Sony TASA-100-WR Service manual

TA-SA100WR

SERVICE MANUAL

Ver. 1.0 2008.02

• TA-SA100WR is the surround amplifi er section

in WAHT-SA1 etc.

• EZW-RT10 or EZW-T100 is necessary to check

S-AIR communication.

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

for the US model

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

With 3 ohm loads,

both channels

driven, from 120 20,000 Hz; rated 50

watts per channel

minimum RMS

power, with no

more than 0.7 %

total harmonic

distortion from 250

milliwatts to rated

output.

Amplifier section

US model:

Surround mode (reference) RMS output power

: 143W (per

channel at 3 ohms,

1 kHz, 10 % THD)

Other models:

Stereo mode (rated) 80 W + 80 W (at

3 ohms, 1 kHz, 1%

THD)

Surround mode (reference) RMS output power

: 143 W (per

channel at 3 ohms,

1 kHz, 10 % THD)

* Depending on the source, there may be no

sound output.

Canadian Model

General

Power requirements:

NorthAmericanmodels: 120VAC, 60Hz

Mexican model: 120 V AC, 60 Hz

Other models: 220 V – 240 V AC,

Power consumption On: 50 W

Dimensions (approx.) 85 mm× 100 mm ×

Mass (approx.) 1.7 kg (3 lb 12 oz)

Design and specifications are subject to change

without notice.

“S-AIR” and its logo are trademarks of Sony

Corporation.

50/60 Hz

330 mm

3

(3

/8 in×4in×

13 in) (w/h/d) (incl.

EZW-RT10)

85 mm × 100 mm ×

345 mm

3

(3

/8 in×4in×

5

13

/8 in) (w/h/d)

incl. speaker cord

cover and speaker

cord holder

incl. speaker cord

cover and speaker

cord holder

US Model

AEP Model

UK Model

E Model

9-887-986-01

2008B05-1

2008.02

©

Rated impedance: 3 - 16 Ω

SURROUND AMPLIFIER

Sony Corporation

Audio Business Group

Published by Sony Techno Create Corporation

TA-SA100WR

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

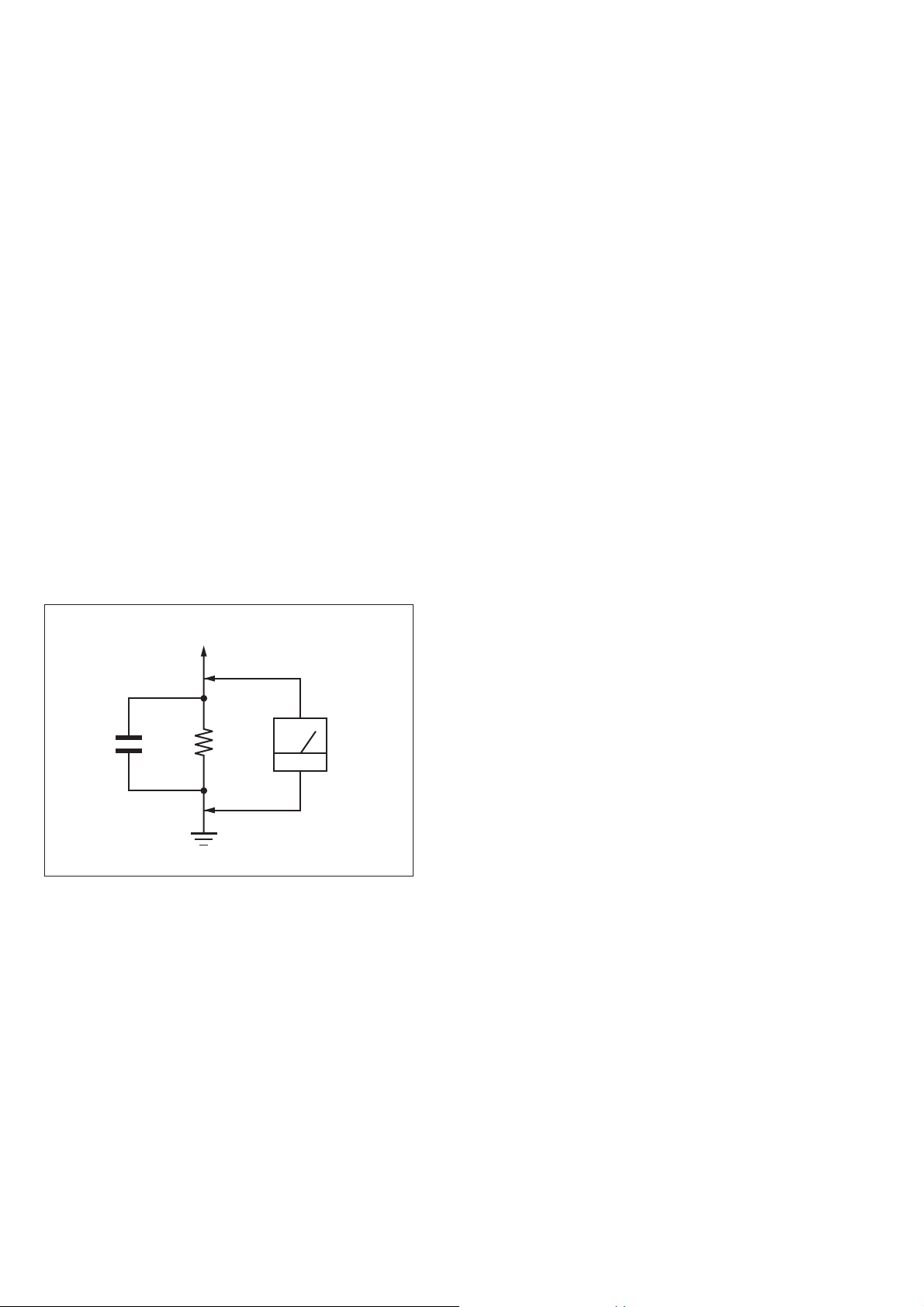

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

TABLE OF CONTENTSNotes on chip component replacement

1. SERVICIN NOTES ................................................. 3

2. GENERAL .................................................................. 6

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 7

3-2. Cover (Cord) ................................................................... 7

3-3. Case ................................................................................. 8

3-4. Shield (Top), Power Cord ............................................... 8

3-5. Power SW Board, PANEL Board, Front Panel Block .... 9

3-6. Back Panel, JOINT Board ............................................... 9

3-7. Power Block .................................................................... 9

3-8. POWER Board, AMP Board ........................................... 9

4. DIAGRAMS

4-1. Block Diagram ................................................................ 10

4-2. Printed Wiring Board

- AMP Board (Component Side) (Suffi x-11) - ................ 12

4-3. Printed Wiring Board

- AMP Board (Conductor Side) (Suffi x-11) - ................. 13

4-4. Printed Wiring Board

- AMP Board (Component Side) (Suffi x-12) -................ 14

4-5. Printed Wiring Board

- AMP Board (Conductor Side) (Suffi x-12) - ................. 15

4-6. Schematic Diagram - AMP Board (1/2) - ....................... 16

4-7. Schematic Diagram - AMP Board (2/2) - ....................... 17

4-8. Printed Wiring Boards - PANEL Section - ..................... 18

4-9. Schematic Diagram - PANEL Section - .......................... 19

4-10. Printed Wiring Boards - POWER Section - .................... 20

4-11. Schematic Diagram - POWER Section - ........................ 21

AC

1.5 kΩ0.15 μF

Earth Ground

voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONET WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

5. EXPLODED VIEWS

5-1. Cover Section .................................................................. 26

5-2. Top Shield Section .......................................................... 27

5-3. Front Panel Section ......................................................... 28

5-4. Chassis Section ............................................................... 29

5-5. Power Section ................................................................. 30

6. ELECTRICAL PARTS LIST .............................. 31

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS QUE

PAR DES PIÈCES SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

2

SECTION 1

SERVICING NOTES

TA-SA100WR

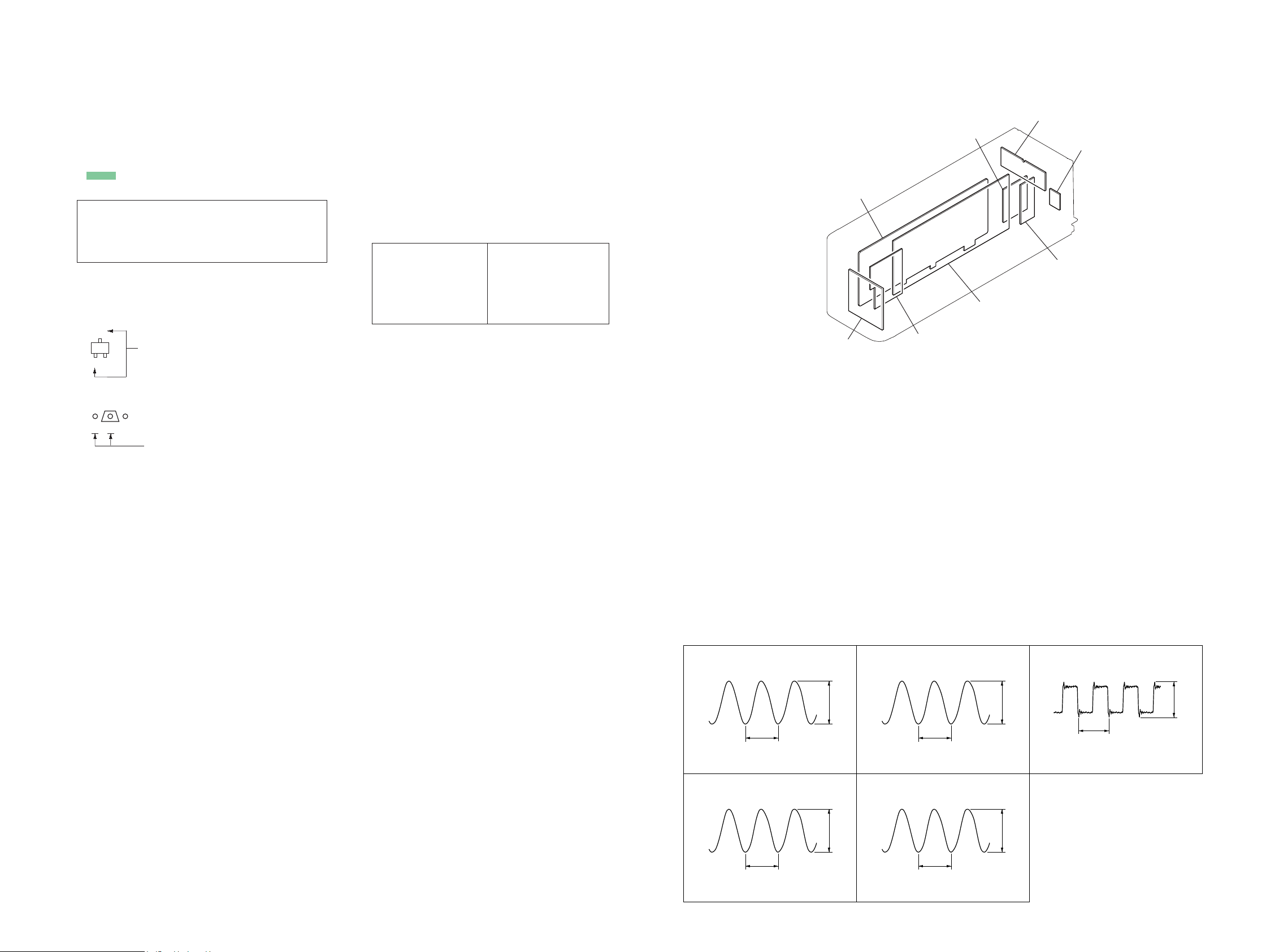

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Checking the transmission status

You can check the status of sound transmission between the S-AIR main

unit and surround amplifier by checking the POWER/ON LINE indicator

on the surround amplifier.

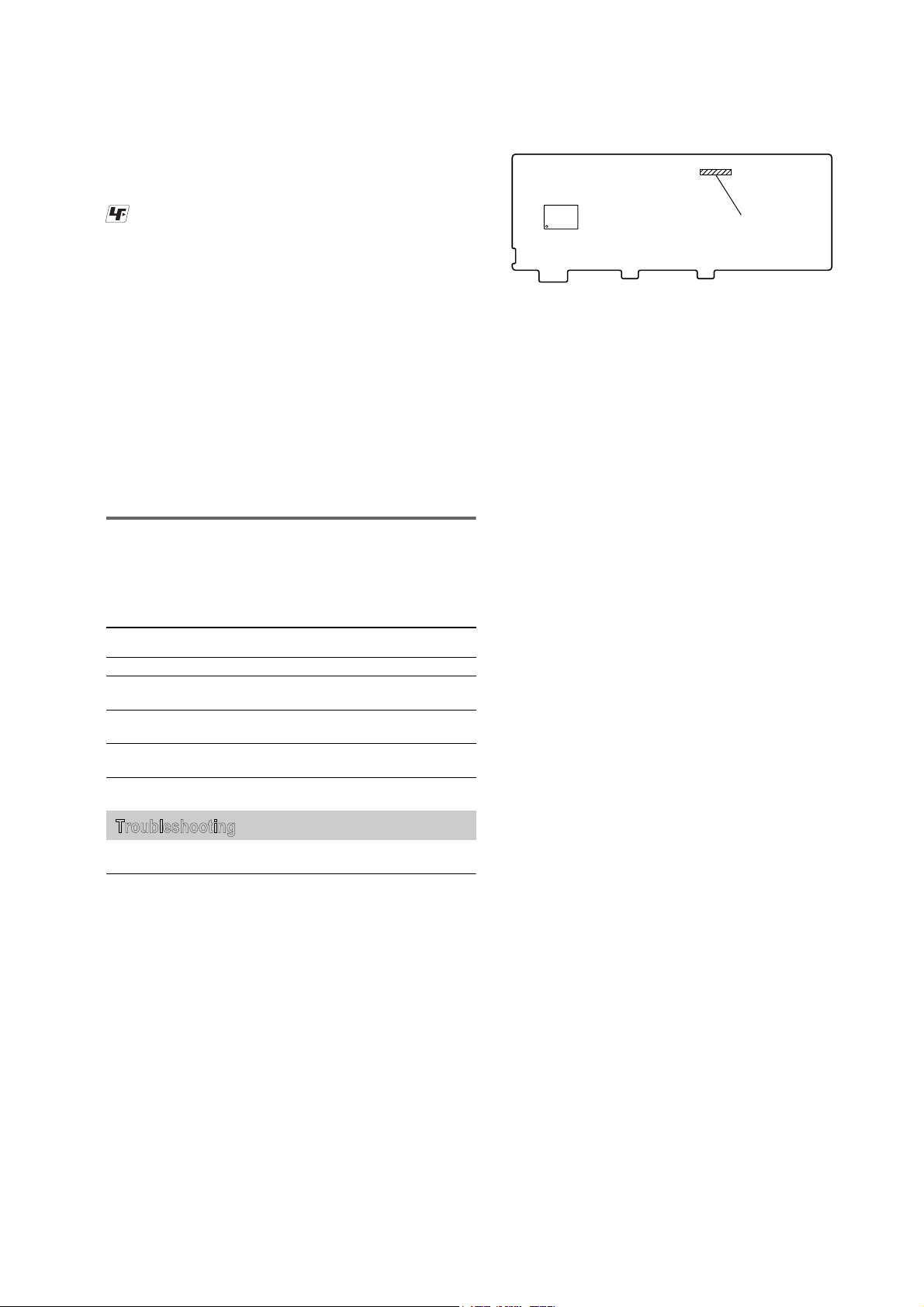

SUFFIX-11/SUFFIX-12 DISCRIMINATION OF AMP BOARD

– AMP Board (Component Side) –

IC500

Suffix-11 : 1-875-376-11

Suffix-12 : 1-875-376-12

POWER/ON

LINE indicator

Turns green Sound transmission is established.

Flashes green Sound transmission is not established. Fordetails, see

Turns red The surround amplifier does not output sound. For details,

Turns off The surround amplifier turns off or its protection is active.

Status

“Troubleshooting”.

see “Troubleshooting”.

For details, see “Troubleshooting”.

Troubleshooting

Sound

There is no sound.

Check the status of the POWER/ON LINE indicator on the surround

amplifier.

– turns green

• The speaker cord is not connected securely.

• Check the speaker connections and settings.

• The volume of the S-AIR main unit is set to minimum.

• The S-AIR main unit is in mute status.

• Depending on the source or thesettings of the S-AIR main unit, the effect of the

speakers may be less noticeable.

• Headphones are connected.

– flashes green

• The S-AIR main unit is not turned on.

• The S-AIR main unit is paired to another S-AIR product.

• The surround amplifier is paired to another S-AIR main unit.

• Confirm the IDs of the S-AIR main unit and surround amplifier.

• Pairing operation is not completed.

• Sound transmission is poor. Move the

surround amplifier so that the POWER/ON LINE indicator turns green.

• Move the system away from any other wireless products.

• Stop using another wireless product.

• The wireless transceiver and/or the wireless transmitter are/is not inserted

correctly.

– turns red

• Change the SURROUND SELECTOR switch (SURROUND or SURROUND

BACK) of the surround amplifier to match the S-AIR main unit.

3

TA-SA100WR

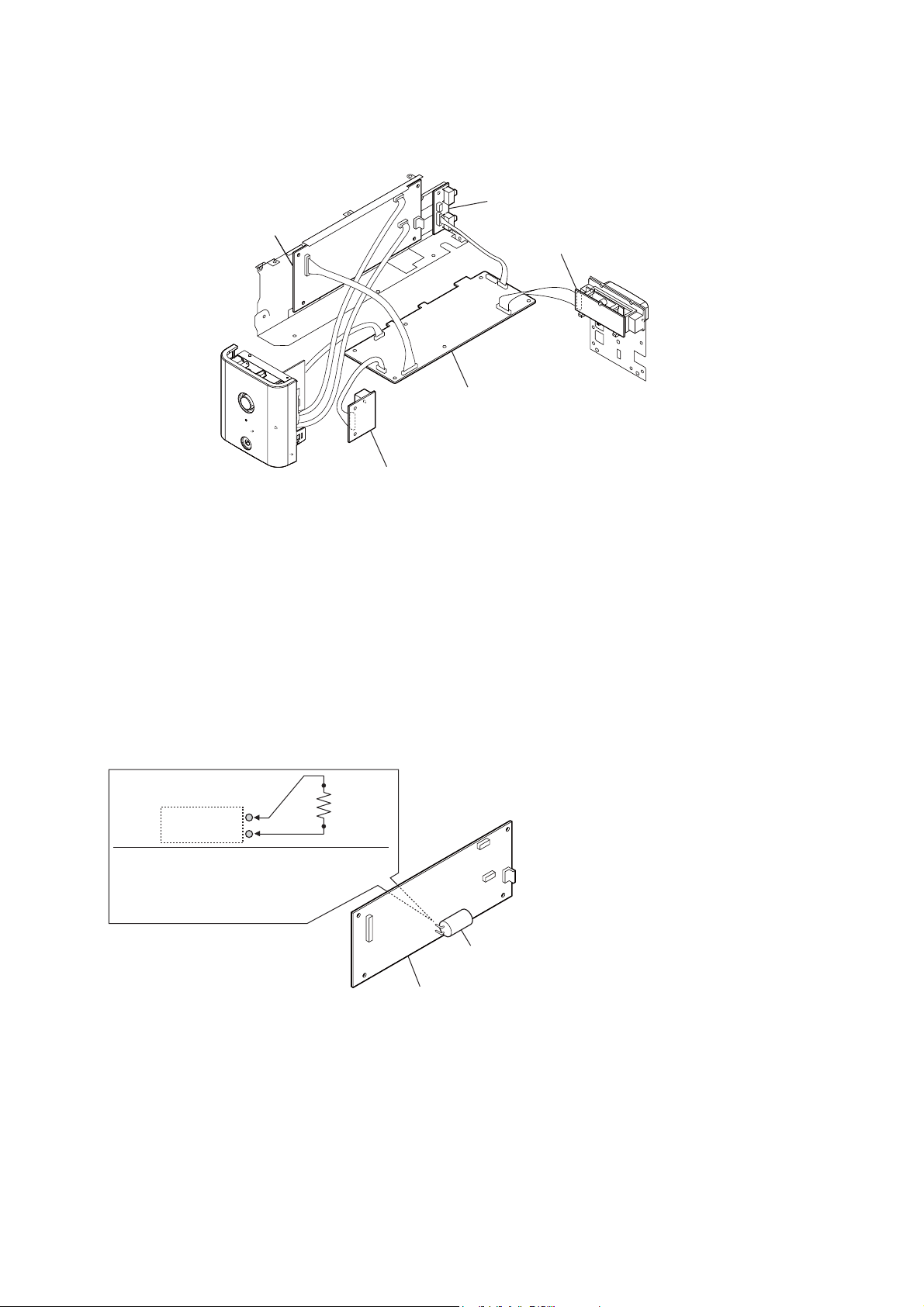

AMP BOARD SERVICE POSITON

POWER board

MODE SW board

JOINT board

AMP board

SP TERM board

CAPACITOR DISCHARGE

C906 or C919

In checking the POWER board,

make a capacitor discharge

of C906 or C919 for electric shock

prevention.

800 Ω/2W

C906 (AEP, UK, E3, MX)

C919 (US, CND)

POWER board

• Abbreviation

CND : Canadian model

E3 : 240V AC area in E model

MX : Mexican model

4

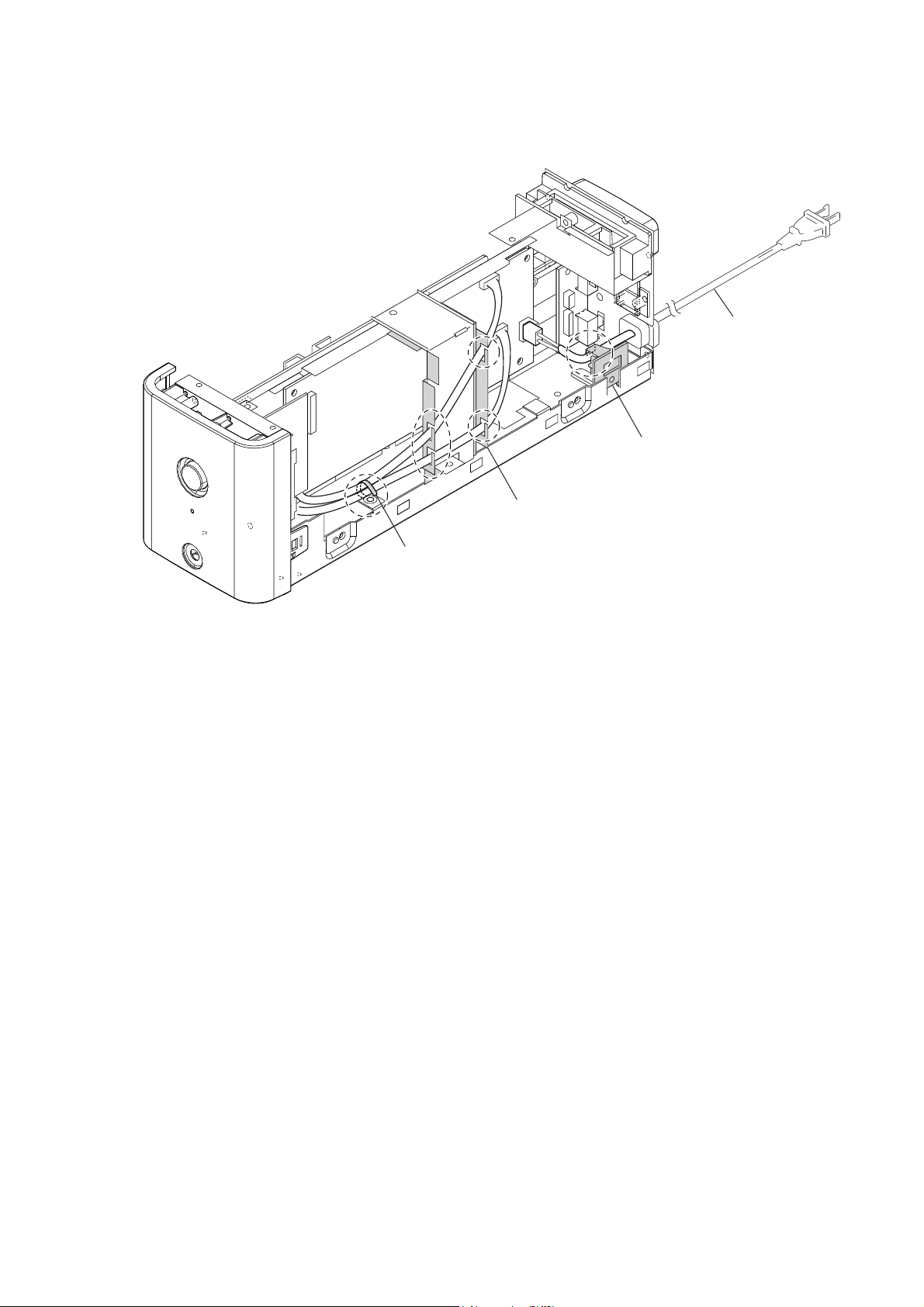

HARNESS SETTING

TA-SA100WR

power cord

holder (P-cord)

clamp

sheet (power-top)

5

TA-SA100WR

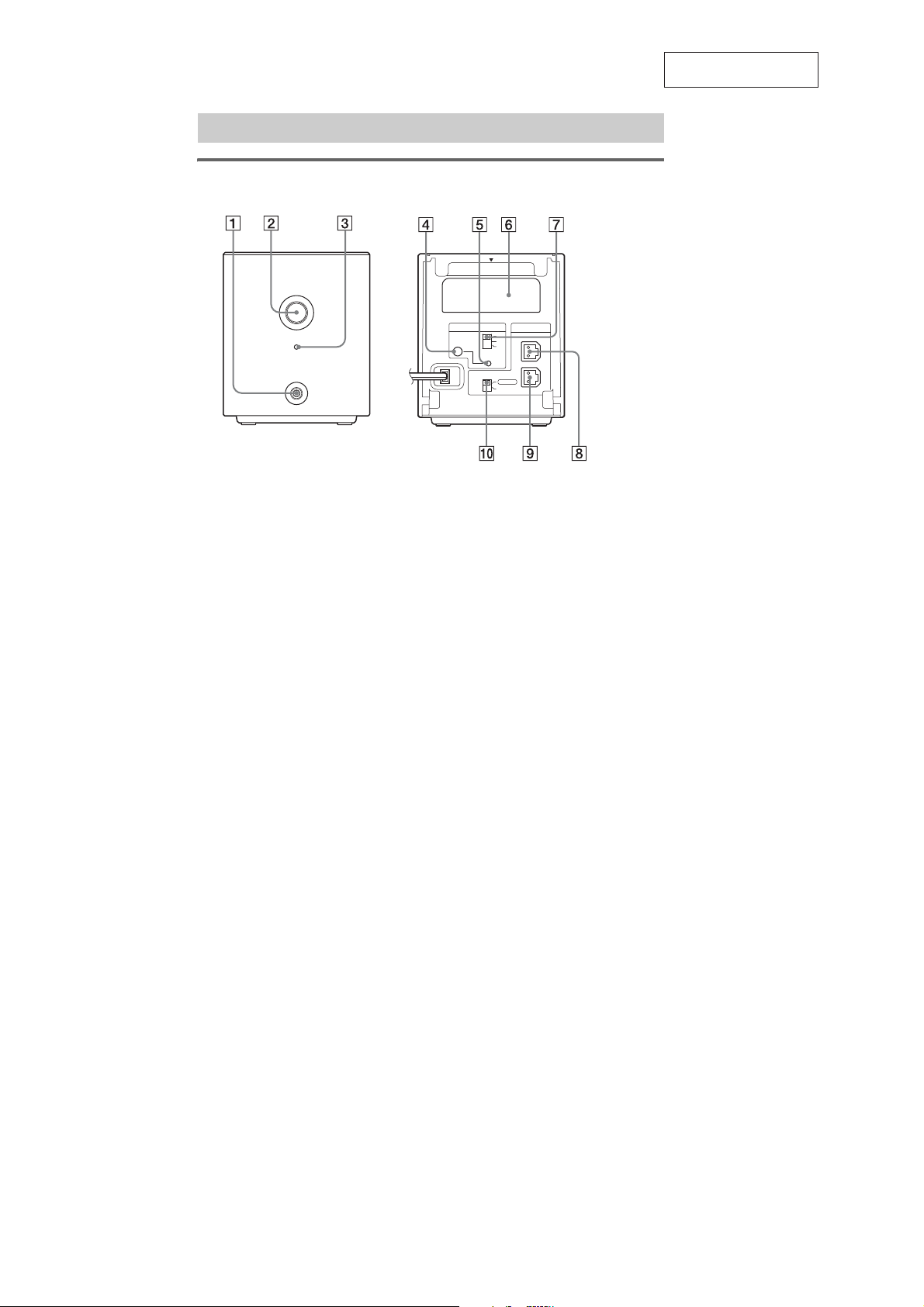

Index to Parts

Surround amplifier

Front panel

POWER

SECTION 2

GENERAL

Rear panel

This section is extracted

from instruction manual.

EZW-RT10

POWER/ON LINE

PHONES

A PHONES jack

B POWER button (ON/OFF)

C POWER / ON LINE indicator

D PAIRING indicator

E PAIRING button

F Wireless transceiver (EZW-RT10) slot

G S-AIR ID switch

H SPEAKER L jack

I SPEAKER R jack

J SURROUND SELECTOR switch

S-AIR ID

PAI RI N G

SURROUND SELECTOR

A

B

C

SURROUND

SURROUND

BACK

SPEAKER

L

R

6

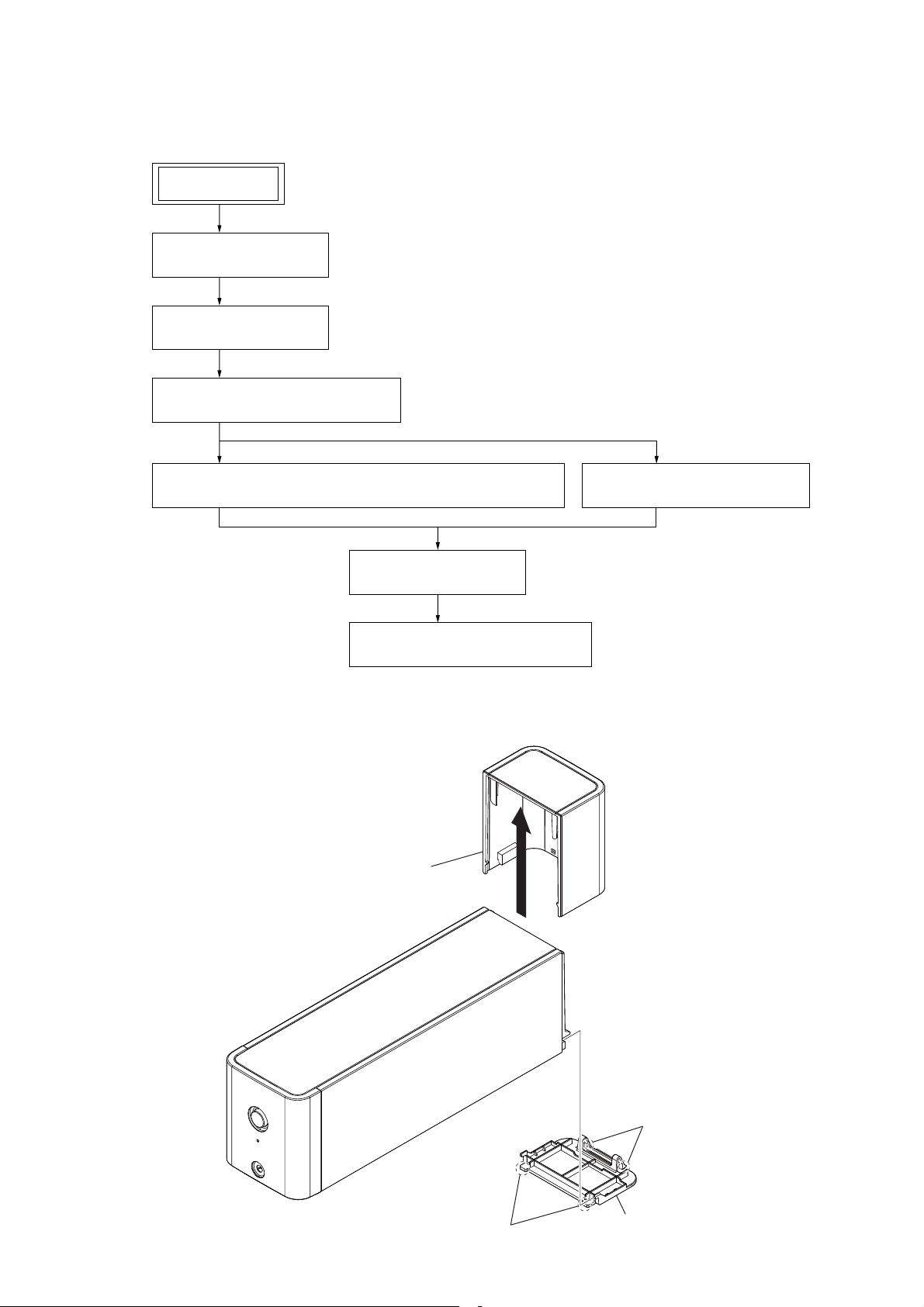

DISASSEMBLY

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2. COVER (CORD)

(Page 7)

3-3. CASE

(Page 8)

3-4. SHIELD (TOP), POWER CORD

(Page 8)

TA-SA100WR

SECTION 3

3-5. POWER SW BOARD, PANEL BOARD, FRONT PANEL BLOCK

(Page 9)

3-7. POWER BLOCK

(Page 9)

3-8. POWER BOARD, AMP BOARD

(Page 9)

Note: Follow the disassembly procedure in the numerical order given.

3-2. COVER (CORD)

cover (cord)

3-6. BACK PANEL, JOINT BOARD

(Page 9)

two claws

two claws

bottom cover (cord)

7

TA-SA100WR

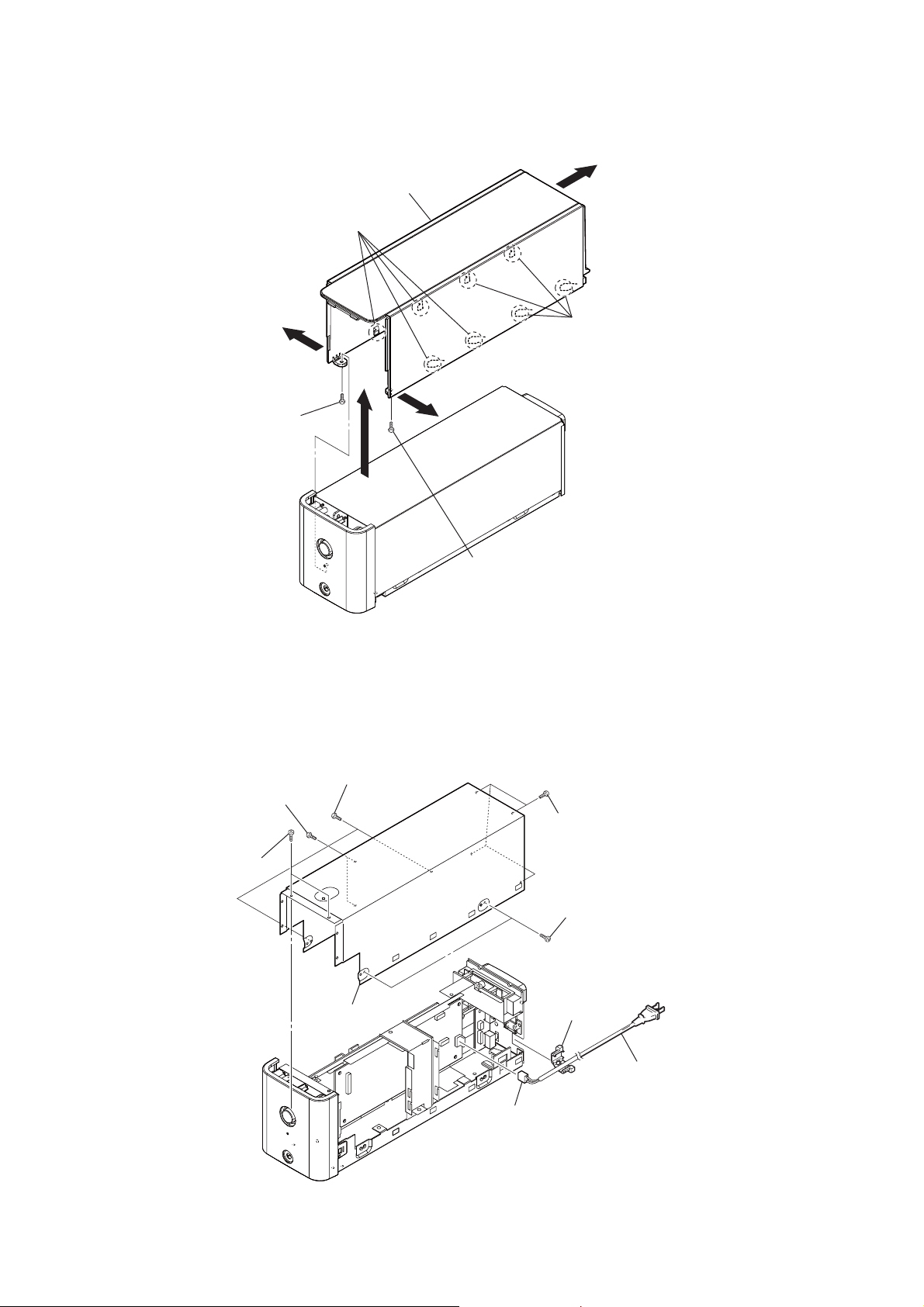

3-3. CASE

screw

(BVTT3 × 6)

four claws

case

four claws

3-4. SHIELD (TOP), POWER CORD

two screws

(BV3)

two screws

(BV3)

two screws

(BV3)

shield (top)

screw

(BVTT3 × 6)

four screws

(BV3)

two screws

(BV3)

cord bushing

power cord

connector

(CN901)

8

TA-SA100WR

TA-SA100WR

99

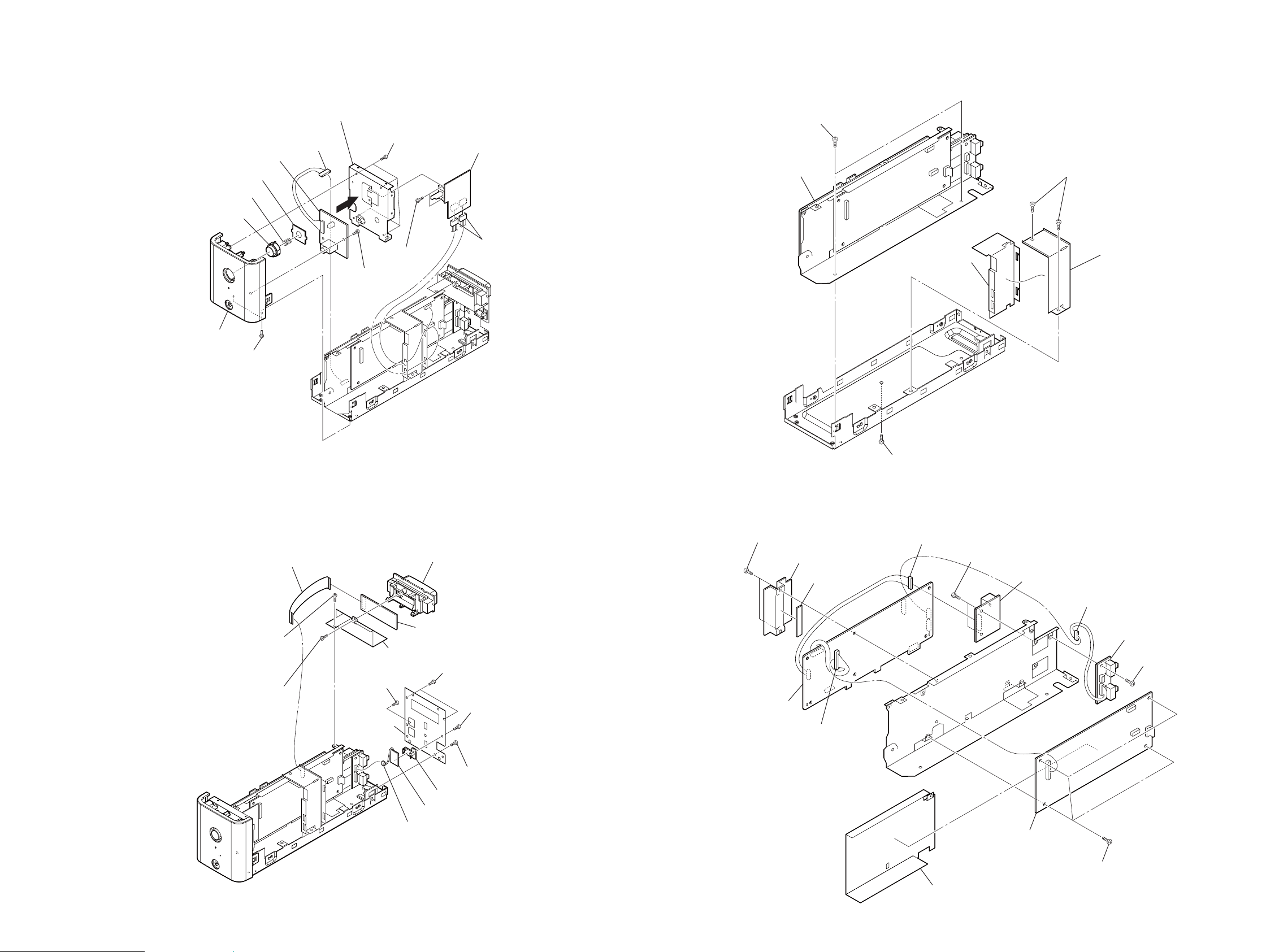

3-5. POWER SW BOARD, PANEL BOARD, FRONT PANEL BLOCK

3-6. BACK PANEL, JOINT BOARD

3-7. POWER BLOCK

3-8. POWER BOARD, AMP BOARD

shield (front)

four screws

(BVTP2.6)

screw

(BVTP2.6)

two screws

(DIA. 2.6)

bracket (button)

RB

spring (button)

RT

button (power)

RE

front panel block

RG

PANEL board

two screws

(BVTT3 × 6)

connector

(CN301)

POWER SW board

two connectors

(CN905, CN906)

(BV3)

power block

two screws

sheet (power-top)

two screws

(BV3)

bracket (POW)

flexible flat cable

(CN507: JOINT board/CN500:AMP board)

screw

(BVTP3 × 8)

screw

RB

(BVTP3 × 10)

screw

(BVTP3 × 8)

back panel

holder (S-AIR)

RE

JOINT board

RG

shield (S-AIR)

RT

connector

(CN509)

two screws

(BVTP3 × 10)

screw

(BVTP3 × 10)

screw

(BVTP3 × 8)

holder (LED)

LED board

two screws (BVTP3 × 8)

RB

heat sink (AMP)

RT

radiation sheet

RE

AMP board

RG

connector

(CN400)

screw

(BVTT3 × 6)

connector (CN302)

two screws

(BV3)

SP TERM board

POWER board

connector (CN501)

MODE SW board

screw

(BV3)

four screws

(BV3)

sheet (power)

TA-SA100WR

TA-SA100WR

1010

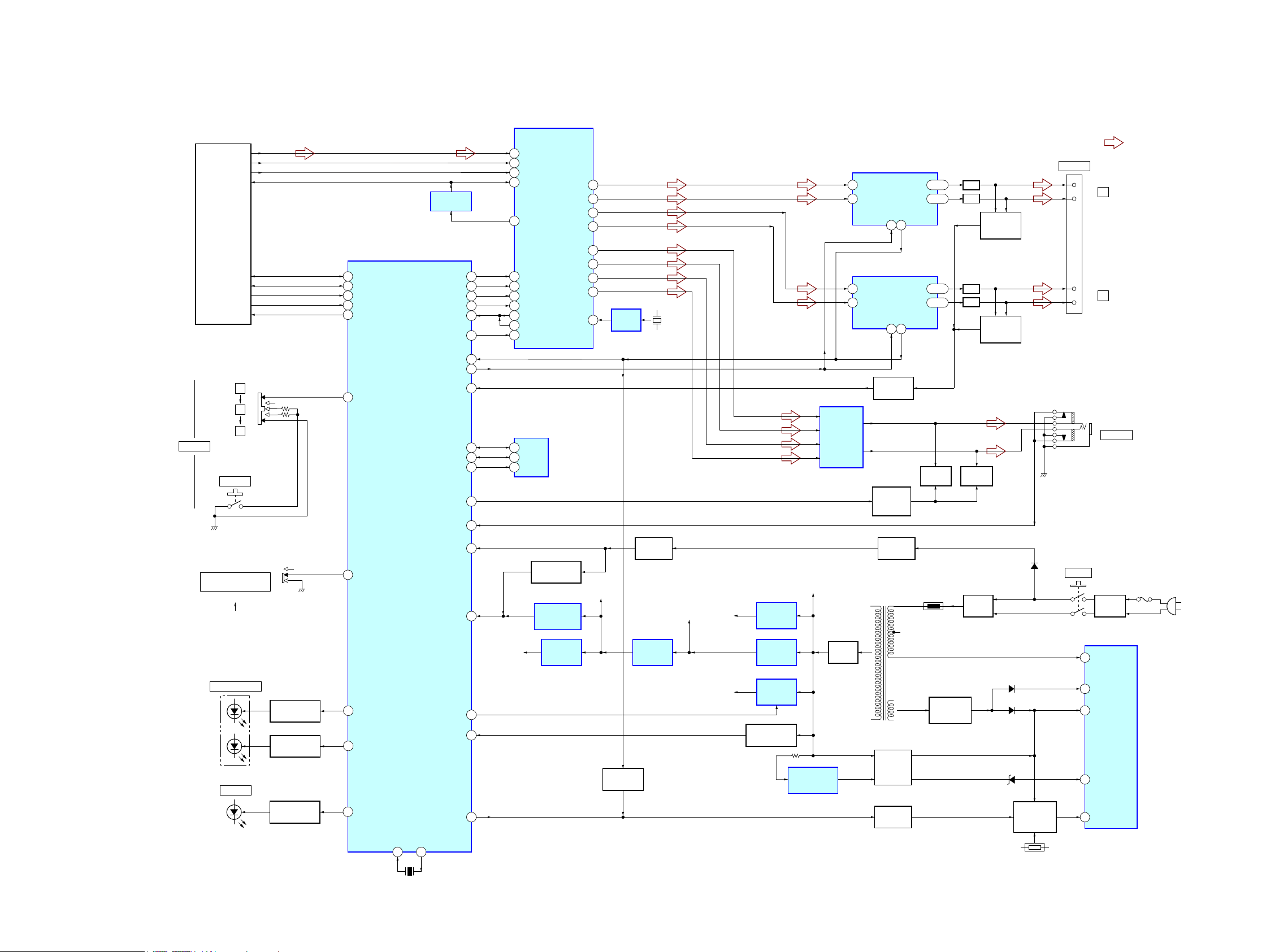

4-1. BLOCK DIAGRAM

SECTION 4

DIAGRAMS

• SIGNAL PATH

: AUDIO

/RESET

/SD

5 4

POWER DRIVER

IC100

POWER DRIVER

IC200

14

PWM_B

6

PWM_A

6

PWM_A

14

PWM_B

TB300

(–)

(+)

OUT_B

OUT_A

STREAM PROCESSOR

IC300

DATA

BCK

LRCK

23

SCLATCH

19

SOFTMUTE

21

SCDT

36

XFSIIN

22

SCSHIFT

6

OUTR1

9

OUTL2

4

OUTR2

11

OUTL1

OVER LOAD

DETECT

Q100, 101

/RESET

/SD

5 4

(+)

(–)

OVER LOAD

DETECT

Q200, 201

SURROUND AMP CONTROLLER

IC500

48

XFSOIN

49

DRIVER_RST(EN)

73

DRIVER_SD

50

DC_DET

20

AC_CUT

12

RESET

SPEAKER

PHONES

14

XFSOOUT

DC DETECT

Q350

OSC

IC301

X300

49.1MHz

35

DAMP_SCDT

37

DAMP_SHIFT

44

DAMP_LATCH

45

DAMP_SOFTMUTE

DAMP_OVF

X500

5MHz

Xout

Xin

27

LED_RED

26

LED_GREEN

D580

POWER/ON LINE

LPF

LPF

LPF

LPF

28 – 30

25 – 27

OUT_A

OUT_B

25 – 27

28 – 30

42DAMP_INIT

27

INIT

1

POWER CONTROL

IC901

D

(AC IN)

F901

TH901

POWER

TRANSFORMER

T901

D911

D908

D910

D907, 909

RECT

D901

LINE

FILTER

ISOLATOR

PC903

OVER LOAD

PROTECT

Q902, 903

4

VCC

7

OCP/BD

5

OLP/SS

ISOLATOR

PC902

TH902

RECT

D921

+32V

+12V

REGULATOR

Q901

ISOLATOR

PC901

6

FB

AC CUT

Q576

PROTECTOR

Q355

RESET SWITCH

Q575

LED DRIVE

Q580, 582

LED DRIVE

Q581, 583

RESET SIGNAL

GENERATOR

IC501

SHUNT

REGULATOR

IC905

+12V

REGULATOR

IC400

VCC2

+3.3V

+1.8V

+1.8V

REGULATOR

IC403

+5V

REGULATOR

IC401

+3.3V

REGULATOR

IC402

53

P_CONT1(MAIN)

S901

POWER

HP_AMP B+

+12V

REGULATOR

IC404

POWER DETECT

Q351, 352

88

PAIRING LED

LED DRIVE

Q560, 561

D560

PAIRING

S503

PAIRING

S502

S-AIR ID

15 13

74

POWER DET

41

P_CONT3(HP)

MUTING

Q170, 171

MUTING

Q270, 271

MUTING

CONTROL

Q370

J300

HEADPHONE

AMP

IC302

41

HPOUTR1

43

HPOUTL2

39

HPOUTR2

45

HPOUTL1

40

HP_SW

39

HP_MUTE

24

FLAGR

25

FLAGL

43

EEPROM

IC502

83

EEP_SDA

82

EEP_SCL

81

EEP_WP

7

WP

5

SDA

6

SCL

D-FLIP-FLOP

IC303

R

L

A

B

C

30 S-AIR_DATA

29 S-AIR_CLK

79 S-AIR_RESET

90 S-AIR_ID_SW

79 SUR_MODE_SW

72 S-AIR_GPIO1

75 S-AIR_GPIO2

31

30

29

S501

SPEAKER

SURROUND SELECTOR

SURROUND

SURROUND BACK

(EZW-RT10)

WIRELESS

TRANSCEIVER

DIND_DOUTB

BCK

LRCK

MCK

I2C_SDA

I2C_SCL

RESN

GPIO1_ASIC_LINK

GPIO2_ASIC_LINK

TA-SA100WR

TA-SA100WR

1111

For Schematic Diagrams.

Note:

• All capacitors are in μF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specifi ed.

• f : internal component.

• 2 : nonfl ammable resistor.

• 5 : fusible resistor.

• C : panel designation.

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

• A : B+ Line.

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark

: POWER ON

* : Impossible to measure

• Voltages are taken with VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

• Abbreviation

CND : Canadian model

E3 : 240V AC area in E model

MX : Mexican model

For Printed Wiring Boards.

Note:

• X : Parts extracted from the component side.

• Y : Parts extracted from the conductor side.

• f : internal component.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Parts face side:

(Conductor Side)

Pattern face side:

(Component Side)

Parts on the parts face side seen from

the pattern face are indicated.

Parts on the pattern face side seen from

the parts face are indicated.

• Waveforms

– AMP Board –

• Circuit Boards Location

• AMP board and JOINT board are multi-layer printed board.

However, the patterns of intermediate layers have not been

included in diagrams.

• Indication of transistor.

Note:

The components identifi ed by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specifi ed.

Note:

Les composants identifi és

par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par

une piéce portant le numéro spécifi é.

C

Q

B

E

Q

B

CE

These are omitted.

These are omitted.

AMP board

PANEL board

JOINT board

SP TERM board

LED board

MODE SW board

POWER board

POWER SW board

IC500 RE (Xout)

1 V/DIV, 100 ns/DIV

IC300 RG (XFSOOUT)

1 V/DIV, 10 ns/DIV

200 ns

20.3 ns

3.1 Vp-p

4.1 Vp-p

IC300 SL (XFSOIN)

1 V/DIV, 10 ns/DIV

IC301 (1A)

1 V/DIV, 10 ns/DIV

20.3 ns

20.3 ns

4.5 Vp-p

4.7 Vp-p

IC303 (2Q)

81.4 ns

4 Vp-p

1 V/DIV, 20 ns/DIV

TA-SA100WR

TA-SA100WR

1212

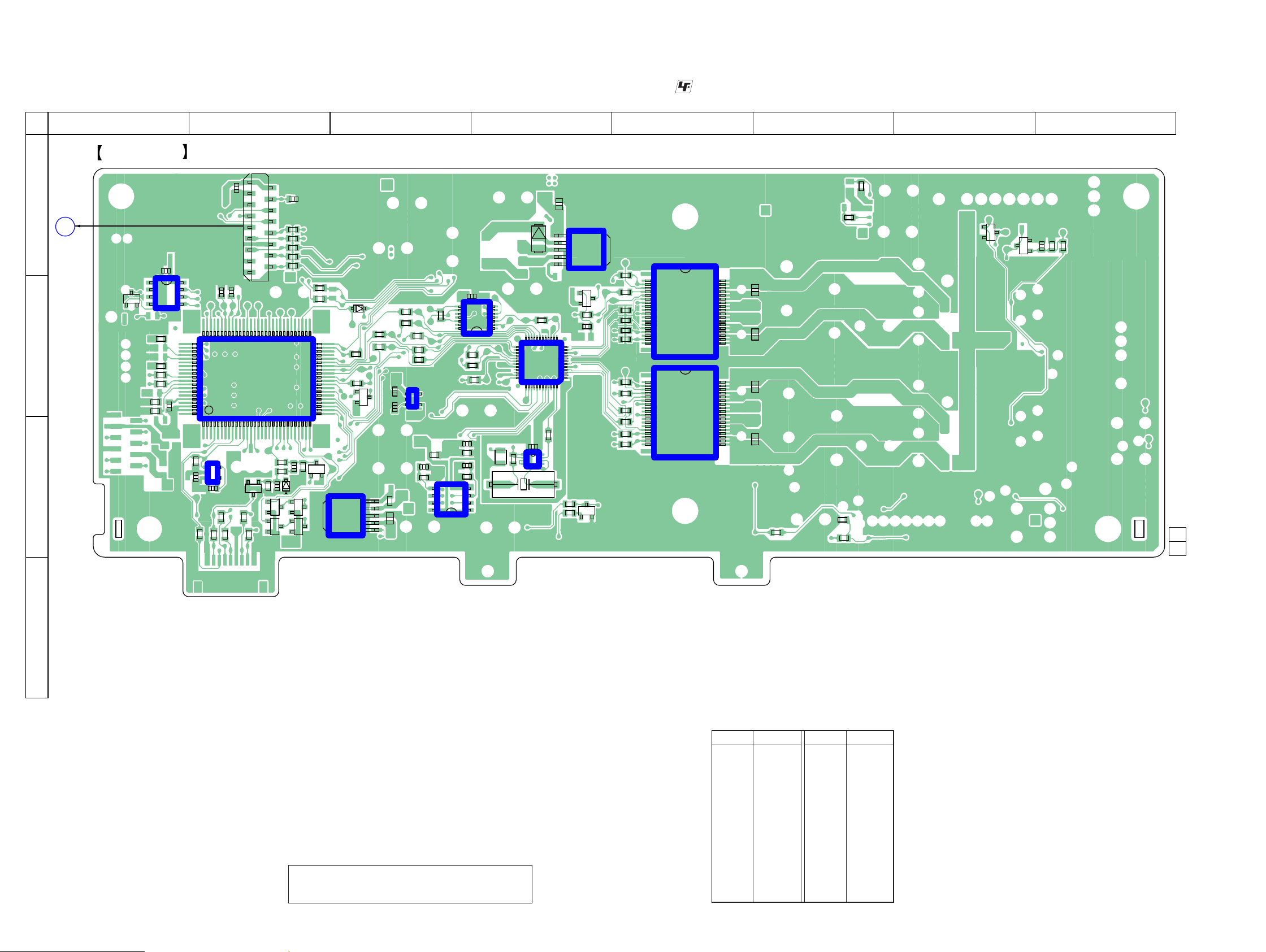

4-2. PRINTED WIRING BOARD - AMP Board (Component Side) (Suffi x-11) -

1

5

1

5

BE

BE

BE

BE

BE

B

E

BE

BE

1

2

16

17

BE

80

81

50

51

31

30

100

1

1

1

1

5

5

4

4

3

3

4

5

8

BE

BE

BE

1

1

1818

19

19

36

36

1

24

25

36

37

48

12

13

8

14

5

1

14

8

7

5

8

1

4

R400

R401

D575

C206

C207

R441

C412

R275

R278

R279

C431

C432

R280

C443

C273

L301

D410

Q350

Q352

R100

Q355

R101

R103

R104

R105

R102

R301

R302

Q170

Q560

Q370

R310

R312

R506

R314

R315

R316

R317

R318

R319

R320

Q575

R321

Q576

R322

R517

R519

R326

CN500

Q580

Q581

Q582

Q583

R524

R525

R526

R527

R528

R357

R358

C106C107

C301

R534

R535

R536

R537

R538

R539

R541

C506

R543

C507

R350

R544

C508

R351

C509

R546

C510

C323

R360

R361

R175

R176

R177

R370

R371

C530

R570

R575

R576

R577

R579

C350

C354

C173

C371

C570

C571

C575

C576

D351

R200

R201

R203

R204

R205

R202

X300

IC300

IC401

IC200 IC100

IC404

IC302

IC500

IC502

IC303

IC301

IC501

IC403

1-875-376-

11

(11)

B1

JOINT

BOARD

CN507

A

B

C

D

12345678

AMP BOARD (COMPONENT SIDE)

(Page 18)

• : Uses unleaded solder.

• See page 11 for Circuit Boards Location.

Ref. No. Location

• Semiconductor Location

Ref. No. Location

D351 B-3

D410 A-4

D575 C-2

IC100 B-5

IC200 B-5

IC300 B-4

IC301 C-4

IC302 C-3

IC303 B-4

IC401 A-4

IC403 B-3

IC404 C-3

IC500 B-2

IC501 C-2

IC502 B-1

Q170 C-4

Q350 A-7

Q352 A-7

Q355 B-4

Q370 B-3

Q560 B-1

Q575 C-2

Q576 C-2

Q580 C-2

Q581 C-2

Q582 C-2

Q583 C-2

Note: Refer to “SUFFIX-11/SUFFIX-12 DISCRIMINATION

OF AMP BOARD” (page 3) of the servicing notes for

suffi x-11 and suffi x-12.

Loading...

Loading...