Page 1

AIT Drive

User’s Guide

GB

CT

SDX-420C/R

Page 2

This document contains proprietary

information which is protected by

copyright.

All rights reserved. No part of this

document may be photocopied,

reproduced or translated to another

language without prior written consent

of Acer.

The information contained in this

document is subject to change without

notice.

Acer MAKES NO WARRANTY OF

ANY KIND WITH REGARD TO

THIS DOCUMENT.

Acer shall not be liable for error

contained herein, indirect, special,

incidental or consequential damages in

connection with the furnishing,

performance or use of this document.

VORSICHT

Diese Ausrüstung erfüllt die

Europäischen EMC-Bestimmungen für

die Verwendung in folgender /

folgenden Umgebung(en):

• Wohngegenden

• Gewerbegebiete

• Leichtindustriegebiete

(Diese Ausrüstung erfüllt die

Bestimmungen der Norm EN55022,

Klasse B.)

Contents

Introduction ....................................... 4

Product Features ........................4

Precautions ................................5

Installation ......................................... 6

Jumper Setting...........................6

Option Switches (DIP Switch) ..7

Mounting Holes........................8

Orientation.................................9

Operation .........................................10

Location of 3 LEDs .................10

LED Indication for Drive

Status ...................................11

Drive Operation....................... 12

Emergency Tape Removal

Procedure .............................13

Interface Implementation................. 16

Supported ATA Commands ....16

Supported ATAPI Packet

Commands ...........................16

Specification ....................................17

Product Specifications............. 17

Acer Contact ....................................19

2

Page 3

SDX-420C/R Tape Drive

The SDX-420C/R drive is a high capacity data storage device using

Advanced Intelligent tape AIT (Advanced Intelligent Tape) technology.

The SDX-420C/R drive achieves high data reliability through Read-AfterWrite, an additional level of Error Correction Code, and other features.

The SDX-420C/R drive stores data on tape using a standard format called

AIT and ALDC formats.

GB

3

Page 4

Introduction

Product Features

SDX-420C/R series

Data Capacity

Transfer Rate

(sustained)

* This is assuming 2.6 : 1 compression ratio.

• Supported Format : AIT-1 (SDX-420C/R)

• Burst Transfer Rate 66 MBytes/sec Ultra DMA (mode 4)

• Large 10 MByte Buffer Memory

• 5.25” Half Height

• ATA/ATAPI-5 Interface

• Support Fixed Record Length Only

• Frame Rewrite Function

• Three levels of Error Correction Code (ECC)

• High Speed search (120 times normal Read/Write speed)

• Random Read, Append Write

35 GByte uncompressed

(with AIT-1 230 m tape)

91 GByte compressed *

(with AIT-1 230 m tape)

4 MByte/sec uncompressed

10.4 MByte/sec compressed *

4

Page 5

Precautions

Installation

Avoid placing the drive in a location subject to:

– high humidity

– high temperature

– mechanical shock and vibration

– direct sunlight

Operation

• Do not move the drive while it is operating. It may cause malfunction.

• Avoid exposing the drive to sudden changes from a low to high in

temperature. This may cause water condensation to collect inside the

drive. If the ambient temperature should suddenly rise while the drive is

turned on , wait at least one hour before turning on the drive. If you

attempt to operate the drive immediately after a sudden increase in

temperature, a malfunction may occur.

• Turning off the power to the drive while it is writing to tape may cause

the tape to become unreadable. All previously negotiated parameters will

be lost, whenever power to the drive is cycled.

Transportation

• Keep the original packing materials to facilitate transportation of the

drive.

• Always remove the tape before moving the drive. After removing the

drive from the computer, repack the drive into its original packing.

5

Page 6

Installation

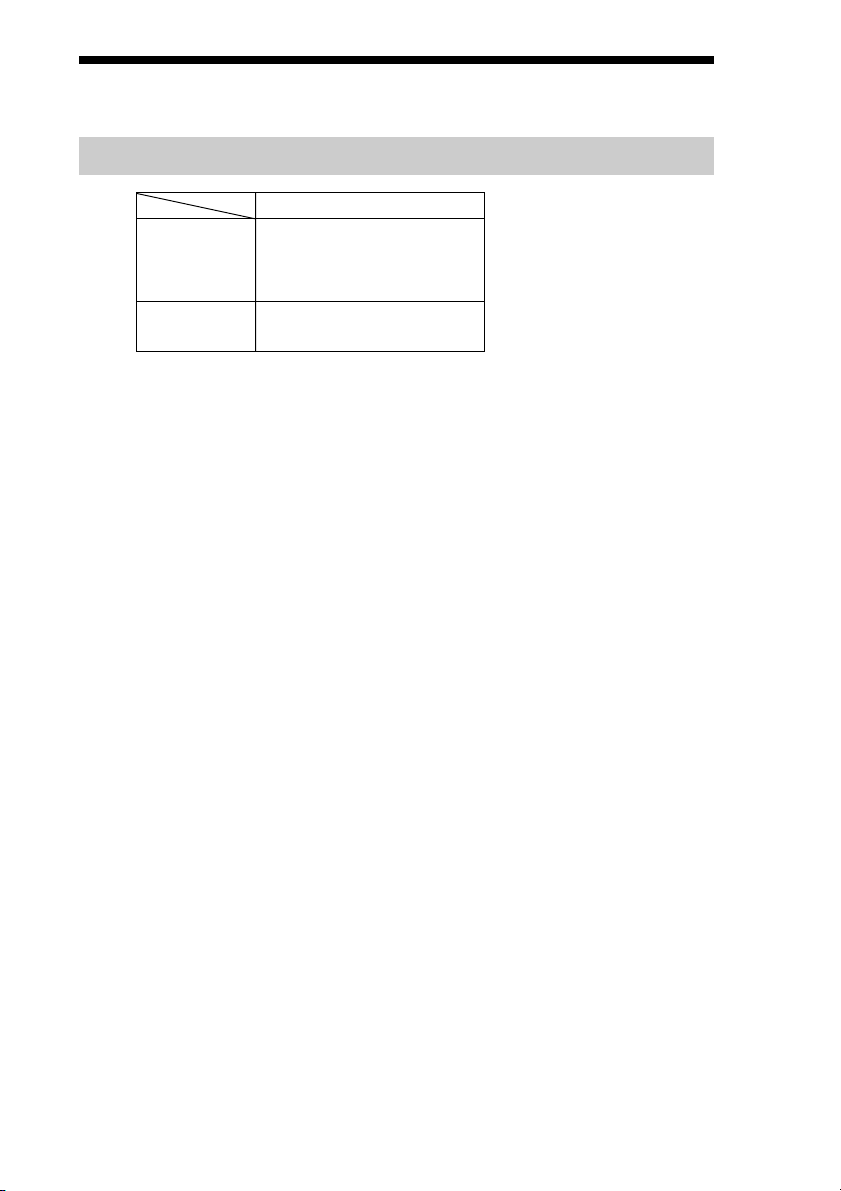

Jumper Setting

IDE Interface Connector

Master

Slave

Cable Select

No Connection

Jumpers Drive Setting

Master

Slave

Cable Select

Power Connector

4 3 2 1

5V GND GND 12V

6

Page 7

Option Switches (DIP Switch)

DIP Switch Positions

DIP Switch

ON

12345678

1 Reserved (OFF)

2 Reserved (OFF)

3 Reserved (OFF)

4 Reserved (OFF)

5 Reserved (OFF)

6 Reserved (OFF)

7 DC Control (1) (ON)

8 DC Control (2) (OFF)

Data Compression Control DIP switch

Data compression can be selected by DIP switches. Data compression is

enabled while position 7 [DC Control (1)] is ON. Control by host can be

disabled when position 8 [DC Control (2)] is ON.

7

Page 8

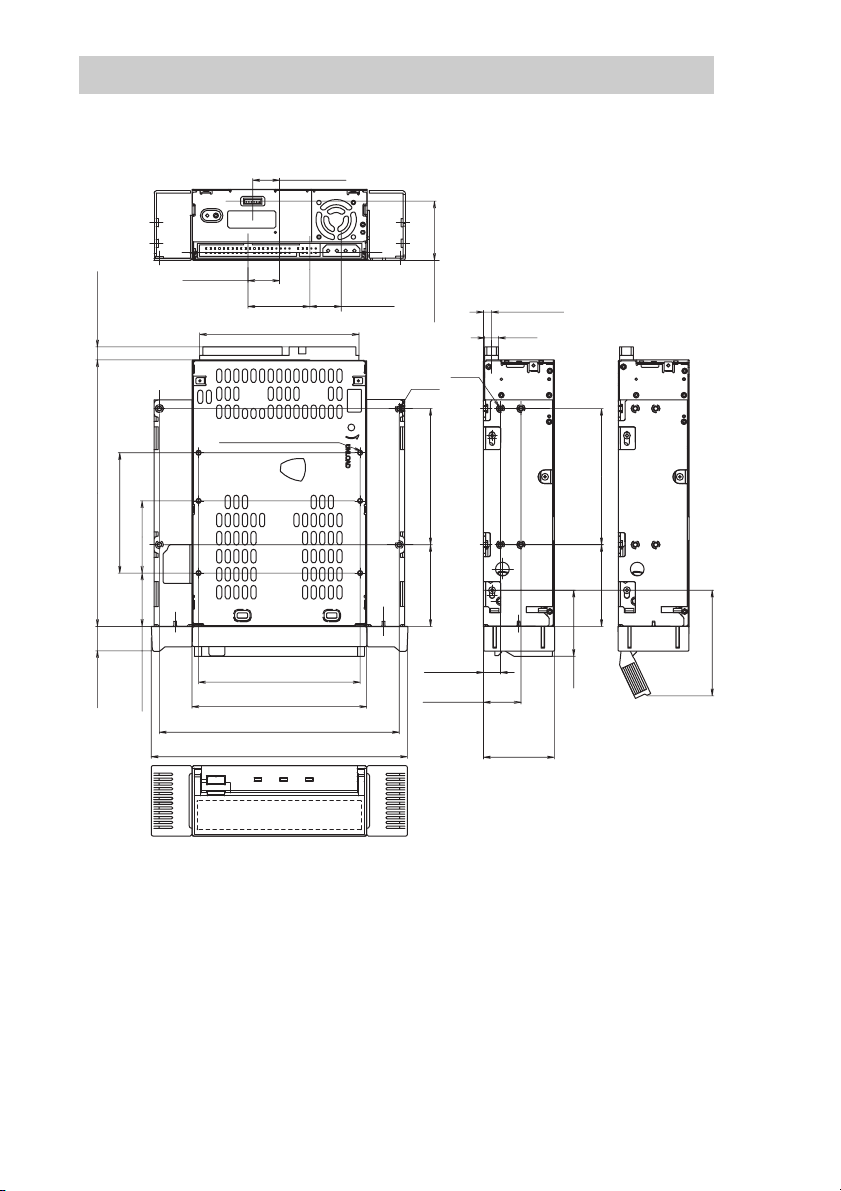

Mounting Holes

For 5.25" Half Height (SDX-420C/R)

15.6 ±0.5 mm

[0.61" ±0.02"]

18.4 ±0.5 mm

7.6 ±0.5 mm

[0.3" ±0.02"]

[6.1" ±0.02"]

155.0 ±0.5 mm

70.0 ±0.3 mm

[2.76" ±0.01"]

42.0 ±0.3 mm

[1.65" ±0.01"]

[0.72" ±0.02"]

35.9 ±0.5 mm

[1.41" ±0.02"]

92.71 mm

[3.65"]

6-M3(depth 2.5mm (0.10") max.)

18.2 ±0.5 mm

[0.72" ±0.02"]

4-M3

0.3 mm

±

79.2

34.3 ±0.5 mm

[1.35" ±0.02"]

[3.12" ±0.01"]

4-3M

4.7 ±0.5 mm

[0.19" ±0.02"]

8 mm

[0.31"]

P

P

P

P

P

79.2 ±0.3 mm

[3.12" ±0.01"]

P

P

P

8

[0.56" ±0.01"]

14.4 ±0.3 mm

31.0 ±0.3 mm

[1.22" ±0.01"]

94.0 ±0.3 mm

[3.7" ±0.01"]

101.6 ±0.5 mm

[4" ±0.02"]

139.6 ±0.5 mm

[5.5" ±0.02"]

149.0 ±0.5 mm

[5.87" ±0.02"]

47.5 ±0.3 mm

[1.87" ±0.01"]

9.9 ±0.5 mm

[0.39" ±0.02"]

21.8 ±0.5 mm

[0.86" ±0.02"]

41.2 ±0.5 mm

[1.62" ±0.02"]

[1.51"]

38.4 mm

47.5 ±0.3 mm

[1.87" ±0.01"]

[2.54" ±0.01"]

62.4 ±0.3 mm

Page 9

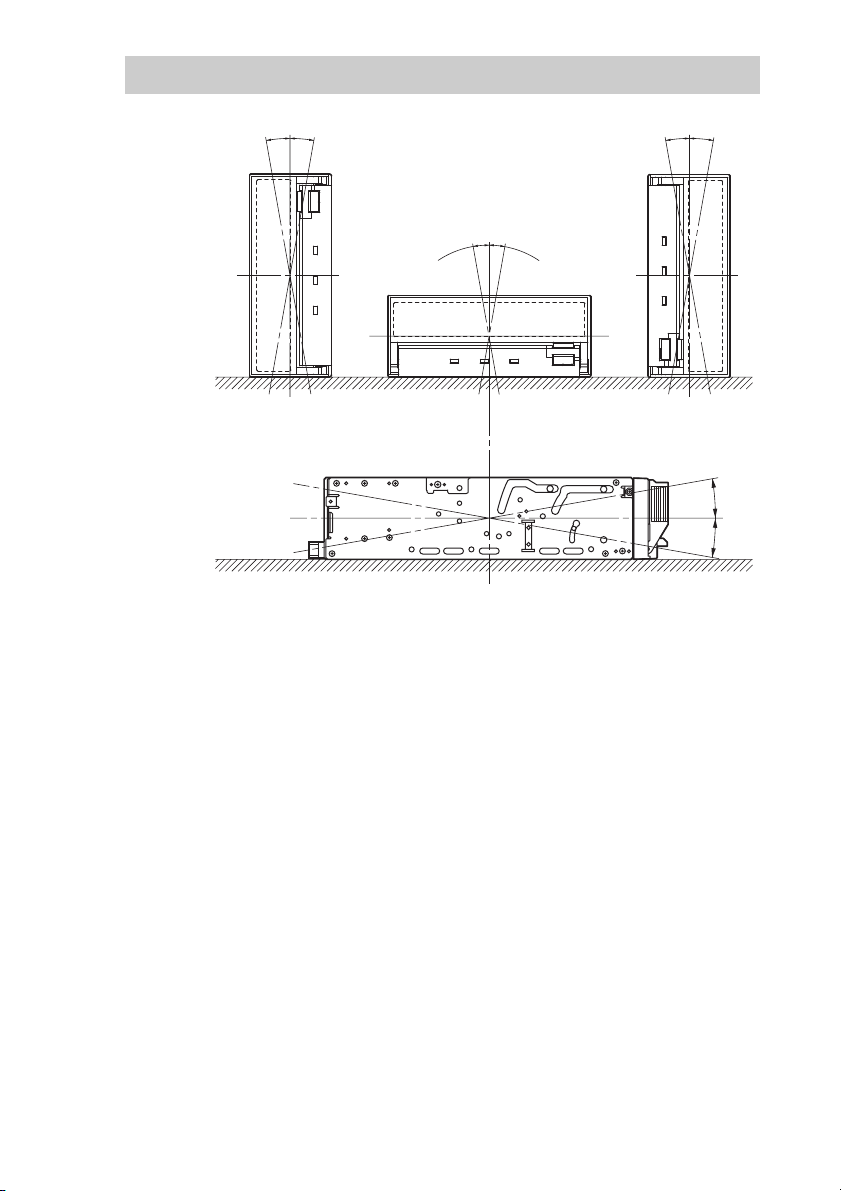

Orientation

10°

10° 10° 10°

10°

10°

10°

10°

9

Page 10

Operation

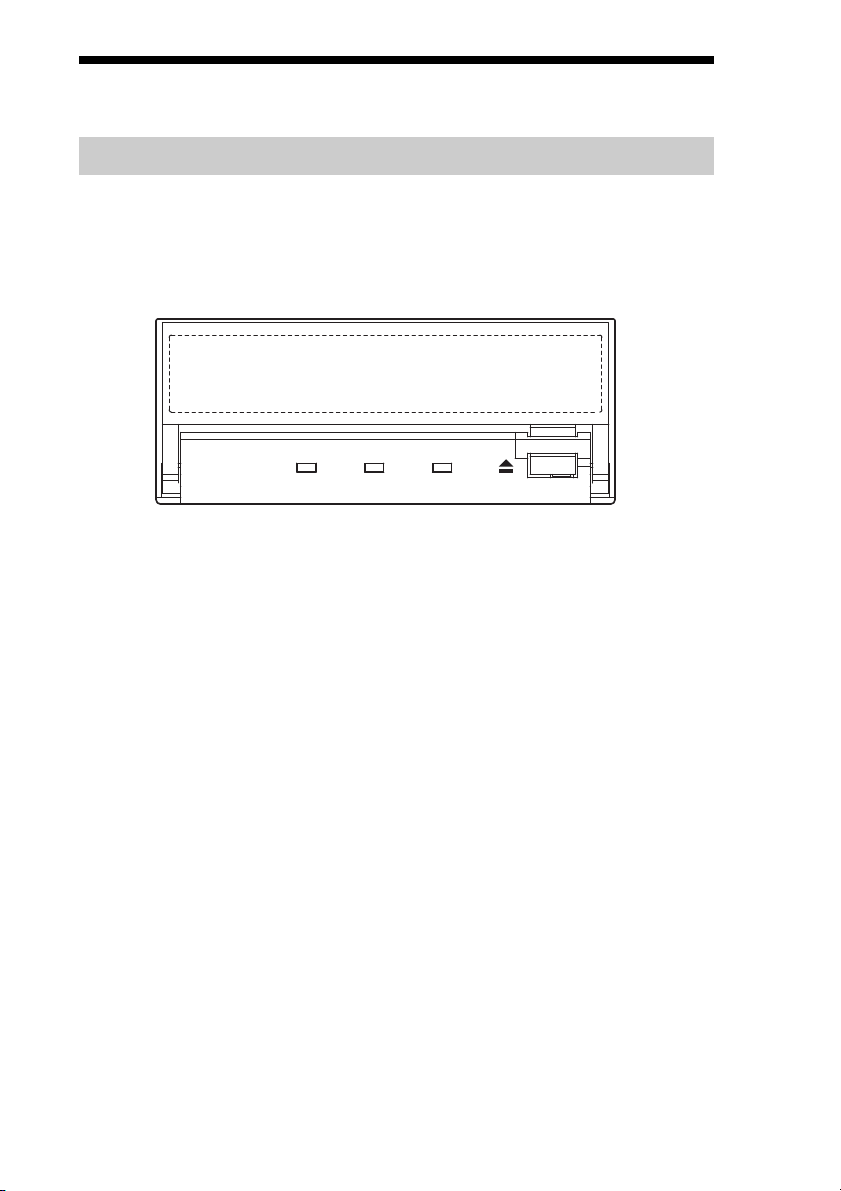

Location of 3 LEDs

There are three LED indications (BUSY,TAPE and STATUS) and an

EJECT button on the front panel of the unit.

Front Panel (for 3.5" Standard Height)

Advanced

Intelligent

Tape

BUSY TAPE STATUS

BUSY TAPE S TATU S

10

Page 11

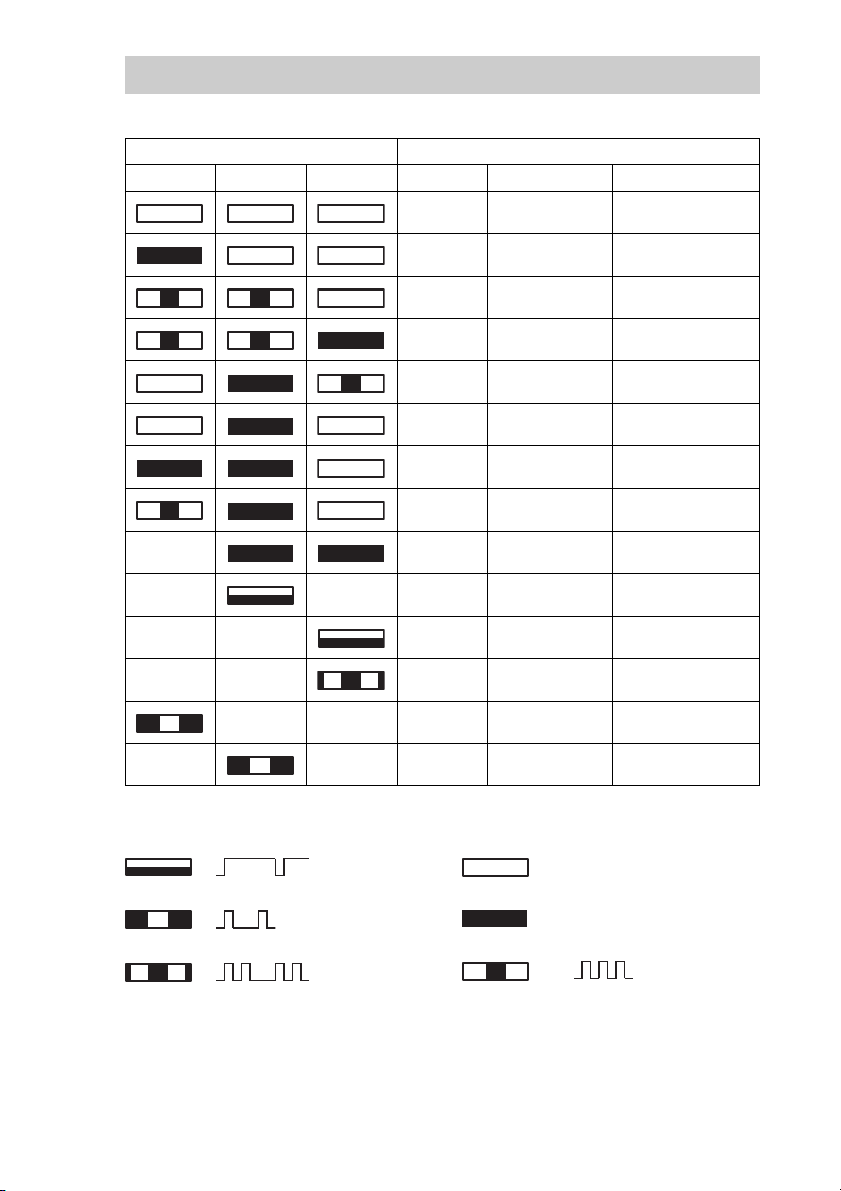

LED Indication for Drive Status

The LED indicators are defined as follows.

LED State

BUSY TAPE STATUS Activity Cartridge Other

None None None

IDE None None

Drive

Drive

None Loaded

None Loaded None

IDE Loaded None

IDE/Drive Loaded None

Independent ✽ Loaded Write Protected

Independent Independent ✽ Loaded Error Rate Warning

✽✽ ✽✽Cleaning Request

✽✽ ✽✽Self test Failure

✽✽✽ ✽Waiting for Reset

✽ ✽✽ ✽Waiting for Eject

1 pulse (3.5 sec on / 0.5 sec off)

1 pulse (0.25 sec on)

Loading/Unloading

Loading/Unloading

off

on

None

Write Protected

Cleaning Tape at EOM

✽ : Not defined.

2 pulses (0.25 sec on/0.5 sec off)

1 pulse (0.25 sec on / 0.25 sec off)

11

Page 12

Drive Operation

Loading a Tape

Insert a cassette into the slot on the front panel with the arrow on the

cassette pointing towards the drive. As the cassette is inserted, the drive

takes it and automatically loads it into drive mechanism.

Unloading a Tape

The cassette can be removed from the SDX-420C/R either in response to a

ATAPI Packet Unload Command, or by pressing the eject bottom.

By pressing Eject button, the tape goes to BOT, the drive unthreads it, and

ejects the cassette from the slot.

Write-protecting a Tape

Cassettes can be write-protected by sliding the tab on the back of the

cassette. In this state, data can be read from the tape but not written onto it.

AIT-1

Using your fingernail, push the switch in the

direction of the arrow to protect the tape from

writing or accidental erasure.

Return the switch to its original position to

re-enable writing.

Using a Cleaning Cassette

In case of SDX-420C/R, a cleaning function is built in the drive and hence,

a periodic cleaning using cleaning cassette such as other format requires is

not necessary. However, when the drive does not recover at the worst case,

cleaning cassette is recommended to use.

12

Page 13

Emergency Tape Removal Procedure

1 Remove the drive from the chassis or enclosure to allow

access to the bottom and right side of the drive.

2 Remove the drive’s top cover.

3 Locate the small opening in the bottom of the drive and

insert the tip of a precision screwdriver so that the Threading

motor shaft can be rotated.

4 Rotate the motor shaft counterclockwise to bring the

threading mechanism back to the initial position. (Refer to

the photo-1 on page 15.)

5 Before manual eject procedure, tape slack must be removed

in order to prevent tape damage. Press and rotate the gear

mechanism located on the right side of the drive clockwise to

tighten the tape.

6 After the tape slack has been removed, turn the screw

located on the right side of the drive clockwise by a precision

screwdriver until the tape cartridge is lifted out of the drive

mechanism and is ejected.

13

Page 14

7 Return the drive to Acer for repair.

3. Cassette Compartment Motor

2. Reel Motor

14

1. Loading Motor

Page 15

A

tape guide surface

tape guide surface

C

B

Photo-1: The Initial Position of the Threading Mechanism

Caution

Stop rotating the motor shaft immediately, when the guide B (see detail A of Photo-1)

gets to the area below the line C-C (This line is defined by 2 circular tape guide surfaces

of the cartridge). Otherwise the gear of the drive can be damaged.

detail A

Cartridge

C

15

Page 16

Interface Implementation

Supported ATA Commands

ATA commands supported:

– ATAPI SOFT RESET (0x08)

– EXECUTE DRIVE DIAGNOSTIC (0x90)

– ATAPI PACKET COMMAND (0xA0)

– ATAPI IDENTIFY DEVICE (0xA1)

– STANDBY IMMEDIATE (0xE0)

– IDLE IMMEDIATE (0xE1)

– CHECK POWER MODE (0xE5)

– SLEEP (0xE6)

– SET FEATURE (0xEF)

Supported ATAPI Packet Commands

Mandatory ATAPI command set:

Supporting most of all SCSI commands in SDX-400C

– ERASE

– INQUIRY

– LOAD/UNLOAD

– LOCATE

– LOG SELECT

– LOG SENSE

– MODE SELECT

– MODE SENSE

– READ

– READ POSITION

– REQUEST SENSE

– REWIND

– SPACE

– TEST UNIT READY

– WRITE

– WRITE FILEMARK

– WRITE BUFFER

16

Page 17

Specification

Product Specifications

Dimensions

SDX-420C/R

Height 41.2 mm (1.62 in)

Width 149.0 mm (5.87 in)

Depth 155.0 mm (6.1 in)

Altitude

Operating 0 to 10,000 feet

Vibration

Operating Swept Sine 5 to 500 Hz

Non-Operating Swept Sine 5 to 500 Hz

Acoustic Noise (A) curve weight

Streaming Write/Read 35 db (A)

Insert/Eject 60 db (A)

*0.25 G Peak 1 Octave/min.

*0.5 G Peak 1 Octave/min.

3 axes, 3 directions

Note

The sound-meter on (A) scale is located 1m in front of

the center of the drive front panel.

Shock

Operating No Data Loss

Half Sine

Performance

5 G Peak 3 ms

3 axes, 3 directions

*Interval 10 seconds

Non-Operating No Device Damage

Half Sine

90 G Peak 3 ms

(30 G Peak 11 ms)

3 axes, 3 directions

17

Page 18

Temperature and Humidity Range

Temperature

Operating 5 ˚C to 40 ˚C (∆T<10 ˚C/h)

Non-Operating (mech.) – 40 ˚C to 70 ˚C (∆T<20 ˚C/h)

Non-Operating (tape) – 40 ˚C to 45 ˚C (∆T<20 ˚C/h)

Humidity

Operating 20 to 80% RH, non-condensing

Maximum wet bulb temperature = 26 ˚C

Non-Operating (mech.) 5 to 95% RH (∆T<30%/h)

Non-Operating (tape) 20 to 80% RH (∆T<30%/h)

Power Requirements

Model Voltage Max Ripple

SDX-420C/R

5 V +/– 5 % 100 mVp-p 1.4 A 2.5 A

12 V +/– 10 % 150 mVp-p 0.45 A 1.2 A

Suspended Particulate

Operating

Less than 150 microgram/m

Based Sampling period 24 hours

3

ESD

Discharge < 15 kV: No operation failure

Voltage < 20 kV: No drive damage

Current

Typical Maximum

Air-cooling Requirement

Surrounding temperature < 40 ˚C

Clean air flow is recommended to minimize the possibility of data loss.

18

Page 19

Acer Contact

For further information, please contact:

http://csd.acer.com.tw/

19

Page 20

This document contains proprietary

information which is protected by

copyright.

All rights reserved. No part of this

document may be photocopied,

reproduced or translated to another

language without prior written consent

of Acer.

The information contained in this

document is subject to change without

notice.

Acer MAKES NO WARRANTY OF

ANY KIND WITH REGARD TO

THIS DOCUMENT.

Acer shall not be liable for error

contained herein, indirect, special,

incidental or consequential damages in

connection with the furnishing,

performance or use of this document.

VORSICHT

Diese Ausrüstung erfüllt die

Europäischen EMC-Bestimmungen für

die Verwendung in folgender /

folgenden Umgebung(en):

•Wohngegenden

• Gewerbegebiete

• Leichtindustriegebiete

(Diese Ausrüstung erfüllt die

Bestimmungen der Norm EN55022,

Klasse B.)

目錄

介紹 ........................22

產品特性 ................ 22

防護措施 ................ 23

安裝 ........................24

IDE 連接及設定 Jumpers ... 24

選擇開關(DIP Switch) .... 25

安裝孔位 ................ 26

方向 .................... 27

操作 ........................28

三個 LED 指示燈的位置 ....28

指示燈號的意義 .......... 29

磁帶機操作 .............. 30

緊急取出卡帶的步驟 ...... 31

界面執行 ....................34

支持的 ATA 命令 ..........34

支持的 ATAPI Packet 命令 . 34

規格 ........................35

產品規格 ................ 35

客戶聯繫 ....................37

20

Page 21

SDX-420C/R 磁帶機

SDX-420 系列磁帶機是一使用 AIT(Advanced Intelligent Tape)科技

的高容量資料儲存裝置。SDX-420C/R 磁帶機經由先寫入後讀取,錯誤

更正編碼的額位水準和其他特徵而達到高資料可靠性。

SDX-420C/R 系列磁帶機儲存資料在一標準格式化稱為 AIT 和 ALDC 格式

的磁帶上。

CT

21

Page 22

介紹

產品特性

SDX-420C/R *

資料儲存容量

傳輸速率

(持續的)

* 資料壓縮功能也適用在 SDX-420C/R 機種。

• 支援格式:AIT-1

• 不相容 DDS 和 EXABYTE 格式磁帶

• 瞬間傳輸速率

–

16.6MB/sec(PIO 模式 4)

–

66MB/sec(DMA 模式 4)

• 大的 10MB 的緩衝記憶體

• 5.25”外型

l

tra DMA66-ATAPI

• U

• 支援可變的或固定的記錄長度

• 先寫入後讀取的功能(RAW),可選用開或關

• 讀取重試可選用開或關

• 資料框重寫功能

• 3 段錯誤改正碼判定(EEC)

• 高速搜尋(一般讀 / 寫速度 120 倍)

• 隨機讀取,添加寫入

35 G 位元組容量(AIT-1 230m 磁帶)

(使用資料壓縮,大約 70 G ∼ 105 G 位元組)

每秒 4 M 位元組

(使用資料壓縮,大約每秒 8 M ∼ 12 M 位元組)

22

Page 23

防護措施

安裝

請勿將磁帶機置於下列場所:

–

高濕度區

–

高溫區

–

有機械衝擊和振動地方

–

陽光直射

操作

• 當磁帶機運作時,請勿移動,否則可能會導致故障發生。

• 避免將磁帶機曝露於溫度突然由低變高的環境,否則可能會造成磁帶

機內部凝結水氣。 如果周圍溫度突然上升而要啟動磁帶機,請在啟

動磁帶機之前要等待至少一小時。 如果你在溫度突然增加之後立即

嘗試操作磁帶機可能會造成故障。

• 若在磁帶正在寫入時關閉電源,可能導致磁帶無法讀取,所有之前寫

入的資料將會遺失,無論何時 , 磁帶機的電源是有週期性的。

運送

• 請保留原始的包裝材料,以備日後磁帶機的運送。

• 在移動磁帶機之前,請先取出磁帶。將磁帶機由電腦內取出後,再裝

於原始的包裝箱內。

23

Page 24

安裝

IDE 連接及設定 Jumpers

IDE 40pin 連接頭

IDE Interface Connector

Jumpers Drive Setting

Master

Slave

Cable Select

No Connection

電源接頭

Power Connector

4 3 2 1

24

Master

5V GND GND 12V

Slave

Cable Select

Page 25

選擇開關(DIP Switch)

DIP 開關位置

DIP Switch

DIP 開關

ON

12345678

1 Reserved (OFF)

2 Reserved (OFF)

3 Reserved (OFF)

4 Reserved (OFF)

5 Reserved (OFF)

6 Reserved (OFF)

7 DC Control (1) (ON)

8 DC Control (2) (OFF)

資料壓縮控制 DIP 開關

資料的壓縮是經由 DIP 開關的選擇,當 DIP 開關的位置“7”撥在“ON”

時,為啟動資料壓縮的功能,若 DIP 開關的位置“8”撥在“ON”時,

則為解除了被主電腦控制。

25

Page 26

安裝孔位

5.25”標準高度(SDX-420C/R)的安裝孔位

15.6 ±0.5 mm

[0.61" ±0.02"]

18.4 ±0.5 mm

7.6 ±0.5 mm

[0.3" ±0.02"]

[6.1" ±0.02"]

155.0 ±0.5 mm

70.0 ±0.3 mm

[2.76" ±0.01"]

42.0 ±0.3 mm

[1.65" ±0.01"]

[0.72" ±0.02"]

35.9 ±0.5 mm

[1.41" ±0.02"]

92.71 mm

[3.65"]

6-M3(depth 2.5mm (0.10") max.)

18.2 ±0.5 mm

[0.72" ±0.02"]

34.3 ±0.5 mm

4-M3

0.3 mm

±

79.2

[1.35" ±0.02"]

[3.12" ±0.01"]

4-3M

4.7 ±0.5 mm

[0.19" ±0.02"]

8 mm

[0.31"]

P

P

P

P

P

79.2 ±0.3 mm

[3.12" ±0.01"]

P

P

P

14.4 ±0.3 mm

26

[0.56" ±0.01"]

31.0 ±0.3 mm

[1.22" ±0.01"]

94.0 ±0.3 mm

[3.7" ±0.01"]

101.6 ±0.5 mm

[4" ±0.02"]

139.6 ±0.5 mm

[5.5" ±0.02"]

149.0 ±0.5 mm

[5.87" ±0.02"]

47.5 ±0.3 mm

[1.87" ±0.01"]

9.9 ±0.5 mm

[0.39" ±0.02"]

21.8 ±0.5 mm

[0.86" ±0.02"]

41.2 ±0.5 mm

[1.62" ±0.02"]

[1.51"]

38.4 mm

47.5 ±0.3 mm

[1.87" ±0.01"]

[2.54" ±0.01"]

62.4 ±0.3 mm

Page 27

方向

10°

10° 10° 10°

10°

10°

10°

10°

27

Page 28

操作

三個 LED 指示燈的位置

前面面板有三個 LED 指示燈(運轉 -BUSY ,磁帶 -TAPE 和狀態 -STATUS)

和一個退出鍵 EJECT 。

3.5”標準高度的前面面板

Advanced

Intelligent

Tape

BUSY TAP E S TATU S

BUSY TAPE STATU S

28

Page 29

指示燈號的意義

LED 意義

BUSY TAPE STATUS 執行 磁帶匣 其他

無無 無

SCSI 無 無

驅動 上帶/未上帶 無

驅動 上帶/未上帶 寫入保護

無 已上帶 清潔中

無 已上帶 無

SCSI 已上帶 無

SCSI/驅動 已上帶 無

無關聯

無關聯 無關聯

*

*

已上帶 寫入保護

已上帶 錯誤速率警告

** **

** **

*** *

* ** *

表內“*”:表沒有定義

滅

3.5秒亮/0.5秒滅

亮

每一次亮0.25秒

0.25秒亮/0.5秒滅(兩次)

0.25秒亮/0.25秒滅

要求清潔

自我測試失敗

等待重置

等待退帶

29

Page 30

磁帶機操作

裝入卡帶

將卡帶上的箭頭朝向磁帶機,插入卡帶,當卡帶被插入時,磁帶機會自

動載入卡帶。

取出卡帶

按下退出鍵可從 SDX-420C/R 取出卡帶。

按下退出鍵,磁帶進入 BOT ,磁帶機導出卡帶,並從插槽退出卡帶。

卡帶寫入保護

將卡帶背面的滑動開關撥向箭頭方向,使其進入寫入保護狀態,在這種

狀態下,資料只可以由磁帶讀取而不能寫入。

AIT-1

Using your fingernail, push the switch in the

用指甲將開關推向箭頭所指的方向以防止寫入

direction of the arrow to protect the tape from

或意外刪除資料。

writing or accidental erasure.

Return the switch to its original position to

將開關扳回原來位置以恢復寫入功能。

re-enable writing.

使用清潔卡匣

SDX-420C/R ,清潔功能建立在磁帶機內,因此,定期使用清潔匣去清

潔或其他要求是不需要的。但是然磁帶機在最差的情況下,仍無法恢復

原有功能,此時建議使用清潔帶。

30

Page 31

緊急取出卡帶的步驟

1 將磁帶機自機座取出或移除外殼取出磁帶機,使磁帶機底部和

右側容易做調整處理。

2 移開磁帶機的上蓋。

3 位於磁帶機底部有一開孔是載入/ 導帶馬達中心軸調整孔,可

用精密螺絲起子插入來旋轉調整。

4 逆時針方向轉動馬達中心軸去帶動導帶機械裝置退回原始位置

(見下圖步驟 1)。

5 在手動退出磁帶之前,必須使磁帶鬆弛部份拉緊,預防磁帶損

壞。順時針方向轉動磁帶機右側的傳動裝置,繃緊磁帶(見下

圖步驟 2)。

6 在繃緊磁帶後,以精密螺絲起子順時針方向轉動磁帶機右側的

螺絲,直到磁帶匣在磁帶機內被升起並退出(見下圖步驟3)。

31

Page 32

7 將磁帶機送回 Acer 修理。

3. Cassette Compartment Motor

2. Reel Motor

32

1. Loading Motor

Page 33

A

tape guide surface

tape guide surface

C

B

相片 -1:上帶機的原始位置

注意

當 guide B(見上圖)的面積在線 C-C 之下,立即停止馬達的旋轉,否則驅動齒輪

會損壞。

(註:線 C-C 的定義:卡匣內兩倍循環帶的引導表面)

detail A

Cartridge

C

33

Page 34

界面執行

支持的 ATA 命令

支持的 ATA 命令︰

– ATAPI SOFT RESET (0x08)

– EXECUTE DRIVE DIAGNOSTIC (0x90)

– ATAPI PACKET COMMAND (0xA0)

– ATAPI IDENTIFY DEVICE (0xA1)

– STANDBY IMMEDIATE (0xE0)

– IDLE IMMEDIATE (0xE1)

– CHECK POWER MODE (0xE5)

– SLEEP (0xE6)

– SET FEATURE (0xEF)

支持的 ATAPI Packet 命令

強制性 ATAPI 命令設定:

支持 SDX-400C 中的絕大多數 SCSI 命令。

– ERASE

– INQUIRY

– LOAD/UNLOAD

– LOCATE

– LOG SELECT

– LOG SENSE

– MODE SELECT

– MODE SENSE

– READ

– READ POSITION

– REQUEST SENSE

– REWIND

– SPACE

– TEST UNIT READY

– WRITE

– WRITE FILEMARK

– WRITE BUFFER

34

Page 35

規格

產品規格

體積

SDX-420C/R

高度 41.2 mm (1.62 in)

寬度 149.0 mm (5.87 in)

厚度 155.0 mm (6.1 in)

高度

工作中 0 到 10000 英尺

振動

工作中 掃描正弦波方式 5 到 500Hz

未工作中 掃描正弦波方式 5 到 500Hz

使用中產生聲響 (A)量化音譜值

寫/讀 35 db (A)

置入/退出 60 db (A)

*振幅0.25 G peak 1 Octave/

min

*振幅0.5 G peak 1 Octave/

min , 3 軸 3 方向

注意

測試時,將音壓計放在 A 單位,並在產品正前方一公尺處量

測。

機械衝擊

工作中 沒有資料損失

半正弦波條件

效率

5 G Peak 3 ms

3軸3方向

*間隔10秒一次

未工作中 產品不損壞

半正弦波條件

90 G Peak 3 ms

(30 G Peak 11 ms)

3軸3方向

*間隔10秒一次

35

Page 36

溫度和濕度範圍

溫度

工作中 5℃到 40℃(溫度變化 < 10℃/h)

未工作中(機械結構) -40℃到 70℃(溫度變化 < 20℃/h)

未工作中(磁帶) -40℃到 45℃(溫度變化 < 20℃/h)

濕度

工作中 20 到 80% RH(不結霜最大濕球溫度 26℃)

未工作中(機械結構) 5 到 95% RH(濕度變化 < 30%/h)

未工作中(磁帶) 20 到 80% RH (濕度變化 < 30%/h)

電源要求

型號 電壓 漣波

Model Voltage Max Ripple

SDX-420C/R

5 V +/-5 % 100 mVp-p 1.4 A 2.5 A

12 V +/-10 % 150 mVp-p 0.45 A 1.2 A

電流 Current

常態 最大

懸浮粒子

工作中 少於 150 微克 /m(以 24 小時取樣為準)

電磁相容

輻射/傳導 EN55022/98 Class B

靜電

放電電壓

< 15kV:無操作失敗

< 20kV:無磁帶機損壞

空氣冷卻要求

周圍溫度 < 40℃

儘可能在空氣良好且流通的環境中使用,才能避免資料讀取或寫入產生流失及錯誤的情形發生!

36

Page 37

客戶聯繫

如需進一步相關訊息,請參閱以下網址:

http://csd.acer.com.tw/

37

Page 38

Page 39

Page 40

Printed in Japan 4-670-559-11 (1)

Loading...

Loading...