Page 1

WX-4500X

SERVICE MANUAL

Ver 1.1 2002. 10

Dolby noise reduction manufactured under license from Dolby Laboratories Licensing Corporation.

“DOLBY” and the double-D symbol ; are trademarks of Dolby

Laboratories Licensing Corporation.

CD

Section

TC

Section

US Model

Model Name Using Similar Mechanism NEW

CD Drive Mechanism Type

Optical Pick-up Name RAF0143A

Model Name Using Similar Mechanism WX-C55

Tape Transport Mechanism Type MG-25E-136

MG-318RW/

A-153

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

23 watts per channel minimum continuous average power into

4 ohms, 4 channels driven from 20 Hz to 20 kHz with no more

than 5% total harmonic distortion.

CD player section

Signal-to-noise ratio 92 dB

Frequency response 10 – 20,000 Hz

Wow and flutter Below measurable limit

Laser Diode Properties

Material GaAlAs

Wavelength 780 nm

Emission Duration Continuous

Laser output power Less than 44.6 µW*

* This output is the value measured at a distance

of 200 mm from the objective lens surface on

the Optical Pick-up Block.

Cassette player section

Tape track 4-track 2-channel stereo

Wow and flutter 0.08 % (WRMS)

Frequency response 30 – 18,000 Hz

Signal-to-noise ratio

Cassette type Dolby B NR Dolby NR off

TYPE II, IV 67 dB 58 dB

TYPE I 64 dB 55 dB

SPECIFICATIONS

Tuner section

FM

Tuning range FM tuning interval:

50 kHz/200 kHz switchable

87.5 – 108.0 MHz

(at 50 kHz step)

87.5 – 107.9 MHz

(at 200 kHz step)

Antenna terminal External antenna connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 65 dB (stereo),

70 dB (mono)

Harmonic distortion at 1 kHz

0.7% (stereo),

0.4% (mono)

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

– Continued on next page –

9-873-326-02

2002J0400-1

© 2002. 10

CHANGER CONTROL AUDIO MASTER

Sony Corporation

e Vehicle Company

Published by Sony Engineering Corporation

1

Page 2

WX-4500X

AM

Tuning range AM tuning interval:

9 kHz/10 kHz switchable

531 - 1,602 kHz

(at 9 kHz step)

530 – 1,710 kHz

(at 10 kHz step)

Antenna terminal External antenna connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity 30 µV

Power amplifier section

Outputs Speaker outputs

(sure seal connectors)

Speaker impedance 4 – 8 ohms

Maximum power output 50 W × 4 (at 4 ohms)

General

Outputs Audio output

Subwoofer outout (mono)

Power antenna relay

control lead

Power amplifier control

lead

Inputs Telephone ATT control lead

Illumination control lead

BUS control input

connector

BUS audio input connector

Remote controller input

connector

Antenna input connector

T one controls Bass ±10 dB at 62 Hz

Treble ±10 dB at 16 kHz

Loudness +8 dB at 100 Hz

+2 dB at 10 kHz

Power requirements 12 V DC car battery

(negative ground)

Dimensions Approx. 178 × 100 × 186 mm

(7 1/8 × 4 × 7 3/8 in.)

(w/h/d)

Mounting dimension Approx. 178 × 100 × 165 mm

(7 1/8 × 4 × 6 1/2 in.)

(w/h/d)

Mass Approx. 2.1 kg (4 lb. 10 oz.)

Supplied accessories Parts for installation and

connections (1 set)

SERVICE NOTE

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

NOTES ON PICK-UP FLEXIBLE BOARD

The pick-up flexible board in this set is secured to the optical pickup with an adhesive tape. Once the tape is removed, an adhering

force becomes weak, and it cannot be reused.

Therefore, if the optical pick-up is replaced, replace also the pickup flexible board with a new one.

NOTE

This unit cannot be connected to a digital preamplifier

or an equalizer.

Design and specifications are subject to change without

notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

Page 3

TABLE OF CONTENTS

WX-4500X

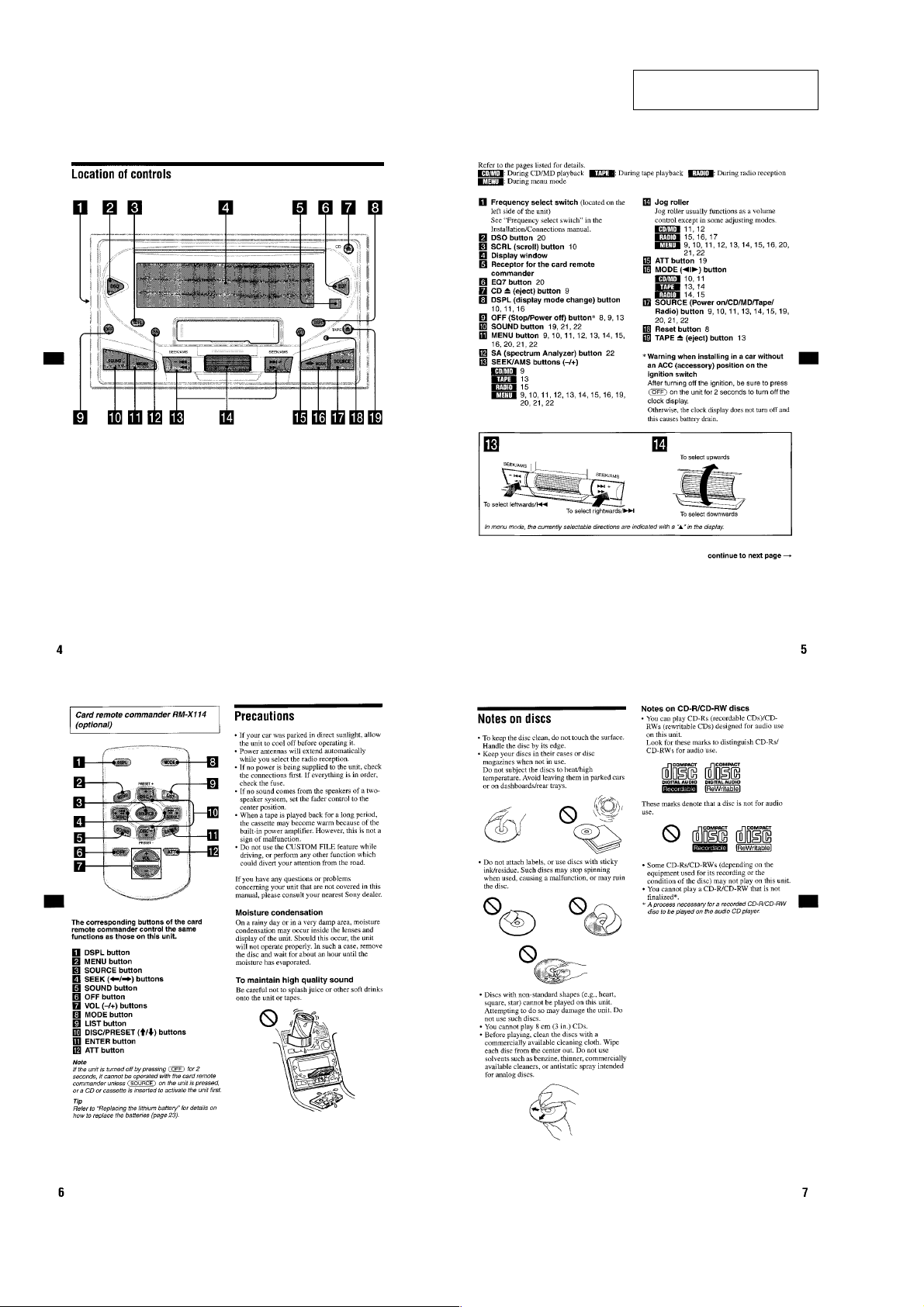

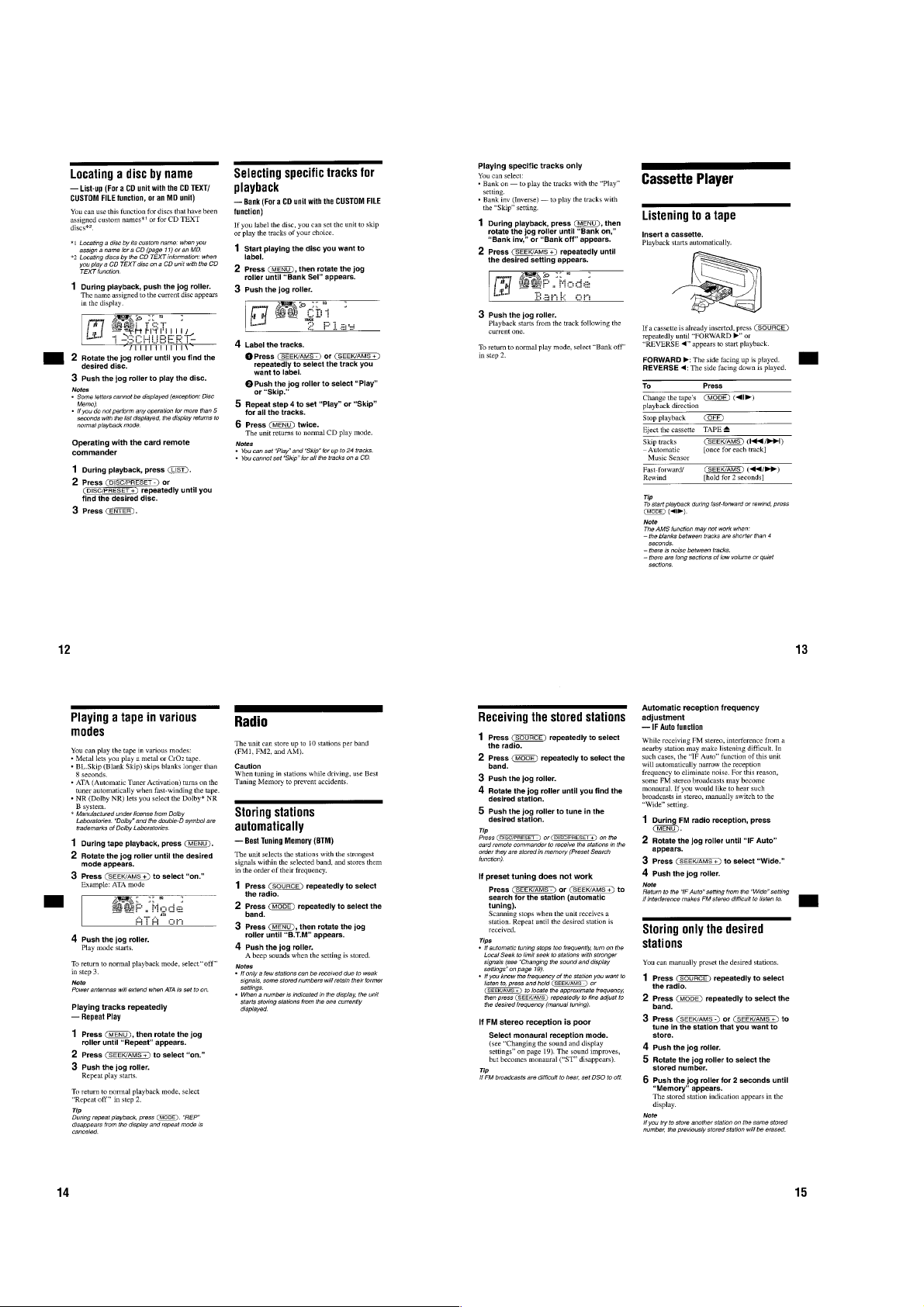

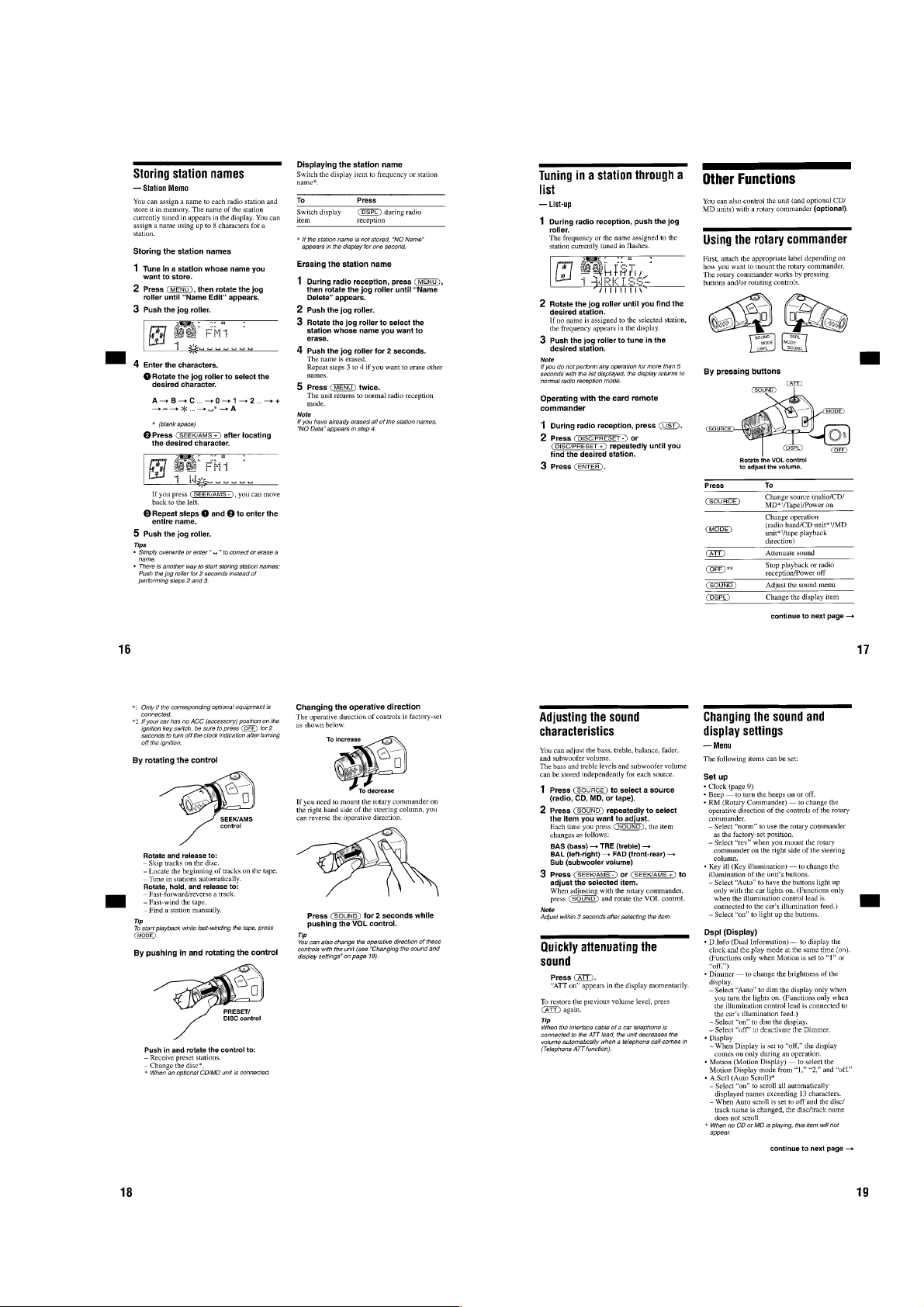

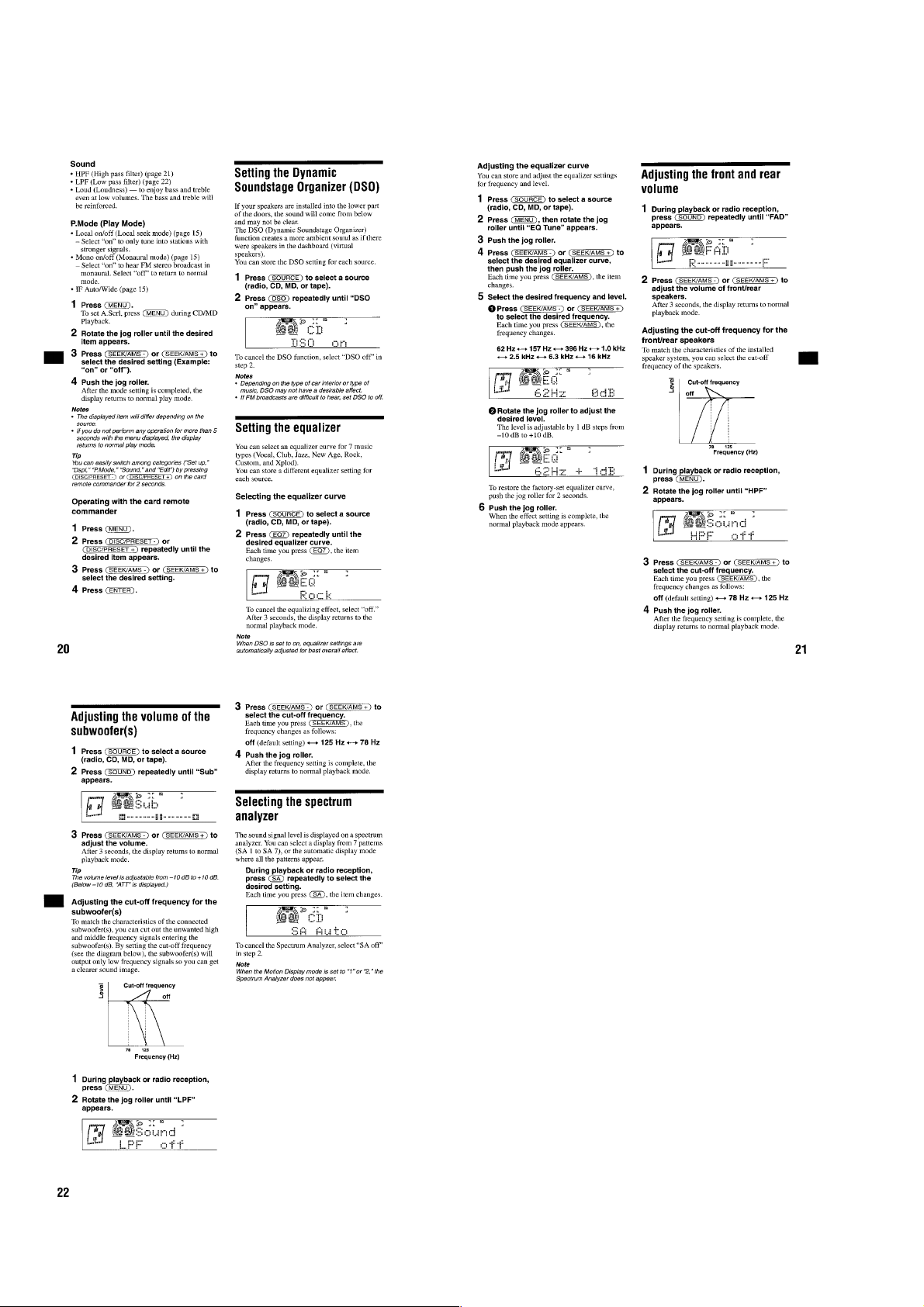

1. GENERAL

Location of Controls............................................................... 4

Getting Started........................................................................ 5

CD Player ............................................................................... 5

Cassette Player ....................................................................... 6

Radio ...................................................................................... 6

Other Functions ...................................................................... 7

Connections ............................................................................ 9

2. DISASSEMBLY

2-1. Front Panel Assy .............................................................. 11

2-2. CD Mechanism Block ...................................................... 12

2-3. CD Main Board ................................................................ 12

2-4. Tension Spring (FL) ......................................................... 13

2-5. Floating Block Assy ......................................................... 13

2-6. Roller Arm Assy ............................................................... 14

2-7. Optical Pick-up Assy........................................................ 14

2-8. Chassis (Top) Assy........................................................... 15

2-9. Main Board ...................................................................... 15

2-10. Heat Sink .......................................................................... 16

2-11. Tape Mechanism Block .................................................... 16

3. ASSEMBLY OF MECHANISM DECK

3-1. Housing ............................................................................ 17

3-2. Arm (Suction)................................................................... 17

3-3. Lever (LDG-A)/(LDG-B) ................................................ 18

3-4. Gear (Loading FT) ........................................................... 18

3-5. Guide (U) ......................................................................... 19

3-6. Main Motor Assy ............................................................. 19

5. ELECTRICAL ADJUSTMENTS

Tape Section ......................................................................... 20

6. DIAGRAMS

6-1. IC Pin Descriptions .......................................................... 22

6-2. Block Diagram –CD Section–.......................................... 26

6-3. Block Diagram –Tuner Section–...................................... 27

6-4. Block Diagram –Tape Section– ....................................... 28

6-5. Circuit Boards Location ................................................... 29

6-6. Printed Wiring Boards –CD Mechanism Section–........... 30

6-7. Schematic Diagram –CD Mechanism Section – .............. 31

6-8. Printed Wiring Board –Main Section–............................. 32

6-9. Schematic Diagram –Main Section (1/3)– ....................... 34

6-10. Schematic Diagram –Main Section (2/3)– ....................... 35

6-11. Schematic Diagram –Main Section (3/3)– ....................... 36

6-12. Printed Wiring Board –Jog Section– ................................ 37

6-13. Printed Wiring Board –Display Section– ......................... 38

6-14. Schematic Diagram –Display, Jog Section– .................... 40

7. EXPLODED VIEWS

7-1. Cover Section ................................................................... 46

7-2. Front Panel Section .......................................................... 47

7-3. Main Board Section ......................................................... 48

7-4. CD Mechanism Section (1) .............................................. 49

7-5. CD Mechanism Section (2) .............................................. 50

7-6. Tape Mechanism Section ................................................. 51

8. ELECTRICAL PARTS LIST ................................... 52

4. MECHANICAL ADJUSTMENTS.............................. 20

3

Page 4

WX-4500X

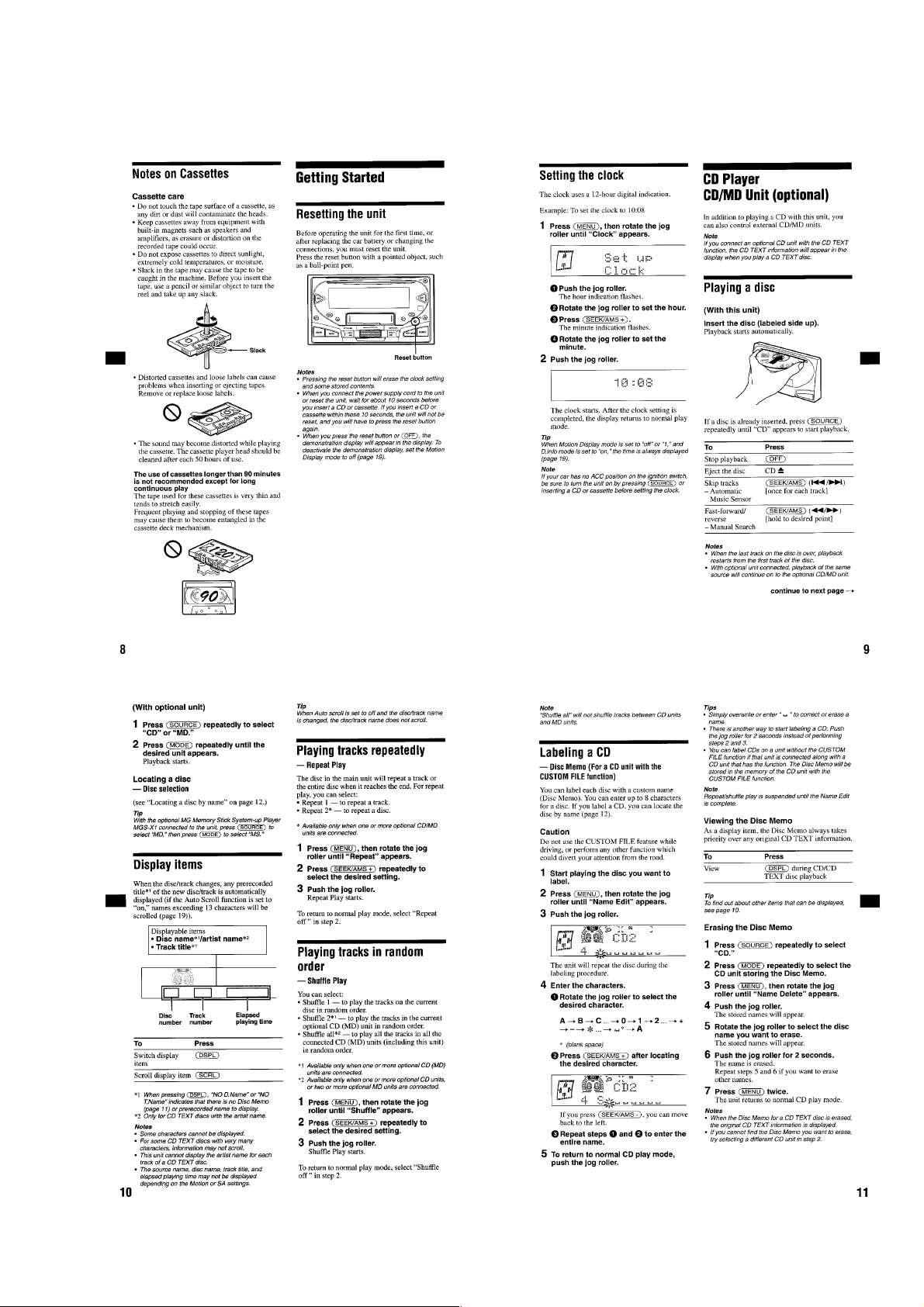

SECTION 1

GENERAL

This section extracted from

instruction manual.

4

Page 5

WX-4500X

5

Page 6

WX-4500X

6

Page 7

WX-4500X

7

Page 8

WX-4500X

8

Page 9

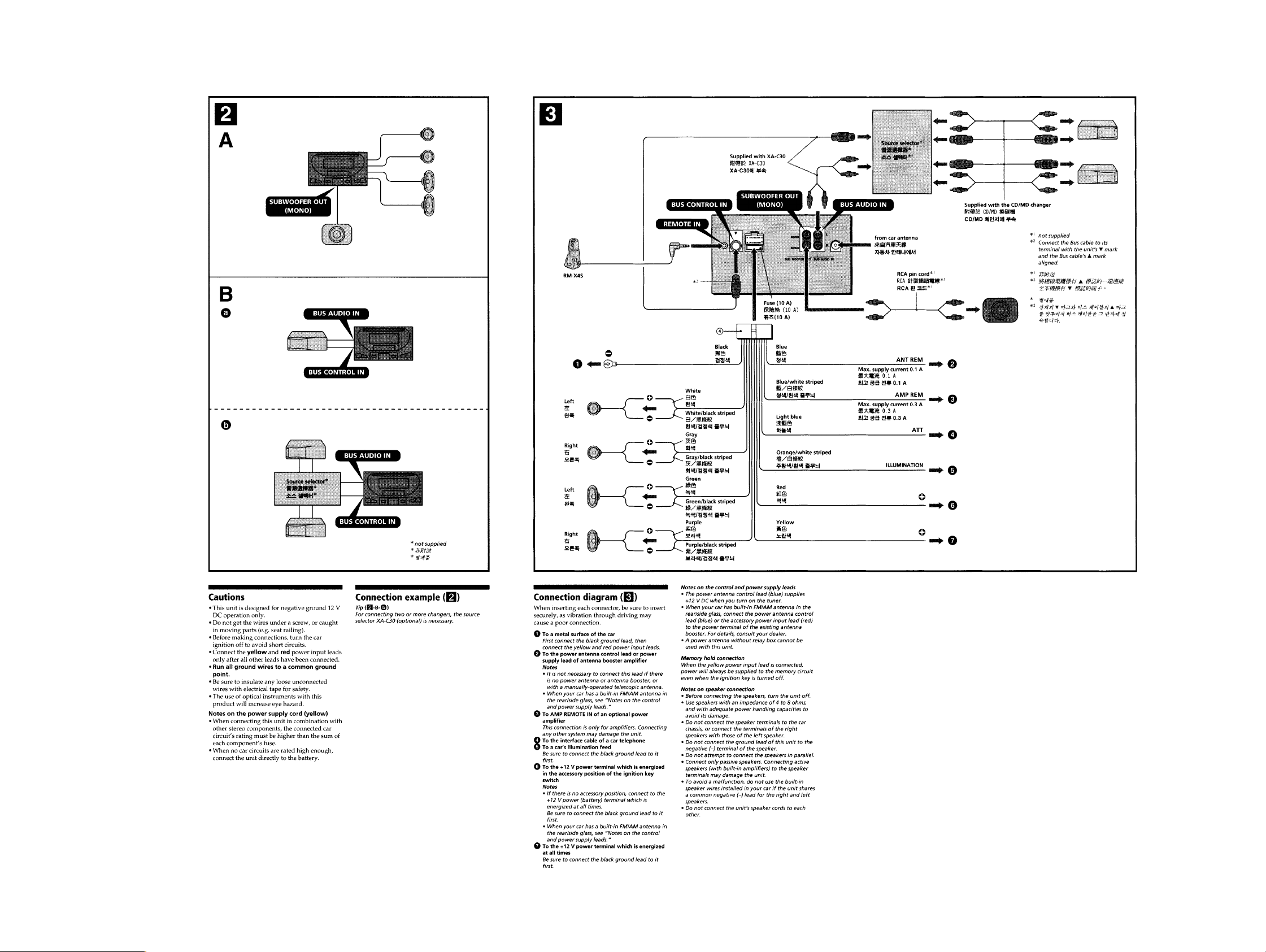

Connections

WX-4500X

99

Page 10

WX-4500X

10 10

Page 11

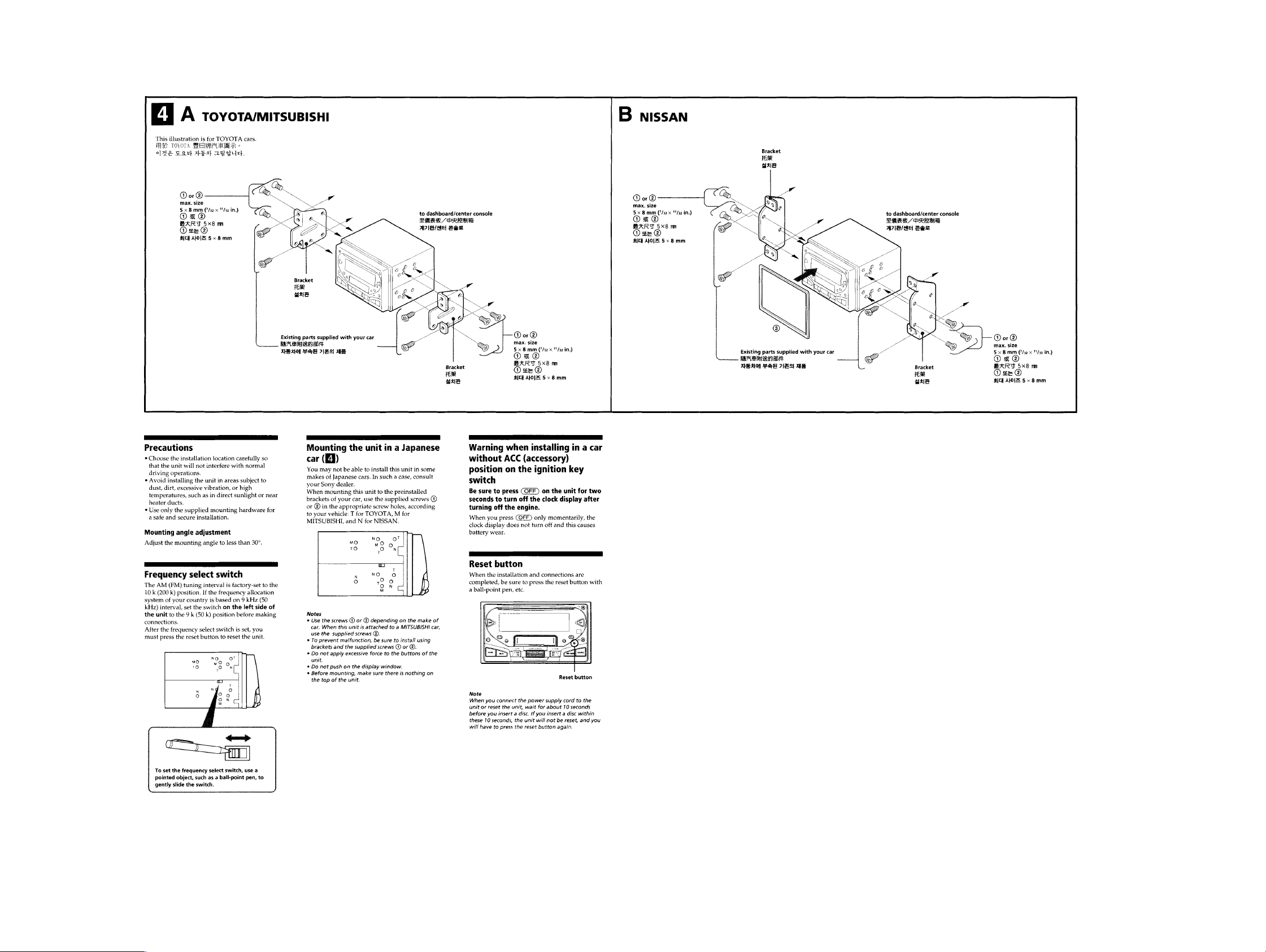

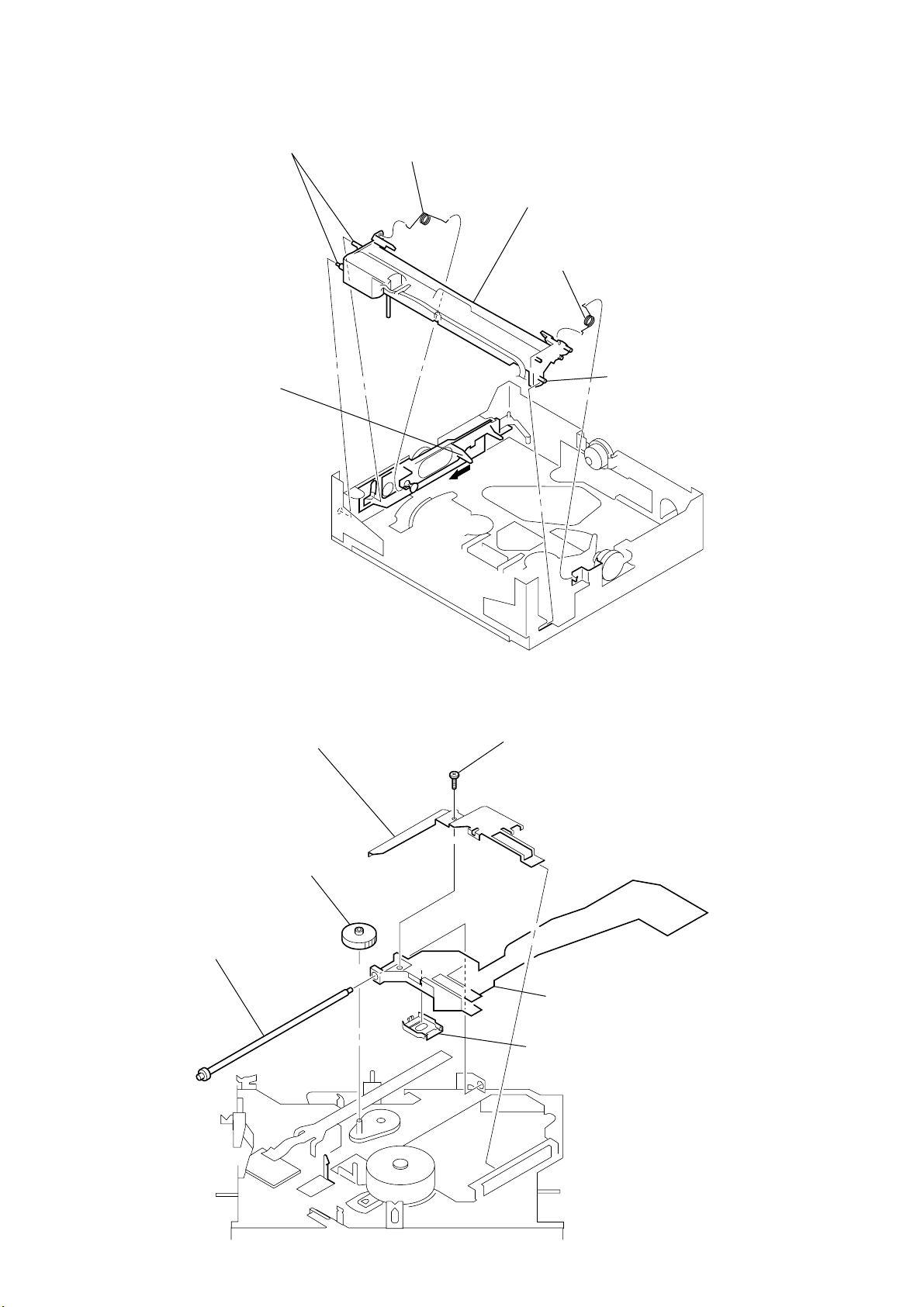

SECTION 2

w

DISASSEMBLY

Note : This set can be disassemble according to the following sequence.

WX-4500X

Set Front Panel Assy CD Mechanism Block

Floating Block Assy Roller Arm Assy

Chassis (Top) Assy

Main Board Heat Sink

Tape Mechanism Block

Note : Follow the disassembly procedure in the numerical order given.

2-1. FRONT PANEL ASSY

1

PTT 2.6x6

CD Main Board Tension Spring (FL)

Optical Pick-up Assy

6

panel assy, front

4

claw

5

CN901

2

PTT 2.6x6

3

cla

11

Page 12

WX-4500X

2

)

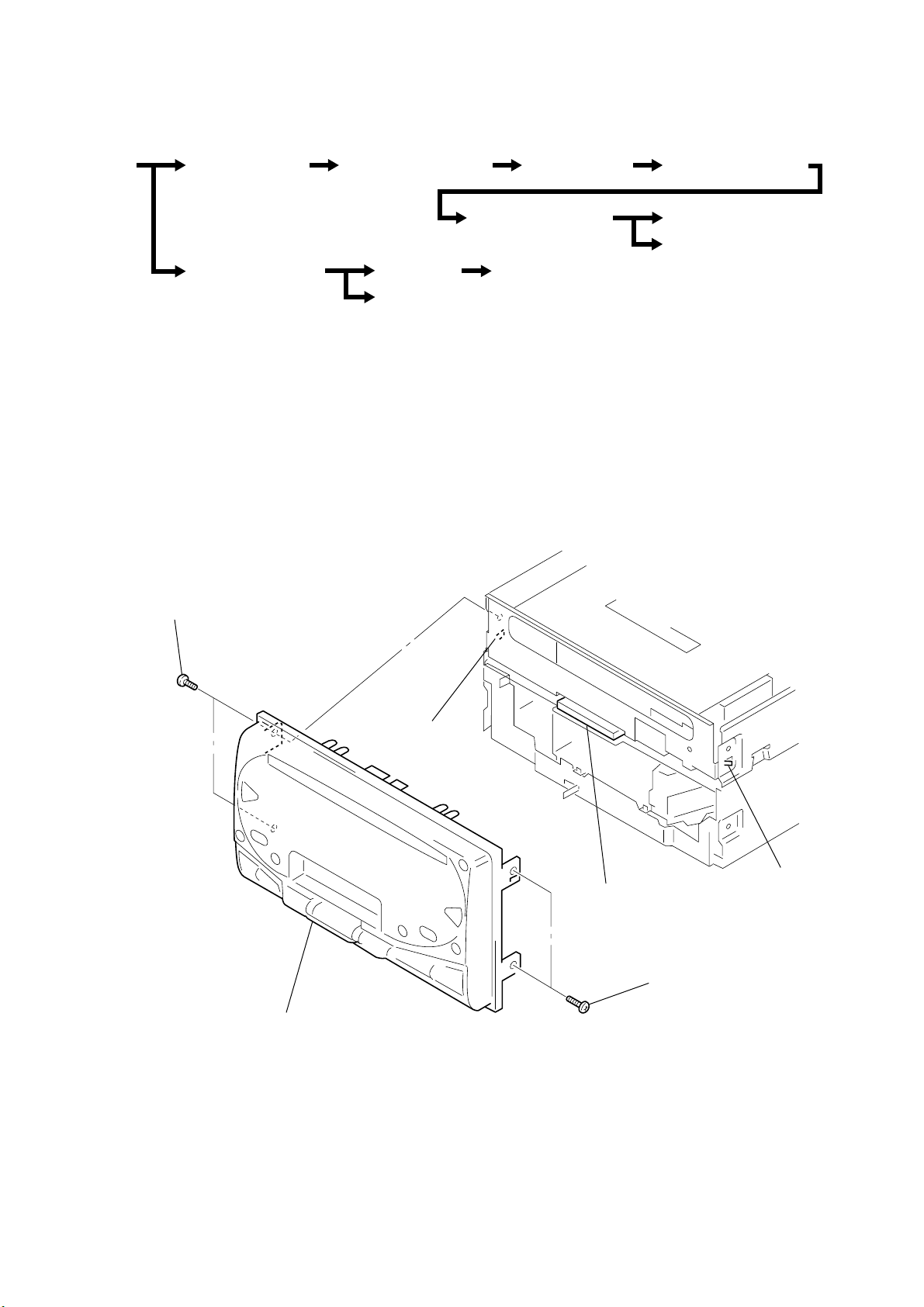

2-2. CD MECHANISM BLOCK

4

CD mechanism block

3

PTT 2.6x6

6

PTT 2.6x6

7

bracket (MD

2-3. CD MAIN BOARD

6

CD MAIN board

1

PTT 2.6x6

4

M 2x3.0

3

CNJ103

5

CNJ101

2

CNJ102

2

PTT 2.6x6

5

M 2x3.0

12

claw

1

CNP10

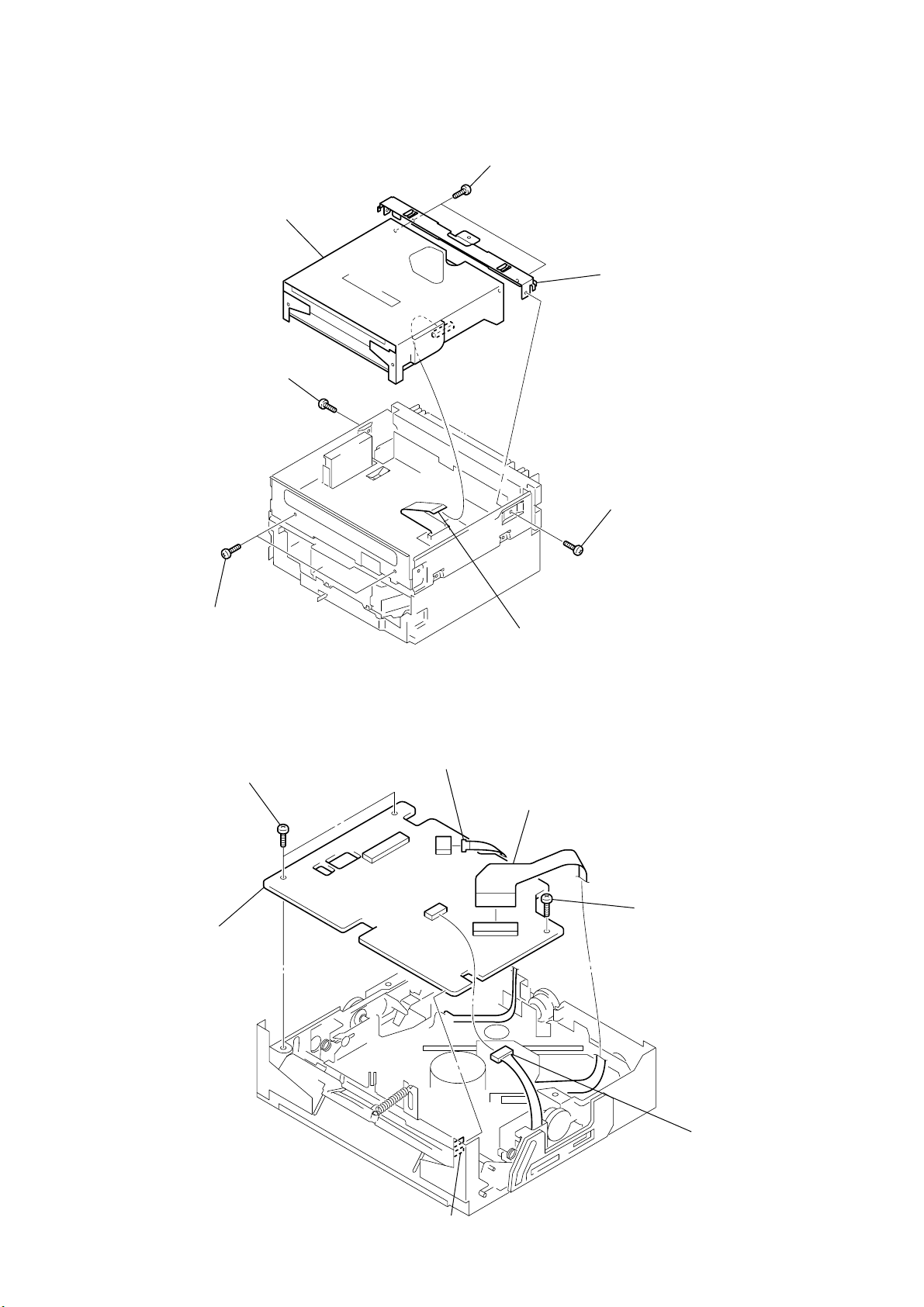

Page 13

y

2-4. TENSION SPRING (FL)

1

spring (FL), tension

2

spring (FL), tension

WX-4500X

2-5. FLOATING BLOCK ASSY

5

spring (angle), tension

6

Fit lever in the

direction of the arrow.

7

shaft

8

shaft

9

4

spring (SPM), tension

0

floating block ass

shaft

3

lever (LE.L)

2

1

washer (M)

13

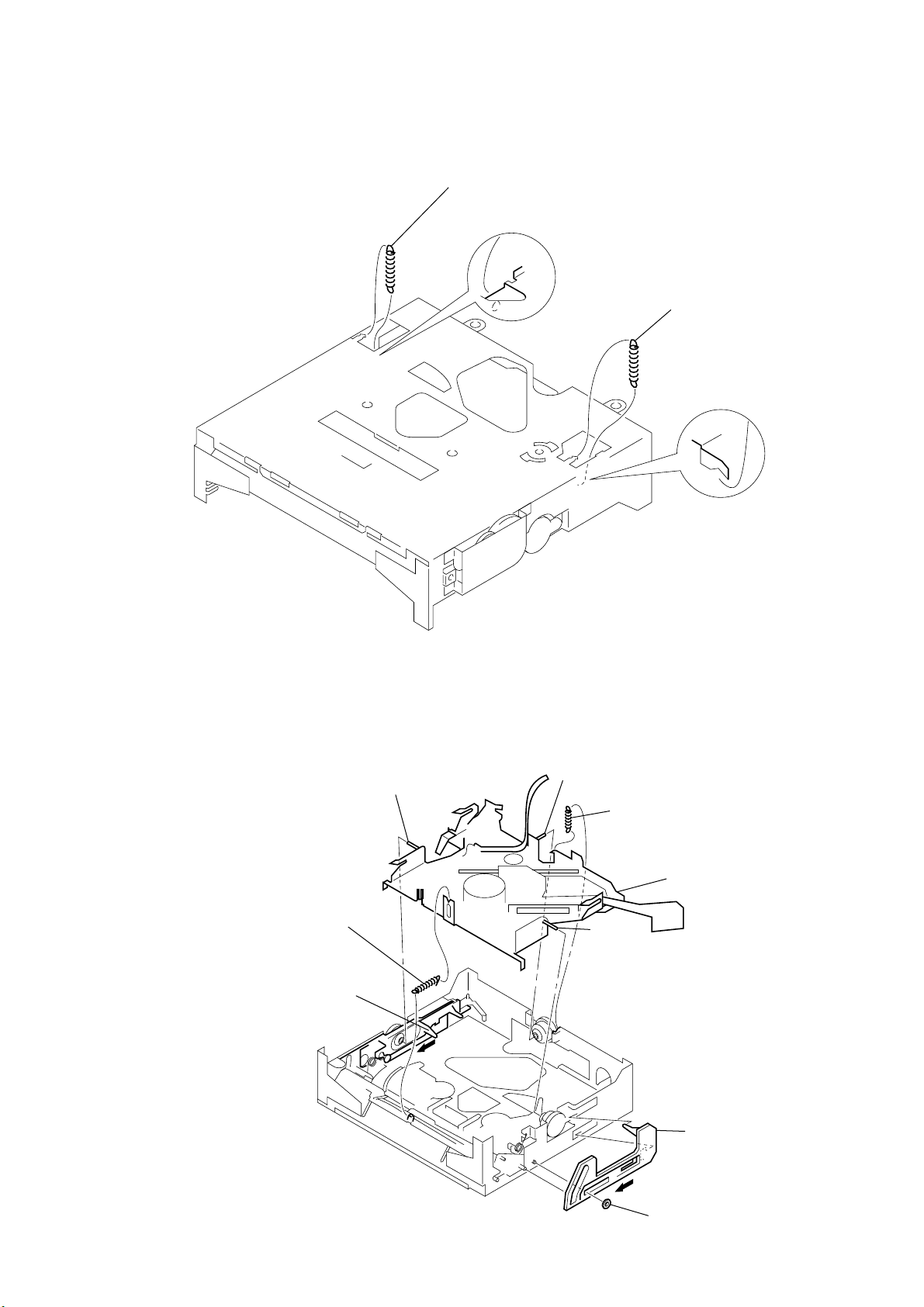

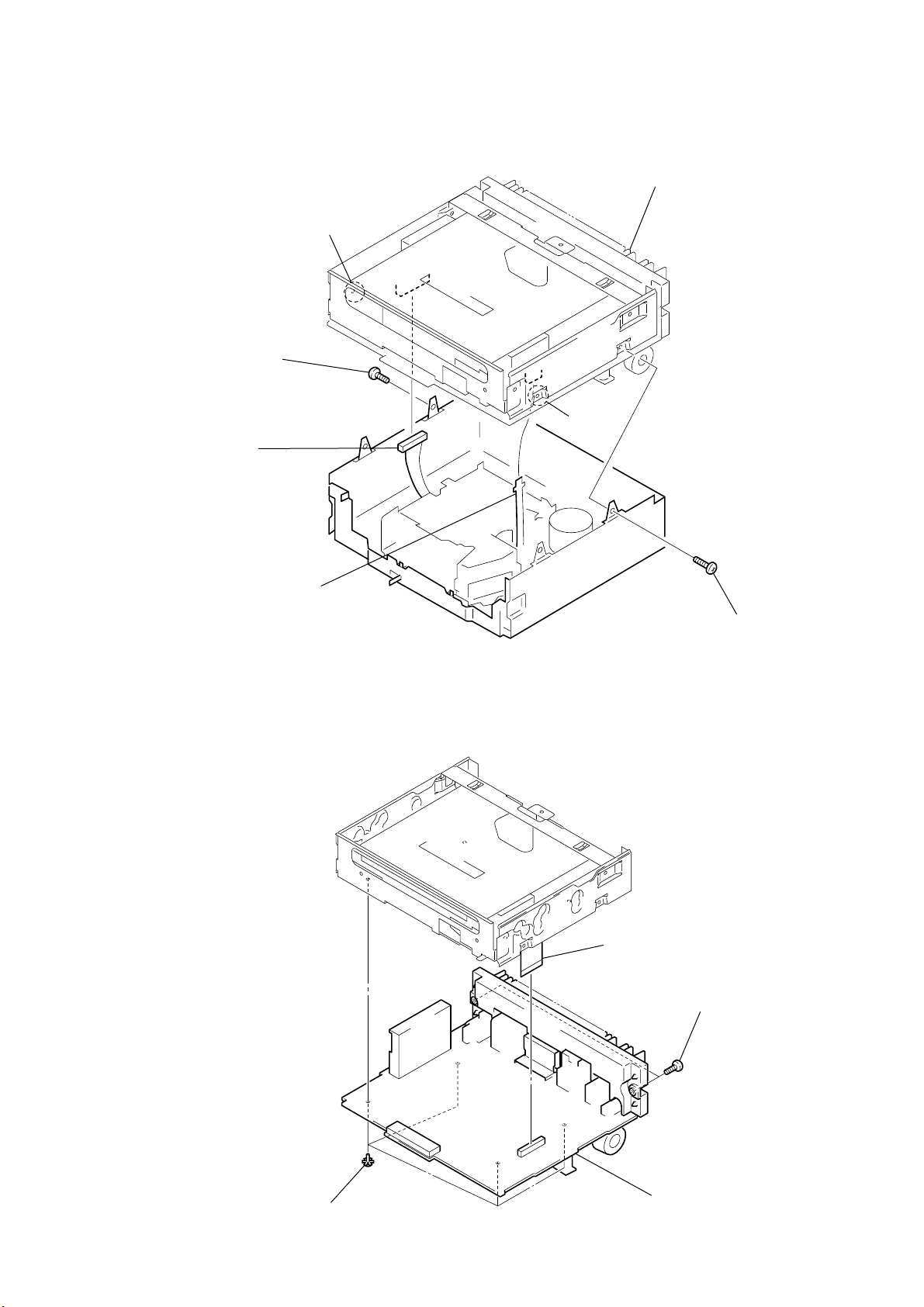

Page 14

WX-4500X

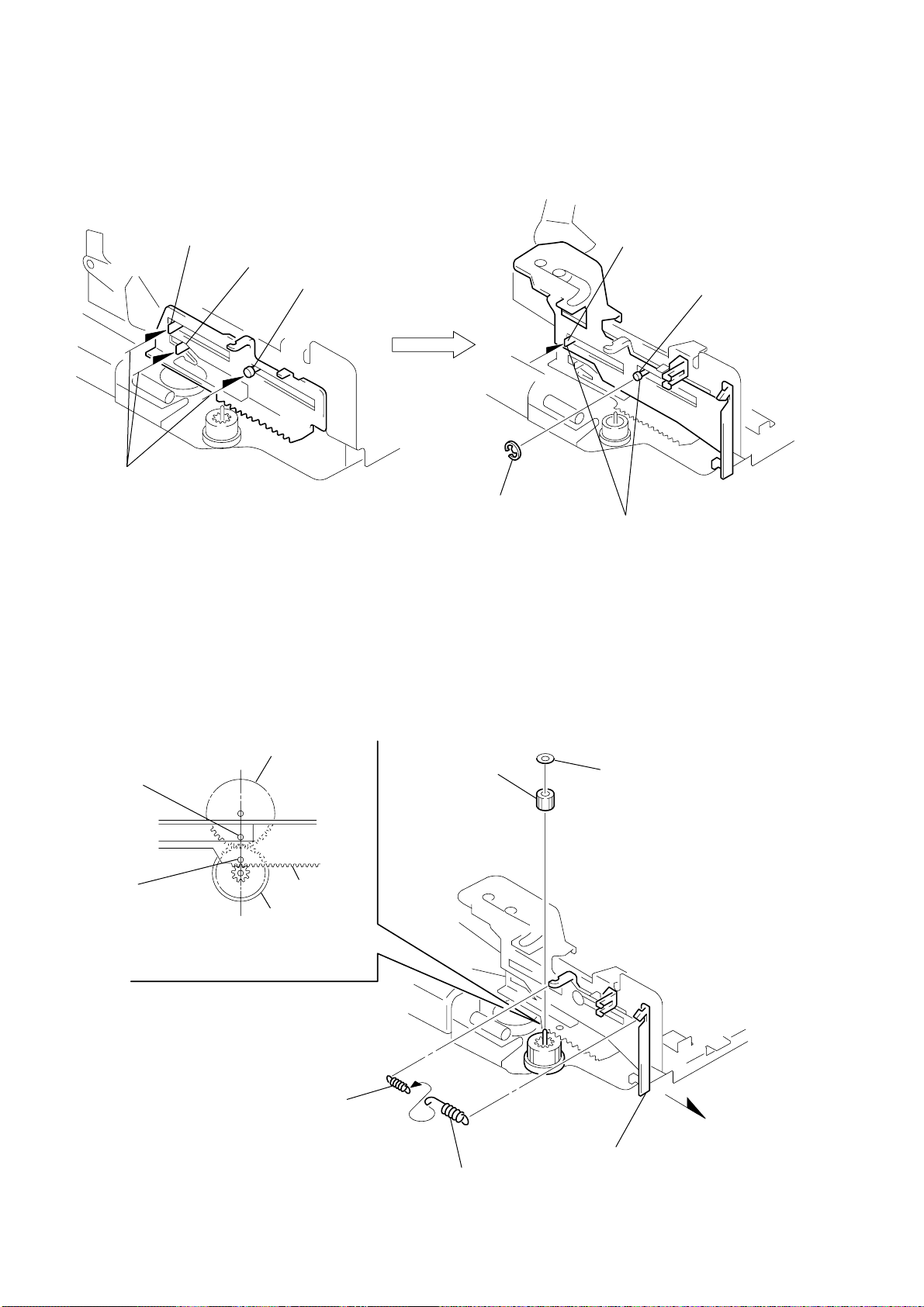

2-6. ROLLER ARM ASSY

3

Fit lever in the

direction of the arrow.

5

shaft

2

spring (roller)

6

arm assy, roller

1

spring (roller)

4

shaft

2-7. OPTICAL PICK-UP ASSY

2

shaft (sled guide)

5

rack (feed)

1

gear (woam wheel)

4

PTP 1.7x4

3

cover (P)

6

pick-up assy, optical

14

Page 15

1

PTT 2.6x10

2

PTT 2.6x6, ground point

3

MAIN board

4

CN450

6

2-8. CHASSIS (TOP) ASSY

2

PTT 2.6x6

4

connector

projection

projection

5

chassis (TOP) assy

WX-4500X

2-9. MAIN BOARD

3

CN400

1

PTT 2.6x

15

Page 16

WX-4500X

2-10. HEAT SINK

6

heat sink

5

4

BTP 2.6x8

PTT 2.6x10

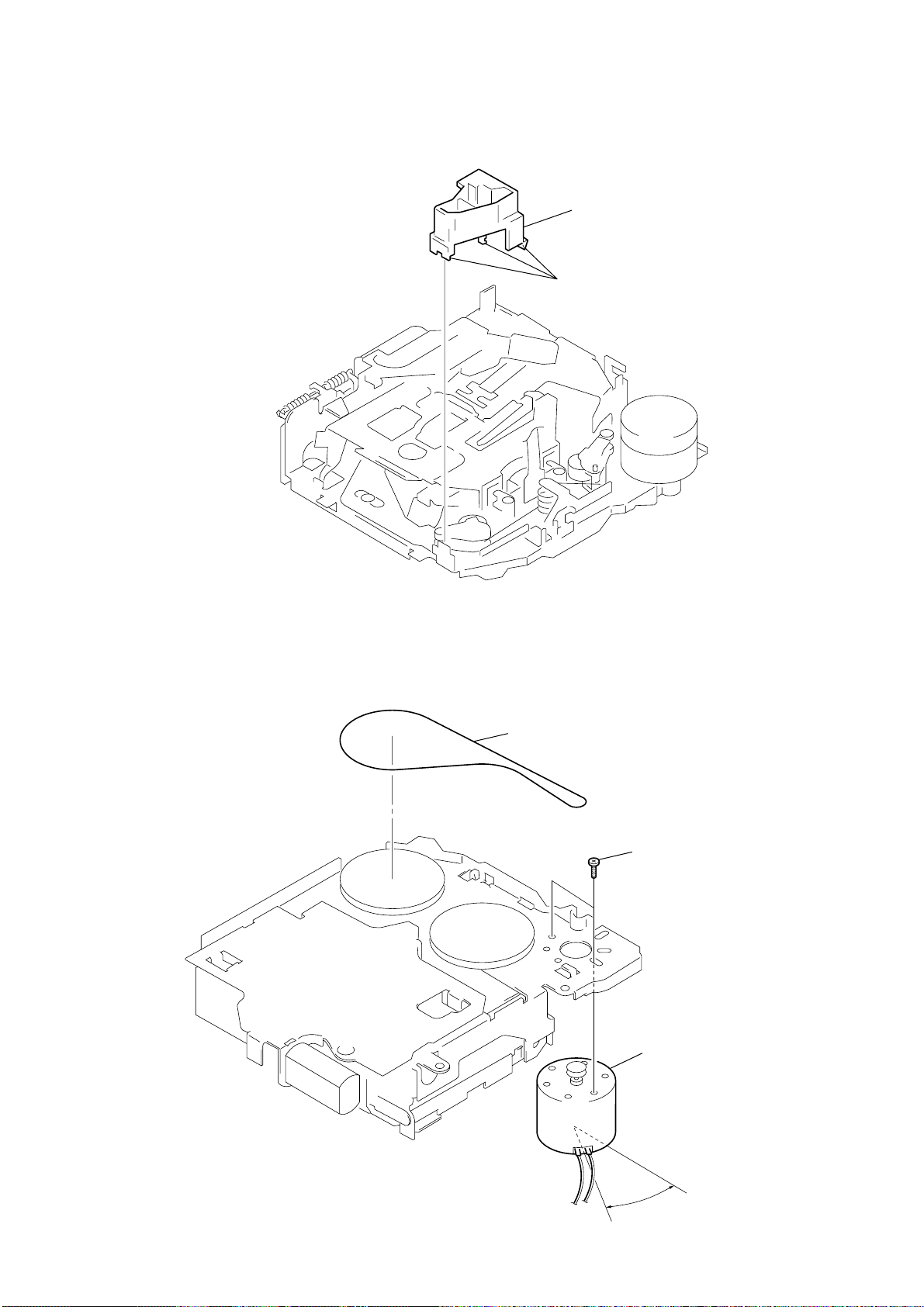

2-11. TAPE MECHANISM BLOCK

3

tape mechaniam block

1

PTT 2.6x10

2

PTT 2.6x10

2

PTT 2.6x5

3

PTT 2.6x10

16

1

PTT 2.6x5

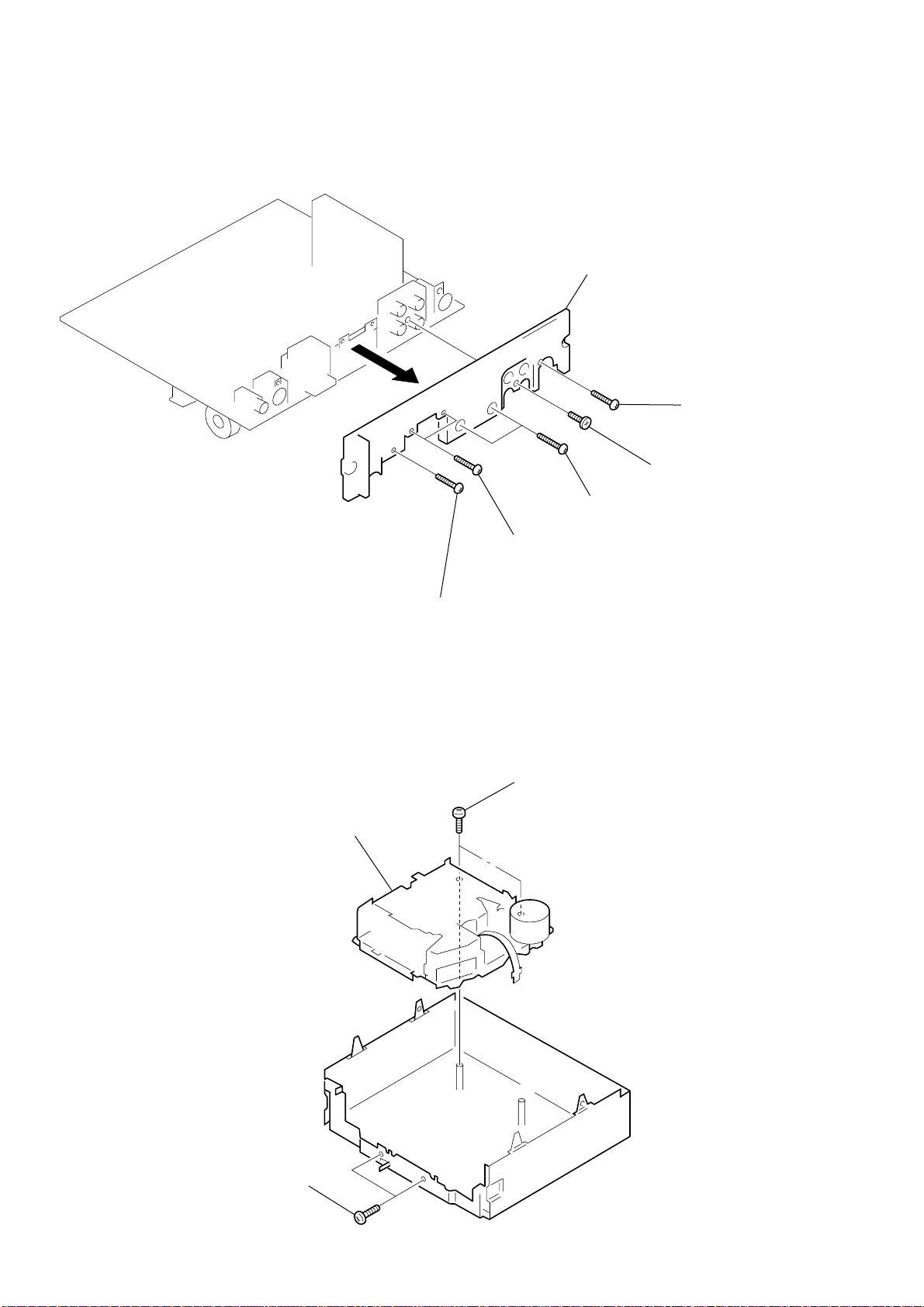

Page 17

w

SECTION 3

ASSEMBLY OF MECHANISM DECK

Note : This set can be assemble according to the following sequence.

Head, Housing Arm (Suction)

Note : Follow the assembly procedure in the numerical order given.

3-1. HOUSING

4

3

Put the housing

under

2

Fit claw on B part.

A

part.

housing

5

Install the hanger onto

two claws of the housing.

Lever (LDG-A) / (LDG-B) Gear (Loading FT)

Guide (U) Main Motor Assy

Fit projection on C part.

C

part

7

Holder the hanger by bending the claw.

1

Install the catcher to the hanger.

hanger

6

Fit projection on D part.

WX-4500X

3-2. ARM (SUCTION)

projection

A

part

B

part

8

Hold the hanger by

bending the claw.

D

part

head

2

Move the arm (suction) in the arro

Direction and fit on projection.

1

Fit the arm (suction) on the shaft.

17

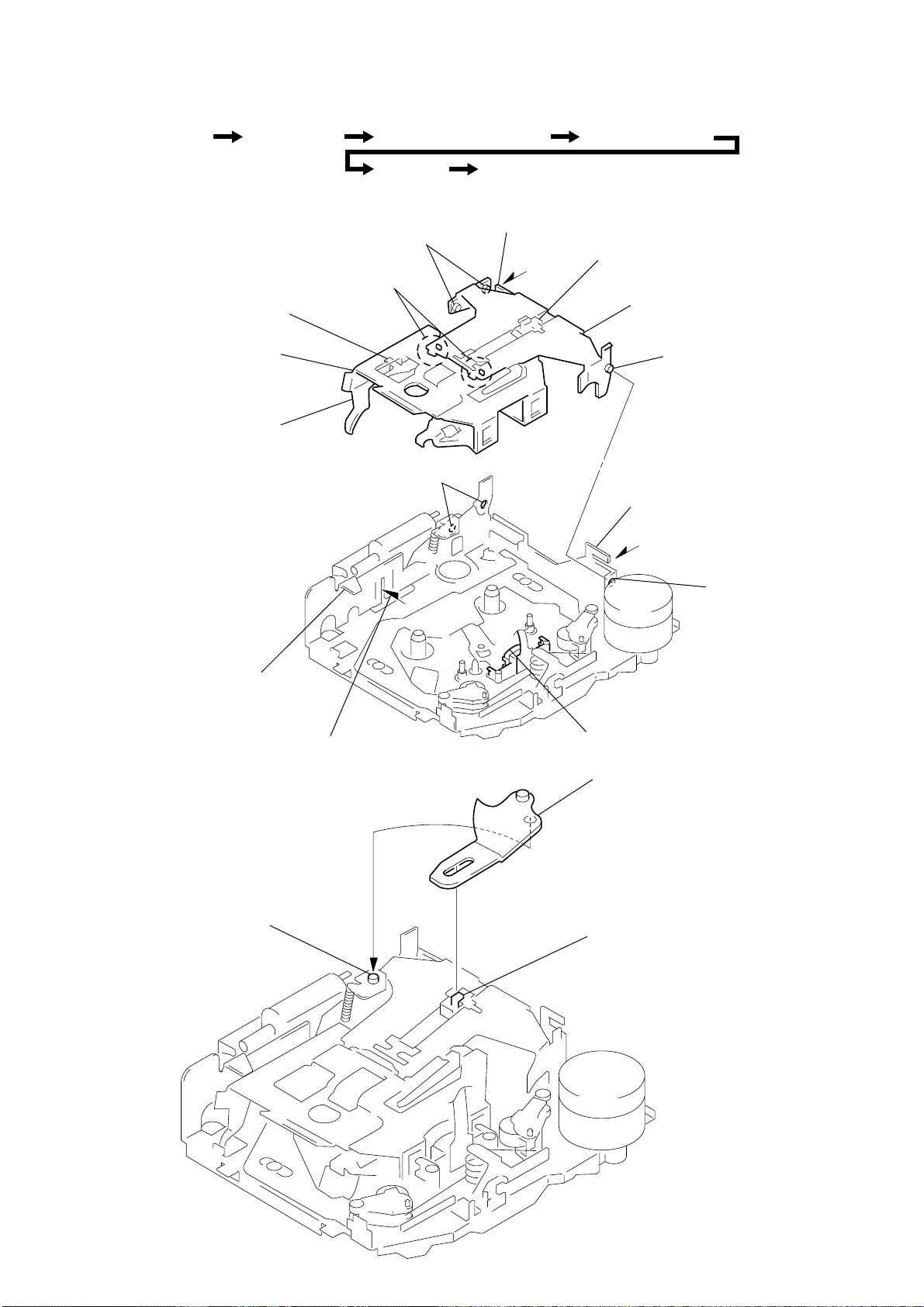

Page 18

WX-4500X

3-3. LEVER (LDG-A) / (LDG-B)

A

shaft

shaft

1

Fit the lever (LDG-A) on

shafts

A

to C and install it.

B

shaft

C

3

type-E stop ring 2.0

shaft

A

2

Fit the lever (LDG-B) on

shafts

A

and B and install it.

shaft

B

3-4. GEAR (LOADING FT)

hole

hole

5

Align hole in the gear (LDG-D)

with hole the lever (LDG-A).

2

gear (LDG-D)

lever (LDG-A)

gear (LDG-FB)

tension spring (LD-2)

6

gear (loading FT)

1

7

polyethylene washer

18

tension spring (LD-1)

3

4

Move the lever (LDG-B)

in the arrow direction.

Page 19

3-5. GUIDE (U)

)

1

2

claws

WX-4500X

guide (C)

3-6. MAIN MOTOR ASSY

3

belt (25)

2

precision screws P 2x2

1

main motor assy

(CAPSTAN/REEL) (M904

30

°

19

Page 20

WX-4500X

SECTION 4

MECHANICAL ADJUSTMENTS

SECTION 5

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Wipe the following components with an absorbent cotton cloth

moistened with alcohol before adjustment :

PB head Pinch roller

Idler Rubber belt

Capstan

2. Demagnetize the PB head using a head demagnetizer.

3. Be careful not to use a magnetized screwdriver.

4. After the adjustment is completed, lock the adjustment parts

using screws.

5. Unless otherwise specified, make adjustments at the specified

voltage (14.4 V).

Torque Measurement

Mode Torque Meter Meter Reading

2.95 – 6.37 mN • m

FWD (30 – 65 g • cm)

CQ-102C

FWD

Back Tension

REV (30 – 65 g • cm)

CQ-102RC

REV

Back Tension

FF, REW CQ-201B (60 – 200 g • cm)

(0.42 – 0.90 oz • inch)

0.05 – 0.44 mN • m

(0.5 – 4.5 g • cm)

(0.01 – 0.06 oz • inch)

2.95 – 6.37 mN • m

(0.42 – 0.90 oz • inch)

0.05 – 0.44 mN • m

(0.5 – 4.5 g • cm)

(0.01 – 0.06 oz • inch)

5.88 – 19.61 mN • m

(0.83 – 2.78 oz • inch)

• Adjustments of the tuner and CD sections have auto adjustments

in this set.

TAPE SECTION

Test tape

Type Signal Use

WS-48A 3 kHz, 0 dB Tape speed adjustment

P-4-D400 400 Hz, 0 dB Dolby level adjustment

Tape Speed Adjustment

Mode : FWD play

test tape

WS-48A

(3 kHz, 0 dB)

Procedure:

1. Playback the test tape in the FWD play mode.

2. V erify that the reading on the digital frequency counter is in the

range between 3,010 and 3,300 Hz at the top of tape.

3. If the specified value is not met, adjust the variable resistor on

the capstan motor so that the reading is 3,000 Hz at the FWD

top of tape.

Adjustment Location :

0 dB = 0.775 V

set

SP OUT

frequency counter

4

Ω

Tape Tension Measurement

Mode Tension Meter Meter Reading

FWD CQ-403A more than 90 g

REV CQ-403R (more than 3.17 oz)

-Tape Mechanism Block upper side-

Tape Speed Adjustment

20

Page 21

t

DOLBY Level Adjustment

Setting :

Light down mark ;

(DOLBY OFF)

test tape

P-4-D400

(400 Hz, 0 dB)

set

main board

TP-L

TP-R

level meter

Procedure :

1. Set the FWD play mode.

2. Push the MENU button and rotate the jog roller to display “NR”.

Then press “ — ” on the SEEK/AMS button to select “NR off”.

(Dolby off)

3. Adjust RV400 for L-ch and RV401 for R-ch so that the level

meter reads –6 ±0.5 dB (0.37 to 0.41 V).

WX-4500X

Adjustment Location :

Dolby level adjustment

(L-CH)

-MAIN BOARD(SIDE A)

Dolby level adjustmen

(R-CH)

-MAIN BOARD(SIDE B)

TP-R TP-L

Dolby level adjustment

21

Page 22

WX-4500X

SECTION 6

DIAGRAMS

6-1. IC PIN DESCRIPTIONS

• IC103 µPD780058GC-259-8BT (CD MECHANISM CONTROLLER)

Pin No. Pin Name I/O Pin Description

1 RST O Reset signal output to the MN6627481RPMF A (IC101) “L” : Reset

2, 3 — O Not used in this set (open)

4 AVSS — Ground pin (for A/D converter)

5 — O Not used in this set (open)

6 J/E, CE I Destination initial setting pin Fixed at “H” in this set

7 A VREF1 I Reference voltage (+5 V) input (for D/A converter)

8 SUBQ I Sub code Q data input from the MN6627481RPMFA (IC101)

9 — O Not used in this set (open)

10 SQCK O Clock signal output for sub code Q data write to the MN6627481RPMFA (IC101)

11 STAT I Internal status signal input from the MN6627481RPMFA (IC101)

12 FL-M- > F O Data write signal to external flash memory Not used in this set (open)

13 MCLK/FL-CLK O Clock signal output for command data from the MN6627481RPMFA (IC101)

14, 15 — O Not used in this set (open)

16 BUS SI I Serial data input from SONY bus interface (IC750)

17 BUS SO O Serial data output to SONY bus interface (IC750)

Serial clock signal input/output for bus interface to the master controller (IC700) and

18 BUS CLK I/O

19 — I

20 TLOCK I Tracking servo pull-in signal input from the MN6627481RPMFA (IC101) “L” : Active

21 FLOCK I Focus servo pull-in signal input from the MN6627481RPMFA (IC101) “L” : Active

22 SENCE I Internal status (SENSE) input from the MN6627481RPMFA (IC101)

23 — I

24 — O Through pin of bus serial data out Connect to the BUS SO (pin qj)

25, 26 — I Through pin of bus serial data in Connect to the BUS SI (pin qh)

27 MLD O Command road signal output from the MN6627481RPMFA (IC101)

28 MDATA O Command data signal output from the MN6627481RPMFA (IC101)

29 LINK OFF O

30 A MUTE O Audio line mute control signal output “H” : mute on

31 MECHA ON O Power on/off control signal output of CD mechanism deck block “H” : Power on

32 — I Through pin of power supply Connect to the VDD (pins yk, uf)

33 VSS — Ground pin

34 — I Through pin of battery down voltage detection signal

35 CD ON O Power on/off control signal output of CD mechanism deck block

36 – 38 — O Not used in this set (open)

39 — I Through pin of bus on/off control signal

40 — O Not used in this set (open)

41 — I Test signal input of auto adjustment

42 SER OK O Effect discrimination out of auto adjustment “H” : OK

43 SER NG O Effect discrimination out of auto adjustment “H” : NG

44 – 51 — O Not used in this set (open)

52 TEXT I

53 SERCHK O Not used in this set (open)

54 P TEST O Not used in this set (open)

55 LIMSW I

56, 57 — O Not used in this set (open)

the display controller (IC900), or serial clock signal output to the SONY bus

interface (IC750)

Through pin of serial clock signal for the bus interface

Connect to the BUS CLK (pin qk)

Through pin of serial clock signal for the bus interface

Connect to the BUS CLK (pin qk)

Link on/off control signal output for SONY bus interface

“L” : Link off, “H” : Link on Not used in this set

Initial setting input used to with/without the CD text decording function

“L” : without, “H” : with

CD sled limit in detection switch input

“L” signal is input when the optical pick-up comes on the innermost perimeter

22

Page 23

WX-4500X

Pin No. Pin Name I/O Pin Description

58 SW3 I

59 SW4 I

60 SYS RESET I

61 — O Not used in this set (open)

62 BUS ON I BUS on/off control signal input from the master controller (IC700) “L” : Bus on

63 SW2 I

64 B/U CHECK I

65 BLKCK I Clock signal input for sub code interrupt from the MN6627481RPMFA (IC101)

66 — O Not used in this set (open)

67 VSS0 — Ground pin

68 VDD — Power supply pin (+5 V)

69 X2 — Main system clock connect pin (5 MHz)

70 X1 — Main system clock connect pin (5 MHz)

71 VPP — Fixed at “L” in this set

72 ——Sub System clock connect pin Not used in this set (open)

73 XT1 — Sub System clock connect pin Not used in this set (Fixed at “H”)

74 VDD — Power supply pin (+5 V)

75 A VREF0 I Reference voltage input (for A/D converter) Fixed at “L” in this set

76 ROUT O

77 FOUT O

78, 79 ——Not used in this set (open)

80 GCTL O FE, TE gain control signal output

CD loading detection switch input

“L” signal is input during CD disc loading and ejecting operations

CD disc detection switch input

“L” signal is input when CD disc catching is completed

System reset signal input from the master controller (IC700) and the reset signal

oscillator (IC701) “L” : Reset

“L” signal is input for several hundreds of microseconds after the power is turned on,

the signal then turns “H”.

CD disc detection switch input

“L” signal is input when a disc is present at the CD disc inlet

Down voltage detection input from the SONY bus interface (IC750) and the battery

detection circuit “L” signal is input when the voltage is reduced

CD loading motor (M903) control signal (direction of eject) output to the

BA5984FP (IC201) of CD mechanism deck block “H” : Active

*1

CD loading motor (M903) control signal (direction of loading) output to the

BA5984FP (IC201) of CD mechanism deck block “H” : Active

*1

*1 CD loading motor (M903) control

Operation

Pin

STOP LOADING EJECT BRAKE

FOUT (Pin uj) “L”“H”“L”“H”

ROUT (Pin uh) “L”“L”“H”“H”

23

Page 24

WX-4500X

• IC700 MB90574CPMT-G-356-BNDDE1 (MAIN SYSTEM CONTROL)

Pin No. Pin Name I/O Pin Description

1 TU ON O Tuner on signal output

2 DOLON I/O

3 – 6 N. C. O O Not used in this set (open)

7 BUS ON O Bus on control signal output

8 VCC — Power supply pin (+5 V)

9 FLASH WR I Flash write mode detection signal input “L” : Flash write mode

10 EEDATA I/O EEPROM data signal input/output

11 EECLK O EEPROM clock signal output

12 RXD I Flash write data signal input

13 TXD O Flash write data signal output

14 N. C. O O Not used in this set (open)

15 BEEP O BEEP signal output

16 DPBOOT O Display microcomputer write control signal output

17 – 19 N. C. O O Not used in this set (open)

20 UNI SI I SONY bus data input

21 UNI SO O SONY bus data output

22 UNI CLK O SONY bus clock output

23 N. C. O O Not used in this set (open)

24 SIRCS I Remote control data signal input

25 – 28 POS0 – 3 I Position signal detection input

29 REEL1 I Reel stand rotation detection signal input

30 LM EJ O Tape mechanism loading motor control signal output (eject direction)

31 LM LOD O Tape mechanism loading motor control signal output (loading direction)

32 TP ON O Tape power control signal output

33 VSS — Ground pin

34 C — Capacitance pin of power stabilized

35 AD ON O Power control signal output of A/D conversion

36 N. C. O O Not used in this set (open)

37 CM-ON O Capstan motor control signal output

38 DVCC — D/A converter VREF input

39 DVSS — D/A converter ground pin

40, 41 N. C. O O Not used in this set (open)

42 AVCC — Analog power supply pin

43 A VRH — A/D converter VREF+ input

44 A VRL — A/D converter VREF– input

45 AVSS — Analog ground pin

46 KEY IN0 I Key 0 signal input

47 KEY IN1 I Key 1 signal input

48 DESTSEL0 I Destination initial setting pin (Fixed at “H” in this set)

49 RC IN0 I Rotary commander signal input

50 QUALITY I Tuner noise detection signal input Not used in this set (open)

51 FM AGC I FM AGC detection signal input

52 MPT I Tuner multi pass signal input Not used in this set (open)

53 VSM I S meter voltage signal input

54 VCC — Power supply pin (+5 V)

55, 56 N. C. O — Not used in this set (open)

57 E VOL MUTE O Electronic volume mute signal output “L” : mute on

58 AMP MUTE O Amplifier mute signal output

59 MUTE O System mute control signal output

60 AMP ON O Amplifier on signal output “L” : off/ “H” : on

61 SA LAT O Serial data lutch pulse output for spectrum analyzer

Dolby control signal output (“H” : dolby on)/dolby function corresponding

detection signal input (“L” : dolby function corresponding)

24

Page 25

Pin No. Pin Name I/O Pin Description

62 FL ON I FL ON control signal input

63 VSS — Ground pin

64 RE IN1 I Rotary encoder signal input

65 FSW IN I Frequency signal input for D/D converter oscillation

66 RE IN0 I Rotary encoder signal input

67 – 69 N. C. O O Not used in this set (open)

70 II DATA O Data signal output for tuner volume communication

71 II CLK O Clock signal output for tuner volume communication

72 RC IN1 I Rotary commander signal input

73 X1A — Low speed oscillation input (32.768 kHz)

74 X0A — Low speed oscillation input (32.768 kHz)

75 W UP O Wake up signal output

76 KEYACK I Key acknowledge detection signal input

77 BU CHK I Back up power detection signal input

78 DAVN I RDS data block synchronization detection signal input

79 TEL ATT I TEL mute detection signal input

80 TEST IN I Test mode setting detection signal input

81 ACC IN I ACC power detection signal input “L” : ACC on

82 FSW SFT O D/D converter control signal output

83 SYS RST O System reset signal output

84 RAM RST I RAM reset detection signal input

85 NS MASK O Noise mask output Not used in this set (open)

86 HTMX I Hardware standby signal input

87 MODE2 I Input for operation mode (Connect to VSS)

88 MODE1 I Input for operation mode (Connect to VSS)

89 MODE0 I Input for operation mode (Connect to VSS)

90 RST I Microcomputer reset signal input

91 VSS — Ground pin

92 X0 — High speed oscillation input (3.58 MHz)

93 X1 — High speed oscillation input (3.58 MHz)

94 VCC — Power supply pin (+5 V)

95 DSTSEL1 I Destination initial setting pin

96, 97 N. C. O O Not used in this set (open)

98 DIM ON O Dimer control signal output

99 ILL ON O Illumination power control signal output

100 ILL IN I Illumination line detection signal input

101 – 103 N. C. O O Not used in this set (open)

104 POWER ON O System power control signal output

105 – 110 N. C. O O Not used in this set (open)

111 PLAY/AMS O AMS music interval detection function control signal output

112 F/R O FWR/REV control signal output “H” : FWD/ “L” : REV

113 MTL I/O

114 – 116 N. C. O O Not used in this set (open)

117 AMS IN I

118 TAPE MUTE O

119 VSS — Ground pin

120 N. C. O O Not used in this set (open)

Metal control signal output (“H” : metal on)/Metal function corresponding detection

signal input

AMS music interval detection signal input

“L” : Audio signal detection, “H” : Audio signal no detection

During FF/REW period, audio signal select control signal output

When the FF/REW mode is selected with ATA ON : “H”

WX-4500X

25 25

Page 26

WX-4500X

6-2. BLOCK DIAGRAM — CD SECTION —

DETECTOR

&

I/V AMP

OPTICAL

PICK-UP

BLOCK

LASER DIODE

NA

NB

F

E

AUTOMATIC

LD

POWER

CONTROL

Q101

PD

A

32

B

30

PDF

28

PDE

27

LD

2

LPD AMP

PD

1

I-V

AMP

RF AMP

RFO RFI

5

ERROR AMP

TRACKING

ERROR AMP

6 8

FOCUS

RF AMP,

FOCUS/TRACKING ERROR AMP

RF

DET

RF AMP

IC102

BDO

DET

AGC

OFER

DET

ENVELOPE

ARF

ENV

NRFDET

OFTR

BDO

FEO

TEO

TEBPF

VDET

TBAL

FBAL

LDON

DIGITAL SIGNAL PROCESSOR,

DIGITAL SIGNAL SERVO,

CLV SERVO,

D/A CONVERTER,CD-TEXT

IC101

ARF

44

53

10

15

14

38

36

DSLB

RFDET

OFT

DSL.

PLL VCO

SERVO TIMING

GENERATOR

68

EFM/SUBCODE

DEMODULATOR,

CD-TEXT

BUFFER

CIRC ERROR

CORRECTION,

16K S-RAM

SUBCODE

BUFFER

TIMING

GENERATOR

SOFT

MUTING,

ATTENUATOR

DIGITAL

DEEMPHASIS

DIGITAL

FILTER

BLKCK

1BIT D/A

CONVERTER,

PWM LOGIC

SUBQ

15 8

SQCK

14 10

13 65

16M

OUTL

OUTR

SUBQ

SQCK

BLKCK

X2

58

59

73

75

35 31

CD-ON

X101

16.93MHz

R-CH

MECHA ON

A-MUTE

2

TUNER

SECTION

CD L

(Page 27)

CD ON

MECHA ON

30

A-MUTE

3

6

SECTION

(Page 28)

TUNER

SECTION

TAPE

(Page 27)

BDO

12

23

20

B.P.F

19

18

26

25

24

39

RFENV

34

FE

32

TE

33

VDET

35

TBAL

31

FBAL

30

LDON

40

A/O

CONVERTER

INPUT

PORT

SERVO CPU

SERVO TIMING

GENERATOR

MICRO

COMPUTER

INTERFACE

SENSE

10 22

FLOCK

11 21

TLOCK

12

MDATA

8

MCLK

7

MLD

9

STAT

17

20

28

13

27

11

SENSE

FLOCK

TLOCK

MDATA

MCLK

MLD

STAT

CD MECHANISM

CONTROLLER

IC103

BUS CLK

BUS SO

BUS SI

BUS ON

B/U CHECK

SYS RESET

18

17

16

62

64

60

BUS CLK

BUS SO

BUS SI

BUS ON

BUS CHECK

SYS RST

7

TAPE

SECTION

(Page 28)

2-AXIS

DEVICE

(FOCUS)

(TRACKING)

F+

F–

T+

T–

• Signal path

: CD

• R-ch is omitted due to same as L-ch.

M902

SLED

M901

SPINDLE

M903

LOADING

18

F+

17

F–

18

T+

15

T–

16

+

M

–

+

M

–

+

M

–

SLED+

12

SLED–

11

SPDL+

14

SPDL–

13

VOL+

10

VOL–

9

FOCUS COIL

DRIVE

TRACKING COIL

DRIVE

SLED MOTOR

DRIVE

SPINDLE MOTOR

DRIVE

LOADING MOTOR

DRIVE

FOCUS/TRACKING COIL DRIVE,

SLED/SPINDLE/LOADING

MOTOR DRIVE

IC201

FIN–

TIN–

SLIN–

SPIN–

FIN

RIN

23

26

6

3

28

1

FOD

28

TRD

27

KICK

26

TVD

22

TRV

21

ECM

24

ECS

25

CLV

SERVO

SW2

(DISC DETECT)

SW3

(LOADING DETECT)

SW4

(CHUCKING DETECT)

SW5

(LIMIT)

RST

X301

5MHz

1

RST

70

X1

X2

69

FOUT

77

ROUT

76

63

SW2

SW3

58

59

SW4

55

LIMSW

2626

Page 27

6-3. BLOCK DIAGRAM — TUNER SECTION —

J1

(ANTENNA)

CD

SECTION

(Page 26)

2

1

2

TAPE

SECTION

(Page 28)

CD L

ANT-AM

ANT-FM

TU1

TUNER UNIT

1

3

AM DET

S-METER

FM AGC

MPX

SDA

SCL

SDA

SCL

TAPE L

8

10

12

13

14

4

17

18

1

LPF

IC451

4

44

40

9

12

CDC L

TAPE L

CD L

AM

MPXI

14

MP IN

ELECTRONIC VOLUME

IC300

ADSO(L-CH)

IC100

X700

32.768kHz

WX-4500X

CN300

-1

L

BUS AUDIO IN

-2

CN900

2

1

10

9

3

4

11

12

13

7

R

-3

L

SUB WOOFER OUT(MONO)

-4

R

FL+

FL–

RL+

RL–

FR+

FR–

RR+

RR–

TEST

ACC

SA OUT

23

21

SA CLK

SW

CD

59

60

58

15

80

81

24

FL

28

RL

27

(Page 26)

TAPE

SECTION

(Page 28)

S MUTE

57

E-VOL MUTE

AMP MUTE

BAL/

FAD

3

A-MUTE

MUTE

AMP ON

BEEP

TEST IN

ACC IN

SECTION

13 3338

53

51

10

11

73

74

VOL TONE

VSM

FM AGC

EE DATA

EE CLK

X1A

XOA

SDA

SCL

19

207117

70

II CLK

II DATA

MAIN

SYSTEM CONTROL

IC700(1/2)

MUTE DRIVE

Q300,301

5

SA AUDIO

SA CLK

RESET

4

SECTION

(Page 28)

ACC CHECK

Q903

TAPE

MUTE

MUTE

MUTE

Q303

Q303

Q303

MUTE

Q302

11

15

22

POWER AMP

IC170

OUT1+

IN1

IN3

MUTE

STBY

4

OUT1–

OUT3+

OUT3–

AC GND

16

R-CH

9

7

17

19

R-CH

• Signal path

: FM

: AM

: CD

: TAPE(PB)

• R-ch is omitted due to same as L-ch.

ILL IN

100

XO

X451

3.58MHz

1

COM8V TU5VAUDIO 10V BATT

+8V REG

4 2

IC301

92

TEL ATT

79

XI

93

BATT

TU ON

+5V REG

Q1

TU8.5V

POWER ON

1

104

1

REG

4 2

IC1

ANT/AMP

REMOTE SW

Q902

BATT

27 27

ILLUM CHECK

ANT REMOTE

SW

Q900(1/2)

AMP REMOTE

SW

Q900(2/2)

Q904

TEL ATT

Q906

BATT

F901

15

ILL

14

ATT

5

ANT REM

6

AMP REM

16

BATT

Page 28

WX-4500X

6-4. BLOCK DIAGRAM — TAPE SECTION —

HP901

PLAYBACK HEAD

FWD

REV

(CAPSTAN/REEL)

L

R

L

R

M904

+8.5V

MECHA ON

6

CD ON

R-CH

R-CH

M

37

39

C-MOTOR

Q653,654

TAPE +8.5V

Q650,651

CD

SECTION

(Page 26)

CD8V

Q450,451

• Signal path

: TAPE

• R-ch is omitted due to same as L-ch.

TAPE EQ/DOLBY/METAL/AMS

RV400

DOLBY LEVEL

(L-CH)

DRIVE

REG

+5V REG

CD5V

IC400

EQ

24

BATT

BATT

R-CH

DOLBY

AUTO

MUSIC

SENSOR

(LOADING)

J900

(REMOTE IN)

BU5V

NR

MECHANISM

M905

FWD/REV

MTL/NORMAL

NR ON

L OUT

MUTE/TAPE

AMS OUT

AMS/PLAY

TAPE

BLOCK

M

KEY

RESET

IC701

TUNER

SECTION

(Page 27)

19

18

16

7

17

14

20

LM

LM–

BU5V

12

5

TAPE L

(Page 27)

S700

(FREQUENCY SELECT)

FM 200k

AM 10k

FM 50k

AM 9k

+

REMOTE CONTROL

7

9

RECEIVER

PH960

KEY ACK SW

Q905

RESET

SW960

(RESET)

RESET

LOADING

MOTOR DRIVE

IC650

EN960

RAM

IC702

1

TUNER

SECTION

4

3

BU5V

MAIN SYSTEM CONTROL

112

F/R

113

MTL

2

DOL ON

118

TAPE MUTE

117

AMS IN

111

AMS ON

DST SEL1

95

POS0

25

POS1

26

POS2

27

28

POS3

29

REEL1

30

LM EJ

31

LM LOD

37

CM ON

SIRCS

24

32

TP ON

KEY ACK

76

35

AD ON

72

RC IN1

49

RC IN0

46

KEY IN0

66

RE IN0

RE IN1

64

8412

RAM RST

RST

90

HTMX

86

RXD

12

IC700(2/2)

UNI SI

UNI SO

BUS ON

UNI CLK

BU CHK

SYS RST

DP BOOT

SA LAT

DIM ON

ILL ON

W UP

FSW SFT

F SW IN

FL ON

CD SECTION

7

BUS CLK

BUS SI

BUS SO

BUS ON

20

21

7

22

77

83

16

61

98

99

75

82

65

62

(Page 26)

BUS CHECK

SYS RST

AUDIO 10V

AUDIO 10V

2

RESET

D/D CONV

ON/OFF SW

FREQ OSC

ON/OFF SW

Q801

FL ON/OFF

IC801,Q803

IC901

Q800

SW

DIMMER

ON/OFF SW

Q907

ILLUM

ON/OFF SW

Q908

BUS CONTROL

IC750

8

9

12

11

10

13

811

57

27

34

82

38

51

97

98

101

62

16

20

21

22

33

28

BUS ON

CONT

BATT

CHECK

RESET

DISPLAY SYSTEM CONTROL

IC900

LINK OFFRES

BOOT

SA LAT

BU IN

NMI

BUS ON

FL ON

UNI SO

UNI SI

UNI CK

FL SI

D903,905

908,911

D902,904,906

POWER CONTROL

CTL1

CTL2

CTL3

DTC4

DTC3

SA DATA

IC800

BATT

DATA

CLK

SA CLK

ILL ON

XTAL

EXTAL

FL LAT

FL BK

FL SCK

FL SO

OUT1RT

OUT2

OUT3

OUT4

6

1

4

3

2

50

1

112

52

85

86

75

74

64

60

BATT

46

44

40

39

FL ON/OFF

SW

Q810

18.432MHz

BATT

BUS ON/OFF

SW

Q750

X901

WAKE-UP

Q807

BATT

BACK-UP

+5V REG

Q804

BATT

OVER VOLTAGE

CHECK

Q751

SA CLK

SA AUDIO

BU5V

SW

CD+8V REG

Q809

AMP

IC803,Q810

Q812-814

ON/OFF SW

POWER

CONTROL

Q805,806

+10V REG

Q808

4

ILLUM

Q901

CD8V

TUNER

SECTION

(Page 27)

BU5V

AUDIO 10V

T800

CN750

(BUS CONTROL IN)

8

6

5

4

7

BATT

VDD

11

LAT

9

BK

10

8

CLK

SI

7

12

VH

F2 F2 F1 F1

16

3

2

1

17

FL700

1

2

2828

Page 29

WX-4500X

d

6-5. CIRCUIT BOARDS LOCATION

SW board

JOG board

DISPLAY board

CD MAIN board

MOTOR boar

MAIN board

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS

AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is

printed in each block.)

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

a

•

•

• : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

• All resistors are in Ω and 1/

• % : indicates tolerance.

•

• C : panel designation.

Note: The components identified by mark 0 or dotted line

• A : B+ Line.

• Power voltage is dc 14.4V and fed with regulated dc power

• Voltage and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: Through hole.

f

: internal component.

(The other layer’s patterns are not indicated.)

50 WV or less are not indicated except for electrolytics

and tantalums.

specified.

f

: internal component.

with mark 0 are critical for safety.

Replace only with part number specified.

supply from ACC and BATT cords.

under no-signal conditions.

Voltage variations may be noted due to normal produc-

tion tolerances.

Voltage variations may be noted due to normal production tolerances.

F : FM

f : AM

E : TAPE

J : CD

4

W or less unless otherwise

• Waveforms

— CD MECHANISM SECTION —

(MODE : CD PLAY)

1

1.2Vp-p

IC102 8 (ARF)

2

0V

Approx. 180mVp-p

IC102 wd (FEO)

3

0V

Approx. 390mVp-p

IC102 w; (TEO)

4

5.4Vp-p

1.9µsec

IC101

(PCK/DSLB)

td

5

3.6Vp-p

16.9344MHz

IC101 tk (16M)

6

4.1Vp-p

5MHz

IC103 u; (X1)

• Waveforms

— MAIN SECTION (2/3) —

1

29 29

2.1Vp-p

32.768kHz

IC700 uf (X0A)

2

3.9Vp-p

3.58MHz

IC700 os (X0)

Page 30

WX-4500X

6-6. PRINTED WIRING BOARD — CD MECHANISM SECTION — • Refer to page 29 for Circuit Boards Location.

(Page 33)

C303

C101

JC102

JC103

JC212

C102

R101

CNJ101

JC213

JC110

JC131

JC114

JC101

CNJ103

JC104

JC105

JC140

JC127

JC130

BP4

JC309

TP303

JC119

TP104

JC112

R149

JC111

R150

TP302

C118

TP103

TP105

JC310

X101

JC128

R148

R121

C104

R302

JC139

R134

C103

TP301

JC106

C117

TP101

R135

IC101

BP3

C133

JC313

BP5

JC138

C115

R119

JC107

C114

R117

JC121

JC123

TP311

R116

C113

C138

C112

R102

C105

R106

R123

C123

C122

C110

R104

R115

R113

R105

R103

C136

JC301

R120

JC109

C127

R122

BP1

C111

R107

R130

JC116

C124

JC142

BP2

C106

JC129

R143

R151

R152

JC137

R114

C116

C120

R144

C126

R112

C141

JC115

C121

C145

C146

JC125

R125

R124

CNP102

C128

JC205

JC122

JC136

JC126

IC102

C147

R137

R145

R147

R110

C129

R146

JC141

JC134

R111

R108

R109

R126

C130

JC135

R129

C108

R133

C137

C131

C125

C132

JC124

R141

R142

JC133

R128

Q101

R132

C139

R127

CNJ102

C140

C119

JC108

C135

M903

(LOADING)

SW3

(LOADING DETECT)

• Semiconductor

M902

(SLED)

+

–

1

6

Location

Ref. No. Location

IC101 D-5

IC102 B-7

IC103 F-4

IC201 F-9

Q101 C-9

SW5

(LIMIT)

2

5

M901

(SPINDLE)

ORG

+

BLU

–

JC305

JC306

TP305

TP304

R301

TP309

JC307

TP308

TP310

C302

TP306

JC311

TP307

JC312

IC103

R307

C301

R305

JC308

JC303

R304

X301

C207

JC202

JC211

JC203 JC210

JC201

JC208

JC209

R204

R206

R202

R208

3030

R203

R207

R205

R209

C206

IC201

C201

SW2

(DISC DETECT)

SW4

CHUCKING

( )

DETECT

1

4

Page 31

6-7. SCHEMATIC DIAGRAM — CD MECHANISM SECTION — • Refer to page 29 for Waveforms. Refer to page 41 for IC Block Diagrams.

WX-4500X

JC103

JC127

JC130

JC102

JC101

R101

JC119

JC110

JC140

C101

JC212

JC213

R149

JC111

R150

JC128

JC131

C102

JC112JC105JC104

JC114

TP103

TP104

TP105

X101

R121 C118

R148

JC139

C104

C138

C133

JC106

R134

TP101

C103

R135

C117

IC101

C115

R119

JC107

R117

C114

JC138

C113R116

C112

IC B/D

R106

JC121 C136

R124

R125

R111

R110

R108

R107

R105

R104

R102

C105

JC142

R103

R120

C122

R152

C110

C106

R137

C108

R109

C111

C120

R122

R113

R112

C123

C127

R123 C124

R115

BP1

C126

JC137

R151

R114

BP2

R130

C145

C146

R144

C128

R143

JC116

C121

JC136

JC109

JC122

JC115

IC102

JC133

IC B/D

C125

C132

C130

C129

R145

R146

JC135

JC141

R141

R142

C131

R133

R126

JC134

JC126

C137

JC124

R147

C147

JC125

C135

R129

C116

C141

R128

C119

Q101

JC108

R127

R132

C139

CNJ102

C140

(Page

35)

CNJ101

C303

JC306

JC305

C302

JC307

JC312

JC311

R301

TP304

TP305

TP306

JC310

JC309

TP303

TP307

BP4

JC313

BP3

TP302

IC103

TP301

TP308

TP310

TP309

R302

JC129

BP5

TP311

R307

JC303 JC301

R304

R305

C301

X301

JC308

JC123

JC209JC208

C207

C201

JC201

JC211

JC202

JC203

IC201

JC205

JC210

R202

R206

IC B/D

R203

R207

R204

R208

R205

R209

C206

CNJ103

CNP102

SW5

M902

M903

M901

SW2

SW3

SW4

Note:

• Voltage and waveforms are dc with respect to ground

under no-signal conditions.

no mark : CD PLAY

: Impossible to measure

∗

31 31

Page 32

WX-4500X

6-8. PRINTED WIRING BOARD — MAIN SECTION — • Refer to page 29 for Circuit Boards Location.

R318

C713

R733

C5

C10

R219

R118

R218

C1

R1

C2

R7

R303

R4

R5

R3

R8

C13

R2

R6

C20

C663

Q1

L2

C16

C651

C662

D650

C660

C661

R11

C652

C312

C19

C18

R10

IC650

D1

C15

C718

R230

R207

C105

R130

R106

R107

C307

D651

C205

C655

C654

C653

C14

R9

IC701

R119

C315

R718

R316

R206

C304

R654

R717

IC200

IC100

R652

R653

Q654

R650

IC1

X700

R302

C305

C709

C711

C108

C303

R305

R655

Q650

C707

R113

C206

C207

R210

R211

R651

R716

C708

R720

R112

R719

C710

R714

R722

R723

Q303

R104

C106

C107

R110

R111

Q653

R656

R755

R721

R724

C103

Q651

R715

R317

C111

C203

R708

R712

X451

R116

R115

R105

C101

C21

R756

R216

IC300

IC301

D700

C712

D701

R204

C201

R711

C211

C204

R725

R215

C705

C323

Q304

R205

C104

R726

R735

R320

R321

C308

R710

IC700

C109

R212

C208

R345

R306

C301

C703

R727

R114

R315

R213

R307

C310

D304

D630

R319

C309

C302

C701

R730

C212

R217

C311

R734

R713

R700

C314

D300

D305

R539

L806

IC702

TP701

RB700

R729

R909

C209

R214

Q302

D306

C327

Q301

R707

RB701

R704

C112

R117

C317

Q905

C328

R308

R702

R911

Q907

R309

Q300

L1

C721

C322

C720

R701

R910

Q908

R313

R312

D909

R923

D806

Q906

D302

C839

L901

C325

C823

C321

R314

R907

D804

C802

C803

R802

R801

R906

C820

Q807

R827

C905

D805

L801

D800

R904

D908

R908

Q806

D807

C804

R803

R905

TH900

Q904

L300

Q805

C821

R828

D813

C470

R472

R122

R340

R824

R800

C805

C472

C865

C901

D900

R912

R913

R825

C825

R829

C819

R805

Q800

R808

R471

C117

C116 C216

R121

D903

Q900

Q902

Q903

C827

R831

Q804

R804

R470

C471

IC451

R200

R341

L803

IC800

R807

C806

C482

R480

C481

R100

C841

R832

C824

C818

D801

R482

C217

D901

R901

D808

Q808

R830

R806

R481

C480

R823

C809

C807

C808

R222

R221

R419

R902

C830

D809

R822

C828

R868

R421

C900

R903

C817

Q801

C902

L802

C815

C810

R811

TH901

D756

L805

Q809

R833

C813

R810

R900

C811

R813

R812

C836

IC801

R404

Q803

R819

R816

R815

R814

D803

R837

R838

R839

R840

R841

R842

Q813

R859

C831

R818

Q812

C832

Q810

R456

C402

L452

R836

G1

R854

R848

R858

C401

Q814

R849

D452

R834

C415

D751

D753

R853

R846

C427

C404

C405

C407

TP4

R860

R850

C462

R400

C403

C903

C833

R852

R847

IC803

R416

C422

R413

R401

R399

R861

R896

R895

C837

455

R

Q450

C424

C400

C409

R864

R402

R403

R406

R417

C423

R405

D752

R753

C834

R894

R893

Q451

C425

L900

C842

T800

C426

C416

C408

D757

C463

C420

R411

IC400

R407

R750

R751

D811

C417

R414

C414

C410

D750

D810

C838

D812

C450

Q751

D755

L804

D453

C465

C418

R418

C412

R752

Q750

C464

C419

R415

C421

R412

R409

R408

R921

TP3

D754

RV400

RV401

R410

C428

R920

C750

IC750

R863

C413

R922

R862

3232

Page 33

WX-4500X

• Semiconductor Location

Ref. No. Location

D1 G-4

D300 D-7

D302 C-8

D304 F-7

D305 F-7

D306 D-7

D452 G-12

D453 G-14

D630 G-6

D650 F-3

D651 F-4

D700 H-6

D701 K-6

D750 C-13

D751 B-12

D752 B-13

D753 B-12

D754 D-14

D755 D-14

D756 C-11

D757 B-13

D800 G-9

D801 I-10

D803 H-11

D804 E-9

D805 D-9

D806 E-8

D807 F-9

D808 F-10

D809 F-11

D810 E-14

D811 E-13

D812 F-14

D813 I-9

D900 B-10

D901 B-10

D903 B-10

(D907) C-12

D908 C-9

D909 K-8

IC1 H-4

IC100 E-5

(IC170) A-7

IC200 D-5

IC300 E-6

IC301 G-6

( ): SIDE B

Ref. No. Location

IC400 K-13

IC451 J-10

IC650 F-4

IC700 I-6

IC701 K-4

IC702 G-7

IC750 B-14

IC800 H-10

IC801 I-11

IC803 F-12

Q1 H-3

Q300 E-7

Q301 E-7

Q302 C-7

Q303 C-5

Q304 C-6

Q450 G-13

Q451 G-13

Q650 G-5

Q651 G-5

Q653 F-5

Q654 F-4

Q750 B-14

Q751 B-14

Q800 H-10

Q801 I-11

Q803 G-11

Q804 F-10

Q805 E-9

Q806 D-9

Q807 E-9

Q808 F-10

Q809 F-11

Q810 G-12

Q812 F-12

Q813 F-11

Q814 E-12

Q900 C-10

Q902 C-10

Q903 C-10

Q904 D-9

Q905 K-7

Q906 J-8

Q907 K-8

Q908 K-8

(Page 30)

C866

C719

J900

CN900

CN300

J1

CN750

IC170

TH750

D907

TU1

CN450

S700

CN901

33 33

(Page 39)

Page 34

WX-4500X

6-9. SCHEMATIC DIAGRAM — MAIN SECTION (1/3) — • Refer to page 43 for IC Block Diagrams.

R107

R106 R130

R207 R206

R230

R118 R119

CN300

Note:

• Voltage is dc with respect to ground under no-signal

condition.

no mark : FM

( ) : AM

< > : CD PLAY

[ ] : TAPE PLAY

: Impossible to measure

∗

C309

IC300

C315

304

D

IC200

321

R

C205

C206

R211 R210

320

307

C310

R

R

C311

R104

R105

R204

R205

R345

C207

C328

D306

Q301

C108

C111

C211

C208

Q300

C314

C327

R115

R112

R113

R116

R215

R216

R213

R212

R315

R308

Q302

R309

D300

C317

R217

D302

R319

C109R114

Q303

C112R117

C212

Q304

R318

C209R214

R314

D305

IC100

TU1

C105

C103

C203

C101

C201

C204

C104

IC B/D

C307

C107R110

R305

R306

C308

C106

R111

J1

C1

R1

C2

IC B/D

Q1

C20

D1

R3

C5

R2

IC1

R9

L2

C15

R11

C18C19

C16

C14

R10

R7

R6

R5

R4

R8

C312

C13C10

R303 C304 C303

R302C305

L1

C21

C321

R317

R316

IC170

R219R218

C325

C323

R312

C322

R313

G1

R539

(Page 35)

Q904

R908

R907

C905

D908

R905

R903

Q903

R902

C900

R901

R900

Q902

D903

Q900(1/2)

TH900 TH901

C901 C902

Q900(2/2)

R341R340

CN900

D901D900

R906

R904

F901

C903

D907

L900

3434

Page 35

6-10. SCHEMATIC DIAGRAM — MAIN SECTION (2/3) — • Refer to page 29 for Waveforms. Refer to page 44 for IC Block Diagrams.

CN400

C420

C421

C422

C423

C417

C418

C419

C424

C425

C426

CN450

R414

R415

R416

R417

R412

R413

C416

C415

RV400

RV401

R411

R402

C414

C400

C413

C403

R410

R409

R400

R401

C427

C428

R418

R399

C401

IC400

C404

C412R408

TP

R419

C405

C402

IC B/D

R403

C407

C410

R407

R100

R421

R405

C408

R404

R121

R482C482

C480

C470

R221

R222

R472

R122C116

R729

R713

R702

R701

R700

R704

RB700

R707

C117

C472

R471

R470

C471

IC451

R406

C409

TP

R200

C481

R480

R481

C217 C216

R727

R730

IC700

R726

(Page 34)

S700

X451

R725

R733

WX-4500X

C713

/

/

R724

C712

R723

TP700

R722

C707

R720

R755

R756

R718

C709

C708

R717

C711

C710

X700

R716

R719

D701

R735

R721

Q906

R912

R913

(Page 36)

(Page 31)

CN650

C650

C663

C662

C462

C660

C661

R456

D650

D452

L452

D630

C652

C651

R455

IC650

Q450

C450

C465

IC B/D

C653

D453

Q451

C654

C464

D651

R650

C655

C463

Q650

Q651

R651

R652

R653

R654

Q653

R655

R656

Q654

RB701

C701

R708

C703

R710

C705

R711

D700

R714

R712

Note:

• Voltage is dc with respect to ground under no-signal

condition.

no mark : FM

( ) : AM

< > : CD PLAY

[ ] : TAPE PLAY

: Impossible to measure

∗

35 35

Page 36

WX-4500X

6-11. SCHEMATIC DIAGRAM — MAIN SECTION (3/3) — • Refer to page 44 for IC Block Diagrams.

(Page

35)

L806

R715

R868

Q801

D801

IC801

Q800

IC701

R807

R806

C807

C808

C836

C809

Q803

D803

C806

R813

R804

R805

C805

C718

R810

R802

R803

R811

C719

C804

R734

C811

R812

C810

TP701

IC800

R815

C720

R814

R819

IC702

C803

R816

R818

R801

R800

C813

IC B/D

C721

C802

IC B/D

C815

R824

R910

R911

R823

C818

R822

C817

C819

Q810

R829

C824

R846

D807

Q804

Q905

R830

L801

R847

R848

D909

C828

R909

Q808

IC803

D800

R849

R850

R858

R859

C831

D808

R827

C823

R828

D809

R852

C832

R853

Q813

L803

D806

C821

C827

L805

R854

Q809R833

Q814

R860

C830

Q812

Q806

C820

C825

Q805

C834

R834

R836

T800

C833

R861

D805

R825

R832

D804

R831

D811

R837

D810

D812

R838

R808

Q807

C301

C837

R839

R862

C865

IC B/D

C839

841

R840

R

R863

R864

C838

IC301

D813

R842

C866

C841

L802

C842

L804

R895

R893

R894

R896

C302

L300

Q907

Q908

G2

R920

CN901

R923

(Page 40)

L901

D754

D756

C750

D755

IC B/D

IC750

Q750

D752

D751

D750 R751

R750

R752

D757

Q751

D753

R753

R921

R922

TH750

J900

CN750

Note:

• Voltage is dc with respect to ground under no-signal

condition.

no mark : FM

( ) : AM

< > : CD PLAY

[ ] : TAPE PLAY

: Impossible to measure

∗

3636

Page 37

6-12. PRINTED WIRING BOARD — JOG SECTION — • Refer to page 29 for Circuit Boards Location.

D904

WX-4500X

R944

D902

D906

R937

EN960

CN904

TB900

(Page 38)

37 37

Page 38

WX-4500X

6-13. PRINTED WIRING BOARD — DISPLAY SECTION — • Refer to page 29 for Circuit Boards Location.

D908

R930

SW973

D905

R931

LSW974

R964

R965

D907

D909

R935

LSW972

D903

PH960

LSW964

R940

R932

D911

SW971

R943

R954

LSW966

LSW970

LSW975

R956

LSW967

R957

R938

R961

LSW969

R959

R960

(Page 37)

CN903

LSW968

R958

LSW963

R991

R922

R923

SW960

LSW965

LSW962

R953

R952

R951

LSW961

• Semiconductor

Location

Ref. No. Location

D903 C-12

D905 C-1

D907 A-7

D908 C-1

D909 A-7

D911 C-13

PH960 D-13

3838

Page 39

R963

WX-4500X

C919

D960

R955

R962

R980

R948

R949

R905

C911

R901

R902

FB900

TP901

R903

R904

RB900

R967

C913

R906

R917

R929

R913

R907

IC900

R936

X901

C906

C905

C920

R921

RB901

R920

RB902

R918

C907

C902

R911

D900

C903

R910

R912

IC901

C904

D901

C909

(Page 33)

Q901

CN902

R939

C910

FL700

R942

39 39

• Semiconductor

Location

Ref. No. Location

D900 B-9

D901 C-7

D960 D-13

IC900 C-10

IC901 C-8

Q901 C-7

Page 40

WX-4500X

6-14. SCHEMATIC DIAGRAM — DISPLAY, JOG SECTION — • Refer to page 45 for IC Block Diagrams.

R930 R932

D908

D905 D903

R935

LSW963(2/2)

R957 R956 R955 R954 R953

LSW967(1/2)

LSW968(1/2)

LSW966(1/2)

R958 R959 R960 R961 R962

LSW965(1/2)

LSW969(1/2)

D911

LSW961(2/2)

LSW962(2/2)

LSW964(2/2)

R940

LSW964(1/2)

LSW970(1/2)

R931

LSW974(2/2)

LSW975(2/2)

LSW970(2/2)

R938

LSW967(2/2)

LSW968(2/2)

LSW969(2/2)

R952 R951

LSW963(1/2) SW960

SW971

LSW962(1/2)

LSW972(1/2)

LSW966(2/2)

LSW965(2/2)

LSW972(2/2)

R939

D909

D907

LSW961(1/2)

R963 R964 R965

LSW974(1/2)

SW973

LSW975(1/2)

R921

R929

R967

RB901

IC900

R907

R906

C920

C910

C909

C904

R912

R936

Q901

C902

C903

R920

R913

C907

C905

IC901

RB902

X901

D901

D900

C906

R910

R911

IC B/D

R918

FL700

R917

C911

C913

CN902

D906

D904

D902

• Waveforms

— DISPLAY SECTION —

1

3.2Vp-p

18.432MHz

IC900 ig (XTAL)

PH960

R937R944

EN960(2/2)

EN960(1/2)

CN904 CN903

TB900

R943

R922

R923

R991

R942

C919

D960

R903

R980

R904

R901

R902

RB900

R949

R905

(Page 36)

R948

FB900

Note:

• Voltage is dc with respect to ground under no-signal

(detuned) condition.

no mark : FM

4040

Page 41

• IC Block Diagrams

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62 61

INTERPOLATION,

SOFT MUTING,

DIGITAL ATTENUATOR

MICRO

COMPUTER

INTERFACE

SERVO

TIMING

GENERATOR

8 TIMES OVER

SAMPLING,

DIGITAL FILTER

OUTPUT PORT

CLV SERVO

SERVO CPU

INPUT PORT

DIGITAL AUDIO

INTERFACE

DIGITAL

DEEMPHASIS

1BIT D/A CONVERTER,

PWM LOGIC

PWM

(R)

VDD VDD

PWM

(L)

DSL,

PLL VCO

SUBCODE

BUFFER

A/D

CONVERTER

D/A

CONVERTER

16K S-RAM

CIRC ERROR

CORRECTION,

DEINTERLEAVE

VCO

TIMING GENERATOR,

PITCH CONTROL

EFM DEMODULATION,

SYNC INTERPOLATION,

SUBCODE

DEMODULATION

CD-TEXT

BUFFER

+– +–

BCLK

LRCK

DATA

DVDD

DVSS

TX

MCLK

MDATA

MLD

SENSE

FLOCK

TLOCK

BLKCK

SQCK/GIO0

SUBQ

DMUTE

STAT

RST

SMCK

PMCK

/PLAY

TRV

TVD

PC

ECM

ECS

KICK

TRD

FOD

VREF

FBAL

TBAL

FE

TE

RFENV

VDET

OFT

TRCRS

RFDET

BDO

LDON

VDD

X2

16M

VSS

SBCK

SUBC

VCOF2

PCK /DSLB

EFM /CK384

AVSS2

AVDD2

VCOF

PLLF

DSLF

DRF

IREF

ARF

WVEL

TOFS

PLLF2

SSEL

MSEL

PSEL

CSEL

RSEL/GIO3

OUTR

AVSS1

OUTL

AVDD1

TEST

IOSEL

RESY/FLAG6

DEMPH

CRC

CLVS

FLAG

IPFLAG

GIO2 /FCLK

GIO1 /CLDCK

BYTCK /TRVSTP

IC101 MN6627481RPMFA

WX-4500X

41

Page 42

WX-4500X

IC102 AN22000A-EA

VREF

17

VDET

18

TEBPF

TEO

TEN

FEN

FEO

VDET

19

20

21

22

23

VCC

SUBT

OFTR

BDO

3TENV

16

15

14

13

12

11

10

9

GND

NRFDET

OFTR

COFTR

BDO

CBDO

ENV

CEA

LDON

24

BCA

FBAL

25

GCA

AMP

TBAL

26

PDE

27

PDF

28

D

29

B

30

C

31

A

32

IC201 BA5984FP-E2

FIN

TIN+

2728 26 25

SUBT

BCA

GCA

AMP

TIN–

BCA

GCA

AMP

TOUT

FIN+

24 23 22 21 20 19 18 17 16 15

BCA

AGC

GCA

NRFDET

AMP

RF EQ

FIN–

FOUT

MUTE

BIAS

GND

8

ARF

7

CAGC

6

RFI

5

RFO

4

RFN

VCC

3

VCC

2

LD

1

PD

F–

F+

T–

T+

42

LOADING DRIVER

REV

FWD

RIN

+–

OUT B

OUT A

+–+–

4 5 6 7 8 9 10 11 12 13 1421 3

SPIN+

SPIN–

SPOUT

SLIN+

+–

–

+

+

–

MUTE

+–

+–

VOL+

– +

LEVEL

SHIFT

LEVEL

SHIFT

– +

+–

SLED–

+–

SLED+

–

+

+

–

VCC

VCC

SLIN–

SLOUT

VOL–

+–

– +

LEVEL

SHIFT

LEVEL

SHIFT

– +

+–

SPDL–

+–

+–

SPDL+

Page 43

IC300 TDA7406T

WX-4500X

SWIN

ACINR

ACOUTR

SWACOUT

AC OUTL

CREF

MIXINFL

MIXINRL

MIXINFR

MIXINRR

SOFT STEP

OUTFL

OUTRL

28 2730 2932 31

MIXER

FADER

OUTPUT SELECTOR

HIGH PASS

7BAND

EQUALIZER

SOFT STEP

VOLUME

SOFT MUTE

LOUDNESS

IN GAIN

+ AUTO

ZERO

OUTFR

OUTRR

26 25 24 23

SOFT STEP

FADER

SPECTRUM

ANALIZER

OUTSW

SOFT STEP

FADER

SUB

WOOFER

FILTER

MONO

FADER

BEEP

PAUSE

II

C-BUS

DIGITAL

CONTROL

HIGH OUT

S & H

25kHz

LP

DEMODULATOR

+STEREO ADJUST

+STEREO BLEND

PILOT

CANCELLATION

SAOUT

QUAL.

PIL, DET

PLL

CREF

MULTI

PATH

DETECTOR

SUPPLY

PULSE

FORMER

AM/FM

NOISE

BLANKER

A/D

22

21

20

19

18

17

16

15

14

13

VDD

SACLK

SCL

SDA

GND

ATT

QUAL

MP OUT

MP IN

LEVEL

ACINL

33

34

35

36

37

38

39

40

CDR

41

CDL

42

MDR

43

MDL

44

TAPEL

IC1 BA00ASFP-E2

CTL

1

VCC

GND

REFERENCE

2

VOLTAGE

3

MAIN SOURCE

SELECTOR

INPUT MULTIPLEXER

1 2 3 4 5 6 7 8 9 10 11

FDL–

FDR+

TAPE R

FDL+

PAUSE

MIXING

SELECTOR

TIM

PHONE

NAVI

VCC

86kHz

LP

STD

IN GAIN

AM/MPX2

4

OUT

5

C

AMIF

CMPX

12

AUX1

43

Page 44

WX-4500X

NF1(MTL)

REVR

VREF

FWDR

VCT

GND

FWDL

VREFL

REVL

NF2(MTL)

IC400 CXA2510AQ-T4

AUXIN2

EQ OUT

–

31

32

33

34

35

36

37

38

39

40

F2

VCT

F1

1

EQOUT

TAPE IN(R)

EQ OUT

GND

120µ/

70µ

+

X1

+

X1

–

+

120µ/

70µ

345 6 7 8 9 10

2

VCC

EQOUT

AUXIN1

TAPE IN(L)

AMS SW

TCL2

TCH2

RCH OUT

DIREF

TCL1

NR

OFF/B

G1FB

2122232627282930

MS

MODE

NR

MODE

DETECT

MS ON/

OFF

20

AMS/PLY

19

FWD/REV

18

MTL/NORMAL

17

MUTE/TAPE

NRON

16

15

B/C

14

AMS OUT

13

AMS GND

12

AMSTC

G2FB

11

2425

T2

LPF

T1

AMSLPF

NR BIAS

TAPE/AUX

TAPE EQ

FWD/RVS

VCC

+

–

F3

–

+

LCH OUT

+

OFF/B

NR

–

TCH1

IC800 MB3785APFV-G-BND-ER

CA 4

CB 3

CA 3

CA 1

CB 2

DTC 4

D

A

3

4 521

CA 2

DTC 1

CB 4

VE 4

OUT 4

OUT 3

VE 3

GND

VE 2

OUT 2

CC

V

OUT 1

VE 1

CB 1

36 35 34 33 32 31 30 29 28 27 26 25

37

38

39

40

41

42

43

44

2

45

46

47

48

D

RE

C

RE

B

RE

A

RE

FB 4

D

FB 1

–IN 4 (C)

–IN 4 (E)

+IN 4 (E)

C

SAW

B

6 7 8 91011 12

+IN 1 (E)

–IN 1 (E)

–IN 1 (C)

DTC 3

DTC 2

FB 3

C

FB 2

–IN 3 (E)

+2.5V

VOLTAGE

REFERENCE

OSC

BA

–IN 2 (E)

+IN 3 (E)

+IN 2 (E)

XTAL

XTAL

24

–IN 3 (C)

23

SCP

22

CTL 3

21

CTL 2

20

CTL 1

19

VREF

18

V

CC

1

17

CT

RT

16

15

14

13

CT

RT

OSCO

OSCI

–IN 2 (C)

44

Page 45

WX-4500X

1

2 3

4

5

CD

NC

OUT

VDD

GND

RESET

IC650 LB1930M-TLM

VCC

1

BUFFER

NC

2

IN1

IN2

S-GND

3

4

BUFFER

5

CONTROL

CIRCUIT

MOTOR

DRIVE

CIRCUIT

IC750 BA8270F-E2

NC

10

BUS ON

9

8

7

6

OUT1

NC

OUT2

P-GND

1

2

RST

BATT

3

4

CLK

5

VREF

6

DATA

GND

7 8

BUS ON

SWITCH

RESET

SWITCH

BATTERY

SWITCH

14

13

12

11

10

9

VCC

RST

BUS ON

CLK IN

B/U–C