Sony VPLVW-100 Service manual

VIDEO PROJECTOR

VPL-VW100

REMOTE COMMANDER

RM-PJVW100

SERVICE MANUAL

1st Edition (Revised 1)

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE RULE IN REGION.

VPL-VW100

Table of Contents

1. Service Information

1-1. Appearance Figure ..........................................................1-1

1-2. Board Locations ..............................................................1-1

1-3. Disassembly ....................................................................1-2

1-3-1. Top Cover Assembly ............................................. 1-5

1-3-2. Lamp Cover ...........................................................1-6

1-3-3. Lamp ...................................................................... 1-6

1-3-4. L Board ..................................................................1-7

1-3-5. Louver (F) Assembly ............................................ 1-7

1-3-6 Front Cover Assembly and HB Board ..................1-8

1-3-7. Hood Section .........................................................1-9

1-3-8. UA Board and UB Board ...................................... 1-9

1-3-9. HA Block Assembly ............................................ 1-10

1-3-10. Hood Assembly and NR Board ...........................1-11

1-3-11. GB Board ............................................................. 1-12

1-3-12. Lamp Power Supply ............................................ 1-12

1-3-13. Optics Unit Assembly-1 ...................................... 1-13

1-3-14. Optics Unit Assembly-2 ...................................... 1-14

1-3-15. Igniter .................................................................. 1-15

1-3-16. TA Board .............................................................1-15

1-3-17. D.C. Motor SFF21C/C-NP (Right)

and D.C. Motor SFF21C/C-NP (Left) ................. 1-16

1-3-18. GA Board ............................................................1-17

1-3-19. D.C. Fan (Sirocco) .............................................. 1-17

1-3-20. Q Board ............................................................... 1-18

1-3-21. F Board ................................................................1-19

1-3-22. Bottom Cover Assembly ..................................... 1-19

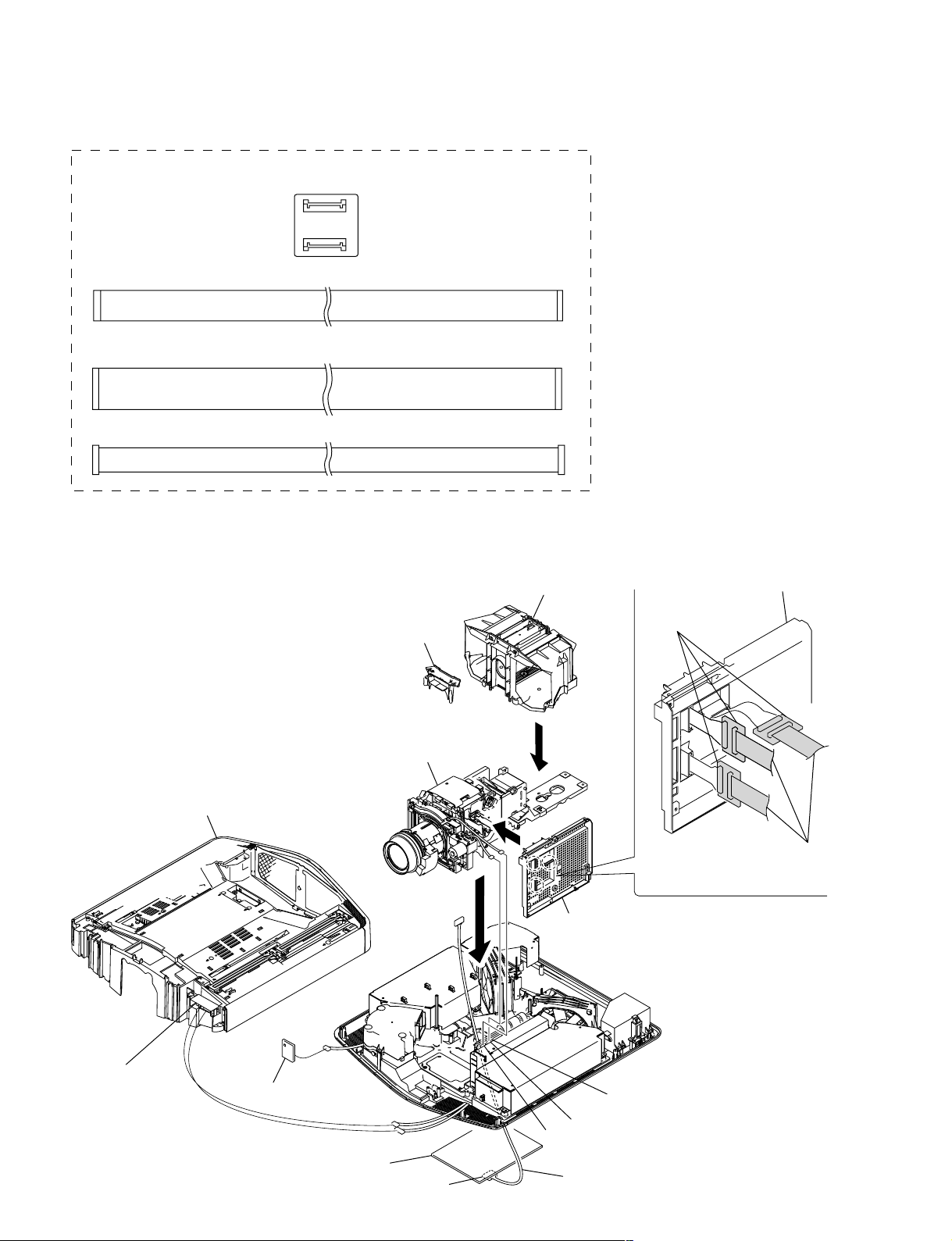

1-3-23. Extension Boards and Extension Cables .............1-20

1-3-24. Extension Boards Connection ............................. 1-20

1-4. Network ........................................................................1-22

1-4-1. Overview ............................................................. 1-22

1-4-2. Service Preparation ............................................. 1-22

1-4-3. Firmware Update Function .................................. 1-24

1-4-4. Event Trace Function .......................................... 1-31

1-4-5. Network Reset ..................................................... 1-34

1-5. Unleaded Solder ............................................................ 1-34

1-6. Service Know-How ...................................................... 1-35

1-6-1. When the Optical Unit ASSY is Replaced ..........1-35

1-6-2. When the Board is Replaced ............................... 1-35

1-6-3. IRIS Adjustment .................................................. 1-35

1-7. Upgrading the Software ................................................1-35

1-8. Memory ......................................................................... 1-37

2. Electrical Adjustments

2-1. Preparations .................................................................... 2-1

2-1-1. Required Equipment .............................................. 2-1

2-1-2. Factory Mode Setting ............................................2-1

2-2. Adjustment Item Initialize Data ...................................... 2-2

2-3. White Balance Adjustment on Servicing ........................2-9

2-3-1. Component ............................................................ 2-9

2-3-2. Computer .............................................................2-10

3. Semiconductors

4. Spare Parts

4-1. Notes on Repair Parts ..................................................... 4-1

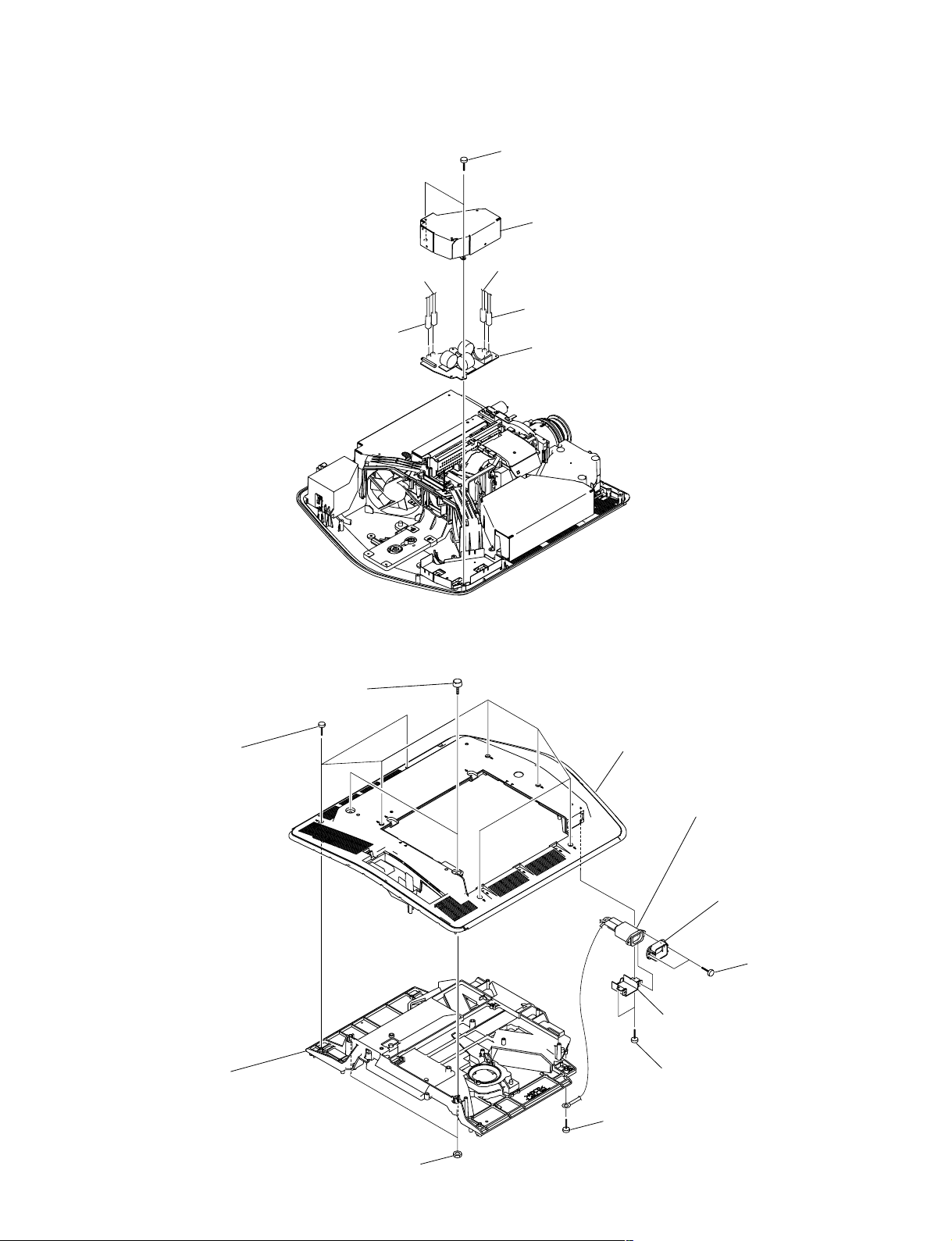

4-2. Exploded Views .............................................................. 4-2

4-3. Electrical Parts List ....................................................... 4-14

5. Block Diagrams

C (1/2) ........................................................................................ 5-1

C (2/2) ........................................................................................ 5-2

GA, GB (1/2), F ......................................................................... 5-3

GB (2/2) ..................................................................................... 5-4

C, F, GA, HA, HB, L, NF, NR, Q, QB, TA, TL, V ..................5-5

Q (1/6) ....................................................................................... 5-6

Q (2/6) ....................................................................................... 5-7

Q (3/6) ....................................................................................... 5-8

Q (4/6) ....................................................................................... 5-9

Q (5/6) ..................................................................................... 5-10

Q (6/6) ..................................................................................... 5-11

VPL-VW100

1

6. Diagrams

6-1. Frame Schematic Diagrams ............................................6-2

6-2. Schematic Diagrams and Printed Wiring Boards ........... 6-3

Schematic Diagrams

Q (1/24) ...........................................................................6-3

Q (2/24) ...........................................................................6-4

Q (3/24) ...........................................................................6-5

Q (4/24) ...........................................................................6-6

Q (5/24) ...........................................................................6-7

Q (6/24) ...........................................................................6-8

Q (7/24) ...........................................................................6-9

Q (8/24) ......................................................................... 6-10

Q (9/24) ......................................................................... 6-11

Q (10/24) ....................................................................... 6-12

Q (11/24) ....................................................................... 6-13

Q (12/24) ....................................................................... 6-14

Q (13/24) ....................................................................... 6-15

Q (14/24) ....................................................................... 6-16

Q (15/24) ....................................................................... 6-17

Q (16/24) ....................................................................... 6-18

Q (17/24) ....................................................................... 6-19

Q (18/24) ....................................................................... 6-20

Q (19/24) ....................................................................... 6-21

Q (20/24) ....................................................................... 6-22

Q (21/24) ....................................................................... 6-23

Q (22/24) ....................................................................... 6-24

Q (23/24) ....................................................................... 6-25

Q (24/24) ....................................................................... 6-26

C (1/9) ...........................................................................6-32

C (2/9) ...........................................................................6-33

C (3/9) ...........................................................................6-34

C (4/9) ...........................................................................6-35

C (5/9) ...........................................................................6-36

C (6/9) ...........................................................................6-37

C (7/9) ...........................................................................6-38

C (8/9) ...........................................................................6-39

C (9/9) ...........................................................................6-40

F .................................................................................... 6-43

GA (1/2) ........................................................................6-46

GA (2/2) ........................................................................6-47

GB (1/5) ........................................................................ 6-50

GB (2/5) ........................................................................ 6-51

GB (3/5) ........................................................................ 6-52

GB (4/5) ........................................................................ 6-53

GB (5/5) ........................................................................ 6-54

HA ................................................................................. 6-56

HB .................................................................................6-57

L ....................................................................................6-58

NF ................................................................................. 6-58

NR .................................................................................6-58

TA ................................................................................. 6-59

TL ................................................................................. 6-59

UA ................................................................................. 6-60

UB .................................................................................6-60

V ................................................................................... 6-60

Printed Wiring Boards

Q ................................................................................... 6-28

C ....................................................................................6-30

F .................................................................................... 6-42

GA ................................................................................. 6-44

GB .................................................................................6-48

HA ................................................................................. 6-56

HB .................................................................................6-57

L ....................................................................................6-58

NF ................................................................................. 6-58

NR .................................................................................6-58

TA ................................................................................. 6-59

TL ................................................................................. 6-59

UA ................................................................................. 6-60

UB .................................................................................6-60

V ................................................................................... 6-60

2

VPL-VW100

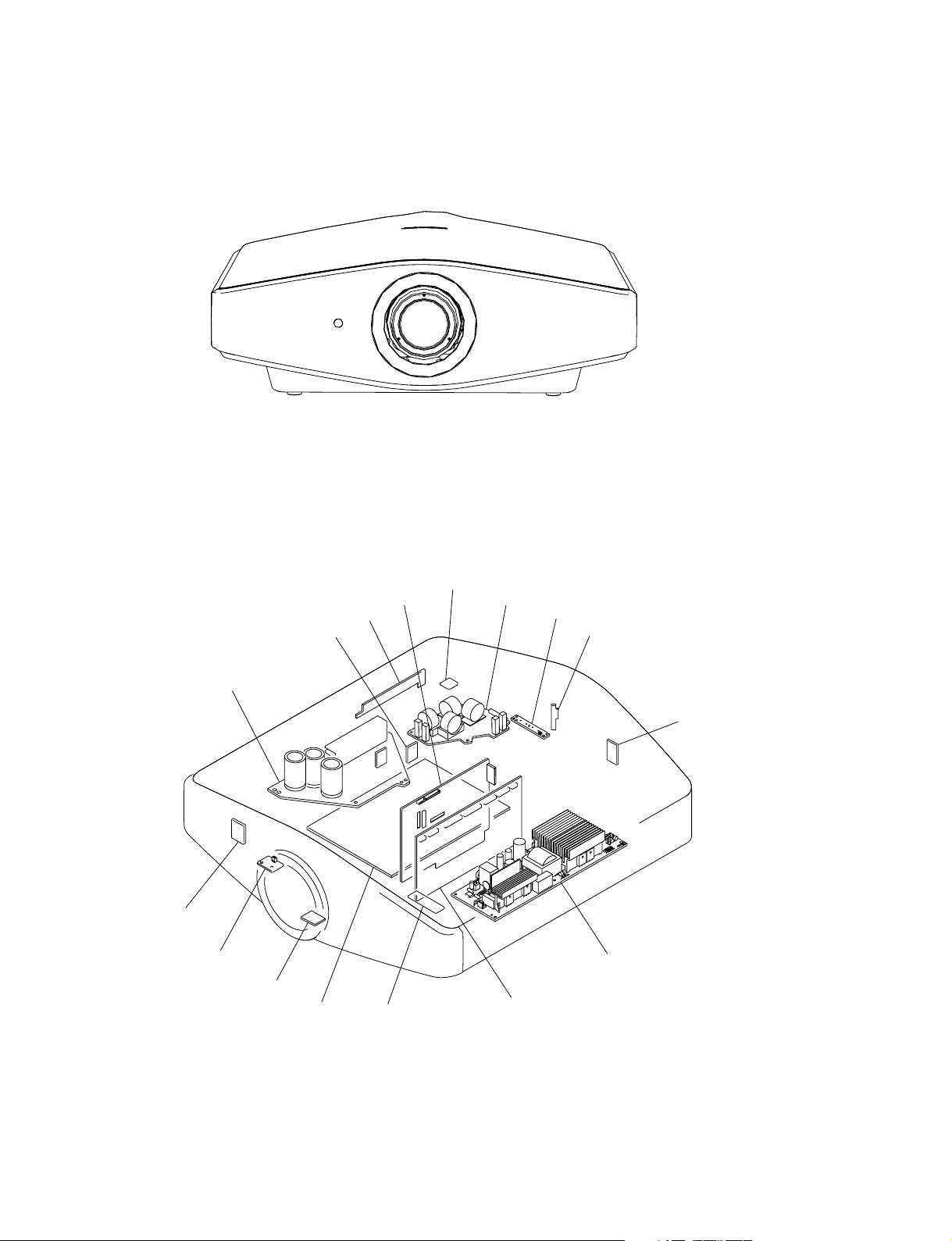

1-1. Appearance Figure

Section 1

Service Information

1-2. Board Locations

GA

NF

TA

UA

HA

C

UB

F

L

TL

NR

Lamp power supply

VPL-VW100

V

Q

HB

GB

1-1

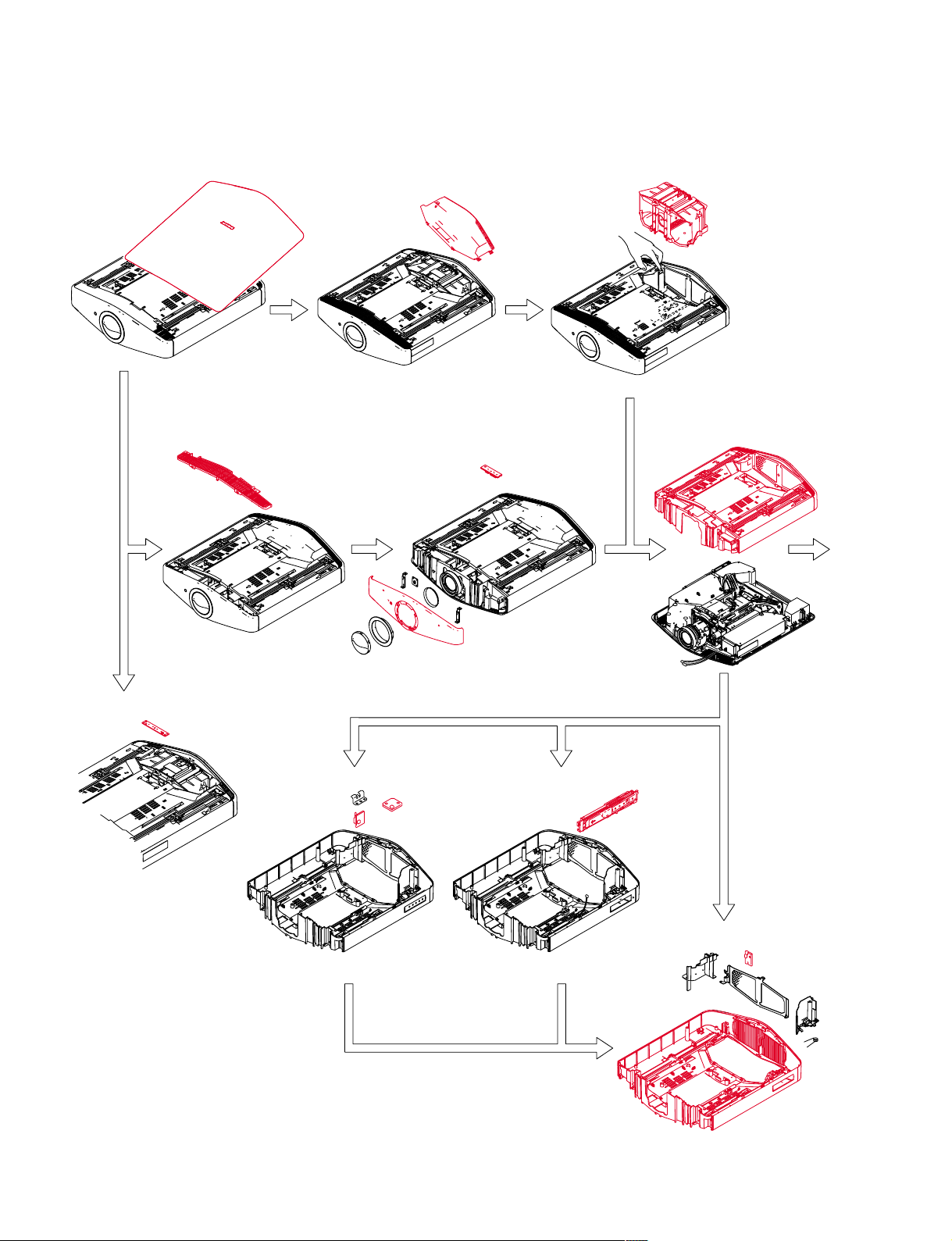

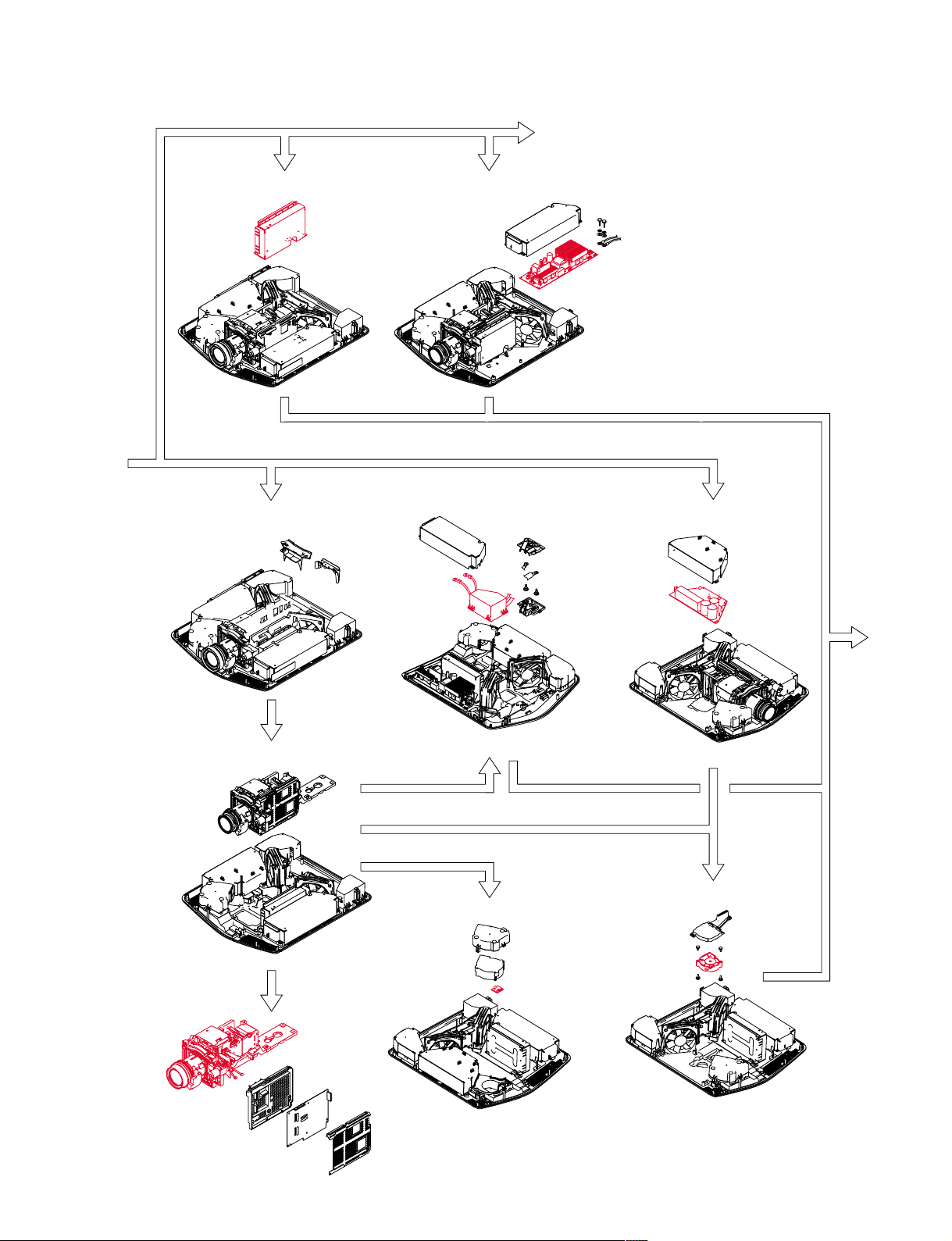

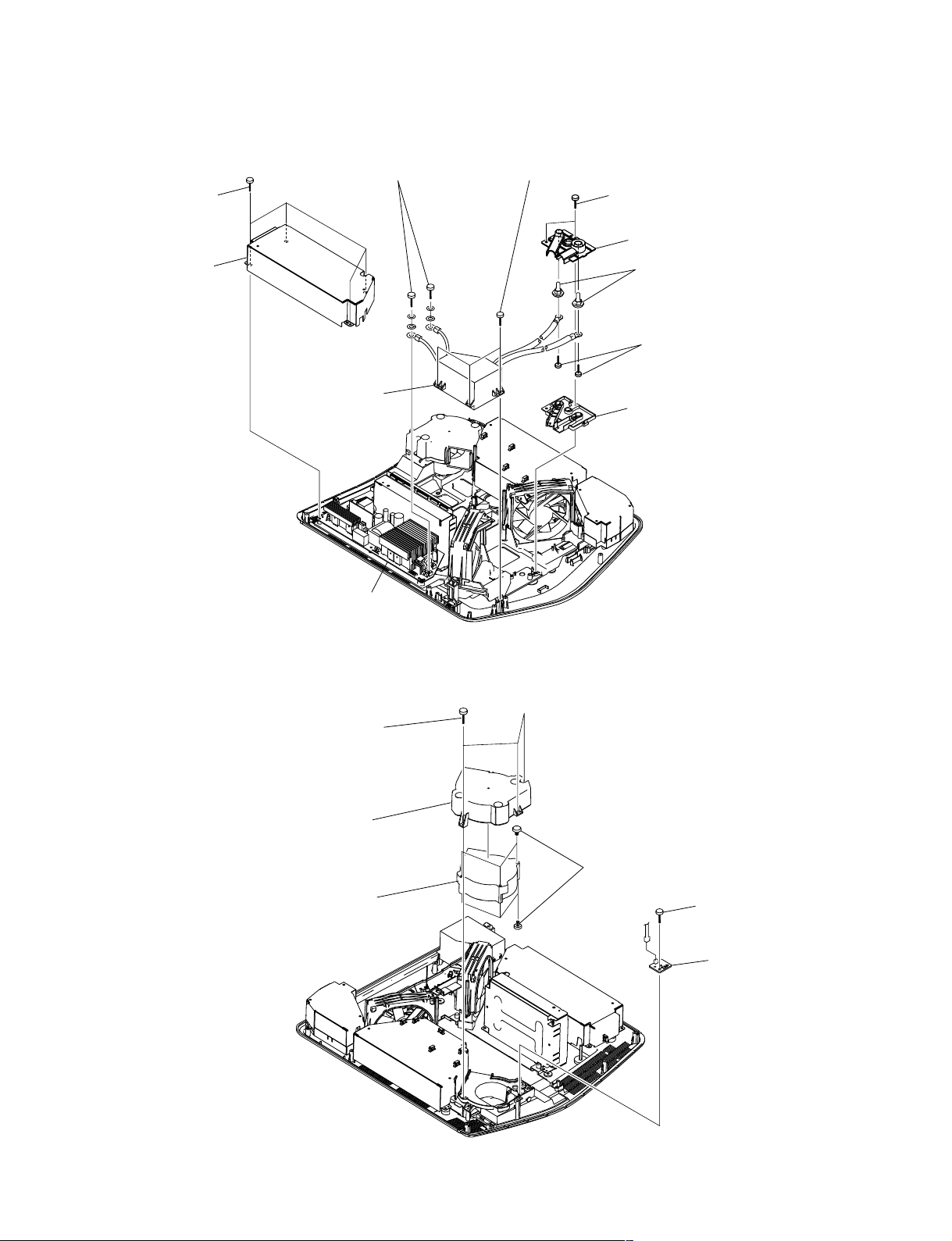

1-3. Disassembly

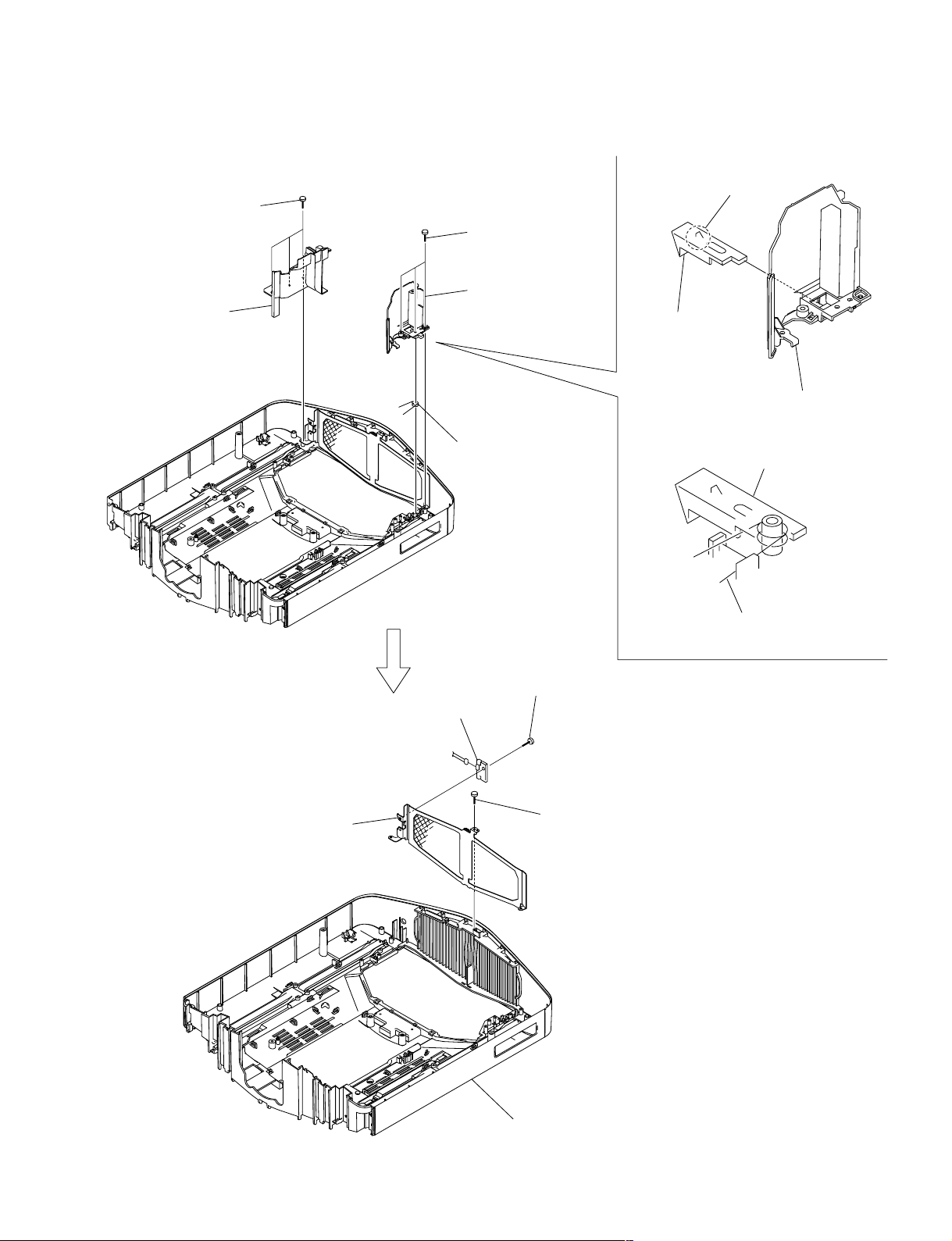

1-3-1. Top Cover Assembly

1-3-5. Louver (F) Assembly 1-3-6. Front Cover Assembly

1-3-2. Lamp Cover 1-3-3. Lamp

and HB Board

1-3-7. Hood Section

A

1-3-4. L Board

1-3-9. HA Block Assembly1-3-8. UA Board and UB Board

1-3-10. Hood Assembly and NR Board

1-2

VPL-VW100

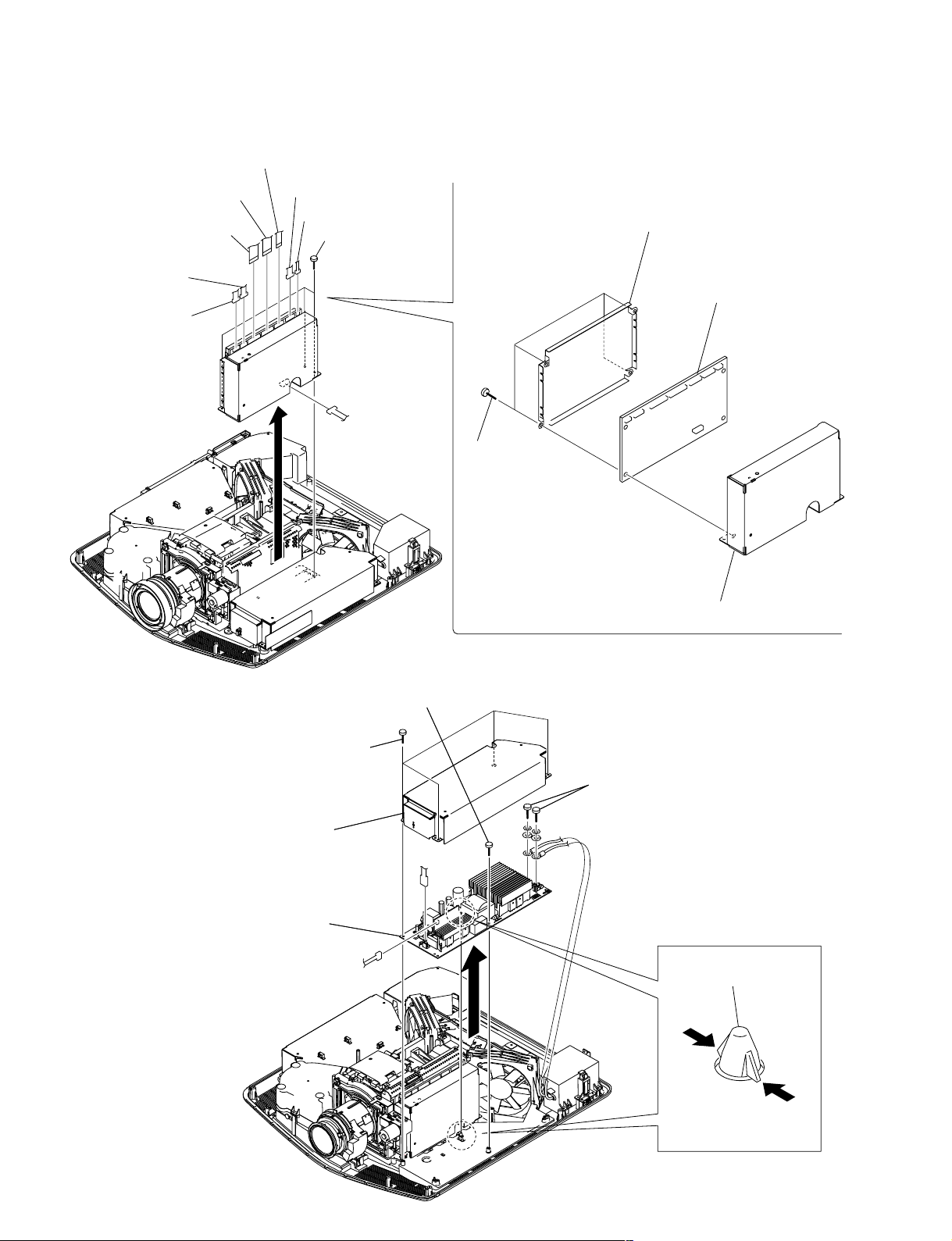

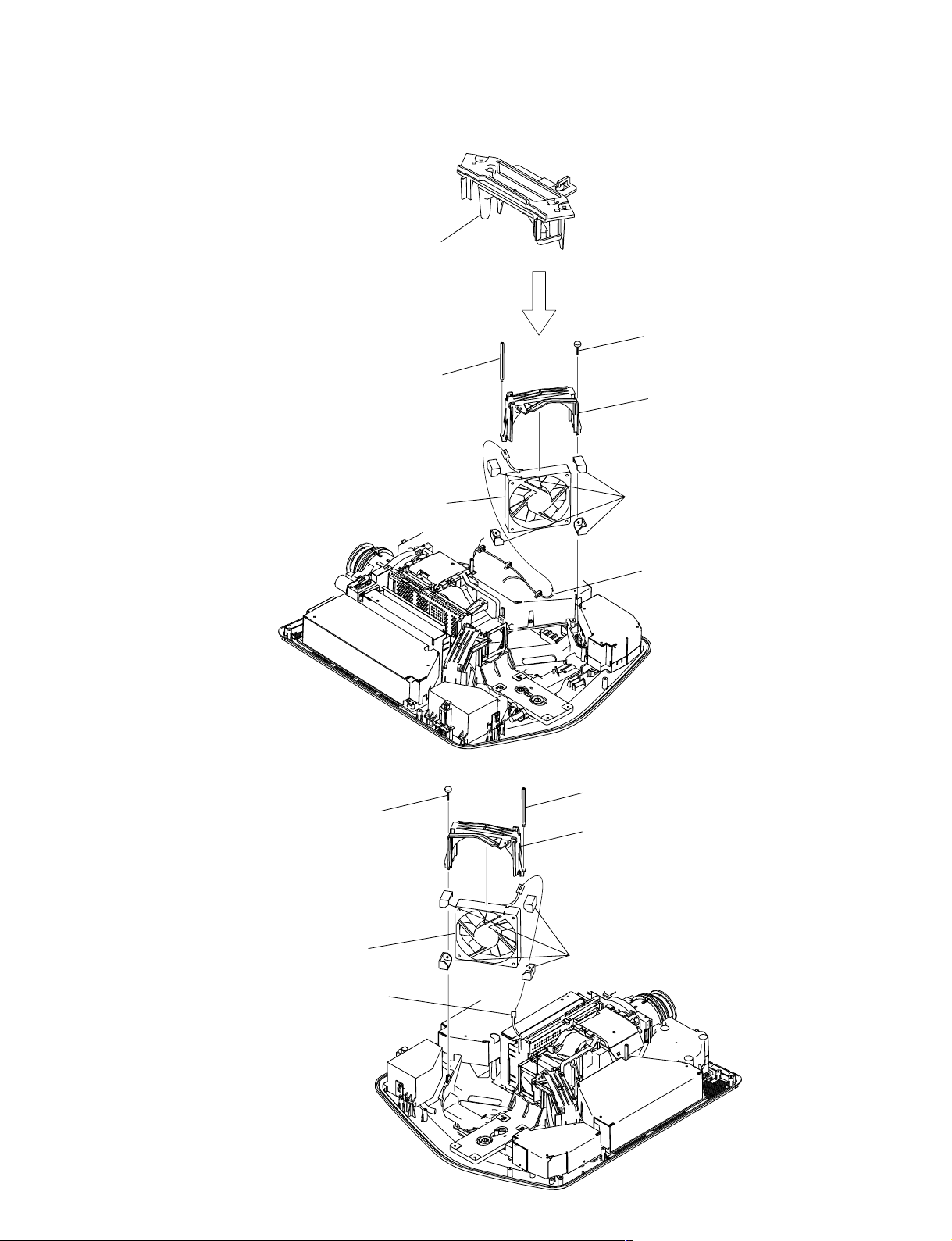

A

1-3-11. GB Board

A

1-3-13. Optics Unit Assembly-1

1-3-12. Lamp Power Supply

1-3-15. Igniter

1-3-18. GA Board

1-3-14. Optics Unit Assembly-2

B

1-3-19. D.C. Fan (Sirocco)

1-3-16. TA Board

VPL-VW100

1-3

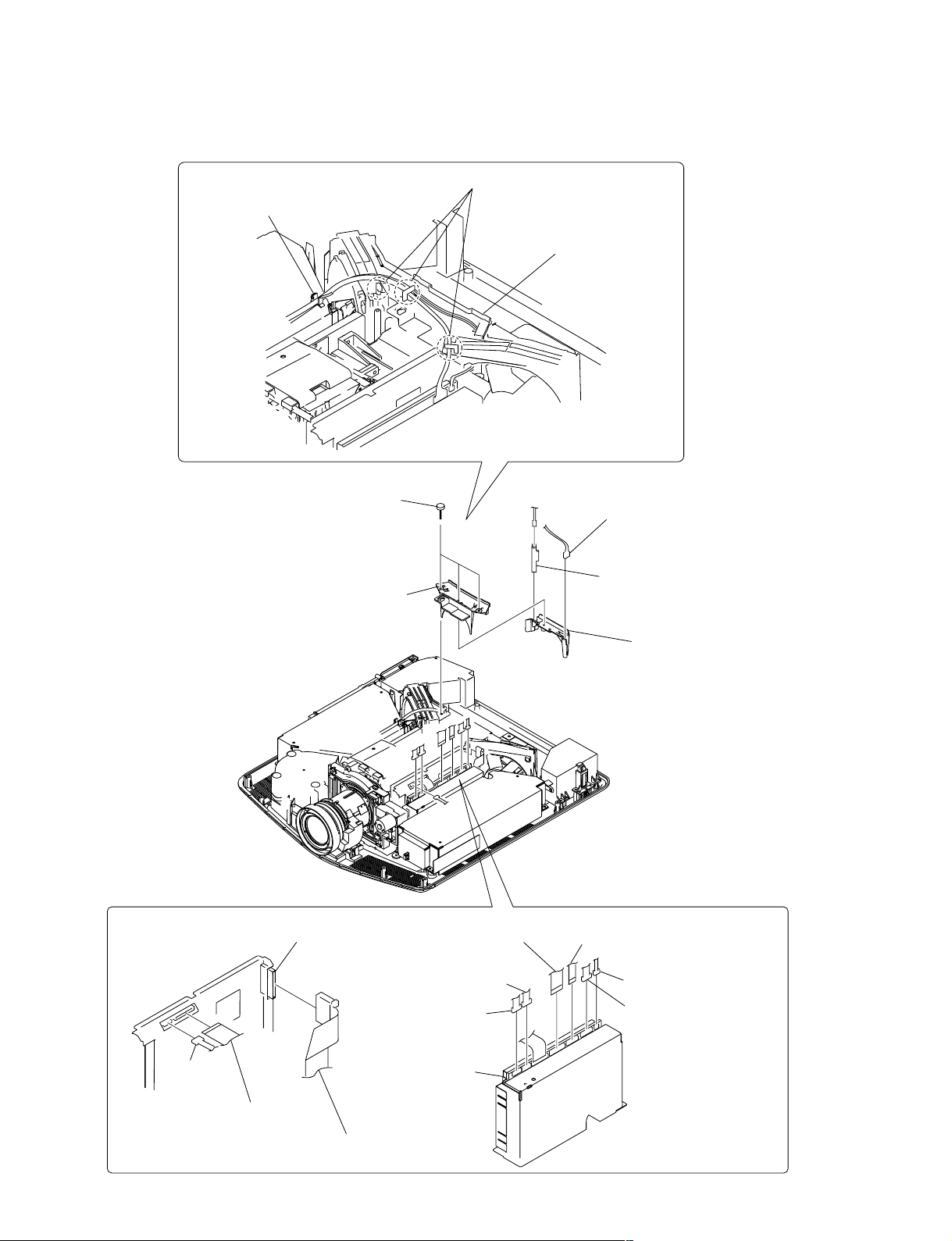

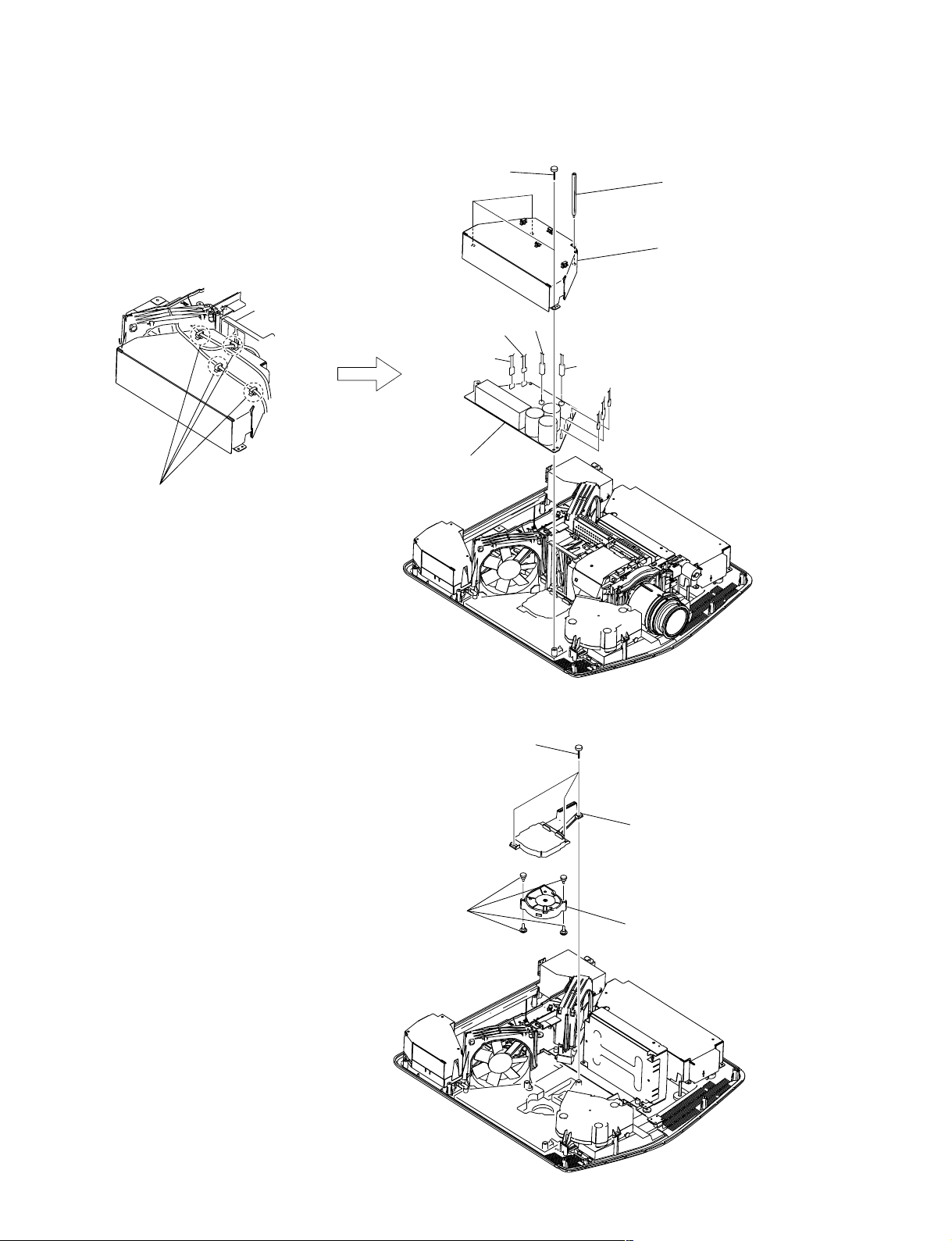

A

1-3-17. 0. Motor SFF21C/C-NP (Right) and

D.C. Motor SFF21C/C-NP (Left)

1-3-21. F Board

B

1-3-20. Q Board

1-3-22. Bottom Cover Assembly

1-4

VPL-VW100

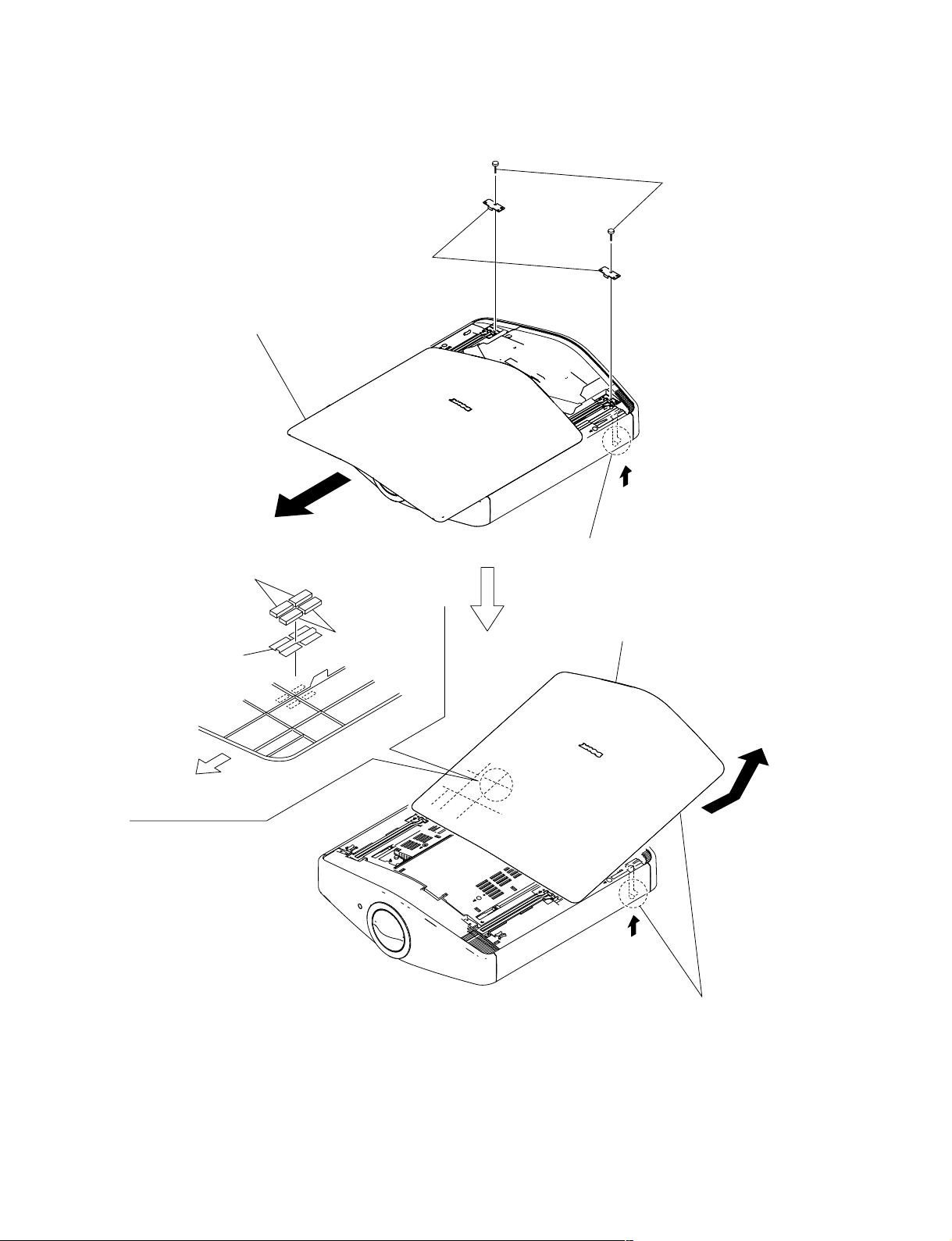

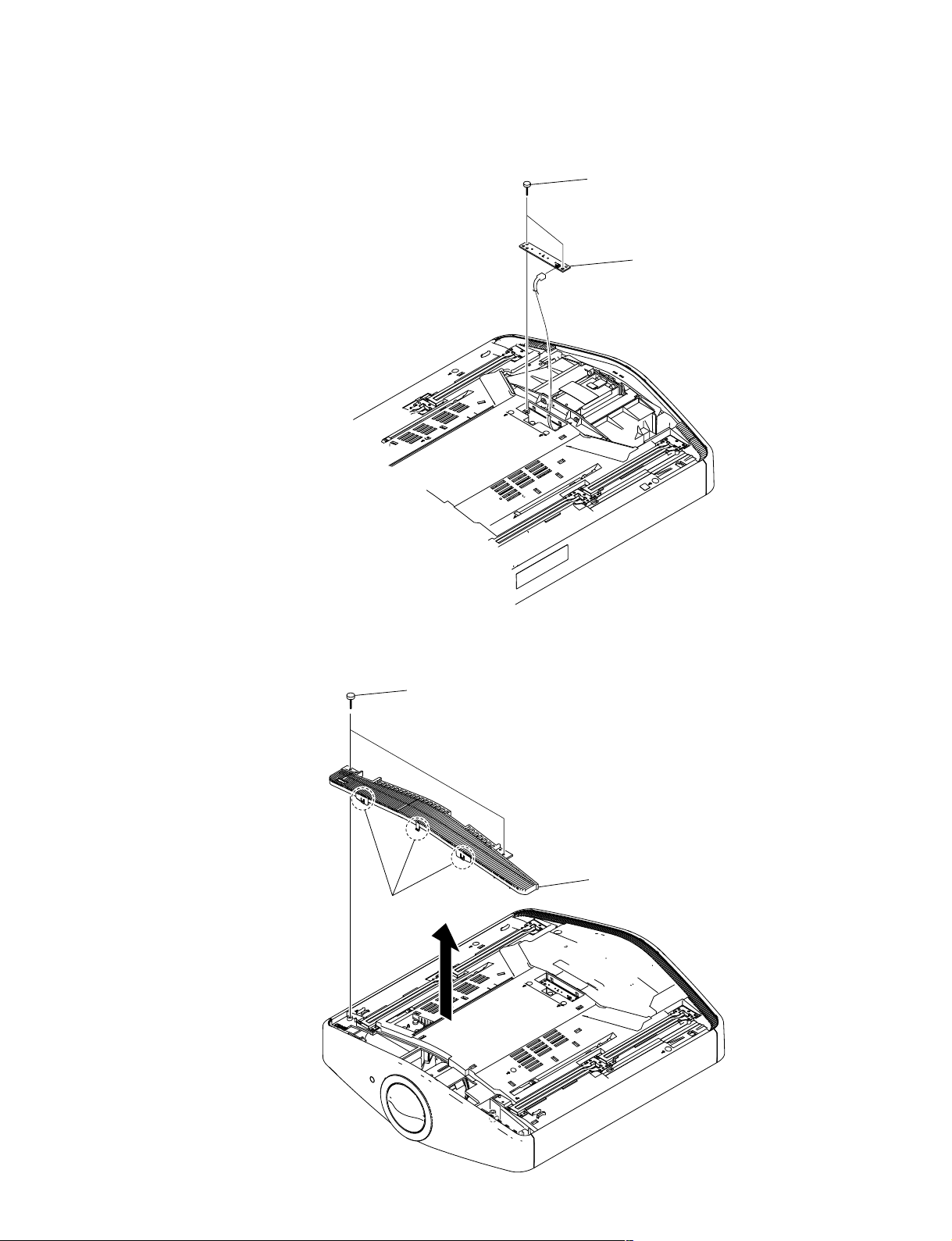

1-3-1. Top Cover Assembly

3

Two screws

(+PSW M3 x 8)

2

Open the top cover assembly

in the direction of the arrow

B

6

Gasket (T)

8

EMC plate (T)

4 Two r

B

.

7

Gasket (T2)

ail ends

A

1

Push the pusher in the direction of arrow A.

9

Top cover assembly

Front Cover Side

of Unit

C

A

5

While pushing the pusher in the direction

of arrow

in the direction of arrow

A

, remove the top cover assembly

C

.

VPL-VW100

1-5

1-3-2. Lamp Cover

2

Two claws

1

Loosen screw.

(+PSW M4 x 12)

4

Remove the lamp cover

in the direction of the arrow.

3

Two claws

1-3-3. Lamp

1

Loosen four screws.

3

Lamp

2

Press the lamp stopper.

1-6

VPL-VW100

1-3-4. L Board

1

(+PSW M3 x 8)

CN10

Two screws

2

L board

1-3-5. Louver (F) Assembly

1

(+PSW M3 x 8)

2

Three claws

Two screws

3 Louver

(F) assembly

VPL-VW100

1-7

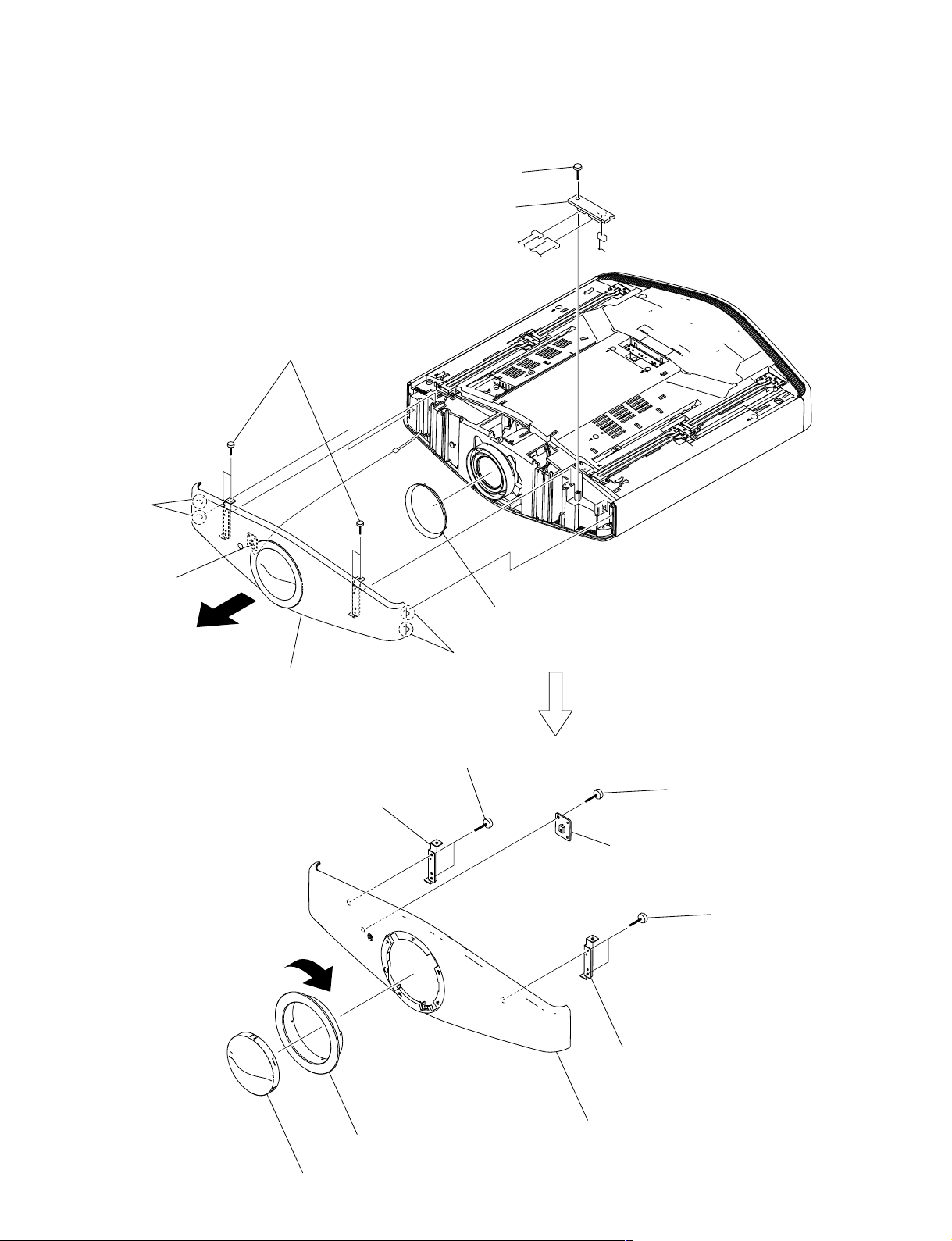

1-3-6 Front Cover Assembly and HB Board

5

(+PSW M3 x 8)

Screw

6 HB board

3

Two claws

NF board

1

Four screws

(+PSW M3 x 8)

A

4 Remove the front cover section

in the direction of the arrow A.

CN40

2

Two claws

CN83

7 Ring

CN80

CN81

(Lens)

1-8

Bracket (FR)

!\

B

8 Lens cap

!] Two screws

(+PSW M3 x 8)

9

Remove the front disk assembly by

turning it in the direction of arrow B.

0

Screw

(+PSW M3 x 8)

!-

NF board

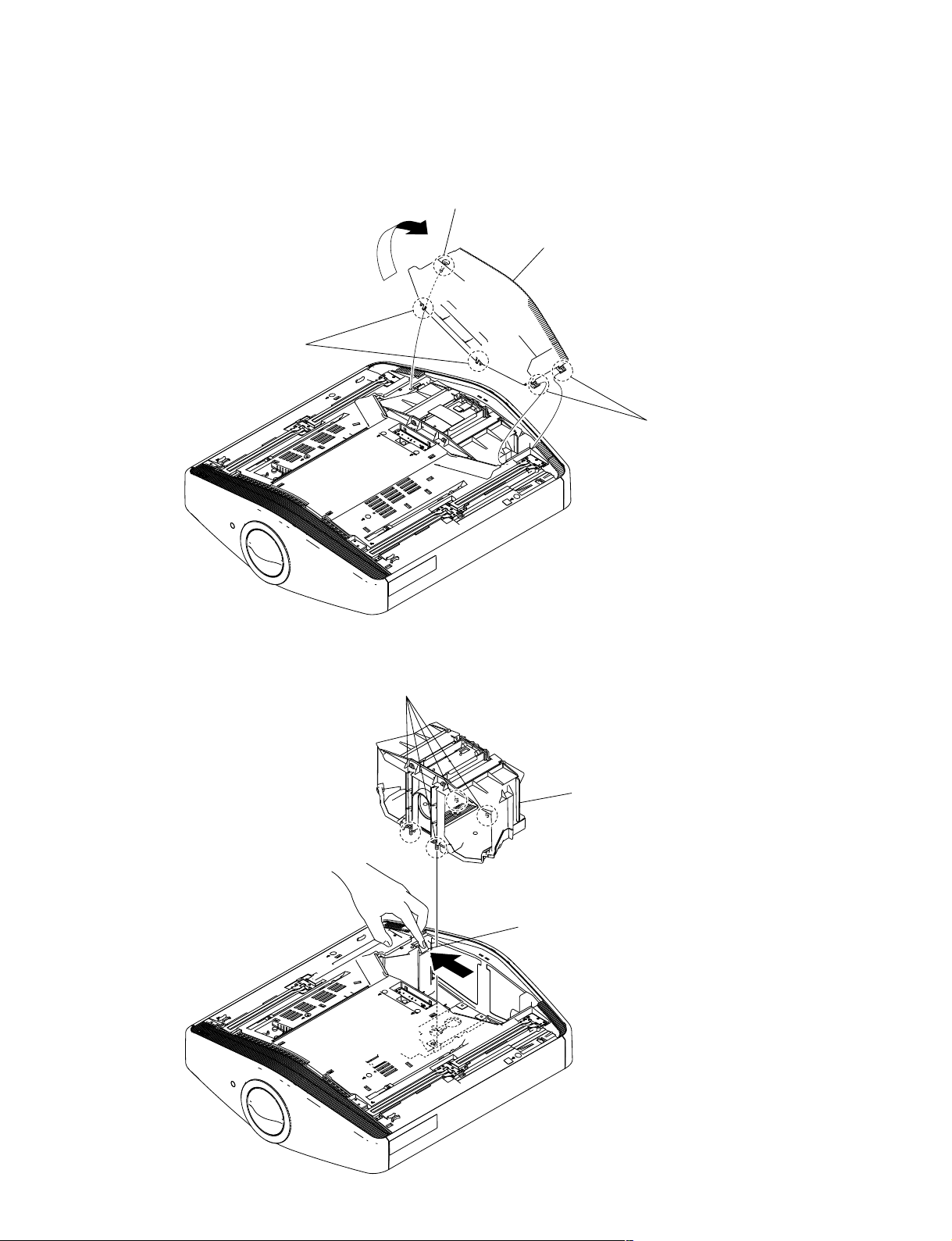

1-3-7. Hood Section

1

Ten screws

(+PSW M3 x 8)

HB board

2

Hood section

CN83

CN81

1-3-8. UA Board and UB Board

1

Screw

(+BV 3 x 12)

2

UA holder

3

UA board

CN26

CN25

4

Two screws

(+BV 3 x 12)

5

UB board

CN20

VPL-VW100

1-9

1-3-9. HA Block Assembly

HA board

CN60

CN60

1

Two screws

(+BV 3 x 12)

5

Shield plate (H)

2

Screw

(+BV 3 x 12)

4

Remove the shield plate (H)

in the direction of the arrow A.

A

3

Two claws

6

Screw

(+BVTP 3 x 12)

8

HA board

!/

HA block assembly

7

Button (+)

B

9

Remove the shield cover (H)

in the direction of the arrow B.

1-10

VPL-VW100

1-3-10. Hood Assembly and NR Board

4

Three screws

(+BV 3 x 12)

5

Rear duct (I)

1

Three screws

(+BV 3 x 12)

2

Rear duct (F),

Lamp stopper

3

Lamp stopper

spring

Lamp stopper

!=

!-

Claw

Lamp stopper

Rear duct (F)

7

Mesh (R)

9

CN50

NR board

8

Screw

(+PSW M3 x 8)

6

Screw

(+BV 3 x 12)

Lamp stopper spring

VPL-VW100

0

Hood assembly

1-11

1-3-11. GB Board

Flat connector assembly

(32P) CN700

Flat connector assembly A

(24P) CN701

Flat connector assembly B

(24P) CN702

CN901

CN800

CN705

CN703

1

Three screws

(+PSW M3 x 8)

CN510

2

Four screws

(+PSW M3 x 8)

4

Shield cover (GB)

5

GB board

3

Shield case (GB)

1-3-12. Lamp Power Supply

1

Four screws

(+PSW M3 x 8)

2

Shield cover

(LP)

6

Lamp power supply

4

Screw

(+PSW M3 x 8)

J202

J101

JH2

JH1

3

Two screws

5 Spacer

, PCB

1-12

VPL-VW100

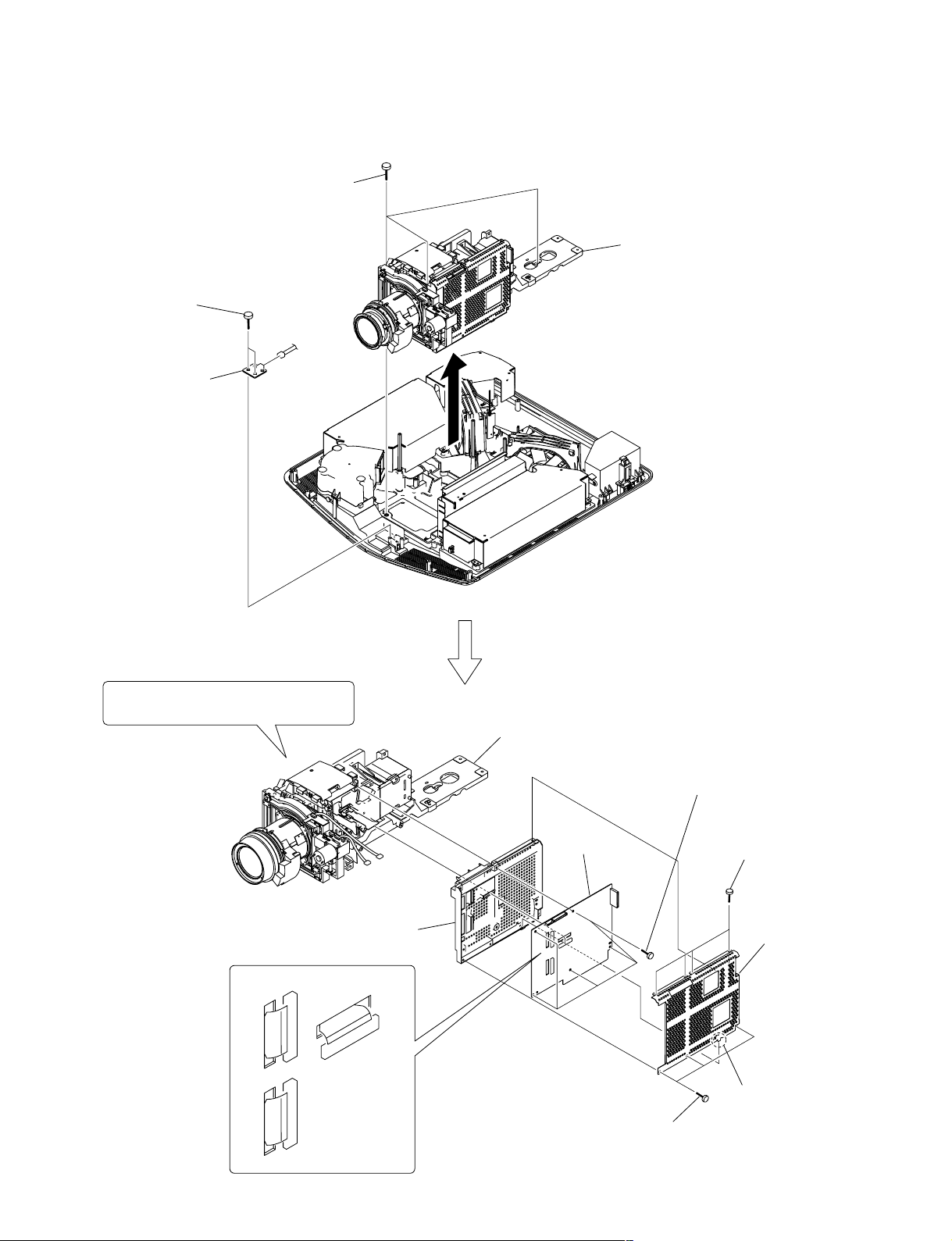

1-3-13. Optics Unit Assembly-1

1

Open the reuse clamp.

2

Remove the harness from the three claws.

Fan cover

(120MDL)

3

Three screws

(+PSW M3 x 8)

4

Fan cover

(120MDL)

C board

CN71

Flat connector assembly A

(24P) CN701

5

Fuse connector assembly

6

TL board

7

Thermo bracket

Flat connector assembly

(32P) CN700

VPL-VW100

CN100

Flat connector assembly B

(24P) CN101

Flexible flat cable

(41P) CN200

CN800

GB board

CN901

CN703

CN705

1-13

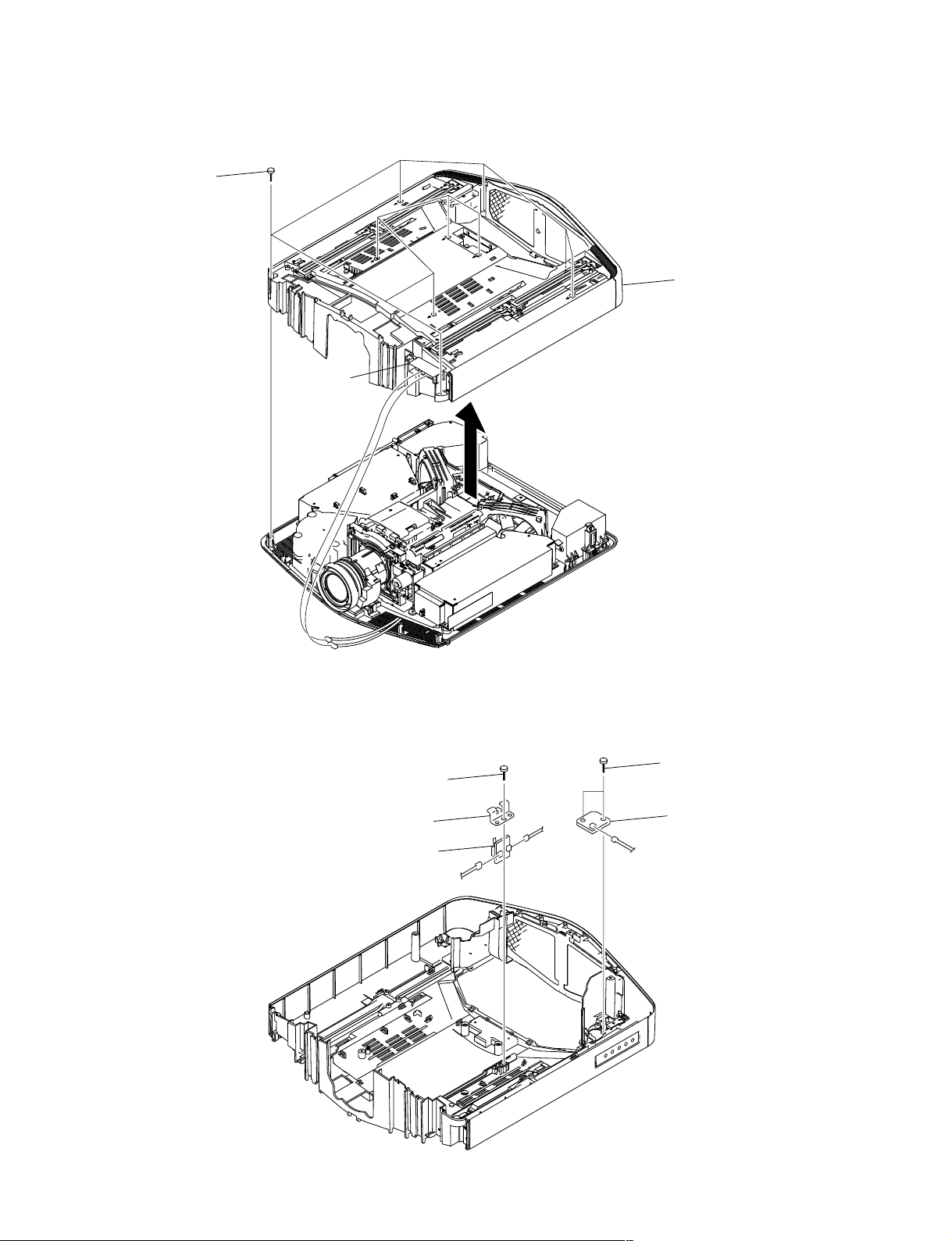

1-3-14. Optics Unit Assembly-2

1

Three screws

(+PSW M4 x 16)

!-Two screws

(+BV 3 x 12)

CN30

!= V board

Remove the optical unit assembly

2

in the direction of the arrow.

When replacing the optical unit assembly,

refer to Service Know-How (page 1-35).

9

C board holder

CN900 (B)

CN800 (G)

Optics unit assembly

0

8

C board

7

Five screws

(+PSW M3 x 8)

4

Four screws

(+PSW M3 x 8)

6

C board cover

1-14

CN700 (R)

3

Three screws

(+PSW M3 x 8)

5

Claw

VPL-VW100

1-3-15. Igniter

1

Four screws

(+PSW M3 x 8)

2

Shield cover

(LP)

0

3

Igniter

Two screws

JH1

9

(+BV 3 x 12)

JH2

Three screws

4

Two screws

(+PSW M3 x 8)

5

Plug cover

7

Two lamp plug

6

Two screws

(+PSW 4 x 8)

8

Plug base

1-3-16. TA Board

Lamp power supply

1

Three screws

(+BV 3 x 12)

2

Fan cover

(84H)

4

D.C. motor

SFF22A/C-NP

3

Six fan dampers

CN70

5

Screw

(+BV 3 x 12)

6

TA board

VPL-VW100

1-15

1-3-17. D.C. Motor SFF21C/C-NP (Right) and D.C. Motor SFF21C/C-NP (Left)

For removal procedure,

refer to optics unit assembly-1.

1

Fan cover (120MDL),

Thermo bracket, etc.

4

Screw

D.C. Motor SFF21C/C-NP (Right)

3 S

pacer

7

D.C. Motor

SFF21C/C-NP (Right)

(+PSW M3 x 8)

5

6

Four fan cushions

2

Connector

Fan cover (120R) (Right)

D.C. Motor SFF21C/C-NP (Left)

1-3-18. GA Board

2

Three screws

(+PSW M3 x 8)

CN220

CN250

3

Spacer

4

Shield cover

(GA)

1

Four reuse clamps

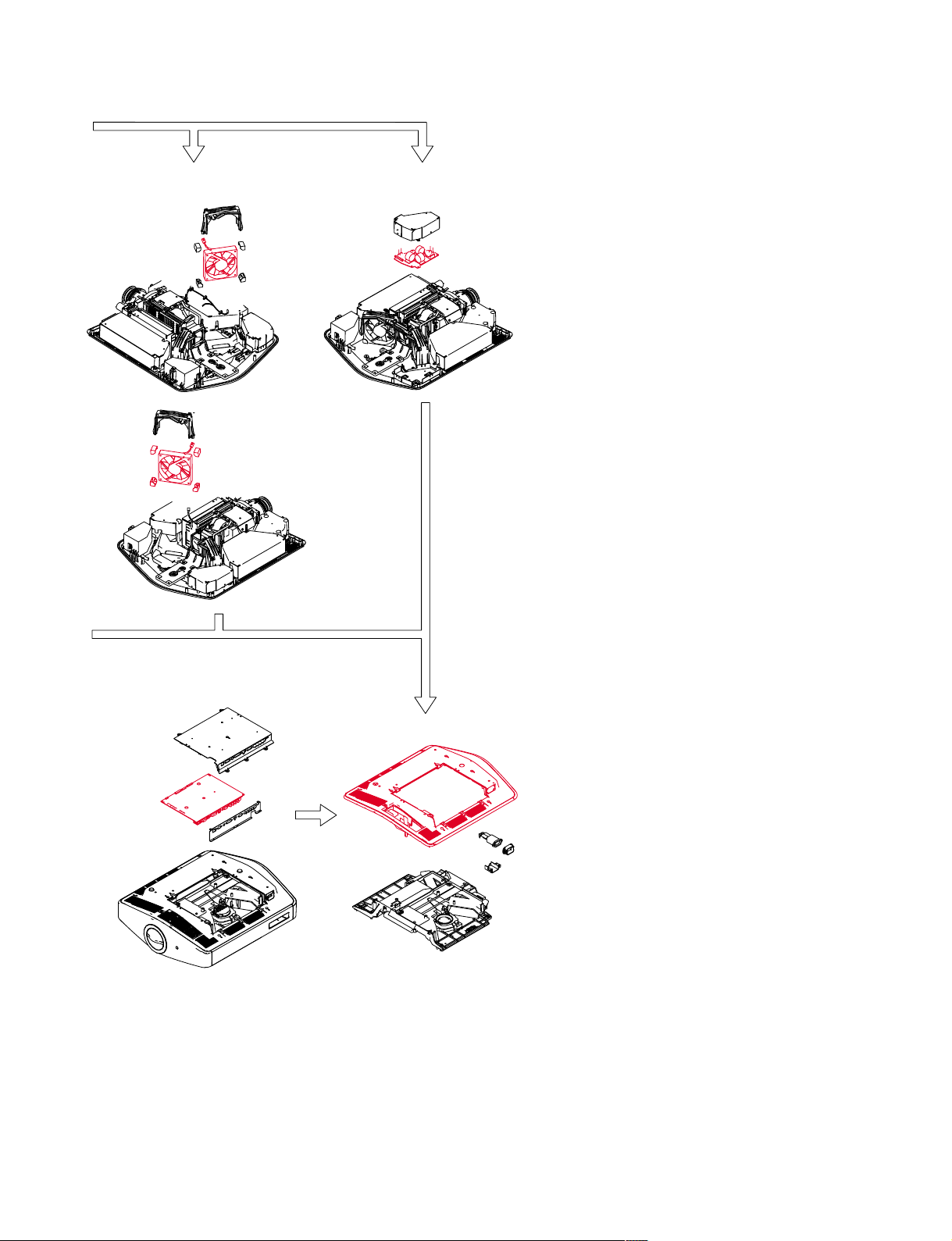

1-3-19. D.C. Fan (Sirocco)

CN200

5

GA board

1

Three screws

(+PSW M3 x 8)

TP200

CN221

CN310

CN301

VPL-VW100

3

Four fan dampers

2

Duct (PS)

4

D.C. Fan (Sirocco)

1-17

1-3-20. Q Board

Q board

Flexible flat cable

(41P)

3

EMC

sheet (Q1)

6

EMC sheet

(Q2)

7

Cover (Q)

4

Film (Q1)

5

Film (Q2)

1

Six screws

(+PSW M3 x 8)

CN1600

CN1812

CN701

CN1811

CN1803

Flat connector assembly A

(24P)

Flat connector assembly

(32P)

!] Q

board

CN1805

CN1801

Terminal plate

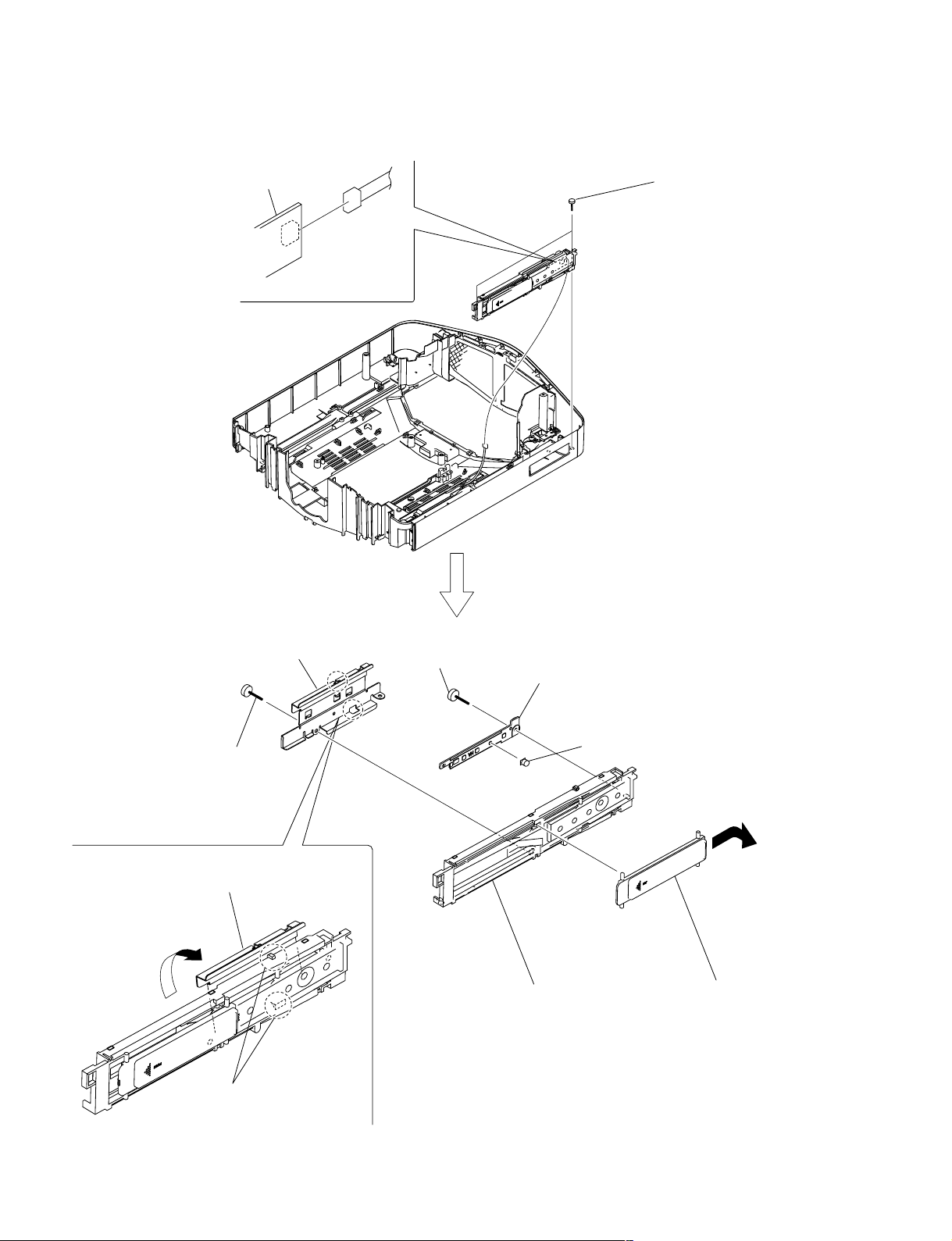

1-3-21. F Board

1

Two screws

(+PSW M3 x 8)

2

Shield case (F)

1-3-22. Bottom Cover Assembly

2

Adjustor assembly

TP1

CN001

CN002

TP4

3

F board

1

Seven screws

(+PSW M3 x 8)

0 Chassis

3

Two hexagon cap nuts

!- Bottom cover assembly

9

AC inlet

8

5

Bracket (AC)

4

Two screws

(+BV 3 x 12)

6

Screw

(+PSW M4 x 12)

Plug holder (A)

7

Two screws

(+B 3 x 12)

VPL-VW100

1-19

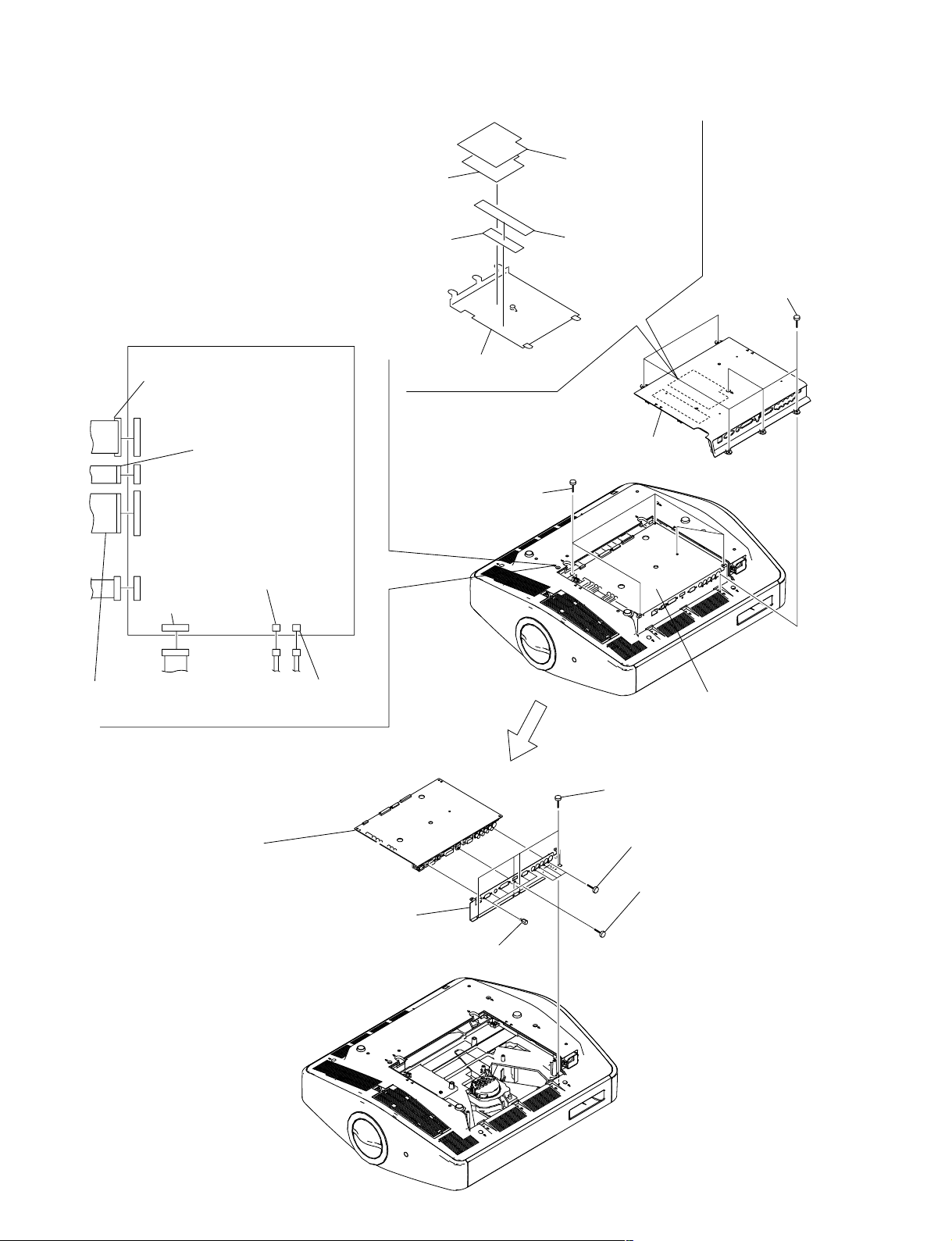

1-3-23. Extension Boards and Extension Cables

X kit assembly (A-1169-713-A)

Three XC boards

Flat cable (24P)

Three flat cables (50P) (There are 3 types of R, G and B. )

Connector cable (12P)

1-3-24. Extension Boards Connection

1. How to Assemble the Extension Boards and the Extension Cables

Lamp

Fan cover (120MDL),

Thermo bracket, etc.

C board holder

Three XC boards

1-20

HB board

Hood section

CN40

NF board

Optics unit assembly

CN83

CN81

Q board

CN1811

Three flat cables 50P

Install the C board holder.

GB board

CN901

CN800

Connector cable (12P)

VPL-VW100

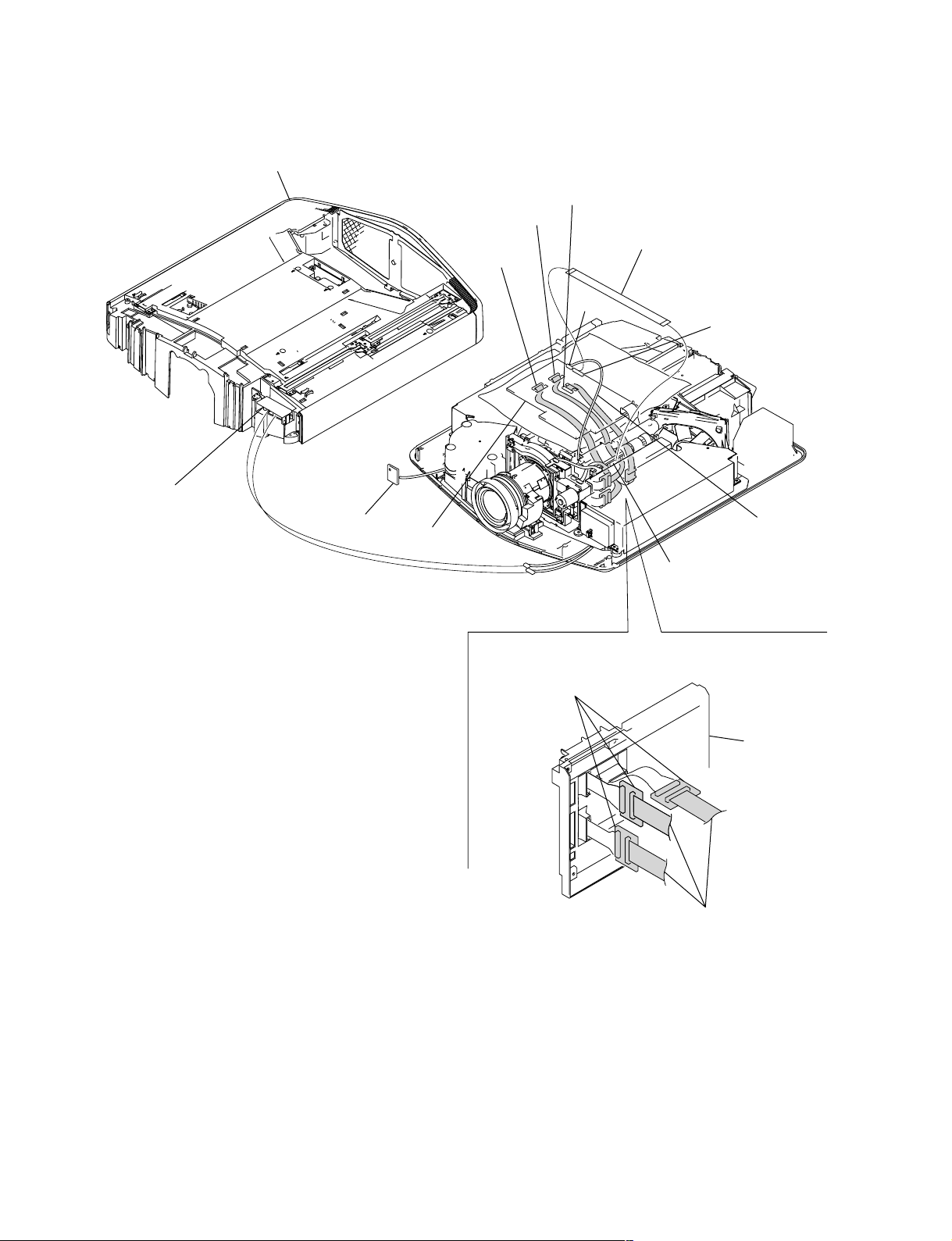

2. Connecting the Extension Boards and the Extension Cables

Hood section

CN800 (G)

CN900 (B)

CN700 (R)

HB board

NF board

C board

CN83

CN81

Flat cable (24P)

CN100

CN101

Connector cable (12P)

(From the Q board CN1811)

GB board

CN702 (24P)

Three XC boards

Three flat cables 50P

C board holder

VPL-VW100

1-21

1-4. Network

1-4-1. Overview

VPL-VW100 is equipped with the Network terminal. The user can check the projector status, and can

implement the various settings such as controls of the projector and setups of the Network block by using

the Web-browser.

In addition, it has dedicated functions for repair service such as the firmware update function via network,

the Event Trace function, and the network block reset function.

The firmware update function enables the user to upgrade the firmware such as the Network (Network

block) firmware, the Main (Main microcomputer) firmware and the Scaler (PixelWorks) firmware.

The Event Trace function enables the user to browse the information such as the logs (Lamp Timer Reset

log, Error log and Mail Report log) of the projector.

1-4-2. Service Preparation

(1) Connecting the Projector to the PC

To connect the projector to the PC directly, use the CAT5 cross-cable. Establish the network setups of the

projector and the PC so that the same subnet mask is set in both of the projector and the PC.

If the projector is connected to LAN, connect the PC to the same LAN and establish the Network setup of

the PC in accordance with the user’s LAN environment.

(2) Confirming the IP Address

Turn on the power of the projector, and have the Menu screen appear on the display. Confirm the IP

address of the projector on the [INFORMATION] screen.

1-22

VPL-VW100

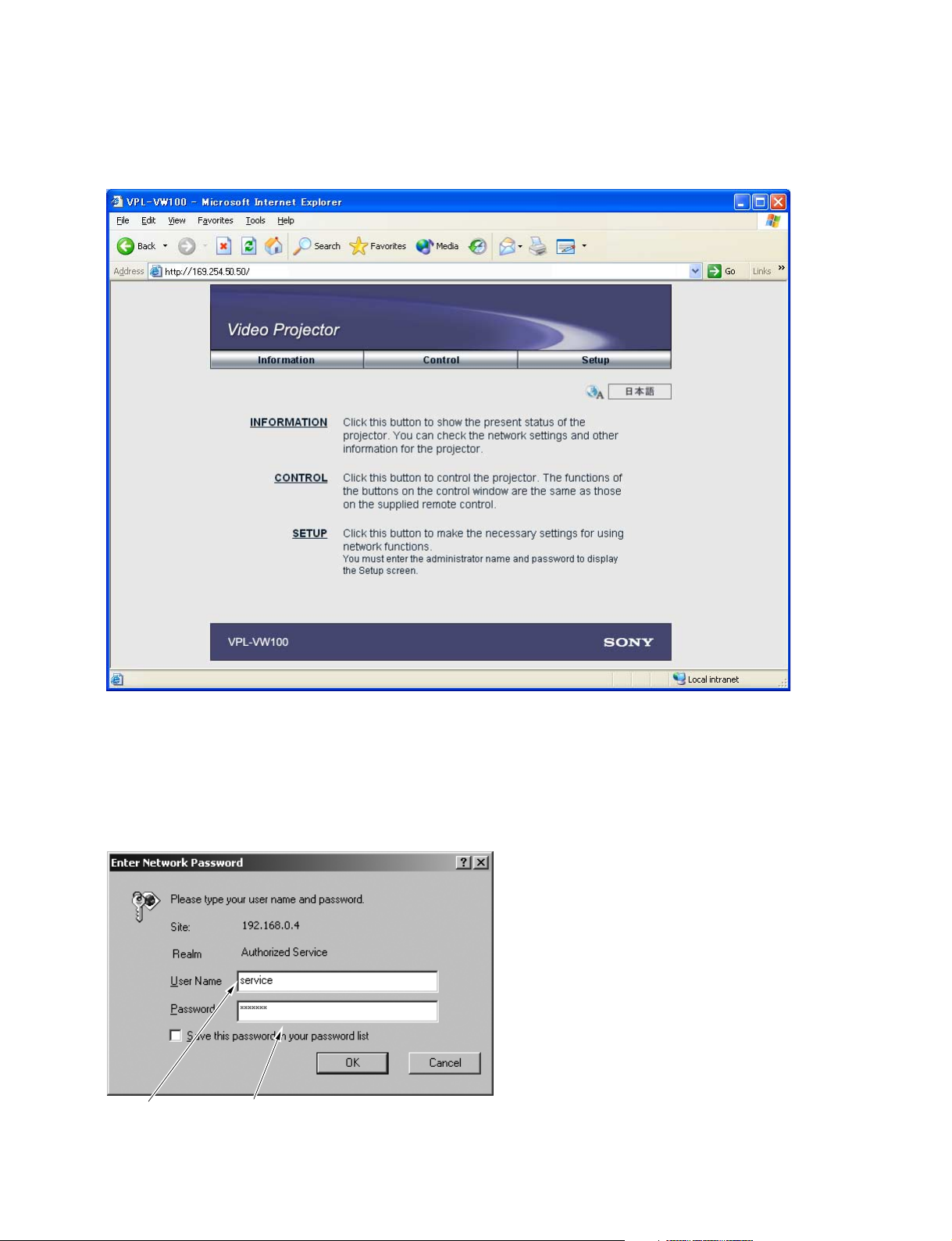

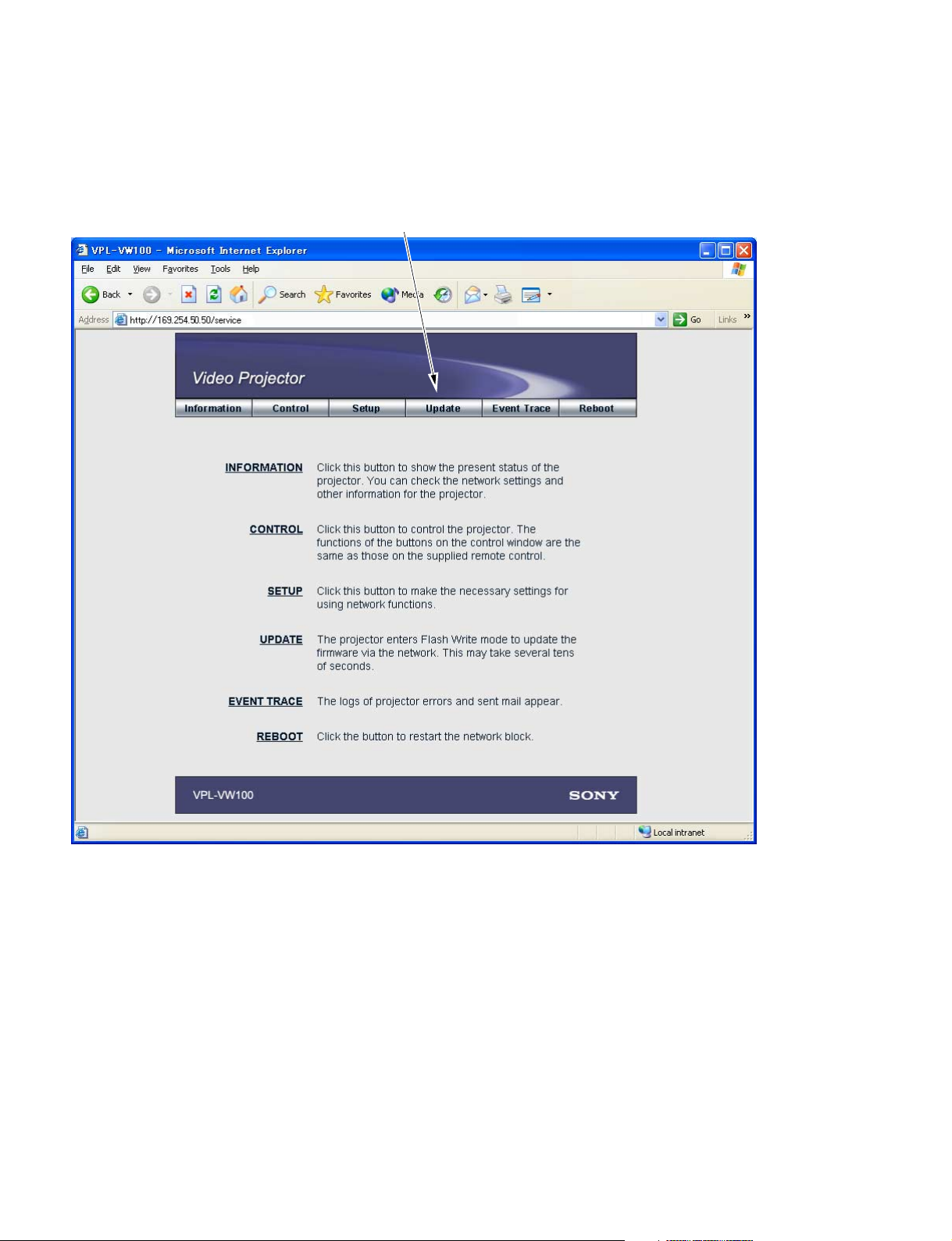

(3) How to Enter the Service Mode

To use the functions dedicated to the repair service, the user should enter the service mode. Type the

following address in the “Address” field of the Web-browser (IE5.0 or more) to enter the service mode.

Fig. 1 Index screen

When the user is prompted to enter the user name and the password, type them as follows.

User name : service

Password : vpl-vw100

If the user wants to move to another page from the service mode once, and then re-enter into it again, exit

the Web-browser and re-launch it.

User name : service Password : vpl-vw100

Fig.2 Password entry screen

VPL-VW100

1-23

1-4-3. Firmware Update Function

(1) Update Preparation

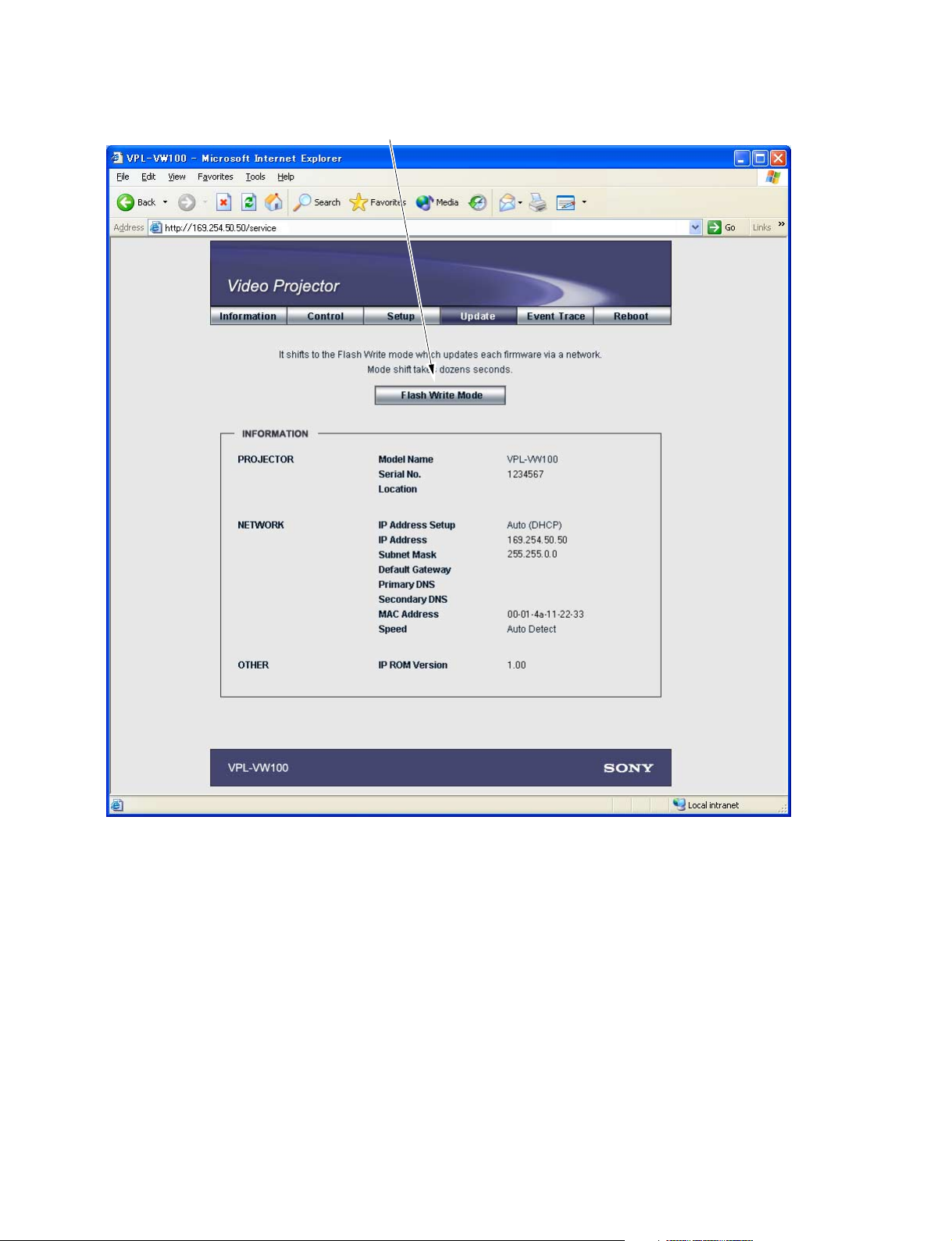

Set the power of the projector in the standby state.

Click the [Update] tab shown on the Service web page.

1-24

Fig.3 Service screen.

VPL-VW100

The Update screen will open. Then click [Flash Write Mode] .

Fig. 4 Upgrade screen

When the user clicks [Flash Write Mode], the Network block enters the upgrade ready state, and disables

the Web-browser not to be displayed. (The Web-browser displays an error indication.)

If the PC does not issue the upgrade requirement command for 15 minutes or more, the Network block

automatically exits the upgrade standby state and returns to the normal state after it is rebooted.

If version upgrade is executed, the Network block remains in the upgrade standby state unless the power

of the projector is turned off or the Network block is rebooted.

n

The upgrade requirement is issued at the moment when the [Update] button is clicked in the Firmware

Updater, which is described later.

The upgrade requirement is not issued if simply the Firmware Updater is launched.

VPL-VW100

1-25

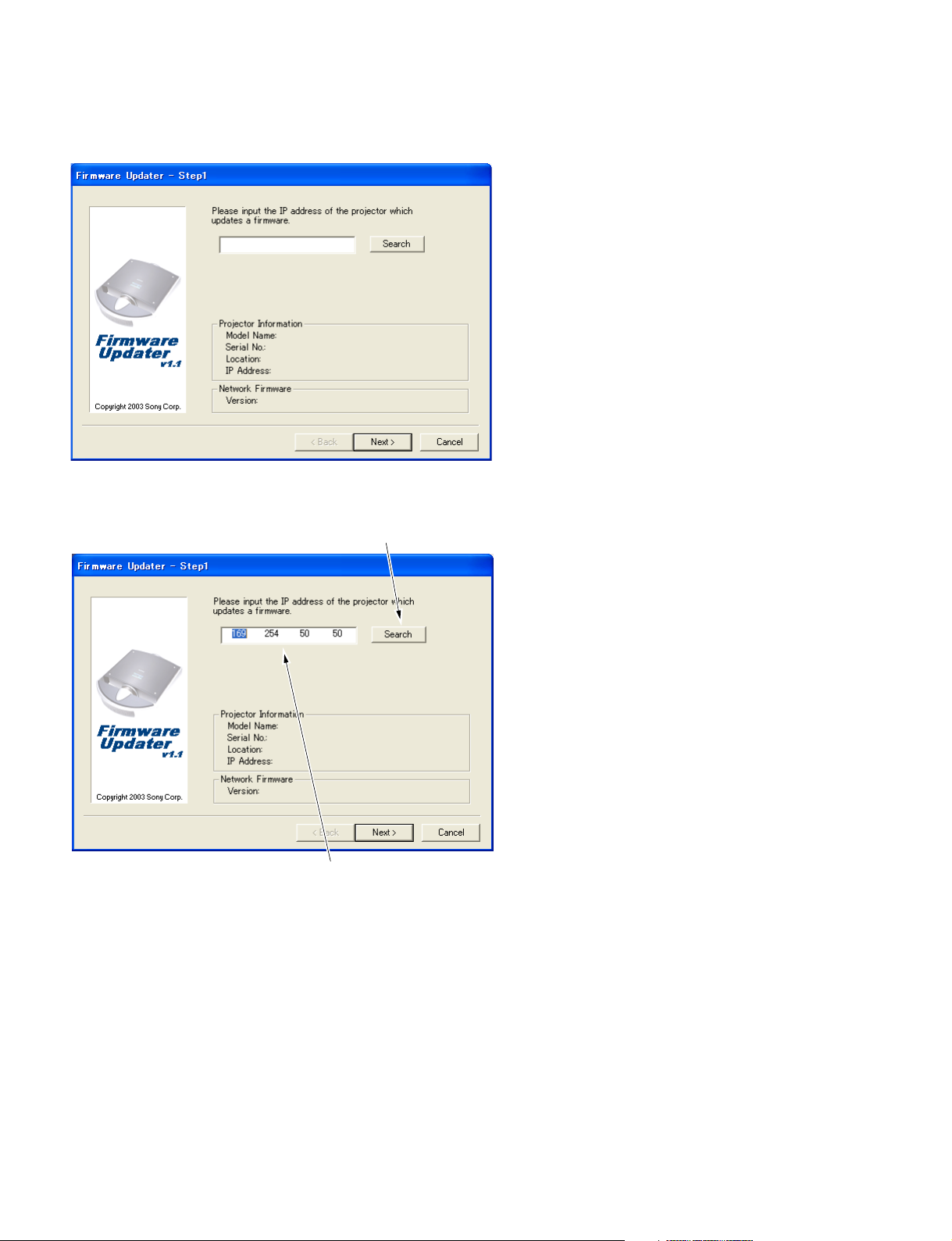

(2) Launching Firmware Updater

Launch “Firmware Updater.exe” on the PC.

Fig.5 Firmware Updater - Step1 screen (1)

(3) Specifying the Projector

Click the [Search] button to specify the projector whose firmware the client wants to upgrade.

If the IP address of the projector to be upgraded is already known,

it can be typed directly in this field.

(Delimit the IP address with a period.)

Fig.6 Firmware Updater - Step1 screen (2)

1-26

VPL-VW100

Loading...

Loading...