Sony MZ-R900 Service manual

MZ-R900

SERVICE MANUAL

Ver 1.1 2000. 12

Photo: Red type

US and foreign patents licensed from Dolby

Laboratories Licensing Corporation.

SPECIFICATIONS

Audio playing system

MiniDisc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength:

Emission duration: continuous

Laser output: less than 44.6 µW

(This output is th e value measured at a distanc e

of 200 mm from the lens surface on the optical

pick-up block with 7 mm aperture.)

Recording and playback time

When using MDW-80:

Maximum 160 min. in monaural

Maximum 320 min. in stereo

Revolutions

350 rpm to 2,800 rpm (CLV)

Error correction

ACIRC (Advanced Cross Interleave Reed

Solomon Code)

Sampling frequency

44.1 kHz

Sampling rate converter

Input: 32 kHz/44.1 kHz/48 kHz

Coding

ATRAC (Adaptive TRansform Acousti c

Coding)

ATRAC3 — L P2

ATRAC3 — L P4

Modulation system

EFM (Eight to Fourteen Modula tion)

Number of channels

2 stereo channels

1 monaural channel

Frequency response

20 to 20,000 Hz ± 3 dB

λ = 790 nm

Wow and Flutter

Below measurable limit

Inputs

Microphone: stereo mini-jack, minimum input

level 0.25 mV

1)

: stereo mini-jack, mini mum input

Line in

level 49 mV

Optical (Digita l) in

Outputs

i/LINE OUT2): stereo mini-jack

headphones/earphones: max imum output

level 5 mW + 5 mW, load impedance 16 ohm

LINE OUT: 194 mV, load impeda nc e 10

kilohm

1)

The LINE IN (OPT) jack is used to connect

either a digital (optica l) ca ble or a line

(analog) cable.

2)

The i/LINE OUT jack connects either

headphones/earphones or a line cable .

Power requirements

Sony AC Power Adaptor connected at the DC

IN 3V jack:

230–240 V AC, 50/60 Hz (UK and Hong

Kong model)

220–230 V AC, 50/60 Hz (European model)

240 V AC, 50 Hz (Australian model)

220 V AC, 50 Hz (Chinese model)

110/220 V AC, 60 Hz (Korean model)

100–240 V AC, 50/60 Hz (Other models)

Nickel metal hydride rechargeable battery NH14WM

LR6 (size AA ) alkaline battery

1)

: optical (digital) mini-jack

AEP Model

UK Model

E Model

Australian Model

Chinese Model

Tourist Model

Model Name Using Similar Mechanism NEW

Mechanism Type MT-MZR900-171

Optical Pick-up Name LCX-4R

Battery operation time

Battery life

When recording

Batteries Stereo LP2 LP4

NH-14WM

nickel metal

hydride

rechargeable

battery

LR6 (SG)

Sony alkaline

dry battery

NH-14WM

nickel metal

hydride

rechargeable

battery

+ One LR6

5)

(SG)

1)

The battery life may be shorter due t o

operating conditions and the temper a ture of

the location.

2)

When you record, use a fully char ge d

rechargeable battery. Recording time may

differ according to the alkaline batteries .

1)

2)

(Unit: approx.hours)(EIAJ3))

8 10.5 13

4)

71014

5)

19 26 30

4)

– Continued on next page –

PORTABLE MINIDISC RECORDER

3)

Measured in accordance with the

EIAJ(Electronic Industries Asso ci ation of

Japan) standard.

4)

When using a 100% fully charged

rechargeable batter y.

5)

When using a Sony LR6 (SG) “STAMINA”

alkaline dry battery (produced in Japa n) .

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 3

2. GENERAL ................................................................... 4

When playing

(Unit: approx.hours)(EIAJ1))

Batteries Stereo LP2 LP4

NH-14WM

21 23 26

nickel metal

hydride

rechargeable

2)

battery

LR6 (SG)

Sony alkaline

dry battery

NH-14WM

30 35 38

3)

53 60 66

nickel metal

hydride

rechargeable

2)

battery

+ One LR6

3)

(SG)

1)

Measured in accordance with the

EIAJ(Electronic Industries Association of

Japan) standard.

2)

When using a 100% fully charged

rechargeable battery.

3)

When using a Sony LR6 (SG) “STAMINA”

alkaline dry battery (produced in Ja pa n).

Dimensions

Approx. 78.9 × 17.1 × 72.0 mm (w/h/d)

1

(3

/8 × 11/16 × 27/8 in.)

Mass

Approx. 110 g (3.9 oz) the recorder only

Supplied accessories

AC power adaptor (1)

Headphones/earphones with a remote co ntr ol

(1)

Rechargeable bat tery (1)

Dry battery case (1)

Rechargeable battery carrying case (1)

Carrying pouch/carrying case with a belt clip (1)

AC plug adaptor (World model only) (1)

Optical cable (1)

On power sources

•

For use in your house: Use the AC power adaptor

supplied with this recorder. Do not use any other

AC power adaptor s ince it may c ause th e rec order

to malfunction.

Polarity of the

plug

3. DISASSEMBLY ......................................................... 5

4. TEST MODE.............................................................. 12

5. ELECTRICAL ADJUSTMENTS......................... 17

6. DIAGRAMS

6-1. Block Diagram –SERVO Section– ................................. 27

6-2. Block Diagram –AUDIO Section– ................................. 29

6-3. Block Diagram –KEY CONTROL/DISPLAY/

POWER SUPPLY Section– ............................................ 31

6-4. Printed Wiring Boards..................................................... 35

6-5. Schematic Diagram ......................................................... 39

6-6. IC Pin Function Description ........................................... 47

7. EXPLODED VIEWS ................................................ 53

8. ELECTRICAL PARTS LIST ............................... 56

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Design and specifications are subject to change

without notice.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

SECTION 1

upper panel assy

MAIN board

Tape

S806

FLEXIBLE board

(Over write head)

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right above when

checking it for adjustment. It is feared that you will lose your sight.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

(LCX-4R)

The laser diode in the optical pick-up block may suffer electrostatic break-down easily. When handling it, perform soldering

bridge to the laser-tap on the flexible board. Also perform measures against electrostatic break-down sufficiently before the operation. The flexible board is easily damaged and should be handled

with care.

• In performing the repair with the power supplied to the set,

removing the MAIN board causes the set to be disabled.

In such a case, fix a conv ex part of the open/close detect s witch

(S806 on MAIN board) with a tape in advance.

Handle the FLEXIBLE board (overwrite head) with care, as it

has been soldered directly to the MAIN board.

In repairing the component side of MAIN board, connect the

FLEXIBLE board (overwrite head) and the MAIN board with

the lead wires in advance. (See page 7)

laser-tap

OPTICAL PICK-UP FLEXIBLE BOARD

• Replacement of CDX2671-202GA (IC801) used in this set

requires a special tool.

• On the set having the microcomputer version 1.000, some

adjusted values were set in the manual mode at the shipment,

but these data will be cleared when the NV is reset. Therefore,

on the set having the microcomputer version 1.000, change the

adjusted values following the Change of Adjusted Values

immediately after the NV was reset. (See page 17)

• If the nonvolatile memory w as replaced on the set, the modified

program data must be written to the nonvolatile memory . In such

a case, write the modified data that meets the microcomputer

version following the patch data rewriting procedure at the

replacement of nonvolatile memory. (See page 22)

– 3 –

SECTION 2

GENERAL

This section is extracted from

instruction manual.

Looking at controls

See pages in ( ) for more details.

The recorder

1

2

3

4

5

6

7

8

9

q;

A END SEARCH button (17) (47)

B Battery compartment (13)

C Jog lever (L) ( MENU/ENTER) (11)

(20) (25) (34) (43) (53)

D VOL +/– button (19) (47)

E REC MODE button (23)

F REC indicator (29)

G Terminals for attaching dry ba t te ry

case (14)

H SYNCHRO REC ON/OFF (synchro-

recording) switch (at the rear) (24)

I DC IN 3V jack (13) (16)

J HOLD switch (at the rear) (14) (55)

K REC (recor d) sw itch (17) (25)

8

qa

qs

qd

qf

qg

qh

qj

qk

ql

w;

L OPEN button (15)

M X (pause) button (17) (19) (27) (31)

(44) (47) (51)

N Display window (24) (34) (53)

O Jog lever (R) (N , ./>) (12)

(17) (19) (44) (47)

P x (stop)/CHARGE button (13) (17)

(19) (23) (43)

Q LINE IN (OPT) jack (16) (22)

R MIC (PLUG IN POWER) jack (25)

S T MARK button (44)

T i (headphones/earphones)/LINE

OUT jack (14) (31) (41)

The display window of the recorder

12 345

6 7 8 9 q; qa qs qd qf

A Alarm indication (53)

B Character information display (2 9)

(34)

Displays the disc and track names,

date, error messages, track numbers,

etc.

C AM/PM indication (30)

Lights up along with the time

indication in the 12-hour system.

D Time display (29) (40)

Shows the recorded time, current

time, elapsed time of the track or MD

being recorded or played.

E Battery indication (13)

Shows approximate battery condition.

F Sound indication (36)

Lights up when Digital Sound Preset

is on.

G Level meter (28)

Shows the volume of the MD being

played or recorded.

H LP2, LP4, MONO (monaural)

indication (2 3)

I SYNC (synchro-recording) indication

(24)

Lights up while synchro-re cording.

J REC indication (17)

Lights up while recording. W hen

flashing, the recorder is in record

standby mode.

K REC DATE (recorded/current date)

indication (4 0)

Lights up along with the date and time

the MD was recorded. When only

“DATE” lights up, the current date

and time are displayed.

L REMAIN (remaining time/tracks)

indication (28) (40)

Lights up along with the remaining

time of the track, the remaining time

of the MD, or the remaining num ber

of tracks.

M Play mode indication (34)

Shows the play mode of the MD.

N Disc indication (24) (34)

Shows that the disc is rotating for

recording, playing or editing an MD.

9

The headphones/earphones with a remote control

G

A B C DE

IJ

A DISPLAY button (29) (38) (46) (48)

(53)

B PLAYMODE button (35) (48)

C RPT/ENT (repeat/enter) but ton (36)

(37)

D SOUND button (36)

E Clip

F X (pause) butt on (19) (48) (51)

F

H

+

K

G Control (./N> ) (12) (19)

(36) (46) (48) (51) (53)

N> : play, AMS, FF

. : REW

H Control (VOL +/–) (12) (19) (48)

Pull and turn to adjust the volume.

I Display window (29) (36)

J HOLD swit ch (14) (55)

K x (stop) button (19) (38) (46) (53)

–

The display window of the remote control

A

A Track number disp l ay (29) (36) (54)

B Character information display (29)

(36) (54)

C Disc indication (29) (36) (54)

D Alarm indication (54)

BCDE

HG

E Play mode i ndi cation (36)

F Battery indication (29) (36) (54)

G REC indication (17) (29)

H SOUND indication (36)

10

F

– 4 –

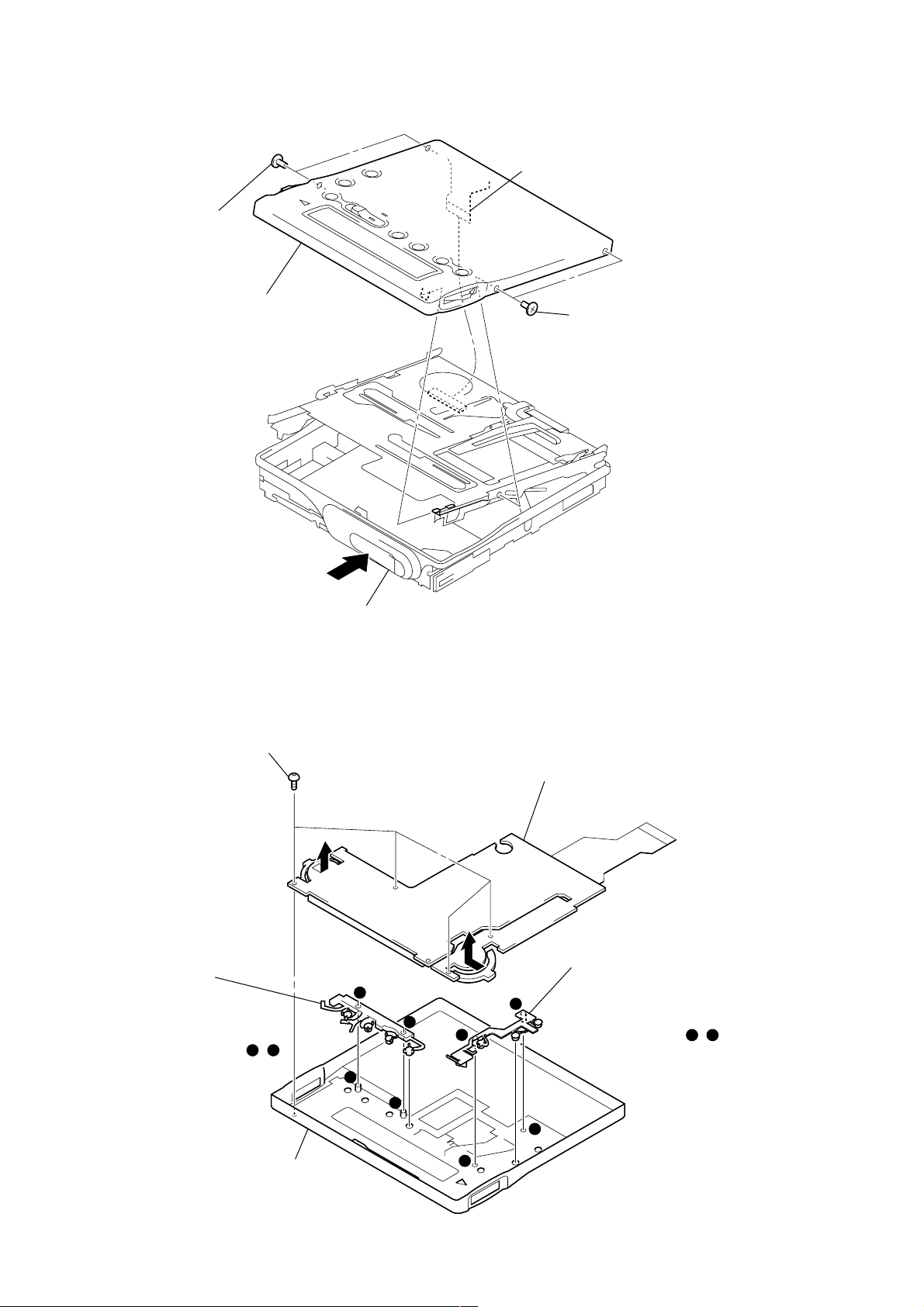

• This set can be disassembled in the order shown below.

Y

SET

SECTION 3

DISASSEMBLY

PANEL ASSY, BOTTOM PANEL ASSY, UPPER SECTION

STRIP, ORNAMENTAL

Note: Follow the disassembly procedure in the numerical order given.

“MD MECHANISM DECK

(MT-MZR900-171)”,

“CHASSIS ASSY, SET”

PANEL ASSY, BOTTOM

MAIN BOARD ASSY

“LCD MODULE”,

“PANEL ASSY, UPPER”

SERVICE ASSY, OP

(LCX-4R)

MOTOR FLEXIBLE BOARD

MOTOR, DC (SLED) (M602)

“MOTOR, DC (SPINDLE) (M601)”,

“MOTOR, DC (OVER WRITE HEAD UP/DOWN) (M603)”

“CASE ASSY, BATTERY”,

“MAIN BOARD”

HOLDER ASS

S801

S802

Note: On installation,

1

4

Close the

battery terminal (plus).

adjust the position of

both two switches (S801, S802)

and two knobs (hold).

3

lid, battery case

Open the

lid, battery case.

2

claw

5

two screws

(1.4)

5

two screws

(1.4)

knob (hold)

A

– 5 –

5

screw (1.4)

6

Remove the “panel assy, bottom”

in the direction of arrow

A

.

PANEL ASSY, UPPER SECTION

s

3

two screws

(1.4)

4

panel assy, upper section

1

flexible board

(CN801)

3

two screw

(1.4)

2

Push button (open).

“LCD MODULE”, “PANEL ASSY, UPPER”

1

four screws (1.7)

3

button (A), control

Note: On installation,

adjust the hole of

“button (A), control”

and boss of “panel assy,

upper”. (in the fig. , )

a

b

a

2

LCD module

4

button (B), control

Note: On installation,

a

b

d

c

adjust the boss of

“button (B), control” and

hole of “panel assy, upper”.

(in the fig. , )

c

d

5

panel assy, upper

b

d

c

– 6 –

MAIN BOARD ASSY

s

3

four screws

(M1.4 toothed lock)

5

6

flexible board

(CN501)

7

main board assy

1

Remove two solder

of flexible board.

“CASE ASSY, BATTERY”, “MAIN BOARD”

4

screw

(1.4)

2

case assy, battery

2

flexible board

(CN502)

3

main board

1

Remove the solder

of terminal (plus).

1

Remove the solder

of terminal (minus).

– 7 –

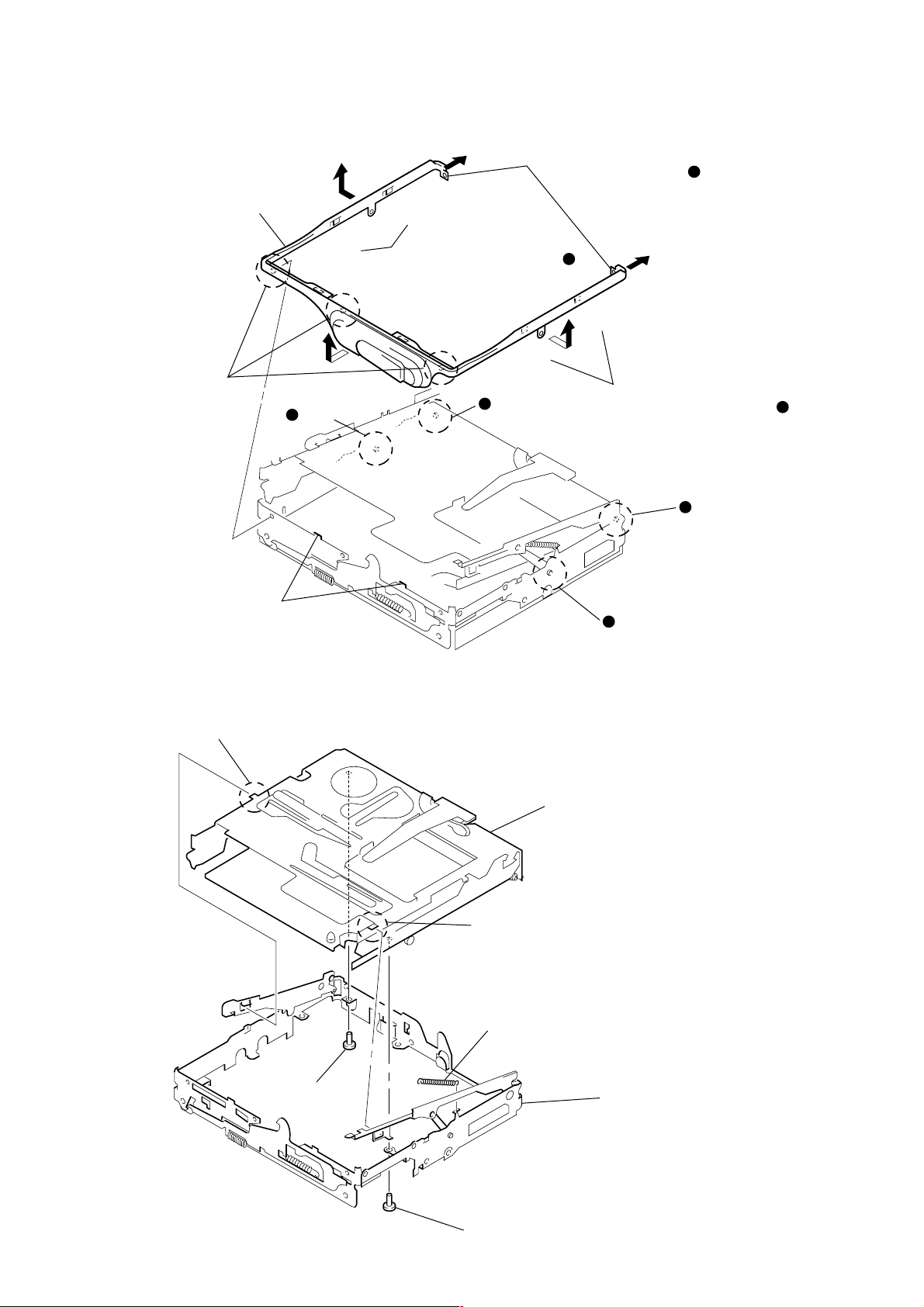

STRIP, ORNAMENTAL

t

5

Remove the “strip, ornamental”

in the direction of arrow

Note: As the “strip, ornamental”

is very fragile, do not

give an excessive force

to the entire assy when

removing it.

3

three bosses

4

two convex portions

pointed with

C

.

@

A

B

1

Pull toward the direction

to disengage two bosses .

A

a

)

)

Open toward the direction

to disengage two bosses

and convex portions pointed

*

with

.

B

b

A

2

)

B

boss

)

2

Open toward the direction

to disengage two bosses

and convex portions pointed

*

with

.

a

boss

B

b

C

boss

b

a

@

@

boss

b

“MD MECHANISM DECK (MT-MZR900-171)”, “CHASSIS ASSY, SET”

2

boss

3

2

boss

4

spring (arm), tension

1

screw

(1.4)

MD mechanism deck

(MT-MZR900-171)

5

chassis assy, se

– 8 –

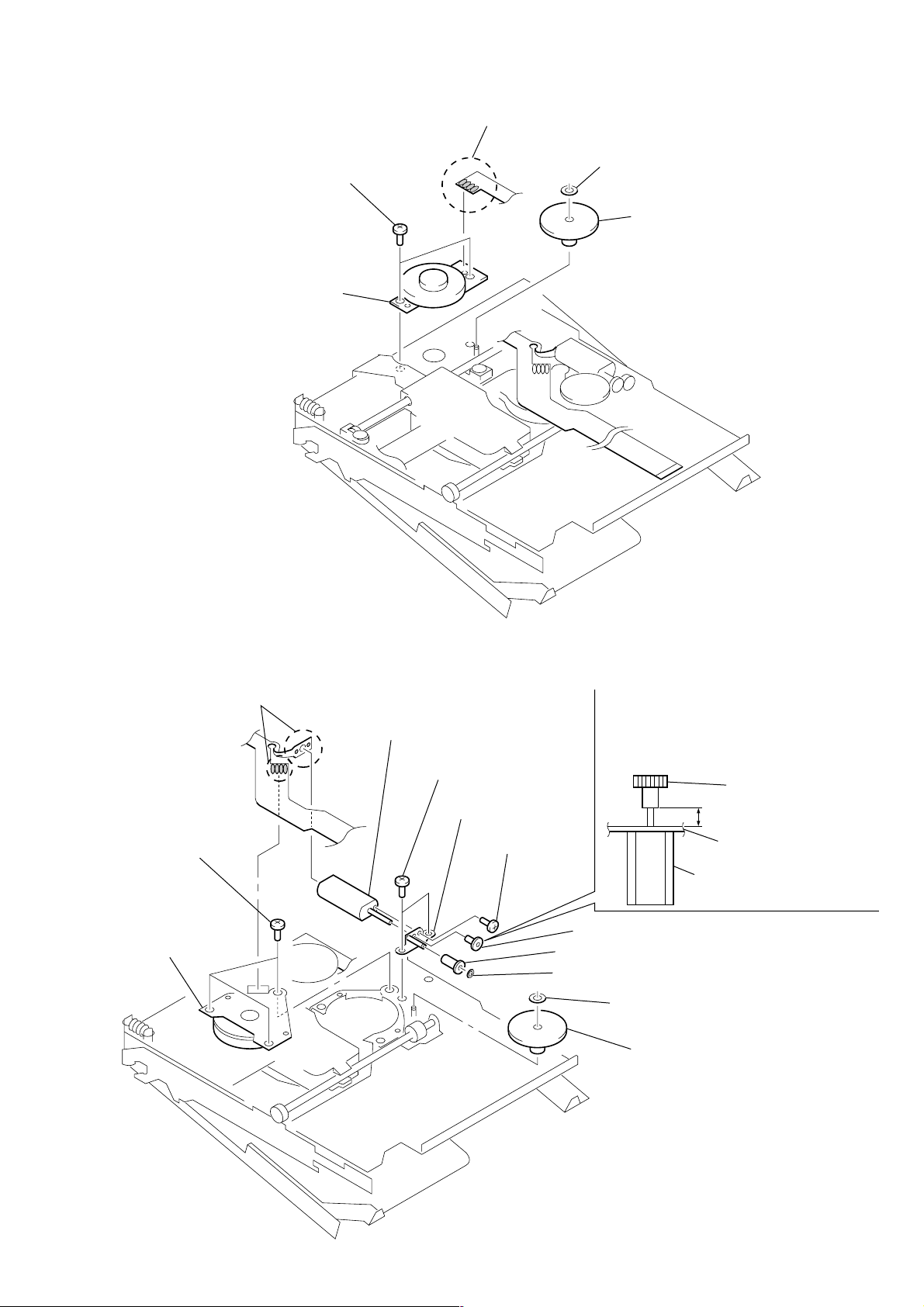

1

screw (1.4)

SERVICE ASSY, OP (LCX-4R)

1

washer (0.8-2.5)

3

screw (M1.4)

4

spring (S), rack

5

screw

2

gear (SA)

6

screw (M1.4)

7

spring, thrust

9

Pull off “screw, lead”

0

bearing (N)

8

B

service assy, OP (LCX-4R)

over write head section

qa

Opening the over write head

toward the direction

(LCX-4R) toward the direction

Note: Do not open the entire assy forcibly,

A

A

, remove the “service assy, OP

B

.

when opening the over write head.

– 9 –

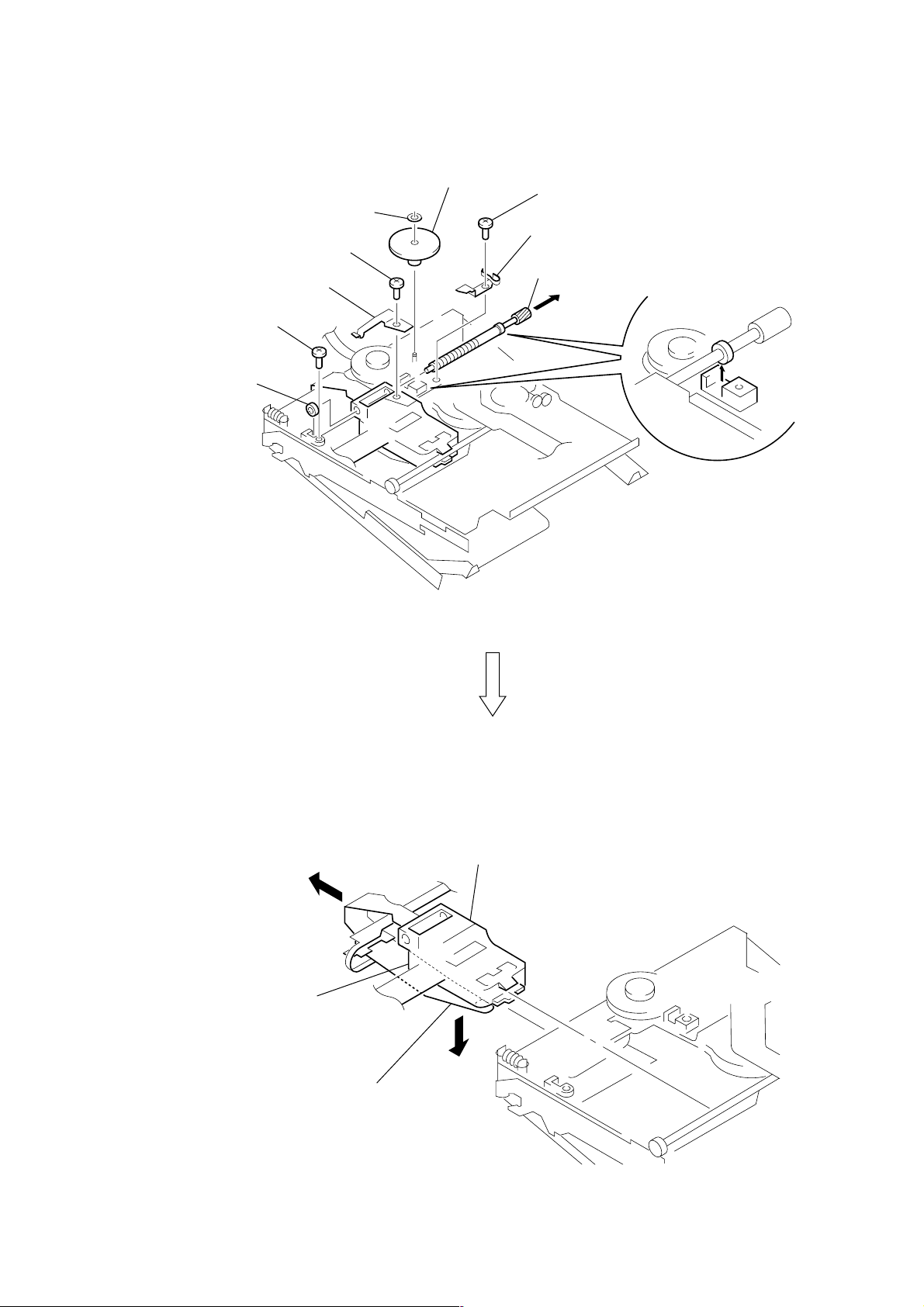

HOLDER ASSY

5

Remove the holder assy in the

direction of arrow

D

1

Open the holder assy.

.

A

D

C

B

2

Push the convex portion

toward the direction

open the holder assy toward

the direction

3

Remove the concave portion

in the direction of arrow

B

A

to erect uprightly.

and

C

.

MOTOR FLEXIBLE BOARD

1

Remove four solders of

“motor, DC (sled) (M602)”.

2

adhesive sheet

Note: Align a circular hole in the

stripping paper with a circular hole

in the “motor, DC (sled)”,

when mounting the motor

flexible board.

4

boss

1

Remove two solders of

DC motor (over write head up/down) (M603).

1

Remove four solders of

“motor, DC (spindle) (M601)”.

3

motor flexible board

DC motor (sled)

circular hole

– 10 –

MOTOR, DC (SLED) (M602)

4

two screws

(M1.4)

5

motor, DC (sled) (M602)

1

Remove four solders of motor flexible board.

2

washer (0.8-2.5)

3

gear (SA)

“MOTOR, DC (SPINDLE) (M601)”, “MOTOR, DC (OVER WRITE HEAD UP/DOWN) (M603)”

1

Remove six solders of

motor flexible board.

4

three screws

(M1.4)

5

motor, DC

(spindle) (M601)

qa

motor, DC (over write head up/down)

(M603)

6

two screws (M1.4)

qs

chassis assy, gear

9

screw (M1.2)

8

7

Note: Press-fit the gear (HA) up to the

position of the “motor, DC (over

write head up/down) (M603) as shown

below.

gear (HA)

2.65 mm

chassis assy, gear

motor, DC (over write head

up/down) (M603)

0

gear (HA)

gear (HB)

washer (0.8-2.5)

2

washer (0.8-2.5)

3

gear (HC)

– 11 –

4

0

3

SECTION 4

TEST MODE

Outline

• This set provides the Overall adjustment mode that allows CD

and MO discs to be automatically adjusted when in the test mode.

In this overall adjustment mode, the disc is discriminate between

CD and MO, and each adjustment is automatically executed in

order. If a fault is f ound, the system displays its location. Also,

the manual mode allows each individual adjustment to be automatically adjusted.

• Operation in the test mode is performed with the set. A key

having no particular description in the text, indicates a set key.

• For the LCD display, the LCD on the remote commander is

shown, but the contents of LCD display on the set are same.

Setting Method of Test Mode

There are two different methods to set the test mode:

1 Short SL801 (TEST) on the MAIN board with a solder bridge

(connect pin 3 of IC801 to the ground). Then, turn on the

power.

– MAIN Board (Conductor Side) –

Operation in Setting the Test Mode

• When the test mode becomes active, first the display check mode

is selected.

• Other mode can be selected from the display check mode.

• When the test mode is set, the LCD repeats the following display.

Remote commander LCD display

All lit

All off

Microcomputer

version

display

• When the X key is pressed and hold down, the display at that

time is held so that display can be checked.

888

001 V1.000

BASS12

Caution: On the set having the microcomputer version 1.000,

some adjusted values were set in the manual mode at

the shipment, but these data will be cleared when the

NV is reset. Therefore, on the set having the microcomputer version 1.000, change the adjusted values

following the Change of Adjusted Values immediately

after the NV was reset (see page 17).

Releasing the Test Mode

For test mode set with the method 1:

Turn off the power and open the solder bridge on SL801 (TEST)

on the MAIN board.

Note: Remove the solders completely. Remaining could be shorted with

the chassis, etc.

For test mode set with the method 2:

5860

81

70

77

79

74

1

133

IC801

615762

63

65

67

565455

68

137

135

534959

667376

+

C830

475044

453635

L801

513031

4224113

262025

401628

381723

341521

22827

189596

9419

7229

316

51048

1112241

C813

C801

C809

+

SL801

(TEST)

Turn off the power.

Note: If electrical adjustment (see page 17) has not been finished com-

pletely, always start in the test mode. (The set cannot start in normal mode)

2 In the normal mode, turn on the [HOLD] switch. While press-

ing the [VOL --] key press the following order:

> t > t . t . t > t

. t > t . t X t X

– 12 –

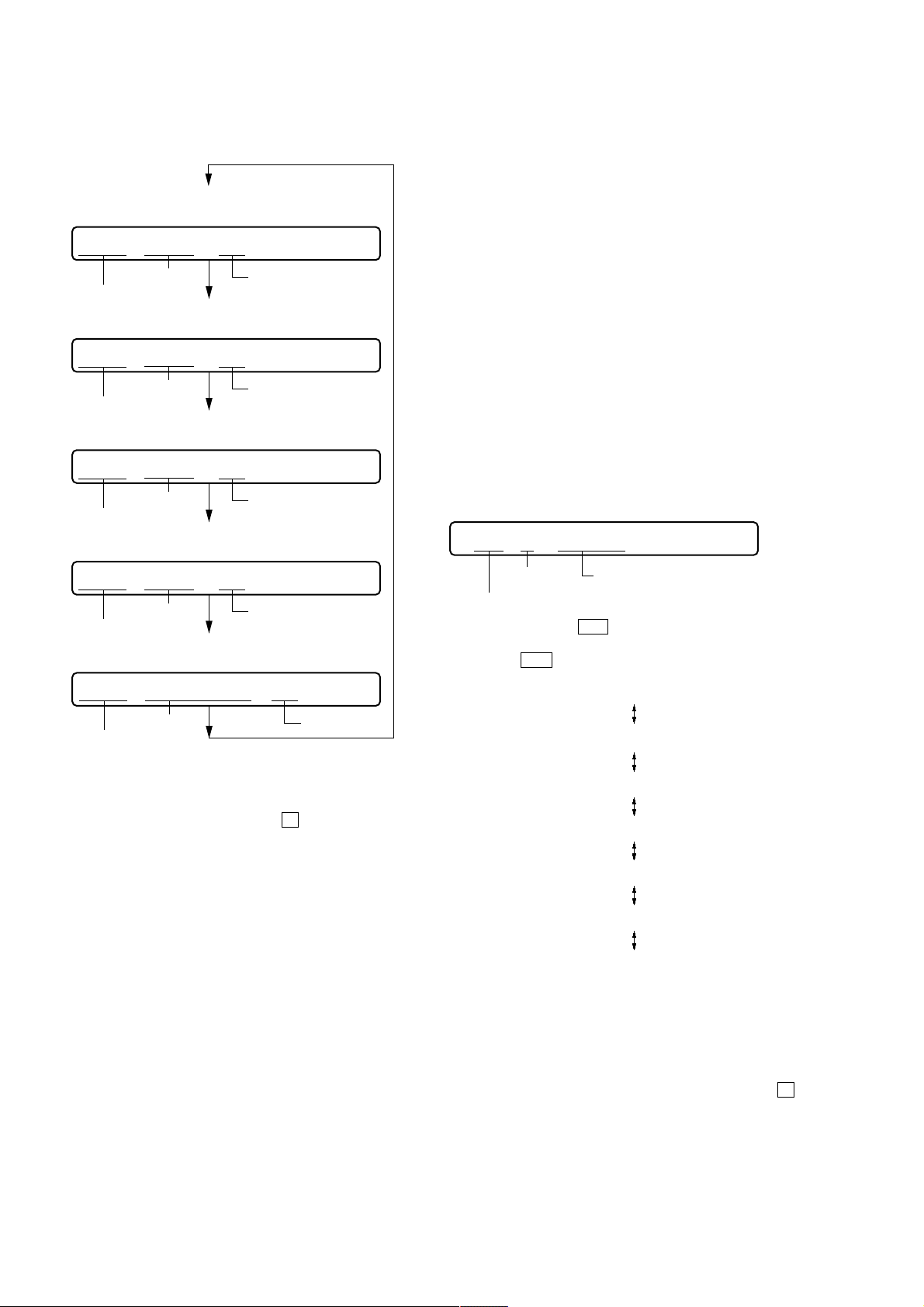

Configuration of Test Mode

[VOL +]

key:100th place of item number

increase.

[VOL --]

key:100th place of item number

decrease.

[Major item switching]

[VOL +]

key:10th place of item number

increase.

[VOL --]

key:10th place of item number

decrease.

[VOL +]

key:Increases the

adjusted value

[VOL --]

key:Decreases the

adjusted value

[Medium item switching]

N

key

N

key

x

key

[Minor item switching]

[Adjusted value variation]

X

key: When adjusted value is

changed:

Adjusted value is written.

When adjusted value is

not changed:

That item is adjusted

automatically.

[Adjusted value write]

N

key: Unit place of item number

increase.

.

key:Unit place of item number

decrease.

x

key

[Test Mode $Display Check Mode%]

Press the

>

or

[VOL +]

key

[Manual Mode]

Press the

Press the

x

key

.

or

[VOL --]

key

[Overall Adjustment Mode]

Press the

Press the

or

x

key

[JOG LEVER $L% ]

[DISPLAY]

key on the remote commander

[Self-Diagnosis Result Display Mode]

Press the

x

key

[Servo Adjustment]

[Audio Adjustment]

[Power Supply Adjustment]

[OP Alignment Adjustment]

[Electrical Offset Adjustment]

Power Supply Adjustment

Auto Item Feed

CD Overall Adjustment/

MO Overall Adjustment

R

(up) key,

Manual Mode

Mode to adjust or check the operation of the set by function.

Normally, the adjustment in this mode is not executed.

However, the Manual mode is used to clear the memory, power

supply adjustment, and laser power check before performing

automatic adjustments in the Overall Adjustment mode.

• Transition method in Manual Mode

1. Setting the test mode (see page 12).

2. Press the > or[VOL +] key activates the manual mode where

the LCD display as shown below.

Remote commander LCD display

3. During each test, the optical pick-up moves outward or inward while the N or . key is pressed for several seconds respectively.

4. Each test item is assigned with a 3-digit item number;

100th place is a major item, 10th place is a medium item, and

unit place is a minor item.

The values adjusted in the test mode are written to the

nonvolatile memory (for the items where adjustment was

made).

Press the

N

or

[REC]

key

[Sound Skip Check Result Display Mode]

Press the

Press the

on the remote commander for several

seconds (about 3 seconds)

x

key

[T MARK]

key, or

[DISPLAY]

[Key Check Mode]

The key check quits, or open the upper panel

000 Manual

key

– 13 –

5. The display changes a shown below each time the

d

[JOG LEVER $L% ] (up) key or [DISPLAY] ke y on the remote

commander is pressed.

• Address & Adjusted Value Display

Remote commander LCD display

R

011 C68S01

item number

address

• Jitter Value & Adjusted Value Display

Remote commander LCD display

adjusted value

011 OFFJ01

item number

jitter value

• Block Error Value & Adjusted Value Display

Remote commander LCD display

adjusted value

011 063B01

block error value

item number

• ADIP Error Value & Adjusted Value Display

Remote commander LCD display

adjusted value

011 059A01

ADIP error value

item number

• Item Title Display

Remote commander LCD display

adjusted value

Self-Diagnosis Result Display Mode

This set uses the self-diagnostic function system in which if an

error occurred during the recording or playing, the mechanism

control block and the power supply control block in the

microcomputer detect it and record its cause as history in the

nonvolatile memory.

By checking this history in the test mode, you can analyze a fault

and determine its location.

Total recording time is recorded as a guideline of how long the

optical pickup has been used, and by comparing it with the total

recording time at the time when an error occurred in the selfdiagnosis result display mode, you can determine when the error

occurred.

Clear both self-diagnosis history data and total recording time, if

the optical pickup was replaced.

• Self-Diagnosis Result Display Mode Setting Method

1. Setting the test mode (see page 12).

2. In the display check mode, press the [JOG LEVER $L% ] (up)

key or [DISPLAY] key on the remote commander activates the

self-diagnosis result display mode where the LCD display as

shown below.

Remote commander LCD display

R

0XX 1 0000

history code

error display code

3. Then, each time the > key is pressed, LCD display descends

by one as shown below. Also, the LCD display ascends by one

when the

. key is pressed.

Total recording time when error occurre

011 LrefPw 01

item number

item title

However in the power mode (item number 700’s), only the

item is displayed.

6. Quit the manual mode, and press the

test mode (display check mode).

Overall Adjustment Mode

Mode to adjust the servo automatically in all items.

Normally, automatic adjustment is executed in this mode at the

repair.

For further information, refer to “Section 5 Electrical Adjustments”

(see page 17).

adjusted value

x key to return to the

1

0XX 1 ****

0XX N ****

0XX N1****

0XX N2****

0XX R_****

1

XX

: Error code

****

: Total recording time

If the [DISPLAY] key on remote commander is pressed with this

display, the LCD switches to the simple display mode.

4. Quit the self-diagnosis result display mode, and press the x key

to return to the test mode (display check mode).

– 14 –

Loading...

Loading...