Page 1

RCD-W3

SERVICE MANUAL

Ver 1.2 2003.12

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

Model Name Using Similar Machanism RCD-W1

CD-R

CD Mechanism Type CDM-700(CD-RW)

Optical Pick-up Type KRS-220C

Model Name Using Similar Mechanism RCD-W1

CDP

CD Mechanism Type CDM-700(CDP)

DECK A (the CD player section)

System Compact disc and digital audio system

Laser Semiconductor laser (λ =780 nm)

Emission duration: continuous

Frequency response 20 Hz – 20,000 Hz (±0.5 dB)

Signal-to-noise ratio More than 100 dB

Dynamic range More than 95 dB

DECK B (the CD-R and CD-RW recording section)

System Compact disc digital audio system

Laser Semiconductor laser (λ =780 nm)

Emission duration: continuous

Playable discs CD, CD-R, CD-RW

Recordable discs CD-R, CD-RW (for music use)

Frequency response 20 to 20,000 Hz ±0.5 dB

Signal-to-noise ratio Over 100 dB during playback

Dynamic range More than 95 dB during playback

Inputs

ANALOG IN

(Phono jacks) impedance 47 kilohms

Rated input 330 mVrms

Minimum input 125 mVrms

DIGITAL OPTICAL IN

(Square optical connector jack) Optical wavelength 660 nm

Outputs

ANALOG OUT

(Phono jacks) Rated output 2 Vrms (at 50 kilohms)

Load impedance over 10 kilohms

OPTICAL DIGITAL OUT

(Square optical connector jack) Wavelength 660 nm

Output level -18 dBm

PHONES

(Phone jacks) 28 mW, 32 ohms

General

Power requirements

U.S.A. and Canada 120 V AC, 60 Hz

Other countries 110 – 240 V AC, 50/60 Hz

Power consumption 20 W

Dimensions (approx.) (w/h/d) incl. projecting parts and control

430 x 108 x 368 mm

Mass (approx.) 4.6 kg

Supplied accessories • Audio connecting cord (2)

• Remote commander (remote) (1)

• Size AA (R6) batteries (2).

Design and specifications are subject to change without notice.

9-874-117-03

2003L02-1

© 2003.12

COMPACT DISC RECORDER

Sony Corporation

Home Audio Company

Pubulished by Sony Engineering Corporation

Page 2

RCD-W3

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

The Laser component in this product is capable of emitting

radiation exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

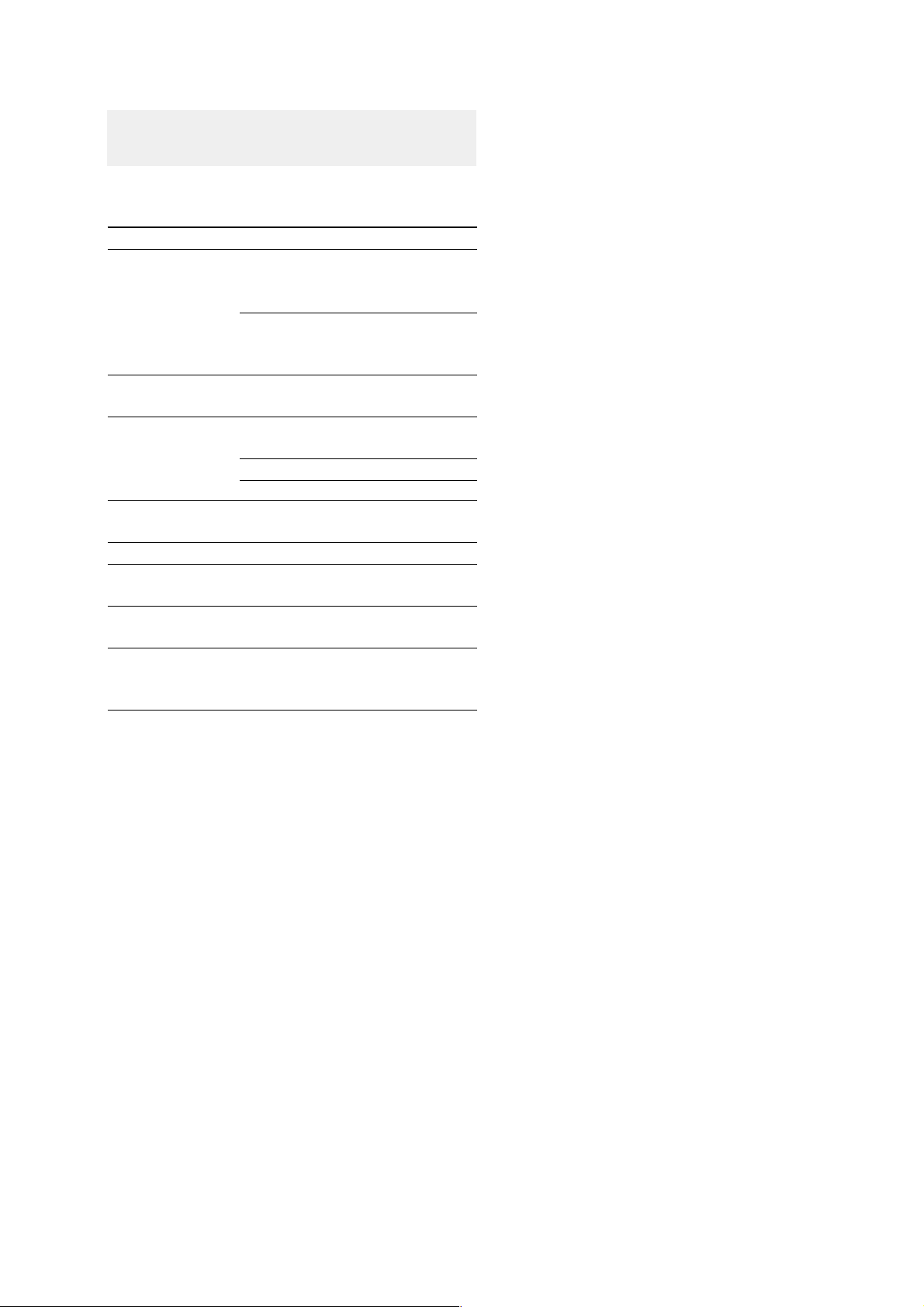

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers). Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75

V, so analog meters must have an accurate low-voltage scale.

The Simpson 250 and Sanwa SH-63Trd are examples of a passive VOM that is suitable. Nearly all battery operated digital

multimeters that have a 2V AC range are suitable. (See Fig. A)

To Exposed Metal

Parts on Set

0.15µF

1.5kΩ

Earth Ground

AC

voltmeter

(0.75V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS

SONT DONNÉS DANS CE MANUEL OU DANS LES

SUPPLÉMENTS PUBLIÉS PAR SONY.

Page 3

Error Messages

The following table explains the error messages that appear in the

display.

RCD-W3

TABLE OF CONTENTS

1. SERVICING NOTE .......................................................... 4

2. GENERAL .......................................................................... 8

Message Explanation

CHECK DISC • A record-related button has been

pressed when a finalized disc is in

the DECK B.

• A record-related button has been

pressed when a standard CD is in

the DECK B.

DATA DISC A non-audio CD-ROM or a CDVideo

disc has been placed in the machine.

DISC ERROR • An unfinalized disc has been placed in

the DECK A.

• There is a problem with the disc.

• A DVD disc has been placed in the unit.

DISC FULL There is not enough time left on the disc

to complete a planned recording.

ERROR There is a problem with the tray.

FAILED A dubbing has not been completed

properly.

FULL More than 20 tracks have been

programmed.

NO AUDIO A record-related button has been

pressed when a non-audio disc is in

the DECK B.

3. DISASSEMBLY

3-1. Top Case............................................................................... 9

3-2. Tray Door, Front Panel Assy.............................................. 10

3-3. HP board, FL board, VOL board........................................ 10

3-4. Back Panel ......................................................................... 11

3-5. Audio Board ....................................................................... 11

3-6. Power Board ...................................................................... 12

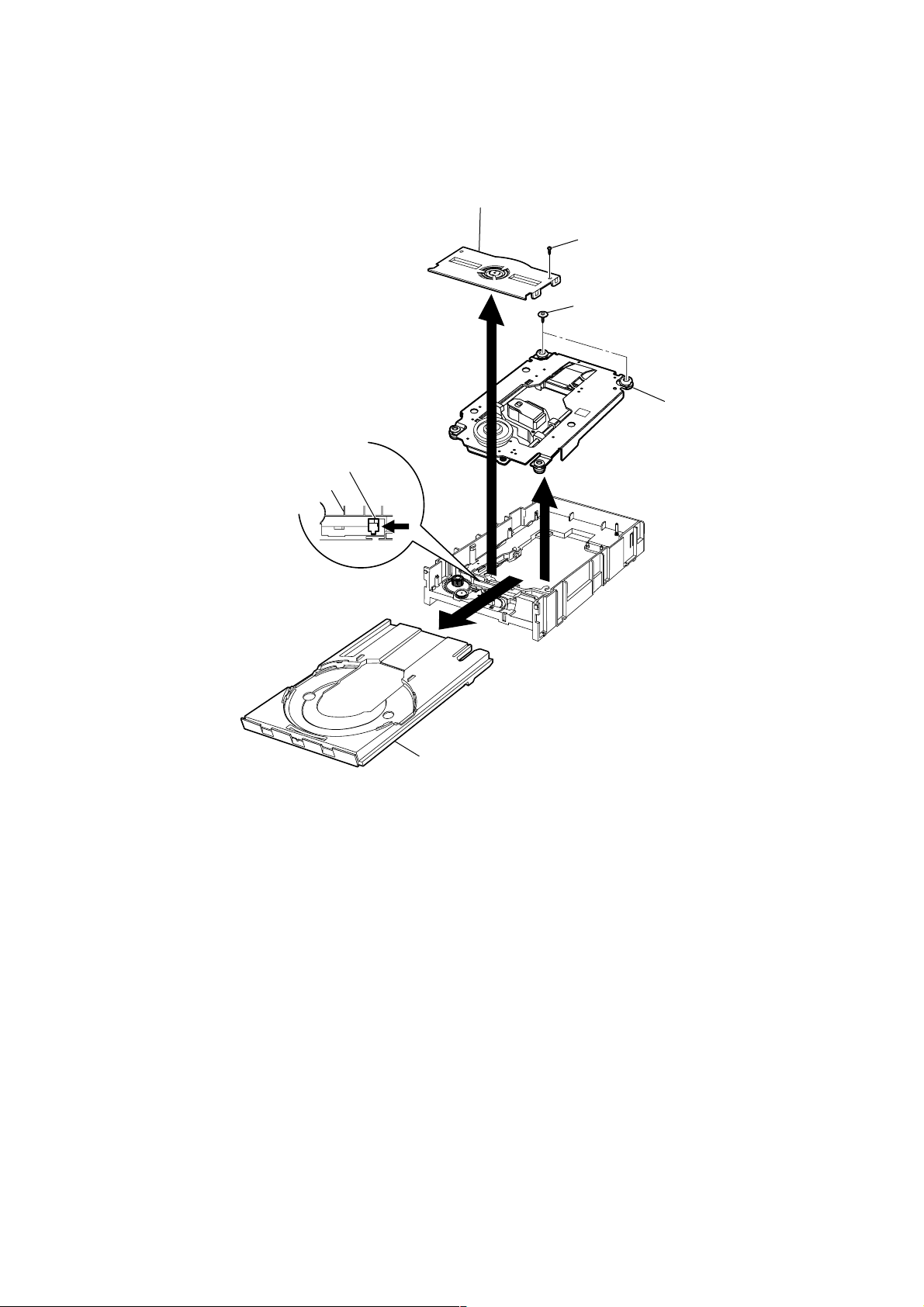

3-7. CDP Deck assy (Deck A), CD-R Deck Assy (Deck B) ..... 12

3-8. BD-P Board (Deck A) ........................................................ 13

3-9. CDP Mechanism Assy (Deck A)........................................ 13

3-10.Spindle Motor Assy, Optical Pick-Up Block (Deck A)...... 14

3-11.BD-R Board........................................................................ 14

3-12.CD-R Mechanism Assy (Deck B)...................................... 15

4. ELECTRICAL ADJUSTMENT ................................... 16

5. DIAGRAMS

5-1. Circuit Boards Location .................................................... 21

5-2. Block diagrams – CD-R Section (1/2) – ........................... 23

Block diagrams – CD-R Section (2/2) – ........................... 24

Block diagrams – CDP Section –...................................... 25

Block diagrams – Audio Section – ................................... 26

Block diagrams – Power Section – ................................... 27

5-3. Printed Wiring Board – BD-R Section (Side A) – ............ 28

Printed Wiring Board – BD-R Section (Side B) – ............ 29

5-4. Schematic Diagram – BD-R Section (1/6) –..................... 30

5-5. Schematic Diagram – BD-R Section (2/6) –..................... 31

5-6. Schematic Diagram – BD-R Section (3/6) –..................... 32

5-7. Schematic Diagram – BD-R Section (4/6) –..................... 33

5-8. Schematic Diagram – BD-R Section (5/6) –..................... 34

5-9. Schematic Diagram – BD-R Section (6/6) –..................... 35

5-10. Printed Wiring Board – Audio Section –........................... 36

5-11. Schematic Diagram – Audio Section – ............................ 37

5-12. Printed Wiring Board – Panel Section – ........................... 38

5-13. Schematic Diagram – Panel Section – ............................. 39

5-14. Printed Wiring Board – Power Section – ......................... 40

5-15. Schematic Diagram – Power Section – ............................ 41

5-16. Printed Wiring Board – BD-P Section –........................... 42

5-17. Schematic Diagram – BD-P Section – ............................. 42

5-18. IC Pin Functions Description ........................................... 43

5-19. IC Block Diagrams ........................................................... 48

6. EXPLODED VIEWS

6-1. Front Panel Section ............................................................. 52

6-2. Chassis Section ................................................................... 53

6-3. CD Play Section (Deck A) .................................................. 54

6-4. CD Record Section (Deck B).............................................. 55

7. ELECTRICAL PARTS LIST .................................56

3

Page 4

RCD-W3

SECTION 1

SERVICING NOTE

NOTES REGARDING HANDLING OF THE PICK-UP

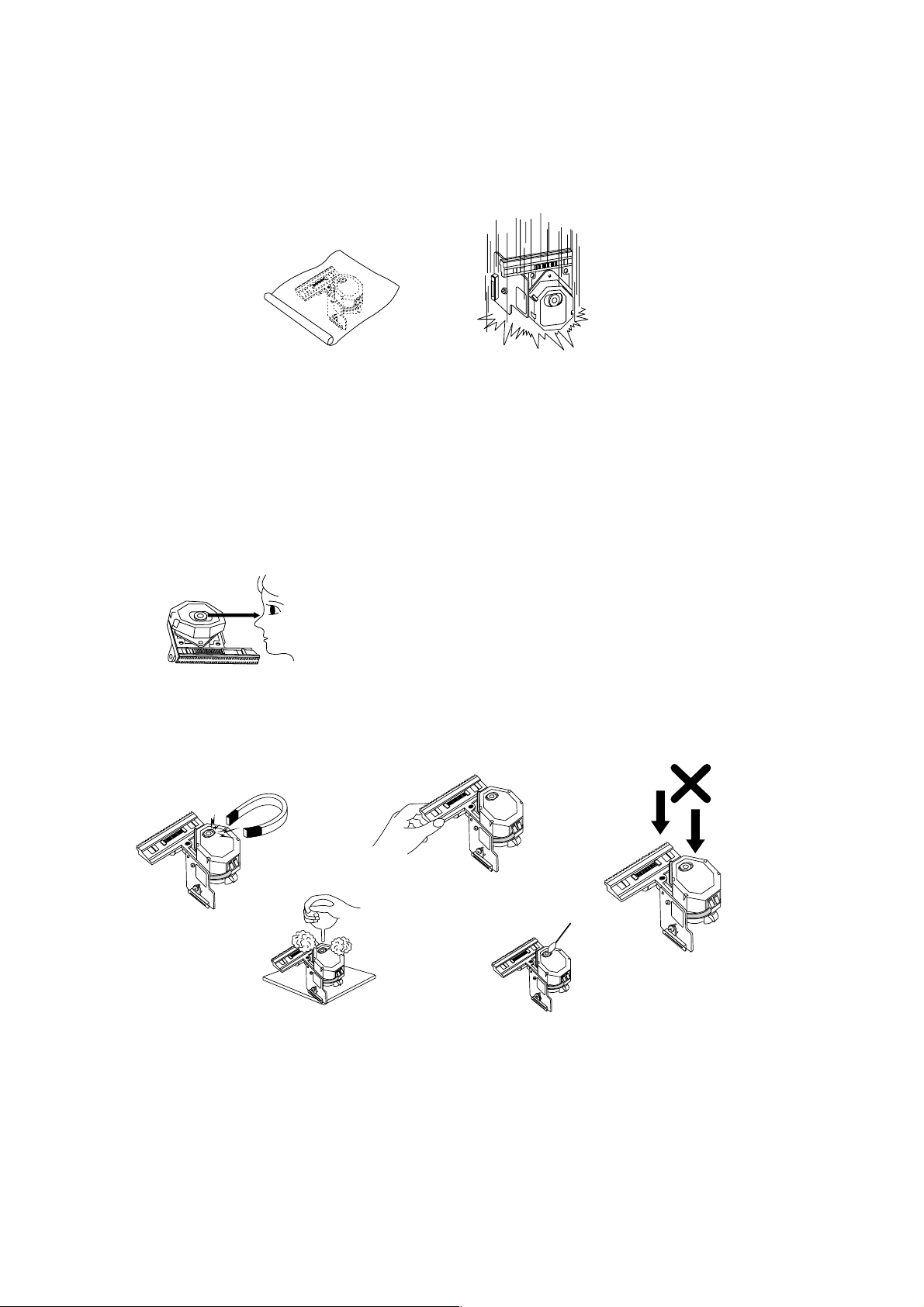

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

Storage in conductive bag

Drop impact

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully , taking care to avoid external pressure and impact.

If it is subjected to pressure or impact, the result may be an operational malfunction and/or damage to the

printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason the

adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

NEVER look directly at the laser beam, and don’t let contact

fingers or other exposed skin.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used for

camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton swab

should be used, taking care not to distort this.

Pressure

Magnet

How to hold the pick-up

Cotton swab

Conductive Sheet

6) Never attempt to disassemble the pick-up.

Spring by excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab. (Do not use any

other liquid cleaners, because they will damage the lens.) Take care not to use too much of this alcohol on the swab,

and do not allow the alcohol to get inside the pick-up.

Pressure

4

Page 5

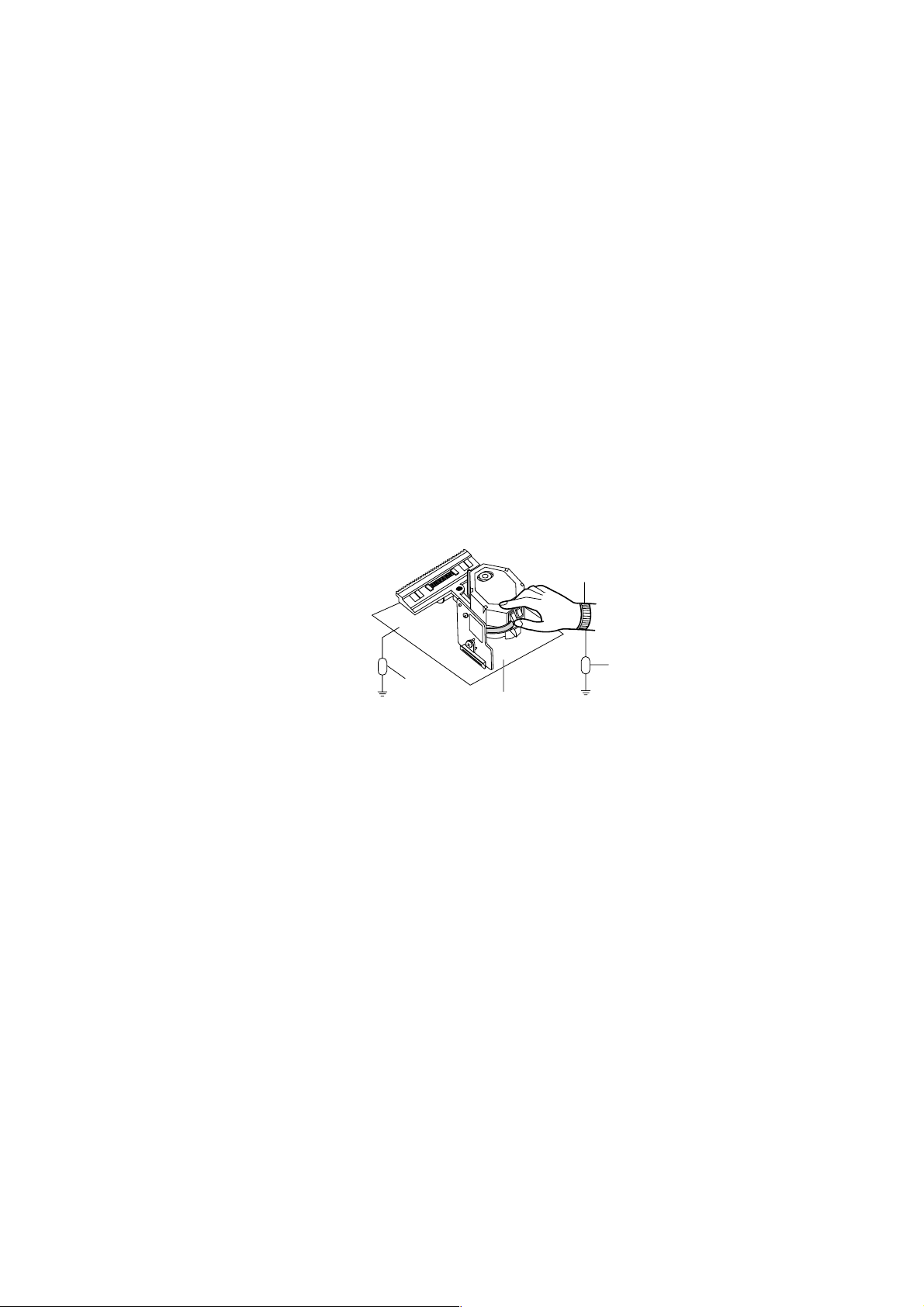

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components are sensitive to, and easily affected by, static electricity. If such static is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must

be taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong

magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1MΩ)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

RCD-W3

Resistor

(1MΩ)

Armband

Resistor

(1MΩ)

Conductive

Sheet

5

Page 6

RCD-W3

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are ready

to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by conductive

foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL

OTHER SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can gen erate static electricity sufficient to damage an ESD device).

6

Page 7

RCD-W3

)

NOTE ON CHECKING POWER SUPPLY CIRCUIT

1. When check the primary part, you must remove the GND pin of

the scope and soldering machine.

Primary GND : C103 – terminal at power board.

2. When check the primary part, you must open the another GND(not

used GND) of scope.

(If another scope GND is connected to secondary GND or other

system, input power line or system have some damage.)

3. When touch the primary part by hand in defected system,

if you use the power line switch, remove the power cord and then

check or touch.

Because in general power switch is switching only one line.

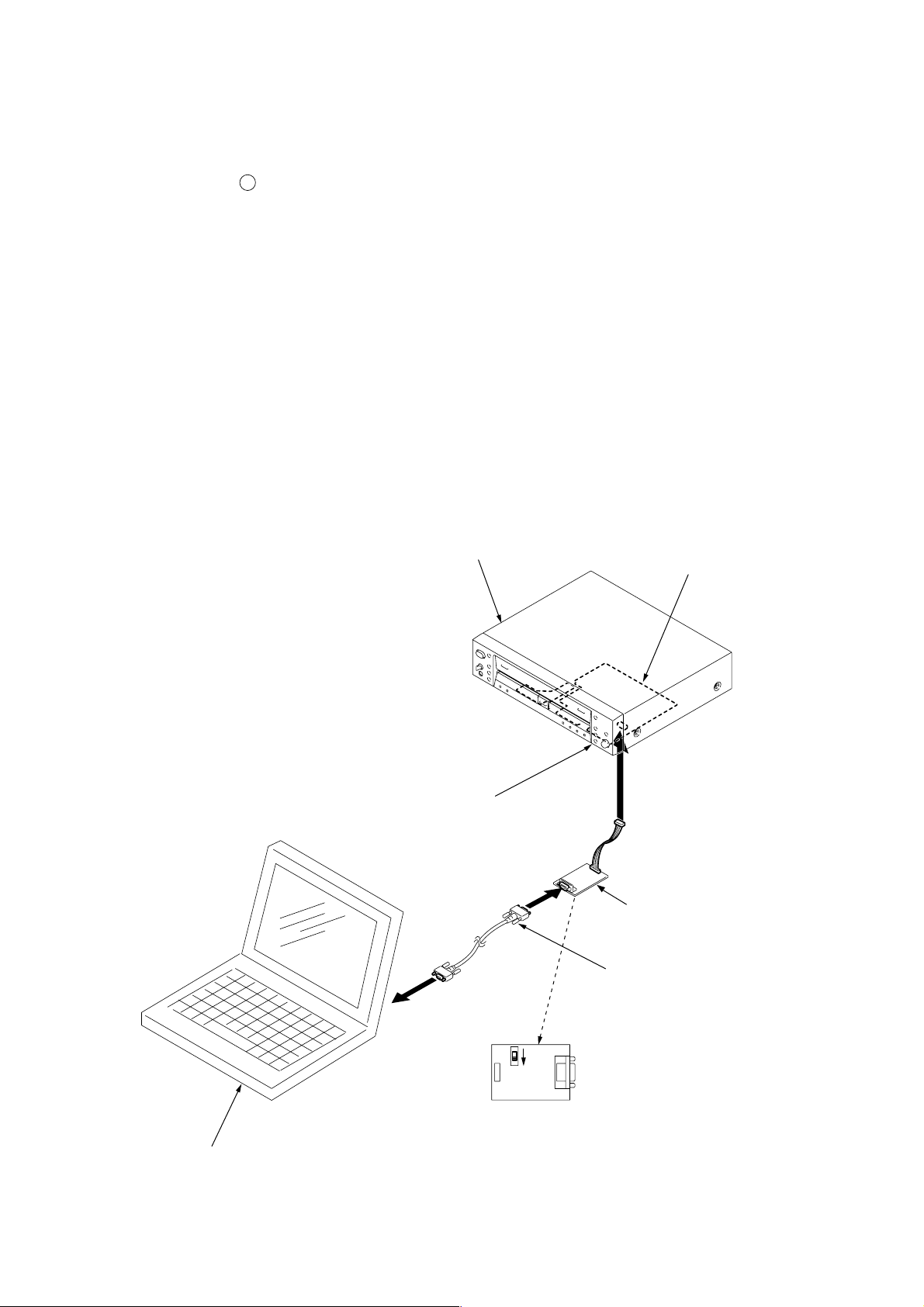

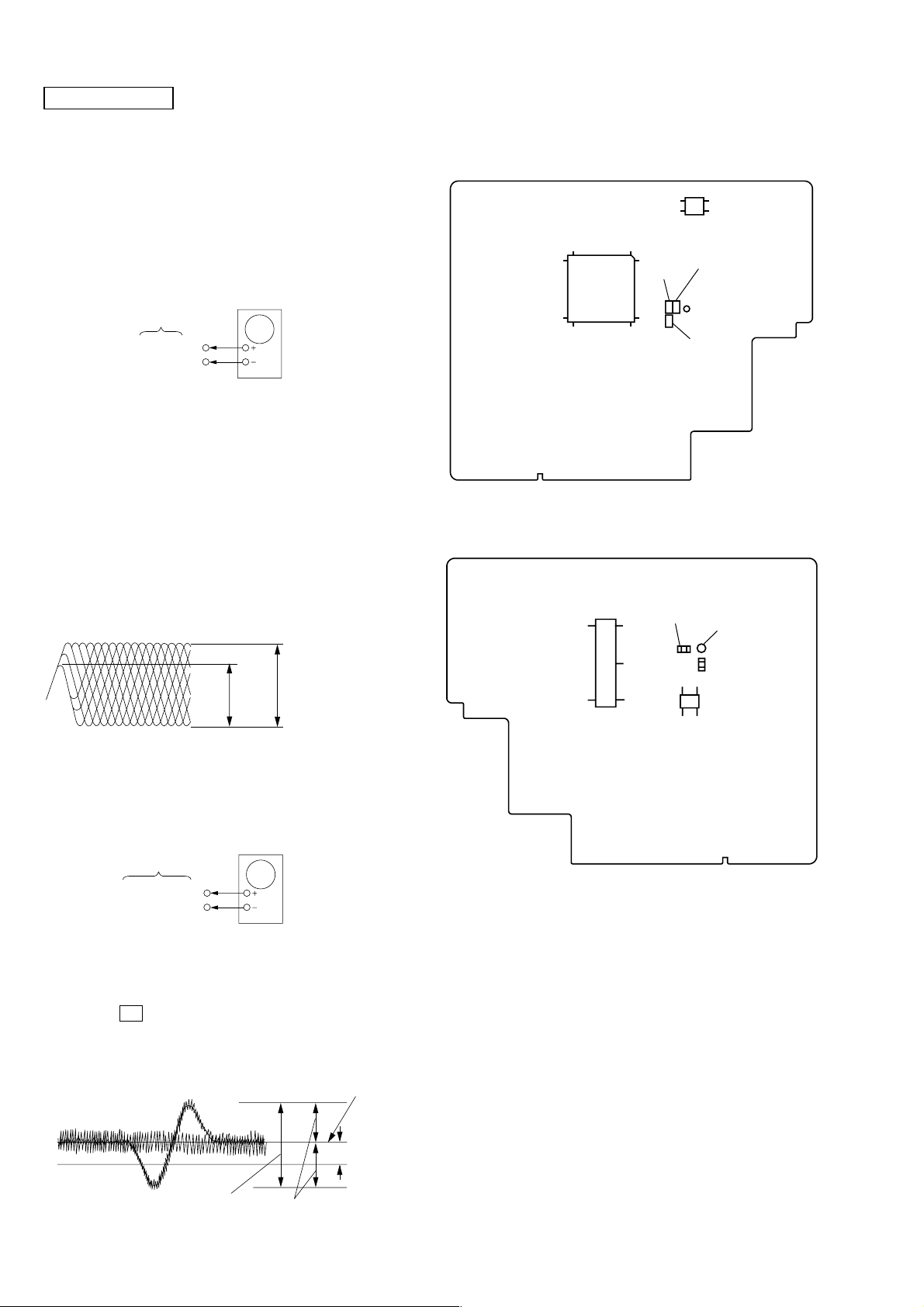

BD-R BOARD CHECK AND ADJUSTING JIGS

In case of checking or adjusting the LD power of BD-R board, the PC connection jig (J-2501-210-A) and the test program are required.

This test program is distributed with the service manual.

4. When check the primary part, after remove power cord and dis

charge the primary capacitor, and then check the system.

In the normal state, the voltage of the capacitor is small

(about 10V), but in the abnormal state is very high ( about 140V

at 100V A.C or 300V at 220V).

When discharge the capacitor , use the wattage resistor(about 100

ohm).

5. In the narrow system, Until set repaired completely,

insert the power cord at the moment repeatedly and then check

the waveform.

6. In the wide system, when insert the power cord, check the wave

form after about 3 second.

Because the wide system is the soft start method.

RCD-W3

CD-R

test connector (PN105)

BD-R board

PC connection jig

(J-2501-210-A)

PS-232C cable (D-sub 9pin

(straight type)

PC

SW501

W

D

CNP501CN505

PC connection jig

Set SW501 to “D” side

7

Page 8

RCD-W3

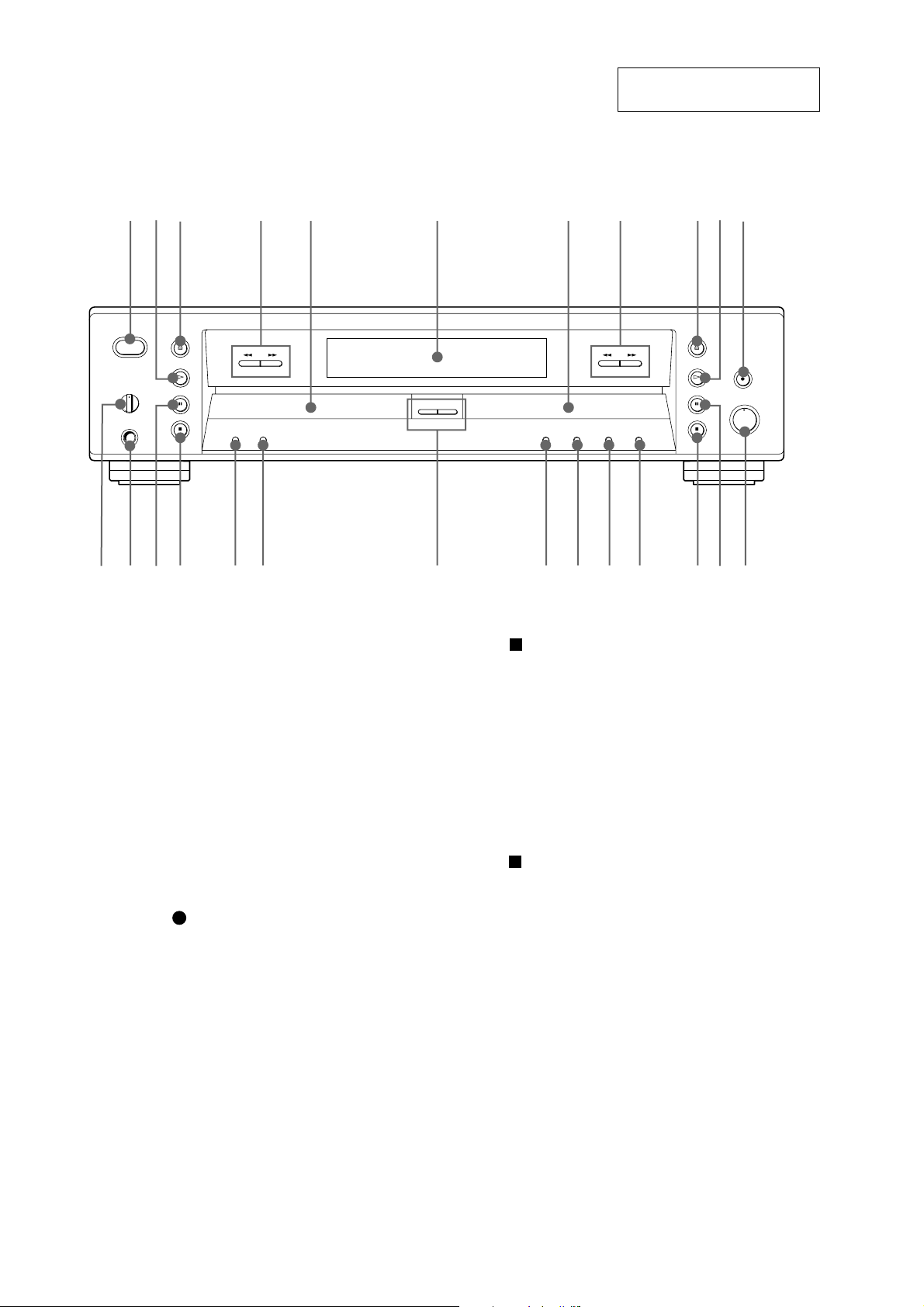

Parts and Controls

SECTION 2

GENERAL

123 4 5 6 7 8 90qa

This section is extracted from

instruction manual.

1 POWER button

2 H (play) button -Deck A

3 OPEN/CLOSE A button -Deck A

4 . AMS > buttons -Deck A

5 Disc tray-Deck A

6 Display window

7 Disc tray-Deck B

8 . AMS > buttons -Deck B

9 OPEN/CLOSE A button -Deck B

0 H (play) button -Deck B

qa REC button -Deck B

qs REC LEVEL knob

qd X (pause) button -Deck B

qfqgqhqjqkqlw;wawswdwfwg qd qs

qf (stop) button -Deck B

qg INPUT button

qh LEVEL SYNC button

qj ERASE button

qk FINALIZE button

ql CD SYNCHRO NORMAL/HIGH buttons

w; TIME button

wa RELAY button

ws (stop) button -Deck A

wd X (pause) button -Deck A

wf PHONES jack

wg PHONE LEVEL knob

8

Page 9

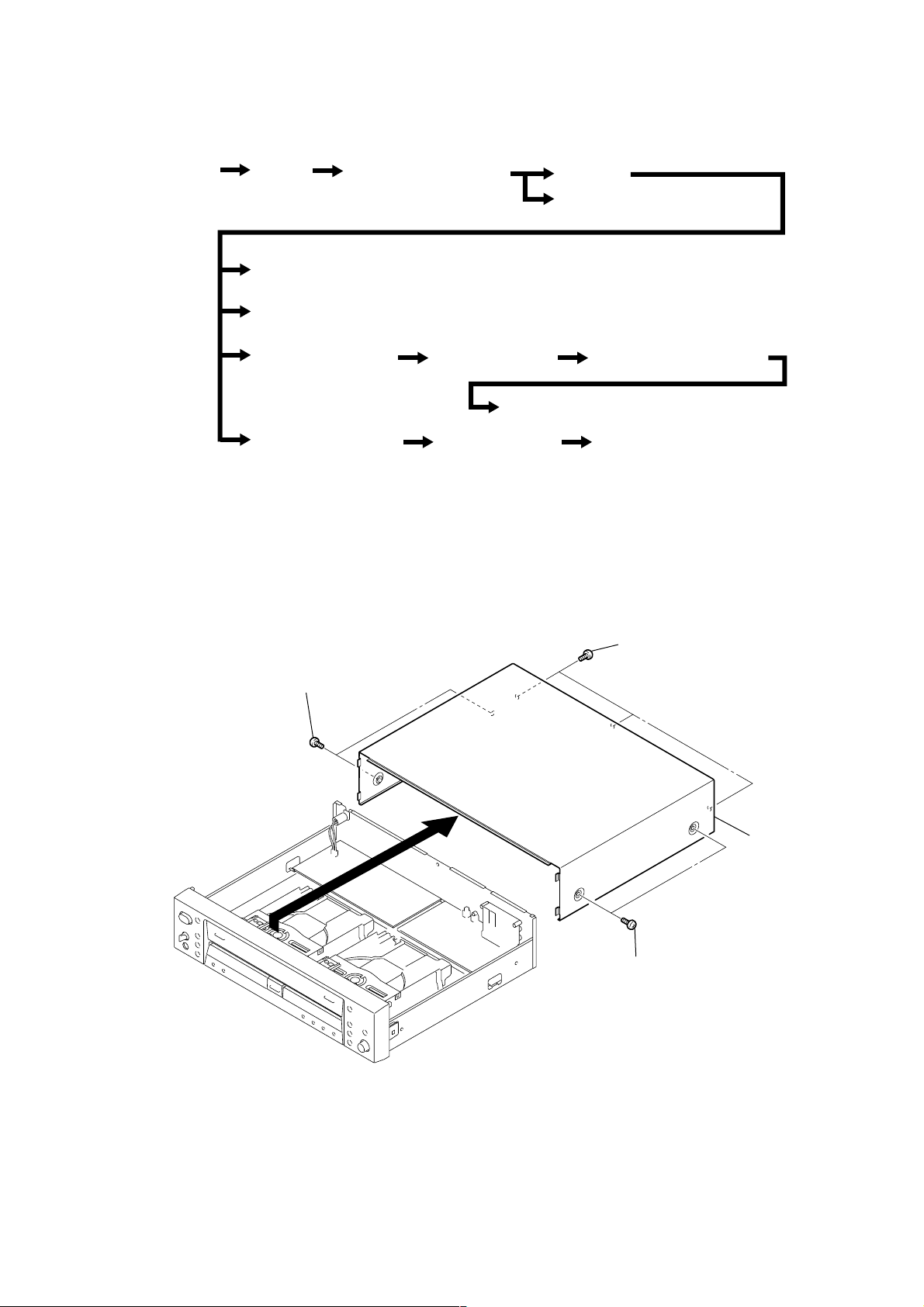

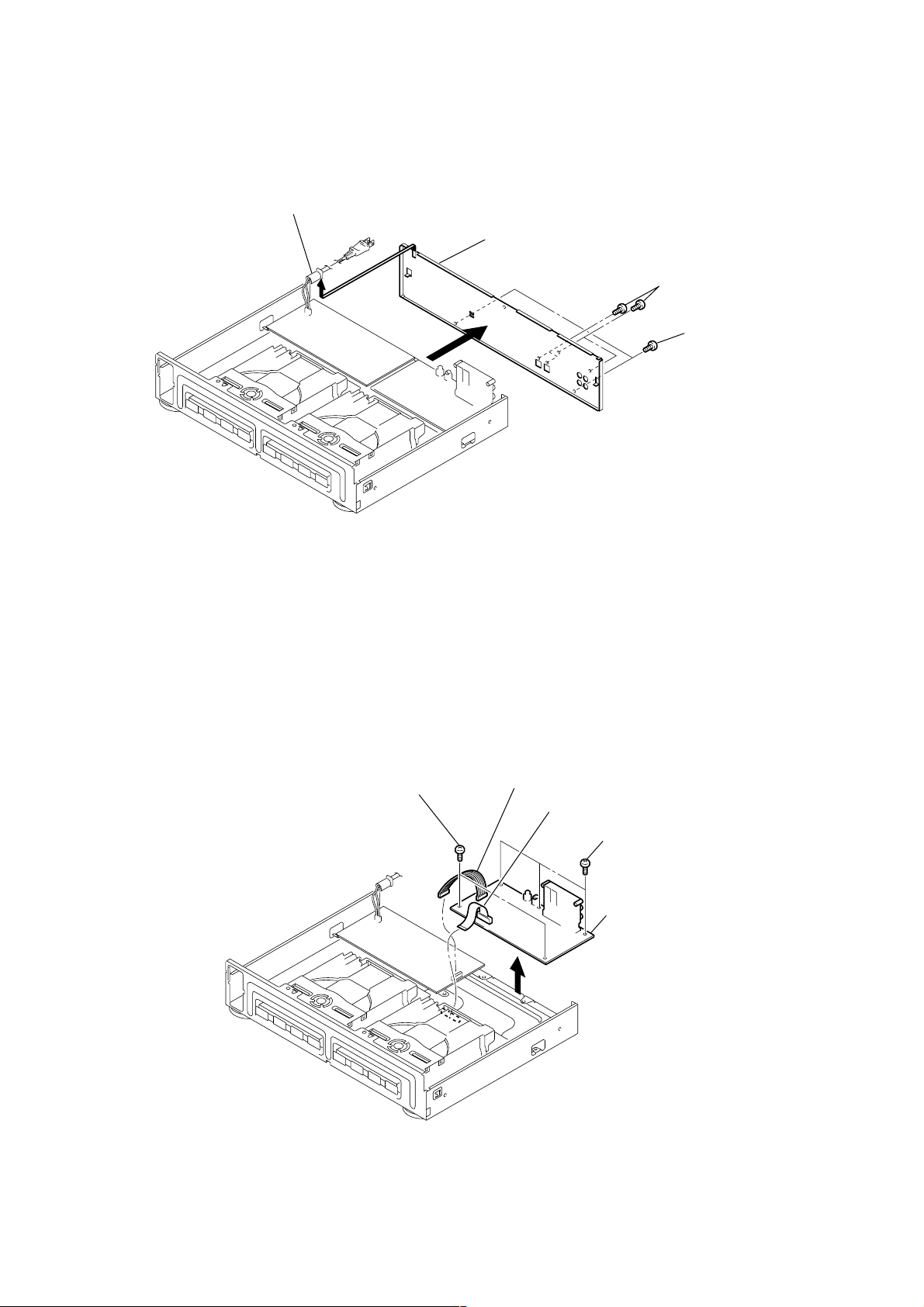

Note: Disassemble the unit in the order as shown below.

e

RCD-W3

SECTION 3

DISASSEMBLY

Set

Note: Follow the disassembly procedure in the numerical order given.

Top case

Audio board

Power board

CDP deck assy (deck A)

CD-R deck assy (deck B)

Tray door, Front panel assy

BD-P board (deck A)

BD-R board (deck B)

3-1. T OP CASE

Back panel

HP board, FL board, VOL board

CDP mechanism assy (deck A)

Spindle motor assy, Optical pick-up block (deck A)

CD-R mechanism assy (deck B)

2

Two screws (case)

4

3

Three screws (case)

1

Two screws (case)

5

Top cas

9

Page 10

RCD-W3

)

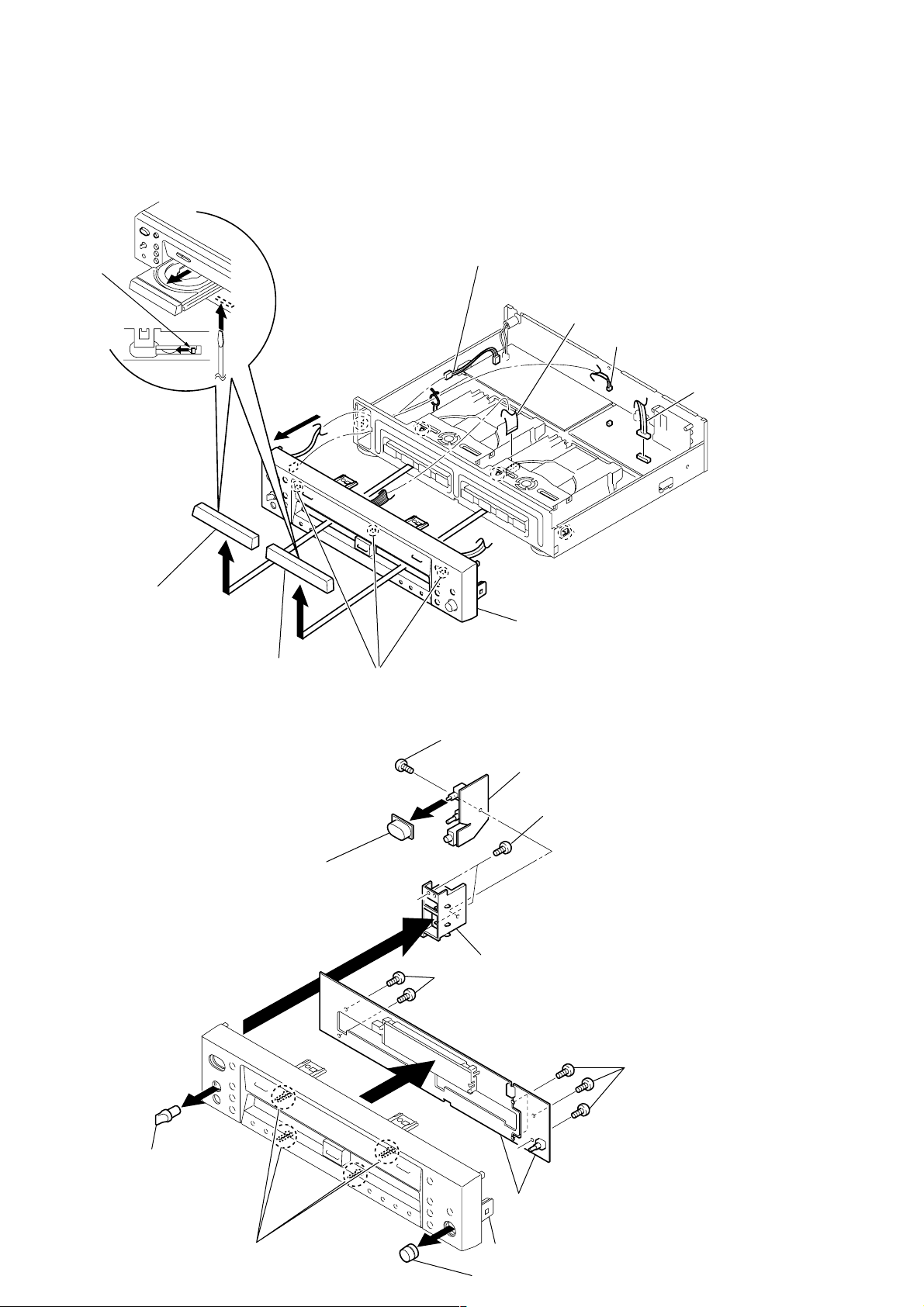

3-2. TRAY DOOR, FRONT PANEL ASSY

1

Insert a screwdriver to the square hole on the bottom,

and slide the white lever in the arrow Adirection to

open the tray.

Then remove the tray door.

(In the case of DECK B, remove it in the same manner.)

White lever

A

7

5

Connector (PN902)

4

Connector (PN401)

3

Connector (CN704)

2

Connector (CN702

Tray door (Play)

(deck A)

Tray door (Rec)

(deck B)

3-3. HP BOARD, FL BOARD, VOL BOARD

6

POWER knob

4

6

Claws

8

7

Screw (Special)

8

5

PWB holder

0

Two screws (Special)

Front panel assy

HP board

3

Two screws (Special)

10

2

P/VOLUME knob

qa

Claws

qs

FL board and VOL board

Front panel

1

REC VOL knob

9

Four screws (Special)

Page 11

3-4. BACK PANEL

)

)

3

Cord power

4

5

Back panel

1

Four screws (3X10)

2

Two screws (3X8 BK

RCD-W3

3-5. AUDIO BOARD

3

Two screws (special)

2

Connector (PN201)

1

Wire (flat type) (PN501)

5

4

Three screws (special

6

AUDIO board

11

Page 12

RCD-W3

3-6. POWER BOARD

1

Connector (PN503)

2

Two screws (special)

4

3

Two screws (special)

5

POWER board

3-7. CDP DECK ASSY (DECK A), CD-R DECK ASSY (DECK B)

2

Two screws (special)

3

Two screws (special)

6

CDP deck assy (deck A)

5

1

Wire (flat type)

(PN403)

4

9

Wire (flat type)

(PN406)

7

Two screws (special)

8

Two screws (special)

0

CD-R deck assy (deck B)

12

Page 13

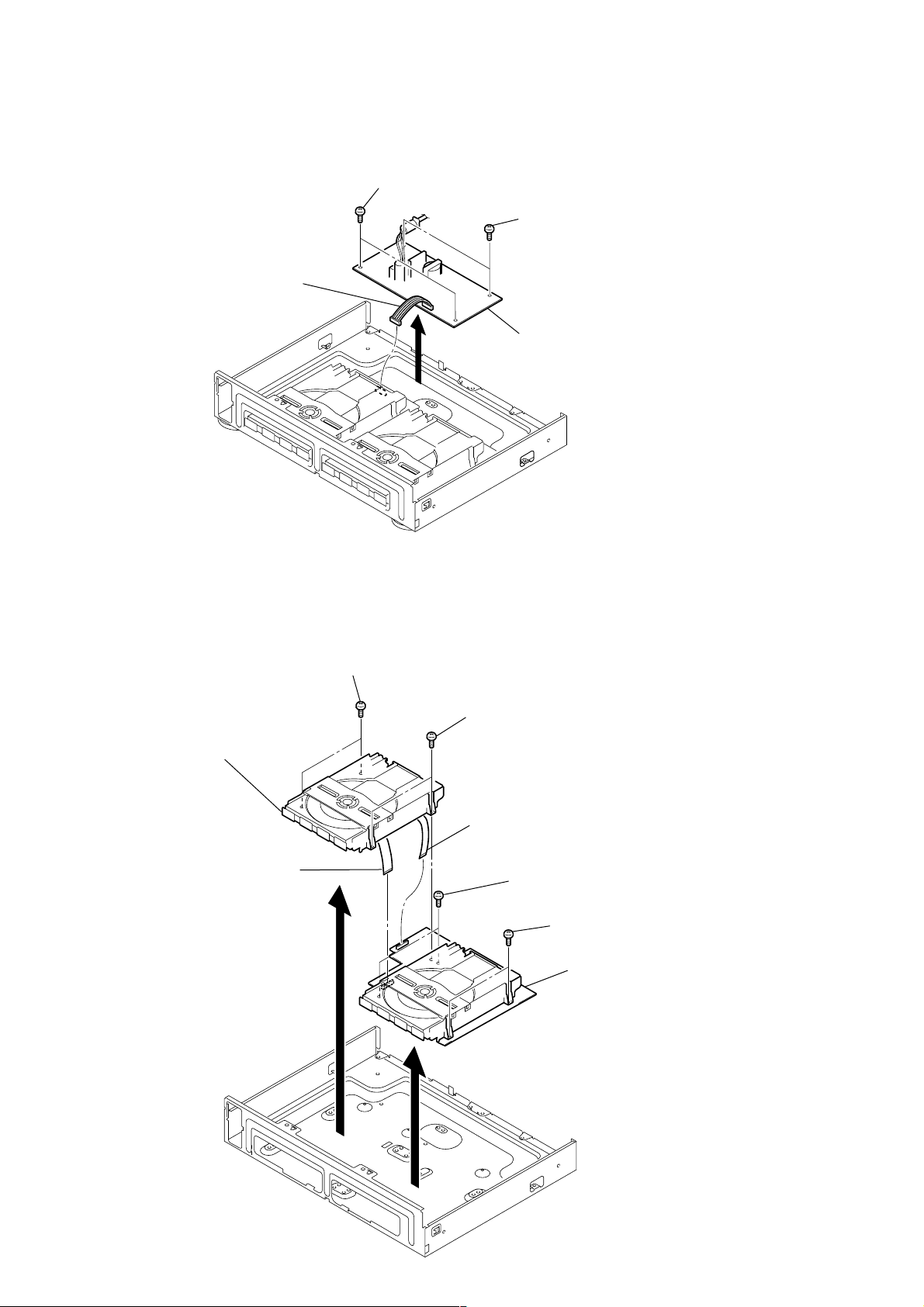

3-8. BD-P BOARD (DECK A)

)

y

1

Wire (flat type) (PN4M3)

5

Connector (PN4M5)

3

Claw

4

6

BD-P board

1

Wire (flat type) (PN4M4

RCD-W3

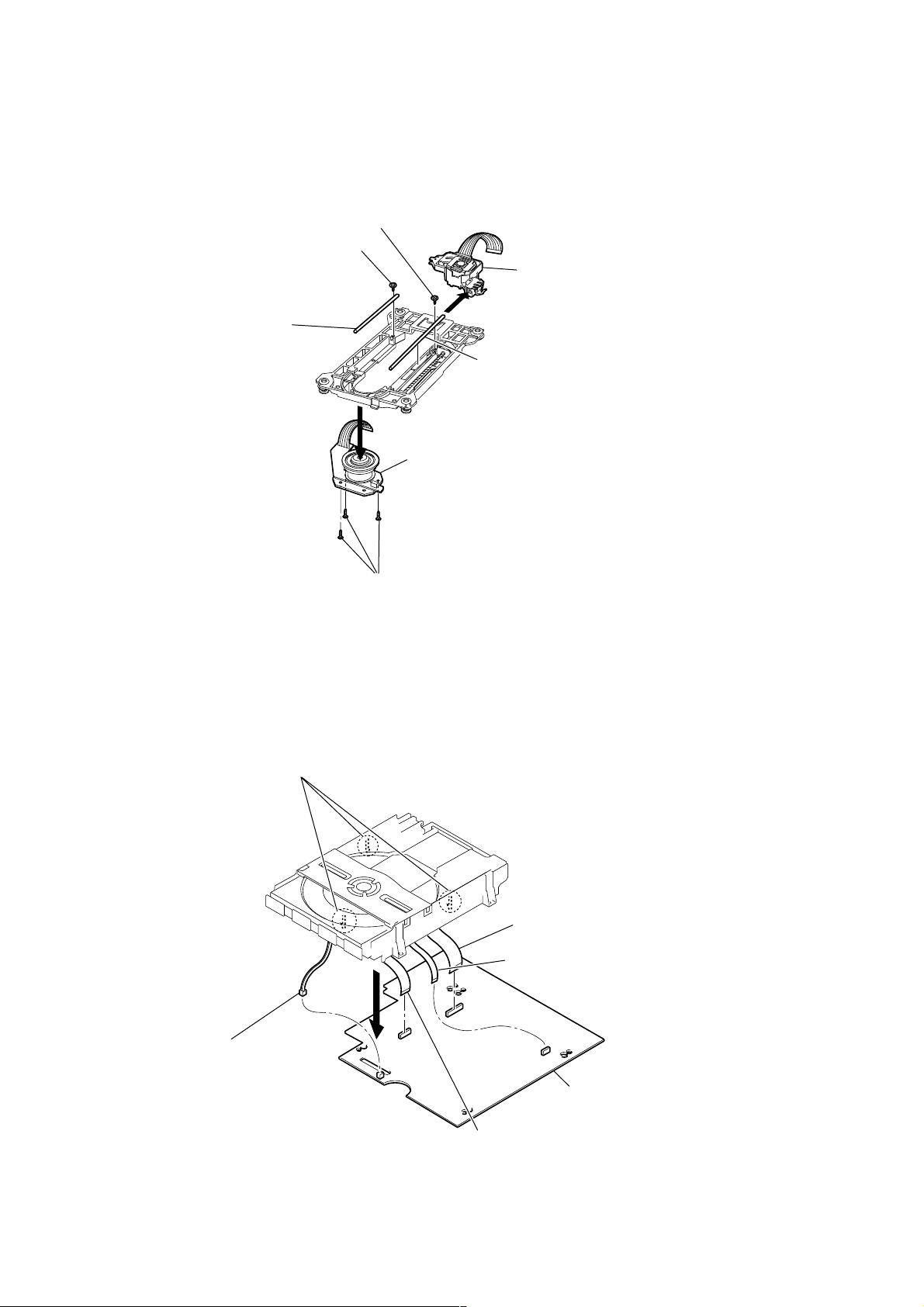

3-9. CDP MECHANISM ASSY (DECK A)

4

Push out the disc tray by pushing the

Up/Down guide un the drrow

Up/Down guide

Main base

A

direction.

A

2

Two screws (2X6)

3

Clamp holder assy

2

1

Screw (1.7X6)

7

Two screws (2.0X10)

9

8

CDP mechanism ass

Bottom view

6

Disc tray

5

13

Page 14

RCD-W3

k

)

3-10. SPINDLE MOTOR ASSY, OPTICAL PICK-UP BLOCK (DECK A)

5

Screw (1.7X5)

3

Screw (1.7X5)

8

Optical pick-up bloc

4

3-11. BD-R BOARD (DECK B)

Shaft L

2

Spindle motor assy

1

Three screws (2X6)

7

6

Shaft R

3

Connector (PN302)

1

Three claws

6

4

Wire (flat type) (PN301

2

Wire (flat type) (PN303)

5

Wire (flat type) (PN304)

7

BD-R board

14

Page 15

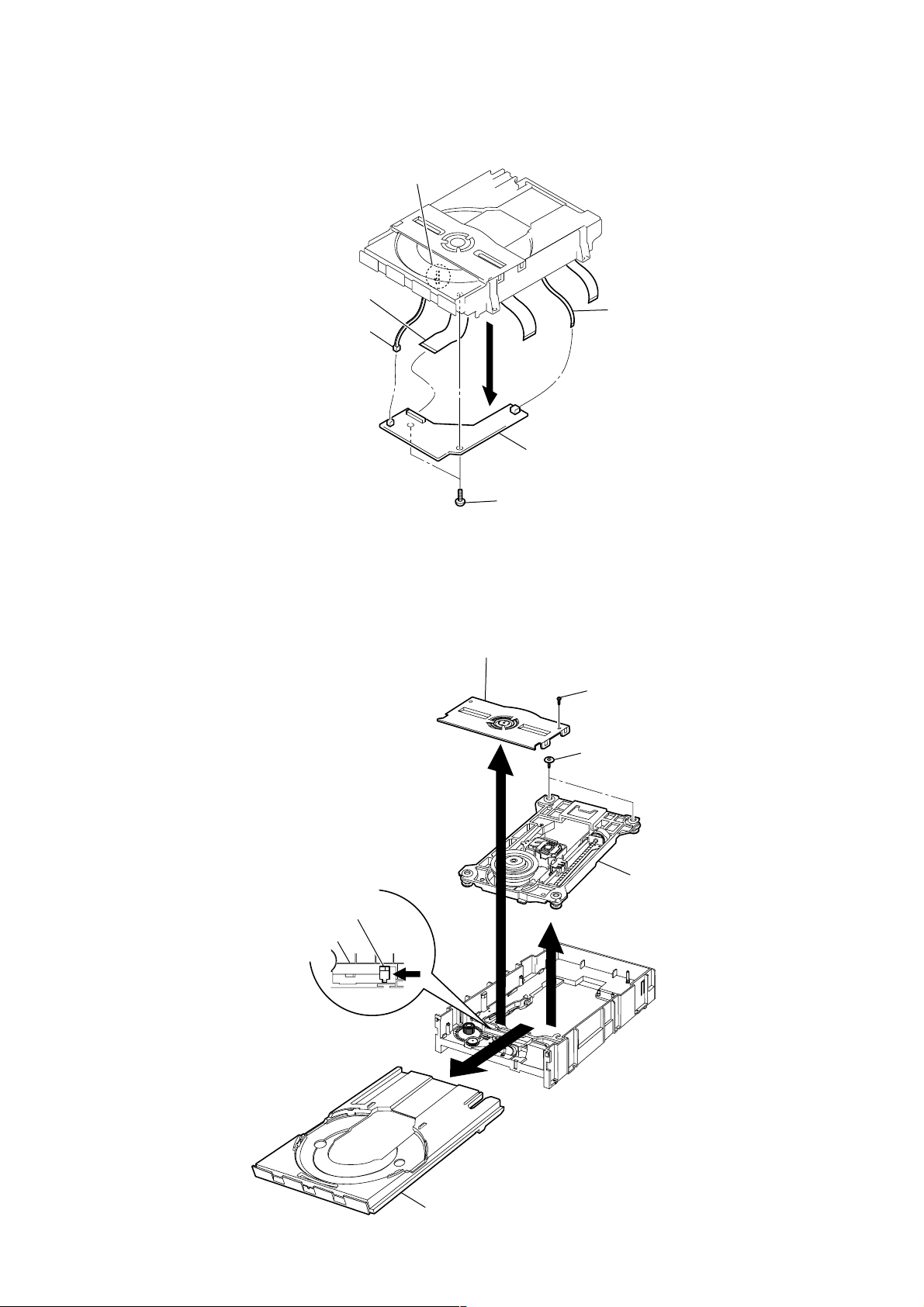

3-12. CD-R MECHANISM ASSY (DECK B)

4

Push out the disc tray by pushing the

Up/Down suide un the drrow

Up/Down guide

Main base

A

direction.

A

3

Clamp holder assy

2

1

Screw (2X6)

7

Two screws (2.0X10)

8

9

CD-R mechanism assy

RCD-W3

Bottom view

6

Disc tray

5

15

Page 16

RCD-W3

SECTION 4

ELECTRICAL ADJUSTMENT

LD Power Adjustment

Jigs used on this adjustment

• LD Power Meter

A laser power meter 10mW or more measurable is required. Don’t use the laser power meter for Mini disc because of 10mW max.

Optical power meter (TQ8210): Product of ADVANTEST (on the market).

A thin type optical sensor (Q82017A): Product of ADVANTEST (on the market).

• PC Connection Jig (J-2501-210-A)

• Test Program FD

Dragon program Tool DV810 Ver. 0.9A

(This test program is distributed with the service manual.)

• PC (Windows 95/98)

• RS-232C Cable (on the market) D-SUB 9 pin, straight type

• Test Disc for Operation Check

A low reflecting rate disc for checking playback performance. OK: It can be played back.

• Low reflecting CD-R disc: TCD-R082LMT (J-2502-063-1)

• Low reflecting CD-RW disc: TCD-W082L (J-2502-063 -2)

• CD test disc (YEDS-18) (3-702-101-01)

• Extension cable (4p, 1.0mm) (J-8000-023-A)

Laser Power Adjustment (CD-R Only)

In case of the following parts are replaced, this adjustment is required.

1. CD-R optical pick-up block (KRS-220C)

2. IC208 (EP- ROM)

Specification of Dragon Program Usage Environment

The Dragon Program programmed by API function of Windows 95 can be surely operated on the W indows 95/98 platform.

It isn’t guaranteed on the other platform.

Start up

Procedure:

1. Connect the PC connection jig with the RS-232C cable between the test connector (PN105) on CD-R of RCD-W3 and COM port on

PC.(Check SW501 on the PC connection jig to “D” side.)

2. Turn power on RCD-W3.

3. Execute Dragon_dv810_svc.exe on Windows.

(Two files Dragon_dv810_svc.exe and Dragon_dv810.cfg are displayed on the setup menu window.)

4. Select “Setup I/F” on “Setup” pull-down menu, then “Select I/F Method” window is open.

5. Select Com Port matching to the Com Port connected the PC connection jig.

6. Select “38400” of “Select Transfer Rate”.

7. Click OK.

Fig 1 : Dragon menu and setup menu windows

16

Fig 2 : Select I/F method window

Page 17

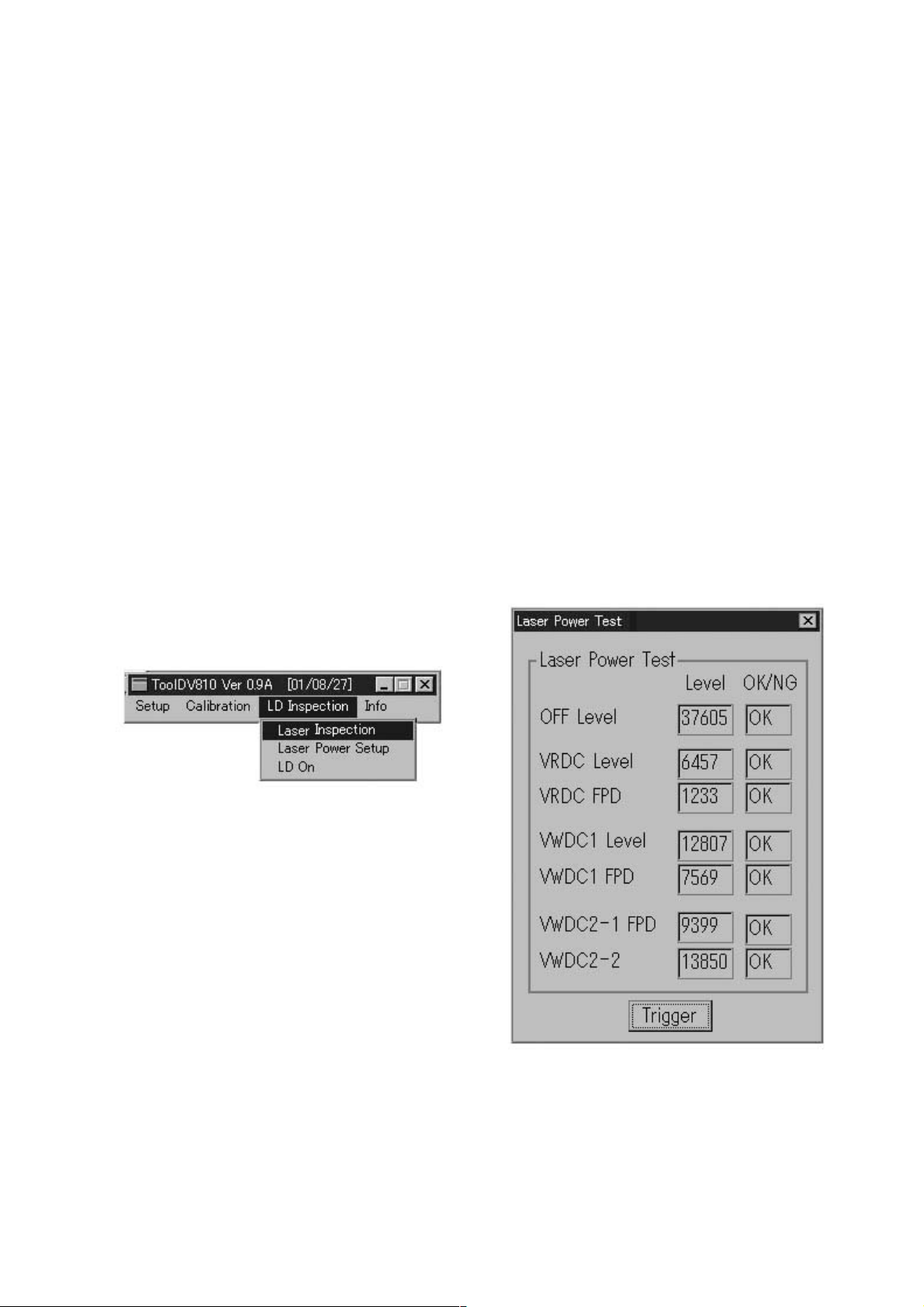

CD-R LD Setting Check

(VRDC/VWDC/FPD Level Value Check)

This routine is for checking performances of the record/playback D-A converter (IC304), the encoder/decoder IC

(IC301), CPLD (IC207), the optical pick-up block (KRS-220C), the microcomputer(IC203) and so on.

It diagnoses malfunctions of interface, the pick-up or so on.

It diagnoses the circuit in the recording mode without disc.

Description of each item

OFF LEVEL: In case of the laser turns off, FPDO output is 3V. Sampling value at this time.

VRDC LEVEL: APC circuit VRDC signal sampling value after READ power setting.

VRDC FPD: Optical pick-up FPDO signal sampling value after READ power setting.

VWDC1 LEVEL:APC circuit VWDC signal sampling value after setting WRITE power to regular value.

VWDC1 FPD: Optical pick-up FPDO signal sampling value after setting WRITE power to regular value.

VWDC2-1 FPD: There are two types of characteristics because of a non-linearity period of laser diode in the

over drive portion. This is FPDO sampling value in case of setting one of them to VWDC2 value.

VWDC2-2 FPD: FPDO sampling value in case of setting the other to VWDC2 value.

Specification of each item

38400-3300<OFF_LEVEL<38400+3300 (3.0±0.25V)

10<VRDC_LEVEL<20000

880<VRDC_FPD<1320

2000<VWDC1_LEVEL<25000

6160<VWDC1_FPD<12960

10<VWDC2-1_FPD<15000

2500<VWDC2-2_FPD<20000

Procedure:

1. Eject a disc from CD-R.

2. Select “Laser Inspection” on “LD Inspection” pull-down menu, then “Laser Power Test” window is open.

3. Click Trigger to execute LD check.

4. LD checked results are displayed.

(“OK”/“NG” is displayed for every items.)

5. Click X to close “Laser Power Test” window.

RCD-W3

Fig 3 : LD inspection menu windows

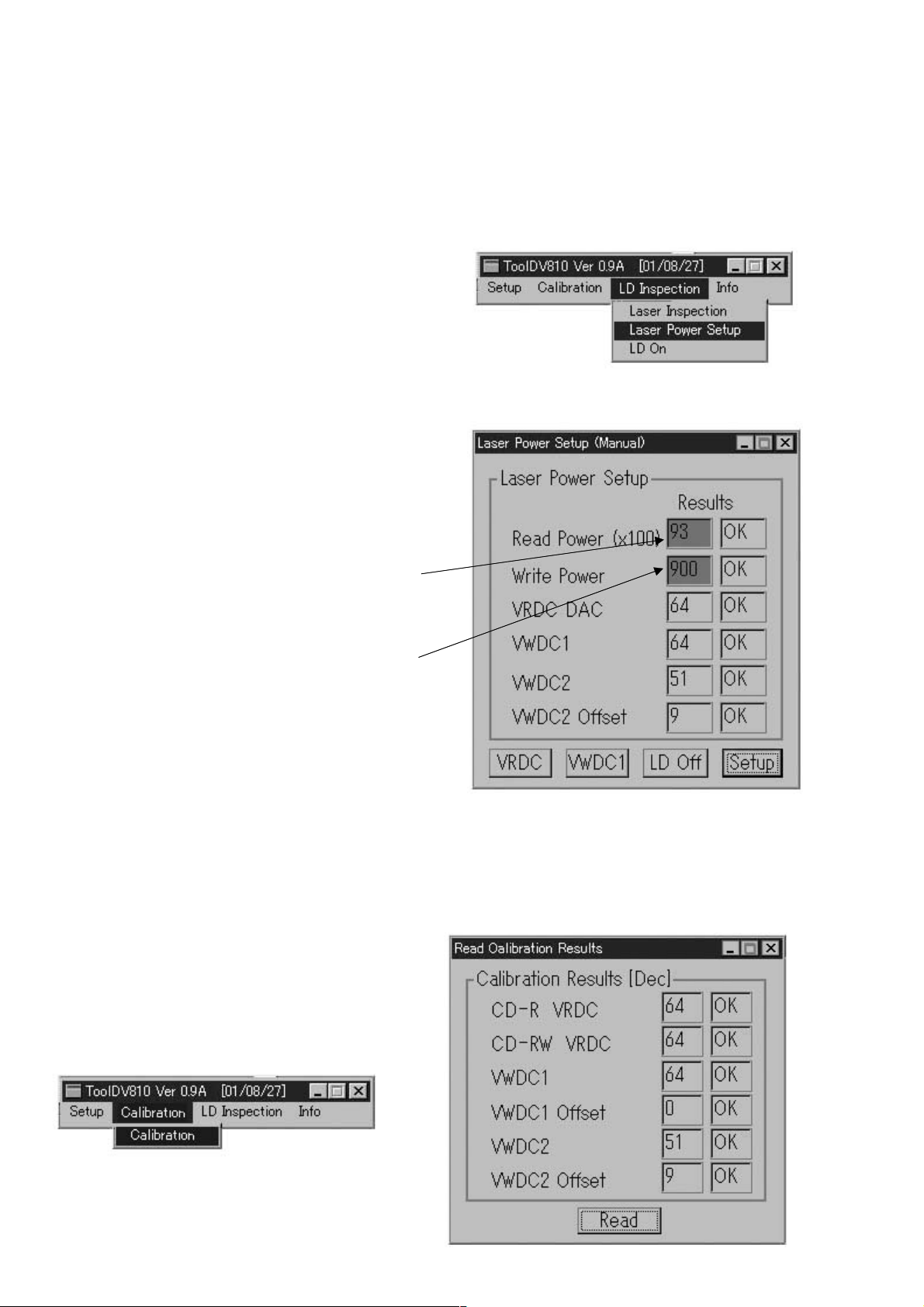

CD-R LD Power Setting

(VRDC/VWDC1 Resetting)

The optical pick-up and ICs in the circuit have a characteristics individually. In this routine, the parameters related to the

recording/playback power are actually measured and set properly.

The parameters are VRDC, VWDC1, VWDC2, VWDC2 Offset and so on. The reading power and playback power are set

properly by computing the related parameters on the basis of actually measuring values.

The preset parameters are used on power setting in case of performing Read/Write CD-R, CD-RW and so on.

Actual operation: The microcomputer receives serial data, then executes the related performances, and send parameter values to PC.

PC checks its related parameters and judges OK/NG.

Fig 4 : Laser power test window

17

Page 18

RCD-W3

Description of each parameter

VRDC: Used on the Read Power setting in case of reading CD-RW and CD-R. (DAC value on 100mW.)

VWDC: There is VWDC1 (Write power) pin in the optical pick-up block. The recording power is set by it and VWDC2

(Over drive) pin. Used on setting VWDC1 pin power on recording. (Unit: DAC value/10mW)

VWDC2: Used on setting VWDC2 (Over drive) pin power on recording. (Unit: DAC value/5mW)

VWDC2 Offset: Used on setting VWDC2 (Over drive) pin power with VWDC2 parameter on recording. (Unit: DAC value)

Specification of each parameter

20<read power<200

100<write power<2000

30<VRDC<150

48<VWDC1<150

50<VWDC2<145

VWDC2 Offset<35

Fig 5 : LD inspection menu windows

Procedure:

1. Eject a disc from CD-R.

2. Select “Laser Power Setup” on “LD Inspection” pull-down

menu, then “Laser Power Setup (Manual)” window is open.

3. Click VRDC, then Pick-up moves outward and LD turns on.

4. Measure the LD power with a LD power meter. W rite its value

to the blank of “Read Power” column.

(Write a value to two decimal places. Ex: W rite “93” in case of

0.93mW.)

5. Click VWDC1, then LD turns on.

6. Measure the LD power with a LD power meter. W rite its value

to the blank of “Write Power” column.

(Write a value to two decimal places. Ex: W rite “1234” in case

of 12.34mW.)

7. Click LD Off to turn LD off.

8. Click Setup, then setting is over and a result is displayed.

(“OK”/“NG” is displayed for every items.)

9. Click X to close “Laser Power Setup (Manual)” window.

Adjustment Data Check

Check if the error has occurred on reading “CD-R LD POWER SETTING” value.

Procedure:

1. Select “Calibration” on “Calibration” pull-down menu, then “Read Calibration Results” window is open.

2. Click Read, then the calibration data are displayed.

3. Data specification

CD-R VRDC DAC: 30-150

VWDC1: 48-150

VWDC2: 50-145

VWDC2 Offset: 0-35

4. Click X to close “Read Calibration Results” window.

Fig 7 : Calibration menu windows

Fig 6 : Laser power setup window

18

Fig 8 : Read calibration results window

Page 19

RCD-W3

level=1.3±0.6Vp-p

symmetry

A (DC voltage)

center of

waveform

B

0V

1 track jump waveform

Specified level: –– × 100=less than ±22%

B

A

e

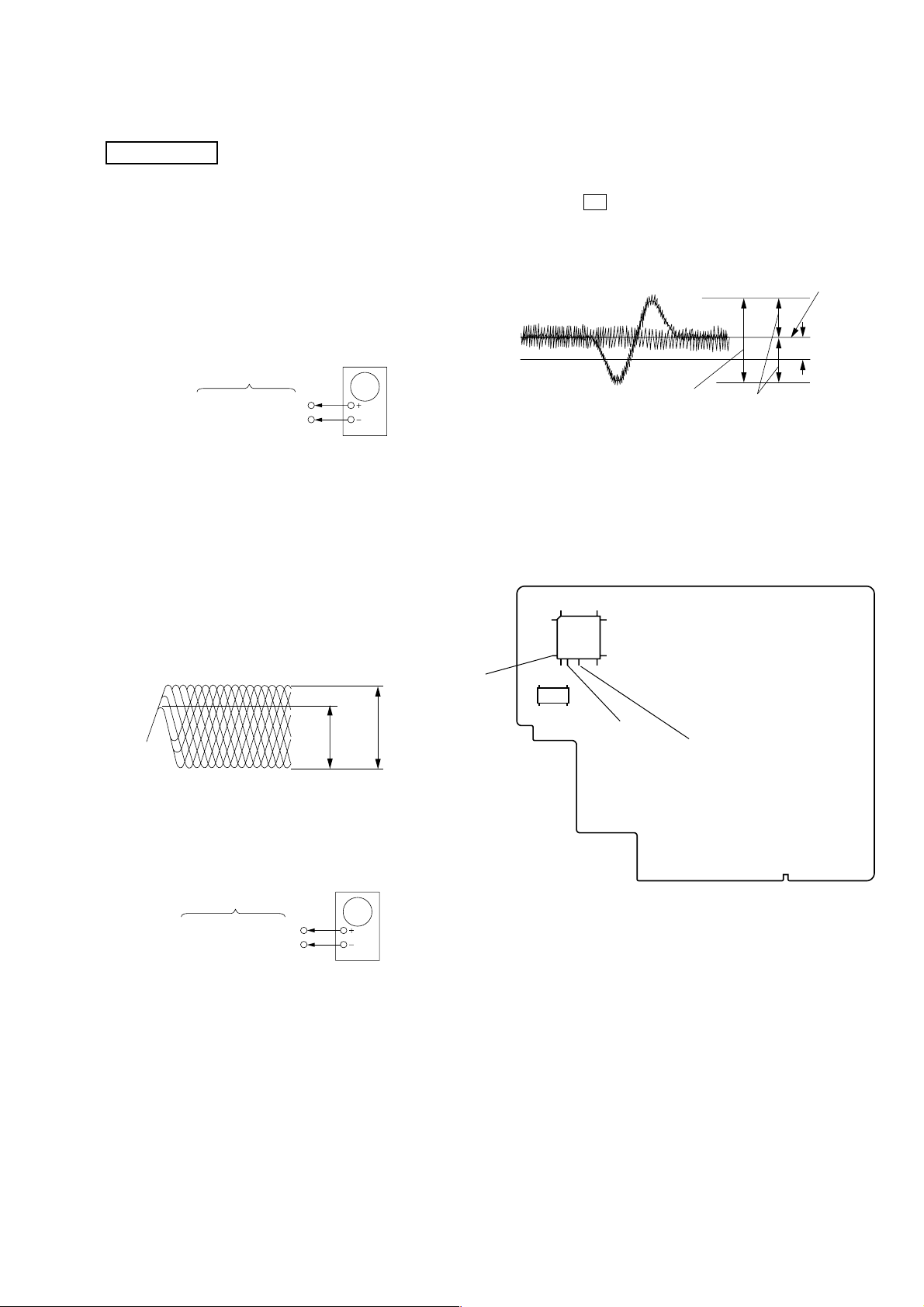

SERVO Check

CD SECTION

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the following checks.

RF Level Check

oscilloscope

BD-R board

IC402 ehpin(RFAC)

IC402 wkpin(VC)

Procedure :

1. Connect oscilloscope to IC402 eh pin (RFAC) and IC402 wk

pin (VC).

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

Note : Clear RF signal waveform means that the shape “ ◊ ” can be clearly

distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

IC402 wg pin

(TE)

Procedure :

1. Connect oscilloscope to IC402 wg pin (TE) and IC402 wk pin

(VC).

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback the number five track.

4. Press the X button. (Becomes the 1 track jump mode.)

5. Confirm that the level B and A (DC voltage) on the oscilloscope waveform.

Adjustment Location:

[BD BOARD] (SIDE B)

100

76

30

25

1

26

IC402

16

75

51

50

E-F Balance (1 Track jump) Check

BD-R board

IC402 wg pin(TE)

wk

IC402

pin(VC)

3T= 0.55

11T= 0.90

oscilloscop

3T

11T

±

0.07Vp-p

±

0.13Vp-p

1

IC403

15

IC402 wk pin

(VC)

IC402 eh pin

(RFAC)

19

Page 20

RCD-W3

e

)

CD-R SECTION

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the following checks.

RF Level Check

oscilloscope

BD-R board

TP(RRF)

1

IC302

Procedure :

1. Connect oscilloscope to TP (RRF) and IC302 1 pin.

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback.

4. Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

Note : Clear RF signal waveform means that the shape “ ◊ ” can be clearly

distinguished at the center of the waveform.

pin

Adjustment Location:

[BD-R BOARD] (SIDE A)

25

26

IC301

50

51

[BD-R BOARD] (SIDE B)

75

8

1

4

5

100

C363

76

IC302

R3C6

TP(RRF)

C396

1

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

3T

3T= 0.55

11T= 0.90

11T

±

0.07Vp-p

±

0.13Vp-p

E-F Balance (1 Track jump) Check

oscilloscop

BD-R board

TP(TE1)

PN301

qk

pin

Procedure :

1. Connect oscilloscope to TP (TE1) and PN301 qk Pin.

2. Turned Power switch on.

3. Load a disc (YEDS-18) and playback the number five track.

4. Press the X button. (Becomes the 1 track jump mode.)

5. Confirm that the level B and A (DC voltage) on the oscilloscope waveform.

1 track jump waveform

center of

waveform

1

31

PN301

18

32

C380

2

TP(TE1)

R369

41

58

0V

level=1.3±0.6Vp-p

Specified level: –– × 100=less than ±22%

A

B

20

B

symmetry

A (DC voltage

Page 21

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed

in each block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• % : indicates tolerance.

¢

•

• C : panel designation.

Note:

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

: internal component.

4

W or less unless otherwise

Les composants identifiés par

une marque

! sont critiques pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

RCD-W3

SECTION 5

DIAGRAMS

• Signal path.

J : CD

c : CD (digital)

I : CD REC

L : CD REC (digital)

• Abbreviation

CND : Canadian model

For printed wiring boards.

Note:

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from the

(Side B) pattern face are indicated.

Parts face side: Parts on the parts face side seen from the

(Side A) parts face are indicated.

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

• AC voltage readings in the bias oscillator with a level

meter.

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : STOP

( ) : PLAY

< > : REC (CD-R only)

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

5-1. CIRCUIT BOARDS LOCATION

BD-P board

HP board

• Indication of transistor

C

Q

These are omitted

EB

• Abbreviation

CND : Canadian model

POWER board

AUDIO

board

C

EB

These are omitted

FL board

BD-R board

VOL board

21

Page 22

RCD-W3

– BD-R SECTION –

IC301 ia (RRF IN)

1

0.2V/div

µ

sec/div

0.5

IC301 tk (FE)

2

0.1V/div

5msec/div

IC301 tj (TE)

3

0.5V/div

5msec/div

IC207 rf (34MCLK)

4

0.8 Vp-p

0.1 Vp-p

0.5 Vp-p

1.8 Vp-p

IC502 qs (ILRCK)

5

10

6

0.2

7

8

1V/div

µ

sec/div

1V/div

µ

21µsec

IC502 qd

sec/div

IC510 td (AD MCLK)

90nsec

IC510 t; (MCLK IN)

(ISCLK)

0.44µsec

3.2 Vp-p

3.2 Vp-p

3.4 Vp-p

1V/div

50nsec/div

3.3 Vp-p

IC403 qg (RF AC)

9

0.5V/div

µ

sec/div

0.5

IC403 qh (FE)

0

0.1V/div

5msec/div

IC403 ql (TE_BAL)

qa

0.5V/div

5msec/div

IC407 yh (EXTAL)

qs

1.6 Vp-p

0.1 Vp-p

0.5 Vp-p

1.5 Vp-p

IC408 2 (XOUT)

qd

1V/div

20nsec/div

IC201 (XIN)

qf

33.86MHz

IC203 yh (EXTAL)

qg

20MHz

4.9 Vp-p

33.86MHz

149

3.3 Vp-p

1V/div

20nsec/div

1.7 Vp-p

0.5V/div

20nsec/div

29nsec

1V/div

20nsec/div

– PANEL SECTION –

IC801 4 (X2)

1

5.3 Vp-p

5MHz

0.1

2V/div

µ

sec/div

33.86MHz

1V/div

20nsec/div

0.5V/div

20nsec/div

20MHz

22

Page 23

5-2. BLOCK DIAGRAMS – CD-R SECTION (1/2) –

RCD-W3

OPTICAL

PICK-UP BLOCK

(KRS-220C)

(DECK B)

LD

PD

FOCUS

COIL

TRACKING

COIL

M609

LOADING

MOTOR

(DECK B)

M301

SLED

MOTOR

(DECK B)

A

A

B

B

C

C

D

D

E

E

F

F

G

G

H

H

VWDC1

VWDC2

FPDO

VRDC

ODON

W/XR

IN3-

OSCEN

LD DRIVER/CONTROL

FPDVC

PDVC

FCS-

TRK+

TRK-

M

M

TRAY+

TRAY-

D301

1 3

7 5

IC302

BUFFER

34

35

32

31

36

37

A

9

A

10

B

5

B

6

+4V

FO+FCS+

FO-

TO+

TO-

LO+

LO-

SL1+

SL1-

SL2+

SL2-

VWDCLMT

VWDC2

FPDO

ODON

W/XR

ENBL

OSCEN

RREF2

BTL MOTOR DRIVE

IC303

DRV

DRV

DRV

DRV

DRV

BAS

Q301

FOIN+

TOIN+

LOIN+

SLIN1

SLIN2

REF

MU1

Q302

ERGCNT

27

28

40

1

2

25

41

FOCUS/TRACKING,ERROR

AIN

98

BIN

97

CIN

96

DIN

95

EIN

93

FIN

92

GIN

91

HIN

90

RREF2

6

VWDCN

7

VWD1

8

FPDO

99

VRDC

4

VRDCN

3

RREF1

5

RREF1

TAO

LDIN

SLD MOVE A

SLD MOVE B

DRV EN

RF EQUALIZER,

DETECT

IC301

S/H

MATRIX

FAO

DVC

RFO

SRFO

FEO

VC

+2V

Q303

HAVC

WREF

1027

WREF

APC

FVREF

MFPDSH

100

3128 94 32 46 15

WFPDSH

CE

RF PDSH

MLDON

RF PDSH

WLDONCEWBLSH

RREF1

VWDC2

RREF2

WREF

HAVCOFS

VWDCLMT

81

82

RRF

RRFIN

RF EQ

CEO

WBLSH

SPDSH

MPDSH

ROPCSH1

33 34 35 38 13 19

SPDSH

MPDSH

ROPCSH_E

+4V

65

MSPP

CEM

MPXOUTCSXLAT

MPXOUT

D/A CONVERTER

AO1

18

AO2

19

AO3

2

3

AO4

AO5

4

5

AO6

6

AO7

7

AO8

AO9

8

9

AO10

AO11

12

AO12

13

CE

IC304

MPX

REGISTER

TFGCNT

4148 42 43 45

/CXACS

DO

CLK

LD

63

RFRPIN

SDATA

SCLK

ERGCNT

CXADATA0

/CXACLK

ERGCNT

17

16

15

ATFG

30 47 61 6253

AGCON

WBLIN

DADATA

/DACLK

/DACS

+4V

REG.

4 2

IC210

PH/BH

FE TE

AGCON

RFCT

RFRP

+5VA

EQRFP

EQRFN

BH01

BH01

TEIN

XTOR

XTOK

RECD

SWRF

7

EFM(RFAC)

BLEVEL0

AGCON

MPXOUT

BS

RP

TE

FE

ASYM2

ASYM1

79

80

78

53

48

59

81

AMYS2

BLEVEL0

AMYS1

XTOK

RECD1

AGCON

MPXO

67

68

NC

71

72

56

TE

57

FE

58

50

51

52

88

IC306 (1/2)

21

TE AMP

BLEVELO

TEBC

+2V

COMPARATOR

IC305(2/2)

6

5

3

2

COMPARATOR

IC305 (1/2)

7

1

IC308

1

2

EFM

BS

RP

TE

FE

RX

TX

CD-R

A

SECTION

(2/2)

(Page 24)

IC307

RPBC

FLAGC

FPDO

WLDON

REPDSH

WFPDSH

WBLSH

SPDSH

MPDSH

W/XR

OSCEN

ENBL

ODON

2 1

4

NC

17MHz

1

NC

ERGCNT

14

13

WLDON

5

REPDSH

WFPDSH

3

WBLSH

6

SPDSH

7

8

MPDSH

W/XR

18

19

OSCEN

ENBL

20

21

ODON

IC207

RDPCON

CDR/RW

WR/RE

ATIP/EFM

ADTRIG

CPLD

EEPROM

IC208

32

33

34

36

38

CS

CK

DI

DO

RDPCON

/CXACS

CXADATA

/CXACLK

1

2

3

4

DADATA

/DACLK

/DACS

23

21

61

83

18

19

24

60

20

7

2

90

/CXACS

EP CS

SDATA IN

FPDO

SDATA

SCLK

/DA CS

RDPCON

CDR/RW

WR/R

ATIP/EFM

ADTRIG

SYSTEM

CONTROL

IC203 (1/2)

M401

SPINDUL

MOTOR

(DECK B)

LIMIT

SW

M

HALL

SENSOR

W

V

U

HU+

HUHV+

HVHW+

HWHH+

+5VA

EEFS

EFM1

W

12

V

U

HU+

HUHV+

HV-

HW+

HW-

HB

DRIVE

CONTROL

SPIN

FG3

26

24

SPNFG

SLD IN SW

13

14

20

21

18

19

16

17

23

DMO

IC306 (2/2)

57

BUFFER

EFM2

EFM3

ROPC1

RESAMP1

EFCK

RESAMP2

39

29

30

40

41

42

43

2

44

EEFS

EFM1

EFM2

EFM3

ROPC1

RESAMP1

EFCK

RESAMP2

34MCLK

WRSMP

MONTITO

LDON

WGATE

HRSW

/RST

WRSMP

12

MONTITO

22

LDON

23

WGATE

27

HRSW

31

/RST

16

DRV EN

SLD IN SW

SLD MOVE A

SLD MOVE B

100

DRV EN

/SLD IN SW

49

SLD MOVE A

84

SLD MOVE B

85

RESET

63

SYS BUS

34MCLK

•Signal Path

: CD PLAY

: CD REC

B

CD-R

SECTION

(2/2)

(Page 24)

23 23

Page 24

RCD-W3

– CD-R SECTION (2/2) –

A

CD-R

SECTION

(1/2)

(Page 23)

B

CD-R

SECTION

(1/2)

(Page 23)

34MCLK

SYS BUS

EFM

JK703

DIGITAL

OPTICAL

IN

163 E F M

BS

RP

TE

FE

RX

TX

WBLIN

FAO

TAO

DMD

EFM1

EFM2

EFM3

WRSMP

RESAMP1

RESAMP2

EFCK

ROPC1

LDON

SPNFG

CE

TEBC

WGATE

FEFS

ROPCSHE

RPBC

FLAGC

WRSMP

WGATE

HFSW

/RST

201 B S

203 R P

198 T E

197 F E

191 R X

192

193

8

132

207

208 T R O

3

NC

2

183 EFM1

184 EFM2

185 EFM3

180 WRSMP

181 RESAMP1

182 RESAMP2

177

186

142

7

204

194

166

179

187

202

139

180

166

167

TX

TC

C34M

WBLIN

FOO

SLO

DMD

EFCK

ROPC1

LDON

FG

CE

TEBC

WGATE

FEFS

ROPC2

RPBC

FLAGC

WRSMP

WGATE

HFSW

UAD0

96-103

I

UAD7

130-122

UA0

DSP

SERVO

IC201

URD

I

UA8

UWR

UCS0#

UCS1#

URDY

UINT0#

UINT1#

SDINT#

FLAGA

FLAGB

EFSF

HRST

104 105

106 107

110 111

112 113

137 138 87

NC

9553

PRST

DOUT

C2PO

ABCK

ALRCK

HD0

I

HD15

HWR

RD0

RD15

RA0

RAD9

ROE#

XIN

I

I

RX

146

143

144

145

85-91

72,73,76-82,

70

69HRD

56ATA CS3

57ATA CS1

60HA0

62HA1

59HA2

21-14

32,33,29-24,

45-81

52-48,

30RCASH#

31RCASL#

38RRAS#

37RWE#

36

149

+5VD

BUS DA0

BUS DA2

CSB1

CSB3

ROUT

DLRCK

DBCK

+3.3V

2-5,7-10,

18-21,

31 /UCAS

32 /LCAS

15 /RAS

14 /WE

30 /DE

ZD201

INTIAL

)

RESET

IC706(1/2)

RAM

IC202

I/O0

I

I/O15

35-38,40-43

A0

I

24-29

A9

)

WAVE

SHAPER

HD0-15

10131

RW DATA

RW LRCK

RW CLK

P DATA

P BLK

P LRCK

P DOUT

FPGA RST

FPGA AS

FPGA WD

FPGA CLK

DAC CS

FPGA CS

CXD MUTE

37 41

R OPT IN DOUT

59

RW DOUT

RW DOUT

36 66

RW DATA

65

RW LRCK

63 44

RW CLK

64

FP.GA

IC510

ATAPIL <0>

I

2-8,

ATAPIL <15>

11-19

1

ATA WR

CS1

60

P DATA

29

P CLK

27

28

P IRCK

32

P DOUT

RESET

52

FPGA AS

67

DA PDATA

26

SDATAO1

23

DA PCLK

25

SCLK1

22

DA PCS

24

FPGACS1

21

CXD MUTE

71

MCLK IN

50

CDR RST

74 53

SRC RXP

SRC DATA

SRC CLK

SRC LRCK

S D TXP

S D DATA

S D LRCK

S D CLK

OMCK

DUB START

DA RDATA

DA RCLK

DA RCS

DA DATA

DA CLK

DA LRCKL

DAC MCLK

CS DAC

SCK DAC

DASDT C

DUB SEL

DAC RST

AD DATA

MCLK IN

AD LRCK

AD MCLK

45

46

62

68

69

70

48

79

78

77

76

49

51

42

55

35

34

33

72

73

43

39

40

F DOUT

DUB START

DA RDATA

DA RCLK

DA RCS

IC706(2/2)

WAVE

SHAPER

85

TX

1

RXP

4

RXN

5

SDIN

14

ISCLK

13

ILRCK

12

TXP

26

TXN

25

NC

SDOUT

18

OLRCK

17

OSCLK

16

OMCK

21

JK705

DIGITAL

OPTICAL

OUT

RECEIVER

SERIAL

AUDIO

INPUT

DRIVER

SERIAL

AUDIO

OUTPUT

OUTPUT CLOCK

GENERATOR

DA DATA

DA CLK

DA LRCK

DA MCLK

CS DAC

SCK DAC

SDT DAC

DUB SEL

DAC RST

AD DATA

AD BCK

AD LRCK

AD MCLK

DUB SEL

CDP 33M

CLOCK&DATA

RECOVERY

AES3

S/PDIF

ENCODER

CONTROL PORT &

REGISTERS

AD0/CS

AD1/CDIN

SDA/CDOUT

1 2 27 28 19 9

SRC CS

SRC DATA

SRC DIN

C

AUDIO

SECTION

(Page 26)

DECODER

INT

SCL/CCLK

SRC INT

SRC CLK

AES3

S/PDIF

CONVERTER

RST

SRC RST

SAMPLE

RATE

DIGITAL AUDIO

SAMPLE RATE

CONVERTER

IC502

27-34

UAD0 IUAD7

36-43,45

UA0 IUA8

70 71

/URD

5458 88 89

UCS1

/UCS0

/UHWR

/WAIT(URDY)

/UNIT0

/UNIT1

93 56 178

FLAGA

FLAGB

SRC CS

DA RCS

SRC DIN

DA ROLK

DA RDATA

DUB START

94 9 6

3

DA RCS

DA RCLK

52 97 98

8 66

ESFS

/OAK RST

SYSTEM CONTROL

IC203 (2/2)

DA RDATA

DUB START

HOT RX

/SRC CS

SRC CLK

SRC DATA

99

51

SRC CLK

SRC DOUT

SRC INT

SRC RST

96

HOT TX

24 24

/SRC RST

X201

20MHz

67

XTAL

EXTAL

/LOAD_SW46/OPEN_SW

47

(LOADING) TRAY

( )

OPEN

REC TXD

REC RXD

TRK INC

FWE

MD2

BTS RXD

BTS TXD

SW201

(LOADING/OPEN)

(DECK B)

DATA BUS

12

14

16

PN105

10

75

15

13

FWEN

FWMD2

RXD

TXD

CHECK

CONNECTOR

REC TXD

REC RXD

TRK INC

D

CDP

SECTION

(Page 25)

•Signal Path

: CD PLAY

: CD (DIGITAL)

: CD REC

: OPTICAL

Page 25

– CDP SECTION –

OPTICAL

PICK-UP BLOCK

(DECK A)

RF

A

A

B

B

C

C

D

D

E

E

F

F

V.C

VCC

LD

PD

FOCUS

COIL

TRACKING

COIL

M902

SLED

MOTOR

(DECK A)

M903

LOADING

MOTOR

(DECK A)

M901

SPINDUL

MOTOR

(DECK A)

LIMIT

SW

M

M

M

HALL

LD

MD

VR

F+

F-

T+

T-

A

A

B

B

L+

L-

SENSOR

+5VA

FCS+

FCS-

TRK+

TRK-

W

V

U

HU+

HUHV+

HVHW+

HWHH+

+5VA

SLEDIN SW

LD

DRIVER

Q501

ERROR AMP

IC404

2

3

RCD-W3

DIGITAL SERVO

DIGITAL SIGNAL PROCESSOR

FOK

FOK

F

IC402

CPU

INTERFACE

DATA

XLAT

CLOCK

CXD XLAT

CXD DATA

SYSTEM

CONTROL

IC407

POW CTL

FLD TXD

FLD CLK

FLD CS

RMC IN

KEY_IN0

KEY_IN1

KEY_IN2

SCLK

SENS

SCLK

CXD CLK

D/A

PROCESSOR

32K

RAM

SENS

MUTE

MD2

GFS

GFS

CXD MD2

59

13

17

18

100

78

79

80

XTSL

CXD XTSL

PWR CTL

FL SDI

FL SCK

FL CE

REMO IN

KEY IN0

KEY IN1

KEY IN2

DIGITAL

SERIAL/

PARALEL

PROCESSOR

SQSO

SCOR

SCOR

SQSO

OUT

CLOCK

SQCK

SQCK

PCMD48

XRST

FPGA RST

FPGA DATA

FPGA CLK

FPGA CS

FPGA AS

PROG ON

DUB SEL

REC TXD

AS DATA

TRK INC

PWR MUTE

DOUT

BCK48

LRCK48

MUTE

XTLO

XTLI

MCKO

DAC CS

MD2

FW EN

XTAL

EXTAL

/RESET

SW

70

48

49

47

71

12

13

67

23

24

25

2

8

75

10

15

38

14

12

6

67

66

63

60

26

NC

NC

CLOCK

OSC

IC408

X402

20MHz

1

DRIVE

XTAL

OSC

XIN

1 2

X401

33.86MHz

IC409

RESET

P DOUT

P DATA

P BCK

P LRCK

6

FS OUT

XOUT

CXD MUTE

FPGA RST

FPGA WD

FPGA CLK

FPGA CS

DAC CS

FPGA AS

2

+5VU

PN402

MD2

FWEN

PROG DN

FL SDI

DATA BUS

CDP 33M

CONNECTOR

CHECK

DUB SEL

REC TXD

REC RXD

TRK INC

PWR MUTE

LEVEL SEL

LEVEL IN

D

E

CD-R

SECTION(2/2)

(Page 24)

AUDIO

SECTION

(Page 26)

RF AMP

IC403

EQ_IN

3

A

6

B

7

C

8

D

9

E

10

F

11

VC

27

DVC

14

LD

1

PD

2

1

FO+

34

FO-

35

TO+

32

TO-

31

SL1+

9

SL1-

10

SL2+

5

SL2-

6

LO+

36

LO-

37

W

12

V

13

U

14

HU+

21

HU-

20

HV+

19

HV-

18

HW+

17

HW-

16

HB

23

VC

APC

DRV

DRV

DRV

DRV

DRV

AC

AMP

BTL MOTOR DRIVE

IC405

MUTE

DRIVE

CONTROL

EQ

RF SUM

AMP

FOCUS

ERROR

AMP

TRACKING

ERROR

AMP

FOIN

TOIN

MU1

SL1IN

SL2IN

LOIN+

SPIN

REF

FG3

RFAC

15

RFDCO

28

RFDCI

29

FEI

17

FE

16

TE

18

CE

20

CEI

21

SWSW

12

VFC

25

VFC

SLD ERR

27

28

41

1

2

40

25

24

26

FAO

TAO

DRV_MUTE

SLDCTLA

SLDCTLB

TRAY CTL

SAO

Q402

SPNFG

MDP

SLD IN

SELECT DATA

IC406(2/2)

12

13

FAO

TAO

SAO

MDP

SPNFG

SW

SLDCTL A

SLDCTL B

TRAYCTL

SLD ERR

DRV MUTE

VFC

SLDIN

14

11

+2.7V +5VA

IC410

+2.7V

REG

RFAC

36

RFDC

23

FE

27

SE

26

TE

25

CE

24

FAO

4

TAO

3

SAO

2

VC

28

MDP

95

DATA SELECTOR

IC406(1/2)

1

2

10

AS FCS/TRK

95

FG

SW

3

84

SLDCTL A

SLDCTL B

85

TRAYCTRL

5

82

SLD ERR

DRV MUTE

9

CXA VFC

4

SLEDIN SW

90

1.35/AUD

83

7

SW REF/AUD

SPD G UP

87

(LOADING)

(LOADING/OPEN)

15

SW4M1

(DECK A)

EFM

DEMODULATOR

ANALOG

SWITCH

•

AMP

•

A/D

CONVERTER

SERVO

DSP

TE/FE

T1 RYSW

52 51

REGISTER

ERROR

CORRECTOR

COUT

89 92 85 86 87 83 82 69 57 66 73 78 79 80

9399 18

45 41 42 43 96 48 40 47 39 89 46 94 20

COUT

TRYSW2

TRAY

( )

OPEN

POWER

SECTION

(Page 27)

25 25

•Signal Path

: CD PLAY

: CD (DIGITAL)

Page 26

RCD-W3

– AUDIO SECTION –

CD-R

SECTION

(2/2)

(Page 24)

DA DATA

DA CLK

DA LRCK

DA MCLK

SDT DAC

SCK DAC

CS DAC

DAC RST

D/A CONVERTER

IC7V1

SDT1

3

BICK

2

LRCK

4

MCLK

1

8

7

6

5

AUDIO I/F

CONTROLLER

I/F

CONTROL

DAC

DAC

AOUTL+

AOUTL-

AOUTR+

AOUTR-

12

11

10

9

L-P-F

IC704

5

6

3

2

7

1

PHONES AMP

JK701

(1/2)

L

ANALOG

OUT

R

IC707

LEVEL METER SELECTOR

IC703

CH1/H

CH0/L

6

7

COM

1

A

C

5

A/D CONVERTER

BUFFER

Q709

BUFFER

Q710

AUDIO MUTE

SWITCH

Q701,702,706

MUTE

MUTE

5

Q703

3

Q704

7

MUTE

Q711

1

MUTE

Q712

VR801

PHONE

LEVEL

MAX

MIN

JK802

PHONES

IC7V2

AD DATA

AD BCK

AD LRCK

AD MCLK

PDN

13

STDO

9

SCLK

12

LRCK

10

MCLK

11

AUDIO I/F

CONTROLLER

ADC

ADC

AIN L

AIN R

2

1

AMP

IC702

1

7

3

5

JK701

(2/2)

L

ANALOG

IN

R

CDP

SECTION

(Page 25)

VR802

REC LEVEL

DUB SEL

RELAY DRIVE

Q705

LY702

•Signal Path

: CD PLAY

LEVEL IN

LEVEL SEL

E

PWR MUTE

: CD REC

26 26

Page 27

– POWER SECTION –

RCD-W3

CDP

SECTION

(Page 25)

KEY IN0

KEY IN1

KEY IN2

RMC IN

S11

FLD TXD

FLD CLK

FLD CS

F

8

SCK1

7

15

P00

FL DRIVER

F0

F15

F16

F35

G1 - 16

80

I

I

65

64

I

P1 - 20

61

I

•

58

I

43

IC801

X1

3

X801

5MHz

4

X2

60

VLOAD

6 3 1

RESET

-34V

RESET

IC802

KEY MATRIX

SW808, 5W810 - 814

FLUORESCENT

INDICATOR TUBE

FLD801

SW801 - 807

SW815 - 822

+5VU

(F1)

(F2)

RMC801

REMOTE

COMMANDER

1

RECIEVER

-34V

-8VA

+8VA

+12V

+8VA

+3.3V

+5VA

+5VM

+5VD

D104 D103

-23V

-28V

ZD101

-8V REG.

3 2

IC106

+8V REG.

3 1

IC107

+3.3V REG.

2

IC105

4

L110

PT101

POWER

TRANSFORMER

D120

D107

D108

D110

D109 D102

1

D106

2

3

DRAIN

DCP

GND

SWITCHING

REGURATOR

IC101

1

VCC

FB

4

BD101 L101

5

LINE

FILTER

F101

T1.6A

POWER

SW801

AC

IN

PWR CTL

+5VU

27 27

REG.

IC104

IC102

1

4

32

Page 28

RCD-W3

5-3.PRINTED WIRING BOARD – BD-R SECTION – • See page 21 for Circuit Board location.

1

BD–R BOARD (SIDE A)

2

3 4 5 6 7

8

9 10

A

B

C

D

E

F

G

C541

R526

R527

R528

10

14 5 1

R507

C540

C525

C539

C523

R504

IC502

20 25 28

15

R533

R534

R532

R530

C520

R5Q1

L505

IC210

PN105

R503

R535

C280

RR501

FOR

CHECK

R502

R506

R5S3

C521

23

IC202

33

34

44

R501

C522

R5T6

C501

5

1

C527

R240

16

C516

C526

C518

22

12

11

R228

1

C221

C517

R284

R285

C277

R277

R261

C208

C281

C222

61

65

70

75

80

C220

C249

C250

60

1

C209

C219

IC510

510

C251

R295

51

55

60

65

70

75

C210

50

76

414520501555

IC203

80 85

R334

R521

R519

R517

40

35

30

25

21

RR202

RR203RR204RR205RR206

R214

R215

R216

R2Q1

R2Q2

26

303595409045

100

SW201

LOADING/OPEN

(DECK B)

R515

R513

R509

RR507

25

20

15

10

R525

R522

R520

R518

R516

R514

R4Q1

C349

C348

C353

C389

C390

R392

R3A2

Q303

R3A3

ECB

R234

R233

R232

R231

R352

25

26

30

35

40

45

50

51

55 60

C377

R391

R3A5

C350

R3C8

C351

R360

R361

R362

R363

R364

R365

RR201

R211

R296

R283

R247

R250

5

1

R291

R290

R280

R281

R255

C259

R251

R249

R248

R394

R3C5

R3A4

C252

C347

R351

IC301

C368

C376

R4E7

R4E5

R4K7

C4E5

R350

C375

C346

C373

C395

R345

R359

R3C7

R4G3

R355

R370

C327

R315

5

8

C326

R314

R316

R313

R357

R354

17551070156520

100

R3A7

IC408

R335

C319

42 40

1

95

90

85

80

76

C344

C343

R373

R372

R371

R4E3

4

1

R323

35

IC303

510

R318

R317

C367

C368

C370

C363

R3A8

IC302

1

4

R301

R302

R3C6

C396

R4K6

C4E1

C4E2

C320

30

C325

C301

C4E3

R326

R324

R327

25

15 21

R303

R3K1

R325

8

5

22

R304

C305

C322

C303

R331

C307

R306

R3A9 R333

R330

R329

R328

R332

R308

R307

C308

R3D1

R3D2

C309

R3C3

R3D3

R3D4

R3D5

R3D6

C4A7

C4A4

C4A3

IC409

R4C6

R4C5

C4A2

C4A1

R4C7

R4C4

1

R4F7

C4A5

C4A0

R4C3

R4F8

R4C8

C4A8

R4C9

C412

C411

3

R432

R4F9

C415

R433

R4A8

R407

D402

C4F7

PN402

1

5

IC405

10

15

21

R4A9

X402

R426

R425

C4F8

CHECK

R4CA

R4CC

C4A9

R4C0

FOR

C495

C534

C439

C437

IC410

C456

13

R455

• Semiconductor

Location

Ref. No. Location

D402 D-7

IC202 D-2

C443

C441

R4E0

R4E8

R4E9

R440

R447

C448

R444

R403

R401

R402

30359540

R4M2

C497

R4A2

R418

C496

R4C1

26

100

90

16

45

50

51

55

60

IC407

65

70

75

76

80 85

C446

25

20

R410

15

10

5

1

R411

89

1

IC406

R437

16

R434

R435

C491

R493

R492

42

40

35

R4A1

R4A0

R499

R496

R497

R495

R498

30

25

22

R4C2

R450

C478

R485

C479

R441

R451

R413

R446

C454

C403

C450

R448

R471

C468

C469

R472

C475

R479

IC404

5

8

R484

R480

C451

BCE

C481

R470

R487

R462

R467

C471

Q501

R488

R491

R483

C453

C470

R478

R482

R461

R466

4

1

R452

R460

R465

R481

R490

C480

R469

R476

R486

R463

C464

C482

R457

R458

R475

R489

IC203 F-3

IC210 E-2

IC301 C-5

IC302 B-6

IC303 G-5

IC404 D-9

IC405 F-7

IC406 D-8

IC407 C-8

IC408 E-5

IC409 D-7

IC410 A-9

IC502 B-1

IC510 B-3

Q303 D-4

Q501 C-9

M609

LOADING

(DECK B)

H

PN302

M

28 28

Page 29

RCD-W3

1

2

3 4 5 6 7

8

9 10 11

OPTICAL PICK-UP

BLOCK

A

BD–R BOARD (SIDE B)

POWER

BOARD

(Page40)

A

(KRS–220C)

(DECK B)

AUDIO

BOARD

(Page36)

C

• Semiconductor

Location

25

R356

PN501

R358

C362

C372

R376

X401

C386

3

C374

R375

R396

L306

R353

R388

C378

R399

IC306

R397

5

4

IC307

29

C352

C388

C399

C354

4

C385

R398

C253

R404

R412

C463

C4G1

C4G2

C4G3

R416

R4F1

R4F0

C401

R421

R420

R419

R4S6

C533

R4S2

12 10 5 1

C530

C529 C531

R400

ZD401

R4S4

A

K

R4S8

C410

R427

R424

R422

R4G2

R423

R4G1

R4G0

C4A6

L507

C532

L502

PN503

C311

1

5

15

25

31

R339

R338

PN301

C336

C310 C312

L301 L302

C304

2

10

R305

20

C306

C339

30

D301

32

K

A

C338

R337

R336

11

20 15

IC304

10

15

R340

C337C335

C342

C302

C364

C340

C341

C365

R3C9

IC305

Q302

Q301

C369

85

114

R374 R377

C381

R3C1

BCEBCE

C371

C387

C457

L441

C438

100 95 90 85 80 76

1

5

10

IC402

15

20

25

26 30 35 40 45 50

R443

C444

R449

R445

C447

C445

R442

C442

75

70

65

60

55

51

C440

R405

B

C455

R456

C420

C421

L442

R453

C

R468

C465

30 25 20 16

IC403

1 5 10 15

17

PN406

R473

C472

15

R474

5

1

C474

C473

C477

R477

C476

16

OPTICAL

D

PICK-UP

BLOCK

10

(DECK A)

C422

C458

C423

R414

C402

R4L9

C4E6

R417

E

C4F6

C494

PN401

C493

L491

FL

BOARD

F

(Page38)

G

BOARD

(Page42)

BD–P

B

H

Q402

R436

R4M1

R4A3

BCE

C492

R494

20

19

15

C414

10

5

2

1

C499

PN403

22

20

10

2

C498

R4A5

R4A4

21

R4A6

R4A7

15

5

1

L304

C398

C392

PN304

1

2

5

10

12

13

C330

C333 C332 C331

C329

C328

C321

C397

C391

R322

C318

R321

C317

R320

C316

R319

C315

M401

SPINDLE

H

MOTOR

R3C2

R389

C255

R235

1

R3A1

15

R590

R390

C380

R369

1

4

IC308

85

85

C382

C384

R241

R237

R236

11

12

15

IC207

20

22

23

25 30 33

R242

C254

R4K1

R4K2

R409

R408

R238

R243

5

R244

R245

15

IC208

1

2102030

R213

44

40

34

C510

R293

R209

R210

C212

C213

C256

R268

85

14

C513

C214

C217

C285

R254

R524

C515

C514

C511

R512

C508

C507

R208

RR506 RR505RR504RR503 RR502

104

105

110

C211

120

130

140

150

156

R217

R219

R223

R259

R253

R252

C258

R260

C216

C263

R266

C264

R267

C265

R286

C266

R287

C215

R218

C290

R269

C218

R221

C291

R271

X201

R270

IC201

R220

C268

C262

R5S1

708090100 60

190180170160157

R224

R222

C270

C271

R262

C503

C504

R206

200

R225

R226

R227

A

K

C269 C261

1

3

ZD201

PN303

C245

C247

C2A1

53

1

206

C223

C260

C502

R5S2

R279

R201

R265

R5T7

52

50

40

30

20

10

R263

2

4

C207

L501

R203

C248

C246

R264

C279

R205

C201

C524

R529

R531

C244

R505

M301

SLED

MOTOR

(DECK B)

M

C202

L201

(DECK B)

R289

M

R294

R292

R288

C225

C224

Ref. No. Location

D301 D-6

IC201 E-9

IC207 F-7

IC208 G-8

IC304 D-5

IC305 D-6

IC306 D-7

IC307 E-6

IC308 D-7

IC402 B-2

IC403 C-2

Q301 C-6

Q302 C-6

Q402 G-3

ZD201 G-9

ZD401 C-4

I

29 29

Page 30

RCD-W3

5-4.SCHEMATIC DIAGRAM – BD-R SECTION (1/6) –

M401

SPINDLE

MOTOR

(DECK B)

(DECK B)

LD

PD

FOCUS

COIL

TRACKING

COIL

M301

SLED

MOTOR

(DECK B)

ALL DETECT

H

A

B

C

D

E

F

G

H

OL

TR

N

ER/CO

LD DRIV

SLEDIN SW

PN303

PN304

GND

HU+

HV+

HW+

HW-

A

B

C

D

E

F

G

H

VWDC1

DC2

VW

FPDO

VRDC

ODON

/XR

W

IN3OSCEN

FPDVC

PDVC

CFREQ

CMOD

FCS+

FCSTRK+

TRKVCC

VCC

PDVCC

FGND

PDGND

PGND

DGND

M609

LOADING

MOTOR

(DECK B)

C391

C325

0.1

4P

A

A

B

B

13P

13

W

10

V

U

H+

HU-

HV-

H-

8VM

GND

C328

470p

5

1

5VA

PN301

32P

1

FCSTRKTRK+

FCS+

5

FGND

PDGND

F

B

A

10

H

PDVCC

PDVC

G

D

15

C

E

NC

FPDVC

FPDO

20

VCC

VCC

CFREQ

CMOD

PGND

25

VRDC

DC2

VW

VWDC1

DGND

OSCEN

30

ODON

W/XR

IN3-

32

R306

680

PN302

2P

LD-

LD+

C397

10

100

25V

16V

C330

C329

470p

470p

C333

0.1

C332

0.1

C331

0.1

R333

22k

2.2

R317

2.2

R318

C307

2.2

R313

R305

0

27p

C308

R307

27p

680

2.2

R314

OSCEN

R308

47k

R3C3 0

ODON

W/XR

ENBL

FPDO

TRK+

RF6

RF2

RF1

RF8

RF7

RF4

RF3

RF5

TRAYTRAY+

FCS-

TRK-

FCS+

C306

47p

C326

2200p

M

MOTOR DRIVER

SL1IN

SL2IN

VM2(8V)

ASL2

SL2+

SL2GND

RSL1

SL1+

SL1GND

W

V

U

RSP

HWHW+

HVHV+

HUHU+

C327

2200p

IC303

63021FP

B1-2

EFM

2V

L301

µH

10

L302

µH

C310

R332

R316

15k

LDIN+

VM3(5V)

VM1(8V)

5VCC

TOIN

SPIN

C311

10

16V

R339

10k

R315

15k

OSC

MU1

BRS

LOLO+

FOFO+

GND

TO+

TO-

GND

FOIN

REF

FG

HB

R329

R330

R331

220

C309

0.1

10

C312

10

0.1

16V

R301

1.2k

C302

R338

R324

10k

2.7k

10

16V

SPNBOOST

TFGCNT

CXA ON

C336

0.1

TAO

SPNFG

R302

3.3k

C335

10

16V

C315

0.01

R319

22

C319

330p

R323

33k

R326

1.8k

C322

0.1

R328

10k

C320

0.1

R3A9

220

C301

0.1

R340

82k

C337

330p

2.2

2.2

2.2

C316

R320

VREF-

AO3

AO4

AO5

AO6

AO7

AO8

AO9

AO10

VREF+

0.01

22

C392

100

16V

C321

220

6.3V

NJM3414AV(TE2)

OUT1

IN1-

IN1+

VEE

IC304

M62352GP-75E