Sony Trinitron KV-ES34K90 Service Manual

http://cxema.ru

SERVICE MANUAL

AG3

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

KV-ES34K90 RM-959 KOREAN SCC-P41B-A

MODEL COMMANDER DEST. CHASSIS NO.

MUTING

DISPLAY DRC-MF POWER

MTS VIDEO

JUMP

TV/VIDEO

TWIN

ZOOM

IN

LEFT

FAVORITE

SOUND

SURROUND WAKE UP

MODE

PIC

MODE

231

564

897

0

FREEZE SWAP PIP

PIP CH

PIP CH

CHVOL

TV

TV

ENTER

MENU

ZOOM

IN

RIGHT

CH

INDEX

SLEEP

VIDEO

POWER

TITLE

TRINITRON

®

COLOR TV

http://cxema.ru

KV -ES34K90

RM-959

Power requirements 110-220 V AC, 60 Hz

Power consumption (W) Indicated on the rear of the TV

Television system M

Color system NTSC3.58

Stereo/Bilingual system Korean Stereo

Channel coverage

˘ (Antenna) 75-ohm external terminal

Audio output (Speaker) 15W + 15W 10% distortion

Number of terminal

Video Input: 4 Output: 1 Phono jacks; 1 VP-P, 75 ohms

Audio Input: 4 Output: 1 Phono jacks; 500 mVrms

S Video Input: 2 Y : 1 Vp-p, 75 ohms,

Component Video

(DVD) IN

DIGITAL IN Input: 1 Phono jack; 0.5 Vp-p, 75 ohms

2 (Headphones) Output: 1 Stereo minijack

Picture tube 34 inch

Tube size (cm) 86 Measured diagonally

Screen size (cm) 80 Measured diagonally

Dimension (w/h/d, mm) 859 x 650 x 573

Mass (kg) 84

SPECIFICATIONS

VHF: 2 ch to 13 ch / UHF: 14 ch to 69 ch / CATV: 1 ch to 125 ch

unbalanced, sync

negative

C : 0.286 Vp-p, 75 ohms

Input: 1 Phono jacks

Y : 1 Vp-p, 75 ohms,

sync negative

C

B : 0.7 Vp-p, 75 ohms

R : 0.7 Vp-p, 75 ohms

C

Audio : 500 mVrms

Note

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND

THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR

CARBON PAINTED ON THE CRT, AFTER REMOVING THE

ANODE.

Design and specifications are subject to change without notice.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMA TIC DIA GRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

http://cxema.ru

TABLE OF CONTENTS

KV-ES34K90

RM-959

Section Title Page

SELF DIAGNOSIS FUNCTION................................ 4

1. GENERAL........................................................................ 8

2. DISASSEMBLY

2-1. Rear Cover Removal................................................ 32

2-2. Speaker Box Removal ............................................. 32

2-3. H2 Board Removal .................................................. 32

2-4. Chassis Assy Removal ............................................. 33

2-5. Service Position ....................................................... 33

2-6. DH Board Removal ................................................. 33

2-7. J Board Removal...................................................... 33

2-8. B3, D1 and E Boards Removal................................ 34

2-9. A and D Boards Removal ........................................ 34

2-10. H1 Board Removal .................................................. 34

2-11. F2 Board Removal ................................................... 34

2-12. Demagnetization Coil Removal .............................. 35

2-13. Top Switch Removal CH3 Board Removal............. 35

2-14. G2 Lead Removal .................................................... 35

2-15. Picture Tube Removal.............................................. 36

2-16. Frame Sub-Assy Disassembly ................................. 36

3. SERVICE JIG

3-1. Jig Required for Servicing....................................... 39

4. SET-UP ADJUSTMENTS

4-1. Beam Landing .......................................................... 40

4-2. Convergence Adjustment......................................... 41

4-3. Focus Adjustment .................................................... 43

4-4. Neck Assy Twist Adjustment................................... 43

4-5. G2 (Screen) and White Balance Adjustments ......... 44

Section Title Page

6. DIAGRAMS

6-1. Block Diagram ......................................................... 67

6-2. Frame Schematic Diagram ..................................... 85

6-3. Circuit Boards Location ......................................... 88

6-4. Schematic Diagrams and Printed Wiring Boards .. 88

(1) Schematic Diagram of A Board ............................. 93

(2) Schematic Diagram of D Board ............................. 97

(3) Schematic Diagram D1 Board............................... 105

(4) Schematic Diagrams of C, F1 and VM Boards...... 113

(5) Schematic Diagram of E Board.............................. 117

(6) Schematic Diagrams of H1, H2 and H3 Boards ....124

(7) Schematic Diagram of B3 (1/6) Board .................. 129

(8) Schematic Diagram of B3 (2/6) Board .................. 133

(9) Schematic Diagram of B3 (3/6) Board .................. 137

(10) Schematic Diagram of B3 (4/6) Board .................. 141

(11) Schematic Diagram of B3 (5/6) Board .................. 145

(12) Schematic Diagrams of B3 (6/6) and F2 Boards ... 149

(13) Schematic Diagram of DH Board .......................... 153

(14) Schematic Diagram of A1 Board ........................... 159

(15) Schematic Diagram of BC4 Board......................... 163

(16) Schematic Diagram of J Board............................... 173

6-5. Semiconductors....................................................... 177

7. EXPLODED VIEWS

7-1. Speaker Bracket ...................................................... 181

7-2. Chassis .................................................................... 182

7-3. Picture Tube ............................................................ 183

8. ELECTRICAL PARTS LIST...................................... 184

5. CIRCUIT ADJUSTMENTS

5-1. Adjustments with Commander ................................ 45

5-2. Adjustment Method ................................................. 46

5-3. Picture Quality Adjustments.................................... 60

5-4. Deflection Adjustment ............................................. 62

5-5. A Board Adjustment After IC003

(memory) Replacement ........................................... 63

5-6. Picture Distortion Adjustment................................. 64

– 3 –

http://cxema.ru

KV -ES34K90

RM-959

SELF DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER lamp will automatically

begin to flash.

The number of times the lamp flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER

lamp flash indicators is listed in the instruction manual for the user’s knowledge and reference. If an error symptom cannot

be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to reveal past

problems and how often these problems occur.

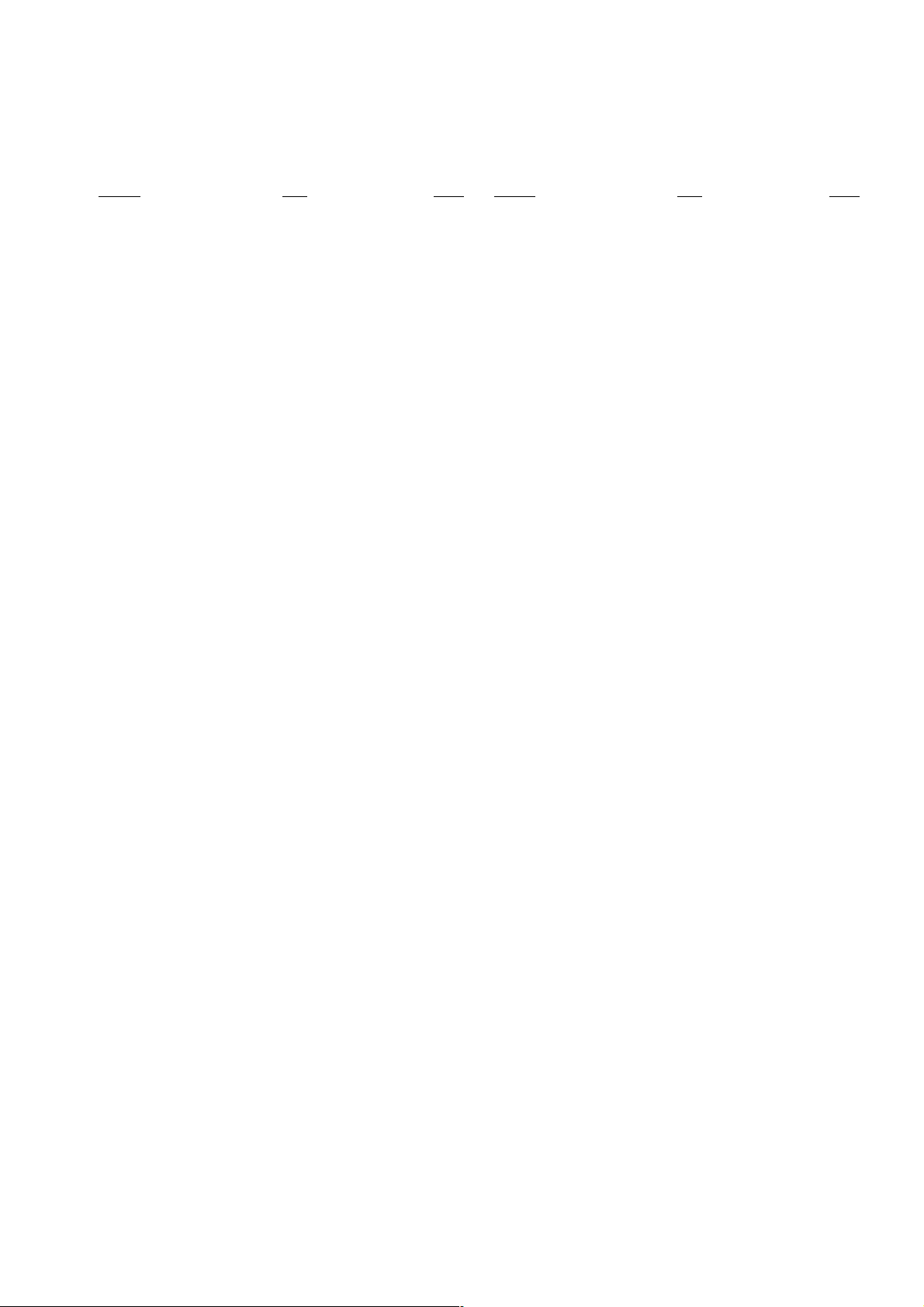

1. DIAGNOSTIC TEST INDICA TORS

When an errors occurs, the STANDBY/TIMER lamp will flash a set number of times to indicate the possible cause of the

problem. If there is more than one error, the lamp will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen. No error has occured if the screen displays a “0”.

Diagnostic

Item

Description

• Power does not

turn on

• +B overcurrent

(OCP)

• +B overvoltage

(OVP)

• Vertical deflection

failure

• White balance

failure (no

PICTURE)

• Horizontal

deflection

failure

• Audio Protection

• Micro reset

No. of times

STANDBY/TIMER

lamp flashes

Does not light

2 times

3 times

4 times

5 times

6 times

7 times

—

Self-diagnostic

display/Diagnostic

result

—

002:000 or

002:001~255

003:000 or

003:001~255

004:000 or

004:001~255

005:000 or

005:001~255

006:000 or

006:001~225

007:000 or

007:001~225

101:00 or

101:001~225

Probable

Cause

Location

• Power cord is not plugged

in.

• Fuse is burned out F1601

(F1 Board)

• H.OUT Q6807 is shorted.

• H.LIM Q6810 is shorted.

• PH 6602 faulty.

• 10.5V is not supplied.

(D board)

• V.OUT IC6800 faulty

D6816 faulty

D6817 faulty

D6824 faulty

R6852 open

R6851 open

• G2 is improperly adjusted.

(Note 2)

• CRT problem.

• Video OUT IC9001, 9002,

9003 are faulty. (C board)

• IC8306 (J board) and

IC4301 (E board) are faulty.

• No connection E board to C

board.

• C6831 is open circuit.

• CN6101 (D1 board) is

disconnected.

• Power supply fails.

• IC1203, IC1204 faulty

• Discharge CRT (C Board)

• Static discharge

• External noise

Detected

Symptoms

• Power does not come on.

• No power is supplied to the

TV.

• AC power supply is faulty.

• Power does not come on.

• Load on power line is

shorted.

• Power does not come on.

• Vertical deflection pulse is

stopped.

• Vertical size is too small.

• Vertical deflection stopped.

• No raster is generated.

• CRT cathode current

detection reference pulse

output is small.

• H pulse output is too high.

• There is picture but speaker

does not release sound.

• Power is shut down shortly,

after this return back to

normal.

• Detect Micro latch up.

Note 1: Refer to screen (G2) Adjustment in section 4-5 of this manual.

– 4 –

http://cxema.ru

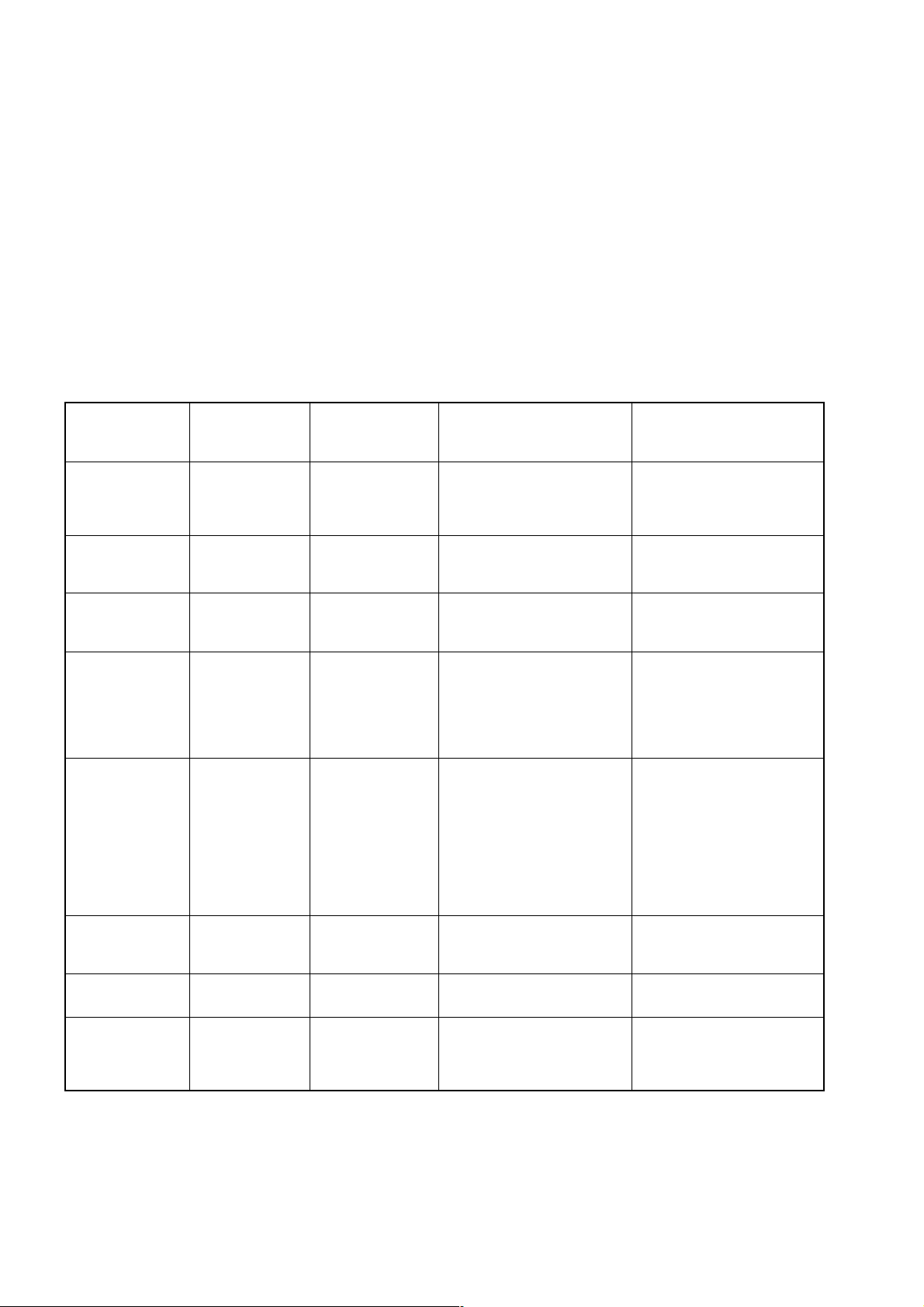

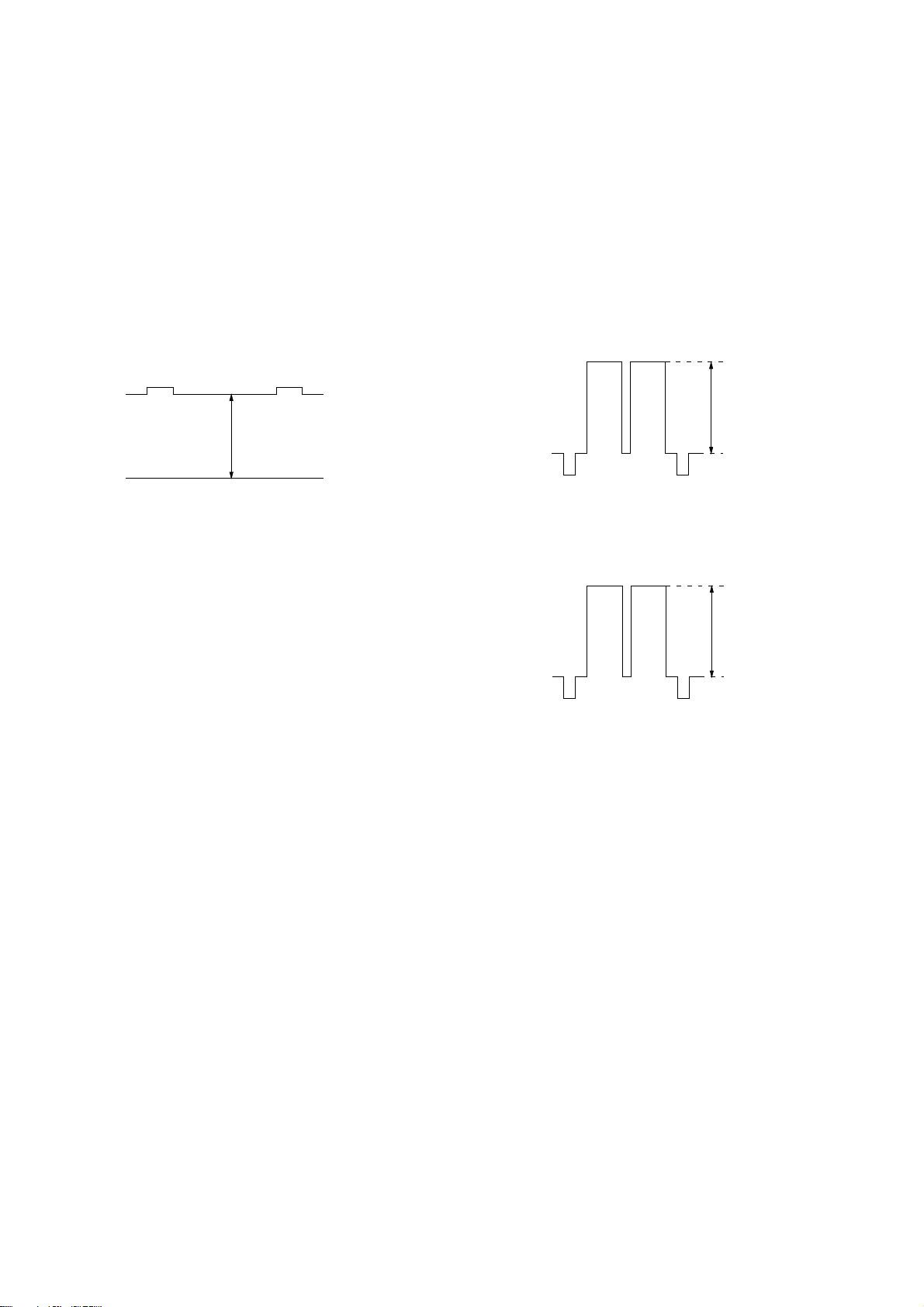

2. DISPLAY OF STANDBY/TIMER LIGHT FLASH COUNT

2 times

3 times

KV-ES34K90

RM-959

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

4 times

5 times

6 times

7 times

Diagnostic Item Flash Count*

+B overcurrent 2 times

+B overvoltage 3 times

V deflection stop 4 times

White balance failure 5 times

High voltage protector 6 times

Audio Protection 7 times

Lamp OFF 3 sec.

STANDBY/SLEEP lamp

* One flash count is not used for self-diagnostic.

3. STOPPING THE STANDBY/TIMER FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER lamp

from flashing.

– 5 –

http://cxema.ru

KV -ES34K90

RM-959

4. SELF-DIAGNOSTIC SCREEN DISPLAY

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it

is possible to bring up past occurances of failure for confirmation on the screen:

[To Bring Up Screen Test]

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

[Screendisplay] / channel [5] / Sound volume [-] / Power ON

˘

Note that this differs from entering the service mode (mode volume [+]).

Self-Diagnosis screen display

SELF DIAGNOSTIC

002 : 000

003 : 000

004 : 000

005 : 001

006 : 002

007 : 000

101 : 000

Numeral "0" means that no fault has been detected.

Numeral "1" means a fault has been detected.

Numeral "2" means two faults have been detected.

5. HANDLING OF SELF-DIAGNOSTIC SCREEN DISPLAY

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

during repairs. When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after

completion of the repairs.

[Clearing the result display]

To clear the result display to “0”, press buttons on the remote commander sequentially as shown below when the diagnostic

screen is being displayed.

Channel [8] / 0

[Quitting Self-diagnostic screen]

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

– 6 –

http://cxema.ru

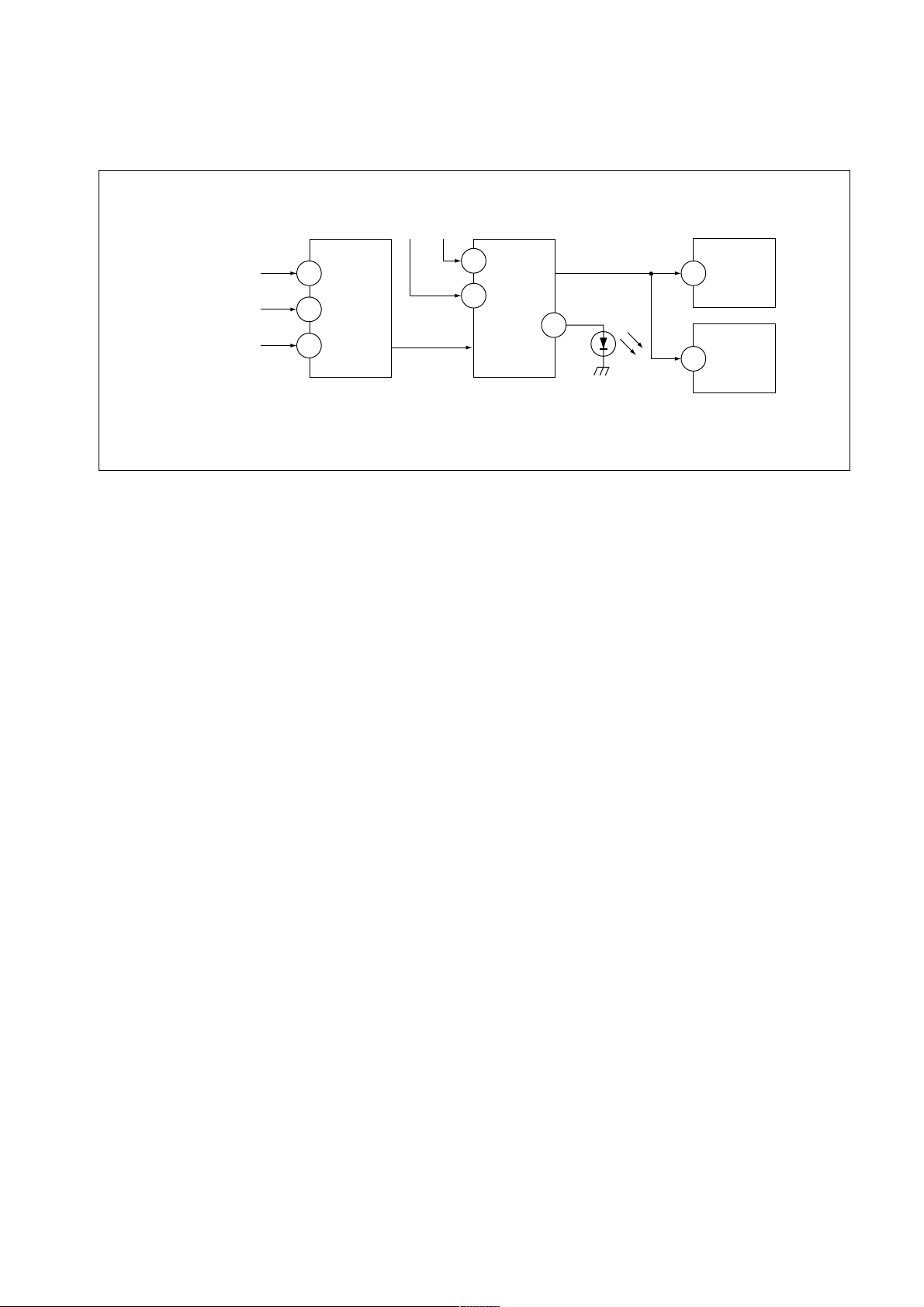

6. SELF-DIAGNOSTIC CIRCUIT

KV-ES34K90

RM-959

FROM

CRT (IK)

[H] IC6801

[V] D6806/D6801

IC4301

RGB JUNGLE

IKIN

20

XRAY

16

V PROT

CXA2100Q

OVP OCP

SDA

SYSTEM

3

6

IC001

LED

54

SDA

IC003

MEMORY

525

5

IC004

MEMORY

[+BovercurrentªOCPº] Occurs when an overcurrent on the +B(135) line is detected by Q6610

and Q6609.

If Q6610 and Q6609 go to ON, the voltage to the pin3 of IC001 go to UP.

The unit will automatically turn off.

[+BovervoltageªOVPº] Occurs when an overvoltage on the +B(135) line is detected by D6635,

Q6611 and Q6612. If Q6611 and Q6612 go to ON, the voltage to pin6 of

IC001 go to UP. The unit will automatically turn off.

[Verticaldeflectionfailure] Occurs when an absence of the vertical deflection pulse is detected by

Q6811, Q6819, Q6820, Q6821 and D6801. Shut down the power supply.

[Whitebalancefailure] If the RGB levels do not balance or become low level within 5 seconds.

This error will be detected by IC4301.

TV will stay on, but there will be no picture.

[HighvoltageprotectorofHorizontalDeflection] Occurs when an overvoltage of horizontal pulse is detected by D6809 and

IC6801.

If the voltage of 7 pin of IC6801 goes to High, the voltage to pin20 of

IC4301 go to UP. The unit will automatically turn off.

– 7 –

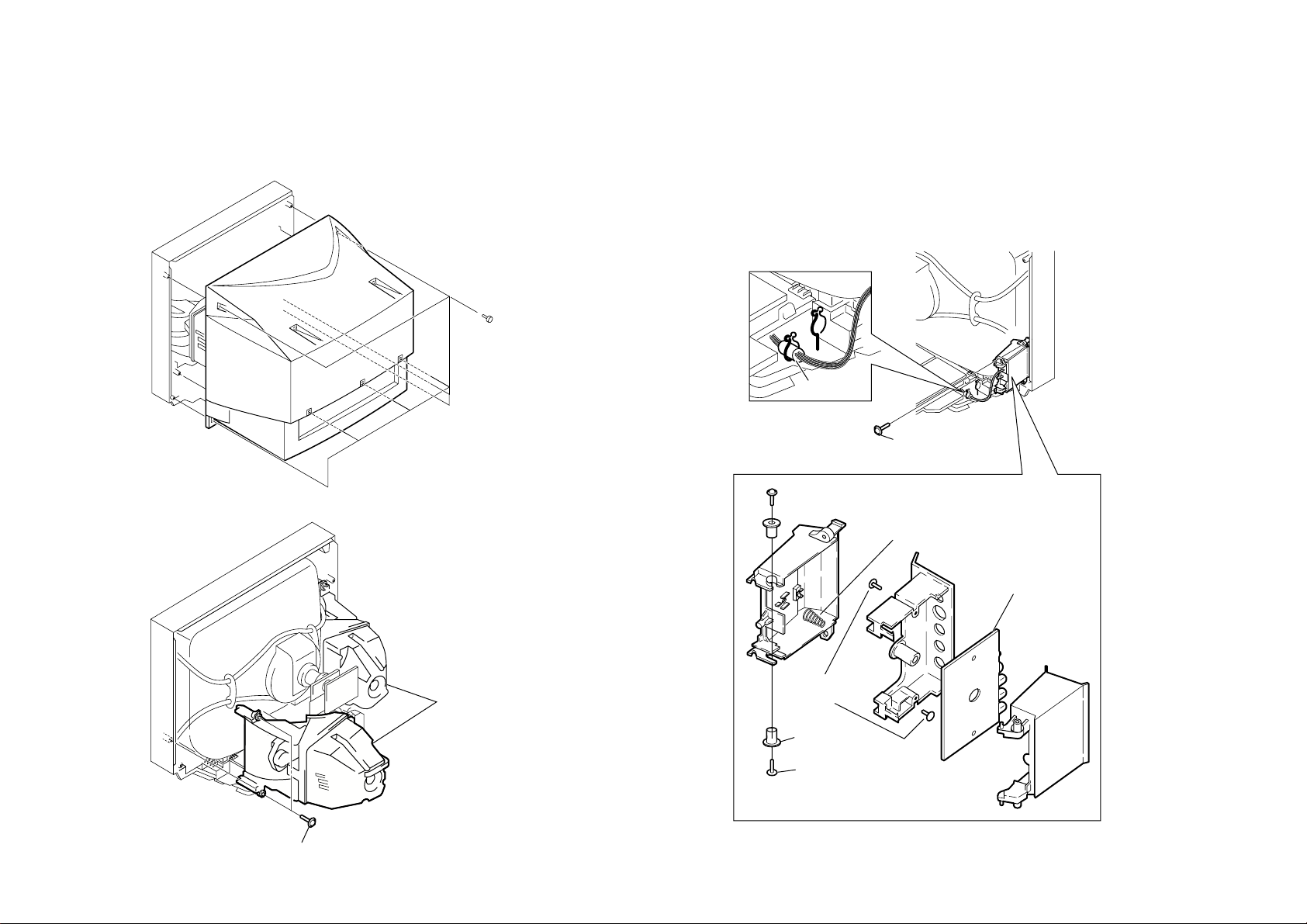

KV -ES34K90

Eight screws

(+BVTP 4X20)

1

Two screws

(TP + TWH 4X25)

2 SPEAKER BOX

L/R ASSEMBLY

1

One screw

(+BVTP 4X20)

Red tape

2

Two screws

(+BVTP 3X25)

4

Two shafts

5

Two screws

(+BVTP 3X12)

1

One spring

3

H2 Board

– 32 –

2-1. REAR COVER REMOVAL

2-2. SPEAKER BOX REMOVAL

SECTION 2

DISASSEMBLY

2-3. H2 BOARD REMOVAL

Caution: Please make sure that the red colour taped point is just placed with the

RM-959

purse lock when treating the leads to H2 board. If lead treatment is wrongly

arranged, it will affect the door opening and closing malfunction.

2-4. CHASSIS ASSY REMOVAL

Chassis

CRT Supporter

Blacket

DH board

1 Six screws

(+BVTP 3X12)

1 Two screws

(+BVTP 3X12)

1 Three screws

(+BVTP 3X12)

(+BVTP 3X12)

Four screws

3

4 J board

5 J sheild cover

Metal Case

Terminal bracket

A board

D board

2-6. DH BOARD REMOVAL

– 33 –

2-5. SERVICE POSITION

2-7. J BOARD REMOVAL

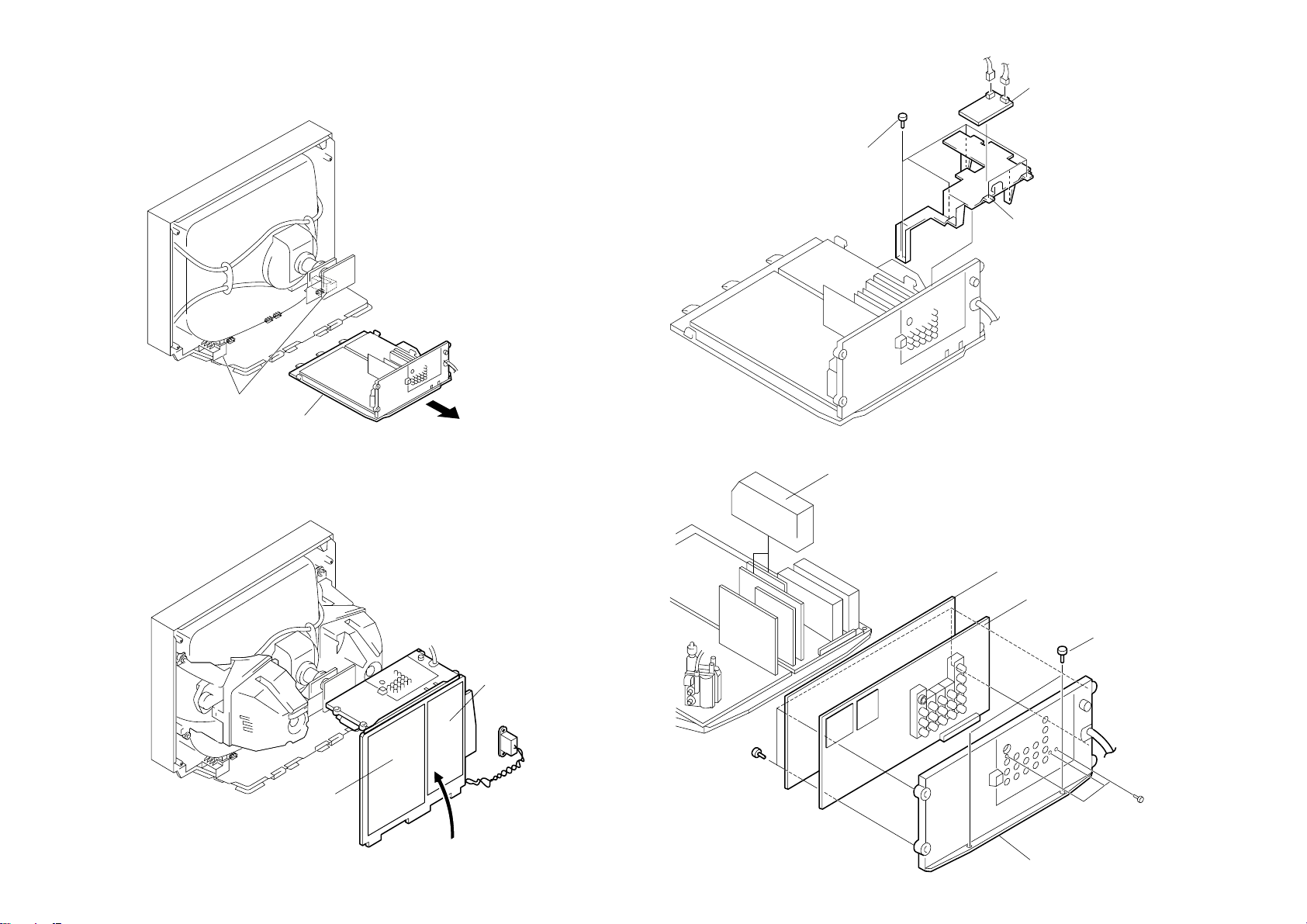

KV-ES34K90

RM-959

KV -ES34K90

2 Two connectors

3 Two connectors

5 V board

4 B3 board

7 D1 board

8 E board

Driver

P board

6 Metal Case

V board

1 Three screws

(+BVTP 3X12)

3

D board

2 A board

1 Three connectors

1 Four screws

(+BVTP 3X12)

Driver

H1 bracket

1

2

Driver

F2 bracket

1

2

2-8. B3, D1 AND E BOARDS REMOVAL

NOTE : V Board is not used for this model.

– 34 –

2-9. A AND D BOARDS REMOVAL

2-10. H1 BOARD REMOVAL

NOTE : Push the hook down using the tip of a screwdriver and at the same time

pull the H1 bracket.

2-11. F2 BOARD REMOVAL

NOTE : To remove F2 board, firstly remove the H1 board. Then, push the hook

down using the tip of a screwdriver and at the same time pull the F2

bracket.

Caution : When removing the F2 board, please turn off the main AC supply and

disconnect the AC plug.

RM-959

– 35 –

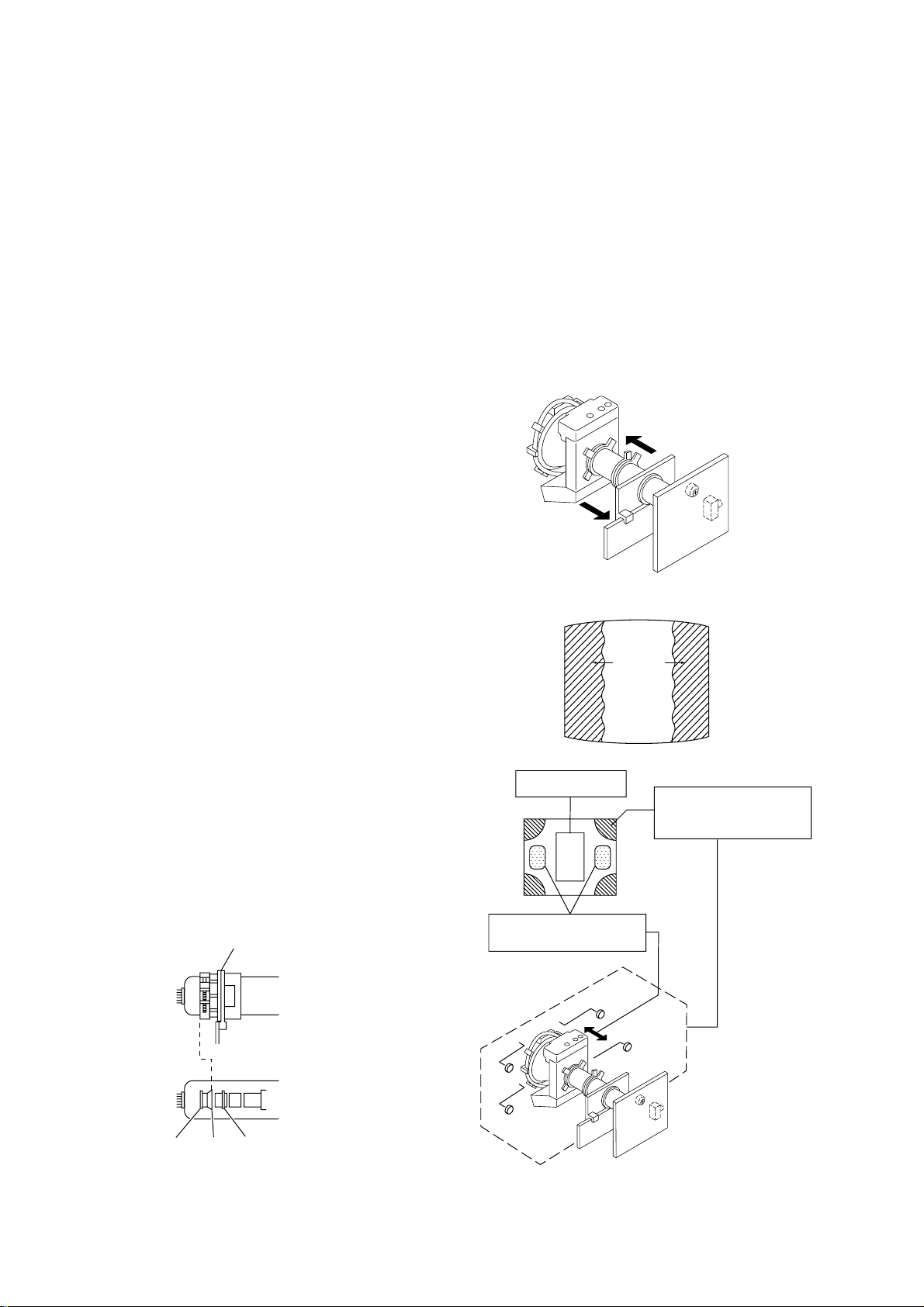

3 Two DGC clips

1 Two DGC holders

2 DGC band

4 Demagnetization

coil

1

2

Pin

4 Top switch

3 H3 board

2 H3 bracket

1 Two screws

(+BVTP 4X12)

5 One screw

(+BVTP 3X8)

2-12. DEMAGNETIZATION COIL REMOVAL

2-13. TOP SWITCH REMOVAL (H3 BOARD REMOVAL)

NOTE : To remove H3 board, the CRT has to be removed first.

2-14. G2 LEAD REMOVAL

NOTE : Insert pin to both edge holes on socket and release the lock.

KV-ES34K90

RM-959

KV -ES34K90

7 C board

5 Chassis assembly

8 Neck assembly

2 Speaker box(L)

assembly

2

Speaker box(R)

assembly

9 Deflection yoke

9 Two springs

4 Two claws

!™Two DGC

holders

!¡ Two hooks

!¢ DGC band

!£ Two DGC clips

3 Anode cap

!§ Four screws

6 Four screws

(+BVTP 4X20)

!¶ Picture tube

Cushion

1 Two screws

(TP+TWH 4X25)

1 Two screws

(TP+TWH 4X25)

!∞ Demagnetization

coil

Screw Special (Dia. 8)

Sp Screw

Fasten

× 1

× 1

× 2

× 1

Sp Screw

× 1

Sp Screw

× 1

Sp Screw

× 2

× 2

× 1

× 1 × 1

(+) TP 4 × 9

CRT Bracket

– 36 –

2-15. PICTURE TUBE REMOV AL

NOTE :i) Pr ior to picture tube removal, please remove the front cover first.

Caution : Aluminium frame is easily scratched if extra caution is not taken when

handling it.

2-16. FRAME SUB-ASSY DISASSEMBLY

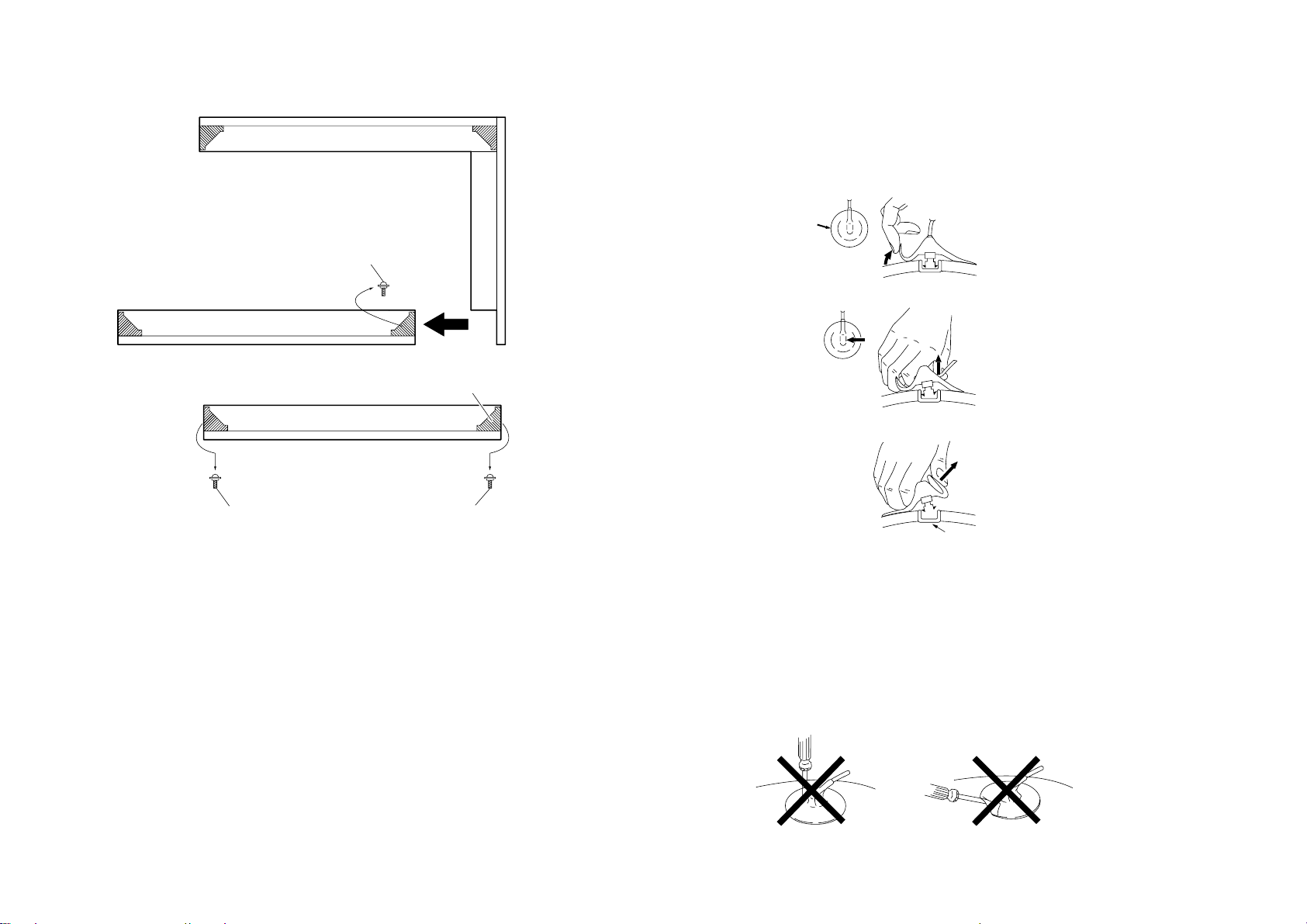

1

RM-959

Corner Block

Slide

Screw Special (Dia. 8)

× 2

(+) TP 4 × 9

Screw Special (Dia. 8)

× 1

(+) TP 4 × 9

FRAME SUB ASSY, RIGHT REMOVAL

Slide

Screw Special (Dia. 8)

× 2

(+) TP 4 × 9

Screw Special (Dia. 8)

× 2

(+) TP 4 × 9

Slide

Screw Special (Dia. 8)

× 2

(+) TP 4 × 9

Screw Special (Dia. 8)

× 2

(+) TP 4 × 9

Screw Special (Dia. 8)

Corner Block

(+) TP 4 × 9

× 2

a)

b)

– 37 –

FRAME SUB ASSY, LEFT REMOVAL

FRAME SUB ASSY, TOP REMOVAL

KV-ES34K90

RM-959

KV -ES34K90

Slide

Screw Special (Dia. 8)

× 2

(+) TP 4 × 9

Screw Special (Dia. 8)

× 2

(+) TP 4 × 9

Screw Special (Dia. 8)

Corner Block

(+) TP 4 × 9

× 2

a)

b)

Anode button

a

a

b

b

c

– 38 –

FRAME SUB ASSY, BOTTOM REMOVAL

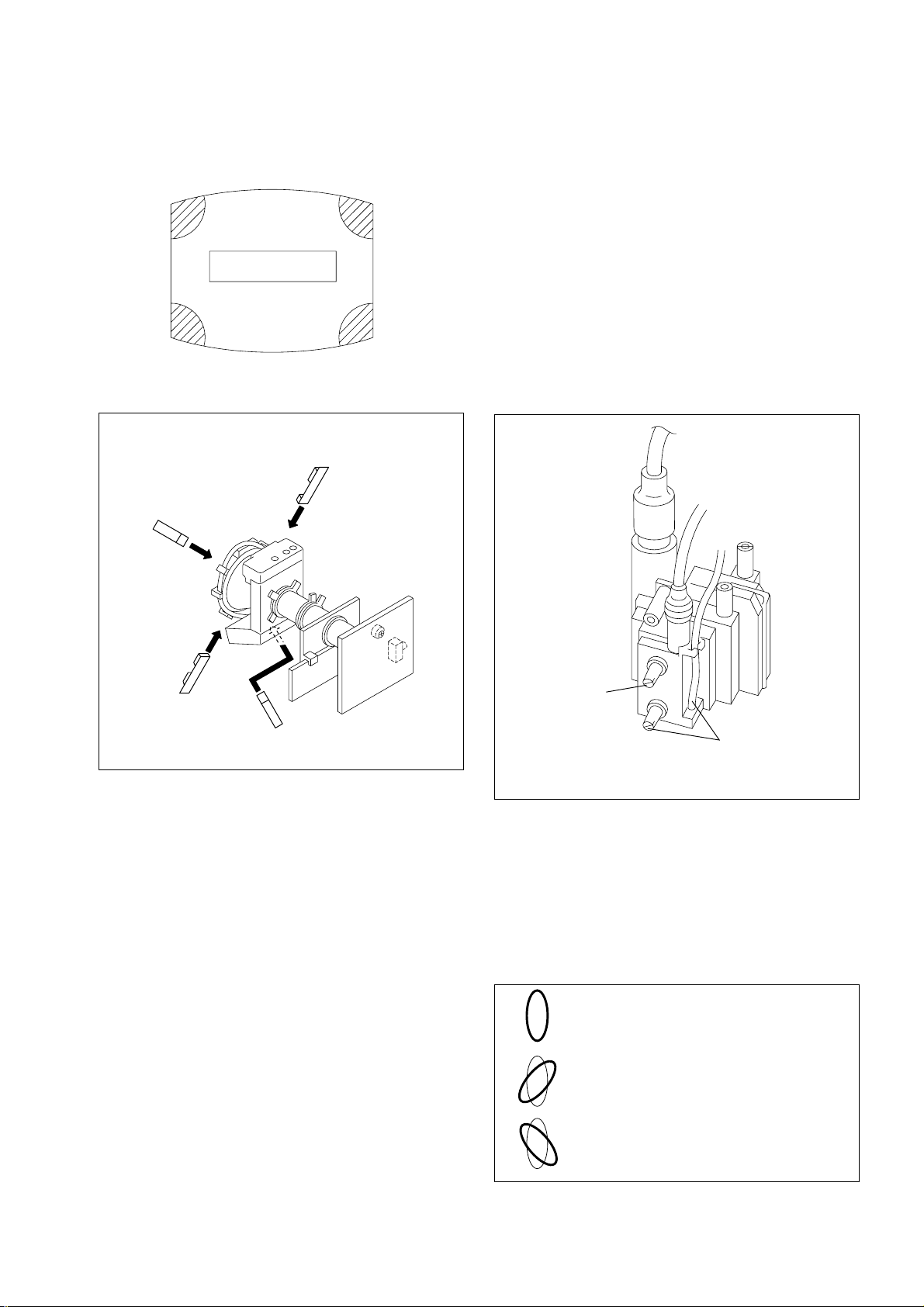

•REMOVAL OF ANODE-CAP

NOTE : After removing the anode, short circuit the anode of the picture tube and

the anode cap to the metal chassis, CRT shield or carbon paint on the

CRT.

•REMOVING PROCEDURES

1 Turn up one side of the rubber cap in the direction indicated by the arrow a.

2 Using a thumb pull up the rubber cap firml y in the direction indicated b y the arro w b.

RM-959

NOTE : When replacing the Frame Sub-Assy Top and Bottom, fix the original cor ner

block to the new part.

3 When one side of the rubber cap is separated from the anode button, the anode-cap

can be removed by turning up the rubber cap and pulling it up in the direction of the

arrow c.

• HOW TO HANDLE AN ANODE-CAP

1 Do not damage the surface of anode-caps with sharp shaped objects.

2 Do not press the rubber too hard so as not to damage the inside of anode-cap.

A metal fitting called the shatter-hook terminal is built into the rubber.

3 Do not turn the foot of rubber over too hard.

The shatter-hook terminal will stick out or damage the rubber.

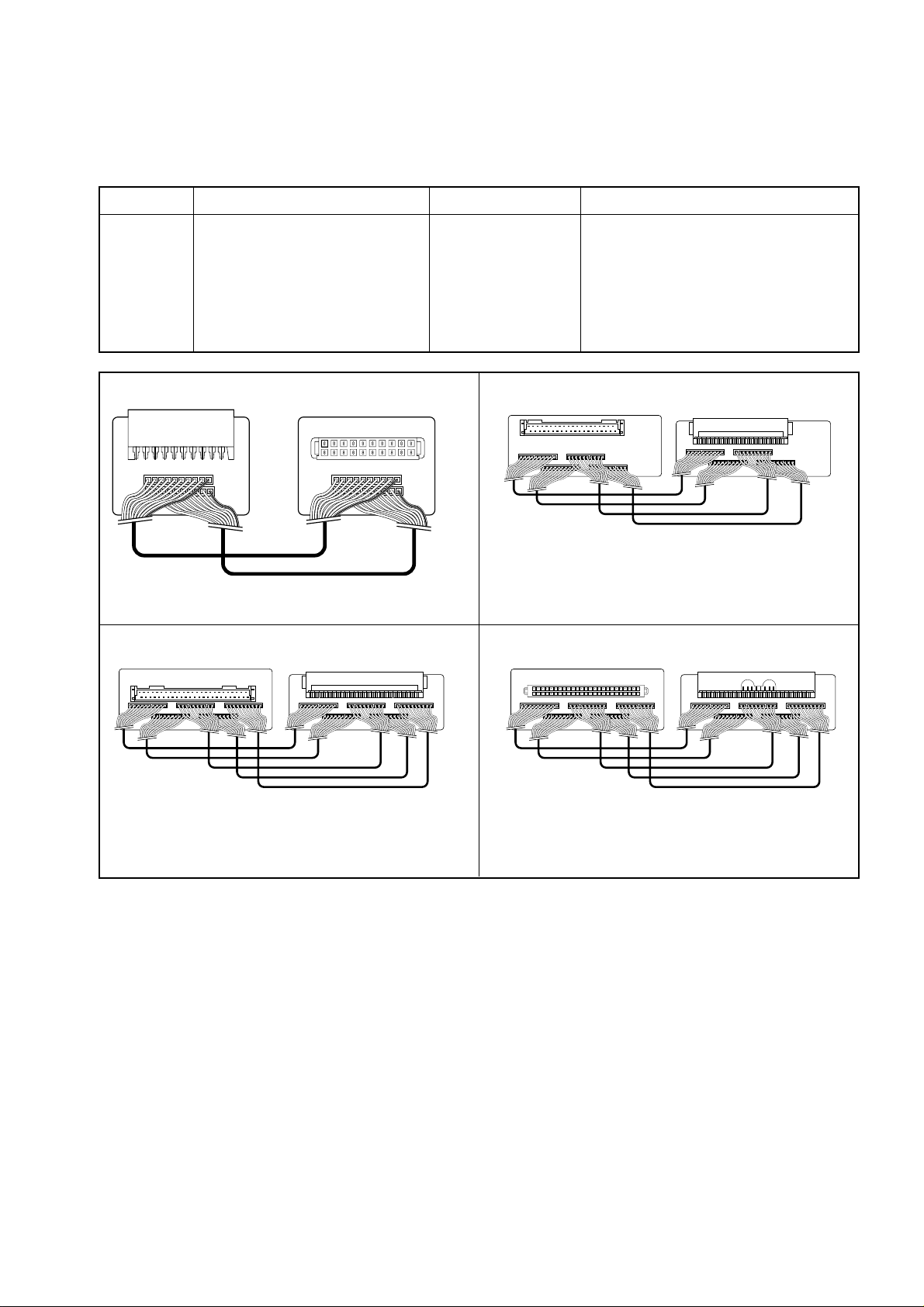

SECTION 3

SERVICE JIG

3-1. JIGS REQUIRED FOR SERVICING

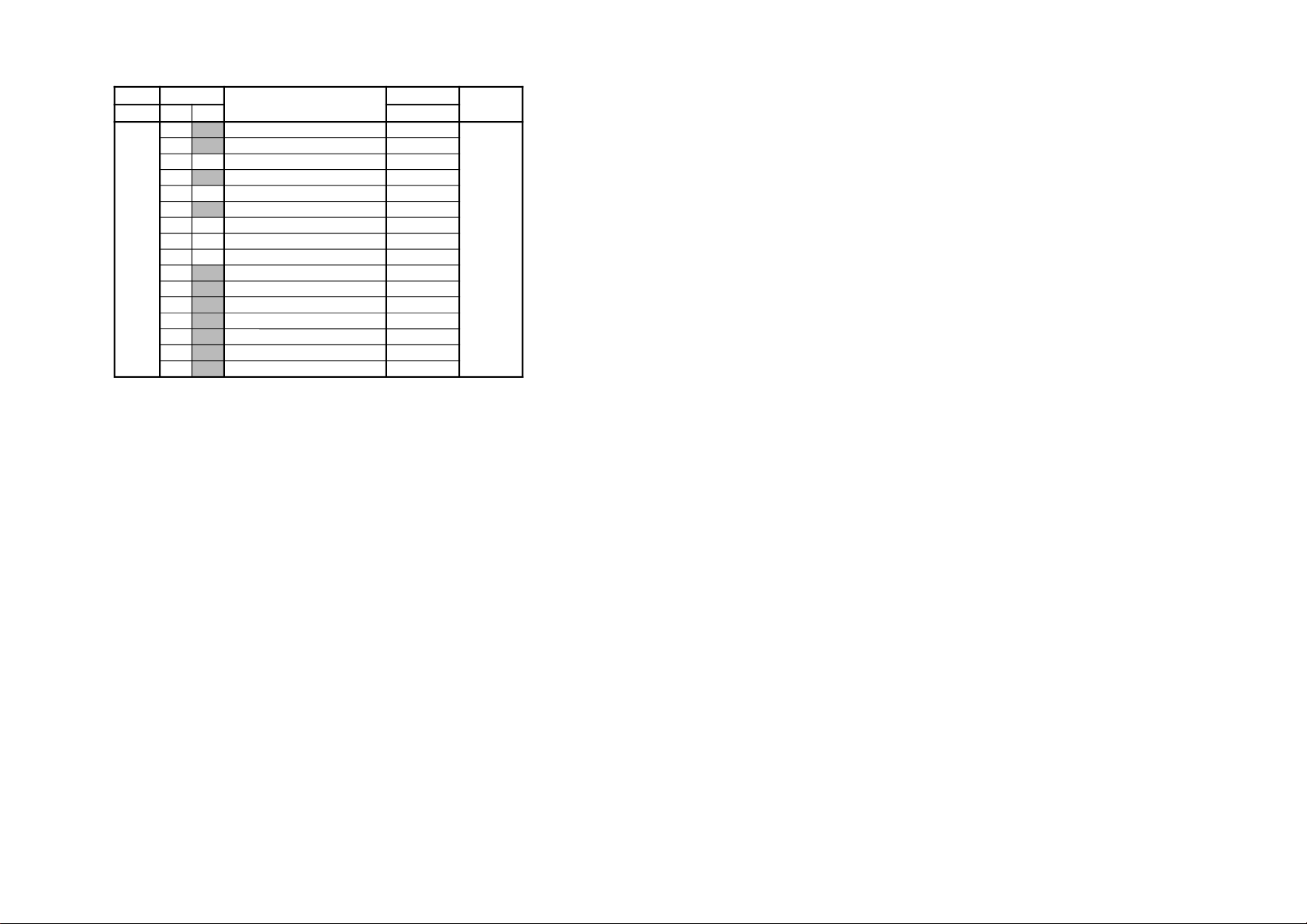

REF NO. DESCRIPTION PART NO. REMARK

J-1 TOOL (20P), SERVICE 3-702-763-01 For A to V board extension

J-2 TOOL (40P), SERVICE 3-702-764-01 For A to E board extension

J-3 TOOL (50P-A), SERVICE 3-702-765-01 For A to B3 board extension

J-4 TOOL (50P-J), SERVICE 3-702-766-01 For A to J board extension

For D to D1 board extension

J-1 J-2

EX

3

EX2EX1

KV-ES34K90

RM-959

EX

4

J-3 J-4

EX

5

EX

6

EX

7

EX

8

– 39 –

KV -ES34K90

RM-959

SECTION 4

SET-UP ADJUSTMENTS

• The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

• These adjustments should be performed with rated power

supply voltage unless otherwise noted.

Controls and switches should be set as follows unless otherwise noted:

PICTURE control........................................................... normal

BRIGHTNESS control................................................... normal

................................................................................................................................................................................................................................

Preparation :

• In order to reduce the influence of geomagnetism on the set's

picture tube, face it east or west.

• Switch on the set's power and degauss with the degausser.

Perform the adjustments in the following order :

1. Beam Landing

2. Convergence

3. Focus

4. White Balance

Note : Test Equipment Required.

1. Color-bar/Pattern Generator

2. Degausser

3. Oscilloscope

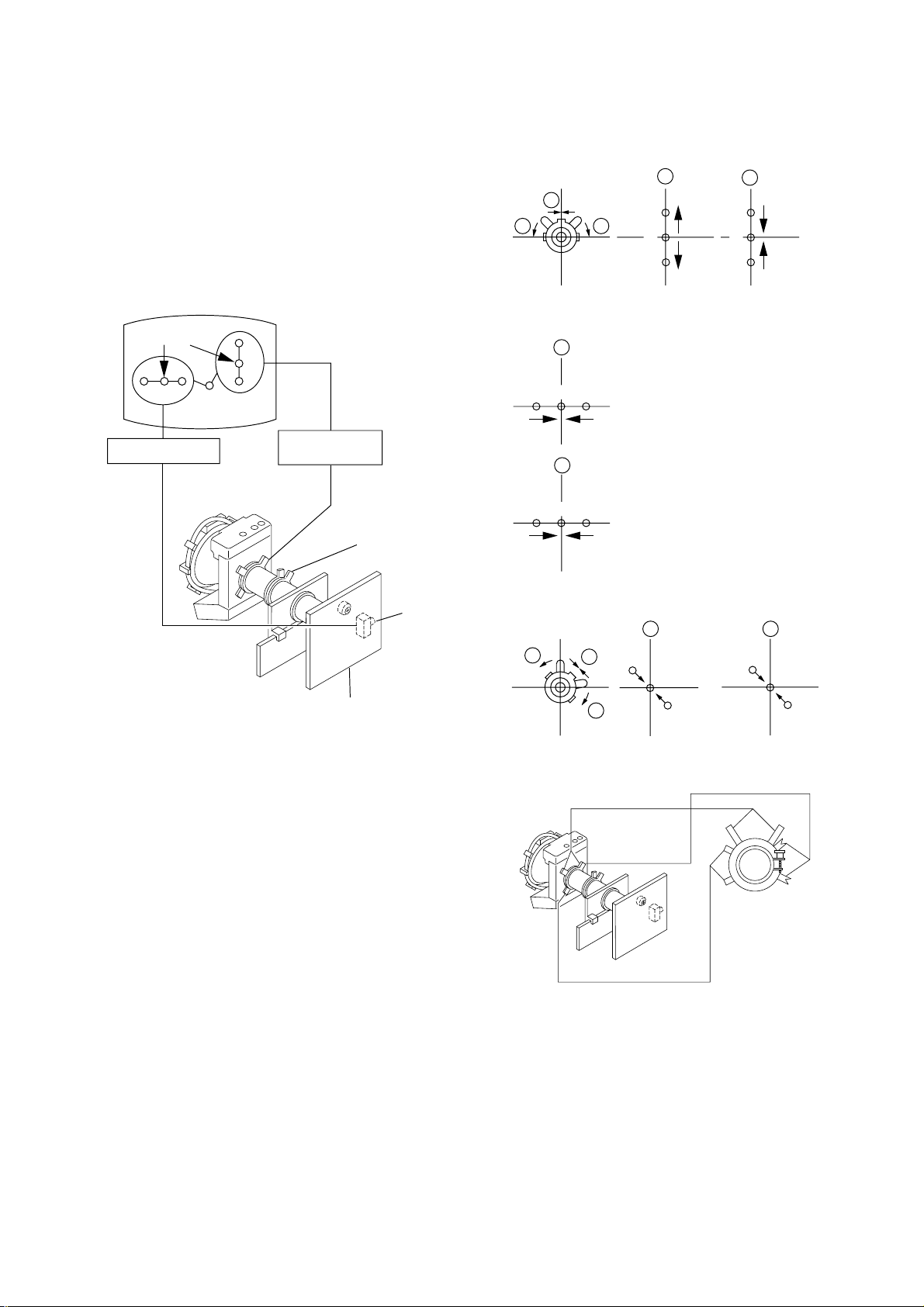

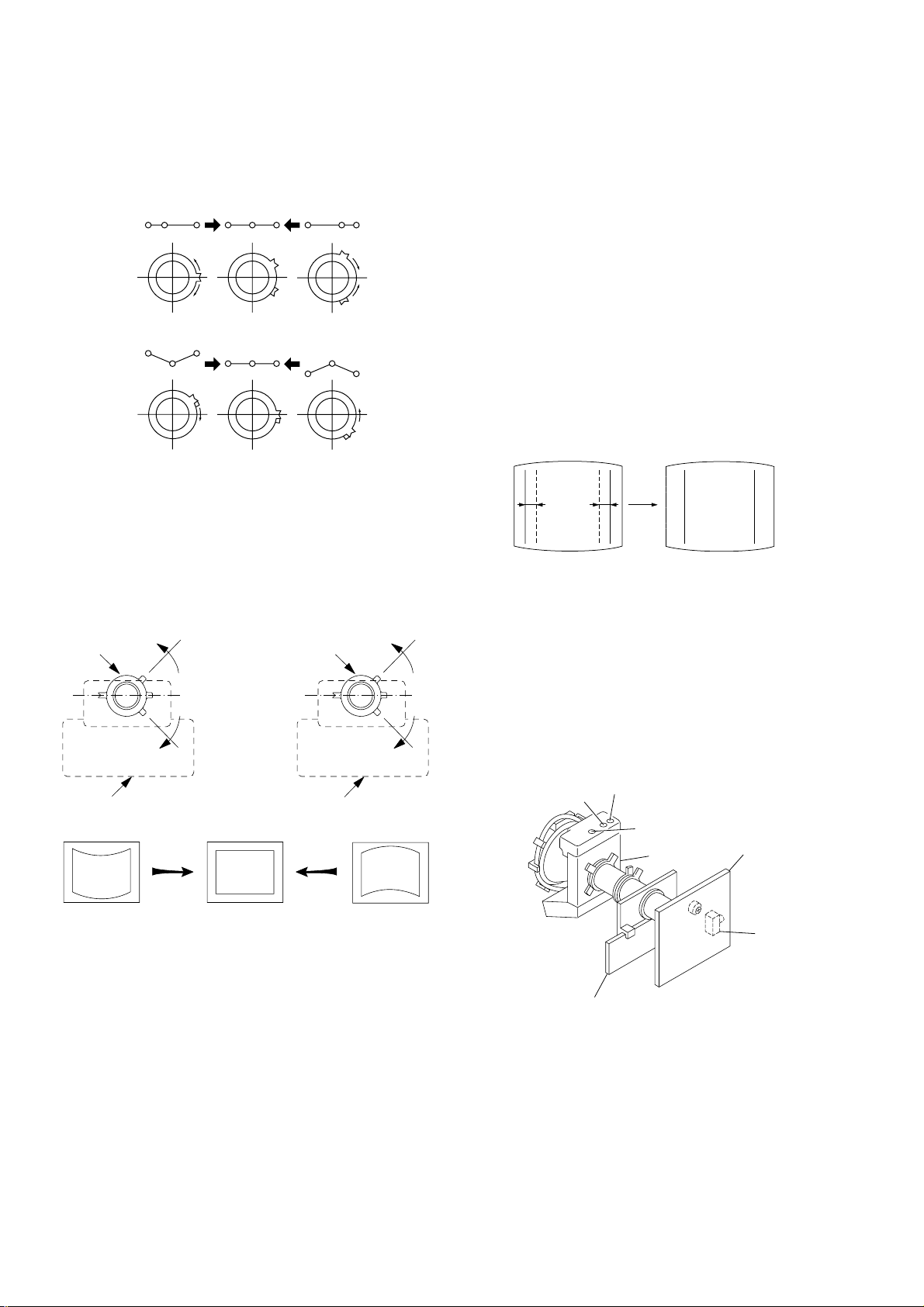

4-1. BEAM LANDING

1. Input a white signal with the pattern generator.

Contrast

Brightness

2. Position neck assy as shown in Fig4-1.

3. Set the pattern generator raster signal to a green raster.

4. Move the deflection yoke to the rear and adjust with the purity

control so that the green is at the center and the blue and the red

take up equally sized areas on each side.

(See Figures 4-1 through 4-3.)

5. Move the deflection yoke forward and adjust so that the entire

screen is green. (See Figure 4-2.)

6. Switch the raster signal to blue, then to green and verify the

condition.

7. When the position of the deflection yoke has been decided,

fasten the deflection yoke with the screws and DY spacers.

8. If the beam does not land correctly in all the corners, use a

magnet to adjust it.

(See Figure 4-4.)

}

normal

Neck assy

Fig. 4-2

Red

Green

Fig. 4-3

Purity control

corrects this area.

b

c

Deflection yoke positioning

corrects these areas.

a

d

Blue

Disk magnets or rotatable

disk magnets correct these

areas (a-d).

Behind the G2 edge

G2G1 G3

Fig. 4-1

b

c

a

d

Fig. 4-4

– 40 –

KV-ES34K90

RM-959

4-2. CONVERGENCE ADJUSTMENT

Preparation :

• Before starting this adjustment, adjust the focus, horizontal size

and vertical size.

• Set the Picture Mode to "STANDARD".

• Cross hatch / Dot pattern.

(1) Horizontal and Vertical Static Convergence

Center dot

R G B

H. STAT VR

R

G

B

V. STAT

Magnet

Y magnet

1 V. STAT

a

b b

2 H. STAT VR

a

RGGBB

b

a

B

G

R

R

b

B

G

R

RV702

H. STAT

C Board

1. (Moving horizontally), adjust the H.STAT control so that the

red, green and blue dots are on top of each other at the center of

the screen.

2. (Moving vertically), adjust the V.STAT magnet so that the red,

green and blue dots are on top of each other at the center of the

screen.

3. Adjust Horizontal Trapezoid with “DAC 04 HTR” in Service

Mode to make H-Trapezoid distortion best.

4. If the H.STAT variable resistor cannot bring the red, green and

blue dots together at the center of the screen, adjust the

horizontal convergence with the H.STAT variable resistor and

the V.STAT magnet in the manner given below.

(In this case, the H.STAT variable resistor and the V.STAT

magnet influence each other, so be sure to perform adjustments

while tracking.)

3

a

b

a

R

b

Purity

B

BMC (Hexapole)

V.STAT

b

B

GG

R

– 41 –

KV -ES34K90

RM-959

4 BMC (Hexapole) Magnet.

If the red, green and blue dots are not balanced or aligned, then

use the BMC magnet to adjust in the manner described below.

RG B R G B R GB

RB

G

RG

GB

RB

5 Y separation axis correction magnet adjustment.

1. Receive the cross-hatch signal and adjust [PICTURE] to [MIN]

and [BRIGHTNESS] to [STANDARD] .

2. Adjust the Y separation axis correction magnet on the neck

assembly so that the horizontal lines at the top and bottom of

the screen are straight.

Neck assy Neck assy

Blue

Red

Red

Blue

(2) Dynamic Convergence Adjustment

Preparation:

• Before starting this adjustment, adjust the horizontal static

convergence and the vertical static convergence

• Set the PICTURE and BRIGHTNESS to normal.

1. Adjust TLH. (TLH correction piece)

1 Receive the dot/hatch pattern signal and adjust picture quality

by the menu.

2 Correct horizontal mis-conv ergence of red and blue of both sides

on the X axis.

When red is outside insert BMC magnet to right side (THL+)

views from D Y neck. And when blue is outside, insert it to left

side (THL–) and take both sides.

R

(B)B(R)

(R)

B

TLH +

R

TLH -

(B)

2. Adjust XCV core.

To able to become balance of XCV on the X axis well.

3. Adjust V -TILT.

Correct the vertical mis-convergence of red and blue of vertically sides on the Y axis.

4. Adjust YCH.

Adjust horizontal mis-convergence of red and blue of vertically sides on the Y axis. Mentioned above steps 2 to 4 are

adjusting respectively perform minuteness tracking.

VM board

VM board

Note

1. The Red and Blue magnets should be equally far from the

horizontal center line.

2. Do not separate the Red and Blue magnets too far. (Less than

8 mm)

– 42 –

H-TRP

YCH

VM board

TLV

BMC magnet

C board

RV9001

KV-ES34K90

RM-959

(3) Screen-corner Convergence

ba

a-d : screen-corner

misconvergence

cd

Fix a Permalloy assy corresponding to the misconverged

areas.

a

b

4-3. FOCUS ADJUSTMENT

Note

Focus adjustment should be completed before W/B adjustment.

(1) Receive digital monoscope pattern.

(2) Set "A/V CONTROL" to "STANDARD".

(3) Adjust FOCUS VR so that the center of the screen becomes

justfocus.

(4) Change the receiving signal to white pattern and blue back.

(5) Confirm MAGENTA RING should not be over the limit sam-

ple. In case MAGENTA RING is over the limit sample, adjust

FOCUS VR to take tracking of MAGENTA RING and FO-

CUS.

d

Permalloy assembly

Focus

c

FLYBACK TRANSFORMER (T6803)

Screen

(No Function)

4-4. NECK ASSY TWIST ADJUSTMENT

(1) Receive dot/hatch pattern.

(2) Turn FOCUS VR fully counter-clockwise.

(3) Confirm the dot shape at the screen center. (Fig. 4-4)

(4) Resume FOCUS VR.

Note

In case of turning NECK ASSY, loosen the screw 3 turns. Do not

move the position.

OK

Turn NECK ASSY clockwise.

– 43 –

Turn NECK ASSY counter clockwise.

Fig. 4-4

KV -ES34K90

RM-959

4-5. G2 (SCREEN) AND WHITE BALANCE

ADJUSTMENTS

1. G2 (SCREEN) ADJUSTMENT

1) Set the PICTURE and BRIGHTNESS to normal.

2) Put to VIDEO input mode without signals.

3) Connect R, G and B of the C board cathode to the oscilloscope.

4) Adjust BRIGHTNESS to obtain the cathode voltage to the value

below.

5) Whilst watching the picture, adjust the screen VR (RV9002)

located on the C board to the point just before the flyback return lines disappear (to the point before cut-off)

170 V ± 2 (VDC)

0 V

2. WHITE BALANCE ADJUSTMENT

1) Set to Service Mode (Refer Section 4-1: ADJUSTMENTS

WITH COMMANDER).

2) Input white raster signal.

3) Set the following condition.

PICTURE minimum, BRIGHTNESS 50%

4) Select GCT (WHB 7) and BCT (WHB 8) with

adjust the level with

5) Set the PICTURE to maximum.

6) Select GDR (WHB 4) and BDR (WHB 5) with [1] and [4], and

adjust the level with

7) Write into the memory by pressing

[3] and [6] for the best white balance.

[3] and [6] for the best white balance.

[MUTING] then [0].

[1] and [4], and

3. SUB PICTURE BRIGHTNESS ADJUSTMENT

1) Tune RF PAL white signal at program No. 1 and No. 2.

2) Select “TWIN PICTURE” mode.

3) Receive different RF PAL white signals in MAIN and Sub

picture.

4) Adjust RV3300 on A PWB, so that the output from the 17 pin

and 20 pin of the CN1180 becomes within the spec.

CVBS 1

17 pin

MAIN

A

CVBS 2

20 pin

SUB

B

Spec: |A - B| ≤ ± 20mV

– 44 –

SECTION 5

231

564

897

0

TV

DRC-MF

TV

CIRCUIT ADJUSTMENTS

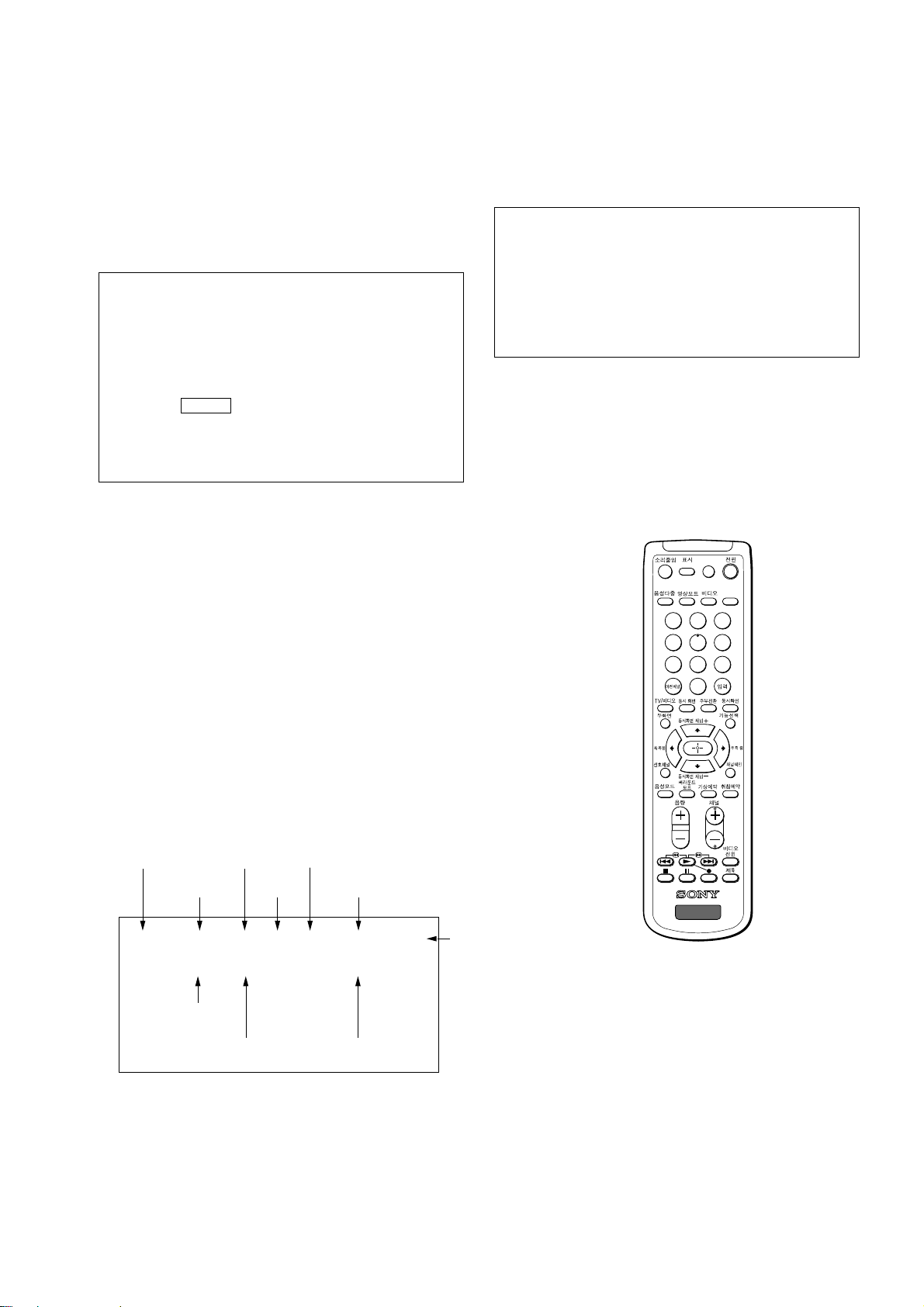

5-1. ADJUSTMENTS WITH COMMANDER

Service adjustments are made with the RM-959 that comes with

this unit.

a. ENTERING SERVICE MODE

With the unit on standby

↓

[DISPLAY]

↓

5

↓

VOL (+)

↓

[POWER]

This operation sequence puts the unit into service mode.

b. METHOD OF CANCELLATION FROM SERVICE

MODE

Set the standby condition (Press [POWER] button on the commander),

then press [POWER] button again, hereupon it becomes TV mode.

KV-ES34K90

RM-959

1, 4 Select the adjustment item.

↓

3, 6 Raise/lower the data value.

↓

[MUTING] Writes.

↓

- Executes the writing.

7, - All the data becomes the values in memory.

8, - All user control goes to the standard state.

5, - Service data initialization (Be sure not to use

usually.)

[DISPLAY], - Write 50Hz adjustment data to 60Hz, or vice

versa.

2, - Copy and write all data.

c. METHOD OF WRITE INTO MEMORY

1) Set to Service Mode.

2) Press [1] (UP) and [4] (DOWN), select an item of adjustment.

3) Press [MUTING] button and it will indicate WRITE on the screen.

4) Press [0] button to write into memory.

d. MEMORY WRITE CONFIRMATION METHOD

1) After adjustment, pull out the plug from AC outlet, and then

plug into AC outlet again.

2) Turn the power switch ON and set to Service Mode.

3) Call the adjusted items again to confirm adjustments were made.

The screen display is :

Marking of virgin NVM

Data

Total Power-On time (hours)

Mode

pp

Device Name

GEO

Item Name

Item No

00

VSZ 29 SERVICE

019Q

Suffix No

(OEM Code)

Software version

1.1N 59 000AFF0

50

PAL, SECAM : 50

NTSC : 60

RM-959

– 45 –

KV -ES34K90

RM-959

5-2. ADJUSTMENT METHOD

Item Number 00 of device GEO

This explanation uses V-size as an example.

1. Select “GEO 00 VSZ” with the 1 and 4 buttons.

2. Raise/lower the data with the 3 and 6 buttons.

3. Select the optimum state. (The standard is 1F for P AL reception.)

4. Write with the

WRITE.)

5. Execute the writing with the - button. (The WRITE

display will be changed to red color while excuting, and back

to SERVICE.)

GEO 00

0 019Q

[MUTING] button. (The display changes to

29 SERVICE 50VSZ

1.1N

59 FF 0 000A

GREEN

Adjusted with [3]

and [6] buttons.

Use the same method for all Items. Use 1 and 4 to select the

adjustment item, use 3 and 6 to adjust, write with

[MUTING],

then execute the write with -.

Note : 1. In

[WRITE], the data for all items are written into memory

together.

2. For adjustment items that have different standard data

between 50Hz or 60Hz, be sure to use the respective

input signal after adjustment.

3. Additional function to skip category (de vice) to category

(device).

example:

GEO 00 VSZ

↕

DAC 00 XXX

The buttons for the function above should be cursor +/–.

GEO 00

0 019Q

GEO 00

0 019Q

1 F WRITE 50VSZ

1.1N

59 FF

Written with [MUTING]

1F SERVICE 50VSZ

1.1N

59 FF

Write executed with [0]

0 000A

0 000A

GREEN

RED

The WRITE (red display)

display returns to SERVICE

(green display)

indicates that write is executed.

– 46 –

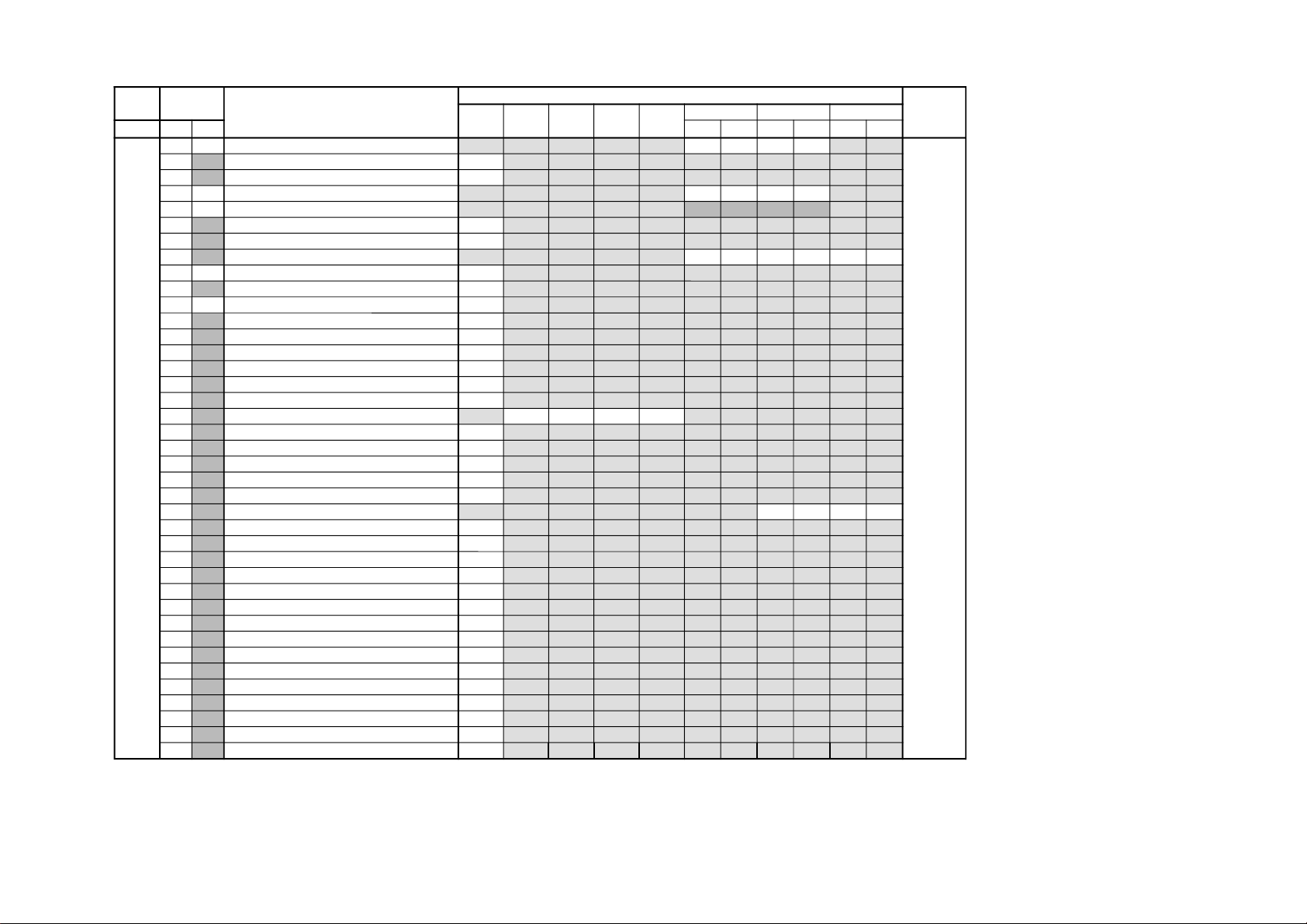

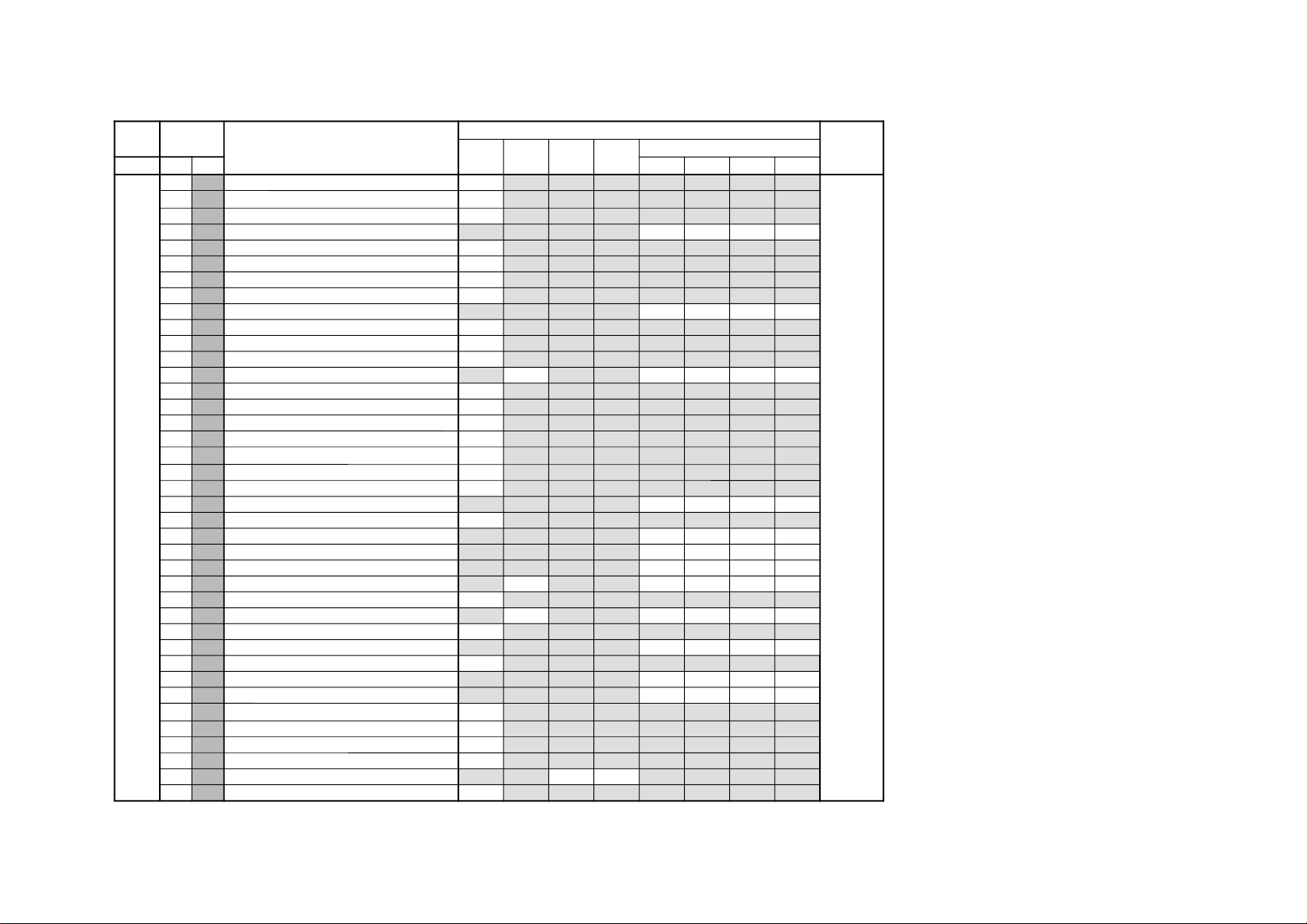

SERVICE LIST ITEM

GVTytilanoitcnuFnoitcnuF emaNeciveD

)LAP(05edoMocE)CSTN(06

yrogetaC.oNemaNCRD

0501

CRD

V0501

evissergorPVevissergorPPniPVPniPXEDNINIWTocE

nO

ocE

ffO

ocE

VnO

ocE

VffO

CRD

0501

CRD

V0501

evissergorPVevissergorPPniPVPniPXEDNINIWT

OEG00ZSVEZISVE1E1E1E1E1E1E1E1

D1D1D1D1D1D1D1D1QA0012AXC

10SPVNOITISOPV8282828282828282

9292929292929292

20NLVYTIRAENILV606060606060

607060706070

30OCSNOITCERROCSA0A0A0A0A0A0

909090909090

40ZSHEZISHF1F1F1F1F1F1F1B1

E1E1E1E1E1E1F1D1

50SPHNOITISOPHB3A3B3A3B3A3B3B3

1303130313037313

60HVDDVDROFTESFFONOITISOPH90

70

70PAPPMANIP333332333333

432343234323

80NPUNIPRENROCREPPU626262626262

62

72

52A252A252A25252

90NPLNIPRENROCREWOL321262626262

62 62

3242324232423232

A0ZRTMUIZEPARTA0A0A0A0A0A0A0A0

8090809080909060

B0LGAELGNACFA808080808080

A0A0A0A0A0A0

C0WOBWOBCFA808080808080

908080908090

D0

LBL GNIKNALBHTFEL1111111111111111

C1C1C1C1C1C1C1C1

E0

LBR GNIKNALBHTHGIRC2C2C2C2C2C2C2C2

3232323232323232

F0

NPM NOITROTSIDNIPELDDIM

NOITASNEPMOC

0000

0000

01

LVU YTIRAENILVREPPU00

00

11

LVL YTIRAENILVREWOL00

00

21

PCH EGATLOVHGIHLATNOZIROH

NOITASNEPMOC

0000

0000

31

PCV EGATLOVHGIHLACITREV

NOITASNEPMOC

0000

0000

41SAVTCEPSAV

F2F2F2F2F2F2F2F2

F203F203F2F203E2

51CSVLLORCSV

2222222222222222

2262125222521212

61

CSU FFO/NOEDOMNACS-REDNU0010

0010

71

WBV LORTNOCHTDIWGNIKNALBV003000300030

003000300030

81

1TA GNIMITECNEREFERBKA203020302030

203020302030

91YPCLLAOTATADOEGEHTYPOC

AERAMVNzH06/05

00

CAD00TCHRETNECHA4

A4

14188BM

10NLHYTIRAENILH131313131313

131313131313

20PDMNIPELDDIM020202020202

020202020202

30

PCC NIPRENROCREWOL010101010101

010101010101

40RTHMUIZEPARTLATNOZIROHF1F1F1F1F1F1

F1F1F1F1F1F1

50

FD HCTIWSFFO/NOFD101010101010

101010101010

60

HPD ESAHPFD323232323232

02F102F102F1

70

HPQ ESAHPPQ313131313131

01F001F001F0

80

CAQ EDUTILPMAPQ424242424242

424242424242

90

CDQ LEVELCDPQE1E1E1E1E1E1

E1E1E1E1E1E1

A0

VDQ NOITALUDOMVPQ828282828282

9292F2F29292

B0

VAQ NOITALUDOMEDUTILPMAPQE1E1E1E1E1E1

020232320202

C0

CBA LORTNOCA/DLBA

0000E7E7

– 47 –

KV-ES34K90

RM-959

KV -ES34K90

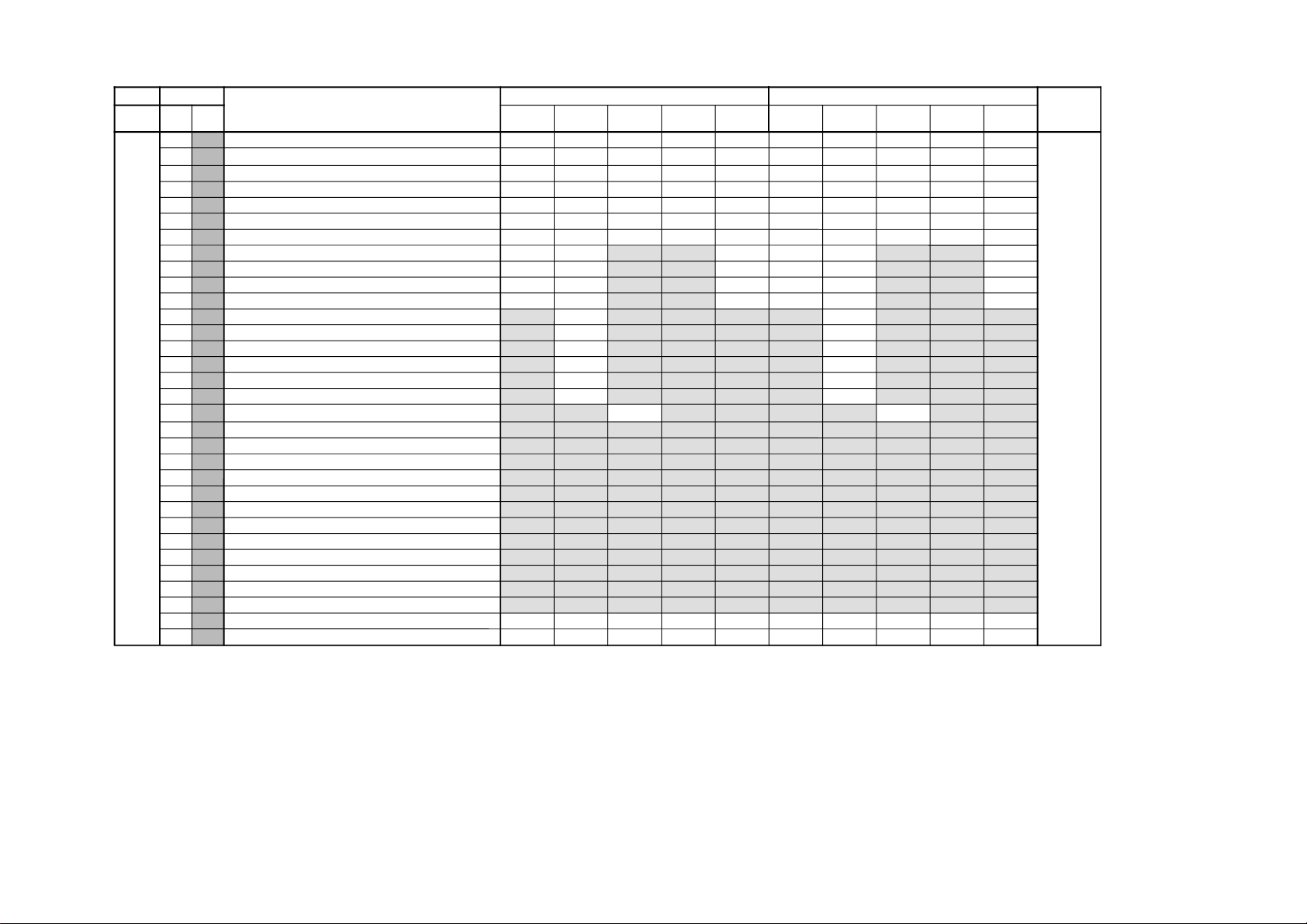

GVTytilanoitcnuFnoitcnuFeciveD

yrogetaC.oNemaNnommoC

BHW00

OBC 1BCROFRELLECNACTESFFOCDA0QA0012AXC

10

ORC 1RCROFRELLECNACTESFFOCDA0

20RBSLORTNOCSSENTHGIRBBUS12

30

RDR EVIRDR92

40RDGEVIRDG52

50

RDB EVIRDB02

60TCRFFOTUCR42

70TCGFFOTUCG70

80TCBFFOTUCBF2

90

OBS TESFFOSSENTHGIRBBUSC1

A0

ODR TESFFOEVIRDRF1

B0

ODG TESFFOEVIRDGB1

C0

ODB TESFFOEVIRDBB1

D0

OCR TESFFOFFOTUCRF1

E0

OCG TESFFOFFOTUCG02

F0

OCB TESFFOFFOTUCB41

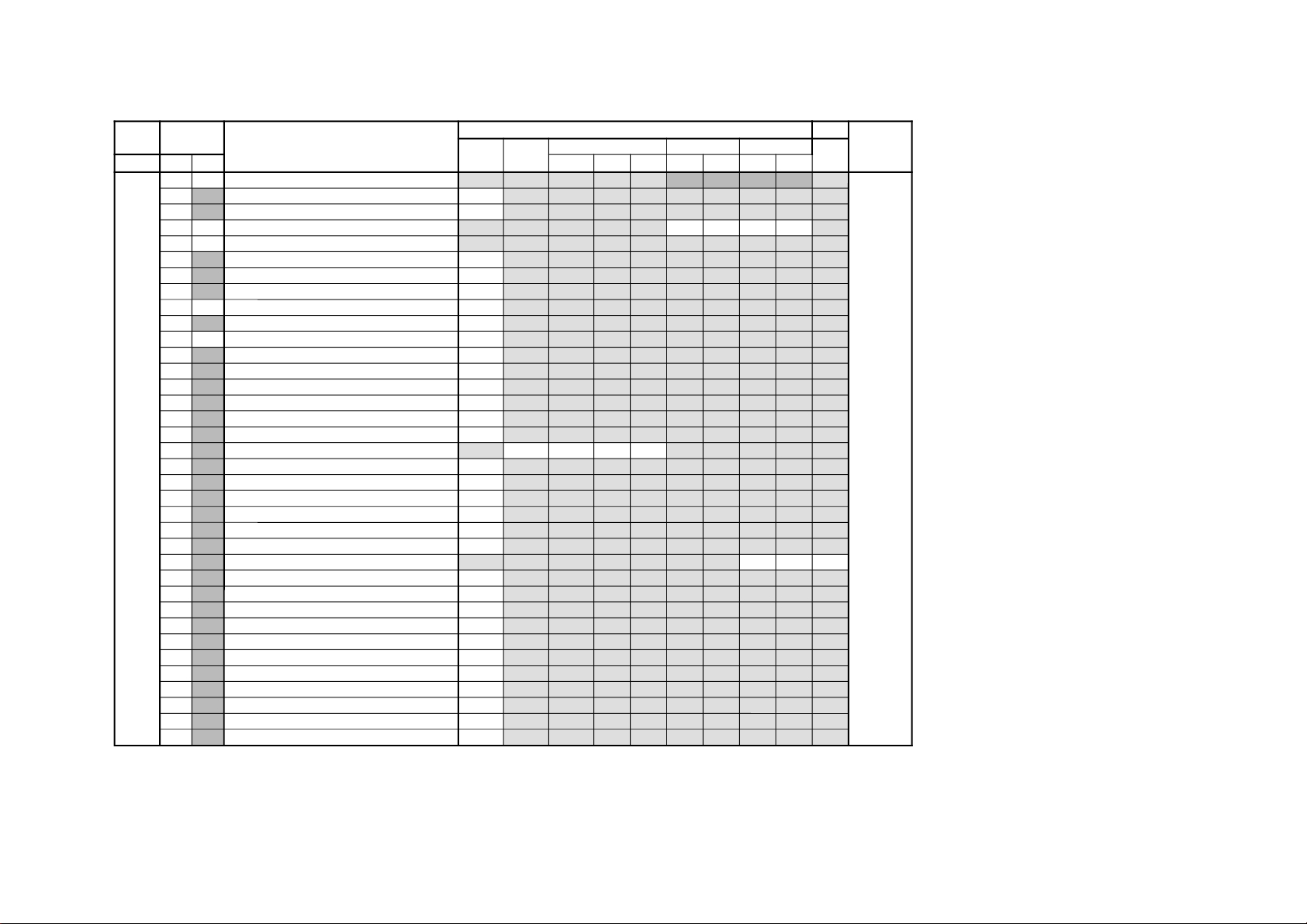

SERVICE LIST ITEM

– 48 –

RM-959

SERVICE LIST ITEM

GVTytilanoitcnuFnoitcnuF emaNeciveD

nommoC0506niwTxednIedoMerutciPedoMocE

yrogetaC.oNemaN VToediVDVDVToediVDVDcimanyDdradnatSeniF-iHlanosrePCNnO-ocECNffO-ocECVnO-ocECVffO-ocE

JAS00

CIP LORTNOCERUTCIP

F32382

QA0012AXC

10

TRB LORTNOCSSENTHGIRB

32F1B1

20

LOC LORTNOCROLOC

A22222

30

EUH LORTNOCEUH

F1F1F1

40

PHS LORTNOCSSENPRAHS

22F1D1

50

LMV LEVELMV

30301030

60

CYD FFO/NOROLOCCIMANYD

10100010

70

MTC ROLOCCIMANYDROFERUTAREPMETROLOC

00000000

80XACNOITACIFICEPSXIRTAMROLOC

202020

10

10 10

90

AMG NOITCERROCAMMAG

20203020

A0

TCD LORTNOCNOISSIMSNARTCD

10100010

B0 LPD LORTNOCLEVELLATSEDEPOTUA

20100010

C0

MBA LORTNOCEDOMLBA

10000000

D0

TBA LORTNOCHTVNOITCETEDTNERRUCLBA

20002000

E0

OLC TESFFOROLOC

9080

6060

F0

WLC N/SFOEGNAHCEHTOTHTDIWPETSROLOC30

01

OUH TESFFOEUH

8080

9090

11

OHS TESFFOSSENPRAHS

4171F000F0F0

21

WHS N/SFOEGNAHCEHTOTHTDIWPETSSSENPRAHS10

31

OIP XEDNI/NIWTROFTESFFOERUTCIP

3040

41

ORB TESFFOSSENTHGIRB

70707070

LGJ00

NOP TUPTUOESLUPECNEREFERBKADNABGR

FFO/NO

10

QA0012AXC

10

BGR NOITCELESTUPTUOBGR70

20

GGA NOITCELESEDOMGNIGA00

30

SPD HCTIWSEDOMSSAPENILYALEDC/Y00

40 TBB LORTNOCRETTIMILMOTTOBBGR30

50 LML LORTNOCRETTIMILEDUTILPMABGR00

60

BAP LBAKAEPROFLEVELCDF0

70

OCS LORTNOCERUTCIPBUS70

80

2VL 2BGRROFLEVELBGR70

90

0FS 0FTIUCRICSSENPRAHS

101010101010

A0

ORP LORTNOCOITARTOOHS-REVO/ERP

003030303030

B0 ITL TNEMEVORPMITNEISNARTECNANIMUL

20200020

C0

ITC TNEMEVORPMITNEISNARTECNANIMORHC

10100010

– 49 –

KV-ES34K90

RM-959

KV -ES34K90

GVTytilanoitcnuFnoitcnuF emaNeciveD

nommoCD2

bmoC

D3

bmoC

tupnI-SsrehtOVToediVDVD

yrogetaC.oNemaN 050605060506

TCY00TNTCSTNROFTNEMTSUJDATNIT

4242F1F1

Q3212AXC

10

GNP HTDIWETAGCSTN/LAP10

20

INP WSYTIVITISNESCSTN/LAP00

30LCSLORTNOCROLOCBUS

50708060

40TCSLORTNOCTSARTNOCBUS

80 50 80

70

50

0FS GNIGNAHCYCNEUQERFRETNECSSENPRAHS20

60

QES CITSIRETCARAHCREZILAUQESSENPRAHS30

70

GHS LORTNOCNIAGSSENPRAHS

506050607070

80LOYLORTNOCLEVELTUPTUO-YF1

90

PSB GNIGNAHCTNIOPTRATSHCTERTSKCALB00

A0LOCLORTNOCLEVELTUPTUORC/BCA1

B0 RCD TNEMTSUJDAOITARNOITAROTSERCD00

C0

0FB TNEMTSUJDA0FFQT/FPB10

D0

QFB TNEMTSUJDAQFQT/FPB20

E0

WSF HCTIWSFQT/FPB10

F0 TDS HCTIWSPARTELBUODMACES10

01

FPL HCTIWSFPLRC/BC/Y10

11

LDY TNEMTSUJDAEMITLD-Y

60503050

21 TMC HCTIWSETUMTUPTUORC/BC00

31

1OB )ETUORNIAM(TNEMTSUJDA1TESFFOBC70

41

1OR TNEMTSUJDA1TESFFORC70

51

FDC HCTIWSYCNEUQERFNWODTNUOCV00

61

MDC HCTIWSEGDUJNWODTNUOCV00

71

CFA HCTIWSYTIVITISNESCFA

00000000

81

MVM KSAMCFA+KSAMNOISIVORCAM00

91

YRS TNEMTSUJDAKCALBY-RMACES70

A1

YBS TNEMTSUJDAKCALBY-BMACES10

B1

LEB GNIHCTIWSFPH/LLEBMACES20

C1

FLB TNEMTSUJDA0FLLEB00

D1

IVS HCTIWSDI-VMACES00

E1

PGS TNEMTSUJDANOITISOPETAGMACES00

F1

DIS HCTIWSYTIVITISNESMACES10

02

HIS HCTIWSNOITIBIHNIMACES00

12

PTS SULPLAPROFPUTESLEVELKCALBY00

22

CVH GNILLECNACRETCARAHCERUTAREPMETOCV-H20

32

RN3 FFO/NONOITAREPORND310

42

6WB FFO/NOLANGISTSUB-NONzH06ROFRND310

52 HSW NOITCUDERESIONROFPETSNIAGSSENPRAHS00

62

OCW TNEMTSUJDAOITARNOITAROTSERCD00

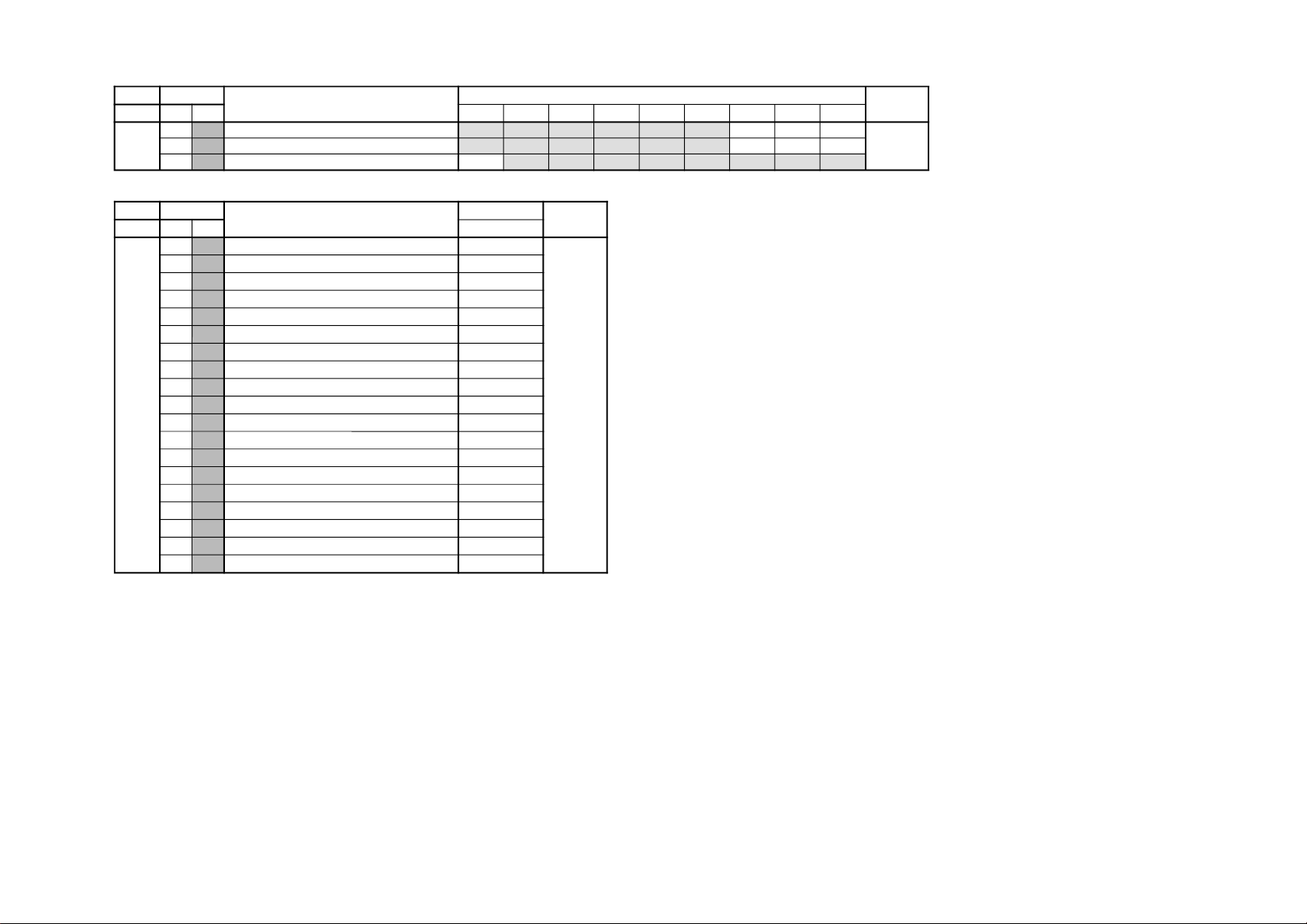

SERVICE LIST ITEM

– 50 –

RM-959

SERVICE LIST ITEM

GVTytilanoitcnuFnoitcnuF emaNeciveD

nommoCtupnI-SedoMloCVToediVDVD

yrogetaC.oNemaN MACESCSTNLAP05060506

CYS00TNTCSTNROFTNEMTSUJDATNIT

12 12 02

02

Q3212AXC

10

GNP HTDIWETAGCSTN/LAP10

20

INP WSYTIVITISNESCSTN/LAP00

30LCSLORTNOCROLOCBUS

60709060

40TCSLORTNOCTSARTNOCBUS

80

40

80 70

50

0FS GNIGNAHCYCNEUQERFRETNECSSENPRAHS20

60

QES CITSIRETCARAHCREZILAUQESSENPRAHS30

70

GHS LORTNOCNIAGSSENPRAHS70

80LOYLORTNOCLEVELTUPTUO-YF1

90

PSB GNIGNAHCTNIOPTRATSHCTERTSKCALB00

A0LOCLORTNOCLEVELTUPTUORC/BCC3

B0 RCD TNEMTSUJDAOITARNOITAROTSERCD00

C0 0FB TNEMTSUJDA0FFQT/FPB10

D0

QFB TNEMTSUJDAQFQT/FPB20

E0

WSF HCTIWSFQT/FPB10

F0 TDS HCTIWSPARTELBUODMACES10

01

FPL HCTIWSFPLRC/BC/Y10

11

LDY TNEMTSUJDAEMITLD-Y

50302030

21

MCN HCTIWSNOITIDDAH-110

31 TMC HCTIWSETUMTUPTUORC/BC00

41 1OB )ETUORNIAM(TNEMTSUJDA1TESFFOBC70

51 1OR TNEMTSUJDA1TESFFORC70

61

FDC HCTIWSYCNEUQERFNWODTNUOCV00

71

MDC HCTIWSEGDUJNWODTNUOCV00

81

CFA HCTIWSYTIVITISNESCFA

000000

91

MVM KSAMCFA+KSAMNOISIVORCAM00

A1 YRS TNEMTSUJDAKCALBY-RMACES70

B1

YBS TNEMTSUJDAKCALBY-BMACES10

C1

LEB GNIHCTIWSFPH/LLEBMACES20

D1

FLB TNEMTSUJDA0FLLEB00

E1

IVS HCTIWSDI-VMACES00

F1

PGS TNEMTSUJDANOITISOPETAGMACES00

02

DIS HCTIWSYTIVITISNESMACES10

12

HIS HCTIWSNOITIBIHNIMACES00

22

PTS SULPLAPROFPUTESLEVELKCALBY00

32

CVH GNILLECNACRETCARAHCERUTAREPMETOCV-H20

– 51 –

KV-ES34K90

RM-959

KV -ES34K90

GVTytilanoitcnuFnoitcnuFeciveD

yrogetaC.oNemaN nommoC

PSM00

TSW DLOHSERHTOERETSG/W51D5143PSM

10 TBW DLOHSERHTLAUGNILIBG/WAE

20

LLW DLOHSERHTLARUAONOMG/W50

30

CAW TNUOCTNEMEERGAG/W10

40

LDW YALEDHCRAESG/W03

50

LDN YALEDHCRAESMACIN02

60

LDS YALEDDAERSUTATSOERETS01

70 CGA TNATSNOC/OTUAHCTIWSCGA10

80

LER EDOMTNATSNOCTANIAGCGA82

90

MRC FFO/NOGNITUMREIRRAC00

A0

OCA FFO/NOKCOLCOIDUA10

B0

PF METSYSM-NONROFELACSERPMFB1

C0

MPF METSYSMROFELACSERPMF23

D0

HF VEDHROFELACSERPMFD2

E0

MHF MDNAVEDHROFELACSERPMF56

F0

PGW ELACSERPG/WA2

01

PIN ELACSERPMACIND6

11

RRE DLOHSERHTHCTIWSMFOTUA05

21 LOV HFF70OTH0070NIAGREKAEPSDUOLD6

GVTytilanoitcnuFnoitcnuF emaNeciveD

yrogetaC.oNemaN nommoCDDVruSPDVruSSRTruSMISruSffOruScimanyDamarDtfoS

PA00

SABLORTNOCSSAB

B080705137ADT

10

ERTLORTNOCELBERT

B09070

20

NDLFFO/NOSSENDUOL10

SERVICE LIST ITEM

– 52 –

RM-959

SERVICE LIST ITEM

GVTytilanoitcnuFnoitcnuF emaNeciveD

nommoCniwTVToediVedoMerutciP

yrogetaC.oNemaN cimanyDdradnatSeniF-iHlanosreP

ITL00

HDL NOITCELESTNEMGESMARGOTSIH10

8719ADT

10

SFC NOITCELESRETLIFRUOTNOC10

20

BLW HCTIWSWODNIWXOBRETTEL00

30

CDV GNIROCTNEDNEPEDOEDIV

10101010

40

MED EDOMNOITARTSNOMED00

50

PDC YALEDECNANIMUL40

60

PSO GNIKAEPTRAMSELURREVO00

70 OPW FFOHCTERTSTNIOPETIHW00

80

KSD HCTIWSENOTNIKS

00000000

90

KSA NOITCELESELGNAENOTNIKS00

A0 KSW NOITCELESHTDIWENOTNIKS00

B0

KSS NOITCELESEZISENOTNIKS00

C0 RGD HCTIWSTNEMECNAHNENEERG

00

10100010

D0

TGD HCTIWSTNEMECNAHNENEERGFODLOHSERHT70

E0

RGG NIAGTNEMECNAHNENEERG00

F0 RGW HDTIWTNEMECNAHNENEERG00

01

RGS EZISTNEMECNAHNENEERG00

11

LBD HCTIWSHCTERTSEULB00

21

LBG NOITCELESNIAGHCTERTSEULB00

31

LBS NOITCELESEZISHCTERTSEULB00

41

SDC SSENPRAHSTNEDNEPEDROLOC

10100010

51

TSC SSENPRAHSTNEDNEPEDROLOCFODLOHSERHT70

61

ITC TNEMEVORPMITNEISNARTROLOC

00000000

71

NOB NOITASNEPMOCTESFFOKCALB

00000000

81

DTB HCTERTSKCALBEVITPADA

00000000

91

DLN REIFILPMAYTIRAENIL-NON

00

51510051

A1

WLN REIFILPMAYTIRAENIL-NONFOHTDIWPETS70

B1 DGV AMMAGELBAIRAV

F1

F1F1F1F1

C1

WGV AMMAGELBAIRAVFOHDTIWPETS00

D1

DKP EDUTILPMAGNIKAEP

F303E003

E1

WKP EDUTILPMAGNIKAEPFOHTDIWPETS80

F1

DPS NOITCERROCSSENPETS

00000000

02

DRC LEVELGNIROC

61610061

12

WRC LEVELGNIROCFOHTDIWPETS90

22

ORC EDOMOEDIVROFTESFFOLEVELGNIROC10

32

DWL NOITCERROCHTDIWENILF1

42

MNS NOITIDNOCN/SELBILAERNUREDNUEDOMN/S00

52

CNS RETNUOCEGAREVAOITARN/S

3030

62

CMF RETNUOCGNIHCTAMEDOMERUTAEF20

– 53 –

KV-ES34K90

RM-959

KV -ES34K90

GVTytilanoitcnuFnoitcnuF05

06

emaNeciveD

yrogetaC.oNemaN 0501CRDPniPNIWTXEDNI-vissergorP

e

0501CRDPniPNIWTXEDNI-vissergorP

e

DIM00

HPH ESAHPAERAYALPSIDEVITCALATNOZIROH 252529D8252525F7F72581949BM

10

HPV ESAHPAERAYALPSIDEVITCALACITREV 0202420202525252E252

20 ZSH EZISAERAYALPSIDEVITCALATNOZIROH F7F7F7F7F7F7F7F7F7F7

30 ZSV EZISAERAYALPSIDEVITCALACITREV F7F7F7F7F7F7F7F7F7F7

40

WPH HTDIWSULPCNYS-HYALPSID F3F3F3F3F3F3F3F3F3F3

50

WPV HTDIWSULPCNYS-VYALPSID 10703030701070303070

60

LDY NOITCERROCYALEDC/YTUPTUOYALPSID 00000000000000000000

70

PHM )PNIP&ELGNIS(NOITISOPLATNOZIROHERUTCIPNIAM F7F7

F7F7F7

F7

80

PVM )PNIP&ELGNIS(NOITISOPLACITREVERUTCIPNIAM F7F7

F7F7F7

F7

90

SHM )PNIP&ELGNIS(EZISLATNOZIROHERUTCIPNIAM F7F7

F7F7F7

F7

A0

SVM )PNIP&ELGNIS(EZISLACITREVERUTCIPNIAM F7F7

F7F7F7

F7

B0

PHP NOITISOPLATNOZIROHERUTCIPBUSPNIP

B6

35

C0 PVP NOITISOPLACITREVERUTCIPBUSPNIP

D5

75

D0

SHP EZISLATNOZIROHERUTCIPBUSPNIP

F7

F7

E0

SVP EZISLACITREVERUTCIPBUSPNIP

F7

F7

F0

OHP TESFFONOITISOPLATNOZIROHERUTCIPBUSPNIP

67

86

01

OVP TESFFONOITISOPLACITREVERUTCIPBUSPNIP

96

46

11

PMT NOITISOPLATNOZIROHERUTCIPNIAMNIWT

00

00

21

PST NOITISOPLATNOZIROHERUTCIPBUSNIWT

31

PVT NOITISOPLACITREVERUTCIPBUS&NIAMNIWT

41

SHT EZISLATNOZIROHERUTCIPBUS&NIAMNIWT

51

SVT EZISLACITREVERUTCIPBUS&NIAMNIWT

61

OHT TESFFONOITISOPLATNOZIROHERUTCIPBUS&NIAMNIWT

71

OVT TESFFONOITISOPLACITREVERUTCIPBUS&NIAMNIWT

81

SHX EZISLATNOZIROHERUTCIPBUSXEDNI

91

SVX EZISLACITREVERUTCIPBUSXEDNI

A1

GHX SERUTCIPNEEWTEBHTDIWPAGLATNOZIROHXEDNI

B1

GVX SERUTCIPNEEWTEBHTDIWPAGLACITREVXEDNI

C1 PHX NOITISOPLATNOZIROHSERUTCIPBUSTS1XEDNI

D1 PVX NOITISOPLACITREVSERUTCIPBUSTS1XEDNI

E1 PHD NOITISOPAERAEVITCALATNOZIROHCRD F7F7F7F7F7F7F7F7F7F7

F1

SHD EZISLEXIPEVITCALATNOZIROHCRD F7F7F7F7F7F7F7F7F7F7

SERVICE LIST ITEM

– 54 –

RM-959

Loading...

Loading...