Sony SDPE-800 Service manual

MODEL IDENTIFICATION

— BACK PANEL —

TABLE OF CONTENTS

1. SERVICING NOTE

.......................................................... 3

2. GENERAL .......................................................................... 4

Parts No.

MODEL PARTS No.

US model

E, SP model

AEP, UK model

AUS model

CND model

CH model

4-992-696-0

4-992-696-1

4-992-696-2

4-992-696-3

4-992-696-4

4-992-696-5

• Abbreviation

CND : Canadian model.

SP : Singapore model.

CH : Chinese model.

AUS : Australian model.

• For detailed Malaysia model refer to E model.

• For detailed German, East European model refer to AEP model.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

3. TEST MODE ..................................................................... 13

4. DIAGRAMS

4-1. Circuit Boards Location ...................................................... 14

4-2. Block Diagrams

• DA Section.......................................................................15

• DSP Section ..................................................................... 17

• Display Section ................................................................ 19

• Panel Section.................................................................... 21

• Power Section .................................................................. 21

4-3. Printed Wiring Board — Main Section — .......................... 23

4-4. Schematic Diagram — D/A Section — .............................. 27

4-5. Schematic Diagram — Control Section —......................... 31

4-6. Schematic Diagram — Dolby AC-3 Section — ................. 35

4-7. Printed Wiring Board — Display Section —......................38

4-8. Schematic Diagram — Display Section — ........................ 41

4-9. IC Block Diagrams.............................................................. 44

4-10. IC Pin Functions................................................................ 48

5. EXPLODED VIEWS

5-1. Case Section........................................................................60

5-2. Main Section ....................................................................... 61

6. ELECTRICAL PARTS LIST ........................................ 62

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLA CER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

— 2 —

SECTION 1

SERVICING NOTE

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a V OM

or battery-operated A C v oltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

RV101 of MAIN Board

RV101 of the MAIN board requires no adjustments. Please note

that it should be dixed to mechanical center position when you moved

and do not know origin position.

L702 of PLL board

Do not touch the L702 on the PLL Board because it is not needed to

adjust.

Connection and Test Disc

Connection of this unit to a AC-3 Dolby surround equipment will

realize outstanding sound playback.

Check if the respective surround channel outputs are playing back

normally by the following method.

Jig :

Discription Part No.

AC-3 TEST LD J-2501-132-A

Connected Equipment:

AC-3 LD player

(This unit is also compatible with the digital versatile disc player

(DVD). The D VD must be checked with the LD player using all

the circuits of this unit.)

Connecting Method:

AC-3 RF output terminal Coaxial digital

connecting cable VMC-10G, etc. (Optional)

0.15

Ω

µ

F

1.5k

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

AC-3 compatible

LD player

AC-3 RF

output terminal

AC-3 RF

input terminal

Unit

Checking Method:

Play back a test disc of the LD player, and check if the contents

recorded on the disc case (printed on the disc case) are played

back normally.

— 3 —

SECTION 2

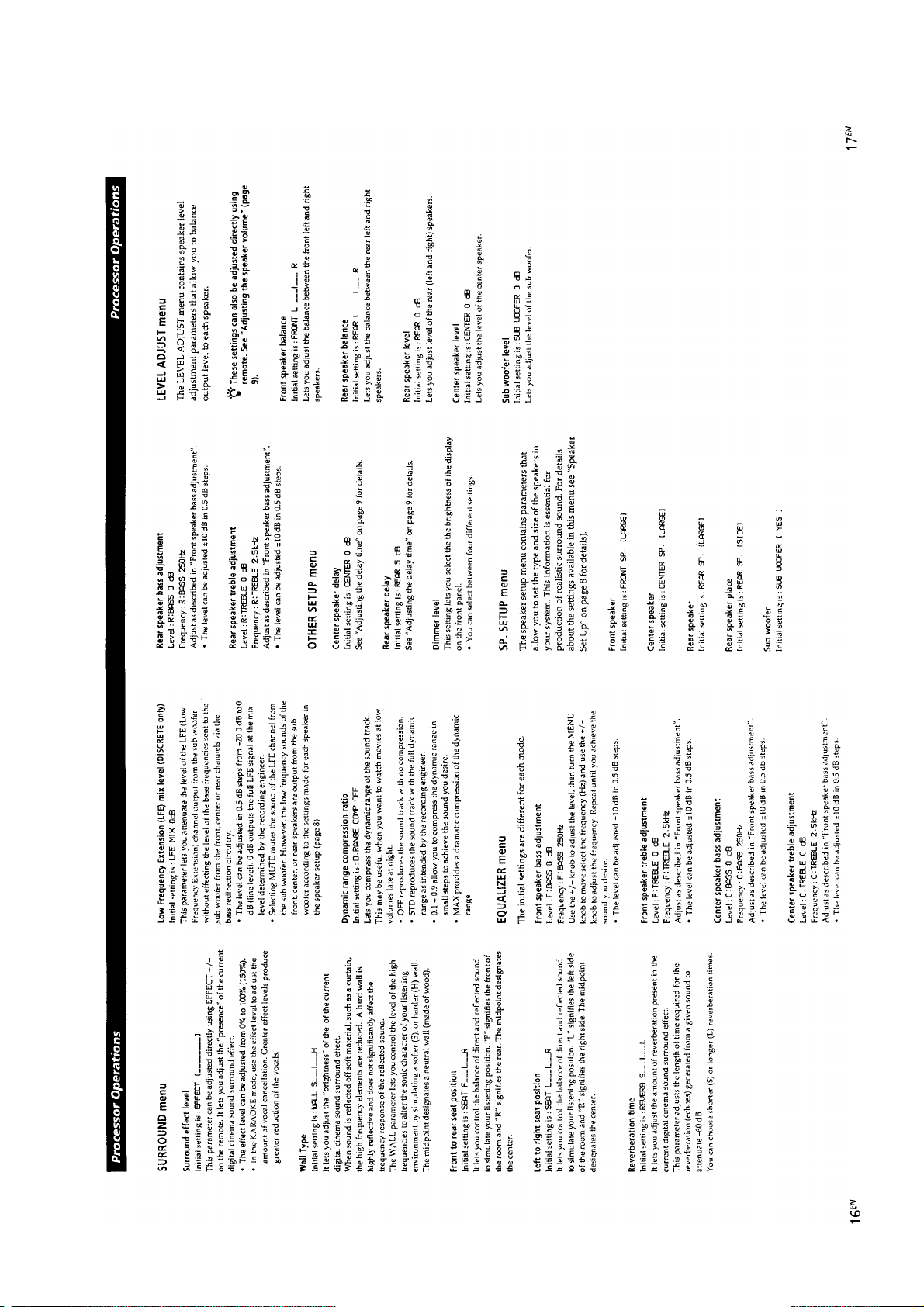

GENERAL

This section is extracted from

instruction manual.

— 4 —

— 5 —

— 6 —

— 7 —

— 8 —

— 9 —

— 10 —

— 11 —

— 12 —

SECTION 3

TEST MODE

[Self-Diagnosis and Test Mode]

This unit is provided with a “self-diagnosis and self-recovery function” which detects DSP errors and automatically recovers the unit,

and a test mode for performing operation checks during repairs.

1. Main Functions

1. DSP Error Messages

2. Various operation check mode

3. Initialization

2. Entering the Test Mode

While pressing the DIGITAL 2 button and ANALOG button

simultaneously in the power OFF state, press the POWER button.

1. DSP Error Messages

When errors occur in the DSP , the y are displayed on the fluorescent

display tube.

(Refer to Table 1 for the error messages displayed.)

Table-1:

Cause of error

(Display)

1 Failed in initial

booting

(BOOT ERROR)

2 DSP does not

operate

(RPLY ERROR)

Mostly due to faulty connection (soldering)

between DSP and microprocessor

Faulty DSP clock (X102 and onwards), faulty

DSP part, etc.

Possible cause

3. Initialization

After executing the test mode, be sure to perform initialization.

When the POWER button is pressed while pressing the DIGIT AL 1

button and DIGITAL 3 button, “All Clear!” is displayed on the

fluorescent display tube and all internal settings are initialized.

[Fluorenscent Display Tube All Lit]

With the power OFF, while pressing the DIGITAL 3 button and ∨

button togher, press the POWER button to turn ON the power.

The fluorenscent display tube all lit modewill be set.

Button name

DIGITAL 1

DIGITAL 2

DIGITAL 3

ANALOG

Fluorenscent display tube state

All lit

Partial lighting 1

Partial lighting 2

OFF

When the other buttons are pressed, press the POWER button to

exit the mode.

Partial lighting 1

Partial lighting 2

3 Communication

port malfunction

(HREQ ERROR)

4 No reply from

DSP

(VRFY ERROR)

Overrunning of DSP due to heat, microprocessor bugging, or IC701 (PLL board PLL) is

faulty

Faulty DSP part, or faulty microprocessor part,

etc.

2. Operation Check Mode

• During the operation check mode, functions can be set by press-

ing the corresponding button. (See Table-2.)

• When a button other than those displayed in Table 2 is pressed,

press the POWER button to exit the check mode.

Table-2:

Button

DIGIT AL1

DIGITAL2

Fluorescent

Display Tube

Display

OPT -1

(L-FL, R-FR)

OPT-2

(L-SL, R-SR)

Like normal operations, Lch is output to

Lch and Rch to Rch.

Outputs the Lch DIGITAL-2 input signal

to the REAR Lch and the Rch to the REAR

Rch.

Function

[Key Check Mode]

When the POWER button is pressed while pressing the DIGITAL 1

button and ANALOG button, “KEY CHECK:12 KEYS” is displayed on the fluorescent display tube and the key check mode is

set.

When the POWER button is pressed during this mode, the number

at “12 KEYS” is counted down. When all other b uttons are pressed,

the number stops at “00 KEYS” (Note: The number is not counted

down when buttons already pressed once are pressed again.).

To exit the mode, press the POWER button and turn OFF the

power.

DIGIT AL3

ANALOG

OPT -3

(L-C, R-SW)

COAX

(L, R-ALL)

Outputs the Lch DIGITAL-3 input signal

to the CENTER and the Rch only to the

WOOFER.

Outputs the Lch DIGITAL 1 COAXIAL

input signal to the FRONT Lch, REAR

Lch, CENTER, and the Rch to the FRONT

Rch, REAR Rch, and CENTER.

— 13 —

4-1. CIRCUIT BOARDS LOCATION

TRANS BOARD

AC SW BOARD

SECTION 4

DIAGRAMS

MAIN BOARD

PLL BOARD

DISPLAY BOARD

VOL BOARD

— 14 —

4-2. BLOCK DIAGRAMS

— DA SECTION —

SDP-E800

C

AC-3 (RF)

SECTION

D

DSP

SECTION

E

DSP

SECTION

SECTION

DIGITAL AUDIO

1

7

INTERFACE RECEIVER

IC107

DATAO

DIN2

2

E/D

OUT

AVOCK

LRCK

BCK

14

SCLK

15

XLAT

SWDT

16

SRDT

17

EROR

24

XMODE

10

A/D CONVERTER

IC203

AINL+

4 15

SDATA

AINL-

5 13

LRCK

SCLK

RST

10

MCLK

17

CLOCK COUNTER

IC115

2QD

1CLK

1

1QB

BUFFER

IC116

2

7

23

3

11

22

21

14

8

4

3

6

12.288MHz

SELECTOR

DIGITAL

DIGITAL 1

OPTICAL

IN

DIGITAL 2

OPTICAL

IN

DIGITAL 3

OPTICAL

IN

J101

DIGITAL 1

COAXIAL

IN

DAO

DIG-IN0

DIG-IN1

DIG-IN2

DIRCLK

DIRLAT

DIWDAT

DIRDAT

DIRERR

DIRRST

J106

ANALOG

IN L

ADINT

EXTAL

F

DSP

09

INPUT

IC101

DIGITAL

INPUT

IC102

DIGITAL

INPUT

IC103

3

OUT

3

OUT

3

OUT

32

IC105

L. P. F

IC201

6

IC106

3 5

D1 OUT

2

D2

1

D3

14

D5

4

D0

ABC

11 10 9

H. P. F

IC202

2

7

6

X102

SELECTOR

IC108 (1/2)

10

B2A2Y2

11

1

VIN

DIGITAL

OUTPUT

IC104

3

2

6

5

SELECTOR

IC108 (2/2)

B0

A0

B1

A1

A

DSP SECTION

9 DATA

BCKO

LRCKO

DIGITAL 3

OPTICAL

OUT

LRCK

Y0

4

7

Y1

S

1

• R-CH, SUPER WOOFER is ommited.

• REAR L-CH and CENTER part was ommited.

(Same as FRONT L-CH)

• Signal path

: Digital in

: Digital out

: Analog

: RF (AC-3)

10

13

BCK

4

1

SOA

SOC

B

DSP SECTION

BUFFER

IC109

CLOCK COUNTER

IC703

9 1

2QC 1CLK

PHASE

COMPARATOR

IC701

S

7

8

R

DATAI

40

LRCKI

39

BCKI

38

8

6

DATAI

40

LRCKI

39

BCKI

38

46

PD OUT

3 13

Q701-705

DIGITAL FILTER, D/A CONVERTER (FRONT)

128FSO

PLL

IC301

DIGITAL

FILTER

GENERATOR

DIGITAL FILTER, D/A CONVERTER

(CENTER, SUPER WOOFER)

DIGITAL

FILTER

GENERATOR

L702

PLL

CLOCK

CLOCK

D/A

CONVERTER

MODE

ATT

XIN

SHIFT

IC1301

D/A

CONVERTER

MODE

ATT

SHIFT

BUFFER

IC702

LATCH

LATCH

L1 (–)

L2 (+)

L1 (+)

L2 (–)

L1 (–)

L2 (+)

L1 (+)

L2 (–)

IC303

MIX

H. P. F.

AMP

ATT

IC305

5dB

5dB

5 2

OUT1

IN1

1dB

1dB

7 8

IN1

OUT

CLKDICE

18 1917

RY301

8

7

MASTER VOLUME

RV601

M

6

/

2

CLK

DI

CE

ATT

SHIFT

LATCH

INIT

J108

OUTPUT

FRONT L

MUTE1

MUTE2

VOL MT

VOL LED

ATCLK

ATDAT

ATCE

DADAT

DACLK

DALAT

DAINT

RY-F

ANADIG

H

DSP

SECTION

I

PANEL

SECTION

J

DSP

SECTION

7 5

CENTER

5 7

AMP

IC304

IC302

L. P. F.

AMP

IC306

61

2

63

4

INIT

3736353410

61

2

63

4

XIN

10

INIT

37363534

8

10

— 16 —— 15 —

SDP-E800

— DSP SECTION —

J102

DIGITAL 1

AC-3

RF

BUFFER

Q101

BUFFER

Q103

6

L.P.F.

7

IC110

IC110

21

BUFFER

Q102

DIGITAL SIGNAL PROCESSOR

(AC-3 RF DEMODULATOR)

ERROR

CORRECTOR

IC114

DAI

CONTROL

DIVIDER

DIGITAL

OUT

DAOUT

70

DAO

C

D/A

SECTION

(Page 17)

FILTER

FL101

1

6

4

9

+

Q106

CPIN

DEMODULATION S/P

82

XIN

DIGITAL

26

PLL

L.P.F.

D101

IC111

X101

18.432MHz

Q104

AMP

Q105

3

+

1

–

2

AMP

IC111

RV901

NO ADJUSTMENT

• Signal path

: RF (AC-3)

09

PDO67

PHASE

63

COMPARATOR

VOUT

56

DIVIDER

55

VIN

X LOCK

MUTI

78

ADDRESS

89

DOUTB

DOUT

88

WE

OE

D0 - D7

51 - 44

36 42

27 22

WE

GENERATOR

A0

17 - 22•30•31•38•39•43•41•34•37•35

11 - 13 • 15 - 19

D0 D7

OE

10 - 3•25•24•21•23•2•26•1

A0 A14

S RAM

IC113

CPU

INTERFACE

A14

RESET

OSCON

MUTO

PDDIS

3

4

AC. RST

G

DSP

SECTION

(Page 21)

66

65

MUTO

— 18 —— 17 —

— DISPLAY SECTION —

A

SECTION

SECTION

SECTION

G

AC-3 (RF)

SECTION

K

PANEL

SECTION

09

DIGITAL SIGNAL PROCESSOR

IC118

57

10

77

54

55

56

57

4

5

6

7

8

2

1

3

BCK

LRCK

DIRDAT

DIRWDT

DIRLAT

DIRCLK

DIRERR

ADCINI

RF RES

RF ERR

RESET

STOPIN

DM REQ

D DATA

DS REQ

D CLK

SDI0

•

56

SDI1

SCKR

51

WSR

55

MEMORY

IC117

PLL

EXTAL

27

5

3

AUDIO

I/F

DIGITAL SIGNAL

PROCESSOR

HOST

I/F

MOSI/HAO

SCK/SCL

MISO/SDA

413526

17 16 14 13 12 15

M9SCLK

M9MISO

M9MOSI

DATA

DA

BCKO

LRCKO

EXTAL

F

DA

DIRDAT

DIWDAT

DIRLAT

E

DIRCLK

DIRERR

DA

DIRRST

ADINT

AC. RST

MUTO

MRST

STOP

U-SREQ

U-MREQ

U-DATA

U-CLOCK

SS/HA2

M9MOSS

HREQ

M9MORQ

SDO0

SDO1

SCKT

WST

RESET

364342

47

46

49

50

M9MRES

•

BCK

LRCK

DIGITAL SIGNAL PROCESSOR

57

SDI0

•

56

SDI1

SCKR

51

WSR

55

SCKT

49

WST

50

MEMORY

PLL

EXTAL

27

7

IC117

1

XO

82

83

X103

4MHz

XI

IC119

AUDIO

I/F

DIGITAL SIGNAL

PROCESSOR

HOST

I/F

MOSI/HAO

SS/HA2

HREQ

SCK/SCL

MISO/SDA

42

41

24 22 20 19 18 21 38

DACLAT

M4SCLK

M4MISO

M4MOSS

M4MORQ

S MUTE

74 76

SWITCH

Q117

SWITCH

Q108

SDO0

SDO2

SDO1

RESET

36

M4MRES

D MUTE

GPIO0

7643

47

45

46

LF LED

D102

REAR

MEMORY

I/F

MRD

MWR

24 29 12

CE

MCAS

MD0 MD7

80 71 • 69-67 • 65-62 25-22 • 20-18 • 16 • 14-11 • 7 • 5-378773526

13-15 • 17-21 23 • 25-28 • 31 • 2

D0 D7

A16

R/W

S RAM

IC120

SYSTEM CONTROL

IC150

SWITCH

Q107

DA0 MA15

A0 A15

MUTE

CONTROL

Q113

DIGITAL 1

VIDEO IN

DIGITAL 2

VIDEO IN

ANALOG

VIDEO IN

MUTE

Q301

MUTE

Q302

VO INH

J103

J104

J105

VIDE B

686971

VIDE A

VIN3

1

VIN2

3

VIN1

12

DSEL2

98 99 100

VIDEO INPUT SELECTOR

DSEL1

DSEL0

D104

SOA

B

SOC

DA

SECTION

IC501

10

MUTE1

SW2

SW1

2

13

11

A

B

INH

MLCCEO

61

MLCDAT

62

MLCCLK

63

24

M4SCLK

DACLAT

26

DACCLK

28

DACDAT

29

MD1

RELAY

80

DRIVE

Q306

50

FSPRY

ATCE

ATDAT

ATCLK

DAINT

DALAT

DACLK

DADAT

RY-F

ANADIG

DIG-IN0

DIG-IN1

DIG-IN2

MUTE1

MUTE2

J107

MONITOR

OUT

SECTION

SECTION

SECTION

J

DA

D

DA

H

DA

• REAR is ommited.

• Signal path

: Digital in (AUDIO)

: VIDEO

— 20 —— 19 —

SDP-E800

— PANEL SECTION —

VOLMT

I

VOLLED

DA

SECTION

U-SREQ

U-MREQ

U-DATA

U-CLOCK

K

DSP

SECTION

L

POWER

SECTION

MRST

STOP

RST

09

VOLUME

MOTOR DRIVER

IC604

8

•

DRIVER

7

LED

DRIVER

Q604

FLUORESCENT INDICATOR TUBE

D603

BASS BOOST

LED

DRIVER

Q603

3

2

40

73

47

48

49

50

VOLUME–

LED VOL

U-SREQ

U-MREQ

U-DATA

U-CLOCK

VOLUME+

39

74

LED BASS.B

U-RESET

STOP

46 45 62

RESET

SWITCH

Q602

MODE CONTROLLER

RESET

5-20 • 41-59

P1 - P35 1G-19G

LAT

CLR

IC601

AD KEY IN1

AD KEY IN2

32

33

KEY

MATRIX

FL601

FL DRIVER

IC602, 603

29

D.IN DOUT

CLK

342426

RECEIVER

27

BUFFER

Q601

1

OUT

SIRCS

IC605

3

SIRCS

17-26 • 16-8

LSCLCLK

FL-LAT

FL-CLEAR

XO

64 65

X601

XI

DIN

302954

24252326

FL-CLK

FL-DATA

— POWER SECTION —

RST

L

PANEL

SECTION

ANA +5V

AMP/PLL +12V

FL. +32V

DA. +5V

DSP +5V

DISP +5V

+5V REG

IC112

T1

POWER

TO

FLUORESCENT

INDICATOR

TUBE

+32V REG

Q901

+5V REG

IC901

13

+5.6V REG

Q902, 903

1

3

31

RESET

IC606

+12V REG

IC902

13

RECT

D909, 910

RECT

D905

RECT

D901,902

F1

F2

TRANSFORMER

S801

POWER

AC IN

AC-3 –5V

ANA –5V

09

–5V REG

IC112

–5V REG

IC205

21

23

–12V REG

IC903

23

RECT

D903,904

— 21 —

Loading...

Loading...