Page 1

AIT Drive

User’s Guide

4-649-283-03(2)

SDX-400 Series

SDX-410 Series

2000 Sony Corporation

Page 2

This document contains proprietary

information which is protected by

copyright.

All rights reserved. No part of this

document may be photocopied,

reproduced or translated to another

language without prior written consent

of Sony.

The information contained in this

document is subject to change without

notice.

SONY MAKES NO WARRANTY

OF ANY KIND WITH REGARD TO

THIS DOCUMENT.

Sony shall not be liable for error

contained herein, indirect, special,

incidental or consequential damages in

connection with the furnishing,

performance or use of this document.

VORSICHT

Diese Ausrüstung erfüllt die

Europäischen EMC-Bestimmungen für

die Verwendung in folgender /

folgenden Umgebung(en):

• Wohngegenden

• Gewerbegebiete

• Leichtindustriegebiete

(Diese Ausrüstung erfüllt die

Bestimmungen der Norm EN55022,

Klasse B.)

Contents

Introduction .......................................4

Product Features........................4

Precautions ................................5

Installation .........................................7

SCSI Connection/Setting the

SCSI ID .................................7

Option Switches (DIP Switch) ..8

Mounting Holes........................9

Remodeling from 5.25" Model

to 3.5" Model .......................12

Orientation...............................13

Operation .........................................14

Location of 3 LEDs ................. 14

LED Indication for

Drive Status .........................15

Drive Operation.......................16

Emergency Tape Removal

Procedure .............................17

Interface Implementation.................20

Supported SCSI Messages ......20

Supported SCSI Commands....20

Specification ....................................21

Product Specifications.............21

Third Party Support Contacts

(In the USA) ...............................23

Sony Contacts .................................. 25

2

Page 3

SDX-400 Tape Drive

The Sony SDX-400 series drive is a high capacity data storage device using

Advanced Intelligent tape (AIT) technology. The SDX-400 series drive

achieves high data reliability through Read-After-Write, an additional level

of Error Correction Code, and other features.

The Sony SDX-400 series drive stores data on tape using a standard format

called AIT (Advanced Intelligent Tape) and ALDC formats.

3

Page 4

Introduction

Product Features

SDX-400 series

Data Capacity

Transfer Rate (sustained)

* Assuming a 2.6 : 1 compression ratio.

(The compression ratio varies according to the type of data.)

• Supported Format : AIT-1

• Burst Transfer Rate

– 12 MB/s Asynchronous

– 40 MB/s Synchronous

• Large 10 MB Buffer Memory

• 3.5” Standard Height, 5.25” Half Height

• Embedded SCSI Interface

(ULTRA/WIDE and LVD/SE model (SDX-400C) or HVD model (SDX-

410C) are available)

• Supports Variable or Fixed Record Length

• Supports SCSI Disconnection/Arbitration

• Frame Rewrite Function

• Three levels of Error Correction Code (ECC)

• High Speed search (120 times normal Read/Write speed)

• Random Read, Append Write

35 GB uncompressed (with AIT-1 230 m tape)

91 GB compressed* (with AIT-1 230 m tape)

4 MB/s uncompressed

4

Page 5

Precautions

Installation

Avoid placing the drive in a location subject to:

– high humidity

– high temperature

– mechanical shock and vibration

– direct sunlight

Operation

• Do not move the drive while it is operating. It may cause malfunction.

• Avoid exposing the drive to sudden changes from a low to high in

temperature. This may cause water condensation to collect inside the

drive. If the ambient temperature should suddenly rise while the drive is

turned on , wait at least one hour before turning on the drive. If you

attempt to operate the drive immediately after a sudden increase in

temperature, a malfunction may occur.

• Turning off the power to the drive while it is writing to tape may cause

the tape to become unreadable. All previously negotiated parameters will

be lost, whenever power to the drive is cycled.

Transportation

• Keep the original packing materials to facilitate transportation of the

drive.

• Always remove the tape before moving the drive. After removing the

drive from the computer, repack the drive into its original packing.

5

Page 6

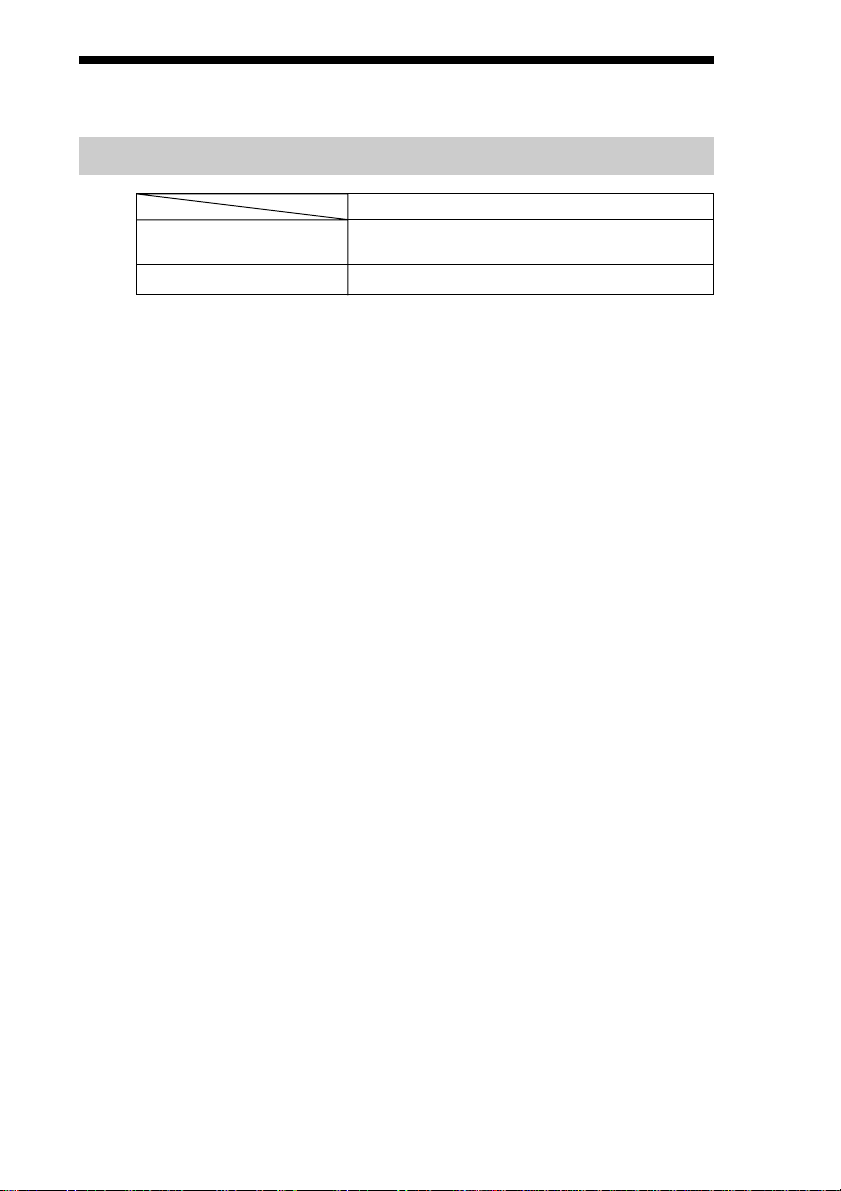

Notice of SCSI Termination

r

The SDX-400C conforms to the Microsoft PC97 standard which requires

the internal (naked) drive to be terminated with an external terminator.

Microsoft PC97 SCSI requirements

SCSI peripherals must not terminate the bus. Both internal and external

cable ends are instead terminated by plug-in connectors.

Host Computer Wide SCSI

68p cable

Example of SCSI set-up

Terminato

This drive

6

Page 7

Installation

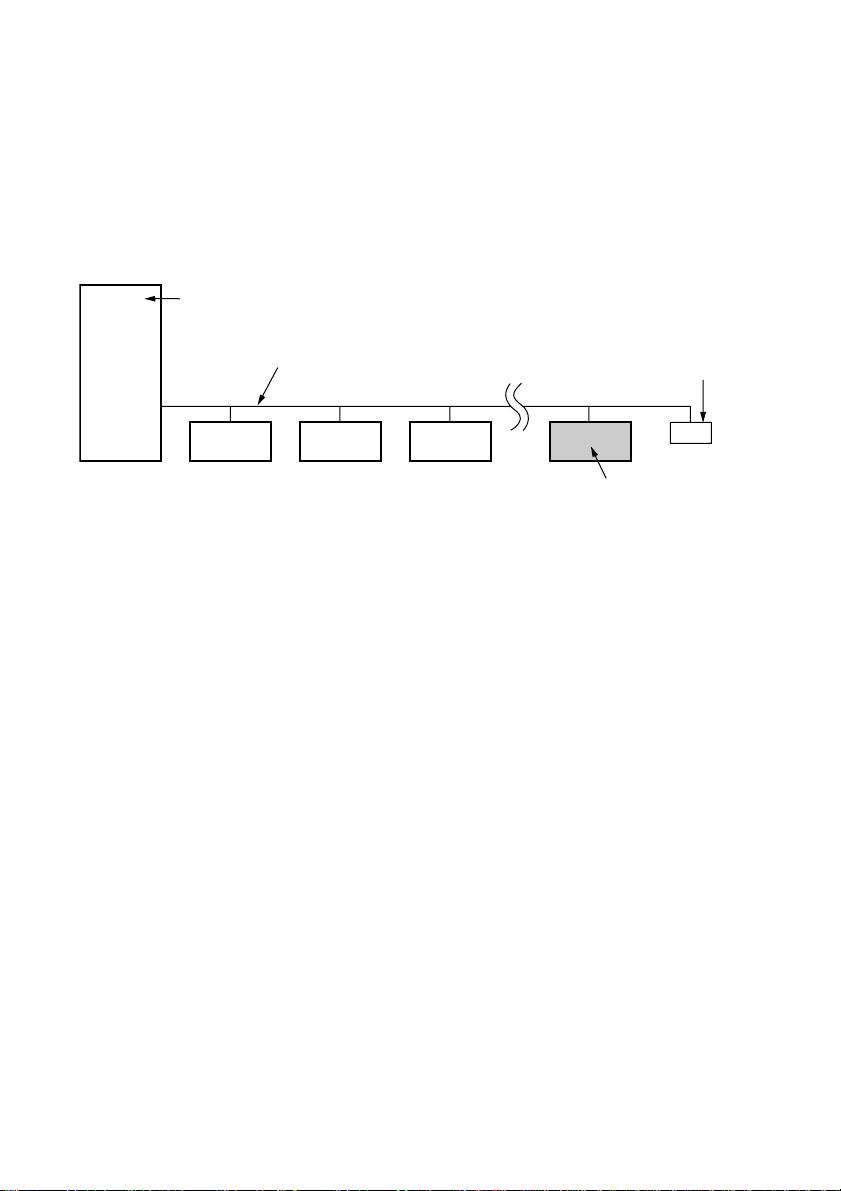

SCSI Connection/Setting the SCSI ID

SCSI ID

210

SCSI ID

0

1

P.D.

N.C.

3

10

11

12

13

14

2

3

4

5

SCSI 68pin Connector

Jumpers

Power Connector

5 V

GND GND 12 V

1234

6

SCSI ID 3

SCSI ID 2

SCSI ID 1

7

Parity Disable

8

No Connection

Parity

SCSI ID 0

9

Disable

Enable

Note := = CLOSED/Jumper

OPEN/Jumper not

installed

Don’t care

15

Parity Disable Jumper

Parity check function can be disabled by Jumper. Parity check is disabled

while left end jumper is installed. Parity generate function is always

enabled.

7

Page 8

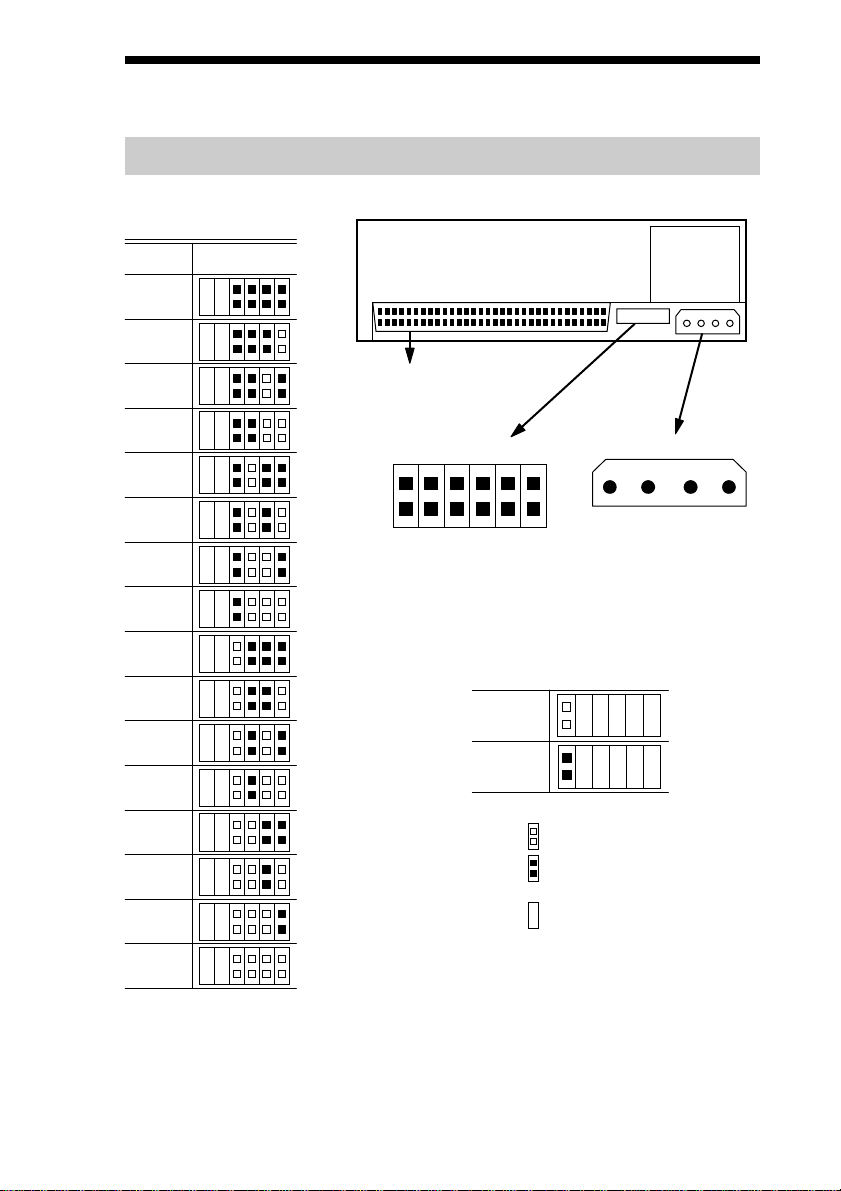

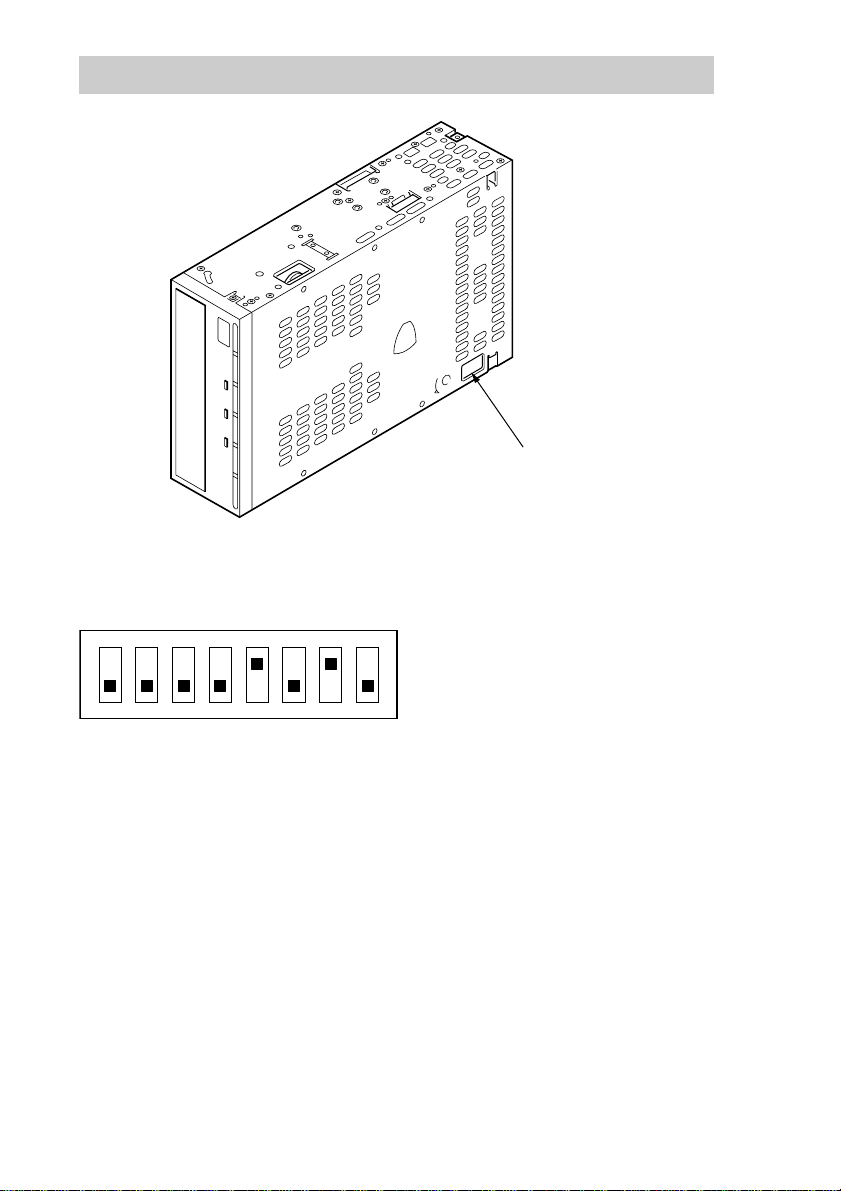

Option Switches (DIP Switch)

DIP Switch Positions

DIP Switch

ON

12345678

1 Reserved (OFF)

2 Reserved (OFF)

3 Reserved (OFF)

4 Reserved (OFF)

5 Terminator Power (ON)

6 Reserved (OFF)

7 DC Control (1) (ON)

8 DC Control (2) (OFF)

Data Compression Control DIP switch

Data compression can be selected by DIP switches. Data compression is

enabled while position 7 [DC Control (1)] is ON. Control by host can be

disabled when position 8 [DC Control (2)] is ON.

8

Page 9

Mounting Holes

For 3.5" Standard Height (SDX-400C)

95.5 mm (3.76 in)

155.0±0.5 mm (6.10±0.02 in) 7.6±0.5 mm (0.30±0.02 in)

94.0±0.3 mm (3.70±0.01 in)

101.6±0.5 mm (4.00±0.02 in)

7.0±0.5 mm (0.28±0.02 in)

5.53±0.5 mm

(0.218±0.02 in)

3-M3 (depth

2.5 mm (0.10 in) max.)

6-M3 (depth

2.5 mm (0.10 in) max.)

70.0±0.3 mm

(2.76±0.01 in)

42.0±0.3 mm

(1.65±0.01 in)

31.0±0.3 mm

(1.22±0.01 in)

90.0±0.3 mm (3.54±0.01 in)

21.0±0.3 mm

(0.83±0.01 in)

8.45 mm (0.333 in)

60.0±0.3 mm (2.36±0.01 in)

5.0±0.3 mm

(0.20±0.01 in)

41.2±0.5 mm

(1.62±0.02 in)

7.4±0.5 mm

(0.29±0.02 in)

9

Page 10

For 3.5" Standard Height (SDX-410C)

92.71mm (3.65 in)

(0.30 in)

7.6±0.5 mm

(6.69 in)

170±0.5 mm

94±0.3 mm

(0.29 in)

7.4±0.5 mm

(3.70 in)

101.6±0.5 mm

(4.00 in)

3-M3 (depth 2.5 mm max.)

(depth 0.10 in max.)

6-M3 (depth 2.5 mm)

(depth 0.10 in)

(2.76 in)

70±0.3 mm

90±0.3 mm

(1.65 in)

42±0.3 mm

(1.22 in)

31±0.3 mm

21±0.3 mm

(3.54 in)

60±0.3 mm

(0.83 in)

(2.36 in)

4.7±0.5 mm

(0.185 in)

8 mm

(0.315 in)

5±0.3 mm

(0.20 in)

41.2±0.5 mm

(1.62 in)

10

Page 11

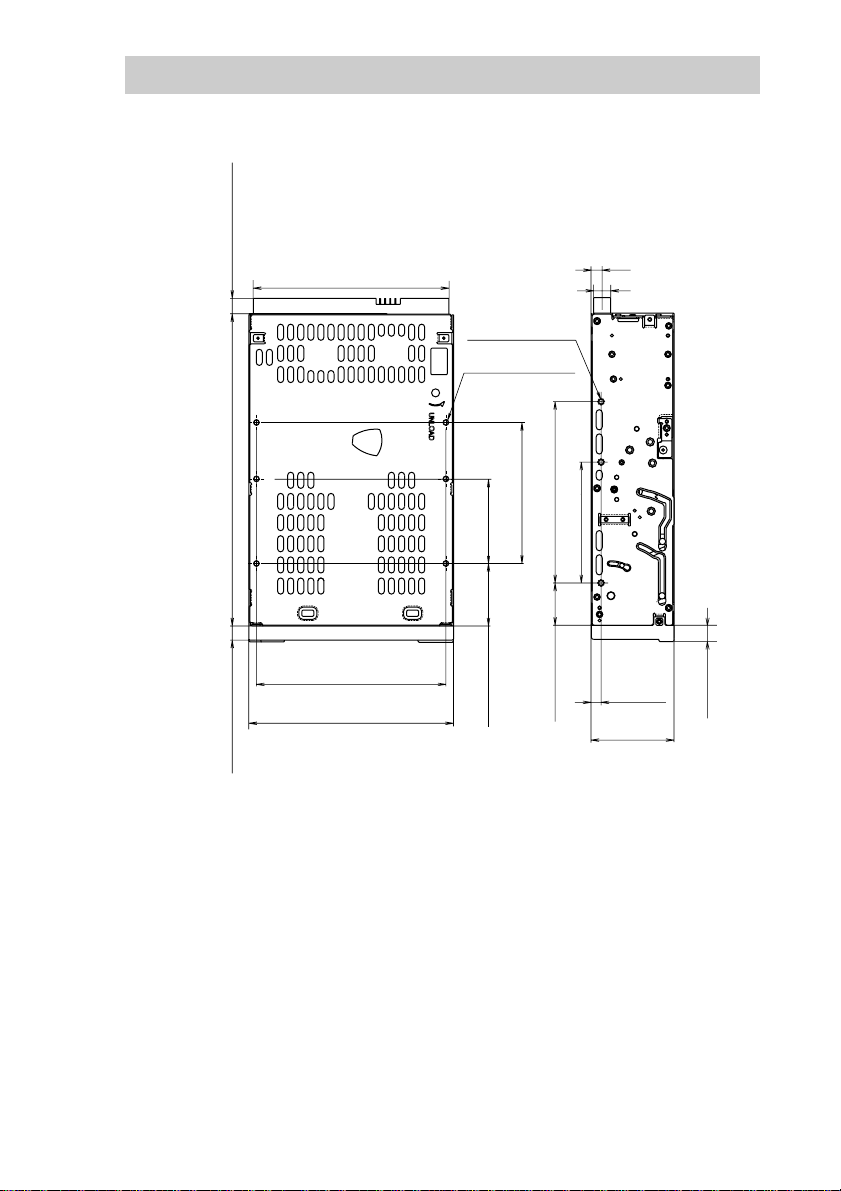

For 5.25" Half Height (SDX-400C/R)

15.6±0.5 mm

(0.61±0.02 in)

21.465 mm

(0.85 in)

7.6±0.5 mm

(0.3±0.02 in)

34.75 mm

(1.37 in)

146±0.5 mm

(5.75±0.02 in)

92.71 mm

(3.65 in)

6-M3 (depth 2.5mm max.)

(depth 0.10 in max.)

19.48 mm

(0.77 in)

4-M3

34.3±0.5 mm

(1.35±0.02 in)

4-M3

4.7±0.5 mm

(0.19±0.02 in)

8 mm

(0.31 in)

(6.1±0.02 in)

155.0±0.5 mm

7±0.5 mm

(0.28±0.02 in)

70.0±0.3 mm

(2.76±0.01 in)

42.0±0.3 mm

(1.65±0.01 in)

31.0±0.3 mm

(1.22±0.01 in)

94.0±0.3 mm

(3.7±0.01 in)

101.6±0.5 mm

(4±0.02 in)

139.6±0.5 mm

(5.5±0.02 in)

149.0±0.5 mm

(5.87±0.02 in)

79.2±0.3 mm

Cassette in ON point

41.0±1.0 mm

(1.61±0.04 in)

47.5±0.3 mm

46.5±1.5 mm

(1.83±0.06 in)

The cartridge eject distance

(3.12±0.01 in)

(1.87±0.01 in)

79.2±0.3 mm

(3.12±0.01 in)

47.5±0.3 mm

(1.87±0.01 in)

57.5±1 mm

9.9±0.5 mm

(0.39±0.02 in)

21.8±0.5 mm

(0.86±0.02 in)

19.7±0.5 mm

(0.78±0.02 in)

41.2±0.5 mm

(1.62±0.02 in)

The cartridge eject distance

Cassette in ON point

(2.26±0.04 in)

63.0±1.5 mm

(2.48±0.06 in)

11

Page 12

Remodeling from 5.25" Model to 3.5" Model

You can remodel the SDX-400C/R (5.25" model) to the SDX-400C (3.5"

model) yourself.

1 Remove the 2 screws for each side rail.

2 Take the side rail off.

Side Rail (L)

Side Rail (R)

12

Page 13

Orientation

10°

10° 10° 10°

10°

10°

10°

10°

13

Page 14

Operation

Location of 3 LEDs

There are three LED indications (BUSY,TAPE and STATUS) and an

EJECT button on the front panel of the unit.

Front Panel (for 3.5" Standard Height)

Advanced

Intelligent

Tap e

BUSY TAPE STATUS

14

Page 15

LED Indication for Drive Status

The LED indicators are defined as follows.

LED State

BUSY TAPE STATUS Activity Cartridge Other

None None None

SCSI None None

Drive

Drive

None Loaded

None Loaded None

SCSI Loaded None

SCSI/Drive Loaded None

Independent ✽ Loaded Write Protected

Independent Independent ✽ Loaded Error Rate Warning

✽✽ ✽✽Cleaning Request

✽✽ ✽✽Self test Failure

✽✽✽ ✽Waiting for Reset

✽ ✽✽ ✽Waiting for Eject

1 pulse (3.5 sec on / 0.5 sec off)

1 pulse (0.25 sec on)

Loading/Unloading

Loading/Unloading

off

on

None

Write Protected

Cleaning Tape at EOM

✽ : Not defined.

2 pulses (0.25 sec on/0.5 sec off)

1 pulse (0.25 sec on / 0.25 sec off)

15

Page 16

Drive Operation

Loading a Tape

Insert a cassette into the slot on the front panel with the arrow on the

cassette pointing towards the drive. As the cassette is inserted, the drive

takes it and automatically loads it into drive mechanism.

Unloading a Tape

The cassette can be removed from the SDX-400/SDX-410 either in

response to a SCSI Unload Command, or by pressing the eject bottom.

By pressing Eject button, the tape goes to BOT, the drive unthreads it, and

ejects the cassette from the slot.

Write-protecting a Tape

Cassettes can be write-protected by sliding the tab on the back of the

cassette. In this state, data can be read from the tape but not written onto it.

AIT-1

Using your fingernail, push the switch in the

direction of the arrow to protect the tape from

writing or accidental erasure.

Return the switch to its original position to

re-enable writing.

Using a Cleaning Cassette

In case of SDX-400 series/SDX-410 series, a cleaning function is built into

the drive and hence the use of a c leaning cartridge is not needed. If

however the drive experiences excessive errors, the use of a cleaning

cartridge is recommended.

16

Page 17

Emergency Tape Removal Procedure

1 Remove the drive from the chassis or enclosure to allow

access to the bottom and right side of the drive.

2 Remove the drive’s top cover.

3 Locate the small opening in the bottom of the drive and

insert the tip of a precision screwdriver so that the Threading

motor shaft can be rotated.

4 Rotate the motor shaft counterclockwise to bring the

threading mechanism back to the initial position. (Refer to

the photo-1 on page 19.)

5 Before manual eject procedure, tape slack must be removed

in order to prevent tape damage. Press and rotate the gear

mechanism located on the right side of the drive clockwise to

tighten the tape.

6 After the tape slack has been removed, turn the screw

located on the right side of the drive clockwise by a precision

screwdriver until the tape cartridge is lifted out of the drive

mechanism and is ejected.

17

Page 18

7 Return the drive to Sony for repair.

3. Cassette Compartment Motor

2. Reel Motor

18

1. Loading Motor

Page 19

A

tape guide surfa ce

tape guide surfa ce

C

B

Photo-1: The Initial Position of the Threading Mechanism

Caution

Stop rotating the motor shaft immediately, when the guide B (see detail A of Photo-1)

gets to the area below the line C-C (This line is defined by 2 circular tape guide surfaces

of the cartridge). Otherwise the gear of the drive can be damaged.

detail A

Cartridge

C

19

Page 20

Interface Implementation

Supported SCSI Messages

Abort Message Parity Error

Bus Device Reset Message Reject

Command Complete No Operation

Disconnect Restore Pointers

Extended Message Save Data Pointer

– Synchronous Data Transfer

Request

– Wide Data Transfer Request

Identify ( w/&w/o Disconnect )

Ignore Wide Residue

Supported SCSI Commands

Erase Receive Density Support

Inquiry Report Luns

Load/Unload Request Block Address

Locate Request Sense

Log Sense Reserve Unit

Log Select Rewind

Mode Select Seek Block

Mode Sense Send Diagnostic

Prevent Allow Medium Removal Space

Read Test Unit Ready

Read Block Limits Verify

Read Buffer Write

Read Position Write Buffer

Report Diagnostic Result Write Filemarks

Release Unit

20

Page 21

Specification

Product Specifications

Dimensions

SDX-400C SDX-410C SDX-400C/R

Height 41.2 mm (1.62 in) 41.2 mm (1.62 in) 41.2 mm (1.62 in)

Width 101.6 mm (4.0 in) 101.6 mm (4.0 in) 146.0 mm (5.75 in)

Depth 155.0 mm (6.1 in) 170.0 mm (6.7 in) 155.0 mm (6.1 in)

Altitude

Operating 0 to 10,000 feet

Vibration

Operating Swept Sine 5 to 500 Hz

Non-Operating Swept Sine 5 to 500 Hz

Acoustic Noise (A) curve weight

Streaming Write/Read 35 db (A)

Insert/Eject 60 db (A)

*0.25 G Peak 1 Octave/min.

3 axes, 3 directions

*0.5 G Peak 1 Octave/min.

3 axes, 3 directions

Note

The sound-meter on (A) scale is located 1m in front of

the center of the drive front panel.

Shock

Operating No Data Loss

Half Sine

5 G Peak 3 ms

3 axes, 3 directions

*Interval 10 seconds

Non-Operating No Device Damage

Half Sine

90 G Peak 3 ms

(30 G Peak 11 ms)

3 axes, 3 directions

21

Page 22

Temperature and Humidity Range

Temperature

Operating 5 ˚C to 40 ˚C (∆T<10 ˚C/h)

Non-Operating (mech.) – 40 ˚C to 70 ˚C (∆T<20 ˚C/h)

Non-Operating (tape) – 40 ˚C to 45 ˚C (∆T<20 ˚C/h)

Humidity

Operating 20 to 80% RH, non-condensing

Maximum wet bulb temperature = 26 ˚C

Non-Operating (mech.) 5 to 95% RH (∆T<30%/h)

Non-Operating (tape) 20 to 80% RH (∆T<30%/h)

Power Requirements

Model Voltage Max Ripple

SDX-400 series

SDX-410 series

5 V +/– 5 % 100 mVp-p 1.3 A 2.5 A

12 V +/– 10 % 150 mVp-p 0.4 A 1.2 A

5 V +/– 5 % 100 mVp-p 1.5 A 2.5 A

12 V +/– 10 % 150 mVp-p 0.45 A 1.2 A

Suspended Particulate

Operating

Less than 150 microgram/m

Based Sampling period 24 hours

3

Current

Typical Maximum

ESD

Discharge < 15 kV: No operation failure

Voltage < 20 kV: No drive damage

Air-cooling Requirement

Surrounding temperature < 40 ˚C

Clean air flow is recommended to minimize the possibility of data loss.

22

Page 23

Third Party Support Contacts (In the USA)

Host Adapter Vendors Phone Numbers

Adaptec 408-945-8600

ATTO 716-691-1999

Bus Logic 408-492-9090

DPT 407-830-5522

Future Domain 714-253-0400

Initio 408-988-1919

Qlogic 714-438-2200

Ultera Systems Inc. 714-367-8800

Operating Systems

DOS Arcada 407-333-7500

Macintosh Cheyenne 516-484-5110

OS/2 Cheyenne 516-484-5110

Windows Arcada 407-333-7500

Windows NT Arcada 407-333-7500

Windows NT Microsoft 206-882-8080

Advanced Server

Backup Software Vendors Phone Numbers

Cheyenne 516-484-5110

Columbia Data Products 407-869-6700

Corel 613-728-8200

NovaStor 805-579-6700

Palindrome 708-505-3300

ST. Bernard Sofware 619-676-2277

Sytron 508-898-0100

Tapedisk 715-235-3388

Corel 613-728-8200

Dantz 510-253-3000

NovaStor 805-579-6700

Corel 613-728-8200

IBM 800-426-3333

NovaStor 805-579-6700

Sytron 407-333-7500

Cheyenne 516-484-5110

Corel 613-728-8200

Creata 909-595-8811

NovaStor 805-579-6700

ST. Bernard Software 619-676-2277

Sytron 508-898-0100

Cheyenne 516-484-5110

Creata 909-595-8811

Microsoft 206-882-8080

NovaStor 805-579-6700

Avail Systems 303-444-4018

* All phone numbers listed are in the USA.

Add the country code (1) prior to those numbers when calling from

outside the USA.

23

Page 24

Operating Systems

Windows 95 NovaStor 805-579-6700

DEC Unix Cheyenne 516-484-5110

SUN Unic Legato 415-812-6000

Solaris Unix Cheyenne 516-484-3150

SCO Unix Cheyenne 516-484-3150

NCR Unix NovaStor 818-707-9900

HP Unix Cheyenne 516-484-3150

AIX Unix Cheyenne 516-484-3150

Interactive Unix Sun Soft 310-348-8649

SGI Unix Software Moguls 612-933-8790

Novell UNIXware Novell 801-263-3500

Novell NLM Arcada 407-263-3500

Banyan Performance Tech 210-979-2110

Lantastic NovaStor 818-707-9900

Amiga Moonlighter 407-384-9484

RS6000 Legato 415-812-6000

Backup Software Vendors Phone Numbers

NovaStor 612-933-8790

Software Moguls 612-933-8790

Work Station Solutions 603-880-0080

NovaStor 818-707-9900

Software Moguls 612-933-8790

Sun Soft 310-348-8649

Work Station Solutions 603-880-0080

Legato 415-812-6000

NovaStor 818-707-9900

Software Moguls 612-933-8790

Sun Soft 310-348-8649

Work Station Solutions 603-880-0080

Legato 415-812-6000

Software Moguls 612-933-8790

Work Station Solutions 603-880-0080

Work Station Solutions 603-880-0080

NovaStor 818-707-9900

Work Station Solutions 603-880-0080

Legato 415-812-6000

NovaStor 818-707-9900

Software Moguls 612-933-8790

Work Station Solutions 603-880-0080

Work Station Solutions 603-880-0080

Avail Systems 303-444-4018

Cheyenne 516-484-3150

Columbia Data Products 407-682-0265

Creata 909-595-8811

Legato 415-812-6000

NovaStor 818-707-9900

Novell 801-419-5544

Palindrome 708-505-3300

Performance Tech 210-979-2110

ST. Bernard Software 619-676-2277

Symantec 310-449-4156

Sytron 508-898-0100

NovaStor 818-707-9900

Software Moguls 612-933-8790

24

Page 25

Sony Contacts

For further information, please contact:

Sony Electronics Inc., Technical Support

3300 Zanker Road San Jose, CA95134, 1940. USA

TEL: (1) 800-801-7927

URL: http://sony.storagesupport.com/

E-mail: tape.support@am.sony.com

Sony Corporation

Electronic Devices Marketing Group, Product Marketing Div.

Computer Peripherals Dept. Tape Streamer Section

Osaki Gate City East Tower, 1-11-1, Osaki

Shinagawa-ku, Tokyo, 141-0032 Japan

TEL: (81) 3-5435-3486 FAX: (81) 3-5435-3565

Sony of Canada Ltd., AV/IT Marketing Group

Computer Peripherals Product Marketing

115 Gordon Baker Road Toronto, Ontario, M2H 3R6 Canada

TEL: (416) 499-1414 or (1) 800-961-7669

FAX: (416) 499-8541

Sony Computer Peripherals & Compornents Europe

URL: http://www.sonyisstorage.com/

Electronics Devices Marketing (Singapore)

(A division company of Sony Electronics (S) Pte. Ltd.)

Enterprise Storage Solutions Dept.

2 International Business Park, #01-10 Tower One,

The Strategy, Singapore 609930

TEL:65-6544-8000 FAX:65-6544-7390

Sony Corporation of Hong Kong Ltd.

Computer Peripheral Sales & Marketing Division

Electronic Devices Marketing Hong Kong

45/F, The Lee Gardens, 33 Hysan Avenue, Causeway Bay, Hong Kong

TEL: (852) 2909-1008 FAX: (852) 2909-2001

Sony Corporation of Hong Kong Ltd. Beijing Rep. Office

Computer Peripheral Div.

Full Link Plaza Tower A 11/F., No.18 Chaoyangmenwai Ave., Beijing

100020 P.R.C.

TEL:86-10-6588-0558 FAX:86-10-6588-0855

URL: http://www.sony.com.cn

25

Page 26

Sony Corporation of Hong Kong Ltd. Shanghai Rep. Office

44F., HSBC Tower, 101 Yin Cheng East Road, Pudong, New Area,

Shanghai, P.R.C. Postcode 200120

TEL: 86-21-6841-3222 FAX: 86-21-6841-0280

Sony Brasil Ltda.

Rua Inocéncio Tobias, 125-BlocoA, CEP01144-000, São Paulo -SP-Brasil

TEL: (55) 11-3824-6586 to 6598 FAX: (55) 11-3611-9064

URL: http://www.sonybrasil.com

Sony Australia Ltd., Information Technology Products Division

P.O. Box 377, NSW 1670, Australia

TEL: 1800-226-429 FAX: (61) 2-9870-8564 A.C.N. 001 215 354

URL: http://www.sony.com.au/home.asp

E-mail: informatica@ssp.br.sony.com

Sony Chile Ltda

Av. Kennedy 8017, Las Condes, Santiago, Chile

TEL: (02) 210-6000 FAX: (02) 210-5417

Sony Taiwan Limited

Optical Devices Storage Dept. Data Storage Section

5F, 145 Changchun Road, Taipei 104, Taiwan

TEL: 886-2-2522-7920 FAX: 886-2-2522-2153

Sony Korea Corporation EDMK CP Sales & Marketing Team

34F, ASEM Tower, World Trade Center, 159-1, Samsung-Dong,

Kangnam-Ku, Seoul, 135-798, Korea

TEL: 82-2-6001-4249 FAX: 82-2-6001-4115

URL: http://www.sony.co.kr/cp/

Sony Gulf FZE Computer Display & Peripheral Div.

P.O.BOX 16871, Jebel Ali, Dubai, U.A.E.

TEL: 971-4-8815488 or 8816912 FAX: 971-4-8817210 or 8816259

Sony Marketing of Japan

Business Solution Dept. Server Solution Marketing Section

URL: http://www.sony.co.jp/STORAGE

26

Page 27

Page 28

Printed in Japan

Loading...

Loading...