3-862-062-14(1)

TSL-A300C/A310C

AIT Autoloader Unit

User’s Guide ––––––––––––––––––– page 2

Mode d’emploi –––––––––––––––– page 33

Bedienungsanleitung–––––––– Seite 64

Guía del usario –––––––––––––––– página 95

Safety Regulations

Owner’s Record

The model and serial numbers are located on the rear. Record the serial

number in the space provided below.

Refer to them whenever you call upon your Sony dealer regarding this

product.

Model No. Serial No.

Information

WARNING

To prevent fire or shock hazard, do not expose the

unit to rain or moisture.

To avoid electrical shock, do not open the cabinet.

Refer servicing to qualified personnel only.

2 Table of Contents

Table of Contents

Chapter 1

Introduction

Chapter 2

Operation

About the AIT Autoloader Unit......................................................... 5

Features....................................................................................................5

Useable Cartridges...................................................................................6

Part Names and Functions............................................................... 7

Front Panel...............................................................................................7

Magazine ...............................................................................................10

Menu Settings and Checks ............................................................ 11

Loading Cartridges ......................................................................... 15

Removing Cartridges from the Magazine .............................................17

How to Use the AIT Auto Loader Unit ........................................... 18

Data Cartridge Selection........................................................................19

Ejecting the Magazine ...........................................................................19

Taking Care of Magazines and Cartridges.................................... 20

Use Precautions .....................................................................................20

Storage Precautions ...............................................................................21

Head Cleaning ................................................................................. 22

How to Clean .........................................................................................22

Installation ....................................................................................... 23

SCSI Connection/Setting the SCSI ID ..................................................23

Option Switches (DIP Switch) ..............................................................24

Interface Implementation................................................................ 25

Supported SCSI Messages..................................................................... 25

Supported SCSI Commands .................................................................. 25

Mounting Holes ............................................................................... 26

Orientation ....................................................................................... 28

English

Appendix

Specifications.................................................................................. 29

Performance........................................................................................... 29

Operating Environment .........................................................................29

Shock .....................................................................................................29

Vibration ................................................................................................29

Altitude .................................................................................................. 29

Acoustic Noise.......................................................................................29

Power Requirements & Miscellaneous..................................................30

Third Party Support Contacts ........................................................ 30

Sony Contacts ................................................................................. 32

For further information, please contact: ................................................32

Table of Contents 3

How to Use this Guide

This Guide describes the AIT Autoloader Unit TSL-A300C/A310C, and how

to take care of it. Please read it carefully before using the unit, and keep it

handy for future reference.

The Guide consists of two parts, plus the specifications. Refer to the parts

that relate to your use of the unit.

Chapter 1 describes the features of the unit, its system components, and the

name and function of each part.

Chapter 2 describes how to use the LCD (display), and handling of

magazines and cartridges. Notes on handling magazines and cartridges, and

head cleaning are also described. Refer to this information when using the

machine.

The Specifications appendix provides the major specifications of the TSLA300C/A310C.

4 Table of Contents

Chapter 1 Introduction

About the AIT Autoloader Unit

The TSL-A300C/A310C is a AIT autoloader unit containing a built-in AIT

drive unit SDX-300C/310C. The magazine provided with the unit

accommodates four data cartridges.

Features

The AIT Autoloader Unit TSL-A300C/A310C has the following features:

• A highly-durable linear guide mechanism provides automatic loading/

unloading of data cartridges to the built-in AIT drive unit SDX-300C/310C.

• The Advanced Intelligent Tape format provides a huge data storage capacity

on AIT cartridges (25GB without data compression). A ‘Read after Write’

function and three-level error correction code guarantee high data

reliability.

• This model includes a data compression function which allows storing even

more data.

• While reading, the drive automatically detects whether data has been stored

with compression, and decompresses the data if necessary.

• Wide SCSI interface. (TSL-A300C:Single-ended, TSL-A310C:Differential)

Chapter 1 Introduction 5

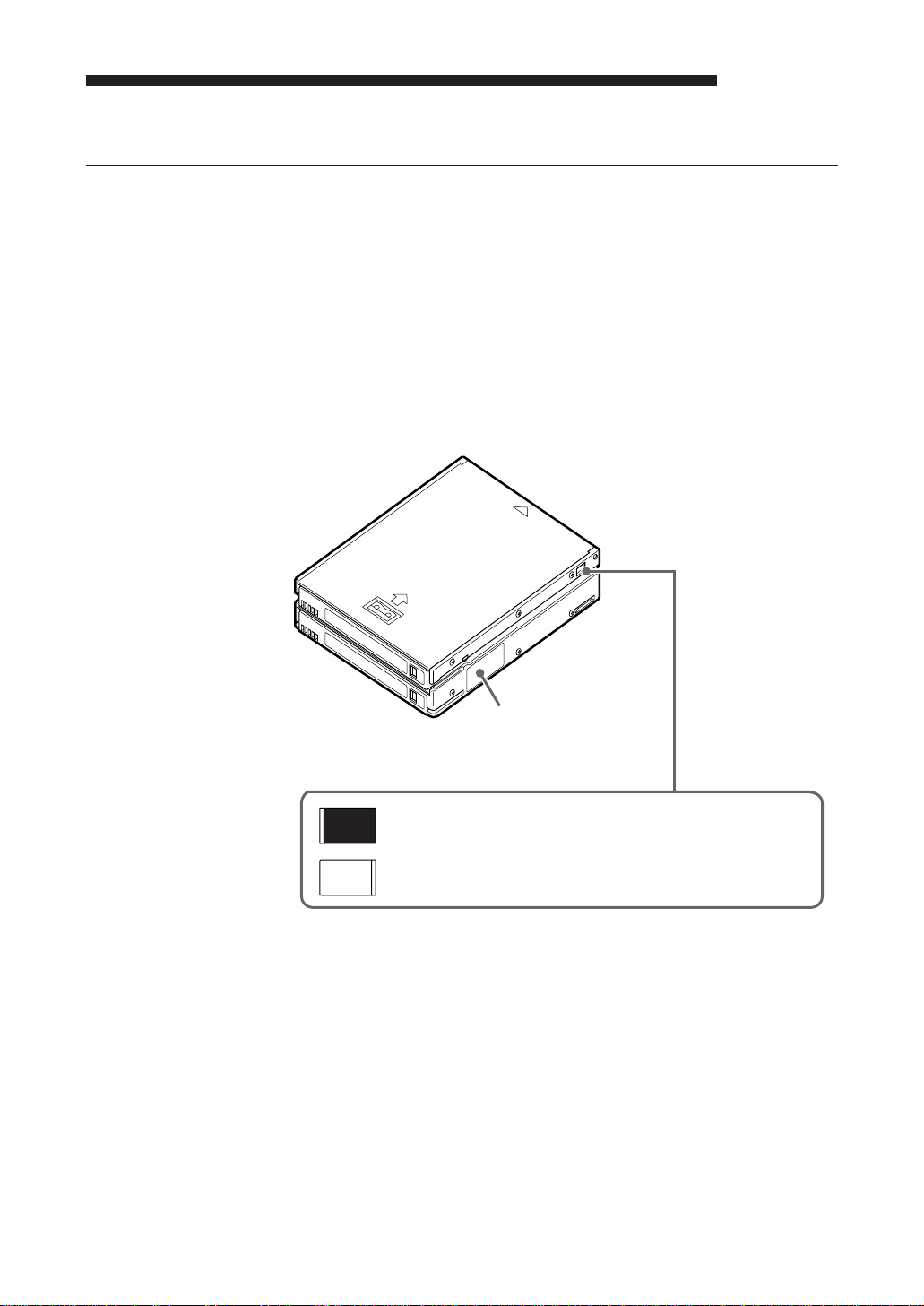

Useable Cartridges

The drive uses AIT cartridges.

AIT Mark

Caution:

Regular 8-mm video tape cartridges look very similar, but are subject to an

entirely different specification, and cannot be used. Do not insert ordinary 8mm video tapes or data cartridges other than AIT cartridges. Insertion of

incorrect cartridge types can cause damage to the equipment.

6 Chapter 1 Introduction

Part Names and Functions

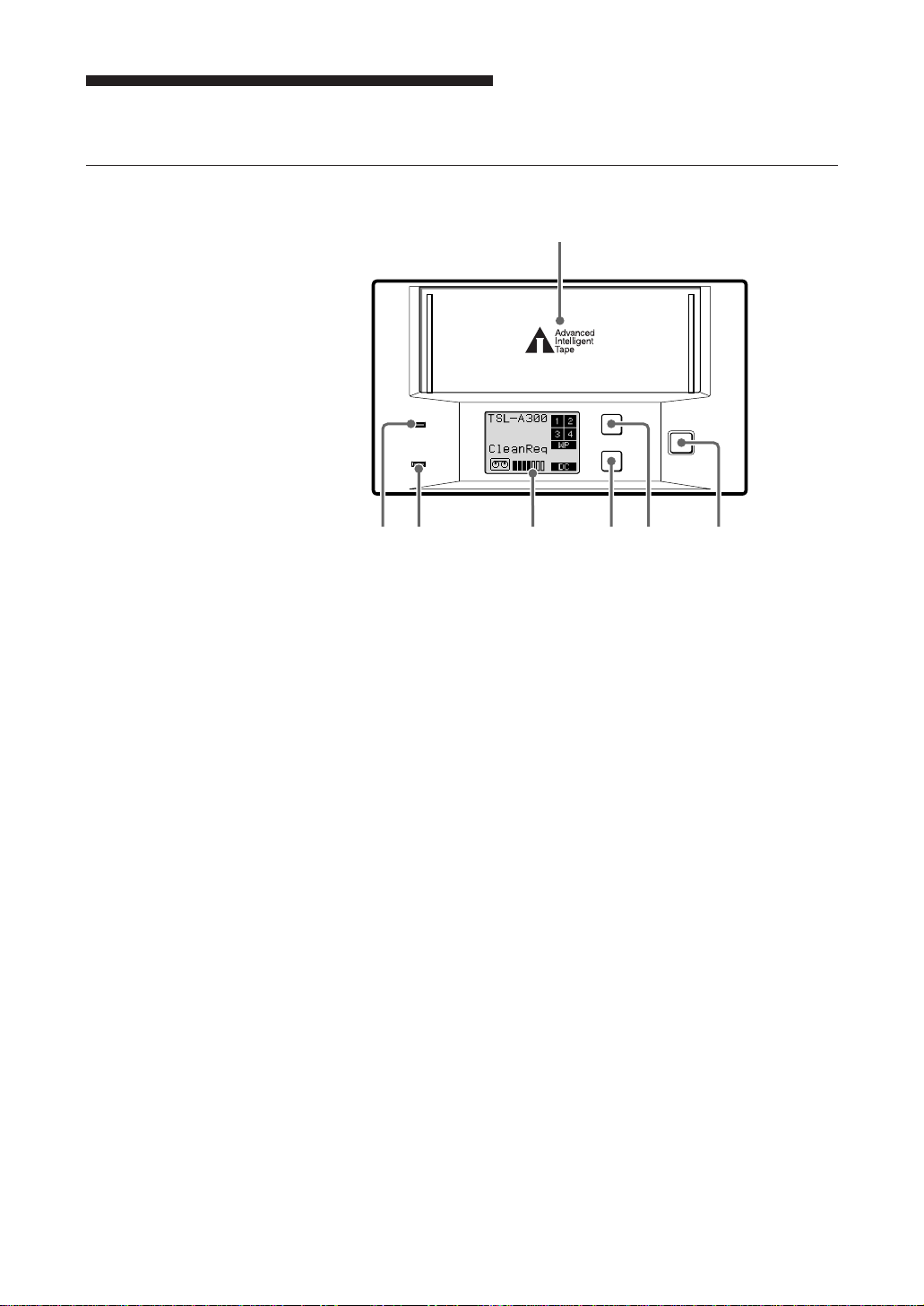

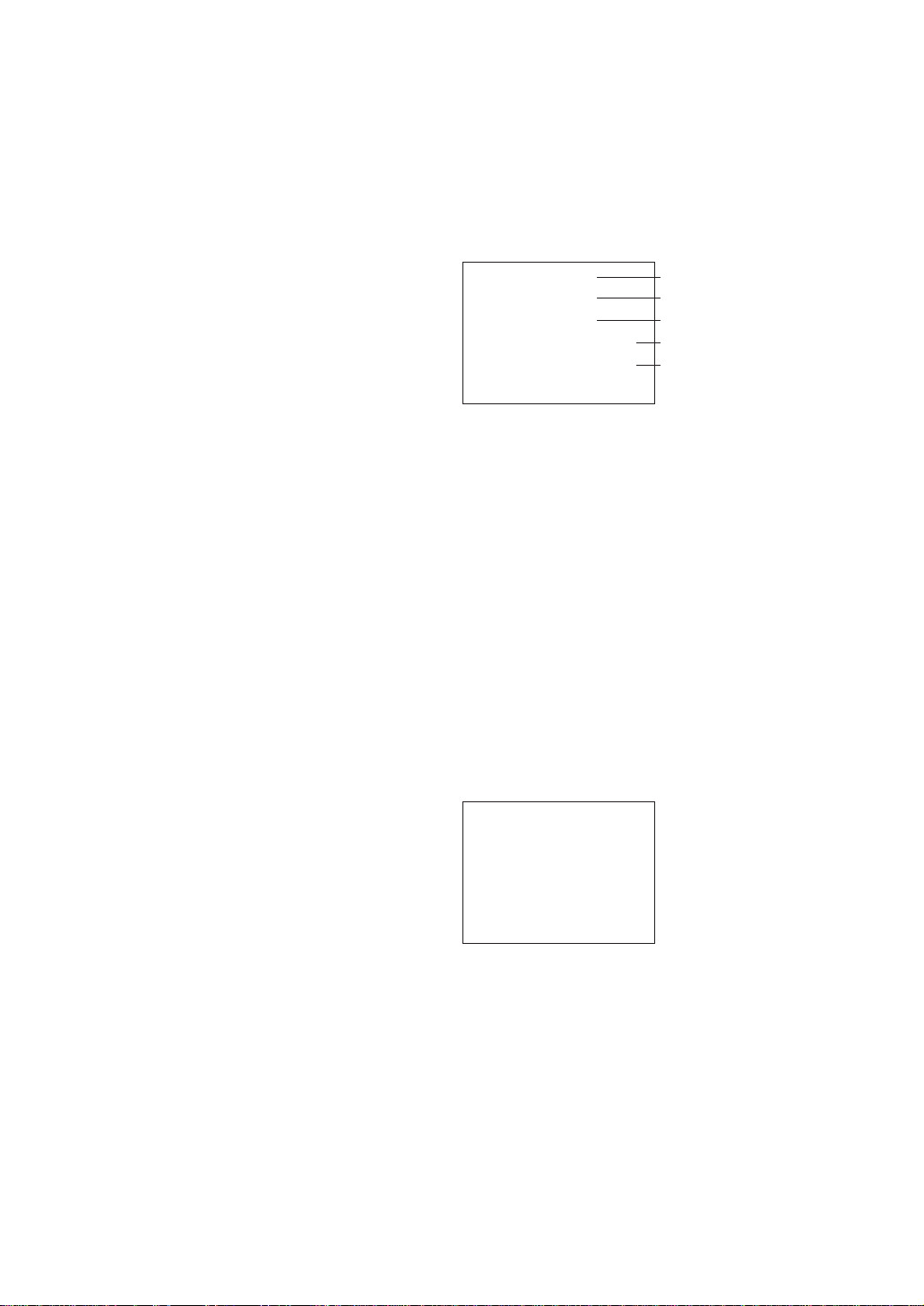

BUSY

EJECT

SELECT

ENTER

TAPE

1

46

37 2

5

Front Panel

1 Magazine receptacle

Insert a magazine here.

Front panel

2 EJECT Button

Press this button to remove a magazine from the machine. It is also used

for menu operations on the display.

3 SELECT Button

Press this button to select a cartridge to be loaded. It is also used for

menu operations on the display.

4 ENTER Button

Press this button to load the cartridge selected by the SELECT button

into the AIT drive. It is also used for menu operations on the display.

Chapter 1 Introduction 7

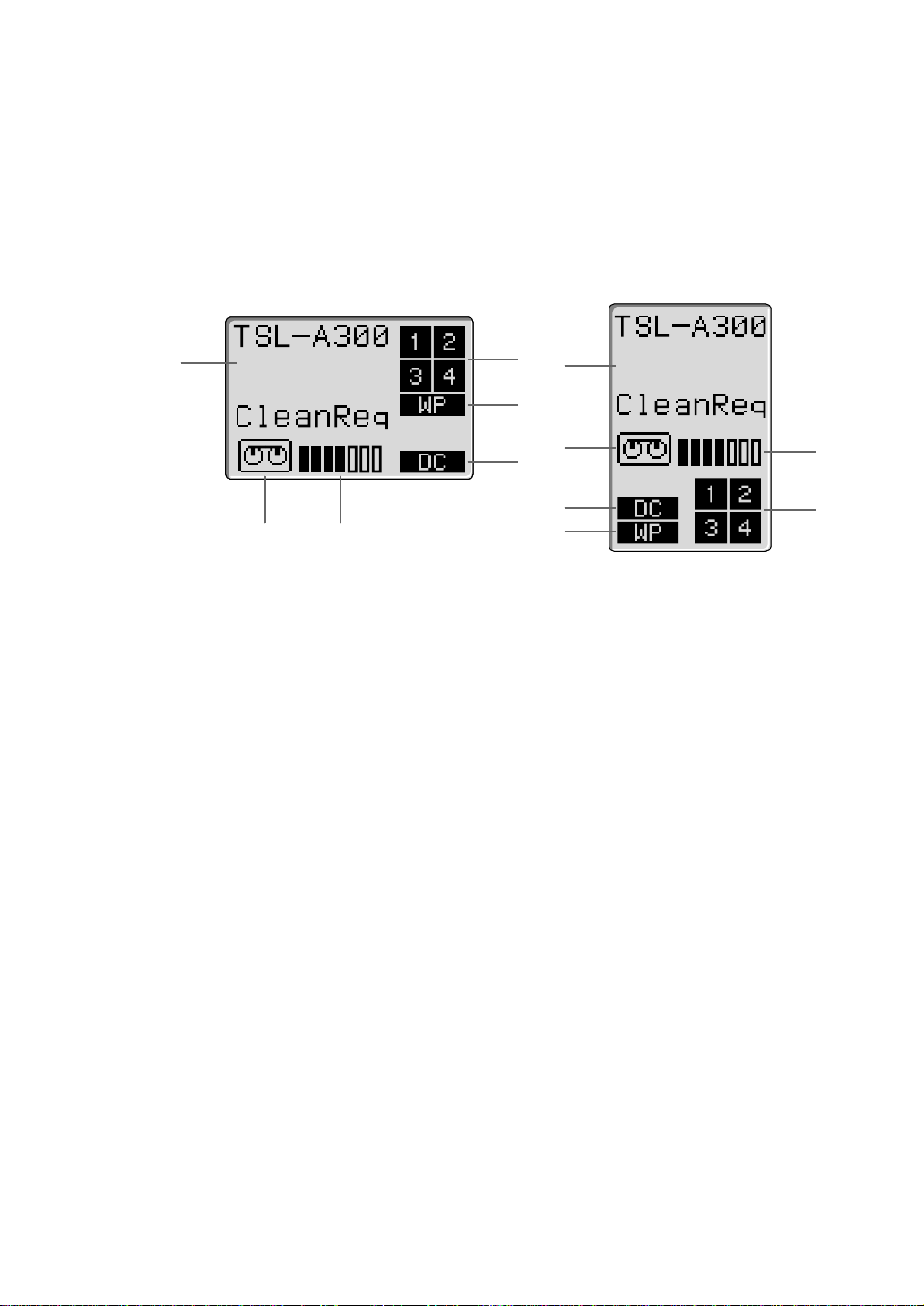

5 Liquid Crystal Display (LCD)

Displays the machine’s status.

The orientation of the display can be changed to match the direction of

viewing as described on page 13.

Horizontal Display Vertical Display

a

f

b

a

c

f

d

d

e

a Message Area

Indicates the machine’s operating status.

Warning or error messages may be displayed here depending on the

operating state.

The language of the messages may be selected from English, French,

German and Spanish as described on page 14.

b Cartridge Number Indicator

Displays the status of the cartridge in the magazine. The cartridge

number blinks while exchanging the cartridge. When a cartridge is

loaded from a magazine to the AIT drive, the cartridge number

disappears. When the cartridge is returned to the magazine, the number

blinks again.

c

Liquid Crystal Display

e

b

8 Chapter 1 Introduction

c Write-Protect Indicator

This indicator appears when the magazine or data cartridge is writeprotected by the write-protect tab.

d Data Compression Indicator

This indicator lights when data compression is enabled for the drive.

e Tape Position Indicator

Indicates the winding position of the tape in the cartridge loaded in the

AIT drive.

ppppppp Positioned near the beginning of the tape.

ppppπππ Positioned near the middle of the tape.

πππππππ Positioned near the end of the tape.

Tape winding position indicated by the Tape Position Indicator

f Cartridge Indicator

This indicator appears when a cartridge is loaded in the internal AIT

drive, and indicates the tape’s load status: when the tape is being loaded

or unloaded from the drive, this indicator blinks.

6 TAPE Indicator

Lights green when a data cartridge is loaded into the AIT-drive. The

indicator flashes while a cartridge is being loaded or unloaded.

7 BUSY Indicator

Lights green when the SCSI interface is ready for data transfer. This

indicator flashes while data is being read from or written to the cartridge

loaded into the AIT drive, while searching for data, or while the tape is

being rewound.

Chapter 1 Introduction 9

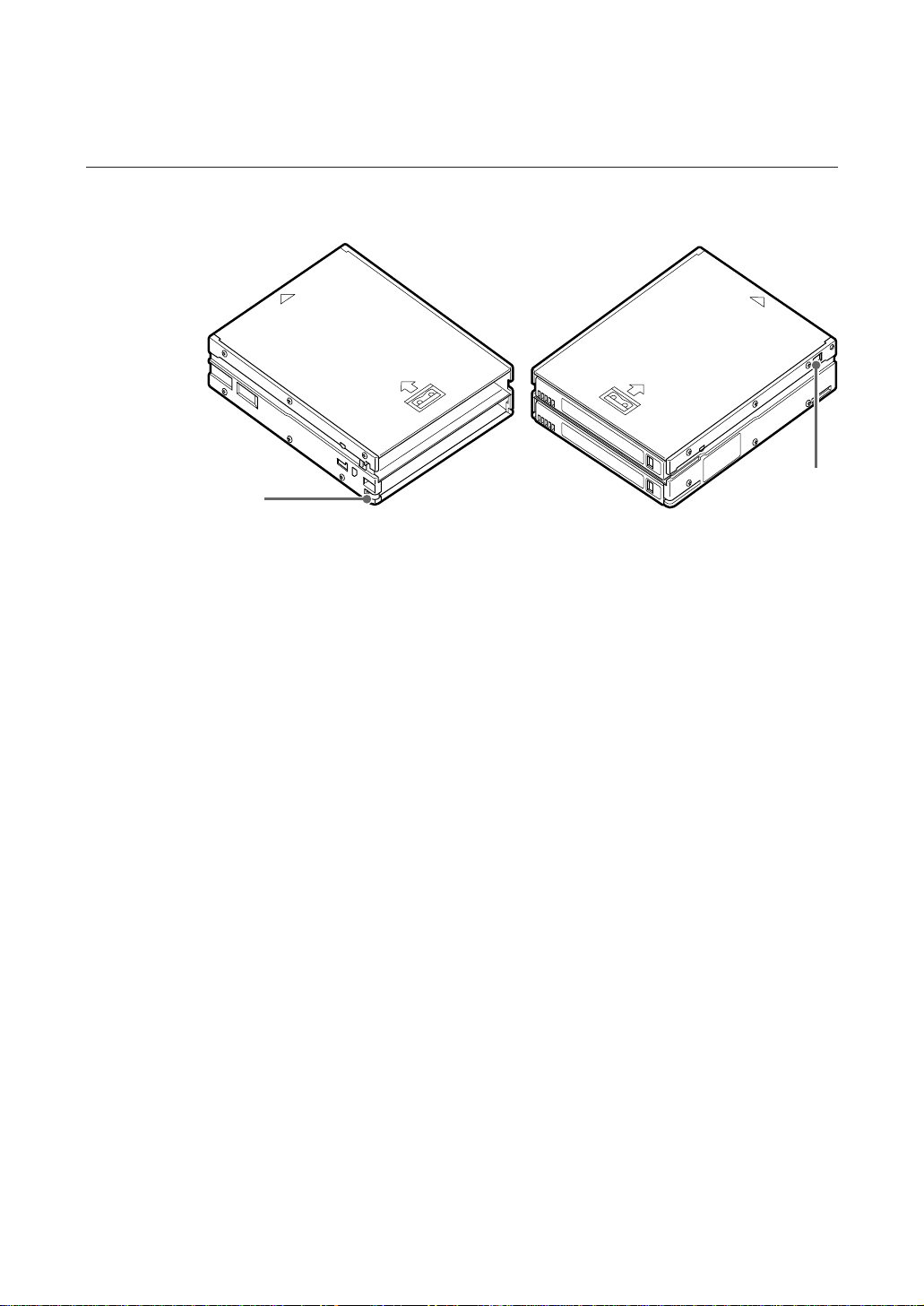

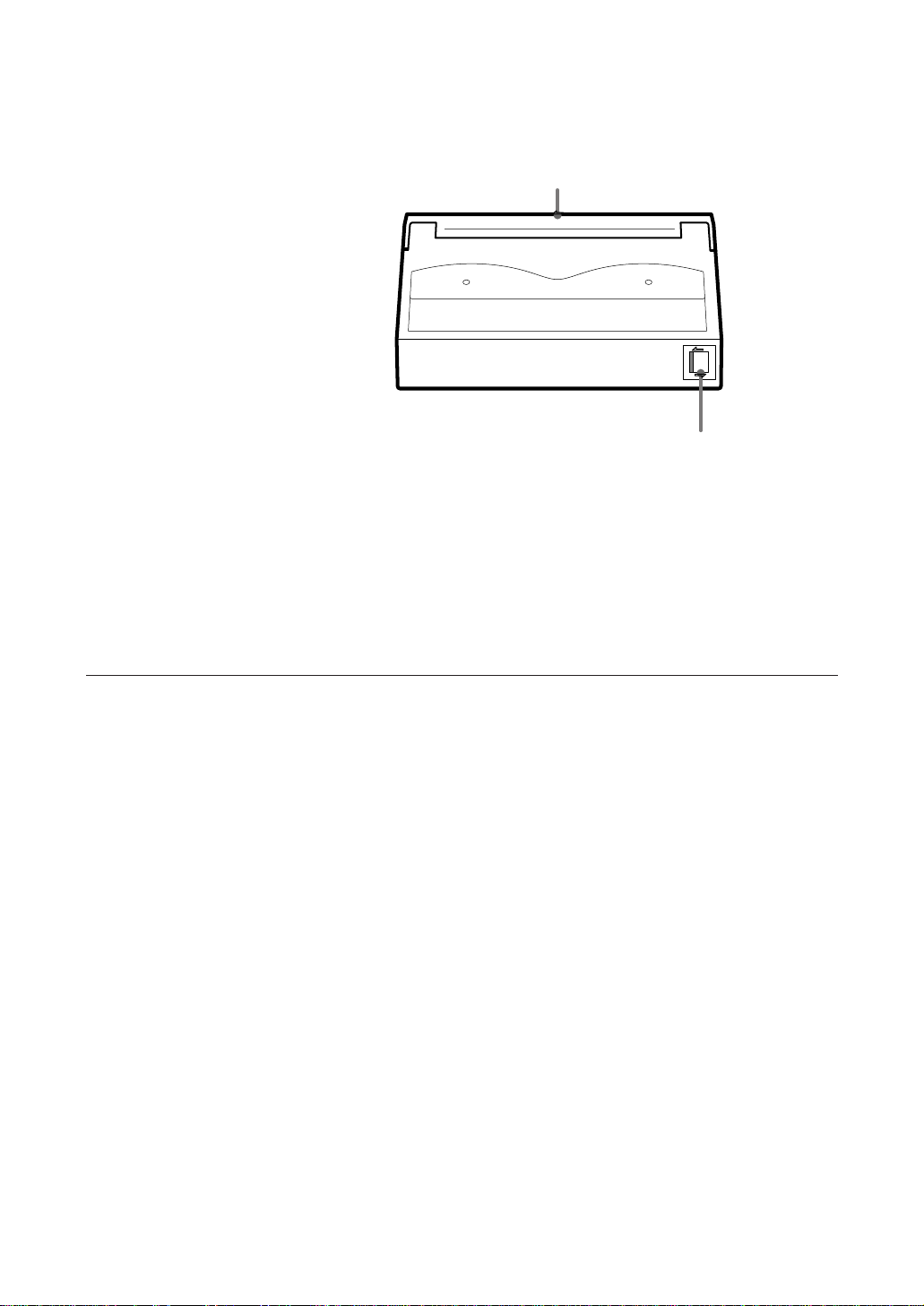

Magazine

1

1 Button

Press the button to remove cartridges from the magazine. Refer to page

15 to load cartridges, and to page 17 to remove cartridges.

2 Write protect tab

Used to inhibit writes to data cartridges. Sliding this tab to the left writeprotects all data cartridges, whether or not write protection is set on the

individual data cartridges.

2

Magazine

10 Chapter 1 Introduction

Chapter 2 Operation

This section describes users of the LCD (display), and procedures for loading

cartridges in the magazine, using the drive unit, and handing magazines and

cartridges.

Menu Settings and Checks

Certain machine settings can be made and viewed from the LCD Menu

screen, including model and firmware version display and the current SCSI

ID setting of the machine.

The Menu screen is controlled by the following procedure.

Note:

The magazine should be removed before switching display to the Menu

screen. When the magazine is inserted into the autoloader, the Menu screen

can only be displayed when the LCD shows “Ready”. To change the

language setting, the magazine must be removed.

1 Press and hold the SELECT button for 5 seconds.

The display changes to the Menu screen.

z Version

Auto Load

Unload

Contrast

Orientation

Language

Menu Screen

2 Press the SELECT button to move the cursor (z) among the menu items.

3 Press ENTER to display the setting screen for the selected item.

4 Choose the desired setting for the selected item as described in the

following descriptions of the choices for each setting screen.

If no further action takes place for 10 seconds, the menu is exited and

display returns to normal.

Chapter 2 Operation 11

Version Display

When Version is selected in the Menu screen, the following screen appears,

where you can confirm the autoloader model, SCSI ID and firmware version.

Auto Load Selection

TSL-A300C

SCSI ID#5

Ver. 0000

S/NL XXXXXXXX

S/ND XXXXXXXX

Version Screen

Model Name of this Machine

SCSI ID Number

Firmware Version

Auto Loader Serial Number

AIT Drive Serial Number

1 Note the displayed information.

2 Press the EJECT button.

The display returns to the Menu screen.

When Auto Load is selected in the Menu screen, the following screen

appears. From this screen you can select whether the first cartridge

automatically loads when a magazine is placed in the auto loader.

OFF: The cartridges are checked and auto loading does not occur. (This is

the factory default setting.)

Please use this as the usual mode of operation.

ON: The first cartridge automatically loads into the AIT drive after the

cartridges in the magazine have been checked.

12 Chapter 2 Operation

Auto Load

z OFF

ON

1 Press the SELECT button, if necessary, to move the cursor (z) to the

desired setting. You can press the EJECT button to cancel any change to

the selection and return to the Menu screen.

2 Press the ENTER button to accept the selection and return to the Menu

screen.

Unload Selection

When Unload is selected in the Menu screen, the following screen appears.

From this screen you can select what happens when the Unload (LUN0)

command is selected while the fourth cartridge is loaded into the AIT drive.

OFF: The cartridge is returned to the magazine and the first cartridge does

not automatically reload. (This is the factory default setting.)

Please use this as the usual mode of operation.

ON: The cartridge is returned to the magazine and the first cartridge is

automatically reloaded into the drive.

Unload

Continuous

z OFF

ON

1 Press the SELECT button, if necessary, to move the cursor (z) to the

desired setting. You can press the EJECT button to cancel any change to

the selection and return to the Menu screen.

2 Press the ENTER button to accept the selection and return to the Menu

screen.

Contrast Adjustment

Orientation Setting

When Contrast is selected in the Menu screen, the following screen appears.

You can adjust the display contrast from this screen.

Contrast

Adjustment

pppππππ

Contrast Adjustment Screen

1 Press the SELECT button, as necessary, to adjust the contrast.

2 Press the ENTER button.

The contrast setting is accepted and the display returns to the Menu

screen.

When Orientation is selected in the Menu screen, the following screen

appears, where you can select the orientation of the display to match your

viewing angle.

Chapter 2 Operation 13

Language Selection

Orientation

z Horizontal

R-side down

L-side down

Orientation Screen

1 Press the SELECT button, as necessary, to move the cursor (z) to the

desired setting.

The orientation of the displayed characters corresponds with the current

selection.

You can press the EJECT button to cancel any change to the selection

and return to the Menu screen.

2 Press the Enter button.

Accepts the selected display orientation and returns to the Menu screen.

The display orientation switches when exiting the Menu screen.

Note:

When making settings with the Menu screen, the display is always

oriented so that the top of the display corresponds with the top of the

unit.

Note:

To change the language setting, remove the magazine from the unit. The

language setting cannot be changed while the magazine is inserted.

When Language is selected in the Menu screen, the following screen appears,

where you can select the language of the displayed messages.

Language

z English

French

German

Spanish

Language Screen

1 Press the SELECT button, as necessary, to move the cursor (z) to the

desired setting.

You can press the EJECT button to cancel any change to the selection

and return to the Menu screen.

2 Press the ENTER button to accept the selection and return to the Menu

screen.

Note:

The Menu screen itself is always displayed in English.

14 Chapter 2 Operation

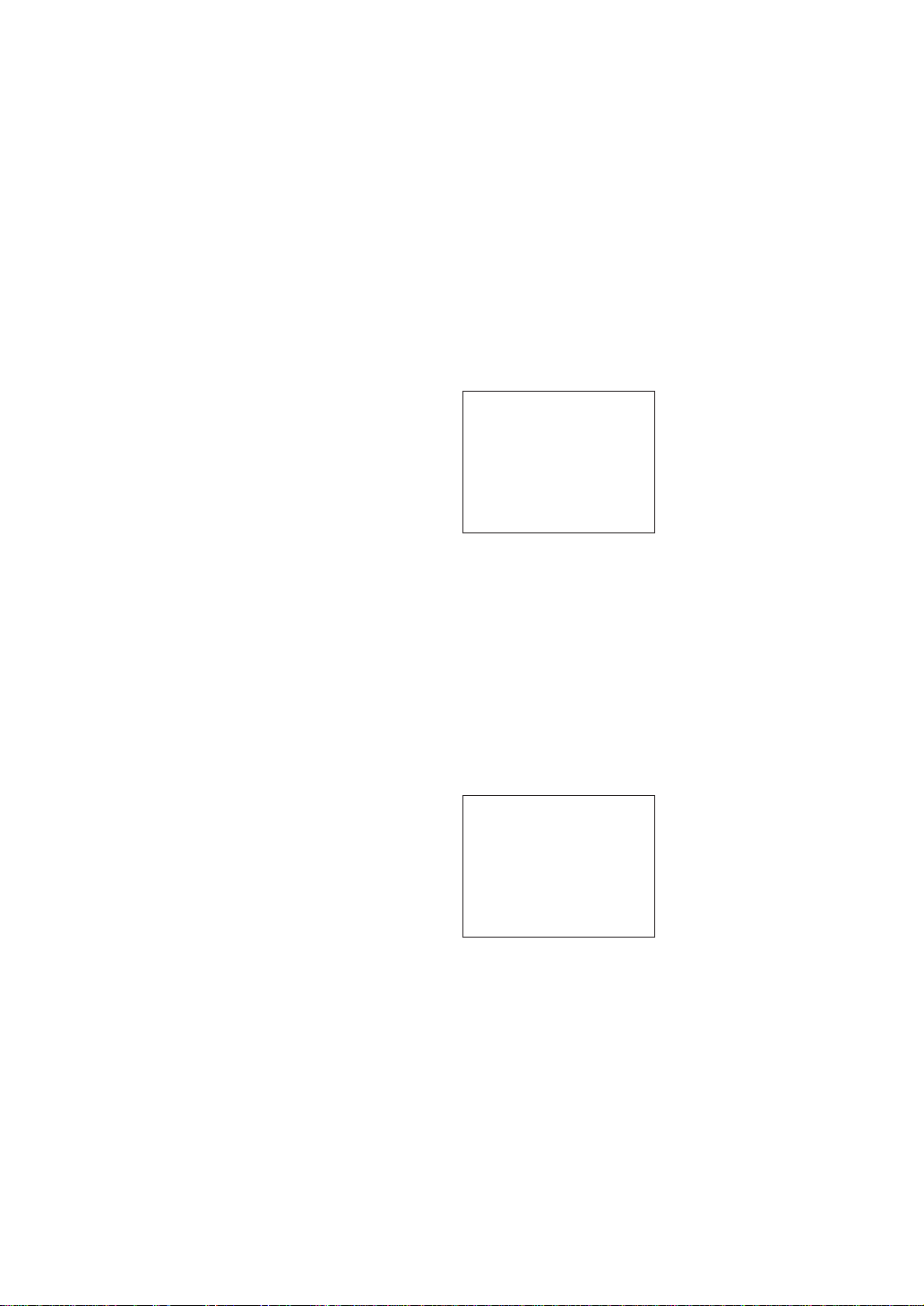

Loading Cartridges

Four data cartridges should be loaded in the magazine.

Cautions:

• Always load four cartridges into the magazine. Make sure that cartridges

are correctly oriented. Damage may result if fewer than four cartridges are

loaded or if the cartridges are loaded incorrectly.

• Incorrect cartridge orientation prevent insertion of the magazine into the

Autoloader. Check to ensure correct cartridge orientation.

Good Bad

Cartridge Orientation

Magazine Cartridge Number

Chapter 2 Operation 15

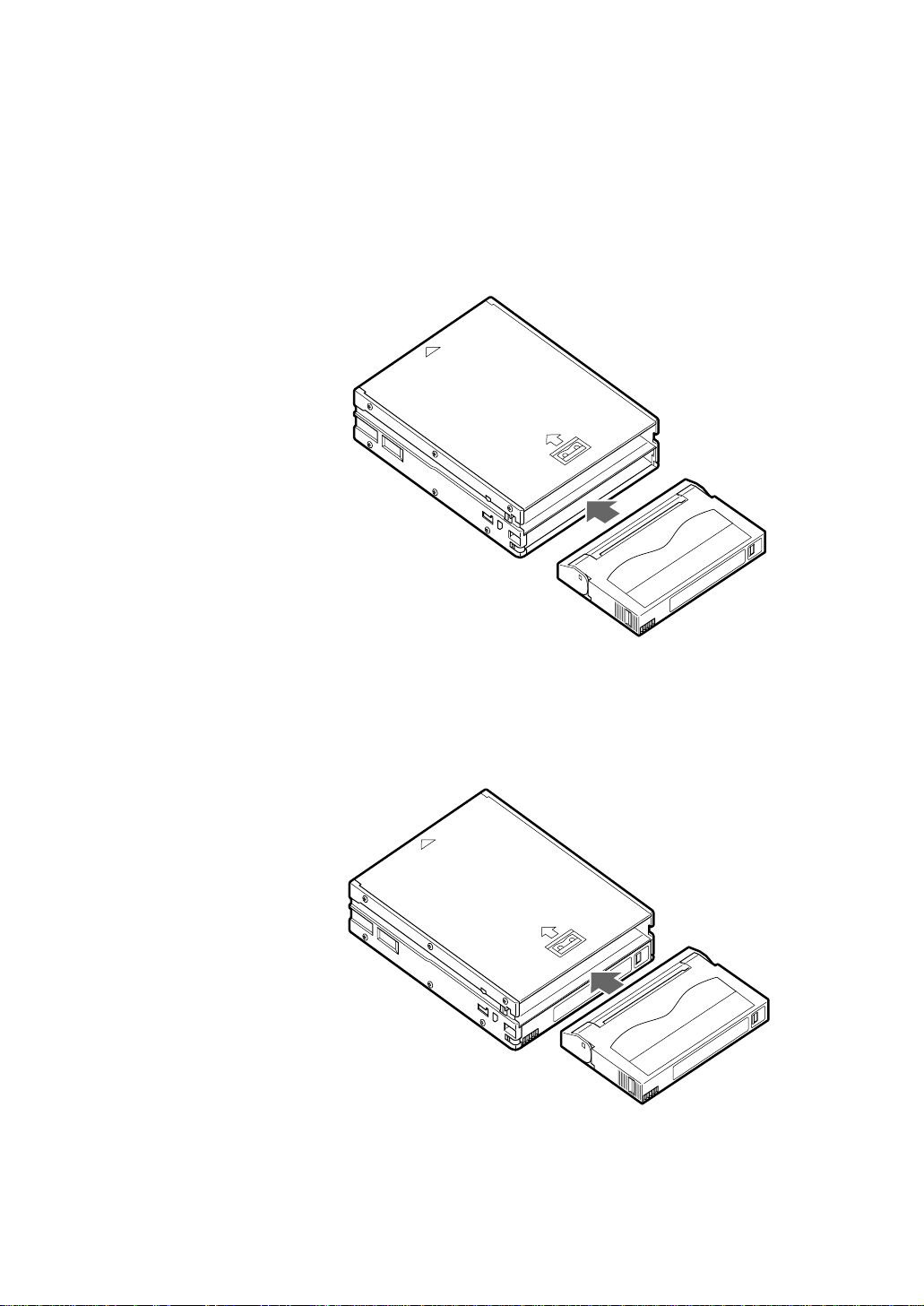

Load data cartridges into the magazine as follows.

1 First, load two data cartridges into the bottom shelf of the magazine as

shown in the figure below.

Load cartridge number 2 first, followed by cartridges 1.

Loading data cartridges into the bottom magazine shelf

2 Load two data cartridges into the top shelf of the magazine as shown in

the figure below.

Load cartridge number 3 first, followed by cartridges 4.

Loading data cartridges into the top magazine shelf

16 Chapter 2 Operation

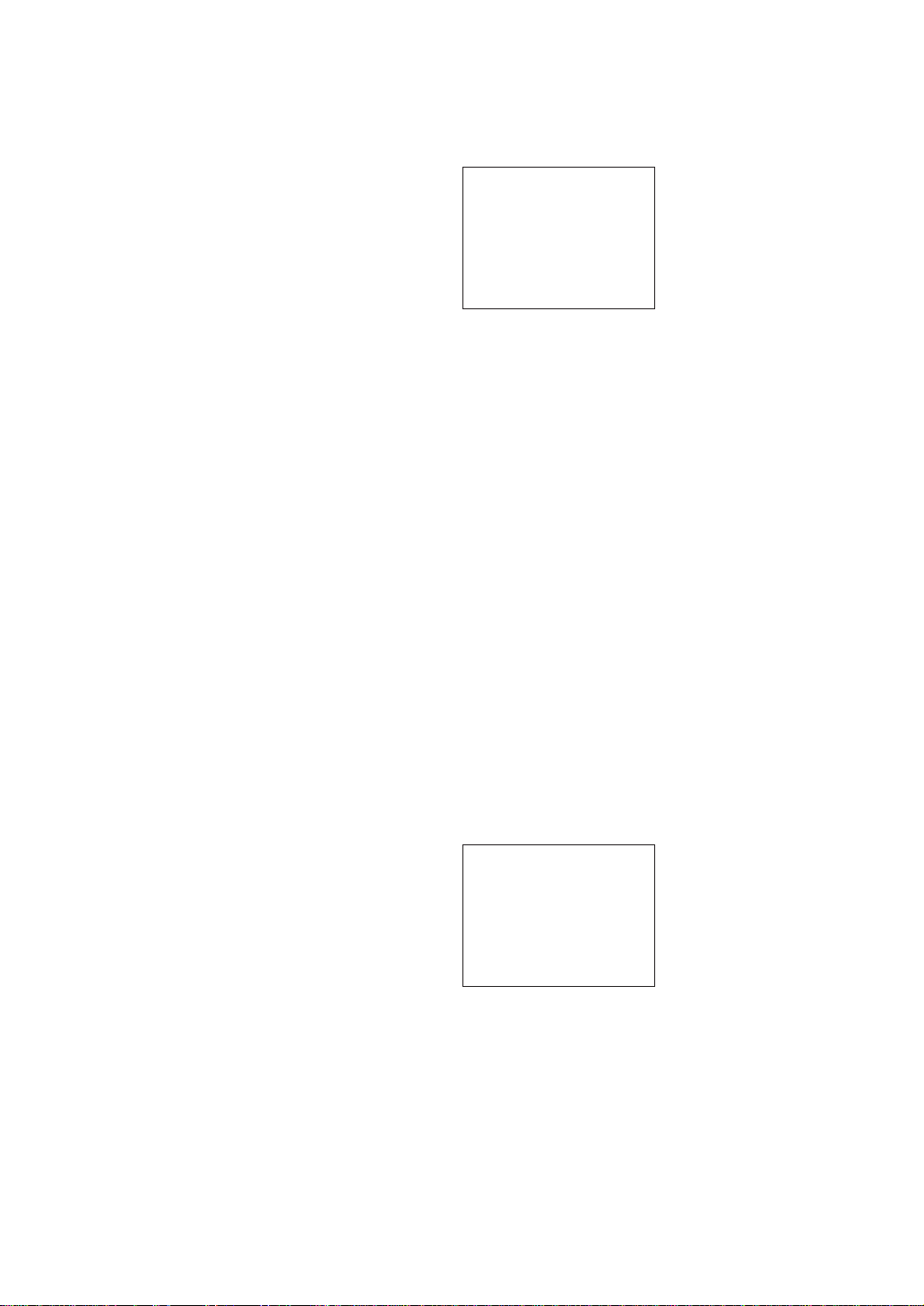

Removing Cartridges from the Magazine

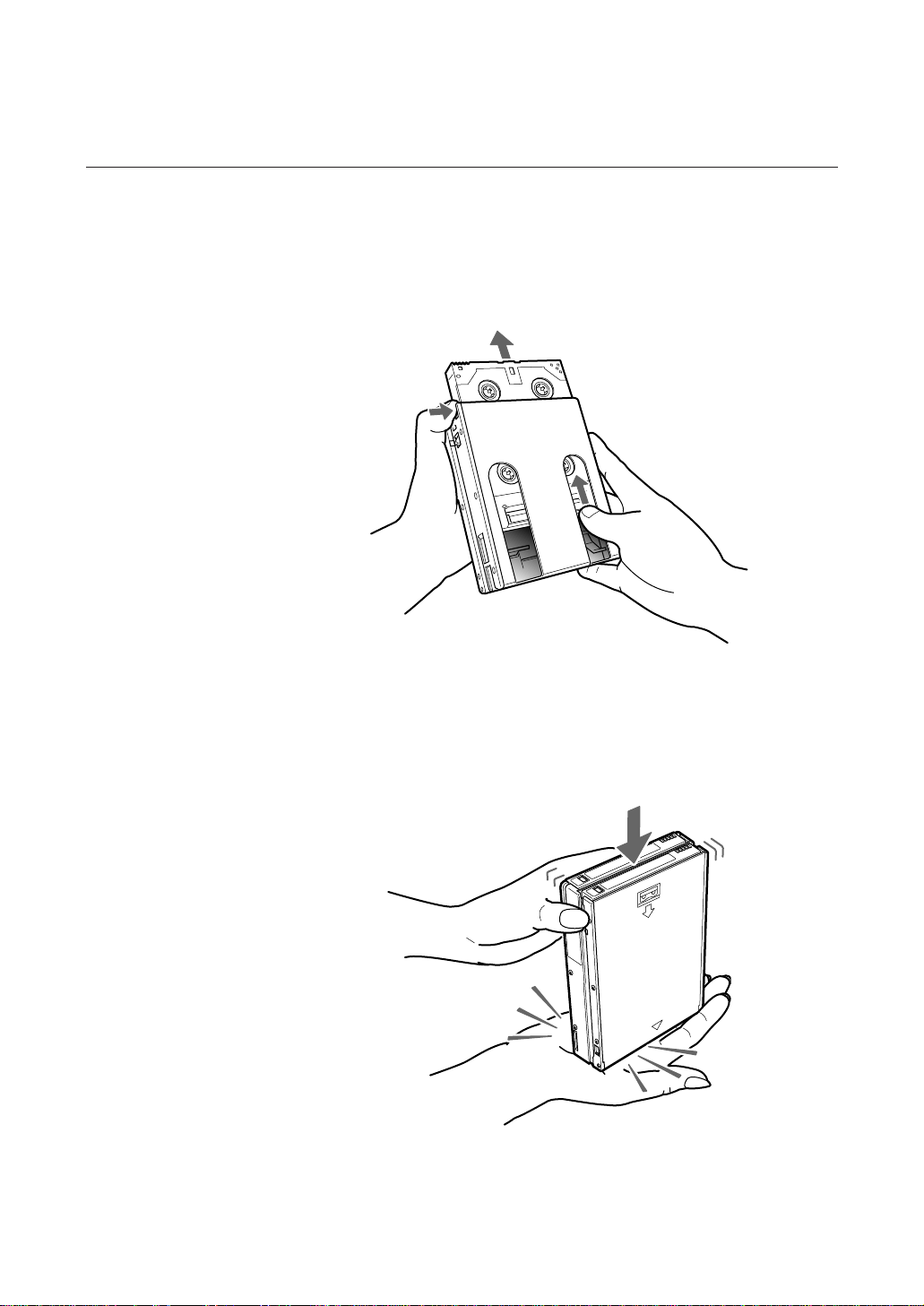

Remove cartridges from the magazine as follows.

1 Pressing down on the magazine stopper, place your finger in the hole at

the rear of the magazine and push data cartridges toward the front of the

magazine.

Pushing cartridges from the rear of the magazine

2 Repeat step 1 to remove three cartridges.

3 Turn the magazine so that the open end faces up and tap it gently against

your hand or a soft object. This makes cartridges move from the top shelf

to the bottom shelf.

Moving top shelf cartridges to the bottom shelf

4 Using the same technique as step 1, slide the cartridge out from the

bottom position.

Chapter 2 Operation 17

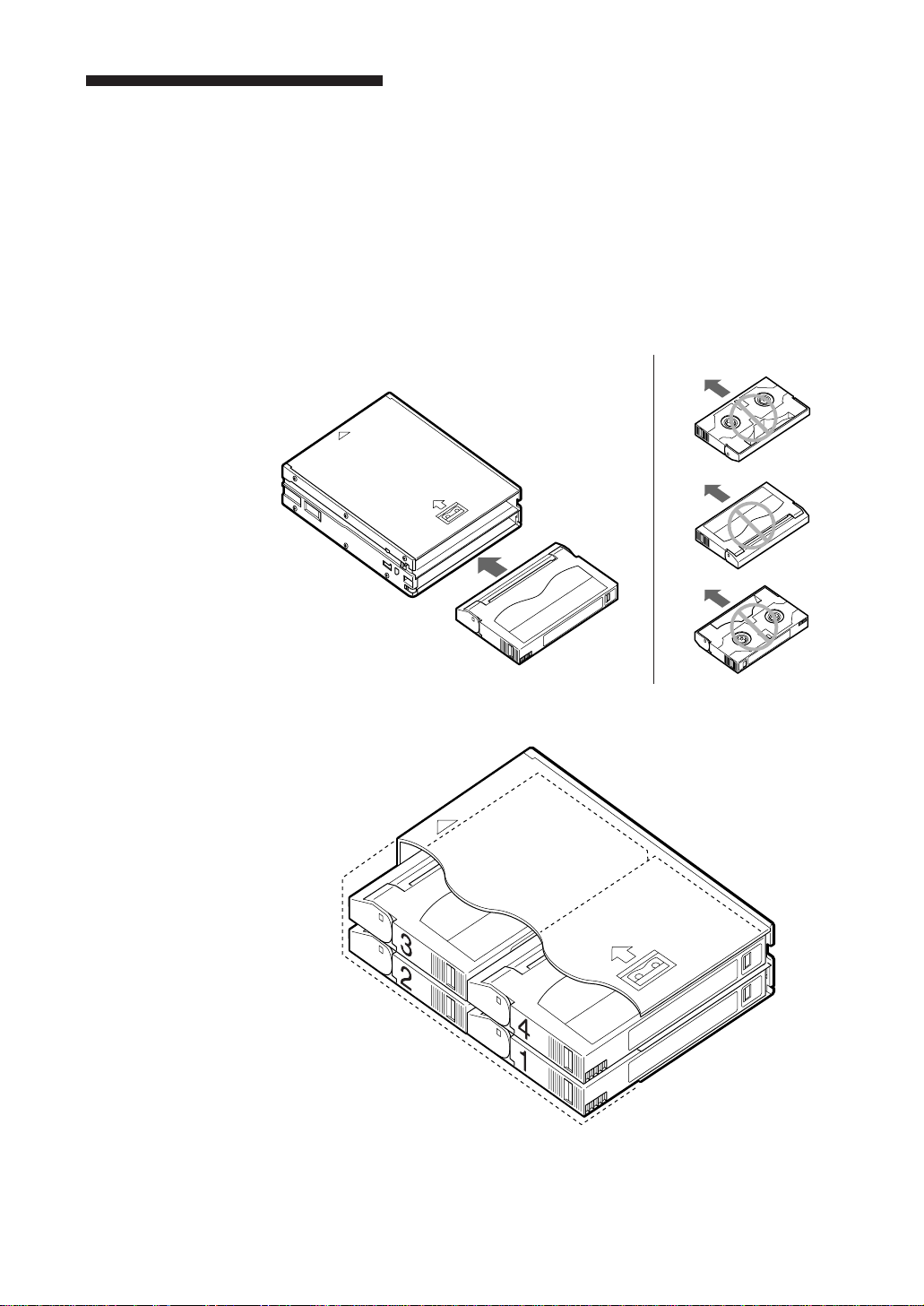

How to Use the AIT Auto Loader Unit

EJECT

SELECT

ENTER

BUSY

TAPE

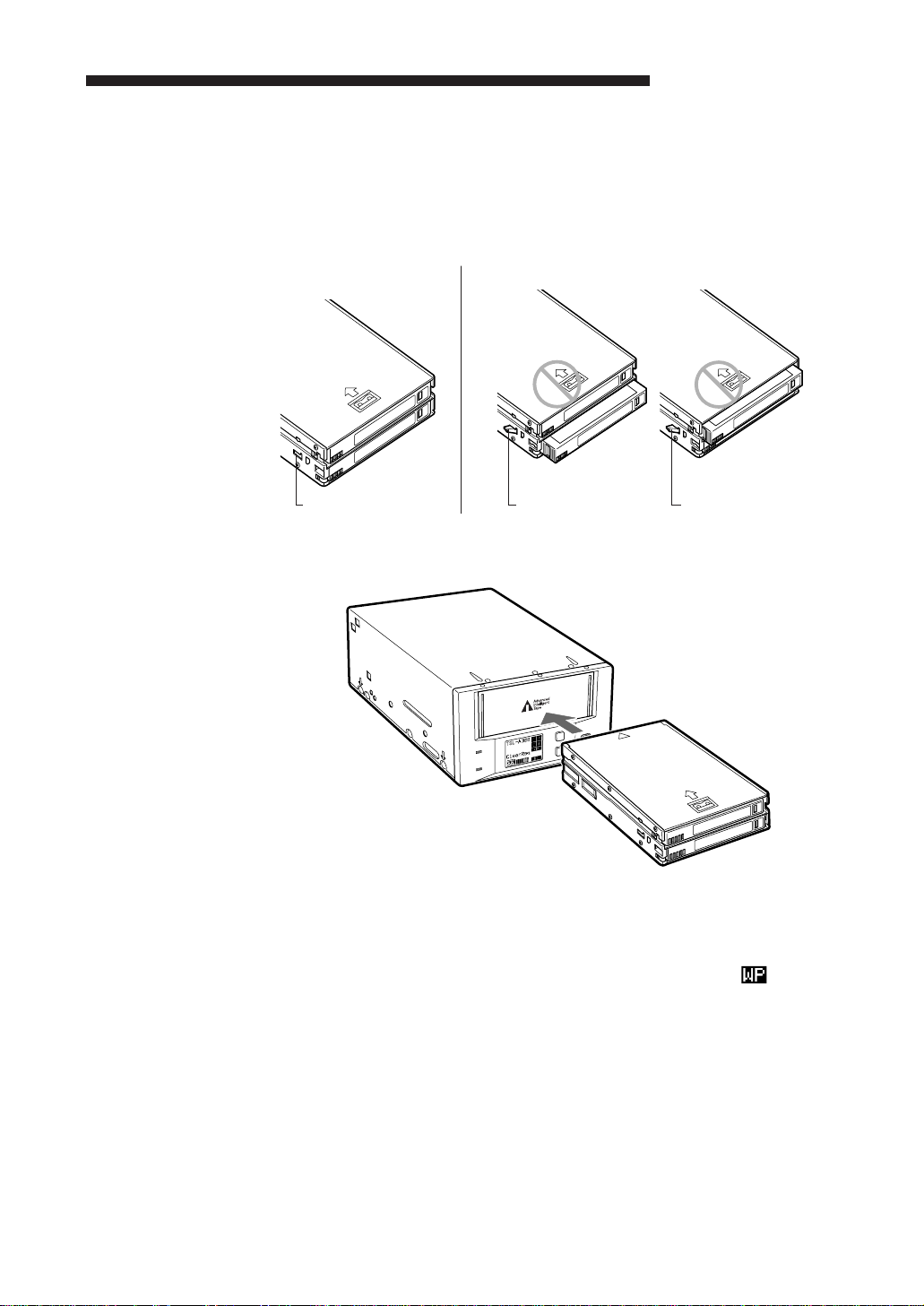

1 Be sure to push the cartridges all the way into the magazine. If the

cartridges are not pushed in all the way, the hook on the magazine

protrudes outward, and will prevent magazine insertion into the

Autoloader.

Good Bad

Hook not protruding Hook protruding Hook protruding

2 Ensure that the BUSY and TAPE indicators off, insert the magazine.

18 Chapter 2 Operation

Inserting the magazine

When the magazine is loaded, the following actions occur:

• After “Magazine Loading” appears, checking of the magazine starts.

• If the magazine is write-protected, the write-protect indicator ( ) appears.

• All cartridges are checked in order.

• As each cartridge is checked, its number blinks.

3 “Scan4 Ok” should be displayed, when all cartridge numbers display on

the LCD, a cartridge to be loaded into the AIT drive may be selected by

computer software or by the SELECT or ENTER buttons on the

machine. When a cartridge is loaded into the AIT drive, the TAPE

indicator lights.

4 Data may be read or written on the tape using computer software. While

reading or writing, the BUSY indicator lights.

Data Cartridge Selection

You can select data cartridges loaded into the magazine as necessary by using

the software on your computer.

Data cartridges can be selected with the SELECT and ENTER buttons on this

machine, by the following procedure.

1 Press the SELECT button to display a cartridge number on the LCD, and

press it repeatedly to change the selected data cartridge number.

2 When the desired cartridge number is selected, press the ENTER button.

The cartridge currently in the AIT drive is unloaded, and the cartridge

selected above is loaded into the drive.

Cautions:

• After inserting the magazine, about 75 seconds are needed for checking

the cartridges in the magazine. During that time, the SELECT button is

disabled. The SELECT button is also disabled when “Ready” is not

displayed.

• The SELECT and ENTER buttons have no effect if pressed while the

BUSY indicator is flashing.

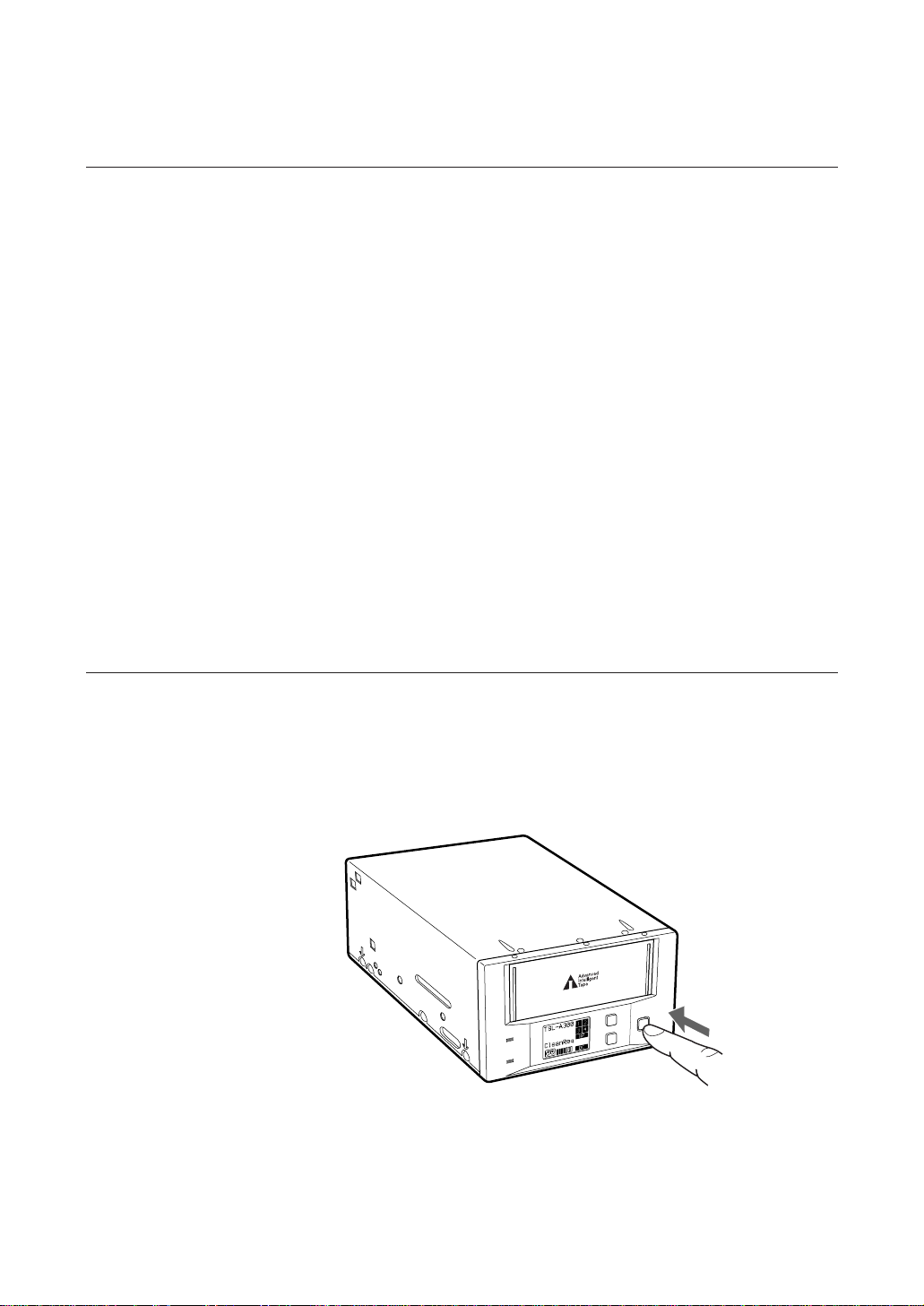

Ejecting the Magazine

Press the EJECT button.

“Ejecting Magazine” appears, and after the cartridge unloads from the AIT

drive to the magazine, the magazine automatically ejects.

As much as two minutes may be required to eject a magazine.

SELECT

EJECT

BUSY

TAPE

Ejecting the magazine

ENTER

Caution:

The EJECT button has no effect if pressed while the BUSY indicator is

flashing.

Chapter 2 Operation 19

Taking Care of Magazines and Cartridges

Use Precautions

• Avoid heavy vibration and dropping.

• The shutter on the face of the cartridge is opened automatically when it is

inserted into the drive. Do not open the shutter by hand, as touching the tape

may damage it.

• Magazines and cartridges are carefully adjusted during assembly at the

factory. Please do not try to open them or take them apart.

• The write-protect tabs on magazines and cartridges prevent the tape from

being written to or accidentally erased. If you do not need to write to the

tape, move the magazine or cartridge write-protect tab to the write-protect

position.

Label attachment

position

SAVE

REC

Slide the tab toward SAVE to prevent data from being written

Slide the tab toward REC to allow data to be written

Magazine write-protect tab and label attachment position.

20 Chapter 2 Operation

• In case of a sudden change in temperature, condensation may interfere with

• Avoid unnecessarily loading/unloading cartridges to/from the AIT drive if

Storage Precautions

Lid

Push the switch to the left to enable writing and erasure. ?

Push the switch to the right to protect the tape from writing or

accidental erasure. /

Cartridge write-protect tab

reading and writing to a tape.

you do not need to write or read a tape.

• Keep the magazine in its case when not in use.

• Avoid storing cartridges in dusty places, in direct sunlight, near heaters or

air conditioners, or in humid locations.

• Do not place cartridges on the dashboard or in a storage tray in a car.

Chapter 2 Operation 21

Head Cleaning

To maintain the reliability of the AIT autoloader unit, clean the head

periodically using a cleaning tape (sold separately).

“CleanReq” is displayed when the head needs to be cleaned.

How to Clean

1 Load three data cartridges and one cleaning cartridge into the magazine.

2 Insert the magazine into the autoloader.

3 Press the SELECT button to select the cartridge number of the cleaning

4 Press the ENTER button.

cartridge.

The cleaning cartridge loads into the AIT drive.

The cleaning cartridge cleans the head automatically and returns to the

magazine.

22 Chapter 2 Operation

Installation

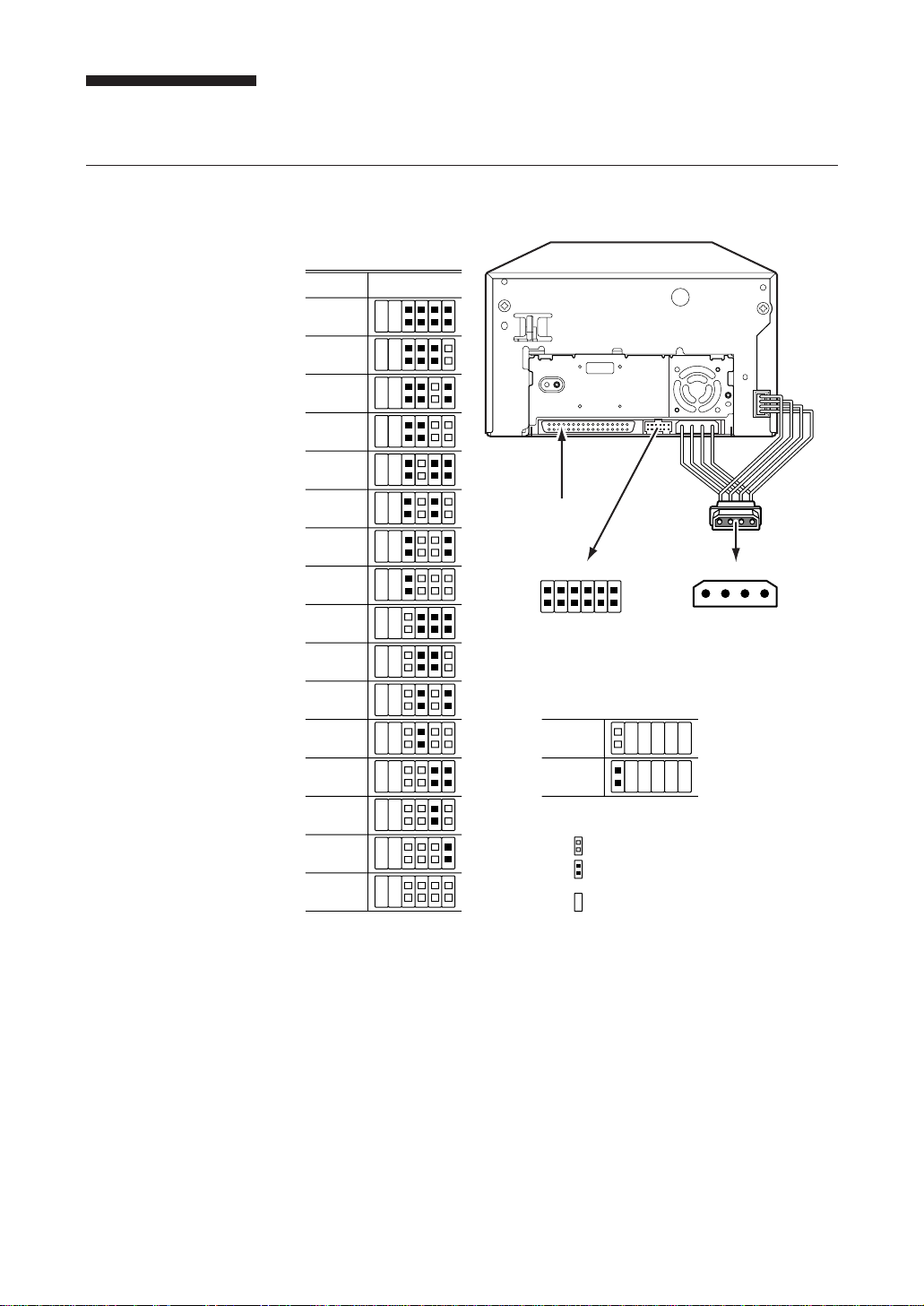

SCSI Connection/Setting the SCSI ID

SCSI ID

SCSI ID

0

1

2

3

4

321

P.D.

N.C.

0

Parity Disable Jumper

5

6

7

8

9

10

11

12

13

14

15

SCSI Connector

Jumpers

Parity Disable

No Connection

Parity

Disable

Enable

Note: = CLOSED / Jumper

Power Connector

5V GND GND 12V

SCSI ID 3

SCSI ID 2

SCSI ID 1

SCSI ID 0

= OPEN / Jumper not installed

Don't care

4 3 2 1

Parity check function can be disabled by Jumper. Parity check is disabled

while left end jumper is installed. Parity generate function is always enabled.

Chapter 2 Operation 23

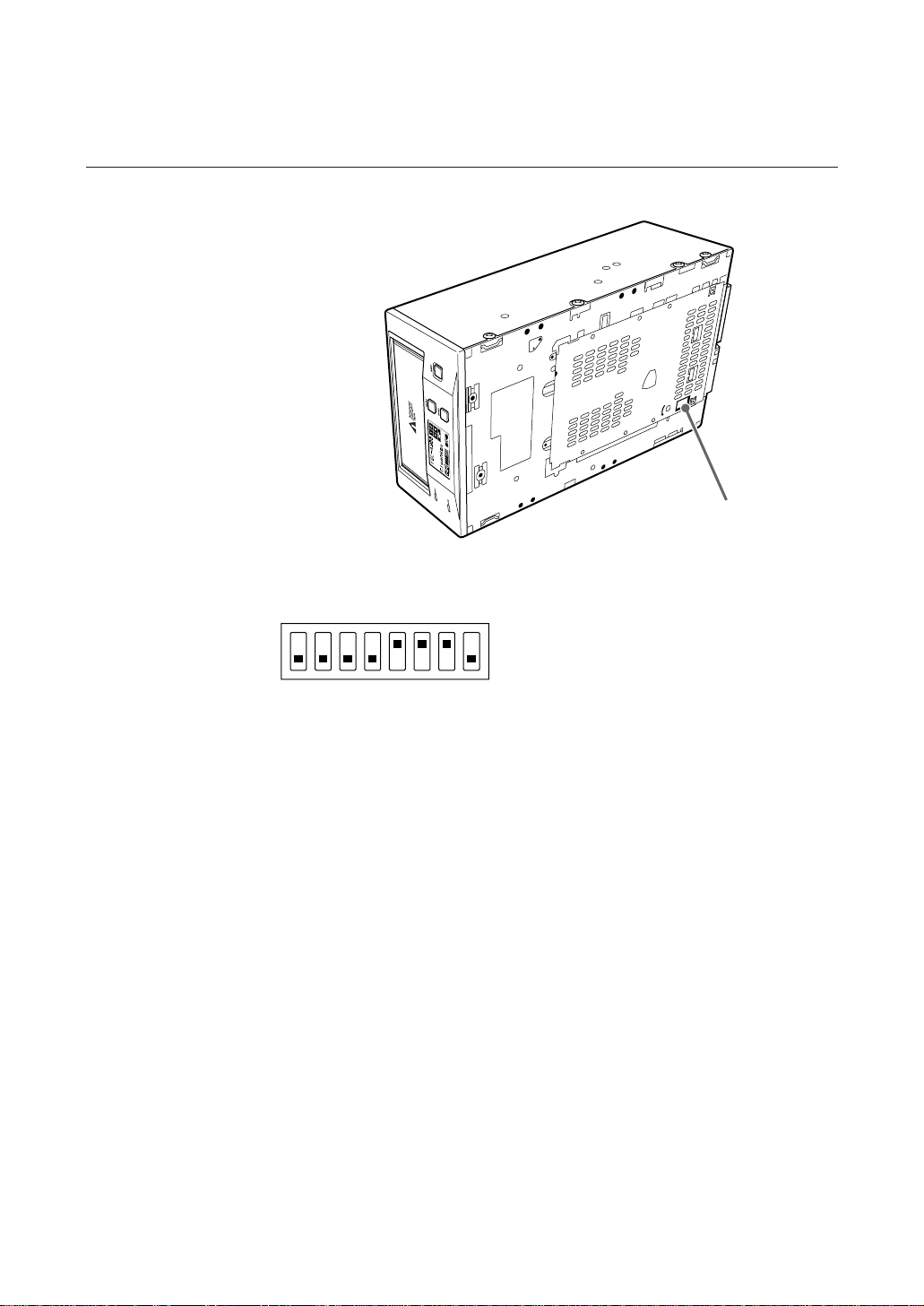

Option Switches (DIP Switch)

DIP Switch Positions

DIP Switch

ON

12345678

Note:

The TSL-A310C is not equipped with internal termination. When using this

unit, connect a differential SCSI bus terminator or a device with internal

termination to the end of the SCSI bus.

The TSL-A300C is equipped with internal termination.

Data Compression Control DIP switch

Data compression can be selected by DIP switches. Data compression is

enabled while position 7 [DC Control (1)] is ON. Control by host can be

disabled when position 8 [DC Control (2)] is ON.

1 Reserved (OFF)

2 Reserved (OFF)

3 Reserved (OFF)

4 Reserved (OFF)

5 Terminator Power (ON)

6 Terminator Enable (No connection for TSL-A310C)

7 DC Control (1) (ON)

8 DC Control (2) (OFF)

24 Chapter 2 Operation

Interface Implementation

Supported SCSI Messages

Abort

Bus Device Reset

Command Complete

Disconnect

Extended Message

-Synchronous Data Transfer Request

Extended Message

-Wide Data Transfer Request

Identify (w/&w/o Disconnect)

Initiator Detected Error

Message Parity Error

Message Reject

No Operation

Restore Pointers

Save Data Pointer

Supported SCSI Commands

Erase

Initialize Element Status (LUN=1)

Inquiry (LUN= 0 or 1)

Load/Unload (LUN= 0 or 1)

Locate

Log Select

Log Sense

Mode Select (6)

Mode Sense (6) (LUN= 0 or 1)

Move Medium (LUN= 0 or 1)

Prevent Allow Medium Removal (LUN= 0 or 1)

Read

Read Block Limits

Read Buffer

Read Element Status (LUN= 0 or 1)

Read Position

Receive Diagnostic Results

Release Unit

Request Block Address

Request Sense

Reserve Unit

Rewind

Seek Block

Send Diagnostic (LUN= 0 or 1)

Space

Test Unit Ready (LUN= 0 or 1)

Verify

Write

Write Buffer

Write Filemarks

Chapter 2 Operation 25

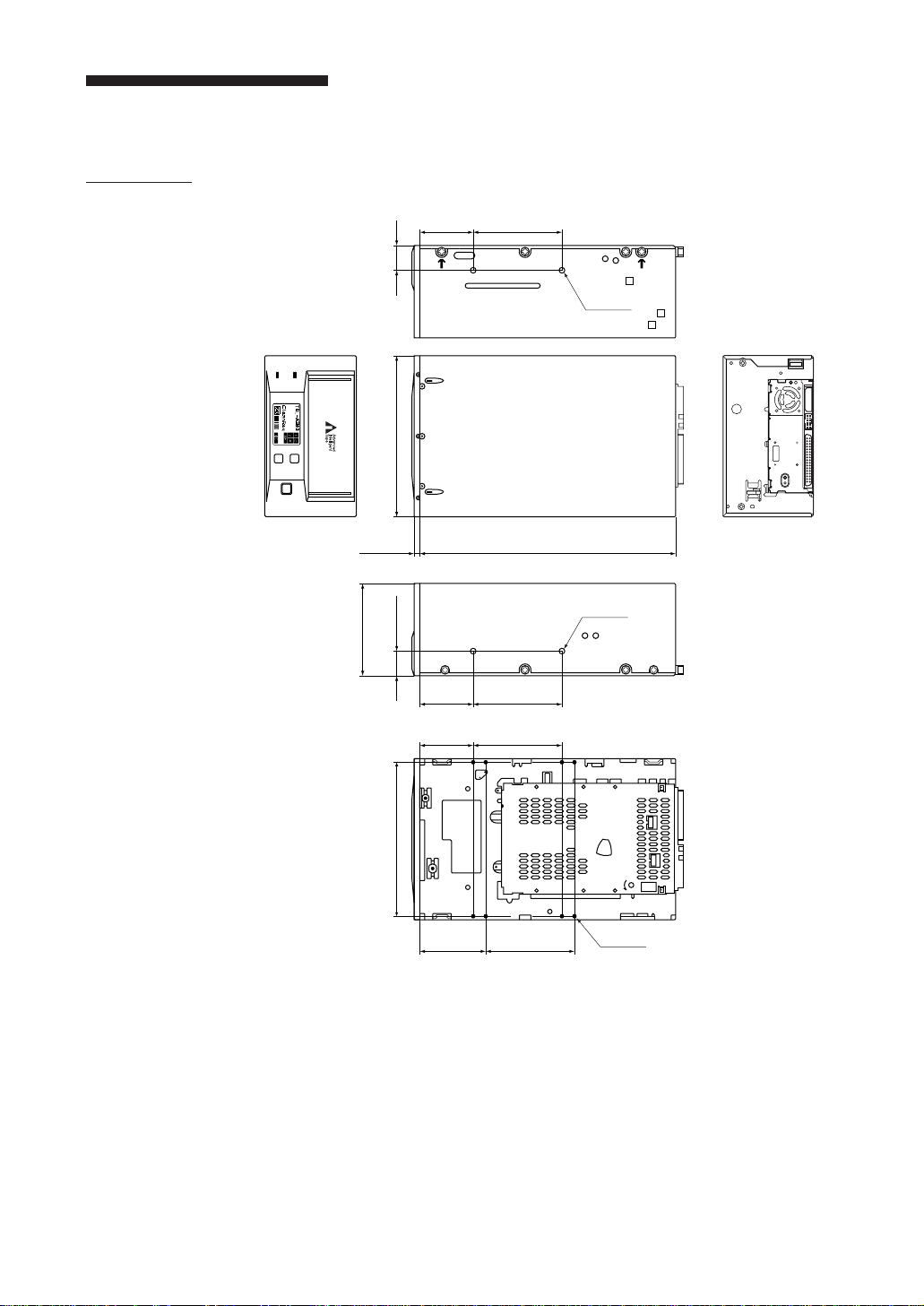

Mounting Holes

TSL-A300C

1.87

[47.5mm]

0.86

[21.8mm]

BUSY

TAPE

3.25

[82.5mm]

5.75

0.20

[5.0mm]

0.86

[146.0mm]

[21.8mm]

[47.5mm]

[47.5mm]

1.87

1.87

SELECT

ENTER

EJECT

3.12

[79.25mm]

[228.6mm]

3.12

[79.25mm]

3.12

[79.25mm]

2–M3

9.00

2–M3

26 Chapter 2 Operation

5.50

[139.7mm]

2.30

[58.5mm]

3.12

[79.25mm]

8–M3

Note:

Maximum mounting screw thread length is 3.0 mm. Longer thread length

may damage the drive.

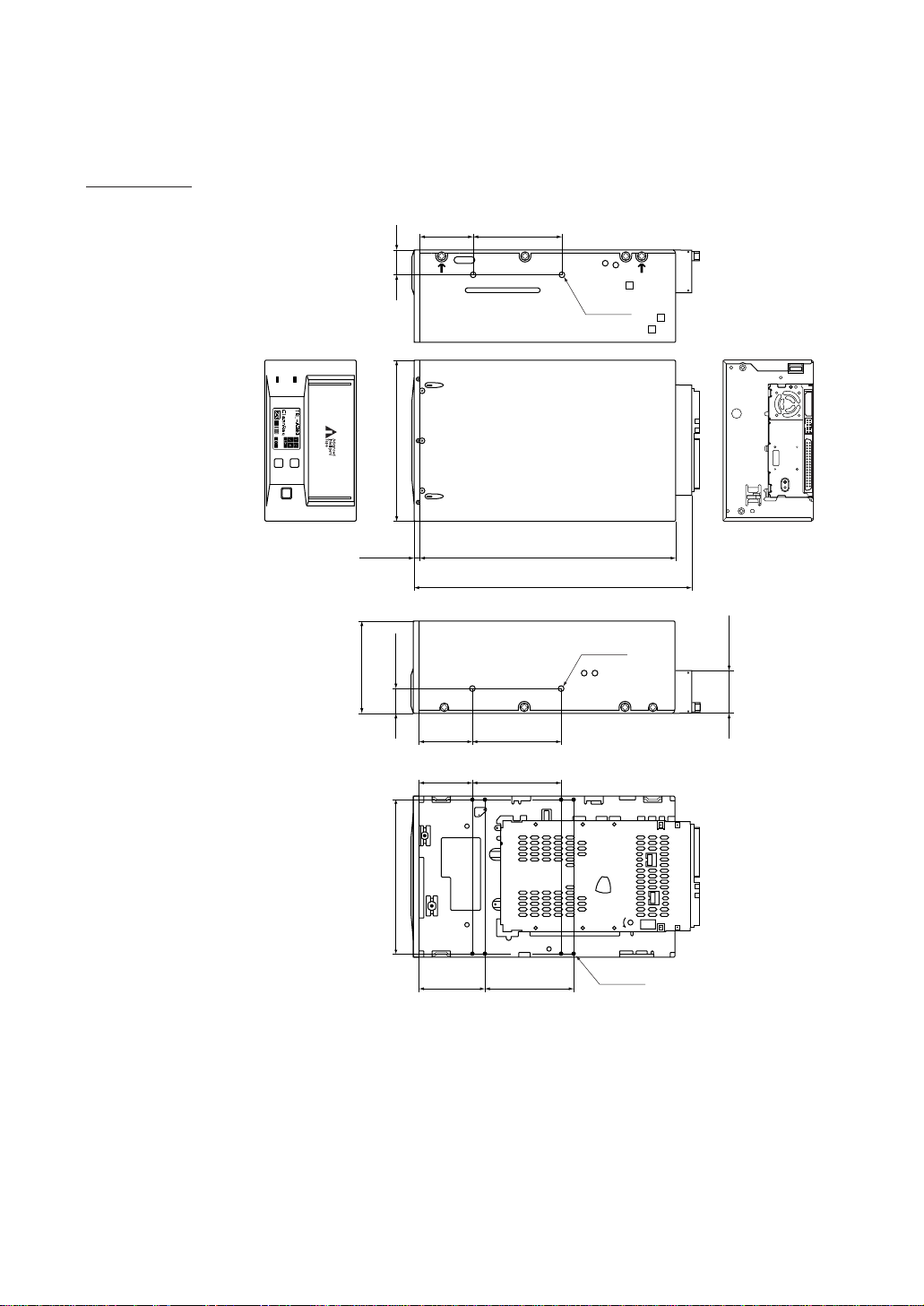

TSL-A310C

1.87

[47.5mm]

0.86

[21.8mm]

BUSY

TAPE

3.25

[82.5mm]

5.75

0.20

[5.0mm]

0.86

[146.0mm]

[21.8mm]

[47.5mm]

[47.5mm]

1.87

1.87

SELECT

ENTER

EJECT

3.12

[79.25mm]

[228.6mm]

3.12

[79.25mm]

3.12

[79.25mm]

9.00

9.55

[242.6mm]

2–M3

2–M3

1.62

[41.2mm]

5.50

[139.7mm]

2.30

[58.5mm]

3.12

[79.25mm]

8–M3

Note:

Maximum mounting screw thread length is 3.0 mm. Longer thread length

may damage the drive.

Chapter 2 Operation 27

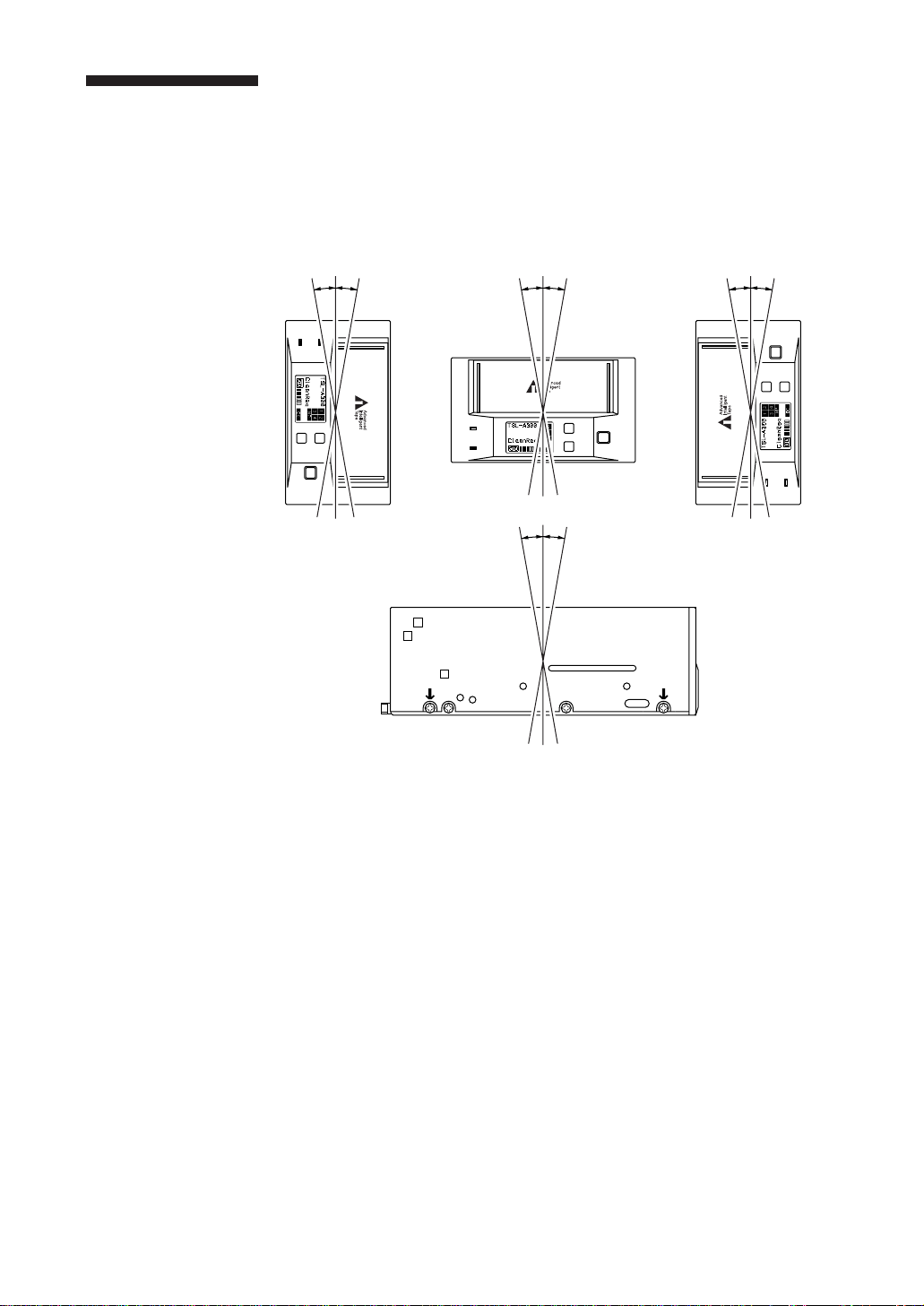

Orientation

The TSL-A300C can be installed in three different mounting positions as

shown in the figure below.

Each position has a maximum tolerance of +/– 10 degrees.

10 °

10 °

BUSY

TAPE

SELECT

ENTER

EJECT

BUSY

TAPE

10 °

10 °

10 °

10 °

SELECT

EJECT

ENTER

10 °

10 °

EJECT

ENTER

SELECT

BUSY

TAPE

28 Chapter 2 Operation

Appendix

Specifications

Performance

Storage Capacity

Approx 100-200 Gbytes

(When using compression with 4

AIT-1 cartridges)

Bit Error Rate

less than 10

Data Transfer Rate (Tape)

3 MB/s uncompressed

6 MB/s compressed

Burst Data Transfer Rate (SCSI)

10 MB/s maximum, asynchronous

20 MB/s maximum, synchronous

Magazine insertion/ejection time

2.5 seconds(typical)

Cartridge exchange time(control by SCSI)

55 seconds(typical, when using

MIC cartridges)

Rewind time less than 80 seconds (with 170 m

tape)

-17

Operating Environment

Operating

Temperature: 5 to 40 °C

Humidity: 20 to 80%

(no condensation)

(Max wet bulb temperature: 26°C)

Non-Operating

Temperature: –40 to +70 °C

Humidity: 10 to 90%

Shock

Operating

No Data Loss

Half Sine

5 G Peak 3 ms

3 axes, 3 directions

*Interval 10 seconds

Non-Operating

No Device Damage

Half Sine

90 G Peak 3 ms

(30 G Peak 11 ms)

3 axes, 3 directions

*Interval 10 seconds

Vibration

Operating

Swept Sine 5 to 500 Hz

*0.25 G Peak 1 Octave/min.

3 axes,3 directions

Non-Operating

Swept Sine 5 to 500 HZ

*0.5 G Peak 1 Octave/min.

3 axes,3 directions

Altitude

Operating

0 to 3048 m

Acoustic Noise

Streaming Write/Read : 35 dBA

Magazine Insert/Eject : 65 dBA

Cartridge Change : 70 dBA

Door Open/Close : 80 dBA

Note: The sound meter, set to the A scale, is

located 1m in front of the center of the

drive front panel.

Appendix 29

Power Requirements &

Miscellaneous

Power 5 VDC Tolerance: ±5 %

Current:1.8 A(typ.)

:3.0 A(max.)

Ripple :100 mVP-P

12 VDC Tolerance: ±10 %

Current:0.35 A(typ.)

:1.5 A(max.)

Ripple :150 mVP-P

AIT Autoloader Dimensions

(TSL-A300C) 146.0 × 82.5 × 228.6 mm

(W × H × D)

(excluding protruding parts)

(TSL-A310C) 146.0 × 82.5 × 242.6 mm

(W × H × D)

(excluding protruding parts)

Magazine Dimensions

104.0 × 36.5 × 131.5 mm

(W × H × D)

Weight

Autoloader 2.5 kg

(not including magazine)

Magazine 250 g

(not including cartridges)

Specifications may be subject to change, in the

interest of technological improvement, without

notice or obligation.

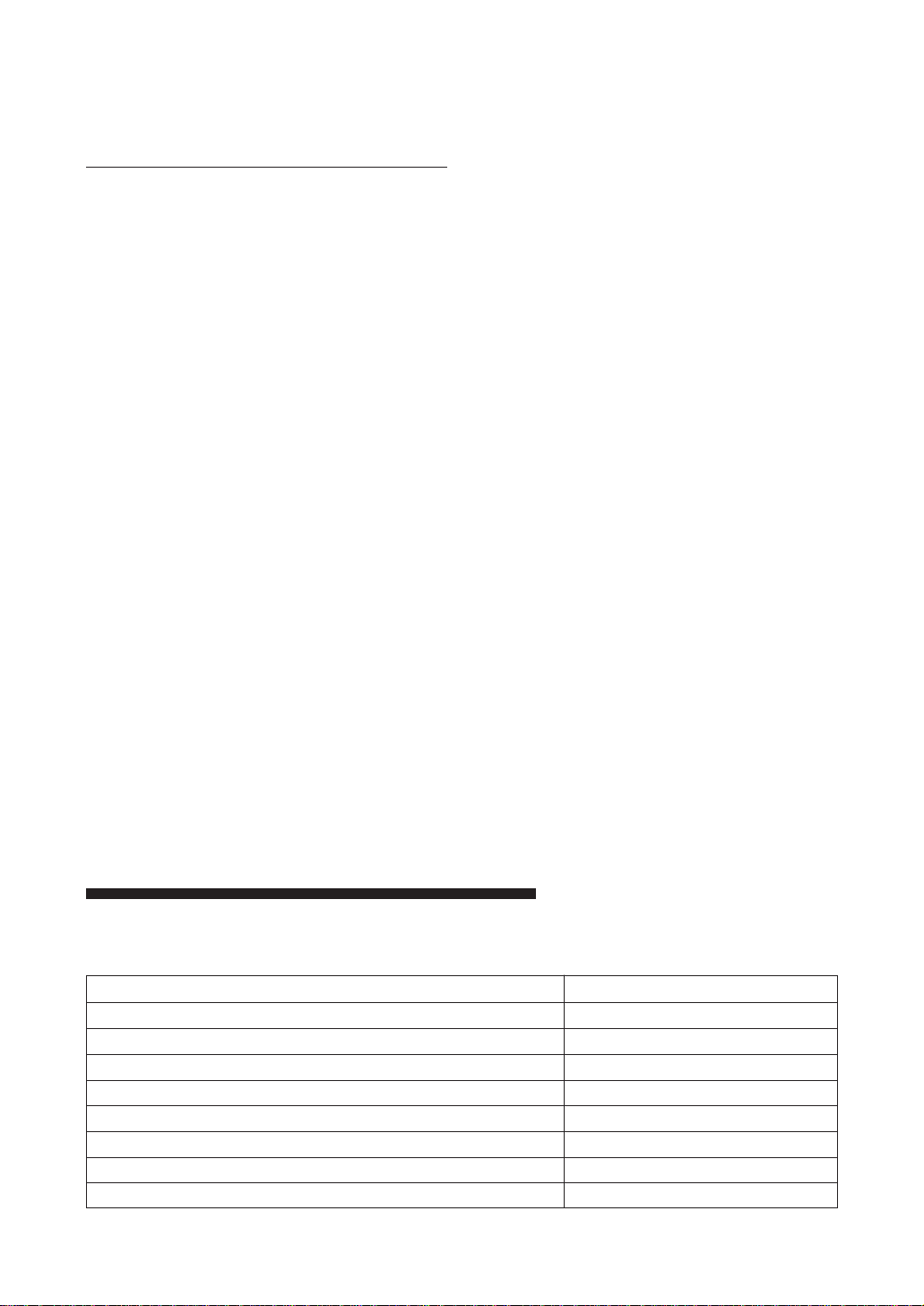

Third Party Support Contacts

Host Adapter Vendors Phone Numbers

Adaptec 408-945-8600

ATTO 716-691-1999

Bus Logic 408-492-9090

DPT 407-830-5522

Future Domain 714-253-0400

Initio 408-988-1919

Qlogic 714-438-2200

Ultera Systems Inc. 714-367-8800

30 Appendix

Loading...

Loading...