Page 1

SERVICE MANUAL

MODEL

.............. ......... ....................

DEST. CHASSIS NO. MODEL DEST. CHASSIS NO.

.............. ......... ....................

VPL-VW12HT WORLD RM-PJVW10 WORLD

VIDEO PROJECTOR

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

WARNING!!

AN INSULATED TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECEIVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY A

DIAGRAMS, EXPLODED VIEWS AND IN THE PARTS LIST ARE

CRITICAL TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE P ART NUMBERS APPEAR

AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY .

!!

! MARK ON THE SCHEMA TIC

!!

ATTENTION!!

AFIN D’ÉVITER TOUT RISQUE D’ÉLECTROCUTION

PROVENANT D’UN CHÂSSIS SOUS TENSION, UN

TRANSFORMA TEUR D’ISOLEMENT DOIT ETRE UTILISÉ LORS

DE TOUT DÉPANNAGE.

LE CHÂSSIS DE CE RÉCEPTEUR EST DIRECTEMENT

RACCORDÉ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS Á LA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE MAPQUE

LES SCHÉMAS DE PRINCIPE, LES VUES EXPLOSÉES ET LES

LISTES DE PIECES SONT D’UNE IMPORTANCE CRITIQUE

POUR LA SÉCURITÉ DU FONCTIONNEMENT. NE LES

REMPLACER QUE PAR DES COMPOSANTS SONY DONT LE

NUMÉRO DE PIÈCE EST INDIQUÉ DANS LE PRÉSENT MANUEL

OU DANS DES SUPPLÉMENTS PUBLIÉS PAR SONY.

!!

! SUR

!!

VPL-VW12HT

Page 3

For the customers in the Netherlands

Voor de klanten in Nederland

Hoe u de batterijen moet verwijderen, leest u in de tekst

van deze handleiding.

Gooi de batterij niet weg maar lever deze in als klein

chemisch afval (KCA).

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

VPL-VW12HT

1 (P)

Page 4

Page 5

TABLE OF CONTENTS

1. Service Informations

1-1. Circuit Boards Location ..............................................................................1-1

1-2. Cabinet Assy Removal ................................................................................ 1-2

1-3. Front Panel Assy Removal..........................................................................1-2

1-4. G and GA Boards Removal.........................................................................1-3

1-5. C Board Removal ....................................................................................... 1-3

1-6. B and Q Boards Removal............................................................................1-4

1-7. Optical Unit Assy Removal ........................................................................1-4

1-8. TH, U, BM and V Boards Removal ............................................................ 1-5

1-9. Power Block Removal.................................................................................1-5

1-10. Lens Assy Removal.....................................................................................1-6

1-11. Prism Block Removal .................................................................................1-6

1-12. Extension Boards ........................................................................................1-7

1-13. Power Cord..................................................................................................1-8

1-14. Software Writing Procedure........................................................................1-8

2. Electrical Adjustments

2-1. Preparations.................................................................................................2-1

2-1-1. Equipment Required...................................................................2-1

2-1-2. Reset the Air Filter .....................................................................2-1

2-1-3. Setting the Factory Mode ...........................................................2-1

2-2. RGB VCOM Adjustment ............................................................................ 2-1

2-3. Signal Level Adjustment.............................................................................2-1

2-3-1. SUB-BRIGHT (NTSC) Adjustment .......................................... 2-1

2-3-2. SUB-CONT, HUE and COLOR Adjustment............................2-1

2-3-2-1.SUB CONT, HUE and COLOR (VIDEO)

Adjustment ...................................................................2-1

2-3-2-2.SUB CONT, HUE and COLOR (Component)

Adjustment ...................................................................2-2

2-3-2-3.SUB CONT, HUE and COLOR (DTV)

Adjustment ...................................................................2-2

2-3-2-4.SUB CONT, HUE and COLOR (15k RGB)

Adjustment ...................................................................2-2

2-3-3. Signal Center and the Amplitude Adjustment ...........................2-3

2-3-4. ODD/EVEN Level Adjustment..................................................2-3

2-3-5. RGB High Gain/Bias Adjustment ..............................................2-3

2-3-5-1.RGB High Gain/Bias Adjustment ................................ 2-3

2-3-5-2.RGB W/B Low and Custom Adjustment .....................2-4

VPL-VW12HT

1

Page 6

2-4. VIDEO W/B Adjustment ............................................................................2-4

2-4-1. Component W/B Hight Adjustment ........................................... 2-4

2-4-2. Component W/B Low Adjustment.............................................2-4

2-4-3. W/B Low Custom Adjustment ................................................... 2-4

2-5. Adjustments in Replacement of Prism and Optical Unit ............................2-5

2-5-1. V-COM Adjustment ................................................................... 2-5

2-5-2. Polarization Plate Adujustment .................................................. 2-5

2-5-3. 3D GAMMA Adujustment (Outline) ......................................... 2-5

2-5-4. 3D GAMMA Adujustment ........................................................2-5

3. Descriptions of Circuit Board Operations

3-1. G/GA/F Boards .......................................................................................... 3-1

3-1-1. Outline .............................................................................................3-1

3-1-2. Detailed Explanation .......................................................................3-1

3-1-2-1. Active Filter Unit .........................................................3-1

3-1-2-2. Main Converter Unit ....................................................3-1

3-1-2-3. Fan Drive Unit..............................................................3-1

3-1-2-4. Sub Coverter Unit ........................................................3-2

3-1-2-5. The Detection of the Fan's Rotation Speed .................. 3-2

3-2. B Board ....................................................................................................... 3-5

3-2-1. Main IC Functions ........................................................................... 3-5

3-2-1-1. MC141627FT (IC3010), Digital Comb Filter..............3-5

3-2-1-2. uPD64082 (IC3014), 3D Comb Filter..........................3-5

3-2-1-3.CXA2123 (IC3006), Chroma Decoder &

Sync Processing ..........3-5

3-2-2.Signal Flows.................................................................................... 3-5

3-2-2-1.VIDEO Signal Flows .................................................... 3-5

3-2-2-2.15k-COMPONENT Signal/15k-RGB Signal Flows.....3-6

3-3. Q Board .......................................................................................................3-6

3-3-1. Outline of Main ICs..........................................................................3-6

3-3-1-1. TLC5733 (IC4029), AD Converter for DRC Use........3-6

3-3-1-2. CXD2095AQ (IC4033), DRC Processing ................... 3-6

3-3-1-3. CXA2101AQ (IC4013), HD Interface, RGB Matrix...3-6

3-3-1-4. M52347FP (IC4006), SYNC SEPARATOR ...............3-7

3-3-1-5. EL4332C (IC4007), RGB Switch, 6dB Amp,

75 Ohm Driver ..... 3-7

3-3-2. Video Signal Flow ............................................................................ 3-7

3-3-2-1. VIDEO Signal Flow ..................................................... 3-7

3-3-2-2. HDTV/DTV (YPbPr, RGB) Double

Speed Component (YUV) Signal Flows...........3-7

3-3-2-3. Computer Signal (RGB) Flows .................................... 3-7

3-3-3. SYNC Processing Flows .................................................................. 3-7

3-3-3-1. When VIDEO Signals and 15k COMPONENT

Signals are Processed ...3-7

2

VPL-VW12HT

Page 7

3-3-3-2. When 15k-RGB Signal are Processed..........................3-8

3-3-3-3. When HDTV/DTV (YPbPr, GBR) Double

Speed Composite Signals are Input ........ 3-8

3-3-3-4. When Computer Signals are Processed........................3-8

3-3-4. RS232C Communication Buffer ...................................................... 3-8

3-3-5. Reception of Remote Control Signal (SIRCS Signal)......................3-9

3-3-6. Power Protector ................................................................................3-9

3-3-7. B Board, Q Board Block Diagram ...................................................3-9

3-3-8. Signal Flow.......................................................................................3-9

3-3-8-1.C-Video (NTSC3.58) ....................................................3-9

3-3-8-2.C-Video (PAL, PAL-M, PAL-N)................................3-10

3-3-8-3.C-Video (SECAM, NTSC4.43) .................................. 3-10

3-3-8-4.S-Video .......................................................................3-11

3-3-8-5.15k-Component...........................................................3-11

3-3-8-6.Double Speed Component...........................................3-12

3-3-8-7.HDTV (GBR, YPbPr) .................................................3-12

3-3-8-8.15k-RGB .....................................................................3-13

3-3-8-9.PC-RGB ...................................................................... 3-13

3-4. C Board ..................................................................................................... 3-14

3-4-1.A/D Converter Unit .........................................................................3-14

3-4-2.SCAN Converter .............................................................................3-14

3-4-2-1.Internal Block Diagram

(Simplified diagram: Unused parts omitted)........3-14

3-4-2-2.Graphics Port Block ....................................................3-14

3-4-2-3.Display Port Block ......................................................3-15

3-4-2-4.OSD MIX Processing..................................................3-15

3-4-2-5.Microprocessor Block .................................................3-15

3-4-3.Functions of Main ICs .....................................................................3-16

3-4-3-1.CXD9512 (IC5304), 3D GAMMA ADJ, TG .............3-16

3-4-3-2.CXD3504R (IC5403), Dot-Line Inversion .................3-16

3-4-3-3.ADV7123 (IC5501, 5502), D/A Converter.................3-16

3-4-3-4.M52749 (IC5504, 5505), RGB Amp .......................... 3-16

3-4-3-5.CXA3512R (IC5601, 5602, 5701, 5702, 5801, 5802),

LCD Driver .. 3-17

3-4-3-6.LCX037 LCD Panel .................................................... 3-17

3-4-4.Signal Flow......................................................................................3-18

3-4-4-1.Between CXD9512 to LCD Panel ...............................3-18

3-4-4-2.LCD Panel Write Sequence ........................................3-19

3-4-5.C Board Block Diagram ..................................................................3-20

3-4-6.Memory Composition......................................................................3-20

3-4-6-1.Memory Composition ................................................. 3-20

3-4-6-2.Memory Structure and Data Access............................3-22

3-4-6-3.Data Access when VIDEO MEM OFF is Selected

(When Status Memory No.1 is Selected) ..... 3-24

3-4-6-4.VIDEO MEM Data Access when 1 to 6 is

Selected (When Status Memory No.1 is Selectsd) .... 3-25

3-4-6-5.CPU Peripheral............................................................3-26

VPL-VW12HT

3

Page 8

4. Semiconductors.................................................4-1

5. Spare Parts

5-1.Notes on Repair Parts ...........................................................................5-1

5-2.Exploded Views .................................................................................... 5-2

5-3.Electrical Parts List for Boards ............................................................. 5-6

5-4.Packing Materials ...............................................................................5-30

6. Block Diagrams

Overall ......................................................................................................6-1

Q................................................................................................................6-2

B ................................................................................................................6-3

BM ............................................................................................................ 6-3

C ................................................................................................................6-4

TH .............................................................................................................6-5

U................................................................................................................6-5

V................................................................................................................6-5

H................................................................................................................6-6

NF .............................................................................................................6-6

NR .............................................................................................................6-6

F ................................................................................................................ 6-7

G................................................................................................................6-7

GA.............................................................................................................6-7

7. Diagrams

7-1. Frame Schematic Diagram .......................................................................... 7-1

Frame ........................................................................................................ 7-1

7-2. Schematic Diagrams and Printed Wiring Boards........................................7-2

Schematic Diagrams

Q (1/6) ....................................................................................................... 7-4

Q (2/6) ....................................................................................................... 7-5

Q (3/6) ....................................................................................................... 7-6

Q (4/6) ....................................................................................................... 7-7

Q (5/6) ....................................................................................................... 7-8

Q (6/6) ....................................................................................................... 7-9

B (1/3) .....................................................................................................7-12

B (2/3) .....................................................................................................7-13

B (3/3) .....................................................................................................7-14

H..............................................................................................................7-16

NF ...........................................................................................................7-17

4

VPL-VW12HT

Page 9

NR ........................................................................................................... 7-17

TH ...........................................................................................................7-17

U..............................................................................................................7-17

V..............................................................................................................7-17

C (1/9) .....................................................................................................7-20

C (2/9) .....................................................................................................7-21

C (3/9) .....................................................................................................7-22

C (4/9) .....................................................................................................7-23

C (5/9) .....................................................................................................7-24

C (6/9) .....................................................................................................7-25

C (7/9) .....................................................................................................7-26

C (8/9) .....................................................................................................7-27

C (9/9) .....................................................................................................7-28

BM .......................................................................................................... 7-31

F .............................................................................................................. 7-33

G (1/3).....................................................................................................7-33

G (2/3).....................................................................................................7-34

G (3/3).....................................................................................................7-35

GA...........................................................................................................7-36

Printed Wiring Boards

Q................................................................................................................7-3

B ..............................................................................................................7-11

H..............................................................................................................7-15

NF ...........................................................................................................7-17

NR ........................................................................................................... 7-17

TH ...........................................................................................................7-17

U..............................................................................................................7-17

V..............................................................................................................7-17

C ..............................................................................................................7-18

BM .......................................................................................................... 7-30

F .............................................................................................................. 7-32

G..............................................................................................................7-32

GA...........................................................................................................7-36

VPL-VW12HT

5

Page 10

Page 11

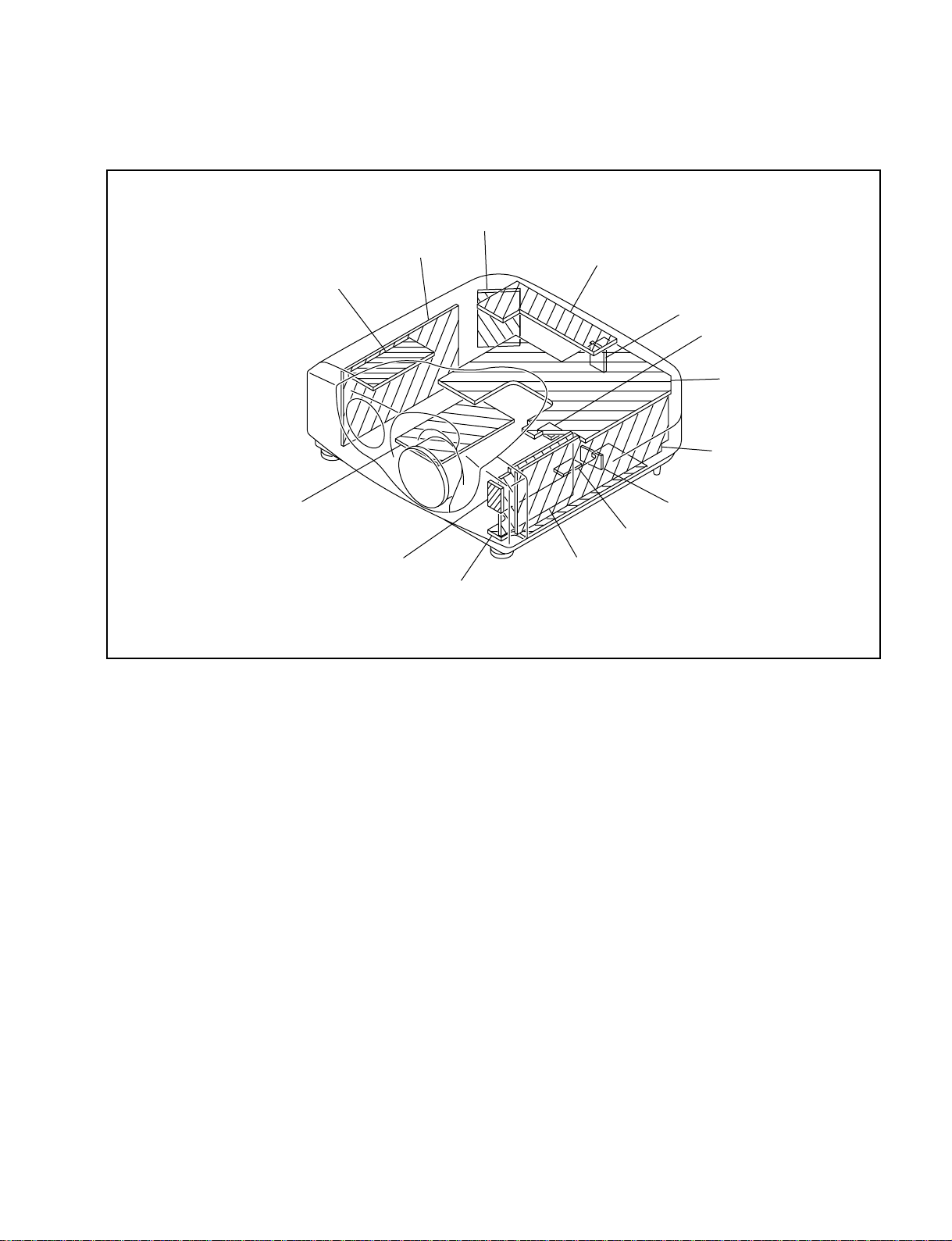

1-1. Circuit Boards Location

Section 1

Service Informations

F

POWER BLOCK

GA

NF

G

BM

H

NR

U

C

Q

V

TH

B

VPL-VW12HT

1-1

Page 12

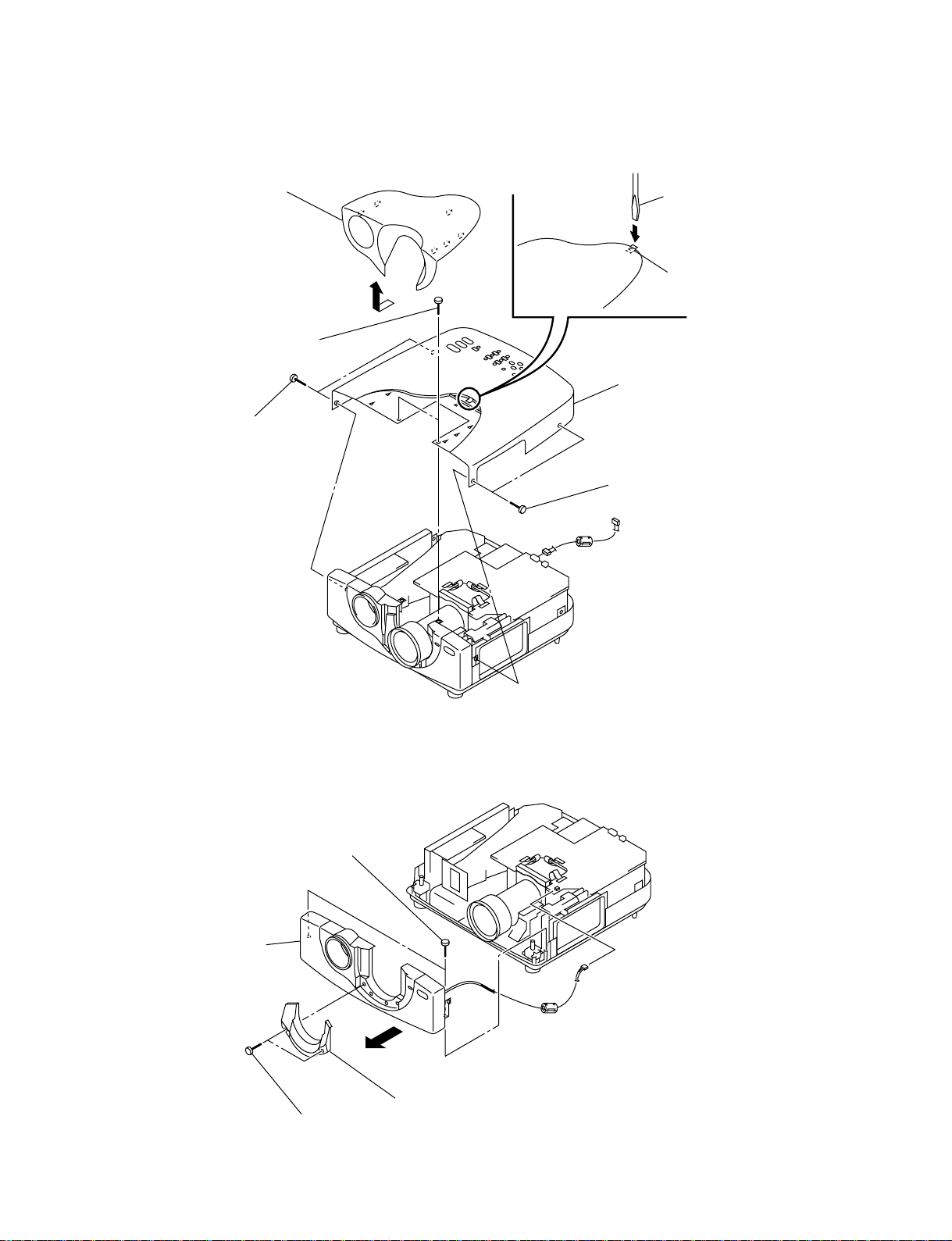

1-2. Cabinet Assy Removal

2 Lens cover (TP)

3 Two screws (+B3 x 6)

4 Two screws (+B3 x 6)

Driver _

1 Push in claw

6 Cabinet assy

5 Two screws (+B3 x 6)

CN7001

1-3. Front Panel Assy Removal

3 Two screws (+B3 x 6)

4 Front panel assy

1 Two screws (+BVTP3 x 8)

1-2

CN5008

2 Lens cover (BT)

VPL-VW12HT

Page 13

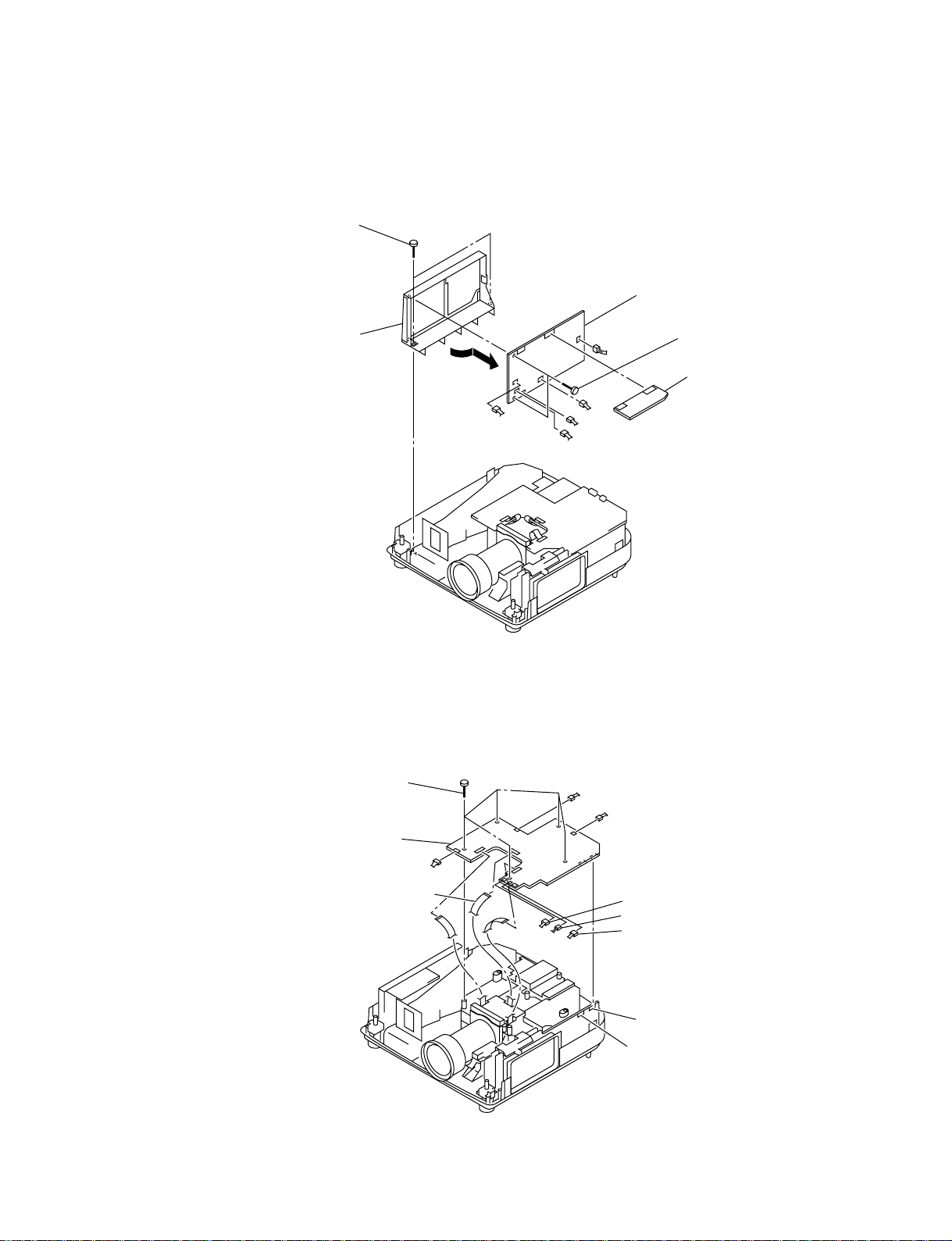

1-4. G and GA Boards Removal

1 Two screws (+B3 x 6)

2 Holder (G)

4 G board

CN2001

CN2002

CN2010

CN2009

CN2008

5 GA board

3 Two screws

(+BVTP3 x 8)

1-5. C Board Removal

1 Five screws (+B3 x 6)

2 C board

CN5010

CN5601

CN5701

CN5801

CN5011

CN5007

CN5006

CN5005

CN5004

Connector (CN4002)

Connector (CN4004)

VPL-VW12HT

1-3

Page 14

1-6. B and Q Boards Removal

• Remove the C Board (Refer to 1-5.).

6 Four screws (+BVTP3 x 8)

3 B board

1-7. Optical Unit Assy Removal

5 Q board

1 Screw (+B3 x 6)

2 Holder (B)

4 Two screws (+B3 x 6)

7 Connector panel

Cover (9P receptacle)

• Remove the C Board (Refer to 1-5.).

2 Two screws (+PWH3 x 6)

1 Six screws (+PSW4 x 12)

4 Optical unit assy

3 Connector (2P)

1-4

VPL-VW12HT

Page 15

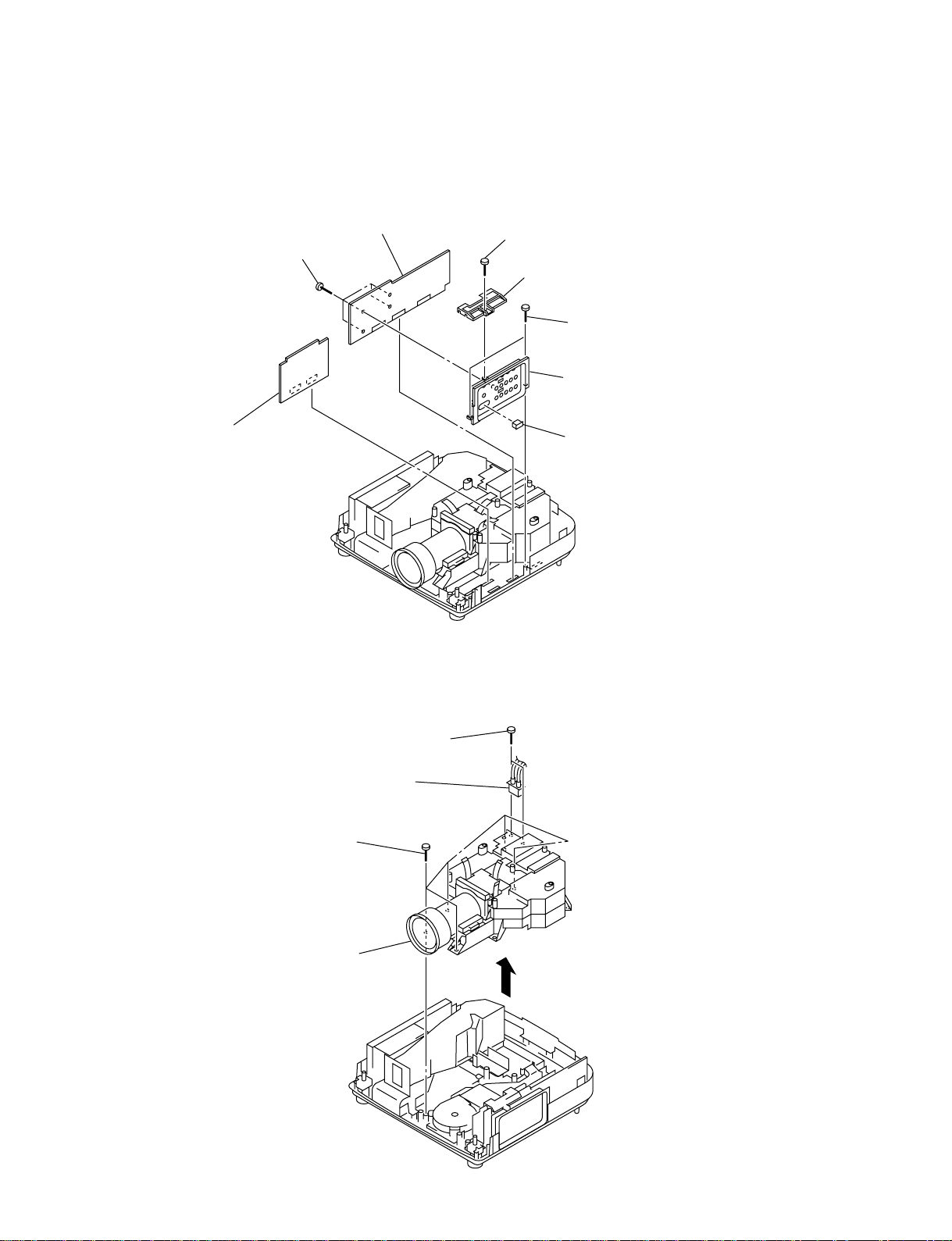

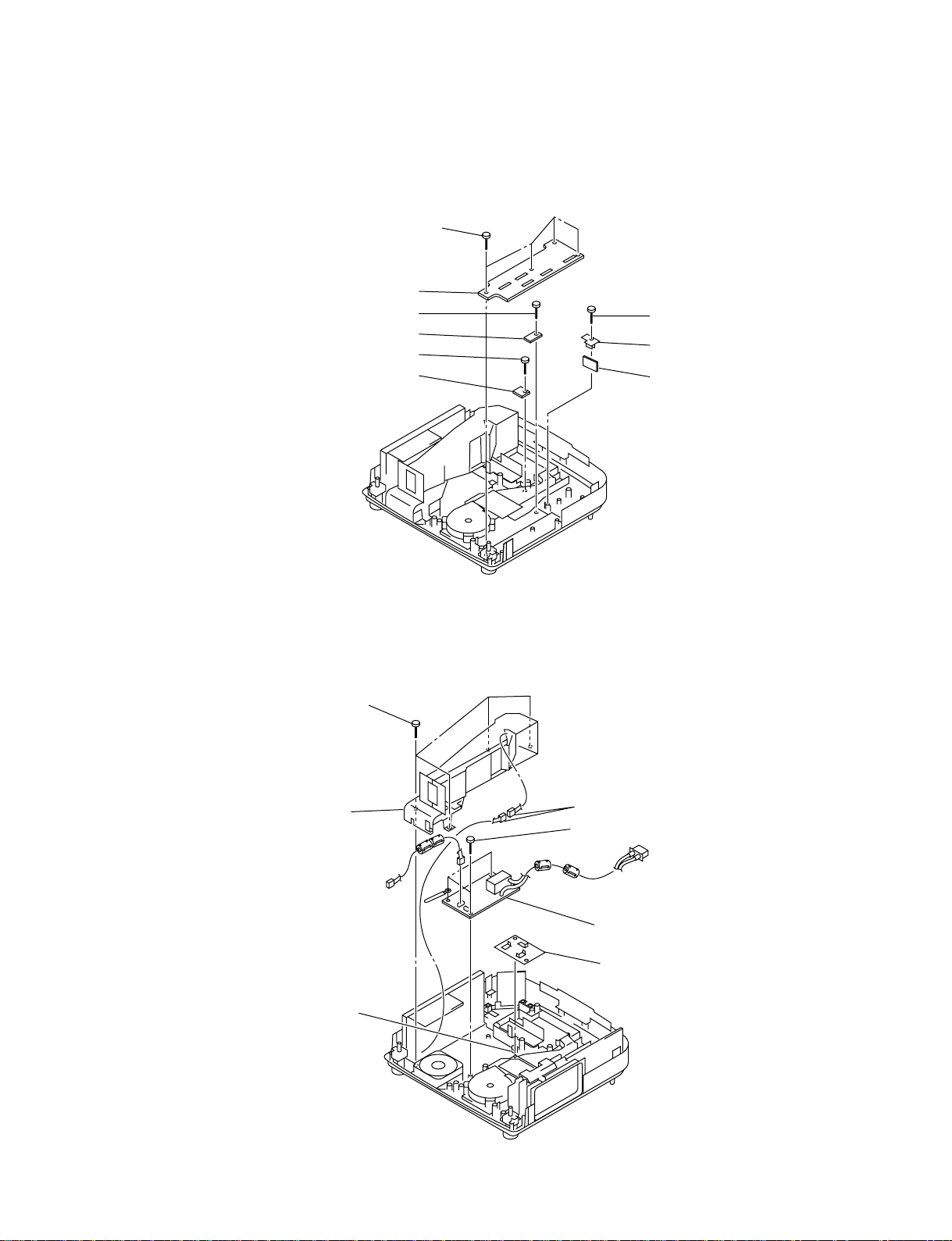

1-8. TH, U, BM and V Boards Removal

• Remove the B and Q Boards (Refer to 1-6.).

• Remove the optical unit assy (Refer to 1-7.).

5 Four screws (+B3 x 6)

6 BM board

1 Screw (+B3 x 6)

2 TH board

3 Screw (+B3 x 6)

4 U board

7 Screw (+B3 x 6)

8 Holder (V)

9 V board

1-9. Power Block Removal

• Remove the optical unit assy (Refer to 1-7.).

1 Four screws (+B3 x 6)

2 Duct

Holder (LPS)

Connector (3P)

3 Three screws (+B3 x 6)

4 Power block

Fin (VW)

VPL-VW12HT

1-5

Page 16

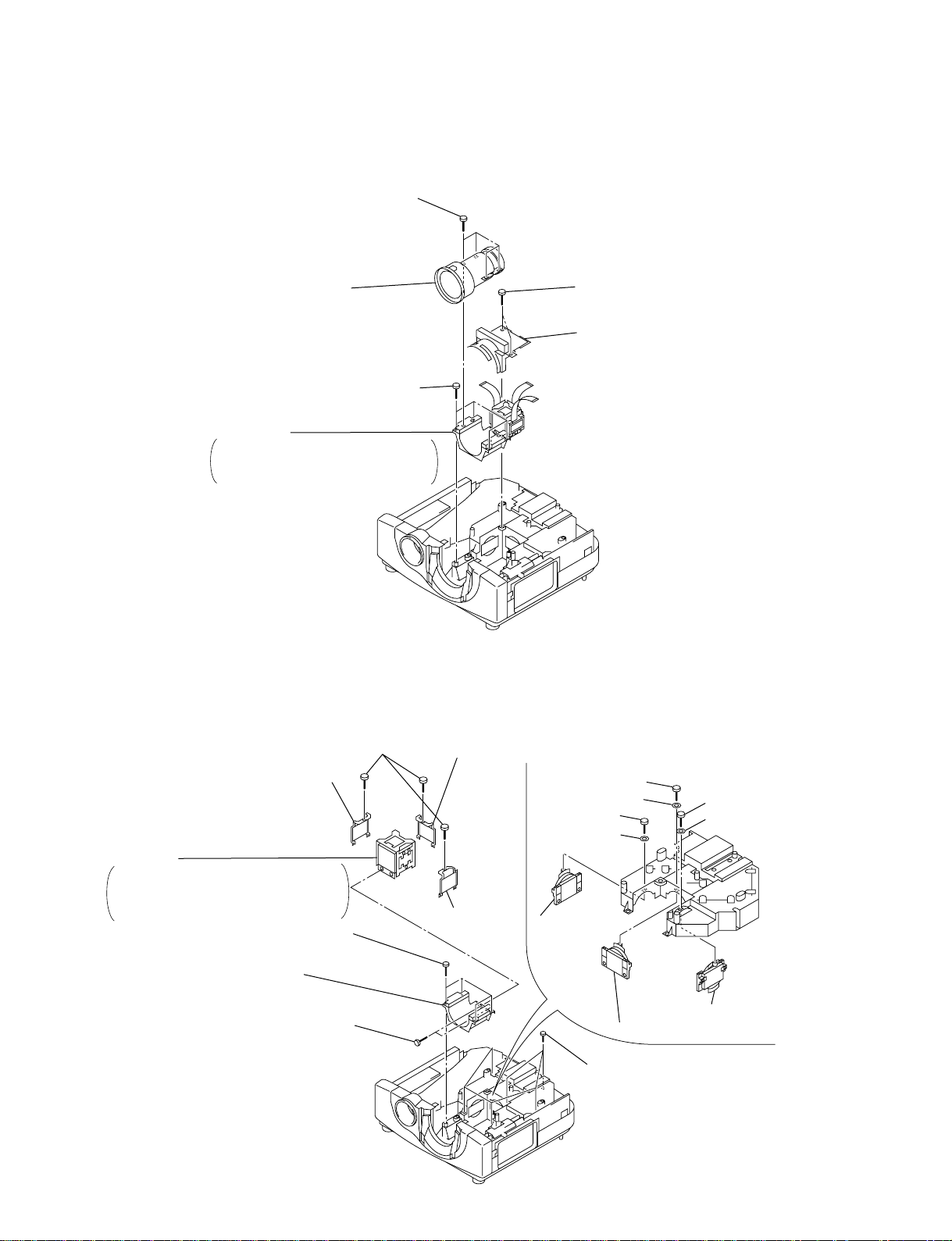

1-10. Lens Assy Removal

• Remove the C Board (Refer to 1-5.).

5 Four screws (+PSW4 x 8)

6 Lens assy

3 Four screws (+B3 x 8)

4 Lens bracket

Remove the lens assembly attached

to the lens bracket instead of the single

lens assembly, if possible.

1-11. Prism Block Removal

• Remove the B and Q Boards (Refer to 1-6.).

• Remove the optical unit assy (Refer to 1-7.).

1 Two screws (+B3 x 8)

2 Lens holder

4 Three screws (+K1.6 x 2)

6 Polarizer, R-OUT plate

5 Prism block

NOTE: Use extreme care not to tuch the

glass section of prism, LCD and

conductive section of the flexible

cable in particular.

1 Four screws (+B3 x 8)

2 Lens bracket

3 Two screws (+B3 x 8)

1-6

7 Polarizer, G-OUT plate

!- Washer

8 Polarizer,

B-OUT plate

!= Polarizer, B-IN

plate

![ Screw

!] Washer

!/ Screw

9 Six screws

!; Screw

!' Washer

!, Polarizer, B-IN plate

!\ Polarizer, G-IN plate

VPL-VW12HT

Page 17

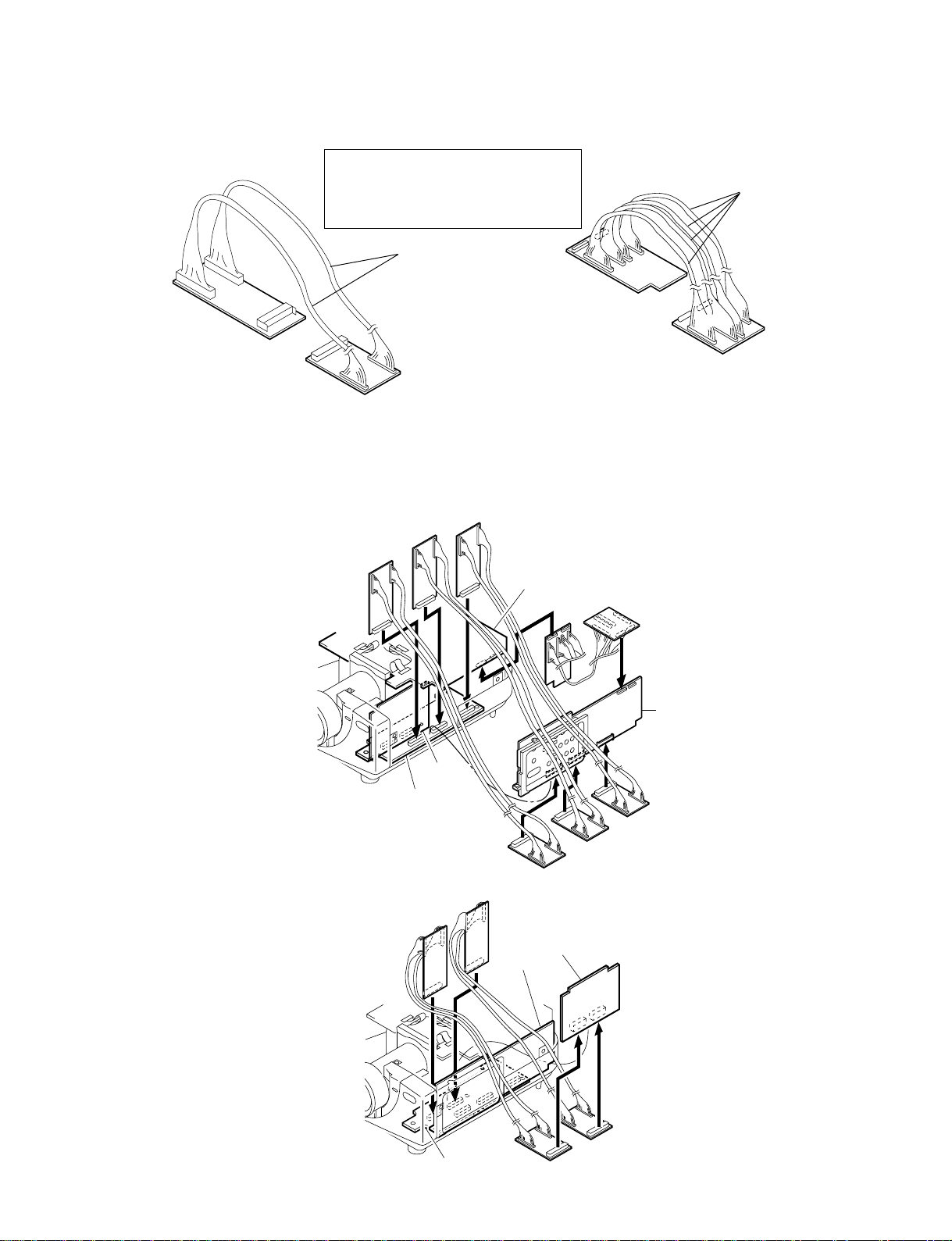

1-12. Extension Boards

XBM

NOTE: Please fit it correctly into the

connector.

Otherwise, Power Board

would be destroyed.

A

XQB

A

XC

XQ

XQB Board : A-1391-180-A

XBM Board : A-1391-181-A

External Cable A : 1-900-262-34

Q 5 BM----used to three extension board

B 5 BM ----used to two extension board

(1)Extension of Q Board

XBM

XBM

XBM

B board

BM board

XC Board : A-1391-182-A

XQ Board : A-1391-183-A

External Cable A : 1-900-262-34

Q 5 C----used to one extension board

C board

XQ

XC

Q board

XQB

XQB

XQB

VPL-VW12HT

(2)Extension of B Board

XBM

BM board

XBM

Q board

B board

XQB

XQB

1-7

Page 18

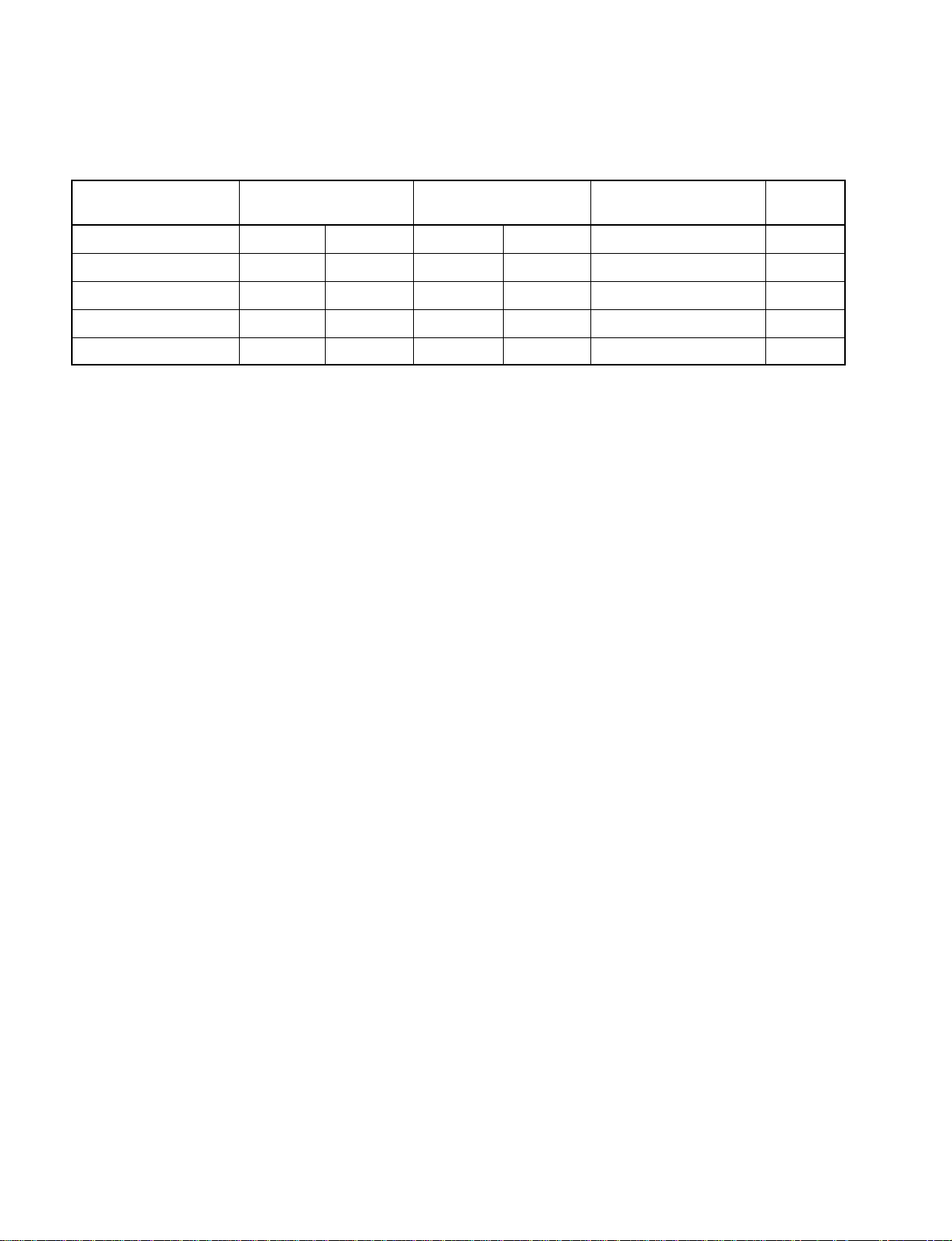

1-13. Power Cord

Use a proper power cord for your local power supply.

The United States, Continental UK, Ireland, Japan

Canada Europe Australia, New Zealand

Plug type VM0233 290B YP-12A COX-07 —

1)

YP332

Female end VM0089 386A YC-13B COX-02 VM0310B YC-13

Cord type SJT SJT H05VV-F H05VV-F N13237/CO-228 VCTF

Rated Voltage & Current 10A/125V 10A/125V 10A/250V 10A/250V 10A/250V 7A/125V

Safety approval UL/CSA UL/CSA VDE VDE VDE DENAN

1) Use the correct Plug for your country.

1-14. Software Writing Procedure

* : Windows is a registered trademark of Microsoft Corporation.

When the following IC is replaced, the writing job should be performed as described below.

Target ICs : Main CPU (IC5005)

Scanning ROM (IC5208)

(1) Writing the Main CPU

This section describes how to use this Windows application for upgrading software of main CPU (H8S/

2633). Jig and application software are available from Hitachi dealer all over the world.

Adaptor board : HS0008EASF4H

Windows interface software : HS6400FWIW4SF

1. Setup before starting the writing

Following setup is required before starting the writing.

1) Open the cabinet of the adaptor board of the jig.

2) Connect pin-2 and pin-3 with a jumper JP1.

3) Set switches as shown below.

S3-1 : 1 S4-1 : E

S3-2 : 1 S4-2 : E

S3-3 : 0 S4-3 : E

S3-4 : 1 S4-4 : D

S3-5 : 1 S4-5 : D

S3-6 : 1 S4-6 : D

S3-7 : 1 S4-7 : E

S3-8 : 1 S4-8 : E

4) Set Power switch as OFF (0).

1-8

VPL-VW12HT

Page 19

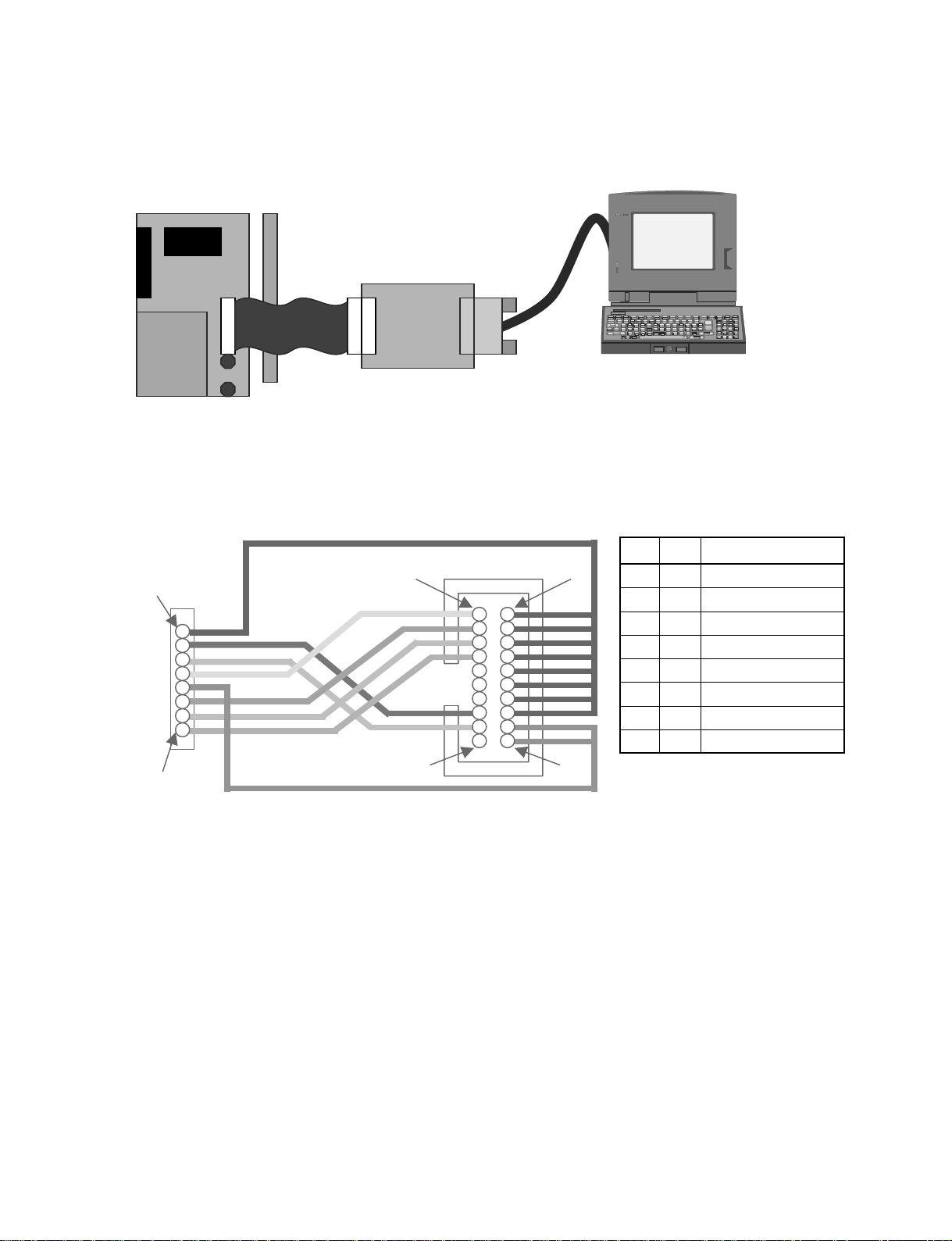

2. Connection

Disconnect the AC power cord of the projector. With the power cord removed, connect equipments as

shown below. Connect all of the equipment and connect the AC power cord.

RS-232C cable

(Supplied)

Cable

VPL-VW12 : C board CN5002

Adaputor board (Tool)

PC

n

Cable must be modified as shown below. 20 pins cable is supplied with jig, modify the other side as 8

pins.

PJ Ref Flash jig

1

1

8

19

20

2

1 GND 2, 4, 6, 8, 10, 12, 14, 16

2 TXD 15

3 RXD 17

4 RES 1

5 VIN 18, 20

6 FWR 3

7 MD1 5

8 MD2 7

VPL-VW12HT

1-9

Page 20

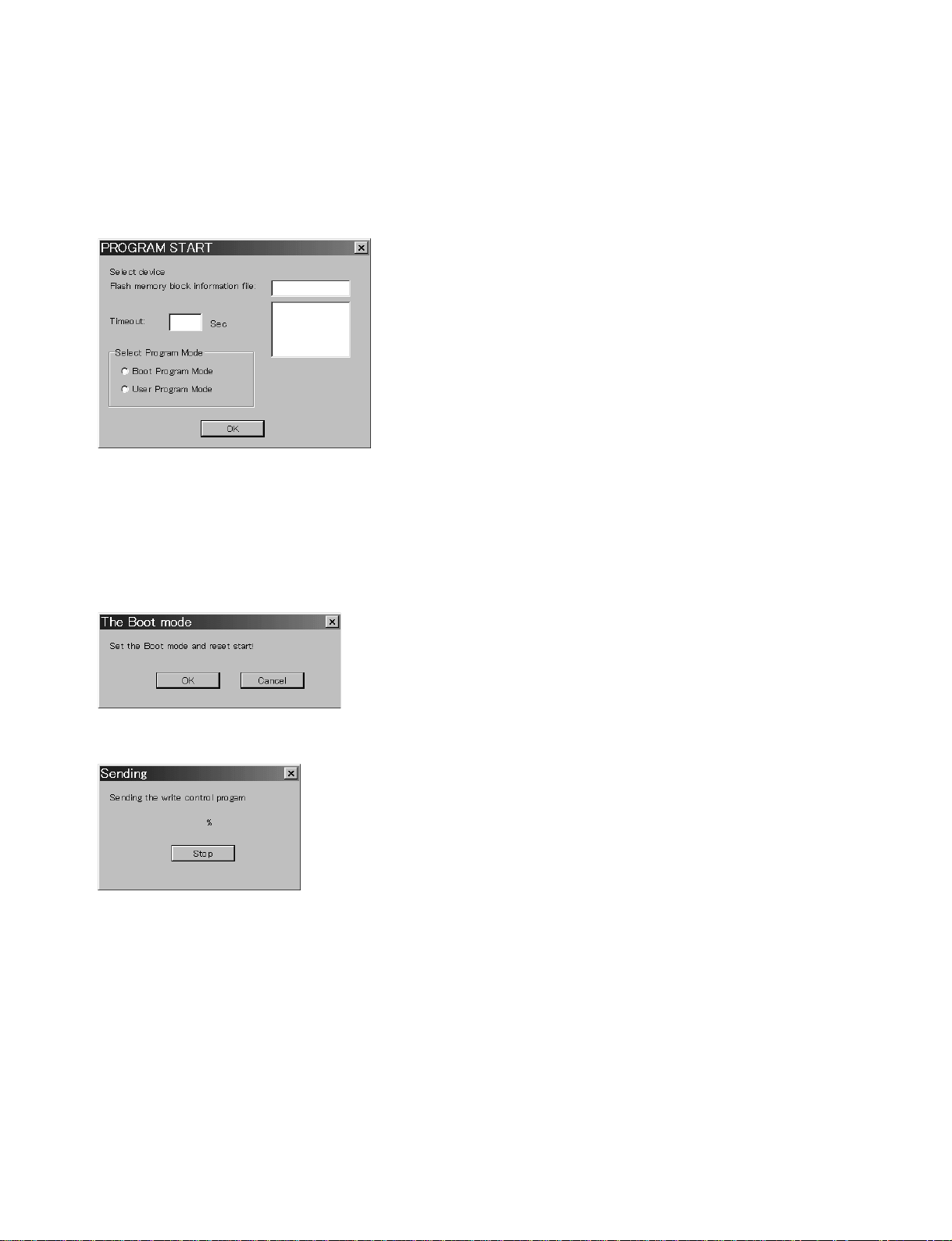

3. How to use application

3-1.Double-click the application icon to start it up.

Projector must be set in the stand-by mode.

Set following items as shown below, and click OK.

Flash memory block information file : 2633f.inf

Timeout : 5 sec

Program Mode : Boot Program Mode

3-2.Following message will be displayed. Press the START/STOP button of the adaptor board, and click

OK.

3-3.The application sends the write control program to the device. Wait for a while.

1-10

VPL-VW12HT

Page 21

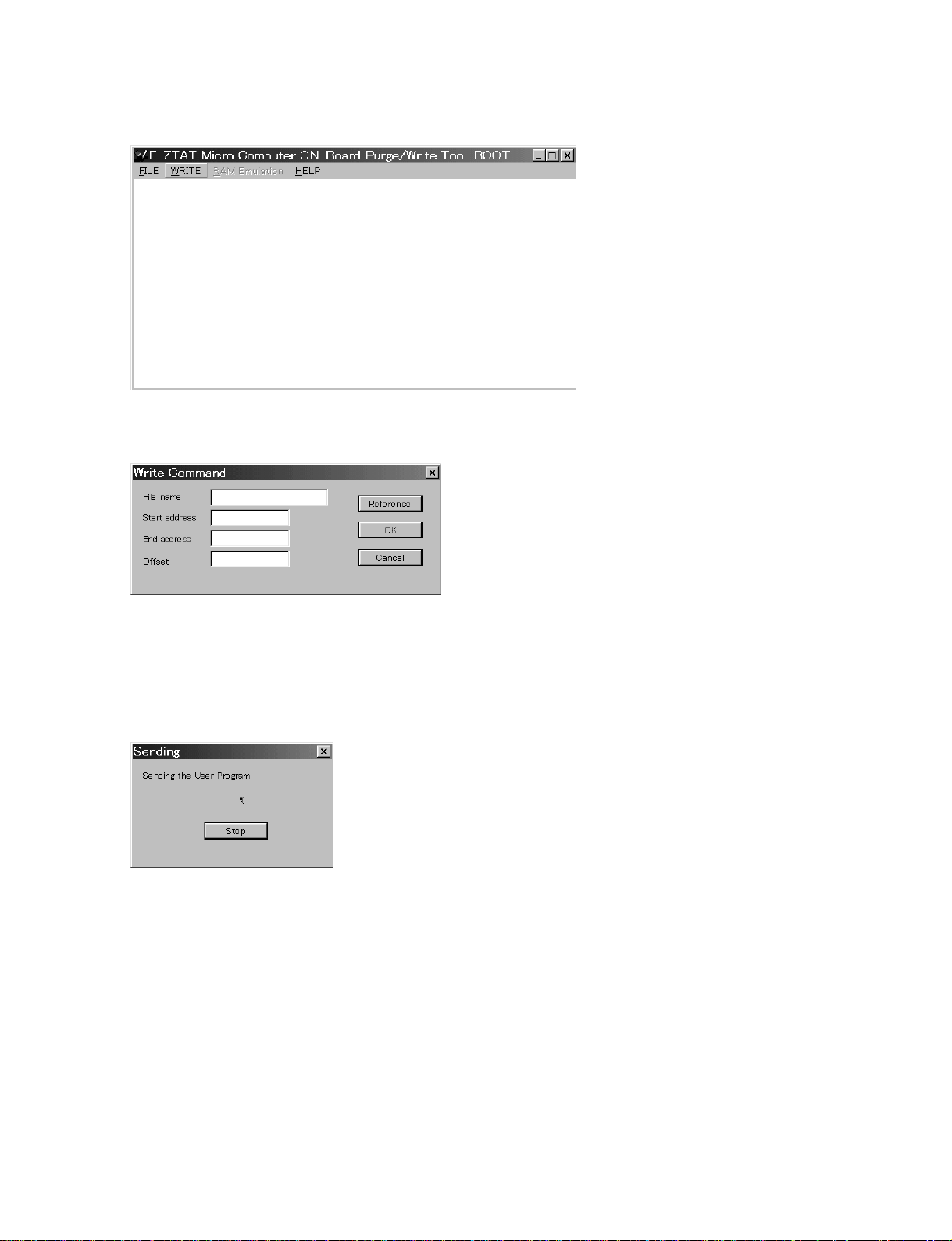

3-4.Upon completion of sending the write control program, select WRITE from the menu.

Following message is displayed.

Enter the filename that you want to update, and set other items as shown below. Click OK.

Start address: 00000000

End address: 0003FFFF

Offset: 0

3-5. Flashing of all data is in progress. Wait for a while.

VPL-VW12HT

1-11

Page 22

(2)Writing the Scanning ROM

This section describes the procedure of upgrading the Flash ROM (IC5208) in which software of the

Pixelworks scan converter (PW264) is written.

1. Setup before starting the writing

The software is supplied as the Zip file.

Unzip the software before starting to execute the application.

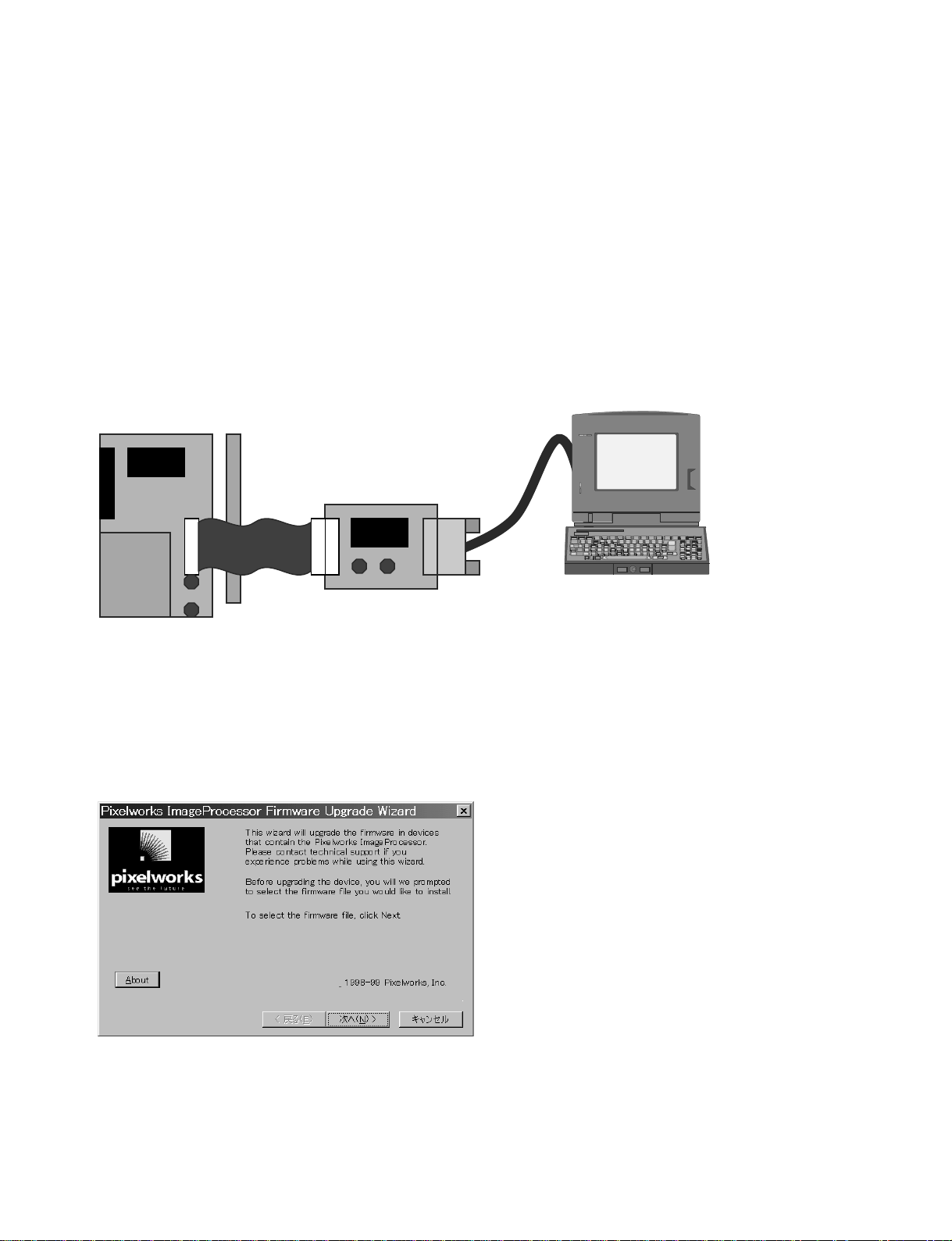

2. Connection

Disconnect the AC power cord. With the AC power cord disconnected, connect the SC board that is

prepared as service part, projector and PC with cable (prepared as service part) and RS-232C straight

cable as shown below. Upon completion of the connections, connect the AC power cord.

RS-232C cable

(Straight)

Cable

VPL-VW12 : C board CN5203

T3 board

PC with COM port

Service parts information

T3 board :A-1394-975-A

Cable : Registration is under way.

3. How to use the application software

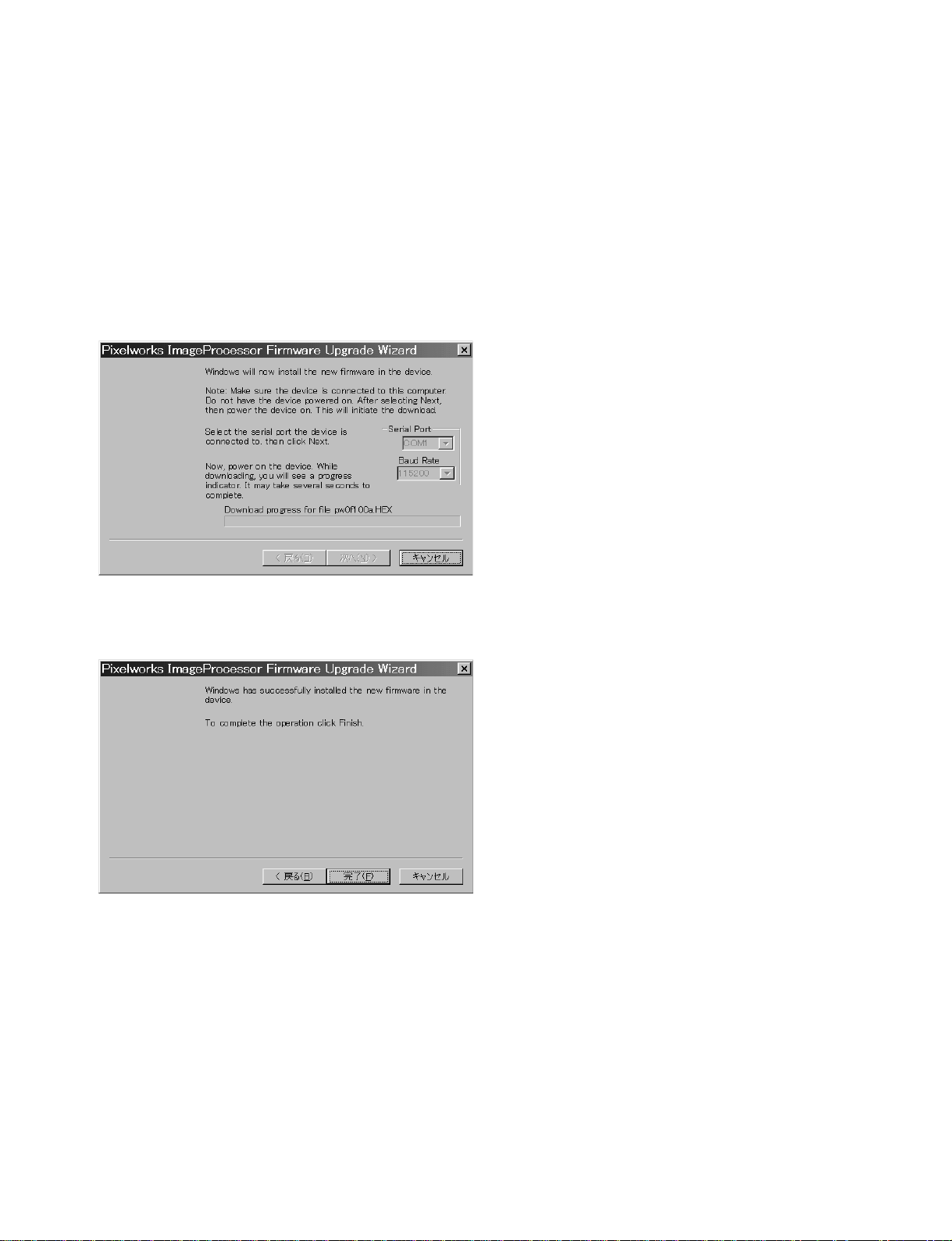

3-1.Double-click the application icon to start it up. Projector must be in the stand-by mode. Click Next.

1-12

VPL-VW12HT

Page 23

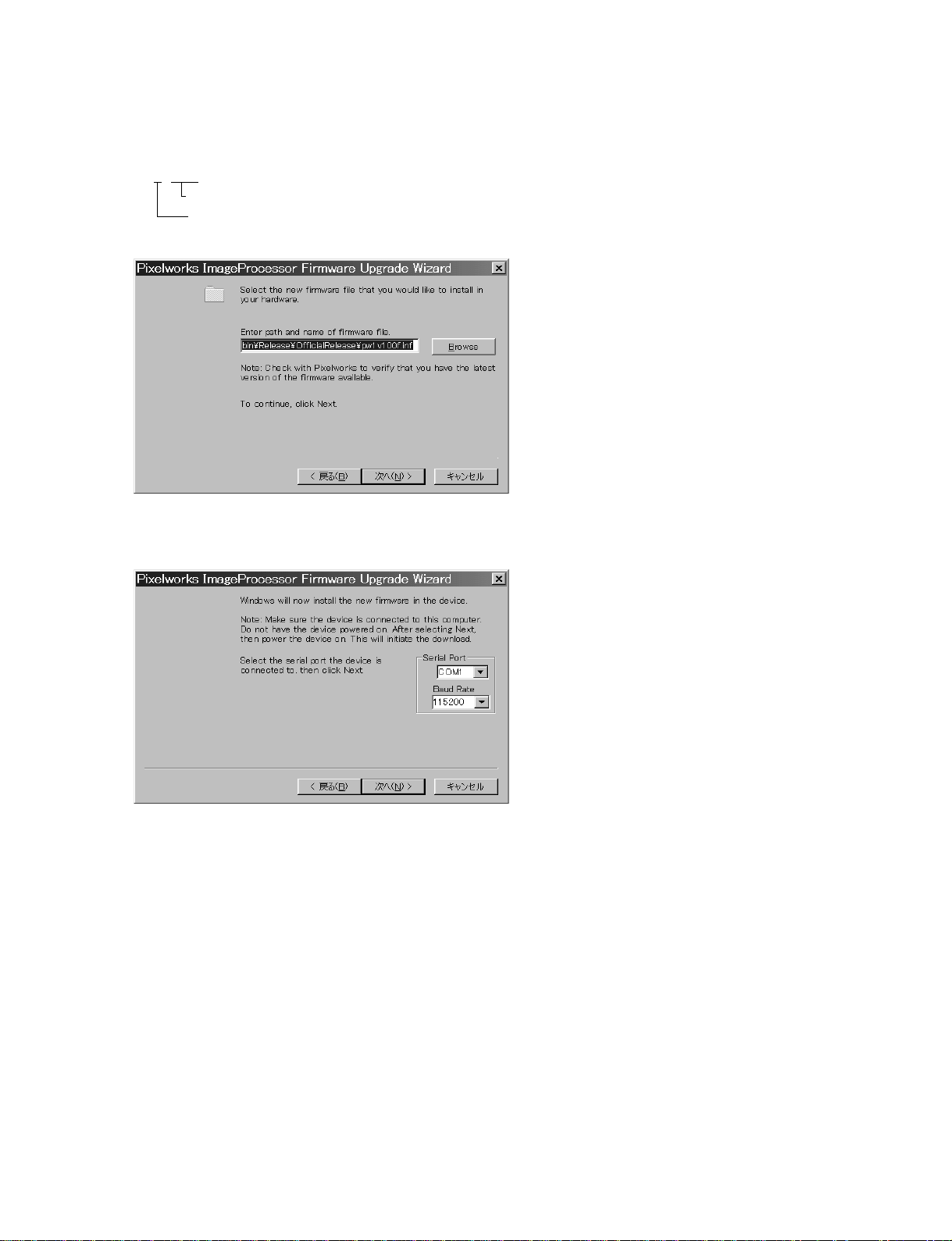

3-2.Enter the inf file that you want to upload to the projector. The rule of naming the version file (*.inf) is

shown below.

pw1v100f . inf

version name

model name 1: For VPL-PX30/20

2: For VPL-VW10/12

3-3.Set the serial communication as follows.

Set baud rate to 115200 (fixed) and click Next.

VPL-VW12HT

1-13

Page 24

3-4.Progress status bar is displayed as shown below, and application waits to turn on the power. Press the

ON key of the projector to start uploading the software. It takes a few minutes for upgrading.

The four hex files are necessary for upgrading the software as shown below. These files should be

placed in the same directory as the *.inf file that you have selected. If not, error message will be shown.

Please note that the version numbers of these hex files do not necessarily match with the v ersion numbers

of *.inf file.

pw*f****.hex

pw*c****.hex

pw*g****.hex

pw*r****.hex

3-5. When upgrading of all of software is completed with success, disconnect cable from the board on the

projector. Keep pressing the Power key to off the projector.

1-14

VPL-VW12HT

Page 25

Section 2

Electrical Adjustments

2-1. Preparations

2-1-1. Equipment Required

. Oscilloscope

Tektronix 2465 or equivalent

(Bandwidth: 350 MHz or more)

. NTSC, PAL, SECAM component signal generator

Tektronix TG2000 + AVG1 (Optional module) +

AWVG1 (Optional module) or equivalent

. VG (Programmable video signal generator)

VG814 or equivalent

. Digital voltmeter

Advantest TR6845 or equivalent

. Luminance meter

Note: Perform the following adjustment at least five

minutes after turning on the power.

2-1-2. Reset the Air Filter

1. Insert the Power Cord and let it standby.

2. Press the keys in the following ORDER:

“RESET” → “MENU” → “DOWN” → “ENTER”

3. Turn the Power ON.

4. Please confirm that the message of “Please exchange

the air filter” does not appear in the picture.

3. Adjust the ← and → keys to minimize the flicker.

Similarly, and perform Red and Blue adjustment

similarly.

(02 VCOM R, 03 VCOM B)

4. Select the SAVE TO MEMORY on the Device adjust

page of the menu. Press the ENTER to save the data.

2-3. Signal Level Adjustment

Perform the following settings:

W/B: LOW mode

INPUT-A: 10 steps

VIDEO: 100% COLOR BARS

CONTRAST: 80

BRIGHT: 50 (Initial value)

2-3-1. SUB-BRIGHT (NTSC) Adjustment

1. Input the NTSC 100% color bars signal to the VIDEO

input.

2. Connect oscilloscorp to TP5023 on the C board.

3. Set the COLOR to 0.

3. Enter the RGB-MTRX on the Device adjust of the

menu.

4. Select the item of 03 SU BRT. Adjust the ← or → key

so that the two bars at the center become flat.

2-1-3. Setting the Factory Mode

1. Make sure that the STATUS in the menu is ON.

2. Exit the menu.

3 Press the keys in the following ORDER:

“ENTER” → “ENTER” → “LEFT” → “ENTER”

4. The message “Do you wish to enter into the FACTORY

MODE?” will be displayed.

5. Select YES.

2-2. RGB VCOM Adjustment

1. Enter the P.DRV of the Device adjust with Factory mode.

2. Enter the item of 01 VCOM G, and check the 1 line ON/

OFF signal.

VPL-VW12HT

2-3-2. SUB-CONT, HUE and COLOR

Adjustment

2-3-2-1.SUB-CONT. HUE and COLOR (VIDEO)

Adjustment

1. Input the NTSC 100% color bars signal to the VIDEO input.

2. Connect oscilloscope to TP5024 on the C board.

3. Set the COLOR to 0.

4. Enter the RGB-MTRX on the Device adjust of the

menu.

5. Select the item of 08 YUV CONT, and adjust the

amplitude of the following waveform for 0.63 Vp-p.

6. Set the COLOR to 50.

7. Select the item of 09 YUV COL. Adjust the ← or →

key so that the right and left bars are equal in level (A

portion).

8. Select the item of 02 SUB HUE. Adjust the ← or →

key so that the two bars in the middle are equal in level

(B portion).

2-1

Page 26

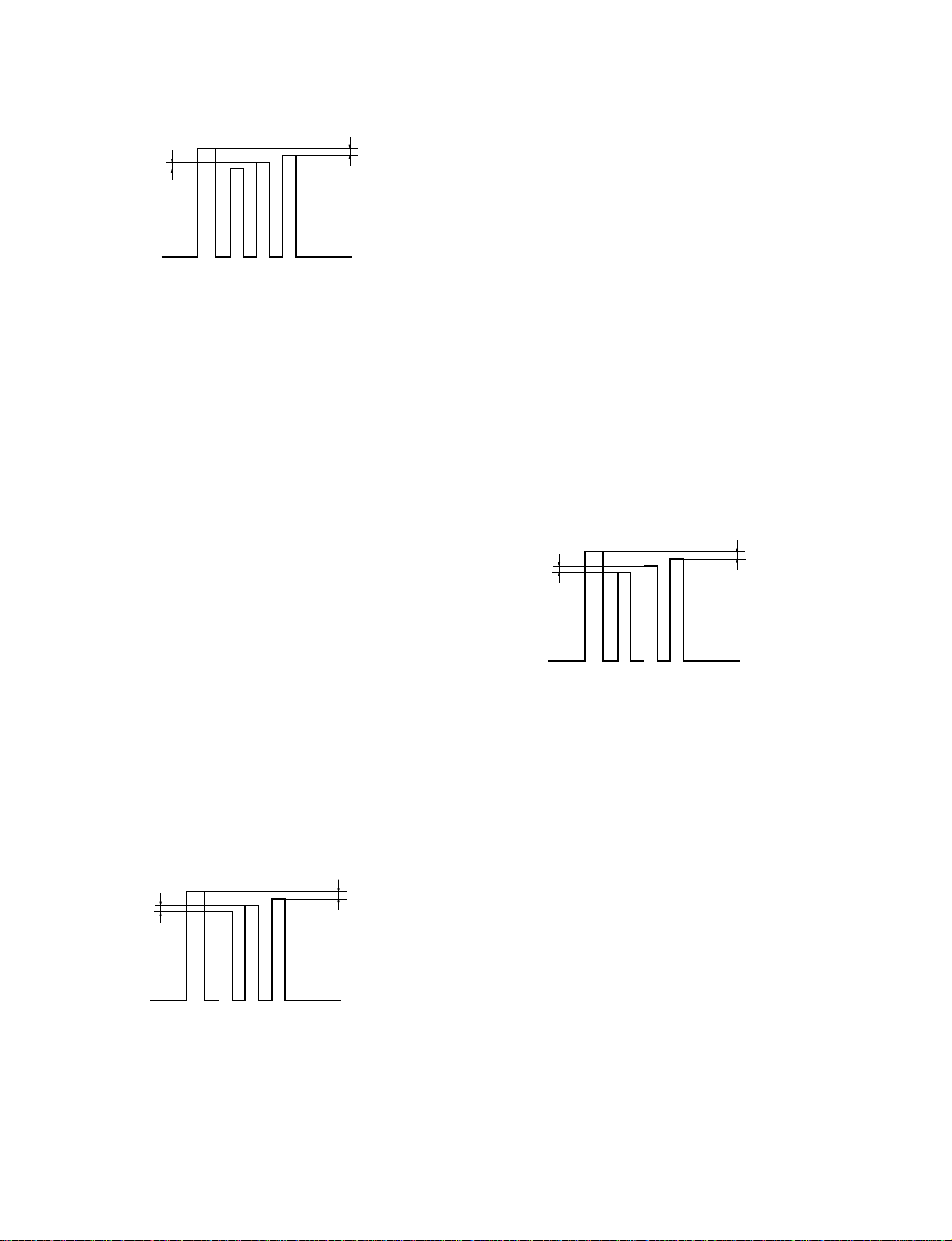

<NTSC 100% Color Bars Signal>

A

B

* Be sure to set the GND level to bottom with DC 0.5V range.

9. Press the MEMORY key to save the data.

10. Similarly, perform steps 1 to 8 with PAL (100% Color

Bars signal) system.

11. Press the MEMORY key to save the data.

2-3-2-2. SUB-CONT, HUE and COLOR

(Component) Adjustment

1. Input the 15k Component 100% Color Bars signal to

INPUT-A (pin 5), and select the COMPONENT by the

INPUT-A of the SET SETTING.

2. Connect an oscilloscope to TP5024 on the C board.

3. Set the COLOR to 0.

4. Enter the RGB-MTRX on the Device adjust of the

menu.

5. Select the item of 08 YUV CONT. Adjust the amplitude

for 0.63 Vp-p.

6. Set the COLOR to 50.

7. Select the item of 09 YUV COL. Adjust the ← or →

key so that the right and left bars are equal in level (A

portion).

8. Select the item of 02 SUB HUE. Adjust the ← or→

key so that the two bars in the middle are equal in level

(B portion).

9. Press the MEMORY key to save the data.

<15k Component 100% Color Bars Signal>

A

B

2-3-2-3.SUB-CONT, HUE and COLOR (DTV)

Adjustment

1. Input the 1080/60i 100% Color Bars signal to INPUTA (pin 5), and select the DTV-YPbPr by the INPUT-A

of the SET SETTING.

2. Connect an oscilloscope to TP5024 on the C board.

3. Set the COLOR to 0.

4. Enter the RGB-MTRX on the Device adjust of the

menu.

5. Select the item of 08 YUV CONT. Adjust the amplitude

for 0.63 Vp-p.

6. Set the COLOR to 50.

7. Select the item of 09 YUV COL. Adjust the ← or →

key so that the right and left bars are equal in level (A

portion).

8. Select the item of 02 SUB HUE. Adjust the ← or →

key so that the two bars in the middle are equal in level

(B portion).

9. Press the MEMORY key to save the data.

10. Switch the format of 1080/60i to GRB output.

Select the DTV-GBR by the INPUT-A of the SET

SETTING.

Similarly, perform steps 2 to 9.

<1080/60i 100% Color Bars Signal>

A

B

2-3-2-4. SUB-CONT, HUE and COLOR (15k RGB)

Adjustment

1. Input the 15k RGB 100% Color Bars signal to INPUTA (pin 5), and select the DTV-GBR by the INPUT-A

of the SET SETTING.

2. Connect an oscilloscope to TP5024 on the C board.

3. Set the COLOR to 0.

4. Enter the RGB-MTRX on the Device adjust of the

menu.

5. Select the item of 08 YUV CONT. Adjust the amplitude for 0.63 Vp-p.

6. Set the COLOR to 50.

7. Select the item of 09 YUV COL. Adjust the ← or →

key so that the right and left bars are equal in level (A

portion).

8. Select the item of 02 SUB HUE. Adjust the ← or →

key so that the two bars in the middle are equal in level

(B portion).

9. Press the MEMORY key to save the data.

2-2

VPL-VW12HT

Page 27

<15k RGB 100% Color Bars Signal>

B

2. Set the unit in Green-only. Adjust so that the vertical

A

line on every other dot become thinner by the P.DRV/

SUB CON G E on the Device adjust.

3. Set the unit in Red-only. Adjust so that the vertical line

on every other dot become thinner by the P.DRV/SUB

CON R E on the Device adjust.

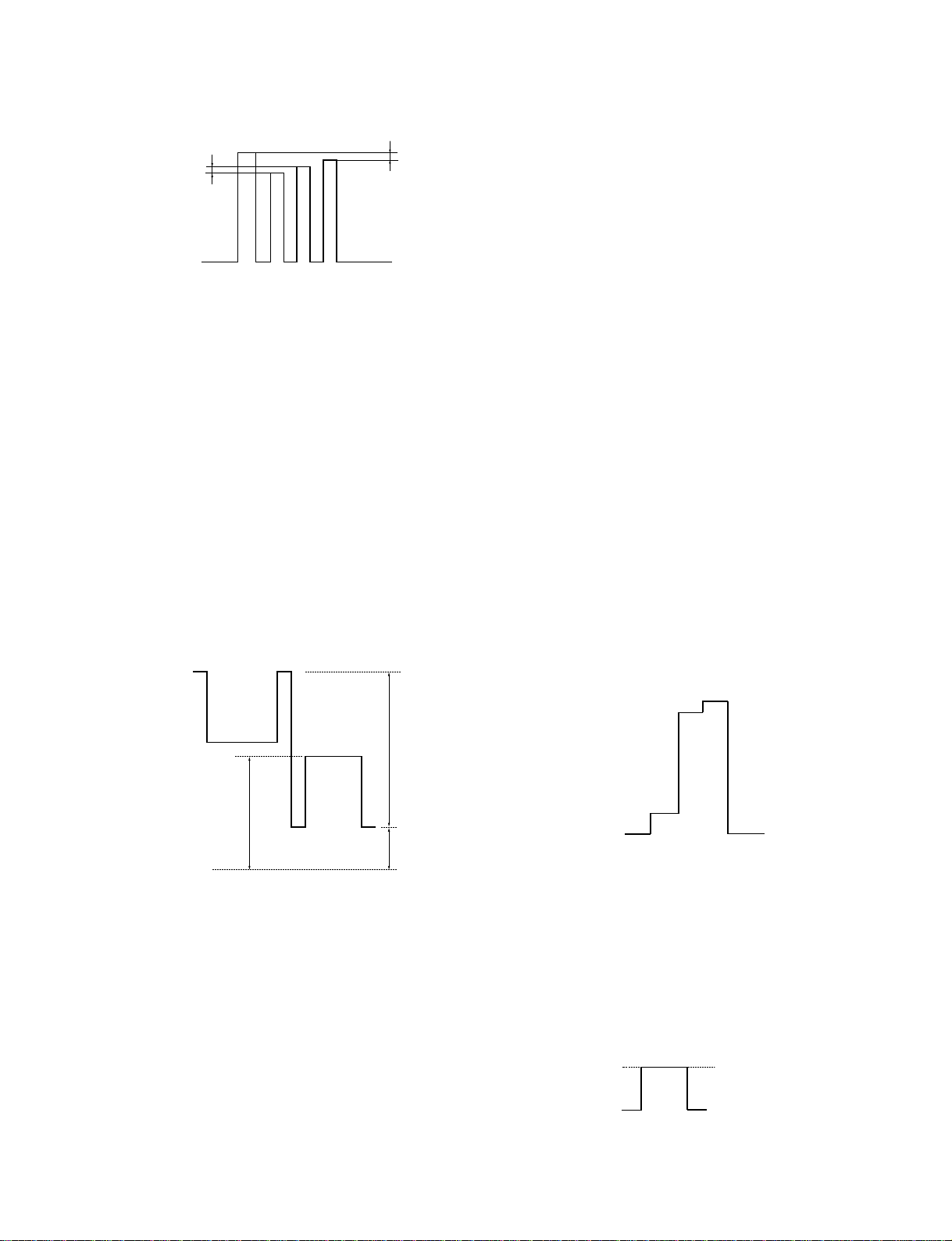

2-3-3. Signal Center and the Amplitude

Adjustment

1. Set the Device Adjust / Other 07 3D GAMMA SW of

the menu into 0.

2. Enter Device Adjust / GAMMA and display Level 7.

3. Install S5202 and 5301 to the sides of SG and W

respectively.

4. Make the following adjustments by using Device

Adjust / P.DRV.

1) 18 VAMP/BRT TP5604 8.0 ± 0.02 Vp-p

2) 23 VAMP2/BRT TP5704 8.0 ± 0.02 Vp-p

3) 04 SIG CEN TP5704 Set the DC level under

the signal to

3.5 ±0.02 V

4) 20 VAMP2/SUB CON R0 TP5704 6.80 ± 0.01 V

5) 16 VAMP/SUB CON G0 TP5604 6.70 ± 0.01 V

6) 22 VAMP2/SUB CON B0 TP5804 6.60 ± 0.01 V

DC

1)

2)

DC

DC

DC

4. Set the unit in Blue-only. Adjust so that the vertical

line on every other dot become thinner by the P.DRV/

SUB CON B E on the Device adjust.

5. Let the picture turn upside down in the INSTALL

SETTING menu. First copy the value of SUB CON G

E, R E, B adjusted within 2 to 4, and then repeat the

adjustment within 2 to4. Next time, adjust to P.DRV/

SUB CON GO, RO, BO.

6. Press the MEMORY key to save the data.

2-3-5. RGB High Gain/Bias Adjustment

2-3-5-1. RGB High Gain/Bias Adjustment

1. Input the W/B HIGH adjusting signal to INPUT-A,

and select the COMPUTER by the INPUT-A of the

SET SETTING.

100 IRE

98 IRE

4)

5)

6)

3)

GND

5. After the adjustment, turn S5202 and 5301 back to N

side.

6. Let the picture turn upside down in the INSTALL

SETTING menu, and copy the adjustment value of 4

1) and 2).

7. After Device Adjust / Other 07 30GAMMA SW is

resumed to 1, store the adjustment data into the

memory.

2-3-4. ODD/EVEN Level Adjustment

1. Input the 50 IRE Flat XGA signal to INPUT-A.

VPL-VW12HT

12.5 IRE

0 IRE

2. Set the CONTRAST to 80, BRIGHT to 50, and COL

TEMP to HIGH respectively.

3. Enter the OTHER on the Device adjust of the menu.

4. Set the 06 3D GAMMA/THROUGH from 0 to 1.

5. Set the 07 3D GAMMA/SW from 1 to 0.

6. Connect an oscilloscope to TP5604 on the C board.

7. Enter the 3D GAMMA on the Device adjust of the

menu, display the Level 0, and put the cursor 1 on the

position shown in the figure below.

Cursor 1

8. Display the Level 7.

2-3

Page 28

9. The same way as in step 7, put the cursor 2 on the

position shown in the figure below.

Cursor 2

2-4. VIDEO W/B Adjustment

2-4-1. Component W/B High Adjustment

Cursor 1

10. Press the GAIN key to enter the GAIN ADJUST

MODE from the 3D GAMMA. Adjust the G GAIN so

that the 100 IRE level of the W/B HIGH adjusting

signal is equal to cursor 2.

11. Press the BIAS key to enter the BIAS ADJUST.

Adjust the G BIAS so that the 12.5 IRE level of the W/

B HIGH adjusting signal is equal to cursor 1.

12. Repeat steps 10 and 11 several times.

13. Connect an oscilloscope to TP5704 on the C board.

Perform the same adjustments as in steps 7 to 12 using

R G GAIN/BIAS.

Note: When you adjust GAIN, please be careful not

to destroy 98IRE.

14. Connect an oscilloscope to TP5804 on the C board.

Perform the same adjustments as in steps 7 to 12 using

B GAIN/BIAS.

15. Press the MEMORY key to save the data.

16. Enter the OTHER on the Device adjust of the menu.

17. Set the 06 3D GAMMA/THROUGH from 1 to 0.

18. Set the 07 3D GAMMA/SW from 0 to 1.

19. Press the MEMORY key to save the data.

Note: Set the COL to 50.

1. Input the Component Flat Field signal to INPUT-A,

and select the COMPONENT by the INPUT-A of the

SET SETTING.

2. Set the 06 3D GAMMA/THROUGH to 0.

3. Set the 07 3D GAMMA/SW to 1 (3D Gamma: ON).

4. Enter the W/B ADJUST HIGH from the menu.

5. Input the 80 IRE Component Flat Field signal to

INPUT-A.

6. Adjust the chromaticity (x, y) to the values shown

below by the G GAIN and B GAIN of the W/B HIGH.

7. Input the 20 IRE Component Flat Field signal to

INPUT-A.

8. Adjust the chromaticity (x, y) to the values shown

below by the R GAIN and B GAIN of the W/B HIGH.

9. Repeat steps 5 to 8 until the chromaticity meets the

below specifications.

10. Press the MEMORY key to save the data.

Specification:

Chromaticity (x) = 0.284 ± 0.005

Chromaticity (y) = 0.297 ± 0.005

2-4-2. Component W/B Low Adjustment

2-3-5-2.RGB W/B Low and Custom

Adjustment

1. Enter the W/B ADJUST LOW from the PIC. CTRL

menu.

2. Copy the adjusted value of the HIGH mode in the R/G/

B BIAS.

3. Write the following values in the R/G/B GAIN.

R GAIN: adjusted value of HIGH mode

G GAIN: adjusted value of HIGH mode _30

B GAIN: adjusted value of HIGH mode _30

4. Press the MEMORY key to save the data.

5. Write the following values in the WB ADJUST

CUSTOM 1 to 4.

CUSTOM 1: B/G GAIN _10

CUSTOM 2: B/G GAIN _20

CUSTOM 3: B/G GAIN _40

CUSTOM 4: B/G GAIN _50

6. Press the MEMORY key to save the data.

2-4

1. Enter the W/B ADJUST LOW from the menu.

2. Input the 80 IRE Component Flat Field signal to

INPUT-A.

3. Adjust the chromaticity (x, y) to the values shown

below by the G GAIN and B GAIN of the W/B LOW.

4. Input the 20 IRE Component Flat Field signal to

INPUT-A.

5. Adjust the chromaticity (x, y) to the values shown

below by the R GAIN and B GAIN of the W/B LOW.

6. Repeat steps 2 to 5 until the chromaticity meets the

below specifications.

7. Press the MEMORY key to save the data.

Specification:

Chromaticity (x) = 0.313 ± 0.005

Chromaticity (y) = 0.329 ± 0.005

VPL-VW12HT

Page 29

2-4-3. W/B Low Custom Adjustment

1. Copy the data in the CUSTOM 1 to 4 using the

menu.

CUSTOM 1: GAIN = RGB/HIGH

BIAS = VIDEO/HIGH

CUSTOM 2: GAIN = RGB/HIGH + 40

BIAS = VIDEO/HIGH

CUSTOM 3: GAIN = VIDEO/LOW + 40

BIAS = VIDEO/LOW

(R GAIN is + 0)

CUSTOM 4: GAIN = VIDEO/LOW _20

BIAS = VIDEO/LOW

(R GAIN is + 0)

2. Press the MEMORY key to save the data.

So altogether 672 adjustments (224*3 (RGB)=672) will be

required, which is in practice not possible. The following

describes a simpler method.

First the “GAMMA” menu consists of the following hierarchy.

GAMMA LEVEL 0 POSITION 4 ALL

POSITION 1 R

POSITION 2 G

:B

POSITION 28

LEVEL 1

:

:

LEVEL 7

When adjusting a certain LEVEL, automatically the

internal signal (flat field) of that level will be displayed.

2-5. Adjustments in Replacement of Prism

and Optical Unit

After replacement of the prism, set the factory mode, and

perform the following adjustment.

2-5-1. V-COM Adjustment

1. Enter the P.DRV of the Device adjust with Factory

mode.

2. Enter the item of 01 VCOM G, and check the 1 line

ON/OFF signal.

3. Adjust the ← and → keys to minimize the flicker.

Similarly, and perform Red and Blue adjustment

similarly.

(02 VCOM R, 03 VCOM B)

4. Select the SAVE TO MEMORY on the Device adjust

page of the menu. Press the ENTER to save the data.

2-5-2. Polarization Plate Adjustment

Press the “PIC MUTE” button and the whole screen will

become black. In this state, adjust the respective polarization plate until the black becomes the darkest.

2-5-3. 3D GAMMA Adjustment (Outline)

The principle of 3D GAMMA is described before the adjustment

of 3D GAMMA.

3D GAMMA is like a function which can individually adjust W/

B at a total of 180 points brightness 8 levels, horizontal direction

7 points, vertical direction 4 points (8*7*4=224 points).

2-5-4. 3D GAMMA Adjustments

1. First input “GAMMA.”

2. Set LEVEL to 1.

3. Study the uniformity of the whole screen, and locate

the areas where uniformity is poor.

4. Changing “POSITION” to 1, 2, or 3 will display the

cursor. The position of the cursor is the position which

will be adjusted.

Move the cursor to the area with poor uniformity.

5. Move “R” and “B” up and down, and adjust so that the

uniformity is the same as the other areas.

6. Set LEVEL 2.

7. Like steps 3, 4, and 5, adjust the areas with poor

uniformity.

8. Adjust up to LEVEL 6.

9. Study the test pattern from LEVEL 1 to LEVEL 6, and

if no problems, return to the first hierarchy, adjust the

device, and save the data in SAVE TO MEMORY.

Precautions:

1. Basically adjust RED and BLUE only without changing GREEN.

2. Do not adjust LEVEL 7.

3. To set back factory settings should adjustments fail,

skip “SAVE TO MEMORY,” and turn off the power.

All the adjusted data will be set back to factory

settings.

Factory settings cannot be set back however if “SAVE

TO MEMORY” has already been implemented. So

check the picture quality carefully prior to implementing “SAVE TO MEMORY.”

VPL-VW12HT

2-5

Page 30

4. For zoom lens, the uniformity will change slightly

according to the zoom position.

As uniformity will change slightly according to the F

number of the lens, perform the adjustments on the

projection system under the normal using conditions.

5. Do not change other items in the Device Adjust Menu.

The device adjust menu contains important parameters

for machine operations.

Unnecessary operations will result in “no image” and

“abnormal image.”

“Factory reset” cannot be performed on device adjust

menu items.

(Implementing SAVE TO MEMORY will completely

overwrite the data.)

Do not change data unnecessarily.

2-6

VPL-VW12HT

Page 31

Section 3

Descriptions of Circuit Board Operations

3-1. G/GA/F Boards

3-1-1. Outline

The G/GA/F boards make up the power supply unit.

• F board

EMI filter for AC power supply line

• G board

Comprises Active filter for improved power

efficiency

Main converter for the secondary circuit power

supply

Fan controller and power supply

• GA board

Sub converter for the standby power supply.

3-1-2. Detailed Explanation

3-1-2-1. Active Filter Unit

This is an active filter using a current critical type rising

voltage chopper system.

Custom IC (IC2001) contains the active filter control unit,

chopper switching FET and the rectification diode components.

L2003 is the chopper choke coil and C2013/2014 are

smoothing capacitors.

The output of the active filter is DC375V which is conducted via the secondary power supply converter and

CN2002 to the lamp power supply board. IC2001 contains

an OVP circuit which latches any oscillation that might

occur if an abnormal rise in output voltage occurs and an

OCP circuit which prevents flow of excess current.

IC2001 also contains heat protection functions that cut in if

an abnormal rise of temperature occurs.

3-1-2-2. Main Converter Unit

This uses a compound current resonance unit.

Custom IC (IC2101) contains a converter control unit and

a transdrive FET.

T2101 is a converter transformer and outputs +4.5V/

+6.0V/ +17.0V/ -6.0V/ FAN+B (13.0V).

These outputs are subjected to full wave rectification in the

rectification circuits (D2201 to 2205 / C2202 to 2206), and

are then output through line filters (L2201 to 2205/C2210

to 2214).

Stabilization of the output voltage is achieved by modulating the oscillation frequency and varying the resonance

current in the primary coil.

Frequency modulation is achieved by detecting the +4.5V

voltage variations with IC2201 and varying the oscillation

frequency.

The control signal is passed via an isolating photocoupler

(PH2102) to the controller IC where it is frequency

modulated.

The primary drive circuit comprises a series resonance

circuit formed by the primary coil of the converter transformer and the resonance capacitors (C2109/2110). When

the load current through the secondary coil changes, the

resonance point (frequency) of this resonant circuit is

moved and the current which flows through the primary

coil also changes. Owing to this characteristic, an increase

in output load causes the current flowing in the primary

coil to also increase so that the output voltage is stabilized.

IC2202 is an OVP circuit which latches the oscillation of

the converter if the output voltage rises abnormally.

Actually it stops the oscillator by turning the PowerCont

signal off. IC2101 also contains an over current protection

circuit (OCP) which latches if it detects an increase in

primary coil resonance current due to shorting of the

output etc.

3-1-2-3. Fan Drive Unit

The four fans inside the set are made to turn at high speed

when the ambient temperature of the set is high and rotate

at low speed when the temperature is low.

The rotation speed of the fan makes is controlled by

varying the supply voltage of the fan. The actual control

signal is sent from the CPU of the C board through

CN2005. The input control signal is sent to regulator

IC2302/2303 through the buffer of IC2301.

This regulator is a variable type series regulator. It subjects

the input power supply (preceding FAN+B) to a voltage

drop in accordance with the amplitude of the control

signal, and then outputs it.

There are 2 output lines. The power supply for the Shirok

fan in the center of the set is output from IC2302. All the

other fans are driven by the output from IC2303.

Also, the circuit consisting of Q2301 to 2304 makes up a

fan protection circuit that stops set operation if a fan stops

due to some abnormality. When a fan stops, Q2301

switches off (opens) and the CPU turns off the set.

VPL-VW12HT

3-1

Page 32

3-1-2-4. Sub Converter Unit

This uses a current resonance type converter using an DC/

AC ferrite transformer.

The resonance circuit consists of T2602 sub converter

transformer and orthogonal transformer T2601 and C2611.

The output from the secondary side of T2602 consists of

sub 5V only, and after full wave rectification by the

rectification circuit consisting of D2602/C2613 this is

output through line filter (L2601/C2615).

The output from the primary side consists of Vcc (19.5V)

only and is output through the rectification circuit of

D2601/C2606.

Stabilization of the output voltage is achieved by detection

of changes in the sub5V voltage by IC2602 and varying of

the oscillation frequency. In reality, this is implemented

by varying the current flowing in the secondary coil of the

orthogonal transformer so as to move the resonance point

(frequency) of the preceding resonance circuit.

IC2603 latches the sub5V output to about 2V by setting the

control current of the secondary coil of the orthogonal

transformer to its maximum value with the sub5V over

voltage protection circuit (OVP).

3-1-2-5.

The Detection of the Fan’s Rotation Speed

Input the detection pulse of the fan’s rotation speed from

CN2008(pin 4). Input the IC5005(pin 28) of C Board

through BM Board. The detection of the fan’s rotation

speed is performed when the power is on. The change (of

the fan’s rotation speed) is measured when the clogging of

air filter is detected and alarmed.

3-2

VPL-VW12HT

Page 33

Power Supply Block Diagram

INLET

Primary

Secondary

AC

F

AC

GA

sub Converter

EMI

Filter

FAN CONT1

FAN CONT2

FAN PROT

G

VC (19.5V)

Active Filter

Main Converter

FAN+B (13.0V)

FAN Driver

DC (375.0V)

+4.5V

+6.0V

+17.0V

-6.0V

sub5v

FAN1.+B

FAN2.+B

FAN3.+B

FAN4.+B

VPL-VW12HT

3-3

Page 34

List of Power Supply System Protectors

PROTECTOR NAME

Power Prot

Mainconverter

OVP

Mainconverter

OCP

Subconverter

OVP1

Subconverter

OVP2

Subconverter

OCP

PFC OVP

PFC OCP

ACTIVE CONDITIONS

TEMP/LAMP LED

lights

Same as P.Prot

Same as P.Prot

Control panel not

effective

LED does not light

LED does not light

Same as P.Prot

Same as P.Prot

ACTIVATION DETAILS

Activates when the secondary output voltage is less

than half.

Activates when the 5V inside C board becomes less

than 4.5V.

Activates when the output voltage of the secondary

rises abnormally.

Stops the oscillation of the converter,so the output

voltage becomes zero. P.Prot activates.

Activates when the output current of the secondary

rises abnormary.

Stops the oscillation of the converter,so the output

voltage becomes zero. P.Prot activates.

Activates when the sub5V voltage rises abnormally.

The voltage becomes approximately 2.3V.

The micro CPU operation latchs and the control

panel becomes ineffective.

Activates when the primary Vcc rises abnormally.

The standby power supply stops completely.

Activates when the sub5V current rises abnormally.

The standby power supply stops completely.

When the PFC output voltage rises abnormally the

PFC stops. At the same time the secondary converter

stops, so the secondary output also becomes zero and

P.Prot activates.

When the PFC output current rises abnormally the

PFC stops. At the same time the secondary converter

stops, so the secondary output also becomes zero and

P.Prot activates.

CIRCUIT LOCATION

Q board

IC4021 to IC4023

G board

IC2202,Q2202 to 2204

G board

IC2101,R2102

GA board

IC2603,Q2603 to 2605

GA board D2605

When this activates,

D2605 becomes deadshort.

GA board R2604 to 2605

When this activates, R2604

to 2605 opens.

G board IC2001.

G board IC2001.

• Most power supply system failures are detected by P.

Prot.

• In addition to the protector activations described

above, P. Prot is also likely to activate in response to

power supply harness disconnection, BM board

failures ( BM has no adjustable) and converter circuit

failures (not operational).

• If the F board fuse (F2500), R2003 on the G board

opens, the cause is an abnormal PFC circuit or abnor

mal lamp power supply. There is little possibility of

this being caused by the secondary side power supply.

3-4

VPL-VW12HT

Page 35

3-2. B Board

This board mainly performs the following processing.

. VIDEO (C-VIDEO, Y/C, 15k-COMPONENT,15k-

RGB), video processing.

. Sync separation processing

3-2-1. Main IC Functions

3-2-1-1. MC141627FT (IC3010), Digital Comb Filter

Performs PAL443, PAL-M, PAL-N 3 line adaptation type

digital Y/C separation.

For the operation clock, the clock (fsc) output from pin 46

of CXA2123 (IC3006) is fed in via pin 45 (IC3010).

The video signal fed in via pin 15 (IC3010) is digitally

processed with this clock.

The resulting Y signal is output from pin 6, and the C

signal from pin 8.

3-2-1-2. uPD64082 (IC3014), 3D Comb Filter

Performs NTSC 3.58 3 dimensional processing digital Y/C

separation.

The reference clock uses the crystal (X3002) connected

between pins 30 & 31, generates fsc and is output from the

FSCO terminal (pin 47). It is then passed through a buffer

into the FSCI terminal (pin 50). As the internal Y-ADC

circuit cannot be used in this IC, the VIDEO signal

subjected to A/D conversion by external A/D converter

uP659AGS (IC3013) to give an 8 bit signal, is fed into pins

74 to 67. The Y signal is output from pin 84 and the C

signal from pin 83.

3-2-1-3. CXA2123 (IC3006), Chroma Decoder &

Sync Processing

This is a chroma decoder/sync processing IC controlled by

the I2C bus. It can process the C-VIDEO signal and the Y/

C signal.

The C-VIDEO signal is fed into pin 1, the Y signal into pin

44 and the C signal into pin 43.

This allows automatic discrimination between NTSC 3.58,

NTSC 4.43, PAL, PAL-M, PAL-N, SECAM and B/W.

When NTSC 3.58 is discriminated Y/C separation is

performed by IC3014 (uPD64081).

When PAL, PAL-M or PAL-N are discriminated

IC3010 (MC141627) is driven by a clock and performs Y/

C separation.

They are respectively fed in via pin 5 and pin 7. In the case

of other signals, this IC performs Y/C separation.

When NTSC4.43, SECAM or B/W are discriminated Y/C

separation is performed by IC3006 (CXA2123).

Following this Y/U/V signal conversion is performed with

Y being output from pin 21, U from pin 22 and V from pin

23.

Sync processing is performed by separating H and V from

the input C-VIDEO/Y signal. H-sync is output from pin 9

and V-sync from pin 4.

In the case of 15k-COMPONENT, Y is input from pin 19,

U from pin 18 and V from pin 17. Then Y is output from

pin 21, U from pin 22 and V from pin 23. Sync processing

is performed by separating H and V from the Y signal.

In the case of 15k-RGB, R is input from pin 27, G from pin

26 and B from pin 25. After conversion to Y/U/V, Y is

output from pin 21, U from pin 22 and V from pin 23.

Sync processing is performed by separating H and V from

the C.SYNC signal fed into pin 41.

In each case the H-sync signal output from pin 9 has been

processed by a PLL so the equalizing pulse is removed.

This IC also controls DYNAMIC PICTURE ON/OFF.

3-2-2. Signal Flows

3-2-2-1. VIDEO Signal Flows

The VIDEO, Y/C signals input from CN3001 are fed into

pins 1, 44 and 43 of IC3006.

In the case of PAL, PAL-M, PAL-N and NTSC 3.58, a

signal amplified by a factor of 2 by IC3001 is output from

pin 3.

PAL signals pass though the low pass filter consisting of

Q3022, L3012, L3011, C3086, 3085 and 3084 and are fed

to pin 15 of IC3010 (Comb Filter). Here Y/C separation is

performed with Y being output from pin 6 and C from pin

8. These are passed though the low pass filters consisting

of L3009, C3078, L3010 and C3079 then Y is fed to pin 3

of IC3007 and C is fed to pin 3 of IC3008.

NTSC 3.58 signals pass through low pass filter FL3009

and are fed to pin 4 of A/D converter IC3013.

The digitized signal is fed to 3D comb filter IC3014, then

following Y/C separation Y is output from pin 84 and C

from pin 83. After passing through low pass filters FL3008

and 3007, Y is fed to pin 1 of IC3007 and C to pin 1 of

IC3008.

VPL-VW12HT

3-5

Page 36

IC3007 and IC3008 switch between PAL/NTSC 3.58 and

respectively output Y and C signals from their pin 7. This

Y signal is fed to pin 5 of IC3006 while the C signal is fed

to pin 7.

The remaining signals are all processed in IC3006 and

converted to Y, U and V signals. Y is output from pin 21,

U from pin 22 and V from pin 23. The signals are then

output from the B board via buffers Q3009 (Y), Q3008 (U)

and Q3007(V).

3-2-2-2. 15k-COMPONENT Signal/15k-RGB Signal

Flows

The Y, Cb and Cr signals input from CN3001 pass though

buffers Q3004, Q3003 and Q3002 and are fed to pin 19

(Y), pin 18 (Cb) and pin 17 (Cr) of IC3006. The signals

fed in as Y, Cb and Cr are output unchanged from pins 21,

22 and 23. 15k-RGB signals likewise pass though buffers

and are then fed to pin 27 (R), pin 26 (G) and pin 25 (B).

The signals fed in as R, G and B signals are converted to

Y, Cb and Cr signals which are output from pins 21, 22

and 23.

3-3. Q Board

The processing performed on this board is mainly as

follows:

• Switching of the video signal

• Video signal input

• Sync separation processing

• Video, HDTV, DTV system image processing

• RS232C communication buffer

• Reception of remote control signal (SIRCS signal)

• Power protector

3-3-1. Outline of Main ICs

3-3-1-1. TLC5733 (IC4029), AD Converter for DRC

Use

This is an AD converter for DRC processing. It inputs the

Y/U/V signals output from the B board, and passes them as

digital signals to CXD2090Q (IC433).

3-3-1-2. CXD2095AQ (IC4033), DRC Processing

CXD2095AQ(IC433) performs DRC (Digital Reality

Creation) processing. It processes the digital signal passed

from TLC5733 (IC4029) and outputs a D/A converted

double frequency color difference signal.

3-3-1-3. CXA2101AQ (IC4013), HD Interface, RGB

Matrix

This is controlled with the 12C bus. The input signals to

this IC are the2Y/2R-Y/2B-Y DRC outputs, the Y/Cb/Cr

double speed component signals, the HDTV, DTV system

RGB signals or the YPbPr signals. The DRC output signals

are fed into pin 23 (2Y), pin 22 (2B-Y) and pin 21 (2R-Y).

The other signals are fed into pin 11 (Y or G), pin 10 (Pb

or B) and pin 9 (Pr or R). After these signals have been

input, they are internally switched and all are converted to

Y/Cb/Cr. These are output from pins 76, 77 and 78, but are

then fed back into the IC via coupling capacitors into pins

75, 74 and 73. The signals input in this way are subjected

to COLOR, HUE and SHARPNESS user control adjustments. Other processing includes detection axis adjustment, chroma transient improvement and conversion and

output as RGB signals. Sync separation for HDTV etc.

(including 3 value sync) is also performed by this IC.

3-6

VPL-VW12HT

Page 37

3-3-1-4. M52347FP (IC4006), SYNC SEPARATOR

This IC performs sync separation mainly for computer

system signals and for signals other than those of the

VIDEO, HDTV and DTV systems.

3-3-1-5. EL4332C (IC4007), RGB Switch, 6dB Amp,

75 Ohm Driver

Switches the video system, HDTV and DTV system

signals that have been converted to RGB and the computer

system RGB signals and outputs them to the C board.

3-3-2. Video signal Flow

3-3-2-1. VIDEO Signal Flow

The VIDEO and Y/C signals are fed respectively into pin 3

of NJM2533M (IC4022, IC4024 and IC4025). The selected VIDEO/S-VIDEO signal passes through the IC (switch)

so that C-VIDEO emerges from CN406 (11), Y from (13)

and C from (15).(These are sent to the B board via the BM

board.)

The 15k-COMPONENT signal and 15k-RGB signal are

input from INPUT-A or INPUT-B, and after selection by

RY4001, RY4002 and RY4003 are output from CN4006

(19), (21) and (23). (These are sent to the B board via the

BM board.) Of the signals processed on the B board, Y is

input from CN4005 pin 25, U from pin 23 and V from pin

21. These signals pass through DRC pre-filters FL4006

(Y), FL4005 (U) and FL4004 (V) and are then fed into

pins 63, 31 and 50 of AD converter TLC5733A (IC4029).

Following this, they are subjected to algorithm processing

in CXD20900 (IC4033), D/A conversion and then output

as double speed frequency color difference signals from

pin 105 (Y), pin 113 (U) and pin 109 (V).

After passing through post filters FL4003 (Y), FL4002 (U)

and FL4001 (V) these signals are fed into pin 23 (Y), pin

22 (U) and pin 21 (V) of RGB matrix CXA2101 (IC4013).

CXA2101 (3-1-3.) converts the signals to RGB signals and

outputs R from pin 35, G from pin 37 and B from pin 39.

These output RGB signals pass through buffers Q4021,

Q4022 and Q4023 and are then selected by EL4332C

(IC4007) which serves as a switch and 75 ohm driver IC.

R is then output from CN4004 (A1, B1), G from (A3, B3)

and B from (A5, B5).

3-3-2-2. HDTV/DTV (YPbPr, RGB) Double Speed

Component (YUV) Signal Flows

The double speed component signals are input from

INPUT-A or INPUT-B and after selection by RY4001,

RY4002 and RY4003 pass though buffers Q4015, Q4016

and Q4017 before being fed to pins 11, 10 and 9 of RGB

matrix CXA2101 (IC4013). CXA2101 (3-1-3.) converts

the signals to RGB signals and outputs R from pin 35, G

from pin 37 and B from pin 39. These output RGB signals

pass through buffers Q4021, Q4022 and Q4023 and are

then selected by EL4332C (IC4007) which serves as a

switch and 75 ohm driver IC. R is then output from

CN4004 (A1, B1), G from (A3, B3) and B from (A5, B5).

3-3-2-3. Computer Signal (RGB) Flows

The computer system signals (RGB) are input from

INPUT-A or INPUT-B and after selection by RY4001,

RY4002 and RY4003 are fed to EL4332C (IC4007) which

serves as a switch and 75 ohm driver IC. After being

selected by this IC, R is output from CN4004 (A1, B1), G

from (A3, B3) and B from (A5, B5).

3-3-3. SYNC Processing Flows

3-3-3-1. When VIDEO Signals and 15k

COMPONENT Signals are Processed

The H/V SYNC processed and output from the B board is

passed via the BM board to CN4005 from which it is input

from pin 19 (H) and pin 17 (V). The H/V SYNC is then

passed through buffers Q4033 and Q4032 and fed to the

DRC block.

CXD2095AQ (IC4033) outputs double speed processed H

SYNC from pin 98 and V SYNC from pin 99. Following

this, the sync is fed into CXA2101 (IC4013) via pin 7 (H)

and pin 8 (V) and is then output from pins 29 and 28.

The output H-SYNC is inverted by IC4014 and is then fed

to IC4012. Here noise is removed before it is output from

pin 7. It is then fed to IC4011 for wave shaping and then to

pin 17 of IC4009. Here CLP pulses are output from pin 5

of IC4012, inverted by IC4014, wave shaped by IC4011

and input to pin 15 of IC4009.

The V-SYNC is wave shaped by IC4014, then after

inversion by IC4039 it is fed to pin 13 of IC4009. In

IC4009 switching is performed with SYNC from the

computer system and 3.3 V level conversion is performed.

H is then output from CN4004 (A7, B7), V from (A9, B9)

and CLP from (A11, B11).

VPL-VW12HT

3-7

Page 38

3-3-3-2. When 15k-RGB Signal are Processed

COMPOSITE-SYNC is first subjected to sync separation

in IC4003, then passed through relay RY4004 and subjected to wave shaping by Q4045 to Q4047 and IC4036 and

IC4038, and is then fed to IC4006 (M52347FP). From here

the COMPOSITE-SYNC is output as is, passes though

buffer BUFF (IC4009) and after level matching is fed to

pin 3 of switch C4027. It is then output from pin 7 of this

IC and output as COMPOSITE-SYNC from pin 25 of

CN4006. (It is then sent to the B board via the BM board.)

It is then input from CN4005 in the form of H/V separate

SYNC from the B board. Further processing is as for

VIDEO.

3-3-3-3. When HDTV/DTV (YPbPr, GBR) Double

Speed Composite Signals are Input

The signals then pass through IC4002 and flow to the C

board via CN4004 (A25, B25) and (A26, B26) to allow

communication with the CPU on the C board.

3-3-5. Reception of Remote Control Signal

(SIRCS Signal)

Signals from a remote control unit connected with a cable

are input via J4002. Following this, they are inverted by

Q4003 and output to the C board via CN4004 (A21, B21).

When a remote control unit is not connected, signals

received by the NF, NR boards are input via CN4004

(A22, B22), pass though J4002 and are output to the C

board via CN4004 (A21, B21).

3-3-6. Power Protector

The H/C and V signals input from INPUT-A and INPUT-B

are selected by relays RY4001 and RY4003. Following

this H/C signals are switched by RY4004 and each signal

is then passed though wave shaping circuits (Q4045 to

Q4050, IC4036, IC4038). Then, after passing through

BUFF (IC4010), H/C is fed to pin 7 of CXA2101 (IC4013)

and V is fed to pin 8. Y/G is fed to pin 11. In IC4013,

SonG (SonY) automatically determines if it is dealing with

C. SYNC or HV separate provides outputs from pin 29 and

pin 28. Further processing is as for VIDEO.

3-3-3-4. When Computer Signals are Processed

The H/C and V signals input from INPUT-A and INPUT-B

are selected by relays RY4001 and RY4003. Following

this H/C signals are switched by RY4004 and each signal

is then passed though wave shaping circuits (Q4045 to

Q4050, IC4036, IC4038). Then, H/C is fed to pin 6 of

IC4006 (M52347) V to pin 8 and the G signal to pin 4.

This IC performs sync separation and outputs H from pin

15, V from pin 13 and CLP from pin 17. These outputs are

fed to IC4009. Here switching is performed with sync

signals other than those of the computer system and 3.3 V

level conversion is performed. H is then output from

CN4004 (A7, B7), V from (A9, B9) and CLP from (A11,

B11).

IC4021, IC4023 and IC4026 make up a protective circuit

for the power supply lines.

If any of the -6V, +17V, +6V or +4.5V lines short to

ground this circuit activates, outputs a high level (+5V)

from pin 1 of IC4026 which is sent via CN4002 (A24,

B24) to the microprocessor on the C board.

3-3-4. RS232C Communication Buffer

RS232C communication uses IC4002 (MAX202CSE) as a

buffer. CN4001 allows connection to a computer.

3-8

VPL-VW12HT

Page 39

3-3-7. B Board, Q Board Block Diagram

VIDEO

C-video

lNPUT A

5PIN

RGB.etc

H(C)V

INPUT B

5PIN

RGB.etc

H(C)V

1

Y

YUV

C

HV

Chroma Dec

CXA2123

C.S (15KRGB)

C

Y

Y

C

Y

C

4M

DRAM

SW

SW

BQ

15KRGB/YUV

A/D

3Line-Comb

MC141627FT

3D-Comb

µPD64081

9

A/D

TLC5733A

H

W-PLL

TLC2932IPW

DRC

CXD2095AQ

V

TLC2932IPW

Field Memory

MSM56V16160D

R-PLL

2YUV

2HV

HDRGB YPbPr

2

RGB-MATRIX

CXA2101

CLP

MC74HC4538

SYNC-SEP

GS4981

M.M.

H

RGB

6

1

RGB-SW

EL4332

RGB

RGB

H/V/CLP

2

3

7

CLP

CXA1875

H/V

To CPU

IIC

1

Sync-SW

74VHC240

2

H/V/CLP

1

Relay

2

x3

3

1

Relay

2

H(C)V

Sync-sep

GS1881

C-V

5

1

Relay

2

SonG

H(C)V

Sync-sep

M52347

H/V/CLP

Polarity Imfo. (H/L)

3-3-8. Signal Flow

3-3-8-1. C-Video (NTSC3.58)

1

VIDEO

Y

C

C-video

lNPUT A

5PIN

RGB.etc

H(C)V

INPUT B

5PlN

RGB.etc

H(C)V

15KRGB/YUV

1

2

1

2

A/D

3

3

Relay

x3

Relay

Chroma Dec

CXA2123

3Line-Comb

MC141627FT

3D-Comb

µPD64081

9

H(C)V

YUV

HV

C.S (15KRGB)

C

Y

Y

C

Y

C

4M

DRAM

Sync-sep

GS1881

C-V

SW

SW

2

R-PLL

2YUV

2HV

RGB-MATRIX

CXA2101

SYNC-SEP

GS4981

RGB

6

1

RGB-SW

EL4332

RGB

H/V/CLP

2

A/D

TLC5733A

H

W-PLL

TLC2932IPW

DRC

CXD2095AQ

V

TLC2932IPW

Field Memory

MSM56V16160D

RGB

CLP

M.M.

HDRGB YPbPr

MC74HC4538

H

7

CLP

CXA1875

H/V

To CPU

IIC

1

Sync-SW

74VHC240

2

H/V/CLP

H(C)V

SonG

Sync-sep

M52347

H/V/CLP

5

1

Relay

2

Polarity Imfo. (H/L)

VPL-VW12HT

• • • Signal Path.

3-9

Page 40

3-3-8-2. C-Video (PAL, PAL-M, PAL-N)

VIDEO

C-video

lNPUT A

5PlN

RGB.etc

H(C)V

INPUT B

5PlN

RGB.etc

H(C)V

1

Y

YUV

C

HV

Chroma Dec

CXA2123

C.S (15KRGB)

C

Y

Y

C

SW

Y

C

DRAM

SW

4M

15KRGB/YUV

A/D

3Line-Comb

MC141627FT

3D-Comb

µPD64081

9

A/D

TLC5733A

H

W-PLL

TLC2932IPW

DRC

CXD2095AQ

V

TLC2932IPW

Field Memory

MSM56V16160D

R-PLL

2

2YUV

2HV

HDRGB YPBPR

RGB-MATRIX

CXA2101

SYNC-SEP

GS4981

CLP

MC74HC4538

M.M.

H

RGB

6

1

RGB-SW

EL4332

RGB

RGB

H/V/CLP

2

3

1

Relay

2

x3

3

1

Relay

2

Sync-sep

GS1881

C-VH(C)V

5

1

Relay

2

SonG

H(C)V

Sync-sep

M52347

Polarity Imfo. (H/L)

H/V/CLP

CXA1875

H/V

CLP

To CPU

IIC

1

Sync-SW

74VHC240

2

H/V/CLP

7

• • • Signal Path.

3-3-8-3. C-Video (SECAM, NTSC4.43)

VIDEO

C-video

lNPUT A

5PlN

RGB.etc

H(C)V

INPUT B

5PlN

RGB.etc

H(C)V

1

Y

C

Chroma Dec

CXA2123

3Line-Comb

MC141627FT

15KRGB/YUV

A/D

3D-Comb

µPD64081

9

3

1

Relay

2

x3

3

1

Relay

2

H(C)V

YUV

HV

C.S (15KRGB)

C

Y

Y

C

Y

C

4M

DRAM

Sync-sep

GS1881

C-V

SW

SW

2

R-PLL

2YUV

2HV

RGB-MATRIX

CXA2101

SYNC-SEP

GS4981

RGB

6

1

RGB-SW

EL4332

RGB

H/V/CLP

2

A/D

TLC5733A

H

W-PLL

TLC2932IPW

DRC

CXD2095AQ

V

TLC2932IPW

Field Memory

MSM56V16160D

RGB

HDRGB YPBPR

CLP

MC74HC4538

M.M.

H

7

CLP

CXA1875

H/V

To CPU

IIC