Sony UP-D6500, UP-D6300, UP-D6400 Operating Instructions Manual

3-864-593-11(1)

Digital Color Printer

Operating Instructions Page 2

Mode d’emploi Page 34

Bedienungsanleitung Seite 66

GB

FR

DE

UP-D6500

UP-D6400

UP-D6300

1998 by Sony Corporation

English

WARNING

To prevent fire or shock hazard, do not expose the unit

to rain or moisture.

To avoid electrical shock, do not open the cabinet. Refer

servicing to qualified personnel only.

For the customers in the U.S.A.

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful

interference when the equipment is operated in a

commercial environment.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause

harmful interference in which case the user will be

required to correct the interference at his own expense.

You are cautioned that any changes or modifications not

expressly approved in this manual could void your

authority to operate this equipment.

For the customers in the United Kingdom

WARNING

THIS APPARATUS MUST BE EARTHED

IMPORTANT

The wires in this mains lead are coloured in accordance

with the following code:

Green-and-yellow: Earth

Blue: Neutral

Brown: Live

As the colours of the wires in the mains lead of this

apparatus may not correspond with the coloured

markings identifying the terminals in your plug proceed

as follows:

The wire which is coloured green-and-yellow must be

connected to the terminal in the plug which is marked by

the letter E or by the safety earth symbol Y or coloured

green or green-and-yellow.

The wire which is coloured blue must be connected to the

terminal which is marked with the letter N or coloured

black.

The wire which is coloured brown must be connected to

the terminal which is marked with the letter L or coloured

red.

The shielded interface cable recommended in this

manual must be used with this equipment in order to

comply with the limits for a digital device pursuant to

Subpart B of Part 15 of FCC Rules.

2

Table of Contents

Introduction

Preparation

Product Features ............................................................... 5

Connection Illustrations ..........................................................6

Part Names and Functions ............................................... 7

Front View ..............................................................................7

Rear View ...............................................................................8

Precautions ........................................................................ 9

Operating Precautions............................................................. 9

Installation Precautions...........................................................9

Cleaning ..................................................................................9

Supplied Accessories ..................................................... 10

Printing

Installing the Ink Ribbon Cassette................................. 11

Installing the Cleaning Rollers ....................................... 13

Installing the Card Tray................................................... 14

Using Optional Accessories........................................... 14

Installing the Auto Card Feeder ............................................15

Installing the Auto Card Stacker...........................................16

Connections..................................................................... 17

Parallel Cable Connection.....................................................17

SCSI Cable Connection (UP-D6500) ...................................18

Setting the SCSI ID...............................................................19

Setting the Terminator ..........................................................19

Before Printing................................................................. 20

Feeding Method ....................................................................20

Things to Know Before Printing...........................................21

Manual-Feed Printing ...................................................... 22

GB

English

Printing with the Auto Card Feeder ............................... 23

Precautions During and After Printing .......................... 25

Table of contents 3

Table of contens

Appendixes

In Case of Problems ........................................................ 26

About Caution Indicator Lamps............................................26

If parts of the Image do not Print ..........................................27

Changing the Print Head................................................. 28

Specifications .................................................................. 31

Printer Specifications ............................................................31

Options ..................................................................................32

4 Table of contents

Product Features

Introduction

Introduction

The UP-D6500, UP-D6400 and UP-D6300 Digital

Color Printers use the dye sublimation thermal transfer

1)

process for duplex printing

of color and monochrome

characters and graphical computer images on ISO or

JIS standard plastic cards.

These models offer progressively higher levels of

printing quality, as follows:

UP-D6300: Equipped with 4 MB of image memory

and duplex printing capability, this model

connects to the computer’s parallel port.

An automatic card feeder is available as

an option.

UP-D6400: This model adds magnetic read/write and

template memory functions to the features

of the UP-D6300. Options are the same as

for the UP-D6300.

2)

UP-D6500: This model adds Smart Card

3)

and SCSI

interface capabilities to the

read/write

features of the UP-D6400. Image memory

is expanded to 8 MB, and data can be

spooled during printing. Two optional

automatic card feeders can be installed

together, and an optional automatic card

stacker can be installed in combination

with the supplied card tray.

This manual describes the common features of the

three models. Features specific to particular models are

described on the applicable pages.

The software supplied with each model lets you easily

combine images and text data to create large quantities

4)

of high-resolution (300 dpi

), full color ID cards (256-

level grayscale and 16.7 M colors).

Supported Applications

Ask your supplier for information about supported

application programs.

..........................................................................................................................................................................................................

1) Duplex Printing

Printing requires cards that comply with ISO

international standard (ISO7810 ID-1 type) or JIS

standard (JIS X6301-1979).

2) Smart Cards

ISO-standard IC cards incorporating CPU and memory.

This type of card provides better security than the

magnetic stripe type, and offers a wider range of uses.

3) SCSI (Small Computer System Interface)

This is a system standard for connecting peripheral

devices such as printers, hard disk drives, scanners and

other devices with the computer. Up to 7 SCSI devices

(SCSI-compliant peripheral devices) can be connected

by daisy chain to one host computer.

4) dpi (dots per inch)

The unit indicating the number of dots in one inch (25.4

mm).

Introduction 5

Product Features

Connection Illustrations

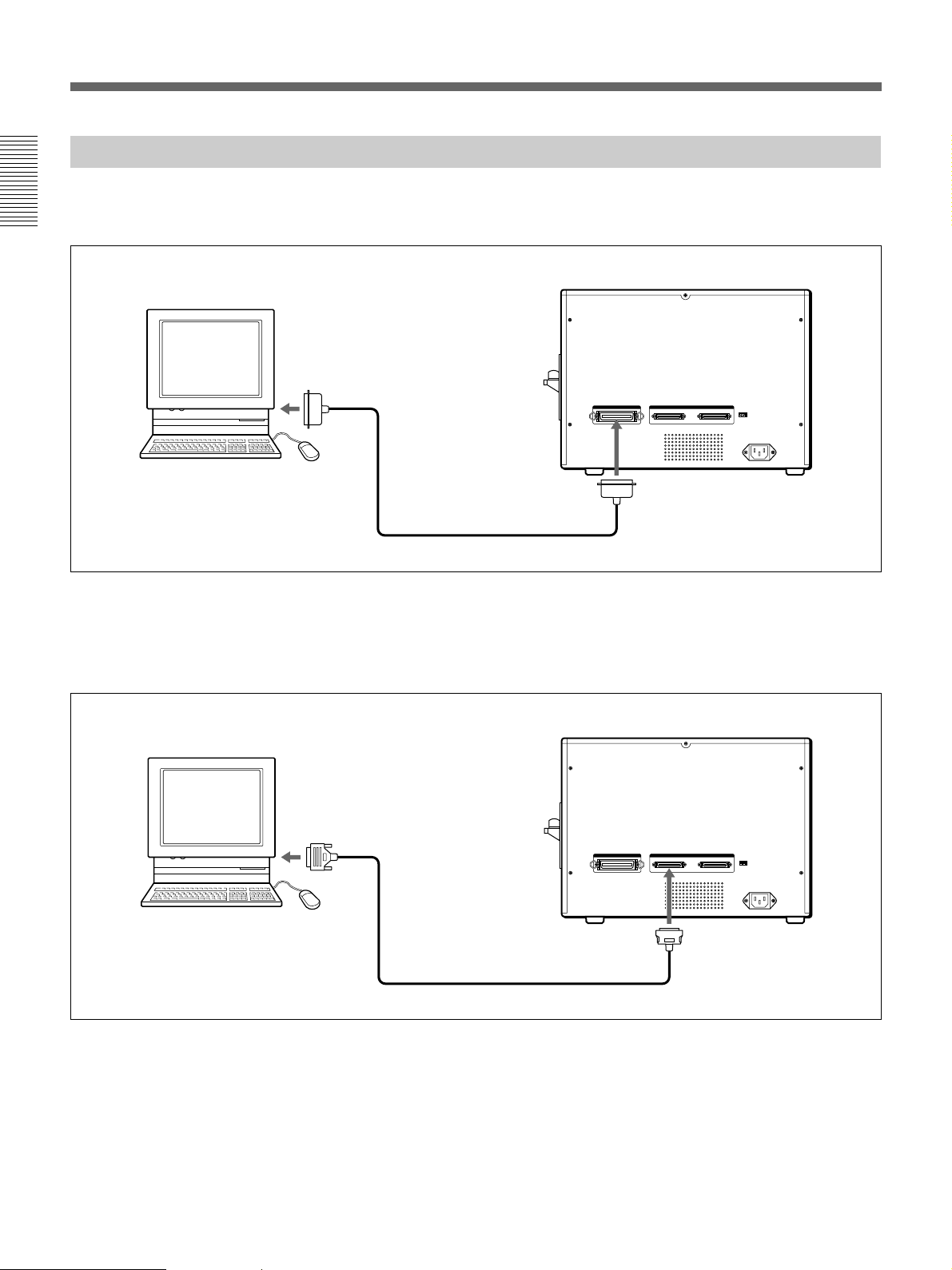

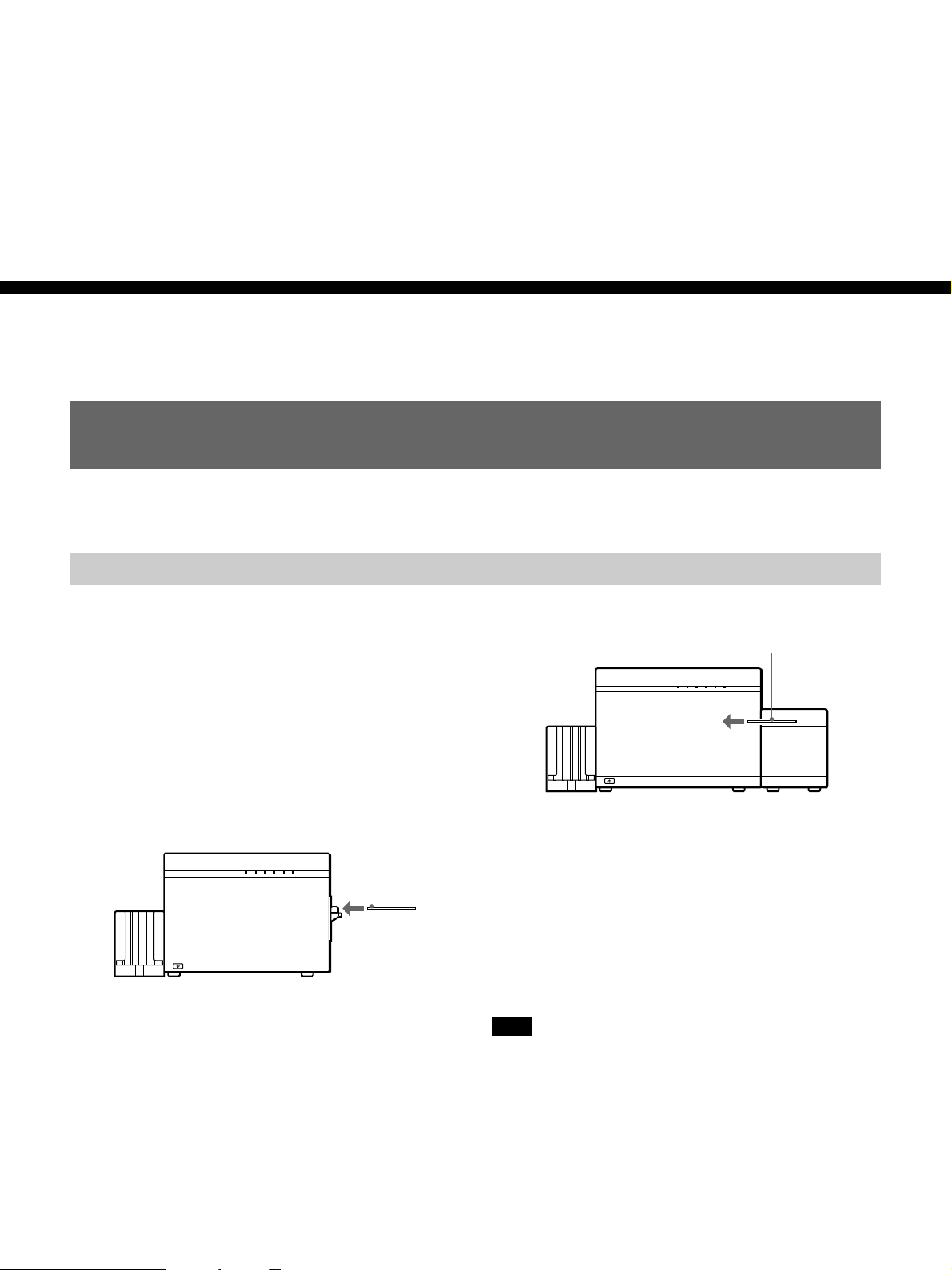

Parallel Cable Connection

The UP-D6300, -D6400 and UP-D6500 connect to the computer by a parallel interface cable.

Introduction

UP-D6300/D6400/D6500

Personal Computer

Parallel Cable

Use an IEEE-1284 compatible parallel cable

Amphenol 36-pin

* The UP-D6300/D6400 do not include a SCSI connector and SCSI ID switch.

SCSI Cable Connection

The UP-D6500 can be connected to the computer by a SCSI cable. When using SCSI connections, other SCSI

devices such as an MO disk drive can be connected in between.

UP-D6500

Personal Computer

Half-pitch 50-pin

(pin end)

SCSI Cable

Use a SCSI-2 compatible SCSI cable

6 Introduction

Part Names and Functions

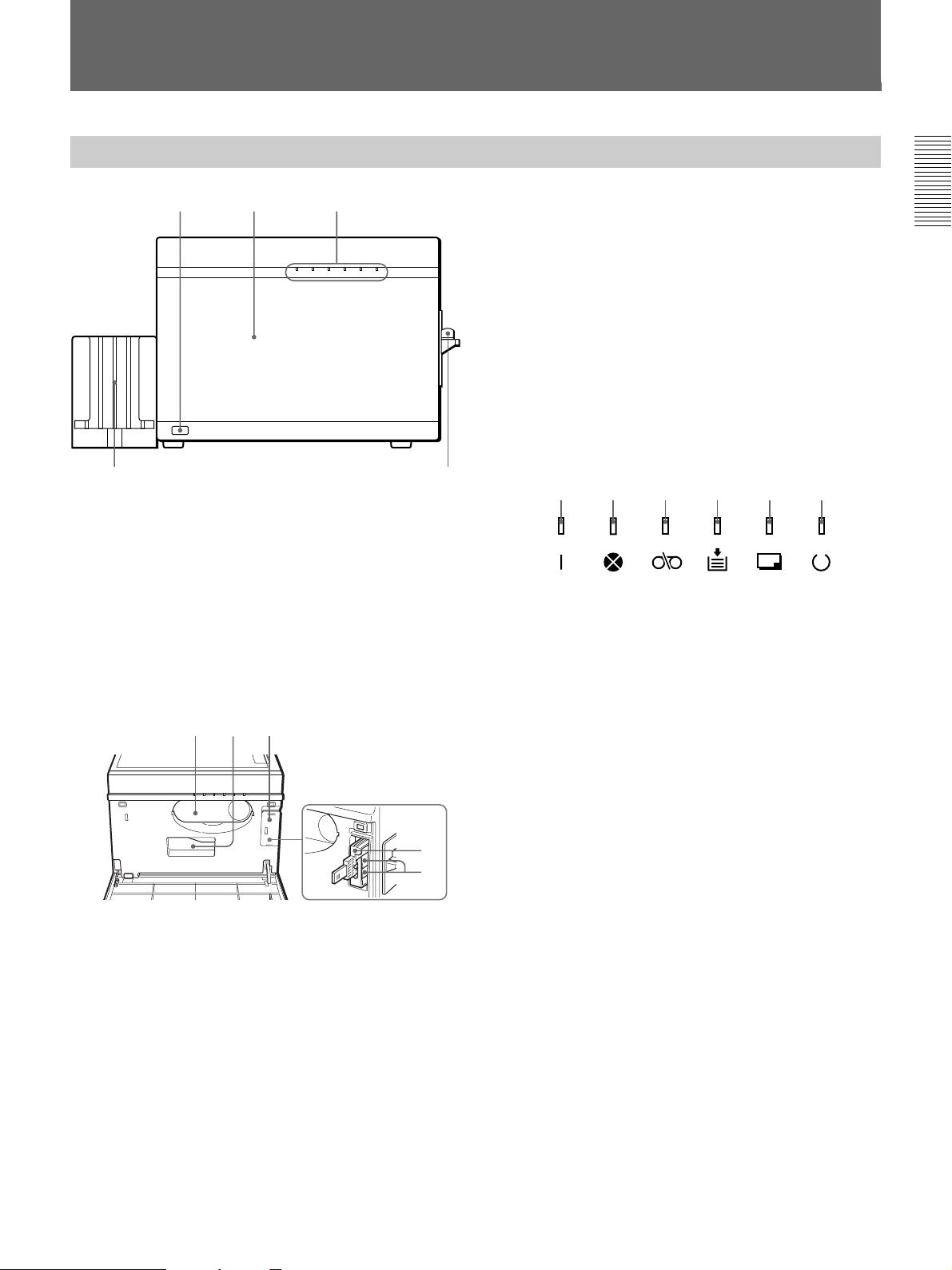

Front View

132

4

1 POWER Switch

This switch turns the printer on and off. When turned

on, the POWER ON lamp on the indicator panel lights

green.

2 Front Door

The ink ribbon cassette and cleaning roll holder are

installed behind this door. Pull on both sides of the

door to open it.

5

ba c

d Cleaning Roller Holder

The cleaning rollers install on this holder. Pull the

knob to remove it.

e Cleaning Rollers

The cleaning rollers are supplied with the printer.

When a card enters the printer, it passes between these

rollers to remove any dust from the card, so the rollers

should always be installed. Wash the rollers

periodically with water (page 27).

3 Indicator Panel Lamps

The panel lamps indicate the status of the printer.

fghijk

POWER ON ALARM RIBBON CARD PRINT READY

f POWER ON lamp (green)

This lamp is lit when the power is on.

g ALARM lamp (orange)

This lamp blinks when an error occurs, and lights

steadily when a fatal error occurs.

h RIBBON lamp (orange)

This lamp blinks when the ink ribbon supply is low,

and lights steadily when the ink ribbon reaches the

end.

Introduction

d

e

a Ink Ribbon Holder

An ink ribbon (sold separately) installs in the ink

ribbon holder.

b Bad Card Stacker

Bad cards are rejected here. Always remove any bad

cards before printing, and when the ALARM lamp

blinks.

c Cleaning Roller Cover

The cleaning rollers are installed behind this cover. To

open it, pull where it says PULL OPEN.

i CARD lamp (orange)

This lamp lights when the optional automatic card

feeder is installed. During manual-feed operation, this

lamp lights when the printer is waiting for a card.

j PRINT lamp (green)

This lamp lights while printing. During manual-feed

operation, this lamp blinks when the printer is waiting

for a card to be inserted.

k READY lamp (green)

This lamp blinks during warm-up, and when data is

being sent to the printer. This lamp light steadily when

the printer is ready to print.

Introduction 7

Part Names and Functions

4 Card Tray

Printed cards are ejected here.

Introduction

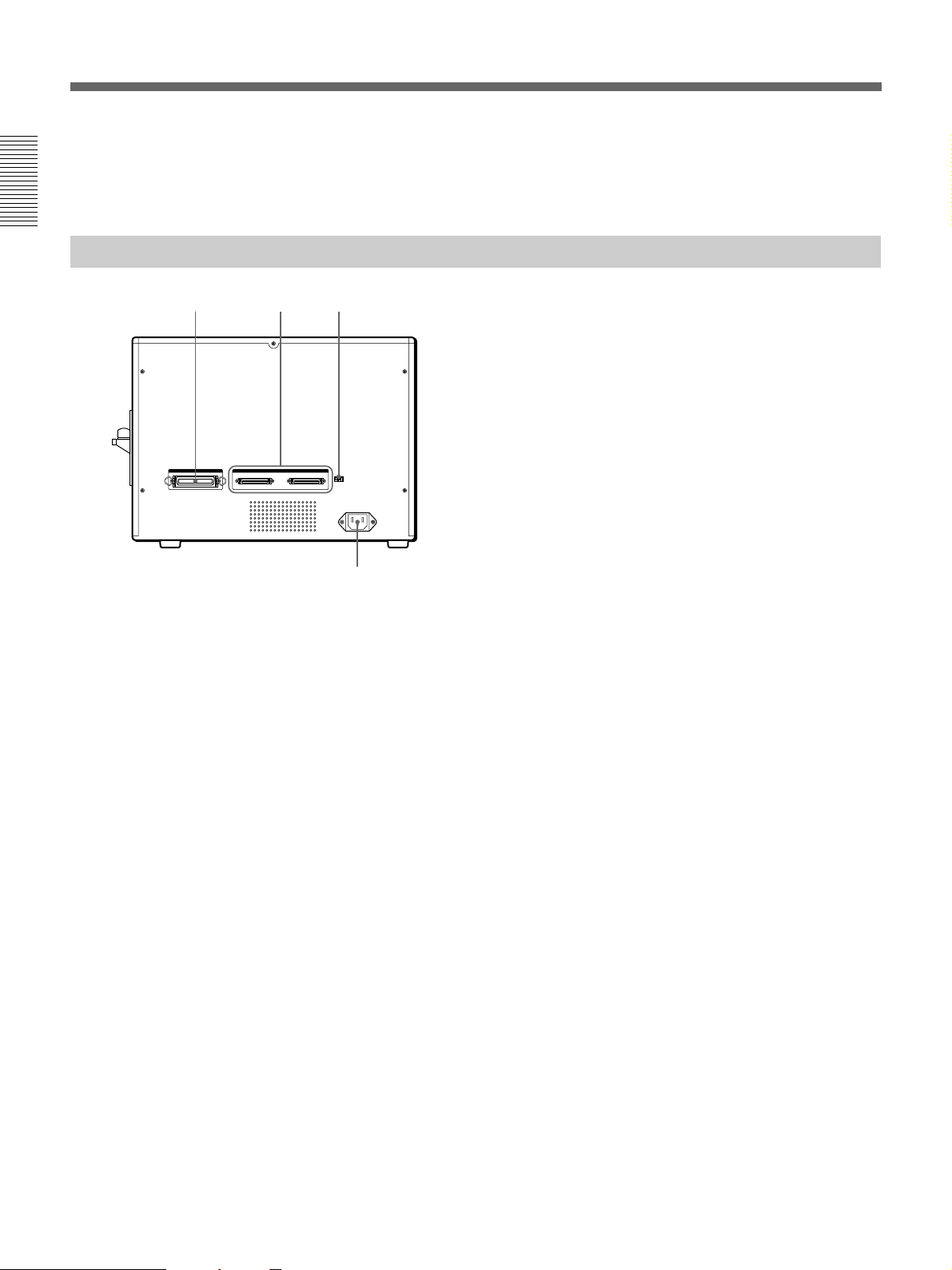

Rear View

5 Card Insertion Slot

Insert a card here for manual feed. The optional

automatic card feeder can also be installed here.

6 87

9

6 Parallel Interface Connector

Connect the parallel port of the controlling computer

here using a parallel interface cable.

7 SCSI Connectors (UP-D6500 only)

The SCSI connectors on the UP-D6500 can be used to

connect this model to the controlling computer and

other peripheral devices via a SCSI cable. The second

connector can be used to connect other SCSI devices

with this printer. However, if one of the connectors is

not used, set the terminator switch (leftmost SCSI ID

switch 8) to the ON position.

8 SCSI ID and SCSI Terminator switch

(UP-D6500 only)

This switch sets the SCSI ID for the printer. Also, if no

other SCSI devices are connected to the printer, so that

one of the SCSI connectors is unused, set the SCSI

terminator switch ON.

9 AC IN (Power Input) Socket

The supplied AC power cord connects here.

8 Introduction

Precautions

Operating Precautions

Power Supply

Connect only to the specified power source (120 or

240 VAC, 50/60 Hz).

Handle the Power Cord Carefully

Do not bend the cord sharply or place heavy objects on

it. The cord could be damaged and cause a fire or

electric shock. Do not use a damaged cord.

Avoid Ingress of Foreign Objects

Do not spill any liquids or drop any flammable or

metallic objects into the printer. Operating the printer

with a foreign object inside may cause fire, electric

shock or damage.

To Avoid Electric Shock

Never remove the outer cabinet. Touching internal

components may cause electric shock and presents

other dangers.

In Case of Abnormal Operation

In the event of an unusual sound or smell, or if smoke

appears or a foreign object falls into the printer, turn

off the power and contact your nearest Sony Service

Center.

If not Using for a Long Time

Turn off the power and unplug the power cord from

the outlet.

About Transporting

Remove all attached accessories before transporting

the printer. Transporting with accessories connected

may result in damage.

Installation Precautions

Do not install or store the printer in the following

conditions:

•Exposed to direct sunlight

•In humid locations

•In very hot or cold locations

•Where it might be exposed to heavy vibration

•Dusty locations

•On an unstable surface

•Avoid blocking the vent on the rear, as damage could

result.

Vent

About Condensation

If the printer is moved from a cool place to a warm

humid place, moisture may condense inside. Operating

the printer in this condition could cause a malfunction

and damage. Therefore, if any possibility of

condensation is suspected, the printer should be turned

off and allowed time to reach equilibrium with the

environment.

Cleaning

Introduction

About Card Stock

Use cards that comply with ISO international standard

(ISO7810 ID-1 type) or JIS standard (JIS X6301-

1979).

Notes

•Use only clean cards, with no debris, dirt or other

adhering matter.

•Some card materials may not be suitable. Contact

your supplier for details.

When the cabinet becomes dirty, wipe it with a cloth

moistened with water or a solution of synthetic

detergent (after wringing out any excess liquid). Do

not use thinner, cleaning fluid, alcohol or a chemically

treated cloth, as these could damage the cabinet finish.

Introduction 9

Preparation

Preparation

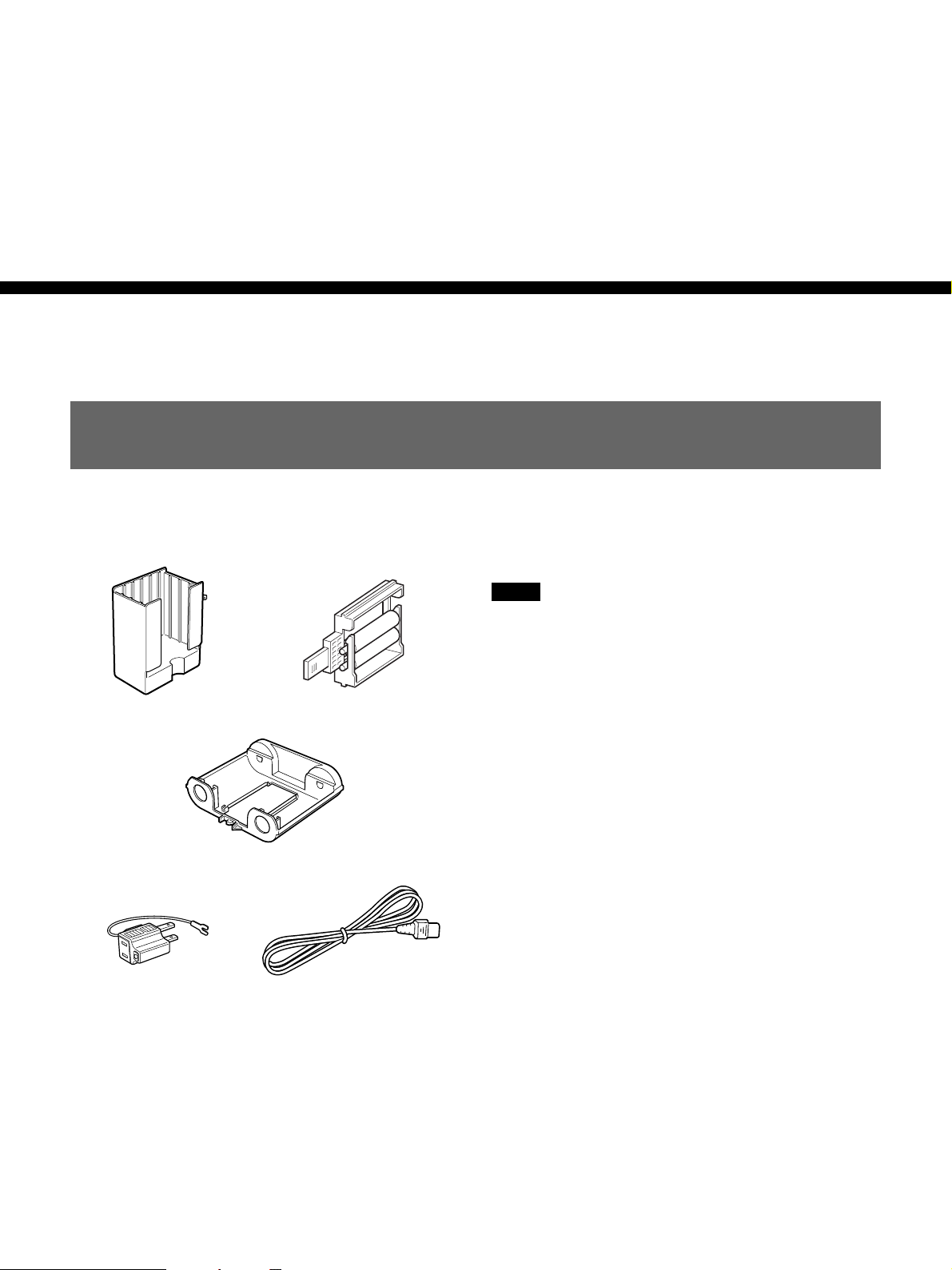

Supplied Accessories

Make certain you have received the following

accessories:

Card Tray (1) Cleaning Roller Holder (1)

Ink Ribbon Holder (1)

Operating Manual (1)

Floppy Diskette (1)

Notes

•The packing materials are needed when transporting

the printer, so we suggest you keep them.

•Before printing, be sure to remove the packing

material that immobilizes the head for transport.

AC Power Plug Adapter (1) AC Power Cord (1)

10 Preparation

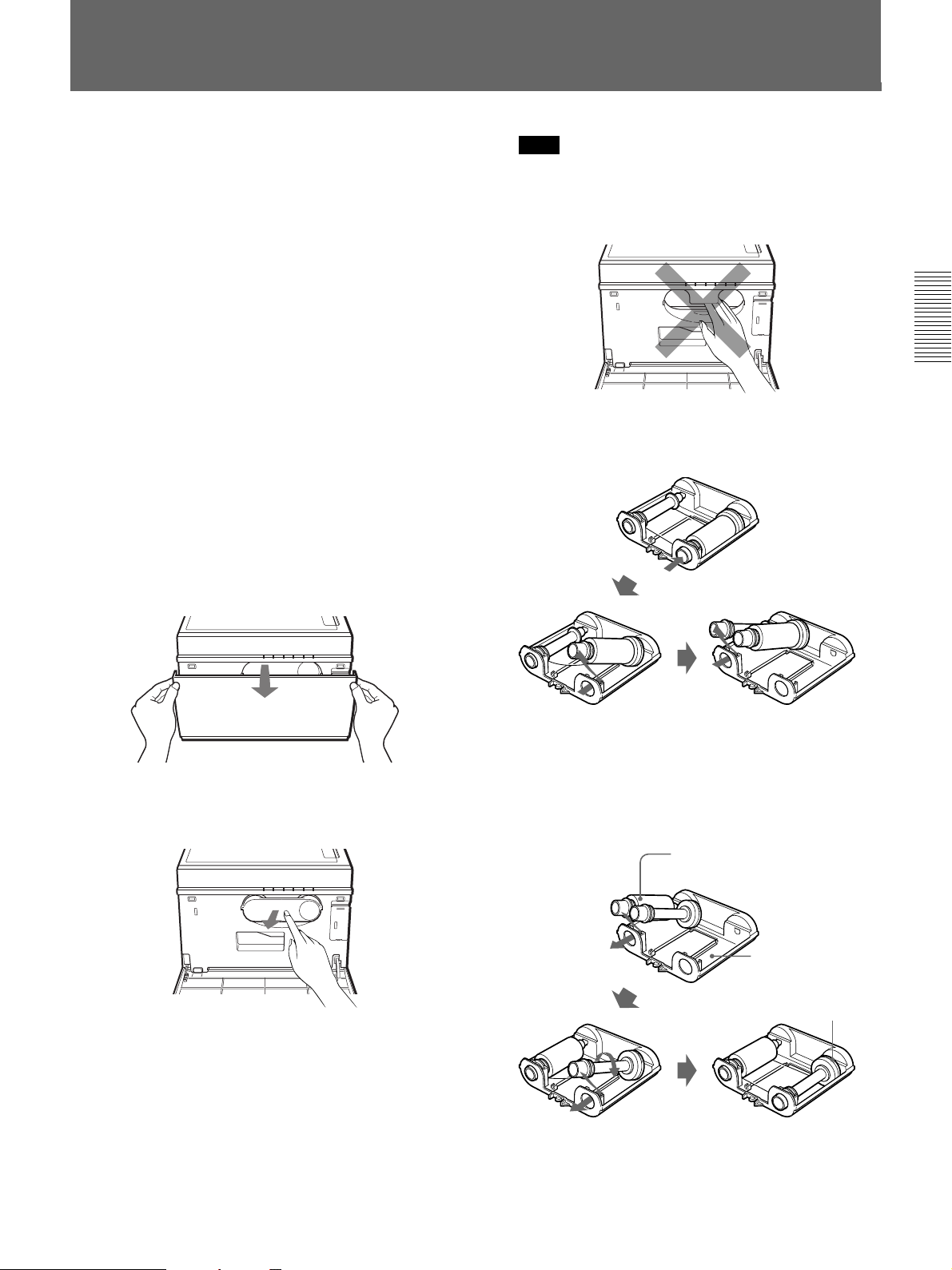

Installing the Ink Ribbon Cassette

This procedure describes how to install the ribbon

cassette in the printer.

Before beginning, obtain the required ink ribbon (sold

separately). The following types of ink ribbon are

available:

Color ink ribbon 5UPR-6040: 3-color CMY and

laminate

Color ink ribbon 5UPR-6080: 4-color CMYK and

laminate

Black ink ribbon UPR-6025: black only

•The 5UPR-6040/6080 ribbons provide lamination

along with color printing.

The color ink ribbon package consists of five pieces

in one set. One roll of 5UPR-6040 can print about

250 single-sided cards, and one roll of 5UPR-6080

can print about 200 single-sided cards.

•The UPR-6025 ribbon package consists of one unit

which prints black only. About 1,000 single-sided

cards can be printed.

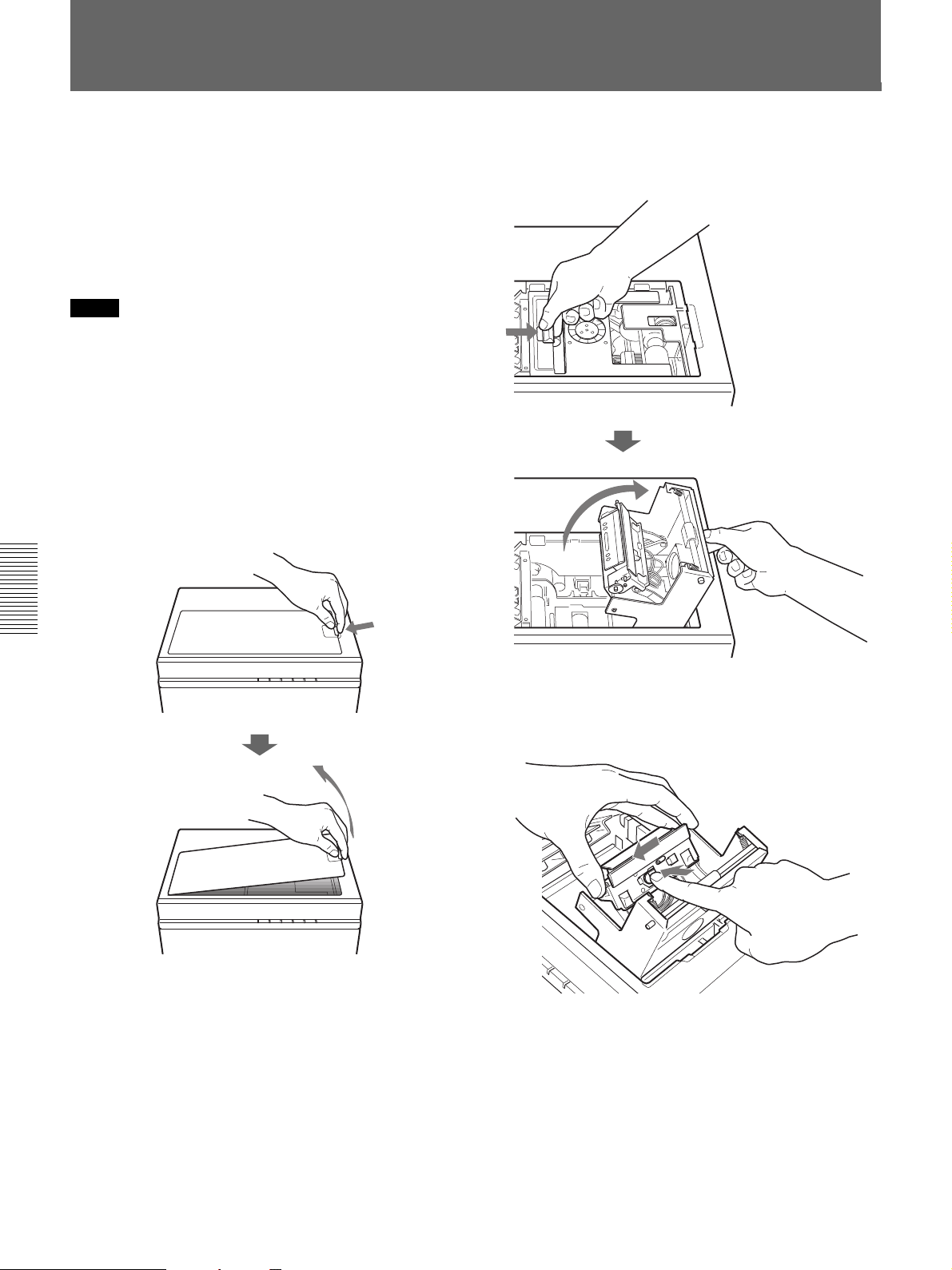

1 Hold both sides of the front door, and pull it down

to open.

Note

Do not touch the inside of the ink ribbon holder

compartment. The print head inside the printer may

be very hot.

Preparation

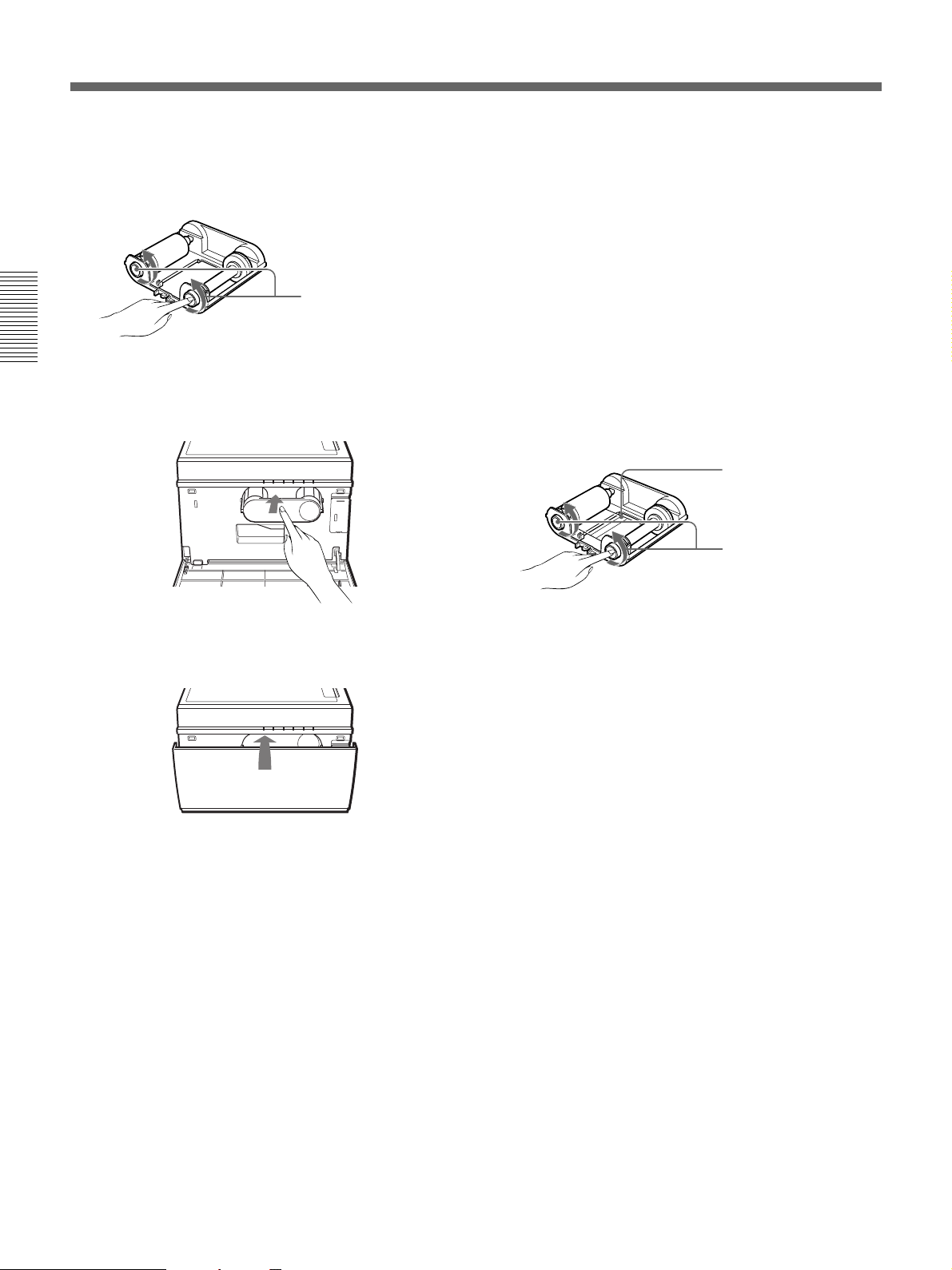

3 When changing the ink ribbon, remove the used

ribbon from the ribbon holder.

2 To change the ink ribbon, press on the part marked

PUSH to remove the ink ribbon holder.

When installing an ink ribbon in the printer the

first time, skip this step and proceed to step 4.

1 Remove take-up spool 2 Remove supply spool

When installing an ink ribbon in the printer the

first time, skip this step and proceed to step 4.

4 Install an ink ribbon in the ink ribbon holder.

1 Install the ink ribbon

supply spool.

2 Install the take-up spool.

Ink ribbon

Ink ribbon holder

Barcode ring

Preparation 11

Installing the Ink Ribbon Cassette

5 Take up any slack in the ribbon.

To avoid damage to the ribbon during installation,

take up the slack.

Turn the spools alternately

to remove slack.

Preparation

6 Insert the ink ribbon holder into its installation slot,

and push until it stops.

Handling Ink Ribbons

•Do not reuse ink ribbons.

•Do not touch the surface of a ribbon, or store it in a

dusty place. Fingerprints and dust may cause

degraded printing.

Storing Ink Ribbons

•Do not store ribbons in hot or humid places.

•To preserve a partially used ribbon, save it in the

humidity-resistant bag in which it was originally

supplied.

If a Ribbon Breaks

You can repair a broken ribbon with plastic tape so

you can use the remaining unused portion.

Repair with plastic tape

Take up slack ribbon

7 Confirm that the installation was done correctly,

and close the front door.

12 Preparation

Installing the Cleaning Rollers

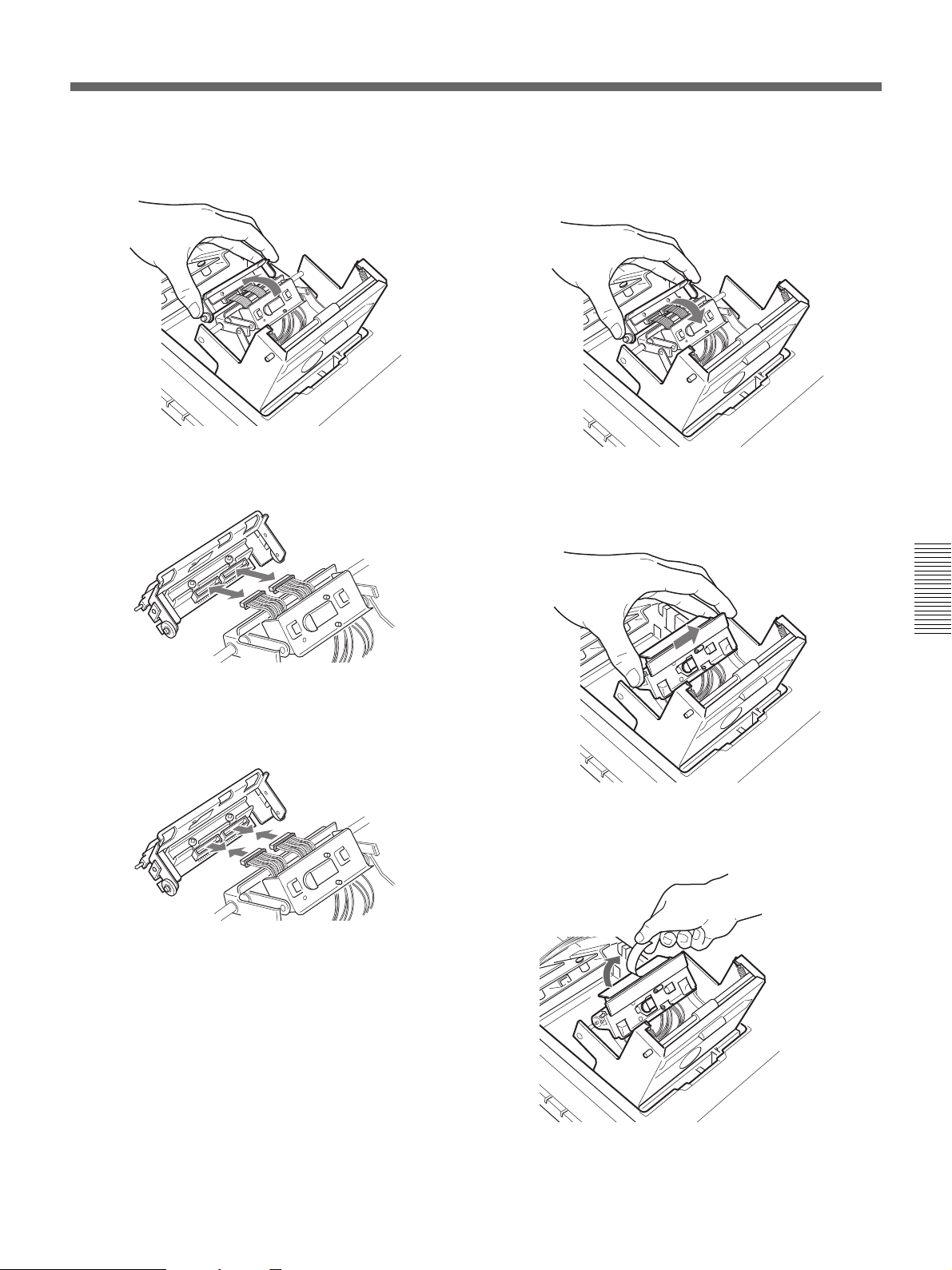

This procedure describes how to install the cleaning

rollers in the printer.

1 Hold both sides of the front door, and pull it down

to open.

2 Pull on the cleaning roller cover marked PULL

OPEN to remove the cover.

4 Insert the cleaning roller holder into the printer,

and push it until it stops.

Rail

Guide

Preparation

Align the top and bottom guides with the rails

when inserting.

5 Install the cleaning roller cover removed in step 2.

Insert the bottom edge of the

cover first, then push the top

edge.

3 Install two cleaning rollers into the cleaning roller

holder.

Be careful to avoid touching the roller surfaces, as

printing could be degraded.

Insert the roller axles into the slots.

When installing cleaning rollers in the printer the

first time, skip this step and proceed to step 4.

6 Close the front door.

Note

After using the cleaning rollers for a long time, their

cleaning ability will be degraded, causing colors to fail

to transfer properly to the printout. To avoid this, wash

the cleaning rollers each time after printing about 200

cards (page 27).

Preparation 13

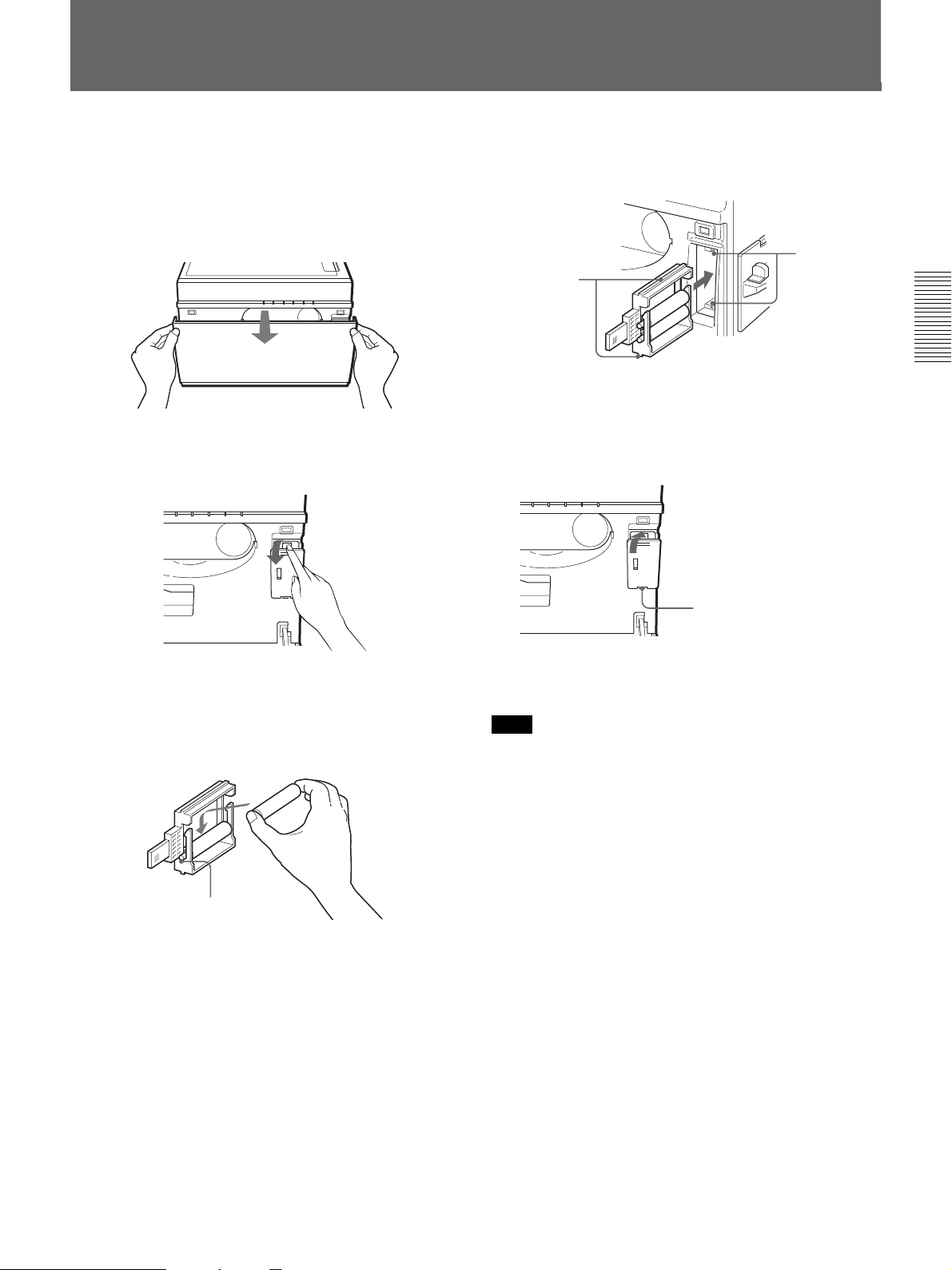

Installing the Card Tray

Printed cards are ejected into the card tray. Install the

card tray with this procedure.

When installing the optional Auto Card Stacker, the

card tray should be installed after the Auto Card

Stacker (page 16).

1 Insert the card tray hook into the insertion slot on

the printer.

Preparation

Hook

Card Tray

Using Optional Accessories

2 Pull the card tray down.

Pull down

Note

Be sure to pull the card tray down completely, or cards

may fail to eject and jam in the printer.

Optional accessories for these printer models include

the UPA-6003 Auto Card Feeder to automatically feed

cards to the printer when printing, and the UPA-6002

Auto Card Stacker to receive printed cards from the

printer.

Option Option

Supplied

card tray

UP-D6400/D6300/D6500 UP-D6500

UPA-6003 UPA-6003UPA-6002

Auto Card Feeder

Supplied

card tray

Continuously prints up to about 125 ISO

standard 0.76-mm-thick cards.

One Auto Card Feeder can be installed on the UPD6400/D6300, and up to two Auto Card Feeders and

one Auto Card Stacker can be installed on the UPD6500. The supplied card tray can also be installed

when the Auto Card Stacker is installed.

UPA-6003

Auto Card Stacker Auto Card Feeder

(1st Unit)

Auto Card Feeder

(2nd Unit)

Continuously prints up to about 250 ISO

standard 0.76-mm-thick cards.

14 Preparation

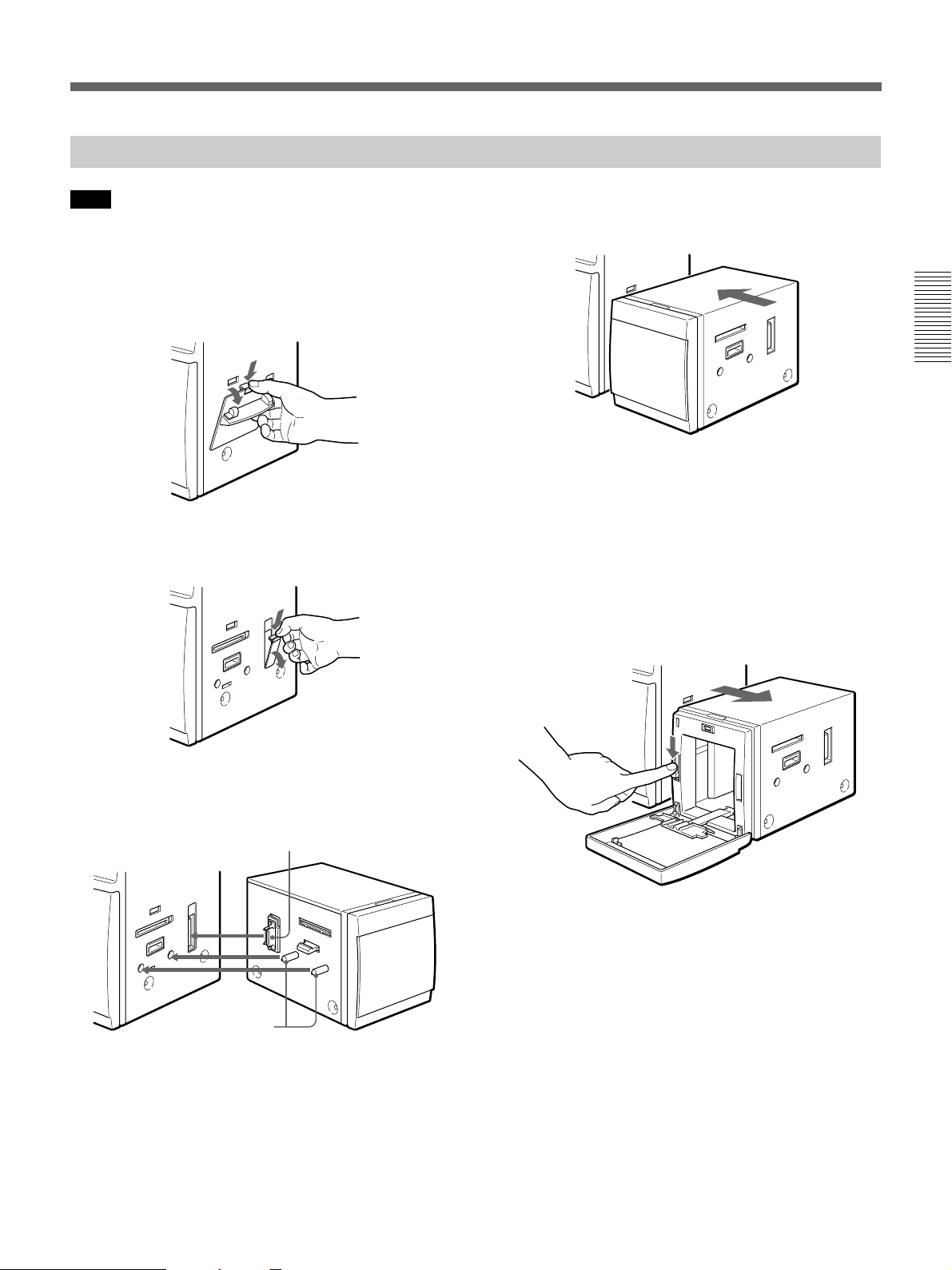

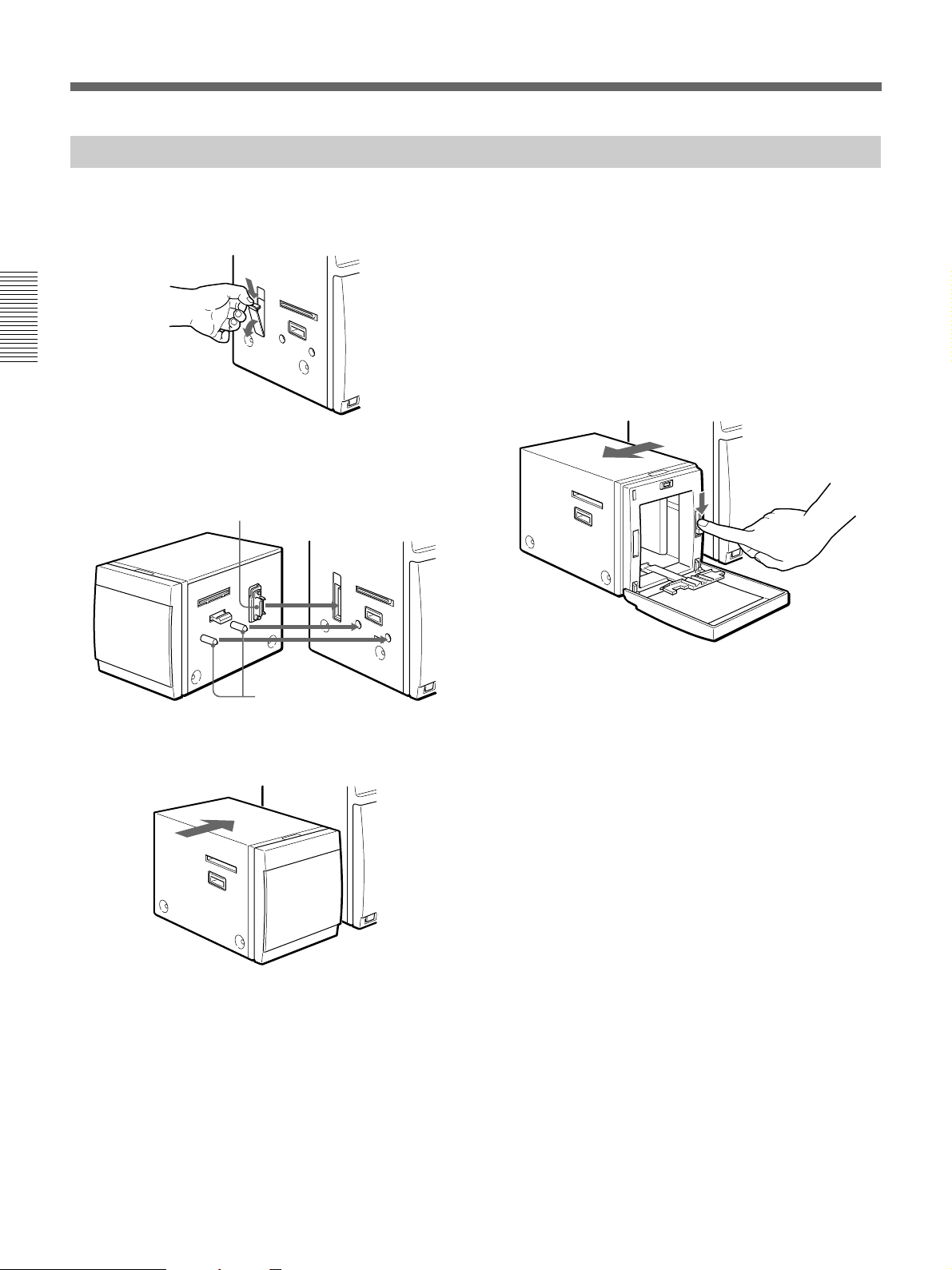

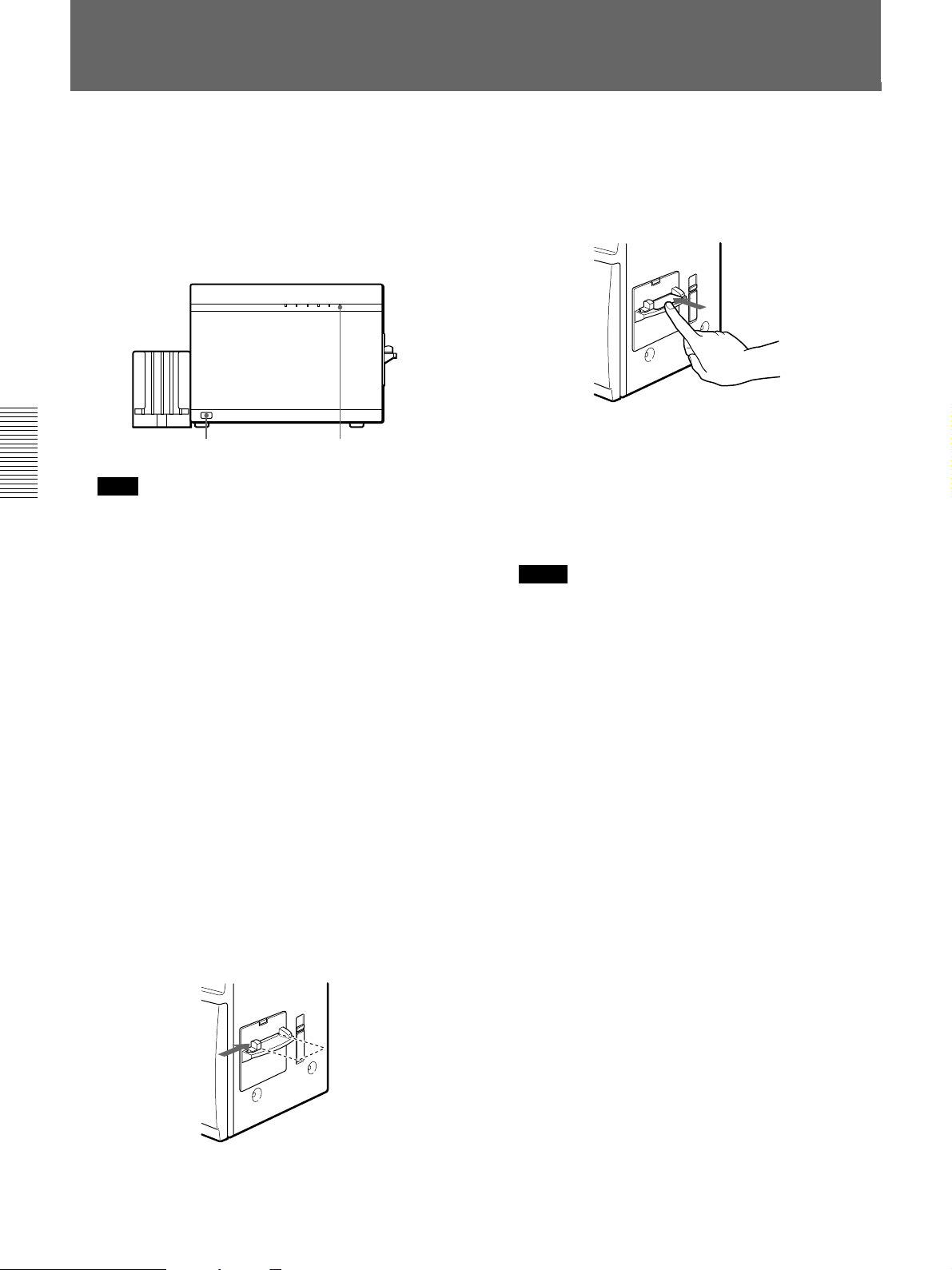

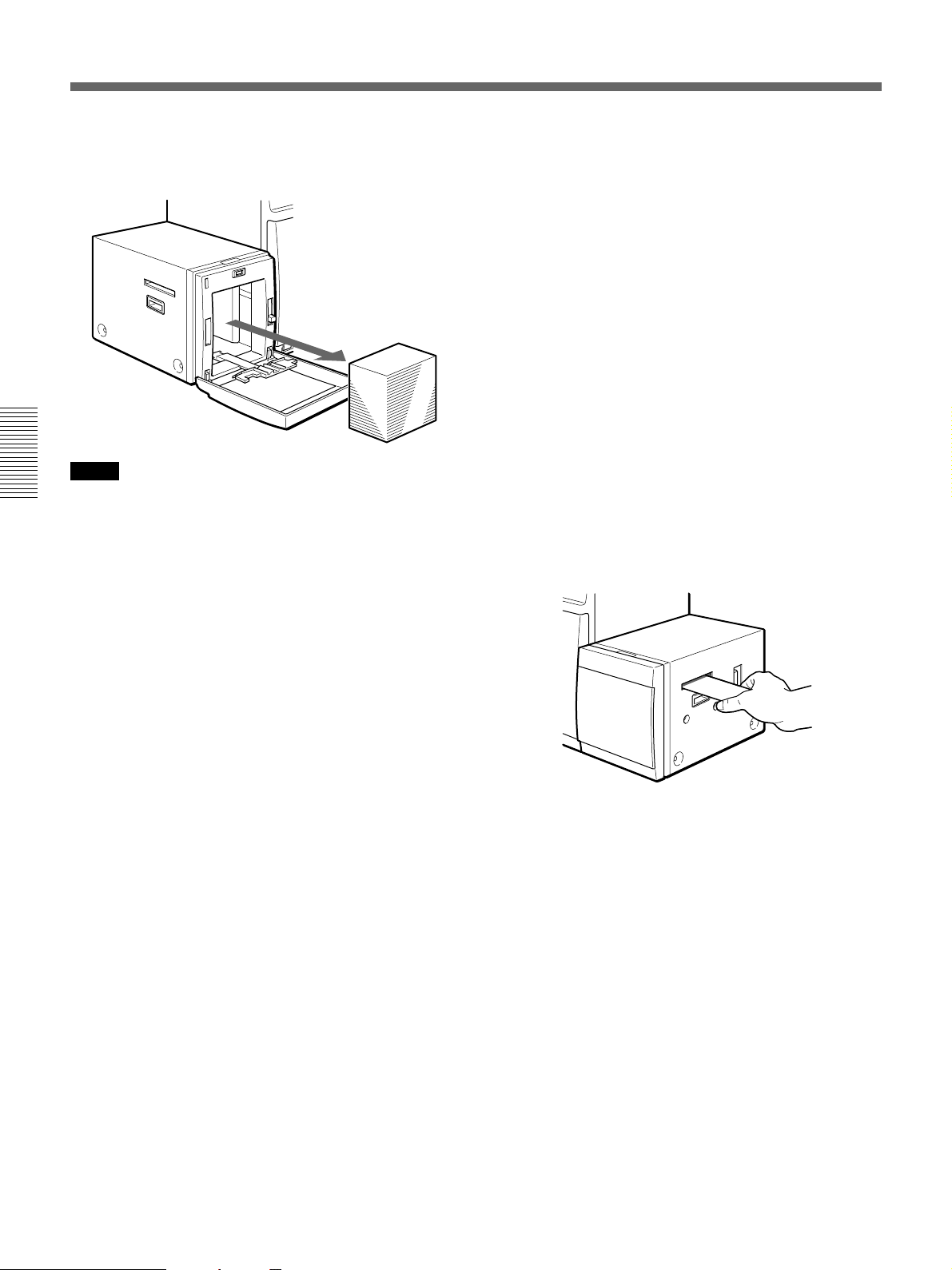

Installing the Auto Card Feeder

Note

Always turn off the power to the printer when

installing or removing options.

1 Remove the manual guide for the card insertion

slot while pushing up on the knob.

Remove the upper edge first,

then the lower edge

2 Push down on the upper knob and remove the

connector cover.

4 Push the Auto Card Feeder so the connectors mate

firmly.

Push firmly

Preparation

Installing a Second Feeder

A second Auto Card Feeder can be installed on the

UP-D6500. The second feeder installs on the outer side

of the first feeder, using the same procedure.

Removing the Feeder

To remove the feeder, open the feeder cover and push

down on the locking level while separating the feeder

from the printer.

Remove the upper edge first,

then the lower edge

3 Align and insert the connector and guide pins on

the Auto Card Feeder to the connector and guide

holes on the printer.

Align the connectors

Align the guide holes

Preparation 15

Using Optional Accessories

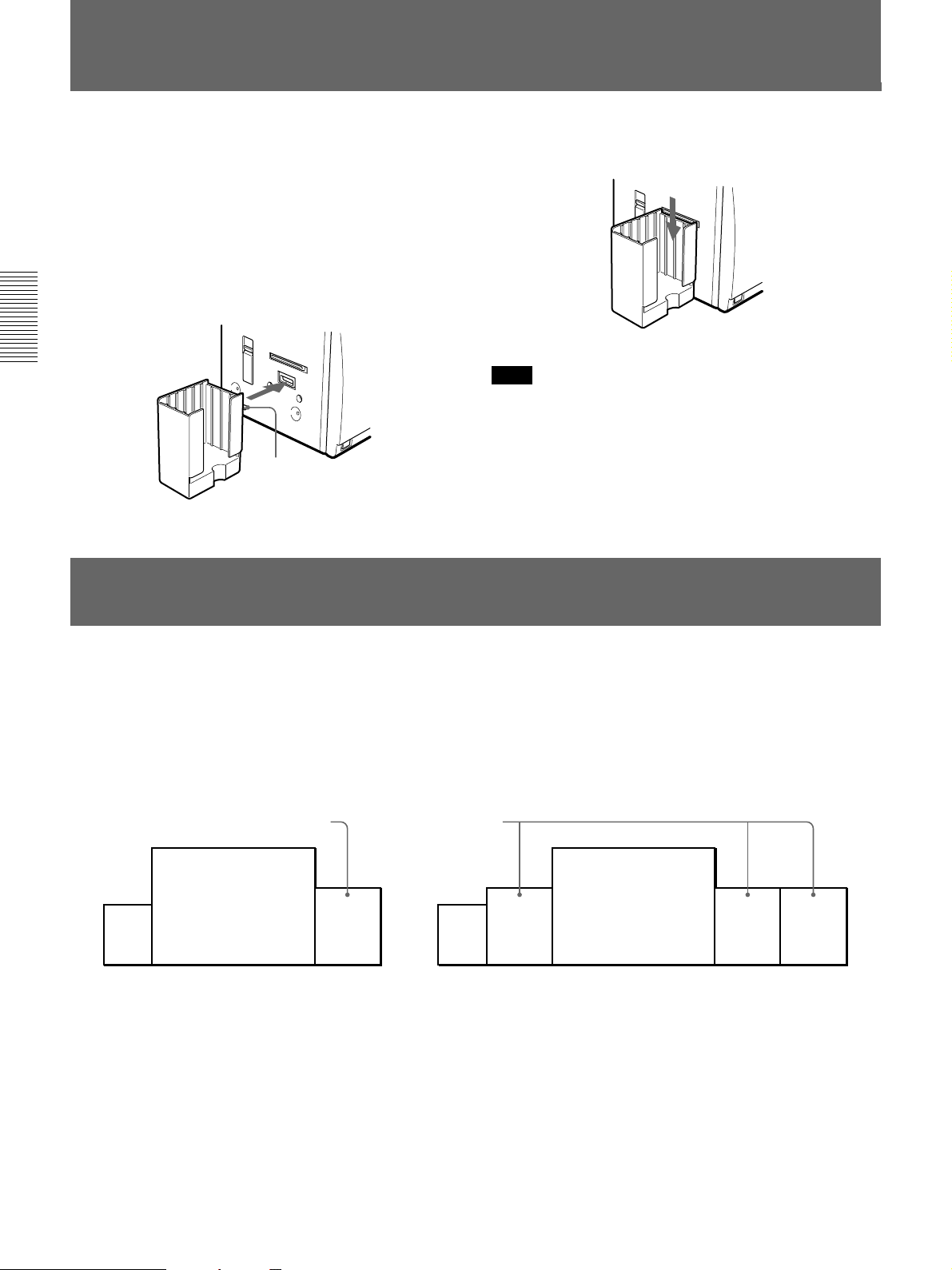

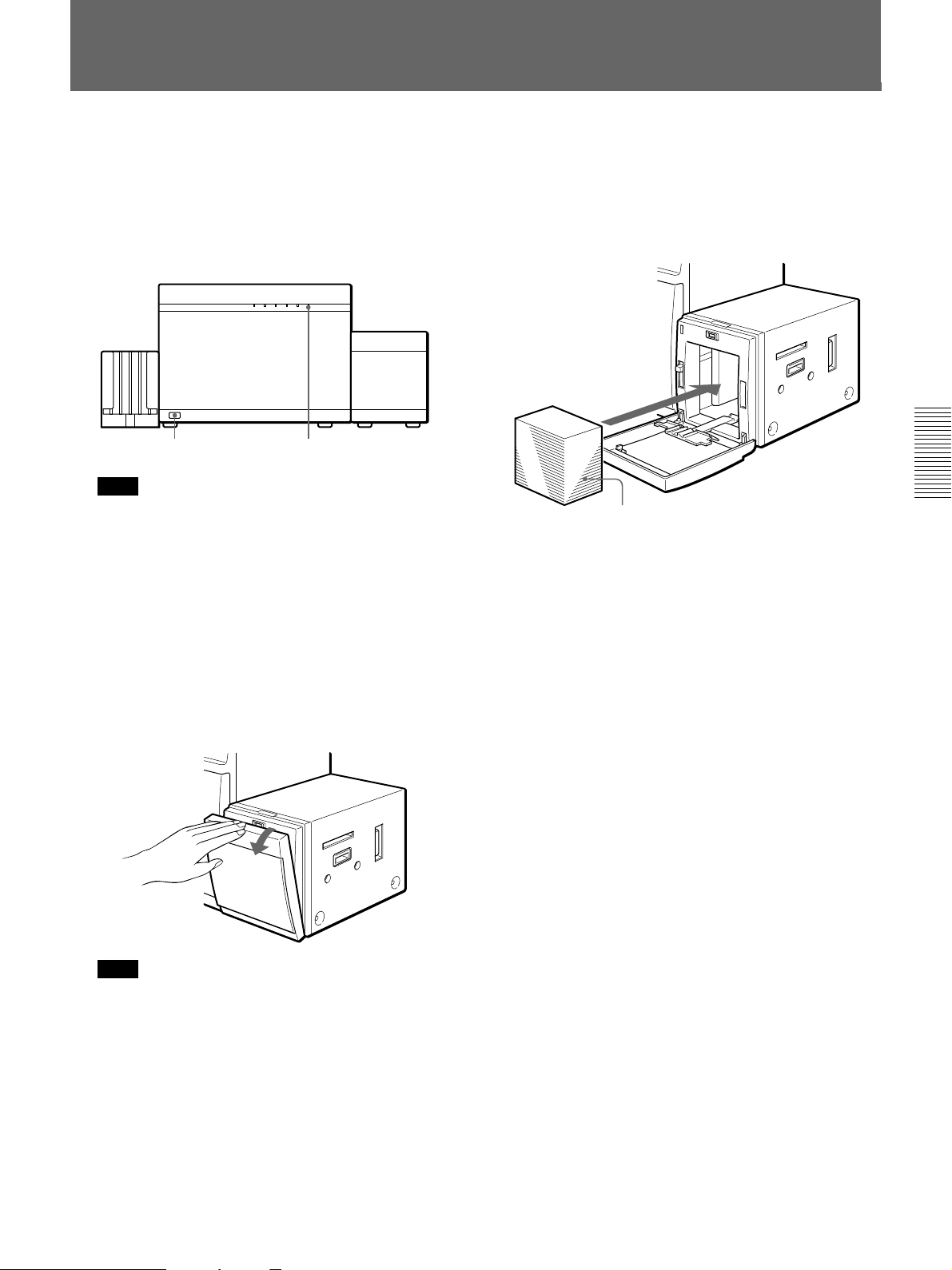

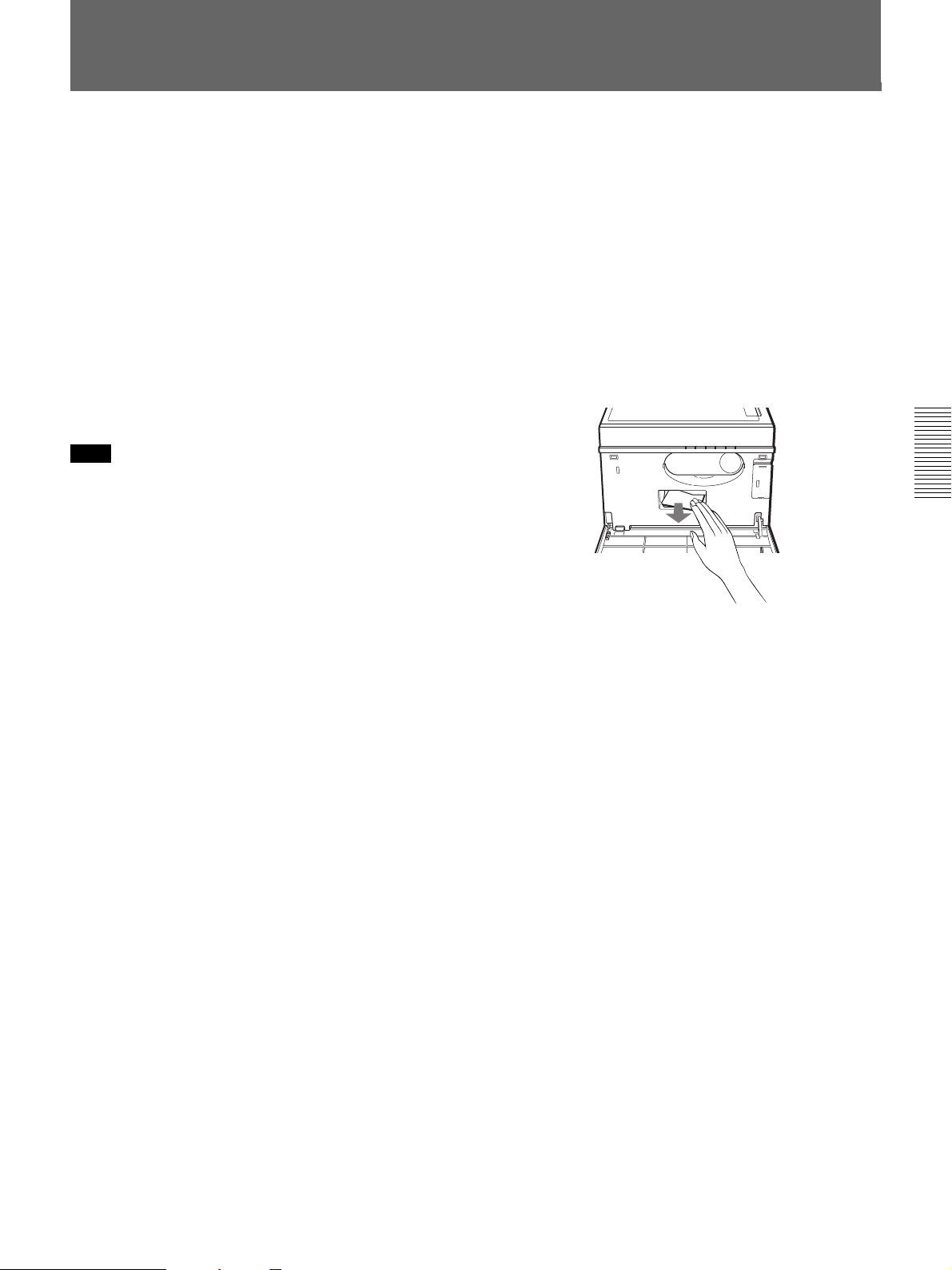

Installing the Auto Card Stacker

1 Push down on the upper knob and remove the

connector cover.

Preparation

Remove the upper edge first,

then the lower edge

2 Align and insert the connector and guide pins on

the Auto Card Stacker to the connector and guide

holes on the printer.

Align the connectors

Also Installing the Supplied Card Tray

Install the supplied card tray after installing the Auto

Card Stacker. The card tray installs on the outside of

the Auto Card Stacker, using the same procedure as for

installing it on the printer (page 14).

Removing the Stacker

To remove the stacker, open the stacker cover and

push down on the locking level while separating the

stacker from the printer.

Align the guide holes

3 Push the Auto Card Stacker so the connectors mate

firmly.

Push firmly

16 Preparation

Connections

The following examples show the connection of the

system to print cards. The UP-D6500/D6400 and

D6300 are equipped with a parallel connector for

D6500 is also equipped with a SCSI connector, which

can be used with a SCSI cable instead of the parallel

connection.

connecting to the computer with a parallel cable. The

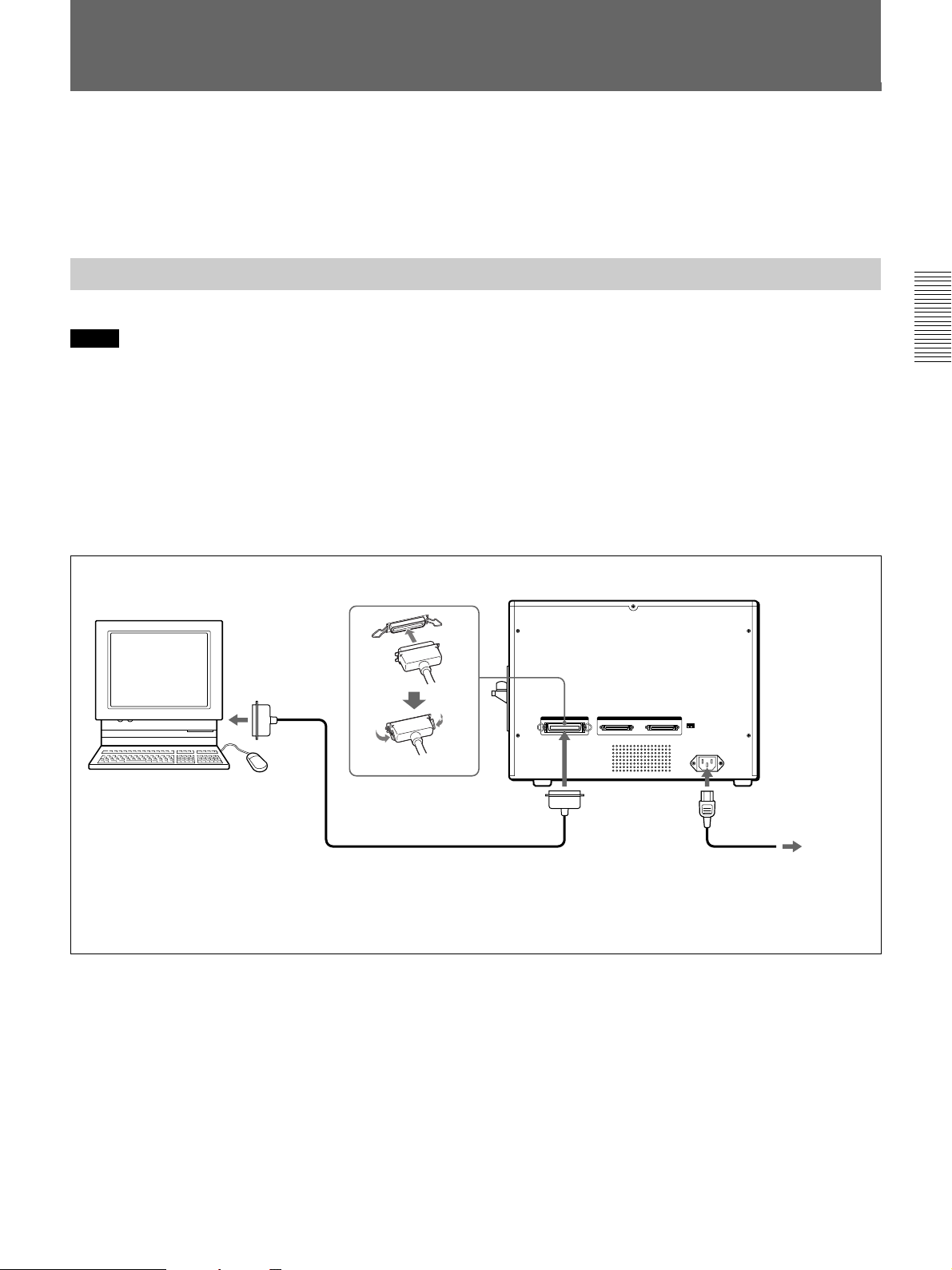

Parallel Cable Connection

Notes

•Turn off the power to all devices when making connections.

•Connect the power cords last.

•Insert the parallel data cable connector firmly, as far as it will go.

•The parallel cable should be no longer than 3 meters, and conform to the Centronics specification. However, the

type of connectors on the parallel cable depends on the computer and other peripheral devices being connected.

Refer to the operating manuals for the devices for details.

•To use the high speed drive mode (ECP mode), the cable should comply with IEEE1284, such as the Hewlett

Packard model C2950A.

•Do not use the SCSI interface when using the parallel interface.

Clip bail locks on both sides

Personal Computer

UP-D6300/D6400/D6500

Preparation

To parallel

connector

To AC IN

Parallel cable

1)

To parallel

connector

To power outlet

1) Use a parallel cable that complies with IEEE-1284. Refer also to the computer operating manual for the type of parallel

cable to use.

* The UP-D6300 and D6400 do not have SCSI connectors or a SCSI ID switch.

Preparation 17

Connection

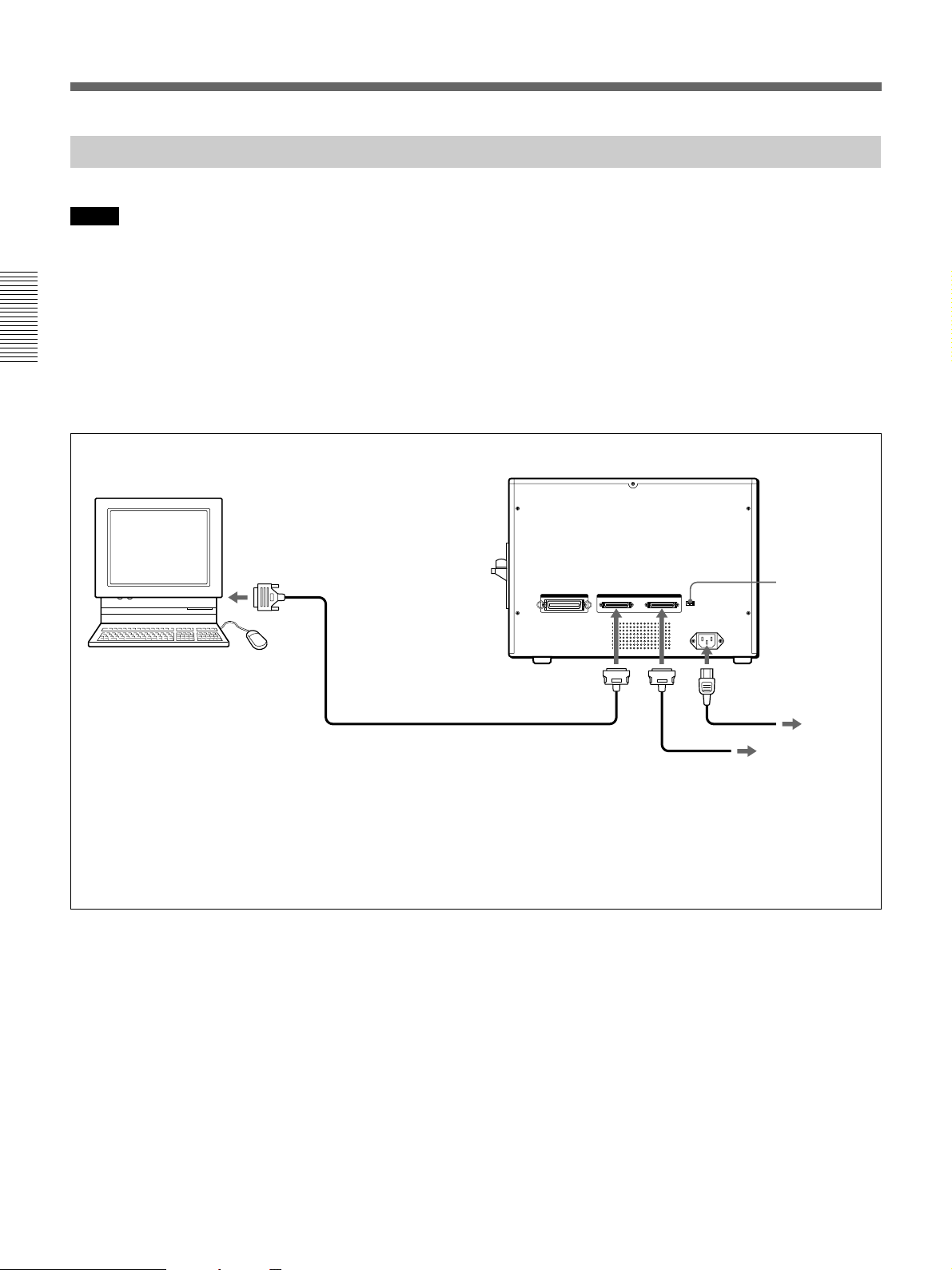

SCSI Cable Connection (UP-D6500)

Notes

•Turn off the power to all devices when making connections.

•Connect the power cords last.

•Up to seven peripheral devices can be connected to the SCSI bus.

•Refer to the operating manual for each device for details about peripheral device connections.

•Insert the SCSI cable connectors firmly, as far as they will go.

•The total length of the SCSI cable connected to one host computer should be no more than three meters.

•When only the printer is connected to one host computer, the SCSI cable length should be no more than one

Preparation

meter.

•Do not use the parallel interface when using the SCSI interface.

UP-D6500

Personal Computer

To SCSI

connector

SCSI ID

SCSI cable

To SCSI connector

1)

Connects to other devices, if needed.

To AC IN

To power outlet

2)

1) Refer to the computer operating manual for the type of SCSI cable to use. When connecting other SCSI devices, refer

also to the manuals supplied with those devices. Use a cable compatible with the SCSI2 standard.

2) The SCSI bus allows connection of other SCSI devices by daisy chain between the computer and printer, and after the

printer. Refer to the operating manuals of those devices for the settings on those devices.

3) For SCSI connections, the SCSI ID should be set by the SCSI ID switch (page 19). Also, if one of the SCSI connectors

on the printer is not used, set the leftmost (terminator) switch on the SCSI ID switches to ON (page 19).

18 Preparation

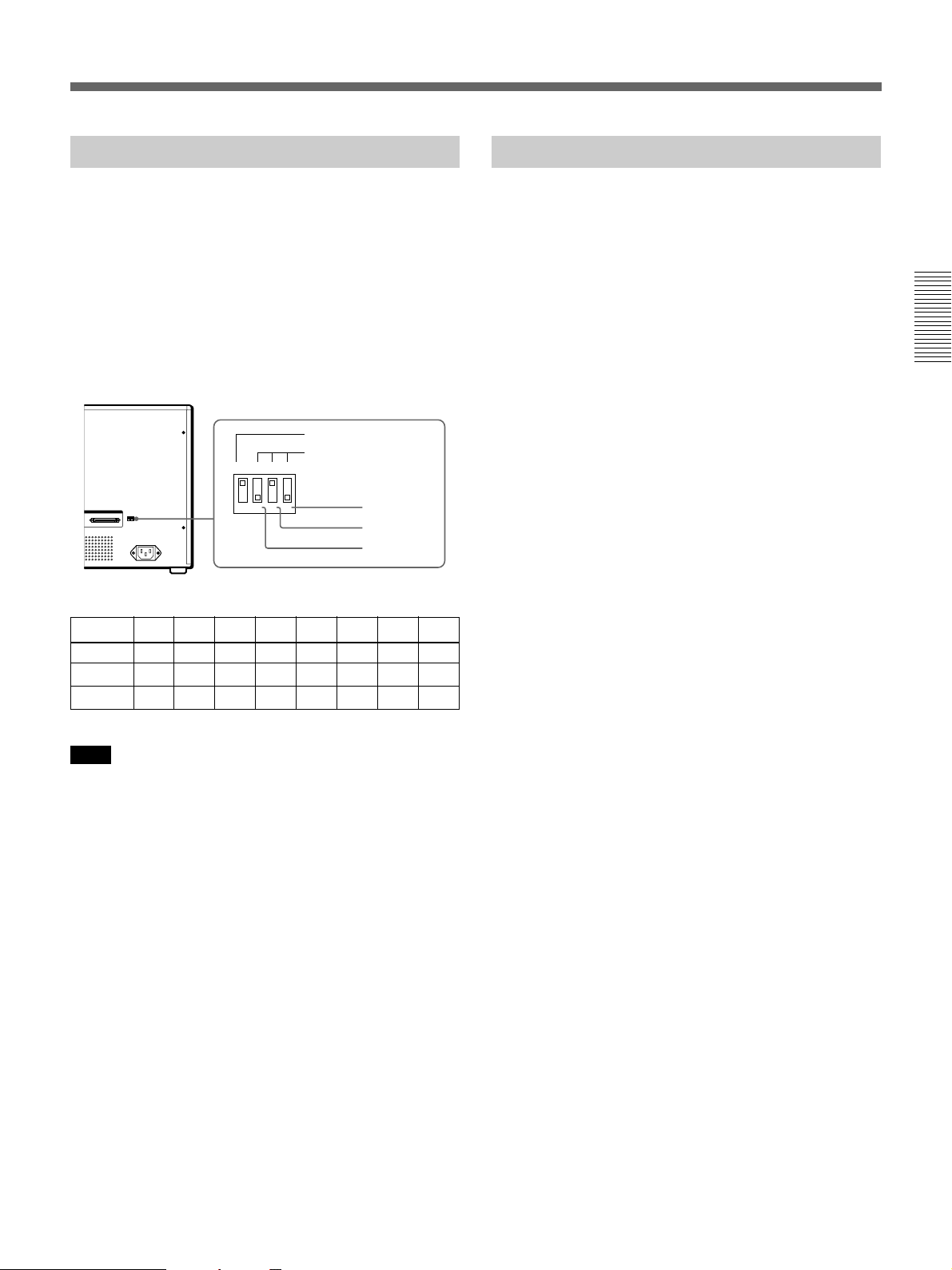

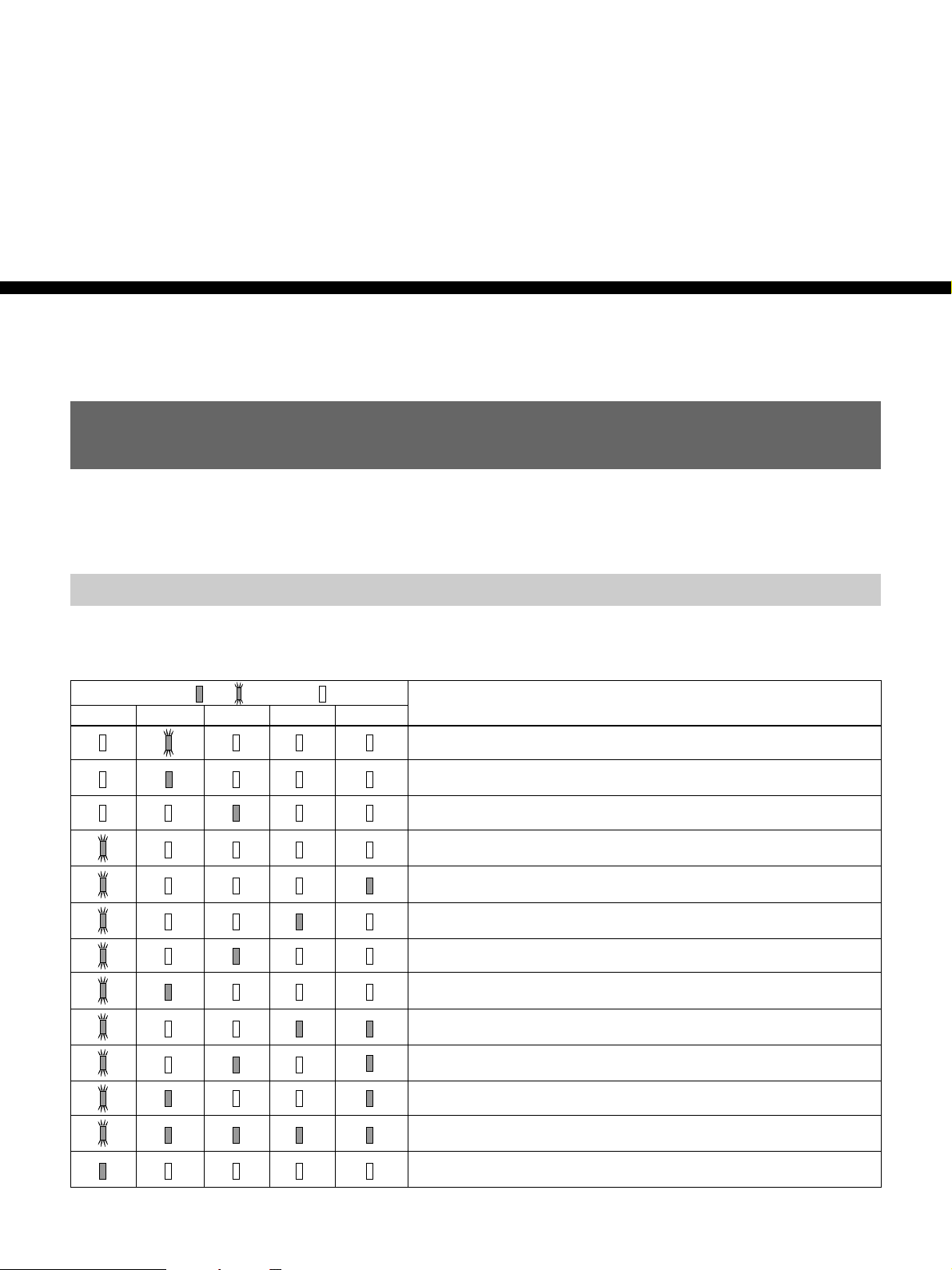

Setting the SCSI ID

Setting the Terminator

Up to seven SCSI devices can be connected to the

SCSI bus by daisy chaining. Each SCSI device is

recognized by its ID number, from 0 to 7.

Turn off the power to the printer, and set the printer ID

number with the SCSI ID switches on the rear, so that

it is unique from any other SCSI device. When shipped

from the factory, the SCSI ID is set to “2”.

The SCSI ID number is set by the combination of three

SCSI ID switch settings.

The SCSI ID consists of the sum of the ID

number of each switch that is turned on.

TERMINATOR

SCSI ID

124ON

1

432

000OFF

ID=0 ID=1 ID=2 ID=3 ID=4 ID=5 ID=6 ID=7

Switch 4 OFF ON OFF ON OFF ON OFF ON

Switch 3 OFF OFF ON ON OFF OFF ON ON

Switch 2 OFF OFF OFF OFF ON ON ON ON

Switch 4

Switch 3

Switch 2

The leftmost switch of the SCSI ID switches is the

terminator switch. Turning this switch on enables the

internal SCSI terminator.

If either of the SCSI connectors is not used in the

installation, turn the terminator switch ON.

Preparation

Note

When setting the SCSI ID, be careful not to duplicate

the number of another device on the SCSI bus. The ID

must be unique for each device.

Preparation 19

Printing

Before Printing

Printing

Confirm the feeding method and precautions before printing.

Feeding Method

The printing feeding method for cards depends on

whether the optional Auto Card Feeder is installed.

Before beginning, confirm the feeding method to be

used for printing.

Standard Case

If the optional Auto Card Feeder is not installed, feed

the cards manually one at a time after sending the print

command.

Feed manually after executing print command

Auto Card Feeder Case

If cards are placed in the Auto Card Feeder, the cards

are fed to the printer after sending the print command.

Cards are fed automatically at print time

If a second Auto Card Feeder is installed on the UPD6500, cards in the first Auto Card Feeder are fed

first, followed by those in the second Feeder when the

first is empty.

Cards can also be fed manually at the card insertion

slot of the Auto Card Feeder. However, do not insert

cards that are a different size from those in the Auto

Card Feeder, or a jam may result.

Note

Cards with fingerprints or dirt on their surface may

degrade printing. To avoid touching the surface, insert

a card by holding it at the edges.

We recommend using the Auto Card Feeder to

minimize the need to touch the cards.

20 Printing

Things to Know Before Printing

Confirm the following preparations have been

completed before printing a card:

•Connect the printer to a computer (page 17).

•If using the SCSI connection, set the SCSI ID (page

19).

•Install the ink ribbon (page 11), cleaning roller (page

13) and card tray (page 14).

•If you use an optional Auto Card Feeder (page 15) or

Auto Card Stacker (page 16), install these

accessories.

Note the following when handling cards:

•Hold cards by the edges, and avoid touching the

surface. Fingerprints on a card may cause dirty

printing or poor ink bonding.

•Soft cotton gloves are recommended when handling

large batches of cards.

•If using the optional Auto Card Feeder, fan the cards

thoroughly to ensure they do not stick together

before loading them into the Feeder.

•Do not store cards in a dirty place. Dirt on a card may

cause dirty printing or poor ink bonding.

•Insert cards with magnetic stripe so that the stripe

faces down and toward the rear.

Note the following when printing:

•Use an application program that supports the printer.

•Color adjustment of the printing image is

accomplished by the program.

•Print quantities are set by the program.

•When using cards with a magnetic stripe, set the

printing size to avoid printing onto the stripes. Even

if no actual image prints on the stripe it will be

laminated over if it is within the printing area, which

may cause later problems reading the strip.

Printing

Printing 21

Manual-Feed Printing

This procedure describes how to print by manually

feeding cards to the printer.

1 Turn on the printer.

The READY lamp blinks for a few seconds, then

lights steadily when ready to print.

Power switch Ready lamp

Note

Printing

When using the SCSI connection, do not turn the

printer on or off while the host computer is

accessing other SCSI devices, such as a hard disk.

2 Confirm the printer’s READY lamp is lit, then turn

on the computer. When using the SCSI connection,

turn on all other SCSI devices before turning on

the computer.

3 Send the image data from the computer. The

READY lamp blinks while the data is being sent to

the printer. Sent image data is temporarily stored in

the image memory of the printer.

6 Put a card in the insertion slot, and push it until

your finger touches the hollow area at the center of

the slot. Insert cards with magnetic stripes so that

the stripe faces down and toward the rear.

The card is pulled into the printer and printing

starts. After printing, the printer returns to the

standby condition.

7 When printing multiple cards, insert the next card

in the slot when one finishes printing.

Notes

•Do not open the front door, Auto Card Feeder

cover or Auto Card Stacker cover while printing.

Opening a cover stops printing.

•Do not put more than 125 cards in the supplied

card tray, as a jam could result.

•Printing cannot be aborted from the computer.

When the computer sends a command to stop

printing, the card being printed finishes before the

printer enters the waiting condition.

4 Send the Print command from the computer to start

printing.

The PRINT lamp on the printer lights.

Refer to the software documentation for details of

program operations on the computer.

5 Adjust the guides on the card insertion slot to

match the width of the cards to print.

22 Printing

To print the same image repeatedly

Send the Print command from the computer and insert

a card manually. The image data stored in the printer’s

image memory will be printed.

Printing with the Auto Card Feeder

This procedure describes how to print with the

optional Auto Card Feeder installed.

1 Turn on the printer.

The READY lamp blinks for a few seconds, then

lights steadily when ready to print.

Power switch Ready lamp

Note

When using the SCSI connection, do not turn the

printer on or off while the host computer is

accessing other SCSI devices, such as a hard disk.

2 Confirm the printer’s READY lamp is lit, then turn

on the computer. When using the SCSI connection,

turn on all other SCSI devices before turning on

the computer.

3 Hold the top of the Auto Card Feeder cover, and

pull it to open.

4 Put the cards on the platform inside the Auto Card

Feeder. Insert cards with magnetic stripe so that

the stripe faces down and toward the rear.

We recommend using soft cotton gloves to handle

cards, to avoid fingerprints and dirt.

Stack the cards neatly. Before placing,

massage the card stack to avoid sticking.

5 Close the Auto Card Feeder cover.

6 Send the image data from the computer. The

READY lamp blinks while the data is being sent to

the printer. Sent image data is temporarily stored in

the image memory of the printer.

7 Send the Print command from the computer to start

printing.

The PRINT lamp on the printer lights, and cards

are fed to the printer automatically as printing

begins.

Refer to the software documentation for details of

program operations on the computer.

After printing, the printer returns to the standby

condition.

Printing

Note

The platform inside the Auto Card Feeder lowers.

Be careful not to pinch your finger beneath it.

Printing 23

Printing with the Auto Card Feeder

8 When the Auto Card Stacker is installed, open the

Auto Card Stacker to remove printed cards.

Notes

•Do not open the front door, Auto Card Feeder cover

Printing

or Auto Card Stacker cover while printing. Opening a

cover stops printing.

•Do not store more than 125 cards in the supplied card

tray, as a jam could result.

•Do not put more than 125 cards in the Auto Card

Feeder, as a jam could result.

•If using the optional Auto Card Feeder, fan the cards

thoroughly to ensure they do not stick together

before loading them into the Feeder.

If cards stick together, they may not feed correctly. If

this occurs, turn the power off, remove the cards from

the Auto Card Feeder, unstack them and then return

them to the Feeder.

•Do not load different types of cards in the Auto Card

Feeder at the same time, as a jam could result.

•Do not move the printer with the Auto Card Feeder or

Stacker installed. Always remove the Auto Card

Feeder, Auto Card Stack and card tray before

moving the printer.

•Printing cannot be aborted from the computer. When

the computer sends a command to stop printing, the

card being printed finishes before the printer enters

the waiting condition.

To print the same image repeatedly

Send the Print command again from the computer. The

image data stored in the printer’s image memory will

be printed.

When the Auto Card Feeder runs out of cards

while printing

Reload the Feeder and send the Print command again.

If multiple copies of the same card are being printed,

the remaining number prints. Cards can also be

inserted manually into the card insertion slot on the

Auto Card Feeder.

Inserting cards manually

Even with the Auto Card Feeder installed, cards can be

inserted manually one at a time into the card insertion

slot on the Feeder. Insert a card before issuing the Print

command.

Be careful to avoid inserting a card that is not the same

size as those in the Auto Card Feeder, as a jam could

result.

24 Printing

Precautions During and After Printing

If you cannot print or a card becomes jammed, see the

following information. Bad cards that have

accumulated in the Bad Card Stacker inside the printer

should be removed periodically.

If you cannot print

•Printing is disabled if the ALARM lamp is blinking

(page 26).

•Turning the printer off deletes the image stored in the

printer’s image memory, so to resume printing, the

image data must be sent from the computer again.

An image must be sent to the printer memory before

sending the Print command, or printing cannot

1)

occur.

Note

Turning the printer power on returns the print quantity

setting to its default value of “1”.

If a card is jammed

The ALARM lamp blinks and one or two other lamps

are lit when a card is jammed inside the printer.

Turning the printer off and back on should cause the

jammed card to be transferred automatically to the Bad

Card Stacker.

If the card is not moved to the Bad Card Stacker,

contact your supplier or nearest Sony Service Center.

Removing bad cards

If only the ALARM lamp blinks, the Bad Card Stacker

is full. Open the front door and remove the bad cards.

Printing

..........................................................................................................................................................................................................

1) About Image Memory

Image data sent from the computer is stored in the image

memory. Data stored in the image memory can be

printed only by sending a Print command. The UPD6400/D6300 have 4 MB of memory, and the UPD6500 has 8 MB. The image transfer method and print

position are set at the computer side.

Printing 25

Appendixes

In Case of Problems

If you encounter a problem while using the printer, please check whether the following information can help you

fix the problem before contacting the Sony Service Center.

About Caution Indicator Lamps

Indicator lamps light or blink when an error occurs, to indicate the cause of the error. The table below shows the

Appendixes

various lamp error conditions and their corresponding remedies.

Lamp State ( =lit, =blinking, =off) Description/Remedy

ALARM RIBBON CARD PRINT READY

The ink ribbon is getting short.

→ Prepare a new ribbon.

End of ribbon.

→ Replace the ribbon (page 11).

The Auto Card Feeder is empty.

→ Add cards (page 23).

The internal Bad Card Stacker is full.

→ Remove the bad cards.

A card is jammed in the manual feeder.

→ Turn the power off and back on.

A card is jammed in the printing mechanism.

→ Turn the power off and back on.

A card is jammed in the card inverting mechanism.

→ Turn the power off and back on.

A card is jammed in the bad card ejecting mechanism.

→ Turn the power off and back on.

A card is jammed in the first Auto Card Feeder.

→ Turn the power off and back on.

A card is jammed in the second Auto Card Feeder.

→ Turn the power off and back on.

A card is jammed in the Auto Card Stacker.

→ Turn the power off and back on.

The print head is dead.

→ Replace the print head.

An error occurred that requires technical service.

→ Contact the nearest Sony Service Center.

1) Turning the printer off and back on should automatically remove a jammed card.

1)

1)

1)

1)

1)

1)

1)

26 Appendixes

If parts of the Image do not Print

If the adhesive capabilities of the cleaning rollers is

degraded so that dirt cannot be remove from a card,

non-printing areas (white spots) may appear. In such

cases, clean the cleaning rollers. We recommend

cleaning the cleaning rollers after printing about every

200 cards.

1 Hold both sides of the front door and pull it

towards you.

The front door opens.

2 Pull on the part of the cleaning roller cover labeled

“PULL OPEN”, and remove the cover.

4 Remove the cleaning rollers from the cleaning

roller holder.

5 Wash the removed cleaning rollers with water, and

wipe completely so as not to attract dust.

Notes

•When wiping the cleaning rollers, make sure that

no cloth fibers remain on the rollers.

•Do not use synthetic detergent.

6 Replace the cleaning rollers as before, and close

the cleaning roller cover and the front door.

Appendixes

3 Pull the knob on the cleaning roller holder to

remove it.

Appendixes 27

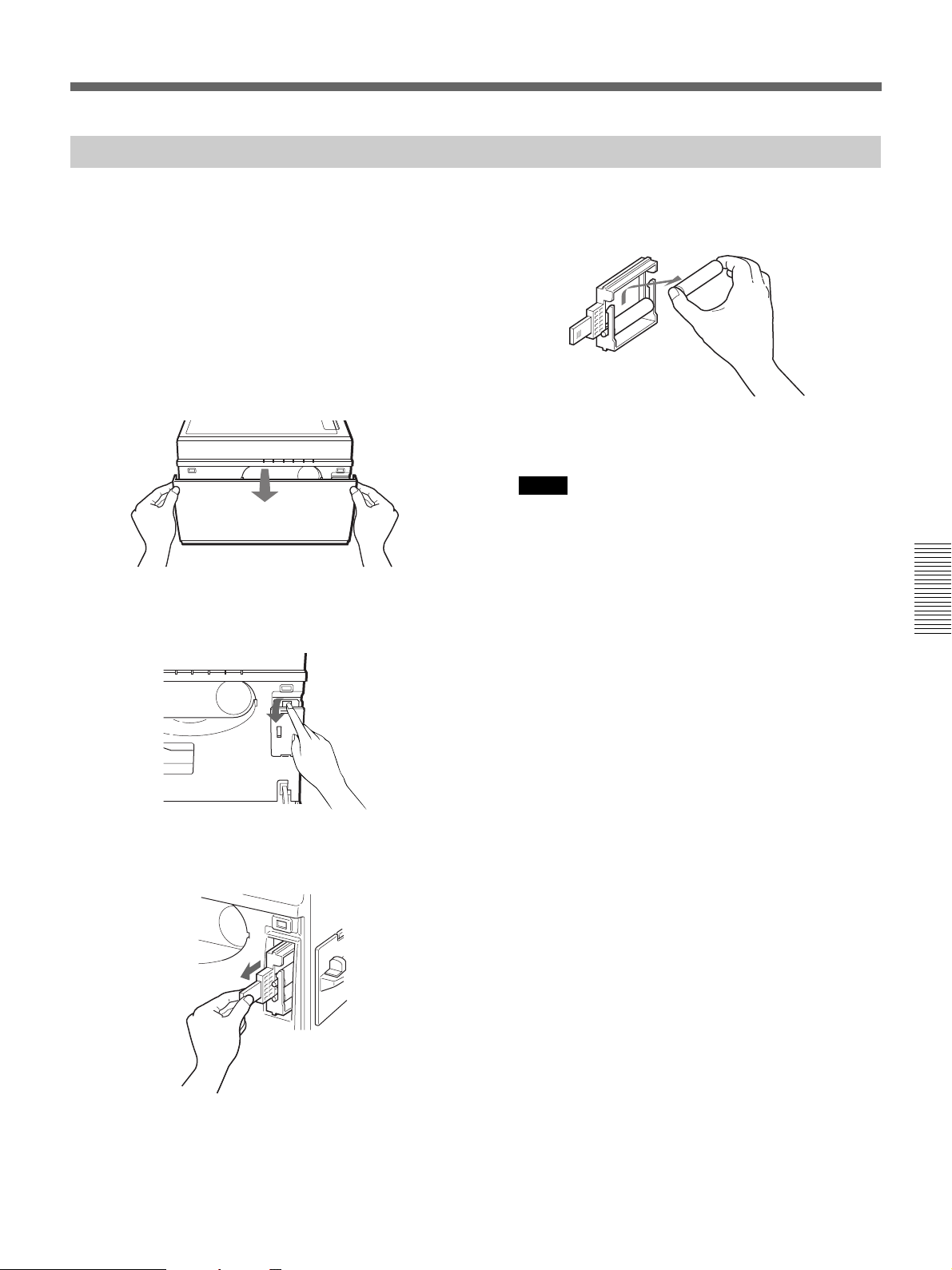

Changing the Print Head

The print head is an expendable. After printing many

cards, or if dirty cards are printed often, the print head

may show signs of wear. If the ALARM lamp blinks

while the other four lamps (RIBBON, CARD, PRINT

and READY) are all lit, the print head must be

replaced. Use optional replacement print head model

UPU-D65H.

Notes

•Be sure to disconnect power from the printer before

changing the print head.

•The print head gets hot when printing, so before

changing the head, allow time for it to cool

sufficiently.

•Be sure to insert the connector to the print head

firmly.

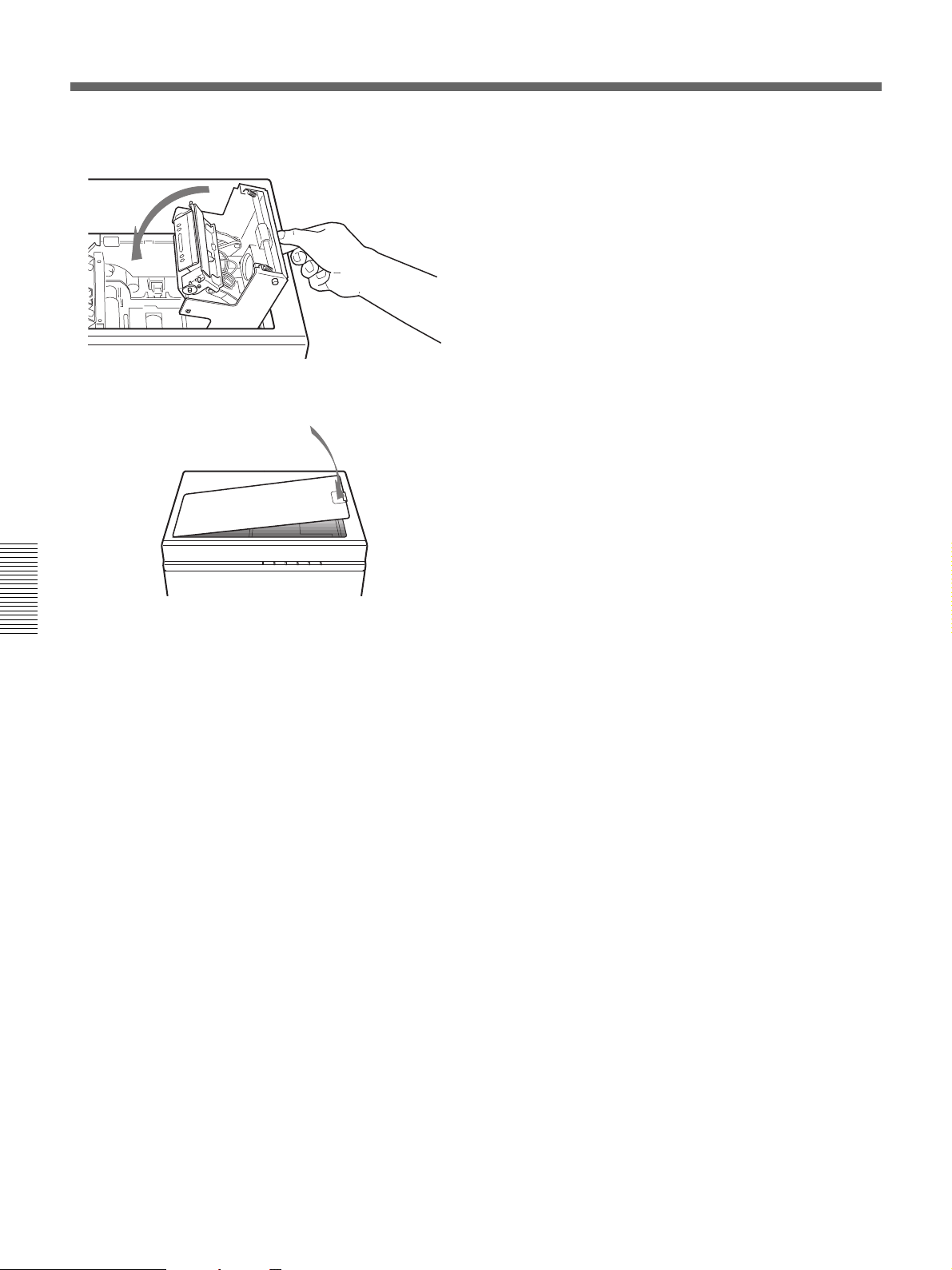

1 Push the top cover knob to the left, open the cover,

and remove it.

2 Pull the blue head holder lock in the direction of

the arrow, and pull the head holder up.

Appendixes

3 While pushing the blue lock button, move the print

head toward you, and remove the head holder from

its hooks.

28 Appendixes

4 While pulling the print head up slightly, rotate it in

the direction shown in the figure.

5 Remove the two connectors at the rear of the print

head.

7 Roll the print head in the direction shown in the

figure so the holes in the print head align with the

hooks in the head holder.

8 Put the hooks in the head holder into the holes in

the print head, and move the print head back until

it locks.

6 Connect the connectors on the new print head in

place of those removed in step 5.

Appendixes

9 Remove the protective cover sheet from the head.

Appendixes 29

Changing the Print Head

10Replace the print head holder.

11Replace the top cover.

Appendixes

Insert the left side of the top cover first, then close

the right side.

30 Appendixes

Loading...

Loading...