Page 1

RCD-W500C

SERVICE MANUAL

Ver 1.2 2004. 08

Model Name Using Similar Mechanism NEW

CD Section

CD-R/CD-RW

Section

CD Mechanism Type CDM53L-30B61M

Base Unit Type BU-30BBD61M

Optical Pick-up Type A-MAX.4T

Model Name Using Similar Mechanism RCD-W100

CD Mechanism Type CDM65-RBD2

Base Unit Type RBD2

Optical Pick-up Type KRM-220CAA

US Model

Canadian Model

DECK A (the CD player section)

System Compact disc digital audio

Laser Semiconductor laser

Playable discs CD, CD-R, CD-RW

Frequency response 20 Hz – 20,000 Hz

Signal to Noise Ratio Over 98 dB during play

Wow and flutter Below measurable limit

DECK B (the CD-R and CD-RW

recording section)

System Compact disc digital audio

Laser Semiconductor laser

Playable discs CD, CD-R, CD-RW

Recordable discs CD-R, CD-RW (for

Frequency response 20 Hz - 20,000 Hz

Signal to Noise Ratio Over 98 dB during play

Wow and flutter Below measurable limit

system

λ

( = 780 nm)

Emission duration:

continuous

(±0.5 dB)

system

λ

( = 780 nm)

Emission duration:

continuous

Audio)

(±0.5 dB)

SPECIFICATIONS

Inputs

ANALOG IN Impedance: 47 kilohms

(Phono jacks) Rated input: 500 mVrms

DIGITAL OPTICAL IN

(Square optical connector jack)

Outputs

ANALOG OUT Rated output: 2 Vrms

(Phono jacks) Load impedance: over

DIGITAL OPTICAL OUT

(Square optical connector jack)

PHONES Load impedance: 32 ohms

(Stereo phone jack) Rated output: 12mW

Minimum input:

250 mVrms

Optical wavelength:

660 nm

10 kilohms

Wavelength: 660 nm

Rated output: –18 dBm

COMPACT DISC RECORDER

General

Power requirements 120 V AC, 60 Hz

Power consumption 25 W

Dimensions (approx.) (w/h/d) incl. projecting parts

and control 430 × 108 × 399 mm

Mass (approx.) 6.8 kg (15 lbs)

Supplied accessories

• Audio connecting cords

Phono plug × 2 (red/white) y Phono plug ×

2 (red/white) (2)

• Remote commander (remote) (1)

• R6 (size AA) batteries (2)

Design and specifications are subject to change

without notice.

( 17 × 4

3

/8 × 15 3/4 inch)

9-877-447-03

2004H16-1

© 2004.08

Sony Corporation

Audio Group

Published by Sony Engineering Corporation

Page 2

RCD-W500C

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

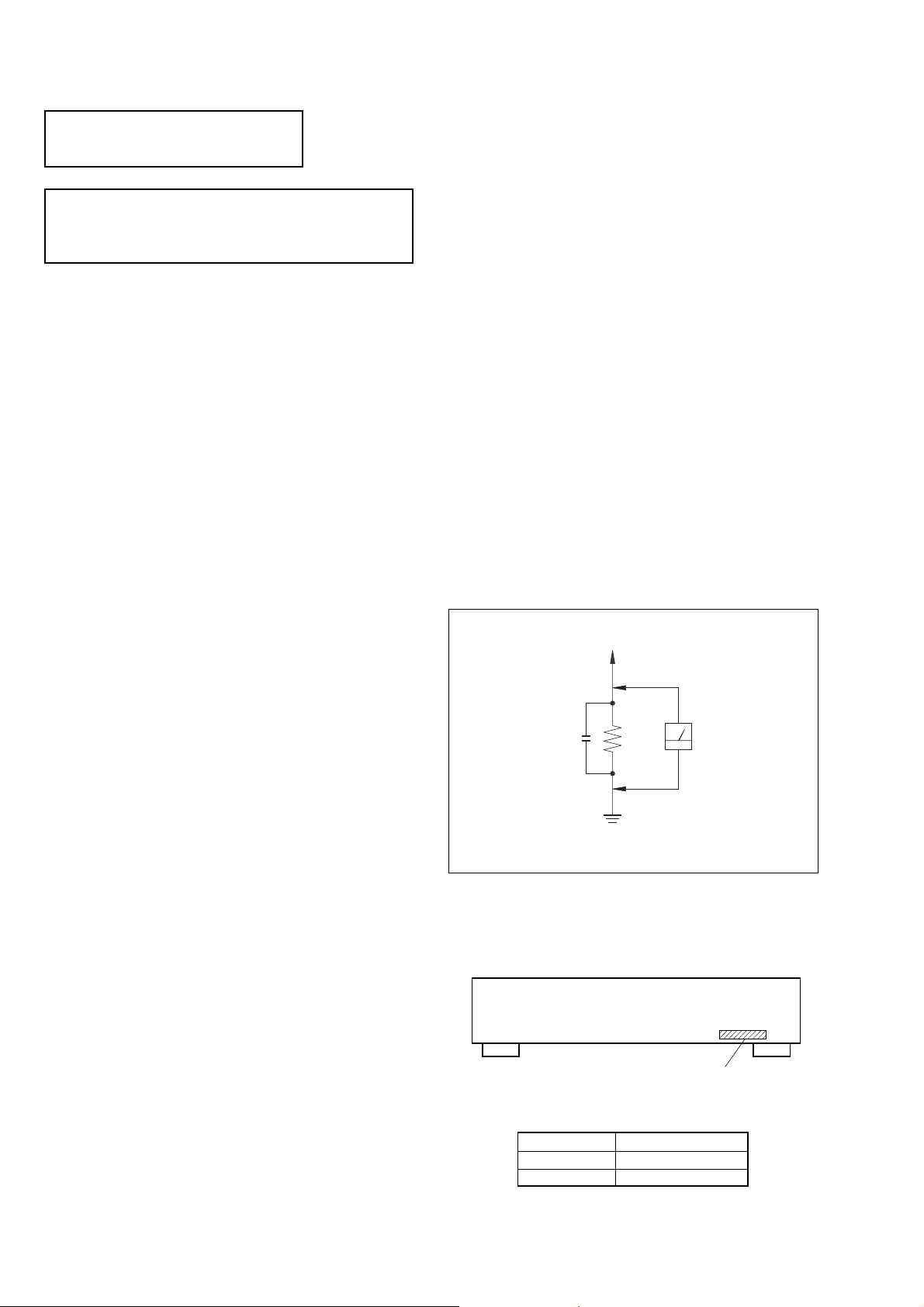

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

To Exposed Metal

Parts on Set

0.15 µF

Fig. A. Using an A C v oltmeter to check A C leakage.

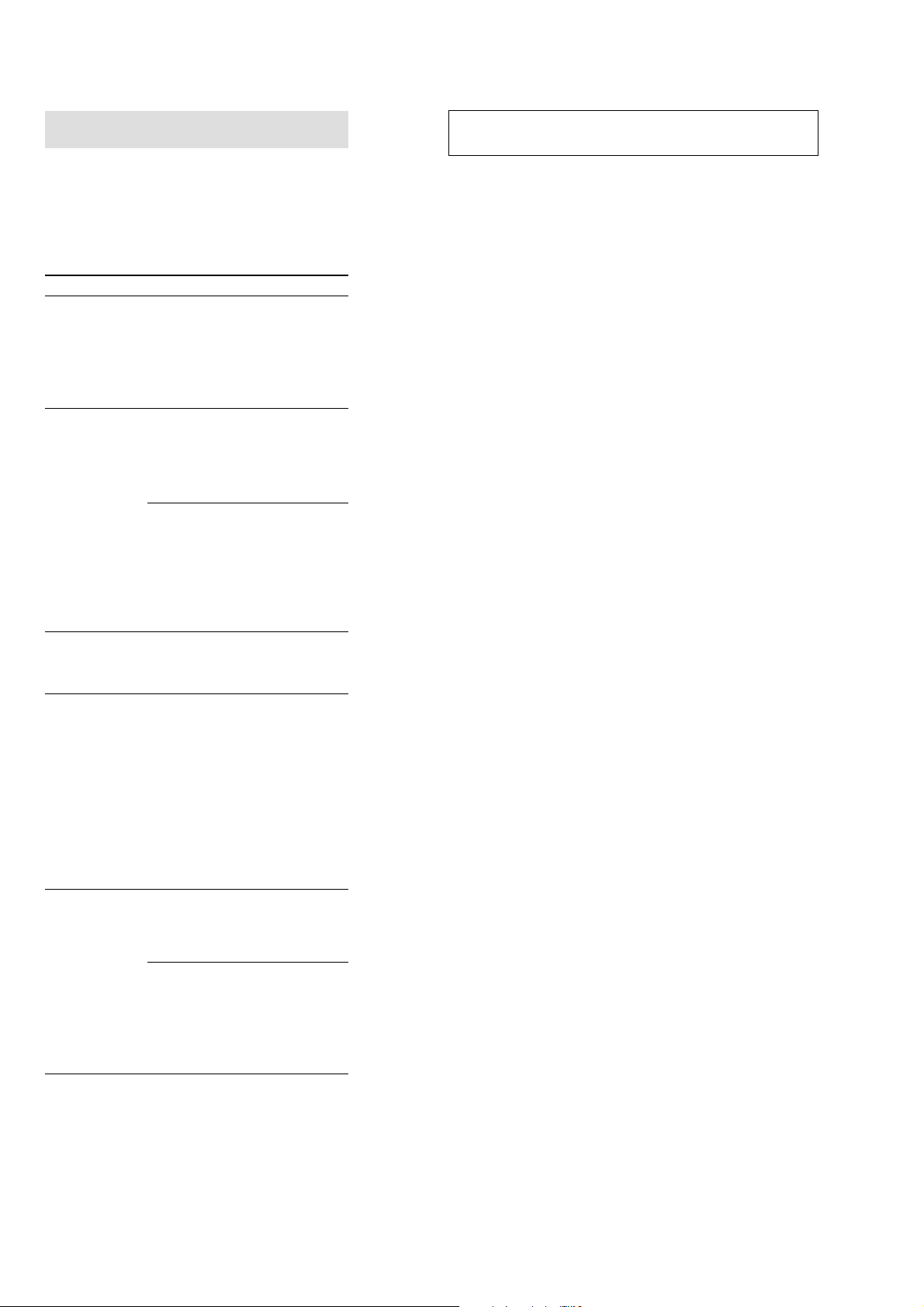

MODEL IDENTIFICATION

— BACK PANEL —

1.5 kΩ

Earth Ground

AC

Voltmeter

(0.75 V)

Parts No.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

2

PA R TS No. MODEL

4-246-074-0s

4-246-074-1sUSCanadian

Page 3

RCD-W500C

TABLE OF CONTENTS

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

1. SERVICING NOTE·····················································4

2. GENERAL ···································································5

3. DISASSEMBLY·························································· 6

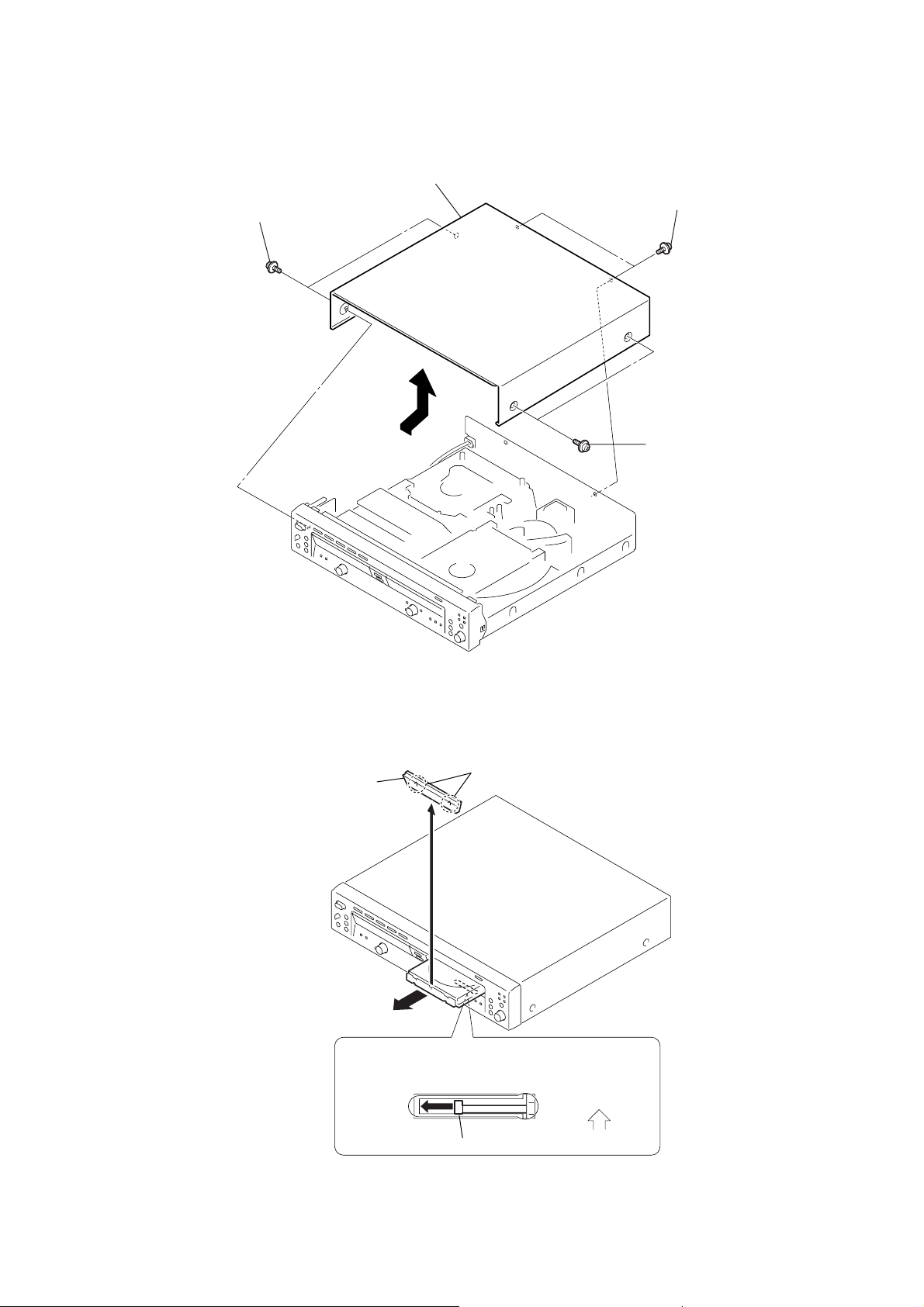

3-1. Case (409538) ······························································· 7

3-2. Loading Panel (CDR) ··················································· 7

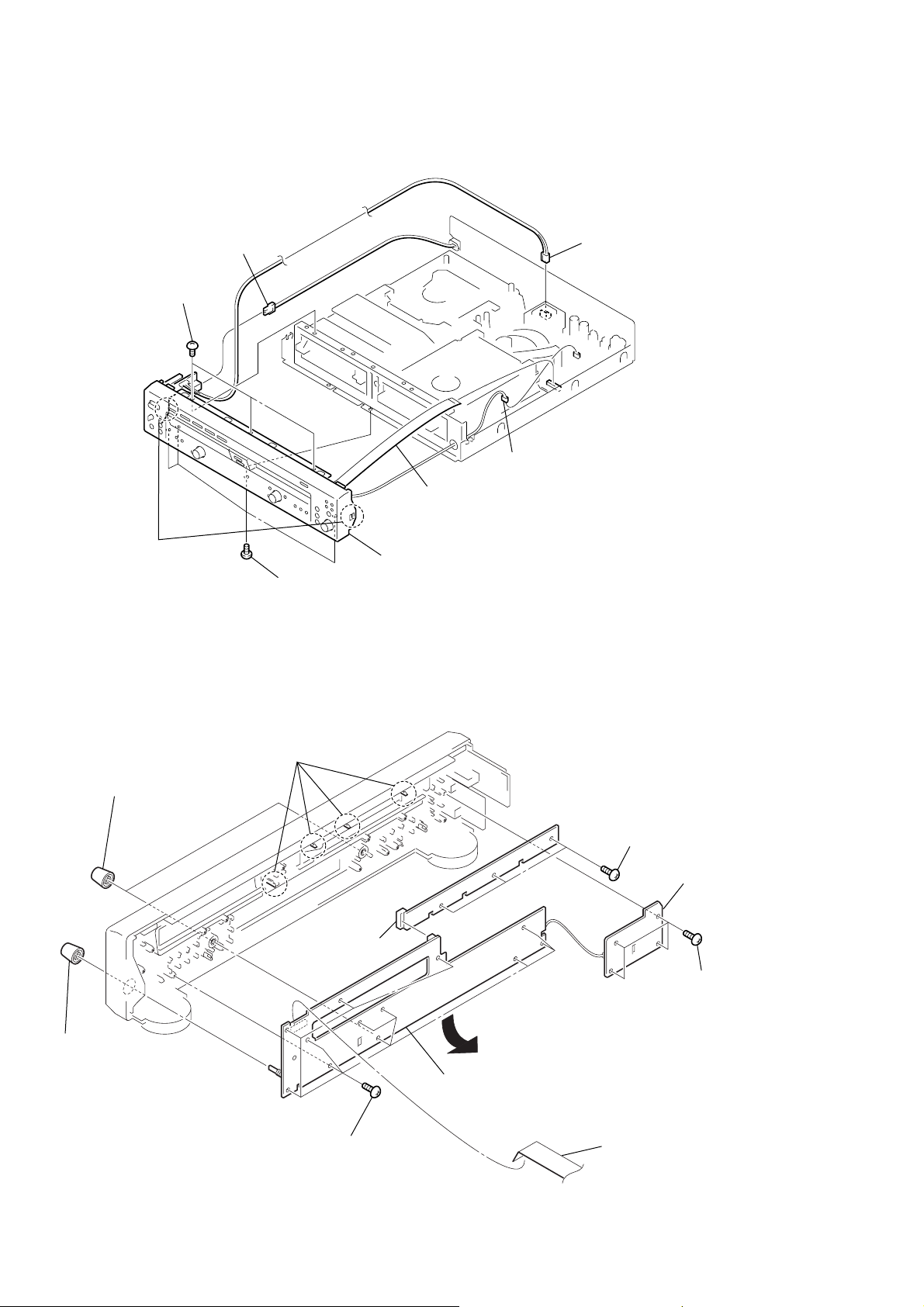

3-3. Front Panel Section ······················································· 8

3-4. SW Board, LED Board, DISP Board···························· 8

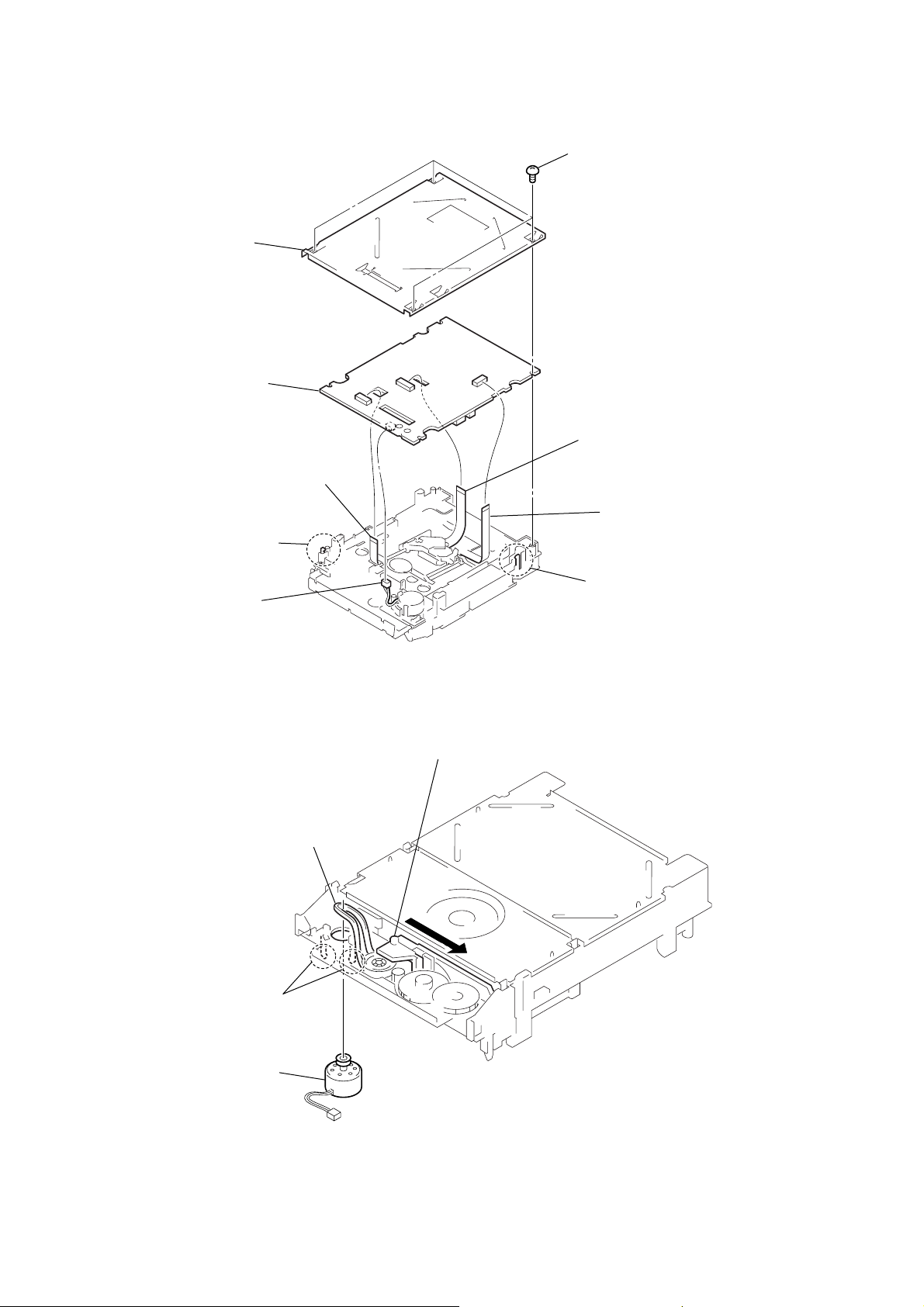

3-5. CD Mechanism Deck (CDM65-RBD2) ······················· 9

3-6. Tray ··············································································· 9

3-7. CDR Board ································································· 10

3-8. Motor Assy (Loading) (M201) ··································· 10

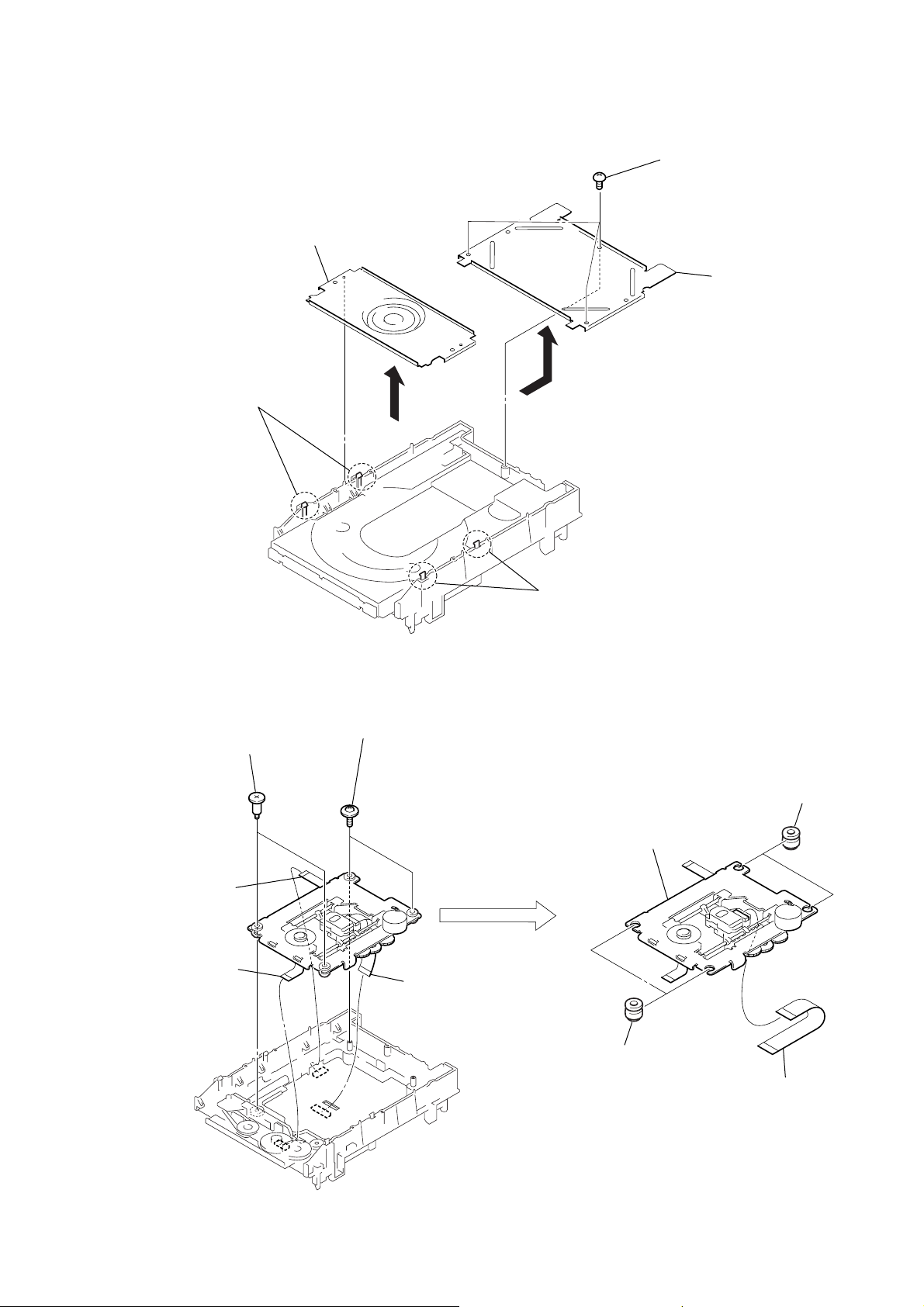

3-9. Holder (MG) Sub Assy, Dust Cover ··························· 11

3-10. Optical Pick-Up (KRM-220CAA) ······························11

3-11. Cam (CH) ···································································· 12

3-12. MAIN Board ······························································· 12

3-13. CD Mechanism Deck (CDM53L-30B61M) ··············· 13

3-14. Fitting Base (Magnet) Assy ········································ 13

3-15. CLAMP MOTOR Board,

Motor (Clamp) Assy (M701) ······································ 14

3-16. Fitting Base (Guide) Assy, Bracket (Chassis)············· 14

3-17. Tray (Sub) ··································································· 15

3-18. Chassis (Mold B) ························································ 15

3-19. LOAD MOTOR Board,

Motor (Loading) Assy (M702) ··································· 16

3-20. Stocker Section ··························································· 16

3-21. Slider (Selection), Tension Spring (Shutter),

Slider (Shutter)···························································· 17

3-22. Gear (Gear A), Gear (Gear B), Gear (U/D Slider) ······ 17

Precaution During Gear (Gear U/D Slider),

Gear (Gear B), Gear (Gear A) Installation·················· 18

3-23. Gear (Chucking) ························································· 18

3-24. BD Board ···································································· 19

3-25. Optical Block Section ················································· 19

4. TEST MODE ···································································· 20

5. ELECTRICAL ADJUSTMENTS

CD SECTION ····························································· 23

CD-R/RW SECTION·················································· 25

6. DIAGRAMS······································································ 55

6-1. Block Diagrams – CD-R Section – ··························· 56

6-2. Printed Wiring Boards – BD Section – ······················· 59

6-3. Schematic Diagrams – BD Section –·························· 60

6-4. Printed Wiring Boards

6-5. Schematic Diagrams

6-6. Printed Wiring Boards – CD-R Section (Side A) – ···· 63

6-7. Printed Wiring Boards – CD-R Section (Side B) – ···· 64

6-8. Schematic Diagrams – CD-R Section (1/4) – ············· 65

6-9. Schematic Diagrams – CD-R Section (2/4) – ············· 66

6-10. Schematic Diagrams – CD-R Section (3/4) – ············· 67

6-11. Schematic Diagrams – CD-R Section (4/4) – ············· 68

6-12. Printed Wiring Boards – MAIN Section (Side A) – ··· 69

6-13. Printed Wiring Boards – MAIN Section (Side B) – ··· 70

6-14. Schematic Diagrams – MAIN Section (1/2) – ············71

6-15. Schematic Diagrams – MAIN Section (2/2) – ············72

6-16. Printed Wiring Boards – LED Section –····················· 73

6-17. Schematic Diagrams – LED Section – ······················· 74

6-18. Printed Wiring Boards – DISPLAY Section – ············ 75

6-19. Schematic Diagrams – DISPLAY Section –···············76

6-20. IC Block Diagrams ····················································· 77

6-21. IC Pin Function Description ······································· 84

– CD Section – ······························· 57

– POWER/DISPLAY Section – ······ 58

– SENSER/MOTOR/SW Section – ····· 61

– SENSER/MOTOR/SW Section – ····· 62

7. EXPLODED VIEWS

7-1. Case Section ·································································· 94

7-2. Front Panel Section ······················································· 95

7-3. Chassis Section ····························································· 96

7-4. Overall Section (CDM53L-30B61M) ··························· 97

7-5.

Chassis (Mold) Assy Section (CDM53L-30B61M)··········

7-6. Chassis Section (CDM53L-30B61M) ·························· 99

7-7. Base Unit Section (BU-30BBD61M) ························· 100

7-8. CDM65-RBD2 ····························································101

98

8. ELECTRICAL PARTS LIST····································· 102

3

Page 4

RCD-W500C

SECTION 1

SERVICING NOTE

Self-diagnosis Function

When the self-diagnosis function is activated to

prevent the player from malfunctioning, three

character service numbers in a combination

with a message appears in the display. In this

case, check the following table.

Message

C12/

Cannot Copy

C13/

Rec Error

C14/

TOC Error

C41/

Cannot Copy

C71/

Din Unlock

Explanation

You are trying to record a disc that

cannot be played back in DECK-A

or with an external device, such as

CD-ROM or VIDEO CD.

• Remove the disc, and then insert a

music CD for playback.

Recording has not been completed

successfully because of vibration.

• Relocate the unit in a place free of

vibration and restart the recording

again.

The disc you try to record is

excessively dirty (such as oilstained or finger marked) or

scratched. Or the disc is not

normal.

• Replace the disc with another one

and restart the recording again.

The unit did not read the TOC

information.

• Insert other discs.

The sound source you are trying to

record is a copy of a commercial

music software. Or you are trying

to record on a CD-R/CD-RW

digitally.

• Because of the restriction of the

Serial Copy Management System,

you cannot record a copy of a

commercial music software.

Neither can you record a CD-R/

CD-RW digitally.

If this message is displayed

momentarily, this is not an error. It

is caused by the digital signal

during recording.

During recording of a digital sound

source, the connecting cable has

been disconnected or the player of

the sound source has turned off.

• Connect the cable or turn on the

digital player.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repain parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

The emission check enables continuous checking of the S curve.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output three times.

4

Page 5

e;

wl

1

2

3

SECTION 2

GENERAL

4

5

6

RCD-W500C

978 q;

qa

qs

qd

wgwh ws

1 POWER button

2 H button

3 DISC 1 to DISC 5 A button and indicators

4 CD SYNCHRO NORMAL button

5 CD SYNCHRO HIGH button

6 OPEN/CLOSE button

7 H button

8 INPUT button

9 FINALIZE button

q; ERASE button

qa SBM button and indicator

qs REC z button

qgqhqjqkqlw;wd wawfwjwk

qh PLAY MODE button

qj TIME button

qk DISPLAY button

ql YES button

w; l AMS L knob

wa CLEAR button

ws MENU/NO button

wd l AMS L knob

wf ALBUM button

wg PLAY MODE button

wh TIME button

wj x button

qf

qd X button

qf REC LEVEL knob

qg x button

wk PHONES jack

wl X button

e; PHONE LEVEL knob

5

Page 6

RCD-W500C

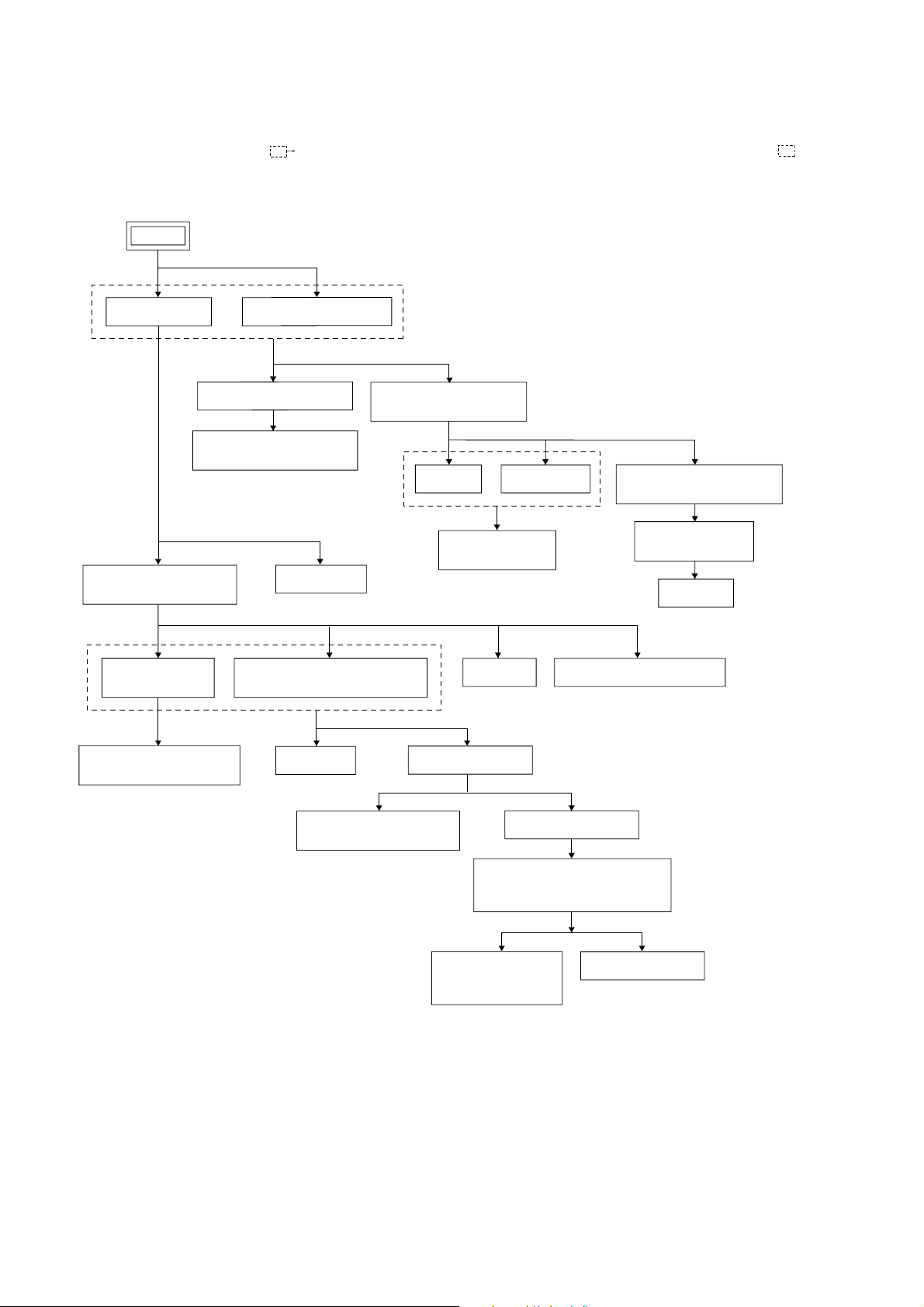

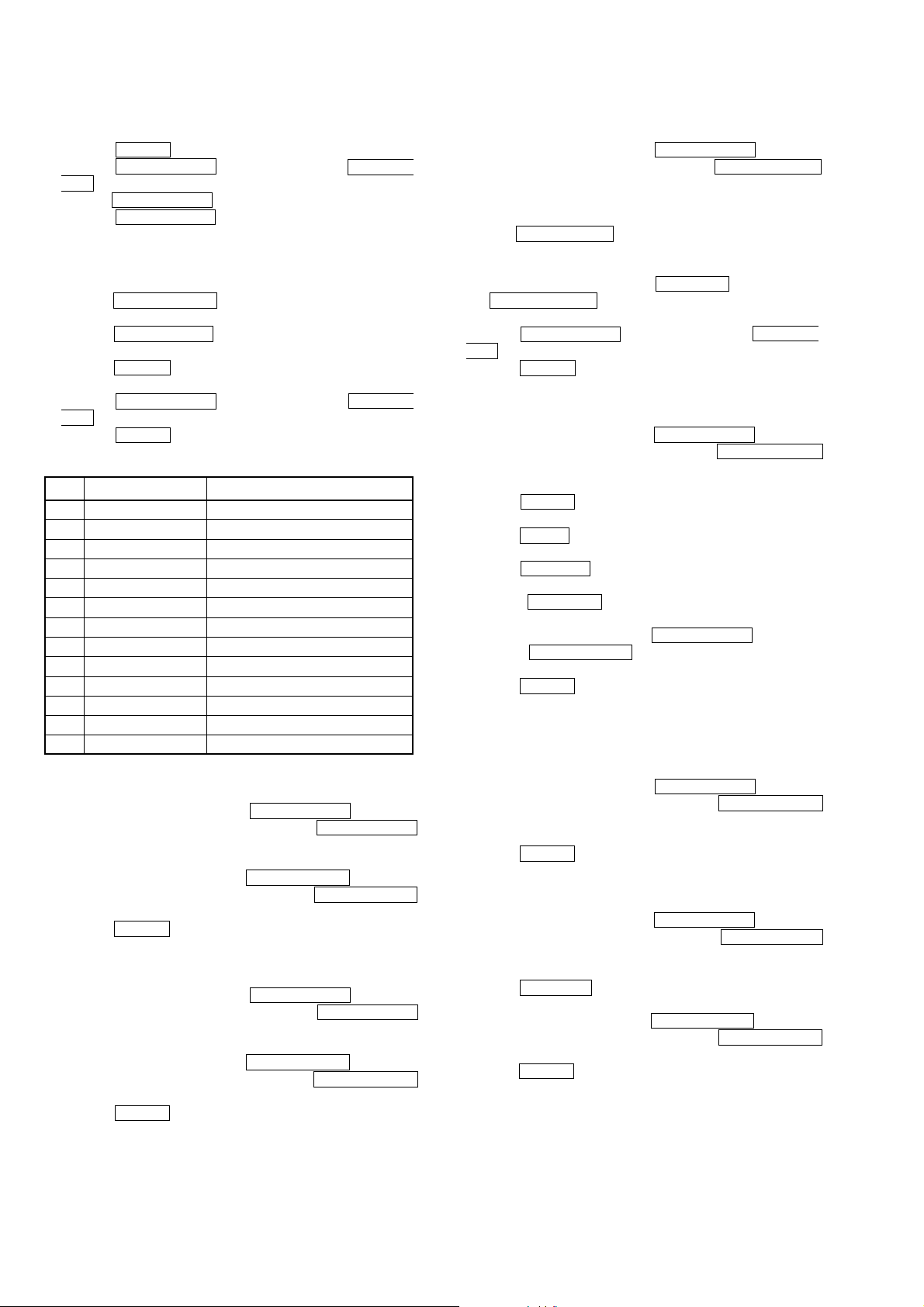

DISASSEMBLY

Note : • Disassemble the unit in the order as shown below.

•This set can be disassemble according to the following sequence.

The dotted square with arrow ( ) prompts you to move to the next job when all of the works within the dotted square ( )

are completed.

SET

SECTION 3

CASE (409538)

FRONT PANEL SECTION

SW BOARD, LED BOARD,

DISP BOARD

CD MECHANISM DECK

(CDM53L-30B61M)

FITTING BASE

(MAGNET) ASSY

CLAMP MOTOR BOARD,

MOTOR (CLAMP) ASSY

LOADING PANEL (CDR)

CD MECHANISM DECK

(CDM65-RBD2)

MAIN BOARD

FITTING BASE (GUIDE) ASSY,

BRACKET (CHASSIS)

TRAY (SUB)

TRAY

MOTOR ASSY

(LOADING) (M201)

CHASSIS (MOLD B)

CDR BOARD

BD BOARD

HOLDER (MG) SUB ASSY,

DUST COVER

OPTICAL PICK-UP

(KRM-220CAA)

CAM (CH)

OPTICAL BLOCK SECTION

LOAD MOTOR BOARD,

MOTOR (LOADING) ASSY

GEAR (GEAR A),

GEAR (GEAR B),

GEAR(U/D SLIDER)

STOCKER SECTION

SLIDER (SELECTION),

TENSION SPRING (SHUTTER),

SLIDER (SHUTTER)

GEAR (CHUCKING)

6

Page 7

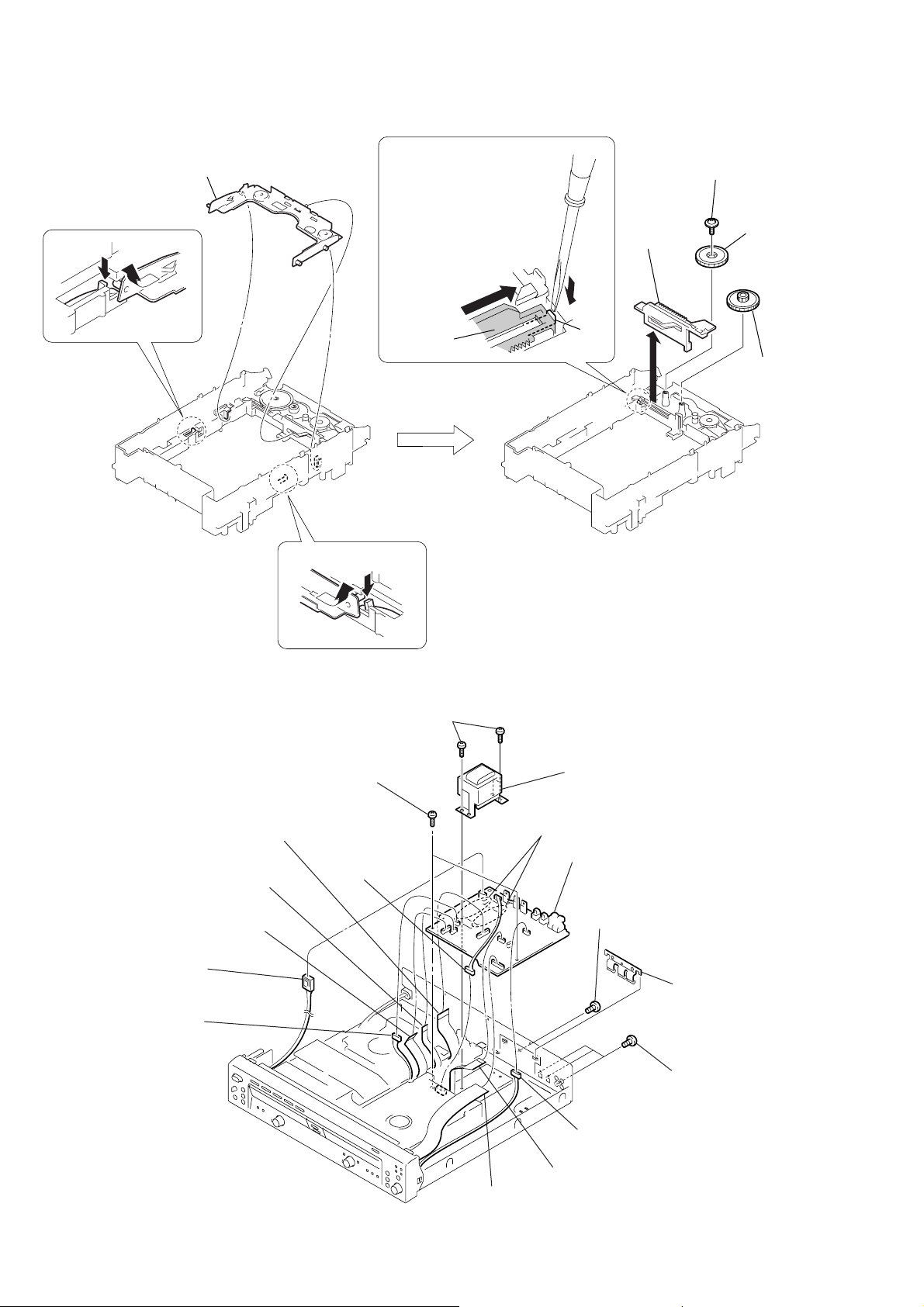

Note : Follow the disassembly procedure in the numerical order given.

3-1. Case (409538)

4

case (409538)

2

two

screws

(case 3 TP2 3

× 8

)

3

two

screws

(case 3 TP2 3

1

two

screws

(case 3 TP2 3

RCD-W500C

× 8

)

× 8

)

3-2. Loading Panel (CDR)

4

loading panel

two hooks

(CDR)

3

2

CD mechanism deck (CDM65-RBD2)

1

Slide the lever (cam (CH)) to the direction of arrow.

Front panel side

lever (cam (CH))

7

Page 8

RCD-W500C

)

3-3. Front Panel Section

4

connector (2pin) (CN920)

5

three

(+BVTP 3

screws

×

8)

1

connector (2pin) (CN900

2

connector (3pin) (CN690)

7

t

wo claws

6

four screws

(+BVTP 3

3-4. SW Board, LED Board, DISP Board

7

four

claws

2

two knobs (AMS)

8

LED board

×

8

front panel section

8)

3

wire (flat type)

(21core) (CN671)

5

three

(+BVTP 2.6

screws

4

SW board

×

8)

1

8

knob (AMS)

6

twelve

(+BVTP 2.6

screws

×

q;

8)

DISP board

3

(+BVTP 2.6

9

wire (flat type)

(21core) (CN700)

four

screws

×

8)

Page 9

3-5. CD Mechanism Deck (CDM65-RBD2)

)

1

Slide the lever (cam (CH)) to the direction of arrow.

4

t

ray

2

Pull the tray while pressing the claw of

the chassis in the direction of the arrow.

3

Pull the tray while pressing the claw of the chassis and the claw

of the tray in the direction of the arrow.

front panel side

lever (cam (CH))

claw

claw

chassis

chassis

4

CDR mechanism deck

(CDM65-RBD2)

1

connector

(4pin) (CN111)

3

four

screws (+BVTP 3

×

8)

2

wire (flat type)

(11core) (CN630

RCD-W500C

3-6. Tray

9

Page 10

RCD-W500C

3-7. CDR Board

2

bottom plate

9

CDR board

5

(11core) (CN103)

flexible flat cable

1

four

screws

(+BVTP 2.6

3

flexible flat cable

(32core) (CN101)

×

8)

6

c

law

8

c

onnector

(2pin) (CN104)

3-8. Motor Assy (Loading) (M201)

2

Remove the belt (loading) from the

pulley of the motor assy.

4

flexible flat cable

(11core) (CN102)

7

c

law

1

Slide the cam (CH) to the direction of arrow.

10

3

t

wo claws

4

m

otor assy

(loading) (M201)

Page 11

3-9. Holder (MG) Sub Assy, Dust Cover

r

)

3

holder (MG) sub assy

1

two claws

4

three s

(+BVTP 2.6

crews

5

dust cove

RCD-W500C

×

8)

3-10. Optical Pick-Up (KRM-220CAA)

4

two step screws

2

flexible flat cable

(11core) (CN102)

1

flexible flat cable

(11core) (CN103)

5

((2X9) (G with), +p tappin)

two screws

3

flexible flat cable

(32core) (CN101)

2

two claws

9

optical pick-up

(KRM-220CAA)

6

two insulators (main)

7

two insulators (main)

8

flexible flat cable

(32core) (from optical device

11

Page 12

RCD-W500C

)

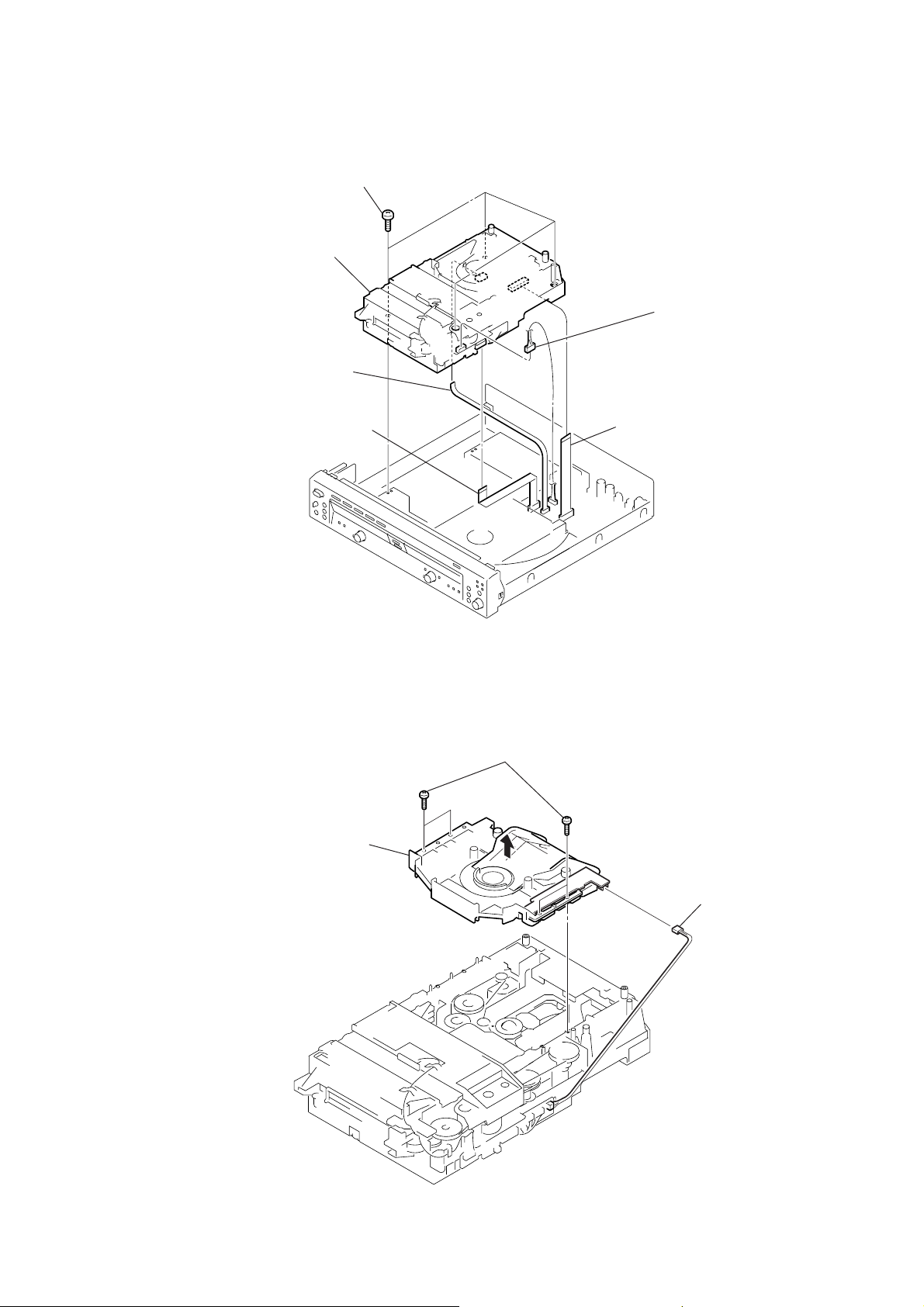

3-11. Cam (CH)

5

holder (BU) sub assy

1

1

1

2

Slide the cam (CH) to the

9

direction of arrow

pressing the claw.

A

A

while

6

(+PTPWH 2.6

qa

cam (CH)

screw

7

×

8)

g

ear (C)

3-12. MAIN Board

1

4

qf

two

screws

(+BVTT 3

cam (CH)

1

3

qd

four

screws

(+BVTT 3

×

6)

× 6

claw

q;

)

qh

power transformer

8

g

ear (B)

6

(25core) (CN660)

7

wire (flat type)

(9core) (CN661)

8

wire (flat type)

(17core) (CN640)

5

connector

(2pin) (CN900)

9

connector

(5pin) (CN641)

wire (flat type)

4

connector

(4pin) (CN111)

qg

1

wire (flat type)

(21core) (CN671)

Remove the soldering.

qj

MAIN board

q;

screw

(+BVTP 3

2

connector

(3pin) (CN690)

3

wire (flat type)

(11core) (CN630)

×

8)

qa

bracket

qs

three

(+BVTP 3

(TR)

screws

×

8

12

Page 13

3-13. CD Mechanism Deck (CDM53L-30B61M)

)

)

2

four

screws (+BVTP 3

6

CD mechanism deck

(CDM53L-30B61M)

4

wire (flat type)

(9core) (CN105)

5

wire (flat type)

(17core) (CN701)

×

RCD-W500C

8)

1

connector

(5pin) (CN713

3

wire (flat type)

(25core) (CN102)

3-14. Fitting Base (Magnet) Assy

3

fitting base (magnet) assy

2

four screws

(+BTTP M2.6 )

1

connector

(3pin) (CN710

13

Page 14

RCD-W500C

)

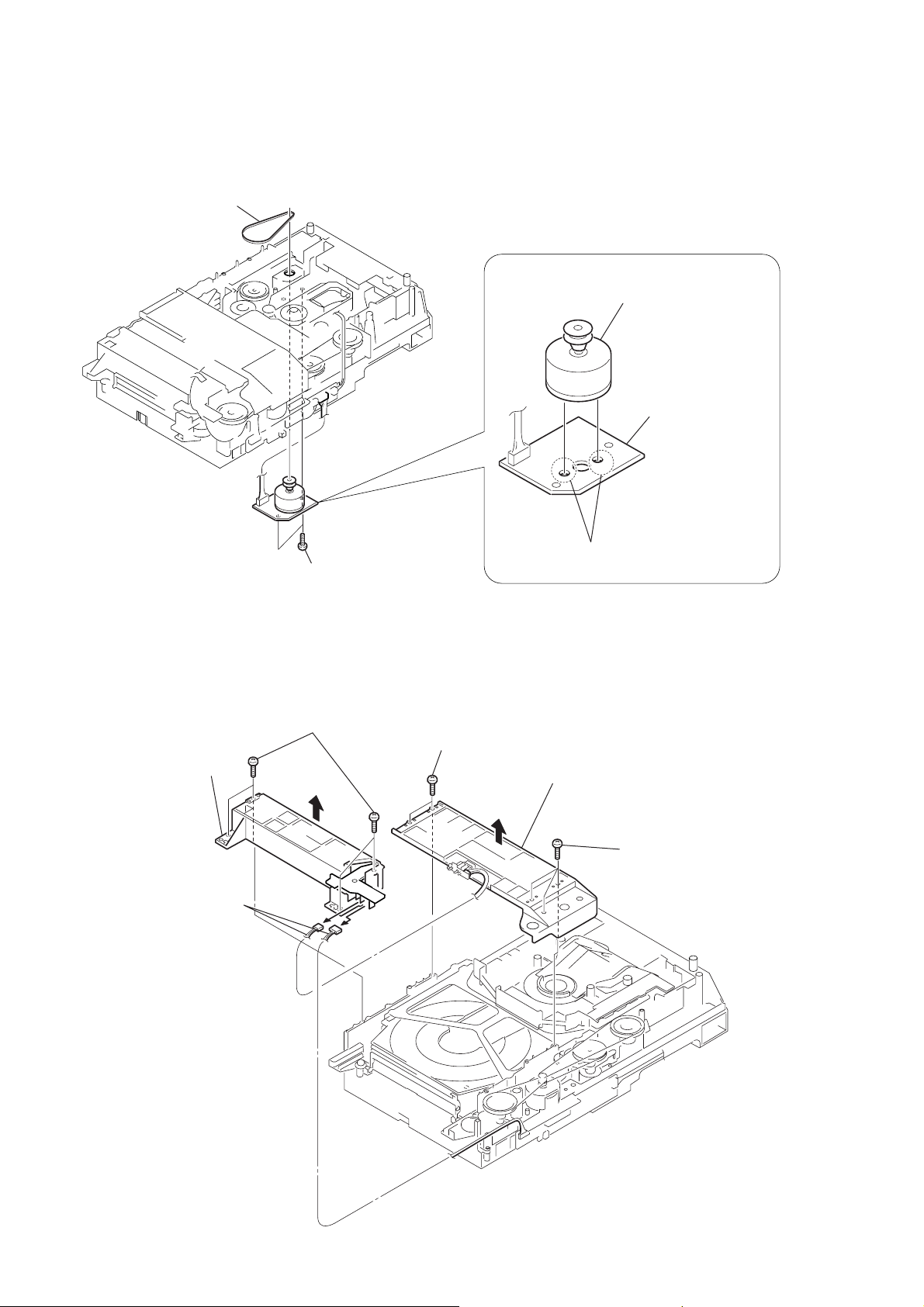

3-15. CLAMP MOTOR Board, Motor (Clamp) Assy (M701)

1

belt (mode)

5

motor (clamp)

assy (M701)

4

CLAMP MOTOR

board

2

two screws

(+BTTP M2.6)

3-16. Fitting Base (Guide) Assy, Bracket (Chassis)

2

3

fitting base

(guide) assy

1

two connectors

(CN709, 715)

four screws

(+BVTP 2.6

×

8)

4

(+BVTP 2.6

two screws

3

Remove the two solderings.

×

8)

6

bracket

(chassis)

5

three screws

(+BVTP 2.6 × 8

14

Page 15

3-17. Tray (Sub)

)

1

three screws

(+BTTP M2.6 )

2

Insert the gear (eject)

under the gear (LD

deceleration).

1

Insert the portion A of

chassis (mold B)

into the portion B of

slider (selection).

gear (eject)

portion A

portion B of

slider (selection)

3

g

ear (eject)

2

c

hassis (mold B)

chassis (mold B)

PRECAUTION DURING CHASSIS (MOLD B) INSTALLATION

1

Rotating the pulley (LD), shift the slider (selection) in the arrow A direction.

2

Rotating the pulley (mode) in the arrow direction, adjust the tray (sub) to be removed.

3

Rotating the pulley (LD), shift the slider (selection) in the arrow B direction.

4

Rotating the pulley (mode) in the arrow direction, remove the tray (sub) to be removed.

slider (selection)

pulley (LD)

RCD-W500C

stocker section

tray (sub)

3-18. Chassis (Mold B)

A

B

pulley (mode

15

Page 16

RCD-W500C

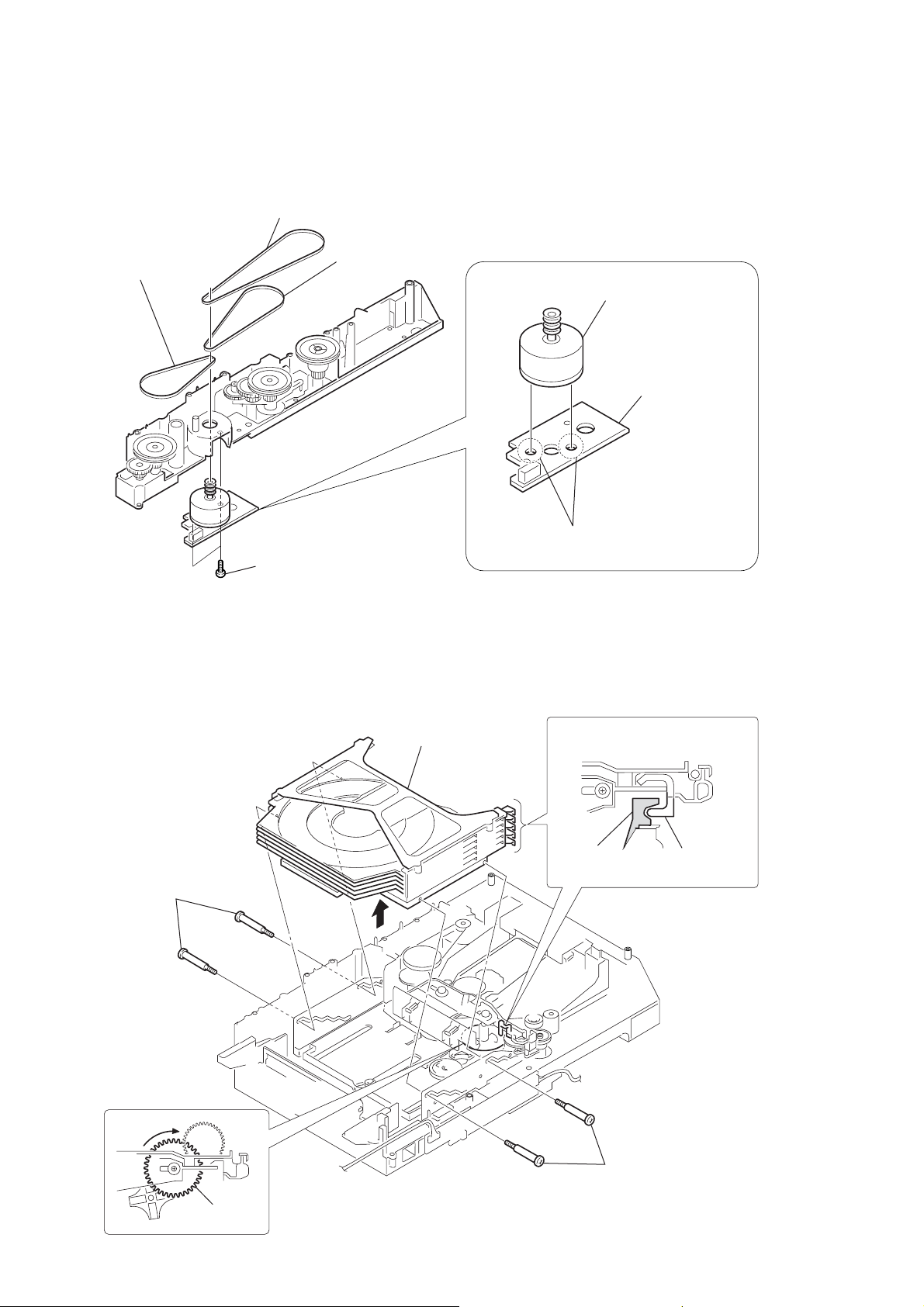

3-19. LOAD MOTOR Board, Motor (Loading) Assy (M702)

1

belt (communication)

2

3

belt (loading1)

belt (loading1)

7

motor (loading)

assy (M702)

6

LOAD MOTOR

board

3-20. Stocker Section

2

two step screws

4

two screws

(+BTTP M2.6)

4

stocker section

5

Remove the two solderings.

PRECAUTION DURING STOCKER

SECTION INSTALLATION

Hook the portion A of tray (SUB)

to the slider (selection).

portion A

of tray (SUB)

sticking of

slider (selection)

16

1

gear (gear A)

3

two step screws

Page 17

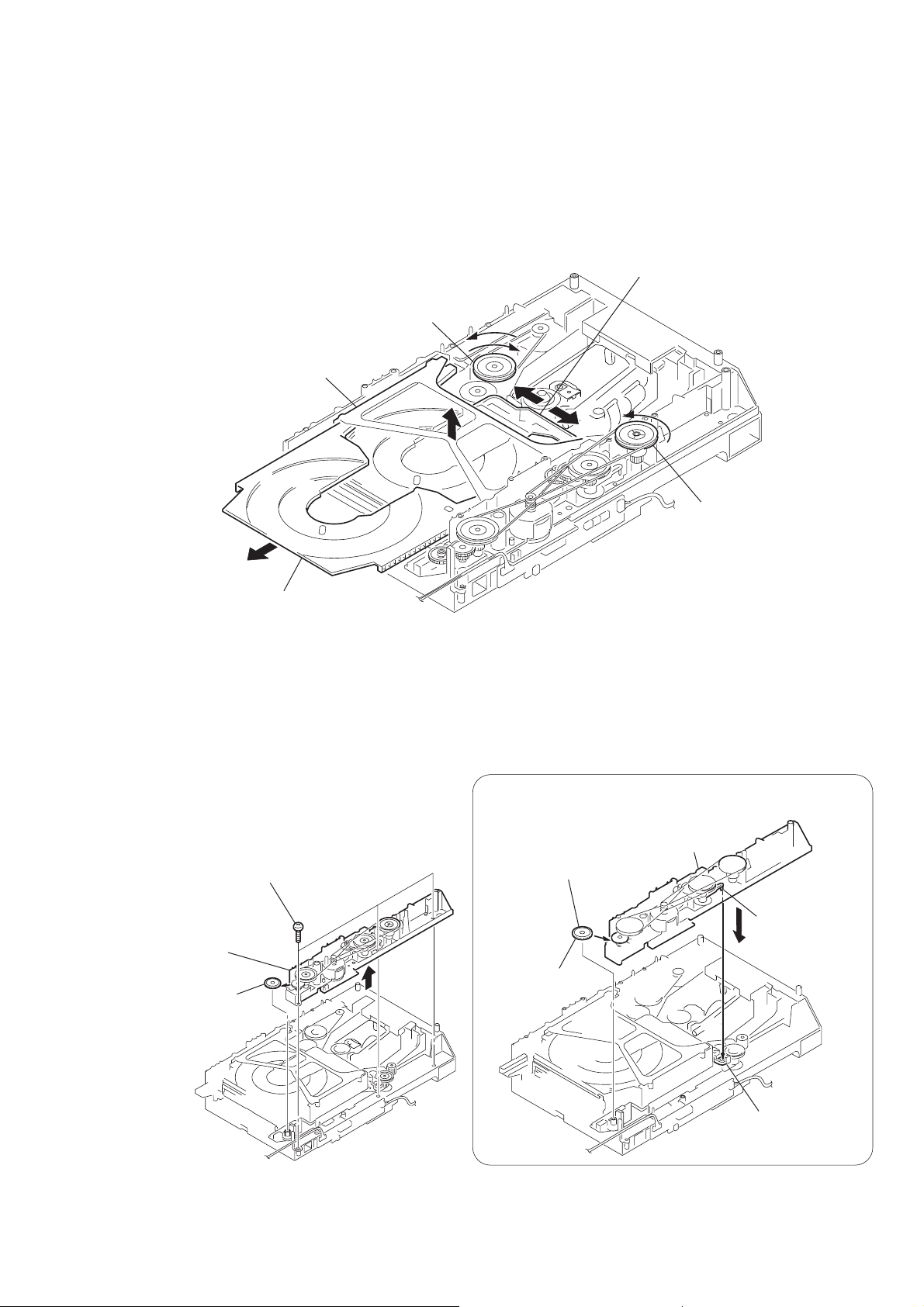

3-21. Slider (Selection), Tension Spring (Shutter), Slider (Shutter)

)

1

two floating screws

(+PTPWHM 2.6 x 6)

2

4

slider (selection),

tension spring (shutter),

slider (shutter)

washer

3

compression

spring (gear)

PRECAUTION DURING SLIDER

(SELECTION) INSTALLATION (1)

RCD-W500C

PRECAUTION DURING SLIDER

(SELECTION) INSTALLATION (2)

Insert the slider (selection)

into the portion A.

portion A

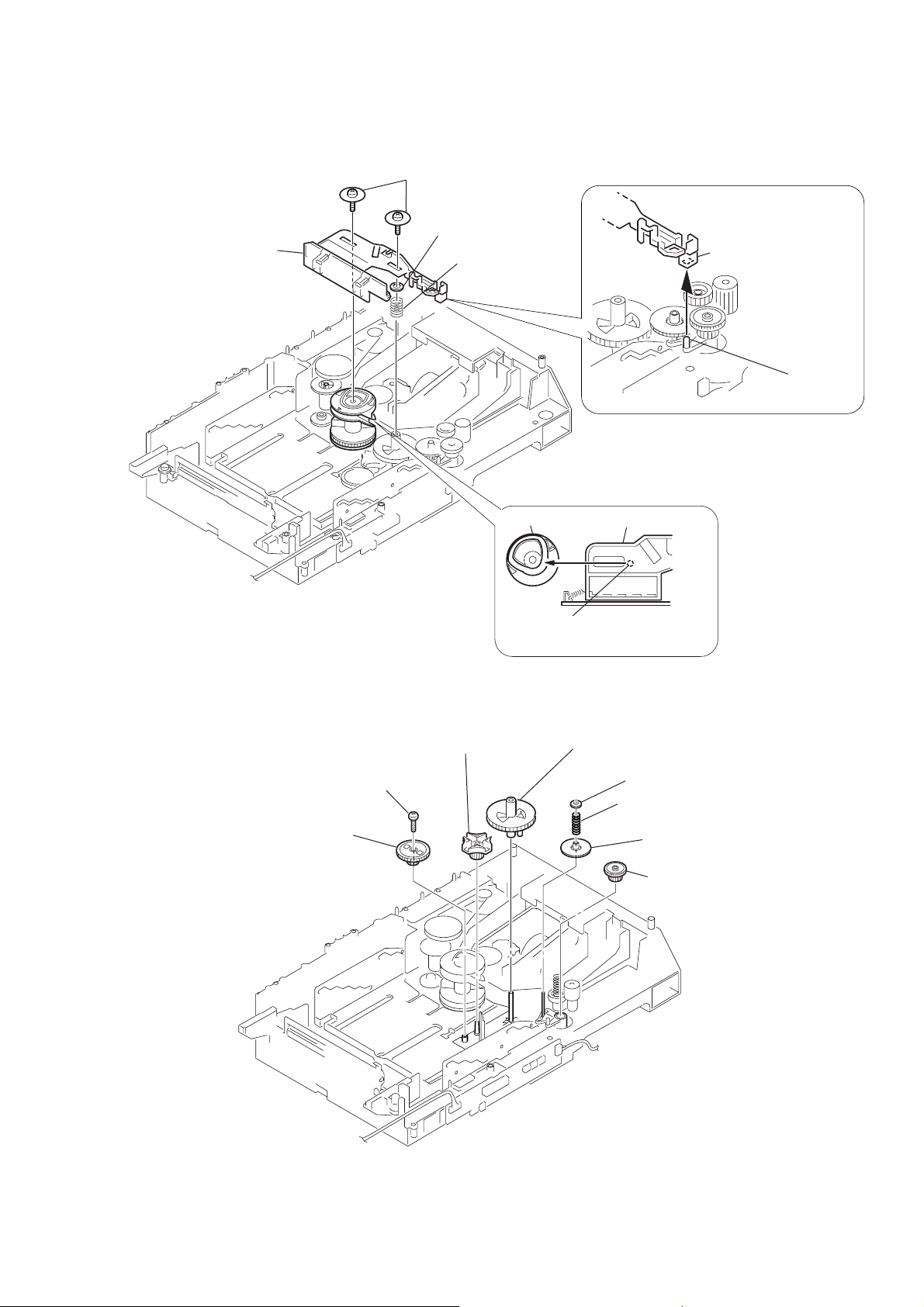

3-22. Gear (Gear A), Gear (Gear B), Gear (U/D Slider)

6

gear (gear B)

7

screw

(+BTTP M2.6)

8

gear (U/D slider)

gear (chuking)

Insert a convex portion into

the groove of gear (chucking).

slider (selection)

5

gear (gear A)

2

washer

3

compression spring

4

gear (selection

1

gear (relay)

17

Page 18

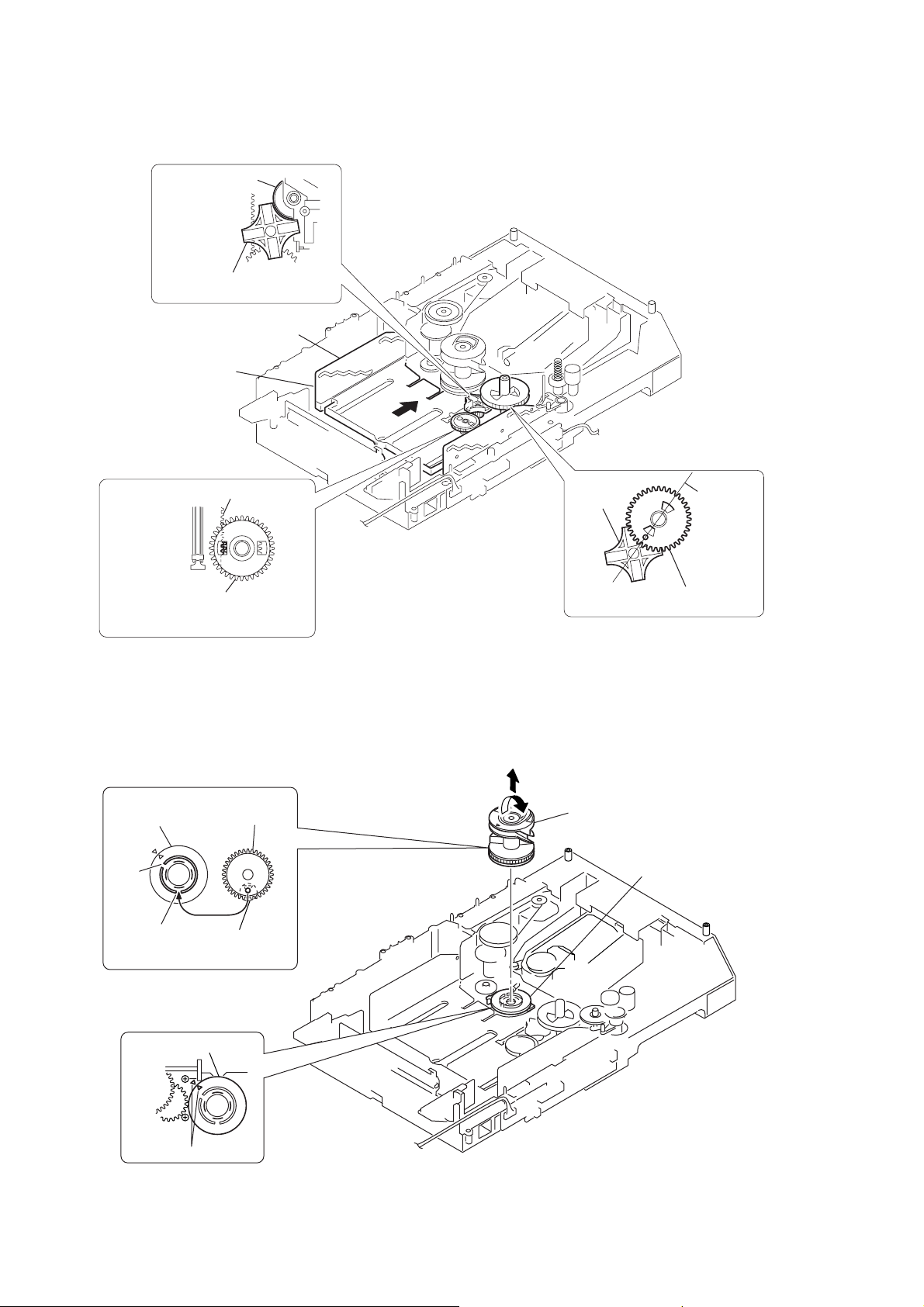

RCD-W500C

Precaution During Gear (Gear U/D Slider), Gear (Gear B), Gear (Gear A) Installation

3

gear (gear B)

portion A

Adjust the gear (gear B) with the

portion A as shown.

slider (U/D)

1

Slide the slider (U/D)

fully in the arrow

direction.

4

2

gear (U/D slider)

slider (U/D) gear

gear (gear A)

gear

(gear B)

linearly

Adjust the gear so that it meshes with

the bottom tooth of slider (U/D) gear,

as shown.

3-23. Gear (Chucking)

PRECAUTION DURING

GEAR (CHUCKING) (2)

rotary encoder

(S707)

NG

OK

Align with the slot of

rotary encoder.

PRECAUTION DURING

GEAR (CHUCKING) (1)

rotary encoder (S707)

gear

(chucking)

2

1

Adjust so as to be aligned with

gear B linearly, as shown.

3

gear (chucking)

rotary encoder (S707)

18

Align marking.

Page 19

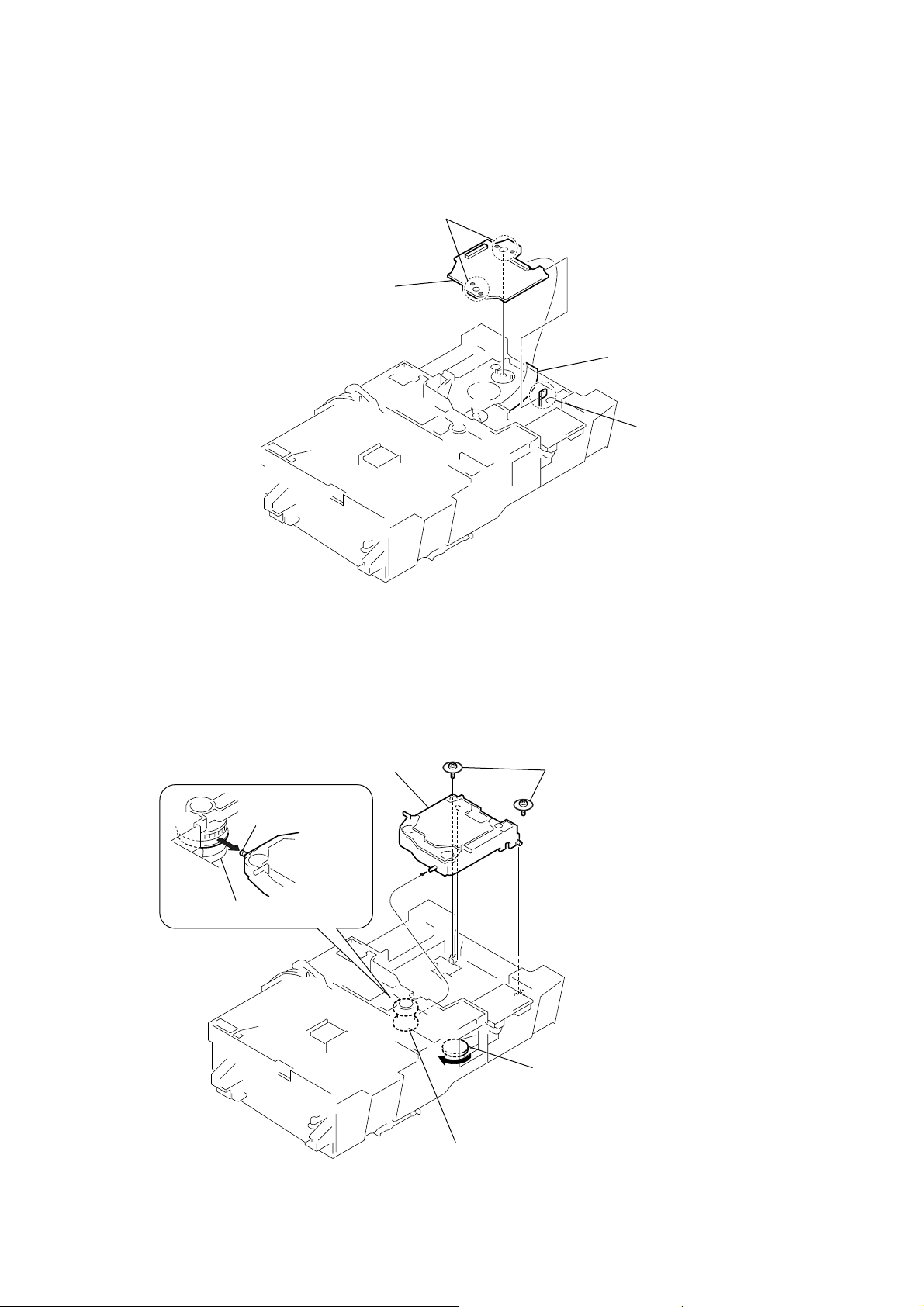

3-24. BD Board

2

Remove soldering from the four points.

4

BD board

1

flexible flat cable

(16core) (CN101)

3

hook

RCD-W500C

3-25. Optical Block Section

4

3

shaft (BU holder)

gear (chucking)

optical block section

2

1

two floating screws

(+PTPWHM 2.6)

Rotate the pulley (LD) in the direction of 2 to move

the shaft (BU holder) upper.

gear (chucking)

19

Page 20

RCD-W500C

SECTION 4

TEST MODE

Setting the Test Mode

Procedure:

1. Press the POWER button to POWER on.

2. Press the l AMS L (DECK A), [SBM] and l AMS

L (DECK B) buttons in order without releasing the button.

3. Turn the l AMS L (DECK B) knob to select the menu.

4. Press the l AMS L (DECK B) knob to execute the test

mode.

Releasing the Test Mode

Procedure 1:

1. Turn the l AMS L (DECK B) knob to select the Ship

Mode.

2. Press the l AMS L (DECK B) knob to execute the Ship

Mode.

3. Press the POWER button to POWER off.

Procedure 2:

1. Press the l AMS L (DECK A), [SBM] and l AMS

L (DECK B) buttons in order without releasing the button.

2. Press the POWER button to POWER off.

Contents of test mode

No. Display Function

1 SYS Version System version display

2 CDR Version CDR version display

3BU Test Deck A BU test mode

4 SERVICE Deck A Service mode

5 Ship Mode CD Shipment mode

6 FL ALL ON Fluorescent indicator tube test

7 FL ALL OFF Fluorescent indicator tube test

8 FL ITIMATSU Fluorescent indicator tube test

9 LED CHECK LED check

10 KEY CHECK Keyboard check

11 RM CHECK Remote commander check

12 CDR History CDR error history display

13 Play Speed Deck A x4 speed

System Version Display

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “SYS Version”, and press the l AMS L

(DECK B) knob.

2. The system version is displayed.

3. To exit from this mode, turn the l AMS L (DECK B)

knob to display “Ship Mode”, and press the l AMS L

(DECK B) knob to execute the Ship Mode.

4. Press the POWER button to POWER off.

CDR Version Display

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “CDR Version”, and press the l AMS L

(DECK B) knob.

2. The CDR version is displayed.

3. To exit from this mode, turn the l AMS L (DECK B)

knob to display “Ship Mode”, and press the l AMS L

(DECK B) knob to execute the Ship Mode.

4. Press the POWER button to POWER off.

BU Test Mode (Deck A)

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “BU Test”, and press the l AMS L

(DECK B) knob.

2. “bdt S CURVE” is displayed. This test mode is used in the Electrical Adjustment section.

3. Turn the l AMS L (DECK B) knob. “bdt RAM READ”,

“bdt RAM WRITE”, “bdt COMOUT”, “bdt FB TUNE” and “bdt

ERR RATE” are displayed.

4. To exit from this mode, press the MENU/NO button and turn

the l AMS L (DECK B) knob to display “bdt ERR

RATE”.

5. Press the l AMS L (DECK A), [SBM] and l AMS

L (DECK B) buttons in order without releasing the button.

6. Press the POWER button to POWER off.

Service Mode (Deck A)

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “SERVICE”, and press the l AMS L

(DECK B) knob.

2. “SERVICE MODE” is displayed.

3. Press the ERASE button, “SLED OUT” is displayed and the

sled moves to the outermost direction.

When the ERASE button is released, “SLED STOP” is displayed

and the sled stops.

4. Press the FINALIZE button, “SLED IN” is displayed and the

sled moves to the innermost direction.

When the FINALIZE button is released, “SLED STOP” is

displayed and the sled stops.

5. To exit from this mode, press the l AMS L (DECK A),

[SBM] and l AMS L (DECK B) buttons in order with-

out releasing the button.

6. Press the POWER button to POWER off.

Note: Always move the pick-up to the most inside position when

exiting from this mode.

Ship Mode

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “Ship Mode”, and press the l AMS L

(DECK B) knob.

2. “Push POWER!” is displayed.

3. Press the POWER button to POWER off.

FL ALL ON Mode

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “FL ALL ON”, and press the l AMS L

(DECK B) knob.

2. All segments of fluorescent indicator tube and LED turn on.

3. Press the MENU/NO button, then “FL ALL ON” is displayed

again.

4. To exit from this mode, turn the l AMS L (DECK B)

knob to display “Ship Mode”, and press the l AMS L

(DECK B) knob to execute the Ship Mode.

5. Press the POWER button to POWER off.

20

Page 21

RCD-W500C

FL ALL OFF Mode

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “FL ALL OFF”, and press the l AMS L

(DECK B) knob.

2. All segments of fluorescent indicator tube and LED turn off.

3. Press the MENU/NO button, then “FL ALL OFF” is displayed

again.

4. To exit from this mode, turn the l AMS L (DECK B)

knob to display “Ship Mode”, and press the l AMS L

(DECK B) knob to execute the Ship Mode.

5. Press the POWER button to POWER off.

FL ITIMATSU Mode

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “FL ITIMATSU”, and press the l AMS

L (DECK B) knob.

2. Checkered patterns of segments are displayed.

3. Press the MENU/NO button, then “FL ITIMATSU” is displayed

again.

4. To exit from this mode, turn the l AMS L (DECK B)

knob to display “Ship Mode”, and press the l AMS L

(DECK B) knob to execute the Ship Mode.

5. Press the POWER button to POWER off.

LED Check Mode

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “LED CHECK”, and press the l AMS L

(DECK B) knob.

2. Turn the l AMS L (DECK A) or (DECK B) knob clock-

wise. The green LED (DISC 1) turns on, then the orange LED

(DISC 1) turns on. The each orange LED turns on after the green

LED from DISC 1 to DISC 5. The LED (SBM) turns on at last.

Counterclockwise rotation gives a performance in reverse order.

3. Press the MENU/NO button, then “LED CHECK” is displayed again.

4. To exit from this mode, turn the l AMS L (DECK B)

knob to display “Ship Mode”, and press the l AMS L

(DECK B) knob to execute the Ship Mode.

5. Press the POWER button to POWER off.

CDR History Display

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “CDR History”, and press the l AMS L

(DECK B) knob.

2. “00 ######## ########” is displayed as the first error hitory.

3. Turn the l AMS L (DECK B) knob to select the error

history. The number of error histories is ten in all.

(Refer to “Contents of CDR error history”.)

4. Press the MENU/NO button, then “CDR History” is displayed

again.

5. To exit from this mode, turn the l AMS L (DECK B)

knob to display “Ship Mode”, and press the l AMS L

(DECK B) knob to execute the Ship Mode.

6. Press the POWER button to POWER off.

Play Speed Selection Mode (Deck A)

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “Play Speed”, and press the l AMS L

(DECK B) knob.

2. “x4 Play” is displayed. If a CD is in the deck A, pressing the

H button executes the 4 times speed playback.

3. Press the x button to stop the playback.

4. Press the MENU/NO button, then “Play Speed” is displayed

again.

5. To exit from this mode, turn the l AMS L (DECK B)

knob to display “Ship Mode”, and press the l AMS L

(DECK B) knob to execute the Ship Mode.

6. Press the POWER button to POWER off.

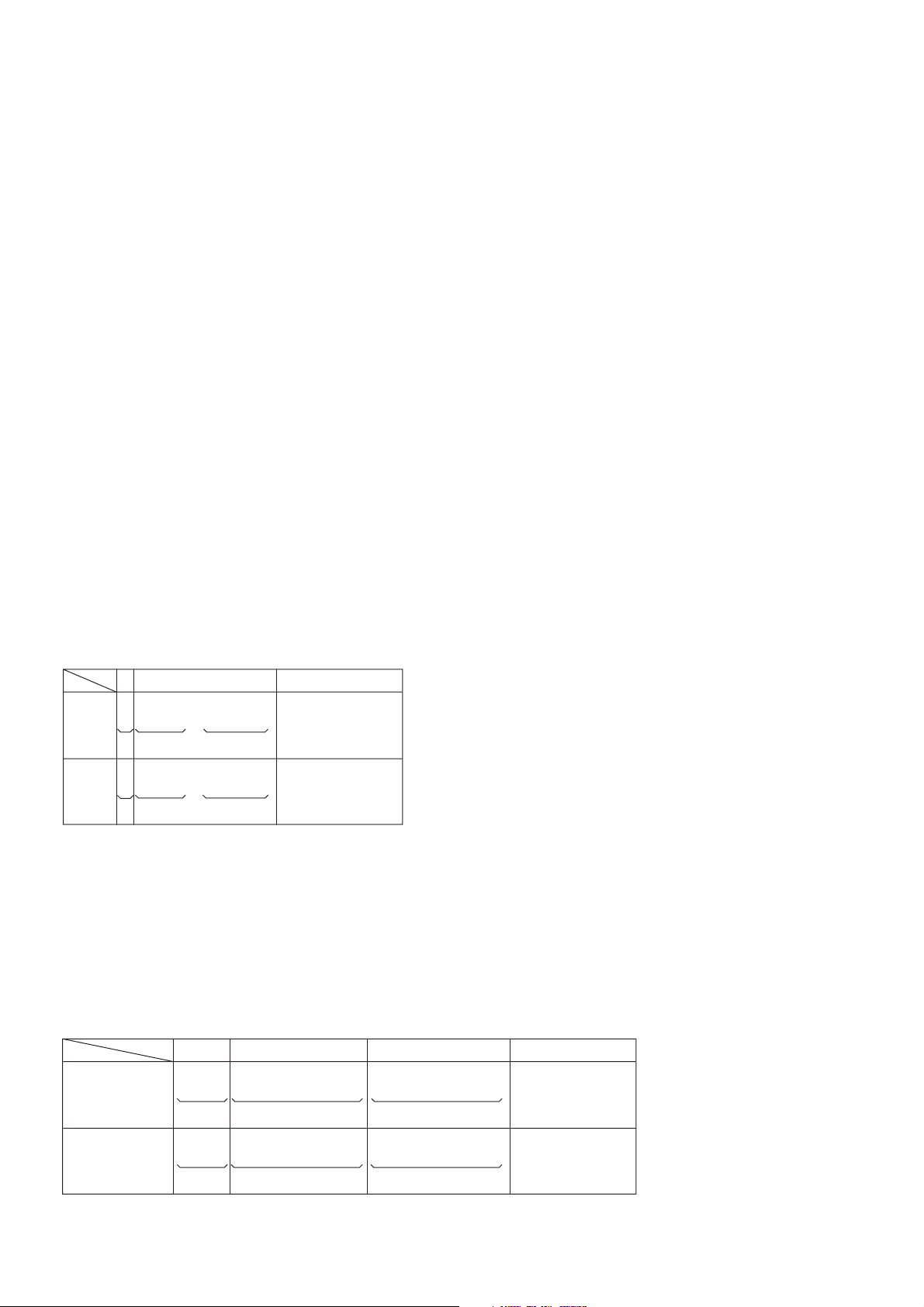

Contents of CDR error history

display(example)

1 2

3 4

00 05070D80

000E2E0D

KEY Check Mode

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “KEY CHECK”, and press the l AMS L

(DECK B) knob.

2. “Got 0 keys” is displayed.

3. Press the buttons, and when all the buttons are pressed (without

the POWER button), “Got 35 keys” will be displayed.

4. To exit from this mode, press the l AMS L (DECK A),

[SBM] and l AMS L (DECK B) buttons in order with-

out releasing the button.

5. Press the POWER button to POWER off.

Remote Commander Check

Procedure:

1. Enter the test mode, then turn the l AMS L (DECK B)

knob to display “RM CHECK”, and press the l AMS L

(DECK B) knob.

2. Press the H key on the remote commander, then “Got

PlayCom” is displayed.

3.

Press the MENU/NO button, then “RM CHECK” is displayed again.

4. To exit from this mode, turn the l AMS L (DECK B)

knob to display “Ship Mode”, and press the l AMS L

(DECK B) knob to execute the Ship Mode.

5. Press the POWER button to POWER off.

5 6

(hexadecimal)

1 Order of the error history

00 to 09: ten error histories in all

2 Error contents

01: unable to focus on

02: Q code/ATIP discontinuous (several frames preceding)

03: Q code/ATIP unreadable

04: search taking more than sixteen seconds

05: focus failure

06: sled over run

07: not passing by start time to write

08: audio buffer over

09: sync failure

OA: Spindle lock taking more than 8 secouds

example : 05 is focus failure

21

Page 22

RCD-W500C

3 Operation mode

bit 7: Speed

0: normal speed

1: x4 speed

bit 6 to bit 0: Number of inner condition

01: POWER off condition/during shift to POWER on

02: POWER off and shipment setting/during shift to POWER

off and shipment setting

03: stop condition/during stop

04: during start up of servo

05: during TOC reading and others

06: during CD TEXT reading

07: during standby(waiting for command from the CD sys-

tem)/during search

08: during playback

09: during manual search(playback)

0A:during pause

0B:during manual search(pause)

0C:during OPC

0D:recording standby/during recording pause

(enable to shift to recording)

0E: during recording

0F: unable to record (waiting for shift to being recordable)

10: PMA updating

11: during operation of unfinalize

12: during operation of finalize

13: PMA erasing

14: emergency

15: recording preparation

16: recording end

5 Write POWER (integer of mW x 10, available during write

processing)

examples: 00 means unavailable

(when 3 operation mode is not recording)

: A3 means 163(decimal), i.e. 16.3 mW

6 ATIME (min)/(sec)/(frame)

example: 0E, 2E, 0D means 14 : 46 : 13

Abbreviations:

AT IP : Absolute Time In Pre-groove

OPC : Optimum Power Control

PMA : Program Memory Area

examples :

bit

HEX

77654 321

0000 0111

07

00

1001 0001

91

11 1

4 Start time of read in(compression method)

bit 15 to bit 13 : (min)

0: 97 min

1: 96 min

2: 95 min

7: others

bit 12 to bit 7: (sec)

bit 6 to bit 0: (frame)

examples :

HEX

bit

0 Operation mode

normal speed, during

standby(waiting for

command from the CD

system)/during search

during operation of

0000 1101 1000 0000

0D,80

97(min) 27(sec)

x4 speed,

unfinalize

7

654 321

0(frame)

015 14 13 12 11 10 9 8 Start time of read in

97 : 27 : 00

11,16

22

0001 0001 0001 0110

34(sec)97(min) 22(frame)

97 : 34 : 22

Page 23

SECTION 5

e

y

e

ELECTRICAL ADJUSTMENTS

RCD-W500C

CD SECTION (DECK A)

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

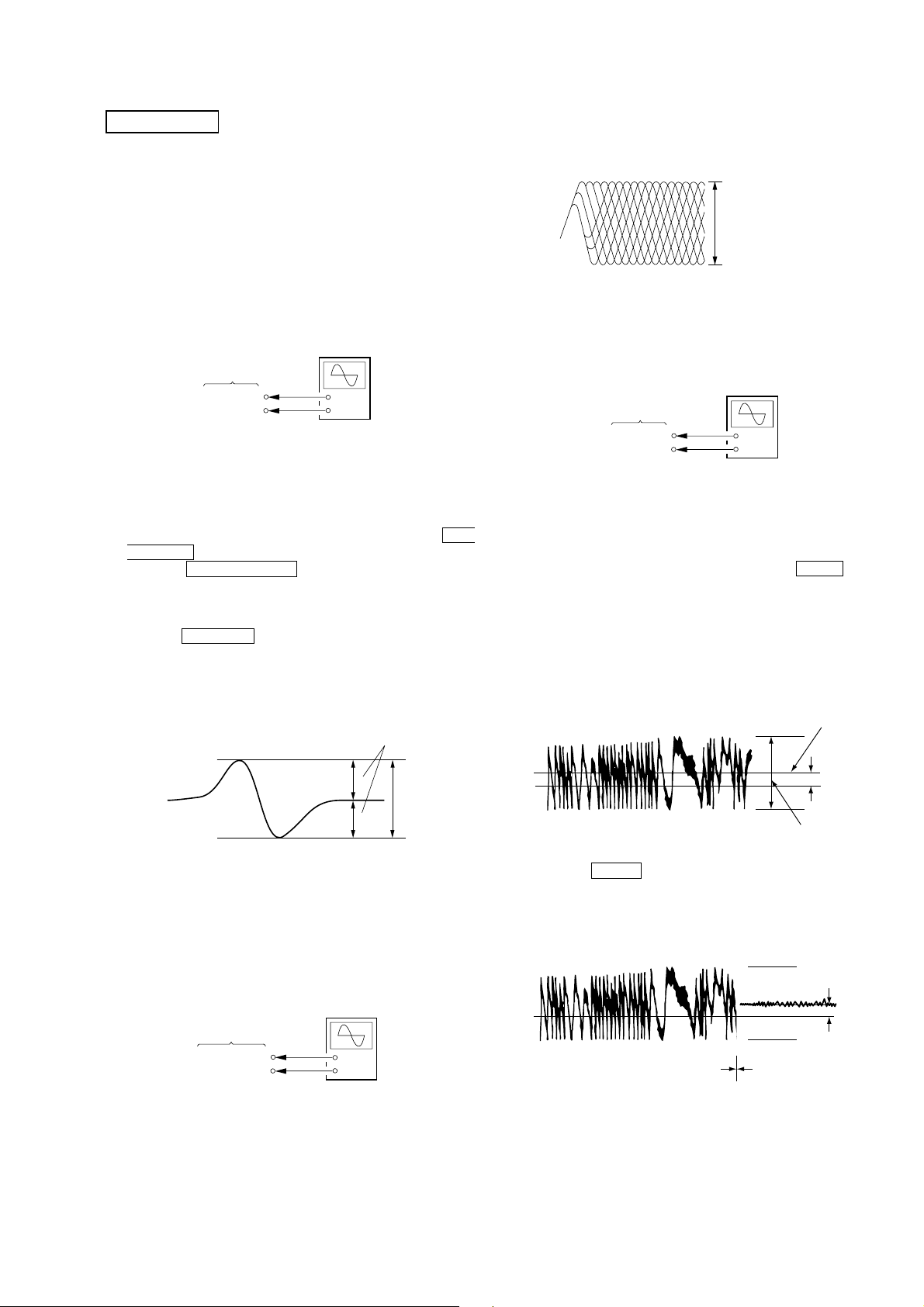

S Curve Check

Connection :

oscilloscop

(DC range)

BD board

TP4 (FE)

TP7 (VC)

Procedure :

1. Connect an oscilloscope to test point TP4 (FE) and TP7 (VC)

on the BD board.

2. Turn the power on.

3. Load the disc (YEDS-18).

4. Enter the test mode, select the BU Test and press the l

AMS L (DECK B) knob to display “bdt S CURVE”.

5. Press the l AMS L (DECK B) knob. “LD AL” is

displayed and playback starts automatically.

6. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B.

7. Press the MENU/NO button to stop playback.

8. Exit from the test mode.

(Refer to the TEST MODE Section)

+

–

symmetr

A

Note: A clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

VOLT/DIV : 200mV

TIME/DIV : 500ns

level : 1.1 ± 0.3Vp-p

Checking Location : BD board (Side B)(See page 24)

E-F Balance Adjustment

Connection :

oscilloscope

(DC range)

BD board

TP2 (TE)

TP7 (VC)

+

–

Procedure:

1. Connect an oscilloscope to TP2 (TE) and TP7 (VC) on the BD

board.

2. Turn the power on.

3. Load the disc (YEDS-18) and playback the number five track.

4. Enter the Service Mode. (see page 20) Press the INPUT button

until “TRV ON” is displayed. (The tracking servo and the

sledding servo are turned off.)

5. Check the level B of the oscilloscope waveform. Rotate the

RV101 on the BD board and adjust so that the A (DC voltage)

of the center of the traverse waveform becomes 0 volt.

Tr averse Waveform

0V

Center of

the waveform

B

A (DC

voltage)

B

Note: Try to measure several times to make sure than the ratio of A

: B or B : A is more than 10 : 7.

Checking Location : BD board (Side B)(See page 24)

RF Level Check

Connection :

oscilloscop

(AC range)

BD board

TP8 (RFAC)

TP7 (VC)

+

–

Procedure :

1. Connect an oscilloscope to TP8 (RFAC) and TP7 (VC).

2. Turn the power on.

3. Load the disc (YEDS-18) and playback the number five track.

4. Confirm that oscilloscope waveform is clear and check RF signal

level is correct or not.

level: 1.1 ± 0.5 Vp-p

6. Press the INPUT button until “TRV OFF” is displayed and

the tracking servo and the sledding servo are turned on. Confirm

that the C (DC voltage) is almost equal to the A (DC voltage).

Tr averse Waveform

0V

Tr acking servo

Sled servo

OFF

Tr acking servo

Sled servo

ON

C (DC

voltage)

7. Exit from the test mode. (see page 20)

Checking Location : BD board (Side B)(See page 24)

Adjustment at Replacement of CD Base Unit

(BU-30BBD61M)

Perform the E-F Balance Adjustment at replacement of CD base

unit (BU-30BBD61M).

23

Page 24

RCD-W500C

Adjustment and Checking Location:

[BD BOARD] — SIDE B —

IC101

RV101

E-F Balance

Adjustment

TP7

(VC)

IC103

TP8

(RFAC)

TP2

(TE)

TP4

(FE)

IC102

24

Page 25

CD-R/RW SECTION

*The following is the method of locating the faulty point and

electrical adjustment.

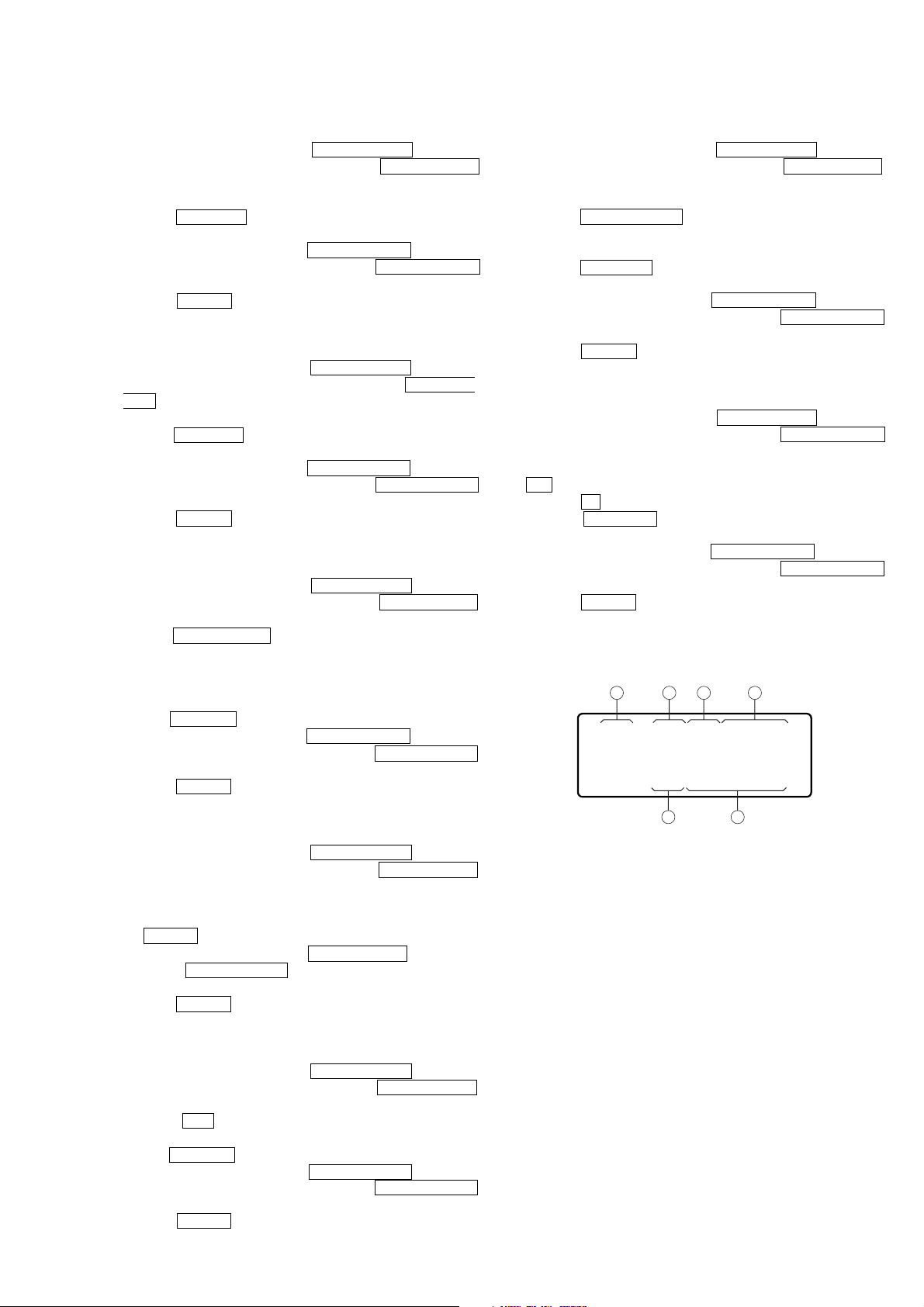

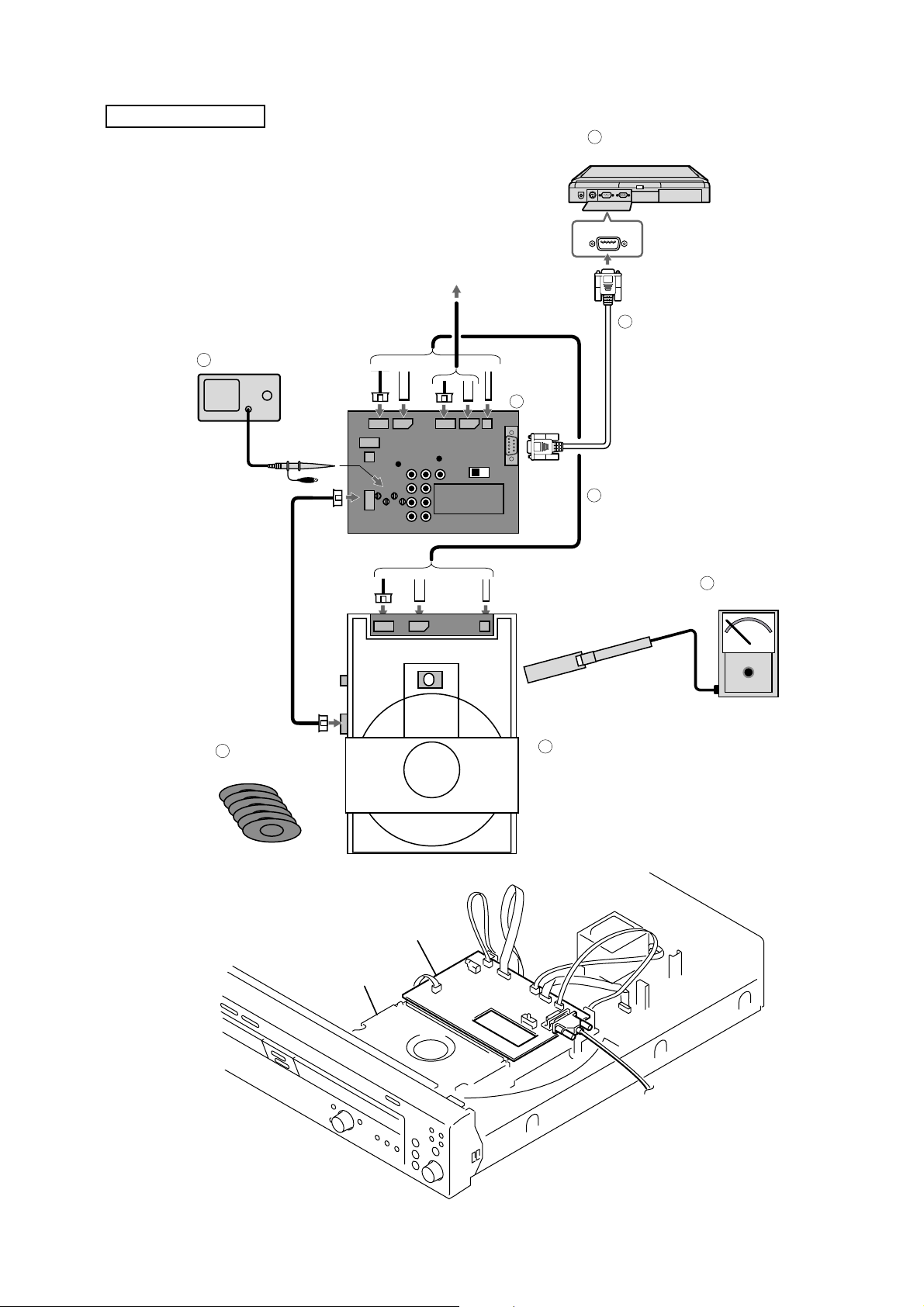

1. Connection and Setting of Programs

PC

3

(w/ Serial I/F)

RCD-W500C

1-1. Connection

5

Oscilloscope

(A)

MPXOUT

To

RCD-W500C

(B) (C) (D)

0-756-358-11

CDM65-RBD1 SERVICE

RESET

Jig

CONTROL FIRM

(B) (C) (D)

COM1

8

RS-232C

Jig

2

9

Cables for Jig connecting

Cable

6

Laser Power

Meter

7

Test Disc

CDM65-RBD2

jig

1

CDM65-RBD2

4 Fig. Position of Jig (Set the jig after removing the cover of CDM65-RBD2)

25

Page 26

RCD-W500C

Ver 1.1 2003.12

1-2. Equipments to prepare

1 Test Object Both RBD2 and CDM65-RBD2 shall be tested.

RBD2 : Flash Memory Writing of of

Circuit Test by Self-diagnostics

CDM65-RBD2 : Electrical Adjustment

Performance Test

2 Jig (With 9 Cables, Parts No.J-2501-223-A)

3 PC Windows95/98/2000/Me with COMport (RS-232C)

4 Programs TeraTerm Pro + Service macro

5 Oscilloscope More than 150MHz

6 Laser Power Meter LEADER LPM-8001 (Parts No.J-2501-046-A)

7 Test Disc

PATD-012 : (Parts No.4-225-203-1) Adjustment for Playback (CD,CD-R)

TCD-W091W : (Parts No.J-2501-226-A) Adjustment for Playback (CD-RW)

CRM74 (Blank CD-R) : Adjustment and Check for Recording (CD-R)

CWM74 (Blank CD-RW) : Check for Recording (CD-RW)

TCD-W032W : (Parts No.J-2501-227-A) Defocus tolerance (CD-RW)

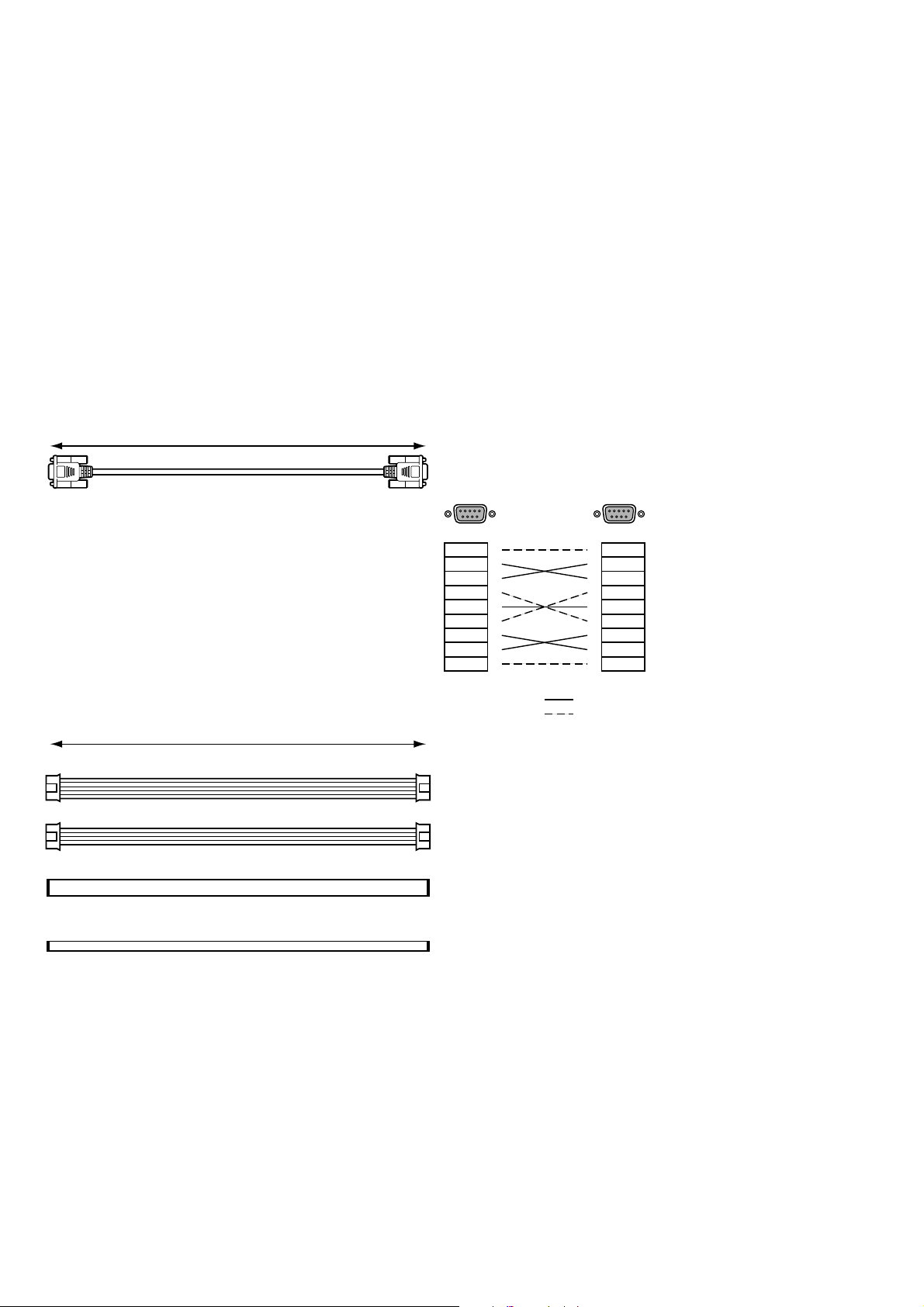

8 RS-232C Cable

L=2000mm

(E)

D-sub 9pin Female cross cable

54321

9876

1

2

3

4

5

6

7

8

9

54321

9876

1

2

3

4

5

6

7

8

9

9 Cables for Jig connecting

:mandatory

: not use

L=300mm

(A)

PH 5p

(B)

PH 4p

(C)

FFC 11p 1.0mm pitch (J-2501-200-A)

(D)

FFC 5p 1.0mm pitch (J-2501-212-A)

26

Page 27

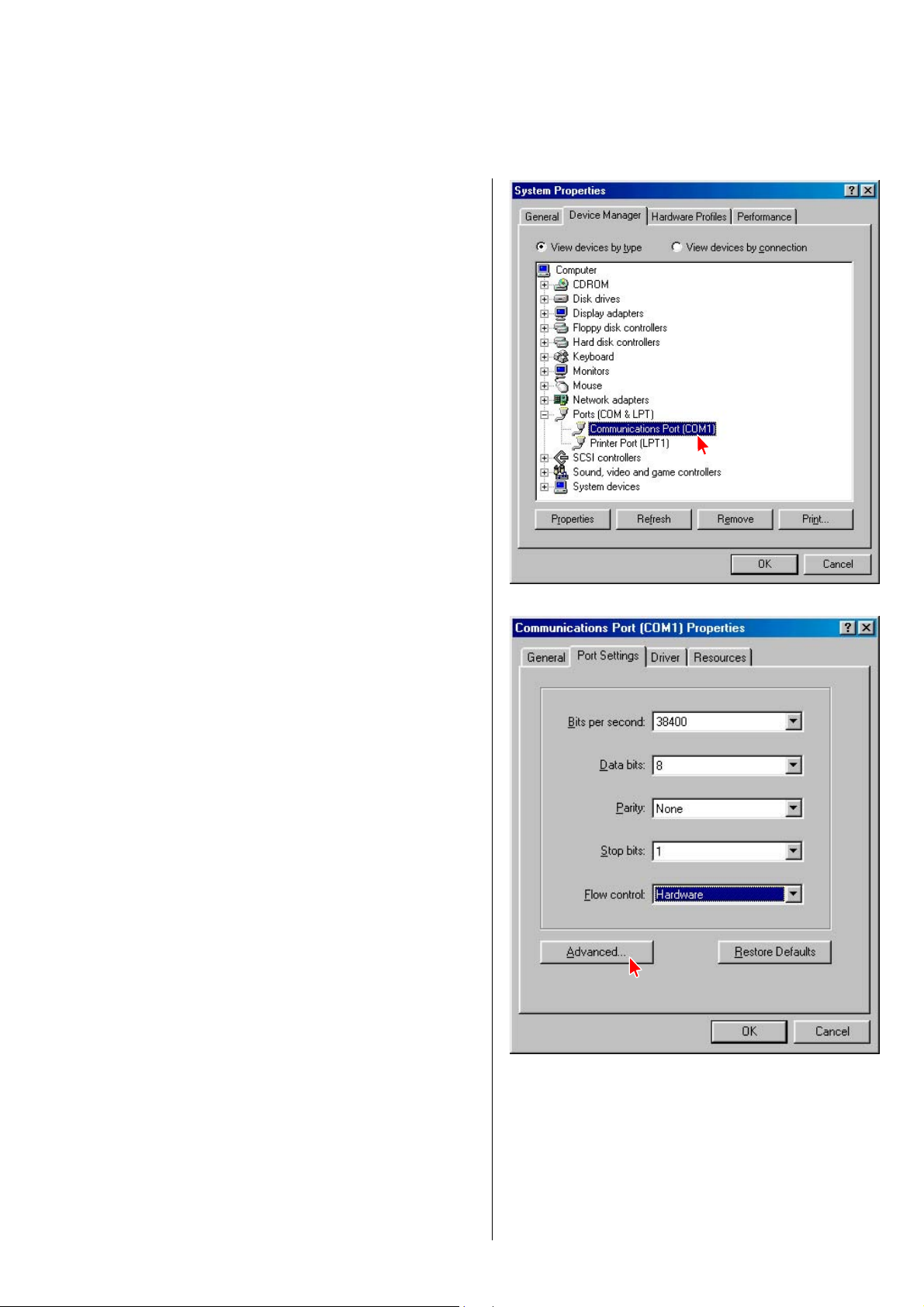

1-3. Setting of Programs (Tera Term Pro and Service macro)

* Confirmation of System (Windows 98 is used in this explanation) Preparation for Terminal software

1) Set up the serial port from OS.

a) Select Start → Settings → Control Panel and select System →

Device manager → Communication Port (COMn)

(see Fig. 1-1)

* Specify the COM port that connected with JIG of CDM65.

RCD-W500C

b) Double click COMn (as you connect to the Jig-CDM65)

Set the parameters as below.

Bits per second : 38400

Data bits : 8

Parity : non

Stop bits : 1

Flow control : hardware

(see Fig.1-2)

4 Fig. 1-1

4 Fig. 1-2

27

Page 28

RCD-W500C

Ver 1.1 2003.12

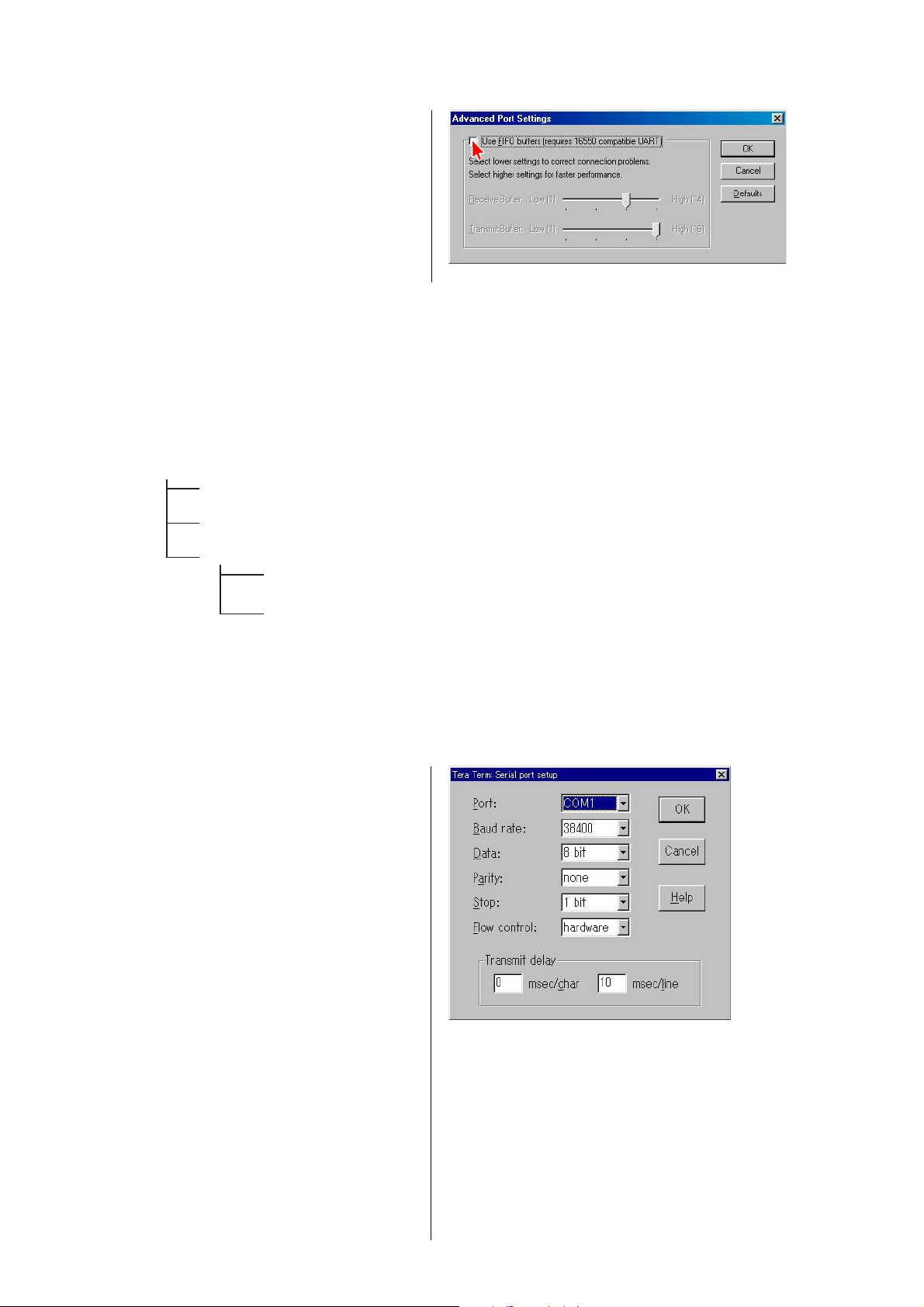

c) Press “Advanced...” button (see Fig.1-2)

Remove the check “Use FIFO buffers ...”

(see Fig.1-3)

4 Fig. 1-3

2) Unzip the file “ttermp23.zip” by PC.

(The file “ttermp23.zip” is distributed together with the service manual.)

3) After unzip the files, you can find setup.exe.

Double click the setup.exe.

Please install as the installer is.

Do not change the directory that files are installed. (use default)

4) Unzip the file “030416_Service.zip” by PC.

Copy all “ttl” file and “FUNC” folder which are contained in “030416_Service” and paste them in the “Ttermpro” file as below.

(The file “030416_Service.zip” is distributed together with the service manual.)

Ttermpro

01ldp_S.ttl

...

10vwdcC_S.ttl

FUNC

AMS.ttl

...

VERCHK.ttl

4 Fig. 1-4

Note : Do not change the directory path.

5) Start-up the TeraTermPro

Double click the ttermpro.exe.

6) Set up the TeraTermPro (IMPORTANT!!)

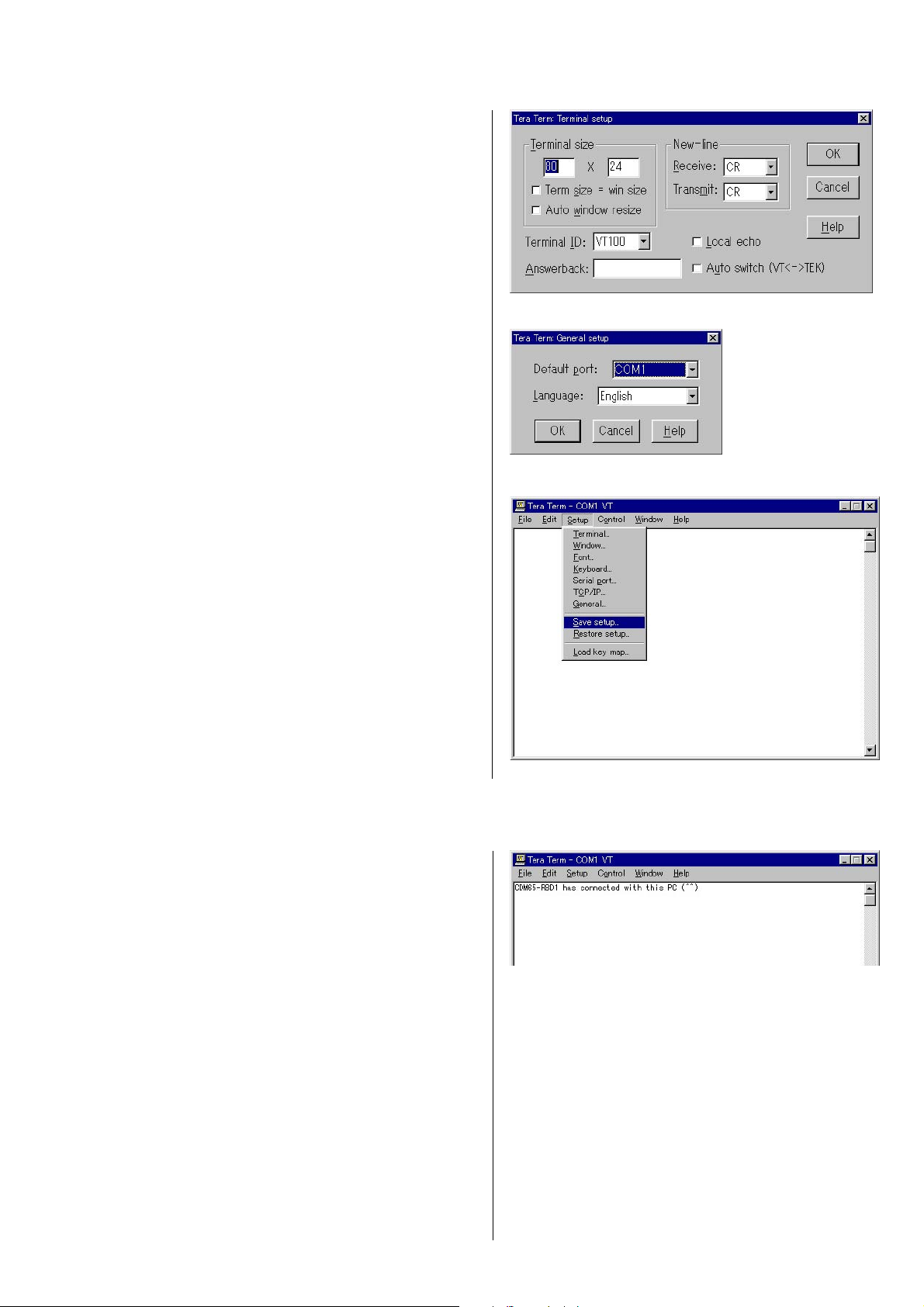

a) Select Setup → Serial Port... and set the parameters as below.

Port : (As you connect to the Jig-CDM65)

Baud rate : 38400

Data : 8 bit

Parity : none

Stop : 1 bit

Flow control : hardware

Transmit delay : 0 msec/char 10 msec/line

After settings, press “OK” button. (see Fig.1-5)

28

4 Fig. 1-5

Page 29

b) Terminal setup

Set the parameters as below.

New-line receive : CR

transmit : CR

After settings, press “OK” button. (see Fig.1-6)

c) General setup

Select the language and press “OK” button. (see Fig.1-7)

RCD-W500C

4 Fig. 1-6

4 Fig. 1-7

d) Saving the setup

Select Setup → Save setup... and save as teraterm.ini in the

Ttermpro directory. (see Fig.1-8)

7) Connect the JIG and CDM65.

8) Confirm the S510 on JIG is ‘CONTROL’.

9) Power on the CDM65 and press SW101(RESET) on JIG.

“CDM65-RBD1 has connected with this PC (^^)” is displayed.

(see Fig.1-9)

If above message is not displayed, you may have some mistakes.

Please confirm previous setting procedures again.

4 Fig. 1-8

4 Fig. 1-9

29

Page 30

RCD-W500C

2.

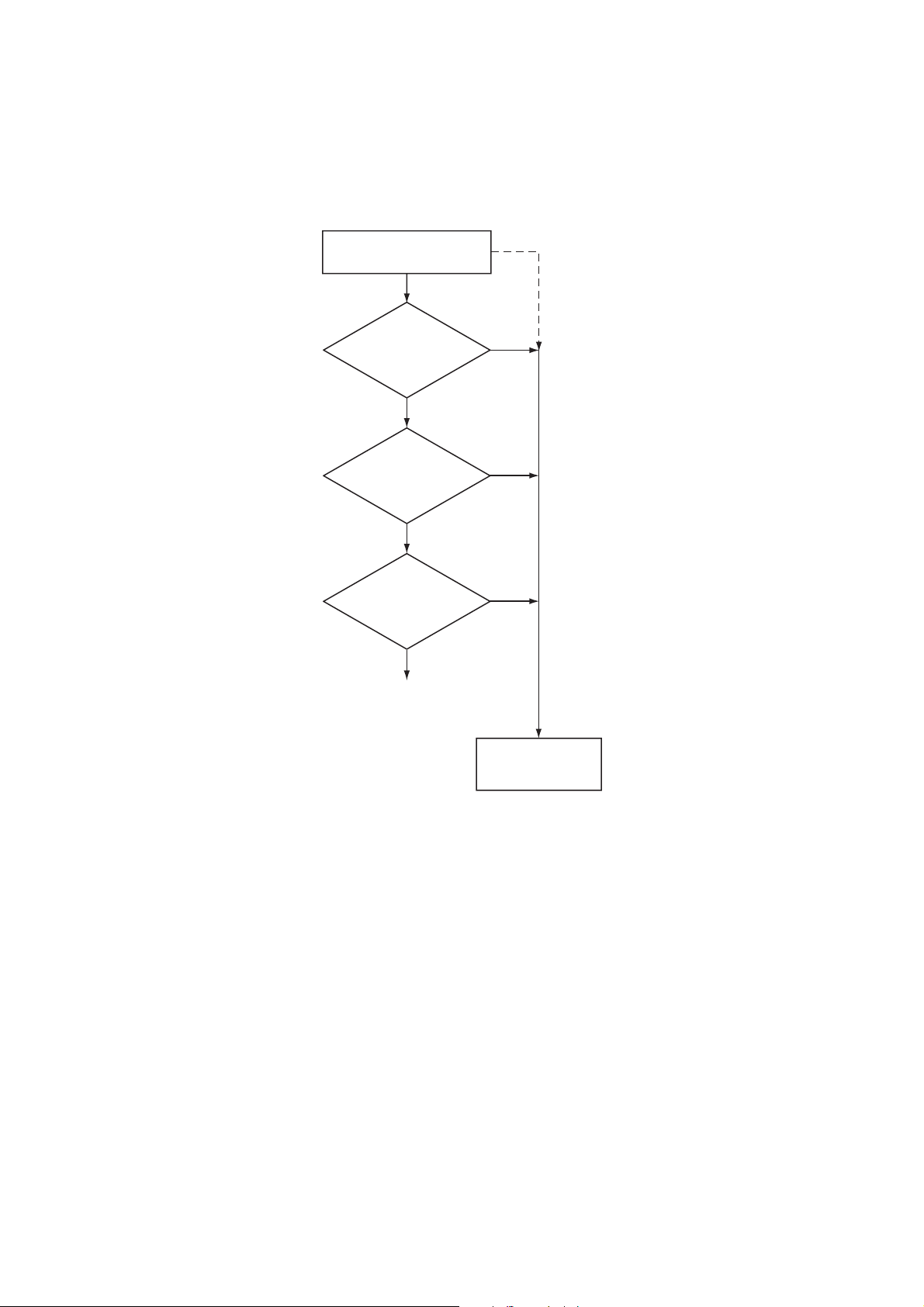

Repair Works That Require Electrical Adjustment

In the case of repair works as shown below, electrical adjustment is required.

Locating the faulty point

KRM-220CAA

is replaced.

No

RBD2

is replaced.

No

The parts shown

in the List (1)

is replaced.

No

Electrical adjustment

is not required.

Ye s

Ye s

Ye s

Electrical adjustment

30

List (1) : IC101, IC103, IC171, IC201, IC502

Page 31

3. Locating the Faulty Point

3-1. Laser Power Check

1) Select the menu as follows. Control → Macro, and select

LDPtestL_S.ttl.

Press “Open”. (Fig. 3-1, 3-2)

RCD-W500C

4 Fig. 3-1

4 Fig. 3-2

2) Press the “RESET” button (SW101) of the jig as prompted by the display.

3) Place probe of a laser power meter in the specified position

following the display as shown in Fig. 3-3. (See Fig. 3-3-a)

4 Fig. 3-3

sensor probe

CDM65-RBD2

jig

optical pick-up

4 Fig. 3-3-a

Note : Do not add stress to an optical pick-up.

31

Page 32

RCD-W500C

4) When the display shown in Fig. 3-4 appears, set the Range of a

laser power meter to “1 mW” and press “OK”.

5) Check that the laser power meter reading satisfies the following

requirement. When the laser power satisfies the required

specification, press “OK”. (Fig. 3-5)

LEADER LPM-8001 : 0.76 to 0.86 mW

4 Fig. 3-4

6) When the display shown in Fig. 3-6 appears, set the Range of a

laser power meter to “10 mW” and press “OK”.

7) Check that the laser power meter reading satisfies the following

requirement. When the laser power satisfies the required

specification, press “OK”. (Fig. 3-7)

LEADER LPM-8001 : 4.5 to 4.7 mW

4 Fig. 3-5

4 Fig. 3-6

4 Fig. 3-7

8) Check that the laser power meter reading satisfies the following

requirement. When the laser power satisfies the required

specification, press “OK”. (Fig. 3-8)

LEADER LPM-8001 : 9.2 to 9.6 mW

32

4 Fig. 3-8

Page 33

9) Check that the message “Power Check End” appears on display.

(Fig. 3-9)

If the measurement result is outside the specification value,

either perform Section 4. CDM65-RBD2 Electrical Adjustment,

or locate the cause of the error by performing the Laser

Deterioration Judgment.

3-2. Laser Deterioration Judgment

1) Select the menu as follows. Control → Macro, and select

10vwdcC_S.ttl.

Press “Open”. (Fig. 3-10, 3-11)

RCD-W500C

4 Fig. 3-9

4 Fig. 3-10

4 Fig. 3-11

2) Press the “RESET” button (SW101) of the jig as prompted by the display.

3) When the message [OK] appears as shown in Fig. 3-12, press

the “OK” button.

When the laser unit KRM-220CAA (Op) is normal without

deterioration of laser, the message [OK] appears. If the laser

unit is deteriorated, the message [NG] appears. Then, replace

the laser unit KRM-220CAA (Op).

4 Fig. 3-12

33

Page 34

RCD-W500C

4) Check that the message “CDRW VWDC-CHECK completed!”

appears. (Fig. 3-13)

NG Judgment Result Indication

When the present VWDC value of the laser unit KRM-220CAA

(Op) does not satisfy the required specification, the message

“VWDC (Line End - Now) [NG]” appears.

Measure: Check the peripheral of CN101.

Replace KRM-220CAA.

4 Fig. 3-13

3-3. Use of Self Diagnosis Function-1 (In the case when result data of the past electrical adjustment, is not needed.)

Perform the self diagnosis as described below in the case when electrical adjustment is not performed yet, or when result data of the

electrical adjustment in the past, is not needed and ready to be erased.)

1) Connect the CDM65-RBD2 (abbreviated as CDM65 hereafter) that is going to be repaired, the jig and a PC following the Connection

Diagram as shown in section 1-1.

2) Turn on the power of the RCD-W500C in which the CDM65 is installed.

3) Start up the TeraTermPro that is installed in PC. Set the switch S510 on the jig to “CONTROL”.

4) Press the “RESET” button (SW101) of the jig. (Fig. 3-14)

4 Fig. 3-14

5) Type portchk [Enter] from keyboard of PC. (Fig. 3-15)

Note 5-1 : When the KRM-220CAA is connected, the spindle

motor rotates at a high speed. If the message “H8/

3064 Port Check END!” appears, press the “RESET”

button and stop the spindle.

Note 5-2 : When the CDM65 (loading mechanism) is installed,

ignore the message “PA (#93-100): NG”.

Confirm that “OK” is displayed in all items except for the cases

as described above.

If “NG” is displayed in any item, it is assumed that the pin

number of IC501 as shown in Fig. 3-15 is defective or its

peripheral has abnormality. Perform the repair work again and

repeat the self diagnosis. Repeat the repair work and self

diagnosis until OK is displayed.

34

4 Fig. 3-15

Page 35

6) Type diagno [Enter] from keyboard of PC.

Note 6-1 : When the KRM-220CAA is connected, the spindle

motor rotates at a high speed. If the message

“Diagnosis END!” appears, press the “RESET”

button and stop the spindle.

Note 6-2 : When the KRM-220CAA is connected (i.e. when

the FFC for optical laser unit is connected to CN101

is connected), ignore the message “AK8567 (w/o OP)

check: NG”.

Confirm that “OK” is displayed in all items except for the cases

as described above.

If “NG” is displayed in any item, it is assumed that the point

indicated by the item in Fig. 3-16 is defective or its peripheral

has abnormality. Perform the repair work again and repeat the

self diagnosis. Repeat the repair work and self diagnosis until

“OK” is displayed.

7) Perform the operation check.

3-4. Use of Self Diagnosis Function-2

(In the case when result data of the past electrical adjustment, should be left saved.)

4 Fig. 3-16

RCD-W500C

Perform the self diagnosis as described below in the case when the faulty point could not be identified even after completion of the repair

work that is defined as “The repair work in which electrical adjustment is not required” in section “2. Repair Works That Require

Electrical Adjustment”.

1) Select the menu as follows. Control → Macro, and select

E2bkupF.ttl.

Press “Open”. (Fig. 3-17, 3-18)

4 Fig. 3-17

4 Fig. 3-18

35

Page 36

RCD-W500C

2) Type the filename in which result of electrical adjustment is

going to be saved. Press “OK”. (Fig. 3-19)

3) Confirm that the message “completed!” appears.

The EEPROM data is backed up. (Fig. 3-20)

4 Fig. 3-19

4 Fig. 3-20

4) Perform step 1) through step 6) of section “3-3. Use of Self Diagnosis Function-1”.

5) Select the menu as follows. Control → Macro, and select E2recvF.ttl.

Press “Open”.

6) Press the “RESET” button (SW101) of the jig as prompted by

the display. (Fig. 3-21)

4 Fig. 3-21

7) Type the filename in which result of electrical adjustment is

saved. Press “OK”. (Fig. 3-22)

36

4 Fig. 3-22

Page 37

8) Confirm that the message “completed!” appears.

The EEPROM data is recovered. (Fig. 3-23)

4 Fig. 3-23

9) Perform the operation check.

3-5. Acquisition of Error History and Acquisition of Elapsed Operating Hours

RCD-W500C

Check if error has occurred or not by performing the following steps. If error has occurred, it is interpreted and saved in the specific

directory. Check contents of the error by viewing the specific directory as described below.

1) Select the menu as follows. Control → Macro, and select

ErrHistGetAll_S.ttl.

Press “Open”. (Fig. 3-24, 3-25)

4 Fig. 3-24

4 Fig. 3-25

37

Page 38

RCD-W500C

2) Press the “RESET” button (SW101) of the jig as prompted by the display.

3) When there is no error, the display as shown in Fig. 3-26

appears.

4 Fig. 3-26

4) When error has occurred, the display as shown in Fig. 3-27

appears showing error history. Contents of the errors are

displayed as shown in Fig. 3-28 after interpretation of the error

log. Check the contents of the error by looking at the file

“EEPROM_Errorlog.txt” in the TeraTermPro directory

5) The elapsed operating hours is shown at the top of

“EEPROM_Errorlog.txt” regardless of presence/absence of the

error history. Check the elapsed operating hours from the

display as shown in Fig. 3-28.

4 Fig. 3-27

SN = xxxx

Op elapsed time: 12:0:56

Spindle elapsed time: 17:9:44

**** Error Log data(0) ****

Error Pointer= 38

Error Code= 05,04,E0,00,00,01,0D,0D

Focus is dropped

1x speed

Servo wakeup

Lead In Start Time= 7:0:0

Laser Power= 0

ATIME= 1:13:13

**** Error Log data(-1) ****

Error Pointer= 30

Error Code= 05,04,E0,00,00,00,14,43

Focus is dropped

1x speed

Servo wakeup

Lead In Start Time= 7:0:0

Laser Power= 0

ATIME= 0:20:67

38

4 Fig. 3-28 : Error log example

Page 39

4. CDM65-RBD2 Electrical Adjustment

4-1. Laser Power Adjustment

1) Start up the TeraTermPro and set the switch S510 on the jig to “CONTROL”.

2) Select the menu as follows. Control → Macro, and select

01ldp_S.ttl.

Press “Open”. (Fig. 4-1)

4 Fig. 4-1

RCD-W500C

3) Press the “RESET” button (SW101) of the jig as prompted by the display.

4) Press the “RESET” button (SW101) of the jig again as prompted by the display.

5) When the display as shown in Fig. 4-2 appears, type the serial

number (see Fig. 4-3) that is printed on the label attached to

the RBD2. (This dialog appears only when the EEPROM IC502

is replaced.)

4 Fig. 4-2

4 Fig. 4-3

When the display as shown in Fig. 4-4 appears, press “No”.

When the display as shown in Fig. 4-5 appears after that, press

“Yes”.

4 Fig. 4-4

4 Fig. 4-5

39

Page 40

RCD-W500C

6) When the display as shown in Fig. 4-6 appears, place the probe

of the laser power meter on top of the optical laser unit, and

press “OK”. (See Fig. 3-3-a, page 31)

7) When the display as shown in Fig. 4-7 appears, set the Range

of a laser power meter to “1 mW” and press “OK”.

8) Adjust the laser output power as follows.

The laser output power (i.e., laser power meter reading) should

satisfy the specification shown below.

LEADER LPM-8001 : 0.81 +/- 0.05 mW (0.76 to 0.86 mW)

*To increase the laser output power

Press [Yes] of the “Up?” dialog box.

*To decrease the laser output power

Press [No] of the “Up?” dialog box and then press [Yes] of the

“Down?” dialog box.

4 Fig. 4-6

4 Fig. 4-7

Repeat until the laser output power satisfies the specification.

(Fig. 4-8, 4-9)

*When the setting value is determined

Press [No] of the “Up?” dialog box

and then press [No] of the “Down?” dialog box

and press [Yes] of the “Save?” dialog box. (Fig. 4-10)

9) When the display shown in Fig. 4-11 appears, set the Range of

a laser power meter to “10 mW” and press “OK”.

4 Fig. 4-8

4 Fig. 4-9

4 Fig. 4-10

4 Fig. 4-11

40

Page 41

10) Adjust the laser output power as follows.

The laser output power (i.e., laser power meter reading) should

satisfy the specification shown below.

LEADER LPM-8001 : 4.6 +/- 0.1 mW (4.5 to 4.7 mW)

*To increase the laser output power

Press [Yes] of the “Up?” dialog box.

*To decrease the laser output power

Press [No] of the “Up?” dialog box

and then press [Yes] of the “Down?” dialog box.

Repeat until the laser output power satisfies the specification.

(Fig. 4-12, 4-13)

RCD-W500C

4 Fig. 4-12

*When the setting value is determined

Press [No] of the “Up?” dialog box

and then press [No] of the “Down?” dialog box

and press [Yes] of the “Save?” dialog box. (Fig. 4-14)

11) Adjust the laser output power as follows.

The laser output power (i.e., laser power meter reading) should

satisfy the specification shown below.

LEADER LPM-8001 : 9.4 +/- 0.2 mW (9.2 to 9.6 mW)

*To increase the laser output power

Press [Yes] of the “Up?” dialog box.

*To decrease the laser output power

Press [No] of the “Up?” dialog box

and then press [Yes] of the “Down?” dialog box.

Repeat until the laser output power satisfies the specification.

(Fig. 4-15, 4-16)

4 Fig. 4-13

4 Fig. 4-14

4 Fig. 4-15

*When the setting value is determined

Press [No] of the “Up?” dialog box

and then press [No] of the “Down?” dialog box

and press [Yes] of the “Save?” dialog box. (Fig. 4-17)

4 Fig. 4-16

4 Fig. 4-17

41

Page 42

RCD-W500C

12) When the display shown in Fig. 4-18 appears, remove probe of

the laser power meter and press OK.

13) Check that the message “Laser Power CAL completed!”

appears. (Fig. 4-19)(The tray opens.)

NG Judgment Result Indication

4 Fig. 4-18

4 Fig. 4-19

4-1-1. Sled Speed NG!

Contents : This message appears when the movement performance of sled is outside the specification.

Measure : Check if there is any abnormality in the sled drive circuit (IC171 peripheral) and the sled drive mechanism.

4-1-2. Power CAL NG!

Contents : This message appears when the laser emission intensity is outside the specification.

Measure : Check peripheral of CN101.

Replace KRM-220CAA.

4-2. CD/CD-R Playback Adjustment

1) Select the menu as follows. Control → Macro, and select 02cdr_S.ttl.

Press “Open”.

2) Place the test CD disc PATD-012 on the tray as prompted by

the display and press “OK”. (Fig. 4-20)(The tray closes.)

4 Fig. 4-20

3) Press the “RESET” button (SW101) of the jig as prompted by the display.

4) As prompted by the message shown in Fig. 4-21, check that

the waveform as shown in Fig. 4-22 appears on an oscilloscope.

42

4 Fig. 4-21

Page 43

Note :The clear RF signal waveform means that the shape “ ” can be clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : suitable value

TIME/DIV : 500ns

4 Fig. 4-22

5) As prompted by the message shown in Fig. 4-24, check that

the waveform as shown in Fig. 4-23 appears on an oscilloscope.

RF signal waveform

VOLT/DIV : suitable value

TIME/DIV : 500ns

RCD-W500C

4 Fig. 4-23

4 Fig. 4-24

6) As prompted by the message shown in Fig. 4-26, check that

the waveform as shown in Fig. 4-25 appears on an oscilloscope.

RF signal waveform

VOLT/DIV : suitable value

TIME/DIV : 500ns

4 Fig. 4-25

4 Fig. 4-26

7) Check that the message “CDR PB-CAL completed!” appears. (The tray opens.)

NG Judgment Result Indication

4-2-1. Playback Measurement NG!

Contents : This message appears when the BLER (Block Error Rate) during playback is outside the specification.

Measure : Check if there is any abnormality in RBD2.

Replace KRM-220CAA.

43

Page 44

RCD-W500C

4-3. CD-RW Playback Adjustment

1) Select the menu as follows. Control → Macro, and select 03cdr_S.ttl.

Press “Open”.

2) Place the test CD TCD-W091W on the tray as prompted by

the display and press “OK”. (Fig. 4-27)(The tray closes.)

4 Fig. 4-27

3) Press the “RESET” button (SW101) of the jig as prompted by the display.

4) As prompted by the message shown in Fig. 4-29, check that

the waveform as shown in Fig. 4-28 appears on an oscilloscope.

RF signal waveform

VOLT/DIV : suitable value

TIME/DIV : 500ns

4 Fig. 4-28

5) As prompted by the message shown in Fig. 4-31, check that

the waveform as shown in Fig. 4-30 appears on an oscilloscope.

RF signal waveform

VOLT/DIV : suitable value

TIME/DIV : 500ns

4 Fig. 4-30

6) As prompted by the message shown in Fig. 4-33, check that

the waveform as shown in Fig. 4-32 appears on an oscilloscope.

RF signal waveform

VOLT/DIV : suitable value

TIME/DIV : 500ns

4 Fig. 4-29

4 Fig. 4-31

44

4 Fig. 4-32

4 Fig. 4-33

Page 45

7) Check that the message “CDRW PB-CAL completed!” appears.

(Fig. 4-34)(The tray opens.)

RCD-W500C

NG Judgment Result Indication

4-3-1. Playback Measurement NG!

Contents: This message appears when the BLER (Block Error Rate) during playback is outside the specification.

Measure : Check if there is any abnormality in RBD2.

Replace KRM-220CAA.

4-4. CD-R Recording Adjustment and Self Record/Playback Check

1) Select the menu as follows. Control → Macro, and select 04cdr_S.ttl.

Press “Open”.

2) Place the test CD disc PATD-012 on the Deck A. Place the

recording CD-R disc (see Note: 4-4-1) on the tray (Deck B)

as prompted by the display and press “OK”. (Fig. 4-35)

(The tray closes.)

Note : 4-4-1

The disc to be used in this step.

* Use the CD-R disc CRM74 for audio, that is manufactured by

Sony.

* The disc that is used by this step cannot be used for the general

purposes and for the purpose of operation check of the RCD

series equipment. The disc that is used for the general purposes

or for the purpose of operation check of the RCD series

equipment, cannot be used in this step.

* If the recording is interrupted by any reasons during the

recording operation (i.e., the WRITE POWER ON LED of the

jig is lighting), the disc cannot be used any more in the

subsequent step. Use the un-used brand new disc and repeat

this step from the very beginning again.

4 Fig. 4-34

4 Fig. 4-35

3) When the disc that is used in step 2) is the disc that has been

used in the electrical adjustment in the past........ Press “Yes”.

When the disc that is used in step 2) is a completely blank disc.

...... Press “No”. (Fig. 4-36)

Note: The recording CD-R disc can be used only for the

electrical adjustment. The recording CD-R disc must be

controlled so that it must not be used for any other

applications.

4 Fig. 4-36

45

Page 46

RCD-W500C

4) Press the H button of Deck A. After playback starts, press

“OK”. (Fig. 4-37)

5) When the message as shown in Fig. 4-38 appears some seconds

later, stop playback (1X) and select 4x of the test mode (refer

to page 21, Play Speed Selection Mode (Deck A)) Playback

Speed. Then press the H button of Deck A. After playback

starts, press “OK”.

6) As prompted by the message shown in Fig. 4-40, check that

the waveform as shown in Fig. 4-39 appears on an oscilloscope.

RF signal waveform

VOLT/DIV : suitable value

TIME/DIV : 500ns

4 Fig. 4-37

4 Fig. 4-38

4 Fig. 4-39

4 Fig. 4-40

7) As prompted by the message shown in Fig. 4-42, check that

the waveform as shown in Fig. 4-41 appears on an oscilloscope.

RF signal waveform

VOLT/DIV : suitable value

TIME/DIV : 500ns

4 Fig. 4-41

4 Fig. 4-42

8) Check that the message “CDR REC-CHECK completed!” appears. (The tray opens.)

Stop playback (4X) and exit from the test mode (Deck A). (refer to page 21.)

NG Judgment Result Indication

4-4-1. CD-R Playback Measurement NG!

Contents : This message appears when the BLER (Block Error Rate) *Beta/m11 of the track that is recorded and played back, is outside

the specification.

Measure : Check if there is any abnormality in RBD2.

Replace KRM-220CAA.

46

Page 47

4-5. CD-RW Recording Adjustment and Self Record/Playback Check

1) Select the menu as follows. Control → Macro, and select 05cdrw_S.ttl.

Press “Open”.

2) Place the test CD disc PATD-012 on the Deck A. Place the

recording CD-RW disc (see Note: 4-5-1) on the tray (Deck B)

as prompted by the display and press “OK”. (Fig. 4-43)

(The tray closes.)

RCD-W500C

Note : 4-5-1

The disc to be used in this step.

* Use the CD-RW disc CWM74 for audio, that is manufactured

by Sony.

* The disc that is used by this step cannot be used for the general

purposes and for the purpose of operation check of the RCD

series equipment as it is. The disc that is used for the general

purposes or for the purpose of operation check of the RCD

series equipment, cannot be used in this step.

When you want to use the CD-RW disc for other applications,

erase the CD-RW disc.

* If the recording is interrupted by any reasons during the

recording operation (i.e., the WRITE POWER ON LED of the

jig is lighting), the disc cannot be used any more in the

subsequent step. In such a case, erase the CD-RW disc and

repeat this step from the very beginning again.

3) When the disc that is used in step 2) is the disc that has been

used in the electrical adjustment in the past........ Press “Yes”.

When the disc that is used in step 2) is a completely blank disc.

......... Press “No”. (Fig. 4-44)

Note: The recording CD-RW disc can be used only for the

electrical adjustment. The recording CD-RW disc must

be controlled so that it must not be used for any other

applications.

4 Fig. 4-43

4 Fig. 4-44

4) Press the H button of Deck A. After playback starts, press

“OK”. (Fig. 4-45)

5) When the message as shown in Fig. 4-46 appears some seconds

later, stop playback (1X) and select 4x of the test mode (refer

to page 21, Play Speed Selection Mode (Deck A)) Playback

Speed. Then press the H button of Deck A. After playback

starts, press “OK”.

4 Fig. 4-45

4 Fig. 4-46

47

Page 48

RCD-W500C

6) As prompted by the message shown in Fig. 4-48, check that

the waveform as shown in Fig. 4-47 appears on an oscilloscope.

RF signal waveform

VOLT/DIV : suitable value

TIME/DIV : 500ns

4 Fig. 4-47

4 Fig. 4-48

7) As prompted by the message shown on display, check that the waveform as shown in Fig. 4-49 appears on an oscilloscope.

RF signal waveform

VOLT/DIV : suitable value

TIME/DIV : 500ns

4 Fig. 4-49

8) Check that the message “CDRW REC-CHECK completed!”

appears. (Fig. 4-50)(The tray opens.)

Stop playback (4X) and exit from the test mode (Deck A).

(refor to page 21.)

NG Judgment Result Indication

4 Fig. 4-50

4-5-1. CD-RW Playback Measurement NG!

Contents : This message appears when the BLER (Block Error Rate) *Beta/m11 of the track that is recorded and played back, is outside

the specification.

Measure : Check if there is any abnormality in RBD2.

Replace KRM-220CAA.

48

Page 49

4-6. VWDC Check

1) Select the menu as follows. Control → Macro, and select 06vwdc_S.ttl.

Press “Open”.

2) As prompted by the message shown in Fig. 4-51, remove the

disc from the tray and press “OK”.

4 Fig. 4-51

3) Because this step saves the result of electrical adjustment in a

file, there can be a case that the dialog as shown in Fig. 4-52

appears.

When you want to overwrite ..................... Press “Yes”.

When you want to create a new file .......... Press “No”.

4 Fig. 4-52

4) Check that the message “CDRW VWDC-CHECK completed!”

appears. (Fig. 4-53)

RCD-W500C

NG Judgment Result Indication

4 Fig. 4-53

4-6-1. EEPROM Write NG!

Contents : This message appears when writing data into EEPROM fails.

Measure : When the steps of 01ldp_S.ttl through 05cdrw_S.ttl have no problem and the error occurs only in this step, it is assumed that

an error has occurred momentarily in the interface between PC and CDM65. Therefore, repeat execution of 06vwdc_S.ttl

again.

4-6-2. VWDC judge [Line Top - End] [NG]

Contents : This message appears when the VWDC value is outside the specification.

Measure : It is assumed that the optical laser unit has deteriorated. If this error occurs after the KRM-220CAA is replaced, the adjustment

error in the step of 01ldp_S.ttl is assumed. Therefore, repeat execution of steps of 01ldp_S.ttl through 05cdrw_S.ttl again. In

the cases other than above, check if the laser power adjustment is correctly performed or not, using LDPtestL_S.ttl.

49

Page 50

RCD-W500C

4-7. NG Message List

Message Cause

Tr ay OPEN NG! The tray has not opened within the specified time.

Tr ay Close NG! The tray has not closed within the specified time.

SLEDIN NG! The sled has not moved toward inner circumference within the specified time.

SLEDOUT NG! The sled has not moved toward outer circumference within the specified time.

RIDR NG! The RID information could not be read out within the specified time.

SNread (1) NG! The SN (1) information could not be read out within the specified time.

SNread (2) NG! The SN (2) information could not be read out within the specified time.

SNread (3) NG! The SN (3) information could not be read out within the specified time.

FBIASADJ NG! The Focus Bias Adjustment has not completed within the specified time.

FEOSADJ NG! The FE Offset Adjustment has not completed within the specified time.

FESAMPADJ NG! The FE Amplitude Adjustment has not completed within the specified time.

RFACCHK NG! The RFAC amplitude is abnormal or the adjustment has not completed within the specified time.

RPINWADJ1 NG! The Read Power (during Write1) Adjustment has not completed within the specified time.

RPINWADJ2 NG! The Read Power (during Write2) Adjustment has not completed within the specified time.

SERVOSET NG! The Servo Setting has not completed within the specified time.

TSa NG! The ATIME Search has not completed within the specified time.

PLAYSW NG! The Play operation has not started within the specified time.

STOP NG! The Stop operation has not completed within the specified time.

AMS NG! The AMS operation has not completed within the specified time.

ATIPPLAY NG! The ATIP Play operation has not started within the specified time.

END TNO get NG! The record-end track information could not be obtained within the specified time.

LEADOUT info.get NG! The record-end time information could not be obtained within the specified time.

Invalid EndTrackNo./LeadoutTime ! The illegal record-end track and its time information were obtained.

Use the Blank disc The disc exceeding the allowable limit is used.

DIR unlock! The equipment could not be synchronized with the signal connected to DIN2.

RWP NG! The CD-R Write Power setting has not completed within the specified time.

RWWP NG! The CD-RW Write Power setting has not completed within the specified time.

REC NG! The record operation could not be started within the specified time.

50

Page 51

5. Operation Check

5-1. Erasing the Error History

1) Select the menu as follows. Control → Macro, and select

ErrHistClear.ttl.

Press “Open”. (Fig. 5-1, 5-2)

RCD-W500C

4 Fig. 5-1

4 Fig. 5-2

2) Press the “RESET” button (SW101) of the jig as prompted by the display.

3) Check that the message “completed!” appears. (Fig. 5-3)

4 Fig. 5-3

51

Page 52

RCD-W500C

5-2. Playback Check using TCD-W032W

1) Install the CDM65 in the equipment and install the TCD-W032W in Deck B.

2) Rotate the l AMS L (Deck B) knob to select the track 16. Start playback by pressing the same knob or by pressing the H

(Deck B) button.

3) Perform playback for 10 seconds or more and confirm that there is no abnormality such as sound skipping and others.

52

Page 53

RCD-W500C

Supplementary Information

Method to Erase the CD-RW Disc

*Erase it in the following procedure, to reuse the CD-RW disc to electrical adjustment, or to use a disc other than blank.

* Be sure to erase it in the following procedure, to use the disc used for electrical adjustment for other uses.

1) Select the menu as follows. Control → Macro, and select

RWeraseA.ttl.

Press “Open”. (Fig. A-1, A-2)

2) Press the “RESET” button (SW101) of the jig as prompted by

the display. (Fig. A-3)

4 Fig. A-1

4 Fig. A-2