SONY SE610, SE710 Service Manual

IEEE

Std

ANSI/IEEE

114-1982

(Revision

Std

114-19691

of

IEEE

Standard

Single-Phase

Test

Procedure

Induction

for

Motors

Published

December

by

The Institute

7,

I982

of

Electrical and Electronics Engineers,

Inc

345 East 47th Street, New York, NY 10017,

USA

SH08938

IEEE

Std

114-1982

IEEE STANDARD TEST PROCEDURE FOR

IEEE

Standard Test Procedure

Single-phase Induction Motors

1.

Scope

This standard covers instructions for conducting and reporting the more generally applicable and acceptable tests to determine

the performance characteristics of singlephase motors, including nonexcited synchronous motors. It is not intended that this standard shall cover all possible tests used in production or tests of a research nature. The standard shall not be interpreted as requiring the

of

the

making of any or all

herein in any given transaction.

2.

References

111

ANSI/IEEE Std 4-1978,

Techniques for High-Voltage Testing

[2] ANSI/IEEE Std 43-1974 (R1979), IEEE

Recommended Practice for Testing Insulation

Resistance of Rotating Machinery

[3] ANSI/IEEE Std 100-1977, IEEE Standard

Dictionary of Electrical and Electronics Terms

[4] ANSI/NEMA MG 1-1978, Motors and

Generators1

[

51 IEEE Std 1-1969, IEEE General Principles

for Temperature Limits in the Rating of Electric Equipment

[6] IEEE Std 85-1973 (R1980), IEEE Test

Procedure for Airborne Sound Measurements

on Rotating Electric Machinery

[7] IEEE Std 118-1978, IEEE Standard Test

Code for Resistance Measurement

ANSI documents are available from

of

partment

1430

Broadway, New York, NY

American National Standards Institute,

tests described

IEEE Standard

the

10018.

Sales De-

for

[8] IEEE Std 119-1974, IEEE Recommended

Practice for General Principles of Temperature

Measurement as Applied to Electrical Apparatus

[9] IEEE Std 120-1955 (R1972) (ASME

PTC 19.6-1955), Master Test Code for Electrical Measurements in Power Circuits

3.

Tests

Single-phase induction motors are normally

given a routine test but may be given a complete test.

3.1

Routine Test. The routine test includes

measurement of power and current input at

no-load and at rated voltage, current input with

locked rotor at rated voltage, and a highpotential test. A suggested form for reporting

such test data is shown in Form

of this standard.

3.2

Complete Test. The complete test, includes

all of the data taken during a routine test plus

the data necessary for determining efficiency,

power factor, starting torque, pull-up torque,

breakdown torque, rated-load slip, and ratedload temperature rise. A suggested test form

for reporting data is shown in Form 2. Additional tests to determine locked-rotor temperature rise, speed-torque characteristics, shaft

current, noise, and vibration may also be con-

ducted.

3.3

Schedule

be obtained by any of the four following

methods:

Method A

Method

Method C

Method D

of

Tests. Input-output data may

-

brake

B

-

dynamometer

-

rope (or cord) and pulley

-

continuous data acquisition

(plotter)

1,

on page 22

6

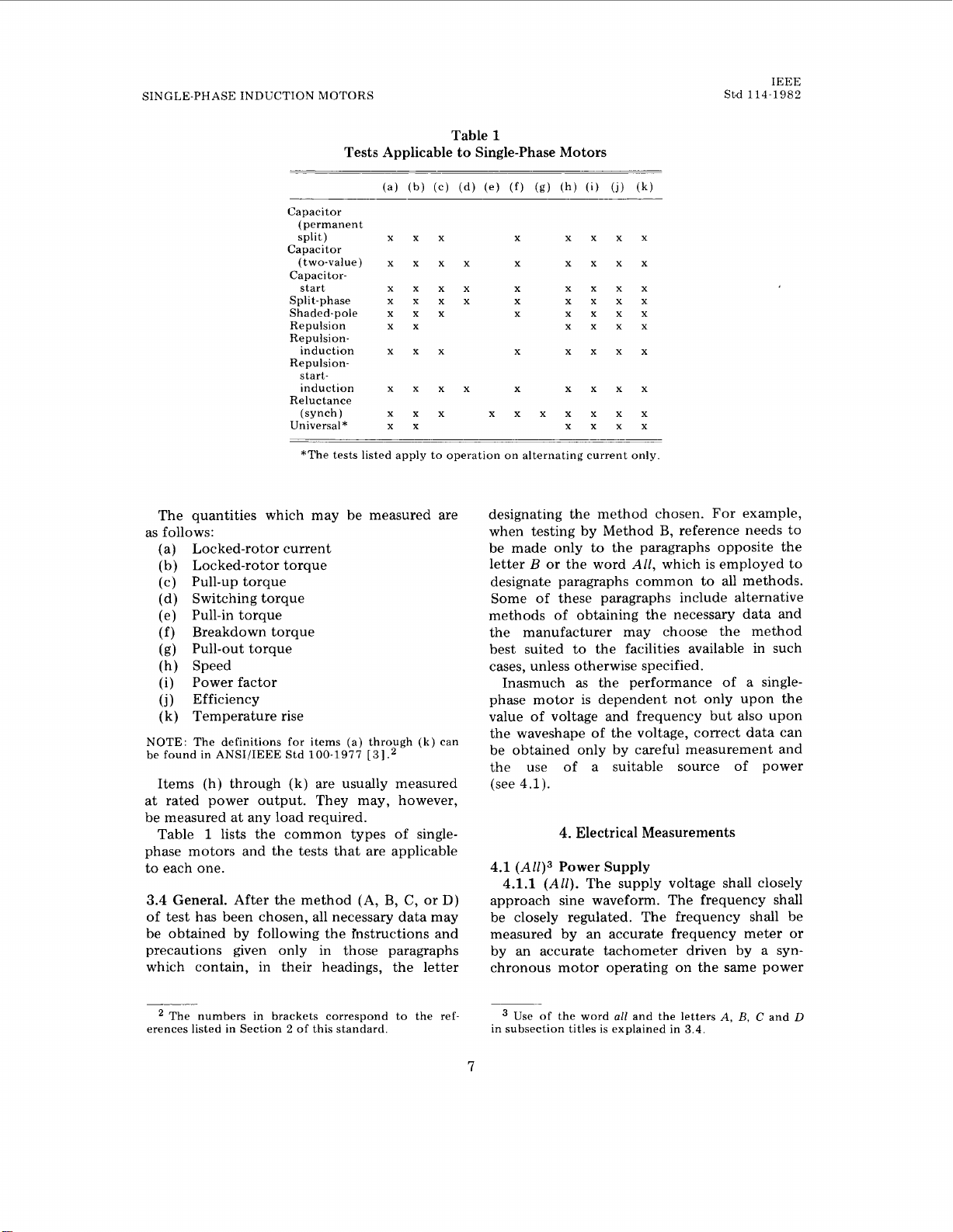

SINGLE-PHASE INDUCTION MOTORS

Capacitor

(permanent

split)

Capacitor

(two-value)

Capacitor-

start

Spli t-phase

Shaded-pole

Repulsion

Repulsion-

induction

Repulsion-

start-

induction

Reluctance

(synch)

Universal*

*The tests listed apply to operation on alternating current only.

xxx

xxxx

xxxx

xxxx

xxx

xx xxxx

xxx

xxxx

xxx xxxxxxx

xx xxxx

X

X

X

X

X

X

X

xxxx

xxxx

xxxx

xxxx

xxxx

xxxx

xxxx

Std

114-1982

IEEE

The quantities which may be measured are

as follows:

(a) Locked-rotor current

(b) Locked-rotor torque

(c) Pull-up torque

(d) Switching torque

(e) Pull-in torque

(f) Breakdown torque

(g) Pull-out torque

(h) Speed

(i) Power factor

(j)

Efficiency

(k) Temperature rise

NOTE: The definitions for items (a) through

be found in ANSI/IEEE Std

100-1977

[3].2

(k)

can

Items (h) through (k) are usually measured

at rated power output. They may, however,

be measured at any load required.

Table

1

lists the common types of singlephase motors and the tests that are applicable

to each one.

3.4

General. After the method (A, B,

C,

or

D)

of test has been chosen, all necessary data may

be obtained by following the lnstructions and

precautions given only in those paragraphs

which contain, in their headings, the letter

designating the method chosen. For example,

when testing by Method B, reference needs to

be made only to the paragraphs opposite the

B

letter

or the word

All,

which is employed to

designate paragraphs common to all methods.

Some of these paragraphs include alternative

methods of obtaining the necessary data and

the manufacturer may choose the method

best suited to the facilities available in such

cases, unless otherwise specified.

Inasmuch as the performance of a single-

is

phase motor

dependent not only upon the

value of voltage and frequency but also upon

the waveshape of the voltage, correct data can

be obtained only by careful measurement and

the use of a suitable source of power

4.1).

(see

4.

Electrical Measurements

4.1

4.1.1

Power Supply

(All).

The supply voltage shall closely

approach sine waveform. The frequency shall

be closely regulated. The frequency shall be

measured by an accurate frequency meter or

by an accurate tachometer driven by a synchronous motor operating on the same power

The numbers in brackets correspond to the ref-

erences listed in Section

2

of

this standard.

Use

of

in subsection titles is explained in

the word

all

7

and the letters

3.4.

A,

B,

C

and

D

IEEE

Std

111-1982

supply. The voltage waveform deviation factor, as defined in ANSI/IEEE Std 100-1977

[3],

shall not exceed

10%.

The equivalent sine

wave referred to is a sine wave having the same

frequency and root-mean-square values as the

wave being tested.

4.1.2

(All).

Rapid changes in frequency cannot be tolerated in input-output tests because

such changes in frequency cause changes in

speed and the variations are transmitted to the

output-measuring device. Any departure from

the assumed frequency directly affects the efficiency. The frequency shall be measured (or

known to be) within an accuracy of

4.2

(A,

B,

C)

Instrument Selection. The instru-

0.1%.

ments used in electrical measurements shall be

on

selected to give indications well up

the scale;

that is, where a fraction of a division is easily

estimated and where such a fraction is a small

percentage

of

the value read. Further information regarding the use of instruments can be

obtained by referring to IEEE Std 120-1955

[91.

4.3

(D)

Transducer Selection. The transducers

used in electrical measurements by continuous

data acquisition (by plotter) shall be selected

to give indications well up on the scale; that is,

full scale on the plotter shall correspond as

much as possible to full scale for the transducer. The time constant of the transducer

selected shall be adequate for the particular

output device (plotter). The internal losses

of the transducer should be shown to be

negligible when compared to the magnitudes

being measured.

4.4

(All)

Instrument Transformers. When current and potential instrument transformers

are used, corrections shall be made for ratio

errors in voltage and current measurements

and for ratio and phase-angle errors in power

measurement. The use of instrument trans-

formers shall be avoided if possible. (See IEEE

Std 120-1955 [9]

4.5

(All)

Voltage. The voltage shall be read at

.)

the motor terminals. Means should be provided

whereby the voltage can be adjusted to the desired value. This control can be effected by the

use of a continuously variable transformer or

autotransformer, by an induction regulator,

or by a controlled motor-generator set.

4.6

(All)

Current. The line current

of

the

motor shall be measured by an accurate am-

IEEE STANDARD TEST PROCEDURE FOR

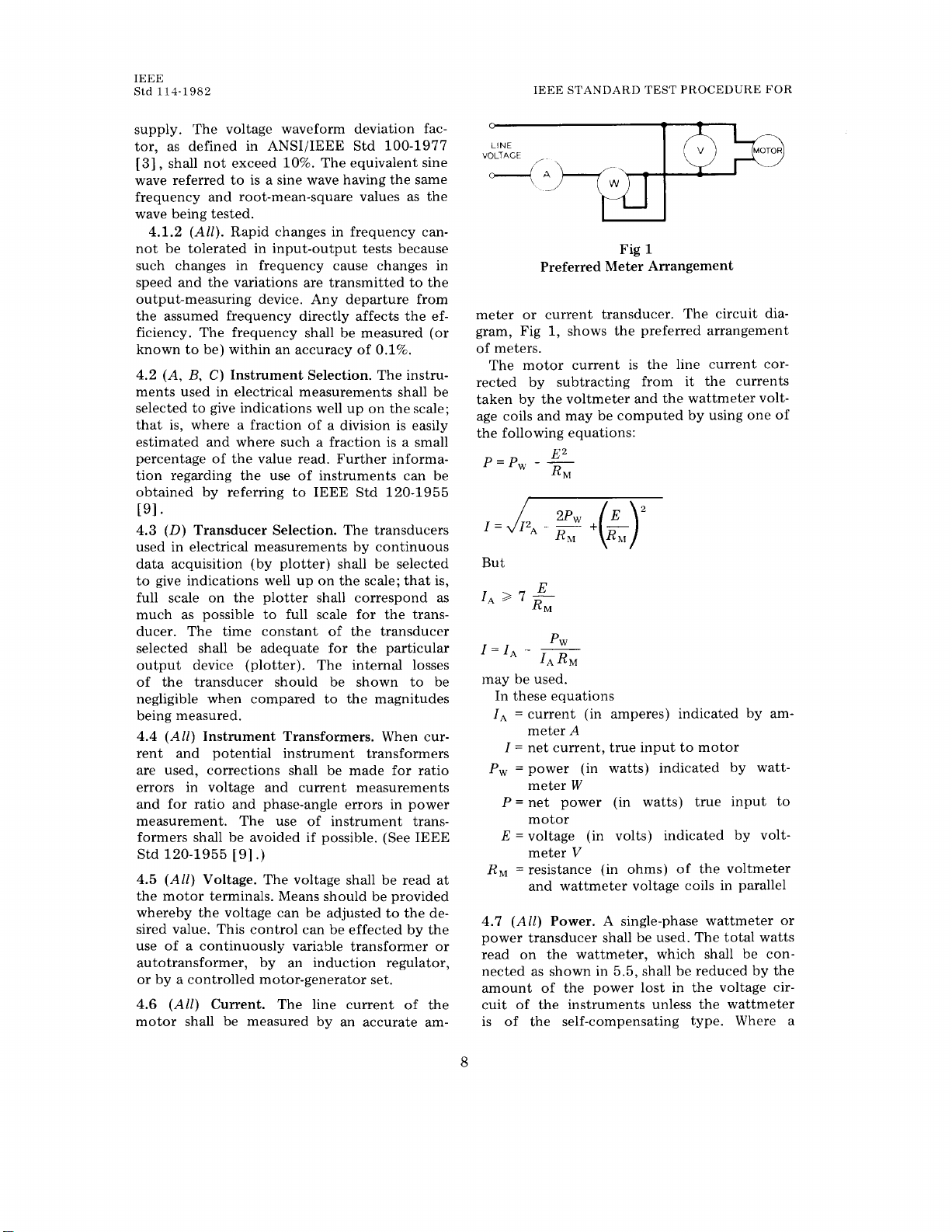

Fig

1

Preferred Meter Arrangement

meter or current transducer. The circuit diagram, Fig

l,

shows the preferred arrangement

of meters.

The motor current is the line current corrected by subtracting from it the currents

taken by the voltmeter and the wattmeter voltage coils and may be computed by using one of

the following equations:

c2

P=P,

--

0-

RM

But

I*>7--

E

RM

may be used.

In these equations

IA

=

current (in amperes) indicated by ammeter

A

I

=

net current, true input to motor

P,

=

power (in watts) indicated by watt-

W

meter

P=

net power (in watts) true input to

motor

E

=voltage (in volts) indicated by volt-

V

meter

RM

=resistance (in ohms) of the voltmeter

and wattmeter voltage coils in parallel

4.7

(All)

Power. A single-phase wattmeter or

power transducer shall be used. The total watts

read on the wattmeter, which shall be connected as shown in 5.5, shall be reduced by the

amount of the power lost in the voltage circuit of the instruments unless the wattmeter

is of the self-compensating type. Where a

SINGLE-PHASE INDUCTION

MOTORS

Std

IEEE

114-1982

properly selected power transducer is used,

the transducer loss shall be shown to be neg-

ligible. All instruments must be read as simultaneously as practical.

5.

Performance Determination

(All)

5.1

Temperature. All performance determinations should be made in an ambient with a

temperature as close as possible to 25 "C. The

ambient temperature should be between 20

"C

and 30 OC, unless otherwise agreed to by the

purchaser and manufacturer.

Locked-rotor and breakdown torque tests

should be made with the motor temperatures

as close to ambient temperature as possible.

Other performance data should be obtained

with the motor operating as close as possible to

its normal operating temperatures, unless otherwise agreed to by the purchaser and manufac-

[8]

turer. (See IEEE Std 119-1974

for tempera-

ture corrections.)

(All)

5.2

Efficiency. Efficiency is the ratio of

output power to input power. The electric

power is measured directly. The output power

may be measured by Method

A,

B, C

or

D.

Unless otherwise specified, the efficiency shall

be determined at rated voltage, frequency,

and temperature rise or actual temperature

rise as determined by heat run. If a curve of

efficiency versus output power is to be plotted,

a minimum of seven points is recommended.

(A,

B,

C)

5.2.1

Direct-Measurement Methods. In all direct-measurement tests the electric and mechanical powers are to be measured directly. The differences between Meth-

B,

ods A,

and C lie in the methods of measuring mechanical power. Readings of power, current, voltage, frequency, slip, torque, ambient temperature, and stator coil end-winding

temperature or stator winding resistance shall be

obtained for no-load and at least six load

points substantially equally spaced from

to

1

f

times rated load. The motor perfor-

4

mance shall be determined as is outlined in

Form

3

(see page 24).

5.2.1.1

(A)

Method

A - Brake. In this

method a brake is mounted on the motor shaft

so

and

arranged that a scale will read the retarding force offered by the brake. The torque

is computed from the product of the scale

reading and the brake arm length. Care shall be

exercised in the construction and use of the

tare,

brake and the brake pulley. The

if

present, shall be determined and compensated.

Performance of a motor shall be calculated

(B)

3.

Method

B

-

Dynamometer. In

as shown on Form

5.2.1.2

this method the motor is connected to a

of

dynamometer usually by means

flexible

coupling. The dynamometer is free to rotate

and has a torque arm which rests on a scale.

The torque output of the motor is a product

of the scale reading and the distance from the

center of the dynamometer to the point where

the torque arm makes contact with the scale.

To obtain the mechanical power output of a

motor by the dynamometer method the following equation may be used:

power (in watts)

T-n

=

__

k

in which

n

=

rotational speed in r/min

k

=

7.043 for Tin lb-ft

=

84.52 for Tin lb-in

=

112.7 for Tin oz-ft

=

1352 for T in oz-in

=

9.549 for Tin N-m

5.2.1.3

(C)

1

Method

C

-

Rope and Pulley.

In this method a small rope or cord suspended

from a spring scale is wrapped around the

motor pulley a sufficient number of times

so

that when the cord is tightened by a small pull

on its free end the scale will measure the

motor's pull. If the cord

is

properly adjusted

with negligible tension in the free end, the

motor will just pull through the minimum

torque points and the scale swings will be slow

enough

so

that even the minimum torque in

one slow revolution will be obtained. This

method may be used to test a motor under

load also if the motor power output is not

great enough to damage the cord. To obtain

accurate results, the following conditons must

be fulfilled

(1)

:

Force may not be exerted on the free end

of the cord unless the magnitude of the force

is known and a correction for

is made.

A

it

distinct curvature in the free end of the cord

as its leaves the pulley is the only conclusive

evidence that there is no force.

(2) The pulley face should be wide enough

to develop the required torque with a single

layer of turns of the cord. If a single layer is not

practicable, multiple layers may be used but

IEEE

Std

114-1982

IEEE STANDARD TEST PROCEDURE

FOR

the first two turns on the scale end of the cord

must be single-layer.

(3)

The pulley must be in proper alignment

with the scale

so

that there is no scale error

caused by a nonrecording component of force

in the cord. The alignment must also be such

that there is a clearance between the cord and

the pulley flange.

5.2.1.3.1

Method C -Correction for Cord

Diameter. In calculating the torque, the radius

at which the force is applied is to be taken

as the pulley radius plus the cord radius.

The cord diameter should be measured with

the cord under tension. The micrometer anvil

and spindle should have flat faces large enough

to span at least two strand pitches. Sufficient

pressure should be applied to flatten minor

irregularities in the cord. Inasmuch

as

the

cord diameter may change because of wear

or stretch, the ratio of cord diameter to pulley

diameter should be as small as practicable.

5.2.1.3.2

Method C - Correction for Pulley Windage Loss or for Dynamometer Windage

Loss. The measured values of torque are to be

corrected by adding to them a torque corresponding to the pulley windage or the

dynamometer windage loss. The allowance for

this loss is made by adding a torque Tw

Tw

=

k(PA

-

PB)_

T

n

D

:

in which

PA

=watts input to the motor driving the

pulley or dynamometer

PB

=

watts input to the motor without the

pulley or dynamometer

n

=

rotational speed in r/min

k

=

7,043

for T in lb- ft

=

84.52

for Tin lb-in

=

112.7

=

1352

=

9.549

5.2.1.3.3

for Tin

for Tin oz.in

for Tin N-m

Method

OZ-ft

C

-

Determination of

Friction and Windage Loss. When motors are

supplied without bearings by the motor manufacturer it may be desirable to quote the efficiencies on the basis of a specified friction

and windage loss and to consider the losses to

be charged against the driven device. In such a

to

case it is the usual practice

jig

or fixture which does have friction in the

a

test the parts in

bearings. The amount of this friction and wind-

is

age

then separately determined and added

to the motor output. For accurate results, the

friction of this jig or fixture should be low

even though a correction is made inasmuch

as

the jig friction may change while a test is

in progress.

5.2.1.3.4

Method C - Dynamometer Method of Measuring Friction and Windage. One

method of determining the friction and windage losses is to measure the torque required to

drive the parts at normal speed by means of

Pf

a dynamometer. The friction

is then ex-

pressed, in watts, as:

Tf

=

7

n

Pf

in which

=

net friction torque

Tf

k

=

same values

n

=

rotational speed in r/min

as

used in

5.2.1.3.2

The dynamometer used for this test should

be such that the measured friction torque Tf

represents at least

15%

of the normal torque

capacity of the dynamometer.

5.2.1.3.5

Method C - No-Load Satura-

tion Method of Determining Friction and

Loss.

Windage

The motor is run at no-load

at normal frequency and voltage until the

power input is constant to assure that the

temperature of the oil or grease and the bearing friction have become constant. Readings

are taken of volt, ampere, and watt input at

rated frequency but with voltages ranging

from

125%

of rated voltage down to a point

where further voltage reduction increases the

current. The voltage adjustment is accomplished preferably by a variable-voltage transformer. Immediately following this test and

before the temperatures can change sensibly,

a reading of input power

I,

at

50%

or

60%

Pf

and input current

of rated voltage should be

taken with the rotor locked and with only

the main or running winding excited. This

test should be followed immediately by a

RI

measurement of the stator resistance

If the input current at any voltage is

P,

total copper loss

voltage is:

I

The copper loss

in the machine at the same

so

calculated should be sub-

.

I,,

the

tracted from the total input power at the same

voltage. The resultant values may then be

plotted against applied voltage with an extrap-

10

Loading...

Loading...