Sony PCS-C150, PCS-C150P Service manual

PCS-C150/C150P

PCS-C150/C150P

SERVICE MANUAL

PCS-C150/PCS-C150P

System

Video signal PCS-C150 : NTSC standards

Picture element 1/3 inch color CCD

Lens Electromotion twelve fold zoom

Point-blank range WIDE end : 10mm

9-928-130-11

99E09008-1

Minimum illumination 7 lux (F1.8)/with 50IRE

Illumination range 7 to 100,000 lux

Shutter speed PCS-C150 : 1/60 to 1/10,000 (VISCA

Gain selector Automatic/manual

Horizontal resolution NTSC : 460 TV

Video S/N 48 dB

Pan/tilt action Horizontal : 100º, Vertical : 25º

PCS-C150P : PAL Color, CCIR

standards

(Total picture element number :

PCS-C150 : Approx. 410,000

PCS-C150P : Approx. 470,000)

(Effective picture element

number :

PCS-C150 : Approx. 380,000

PCS-C150P : Approx. 440,000)

lens

f=5.4 to 64.8mm, F1.8 to F2.7

Horizontal angle : 4.4º to 48.8º

TELE end : 800mm

control)

PCS-C150P : 1/50 to 1/10,000 (VISCA

control)

PAL : 450 TV

PCS-C150 (NTSC)

PCS-C150P (PAL)

SPECIFICATIONS

Input/output terminals

Processor terminal D-sub 15 pin

Output control terminal 8 pin mini DIN

General

Input voltage DC 12 to 14 V

Power consumption 11 W (Refference value)

Operating temperature 0º to 40º (32º to 104ºF)

Storage temperature – 20º to 60º (– 4º to 140ºF)

Dimensions Approx 142 × 109 × 162 mm

(w/h/d)

Mass Approx. 1,200 g (42.3 oz.)

9-928-130-11

Sony Corporation

Information Tec hnology Company

– 80 –

Printed in Japan C1999. 5

99E09008-1

Published by VAIO Custormer Link

COLOR VIDEO CAMERA

9-928-130-11

Y

Y

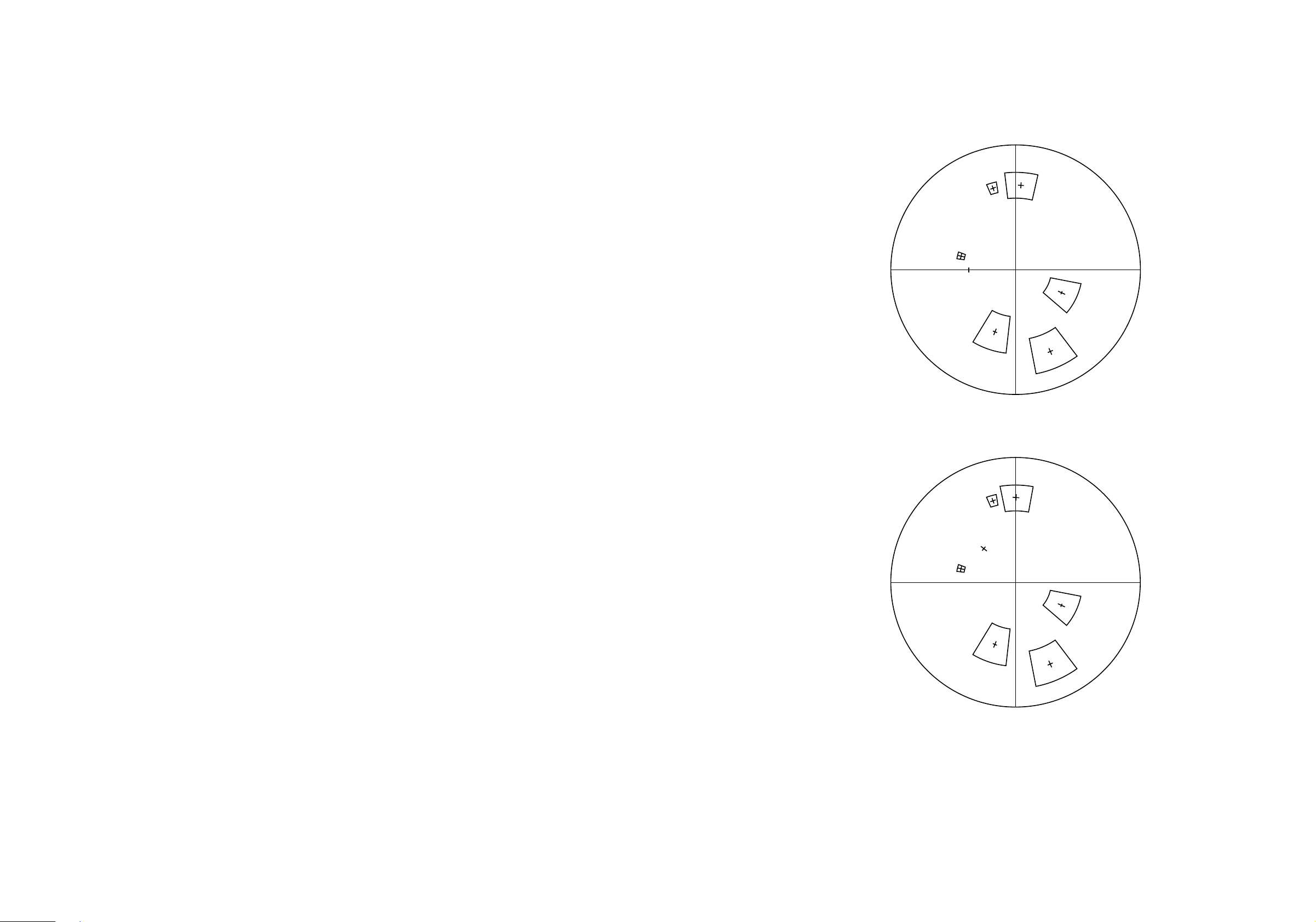

FOR CAMERA COLOR REPRODUCTION ADJUSTMENT

R

Y

L

G

R-Y

G

M

B-

B

C

Y

PCS-C150 (NTSC)

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer :

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are “pinched”

or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transis-

tors, that were installed during a previous repair. Point them out to

the customer and recommend their replacement.

SAFETY-RELATED COMPONENT WARNING!!

4. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and recommend

their replacement.

5. Check the line cord for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C during

repairing.

• Do not touch the soldering iron on the same conductor of the cir

cuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

R-Y

G

R

Y

L

G

M

B-

B

C

Y

PCS-C150P (PAL)

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

P ART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 – – 79 –

TABLE OF CONTENTS

1. GENERAL

• Locations of Controls ............................................................ 1-1

• Precautions ............................................................................ 1-1

• Connections.........................................................................1-2E

• Turning on the Power ..........................................................1-2E

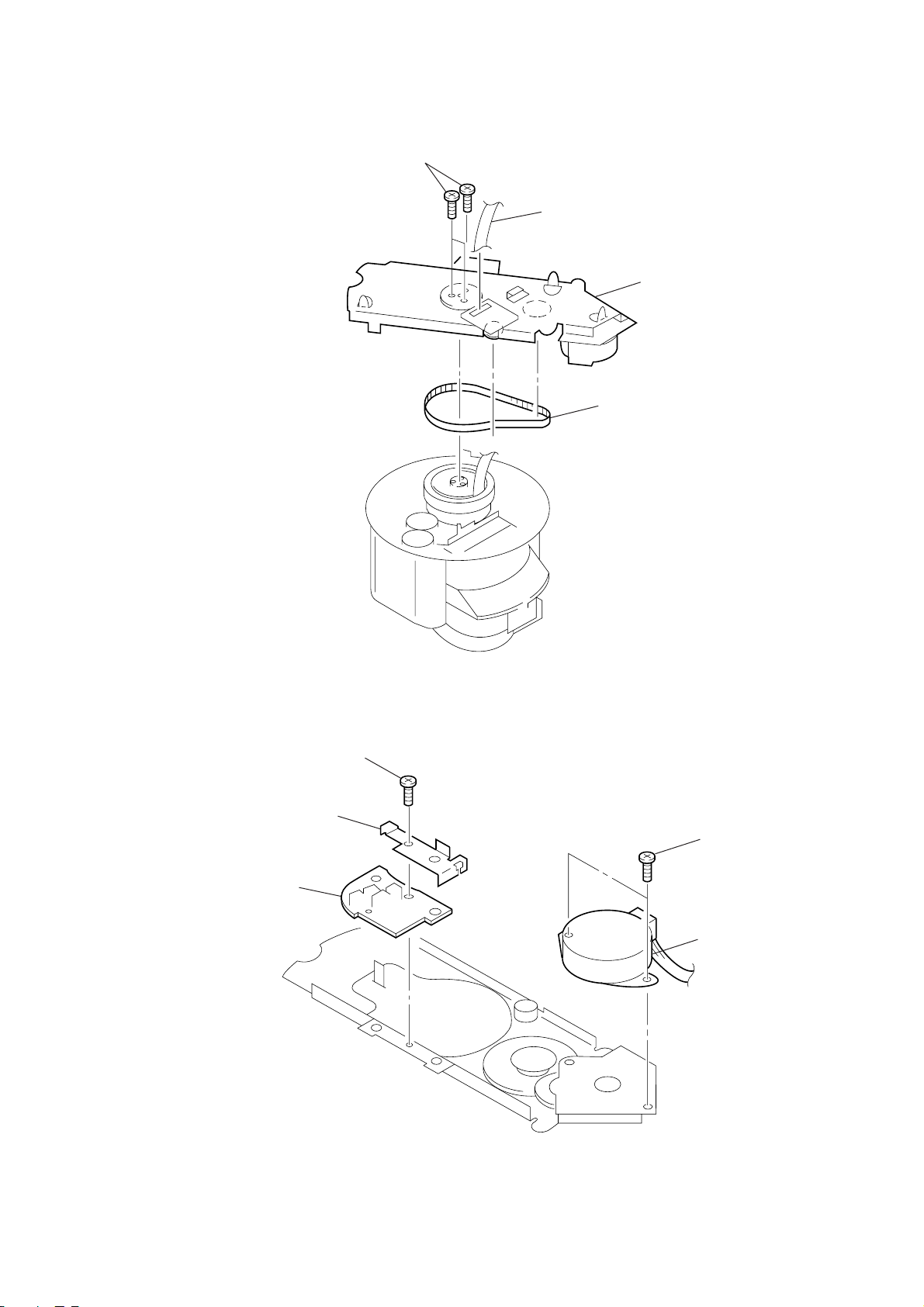

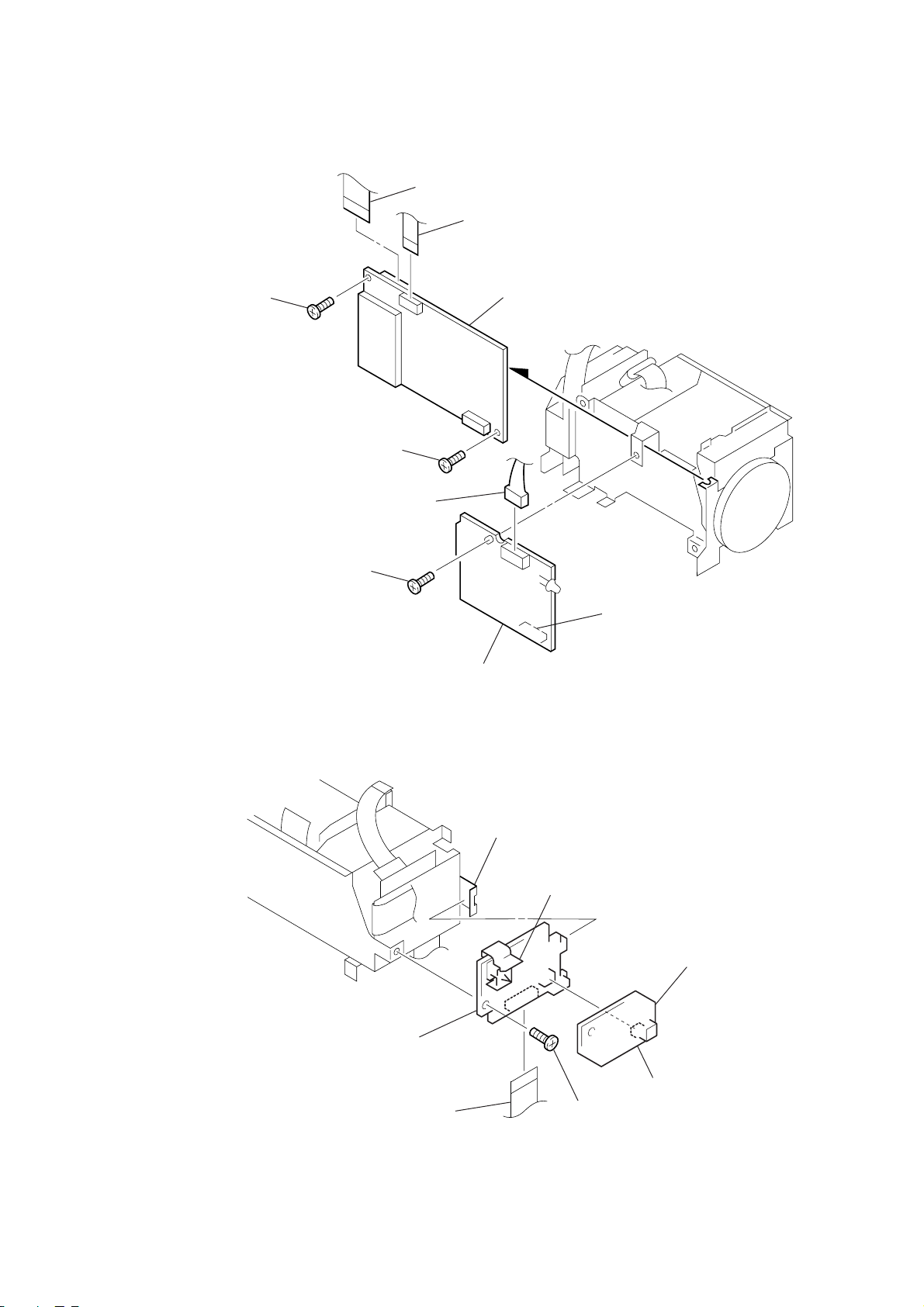

2. DISASSEMBLY

2-1. Camera Cabinet (Upper) ............................................... 2-1

2-2. Bottom Plate Assy......................................................... 2-1

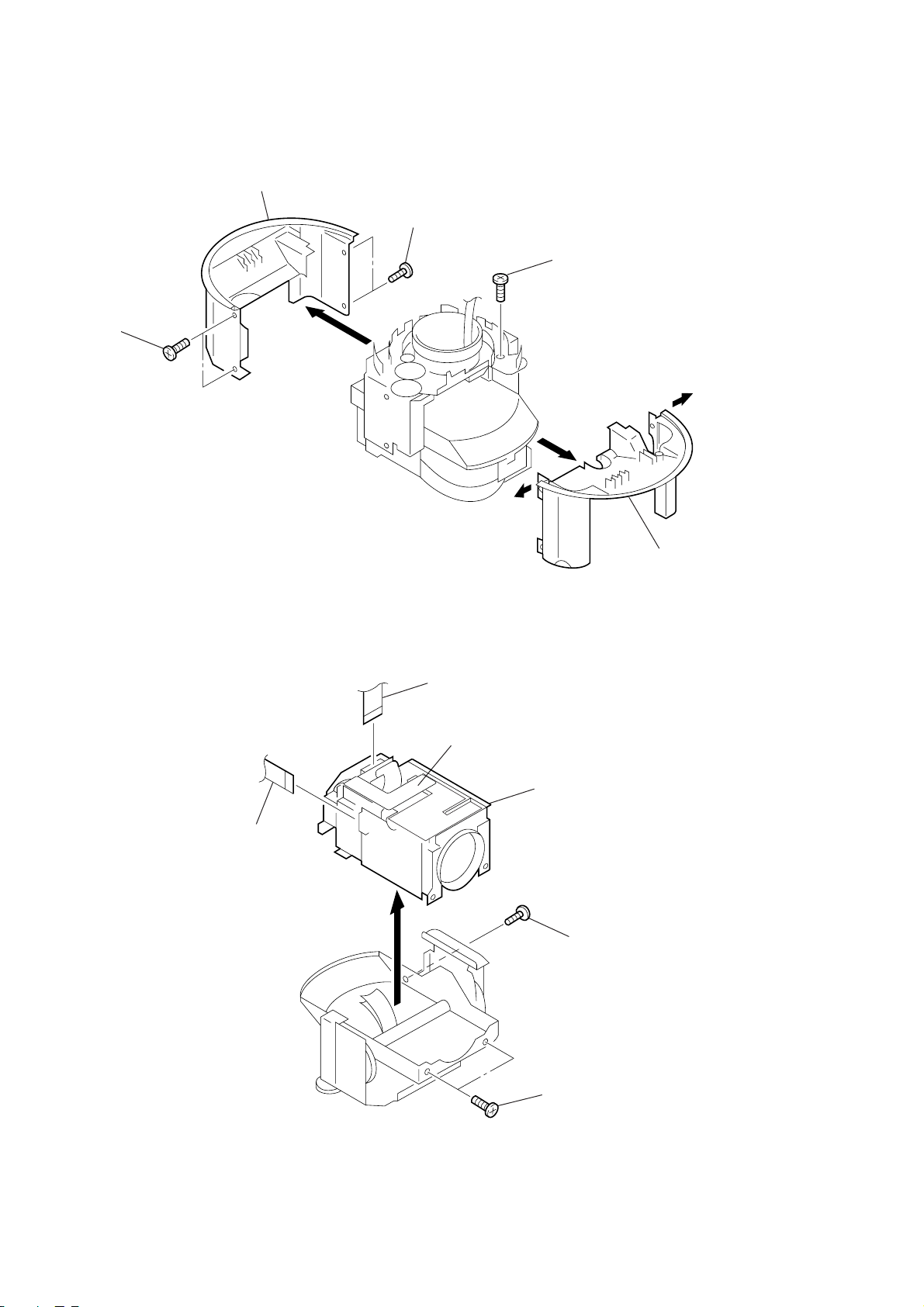

2-3. Main Block.................................................................... 2-2

2-4. ID-11A (A) Board ......................................................... 2-2

2-5. Pan Base Assy ............................................................... 2-3

2-6. LI-55A (A) Board ......................................................... 2-3

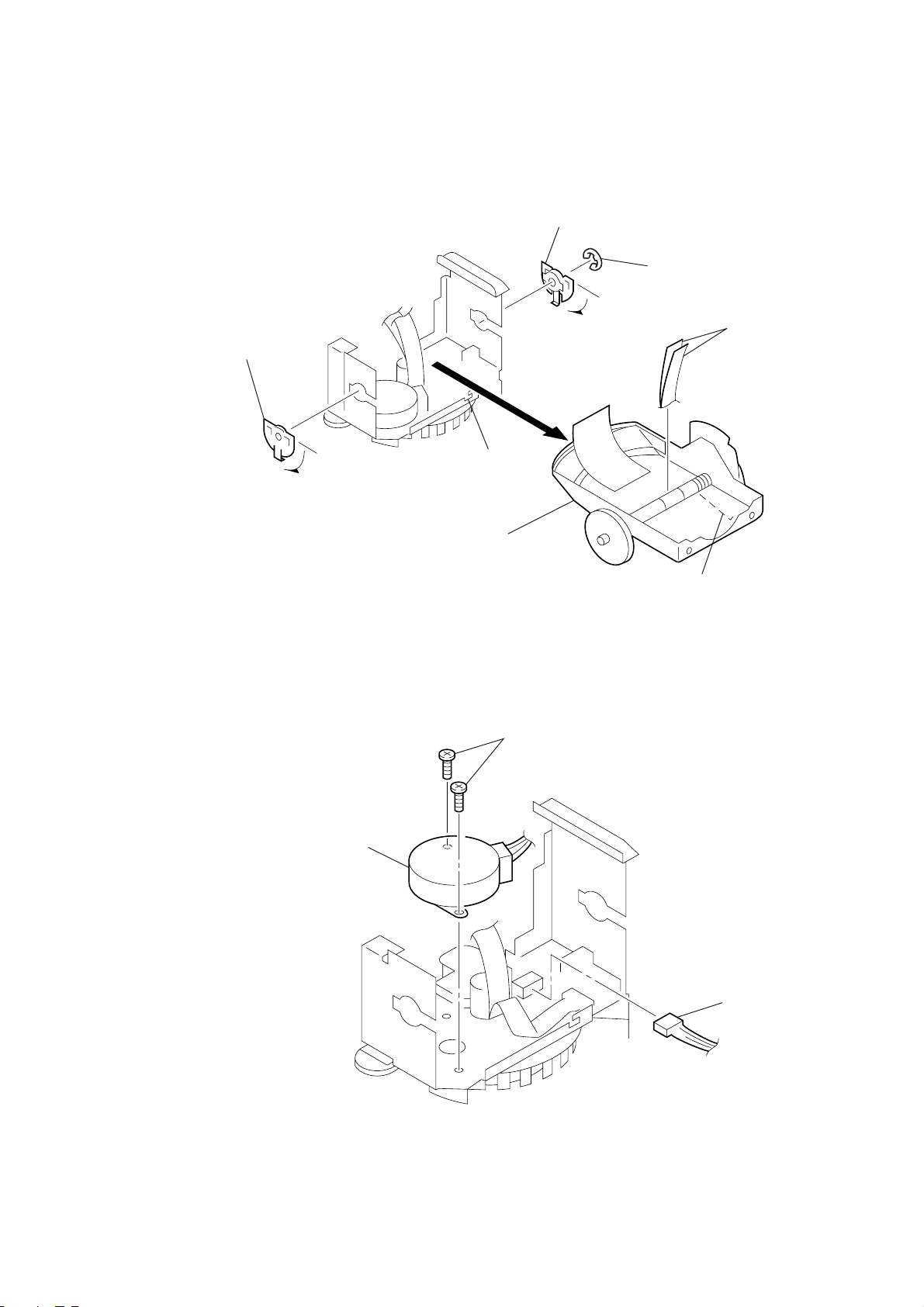

2-7. Pan Cabinet ................................................................... 2-4

2-8. CCD Lens Assy............................................................. 2-4

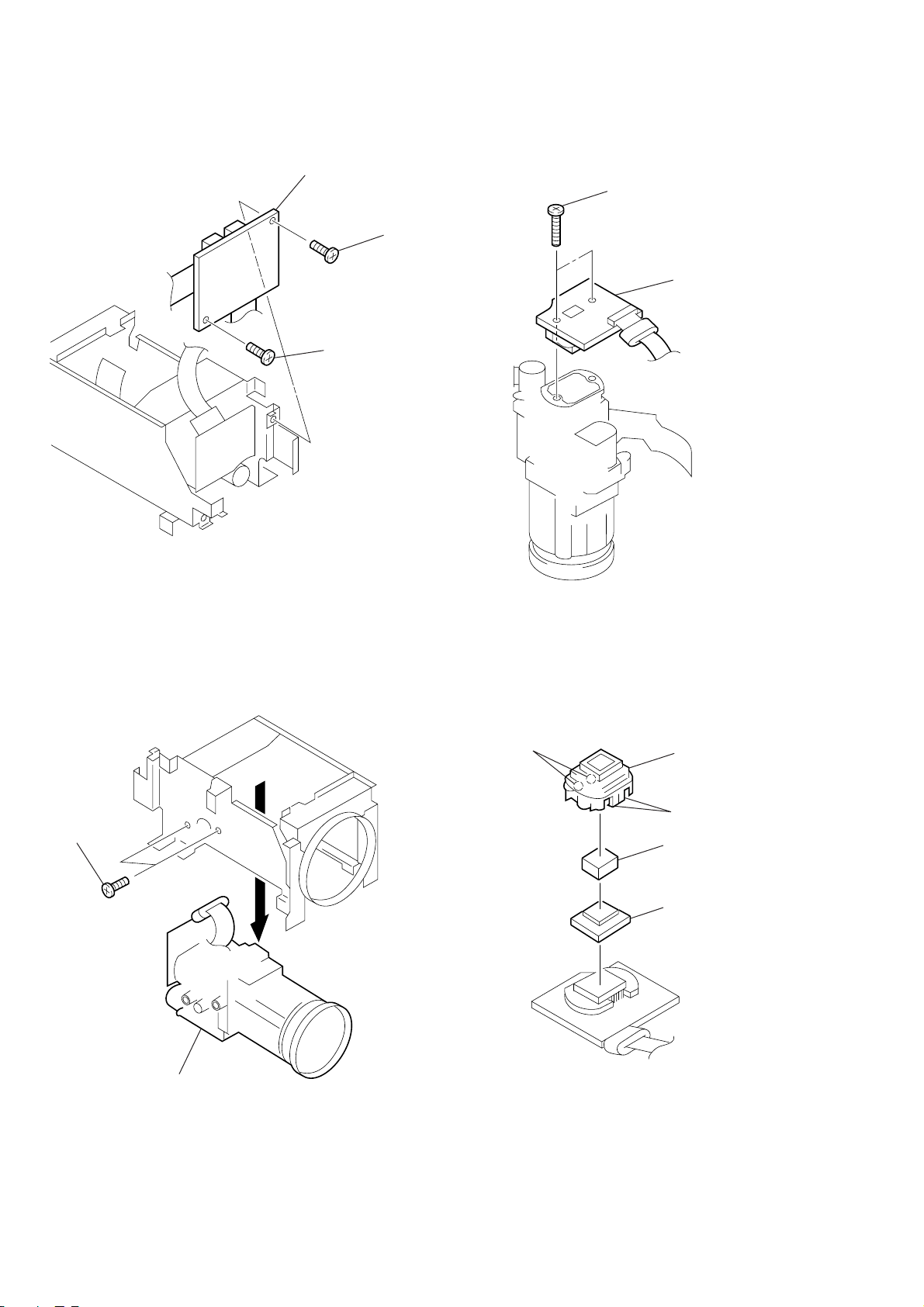

2-9. Camera Cabinet (Lower)............................................... 2-5

2-10. Stepping Motor ............................................................. 2-5

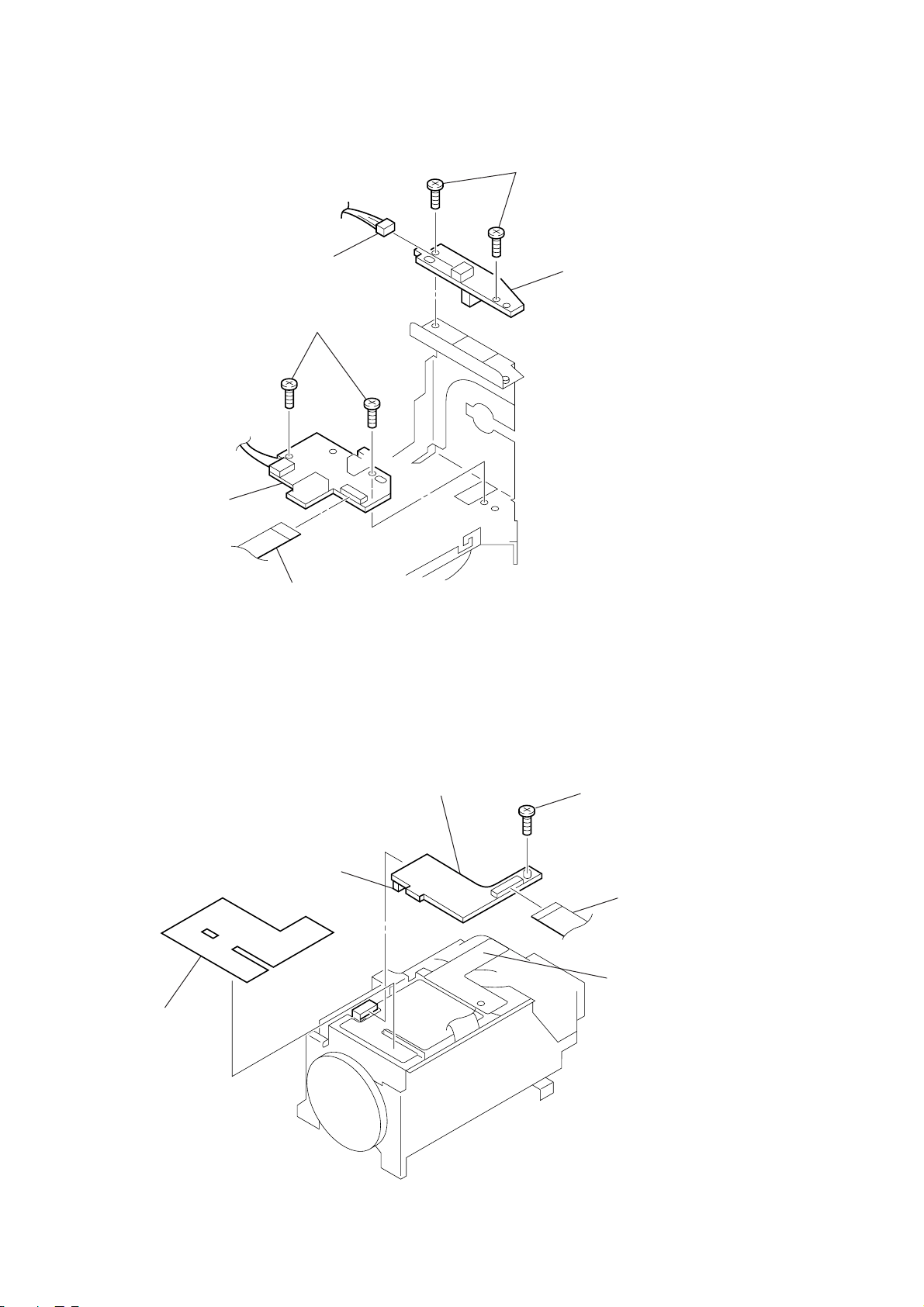

2-11. LI-59A (A) Board ......................................................... 2-6

2-12. LD-84A (A)/84A (B) Board.......................................... 2-6

2-13. VC-179 (A)/179 (B) Board ........................................... 2-7

2-14. RS-67A (A)/LB-47A (A) Board ................................... 2-7

2-15. MD-68 (A) Board........................................................2-8E

2-16. Lens Block .................................................................. 2-8E

2-17. CD-154A (A) Board....................................................2-8E

2-18. CCD Fitting Adaptor (H) ............................................2-8E

4. BLOCK DIAGRAM/SCHEMATIC DIAGRAM

(Extra number: 9-928-130-41)

4-1. Overall Block Diagram ................................................... 4-1

4-2. Schematic Diagram

• This Note is Common for Schematic Diagrams ............... 4-3

4-2-1. CD-154A (A) Board .............................................. 4-3

4-2-2. LI-52A (A), LI-55A (A) and LI-59A (A) Boards.. 4-5

4-2-3. LD-84A (A)/84A (B) Board .................................. 4-7

4-2-4. RS-67A (A) Board, LB-47A (A) Board,

RM-77A (A) Board................................................ 4-9

4-2-5. VC-179 (A)/179 (B) Board (1/4) ......................... 4-11

4-2-6. VC-179 (A)/179 (B) Board (2/4) ......................... 4-13

4-2-7. VC-179 (A)/179 (B) Board (3/4) ......................... 4-15

4-2-8. VC-179 (A)/179 (B) Board (4/4) ......................... 4-17

4-2-9. MD-68 (A) Board ................................................ 4-20

4-2-10. ID-11A (A) Board................................................ 4-23

4-2-11. AT-21A (A) Board ............................................... 4-26

5. PRINTED WIRING BOARDS

5-1. Circuit Boards Location .................................................. 5-1

5-2. Printed Wiring Boards

• This Note is Common for Printed Wiring Boards ............. 5-2

• CD-154A (A) Board.......................................................... 5-2

• VC-179 (A)/179 (B) Board ............................................... 5-3

• MD-68 (A) and RS-67A (A) Boards................................. 5-5

• ID-11A (A) Boards ........................................................... 5-7

• AT-21A (A), LI-52A (A), LI-55A (A) and

LI-59A (A) Boards ............................................................ 5-9

• LD-84A (A)/84A (B) Board............................................ 5-11

• LB-47A (A) and RM-77A (A) Board ........................... 5-12E

6. ADJUSTMENTS

6-1. Preparation for Adjustment

6-1-1. List of Servicing Jigs ............................................ 6-1

6-1-2. Preparations .......................................................... 6-2

6-1-3. Precautions ........................................................... 6-5

6-1-4. Adjusting Remote Commander ............................ 6-6

6-1-5. Page D Address List ............................................. 6-7

6-1-6. Page F Address List .............................................. 6-9

6-1-7. Page 5 Address List ............................................ 6-12

6-1-8. Data Processing .................................................. 6-14

6-2. Camera System Adjustment

6-2-1. Power Supply Voltage Check.............................. 6-15

6-2-2. Page D Data Initialization................................... 6-15

6-2-3. Page D Data Modification 1 ............................... 6-15

6-2-4. Page F Data Initialization ................................... 6-15

6-2-5. Page F Data Modification................................... 6-15

6-2-6. 28 MHz Original Oscillation Adjustment........... 6-16

6-2-7. V SUB Adjustment ............................................. 6-16

6-2-8. VRG Adjustment ................................................ 6-16

6-2-9. Flange Back Adjustment..................................... 6-17

6-2-10. Flange Back Check ............................................. 6-17

6-2-11. Hall Adjustment .................................................. 6-18

6-2-12. Picture Frame Setting ......................................... 6-19

6-2-13. Color Reproduction Adjustment......................... 6-20

6-2-14. Iris IN/OUT Adjustment..................................... 6-21

6-2-15. Max Gain Adjustment......................................... 6-21

6-2-16. Auto White Balance Standard Data Input .......... 6-22

6-2-17. Auto White Balance Adjustment ........................ 6-22

6-2-18. White Balance Check ......................................... 6-23

6-2-19. VIDEO OUT Level Check ................................. 6-23

6-2-20. Page D Data Modification 2 ............................. 6-24E

6-2-21. Page 5 Data Initialization .................................6-24E

6-2-22. Home Position Adjustment............................... 6-24E

6-3. Electrical Block Check

6-3-1. Pan Tilter Operation Check .............................. 6-24E

7. VISCA COMMAND LIST

7-1. VISCA Summary ............................................................. 7-1

7-2. PCS-C150/C150P-VISCA Connection............................ 7-2

7-3. VISCA Communication Formats

7-3-1. VISCA Packet Structure .......................................... 7-2

7-3-2. Commands and Inquiries ...................................... 7-3

7-3-3. Responses to Commands and Inquiries ................ 7-3

7-3-4. Socket Number ..................................................... 7-3

7-3-5. Command Execution Stop .................................... 7-3

7-4. PCS-C150/C150P Setting Commands (Network setting)

7-4-1. VISCA Network Management Commands .......... 7-4

7-4-2. VISCA Interface Commands................................ 7-4

7-4-3. PCS-C150/C150P Functions ................................ 7-5

7-5. PCS-C150/C150P Commands ......................................... 7-6

7-6. PCS-C150/C150P Inquiry Command ............................ 7-10

7-7. Code List

7-7-1. Code list for Shutter, Iris, Gain and

Wide con lens ..................................................... 7-12

7-7-2. Code list for Pan/Tilter status,

AT mode status and MD mode status ................. 7-13

7-8. VISCA Communications Examples ............................7-14E

– 3 –

8. REPAIR PARTS LIST

8-1. Exploded Views

8-1-1. Camera Cabinet Section........................................... 8-1

8-1-2. Pan Base Section ...................................................... 8-2

8-1-3. Tilt Base Section ...................................................... 8-3

8-1-4. Lens Section ............................................................. 8-5

8-2. Electrical Parts List

• AT-21A (A) Board ............................................................ 8-6

• CD-154A (A) Board ......................................................... 8-6

• ID-11A (A) Board ............................................................ 8-7

• LB-47A (A) Board ........................................................... 8-8

• LD-84A (A)/84A (B) Board ............................................. 8-8

• LI-52A (A) Board ............................................................. 8-9

• LI-55A (A) Board ............................................................. 8-9

• LI-59A (A) Board ............................................................. 8-9

• MD-68 (A) Board ............................................................. 8-9

• RM-77A (A) Board ........................................................ 8-11

• RS-67A (A) Board.......................................................... 8-11

• VC-179 (A)/179 (B) Board ............................................ 8-12

• For Camera Color Reproduction Adjustment .................... 79

– 4 –

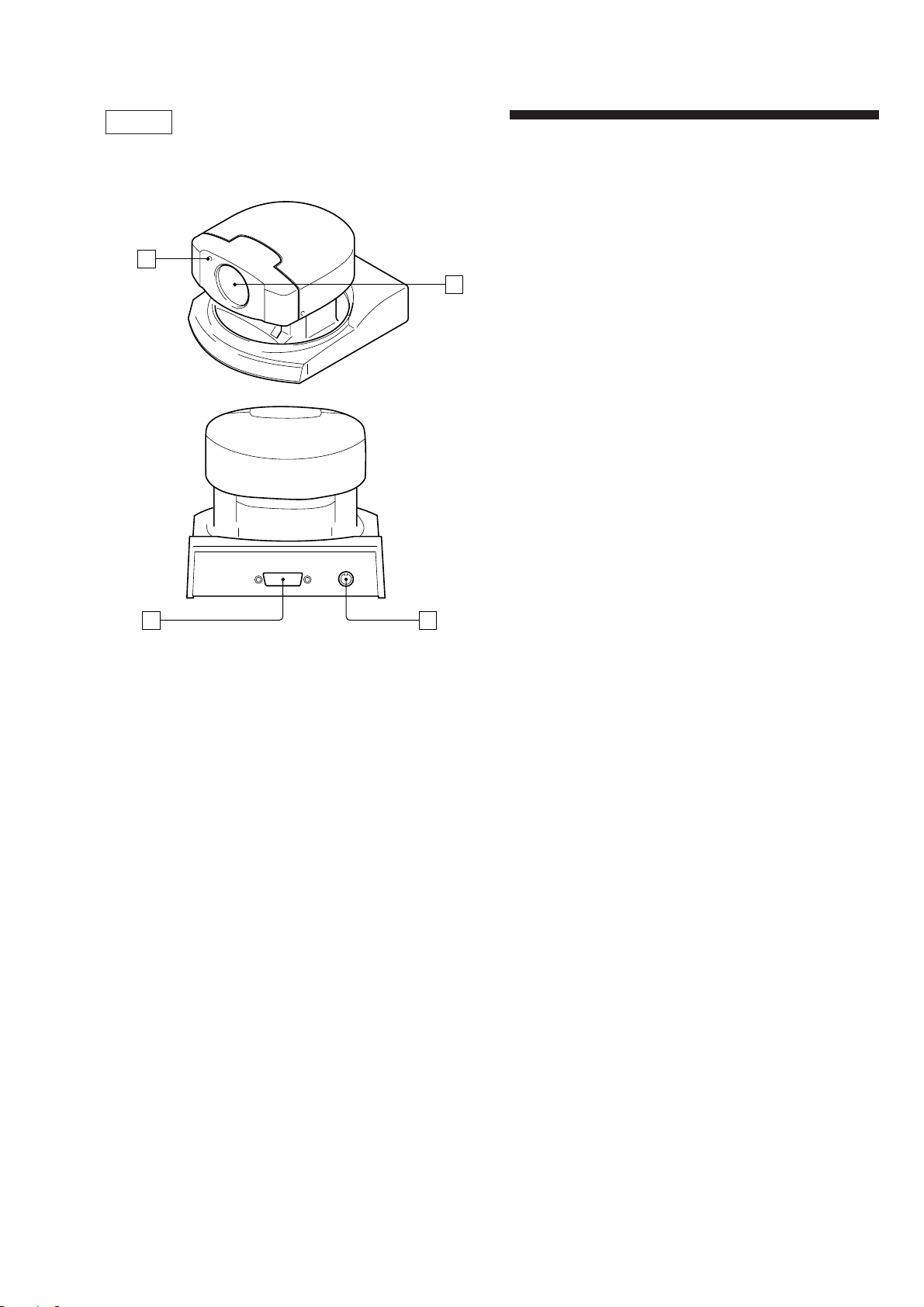

General

Locations of Controls

1

SECTION 1

GENERAL

Precautions

• After operating the unit with an AC power adaptor, disconnect the AC

power adaptor from the wall outlet if the set is not to be used for an extended period of time.

Brightness of a subject

Color Video Camera might not work with its best performance in a place

where brightness exceeds the illumination range (such as a place exposed to

2

direct sunlight).

Avoid specialized application

Avoid using Color Video Camera f or monitoring application where it would

be forced to focus on a stationary object for a long period of time. Also

avoid focusing the camera on an extremely bright object such as sunlight or

a fluorescent lamp. Otherwise the color filter might be damaged.

Precaution on copyright

Tele vision programs, pictures, magazines, and other materials may be copyrighted. Unauthorized recording or storing of such materials violates the

provision of the copyright laws.

PCS-C150/C150P

1 Caution lamp

2 Lens

3 VISCA OUT jack

4 PROCESSOR jack

34

1-1

Preparations

Input/Output

Conversion board

Connections

Be sure to use the tool board (J-2500-222-1) to connect to this unit.

Connect the power supply, connect the tool board to the unit, and connect

the terminals of the tool board to the personal computer, TV, or VCR equipped

with an S-Video input. Some connections may require e xtra cables. Refer to

the instructions manual of the equipment to be connected.

S-VIDEO cable

(not supplied)

to S VIDEO OUT to S-VIDEO input

VISCA cable

(not supplied)

to VISCA IN

Input/Output Conversion board

J-2500-222-1

AC power adaptor AC-EV2

(not supplied) (for PCS-C150)

*

to RS-232C

Personal computer,

TV or VCR with an

audio/video input

jack

to AC outlet

• Do not grasp the camera head when carrying the video camera.

• Do not turn the camera head manually. Doing so will result in the camera

malfunctioning.

Installation

Be sure to place the main unit on a flat surface.

to DC IN 13.5V

AC power adaptor AC-EV3

(not supplied) (for PCS-C150P)

* When the video camera is connected to a personal computer with a VISCA

cable, you can operate the video camera with the personal computer.

If you have a personal computer or video equipment with the S-Video input

You can connect it to your Color Video Camera with a commercially available S-video cable.

Notes

• You cannot connect your Color Video Camera to a personal computer

that is not equipped with S-Video input jack.

And you might not be able to use your existing personal computer with

your Color Video Camera unless you provide the computer with a video

capture board and/or software.

Consult your computer dealer or manufacturer for details.

• To supply power to the tool board, use only the AC power adaptor that

has plug of EIAJ type 4 (not supplied). Do not use any other AC power

adaptor.

Polarity of the plug

Turning on the Power

When the tool board is connected to this unit and power is supplied to the

tool board, it will set into the POWER ON state and the camera will automatically face toward the lower right-hand side and then the front, which is

the home position of the camera. (Pan/tilt reset action)

If the lamp at the side of the lens flashes umber

The micro computer inside the camera might not memorize the current

pan/tilt position properly. Use Reset command to reset the pan/tilt position.

Flashes.

PCS-C150/C150P is controlled by VISCA communication.

Refer to VISCA COMMAND LIST.

1-2

E

4

)

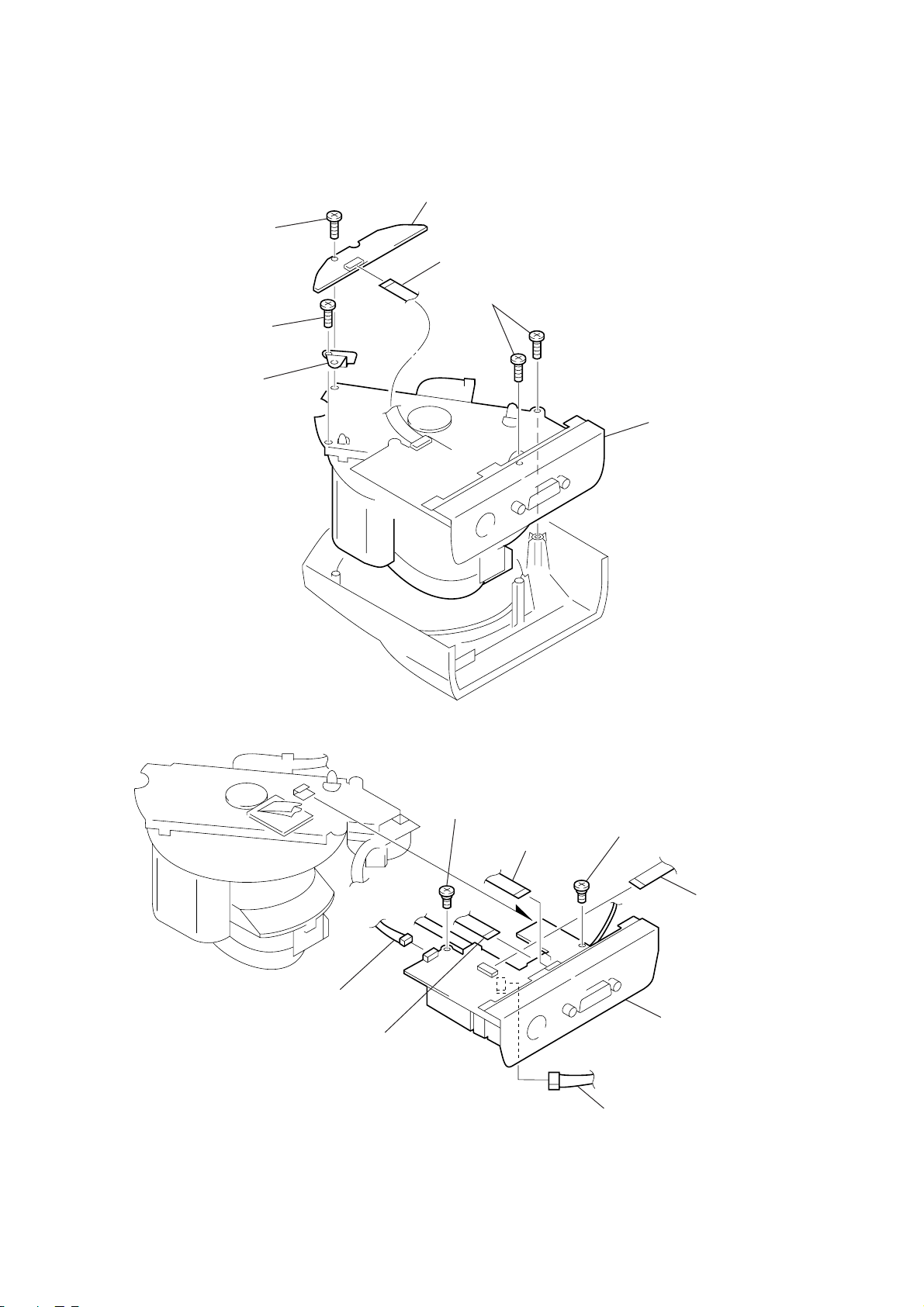

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. CAMERA CABINET (UPPER)

2

M 2x4

4

camera cabinet (front) assy

3

claw

5

6

camera cabinet (upper

1

M 2x4

PCS-C150/C150P

M 2x4

2-2. BOTTOM PLATE ASSY

5

buttom plate assy

1

M 2x4

3

PTP 2.6x8

4

M 2x4

2

M 2x

2-1

2-3. MAIN BLOCK

k

d

5

ground plate (P)

1

PTP 2.6x8

4

PTP 2.6x8

3

RM-77A(A) board

2

CN381

6

PTP 2.6x8

7

main bloc

2-4. ID-11A (A) BOARD

1

CN102

4

CN103

5

M 2x2.2

3

CN104

6

M 2x2.2

2

CN109

8

7

CN110

ID-11A (A) boar

2-2

)

Y

2-5. PAN BASE ASSY

1

P 2x6

3

flexible flat cable

2

timing belt

4

pan base ASS

2-6. LI-55A (A) BOARD

2

3

LI-55A(A) board

retainer

1

M 2x4

4

P 3x4

5

stepping motor (PAN

2-3

Y

2-7. PAN CABINET

2

M 2x4

3

pan cabinet (front)

1

M 2x4

4

tapping screw

5

Extend the pan cabinet

(rear) out and remove

the cabinet.

2-8. CCD LENS ASSY

4

CN893

3

CN105

PCS-C150P only

5

CCD lens ASS

1

M 2x4

2-4

2

M 2x4

2

2-9. CAMERA CABINET (LOWER)

4

Turn the tilt bearing in the

direction of the arrow and

remove the bearing.

3

Turn the tilt bearing in the

direction of the arrow and

remove the bearing.

A

6

camera cabinet ASSY (lower)

2

type-E stop ring 3.0

5

flexible flat cable

2-10. STEPPING MOTOR

3

stepping motor (TILT)

2

P 3x4

1

Remove the spring from

portion A.

1

CN34

2-5

y

)

2-11. LI-59A (A) BOARD

6

LI-52A(A)

1

CN351

5

M 2x3

2

M 2x3

3

LI-59A(A

4

2-12. LD-84A (A)/84A (B) BOARD

2

CN702

4

Sheet,electrostatic

CN341

5

LD-84A(A)/84A(B) board

1

M 2x3

3

PCS-C150P onl

CN701

2-6

2-13. VC-179 (A)/179 (B) BOARD

6

M 2x3

5

M 2x3

3

8

CN894

CN504

7

CN401

9

VC-179(A)/179 (B) board

1

M 2x3

2-14. RS-67A (A)/LB-47A (A) BOARD

4

AT-21A(A) board

5

claw

1

claw

2

CN845

2

CN403

7

RS-67A(A) board

6

CN401

2-7

4

M 2x3

3

LB-47A(A) board

3

)

2-15. MD-68 (A) BOARD 2-17. CD-154A (A) BOARD

3

MD-68 (A) board

1

BTP 2x12

2

M 2x

1

M 2x3

2

CD-154A(A) board

2-16. LENS BLOCK

1

BTP 2x5

2

lens block

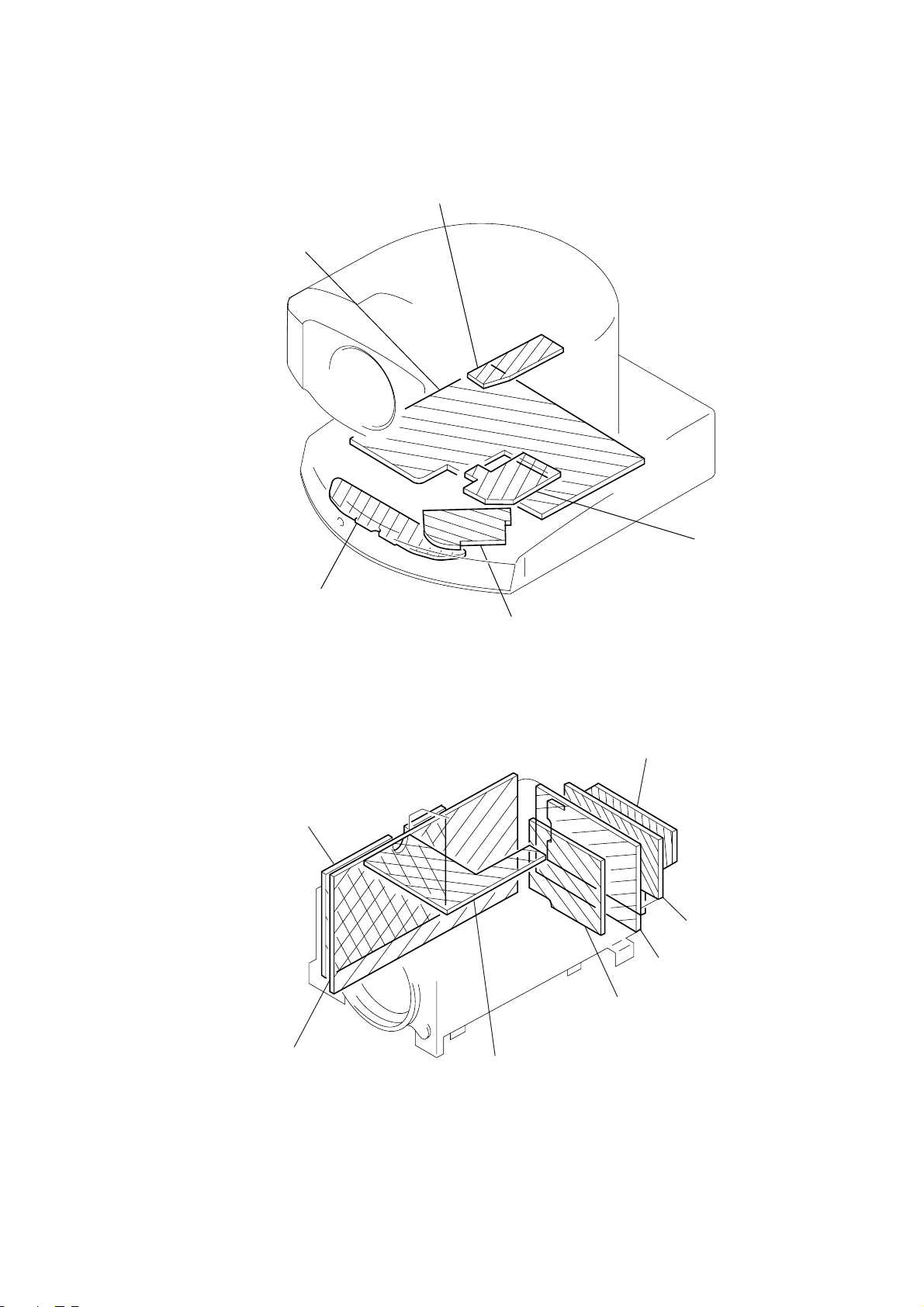

2-18. CCD FITTING ADAPTOR (H)

1

claw

3

CCD fitting adaptor (H

2

claw

4

optical filter block

5

seal rubber (3)

2-8

2-8E

d

d

PRINTED WIRING BOARDS

5-1. CIRCUIT BOARDS LOCATION

ID-11A(A) board

PCS-C150/C150P

SECTION 5

LI-59 A(A) board

RM-77A(A) board

AT-21A(A) board

LI-52A(A) boar

LI-55A(A) board

LB-47A(A) board

RS-67A(A) boar

MD-68 (A) board

VC-179 (A)/179 (B) board

CD-154A(A) board

LD-84A(A)/84A(B) board

5-1

PCS-C150/C150P

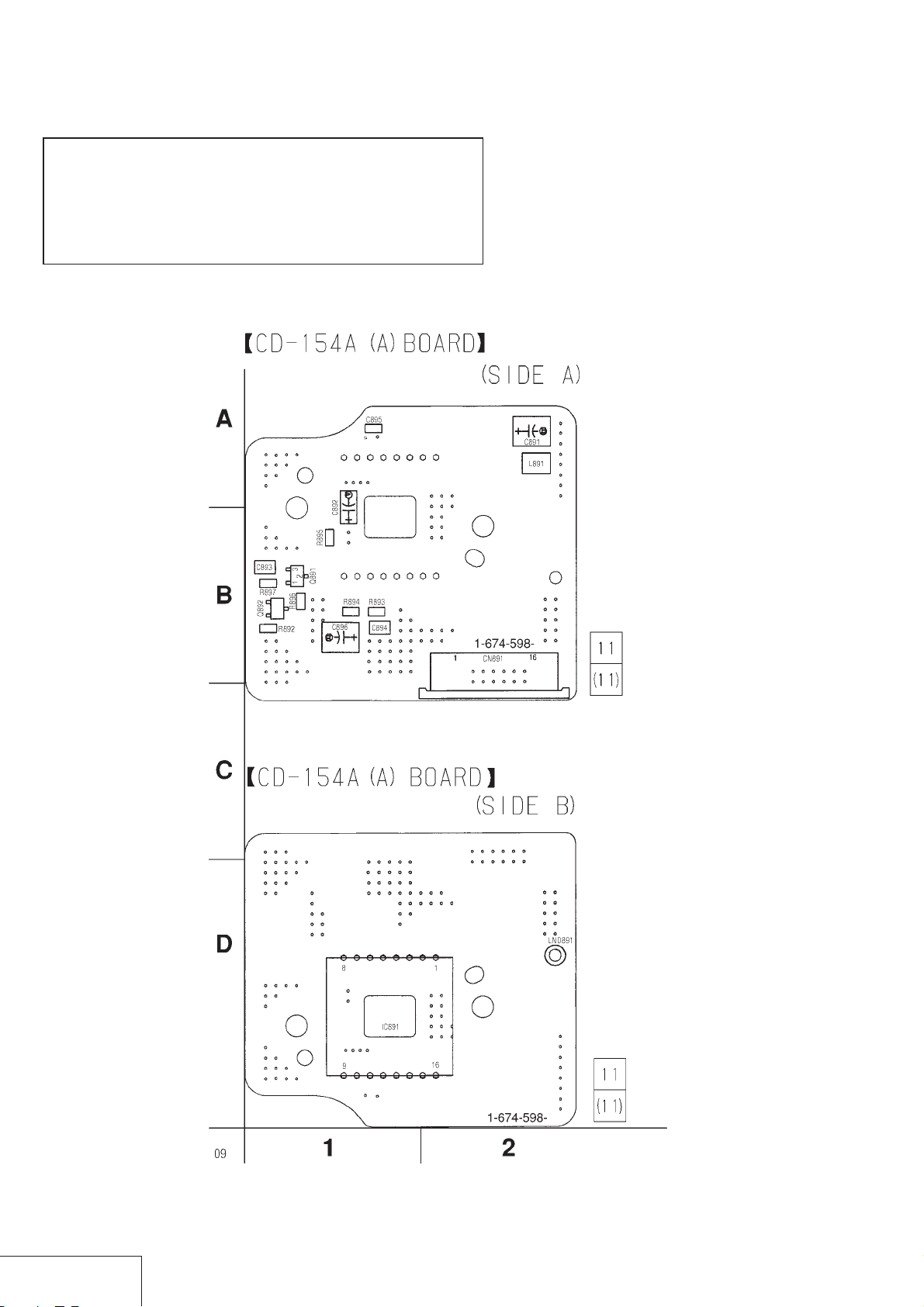

5-2. PRINTED WIRING BOARDS

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS.

For printed wiring boards.

•

• Through hole is omitted.

• Pattern is omitted.

CD-154A (A) (CCD IMAGER) PRINTED WIRING BOARD

– Ref. No. CD-154A (A) BOARD : 1,000 series –

CD-154A (A)

BOARD

IC891 D-1

Q891 B-1

Q892 B-1

CCD IMAGER

CD-154A (A)

5-2

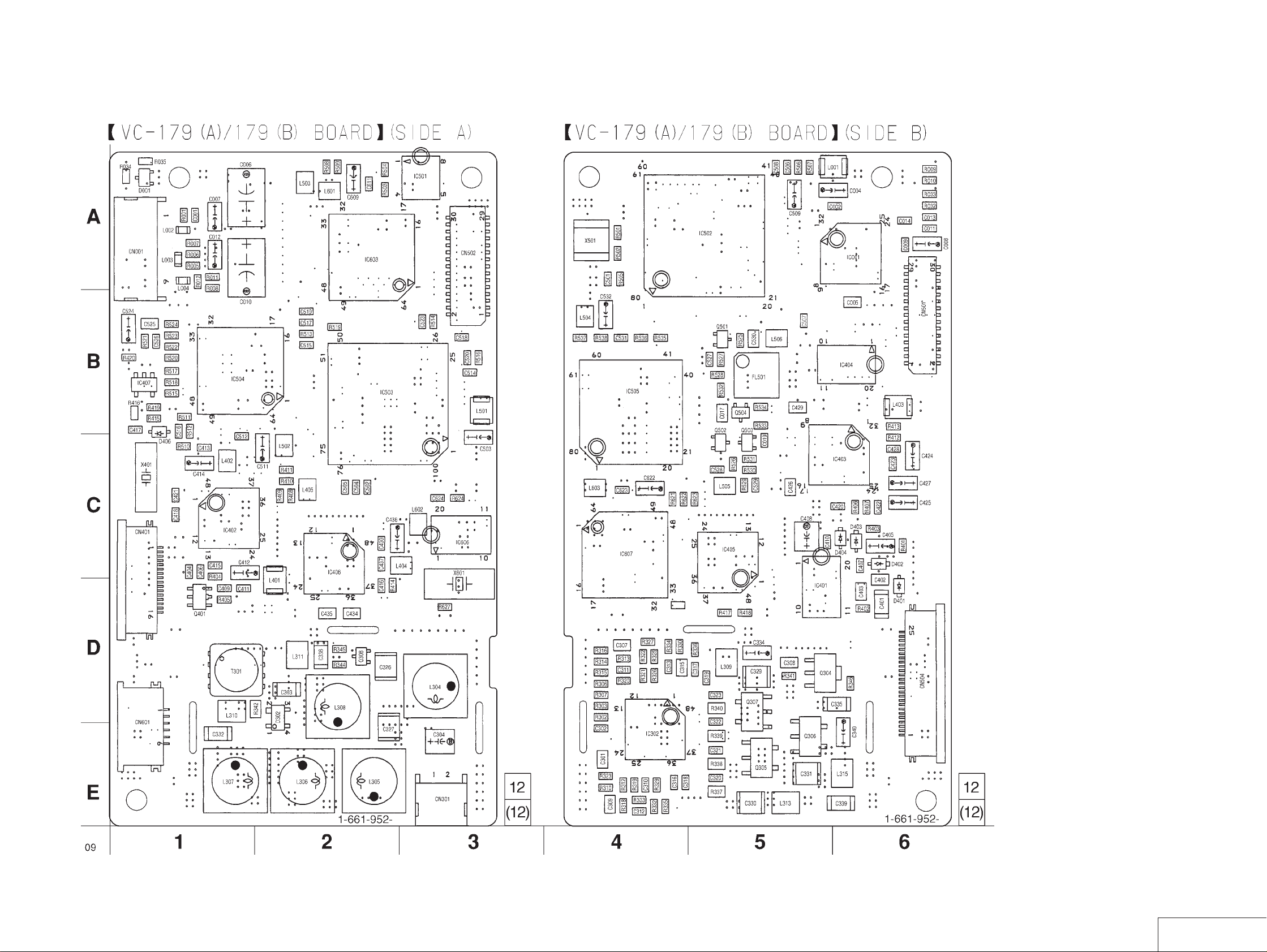

VC-179 (A)/179 (B) (CAMERA) PRINTED WIRING BOARD

– Ref. No. VC-179 (A)/179 (B) BOARD : 1,000 series –

VC-179 (A)/179 (B)

BOARD

D001 A-1

D302 D-2

D401 D-6

D402 C-6

D403 C-6

D404 C-6

D406 B-1

IC001 A-6

IC302 E-4

IC401 D-5

IC402 C-1

IC403 C-6

IC404 B-6

IC405 C-5

IC406 C-2

IC407 B-1

IC501 A-3

IC502 A-5

IC503 B-2

IC504 B-1

IC505 B-4

IC603 A-2

IC606 C-3

IC607 C-4

Q304 D-5

Q305 E-5

Q306 E-5

Q307 D-5

Q308 D-2

Q401 D-1

Q502 C-5

Q503 C-5

Q504 B-5

Q601 B-5

PCS-C150/C150P

5-3

5-4

CAMERA

VC-179 (A)/179 (B)

PCS-C150/C150P

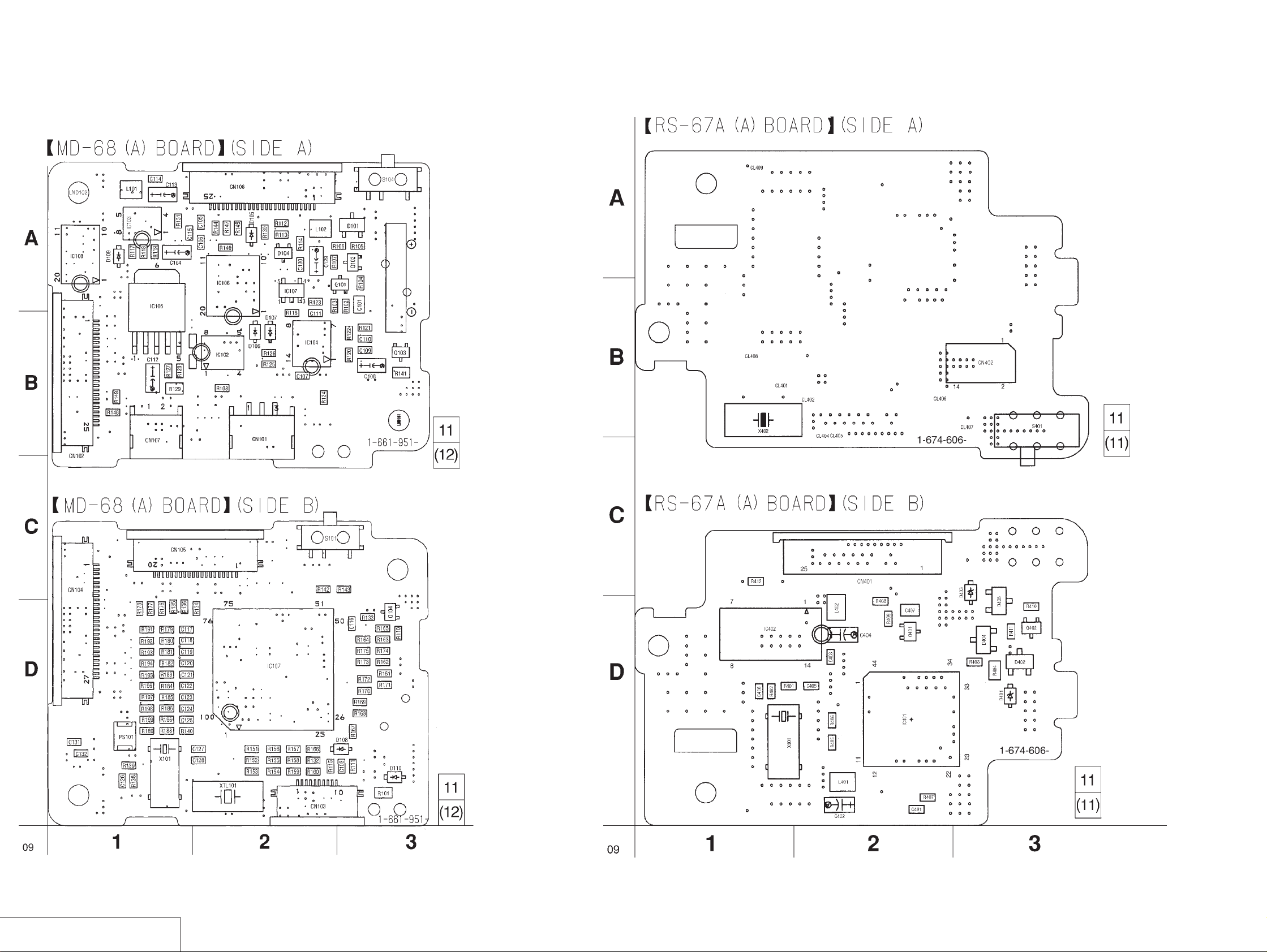

MD-68 (A) (MODE CONTROL) RS-67A (A) (BACK UP) PRINTED WIRING BOARDS

– Ref. MD-68 (A) BOARD : 1,000 series, RS-67A (A) BOARD : 2,000 series –

MD-68 (A)

BOARD

D101 A-3

D104 A-2

D105 A-2

D106 B-2

D107 B-2

D108 D-3

D109 A-1

D110 D-3

IC101 D-2

IC102 B-2

IC103 A-1

IC104 B-2

IC105 A-1

IC106 A-2

IC107 A-2

IC108 A-1

Q101 A-2

Q102 A-3

Q103 B-3

Q104 D-3

RS-67A (A)

BOARD

D401 D-3

D402 D-3

D403 C-3

D404 D-3

D405 D-3

IC401 D-2

IC402 D-3

Q401 D-2

Q402 D-3

MODE CONTROL, BACK UP

MD-68 (A), RS-67A (A)

5-5

5-6

PCS-C150/C150P

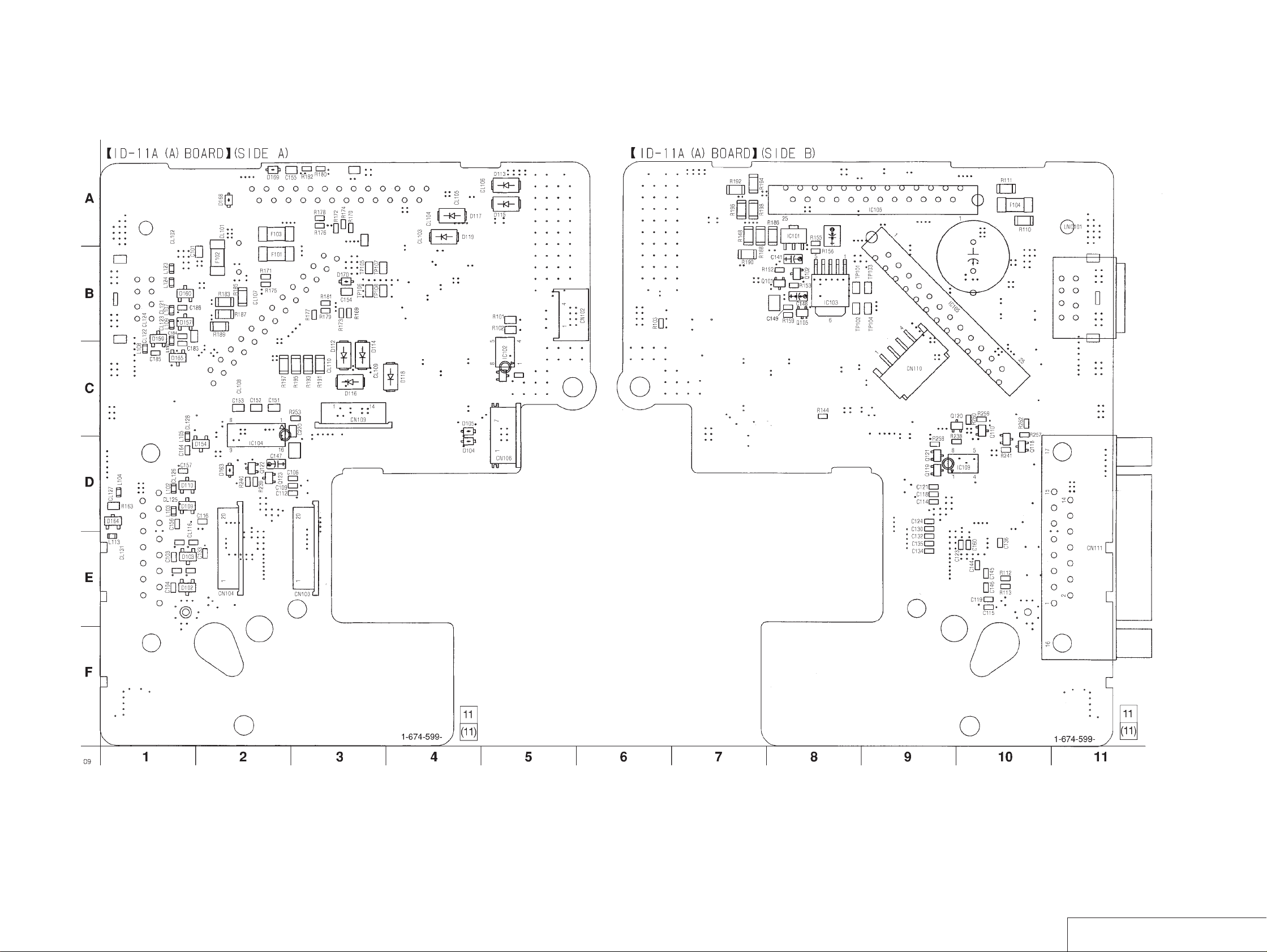

ID-11A (A) (MOTOR DRIVE, INPUT/OUTPUT) PRINTED WIRING BOARDS

– Ref. No. ID-11A (A) BOARD : 2,000 series

ID-11A (A)/11A (A)

BOARD

D102 E-1

D103 E-1

D104 D-4

D105 C-4

D109 D-1

D110 D-1

D112 C-3

D113 A-5

D114 C-3

D115 A-5

D116 C-3

D117 A-4

D118 C-4

D119 A-4

D154 D-2

D157 B-1

D159 B-1

D160 B-1

D163 D-2

D164 D-1

D165 C-1

D168 A-2

D169 A-2

D170 B-3

IC101 A-8

IC102 C-5

IC103 B-8

IC104 C-2

IC105 B-9

IC106 A-9

IC109 D-9

Q101 B-8

Q102 B-8

Q105 B-8

Q110 C-10

Q118 D-10

Q119 D-9

Q120 C-9

Q121 D-9

Q122 D-2

Q123 D-2

5-7

5-8

MOTOR DRIVE, INPUT/OUTPUT

ID-11A (A)

PCS-C150/C150P

AT-21A (A) (VIDEO PROCESS, MAIN CONTROL) LI-52A (A) (TILT END SENSOR) LI-59A (A) (TILT R SENSOR) LI-55A (A) (PAN R SENSOR) PRINTED WIRING BOARDS

– Ref. No. AT-21A (A) BOARD : 1,000 series, LI-52A (A) BOARD : 2,000 series, LI-55A (A) BOARD : 2,000 series, LI-59A (A) BOARD : 2,000 series –

AT-21A (A)

BOARD

D801 C-1

D802 B-3

D803 A-2

D804 A-1

D805 A-1

D806 A-3

D807 B-3

D808 B-1

D809 A-1

IC801 E-2

IC802 B-2

IC803 D-2

IC804 E-4

Q801 D-2

Q802 E-3

Q803 D-3

VIDEO PROCESS, MAIN CONTROL, SENSOR

AT-21A (A), LI-52A (A), LI-55A (A), LI-59A (A)

5-9

5-10

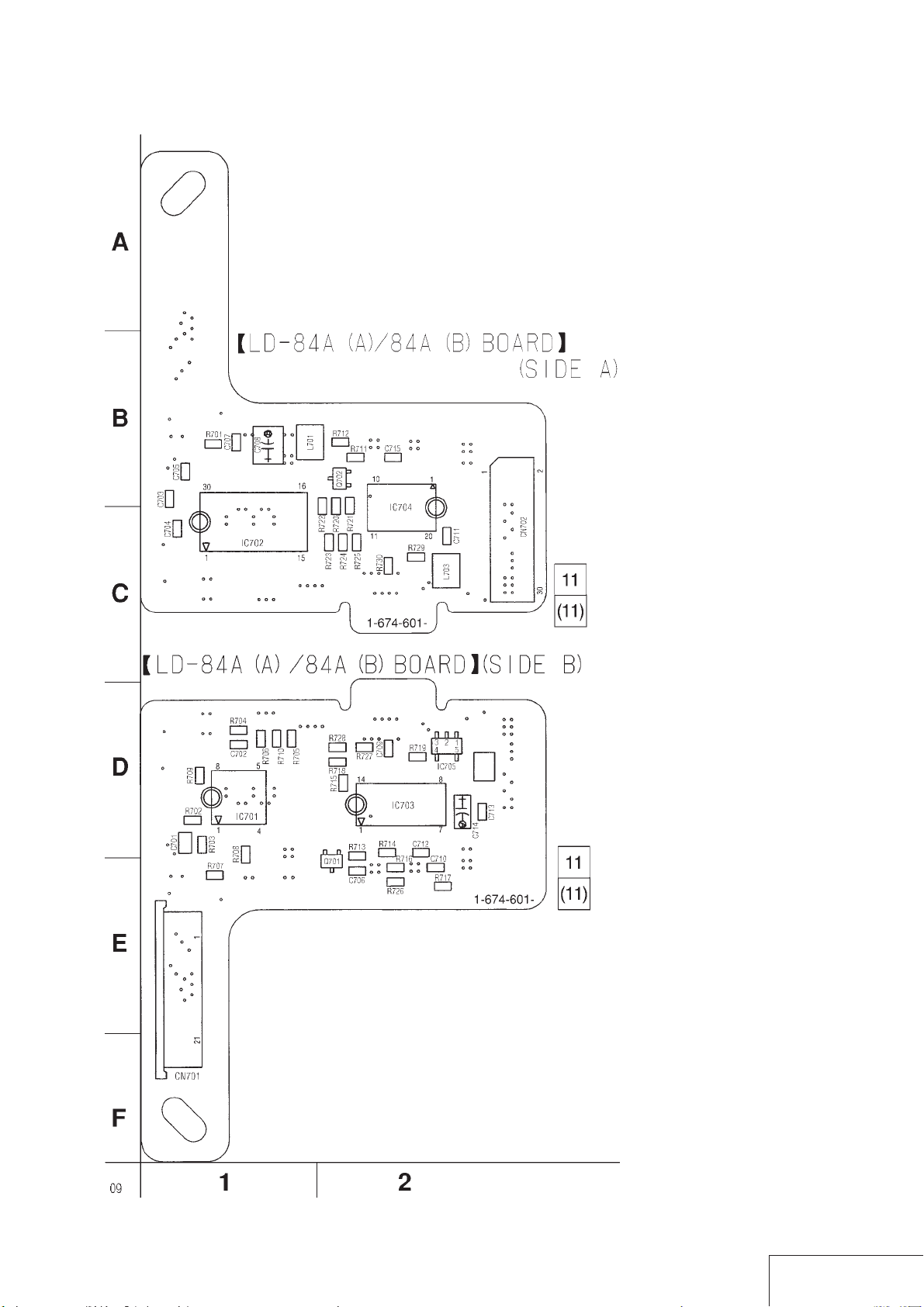

LD-84A (A)/84A (B) (LENS DRIVE) PRINTED WIRING BOARD

– Ref. No. LD-84A (A)/84A (B) BOARD : 2,000 series –

LD-84 A (A)/84A (B)

BOARD

IC701 D-1

IC702 C-1

IC703 D-2

IC704 C-2

IC705 D-2

Q701 E-2

Q702 B-2

PCS-C150/C150P

5-11

LENS DRIVE

LD-84A (A)/84A (B)

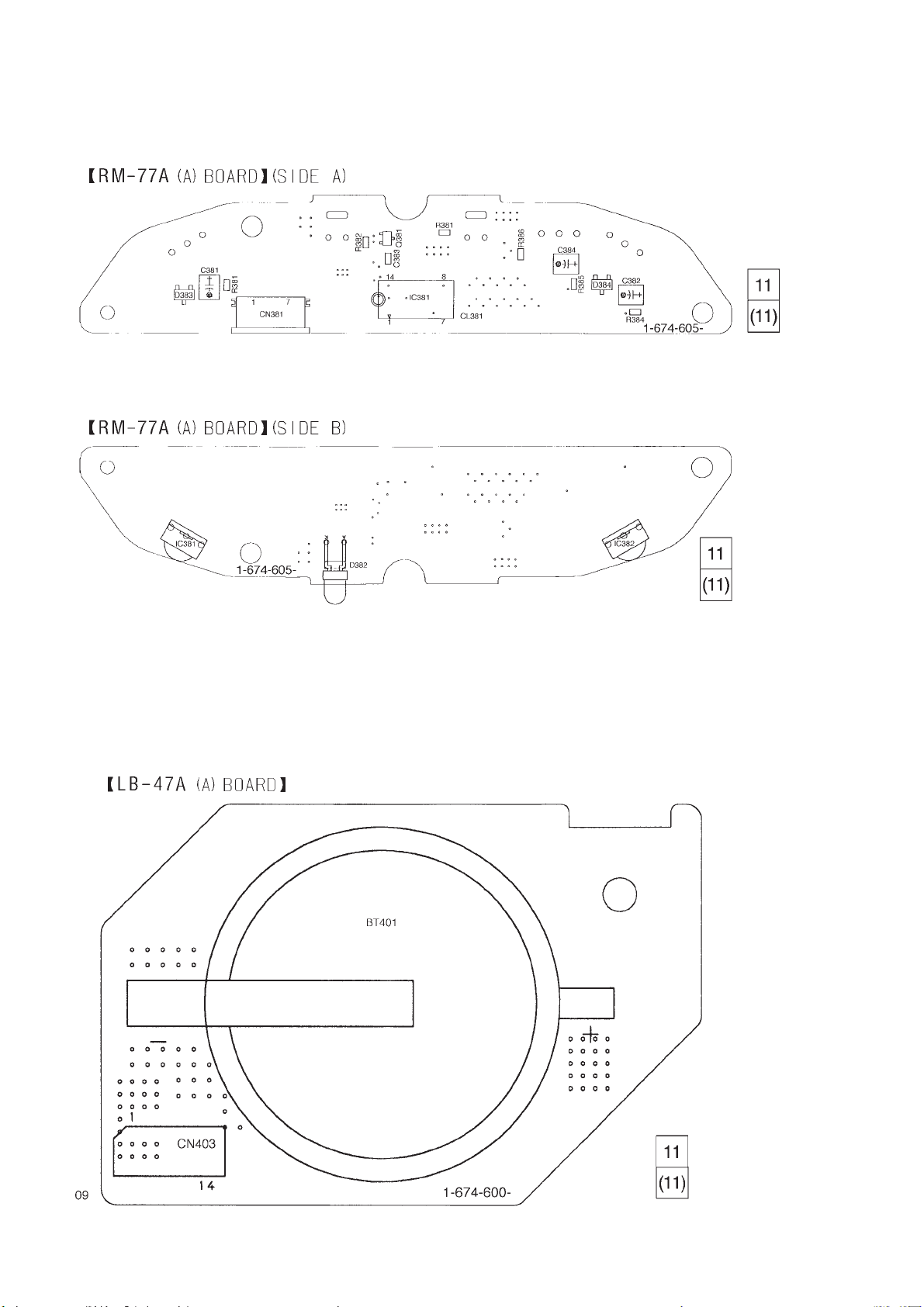

RM-77A (A) (REMOCON RECEIVING OPTICAL), LB-47A (A) (B ATTER Y) PRINTED WIRING BO ARD

– Ref. No. RM-77A BOARD : 1,000 series, LB-47A (A) BOARD : 1,000 series –

5-12

E

SECTION 6

PCS-C150/C150P

ADJUSTMENTS

6-1. PREPARATION FOR ADJUSTMENT

6-1-1. List of Servicing Jigs

• Oscilloscope • Regulated power supply • Audio generator • Audio level meter

• Color monitor • Vectorscope • Desk-top calculator • Digital voltmeter

Ref. No. Name Part No. Use

J-1 Filter for color temperature correction J-6080-058-A Auto white balance adjustment/check

(C14) White balance adjustment/check

J-2 ND filter 1.0 J-6080-808-A White balance check

ND filter 0.3 J-6080-818-A White balance check

J-3 Pattern box PTB-450 J-6082-200-A

J-4 Color chart for pattern box J-6020-250-A

J-5 Siemens star J-6080-875-A For checking the flange back

J-6 Extension cable (30P, 0.8mm) J-6082-189-A For extension between LD-84A (A)/84A (B) board

(CN702) and VC-179 (A)/179 (B) board (CN501),

AT-21A (A) board (CN845) and

VC-179 (A)/179 (B) board (CN502).

J-7 Adjusting remote commander (*1) J-6082-053-B

(RM-95 remodeled partly)

J-8 Extension cable 3 J-6082-291-A For adjusting remote commander (J-7)

J-9 Video/S video out cable J-6082-293-A For checking the video signal

J-10 DC-57 harness (2P) 1-951-473-11 For DC-supply to VC-179 (A)/179 (B) board

(CN301)

J-11 RS-232C cable (8P DIN-8P DIN) 1-590-879-11 For connection between processor terminal

and Macintosh PC

J-12 RS-232C cable (8P DIN-25P DSUB) 1-751-195-11 For connection between processor terminal

SMF-532A and NEC PC98

(79-6363-00)

J-13 RS-232C cable (8P DIN-9P DSUB female) 1-690-391-21 For connection between processor terminal

SMF-533 and IBM PC, Quarter-L

(48-5233-00)

J-14 VISCA Control Software J-6082-297-A For IBM PC/NEC PC98

J-6082-296-A For Macintosh PC

AC Adaptor 1-473-789-11 AC-EV2 (AC120V)

(Output voltage: 13.5Vdc) 1-473-790-11 AC-EV3 (AC220-230V)

J-15 Input/Output conversion board J-2500-222-1 D SUB Video/VISCA Conversion (*2)

*1 Microcomputer IC in the adjusting remote commander except for µPD7503G-C56-12 (8-759-148-35) does not allow the page select-

ing. Replace the microcomputer in such a case.

*2 Remove the hexagonal screws of the D-SUB on the board before using the tool board.

6-1

J-1

J-2

J-3

J-4

J-5

J-6

J-11

J-7

J-12

J-8

J-13

6-1-2. Preparations

Note: When adjusting only, it is not needed to remove the camera

block from the pan tilt mechanism chassis.

The adjustments can be performed only by removing the

camera cabinet.

1) Connect the equipments for adjusting as shown in Fig. 6-3.

2) Turning OFF the auto focus using the adjusting remote

commander.

1. Set data: 01 to page: 6, address: 25.

(The auto focus will turn OFF. The focus can be adjusted

using the focus button on the adjusting remote commander.

But the HOLD switch must be set to OFF.)

2. After completing the adjustment/operation check, set data:

00 to page: 6, address: 25.

3) To adjust the camera block only, there are two procedures.

1. Adjust with the camera block mounted to the pan tilt

mechanism chassis. (Fig. 6-2 (1), Fig. 6-3 (1))

Note: AT-21A (A) board must be removed before 28MHz

original oscillation adjustment can be performed.

2. Remove the camera block from the pan tilt mechanism

chassis and perform adjustment to the camera block only.

(Fig. 6-2 (2), Fig. 6-3 (2))

Note: Be sure to change the data of page: D, address: 01 to 00

(NTSC) or 01 (PAL). Then, remove the camera block

from the pan tilt mechanism chassis.

After this adjustment, be sure to perform the operation

described in 6-2-20 and 6-2-22.

Fig. 6-1.

J-9

J-14

J-10

J-15

1.5m

Front of the

lens

Fig. 6-2 (1) .

Fix the

block on table.

Fig. 6-2 (2) .

Note: The camera block has no screw plate for tripod. So, fix the

block on a table when adjusting.

6-2

VC-179(A)/179(B) board

LD-84A(A)/84A(B) board

CN101

Extension cable

(J-6082-189-A)

CN502

CN845

AT-21A(A) board

Personal computer

IBM PC/NEC PC98/

Macintosh

AC adaptor

AC-EV2 (D30)

AC-EV3 (D31)

MD-68(A) board

RS-67A(A) board

Adjusting remote commander

(J-6082-053-B)

VISCA

IN

Extension cable 3

for adjusting

remote commander

(J-6082-291-A)

Fig. 6-3 (1).

S VIDEO

OUT

J-2500-222-1

Input/output

conversion board

DC IN 13.5V

Vectorscope Color monitor

RS-232C cable

1-590-879-11 (Macintosh)

1-690-391-21 (IBM PC)

1-751-195-11 (NEC PC98)

6-3

d

Color monitor Vectorscope

)

Ω

(Terminated at 75

AT-21A (A) boar

CN845

0.1Vdc)

Extension cable

(J-6082-189-A)

CN001

CN502

±

Regulated power supply

(6.3

Adjusting remote commander

(J-6082-053-B)

CN702

LD-84A (A)/84A (B) board

Extension cable

Extension cable 3

for adjusting

remote commander

(J-6082-291-A)

CN501

(J-6082-189-A)

VC-179 (A)/179 (B) board

CN101

CN301

CN105

DC-57 harness

(1-951-473-11)

MD-68 (A) board

Fig. 6-3 (2).

6-4

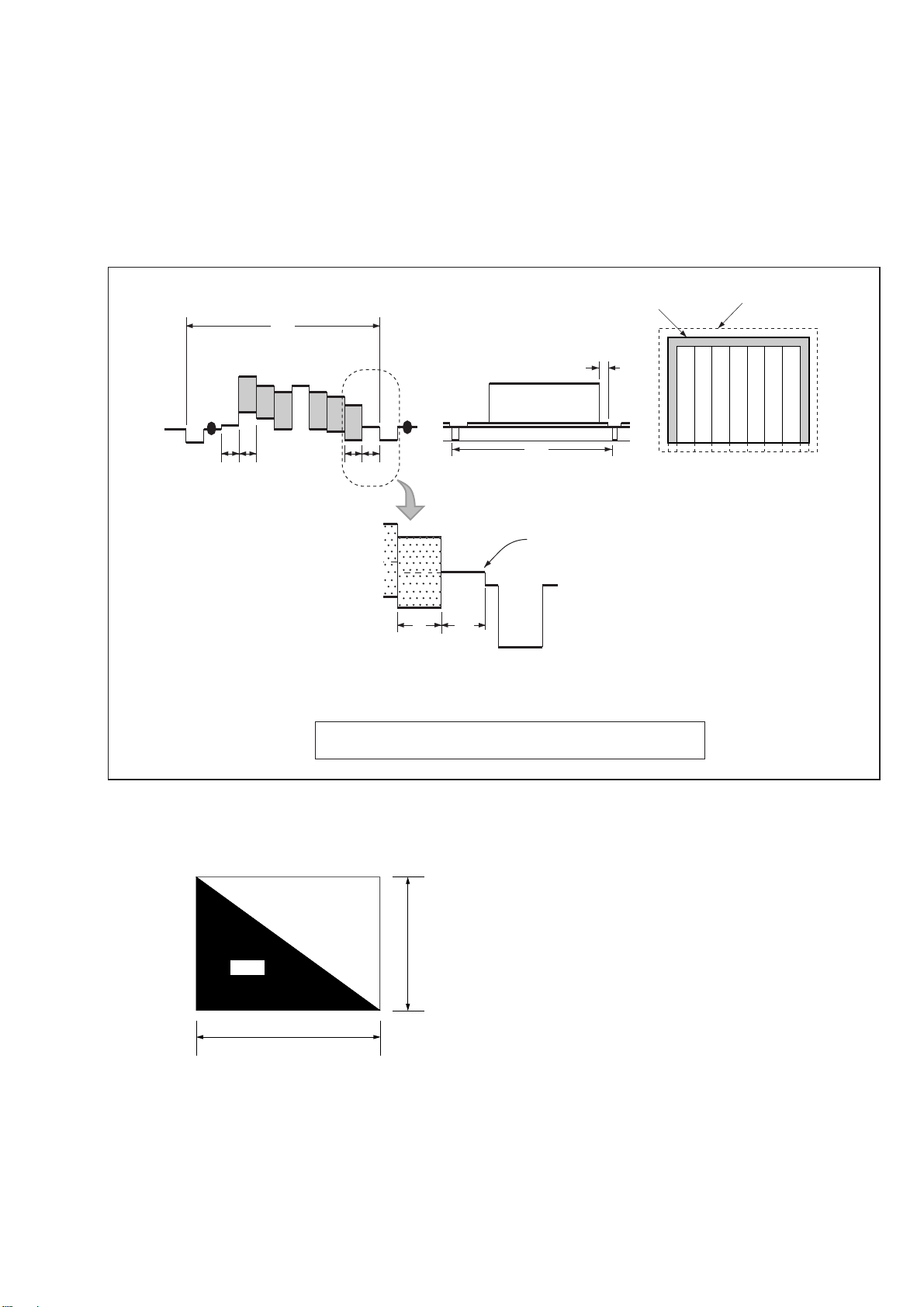

Fig. b. (TV monitor picture)

Fig. a. (Video output terminal

output waveform)

CRT picture frame

0 ± 0.1 msec

V

Difference in level

Enlargement

AB

ABABHA = B

Color bar chart standard picture frame

Yellow

Cyan

Green

White

Magenta

Red

Blue

Yellow

Cyan

Green

White

Magenta

Red

Blue

Electoronic beam

scanning frame

6-1-3. Precautions

1. Adjusting Procedure

Adjust in the given order.

2. Subject

1) Color bar chart (Standard picture frame)

Adjust the picture frame as shown in Fig. 6-4. if adjustments

are performed using the color bar chart. (Standard picture frame)

2) White pattern (Standard picture frame)

Remove the color bar chart from the pattern box, and so that

the white pattern will be displayed.

Don’t touch the zoom switch.

3) Chart for flange back adjustment

Combine a white A0 size (1189 mm × 841 mm) paper to a

black one, and make the chart shown in Fig. 6-5.

Note: Use the non-reflecting and non-glazing vellum paper whose

size is more than A0, and make the boundary between white

and black to be smoothly flat.

Black

Fig. 6-5.

Adjust the camera zoom and direction to obtain the output waveform

shown in Fig. a and the TV monitor display shown in Fig. b.

White

1189mm

Fig. 6-4.

841mm

6-5

Loading...

Loading...