

(J-2502-067-1)

CNP370

CN403

extension cable (main board-servo (CD) board

(J-2502-062-1)

CN331

CN1

4

Page 5

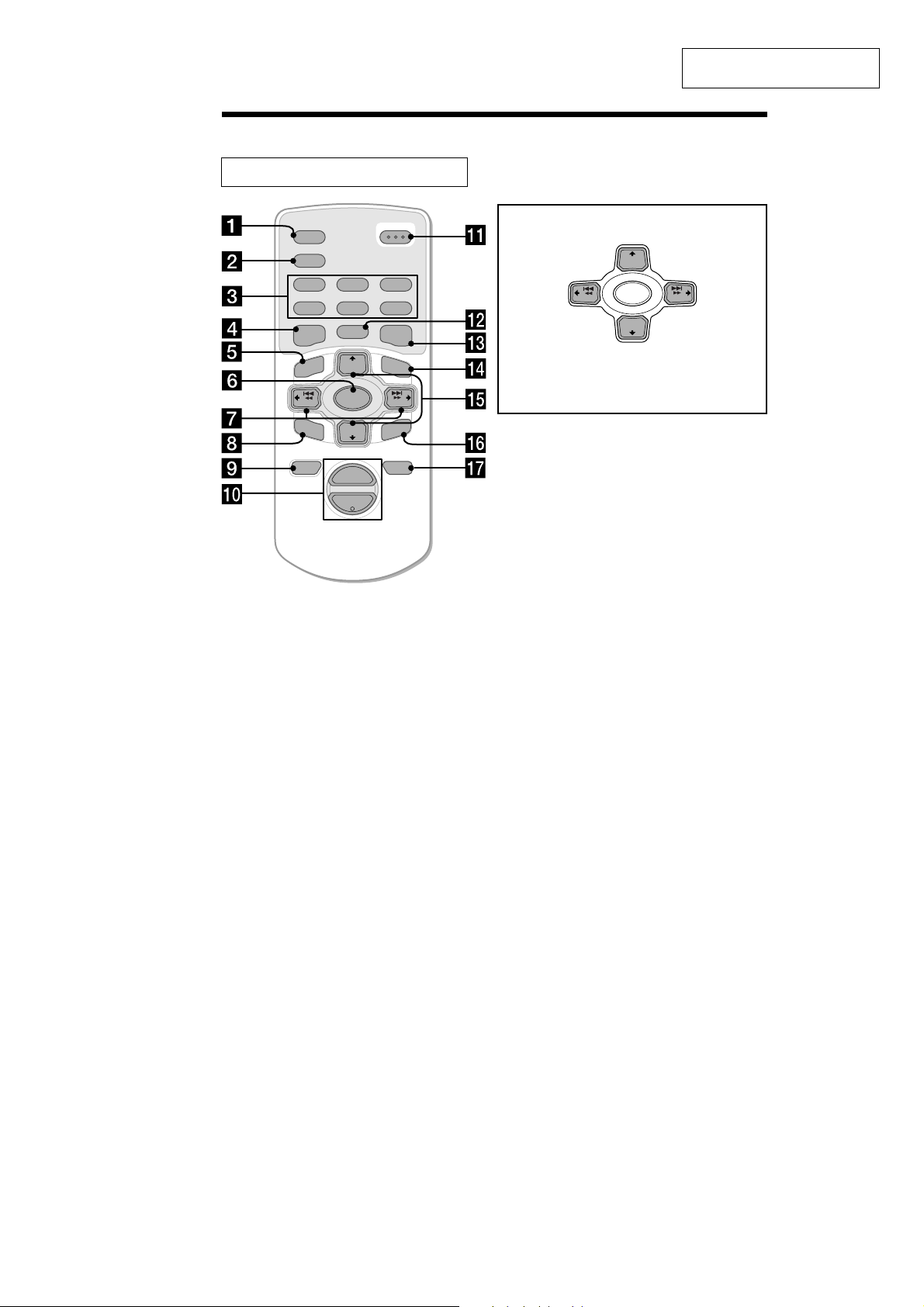

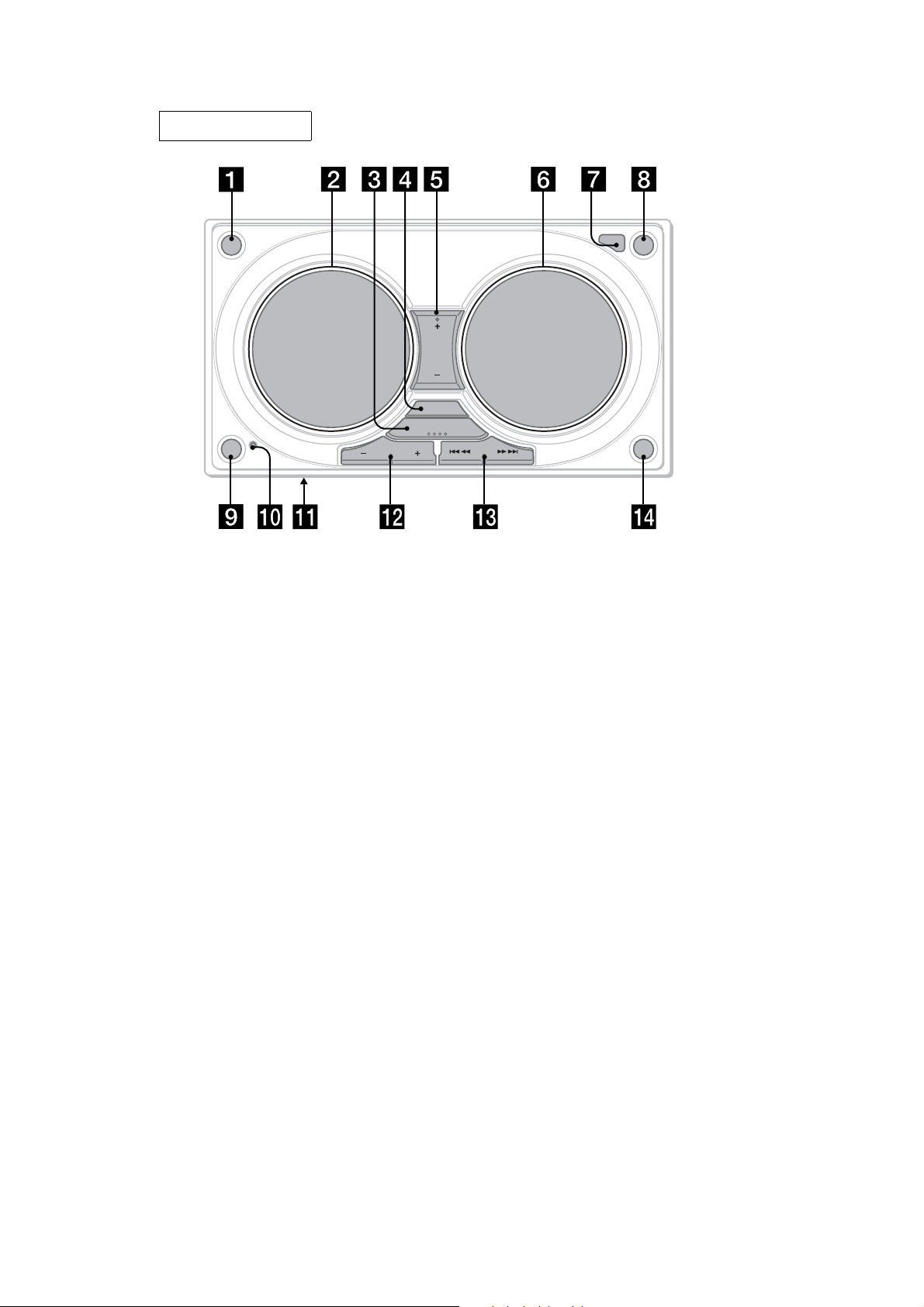

Location of controls

Card remote commander RM-X110

SECTION 2

GENERAL

WX-7700MDX

This section is extracted from

instruction manual.

2

5

MODE

+

DISC

SOURCE

–

DISC

+

VOL

OPEN/CLOSE

3

6

LIST

+

SEEK

ENTER

ATTOFF

SCRL

DSPL

REP SHUF

1

4

EQ7 DSO

MENU

–

SEEK

SOUND

–

Instructions in this manual describe how

to use the unit by mainly using the card

remote commander.

(DISC) (M):

to select upwards

+

DISC

(SEEK) (<):

to select

leftwards

In Menu mode, the currently selectable button(s) of

these four are indicated with a “ v” in the display.

Note

If the unit is turned off by pressing (OFF) for 2

seconds, the unit cannot be operated with the card

remote commander unless (SOURCE) on the unit is

pressed, or a disc is inserted to activate the unit first.

Tip

Refer to “Replacing the lithium battery” for details on

how to replace the batteries.

SOURCE

–

SEEK

–

DISC

(DISC) (m):

to select downwards

(SEEK) (,):

+

SEEK

to select

rightwards

a SCRL (scroll) button

b DSPL (display mode change) button

c Number buttons

(1) REP

(2) SHUF

To store station s/ r eceive stored stations.

d EQ7 button

e MENU button

To display the menus.

f SOURCE (Power on/Radio/CD/MD/

AUX-Audio) button

To select the source.

g SEEK (</,) buttons

To skip tracks/fast-f orward, reverse a track/

tune in stations automatically, find a station

manually/select a setting.

h SOUND button

i OFF (Stop/Power off) button

j VOL ( +/–) buttons

To turn up or down the volume.

k

OPEN/CLOSE button

l MODE button

To change the operation.

m DSO button

n LIST button

o DISC (M/m) buttons

To receive preset stations/change the disc*/

select an item in Menu.

* When an optional CD/MD unit is connected.

p ENTER button

To enter a setting.

q ATT button

5

Page 6

WX-7700MDX

Controls of the unit

ANGLE

ATT

DISC AMS

The buttons on the unit share the same

functions as those on the car d re mote

commander.

a ANGLE button

b Sound window

c SOURCE button

d MODE button

e VOL (+/–) button

f Operation window

g Receptor for the card remote

commander

h OPEN/CLOSE button

i ATT button

j Reset button

k Frequency select switch (located on the

bottom of the unit)

See “Frequency sel ect switch” in the

Installation/Con nections manual.

l DISC (–/+) button s

m AMS (. m/M >) buttons

AMS (. m/M >) buttons share

the same functions as SEEK (</,)

buttons on the card remote commander.

n OFF (Stop/Power off) button*

OPEN/

CLOSE

VOL

MODE

SOURCE

OFF

WX-7700MDX

* Warning when installing in a car without

an ACC (accessory) position on the

ignition switch

After turning off the ignition switch, be sure to

press (OFF) on the unit for 2 seconds to turn

off the clock display.

Otherwise, the clock display does not turn off

and this causes battery drain.

6

Page 7

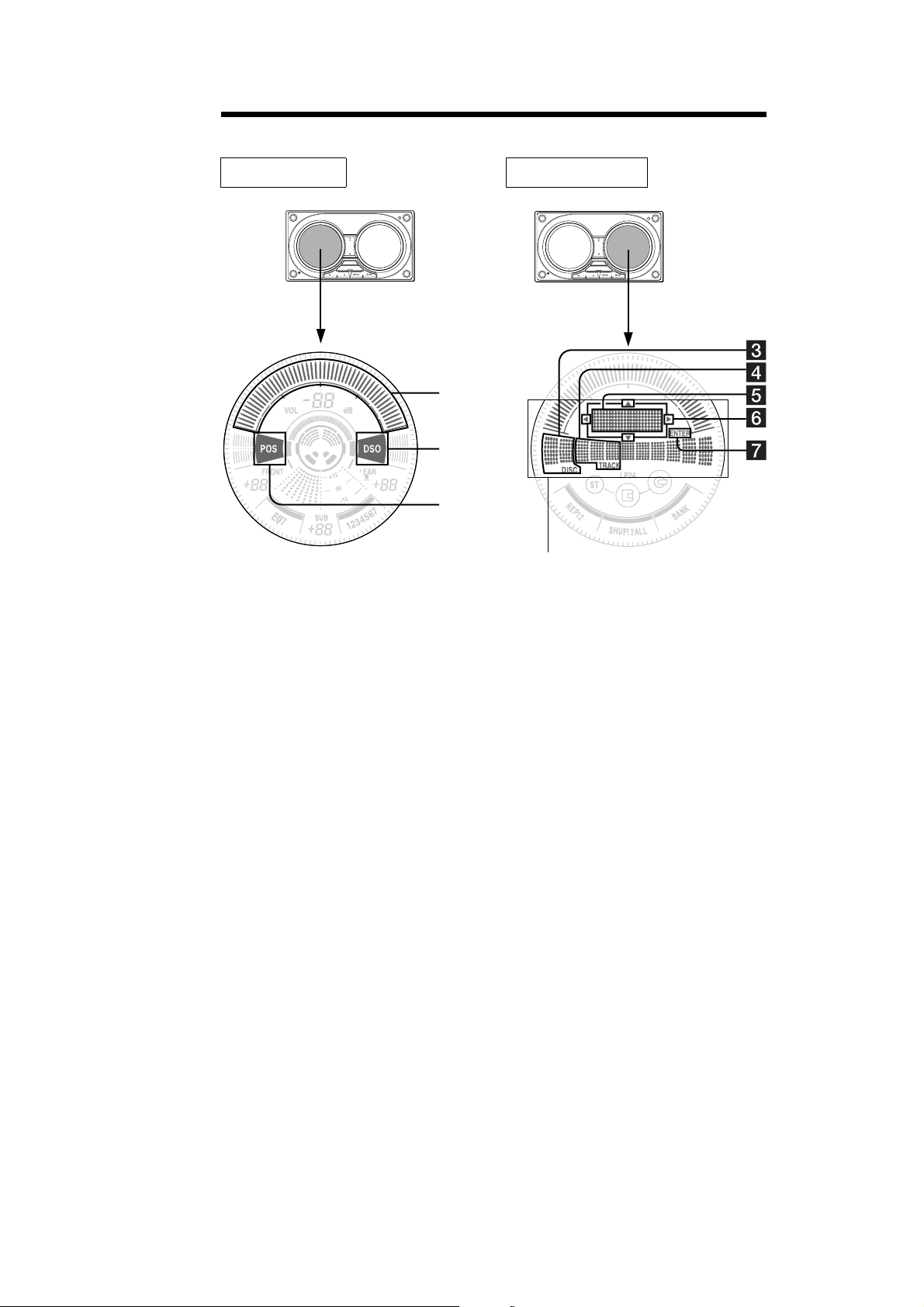

Display windows

Sound window Operation window

WX-7700MDX

ANGLE

VOL

MODE

SOURCE

DISC AMS

ATT

OPEN/

CLOSE

OFF

a DSO

Lights up while you are set t in g t he DSO

mode.

b POS

Lights up while you are set t in g t he POS

mode.

c DISC number

Appears only when an optional CD/MD unit

is connected and a disc in the optional un it is

played.

d Track number

Appears during CD/MD playback.

Level meter

(volume)

1

2

ANGLE

VOL

MODE

SOURCE

DISC AMS

ATT

This manual illustrates the

operation window mainly.

OPEN/

CLOSE

OFF

e Various items for a setting or a source

f Cursor directions

The selectable cu rsor direction appear s as a

“v”.

By pressing a cursor button (M/,/m/<) in

the same direction as any “v” that appears,

you can select an item or proceed with the

operation.

g

ENTER

Appears when it's necessary to press

(ENTER)

after you select an item.

7

Page 8

WX-7700MDX

2

SUBWOOFER OUT

A

(MONO)

AUDIO OUT

B

Source selector

XA-C30

(REAR)

BUS AUDIO IN

BUS CONTROL IN

*

AUDIO OUT

(FRONT)

BUS AUDIO IN

Cautions

• This unit is designed for negative earth 12 V

DC operation only.

• Do not get the wires under a screw, or caught

in moving parts (e.g. seat railing).

• Before making connections, turn the car

ignition off to avoid short circuits.

• Connect the yellow and red power input leads

only after all other leads have been connected.

• Run all earth wires to a common earth

point.

• Be sure to insulate any loose unconnected

wires with electrical tape for safety.

Notes on the power supply cord (yellow)

• When connecting this unit in combination with

other stereo components, the connected car

circuit’s rating must be higher than the sum of

each component’s fuse.

• When no car circuits are rated high enough,

connect the unit directly to the battery.

Parts Iist (1)

The numbers in the list are keyed to those in the

instructions.

Connection example (2)

Notes

(2-A)

• Be sure to connect the earth lead before

connecting the amplifier.

• If you connect an optional power amplifier and do

not use the built-in amplifier, the beep sound will

be deactivated.

Tip

(2-B- )

For connecting two or more changers, the source

selector XA-C30 (optional) is necessary.

Connection diagram (3)

When inserting each connector, be sure to insert

securely, as vibration through driving may

cause a poor connection.

1

To a metal surface of the car

Make sure to connect the black earth lead first of

all, then proceed with connection steps 2-7.

Check the black earth lead is connected properly,

before connecting the orange/white striped lead,

yellow and red power input leads.

2

To AMP REMOTE IN of an optional power

amplifier

This connection is only for amplifiers. Connecting

any other system may damage the unit.

3

To the power aerial control lead or power supply

lead of aerial booster amplifier

Notes

•It is not necessary to connect this lead if there

is no power aerial or aerial booster, or with a

manually-operated telescopic aerial.

•When your car has a built-in FM/AM aerial in

the rear/side glass, see “Notes on the control

and power supply leads.”

4

To the interface cable of a car telephone

5

To a car’s illumination signal

Be sure to connect the black earth lead to it first.

6

To the +12 V power terminal which is energized

in the accessory position of the ignition key

switch

Notes

• If there is no accessory position, connect to the

+12 V power (battery) terminal which is

energized at all times.

Be sure to connect the black earth lead to it

first.

•When your car has a built-in FM/AM aerial in

the rear/side glass, see “Notes on the control

and power supply leads.”

7

To the +12 V power terminal which is energized

at all times

Be sure to connect the black earth lead to it first.

Notes on the control and power supply leads

• The power aerial control lead (blue) supplies +12 V

DC when you turn on the tuner.

•When your car has built-in FM/AM aerial in the

rear/side glass, connect the power aerial control

lead (blue) or the accessory power input lead (red)

to the power terminal of the existing aerial

booster. For details, consult your dealer.

•A power aerial without relay box cannot be used

with this unit.

Memory hold connection

When the yellow power input lead is connected,

power will always be supplied to the memory circuit

even when the ignition key is turned off.

Notes on speaker connection

• Before connecting the speakers, turn the unit off.

• Use speakers with an impedance of 4 to 8 ohms,

and with adequate power handling capacities to

avoid its damage.

• Do not connect the speaker terminals to the car

chassis, or connect the terminals of the right

speakers with those of the left speaker.

• Do not connect the earth lead of this unit to the

negative (–) terminal of the speaker.

•Do not attempt to connect the speakers in parallel.

• Connect only passive speakers. Connecting active

speakers (with built-in amplifiers) to the speaker

terminals may damage the unit.

• To avoid a malfunction, do not use the built-in

speaker wires installed in your car if the unit shares

a common negative (–) lead for the right and left

speakers.

• Do not connect the unit’s speaker cords to each

other.

BUS CONTROL IN

*

not supplied

8

Page 9

WX-7700MDX

3

4

*

RCA pin cord

Left

Right

Left

SUBWOOFER OUT

(MONO)

1

*

BUS CONTROL IN

1

Supplied with XA-C30

*

AUX IN

2

*

3

4

Black

White

White/black striped

Grey

Grey/black striped

Green

Green/black striped

Fuse (10 A)

L

R

AUX IN

AUDIO OUT

(FRONT)

AUDIO OUT

(REAR)

L

R

REAR

Blue/white striped

Blue

Light blue

Orange/white striped

Red

Source selector

XA-C30

FRONT BUS AUDIO

AUDIO OUT IN

Supplied with the CD/MD changer

BUS AUDIO IN

RCA pin cord

*

Max. supply current 0.3 A

AMP REM

ANT REM

Max. supply current 0.1 A

ILLUMINATION

1

ATT

from car aerial

2

3

4

5

6

*1 not supplied

2

*

Connect the Bus cable to its

terminal with the unit’s V mark and

the Bus cable’s v mark aligned.

3

*

supplied with the auxiliary

equipment

4

*

Auxiliary optional equipment such

as portable DVD player (not

supplied)

4 A

TOYOTA/MITSUBISHI

This illustration is for TOYOTA cars.

1

or

2

max. size 5 × 8 mm

Precautions

• Choose the installation location carefully so

that the unit will not interfere with normal

driving operations.

• Avoid installing the unit in areas subject to

dust, dirt, excessive vibration, or high

temperatures, such as in direct sunlight or near

heater ducts.

• Use only the supplied mounting hardware for

a safe and secure installation.

To open/close the front panel smoothly, to insert/

eject a disc easily, and especially to drive safely, a

certain distance between the front panel and the

shift lever is necessary. The necessary distance

differs, depending on the shift lever position of

your car. Before installing the unit, choose the

installation location carefully so that you can

drive safely.

Shift lever

Mounting angle adjustment

Adjust the mounting angle to less than 30°.

88 mm

Right

Bracket

Existing parts supplied with your car

Purple

Purple/black striped

WX-7700MDX

to dashboard/centre console

Bracket

Frequency select switch

The AM (FM) tuning interval is factory-set to the

9 k (50 k) position. If the frequency allocation

system of your country is based on 10 kHz (200

kHz) interval, set the switch on the bottom of

the unit to the 10 k (200 k) position before

making connections.

After the frequency select switch is set, you must

press the reset button to reset the unit.

Yellow

B

NISSAN

1

or

max. size 5 × 8 mm

1

or

2

max. size 5 × 8 mm

Mounting the unit in a Japanese

car (4)

You may not be able to install this unit in some

makes of Japanese cars. In such a case, consult

your Sony dealer.

When mounting this unit to the preinstalled

brackets of your car, use the supplied screws 1

or 2 in the appropriate screw holes, according

to your vehicle: T for TOYOTA, M for

MITSUBISHI, and N for NISSAN.

Notes

• Use the screws 1 or 2 depending on the make of

•To prevent malfunction, be sure to install using

• Do not apply excessive force to the buttons of the

• Do not push on the display window.

• Before mounting, make sure there is nothing on

N

T

M

M

T

N

T

T

N

N

T

N

M

car. When this unit is attached to a MITSUBISHI car,

use the supplied screws 2.

brackets and the supplied screws 1 or 2.

unit.

the top of the unit.

7

2

Bracket

3

Existing parts supplied with your car

Warning when installing in a car

without ACC (accessory)

position on the ignition key

switch

Be sure to press (OFF) on the unit for two

seconds to turn off the clock display after

turning off the engine.

When you press (OFF) only momentarily, the

clock display does not turn off and this causes

battery wear.

WX-7700MDX

to dashboard/centre console

Bracket

Reset button

When the installation and connections are

completed, be sure to press the reset button with

a ballpoint pen, etc.

ANGLE

DISC AMS

ATT

Reset button

Note

When you connect the power supply cord to the

unit or reset the unit, wait for about 10 seconds

before you insert a disc. If you insert a disc within

these 10 seconds, the unit will not be reset, and you

will have to press the reset button again.

1

or

2

max. size 5 × 8 mm

VOL

MODE

SOURCE

OPEN/

CLOSE

OFF

9

Page 10

WX-7700MDX

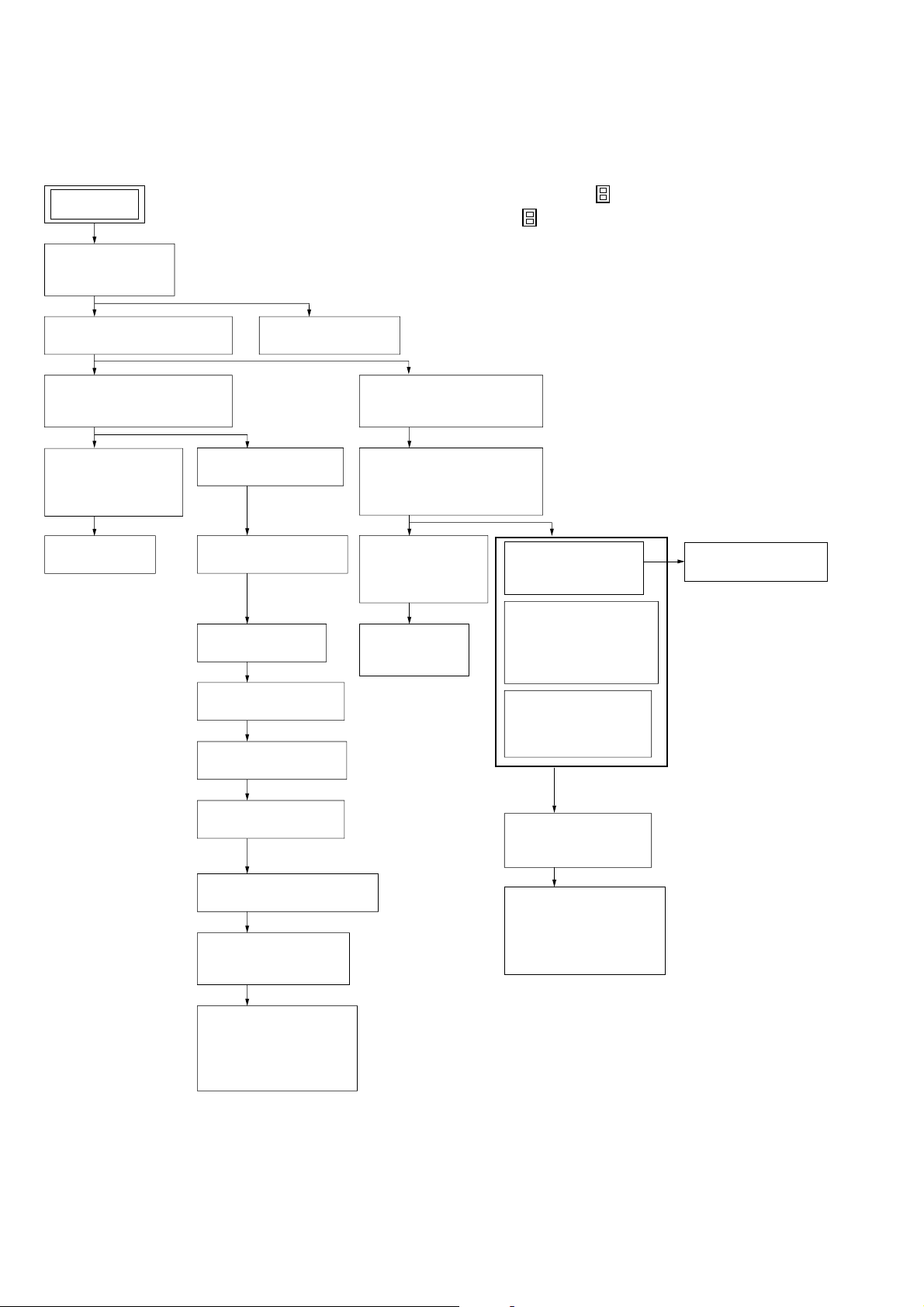

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SECTION 3

DISASSEMBLY

SET

3-2. FRONT PANEL

SECTION

(Page 11)

3-4. CHASSIS (T) SECTION

(Page 12)

3-5. MD MECHANISM DECK

(MG-164MF-138)

(Page 12)

3-6. POWER BOARD,

CHASSIS (T)

ASSY

(Page 13)

3-7. HEAT SINK

(Page 13)

3-8. SERVO (MD)

3-9. MD COVER ASSY

3-10. FLOAT BLOCK

3-11. LO MOTOR ASSY

3-12. LEVER ASSY (LE)

Note 1: The process can be removed in every turn in the .

Note 2: Unless finishes all processes in the , it cannot progress to the following process.

3-3. DISPLAY BOARD

(Page 11)

3-17. CD MECHANISM DECK

(MG-398D-121)

(Page 18)

BOARD (Page 14)

(Page 14)

(Page 15)

(Page 15)

(Page 16)

3-18. MOTOR ASSY

(FRONT PANEL OPEN/

CLOSE) (M640)

(Page 19)

3-19. MAIN BOARD,

CHASSIS (B)

ASSY

(Page 19)

3-20. BRACKET

(MAIN)

(Page 20)

3-21. CHASSIS (T388)

ASSY

(Page 20)

3-23. SERVO (CD)

BOARD, LO

MOTOR SUB ASSY

(LOADING) (M103)

(Page21)

3-24. ARM ROLLER

ASSY,

LOAD BOARD

(Page 22)

3-22. SENSOR (CD)

BOARD (Page 21)

3-13. HOLDER ASSY

(Page 16)

3-14. CHUCKING ARM ASSY

(Page 17)

3-15. OPTICAL PICK-UP

(KMS-241C)

(Page 17)

3-16. SL MOTOR ASSY

(SLED) (M902)/

SP MOTOR ASSY

(SPINDLE) (M901)

(Page 18)

3-25. FLOATING BLOCK

ASSY

(Page22)

3-26. OPTICAL PICK-UP

(KSS-720A),

SLED MOTOR ASSY

(M101)

(Page23)

10

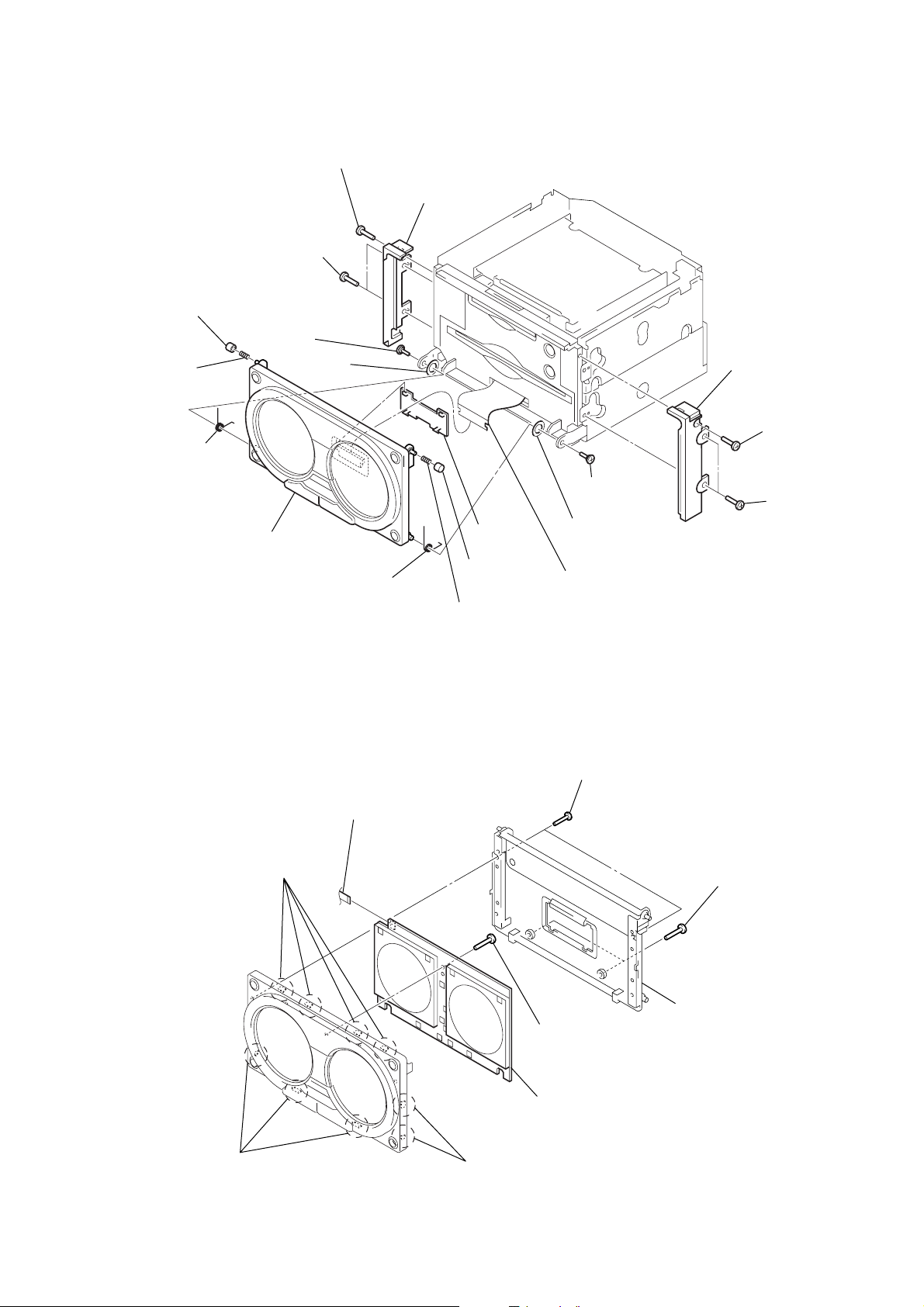

Page 11

Note: Follow the disassembly procedure in the numerical order given.

w

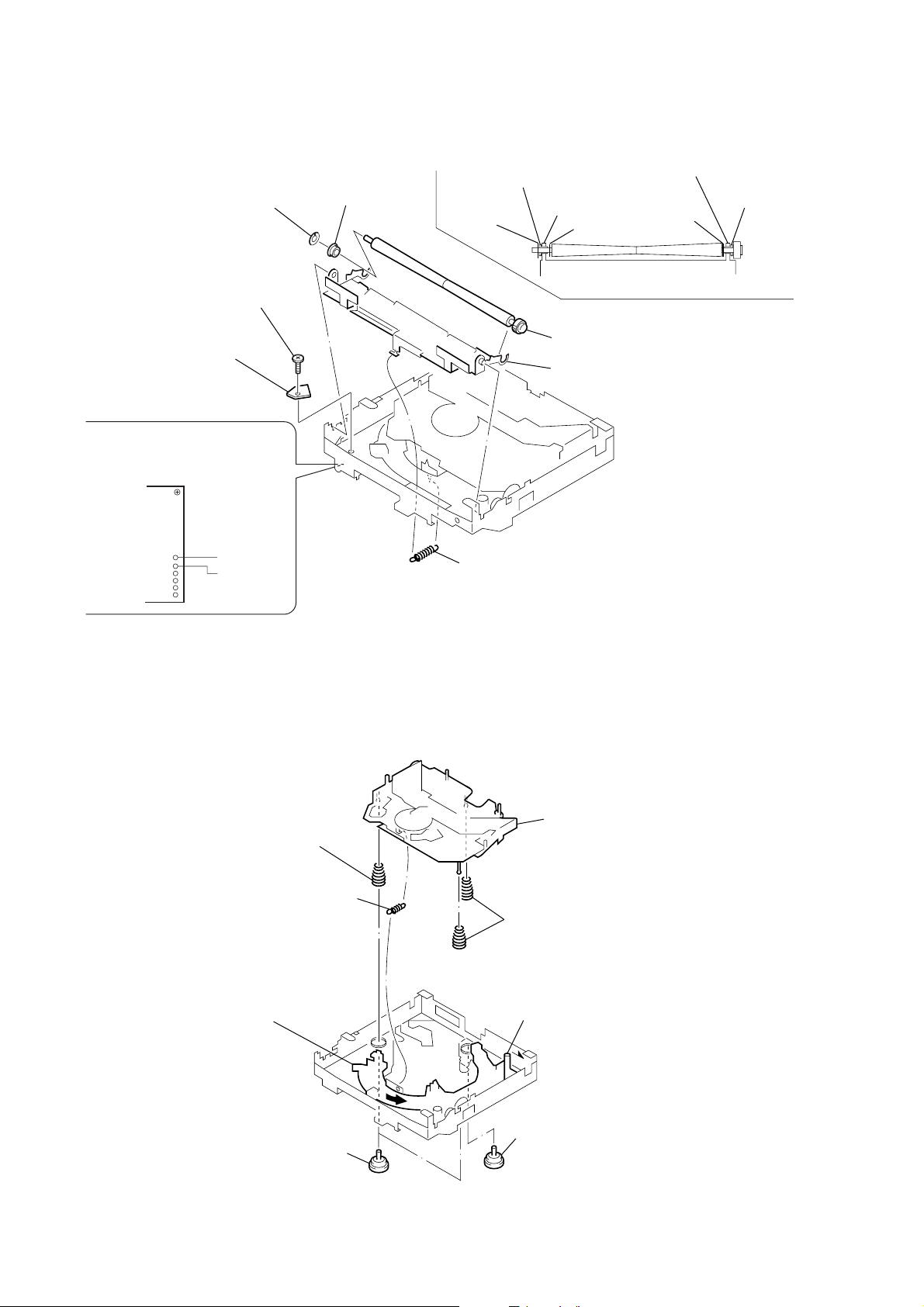

3-2. FRONT PANEL SECTION

1

tapping screw

3

guide panel (L)

2

two screws

(PTT2.6 × 6)

4

roller

(guide)

5

spring

(guide)

8

torsion spring

(fulcrum: R)

qa

6

ornamental

screw

7

front panel section

8

sleeve

torsion spring

(fulcrum: L)

5

spring

(guide)

4

9

cover

(flexible)

roller

(guide)

6

ornamental

screw

7

sleeve

0

key connection

flexible board

WX-7700MDX

3

guide panel (R)

1

tapping scre

2

two screws

(PTT2.6 × 6)

3-3. DISPLAY BOARD

3

four claws

5

flaxible frat cable (7P)

(CN711)

1

two screws

(P2

×

6

tapping screws

7

display board

5)

2

two tapping screws

4

front back panel

3

three claws

3

two claws

11

Page 12

WX-7700MDX

n

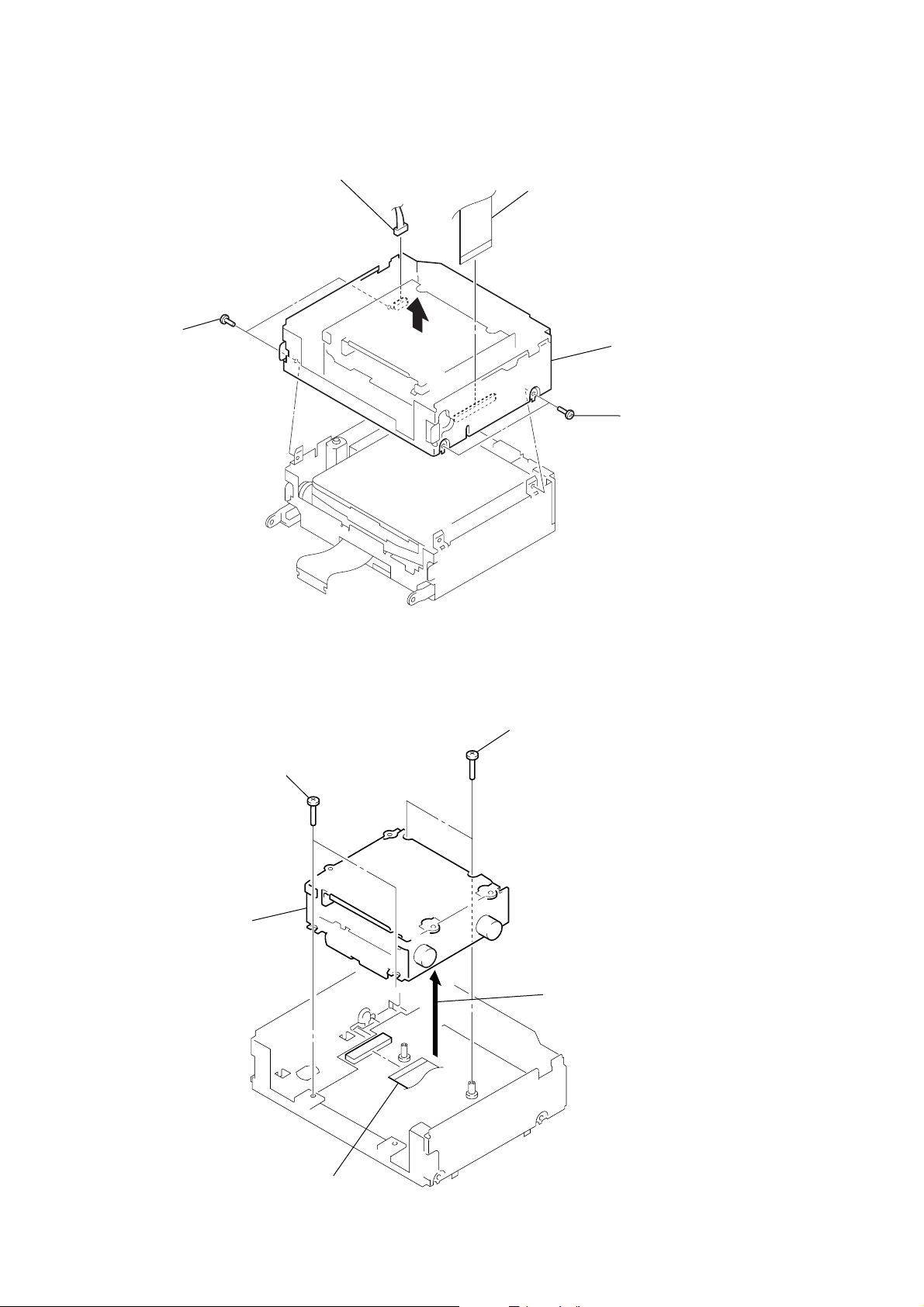

3-4. CHASSIS (T) SECTION

3

two screws

(PTT2.6

×

6)

2

connector (CN400)

1

flexible flat cable (40P)

(CN403)

4

chassis (T) sectio

3

two screws

(PTT2.6

×

6)

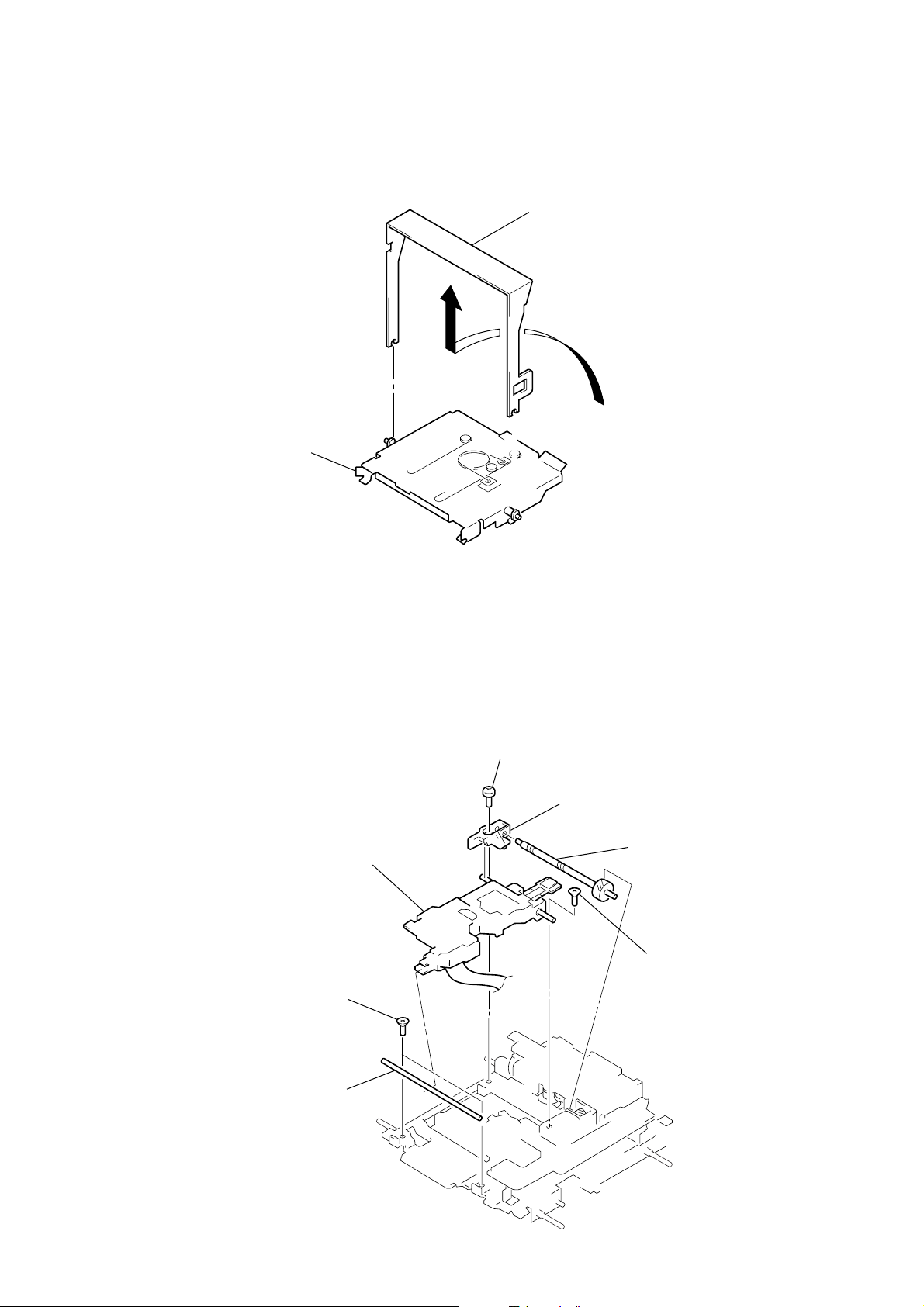

3-5. MD MECHANISM DECK (MG-164MF-138)

1

4

MD mechanism deck (MG-164MF-138)

two screws

(PTT2.6

×

5)

1

two screws

(PTT2.6

×

5)

2

Rifting up the MD mechanism deck.

12

3

flexible flat cable (30P)

(CN402)

Page 13

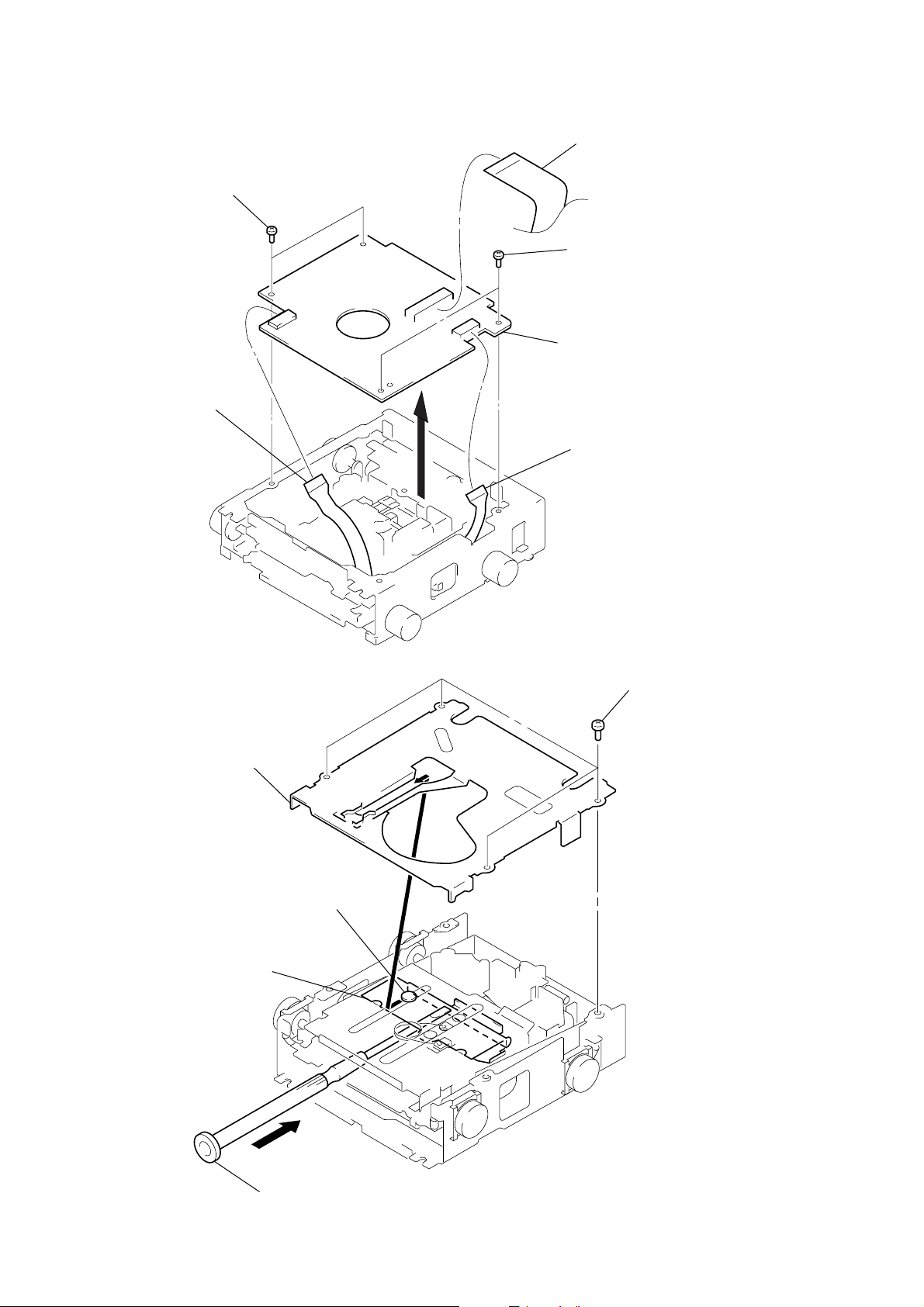

3-6. POWER BOARD, CHASSIS (T) ASSY

)

)

2

four ground point screws

3

power board

1

two screws

(PTT2.6 × 6

WX-7700MDX

4

chassis (T) assembly

3-7. HEAT SINK

2

heat sink

1

four screws

(PTT2.6 × 10

power board

13

Page 14

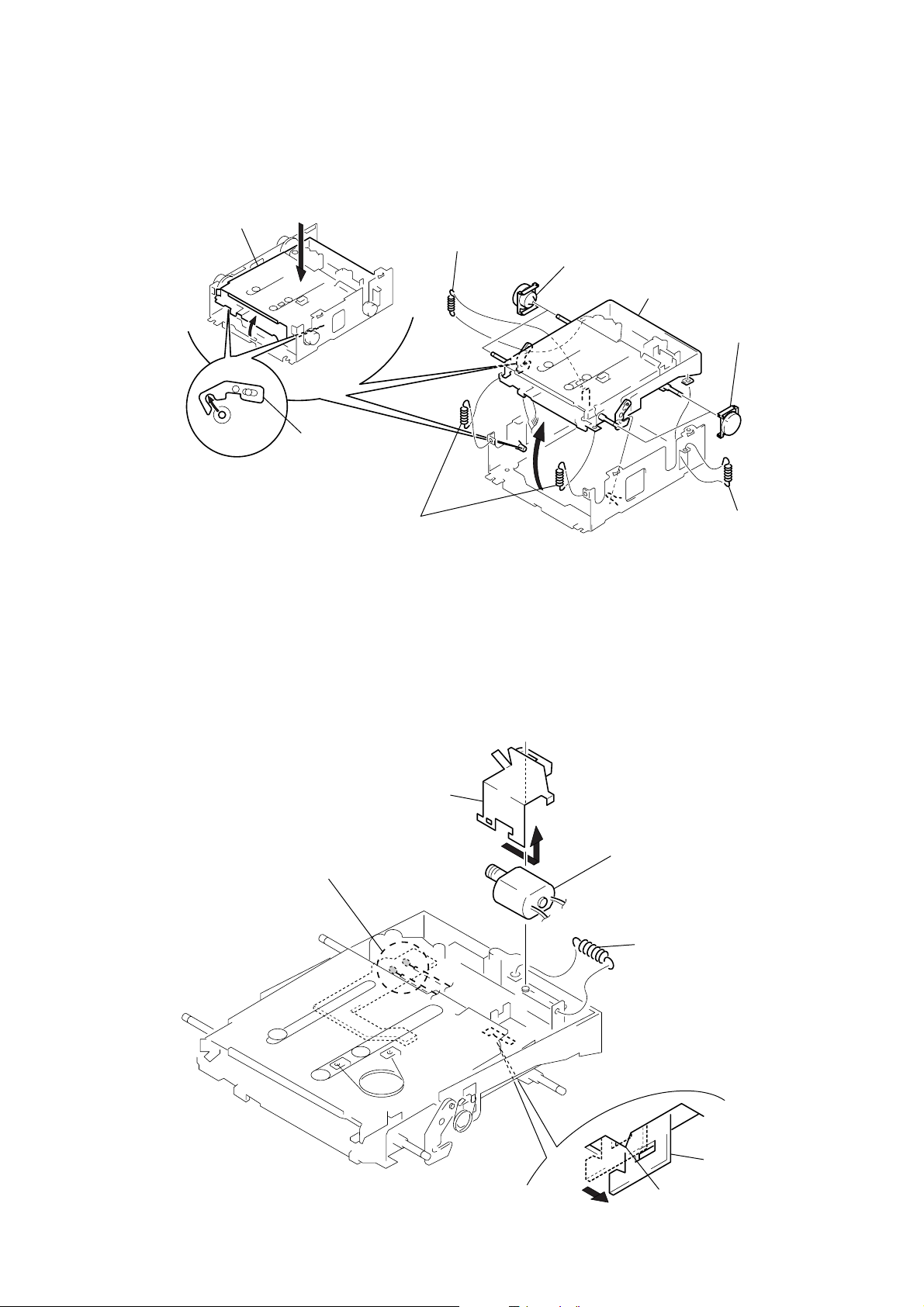

WX-7700MDX

d

3-8. SERVO (MD) BOARD

2

two screws

(BVTT2 × 4)

1

sensor connection

flexible board

(CN103)

1

MD flexible board

(CN101)

2

two screws

(BVTT2 × 4)

3

servo (MD) boar

1

flexible board

(CN103)

3-9. MD COVER ASSY

3

MD cover assy

casset holder

ring (MD cover guide)

1

four screws

(B2

×

3)

14

A

2

Pushing the cassette holder in the direction of arrow A with a screwdriver,

disengage the shaft (MD cover guide) from the groove of MD cover ass’y.

Note : Be careful not to damage the optical pick-up

when pushing the cassette holder with a screwdriver.

Page 15

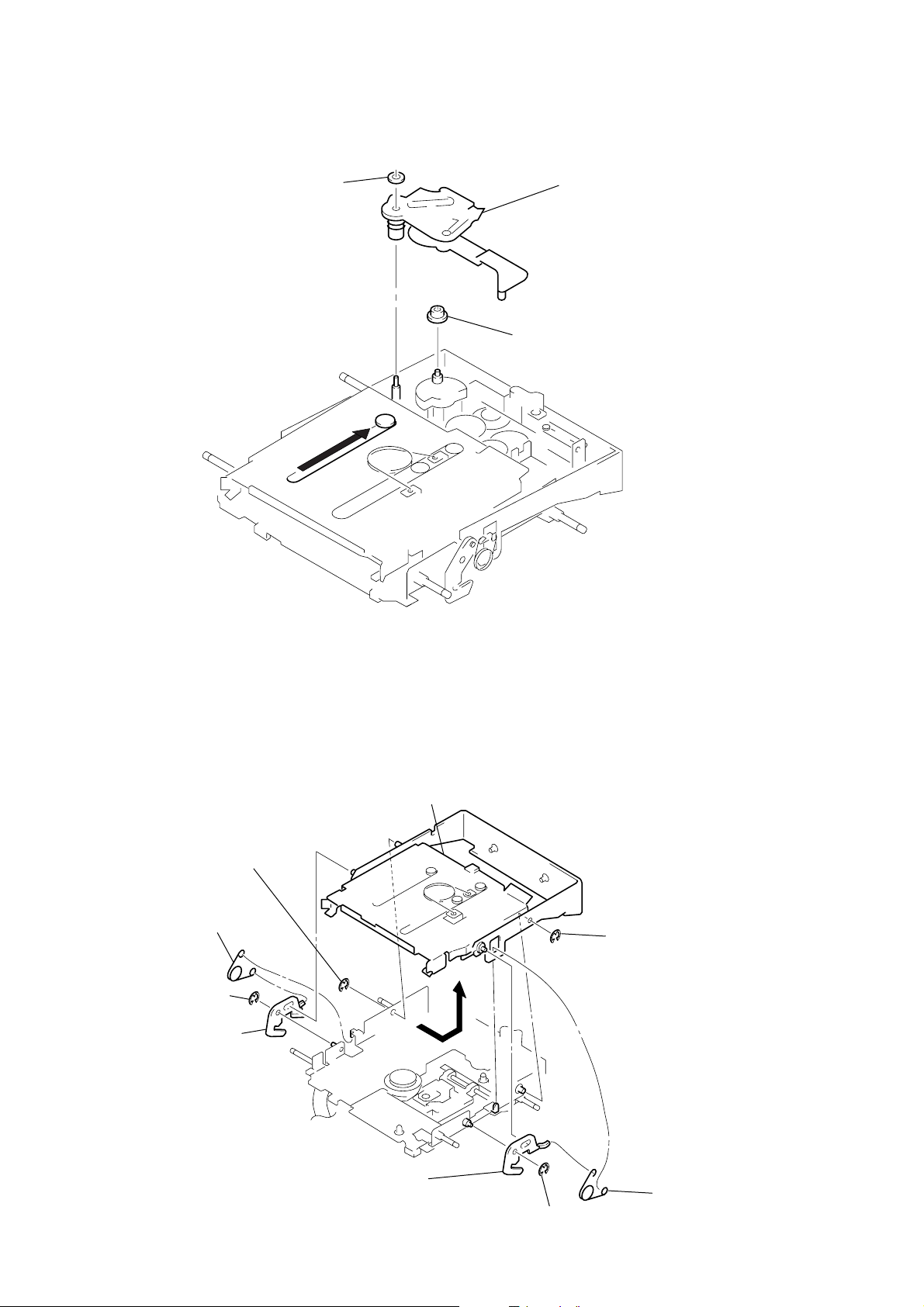

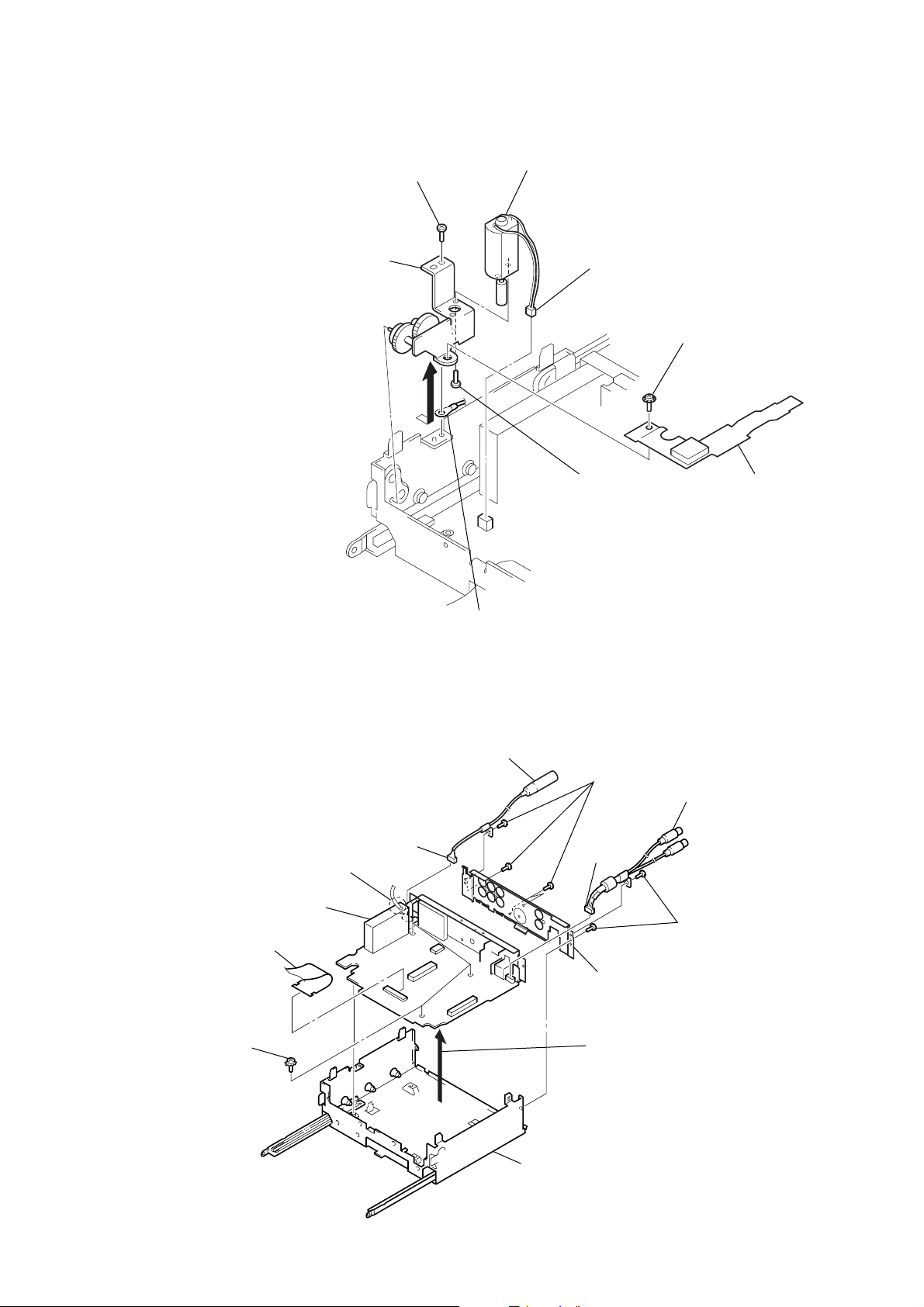

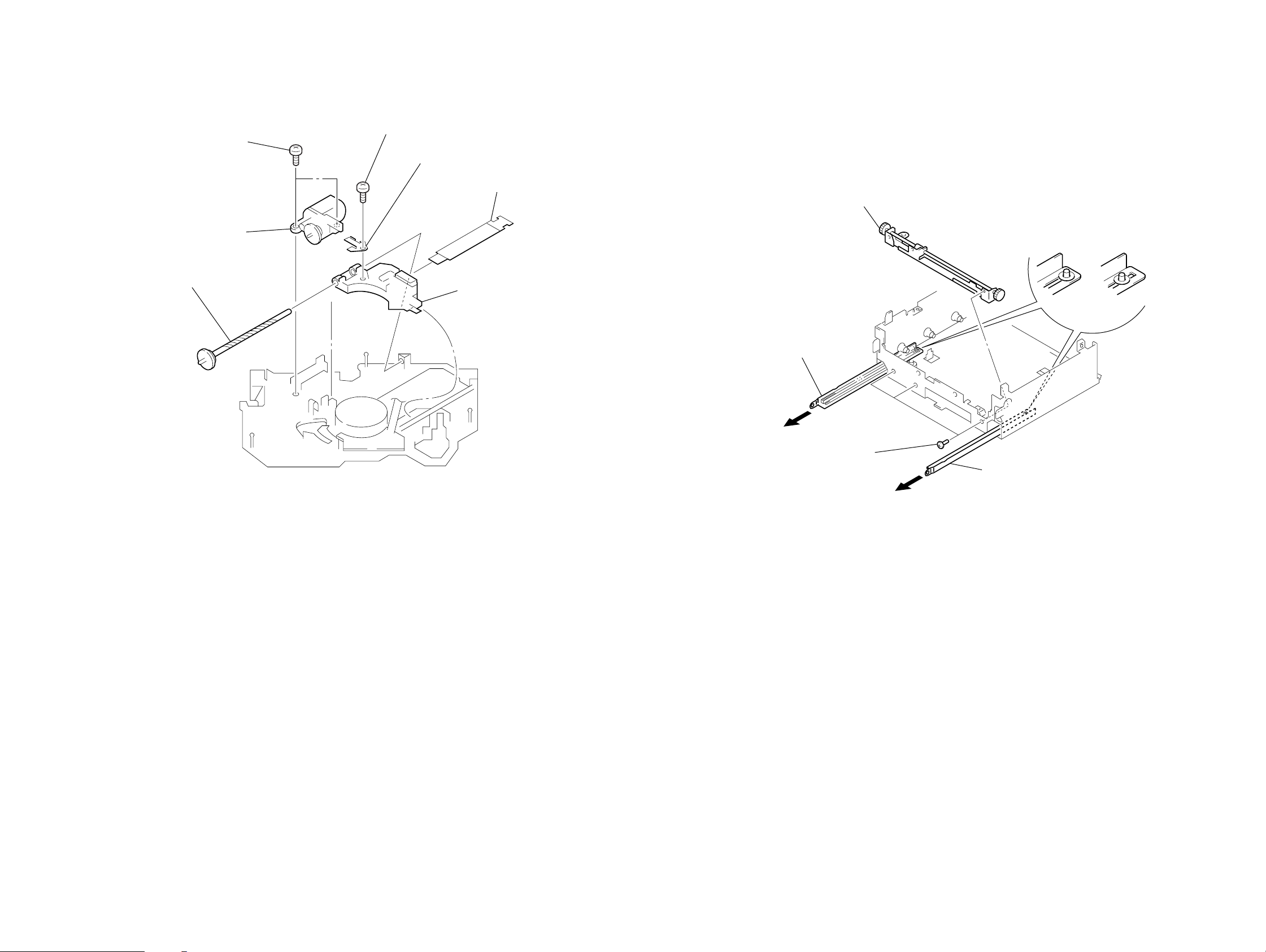

3-10. FLOAT BLOCK

float block

A

3

Pushing an arrow A part, raise the float block

up ward at the front to release a lock.

1

tension spring (float B)

5

two damper assies

6

float block

WX-7700MDX

5

two damper assies

lock open

3-11. LO MOTOR ASSY

1

Remove solders of motor (M903)

lever (lock R)

lever (lock L)

2

two tension springs (float F)

4

Remove the bracket (LO)

in the direction of arrow

A

4

1

tension spring (float B)

.

5

A

LO motor ass’y (loading)

(M903)

2

tension spring (rack)

3

claw

– bottom view –

bracket (LO)

15

Page 16

WX-7700MDX

)

3-12. LEVER ASSY (LE)

2

stopper washer

1

3

4

roller (gear E)

lever (LE) ass’y

3-13. HOLDER ASSY

7

type-E stopring 1.5

4

spring (CHKG)

5

type-E stopring 1.5

6

lever (lock R)

8

Remove the holder ass’y in the

direction of the arrow.

7

type-E stopring 1.5

16

3

lever (lock L)

2

type-E stopring 1.5

1

spring (CHKG

Page 17

y

y

3-14. CHUCKING ARM ASSY

holder ass’y

1

Remove the chucking arm ass’

in the direction of the arrow.

WX-7700MDX

3-15. OPTICAL PICK-UP (KMS-241C)

7

optical pick-up (KMS-241C)

1

two screws

(K2 × 3)

2

guide shaft (OPT L)

4

screw

(B2 × 3)

6

bearing (SL)

5

feed screw ass’

3

screw

(K2 × 3)

17

Page 18

WX-7700MDX

)

3-16. SL MOTOR ASSY (SLED) (M902)/SP MOTOR ASSY (SPINDLE) (M901)

5

screw

×

1.8)

(P1.7

0

two screws

×

1.8)

qa

bracket (SP)

qs

SP motor ass’y

(spindle) (M901)

(P1.7

6

7

SL motor ass’y

(sled) (M902)

8

screw

×

(B2

9

base (SL)

bracket (SL)

3)

3

screw (PS2 × 8)

2

screw (PS2 × 4)

4

sensor (MD) board

3-17. CD MECHANISM DECK (MG-398D-121)

5

CD mechanism deck (MG-398D-121)

4

bracket (CD)

1

two screws

(PTT2.6

2

1

Remove solders of motors

(M901, M902)

×

6)

3

connector

(CNP370)

two screws

(PTT2.6

×

6

18

1

two screws

(PTT2.6

×

6)

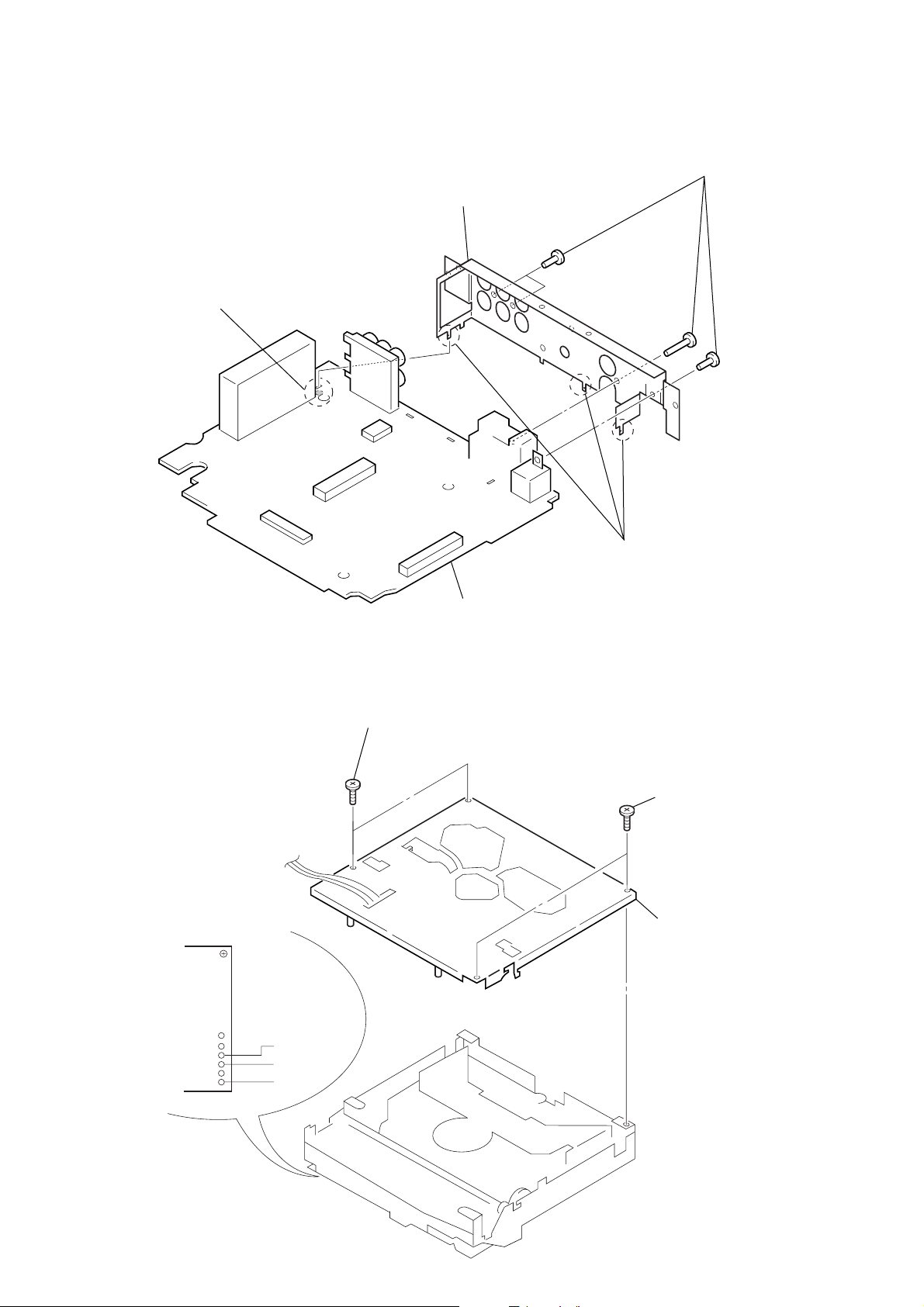

Page 19

2

two screws

(PTT2.6

×

6)

2

four screws

(PTT2.6

×

6)

8

cord (with connector) (RCA)

qa

cord (with connector)

(ANT)

0

connector

(CN1)

9

Remove a solder of earth wire.

qs

main board

1

key connection flexible board

(CN670)

4

ground point screw

5

Remove the main board

from the chassis (B) assy.

6

chassis (B) assy

3

rear panel

7

connector

(CN3)

3-18. MOTOR ASSY (FRONT PANEL OPEN/CLOSE) (M640)

8

motor assy (front panel open/close) (M640)

5

Remove the bracket (motor) assy

in the direction of arrow.

4

two screws

(PTT2.6 × 6)

1

connector

(CN640)

7

two screws

(P2 × 2.5)

2

ground point screw

WX-7700MDX

3

heat sink

3-19. MAIN BOARD, CHASSIS (B) ASSY

6

harness

19

Page 20

WX-7700MDX

)

3-20. BRACKET (MAIN)

2

Remove a solder of bracket (main).

4

bracket (main)

1

four screws

(PTT2.6

×

6

3-21. CHASSIS (T388) ASSY

1

Remove three solders

of lead wire from sensor board.

2

two screws

(PTT2

×

3)

main board

3

Bend three claws.

3

two screws

(PTT2

4

chassis (T388) assy

×

3)

20

black

blue

red

Page 21

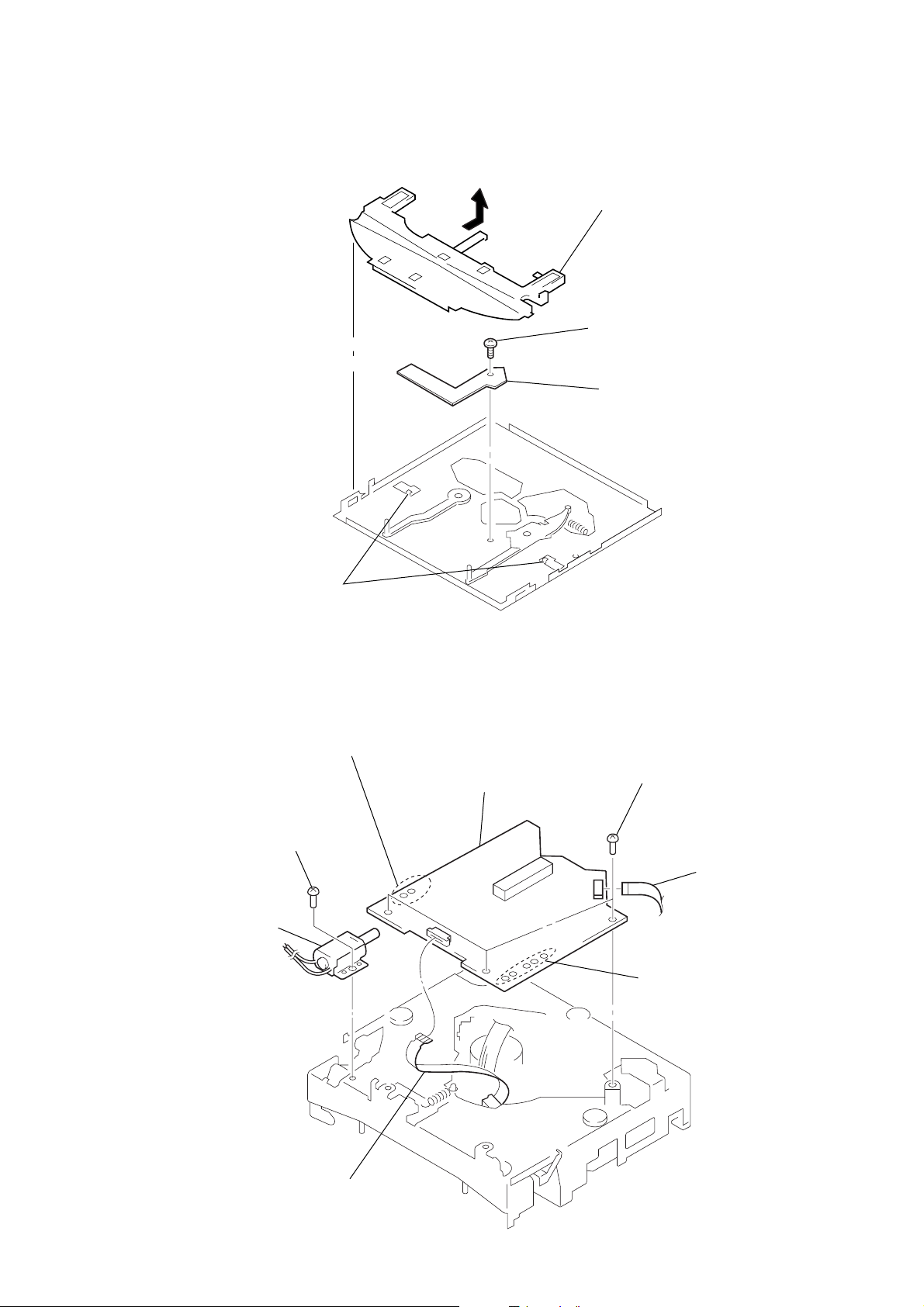

d

3-22. SENSOR (CD) BOARD

WX-7700MDX

two claws

1

2

3

guide (disc M)

4

special screw

5

sensor (CD) boar

3-23. SERVO BOARD, LO MOTOR SUB ASSY (LOADING) (M103)

2

Remove two solders of lead wire

of loading motor.

4

servo board

5

screw

×

3)

(P2

6

LO motor sub assy

(loading) (M103)

3

three screws

(PS2

2

×

4)

1

pick-up flexible board

(CN2)

Remove five solders of lead wire

of sensor board and load board.

1

motor frexible board (CN3)

21

Page 22

WX-7700MDX

3-24. ARM ROLLER ASSY, LOAD BOARD

3

retaining ring

(RA)

7

special screw

8

load board

6

Remove two solders of lead wire

from load board.

yellow

black

4

shaft retainer

(roller)

shaft retainer (roller)

retaining ring

(RA)

1

tension spring (RA)

arm (roller)

washer

5

arm roller assy

2

arm (roller)

arm (roller)

shaft retainer

(roller)

washer

3-25. FLOATING BLOCK ASSY

8

compression spring

(FL)

1

tension spring (KF1)

5

Turn loading ring in the direction of arrow.

3

damper (T)

6

floating block assy

7

compression spring

(FL)

4

Slide the lever (D) in the direction of arrow.

2

damper (T)

22

Page 23

)

SECTION 4

PHASE ALIGNMENT

WX-7700MDX

3-26. OPTICAL PICK-UP (KSS-720A), SLED MOTOR ASSY (M101)

1

2

sled motor assy

(M101)

7

shaft (feed) assy

two screws

(PS2

×

3)

5

two screws (PS2 × 3)

6

plate spring (feed)

4

pick up flexible board

3

optical pick-up (KSS-720A

Note: Follow the assembly procedure in the numerical order given.

4-1. ASSEMBLY OF ARM (L/R) ASSY

2

drive shaft assy

1

Pull the arm (L) assy

in the direction of arrow

at the full.

OK NG

3

three screws

(PS2.6 × 4)

1

Pull the arm (R) assy in the direction of arrow

at the full.

2323

Page 24

WX-7700MDX

SECTION 5

DIAGRAMS

5-1. BLOCK DIAGRAM – CD SERVO Section –

DETECTOR

A

B

C

D

I-V AMP

A

B

C

D

B

84

A

82

D

85

C

83

RFO

77

AGCI

76

RF AMP,

FOCUS/TRACKING ERROR AMP,

DIGITAL SIGNAL PROCESSOR,

DIGITAL SERVO PROCESSOR,

DIGITAL FILTER, D/A CONVERTER.

CD-TEXT

IC1

AGCO

• SIGNAL PATH

: CD PLAY

EFM

75

RFI

74

71

ASY

72

DOUT

SCKO

LRCK

XTAL

EMPH

30

32

34

24

27

CD-DATA

CD-BCK

CD-LRCK

IC3

CD CLOCK

SWITCH

IC503

CD-DATA,

CD-BCK,

CD-LRCK

BFOT

CDM ON

CD EMPH

A

B

C

D

(Page 26)

(Page 26)

(Page 28)

(Page 26)

E

F

LASER DIODE

PICK-UP BLOCK

(KSS-720A)

2-AXIS DEVICE

(FOCUS)

(TRACKING)

PD LD

OPTICAL

PD

FCS+

FCS–

TRK+

TRK–

E

F

LD

AUTOMATIC

POWER

CONTROL

M101

(SLED)

Q1

M

87

86

98

LD

FOCUS/TRACKING COIL DRIVE,

16

15

17

18

14

13

FEO

E

F

SLED/SPINDLE/LOADING

VO4–

VO4+

VO3+

VO3–

VO1+

VO1–

91

TEO

93

97

PD

MOTOR DRIVE

IC2

OPIN4–

OPIN3–

IN1

FE–

90

TE2

TE–

92

26

23

5

94

TEC

95

FD

62

TD

63

SD

64

SCK

TSI

TSO

TSOI

TSCK

RFOK

PACK

STB

TSTB

RST

7

SO

8

SI

6

54

53

39

55

2

52

5

56

4

A0

3

DISC IN DETECT

D12, Q6

DISC SIZE

(8cm/12cm) DETECT

D11, Q7

LOADING

COMPLETION DETECT

D10, Q8

SW3

(DISC SET)

SW1

(SELF)

CD SI/TSI

25

CD SO/TSO

26

CD CKO/TCKO

27

CD RFOK

59

CD PACK

64

CD STB

37

CD TSTB

41

CD A0

36

CD XRST

35

MASTER CONTROLLER

(CD MECHANISM CONTROLLER)

IC550 (1/4)

CD PH1

60

CD PH2

66

CD PH3

61

CD DSW

62

CD SELFSW

67

M102

(SPINDLE)

M103

(LOADING)

11

M

M

VO2–

12

VO2+

10

VOL+

9

VOL–

FWD

REV

IN2

6

1

2

MD

65

SW4

(LIMIT)

68

57

58

CD LIMIT

CD LM LO

CD LM EJ

2424

Page 25

5-2. BLOCK DIAGRAM – MD SERVO Section –

OPTICAL PICK-UP BLOCK

(KMS-241C)

F

C B

I J

A

D

E

DETECTOR

LDPD

LASER DIODE

ILCC

I

J

B

A

C

D

E

F

RM

AUTOMATIC

POWER CONTROL

Q302

48 47

MORFI

MORFO

I

1

RF AMP

J

2

A

4

B

5

I-V

C

AMP

6

D

7

E

8

I-V

F

AMP

9

APC

LD/PD

11

10

AMP

PD

RFO

46 40

B.P.F.

3T

TEMP

WBL

AT

B.P.F.

AMP

ABCD

AMP

COMMAND

SERIAL/PARALLEL

CONVERTER,

DECODER

APCREF

12

SWDT

EFM/ACIRC ENCODER/DECODER,

SHOCK PROOF MEMORY CONTROLLER,

FOCUS/TRACKING ERROR AMP

AGCI

WBL

PEAK &

BOTTOM

ADFM ADIN

SCLK

181716

FOCUS

ERROR AMP

TRACKING

ERROR AMP

XLAT

3029

EQ

CONVERTER

DIGITAL SIGNAL PROCESSOR,

ATRAC ENCODER/DECODER

IC301 (1/2)

RF AMP,

IC302

RF

V-I

RF AGC

& EQ

EQ

3T

WBL

AUX

PEAK

BOTM

ADFG

ABCD

F0CNT

38

33

37

36

32

35

FE

34

TE

26

SE

28

20

FILTER

100

60

59

62

61

53

54

57

78

79

EFMO

FILI

PCO

CLTV

FILO

ASYO

ASYI

RFI

ADFG

F0CNT

PLL

COMPA-

RATOR

ADIP

DEMODULATOR/

DECODER

+3.3V

SPINDLE

SERVO

SPFD

94 93

PROCESSOR

SPRD

15

EFM/ACIRC

ENCODER/DECODER

SUBCODE

DQSY11SQSY14XINT

12

LEVEL SHIFT

IC502 (1/2)

TX

SHOCK PROOF

MEMORY CONTROLLER

CPU

INTERFACE

SENS

SRDT

SWDT

9 8 5 6 7

17

111315

975

3

SAMPLING

CONVERTER

ATRAC

DIGITAL

AUDIO

INTERFACE

ENCODER/DECODER

INTERNAL BUS

SCLK

XLAT

RATE

MONITOR

CONTROL

MNT0

MNT1

1 2 3 4

246

LEVEL SHIFT

IC502 (2/2)

181614

ADDT

DATAI

XBCKI

LRCKI

DIN0

DIN1

DOUT

DADT

MNT2

MNT3

8

12

WX-7700MDX

• SIGNAL PATH

: MD PLAY

25

22

24

23

19

20

21

MD-DATA, MD-BCK, MD-LRCK

DIVIDER

IC304

512FS

E

F

(Page 26)

(Page 26)

28

2927

LRCK

XBCK

FS256

CLOCK

GENERATOR

MD-DATA

MD-BCK

MD-LRCK

OSCI

OSCO

XOE

XWE

XRAS

XCAS

16

17

D0 – D3A00 – A09

49, 48, 50, 5134 – 31, 36 – 40, 45

43

47

46

44

DELAY BUFFER

IC306

D0 – D3

1, 2, 24, 25

D-RAM

IC307

A00 – A09

9 – 12, 14 – 18, 5

22

OE

3

WE

RAS

4

CAS

23

26

2-AXIS

DEVICE

(TRACKING)

FCS+

(FOCUS)

FCS–

TRK+

TRK–

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

IC303

M901

M902

(SLED)

MM

M

(SPINDLE)

FOK

SLOCK

XBUSY

TH501

X501

10MHz

Q301

ABCD

FE

AUX1

ABCD

ANALOG MUX

A/D CONVERTER

FROM CPU

INTERFACE

AUTO

SEQUENCER

3159

32 2664 27 28 2945

XTAL

EXTAL

MD-RST

TE

SE

PEAK

BOTM

XLRF

80

CKRF

81

DTRF

82

EJECT

LOAD

7 6

5 4

FIN

RIN

LOADING

MOTOR DRIVE

IC305

OUT1

OUT2

1 7

62 55 5254 51

39

SQSY

TEMP

6

VREF

SENS

CC-XINT

LIMIT-IN

(LIMIT)

REFERENCE VOLTAGE

REGULATOR

Q303

M

M903

(LOADING)

PEAK HOLD

16

PSB

OUT4F

6

OUT4R

8

OUT2F

27

OUT2R

25

OUT1F

21

23

OUT1R

OUT3F

12

10

OUT3R

IN4R

IN4F

IN2F

IN2R

IN1F

IN1R

IN3F

IN3R

SPFD

3

SPRD

4

29

30

19

18

14

15

83 13 67 65 66 75 74 63 64

10

XRST

APCREF

SFDR

92

SRDR

91

FFDR

88

FRDR

89

86

85

PWM GENERATOR

TFDR

TRDR

RECP

AUTOMATIC

POWER

CONTROL

DIGITAL SERVO

SIGNAL

PROCESS

DIGITAL SERVO

SIGNAL PROCESSOR

IC301 (2/2)

MD-SI

SCLK

SWDT

MD-SO

E-SW

LOADING

END

XLAT

MD-CKO

SHOCK

MNT0

MNT1

MNT2

MD-LAT

MD MECHANISM CONTROLLER

C-SW

631156

LOADING START/

LO +12V

MNT3

IC501 (1/2)

EJECT END

DEEMP

MDM-ON

MD-ON

66

10

65

MD EMPH

MD-ON, MDM-ON

G

H

(Page 26)

(Page 28)

2525

Page 26

WX-7700MDX

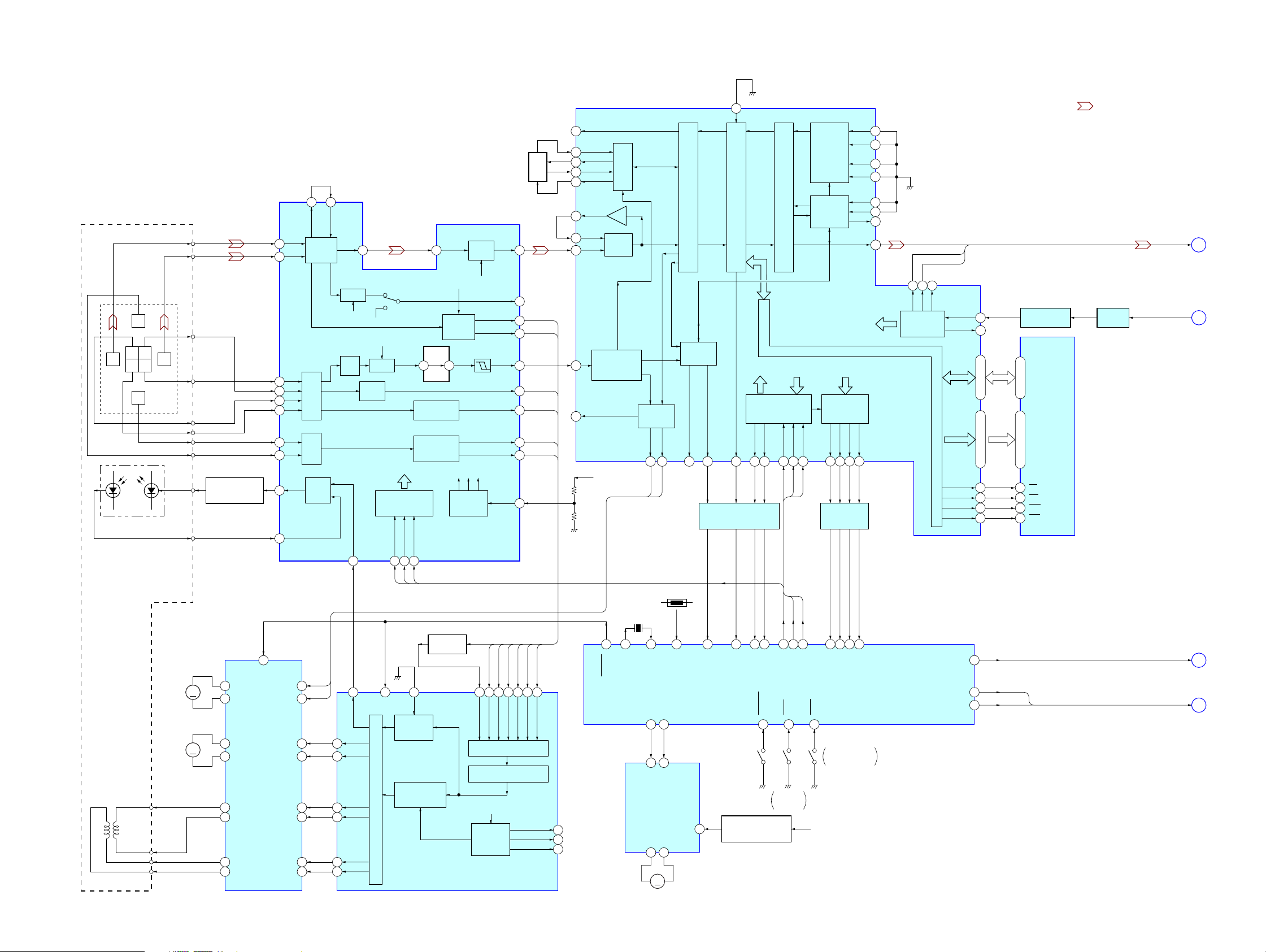

5-3. BLOCK DIAGRAM – MAIN Section –

A

(Page 24)

(Page 25)

E

(Page 24)

B

F

(Page 25)

BUS AUDIO

J

(Page 27)

CD-DATA,

CD-BCK,

CD-LRCK

MD-DATA,

MD-BCK,

MD-LRCK

BFOT

512FS

PNJ2

AUX IN

PNJ1 (1/2)

IN

ANT

SP SI,

SP CLK

R-CH

DSP +3.3V

(FOR DIGITAL)

77

XMST

71

SI1

75

BCK

76

LRCK

35

LIN

46

RIN

58

BFOT

81

PLCKL

FD2L+

7

FD1L+

3

AM

11

AMIF

12

MPX

13

DIGITAL SIGNAL PROCESSOR,

DIGITAL FILTER,

D/A CONVERTER

IC500

XLAT

RVDT59SCK

62 57

XLAT

SCK

RVDT

IC300 (1/2)

LOUDNESS/

VOLUME

PLL

REDY

6061

REDY

CANCELATION

TRDT

63

TRDT

INPUT SELECTOR, FM MPX

INPUT

MULTIPLEXER

AM/FM

NOISE

BLANKER

L.P.F.

11 10

EE SIO

EE CKO

XRST

DSPRST

PILOT

PILOT

DET

AOUTL1

AOUTR1

AOUTR3

AOUTL3

AOUTR2

XTLI38

XTLO38

XECKSTP64XS24

82

XECSKTP

27

29

54

52

43

41

40

SOFT

MUTE

QUAL

QUALITY

17

FL-OUT

RL-OUT

FR-OUT

R-CH

RR-OUT

R-CH

SUB-OUT

X500

16.9344MHz

TONE

CONTROL

LOUDNESSMUTE

DEMODULATOR

+STEREO ADJUST

+STEREO BLEND

MULTIPATH

DETECTOR

MPOUT16MPIN

15

53

VSM

LOW-PASS

FILTER

IC200

LOW-PASS

FILTER

IC101

OUTPUT

SELECTOR

L.P.F.

CONVERTER

R-CH

ACOUTL

38

TO

S & H HIGH-CUT

D/A

LEVEL

14

ACINLF

34

ACINLR

33

SWINL

36

35

SWINR

DIGITAL

CONTROL

IIC BUS

SDA

20

70 71

I2CSIO

R-CH

SCL

21

SM

I2CCKO

OUTPUT

18

ELECTRICAL VOLUME

IC300 (2/2)

MONO FADER MIXER

SELECTOR

SUBWOOFER

+PHASE CONTROL

XMST

TRDT

RVDT

SCK

XLAT

REDY

DSPRST

XECKSTP

SP SI

SP CLK

(CD MECHANISM CONTROLLER)

OUTLF

OUTLR

OUTSWL

MONO

OUTSWR

FADER

7

D AUDSEL

31

VOLATT

DSPMST

29

20

DSPSI

DSPSO

21

22

DSPCKO

DSPLAT

3

76

DSPREDY

4

DSPRST

28

DSPPLL

MASTER CONTROLLER

IC550 (2/4)

30

29

26

25

AMPON

TESTIN

TELMUTE

BEEP

R-CH

FL

K

(Page 27)

PNJ1 (2/2)

LINE

AMP

IC102

LINE

AMP

IC104

R-CH

LOW-PASS

FILTER

IC103

BZ300

BUZZER

DRIVE

Q307

15

120

84

16

115EMPH IN

LEVEL SHIFT

Q310

• R-ch is omitted due to same as L-ch.

MUTING

Q104

MUTING

Q203

MUTING

Q103

CENTER VOLTAGE

GENERATOR

(FOR BIAS)

IC303

MUTING

Q100

R-CH

MUTING

Q201

R-CH

BATTERY OFF

MUTE DRIVER

Q306

AUDIO +8V

FL

IN1

11

FR

12

IN2

RL

13

IN3

RR

IN4

14

MUTE

22

ST-BY

4

D304

MUTING CONTROL

MUTING CONTROL

R-CH

R-CH

R-CH

POWER AMP

IC402

BATT B+

SWITCH

Q305

SWITCH

Q303

D371

OUT1+

OUT1–

OUT2+

OUT2–

OUT3+

OUT3–

OUT4+

OUT4–

• SIGNAL PATH

: CD PLAY

D552

9

7

5

3

17

19

21

23

(L)

FRONT

(R)

(L)

REAR

(R)

(L)

SUB WOOFER

OUT (MONO)

(R)

CNP400 (1/2)

MUTE

CD EMPH

MD EMPH

AUDIO OUT

2

1

3

4

10

9

11

12

13

TEST

14

ATT

(Page 27)

(Page 24)

(Page 25)

FL+

FL–

FR+

FR–

RL+

RL–

RR+

RR–

L

D

G

: MD PLAY

: FM

: AM

B+ SWITCH

CD/MD

SELECTOR

IC504

MPX

16

11

3A

VCC

10

3B

2

1A

3

1B

5

2A

6

2B

SEL

8

10

12

13

17

18

14

CD-DATA

MD-DATA

CD-BCK

MD-BCK

CD-LRCK

MD-LRCK

(L)

(R)

(L)

(R)

R-CH

R-CH

AM ANT IN

1

2

FM ANT IN

TUNER UNIT

TU1

DAT-EEP

CKL-EEP

S-METER

AM DET

DAT IIC

CKL IIC

Q501

9

3Y

4

1Y

7

2Y

1

XMST

: BUS AUDIO IN

: AUX IN

2626

Page 27

WX-7700MDX

5-4. BLOCK DIAGRAM – DISPLAY/BUS CONTROL Section –

(Page 26) (Page 28)

FL

K

ILLON

M

LIQUID CRYSTAL

DISPLAY

LCD740

LIQUID CRYSTAL

DISPLAY

LCD741

BACK UP +5V

BACK UP +5V

FRONT PANEL

OPEN/CLOSE MOTOR DRIVE

IC641

M

M640

FRONT PANEL

OPEN/CLOSE

3

14

82-87, 91-101, 110-132

1-12, 18, 45, 51-53, 62-78,

54-61

79-81, 88-90

13-17, 19-25, 46-50,

133-140

53-80, 105-140

1-8

RESET SIGNAL

GENERATOR

IC551

RESET SIGNAL GENERATOR

(FOR INTERNAL RAM)

IC552

12

45

VCC

MOTOR

DRIVE

M BATT

OUT1

OUT2

SW800

(RESET)

VOLTAGE SWITCH

VREF

OPEN

CLOSE

RNF

SEG1 – SEG15,

SEG17 – SEG75

1 – 15, 17 – 75

83 – 76

COM1 – COM8

LIQUID CRYSTAL

DISPLAY DRIVER

LIQUID CRYSTAL

DISPLAY DRIVER

SEG1 – SEG15,

1 – 15, 17 – 56,

58 – 62, 68 – 75

83 – 76

COM1 – COM8

REGULATOR

REFERENCE

Q640, 641

6

11

16

LCD-DATA

LCD-CLK

LCD-CE1

LCD-INH

IC740

IC741

LCD-DATA

LCD-CLK

LCD-CE0

LCD-INH

SEG68 – SEG75

SEG17 – SEG56,

SEG58 – SEG62,

+7V

IC640

MOTOR OVER LOAD

DETECT

IC642, Q642

OSC

OSC

100

99

98

97

96

100

99

98

97

96

90

86

85

BATT B+

OSC

C746, R751

OSC

C740, R742

RSTX

HSTX

RAMBU

D640

DATA

CLK

CE1

INH

DATA

CLK

CE0

INH

FP CTRL

40

MOT+

98 97

BACK UP +5V

MOT–

IDET

96

CLOSE SW

OPEN SW

S640

S641

S640

FRONT PANEL

OPEN DETECT

S641

FRONT PANEL

CLOSE DETECT

FRONT PANEL VIEW

BUFFER

IC701

B+ SWITCH

Q792

LED749 – 758

(LCD BACK LIGHT)

FP PULSE

75100 99

ANGLE SENSOR

IC553

PULL UP +5V

PEAK DETECT

IC790

PEAK HOLD

RESET SWITCH

Q790

LED DRIVE

(COLOR SWITCHING)

Q747 – 749

MASTER CONTROLLER

(CD MECHANISM CONTROLLER)

IC550 (3/4)

X1

X0A

X1A

92

93

74

73

X550

32.768kHz

X551

3.6864MHz

SAMPLING

TIMER

IC791

X0

LSW803 – 813,

DATA

CLK

CE0

CE1

INH

KEYIN047KEYIN1

46

LSW801,

S820, 821

60

LCD SO/TX

64

LCD CLK

66

LCD CE0

LCD CE1

70

69

LCD INH

DISPLAY CONTROLLER

IC710

ILLON

52

LVL L

105

R-CH

D639

LVL R

106

PEAK RST

24

LVL RD

29

PWM B

120

PWM G

121

PWM R

122

SCHMITT

TRIGGER

D713

6 1

SYSRST

SIRCS B+

D551

D550

IC712

KEYACK

79

SP SI

SP CLK

SP-LAT

LINKOFF

UNISO

UNISI

UNICKI

BUSON

NMI

BU IN

BOOT

EXTAL

XTAL

RES

81

KEY ACTIVE

SWITCH

Q551

61

63

33

50

97

98

101

38

82

34

D714

57

86

85

18.432MHz

BACK UP +5V

DATA

CLK

BUS-ON

BU CHECK

X701

80

SP CLK

BOOT

AD ON

SP SI

SP SI,

SP CLK

MUTE

D301

67 A-ATT

MD MECHANISM

CONTROLLER

IC501 (2/2)

RESET

30

FP DATA

5101

ATT

UNISO

18

SP LATCH

UNISI

UNICKO

BUSON

BU IN

SIRCS RST

SIRCS

DATA

17

CLK

19

BUS-ON

14

BU CHECK

78

82

24

MD DATA

FP DATA

UNISO

UNISI

UNICKI

BUS-ON

BU-IN

D636

D637

SIRCS

CONTROLLER

IC660

50

49

48

61

60

SONY BUS INTERFACE

RESET

13

DATA

IN

9

DATA

OUT

8

CLK

IN

11

BUS

ON

12

BU

CHECK

10

6

RESET

D3/K GO/INT

17

XOUT

4

X660

4MHz

DATA

CLK

BUS-ON

BU CHECK

IC630

RESET

SWITCH

BUS ON

SWITCH

BATTERY

CHECK

SIRCS B+

1

VDD

XIN

3

BATT B+

MD DATA

RST

2

DATA

6

D638

CLK

4

BUS

ON

1

BATT

9

Q632

3

D631

BUS ON

BUS ON/OFF

BATTERY CHECK

REMOTE CONTROL

D781, IC780

J

L

TH630

CN630

BUS CONTROL IN

(FOR SONY BUS)

BATT B+

SWITCH

Q632

Q631

RECEIVER

N

(Page 26)

(Page 26)

7

BATT

2

RESET

5

DATA

4

CLK

6

BUS ON

D635

(Page 28)

BATT B+

2727

Page 28

WX-7700MDX

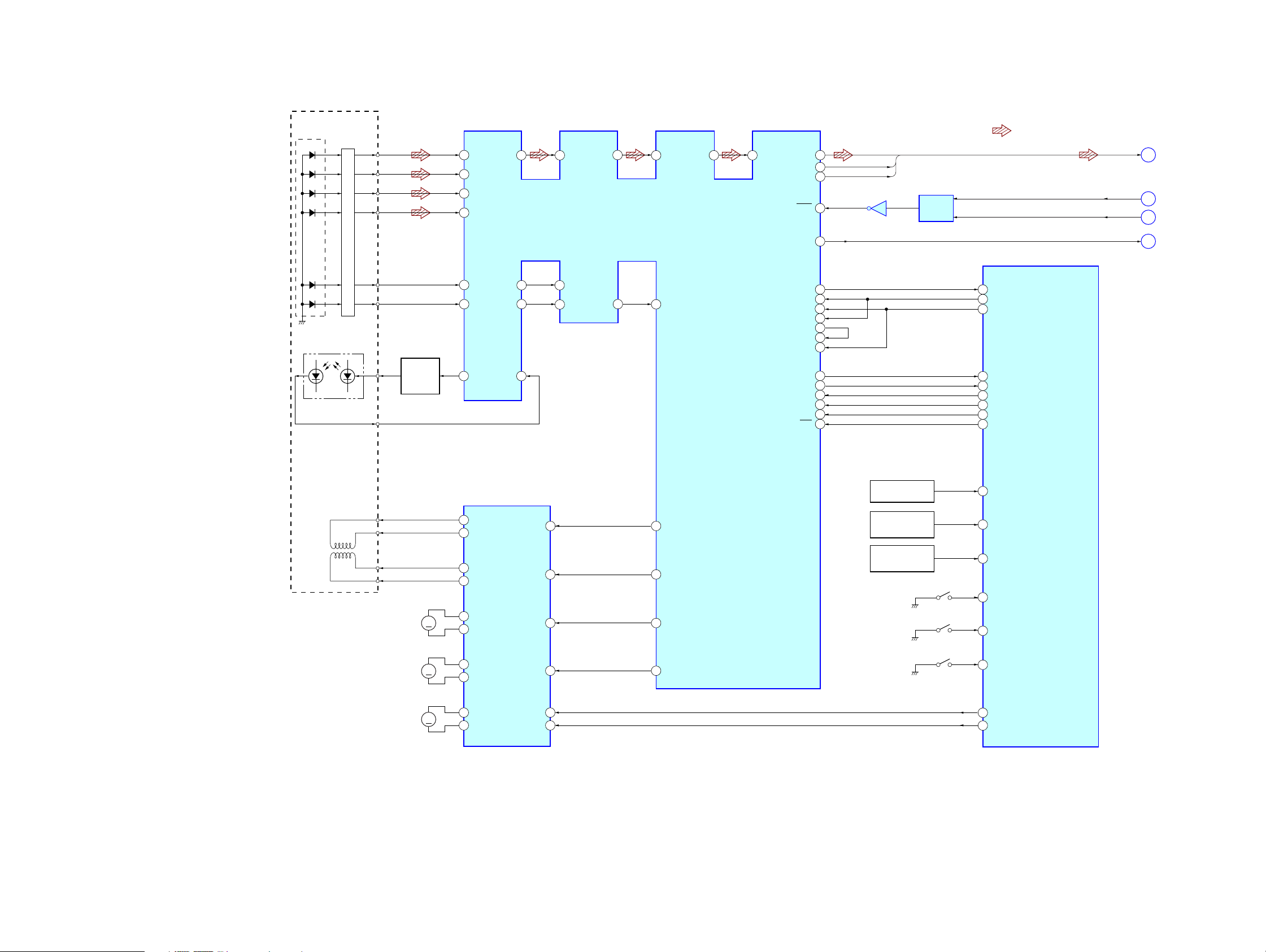

5-5. BLOCK DIAGRAM – POWER SUPPLY Section –

95

ILLIN

ACCIN

PACK-IN

TUNON

POWON

DSPON

SUBP ON

MASTER CONTROLLER

(CD MECHANISM CONTROLLER)

IC550 (4/4)

MD ON

81

116

118

83

2

105

77

MD-ON

MDM-ON

Q820

MD SECTION

D820, Q820

MD DISC IN

DETECT SENSOR

DSP (IC500) B+

(FOR ANALOG)

DSP (IC500) B+

(FOR DIGITAL)

MD BACK UP

B+

PULL UP +5V,

D820

+5V B+

+5V

LO +12V

B+ 3.3V

DRIVER +5V

D/D +5V

VCC

+3.3V REGULATOR

IC401, Q401

B+ SWITCH

Q500

+3.3V REGULATOR

IC502

+3.3V REGULATOR

IC501

B+ SWITCH

Q402, 403

B+ SWITCH

Q413, 414

TUNER

SECTION B+

+12V REGULATOR

Q416

REGULATOR

CONTROL SWITCH

Q415

TUNER

BACK UP +5V

TUNER +8.5V

TUNER +5V

AUDIO +10V

AUDIO +8V

D801-803,

LSW805-812

(FOR ILLUMINATION)

LSW801, 803

LSW804, 813

(FOR ILLUMINATION)

ILL ON

LCD B+

D821-826

(FOR ILLUMINATION)

D406

+5V REGULATOR

µCOM +5V,

BACK UP +5V

Q2

D404

CONTROL SWITCH

D405

P ON

LED B+

ILL ON

LED B+

SUB ON

LED B+

REGULATOR

Q406, 407

REGULATOR

Q409, 410

+8.5V REGULATOR

IC2

+8V REGULATOR

IC301

B+ SWITCH

Q676

B+ SWITCH

Q672, 673

B+ SWITCH

Q674, 675

B+ SWITCH

Q417

VOLTAGE

DETECT

IC403

POWER CONTROL

IC400

IN2

ERROR

14

3

IN1

CT

AMP

ERROR

AMP

ACCIN

OSC

ILLIN

PWM

COMPARATOR

PWM

COMPARATOR

DIMMER DETECT

SWITCH

Q308

ACCESSORY CHECK

Q304

OUT2

OUTPUT

CIRCUIT

OUT1

OUTPUT

CIRCUIT

VCC

TH401

TH400

ANTENNA REMOTE

B+ SWITCH

Q313-2, 314-2

AMP REMOTE

B+ SWITCH

Q313-1, 314-1

10

7

91

D412

D414

D413

DC/DC

CONVERTER

Q450, 451

SWITCHING

REGULATOR

Q408

CNP400 (2/2)

(POWER)

15

7

6

5

16

BATT B+

ILL

ACC

AMP REM

ANT REM

B+

(Page 27)

(Page 25)

(Page 24)

OUT2

OUT1

VCC

SWITCHING

REGULATOR

Q405

10

7

9

DC/DC

CONVERTER

IC302

D422

B+ SWITCH

Q400

REGULATOR

Q310, 311

BUSON

N

(Page 27)

DRIVER +6V

CD SECTION

B+

CD ON +5V

49

CD ON

CDM ON

55

WAKEUP

106

114

FSW SFT

FSW IN

65

M

H

C

ILLON

MD-ON, MDM-ON

CDM ON

+6V REGULATOR

Q375, 376

REGULATOR

CONTROL SWITCH

Q374

+5V REGULATOR

Q373

REGULATOR

CONTROL SWITCH

Q372

D400

D411, 413

BUS ON WAKE UP

SWITCH

Q402

POWER CONTROL

IC401

IN2

14

ERROR

IN1

ERROR

3

AMP

AMP

CT

OSC

1RT2

PWM

COMPARATOR

PWM

COMPARATOR

OSC

SWITCH

Q403

LINE AMP

OUTPUT

CIRCUIT

OUTPUT

CIRCUIT

B+

TO

B–

2828

Page 29

WX-7700MDX

d

5-6. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

Note: The components identified by mark 0 or dotted line

• A : B+ Line.

• B : B– Line.

•Power voltage is dc 14.4V and fed with regulated dc power

•Voltages and waveforms are dc with respect to ground

•Voltages are taken with a VOM (Input impedance 10 MΩ).

•Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

with mark 0 are critical for safety.

Replace only with part number specified.

supply from ACC and BATT cords.

under no-signal (detuned) conditions.

– SERVO (CD)/MAIN/DISPLAY/SUB/POWER Boards –

no mark : FM

(): AM

[]: CD PLAY

〈〈 〉〉 : MD PLAY

{ } : Front panel open/close motor is operating

– SERVO (MD) Board –

no mark : MD PLAY

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

F : FM

f : AM

J : CD PLAY

E : MD PLAY

L : BUS AUDIO IN

a : AUX IN

: Impossible to measure

∗

: Impossible to measure

∗

4

W or less unless otherwise

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

z

•

•

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

: Through hole.

f

: internal component.

• Circuit Boards Location

sensor (MD) board

servo board

key board

power boar

display board

sub board

SL SW board

sensor (CD) board

load board

servo (CD) board

main board

2929

Page 30

WX-7700MDX

5-7. PRINTED WIRING BOARDS – CD Section (1/2) – • See page 29 for Circuit Boards Location.

A

D

1

2 3 4 5 6 7 8 9 10 11

12

13

PICK-UP

C43

C16

C10

C9

C8

FLEXIBLE BOARD

1

C11

C15

C14

IC1

OPTICAL

PICK-UP

BLOCK

(KSS-720A)

LOAD BOARD

(DISC SET)

R5

C13

C20

C18

76100

C19

R9

75

C23

R8

C24

YEL

BLK

1-659-837-

SENSOR (CD) BOARD

D10

LOADING

COMPLETION DETECT

11

(11)

RED

BLU

BLK

SW1

(SELF)

D12

DISC IN

DETECT

SERVO (CD) BOARD

(COMPONENT SIDE)

B

R54

C

A

MAIN BOARD

CNP370

CN1

(Page 37)

CN2

R18

C41

16

C5

C1

R29

C3

C17

1

C29

C4

R17

R19

Q1

R26

FB1

R30

C

E

B

R3

C6

C40

C25

C45

G

H

54

IC3

R55

312

C34

C55

DISC IN

DETECT

25

26

C36

R52

Q6

R7

1

R6

7

C22

8

C21

14

R53

R24

R25

R51

R50

FB4

IC2

C38

FB2

51

C35

50

28

R15

R12

22

R10

C30

21

15

R14

1-682-831-

BLU

BLK

BLK

RED

YEL

SL SW BOARD

(LIMIT)

M102

(SPINDLE)

M

RED

BLK

1-676-708-

11

(11)

M

M101

(SLED)

YEL

WHT

D11

DISC SIZE

(8cm/12cm) DETECT

SW4

11

(11)

1-660-797-

(11)

• Semiconductor

Location

Ref. No. Location

D10 E-9

D11 E-10

D12 C-13

IC1 D-6

IC2 G-6

IC3 E-5

Q1 B-5

31

E

JR51

F

RED

M103

(LOADING)

M

WHT

LOADING

COMPLETION

DETECT

Q8

Q8

(8cm/12cm) DETECT

JR52

R20

JR50

FB3

DISC SIZE

C44

Q7

16

CN3

MOTOR FLEXIBLE BOARD

Q6 F-6

Q7 H-3

I

Q8 H-2

3030

Page 31

5-8. PRINTED WIRING BOARD – CD Section (2/2) – • See page 29 for Circuit Boards Location.

WX-7700MDX

1

A

SERVO (CD) BOARD

(CONDUCTOR SIDE)

B

C

D

2 3 4 5 6

7

H

E

G

F

11

1-682-831-

(11)

3131

Page 32

WX-7700MDX

5-9. SCHEMATIC DIAGRAM – CD Section – • See page 52 for Waveforms. • See page 55 for IC Block Diagram.

A

(Page 38)

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

3232

Replace only with part number specified.

Page 33

5-10. PRINTED WIRING BOARDS – MD Section – • See page 29 for Circuit Boards Location.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

WX-7700MDX

A

B

C

D

E

F

G

H

I

OPTICAL

PICK-UP BLOCK

(KMS-241C)

C322

Q302

BCE

R348

R349

R357

R336

R350

IC302

R340

R338

C324

C347

R342

R344

C346

R526

R529

R337

C321

C320

12 1

13

24

25 36

R346

+

R527

R528

R507

R506

20

L302

X501

C325

C326

SERVO (MD) BOARD

CN102

1

+ +

C319

C318

R356

C331

R355

48

C329

37

C328

C330

C327

R505

R535

C516

R539

R504

C501

24 1

25

40

41 64

R511

(COMPONENT SIDE)

1

IC303

16

C336

TP2 (SE) TP3 (TE) TP4 (FE)

R531

R501

R502

R503

IC501

R516

C363

5

8

IC307

IC305

(CONDUCTOR SIDE)

C307

C309

26

C317

22

C358

C301

18

14

R362

IC306

C353

C345

+

18

45

R358

C352

C359

C344

L301

4

1

C356

C357

C511

L501

C365

R547

R332

C350

C351

+

C316

C333

R335

R333

R334

RB503

R540

R542

+

C505

C506

R534

R533

C515

C504

C514

C513

R520R521

R519

C503

R510

R512

TH501

11

1-679-848-

(11)

SERVO (MD) BOARD

R325

IC301

R308

C311

148

R328

R327

R354

C310

R326

R324

5

R360

R320

C308

R318

R319

50

26

25

R314

R313R311

C305

C306

1

5

9

C361

+

13

C362

BCE

Q301

C339

32

17

C349

R351

C343

C342

R353

R352

C315

R330

C314

R329

75 51

76

R331

100

1

IC304

R306

R304

R302

R301

R307

R305

R303

20 11

IC502

110

R404

R405

C402

E

C

C403

Q401

85

IC401

14

D401

AK

1-679-848-

B

C11

11

(11)

R406

1

CN101

80

TP1

R525

R524

R523

65

R522

R537

R518

R538

R517

111

CN103

C510

30

R402

R361

R401

R403

B

E

D301

BCE

Q403

Q402

Q303

BCE

AK

C

B

POWER BOARD

CN402

(Page 50)

(LIMIT)

• Semiconductor

Location

Ref. No. Location

D301 G-9

D401 F-7

IC301 B-6

IC302 D-2

M902

(SLED)

J

RED

M901

MM

K

(SPINDLE)

BLK

MM

111

SENSOR (MD) BOARD

(COMPONENT SIDE)

(LOADING END)

BLK

RED

1-679-849-

11

(11)

SENSOR (MD) BOARD

LOADING START/

EJECT END

(CONDUCTOR SIDE)

1-679-849-

11

(11)

IC303 B-4

IC304 C-6

IC305 G-10

IC306 D-11

IC307 B-10

IC401 F-7

IC501 G-3

IC502 D-6

Q301 A-5

Q302 C-1

Q303 F-9

Q401 E-7

Q402 F-9

MM

M903

(LOADING)

3333

Q403 E-9

Page 34

WX-7700MDX

5-11. SCHEMATIC DIAGRAM – MD Section (1/2) – • See page 52 for Waveforms. • See page 55 for IC Block Diagrams.

(Page 35)

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

3434

Replace only with part number specified.

Page 35

5-12. SCHEMATIC DIAGRAM – MD Section (2/2) – • See page 52 for Waveform. • See page 55 for IC Block Diagram.

WX-7700MDX

(Page

49)

(Page 34)

3535

Page 36

WX-7700MDX

E

E

S

1

E

7

8

14

1

2

E

B1

B2

C2

C1

E

E

39

40

E

E

31

60

61

30

1

120

91

90

5

4

1

2

3

E

E

E

C2

C1

EB2

B1

B2

E2

E1

C2

B1

C1

41

58

4

1

58

E

E

E2

C2

C/B

E1

B1

E

1

4

8

5

14

85

1

4

8

5

1

4

8

5

1

4

8

5

30

1

100

81

80

51

51

31

10

11

20

E

E

8

1

9

16

9

16

8

1

1

4

8

5

2

1

3

2

4

5

E

34

111

12

22

2333

44

1-682-238-

21

MAIN BOARD

(COMPONENT SIDE)

3

2

1

1

FRONT PANEL

CLOSE DETECT

S641

POWER BOARD

CN400

FRONT PANEL

OPEN DETECT

E1

B1

C2

C1

B2

E2

KEY CONNECT

FLEXIBLE BOARD

POWER

BOARD

CN403

14

85

1

5

1

5

M640

M

FRONT PANEL

OPEN/CLOSE

15

BP670

(CHASSIS)

(CHASSIS)

E

C

B

(CHASSIS)

D

DISPLAY BOARD

CN710

E

C

IC102

IC201

IC2

IC300

IC100

IC503

IC641

IC642

IC504

IC640

IC660

IC553

IC500

IC200

IC551

IC552

IC550

IC301

IC303

IC302

IC630

IC104

C542

FB504

C541

FB503

FB507

FB508

FB509

R501

R153

C146

B

C

D

E

F

G

H

I

J

K

1

2 3 4 5 6 7 8 9 10 11 12 13

14

A

L

• Semiconductor Location

Ref. No. LocationRef. No. Location

D101 C-5

D102 C-5

D103 B-10

D301 E-13

D304 E-12

D305 E-13

D370 G-10

D371 I-9

D372 F-11

D373 F-11

D550 J-12

D551 J-12

D552 I-13

D631 C-13

D632 C-12

D633 C-12

D634 C-12

D635 C-12

D636 E-12

D637 D-12

D638 C-13

D639 D-14

D640 K-4

D641 J-3

D670 L-7

D671 L-8

D672 L-9

D673 L-9

D674 L-8

D675 L-7

IC2 G-5

IC100 H-5

IC102 D-5

IC104 B-8

IC200 H-7

IC201 D-6

IC300 F-6

IC301 E-11

IC302 D-9

IC303 D-10

IC500 I-6

IC503 I-4

IC504 J-5

IC550 J-11

IC551 H-10

IC552 H-10

IC553 L-6

IC630 D-13

IC640 K-4

IC641 J-4

IC642 J-4

IC660 K-5

Q103 C-11

Q202 C-11

Q300 D-11

Q303 E-13

Q305 E-13

Q306 E-12

Q307 J-12

Q308 H-11

Q309 H-12

Q310 H-12

Q311 D-11

Q313 H-13

Q314 H-13

Q372 G-10

Q373 G-10

Q374 F-11

Q375 F-10

Q376 F-11

Q551 H-9

Q631 C-13

Q632 D-13

Q640 K-4

Q642 K-5

Q672 J-9

Q673 I-9

Q674 K-12

Q675 K-11

Q676 J-9

5-13. PRINTED WIRING BOARDS – MAIN Board (Component Side) – • See page 29 for Circuit Boards Location. :Uses unleaded solder.

(Page 51)

(Page 50)