HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

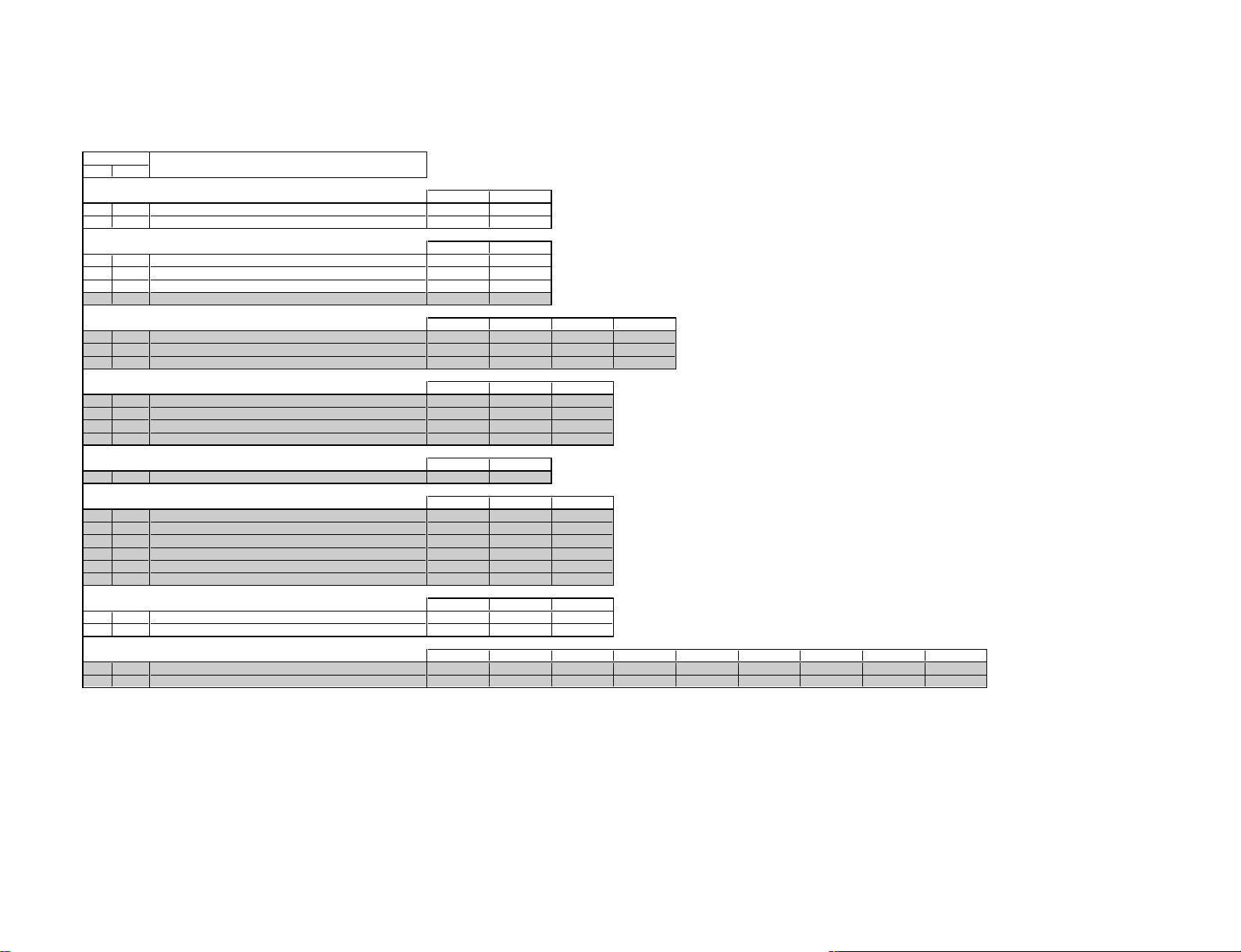

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KDP-57XBR2

KDP-57XBR2

KDP-65XBR2

KDP-65XBR2

RM-Y185 US SCC-P69B-A

RM-Y185 Canadian SCC-P69B-A

RM-Y185 US SCC-P69A-A

RM-Y185 Canadian SCC-P69A-A

RA-5A

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 7/2001

ALL REVISIONS AND UPDATES TO THE ORIGINAL MANUAL ARE APPENDED TO THE END OF THE PDF FILE.

REVISION DATE REVISION TYPE SUBJECT

7/2001 No revisions or updates are applicable at this time.

11/2001 Supplement - 1 Adjustment Manual Added

1/2002 Correction - 1 Exploded View - Screen Frame Block P/N Corrected

7/2002 Supplement - 2 B Board, Q-Box Assembly P/N Correction; IC001 P/N Correction

DIGITAL HIGH DEFINITION PROJECTION TV

9-965-432-04

SERVICE MANUAL

RA-5A

CHASSIS

MODEL

KDP-57XBR2 RM-Y185 US SCC-P69B-A

KDP-57XBR2 RM-Y185 Canadian SCC-P69B-A

KDP-65XBR2 RM-Y185 US SCC-P69A-A

KDP-65XBR2 RM-Y185 Canadian SCC-P69A-A

COMMANDER

DEST. CHASSIS NO.

RM-Y185

DIGITAL HIGH DEFINITION PROJECTION TV

KDP-57XBR2/65XBR2

SPECIFICATIONS

Projection System 3 picture tubes, 3 lenses, horizontal in-line system

Picture Tube 7-inch high-brightness monochrome tubes (6.3 raster size),

with optical coupling and liquid cooling system

Projection Lenses High performance, large diameter hybrid lens F1.05

Antenna 75 ohm external terminal for VHF/UHF

Television System NTSC, American TV Standard, ATSC

Channel Coverage

DTV 2-69

VHF 2-13

UHF 14-69

CATV 1-125

Power Requirements 120V AC, 60 Hz

Number of Inputs/Outputs

Video (IN) 4 total (1 on front panel) 1 Vp-p, 75 ohms unbalanced, sync negative

S Video (IN) 4 (1 on front panel) Y: 1 Vp-p, 75 ohms unbalanced, sync negative

Component Video Input 2 (Y, P

Audio (IN) 6 total (1 on front panel) 500 mVrms (100% modulation)

Audio (OUT) 1 More than 408 mVrms at the maximum volume setting (Variable)

Subwoofer (Out) 1 More than 408 mVrms at the maximum volume setting

SELECT OUT 1 Video 1 Vp-p, 75 ohms unbalanced, sync negative

Digital Audio Optical Output 1 Optical Rectangular (1)

Dolby Digital/PCM

CONTROL S (IN/OUT) 1

i.LINK S200 2 4-pin S200 i.LINK terminal (2)

Supplied Accessories

Remote Control RM-Y185

AA (R6) Batteries 2 supplied for remote control

Optional Accessories

AV Cable VMC-810/820/830 HG

Audio Cable RKC-515HG

i.LINK Cable VMC-IL4415 (4-pin to 4-pin, 1.5 meters), VMC-IL4435 (4-pin to 4-pin, 3.5 meters)

Component Video Cable VMC-10/30 HG

Rear Speakers SS-MB115

Screen Size 57 in measured diagonally (KDP-57XBR2)

Speakers Tweeter 100 mm (4") × 2

Speaker Output Front 20 W × 2

Dimensions (W × H × D) 1380 × 1400 × 680 mm (54 3/8 × 55 1/8 × 26 7/8 in) (KDP-57XBR2)

Mass 126 kg (277 lbs) (KDP-57XBR2)

Power Consumption

In Use 280 W

In Standby 0.9 W

In i.LINK Standby 24 W

Design and specifications are subject to change without notice.

, PR) Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative

B

1 Audio More than 408 mVrms (100% modulation)

65 in measured diagonally (KDP-65XBR2)

Woofer 160 mm (6 3/8") × 2

Center 100 mm (4") × 2

Center 20 W × 1

Rear 20 W × 2

1558 × 1574 × 735 mm (61 3/8 × 62 × 29) (KDP-65XBR2)

148 kg (326 lbs) (KDP-65XBR2)

C: 0.286 Vp-p, (Burst signal), 75 ohms

PB: 0.7 Vp-p, 75 ohms

PR: 0.7 Vp-p, 75 ohms

Impedance: 47 kilohm

More than 408 mVrms (Fixed)

Impedance (output): 2 kilohms

Impedance (output): 2 kilohms

Cutoff frequency: 100 Hz

Impedance (output): 2 kilohms

RM-Y185

– 2 –

SAFETY CHECK-OUT

(US Model only)

KDP-57XBR2/65XBR2

RM-Y185

After correcting the original service problem, perform the following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps,

and mounting hardware have been replaced. Be absolutely

certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the condition of the monopole antenna (if any).

Make sure the end is not broken off, and has the plastic cap on

it. Point out the danger of impalement on a broken antenna to

the customer, and recommend the antenna’s replacement.

8. Check the B+ and HV to see if they are specified values. Make

sure your instruments are accurate; be suspicious of your HV

meter if sets always have low HV.

9. Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC Leakage.

Check leakage as described below.

To Exposed Metal

Parts on Set

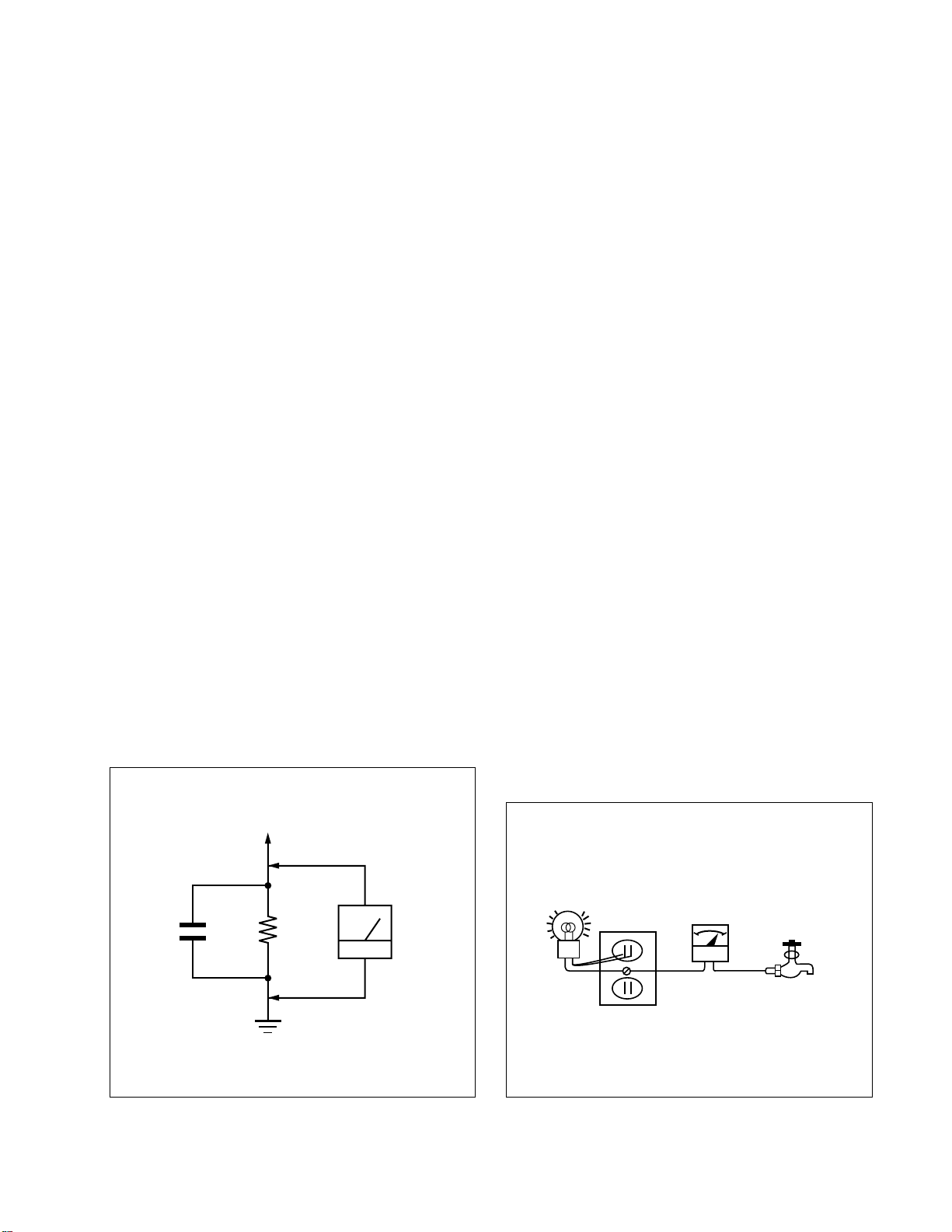

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to

use these instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indica-

tion is 0.75 V, so analog meters must have an accurate low-

voltage scale. The Simpson 250 and Sanwa SH-63Trd are ex-

amples of a passive VOMs that are suitable. Nearly all battery

operated digital multimeters that have a 2 V AC range are suit-

able. (See Fig. A)

HOW TO FIND A GOOD EARTH GROUND

A cold-water pipe is guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If

the retaining screw is to be used as your earth-ground, verify that it

is at ground by measuring the resistance between it and a coldwater pipe with an ohmmeter. The reading should be zero ohms. If

a cold-water pipe is not accessible, connect a 60 – 100 watts

trouble light (not a neon lamp) between the hot side of the receptacle and the retaining screw. Try both slots, if necessary, to locate

the hot side of the line, the lamp should light at normal brilliance if

the screw is at ground potential. (See Fig. B)

0.15 µF

1.5 k

Ω

Earth Ground

AC

Voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

– 3 –

Trouble Light

AC Outlet Box

Ohmmeter

Fig. B. Checking for earth ground.

Cold-water Pipe

TABLE OF CONTENTS

Section Title PageSection Title Page

KDP-57XBR2/65XBR2

RM-Y185

1. SELF DIAGNOSIS FUNCTION ...................... 6

2. DISASSEMBLY

2-1. Rear Board Removal ......................................... 9

2-2. Main Bracket Block Removal ........................... 9

2-3. Service Position ................................................. 9

2-4. Terminal board Removal .................................. 9

2-5. G Board Removal............................................... 10

2-6. D Board Removal............................................... 10

2-7. AD, U, B and A Boards Removal...................... 11

2-8. Q-box Assembly Removal ................................. 11

2-9. K Board Removal............................................... 12

2-10. Resistor Assembly (Focus Pack) Removal ........ 12

2-11. Screen Frame Block Assembly .......................... 13

2-12. S Board Removal................................................ 13

2-13. Control Panel Block Removal ........................... 14

2-14. HD Board Removal ............................................ 14

2-15. Control Door Block Assembly........................... 15

2-16. HB Board Removal ............................................ 15

2-17. HA Board Removal ............................................ 16

2-18. Picture Tube Block Removal ............................. 16

2-19. High-Voltage Cable Removal and Installation ... 17

2-20. Picture Tube Removal........................................ 17

3. SET-UP ADJUSTMENTS

3-1. Screen Voltage Adjustment

(Rough Alignment) ........................................... 18

3-2. Screen (G2) Adjustment .................................... 18

3-3. Deflection Yoke Tilt Adjustment ...................... 18

3-4. Focus Lens Adjustment...................................... 19

3-5. Focus VR Adjustment ....................................... 19

3-6. 2-Pole Magnet Adjustment ................................ 19

3-7. Centering Magnet Adjustment .......................... 20

3-8. 4-Pole Magnet Adjustment ................................ 20

3-9. Defocus Adjustment (Blue) ............................... 20

3-10. Electrical Adjustment

by Remote Commander...................................... 21

3-11. Registration Adjustment ................................... 40

3-11-1. Setup for Adjustment .................................... 40

3-11-2 Main Deflection Adjustment ........................ 40

3-11-3. Operation Method

for Projectoe Engine Mode ............................ 41

3-11-4. Projector Engine Adjustment

(Sub Deflection Adjustment)......................... 42

3-12. Auto Registration Offset .................................... 44

3-13. Auto Registration Error Code List..................... 45

4. CIRCUIT ADJUSTMENTS

4-1. 480p Y, PB, PR Gain Adjustment ..................... 46

4-2. Main Y/C Level Adjustment

(for the DRC Path) ............................................. 46

4-3. Main Y/C Level Adjustment

(for the VDO Path) ............................................. 46

4-4. SUB Y/C Level Adjustment

(for the DRC Path) ............................................. 47

4-5. SUB Y/C Level Adjustment

(for the VDO Path) ............................................. 47

4-6. Main Decoder Sub Contrast Adjustment

(for Composite and Y/C Inputs) ........................ 47

4-7. Main Decoder Sub Color and Sub Hue

Adjustment (for Composite and Y/C Inputs) .... 47

4-8. Sub Decoder Sub Contrast Adjustment

(for Y/C Input).................................................... 48

4-9. Sub Decoder Sub Color and Sub Hue

Adjustment (for Y/C Input)................................ 48

4-10. Sub Decoder Sub Contrast Adjustment

(for Composite Input)......................................... 48

4-11. Sub Decoder Sub Color and Sub Hue

Adjustment (for Composite Input)..................... 48

4-12. Main Decoder PB and PR Offset Adjustment ... 49

4-13. Sub Decoder PB and PR Offset Adjustment ..... 49

4-14. Blue Offset Adjustment...................................... 49

4-15. Sub Contrast Adjustment ................................... 49

4-16. Sub Color and Sub Hue Adjustment.................. 50

4-17. RF Sub Contrast Adjustment ............................. 50

4-18. RF Sub Color and Sub Hue Adjustment............ 50

5. SAFETY RELATED ADJUSTMENTS

5-1. HV Regulation Circuit Check and

Adjustment ......................................................... 51

5-2. HV Hold Down Circuit Operation Check and

Adjustment ......................................................... 51

5-3. +B Max Voltage Confirmation .......................... 51

5-4. +B OVP Confirmation ....................................... 51

6. FIRMWARE UPGRADES

6-1. Overview ............................................................ 52

6-2. Transferring the New Firmware

from the Memory Stick to the Q-Box ................ 52

7. DIAGRAMS

7-1. Block Diagram (1).............................................. 53

Block Diagram (2).............................................. 54

Block Diagram (3).............................................. 55

Block Diagram (4).............................................. 56

Block Diagram (5).............................................. 57

Block Diagram (6).............................................. 58

Block Diagram (7).............................................. 59

– 4 –

KDP-57XBR2/65XBR2

RM-Y185

Section Title PageSection Title Page

Block Diagram (8).............................................. 60

Block Diagram (9).............................................. 61

Block Diagram (10)............................................ 62

7-2. Frame Schematic Diagram................................. 63

7-3. Circuit Boards Location ..................................... 64

7-4. Schematic Diagrams and Printed Wiring

Boards ................................................................. 64

(1) Schematic Diagram of A (1/3) Board ................ 65

(2) Schematic Diagram of A (2/3) Board ............... 66

(3) Schematic Diagram of A (3/3) Board ............... 67

(4) Schematic Diagram of AD (1/2) Board ............ 68

(5) Schematic Diagram of AD (2/2) Board ............. 69

(6) Schematic Diagram of B (1/7) Board ................ 70

(7) Schematic Diagram of B (2/7) Board ................ 71

(8) Schematic Diagram of B (3/7) Board ................ 72

(9) Schematic Diagram of B (4/7) Board ................ 73

(10) Schematic Diagram of B (5/7) Board ................ 74

(11) Schematic Diagram of B (6/7) Board ................ 75

(12) Schematic Diagram of B (7/7) Board ................ 76

(13) Schematic Diagrams of CB and CG Boards ...... 77

(14) Schematic Diagrams of CR and V Boards ........ 78

(15) Schematic Diagram of D (1/3) Board ................ 79

(16) Schematic Diagram of D (2/3) Board ................ 80

(17) Schematic Diagram of D (3/3) Board ................ 81

(18) Schematic Diagram of G (1/2) Board ................ 82

(19) Schematic Diagram of G (2/2) Board ................ 83

(20) Schematic Diagrams of HA, HB, HC and

HD Boards .......................................................... 84

(21) Schematic Diagram of K (1/3) Board ................ 85

(22) Schematic Diagram of K (2/3) Board ................ 86

(23) Schematic Diagram of K (3/3) Board ................ 87

(24) Schematic Diagrams of S and U Boards............ 88

Printed Wiring Boards

• A Board ............................................................ 89

• AD Board ......................................................... 91

• B Board ............................................................ 92

• CB and CG Boards .......................................... 94

• CR and V Boards ............................................. 95

• D Board ............................................................ 96

• G Board ............................................................ 97

• HA, HB, HC and HD Boards .......................... 99

• K Board ............................................................ 100

• U and S Boards ................................................ 102

7-5. Waveforms ........................................................ 103

7-6. IC Block Diagrams ............................................ 105

7-7. Semiconductors ................................................. 108

8. EXPLODED VIEWS

8-1. Screen and Screen Frame Block ...................... 109

8-2. Cabinet Block .................................................... 110

8-3. Control Panel Block ........................................... 111

8-4. Main Bracket Block ........................................... 112

8-5. Picture Tube Block ............................................. 113

9. ELECTRICAL PARTS LIST ............................ 114

WARNING!!

NEVER TURN ON THE POWER IN A CONDITION IN

WHICH THE DEGAUSS COIL HAS BEEN REMOVED.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

¡ ON THE SCHEMATIC DIAGRAMS, EXPLODED

VIEWS AND IN THE PARTS LIST ARE CRITICAL FOR

SAFE OPERATION. REPLACE THESE COMPONENTS

WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE CRITICAL FOR SAFE OPERATION

ARE IDENTIFIED IN THIS MANUAL. FOLLOW THESE

PROCEDURES WHENEVER CRITICAL COMPONENTS

ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

AVERTISSEMENT!!

NE JAMAIS METTRE SOUS TENSION QUAND LA

BOBINE DE DEMAGNETISATION EST ENLEVÉE.

ATTENTION AUX COMPOSANTS RELATIFS À LA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE TRAME ET

UNE MARQUE

NE LES REMPLACER QUE PAR UNE PIÈCE PORTANT LE

NUMÉRO SPECIFIÉ. LES RÉGLAGES DE CIRCUIT DONT

L’IMPORTANCE EST CRITIQUE POUR LA SÉCURITÉ DU

FONCTIONNEMENT SONT IDENTIFIÉS DANS LE

PRÉSENT MANUEL. SUIVRE CES PROCÉDURES LORS

DE CHAQUE REMPLACEMENT DE COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS FONCTIONNEMENT

EST SUSPECTÉ.

¡ SONT CRITIQUES POUR LA SÉCURITÉ.

– 5 –

KDP-57XBR2/65XBR2

Note1: If a +B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously. The sympton that is diagnosed first by the microcontroller is displayed on screen.

Note 2: Refer to Screen (G2) Adjustment in Section 3-1, 2 of this manual.

Note 3: If STANDBY/i. LINK STANDBY indicator blinks six (6) times, unplug the unit and wait 10 minutes before performing the adjustment.

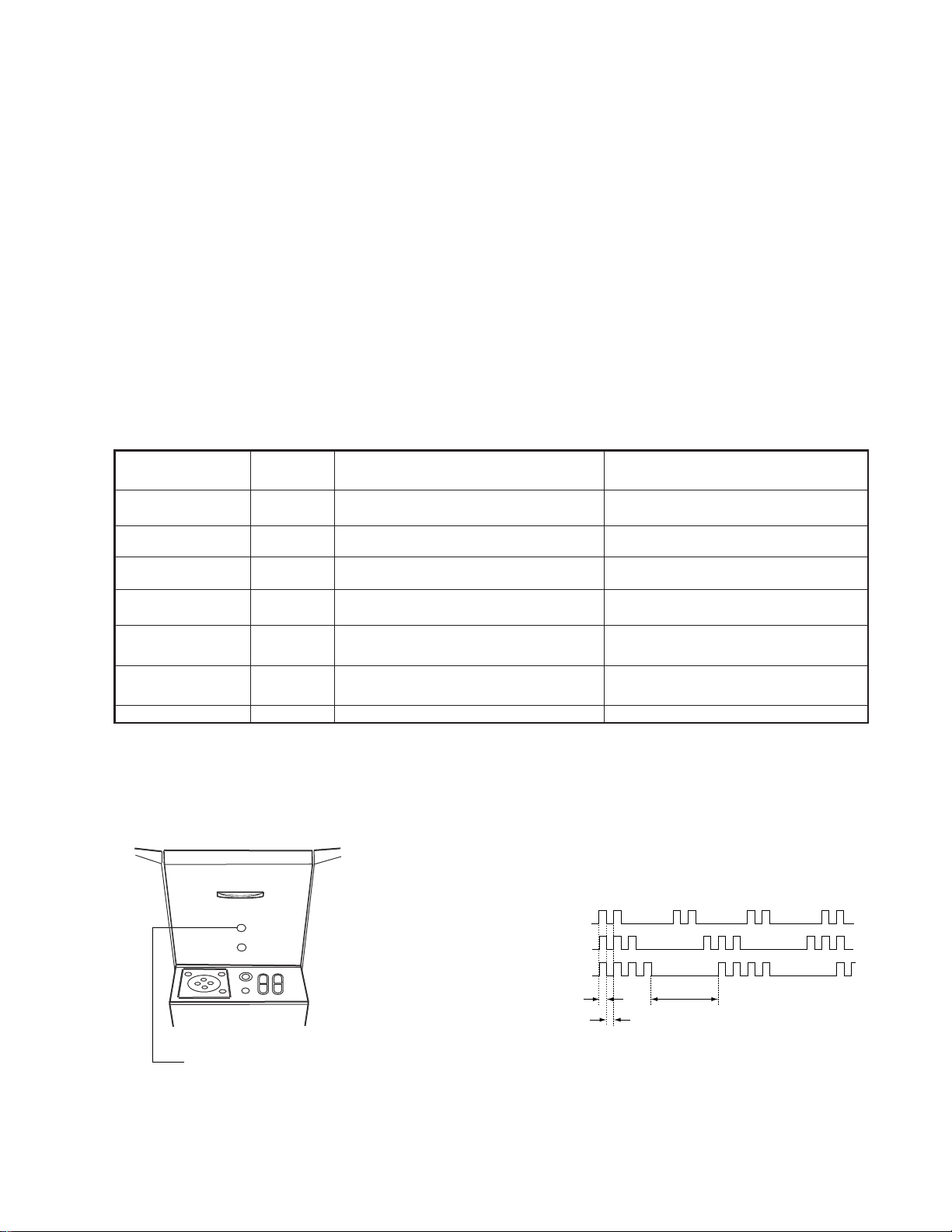

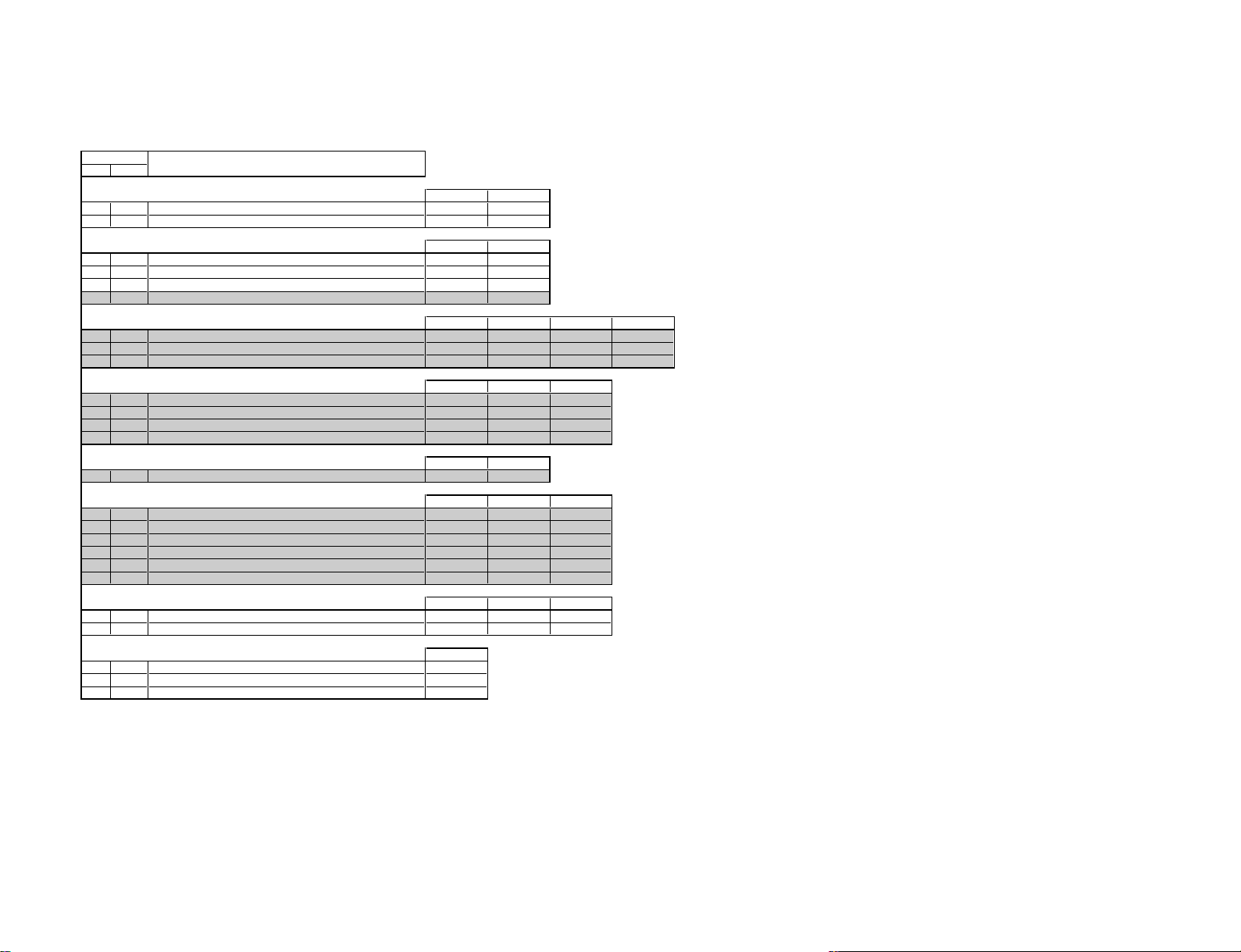

Deteced symptoms

Diagnosis Item

No. of times

STANDBY / i. STANDBY

indicator blinks

Probable Cause Location

7 timesHorizontal deflection stopped • Q8035, 8038 is shorted. (D board)

0Power does not turn on

• Power cord is not plugged in.

• Fuse is burned out (F6001) (G board)

• Power does not come on.

• No power is supplied to the unit.

• AC power supply is faulty.

2 times

+B overcurrent (OCP)

(See Note 1)

• H. OUT (Q8024) is shorted. (D board)

• +B PWM (Q8035, 8038) is shorted. (D board)

• Power does not come on.

• Load on power line is shorted.

3 times+B overvoltage (OVP)

• IC6104 is faulty (G board)

• PH6002 is faulty (G board)

• Has entered standby mode.

4 timesVertical deflection stopped

• ±15 V is not supplied. (D board)

• IC8003 is faulty. (D board)

• Has entered standby state after horizontal raster.

• Vertical deflection pulse is stopped.

• Power line is shorted or power supply is stopped.

5 times

White balance failure

(Not balanced)

• Video out (IC3701, 3801, 3901) is faulty. (CR, CG, CB board)

• CRT drive (IC3006) is faulty. (A board)

• G2 is improperly adjusted. (See Note 2)

• No raster is generated.

• CRT cathode current detection reference pulse output is small.

6 times

LOW +B OCP/OVP

(Overcurrent/over voltage)

(See Note 3)

• LOW +B line is overloaded. (A, B boards)

• LOW +B line is shorted. (A, B boards)

• No picture

SECTION 1

SELF DIAGNOSIS FUNCTION

1. Summary of Self-Diagnosis Function

• This device includes a self-diagnosis function.

• In case of abnormalities, the STANDBY/i. LINK STANDBY indicator automatically blinks. It is possible to predict the abnormality

location by the number of blinks. The Instruction Manual describes blinking of the STANDBY/i. LINK STANDBY indicator.

• If the symptom is not reproduced sometimes in case of a malfunction, there is recording of whether a malfunction was generated or

not. Operate the remote command to confirm the matter on the screen and to predict the location of the abnormality.

2. Diagnosis Items and Prediction of Malfunction Location

• When a malfunction occurs the STANDBY/i. LINK STANDBY indicator only blinks for one of the following diagnosis items. In

case of two or more malfunctions, the item which first occurred blinks. If the malfunctions occurred simultaneously, the item with

the lower blink count blinks first.

• The screen display displays the results regarding all the diagnosis items listed below. The display “ 0 ” means that no malfunctions

occurred.

RM-Y185

3. Blinking count display of STANDBY / i. LINK STANDBY indicator

* One blink is not used for self-diagnosis.

< FRONT PANEL >

•EXAMPLE

POWER

STAND BY/

Release of STANDBY/i. LINK STANDBY indicator blinking.

• The STANDBY/i. LINK STANDBY indicator blinking display is released by turning OFF

the power switch on the TV main unit or removing the plug from the power.

i.LINK STAND BY

TIMER

STANDBY/i. LINK STANDBY indicator

<Diagnosis Items> <Number of Blinks>

• +B overcurrent 2 times

• +B overvoltage 3 times

• Vertical deflection stop 4 times

Lamp ON : 0.3 seconds

Lamp OFF : 0.3 seconds

– 6 –

Lamp OFF :

3.0 seconds

KDP-57XBR2/65XBR2

4. Self-diagnosis screen displays

• In cases of malfunctions where it is not possible to determine the symptom such as when the power goes off occasionally or when the

screen disappears occasionally, there is a screen display on whether the malfunction occurred or not in the past (and whether the

detection circuit operated or not) in order to allow confirmation.

<Screen Display Method>

• Quickly press the remote command button in the following order from the standby state.

DISPLAY b Channel 5 b VOL – b POWER

J

Be aware that this differs from the method of

entering the service mode (volume + ).

Self-Diagnosis screen display

Self Diagnosis

RM-Y185

2:+B OCP 0

Numeral “0” means that no fault has been detected.

3:+B OVP 0

4:V STOP 0

5:AKB 1

Numeral “1” means a fault was detected one time only.

6:Low B 0

7:H STOP 0

101:WDT 0

Serial: xxxxxxx

Model:xxxxxxxx

5. Self-Diagnosis Screen Display

• The results display is not automatically cleared. In case of repairs and after repairs, check the self-diagnosis screen and be sure to

return the results display to “ 0 ”.

• If the results display is not returned to “ 0 ” it will not be possible to judge a new malfunction after completing repairs.

<Method of Clearing Results Display>

1. Power off (Set to the standby mode)

2. DISPLAY b Channel 5 b VOL + b POWER (Service Mode)

3. Channel 8 b ENTER (Test reset = Factory preset condition)

<Method of Ending Self Diagnosis Screen>

• When ending the self-diagnosis screen completely, turn the power switch OFF on the remote commander or the main unit.

– 7 –

KDP-57XBR2/65XBR2

6. Self-diagnosis function operation

OCP Low B and +B line detect DET SHORT, and shut-down POWER ON RELAY.

Reset by turning power on/off.

In case of +B is loaded approx. 1.5 A or more, microcomputer detects it via IC6102.

OVP In case of +B becomes approx. 150 V or more, POWER ON RELAY shuts down and microcomputer detects it

via IC6102.

Reset by turning power on/off just the same as OCP.

Low B Occurs when set +6.5 V (D) is out.

V Stop In case of V DRIVE is disappeared, IC3006 detects it and shut-down POWER ON RELAY. Microcomputer

detects it and makes LED blinking.

AKB IK detection. Makes LED blinking in case of microcomputer doesn't detect IK returns of IC3006 (CXA2150AQ)

20 seconds or more.

H Stop In case of H DRIVE is disappeared, IC3006 detects it and shut-down POWER ON RELAY. Microcomputer

receives H Stop data from IC3006 and makes LED blinking.

RM-Y185

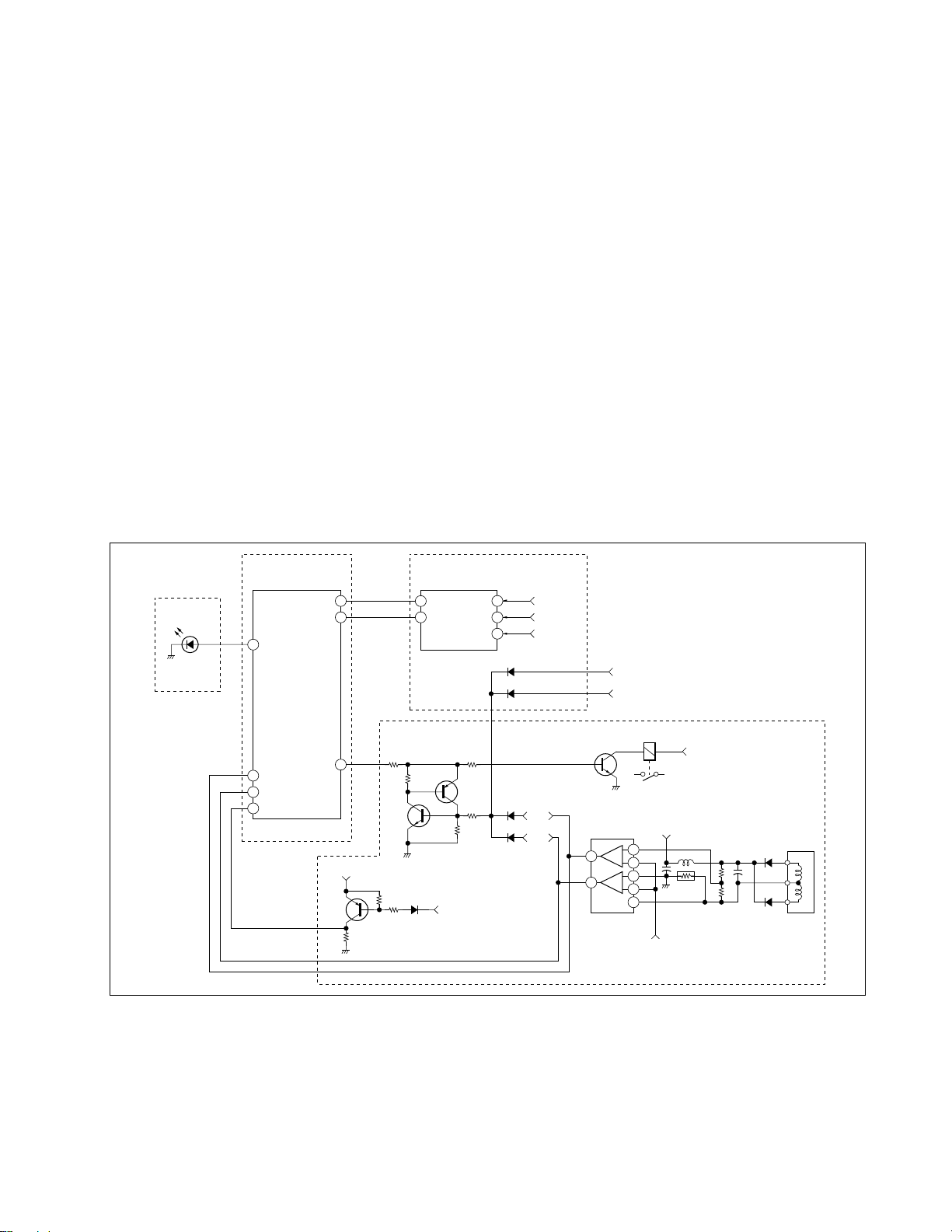

Self-diagnosis block diagram

IC001

MAIN CPU

D1350

STBY LED

48 STR/

STBY LED

HD board

45 OVP

44 OCP

43 LOW B ERR

B board

CLKO 29

DATO

AC RLY

30

69

STBY 5V

Q6121

IC3006

Y/C JUNGLE

26 SCL

25 SDA

A board

Q6105

Q6119

+6.5V (D)

AKB 58

VPROT 35

HPROT 34

D3003

D3013

D6123

D6124

OVP

OCP

IK

VP

HP

HV PROT

AUDIO PROT

RY6001

Q6120

IC6102

OVP/OCP DET

+

5

7

–

6

+

3

1

–

2

4

COM

From D board

+B

+

V REF

From K board

SET ON

T6001

+

– 8 –

G board

SECTION 2

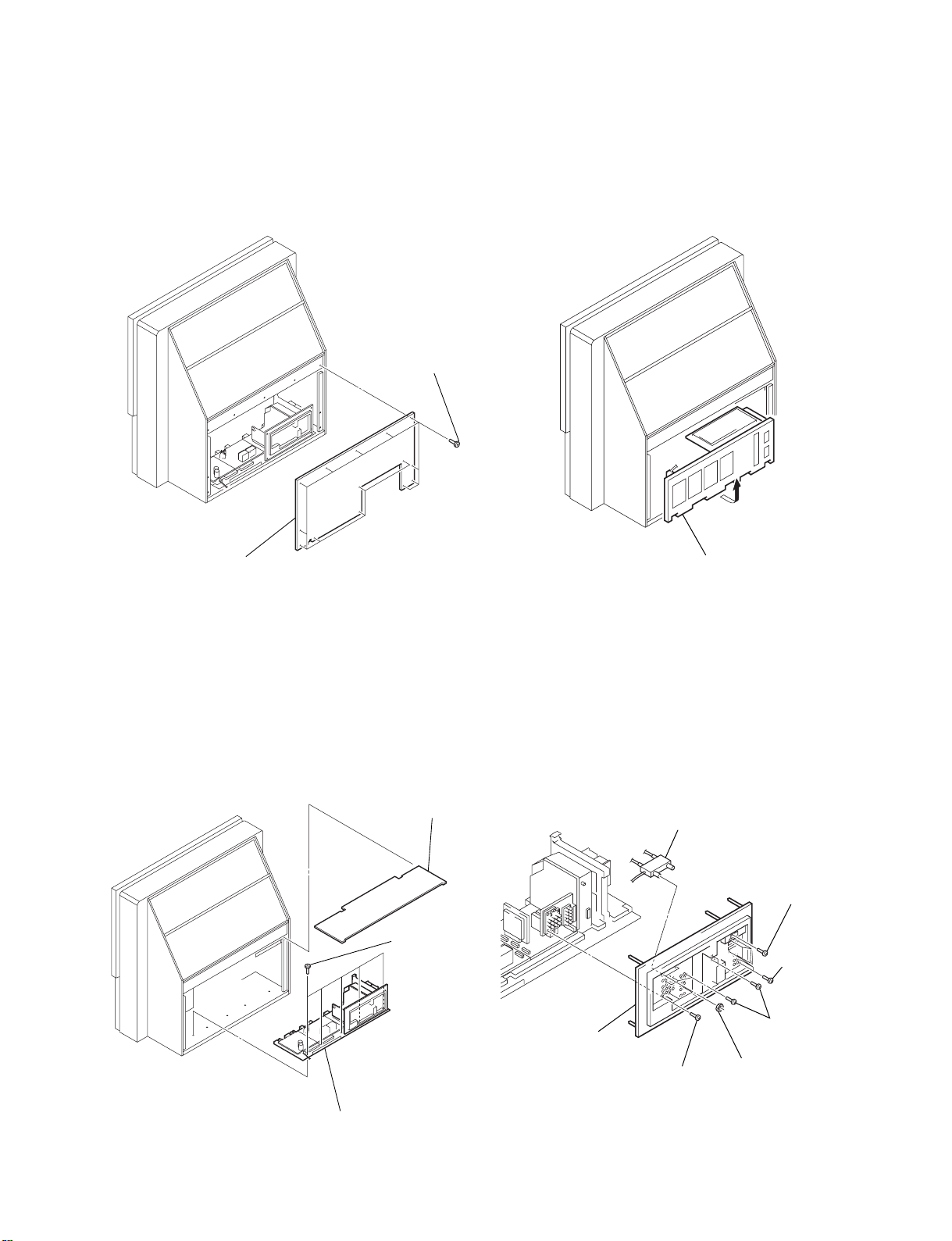

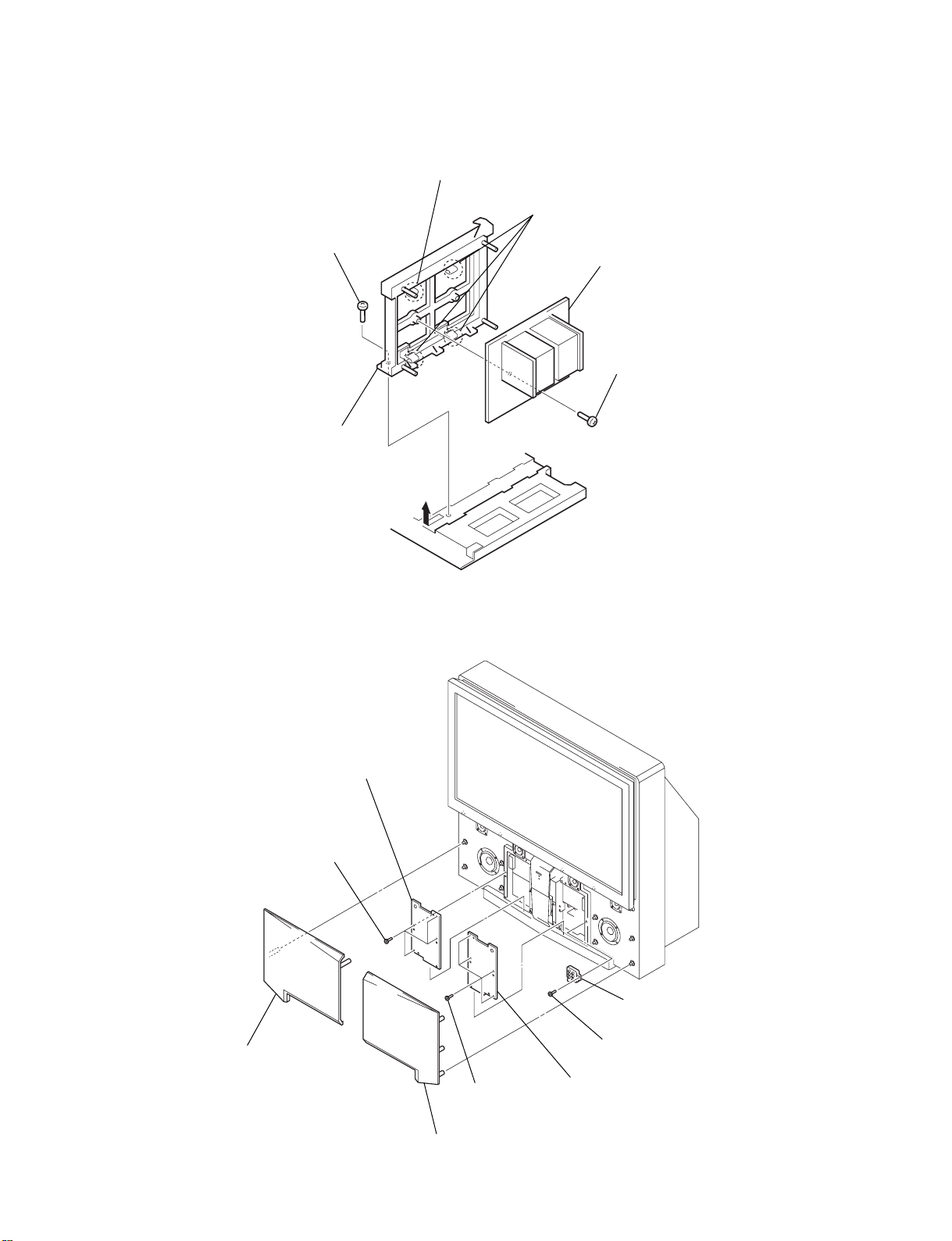

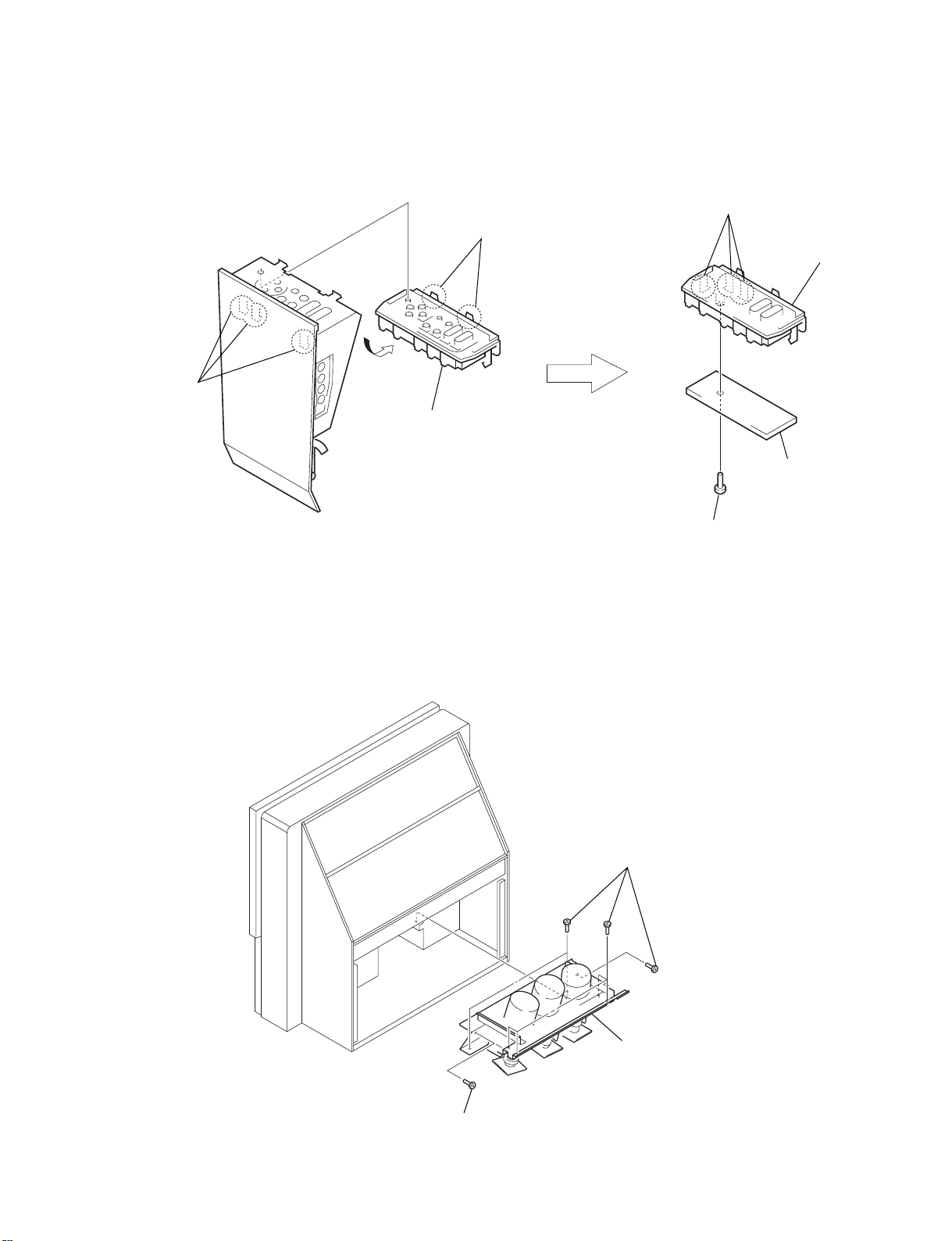

1 Three screws

(+BVTP 3 x 12)

3 Two washers

4 Anntenna switch

5 Terminal board

1 Five screws

(+BVTP 3 x 12)

1 Six screws

(+BVTP 3 x 12)

2 Screw

(+BVTP 4 x 12)

DISASSEMBLY

KDP-57XBR2/65XBR2

RM-Y185

2-1. REAR BOARD REMOVAL

2 Rear board

2-3. SERVICE POSITION

1 Fourteen

(HEX tap)

Main bracket block

2-2. MAIN BRACKET BLOCK REMOVAL

1 Shield board

2 Five screws

3 Main bracket block

(HEX tap)

2-4. TERMINAL BOARD REMOVAL

– 9 –

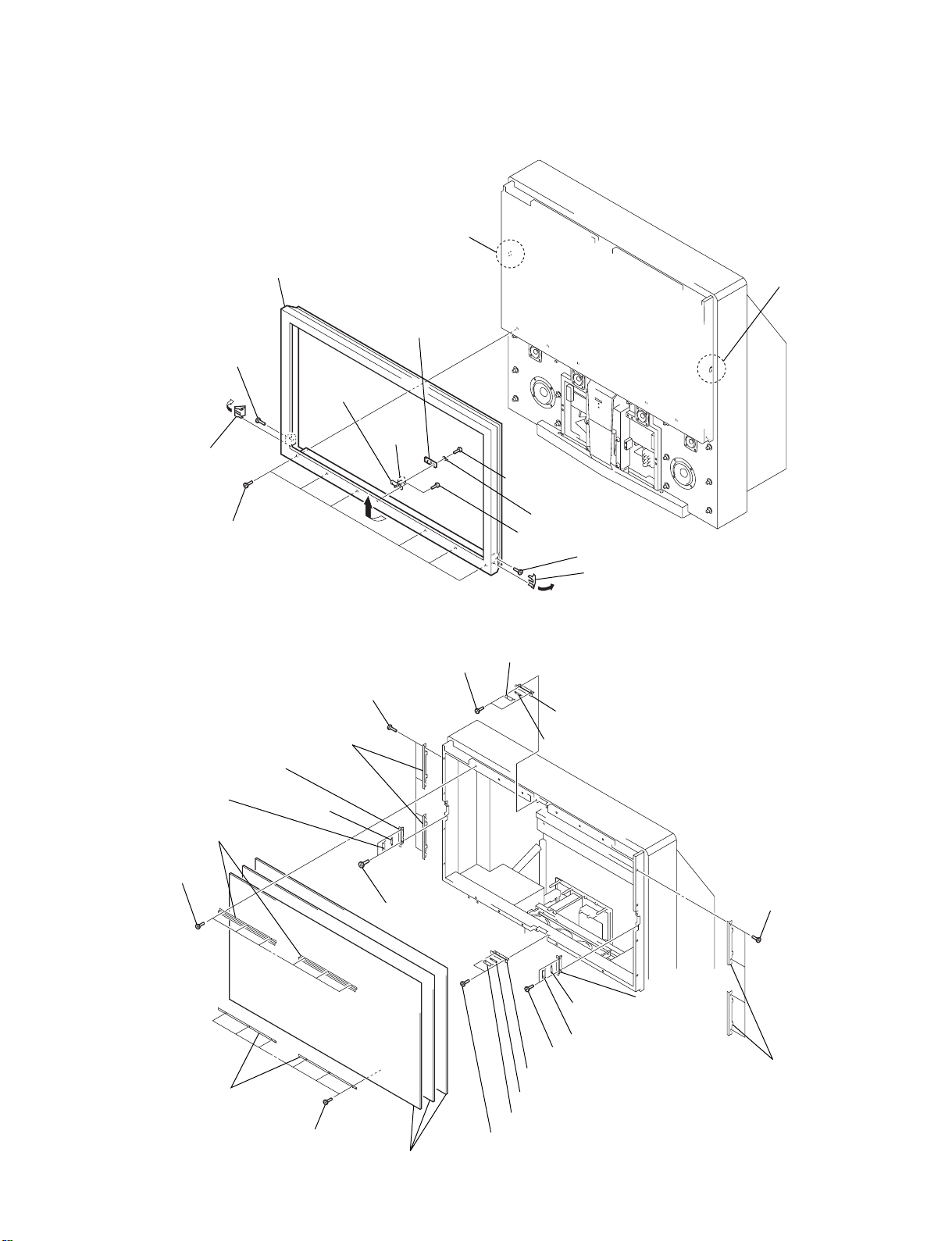

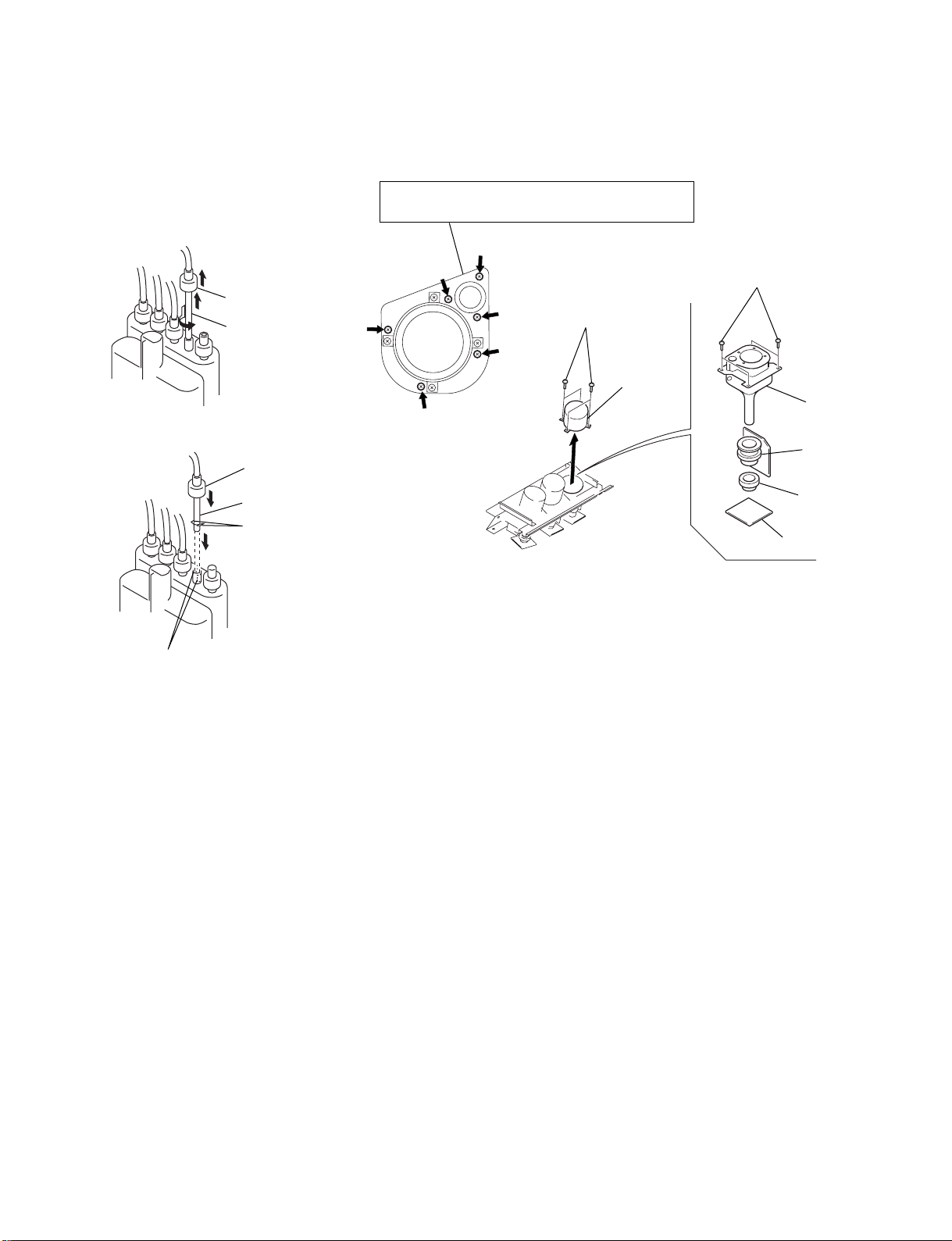

2-5. G BOARD REMOVAL

3 G board

KDP-57XBR2/65XBR2

RM-Y185

1 Four screws

(+BVTP 3X12)

2-6. D BOARD REMOVAL

2 Two claws

1 Five screws

(+BVTP 3X12)

3 D board

– 10 –

2 Three claws

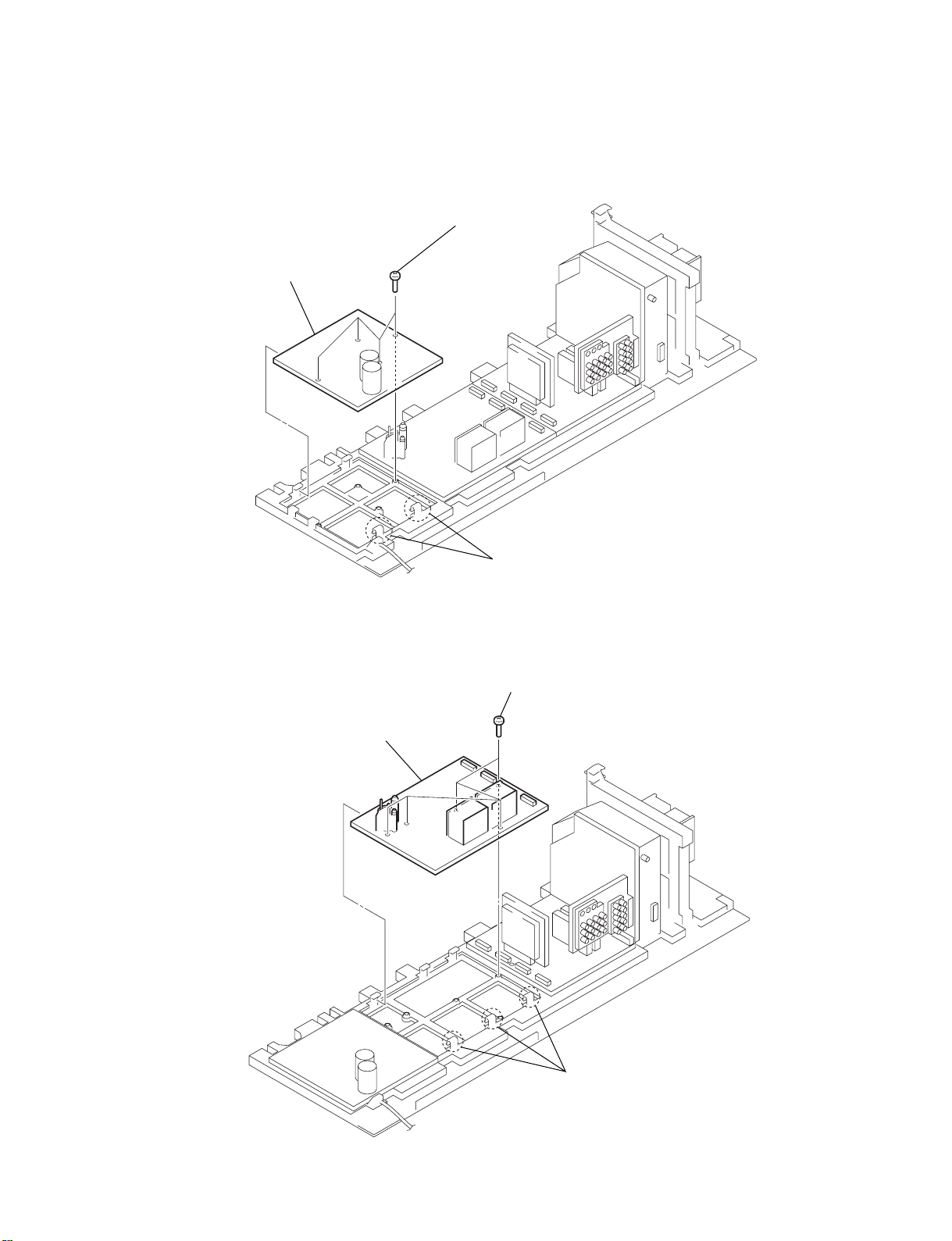

2-7. AD, U, B, AND A BOARDS REMOVAL

4 U board

6 Three screws

2 AD board

1 Two claws

(+BVTP 3X12)

KDP-57XBR2/65XBR2

RM-Y185

5 B board

3 Two claws

7 A board

2-8. Q-BOX ASSEMBLY REMOVAL

3 Q-box assembly

1 Cord with connector

(F-type)

2 Two screws

(+BVTP 4X12)

– 11 –

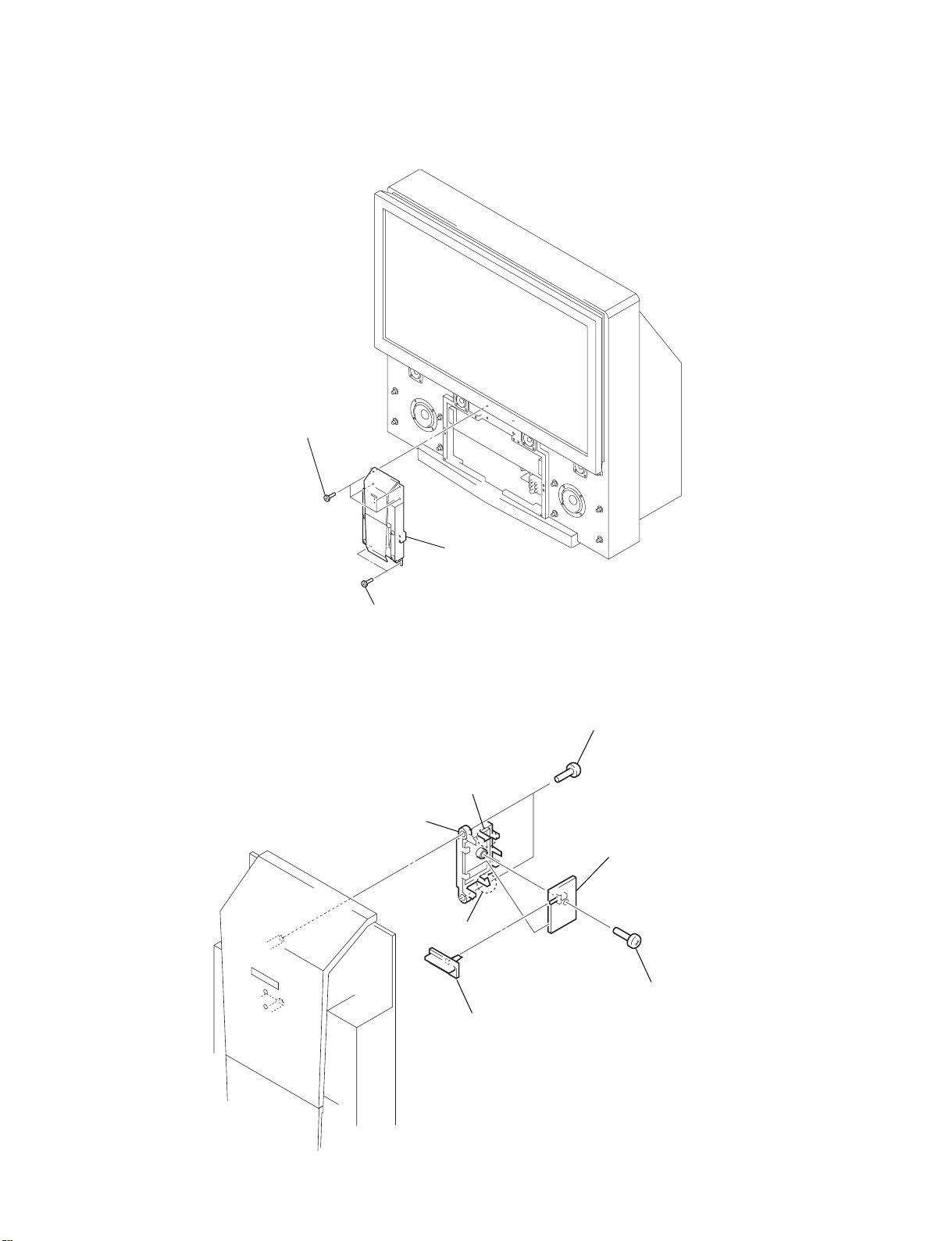

2-9. K BOARD REMOVAL

1 Screw

(+BVTP 4X12)

5 K board

bracket

KDP-57XBR2/65XBR2

RM-Y185

4 Claw

4 Tree claws

6 K board

3 Screw

(+BVTP 3X12)

2

2-10. RESISTOR ASSEMBLY (FOCUS PACK) REMOVAL

6 Front board (65)

5 Four screws

(HEX tap)

2 Speaker grille (L)

assembly

3 Four screws

(HEX tap)

1 Speaker grille (R)

assembly

– 12 –

8 Resistor assembly

(forcus pack)

7 Screw

(+BVTP 3X12)

4 Front board (65)

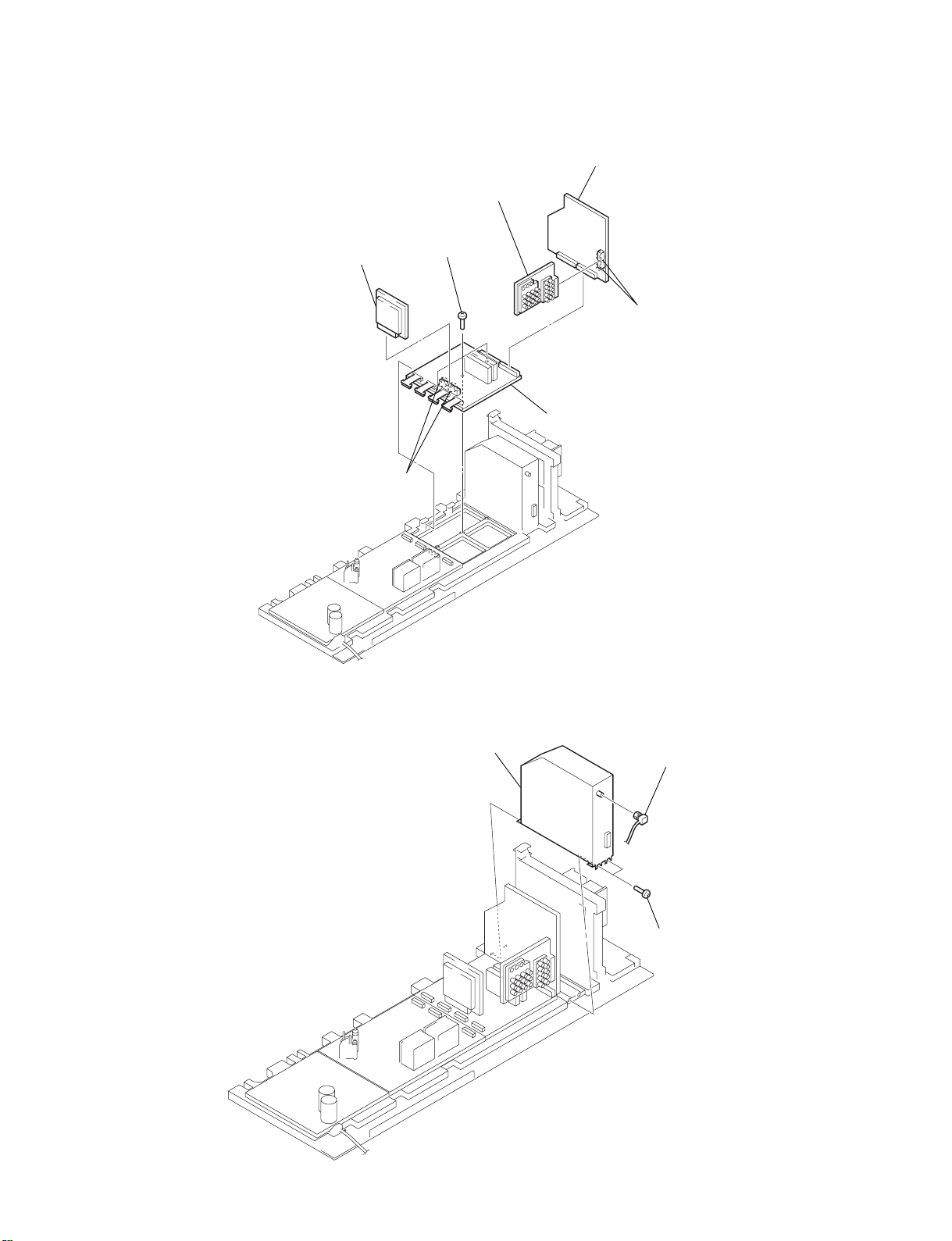

2-11. SCREEN FRAME BLOCK ASSEMBLY

7 Six screws

(HEX tap)

9 Screen block

1 Four screws

(HEX tap)

0 Two screws

(HEX tap)

0 Two screws

(HEX tap)

qs Sensor bracket (B)

qs Sensor bracket (B)

qa AR sensor bracket

qa AR sensor bracket

qd S board

qs Sensor bracket (B)

qa AR sensor bracket

qd S board

qd S board

qd S board

0 Two screws (HEX tap)

0 Two screws

(HEX tap)

qs Sensor bracket (B)

qa AR sensor

bracket

3 Four screws

(HEX tap)

2 Two screen holders (S)

4 Two screen

holders (S)

8 Two screen

holders (L)

6 Two screen

holders (L)

5 Six screws

(HEX tap)

8 Claw

9 Screen frame block

assembly

qg HC board

6 Screw (HEX tap)

KDP-57XBR2/65XBR2

RM-Y185

8 Claw

4

5 Screw cover

7 Six screws (HEX tap)

2-12. S BOARD REMOVAL

qf HC bracket

qd Claw

qa Screw

(+BVTP 4 x 12)

qs Harness

q; Screw (+BVTP 4 x 12)

3 Screw (HEX tap)

2 Screw cover

1

– 13 –

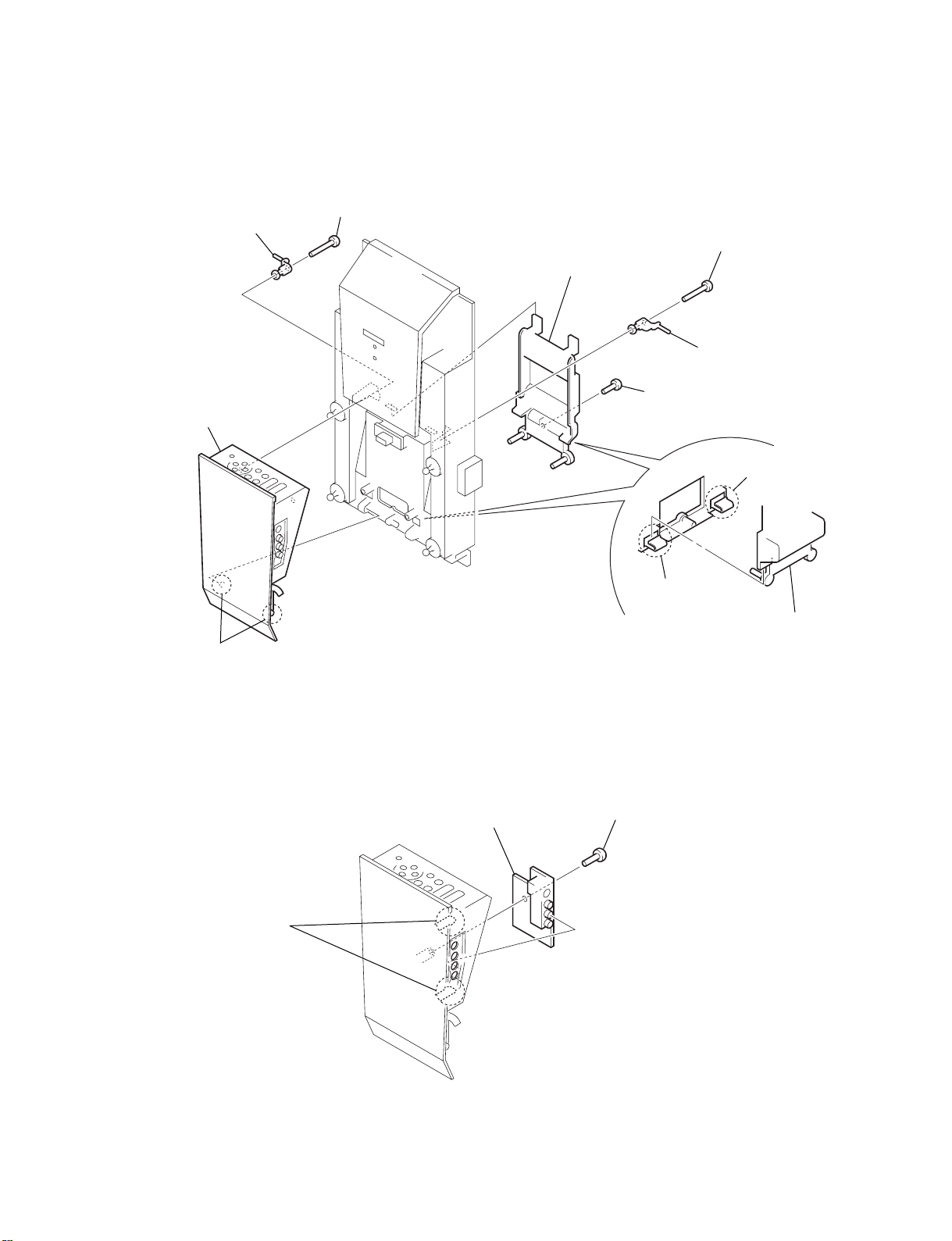

2-13. CONTROL PANEL BLOCK ASSEMBLY

1 Four screws

(HEX tap)

KDP-57XBR2/65XBR2

RM-Y185

2-14. HD BOARD REMOVAL

2 Control panel

block assembly

1 Two screws

(HEX tap)

1 Two screws (+BVTP 4 x 12)

4 Claw

5 HD bracket

6 HD board

4 Claw

3 Screw (+BVTP 4 x 12)

2 Power button

– 14 –

2-15. CONTROL DOOR BLOCK ASSEMBLY

KDP-57XBR2/65XBR2

RM-Y185

7 Door stopper (u)

9 Control door block

assembly

8 Two bosses

6 Screw (+BV 3 x 25)

4 Screw (+BV 3 x 25)

3 DV block bracket

5 Door stopper (u)

1 Screw (+BVTP 3 x 12)

2 Claw

2 Claw

DV block bracket

2-16. HB BOARD REMOVAL

2 Two claws

3 HB board

– 15 –

1 Screw (+BVTP 3 x 12)

2-17. HA BOARD REMOVAL

1 Three claws

5 Three claws

6 Multi button

7 HA board

2 Two claws

3 Multi button block

4 Screw (+BVTP 3 x 12)

KDP-57XBR2/65XBR2

RM-Y185

2-18. PICTURE TUBE BLOCK REMOVAL

1 Seven screws (HEX tap)

2 Picture tube block

1 Screw (HEX tap)

– 16 –

CABLE REMOVAL

AND INSTALLATION

(1) Removal

1 Rubber cap

2 HV cable

turn 90°

(2) Installation

2 Rubber cap

KDP-57XBR2/65XBR2

RM-Y185

2-20. PICTURE TUBE REMOVAL2-19. HIGH-VOLTAGE

Removing the arrow-marked screw is strictly inhibited.

If removed, it may cause liquid spill.

6 Four screws

(+BVTP 4 x 12)

1 Four screws

(HEX TAP 4 x 20)

2 Lens

7 Picture

tube

5 Deflection

yoke

Gutter

1 HV cable

Hook

4 Neck

assembly

3 CR board

– 17 –

SECTION 3

SET-UP ADJUSTMENTS

KDP-57XBR2/65XBR2

K RM-Y185

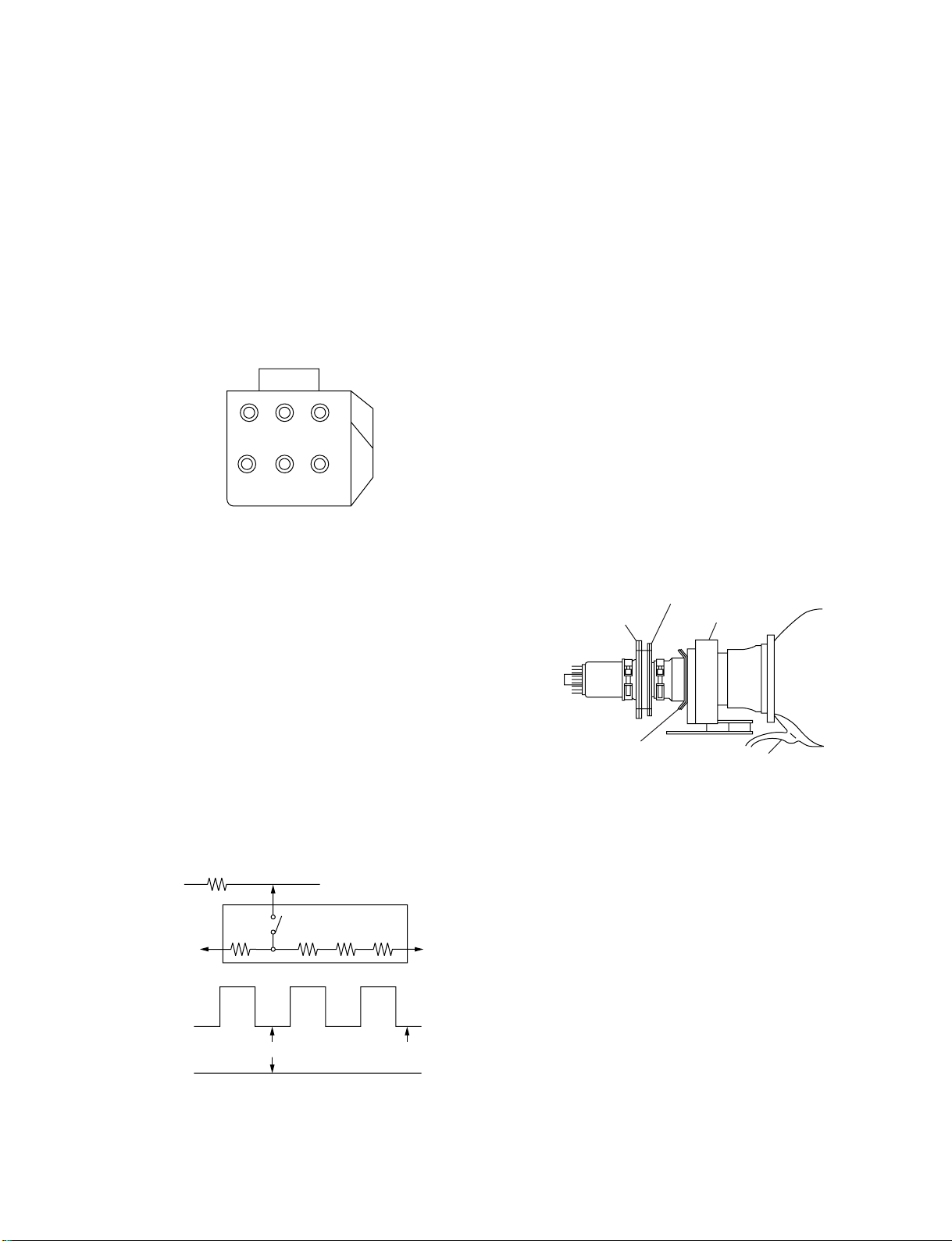

3-1. SCREEN VOLTAGE ADJUSTMENT

(ROUGH ALIGNMENT)

1. Receive the monoscope signal.

2. Set 50% BRIGHTNESS and minimum PICTURE.

3. Turn the red VR on the focus pack all the way to the left and

then gradually turn it to the right until the point where you

can see the retrace line.

4. Next gradually turn it to the left to the position where the

retrace line disappears.

RG

SCREEN

RG

FOCUS

B

B

Focus Pack

Fig. 3-1

3-2. SCREEN (G2) ADJUSTMENT

Fine Mode is recommended to set screen controls to their optimal condition. It is necessary to build the simple jig, illustrated

below, using 3-watt resistors. Please note, that if the proper voltage is not obtained with their listed values, resistors, then please

increase or decrease one of the values in the resistor network to

obtain the correct voltage.

1. Select VIDEO1 mode without signals.

2. Connect G2 JIG to TP3802 (200V) of CG board and GND.

3. SW on JIG.

4. Connect an oscilloscope to the SG3701(KR), SG3801(KG)

and SG3901(KB) of CR board, CG board and CB board.

5. Adjust R, G and B screen voltage to 175 ± 1V with screen

VR on the focus pack.

3-3. DEFLECTION YOKE TILT ADJUSTMENT

1. Connect the color bar generator monoscope pattern to

VIDEO1 input.

2. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

3. Loosen the deflection yoke set screw and align the tilt of the

Deflection Yoke so that the bars at the center of the

monoscope pattern are horizontal.

4. After aligning the deflection yoke, fasten it securely to the

funnel-shaped portion (neck) of the CRT.

5. The tilt of the deflection yoke for red is aligned in the mode

Cover the both green and blue picture lenses with the lens

caps and the tilt of the deflection yoke for blue is aligned

with in the mode Cover the both green and red picture lenses

with the lens caps is aligned the same as was done for green.

Note: Instead of items 2 and 5, you can cut off the unnecessary

color beams by controlling the service mode “1 RGBS” of

“2150P-2”.

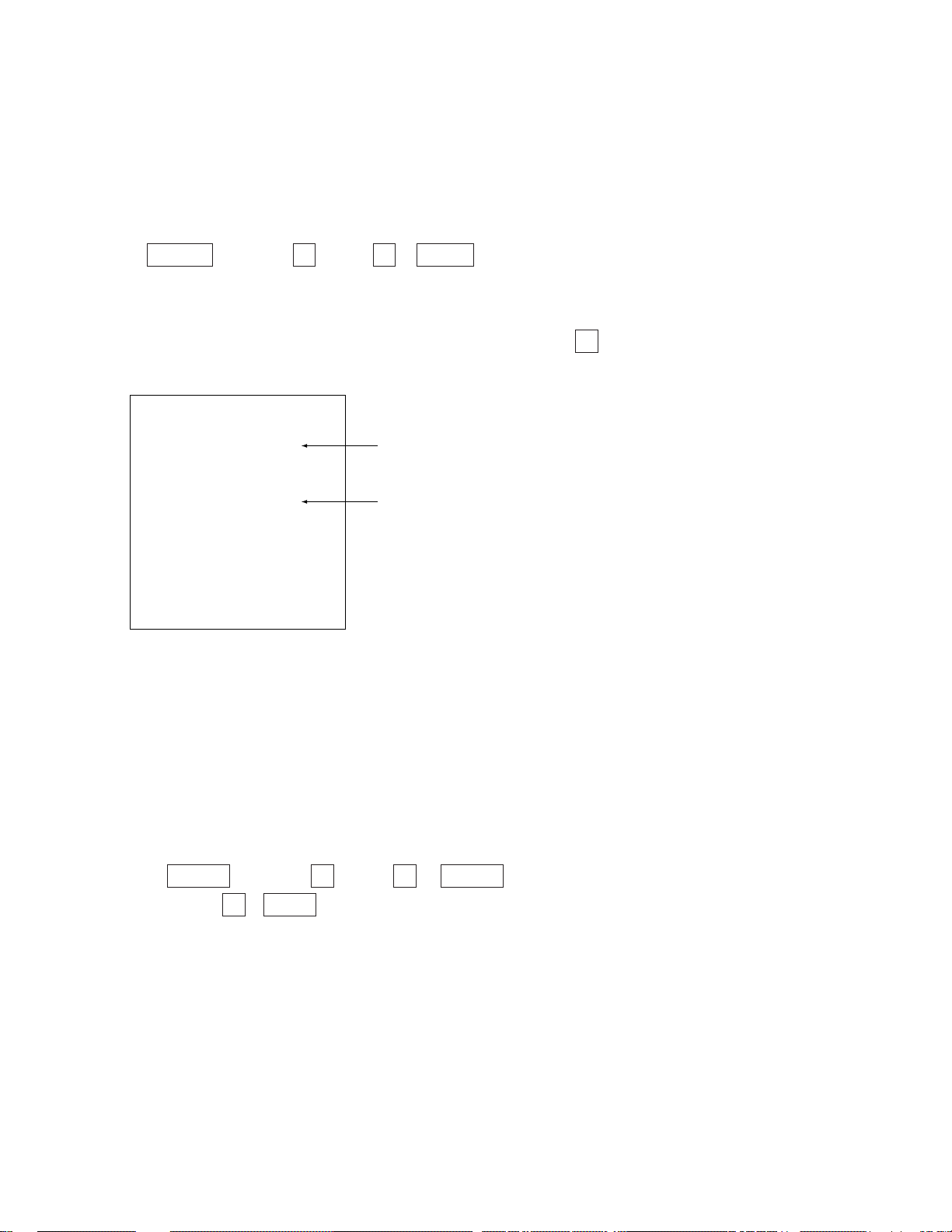

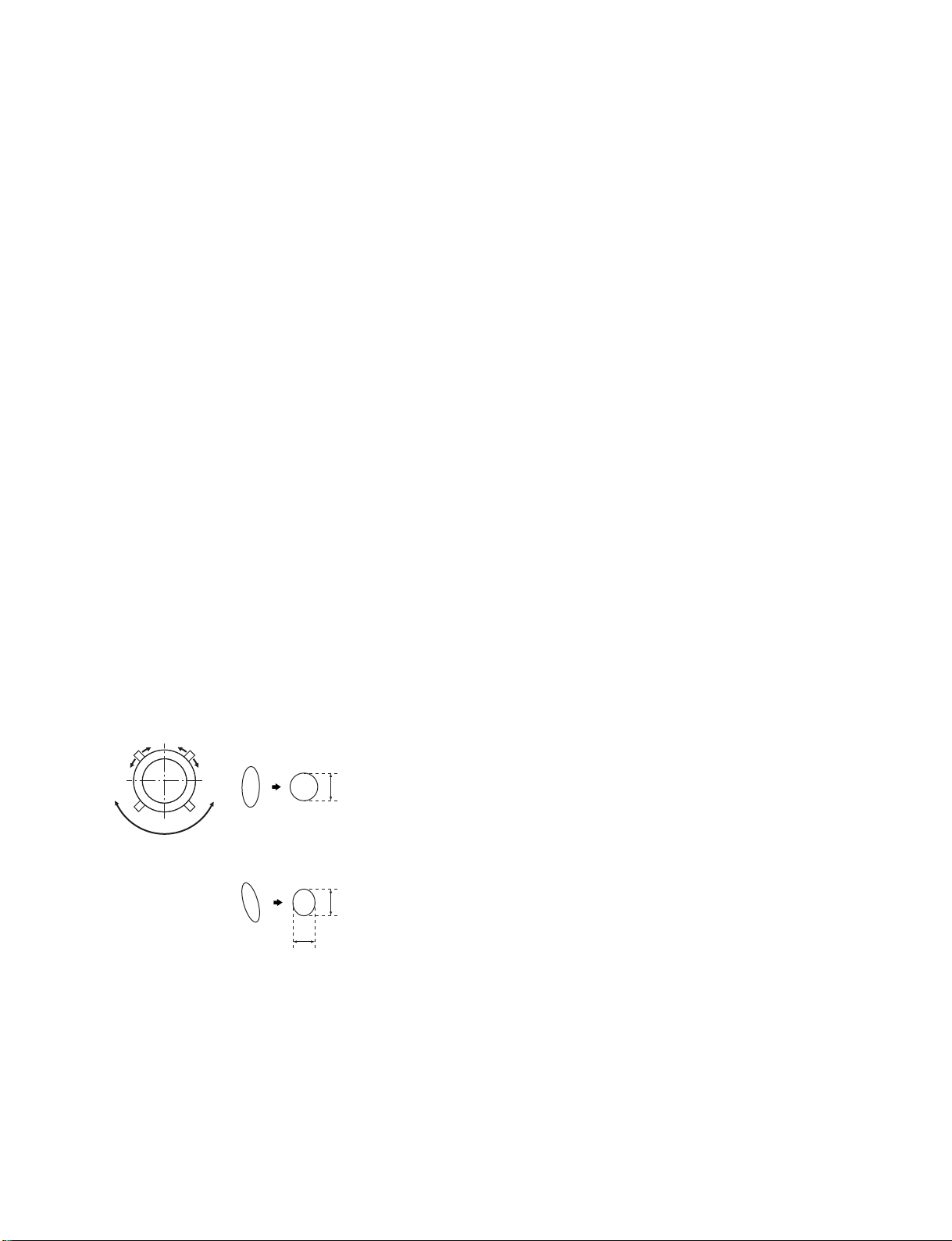

4-pole magnet

2-pole magnet

Centering magnet

Deflection yoke

Anode cap

Fig. 3-3

G2 JIG

TO CG BOARD

TP3802

(200V)

GND

KR, KG, KB

SW

3.3k 5.6k 5.6k 5.6k

All resistors are 3W type

175 ± 1V

pedestal level

Fig. 3-2

GND

– 18 –

KDP-57XBR2/65XBR2

K RM-Y185

3-4. FOCUS LENS ADJUSTMENT

In this adjustment, use the remote commander in the service mode.

For details of the usage of the service mode and the remote commander,

please refer the item 3-10. ELECTRICAL ADJUSTMENT BY

REMOTE COMMANDER.

1. Loosen the lens screw.

2. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

3. Turn the green lens to adjust to the optimum focus point with

the crosshatch signal.

4. Tighten the lens screw.

5. Cover the both green and blue picture lenses with the lens

caps to show only the red color.

6. Adjust red CRT lens just the same as green.

7. Cover the both green and red picture lenses with the lens

caps to show only the blue color.

8. Adjust blue CRT lens just the same as green.

9. After adjusting the items 3-5. FOCUS VR ADJUSTMENT,

3-6. 2-POLE MAGNET ADJUSTMENT, 3-7. CENTER

MAGNET ADJUSTMENT and 3-8. 4-POLE MAGNET

ADJUSTMENT, adjust again to the optimum focus point.

3-5. FOCUS VR ADJUSTMENT

1. Set generator to crosshatch.

2. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

3. Turn the green focus VR on the focus pack to adjust to the

optimum focus point with the crosshatch signal.

4. Cover the both green and blue picture lenses with the lens

caps to show only the red color.

5. Turn the red focus VR on the focus pack to adjust to the

optimum focus point with the crosshatch signal.

6. Cover the both green and red picture lenses with the lens

caps to show only the blue color.

7. Turn the blue focus VR on the focus pack to adjust to the

optimum focus point with the crosshatch signal.

8. After adjusting the items 3-4. FOCUS LENS ADJUSTMENT,

3-6. 2-POLE MAGNET ADJUSTMENT, 3-7. CENTER

MAGNET ADJUSTMENT and 3-8. 4-POLE MAGNET

ADJUSTMENT, adjust again to the optimum focus point.

Note: Instead of items 2, 4 and 6, you can cut off the unneces-

sary color beams by controlling the service mode “1

RGBS” of “2150P-2”.

Note: Instead of items 2, 5 and 7, you can cut off the unneces-

sary color beams by controlling the service mode “1

RGBS” of “2150P-2”.

*:Every time you press 6, the test signal changes to

“crosshatch+video signal” “crossbatch+borderline(black)” - “crosshach(black)” “dots(black)” - off.

Test signal

Fig. 3-4

A

Minimize both A and B.

Lens

Fig. 3-5

B

Fig. 3-6

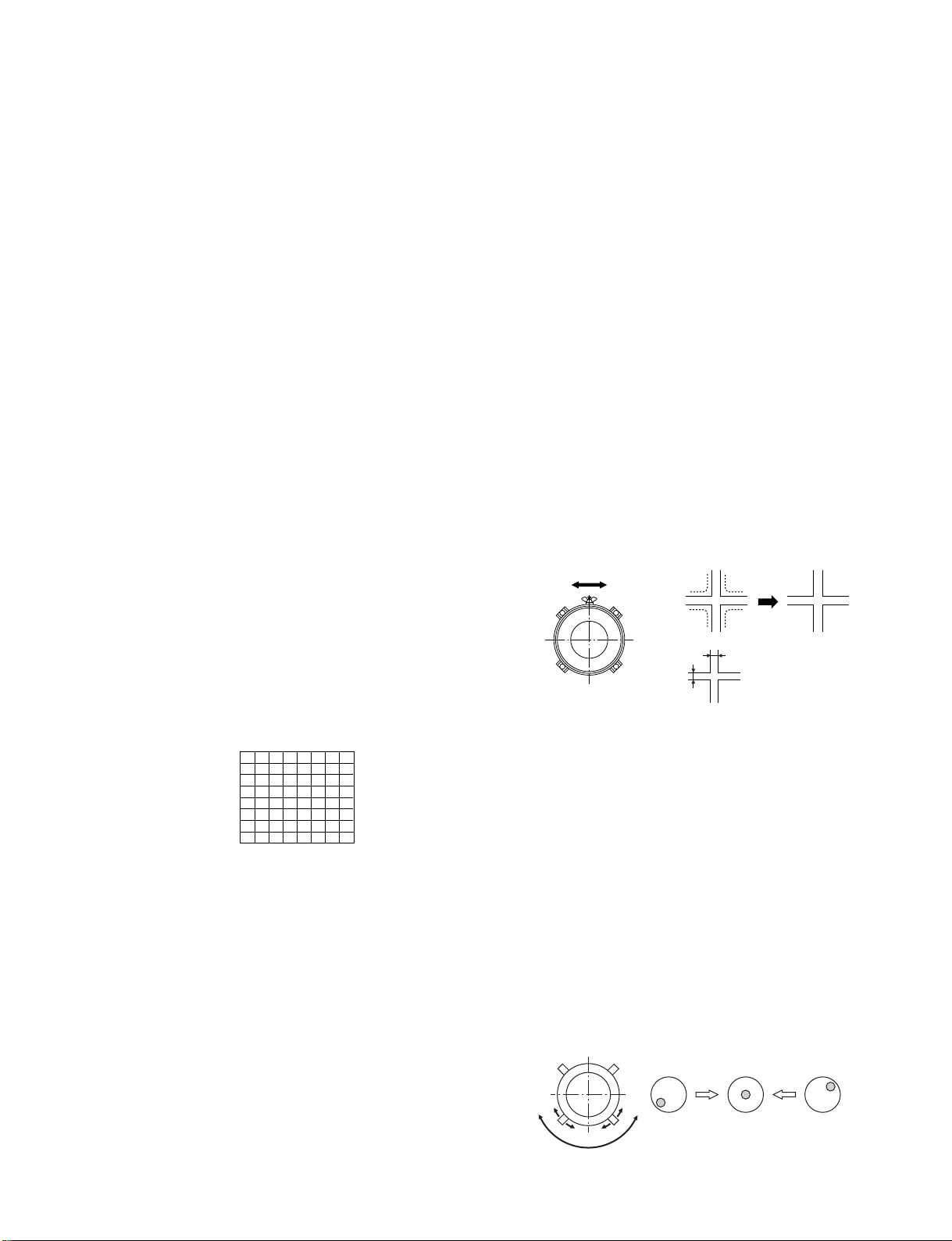

3-6. 2-POLE MAGNET ADJUSTMENT

1. Set the picture mode to“Pro” and picture to MAX.

2. Receive the dot signal.

3. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

4. Turn the green focus VR on the focus pack to the left and set

to overfocus to enlarge the spot.

5. Adjust 2-pole magnet so that the bright spot should be

centered.

6. Align the green focus VR and set for just (precise) focus.

7. Perform the same alignment for red and blue.

Note: Instead of item 2 you can cut off the unnecessary color

beams by controlling the service mode “1 RGBS” of

“2150P-2”.

Use the center dot

– 19 –

Fig. 3-7

KDP-57XBR2/65XBR2

K RM-Y185

3-7. CENTERING MAGNET ADJUSTMENT

1. Set the picture mode to “Pro”.

2. Receive the monoscope signal.

3. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

4. Adjust the green centering magnet to put the center of the

monoscope signal to the center of the screen.

5. Adjust the red centering magnet in the same way.

6. Adjust the blue centering magnet in the same way.

Note: Instead of item 2 you can cut off the unnecessary color

beams by controlling the service mode “1 RGBS” of

“2150P-2”.

3-8. 4-POLE MAGNET ADJUSTMENT

1. Set the picture mode to“Pro” and picture to MAX.

2. Receive the dot signal.

3. Cover the both red and blue picture lenses with the lens caps

to show only the green color.

4. Turn the green focus VR on the focus pack to the right and

set the spot will become smaller.

5. Adjust the 4-Pole Magnet so that the spot becomes round for

green and red.

6. Adjust blue spot to an oval shape. x : y = 1 : 1.2

3-9. DEFOCUS ADJUSTMENT (BLUE)

Note: Please adjust the blue dot to be slightly larger than red and

green dots. This adjustment provides a more pleasing picture to the customer.

1. Select the picture mode to “Pro”.

2. Receive the dot signal.

3. Cover the both red md green picture lenses with the lens caps

to show only the blue color.

4. Turn the blue focus VR on the focus pack to right to make

the round dot elipical.

5. Check flare with high luminace signal, make sure flare is

minimal while dot shape is elipical.

6. Set generdtor to all white signal and check uniformity.

Note: Instead of item 3 you can cut off the unnecessary color

beams by controlling the service mode “1 RGBS” of

“2150P-2”.

Note: Instead of item 2 you can cut off the unnecessary color

beams by controlling the service mode “1 RGBS” of

“2150P-2”.

Use the center dot

[GREEN and RED]

NG

NG

OK

[BLUE]

OK

x

Fig. 3-8

57 inch : 19 to 26 mm

65 inch : 22 to 30 mm

y

x : y = 1 : 1.2

– 20 –

KDP-57XBR2/65XBR2

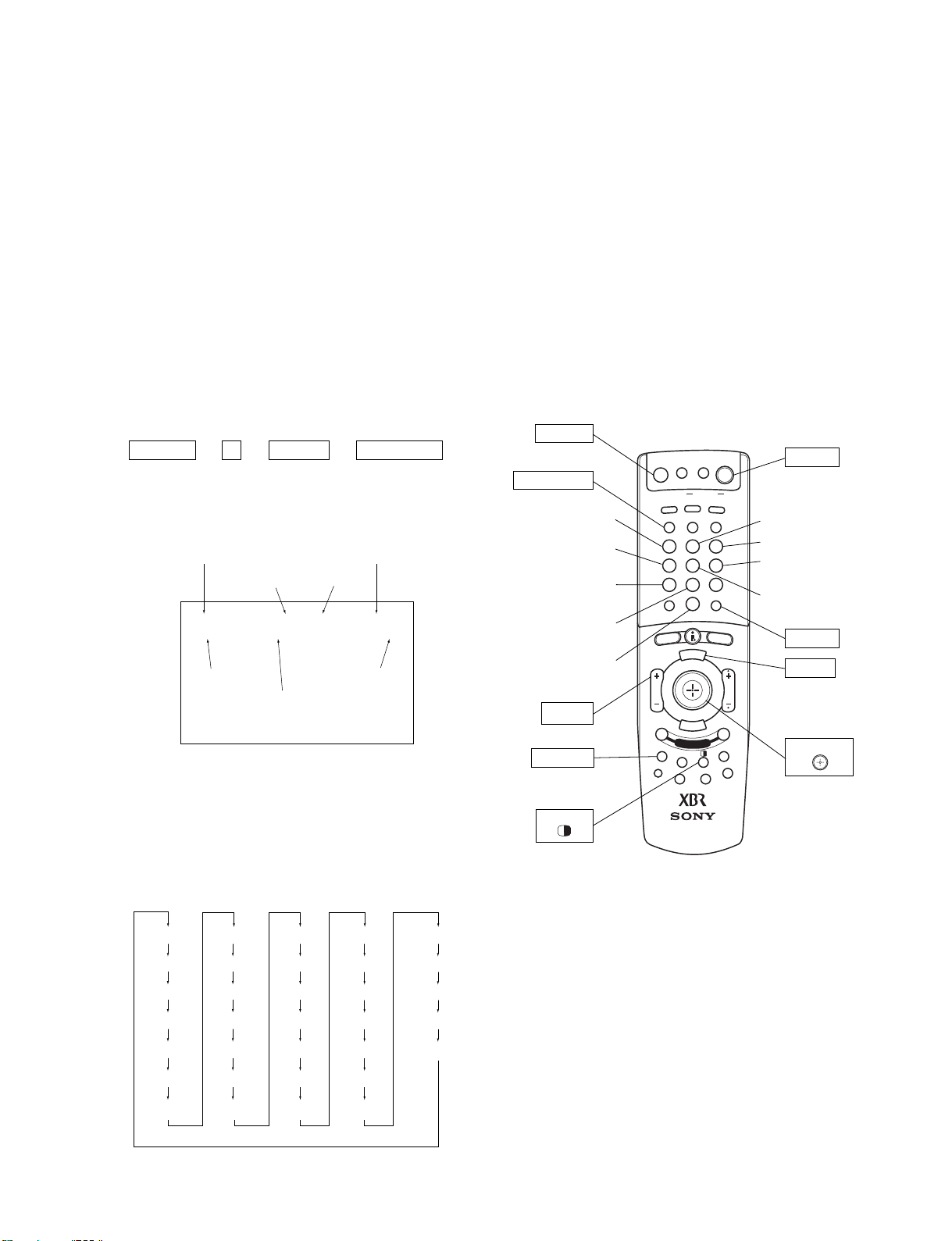

DISPLAY

JUMP

ADD SURF

SLEEP SAT/CABLE

SAT/CABLE

FUNCTION

MENU

ENTER

VOL

EXIT

IN

D

E

X

G

U

ID

E

PIC MODE

WIDE MODE

TV/VIDEOANT

TV

TV

123

456

7.89

0

MUTING

POWER

FREEZE

RESET

DRC

CINEMOTION

RM-Y185

MTS/SAP

TIMER

CH

F

A

V

O

R

I

T

E

DISPLAY

Adjustment item

up

Adjustment item

down

JOYSTICK

Adjustment category

up

Read data from

NVM

Write data to NVM

POWER

MUTING

VOL +

ENTER

MENU

WIDE MODE

Adjustment category

down

Data up

Move : V,v,B,b

Push : Enter

Data down

TWIN

Initialize data

(Not stored)

User control goes

to the standerd state

RM-Y185

K RM-Y185

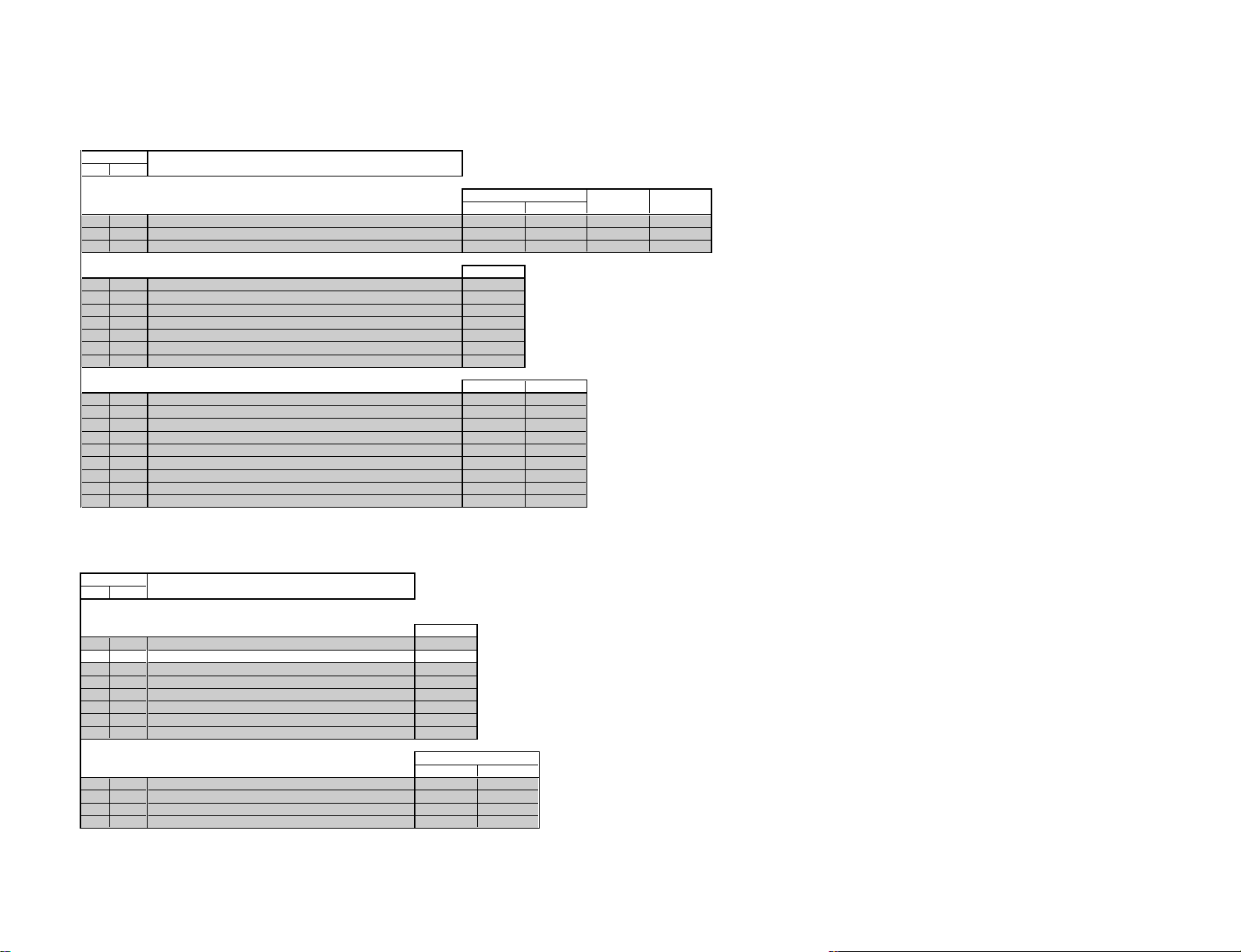

3-10. ELECTRICAL ADJUSTMENT BY REMOTE

COMMANDER

By using remote commander (RM-Y185), all circuit adjustments can be made.

NOTE : T est Equipment Required.

1. Pattern Generator (with component outputs)

2. Frequency counter

3. Digital multimeter

4. Audio oscillator

1. Method of Setting the Service Adjustment

Mode

SERVICE MODE PROCEDURE

1. Standby mode. (Power off)

2. DISPLAY t 5 t VOL (+) t TV POWER

on the remote commander.

(Press each button within a second.)

SERVICE MODE ADJUSTMENT

Category Name

Item No.

Mode

Data

7. If you want to recover the latest values press “-” then

“[ENTER]” to read the memory.

8. Press “[MUTING]” then “[ENTER]” to write into memory.

9. Turn power off.

Note: Press “8” then “[ENTER]” on the remote commander to

initialize or turn set off and on to exit.

2. Memory Write Confirmation Method

1. After adjustment, turn power off with the remote commander.

2. Turn power on and set to service mode.

3. Call the adjusted items again and confirm they were adjusted.

3. Adjusting Buttons and Indicator

VERSION 0 0 SERVICE

VER Full TV

Item Name Input Signal

Screen Mode

F/A: 11111111 11111111

CBA: 11111111 11111111

3. The SCREEN displays the item being adjusted.

4. Press “1” or “4” on the remote commander to select the

adjustment item.

5. Press “3” or “ 6” on the remote commander to change the data.

6. Press “2” or “5” on the remote commander to select the category.

Every time you press “2” (Category up), Service mode

changes in the order as shown below.

VERSION

3D-COMB

2103-1

2103-2

2150P-4

2150D-1

2150D-2

2150D-3

2150P-1 D-CONV MID5

2150P-2 CXA2026 CXA3506R

2150P-3 CXA2151 BH3868

MID1

MID2

MID3

MID4

TDA7312F

TDA7312R

TDA7312C

* : GRN , RED or BLU

SNNR

CCD

DTV

TP

PJE (00 FDIS)

PJE (44 COGV)

GRN* (CENT)

OP

ID

Note : When the PJE mode is activated, which displays an inter-

nally generated signal, several buttons on the remote

commander will have different functions than listed

above. Therefore, when in the PJE mode, refer to page 41

for button functions.

– 21 –

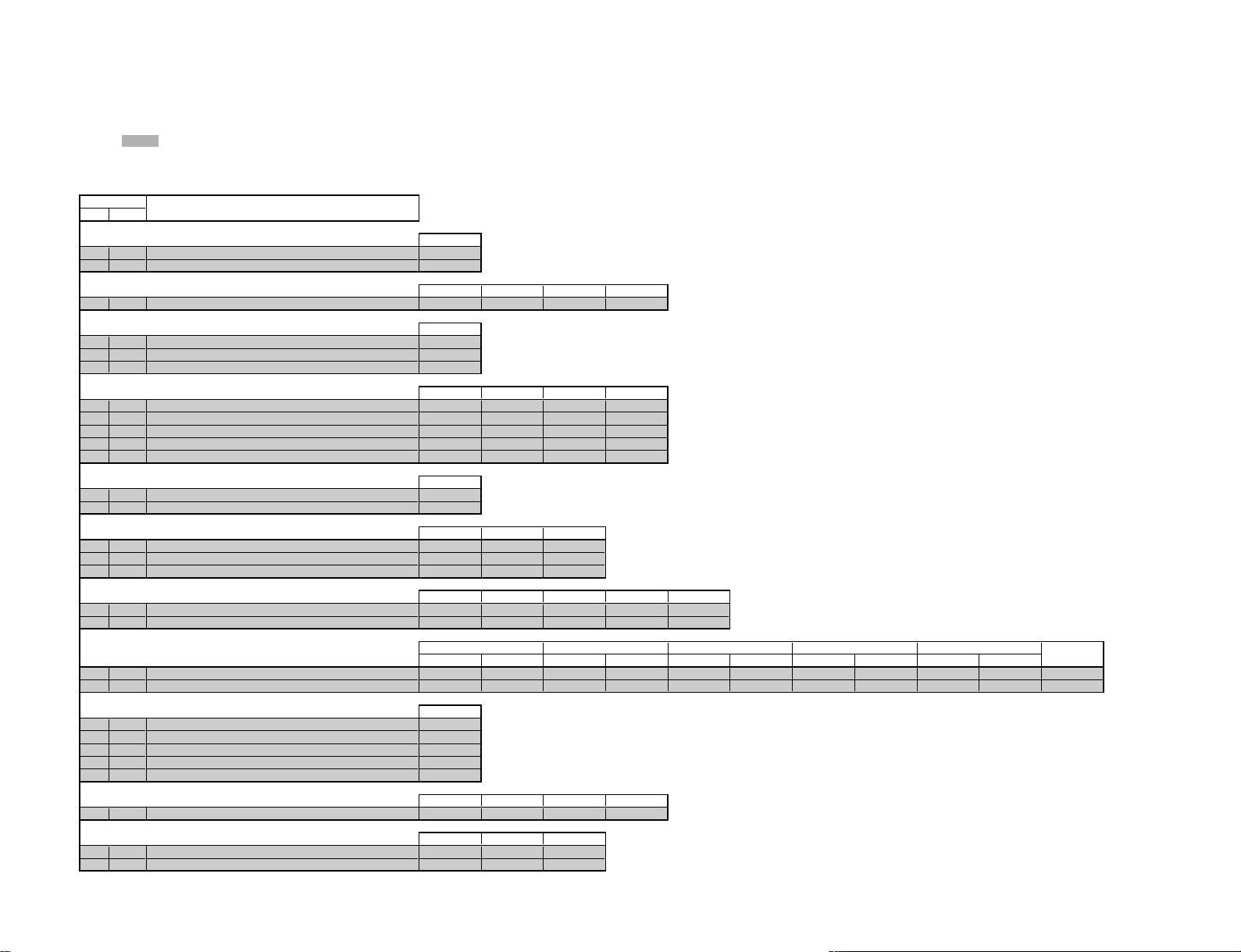

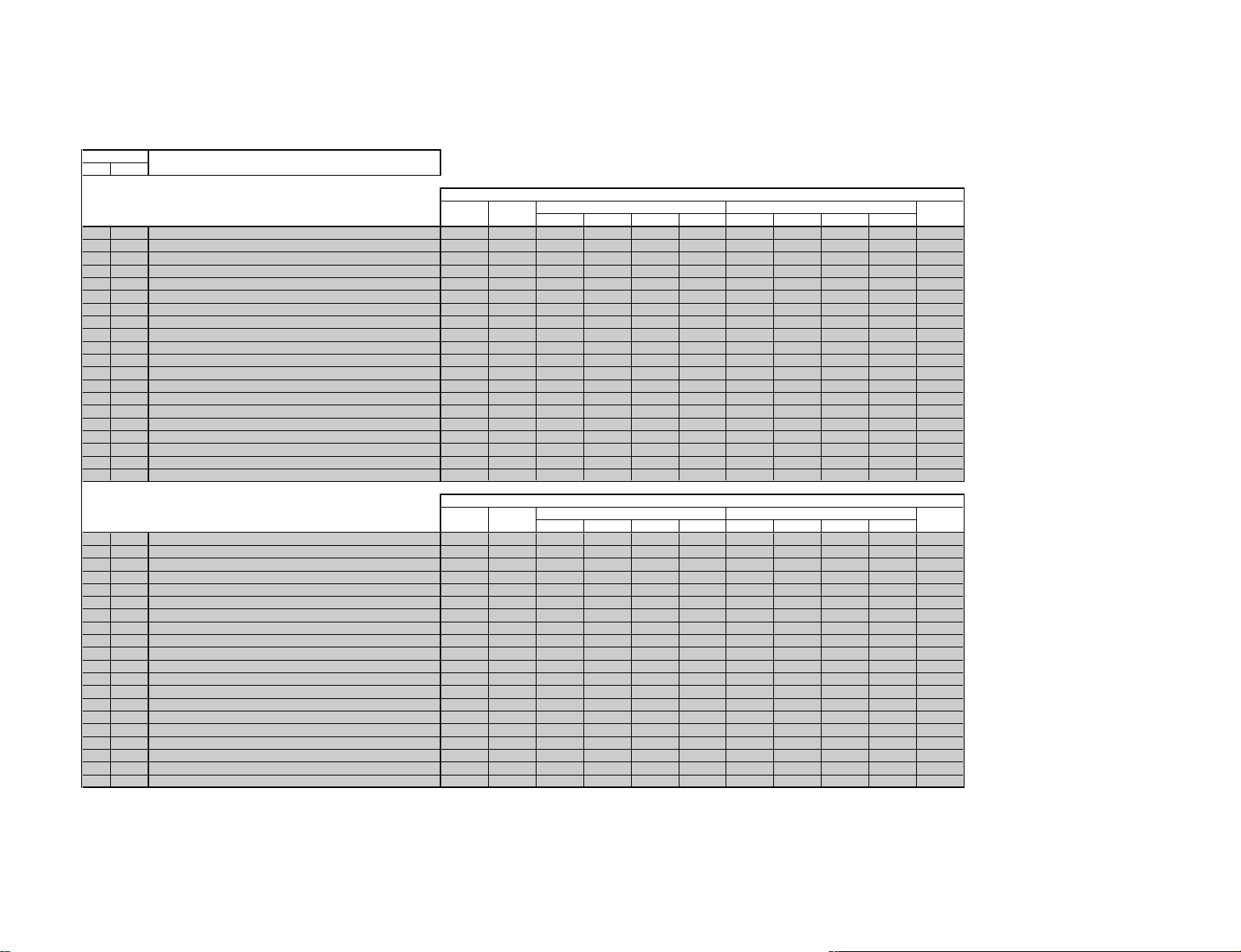

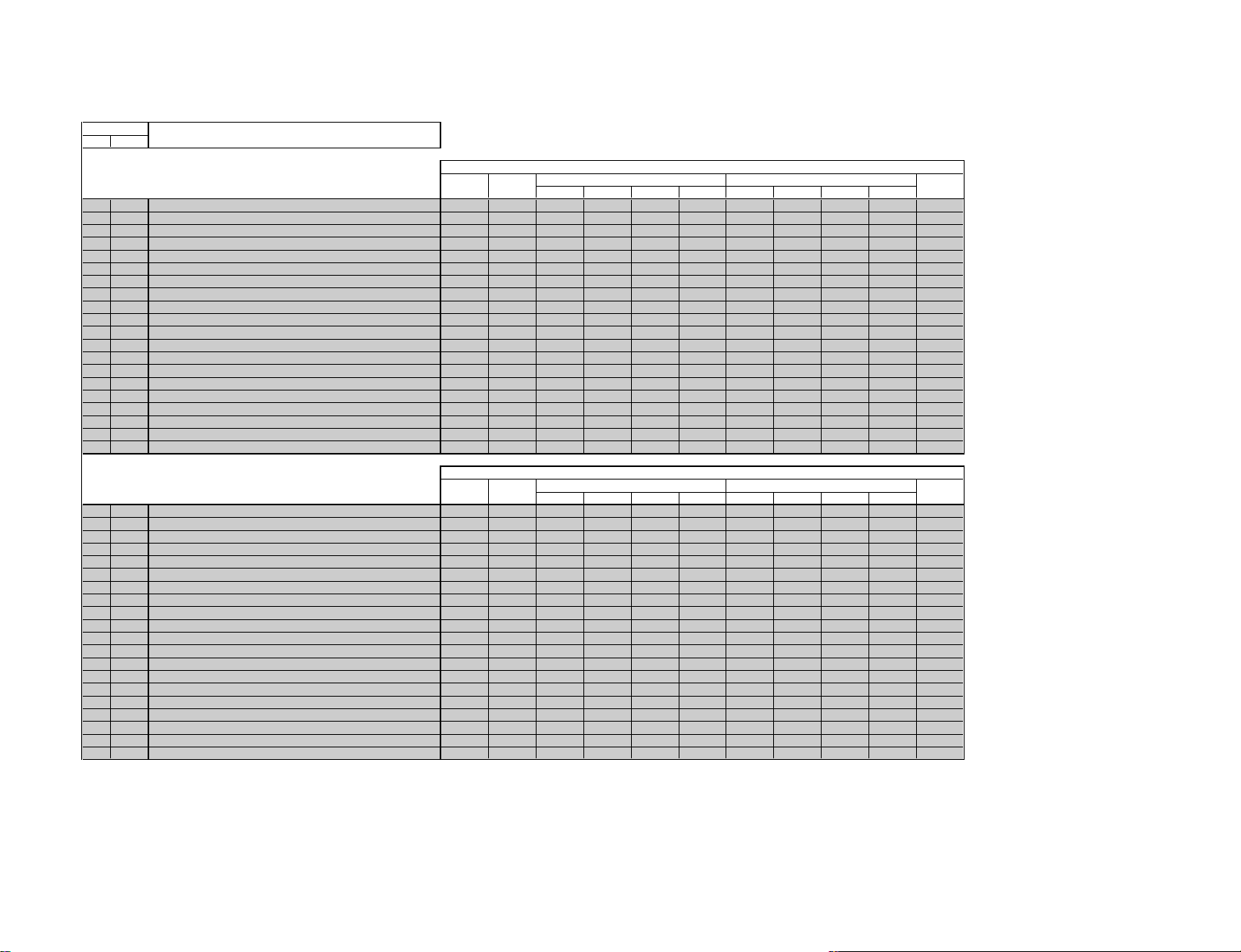

4. Service Mode List

Note: • shaded items are fixed. There is no need to change data. Others are different a little

in the sets individually. Basically, there is no need to change data, too.

3D-COMB

3D Comb Filter (µPD64082)

Item

No. Name

0 NRMD Noise reduction mode [0: YCS, 1: YCS+, 2: MNNR, 3: YCNR] 0

1 YAPS Y aperture/peaking [0: OFF, 1: A-ON, 2: D-ON, 3: A/D-ON] 3

2 CLKS System CLK [0: Auto, 1: Forced-Burst, 2/3: Forced-H freq.] 1111

3 NSDS Signal [0: Auto, 1: F-ST, 2: F-nonST (H), 2/3: F-nonST(V)] 3

4 MSS Processing [0: Auto, 1: F-Inter Frame, 2/3: F-InterLine] 0

5 KILS Color Killer [0: Auto, 1: Port Cont., 2/3: F-Killer] 2

6 CDL Chroma delay time [0: –280 ns, 4: 0 ns, 7: +210 ns] 3333

7 DYCO Y coring level [0: Coring 0, 15: Large amount of Coring] 2222

8 DYGA Y coring gain [0: 0 gain, 15: Maximum gain] 11 11 11 11

9 DCCO C coring level [0: Coring 0, 15: Large amount of Coring] 4444

10 DCGA C coring gain [0: 0 gain, 15: Maximum gain] 8888

– 22 –

11 YNRL YNR limit [0: YNR off (0LSB), 3: YNR 3LSB] 1

12 CNRL CNR limit [0: CNR off (0LSB), 3: CNR 3LSB] 1

13 VTRH H hysteresis of nonST signal det. [0: Hys-off, 3: Hys-high] 1 1 1

14 VTRR H sensitivity of nonST signal det. [0: High, 3: Off] 1 1 1

15 LDSR Frame sensitivity of nonST signal det. [0: High, 3: Off] 2 2 2

16 VAPG Vertical aperture gain [0: Off, 7: Maximum] 00000

17 VAPI Vertical aperture conv. point [0: Off, 31: Max correction] 00000

18 YPFT Y peaking freq. [0: 3.58 MHz, 1: 3.86 MHz, 2: 4.08 MHz, 3: 4.22 MHz] 33333333333

19 YPFG Y peaking gain [0: –1 times, 8: 0 times, 15: +0.875 times] 75757575757

20 YHCO Y coring for y [0: Off, 1: Small, 2: Mid, 3: Large] 0

21 YHCG Y coring gain for High frequency [0: Normal, 1: 0.5 gain] 1

22 HSSL Horizontal sync slice level [0: 4LSB, 15: 19LSB] 12

23 VSSL Vertical sync slice level [0: HSSL+0 LSB, 15: HSSL+15 LSB] 8

24 ADCL ADC clock delay [0: 0 ns, 1: 3 ns, 2: 17.5 ns, 3: 20.5 ns] 3

25 D2GA Motion detect gain 4444

26 SEDY Select DY detect [0: Low sensitivity, 1: High sensitivity] 1 1 1

27 SEDC Select DC detect [0: Low sensitivity, 1: High sensitivity] 0 0 0

Depends on NRMD data

Depends on NRMD data

Depends on Signal Input

Depends on Picture Pallete

Depends on Picture Pallete and Video Input

Depends on NRMD data

Depends on Signal Input

Function

Common

NRMD (0) NRMD (1) NRMD (2) NRMD (3)

Common

NRMD (0) NRMD (1) NRMD (2) NRMD (3)

Common

RF CV/YC

Vivid Standard Movie Game Pro

Vivid Standard Movie Game Pro

RF CV/YC RF CV/YC RF CV/YC RF CV/YC RF CV/YC

Common

NRMD (0) NRMD (1) NRMD (2) NRMD (3)

RF CV/YC

Video5/Video6

Video5/Video6

TWIN

Any

K RM-Y185

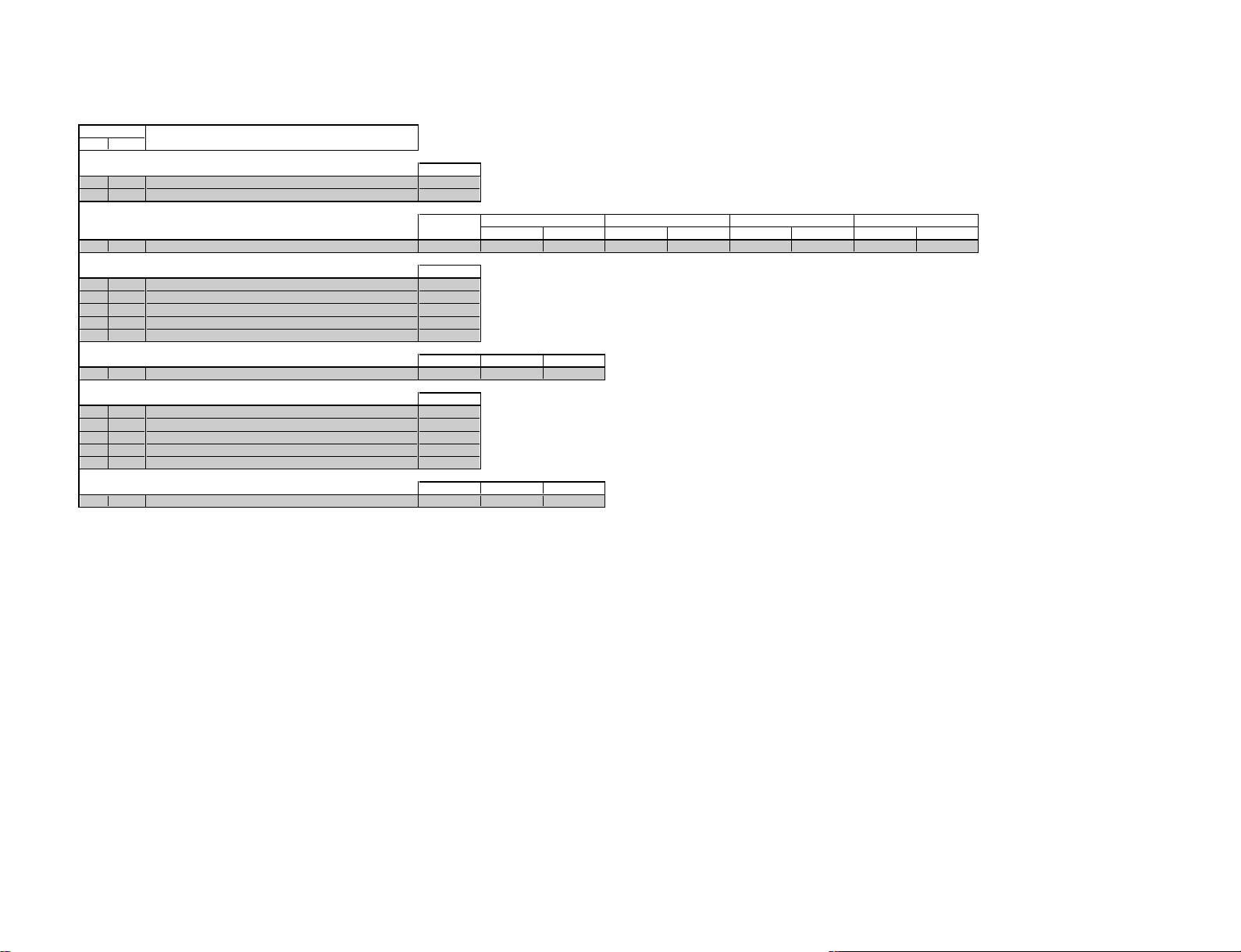

KDP-57XBR2/65XBR2

3D Comb Filter (µPD64082)

Item

No. Name

28 KILR Killer detector [0: Off, 1: Low sensitivity, 15: High sensitivity] 3

29 OP NRMD for Y/C input [0: Recursive Type, 1: Comb Type] 1

30 NR1 Initial setting of NR On/Off [0: On, 1: Off] 000000000

31 NR2 S/N adaptive processing [0: On, 1: Off] 0

32 HPLL H PLL filter [0: Slow convergence, 1: Quick convegence 1

33 BPLL Burst PLL filter [0: Quick convergence, 1: Slow convergence] 1

34 FSCF Burst extraction gain [0: High gain, 1: Low gain] 0

35 PLLF PLL loop gain [0: Low gain, 1: High gain] 1

36 CC3N C filter characteristic of comb filter [0: Narrow, 1: Wide] 0 0 0

37 HDP Horizontal phase [0: –1.12 µs, 4: 0 µs, 7: +0.84 µs] 5

38 BGPS Burst gate start [0: HS center +2 µs, 15: HS center +5.75 µs] 4

39 BGPW Burst gate width [0: 0.5 µs, 15: 4.25 µs] 10

40 TEST Test bit [0: Normal, 1: Test mode] 0

41 WSC Noise det. coring [0: 0LSB, 1: 1LSB, 2: 2LSB, 3: 3LSB] 1

– 23 –

42 LIND 262P detect [xx1: nonST H, x1x: nonST V, 1xx: LD still] 0 0 2

Depends on Signal Input

Depends on Signal Input

Depends on Signal Input

Function

Common

RF CV YC CV YC CV YC CV YC

Common

RF CV/YC

Common

RF CV/YC

V1 V2 V3 V4

Video5/Video6

Video5/Video6

K RM-Y185

KDP-57XBR2/65XBR2

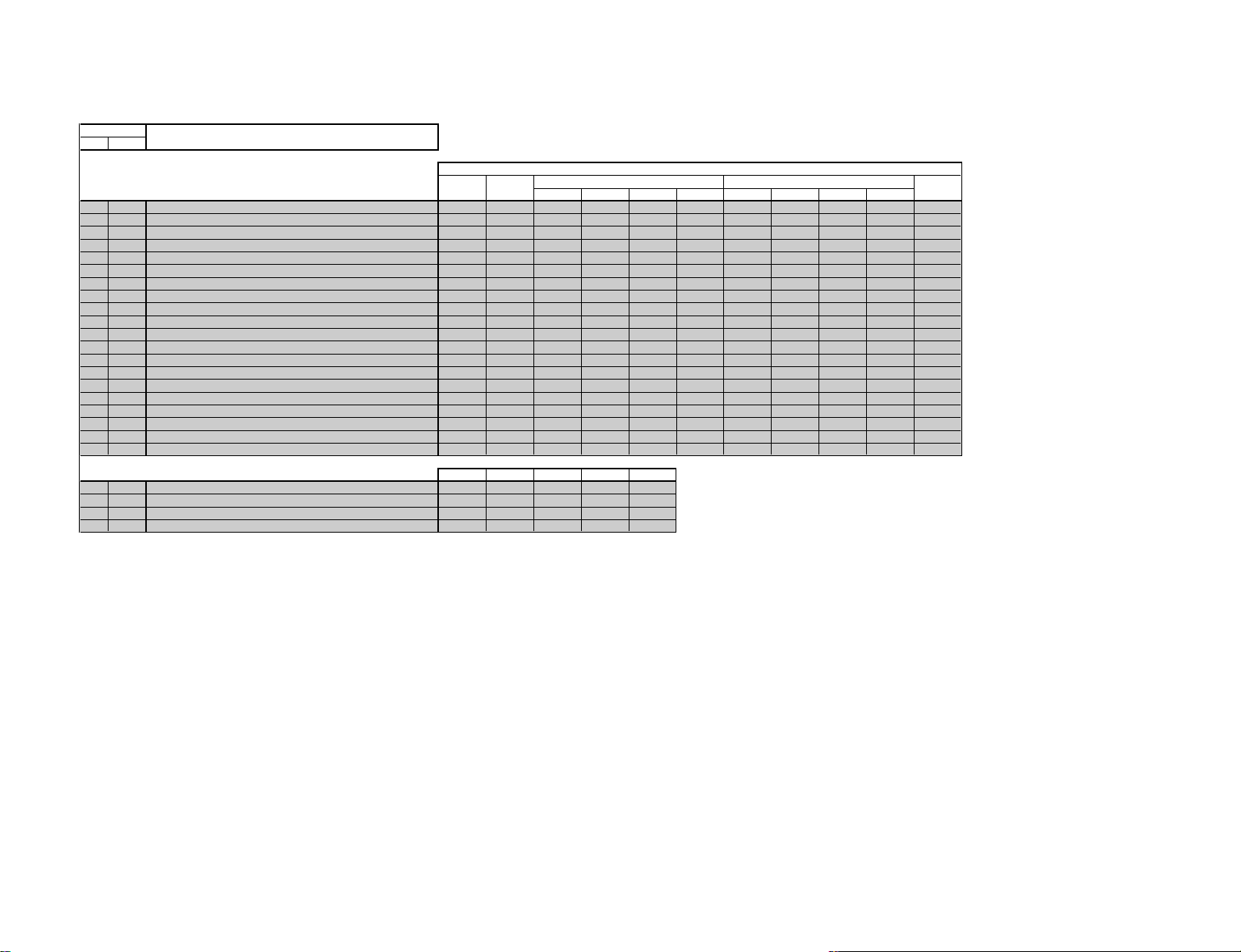

2103-1

Main Chroma Decoder (CXA2103)

Item

No. Name

0 YLEV Y out level gain [0: 2.9 dB, 63: 9.0 dB] 35 35

1 CLEV CbCr out level gain [0: 2.9 dB, 63: 9.0 dB] 50 42

2 SCON Sub contrast [0: –2 dB, 15: +2 dB] 9 9

3 SCOL Sub color [0: –2 dB, 15: +2 dB] 2 2

4 SHUE Sub hue [0: –8.8 deg, 15: +8.8 deg] 11 5

5 YDLY Y/C delay [0: Ref, 1: 30 ns Y delay, 2: 60 ns, 3: 100 ns] 0 0

6 SHAP Sharpness [0: –3 dB, 15: +3 db] 6884

7 SHFO Sharpness F0 [0: 2.5 MHz, 1: 3.0 MHz, 2: 3.5 MHz, 3: 4.0 MHz] 0003

8 PREO Pre-over ratio [0: 1.5:1, 1: 1:1, 2: 1:1.5, 3: 1:2] 3333

9 BPFO Chroma BPF F0 [0: fsc, 1: fsc+400 kHz, 2: fsc+800 kHz, 3: fsc+1.2 MHz] 3 0 0

10 BFFQ Chroma BPF Q [0: 2.0, 1: 1.5, 2: 1.2, 3: 1.0] 0 3 3

11 BPSW Chroma BPF On/Off [0: Off, 1: On] 1 0 0

12 TRAP Chroma trap on Y On/Off [0: Off, 1: On] 0 0 0

– 24 –

13 LPF Output LPF (YCbCr) [0: On, 1: Off (through)] 1 0

14 AFCG PLL loop gain [0: fast, 1: slow] 1 0 0

15 CDMD

16 SSMD Slice level [0: auto, 1: HV 65%, 2: H 25% V 65%, 3: HV 25%] 0 0 0

17 HMSK Mask for Macro Vision [0: Off, 1: On] 0 1 1

18 HALI Auto H alignment [0: Off, 1: On (AFC free run)] 0 0 0

19 PPHA Picture/H Tim phase [0: –0.5 µs, 15: +0.5 µs] 777

20 CBOF Cb/Ext Cb offset [0: –16 mV, 63: +16 mV] 26 29 25

21 CROF Cr/Ext Cr offset [0: –16 mV, 63: +16 mV] 23 30 25

ATPD Auto pedestal point [0: Through, 1: 20 IRE, 2: 30 IRE, 3: 40 IRE] 001222231

**22

DCTR DC transfer ratio [0: 100%, 1: 85%, 2: 90%, 3: 85%] 002113322

**23

Function

Depends on Signal Path

Depends on Signal Input

Depends on Signal Input

Depends on Signal Input

Depends on Signal Path

Depends on Signal Input

Count down mode [0/1/3: CountDown, 2: H look *

Depends on Signal Input

Depends on CXA2150P-4 BLK

** Main and Sub CXA2103 share the same data for items 22 and 23.

Tc: 0>1>3]

DRC VDO

RF CV/YC

RF CV YC Video5

RF CV YC

DRC VDO

RF CV/YC

333

RF Video5 Video6

Single BLK (0) BLK (1) BLK (2) BLK (3) BLK (4) BLK (5) BLK (6) BLK (7)

Video5/Video6

K RM-Y185

KDP-57XBR2/65XBR2

2103-2

Sub Chroma Decoder (CXA2103)

Item

No. Name

0 YLEV Y out level gain [0: 2.9 dB, 63: 9.0 dB] 35 35

1 CLEV CbCr out level gain [0: 2.9 dB, 63: 9.0 dB] 50 42

2 SCON Sub contrast [0: –2 dB, 15: +2 dB] 8 8

3 SCOL Sub color [0: –2 dB, 15: +2 dB] 3 3

4 SHUE Sub hue [0: –8.8 deg, 15: +8.8 deg] 10 3

5 YDLY Y/C delay [0: Ref, 1: 30 ns Y delay, 2: 60 ns, 3: 100 ns] 0 0

6 SHAP Sharpness [0: –3 dB, 15: +3 db] 0884

7 SHFO Sharpness F0 [0: 2.5 MHz, 1: 3.0 MHz, 2: 3.5 MHz, 3: 4.0 MHz] 0003

8 PREO Pre-over ratio [0: 1.5:1, 1: 1:1, 2: 1:1.5, 3: 1:2] 3333

9 BPFO Chroma BPF F0 [0: fsc, 1: fsc+400 kHz, 2: fsc+800 kHz, 3: fsc+1.2 MHz] 0 0 0

10 BPFQ Chroma BPF Q [0: 2.0, 1: 1.5, 2: 1.2, 3: 1.0] 3 3 3

11 BPSW Chroma BPF On/Off [0: Off, 1: On] 0 1 1

12 TRAP Chroma trap on Y On/Off [0: Off, 1: On] 0 0 0

– 25 –

13 LPF Output LPF (YCbCr) [0: On, 1: Off (through)] 1 0

14 AFCG PLL loop gain [0: fast, 1: slow] 1 0 0

15 CDMD

16 SSMD Slice level [0: auto, 1: HV 65%, 2: H 25% V 65%, 3: HV 25%] 0 0 0

17 HMSK Mask for Macro Vision [0: Off, 1: On] 0 1 1

18 HALI Auto H alignment [0: Off, 1: On (AFC free run)] 0 0 0

19 PPHA Picture/H Tim phase [0: –0.5 µs, 15: +0.5 µs] 777

20 CBOF Cb/Ext Cb offset [0: –16 mV, 63: +16 mV] 27 31 31

21 CROF Cr/Ext Cr offset [0: –16 mV, 63: +16 mV] 22 31 31

22 2SCO SCON offset of CV for 2H Conb [0: –7step, 7: ±0step, 15: +8step] 7

23 2SCL SCOL offset of CV for 2H Conb [0: –7step, 7: ±0step, 15: +8step] 7

24 2SHU SHUE offset of CV for 2H Conb [0: –7step, 7: ±0step, 15: +8step] 7

Function

Depends on Signal Path

Depends on Signal Input

Depends on Signal Input

Depends on Signal Input

Depends on Signal Path

Depends on Signal Input

Count down mode [0/1/3: CountDown, 2: H look *Tc: 0>1>3]

Depends on Signal Input

DRC VDO

RF CV/YC

RF CV YC Video5

RF CV YC

DRC VDO

RF CV/YC

333

RF Video5 Video6

Common

Video5/Video6

K RM-Y185

KDP-57XBR2/65XBR2

2150P-1

Video Processor (CXA2150)

Item

No. Name

0 YOF Y offset [0: –39 mV, 7: 0 mV, 15: +45 mV] 7 7 7 7

1 CBOF Cb offset [0: B –36 mV G +16 mV, 31: B 0 mV G 0 mV, 63: B +43 mV G –20 mV] 31 37 28 40

2 CROF Cr offset [0: R –46 mV G +10 mV, 31: R 0 mV G 0 mV, 63: R +55 mV G –12 mV] 31 37 28 40

3 SBRT Sub brightness [0: –15 IRE, 31: 0 IRE, 63: 15 IRE] 31

4 RDRV R drive gain [0: –4 dB, 41: 0 dB, 63: +2 dB] 39

5 GDRV G drive gain [0: –4 dB, 41: 0 dB, 63: +2 dB] 39

6 BDRV B drive gain [0: –4 dB, 41: 0 dB, 63: +2 dB] 39

7 RCUT R cut-off [0: –9 dB, 31: 0 dB, 63: +4 dB] 31

8 GCUT G cut-off [0: –9 dB, 31: 0 dB, 63: +4 dB] 31

9 BCUT B cut-off [0: –9 dB, 31: 0 dB, 63: +4 dB] 31

10 WBSW White balance offset [0: Normal, 1: R 100% G 90% B 70%] 0 0

11 SBOF Sub brightness offset color temperature [0: –7, 7: 0, 15: +8] 7 7

12 RDOF RDRV offset [0: –15, 15: 0, 31: +16] 15 15

13 GDOF GDRV offset [0: –15, 15: 0, 31: +16] 15 15

14 BDOF BDRV offset [0: –15, 15: 0, 31: +16] 15 15

– 26 –

15 RCOF RCUT offset [0: –15, 15: 0, 31: +16] 15 15

16 GCOF GCUT offset [0: –15, 15: 0, 31: +16] 15 15

17 BCOF BCUT offset [0: –15, 15: 0, 31: +16] 15 15

18 DCOL Dynamic color, Cool [0: Off, 1: High (2025), 2: Mid (2100), 3: Low] 3 --

2150P-2

Video Processor (CXA2150)

Item

No. Name

Depends on Signal Path and Source

Depends on Color Temperature

Function

Function

Analog *1 Used when a 1080i signal by-passes the MID

1080i *1 other *2

Common

Warm Cool

DTV TWIN

*2 Used for Analog signals passing through the MID

0 ALBK Picture + Ref. Pulse on/off for G2 adjustment [0: RGB off, 1: RGB on] 1

1 RGBS [0: All off, 1: B, 2: G, 3: BG, 4: R, 5: BR, 6: GR, 7:BGR] 7

2 BLKB Bottom limiter level [Ref. Pulse DC voltage 0: –1.25, 3: –0.65] 3

3 LIML RGB limiter level [0: 115 IRE, 1: 123 IRE, 2: 131 IRE, 3: 140 IRE] 0

4 PABL Peak ABL [0: 4.9 Vdc, 15: 6.8 Vdc] 15

5 SABL Signal ABL level [0: Off, 3: maximum gain] 0

6 AGNG Black/White aging [0: Normal, 1: Black, 2: White, 3: Inhibit] 0

7 AKBO AKB on/off [0: On, 1: Off] 0

Depends on Signal Format

8 SYPH H sync delay [0: 0%, 1: –3.125%] 0 0

9 CLPH Clamp pulse phase [0: +5%, 1: +4%, 2: +1%, 3: +2%] 2 2

10 CLGA Clamp gate on/off [0: Not gated, 1: Gated with input H sync] 0 0

11 CLSH Clamp pulse start shift [0: No shift, 1: –3.125% shift from CLPH] 0 0

Common

Analog *1 Used when a 1080i signal by-passes the MID

*1

1080i

other

*2 Used for Analog signals passing through the MID

*2

K RM-Y185

KDP-57XBR2/65XBR2

2150P-3

Video Processor (CXA2150)

No. Name

0 SYSM Bandwidth [0: NTSC, 1: FF, 2: HD, 3: DTV] 1 1 1 1 3 3 1 1 3 3 2

1 VMLV VM level [0: VM0, 1: VM1, 2: VM2, 3: VM3, 4: VM4, 5: VM5, 6: VM6, 7: VM7] 7 7 7 7 7 7 7 7 7 7 7

2 VMMO VM mode (VM_LEV) [0: Off, 1: Low, 2: Mid, 3: High] 3 3 3 3 3 3 3 3 3 3 3

3 VMCR VM coring level [0: Off, 1: ±5%, 2: ±10%, 3: ±15%] 1 0 0 0 0 0 0 0 0 0 1

4 VMLM VM limiter level [0: Off, 1: ±83%, 2: ±67%, 3: ±50%] 0 0 0 0 0 0 0 0 0 0 0

5 VMF0 VM f0 [0: Low, 1: Mid, 2: High, 3: Inhibit] 1 1 1 1 2 2 1 1 2 2 0

6 VMDL VM delay [0: Short, 3: Long] 1 1 1 1 0 0 1 1 0 0 2

7 SHOF Sharpness offset [0: 0step, 1: +4step, 2: +8step, 3: +12step] 3 1 1 0 2 2 0 0 2 2 0

8 SHF0 Sharpness f0 [0: Low, 1: Mid, 2: High, 3: Inhibit] 1 1 1 1 1 1 1 1 1 1 1

9 PROV Pre-over ratio [0: 1:1.5, 1: 1:1, 2: 1.5:1, 3: 2:1] 3 3 3 3 3 3 3 3 3 3 2

10 F1LV Sharpness f1 [0: 0 dB, 1: +1 dB, 2: +2 dB, 3: +3 dB] 0 0 0 0 3 3 0 0 3 3 0

11 CDSP Sharpness at color high [0: 0 dB, 1: +2 dB, 2: +4 dB, 3: +6 dB] 0 0 0 0 0 0 0 0 0 0 0

12 LTLV LTI level [0: Off, 1: Low, 2: Mid, 3: High] 3 3 3 3 3 3 3 3 3 3 3

13 LTMD LTI mode [0: for Black & White, 1: for Black, 2: for White, 3: Inhibit] 1 1 1 1 1 1 1 1 1 1 0

14 CTLV CTI level [0: Off, 1: Low, 2: Mid, 3: High] 0 0 0 0 0 0 0 0 0 0 0

15 CTMD CTI mode [0: for Black & White, 1: for Black, 2: for White, 3: Inhibit] 0 0 0 0 0 0 0 0 0 0 0

16 UBOF User bright offset [0: BRIGHT +0, ..., 3: BRIGHT +6, ..., 7: BRIGHT +14] 2 2 3 3 0 2 2 2 2 2 0

17 UCOF User color offset [0: COLOR +0, ..., 3: COLOR +6, ..., 7: COLOR +14] 0 0 0 0 0 0 0 0 0 0 0

– 27 –

18 UHOF User hue offset [0: HUE +0, 1: HUE +1, 2: HUE +2, 3: HUE +3] 2 2 2 2 2 2 2 2 2 2 2

19 MIDE MID Enhancement setting table [0: Soft, ..., 63: Sharp] 7 12 17 22 27 32 37 42 47 52 57

0 SYSM Bandwidth [0: NTSC, 1: FF, 2: HD, 3: DTV] 1 1 1 1 3 3 1 1 3 3 2

1 VMLV VM level [0: VM0, 1: VM1, 2: VM2, 3: VM3, 4: VM4, 5: VM5, 6: VM6, 7: VM7] 7 7 7 7 7 7 7 7 7 7 7

2 VMMO VM mode (VM_LEV) [0: Off, 1: Low, 2: Mid, 3: High] 3 3 3 3 3 3 3 3 3 3 3

3 VMCR VM coring level [0: Off, 1: ±5%, 2: ±10%, 3: ±15%] 1 0 0 0 0 0 0 0 0 0 1

4 VMLM VM limiter level [0: Off, 1: ±83%, 2: ±67%, 3: ±50%] 0 0 0 0 0 0 0 0 0 0 0

5 VMF0 VM f0 [0: Low, 1: Mid, 2: High, 3: Inhibit] 1 1 1 1 2 2 1 1 2 2 0

6 VMDL VM delay [0: Short, 3: Long] 1 1 1 1 0 0 1 1 0 0 2

7 SHOF Sharpness offset [0: 0step, 1: +4step, 2: +8step, 3: +12step] 2 2 2 0 2 3 0 0 2 3 0

8 SHF0 Sharpness f0 [0: Low, 1: Mid, 2: High, 3: Inhibit] 1 1 1 1 1 1 1 1 1 1 1

9 PROV Pre-over ratio [0: 1:1.5, 1: 1:1, 2: 1.5:1, 3: 2:1] 3 3 3 3 3 3 3 3 3 3 2

10 F1LV Sharpness f1 [0: 0 dB, 1: +1 dB, 2: +2 dB, 3: +3 dB] 0 0 0 0 3 3 0 0 3 3 0

11 CDSP Sharpness at color high [0: 0 dB, 1: +2 dB, 2: +4 dB, 3: +6 dB] 0 0 0 0 0 0 0 0 0 0 0

12 LTLV LTI level [0: Off, 1: Low, 2: Mid, 3: High] 2 2 3 3 3 3 3 3 3 3 3

13 LTMD LTI mode [0: for Black & White, 1: for Black, 2: for White, 3: Inhibit] 1 1 1 1 1 1 1 1 1 1 0

14 CTLV CTI level [0: Off, 1: Low, 2: Mid, 3: High] 0 0 0 0 0 0 0 0 0 0 0

15 CTMD CTI mode [0: for Black & White, 1: for Black, 2: for White, 3: Inhibit] 0 0 0 0 0 0 0 0 0 0 0

16 UBOF User bright offset [0: BRIGHT +0, ..., 3: BRIGHT +6, ..., 7: BRIGHT +14] 3 3 5 5 7 6 7 7 7 6 2

17 UCOF User color offset [0: COLOR +0, ..., 3: COLOR +6, ..., 7: COLOR +14] 0 0 0 0 0 0 0 0 0 0 0

18 UHOF User hue offset [0: HUE +0, 1: HUE +1, 2: HUE +2, 3: HUE +3] 2 2 2 2 2 2 2 2 2 2 2

19 MIDE MID Enhancement setting table [0: Soft, ..., 63: Sharp] 5 11 16 21 26 31 36 41 46 51 56

Item

Depends on Signal Format and Picture Pallet

Depends on Signal Format and Picture Pallet

Function

RF CV/YC

RF CV/YC

Component DTV

Vivid Mode

480i 480p 1080i 720p 480i 480p 1080i 720p

Standard Mode

Component DTV

480i 480p 1080i 720p 480i 480p 1080i 720p

TWIN

TWIN

K RM-Y185

KDP-57XBR2/65XBR2

Video Processor (CXA2150)

No. Name

0 SYSM Bandwidth [0: NTSC, 1: FF, 2: HD, 3: DTV] 1 1 1 1 3 3 1 1 3 3 2

1 VMLV VM level [0: VM0, 1: VM1, 2: VM2, 3: VM3, 4: VM4, 5: VM5, 6: VM6, 7: VM7] 2 2 2 2 2 2 2 2 2 2 2

2 VMMO VM mode (VM_LEV) [0: Off, 1: Low, 2: Mid, 3: High] 3 3 3 3 3 3 3 3 3 3 3

3 VMCR VM coring level [0: Off, 1: ±5%, 2: ±10%, 3: ±15%] 1 0 0 0 0 0 0 0 0 0 1

4 VMLM VM limiter level [0: Off, 1: ±83%, 2: ±67%, 3: ±50%] 0 0 0 0 0 0 0 0 0 0 0

5 VMF0 VM f0 [0: Low, 1: Mid, 2: High, 3: Inhibit] 1 1 1 1 2 2 1 1 2 2 0

6 VMDL VM delay [0: Short, 3: Long] 1 1 1 1 0 0 1 1 0 0 2

7 SHOF Sharpness offset [0: 0step, 1: +4step, 2: +8step, 3: +12step] 0 0 1 0 2 0 0 0 2 0 0

8 SHF0 Sharpness f0 [0: Low, 1: Mid, 2: High, 3: Inhibit] 1 1 1 1 1 1 1 1 1 1 1

9 PROV Pre-over ratio [0: 1:1.5, 1: 1:1, 2: 1.5:1, 3: 2:1] 3 3 3 3 3 3 3 3 3 3 2

10 F1LV Sharpness f1 [0: 0 dB, 1: +1 dB, 2: +2 dB, 3: +3 dB] 0 0 0 0 3 3 0 0 3 3 0

11 CDSP Sharpness at color high [0: 0 dB, 1: +2 dB, 2: +4 dB, 3: +6 dB] 0 0 0 0 0 0 0 0 0 0 0

12 LTLV LTI level [0: Off, 1: Low, 2: Mid, 3: High] 1 1 1 1 1 1 1 1 1 1 1

13 LTMD LTI mode [0: for Black & White, 1: for Black, 2: for White, 3: Inhibit] 0 0 0 0 0 0 0 0 0 0 0

14 CTLV CTI level [0: Off, 1: Low, 2: Mid, 3: High] 0 0 0 0 0 0 0 0 0 0 0

15 CTMD CTI mode [0: for Black & White, 1: for Black, 2: for White, 3: Inhibit] 0 0 0 0 0 0 0 0 0 0 0

16 UBOF User bright offset [0: BRIGHT +0, ..., 3: BRIGHT +6, ..., 7: BRIGHT +14] 6 6 3 3 3 3 3 3 3 3 4

17 UCOF User color offset [0: COLOR +0, ..., 3: COLOR +6, ..., 7: COLOR +14] 0 0 0 0 0 0 0 0 0 0 0

18 UHOF User hue offset [0: HUE +0, 1: HUE +1, 2: HUE +2, 3: HUE +3] 2 2 2 2 2 2 2 2 2 2 2

19 MIDE MID Enhancement setting table [0: Soft, ..., 63: Sharp] 3 10 15 20 25 30 35 40 45 50 55

– 28 –

0 SYSM Bandwidth [0: NTSC, 1: FF, 2: HD, 3: DTV] 1 1 1 1 3 3 1 1 3 3 2

1 VMLV VM level [0: VM0, 1: VM1, 2: VM2, 3: VM3, 4: VM4, 5: VM5, 6: VM6, 7: VM7] 7 7 7 7 7 7 7 7 7 7 7

2 VMMO VM mode (VM_LEV) [0: Off, 1: Low, 2: Mid, 3: High] 3 3 3 3 3 3 3 3 3 3 3

3 VMCR VM coring level [0: Off, 1: ±5%, 2: ±10%, 3: ±15%] 1 0 0 0 0 0 0 0 0 0 1

4 VMLM VM limiter level [0: Off, 1: ±83%, 2: ±67%, 3: ±50%] 0 0 0 0 0 0 0 0 0 0 0

5 VMF0 VM f0 [0: Low, 1: Mid, 2: High, 3: Inhibit] 1 1 1 1 2 2 1 1 2 2 0

6 VMDL VM delay [0: Short, 3: Long] 1 1 1 1 0 0 1 1 0 0 2

7 SHOF Sharpness offset [0: 0step, 1: +4step, 2: +8step, 3: +12step] 2 2 2 0 2 3 0 0 2 3 0

8 SHF0 Sharpness f0 [0: Low, 1: Mid, 2: High, 3: Inhibit] 1 1 1 1 1 1 1 1 1 1 1

9 PROV Pre-over ratio [0: 1:1.5, 1: 1:1, 2: 1.5:1, 3: 2:1] 3 3 3 3 3 3 3 3 3 3 2

10 F1LV Sharpness f1 [0: 0 dB, 1: +1 dB, 2: +2 dB, 3: +3 dB] 0 0 0 0 3 3 0 0 3 3 0

11 CDSP Sharpness at color high [0: 0 dB, 1: +2 dB, 2: +4 dB, 3: +6 dB] 0 0 0 0 0 0 0 0 0 0 0

12 LTLV LTI level [0: Off, 1: Low, 2: Mid, 3: High] 0 0 0 0 0 0 0 0 0 0 0

13 LTMD LTI mode [0: for Black & White, 1: for Black, 2: for White, 3: Inhibit] 1 1 1 1 1 1 1 1 1 1 0

14 CTLV CTI level [0: Off, 1: Low, 2: Mid, 3: High] 0 0 0 0 0 0 0 0 0 0 0

15 CTMD CTI mode [0: for Black & White, 1: for Black, 2: for White, 3: Inhibit] 0 0 0 0 0 0 0 0 0 0 0

16 UBOF User bright offset [0: BRIGHT +0, ..., 3: BRIGHT +6, ..., 7: BRIGHT +14] 3 3 5 5 7 6 7 7 7 6 2

17 UCOF User color offset [0: COLOR +0, ..., 3: COLOR +6, ..., 7: COLOR +14] 0 0 0 0 0 0 0 0 0 0 0

18 UHOF User hue offset [0: HUE +0, 1: HUE +1, 2: HUE +2, 3: HUE +3] 2 2 2 2 2 2 2 2 2 2 2

19 MIDE MID Enhancement setting table [0: Soft, ..., 63: Sharp] 1 9 14 19 24 29 34 39 44 49 54

Item

Depends on Signal Format and Picture Pallet

Depends on Signal Format and Picture Pallet

Function

RF CV/YC

RF CV/YC

Movie Mode

Component DTV

480i 480p 1080i 720p 480i 480p 1080i 720p

Game Mode

Component DTV

480i 480p 1080i 720p 480i 480p 1080i 720p

TWIN

TWIN

K RM-Y185

KDP-57XBR2/65XBR2

Video Processor (CXA2150)

Item

No. Name

Depends on Signal Format and Picture Pallet

0 SYSM Bandwidth [0: NTSC, 1: FF, 2: HD, 3: DTV] 1 1 1 1 3 3 1 1 3 3 2

1 VMLV VM level [0: VM0, 1: VM1, 2: VM2, 3: VM3, 4: VM4, 5: VM5, 6: VM6, 7: VM7] 0 0 0 0 0 0 0 0 0 0 0

2 VMMO VM mode (VM_LEV) [0: Off, 1: Low, 2: Mid, 3: High] 3 3 3 3 3 3 3 3 3 3 3

3 VMCR VM coring level [0: Off, 1: ±5%, 2: ±10%, 3: ±15%] 1 0 0 0 0 0 0 0 0 0 1

4 VMLM VM limiter level [0: Off, 1: ±83%, 2: ±67%, 3: ±50%] 0 0 0 0 0 0 0 0 0 0 0

5 VMF0 VM f0 [0: Low, 1: Mid, 2: High, 3: Inhibit] 1 1 1 1 2 2 1 1 2 2 0

6 VMDL VM delay [0: Short, 3: Long] 1 1 1 1 0 0 1 1 0 0 2

7 SHOF Sharpness offset [0: 0step, 1: +4step, 2: +8step, 3: +12step] 0 0 0 0 2 0 0 0 2 0 0

8 SHF0 Sharpness f0 [0: Low, 1: Mid, 2: High, 3: Inhibit] 1 1 1 1 1 1 1 1 1 1 1

9 PROV Pre-over ratio [0: 1:1.5, 1: 1:1, 2: 1.5:1, 3: 2:1] 3 3 3 3 3 3 3 3 3 3 2

10 F1LV Sharpness f1 [0: 0 dB, 1: +1 dB, 2: +2 dB, 3: +3 dB] 0 0 0 0 3 3 0 0 3 3 0

11 CDSP Sharpness at color high [0: 0 dB, 1: +2 dB, 2: +4 dB, 3: +6 dB] 0 0 0 0 0 0 0 0 0 0 0

12 LTLV LTI level [0: Off, 1: Low, 2: Mid, 3: High] 0 0 0 0 0 0 0 0 0 0 0

13 LTMD LTI mode [0: for Black & White, 1: for Black, 2: for White, 3: Inhibit] 1 1 1 1 1 1 1 1 1 1 0

14 CTLV CTI level [0: Off, 1: Low, 2: Mid, 3: High] 0 0 0 0 0 0 0 0 0 0 0

15 CTMD CTI mode [0: for Black & White, 1: for Black, 2: for White, 3: Inhibit] 0 0 0 0 0 0 0 0 0 0 0

16 UBOF User bright offset [0: BRIGHT +0, ..., 3: BRIGHT +6, ..., 7: BRIGHT +14] 6 6 3 3 3 3 3 3 3 3 4

17 UCOF User color offset [0: COLOR +0, ..., 3: COLOR +6, ..., 7: COLOR +14] 0 0 0 0 0 0 0 0 0 0 0

18 UHOF User hue offset [0: HUE +0, 1: HUE +1, 2: HUE +2, 3: HUE +3] 0 0 0 0 0 0 0 0 0 0 0

19 MIDE MID Enhancement setting table [0: Soft, ..., 63: Sharp] 0 8 13 18 23 28 33 38 43 48 53

– 29 –

20 TVVM Initial VM level [0: VM Off, 1: VM Low, 2: VM Mid, 3: VM Highi] 3 3 1 3 0

21 VM_H VM Highi level asignment [0: weak, ..., 7: strong] 7 7 6 7 6

22 VM_M VM Mid level asignment [0: weak, ..., 7: strong] 5 5 4 5 4

23 VM_L VM Low level asignment [0: weak, ..., 7: strong] 3 3 2 3 2

Function

RF CV/YC

Vivid Standard Movie Game Pro

480i 480p 1080i 720p 480i 480p 1080i 720p

Component DTV

Pro Mode

TWIN

K RM-Y185

KDP-57XBR2/65XBR2

Loading...

Loading...