Sony SCD-XE597 Service manual

SCD-XE597

SERVICE MANUAL

Ver. 1.3 2006.02

SPECIFICATIONS

AEP Model

UK Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM66D-DVBU50

Optical Pick-up Name DBU-3

When a Super Audio CD is played

Playing frequency range 2 Hz to 100 kHz

Frequency response 2 Hz to 40 kHz (–3 dB)

Dynamic range 100 dB or more

Total harmonic distortion rat e

Wow and flutter Value of measurable limit

When a CD is played

Frequency response 2 Hz to 20 kHz

Dynamic range 96 dB or more

Total harmonic distortion rat e

Wow and flutter Value of measurable limit

Output connector

Jack type Output

ANALOG

5.1CH OUT

DIGITAL

(CD) OUT

OPTICAL*

*Output only the audio signals of the CD

Phono

jacks

Square

optical

output

connector

0.0035 % or less

(±0.001 % W. PEAK) or

less

0.0039 % or less

(±0.001 % W. PEAK) or

less

level

2 Vrms (at

50 kilohms)

–18 dBm (Light

Load

impedance

Over 10

kilohms

emitting

wave length:

660 nm)

General

Laser Semiconductor laser

Power requirements 230 V AC, 50/60 Hz

Power consumption 15 W

Dimensions (w/h/d) 430 95 283 mm incl.

Mass (approx.) 3.1 kg

Supplied accessories

Audio connecting cord Red and White 2 (1)

Remote commander RM-SX800 (1)

Battery R6 (size-AA) (2)

Design and specifications are subject to change

without notice.

(Super Audio CD: λ = 650

nm) (CD: λ = 780 nm)

Emission duration:

continuous

××

projecting parts

×

9-879-005-04

2006B16-1

© 2006.02

SUPER AUDIO CD PLAYER

Sony Corporation

Home Audio Division

Published by Sony Techno Create Corporation

SCD-XE597

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 3

2. GENERAL ................................................................... 4

3. DISASSEMBLY

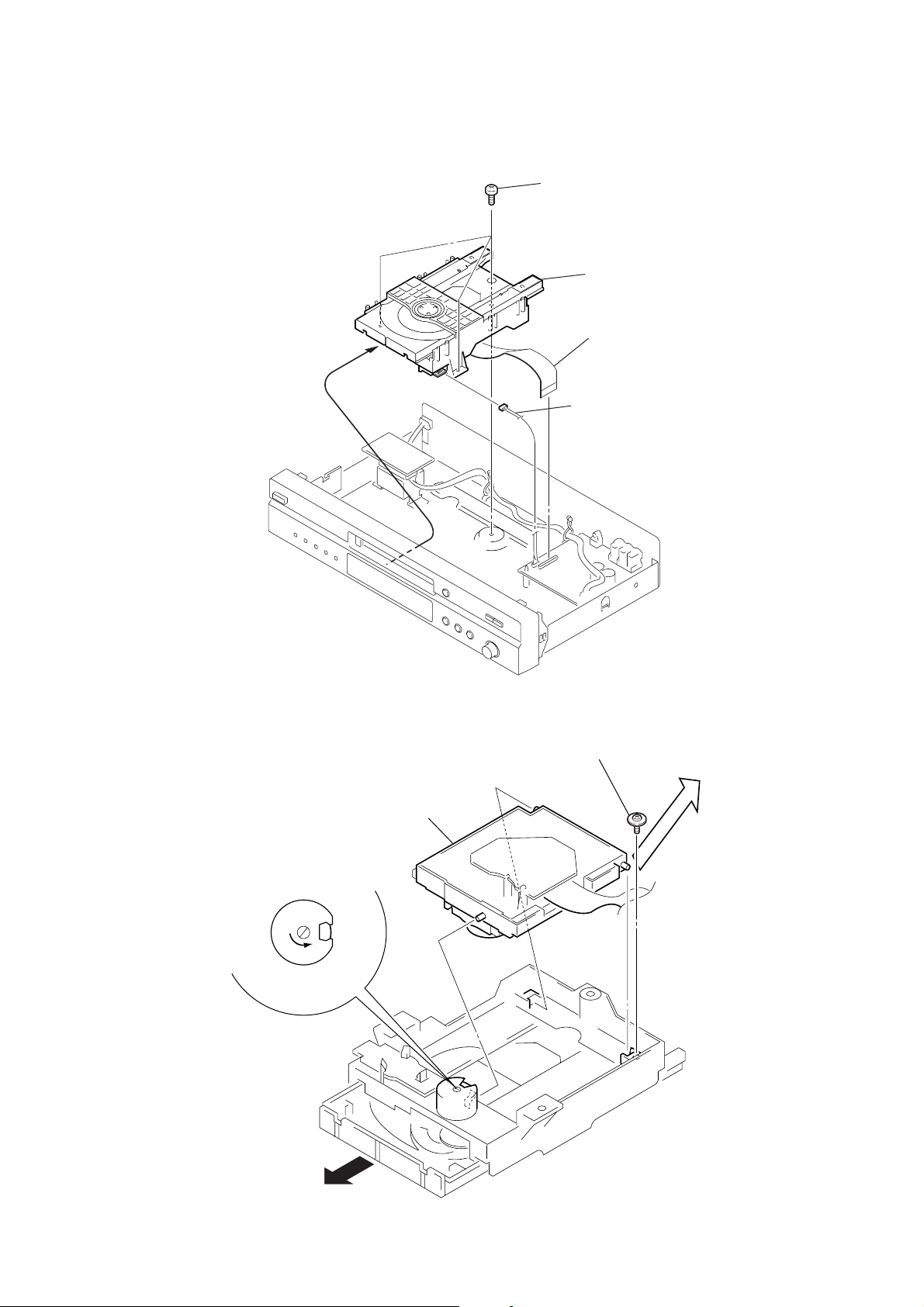

3-1. Disassembly Flow ........................................................... 6

3-2. Cover ............................................................................... 6

3-3. MAIN Board.................................................................... 7

3-4. Loading Panel..................................................................7

3-5. Front Panel Section ......................................................... 8

3-6. KEY Board, DISPLAY Board ......................................... 8

3-7. CD Mechanism Deck (CDM66D-DVBU50) .................. 9

3-8. Base Unit (DVBU50) ...................................................... 9

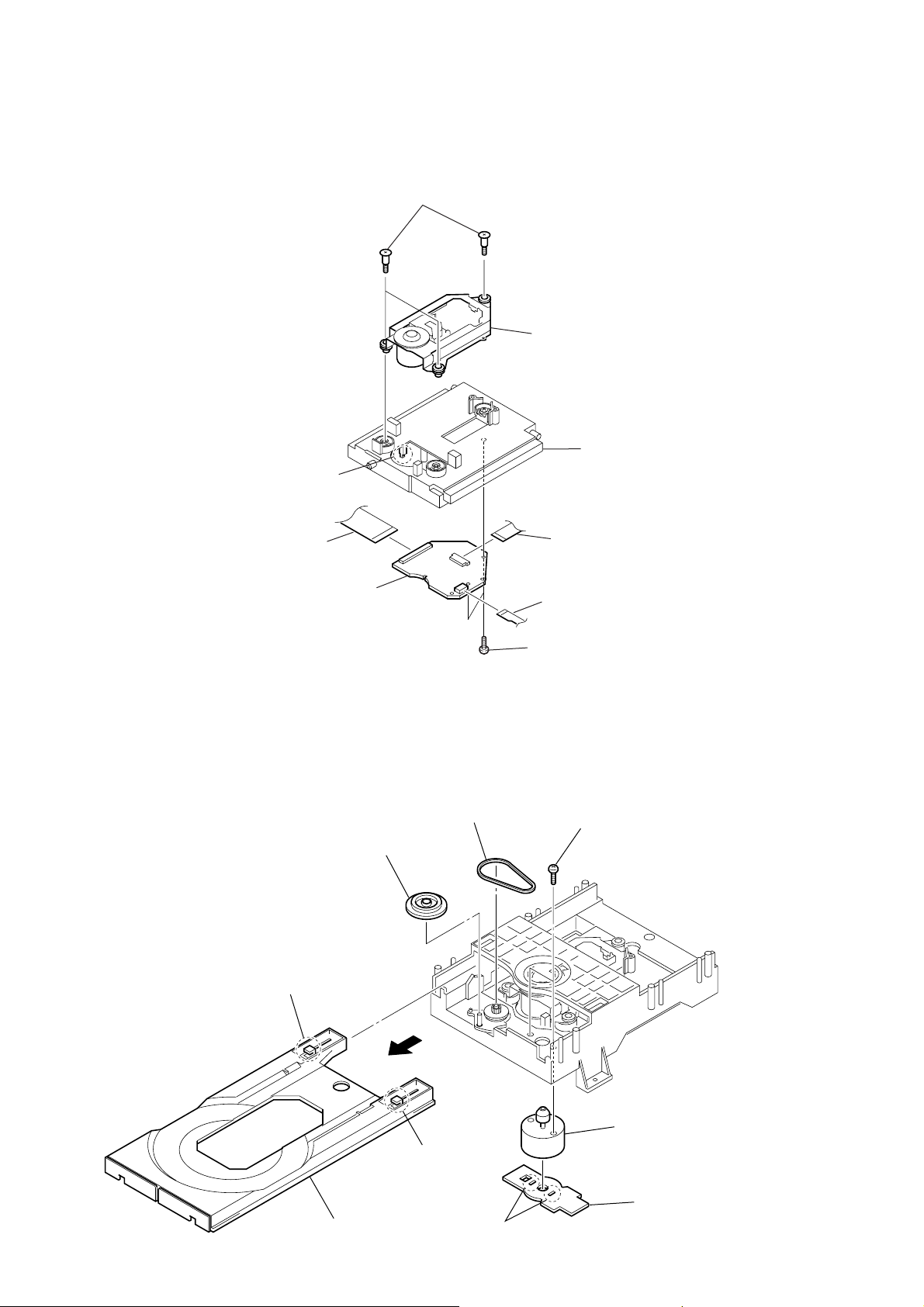

3-9. RF Board, Pick-up Unit (DBU-3) ................................... 10

3-10. Belt (LD), LOADING Board, Motor (L) Assy................ 10

4. DIAGRAMS

4-1. Block Diagram ................................................................ 12

4-2. Printed Wiring Board — RF Section — ......................... 13

4-3. Schematic Diagram — RF Section — ........................... 14

4-4. Printed Wiring Board — MAIN Section — ................... 15

4-5. Schematic Diagram — MAIN Section (1/4) — ............ 16

4-6. Schematic Diagram — MAIN Section (2/4) — ............ 17

4-7. Schematic Diagram — MAIN Section (3/4) — ............ 18

4-8. Schematic Diagram — MAIN Section (4/4) — ............ 19

4-9. Printed Wiring Board — DISPLAY Section — ............ 20

4-10. Schematic Diagram — DISPLAY Section — ................ 21

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

This appliance is

classified as a CLASS 1

LASER product. This

label is located on the

rear exterior.

5. TEST MODE ............................................................... 22

6. EXPLODED VIEWS

6-1. Main Section.................................................................... 23

6-2. Front Panel Section ......................................................... 24

6-3. CD Mechanism Deck ...................................................... 25

6-4. Base Unit (DVBU50) ...................................................... 26

7. ELECTRICAL PARTS LIST................................27

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output three times.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 °C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

SECTION 1

SERVICING NOTES

SCD-XE597

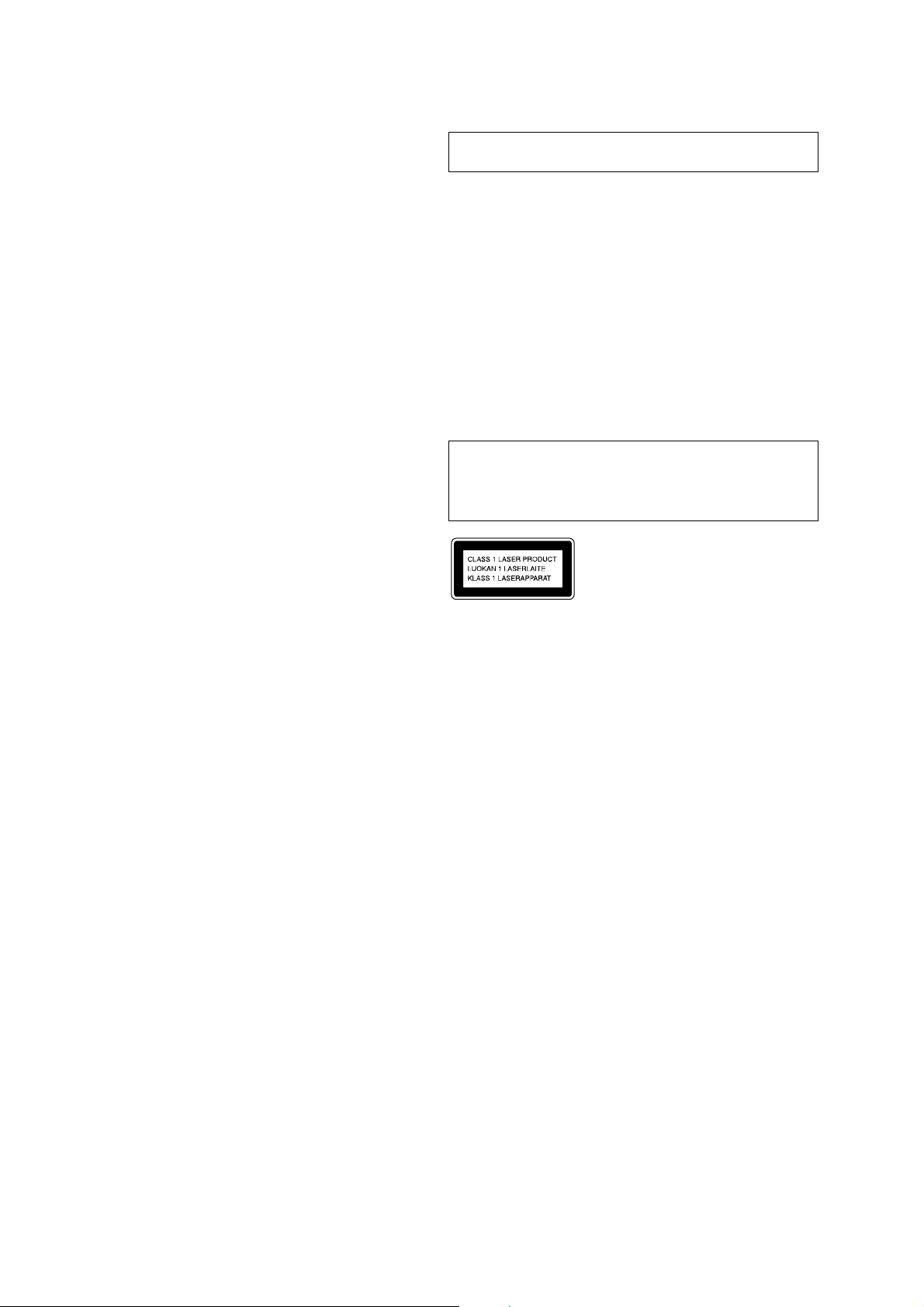

HOW TO OPEN THE DISC TRAY WHEN POWER SWITCH

TURNS OFF

Insert a tapering driver into the aperture of the unit bottom, and turn

in the direction of arrow.

Use a flat (-) head screwdriver to open the disc tray by manual

operation. (Flat head screwdriver with nominal blade length of

3mm.)

* To close the disc table, turn the driver in the reverse direction.

tapering driver

MODEL IDENTIFICATION

– Back Panel –

Parts No.

MODEL Part No.

AEP Model 4-255-245-0[ ]

UK Model 4-255-245-1[ ]

3

SCD-XE597

9q

q

q

q

q

q

q

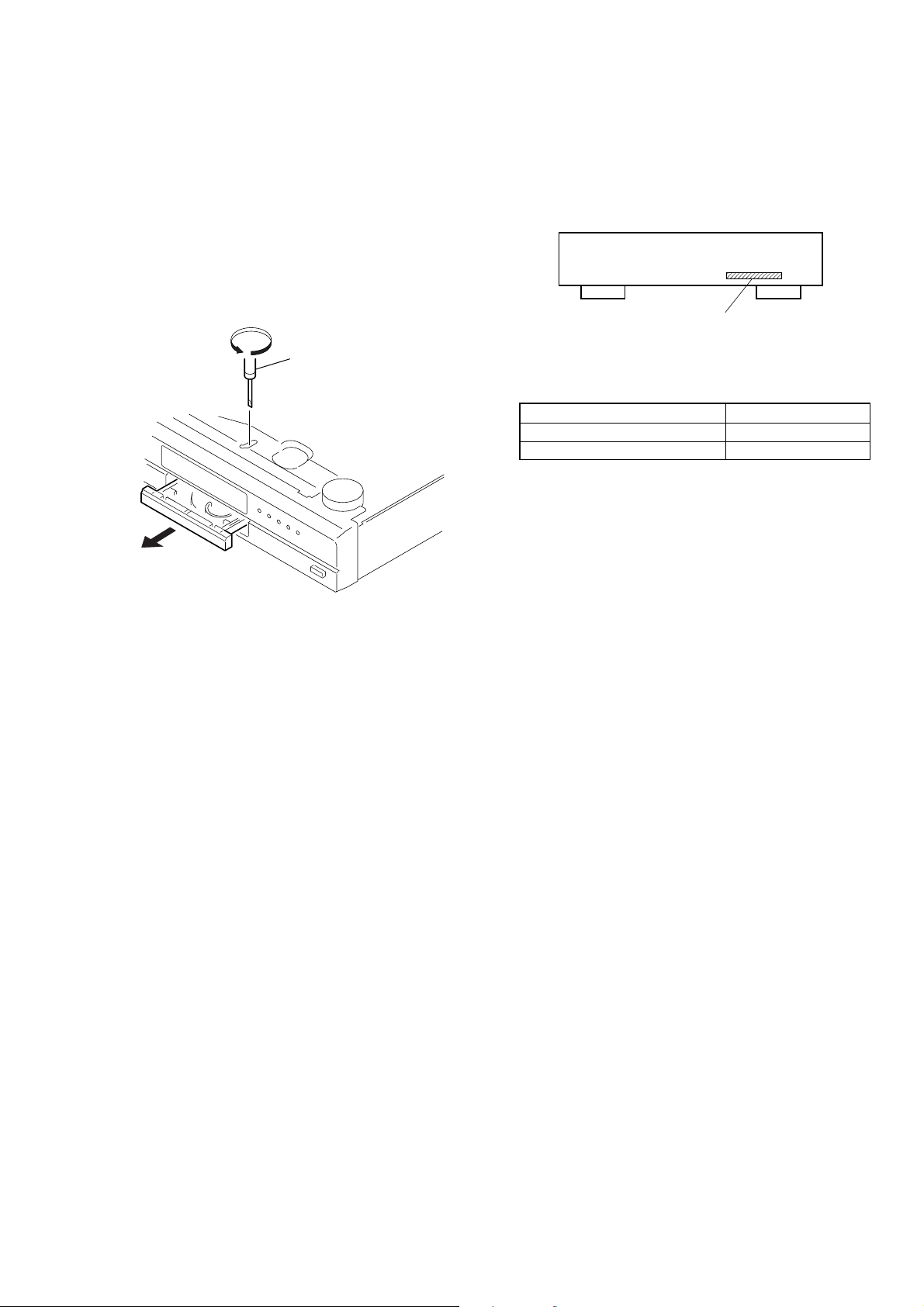

Front Panel

123 45 678

SECTION 2

GENERAL

d

h

g

f

s

a

This section is extracted

from instruction manual.

lL

;

A POWER switch (9)

B SA-CD/CD button (5, 9)

Each time you press the button while playing back

a hybrid disc, the layer to be played back switches

between the SA - CD layer and the CD la yer.

C PLAY MODE button (13, 14)

Press to select the pl ay mo de .

D Disc tray (9)

E MULTI CHANNEL DECODING indicator

Turns on when you turn on the player, or when the

Multi-channel Super Audio CD is loaded and

select the multi-channel playback area by pressing

MULTI/2CH.

F A button (9)

G x button (9, 14)

H m/M buttons (12)

I l AMS L dial

(AMS: Automatic Music Sensor) (8, 9, 10,

12, 14, 15, 16, 18)

J X button (9)

K H button (9, 12, 13, 14)

L Display window (10)

M Remote sensor (6)

N TIME/TEXT button (11)

Each time you press the button, the playing time of

the track, the remaining time of the disc, or TEXT

information appea r s in the display.

O MULTI/2CH button (5, 9)

Press to select the playback area when a disc with

the 2 channel area and the multi-channel area

(page 5) is loaded.

P MENU button (8, 9, 10, 12, 15, 16, 18)

Press to enter the menu.

Press to exit from the menu and return to the

normal display.

4

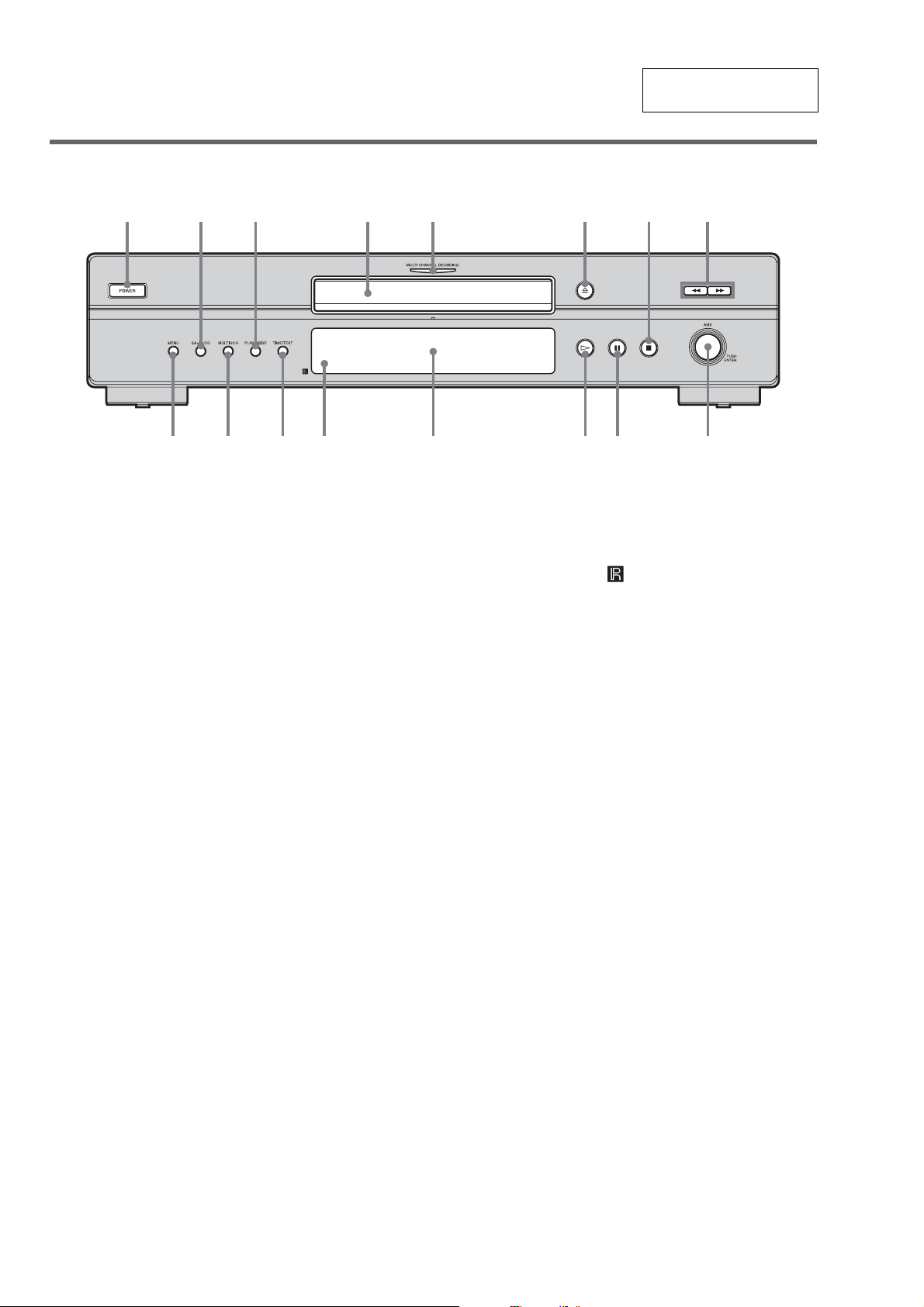

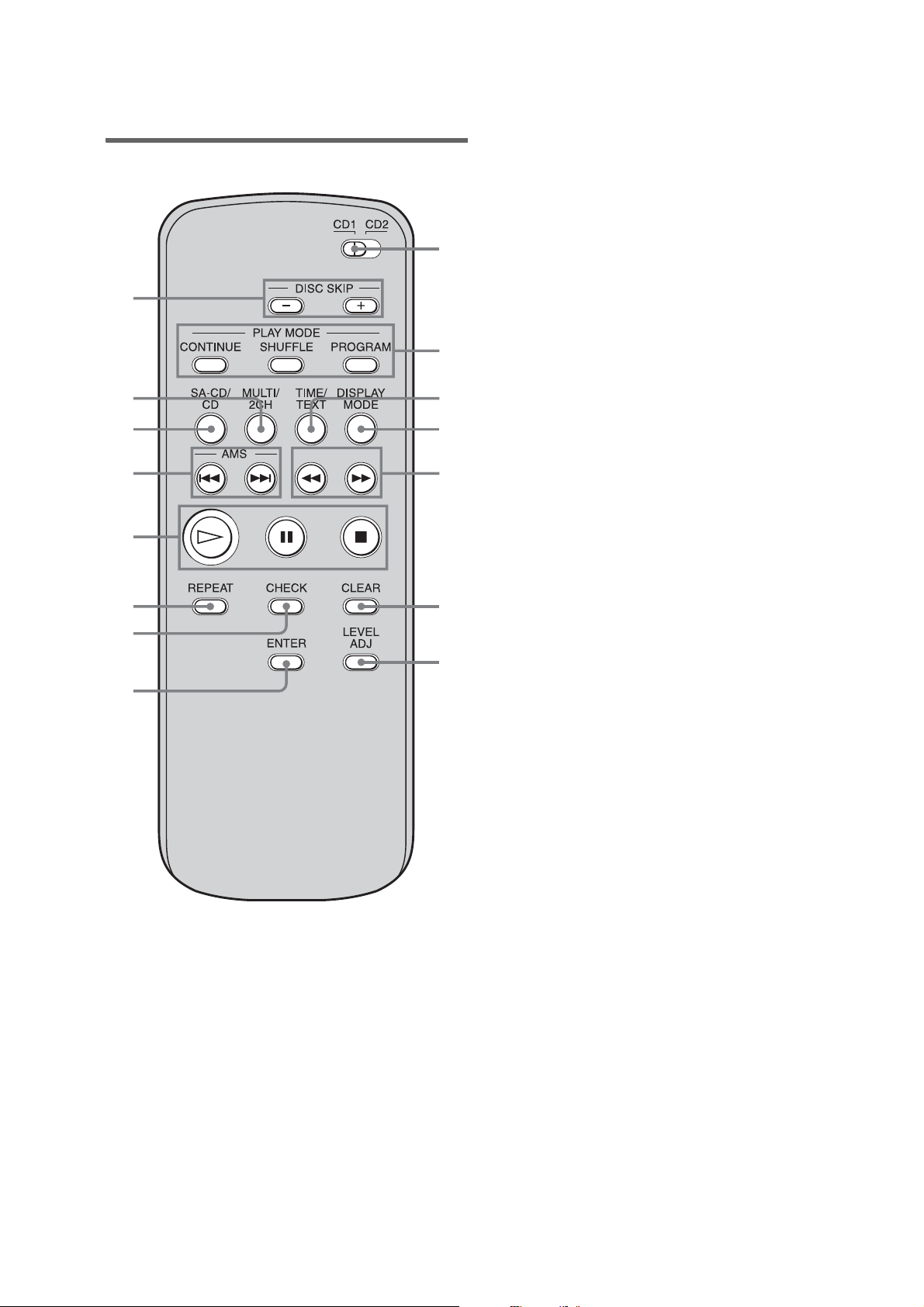

Remote

A CD1/ 2 (command mode ) switch (8)

Select the comman d mod e.

B CONTINUE button (13, 14)

Press to resume Continuous Play from Shuffle Play

or Program Play.

SHUFFLE button (13)

PROGRAM button (14)

C TI ME/TEXT button (11)

Each time you press the button, the playing time of

the track, the remaining time of the disc, or TEXT

information appe ars in the display.

D DISPLAY MODE button (12)

Press to turn the display information off or on.

E m/M buttons (12)

F CLEAR button (14)

Press to delete a progra me d tr a ck number.

G LEVEL ADJ button (17)

Press to adjust the output level balance for the

Multi-channel management fun ct ion ( pa g e 15).

H ENTER button (8, 9, 10, 12, 14, 15, 17, 18)

I CHECK button (14)

Press to check the programed order.

J REPEAT button (13)

K H button (9, 12, 13, 14)

X button (9)

x button (9, 14)

L AMS ./> buttons

(AMS: Automatic Music Sensor) (8, 9, 10,

12, 14, 15, 17, 18)

M SA-CD/CD button (5, 9)

Each time you press the button while playing back

a hybrid disc, the layer to be played back switches

between the SA-CD layer and the CD layer.

N MUL TI/2CH button (5, 9)

Press to select the playback area when a disc with

the 2 channel area and the multi-channel area

(page 5) is loaded.

O DI SC SKIP +/– buttons*

Press to select the disc .

*This button cannot be used in this player.

qg

qf

qd

qs

qa

q;

9

8

1

2

3

4

5

6

7

SCD-XE597

5

SCD-XE597

s

•This set can be disassembled in the order shown below.

•The dotted square with arrow (

completed.

3-1. DISASSEMBLY FLOW

SET

) prompts you to move to the next job when all of the works within the dotted square ( ) are

SECTION 3

DISASSEMBLY

3-2.COVER

(Page 6)

3-3.MAIN BOARD

(Page 7)

3-5. FRONT PANEL SECTION

(Page 8)

3-6.KEY BOARD,

DISPLAY BOARD

(Page 8)

Note: Follow the disassembly procedure in the numerical order given.

3-4.LOADING PANEL

3-7.CD MECHANISM DECK

(CDM66D-DVBU50)

3-8.BASE UNIT (DVBU50)

3-9. RF BOARD,

PICK-UP UNIT (DBU-3)

3-2. COVER

1

two screws

(case 3)

(Page 7)

(Page 9)

(Page 9)

(Page 10)

cover

3

screw

(+BVTP 3

3-10. BELT (LD), LOADING BOARD,

MOTOR (L) ASSY

(Page 10)

×

8)

4

5

4

2

two screw

(case 3)

6

3-3. MAIN BOARD

)

3

wire (flat type)

(13 core) (CN703)

4

wire (flat type)

(31 core) (CN702)

6

screw

(+BVTP 3

2

×

8)

connector

(8p) (CN901)

8

MAIN board

5

three screws

(+BVTP 3

SCD-XE597

×

8

3-4. LOADING PANEL

1

1

tapering driver

connector

(5p) (CN151)

7

PWB holder

3

two claws

4

loading panel

2

7

SCD-XE597

)

)

3-5. FRONT PANEL SECTION

3

connector (CN101)

2

connector (CN891)

4

claw

5

1

claw

wire (flat type)

(13 core) (CN703

3-6. KEY BOARD, DISPLAY BOARD

6

LED board

1

knob (AMS)

3

6

bracket

7

front panel section

three screws

(+BVTP 3 × 8)

8

connector (CN813)

9

KEY board

7

three screws

(+BVTP 2.6

×

8

5

connector (CN814)

4

two screws

(+BVTP 2.6

×

8)

2

two screws

(+BVTP 2.6

×

8)

qa

DISPLAY board

q;

seven screws

(+BVTP 2.6

×

8)

8

3-7. CD MECHANISM DECK (CDM66D-DVBU50)

k

3

three screws

(+BVTP 3

4

CD mechanism dec

(CDM66D-DVBU50)

1

wire (flat type)

(31 core) (CN702)

2

connector

(5p) (CN151)

SCD-XE597

×

8)

3-8. BASE UNIT (DVBU50)

1

Turn the cam to the direction of

arrow (counter clock wise) by

tapering driver.

DVBU50

3

screw (DIA. 12), floating

4

Remove the Base unit

(DVBU50) to the direction

of arrow.

2

Take off the tray.

9

SCD-XE597

)

3-9. RF BOARD, PICK-UP UNIT (DBU-3)

2

hook

7

three screws

(step screw (M))

8

pick-up unit (DBU-3)

holder (66D)

5

wire (flat type) (CN002)

6

RF board

3-10. BELT (LD), LOADING BOARD, MOTOR (L) ASSY

5

gear (LD)

1

claw

6

belt (LD)

4

CN001

3

flexible board (

1

two screws

(BTTP M2.6)

7

CN003

two screws

×

4)

(B 2.6

10

4

tray (66)

3

2

claw

8

Removal the solders.

0

motor (L) assy

9

LOADING board

SECTION 4

d

DIAGRAMS

SCD-XE597

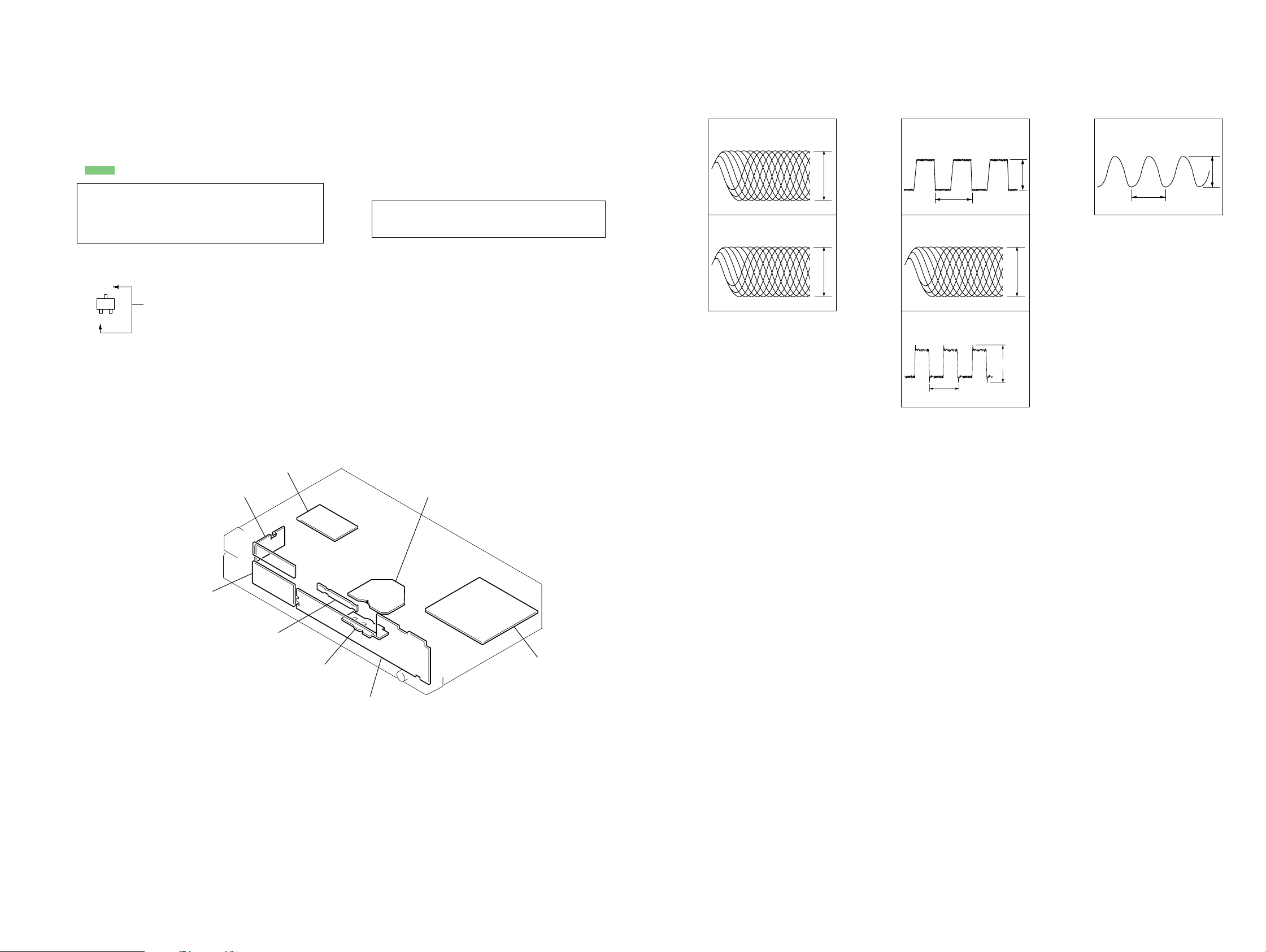

NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• W : indicates side identified with part number.

• f : internal component.

• : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

• Indication of transistor.

C

Q

B

E

These are omitted.

Note Schematic Diagrams.

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except f or electrolytics and

tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• C : panel designation.

Note: The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

• A : B+ Line.

• B : B– Line.

•Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark: SACD PLAY

( ): CD PLAY

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD

c : CD DIGITAL OUT (OPTICAL)

4

W or less unless otherwise

•Waveforms

– RF Board –

1 IC001 tl SIGO (CD)

200 ns/DIV

1 IC001 tl

40 ns/DIV

1.4 Vp-p

SIGO (SACD)

1.4 Vp-p

– MAIN Board – – DISPLAY Board –

2 IC706 uk DSPHREFO

354 ns

3 IC706 <z./

40 ns/DIV

3.5 Vp-p

RF IN (SACD)

1.4 Vp-p

5 IC801 5 IC

200 ns

4 IC320 2,4,6,q;,qs

3.3 Vp-p

88.6 ns

3.5 Vp-p

• Circuit Boards Location

POWER SW board

KEY board

PT board

LED board

LOADING board

RF board

MAIN boar

DISPLAY board

SCD-XE597

1111

Loading...

Loading...