Page 1

SOLID-STATE MEMORY CAMCORDER

PMW-EX3

SERVICE MANUAL

1st Edition

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

PMW-EX3

Page 3

CAUTION

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

ADVARSEL

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

PMW-EX3

1 (P)

Page 4

Page 5

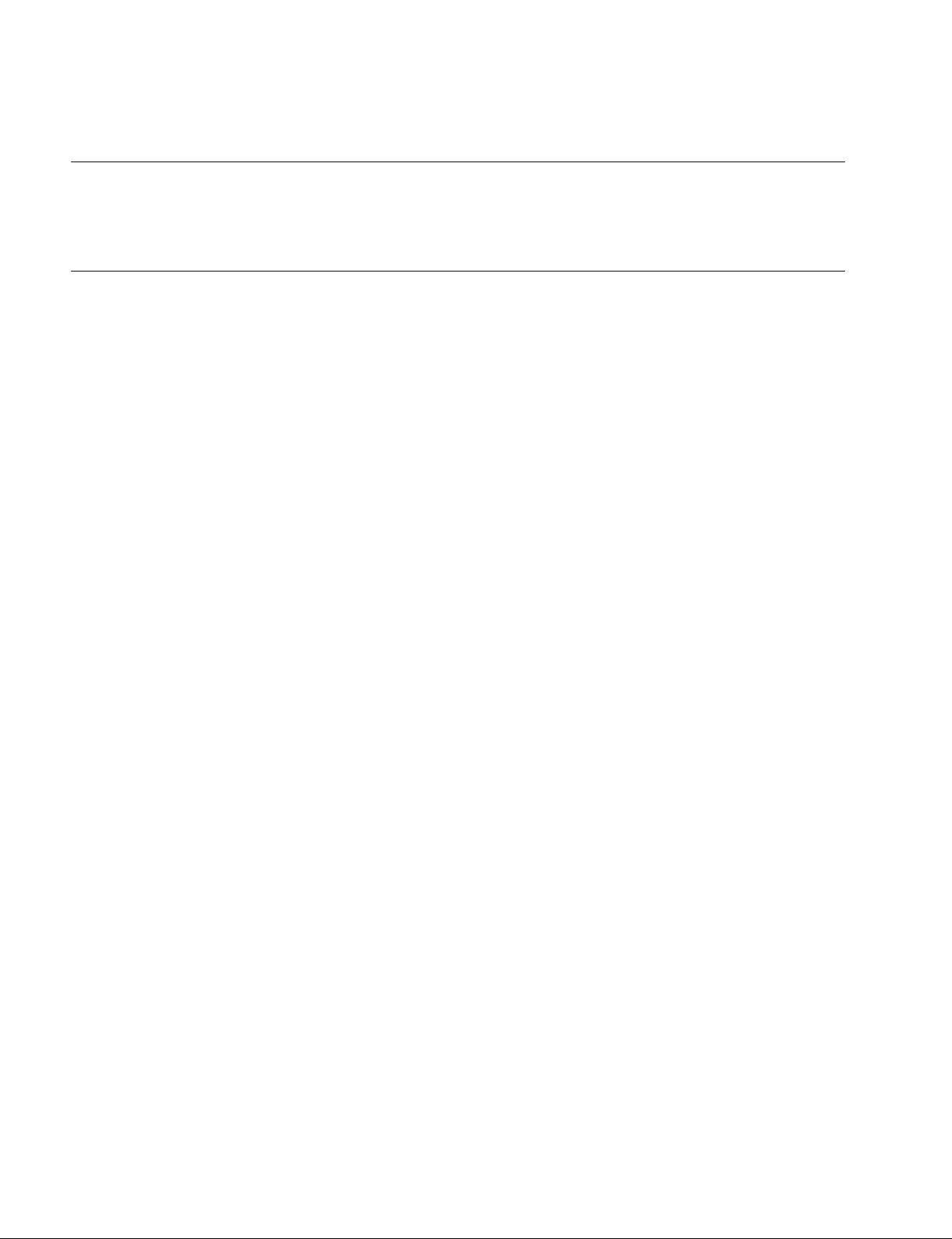

Table of Contents

Manual Structure

Purpose of this manual ................................................................. 4

Related manuals ........................................................................... 4

1. Service Overview

1-1. External Connectors ........................................................ 1-1

1-1-1. Signal Inputs and Outputs ..................................... 1-1

1-2. Location of the Printed Wiring Boards ........................... 1-4

1-3. Circuit Description .......................................................... 1-5

1-4. Service Tools/Measuring Equipment List .................... 1-11

1-4-1. Service Tools ....................................................... 1-11

1-4-2. Measuring Equipment ......................................... 1-11

1-5. Firmware Upgrade ........................................................ 1-12

1-6. Recommended Replacement Parts ............................... 1-13

1-7. Note on Service ............................................................. 1-14

1-7-1. Requirements on Replacement of

Boards or Parts .................................................... 1-14

1-7-2. Note on Replacement of Parts on the Board ....... 1-14

1-7-3. Description of Number Seal on the Prism ........... 1-14

1-7-4. Memory Backup Battery ..................................... 1-14

1-7-5. Unleaded Solder .................................................. 1-14

1-8. Connector Location Diagram on Board ........................ 1-15

1-9. Replacing the Flexible Card Wires ...............................1-16

1-10. Replacing the Coaxial Cable with Connector

(Fine Pitch Coaxial Cable) ............................................ 1-16

1-11. List of Error Numbers on the LCD Display .................1-18

1-12. Servicing software “ServiceNavi-EX” ......................... 1-18

2. Replacement of Main Parts

2-1. Outline of Replacement Procedures ...............................2-1

2-2. Replacement Procedures ................................................. 2-2

2-2-1. Lithium Battery ..................................................... 2-2

2-2-2. Bottom Panel .........................................................2-2

2-2-3. Pad Sub Assembly, Pad Cover ..............................2-3

2-2-4. LCD Assembly, CT-251 Board ............................. 2-4

2-2-5. Handle Top Cover Assembly ................................ 2-5

2-2-6. KSW-54 Board, Control Switch Block .................2-6

2-2-7. IF-1069 Board, LED-469 Board ...........................2-7

2-2-8. AXM-36 Board, HN-349 Board ............................ 2-8

2-2-9. Handle Assembly ..................................................2-9

2-2-10. Microphone Assembly ........................................ 2-10

2-2-11. Microphone Unit, MA-164 Board,

RM-214 Board ..................................................... 2-11

2-2-12. SWC-49 Board .................................................... 2-12

2-2-13. Inside Panel Assembly ........................................ 2-13

2-2-14. CN-3050 Board ................................................... 2-14

2-2-15. Connector Rear Assembly ................................... 2-15

2-2-16. ASW-66 Board, SW-1412 Board ........................2-16

2-2-17. SW-1410 Board ...................................................2-17

2-2-18. HN-344 Board .....................................................2-18

2-2-19. HN-343 Board, SWC-48 Board .......................... 2-19

2-2-20. SW-1411 Board ...................................................2-21

2-2-21. Outside Panel Sub Assembly .............................. 2-21

2-2-22. SW-1389 Board ...................................................2-22

2-2-23. Battery Case Assembly ....................................... 2-23

2-2-24. EX-DD Assembly ............................................... 2-24

2-2-25. CN-3023 Board ................................................... 2-26

2-2-26. RE-260 Board ...................................................... 2-26

2-2-27. EC-63 Board ........................................................ 2-27

2-2-28. PS-747 Board ...................................................... 2-28

2-2-29. TX-129 Board ..................................................... 2-29

2-2-30. Outside Connector Assembly ..............................2-30

2-2-31. DPR-289A Board ................................................ 2-31

2-2-32. Lens Mount Block ...............................................2-32

2-2-33. Prism Block Unit .................................................2-32

2-2-34. SE-923 Board ...................................................... 2-33

2-2-35. AU-318 Board .....................................................2-34

2-2-36. IR-42 Board ......................................................... 2-35

2-2-37. Replacing the Parts in the Lens Grip ................... 2-36

3. SERVICE Menu

3-1. SERVICE Menu List ...................................................... 3-1

3-2. SERVICE Menu Description .......................................... 3-3

3-2-1. Basic Menu Operations ......................................... 3-3

3-2-2. SERVICE Menu Structure .................................... 3-3

3-2-3. Displaying the SERVICE Menu ........................... 3-3

3-3. SERVICE Menu Description .......................................... 3-3

3-3-1. MAINTENANCE Menu ....................................... 3-3

3-3-2. RPN CORRECT Menu ......................................... 3-7

3-3-3. INFORMATION Menu ......................................... 3-8

4. Spare Parts

4-1. Notes on Repair Parts .....................................................4-1

4-2. Exploded Views ..............................................................4-2

4-3. Electrical Parts List .......................................................4-22

4-4. Supplied Accessories .................................................... 4-60

PMW-EX3

1

Page 6

5. Semiconductor Pin Assignments

6. Block Diagrams

Overall ............................................................................ 6-2

ASW-66 .......................................................................... 6-3

HN-337 ....................................................................... 6-3, 6

HP-144 ............................................................................6-3

LED-469 ......................................................................... 6-3

SW-1412 .........................................................................6-3

AU-318 ..................................................................... 6-4, 10

AXM-36 ...................................................................... 6-4, 9

HN-326 ..................................................................... 6-4, 10

HN-328 ........................................................................... 6-4

HN-343 ........................................................................... 6-4

HN-344 ..................................................................... 6-4, 10

HN-349 ....................................................................... 6-4, 9

KSW-54 ...................................................................... 6-4, 9

MA-164 ........................................................................... 6-4

SWC-48 ....................................................................6-4, 10

BI-202 .............................................................................6-5

BI-203 .............................................................................6-5

BI-204 .............................................................................6-5

DPR-289A ..........................................................6-5, 6, 7, 8

CN-3050 ......................................................................... 6-6

EC-63 ..............................................................................6-6

HN-347 ....................................................................... 6-7, 8

JK-81 ........................................................................... 6-7, 8

JK-84 ........................................................................... 6-7, 8

CT-251 ............................................................................6-9

HN-348 ........................................................................... 6-9

IF-1069 ........................................................................... 6-9

RM-214 ...........................................................................6-9

SWC-49 ..........................................................................6-9

BP-42 ............................................................................ 6-10

HN-345 ......................................................................... 6-10

HN-346 ......................................................................... 6-10

IR-42 .............................................................................6-10

SE-923 .......................................................................... 6-10

SW-1389 .......................................................................6-10

SW-1410 .......................................................................6-10

SW-1411 .......................................................................6-10

CN-3024 ....................................................................... 6-11

TX-129 .......................................................................... 6-11

CN-3022 ....................................................................... 6-12

DC-146 ......................................................................... 6-12

PS-747 ...........................................................................6-12

RE-260 ..........................................................................6-12

CN-3023 ....................................................................... 6-13

RE-261 ..........................................................................6-13

7. Schematic Diagrams

ASW-66 .......................................................................... 7-2

AU-318 ........................................................................... 7-5

AXM-36 .......................................................................... 7-8

BI-202 .............................................................................7-9

BI-203 ...........................................................................7-10

BI-204 ...........................................................................7-11

BP-42 ............................................................................ 7-12

CN-3022 ....................................................................... 7-12

CN-3023 ....................................................................... 7-13

CN-3024 ....................................................................... 7-14

CN-3050 ....................................................................... 7-14

CT-251 ..........................................................................7-15

DC-146 ......................................................................... 7-15

DPR-289A .................................................................... 7-16

EC-63 ............................................................................7-46

HN-328 ......................................................................... 7-46

HN-343 ......................................................................... 7-46

HN-326 ......................................................................... 7-47

HN-337 ......................................................................... 7-47

HN-344 ......................................................................... 7-48

HN-345 ......................................................................... 7-48

HN-346 ......................................................................... 7-48

HN-347 ......................................................................... 7-49

HN-348 ......................................................................... 7-49

HN-349 ......................................................................... 7-49

HP-144 ..........................................................................7-50

IF-1069 ......................................................................... 7-50

IR-42 .............................................................................7-51

JK-81 .............................................................................7-52

JK-84 .............................................................................7-53

KSW-54 ........................................................................ 7-54

2

PMW-EX3

Page 7

LED-469 ....................................................................... 7-55

PS-747 ........................................................................... 7-55

MA-164 ......................................................................... 7-56

RE-260 ..........................................................................7-57

RE-261 ..........................................................................7-61

RM-214 .........................................................................7-64

SE-923 .......................................................................... 7-64

SW-1411 .......................................................................7-64

SW-1389 .......................................................................7-65

SW-1410 .......................................................................7-65

SW-1412 .......................................................................7-65

SWC-48 ........................................................................7-66

SWC-49 ........................................................................7-68

TX-129 .......................................................................... 7-69

Frame Wiring ................................................................7-77

8. Board Layouts

ASW-66 .......................................................................... 8-2

AU-318 ........................................................................... 8-2

AXM-36 .......................................................................... 8-3

BI-202 .............................................................................8-3

BI-203 .............................................................................8-3

BI-204 .............................................................................8-4

BP-42 .............................................................................. 8-4

CN-3022 ......................................................................... 8-4

CN-3023 ......................................................................... 8-4

CN-3024 ......................................................................... 8-4

CN-3050 ......................................................................... 8-4

CT-251 ............................................................................8-5

DC-146 ........................................................................... 8-5

DPR-289A ......................................................................8-5

EC-63 ..............................................................................8-7

HN-326 ........................................................................... 8-7

HN-328 ........................................................................... 8-7

HN-337 ........................................................................... 8-8

HN-343 ........................................................................... 8-8

HN-344 ........................................................................... 8-8

HN-345 ........................................................................... 8-8

HN-346 ........................................................................... 8-8

HN-347 ........................................................................... 8-8

HN-348 ........................................................................... 8-8

HN-349 ........................................................................... 8-9

HP-144 ............................................................................8-9

IF-1069 ........................................................................... 8-9

IR-42 ............................................................................... 8-9

JK-81 ............................................................................... 8-9

JK-84 ............................................................................... 8-9

KSW-54 ........................................................................ 8-10

LED-469 ....................................................................... 8-10

MA-164 ......................................................................... 8-10

PS-747 ........................................................................... 8-10

RE-260 ..........................................................................8-11

RE-261 ..........................................................................8-11

RM-214 .........................................................................8-12

SE-923 ..........................................................................8-12

SW-1389 .......................................................................8-12

SW-1410 .......................................................................8-12

SW-1411 .......................................................................8-12

SW-1412 .......................................................................8-12

SWC-48 ........................................................................8-13

SWC-49 ........................................................................8-13

TX-129 .......................................................................... 8-14

PMW-EX3

3

Page 8

Purpose of this manual

Related manuals

Manual Structure

The service manual is intended for use by trained system and service engineers, and

provides the information of maintenance and detailed service.

The following manuals are available in this model.

If this manual is required, please contact your local Sony Sales Office/Service

Center.

..

. Operating Instructions (Supplied with the unit)

..

This manual is necessary for application and operation (and installation) of this

unit.

..

. “Semiconductor Pin Assignments” CD-ROM

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in Broadcast and Professional equipment.

This manual contains a complete list of semiconductors and their ID Nos., and

thus should be used together with the CD-ROM.

Part number: 9-968-546-06

4

PMW-EX3

Page 9

Section 1

Service Overview

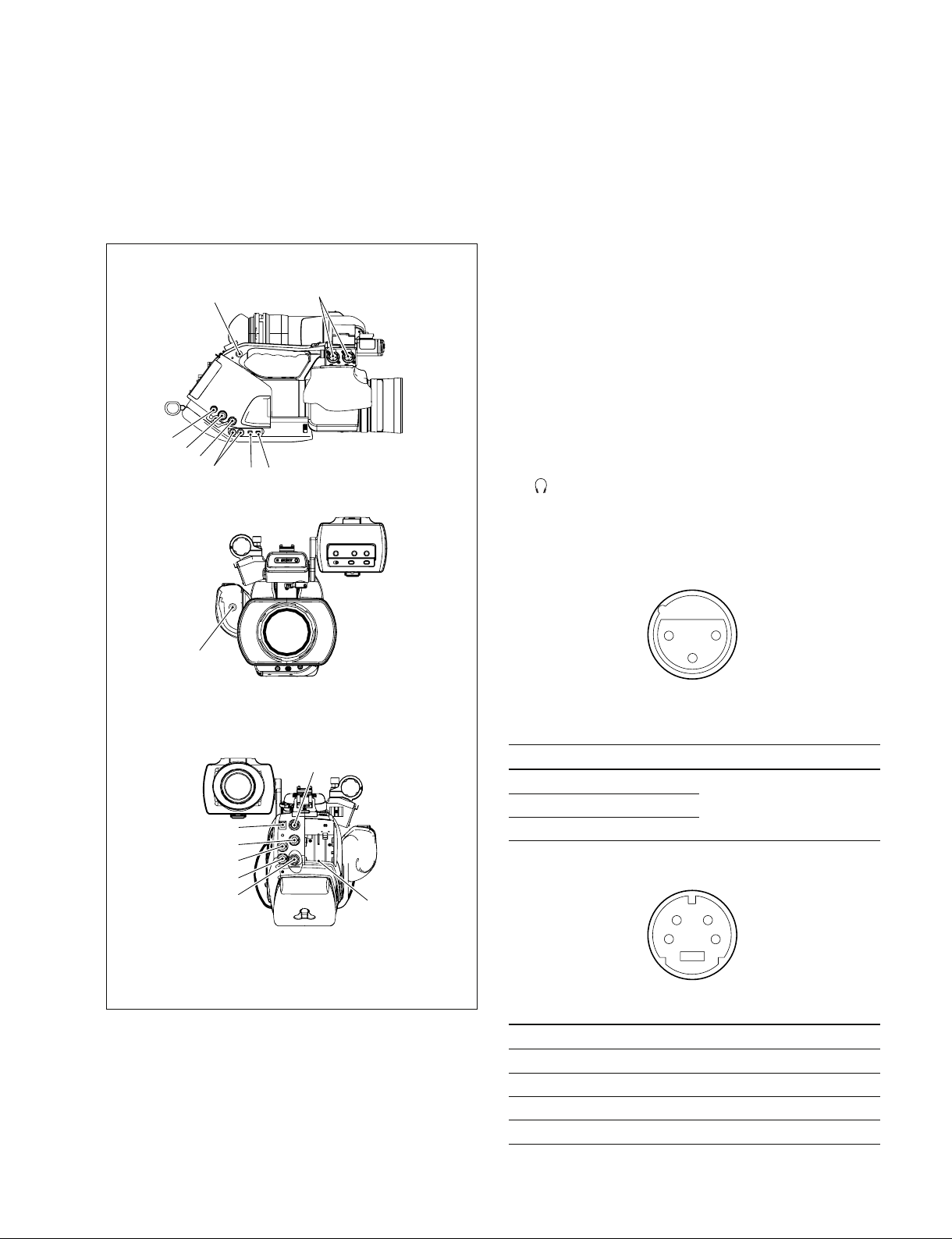

1-1. External Connectors

1-1-1. Signal Inputs and Outputs

SIDE VIEW

7

!=

![

2

8

FRONT VIEW

6

9

0

1 SDI OUT : BNC type

SDI output signal

2 MONITOR OUT : BNC type

1.0 V p-p, 75 Z

3 TC IN : BNC type

0.5V to 18V, 10 kZ

4 TC OUT : BNC type

1.0 V p-p, 75 Z

5 GENLOCK IN : BNC type

1.0 V p-p, 75 Z

6 (HEADPHONES) : Stereo mini jack

Sound monitor, monaural/stereo selectable

_20.5 dBu (Reference level 16 Z loaded)

7 AUDIO IN CH-1, CH-2 : XLR (3P, Female)

REAR VIEW

!\

!5

3

4

!]

1

!;

2

__

_ EXT VIEW

__

1

3

__

_

__

(0 dBu = 0.775 V rms)

No. Signal I/O Specifications

1 MIC/LINE (G) __60 dBu/_50 dBu/_40 dBu/

2 MIC/LINE (H) IN +4 dBu, selectable

3 MIC/LINE (C) IN High impedance, Balanced

8 S-VIDEO OUT : S-video connector (4P)

34

12

__

_ EXT VIEW

__

No. Signal I/O Specifications

1 Y/C_GND _ GND

2 Y/C_GND _ GND

3 S-Y O S OUT (Y)

4 S-C O S OUT (C)

__

_

__

PMW-EX3

1-1

Page 10

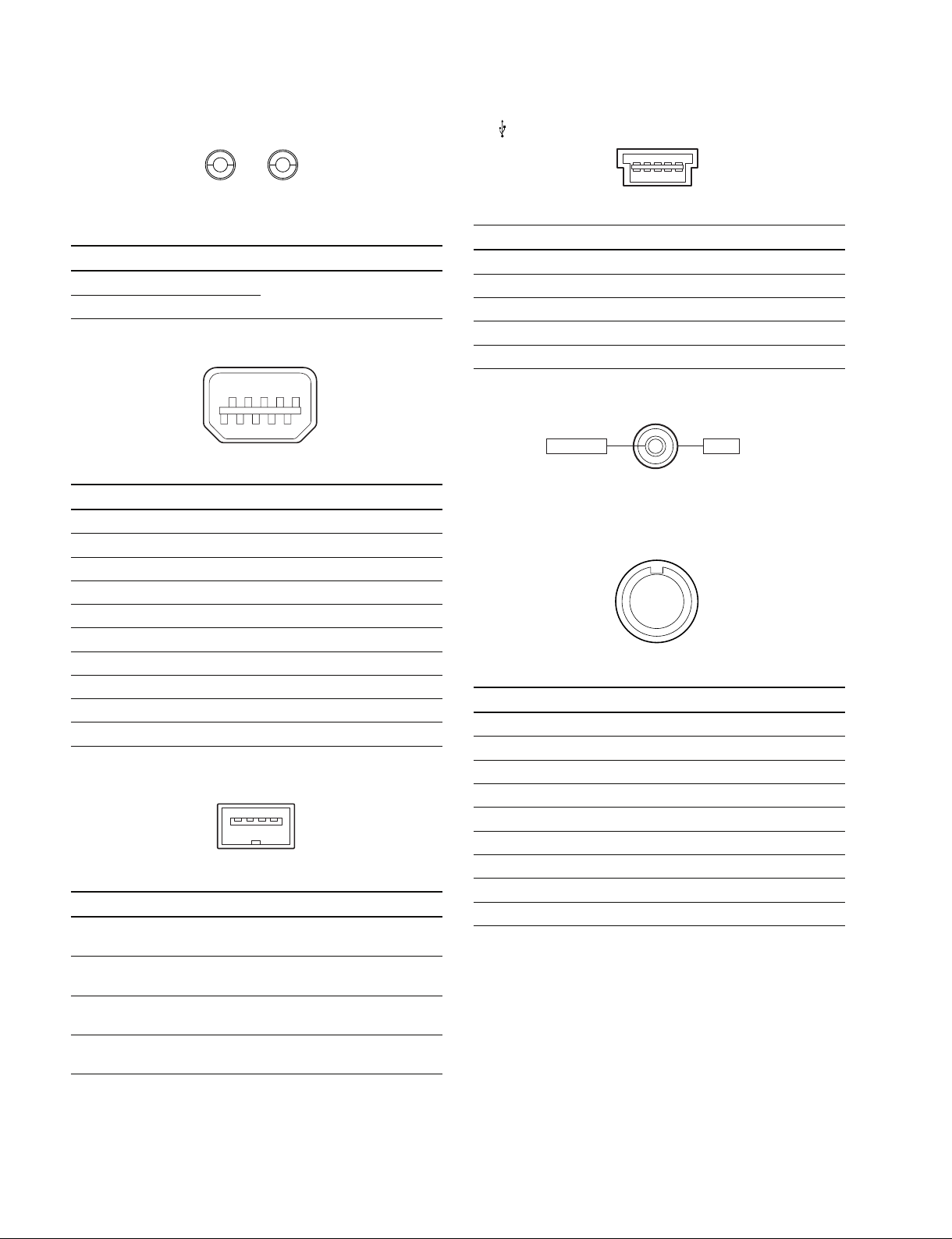

9 AUDIO OUT : RCA PIN

15

!= (USB) : Mini-B connector (5P)

1

__

_ EXT VIEW

__

2

__

_

__

No. Signal I/O Specifications

1 AUDIO CH-1 O _10 dBu

2 AUDIO CH-2 O

0 COMPONENT OUT : Mini D connector (10P)

19

210

__

_ EXT VIEW

__

__

_

__

No. Signal I/O Specifications

1 Y O COMPONENT (Y)

2 Y_GND _ Y GND

3 PB O COMPONENT (Pb)

4 PBPR_GND _ PBPR GND

5 PR O COMPONENT (Pr)

6NC _

7NC _

8NC _

9 SW_GND _

10 SW I

!- HDV : i.LINK connector (IEEE1394, S400) (4P)

14

__

_ EXT VIEW

__

No. Signal I/O Specifications

1TPB_ I/O Strobe on receive, data on

2TPB+ I/O Strobe on receive, data on

3TPA_ I/O Data on receive, strobe on

4TPA+ I/O Data on receive, strobe on

__

_

__

transmit B (_)

transmit B (+)

transmit A (_)

transmit A (+)

__

_ EXT VIEW

__

__

_

__

No. Signal I/O Specifications

1 VCC _ USB Vcc

2D _ I/O USB_

3D + I/O USB+

4ID _ NC

5 GND _ Ground

![ DC IN : 2P (DC JACK TYPE 4)

GNDEXT DC

__

_ EXT VIEW

__

__

_

__

!] REMOTE : (8P Female)

1

27

8

36

45

__

_ EXT VIEW

__

No. Signal I/O Specifications

1 TX RCP DATA (X) O SERIAL DATA OUT

2 TX RCP DATA (Y) O SERIAL DATA OUT

3 RX RCP DATA (X) I SERIAL DATA IN

4 RX RCP DATA (Y) I SERIAL DATA IN

5 DATA GND _ GND for VIDEO and DATA

6 UNREG +12 V O +11 V to 17 V

7 UNREG (GND) _ GND for UNREG

8 VIDEO (X) O 1.0 V p-p, Zo = 75 Z

CHASSIS GND _ CHASSIS GND

__

_

__

1-2

PMW-EX3

Page 11

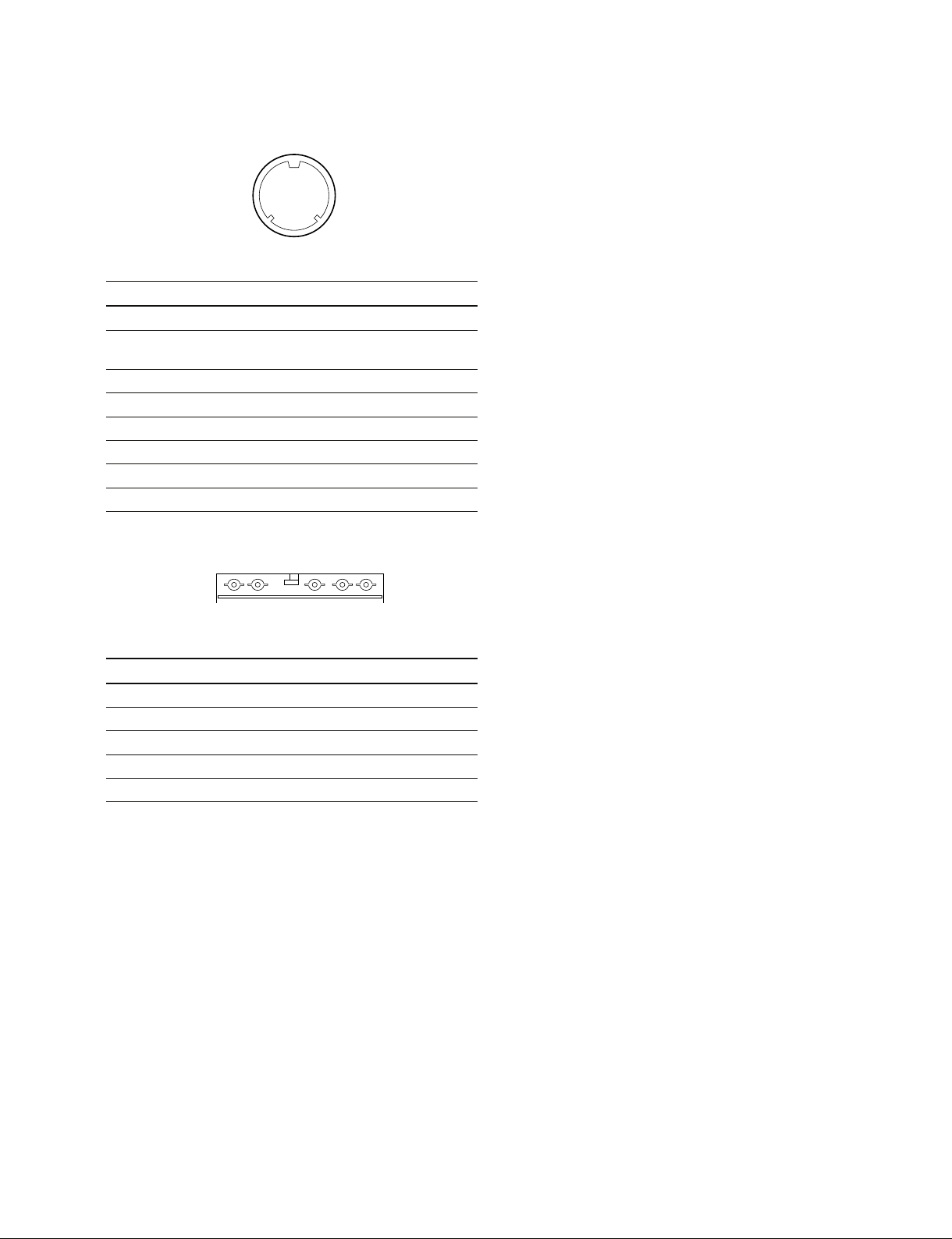

!\ LENS REMOTE : (8P Female)

18

2

7

3

4

6

5

__

_ EXT VIEW

__

__

_

__

No. Signal I/O Specifications

1 COMMON_V O GND

2 ZOOM I GND: WIDE 1.66V: STOP

3.33V: TELE

3 COMMON+V O 3.33V

4 COMMON I 1.66V

5 REC I GND: ON OPEN: OFF

6 RET I GND: ON OPEN: OFF

7 SW COMMON O GND

8 FRAME GND _

!; Battery : (5P)

12

__

_ EXT VIEW

__

No. Signal I/O Specifications

1 BATT (+) _ +11 to +17 V dc

2 BAT_SCL O

3 BAT_SDA I/O

4 BATT_ID_DATA I

5 BATT (_) _

345

__

_

__

PMW-EX3

1-3

Page 12

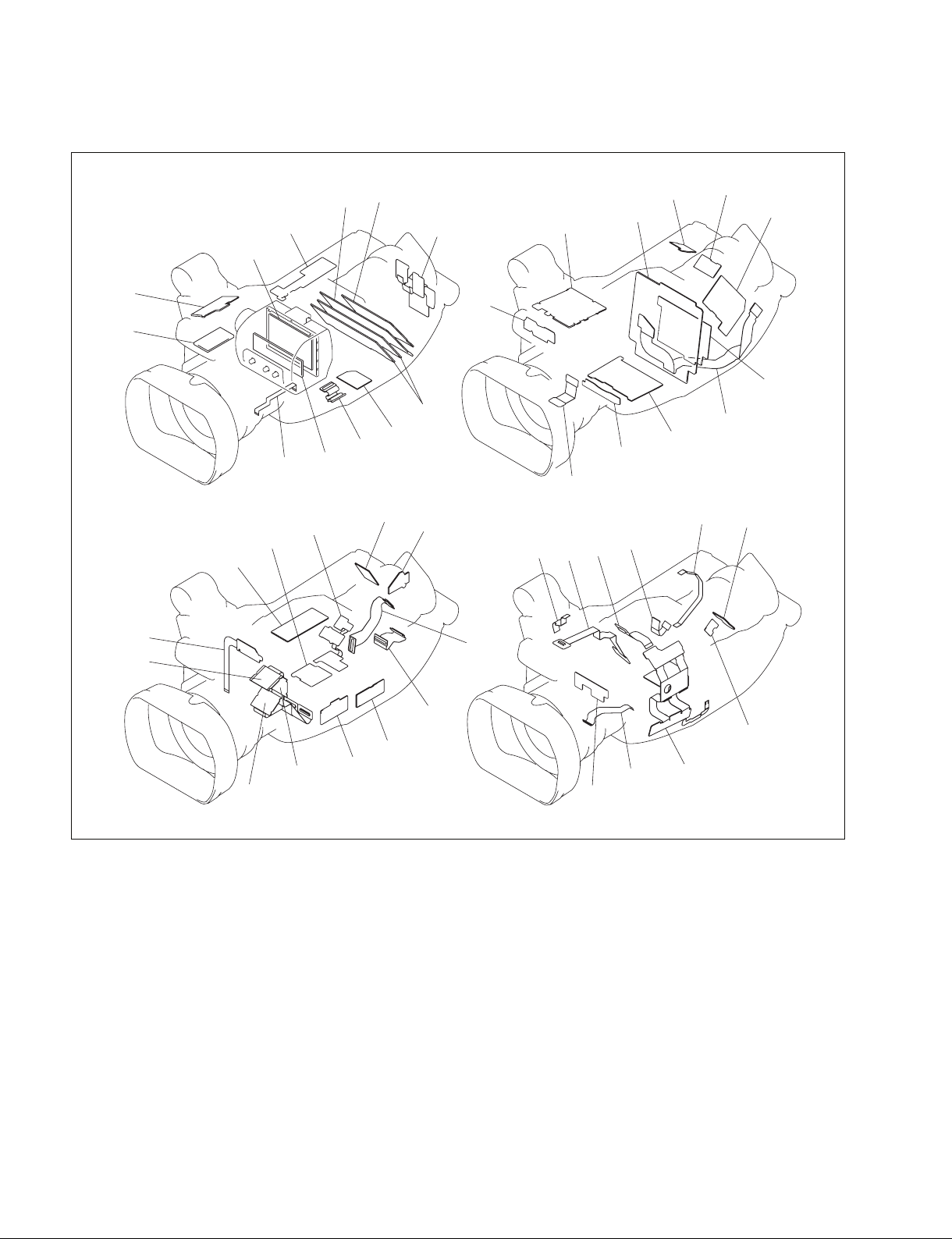

1-2. Location of the Printed Wiring Boards

#]

3

#.

6

$\

@,

#/

@-

@'

#-

!=

#;

@/

#'

@;

7

!\

!-

0

9

#,

@\

#=

!'

!;

!.

$/

@[

!]

#[

2

@]

![

1

$;

!,

#\

1 ASW-66 board

2 AU-318 board

3 AXM-36 board

4 BI-202 board

5 BI-203 board

6 BI-204 board

7 BP-42 board

8 CN-3022 board

9 CN-3023 board

0 CN-3024 board

!- CN-3050board

!= CT-251 board

4

5

![ DC-146 board

!] DPR-289A board

!\ EC-63 board

!; HN-326 board

!' HN-328 board

!, HN-337 board

!. HN-343 board

@/ HN-344 board

@- HN-345 board

@= HN-346 board

@[ HN-347 board

@] HN-348 board

$=

$-

8

@\ HN-349 board

@; HP-144 board

@' IF-1069 board

@, IF-1072 board

@. IR-42 board

#/ JK-81 board

#- JK-84 board

#= KSW-54 board

#[ LED-469 board

#] MA-164 board

#\ PS-747 board

#; RE-260 board

@.

@=

$]

#' RE-261 board

#, RM-214 board

#. SE-923 board

$/ SW-1389 board

$- SW-1410 board

$= SW-1411 board

$[ SW-1412 board

$] SWC-48 board

$\ SWC-49 board

$; TX-129 board

$[

1-4

PMW-EX3

Page 13

1-3. Circuit Description

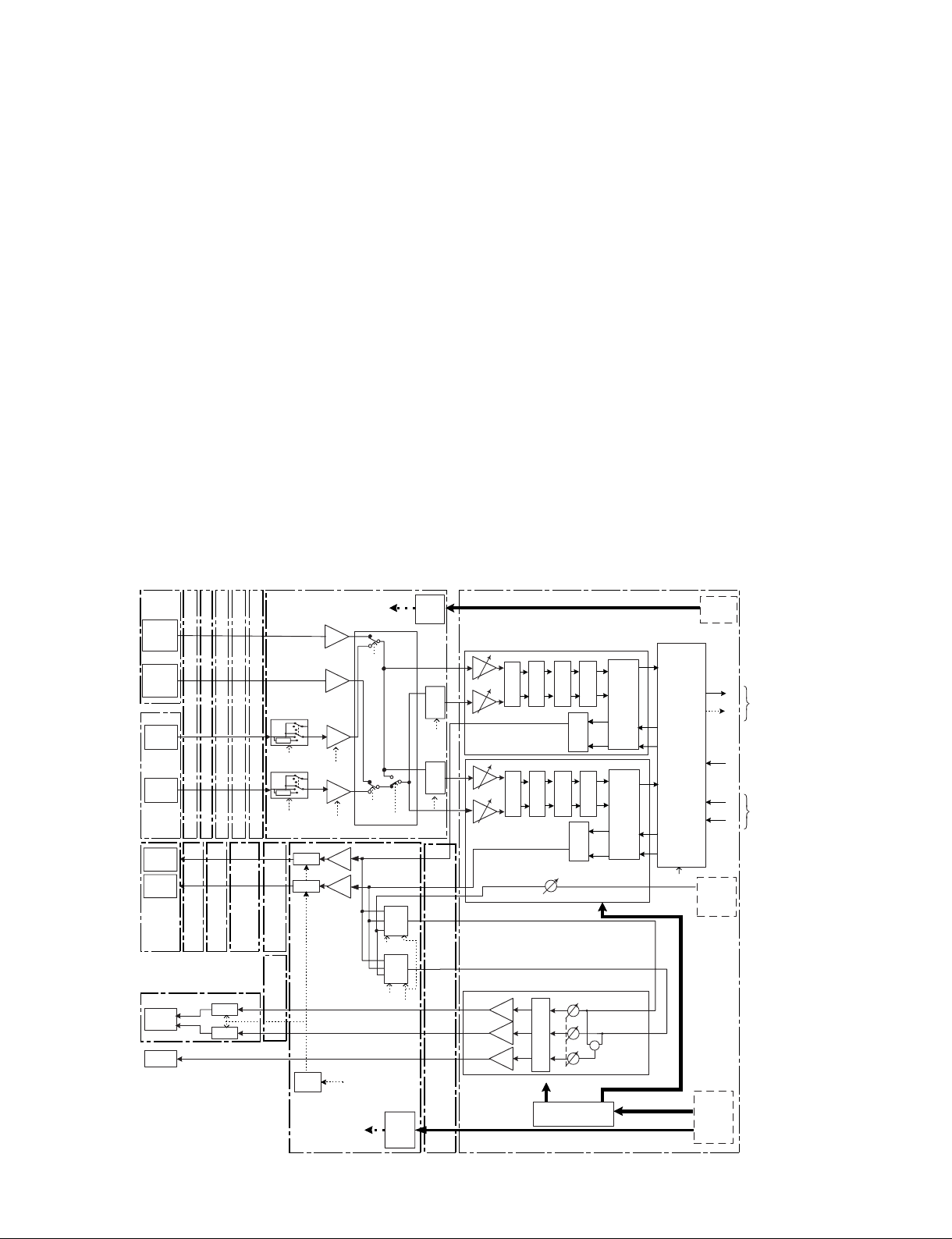

1. CMOS Block System

BI-202/203/204 Board

The BI-202, BI-203 and BI-204 boards are the rigid

flexible boards connecting the CMOS image sensors (IC1)

to the DPR-289A board.

the following AUTO operations of the camera are detected.

The detected signals are sent to the CAMERA MICON

(camera u-processor: IC314).

. Auto white balance

. Auto black balance

. Auto focus

. Auto iris

. Auto knee

The CMOS image sensor receives the three primary colors

of R, G and B that are separated from the incoming light

by the prism. The CMOS image sensor converts the

incoming primary color to electric signal. The built-in 12bit column A/D converters then convert the R, G and B

analog video signals to the digital video signals respectively.

The electronic shutter, analog gain amplifier and black

level clamp functions are also provided in the above

boards.

The BI-202 board is for the R-channel signal, the BI -203

board is for the G-channel signal and the BI -204 board is

for the B-channel signal.

The CMOS image sensor receives the sync signal and the

serial communication signal from the DPR-289A board.

The 12-bit digital video signals that are supplied from the

CMOS image sensors pass through the EMI filters (FL1 to

FL4) and are input to the DPR-289A board.

Various decoupling capacitors and the damping resistors

are also mounted in the above boards.

IC3 of the BI-203 board is a temperature sensor that sends

the temperature data to the CAMERA MICON (camera u-

processor: IC314) on the DPR-289A board via I2C bus.

2. Camera Block System

DPR-289A Board

The DPR-289A board consists of the Camera Signal

Processor IC (IC100) and the CAMERA MICON (camera

u-processor: IC314) whereas the Camera Signal Processor

IC (IC100) performs various processing on the digital

video signal supplied from the CMOS image sensor, and

the CAMERA MICON (IC314) performs control of IC100

and other various controls such as control of the CMOS

image sensor and of lens. The output digital video (Y/C)

signal is sent to the next circuit the video (baseband video)

signal processing circuit.

The 12-bit digital video (RGB) signals supplied from the

CMOS block (BI-202, BI-203 and BI-204 boards) first

enter the camera signal processor IC (IC100). In the

camera signal processor IC (IC100), average value, peak

value of the RGB digital video signals that are required for

The digital video signal from the CMOS image sensor

enters first the selector circuit selecting either the digital

video signal from the CMOS image sensor or the internal

TEST signal. The output video signal from the selector

enters the compensation circuits consisting of the CMOS

imager-related compensation circuit and the lens-related

compensation circuit. The video signal then receives the

white balance processing, and the matrix signal and the

detail signal are added to the video signal. The video signal

then receives the pedestal control, knee compensation,

gamma correction and white/black clip processing. The

video signal finally enters the baseband processing IC

(IC400).

The pixel number conversion processing from 1920/1080

to 1440/1080 or 1280/720 is also performed inside IC100.

The CAMERA MICON (camera u-processor: IC314)

performs the overall control over the entire camera system

and is controlled by the camera system controller

(IC1600).

Peripheral ICs of the CAMERA MICON (camera u-

processor: IC314) are FLAH ROM (IC312) and SRAM

(IC313). The CAMERA MICON (camera μ–processor:

IC314) confirms the iris control and lens setup when the

analog I/F lens is installed.

3. Video Signal System

DPR-289A Board

The digital video (Y/C) signal output from the camera

signal processor IC (IC100) enters the baseband processing

IC (IC400).

The baseband processing IC (IC400) performs the overall

baseband processing of video and audio signals with a

single chip IC containing the various scaler functions

(supporting the multiple format outputs), various OSD

functions, PLL function (54 MHz → 74 MHz) and CPU.

The baseband processing IC (IC400) provides the following outputs:

. HD/SD-SDI (digital): To TX-129 board

. HD/SD Component (analog): To JK-81 board

. Composite (analog): To JK-84 board

. S-Video (analog): To JK-84 board

. LCD signal (digital): To IF-1072 board

PMW-EX3

1-5

Page 14

The input/output signals of the baseband processing IC

(IC400) are the following signals:

. MPEG encoder/decoder I/F signal (digital): To IC901

. Audio I/F signal (digital): To IC804

PAM memory (IC700, IC701).

Peripheral circuits of the built-in CPU are FLASH ROM

(IC603) and SDRAM (IC607).

The baseband processing IC (IC400) is controlled by the

system controller (IC1600). The LCD driver IC, SDI Copro, the audio system and the power save control of the

output systems are controlled by the built-in CPU inside

IC400.

4. Media Recording and Playback

DPR-289A board

Output from the baseband processing IC (IC400) is input

into the MPEG encoder/decoder (IC901).

The MPEG encoder/decoder (IC901) is the single-chip

MPEG Codec IC that encodes and decodes both the highquality HD video signal and audio signal in real-time. It

has various interfaces with signals such as MPEG video,

video input/output, MPEG audio, audio input/output, bit

stream input/output, and interface with the host.

IC901 output is then input into LSI (IC900) for AVIT

signal processing.

LSI (IC900) for AVIT signal processing contains the builtin CPU and has interfaces for DDR2 SDRAM memory

(IC1000, IC1001), PCI bus, PCI-Express bus, I/O for

IC901, and serial communication with system controller

(IC1600).

IC900 is also connected to the NOR-type Flash ROM

(IC1100) to read the CPU program in the IC900 during

initial startup.

LSI (IC900) for AVIT signal processing is controlled by

the system controller (IC1600), in the same way as other

main devices, and provides the following types of functions: video/audio stream control, access to the SxS

memory card, mass storage operations when connected to

USB and HDV device controls when connected to i-LINK.

Explanation of peripheral devices

<SxS memory card slot>

Two memory card slot boards (EC-63) are connected to the

dual channel PCI-Express signals coming from IC900

through a 0.5 mm pitch, 30-pin fine coaxial cables connected to CN1300 and CN1301.

Furthermore, dual channel USB host signals output from

USB host controller (IC1302) are connect to the EC-63

board through fine coaxial cables just as with the PCIExpress signals.

IC1302 is controlled by PCI bus from IC900.

<USB device controller>

USB device signal output from USB device controller

(IC1101) is connected to output board (JK-81) through the

both-sided flexible board (HN-347) from CN1805 connector, and then it is connected to USB Mini-B connector

(CN6) on the JK-81 board.

IC1101 is controlled by the dedicated bus from IC900.

If there is no USB connection, the power supply for

IC1101 drops off.

<i-Link controller >

The i-Link signal output from the i-Link controller

(IC1200) passes through the both-sided flexible board

(HN-337) from the CN1803 connector. Then, the signal is

sent from CN3 on HN-337 to the i-Link connector board

(CN-3050) through the shielded wire, and connected to the

4 Pin i-Link connector (CN3) on the CN-3050 board.

IC1200 is controlled by the PCI bus from IC900.

5. Audio system

This overview explains the audio system according to the

audio block diagram shown in Fig. 1.

MA-164 board

The MA-164 board contains a built-in microphone unit.

The MA-164 board amplifies the audio signal with the

microphone bias power supply and head amplifier (Q5,

Q7, and Q9, and Q6, Q8, and Q10). It provides the balanced output for the audio signal.

AXM-36 board

The AXM-36 board is a connector board on which XLR

(3-pin) connector for external LINE/MIC input and the

[LINE/MIC/MIC +48V] input selection switch for two

channels are mounted on this connector board.

KSW-54 board

This board performs the read and tally controls for the

switch on the handle. The audio signal block relays the

audio signal between the MA-164 board and AXM-36

board.

HN-328/HN-343/SWC-48/HN-344 flexible board

This board relays the audio signal between the KSW-54

board and the AU-318 board.

AU-318 board (Audio block)

This board controls the analog audio input signal processing, as well as microphone +48 V power supply and serial

signal.

(RTC is also built on this board, but the explanation has

been omitted here.)

1-6

PMW-EX3

Page 15

. Audio signal from the built-in microphone on the MA-

164 board is input to the balanced input amplifier IC101

and IC201 of this board. Output of the balanced amplifier is connected to the analog switch (IC105, IC205) for

switching between [INT/EXT].

. The DC-DC converter (IC1, Q1) for microphone power

+48 V is built-in, and when EXT MIC +48 V is going to

be supplied, the EXT MIC +48 V is supplied by the

switch (Q301, Q302, Q321 and Q322).

. The audio input signals from MIC and LINE are input to

a common circuit that receives both of the MIC input

level (_8 dBu to _65 dBu) and the LINE input level (+4

dBu). The input attenuator is inserted in the circuit

switch (Q103 to Q105, Q203 to Q205) as required. This

audio input signal is received by the balanced input

amplifier (IC102, IC202) that performs amplification of

0/+12 dB and switching (Q110, Q111, Q210, Q211) in

accordance with the level that is set by INPUT TRIM.

After that, the audio signal is connected to the [INT/

EXT] switch (IC105, IC205).

. The [INT/EXT] switch (IC105, IC205) performs not only

the INT/EXT switching but also performs the input

channel mode selection [CH1/ (CH1/CH2)].

. SEL/AMP (1, 2) is a signal selector and buffer amplifier

to perform AGC link.

. Serial control

2

C control signal from Display Block (T-one) is

The I

converted into GPI, and performs switching such as

[INT/EXT], [LINE/MIC/MIC+48], [CH1/ (CH/CH)],

and AGC [Linked/Separated] for CH1 and CH2.

DPR-289A board (Audio block)

The AU-318 board is comprised of two pieces of the

Audio Codec IC and the C-PLD.

. Audio Codec (IC800, IC801)

The analog audio signal from the AU-318 board is

connected to IC800 and IC801 that are the Audio Codec

(PGA, ADC, DSP, Digital IF, headphones amplifier,

speaker amplifier are built on one chip and the parameters are set with I

2

C).

The Input TRIM (PGA) functions in the [MANUAL]

mode, and AGC functions in the [AUTO] mode to

control the audio signal level. The analog signal after

MA-164

Q5,Q7,Q9

INT MIC1

with

HEAD AMP

+12dB

Q6,Q8,Q10

INT MIC2

with

HEAD AMP

+12dB

MIC/LINE1

(XLR)

MIC/LINE 2

(XLR)

AXM-36

AV Monitor

Out1

(Line Out1)

AV Monitor

Out2

(Line Out2)

JK-84

HP-144

HP OUT

(PHONE

MINI)

CN2

SPEAKER

KSW-54

JK-81

HN-328

HN-347

Q1

MUTE

Q2

MUTE

HN-343

Q103 to Q105, Q301,Q302

HN-344

SWC-48

+48V /MIC / LINE -1

Q203 to Q205,

Q321,Q322

+48V /MIC / LINE -2

(2/2)

DPR-289A

AU-318

-24

-24

MUTE AMP

MUTE

HN-337(2/2)

LED-469

PWR or

ASW-66

DET

INT/EXT1,INT/EXT2

MIC/LINE/+48V-1,

MIC/LINE/+48V-2,

COPY1to2, LINK2to1, LINK1to2

BAL

AMP

IC101

INT/

EXT 1

BAL

AMP

IC201

IC105,

BAL

AMP

IC102

Q110,

Q111

(GAIN SEL

CH1)

BAL

AMP

IC202

Q210,

Q211

(GAIN SEL

CH2)

AMP

MONI1-1,2-1,

MONI2-2,2-1,

BEEP,

MUTE

IC101,

IC102(2/2)

MONI CH2-2

MONI CH2-2

MUTE

IC205

INT/EXT 2

+48V

+48V

Q103

Q104

Q100 to Q102

IIC to

CH1 CH1/CH2

IC100,

IC102(1/2)

SEL/

MIX1

MONI CH-1

MONI CH2-1

SEL/

MIX2

IC104, IC105

GPIO

BEEP

GPIO

IC401 to

IC404

Linked/

Separated

Linked/

Separated

IC103,

IC104

SEL/

AMP1

IC203,

IC204

SEL/

AMP2

HN-337

(1/2)

DPR-289A

(1/2)

PGA

GAIN

PGA

GAIN

PGA

GAIN

PGA

GAIN

A/D

A/D

AMP

AMP

AMP

Fig. 1. Audio block diagram

IC800(1/2)

FIL AGC LVL

D/A

FIL AGC LVL

D/A

IC801

IC800(2/2)

MIX

AMP

IC800

IC803

I2C MPX

(DEVICE CONTROL)

I2S

AUDIO IF

I2S

AUDIO IF

AUX IN( L)

AUX IN( R)

+

MONITOR LEVEL

I2C

I2C

I2C

Digital Audio

OUT 1

Digital Audio

IN 1 or 3

CLOCK DIV

(1fs,64fs,256fs)

GAIN MAKE

OUT 2

Digital Audio

IN 2 or 4

CLOCK DIV

(1fs,64fs,256fs)

IC804

C-PLD

DP_O_CAM_

AU_DT12O

(DP_O_CAM

_AU_DT34O)

CLOCK DIV

(1fs,64fs,256fs)

DP_I_CAM_A

U_DT12O

DP_I_CAM_A

U_DT34O

LINE 3/4

Display

Block(T-on)

BEEP

(T-one)

Display

Block

(T-one)

Recording

signal

Playback

signal

PMW-EX3

1-7

Page 16

level adjustment is converted to the digital signal with

the ADC.

The digital signal receives the audio level control

processing from the DSP. After the audio signal receives

the [Wind Filter] (on/off) processing, the digital signal is

output for audio recording.

Playback output (including EE) is the digital signal that

is connected to Audio Codec where it is converted to the

analog signal with DAC and output to the ASW-66

board.

Furthermore, the audio signal that is processed for audio

monitoring in the ASW-66 board is connected to the

headphones amplifier and speaker amplifier through the

monitor level control from the AUX input of IC800.

. C-PLD (IC804)

After the digital signal output signal from the Audio

Codec is amplified by +12 dB, it is supplied to the

Display Block (T-one). C-PLD (IC804) also receives the

playback output signal from the Display Block.

The playback system selects CH1/CH2 or CH3/CH4,

connects EE, and connects TEST TONE from the

Display Block depending on the data.

Furthermore, C-PLD divides the clock signal that is

supplied from the Display Block to Audio Codec.

. Serial control

The I2C control from Display Block (T-one) selects

either IC800 or IC801 for the target with I2C MPX and

sets the register of IC800 or IC801.

HN-337 flexible board

It relays the audio signal from the DPR-289A board to the

ASW-66 board.

ASW-66 board (Audio block)

. Analog output from the DPR-289A board Audio Codec

is buffered by IC103 and is output to the A/V connector

after passing through the audio MUTE control.

. Analog output from DAC on the DPR-289A board re-

enters into the AUX input of the DPR-289A board

AUDIO CODEC after passing through the monitor

selector/mixer (IC100, IC101, IC102), and becomes the

monitor signal.

. Serial control

I2C control signal from Display Block (T-one) is output

at GPI, and performs the switching between MONITOR

[CH1/CH2] / [CH1+CH2] / [CH1] / [CH2] for CH1 and

CH2 respectively, and at the same time controls the

BEEP on/off.

JK-84 board (Audio block)

This is the connector board. The audio output from the

ASW-66 board is connected to RCA PIN connector.

HP-144 board (Audio block)

The headphones output signal is connected to the headphones jack of the DPR-289A board.

The headphones output is muted by the MUTE (Q1, Q2).

Switch/Volume control/Menu panel (Audio

controller block)

Operation panel functions relating to audio signal are built

into the following blocks.

ASW-66 board (Audio block)

For CH1 and CH2, the switches [INT/EXT] and [AUTO/

MANUAL] are connected to PIO of CPU (IC106), and the

volume control [AUDIO LEVEL] is connected to ADC of

CPU (ICl06).

KSW-54 board (Audio block)

The switch [LINE/MIC/MIC+48] on the AXM-36 board is

connected to PIO of CPU (IC100) for CH1 and CH2

respectively. The switch [MONITOR (AUDIO) +/_] that

is common to CH1 and CH2 is connected to PIO of CPU

(IC100).

MENU processing

(1) Audio Input

. CH1, CH2 [INPUT TRIM]: _8 dBu to _65 dBu

. CH1, CH2 common [AGC Link]: Linked/Separated

. CH1, CH2 [WIND FILTER]: ON/OFF

. CH1, CH2 common [EXT CH Select]: [CH1] /

[CH1/CH2] selection

(2) Audio Output

. [MONITOR CH]: [CH1/CH2] / [CH1+CH2] /

[CH1] / [CH2] selection

. [Alarm Level]: 0 to 10

. [Beep]: ON/OFF

. [BARS]: TEST TONE (DPR-289A board Display

Block internal processing)

6. System Control

DPR-289A board

The 32-bit RISC CPU (ARM) with ARM core is built-in as

the system controller (IC1600).

It has the peripheral interface functions of SDRAM, USB,

SCI, and I2C. It operates on a 27 MHz clock (X1600).

FLASH ROM (IC1603), SDRAM (IC1604), and EEPROM (IC1703) are mounted as the peripheral ICs.

It performs the system control through serial communication with IC314 of the camera block system, IC400 of the

video signal system, and IC900 of the media recording/

playback system.

1-8

PMW-EX3

Page 17

Main functions of the system controller and

peripherals

(1) Reading operation switch information

Reading the switch information and the LED control

are performed by I2C bus communication with each

sub-microprocessor.

. Handle switch: IC100 on the KSW-54 board

. Inside panel front switch: IC601 on the SWC-48

board

. Rear panel switch: IC106 on the ASW-66 board

. Power supply switch: IC1001 on the RE-261 board

(2) Watch IC (RTC) control

The watch IC (IC50) is built onto the AU-318 board.

The watch IC (IC50) is backed up by a lithium coin

battery, and the current time is read or set via IC601 on the

SWC-48 board.

(3) Infrared remote control demodulation

The RM-214 board has an IC (IC1) for infrared remote

control signal demodulation, and it receives the command

codes via IC100 on the KSW-54 board.

(4) Info-Battery communication

The Info-Battery of SM bus specifications is supported.

The serial terminal of the battery connector is connected to

IC1001 on the RE-261 board. This IC1001 reads the

battery authentication, battery type, remaining power, and

other information and send them to the system controller

via I2C bus communication.

(5) Power supply voltage detection

The power supply voltage at the DC IN connector is

measured by the A/D port on IC1001 on the RE-261 board,

and it is posted to the system controller as the input voltage

value.

(6) Power system control

IC1001 on the RE-261 board checks that the power switch

on the PMW-EX1 is turned ON, and turns on the system

controller of IC1600. After that, it controls the power for

each circuit block according to the system controller.

The system controller controls the respective power supply

systems in the RE-260 and RE-261 boards according to the

operation mode of the device, via the power supply uprocessor on the RE-261 board.

By turning off the power systems to unnecessary circuits

blocks, power can be saved.

(7) 700P communication

The serial communication driver (IC803) is mounted on

the TX-129 board.

Serial communication with the remote control unit connected to the REMOTE connector is performed.

7. SDI/GENLOCK/TC IN/TC OUT

TX-129 board

(1) SDI output

This board receives the parallel video signal with FPGA

(IC100) and IC500 and outputs the SDI signal.

Furthermore, it performs audio or timecode embedding.

The video and audio signals are supplied from CN400 on

the DPR-289A board to CN100 on the TX-129 board with

a 0.4 mm pitch, 40-pin fine coaxial cable.

The power voltages are supplied from CN401 on the DPR289A board to CN700 on the TX-129 board with a 15-pin

harness.

Output SDI signals are supplied to CN500.

Output SDI signals are then supplied from CN500 to the

coaxial connector via the mini coaxial connector and mini

coaxial cable.

The PLL circuit is used to reduce jitter of the HD-SDI

clock signal.

The FPGA (IC100) is controlled by IC400 on the DPR289A board through 4-line serial communication.

The FPGA program is stored in the IC203 ROM, and

JTAG can be used to overwrite the data from IC1600 on

the DPR-289A board.

When not using SDI, the power to cable driver inside

IC500 is turned off.

(2) GENLOCK

In IC902, sync signal separation is performed for GNELOCK. The separated sync signal enters IC400 on the

DPR-289A board where phase is compared by the internal

counter of IC400 and by IC521 to control the VCXO

(X500).

(3) TC IN/TC OUT

IC900, IC901, and IC907 reshape the waveform of the

time code connected to the TC IN connector and input it to

IC100.

IC903 is the external output circuit for the time code OUT

signal, which outputs the signal to the TC OUT connector.

They communicate with the FPGA (IC100) through the 4line serial interface on the DPR-289A board.

PMW-EX3

1-9

Page 18

8. Power supply system

RE-260/261 board

This board is comprised of the power supply circuit and

the POWER SUPPLY MICON (power supply u-processor:

IC1001 on the RE-261 board).

However, part of the low-voltage power supply is mounted

on the DPR-289A board.

(1) Input power supply (UNREG) system operations

When the UNREG power is input, the EVER power state

is established.

In this state, the ON/OFF state of the Power switch can be

recognized.

If the POWER SUPPLY MICON (power supply uprocessor: IC1001) recognizes that Power switch is ON,

the power is turned on for the system control system and

the POWER SUPPLY MICON (power supply u-processor:

IC1001) controls the power supply for each block according to the system controller (DPR-289A board: IC1600).

The normal value for the input power supply (UNREG) is

in the range of about +10.5 V to +18 V.

. Battery/EXT-DC select

Input power comes in two systems: Battery and EXTDC. This switch monitors the input voltage for each

input and automatically switches the circuit settings with

priority given to EXT-DC.

. Input overvoltage protection

If the voltage is too high in the UNREG power supply,

the overvoltage protection circuit starts operating around

the set value of +17.9 V, and the camera shuts down.

When the input power supply voltage to this circuit

becomes less than +17.9 V, the power supply immediately switches on with automatic recovery.

. Input low-voltage protection

If the voltage is too low in the UNREG power supply,

the low-voltage protection circuit starts operating around

the set value of +10.5 V according to the control by the

POWER SUPPLY MICON (power supply u-processor:

IC1001), and the camera shuts down. When the input

power supply voltage becomes higher than +10.5 V, the

power supply immediately switches on with automatic

recovery according to the control by the POWER

SUPPLY MICON (power supply u-processor: IC1001).

. Overcurrent detection

The overcurrent detection circuit is comprised of IC308

on the RE-260 board. The setting value is approximately

4.3 (A). Even after clearing IC308 after overcurrent

detection, automatic recovery is not performed and the

power must be turned on again.

1-10

. Power supply reverse connection protection

If the input power has reverse voltage, Q301 on the RE260 board is immediately turned off and UNREG power

is stopped on the GND side, and the protection function

works.

(2) DC/DC converter function

The power supply output is divided into 25 systems, which

are separated into four blocks as seen below.

. CMOS/camera block system, 7 systems

(+4.6 V, +3.1 V, UNREG, etc.)

. Audio/video signal system, 7 systems

(+13.5 V, _4.6 V, +4.6 V, etc.)

. System controller system, 5 systems

(+4.6 V, +3.1 V, +2.5 V, etc.)

. Media recording/playback system, 6 systems

(+3.1 V, +2.5 V, +1.8 V, etc.)

The sequence control (powering up and powering down)

for the power supply system is controlled by the POWER SUPPLY MICON (power supply u-processor:

IC1001) for the respective power supply blocks of each

block.

By turning off the power for each block according to the

operation mode (camera mode or media mode), the

optimal power consumption for each operation is

achieved.

. Short-circuit protection for each power supply system

The circuit settings monitor each output voltage or

current for each power supply system and operate the

protection circuits per block.

Even after the protection circuit is cleared, automatic

recovery is not performed and the power must be turned

on again.

Even after short-circuit is cleared, the protection circuit

does not recover automatically and the power must be

turned on again.

Battery information functions

. Battery authentication function

The authentication function checks whether the battery is

of the specified type. This helps prevent one cause of

major accidents when using batteries as a power supply.

If the attached batter is not the specified type of batter,

the camera immediately turns off.

. Battery Info function

In an intelligent (specified) battery, the battery can

monitor information, such as how many times the battery

has been recycled or the internal temperature for the

battery. This helps provide detailed information about

the battery, including whether the battery is damaged or

how long the life is, in order to provide optimal operations.

PMW-EX3

Page 19

1-4. Service Tools/Measuring Equipment List

1-4-1. Service Tools

Part No. Name Usage/Note

Commercially available Grayscale chart Reflective type (16 : 9), Camera adjustment on market

Commercially available Star chart Reflective type, camera adjustment on market

J-6394-080-A Grayscale chart Transparent type (16 : 9), Camera adjustment on market

J-6029-140-B Pattern box PTB-500 Camera adjustment

* Mini USB cable For firmware version-upgrade

3-292-755-01 XLR JIGU For removing the mounted circuit board

* : This cable is supplied with PMW-EX3.

1-4-2. Measuring Equipment

Use the calibrated equipment or equivalent as listed below for the adjustments.

Equipment Model name

Oscilloscope Tektronix TDS3054 or equivalent (150 MHz or more)

HD waveform monitor LEADER ELECTRONICS CORP.LV5152DA or equivalent

Frequency counter Advantest TR5821AK or equivalent

Digital voltmeter Advantest TR6845 or equivalent

Color monitor Sony HDM-20E1U/14E1U/14E5U or equivalent

Luminance meter Konica Minolta LS-110 or equivalent

PMW-EX3

1-11

Page 20

1-5. Firmware Upgrade

Upgrade the firmware for the PMW-EX1 through a USB connection to a computer.

For detailed information about the upgrade procedure, check the readme file that comes with the upgrade

software.

For inquiry or comments about the firmware upgrade, please contact your local Sony Sales Office/Service

Center.

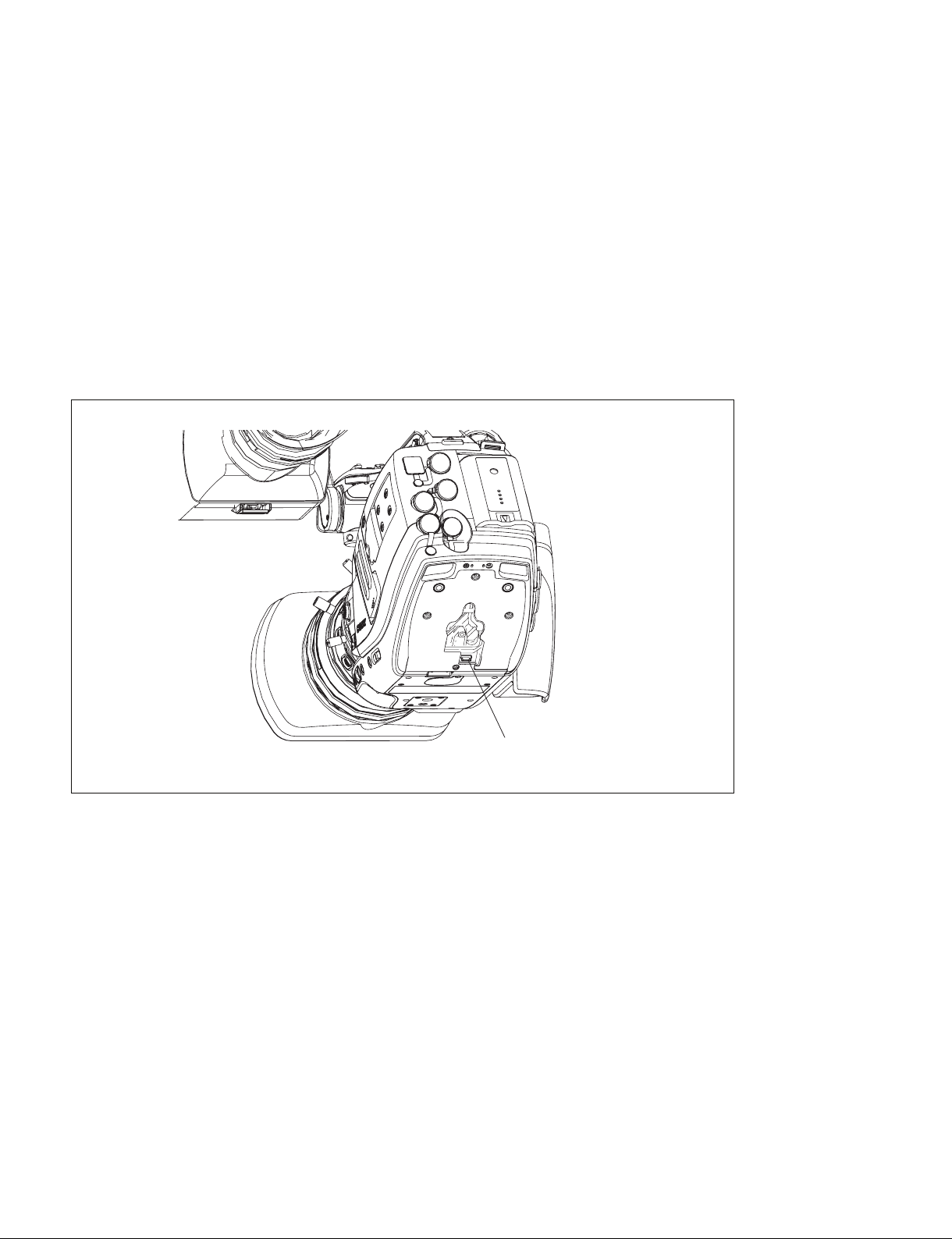

Firmware Upgrade Procedure

Download the software for the new firmware upgrade onto the computer before starting these operations.

1. Check that the power switch on the PMW-EX3 is turned OFF.

2. Remove the pad sub assembly and pad center cover. (Refer to Section 2-2-3.)

USB maintenance connector

3. Use the USB connector that comes with the PMW-EX3 to connect the computer and the USB

maintenance connector.

4. Switch the power switch to CAMERA and turn the power ON.

5. Run the software for the firmware upgrade on the computer.

6. When the upgrade is complete, turn OFF the power and remove the USB cable.

7. Attach the pad sub assembly and pad center cover.

When the PMW-EX3 is connected to the computer for the first time, the driver software will need to be

installed into the computer. For more details, check the readme file that comes with the upgrade software.

1-12

PMW-EX3

Page 21

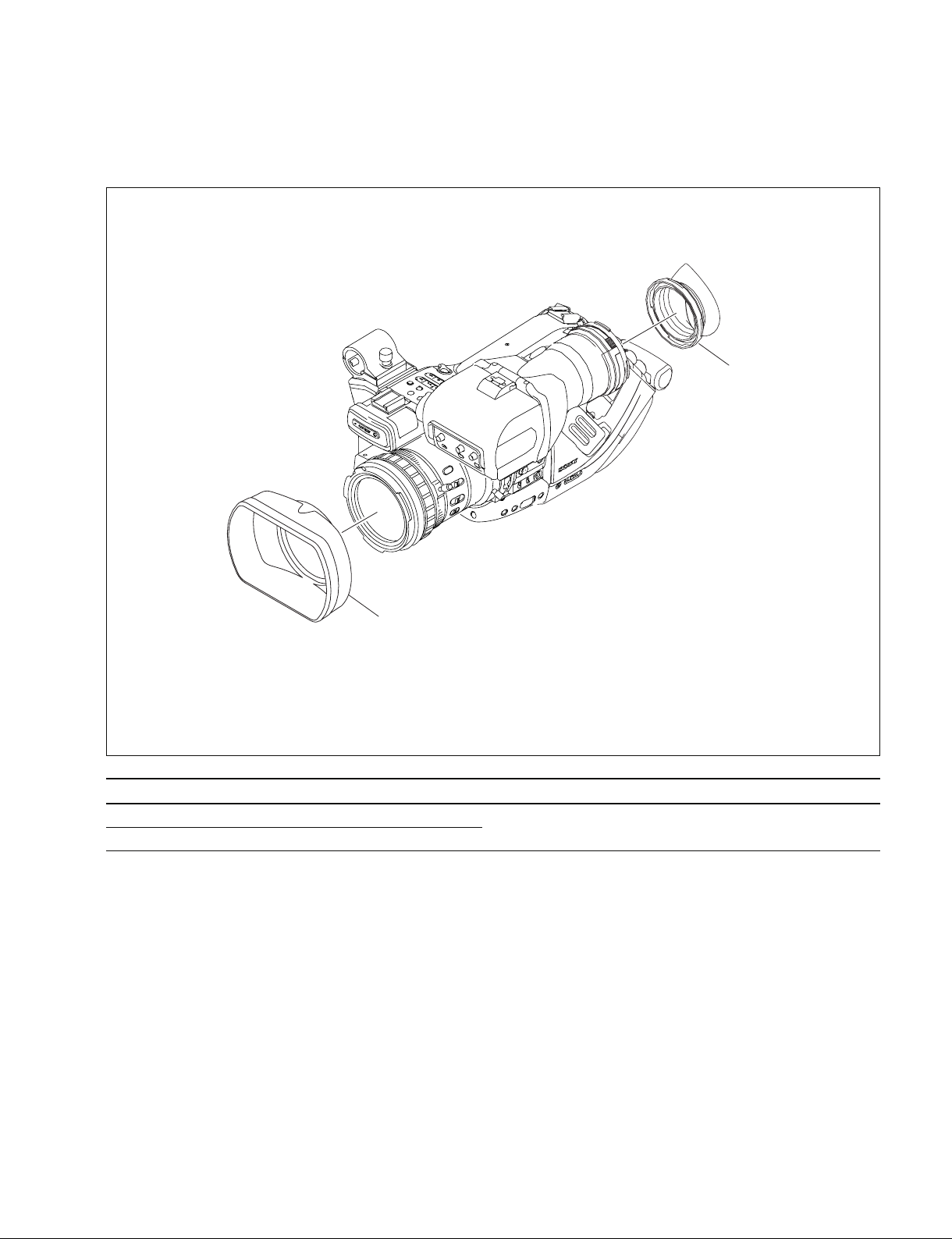

1-6. Recommended Replacement Parts

This section describes the recommended replacement parts and recommended replacement time.

2

1

ID Part name Sony part No. Recommended replacement timing

1 Lens hood 4-110-064-01

2 I cup 3-878-208-02

Check for deformation and deterioration from time to time.

Replace it as necessary.

PMW-EX3

1-13

Page 22

1-7. Note on Service

1-7-1. Requirements on Replacement of

Boards or Parts

This section explains the necessary setups required when

replacing boards or parts.

1. When any of the following boards is replaced, upgrade

the firmware version.

All data are written at once when upgrading the

firmware version. (Refer to Section 1-5.)

1-7-2. Note on Replacement of Parts on the

Board

1. The BI-202, BI-203 and BI-204 boards cannot be

replaced on the board-level service or part-level service.

If parts become defective, replace the entire CMOS

block.

2. Parts labels also cannot be replaced in the DPR-289A

board.

If parts become defective, replace the entire mounted

board.

Board name Ref. No.

DPR-289A IC312, IC603, IC1100, IC1603

KSW-54 IC100

SWC-48 IC601

ASW-66 IC106

RE-261 IC1001

TX-129 IC203

2. Adjusted values are stored in the following boards and

parts. The values need to be readjusted when they are

replaced.

Board/part name Ref. No.

DPR-289A

CMOS block IC312/DPR-289A board

LCD module

*1: The adjusted values for the CMOS block and the LCD module are

*2: The adjusted values for the LCD module are stored in the LCD module,

*1

*2

stored in the DPR-289A board.

but the adjusted values need to be copied to the DPR-289A board.

IC202/IF-1072 board, IC603/DPR289A board

3. The user setting values are stored in IC1703 on the

DPR-289A board. The user data must be stored

(Restore) in SxS before replacing the board and it must

be read (Recall) after replacing the board.

1-7-3. Description of Number Seal on the

Prism

The number seal is put in the prism unit, the serial number

of prism unit.

Every prism unit has its own number called prism serial

number.

1-7-4. Memory Backup Battery

For replacing the battery, refer to “Backup Battery” of the

“Appendixes” in the Operating Instructions.

When the backup battery is replaced, the date and time in

the internal clock need to be set. Refer to “Setting the

Clock” of the “Preparations” in the Operating Instructions.

1-7-5. Unleaded Solder

Boards requiring use of unleaded solder are printed with a

lead free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come

printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

1-14

m

. Be sure to use the unleaded solder for the printed circuit

board printed with the lead free mark.

. The unleaded solder melts at a temperature about 40 dC

higher than the ordinary solder, therefore, it is recommended to use the soldering iron having a temperature

regulator.

. The ordinary soldering iron can be used but the iron tip

has to be applied to the solder joint for a slightly longer

time. The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful.

PMW-EX3

Page 23

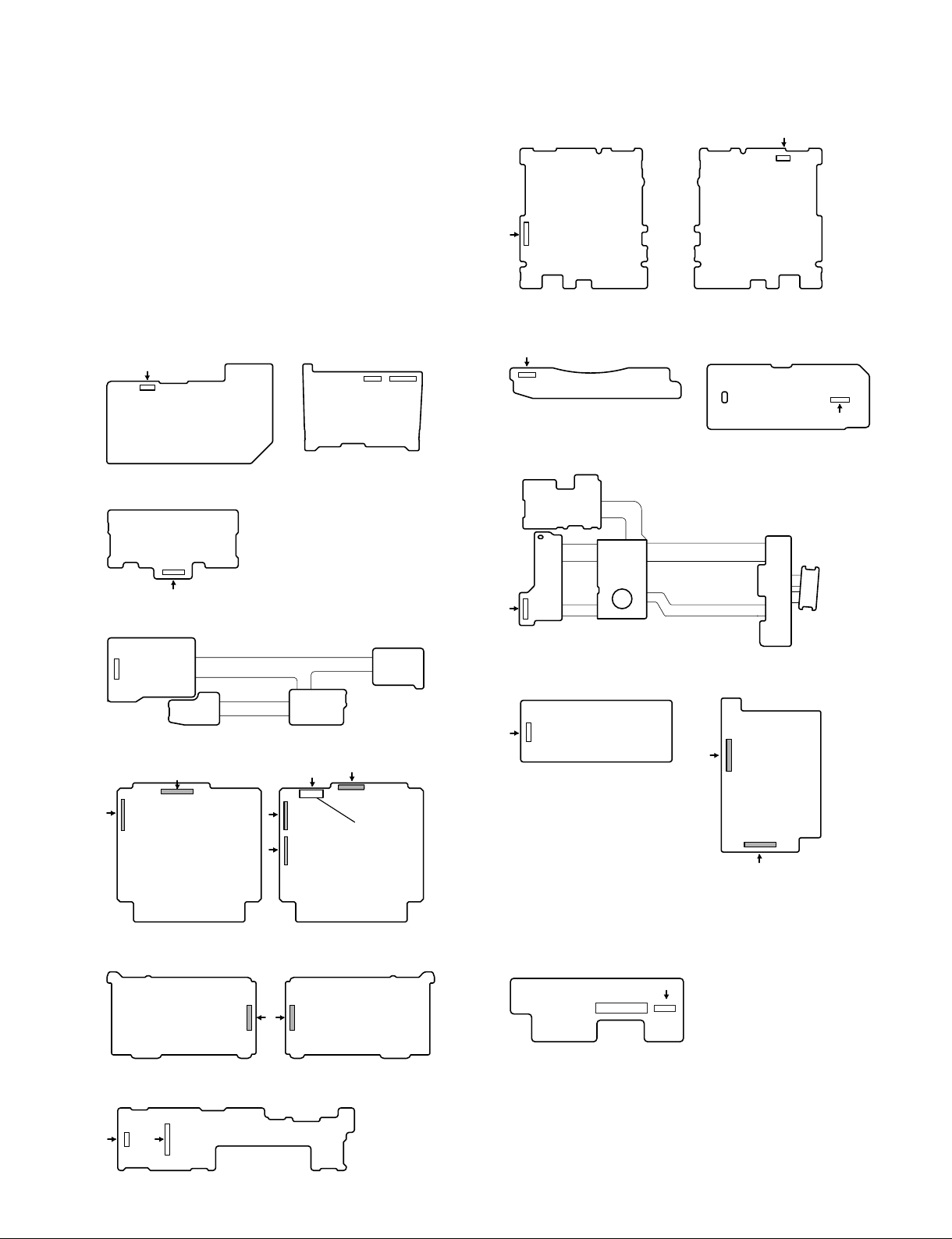

1-8. Connector Location Diagram on

CN500

1

CN300

1

Board

The PWM-EX1 uses flexible card wires and coaxial cables

with connector. The following diagrams indicate the

location of each connector. The location of flexible card

cables are indicated by the circle number 1 and 2, while

the coaxial cables with connector are not indicated by the

circle number.

KSW-54 board (A side) KSW-54 board (B side)

1

CN4

1

CN5

ASW-66 board (A side) AU-318 board (A side)

CN100

1

CN1 CN2

22

AXM-36 board (A side)

1

CN3

CN-3024 board (A side)

2

CN6

DPR-289 board (A side) DPR-289 board (B side)

SW-1389 board (B side) SW-1410 board (B side)

SWC-48 board (A side)

1

CN700

SWC-49 board (B side) TX-129 board (A side)

1

CN100

CN100

CN1301

CN1300

CN601

1

CN1804

CN400

CN402

EC-63 board (A side) EC-63 board (B side)

CN2 CN1

IF-1069 board (A side )

CN5

1

CN4

1

PMW-EX3

IR-42 board (A side )

CN103

2

CN102

CN800

1

1-15

Page 24

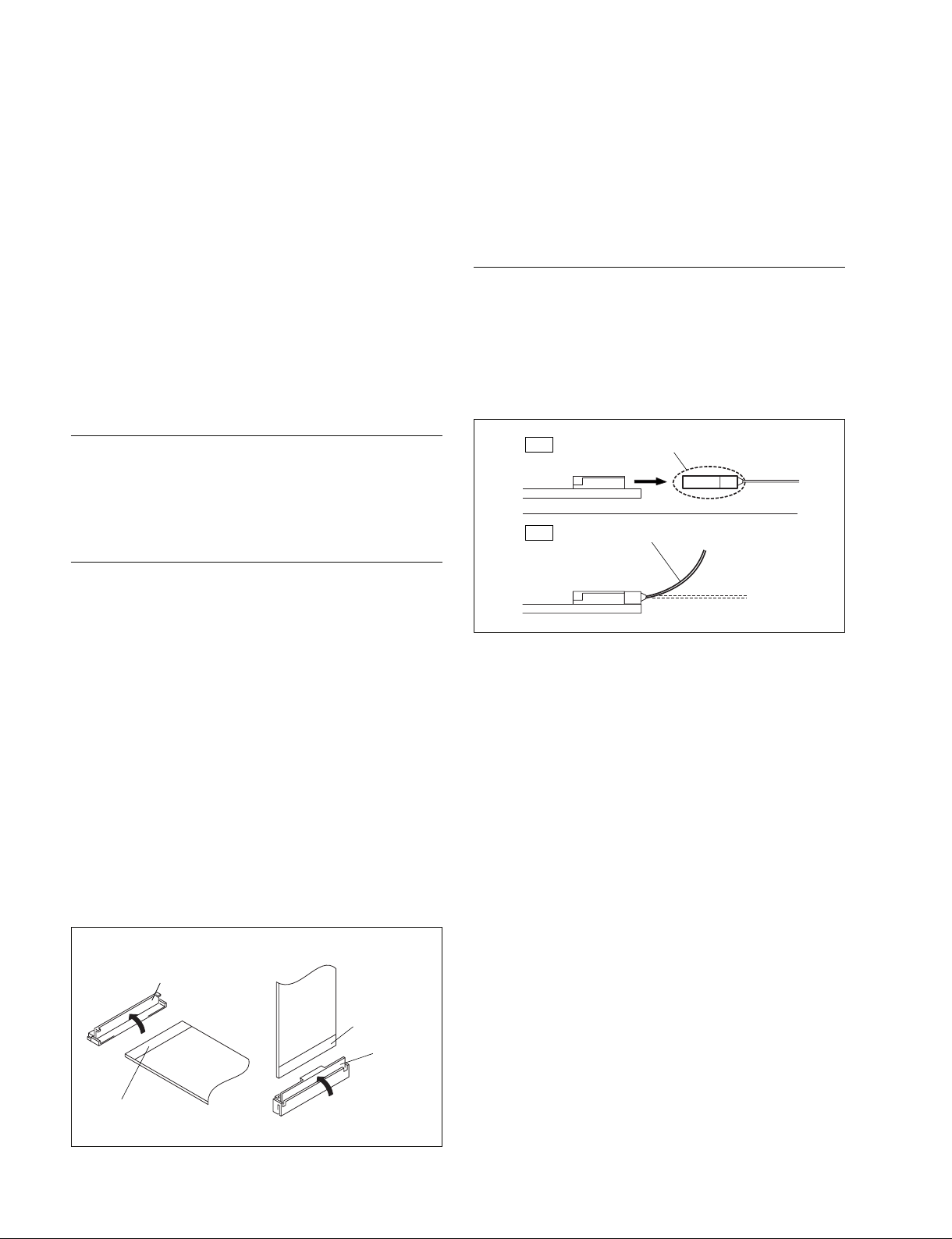

1-9. Replacing the Flexible Card Wires

n

The flat cables, flexible card wires and boards are used to

connect between the following boards. Life of flexible card

wire will be significantly shortened if it is folded. Be very

careful not to fold the flat cables, flexible card wires and

boards.

The two types of different shape connectors are used in

this unit.

Because the direction of the flat cables, flexible card wires

and boards are different depending on the shape of the

connector, be careful when connecting the flat cables,

flexible card wires and boards.

Disconnecting

1. Turn off the power.

2. Slide or lift up the portion A in the direction of the

arrow to unlock and pull out the flexible card wire.

Connecting

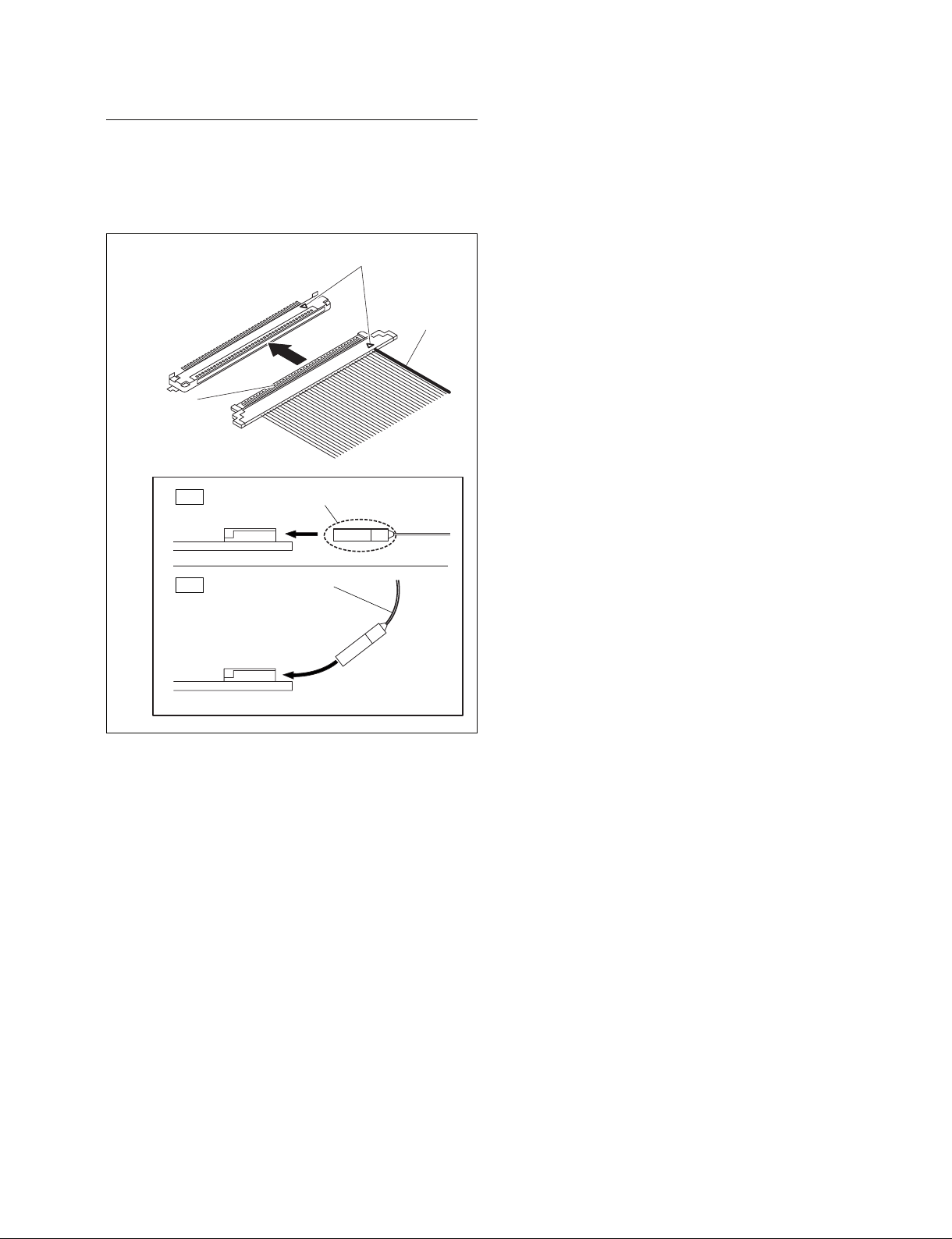

1-10. Replacing the Coaxial Cable with

Connector (Fine Pitch Coaxial Cable)

The PWM-EX1 uses coaxial cables with connector.

The following precautions must be observed when removing or connecting the coaxial cable with connector.

Note on Disconnecting

The coaxial cable with connector uses fine pitch coaxial

cables. Be careful when arranging the cable. When disconnecting the coaxial cable with connector, do not attempt to

remove by pulling the cable. Be sure to hold the connector

to remove.

Hold the connector to remove.

OK

Do not attempt to remove by pulling

NG

the cables.

m

. Do not insert the coaxial cable with connector sideways.

. Confirm that there is no stain or dust on the contact

surface of the coaxial cable with connector.

1. Slide or lift up the portion A in the direction of the

arrow and securely insert the flexible card wire into

the deep end of the connector.

2. Return the portion A to its original position and lock

the connector.

n

When connecting the flexible card wire, check the connector shape, and great care should be taken for the direction

of the contact surface or isolation surface (blue).

Connector : 1 Connector : 2

A

Isolation surface

(blue)

A

Isolation surface

(blue)

1-16

PMW-EX3

Page 25

Note on Connecting

When connecting the coaxial cable with connector, hold

the connector matching the polarity marks and insert the

coaxial cable straight into the corresponding connector.

Polarity marks

Yellow

Terminal side

Hold the connector to connect.

OK

Not to bend the cable.

NG

PMW-EX3

1-17

Page 26

1-11. List of Error Numbers on the LCD Display

Error numbers are displayed as E-XXXXX (X indicates a number).

Error No. Description Service action

15030 System error Repair the DPR-289A board or replace it.

17001 Abnormality in the Media ID data in Rewrite the media ID data in the EEPROM using

the EEPROM “ServiceNavi-EX”.

17002 The image processor block does not start up. Repair the DPR-289A board or replace it.

17003 The display block does not start up

17004 The media block does not start up

17005 Abnormality in the start-up process of

17006 Abnormality in the start-up process of

17007 Abnormality in the start-up process of

17014 Abnormality in lens communication Check the connection with the lens unit. If there is

17015 Abnormality in the media block Repair the DPR-289A or replace it.

17016 Abnormality in obtaining the lens switch Check the connection with the lens unit. If there is

17017 Internal error in the media block Repair the DPR-289A board or replace it.

or

4XXXX

the image processor block

the display block

the media block

no defect, replace the lens unit.

no condition defect, replace the lens unit.

1-12. Servicing software “ServiceNavi-EX”

Servicing software “ServiceNavi-EX” is required for electrical adjustment and self diagnosis.

For how to obtain the “ServiceNavi-EX”, contact your local Sony Sales Office/Service Center.

1-18

PMW-EX3

Page 27

Section 2

Replacement of Main Parts

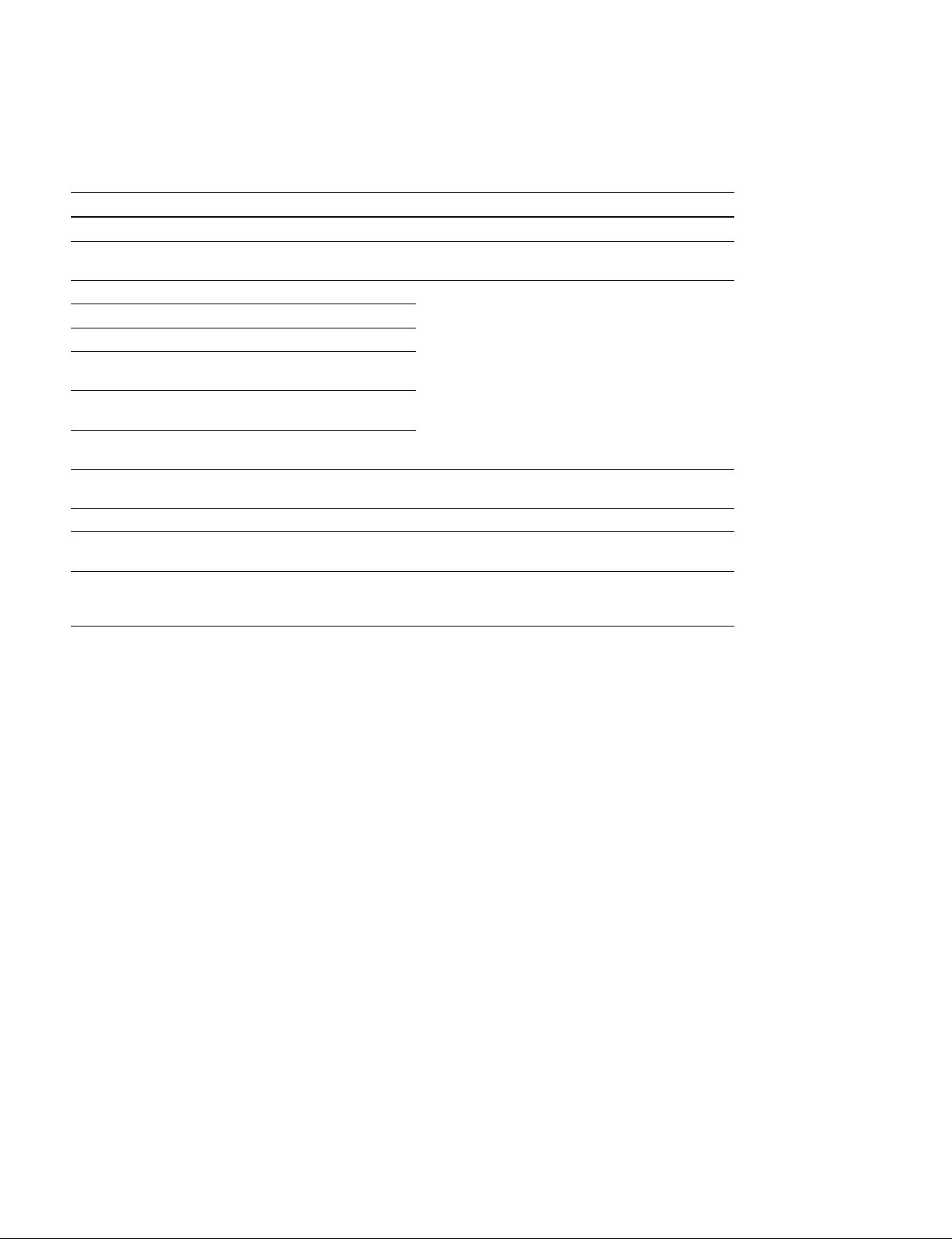

2-1. Outline of Replacement Procedures

. The following figures show the flow for removing the main parts. Refer to Section 2-2 for details of the

replacement procedures.

Microphone

holder assembly

Spring

Handle assembly

Button

battery lid

Bracket

(tripod)

Bottom

panel

START

Battery

Connector rear

assembly

Pad sub assembly

Pad center

cover

Accessory

shoe

Pad cover

Inside panel

assembly

Handel top cover

assembly

Prism block

unit

Outside panel

sub assembly

TX block

Main frame

block

Lens mount

block

Lens

Front cover handle

HN-337 board

Out side connector

assembly

DPR-289A

board

PMW-EX3

2-1

Page 28

2-2. Replacement Procedures

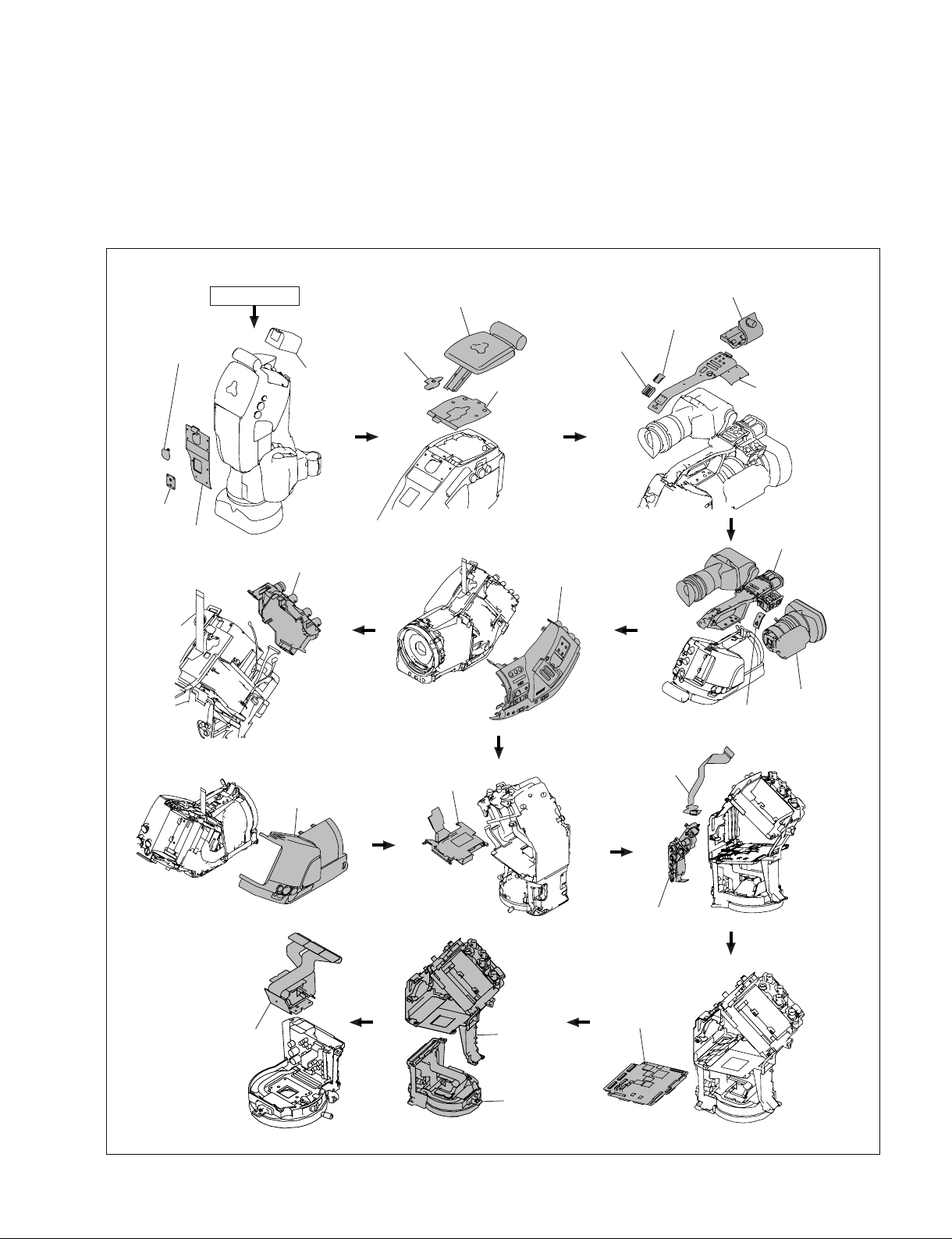

2-2-1. Lithium Battery

1. Loosen the screw, and remove the button

battery lid.

2. Remove the lithium battery.

Lithium battery

Battery holder

Lithium battery removal

Button battery lid

M2 x 4

Lithium battery

3. Reinstall the lithium battery by reversing the

steps of removal.

2-2-2. Bottom Panel

1. Remove the button battery lid. (Refer to

Section 2-2-1.)

2. Remove the four screws, and remove the

bracket (tripod).

3. Remove the four screws, and remove bottom

panel.

4. Reinstall the removed parts by reversing the

steps of removal.

Bottom panel

M2 x 4

M2 x 6

Bracket (tripod)

2-2

PMW-EX3

Page 29

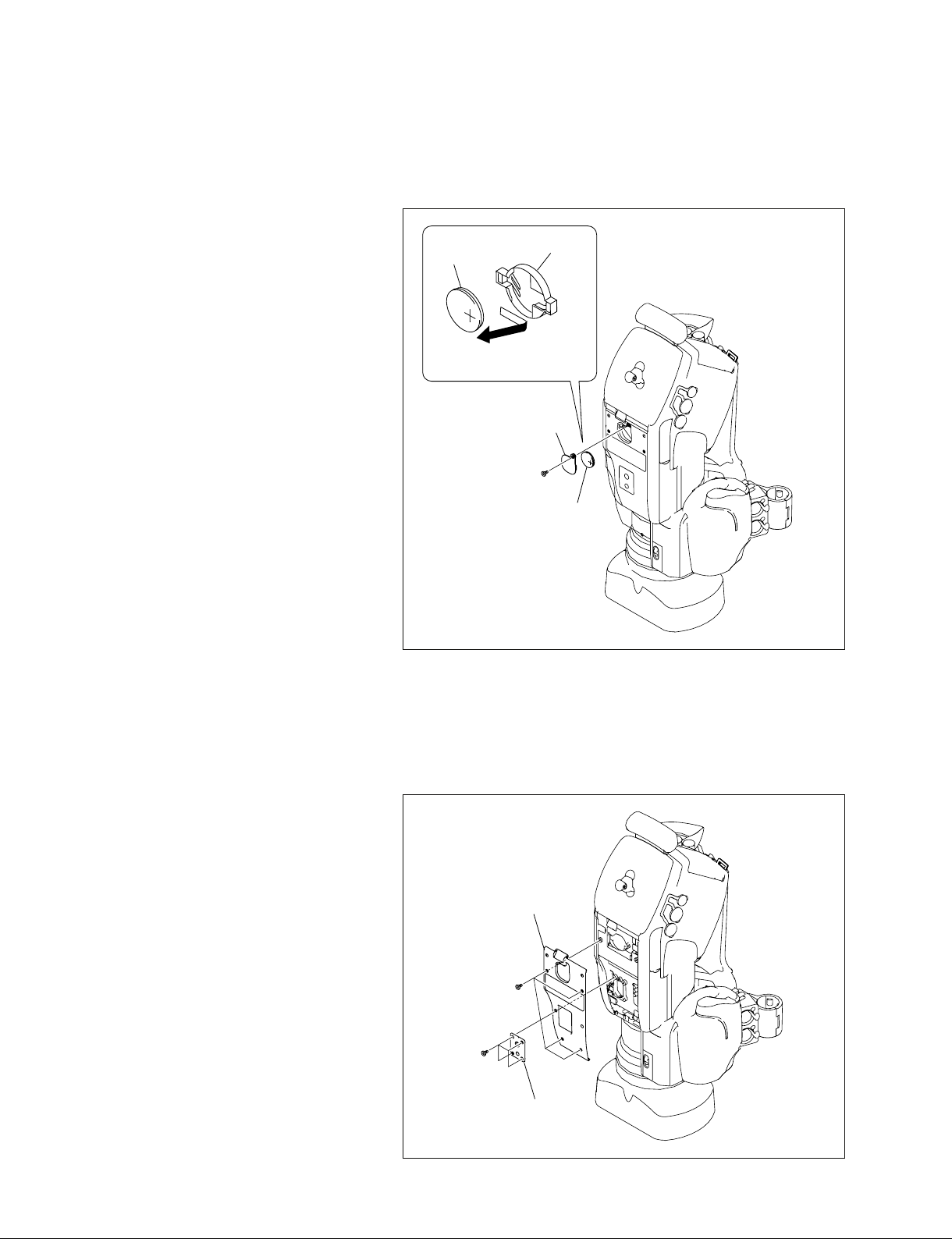

2-2-3. Pad Sub Assembly, Pad Cover

1. Press the pad stopper in the direction of the

arrow A, while the pad stopper is being

unlocked, lift up the pad sub assembly in the

direction of the arrow B.

2. Remove the screw, and remove the pad

center cover.

3. Press the pad stopper in the direction of the

arrow A, while the pad stopper is being

unlocked, remove the pad sub assembly in

the direction of arrow B.

4. Remove the four screws, and remove the pad

cover.

Pad sub assembly

B2.6 x 6

Pad center cover

B

A

Pad stopper

M2 x 4

5. Reinstall the removed parts by reversing the

steps of removal.

Pad cover

PMW-EX3

2-3

Page 30

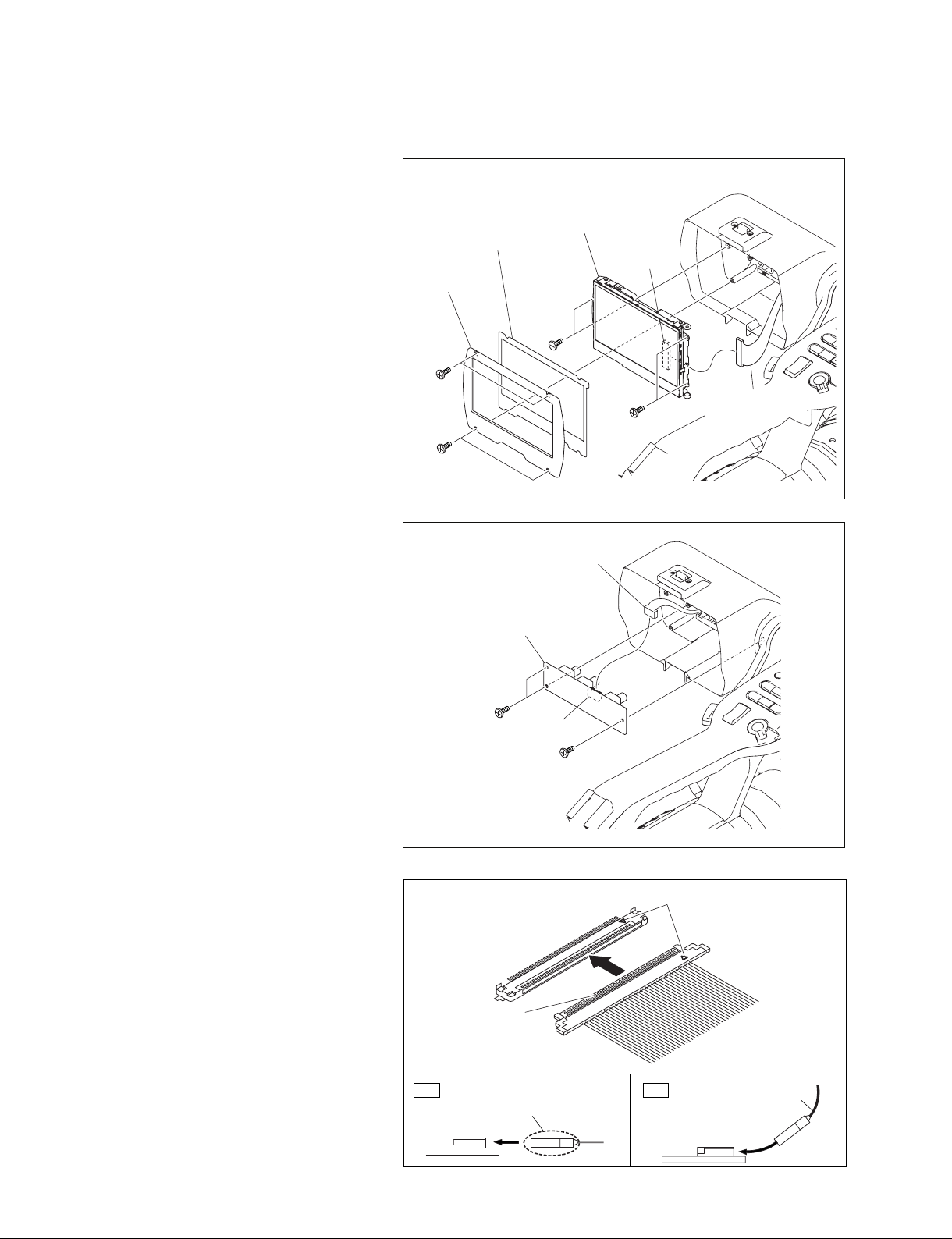

2-2-4. LCD Assembly, CT-251 Board

1. Remove the four screws, and remove the

display plate and the LCD cover.

2. Remove the four screws of the LCD assembly.

3. Disconnect the coaxial cable with connector

from the connector, and remove the LCD

assembly.

n

The coaxial cable with connector uses the

fine pitch coaxial cable. Be careful when

arranging the harness. When disconnecting

the coaxial cable with connector, never

remove it by pulling the harness. Be sure to

hold the connector to remove.

4. Remove the three screws from the CT-251

board.

5. Disconnect the harness from the connector

(CN1), and remove the CT-251 board.

LCD cover

Display plate

M2 x 4

M2 x 4

LCD assembly

Connector

M2 x 4

Coaxial cable

with connector

M2 x 4

Harness

6. Reinstall the removed parts by reversing the

steps of removal.

m

When connecting the coaxial cable with

connector, be careful of the following points:

. Do not insert the connector at a slant angle.

. Check to see that the contacting surface is

free from stain and dust.

. Hold the connector with its contacting

surface facing upward, and check that the

polarity marks are aligned.

CT-251 board

M2 x 4

Contacting

surface

OK

Insert the cable by holding

the connector.

CN1

M2 x 4

Polarity marks

NG

Do not bend the cable.

2-4

PMW-EX3

Page 31

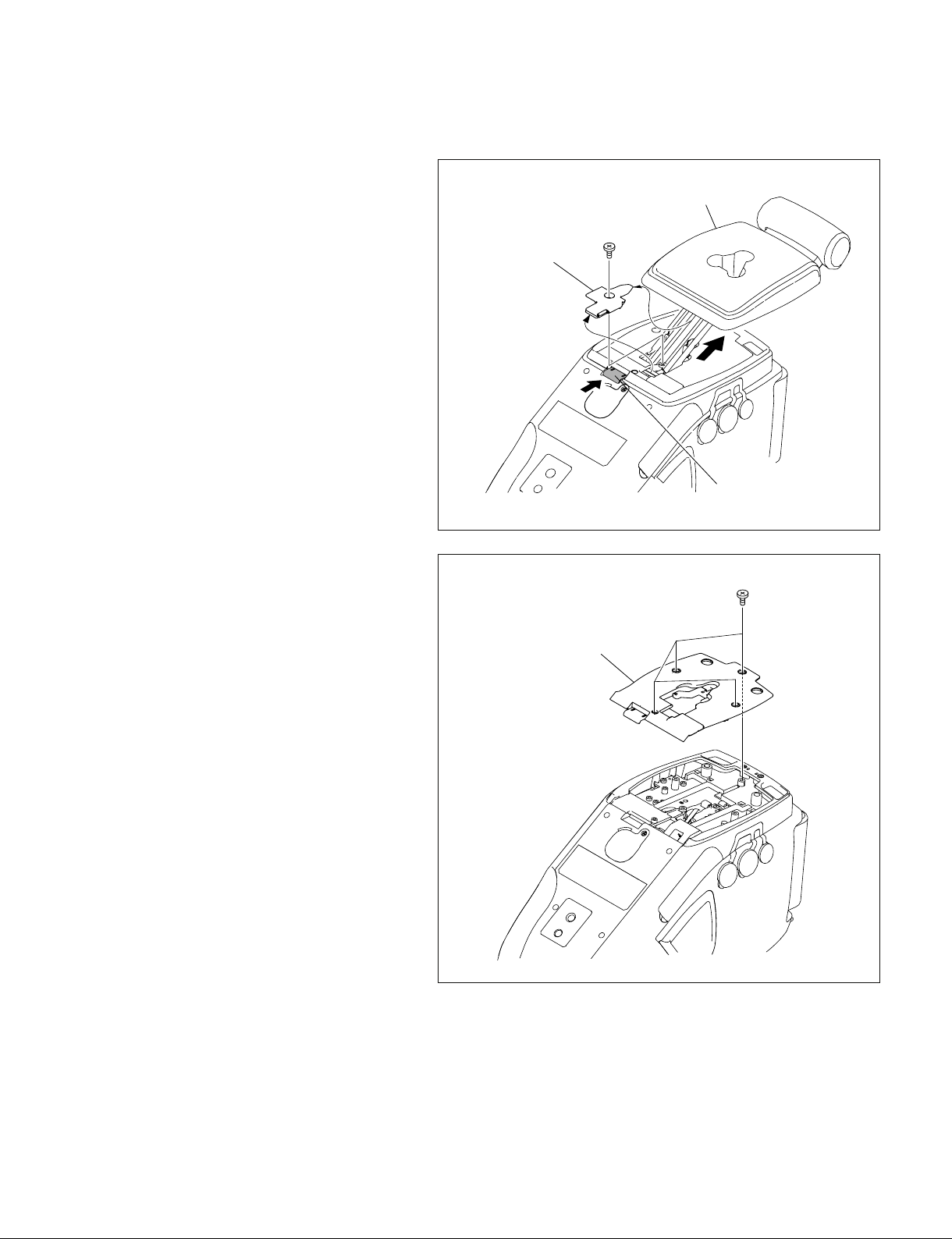

2-2-5. Handle Top Cover Assembly

1. Open the microphone holder assembly.

2. Remove the two screws, and remove the

microphone holder assembly.

B2.6 x 6

Microphone holder

assembly

3. Remove the spring and the four screws, and

remove the accessory shoe.

4. Remove the five screws, and remove the

handle top cover assembly.

5. Reinstall the removed parts by reversing the

steps of removal.

M2 x 6

Accessory

shoe

M2 x 4

Spring

Handle top

cover assembly

PMW-EX3

2-5

Page 32

2-2-6. KSW-54 Board, Control Switch

Block

1. Refer to Section 2-2-5 and remove the

“Handle Top Cover Assembly”.

2. Remove the rubber switch key.

3. Disconnect the HN-349 board from the

connector (CN5).

4. Disconnect the three harnesses from the three

connectors (CN2, CN7 and CN301).

Rubber switch key

KSW-54 board

CN301

CN5

CN7

Harness

CN2

5. Remove the three screws securing the control

switch block.

6. Remove the four screws securing the KSW54 board.

7. Disconnect the harness from the connector

(CN300) on side-B of the KSW-54 board.

8. Disconnect the control switch block from the

connector (CN4) on side-B of the KSW-54

board.

9. Disconnect the HN-328 board from the

connector (CN1) on side-B of the KSW-54

board.

Harness

PSW2 x 5

Control switch block

Harness

PSW2 x 5

M2 x 4

HN-349 board

KSW-54 board

CN4

CN300

CN1

Harness

M2 x 4

HN-328 board

10. Reinstall the removed parts by reversing the

steps of removal.

2-6

PMW-EX3

Page 33

2-2-7. IF-1069 Board, LED-469 Board

1. Refer to Section 2-2-5 and remove the

“Handle Top Cover Assembly”.

2. Disconnect the flexible flat cable from the

connector (CN4) on the IF-1069 board.

n

The life of the flexible board and the flexible

flat cable will be significantly shortened if

they are folded. Be very careful not to fold

them.

3. Disconnect the HN-348 board from the

connector (CN5) on the IF-1069 board.

4. Disconnect the harness from the connector

(CN3) on the IF-1069 board.

5. Remove the two screws, and remove the IF1069 board.

6. Disconnect the three harnesses from the three

connectors (CN1, CN2, CN3) on the LED469 board.

7. Remove the screw, and remove the LED-469

board.

Knob

M2 x 4

IF-1069 board

S1

CN3

Harness

M2 x 4

CN4

CN5

HP-144 board

Flexible flat cable

HN-348 board

LED-469 board

CN1

CN3

M2 x 4

CN2

8. Reinstall the removed parts by reversing the

steps of removal.

n

Check that the switch (S1) on the IF-1069

board engages with the knob.

IF-1069

board

S1

Knob

PMW-EX3

2-7

Page 34

2-2-8. AXM-36 Board, HN-349 Board

1. Refer to Section 2-2-5 and remove the

“Handle Top Cover Assembly”.

2. Remove the rubber switch key.

3. Remove the two screws, and remove the out

microphone bracket.

4. Disconnect the HN-349 board from the

connector (CN5) on the KSW-54 board.

5. Remove the four screws, and remove the

AXM-36 board in the direction of the arrow.

6. Disconnect the HN-349 board from the

connector (CN3) on the AXM-36 board.

icrophone

Out m

bracket

HN-349 board

AXM-36 board

B2.6 x 5

Rubber switch key

CN3

KSW-54 board

7. Reinstall the removed parts by reversing the

steps of removal.

P2.6 x 6

CN5

P2.6 x 6

2-8

PMW-EX3

Page 35

2-2-9. Handle Assembly

1. Refer to Section 2-2-5 and remove the

“Handle Top Cover Assembly”.

2. Remove the two screws, and remove the rear

shoe bracket.

3. Disconnect the harness from the connector

(CN1) on the HP-144 board.

4. Remove the connector cover (HP) and the

two screws, and remove the HP-144 board.

5 Remove the lens from the main unit.

M2 x 4

B2.6 x 6

HP-144 board

CN1

Rear shoe bracket

Lens

Main unit

Connector cover (HP)

6. Disconnect the flexible flat cable from the

connector (CN4) on the IF-1069 board.

n

The life of the flexible board and the flexible

flat cable will be significantly shortened if

they are folded. Be very careful not to fold

them.

7. Disconnect the harness from the connector

(CN2) on the LED-469 board.

8. Remove the two screws, and remove the front

cover handle.

9. Disconnect the connector (CN2) of the HN328 board from the connector (CN800) on the

HN-343 board.

10. Remove the three screws. Lift up the handle

assembly and disconnect the connector on the

DPR-289A board.

LED-469 board

CN2

Coaxial cable

with connector

Flexible flat cable

B2.6 x 6

IF-1069 board

CN4

Handle assembly

B2.6 x 6

HN-343 board

CN800

DPR-289A board

connector

Front cover

handle

M2 x 4

HN-328 board

CN2

11. Reinstall the removed parts by reversing the

steps of removal.

PMW-EX3

2-9

Page 36

2-2-10. Microphone Assembly

1. Refer to Sections 2-2-5, 2-2-6 and 2-2-9, and

remove the “Handle Assembly” removal.

2. Turn the lock lever in the direction of arrow

A, loosen the two screws of a, and remove

the lock lever.

3. Remove the two screws securing the front

bottom cover.

4. While pushing the front bottom cover in the

direction of arrow B paying attention not to

damage the three claws, remove the front

bottom cover in the direction of arrow C.

5. Remove the two screws, and pull out the

microphone assembly in the direction of

arrow D.

Loosen screws of a.

M2 x 4

B

A

Lock lover

M2 x 4

C

Front bottom cover

Claws

M2 x 4

Microphone

assembly

D

6. Reinstall the removed parts by reversing the

steps of removal.

a : Double-point set screw