AIT Drive

2-891-321-12(1)

User’s Guide

AIT-5 TAPE DRIVE

SDX-1100V Series

AIT-4 TAPE DRIVE

SDX-900V Series

AIT-3 Ex TAPE DRIVE

GB

CS

CT

SDX-800V Series

2006 Sony Corporation

WARNING

To reduce the risk of fire or

electric shock, do not expose

this apparatus to rain or

moisture.

To avoid electrical shock, do not

open the cabinet.

Refer servicing to qualified

personnel only.

This document contains proprietary

information which is protected by

copyright.

All rights reserved. No part of this

document may be photocopied,

reproduced or translated to another

language without prior written consent

of Sony.

The information contained in this

document is subject to change without

notice.

SONY MAKES NO WARRANTY

OF ANY KIND WITH REGARD TO

THIS DOCUMENT.

Sony shall not be liable for errors

contained herein, indirect, special,

incidental or consequential damages in

connection with the furnishing,

performance or use of this document.

Your SDX-1100V is assigned a Model

No. SDX-1100 for regulatory

compliance certifications.

Your SDX-900V and SDX-800V are

assigned a Model No. ATDNA4 for

regulatory compliance certifications.

The number is indicated on the model

number label on your drive along with

the rated voltage and current.

Hinweis

MaschinenlärminformationsVerordnung - 3. GPSGV, der höchste

Schalldruckpegel beträgt 70 dB(A)

oder weniger gemäss EN ISO 7779.

ATTENTION

According to the EU Directives related

to product safety, EMC and R&TTE

the manufacturer of this product is

Sony Corporation, 1-7-1 Konan

Minato-ku Tokyo, 108-0075 Japan.

The Authorised Representative is Sony

Deutschland GmbH, Hedelfinger

Strasse 61,70327 Stuttgart, Germany.

For any service or guarantee matters

please refer to the addresses given in

separate service or guarantee

documents.

AUFMERKSAMKEIT

Im Sinne der EU Richtlinien bezüglich

Produktsicherheit, EMV und R&TTE

ist Sony Corporation, 1-7-1 Konan

Minato-ku Tokyo, 108-0075 Japan der

Hersteller dieses Produktes.

Bevollmächtigter ist Sony

Deutschland GmbH, Hedelfinger

Strasse 61, D-70327 Stuttgart. Für

Service oder Garantieangelegenheiten

wenden Sie sich bitte an die in

separaten Service oder

Garantiedokumenten angegebenen

Adressen.

European Union Restriction of

Hazardous Substances Directive

compliant.

Entspricht der Richtlinie der

Europäischen Union zur

Beschränkung der Verwendung

gefährlicher Stoffe.

2

VORSICHT

Für kunden in Deutshland

Diese Ausrüstung erfüllt die

Europäischen EMC-Bestimmungen für

die Verwendung in folgender /

folgenden Umgebung(en):

• Wohngegenden

• Gewerbegebiete

• Leichtindustriegebiete

(Diese Ausrüstung erfüllt die

Bestimmungen der Norm EN55022,

Klasse B.)

IMPORTANT SAFEGUARDS

For your protection, please read these

safety instructions completely before

operating the appliance, and keep this

manual for future reference.

Carefully observe all warnings,

precautions and instructions on the

appliance, or described in the

operating instructions and adhere to

them.

USE

Power Sources – This unit should be

operated only from the type of power

source indicated on the marking label.

If you are not sure of the type of

electrical power, consult your dealer or

local power company.

For the unit with a three-wire

grounding type ac plug:

If you are unable to insert the plug into

the outlet, contact your electrician to

have a suitable plug installed. Do not

defeat the safety purpose of the

grounding plug.

AC Power cord: (for AC mains

operating unit only)

The AC power cord should have

appropriate safety approvals or

marking for the country in which the

equipment will be used. Consult your

dealer or local power company.

Cleaning – Unplug the unit from the

wall outlet before cleaning or

polishing it. Do not use liquid

cleaners or aerosol cleaners.

Use a cloth lightly dampened with

water for cleaning the exterior of the

unit.

Object and Liquid Entry – Never

push objects of any kind into the unit

through openings as they may touch

dangerous voltage points or short out

parts that could result in a fire or

electric shock. Never spill liquid of

any kind on the unit.

GB

3

INSTALLATION

Water and Moisture – Do not use

power-line operated units near water –

for example, near a bathtub,

washbowl, kitchen sink, or laundry

tub, in a wet basement, or near a

swimming pool, etc.

Power-Cord Protection – Route the

power cord so that it is not likely to be

walked on or pinched by items placed

upon or against it, paying particular

attention to the plugs, receptacles, and

the point where the cord exits from the

appliance.

Accessories – Do not place the unit on

an unstable cart, stand, tripod, bracket,

or table. The unit may fall, causing

serious injury to a child or an adult,

and serious damage to the unit. Use

only a cart, stand, tripod, bracket, or

table recommended by the

manufacturer.

Ventilation – The slots and openings

in the cabinet are provided for

necessary ventilation. To ensure

reliable operation of the unit, and to

protect it from overheating, these slots

and openings must never be blocked or

covered.

• Never cover the slots and openings

with a cloth or other materials.

• Never block the slots and openings

by placing the unit on a bed, sofa,

rug, or other similar surface.

• Never place the unit in a confined

space, such as a bookcase, or builtin cabinet, unless proper ventilation

is provided.

SERVICE

Damage Requiring Service – Unplug

the unit from the wall outlet and refer

servicing to qualified service

personnel under the following

conditions:

• When the power cord or plug is

damaged or frayed.

• If liquid has been spilled or objects

have fallen into the unit.

• If the unit has been exposed to rain

or water.

• If the unit has been subject to

excessive shock by being dropped,

or the cabinet has been damaged.

• If the unit does not operate normally

when following the operating

instructions. Adjust only those

controls that are specified in the

operating instructions. Improper

adjustment of other controls may

result in damage and will often

require extensive work by a

qualified technician to restore the

unit to normal operation.

• When the unit exhibits a distinct

change in performance - this

indicates a need for service.

Servicing – Do not attempt to service

the unit yourself as opening or

removing covers may expose you to

dangerous voltage or other hazards.

Refer to all servicing to qualified

service personnel.

4

Table of Contents

Overview .................................................................................................................. 6

Introduction .............................................................................................................. 6

About AIT Drives ............................................................................................ 6

Precautions ....................................................................................................... 8

Installation .............................................................................................................. 11

SCSI Connection/Setting the SCSI ID ...........................................................11

Option Switches (DIP Switch) ....................................................................... 12

Mounting Holes .............................................................................................. 15

Reconfiguring From 5.25" Model to 3.5" Model ........................................... 16

Orientation......................................................................................................16

Attaching and Removing the Dust Cover ............................................................... 17

Attaching the Dust Cover ............................................................................... 17

Removing the Dust Cover ..............................................................................18

Operation ................................................................................................................ 19

Location of 3 LEDs ........................................................................................19

Drive Operation .............................................................................................. 20

Emergency Tape Removal Procedure ............................................................22

Interface Implementation........................................................................................25

Supported SCSI Messages ............................................................................. 25

Supported SCSI Commands ........................................................................... 25

Specifications ......................................................................................................... 26

Product Specifications .................................................................................... 26

Sony Contacts .........................................................................................................28

• Sony cannot accept liability for data written to cartridges lost as a result of using this product.

• Sony bears no responsibility for any financial damages, lost profits, or claims made by third

parties arising from the use of this product.

5

Overview

The SDX-1100V, SDX-900V, and SDX-800V series drives are high

capacity data storage devices using Advanced Intelligent tape (AIT)

technology. The SDX-1100V, SDX-900V, and SDX-800V series drives

achieve high data reliability through Read-After-Write, an additional level

of Error Correction Code, and other features.

The SDX-1100V, SDX-900V, and SDX-800V series drives store data on

tape using standard formats called AIT (Advanced Intelligent Tape) and

ALDC.

Introduction

About AIT Drives

The SDX-1100V Series AIT-5 Tape Drives are internal AIT drive units that

use data cartridges conforming to the AIT-5 format.

The SDX-900V Series AIT-4 Tape Drives are internal AIT drive units that

use data cartridges conforming to the AIT-4 format.

The SDX-800V Series AIT-3 Ex Tape Drives are internal AIT drive units

that use data cartridges conforming to the AIT-3 Ex format.

The SDX-1100V series drives support the AIT-5, AIT-4, AIT-3 Ex, and

AIT-3 formats.

The SDX-900V series drives support the AIT-4 and AIT-3 Ex format.

The SDX-800V series drives support the AIT-3 Ex, AIT-3, AIT-2 Turbo,

AIT-2 (Read only), AIT-1 Turbo (Read only), AIT-1 (Read only), and

AIT-E Turbo (Read only) formats.

6

Features

The SDX-1100V series drives have the following features:

• Supports reading and writing to data cartridges conforming to the AIT-5,

AIT-4, AIT-3 Ex, and AIT-3 formats.

• The second-level error correction code guarantees high data reliability

writing to data cartridges conforming to the AIT-5, AIT-4, and AIT-3 Ex

formats.

• The third-level error correction code guarantees high data reliability

writing to data cartridges conforming to the AIT-3 format.

• Data compression provides 1,040 gigabytes of storage on SDX5-400C

data cartridges.*

The native capacity is 400 gigabytes of storage on SDX5-400C data

cartridges.

• Stored data are automatically checked for compression.

• Ultra 160 SCSI interface is fully supported for host computer access.

• Fragment rewrite function (AIT-5, AIT-4, AIT-3 Ex)

• Frame rewrite function (AIT-3)

The SDX-900V series drives have the following features:

• Supports reading and writing to data cartridges conforming to the AIT-4

and AIT-3 Ex formats.

• The second-level error correction code guarantees high data reliability

writing to data cartridges conforming to the AIT-4 and AIT-3 Ex formats.

• Data compression provides 520 gigabytes of storage on SDX4-200C data

cartridges.

The native capacity is 200 gigabytes of storage on SDX4-200C data

cartridges.

• Stored data are automatically checked for compression.

• Ultra 160 SCSI interface is fully supported for host computer access.

• Fragment rewrite function

*

*

This is assuming 2.6 : 1 compression ratio.

The degree of data compression attained while recording data varies according to

system environment and data type.

7

The SDX-800V series drives have the following features:

• Supports reading and writing to data cartridges conforming to the

AIT-3 Ex, AIT-3, and AIT-2 Turbo formats.

• Supports reading from data cartridges conforming to the AIT-2,

AIT-1 Turbo, AIT-1, and AIT-E Turbo formats.

• The second-level error correction code guarantees high data reliability

writing to data cartridges conforming to the AIT-3 Ex format.

• The third-level error correction code guarantees high data reliability

writing to data cartridges conforming to the AIT-3 format.

• Data compression provides 390 gigabytes of storage on SDX3X-150C

data cartridges.

*

The native capacity is 150 gigabytes of storage on SDX3X-150C data

cartridges.

• Stored data are automatically checked for compression.

• Ultra 160 SCSI interface is fully supported for host computer access.

• Fragment rewrite function (AIT-3 Ex)

• Frame rewrite function (AIT-3)

*

This is assuming 2.6 : 1 compression ratio.

The degree of data compression attained while recording data varies according to

system environment and data type.

Precautions

Installation

Avoid placing the drives in locations subject to:

– high humidity

– high temperature

– mechanical shock and vibration

– direct sunlight

*

For details, see “Specifications” on page 26.

8

Operation

• Do not move the drives while they are operating. It may cause

malfunctions.

• Avoid exposing the drives to sudden changes from low to high

temperatures. This may cause condensation to collect inside the drives. If

the ambient temperature should suddenly rise while the drives are turned

on, turn them off and wait at least one hour before turning them back on.

If you attempt to operate the drives immediately after a sudden increase

in temperature, malfunctions may occur.

• Turning off the power to the drives while they are writing to tape may

cause the tape to become unreadable. All previously negotiated

parameters will be lost, whenever power to the drives is cycled.

Transportation

• Keep the original packing materials to facilitate safe transportation of the

drives.

• Always remove the tape/media cartridge before moving the drives. After

removing the drives from the computer, repack them into their original

packing.

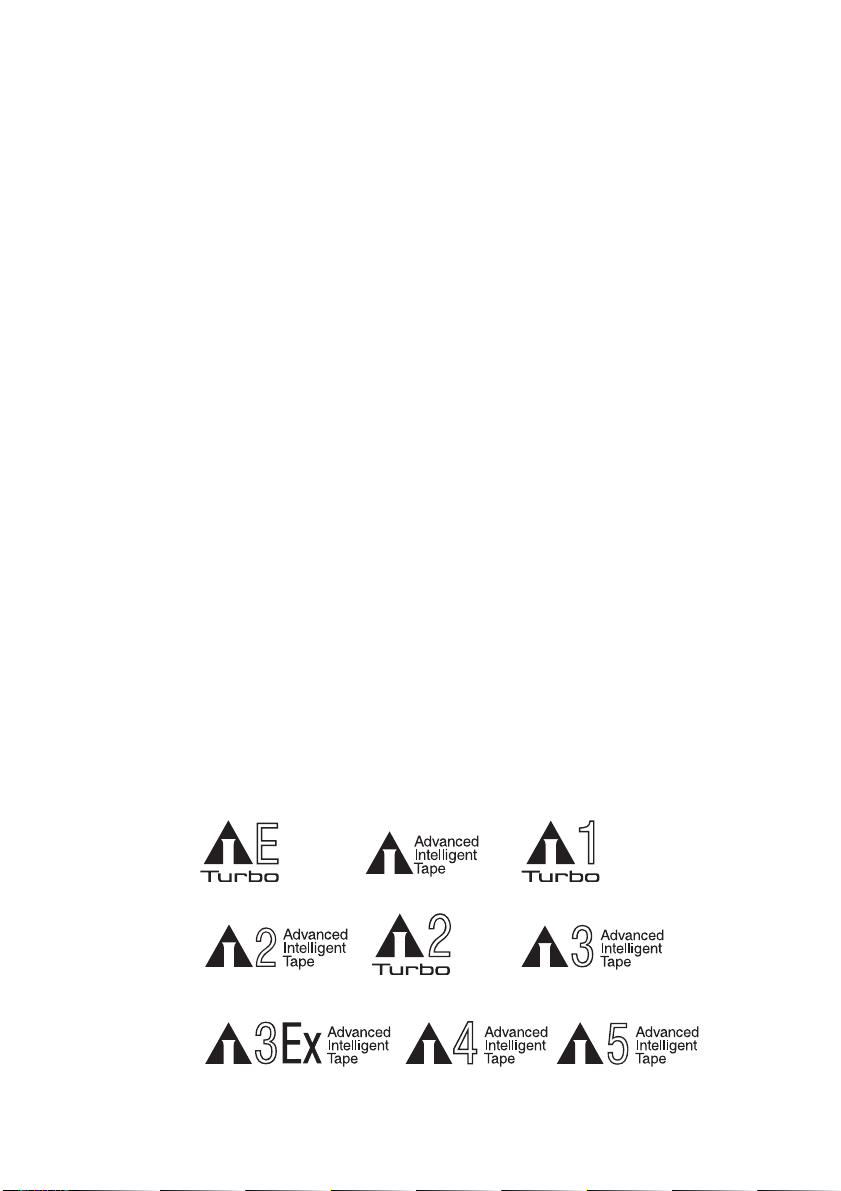

Compatible Data Cartridges

The SDX-1100V series drives can be used with data cartridges marked with

the AIT-5, AIT-4, AIT-3 Ex, or AIT-3 logo.

The SDX-900V series drives can be used with data cartridges marked with the

AIT-4 or AIT-3 Ex logo.

The SDX-800V series drives can be used with data cartridges marked with the

AIT-3 Ex, AIT-3, AIT-2 Turbo, AIT-2 (read only), AIT-1 Turbo (read only),

AIT-1 (read only), or AIT-E Turbo (read only) logo.

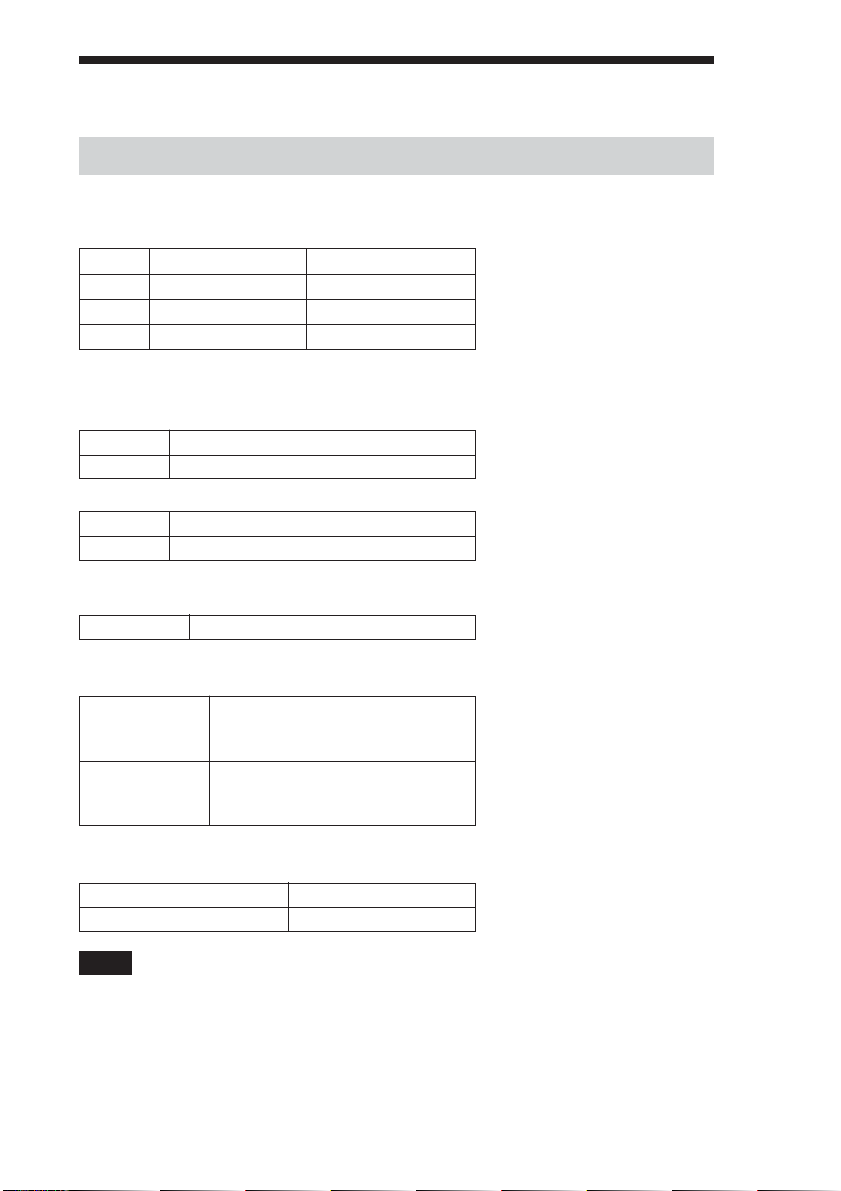

AIT-E Turbo LOGO AIT-1 LOGO AIT-1 Turbo LOGO

AIT-2 LOGO AIT-2 Turbo LOGO AIT-3 LOGO

AIT-3 Ex LOGO AIT-4 LOGO AIT-5 LOGO

9

Caution

• Do not use cartridges other than the ones described above with this drive.

Be sure to use only the cartridges designed specifically for AIT.

• Do not use anything but AIT cartridges with this drive, as doing so can

damage the drive. Although commercially available 8 mm videotapes

resemble AIT cartridges in appearance, they have entirely different

specifications and cannot be used.

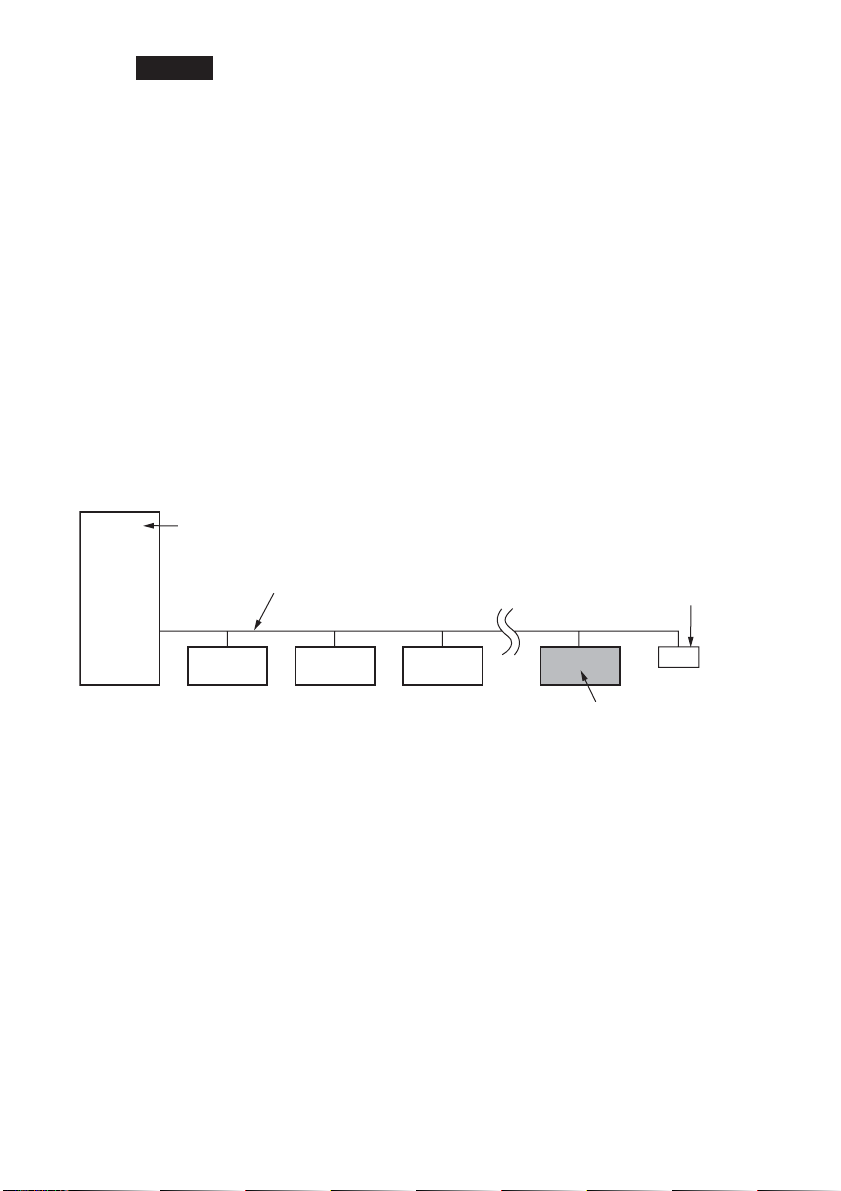

SCSI Termination

The SDX-1100V, SDX-900V, and SDX-800V series drives conform to the

Microsoft PC97 standard, which requires the internal (naked) drive to be

terminated with an external terminator.

Microsoft PC97 SCSI requirements

SCSI peripherals must not terminate the bus. Both internal and external cable ends are

instead terminated by plug-in connectors.

Host Computer Wide SCSI

68-pin cable

SDX-1100V/SDX-900V/SDX-800V series drive

Example connection to the host computer and other peripheral devices

10

Terminator

Installation

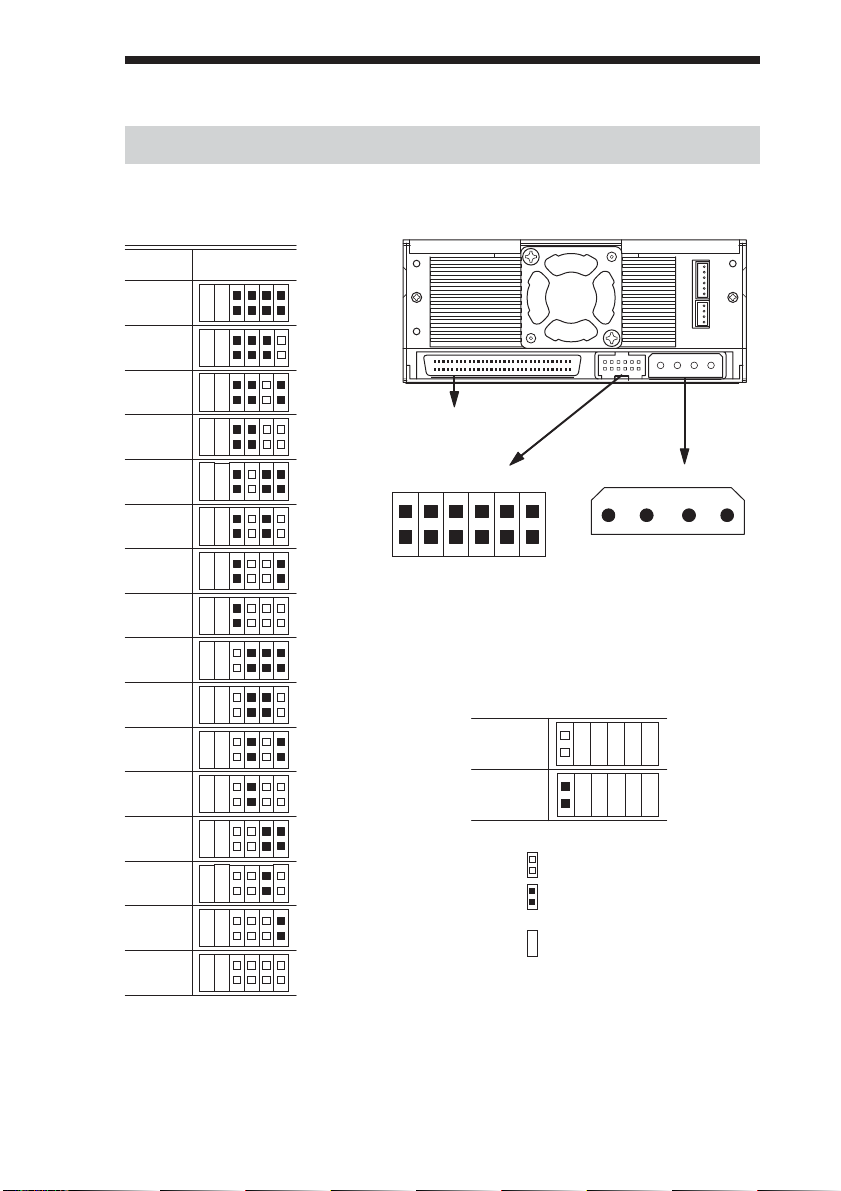

SCSI Connection/Setting the SCSI ID

Rear view figures are examples of the SDX-1100V drive.

SCSI ID

210

SCSI ID

0

1

2

3

P.D.

N.C.

3

SCSI 68pin Connector

4

Jumpers

Power Connector

5

5 V

6

7

SCSI ID 3

SCSI ID 2

SCSI ID 1

SCSI ID 0

10

1

8

9

1

Parity Disable

No Connection

Parity

Disable

Enable

12

13

Note :

14

= CLOSED/Jumper

OPEN/Jumper not

=

installed

=

Don’

t care

15

Parity Disable Jumper

Parity check function can be disabled by Jumper. Parity check is disabled

while left end jumper is installed. Parity generate function is always

enabled.

1234

GND GND 12 V

11

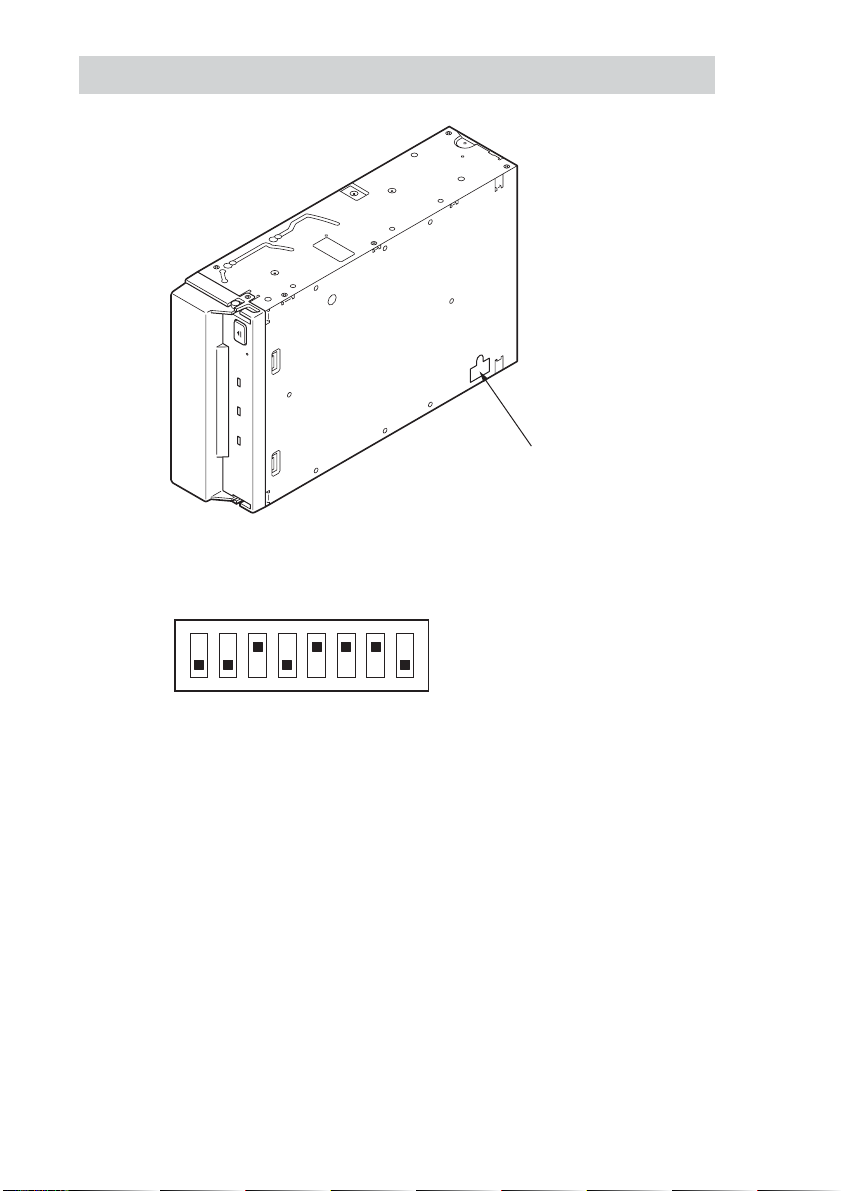

Option Switches (DIP Switch)

DIP Switch Positions

Default

ON

OFF

12345678

DIP Switch

1 DR (Disaster Recovery) Mode (OFF)

2 Emulation Mode (OFF)

3 AIT Library Interface Mode (ON)

4 Reserved (OFF)

5 Terminator Power (ON)

6 Periodic Cleaning Req (ON)

7 DC Control (1) (ON)

8 DC Control (2) (OFF)

12

Emulation Mode

*

To enable Emulation Mode, set the DIP switch 2 [Emulation Mode] to ON.

ON

OFF

12345678

*

Emulation Mode for the SDX-1100V series drives return the following as

the Product Identification field of the Inquiry command.

SDX-900V

*

Emulation Mode for the SDX-900V series drives return the following as

the Product Identification field of the Inquiry command.

SDX-700C

*

Emulation Mode for the SDX-800V series drives return the following as

the Product Identification field of the Inquiry command.

SDX-700C

AIT Library Interface Mode

To enable AIT Library Interface Mode, set DIP switch 3 [AIT Library

Interface Mode] to ON.

ON

OFF

12345678

When switch 3 is ON, AIT Legacy Library Interface Mode is enabled. With

this switch OFF, ACI Mode is enabled.

Terminator Power

To enable terminator power, set DIP switch 5 [Terminator Power] to ON.

ON

OFF

12345678

13

Periodic Cleaning Request Mode

To enable Periodic Cleaning Request Mode, set DIP switch 6 [Periodic

Cleaning Req] to ON.

ON

OFF

12345678

The “CLEANING REQUEST” LED on the front panel lights after every

100 hours of operation.

When this LED lights, clean the drive with a cleaning cartridge.

Note

To maintain the drive in optimum condition in environments affected by dust and other

contaminants, we recommend keeping cleaning requests enabled.

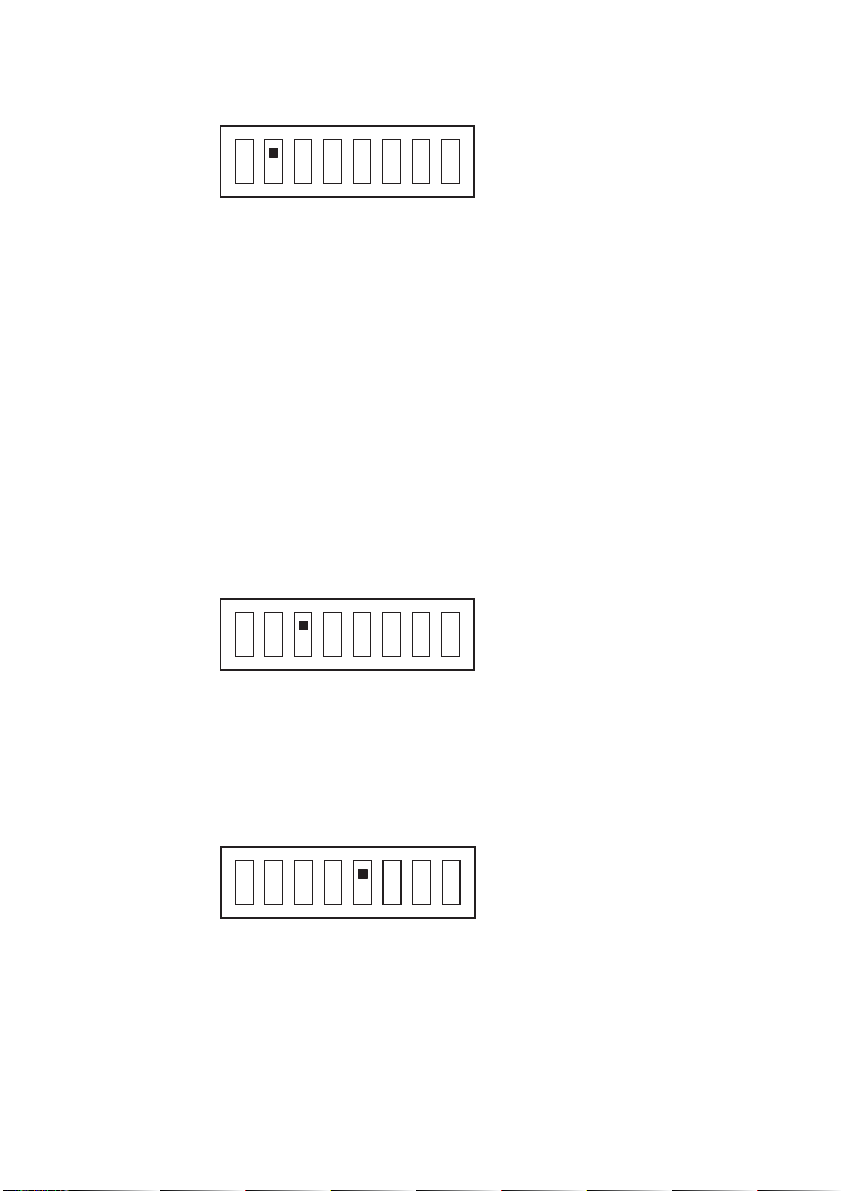

Data Compression Control

Data compression can be selected by DIP switches.

Data compression is enabled when DIP switch 7 [DC Control (1)] is ON.

ON

OFF

12345678

Control by host can be disabled when DIP switch 8 [DC Control (2)] is ON.

14

ON

OFF

12345678

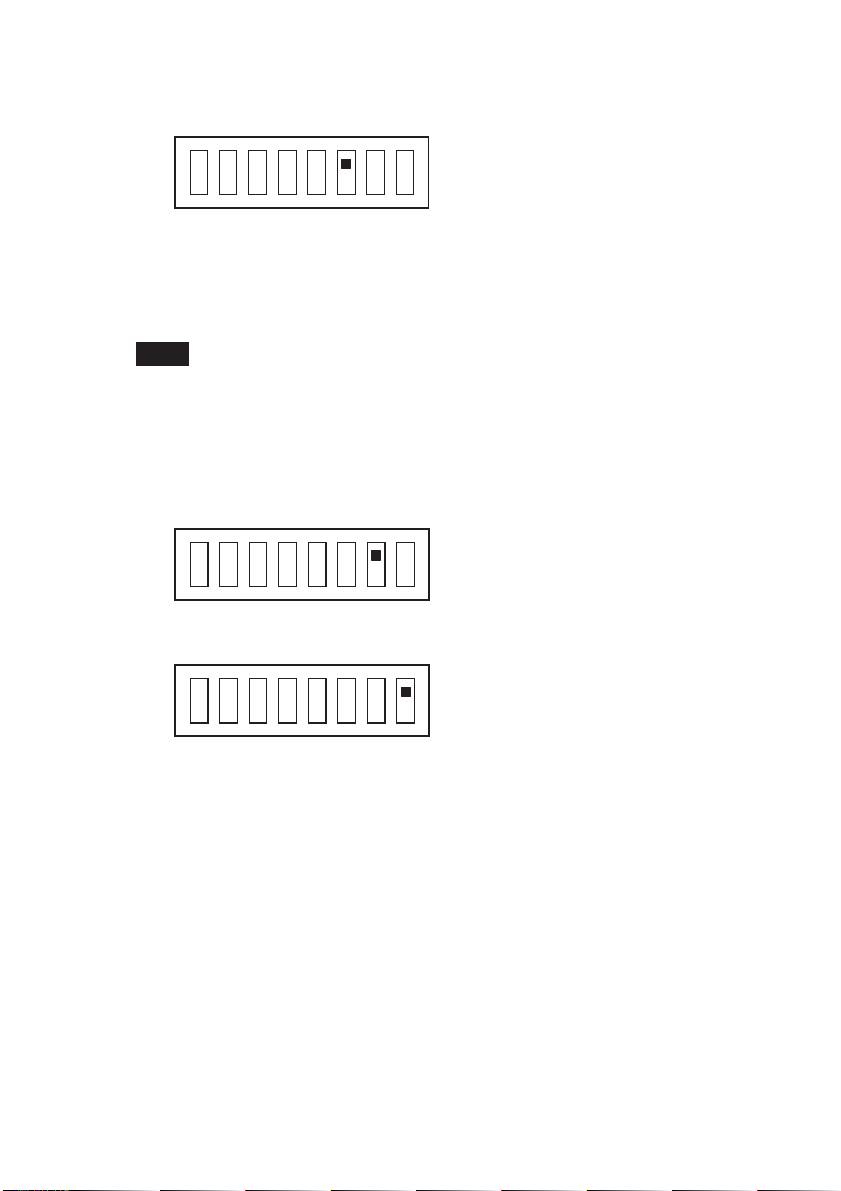

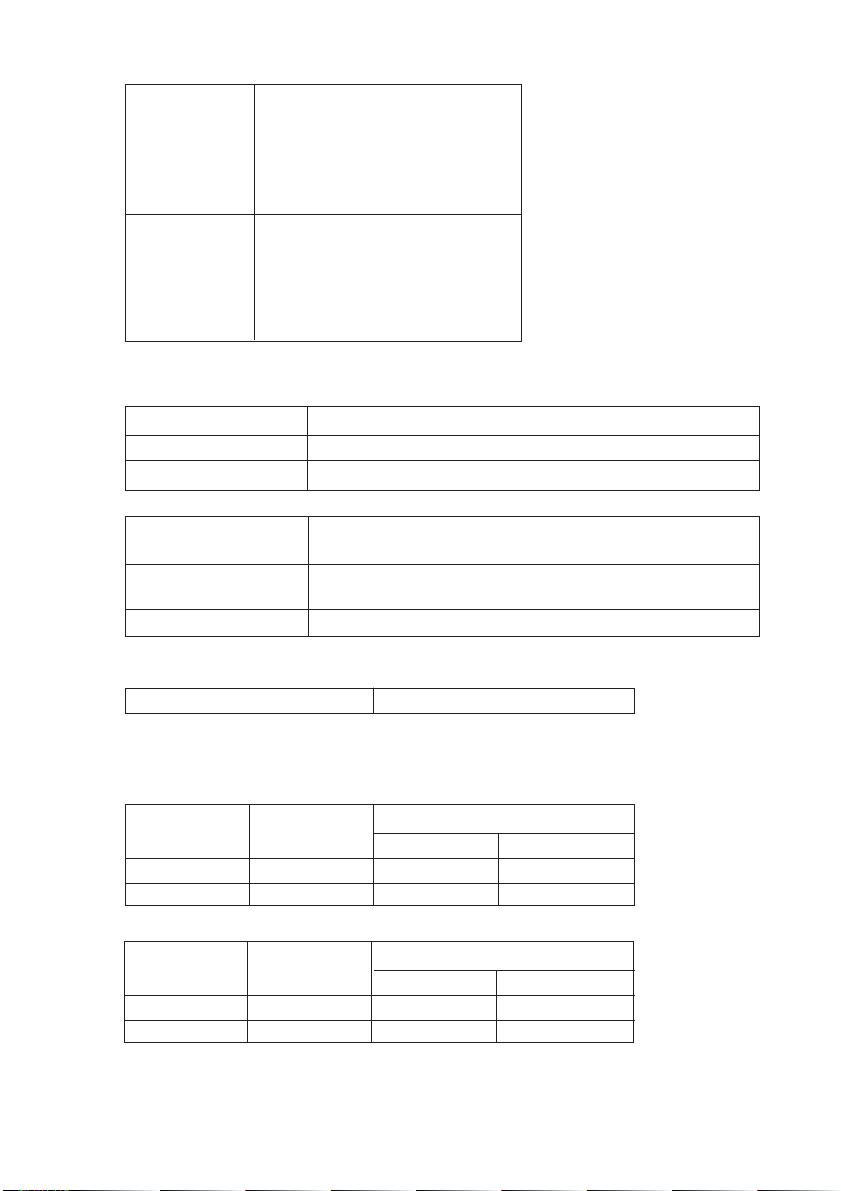

Mounting Holes

The following figures apply to the SDX-800V series drives. However, the

locations of the mounting holes for the other models are the same.

For 3.5" Standard Height

(Connecter

Dimensions)

For 5.25" Half Height

(Connecter

Dimensions)

15

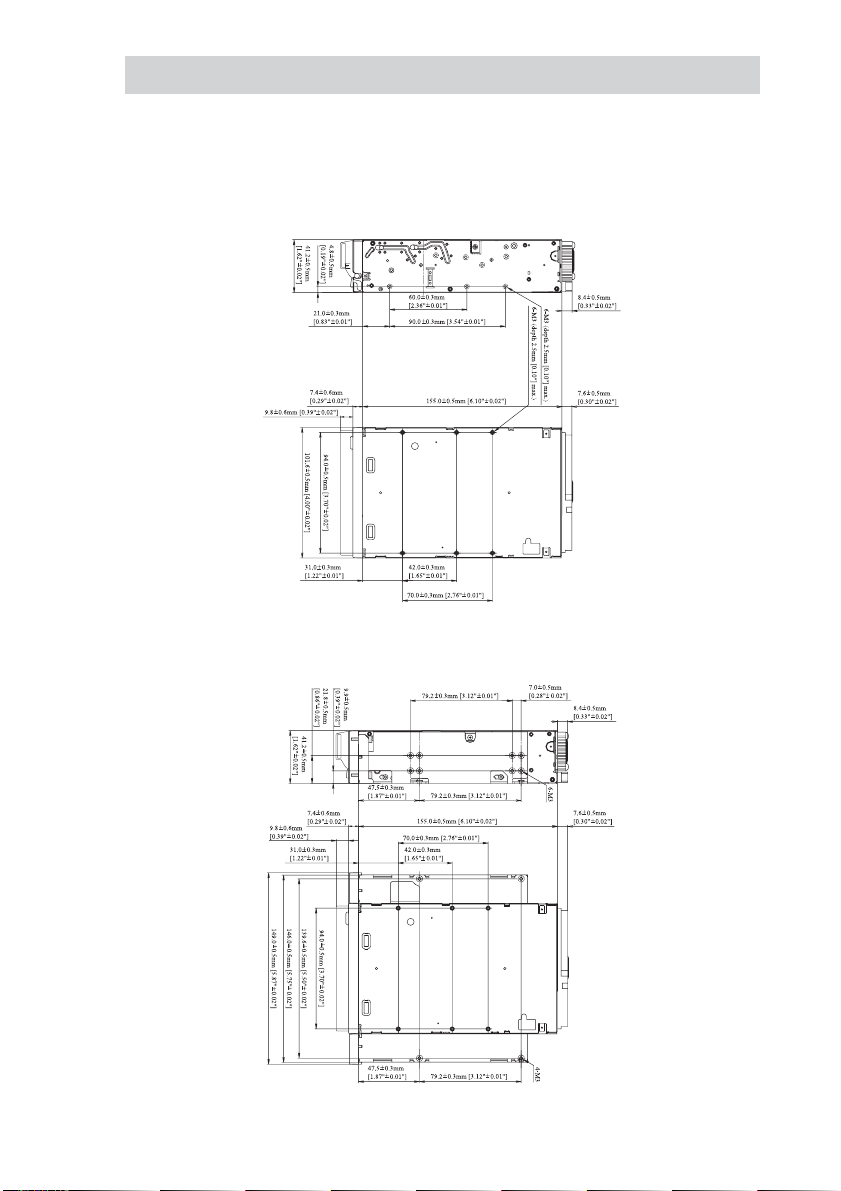

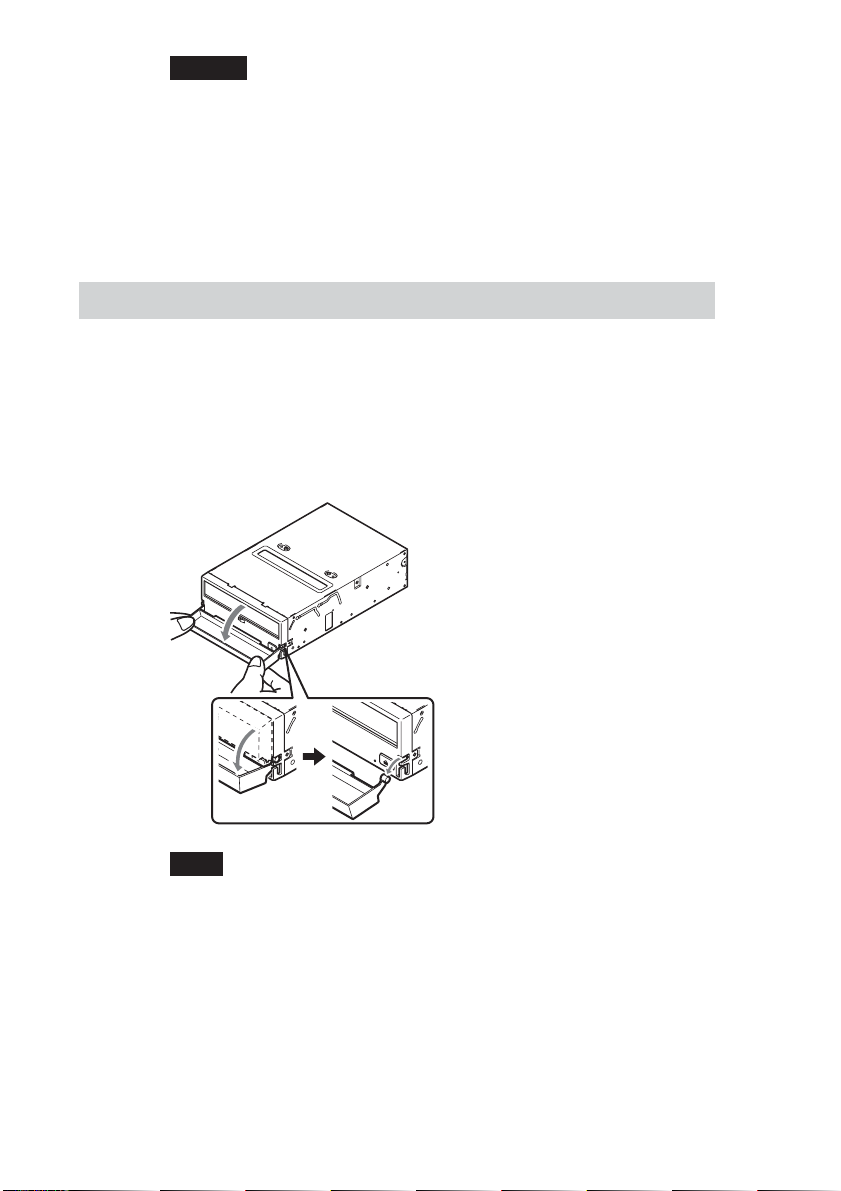

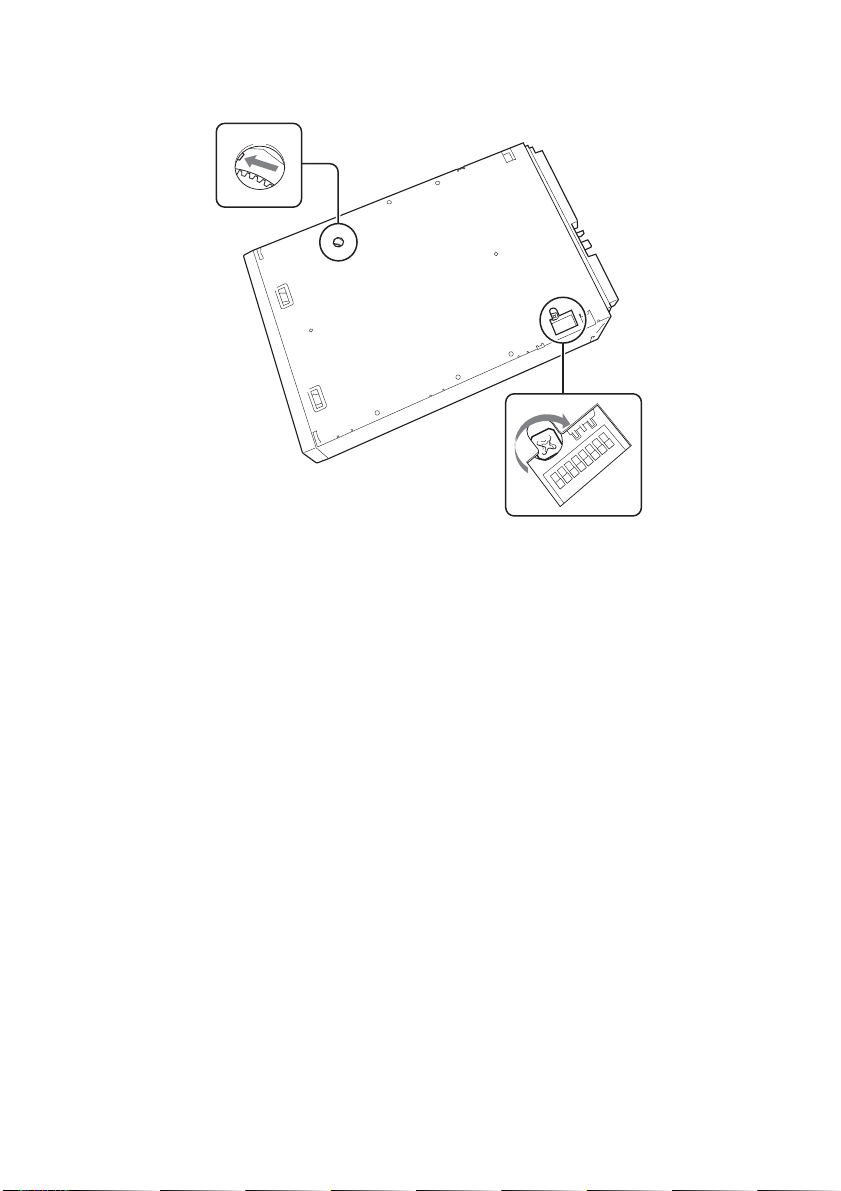

Reconfiguring From 5.25" Model to 3.5" Model

You can reconfigure the 5.25" model to the 3.5" model yourself.

1 Remove the 2 screws for each side rail.

2 Take the side rail off.

Side Rail (L)

Side Rail (R)

Orientation

16

10

10

10

10

10 10

10

10

Attaching and Removing the Dust

Cover

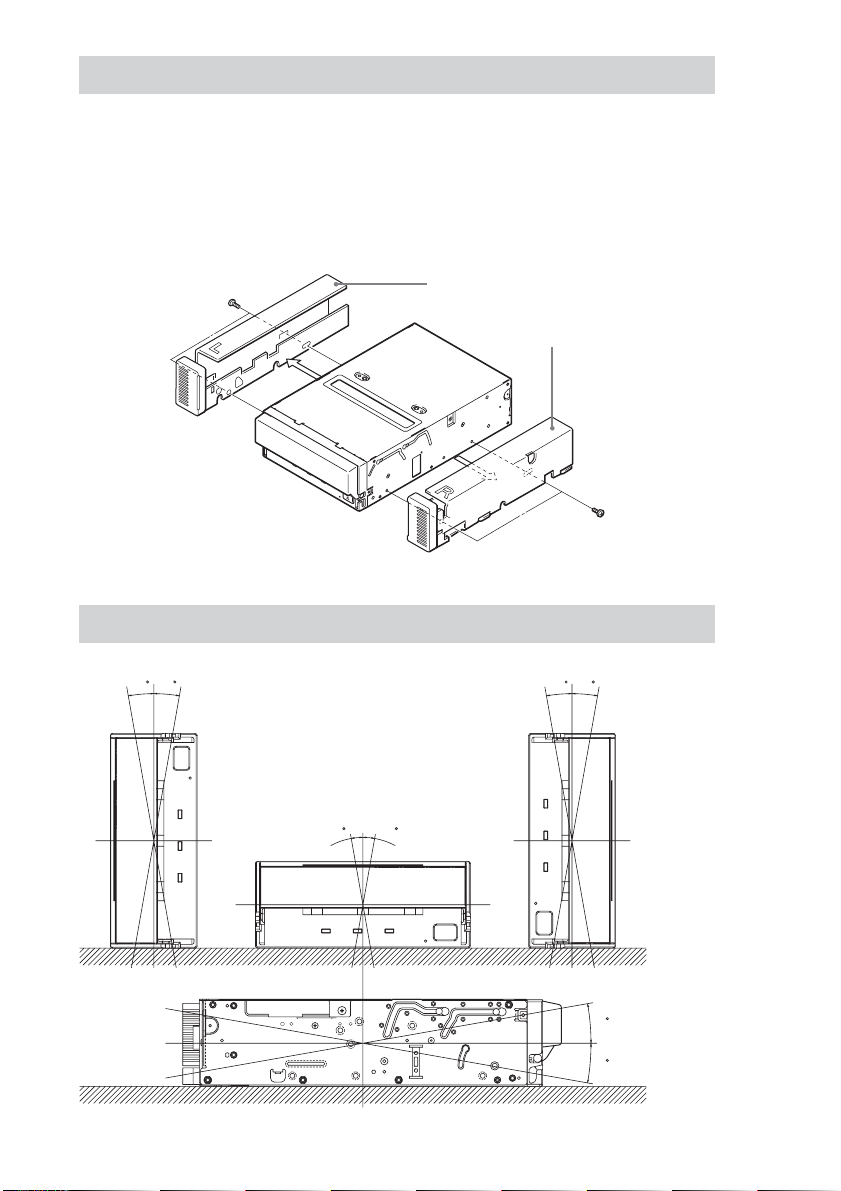

Attaching the Dust Cover

1 Align the dust cover’s hinge clips (one on each side) with the

pins of the drive bezel.

• The dust cover should be positioned so that the magnets* on the

cover’s back face the drive bezel.

*

This magnet does not affect the tape of the cartridge.

• Holding the dust cover at an angle, as shown in the figure below,

set the hinge clips on top of the bezel pins, positioning them so that

they bracket the pins.

2 Press down at an angle on each side in turn until you hear

the hinge clips click into place.

17

Caution

Do not press the dust cover in horizontally from the front. Doing so

could cause the dust cover to break.

3 Close the dust cover.

This completes attachment of the dust cover.

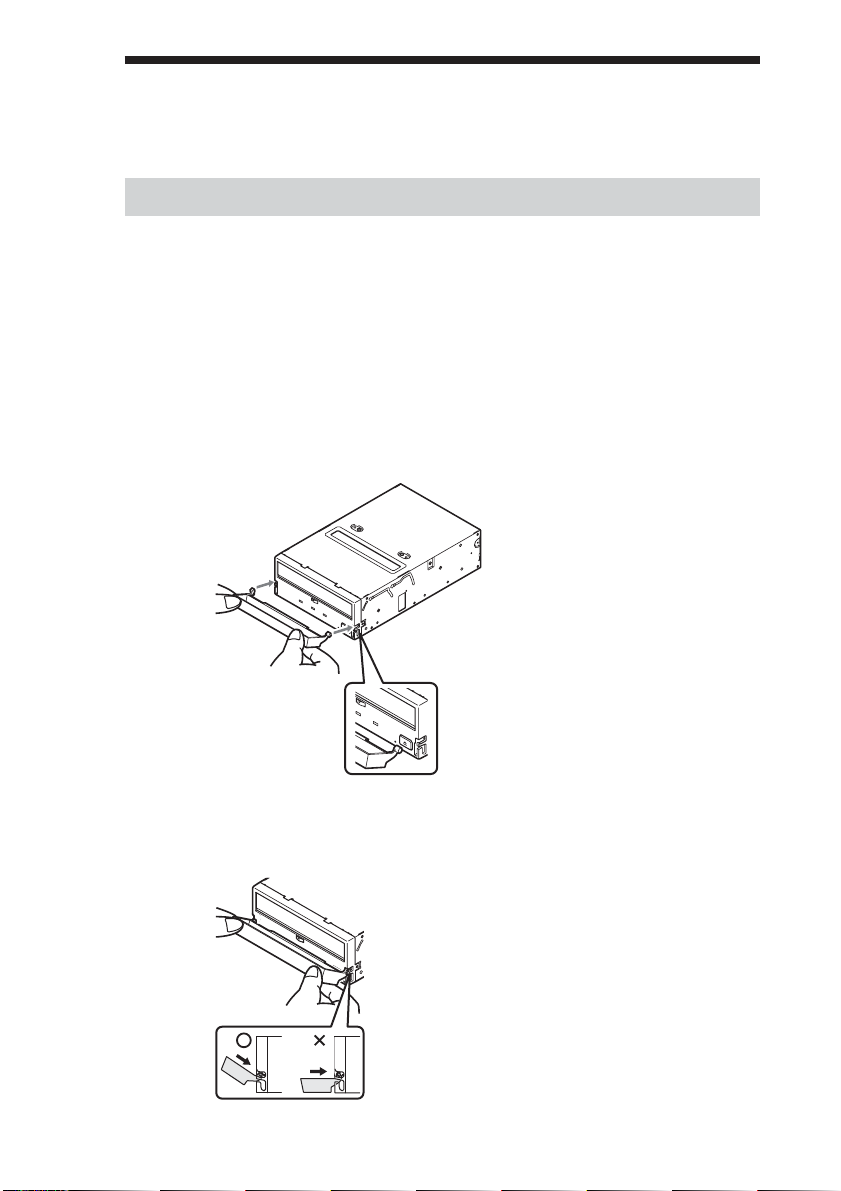

Removing the Dust Cover

1 Open the dust cover.

2 Holding the dust cover at both corners, carefully raise the

dust cover.

The dust cover hinge clips and drive bezel pins uncouple.

18

Note

We recommend that you use the drive with the dust cover.

Operation

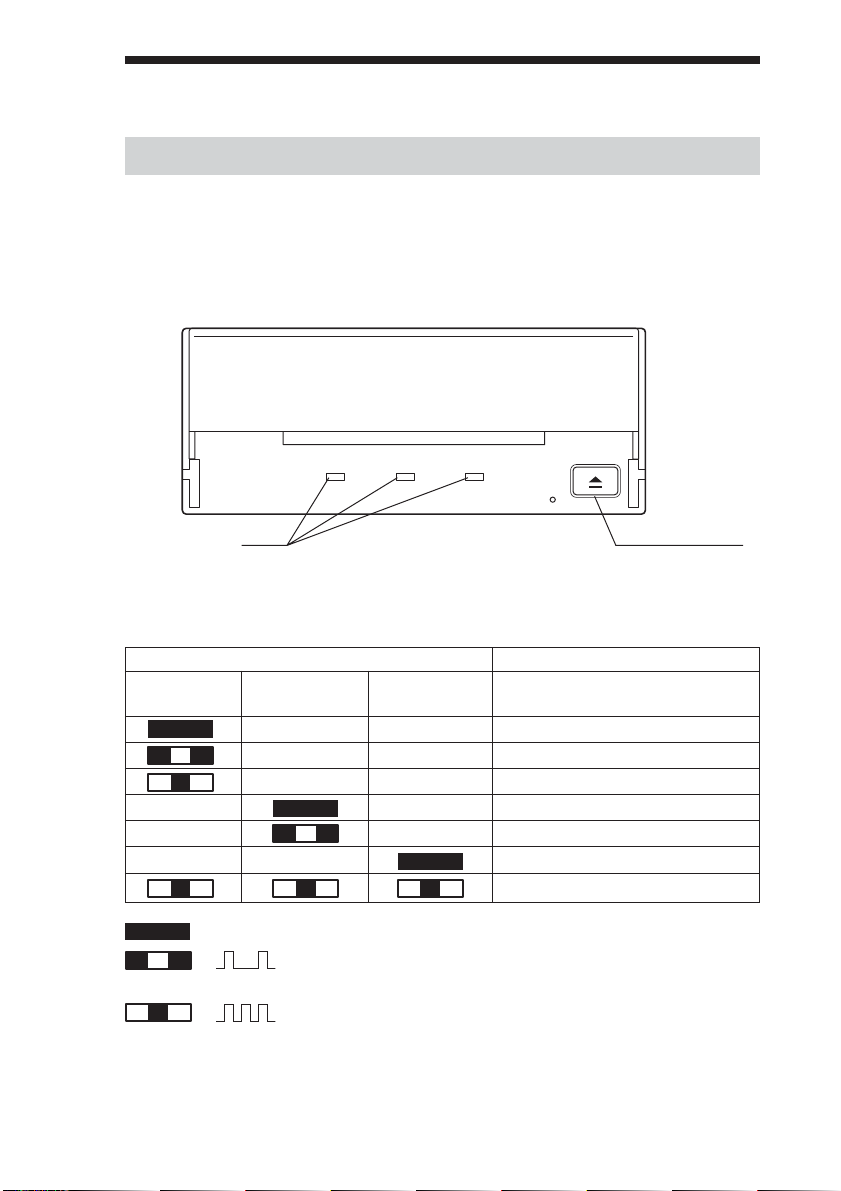

Location of 3 LEDs

There are three LED indicators (TAPE MOTION LED, CLEANING

REQUEST LED, REPLACE TAPE LED) and an EJECT button on the

front panel of the SDX-1100V, SDX-900V, and SDX-800V series drives.

Front Panel

Advanced

Intelligent

Tap e

TAPE

MOTION

CLEANING

REQUEST

REPLACE

TAPE

LED

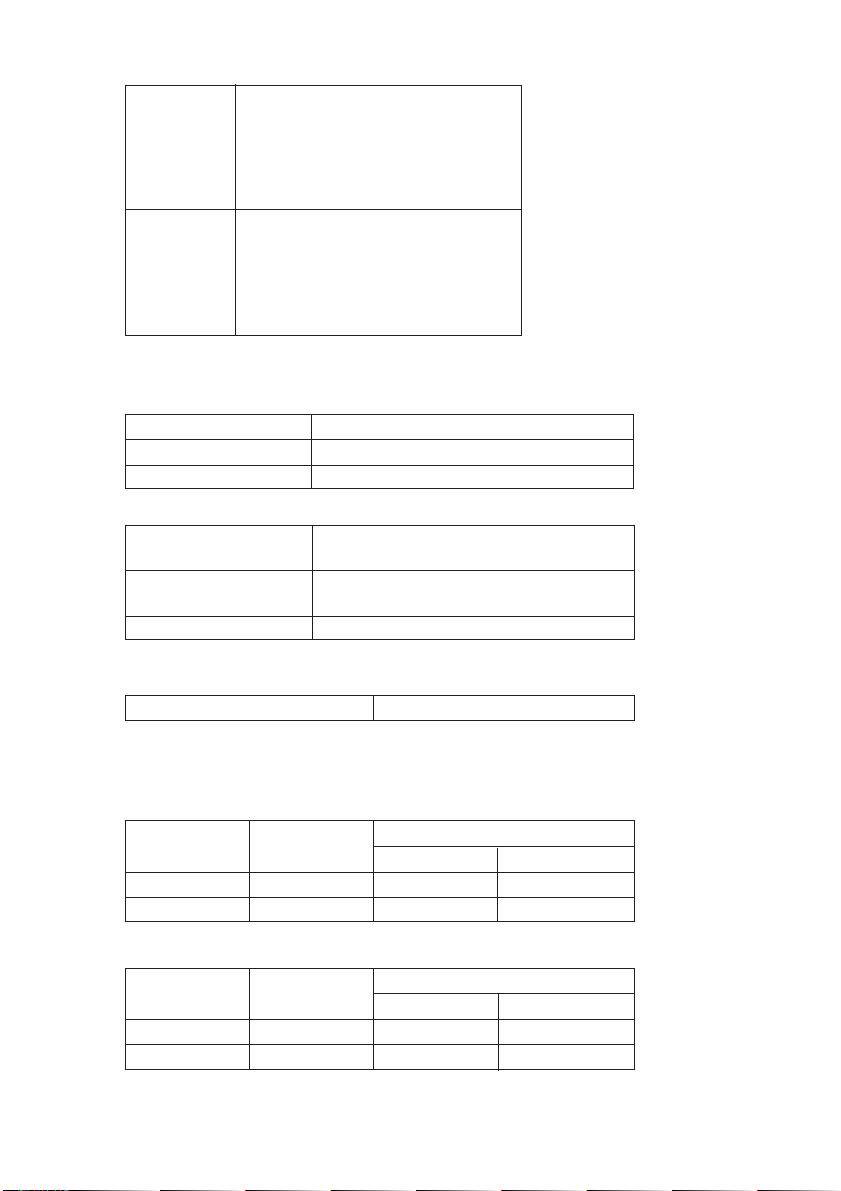

LED Indication for Drive Status

The LED indicators are defined as follows

LED

TAPE CLEANING REPLACE

MOTION REQUEST TAPE

Independent Independent Tape loaded

Independent Independent Tape access in progress (write/read)

Independent Independent Tape access in progress (others)

Independent Independent Cleaning is requested

Independent Independent Cleaning is not completed

Independent Independent Media error occurred

H/W error occurred

on

Slow

1 pulse (0.9 sec on/0.3 sec off)

Fast

1 pulse (0.3 sec on/0.3 sec off)

Sense

EJECT button

19

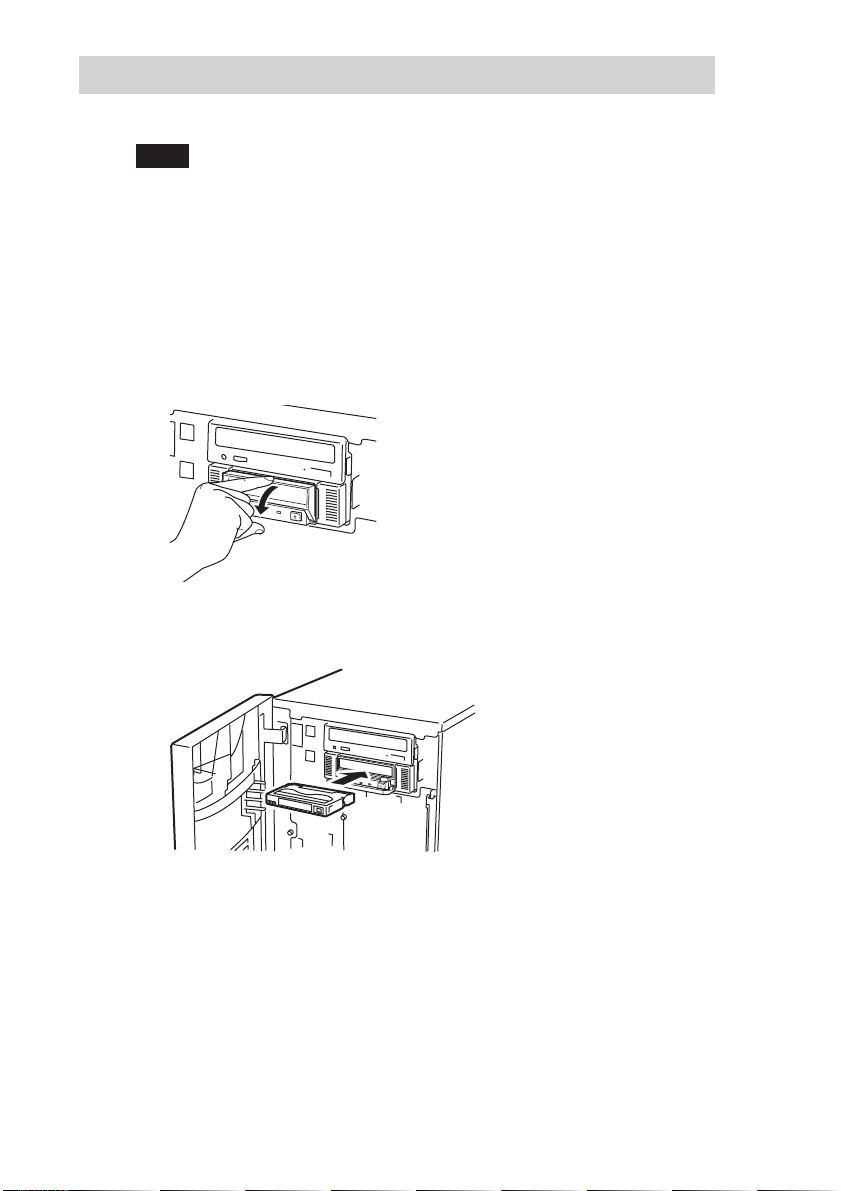

Drive Operation

Loading a Cartridge

Note

While setting the data cartridge, do not turn off the host computer. This

may cause a malfunction or damage data.

1 Turn on the host computer. Check that the drive’s TAPE

MOTION LED, CLEANING REQUEST LED and REPLACE

TAPE LED go off.

2 Open the dust cover.

3 Set the AIT data cartridge orientation as shown here and

insert it into the data cartridge slot.

By fully inserting the data cartridge, it is automatically set in the drive

and the TAPE MOTION LED lights.

Unloading a Cartridge

The cartridge can be removed from the SDX-1100V, SDX-900V, and

SDX-800V series drives either in response to a SCSI Unload command, or

by pressing the EJECT button.

When the EJECT button is pressed, the tape is rewound and the cartridge

ejected from the slot.

20

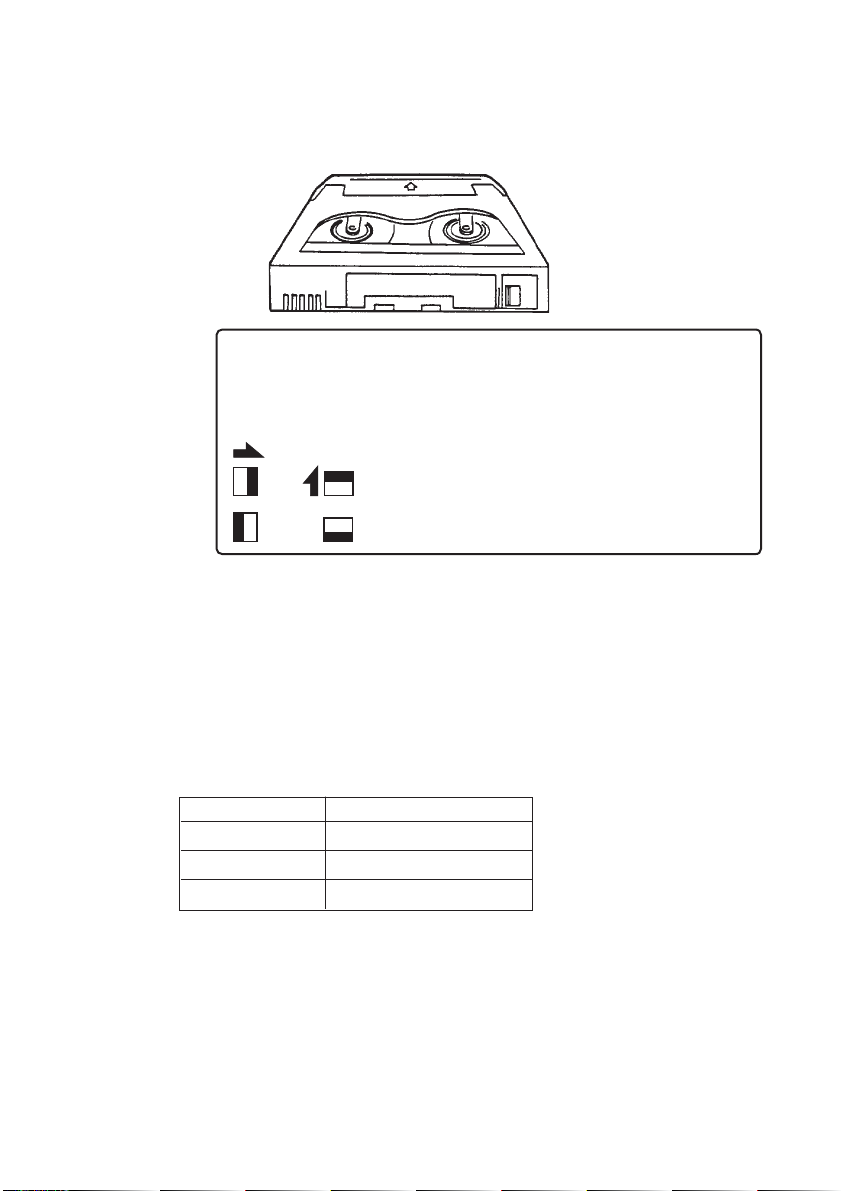

Write-protecting a Cartridge

Cartridges can be write-protected by sliding the tab on the back of the

cartridge. In this state, data can be read from the tape but not written onto it.

AIT-5

AIT-4

AIT-3 Ex

AIT-3

AIT-2 Turbo

AIT-1

AIT-2

AIT-1 Turbo

AIT-E Turbo

Using your fingernail, push the switch in the

direction of the arrow to protect the tape from

writing or accidental erasure.

Return the switch to its original position to

re-enable writing.

Using a Cleaning Cartridge

To keep the AIT drive in top condition, clean the drive unit as needed using

a cleaning cartridge with the AIT logo. When the drive unit needs cleaning,

the CLEANING REQUEST indicator lights. (For the SDX-1100V,

SDX-900V, and SDX-800V series drives, use the SDX-1100V, SDX-900V,

and SDX-800V series cleaning cartridges respectively.)

Use the cleaning cartridge made exclusively for each model.

Cleaning cartridge to use

SDX-1100V SDX5-CL

SDX-900V SDX4-CL, SDX4-CLL

SDX-800V SDX3X-CL

21

How to Clean

1 Load the cleaning cartridge into the AIT drive. Cleaning

starts automatically.

2 Cleaning takes from a few seconds to a minute for the

SDX-1100V, SDX-900V, and SDX-800V *, and the cartridge

is automatically ejected when finished.

*

The cleaning time varies depending on the condition of the drive.

Caution

Do not rewind the cleaning cartridge and reuse it. When you reach the

end of the cartridge, dispose it and buy a new cleaning cartridge with

the AIT logo.

Storage Precautions

• Keep cartridges in their cases when not in the drives.

• Avoid storing cartridges in dusty locations, in direct sunlight, near heaters

or air conditioners, or in humid locations.

• Do not place cartridges on dashboards or in car storage trays.

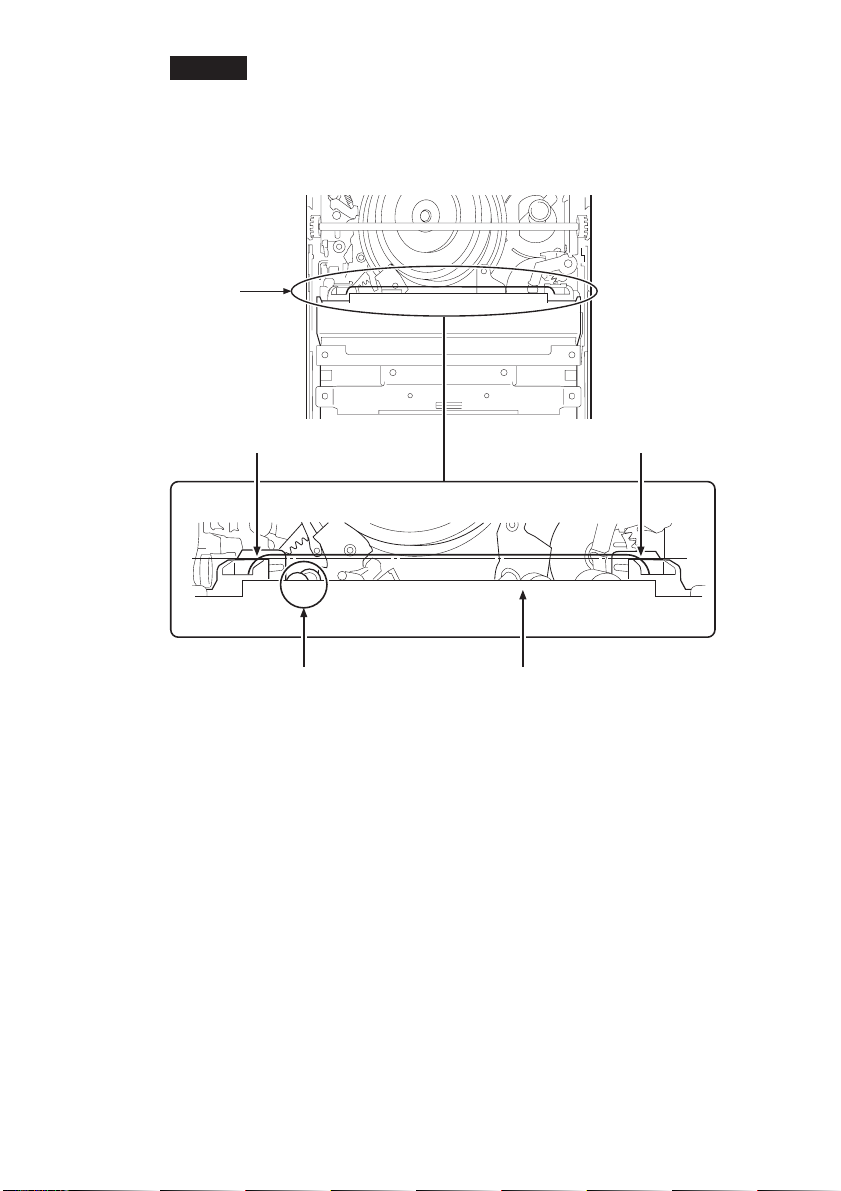

Emergency Tape Removal Procedure

1 Remove the drive from the chassis or enclosure to allow

access to the bottom of the drive.

2 Remove the drive’s top cover.

3 Locate the small opening in the bottom of the drive and

insert the tip of a precision screwdriver so that the Loading

motor shaft can be rotated.

22

4 Rotate the motor shaft clockwise to bring the threading

mechanism back to the initial position.

Reel motor

Loading motor

Emergency Tape Removal Procedure

23

Caution

Stop rotating the motor shaft immediately, when the Guide B gets to

the area below the line C-C (This line is defined by 2 circular tape

guide surfaces of the cartridge). Otherwise, the gears of the drive can

be damaged.

A

Tape guide surface

C

The Initial Position of the Threading Mechanism

Guide B

detail A

Cartridge

Tape guide surface

5 Before the manual ejection procedure, tape slack must be

removed in order to prevent tape damage. Rotate the gear

mechanism located on the bottom of the drive

counterclockwise to tighten the tape.

6 After the tape slack has been removed, continue to turn the

Loading motor shaft located on the bottom of the drive

clockwise with a precision screwdriver until the tape

cartridge is lifted out of the drive mechanism and is ejected.

C

7 Return the drive to Sony for repair.

24

Interface Implementation

Supported SCSI Messages

Abort Identify

Target Reset Ignore Wide Residue

Command Complete Message Parity Error

Disconnect Message Reject

Extended Message No Operation

– Synchronous Data Transfer

Request

– Wide Data Transfer Request

– Parallel Protocol Request

Supported SCSI Commands

Erase

Inquiry

Load/Unload

Locate

Log Sense

Log Select

Mode Select (6)

Mode Select (10)

Mode Sense (6)

Mode Sense (10)

Persistent Reserve In

Persistent Reserve Out

Prevent Allow Medium Removal

Read

Read Attribute

Read Block Limits

Read Buffer

Read Position

Receive Diagnostic Result

Release (6)

Release (10)

Report Density Support

Report Device Identifier

Report Luns

Request Sense

Reserve (6)

Reserve (10)

Rewind

Send Diagnostic

Set Device Identifier

Space

Test Unit Ready

Write

Write Attribute

Write Buffer

Write Filemarks

25

Specifications

Product Specifications

Dimensions

(not including bezel and protruding parts)

3.5" 5.25"

Height 41.2 mm (1.62 in) 41.2 mm (1.62 in)

Width 101.6 mm (4.0 in) 146.0 mm (5.75 in)

Depth 155.0 mm (6.1 in) 155.0 mm (6.1 in)

Mass

SDX-1100V

3.5" 0.8 kg (28.2 oz.)

5.25" 1.1 kg (38.8 oz.)

SDX-900V, SDX-800V

3.5" 780 g (27.5 oz.)

5.25" 1010 g (35.6 oz.)

Altitude

Operating 0 to 3048 m (0 to 10,000 ft.)

Vibration

Operating Swept Sine 5 to 500 Hz

*0.25 G Peak 1 Octave/min.

3 axes, 3 directions

Non-operating Swept Sine 5 to 500 Hz

*0.5 G Peak 1 Octave/min.

3 axes, 3 directions

Acoustic Noise (A) curve weight

Streaming Write/Read 35 dB (A)

Insert/Eject 60 dB (A)

Note

The sound-meter on (A) scale is located 1m (3.3 ft.) in front of the center of the

drive front panel.

26

Shock

Operating No Data Loss

Non-operating No Device Damage

Half Sine

Performance

5 G Peak 3 ms

3 axes, 3 directions

*Interval of 10 seconds

Half Sine

90 G Peak 3 ms

(30 G Peak 11 ms)

3 axes, 3 directions

*Interval of 10 seconds

Temperature and Humidity Range

Temperature

Operating 5 ˚C to 40 ˚C (∆T<10 ˚C/h) (41 ˚F to 104 ˚F (∆T<18 ˚F/h))

Non-operating (mech.) – 40 ˚C to 70 ˚C (∆T<20 ˚C/h) (– 40 ˚F to 158 ˚F (∆T<36 ˚F/h))

Non-operating (tape) – 40 ˚C to 45 ˚C (∆T<20 ˚C/h) (– 40 ˚F to 113 ˚F (∆T<36 ˚F/h))

Humidity

Operating 20 to 80% RH, non-condensing

Maximum wet bulb temperature : 26 ˚C (78.8 ˚F)

Non-operating (mech.) 5 to 95% RH (∆RH<30%/h)

Non-operating (tape) 20 to 80% RH (∆RH<30%/h)

Maximum wet bulb temperature : 45 ˚C (113 ˚F)

Air-cooling Requirement

Surrounding temperature < 40 ˚C (104 ˚F)

Clean air flow is recommended to minimize the possibility of data loss.

Power Requirements

SDX-1100V

Voltage Max Ripple

5 V +/– 5% 100 mVp-p 1.7 A 2.5 A

12 V +/– 10% 150 mVp-p 0.87 A 3.0 A

SDX-900V, SDX-800V

Voltage Max Ripple

5 V +/– 5% 100 mVp-p 1.5 A 2.5 A

12 V +/– 10% 150 mVp-p 0.75 A 3.0 A

Typical Maximum

Typical Maximum

Current

Current

27

Sony Contacts

For further information, please contact:

Sony Electronics Inc., Tape Storage Solutions (USA)

URL: http://www.storagebysony.com

Sony of Canada Ltd., AV/IT Marketing Group

Computer Peripherals Product Marketing

115 Gordon Baker Road Toronto, Ontario, M2H 3R6 Canada

TEL: (416) 499-1414 or (1) 800-961-7669

FAX: (416) 499-8541

Sony Business Europe

URL: http://www.sonyisstorage.com/

Electronics Devices Marketing (Singapore)

(A division company of Sony Electronics (S) Pte. Ltd.)

Enterprise Storage Solutions Dept.

2 International Business Park, #01-10 Tower One, The Strategy,

Singapore 609930

TEL: 65-6544-8000 FAX: 65-6544-7390

Sony Corporation of Hong Kong Ltd.

Computer Peripheral Sales & Marketing Division

Electronic Devices Marketing Hong Kong

45/F, The Lee Gardens, 33 Hysan Avenue, Causeway Bay, Hong Kong

TEL: (852) 2909-1008 FAX: (852) 2909-2001

Sony Corporation of Hong Kong Ltd. Beijing Rep. Office

Computer Peripheral Div.

Full Link Plaza Tower A 11/F., No.18 Chaoyangmenwai Ave., Beijing

100020 P.R.C.

TEL: 86-10-6588-0633 FAX: 86-10-6588-0855

URL: http://www.sony.com.cn/ed/cp/ait/

Sony Corporation of Hong Kong Ltd.,

Electronic Devices Marketing Hong Kong

Computer Peripherals Sales & Marketing Div.

8/F, One Corporate Avenue, 222 Hu Bin Road. Luwan District,

Shanghai. P.R.C. Postcode 200021

TEL: 86-21-6121-6878

URL: http://www.sony.com.cn/ed/cp/ait/

28

Sony Brasil Ltda.

Rua Inocéncio Tobias, 125, Barra Funda

São Paulo-SP, Brasil 01144-000

TEL: (55) 11-2196-9000 FAX: (55) 11-2196-9186

URL: http://www.sonybrasil.com.br

Sony Australia Limited

33-39 Talavera Rd.

NORTH RYDE, NSW 2113

TEL: 1300-13-7669 FAX: 02-9870-5864

e-mail: CIC-customerissues@ap.sony.com

Sony New Zealand

Akoranga Business Park

NORTH SHORE, AUCKLAND

TEL: 0800-76-6969 FAX: 09-308-9300

e-mail: CIC-customerissues@ap.sony.com

Sony Chile Ltda

Av. Kennedy 8017, Las Condes, Santiago, Chile

TEL: (02) 210-6000 FAX: (02) 210-5417

Sony Taiwan Limited

Optical Devices Storage Dept. Data Storage Section

5F, 145 Changchun Road, Taipei 104, Taiwan

TEL: 886-2-2522-7920 FAX: 886-2-2522-2153

Sony Korea Corporation EDMK CP Sales & Marketing Team

34F, ASEM Tower, World Trade Center, 159-1, Samsung-Dong,

Kangnam-Ku, Seoul, 135-798, Korea

TEL: 82-2-6001-4249 FAX: 82-2-6001-4115

URL: http://www.sony.co.kr/cp/

Sony Gulf FZE Computer Display & Peripheral Div.

P.O.BOX 16871, Jebel Ali, Dubai, U.A.E.

TEL: 971-4-8815488 or 8816912 FAX: 971-4-8817210 or 8816259

Sony Marketing of Japan

Business Solution Dept. Server Solution Marketing Section

URL: http://www.sony.co.jp/STORAGE

29

本文包含受版权保护的专利信息。

版权所有。未经 Sony公司书面同意

不得拍摄、复制本文的任何部分或将

其翻译成其他语言。

Sony 公司不对本文档中包含的错误

以及本文档的供应、履行或使用相关

的间接、特殊、意外或导致的损害负

责。

本文中的信息如有更改,恕不通知。

您的SDX-1100V配有型号SDX-1100,

该型号通过规范达标认证。

Sony 公司不承诺任何有关本文档的

保证。

您的SDX-900V和 SDX-800V配有

型号 ATDNA4,该型号通过规范达

标认证。

驱动器的型号标签上列出了该号码以

及额定电压和电流。

产品中有毒有害物质或元素的名称及含量

使用环境条件:参考使用说明书中的操作条件

有毒有害物质或元素

部件名称

实装基板 × ○ ○ ○ ○ ○

驱动单元 × ○ ○ ○ ○ ○

○:表示该有毒有害物质在该部件所有均质材料中的含量均在 SJ/T11363-2006 标准规定的限量

要求以下。

×:表示该有毒有害物质至少在该部件的某一均质材料中的含量超出 SJ/T11363-2006 标准规定

的限量要求。

铅汞镉六价铬 多溴联苯 多溴二苯醚

(Pb) (Hg) (Cd) (Cr (VI)) (PBB) (PBDE)

30

重要安全说明

为了您的安全,请在使用本装置前通

读这些安全指示,并妥善保存本手册

以备将来参考。

请认真并始终遵守本装置上或操作说

明中说明的所有警告、事先注意事项

和指示。

使用

电源 – 本装置只能使用标牌上标识的

电源类型。如果不能确定电源的类

型,请咨询经销商或当地电力公司。

清洁 – 在清洁或给本装置上光前,请

从墙壁插座拔出电源插头。请勿使用

液体清洁剂或气雾清洁剂。请用蘸了

少量水的布清洁本装置外壳。

异物和液体进入 – 切勿从本装置的孔

槽中塞入任何异物,因为它们可能碰

到高压点或使部件短路,从而导致火

灾或触电。切勿让任何液体溅到本装

置上。

CS

31

安装

水和潮湿 – 请勿在水边使用电源线操

作本装置-例如,浴缸、洗脸盆、厨

房水槽、洗衣水池、潮湿的地下室或

游泳池等附近。

补充 – 请勿将本装置放在不稳定的车

子、台子、三脚架、托架或桌子上,

否则本装置可能掉落,导致儿童或成

人严重受伤以及本装置严重受损。请

只使用制造商推荐的车子、台子、三

脚架、托架或桌子。

通风 – 机壳上的槽和孔用于必要的通

风。为确保本装置的正常工作并防止

过热,切勿堵塞或覆盖这些槽和孔。

• 切勿用布或其它材料覆盖这些槽和

孔。

• 切勿把本装置放在床、沙发、垫子

或其它类似物体上,以免堵塞这些

槽和孔。

• 切勿把本装置放在诸如书柜、壁柜

等封闭的空间里,除非提供了适当

的通风。

维修

故障维修 – 在下列情况下,请从墙壁

插座拔下电源插头并请合格的维修人

员进行维修。

• 如果液体溅入本装置或异物掉入本

装置。

• 如果本装置淋雨或进水。

• 如果本装置因掉落而受到强烈震

动,或外壳已损坏。

• 如果虽按操作说明进行操作,本装

置工作不正常。请只调节操作说明

指定的控制钮。错误的调节其它控

制钮可能导致装置损坏,同时经常

导致需要合格的技术人员进行大量

的修理工作,才能使本装置恢复正

常。

• 当本装置的性能发生显著变化 - 这

时表示需要维修。

维修 – 请勿自行维修本装置,因为打

开或取下外壳可能使您暴露在高压

下,或受到其它伤害。务必请合格的

维修人员进行所有的维修。

32

目录

概述................................................................................................................34

介绍................................................................................................................34

关于 AIT 驱动器 .................................................................................... 34

事先注意事项 ......................................................................................... 36

安装................................................................................................................39

SCSI 连接 / 设置 SCSI ID ...................................................................... 39

可选开关(DIP 开关)............................................................................40

安装孔 .................................................................................................... 43

从 5.25" 型号重新配置为 3.5" 型号 .......................................................44

方向........................................................................................................ 44

安装和拆除防尘盖 ......................................................................................... 45

安装防尘盖............................................................................................. 45

拆除防尘盖............................................................................................. 46

操作................................................................................................................47

3个LED 的位置 ..................................................................................... 47

驱动器操作............................................................................................. 48

紧急磁带取出步骤 .................................................................................51

接口实现 ........................................................................................................ 53

支持的 SCSI 讯息 ..................................................................................53

支持的 SCSI 命令 ..................................................................................53

规格................................................................................................................54

产品规格 ................................................................................................54

Sony 公司联系方式 ........................................................................................ 56

• 由于使用本产品而造成的写入盒式磁带的数据丢失,Sony 不承担责任。

• 对于因使用本产品而引起的财政损失、利益损失或由第三方提出的索赔,Sony 不承

担责任。

33

概述

SDX-1100V、SDX-900V 和 SDX-800V 系列驱动器是采用高级智能

磁带(AIT)技术的高容量数据存储装置。SDX-1100V、SDX-900V 和

SDX-800V 系列驱动器通过写后读、第二级纠错编码和其他特性实现

了数据高可靠性。

SDX-1100V、SDX-900V 和 SDX-800V 系列驱动器采用 AIT(高级

智能磁带)标准格式和 ALDC 格式将数据存储在磁带上。

介绍

关于 AIT 驱动器

SDX-1100V 系列是使用符合 AIT-5 格式数据磁带的内置AIT 驱动器

装置。

SDX-900V系列是使用符合AIT-4 格式数据磁带的内置 AIT 驱动器装

置。

SDX-800V 系列是使用符合 AIT-3 Ex 格式数据磁带的内置 AIT 驱动

器装置。

SDX-1100V 系列支持 AIT-5、AIT-4、AIT-3 Ex 和 AIT-3 格式。

SDX-900V 系列支持 AIT-4 和 AIT-3 Ex 格式。

SDX-800V 系列支持 AIT-3 Ex、AIT-3、AIT-2 Turbo、AIT-2(只

读)、AIT-1 Turbo(只读)、AIT-1(只读)和 AIT-E Turbo(只读)

格式。

34

特性

AIT 驱动器装置 SDX-1100V 系列具有如下功能:

• 支持对符合 AIT-5、AIT-4、AIT-3 Ex 和 AIT-3 格式数据磁带的读

写操作。

• 第二级纠错编码保证符合 AIT-5、AIT-4 和 AIT-3 Ex 格式数据磁

带的高数据可靠性。

• 第三级纠错编码保证符合 AIT-3 格式数据磁带的高数据可靠性。

• 数据压缩能在 SDX5-400C 上存储 1040G 字节。*

SDX5-400C 的正常存储容量为 400G 字节。

• 压缩时自动检查存储的数据。

• 完全支持以 Ultra 160 SCSI 接口进行主机访问。

• 分段重写功能(AIT-5、AIT-4、AIT-3 Ex)

• 帧重写功能(AIT-3)

AIT 驱动器装置 SDX-900V 系列具有如下功能:

• 支持对符合 AIT-4 和 AIT-3 Ex 格式数据磁带的读写操作。

• 第二级纠错编码保证符合 AIT-4 和 AIT-3 Ex 格式数据磁带的高数

据可靠性。

• 数据压缩能在 SDX4-200C 上存储 520G 字节。*

SDX4-200C 的正常存储容量为 200G 字节。

• 压缩时自动检查存储的数据。

• 完全支持以 Ultra 160 SCSI 接口进行主机访问。

• 分段重写功能

* 假定压缩率为 2.6 : 1。

记录数据时可达到的数据压缩程度根据系统环境和数据类型而不同。

35

AIT 驱动器装置 SDX-800V 系列具有如下功能:

• 支持对符合 AIT-3 Ex、AIT-3 和 AIT-2 Turbo 格式数据磁带的读

取操作。

• 支持对符合 AIT-2、AIT-1 Turbo、AIT-1 和AIT-E Turbo 格式数

据磁带的读取操作。

• 第二级纠错编码保证符合 AIT-3 Ex 格式数据磁带的高数据可靠性。

• 第三级纠错编码保证符合 AIT-3 格式数据磁带的高数据可靠性。

• 数据压缩能在 SDX3X-150C 上存储 390G 字节。*

SDX3X-150C 的正常存储容量为 150G 字节。

• 压缩时自动检查存储的数据。

• 完全支持以 Ultra 160 SCSI 接口进行主机访问。

• 分段重写功能(AIT-3 Ex)

• 帧重写功能(AIT-3)

* 假定压缩率为 2.6 : 1。

记录数据时可达到的数据压缩程度根据系统环境和数据类型而不同。

事先注意事项

安装

避免将驱动器置于下列环境:

– 高湿度

– 高温

– 机械撞击或震动

– 阳光直射

*

详细信息请参考第 54 页“规格”。

36

操作

• 当磁带机运作时,请勿移动,否则可能会导致故障发生。

• 避免将磁带机暴露于温度突然由低变高的环境,否则可能会造成磁带

机内部结露。如果在磁带机开启时周围温度突然升高,请关闭磁带机

的电源,至少等待一小时再启动磁带机。如果在温度突然升高之后立

即尝试操作磁带机,则可能会造成故障。

• 如果在磁带机向磁带写入资料时关闭磁带机的电源,则可能无法读取

磁带上的资料。磁带机恢复供电时,先前设定的所有参数都将丢失。

运输

• 请保留原始包装材料,以便安全地运输驱动器。

• 在移动驱动器之前必须取出磁带 / 介质盒。将驱动器从计算机上卸下

后,应将驱动器放入原始包装内。

可用数据盒式磁带

SDX-1100V 系列可与带有 AIT-5、AIT-4、AIT-3 Ex 或 AIT-3 标志

的数据盒式磁带一同使用。

SDX-900V 系列可与带有 AIT-4 或 AIT-3 Ex 标志的数据盒式磁带一

同使用。

SDX-800V 系列可与带有 AIT-3 Ex、AIT-3、AIT-2 Turbo、AIT-2

(只读)、AIT-1 Turbo(只读)、AIT-1(只读)或 AIT-E Turbo(只

读)标志的数据盒式磁带一同使用。

AIT-E Turbo标志 AIT-1标志 AIT-1 Turbo标志

AIT-2标志 AIT-2 Turbo标志 AIT-3标志

AIT-3 Ex标志 AIT-4标志 AIT-5标志

37

注意

• 请勿在本驱动器上使用非上述所列盒式磁带。务必仅使用专为 AIT

设计的数据盒式磁带。

• 请勿在本系统内使用除 AIT 盒式磁带以外的其他磁带。否则,会损

坏 AIT 驱动器。尽管市售的 8 mm 盒式录像带与AIT 盒式磁带外观

相似,但二者规格完全不同,因此不能使用盒式录像带。

SCSI 端接

SDX-1100V、SDX-900V和SDX-800V系列驱动器符合Microsoft

PC97 标准,该标准要求内置(裸机)驱动器用一个外部端接器进行

端接。

Microsoft PC97 SCSI 要求

SCSI外设必须不端接总线。内部和外部电缆末端均通过插入式连接器

进行端接。

38

主机与其他外围设备连接示例

安装

SCSI 连接 / 设置 SCSI ID

后视图以 SDX-1100V 磁带机为例。

SCSI ID

210

SCSI ID

0

1

2

3

3

P. D .

N.C.

4

5

5 V

6

7

SCSI ID 3

SCSI ID 2

SCSI ID 1

SCSI ID 0

8

9

10

11

12

13

14

=

=

=

15

奇偶校验禁止跳线

可通过跳线开关禁止奇偶校验功能。当最左端跳线插上后奇偶校验被禁

止。奇偶校验生成功能一直启用。

1234

GND GND 12 V

39

可选开关(DIP 开关)

DIP 开关位置

默认

ON

OFF

12345678

DIP 开关

1DR(灾难恢复)模式(OFF/ 关)

2 仿真模式(OFF/ 关)

3 AIT 库接口模式(ON/ 开)

4保留(OFF/ 关)

5 端接器电源(ON/ 开)

6 定期清洁要求(ON/ 开)

7DC控制(1)(ON/ 开)

8DC控制(2)(OFF/ 关)

40

仿真模式 *

若要启用仿真模式,请将 DIP 开关 2[仿真模式]设为 ON。

ON

OFF

12345678

*

仿真模式在 SDX-1100V 系列查询的产品标识字段返回下列值。

SDX-900V

*

仿真模式在 SDX-900V 系列查询的产品标识字段返回下列值。

SDX-700C

*

仿真模式在 SDX-800V 系列查询的产品标识字段返回下列值。

SDX-700C

AIT 库接口模式

若要启用 AIT 库接口模式,请将 DIP 开关 3[AIT 库接口模式]设

为ON。

ON

OFF

12345678

开关 3 处于 ON 时,AIT 库接口模式被启用。当该开关处于 OFF 时,

ACI 模式被启用。

端接器电源

要启用端接器电源,将 DIP 开关 5[端接器电源]开关设为 ON。

ON

OFF

12345678

41

定期清洁要求模式

若要启用定期清洁要求模式,请将 DIP 开关 6[定期清洁要求]设为

ON。

ON

OFF

12345678

当该模式启用后,每工作 100 小时后,前面板上的“CLEANING

REQUEST”LED 亮起。

LED 亮起时,可使用清洁盒式磁带清洁驱动器。

注

要使驱动器在易受灰尘或其他污染物影响的环境中保持最佳工作状态,

建议将清洁要求模式处于启用状态。

数据压缩控制

可通过 DIP 开关选择数据压缩。

当 DIP 开关 7[DC 控制(1)]处于 ON 时,数据压缩启用。

ON

OFF

12345678

当 DIP开关 8[DC 控制(2)]处于 ON 时,主机控制被禁止。

ON

OFF

12345678

42

安装孔

以下数据适用于 SDX-800V 系列驱动器。然而其他型号安装孔的位置

是相同的。

对于 3.5" 标准高度

(连接器尺寸)

对于 5.25" 半高度

(连接器尺寸)

43

从 5.25" 型号重新配置为 3.5" 型号

您可以自己将 5.25" 型号重新配置为 3.5" 型号。

1 松开两侧边条上各自的两个螺丝。

2 卸下侧边条。

方向

侧边条(左)

侧边条(右)

44

10

10

10

10

10 10

10

10

安装和拆除防尘盖

安装防尘盖

1 将防尘盖的铰接销(一边一个)与驱动器前盖上的销孔对齐。

• 防尘盖的放置应该使该盖背面的磁体 * 面向驱动器前盖。

*

该磁体不会影响磁带。

• 如下图所示以一个角度握住防尘盖,将铰接销装入前盖销孔的

顶部,使铰接销挂在销孔上。

2 从一个角度依次按压两端,直到您听见铰接销到位的“喀哒”

声。

注意

不要从前面水平地按压防尘盖。这样可能导致防尘盖断裂。

45

3 关上防尘盖。

这样即完成了防尘盖的安装。

拆除防尘盖

1 打开防尘盖。

2 握住防尘盖的两端,小心地抬起防尘盖。

防尘盖铰接销与驱动器前盖销孔脱离。

46

注

建议使用防尘盖。

操作

3个LED 的位置

该装置的前面板上有三个 LED 指示灯(TAPE MOTION LED,

CLEANING REQUEST LED, REPLACE TAPE LED)和一个

EJECT 按钮。

前面板

Advanced

Intelligent

Tape

TAPE

MOTION

CLEANING

REQUEST

REPLACE

TAPE

LED

LED 驱动器状态指示灯

LED 指示灯定义如下。

LED

TAPE CLEANING REPLACE

MOTION REQUEST TAPE

无关 无关 磁带已装载

无关 无关 磁带访问进行中(写/读)

无关 无关 磁带访问进行中(其他)

无关 无关 请求清洁

无关 无关 清洁未完成

无关 无关 出现介质错误

出现H/W错误

亮

慢闪烁

一个脉冲(0.9秒亮/0.3秒灭)

快闪烁

一个脉冲(0.3秒亮/0.3秒灭)

含义

47

驱动器操作

装载磁带

注

当装入数据磁带时,请勿关闭主机电源。否则可能导致故障或损坏数

据。

1 开启主机电源。检查驱动器的 TAPE MOTION LED、

CLEANING REQUEST LED 和 REPLACE TAPE LED 指

示灯是否熄灭。

2 打开防尘盖。

3 按如图所示的方向将 AIT 数据磁带插入数据磁带槽。

插入数据磁带至一定深度时,它将自动装入驱动器并且 TAPE

MOTION LED 指示灯亮。

卸载磁带

可通过 SCSI Unload 命令或通过按 EJECT 按钮,将磁带从 SDX1100V、SDX-900V 和 SDX-800V 系列驱动器中卸载。

按 EJECT 按钮后,磁带倒绕,盒式磁带从槽中弹出。

48

设置磁带写保护

通过滑动盒式磁带背面的凸起可以设置磁带写保护。在该状态下,磁带

可以读但不能写入。

AIT-5

AIT-4

AIT-3 Ex

AIT-3

AIT-2 Turbo

AIT-1

AIT-2

AIT-1 Turbo

AIT-E Turbo

用指甲按箭头方向推动开关,以保护磁带不

被写入或意外擦除。

将开关置回原始位置即可重新进行写入操作。

使用清洁带

为保持 AIT 磁带机的最佳状态,请根据需要使用带有 AIT 标志的清洁

磁带匣清洁磁带机。当磁带机需要清洁时,CLEANING REQUEST

指示灯亮。(SDX-1100V、SDX-900V 和 SDX-800V 系列分别使用

SDX-1100V、SDX-900V 和 SDX-800V 系列清洁带。)

请使用专为各型号量身定做的清洁带。

应使用的清洁带

SDX-1100V SDX5-CL

SDX-900V SDX4-CL、SDX4-CLL

SDX-800V SDX3X-CL

49

如何清洁

1 将清洁带装入 AIT 驱动器。即自动开始清洁。

2 SDX-1100V、SDX-900V 和 SDX-800V 清洁需要几秒钟到

一分钟 *,完成后磁带自动弹出。

* 清洁时间因驱动器的条件而异。

注意

请勿倒回清洁带并再次使用。当用至清洁带末端时,请将其丢弃并

购买带有 AIT 标志的新的清洁带。

存储事先注意事项

• 当磁带不在驱动器中时,请将其放在磁带盒中。

• 避免将磁带存放在积满灰尘、阳光直射、靠近加热器或空调、或者潮

湿的地方。

• 请勿将磁带放在汽车的仪表板或储物盘上。

50

紧急磁带取出步骤

1 从机箱或机壳上将驱动器拆下,以便能触及驱动器底部。

2 拆下驱动器的顶盖。

3 在驱动器底部确定小孔的位置,插入精密螺丝刀的尖端使装载

马达轴可以转动。

4 顺时针转动马达轴,将卷带机构返回至初始位置。

卷带马达

装载马达

紧急磁带取出步骤

51

注意

当导轨B 到达 C-C 线(该线由盒式磁带的2个圆形磁带导轨的表面

而确定)下面的区域时,应立即停止转动马达轴,否则会损坏驱动

器的齿轮。

A

磁带导轨表面 磁带导轨表面

CC

详图 A

导轨 B

盒式磁带

卷带机构的初始位置

5 在进行手动弹出步骤前,必须消除磁带松弛现象以防磁带受损。

逆时针转动驱动器底部的齿轮机构将磁带绷紧。

6 磁带松弛现象消除后,用精密螺丝刀继续转动位于驱动器底部

的装载马达轴,直到盒式磁带伸出驱动机构并弹出为止。

7 将驱动器返回至 Sony 公司进行修理。

52

接口实现

支持的 SCSI 讯息

异常中止

目标重置

命令完成

断开连接

扩展消息

–

同步数据传输请求

–

宽数据传输请求

–

并行协议请求

支持的 SCSI 命令

擦除

查询

装载 / 卸载

定位

日志检测

日志选择

模式选择(6)

模式选择(10)

模式检测(6)

模式检测(10)

持续保留 IN

持续保留 OUT

防止允许介质移除

读

读属性

读取块限制

读缓冲区

读取位置

接收诊断结果

识别

忽略宽余数

消息奇偶校验错误

消息拒绝

无操作

释放(6)

释放(10)

报告密度支持

报告装置识别

报告 Luns

请求检测

保留(6)

保留(10)

倒带

发送诊断

设置装置识别

空白

测试装置就绪

写

写属性

写缓冲区

写文件标记

53

规格

产品规格

尺寸(不包括前盖和伸出部分)

3.5" 5.25"

高度 41.2 mm 41.2 mm

宽度 101.6 mm 146.0 mm

深度 155.0 mm 155.0 mm

重量

SDX-1100V

3.5" 0.8 kg

5.25" 1.1 kg

SDX-900V、SDX-800V

3.5" 780 g

5.25" 1010 g

高度

工作时 0 至 3048 m

振动

工作时 正弦扫频 5 至 500 Hz

*0.25 G 峰值 1 倍频程 / 分钟

3 轴、3 方向

不工作 正弦扫频 5 至 500 Hz

*0.5 G 峰值 1 倍频程 / 分钟

3轴、3方向

声噪 (A) A 曲线计权声压级

连续写入 / 读取 少于 35 dB (A)

插入 / 弹出 少于 60 dB (A)

注

(A)分贝级声级表位于磁带机前面板中央前方 1 m 处。

54

震动

工作时 无数据损失

半正弦

性能

5 G 峰值 3 毫秒

3轴、3方向

*10 秒间隔

不工作 无设备损失

半正弦

90 G 峰值 3 毫秒

(30 G 峰值 11 毫秒)

3轴、3方向

*10 秒间隔

温度和湿度范围

温度

工作时 5 ℃至 40 ℃ (∆T<10 ℃/h)

不工作(装置) -40 ℃至 70 ℃ (∆T<20 ℃/h)

不工作(磁带) -40 ℃至 45 ℃ (∆T<20 ℃/h)

湿度

工作时 20 至 80% 相对湿度,无结露

最高湿球温度计温度 : 26 ℃

不工作(装置) 5 至 9 5 % 相对湿度 (∆ RH<30%/h)

不工作(磁带) 20 至 80% 相对湿度 (∆RH<30%/h)

最高湿球温度计温度 : 45 ℃

空气冷却要求

环境温度 <40 ℃

推荐使用洁净的气流以使数据丢失的可能性最小。

电源要求

SDX-1100V

电压 最大波动

5 V +/– 5% 100 mVp-p 1.7 A 2.5 A

12 V +/– 10% 150 mVp-p 0.87 A 3.0 A

SDX-900V、SDX-800V

电压 最大波动

5 V +/– 5% 100 mVp-p 1.5 A 2.5 A

12 V +/– 10% 150 mVp-p 0.75 A 3.0 A

典型 最大

典型 最大

电流

电流

55

Sony 公司联系方式

更详细的信息,请联系:

Sony Electronics Inc., Tape Storage Solutions (USA)

URL: http://www.storagebysony.com

Sony of Canada Ltd., AV/IT Marketing Group

Computer Peripherals Product Marketing

115 Gordon Baker Road Toronto, Ontario, M2H 3R6 Canada

TEL: (416) 499-1414 or (1) 800-961-7669

FAX: (416) 499-8541

Sony Business Europe

URL: http://www.sonyisstorage.com/

Electronics Devices Marketing (Singapore)

(A division company of Sony Electronics (S) Pte. Ltd.)

Enterprise Storage Solutions Dept.

2 International Business Park, #01-10 Tower One, The Strategy,

Singapore 609930

TEL: 65-6544-8000 FAX: 65-6544-7390

Sony Corporation of Hong Kong Ltd.

Computer Peripheral Sales & Marketing Division

Electronic Devices Marketing Hong Kong

45/F, The Lee Gardens, 33 Hysan Avenue, Causeway Bay, Hong Kong

TEL: (852) 2909-1008 FAX: (852) 2909-2001

Sony Corporation of Hong Kong Ltd. Beijing Rep. Office

Computer Peripheral Div.

Full Link Plaza Tower A 11/F., No.18 Chaoyangmenwai Ave., Beijing

100020 P.R.C.

TEL: 86-10-6588-0633 FAX: 86-10-6588-0855

URL: http://www.sony.com.cn/ed/cp/ait/

Sony Corporation of Hong Kong Ltd.,

Electronic Devices Marketing Hong Kong

Computer Peripherals Sales & Marketing Div.

8/F, One Corporate Avenue, 222 Hu Bin Road. Luwan District,

Shanghai. P.R.C. Postcode 200021

TEL: 86-21-6121-6878

URL: http://www.sony.com.cn/ed/cp/ait/

56

Sony Brasil Ltda.

Rua Inocéncio Tobias, 125, Barra Funda

São Paulo-SP, Brasil 01144-000

TEL: (55) 11-2196-9000 FAX: (55) 11-2196-9186

URL: http://www.sonybrasil.com.br

Sony Australia Limited

33-39 Talavera Rd.

NORTH RYDE, NSW 2113

TEL: 1300-13-7669 FAX: 02-9870-5864

e-mail: CIC-customerissues@ap.sony.com

Sony New Zealand

Akoranga Business Park

NORTH SHORE, AUCKLAND

TEL: 0800-76-6969 FAX: 09-308-9300

e-mail: CIC-customerissues@ap.sony.com

Sony Chile Ltda

Av. Kennedy 8017, Las Condes, Santiago, Chile

TEL: (02) 210-6000 FAX: (02) 210-5417

Sony Taiwan Limited

Optical Devices Storage Dept. Data Storage Section

5F, 145 Changchun Road, Taipei 104, Taiwan

TEL: 886-2-2522-7920 FAX: 886-2-2522-2153

Sony Korea Corporation EDMK CP Sales & Marketing Team

34F, ASEM Tower, World Trade Center, 159-1, Samsung-Dong,

Kangnam-Ku, Seoul, 135-798, Korea

TEL: 82-2-6001-4249 FAX: 82-2-6001-4115

URL: http://www.sony.co.kr/cp/

Sony Gulf FZE Computer Display & Peripheral Div.

P.O.BOX 16871, Jebel Ali, Dubai, U.A.E.

TEL: 971-4-8815488 or 8816912 FAX: 971-4-8817210 or 8816259

Sony Marketing of Japan

Business Solution Dept. Server Solution Marketing Section

URL: http://www.sony.co.jp/STORAGE

57

本文檔包含受版權保護的專利資訊。

保留所有權利。事先未經 Sony 公司

書面許可,不得影印、拷貝本文檔的

任何部分,或將本文檔翻譯成其他語

言。

本文檔中的資訊會有改變,恕不事先

通知。

Sony 不對本文檔做任何擔保。

Sony 不對此處的錯誤負責,也不對

因設備、執行或使用本文檔而產生的

間接損失、特別損失、附帶損失或後

續損失負責。

您的 SDX-1100V 有一個 SDX-1100 的

機型號,它表示符合法規認證。

您的 SDX-900V 和 SDX-800V 有一個

ATDNA4 的機型號,它表示符合法規

認證。

該號和額定電壓及額定電流一起,位

於磁帶機型號標籤上。

58

重要安全須知

為保證安全,使用本設備前,請詳盡

閱讀“安全說明”,並妥善保管本說

明書以備參考。

請認真並始終遵守本裝置上或操作說

明中說明的所有警告、事先注意事項

和指示。

使用

電源 – 本設備僅使用標籤上指明的電

源類型。如果不能確認電源類型,請

向經銷商或當地電力公司咨詢。

關於帶有三相接地型 AC 插頭的本設

備:

如果無法將插頭插入插座,請與電工

聯繫要求安裝合適的插頭。不要使接

地插頭的安全作用失效。

AC 電源線︰(僅用於 AC 電源操作本

設備時)

AC 電源線應具有可在該國使用於本

設備的安全許可或標誌。請向經銷商

或當地電力公司咨詢。

清潔 – 清潔或擦亮本設備前,應從牆

壁插座上拔下本設備。請勿使用液體

或氣霧型清潔劑清洗本設備。可使用

略微浸濕的軟布擦拭本設備的外表。

進入異物和液體 – 切勿將任何類型的

異物透過開口放入本設備,因為這些

異物可能會碰及危險的帶電體,或造

成部件短路,從而引發火災或觸電事

故。切勿使任何類型的液體濺落到本

設備上。

CT

59

安裝

水和濕氣 – 不要在有水的地方使用帶

有電源線的本設備,如浴缸、臉盆、

廚房水槽或洗衣盆旁邊,潮濕的地下

室中或游泳池附近等。

保護電源線 – 請妥善布置電源線,使

它不會被踩到或被放在上面或靠著的

東西夾住。請特別注意插頭、插座以

及電線和本裝置的結合處。

附件 – 車、工作臺、三腳架、支架或

桌子上。否則,本設備可能會掉落,

給人員造成嚴重傷害,並使本設備嚴

重損壞。僅使用製造商推薦的手推

車、工作臺、三腳架、支架或桌子。

通風 – 機櫃上設置孔和開口以進行必

要的通風。為確保本設備的可靠操

作,防止本設備過熱,切勿堵塞或覆

蓋這些孔和開口。

• 切勿用布或其他材料覆蓋孔和開

口。

• 切勿將本設備置於床、沙發、毛毯

或其他類似的表面上,以免堵塞孔

和開口。

• 切勿將本設備置於密閉的空間,如

書櫥或內建的箱體中,除非提供適

當的通風條件。

維修

–

裝置損壞維修

設備,根據下列情形交給有資質的維

修人員進行維修:

• 電源線或插頭損壞或磨損時。

• 本設備被液體濺濕或有異物掉入本

設備。

• 本設備浸水或受到雨淋。

• 本設備掉落遭受嚴重的撞擊,或機

櫃受損。

• 本設備不能按使用說明正常工作。

只能調整使用說明書中所規定的控

制部件。對其他控制部件的不適當

調整會導致損壞,並經常需要有資

質的技術人員工作大量時間以使本

設備恢復正常工作。

• 本設備在性能上有明顯的改變-表

明需要進行維修。

維修 – 不要試圖擅自檢修本設備,因

為打開或取出蓋子會招致高壓或其他

的危險。

應將所有的維修工作交給有資質的維

修人員。

從牆壁插座上拔下本

60

目錄

概述........................................................... 62

介紹........................................................... 62

關於 AIT 磁帶機 ............................................. 62

防護措施 ................................................... 64

安裝........................................................... 67

連接 SCSI/SCSI 識別碼設定 ................................... 67

選擇開關(DIP 開關)........................................ 68

安裝孔位 ................................................... 71

從 5.25" 型號改裝為 3.5" 型號 ................................ 72

方向....................................................... 72

安裝和取下防塵罩 ............................................... 73

安裝防塵罩 ................................................. 73

取下防塵罩 ................................................. 74

操作........................................................... 75

三個 LED 指示燈的位置 ....................................... 75

磁帶機操作 ................................................. 76

緊急取出磁帶的步驟 ......................................... 79

界面應用 ....................................................... 81

支援的 SCSI 訊息 ............................................ 81

支援的 SCSI 指令 ............................................ 81

規格........................................................... 82

產品規格 ................................................... 82

客戶聯繫 ....................................................... 84

• Sony 公司對因使用本設備而導致寫入磁帶匣中資料的丟失概不負責。

• Sony公司對因使用本產品而導致的任何經濟損失、利益喪失或由第三方提出的索賠概

不負責。

61

概述

SDX-1100V 、 SDX-900V 和 SDX-800V 系列磁帶機是使用 AIT (Advanced

Intelligent Tape)的高容量資料儲存娊置。 SDX-1100V 、 SDX-900V

和 SDX-800V 系列磁帶機通過寫後讀、第二級糾錯編碼和其他特性實現

了資料高可靠性。

SDX-1100V 、 SDX-900V 和 SDX-800V 系列磁帶機儲存資料在一標準格式

化稱為 AIT (Advanced Intelligent Tape)和 ALDC 格式的磁帶上。

介紹

關於 AIT 磁帶機

SDX-1100V 系列是一種內部 AIT 磁帶機,使用與 AIT-5 格式相容的資料

磁帶匣。

SDX-900V 系列是一種內部 AIT 磁帶機,使用與 AIT-4 格式相容的資料

磁帶匣。

SDX-800V 系列是一種內部 AIT 磁帶機,使用與 AIT-3 Ex 格式相容的資

料磁帶匣。

SDX-1100V 系列支援 AIT-5 、 AIT-4 、 AIT-3 Ex 和 AIT-3 格式。

SDX-900V 系列支援 AIT-4 和 AIT-3 Ex 格式。

SDX-800V系列支援AIT-3 Ex、 AIT-3、 AIT-2 Turbo 、 AIT-2(只讀)、

AIT-1 Turbo(只讀)、 AIT-1(只讀)和 AIT-E Turbo(只讀)格式。

62

特性

AIT 磁帶機 SDX-1100V 系列具有以下特性:

• 支援寫入和讀取與 AIT-5 、 AIT-4 、 AIT-3 Ex 和 AIT-3 格式相容的

資料磁帶匣。

• 二級錯誤更正編碼可確保高資料可靠性,使資料磁帶匣符合AIT-5、

AIT-4 和 AIT-3 Ex 格式。

• 三級錯誤更正編碼可確保高資料可靠性,使資料磁帶匣符合 AIT-3

格式。

• 可使用資料壓縮在 SDX5-400C 上儲存 1040G 位元組資料 * 。

SDX5-400C 上的自然容量為 400G 位元組儲存量。

• 自動檢查儲存資料的壓縮狀況。

• 充分支援 Ultra 160 SCSI 界面以訪問主電腦。

• 分段重寫功能(AIT-5 、 AIT-4 、 AIT-3 Ex)

• 幀重寫功能(AIT-3)

AIT 磁帶機 SDX-900V 系列具有以下特性:

• 支援寫入和讀取與 AIT-4

• 二級錯誤更正編碼可確保高資料可靠性,使資料磁帶匣符合 AIT-4

和 AIT-3 Ex

• 可使用資料壓縮在 SDX4-200C 上儲存 520G 位元組資料 * 。

SDX4-200C 上的自然容量為 200G 位元組儲存量。

• 自動檢查儲存資料的壓縮狀況。

• 充分支援 Ultra 160 SCSI 界面以訪問主電腦。

• 分段重寫功能

格式。

和 AIT-3 Ex

格式相容的資料磁帶匣。

* 假定壓縮比為 2.6:1 。

記錄資料時的資料壓縮等級因系統環境和資料類型而有所不同。

63

AIT 磁帶機 SDX-800V 系列具有以下特性:

• 支援寫入和讀取與 AIT-3 Ex 、 AIT-3 和

AIT-2 Turbo

格式相容的資

料磁帶匣。

• 支援讀取與 AIT-2 、

AIT-1 Turbo、AIT-1

和 AIT-E

Turbo

的資料磁帶匣。

• 二級錯誤更正編碼可確保高資料可靠性,使資料磁帶匣符合AIT-3 Ex

格式。

• 三級錯誤更正編碼可確保高資料可靠性,使資料磁帶匣符合AIT-3格

式。

• 可使用資料壓縮在 SDX3X-150C 上儲存 390G 位元組資料 * 。

SDX3X-150C 上的自然容量為 150G 位元組儲存量。

• 自動檢查儲存資料的壓縮狀況。

• 充分支援 Ultra 160 SCSI 界面以訪問主電腦。

• 分段重寫功能(AIT-3 Ex)

• 幀重寫功能(AIT-3)

* 假定壓縮比為 2.6:1 。

記錄資料時的資料壓縮等級因系統環境和資料類型而有所不同。

防護措施

格式相容

安裝

請勿將磁帶機置於下列場所︰

– 高濕度區

– 高溫區

– 有機械衝擊和震動的地方

– 陽光直射的地方

*

詳情請參閱第 82 頁上的“規格”。

64

操作

• 當磁帶機運作時,請勿移動,否則可能會導致故障發生。

• 避免將磁帶機暴露於溫度突然由低變高的環境,否則可能會造成磁帶

機內部結露。如果在磁帶機開啟時周圍溫度突然升高,請關閉磁帶機

的電源,至少等待一小時再啟動磁帶機。如果在溫度突然升高之後立

即嘗試操作磁帶機,則可能會造成故障。

• 如果在磁帶機向磁帶寫入資料時關閉磁帶機的電源,則可能無法讀取

磁帶上的資料。磁帶機恢復供電時,先前設定的所有參數都將丟失。

運送

• 請保留原始的包裝材料,以備日後磁帶機的安全運送。

• 在移動磁帶機之前,應先取出磁帶/介質磁帶匣。將磁帶機由電腦內

取出後,再裝於原始的包裝箱內。

可用的磁帶匣

SDX-1100V 系列可以使用帶有 AIT-5 、 AIT-4 、 AIT-3 Ex 或 AIT-3 標

誌的磁帶匣。

SDX-900V 系列可以使用帶有 AIT-4 或 AIT-3 Ex 標誌的磁帶匣。

SDX-800V 系列可以使用帶有 AIT-3 Ex 、 AIT-3 、 AIT-2 Turbo 、 AIT-2

(只讀)、 AIT-1 Turbo(只讀)、AIT-1(只讀)或 AIT-E Turbo(只

讀)標誌的磁帶匣。

AIT-E Turbo標誌 AIT-1標誌 AIT-1 Turbo標誌

AIT-2標誌 AIT-2 Turbo標誌 AIT-3標誌

AIT-3 Ex標誌 AIT-4標誌 AIT-5標誌

注意

• 請勿在本磁帶機上使用非上述所列盒式磁帶。請務必使用AIT專用磁

帶匣。

• 請勿將非AIT磁帶匣用於本系統,否則會損壞AIT磁帶機。雖然市售

8 mm磁帶與AIT磁帶匣的外觀類似,但其規格完全不同,因而不能使

用。

65

SCSI 的終端連結

SDX-1100V 、 SDX-900V 和 SDX-800V 系列磁帶機符合 Microsoft PC97

標準,該標準需要內部(裸露)磁帶機終端連結外部的終端器。

Microsoft PC97 SCSI 的需求

SCSI 的周邊不可在匯流排線上終端連結,而在內部和外部連線末端用

插入式連結器取代終端連結。

主電腦 Wide SCSI

68p 匯流排(cable)

主機與其他外圍設備連接示例

終端器

SDX-1100V/SDX-900V/SDX-800V系列磁帶機

66

安裝

連接 SCSI/SCSI 識別碼設定

後視圖以 SDX-1100V 磁帶機為例。

SCSI ID

210

SCSI ID

0

1

2

3

P.D.

N.C.

3

SCSI 68針腳接頭

4

接線座

5

5 V

6

無連結

SCSI ID 3

SCSI ID 2

同位檢查解除

同位檢查

接通

不接通

SCSI ID 1

SCSI ID 0

10

1

7

8

9

1

12

13

註:

= 關閉/接線

=

打開/未接通接線

14

=

無關聯

15

同位檢查解除接線

同位檢查功能可用接線方式解除。當左邊接線接通時,同位檢查功能將

被解除。不然,一般情況下同位檢查功能一直是開啟的。

電源接頭

1234

GND GND 12 V

67

選擇開關(DIP 開關)

DIP 開關位置

預設值

ON

OFF

12345678

DIP 開關

1DR(故障恢復)模式 (OFF)

2 仿真模式(OFF)

3 AIT 程式庫界面模式(ON)

4保留(OFF)

5 終端器電源 (ON)

6 定期清潔請求(ON)

7 DC 控制 (1) (ON)

8 DC 控制 (2) (OFF)

68

仿真模式 *

若要啟用仿真模式,請將 DIP 開關 2〔仿真模式〕設為 ON 。

ON

OFF

12345678

*

在查詢SDX-1100V系列的產品識別區中,仿真模式返回到以下狀況。

SDX-900V

*

在查詢 SDX-900V 系列的產品識別區中,仿真模式返回到以下狀況。

SDX-700C

*

在查詢 SDX-800V 系列的產品識別區中,仿真模式返回到以下狀況。

SDX-700C

AIT 程式庫界面模式

若要啟用 AIT 程式庫界面模式,請將 DIP 開關 3〔AIT 程式庫界面模式〕

設為 ON 。

ON

OFF

12345678

開關3處於ON時, AIT 程式庫界面模式被啟用。當該開關處於 OFF 時,

ACI 模式被啟用。

終端器電源

要啟用終端器電源,請將 DIP 開關 5〔終端器電源〕開關設為 ON 。

ON

OFF

12345678

69

定期清潔請求模式

若要啟用定期清潔請求模式,請將 DIP 開關 6〔定期清潔請求〕設為

ON 。

ON

OFF

12345678

啟用後,每操作100小時,前面板上的“CLEANING REQUEST” LED 指示

燈均會點亮。

該 LED 指示燈點亮時,請使用清潔帶清潔磁帶機。

註

建議您啟用清潔請求模式,以便在受灰塵和其他汙染物影響的環境中保

持磁帶機的最佳狀態。

資料壓縮控制

資料的壓縮是經由 DIP 開關的選擇。

當 DIP 開關 7〔DC 控制(1)〕撥在 ON 時,啟動資料壓縮的功能。

ON

OFF

12345678

當 DIP 開關 8〔DC 控制(2)〕撥在 ON 時,解除由主電腦控制。

ON

OFF

12345678

70

安裝孔位

以下資料適用於SDX-800V 系列磁帶機。然而其他型號安裝孔的位置是

相同的。

3.5" 標準高度的安裝孔位

(連接器尺寸)

5.25" 高度的安裝孔位

(連接器尺寸)

71

從 5.25" 型號改裝為 3.5" 型號

您可以自己將 5.25" 型號改裝為 3.5" 型號。

1 擰掉兩側側板上的 2 個螺絲。

2 取下側板。

方向

側板(左)

側板(右)

72

10

10

10

10

10 10

10

10

安裝和取下防塵罩

安裝防塵罩

1 將防塵罩的鉸鏈夾(每側各一個)與磁帶機前蓋上的銷針對

準。

• 確定防塵罩的位置,使防塵罩背面的磁鐵 * 面朝磁帶機前蓋。

*

磁鐵不會影響磁帶匣中的磁帶。

• 如下圖所示的某一角度抓住防塵罩,將鉸鏈夾裝在前蓋銷針的

頂端,確定鉸鏈夾的位置使其托住銷針。

2 以某一角度輪流按壓兩側,直至聽見鉸鏈夾到位的“卡嗒”

聲。

注意

不要從正面水平方向擠壓防塵罩,否則會使防塵罩破損。

73

3 關閉防塵罩。

到此結束防塵罩的安裝工作。

取下防塵罩

1 打開防塵罩。

2 抓住防塵罩的兩角,將防塵罩小心抬起。

防塵罩鉸鏈夾和磁帶機前蓋銷針分離。

74

註

建議使用帶有防塵罩的磁帶機。

操作

三個 LED 指示燈的位置

SDX-1100V 、 SDX-900V 和 SDX-800V 系列磁帶機前面面板有三個 LED 指

示燈(TAPE MOTION LED(磁帶運轉指示燈)、 CLEANING REQUEST LED

(請求清潔指示燈)和 REPLACE TAPE LED(更換磁帶指示燈))以及一

個退出鍵 EJECT 。

前面面板

Advanced

Intelligent

Tape

TAPE

MOTION

CLEANING

REQUEST

REPLACE

TAPE

LED

磁帶機 LED 指示燈

LED 指示燈定義如下。

LED

TAPE CLEANING REPLACE

MOTION REQUEST TAPE

無關聯 無關聯 已裝入磁帶

無關聯 無關聯 正在訪問磁帶(寫入/讀取)

無關聯 無關聯 正在訪問磁帶(其他)

無關聯 無關聯 請求清潔

無關聯 無關聯 清潔未完成

無關聯 無關聯 發生介質錯誤

發生 H/W 錯誤

亮

慢

1脈衝(0.9 秒亮 /0.3 秒滅)

快

1脈衝(0.3 秒亮 /0.3 秒滅)

EJECT

意義

75

磁帶機操作

裝入磁帶匣

註

安裝資料磁帶匣時,請勿關閉主電腦的電源。否則會造成故障或損壞資

料。

1 打開主電腦的電源,檢查磁帶機的 TAPE MOTION LED(磁帶運

轉指示燈)、 CLEANING REQUEST LED(請求清潔指示燈)和

REPLACE TAPE LED(更換磁帶指示燈)是否已經熄滅。

2 打開防塵罩。

3 按此處所示的方向安放 AIT 資料磁帶匣,將其插入磁帶匣插

槽。

76

將磁帶匣一直插入,磁帶匣將被自動裝入磁帶機,此時, TAPE

MOTION LED 亮起。

取出磁帶匣

可透過 SCSI Unload 命令或透過按 EJECT 鍵,將磁帶從 SDX-1100V 、

SDX-900V 和 SDX-800V 系列磁帶機中卸載。

按 EJECT 鈕,磁帶倒帶,磁帶匣從插槽中彈出。

磁帶匣寫入保護

將磁帶匣背面的滑動開關撥向箭頭方向,使其進入寫入保護狀態,在這

種狀態下,資料只可以由磁帶讀取而不能寫入。

AIT-5

AIT-4

AIT-3 Ex

AIT-3

AIT-2 Turbo

AIT-1

AIT-2

AIT-1 Turbo

AIT-E Turbo

用指甲將開關推向箭頭所指的方向以防止寫入

或意外刪除資料。

將開關扳回原始位置以恢複寫入功能。

使用清潔磁帶匣

為保持 AIT 磁帶機的最佳狀態,請根據需要使用帶有 AIT 標誌的清潔

磁帶匣清潔磁帶機。磁帶機需要清潔時,CLEANING REQUEST 指示燈會

點亮。(對於 SDX-1100V 、 SDX-900V 和 SDX-800V 系列、請分別使用

SDX-1100V 、 SDX-900V 和 SDX-800V 系列清潔磁帶匣。)

請使用各型號專用的清潔磁帶匣。

應使用的清潔磁帶匣

SDX-1100V SDX5-CL

SDX-900V SDX4-CL 、 SDX4-CLL

SDX-800V SDX3X-CL

77

清潔方法

1 將清潔磁帶匣裝入 AIT 磁帶機。清潔自動開始。

2 SDX-1100V 、 SDX-900V 和 SDX-800V 系列的清潔過程需要數秒

至一分鐘的時間 * ,完成清潔後帶匣會自動彈出。

* 清潔時間因磁帶機的狀況而異。

注意

請勿重繞清潔磁帶匣並重新使用。磁帶匣到頭時,請將其丟棄並購

買帶有 AIT 標誌的新的清潔磁帶匣。

存儲須知

• 未放入磁帶機時,請將磁帶匣放在盒內。

• 避免在多塵、陽光直射處、加熱器或空調附近、或潮濕處存放磁帶

匣。

• 請勿將磁帶匣放置在儀表板或汽車儲存箱內。

78

緊急取出磁帶的步驟

1 將磁帶機自機座取出或移除外殼取出磁帶機,以便可以對磁帶

機底部進行處理。

2 移開磁帶機的上蓋。

3 找到磁帶機底部一處小的開孔,插入精密螺絲起子轉動載入馬

達中心軸。

4 順時針方向轉動馬達中心軸,帶動導帶機械裝置退回原始位

置。

導帶馬達

載入馬達

緊急取出磁帶的步驟

79

注意

當 Guide B 處於線 C-C(註︰線 C-C 由磁帶匣內的兩個循環帶引導

表面而定義)以下區域時,立即停止馬達的旋轉,否則會損壞磁帶

機的齒輪。

A

磁帶引導表面 磁帶引導表面

CC

詳圖 A

Guide B

磁帶匣

導帶機械裝置的原始位置

5 在手動退出磁帶之前,必須將磁帶鬆弛部份拉緊,防止磁帶損

壞。逆時針方向轉動磁帶機底部的傳動裝置,將磁帶繃緊。

6 在繃緊磁帶後,繼續用精密螺絲起子順時針方向轉動磁帶機底

部的載入馬達中心軸,直到磁帶匣在磁帶機內被升起並退出。

7 將磁帶機送回 Sony 修理。

80

界面應用

支援的 SCSI 訊息

Abort

Target Reset

Command Complete

Disconnect

Extended Message

– Synchronous Data Transfer

Request

– Wide Data Transfer Request

– Parallel Protocol Request

支援的 SCSI 指令

Erase

Inquiry

Load/Unload

Locate

Log Sense

Log Select

Mode Select (6)

Mode Select (10)

Mode Sense (6)

Mode Sense (10)

Persistent Reserve In

Persistent Reserve Out

Prevent Allow Medium

Removal

Read

Read Attribute

Read Block Limits

Read Buffer

Read Position

Receive Diagnostic Result

Release (6)

Release (10)

Identify

Ignore Wide Residue

Message Parity Error

Message Reject

No Operation

Report Density Support

Report Device Identifier

Report Luns

Request Sense

Reserve (6)

Reserve (10)

Rewind

Send Diagnostic

Set Device Identifier

Space

Test Unit Ready

Write

Write Attribute

Write Buffer

Write Filemarks

81

規格

產品規格

體積 (不含前蓋和突出部位)

3.5" 5.25"

高度 41.2 mm (1.62 in) 41.2 mm (1.62 in)

寬度 101.6 mm (4.0 in) 146.0 mm (5.75 in)

厚度 155.0 mm (6.1 in) 155.0 mm (6.1 in)

重量

SDX-1100V

3.5" 0.8 kg (28.2 oz.)

5.25" 1.1 kg (38.8 oz.)

SDX-900V 、 SDX-800V

3.5" 780 g (27.5 oz.)

5.25" 1010 g (35.6 oz.)

高度

工作中 0 至 3048 m

振動

工作時 正弦掃頻 5 至 500 Hz

*0.25 G 峰值 1 倍頻程 / 分鐘

3 軸、 3 方向

不工作 正弦掃頻 5 至 500 Hz

*0.5 G 峰值 1 倍頻程 / 分鐘

3軸、3方向

噪音 (A) A 曲線計權聲壓級

流寫入 / 讀取 小於 35 dB (A)

裝入 / 彈出 小於 60 dB (A)

註

(A)分貝級聲級表位於磁帶機前面板中央前方 1 m 處。

82

震動

工作時 無資料損失

不工作 無設備損失

半正弦

性能

5 G 峰值 3 毫秒

3軸、3方向

*10 秒間隔

半正弦

90 G 峰值 3 毫秒

(30 G 峰值 11 毫秒)

3軸、3方向

*10 秒間隔

溫度和濕度範圍

溫度

工作中 5 ℃到 40 ℃(溫度變化 <10 ℃/h)

未工作中(機械結構) -40 ℃到 70 ℃(溫度變化 <20 ℃/h)

未工作中(磁帶) -40 ℃到 45 ℃(溫度變化 < 20 ℃/h)

濕度

工作中 20 到 80% RH ,不結霜

最大濕球溫度﹕26 ℃

未工作中(機械結構) 5 到 95% RH(濕度變化 < 30%/h)

最大濕球溫度﹕45 ℃

未工作中(磁帶) 20 到 80% RH(濕度變化 < 30%/h)

空氣冷卻要求

環境溫度 < 40 ℃

為將資料丟失的可能性降至最低限度,建議在清新流動的空氣環境中使用。

電源要求

SDX-1100V

電壓 最大漣波

5 V +/– 5% 100 mVp-p 1.7 A 2.5 A

12 V +/– 10% 150 mVp-p 0.87 A 3.0 A

SDX-900V 、 SDX-800V

電壓 最大漣波

5 V +/– 5% 100 mVp-p 1.5 A 2.5 A

12 V +/– 10% 150 mVp-p 0.75 A 3.0 A

常態 最大

常態 最大

電流

電流

83

客戶聯繫

如需進一步相關訊息,請參考以下網址:

Sony Electronics Inc., Tape Storage Solutions (USA)

URL: http://www.storagebysony.com

Sony of Canada Ltd., AV/IT Marketing Group

Computer Peripherals Product Marketing

115 Gordon Baker Road Toronto, Ontario, M2H 3R6 Canada

TEL: (416) 499-1414 or (1) 800-961-7669

FAX: (416) 499-8541

Sony Business Europe

URL: http://www.sonyisstorage.com/

Electronics Devices Marketing (Singapore)

(A division company of Sony Electronics (S) Pte. Ltd.)

Enterprise Storage Solutions Dept.

2 International Business Park, #01-10 Tower One, The Strategy,

Singapore 609930

TEL: 65-6544-8000 FAX: 65-6544-7390

Sony Corporation of Hong Kong Ltd.

Computer Peripheral Sales & Marketing Division

Electronic Devices Marketing Hong Kong

45/F, The Lee Gardens, 33 Hysan Avenue, Causeway Bay, Hong Kong

TEL: (852) 2909-1008 FAX: (852) 2909-2001

Sony Corporation of Hong Kong Ltd. Beijing Rep. Office

Computer Peripheral Div.

Full Link Plaza Tower A 11/F., No.18 Chaoyangmenwai Ave., Beijing

100020 P.R.C.

TEL: 86-10-6588-0633 FAX: 86-10-6588-0855

URL: http://www.sony.com.cn/ed/cp/ait/

Sony Corporation of Hong Kong Ltd.,

Electronic Devices Marketing Hong Kong

Computer Peripherals Sales & Marketing Div.

8/F, One Corporate Avenue, 222 Hu Bin Road. Luwan District,

Shanghai. P.R.C. Postcode 200021

TEL: 86-21-6121-6878

URL: http://www.sony.com.cn/ed/cp/ait/

84

Sony Brasil Ltda.

Rua Inocéncio Tobias, 125, Barra Funda

São Paulo-SP, Brasil 01144-000

TEL: (55) 11-2196-9000 FAX: (55) 11-2196-9186

URL: http://www.sonybrasil.com.br

Sony Australia Limited

33-39 Talavera Rd.

NORTH RYDE, NSW 2113

TEL: 1300-13-7669 FAX: 02-9870-5864

e-mail: CIC-customerissues@ap.sony.com

Sony New Zealand

Akoranga Business Park

NORTH SHORE, AUCKLAND

TEL: 0800-76-6969 FAX: 09-308-9300

e-mail: CIC-customerissues@ap.sony.com

Sony Chile Ltda

Av. Kennedy 8017, Las Condes, Santiago, Chile

TEL: (02) 210-6000 FAX: (02) 210-5417

Sony Taiwan Limited

Optical Devices Storage Dept. Data Storage Section

5F, 145 Changchun Road, Taipei 104, Taiwan

TEL: 886-2-2522-7920 FAX: 886-2-2522-2153

Sony Korea Corporation EDMK CP Sales & Marketing Team

34F, ASEM Tower, World Trade Center, 159-1, Samsung-Dong,

Kangnam-Ku, Seoul, 135-798, Korea

TEL: 82-2-6001-4249 FAX: 82-2-6001-4115

URL: http://www.sony.co.kr/cp/

Sony Gulf FZE Computer Display & Peripheral Div.

P.O.BOX 16871, Jebel Ali, Dubai, U.A.E.

TEL: 971-4-8815488 or 8816912 FAX: 971-4-8817210 or 8816259

Sony Marketing of Japan

Business Solution Dept. Server Solution Marketing Section

URL: http://www.sony.co.jp/STORAGE

85

86

87

Printed in Japan

Loading...

Loading...