Sony SA-WMS356, SA-WMS556 Service Manual

SERVICE MANUAL

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

AEP Model

UK Model

SUBWOOFER

9-877-843-01

2004E0478-1

© 2004.05

Ver 1.0 2004.05

SPECIFICATIONS

SA-WMS356/WMS556

• SA-WMS356/WMS556 are the subwoofer

section in SA-VE356T/VE556H.

Speaker system Active subwoofer,

magnetically shielded

Speaker unit Woofer: 15 cm × 2, cone type

Enclosure type Acoustically loaded

Bass Reflex

Reproduction frequency range

28 Hz - 200 Hz

Amplifier section

Continuous RMS power output

SA-WMS356:

120 W (6 ohms, 100 Hz,

10 % THD)

SA-WMS556:

150 W (6 ohms, 100 Hz,

10 % THD)

Inputs

INPUT (input pin jack)

General

Power requirements

230 - 240 V AC, 50/60 Hz

Power consumptions

120 W

1 W (standby mode)

Dimensions (w/h/d)

Approx. 180 × 405 × 501 mm,

including front grille

Mass Approx. 12 kg

Design and specifications are subject to change

without notice.

2

SA-WMS356/WMS556

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PAR TS WHOSE

PART NUMBERS APPEAR AS SHO WN IN THIS MANU AL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

TABLE OF CONTENTS

1. DIAGRAMS

1-1. Printed Wiring Board – MAIN Section – ........................ 5

1-2. Schematic Diagram – MAIN Section –........................... 6

1-3. Printed Wiring Board – CONTROL Section –................ 7

1-4. Schematic Diagram – CONTROL Section –................... 8

2. EXPLODED VIEWS

2-1. Front Panel Section ......................................................... 9

2-2. Rear Cover Section .......................................................... 10

2-3. Bottom Panel Section ...................................................... 11

3. ELECTRICAL PARTS LIST .................................. 12

3

SA-WMS356/WMS556

SECTION 1

DIAGRAMS

For Schematic Diagrams.

Note:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except f or electrolytics and

tantalums.

• All resistors are in Ω and 1/

4

W or less unless otherwise

specified.

• f : internal component.

• C : panel designation.

• A : B+ Line.

• B : B– Line.

•Voltages and wavef orms are dc with respect to ground under no-signal (detuned) conditions.

no mark: Power on

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage v ariations ma y be noted due to normal production

tolerances.

• Signal path.

F : AUDIO

For Printed Wiring Boards.

Note:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

Note: The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

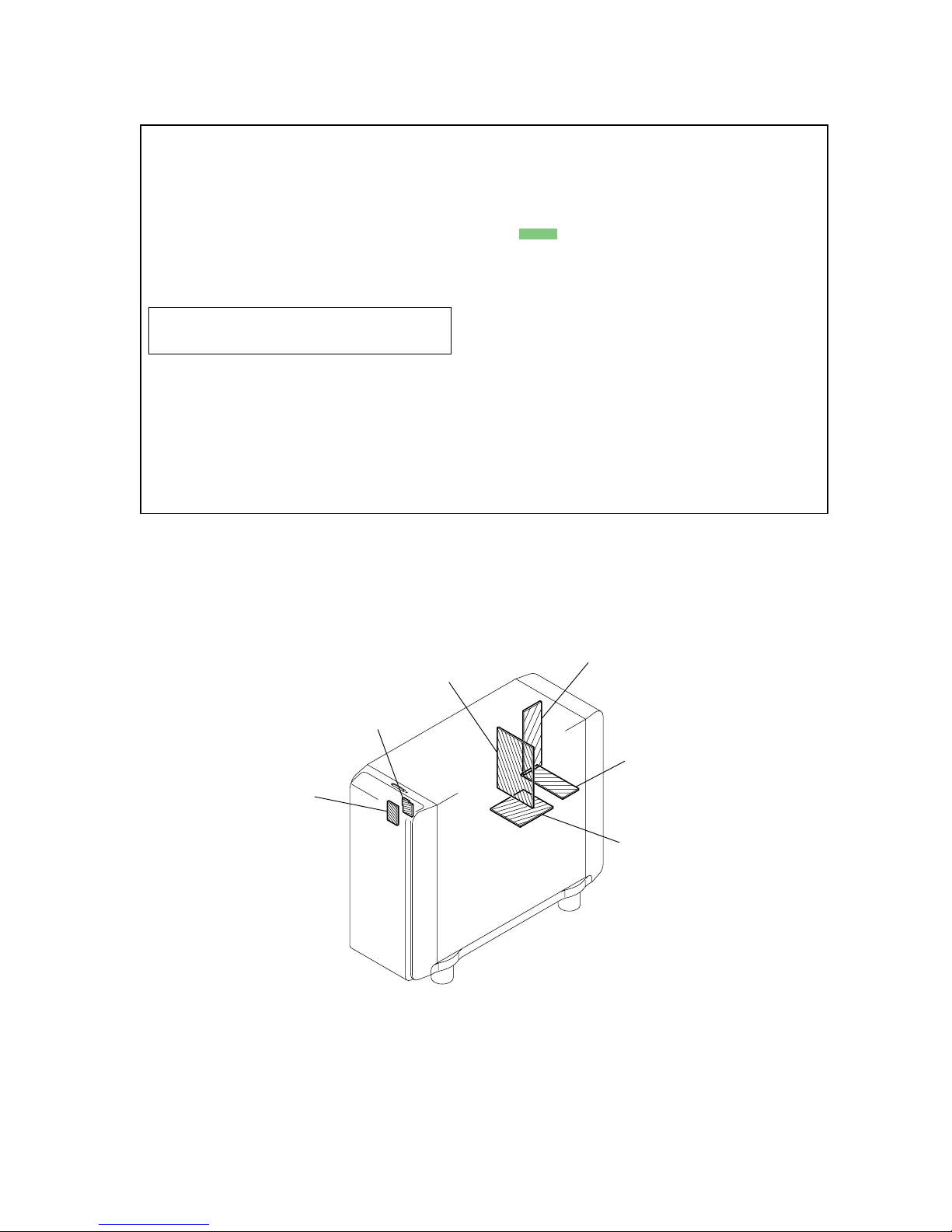

LED board

MAIN board

CONTROL board

POWER AMP board

POWER SUPPLY board

POWER SWITCH board

NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

• Circuit Boards Location

4

SA-WMS356/WMS556

1 2 3 4 5 6 7 8 9 10 11 12 13

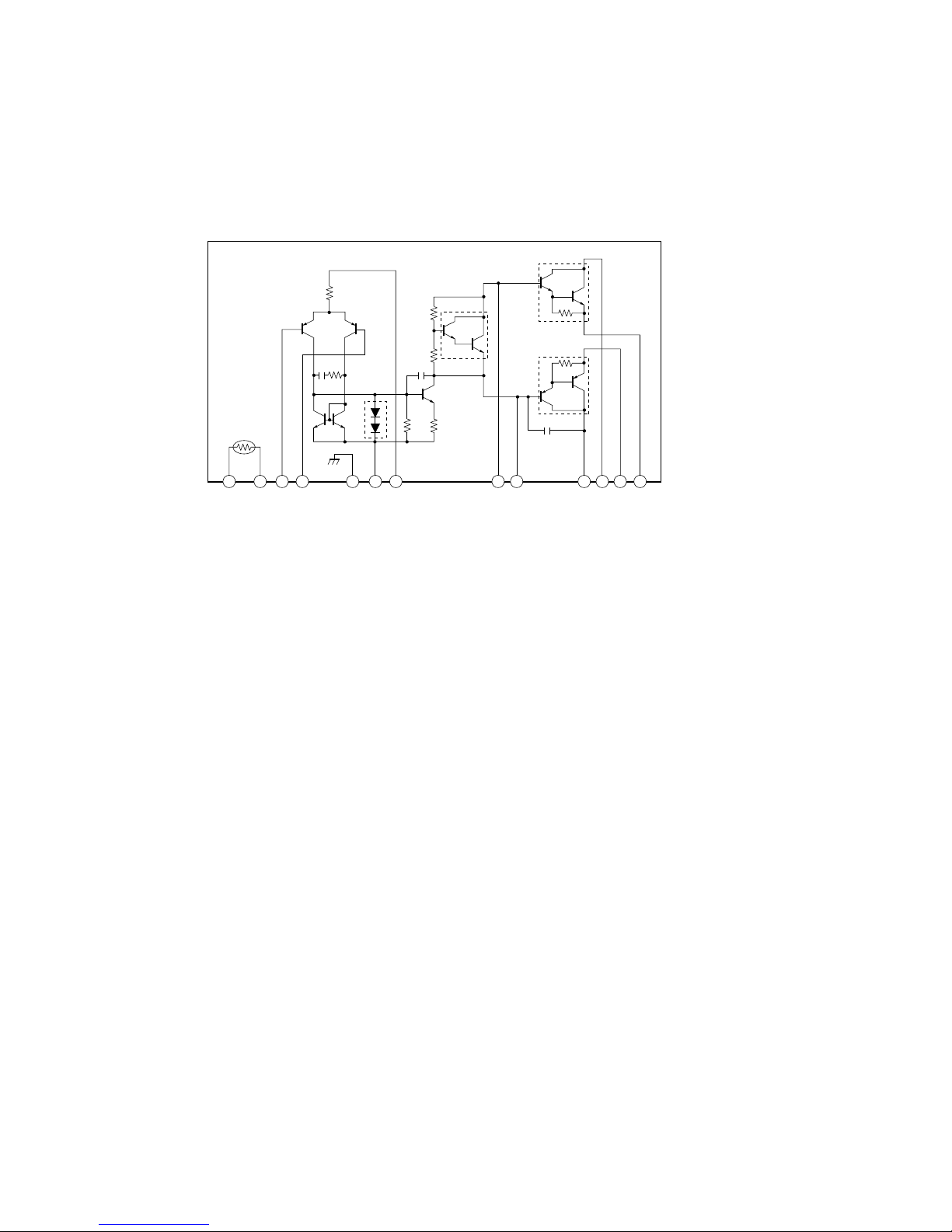

IC701 STK404-140S

• IC Block Diagram

– POWER AMP Board –

55

SA-WMS356/WMS556

1

A

B

C

D

E

F

G

H

I

234567891011 12 13 14

C713

Q702

R706

C701

R702

R703

R701

CN701

C707

R708

R714

C710

D701

D702

D703

Q701

R711

R709

R710

R707

C705

R705

R712

R713

R704

C712

JW703

JW704

JW

707

C702

C704

IC701

R715

R716

R717

C703

C708

C709

C706

JW

705

JW

708

JW

702

JW

701

CN702

C711

JW

709

C716

JW

711

C715

C714

D202

BC201

BC903

T102

CN1

F901

T202

C901

D901

RY901

BC901

BC902

F11

F12

JW

053

JW

052

JW

051

C902

CN904

C201

S201

BC202

BC801

D805

C801

C802

C803

C804

BC802

R303

R304

C301

C302

C305

C306

C307

C308

D301

D302

D303

D304

D305

D306

R101

R102

R103

R104

R105

R106

C101

C102

Q104

Q105

R531

R532

R534

R535

R536

R537

R538

R539

R540

R542

C531

D532

D533

R404

R405

R400

D400

D401

C401

C403

Q401

Q402

Q403

RY400

BC401

CN804

CN805

IC530

BC803

Q532

R533

D531

R401

R406

G1

G2

JW

801

JW802

JW807

JW

809

JW

810

JW

811

JW813

JW814

JW816

JW

817

JW

818

JW

819

JW820

JW821

JW822

JW823

JW

824

JW825

JW826

JW

828

JW

829

JW830

JW832

JW833

C303

C304

JW808

C532

Q404

Q533

Q534

Q535

JW

834

JW835

JW812

Q102

Q101

Q103

JW837

C402

JW827

R402

R403

Q301

Q302

Q531

C806

JW

805

JW804

C805

R800

JW301

JW302

R541

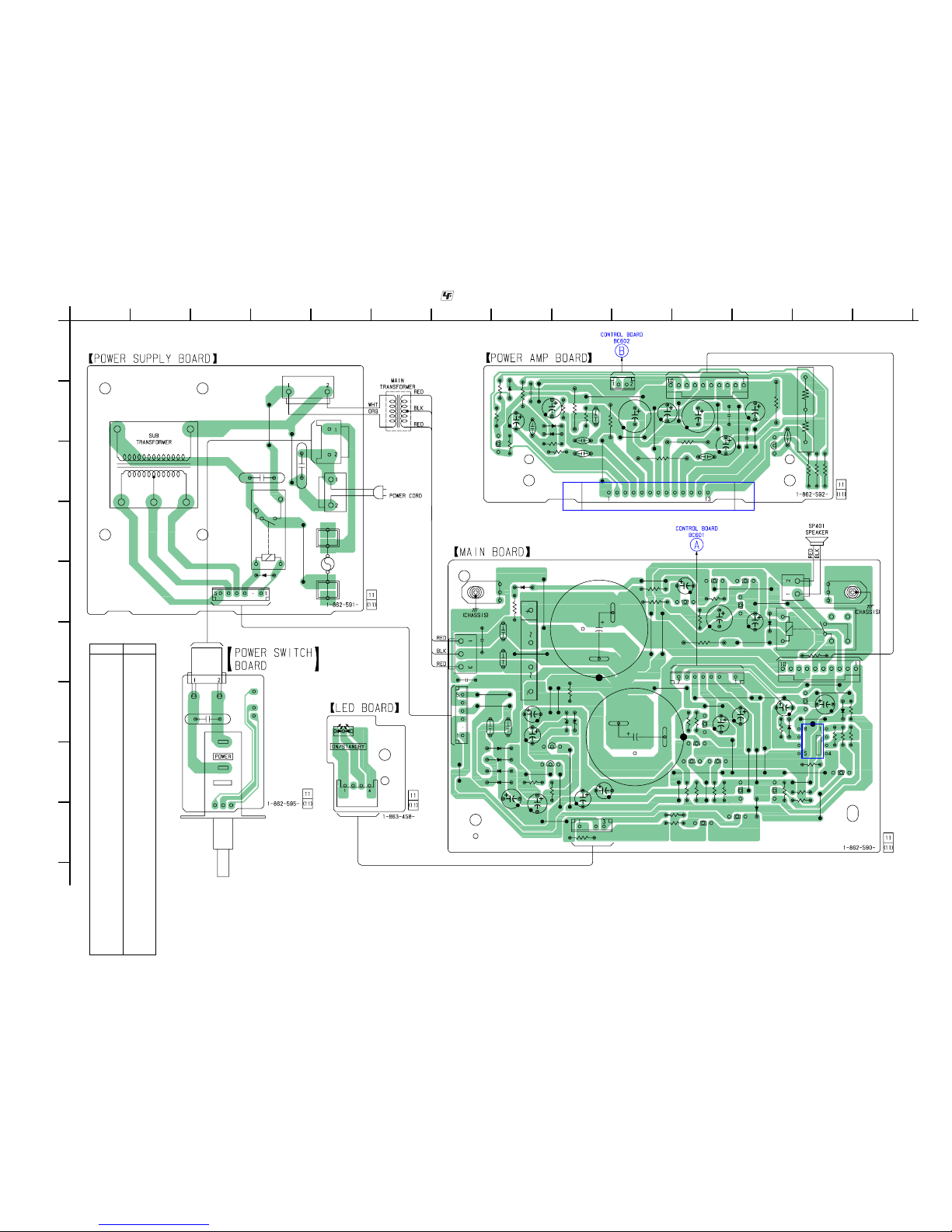

1-1. PRINTED WIRING BOARD — MAIN SECTION —

• See page 3 for Circuit Boards Location. :Uses unleaded solder.

• Semiconductor

Location

Ref. No.

Location

D202 I-3

D301 H-8

D302 H-8

D303 H-8

D304 I-8

D305 H-9

D306 H-9

D400 F-12

D401 E-8

D531 H-12

D532 G-13

D533 I-12

D701 B-9

D702 B-9

D703 B-8

D805 F-8

D901 E-4

IC530 H-13

IC701 C-10

Q101 H-11

Q102 H-11

Q103 H-11

Q104 I-12

Q105 H-11

Q301 H-9

Q302 H-9

Q401 F-11

Q402 E-11

Q403 F-12

Q404 E-12

Q531 G-13

Q532 I-12

Q533 H-13

Q534 I-12

Q535 I-11

Q701 C-8

Q702 C-12

(Page 7)

(Page 7)

Loading...

Loading...