Sony PVM-9L1, PVM-14L1, PVM-20L1, PVM-SSM-14L1 Service Manual

TRINITRON® COLOR VIDEO MONITOR

PVM-14L1

PVM-14L1MDE

PVM-20L1

SSM-14L1

SSM-20L1

SERVICE MANUAL

1st Edition (Revised 1)

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

. Equipment energized from an external electrical power source :

Class I Equipment

. Degree of protection against electric shock :

No applied part

. Mode of operation :

Continuous operation

WARNING!!

ATTENTION!!

AN INSULATED TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECEIVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING !!

COMPONENTS IDENTIFIED BY A

DIAGRAMS, EXPLODED VIEWS AND IN THE PARTS LIST ARE

CRITICAL TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY PAR TS WHOSE P ART NUMBERS APPEAR

AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY . CIRCUIT ADJUSTMENTS THA T ARE CRITICAL TO SAFE OPERATION ARE IDENTIFIED IN THIS MANU AL.

FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS

SUSPECTED.

!!

! MARK ON THE SCHEMA TIC

!!

AFIN D’ÉVITER TOUT RISQUE D’ÉLECTROCUTION

PROVENANT D’UN CHÂSSIS SOUS TENSION, UN

TRANSFORMA TEUR D’ISOLEMENT DOIT ETRE UTILISÉ LORS

DE TOUT DÉPANNA GE.

LE CHÂSSIS DE CE RÉCEPTEUR EST DIRECTEMENT

RACCORDÉ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS Á LA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE MAPQUE

LES SCHÉMAS DE PRINCIPE, LES VUES EXPLOSÉES ET LES

LISTES DE PIECES SONT D’UNE IMPORTANCE CRITIQUE

POUR LA SÉCURITÉ DU FONCTIONNEMENT. NE LES

REMPLACER QUE PAR DES COMPOSANTS SONY DONT LE

NUMÉRO DE PIÈCE EST INDIQUÉ DANS LE PRÉSENT MANUEL

OU DANS DES SUPPLÉMENTS PUBLIÉS PAR SONY. LES

RÉGLAGES DE CIRCUIT DONT L’IMPORT ANCE EST CRITIQUE

POUR LA SÉCURITÉ DU FONCTIONNEMENT SONT

IDENTIFIÉS DANS LE PRÉSENT MANUEL. SUIVRE CES

PROCÉDURES LORS DE CHAQUE REMPLACEMENT DE

COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS

FONCTIONNEMENT EST SUSPECTÉ.

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

!!

! SUR

!!

Table of Contents

1. Service Overview

1-1. Appearance Figure (14 inch).......................................................................1-1

1-2. Board Locations (14 inch)...........................................................................1-1

1-3. Disassembly (14 inch).................................................................................1-2

1-3-1. Cabinet and Rear Panel (14 inch)...............................................1-2

1-3-2. Q Block Assembly and Q Board (14 inch) ................................1-3

1-3-3. A Board Assembly (14 inch)......................................................1-4

1-3-4. C Board (14 inch)....................................................................... 1-4

1-3-5. Picture Tube and Bezel Complete Assembly (14 inch) .............1-5

1-3-6. Anode Cap (14 inch) ..................................................................1-6

1-4. Appearance Figure (20 inch).......................................................................1-7

1-5. Board Locations (20 inch)...........................................................................1-7

1-6. Disassembly (20 inch).................................................................................1-8

1-6-1. Cabinet and Rear Panel (20 inch)...............................................1-8

1-6-2. Q Block Assembly and Q Board (20 inch) ................................1-9

1-6-3. A Board (20 inch).....................................................................1-10

1-6-4. C Board (20 inch)..................................................................... 1-10

1-6-5. Picture Tube and Bezel Complete Assembly (20 inch) ...........1-11

1-6-6. Anode Cap (20 inch) ................................................................1-12

1-7. Warning on Power Connection .................................................................1-12

2. Set-up Adjustment

2-1. Equipment Required....................................................................................2-1

2-2. Preparations (1) ...........................................................................................2-1

2-3. Preparation (2). Initialization .....................................................................2-6

2-4. Writing Model Data .................................................................................... 2-6

2-5. Picture Output ............................................................................................. 2-6

2-6. Landing Adjustment (1) ..............................................................................2-6

2-7. Deflection Yoke Neck Rotation Adjustment .............................................. 2-8

2-8. Convergence Adjustment (1) ...................................................................... 2-9

2-9. Convergence Adjustment (2) .................................................................... 2-10

2-10. Landing Adjustment (2) ............................................................................2-10

2-11. Focus Adjustment......................................................................................2-10

2-12. White Balance Adjustment .......................................................................2-11

2-12-1. Sub Bright Adjustment.............................................................2-11

2-12-2. White Balance Adjustment [D65] ............................................2-11

2-12-3. White Balance Adjustment [D93] ............................................2-11

2-13. Deflection Adjustment ..............................................................................2-12

2-13-1. 525 Vertical Deflection Adjustment ........................................2-12

2-13-2. 625 Vertical Deflection Adjustment ........................................2-13

2-14. Horizontal Deflection Adjustment ............................................................2-13

2-14-1. 525 Horizontal Deflection Adjustment ....................................2-13

2-14-2. 625 Horizontal Deflection Adjustment ....................................2-14

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

1

2-15. Sub Contrast Adjustment .......................................................................... 2-14

2-16. Adjustment of NTSC Mode ......................................................................2-15

2-16-1. NTSC Composite Input............................................................ 2-15

2-16-2. NTSC Y/C Input ......................................................................2-15

2-17. Adjustment of PAL Mode ......................................................................... 2-15

2-17-1. PAL Composite Input ..............................................................2-15

2-17-2. PAL Y/C Input .........................................................................2-15

3. Safety Related Adjustment

3-1. +B Voltage Check ......................................................................................3-1

3-2. Protection Circuit Confirmation..................................................................3-1

3-2-1. HV Protector Circuit Confirmation............................................3-1

4. Semiconductors................................................................................. 4-1

5. Spare Parts

5-1. Notes on Repair Parts..................................................................................5-1

5-2. Exploded Views ..........................................................................................5-2

5-3. Electrical Parts List ...................................................................................5-10

6. Block Diagrams

Q, A (1/2), C ........................................................................................................... 6-1

A (2/2), DY.............................................................................................................6-2

7. Diagrams

7-1. Frame Schematic Diagram .......................................................................... 7-2

Frame ........................................................................................................ 7-2

7-2. Schematic Diagrams and Board Layouts ....................................................7-3

Schematic Diagrams

Q................................................................................................................7-4

A (1/3) ....................................................................................................... 7-5

A (2/3) ....................................................................................................... 7-6

A (3/3) ....................................................................................................... 7-7

C (14 Inch) ..............................................................................................7-12

C (20 Inch) ..............................................................................................7-14

Board Layouts

Q................................................................................................................7-3

A................................................................................................................7-8

C (14 Inch) ..............................................................................................7-11

C (20 Inch) ..............................................................................................7-13

2

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

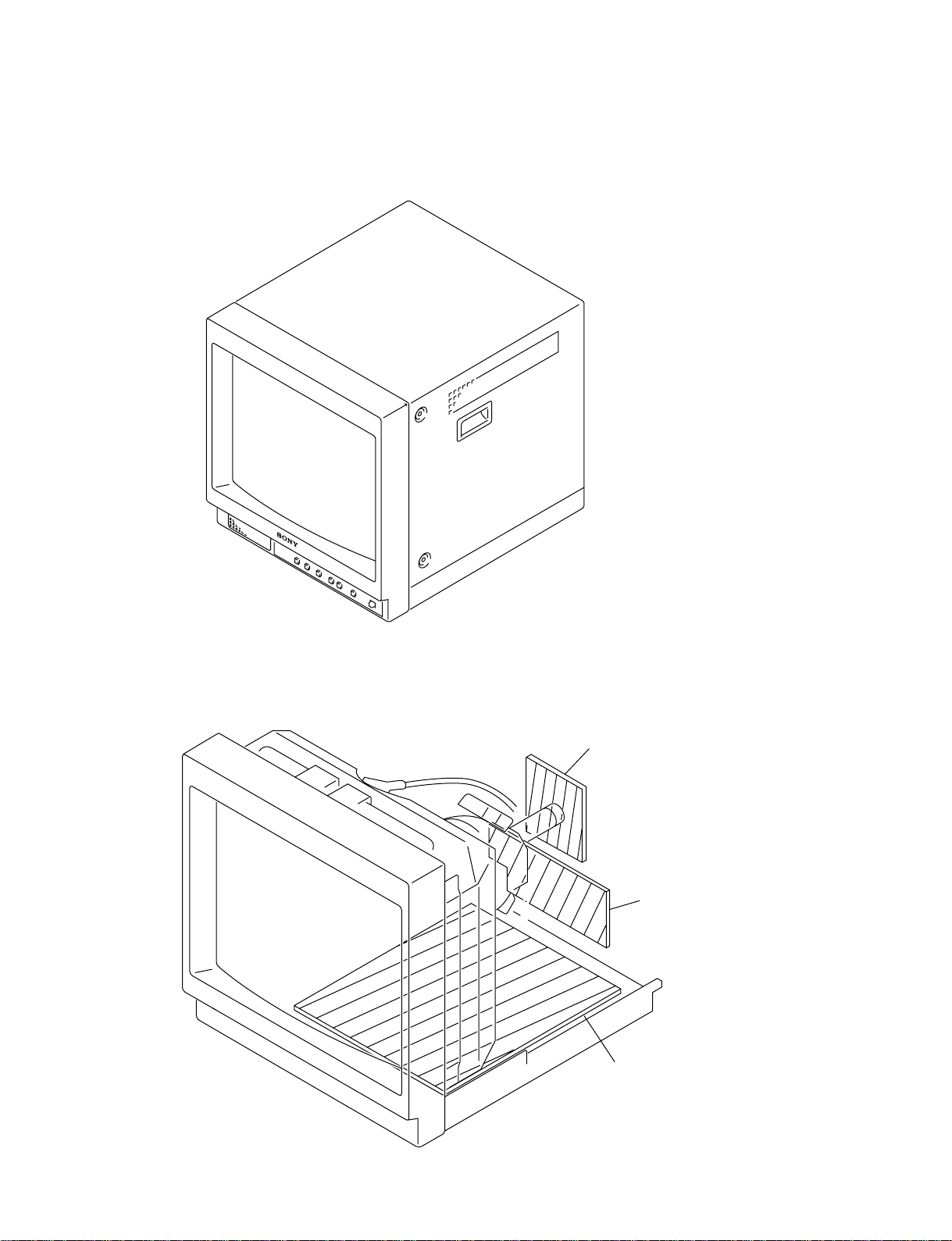

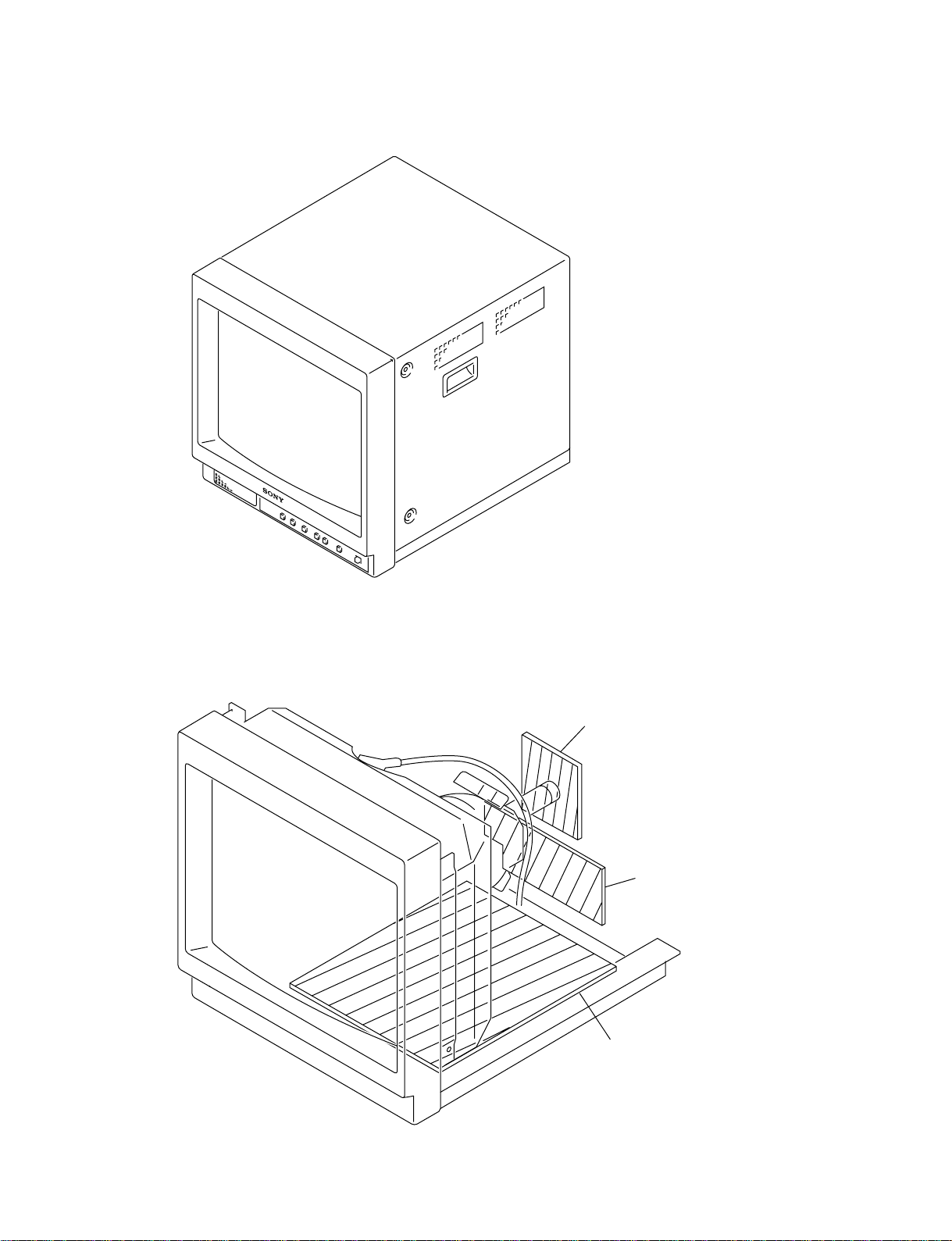

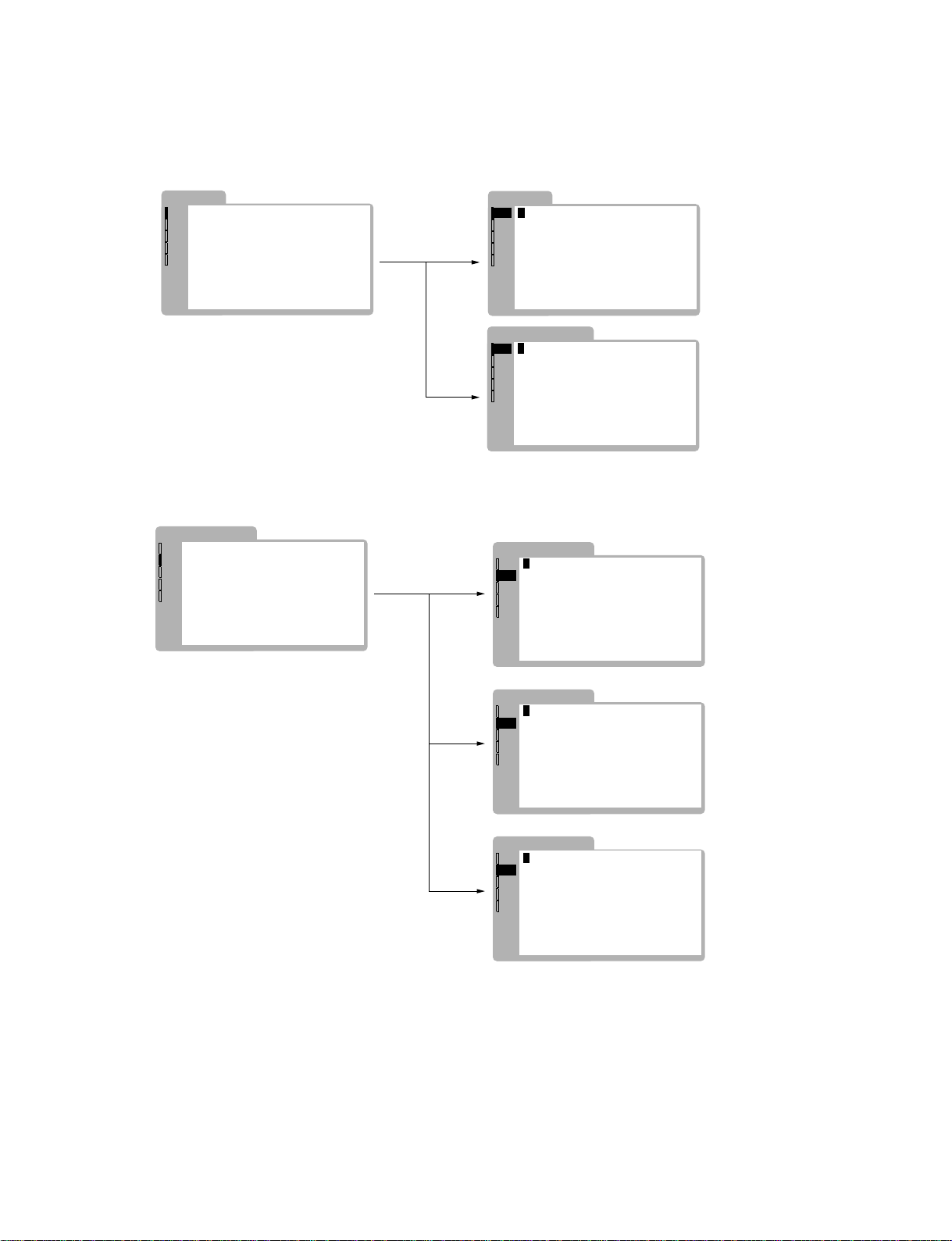

1-1. Appearance Figure (14 inch)

Section 1

Service Overview

1-2. Board Locations (14 inch)

C

Q

A

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

1-1

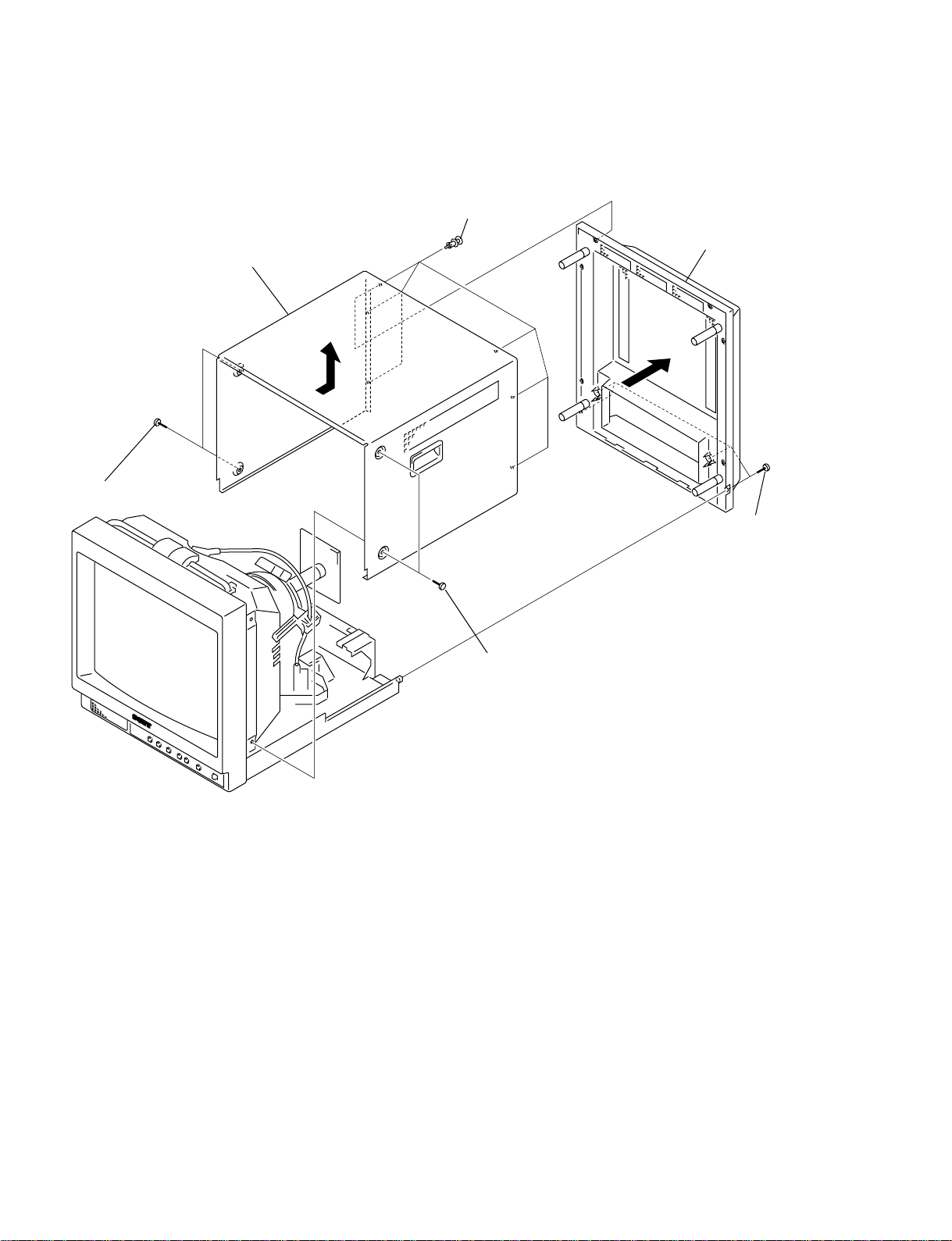

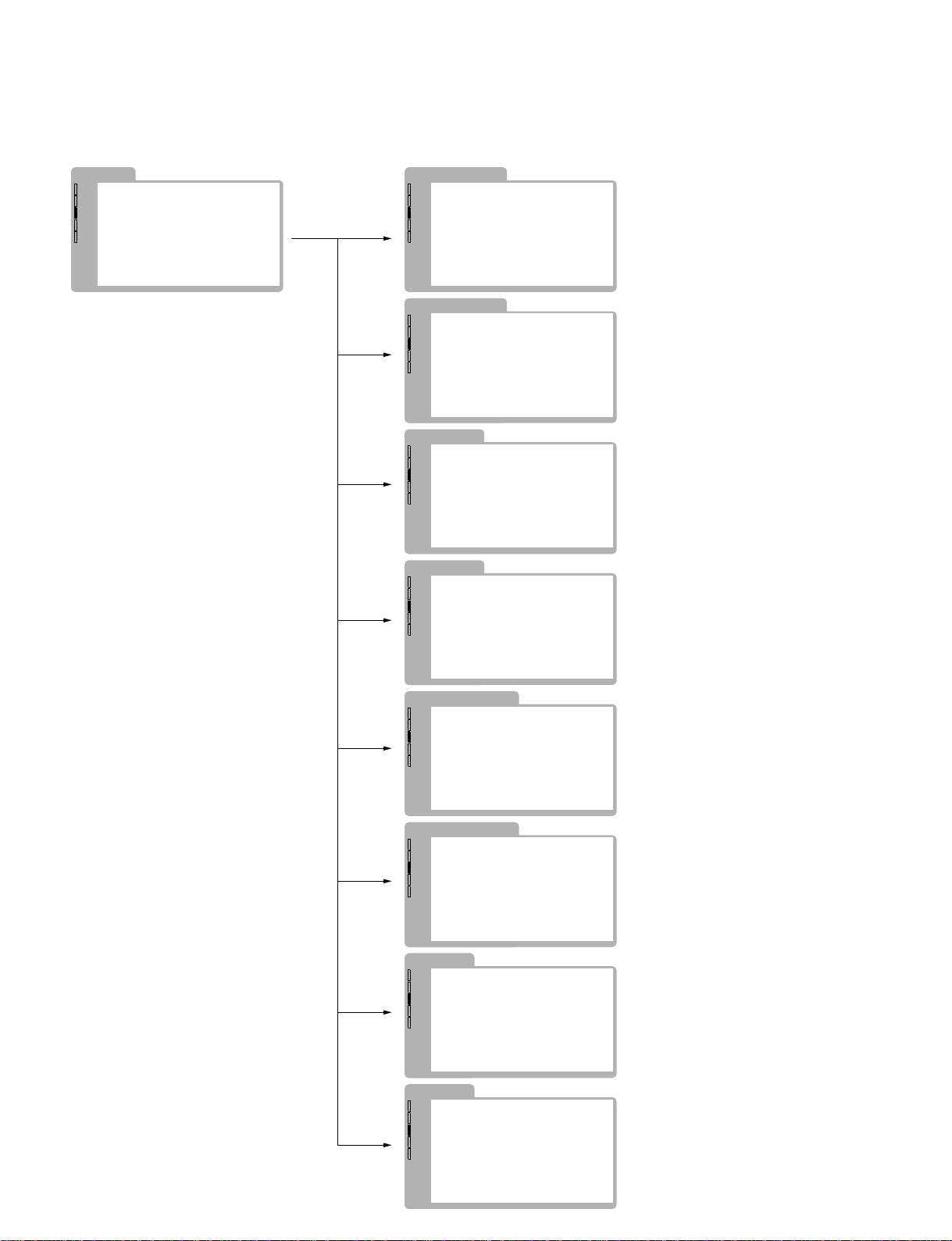

1-3. Disassembly (14 inch)

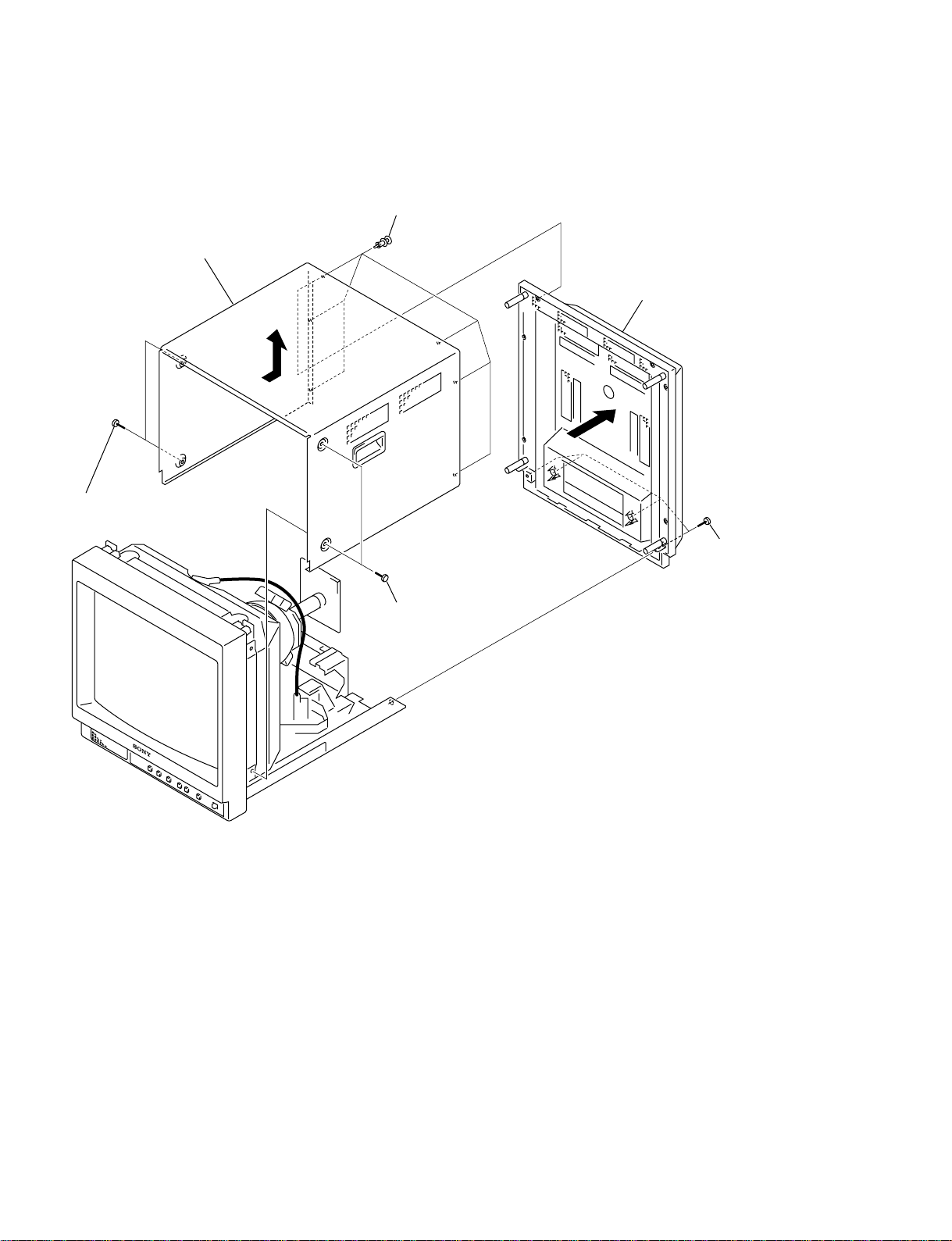

1-3-1. Cabinet and Rear Panel (14 inch)

4 Remove the cabinet

in the direction of the arrow A.

A

Two case claw screws

3

(M 4 x 8)

1 Six nylon rivets

6 Remove the rear panel

in the direction of the arrow B.

B

5 Four screws

(+BVTP 4 x 16)

Two case claw screws

2

(M 4 x 8)

1-2

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

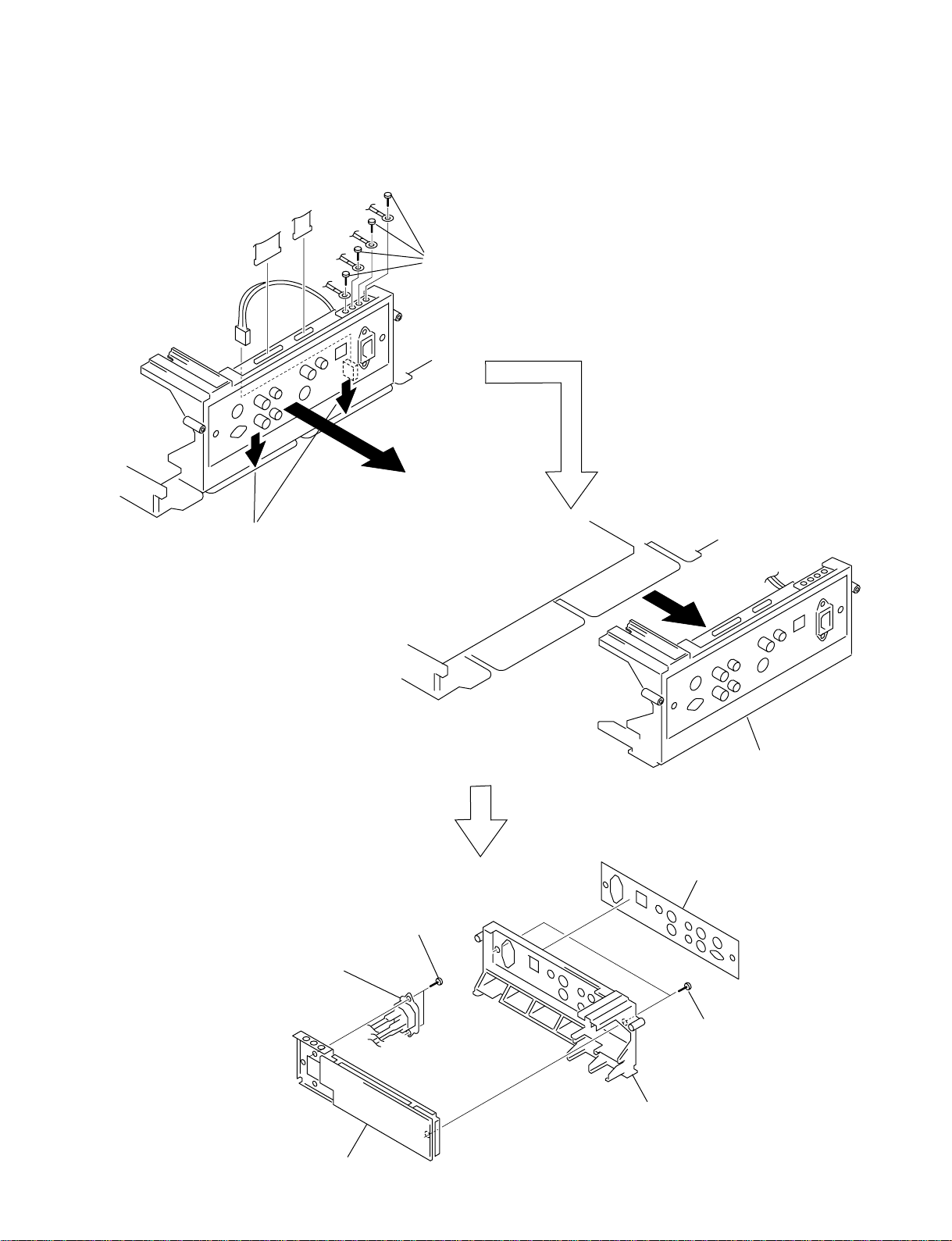

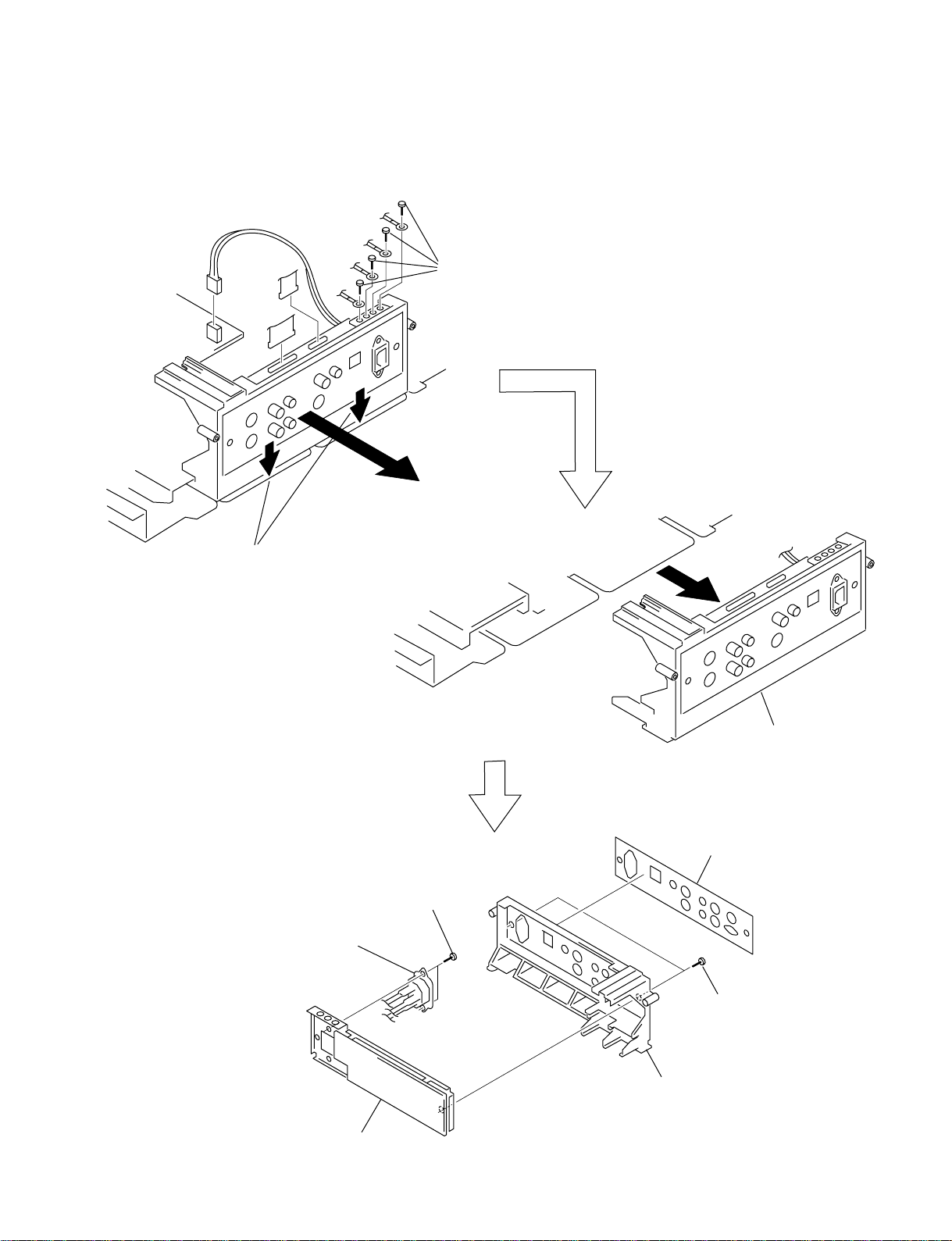

1-3-2. Q Block Assembly and Q Board (14 inch)

. Remove the cabinet and rear panel. (Refer to 1-3-1.)

CN204

CN201

1 Four screws

(+PS 4 x 8)

CN601

A

A

B

Push the two areas in the bottom of beznet in the direction of arrow A,

and pull the Q block assembly in the direction of the arrow B.

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

8 AC inlet

9 Q board

7 Two screws

(+PSW 3 x 10)

4

Connector label

5 Two screws

(+PSW 3 x 10)

6

Connector panel

3

Q block assembly

1-3

1-3-3. A Board Assembly (14 inch)

. Remove the cabinet and rear panel. (Refer to 1-3-1.)

1-3-4. C Board (14 inch)

. Remove the cabinet and rear panel. (Refer to 1-3-1.)

1-4

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

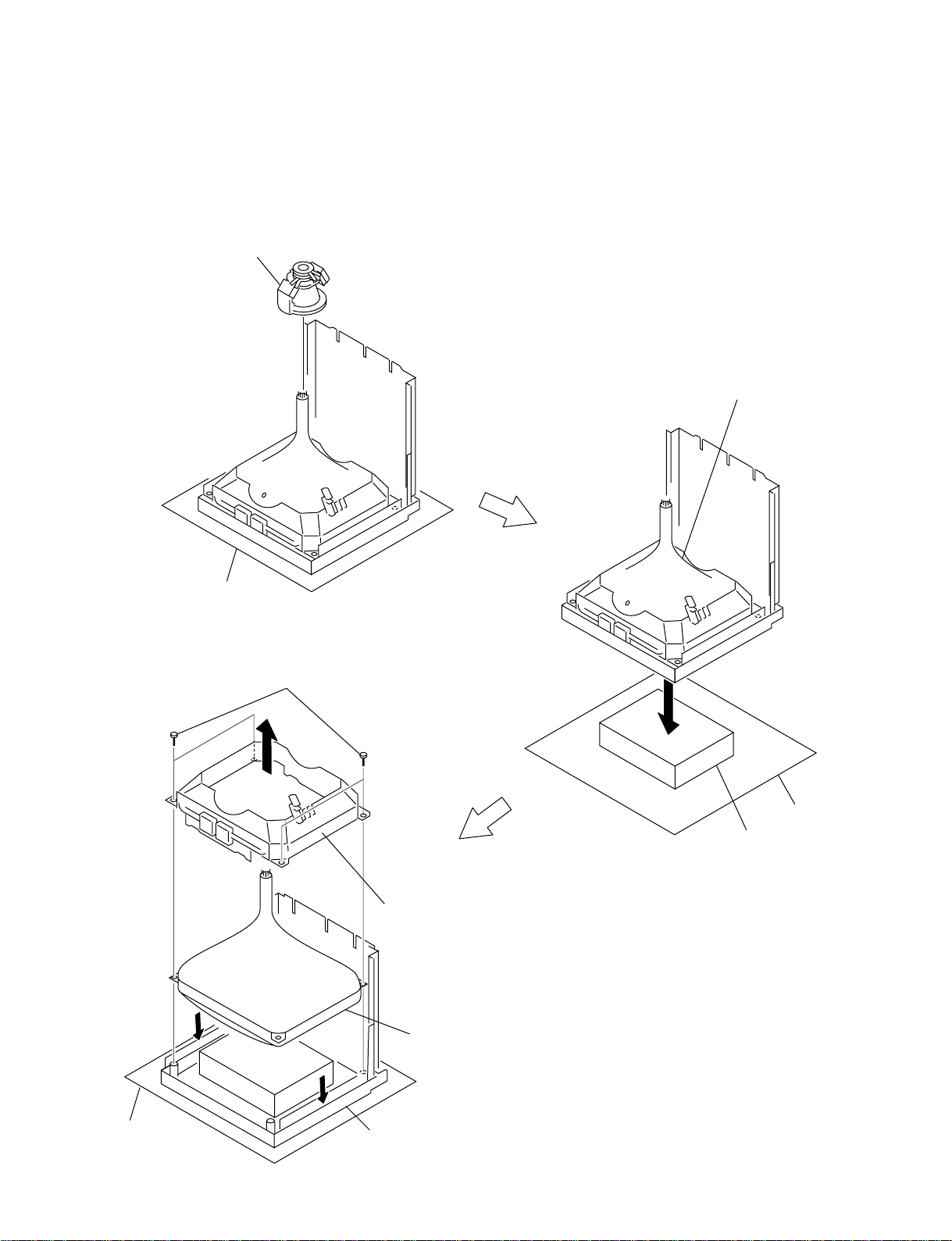

1-3-5. Picture Tube and Bezel Complete Assembly (14 inch)

B

B

A

Note:

Prepare a work bench that can protect surface

of CRT and can withstand the weight of the CRT.

1 Deflection yoke

Cushion

2

Prepare a work bench on the cushion

and place the CRT and bezel assembly

on the work bench.

Cushion

Bench

3 Four self tapping screws (M5)

4 Remove the CRT shield assembly

in the direction of the arrow A.

6 Picture tube

5 Remove the bezel complete assembly

in the direction of the arrow B.

Cushion

. Remove the cabinet and rear panel. (Refer to 1-3-1.)

. Remove the Q block assembly. (Refer to 1-3-2.)

. Remove the A board. (Refer to 1-3-3.)

. Remove the C board. (Refer to 1-3-4.)

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

1-5

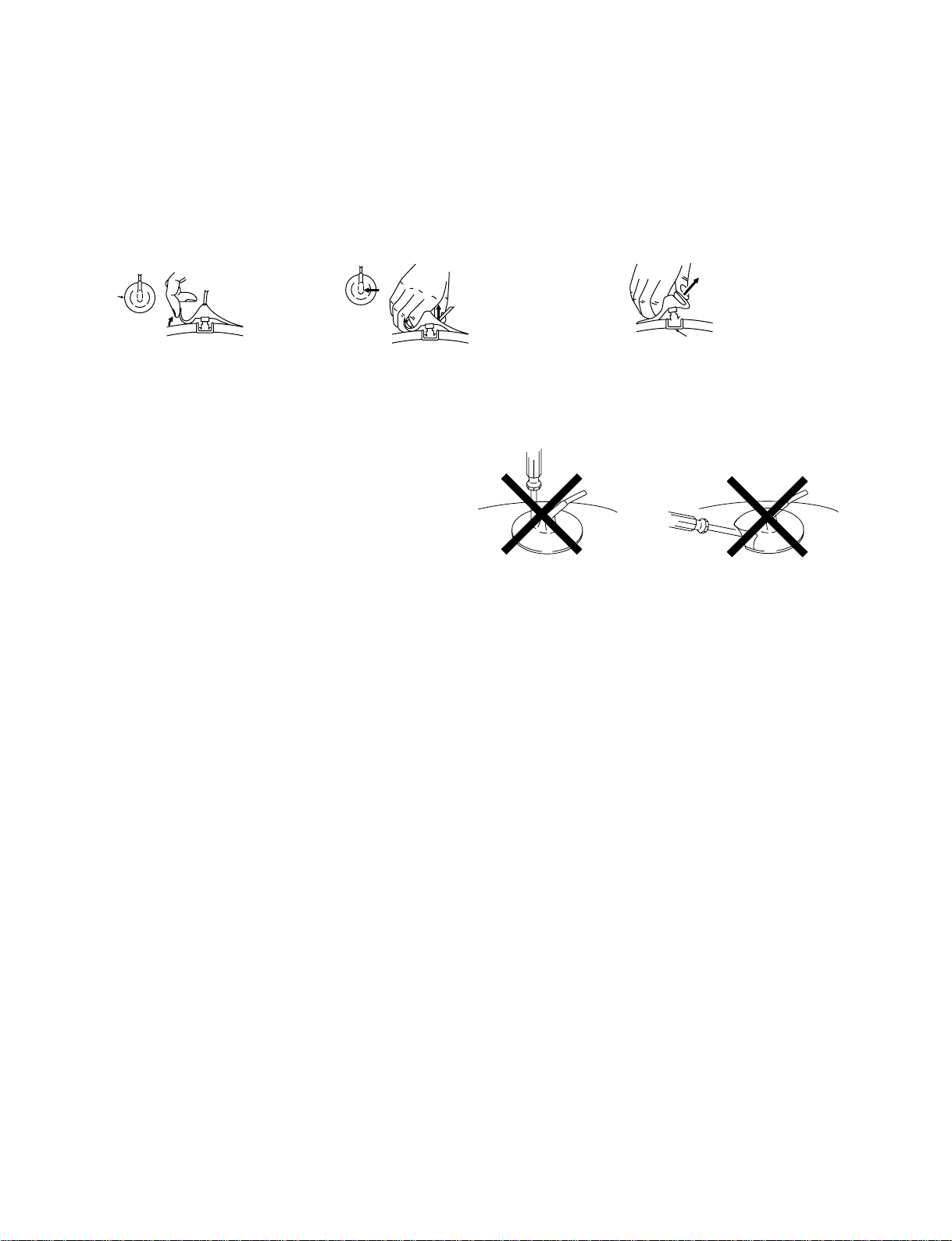

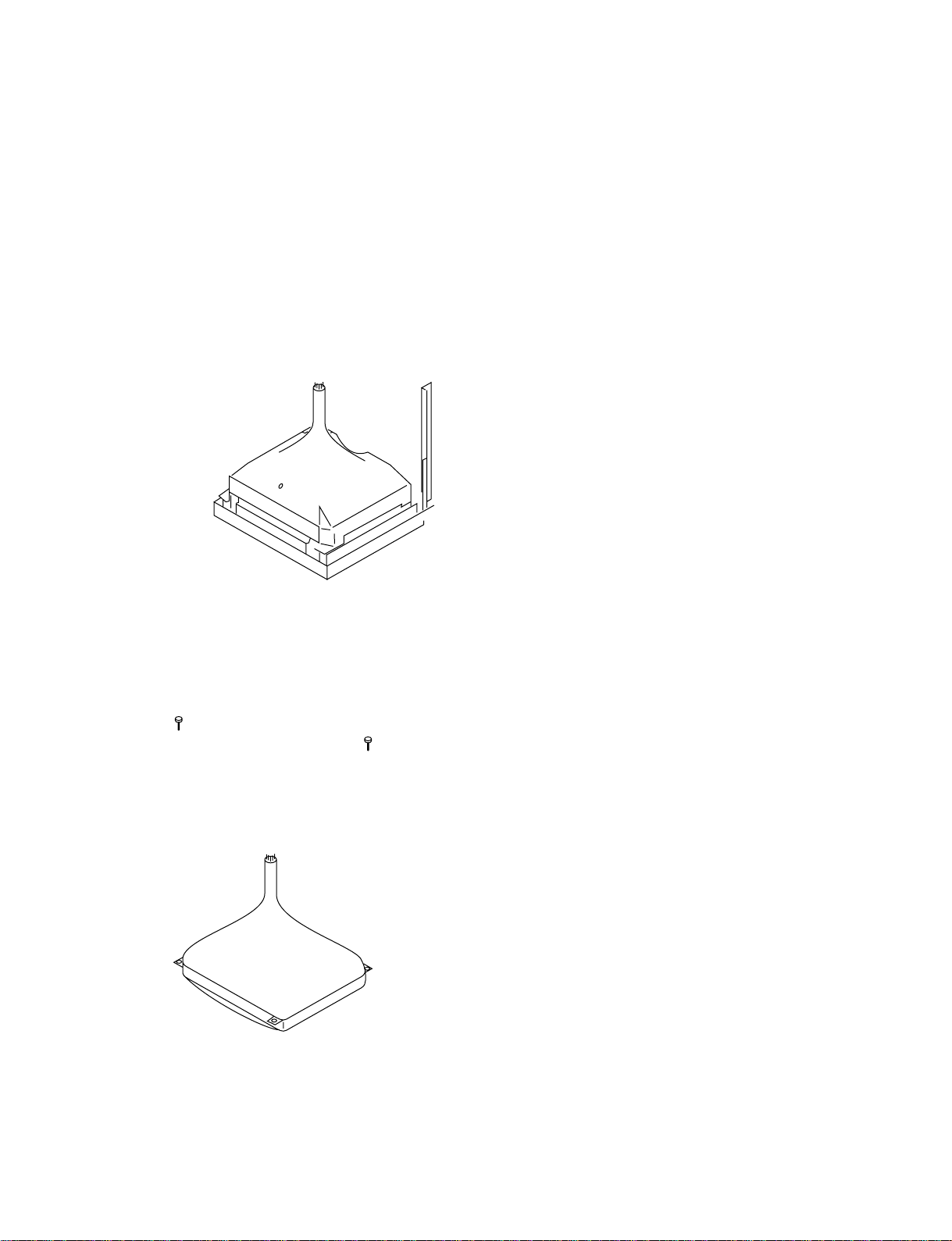

1-3-6. Anode Cap (14 inch)

n

Short-circuit the anode of the picture tube and the anode cap to the metal chassis, picture tube shield or carbon painted on

the picture tube, after removing the anode.

..

. Removal Procedure

..

c

Anode button

a

b

b

a

(1) Turn up one side of the rubber cap in the

direction indicated by arrow a.

..

. Handling Precautions

..

(1) Do not scratch the surface of anode cap with a sharp object.

(2) Do not press the rubber so hard that it damages the inside of

anode caps. A shatter-hook terminal is built into the rubber.

(3) Do not turn the foot of the rubber over.

The shatter-hook terminal will stick out or damage the rubber.

(2) Using a thumb, pull up the rubber cap

firmly in the direction indicated by

arrow b.

(3) When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling up it in

the direction of the arrow c.

1-6

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

1-4. Appearance Figure (20 inch)

1-5. Board Locations (20 inch)

C

Q

A

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

1-7

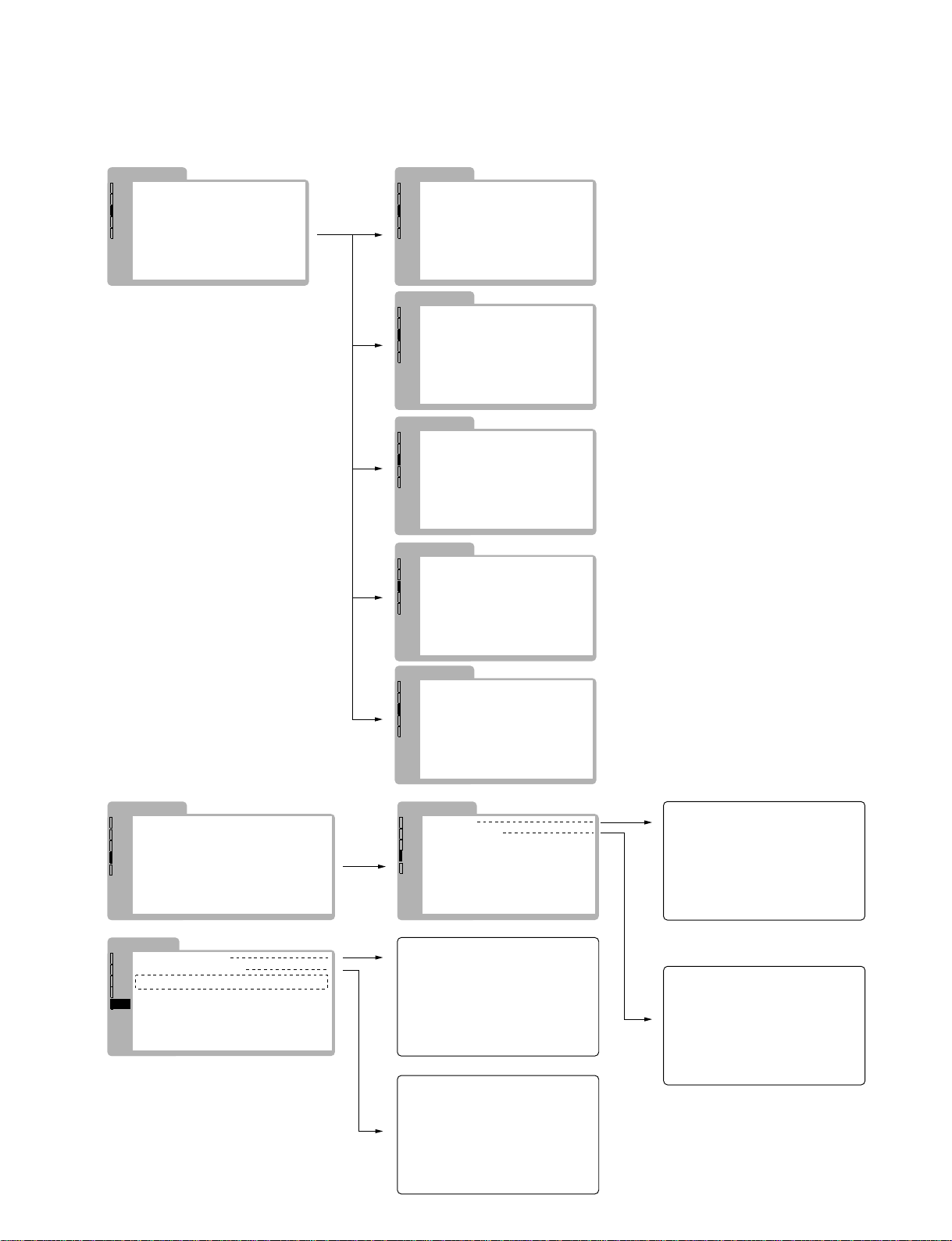

1-6. Disassembly (20 inch)

1-6-1. Cabinet and Rear Panel (20 inch)

1 Six nylon rivets

4 Remove the cabinet

in the direction of the arrow A.

A

3

Two case claw screws

(M 4 x 8)

6 Remove the rear panel

in the direction of the arrow B.

B

5 Four screws

(+BVTP 4 x 16)

Two case claw screws

2

(M 4 x 8)

1-8

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

1-6-2. Q Block Assembly and Q Board (20 inch)

. Remove the cabinet and rear panel. (Refer to 1-6-1.)

CN204

CN601

CN201

A

A

Push the two areas in the bottom of beznet in the direction of arrow A,

and pull the Q block assembly in the direction of the arrow B.

Four screws

1

(+PS 4 x 8)

B

8 AC inlet

9 Q board

7 Two screws

(+PSW 3 x 10)

4

5 Two screws

(+PSW 3 x 10)

6

Connector panel

3

Q block assembly

Connector label

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

1-9

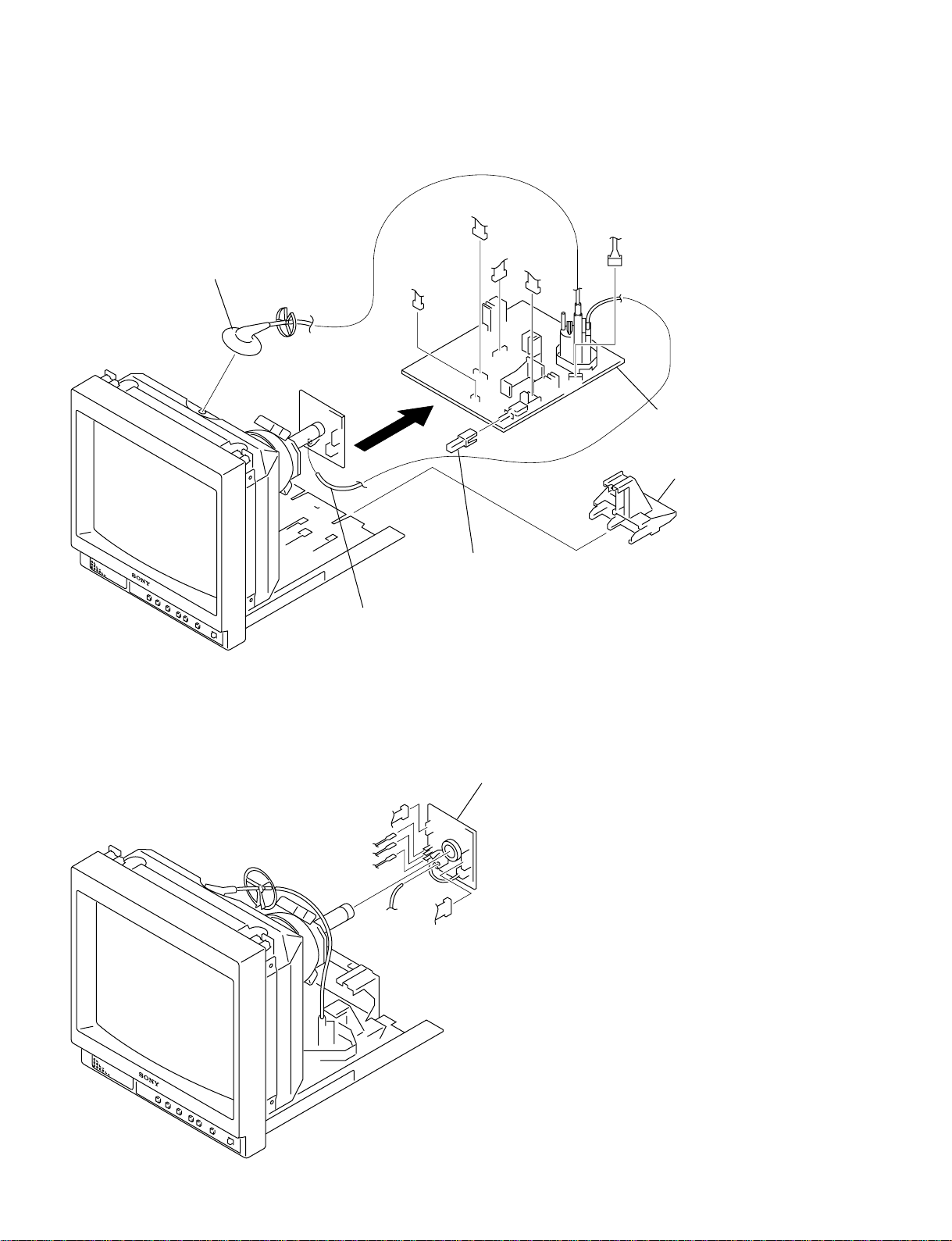

1-6-3. A Board (20 inch)

. Remove the cabinet and rear panel. (Refer to 1-6-1.)

2 Anode cap

CN3502

CN002

CN502

CN501

CN602

A

3 Focus lead assembly

1-6-4. C Board (20 inch)

. Remove the cabinet and rear panel. (Refer to 1-6-1.)

CN701

CN720

CN721

CN722

5

Power switch button

1

C board

4 Remove the A board

in the direction of the arrow A.

1 PWB holder

1-10

CN710

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

1-6-5. Picture Tube and Bezel Complete Assembly (20 inch)

. Remove the cabinet and rear panel. (Refer to 1-6-1.)

. Remove the Q block assembly. (Refer to 1-6-2.)

. Remove the A board. (Refer to 1-6-3.)

. Remove the C board. (Refer to 1-6-4.)

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

1-11

1-6-6. Anode Cap (20 inch)

n

Short-circuit the anode of the picture tube and the anode cap to the metal chassis, picture tube shield or carbon painted on

the picture tube, after removing the anode.

..

. Removal Procedure

..

c

Anode button

a

b

b

a

(1) Turn up one side of the rubber cap in the

direction indicated by arrow a.

(2) Using a thumb, pull up the rubber cap

firmly in the direction indicated by

arrow b.

(3) When one side of the rubber cap is

separated from the anode button, the

anode-cap can be removed by turning

up the rubber cap and pulling up it in

..

. Handling Precautions

..

the direction of the arrow c.

(1) Do not scratch the surface of anode cap with a sharp object.

(2) Do not press the rubber so hard that it damages the inside of

anode caps. A shatter-hook terminal is built into the rubber.

(3) Do not turn the foot of the rubber over.

The shatter-hook terminal will stick out or damage the rubber.

1-7. Warning on Power Connection

Use a proper power cord for your local power supply.

United State, Canada Europe Japan

Plug type LP-30B ––

Female end LS-13 VM0303B YC-35

Cord type SB-SVT H05VV-F VCTF

Minimum cord set rating 10A/125V 10A/250V 7A/125V

Safety approval UL/CSA SEMKO, NEMKO, DEMKO, SEV, DENAN-HO

a) Note : Use an appropriate rating plug which is applied to local regulations.

a)

KEMA, EI (FIMKO), CEBEC, VDE, BS

YP332

1-12

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

Section 2

Set-up Adjustment

2-1. Equipment Required

. Oscilloscope

Tektronix 2465 or equivalent (with bandwidth of 350

MHz)

. VG (programmable video signal generator)

VG-854 or equivalent

. Digital VOM

Advantest TR6845 or equivalent

. Slide induction transformer

. DC power supply

n

Start the following adjustments 5 minutes after the main

power is turned on.

* In this chapter, [||||||] indicates the control items in the

service mode.

Example : [60|H-FREQ]

2-2. Preparations (1)

Service Mode

This set is provided with a switch for service on the front

panel that can be used to make various adjustments. The

operation method of this switch is explained in detail below.

1. Entering the service mode

Simultaneously press the [ENTER] key and the

[MENU] key shown on the display of the menu 3

seconds or more.

SIGNAL

SIG

LEVEL...

•

DEF

WHITE BALANCE...

•

DES

SYS

ENG

2. Operating the Service Mode

Select the desired service item with the [9], [0] key

and press the [ENTER] key to enter the adjustment

mode.

Press the [+] key to increase the adjustment value.

Press the [_] key to decrease the adjustment value.

Press the [ENTER] key to save the adjustment value.

Press the [MENU] key to cancel the entry.

3. Finishing the service mode

Simultaneously press the [ENTER] key and the

[MENU] key shown on the display of the menu 3

seconds or more.

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

2-1

4. Executing FACTORY LOAD

If the adjustment data is damaged or lost by some

reasons, you can restore the default factory adjustment

data by executing FACTORY LOAD as described

below.

Select the following sub menus from the Service Menu

in the order of : [SYSTEM] → [FACTORY...] →

[LOAD...] to read the default factory data. If the

default factory data is damaged or the ROM is replaced without executing FACTORY SAVE as

described in the following paragraph, you cannot

execute FACTORY LOAD.

5. Executing FACTORY SAVE

This operation is to write the FACTORY LOAD data

into the factory data area in the memory.

Select the following sub menus from the Service Menu

in the order of : [SYSTEM] → [MAINTENANCE ID]

and type 111. Then select the following sub menus

from the Service Menu in the order of : [ENGINEER]

→ [FACTORY SAVE] to write the factory data in the

memory. FACTORY SAVE is protected from miss

operation so that FACTORY SAVE cannot be executed unless MAINTENANCE ID is set.

FACTORY SET

If the following circuit board is replaced or the following

IC on the respective board is replaced, perform the following settings.

A board, IC001, IC003

1. Select the following sub menus from the Service Menu

in the order of : [SYSTEM]-[MAINTENANCE ID]

and type 111.

2. If the IC003 is replaced, select the following sub

menus from the Service Menu : [ENGINEER][CLEAR NVM ON A] and write data.

3. Select the following sub menus from the Service

Menu in the order of : [SYSTEM]-[MODEL INCH],

[SYSTEM]-[MODEL TYPE] and write the model data

of each model in the [MODEL TYPE] referring to

table 2-2.

4. Perform all adjustment items of the [SIGNAL] menu

and of the [DEFLECTION] menu.

5. Upon completion of adjustment, select the menus

[ENGINEER]-[FACTORY SAVE] to save the

adjustment data.

2-2

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

Service Mode screen display

SIGNAL

LEVEL...

SIG

•

WHITE BALANCE...

DEF

•

DES

SYS

ENG

DEFLECTION

SIG

• RASTER H...

DEF

• RASTER V...

DES

• GEOMETRY...

SYS

ENG

LEVEL

SIG

• SUB BRIGHT

DEF

• LUMI DELAY

DES

• SUB CHROMA

SYS

• SUB PHASE

ENG

• PEAK FREQ

• SCO

• WHITE PEAK

• SUB SHARP

WHITE BALANCE

• SUB CONTRAST

SIG

• CDL

DEF

• SUB BRIGHT

DES

• COLOR TEMP

SYS

• ADJUST

ENG

• ADJUST GAIN...

• ADJUST BIAS...

RASTER H

DEFLECTION

SIG

• H SIZE

DEF

•

LEFT H BLK

DES

•

RIGHT H BLK

SYS

• H POSITION

ENG

D65

4

11

3

6

0

0

0

15

9

4

4

47

0

0

46

RASTER V

DEFLECTION

SIG

• V SIZE

V CENTER

•

DEF

V SCROLL

•

DES

V SLOPE

SYS

•

• V ZOOM

ENG

GEOMETRY

DEFLECTION

SIG

• V LINEARITY

• S CORRECTION

DEF

• PIN AMP

DES

• PIN PHASE

SYS

• U CORNER PIN

ENG

• L CORNER PIN

• V ANGLE

• V BOW

45

45

13

31

31

30

11

57

19

37

32

29

0

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

2-3

n

When changing DESIGN ITEMS 1/2 and 2/2, set the MAINTENANCE ID to 111 in SYSTEM.

DESIGN 1/2

SIG

• COLOR DECODER 0...

DEF

• COLOR DECODER 1...

DES

• AV SWITCH 0...

SYS

• AV SWITCH 1...

ENG

• SYNCHRONIZATION 0...

• SYNCHRONIZATION 1...

• DEFLECTION...

• SOUND 0...

4

11

3

6

0

0

0

15

COLOR DECODER 0

SIG

• CB...

DEF

• ALC...

DES

• MUS

SYS

• MAT

ENG

• CM 3210

COLOR DECODER 1

SIG

• FC0

DEF

• BPS

DES

SYS

ENG

AV SWITCH 0

SIG

• INABC

DEF

• CMB10

DES

• STR

SYS

ENG

AV SWITCH 1

SIG

• CS2ABC

DEF

• CS1ABC

DES

• FB0

SYS

ENG

0

1

0

1

8

0

0

3

1

0

0

7

0

SYNCHRONIZATION 0

SIG

• VID

DEF

• VIM

DES

• STB

SYS

• POC

ENG

• F0AB

• HP2

• SDC

SYNCHRONIZATION 1

SIG

• NCIN

DEF

• DL

DES

• FORFS

SYS

• OSO

ENG

• FSL

• STM

DEFLECTION

SIG

• HCO

DEF

• EVG

DES

• AVG

SYS

• SBL

ENG

• XDT

• DFL

• OSVE

SOUND 0

SIG

• AVL

DEF

• SM

DES

SYS

ENG

0

0

1

0

3

0

0

0

0

2

1

0

0

0

1

0

0

1

1

0

0

0

2-4

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

n

When changing DESIGN ITEMS 1/2 and 2/2, set the MAINTENANCE ID to 111 in SYSTEM.

DESIGN 2/2

SIG

• CONTROL 0...

DEF

• CONTROL 1...

DES

• CONTROL 2...

SYS

• FEATURES 0...

ENG

• FEATURES 1...

DESIGN 2/2

SIG

• CL3210

DEF

• AKB

DES

• RBL

SYS

• IE2

ENG

DESIGN 2/2

SIG

• HBL

DEF

• YUV10

DES

• TFR

SYS

• SOY

ENG

• RGBL 0

• SWO 0

DESIGN 2/2

SIG

• PWL

DEF

• FBC

DES

• CLD

SYS

ENG

DESIGN 2/2

SIG

• BKS

DEF

• BLS

DES

• COR10

SYS

• SVM10 0

ENG

1

0

0

0

1

0

0

0

1

0

0

0

0

3

SYSTEM

SIG

VERSION

• MODEL INCH

DEF

•

MODEL TYPE WW EXCEPT J

DES

• AGING MODE

SYS

• MUTE TIME (

ENG

• FACTORY...

MAINTENANCE ID

•

ENGINEER

SIG

• FACTORY SAVE...

DEF

• CLEAR NVM ON A...*

DES

• COMB FILTER

SYS

↑

ENG

(

Ver 1.2 or more

* MAINTENANCE ID = 111 selection possible

Ver 1.2 or more

)

20 or 14 or 9

WW EXCEPT J or J

)

AUTO*

XXX

DESIGN 2/2

SIG

• WS10

DEF

• VMA10

DES

• RP010

SYS

• EVB 1

ENG

SYSTEM

• LOAD...

SIG

• STANDARD

DEF

DES

SYS

ENG

SAVE FACTORY DATA

CLEAR NVM ON A BOARD

...

[ENTER]: ENTER

[MENU]: CANCEL

[ENTER]: ENTER

[MENU]: CANCEL

0

0

0

LOAD FACTORY DATA

[ENTER]: ENTER

[MENU]: CANCEL

MAKE USER SETTING

STANDARD

[ENTER]: ENTER

[MENU]: CANCEL

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

2-5

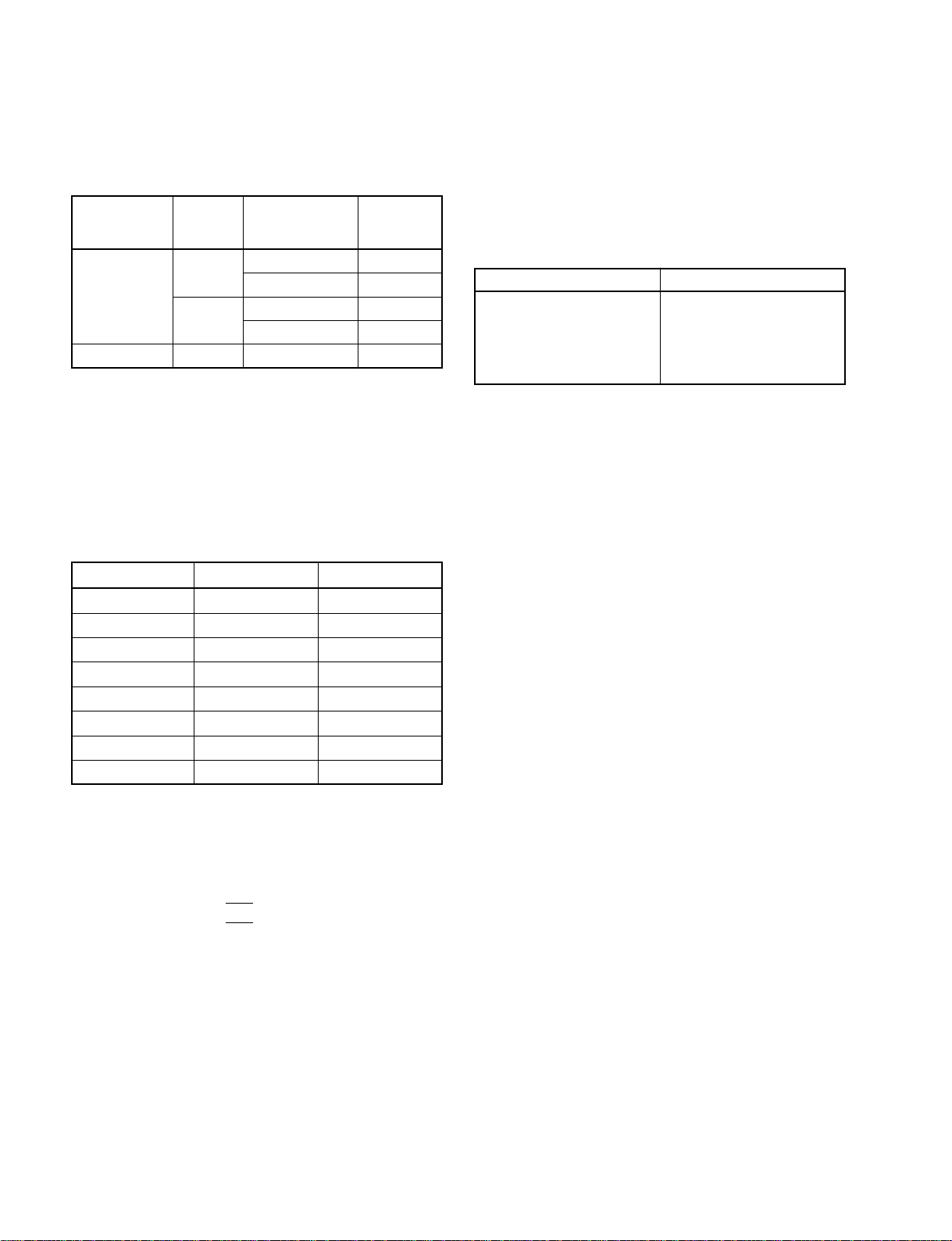

2-3. Preparation (2). Initialization

2-5. Picture Output

* Supply composite video signal as shown in Table 2-1.

Signal Details of signal Standard

level

P-W

Composite 358NT 100 % white 0.714 V

video 75 % white 0.536 V

PAL 100 % white 0.7 V

75 % white 0.525 V

Voice/sound _5 dBu 0.436Vrms

Table 2-1

2-4. Writing Model Data

1. Select the following sub menus from the Service Menu

in the order of : [SYSTEM] → [MODEL INCH],

[SYSTEM] → [MODEL TYPE] and write the model

data of each model in the [MODEL TYPE] referring

to table 2-2.

Model name Model type Model inch

PVM-14L1 J 14

PVM-14L1 WW EXCEPT J 14

SSM-14L1 J 14

SSM-14L1 WW EXCEPT J 14

PVM-20L1 J 20

PVM-20L1 WW EXCEPT J 20

SSM-20L1 J 20

SSM-20L1 WW EXCEPT J 20

Table. 2-2

2. Select the following sub menus from the Service Menu

in the order of : [SIGNAL] → [WHITE BALANCE]

and type the following data in [COLOR TEMP].

WW EXCEPT J D65

J D93

* Standard inspection state

Unless otherwise specified in this manual, make adjustment under the following conditions.

VOLUME 0

CONTRAST 80

BRIGHTNESS 0

CHROMA 50

PHASE 0

ASPECT RATIO 4 : 3

1. AC input voltage setting

1. Input VIDEO signals and AUDIO signals to respective

terminals on the connector panel.

2. Set the slide induction transformer AC voltage as

shown in Table 2-3.

Model name Voltage

PVM-14L1 AC 100 V to 240 V ±10 %

PVM-20L1

SSM-14L1

SSM-20L1

Table. 2-3

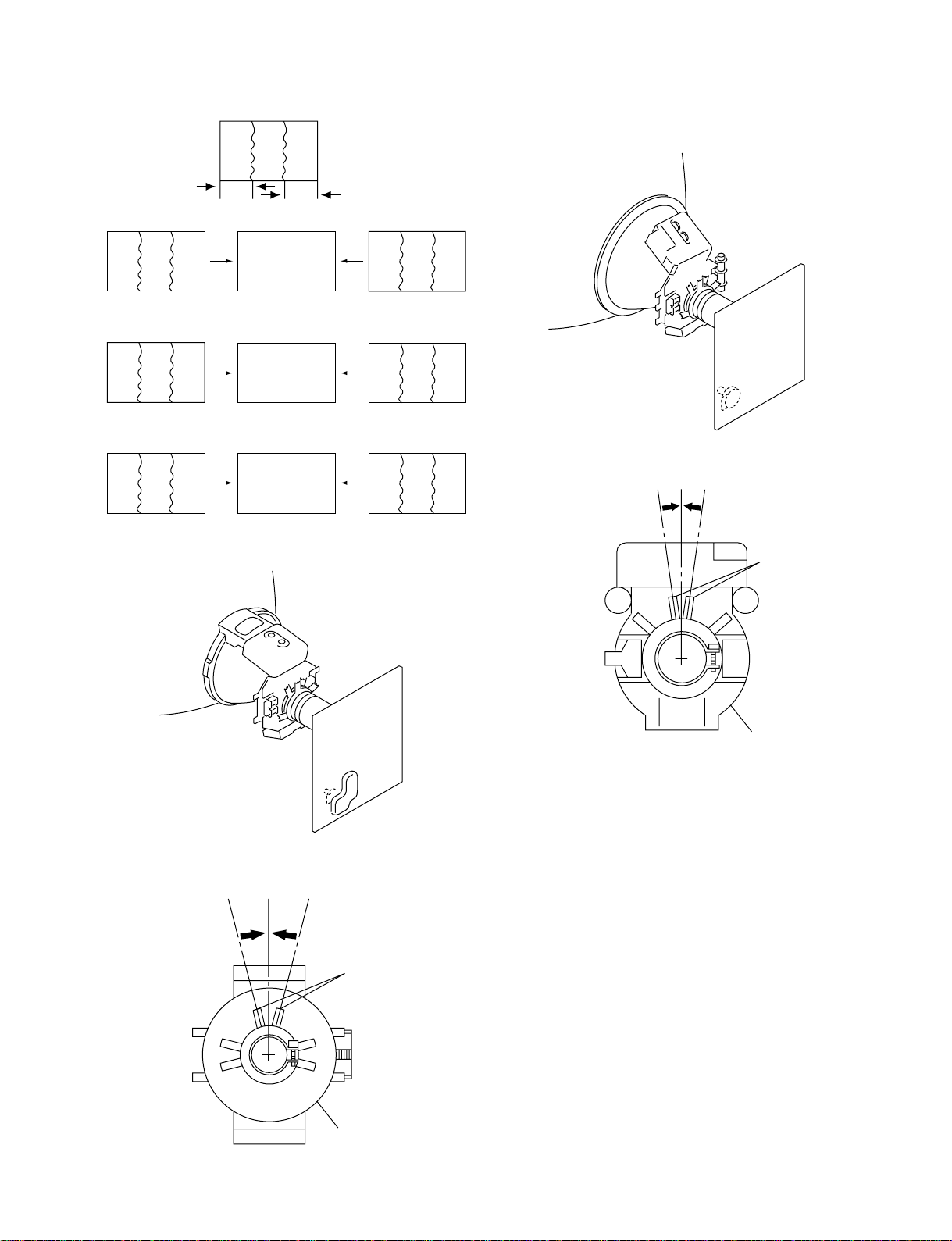

2-6. Landing Adjustment (1)

1. CONTRAST... MAX

BRIGHT... Conspicuous position

2. Roughly adjust the white balance, G2, and convergence.

3. Switch the video signal generator output signal to

green only.

4. Move back the DY backward (in the direction toward

neck).

5. Adjust the purity knob so that the green will come to

the center of the screen. Make R and B almost

identical. (Fig. 2-1)

6. Switch to B only, R only, and G only and verify each.

7. Bring the deflection yoke gradually forward and adjust

the deflection yoke so that R and B on both sides of

the screen will be green. (Fig.2-2 → Fig. 2-3)

8. If the deflection yoke comes forward too much, the

pattern shown in Fig.2-4 will appear. If so, move the

deflection yoke backward. (Fig.2-4 → Fig.2-3)

9. Switch the signal generator output signal to the BLUE

only color and confirm the screen. (Fig. 2-6)

10. Switch the signal generator output signal to the RED

only color and confirm the screen. (Fig. 2-9)

11. When two colors are mixed, set the mixed color as the

standard, and repeat operations 6 and 7.

12. Switch to an all-white signal and check the uniformity.

13. When the deflection yoke position is determined,

fasten it with the DY screw.

2-6

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

Fig. 2-1

Purity control

Purity

DY (Deflection yoke)

R

GB

20 inch

A' = A

A

Fig. 2-2 Fig. 2-3 Fig. 2-4

BRG

Fig. 2-5 Fig. 2-6 Fig. 2-7

RGB

Fig. 2-8 Fig. 2-9 Fig. 2-10

A'

GGBR

B

R

14 inch

GRB

BGR

Fig. 2-11

RBG

PVM-14L1/14L1MDE/20L1

SSM-14L1/20L1

Fig. 2-12

Fig. 2-11

Purity control

Purity

DY (Deflection yoke)

Fig. 2-12

2-7

Loading...

Loading...