Page 1

DATA PROJECTOR

VPL-ES4

VPL-EX4

REMOTE COMMANDER

RM-PJ4

SERVICE MANUAL

1st Edition

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE RULE IN REGION.

VPL-ES4/EX4

Page 3

Table of Contents

1. Service Information

1-1. Appearance Figure ..........................................................1-1

1-2. Board Locations ..............................................................1-1

1-3. Disassembly ....................................................................1-2

1-3-1. Upper Case Assembly ........................................... 1-2

1-3-2. Front Case Assembly and

Sub Rear Case Assembly ......................................1-2

1-3-3. Main Board ............................................................ 1-3

1-3-4. Tunnel Outlet Section ............................................ 1-4

1-3-5. Main Board Bracket Section ................................. 1-4

1-3-6. Lamp Power Supply ..............................................1-5

1-3-7. Power Board ..........................................................1-5

1-3-8. Optics Section ....................................................... 1-6

1-3-9. Detection Switch Board ........................................ 1-7

1-3-10. DC Fan .................................................................. 1-7

1-4. Warning on Power Connection ....................................... 1-8

2. Electrical Adjustments

4. Spare Parts

4-1. Notes on Repair Parts ..................................................... 4-1

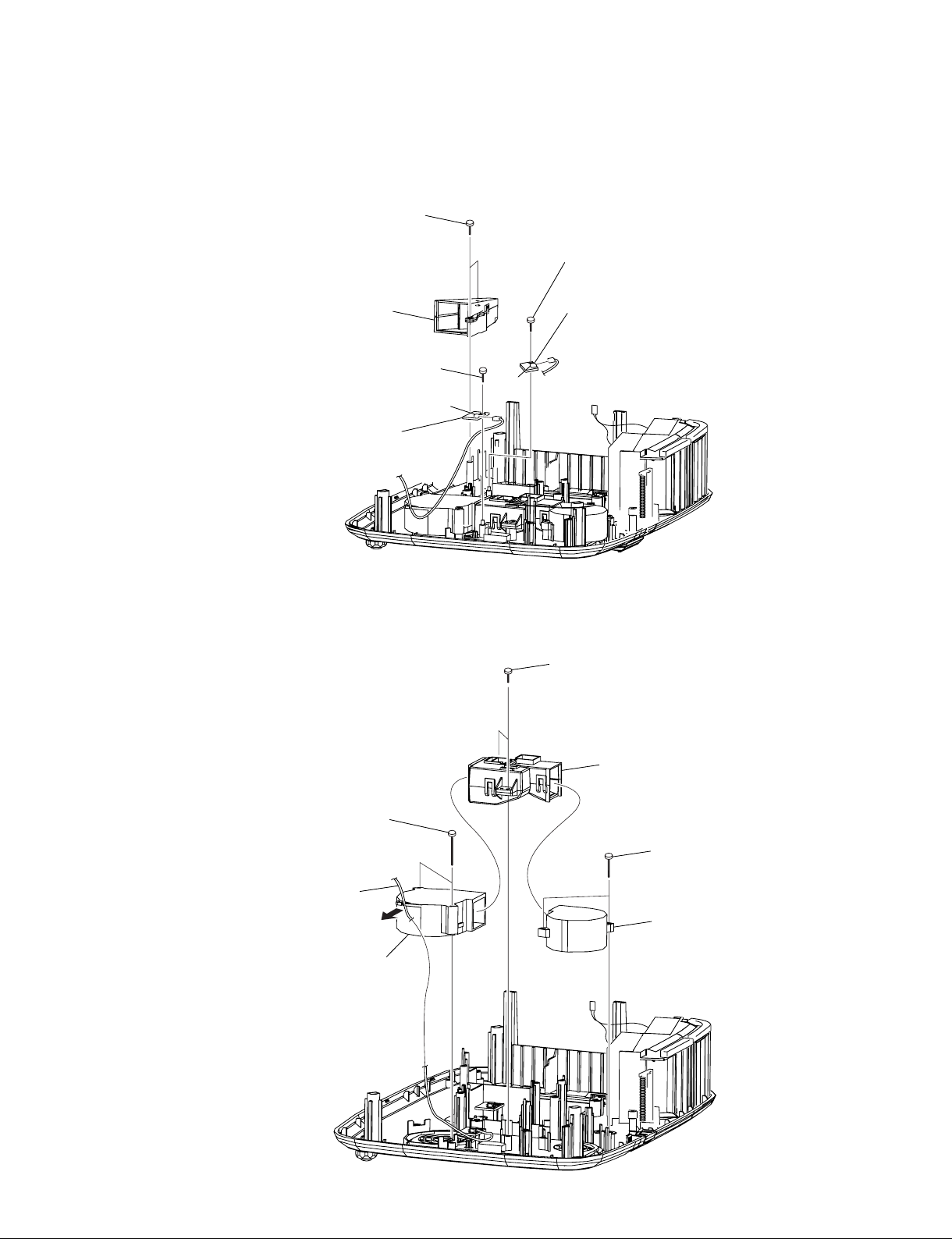

4-2. Exploded Views .............................................................. 4-2

4-3. Electrical Parts List ......................................................... 4-4

4-4. Packing Materials & Supplied Accessories ....................4-4

5. Block Diagram

Overall ............................................................................ 5-1

6. Diagram

6-1. Frame Schematic Diagram ............................................. 6-1

2-1. Initial Values of Adjustment Items ................................. 2-1

2-2. Memory Structure ...........................................................2-5

3. Troubleshooting

3-1. Electric Troubleshooting ................................................ 3-1

3-2. Power Board Troubleshooting ........................................3-3

3-2-1. No Power ...............................................................3-3

3-2-2. Failure of Turn on Lamp ....................................... 3-4

VPL-ES4/EX4

1

Page 4

Page 5

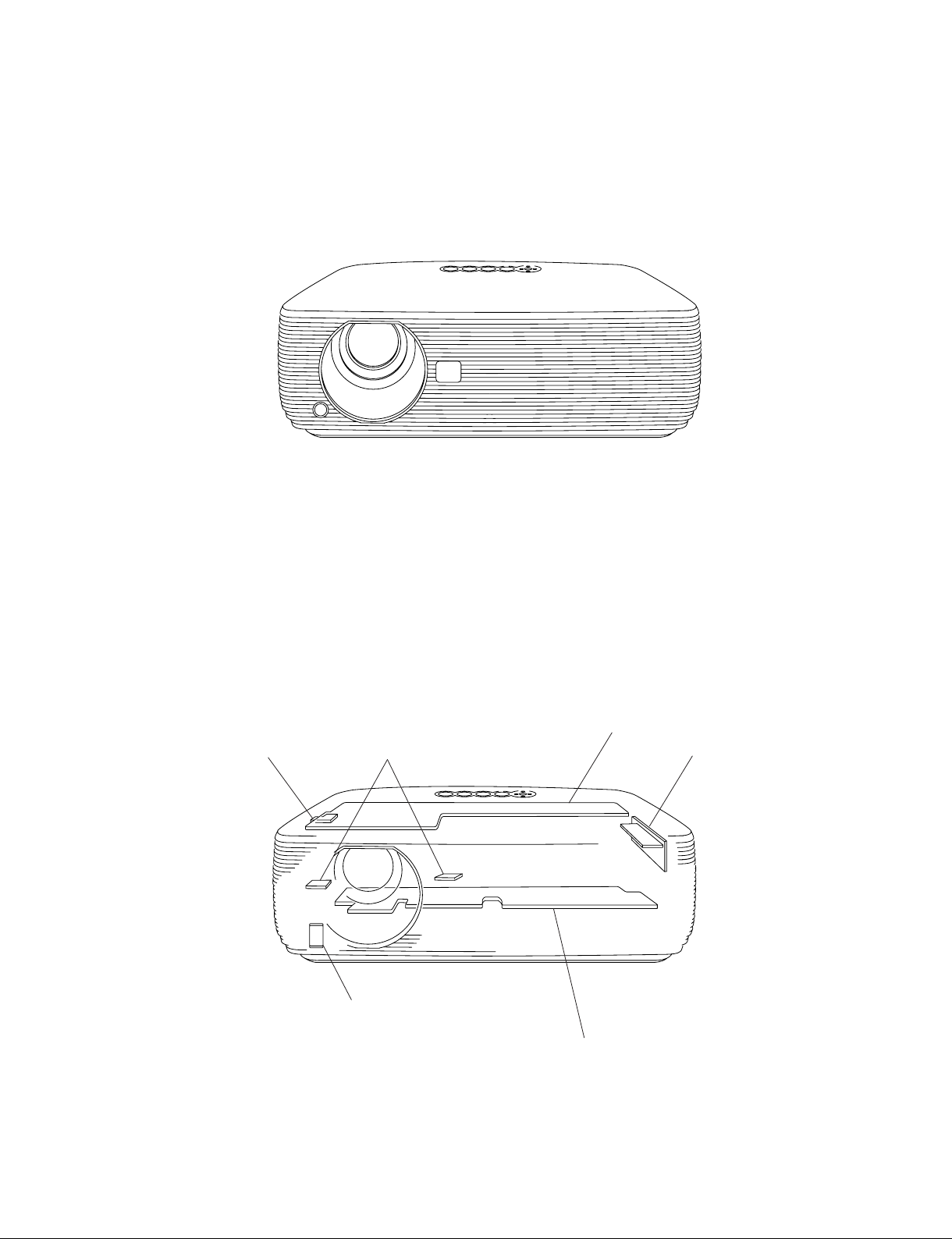

1-1. Appearance Figure

Section 1

Service Information

1-2. Board Locations

Thermal sensor

Detection switch

IR sensor

Main

Lamp power supply

Power

VPL-ES4/EX4

1-1

Page 6

1-3. Disassembly

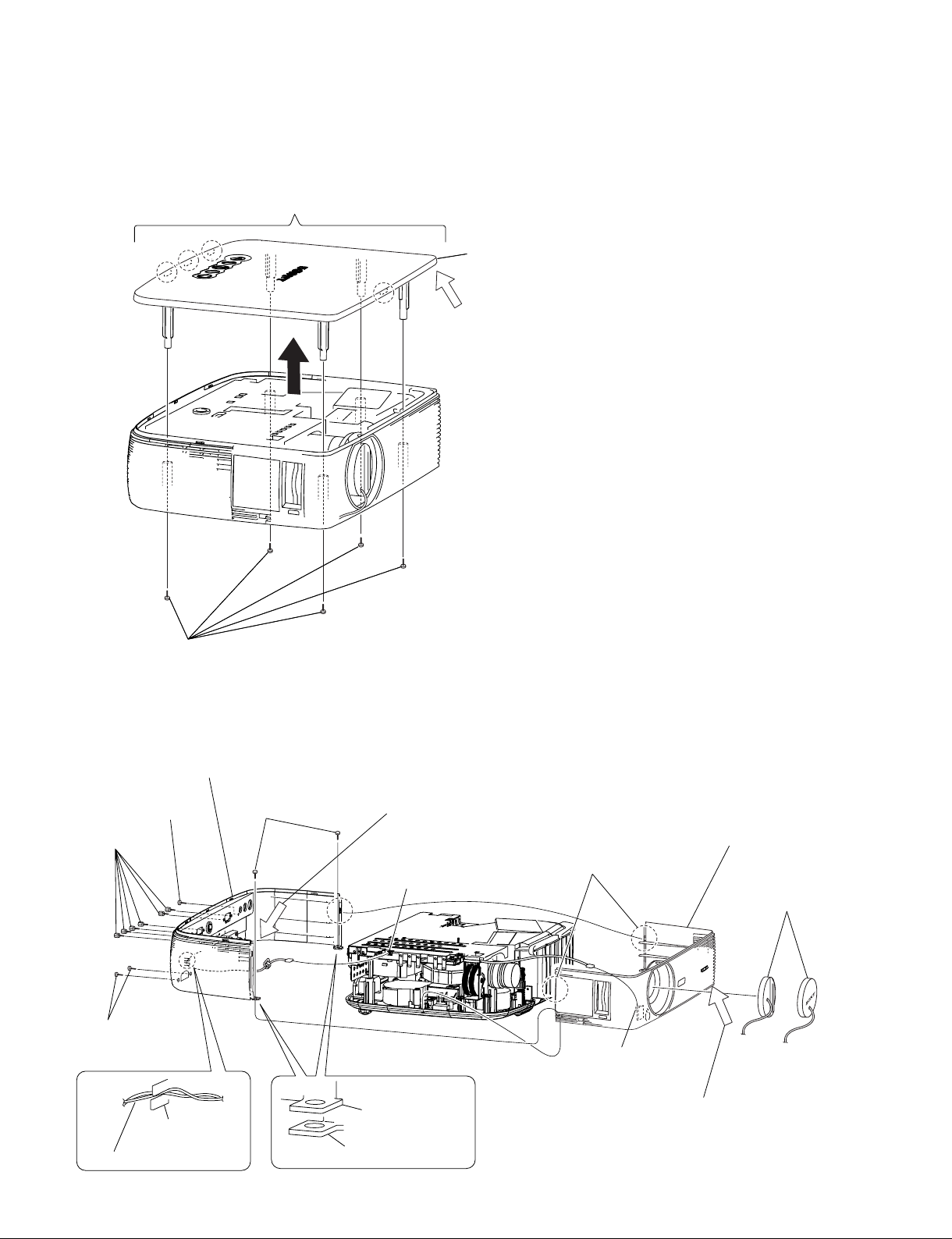

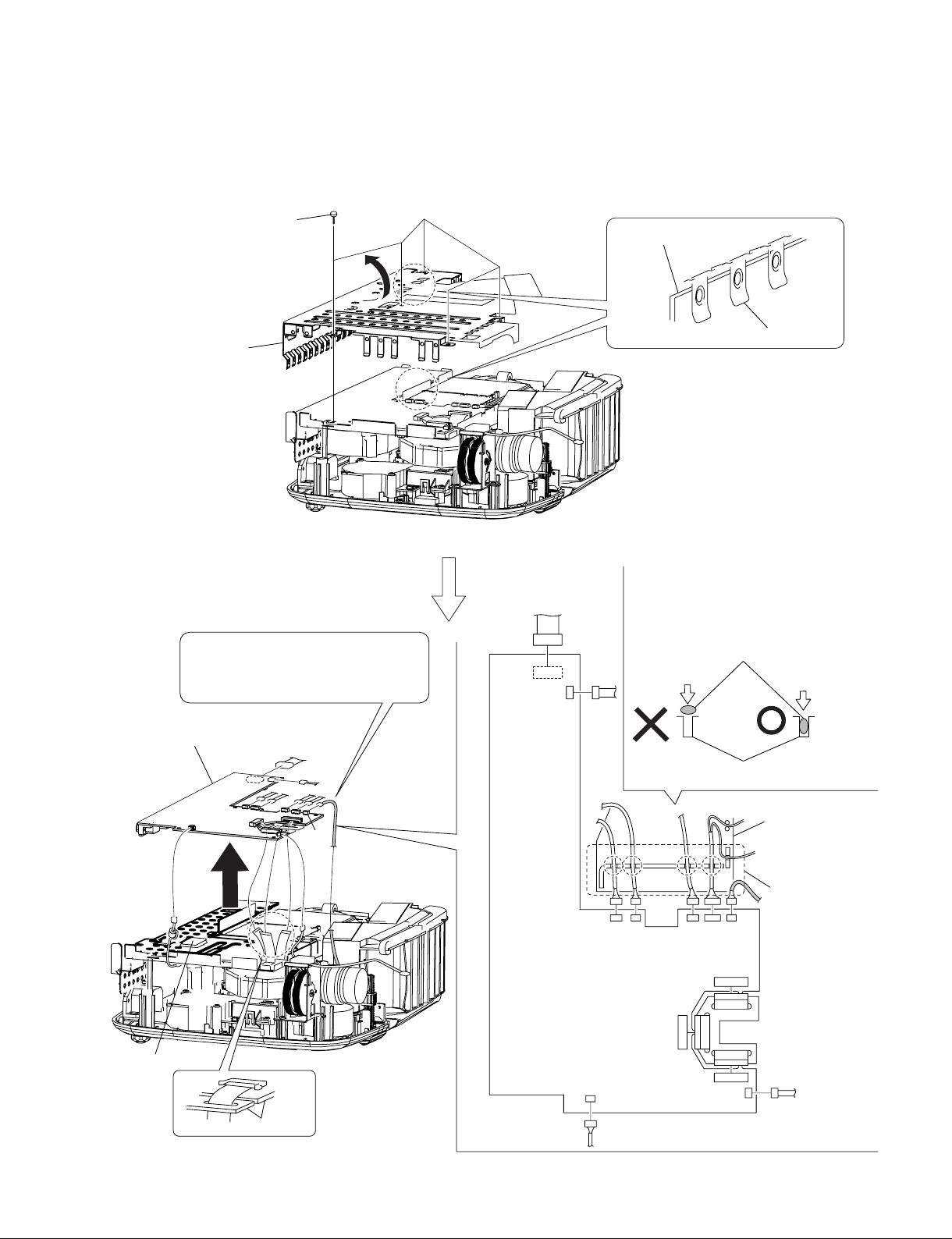

1-3-1. Upper Case Assembly

2

Four claws

4 Upper case assembly

3

Remove the upper case assembly from this corner with the

strong force to the extent that the upper case assembly will

not be damaged.

1

Five screws (M 3 x 6)

1-3-2. Front Case Assembly and Sub Rear Case Assembly

Remove the upper case assembly before starting the removal work.

!=

5 S

(M 3)

6

Six

hexagon

screws

7

Two screws

(+K 3 x 12)

Sub rear case assembly

4

crew

Two screws

(M 3 x 6)

9

Remove the upper case assembly from this corner with the

strong force to the extent that the upper case assembly will

not be damaged.

2

Main board

connector (J6)

0

Two claws

3

IR sensor board

connector (J1)

Front case assembly

1-3-3. Main Board

Remove the front case assembly and sub rear case assembly before starting the removal work.

1

five screws

(M 3 x 6)

2

Remove the main

shield in the direction

of the arrow.

Note:

The fan harness has been secured by the

main board bracket with a fixing screw.

(See section 1-3-5. mein bracket)

J17

J16

Main board bracket section

Because the harnesses has the shape of flat

cross-section, do not insert the harnesses with

excessive force. Find out the direction in

which the harnesses can be inserted easily,

and then insert the harnesses.

Main shield

Harnesses

3

Main board

Radiation sheet

Main board

J22

Main board

J18

Harnesses clamp section

J14 J20 J19 J21 J22

J25

J24

J23

Lamp box assembly

When re-assembling,

give an appropriate

amount of extra slack

of this harnesses.

J6

VPL-ES4/EX4

1-3

Page 8

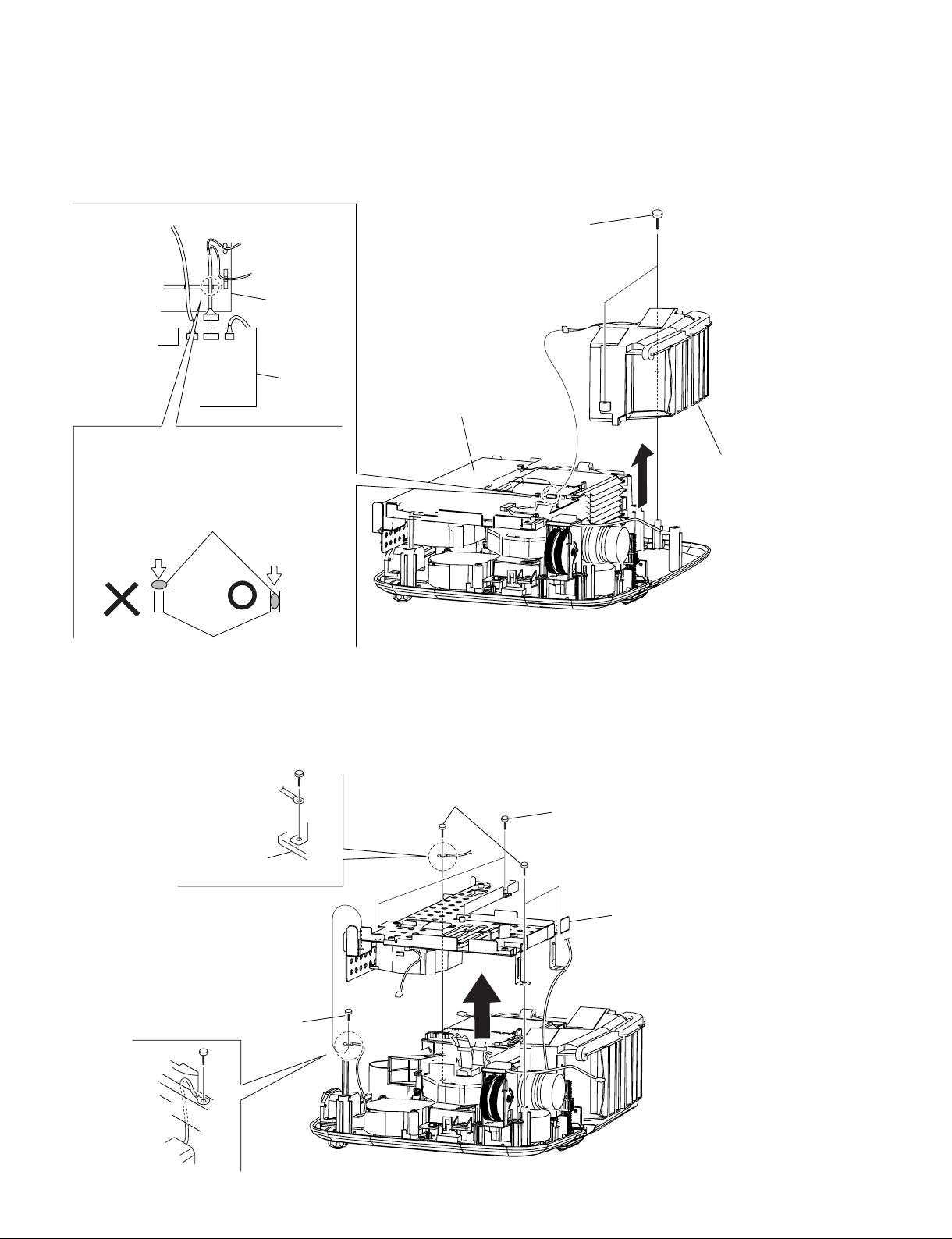

1-3-4. Tunnel Outlet Section

Remove the front case assembly and sub rear case assembly before starting the removal work.

1

Two tapping screws

(PAN 3 x 7)

Lamp box

assembly

J21

Main board

Main board

Because the harnesses has the shape of flat

cross-section, do not insert the harnesses with

excessive force. Find out the direction in

which the harnesses can be inserted easily,

and then insert the harnesses.

Harnesses

J21

2

Tunnel outlet section

Harnesses clamp section

1-3-5. Main Board Bracket Section

Remove the main board before starting the removal work.

2

Three tapping screws

(PAN 3 x 7)

Power board

3 S

crew

(M 4 x 6)

1

Two screws

(M 3 x 6)

4

Main board bracket section

1-4

VPL-ES4/EX4

Page 9

1-3-6. Lamp Power Supply

4

Lamp

9

Lamp power supply

2

Lamp door

1

loosen screw.

3

Loosen two screws.

5 Screw

(+PWH 3 x 8)

8

Connector (P1)

B

A

To the main board J16

From the Main board CN602

(Red and Black wires)

6

Remove the lamp power supply

connector in the direction of the

arrow A.

7

Remove the lamp power supply in the

direction of the arrow B.

Remove the main board bracket section before starting the removal work.

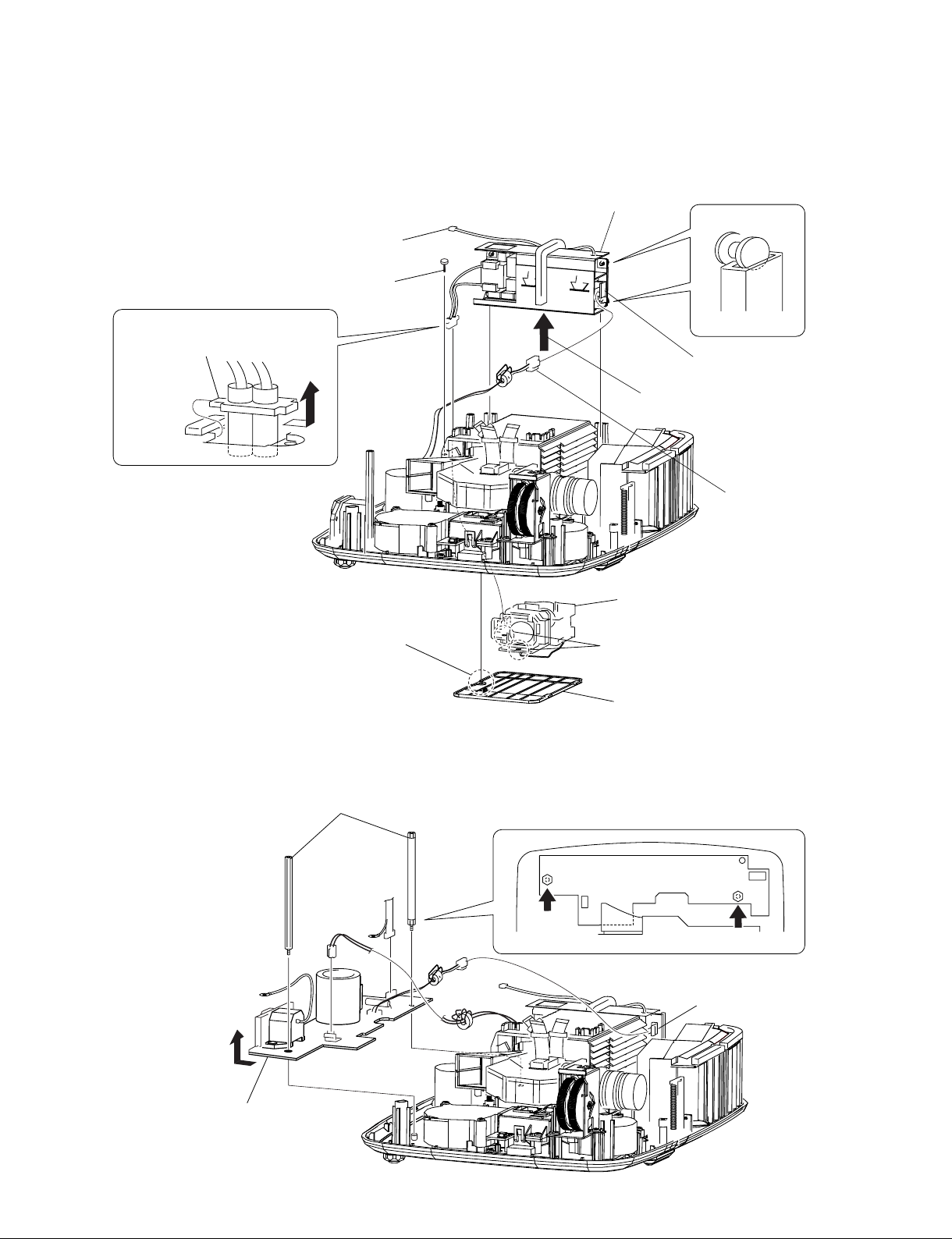

1-3-7. Power Board

Remove the main board bracket section before starting the removal work.

VPL-ES4/EX4

2

Remove the power board in

the direction of the arrow.

1 Two

stand assemblies

CN701

CN603

Power board

CN603

Lamp power supply (P1)

CN701

1-5

Page 10

1-3-8. Optics Section

Remove the lamp power supply and power board before starting the removal work.

1

Two tapping screws

(PAN 3 x 7)

7

Dowel

2

Two claws

4

Gasket

6

Two tapping screws

(PAN 3 x 7)

5 Harness

8

Focus/Zoom adjust

assembly

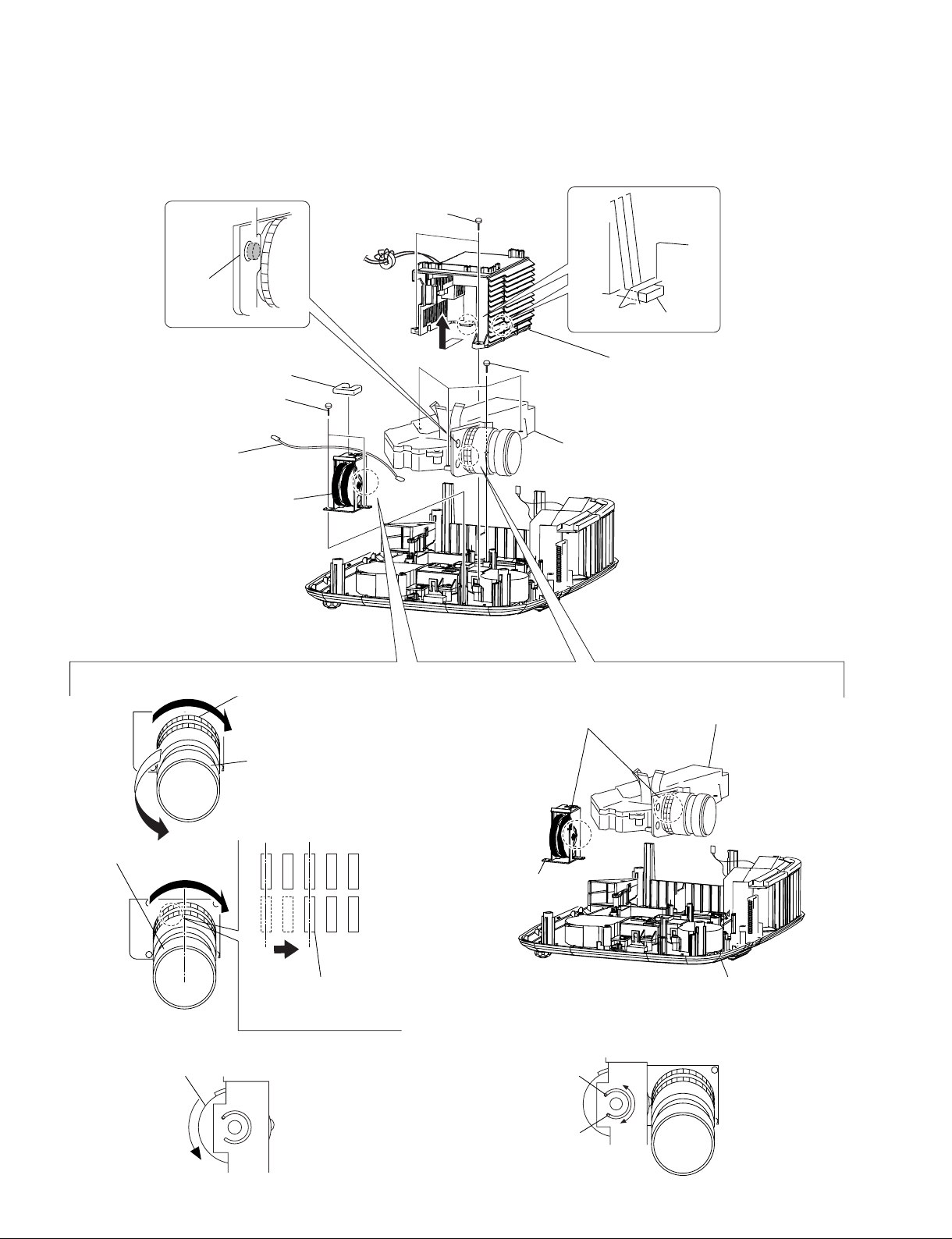

Assembling Method of Optucs section and

Focus/Zoom Adjust Assembly

Phase matching

Rotate the Zoom dial clockwise

!-

as shown until it is stopped.

!= Rotate the Focus dial

counter-clockwise as

shown until it is stopped.

A

9

Four screws

(+P 2.5 x 8)

0

During the assembling process,

never change the gear position

that is set by step ![.

3

Remove the lamp box assembly in the

direction of the arrow

Optucs section

A

.

!\ Install the Optucs section

in the Lower Case.

Focus dial

Rotate the Focus dial

![

counter-clockwise as

shown until it is stopped.

!] Rotate the Focus/Zoom Adjust Assembly

counter-clockwise until it is stopped.

1-6

!;

Install the Focus/Zoom

Adjust Assembly as shown.

!' After installation is completed, verify that the Optucs

section can rotate from the position

B

smoothly.

A

B

Lower case

A

to the position

VPL-ES4/EX4

Page 11

1-3-9. Detection Switch Board

Remove the optics section before starting the removal work.

3

Two tapping screws

(PAN 3 x 7)

4

Duct lamp

1

Tapping screw

(PAN 3 x 7)

CN1

2

Detection switch board

CN1

5

Tapping screw

(PAN 3 x 7)

6

Detection switch board

1-3-10. DC Fan

Remove the optics section before starting the removal work.

6

Two tapping screws

(M 3 x 25)

5 harness

7 DC fan

1

Two tapping screws

(PAN 3 x 7)

2

Duct

LCD assembly

3

Two tapping screws

(PAN 3 x 10)

4 DC fan

VPL-ES4/EX4

1-7

Page 12

1-4. Warning on Power Connection

Use a proper power cord for your local power supply.

The United States, Continental UK, Ireland, Japan

Canada Europe Australia, New Zealand

Plug type VM0233 290B YP-12A COX-07 _

Connector type VM0089 386A YC-13B COX-02 VM0310B YC-13

Cord type SJT SJT H05VV-F H05VV-F N13237/CO-228 VCTF

Rated Voltage/Current 10A/125V 10A/125V 10A/250V 10A/250V 10A/250V 7A/125V

Safety approval UL/CSA UL/CSA VDE VDE VDE DENAN

Cord length (max.) 4.5m (14 feet 9 inches) _

(1) Use an appropriate rating plug which is applied to local regulations.

1)

YP332

1-8

VPL-ES4/EX4

Page 13

Set

Memory

Dynamic Standard N

atural

Game Living Cinema

Presen-

tation Dynamic N

atural

Standard Game Living Cinema

Presen-

tation Dynamic Standard N

atural

Game Living Cinema

Presen-

tation Dynamic N

atural

Standard Game Living Cinema

Presen-

tation

Picture Mode * * * *

Adjust Picture

Contrast

90 80 85 90 90 75 85 90 75 80 90 90 75 75 90 80 85 90 90 75 85 90 85 80 90 90 60 85

Bright

60 50 55 60 50 50 55 60 55 50 60 50 50 55 60 50 55 60 50 50 55 60 55 50 60 50 50 55

Color

50 50 50 68 60 58 50 50 50 50 68 60 58 50 50 50 50 68 60 58 50

Hue

50 50 50 50 50 50 50 50 50 50 50 50 50 50

Sharp

ness 60 30 50 50 50 30 50 60 40 30 40 40 30 40 60 30 40 40 40 30 40

DDE

Film Film Film Film Film Film Film Film Film Film Film Film Film Film Film Film Film Film Film Film Film

Gamma Mode

Graphics Graphics

Color Temp

High Low Mid High Low Low High High Mid Low Low Low Low Mid Low Low Mid Low Low

Volume

30

Adjust Signal

Dot Phase 31

H Size

Shift

W

ild Mode OFF OFF OFF OFF OFF ON OFF OFF OFF OFF OFF OFF ON OFF OFF OFF OFF OFF OFF ON OFF

Scan Conv ON ON ON ON ON ON ON

Smart APA On

Auto Input Search Off

Input-A Signal Sel. Auto

Color System Auto

Power Saving Mode Off

IR Receiver

Front &

Rear

Panel Key Lock Off

Status On

Language English

Menu Position Center

Start Up Image On

V Keystone 0

Image Flip Off

Background Blue

Lamp Mode Standard

High Altitude Mode Off

Security Lock Off

Key Enter x 4

INFOR-

MATION

All information is

display only

Picture Memory

INPUT

SETTING

SET

SETTING

MENU

SETTING

INSTALL

SETTING

VIDEO INPUT A (

Component

/VideoGBR)

INPUT A (

Computer

)

, INPUT B (Computer)

PICTURE

SETTING

S VIDEO

Menu

Title

ItemName

MemoryName

High High High High High High High High High

Graphics Graphics Graphics Graphics Graphics

Section 2

Electrical Adjustments

Y No.).

2-1. Initial Values of Adjustment Items

VPL-ES4/EX4

* The “Picture Mode” items in the “PICTURE SETTING” menu have their respective initial values for each input signal (PRESET MEMOR

n

There are some adjustment items that cannot be adjusted, depending on the input signal.

2-1

Page 14

Color

Page Item Name Set R G B

TGHST Phase Hi 0

TGHST Phase Lo 109

SHSH1 38

TGHST Position 12

P1-1

CXD9809-page1

DEHPF On ON

DEHPF AAC ON

DEHPF TAP 3

DEUSC On OFF

3D GammaSubCont 0

3D GammaSubBrt 150

DELUT SW OFF

DEUF SW ON

PC Hi Gain-R 128

PC Hi Gain-G 128

PC Hi Gain-B 128

PC Hi Bias-R 0

PC Hi Bias-G 0

P1-2

CXD9809-page2

PC Hi Bias-B 0

PC Lo Gain-R 128

PC Lo Gain-G 70

PC Lo Gain-B 100

PC Lo Bias-R 0

PC Lo Bias-G 0

PC Lo Bias-B 0

P1-3

CXD9809-page3

2-2

Video Hi Gain-R 128

Video Hi Gain-G 128

Video Hi Gain-B 128

PC Mid Bias-R 0

Video Hi Bias-G 0

Video Hi Bias-B 0

Video Lo Gain-R 128

Video Lo Gain-G 70

Video Lo Gain-B 100

Video Lo Bias-R 0

Video Lo Bias-G 0

Video Lo Bias-B 0

VPL-ES4/EX4

Page 15

Color

Page Item Name Set R G B

PC Mid Gain-R 128

PC Mid Gain-G 90

PC Mid Gain-B 115

PC Mid Bias-R 0

PC Mid Bias-G 0

P1-4

CXD9809-page4

PC Mid Bias-B 0

Video Mid Gain-R 128

Video Mid Gain-G 75

Video Mid Gain-B 105

Video Mid Bias-R 0

Video Mid Bias-G 0

Video Mid Bias-B 0

Temperature 1 Display only

Temperature 2 Display only

Temperature 3 N/A

FanSpeed 1 Display only

FanSpeed 2 Display only

P2

Fan Control

FanSpeed 3 Display only

FanSpeed 4 Display only

ManualFanSpeed OFF

Burn-In Cycle 0

Burn-In Cycle On min 210

Burn-In Cycle Off min 30

Burn-In Hour 50

Burn-In active OFF

P3-1

CXA7005-page1

VPL-ES4/EX4

Gain-R 188

Gain-G 188

Gain-B 188

SigCen-R 35

SigCen-G 35

SigCen-B 35

SidA-R 22

SidA-G 22

SidA-B 22

SidB-R 85

SidB-G 85

SidB-B 85

2-3

Page 16

Color

Page Item Name Set R G B

Bias-R Normal 122

Bias-G Normal 122

Bias-B Normal 122

Bias-R Flip 122

Bias-G Flip 122

P3-2

CXA7005-page2

Bias-B Flip 122

Vcom-R Normal 88

Vcom-G Normal 88

Vcom-B Normal 88

Vcom-R Flip 88

Vcom-G Flip 88

Vcom-B Flip 88

RGB Calibrate

YUV Calibrate

RGB Offset 164 222 164

RGB Gain 93 105 93

YUV Offset 164 222 164

P4

ADC Calibration

YUV Gain 93 105 93

R Offset 164

G Offset 222

B Offset 164

R Gain 93

G Gain 105

B Gain 93

Error Count

2-4

P5

P6

Power Saving Time 10

System Protect ON

Data Reset

Hard Reset

ROM Version Display only

Lamp Timer Display only

Operation Timer Display only

Prev. Lamp Timer Display only

SOG Threshold N/A

All value is display only

VPL-ES4/EX4

Page 17

2-2. Memory Structure

Set memory Set memory Set memory

No.01

No.02 No.02

No.03

No.04 No.04

status

memory

Picture

memory

W/B

memory

Channel

Memory

Common

Memory

No.05 No.05

No.50 No.50

No.55 No.55

No.56 No.56

No.101 No.101

No.102 No.102

Video

S-Video

Input-A

Input-B

Component

Computer

Other than

Computer

Input-A

Input-B Input-B

Input-A

Component

Input-A

Video-GBR

Video Video

S-Video S-Video

Wide Mode

(other than computer)

Scan Converter

(Computer only)

Smart APA

(Computer only)

Volume Volume

Auto Input Search Auto Input Search

Input-A Signal Sel. Input-A Signal Sel.

Color System

(Video/S-Video Only)

Speaker Speaker

Power Saving Power Saving

IR Receiver IR Receiver

Panel Key Lock Panel Key Lock

Status Status

Language Language

Menu Position Menu Position

Image Flip Image Flip

Background Background

Lamp Mode Lamp Mode

High Altitude High Altitude

Security Lock Security Lock

FLASH ROM EEPROM

Video/Svideo

status

memory

Dynamic

Standard Standard

Natural Natural

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic

Standard Standard

Natural Natural

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic

Standard Standard

Natural Natural

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic

Standard Standard

Natural Natural

Game Game

Living Living

Cinema Cinema

Presentation Presentation

Dynamic

Standard Standard

Natural Natural

Game Game

Living Living

Cinema Cinema

Presentation Presentation

High

Mid Mid

Low Low

High

Mid Mid

Low Low

picture

memory

W/B memory

Channel

Memory

Common

Memory

Input-A/Input-B

/Component

Video

S-Video

Input-A

Input-B

Component

Computer

Other than

Computer

Input-A Channel Memory

Input-A

Component

Input-A

Video-GBR

Wide Mode

(other than computer)

Scan Converter

(Computer only)

Smart APA

(Computer only)

Color System

(Video/S-Video Only)

No.01 Status memory

No.03

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

High

High

Picture memory

W/B memory

Common Memory

CPU RAM

VPL-ES4/EX4

2-5

Page 18

Memory structure of this model consists of the followings.

1 Set memory

2 Status memory

3 Picture memory

4 Chroma memory

5 W/B memory

6 Channel memory

* The gamma memory is realized by giving offset to the Contrast and Brightness output values to the

devices in the gamma mode function.

Flow of data is described briefly. When the power plug is connected to the wall outlet for the first time

(Standby state), all data that are stored in the internal ROM are written in the NVM (non-volatile memory). When the POWER is turned ON, all the status memory data and other memory data that are required

for the present picture are selected from each memory block and expanded in the internal RAM.

When any adjustment is performed at this moment, the adjustment data (user mode items) are written in

the NVM (Service/Special Service) automatically triggered by the memory operation.

The adjustment items (W/B, Device Adjust) that can be adjusted in the Service Mode or in the Special

Service Mode, are memorized in the NVM at the time when the user performs adjustment and performs

the memory operation. Note that the factory adjustment data will be lost at this moment.

2-6

VPL-ES4/EX4

Page 19

3-1. Electric Troubleshooting

Connect the Power

Section 3

Troubleshooting

System Standby?

Yes

Power projector

Lamp ON ?

Yes

System shut-down

And cooling

No

No Picture ?

No

No

No

Yes

Yes

1. Check the LED Message and find error.

2. Check lamp door, dust door.

3. Check the power board out voltage 5V.

4. Change main board.

1. check the Ballast power and control

signal wire.

2. Check lamp door status.

3. Check lamp status.

1. Check the LED message and find error.

2. Check the Fan status or Thermal sensor

status.

3. Check the lamp door or dust door.

1. The picture is full-white pattern; please

check the LCD panel connector.

2. The picture is full-black pattern; please

check the LCD driver on the main board.

3. Check the system status: Is system in

burn-in mode?

VPL-ES4/EX4

Picture quality

No good ?

No

1

Yes

1. The picture a little green, blue, red,

please check the LCD panel connector.

2. The picture has dust, please check the

lens.

3. The picture flicker, please alignment

again.

3-1

Page 20

1

OSD flicker ?

No

Color temp wrong ?

No

Picture has

Vertical bar ?

No

IR remote control

No good ?

Yes

Yes

Yes

Yes

Please alignment V-com again.

Please alignment color temperature again.

Check the vertical bar color and find the

LCD panel connector. Then check the pin

of connector.

1. Please check the OSD setting

2. Check the front IR board.

No

Audio function is

No good ?

Yes

1. Check the OSD setting.

2. Check the speak wire.

3-2

VPL-ES4/EX4

Page 21

3-2. Power Board Troubleshooting

3-2-1. No Power

No Power

Replace Q601 and F601

with new ones, and then

put power board into set.

If Q601 damages again,

check if other parts are

shorted.

Check if 15.25V or 12V

exist. If any voltage is

wrong, replace IC701 or

T602 with new ones.

Yes

Yes

F601

Open?

Yes

Q601(D-S)

Short ?

No

Output

5V DC

exists ?

No

Voltage

outputs shut

down and built

repeatly ?

No

Yes

Check if CN701 inserted

properly.

Check if miss to solder

any SMD type of

components.

Check if D602 or IC602 is

broken.

if yes,replace it with now

one.

VPL-ES4/EX4

No

Check LED circuit of

main board.

Check CN701 and find

out if some points are

shorted to gound.

3-3

Page 22

3-2-2. Failure of Turn on Lamp

Failure of turn on ballast.

Check main board.

A

Check if the input

voltage of ballast is

380V DC

No

Lamp

Broken ?

No

No

Control

Pin (SCI) is

normal ?

Yes

Replace ballast with new

one.

Yes

Yes

B

Replace lamp with new

one.

3-4

VPL-ES4/EX4

Page 23

B

Check mian board.

A

No

exists at c-terminal

Yes

Check if there

is PFC_On/Off

signal.

Yes

Check if 18V

of Q603.

Yes

F602 Open ?

No

Q602 works

normally ?

No

Yes

Check Q701 IC604,

Q604, Q603 or ZD603.

And then replace broken

parts.

Replace F602 with new

one.

VPL-ES4/EX4

No

Check ZD602, R655 and

R656.

3-5

Page 24

Page 25

4-1. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

[WARNHINWEIS][WARNHINWEIS]

[WARNHINWEIS]

[WARNHINWEIS][WARNHINWEIS]

Les composants identifiés par la marque ! sont

critiques pour la sécurité.

Ne les remplacer que par une pièce portant le numéro

spécifié.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

Parts List has the present standardized repair parts.

Section 4

Spare Parts

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the Spare Parts list may not be stocked. Therefore, the

delivery date will be delayed.

Items with no part number and no description are not

stocked because they are seldom required for routine

service.

4. Units for Capacitors, Inductors and Resistors

The following units are assumed in Schematic Diagrams, Electrical Parts List and Exploded Views

unless otherwise specified.

Capacitors : μF

Inductors : μH

Resistors : Ω

VPL-ES4/EX4

4-1

Page 26

Overall

4-2. Exploded Views

10

38

38

36

38

41

38

33

+PSW 4x8

32

25

9

12

+PSW 3x25

+PWH

3x8

42

20

38

32

6

32

30

1

3

32

2

13

+P 2.5x8

32

14

37

32

38

32

29

4

39

28

30

24

7

+K 3x12

+K 3x12

4-2

27

17

26

21

VPL-ES4

8

38

22

38

34

VPL-EX4

+BVTP 3x6

35

11

15

16

VPL-ES4/EX4

Page 27

No. Part No. SP Description

1 ! 1-576-973-11 s FUSE, CYLINDERICAL (F602)

2 ! 1-576-233-51 s FUSE (H.B.C.) (F601)

3 ! 1-576-974-11 s THERMOSTAT

4 1-789-603-11 s DOOR DETECTION SWITCH BOARD

6 ! 9-885-114-11 s FAN, DC (AXIAL FAN UNIT)

7 ! 9-885-114-12 s FAN, DC

8 ! 1-787-496-11 s FAN, DC (DC)

9 ! 1-787-496-21 s FAN, DC (DC)

10 9-885-114-05 s MOUNTED CIRCUIT BOARD, MAIN (VPL-ES4)

10 9-885-114-07 s MOUNTED CIRCUIT BOARD, MAIN (VPL-EX4)

11 1-789-543-11 s MOUNTED CIRCUIT BOARD, IR SENSOR

12 1-789-544-11 s MOUNTED CIRCUIT BOARD, THERMAL SENSOR

13 9-885-114-04 s MOUNTED CIRCUIT BOARD, POWER

14 9-885-114-06 s SPEAKER

15 9-885-113-91 s LAMP DOOR

16 9-885-113-92 s DOOR, FILTER

17 2-670-067-01 s MESH FILTER

20 2-675-465-01 s ASSY, LAMP BOX

21 9-885-113-93 s ASSY,FOOT ADJUST RUBBER

22 9-885-113-94 s FOOT, ADJUST

24 9-885-113-95 s LENS CAP (VPL-ES4)

24 9-885-114-08 s LENS CAP (VPL-EX4)

25 9-885-114-34 s MYLAR BALLAST

26 9-885-113-96 s LOWER CASE

27 9-885-114-00 s ASSY, SUB REAR CASE (VPL-ES4)

Overall

27 9-885-114-33 s ASSY, SUB REAR CASE (VPL-EX4)

28 9-885-113-97 s ASSY, FRONT CASE (VPL-ES4)

28 9-885-114-09 s ASSY, FRONT CASE (VPL-EX4)

29 9-885-113-98 s ASSY, FOCUS/ZOOM ADJUST (VPL-ES4)

29 9-885-114-10 s ASSY, FOCUS/ZOOM ADJUST (VPL-EX4)

30 2-681-547-02 s SCREW, TAP PH W/FL M3*27L

32 2-681-550-01 s SCREW, TAP PAN M3*7L

33 2-681-552-02 s SCREW, EX-HE 4#-40X4+6 STLESS

34 2-681-553-01 s SCREW, TAP PAN M2*6L

35 9-885-114-32 s RUBBER PAD,ADJUST FOOT

36 9-885-113-90 s ASSY, UPPER CASE (WHITE COLOR)

36 9-885-113-99 s ASSY, UPPER CASE (BLOCK COLOR) (VPL-ES4)

37 4-672-839-11 s HEAD, M3 FLAT

38 3-918-696-11 s SCREW (M3X6 LOCK ACE)

39 2-580-621-01 s SCREW, +PWH 3X10

41 9-885-114-02 s SWITCH,TACT

42 ! 1-474-023-11 s POWER SUPPLY BLOCK (BALLAST)

7-682-903-21 s SCREW, +PWH 3X8

7-682-954-01 s SCREW, +PSW 3X25

7-685-645-91 s SCREW +BVTP 3X6

7-621-262-40 s SCREW, +P 2.5X8

7-682-250-09 s SCREW, +K 3X12

7-682-961-01 s SCREW +PSW 4X8

VPL-ES4/EX4

4-3

Page 28

4-3. Electrical Parts List

Ref. No.

or Q’ty Part No. SP Description

1pc ! 1-576-233-51 s FUSE (H.B.C) (F601)

1pc ! 1-576-973-11 s FUSE, CYLINDERICAL (F602)

4-4. Packing Materials & Supplied

-------------------SUPPLIED ACCESSORIES

------------------- Ref. No.

or Q’ty Part No. SP Description

1pc 1-479-775-12 s REMOTE COMMANDER (RM-PJ4)

1pc 1-832-428-11 s CABLE, VGA

1pc 2-679-319-01 s BAG,CARRY

1pc 3-210-513-02 s CD MANUAL

1pc 3-100-207-01 s GUIDE QS MANUAL

(JAPANESE, ENGLISH, FRENCH,

SPANISH, GERMAN, ITALIAN,

SIMPLIFIED CHINESE)

1pc ! ------------ s CORD SET, POWER

(See 1-4. Warning on Power Connection)

Accessories

4-4

VPL-ES4/EX4

Page 29

Section 5

GPSIG

HCKx_R

DCK1_B

DCK1x_R

DCK1_B

HCK_R

HCK

LCDPCG

LCDENB

VST

VD

DCK1x_G

HCKx_R

HST

HCKx

VCK

DCK2_G

HCKx

CLK_B

FRP

DCK1x_G

HST

PRG

DCK1_R

CLK_G

RPSIG

DCK2x_R

VD

DCK1_G

DCK1_R

RGT

HCKx

GSIG[6:1]

DWN

HCK_G

VCK

HCK_R

HCKx_G

HCK_B

DCK2x_B

LCDVCK

LCDRGTx

PCG

HCK_G

ENB

DCK2x_B

DCK2_G

DWN

HCK

ENB

FRP

PRG

DCK1x_R

PCG

LCDVST

RSIG[6:1]

VCK

HCKx_B

PCG

LCDRGT

HCK

BSIG[6:1]

VD

DCK2_B

PRG

DCK2x_G

VST

DCK2x_R

DCK2_R

LCDHST

BPSIG

RGTx

HST

LCDR[11:0]

DCK1_G

DCK2_R

DWN

RGT

VCK

PRG

DCK1x_B

GVCOM

CLK_R

HST

HCK_B

FRP

DWN

HCKx_G

HCKx_B

BVCOM

LCDG[11:0]

RVCOM

ENB

RGT

DCK2_B

VD

FRP

RGTx

DCK[6:1]

LCDDWN

LCDB[11:0]

ENB

PCG

DCK2x_G

DCK1x_B

VST

VST

SDA

SCL

WP

DR[9:0]

DG[9:0]

DB[9:0]

DCLK

DHS

DVS

SDATA

SEN

SDATA

SDATA

SCLK

SEN

SCLK

SEN

SCLK

SDATAi

SCLKi

SENi

PC-RIN1

PC-GIN1

PC-BIN1

HSYNC1

VSYNC1

PC-RIN2

PC-GIN2

PC-BIN2

HSYNC2

VSYNC2

R_OUT

G_OUT

B_OUT

HSYNCO

VSYNCO

LUMA

CHROMA

CVBS

PC-RIN

PC-GIN

PC-BIN

HSYNC

VSYNC

AUDIO_S

AUDIO_O_

AUDIO_O

AUDIO_MUT

AUDIO_VOL1

AUDIO_VOL2

TXD

RXD

AUDIO_M

TX.DL

RX.DL

AUDIO_O+

I2C_SW

FAN_SW

FG1

FG2

Fan3

FG3

Fan4

FG4

Fan5

FG5

Fan2

AUDIO_SW

SDA

IRR5

IRF5

IRR

IRF

SCL

LED[4:1]

P15VP

P12V

P5V

PWR_fail

POWER_ON

LCD_SCL

LCD_SDA

Dust_SW

ROMOEn

ROMWEn

A[0:21]

D[0:15]

LampLIT

LampEN

Eco_mode

Door_SW

P15VP

P12V

P5V

P15VP

P5V

P15V

P5VC

P5V

P5V

P1P8V

P2P5V

P3P3V

P33V

P5VC

V33

P2P5V

P135V

P15V

R

LCD

Drver

R

LCD

B

LCD

B

LCD

Driver

LCD

Timing

Generator

G

LCD

G

LCD

Driver

Video

Processor

&

Controller

Reset

IC

EEPROM

Speaker

RS232

Driver

Receiver

Fan Control

EEPROM

IR Receiver

IR Receiver

S-Video

Video

INPUT A

INPUT B

Monitor

Output

Audio

Audio A/B

Audio out

RS-232

Remote

Control

Thermal

Sensor 1

Thermal

Sensor 2

Analog RGB

Input/Output

32.768 KHz

LED

Driver

Keypad

Input

27 MHz

Power

Fail DET

Dust SW

Door SW

Flash

memory

Reset

IC

Power

Control

Power

Switch

Ballast

Fan 1

Fan 2

Fan 3

Fan 4

Audio

Input/Output

&

volume

control

+2.5V

REG

+3.3V

REG

+3.3V

REG

+1.8V

REG

+3.3V

REG

+1.8V

REG

+3.3V

REG

Block Diagram

OverallOverall

VPL-ES4/EX4

5-1

5-1

Page 30

Page 31

Section 6

CN601

CN602

HALOGEN

LAMP

BALLAST UNIT

POWER BOARD

FAN2

FAN2

FAN1(FRONT BOTTOM)

FAN3

(REAR BOTTOM)

FAN4

(REAR TOP)

CN701J17

SPEAKER

J11

J22

J6

J1

J20

J19

J14

J21

J16

J23

J24

J25

J1

INPUT

INPUT B

J2

INPUT

INPUT A

J3

OUTPUT

MONITOR

J4

VIDEO

J5

S VIDEO

INPUT

INPUT

J7

RS-232CREMOTE

CN1

CN1

J18

J1

THERMAL

SENSOR

BOARD

DETECTION

SWITCH

BOARD

(RIGHT)

DETECTION

SWITCH

BOARD

(LEFT)

LCD R

IR

SENSOR

BOARD

MAIN

BOARD

LCD G

LCD B

INPUT

J8

AUDIO A/B

INPUT

J9

AUDIO

OUTPUT

J10

AUDIO

Diagram

Frame Frame

6-1. Frame Schematic Diagram

1

2

3

4

5

VPL-ES4/EX4

6-1

6-1

A BCDEFGH

Page 32

Page 33

SAFETY CHECK-OUT

After correcting the original service problem,

perform the following safety checks before

releasing the set to the customer :

Check the metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC

leakage. Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to

earth ground and from all exposed metal parts to

any exposed metal part having a return to

chassis, must not exceed 3.5 mA. Leakage

current can be measured by any one of three

methods.

1. A commercial leakage tester, such as the

Simpson 229 or RCA WT-540A. Follow the

manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The

Data Precision 245 digital multimeter is

suitable for this job.

3. Measuring the voltage drop across a resistor

by means of a VOM or battery-operated AC

voltmeter. The “limit” indication is 5.25 V, so

analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa

SH-63Trd are examples of a passive VOM

that is suitable. Nearly all battery operated

digital multimeters that have a 20 V AC range

are suitable. (See Fig. A)

VPL-ES4/EX4

To Exposed Metal

Parts on Set

0.15 μF 1.5 k

Fig A. Using an AC voltmeter to check AC leakage.

Z

Earth Ground

AC

voltmeter

(5.25V)

Page 34

VPL-ES4 (SY)

VPL-EX4 (SY) E

9-883-627-01

English

Sony EMCS Corporation 2007DR16-1

Ichinomiya Tec ©2007

Loading...

Loading...