Page 1

HT-GT1

T

SA-WGT1

SERVICE MANUAL

Ver. 1.2 2015.01

• All of the units included in the HT-GT1 (SA-WGT1/SS-GT1)

are required to confi rming operation of SA-WGT1. Check in

advance that you have all of the units.

Note:

Be sure to keep your PC used for service and

checking of this unit always updated with the

latest version of your anti-virus software.

In case a virus affected unit was found during

service, contact your Service Headquarters.

COMPONENT MODEL NAME

HT-GT1

Bar Speaker (Speaker System) SS-GT1

Subwoofer (Active Subwoofer) SA-WGT1

• Please refer to service manual separately issued for Bar

Speaker.

US Model

AEP Model

UK Model

E Model

Australian Model

Amplier section

U.S. model:

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION (FTC output

power):

Front L/Front R:

With 3 ohms loads, both channels

driven, from 400 – 10,000 Hz;

rated 32 watts per channel

minimum RMS power, with no

more than 1.0% total harmonic

distortion from 250 milliwatts to

rated output.

Output power (reference):

Front L/Front R:

40 W + 40 W (per channel at 3

kHz)

ohms, 1

Subwoofer:

180 W (at 4 ohms, 100 Hz)

Brazilian model:

otal RMS output power:

200W

Front L/Front R:

RMS output power:

80W (40W per channel × 2, at

3ohms, 1kHz, 10% THD*)

Subwoofer:

RMS output power:

120W (at 4ohms, 100Hz, 10%

THD*)

Other models:

Power output (rated):

Front L/Front R:

32 W + 32 W (at 3 ohms, 1 kHz, 1%

THD*)

Power output (reference):

Front L/Front R:

40 W + 40 W (per channel at

3ohms, 1 kHz)

Subwoofer:

180 W (at 4 ohms, 100 Hz)

* Total Harmonic Distortion

Speaker section

Speaker system:

Subwoofer, Bass reflex

Speaker unit:

1

180 mm (7

Rated impedance:

Inputs

AUDIO IN/PARTY CHAIN IN L/R:

OPT IN:

Outputs

AUDIO OUT/PARTY CHAIN OUT L/R:

Tuner section

FM stereo, FM superheterodyne tuner

Antenna:

Tuning range:

/8 in), cone type

4 ohms

Voltage 0.8 V, impedance

47 kilohms

Supported audio signal:

2-channel Linear PCM

Voltage 2 V, impedance 1 kilohm

FM lead antenna

USA and Brazilian models:

87.5MHz - 108.0MHz (100kHz

step)

Other models:

87.5MHz - 108.0MHz (50kHz

step)

SPECIFICATIONS

BLUETOOTH section

Communication system:

BLUETOOTH Standard version 3.0

Output:

BLUETOOTH Standard Power

Class 2

Maximum communication range:

Line of sight approx. 10 m

1)

(33 feet)

Frequency band:

2.4 GHz band (2.4000 GHz –

2.4835 GHz)

Modulation method:

FHSS (Freq Hopping Spread

Spectrum)

Compatible BLUETOOTH profiles

A2DP (Advanced Audio

Distribution Profile)

AVRCP 1.3 (Audio Video Remote

Control Profile)

Supported codecs:

SBC (Sub Band Codec)

AAC (Advanced Audio Coding)

1)

The actual r ange will vary depending

on factors such as obstacles between

devices, magnetic fields around a

microwave oven, static electricity,

reception sensitivity, antenna’s

performance, operating system,

software application, etc.

2)

BLUETOOTH standard profiles

indicate the purpose of BLUETOOTH

communication between devices.

2)

:

USB section

Supported format:

MP3 (MPEG 1 Audio Layer-3):

32 kbps – 320 kbps, VBR

WMA:

48 kbps – 192 kbps

AAC:

48 kbps – 320 kbps

WAV:

16 bit PCM

Sampling frequencies:

MP3 (MPEG 1 Audio Layer-3):

32 kHz/44.1 kHz/48 kHz

WMA:

32 kHz/44.1 kHz/48 kHz

AAC:

32 kHz/44.1 kHz/48 kHz

WAV:

8 kHz – 48 kHz

Supported USB device:

Mass Storage Class

Maximum current:

1 A

(USB) port:

Type A

General

Power requirements:

USA and Mexican models:

AC 120 V, 60 Hz

Latin American model (except for

Bolivian, Chilean, Argentine, and

Mexican models):

AC 110 V – 240 V, 50/60 Hz

Saudi Arabian,African and Irarian

models:

AC 120 V – 240 V, 50/60 Hz

Other models:

AC 220 V – 240 V, 50/60 Hz

Power consumption:

70 W

Power consumption (at the Power

Saving mode):

European model:

0.5 W (When BLUETOOTH standby

mode is set to off)

6 W (When BLUETOOTH standby

mode is set to on)

Other models:

0.5 W

Dimensions (W/H/D) (Approx.):

Active subwoofer:

290 mm × 420 mm × 275 mm

3

/8 in × 16 1/2 in × 10 7/8 in )

(11

Speaker system:

800 mm × 110 mm × 102 mm

1

/2 in × 4 3/8 in × 4 in )

(31

Mass (Approx.):

Active subwoofer:

1

7.1 kg (15 lb 10

/2 oz)

Speaker system:

3

/4 oz)

2.8 kg (6 lb 2

Quantity:

Active subwoofer:

1 piece

Speaker system:

1 piece

Supplied accessories

Optical digital cable (1)

Remote control (1)

R03 (Size AAA) batteries (2)

FM lead antenna (1)

Design and specifications are subject

to change without notice.

HT-GT1

SOUND BAR

SA-WGT1

ACTIVE SUBWOOFER

9-896-032-03

2015A33-1

2015.01

©

Sony Corporation

Published by Sony Techno Create Corporation

Page 2

HT-GT1

Ver. 1.1

License and Trademark Notice

MPEG Layer-3 audio coding

technology and patents licensed

from Fraunhofer IIS and Thomson.

Windows Media is either a

registered trademark or trademark

of Microsoft Corporation in

the United States and/or other

countries.

This product is protected by

certain intellectual property rights

of Microsoft Corporation. Use or

distribution of such technology

outside of this product is prohibited

without a license from Microsoft or

an authorized Microsoft subsidiary.

The BLUETOOTH® word mark and

logos are registered trademarks

owned by Bluetooth SIG, Inc. and

any use of such marks by Sony

Corporation is under license. Other

trademarks and trade names are

those of their respective owners.

The N Mark is a trademark or

registered trademark of NFC Forum,

Inc. in the United States and in other

countries.

Android™ is a trademark of Google

Inc.

Google Play™ is a trademark of

Google Inc.

iPhone and iPod touch are

trademarks of Apple Inc., registered

in the U.S. and other countries. App

Store is a service mark of Apple Inc.

“Made for iPod” and “Made for

iPhone” mean that an electronic

accessory has been designed

to connect specifically to iPod

or iPhone, respectively, and has

been certified by the developer

to meet Apple performance

standards. Apple is not responsible

for the operation of this device

or its compliance with safety and

regulatory standards. Please note

that the use of this accessory with

iPod or iPhone may affect wireless

performance.

All other trademarks and registered

trademarks are of their respective

holders. In this manual, ™ and ®

marks are not specified.

NOTES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

1.5 kΩ0.15 μF

Earth Ground

voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

Page 3

TABLE OF CONTENTS

HT-GT1

1. SERVICING NOTES ............................................. 4

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 6

2-2. Side L, R Panel ............................................................... 7

2-3. Top Panel Block .............................................................. 8

2-4. Front Panel Block ........................................................... 9

2-5. NFC Module (NFC1) ...................................................... 10

2-6. Bluetooth Module (BT1) ................................................ 11

2-7. PANEL Board Block ....................................................... 12

2-8. Button Assy ..................................................................... 13

2-9. Knob Assy ....................................................................... 14

2-10. Top Panel Assy ................................................................ 15

2-11. Rear Panel Block ............................................................ 16

2-12. DC Fan (M1) ................................................................... 17

2-13. TUNER Board ................................................................ 17

2-14. MAIN Board-1 ................................................................ 18

2-15. MAIN Board-2 ................................................................ 19

2-16. Sub Chassis ..................................................................... 20

2-17. Power Cord (AC1) .......................................................... 21

2-18. SMPS Board ................................................................... 22

2-19. Loudspeaker (18 cm) (SP1) ............................................ 23

2-20. Service Position .............................................................. 24

3. TEST MODE ............................................................ 25

4. ELECTRICAL CHECK ......................................... 27

5. TROUBLESHOOTING .......................................... 28

6. DIAGRAMS

6-1. Block Diagram - MAIN Section - ................................... 29

6-2. Block Diagram - AMP Section - ..................................... 30

6-3. Block Diagram

- PANEL/POWER SUPPLY Section - ............................ 31

6-4. Schematic Diagram - MAIN Section (1/5) - ................... 33

6-5. Schematic Diagram - MAIN Section (2/5) - ................... 34

6-6. Schematic Diagram - MAIN Section (3/5) - ................... 35

6-7. Schematic Diagram - MAIN Section (4/5) - ................... 36

6-8. Schematic Diagram - MAIN Section (5/5) - ................... 37

6-9. Printed Wiring Boards - MAIN Section (1/2) - .............. 38

6-10. Printed Wiring Board - MAIN Section (2/2) - ................ 39

6-11. Printed Wiring Boards - KEY Section - .......................... 40

6-12. Schematic Diagram - KEY Section - .............................. 41

6-13. Printed Wiring Board - PANEL Board - ......................... 42

6-14. Schematic Diagram - PANEL Board - ............................ 43

6-15. Printed Wiring Board - SMPS Board - ........................... 44

6-16. Schematic Diagram - SMPS Board - .............................. 45

7. EXPLODED VIEWS

7-1. Side Panel Section .......................................................... 53

7-2. Top Panel Section ........................................................... 54

7-3. Front Panel Section ......................................................... 55

7-4. MAIN Board Section ...................................................... 56

7-5. SMPS Board Section ...................................................... 57

7-6. Speaker Cabinet Section ................................................. 58

8. ELECTRICAL PARTS LIST .............................. 59

Accessories are given in the last of the electrical parts list.

3

Page 4

HT-GT1

Ver. 1.2

SECTION 1

SERVICING NOTES

The SERVICING NOTES contains important information for servicing. Be sure to read this section before repairing the unit.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

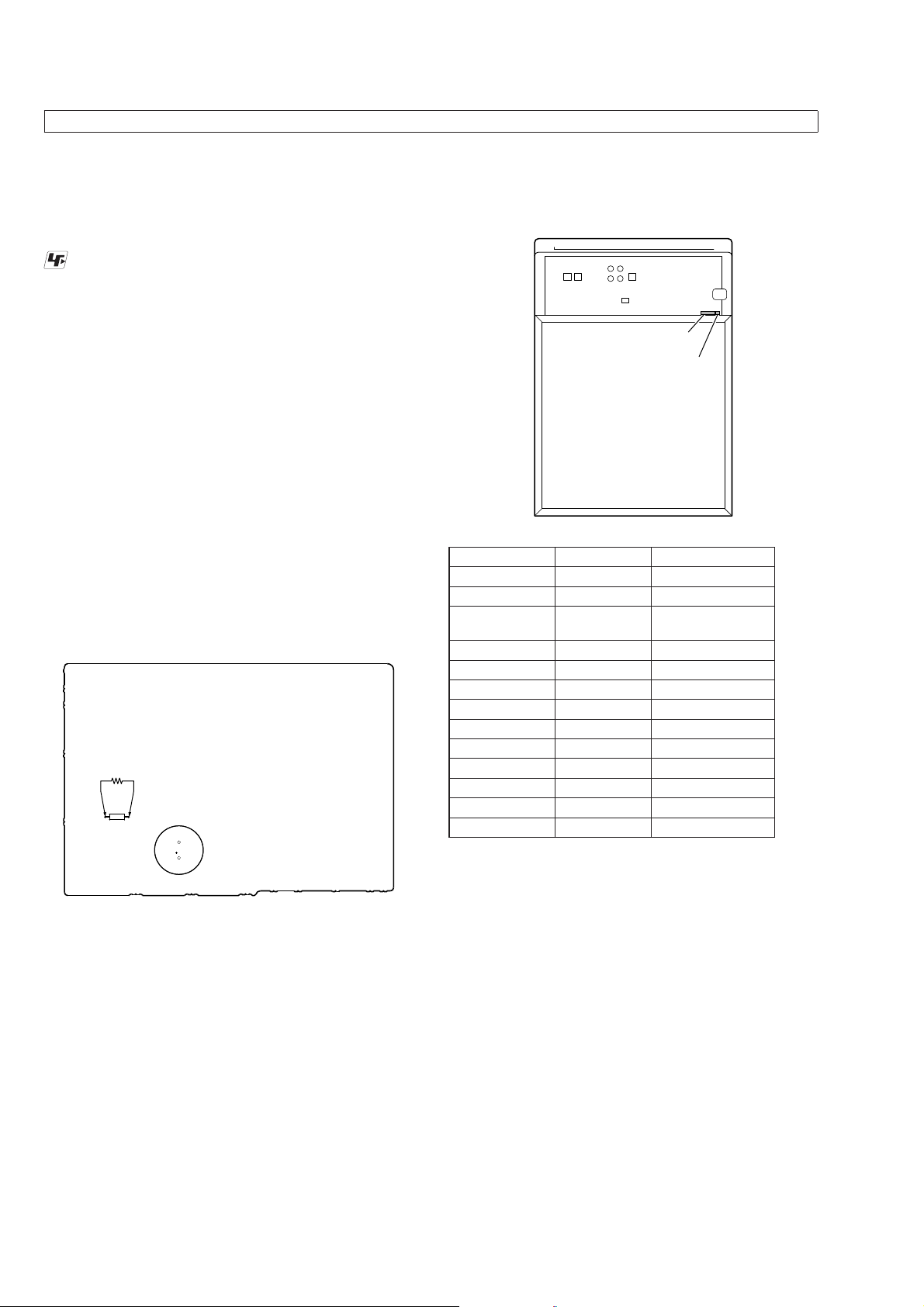

CAPACITOR ELECTRICAL DISCHARGE PROCESSING

When checking the board, for the electric shock prevention, connect the resistors to both ends of resistor (R156) to discharge the

capacitor (C129).

– SMPS Board (Component Side) –

800 :/2 W

R156

C129

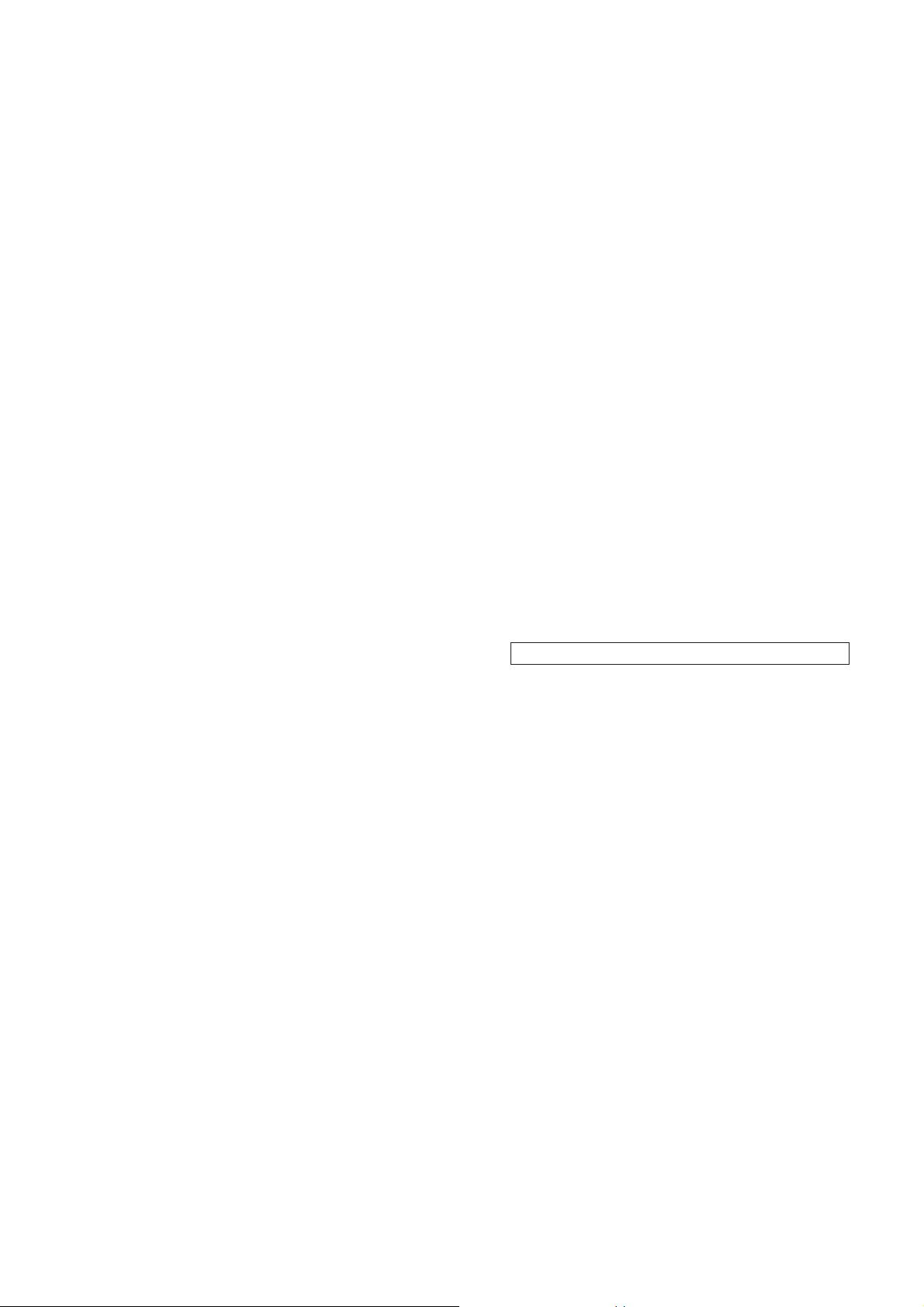

MODEL IDENTIFICATION

Distinguish by Part No. and destination code on the back side of

a main unit.

– Back panel view –

Part No.

Destination code

Destination Part No. Destination code

Latin American

US

Indian, African,

Iranian

AEP, UK

Brazilian

Chilean, Peruvian

Mexican

Argentina

Saudi Arabia

Russian

Singapore

Australian

Thai

4-540-495-0[]

4-540-495-1[]

4-540-495-2[]

4-540-495-3[]

4-540-495-4[]

4-540-495-5[]

4-540-495-6[]

4-540-495-7[]

4-540-495-8[]

4-540-495-9[]

4-543-516-0[]

4-543-516-1[]

4-543-516-2[]

E32

U2

E12, E3

CEL, CEK

BR1

E51

MX2

AR2

EA3

RU3

SP1

AU1

TH1

DESTINATION ABBREVIATIONS

The following abbreviations for model destinations are used in this

service manual.

• Abbreviations

AR : Argentina model

AUS : Australian model

BR : Brazilian model

E3 : African and Iranian models

E12 : Indian model

E32 : Latin American model

E51 : Chilean and Peruvian models

EA : Saudi Arabia model

MX : Mexican model

RU : Russian model

SP : Singapore model

TH : Thai model

4

Page 5

ADVANCE PREPARATION WHEN CONFIRMING OPERATION

All of the units included in the HT-GT1 (SA-WGT1/SS-GT1) are

required to confi rming operation of SA-WGT1. Check in advance

that you have all of the units.

NOTE OF PERFORMING THE OPERATION CHECK IN

THE STATE THAT HEAT SINK WAS REMOVED

When performing the operation check in the state that this unit was

disassembled, it is possible to perform the operation check in the

state that heat sink was removed. But don’t perform the operation

check in the long time, and perform the operation check in the

volume state as low as possible.

NOTE OF REPLACING THE TUNER BOARD

When the TUNER board is defective, replace the complete mounted board.

NOTE OF REPLACING THE IC1002 AND IC4001 ON

THE MAIN BOARD

IC1002 and IC4001 on the MAIN board cannot replace with single. When these parts are damaged, replace the complete mounted

board.

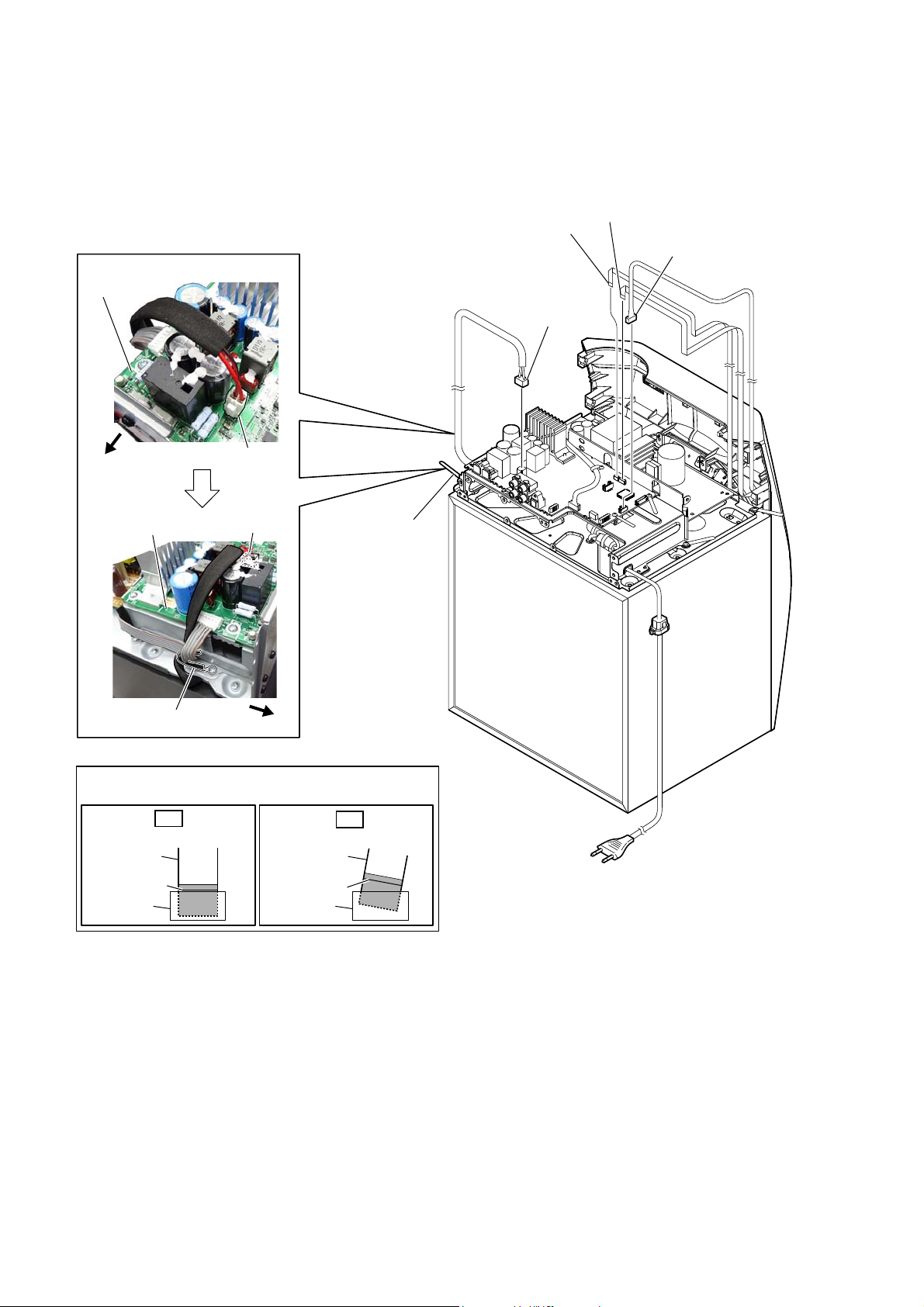

HT-GT1

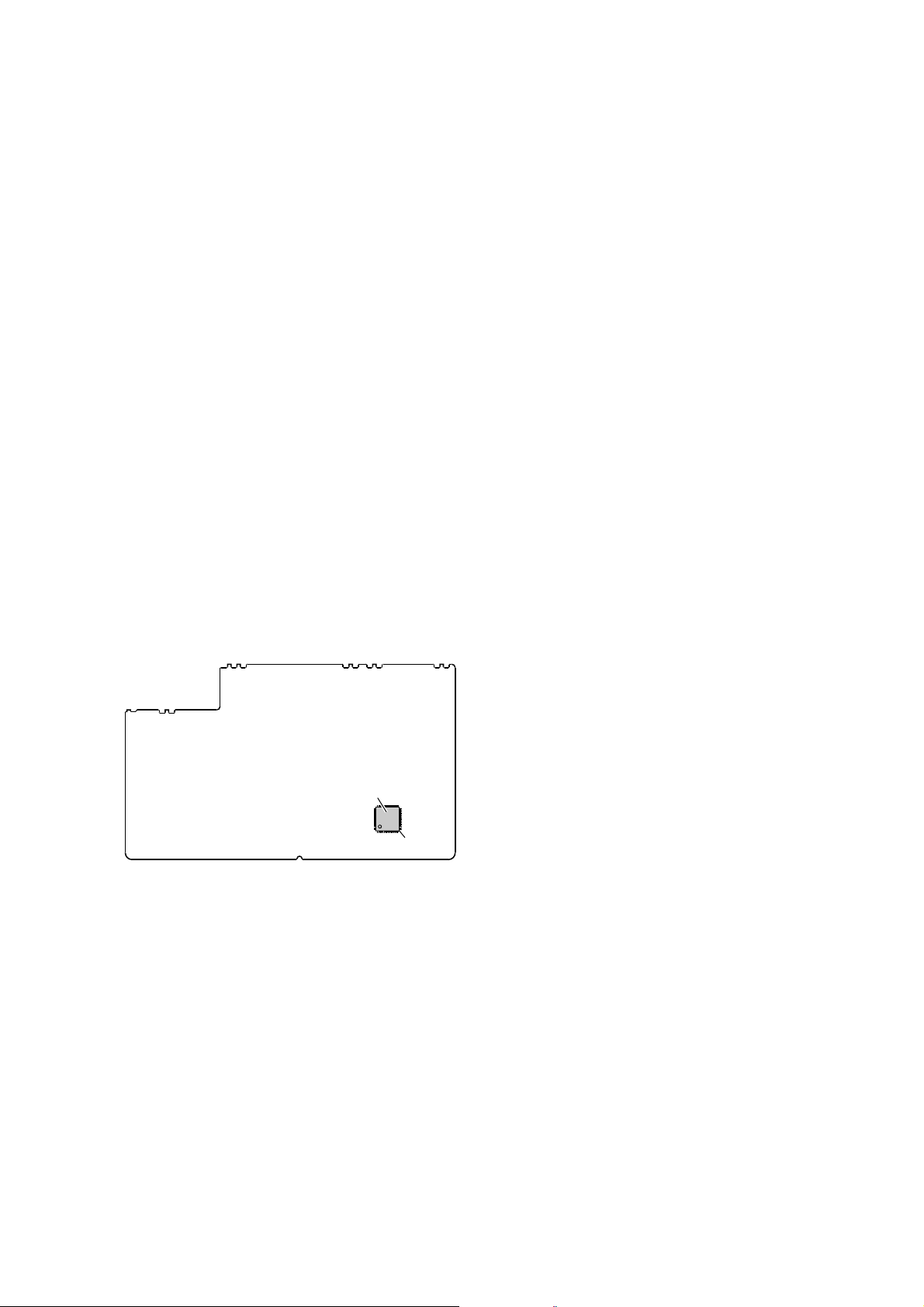

NOTE OF REPLACING THE IC002 ON THE MAIN

BOARD AND THE COMPLETE MAIN BOARD

When IC002 on the MAIN board and the complete MAIN board

are replaced, it is necessary to spread the compound between the

MAIN board and the heat sink.

Spread the compound (THERMAL COMPOUND (G747)) referring to the fi gure below.

– MAIN Board (Component Side) –

thermal compound (G747)

IC002

5

Page 6

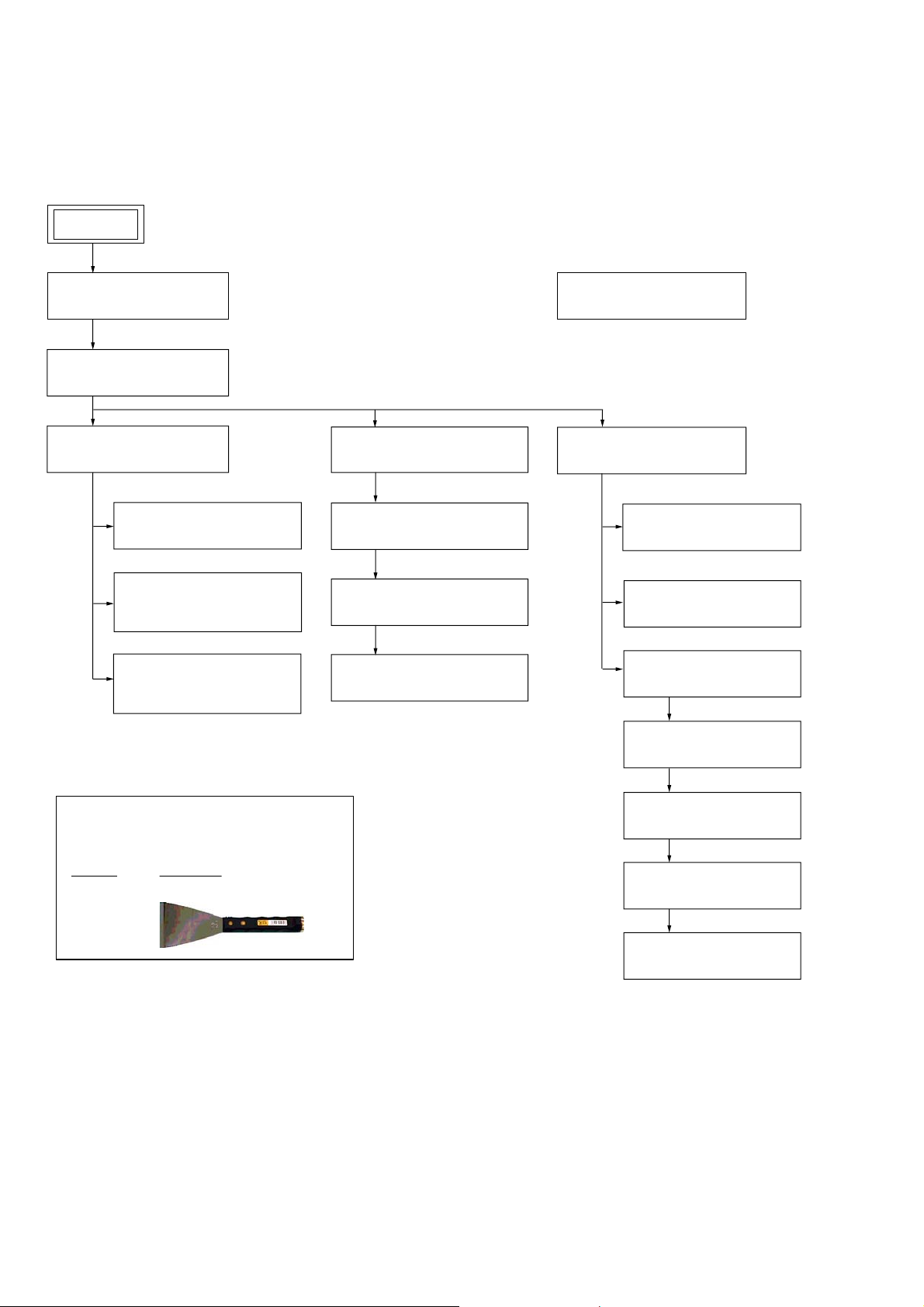

HT-GT1

DISASSEMBLY

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SET

SECTION 2

2-2. SIDE L, R PANEL

(Page 7)

2-3. TOP PANEL BLOCK

(Page 8)

2-4. FRONT PANEL BLOCK

(Page 9)

2-5. NFC MODULE (NFC1)

(Page 10)

2-6. BLUETOOTH MODULE

(BT1)

(Page 11)

2-19. LOUDSPEAKER (18 cm)

(SP1)

(Page 23)

2-7. PANEL BOARD BLOCK

(Page 12)

2-8. BUTTON ASSY

(Page 13)

2-9. KNOB ASSY

(Page 14)

2-10. TOP PANEL ASSY

(Page 15)

2-20. SERVICE POSITION

(Page 24)

2-11. REAR PANEL BLOCK

(Page 16)

2-12. DC FAN (M1)

(Page 17)

2-13. TUNER BOARD

(Page 17)

2-14. MAIN BOARD-1

(Page 18)

2-15. MAIN BOARD-2

(Page 19)

JIG

When disassembling the unit, use the following

jig for speaker removal.

Part No. Description

J-2501-238-A JIG FOR SPEAKER REMOVAL

2-16. SUB CHASSIS

(Page 20)

2-17. POWER CORD (AC1)

(Page 21)

2-18. SMPS BOARD

(Page 22)

6

Page 7

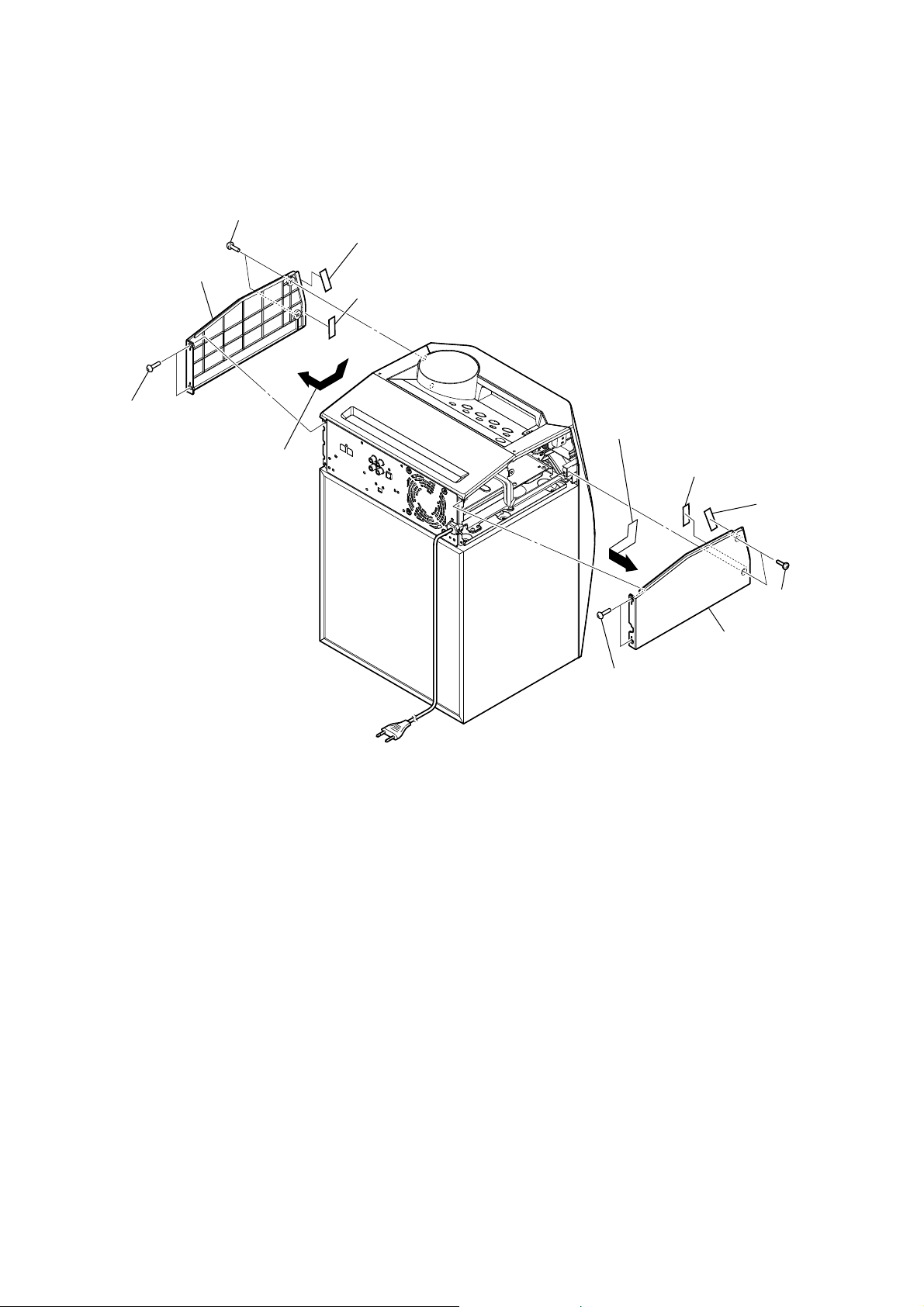

Note: Follow the disassembly procedure in the numerical order given.

2-2. SIDE L, R PANEL

1 two tapping

screws (HEX)

6 side R panel

2 two screws

(BVTP3 u 10)

3 Remove the side R panel block

in the direction of the arrow.

4 saranet cushion

(10T25)

4 saranet cushion

(10T25)

HT-GT1

3 Remove the side L panel block

in the direction of the arrow.

5 saranet cushion

(7T25)

4 saranet cushion

(10T25)

– Rear view –

1 two tapping

screws (HEX)

6 side L panel

2 two screws

(BVTP3 u 10)

7

Page 8

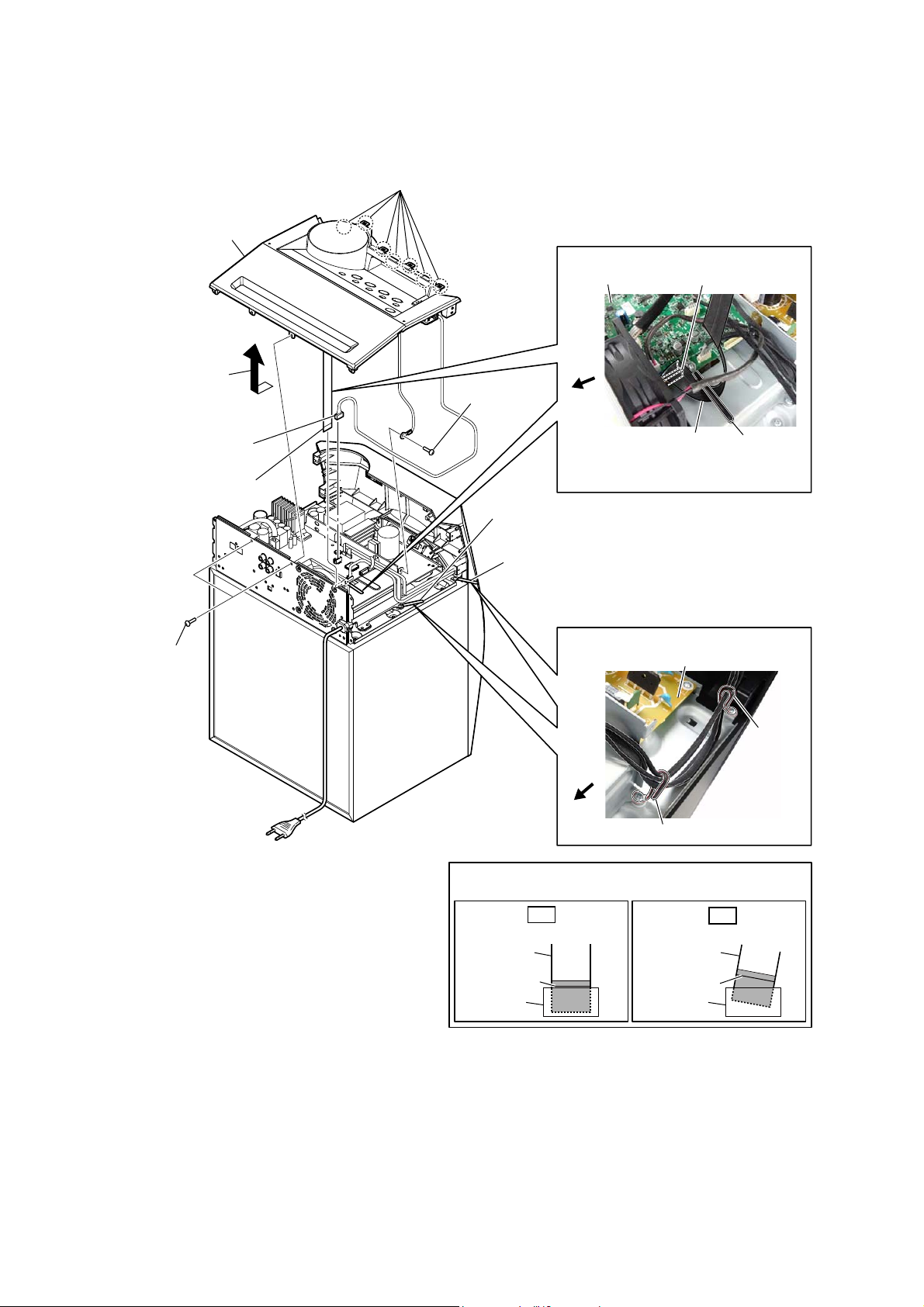

HT-GT1

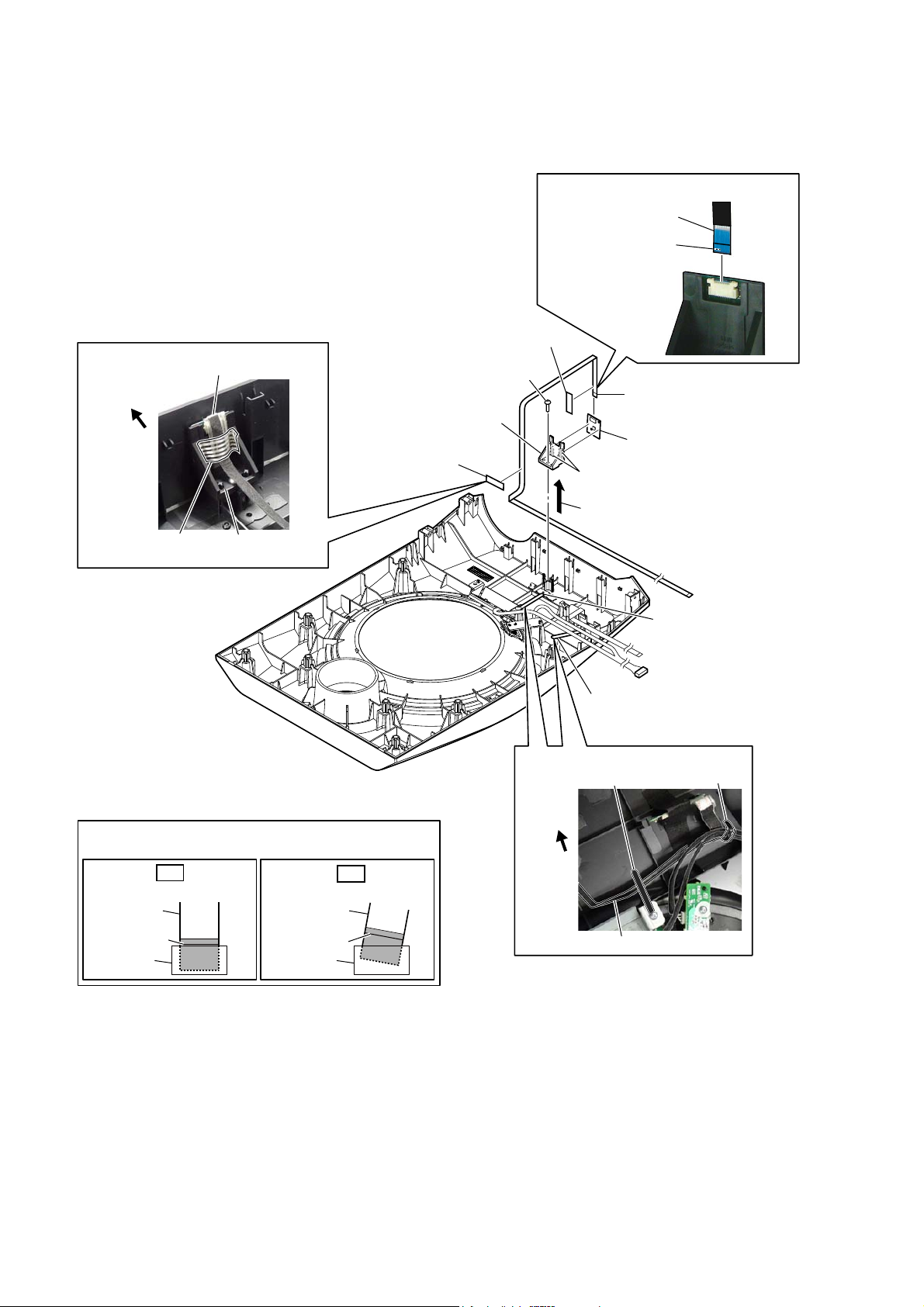

2-3. TOP PANEL BLOCK

8 top panel block

5 Lift up the top panel block

in the direction of the arrow.

4 seven claws

2 screw

(BV3)

:LUHVHWWLQJ

MAIN board

rear

side

CN3004

6 connector

(CN1001)

7 flexible flat cable (13P)

(CN3004)

3 two screws

(BVTP3 u 10)

– Rear view –

flexible flat cable (13P)

Pass the flexible flat cable (13P)

Note 1:

underneath the clamp.

1 Remove the wire

from the clamp.

1 Remove the wire

from the clamp.

:LUHVHWWLQJ

SMPS board

rear

side

When installing the flexible flat cable, ensure that

Note 2:

the colored line is parallel to the connector after insertion.

OK

Insert straight into the interior.

flexible flat

cable

colored line

connector

clamp

Insert at a slant.

flexible flat

cable

colored line

connector

clamp

clamp

NG

8

Page 9

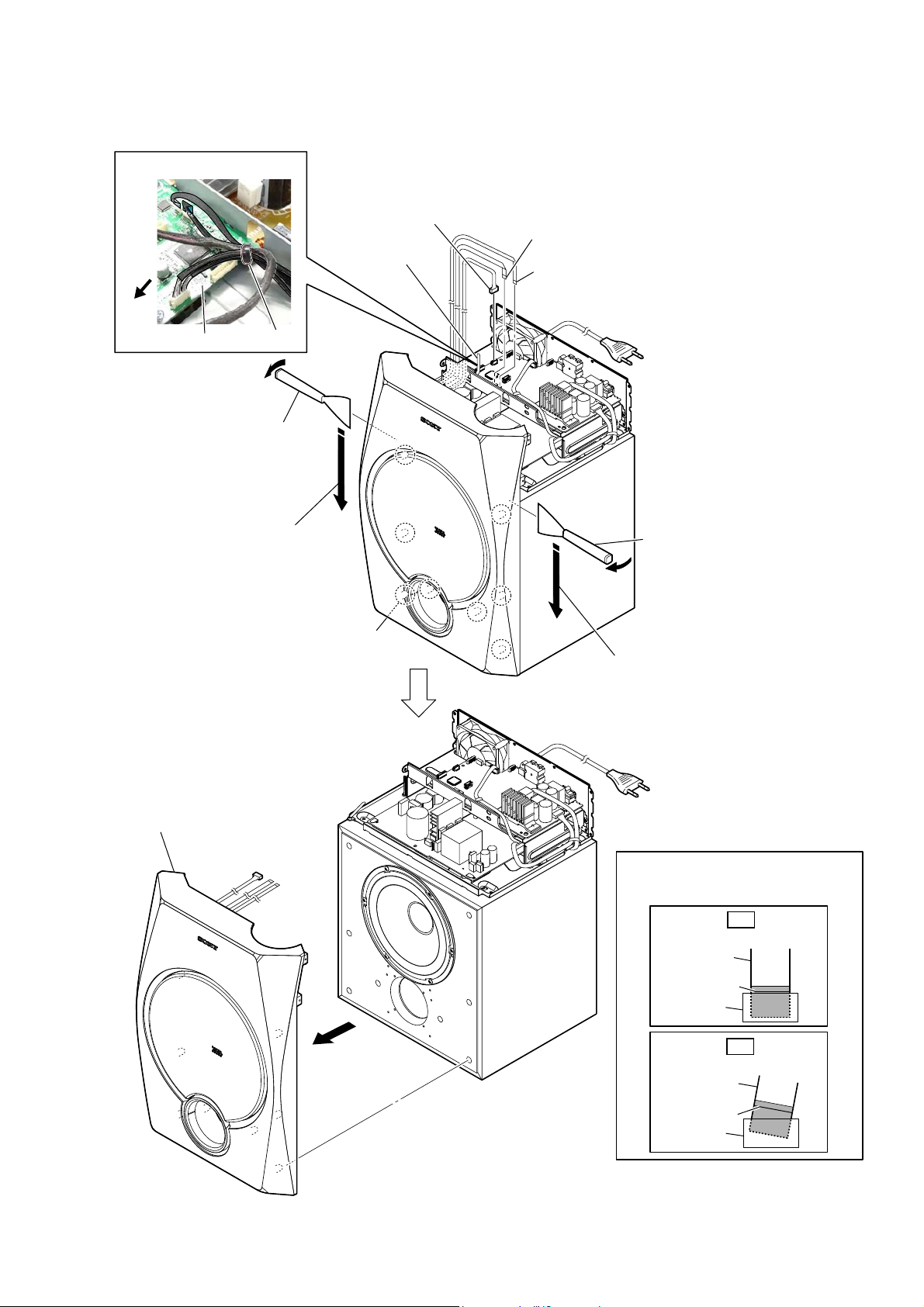

2-4. FRONT PANEL BLOCK

:LUHVHWWLQJ

rear

side

MAIN board

5 Insert the jig into the space and slowly

remove the front panel block.

Note 1: When using a jig, please work

carefully so as not to damage

the front panel block and

speaker cabinet.

clamp

4 connector

(CN3005)

1 Remove the wire

from the clamp.

HT-GT1

3 flexible flat cable (14P)

(CN3003)

2 flexible flat cable (8P)

(CN3002)

6 While moving the jig in the direction

of the arrow, remove all bosses and

the front panel block.

total eight bosses

7 front panel block

5 Insert the jig into the space and slowly

remove the front panel block.

Note 1: When using a jig, please work

carefully so as not to damage

the front panel block and

speaker cabinet.

6 While moving the jig in the direction

of the arrow, remove all bosses and

the front panel block.

When installing the flexible flat cable,

Note 2:

ensure that the colored line is parallel

to the connector after insertion.

OK

Insert straight into the interior.

flexible flat

cable

colored line

connector

Insert at a slant.

flexible flat

cable

colored line

connector

NG

9

Page 10

HT-GT1

2-5. NFC MODULE (NFC1)

:LUHVHWWLQJ

top side

filament tape

(sub material)

flexible flat cable (8P)

NFC holder

NFC holder block

2 filament tape

(sub material)

5 filament tape

(sub material)

3 screw

(BVTP2.6)

+RZWRLQVWDOOWKHIOH[LEOHIODWFDEOH3

flexible flat cable (8P)

The lower side is

the terminal side.

6 flexible flat cable (8P)

(FFC3)

8 NFC module

(NFC1)

7 Peel the NFC module (NFC1)

off of the PSA tape (5T15).

Remove the

4

in the direction of the arrow.

NFC module block

–)URQWSDQHOEORFNUHDUERWWRPYLHZ–

When installing the flexible flat cable, ensure that

Note:

the colored line is parallel to the connector after insertion.

OK

Insert straight into the interior.

flexible flat

cable

colored line

connector

flexible flat

cable

colored line

connector

NG

Insert at a slant.

1 Remove the wire

from the clamp.

:LUHVHWWLQJ

top side

flexible flat cable (8P)

clamp

1 Remove the wire

from the clamp.

clamp

10

Page 11

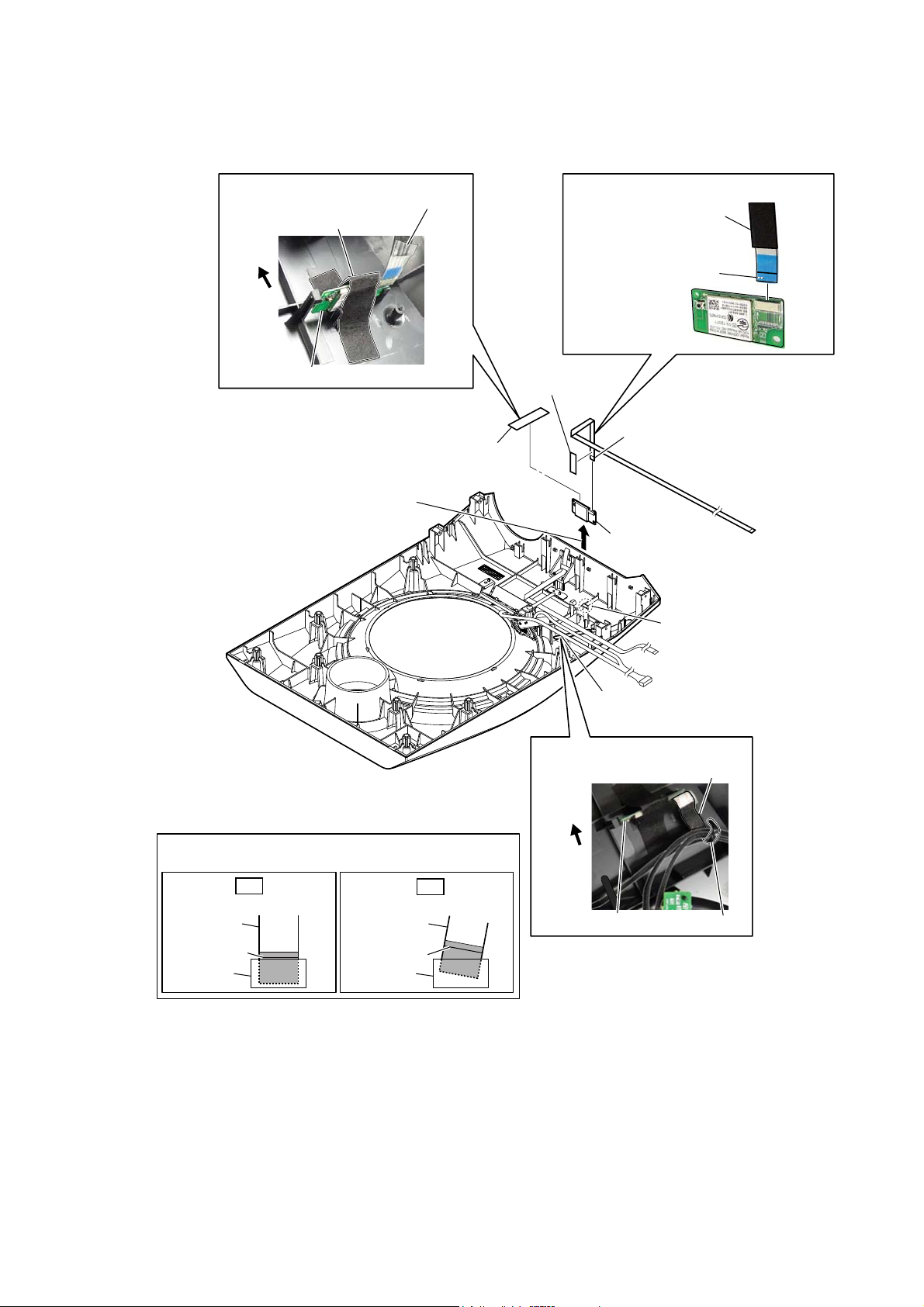

2-6. BLUETOOTH MODULE (BT1)

HT-GT1

:LUHVHWWLQJ

flexible flat cable (14P)

saranet cushion (15T50)

top side

bluetooth module

Remove the

4

in the direction of the arrow.

bluetooth module block

2 saranet cushion

(15T50)

+RZWRLQVWDOOWKHIOH[LEOHIODWFDEOH3

flexible flat cable (14P)

The lower side is

the terminal side.

5 filament tape

(sub material)

6 flexible flat cable (14P)

(FFC4)

7 bluetooth module

(BT1)

3 claw

–)URQWSDQHOEORFNUHDUERWWRPYLHZ–

When installing the flexible flat cable, ensure that

Note:

the colored line is parallel to the connector after insertion.

OK

Insert straight into the interior.

flexible flat

cable

colored line

connector

flexible flat

cable

colored line

connector

NG

Insert at a slant.

1 Remove the wire

from the clamp.

:LUHVHWWLQJ

flexible flat cable (14P)

top side

bluetooth module

clamp

11

Page 12

HT-GT1

2-7. PANEL BOARD BLOCK

1 Remove the wire

from the clamp.

– Top panel block rear bottom view –

3 clamp

5 connector

(CN301)

2 screw

(BVTP2.6)

6 PANEL board block

:LUHVHWWLQJ

clamp

2 screw

(BVTP2.6)

BUTTON board

PANEL board

Lift up the

4

in the direction of the arrow.

PANEL board block

12

Page 13

2-8. BUTTON ASSY

– Top panel block rear bottom view –

1 two screws

(BVTP2.6)

2 USB board

6

in the direction of the arrow.

3 Remove the wire

from the clamp.

8 BUTTON board block

Lift up the

BUTTON board block

:ire VettinJ

HT-GT1

VOL board

clamp

Do not touching to

Note:

top panel assy.

top panel assy

4 four screws

(BVTP2.6)

4 screw

(BVTP2.6)

5 clamp

7 connector

(CN302)

9 seven screws

(BVTP2.6)

0 BUTTON board block

qd button assy

qa saranet cushion (7T25)

qs saranet cushion (7T25)

qa saranet cushion (7T25)

qa saranet cushion (7T25)

,nVtallation poVition oI tKe Varanet cXVKion T

button assy

guide line

guide line

saranet cushion

(7T25)

saranet cushion

(7T25)

saranet cushion

(7T25)

saranet cushion

(7T25)

guide line

13

Page 14

HT-GT1

2-9. KNOB ASSY

+RZWRLQVWDOOWKHNQREDVV\

When installing the knob assy, aline the two ribs of knob assy and the shaft.

Note:

1 eight screws

(BVTP2.6)

3 VOL board block

– Bottom view – – Top view –

knob assy

rib

shaft

4 Draw the knob assy in

the direction of the arrow.

5 knob assy

VOL board block

– Top panel block rear bottom view –

2 Remove the VOL board block

in the direction of the arrow.

14

Page 15

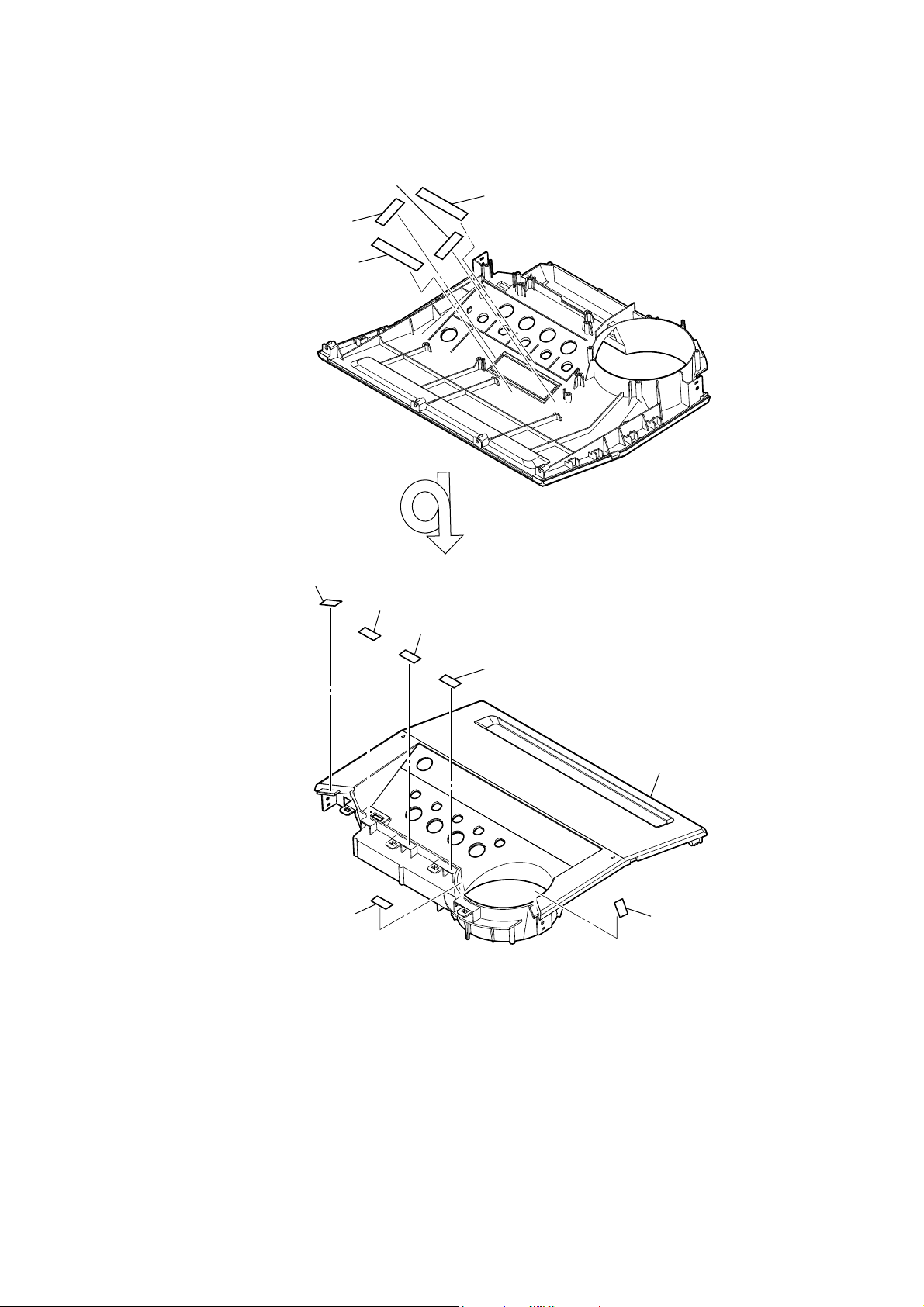

2-10. TOP PANEL ASSY

HT-GT1

2 PEF cushion

(7T100)

2 PEF cushion

(7T100)

1 PEF cushion

(7T100)

3 saranet cushion

(15T50)

1 PEF cushion

(7T100)

– Top panel block rear bottom view –

4 saranet cushion

(15T50)

4 saranet cushion

(15T50)

4 saranet cushion

(15T50)

4 saranet cushion

(15T50)

5 top panel assy

3 saranet cushion

(15T50)

15

Page 16

HT-GT1

2-11. REAR PANEL BLOCK

:ire VeWWiQJ

MAIN board

rear

side

Rear panel block

CN4003

clamp

When installing the flexible flat cable, ensure that

Note:

the colored line is parallel to the connector after insertion.

OK

Insert straight into the interior.

flexible flat

cable

colored line

connector

flexible flat

cable

colored line

connector

2 Remove the wire

from the clamp.

NG

Insert at a slant.

5 Remove the rear panel block

in the direction of the arrow.

6 flexible flat cable (9P)

(CN3006)

7 rear panel

block

4 eight screws

(BVTP3 u 8)

4 five screws

(BVTP3 u 8)

3 connector

(CN4003)

– Rear view –

1 Draw the cord bushing

out of the groove.

16

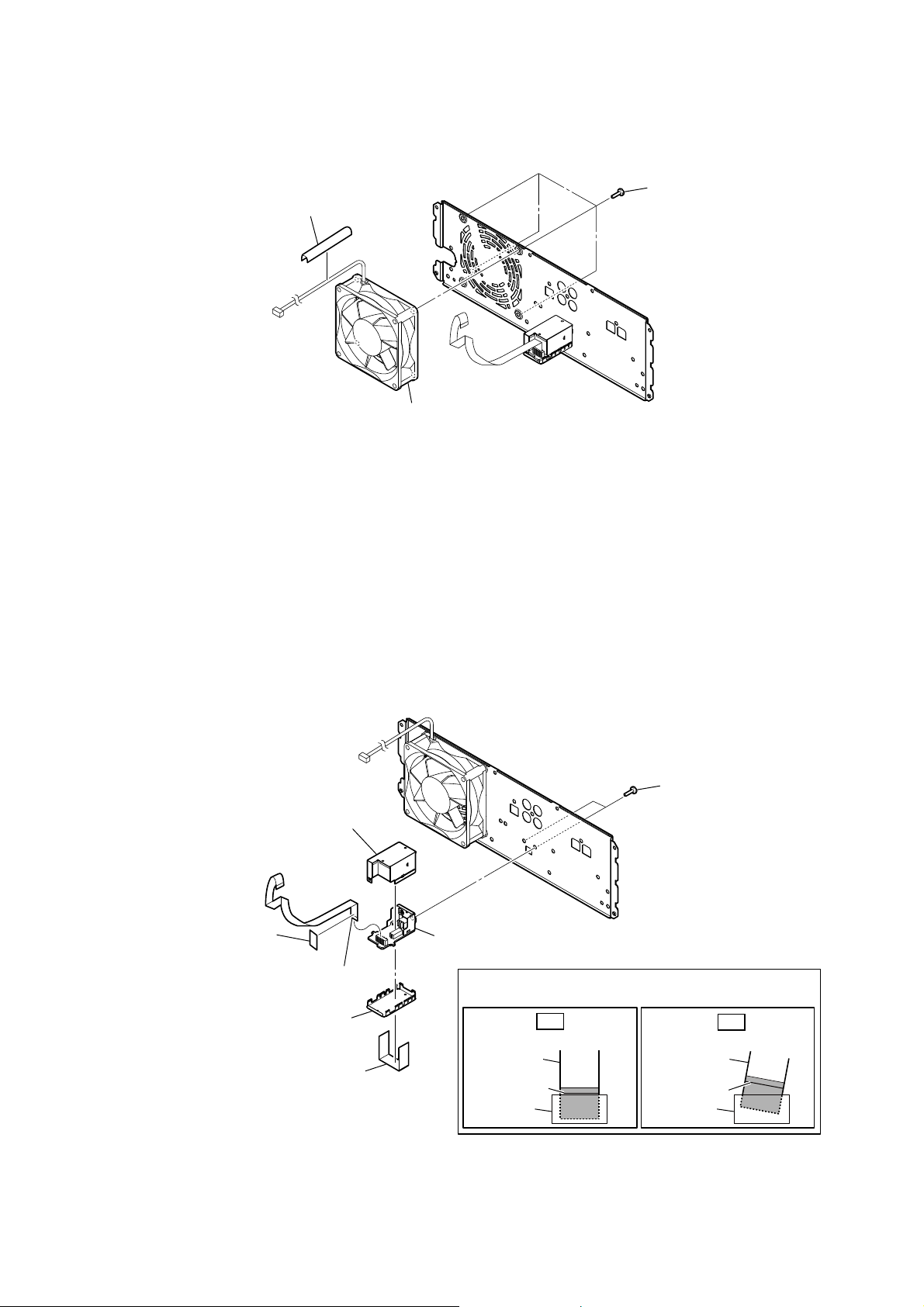

Page 17

2-12. DC FAN (M1)

2 EVA cushion (20T50)

HT-GT1

1 four screws

(BVTP3 u 8)

3 DC fan (M1)

2-13. TUNER BOARD

6 plate (top) shield

1 filament tape

(sub material)

2 flexible flat cable (9P)

(CN802)

5 plate (bottom) shield

4 filament tape

(sub material)

3 two screws

(BVTP3 u 8)

7 TUNER board

When installing the flexible flat cable, ensure that

Note:

the colored line is parallel to the connector after insertion.

OK

Insert straight into the interior.

flexible flat

cable

colored line

connector

flexible flat

cable

colored line

connector

NG

Insert at a slant.

17

Page 18

HT-GT1

2-14. MAIN BOARD-1

• Continued on 2-15 (page 19).

:LUHVHWWLQJ

MAIN board

rear side

MAIN board

CN2001

CN2001

1 Remove the wire

from the clamp.

3 flexible flat cable (8P)

(CN3002)

2 connector

(CN2001)

4 flexible flat cable (14P)

(CN3003)

5 connector

(CN3005)

clamp

When installing the flexible flat cable, ensure that

Note:

the colored line is parallel to the connector after insertion.

OK

Insert straight into the interior.

flexible flat

cable

colored line

connector

rear side

NG

Insert at a slant.

flexible flat

cable

colored line

connector

–5HDUYLHZ–

18

Page 19

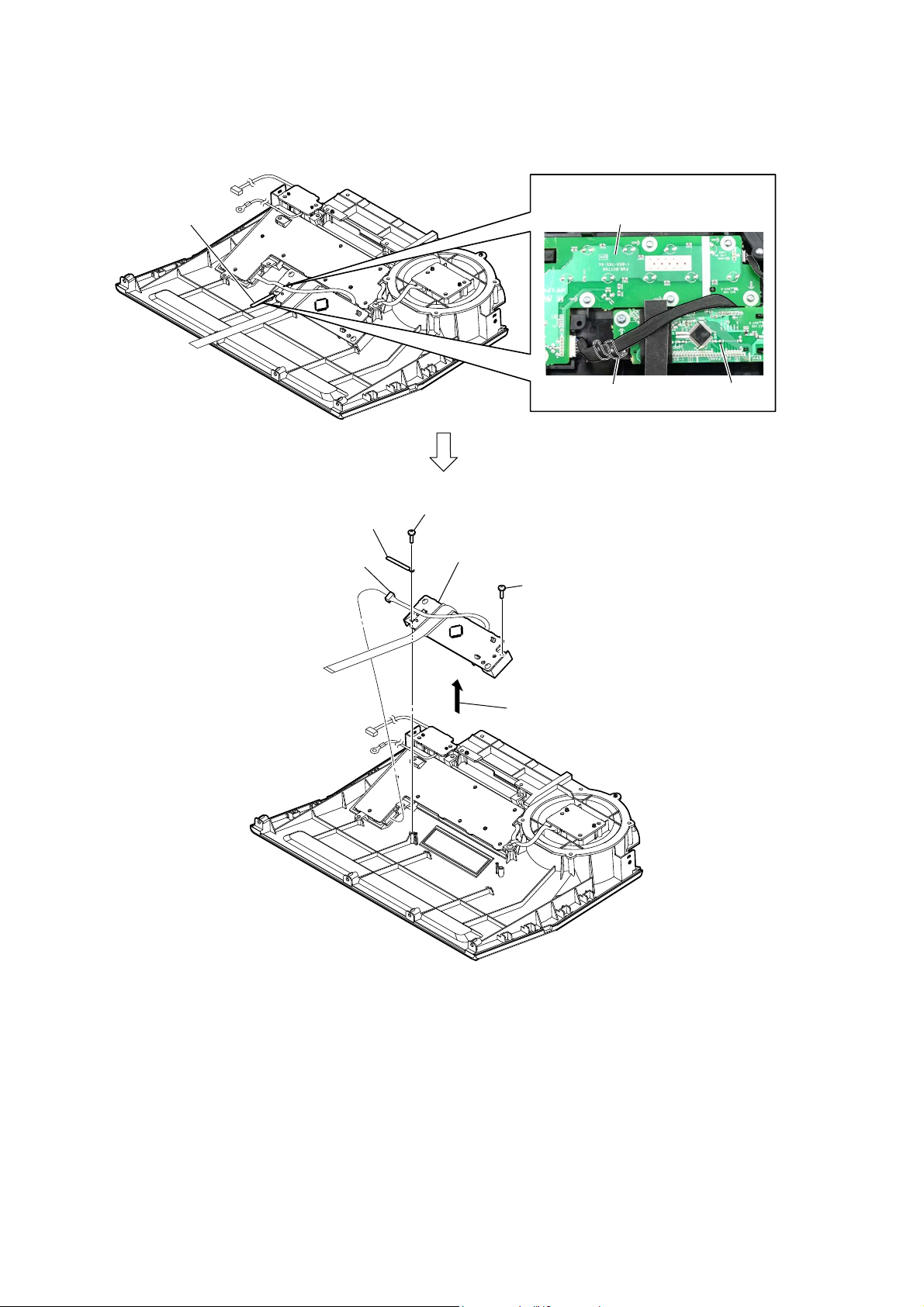

2-15. MAIN BOARD-2

HT-GT1

4 screw (BV3)

5 clamp

4 screw (BV3)

2 connector

(CN4002)

1 Remove the wire

from the clamp.

4 screw

(BV3)

8 AMP heatsink

4 two screws

(BV3)

:LUHVHWWLQJ

clamp

CN4002

rear side

MAIN board

5 clamp

4 screw (BV3)

5 clamp

7 two screws

(BV3)

9 MAIN board

3 connector

(CN4001)

6 Remove the MAIN board block

in the direction of the arrow.

19

Page 20

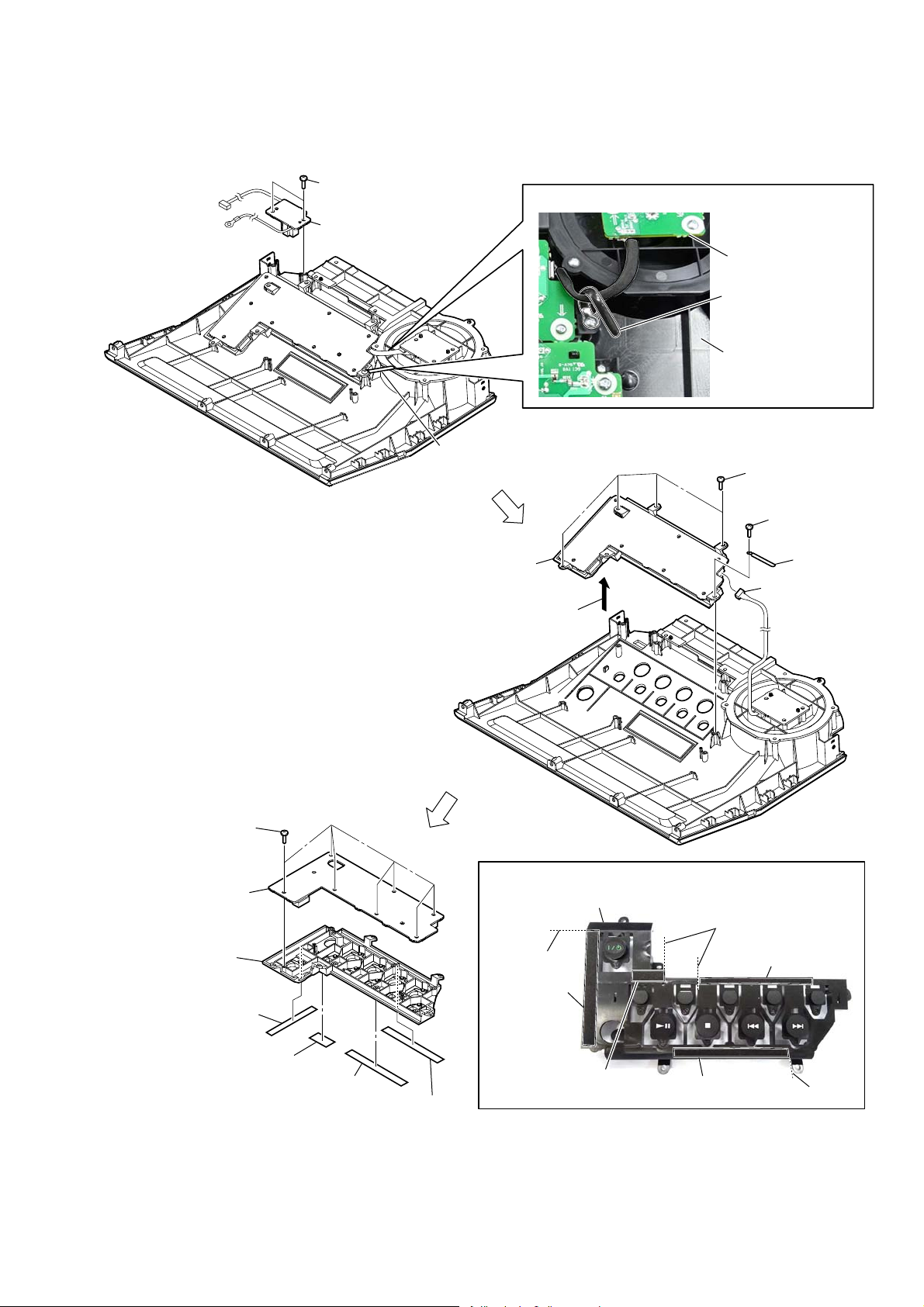

HT-GT1

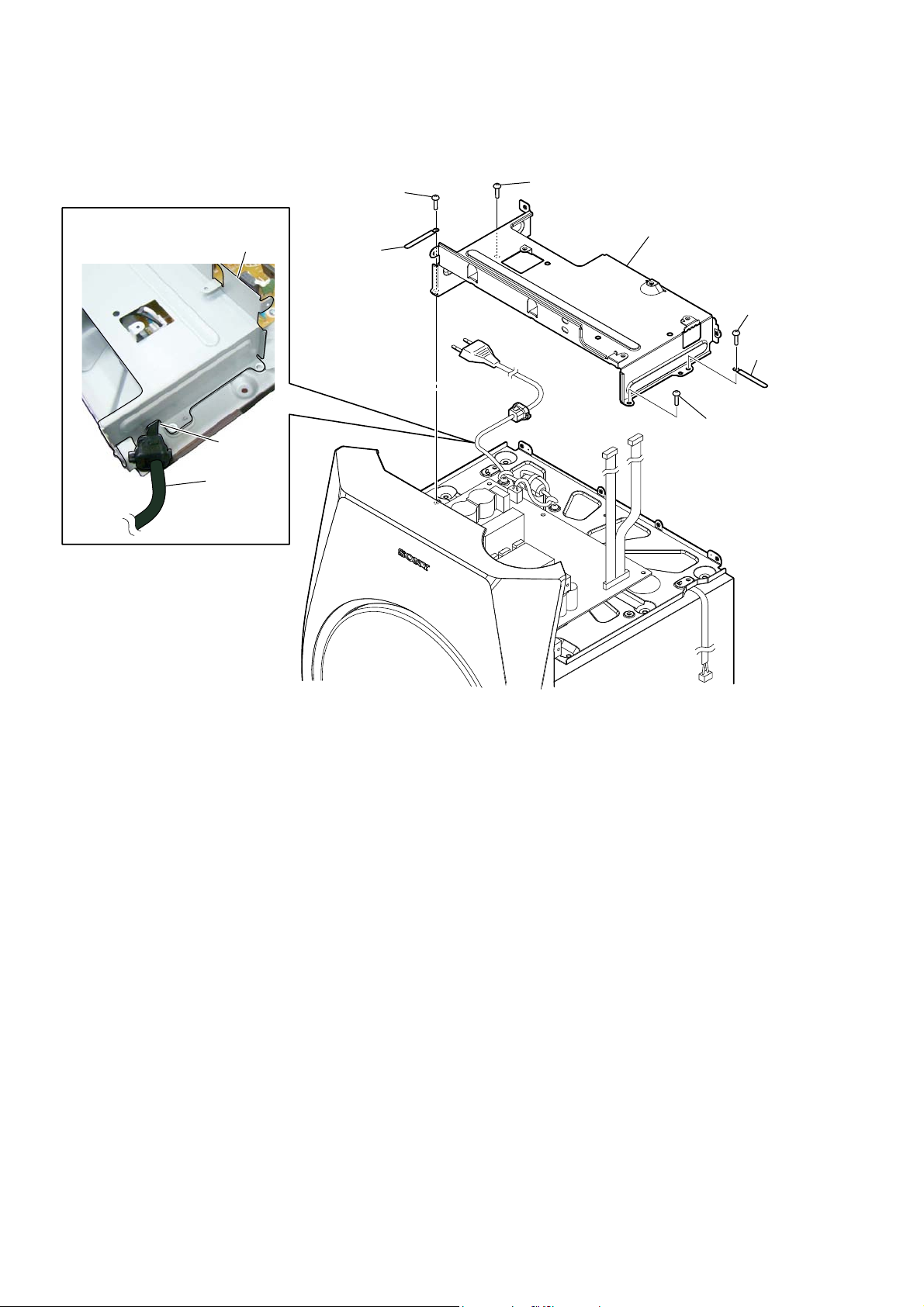

2-16. SUB CHASSIS

3RZHUFRUGVHWWLQJ

sub chassis

groove

power cord

1 screw

(BV3)

2 clamp

1 screw

(BV3)

3 sub chassis

1 screw

(BV3)

2 clamp

1 screw

(BV3)

20

Page 21

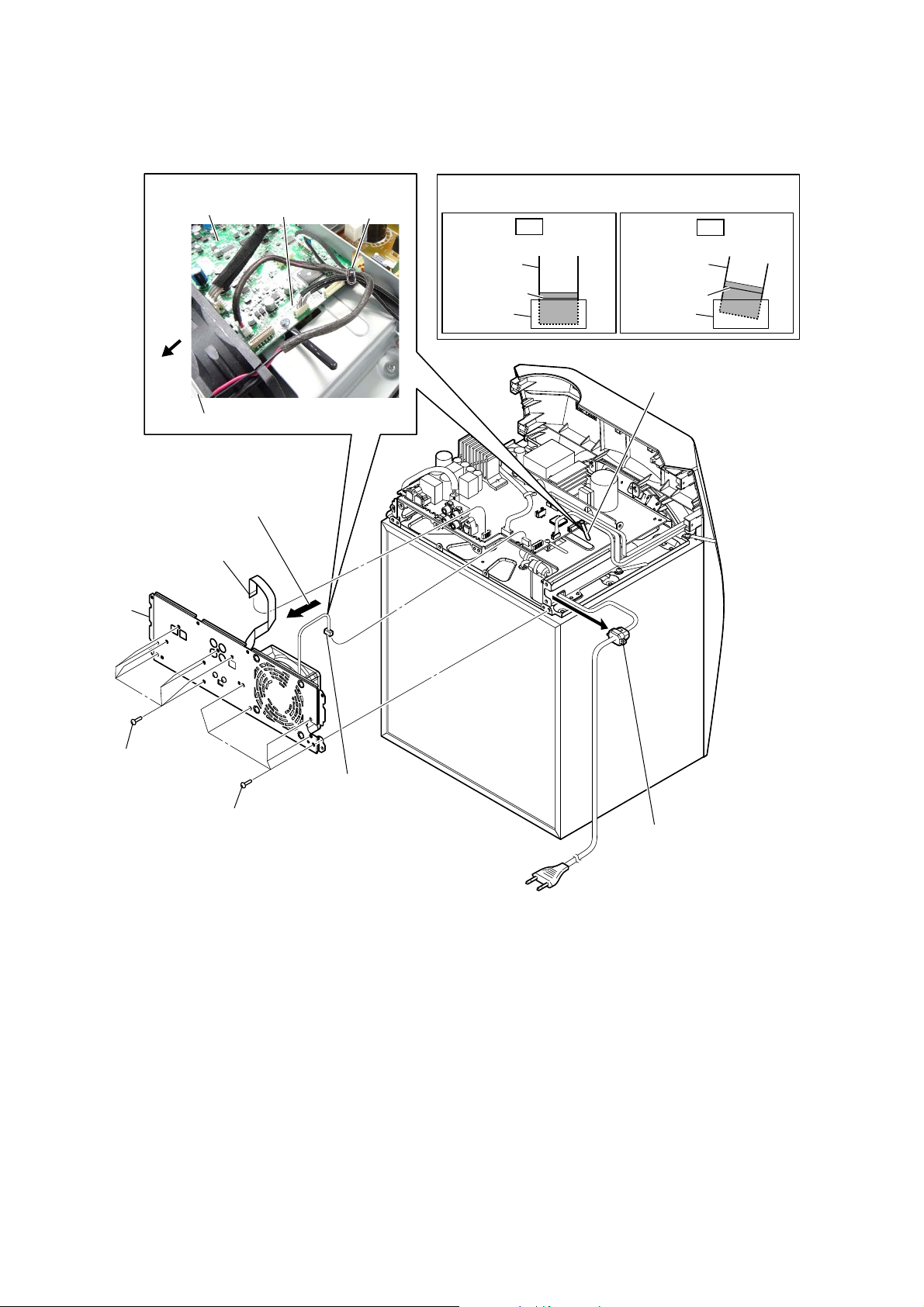

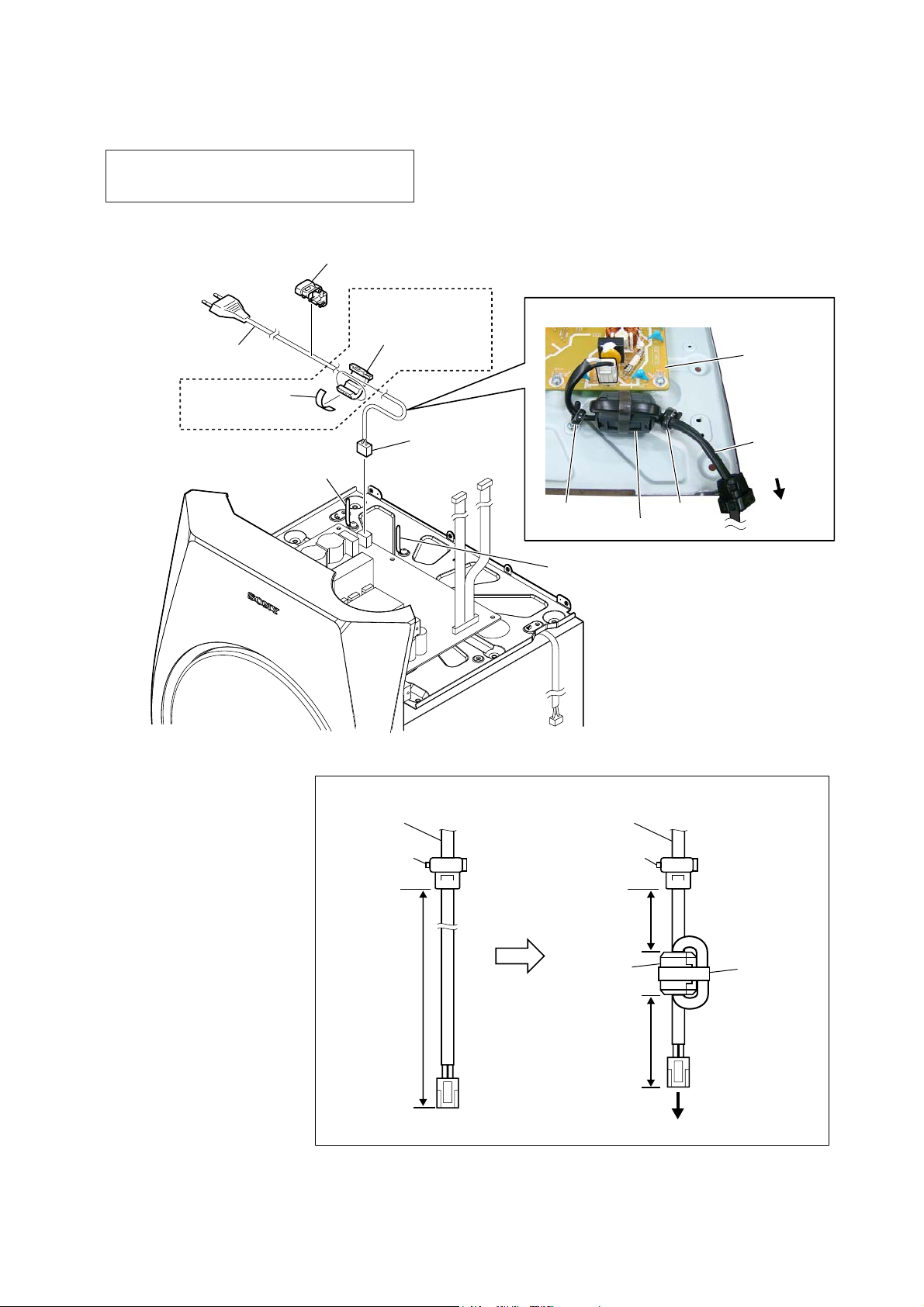

2-17. POWER CORD (AC1)

Note: Ferrite core (Ref. No. FC1) and PEF cushion (T100)

are deleted from the midway of production.

(E3, E12, E32, E51, MX, BR, SP)

5 cord bushing

(FBS001)

HT-GT1

Ver. 1.1

6 power cord

(AC1)

3 PEF cushion

(T100)

1 Remove the wire

from the clamp.

86$(3588.

$86($

4 ferrite core

(FC1)

2 connector

(CN100)

3RZHUFRUGVHWWLQJ

ferrite core

1 Remove the wire

from the clamp.

SMPS board

power cord

clampclamp

rear side

+RZWRLQVWDOOWKHFRUGEXVKLQJ)%6DQGWKHIHUULWHFRUH

power cord

cord bushing

(FBS001)

265 +5, -0 mm

power cord

cord bushing

(FBS001)

70 +5, -0 mm

ferrite core

60 +5, -0 mm

to SMPS board

PEF cushion

(T100)

21

Page 22

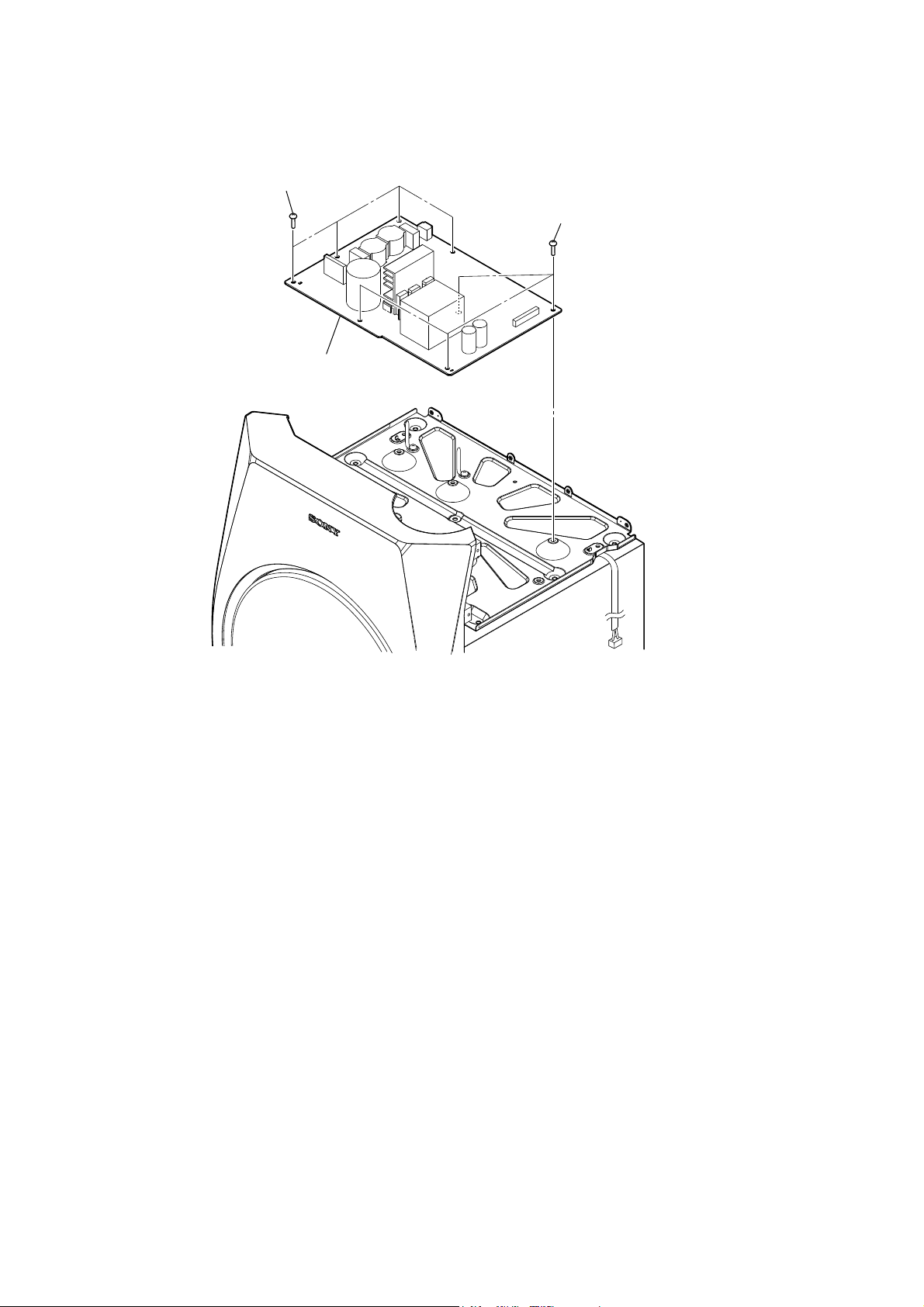

HT-GT1

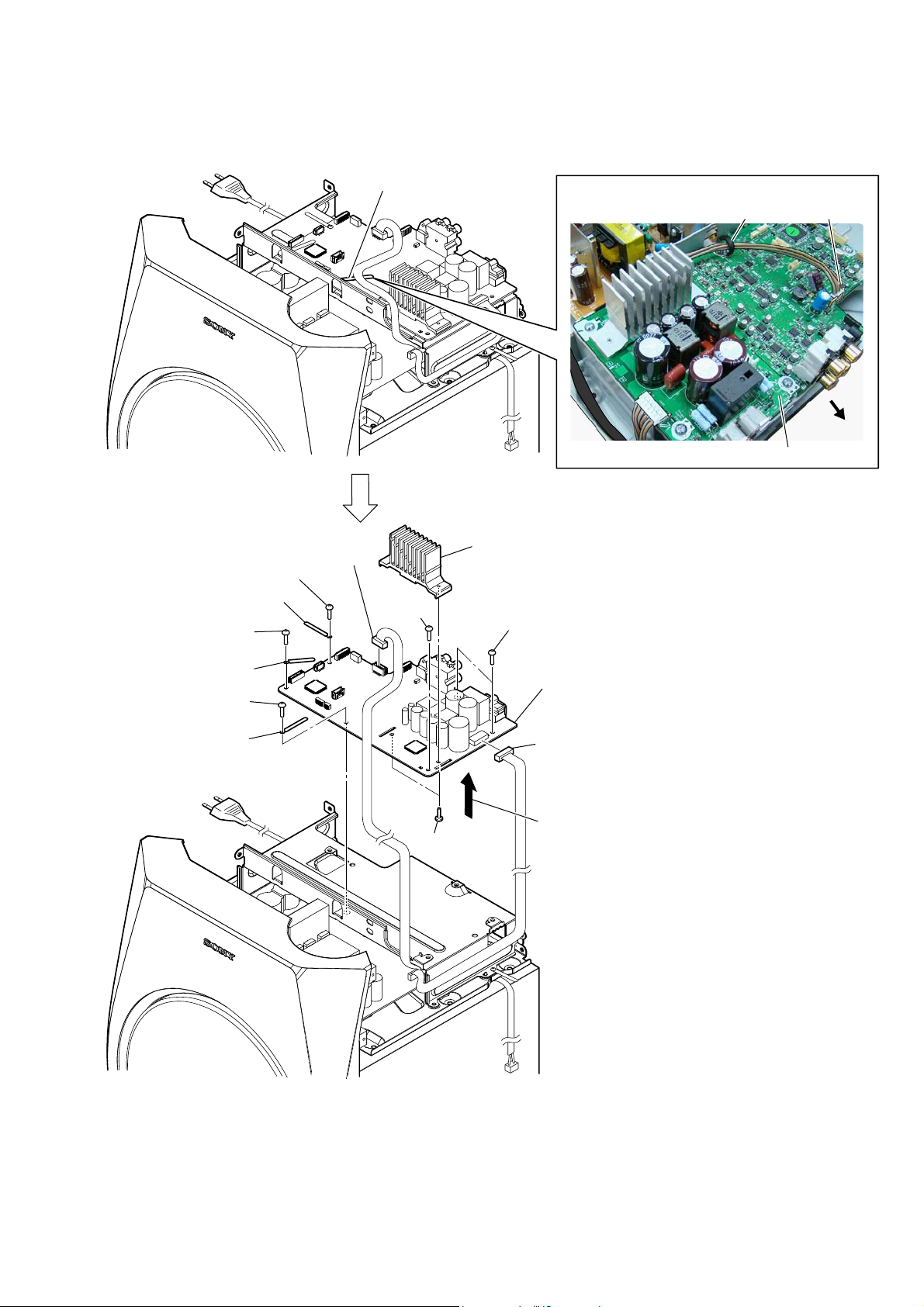

2-18. SMPS BOARD

1 four screws

(BV3)

1 four screws

(BV3)

2 SMPS board

22

Page 23

2-19. LOUDSPEAKER (18 cm) (SP1)

,QVWDOODWLRQGLUHFWLRQIRUWKHORXGVSHDNHUFP

loudspeaker (18 cm)

4 loudspeaker (18 cm)

(SP1)

terminal position

HT-GT1

1 six tapping screws

(3.5 u 14)

:LUHVHWWLQJ

terminal

(narrow side)

terminal

(wide side)

terminal

(narrow side)

terminal

(wide side)

protrusion

protrusion

2 Remove the loudspeaker (18 cm) (SP1)

in the direction of the arrow.

3 Push the protrusion,

and remove the terminal

(narrow side).

3 Push the protrusion,

and remove the terminal

(wide side).

23

Page 24

HT-GT1

2-20. SERVICE POSITION

top panel block

MAIN board

insulating sheet

stand

24

Page 25

SECTION 3

TEST MODE

HT-GT1

1. TEST MODES OTHER THAN THE TEST MODE

MENU

These are executable test mode even if not entering the test mode

menu.

1-1. User Reset

It can initialize various backup information.

Procedure:

1. Press the [

2. Press two buttons of the [FUNCTION] and [

ously for one second.

3. The message “RESET” is displayed on the liquid crystal display, then turn the power off.

1-2. Bluetooth Power Control

It can turn on or off the Bluetooth signal.

Procedure:

1. Press the [

2. Press the [FUNCTION] button to turn the Bluetooth function.

3. Press two buttons of the [u] and [BLUETOOTH PAIRING] simultaneously for three seconds.

4. The message “BT ON” or “BT OFF” is displayed on the liquid

crystal display, it turn on or off the Bluetooth signal.

] button to turn the power on.

?/1

Screen display

] button to turn the power on.

?/1

Screen display

] simultane-

?/1

2. TEST MODES IN THE TEST MODE MENU

These are the test modes done in the test mode menu.

Setting method of the test mode menu:

1. Press the [

2. Press the two buttons of the [

taneously for fi ve seconds.

3. The message “COLD RST” is displayed on the liquid crystal

display and enter the test mode menu.

Releasing method of the test mode menu:

Press the two buttons of the [u] and [PARTY CHAIN] simultaneously for fi ve seconds.

2-1. Cold Reset

It can initialize various backup information.

Procedure:

1. Enter the test mode menu. (Refer to “Setting method of the test

mode menu”)

2. Press the [

lect the “COLD RST”, press the [

3. The message “RESET” is displayed on the liquid crystal display, then turn the power off.

] button to turn the power on.

?/1

] and [P AR TY CHAIN] simul-

u

Screen display

– TUNING]/[> TUNING +] buttons to se-

.

] button.

u

Screen display

or

1-3. Bluetooth History Clear

It can clear the Bluetooth pairing history.

Procedure:

1. Press the [

2. Press the [FUNCTION] button to turn the Bluetooth function.

3. Press two buttons of the [x] and [BLUETOOTH P AIRING]

simultaneously for one second.

4. The message “BT HIST” → “CLEAR” is displayed on the

liquid crystal display, and the pairing history of Bluetooth is

cleared.

] button to turn the power on.

?/1

Screen display

25

Page 26

HT-GT1

2-2. Panel Test Mode

It can confi rm the lighting of liquid crystal display and LEDs, op-

eration of buttons, display of model name, destination and software version.

Procedure:

1. Enter the test mode menu. (Refer to “Setting method of the test

mode menu” on page 25)

2. Press the [

– TUNING]/[> TUNING +] buttons to se-

.

lect the “PNL TEST”, press the [u] button.

3. All segments in the liquid crystal display and all LEDs are

lighted up.

4. When pressing the [x] button, the display on the liquid crystal

display repeatedly changes in order from all lighting → pattern

1 (Bluetooth LED is lighted up) → pattern 2 (speaker LED is

lighted up) → all lighting → all turned off.

All lighting

REC

PRESET

c

SLEEP

N X

Pattern 1

SLEEP

N

Pattern 2

REC

c

AUTO MONO ST TUNED

AUTO MONO TUNED

PRESET

ST

SUBWOOFER BASS

BASS

SUBWOOFER

FLDR

SHUF

PGM

FLDR

PGM

SHUF

1

1

5. In the state of step 4, press the [> TUNING +] button and

model name “GV” is displayed on the liquid crystal display.

Screen display

Each time the [> TUNING +] button is pressed, the display

changes from destination → SC version → UI version→ PF

version → SYS version → MM version 1 → MM version 2 →

iPod version 1 → iPod version 2 → ST version → TA version

→ T AS version → TM version → BTM version → BT version

→ NFC version → PCT version in this order, and returns to the

model name display.

Model name

iPod version 2

Destination

ST version

SC version

TA version

UI version

TAS version

PF version

All lighting

REC

PRESET

c

SLEEP

N X

All turned off

AUTO MONO ST TUNED

SUBWOOFER BASS

FLDR

SHUF

PGM

TM version

SYS version

1

BTM version

MM version 1

BT version

MM version 2

NFC version

iPod version 1

PCT version

(Displayed values in the above fi gure are example)

6. When [FUNCTION] button is pressed while the each version

is displayed on the liquid crystal display, month and day of the

software creation is displayed on the liquid crystal display.

Screen display

26

(Displayed values in the above fi gure are example)

When [FUNCTION] button is pressed again, the display re-

turns to the each version display.

– Continued on next page –

Page 27

SECTION 4

ELECTRICAL CHECK

HT-GT1

7. When pressing the [. – TUNING] button, “K 0 V0” is displayed on the liquid crystal display.

Screen display

8. Each time a button is pressed, “K 0” value increases. However,

once a button is pressed, it is no longer taken into account.

When pressing the all buttons, “OK” and “K10” are alternately

displayed on the liquid crystal display.

Screen display

9. “V0” value increases “V0”, “V1”, “V2”, “V3”... if turn the

[VOLUME] knob clockwise, or it decreases “V0”, “V9”,

“V8”, “V7”... if turn the [VOLUME] knob counterclockwise.

Releasing method:

Press the two buttons of the [u] and [PARTY CHAIN] simultaneously for fi ve seconds.

TUNER SECTION

FM TUNE LEVEL CHECK

generator

Procedure:

1. Press the [?/1] button to turn the power on.

2. Input the following signal from signal generator to FM antenna

input directly.

Carrier frequency : A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Use 75 ohm coaxial cable to connect signal generator and the unit.

You cannot use video cable for checking.

Use signal generator whose output impedance is 75 ohm.

3. Set to FM tuner function and tune A, B and C signals.

4. Confi rm “TUNED” is lit on the display for A, B and C signals.

When the selected station signal is received in good condition,

“TUNED” is displayed.

signal

0 dB = 1 V

unit

2-3. Factory Preset Mode

It can memorize specialized preset station for each destination of

FM preset.

Procedure:

1. Enter the test mode menu. (Refer to “Setting method of the test

mode menu” on page 25)

2. Press the [. – TUNING]/[> TUNING +] buttons to select the “FCT PSET”, press the [u] button.

3. The message “FACTORY” is displayed on the liquid crystal

display, FM preset station setting is complete.

Screen display

2-4. Safety Mode

(It is displayed “SAFETY” on the liquid crystal display)

Not used for the servicing.

2-5. NFC test Mode 1

(It is displayed “NFC TST1” on the liquid crystal display)

Not used for the servicing.

2-6. NFC test Mode 2

(It is displayed “NFC TST2” on the liquid crystal display)

Not used for the servicing.

27

Page 28

HT-GT1

1. When sound is not outputted

Sound is not outputted

Sound is not output from all

functions.

Yes

SECTION 5

TROUBLESHOOTING

The voltage of the following

pin is 36 V.

MAIN board: CN4001

Between the pin 1 (V1) and

pin 4 (V1_GND).

Yes

The voltage of the following

pin is “H”.

MAIN board: IC002

pin 2 (RESET)

Yes

Replace the IC002 on the

MAIN board.

No

Fuse (F100) on the SMPS

board conduct the electricity.

Replace the Q101 and Q103

on the SMPS board.

Check and repair the IC002

on the MAIN board and the

surrounding circuit.

2. When liquid crystal display is not displayed

Yes

NoNo

Replace the fuse (F100) on the

SMPS board.

Liquid crystal display is

not displayed

Display does not change when

you press the [DISPLAY] button

on the remote commander.

Yes

The liquid crystal display is

displayed, when pull out the

speaker cable (CN2001 (for

SP1) and TB003 (for SS-GT1)

on the MAIN board), and then

turn the AC power on/off again.

Yes

Replace check the wire

and speaker.

No

DC detection of IC002 is working.

Check the short-circuit (the power

source or the earth fault) of the

audio output line of the IC002.

Replace the IC002 if there is

no problem.

28

Page 29

6-1. BLOCK DIAGRAM - MAIN Section -

X1001

OPTICAL

RECEIVER

IC5005

22 USB_DP

21 USB_DM

15

XOUT_PLL

14

XIN_PLL

SDA

9

USB DECODER

IC1002

SCL

BUSY

8

7

OPT IN

CN701

5V 1A

3

D+

2

D–

16.9344MHz

SECTION 6

DIAGRAMS

X1003

24.576MHz

27DATA

26BCK

25LRCK

MCHNG

SEARCH

IRPTO

RESETX

6

5

4

2

DIGITAL AUDIO

INTERFACE RECEIVER

IC1006

31 RXIN4

40

XTO

39

XTI

MDI/SDA23MDO/ADR025MC/SCL26MS/ADR12ERROR/INT0

24

NPCM/INT134RST

1

HT-GT1

17DOUT

19BCK

18LRCK

AMP_DATA_LR,

AMP_DATA_SW,

AUDIOLINK_DATA,

AMP_BCK, AMP_MCK,

AMP_LRCK, BCK, DOUT

(Page 30)

>001B

BT_PCM_OUT

BT_PCM_CLK

DIGITAL AUDIO SELECTOR

IC1005

51C1

61C0

41C2

11 2C1

10 2C0

12 2C2

CLOCK SIGNAL SELECTOR

IC1009

71Y

92Y

A14B

2

SAMPLE RATE

CONVERTER

4SDIN

5BCKI

6 LRCKI

2 RCKI

IC1003

13

RST

BCK

DOUT

23SDOUT

25BCKO

24LRCKO

X1002

12.288MHz

12

SDIN2

11

SDIN1

22

SCLKOUT1

19

LRCK

4XTALO

3XTALI

32

AUDIO DSP

IC1008

RESET8GPIO14SDIN416SCL115SDA1

27SDOUT1

26SDOUT2

25SDOUT3

23SCLKOUT2

21MCLKO

AMP_DATA_LR

AMP_DATA_SW

AUDIOLINK_DATA

AMP_BCK

AMP_MCK

AMP_LRCK

BT1

Bluetooth

MODULE

PCM_OUT

PCM_CLK

PCM_SYNC

UART_TX

UART_RX

UART_RTS

UART_CTS

MUTE

RESET

BT_PCM_OUT

BT_PCM_CLK

BT_PCM_SYNC

75

76

77

USB SCL

USB SDA

BLUETOOTH RXD

34

BLUETOOTH TXD

33

BLUETOOTH CTS

32

BLUETOOTH RTS

36

BLUETOOTH MUTE

18

BLUETOOTH RESET

35

73

79

USB BUSY

USB MCHNG

74

78

USB IRPTO

USB RESET

USB SEARCH

54

55 56

DIR_DOUT

52

DIR_DIN

DIR_CLK

57

DIR_CS

DIR_FLAG158DIR_FLAG2

53

DIR_RESET

BT_PCM_SYNC

89

83

DSEL

EXT_SEL_D-A

51C1

61C0

41C2

A14B

2

SYSTEM CONTROLLER

IC3001 (1/3)

71Y

EEPROM

IC3002

SDA6SCL7RST

2

22

CP IIC SDA

20

CP IIC CLK

23

CP RESET

11

X3001

8MHz

Xout

X3002

32.768kHz

43

65

42

46

DSP INT

DSP RESET

DSP MUTE

45

DSP IIC_CLK

DSP IIC_SDA

13

Xin

9

Xcout

8

XcIN

SIGNAL PATH

: AUDIO (DIGITAL)

: USB

: Bluetooth

HT-GT1

2929

Page 30

HT-GT1

6-2. BLOCK DIAGRAM - AMP Section -

AMP_DATA_LR,

AMP_DATA_SW,

AUDIOLINK_DATA,

AMP_BCK, AMP_MCK,

AMP_LRCK, BCK, DOUT

>001B

(Page 29)

AMP_DATA_LR

AMP_BCK

AMP_LRCK

AMP_MCK

AMP_DATA_SW

AMP_BCK

AMP_LRCK

AMP_MCK

AUDIOLINK_DATA

AMP_BCK

AMP_LRCK

AMP_MCK

D/A CONVERTER

IC004

2

DATA

1

BCK

3

LRCK

16 SCK

D/A CONVERTER

IC005

2

DATA

1

BCK

3

LRCK

16

SCK

D/A CONVERTER

IC5003

2

DATA

1

BCK

3

LRCK

16

SCK

POWER AMP

IC002

7VOUTL

8VOUTR

7VOUTL

8VOUTR

7VOUTL

8VOUTR

R-CH

DAC LPF

IC006

DAC LPF

IC007

LINE AMP

IC5004

PRE AMP

IC003

PRE AMP

IC001

10 INPUT_C

11 INPUT_D

5 INPUT_B

4 INPUT_A

15SD2

RESET

36OUT_C_36

37OUT_C_37

28OUT_D_28

29OUT_D_29

OVER LOAD

DETECT

Q004, 005

44OUT_B_44

45OUT_B_45

52OUT_A_52

53OUT_A_53

OVER LOAD

DETECT

Q006, 007

OVER LOAD

DETECT

Q002, 003

–2

–1

RY001

RELAY DRIVE

Q008

TB003

+

–

–

+

L

SPEAKERS

FRONT

R

SP1

(SUBWOOFER)

ANTENNA

FM

TUNER BOARD

TUNER_SDA_UCOM

TUNER_SCL_UCOM

AUDIO IN

PARTY CHAIN IN

LOUT

ROUT

TUNER_OE

RDS_INT

J5001 (1/2)

L

R

R-CH

TUNER_SDA_UCOM

TUNER_SCL_UCOM

TUNER_OE

RDS_INT

R-CH

TUNER_SCL_UCOM

TUNER_SDA_UCOM

RDS_INT

TUNER_OE

LINK BIAS

DETECT

Q5003, 5004

ANALOG AUDIO

SELECTOR

IC1007

12Y0

52Y1

DOUT

A/D CONVERTER

IC1004

32-COM

A

10

ANALOG AUDIO

SELECTOR

IC5001

Q1001

12Y0

42Y3

INVERTER

10 9

Q5006

32-COM

AB

R-CH

BCK

AMP_LRCK

AMP_MCK

LINE AMP

IC5002

R-CH

13

14

8

7

6

MUTING

Q5002, 5005

VINL

VINR

BCK

LRCK

SCKI

DOUT

9

J5001 (2/2)

L

PARTY CHAIN OUT

R

AUDIO OUT

DC DETECT

Q012

PROTECT_DET

>002B

(Page 31)

R-ch is omitted due to same as L-ch.

SIGNAL PATH

: AUDIO (ANALOG)

: AUDIO (DIGITAL)

: TUNER

MUTING

CONTROL

Q5007

LINK BIAS

CONTROL

Q5001

: AUDIO IN

HT-GT1

27

28

TUNER SCL

TUNER SDA

25

72

TUNER ON

RDS-INT

16

I-BIAS DETECT

40

EXT SEL_A

19

38

O_LINK_A

O_LINK_B

41

O-LINK MUTE (LINK)

21

O-BIAS

SYSTEM CONTROLLER

IC3001 (2/3)

3030

50

47

DAMP_RESET

PROTECT_DET

87

DC-OFFSET

82

F_SPK_RELAY

Page 31

6-3. BLOCK DIAGRAM - PANEL/POWER SUPPLY Section -

HT-GT1

ND401

LIQUID

CRYSTAL

DISPLAY

D401

(LCD BACK LIGHT)

D301

BLUETOOTH

PAIRING

D911

SPEAKER

ILLUMINATION

S304 – 307, 309

(TOP PANEL KEYS)

S301 – 303, 308, 310

(TOP PANEL KEYS)

M1

(FAN)

EN501

VOLUME

M

REMOTE CONTROL

LCD DRIVER

IC401

COM0 – COM3

LED DRIVE

Q401

LED DRIVE

Q3007, 3008

LED DRIVE

Q3013, 3015

ROTARY

ENCODER

NFC1

NFC MODULE

(RC-S801)

FAN MOTOR

CONTROL

Q4003, 4007

RECEIVER

DATA

CLK

IRQ

Standby

SEL

RF-DET

IC601

5

SIRCS

SWITCHING

Q4006

PVDD

D4010

D4017

D4013

D4014

PROTECT

DETECT

Q4010

DC/DC

CONVERTER

IC4004

REGULATOR

Q4001, 4002, 4005

VOLTAGE

DETECT

IC4003

D4019

D4018

D4012

D4015

D1026, 1027

POWER VOLTAGE

CONTROL

Q1003, 1004

PROTECT

DETECT

Q4008, 4009

D1021

SHUNT

REGULATOR

IC1858

PROTECT

DETECT

Q1001, 1002

D1007

D1006

ISOLATOR

PH100

ISOLATOR

PH101

D116

RECT

D1010

PROTECT_DET

OVER LOAD

PROTECT

Q109, 110, 112, 113

SWITCHING

Q111

SWITCHING

Q114

REGULATOR

Q115

T100

POWER

TRANSFORMER

(Page 30)

>002B

D114

D109, 108

D124 D121 D119

D122

RECT

D113

POWER ON/OFF

CONTROL

Q101, 103, 106, 107

TH101

POWER CONTROL

3

OLP

4

FB

2

VCC

OCP1BD5

7

OCP2

8

DRIVE

LINE FILTER

L100, 102

IC100

F100

AC1

(AC IN)

10SEG0 – SEG31 SDA

9SCL

8CSB

13INHB

7OSC

99 DP SDA

100 DP SCL

95 DP CS

98 DP INH

24 DP DRV CLK

SYSTEM CONTROLLER

IC3001 (3/3)

59 BLUETOOTH_LED

26 LED_RED

90 KEY 1

91 KEY 2

92

VOLUME-JOG

67 NFC DATA

68 NFC CLOCK

69 NFC IRQ

63 NFC STANDBY

64 NFC DATA SEL

66 NFC RF DETECT

71 FAN_SPEED

USB POWER 80

USB OVERCURRENT

PROTECT

PVDD-ON

P-ON

BLUETOOTH ON

AC-CUT

VBUS

81

D5.2V

D3.3V

48

CNETER

VOLTAGE

AMP B+

88

AVDD+5V

84

37

17

+12V

BT3.3V

E3.3V

BTLED_POWER

VBUS

SWITCH

IC1001

CENTER VOLTAGE

GENERATOR

Q5009

B+ SWITCH

Q3001, 3002

DC/DC CONVERTER

3

SW1

14

SW2

5

EN1

B+ SWITCH

Q5008

+5V

REGULATOR

IC4005

+3.3V

REGULATOR

IC4002

IC4001

VIN1 1

VIN2 16

D4007

D4008

HT-GT1

3131

Page 32

HT-GT1

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Printed Wiring Boards.

Note:

• X : Parts extracted from the component side.

• Y : Parts extracted from the conductor side.

• : Pattern from the side which enables seeing.

(The other layers’ patterns are not indicated.)

Caution:

Pattern face side:

(Conductor Side)

Parts face side:

(Component Side)

Caution:

Pattern face side:

(SIDE B)

Parts face side:

(SIDE A)

• Indication of transistor.

C

Q

B

E

Note: When the complete MAIN board is replaced, refer to

“NOTE OF REPLACING THE IC002 ON THE MAIN

BOARD AND THE COMPLETE MAIN BOARD” on

page 5.

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

These are omitted.

For Schematic Diagrams.

Note:

• All capacitors are in μF unless otherwise noted. (p: pF) 50

WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specifi ed.

• 2 : Nonfl ammable resistor.

• 5 : Fusible resistor.

• C : Panel designation.

Note: The components identifi ed by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specifi ed.

• A : B+ Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : TUNER (FM)

* : Impossible to measure

• Voltages are taken with VOM (Input impedance 10 M).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO (ANALOG)

J : AUDIO (DIGITAL)

f : TUNER

L : AUDIO IN

E : USB

a : Bluetooth

Note: When the complete MAIN board is replaced, refer to

“NOTE OF REPLACING THE IC002 ON THE MAIN

BOARD AND THE COMPLETE MAIN BOARD” on

page 5.

• Circuit Boards Location

NFC module

(RC-S801) (NFC1)

Bluetooth module

(BT1)

SPK-LED-H-L board

IR board

BUTTON board

USB board

PANEL board

TUNER board

MAIN board

SMPS board

VOL board

HT-GT1

3232

Page 33

HT-GT1

6-4. SCHEMA TIC DIAGRAM - MAIN Section (1/5) -

A

B

C

(Page 36)

D

E

F

G

H

I

J

K

L

M

N

>101S

MAIN

BOARD

(4/5)

(Page 36)

>102S

MAIN

BOARD

(4/5)

>103S

MAIN

BOARD

(Page 35)

>01S

USB

BOARD

CN702

(Page 41)

>104S

(Page 37)

>105S

MAIN

BOARD

(4/5)

(Page 36)

(3/5)

MAIN

BOARD

(5/5)

BT_PCM_OUT

BT_PCM_SYNC

BT_PCM_CLK

DIR_DIN

DIR_DOUT

DIR_RESET

DIR_CLK

DIR_ERR

DIR_NPCM

USB_IP_OCP

USB_MCHNG

USB_SEARCH

2

MAIN BOARD (1/5)

D3.3V

DIR_CS

D3.3V

OPTIN

DGND

CN1001

4P

CL1035

VBUS 1

CL1036

D– 2

CL1037

D+ 3

USB_ON

CL1038

D3.3V

D5.2V

DGND

AGND

DGND

VBUS GND 4

AVDD+5V

USB_SDA

USB_SCL

USB_BUSY

USB_IRPTO

USB_RST

FL1003

10R1092

C1074

0.01

C1059

47p

C1077

0.1

USB_SDA

USB_SCL

USB_BUSY

USB_MCHNG

USB_IRPTO

USB_RST

USB_SEARCH

3

45 7 1989

5

CL1061

3.3

20

21

22

DVDD

SCKO

DGND

IC1006

DIGITAL AUDIO

INTERFACE RECEIVER

PCM9211PTR

XTI39XTO40AGND41VCC42FILT

1.7

1.7

4700p

C1067

IC1001

FL1001

4

1.6

1.6

0

17

18

19

BCK

LRCK

IC1006

43

0

3.3

680

R1081

0.068

C1068

OUT

ILIM

FAULT

C1063

C1064

C1076

0.1

10

100R1094

R1091

10

10R1093

0.1

3.3

1.3

23

24

MDI/SDA

3.3

MC/SCL

25

3.3

MS/ADR1

26

3.3

MODE

27

RXIN7

28

RXIN6

29

RXIN5

30

3.3

RXIN4

31

RXIN3

32

RXIN2

33

3.3

RST

34

RXIN1

35

3.3

VDDRX

36

MDO/ADR0

RXIN037GNDRX

38

6

R1080

1M

C1065

10p

C1009

X1003

24.576MHz

1

R1079

100

C1066

12p

5.2

IN

1

GND

2

3.3

EN

3

IC1001

C1044

100p

VBUS SWITCH

TPS2553DBVR

• See page 42 for Waveforms. • See page 46 for IC Block Diagrams. • See page 50 for IC Pin Function Description.

R1076

100

R1077

100

R1078

100

16

14

DOUT

MPO015MPO1

VCOM44AGNDAD45VCCAD46VINL47VINR

48

0

0

4.9

C1070

100p

5.1

6

0.3

5

3.3

4

R1062

R1063

22k

R1006

10k

R1007

10k

6

R11010R1102

MPIO_B213MPIO_B3

MPIO_B1

12

MPIO_B0

11

MPIO_C3

10

MPIO_C2

9

MPIO_C1

8

MPIO_C0

7

MPIO_A3

6

MPIO_A2

5

MPIO_A1

4

MPIO_A0

3

0

NPCM/INT1

2

3.3

ERROR/INT0

1

C1071

100p

R1013

0

C1069

0.1

C1010

0.1

0

C1011

10

C1008

10

CL1022

CL1023

CL1024

3

CL1034

3.301.60001.6

28

29

30

AMUTE

31

DAVSS

32

RDACO

33

1.4

VCDACO

34

LDACO

35

3.3

DAVDD

36

3.3

SD_CON

37

3.3

SD_DO

38

SD_CLK

39

SD_DI

40

SD_CS

DVDDIO_29

DVSSIO_11RESETX2TMODE3IRPTO4SEARCH5MCHNG6BUSY7SCL8SDA9DVDD_M

3.3

CL1005

C1075

0.1

10R1095

USB_RST

100R1009

100R1008

26

27

DATA

MCLK

IC1002

USB DECODER

IC1002

BU94502AMUV

000

100R1003

100R1004

USB_IRPTO

USB_SEARCH

10R1048

10R1041

100R1040

25

BCK

LRCK

100R1084

USB_MCHNG

R1049

10

C1046

10p

24

0

10R1098

USB_BUSY

12kR1012

CLK24MI

10R1096

0

23

3.3

USB_SCL

100R1042

REXTI

R1052

10R1051

10R1050

R1044

4.7R1010

22

3.2

10R1097

USB_SDA

10

100

USB_DP

IC1005

DIGITAL AUDIO SELECTOR

TC74VHC153FT(EL)

1

1G

2

0

B

3

1C3

4

0

1C2

5

0

1C1

6

0

1C0

7

0

1Y

8

GND

IC1009

CLOCK SIGNAL SELECTOR

TC74VHC153FT(EL)

1

1G

2

0

B

3

1C3

4

0

1C2

5

1.6

1C1

6

1.6

1C0

7

1.6

1Y

8

GND

4.7R1011

2

21

USB_DM

20

AVSSC

3.3

19

AVDDC

18

SEL_SLAVE

3.3

17

TEST3

3.3

16

TEST2

1.4

15

XOUT_PLL

1.3

14

XIN_PLL

13

TEST1

3.3

12

DVDDIO_12

11

DVSSIO_11

10

0

C1005

0.1

10 11 12 13 14

R1103

0

IC1005

VCC

2C3

2C2

2C1

2C0

IC1009

VCC

2C3

2C2

2C1

2C0

CL1003

CL1002

R105310R1054

10

16

3.3

15

2G

14

0

A

13

12

0

11

1.6

10

1.6

9

1.6

2Y

16

3.3

15

3.3

2G

14

0

A

13

12

11

10

9

2Y

R1001

R1043

100

C1040

0.1

10R1055

1k

X1001

16.9344MHz

1

R1002

1M

C1042

C1057

C1072

C1073

0.1

0.1

0.1

50V

R1056

0

10R1057

10R1045

10R1046

R1058

0

LTC014EUBFS8TL

Q1001

INVERTER

3.3

1.7

0

1.6

1.6

3.3

3.3

3.3

0

R1014

10k

C1013

4.7

R1047

10

C1043

0.01

JL1003

C1041

R1090

0.1

100

C1035

0.1

C1007

0.1

C1004

0.1

C1003

0.1

C1001

10p

C1002

10p

C1031

0.1

10

IC1003

SAMPLE RATE CONVERTER

1

LGRP

2

RCKI

3

NC

4

SDIN

5

BCKI

6

LRCKI

7

VIO

8

DGND_8

9

BYPAS

10

IFMT0

11

IFMT1

12

IFMT2

13

RST

14

MUTE

R1018

1k

0

R1015

100k

R1017

1k

IC1003

SRC4182

JL1002

28

MODE2

27

MODE1

26

MODE0

25

1.6

BCKO

24

1.6

LRCKO

23

0.3

SDOUT

22

3.3

VDD

21

DGND_21

20

TDMI

19

3.3

OFMT0

18

OFMT1

17

OWL0

16

OWL1

15

0

RDY

R1064

1k

JL1004

R1016

R1066

100k

100k

R1067

100k

C1014

10

JL1007

C1012

4.7

15

R1036

100

R1061

10

10R1060

R1059

22

0R10690R1070

0R10720R1074

R1071

10k

R1086

0

R1034

10k

R1035

10k

R1087

100

R1023

10

R1021

0

C1053

4.9

2.4

2.4

2.4

12

13

15

16

1Y1141Y2

VCC

1-COM

2Y012Y222-COM32Y342Y15INH6GND_77GND_8

2.4

2.4

2.4

1Y3111Y0

0.1

0

9A10

8

C1025

R1030

R1073

100

R1027

0

JL1005

B

IC1007

ANALOG AUDIO SELECTOR

SN74LV4052APWR

C1015

JL1006

16

10p

12.288MHz

0

IC1007

4.7

17

C1026

C1024

10p

0.01

X1002

1

2

1.7

3

0.8

4

0.6

5

6

7

8

0

9

3.3

10

11

0.3

12

1.2

13

14

0

15

2

16

2

17

3.3

18

3.3

19

1.6

CL1048

CL1049

7

100R1039

CL1051

100R1037

CL1052

100R1038

CL1055

8

10R1024

10R1025

C1016

4.7

R1019

100

JL1001

R1020

100

C1050

C1051

100p

100p

AVSS

VR_PLL

XTALI

XTALO

MCLKI

MICROCLK_DIV

CS0

GPIO

DVDD_9

DVSS_10

SDIN1

SDIN2

SDIN3

SDIN4

SDA1

SCL1

SDA2

SCL2

LRCLK

L1001

10uH

IC1008

AUDIO DSP

IC1008

TAS3108DCPR

RESERVED_37

RESERVED_33

C1019

10

C101810C1017

0.1

IC1004

A/D CONVERTER

IC1004

PCM1808PWR

18

DVDD_30

DVSS_29

SDOUT1

SDOUT2

SDOUT3

SDOUT4

SCLKOUT2

SCLKOUT1

C1022

10

C1020

0.1

16V

RESET

VR_DIG

MCLKO

SCLKIN

20

SL1001

SL1002

FL1002

C1027

C1028

10

0.1

R1075

38

3.3

AVDD

37

36

PLL2

35

PLL1

34

PLL0

33

32

3.3

31

3.3

PDN

30

3.3

29

28

1.7

27

1.2

26

1.2

25

1.2

24

CL1060

23

1.6

22

1.6

21

1.7

20

10

9

C1023

R1022

0.1

0

2.4

4.9

1

2

VREF

AGND

14

2.4

2.4

100

3.3

4

VCC3VDD

50V

R1031

3.3

C1058

0.01

4.7C1032

100R1068

100R1033

100R1085

R1028

100

R1026

100

CL1045

CL1042

CL1041

CL1039

CL1040

CL1059

11

R1088

100

1.7

1.6

5

6

7

SCKI

LRCK

DGND

MD010MD111FMT12VINL13VINR

DOUT

BCK

8

9

1.2

1.6

R1065

100

211

EXT_SEL_D-B

EXT_SEL_D-A

TAS_INT

TAS_IIC_CLK

TAS_IIC_DATA

TAS_MUTE

TAS_RESET

AMP_DATA_LR

AMP_DATA_SW

AMP_BCK

DGND

AVDD+5V

AMP_MCK

AMP_LRCK

AMP_MCK

AUDIOLINK_DATA

AMP_BCK

AMP_LRCK

AGND

AU-IN-L

AU-IN-R

AVDD+5V

AGND

TUNER-L

EXT_SEL_A

TUNER-R

>106S

MAIN

BOARD

(4/5)

(Page 36)

>107S

MAIN

BOARD

(2/5)

(Page 34)

>108S

MAIN

BOARD

(3/5)

(Page 35)

>109S

MAIN

BOARD

(4/5)

(Page 36)

HT-GT1

Note: IC1002 on the MAIN board cannot replace with single. When

this part is damaged, replace the complete mounted board.

3333

Page 34

HT-GT1

6-5. SCHEMA TIC DIAGRAM - MAIN Section (2/5) -

A

(Page 33)

B

C

D

E

F

G

H

I

J

K

(Page 36)

L

M

>107S

MAIN

BOARD

(1/5)

>111S

MAIN

BOARD

(3/5)

(Page 35)

(Page 37)

>117S

MAIN

BOARD

(5/5)

>110S

MAIN

BOARD

(4/5)

(Page 37)

>112S

BOARD

>113S

MAIN

BOARD

(5/5)

(Page 37)

2

MAIN BOARD (2/5)

AMP_DATA_LR

AMP_LRCK

AMP_DATA_SW

AMP_BCK

AMP_MCK

DGND

AVDD+5V

AVDD+5V

+12V

E3.3V

PROTECT_DET

DC_OFFSET

E3.3V

LINE_MUTE

O-DAMP-RESET

F_SPK_RELAY

PROTECT_DET

E3.3V

12V_GND

MAIN

+12V

(5/5)

PVDD_GND

JL016

PVDD

3

C039

C040

C042

C041

0.001

0.001

R096

C038

0.001

R085

C030

C033

2.2k

0.001

0.001

45 7 1989 22

IC004

D/A CONVERTER

IC004

PCM1754DBQR

16

1.7

SCK

15

FMT

14

MUTE

13

DEMP

12

TEST

11

ZEROA

10

2.4

VCOM

9

AGND

R111

0

R109

2.2k

R110

C121

2.2k

100

10V

R125

0

6.2

12.4

6

7

8

VCC

IC007

DAC LPF

IC007

BA4558F-E2

123

12.4

12.4

C027

0.001

R091

C034

2.2k

0.001

R080

2.2k

10

10

2.2k

2.2kR090

2.2kR086

2.2kR097

2.2kR098

R089

2.2k

LTA014EUBFS8TL

R095

2.2k

R093

2.2k

3.3

Q013

(NOT USE)

R071

10

C013

10

16V

CL014

CL013

CL015

CL003

R099

C035

1k

0.001

R094

2.2k

6.2

6.2

VEE

45

R083

C028

2.2k

4.7

50V

C029

4.7

R084

50V

2.2k

C032

4.7

R088

50V

2.2k

C031

4.7

R087

50V

2.2k

3.3

-0.5

R124

0

• See page 46 for IC Block Diagrams.

6

R072

VOUTR

R07410R073

1.6

1

BCK

1.2

2

DATA

1.6

3

LRCK

4

DGND

5

NC

4.9

6

VCC

2.5

7

VOUTL

2.5

8

C122

R058

0.1

10k

6.2

45

VEE

6.2

6.2

R054

10k

C023

0.001

R117

R081

2.2k

2.2k

6.2

6.2

6.2

123

45

VEE

6.2

6.2

IC006

BA4558F-E2

VCC

6

7

8

6.2

12.4

R082

R118

2.2k

2.2k

C022

0.001

10

10

C014

C015

10

16V

R059

C003

10k

100p

6.2

6.2

123

IC001

BA4558F-E2

VCC

6

7

8

6.2

12.4

R126

R116

0

10k

R119

R101

10k

1k

DAC LPF

IC006

R079

R092

2.2k

2.2k

0.1

PRE AMP

IC001

R103

1k

CL019

R0550R056

10k

C009

100p

R068

10k

R070

10k

R062

10k

R120

10k

R075

10

C016

10

16V

R057

C001

100p

R067

0

6.2

6.2

45

VEE

6

6.2

6.2

6.2

16

1.7

SCK

15

FMT

14

MUTE

13

DEMP

12

TEST

11

ZEROA

10

2.4

VCOM

9

AGND

R061

100

C005

10

10k

R060

C004

100

10

R066

C008

100

4.7

50V

6.2

123

IC003

PRE AMP

IC003

BA4558F-E2

VCC

7

8

12.4

C007

4.7

50V

R065

100

R064

R063

0

10k

C006

100p

IC005

D/A CONVERTER

IC005

PCM1754DBQR

10 11 12 13 14 15

R07710R076

R078

10

10

1.6

1

BCK

1.2

2

DATA

1.6

3

LRCK

4

DGND

5

NC

4.9

6

VCC

2.5

7

VOUTL

2.5

8

VOUTR

C017

C018

0.1

10

16V

R121

100

1.2

Q012

LSCR523UBFS8TL

DC DETECT

C097

C098

0.1

4.7

R015

3.3

3.3R014

R009

0

R007

R005

15k

15k

C089

0.0047

C096

220p

R004

100

CL016

CL017

CL018

CL005

CL006

1C092

CL001

CL002

CL007

CL008

R006

10k

JL003

R001

C120

100

100

16V

C093

0.1

R016

3.3

R017

C021

3.3

0.1

C020

0.1

C037

0.1

C026

0.1

R025

10k

1.1

3.2

3.2

1.9

1.9

1.9

3.2

1.9

1.9

0.9

R008

10k

3.3

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

OC_ADJ

RESET

C_STARTUP

INPUT_A

INPUT_B

VI_CM

GND_7

AGND

VREG

INPUT_C

INPUT_D

FREQ_ADJ

OSC_IO+

OSC_IOSD

OTW1

12.4

1.9

62

63

64

VDD

PSU_REF

CLIP

READY19M120M221M3

OTW2

17

18

3.2

JL002

JL007

R012

0

R011

0

NC_5959NC_6060NC_6161NC_62

IC002

POWER AMP

TAS5613APHDR

GND_23

22

0.1C099

12.4

58

GND_5757GND_58

GVDD_B

IC002

GND_2424GVDD_C25GVDD_D

23

12.4

0.1C100

0

C101

0.1C012

12.4

29.1

55

56

GVDD_A

26

29.1

12.4

0.1C103

C102

R107

100k

0.1

17.4

17.4

53

54

BST_A

OUT_A_5252OUT_A_53

BST_D27OUT_D_2828OUT_D_29

17.4

17.4

0.1

C046

2.2

50V

D009

36.2

PVDD_D_3030PVDD_D_31

29

36.2

D012

SK310A-R3

SK310A-R3

36.2

51

PVDD_A_5050PVDD_A_51

36.2

31

C114

220p

C113

220p

49

GND_A_49

GND_D_32

32

C110

220p

C111

220p

R022

10

1/2W

PVDD_B_43

PVDD_B_42

PVDD_C_39

PVDD_C_38

R019

10

1/2W

R108

100

GND_A_48

GND_B_47

GND_B_46

OUT_B_45

OUT_B_44

OUT_C_37

OUT_C_36

GND_C_35

GND_C_34

GND_D_33

16

17.9

17.9

0

Q002

2PB709ART

17.9

17.9 17.9

0

Q003

2PB709ART

C080

47

R041

R040

220k

BST_B

BST_C

220k

C050

C051

C049

C104

C105

470

470

470

2.2

50V

50V

50V

48

47

46

17.4

45

17.4

44

36.2

43

36.2

42

29.1

41

29.1

40

36.2

39

36.2

38

17.4

37

17.4

36

35

34

33

R031

10k

C052

C053

R030

470

2200

2.2

50V

10k

50V

SK310A-R3

SK310A-R3

C081

10

R042

R043

220k

220k

JL008

JL009

R021

10

1/2W

C108

D010

2.2

JL011

0.1C106

0.1C107

JL012

D011

C109

2.2

R020

10

1/2W

JL014

JL015

Q002 - 007

OVER LOAD DETECT

17.9

0

Q004

2PB709ART

17.9

0

Q005

2PB709ART

R044

220k

C116

C115

220p

220p

C112

C117

220p

220p

17

17.9

R045

220k

R029

R028

L006

10uH

JL010

JL013

L005

10uH

18

17.9

17.9

0

Q006

2PB709ART

17.9

17.9

0

Q007

2PB709ART

C082

10

R047

R046

220k

10k

10k

220k

R048

220k

R049

2.2k

R050

10k

C072

C064

0.022

0.0022

C073

C065

0.022

0.0022

R032

C058

C059

C088

0.01

C085

0.01

C060

C061

R036

3.3

1

63V

63V

63V

63V

3.3

R033

R037

1

3.3

3.3

C074

C066

0.022

0.0022

C067

C075

0.0022

0.022

C062

1000

50V

C068

0.0022

C069

0.0022

R034

1

3.3

R035

1

3.3

C070

0.0022

C071

0.0022

C076

0.022

C077

0.022

R026

R051

R038

330

330

2W

R027

330

2W

C063

1000

50V

3.3

2W

R053

0

R039

3.3

C078

R052

0.022

330

2W

C079

0.022

20

0.7

0

Q008

LSCR523UBFS8TL

RELAY DRIVE

C083

0.0047

C084

0.0047

-1

-2

RY001

D008

DA2J10100L

211

CN2001

2P

CL009

SW+1

CL010

SW–2

C087

JL018

0.01

C086

JL017

0.01

CL011CL012

C126

0.1

ET010

R112

R113

C123

0.1

E

ET001

0

E

ET002

0

E

ET003

E

TB003

(CHASSIS)

(CHASSIS)

(CHASSIS)

(CHASSIS)

SP1

(SUBWOOFER)

+

R

–

SPEAKERS

FRONT

+

L

–

HT-GT1

Note: When the IC002 on the MAIN board is replaced, refer to

“NOTE OF REPLACING THE IC002 ON THE MAIN

BOARD AND THE COMPLETE MAIN BOARD” on page 5.

3434

Page 35

HT-GT1