1

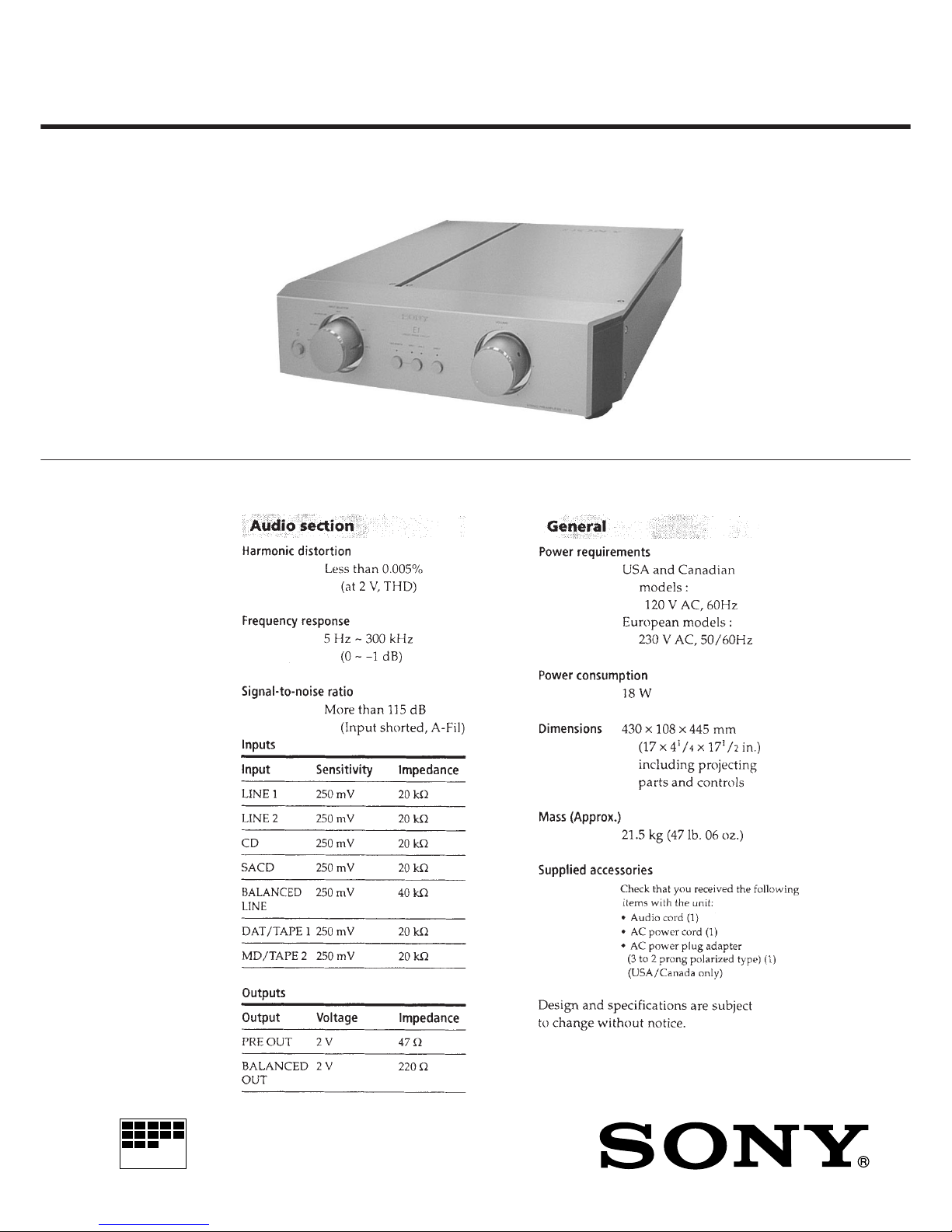

TA-E1

SPECIFICATIONS

STEREO PRE AMPLIFIER

SERVICE MANUAL

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

MICROFILM

2

TABLE OF CONTENTS

1. GENERAL ........................................................................... 3

2. ELECTRICAL ADJUSTMENT .................................... 5

3. DIAGRAMS

3-1. Circuit Boards Location ........................................................ 5

3-2. Schematic Diagram – Main Section (1/3) –..........................6

3-3. Schematic Diagram – Main Section (2/3) –..........................7

3-4. Schematic Diagram – Main Section (3/3) –..........................8

3-5. Printed Wiring Board – Main Section –................................ 9

3-6. Schematic Diagram – Power Section –............................... 10

3-7. Printed Wiring Board – Power Section –............................ 11

4. EXPLODED VIEWS

4-1. Top Plate and Back Panel Section....................................... 12

4-2. Front Panel Section ............................................................. 12

4-3. Bottom Plate Section .......................................................... 13

5. ELECTRICAL PARTS LIST ................................... 14

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter . The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

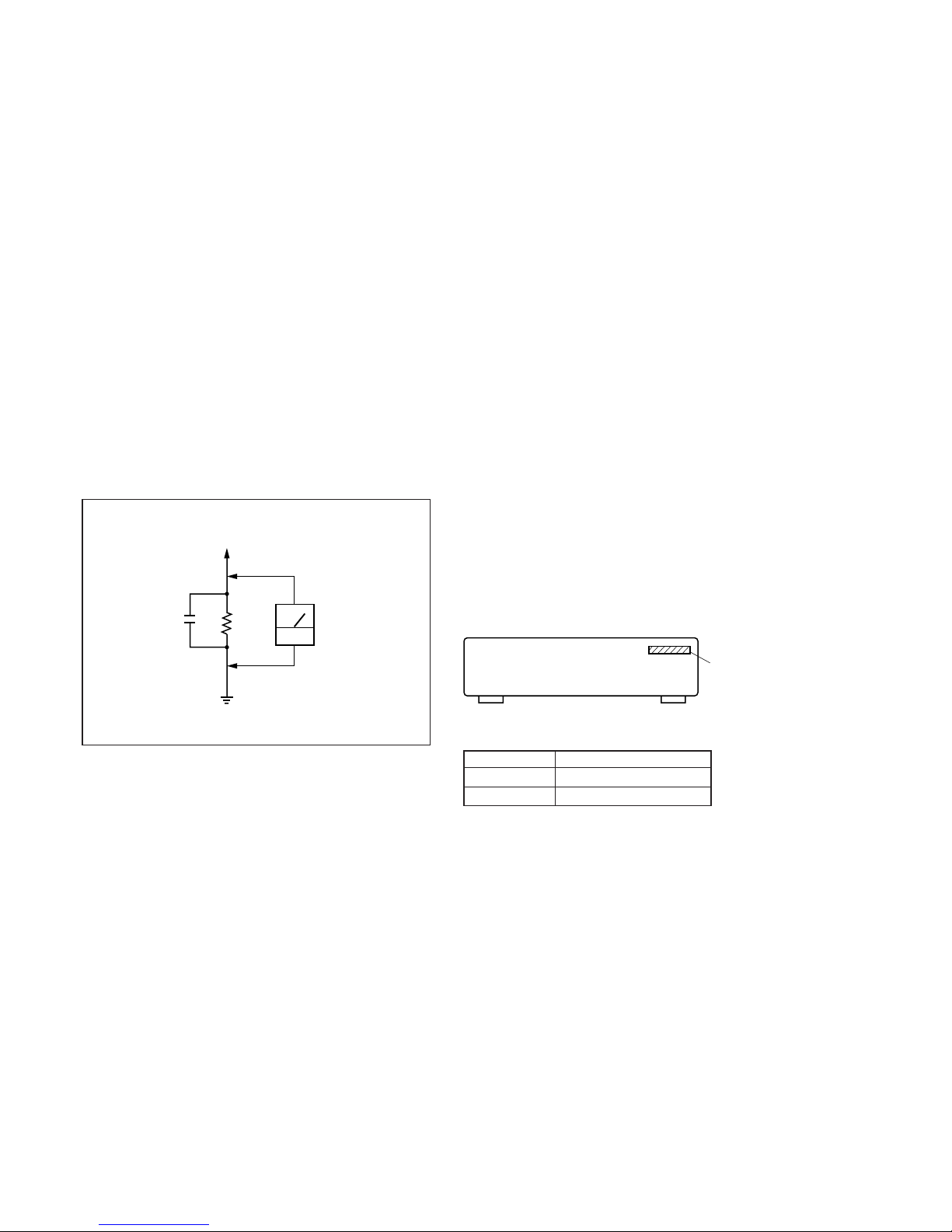

multimeters that have a 2V AC range are suitable. (See Fig. A)

Fig. A. Using an AC voltmeter to check AC leakage.

0.15µF

To Exposed Metal

Parts on Set

1.5k

Ω

AC

voltmeter

(0.75V)

Earth Ground

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

MODEL IDENTIFICATION

— BACK PANEL —

PARTS No. MODEL

4-214-526-1π US , CND

4-214-526-2π AEP, UK, E, AUS

Parts No.

• Abbreviation

CND : Canadian model

AUS : Australian model

3

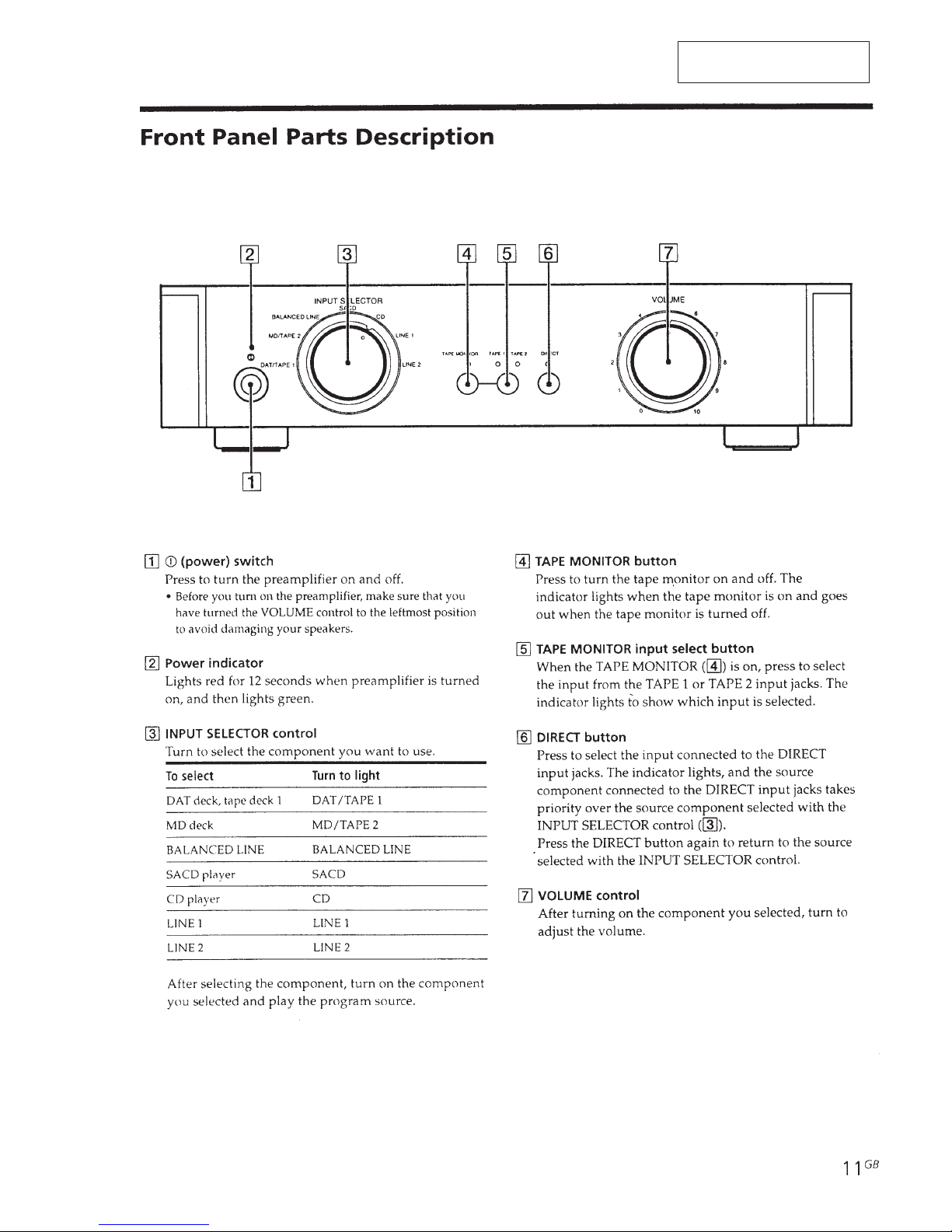

SECTION 1

GENERAL

This section is extracted from

instruction manual.

4

TA-E1

55

SECTION 3

DIAGRAMS

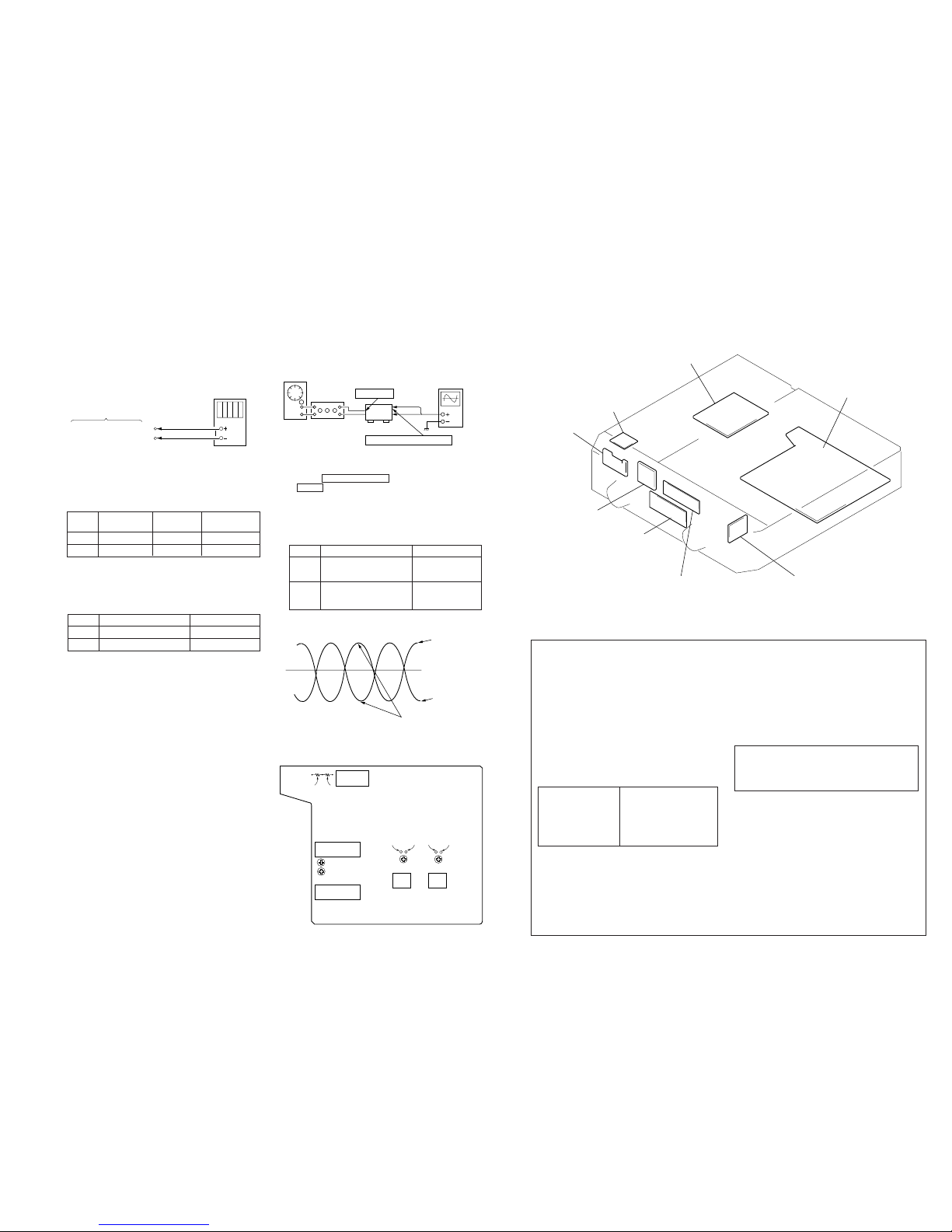

3-1. CIRCUIT BOARDS LOCATION

SECTION 2

ELECTRICAL ADJUSTMENTS

IDLING ADJUSTMENT AND OFFSET VOLTAGE

CHECK

• Perform this adjustment after replacing CP103 and CP104.

• Perform this adjustment more than 10 minutes after supplying

the power.

Connection:

BALANCE OUTPUT LEVEL ADJUSTMENT

• Perform this adjustment when replacing CP102.

• Perform this adjustment after the idling adjustment

Connection:

MAIN board

SW L board

AC J board

LED A board

LED B board

SW P board

PS board

VOL board

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed

in each block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

4

W or less unless otherwise

specified.

• % : indicates tolerance.

• 2 : nonflammable resistor.

• 5 : fusible resistor.

• C : panel designation.

• S : B+ Line.

• T : B– Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground in

playback mode.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Signal path.

F : TUNER

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

For printed wiring boards.

Note:

• X : parts extracted from the component side.

•®: Through hole.

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

Digital voltmeter

TP501 (L-CH), TP502 (R-CH)

TP503 (L-CH), TP504 (R-CH)

MAIN board

Procedure:

1. Connect the digital voltmeter as shown above.

2. Adjust RV501 (L-CH) and RV502 (R-CH) of the MAIN board

so that the digital voltmeter reads 50 mV ±5 mV. (Idling adjustment)

3. Measure the voltage of both terminals of R221 (L-CH) and R222

(R-CH) of the MAIN board, and check that the voltage is within

2 mV.

(Offset voltage check)

Measuring Adjusting Adjusting

Point Point Value

L-CH TP501 to TP503 RV501 50 mV ± 5 mV

R-CH TP502 to TP504 RV502 50 mV ± 5 mV

Measuring Point Specified Value

L-CH Both terminals of R221 Within 2 mV

R-CH Both terminals of R222 Within 2 mV

Procedure:

1. Connect as shown above.

2. Rotate the INPUT SELECTOR knob, and set the input source

to LINE 1 .

3. Set the input level so that the oscilloscope waveform level becomes approx 3 V.

4. Adjust RV401 (L-CH) and R V402 (R-CH) so that the two waveform levels on the oscilloscope become equal and their phases

are reversed.

BALANCED-OUT 2 3 pin

LINE1 input

Set

AF OSC

attenuator

Oscilloscope

Adjusting Value:

Adjusting Point Adjusting Value

L-CH Pin 2 (CH1) and RV401

Pin 3 (CH2) of CN203

R-CH Pin 2 (CH1) and RV401

Pin 3 (CH2) of CN203

Phases of waveforms of

Pins

2

and 3 should be reversed

Waveform of

Pin

2

(CH1)

Waveform of

Pin

3

(CH2)

Adjustment Location:

[MAIN board] (Component Side)

OFFSET

VOLTAGE

R222

R221

RV401

BALANCE OUT

LEVEL L CH

RV402

BALANCE OUT

LEVEL R CH

RV501

IDLE

L CH

TP503

RV502

IDLE

R CH

TP501 TP504 TP502

TA-E1

6

6

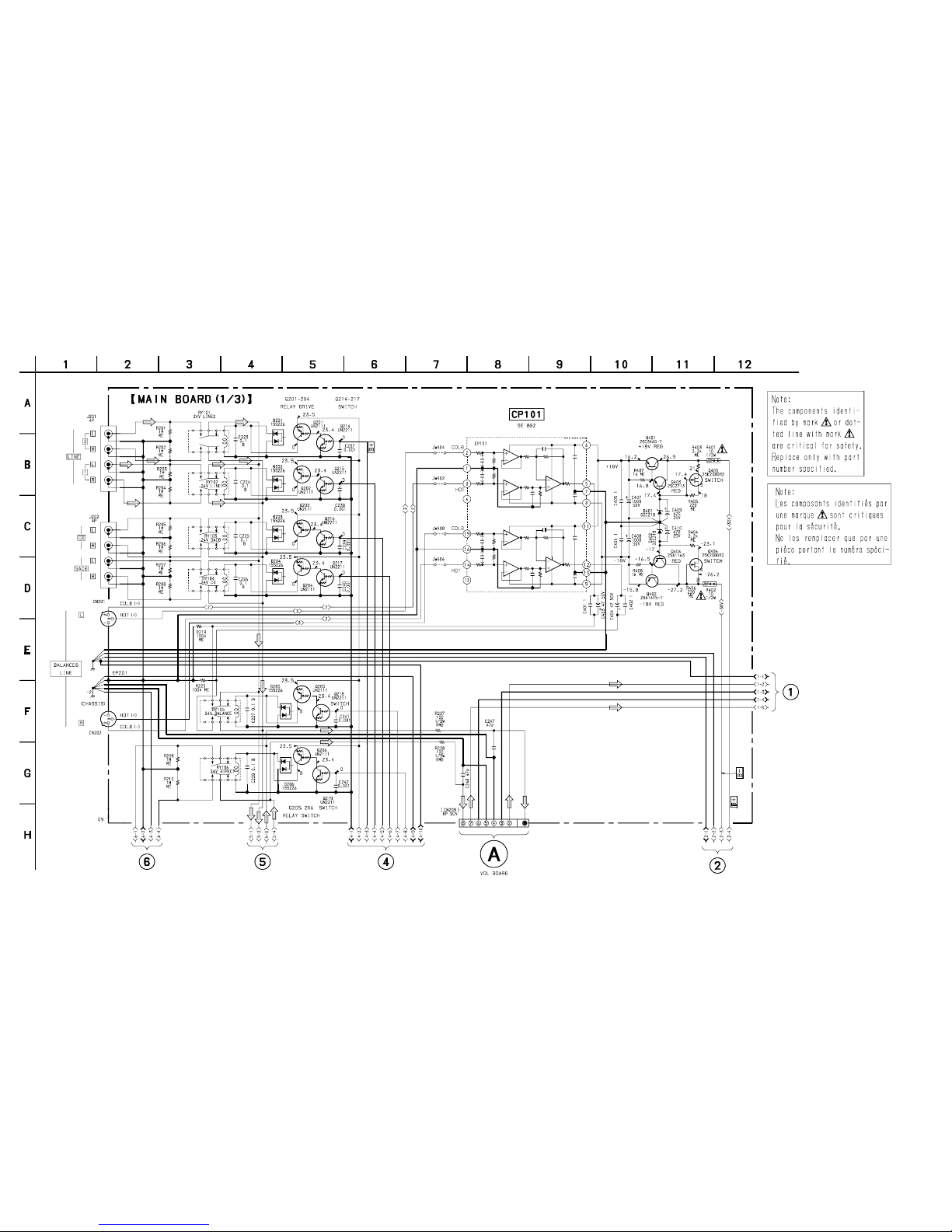

3-2. SCHEMATIC DIAGRAM – MAIN SECTION (1/3) –

• Refer to page 9 for Printed Wiring Board.

(Page 7) (Page 7) (Page 7)

(Page 7)

(Page 8)

(Page 10)

TA-E1

77

3-3. SCHEMATIC DIAGRAM – MAIN SECTION (2/3) –

• Refer to page 9 for Printed Wiring Board.

(Page 6) (Page 6) (Page 6) (Page 8)

(Page 6)

(Page 8)

(Page 10)(Page 10)(Page 10)

TA-E1

8

8

3-4. SCHEMATIC DIAGRAM – MAIN SECTION (3/3) –

(Page 6) (Page 7) (Page 7)

TA-E1

99

3-5. PRINTED WIRING BOARD – MAIN SECTION –

• Refer to page 5 for Circuit Boards Location.

Ref. No Location

D201 B-1

D202 B-1

D203 B-2

D204 B-3

D205 B-4

D206 B-5

D207 B-6

D208 B-8

D209 B-8

D210 B-7

D211 B-10

D212 B-10

D401 I-2

D402 I-2

D403 I-9

D404 I-9

D405 I-8

D406 I-8

D407 I-7

D408 I-7

D501 I-6

D502 I-5

D503 I-4

D504 I-4

D505 I-3

D506 I-4

Q201 B-1

Q202 B-2

Q203 B-3

Q204 B-3

Q205 B-5

Q206 B-6

Q207 B-6

Q208 B-8

Q209 B-7

Q210 B-7

Q211 B-7

Q212 B-10

Q214 B-1

Q215 B-2

Q216 B-3

Q217 B-4

Q218 B-5

Q219 B-6

Q220 B-7

Q221 B-8

Q222 B-7

Q223 B-7

Q224 B-10

Q225 B-11

Q401 I-2

Q402 I-2

Q403 I-2

Q404 I-2

Q405 I-3

Q406 I-2

Q407 I-10

Q408 I-9

Q409 I-9

Q410 I-9

Q411 I-10

Q412 I-9

Q501 F-5

Q502 F-3

Q503 I-8

Q504 I-7

Q505 I-8

Q506 I-7

Q507 I-8

Q508 I-7

Q509 I-6

Q510 I-5

Q511 I-6

Q512 I-5

Q513 I-6

Q514 I-5

Q515 I-4

Q516 I-3

Q517 I-4

Q518 I-3

Q519 I-4

Q520 I-4

• Semiconductor

Location

(Page 11)

(Page 11)

(Page 11)

(Page 11)

VOL

BOARD

SW L

BOARD

SW L

BOARD

PS

BOARD

TA-E1

10

10

3-6. SCHEMATIC DIAGRAM – POWER SECTION –

(Page 6)

(Page 7)

(Page 7)

(Page 7)

TA-E1

11 11

3-7. PRINTED WIRING BOARD – POWER SECTION –

• Refer to page 5 for Circuit Boards Location.

(Page 9)

MAIN BOARD

(Page 9) (Page 9)

MAIN

BOARD

MAIN

BOARD

(Page 9)

MAIN

BOARD

F H 2F H 1

Ref. No Location

D701 C-1

D702 C-1

D703 B-4

D704 B-3

D705 B-3

D706 B-2

D707 C-5

D708 A-5

D709 A-5

D710 D-5

IC701 C-5

Q701 A-4

Q702 A-2

Q703 A-4

Q704 A-2

Q705 C-4

Q706 B-3

Q707 B-5

Q708 A-5

Q709 A-5

Q710 B-5

• Semiconductor

Location

12 12

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

SECTION 4

EXPLODED VIEWS

Ref. No. Part No. Description Remark

Ref. No. Part No. Description Remark

NOTE:

• -XX, -X mean standardized parts, so they may have

some difference from the original one.

• Items marked “*” are not stocked since they are

seldom required for routine service. Some delay

should be anticipated when ordering these items.

• The mechanical parts with no reference number in

the exploded views are not supplied.

• Hardware (# mark) list and accessories and packing materials are given in the last of this parts list.

• Abbreviation

CND : Canadian model

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiques pour la

sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

7 4-911-049-21 SCREW (3X8)

8 4-970-124-11 CUSHION (F50180S)

9 3-703-685-41 SCREW (A+BV 3X8)

10 X-4951-584-1 FOOT ASSY

11 4-974-510-01 SCREW (+BV 3X8 CU)

12 X-4951-020-1 PLATE (L) ASSY,ORNAMENTAL SIDE

13 X-4951-021-1 PLATE (R) ASSY,ORNAMENTAL SIDE

* 14 3-703-044-26 LABEL, CAUTION (US,CND)

1 4-214-524-01 PLATE (L), TOP

2 4-214-525-01 PLATE (R), TOP

3 4-988-742-11 SCREW (M3X8), HEXAGON SOCKET

4 4-214-526-13 PANEL, BACK (US,CND)

4 4-214-526-22 PANEL, BACK (EXCEPT US,CND)

* 5 3-910-074-01 BOLT (M3)

6 1-580-375-41 INLET 3P

60 X-4950-854-1 BUTTON ASSY, POWER

61 1-673-514-11 AC J BOARD

62 1-673-518-11 SW P BOARD

63 1-673-513-11 SW L BOARD

64 1-673-517-11 LED B BOARD

65 1-673-519-11 VOL BOARD

66 3-655-653-21 BAND (TAITON), BINDING

67 4-221-587-01 TUBE, LIGHT INTERCEPTION

51 4-214-521-01 PANEL, FRONT

* 52 4-986-734-01 LENS, LED

53 4-214-533-01 RETAINER, LENS

54 4-214-620-01 SUPPORT (C)

55 4-214-532-01 KNOB (VOL)

56 4-214-545-01 KNOB (SELECTER)

57 X-4950-674-1 BUTTON ASSY

58 4-214-535-01 WINDOW, MIRROR

59 1-673-516-11 LED A BOARD (EXCEPT US,CND)

4-2. FRONT PANEL SECTION

4-1. TOP PLATE AND BACK PANEL SECTION

12

13

not supplied

not supplied

not supplied

not supplied

not supplied

not supplied

not supplied

not supplied

not supplied

not supplied

not supplied

not supplied

not supplied

FRONT PANEL

#1

#1

#1

#1

#1

#1

#1

#1

#1

#2

#2

#2

#2

#3

#3

#3

1

2

3

3

3

3

3

3

4

5

5

6

7

8

8

8

8

9

9

10

10

10

10

11

11

11

11

14

#5

#5

#5

#5

#4

#7

#7

#7

#7

#4

#4

#10

#10

#4

not supplied

not supplied

not supplied

not supplied

Supplied

with S601

Supplied

with RV301

not supplied

51

52

52

53

53

54

55

56

57

58

59

58

60

61

62

63

64

65

66

67

13

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

Les composants identifiés par une

marque ! sont critiques pour la sécurité.

Ne les remplacer que par une piéce

portant le numéro spécifié.

The components identified by mark !

or dotted line with mark ! are critical

for safety.

Replace only with part number specified.

109 4-967-960-01 SCREW (4X8)

* 110 4-931-964-01 SCREW (M4X6)

* 111 1-641-950-11 PC BOARD, BOTTOM LID

112 A-4426-205-A MAIN BOARD, COMPLETE (US,CND)

112 A-4426-208-A MAIN BOARD, COMPLETE (EXCEPT US,CND)

113 4-974-510-01 SCREW (+BV 3X8 CU)

! T1 1-433-981-11 TRANSFORMER, POWER (EXCEPT US,CND)

! T1 1-433-982-11 TRANSFORMER, POWER (US,CND)

101 4-219-714-01 PLATE (A), BOTTOM

102 4-214-527-01 PLATE, BOTTOM

103 4-219-712-01 PLATE (A), TOP

104 4-219-713-01 PLATE (B), TOP

105 A-4426-207-A PS BOARD, COMPLETE (US,CND)

105 A-4426-210-A PS BOARD, COMPLETE (EXCEPT US,CND)

* 106 4-941-237-01 HEAT SINK

107 4-902-345-01 HEAT SINK

108 2-259-121-01 SCREW, TR

4-3. BOTTOM PLATE SECTION

#6

#6

#7

#7

#8

#7

#7

#9

#7 (EXCEPT,

US, CND)

#8 (US, CND)

#7 (EXCEPT,

US, CND)

#8 (US, CND)

#7

#3

101

102

103

104

109

109

109 109

109

105

106

108

108

108

110

111

111

107

113

113

113

not supplied

not supplied

not supplied

not supplied

not supplied

not supplied

T1

not supplied

not supplied

not supplied

112

(US, CND)

14

SECTION 5

ELECTRICAL PARTS LIST

AC J

Note:

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

• SEMICONDUCTORS

In each case, u: µ , for example:

uA...: µ A..., uPA...: µ PA..., uPB...: µ PB...,

uPC...: µ PC..., uPD...: µ PD...

• CAPACITORS

uF : µ F

• COILS

uH : µ H

• Abbreviation

CND : Canadian model

• Due to standardization, replacements in the parts list

may be different from the parts specified in the

diagrams or the components used on the set.

• -XX, -X mean standardized parts, so they may have

some difference from the original one.

• Items marked “*” are not stocked since they are

seldom required for routine service. Some delay

should be anticipated when ordering these items.

• RESISTORS

All resistors are in ohms

METAL: Metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F : nonflammable

When indicating parts by reference

number, please include the board

name.

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiques pour la

sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

1-673-514-11 AC J BOARD

*********

1-533-798-11 HOLDER, FUSE

< CAPACITOR >

! C901 1-113-920-11 CERAMIC 0.0022uF 20% 250V

< CONNECTOR >

CN902 1-564-321-00 PIN, CONNECTOR 2P

< FUSE >

! F901 1-532-463-51 FUSE (1A/250)(EXCEPT US,CND)

! F901 1-532-742-11 FUSE, GLASS TUBE (1.6A/125V)(US,CND)

< SWITCH >

! S901 1-771-187-11 SWITCH, AC POWER (U)

**************************************************************

1-673-516-11 LED A BOARD

**********

< CAPACITOR >

C801 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C802 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

< CONNECTOR >

CN801 1-691-765-11 PLUG (MICRO CONNECTOR) 3P

< DIODE >

D801 8-719-313-40 DIODE SML1516W (U)

**************************************************************

1-673-517-11 LED B BOARD

**********

< CAPACITOR >

C605 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

C606 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

C607 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

C608 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

< DIODE >

D601 8-719-046-38 DIODE SEL5821A-TH8F (TAPE MONITOR)

D602 8-719-046-38 DIODE SEL5821A-TH8F (TAPE 1)

D603 8-719-046-38 DIODE SEL5821A-TH8F (TAPE 2)

D604 8-719-046-38 DIODE SEL5821A-TH8F (DIRECT)

**************************************************************

A-4426-205-A MAIN BOARD, COMPLETE (US,CND)

*********************

A-4426-208-A MAIN BOARD, COMPLETE (EXCEPT US,CND)

*********************

4-835-639-00 PLATE, GROUND

< CAPACITOR >

C223 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C224 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C225 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C226 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C227 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C228 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C229 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C230 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C231 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C232 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C233 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C234 1-115-339-11 CERAMIC CHIP 0.1uF 10% 50V

C237 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C238 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C239 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C240 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C241 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C242 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C243 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C244 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C245 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C246 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C247 1-125-845-21 FILM 47PF 10% 50V

C248 1-125-845-21 FILM 47PF 10% 50V

C249 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C250 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C401 1-110-512-51 FILM 1uF 10% 50V

C402 1-110-512-51 FILM 1uF 10% 50V

LED A

MAIN

LED B

15

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

C403 1-128-200-11 ELECT 47uF 20% 50V

C404 1-128-200-11 ELECT 47uF 20% 50V

C405 1-110-512-51 FILM 1uF 10% 50V

C406 1-110-512-51 FILM 1uF 10% 50V

C407 1-128-972-11 ELECT 1000uF 20% 50V

C408 1-128-972-11 ELECT 1000uF 20% 50V

C409 1-128-973-11 ELECT 470uF 20% 25V

C410 1-128-973-11 ELECT 470uF 20% 25V

C411 1-128-200-11 ELECT 47uF 20% 50V

C412 1-128-200-11 ELECT 47uF 20% 50V

C413 1-128-200-11 ELECT 47uF 20% 50V

C414 1-128-200-11 ELECT 47uF 20% 50V

C419 1-110-512-51 FILM 1uF 10% 50V

C420 1-110-512-51 FILM 1uF 10% 50V

C421 1-128-972-11 ELECT 1000uF 20% 50V

C422 1-128-972-11 ELECT 1000uF 20% 50V

C423 1-128-973-11 ELECT 470uF 20% 25V

C424 1-128-973-11 ELECT 470uF 20% 25V

C501 1-125-850-21 FILM 220PF 5% 50V

C502 1-125-850-21 FILM 220PF 5% 50V

C503 1-110-512-51 FILM 1uF 10% 50V

C504 1-110-512-51 FILM 1uF 10% 50V

C505 1-128-971-11 ELECT 220uF 20% 50V

C506 1-128-971-11 ELECT 220uF 20% 50V

C507 1-128-971-11 ELECT 220uF 20% 50V

C508 1-128-971-11 ELECT 220uF 20% 50V

C509 1-128-973-11 ELECT 470uF 20% 25V

C510 1-128-973-11 ELECT 470uF 20% 25V

C511 1-128-972-11 ELECT 1000uF 20% 50V

C512 1-128-972-11 ELECT 1000uF 20% 50V

C513 1-110-512-51 FILM 1uF 10% 50V

C514 1-110-512-51 FILM 1uF 10% 50V

C515 1-128-973-11 ELECT 470uF 20% 25V

C516 1-128-973-11 ELECT 470uF 20% 25V

C517 1-126-017-11 ELECT 6800uF 20% 16V

C518 1-126-017-11 ELECT 6800uF 20% 16V

C519 1-110-512-51 FILM 1uF 10% 50V

C520 1-110-512-51 FILM 1uF 10% 50V

C521 1-128-973-11 ELECT 470uF 20% 25V

C522 1-128-973-11 ELECT 470uF 20% 25V

C523 1-128-972-11 ELECT 1000uF 20% 50V

C524 1-128-972-11 ELECT 1000uF 20% 50V

C525 1-110-512-51 FILM 1uF 10% 50V

C526 1-110-512-51 FILM 1uF 10% 50V

< CONNECTOR >

CN201 1-766-803-11 CONNECTOR (CANON)

CN202 1-766-803-11 CONNECTOR (CANON)

CN203 1-785-548-11 CONNECTOR (RECEPTACLE)

CN204 1-785-548-11 CONNECTOR (RECEPTACLE)

CN205 1-691-768-11 PLUG (MICRO CONNECTOR) 6P

CN206 1-691-769-11 PLUG (MICRO CONNECTOR) 7P

* CN207 1-564-241-11 PIN, CONNECTOR (B4P-VH) 4P

< COMPOSITION CIRCUIT BLOCK >

CP101 1-233-250-11 ENCAPSULATED COMPONENT

CP102 1-418-106-11 AMPLIFIER UNIT

CP103 1-418-107-11 AMPLIFIER UNIT

CP104 1-418-107-11 AMPLIFIER UNIT

< DIODE >

D201 8-719-800-76 DIODE 1SS226

D202 8-719-800-76 DIODE 1SS226

D203 8-719-800-76 DIODE 1SS226

D204 8-719-800-76 DIODE 1SS226

D205 8-719-800-76 DIODE 1SS226

D206 8-719-800-76 DIODE 1SS226

D207 8-719-800-76 DIODE 1SS226

D208 8-719-800-76 DIODE 1SS226

D209 8-719-800-76 DIODE 1SS226

D210 8-719-800-76 DIODE 1SS226

D211 8-719-800-76 DIODE 1SS226

D212 8-719-800-76 DIODE 1SS226

D401 8-719-025-51 DIODE 02CZ18-TE85L

D402 8-719-025-51 DIODE 02CZ18-TE85L

D403 8-719-025-51 DIODE 02CZ18-TE85L

D404 8-719-025-51 DIODE 02CZ18-TE85L

D405 8-719-025-47 DIODE 02CZ12-TE85L

D406 8-719-025-47 DIODE 02CZ12-TE85L

D407 8-719-025-47 DIODE 02CZ12-TE85L

D408 8-719-025-47 DIODE 02CZ12-TE85L

D501 8-719-025-51 DIODE 02CZ18-TE85L

D502 8-719-025-51 DIODE 02CZ18-TE85L

D503 8-719-025-47 DIODE 02CZ12-TE85L

D504 8-719-025-47 DIODE 02CZ12-TE85L

D505 8-719-025-47 DIODE 02CZ12-TE85L

D506 8-719-025-47 DIODE 02CZ12-TE85L

< JACK >

J201 1-785-547-11 JACK, PIN (LINE 1, 2 L/R)

J202 1-785-547-11 JACK, PIN (CD, SACD L/R)

J203 1-785-547-11 JACK, PIN (DIRECT L/R, TAPE2/MD IN L/R)

J204 1-785-547-11 JACK, PIN

(TAPE2/MD OUT L/R, TAPE1/DAT IN L/R)

J205 1-785-547-11 JACK, PIN (TAPE1/DAT OUT L/R, PRE OUT L/R)

< BUS BAR >

* JWH201 1-569-135-11 BAR, BUS 4P

* JWH202 1-569-135-11 BAR, BUS 4P

* JWH203 1-691-275-11 BUS BAR

* JWH204 1-569-135-11 BAR, BUS 4P

* JWH205 1-569-135-11 BAR, BUS 4P

* JWH206 1-691-275-11 BUS BAR

< TRANSISTOR >

Q201 8-729-424-08 TRANSISTOR UN2111

Q202 8-729-424-08 TRANSISTOR UN2111

Q203 8-729-424-08 TRANSISTOR UN2111

Q204 8-729-424-08 TRANSISTOR UN2111

Q205 8-729-424-08 TRANSISTOR UN2111

Q206 8-729-424-08 TRANSISTOR UN2111

Q207 8-729-424-08 TRANSISTOR UN2111

Q208 8-729-424-08 TRANSISTOR UN2111

Q209 8-729-424-08 TRANSISTOR UN2111

Q210 8-729-424-08 TRANSISTOR UN2111

MAIN

16

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

Les composants identifiés par une

marque ! sont critiques pour la sécurité.

Ne les remplacer que par une piéce

portant le numéro spécifié.

The components identified by mark !

or dotted line with mark ! are critical

for safety.

Replace only with part number specified.

Q211 8-729-424-08 TRANSISTOR UN2111

Q212 8-729-424-08 TRANSISTOR UN2111

Q214 8-729-421-22 TRANSISTOR UN2211

Q215 8-729-421-22 TRANSISTOR UN2211

Q216 8-729-421-22 TRANSISTOR UN2211

Q217 8-729-421-22 TRANSISTOR UN2211

Q218 8-729-421-22 TRANSISTOR UN2211

Q219 8-729-421-22 TRANSISTOR UN2211

Q220 8-729-421-22 TRANSISTOR UN2211

Q221 8-729-421-22 TRANSISTOR UN2211

Q222 8-729-421-22 TRANSISTOR UN2211

Q223 8-729-421-22 TRANSISTOR UN2211

Q224 8-729-421-22 TRANSISTOR UN2211

Q225 8-729-421-22 TRANSISTOR UN2211

Q401 8-729-047-96 TRANSISTOR 2SC3645-S

Q402 8-729-047-94 TRANSISTOR 2SA1415-S

Q403 8-729-271-31 TRANSISTOR 2SC2713-G

Q404 8-729-216-31 TRANSISTOR 2SA1163-G

Q405 8-729-232-69 TRANSISTOR 2SK208-GRT5LSONY-1

Q406 8-729-232-69 TRANSISTOR 2SK208-GRT5LSONY-1

Q407 8-729-047-96 TRANSISTOR 2SC3645-S

Q408 8-729-047-94 TRANSISTOR 2SA1415-S

Q409 8-729-271-31 TRANSISTOR 2SC2713-G

Q410 8-729-216-31 TRANSISTOR 2SA1163-G

Q411 8-729-232-69 TRANSISTOR 2SK208-GRT5LSONY-1

Q412 8-729-232-69 TRANSISTOR 2SK208-GRT5LSONY-1

Q501 8-729-271-31 TRANSISTOR 2SC2713-G

Q502 8-729-271-31 TRANSISTOR 2SC2713-G

Q503 8-729-047-96 TRANSISTOR 2SC3645-S

Q504 8-729-047-94 TRANSISTOR 2SA1415-S

Q505 8-729-271-31 TRANSISTOR 2SC2713-G

Q506 8-729-216-31 TRANSISTOR 2SA1163-G

Q507 8-729-232-69 TRANSISTOR 2SK208-GRT5LSONY-1

Q508 8-729-232-69 TRANSISTOR 2SK208-GRT5LSONY-1

Q509 8-729-047-96 TRANSISTOR 2SC3645-S

Q510 8-729-047-94 TRANSISTOR 2SA1415-S

Q511 8-729-271-31 TRANSISTOR 2SC2713-G

Q512 8-729-216-31 TRANSISTOR 2SA1163-G

Q513 8-729-232-69 TRANSISTOR 2SK208-GRT5LSONY-1

Q514 8-729-232-69 TRANSISTOR 2SK208-GRT5LSONY-1

Q515 8-729-232-69 TRANSISTOR 2SK208-GRT5LSONY-1

Q516 8-729-232-69 TRANSISTOR 2SK208-GRT5LSONY-1

Q517 8-729-047-96 TRANSISTOR 2SC3645-S

Q518 8-729-047-94 TRANSISTOR 2SA1415-S

Q519 8-729-271-31 TRANSISTOR 2SC2713-G

Q520 8-729-216-31 TRANSISTOR 2SA1163-G

< RESISTOR >

R201 1-260-032-11 CARBON MELF 1M 2% 1/8W

R202 1-260-032-11 CARBON MELF 1M 2% 1/8W

R203 1-260-032-11 CARBON MELF 1M 2% 1/8W

R204 1-260-032-11 CARBON MELF 1M 2% 1/8W

R205 1-260-032-11 CARBON MELF 1M 2% 1/8W

R206 1-260-032-11 CARBON MELF 1M 2% 1/8W

R207 1-260-032-11 CARBON MELF 1M 2% 1/8W

R208 1-260-032-11 CARBON MELF 1M 2% 1/8W

R209 1-260-032-11 CARBON MELF 1M 2% 1/8W

R210 1-260-032-11 CARBON MELF 1M 2% 1/8W

R211 1-260-032-11 CARBON MELF 1M 2% 1/8W

R212 1-260-032-11 CARBON MELF 1M 2% 1/8W

R213 1-260-032-11 CARBON MELF 1M 2% 1/8W

R214 1-260-032-11 CARBON MELF 1M 2% 1/8W

R215 1-260-032-11 CARBON MELF 1M 2% 1/8W

R216 1-260-032-11 CARBON MELF 1M 2% 1/8W

R217 1-260-032-11 CARBON MELF 1M 2% 1/8W

R218 1-260-032-11 CARBON MELF 1M 2% 1/8W

R219 1-260-020-11 CARBON MELF 100K 2% 1/8W

R220 1-260-020-11 CARBON MELF 100K 2% 1/8W

R221 1-260-032-11 CARBON MELF 1M 2% 1/8W

R222 1-260-032-11 CARBON MELF 1M 2% 1/8W

R223 1-260-032-11 CARBON MELF 1M 2% 1/8W

R224 1-260-032-11 CARBON MELF 1M 2% 1/8W

R225 1-260-032-11 CARBON MELF 1M 2% 1/8W

R226 1-260-032-11 CARBON MELF 1M 2% 1/8W

R227 1-249-186-11 CARBON 100 1% 1/3W

R228 1-249-186-11 CARBON 100 1% 1/3W

R229 1-259-644-11 CARBON 47 2% 1W

R230 1-259-644-11 CARBON 47 2% 1W

R231 1-259-531-11 CARBON 100 1% 1/2W

R232 1-259-531-11 CARBON 100 1% 1/2W

R233 1-249-186-11 CARBON 100 1% 1/3W

R234 1-249-186-11 CARBON 100 1% 1/3W

R235 1-259-995-11 CARBON MELF 1K 2% 1/8W

R236 1-259-995-11 CARBON MELF 1K 2% 1/8W

! R401 1-202-937-41 FUSIBLE 10 5% 1/2W

! R402 1-202-937-41 FUSIBLE 10 5% 1/2W

R403 1-259-999-11 CARBON MELF 2.2K 2% 1/8W

R404 1-259-999-11 CARBON MELF 2.2K 2% 1/8W

R405 1-259-987-11 CARBON MELF 220 2% 1/8W

R406 1-259-987-11 CARBON MELF 220 2% 1/8W

R407 1-259-995-11 CARBON MELF 1K 2% 1/8W

R408 1-259-995-11 CARBON MELF 1K 2% 1/8W

! R409 1-202-937-41 FUSIBLE 10 5% 1/2W

! R410 1-202-937-41 FUSIBLE 10 5% 1/2W

R411 1-259-999-11 CARBON MELF 2.2K 2% 1/8W

R412 1-259-999-11 CARBON MELF 2.2K 2% 1/8W

R413 1-259-987-11 CARBON MELF 220 2% 1/8W

R414 1-259-987-11 CARBON MELF 220 2% 1/8W

R415 1-259-995-11 CARBON MELF 1K 2% 1/8W

R416 1-259-995-11 CARBON MELF 1K 2% 1/8W

R501 1-259-668-61 CARBON 470 2% 1W

R502 1-259-668-61 CARBON 470 2% 1W

R503 1-259-535-61 CARBON 150 1% 1/2W

R504 1-259-535-61 CARBON 150 1% 1/2W

R505 1-259-668-61 CARBON 470 2% 1W

R506 1-259-668-61 CARBON 470 2% 1W

R507 1-260-002-11 CARBON MELF 3.3K 2% 1/8W

R508 1-259-991-11 CARBON MELF 470 2% 1/8W

R509 1-260-002-11 CARBON MELF 3.3K 2% 1/8W

R510 1-259-991-11 CARBON MELF 470 2% 1/8W

R511 1-259-999-11 CARBON MELF 2.2K 2% 1/8W

R512 1-259-999-11 CARBON MELF 2.2K 2% 1/8W

R513 1-259-987-11 CARBON MELF 220 2% 1/8W

R514 1-259-987-11 CARBON MELF 220 2% 1/8W

! R515 1-202-937-41 FUSIBLE 10 5% 1/2W

MAIN

17

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

Les composants identifiés par une

marque ! sont critiques pour la sécurité.

Ne les remplacer que par une piéce

portant le numéro spécifié.

The components identified by mark !

or dotted line with mark ! are critical

for safety.

Replace only with part number specified.

! R516 1-202-937-41 FUSIBLE 10 5% 1/2W

! R517 1-202-937-41 FUSIBLE 10 5% 1/2W

! R518 1-202-937-41 FUSIBLE 10 5% 1/2W

R519 1-259-995-11 CARBON MELF 1K 2% 1/8W

R520 1-259-995-11 CARBON MELF 1K 2% 1/8W

R521 1-259-999-11 CARBON MELF 2.2K 2% 1/8W

R522 1-259-999-11 CARBON MELF 2.2K 2% 1/8W

R523 1-259-987-11 CARBON MELF 220 2% 1/8W

R524 1-259-987-11 CARBON MELF 220 2% 1/8W

R525 1-259-995-11 CARBON MELF 1K 2% 1/8W

R526 1-259-995-11 CARBON MELF 1K 2% 1/8W

! R527 1-202-937-41 FUSIBLE 10 5% 1/2W

! R528 1-202-937-41 FUSIBLE 10 5% 1/2W

R529 1-259-999-11 CARBON MELF 2.2K 2% 1/8W

R530 1-259-999-11 CARBON MELF 2.2K 2% 1/8W

R531 1-259-987-11 CARBON MELF 220 2% 1/8W

R532 1-259-987-11 CARBON MELF 220 2% 1/8W

R533 1-259-995-11 CARBON MELF 1K 2% 1/8W

R534 1-259-995-11 CARBON MELF 1K 2% 1/8W

R535 1-249-162-11 CARBON 10 1% 1/3W

R536 1-249-162-11 CARBON 10 1% 1/3W

< VARIABLE RESISTOR >

RV401 1-224-250-11 RES, ADJ, METAL GLAZE 2.2K

(BALANCED LEVEL LCH)

RV402 1-224-250-11 RES, ADJ, METAL GLAZE 2.2K

(BALANCED LEVEL RCH)

RV501 1-224-249-11 RES, ADJ, METAL GLAZE 1K (IDLER LCH)

RV502 1-224-249-11 RES, ADJ, METAL GLAZE 1K (IDLER RCH)

< RELAY >

RY101 1-755-062-11 RELAY

RY102 1-755-062-11 RELAY

RY103 1-755-062-11 RELAY

RY104 1-755-062-11 RELAY

RY105 1-755-062-11 RELAY

RY106 1-755-062-11 RELAY

RY107 1-755-062-11 RELAY

RY108 1-755-062-11 RELAY

RY109 1-755-062-11 RELAY

RY110 1-755-062-11 RELAY

RY111 1-755-062-11 RELAY

RY112 1-755-062-11 RELAY

RY113 1-755-062-11 RELAY

< TEST PIN >

* TP501 3-657-235-00 POINT, TEST

* TP502 3-657-235-00 POINT, TEST

* TP503 3-657-235-00 POINT, TEST

* TP504 3-657-235-00 POINT, TEST

**************************************************************

A-4426-207-A PS BOARD, COMPLETE (US,CND)

******************

A-4426-210-A PS BOARD, COMPLETE (EXCEPT US,CND)

*******************

< CAPACITOR >

C701 1-136-880-11 FILM 2.2uF 10% 160V

C702 1-128-998-11 ELECT 6800uF 20% 35V

C703 1-128-998-11 ELECT 6800uF 20% 35V

C706 1-128-200-11 ELECT 47uF 20% 50V

C707 1-128-200-11 ELECT 47uF 20% 50V

C708 1-117-775-31 FILM 0.1uF 10% 250V

C709 1-117-775-31 FILM 0.1uF 10% 250V

C710 1-127-982-11 ELECT 3900uF 20% 50V

C711 1-127-981-11 ELECT 3900uF 20% 50V

C716 1-130-955-11 FILM 0.01uF 2% 100V

C717 1-119-847-11 ELECT 2.2uF 20% 100V

C718 1-119-815-21 ELECT 2200uF 20% 35V

C719 1-126-025-11 ELECT 330uF 20% 25V

C720 1-119-804-21 ELECT 1000uF 20% 25V

< CONNECTOR >

CN702 1-564-510-11 PLUG (MICRO CONNECTOR) 6P

CN704 1-564-320-00 PIN, CONNECTOR (B2P-VH) 2P

* CN705 1-564-241-11 PIN, CONNECTOR (B4P-VH) 4P

< DIODE >

D701 8-719-200-39 DIODE C16P20F

D702 8-719-200-40 DIODE C16P20FR

D703 8-719-025-49 DIODE 02CZ15-TE85L

D704 8-719-025-49 DIODE 02CZ15-TE85L

D705 8-719-025-49 DIODE 02CZ15-TE85L

D706 8-719-025-49 DIODE 02CZ15-TE85L

D707 8-719-200-82 DIODE 11ES2

D708 8-719-025-47 DIODE 02CZ12-TE85L

D709 8-719-200-82 DIODE 11ES2

D710 8-719-070-64 DIODE RBV-602L

< IC >

IC701 8-759-605-03 IC M5F78M24L

< TRANSISTOR >

Q701 8-729-141-58 TRANSISTOR 2SC2275A-Q

Q702 8-729-141-10 TRANSISTOR 2SA985A-Q

Q703 8-729-271-31 TRANSISTOR 2SC2713-G

Q704 8-729-216-31 TRANSISTOR 2SA1163-G

Q705 8-729-232-69 TRANSISTOR 2SK208-GRT5LSONY-1

Q706 8-729-232-69 TRANSISTOR 2SK208-GRT5LSONY-1

Q707 8-729-271-31 TRANSISTOR 2SC2713-G

Q708 8-729-424-08 TRANSISTOR UN2111

Q709 8-729-424-08 TRANSISTOR UN2111

Q710 8-729-424-08 TRANSISTOR UN2111

< RESISTOR >

! R701 1-202-937-41 FUSIBLE 10 5% 1/2W

! R702 1-202-937-41 FUSIBLE 10 5% 1/2W

R703 1-259-999-11 CARBON MELF 2.2K 2% 1/8W

R704 1-259-999-11 CARBON MELF 2.2K 2% 1/8W

R705 1-259-987-11 CARBON MELF 220 2% 1/8W

R706 1-259-987-11 CARBON MELF 220 2% 1/8W

! R707 1-202-937-41 FUSIBLE 10 5% 1/2W

R708 1-259-995-11 CARBON MELF 1K 2% 1/8W

MAIN PS

18

Ref. No. Part No. Description Remark

Ref. No. Part No. Description Remark

R709 1-259-995-11 CARBON MELF 1K 2% 1/8W

! R710 1-202-937-41 FUSIBLE 10 5% 1/2W

! R711 1-202-937-41 FUSIBLE 10 5% 1/2W

R712 1-260-002-11 CARBON MELF 3.3K 2% 1/8W

R713 1-260-008-11 CARBON MELF 10K 2% 1/8W

R717 1-260-020-11 CARBON MELF 100K 2% 1/8W

R718 1-260-008-11 CARBON MELF 10K 2% 1/8W

R719 1-260-020-11 CARBON MELF 100K 2% 1/8W

R720 1-260-002-11 CARBON MELF 3.3K 2% 1/8W

R721 1-260-002-11 CARBON MELF 3.3K 2% 1/8W

1-673-519-11 VOL BIARD

**************************************************************

1-673-513-11 SW L BOARD

*********

< CAPACITOR >

C601 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C609 1-119-847-11 ELECT 2.2uF 20% 100V

< CONNECTOR >

CN601 1-691-769-11 PLUG (MICRO CONNECTOR) 7P

CN602 1-691-768-11 PLUG (MICRO CONNECTOR) 6P

< DIODE >

D605 8-719-800-76 DIODE 1SS226

< TRANSISTOR >

Q601 8-729-047-96 TRANSISTOR 2SC3645-S

< RESISTOR >

R602 1-260-008-11 CARBON MELF 10K 2% 1/8W

R608 1-259-978-11 CARBON MELF 39 2% 1/8W

R609 1-260-008-11 CARBON MELF 10K 2% 1/8W

< SWITCH >

S601 1-771-566-11 SWITCH, ROTARY (INPUT SELECTOR)

**************************************************************

1-673-518-11 SW P BOARD

*********

< CAPACITOR >

C602 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C603 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C604 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

< CONNECTOR >

CN606 1-691-770-11 PLUG (MICRO CONNECTOR) 8P

CN607 1-691-768-11 PLUG (MICRO CONNECTOR) 6P

< DIODE >

D606 8-719-025-19 DIODE 02CZ2.2-TE85L

D607 8-719-043-82 DIODE 02CZ5.1Y-TE85L

< RESISTOR >

R601 1-260-008-11 CARBON MELF 10K 2% 1/8W

R603 1-260-008-11 CARBON MELF 10K 2% 1/8W

R604 1-260-008-11 CARBON MELF 10K 2% 1/8W

< SWITCH >

S602 1-771-567-11 SWITCH, PUSH (3 KEY)

(TAPE MONITOR, TAPE 1/2, DIRECT)

**************************************************************

1-673-519-11 VOL BOARD

*********

< CONNECTOR >

CN301 1-691-770-11 PLUG (MICRO CONNECTOR) 8P

< VARIABLE RESISTOR >

RV301 1-225-742-11 RES, VAR, CARBON 20K/20K

**************************************************************

MISCELLANEOUS

*************

6 1-580-375-41 INLET 3P

! T1 1-433-981-11 TRANSFORMER, POWER (EXCEPT US,CND)

! T1 1-433-982-11 TRANSFORMER, POWER (US,CND)

**************************************************************

ACCESSORIES & PACKING MATERIALS

*******************************

1-506-411-21 ADAPTOR, AC PLUG 3P-2P(US,CND)

1-551-631-22 CORD, POWER (EXCEPT US,CND)

1-551-812-11 CORD, POWER (US,CND)

1-558-271-11 CORD, CONNECTION (AUDIO, 108cm)

3-866-956-11 MANUAL, INSTRUCTION (ENGLISH,FRENCH)

3-866-956-21 MANUAL, INSTRUCTION (GERMAN,SPANISH,

DUTCH,SWEDISH,ITALIAN,PORTUGUESE)(EXCEPT US,CND)

**************************************************************

*************

HARDWARE LIST

*************

#1 7-621-775-10 SCREW +B 2.6X4

#2 7-682-566-04 SCREW +B 4X20

#2 7-682-567-09 SCREW +B 4X25 (US,CND)

#3 7-682-549-04 SCREW +B 3X10

#4 7-621-770-87 SCREW +B 2.6X5

#5 7-621-770-XX SCREW +B 2.6X8

#6 7-682-571-09 +B 4X45 (EXCEPT US,CND)

#7 7-685-871-09 SCREW +BVTT 3X6 (S)

#8 7-682-550-09 SCREW +B 3X12

#9 7-682-962-01 +PSW 4X10

#10 7-683-255-58 SET SCREW 5X6 HEXAGON SOCKET

Les composants identifiés par une

marque ! sont critiques pour la sécurité.

Ne les remplacer que par une piéce

portant le numéro spécifié.

The components identified by mark !

or dotted line with mark ! are critical

for safety.

Replace only with part number specified.

SW LPS

SW P VOL

Sony Corporation

Home Audio Company

9-928-912-11

99G0989-1

Printed in Japan © 1999. 7

Published by Quality Assurance Dept.

TA-E1

Loading...

Loading...