Page 1

CTC184

SERVICE ADJUSTMENTS

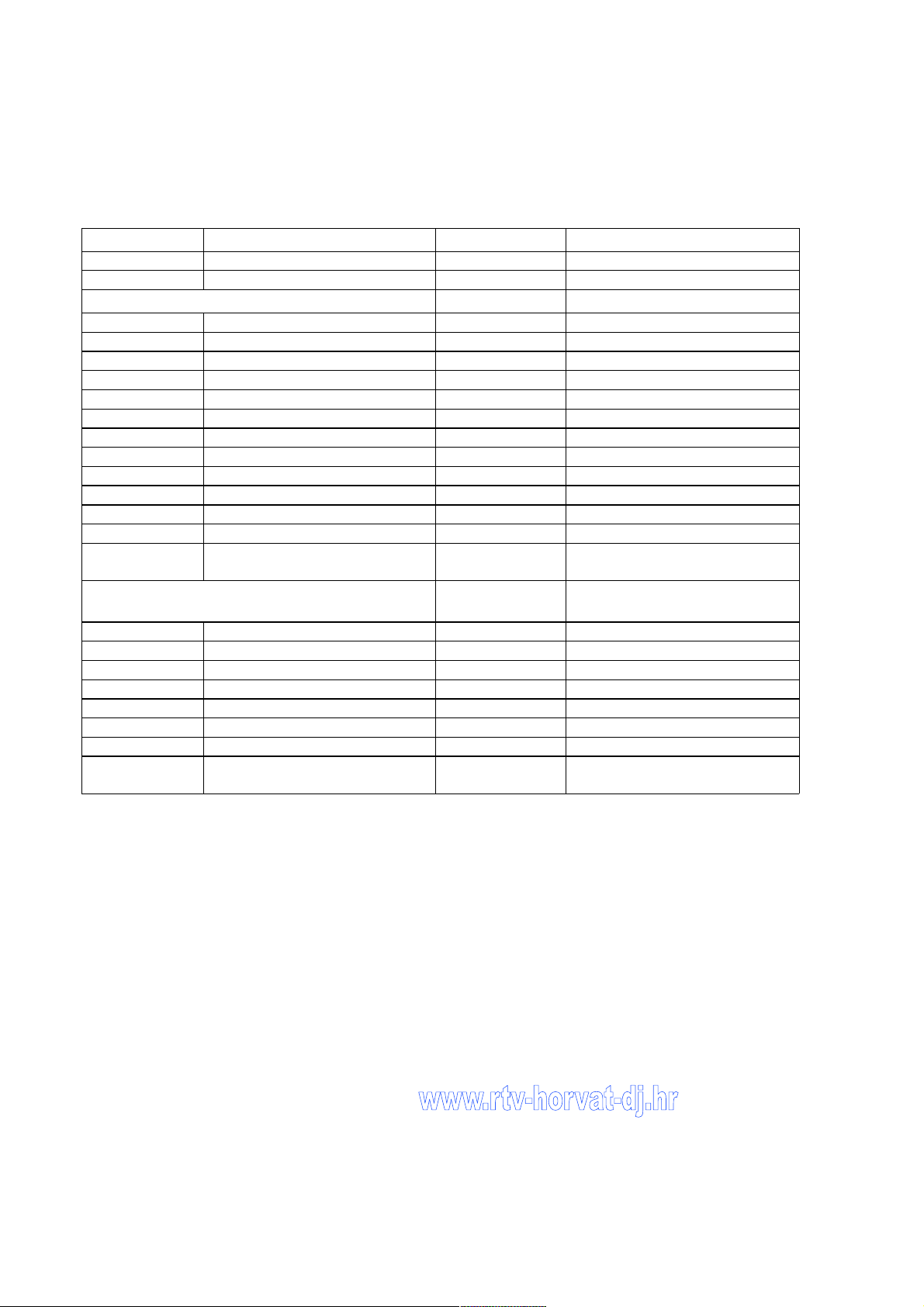

SERVICE MENU CHART

NOTE: During the Service Menu Mode the channel up/ dn will change the parameter # while the volume +/- will change

the value range. Therefore channel changes, when in the service menu mode, must be accomplished by random access

using the remote transmitter. To access channels 100 thru 125, press and hold the channel 1 button on the remote control

until the number 1 and two dashes are displayed on the screen; then press the second and third digits.

Parameter# Parameter Name Value Range Comment

Chan to change Vol to adjust

00 Pass No. for Serv. adjust Must set to 76 May not advance until value set

Service Adjustment Parameters

01 Horiz. Freq. 00-63 Sync is killed

02 Not used

03 Vertical S Bias 00

04 Vertical S Amplitude 07

05 not used

06 not used

07 Red Bias 00-127

08 Green Bias 00-127

09 Blue Bias 00-127

10 Red Drive 00-63

11 Green Drive 00-63

12 Blue Drive 00-63

13 Security pass number for chassis

align parameters

Chassis Adjustment Parameters

Must set to 77 May not advance to higher

parameter until value set

14 PLL Tuning 00-63

15 4.5 MHz Trap 00-07

16 Video Level 00-07

17 FM Level 00-15

18 not used

19 RF AGC 00-31 Manual tune channel 6

24 Factory tint 00-63

25 Security pass no. for tuner

alignment

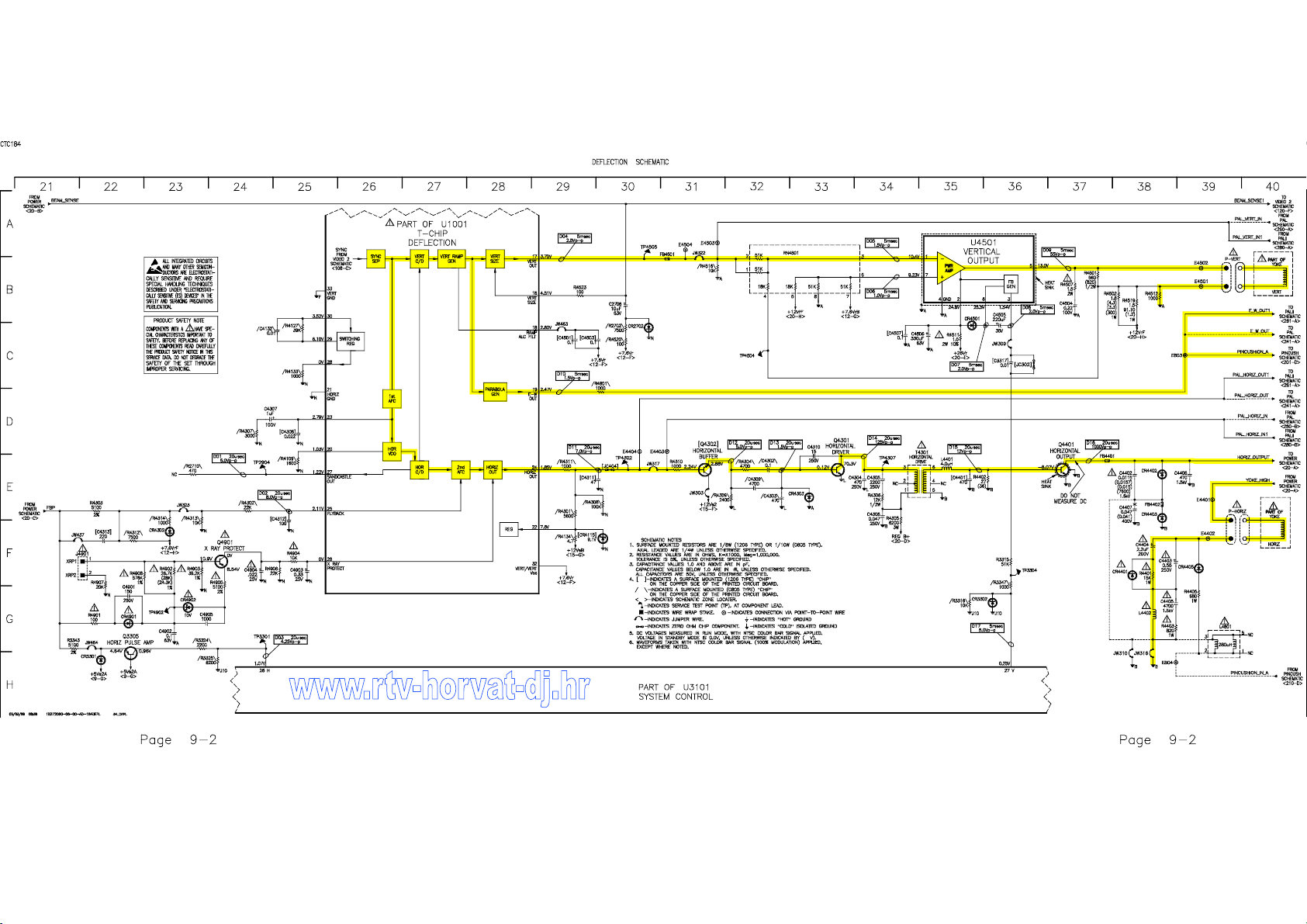

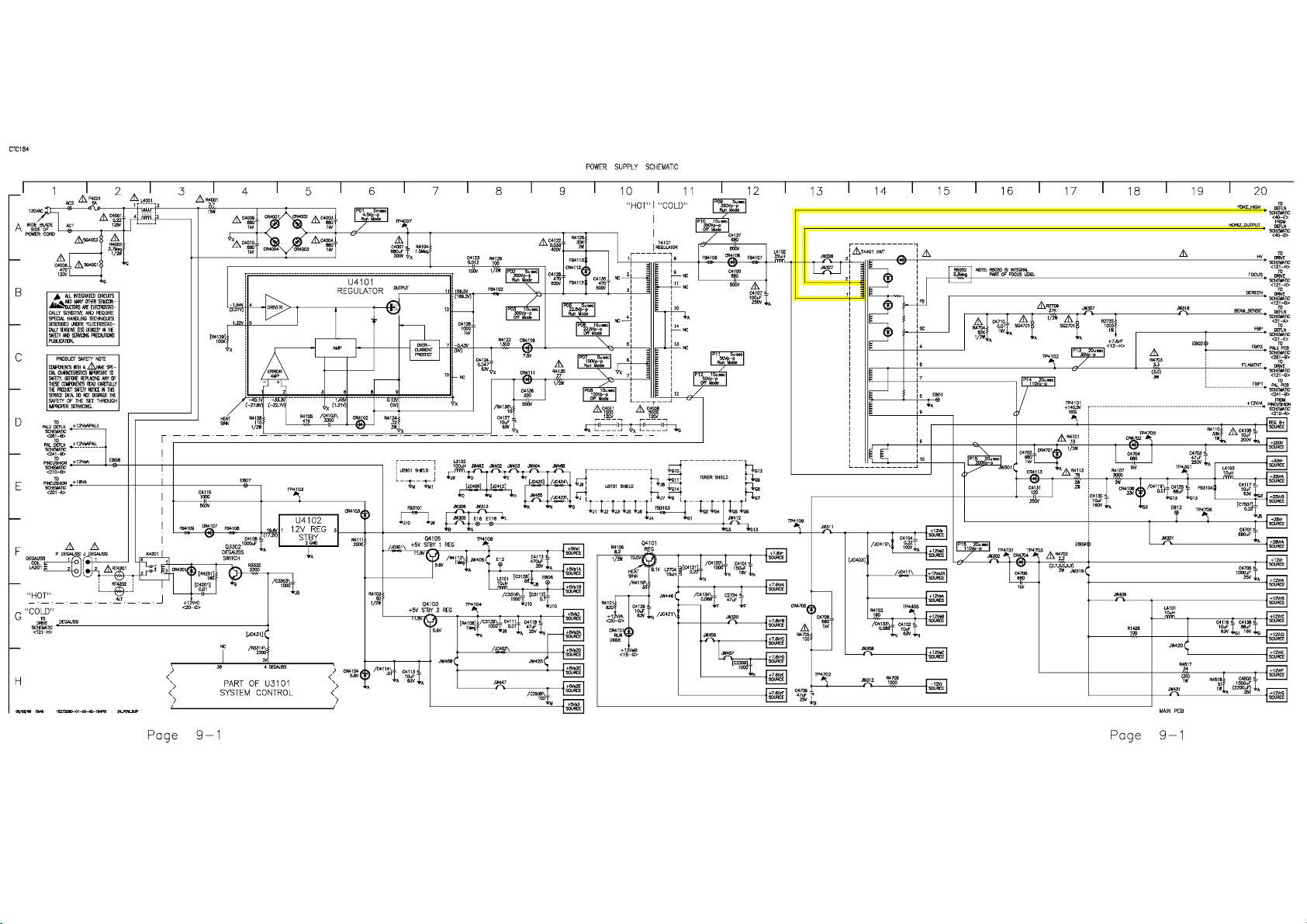

High Voltage

High voltage on this chassis is NOT adjustable. To

check high voltage connect a VTVM with high voltage

probe to the picture tube high voltage anode, negative

lead to picture tube ground strap (use 500 volt scale).

NOTE: The meter (VTVM with high voltage probe)

used for measuring high voltage must have a

resistance of 1000 megohm or more and be

accurate within 5% or better.

Nominal high voltage for this chassis (at maximum beam

current) is 25.5 kV (19 inch) and 24 kV (13 inch) when

measured with a VTVM (with high voltage probe) as

described and must not exceed 30.0kV under any

circumstances.

Must set to 78 May not advance to higher param.

until value set

X-Radiation Protection Shutdown Check

NOTE: When service is required, especially in the

horizontal deflection, high voltage, or regulated

B+ circuits the X-Radiation Protection circuit

should be tested for proper operation as follows:

1. Allow for instrument warm up and adjust user

controls or maximum brightness and contrast levels.

2. Locate the x-ray protect test stakes labeled XRP1 and

XRP2(J4901 located to the rear and center of the

chassis).

3. Momentarily short stake XRP1 to stake XRP2. The

instrument must shutdown and then restart.

Page 3-1

Page 2

CTC184

SERVICE ADJUSTMENTS

Service Menu

The service menu is provided to facilitate instrument

alignment and service adjustments. The service menu is

accessed by pressing two combinations of buttons on the

front panel keyboard. With the instrument “on” press

and hold the menu button and simultaneously press the

power button, then while continuing to hold the menu

button release the power button and press the volume +

button. The instrument should immediately display a one

line menu on the screen, release buttons.

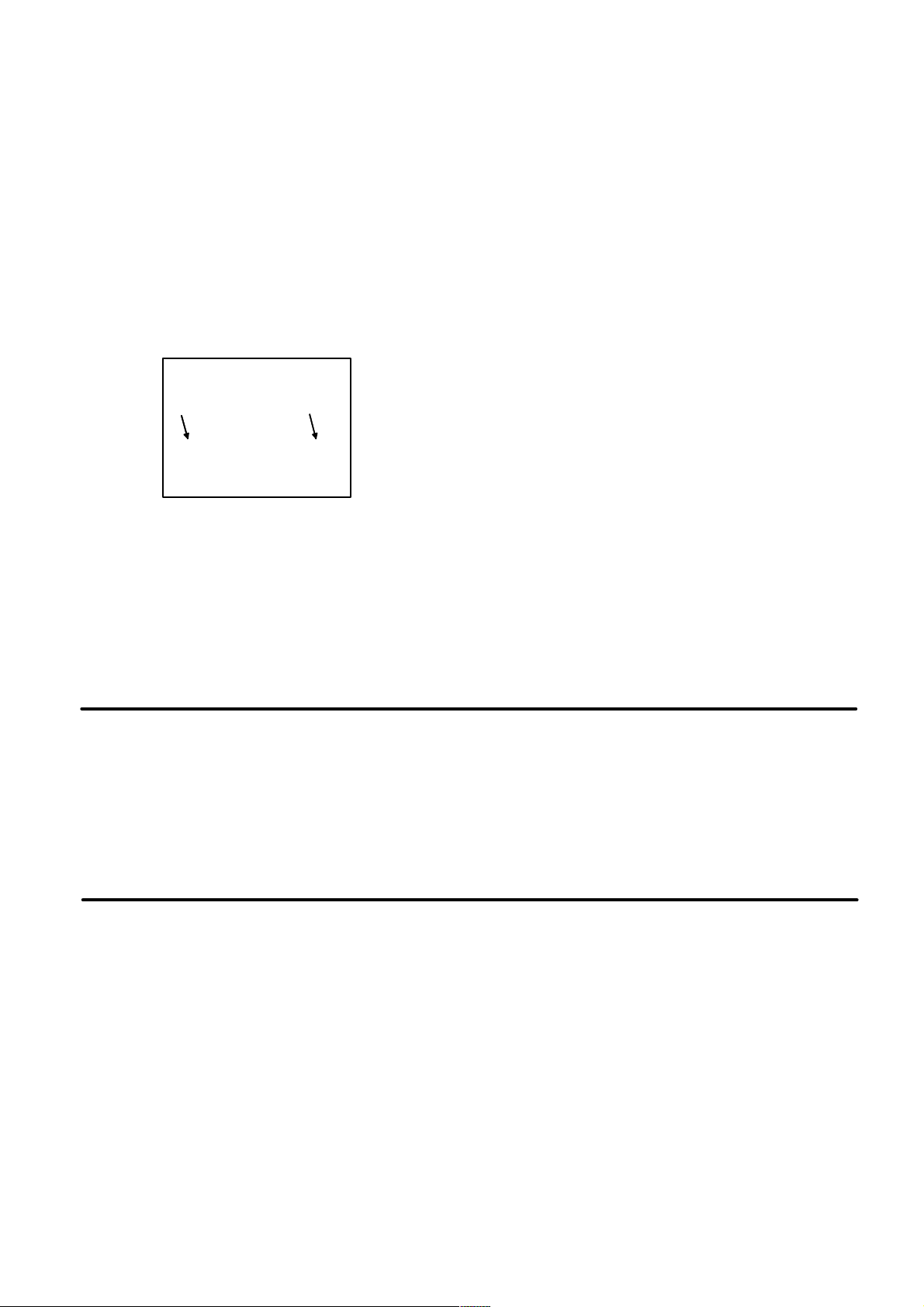

ParameterControlled

by Channel Up/Down

P00

The decimal value on the left is the parameter number

and the decimal value on the right is the current value of

that parameter. The channel up and down buttons

increment and decrement the parameter number. The

volume + and the volume - buttons adjust the current

value of that parameter. There are three parameter

catagories which are used for security reasons. They are

employed to protect the factory alignments from being

modified by the user. The first security parameter, 00,

requires a specific value to be selected

Value controlled

by Volume Up/Down

V00

with the volume +/- keys before other parameters may be

selected.

NOTE: If the channel up/down buttons are pressed

without the correct security pass-number set, the

service mode is exited.

There are three main groups of parameters: the service

adjustment parameters, the chassis alignment

parameters, and the tuner alignment parameters. The

chassis and tuner alignment parameters are each

preceded by a security pass-number for added protection.

Most of the service adjustment and chassis alignment

parameters correspond to individual (unpacked) register

fields in the T-Chip. When these parameters are

modified, the T-Chip and the corresponding EEPROM

location is updated.

NOTE: When setting the kine bias/drive parameters, the

Menu button may be used to enable the vertical collapse

setup line-it functions as a toggle. The setup line has the

following characteristics: -Selects S-Video source (make

sure no signal is connected to the S-Video input); Contrast is automatically set to minimum; -Brightness is

set to 7.5 IRE; -Vertical kill is enabled. When the setup

line is toggled off, the characteristics modified above will

return to their prior settings. Changing to another

parameter (with channel up/down buttons) will also

toggle off the setup line.

Test Equipment Required

External Marker Generator - Capable of furnishing

41.25 MHz, 45.75 MHz and 4.5 MHz markers and AF

modulation.

Digital Voltmeter

External Bias Supply - Well regulated, isolated AC

operated

variable DC bias supply.

Focus Adjust

Adjust Focus control to provide best overall picture

focus.

Horizontal Frequency

1. Enter parameter # 01 (see chart).

2. Adjust value range for stable or slowly moving

horizontal lines.

Horizontal Phase

1. Adjust the Horizontal Phase control to center the

picture horizontally.

Vertical S Bias

1. Enter parameter # 03 (see chart) and set the value

range to 00.

NTSC/PAL Signal Generator - Capable of producing

PAL M and N signals with an anti-PAL source available.

NOTE: All service adjustments, except Focus and

Screen adjust, are bus controlled. They are

accessable only through entry of the correct

parameter #. See the Service Menu Chart in

this service data.

Vertical S Amplitude

1. Enter parameter # 04 (see chart) and set the value

range to 07.

Vertical DC

1. Adjust the Vertical DC control (R4563) to center the

picture vertically.

Vertical Size

1. Input a PAL M or NTSC test pattern.

2. Adjust the Vertical Size control (R4574) for

approximately 1/4" overscan at the top and bottom of

the screen.

Page 3-2

Page 3

CTC184

SERVICE ADJUSTMENTS

3.58MHz Oscillator

1. Disconnect any signals to the instrument.

2. Connect a frequency counter using a low capacitance

probe to U4881V - pin 20.

3. Adjust C4883V for 3.579545MHz ± 10Hz.

Delay Line Amp

1. Input an anti-PAL test pattern.

2. Adjust the Delay Line Amp control (R4846V) to null

the "Venetian Blinds" effect in the anti-Pal area of

the test pattern.

PAL M Delay

1. Input an anti-PAL coded PAL M test pattern.

2. Adjust the PAL M Delay control (L4842V) to null

the chroma in the anti-Pal area of the test pattern.

PAL N Delay

1. Input an anti -PAL coded PAL N test pattern.

2. Adjust the PAL N Delay control (L4841V) to null

the chroma in the anti-Pal area of the test pattern.

Vertical Ramp

1. Input a PAL M crosshatch test pattern.

2. Note the position of the top vertical line in reference

to the top edge of the screen.

3. Input a PAL N crosshatch test pattern and adjust the

Vertical Ramp control (R4567VZ) to place the top

vertical line in the same position as the PAL M top

line.

PLL Tuning (IF VCO Free Run)

1. Enter parameter # 14 (see c hart).

2. Apply 4.0 volt DC bias to IF AGC TP2305 (pin 14 of

U1001).

3. Short RF AGC TP7102 (tuner side of R2313) to

ground.

4. Apply 41.25 MHz marker (300 mV output)) to IF

input (pin 1 of SF2301).

5. Connect oscilloscope to TP1201 (pin 55 of U1001).

Set scope for 1{S per division.

6. Adjust parameter reading to provide a 2.2{S sine

wave response.

NOTE: If a 2.2{S sine wave response cannot be

achieved set parameter reading to approximate

mid range and adjust L2302 for a 2.2{S

response. L2302 is preset at the time of

manufacture and should require no further

adjustment unless a 2.2{S response cannot be

achieved during the parameter adjustment.

4.5 MHz Trap

1. Enter parameter # 15 (see chart).

2. Short RF AGC TP7102 (tuner side of R2313) to

ground.

3. Apply 45.75 MHz (300mV output) and 41.25 MHz

(100mV output) to IF input (pin 1 of SF2301).

4. Connect oscilloscope to TP2302 (pin 63 of U1001).

5. Adjust parameter reading to produce minimum 4.5

MHz indication (sine wave just stops losing

amplitude).

Video Level

1. Enter parameter # 16 (see chart).

2. Connect color bar generator to anteanna input

(100% modulation) set for super pulse display.

3. Connect oscilloscope to TP2302 (pin 63 of U1001).

4. Adjust value range to produce 2.0 volt p-p (sync to

white) response.

FM Level (Wideband Audio)

1. Enter parameter # 17 (see chart).

2. Connect signal generator to sound output TP1201

(pin 55 of U1001) with 4.5 MHz carrier, 1 KHz

modulation, with 25 KHz deviation

3. Apply 4.0 volts DC bias to IF AGC TP2305.

4. Connect oscilloscope to TP1202 (WBA output pin 3

U1001).

5. Adjust value range for 1.2 volt p-p indication of the

1KHz component (a 1.8 KHz component also exists).

RF AGC

The RF AGC has been preset at the time of manufacture

for optimum operation over a wide range of RF signal

input conditions. Readjustment should not be required

unless — the tuner has been repaired, IC 1001 has been

replaced, IC 3101 has been replaced, IC 3201 has been

replaced, or unusual signal conditions exist such as:

1. Cable TV— adjacent channel interference.

2. Picture bending and/or channel 6 color beats which

are usually due to excessive RF signal input. This

occurs when the receiver location is too close to the

transmitting tower. It may also occur when the

receiver is connectedto an antenna distribution

system where the RF signal has been amplified. The

signal should be attenuated at the antenna input to a

more satisfactory level.

3. Picture Noise caused by “broadcast noise” or weak

signal. If the broadcast is “clean” and the received

signal is at least 1 mV, the picture will be noise free

in any area.

NOTE: Adjustment of the RF AGC parameters may not

have any visible effect except under unusual

conditions. Ajusting the RF AGC to one

extreme of it’s parameter limits will usually

provide a relatively poor signal-to-noise ratio,

while adustment to the other extreme of it’s

parameter limits will cause a degradation of

overload conditions such as channel 6 color

beats or Cable TV adjacent channel interference.

If the RF AGC parameter setting is adjusted,

check all local channels for proper operation.

Page 3-3

Page 4

CTC184

SERVICE ADJUSTMENTS

Use weakest local signal to adjust RF AGC

parameter setting.

Color Temperature

1. Set instrument for Auxiliary Input (Channel 00).

Make sure that there is no signal input to the SVHS

input on models with SVHS jacks.

2. Preset red, green and blue drive parameter values to

mid-range (approximate setting of 32).

3. Enter parameter # 07 for red bias adjustment. Press

Menu button (on instrument front panel) and short

JW303 (on the PAL module) to ground (JW804) for

setup line.

4. Using an DC voltmeter, preset red, green and blue

bias parameters to provide 120 volts DC at the

collector of their respective output transistors on the

kine socket circuit board.

NOTE: When the voltmeter probe is placed on the

green cathode, the Service Menu On-ScreenDisplay may be difficult to read.

5. Adjust the screen control to just produce a centerline

(red, green or blue).

6. Enter parameter #s for the remaining two bias

control colors and obtain proper mix to produce a

white setup line.

NOTE: Each time a parameter is exited and a new

parameter is entered the Menu button (on

instrument front panel) must be pressed to

reinstate the setup line.

7. Set brightness and contrast contr ols to maximum.

8. Enter access codes for the color drive controls (10 for

red, 11 for green and 12 for blue) in random

sequence. Adjust their respective parameters to

obtain a 6500 degree kelvin color temperature

(warm white) raster.

9. Check the low light to high light gray scale tracking

(black and white picture). Should any color other

than gray or white be dominant in low light to high

light areas the color temperature settings have not

been properly performed. Repeat the procedure if

necessary.

NOTE: Color bias adjustments affect the low light

(dark) areas while color drive adjustments affect

the high light (white) areas.

TUNER ALIGNMENT

Equipment Required

Service Alignment Fixture- RCA Stock No

215568 (TAG001)

VCR- Used as signal source for TOB service

alignment fixture (tuner service modulator).

DVM- Digital volt meter.

External DC Power Supply- Voltage source to

power service modulator.

Electronic Tuner Alignment Parameters

Parameter Parameter Name Value Range

100 Ch. 2 secondary 00-63

101 Ch. 2 primary 00-63

102 Ch. 2 single 00-63

103 Ch. 6 secondary 00-63

104 Ch. 6 primary 00-63

105 Ch. 6 single 00 63

106 Ch. 14 secondary 00-63

107 Ch. 14 primary 00-63

108 Ch. 14 single 00-63

109 Ch. 17 secondary 00-63

110 Ch. 17 primary 00-63

111 Ch. 17 single 00 63

112 Ch. 18 secondary 00-63

113 Ch. 18 primary 00-63

114 Ch. 18 single 00-63

115 Ch. 13 secondary 00-63

116 Ch. 13 primary 00-63

NOTE: Monitor RF AGC at + leg of C2306 (TP7102) or

pin 12 of the T-Chip (U1001) and adjust for

minimum voltage each step. Top and bottom

covers must be in place with bottom cover

soldered. The entire electronic tuner alignment

procedure, once started, must be completed in its

entirety.

117 Ch. 13 single 00-63

118 Ch. 34 secondary 00-63

119 Ch. 34 primary 00-63

120 Ch. 34 single 00-63

121 Ch. 37 secondary 00-63

122 Ch. 37 primary 00-63

123 Ch. 37 single 00-63

124 Ch. 48 secondary 00-63

125 Ch. 48 primary 00-63

126 Ch. 48 single 00-63

127 Ch. 50 secondary 00-63

128 Ch. 50 primary 00-63

129 Ch. 50 single 00-63

130 Ch. 51 secondary 00-63

131 Ch. 51 primary 00 63

132 Ch. 51 single 00-63

133 Ch. 57 secondary 00-63

134 Ch. 57 primary 00-63

Page 3-4

Page 5

CTC184

SERVICE ADJUSTMENTS

135 Ch. 57 single 00-63

136 Ch. 63 secondary 00-63

137 Ch. 63 primary 00-63

138 Ch. 63 single 00 63

139 Ch. 76 secondary 00-63

140 Ch. 76 primary 00-63

141 Ch. 76 single 00-63

142 Ch. 83 secondary 00-63

143 Ch. 83 primary 00-63

144 Ch. 83 single 00-63

145 Ch. 93 secondary 00-63

146 Ch. 93 primary 00-63

Tuner Coil Alignment (Mechanical)

NOTE: The tuner coil alignment is preset at the time of

manufacture and should require no further

adjustment.The following recommended

procedure should be performed only in the

unlikely event that complete tuner alignment is

necessary (when necessary this procedure must

be performed prior to the electronic tuner

alignment). Bottom cover must be in place and

soldered. Use a plastic or wooden stick for

knifing coils.

1. Manually tune instrument and tuner service

modulator to channel 125 (Band 3) and enter

parameter # 154.

2. Connect DVM to tuner side of R7525.

3. If voltage reading is not between 4.55V and 4.75V

expand or compress L303 to set voltage within these

limits.

4. Manually tune instrument and tuner service

modulator to channel 50 (Band 2) and enter

parameter # 127.

5. Retain DVM connection step 2.

6. If voltage reading is not between 4.80V and 5.00V

expand or compress L304 to set voltage within these

limits.

7. Manually tune instrument and tuner service

modulator to channel 17 (Band 1) and enter

parameter # 109.

8. Retain DVM connection step 2.

9. If voltage reading is not between 4.40V and 4.60V

expand or compress L305 to set voltage within these

limits.

10. Manually tune instrument and tuner service

modulator to channel 125 (band 3) and enter

parameter 154.

11. Connect DVM to positive leg of C7503 (RF AGC to

tuner).

12. Set parameter value range to 31.

13. Expand or compress L105 for minimum RF AGC

voltage.

147 Ch. 93 single 00-63

148 Ch. 110 secondary 00-63

149 Ch. 110 primary 00-63

150 Ch. 110 single 00-63

151 Ch. 117 secondary 00-63

152 Ch. 117 primary 00 63

153 Ch. 117 single 00-63

154 Ch. 125 secondary 00-63

155 Ch. 125 primary 00-63

156 Ch. 125 single 00-63

14. Enter parameter 155 and set parameter value range to

31.

15. Expand or compress L104 for minimum RF AGC

voltage.

16. Enter parameter 156 and set parameter value range to

31.

17. Expand or compress L102 for minimum RF AGC

voltage.

18. Manually tune instrument and tuner service

modulator to channel 50 (band 2) and enter

parameter 127.

19. Set parameter value range to 31.

20. Expand or compress L113 for minimum RF AGC

voltage.

21. Enter parameter 128 and set parameter value range to

31.

22. Expand or compress L111 for minimum RF AGC

voltage.

23. Enter Parameter 129 and set parameter value range to

31.

24. Expand or compress L107 for minimum RF AGC

voltage.

25. Manually tune instrument and service modulator to

channel 17 (band 1) and enter parameter 109.

26. Set parameter value range to 31.

27. Expand or compress L114 for minimum RF AGC

voltage.

28. Enter parameter 110 and set parameter value range to

31.

29. Expand or compress L112 for minimum RF AGC

voltage.

30. Enter parameter 111 and set parameter value range to

31.

31. Expand or compress L106 for minimum RF AGC

voltage.

32. Perform electronic tuner alignment in its entirety.

Page 3-5

Page 6

CTC184

SERVICE ADJUSTMENTS

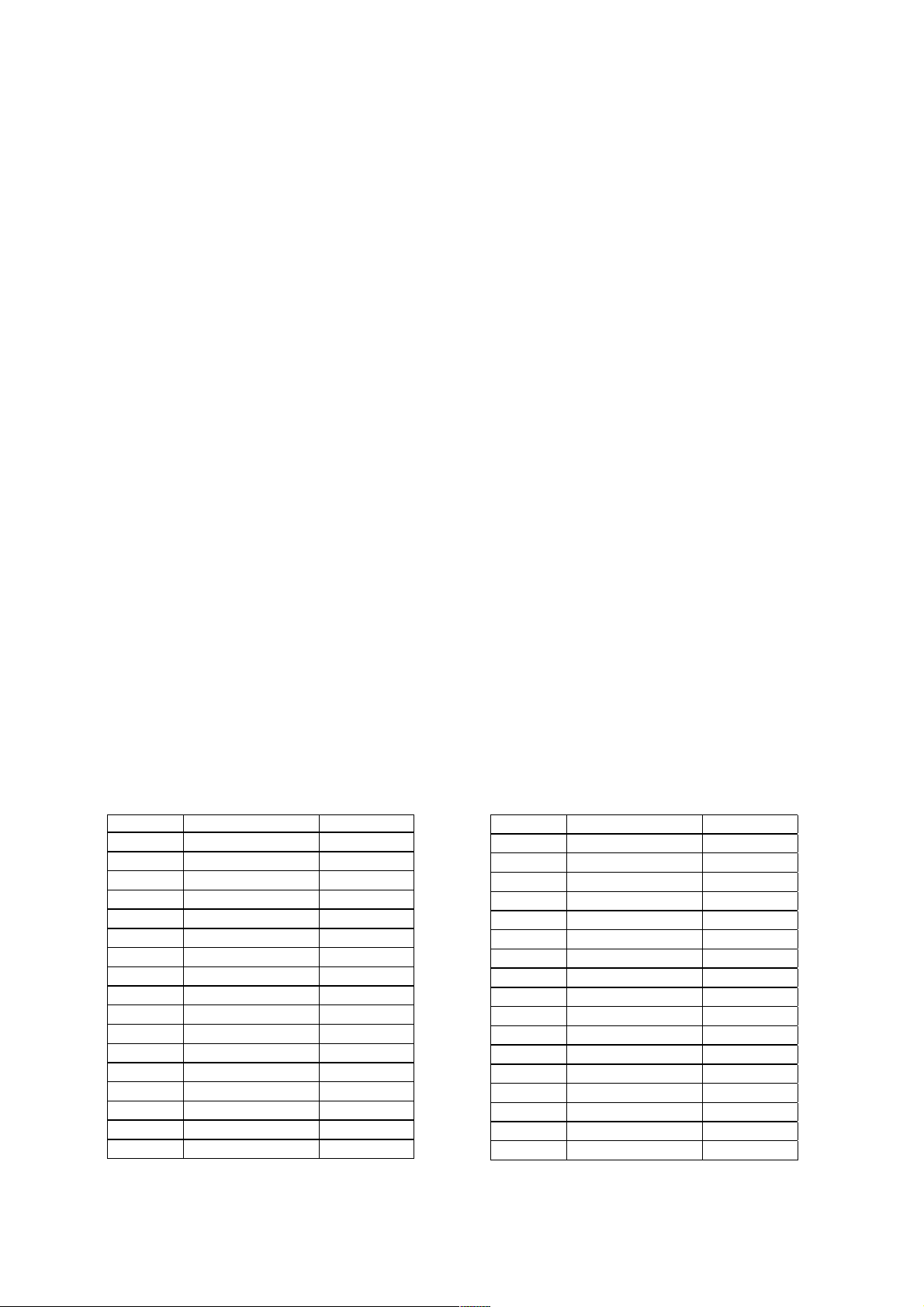

TUNER VOLTAGE CHARTS

OFF-AIR OPERATION

U7301

Pin Lo V Chan. Hi V Chan.

UHF Chan.

No. 2 6 7 13 14 40 69

1. 5.43V 5.42V 5.38V 5.38V 5.30V 5.22V 5.30V

2. 2.93V 2.98V 2.95V 2.95V 3.18V 3.16V 3.18V

3. 7.80V 7.81V 7.75V 7.69V 7.56V 7.51V 7.56V

4. 2.99V 2.99V 2.96V 2.97V 3.18V 3.16V 3.18V

5. 7.82V 7.81V 7.75V 7.71V 7.56V 7.51V 7.56V

6. 0V 0V 0V 0V 0V 0V 0V

7. 3.06V 3.06V 3.04V 3.01V 0V 0V 0V

8. 9.06V 9.03V 8.97V 8.89V 8.84V 8.80V 8.84V

9. 3.02V 3.02V 2.98V 2.98V 3.36V 3.33V 3.36V

10. 3.25V 3.25V 3.22V 3.19V 2.88V 2.87V 2.88V

11. 4.94V 5.00V 5.06V 5.02V 9.62V 9.58V 9.62V

12. 3.25V 3.23V 3.22V 3.19V 2.87V 2.87V 2.88V

13. 0V 0V 0V 0V 0V 0V 0V

14. 9.05V 9.04V 8.97V 8.90V 5.43V 5.39V 5.46V

15. 3.43V 3.43V 3.40V 3.37V 2.88V 2.84V 2.88V

16. 3.44V 3.43V 3.40V 3.38V 2.89V 2.89V 2.89V

U7501

Pin Lo V Hi V UHF

No. 2 6 7 13 14 40 69

1. 1.36V 1.96V 1.58V 1.93V 1.74V 2.90V 4.84V

2. 1.36V 1.96V 1.58V 1.93V 1.74V 2.90V 4.84V

3. 1.35V 1.95V 1.57V 1.92V 1.73V 2.89V 4.83V

4. 33.0V 33.0V 33.0V 33.0V 33.0V 33.0V 33.0V

5. 1.06V 1.74V 1.47V 1.87V 1.46V 2.53V 4.08V

6. 1.06V 1.74V 1.47V 1.87V 1.46V 2.54V 4.09V

7. 1.06V 6.05V 4.09V 7.03V 3.95V 11.8V 23.2V

8. 0.68V 4.57V 3.46V 6.19V 4.41V 12.3V 24.0V

9. 1.01V 1.54V 1.39V 1.76V 1.52V 2.60V 4.19V

10. 1.01V 1.54V 1.39V 1.76V 1.52V 2.60V 4.19V

11. 0V 0V 0V 0V 0V 0V 0V

12. 1.05V 1.75V 1.36V 1.72V 1.44V 2.51V 4.15V

13. 1.05V 1.75V 1.36V 1.72V 1.44V 2.51V 4.15V

14. 1.01V 6.10V 3.24V 5.92V 3.78V 11.6V 23.6V

U7401

Lo V Hi V UHF

1. 1.75V 2.1IV 1.72V

2. 2.11V 2.11V 2.11V

3. 2.11V 2.11V 2.11V

4. 4.78V 4.78V 4.78V

5. 4.71V 4.71V 4.71V

6. 0V 0V 0V

7. 1.32V 1.32V 1.34V

8. 11.5V 0V 0V

9. 7.41V 7.41V 0V

10. 4.85V 4.85V 4.85V

11. 2.30V 2.30V 2.30V

12. 2.30V 2.30V 2.30V

13. 0V 0V 0V

14. 0.60V 0.60V 0.60V

Q7101

Lo V Hi V UHF

2714

Gl 0V 0V 4.84V

G2 5.03V 6.54V 7.19V

D 0.16V 0.20V 11.3V

S 0.19V 0.17V 4.83V

Q7102

Gl 4.64V 4.58V 4.61V

G2 5.32V 6.85V 7.19V

D 11.3V l1.2V 11.4V

S 4.08V 4.20V 11.3V

Q7401

E0V 0V0V

B 0.60V 0.60V 0.60V

C 2.06V 3.85V 17.8V

Q7402

E 11.4V 11.2V 11.3V

B 11.3V 10.5V 10.6V

C -14.9V 11.1V 11.2V

Q7403

E0V 0V0V

B 0.70V 0.70V 0V

C 0.10V 0.10V 11.3V

Page 3-6

Q7404

E 11.4V 11.2V 11.3V

B 11.0V 10.9V 10.6V

C 0.llV 0.llV 11.3V

Page 7

CTC184

SERVICE ADJUSTMENTS

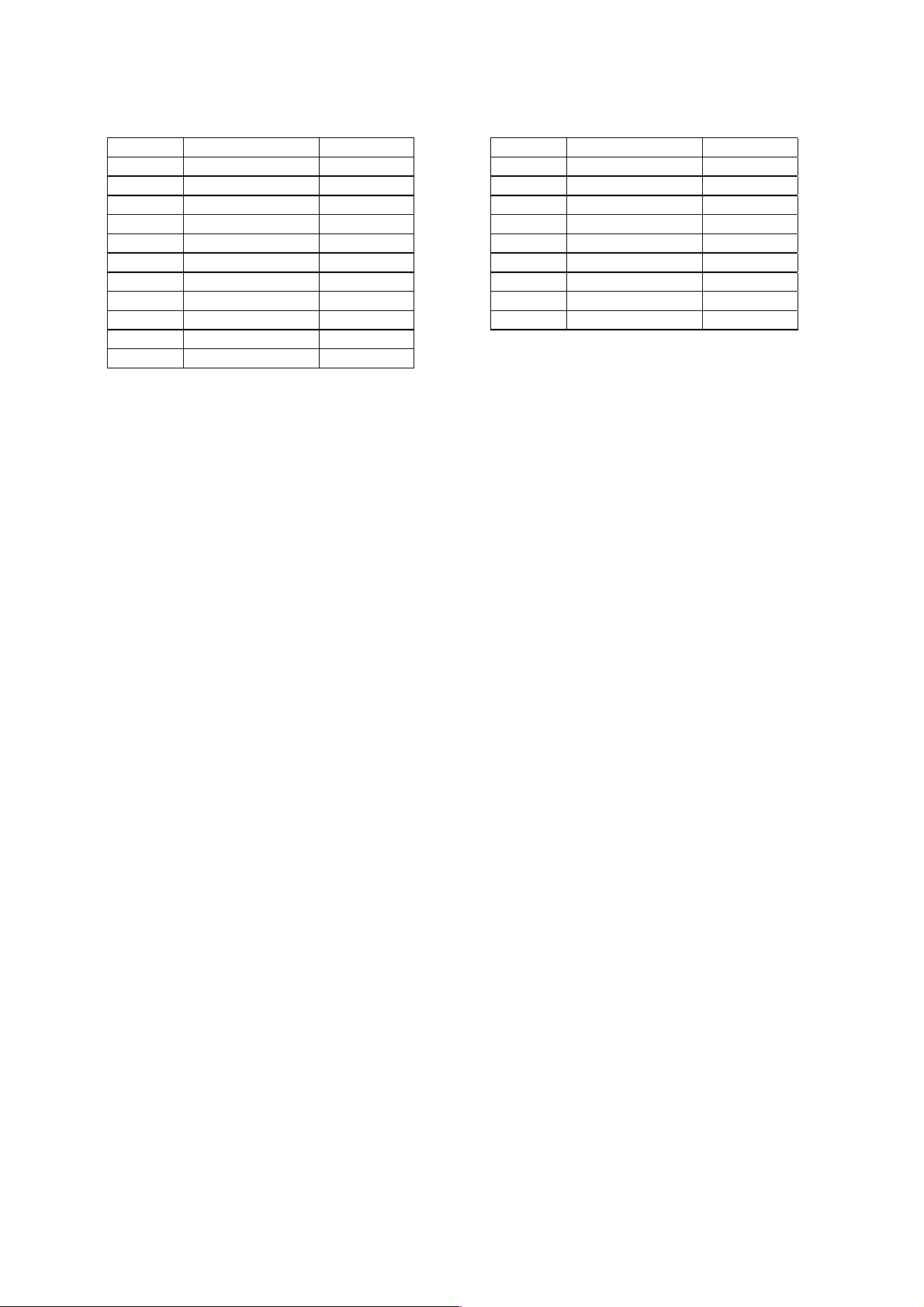

TUNER VOLTAGE CHARTS

CABLE OPERATION

U7301

Pin Band 1 Band 2 Band 3

No. 2 17 18 50 51 75

99

1. 5.44V 5.40V 5.41V 5.40V 5.30V 5.28V 5.48V

2. 2.99V 2.96V 2.96V 2.96V 3.18V 3.17V 3.00V

3. 7.80V 7.78V 7.77V 7.75V 7.57V 7.57V 7.89V

4. 2.99V 2.96V 2.96V 2.97V 3.18V 3.17V 3.00V

5. 7.82V 7.78V 7.75V 7.77V 7.56V 7.57V 7.89V

6. 0V 0V 0V 0V 0V 0V 0V

7. 3.06V 3.04V 3.05V 3.05V 0V 0V 3.08V

8. 9.02V 9.01V 8.97V 8.89V 8.84V 8.83V 9.14V

9. 3.02V 3.02V 2.98V 2.98V 3.36V 3.35V 3.01V

10. 3.25V 3.23V 3.22V 3.23V 2.88V 2.87V 3.28V

11. 4.96V 5.04V 5.06V 5.16V 9.62V 9.58V 5.14V

12. 3.26V 3.23V 3.22V 3.23V 2.87V 2.87V 3.28V

13. 0V 0V 0V 0V 0V 0V 0V

14. 9.05V 9.00V 8.97V 9.00V 5.43V 5.42V 9.13V

15. 3.43V 3.41V 3.42V 3.41V 2.88V 2.87V 3.46V

16. 3.41V 3.41V 3.40V 3.41V 2.89V 2.89V 3.47V

U7501

Pin Band 1 Band 2 Band 3

No. 2 17 18 50 51 75

99

1. 1.36V 4.63V 1.30V 5.52V 1.20V 2.21V 2.86V

2. 1.36V 4.63V 1.30V 5.52V 1.20V 2.21V 2.86V

3. 1.36V 4.63V 1.30V 5.52V 1.20V 2.21V 2.86V

4. 33.0V 33.0V 33.0V 33.0V 33.0V 33.0V 33.0V

5. 1.06V 3.62V 1.16V 4.68V 0.99V 1.90V 2.54V

6. 1.06V 3.62V 1.16V 4.68V 0.99V 1.90V 2.54V

7. 1.06V 19.8V 1.78V 27.6V 0.54V 7.2V 11.9V

8. 0.68V 24.2V 1.03V 25.3V 0.86V 7.63V 12.5V

9. 1.01V 4.22V 1.10V 4.38V 1.01V 1.96V 2.62V

10. 1.01V 4.22V 1.10V 4.38V 1.01V 1.96V 2.62V

11. 0V 0V 0V 0V 0V 0V 0V

12. 1.05V 4.36V 1.07V 4.76V 0.99V 1.86V 2.66V

13. 1.05V 4.36V 1.07V 4.76V 0.99V 1.86V 2.66V

14. 1.01V 25.2V 1.12V 28.1V 0.54V 6.91V 12.7V

U7401

Band 1 Band 2 Band 3

21851

1. 1.75V 1.74V 1.74V

2. 2.11V 2.11V 2.11V

3. 2.11V 2.11V 2.11V

4. 4.78V 4.78V 4.78V

5. 4.71V 4.71V 4.71V

6. 0V 0V 0V

7. NC NC NC

8. 11.5V 0V 0V

9. 7.47V 7.42V 0V

10. 4.85V 4.85V 4.85V

11. 2.30V 2.30V 2.30V

12. 2.30V 2.30V 2.30V

13. 0V 0V 0V

14. 0.60V 0.60V 0.60V

Q7101

Band 1 Band 2 Band 3

21751

Gl 0V 0V 4.84V

G2 5.05V 4.17V 7.19V

D 0V 0.10V 11.3V

S 0.10V 0.10V 4.83V

Q7102

Gl 4.59V 4.65V 4.61V

G2 5.44V 4.50V 7.19V

D 11.3V l1.2V 11.1V

S 4.08V 3.71V 11.0V

Q7401

E0V 0V0V

B 0.60V 0.60V 0.60V

C 2.06V 1.65V 1.00V

Q7402

E 11.3V 11.4V 11.4V

B 11.4V 10.6V 10.6V

C -14.5V 11.2V 11.2V

Q7403

E0V 0V0V

B 0.70V 0.70V 0V

C 0.10V 0.10V 11.3V

Page 3-7

Q7404

E 11.4V 11.4V 11.3V

B 11.0V 10.9V 10.6V

C 0.llV 0.llV 11.3V

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

REPLACEMENT PARTS

MAY 1999

BEFORE REPLACING PARTS, READ THE FOLLOWING:

Approved Substitute Stock Numbers - Before ordering stock numbers

in the part list, look for an approved substitute stock number in the

current Price Schedule. This will minimize your service time and avoid

ordering parts you already have in stock.

PRODUCT SAFETY NOTE: Components marked with a , have

special characteristics important to safety. Before replacing any of

these components, carefully read the PRODUCT SAFETY NOTICE in

the basic service data. Do not degrade the safety of the set through

improper servicing. Although assemblies as a whole may not be

marked with a , replacement of assemblies with other assemblies

not approved may result in a safety hazard.

@NOTE: When ordering components that are listed more than once in this part list, always adhere to the serial number application guidelines

given in the description column. If a serial number application guideline is not given, always select the component with a value, rating, other

specification or identification marking(s) that match those of the corresponding component in the instrument you are servicing.

StockSymbol DescriptionDrawing Symbol Stock Description Drawing

Warranty Status of Assemblies and Parts - All assemblies and

components shown in this part list are eligible for warranty exchange

or replacement except those with a dot • shown to the left of the

Description. Assemblies and components with a dot • to the left of the

Description are NOT eligible for warranty exchange or replacement.

Warranty replacement of cabinet parts requires the approval of a

Thomson Consumer Electronics Field Service Manager.

Warranty Status and Specifications of assemblies and components are

subject to change without notice. Consult the TCE Parts Pricing for

the latest warranty status information.

Chassis Common Parts

Chassis

BRA

BRA

C1201

C1205

C1401

C1401

C1402

C1402

C1403

C1403

C1404

C1405

C1406

C1408

C1409

C1410

C1411

C1412

C1701

239281 XX90576-45 BRACKET, FM RADIO

239284 XX15046-15 BRACKET, IR RCVR HOOD

220998 XX60438-93 CAP LYTC 1UF M 100V

220998 XX60438-93 CAP LYTC 1UF M 100V

220998 XX60438-93 CAP LYTC 1UF M 100V (SEE

151119 XX11054-84 CAP LYTC 3.3UF M 100V

220998 XX60438-93 CAP LYTC 1UF M 100V (SEE

151119 XX11054-84 CAP LYTC 3.3UF M 100V

197605 XX20466-94 CAPCC 1000PF K SL 50V

181460 XX50879-87 CAPCC 1000PF K X7R 50V

220998 XX60438-93 CAP LYTC 1UF M 100V

215555 XX40432-77 CAPCC .01UF K X7R 50V

220998 XX60438-93 CAP LYTC 1UF M 100V

214728 XX80434-33 CAP LYTC 100UF M 10V

220998 XX60438-93 CAP LYTC 1UF M 100V

214728 XX80434-33 CAP LYTC 100UF M 10V

220998 XX60438-93 CAP LYTC 1UF M 100V

207855 XX60438-88 CAP LYTC 470UF M 25V

222008 XX15041-17 CAPCC .1UF K X7R 25V

(AD,BD,BD3,CD,CD3)

(AA,AB,AD,B,BA,BD)

NOTE@)

(SEE NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

NOTE@)

(SEE NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

(SEE NOTE@)

(AD,BD,BD3,CD,CD3)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

(AA,AB,B,BA,CA,CA3)

C1702

C1703

C1703

C1704

C1705

C1706

C1707

C1708

C1709

C1710

C1713

C1714

C1715

C1716

C1717

C1901

C1902

C1903

C1904

C1904

C1905

197601 XX30939-24 CAPCC .022UF K X7R 50V

(AA,AB,B,BA,CA,CA3)

190499 XX40433-16 CAP LYTC 4.7UF M 100V

(AA)

189992 XX40433-16 CAP LYTC 4.7UF M 100V

(AB,B,BA,CA,CA3)

189979 XX80434-35 CAP LYTC 47UF M 25V

(AA,AB,B,BA,CA,CA3)

220998 XX60438-93 CAP LYTC 1UF M 100V

(AA,AB,B,BA,CA,CA3)

220998 XX60438-93 CAP LYTC 1UF M 100V

(AA,AB,B,BA,CA,CA3)

190534 XX40433-65 CAPCD 4700PF K Z5P 250V

(AA,AB,B,BA,CA,CA3)

181462 XX40432-85 CAPCC .22UF Z Y5V 50V

(AA,AB,B,BA,CA,CA3)

220998 XX60438-93 CAP LYTC 1UF M 100V

(AA,AB,B,BA,CA,CA3)

195691 XX50880-22 CAP LYTC 2.2UF M 100V

(AA,AB,B,BA,CA,CA3)

190552 XX70427-61 CAPCC .1UF K X7R 50V

(AA,AB,B,BA,CA,CA3)

174422 XX60438-49 CAPCC 2700PF K X7R 50V

(AA,AB,B,BA,CA,CA3)

181462 XX40432-85 CAPCC .22UF Z Y5V 50V

181462 XX40432-85 CAPCC .22UF Z Y5V 50V

156239 XX30935-88 CAP LYTC 10UF M 63V

(AA,AB,B,BA,CA,CA3)

220998 XX60438-93 CAP LYTC 1UF M 100V

220998 XX60438-93 CAP LYTC 1UF M 100V

162787 XX70427-97 CAP LYTC 22UF M 50V

223690 XX60444-68 CAP LYTC 1000UF M 25V

(AB,AD,BA,BD,BD3,CA,CA3,

CD,CD3)

214729 XX50880-17 CAP LYTC 220UF M 35V

(AA,B)

162787 XX70427-97 CAP LYTC 22UF M 50V

Page 8-1

Page 21

REPLACEMENT PARTS

MAY 1999

StockSymbol DescriptionDrawing Symbol Stock Description Drawing

C1906 223690 XX60444-68 CAP LYTC 1000UF M 25V

C1906

C1907

C1908

C1909

C1909

C1910

C1911

C1912

C1913

C1914

C1915

C1917 195689 XX11059-34 CAPCC .01UF K X7R 50V

C1917

C1918

C1919

C1920

C2301

C2302

C2306

C2307

C2308

C2309

C2309

C2311

C2312

C2313

C2702

C2702

C2703

C2704

C2705

C2706

C2707

C2707

C2708

C2708

214729 XX50880-17 CAP LYTC 220UF M 35V

200141 XX20467-04 CAP POLY .1UF K 63V

190552 XX70427-61 CAPCC .1UF K X7R 50V

175119 XX80440-78 CAP LYTC 1000UF M 35V

214730 XX40438-58 CAP LYTC 330UF M 35V

189979 XX80434-35 CAP LYTC 47UF M 25V

200141 XX20467-04 CAP POLY .1UF K 63V

214731 XX80436-85 CAPCC .015UF K X7R 50V

214731 XX80436-85 CAPCC .015UF K X7R 50V

205230 XX20469-34 CAPCC 4700PF K X7R 50V

205230 XX20469-34 CAPCC 4700PF K X7R 50V

205230 XX20469-34 CAPCC 4700PF K X7R 50V

222008 XX15041-17 CAPCC .1UF K X7R 25V

195689 XX11059-34 CAPCC .01UF K X7R 50V

222008 XX15041-17 CAPCC .1UF K X7R 25V

195689 XX11059-34 CAPCC .01UF K X7R 50V

214732 XX30938-74 CAPCC 470PF J NPO 50V

190520 XX70427-65 CAP POLY .22UF K 63V

214734 XX11059-43 CAPCC .047UF Z Z5U 50V

197601 XX30939-24 CAPCC .022UF K X7R 50V

197605 XX20466-94 CAPCC 1000PF K SL 50V

181460 XX50879-87 CAPCC 1000PF K X7R 50V

221142 XX11054-71 CAP LYTC 33UF M 35V

181462 XX40432-85 CAPCC .22UF Z Y5V 50V

197601 XX30939-24 CAPCC .022UF K X7R 50V

189992 XX40433-16 CAP LYTC 4.7UF M 100V

190499 XX40433-16 CAP LYTC 4.7UF M 100V

220998 XX11067-09 CAP LYTC 1UF M 100V

220998 XX11067-09 CAP LYTC 1UF M 100V

195691 XX50880-22 CAP LYTC 2.2UF M 100V

162787 XX70427-97 CAP LYTC 22UF M 50V

220998 XX60438-93 CAP LYTC 1UF M 100V (SEE

190551 XX90568-21 CAPCC .022UF K X7R 50V

220998 XX60438-93 CAP LYTC 1UF M 100V (SEE

190551 XX90568-21 CAPCC .022UF K X7R 50V

(AB,AD,BA,BD,BD3,CA,CA3,

CD,CD3)

(AA,B)

(AB,AD,BA,BD,BD3,CA,CA3,

CD,CD3)

(AA,B)

(AA,AB,B,BA,CA,CA3)

(AA,AB,B,BA,CA,CA3)

(AB,B,BA,CA,CA3)

(AD,BD,BD3,CD,CD3)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

(AB,AD,B,BA,BD,BD3,CA,

CA3,CD,CD3)

(AA)

NOOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

(SEE NOTE@)

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

(SEE NOTE@)

C2709

C2709

C2713

C2718

C2724

C2801

C2803

C3101

C3102

C3103

C3104

C3106

C3107

C3107

C3109

C3110

C3111

C3111

C3112

C3113

C3114

C3115

C3117

C3118

C3119

C3122

C3123

C3124

C3125

C3126

C3127

C3128

C3129

C3201

C3301

C3303

C3306

C3307

C3310

C3311

C3312

C3313

C3314

C3315

220998 XX60438-93 CAP LYTC 1UF M 100V (SEE

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

190551 XX90568-21 CAPCC .022UF K X7R 50V

(SEE NOTE@)

190499 XX30935-95 CAP LYTC 4.7UF M 100V

205551 XX30938-73 CAPCC 220PF J NPO 50V

189979 XX80434-35 CAP LYTC 47UF M 25V

220998 XX60438-93 CAP LYTC 1UF M 100V

214736 XX11059-46 CAPCC 16PF G NPO 50V

193340 XX11058-67 CAPCC 100PF J NPO 50V

193340 XX11058-67 CAPCC 100PF J NPO 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197604 XX11058-64 CAPCC 27PF J NPO 50V (SEE

NOTE@)

(AA,AB,AB,AD,B,BA,BD,

BD3,CA,CA3,CD,CD3)

193339 XX30938-70 CAPCC 68PF J NPO 50V (SEE

NOTE@) (AA,B)

197600 XX11059-32 CAPCC 1000PF K X7R 50V

193340 XX11058-67 CAPCC 100PF J NPO 50V

197605 XX20466-94 CAPCC 1000PF K SL 50V

(AD,BD,BD3,CD,CD3)

181460 XX50879-87 CAPCC 1000PF K X7R 50V

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

190552 XX70427-61 CAPCC .1UF K X7R 50V

195689 XX11059-34 CAPCC .01UF K X7R 50V

197604 XX11058-64 CAPCC 27PF J NPO 50V

197604 XX11058-64 CAPCC 27PF J NPO 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

(AA,AB,B,BA,CA,CA3)

178188 XX20466-85 CAPCC 220PF J NPO 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

(AA,AB,B,BA,CA,CA3)

197600 XX11059-32 CAPCC 1000PF K X7R 50V

(AA,AB,B,BA,CA,CA3)

197600 XX11059-32 CAPCC 1000PF K X7R 50V

217298 XX15040-86 CAPCC .22UF Z Y5V 25V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

222396 XX50879-71 CAPCC 56PF K NPO 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

190552 XX70427-61 CAPCC .1UF K X7R 50V

195689 XX11059-34 CAPCC .01UF K X7R 50V

192060 XX11059-30 CAPCC 1000PF K SL 50V

194903 XX60441-08 CAPCC 22PF J NPO 50V

210689 XX40435-18 CAPCC 47PF J NPO 50V

197607 XX11059-33 CAPCC 2200PF K X7R 50V

192049 XX40435-19 CAPCC 82PF J NPO 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

194903 XX60441-08 CAPCC 22PF J NPO 50V

194903 XX60441-08 CAPCC 22PF J NPO 50V

220998 XX60438-93 CAP LYTC 1UF M 100V

Page 8-2

Page 22

REPLACEMENT PARTS

MAY 1999

StockSymbol DescriptionDrawing Symbol Stock Description Drawing

C3316 218986 XX11058-68 CAPCC 200PF J NPO 50V

C3316

C3317

C3318

C3401

C3402

C4001

C4003 190538 XX11057-25 CAPCD 680PF M Z5P 1KV

C4004 190538 XX11057-25 CAPCD 680PF M Z5P 1KV

C4006 250102 XX11055-04 CAP CAPRISTOR

C4007 203734 XX70401-00 CAP LYTC 330UF M 400V

C4008 223330 XX15068-44 CAPCD 3400PF M Z5V 120V

C4008 195697 XX40433-27 CAPCD 5000PF M Z5V 120V

C4009 190538 XX11057-25 CAPCD 680PF M Z5P 1KV

C4010 190538 XX11057-25 CAPCD 680PF M Z5P 1KV

C4101 161027 XX70427-92 CAP LYTC 150UF M 16V

C4103 214742 XX60441-44 CAPCC 3300PF K X7R 50V

C4104

C4105

C4105 223809 XX15050-79 CAP LYTC 10UF M 250V

C4105 225667 XX15065-55 CAP LYTC 22UF +30%-10%

C4107 218374 XX15045-95 CAP LYTC 100UF +30-10%

C4108 214745 XX30935-91 CAP LYTC 1000UF M 50V

C4109

C4110

C4111

C4112

C4114

C4115

C4116

C4117

C4118

C4119

C4120

C4121

C4122

C4123 217652 XX11054-32 CAP POLY .012UF K 100V

C4124

C4125

C4126

C4127

C4128

C4129

C4130

C4131

C4133

205551 XX30938-73 CAPCC 220PF J NPO 50V

215555 XX40432-77 CAPCC .01UF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

195689 XX11059-34 CAPCC .01UF K X7R 50V

162787 XX70427-97 CAP LYTC 22UF M 50V

223820 XX15245-16 CAP POLY .22UF M 250V

190523 XX30935-55 CAP POLY .22UF M 100V

214743 XX15066-40 CAP LYTC 10UF M 200V

104135 XX40434-50 CAPCD 680PF K Z5P 500V

190536 XX11057-18 CAPCD 1000PF M Z5P 500V

215555 XX40432-77 CAPCC .01UF K X7R 50V

214746 XX11054-91 CAP LYTC 470UF M 25V

195689 XX11059-34 CAPCC .01UF K X7R 50V

156239 XX30935-88 CAP LYTC 10UF M 63V

194366 XX80434-39 CAP LYTC 100UF M 16V

156239 XX30935-88 CAP LYTC 10UF M 63V

189979 XX80434-35 CAP LYTC 47UF M 25V

195689 XX11059-34 CAPCC .01UF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

181462 XX40432-85 CAPCC .22UF Z Y5V 50V

214747 XX40434-58 CAP POLY .033UF J 400V

205237 XX80434-08 CAP POLY .056UF J 63V

214749 XX90568-51 CAP LYTC 68UF M 50V

160461 XX11057-23 CAPCD 1000PF K Z5P 1KV

156239 XX30935-88 CAP LYTC 10UF M 63V

102230 XX60440-27 CAPCD 470PF K Z5P 500V

194366 XX80434-39 CAP LYTC 100UF M 16V

193039 XX10038-46 CAP LYTC 10UF M 160V

204293 XX50881-17 CAPCD 120PF M Z5P 250V

201163 XX70427-59 CAPCC .068UF K X7R 50V

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

(AD,BD,BD3,CD,CD3)

(AA,B)

(AA,AB,B,BA,BD)

(SEE NOTE@)

(SEE NOTE@) (AA,B)

(SEE NOTE@)

(SEE NOTE@) (AA,B)

200V (SEE NOTE@) (AA,B)

250V

C4134

C4135

C4136

C4137

C4138

C4201

C4302

C4303

C4304

C4305

C4306

C4307

C4308

C4309

C4310

C4311

C4313

C4401

C4402

C4402 206008 XX30911-69 CAP POLY .0157UF HP 1.6KV

C4402 206007 XX20439-66 CAP POLY .015UF HP 1.6KV

C4402 218989 XX15231-08 CAP POLY 7600PF E 1.6KV

C4403 223819 XX15053-92 CAP POLY .32UF J 250V (B)

C4403 218369 XX90578-12 CAP POLY .43UF J 250V

C4403 214753 XX15000-55 CAP POLY .55UF J 250V

C4404 196050 XX70428-06 CAP LYTC 2.2UF M 200V

C4405 190534 XX40433-65 CAPCD 4700PF K Z5P 250V

C4406 227068 XX15065-09 CAPCD 470PF J SL 2KV

C4407 218492 XX15042-29 CAP POLY .041UF J 400V

C4407

C4501 190552 XX70427-61 CAPCC .1UF K X7R 50V

C4502

C4502

C4503

C4504

C4505

C4506

C4506

C4507

C4701

C4702

C4703

C4704

214750 XX30939-30 CAPCC .068UF Z Z5U 50V

102230 XX60440-27 CAPCD 470PF K Z5P 500V

146764 XX90569-77 CAPCD 330PF K Z5P 500V

104135 XX40434-50 CAPCD 680PF K Z5P 500V

192846 XX40433-18 CAP LYTC 68UF M 16V

215555 XX40432-77 CAPCC .01UF K X7R 50V

190552 XX70427-61 CAPCC .1UF K X7R 50V

214732 XX30938-74 CAPCC 470PF J NPO 50V

146179 XX30937-37 CAPCD 470PF K Z5P 250V

142762 XX60440-21 CAPCD 2200PF K Z5P 250V

188594 XX30935-72 CAP POLY .047UF K 250V

220998 XX60438-93 CAP LYTC 1UF M 100V

190551 XX90568-21 CAPCC .022UF K X7R 50V

190548 XX30935-33 CAPCC 4700PF K X7R 50V

223899 XX60439-48 CAPCD 15PF F NPO 250V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

178188 XX20466-85 CAPCC 220PF J NPO 50V

195918 XX90568-08 CAPCC 470PF J NPO 50V

223177 XX15053-23 CAP POLY .0115UF G 1.6KV

(AA,AB,AD)

(CA,CA3,CD)

(BA,BD,BD3)

(B)

(AA,AB,AD)

(BA,BD,BD3,CA,CA3,CD,CD3)

(AA,AB,AD,BA,BD,BD3,CA,

CA3,CD,CD3)

(CA,CA3,CD,CD3)

214754 XX80428-94 CAP POLY .047UF J 400V

(AA,B,BA,BD,BD3)

190495 XX80434-40 CAP LYTC 1500UF M 25V

(B,BA,BD,BD3)

214755 XX30935-90 CAP LYTC 2200UF M 25V

(AA,AB,AD,CA,CA3,CD,CD3)

190552 XX70427-61 CAPCC .1UF K X7R 50V

190523 XX30935-55 CAP POLY .22UF M 100V

245280 XX20467-28 CAP LYTC 220UF M 35V

190721 XX30935-96 CAP LYTC 1000UF M 35V

(SEE NOTE@)

214047 XX70428-04 CAP LYTC 330UF M 63V

(SEE NOTE@) (AA,B)

190552 XX70427-61 CAPCC .1UF K X7R 50V

190497 XX70428-03 CAP LYTC 680UF M 50V

190538 XX11057-25 CAPCD 680PF M Z5P 1KV

190479 XX50880-34 CAP LYTC 47UF M 250V

190538 XX11057-25 CAPCD 680PF M Z5P 1KV

Page 8-3

Page 23

REPLACEMENT PARTS

MAY 1999

StockSymbol DescriptionDrawing Symbol Stock Description Drawing

C4705 201162 XX90568-62 CAP LYTC 1000UF M 25V

C4705

C4706

C4708

C4709

C4709

C4710

C4901

C4902

C4903

C4904

C4904 181462 XX40432-85 CAPCC .22UF Z Y5V 50V

C4905 143879 XX80434-80 CAPCD 1000PF K Y5P 50V

C7102

C7103

C7104

C7105

C7106

C7107

C7108

C7109

C7110

C7111

C7112

C7113

C7115

C7116

C7117

C7118

C7119

C7122

C7123

C7124

C7125

C7126

C7127

C7128

C7130

C7131

C7132

C7134

C7136

C7137

C7139

C7140

214755 XX30935-90 CAP LYTC 2200UF M 25V

190538 XX11057-25 CAPCD 680PF M Z5P 1KV

190538 XX11057-25 CAPCD 680PF M Z5P 1KV

189979 XX80434-35 CAP LYTC 47UF M 25V

193043 XX60438-95 CAP LYTC 47UF M 35V

137583 XX40434-57 CAPCD .01UF M Z5V 1KV

146181 XX60440-01 CAPCD 150PF K Z5P 250V

202011 XX90568-30 CAP POLY .1UF J 63V

190530 XX11053-05 CAPCC .33UF Z Y5V 25V

214739 XX40441-96 CAPCC .22UF Z Y5V 25V

214757 XX20475-60 CAPCC 4PF +0-.25PF NPO 50V

194903 XX60441-08 CAPCC 22PF J NPO 50V

194902 XX50882-37 CAPCC 120PF J NPO 50V

214758 XX11058-32 CAPCC .75PF C NPO 50V

214759 XX11038-95 CAPCC 39PF J SL 50V

195689 XX11059-34 CAPCC .01UF K X7R 50V

214760 XX20459-49 CAPCC 27PF J N750 50V

197606 XX20469-36 CAPCC .033UF Z Y5V 50V

192060 XX11059-30 CAPCC 1000PF K SL 50V

195689 XX11059-34 CAPCC .01UF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

193340 XX11058-67 CAPCC 100PF J NPO 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

194903 XX60441-08 CAPCC 22PF J NPO 50V

192060 XX11059-30 CAPCC 1000PF K SL 50V

197605 XX20466-94 CAPCC 1000PF K SL 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197604 XX11058-64 CAPCC 27PF J NPO 50V

192060 XX11059-30 CAPCC 1000PF K SL 50V

197605 XX20466-94 CAPCC 1000PF K SL 50V

194902 XX50882-37 CAPCC 120PF J NPO 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

195689 XX11059-34 CAPCC .01UF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197605 XX20466-94 CAPCC 1000PF K SL 50V

192061 XX20468-96 CAPCC 75PF J NPO 50V

197605 XX20466-94 CAPCC 1000PF K SL 50V

214761 XX80426-88 CAPCC 20PF G N220 50V

194901 XX11058-39 CAPCC 4PF D NPO 50V (SEE

(SEE NOTE@) (AA,B)

(SEE NOTE@)

(AA,AB,AD,B,BA,BD,BD3)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

(AD,BD,BD3,CD,CD3)

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

C7140

C7142

C7143

C7144

C7145

C7149

C7150

C7151

C7152

C7153

C7301

C7302

C7303

C7304

C7305

C7306

C7307

C7307

C7307

C7308

C7309

C7310

C7310

C7311

C7312

C7313

C7313

C7313

C7314

C7315

C7316

C7318

C7319

C7320

C7320

C7321

C7322

C7323

C7325

C7401

C7402

C7403

194909 XX11058-40 CAPCC 8PF D NPO 50V (SEE

NOTE@)

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

192060 XX11059-30 CAPCC 1000PF K SL 50V

194903 XX60441-08 CAPCC 22PF J NPO 50V

214032 XX30938-72 CAPCC 150PF J NPO 50V

220150 XX40435-17 CAPCC 20PF J NPO 50V

214029 XX20468-95 CAPCC 43PF J NPO 50V

202905 XX11058-65 CAPCC 39PF J NPO 50V

223146 XX11059-53 CAPCC 1.5PF B NPO 50V

223146 XX11059-53 CAPCC 1.5PF B NPO 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

214762 XX60441-51 CAPCC 68PF G NPO 50V

215556 XX20469-40 CAPCC 39PF G NPO 50V

214762 XX60441-51 CAPCC 68PF G NPO 50V

214765 XX11059-44 CAPCC 10PF G NPO 50V (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

200537 XX50882-23 CAPCC 10PF J NPO 50V

(AA,AB,B,BA,BD,CA,CA3,

CD,CD3)

214740 XX50882-23 CAPCC 10PF J NPO 50V (SEE

NOTE@) (AD)

214764 XX11067-43 CAPCC 5.6PF C N750 50V

214765 XX11059-44 CAPCC 10PF G NPO 50V

214766 XX70429-97 CAPCC 8PF D N750 50V

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

194909 XX11058-40 CAPCC 8PF D NPO 50V (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

193917 XX30938-51 CAPCC 5PF D NPO 50V

214767 XX80436-38 CAPCC 3PF D NPO 50V

214765 XX11059-44 CAPCC 10PF G NPO 50V (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

200537 XX50882-23 CAPCC 10PF J NPO 50V

(AA,AB,B,BA,BD,CA,CA3,

CD,CD3)

214740 XX50882-23 CAPCC 10PF J NPO 50V (SEE

NOTE@) (AD)

192060 XX11059-30 CAPCC 1000PF K SL 50V

192060 XX11059-30 CAPCC 1000PF K SL 50V

194909 XX11058-40 CAPCC 8PF D NPO 50V

197605 XX20466-94 CAPCC 1000PF K SL 50V

195689 XX11059-34 CAPCC .01UF K X7R 50V

197601 XX30939-24 CAPCC .022UF K X7R 50V

(SEE NOTE@)

197600 XX11059-32 CAPCC 1000PF K X7R 50V

(SEE NOTE@) (AA,B)

197600 XX11059-32 CAPCC 1000PF K X7R 50V

214762 XX60441-51 CAPCC 68PF G NPO 50V

214768 XX20469-38 CAPCC 7PF G NPO 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

195689 XX11059-34 CAPCC .01UF K X7R 50V

200141 XX20467-04 CAP POLY .1UF K 63V

205230 XX20469-34 CAPCC 4700PF K X7R 50V

Page 8-4

Page 24

REPLACEMENT PARTS

MAY 1999

StockSymbol DescriptionDrawing Symbol Stock Description Drawing

C7404 214762 XX60441-51 CAPCC 68PF G NPO 50V (SEE

C7404

C7405

C7405

C7406

C7407

C7408

C7410

C7410

C7410

C7411

C7411

C7411

C7412

C7413

C7414

C7415

C7416

C7501

C7502

C7503

C7504

C7505

C7506

C7507

C7602

C7603

C7604

C7605

CAB

CAB

CF1201 195702 XX70438-30 FILTER CERAMIC

CLI

CLI

CLI

CLI

CLI

CON

CON 242205 XX15087-68 CONNECTOR, YOKE VERT

COV 218877 XX70436-48 COVER, TUNER BOTTOM

COV

193339 XX30938-70 CAPCC 68PF J NPO 50V

214762 XX60441-51 CAPCC 68PF G NPO 50V (SEE

193339 XX30938-70 CAPCC 68PF J NPO 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

195689 XX11059-34 CAPCC .01UF K X7R 50V

214765 XX11059-44 CAPCC 10PF G NPO 50V

200537 XX50882-23 CAPCC 10PF J NPO 50V

214740 XX50882-23 CAPCC 10PF J NPO 50V (AD)

214765 XX11059-44 CAPCC 10PF G NPO 50V (SEE

200537 XX50882-23 CAPCC 10PF J NPO 50V

214740 XX50882-23 CAPCC 10PF J NPO 50V (SEE

197600 XX11059-32 CAPCC 1000PF K X7R 50V

205230 XX20469-34 CAPCC 4700PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

197606 XX20469-36 CAPCC .033UF Z Y5V 50V

197606 XX20469-36 CAPCC .033UF Z Y5V 50V

197606 XX20469-36 CAPCC .033UF Z Y5V 50V

197601 XX30939-24 CAPCC .022UF K X7R 50V

197601 XX30939-24 CAPCC .022UF K X7R 50V

197601 XX30939-24 CAPCC .022UF K X7R 50V

181462 XX40432-85 CAPCC .22UF Z Y5V 50V

197600 XX11059-32 CAPCC 1000PF K X7R 50V

192060 XX11059-30 CAPCC 1000PF K SL 50V

194903 XX60441-08 CAPCC 22PF J NPO 50V

197604 XX11058-64 CAPCC 27PF J NPO 50V

239287 XX15230-87 CABLE ASY, P2705/P801

225766 XX15040-89 CABLE, AC POWER

176642 XX15073-56 CLIP, F4001

238768 XX15166-33 CLIP, FLYBACK

181032 XX15089-44 CLIP, Q4401

173269 XX15089-49 CLIP, U1901/U4501

227719 XX15073-14 CLIP, U4101

242206 XX15087-69 CONNECTOR, YOKE HORIZ

218876 XX11070-63 COVER, TUNER TOP

NOTE@)

(AD,BD,BD3,CD,CD3)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

NOTE@)

(AD,BD,BD3,CD,CD3)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

(AD,BD,BD3,CD,CD3)

(AA,AB,B,BA,BD,CA,CA3,

CD,CD3)

NOTE@)

(AD,BD,BD3,CD,CD3)

(AA,AB,B,BA,BD,CA,CA3,

CD,CD3)

NOTE@) (AD)

(AD,BD,BD3,CD,CD3)

CR1401

CR1402

CR1403

CR1404

CR2702

CR2904

CR2904

CR3102

CR3102

CR3110 201133 1A40101-01 DIODE (HSM221)(SEE

CR3110

CR3111

CR3111

CR3301

CR3302

CR3303

CR3303

CR4001

CR4001

CR4002

CR4002

CR4003

CR4003

CR4004

220638 XX50890-65 DIODE ZENER 6.8V .5W

(AB,AD,BA,BD,BD3,CA,CA3,

CD,CD3)

220638 XX50890-65 DIODE ZENER 6.8V .5W

(AB,AD,BA,BD,BD3,CA,CA3,

CD,CD3)

220638 XX50890-65 DIODE ZENER 6.8V .5W

(AB,AD,BA,BD,BD3,CA,CA3,

CD,CD3)

198589 XX70436-54 DIODE

198589 XX70436-54 DIODE

201133 XX15047-54 DIODE (HSM221)(SEE

NOTE@) (AD,BD,CD,CD3)

232709 XX15077-06 DIODE (LS4148)(SEE

NOTE@) (AD,BD,CD,CD3)

201133 1A40101-01 DIODE (HSM221)(SEE

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

232709 XX15077-06 DIODE (LS4148)(SEE

NOTE@)

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

232709 XX15077-06 DIODE (LS4148)(SEE

NOTE@)

(AA,AB,AD,B,BA,BD,BD3,

CA,CA3,CD3)

218987 XX15042-36 DIODE ZENER 5.1V .2W (SEE

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

239195 XX15196-09 DIODE ZENER 5.1V .5W (SEE

NOTE@)

198589 XX70436-54 DIODE

201133 1A40101-01 DIODE (AA,B)

201133 XX15047-54 DIODE (HSM221)(SEE

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

232709 XX15077-06 DIODE (LS4148)(SEE

NOTE@)

147015 XX11070-79 DIODE (S5456L)(SEE

NOTE@)

176751 2811925-00 DIODE (TVR4N)(SEE

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

147015 XX11070-79 DIODE (S5456L)(SEE

NOTE@)

176751 2811925-00 DIODE (TVR4N)(SEE

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

147015 XX11070-79 DIODE (S5456L)(SEE

NOTE@)

176751 2811925-00 DIODE (TVR4N)(SEE

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

147015 XX11070-79 DIODE (S5456L)(SEE

NOTE@)

Page 8-5

Page 25

REPLACEMENT PARTS

MAY 1999

StockSymbol DescriptionDrawing Symbol Stock Description Drawing

CR4004 176751 2811925-00 DIODE (TVR4N)(SEE

CR4101

CR4102

CR4103

CR4104

CR4106

CR4107

CR4108

CR4109

CR4111

CR4112

CR4113

CR4114

CR4115

CR4201

CR4302

CR4303

CR4401

CR4402 242907 XX15319-70 DIODE

CR4403

CR4405

CR4405

CR4501

CR4701

CR4702

CR4704

CR4705

CR4901

CR4902 159429 XX30946-70 DIODE ZENER 10V .2W

CR7101 215492 XX60445-48 DIODE KIT

CR7105

CR7106

CR7109

CR7110

CR7112

CR7303

F4001

F4001 227481 XX15066-59 FUSE 5A 250V (SEE NOTE@)

FB3101 226467 XX50895-75 BEAD

FB3101

FB3103

FB3103

FB3104

FB3104

FB4102

164874 XX30946-68 DIODE

176296 XX30946-67 DIODE

198589 XX70436-54 DIODE

215488 XX11073-65 DIODE ZENER 5.6V .5W

164589 XX50888-80 DIODE

164590 XX20474-07 DIODE

217306 XX15053-31 DIODE ZENER 33V 1.3W

215490 XX11070-81 DIODE ZENER 7.5V 1.3W

176296 XX30946-67 DIODE

140971 XX70436-53 DIODE

176296 XX30946-67 DIODE

164874 XX30946-68 DIODE

215491 XX10050-32 DIODE ZENER 9.1V .2W

198589 XX70436-54 DIODE

198589 XX70436-54 DIODE

176296 XX30946-67 DIODE

140971 XX70436-53 DIODE

164589 XX50888-80 DIODE

207878 XX60341-80 DIODE (AD)

241304 XX60341-80 DIODE (AA,AB,B,BA)

155276 XX11070-78 DIODE

241304 XX60341-80 DIODE

176296 XX30946-67 DIODE

207878 XX15047-71 DIODE

176296 XX30946-67 DIODE

157301 XX60446-58 DIODE

215493 XX50887-84 DIODE

215494 XX40439-39 DIODE KIT

215493 XX50887-84 DIODE

215493 XX50887-84 DIODE

215493 XX50887-84 DIODE

215493 XX50887-84 DIODE

175425 XX40441-86 FUSE 5A 125V (SEE NOTE@)

153328 2843165-00 BEAD (SEE NOTE@) (AB)

226467 XX50895-75 BEAD

153328 2843165-00 BEAD (SEE NOTE@) (AB)

226467 XX50895-75 BEAD

153328 2843165-00 BEAD (SEE NOTE@) (AB)

161237 XX60452-60 BEAD

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

(AA,AB,AD,BA,BD,BD3,CA,

CA3,CD,CD3)

(B,BA,BD,BD3,CA,CA3,CD,

CD3)

(B,BA,BD,BD3,CA,CA3,CD,

CD3)

(AA,AB,AD,B,BA,BD,BD3)

(AA,B)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

Page 8-6

FB4102

FB4106

FB4107

FB4108

FB4109

FB4110

FB4111

FB4112

FB4113

FB4401

FB4401

FB4402

FB4402

FB4501

FL7102

FRA

FRA

FRA

GRO

HEA

HEA

HEA

HEA

HEA

HEA

HEA

INS

INS

IR3401 245282 XX15379-32 IC IR RECEIVER

J1401

J1402

J1403

J1404

J1405

J1406

J1901

J3001

J7101

227410 XX60452-60 BEAD (BD3)

154322 2843117-00 BEAD

154322 2843117-00 BEAD

154042 2843117-00 BEAD

154042 2843117-00 BEAD

215546 XX10045-07 BEAD

215546 XX10045-07 BEAD

154042 2843117-00 BEAD

154042 2843117-00 BEAD

227410 XX60452-60 BEAD (BD3)

161237 XX60452-60 BEAD

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

206390 2843117-01 BEAD (B)

232765 XX15091-67 BEAD

(BA,BD,CA,CA3,CD,CD3)

215547 XX70443-98 BEAD

181470 XX30953-36 FILTER LC HIGH PASS

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

234389 XX15148-76 FRAME, TUNER TOP (SEE

NOTE@)

218875 XX11070-64 FRAME, TUNER TOP (SEE

NOTE@) (AA,B)

232766 XX15117-34 FRAME, TUNER TOP (SEE

NOTE@) (AA,B,BA)

233125 XX15120-24 GROMMET, CHASSIS

240028 XX15128-24 HEATSINK, AUDIO

(AB,AD,BA,BD,BD3,CA,CA3,

CD,CD3)

220470 XX15332-50 HEATSINK, Q4101

242220 XX15347-10 HEATSINK, Q4401

(AD,BD,BD3,CD,CD3)

242209 XX40440-46 HEATSINK, Q4401

(AA,AB,B,BA,CA,CA3)

242222 XX11070-62 HEATSINK, U1901 (AA,B)

216001 XX11090-32 HEATSINK, U4101

239282 XX30957-05 HEATSINK, VERTICAL

233211 XX15046-44 INSULATOR, TUNER

SHIELD

(AA,AB,B,BA,CA,CA3,CD,

CD3)

222518 XX15314-55 INSULATOR, U4101

TSOP1556SD (SEE NOTE@)

(AA,AB,AD,B,BA,BD)

239389 XX15246-72 JACK PHONO 3 HIGH VIDEO

IN

195705 XX15091-48 SOCKET SVHS

JACK PHONO 3 HIGH AUDIO

IN R (PART OF J1401) (BD3)

JACK PHONO 3 HIGH AUDIO

IN L (PART OF J1401) (BD3)

215545 XX15092-46 JACK PHONO 2 HIGH HIFI

OUT R

JACK PHONO 2 HIGH HIFI

OUT L (PART OF J1405) (BD3)

215542 XX60430-77 CONNECTOR 4 PIN SPKRS

218375 XX20459-46 CONNECTOR 7 PIN FPA

(BD3,CA,CA3,CD,CD3)

215543 XX11043-55 CONNECTOR F TYPE ANT

Page 26

REPLACEMENT PARTS

MAY 1999

StockSymbol DescriptionDrawing Symbol Stock Description Drawing

JC301 205408 XX80440-51 RES CMF 1/10W 0% 0R

JC302

JC330

JC331

JC332

JC333

JC334

JC401

JC402

JC403

JC404

JC405

JC407

JC410

JC411

JC413

JC414

JC417

JC418

JC419

JC420

JC421

JC422

JC423

JC424

JC425

JC427

JC428

JC429

JC430

JC431

JC432

JC441

JC450

JC451

K4201

L2302 215502 XX50875-31 COIL

L2304

L2701

L2702

L2703

L2704

L3101

L3102

L4001

L4101 175409 XX80440-61 COIL 10UH

L4102

181161 XX50885-53 RES CMF 1/8W 0% 0R

181161 XX50885-53 RES CMF 1/8W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

(AA,AD,B,BA,BD,BD3,CA,

CA3,CD,CD3)

181161 XX50885-53 RES CMF 1/8W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

(AA,AD,B,BA,BD,BD3,CA,

CA3,CD,CD3)

181161 XX50885-53 RES CMF 1/8W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

(AD,BD,BD3,CD,CD3)

205408 XX80440-51 RES CMF 1/10W 0% 0R

(AA,AD,B,BA,BD,BD3,CA,

CA3,CD,CD3)

181161 XX50885-53 RES CMF 1/8W 0% 0R

181161 XX50885-53 RES CMF 1/8W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

181161 XX50885-53 RES CMF 1/8W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

181161 XX50885-53 RES CMF 1/8W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

181161 XX50885-53 RES CMF 1/8W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

181161 XX50885-53 RES CMF 1/8W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

(AD,BD,BD3,CD,CD3)

205408 XX80440-51 RES CMF 1/10W 0% 0R

(AD,BD,BD3,CD,CD3)

205408 XX80440-51 RES CMF 1/10W 0% 0R

181161 XX50885-53 RES CMF 1/8W 0% 0R

181161 XX50885-53 RES CMF 1/8W 0% 0R

(AD,BD,BD3,CD,CD3)

205408 XX80440-51 RES CMF 1/10W 0% 0R

181161 XX50885-53 RES CMF 1/8W 0% 0R

205408 XX80440-51 RES CMF 1/10W 0% 0R

190490 XX90578-04 RELAY DEGAUSSING

197616 XX90574-54 COIL 2.2UH

197616 XX90574-54 COIL 2.2UH

197616 XX90574-54 COIL 2.2UH

197616 XX90574-54 COIL 2.2UH

175409 XX80440-61 COIL 10UH

160518 XX11066-63 COIL 10UH (AA,BD3)

160186 XX30944-68 COIL 100UH

190507 1C59100-02 TRANSFORMER

215504 XX10038-07 COIL 22UH

L4103

L4104

L4401

L4401

L4402

L4402 223176 XX15053-93 COIL (B)

L4402 210895 XX40451-92 COIL 17.5UH

L4402 196064 XX80440-64 COIL 29UH (BA,BD,BD3)

L4801 215506 XX11068-37 COIL 360UH

L7101

L7102

L7103

L7104

L7105

L7106

L7107

L7108

L7108

L7109

L7110

L7111

L7112

L7113

L7114

L7115

L7116

L7117

L7118

L7301

L7302

L7303

L7304

L7305

L7306

L7601

NUT

OVE

OVE

OVE

OVE

OVE

OVE

OVE 235461 XX15277-07 OVERLAY, JACK PANEL

175409 XX80440-61 COIL 10UH

175409 XX80440-61 COIL 10UH

215505 XX10021-62 COIL 4UH

(AA,AB,AD,BA,BD,BD3,CA,

CA3,CD,CD3)

191141 XX11082-64 COIL 6.8UH (B)

192844 1C51400-01 COIL (AA,AB,AD)

(CA,CA3,CD,CD3)

(BA,BD,BD3,CA,CA3,CD,CD3)

215507 XX15209-41 COIL AIR

236641 XX15201-07 COIL AIR

223929 XX15209-51 COIL AIR

223917 XX15180-56 COIL AIR

223917 XX15180-56 COIL AIR

215509 XX15229-07 COIL AIR

215510 XX15209-42 COIL AIR

215511 XX15230-47 COIL AIR (AA)

215511 XX15230-47 COIL AIR

(AA,AB,AB,AD,AD,B,B,BA,

BA,BD,BD3,CA,CA,CA3,

CA3,CD,CD3,CD3)

200559 XX47025-30 COIL 3.9UH

223288 XX15203-37 COIL AIR

215512 XX15208-81 COIL AIR

231441 XX15208-85 COIL AIR

215514 XX15208-80 COIL AIR

231441 XX15208-85 COIL AIR

215515 XX15230-43 COIL AIR

243162 XX15363-21 COIL AIR

237460 XX15229-32 COIL AIR

237461 XX15180-72 COIL AIR

223928 XX15230-45 COIL AIR

231444 XX15229-01 COIL AIR

215510 XX15209-42 COIL AIR

223920 XX15209-37 COIL AIR

231447 XX15201-10 COIL AIR

231448 XX15209-43 COIL AIR

195708 XX50886-80 COIL .0068UH

233126 XX15089-00 NUT, HEX 3/8"-32

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

223612 XX15277-01 OVERLAY, JACK PANEL

(AA,AB,B)

215571 XX15276-88 OVERLAY, JACK PANEL

(AD,BD,BD3)

232763 XX15277-11 OVERLAY, JACK PANEL (BA)

235456 6R16020-18 OVERLAY, JACK PANEL

(CA,CA3)

223956 6R16020-10 OVERLAY, JACK PANEL

(CA,CA3)

245290 XX15276-99 OVERLAY, JACK PANEL

(CD,CD3)

(SEE NOTE@) (AB)

Page 8-7

Page 27

REPLACEMENT PARTS

MAY 1999

StockSymbol DescriptionDrawing Symbol Stock Description Drawing

Q1401 215495 XX11070-77 TRANSISTOR L BUFFER

Q1402

Q1403

Q1404

Q1405

Q1701

Q1901

Q1902

Q1903

Q2301

Q2701

Q2702

Q2703

Q2704

Q3101

Q3102

Q3301

Q3302

Q3302

Q3303

Q3304

Q3305

Q4101

Q4103

Q4103

Q4105

Q4106

Q4301

Q4302

Q4401

Q4401

Q4401

Q4901

Q5002 220638 XX50890-65 DIODE ZENER 6.8V .5W (B)

Q5002

Q5002

Q7101

Q7102

Q7401

Q7402

Q7403

Q7404

Q7501

215495 XX11070-77 TRANSISTOR R BUFFER

215496 XX30946-66 TRANSISTOR LIMITER

215496 XX30946-66 TRANSISTOR LIMITER

215495 XX11070-77 TRANSISTOR VOLT REG

215496 XX30946-66 TRANSISTOR L-R BUFFER

(AA,AB,B,BA,CA,CA3)

215495 XX11070-77 TRANSISTOR TONE CONT

215495 XX11070-77 TRANSISTOR TONE CONT

215495 XX11070-77 TRANSISTOR TONE CONT

215495 XX11070-77 TRANSISTOR

215496 XX30946-66 TRANSISTOR VIDEO BUFF

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

215496 XX30946-66 TRANSISTOR SYNC AMP

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

215496 XX30946-66 TRANSISTOR VIDEO BUFF

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

215496 XX30946-66 TRANSISTOR SYNC AMP

215495 XX11070-77 TRANSISTOR RESET

215496 XX30946-66 TRANSISTOR RESET

215496 XX30946-66 TRANSISTOR SYNC AMP

229220 XX15064-30 TRANSISTOR DEGAUS SW

223704 XX50888-77 TRANSISTOR DEGAUS SW

(AA,B)

215496 XX30946-66 TRANSISTOR VIDEO AMP

215495 XX11070-77 TRANSISTOR VIDEO BUFF

215496 XX30946-66 TRANSISTOR HORIZ PULSE

157627 XX40440-53 TRANSISTOR 7.6V REG

223704 XX50888-77 TRANSISTOR +5V STDBY 2

REG (SEE NOTE@) (AA,B)

229220 XX15064-30 TRANSISTOR +5V STDBY 2

REG (SEE NOTE@)

146851 XX20474-06 TRANSISTOR +5V STDBY 1

REG

215495 XX11070-77 TRANSISTOR 7.5 REG

146851 XX20474-06 TRANSISTOR

215495 XX11070-77 TRANSISTOR HORIZ BUFF

191142 1A03100-02 TRANSISTOR HORIZ OUT

(AA,AB,AD)

217654 XX15042-22 TRANSISTOR HORIZ OUT (B)

223942 XX15047-72 TRANSISTOR HORIZ OUT

(BA,BD,BD3,CA,CA3,CD,CD3)

147665 XX50888-78 TRANSISTOR X-RAY PROT

220638 XX50890-65 DIODE ZENER 6.8V .5W (B)

220638 XX50890-65 DIODE ZENER 6.8V .5W (B)

200566 XX60104-20 TRANSISTOR UHF RF AMP

200566 XX60104-20 TRANSISTOR VHF RF AMP

215495 XX11070-77 TRANSISTOR PLL

215496 XX30946-66 TRANSISTOR BAND SWITCH

215495 XX11070-77 TRANSISTOR B V/U SW

215496 XX30946-66 TRANSISTOR B V/U SW

215495 XX11070-77 TRANSISTOR TUNE VOLT

REF

Q7502

Q7601

R1201

R1201

R1203

R1401

R1402 175756 XX70430-52 RES CF 1/4W 5% 75R

R1403 242629 XX80435-85 RES CC 1/4W 10% 100R (SEE

R1403 149602 XX50881-81 RES CC 1/4W 5% 100R (SEE

R1404 175756 XX70430-52 RES CF 1/4W 5% 75R

R1405 242629 XX80435-85 RES CC 1/4W 10% 100R (SEE

R1405 149602 XX50881-81 RES CC 1/4W 5% 100R (SEE

R1406 237429 XX15369-03 RES CC 1/4W 20% 2.2K (SEE

R1406 241050 XX40434-77 RES CC 1/4W 5% 2.2K (SEE

R1407 215221 XX40440-83 RES CMF 1/10W 1% 100K

R1407

R1408

R1408 241050 XX40434-77 RES CC 1/4W 5% 2.2K (SEE

R1409 215221 XX40440-83 RES CMF 1/10W 1% 100K

R1409

R1410

R1411

R1412

R1413

R1414

R1415

R1415 241050 XX40434-77 RES CC 1/4W 5% 2.2K (SEE

R1416 197638 XX30944-15 RES CMF 1/10W 2% 1K (SEE

R1416

R1417

R1418

R1419

Page 8-8

215495 XX11070-77 TRANSISTOR TUNE VOLT

REF

146848 XX70436-51 TRANSISTOR IF AMP

197637 XX20471-94 RES CMF 1/10W 5% 680R

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

215200 XX50886-56 RES CMF 1/10W 5% 750R

(AD,BD,BD3,CD,CD3)

192097 XX30944-31 RES CMF 1/10W 5% 4.7K

175756 XX70430-52 RES CF 1/4W 5% 75R

NOTE@)

NOTE@)

(AA,AB,AD,B,BA,BD,CA,CA3)

NOTE@)

NOTE@)

(AA,AB,AD,B,BA,BD,CA,CA3)

NOTE@)

NOTE@)

(AA,AB,AD,B,BA,BD,CA,CA3)

(SEE NOTE@)

(AD,BD,BD3,CD,CD3)

192084 XX50886-63 RES CMF 1/10W 5% 100K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

237429 XX15369-03 RES CC 1/4W 20% 2.2K (SEE

NOTE@)

NOTE@)

(AA,AB,AD,B,BA,BD,CA,CA3)

(SEE NOTE@)

(AD,BD,BD3,CD,CD3)

192084 XX50886-63 RES CMF 1/10W 5% 100K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

174348 XX30942-99 RES CMF 1/8W 5% 1K

194920 XX70434-23 RES CMF 1/10W 5% 1.2K

218508 XX70434-20 RES CMF 1/10W 5% 100R

192097 XX30944-31 RES CMF 1/10W 5% 4.7K

176816 XX60443-74 RES CMF 1/8W 5% 100K

237429 XX15369-03 RES CC 1/4W 20% 2.2K (SEE

NOTE@)

NOTE@)

(AA,AB,AD,B,BA,BD,CA,CA3)

NOTE@)

(AD,BD,BD3,CD,CD3)

192100 XX20471-95 RES CMF 1/10W 5% 1K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

194920 XX70434-23 RES CMF 1/10W 5% 1.2K

218508 XX70434-20 RES CMF 1/10W 5% 100R

192097 XX30944-31 RES CMF 1/10W 5% 4.7K

Page 28

REPLACEMENT PARTS

MAY 1999

StockSymbol DescriptionDrawing Symbol Stock Description Drawing

R1420 215221 XX40440-83 RES CMF 1/10W 1% 100K

R1420 192084 XX50886-63 RES CMF 1/10W 5% 100K

R1421

R1421 241050 XX40434-77 RES CC 1/4W 5% 2.2K (SEE

R1422 238678 XX30937-70 RES CC 1/4W 10% 22R (SEE

R1422 242911 XX60440-51 RES CC 1/4W 5% 22R (SEE

R1423 194926 XX90574-40 RES CMF 1/10W 5% 470R

R1424

R1425

R1425

R1425 151903 XX11057-59 RES CC 1/4W 5% 82R (SEE

R1426

R1426

R1427

R1428

R1429

R1701

R1702

R1703

R1704

R1705

R1710

R1711 195938 XX80440-33 RES CMF 1/10W 2% 3.3K

R1712

R1717

R1901

R1901

R1902

R1902

R1903

R1904

237429 XX15369-03 RES CC 1/4W 20% 2.2K (SEE

192097 XX30944-31 RES CMF 1/10W 5% 4.7K

238679 XX30937-71 RES CC 1/4W 10% 82R

177712 XX11057-59 RES CC 1/4W 5% 82R

238680 XX11057-42 RES CC 1/4W 10% 220R

242910 XX90569-97 RES CC 1/4W 5% 220R

195935 XX90574-37 RES CMF 1/10W 5% 82R

210245 XX50882-95 RES CF 1/4W 5% 100R

194926 XX90574-40 RES CMF 1/10W 5% 470R

206261 XX60443-71 RES CMF 1/8W 5% 10K

194926 XX90574-40 RES CMF 1/10W 5% 470R

206301 XX70434-25 RES CMF 1/10W 5% 15K

195937 XX50886-61 RES CMF 1/10W 5% 10K

201143 XX20471-98 RES CMF 1/10W 5% 6.2K

195937 XX50886-61 RES CMF 1/10W 5% 10K

215195 XX20471-92 RES CMF 1/10W 5% 220R

205346 XX80440-40 RES CMF 1/10W 5% 5.6K

197638 XX30944-15 RES CMF 1/10W 2% 1K (SEE

192100 XX20471-95 RES CMF 1/10W 5% 1K

197638 XX30944-15 RES CMF 1/10W 2% 1K

192100 XX20471-95 RES CMF 1/10W 5% 1K

175317 XX30939-48 RES CF 1/4W 5% 10K

210245 XX50882-95 RES CF 1/4W 5% 100R (SEE

(SEE NOTE@)

(AD,BD,BD3,CD,CD3)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

NOTE@)

NOTE@)

(AA,AB,AD,B,BA,BD,CA,CA3)

NOTE@)

NOTE@)

(AA,AB,AD,B,BA,BD,CA,CA3)

(AB,BA,CA,CA3)

NOTE@) (AD,BD,CD)

(AB,AD,BA,BD,CA,CA3)

(AA,AB,B,BA,CA,CA3)

(AA,AB,B,BA,CA,CA3)

(AA,AB,B,BA,CA,CA3)

(AA,AB,B,BA,CA,CA3)

(AA,AB,B,BA,CA,CA3)

(AA,AB,B,BA,CA,CA3)

(AA,AB,B,BA,CA,CA3)

(AA,AB,B,BA,CA,CA3)

(AA,AB,B,BA,CA,CA3)

NOTE@)

(AD,BD,BD3,CD,CD3)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

(AD,BD,BD3,CD,CD3)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

NOTE@)

R1904

R1905

R1906

R1906

R1907

R1908 181234 XX60442-74 RES MFFP 3W 5% 18R (AA,B)

R1908 235825 XX15127-94 RES WW 5W 5% 18R

R1909 200197 XX80439-85 RES CFFP 1/4W 5% 4.7R

R1910 175317 XX30939-48 RES CF 1/4W 5% 10K

R1911

R1912

R1912

R1913

R1913

R1914

R1915

R1916

R1917

R1917

R1918

R1919

R1919

R1920

R1959

R1962

R1962

R1963

R1963

Page 8-9

176645 XX50882-96 RES CF 1/4W 5% 150R (SEE

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

175317 XX30939-48 RES CF 1/4W 5% 10K

210245 XX50882-95 RES CF 1/4W 5% 100R (SEE

NOTE@)

176645 XX50882-96 RES CF 1/4W 5% 150R (SEE

NOTE@)

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

200197 XX80439-85 RES CFFP 1/4W 5% 4.7R

(BD3)

(AB,AD,BA,BD,BD3,CA,CA3,

CD,CD3)

(BD3)

175317 XX30939-48 RES CF 1/4W 5% 10K

215216 XX30947-65 RES CMF 1/10W 1% 1M (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

201144 XX50886-67 RES CMF 1/10W 5% 1M

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

215216 XX30947-65 RES CMF 1/10W 1% 1M (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

201144 XX50886-67 RES CMF 1/10W 5% 1M

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

175044 XX30939-51 RES CF 1/4W 5% 100K

175042 XX20469-46 RES CF 1/4W 5% 2.2K

175412 XX50882-97 RES CF 1/4W 5% 470R

215217 XX80443-08 RES CMF 1/10W 1% 10K (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

195937 XX50886-61 RES CMF 1/10W 5% 10K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

205349 XX11066-46 RES CMF 1/10W 5% 8.2K

215217 XX80443-08 RES CMF 1/10W 1% 10K (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

195937 XX50886-61 RES CMF 1/10W 5% 10K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

205349 XX11066-46 RES CMF 1/10W 5% 8.2K

175324 XX20469-45 RES CF 1/4W 2% 220R

(AA,AB,B,BA,CA,CA3)

197638 XX30944-15 RES CMF 1/10W 2% 1K (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

192100 XX20471-95 RES CMF 1/10W 5% 1K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

197638 XX30944-15 RES CMF 1/10W 2% 1K (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

192100 XX20471-95 RES CMF 1/10W 5% 1K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

Page 29

REPLACEMENT PARTS

MAY 1999

StockSymbol DescriptionDrawing Symbol Stock Description Drawing

R2301 205339 XX70434-21 RES CMF 1/10W 5% 620R

R2302

R2302

R2312

R2313

R2313

R2314

R2314 200174 XX40438-34 RES CMF 1/10W 5% 200K

R2315

R2316

R2702

R2703

R2704

R2705

R2706

R2706

R2707

R2707

R2708

R2708

R2709

R2709 206037 XX60440-85 RES CC 1/2W 5% 27K

R2711 175321 XX11059-66 RES CF 1/4W 5% 2K

R2712

R2713

R2714

R2715

R2716

R2717

R2718

R2721

R2726 192081 XX50886-59 RES CMF 1/10W 5% 2.7K

R2728

215217 XX80443-08 RES CMF 1/10W 1% 10K (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

195937 XX50886-61 RES CMF 1/10W 5% 10K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

197644 XX70434-22 RES CMF 1/10W 5% 820R

215217 XX80443-08 RES CMF 1/10W 1% 10K (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

195937 XX50886-61 RES CMF 1/10W 5% 10K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

200197 XX80439-85 RES CFFP 1/4W 5% 4.7R

(AB,AD,AD,B,BA,BD,BD,CA,

CA3,CD,CD3,CD3)

197471 XX11066-50 RES CMF 1/10W 5% 68K

195929 XX50886-54 RES CMF 1/10W 5% 330R

207838 XX80440-41 RES CMF 1/10W 5% 7.5K

215196 XX30944-36 RES CMF 1/10W 5% 390K

197638 XX30944-15 RES CMF 1/10W 2% 1K

197638 XX30944-15 RES CMF 1/10W 2% 1K

242629 XX80435-85 RES CC 1/4W 10% 100R

149602 XX50881-81 RES CC 1/4W 5% 100R

(AB,AD,BA,BD,CA,CA3)

242629 XX80435-85 RES CC 1/4W 10% 100R

149602 XX50881-81 RES CC 1/4W 5% 100R

(AB,AD,BA,BD,CA,CA3)

242629 XX80435-85 RES CC 1/4W 10% 100R

(AA,AD,B,BA,BD,BD3,CA,

CA3,CD,CD3)

149602 XX50881-81 RES CC 1/4W 5% 100R

(AB,AD,BA,BD,CA,CA3)

238958 XX80436-16 RES CC 1/2W 10% 27K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

162001 XX11064-76 RES CMF 1/8W 5% 1.5K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

218508 XX70434-20 RES CMF 1/10W 5% 100R

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

162001 XX11064-76 RES CMF 1/8W 5% 1.5K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

218508 XX70434-20 RES CMF 1/10W 5% 100R

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

162001 XX11064-76 RES CMF 1/8W 5% 1.5K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

218508 XX70434-20 RES CMF 1/10W 5% 100R

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

202069 XX11059-64 RES CF 1/4W 5% 1K

176367 XX80439-63 RES CMF 1/8W 5% 47R

205381 XX90574-33 RES CMF 1/10W 2% 470K

R2729

R2731

R2732

R2733

R2734

R2735

R2801

R2802

R2803

R2804

R2904

R2912

R3101

R3101

R3102

R3103

R3104

R3105

R3105

R3106

R3109

R3109

R3111

R3112

R3114

R3115

R3117

R3118

R3118

R3119

R3119

R3120

R3120

R3121

215687 XX60443-88 RES CMF 1/8W 2% 240K

194926 XX90574-40 RES CMF 1/10W 5% 470R

179753 XX20470-04 RES MF 1/4W 1% 1K

175412 XX50882-97 RES CF 1/4W 5% 470R

192075 XX90574-36 RES CMF 1/10W 5% 51R

192075 XX90574-36 RES CMF 1/10W 5% 51R

215198 XX20474-60 RES CMF 1/10W 1% 15K

215199 XX90576-86 RES CMF 1/10W 1% 15.8K

215200 XX50886-56 RES CMF 1/10W 5% 750R

215195 XX20471-92 RES CMF 1/10W 5% 220R

202069 XX11059-64 RES CF 1/4W 5% 1K

(AD,BD,CD,CD3)

175317 XX30939-48 RES CF 1/4W 5% 10K

(AD,BD,CD,CD3)

215221 XX40440-83 RES CMF 1/10W 1% 100K

(SEE NOTE@)

(AD,BD,BD3,CD,CD3)

192084 XX50886-63 RES CMF 1/10W 5% 100K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

175044 XX30939-51 RES CF 1/4W 5% 100K

206261 XX60443-71 RES CMF 1/8W 5% 10K

206261 XX60443-71 RES CMF 1/8W 5% 10K

215217 XX80443-08 RES CMF 1/10W 1% 10K (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

195937 XX50886-61 RES CMF 1/10W 5% 10K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

192097 XX30944-31 RES CMF 1/10W 5% 4.7K

197638 XX30944-15 RES CMF 1/10W 2% 1K (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

192100 XX20471-95 RES CMF 1/10W 5% 1K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

215195 XX20471-92 RES CMF 1/10W 5% 220R

215195 XX20471-92 RES CMF 1/10W 5% 220R

174348 XX30942-99 RES CMF 1/8W 5% 1K

174348 XX30942-99 RES CMF 1/8W 5% 1K

206261 XX60443-71 RES CMF 1/8W 5% 10K

215217 XX80443-08 RES CMF 1/10W 1% 10K (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

195937 XX50886-61 RES CMF 1/10W 5% 10K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

192072 XX70434-30 RES CMF 1/10W 5% 330K

(AA,AB,AD,B,BA,BD,CA,

CA3,CD,CD3)

215196 XX30944-36 RES CMF 1/10W 5% 390K

(SEE NOTE@)

(AD,BD,BD3,CD,CD3)

206261 XX60443-71 RES CMF 1/8W 5% 10K

174348 XX30942-99 RES CMF 1/8W 5% 1K

(AA,AB,B,BA)

215217 XX80443-08 RES CMF 1/10W 1% 10K (SEE

NOTE@)

(AD,BD,BD3,CD,CD3)

Page 8-10

Page 30

REPLACEMENT PARTS

MAY 1999

StockSymbol DescriptionDrawing Symbol Stock Description Drawing

R3121 195937 XX50886-61 RES CMF 1/10W 5% 10K

R3122

R3122

R3123

R3124

R3124

R3125

R3125

R3129

R3129

R3130

R3130

R3131

R3131

R3132

R3133

R3133

R3134

R3134

R3135

R3138

R3138

R3140

197638 XX30944-15 RES CMF 1/10W 2% 1K (SEE

192100 XX20471-95 RES CMF 1/10W 5% 1K

195937 XX50886-61 RES CMF 1/10W 5% 10K

215221 XX40440-83 RES CMF 1/10W 1% 100K

192084 XX50886-63 RES CMF 1/10W 5% 100K