Page 1

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KP-53XBR300

KP-53XBR300

KP-61XBR300

KP-61XBR300

RM-Y902 US SCC-P21A-A

RM-Y902 Canadian SCC-P21A-A

RM-Y902 US SCC-P21B-A

RM-Y902 Canadian SCC-P40B-A

RA-4A

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 9/1999

ALL REVISIONS AND UPDATES TO THE ORIGINAL MANUAL ARE APPENDED TO THE END OF THE PDF FILE.

REVISION DATE REVISION TYPE SUBJECT

9/1999 No revisions or updates are applicable at this time.

6/2002 Correction - 1 D Board Corrections - Q5031 Voltage; Waveforms

COLOR REAR VIDEO PROJECTOR

9-965-406-02

Page 2

RA-4ASERVICE MANUAL

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

–––––––– ––––––––––––––– –––––– ––––––––––––––

KP-53XBR300

KP-53XBR300

KP-61XBR300

KP-61XBR300

RM-Y902 US SCC-P21A-A

RM-Y902

Canadian

SCC-P21A-A

RM-Y902 US SCC-P21B-A

RM-Y902

Canadian

SCC-P21B-A

MODEL COMMANDER DEST. CHASSIS NO.

–––––––– ––––––––––––––– –––––– ––––––––––––––

POWER

SYSTEM

DVD/

DBS

MUTING

TV

OFF

VTR

CABLE

DVD/VTR

DBS/CABLE

TV

FUNCTION

OFF

FREEZE

AUDIO SWAP

POTITION

ZOOM IN

LEFT RIGHT

TV/DBS

GUIDE ACTIVE

CC

PICTURE

MODE

DISPLAY TV/VIDEO

ANT

3

1

2

6

4

5

9

7

8

ENTER

JUMP

0

MENU

VOL CH

RESET

TV

RM-Y902

MICROFILM

∗ Please file according to model size........

KP-61XBR300KP-53XBR300

COLOR REAR VIDEO PROJECTOR

53 61

Page 3

KP-53XBR300/61XBR300

RM-Y902RM-Y902

SPECIFICATIONS

– 2 –

Page 4

SAFETY CHECK-OUT

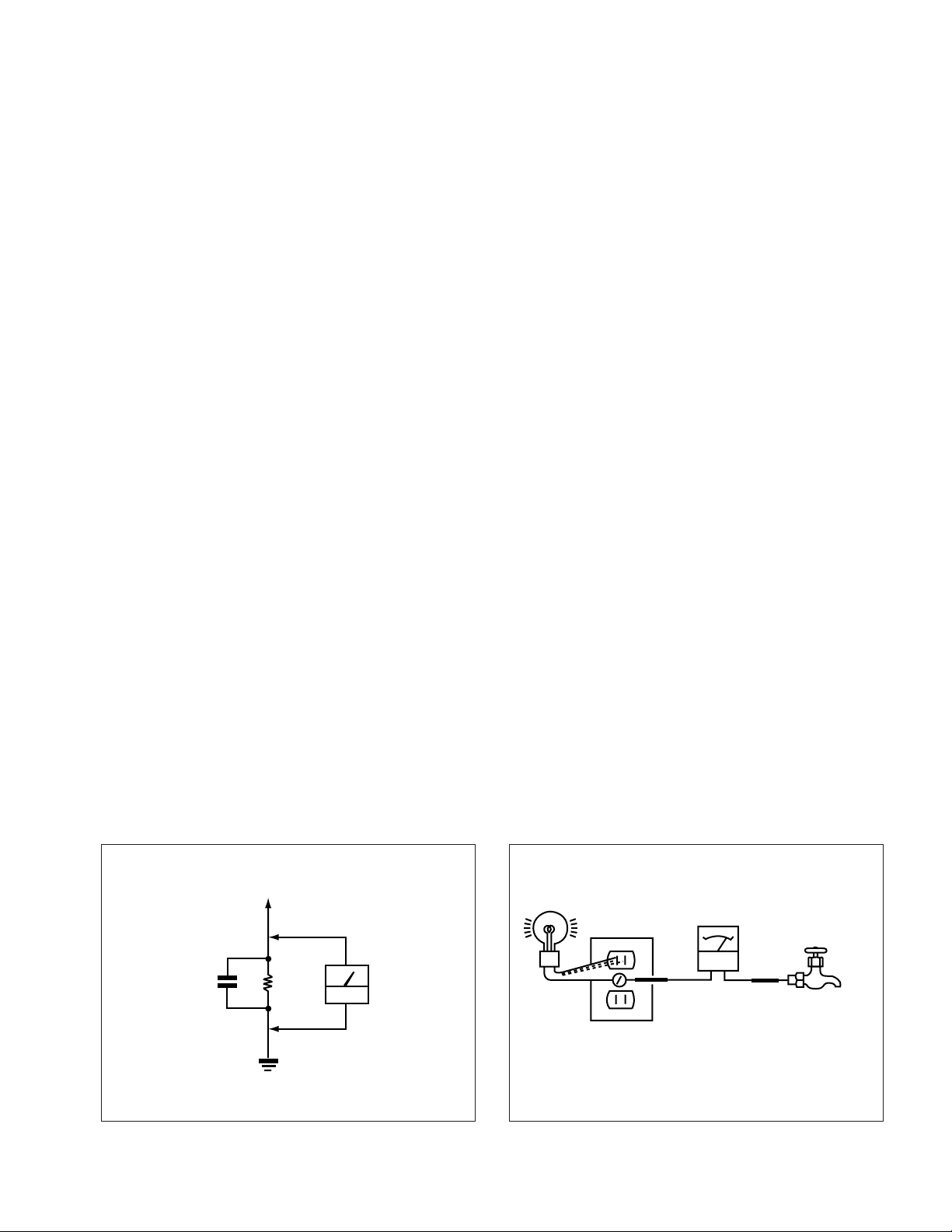

Fig. B. Checking for earth ground.

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

( US model only )

KP-53XBR300/61XBR300

RM-Y902RM-Y902

After correcting the original service problem, perfom the follow-

ing safety checks before releasing the set to the customer:

l. Check the area of your repair for unsoldered or poorly-sol-

dered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps,

and mounting hardware have been replaced. Be absolutely

certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

5. Look for parts which, through functioning, show obvious

signs of deterioration. Point them out to the customer and

recom mend their replacement.

6. Check the line cords for cracks and abrasion. Recommend

the replacement of any such line cord to the customer.

7. Check the condition of the monopole antenna (if any). Make

sure the end is not broken off, and has the plastic cap on it.

Point out the danger of impalement on a broken antenna to

the customer, and recommend the antenna’s replacement.

8. Check the B+ and HV to see they are at the values specified.

Make sure your instruments are accurate;be suspicious of

your HV meter if sets always have low HV.

9. Check the antenna temminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

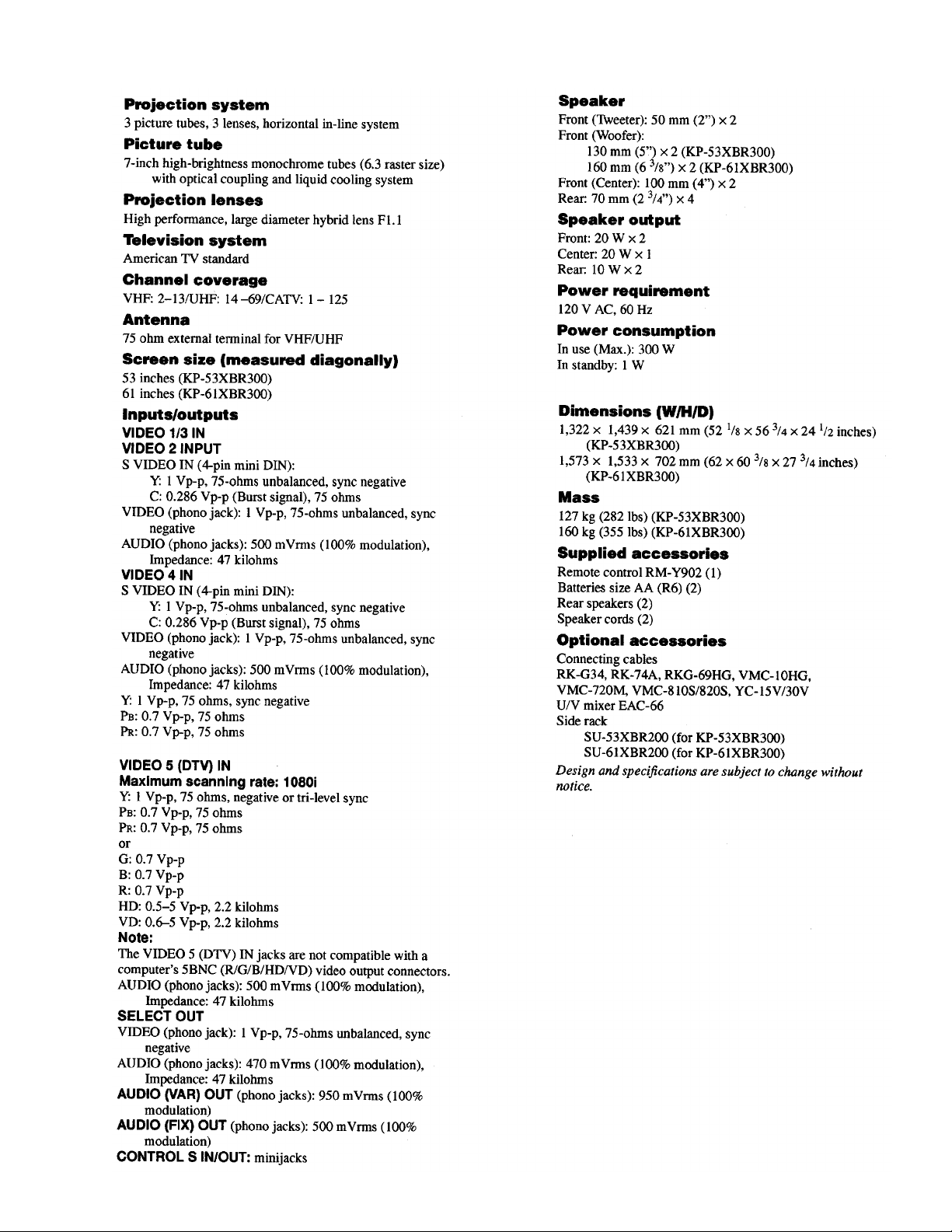

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5mA (500 microampers) . Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to

usc these instruments.

2. A battery-operated AC milliammeter . The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are

examples of a passive VOM that is suitable. NearIy all battery operated digital multimeters that have a 2V AC range

are suitable. (See Fig. A)

HOW TO FIND A GOOD EARTH GROUND

A cold-water pipe is guaranteed earth ground;the cover-plate retaining screw on most AC outlet boxes is also at earth ground. If

the retaining screw is to be used as your earth-ground, verify that it

is at ground by measuring the resistance between it and a coldwater pipe with an ohmmeter. The reading should be zero ohms. If

a cold-water pipe is not accessible, connect a 60-l00 watts trouble

light (not a neon lamp) between the hot side of the receptacle and

the retaining screw. Try both slots, if necessary, to locate the hot

side of the line, the lamp should light at normal brilliance if the

screw is at ground potential. (See Fig. B)

Fig. A. Using an AC voltmeter to check AC leakage.

1.5

µ

F

To Exposed Metal

Parts on Set

1.5k

Ω

Earth Ground

AC

voltmeter

(0.75V)

– 3 –

Page 5

KP-53XBR300/61XBR300

RM-Y902RM-Y902

SELF DIAGNOSIS FUNCTION

1. Summary of Self-Diagnosis Function

• This device includes a self-diagnosis function.

• In case of abnormalities, the TIMER/STANDBY indicator automatically blinks. It is possible to predict the abnormality location

by the number of blinks. The Instruction Manual describes blinking of the TIMER/STANDBY indicator.

• If the symptom is not reproduced sometimes in case of a malfunction, there is recording of whether a malfunction was generated

or not. Operate the remote command to confirm the matter on the screen and to predict the location of the abnormality.

2. Diagnosis Items and Prediction of Malfunction Location

• When a malfunction occurs the TIMER/STANDBY indicator only blinks for one of the following diagnosis items. In case of two

or more malfunctions, the item which first occurred blinks. If the malfunctions occurred simultaneously, the item with the lower

blink count blinks first.

• The screen display displays the results regarding all the diagnosis items listed below. The display “ 0 ” means that no malfunctions occurred.

metisisongaiD

NOtonrewoP•0

noitcetedPCOB+semit2.tiucrichcaenimetsysylppusrewopfotiucrictrohS

noitcetedPVOB+semit3

potsnoitcelfedlacitreVsemit4

noitcetedytilamronbatuooediVsemit5

potsnoitcelfedlatnoziroHsemit6

noitceted

ytilamronbaegatlovhgiH

noitcetedytilamronbaoiduAsemit8

* : 000 the range of values for number of operations is 000-255. For 256 or higher there is

no count up and the number remains at 255.

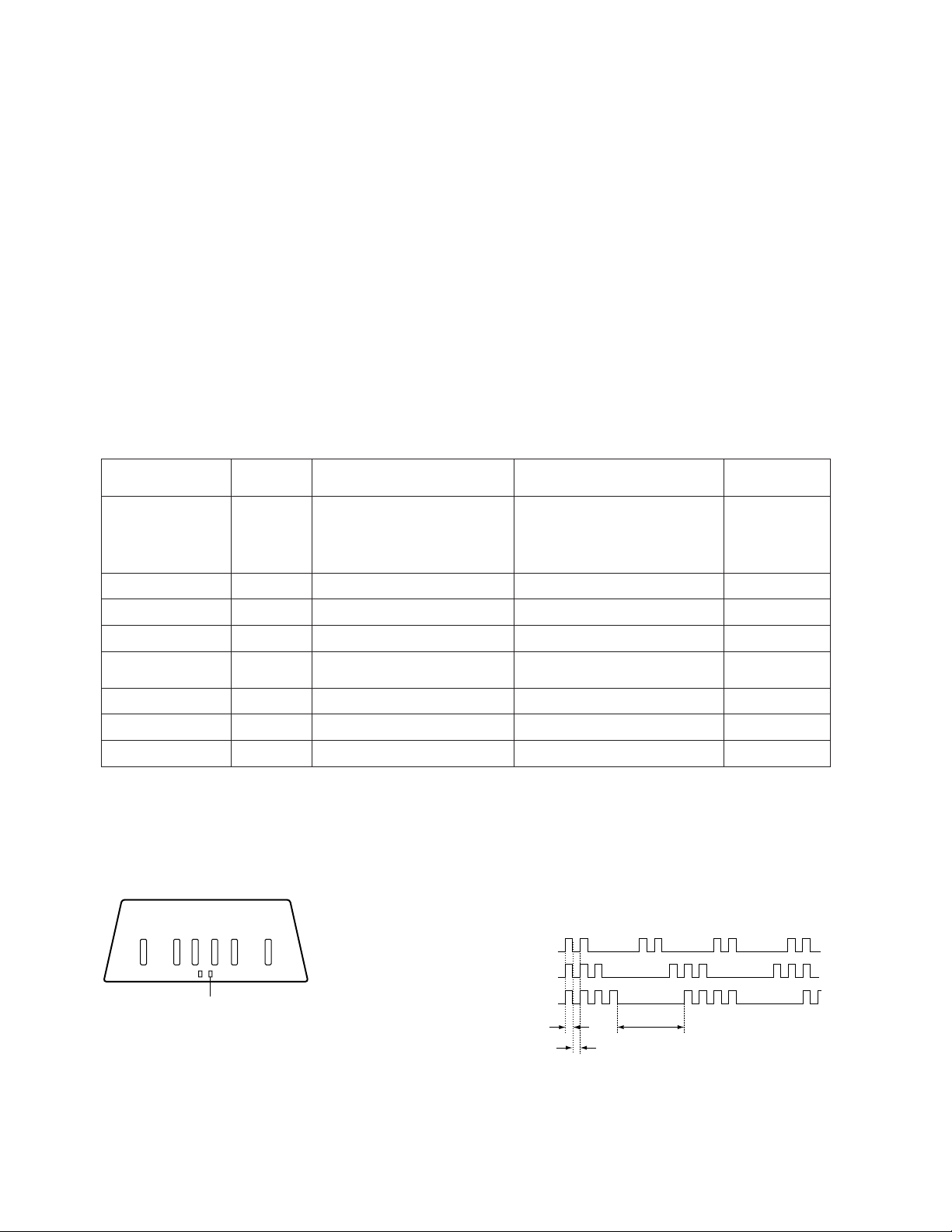

3. Blinking count display of TIMER/STANDBY indicator

YBDNATS/REMIT

retacidnI

sknilbforebmuN

semit7nekorbsi8008Q .raeppat'useodretsaR000VH:7

noitcnuflamdesoppuSnoitidnoC

.nepo106F

.nepo706R

tiucrictrohs106Q

tiucric-trohs106RDV

.nekorbsi5006CI

.nekorbsi1016CI

.nekorbsi)tuoV(4005CI

.nekorbsi)PSDV(215CI

.tiucricdraob

)draobA(425,615,015Q

.nekorbera4016,3016SP

* One blink is not used for self-diagnosis.

]metsySylppuSrewoPybdnatS[

]metsySylppuSrewoPniaM[

.nekorbera216Rdna106CI

.nekorbsi)TUOH(3105Q

.nekorbsi)elgnuJH(705CI

.nekorbera3062,2062,1062CI

sisongaid-fleS

,yalpsidneercs

stluseR:metisisongaiD

.rewopehtnonruttonnaC

.knilbt'nseodDEL

edomybdnatsehtotseoG

enilB+fotiucrictrohS

edomybdnatsehtotseoG

tiucricylppusrewopfonoitcnuflaM

.yllatnozirohenilenootseogretsaR000potSV:4

Cnisrehtodna1037,1027,1017CI,tuooediV

.raeppat'nseodretsaR000potSH:6

.tuotonsidnuosehT

.sisongaidflesehtrofsknilbnehtdna

edomybdnatsehtotseoG

,sdnoces03.xorppasknilbDELYBDNATS/REMIT

000PCOB+:2

000PVOB+:3

000BKA:5

000oiduA:8

< FRONT PANEL >

•EXAMPLE

<Diagnosis Items> <Number of Blinks>

• +B overcurrent 2 times

• +B overvoltage 3 times

TIMER/STANDBY indicator

• Vertical deflection stop 4 times

Lamp ON : 0.3 seconds

Lamp OFF : 0.3 seconds

Lamp OFF :

3.0 seconds

Release of TIMER/STANDBY indicator blinking.

• The TIMER/STANDBY indicator blinking display is released by turning OFF the power switch

on the TV main unit or removing the plug from the power.

– 4 –

Page 6

KP-53XBR300/61XBR300

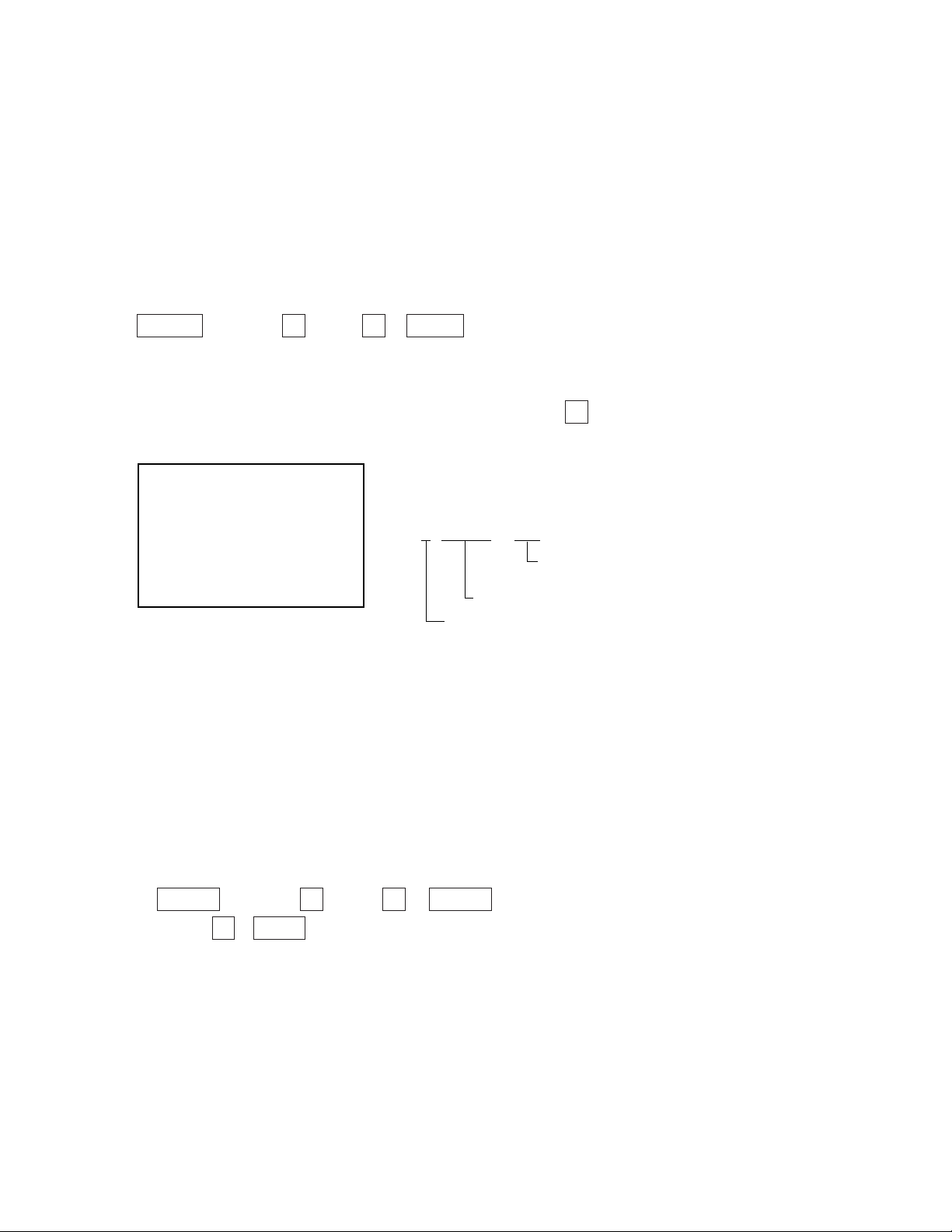

4. Self-diagnosis screen displays

• In cases of malfunctions where it is not possible to determine the symptom such as when the power goes off occasionally or when

the screen disappears occasionally, there is a screen display on whether the malfunction occurred or not in the past (and whether

the detection circuit operated or not) in order to allow confirmation.

<Screen Display Method>

• Quickly press the remote command button in the following order from the standby state.

DISPLAY b Channel 5 b VOL – b POWER

˘

Be aware that this differs from the method of

entering the service mode (volume + ).

Self-diagnosis screen display

Self Check

2 : +B OCP 000

3 : +B OVP 000

4 : V Stop 000

5 : AKB 000

6 : H Stop 000

7 : HV 000

8 : Audio 000

9 : WDT 000

÷

2 : +B OCP 000

Diagnosis

Results

000 the range of values for number of

operations is 000-255.

For 256 or higher there is no count up

and the number remains at 255.

RM-Y902RM-Y902

5. Self-Diagnosis Screen Display

• The results display is not automatically cleared. In case of repairs and after repairs, check the self-diagnosis screen and be sure

to return the results display to “ 0 ”.

• If the results display is not returned to “ 0 ” it will not be possible to judge a new malfunction after completing repairs.

<Method of Clearing Results Display>

1. Power off (Set to the standby mode)

2. DISPLAY b Channel 5 b VOL + b POWER (Service Mode)

3. Channel 8 b ENTER (Test reset = Factory preset condition)

<Method of Ending Self Diagnosis Screen>

• When ending the self-diagnosis screen completely, turn the power switch OFF on the remote commander or the main unit.

– 5 –

Page 7

KP-53XBR300/61XBR300

RM-Y902RM-Y902

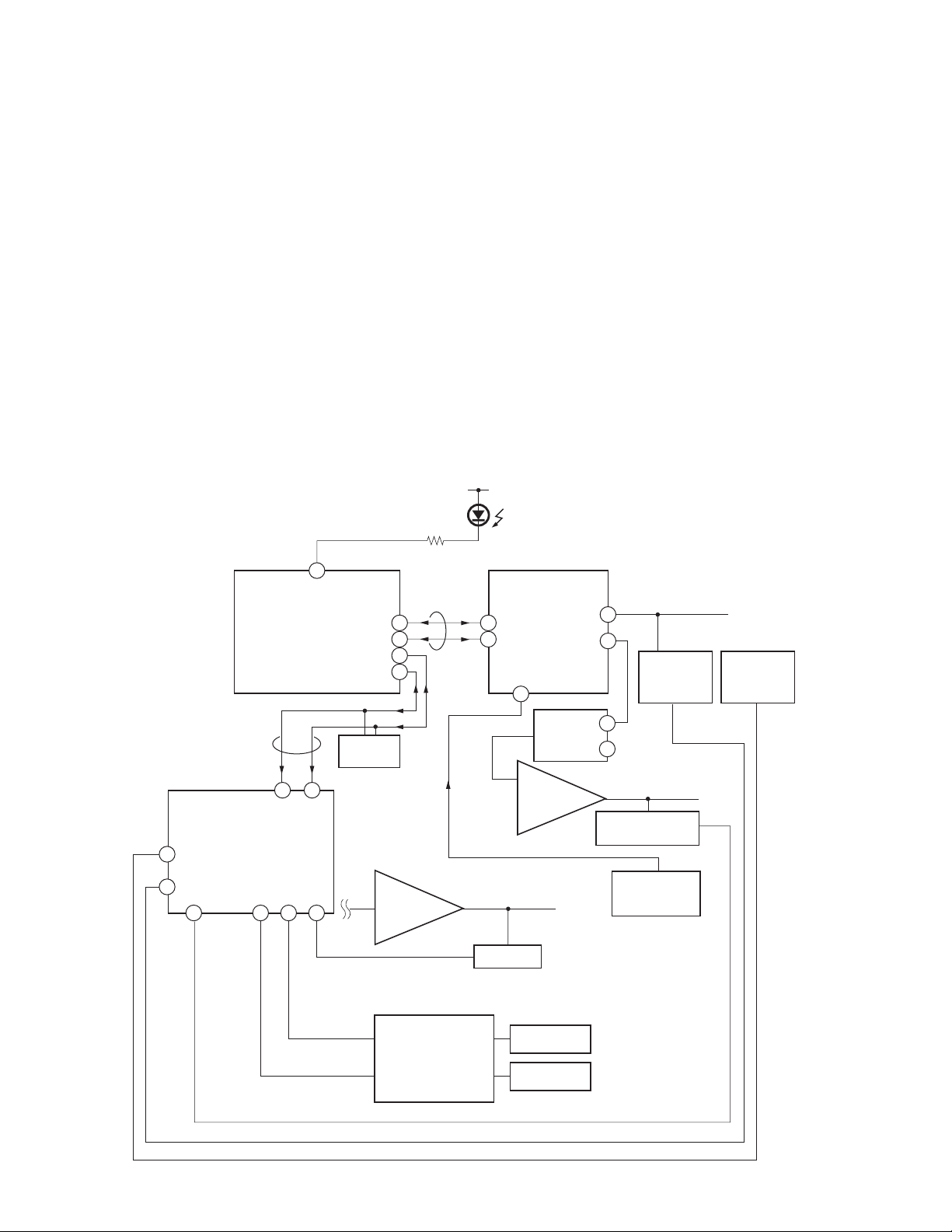

6. Self-diagnosis function operation

OCP Low B and +B line detect DET SHORT, and shut-down POWER ON RELAY.

Reset by turning power on/off.

In case of +B is loaded approx. 1.5A or more, microcomputer detects it via IC6102.

OVP In case of +B becomes approx. 150V or more, POWER ON RELAY shuts down and microcomputer detects it via IC6102.

Reset by turning power on/off just the same as OCP.

V Stop In case of V Drive disappeared, Q5005 detecs it and shut-down POWER ON RELAY. Microcomputer detects it and makes LED

blinking.

AKB IK detection. Makes LED blinking in case of microcomputer doesn’t detect IK returns of IC511 (CXA2101AQ) 30 seconds or

more.

H Stop In case of H DRIVE is disappeared, Q5006 detects it and shut-down POWER ON RELAY shuts down.

Microcomputer receives H Stop data from Q5006 and makes LED blinking.

HV Stop In case of HV becomes 33KV or more. IC8006 and IC8010 detect it and shut-down

POWER ON RELAY. Microcomputer makes LED blinking.

Audio In case of DC component overlaps the output of Audio Amp., POWER ON RELAY shuts down.

Microcomputer detects it and makes LED blinking.

Self-diagnosis block diagram

D3102

TIMER/STANDBY

3

4

5 6713

2. OVP

3. OCP

4. V.STOP

6. H.STOP

7. HV STOP

8. AUDIO

IC1009

OSD-CPU

53

IC1008

MAIN-CPU

BUS

4850

8. Audio

IC1007

EEPROM

Audio AMP

R1802

5. AKB

49

47

50

BUS

48

5. AKB

IC2601, 2602, 2603

55

CXA2101AQ

56

27

DC Detect

IC511

MCP

IC512

CXD2018Q

VDSP

IC5004

V Drive

33

28

6. H STOP

Q5006

H PULSE

Detector

22

16

Q5005

V Pulse Detector

C Board

IC8006,8010

HV Detector

4. V.STOP (V Pulse)

6. H.STOP

7. HV.STOP

3. OVP

2. OCP

IC6102

OVP Buffer

OCP Buffer

– 6 –

OVP DETECT

OCP DETECT

Page 8

TABLE OF CONTENTS

KP-53XBR300/61XBR300

RM-Y902RM-Y902

Section Title Page

–––––– –––– ––––

SELF DIAGNOSIS FUNCTION............................................ 4

1. GENERAL

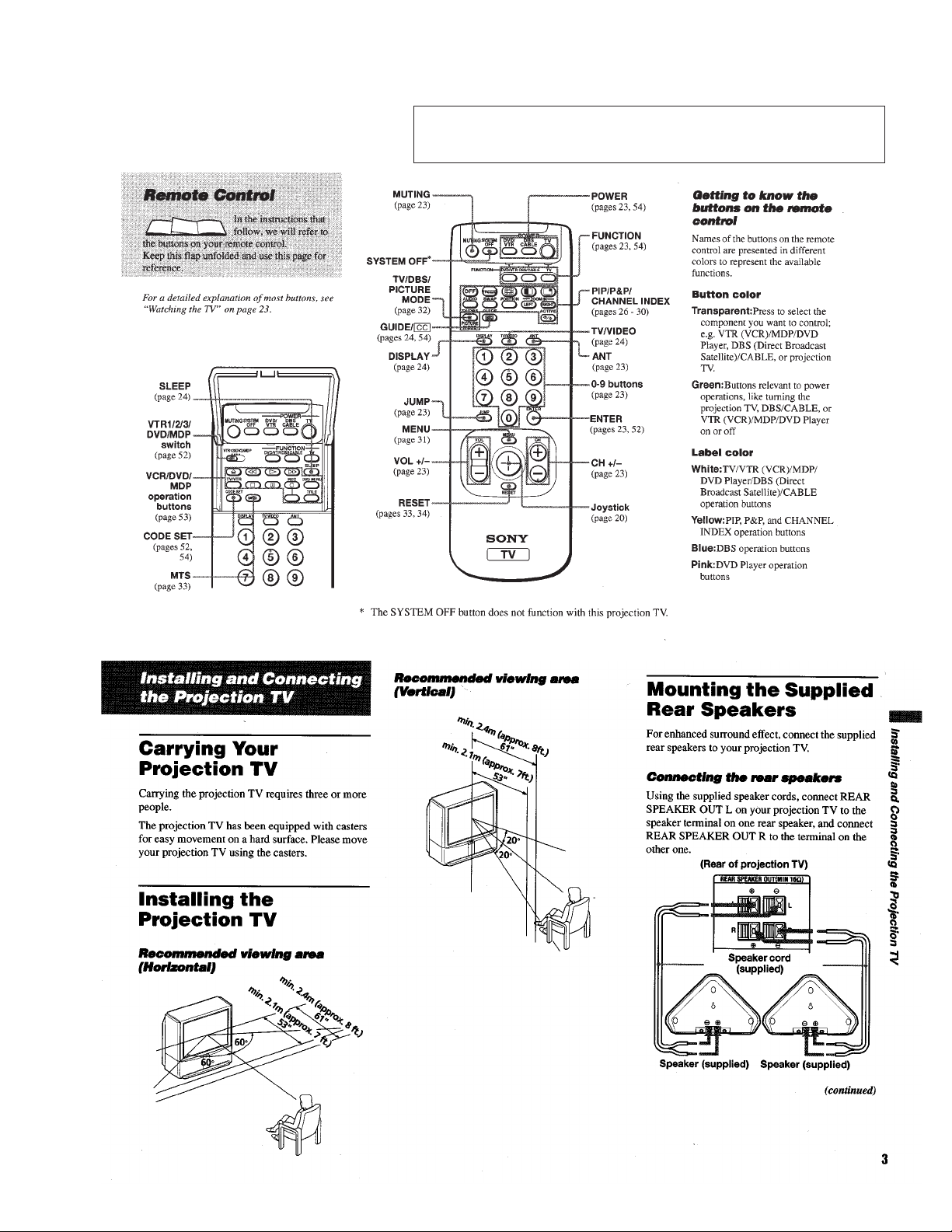

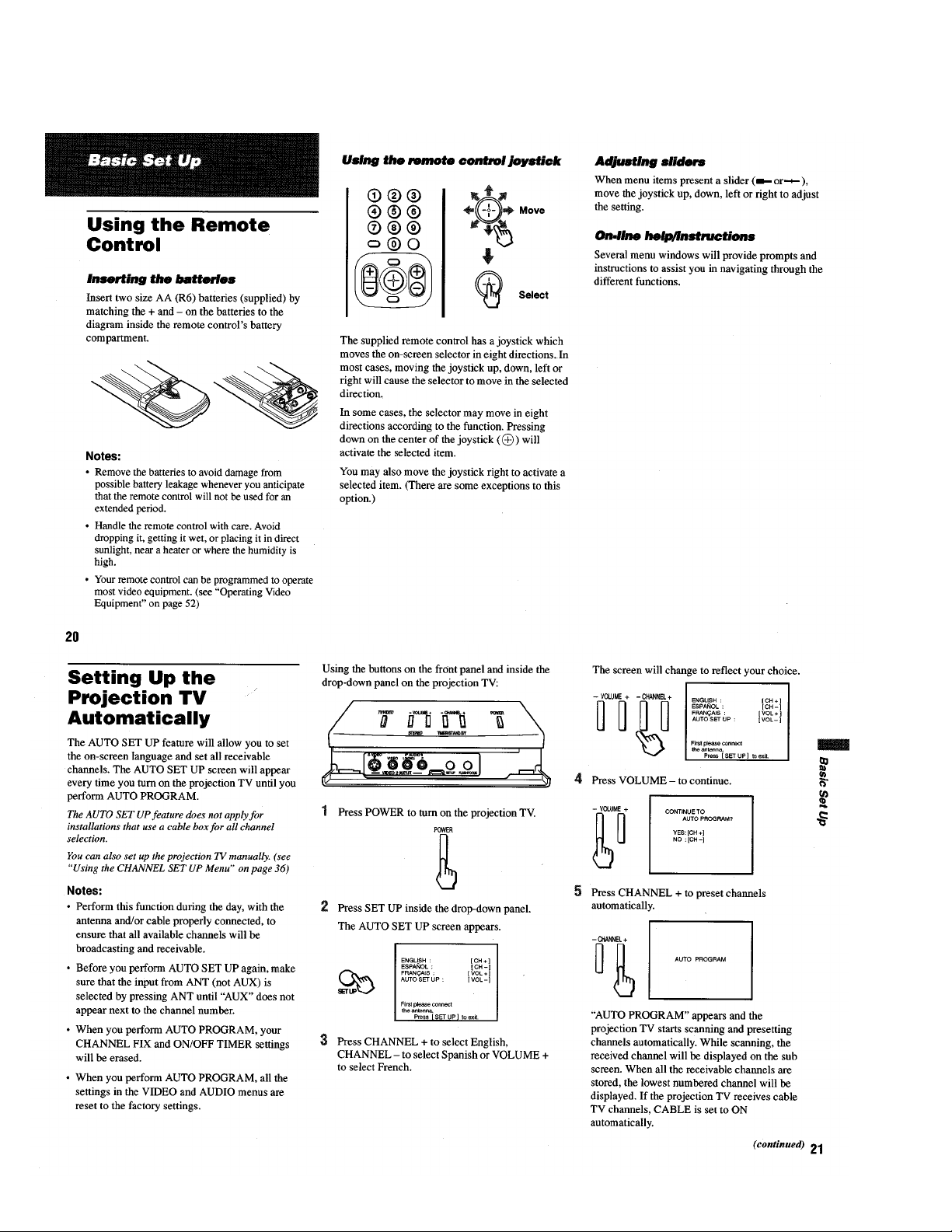

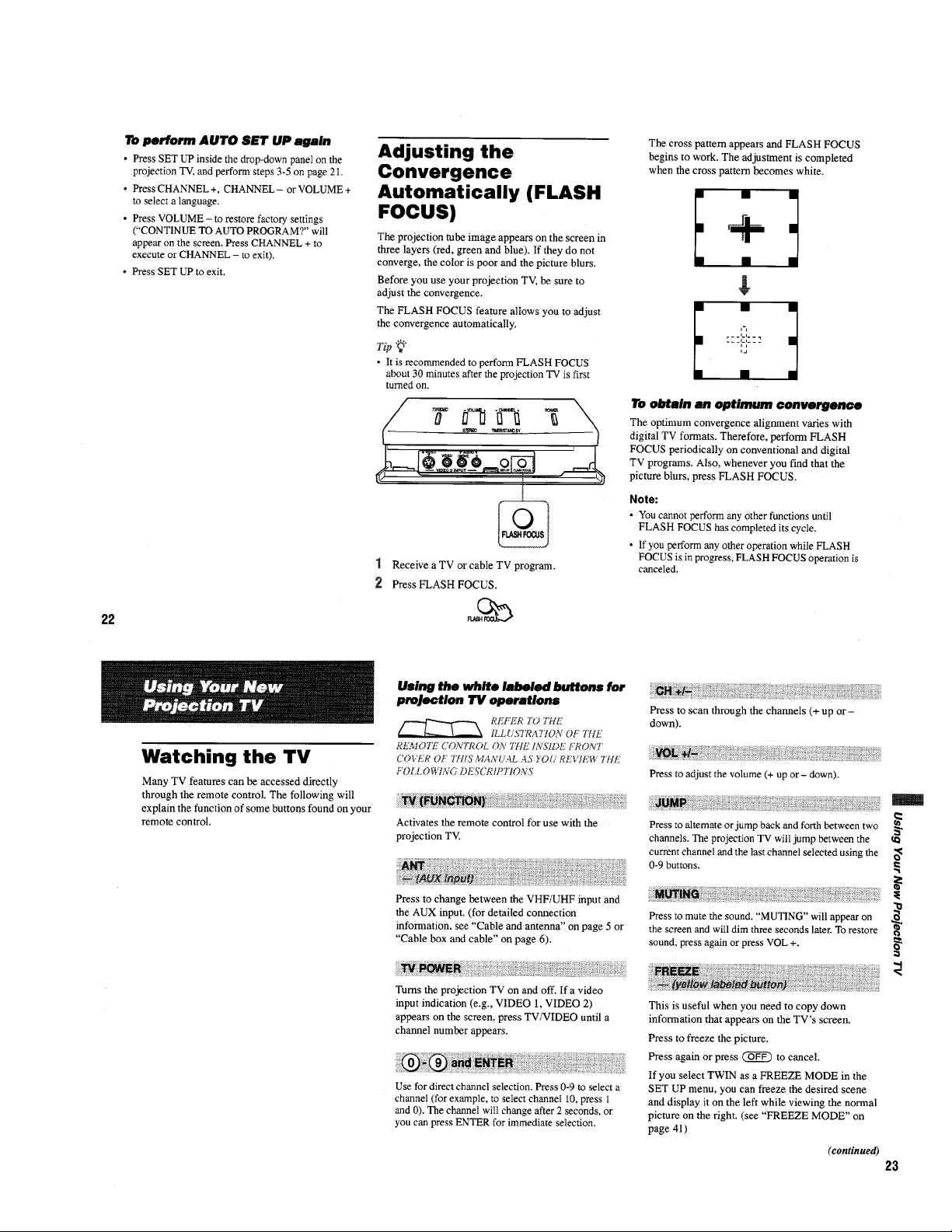

Remote Control ....................................................................... 9

Installing and Connecting the Projection TV .......................... 9

Basic Set Up .......................................................................... 18

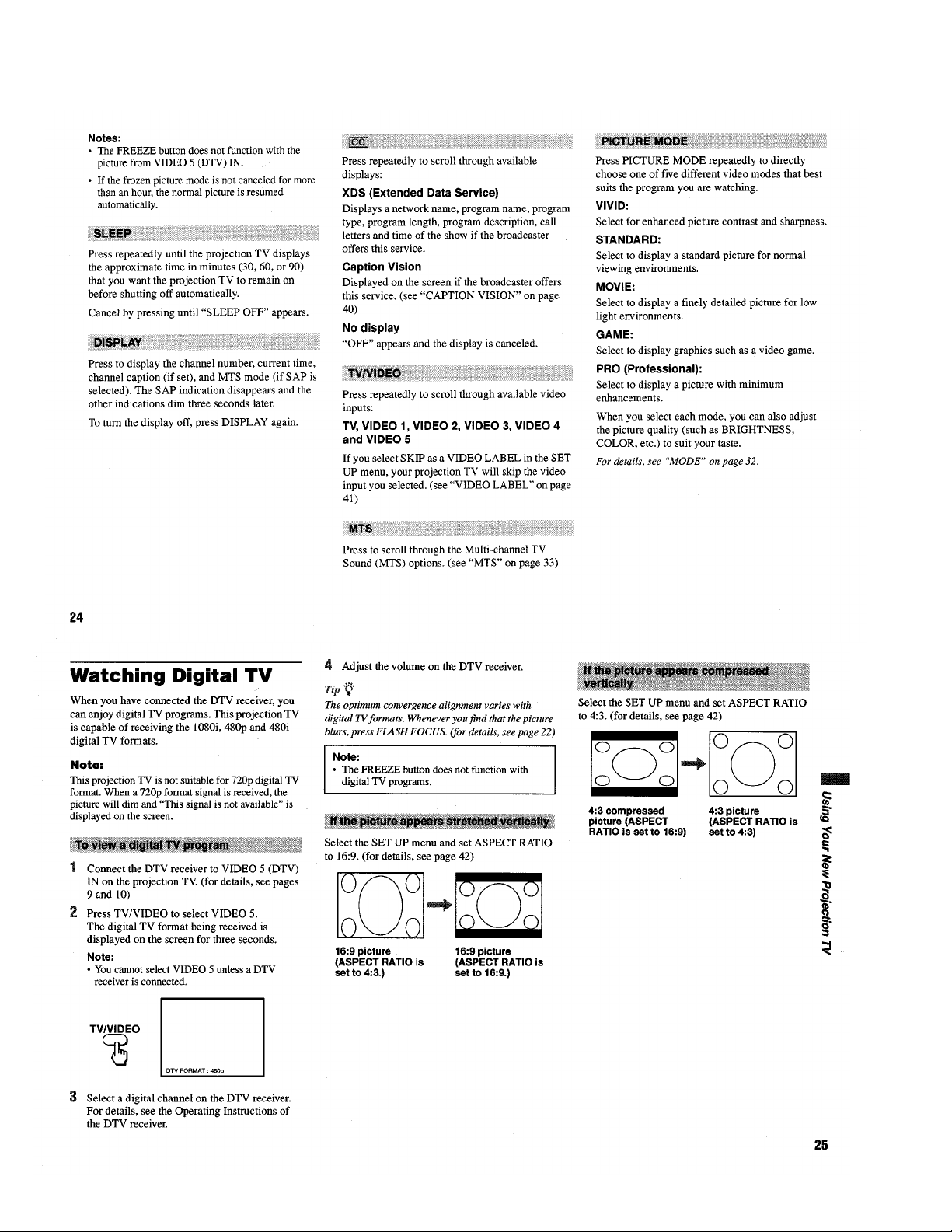

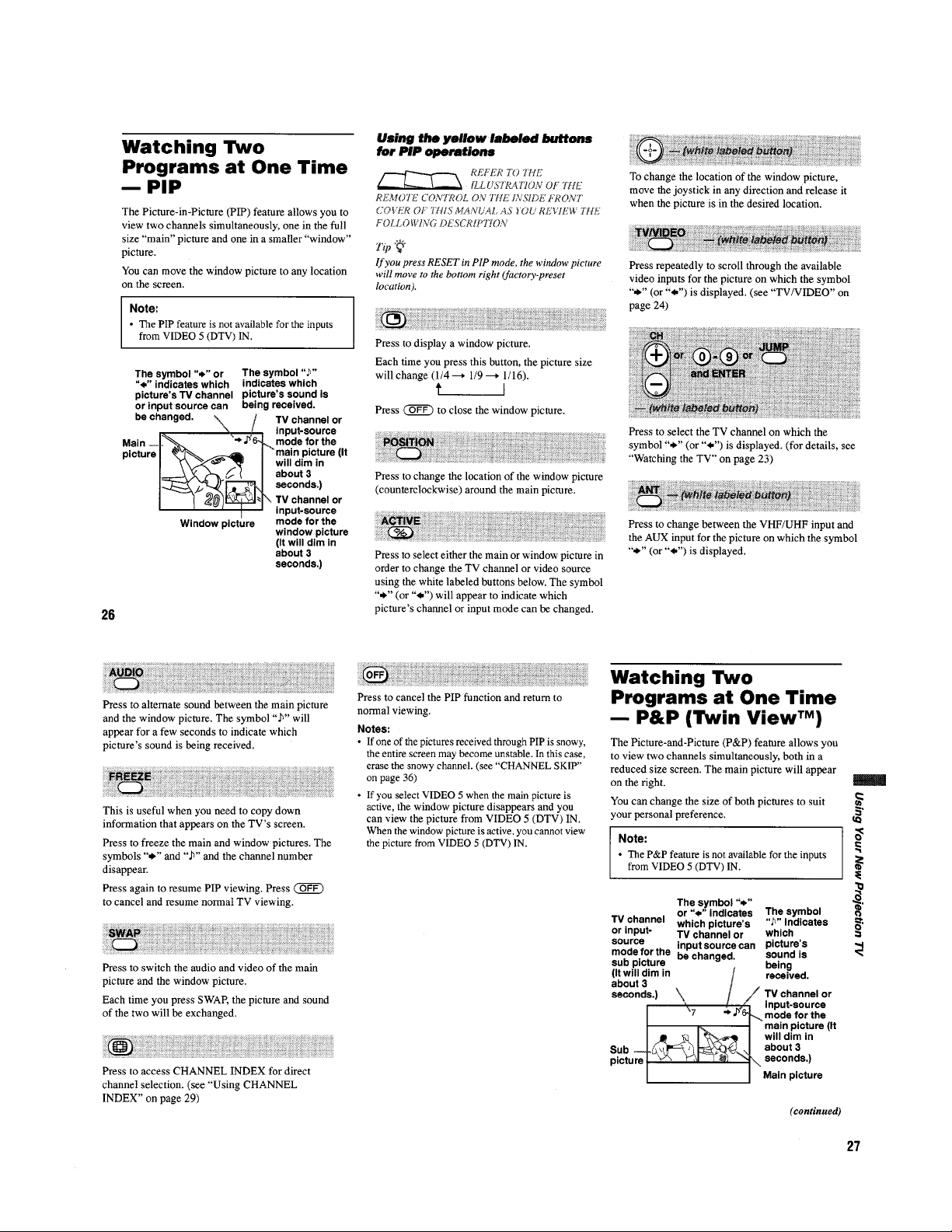

Using Your New Projection TV ............................................ 19

Adjusting Your SET UP (menus) .......................................... 23

Operating Video Equipment.................................................. 34

Operating a Cable Box or DBS Receiver.............................. 35

2. DISASSEMBLY

2-1. Screen Frame Assy and HC Board Removal ............ 37

2-2. Rear Board Removal ................................................. 37

2-3. Main Bracket Removal ............................................. 37

2-4. Service Position......................................................... 37

2-5. G Board Removal...................................................... 38

2-6. Terminal Board and U Board Removal ..................... 38

2-7. K Board Removal...................................................... 38

2-8. BM, BR and BD Board Removal.............................. 38

2-9. BA Board Removal ................................................... 39

2-10. DS Board Removal ................................................... 39

2-11. A and D Board Removal ........................................... 39

2-12. Reflection Mirror Removal ....................................... 40

2-13. HA and HB Board Removal...................................... 40

2-14. Picture Tube Removal ............................................... 41

2-15. High-Voltage Cable Installation and Removal .......... 41

3. SET-UP ADJUSTMENTS

3-1. Screen Voltage Adjustment (Rough Alignment) ....... 42

3-2. Focus Lens Adjustment............................................. 42

3-3. Screen (G2) Adjustment............................................ 42

3-4. Focus VR Adjustment ............................................... 42

3-5. Deflection Y ork Tilt Adjustment ............................... 43

3-6. 2-Pole Magnet Adjustment (Green, Red).................. 43

3-7. 4-Pole Magnet Adjustment........................................ 43

3-8. Defocus Adjustment (Blue) ....................................... 43

3-9. Electrical Adjustment by Remote Commander......... 44

3-10. Registration Adjustment............................................ 50

3-11. Auto Registration Error Code List ............................ 53

4. SAFETY RELATED ADJUSTMENTS

4-1. HV Regulation Circuit Check and Adjustment......... 54

4-2. HV Hold Down Circuit Operation and Adjustment .. 54

4-3. +B OVP Confirmation .............................................. 54

5. CIRCUIT ADJUSTMENTS

5-1. TV Input Sub Contrast Adjustment

(MCD1 SCON) ......................................................... 55

5-2. Video Input Sub-Contrast Adjustment

(MCD3-SCON) ......................................................... 55

5-3. P & P Sub-Contrast Adjustment (MCD2-SCON) ..... 55

5-4. P & P Sub-Contrast Adjustment (MCD4-SCON) ..... 55

5-5. 480 I Sub-Contrast Adjustment(MCP2-SCON)....... 56

5-6. Video 5 Input Sub-Contrast Adjustment

(MCP3-scon) ............................................................. 56

5-7. Sub-HUE and Sub-Color Adjustment

(MCD1-SHUE,SCOL) .............................................. 56

5-8. Video Input Sub-HUE and Sub-Color Adjustment

(MCD3-SHUE,SCOL) .............................................. 56

5-9. P & P Sub-HUE and Sub-Color Adjustment

(MCD2-SHUE,SCOL) .............................................. 57

Section Title Page

–––––– –––– ––––

5-10. P & P Sub-HUE and Sub-Color Adjustment

(MCD4-SHUE,SCOL) .............................................. 57

5-11. P & P Sub Contrast Adjustment (MCD1-SCON)...... 57

5-12. P & P Sub Contrast Adjustment (MCD2-SCON)...... 57

5-13. Sub-HUE and Sub-Color Adjustment

(SCD1-SHUE,SCOL) ............................................... 58

5-14. Sub-HUE and Sub-Color Adjustment

(SCD2-SHUE,SCOL) ............................................... 58

5-15. Video 5 Input Sub-HUE and Sub-Color Adjustment

(MCP3-SHUE,SCOL)............................................... 58

5-16. Display Position Adjustment (OSD-HPOS)............. 59

5-17. Caption Vision Position Adjustment

(MCCD-CCDH) ........................................................ 59

5-18. Mid Display Position Adjustment (MID-HPOS) ..... 59

6. DIAGRAMS

6-1. Block Diagram (1)..................................................... 61

Block Diagram (2)..................................................... 64

Block Diagram (3)..................................................... 67

Block Diagram (4)..................................................... 69

Block Diagram (5)..................................................... 71

Block Diagram (6)..................................................... 74

Block Diagram (7)..................................................... 77

Block Diagram (8)..................................................... 79

6-2. Frame Schematic Diagram ........................................ 81

6-3. Circuit Boards Location ............................................ 84

6-4. Printed Wiring Boards and Schematic Diagrams...... 84

• A (1/4)Board ........................................................... 89

• A (2/4)Board ........................................................... 93

• A (3/4)Board ........................................................... 97

• A (4/4)Board ......................................................... 100

• BA Board .............................................................. 104

• BM Board ............................................................. 107

• BR Board .............................................................. 115

• BD Board .............................................................. 120

• DS Board .............................................................. 123

• D(1/2) Board ......................................................... 127

• D(2/2) Board ......................................................... 130

• K Board................................................................. 139

• CR Board .............................................................. 143

• CG Board .............................................................. 144

• CB Board .............................................................. 145

• ZR Board .............................................................. 147

• ZG Board .............................................................. 148

• ZB Board .............................................................. 150

• U Board................................................................. 151

• HA Board .............................................................. 153

• HB Board .............................................................. 153

• HC Board .............................................................. 153

• G Board................................................................. 157

6-5. Semiconductors ....................................................... 160

7. EXPLODED VIEWS

7-1. Cover (KP-53XBR300)........................................... 162

7-2. Cover (KP-61XBR300)........................................... 163

7-3. Chassis..................................................................... 164

7-4. Picture Tube ............................................................ 165

8. ELECTRICAL PARTS LIST ................................. 166

– 7 –

Page 9

KP-53XBR300/61XBR300

RM-Y902RM-Y902

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

(CAUTION)

ANODE CAP TO THE METAL CHASSIS, CR T SHIELD, OR CARBON PAINTED ON THE CRT, AFTER REMOVING THE ANODE.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECElVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESECOMPONENTS WITH SONY P ARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL T O SAFEOPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

APRES A VOIR DECONNECTE LE CAP DE L ’ANODE, COUR TCIR-

(ATTENTION)

CUITER L’ANODE DU TUBE CATHODIQUE ET CELUI DE

L’ANODE DU CAP AU CHASSIS METALLIQUE DE L’APPAREIL,

OU AU COUCHE DE CARBONE PEINTE SUR LE TUBE CATHOD-

IQUE OU AU BLINDAGE DU TUBE CATHODIQUE.

ATTENTION!!

AFIN D’EVITER TOUT RISQUE DELECTROCUTION PROVENANT D’UN CHÁSSIS SOUS TENSION, UN TRANSFORMA TEUR

D’ISOLEMENT DOIT ETRE UTILISÉ LORS DE TOUT DEPANNAGE.

LE CHÁSSIS DE CE RECEPTEUR EST DIRECTEMENT RACCORDÉ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS ÁLA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE TRAME ET PAR UNE

MAPQUE ! SUR LES SCHÉMAS DE PRINCIPE, LES VUES EX-

PLOSÉES ET LES LISTES DE PIECES CONT D’UNEIMPORTANCE

CRITIQUE POUR LA SÉCURITÉ DU FONCTIONNEMENT. NE LES

REMPLACER QUE PAR DES COMPOSANTS SONY DONT LE

NUMÉRO DE PIÉCE EST INDIQUÉ DANS LE PRÉSENT MANUEL OU DANS DES SUPPLÉMENTS PUBLIÉS PAR SONY. LES

RÉGLAGES DE CIRCUIT DONT L ’IMPORTANCE EST CRITIQUE

POUR LA SÉCURITÉ DU FONCTIONNEMENT SONT IDENTIFIES

DANS LE PRÉSENT MANUEL. SUIVRE CES PROCÉDURES

LORS DE CHAQUE REMPLACEMENT DE COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS FONCTIONNEMENT EST

SUSPECTÉ.

– 8 –

Page 10

SECTION 1

GENERAL

The operating instructions mentioned here are partial abstracts from the

Operating Instructions Manual. The page numbers of the Operating

Instruction Manual remain as in the manual. (Part no : 3-867-651-11)

– 9 –

Page 11

– 10 –

Page 12

– 11 –

Page 13

– 12 –

Page 14

– 13 –

Page 15

– 14 –

Page 16

– 15 –

Page 17

– 16 –

Page 18

– 17 –

Page 19

– 18 –

Page 20

– 19 –

Page 21

– 20 –

Page 22

– 21 –

Page 23

– 22 –

Page 24

– 23 –

Page 25

– 24 –

Page 26

– 25 –

Page 27

– 26 –

Page 28

– 27 –

Page 29

– 28 –

Page 30

– 29 –

Page 31

– 30 –

Page 32

– 31 –

Page 33

– 32 –

Page 34

– 33 –

Page 35

– 34 –

Page 36

– 35 –

Page 37

– 36 –

Page 38

SECTION 2

Cabinet assy

Main Bracket assy

1 Four screws

(Tapping head

screw 4x20)

3

2 Four screws

(Tapping head screw 4x20)

DISASSEMBLY

KP-53XBR300/61XBR300

RM-Y902RM-Y902

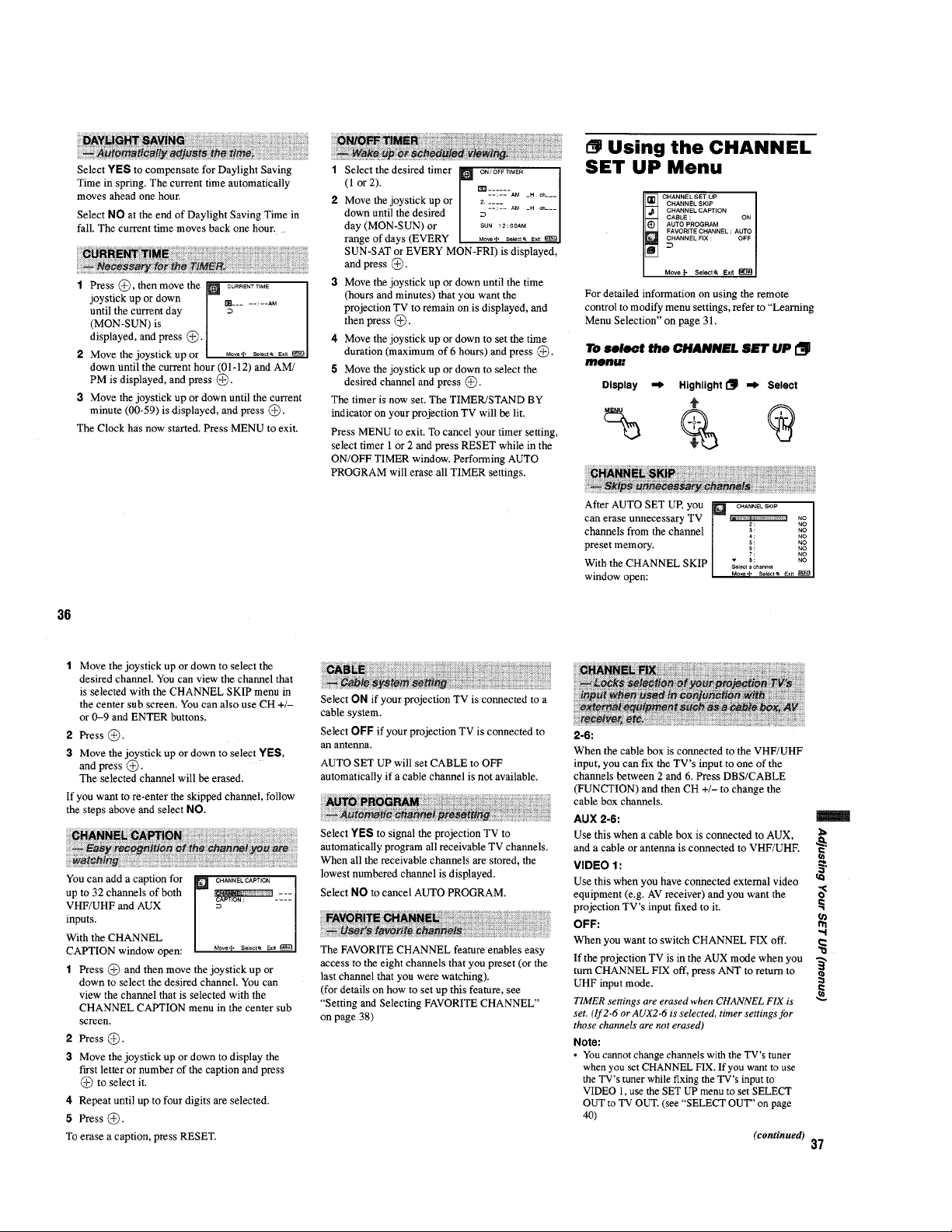

2-1. SCREEN FRAME ASSY AND HC BOARD

REMOVAL

2 Top grille (L) assy

4 Three claws

1 Top grille (R) assy

5 Three claws

6 HC board

2-3. MAIN BRACKET REMOVAL

3 Four screws (KP-53XBR300)

Three screws (KP-61XBR300)

(Tapping screw 4x20)

2-2. REAR BOARD REMOVAL

2-4. SERVICE POSITION

Cabinet assy

Cabinet assy

1 Three screws

(Screw, tapping

hexagon head)

3 Rear board

2 Nine screws

(Tapping screw 4x20)

Main bracket assy

– 37 –

Page 39

KP-53XBR300/61XBR300

RM-Y902RM-Y902

2-5. G BOARD REMOVAL

3 Four claws

4 G board

2-7. K BOARD REMOVAL

G board bracket

K board bracket

2 Four claws

2 K board

2 Two screws

(+BVTP 3x12)

1 Power cord

2-6. TERMINAL BOARD AND U BOARD REMOVAL

4 Five screws

(+BVTP 3x12)

5 U board

3

Main bracket

2

Claw

1

Eleven screws

(+BVTP 3x12)

2 Two screws

(+BVTP 3x12)

2-8. BM, BR AND BD BOARD REMOVAL

3 BM board

2 BR board

1 BD board

D board

Terminal board

A board

– 38 –

Page 40

KP-53XBR300/61XBR300

1 DS board

D board

Main bracket

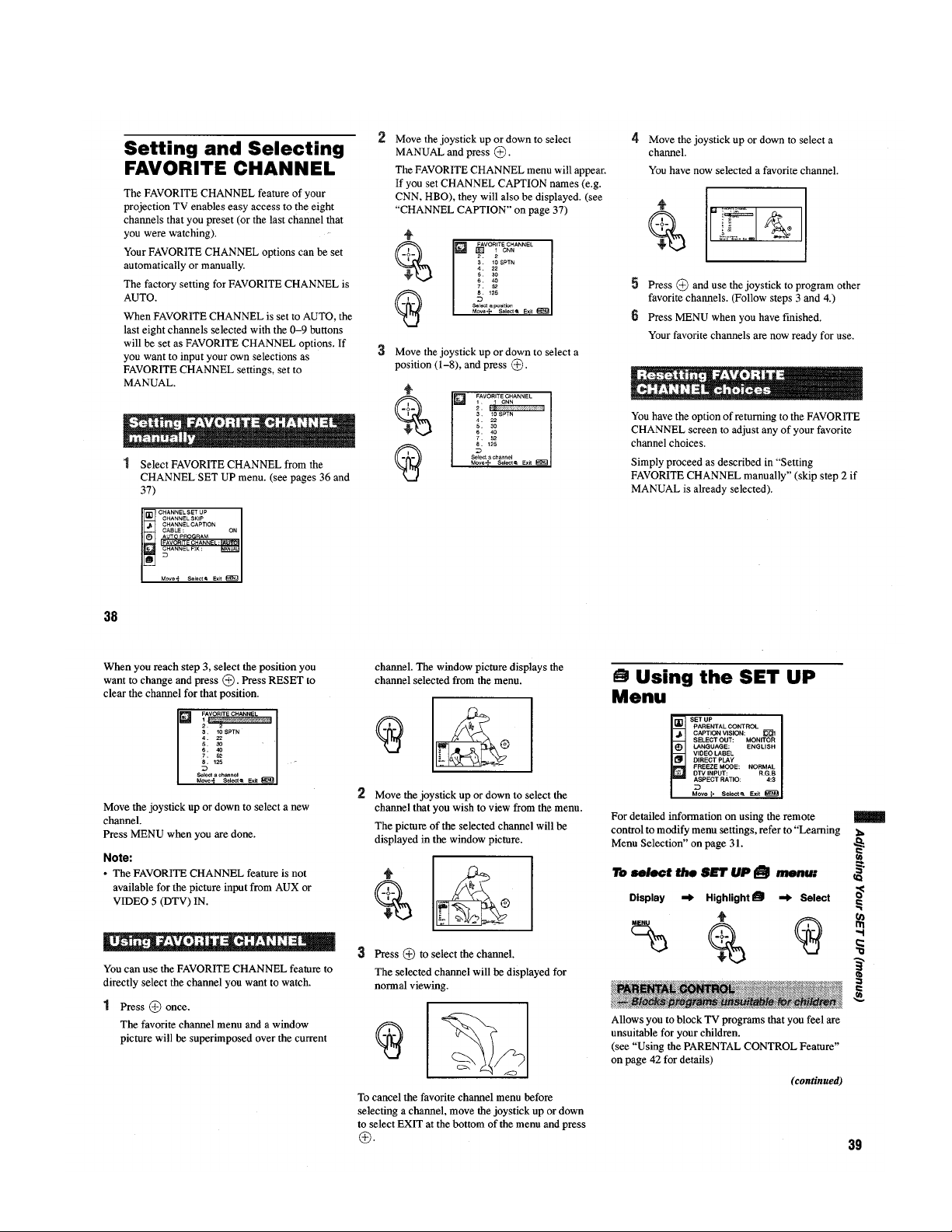

2-9. BA BOARD REMOVAL 2-10. DS BOARD REMOVAL

1 BA board

A board

RM-Y902RM-Y902

Main bracket

2-11. A AND D BOARD REMOVAL

1 Seven screws

(+BVTP 3x8)

2 A board

3 Seven screws

(+BVTP 3x8)

4 D board

Main bracket

– 39 –

Page 41

KP-53XBR300/61XBR300

RM-Y902RM-Y902

2-12. REFLECTION MIRROR REMOVAL

5 Reflection mirror

3 Thirteen screws

(Tapping screw 4x20)

Mirror board

4

Top board

2

2-13. HA AND HB BOARD REMOVAL

Control panel

!º Three screws

(+BVTP 3X12)

1 Bottom speaker

grille (L) assy

3 Two Screws

(Screw, tapping

hexagon head)

2 Two screws

(Tapping screw 4x20)

9 Four claws

!¡ HA board

7 Three screws

(+BVTP 3X12)

8 HB board

6 Panel assy

5

Two Screws

(Tapping screw 4x20)

4 Front panel assy

2 Bottom speaker

grille (R) assy

– 40 –

Page 42

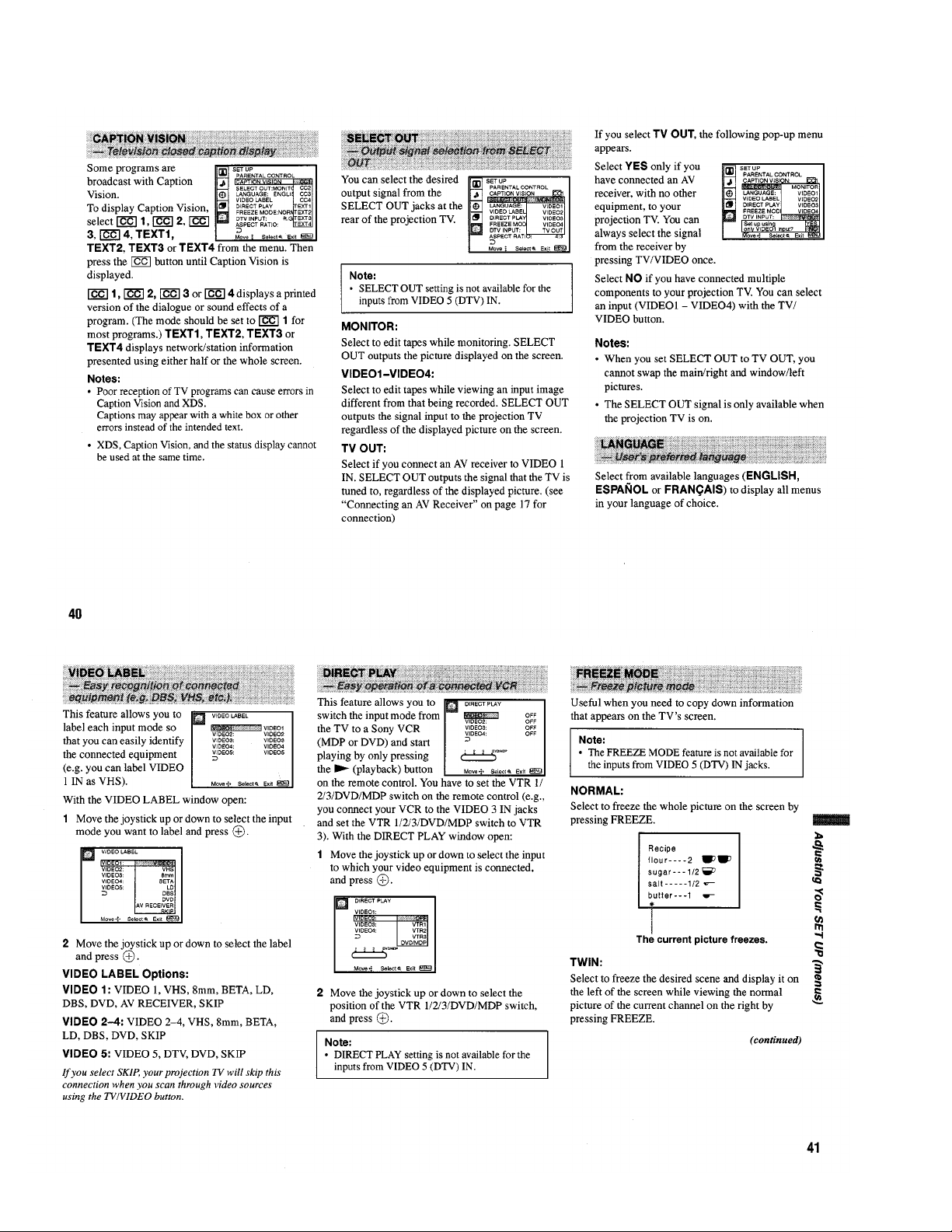

2-14. PICTURE TUBE REMOVAL

CAUTION: Removing the arrow-marked

screws is strictly prohibited.

If removed, it may cause liquid spill.

KP-53XBR300/61XBR300

RM-Y902RM-Y902

Lens

Picture tube

2 Four screws

(Tapping head

screw 4x20)

3

4 Four screws

(+BVTP 4x20)

5 Lens

9 Four screws

(+BVTP 4x20)

!º Picture tube

8 Diflection yoke

7 Neck assy

6 CR board

1 Four screws

(Tapping head

screw 4x20)

2-15. HIGH-VOLTAGE INSTALLATION AND REMOVAL

(1) Remover

1 Rubber cap

2 HV cable

turn 90°

– 41 –

(2) Installation

1 HV cable

Hook

Gutter

Page 43

KP-53XBR300/61XBR300

RM-Y902RM-Y902

SECTION 3

SET-UP ADJUSTMENTS

3-1. SCREEN VOL T A GE ADJUSTMENT

(ROUGH ALIGNMENT)

1. Receive the Monoscope signal.

2. Set 50% BRIGHTNESS and minimum PICTURE.

3. Turn the red VR on the FOCUS block all the way to the left

and then gradually turn it to the right until the point where you

can see the retrace line.

4. Next gradually turn it to the left to the position where the

retrace line disappears.

R G B

SCREEN

R G B

FOCUS

FOCUS block

Fig. 3-1

3-2. FOCUS LENS ADJUSTMENT

In this adjustment, use the remote commander in the

service mode.

For details of the usage of the service mode and the remote

commander, please refer the item 3-9. ELECTRICAL

ADJUSTMENT BY REMOTE COMMANDER.

1. Loosen the lens screw.

2. Set to the service mode.

3. Receive the all-white signal.

4. Set MCP1 07 RON to “000”, 08 GON to “001” and 09 BON

to “000” to show only the green color.

5. Set to PJE, and press 6 to display the test signal (crosshatch)“

on the screen.

6. Turn the green lens to adjust to the optimum focus point with

the test signal.

7. Tighten the lens screw.

8. Set MCP1 07 RON to “001”, 08 GON to “000” and 09 BON

to “000” to show only the red color.

9. Set to PJE, and press 6 to display the test signal (crosshatch)“

on the screen.

10. Adjust red CRT lens just the same as green.

11. Set MCP1 07 RON to “000”, 08 GON to “000” and 09 BON

to “001” to show only the blue color.

*:Every time you press 6, the test signal changes to

“crosshatch+video signal” - “dots+video signal” “crosshach(black)” - “dots(black)” - off.

Note: Instead of items 4, 8 and 11, you can use the lens caps to cut

off the unnecessary color beams.

3-3. SCREEN (G2) ADJUSTMENT

1. Select VIDEO1 mode without signals.

2. Connect an oscilloscope to the TP7103(KR), TP7203(KG) and

TP7303(KB) of CR board, CG board and CB board.

3. Adjust R, G and B screen voltage to 175 ± 2V with screen VR

on the Focus block.

175 ± 2V

GND

pedestal level

Fig. 3-3

3-4. FOCUS VR ADJUSTMENT

1. Set to the service mode.

2. Receive the all-white signal.

3. Set MCP1 07 RON to “000”, 08 GON to “001” and 09 BON

to “000” to show only the green color.

4. Set to PJE, and press 6 to display the test signal (crosshatch)

on the screen.

5. Turn the green VR on the focus block to adjust to the optimum

focus point with the test signal.

6. Set MCP1 07 RON to “001”, 08 GON to “000” and 09 BON

to “000” to show the red color.

7. Set to PJE, and press 6 to display the test signal (crosshatch)

on the screen.

8. Turn the red VR on the focus block to adjust to the optimum

focus point with the test signal.

9. Set MCP1 07 RON to “000”, 08 GON to “000” and 09 BON

to “001” to show the blue color.

10. Set to PJE, and press 6 to display the test signal (crosshatch)

on the screen.

11. Turn the blue VR on the focus block to adjust to the optimum

focus point with the test signal.

Note: Instead of items 3, 6 and 9, you can use the lens caps to cut

off the unnecessary color beams.

Scanning line visible.

Test signal

Fig. 3-2

12. Set to PJE, and press 6 to display the test signal (crosshatch)“

on the screen.

13. Adjust blue CRT lens just the same as green.

– 42 –

Lens

Fig. 3-4

A

Minimize both A and B.

B

Center of crosshatch

Fig. 3-5

Page 44

KP-53XBR300/61XBR300

/

x

y

x : y = 1:1.5 (BIue)

x : y = 1:1 (Green, Red)

Use the center dot

RM-Y902RM-Y902

3-5. DEFLECTION YOKE TIL T ADJUSTMENT

1. Receive the Monoscope signal.

2. Set in service mode.

3. Set MCP1 07 GON to “001” 08 RON to “000” and 09 BON to

“000” to show only the green color.

4. Loosen the deflection yoke set screw and align the tilt of the

Deflection Yoke so that the bars at the center of the

monoscope pattern are horizontal.

5. After aligning the deflection yoke, fasten it securely to the

funnel-shaped portion (neck) of the CRT.

6. The tilt of the deflection yoke for red is aligned in the mode

MCP1 07 RON “001”, 08 GON “000”, 09 BON “000” on the

service mode menu, and the tilt of the deflection yoke for blue

is aligned with in the mode MCP1 07 RON “000”, 08 GON

“000”, 09 BON “001” on the service menu, is aligned the

same as was done for green.

Note: Instead of item 3, you can use the lens caps to cut off the

unnecessary color beams.

4-pole magnet

2-pole magnet

Fig. 3-6

Deflection yoke

Anode cap

3-6. 2-POLE MAGNET ADJUSTMENT

(GREEN,RED)

1. Receive the Dot signal.

2. Set in service mode.

3. Set MCP1 07 GON to “001” 08 RON to “000” and 09 BON to

“000” to show only the green color.

4. Turn the green VR on the focus block to the right and set to

overfocus to enlarge the spot.

5. Now align the 2-Pole Magnet so that the enlarged spot is in the

center of the Just Focus spot.

6. Align the green focus VR and set for just (precise) focus.

7. Perform the same alignment for red.

Use the center dot

3-7. 4-POLE MAGNET ADJUSTMENT

1. Receive the Dot signal.

2. Set in service mode.

3. Set MCP1 07 GON to “001” 08 RON to “000” and 09 BON to

“000” to show only the green color.

4. Turn the green VR on the focus block to the left and set to

underfocus to enlarge the spot.

5. Now align the 4-Pole Magnet so that the enlarged spot

becomes a perfect circle for green and red.

6. Perform the same alignment for blue.

Fig. 3-8

3-8. DEFOCUS ADJUSTMENT (BLUE)

1. Select the video menu and set the mode to “VIVID” mode.

2. Set to the service mode.

3. Change TV mode to the video input mode.

4. Set to PJE, and press 6 to display the test signal (dots) on the

screen.

5. Turn the blue VR on the focus block to adjust to the diameter

of the dots as shown in the figure below.

[Focus adjustment point]

Lmm Max

Inch

L

53"

8

Fig. 3-9

61"

9

Fig. 3-7

– 43 –

Page 45

KP-53XBR300/61XBR300

RM-Y902RM-Y902

3-9. ELECTRICAL ADJUSTMENT BY REMOTE

COMMANDER

By using Remote Commander (RM-Y902),all circuit adjustments

can be made.

NOTE : Test Equipment Required.

1. Pattern Generator (with component outputs)

2. Frequency counter

3. Digital multimeter

4. Audio oscillator

1. METHOD OF SETTING THE SERVICE ADJUSTMENT MODE

SERVICE MODE PROCEDURE

1. Standby mode. (Power off)

2. DISPLAY n 5 n VOL (+) n TV POWER

on the Remote Commander.

(Press each button within a second.)

SERVICE MODE ADJUSTMENT

Category Adjustment item

DATA

SERVICE VPNT VPOS 031

000000 00

2. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, remove the plug from AC outlet, and then

replace the plug in AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again and confirm they were adjusted.

3. ADJUST BUTTONS AND INDICATOR

TV POWER ON

POWER

SYSTEM

DVD/

MUTING

DISPLAY

Adjustment item up

Adjustment item down

MUTING

OFF

FUNCTION

FREEZE

OFF

AUDIO SWAP

TV/DBS

GUIDE ACTIVE

CC

PICTURE

MODE

DISPLAY TV/VIDEO

1

4

7

JUMP

VOL CH

VTR

DVD/VTR

POTITION

2

5

8

0

MENU

DBS

CABLE

DBS/CABLE

ZOOM IN

LEFT RIGHT

ANT

3

6

9

ENTER

TV

TV

Category up

Data up

Data down

Category down

ENTER

(SCREEN DISPLAY)

3. The SCREEN displays the item being adjusted.

4. Press 1 or 4 on the Remote Commander to select the

adjustment item.

5. Press 3 or 6 on the Remote Commander to change the data.

6. Press 2 or 5 on the Remote Commander to select the

category.

7. If you want to recover the latest values press - then [ENTER] to

read the memory.

8. Press [MUTING] then [ENTER] to write into memory.

9. Turn power off.

Note: Press 8 then [ENTER] on the Remote Commander to initialize

or turn set off and on to exit.

RM-Y902

Note : In the PJE mode these are different a little. See page 47.

– 44 –

Page 46

Note Device

44 0–63 USER PICTURE(STANDARD)

40 0–63 USER PICTURE(MOVIE)

38 0–63 USER PICTURE(GAME)

31 0–63 USER BRIGHTNESS(STANDARD)

38 0–63 USER PICTURE(PRO)

KP-53XBR300/61XBR300

31 0–63 USER BRIGHTNESS(MOVIE)

27 0–63 USER BRIGHTNESS(GANE)

31 0–63 USER BRIGHTNESS(PRO)

31 0–63 USER COLOR(STANDARD)

31 0–63 USER COLOR(MOVIE)

31 0–63 USER COLOR(GAME)

31 0–63 USER COLOR(PRO)

40 0–63 USER SHARPNESS(STANDARD)

33 0–63 USER SHARPNESS(MOVIE)

36 0–63 USER SHARPNESS(GAME)

RM-Y902RM-Y902

40 0–63 USER SHARPNESS(PRO)

Item Adjustment Standard Data

number item data range

Category

01 SBRT 31 0-63 SUB BRIGHTNESS

02 SHUE 7 0-15 SUB HUE

03 SCOL 12 0-15 SUB COLOR

MCP2 00 SCON 5 0-15 SUB CONTRAST

(DRC/480ip)

( ) : 1080I

MCP3 00 SCON 3 0-15 SUB CONTRAST

Note Device

02 SHUE 7 0-15 SUB HUE

03 SCOL 5 0-15 SUB COLOR

01 SHPF 1 0–3 SHARPNESS f0

(1080i) 01 SBRT 31 0-63 SUB BRIGHTNESS

(STANDARD)

MCP 4 00 SSHP 3 0–3 SUB SHARPNESS

02 VMDL 3 0–3 VM DELAY

03 SYS 2 0–3 SYSTEM

04 PREO 2 0–3 PRE/OVER RATIO

02 VMDL 3 0–3 VM DELAY

03 SYS 2 0–3 SYSTEM

(VIVID) 01 SHPF 1 0–3 SHARPNESS f0

MCP 5 00 SSHP 3 0–3 SUB SHARPNESS

04 PREO 1 0–3 PRE/OVER RATIO

01 SHPF 2 0–3 SHARPNESS f0

02 VMDL 3 0–3 VM DELAY

MCP6 00 SSHP 3 0–3 SUB SHARPNESS

(1080 - 480)

Note Device

03 SYS 2 0–3 SYSTEM

04 PREO 0 0–3 PRE/OVER RATIO

MCP 7 00 UPIC 63 0–63 USER PICTURE(VIVID)

CXA2101AQ

01 UBRT 28 0–63 USER BRIGHTNESS(VIVID)

02 UCOL 31 0–63 USER COLOR(VIVID)

03 USHP 40 0–63 USER SHARPNESS(VIVID)

Item Adjustment Standard Data

number item data range

4. SERVICE MODE LIST

VDSP

: Fixed data

VDSP 00 VPOS 31 0–63 V SHIFT CXD2018Q

Category

01 V ANG 7 0–15 V ANGLE

02 VBOW 7 0–15 V BOW

03 VLIN 7 0–15 V LIN

04 VSIZ 31 (10) 0–63 V SIZE

05 VSCO 7 0–15 S CORRECTION

06 HPOS 41 0–63 H SHIFT

07 HSIZ 31 0–63 H SIZE

08 HKEY 11 0–15 TILT

11 LPIN 7 0–15 LOWER CORNER PIN

09 PAMP 15 0–63 PIN AMP

10 UPIN 7 0–15 UPPER CORNER PIN

MCP

Item Adjustment Standard Data

number item data range

Category

– 45 –

01 GDRV 31 0–63 G DRIVE

MCP 1 00 RDRV 31 0–63 R DRIVE

02 BDRV 31 0–63 B DRIVE

03 RCUT 31 0–63 R CUTOFF

04 GCUT 10 0–63 G CUTOFF

05 BCUT 31 0–63 B CUTOFF

06 P ON 1 0,1 PICON

07 R ON 1 0,1 R ON

08 G ON 1 0,1 G ON

09 B ON 1 0,1 B ON

10 P ABL 15 0–15 PEAK ABL LEVEL

11 LTIL 0 0–3 LTI LEVEL

12 CTIL 0 0,1 CTI LEVEL

13 LIMT 2 0–3 INPUT LEVEL LIMIT

14 CB01 7 0–15 CB OFFSET 1

15 CR01 7 0–15 CR OFFSET 1

16 CB02 7 0–15 CB OFFSET 2

17 CR02 7 0–15 CR OFFSET 2

18 DCTR 1 0–3 DC TRAN

19 DPIC 1 0–3 D PIC

20 ABLT 3 0–3 ABL T/H (ACTIVE ON 16 :9)

21 VTC 2 0–3 V SYNC SFP TC

22 CB03 7 0–15 CB OFFSET3

23 CR03 7 0–15 CR OFFSET3

Page 47

KP-53XBR300/61XBR300

RM-Y902RM-Y902

CXA2019AQ

SCD

Note Device

Item Adjustment Standard Data

number item data range

(TV) 01 SHUE 6 0–15 SUB HUE(TV)

SCD 1 00 SCON 6 0–15 SUB CONTRAST(TV)

Category

02 SCOL 6 0–15 SUB COLOR(TV)

SCD 2 00 SCON 6 0–15 SUB CONTRAST(VIDEO)

(VIDEO) 01 SHUE 6 0–15 SUB HUE(VIDEO)

01 Y2DR 31 0–31 Y2 DRIVE

02 SCOL 6 0–15 SUB COLOR(VIDEO)

SCD 3 00 MYDR 3 0–31 YDRIVE

02 U2DR 15 0–31 U2 DRIVE

03 V2DR 15 0–31 V2 DRIVE

04 MUPE 7 0–15 U PED

05 MVPE 7 0–15 V PED

06 U2PE 7 0–15 U2 PED

07 V2PE 7 0–15 V2 PED

08 DPIC 1 0,1 D PIC

09 DCTR 0 0–7 DC TRAN

3DCM

Note Device

Item Adjustment Standard Data

number item data range

Category

02 DYGA 11 0–15 DYGAIN

(YCS) 01 DYCO 2 0,1 DYCOR

3DCM 1 00 NRMD 0 0–3 NRMD UPD64081

03 DCCO 1 0,1 DCCOR

04 DCGA 12 0–15 DCGAIN

05 SELD 1 0,1 SELD

CXA2019AQ

06 D2GA 4 0–7 D2GAIN

3DCM 2 00 NRMD 3 0–3 NRMD

02 DYGA 11 0–15 DYGAIN

(YCNR) 01 DYCO 2 0,1 DYCOR

03 DCCO 1 0,1 DCCOR

04 DCGA 12 0–15 DCGAIN

05 SELD 1 0,1 SELD

06 D2GA 4 0–7 D2GAIN

3DCM 3 00 WSC 0 0–3 WSC

02 VTRR 1 0–3 VTRR

(TV) 01 VTRH 1 0–3 VTRH

03 LDSR 3 0–3 LDSR

04 YPFT 3 0–3 YPFT(TV:NR OFF)

05 YPFG 12 0–15 YPFG(TV:NR OFF)

06 YPFC 0 0,1 YPFT CORING(TV:NR OFF)

Note Device

Item Adjustment Standard Data

number item data range

Category

1 0–3 USER TRINITONE(ST ANDARD)

0 0–3 USER TRINITONE(MOVIE)

04 UTRI 2 0–3 USER TRINITONE(VIVID)

2 0–3 USER TRINITONE(GAME)

1 0–3 USER TRINITONE(PRO)

0 0–3 USER NR MODE(STANDARD)

0 0–3 USER NR MODE(MOVIE)

05 UNR 0 0–3 USER NR MODE(VIVID)

USER DYNAMIC PICTURE(VIVID)

USER DYNAMIC PICTURE(STANDARD)

USER DYNAMIC PICTURE(MOVIE)

USER DYNAMIC PICTURE(GAME)

0 0–3 USER NR MODE(GAME)

0 0–3 USER NR MODE(PRO)

1 0,1

0 0,1

0 0,1

1 0,1 USER DYNAMIC PICTURE(PRO)

06 UDPI 1 0,1

07 UVML 3 0–3 USER VM LEVEL(VIVID)

2 0–3 USER VM LEVEL(STANDARD)

1 0–3 USER VM LEVEL(MOVIE)

3 0–3 USER VM LEVEL(GAME)

1 0–3 USER VM LEVEL(PRO)

MCD

– 46 –

Note Device

Item Adjustment Standard Data

number item data range

Category

02 SCOL 4 0–15 SUB COLOR

MCD 1 00 SCON 5 0–15 SUB CONTRAST

MCD 2 00 SCON 5 0–15 SUB CONTRAST

(DRC-TV) 01 SHUE 6 0–15 SUB HUE

(P&P-TV) 01 SHUE 6 0–15 SUB HUE

02 SCOL 5 0–15 SUB COLOR

MCD 3 00 SCON 5 0–15 SUB CONTRAST

VIDEO) 02 SCOL 5 0–15 SUB COLOR

(DRC- 01 SHUE 8 0–15 SUB HUE

01 Y2DR 31 0–31 Y2 DRIVE

MCD 4 00 SCON 5 0–15 SUB CONTRAST

MCD 5 00 MYDR 3 0–31 YDRIVE

VIDEO) 02 SCOL 7 0–15 SUB COLOR

(P&P- 01 SHUE 7 0–15 SUB HUE

02 U2DR 15 0–31 U2 DRIVE

03 V2DR 15 0–31 V2 DRIVE

04 MUPE 7 0–15 U PED

05 MVPE 7 0–15 V PED

06 U2PE 7 0–15 U2 PED

07 V2PE 7 0–15 V2 PED

08 DPIC 1 0,1 D PIC

09 DCTR 0 0–7 DC TRAN

Page 48

KP-53XBR300/61XBR300

RM-Y902RM-Y902

Item Adjustment Standard Data

SNNR

Note Device

01 LTIL 0 0-3 MCP LTI

number item data range

Category

02 YPFT 3 0-3 3DCM YPFT

SNNR1 00 SSHP 3 0-3 MCP SUB SHARPNESS

03 YPFG 10 0-15 3DCM YPFG

04 YPFC 0 0,1 3DCM YPFC

05 WSLT 15 0-255 3DCM WSL THRESHOLD

01 LTIL 0 0-3 MCP LTI

02 YPFT 3 0-3 3DCM YPFT

03 YPFG 9 0-15 3DCM YPFG

04 YPFC 0 0,1 3DCM YPFC

05 WSLT 79 0-255 3DCM WSL THRESHOLD

SNNR2 00 SSHP 3 0-3 MCP SUB SHARPNESS

SNNR3 00 SSHP 3 0-3 MCP SUB SHARPNESS

01 LTIL 0 0-3 MCP LTI

02 YPFT 1 0-3 4DCM YPFT

03 YPFG 7 0-15 4DCM YPFG

04 YPFC 1 0,1 4DCM YPFC

05 WSLT 175 0-255 4DCM WSL THRESHOLD

SNNR4 00 SSHP 2 0-3 MCP SUB SHARPNESS

01 LTIL 0 0-3 MCP LTI

02 YPFT 1 0-3 4DCM YPFT

03 YPFG 5 0-15 4DCM YPFG

04 YPFC 1 0,1 4DCM YPFC

OSD

Note Device

Item Adjustment Standard Data

number item data range

Category

OSD U-COM

01 HPOS 26 0–255 H POSITION

02 VPOS 30 0–255 V POSITION

OSD 00 FREQ 95 0–255 OSD FREQ MB9091 &

Note Device

Item Adjustment Standard Data

MCCD

Category

MAIN U-COM

CRI TIME CONSTANT(MASK=1,OTP=2)

01 CFLD 5 0–15 CAPTION FIXED-FIELD COUNT

02 CCDI 3 0–7 CCD INT

03 CRIP 4 0–7 CRI & PARITY

04 CRIT 1 0–3

number item data range

MCCD 00 CRIL 2 0–15 CRI COUNT LOW

05 CSB1 3 0–3 SYNC SLICE BIAS 1

Item Adjustment Standard Data

VDSP

Note Device

number item data range

3DCM 4 00 WSC 0 0–3 WSC

Category

02 VTRR 1 0–3 VTRR

(VIDEO) 01 VTRH 1 0–3 VTRH

03 LDSR 1 0–3 LDSR

04 YPFT 3 0–3 YPFT(VIDEO:NR OFF)

05 YPFG 12 0–15 YPFG(VIDEO:NR OFF)

06 YPFC 0 0,1 YPFT CORING(VIDEO:NR OFF)

01 YNKI 2 0–3 YNRK & YNRIV

3DCM 5 00 MSS 0 0–3 MSS

02 YNRL 0 0–3 YNRLIM

03 CNKI 2 0–3 CNRK & CNRINV

04 CNRL 0 0–3 CNRLIM

05 V1PS 2 0–3 V1PS

06 VEGS 1 0–3 VEGS

07 CC3N 0 0,1 CC3N

08 HDP 4 0–7 HDP

09 CDL 3 0–7 CDL

10 HSSL 12 0–15 HSSL

11 VSSL 3 0–15 VSSL

12 HPLF 1 0,1 HPLLFS

– 47 –

13 BPLF 1 0,1 BPLLFS

14 FSCF 0 0,1 FSCFG

15 EXAD 1 0,1 ADIN

16 WSLT 2 3 WSL THRESHHOLD

Page 49

KP-53XBR300/61XBR300

RM-Y902RM-Y902

Note Device

14 ADSW 1 0,1 A/BCH ADC INT/EXT(EXT=1)

Item Adjustment Standard Data

number item data range

Category

WKCA/WKCB(A/BCH WINDOW COLOR)

15 OSDH 25 0–63 OSD H POSITION

16 OSDV 7 0–63 OSD V POSITION

17 WCOL 2 0–3

OP

Note Device

Item Adjustment Standard Data

number item data range

Category

U-COM

PICTURE BOOSTER SETTING(VIVID)

01 16:9 0 0,1 16:9 ON/OFF (ON = 1)

02 DRCP 0 0,1 DRC INTERLACE/PROGRESSIVE

03 1080 0 0,1 FORCED 1080I(VIDEO5)

04 IDXT 2 0-15 INDEX CH SCAN TIME

05 VPI 0 0-3

OP 00 AGCA 152 0–255 AGC ATT LEVEL MAIN

PJED U-COM

CM0006AF &

( ) : 1080I < > 16 :9

Note Device

FINE ADJUST DISPLAY ON(ON=1, OFF=0)

Item Adjustment Standard Data

PJED

01 OSDH 32 0–255 PJED OSD H POSITION

number item data range

PJED 00 FDIS 00 0,1

Category

02 OSDV 55 0–255 PJED OSD V POSITION

03 FVST 51(00) 0–255 FINE V START LINE

04 V1ST 00 0–255 V1 START

0–255 TEST PATTERN H PHASE

49(55)<46>

05 V1CU 31(29) 0–255 V1 COUNT UP

06 COHP 00(248) 0–255 COARSE H PHASE

07 FIHP 206(200) 0–255 FINE H PHASE

08 TPHP

DF H GAIN

DF V GAIN

-128–+127

-128–+127

11 DFVG 15

09 DFHP 00 0–255 DF H PHASE

10 DFHG 95

12 PWM1 00 0–255 PWM1

13 PWM2 29 0–255 PWM2

14 HBLD 222(212) 0–255 HBLKOUT H DELAY

GV CENTER OFFSET OF AUTO REGI

RV CENTER OFFSET OF AUTO REGI

BV CENTER OFFSET OF AUTO REGI

0–63 HBLKOUT PULSE WIDTH

0-255 V BLANKING PULSE

-127–+127

-127–+127

-127–+127

00(10)<10>

44(75)<49>

16 BLKP

18 CORV 00

15 HBLW

19 COBV 00

17 COGV 00

GH CENTER OFFSET OF AUTO REGI

RH CENTER OFFSET OF AUTO REGI

-127–+127

-127–+127

20 COGH 00

21 CORH 00

BH CENTER OFFSET OF AUTO REGI

-127–+127

22 COBH 00

Note Device

06 CSB2 4 0–7 SYNC SLICE BIAS 2

Item Adjustment Standard Data

number item data range

Category

07 CREP 142 0–255 CRI SIGNAL END POSITION

08 CDSD 8 0–31 DATA START DELAY

11 CHSY 136 0–255 P8 HSYNC

09 CCDS 9 0–31 CAPTION DATA THRESHOLD

10 CHMK 42 0–63 P8 HMASK

12 CCDH 27 0–63 CCD H POSITION

APLR

Note Device

Item Adjustment Standard Data

number item data range

Category

01 ATTL 0 0–15 ATT LCH

02 ATTR 0 0–15 ATT RCH

APLR 00 SVOL 0 0–15 SUB VOLUME TDA7321

03 SBAS 7 0–15 SUB BASS

04 STRE 7 0–15 SUB TREBLE

Item Adjustment Standard Data

APCS

Note Device

number item data range

APCS 00 SVOL 0 0–15 SUB VOLUME TDA7321

Category

01 ATTC 0 0–15 ATT CCH

02 ATTS 0 0–15 ATT SCH

03 SBAS 7 0–15 SUB BASS

04 STRE 7 0–15 SUB TREBLE

Item Adjustment Standard Data

MID

CXD2079Q &

Note Device

number item data range

MID 00 DLYC 3 0–7 DELAY(Y OUTPUT DELAY)

Category

MID U-COM

HPOSIA(ACH H POSITION:NOT USE)

01 YSDY 1 0–7 YSDY(YS DELAY)

02 VJTC 0 0–3 VJITTC(V JITTER MODE)

03 HPHA 43 0–255 HPHASA(ACH H PHASE)

04 VPHA 11 0–255 VPHASA(ACH V PHASE)

05 DLY A 4 0–7 DELAY A(ACH Y DELA Y)

06 HPOA 87 0–255

VPOSIA(ACH V POSITION:NOT USE)

07 VPOA 64 0–255

08 HPHB 43 0–255 HPHASB(BCH H PHASE)

09 VPHB 11 0–255 VPHAHB(BCH V PHASE)

10 DLYB 4 0–7 DELA YB(BCH Y DELAY)

HPOSIB(BCH H POSITION:PIP ONLY)

11 HPOB 4 0–15

VPOSIB(BCH V POSITION:PIP ONLY)

12 VPOB 6 0–15

13 BPDY 0 0–15 BPDELAY(BP DELAY)

– 48 –

Page 50

KP-53XBR300/61XBR300

RM-Y902RM-Y902

Note Device

Item Adjustment Standard Data

number item data range

Category

GV SKEW OFFSET OF AUTO REGI

RV SKEW OFFSET OF AUTO REGI

-127–+127

-127–+127

23 SOGV 00

24 SORV 00

BV SKEW OFFSET OF AUTO REGI

GH SKEW OFFSET OF AUTO REGI

-127–+127

-127–+127

25 SOBV 00

26 SOGH 00

RH SKEW OFFSET OF AUTO REGI

BH SKEW OFFSET OF AUTO REGI

AUTO REGI ERROR CODE

-127–+127

-127–+127

27 SORH 00

28 SOBH 00

29 ERR 00

30 ADTM 144 0-255 AUTO REGI AD TIMING

31 VUP 01 0-255 AUTO REGI VUP POS

32 VMID 120(120) 0-255 AUTO REGI VMID POS

33 VLOW 240(238) 0-255 AUTO REGI VLOW POS

34 HPR 01 0-255 AUTO REGI H POS REGIS

35 SFTF 00 0,1 V SIZE SHIFT FAST

COARSE GREEN H/V CENT

COARSE GREEN H/V SKEW

COARSE GREEN H/V SIZE

- COARSE GREEN H/V LIN

-512 - +511

-512 - +511

-512 - +511

XXXX / XXXX

SKEW 000 / 000

GRN SIZE 000 / 000

LIN

CENT 000 / 000

36 ACTL 00 0-255 ACTIVE CRT TIME(LOW BYTE)

37 ACTH 00 0-255 ACTIVE CRT TIME(HIGH BYTE)

COARSE GREEN H/V PIN

COARSE BLUE H/V CENT

COARSE BLUE H/V SKEW

COARSE BLUE H/V SIZE

COARSE BLUE H/V LIN

COARSE BLUE H/V KEY

COARSE BLUE H/V PIN

- COARSE GREEN H/V KEY

-512 - +511

-512 - +511

-512 - +511

-512 - +511

-512 - +511

-512 - +511

-512 - +511

000 / XXXX

XXXX / XXXX

PIN

KEY

CENT 000 / 000

SKEW 000 / 000

000 / XXXX

XXXX / 000

000 / XXXX

PIN

LIN

KEY

BLU SIZE 000 / 000

– 49 –

COARSE RED H/V CENT

COARSE RED H/V SKEW

COARSE RED H/V SIZE

COARSE RED H/V LIN

COARSE RED H/V KEY

COARSE RED H/V PIN

-512 - +511

-512 - +511

-512 - +511

-512 - +511

-512 - +511

-512 - +511

000 / XXXX

XXXX / 000

000 / XXXX

PIN

LIN

CENT 000 / 000

SKEW 000 / 000

KEY

RED SIZE 000 / 000

Page 51

KP-53XBR300/61XBR300

RM-Y902RM-Y902

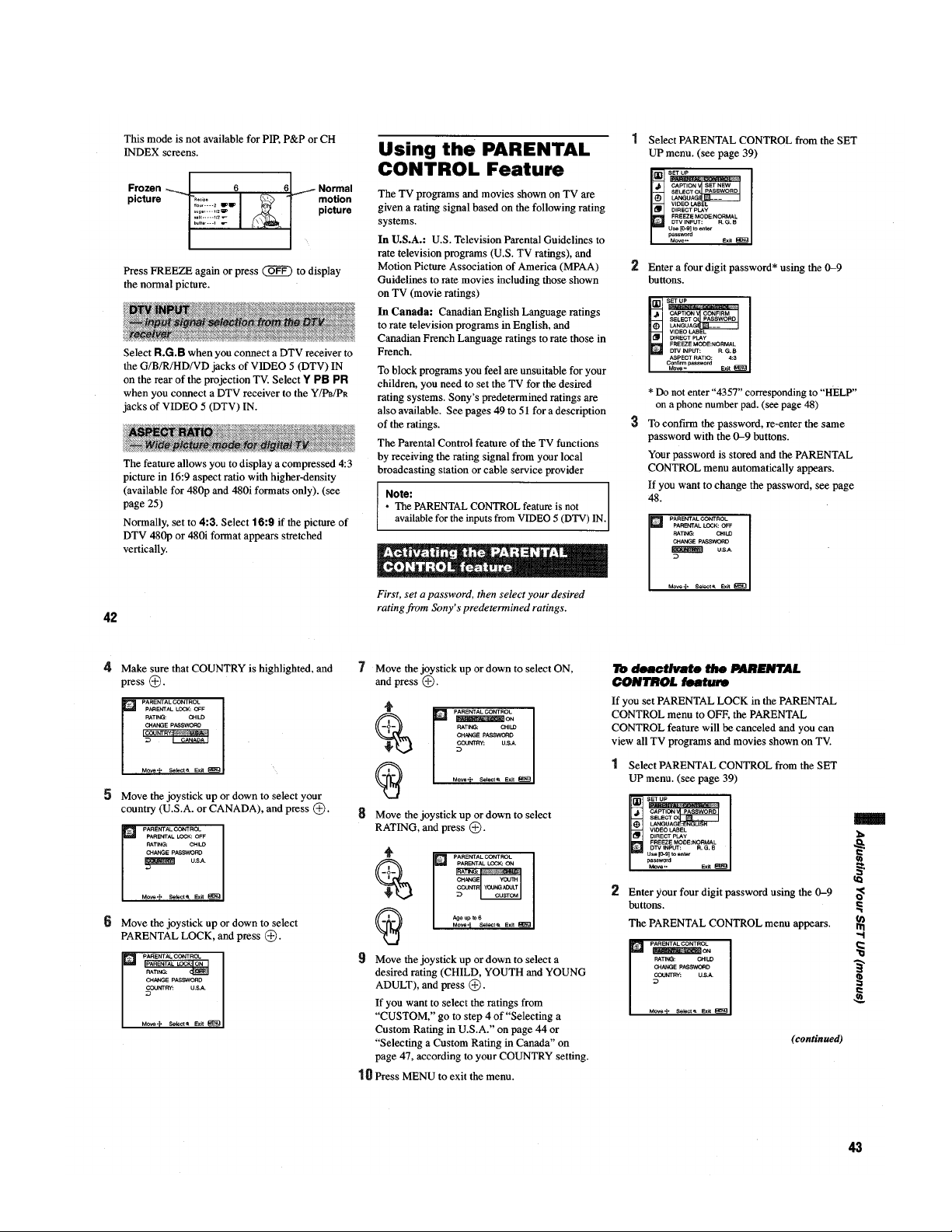

3-10. REGISTRATION ADJUSTMENT

• ADJUST BUTTONS AND INDICATOR

MUTING

DISPLAY

Adjustment item

up

Adjustment item

down

Category down

Category up

MUTING

FUNCTION

OFF

AUDIO SWAP

TV/DBS

PICTURE

MODE

" PJED "

data up/down

POWER

SYSTEM

DVD/

DBS

OFF

VTR

CABLE

DVD/VTR

DBS/CABLE

FREEZE

POTITION

LEFT RIGHT

GUIDE ACTIVE

CC

DISPLAY TV/VIDEO

1

2

4

5

7

8

JUMP

0

MENU

VOL CH

RESET

TV

ENTER

TV

TV

ZOOM IN

ANT

3

6

9

TV POWER ON

Data up

(Rough adjustment)

PJED mode

Color change

n

BLUnRED

GRN

Data down

(Rough adjustment)

PJED mode

Test signal

crosshach+video signal

dots+video signal

crosshach+black

dots+black

off

Mode select

Rough adjustment

(

Fine adjustment

ENTER

[SETUP FOR ADJUSTMENT]

• Current flow in circuit should be stable before attempting

adjustment. So wait 5 minutes after turning on the TV power.

• The adjustments should be done in the 4 : 3 mode, 16 : 9 mode

and VIDEO 5 1080i mode respectively.

Adjust every color registrations in one mode.

Forced 16 : 9 mode setting:

In the service mode, set OP 01 16 : 9 to 001.

VIDEO 5 forced 1080i mode setting:

Connect RCA pin plug to VIDEO IN 5 red pin jack, and set

OP 03 1080 to 001 in the service mode.

1. Set to the service mode by pressing quickly keys on the

remote commander in the standby mode in the following

order:

[DISPLAY] n 5 n [VOL+] n [TVPOWER]

4. Set FDIS data to “01” to display the registration data of each

spot in the fine adjustment.

PJE 00 00

FDIS

5. Press 6 to display the test signal (crosshatch) on the screen.

6. Select GRN CENT(*) with the 1 and 4 keys on the remote

commander and check that the adjustment data is now “000”

both vertically and horizontally.

(H) (V)

GRN 000 000

CENT

*: In the factory preset, “GRN CENT” appears on the screen first.

)

In case of other colors “RED” or “BLU”, change color by

every pressing 3 key.

7. Set MCP1 07 RON to “000”, 08 GON to “001” and 09 BON to

“000” to show only the green color.

8. Change the MCP1 mode to the PJE mode.

SUB DEFLECTION ADJUSTMENT ITEM

Adjustment O : Yes – : No

Adjustment type

Display Adjustment item G R B

H/V H/V H/V

CENT CENT O/O O/O O/O

SKEW SKEW O/O O/O O/O

SIZE SIZE O/O O/O O/O

LIN LIN –/– O/– O/–

KEY KEY –/– –/O –/O

PIN PIN –/O –/O –/O

Category Adjustment item

DATA

SERVICE VDSP VPOS 031

0000 0

0000 00 00

(SCREEN DISPLAY)

2. Change TV mode to the video input mode.

3. Change the VDSP mode to the PJE 00 FDIS.

– 50 –

Page 52

KP-53XBR300/61XBR300

RM-Y902RM-Y902

[GREEN REGISTRATION ADJUSTMENT]

<GREEN CENTER, SIZE>

1. Select GRN CENT or GRN SIZE with the 1and 4 keys on

the remote commander.

2. Adjust the crosshatch line goes center horizontally (GRN

CENT) and set the size correctly (GRN SIZE) with the

joystick on the remote commander.

GRN

CENT

<GREEN SKEW>

1. Select GRN SKEW with the 1and 4 keys on the remote

commander.

2. Adjust the crosshatch line goes straight vertically and horizontally with the joystick on the remote commander.

000 000

<FINE ADJUSTMENT>

1. Press 9 key on the remote commander to shift to the fine

adjustment mode.

The green marker (in the GRN mode) appears on the center of

the screen.

2. Use the 1and 4 keys or the joystick on the remote commander, move the marker (see below) everywhere you want to

adjust and adjust with the joystic keys on the remote commander.

Marker movement by the 1 and 4 keys:

Press once the joystick the marker turns sreen to white.

Then you can move the marker up and down left and right.

GRN

SKEW

000 000

<GREEN PINCUSHION>

1. Select GRN PIN with the 1and 4 keys on the remote

commander.

2. Adjust the crosshatch line goes straight vertically and horizontally with the joystick on the remote commander.

GRN

XXXX 000

PIN

GRN

PIN

3. Press 9 key on the remote commander to shift to the rough

adjustment mode.

– 51 –

Page 53

KP-53XBR300/61XBR300

RM-Y902RM-Y902

[RED REGISTRATION ADJUSTMENT]

<RED CENTER>

1. Change to MCP1 mode and set MCP1 07 RON to “001”, 08

GON to “001” and 09 BON to “000” to show the green and

red colors.

2. Change the MCP1 mode to the PJE mode.

3. Press 3 key on the remote commander to shift the GRN

mode to the RED mode.

4. Select RED CENT with the 1 and 4 keys on the remote

commander.

5. Adjust the red crosshatch lines go straight vertically and

horizontally and overlaps the green lines with the joystick on

the remote commander.

<RED SKEW>

1. Select RED SKEW with the 1 and 4 keys on the remote

commander.

2. Adjust the red crosshatch lines go straight vertically and

horizontally and overlaps the green lines with the joystick on

the remote commander.

<RED LINEARITY>

1. Select RED SIZE (vertically and horizontally) or RED LIN

(vertically) with the 1 and 4 keys on the remote commander and adjust while tracking each other alternately.

2. Adjust the red crosshatch lines go straight vertically and

horizontally and overlaps the green lines with the joystick on

the remote commander.

2. Use the 1 and 4 keys or the joystick on the remote commander, move the marker everywhere you want to adjust and

adjust with the joystick on the remote commander.

[BLUE REGISTRATION ADJUSTMENT]

1. Change to MCP1 mode and set MCP1 07 RON to “001”, 08

GON to “001” and 09 BON to “001” to show full color.

2. Change the VPNT mode to the PJE mode.

3. Press 3 key on the remote commander to shift the RED mode

to the BLU mode.

4. Adjust BLU CENT, BLU SKEW, BLU SIZE, BLU LIN, BLU

KEY and BLU PIN in the same procedure of the red registration adjustment.

[FINAL CHECK]

1. Store the new adjustment (offset) value on the remote control

by pressing [MUTING] and [ENTER].

2. Press the FLASH FOCUS button on the front panel.

(The Offset value is now automatically stored.)

3. Check that no error message appears.

If an error message appears, recheck.

<RED KEY>

1. Select RED KEY with the 1 and 4 keys on the remote

commander.

2. Adjust the red crosshatch lines go straight horizontally and

overlaps the green lines

with the joystick on the remote commander.

<RED PINCUSHION>

1. Select RED PIN with the 1 and 4 keys on the remote

commander.

2. Adjust the red crosshatch lines go straight horizontally and

overlaps the green lines with the joystick on the remote

commander.

<FINE ADJUSTMENT>

1. Press 9 key on the remote commander to shift to the fine

adjustment mode.

The red marker (in the RED mode) appears on the center of the

screen.

– 52 –

Page 54

3-11. AUTO REGISTRATION ERROR CODE LIST

[ERROR CODE LIST]

ERROR

CODE

00 No Error

10 Sensor Output Level Low * Check wiring, beam position, sensor. 0 : Upper Center

20 Sensor Output Level High * Check OP-amp circuit. 0 : Upper Center

30 Adjustment Loop Counter Overflow * Check the data go far from the standard or not.

40 Regi Data Overflow * Check the data go far from the standard or not.

50 Regi Data Overflow * Check the data go far from the standard or not.

60 Offset Overflow * Check the data go far from the standard or not.

70 Offset Overdrow * Check the data go far from the standard or not.

DISCRIPTION NOTE

1 : Middle Left

2 : Middle Right

3 : Lower Center

1 : Middle Left

2 : Middle Right

3 : Lower Center

KP-53XBR300/61XBR300

RM-Y902RM-Y902

* In case of multiple error, last error is displayed.

• ERROR CODE SCREEN DISPLAY

E 11 B

E 11 B

* Error code will be displayed on center of screen for 3 seconds.

• ERROR CODE DISPLAY IN REGI SERVICE MODE

PJE 2 9 1 4 0

ERR

ITEM NUMBER-29

SENSOR NUMBER

(ONLY "10"or "20")

ERROR CODE 40

R.G.B

G-0 (Blank)

R-1

B-2

R. G. B

SENSOR NUMBER

ERROR CODE 10

ERROR

[SENSOR POSITION]

0

4

1

6

SCREEN

3

0 : UPPER SENSOR

1 : LEFT SENSOR

2 : RIGHT SENSOR

3 : LOWER SENSOR

4 : UL

5 : UR

6 : LL

7 : LR

5

2

7

– 53 –

Page 55

KP-53XBR300/61XBR300

RM-Y902RM-Y902

[ D BOARD]

SECTION 4

SAFETY RELATED ADJUSTMENTS

4-1. HV REGULATION CIRCUIT CHECK AND

ADJUSTMENT

When replacing the following components marked with on

the schematic diagram always check HV regulation, and if necessary re-adjust.

: R8194, R8202

: C8064, C8066, C8070, C8074, C8076,C8082

D8042

IC8002, IC8007, IC8008

Q8022

R8093, R8095, R8096, R8105, R8108

R8112, R8113, R8114, R8115, R8126

R8128, R8136, R8138, R8139, R8154

R8157, R8168, R8173, R8174, R8177

R8178, R8195, R8196, R8201

T8002 (LOT), T8003 (FBT)

HV BLOCK, D BOARD

OPERATION CHECK

1. Connect a HV static voltmeter to the unconnected plug of

the high-voltage block.

2. Connect a 33kΩ variable resistor, set to maximum value,

across CN8008.

3. Power on the set.

4. Receive dot signal pattern.

5. Gradually lower the value of the variable resistor and check

that the hold-down circuit operates at a static voltmeter reading of 31.0 ± 0.5kV dc when the raster disappears.

HV HOLD-DOWN ADJUSTMENT

1. REPART STEPS 1 ~ 5 as above.

2. Just at the point hold-down circuit begins to operate switch

off the set.

3. Remove the VR connected across CN8008, and measure it’s

resistance.

4. Solder a resistor value, nearest to the measured value, across

CN8008.

5. Reconfirm operation check.

4-2. HV HOLD DOWN CIRCUIT OPERATION

CHECK AND ADJUSTMENT

When replacing the following components marked with on

the schematic diagram always check hold-down voltage and if

necessary re-adjust.

: R8196, R8201

: D8026, D8032, D8035, D8050

IC8006, IC8009, IC8010

Q8021, Q8031

R8092, R8094, R8097, R8109, R81 10,R8117,

R81 18, R8121, R8123, R8125, R8129, R8135,

R8140, R8155, R8190, R8191, R8192, R8193,

R8194, R8198, R8202

T8002 (LOT), T8003(FBT)

HV BLOCK, D BOARD

OPERATION CHECK

1. Connect a HV static voltmeter to the unconnected plug of

the high-voltage block.

2. Power on the set.

3. Receive dot signal patterm.

4. Check that the HV static voltmeter is readind 34.0 ± 0.5V dc.

HV Regulation ADJUSTMENT

1. Repart step 1 as above.

2. Connect 33kΩ variable resistor, set to maximum value, to

CN8008.

3. Power on the set.

4. Receive dot signal pattern.

5. Gradually lower the value of the variable resistor until the

static voltmeter is reading 34.0 ± 0.5 kVdc.

6. Switch off the swt.

7. Remove the VR connected across CN8008, and measure its

value.

8. Solder a resistor value, nearest to the measured value, across

CN8008.

9. Reconfirm operation check.

Fig. 4-1

Remove the cap off from

the unused terminal and

connect a static voltmeter

there.

4-3. +B OVP CONFIRMATION

1. Connect a voltmeter to TP. OVP and ground.

2. Supply 120VAC to variable autotransformer.

3. Power on the Set.

4. Supply 150VDC to TP. OVP.

5. Check the OVP operate.

– 54 –

Page 56

SECTION 5

CIRCUIT ADJUSTMENTS

[ MCD MODE]

5-1. TV INPUT SUB CONTRAST ADJUSTMENT

(MCD1-SCON)

1. Receive the color-bar signal.

2. Set to service mode.

3. Connect an oscilloscope between pin 2 of CN511 (A board)

and ground.

4. Select “ MCD1-SCON ”, and adjust so that the waveform

level is 0.525 ± 0.015Vp-p.

5. Write the data into memory.

MUTING n ENTER

White

±

0.015Vp-p

0.525

Pedestal

KP-53XBR300/61XBR300

5-3. P & P SUB CONTRAST ADJUSTMENT

(MCD2-SCON)

1. Receive the signal.

TV terminal (main) : color-bar signal

VIDEO terminal (sub) : no signal

2. Set to P & P mode, set to service mode.

3. Connect an oscilloscope between pin @º of CN513 (A board)

and ground.

4. Select “ MCD2-SCON ”, and adjust so that the waveform

level is 0.525 ± 0.015Vp-p.

5. Write the data into memory.

MUTING n ENTER

White

±

0.015Vp-p

0.525

Pedestal

RM-Y902RM-Y902

Fig. 5-1

5-2. VIDEO INPUT SUB CONTRAST ADJUSTMENT

(MCD3-SCON)

1. VIDEO 1 input the color-bar signal.

2. Set to service mode.

3. Connect an oscilloscope between pin 2 of CN511 (A board)

and ground.

4. Select “ MCD3-SCON ”, and adjust so that the waveform

level is 0.525 ± 0.015Vp-p.

5. Write the data into memory.

MUTING n ENTER

White

±

0.015Vp-p

0.525

Fig. 5-3

5-4. P & P SUB CONTRAST ADJUSTMENT

(MCD4-SCON)

1. Receive the signal.

TV terminal (sub) : no signal

VIDEO terminal (main) : color-bar signal

2. Set to P & P mode, and set to service mode.

3. Connect an oscilloscope between pin @º of CN513 (A board)

and ground.

4. Select “ MCD4-SCON ”, and adjust so that the waveform

level is 0.525 ± 0.015Vp-p.

5. Write the data into memory.

MUTING n ENTER

White

±

0.015Vp-p

0.525

Fig. 5-2

Pedestal

Pedestal

Fig. 5-4

– 55 –

Page 57

KP-53XBR300/61XBR300

RM-Y902RM-Y902

5-5. SUB-CONTRAST ADJUSTMENT

(MCP2-SCON)

1. Receive the color-bar signal.

2. VIDEO MODE : PRO

PICTURE : maximum

COLOR : minimum

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA MCP2-SBRT : 25

3. Set to service mode.

4. Connect an oscilloscope between pin 3 of CN503 (A board)

connecter and ground.

5. Select “ MCP 2-SCON ”, and adjust so that the waveform

level is 1.750 ± 0.030Vp-p.

6. Write the data into memory.

MUTING n ENTER

White

±

0.030Vp-p

1.750

Black

Fig. 5-5

5-7. SUB-HUE AND SUB-COLOR ADJUSTMENT

(MCD1-SHUE, SCOL)

1. Receive the color-bar signal.

2. VIDEO MODE : PRO

PICTURE : maximum

COLOR : center

HUE : HUE

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA MCP2-SBRT : 25

MCP2-SHUE : 7

MCP2-SCOL : 12

3. Set to service mode.

4. Connect an oscilloscope between pin 5 of CN503 (A board)

connecter and ground.

5. Select “ MCD 1-SHUE, SCOL ”, and adjust them to have

VB1 = VB4 and VB2 = VB3 in the waveform levels.

6. Write the data into memory.

MUTING n ENTER

VB1 VB2 VB3 VB4

Fig. 5-7

5-6. VIDEO 5 INPUT SUB-CONTRAST

ADJUSTMENT (MCP3-SCON)

1. VIDEO 5 input the color-bar signal.

2. PICTURE : maximum

COLOR : minimum

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA MCP3-SBRT : 25

3. Set to service mode.

4. Connect an oscilloscope between pin 3 of CN503 (A board)

connecter and ground.

5. Select “ MCP 3-SCON ”, and adjust so that the waveform

level is 1.750 ± 0.030Vp-p.

6. Write the data into memory.

MUTING n ENTER

White

±

0.030Vp-p

1.750

Black

Fig. 5-6

5-8. VIDEO INPUT SUB-HUE AND SUB-COLOR

ADJUSTMENT (MCD3-SHUE, SCOL)

1. VIDEO input the color-bar signal.

2. VIDEO MODE : PRO

PICTURE : maximum

COLOR : center

HUE : HUE

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA MCP2-SBRT : 25

MCP2-SHUE : 7

MCP2-SCOL : 12

3. Set to service mode.

4. Connect an oscilloscope between pin 5 of CN503 (A board)

connecter and ground.

5. Select “ MCD 3-SHUE, SCOL ”, and adjust them to have

VB1 = VB4 and VB2 = VB3 in the waveform levels.

6. Write the data into memory.

MUTING n ENTER

VB1 VB2 VB3 VB4

– 56 –

Fig. 5-8

Page 58

5-9.

P & P SUB-HUE AND SUB-COLOR ADJUSTMENT (MCD2-SHUE, SCOL)

1. Receive the signal.

TV terminal (main) : color-bar signal

VIDEO terminal (sub) : no signal

2. VIDEO MODE : PRO

PICTURE : maximum

COLOR : center

HUE : HUE

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA MCP2-SBRT : 25

SERVICE DATA MCP2-SHUE : 7

SERVICE DATA MCP2-SCOL : 12

3. Set to P & P mode, set to service mode.

4. Connect an oscilloscope between pin 5 of CN503 (A board)

connecter and ground.

5. Select “ MCD 2-SHUE, SCOL ”, and adjust them to have

VB1 = VB4 and VB2 = VB3 in the waveform levels.

6. Write the data into memory.

MUTING n ENTER

KP-53XBR300/61XBR300

[ SCD MODE]

5-11. P & P SUB CONTRAST ADJUSTMENT

(SCD1-SCON)

1. Receive the signal.

TV terminal (sub) : color-bar signal

VIDEO terminal (main) : no signal

2. Set to P & P mode, and set to service mode.

3. Connect an oscilloscope between pin @º of CN513 (A board)

and ground.

4. Select “ SCD1-SCON ”, and adjust so that the wave from

level is 0.525 ± 0.015Vp-p.

5. Write the data into memory.

MUTING n ENTER

White

±

0.015Vp-p

0.525

Pedestal

RM-Y902RM-Y902

VB1 VB2 VB3 VB4

Fig. 5-9

5-10.

P & P SUB-HUE AND SUB-COLOR ADJUSTMENT

(MCD4-SHUE, SCOL)

1. Receive the signal.

TV terminal (main) : no signal

VIDEO terminal (sub) : color-bar signal

2. VIDEO MODE : PRO

PICTURE : maximum

COLOR : center

HUE : HUE

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA MCP2-SBRT : 25

SERVICE DATA MCP2-SHUE : 7

SERVICE DATA MCP2-SCOL :12

3. Set to P & P mode, set to service mode.

4. Connect an oscilloscope between pin 5 of CN503 (A board)

connecter and ground.

5. Select “ MCD 4-SHUE, SCOL ”, and adjust them to have VB1

= VB4 and VB2 = VB3 in the waveform levels.

6. Write the data into memory.

MUTING n ENTER

Fig. 5-11

5-12. P & P SUB CONTRAST ADJUSTMENT

(SCD2-SCON)

1. Receive the signal.

TV terminal (main) : no signal

VIDEO terminal (sub) : color-bar signal

2. Set to P & P mode, and set to service mode.

3. Connect an oscilloscope between pin @º of CN513 (A board)

and ground.

4. Select “ SCD2-SCON ”, and adjust so that the wave from

level is 0.525 ± 0.015Vp-p.

5. Write the data into memory.

MUTING n ENTER

White

±

0.015Vp-p

0.525

Pedestal

VB1 VB2 VB3 VB4

Fig. 5-10

Fig. 5-12

– 57 –

Page 59

KP-53XBR300/61XBR300

RM-Y902RM-Y902

5-13. SUB-HUE AND SUB-COLOR ADJUSTMENT

(SCD1-HUE, SCOL)

1. Receive the color-bar signal.

2. VIDEO MODE : PRO

PICTURE : maximum

COLOR : center

HUE : HUE

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA MCP2-SBRT : 25

SERVICE DATA MCP2-SHUE : 7

SERVICE DATA MCP2-SCOL : 12

3. Set to service mode.

4. Connect an oscilloscope between pin 5 of CN503 (A board)

connecter and ground.

5. Select “ SCD1-SHUE, SCOL ”, and adjust them to have VB1

= VB4 and VB2 = VB3 in the waveform levels.

6. Write the data into memory.

MUTING n ENTER

VB1 VB2 VB3 VB4

Fig. 5-11

5-14. SUB-HUE AND SUB-COLOR ADJUSTMENT

(SCD2-HUE, SCOL)

1. Receive the color-bar signal.

2. VIDEO MODE : PRO

PICTURE : maximum

COLOR : center

HUE : HUE

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA MCP2-SBRT : 25

SERVICE DATA MCP2-SHUE : 7

SERVICE DATA MCP2-SCOL : 12

3. Set to service mode.

4. Connect an oscilloscope between pin 5 of CN503 (A board)

connecter and ground.

5. Select “ SCD2-HUE, SCOL ”, and adjust them to have VB1

= VB4 and VB2 = VB3 in the waveform levels.

6. Write the data into memory.

MUTING n ENTER

5-15. VIDEO 5 INPUT SUB-HUE AND SUB-COLOR

ADJUSTMENT (MCP3-SHUE, SCOL)

1. VIDEO 5 input the color-bar signal.

2. PICTURE : maximum

COLOR : minimum

HUE : HUE

BRIGHTNESS : center

TRINITONE : medium

SERVICE DATA MCP3-SBRT : 25

3. Set to service mode.

4. Connect an oscilloscope between pin 3 of CN503 (A board)

connecter and ground.

5. Select “ MCP 3-SHUE, SCOL ”, and adjust them to have

VB1 = VB4 and VB2 = VB3 in the waveform levels.

6. Write the data into memory.

MUTING n ENTER

VB1 VB2 VB3 VB4

Fig. 5-15

VB1 VB2 VB3 VB4

Fig. 5-12

– 58 –

Page 60

[ MCD MODE]

5-16. DISPLAY POSITION ADJUSTMENT

(OSD-HPOS)

1. Receive the monoscope signal.

2. Set to Service mode.

3. Select “ OSD-HPOS ”, and adjust so that the left edge of

MENU is as shown to the spec.

4. Write the data into memory.

MUTING n ENTER

KP-53XBR300/61XBR300

5-18. MID DISPLAY POSITION ADJUSTMENT

(MID-HPOS)

1. Display 1/9 size PIP.

2. Set to Service mode.

3. Select “ MID-HPOS ”, and adjust data so that

4. Write the data into memory.

MUTING n ENTER

A=B

RM-Y902RM-Y902

.

MENU

-7

0

Fig. 5-16

7

5-17. CAPTION VISION POSITION ADJUSTMENT

(MCCD-CCDH)

1. Receive signal with CAPTION VISION data.

2. Set to Service mode.

3. Display TEXT BOX.

A=B

4. Select “ MCCD-CCDH ”, and adjust data so that

.

5. Write the data into memory.

MUTING n ENTER

A

A=B

Fig. 5-18

00

••••••

B

00

A

A=B

Fig. 5-17

B

– 59 –

Page 61

KP-53XBR300/61XBR300

RM-Y902RM-Y902

MEMO

– 60 –

Page 62

6-1. BLOCK DIAGRAM (1)

J508

L

AUDIO

R

VIDEO3

INPUT

S–VIDEO

V

L

R

J3501

SIRCS

INPUT

J3502

SIRCS

OUTPUT

J3503

HD

VD

1

OUT

IC3301

SENSOR

HC

(

SIRCS RECEIVER

VIDEO2

INPUT

S–VIDEO

J506

4

3

2

1

V

L

R

SW

Q3504 3505

(SIRCS INPUT/OUT)

U

CN3301

CN3103

2

SIRCS

2

)

HA

V

L

R

(VIDEO2 INPUT)

VIDEO1

INPUT

S–VIDEO

VIDEO4

INPUT

S–VIDEO

SW

Q3504 3505

SW

Q3504 3505

D3101

+5V

D3102

S3101-3106

(FUNCTION KEY)

S3201,3202

J3201

4

3

2

1

V

L

R

DET OUT2

L OUT

R OUT

MUTE

ST IND

AFT OUT

F MONO

MODE

RF AGC

DET OUT

SDA

SCL

V

L

R

V

L

R

CN3101

CN3102

CN3202

CN3201

HB

CN3501

TU501

MAIN

TUNER

BUFFER

Q506, 517

INVERTER

J505

3

1

V

L

R

J507

3

1

V

L

R

1

HD

3

VD

7

RM IN

4

KEY0

5

STLED

6

TIMER LED

3

SIRCS

SIRCS

1

TO K BOARD

CN2102

1

KEY0

2

FR R IN

4

FR L IN

6

FR V IN

8

FR C IN

9

F SW

11

FR Y IN

SECTION 6

DIAGRAMS

BUFFER

Q502

Q507

4

2

4

2

Q801,804

SW

G

TO ANT SW

F

TO K BOARD

CN2103

SDA

SCL

RM IN

SIRCS

KEY0

STLED

TIMER LED

DATA

MSCL

MSDA

ENABLE

A PROT

FR R IN

FR L IN

FR V IN

FR C IN

FRONT SW

FR Y IN

ANT SW1

ANT SW2

SP SW

F MUTE

C MUTE

S MUTE

FIX MUTE

A MUTE

DET OUT

HD

VD

CLK

L

R

1

1

2

3

3

7

3

4

5

6

1

2

5

6

3

7

2

4

6

8

9

11

1

2

1

3

5

6

7

8

9

10

BUFFER

Q512

CN526

CN514

CN510

CN515

CN508

CN512

15

TU502

AFT OUT

FMONO

SAP IND

ST INO

MODE

MUTE

13

14

IC1010

ST5V RESET

RST

9

ROUT

4

LOUT

DET OUT2

17

TUNER

BUFFER

Q518, 526

X1001

12MHz

SUB

TV V

63 56

TV L

62

TV R

64

TV SUB V

60

TV SUB L

59

TV SUB R

61

Y 1

3

C 1

5

SSW 1

6