Sony RCDW-7-V Service manual

RCD-W7V

SERVICE MANUAL

Ver 1.2 2002.09

CD-R

CD/DVD

SPECIFICATIONS

DECK A (the CD/DVD player section)

System CD/DVD player

Laser Semiconductor laser

Signal format system NTSC

Playable discs DVD, CD, CD-R/CD-RW

(for music use), MP3 disc

Frequency response DVD (PCM 96 kHz):

20 Hz to 44 kHz (±1.0 dB)

DVD (PCM 48 kHz):

20 Hz to 22 kHz (±0.5 dB)

CD: 20 Hz to 20 kHz

(±0.5 dB)

Signal-to-noise ratio More than 100dB

(ANALOG OUT connectors only)

Harmonic distortion Less than 0.015%

Dynamic range More than 95 dB (DVD)

More than 95 dB (CD)

Wow and flutter Less than detected value

(±0.001% W PEAK)

Outputs

VIDEO OUT 1.0 Vp-p 75 ohms,

sync negative

S-VIDEO OUT Luminance signal:

1.0 Vp-p, 75 ohms

C: 0.3 Vp-p, 75 ohms

COMPONENT VIDEO OUT Y: 1.0 Vp-p, 75 ohms,

sync negative

(Phono jacks) CB/B-Y, CR/R-Y:

0.7 Vp-p, 75 ohms

US Model

Model Name Using Similar Machanism RCD-W1

CD Mechanism Type CDM-700(CD-RW)

Optical Pick-up Type KRS-220C

Model Name Using Similar Mechanism NEW

CD/DVD Mechanism Type DP-4RM

Signal-to-noise ratio Over 100 dB during playback

Dynamic range More than 95 dB during playback

Input

ANALOG IN (Phono jacks) Impedance 47 kilohms,

Rated input 330 mVrms

DIGITAL OPTICAL IN Optical wavelength 660 nm

(Square optical connector jack)

Outputs

ANALOG OUT (Phono jacks) Impedance 47 kilohms, Rated input

2 Vrms

Load impedance over 10 kilohms

DIGITAL OPTICAL OUT Wavelength 660 nm

(Square optical connector jack) Output level -18 dBm

PHONES (Phone jacks) 28 mW, 32 ohms

General

Power requirements 120 V AC, 60 Hz

Power consumption 25W (120 V AC)

Dimensions (approx.) 430 x 107.5 x 370 mm (w/h/d) incl.

projecting parts

Mass (approx.) 5.1 kg

Supplied accessories

• Video cord (1)

• Audio cords (2)

• Remote commander (remote) RM-R70 (1)

• R6 (size AA) batteries (2)

DECK B (the CD-R and CD-RW recording section)

System Compact disc digital audio system

Laser Semiconductor laser

Playable discs CD, CD-R, CD-RW (for music use)

Frequency response 20 Hz to 20,000 Hz (±0.5 dB)

9-873-470-03

2002I0200-1

© 2002.09

Sony Corporation

Home Audio Company

Published by Sony Engineering Corporation

Design and specifications are subject to change without notice.

COMPACT DISC RECORDER

RCD-W7V

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

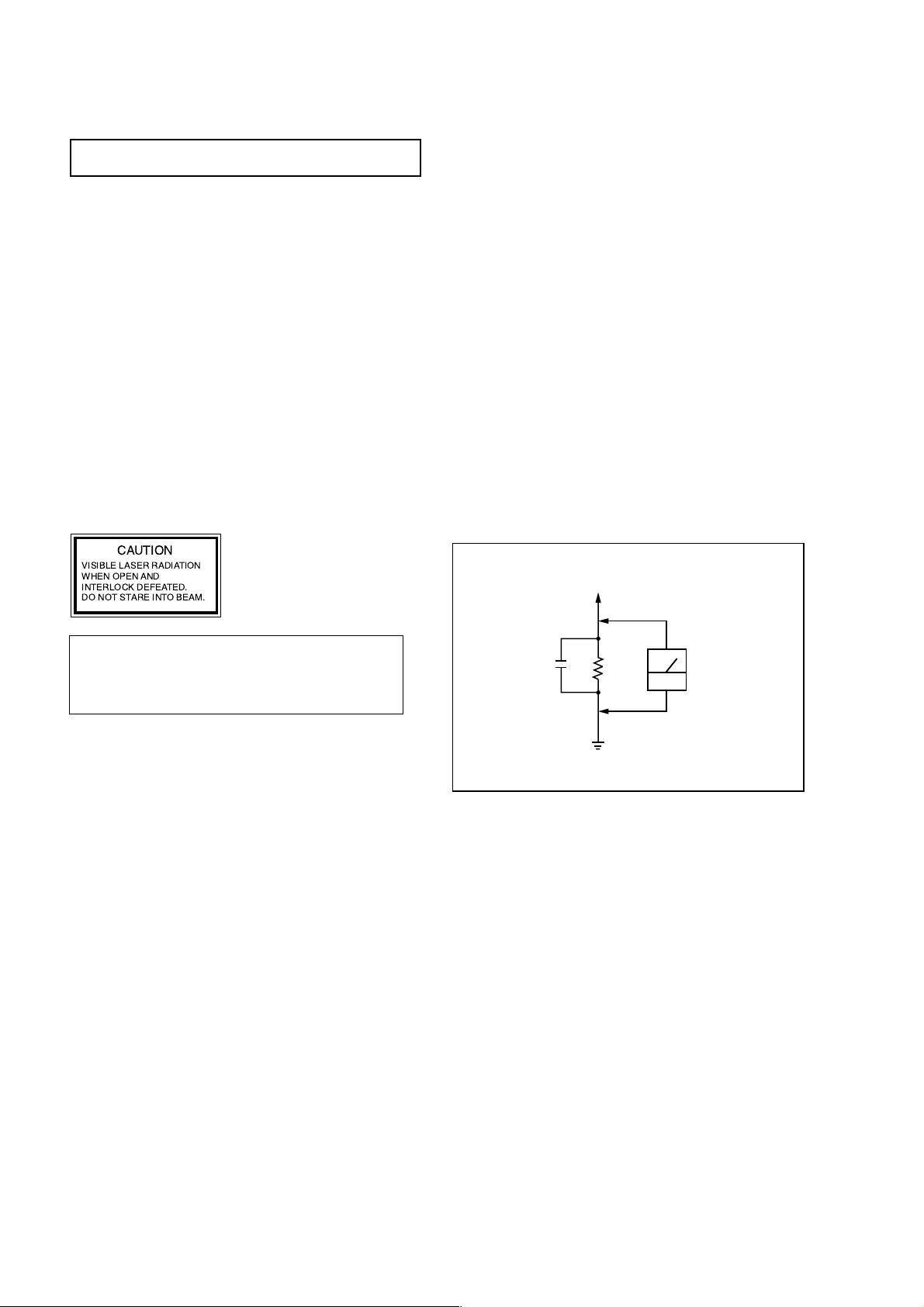

CAUTION

The use of optical instruments with

hazard. As the laser beam

used

harmful to eyes, do not attempt to

Refer servicing to qualified

CAUTION

VISIBLE LASER RADIATION

WHEN OPEN AND

INTERLOCK DEFEATED.

DO NOT STARE INTO BEAM.

this product will increase eye

in

this Compact Disc Recorder is

disassemble the cabinet.

personnel only

This label is located on the rear

panel of your recorder.

.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter . The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

0.15µF

1.5kΩ

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

2

RCD-W7V

ERROR MESSAGE

The following table explains the error

messages that appear in the display.

CHECK DISC

, A record-related button has been pressed

when a finalized disc is in the DECK B.

, A record-related button has been pressed

when a standard CD is in the DECK B.

, An unplayable disc (CD-ROM, Video CD etc.) is inserted.

DATA DISC

, A non-audio CD-ROM or a CD-Video disc has been

placed in the machine.

DISC ERROR

, An unfinalized disc has been placed in the DECK A.

, A DVD disc has been placed in the DECK B .

, The disc is not seated properly.

, There is a problem with the disc.

DISC FULL

, There is not enough time left on the disc to complete a

planned recording.

ERROR

, The disc tray is not seated properly.

NO AUDIO

, A record-related button has been pressed

when a non-audio disc is in the DECK B.

CAN NOT COPY

, A recording is not possible due to the Serial

Copy Management System (SCMS).

UNLOCK

, There is not source for recording through

DIGITAL OPTICAL IN jack.

NO DISC

, No disc is inserted in the recorder.

TABLE OF CONTENTS

1. SERVICING NOTE

.......................................................... 4

2. GENERAL .......................................................................... 8

3. DISASSEMBLY

3-1. Top Case............................................................................... 9

3-2. Tray Door, Front Panel Assy.............................................. 10

3-3. HP board, FL board, VOL board........................................ 10

3-4. Back Panel ......................................................................... 11

3-5. Audio Board ....................................................................... 11

3-6. Power Board ...................................................................... 12

3-7. DVD Deck Assy (Deck A), CD-R Deck Assy (Deck B) ...12

3-8. BD Board (Deck A) ...........................................................13

3-9. Sled Base Assy (Deck A) ...................................................13

3-10.CD-R Board (Deck B)........................................................ 14

3-11.PU Mechanism Assy (Deck B)........................................... 14

4. TEST MODE ......................................................................15

5. ELECTRICAL ADJUSTMENT ................................... 16

6. DIAGRAMS

6-1. Circuit Boards Location.................................................... 23

6-2. Block diagrams – Overall Section – ................................. 24

Block diagrams – CD/DVD Section – .............................. 25

Block diagrams – CD-RW Section – ................................ 26

Block diagrams – I/O Section – ........................................ 27

Block diagrams – Power Section – ...................................28

6-3. Schematic Diagram – BD Section (1/5) –......................... 29

6-4. Schematic Diagram – BD Section (2/5) –......................... 30

6-5. Schematic Diagram – BD Section (3/5) –......................... 31

6-6. Schematic Diagram – BD Section (4/5) –......................... 32

6-7. Schematic Diagram – BD Section (5/5) –......................... 33

6-8. Printed Wiring Board – BD Section (Side A) – ................34

Printed Wiring Board – BD Section (Side B) – ................ 35

6-9. Schematic Diagram – BD-R Section (1/4) –.................... 36

6-10. Schematic Diagram – BD-R Section (2/4) –.................... 37

6-11. Schematic Diagram – BD-R Section (3/4) –.................... 38

6-12. Schematic Diagram – BD-R Section (4/4) –.................... 39

6-13. Printed Wiring Board – BD-R Section (Side A) – ............ 40

Printed Wiring Board – BD-R Section (Side B) –............. 41

6-14. Printed Wiring Board – Audio Section –........................... 42

6-15. Schematic Diagram – Audio Section – ............................43

6-16. Printed Wiring Board – Display Section –........................ 44

6-17. Schematic Diagram – Display Section –........................... 45

6-18. Schematic Diagram – Power Section – ............................. 46

6-19. Printed Wiring Board – Power Section – .......................... 47

6-20. IC Pin Functions................................................................ 48

6-21. IC Block Diagrams............................................................ 54

7. EXPLODED VIEWS

7-1. Front Panel Section ............................................................. 56

7-2. Chassis Section ................................................................... 57

7-3. DVD Play Section (Deck A) (DP-4RM)............................. 58

7-4. CD Record Section (Deck B) (CDM-700(CD-RW)).......... 59

8. ELECTRICAL PARTS LIST .................................60

3

RCD-W7V

SECTION 1

SERVICING NOTE

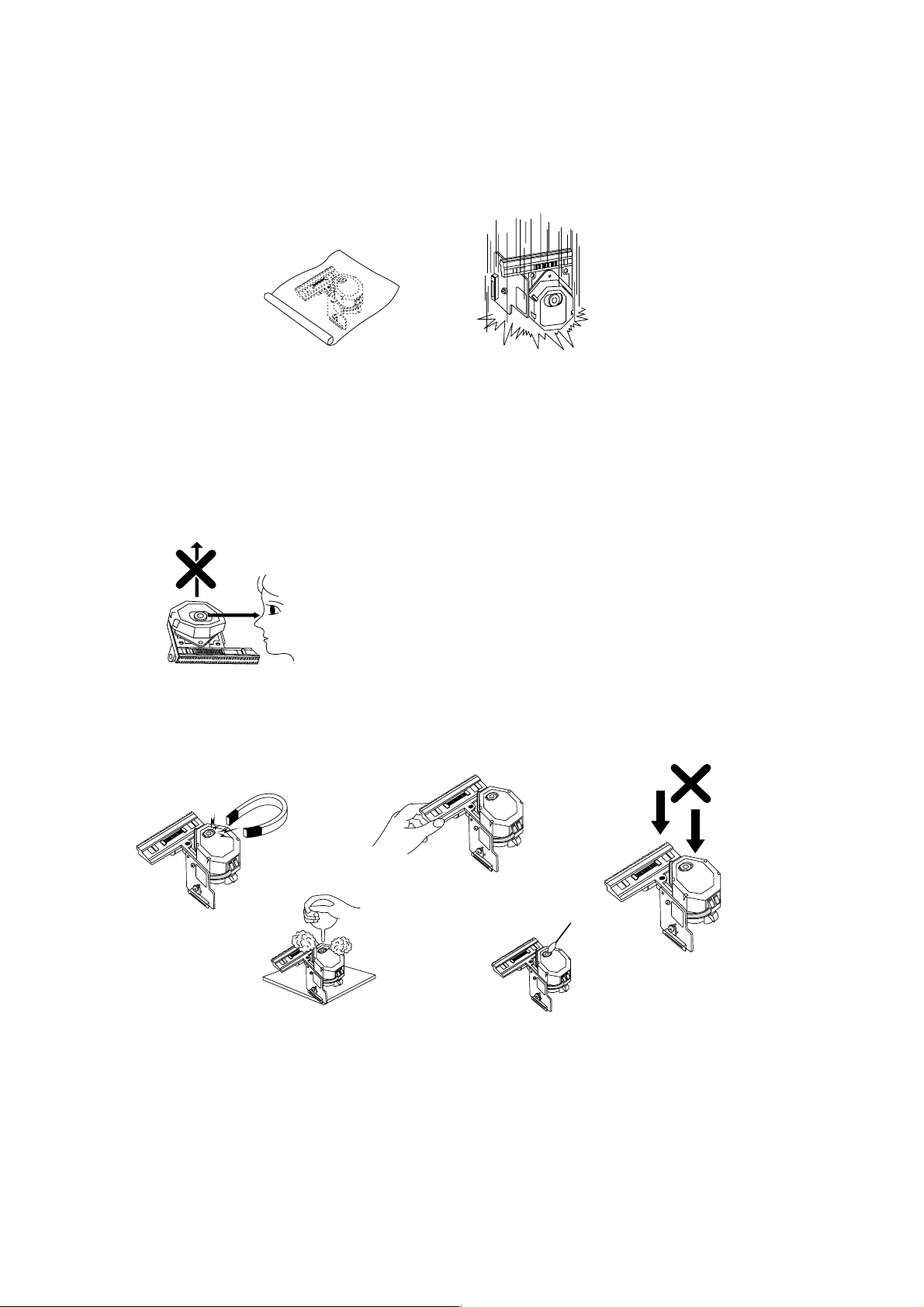

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

Storage in conductive bag

Drop impact

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully , taking care to avoid external pressure and impact.

If it is subjected to pressure or impact, the result may be an operational malfunction and/or damage to the

printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason the

adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

NEVER look directly at the laser beam, and don’t let contact

fingers or other exposed skin.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used for

camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton swab

should be used, taking care not to distort this.

Pressure

Magnet

How to hold the pick-up

Cotton swab

Conductive Sheet

6) Never attempt to disassemble the pick-up.

Spring by excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab. (Do not use any

other liquid cleaners, because they will damage the lens.) Take care not to use too much of this alcohol on the swab,

and do not allow the alcohol to get inside the pick-up.

Pressure

4

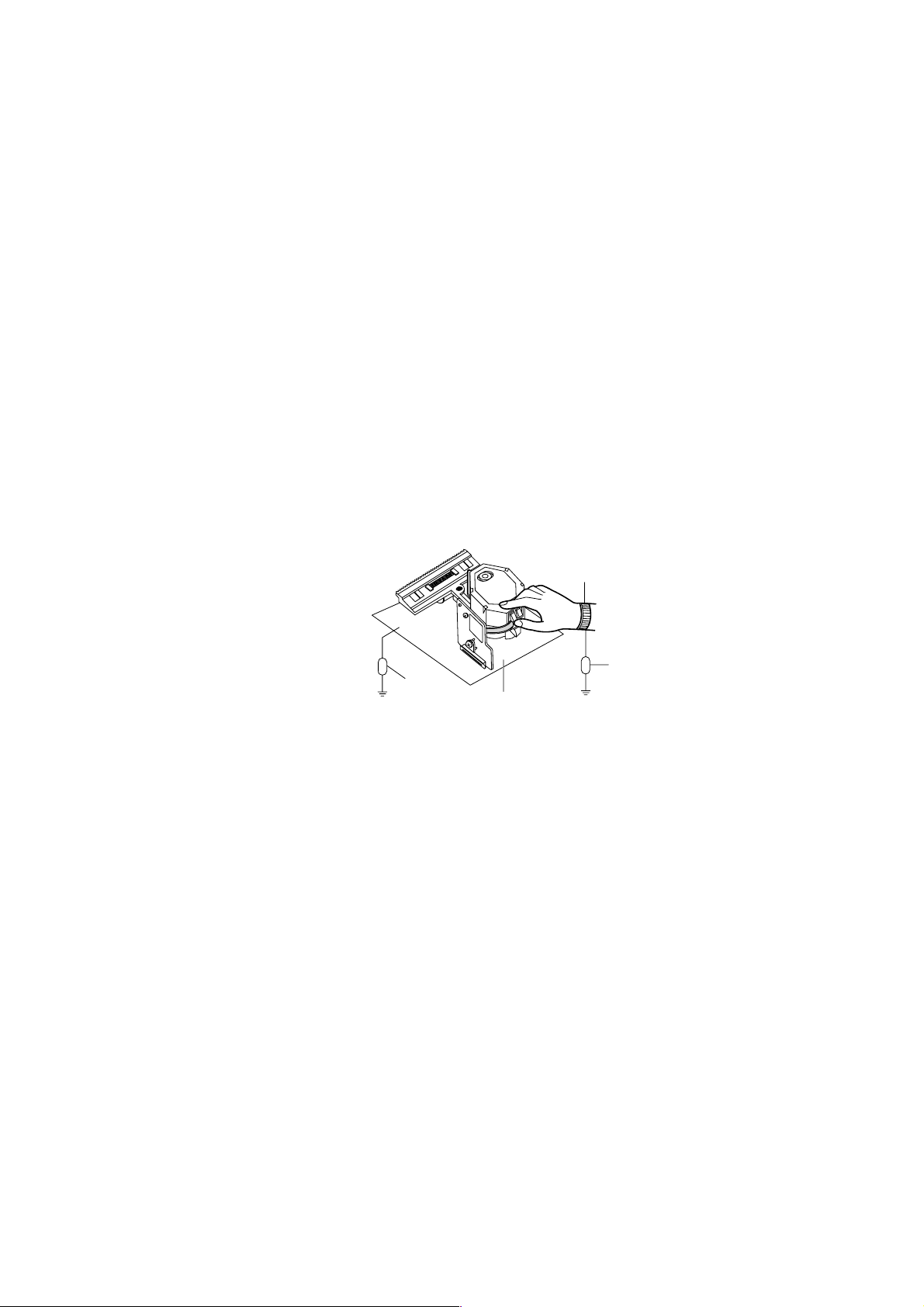

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components are sensitive to, and easily affected by, static electricity. If such static is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must

be taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong

magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1MΩ)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

RCD-W7V

Resistor

(1MΩ)

Armband

Resistor

(1MΩ)

Conductive

Sheet

5

RCD-W7V

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are ready

to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by conductive

foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL

OTHER SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can gen erate static electricity sufficient to damage an ESD device).

MAKING THE ADJUSMENT DISCS (CDR1/CDR2)

Copy the test programs to a blank CD-R or CD-RW disc.

(This test program is distributed with the service manual)

Note: CD-R or CD-RW must be written by “Easy CD Creator”.

6

RCD-W7V

)

NOTE ON CHECKING POWER SUPPLY CIRCUIT

1. When check the primary part, you must remove the GND pin of

the scope and soldering machine.

Primary GND : C103 – terminal at power board.

2. When check the primary part, you must open the another GND(not

used GND) of scope.

(If another scope GND is connected to secondary GND or other

system, input power line or system have some damage.)

3. When touch the primary part by hand in defected system,

if you use the power line switch, remove the power cord and then

check or touch.

Because in general power switch is switching only one line.

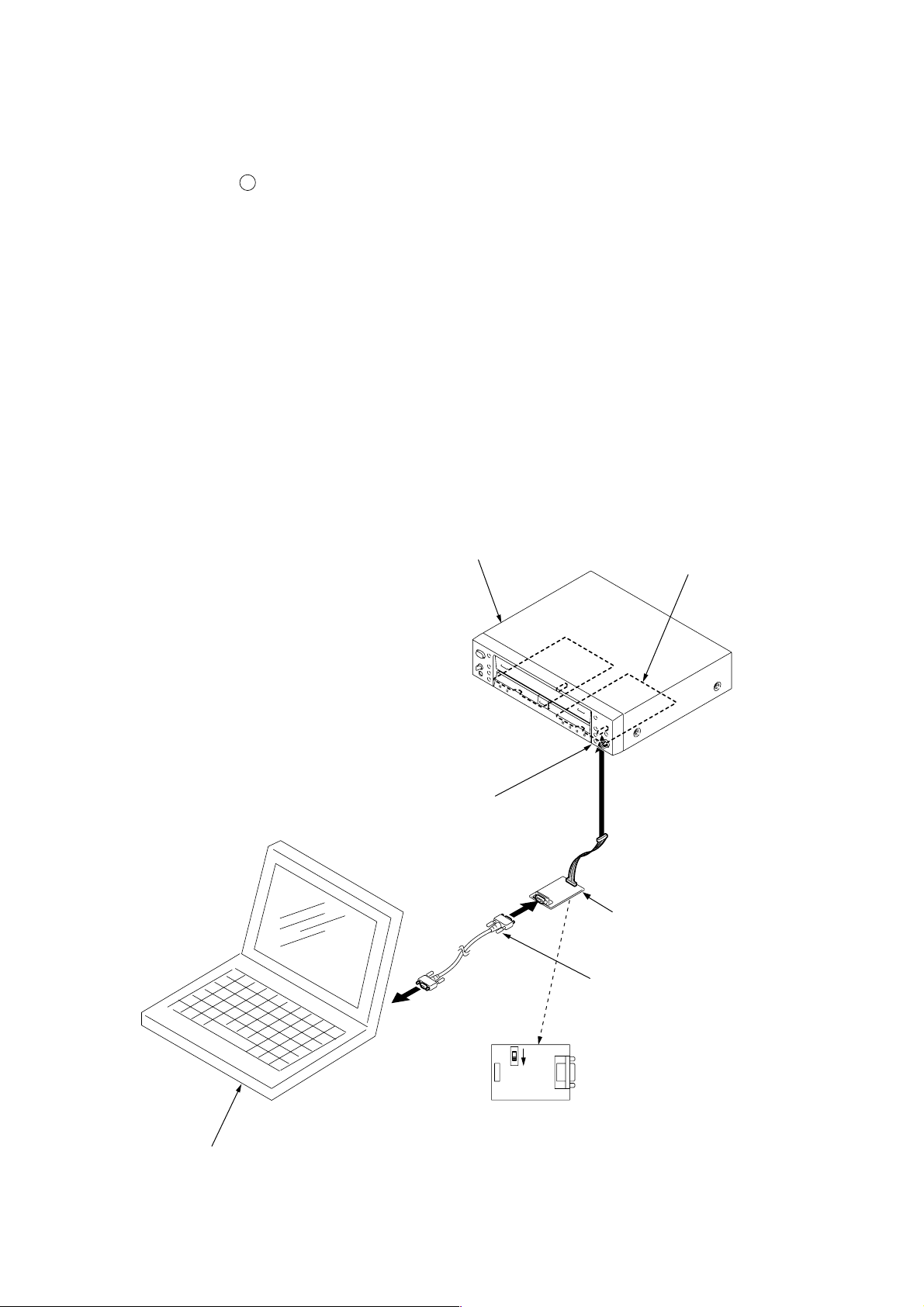

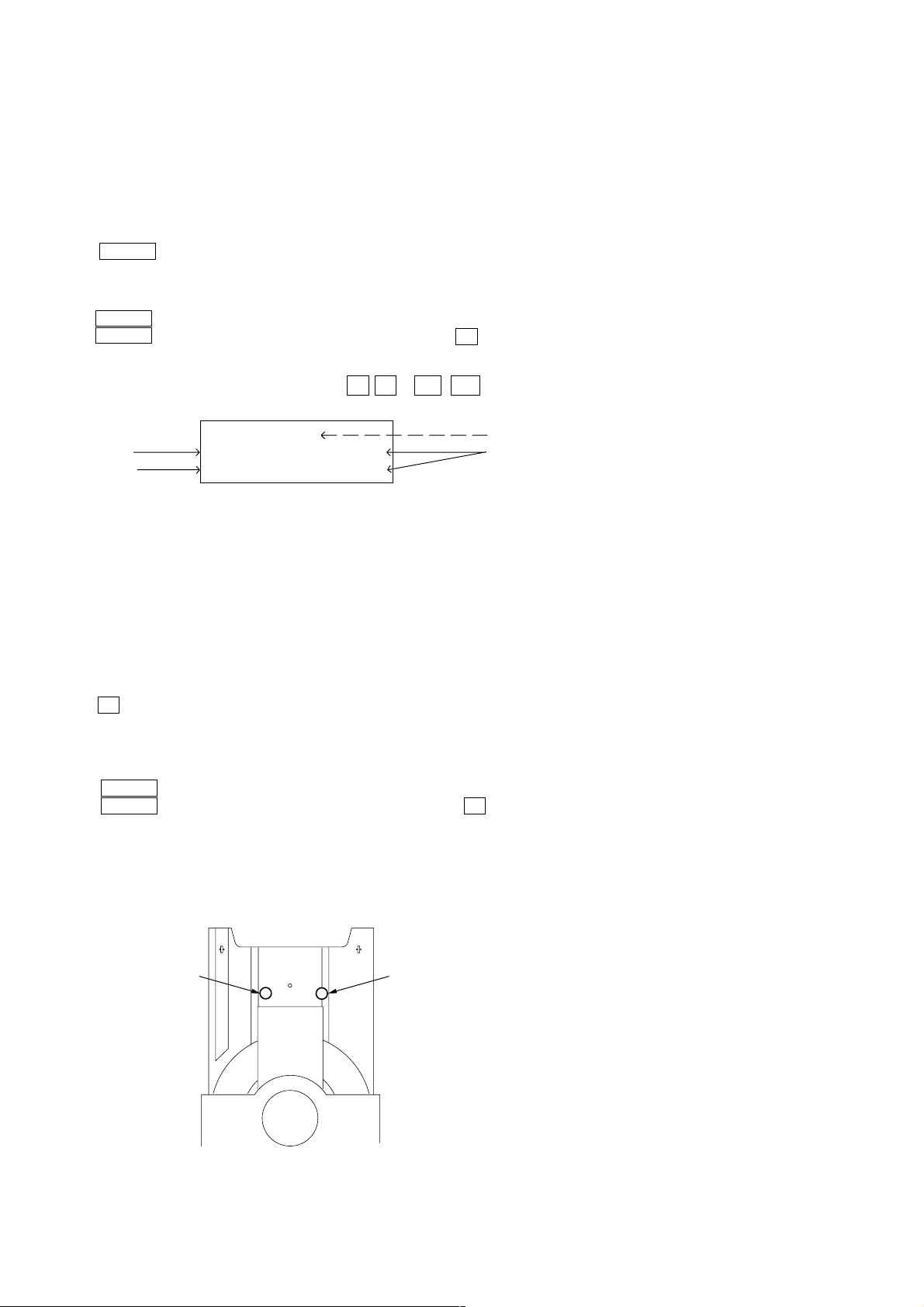

BD-R BOARD CHECK AND ADJUSTING JIGS

In case of checking or adjusting the LD power of BD-R board, the PC connection jig (J-2501-210-A) and the test program are required.

This test program is distributed with the service manual.

4. When check the primary part, after remove power cord and dis

charge the primary capacitor, and then check the system.

In the normal state, the voltage of the capacitor is small

(about 10V), but in the abnormal state is very high ( about 140V).

When discharge the capacitor , use the wattage resistor(about 100

ohm).

5. In the narrow system, Until set repaired completely,

insert the power cord at the moment repeatedly and then check

the waveform.

6. In the wide system, when insert the power cord, check the wave

form after about 3 second.

Because the wide system is the soft start method.

RCD-W7V

CD-R

test connector (PN105)

BD-R board

PC connection jig

(J-2501-210-A)

PS-232C cable (D-sub 9pin

(straight type)

PC

SW501

W

D

CNP501CN505

PC connection jig

Set SW501 to “D” side

7

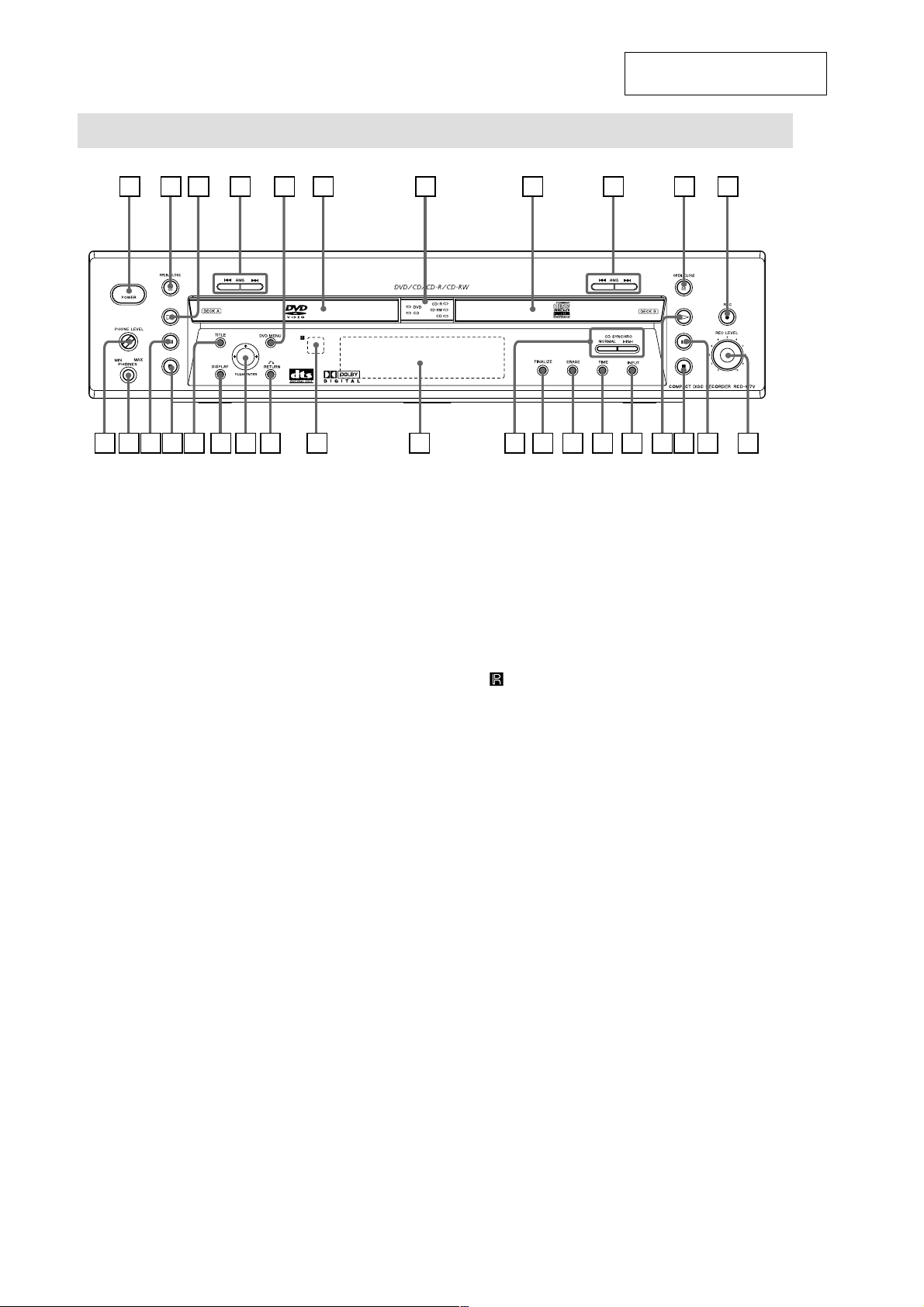

RCD-W7V

Front Panel

SECTION 2

GENERAL

This section is extracted from

instruction manual.

2 3 4 5 6 7 8 9

1

10 11

30 2928 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12

1

POWER switch (23)

2

3

4

5

6

7

8

9

0

qa

qs

qd

qf

qg

(open/close)-Deck A (23)

A

(play)-Deck A (23)

H

AMS / -Deck A (24)

DVD MENU (27)

Disc tray-Deck A (23)

Disc sort indicator

Disc tray-Deck B (23)

AMS / -Deck B (24)

(open/close)-Deck B (23)

A

(record)-Deck B (48)

z

REC LEVEL control-Deck B (49)

(pause)-Deck B (24)

X

(stop)-Deck B (24)

x

(play)-Deck B (23)

H

.

>.

>

INPUT select (48)

qh

TIME (50)

qj

ERASE (52)

qk

FINALIZE (51)

ql

CD SYNCHRO (NORMAL/HIGH)

w;

(46, 47)

DISPLAY

wa

ws

wd

wf

wg

wh

wj

wk

wl

e;

(remote sensor)

RETURN (22)

O

Arrow(C/X/x/c)/PUSH ENTER (27)

DISPLAY (31)

TITLE (27)

(stop)-Deck A (24)

x

(pause)-Deck A (24)

X

Headphone jack (24)

Headphone level control (24)

8

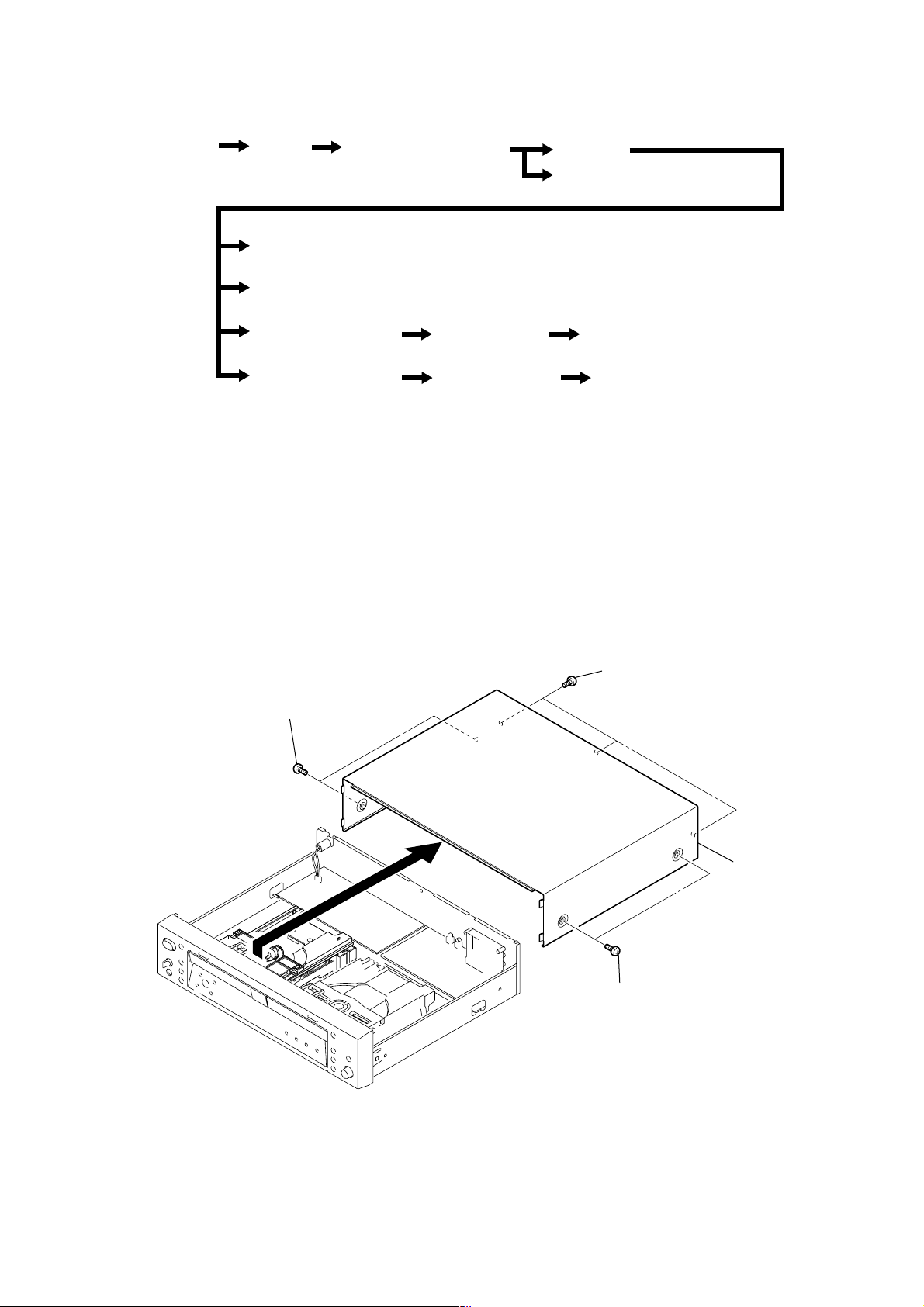

Note: Disassemble the unit in the order as shown below.

RCD-W7V

SECTION 3

DISASSEMBLY

Set

Note: Follow the disassembly procedure in the numerical order given.

Top case

Audio board

Power board

DVD deck assy (deck A)

CD-R deck assy (deck B)

Tray door, Front panel assy

BD board (deck A)

BD-R board (deck B)

3-1. T OP CASE

Back panel

HP board, FL board, VOL board

Sled base assy (deck A)

PU mechanism assy (deck B)

1

Two screws (case)

3

2

Three screws (case)

1

Two screws (case)

4

Top case

9

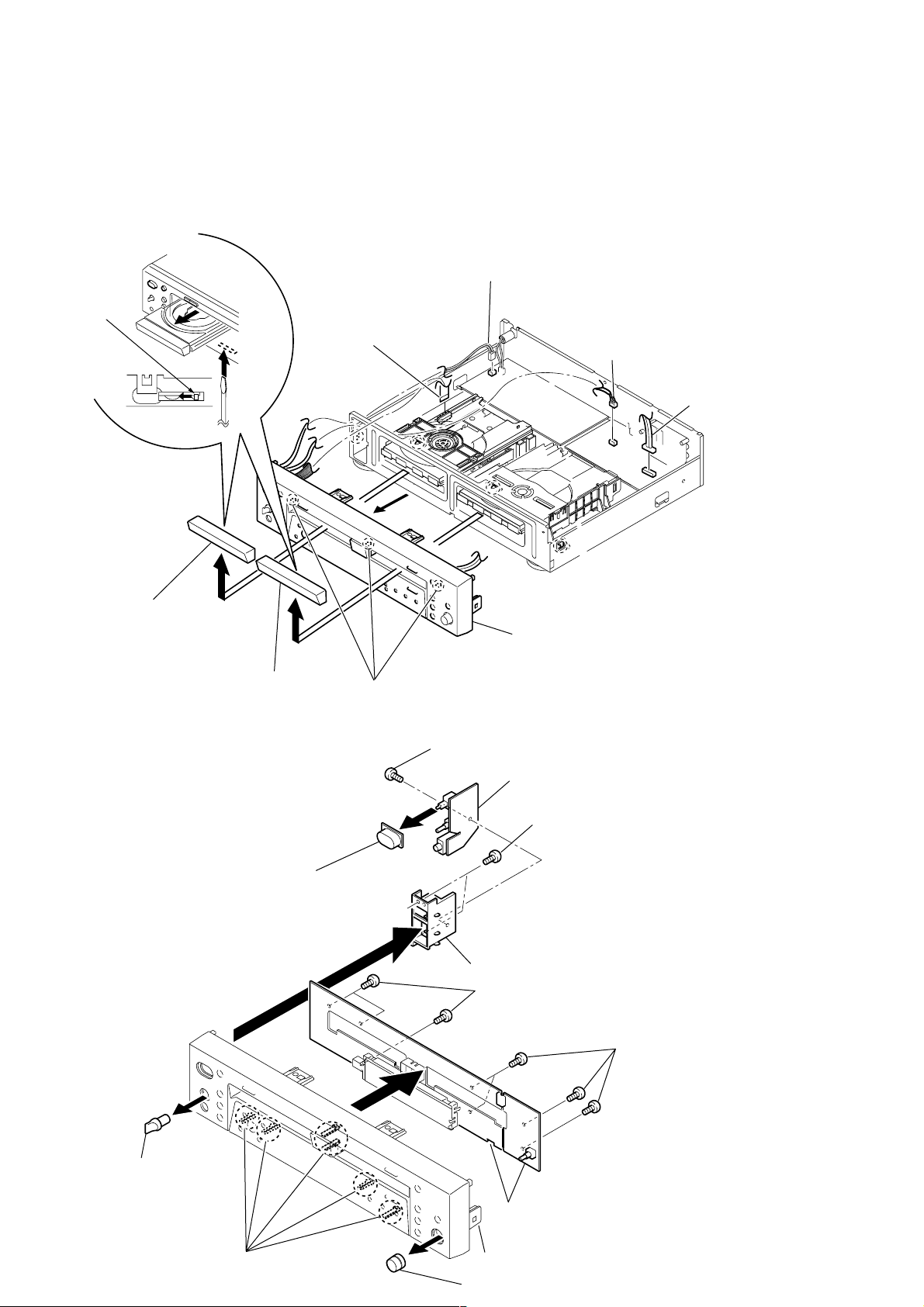

RCD-W7V

)

)

3-2. TRAY DOOR, FRONT PANEL ASSY

1

Insert a screwdriver to the square hole on the bottom,

and slide the white lever in the arrow

open the tray.

Then remove the tray door.

(In the case of DECK B, remove it in the same manner.)

White lever

A

A

direction to

5

Flat cable (PN4013)

4

Connector (PN101)

3

Connector (CN701)

2

Connector (CN702

Tray door (DVD)

(deck A)

Tray door (CDR)

(deck B)

3-3. HP BOARD, FL BOARD, VOL BOARD

6

POWER knob

6

Claws

7

7

8

Screw (Special)

8

Front panel assy

HP board

3

Two screws (Special)

10

2

P/VOLUME knob

qa

Claws

4

5

PWB holder

0

Two screws (Special)

qs

FL board and VOL board

Front panel

1

REC VOL knob

9

Four screws (Special

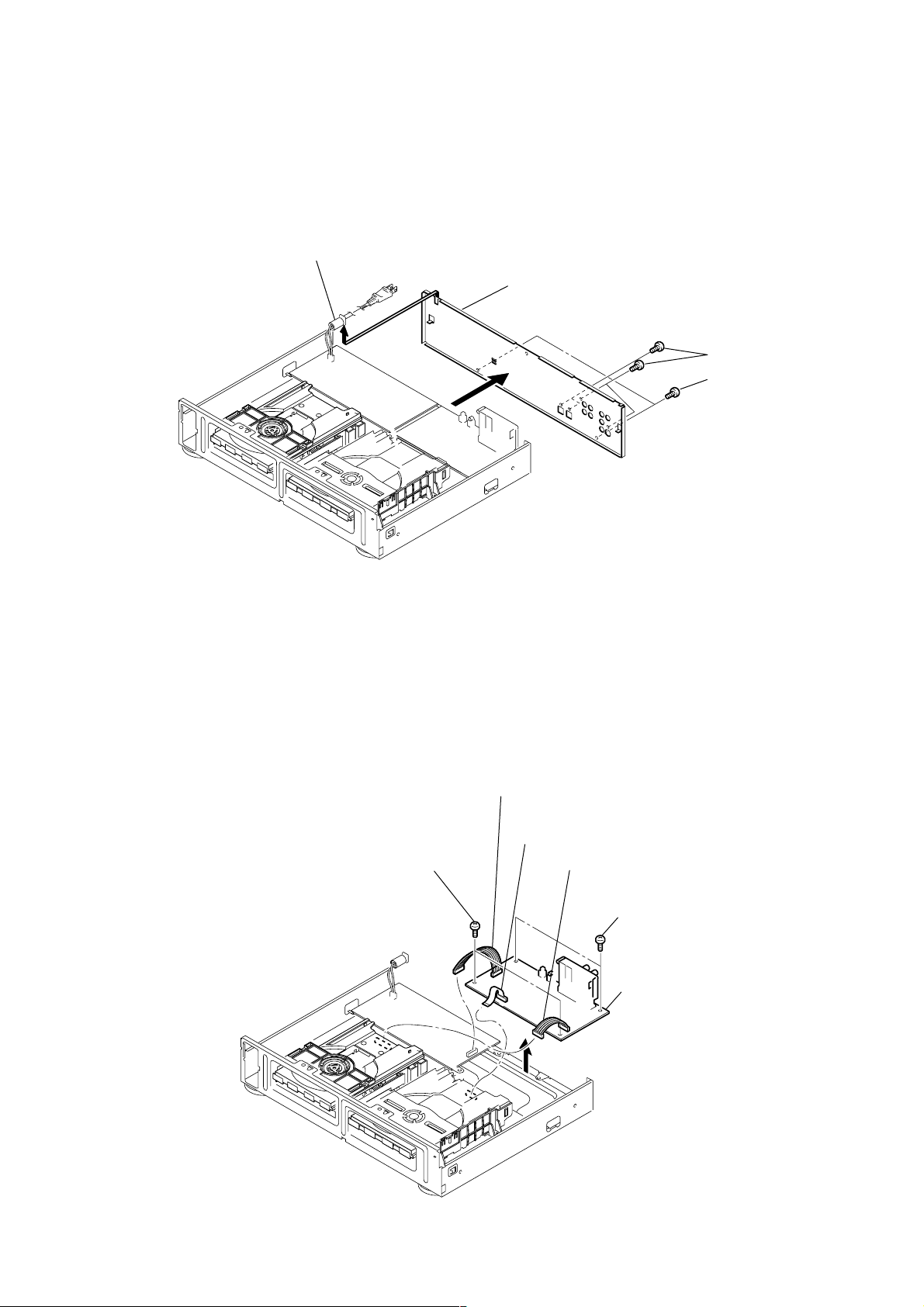

3-4. BACK PANEL

)

)

3

Cord power

4

5

Back panel

RCD-W7V

1

Four screws (3X10)

2

Two screws (3X8 BK

3-5. AUDIO BOARD

4

Two screws (special)

3

Connector (CN103)

2

Wire (flat type) (PN501)

1

Connector (PN3401)

5

Two screws (special

6

AUDIO board

11

RCD-W7V

)

3-6. POWER BOARD

1

Connector (CN4012)

4

PWB holder

2

Two screws (special)

5

3

Two screws (special)

6

POWER board

3-7. DVD DECK ASSY (DECK A), CD-R DECK ASSY (DECK B)

2

Two screws (special)

3

Two screws (special)

5

DVD deck assy (deck A)

4

8

1

Wire (flat type)(PN3402)

6

Two screws (special)

7

Two screws (special)

9

CD-R deck assy (deck B

12

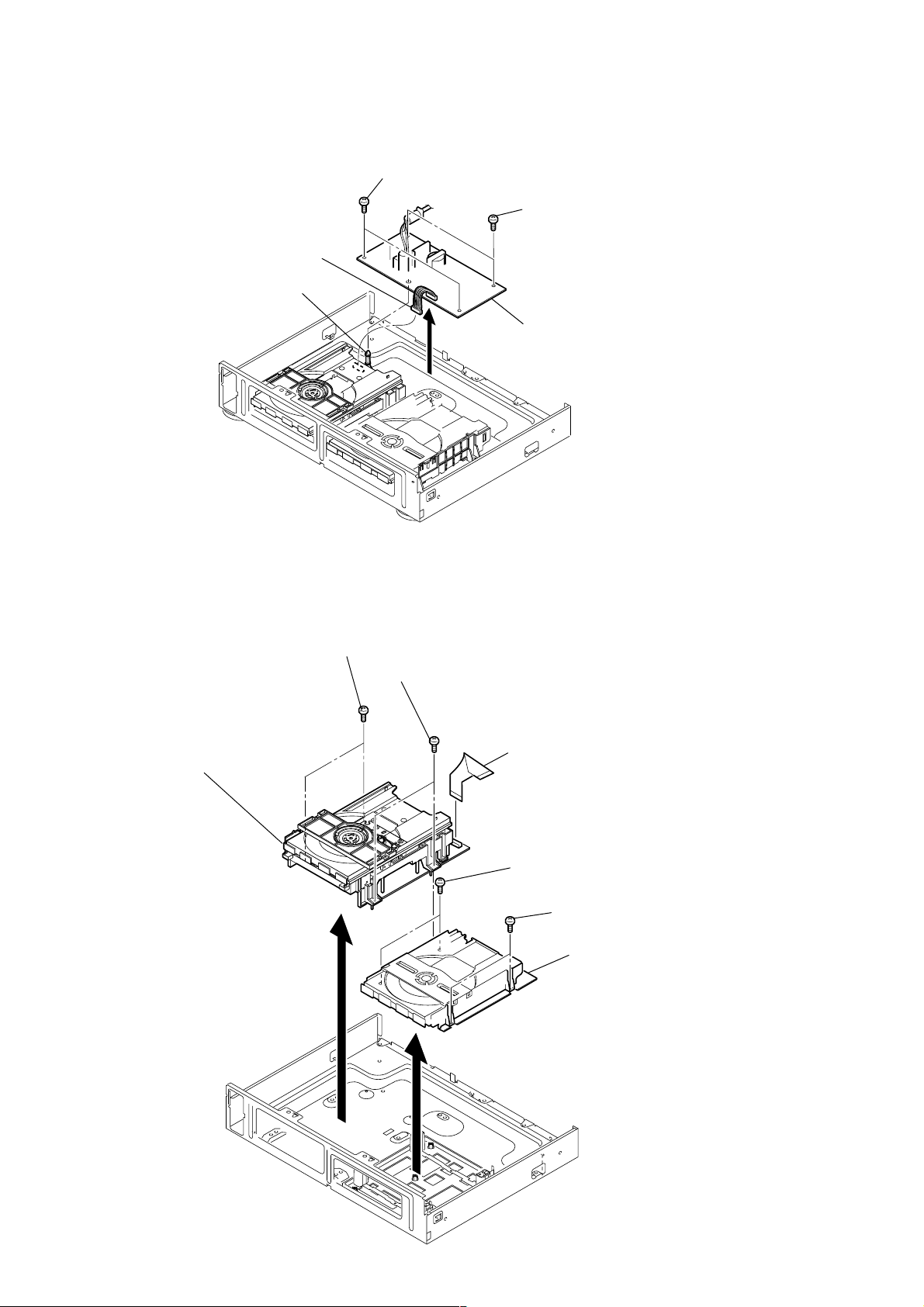

3-8. BD BOARD (DECK A)

)

1

Three claws

4

2

Wire (flat type) (PMD02)

3

Wire (flat type) (PMD03

RCD-W7V

3-9. SLED BASE ASSY (DECK A)

Push out the disc tray by pushing the

4

Up/Down guide un the drrow A direction.

Up/Down guide

A

Main base

3

Clamp holder assy

7

Two screws

(D2.0X6)

2

Two claws

5

BD board

8

1

Screw (1.7X6)

7

Two screws (D2.0X6)

9

Sled base assy

Bottom view

5

6

Disc tray

13

RCD-W7V

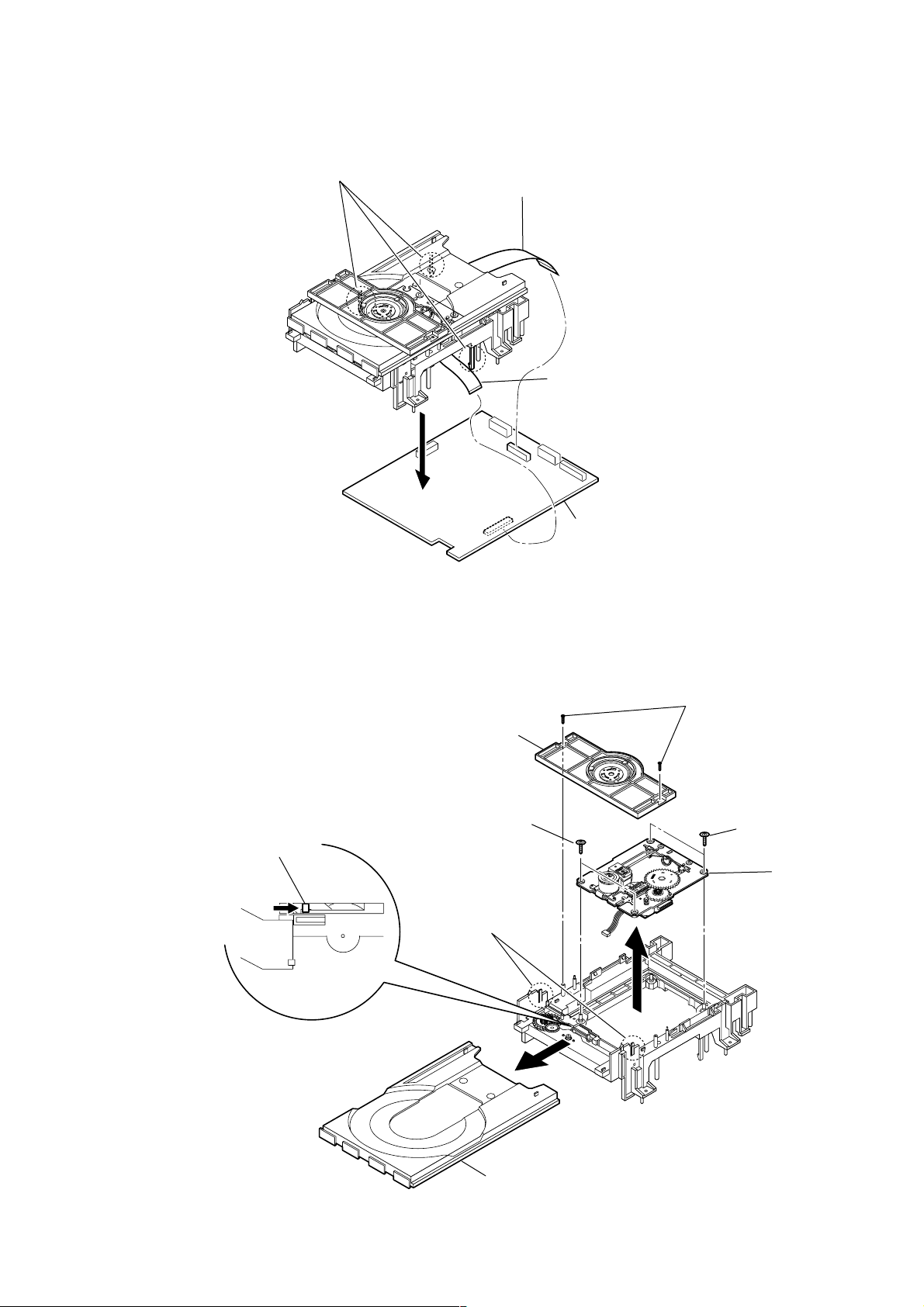

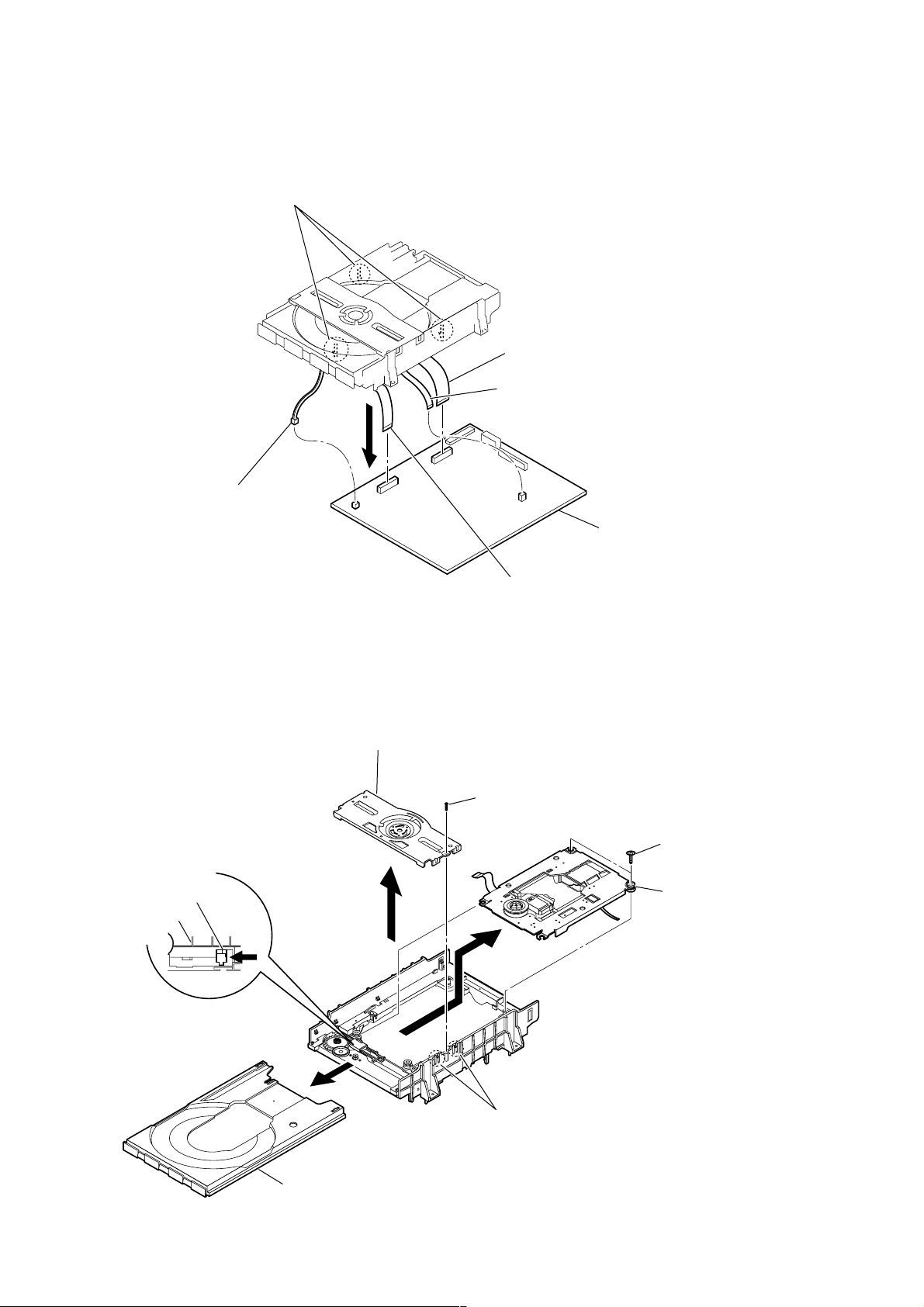

3-10. CD-R BOARD (DECK B)

1

Three claws

6

3

Wire (fiat type) (PN301)

4

Wire (fiat type) (PN303)

2

Connector (PN302)

3-11. PU MECHANISM ASSY (DECK B)

5

Push out the disc tray by pushing the

Up/Down suide un the drrow

Up/Down guide

Main base

A

direction.

4

Clamp holder assy

3

5

Wire (flat type) (PN304)

1

Screw (2X6)

7

BD-R board

8

Two screws (2.0X10)

PU mechanism assy

0

14

Bottom view

A

6

7

Disc tray

9

Two claws

2

SECTION 4

TEST MODE

4-1. MICROCOMPUTER VERSION DISPLAY

Setting Procedure

1. Connect a monitor to the “VIDEO OUT” terminal on RCD-W7V.

2. Insert the DVD disc to DVD player side (deck A).

3. Press x (DVD) button to stop the disc rotating.

4. Press DVD DISPLAY button.

5. MENU is displayed on the monitor screen.

6. Select “SET UP” with M or m buttons and press ENTER button.

7. Select “TV Aspect” in the “SET UP MENU” with M or m buttons and press ENTER button.

8. Select “16:9 Wide” in the “TV Aspect” with M or m buttons. (Don’t press ENTER button.)

9. Press the numerical buttons 1, 3, 9, 7, 1, 3, 9 in the order and press ENTER button.

10. The microcomputer version is displayed on the monitor screen.

MODEL : SONY RCD W7V

REGION : NO. 01

NATION : US 00

RID : LGESY0200001

UCOM. P : VO.1 20020204 01

UCOM. R : VO.1 20020102 01

SERVO : D104

MPEG : OL4O 22MAR01

MISCEL : 11 E0

55 53 00 4C 12 00 FF FF

RCD-W7V

Microcomputer version display

11. Press Z (DVD) button to quit the test mode.

15

RCD-W7V

e

SECTION 5

ELECTRICAL ADJUSTMENT

DVD MD Skew Adjustment

Equipments to be required:

• TV monitor (With RCA pin jack inputs)

• Adjustment disc (CDR1/CDR2) (See page 6)

• Test disc (0.8mm off-centered disc) TDV-534C (J-2501-222-A)

• L-Wrench (3mm) (Impossible to use an inch size)

Adjustment Procedure:

1. Press POWER button and insert CDR1 disc to the DVD player.

2. The display on the set changes automatically.

Wait until the display turns off. (Takes few minutes the display turns off completely.)

(Note: In case of the long time display stopped in progress or displays abnormally, do not anything and wait.)

3. Press POWER button to turn power “OFF”.

4. Press POWER button to turn power “ON” and instantaneously press Z button to take out CDR1 disc.

5. Insert the TDV-534C disc and play it.

6. The error rate appears on the screen.

7. Set the position start to play to 200000 sector with M , m or < , , buttons on the remote commander.

SECTOR : 200123 SECTOR

UPPER BAR | 0000 ERROR RATE

LOWER BAR | 0000

Error rate display

SECTOR : Current position of pick-up

UPPER BAR : Peak to peak level of error rate.

LOWER BAR : Average level of error rate.

Error rate specified value: 30 or less.

8. Adjust the R skew to minimize the error rate.

9. Adjust the T skew to minimize the error rate.

10. Adjust the R skew and T skew mutually several times to minimize the error rate.

11. After adjustment the error rate should be lower than the specified value.

12. Press Z button to take out the test disc (TDV-534V).

13. Insert CDR2 disc to the DVD player.

14. The display on the set changes automatically.

Wait until the display turns off. (Takes few minutes the display turns off completely.)

(Note: In case of the long time display stopped in progress or displays abnormally, do not anything and wait.)

15. Press POWER button to turn power “OFF”.

16. Press POWER button to turn power “ON” and instantaneously press Z button to take out CDR2 disc.

Adjustment point:

16

Adjusting hole

for T scew

Adjusting hol

for R scew

DVD deck (Deck A)

RCD-W7V

LD Power Adjustment

Jigs used on this adjustment

• LD Power Meter

A laser power meter 10mW or more measurable is required. Don’t use the laser power meter for Mini disc because of 10mW max.

Optical power meter (TQ8210): Product of ADVANTEST (on the market).

A thin type optical sensor (Q82017A): Product of ADVANTEST (on the market).

• PC Connection Jig (J-2501-210-A)

• Test Program FD

Dragon program Tool DV810 Ver. 0.9A

(This test program is distributed with the service manual.)

• PC (Windows 95/98)

• RS-232C Cable (on the market) D-SUB 9 pin, straight type

• Test Disc for Operation Check

A low reflecting rate disc for checking playback performance. OK: It can be played back.

• Low reflecting CD-R disc: TCD-R082LMT (J-2502-063-1)

• Low reflecting CD-RW disc: TCD-W082L (J-2502-063 -2)

• CD test disc (YEDS-18) (3-702-101-01)

• DVD test disc (HLX-503) (J-6090 -069 -A) (single layer)

• DVD test disc (HLX-504) (J-6090 -088 -A) (single layer)

• DVD test disc (HLX-505) (J-6090 -089 -A) (dual layer)

• Extension cable (4p, 1.0mm) (J-8000-023-A)

• Extension cable (23p, 1.0mm) (J-501-157-A)

Laser Power Adjustment (CD-R Only)

In case of the following parts are replaced, this adjustment is required.

1. CD-R optical pick-up block (KRS-220C)

2. IC208 (EP- ROM)

Specification of Dragon Program Usage Environment

The Dragon Program programmed by API function of Windows 95 can be surely operated on the Windows 95/98 platform.

It isn’t guaranteed on the other platform.

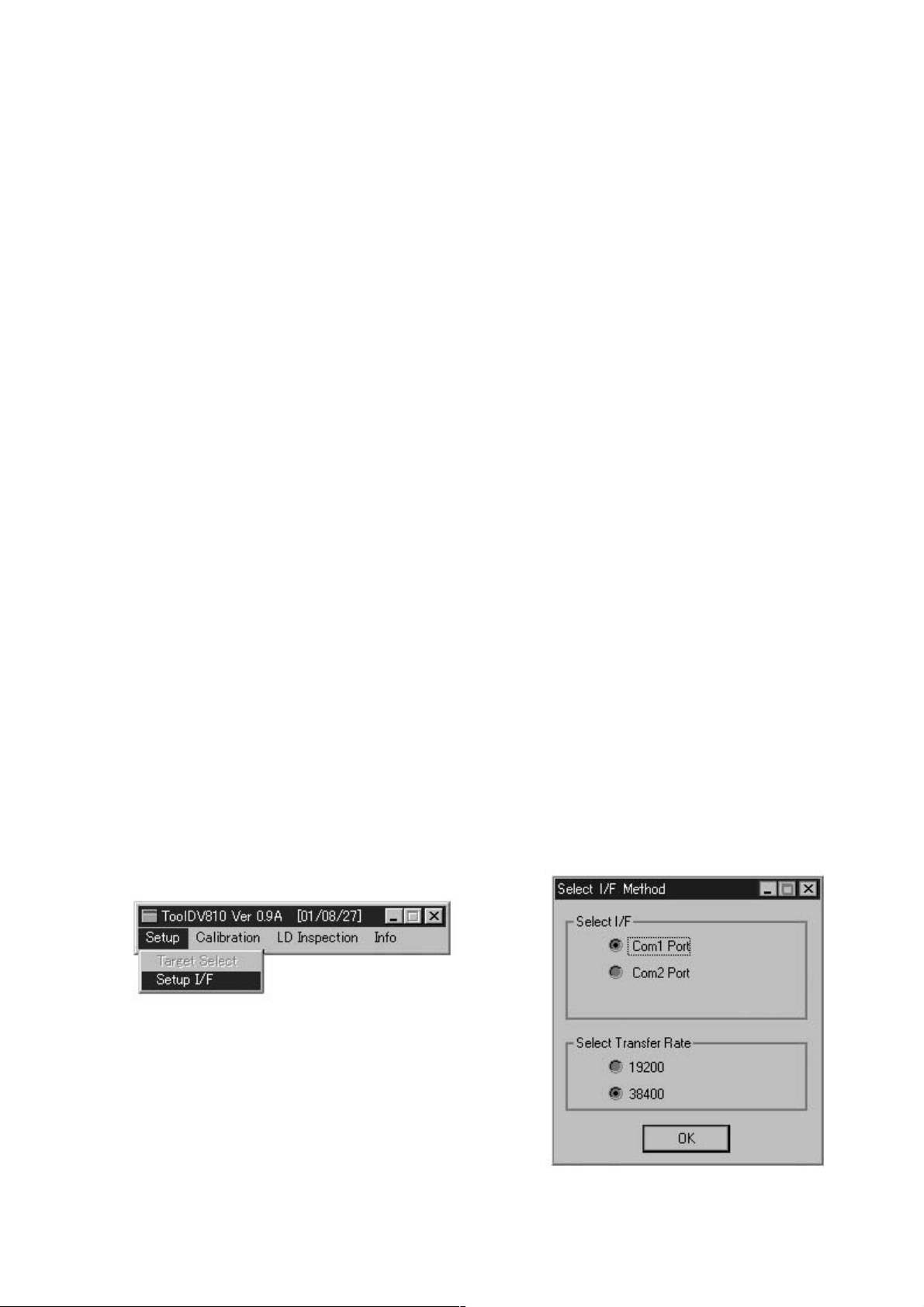

Start up

Procedure:

1. Connect the PC connection jig with the RS-232C cable between the test connector (PN105) on CD-R of RCD-W7V and COM port on

PC.(Check SW501 on the PC connection jig to “D” side.)

2. Turn power on RCD-W7V.

3. Execute Dragon_dv810_svc.exe on Windows.

(Two files Dragon_dv810_svc.exe and Dragon_dv810.cfg are displayed on the setup menu window.)

4. Select “Setup I/F” on “Setup” pull-down menu, then “Select I/F Method” window is open.

5. Select Com Port matching to the Com Port connected the PC connection jig.

6. Select “38400” of “Select Transfer Rate”.

7. Click OK.

Fig 1 : Dragon menu and setup menu windows

Fig 2 : Select I/F method window

17

RCD-W7V

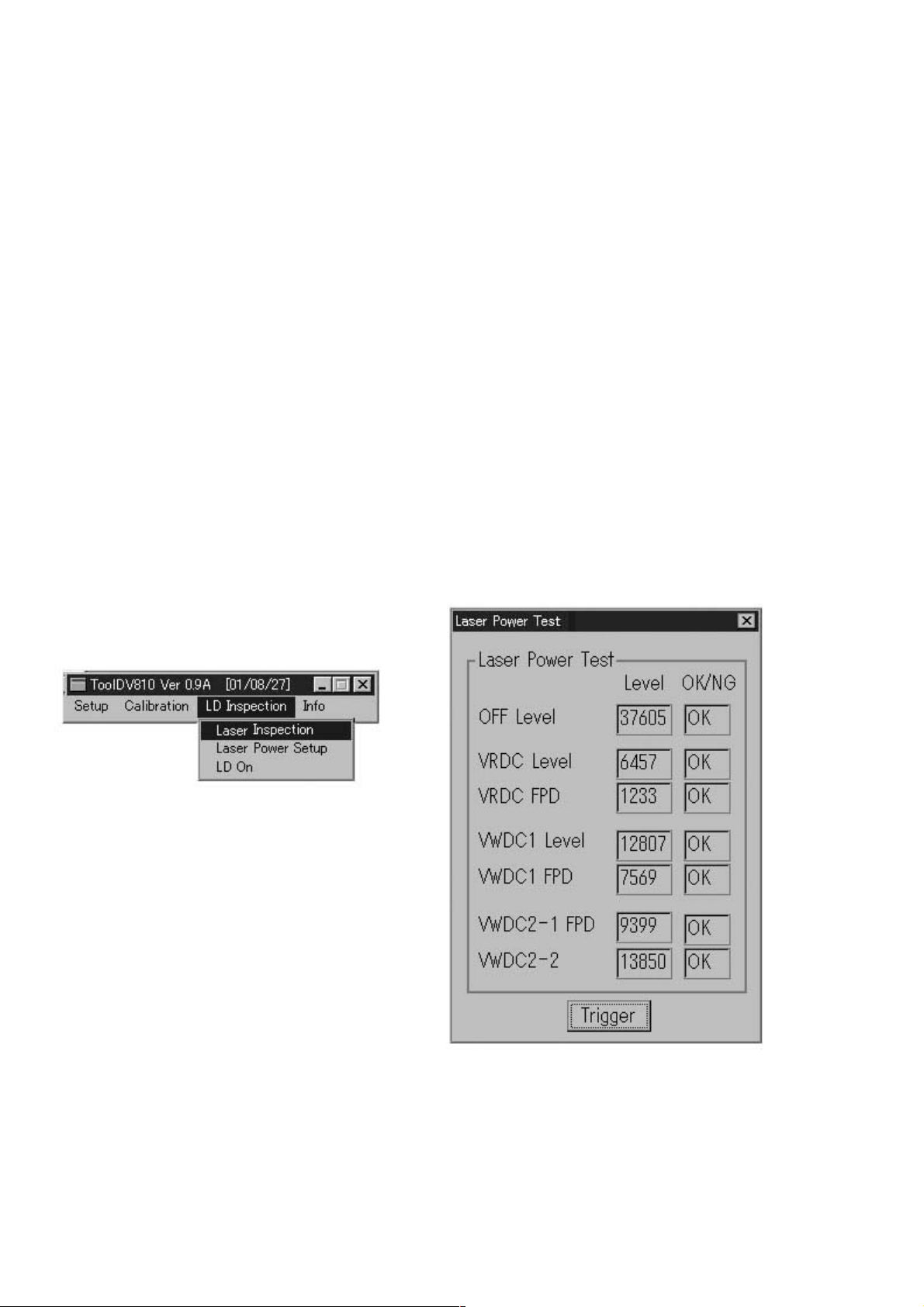

CD-R LD Setting Check

(VRDC/VWDC/FPD Level Value Check)

This routine is for checking performances of the record/playback D-A converter (IC409), RFIC (IC413), the encoder/decoder IC

(IC401), CPLD (IC601), the optical pick-up block (KRS-220C), the microcomputer(IC701) and so on.

It diagnoses malfunctions of interface, the pick-up or so on.

It diagnoses the circuit in the recording mode without disc.

Description of each item

OFF LEVEL: In case of the laser turns off, FPDO output is 3V. Sampling value at this time.

VRDC LEVEL: APC circuit VRDC signal sampling value after READ power setting.

VRDC FPD: Optical pick-up FPDO signal sampling value after READ power setting.

VWDC1 LEVEL:APC circuit VWDC signal sampling value after setting WRITE power to regular value.

VWDC1 FPD: Optical pick-up FPDO signal sampling value after setting WRITE power to regular value.

VWDC2-1 FPD: There are two types of characteristics because of a non-linearity period of laser diode in the

over drive portion. This is FPDO sampling value in case of setting one of them to VWDC2 value.

VWDC2-2 FPD: FPDO sampling value in case of setting the other to VWDC2 value.

Specification of each item

38400-3300<OFF_LEVEL<38400+3300 (3.0±0.25V)

10<VRDC_LEVEL<20000

880<VRDC_FPD<1320

2000<VWDC1_LEVEL<25000

8640<VWDC1_FPD<12960

10<VWDC2-1_FPD<9500

2000<VWDC2-2_FPD<16000

Procedure:

1. Eject a disc from CD-R.

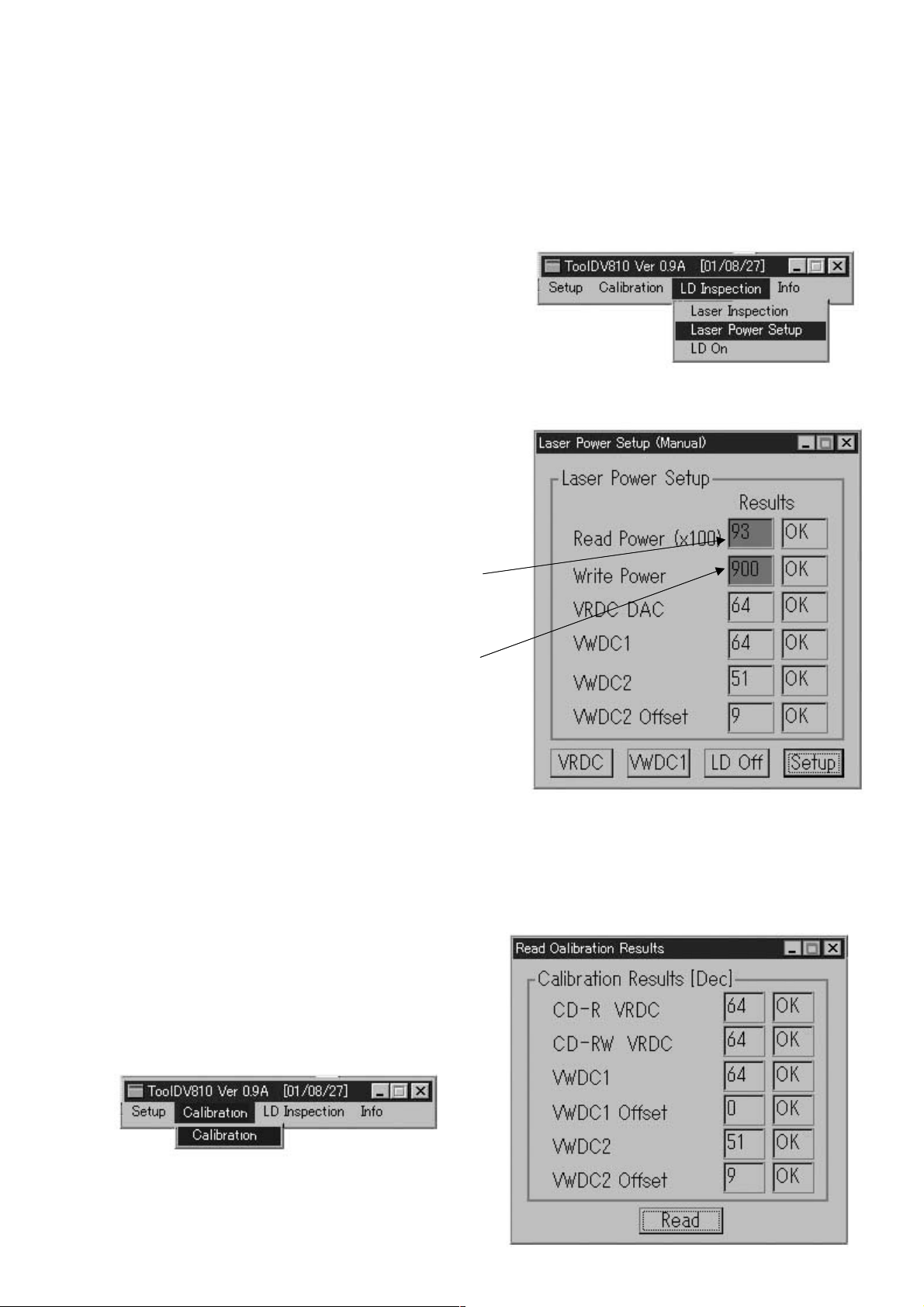

2. Select “Laser Inspection” on “LD Inspection” pull-down menu, then “Laser Power Test” window is open.

3. Click Trigger to execute LD check.

4. LD checked results are displayed.

(“OK”/“NG” is displayed for every items.)

5. Click X to close “Laser Power Test” window.

Fig 3 : LD inspection menu windows

CD-R LD Power Setting

(VRDC/VWDC1 Resetting)

The optical pick-up and ICs in the circuit have a characteristics individually. In this routine, the parameters related to the

recording/playback power are actually measured and set properly.

The parameters are VRDC, VWDC1, VWDC2, VWDC2 Offset and so on. The reading power and playback power are set

properly by computing the related parameters on the basis of actually measuring values.

The preset parameters are used on power setting in case of performing Read/Write CD-R, CD-RW and so on.

Actual operation: The microcomputer receives serial data, then executes the related performances, and sendparameter values to PC.

PC checks its related parameters and judges OK/NG.

Fig 4 : Laser power test window

18

RCD-W7V

Description of each parameter

VRDC: Used on the Read Power setting in case of

reading CD-RW and CD-R. (DAC value on 100mW.)

VWDC: There is VWDC1 (Write power) pin in the optical pick-up block. The recording power is set by it and VWDC2

(Over drive) pin. Used on setting VWDC1 pin power on recording. (Unit: DAC value/10mW)

VWDC2: Used on setting VWDC2 (Over drive) pin power on recording. (Unit: DAC value/5mW)

VWDC2 Offset: Used on setting VWDC2 (Over drive) pin power with VWDC2 parameter on recording. (Unit: DAC value)

Specification of each parameter

20<read power<200

100<write power<2000

30<VRDC<150

48<VWDC1<150

50<VWDC2<126

VWDC2 Offset<35

Fig 5 : LD inspection menu windows

Procedure:

1. Eject a disc from CD-R.

2. Select “Laser Power Setup” on “LD Inspection” pull-down

menu, then “Laser Power Setup (Manual)” window is open.

3. Click VRDC, then Pick-up moves outward and LD turns on.

4. Measure the LD power with a LD power meter. W rite its value

to the blank of “Read Power” column.

(Write a value to two decimal places. Ex: W rite “93” in case of

0.93mW.)

5. Click VWDC1, then LD turns on.

6. Measure the LD power with a LD power meter. W rite its value

to the blank of “Write Power” column.

(Write a value to two decimal places. Ex: W rite “1234” in case

of 12.34mW.)

7. Click LD Off to turn LD off.

8. Click Setup, then setting is over and a result is displayed.

(“OK”/“NG” is displayed for every items.)

9. Click X to close “Laser Power Setup (Manual)” window.

Adjustment Data Check

Check if the error has occurred on reading “CD-R LD POWER SETTING” value.

Procedure:

1. Select “Calibration” on “Calibration” pull-down menu, then “Read Calibration Results” window is open.

2. Click Read, then the calibration data are displayed.

3. Data specification

CD-R VRDC DAC: 30-150

VWDC1: 48-150

VWDC2: 50-126

VWDC2 Offset: 0-35

4. Click X to close “Read Calibration Results” window.

Fig 7 : Calibration menu windows

Fig 6 : Laser power setup window

Fig 8 : Read calibration results window

19

RCD-W7V

)

e

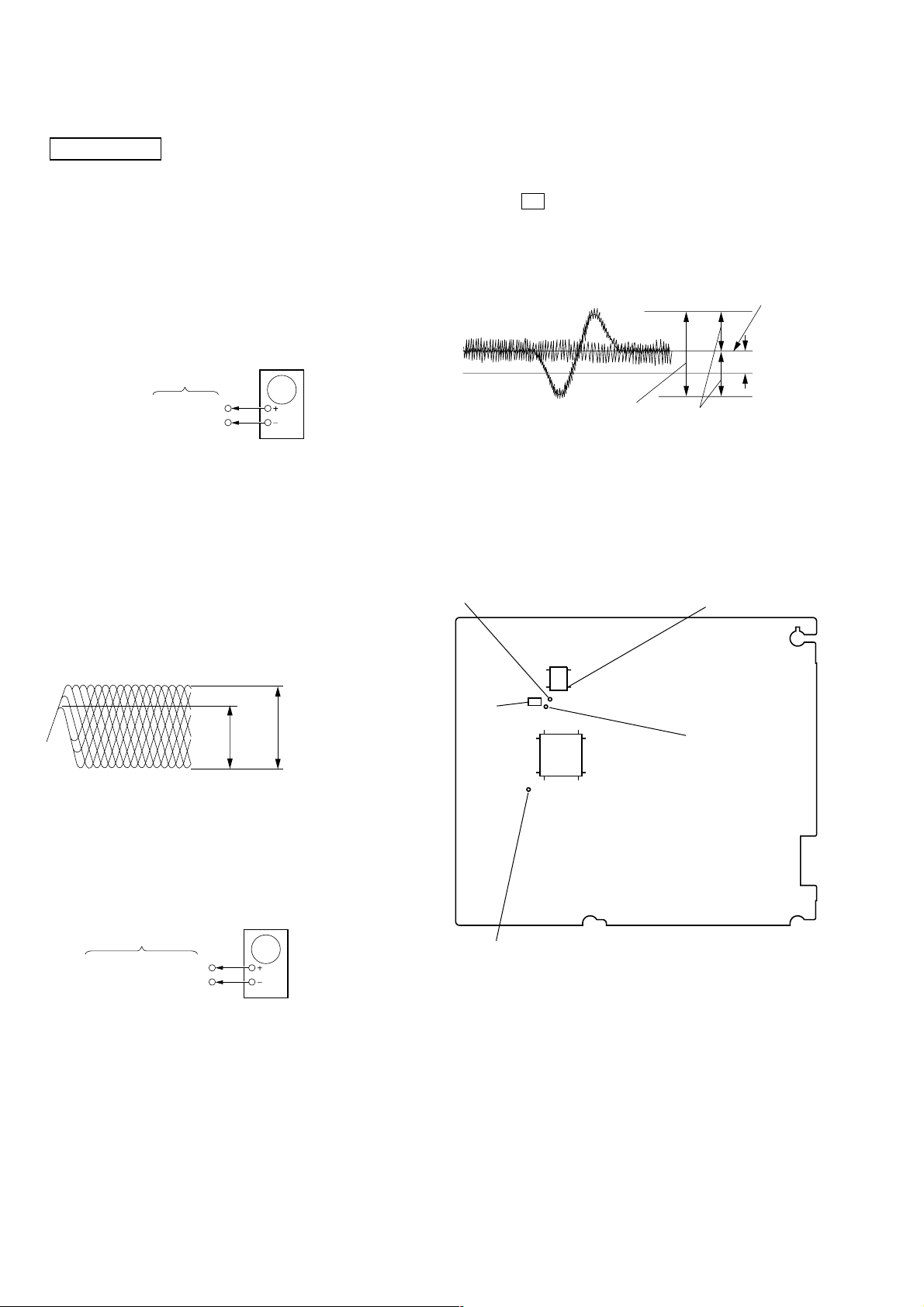

SERVO Check

DVD SECTION

Note :

1. DVD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use HLX-503 disc unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the following checks.

RF Level Check

oscilloscope

BD board

IC4B1 1 pin

IC4B2 1 pin

Procedure :

1. Connect oscilloscope to IC4B1 1 pin and IC4B2 1 pin.

2. Turned Power switch on.

3. Load a disc (HLX-503) and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

Note : Clear RF signal waveform means that the shape “ ◊ ” can be clearly

distinguished at the center of the waveform.

Procedure :

1. Connect oscilloscope to TP4B3 (IC4B2 1 pin) and IC4B2 1

pin.

2. Turned Power switch on.

3. Load a disc (HLX-503) and playback the number one track.

4. Press the X button. (Becomes the 1 track jump mode.)

5. Confirm that the level B and A (DC voltage) on the oscilloscope waveform.

1 track jump waveform

0V

level=1.3±0.6Vp-p

Specified level: –– × 100=less than ±22%

A

B

B

symmetry

center of

waveform

A (DC voltage

Adjustment Location:

[BD BOARD] (SIDE B)

TP4B3 (TE)

VC (IC4B2 1 pin)

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

3T

3T= 0.55

11T= 0.90

E-F Balance (1 Track jump) Check

BD board

TP4B3 (IC4B1 ra pin)

IC4B2

1

pin

oscilloscop

11T

±

0.07Vp-p

±

0.13Vp-p

IC4B2

5

8

R4B4

33

49

IC4B1

64

1

TP (IC4B1 1 pin)(RF)

4

1

48

32

17

16

TP4B2 (FE)

20

RCD-W7V

e

)

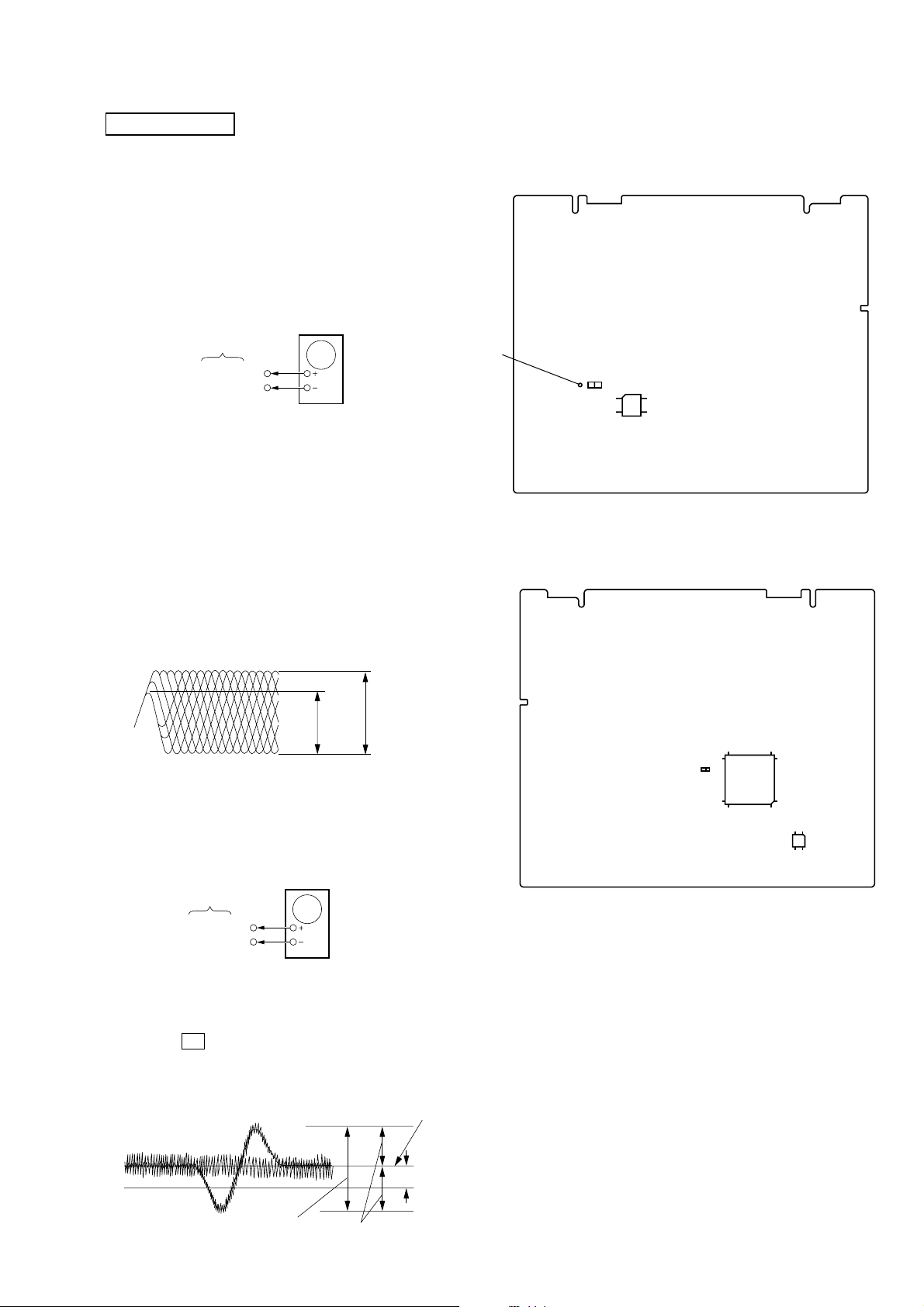

CD-R SECTION

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the following checks.

RF Level Check

oscilloscope

BD-R board

TP(RRF)

1

IC302

pin

Procedure :

1. Connect oscilloscope to TP (RRF) and IC302 1 pin.

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

Note : Clear RF signal waveform means that the shape “ ◊ ” can be clearly

distinguished at the center of the waveform.

TP (TE1)

Adjustment Location:

[BD-R BOARD] (SIDE B)

R369

1

4

IC306

[BD-R BOARD] (SIDE A)

8

5

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

3T

3T= 0.55

11T= 0.90

11T

±

0.07Vp-p

±

0.13Vp-p

E-F Balance (1 Track jump) Check

oscilloscop

BD-R board

TP(TE1)

1

IC302

pin

Procedure :

1. Connect oscilloscope to TP (TE1) and IC302 1 Pin.

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback the number five track.

4. Press the X button. (Becomes the 1 track jump mode.)

5. Confirm that the level B and A (DC voltage) on the oscilloscope waveform.

1 track jump waveform

center of

waveform

R368

51

75

50

IC301

76

26

100

25

1

4

1

IC302

5

8

0V

level=1.3±0.6Vp-p

Specified level: –– × 100=less than ±22%

A

B

B

A (DC voltage

symmetry

21

RCD-W7V

C

These are omitted

EB

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed

in each block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• % : indicates tolerance.

¢

•

• C : panel designation.

Note:

The components identified by mark ! or dotted line

with mark ! are critical for safety.

Replace only with part number specified.

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

• AC voltage readings in the bias oscillator with a level

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

: internal component.

meter.

under no-signal conditions.

no mark : STOP

( ) : PLAY

< > : REC (CD-R only)

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

4

W or less unless otherwise

SECTION 6

DIAGRAMS

• Signal path.

F : DVD

J : CD

c : CD (digital)

I : CD REC

L : CD REC (digital)

g : VIDEO

For printed wiring boards.

Note:

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

• Indication of transistor

C

Q

These are omitted

EB

22

Loading...

Loading...