Sony MZ-R55 Service Manual

MICROFILM

MZ-R55

SERVICE MANUAL

Ver 1.5 2001. 01

With SUPPLEMENT-1

(9-924-964-85)

US and foreign patents licensed from Dolby Laboratories

Licensing Corporation.

SPECIFICATIONS

System

Audio playing system

MiniDisc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength: λ = 780 nm

Emission duration: continuous

Laser output: less than 44.6 µW

(This output is the value measured at a

distance of 200 mm from the lens surface on

the optical pick-up block with 7 mm

aperture.)

Recording and playback time

Maximum 74 minutes (MDW-74, stereo

recording)

Maximum 148 minutes (MDW-74, monaural

recording)

Revolutions

400 rpm to 900 rpm (CLV)

Error correction

Advanced Cross Interleave Reed Solomon

Code (ACIRC)

Sampling frequency

44.1 kHz

Sampling rate converter

Input: 32 kHz / 44.1 kHz / 48 kHz

Coding

Adaptive TRansform Acoustic Coding (ATRAC)

Modulation system

EFM (Eight to Fourteen Modulation)

Number of channels

2 stereo channels

1 monaural channel

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Tourist Model

Model Name Using Similar Mechanism NEW

MD Mechanism T ype MT-MZR55-161

Optical Pick-up T ype KMS-280A

Frequency response

20 to 20,000 Hz ± 3 dB

Wow and Flutter

Below measurable limit

Inputs

Microphone: stereo mini-jack, 0.22-0.78 mV

Line in: stereo mini-jack, 69-194 mV

Optical (Digital) in: optical (digital) mini-jack

Outputs

Headphones: stereo mini-jack, maximum

output level 5 mW+ 5 mW, load impedance

16 ohm

Line out: stereo mini-jack, 194 mV, load

impedance 10 kilohm

General

Power requirements

Sony AC Power Adaptor (supplied)

connected at the DC IN 3V jack:

120 V AC, 60 Hz (US model)

220-240 V AC, 50/60 Hz (Hong Kong model)

100-240 V AC, 50/60 Hz (Tourist model)

Nickel metal hydride rechargeable battery NH-14WM (supplied)

Two LR6 (size AA) alkaline batteries (not supplied)

– Continued on next page –

PORTABLE MINIDISC RECORDER

– 1 –

Battery operation time

Batteries Recording Playback

NH-14WM nickel Approx. Approx.

metal hydride

rechargeable battery

Two LR6 (SG) Approx. Approx.

Sony alkaline dry batteries 5 hours 10 hours

NH-14WM + Two LR6 (SG)

Dimensions

Approx. 78.9 × 18.9 × 84 mm (w/h/d)

(3 1/8 × 3/4 × 3 3/8 in.)

Mass

Approx. 147 g (5.2 oz) the recorder only

Approx. 190 g (6.7 oz) incl. a recordable MD,

and NH-14WM nickel metal hydride rechargeable battery

Supplied accessories

AC power adaptor AC-MZR55 (1)

Headphones with a remote control

MDR-A34SP (US model)/MDR-E838SP (Hong Kong, Tourist model)

and RM-MZR55 (1)

NH-14WM nickel metal hydride rechargeable battery (1)

Dry battery case (1)

Rechargeable battery carrying case (1)

Carrying pouch (1)

AC plug adaptor (1) (Tourist model only)

Design and specifications are subject to change without notice.

2.5 hours 4 hours

Approx. Approx.

9.5 hours 16 hours

Precautions for Laser Diode Emission Check

When checking the emission of the laser diode during adjustments, never view directly downwards as this may lead to

blindness.

This MiniDisc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER

PRODUCT label is located on the

bottom exterior.

IN NO EVENT SHALL SELLER BE

LIABLE FOR ANY DIRECT,

INCIDENTAL OR CONSEQUENTIAL

DAMAGES OF ANY NATURE, OR

LOSSES OR EXPENSES RESULTING

FROM ANY DEFECTIVE PRODUCT

OR THE USE OF ANY PRODUCT.

“MD WALKMAN” is a trademark of Sony

Corporation.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Precautions for Using Optical Pick-up (KMS-280A)

As the laser diode inside the optical pick-up damages by static

electricity easily, solder the laser tap of the Optical pick-up

flexible board when handling. Also take the necessary measures

to prevent damages by static electricity. Handle the Optical pickup flexible board with care as it breaks easily.

Laser tap

Optical Pick-up flexible board

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

TABLE OF CONTENTS

1. GENERAL....................................................................... 4

2. SELF-DIAGNOSTIC

2-1. General ..................................................................... 5

2-2. Test Mode Setting..................................................... 5

2-3. Operation in Test Mode Setting ................................ 5

2-4. Releasing the Test Mode........................................... 5

2-5. Self-Diagnostic Mode............................................... 5

2-6. Clearing the Error Indication Code

and Total Recording Time ........................................ 6

3. DISASSEMBLY

3-1. Bottom Panel Assy ................................................... 7

3-2. Connector ................................................................. 7

3-3. Upper Panel Block Assy........................................... 8

3-4. LCD Block Assy....................................................... 8

3-5. Ornamental Belt Block Assy .................................... 9

3-6. Main Board ............................................................... 9

3-7. Chassis (Main) Assy............................................... 10

3-8. OP Block Assy........................................................ 10

3-9. Holder Assy ............................................................ 11

4. TEST MODE

4-1. General ................................................................... 12

4-2. Test Mode Setting................................................... 12

4-3. Test Mode Structure ............................................... 12

4-4. Manual Mode ......................................................... 12

4-5. Overall Adjustment Mode ...................................... 15

4-6. Hybrid Mode, Key Check Mode ............................ 16

5. ELECTRICAL ADJUSTMENTS........................... 17

6. DIAGRAMS

6-1. IC Pin Descriptions ................................................ 21

6-2. Block Diagram – Servo Section – .......................... 25

6-3. Block Diagram – Audio Section –.......................... 27

6-4. Block Diagram – System Control Section –........... 29

6-5. Printed Wiring Board (-11)..................................... 31

6-6. Printed Wiring Board (-12)..................................... 34

6-7. Printed Wiring Board (-13)..................................... 37

6-8. Schematic Diagram – Main Section (1/3) – ........... 40

6-9. Schematic Diagram – Main Section (2/3) – ........... 43

6-10. Schematic Diagram – Main Section (3/3) – ........... 46

7. EXPLODED VIEWS

7-1. Panel Section .......................................................... 54

7-2. Chassis Section ....................................................... 55

7-3. Mechanism Deck Section ....................................... 56

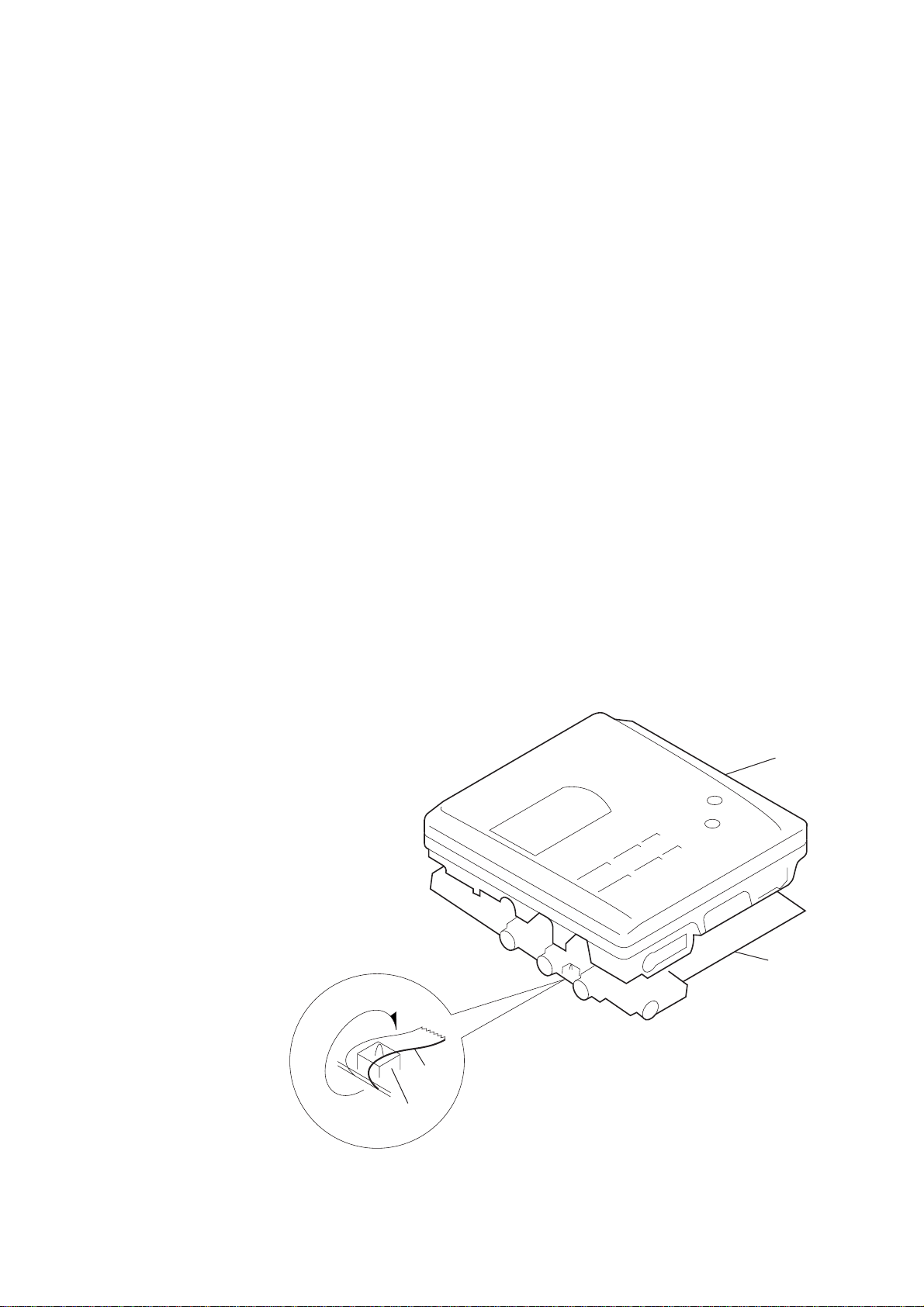

SERVICING NOTE

1) When repairing this device with the power on, if you remove

the main board or open the upper panel assy, this device stops

working.

In this case, you can work without the device stopping by

fastening the hook of the DOOR OPEN switch (S801) with tape.

8. ELECTRICAL PARTS LIST................................... 57

upper panel assy

MAIN board

tape

S801

2) This set is designed to perform automatic adjustment for each

adjustment and write its value to EEPROM. Therefore, when

EEPROM (IC801) has been replaced in service, be sure to perform automatic adjustment and write resultant values to the new

EEPROM.

Refer to page 12 for details.

– 3 –

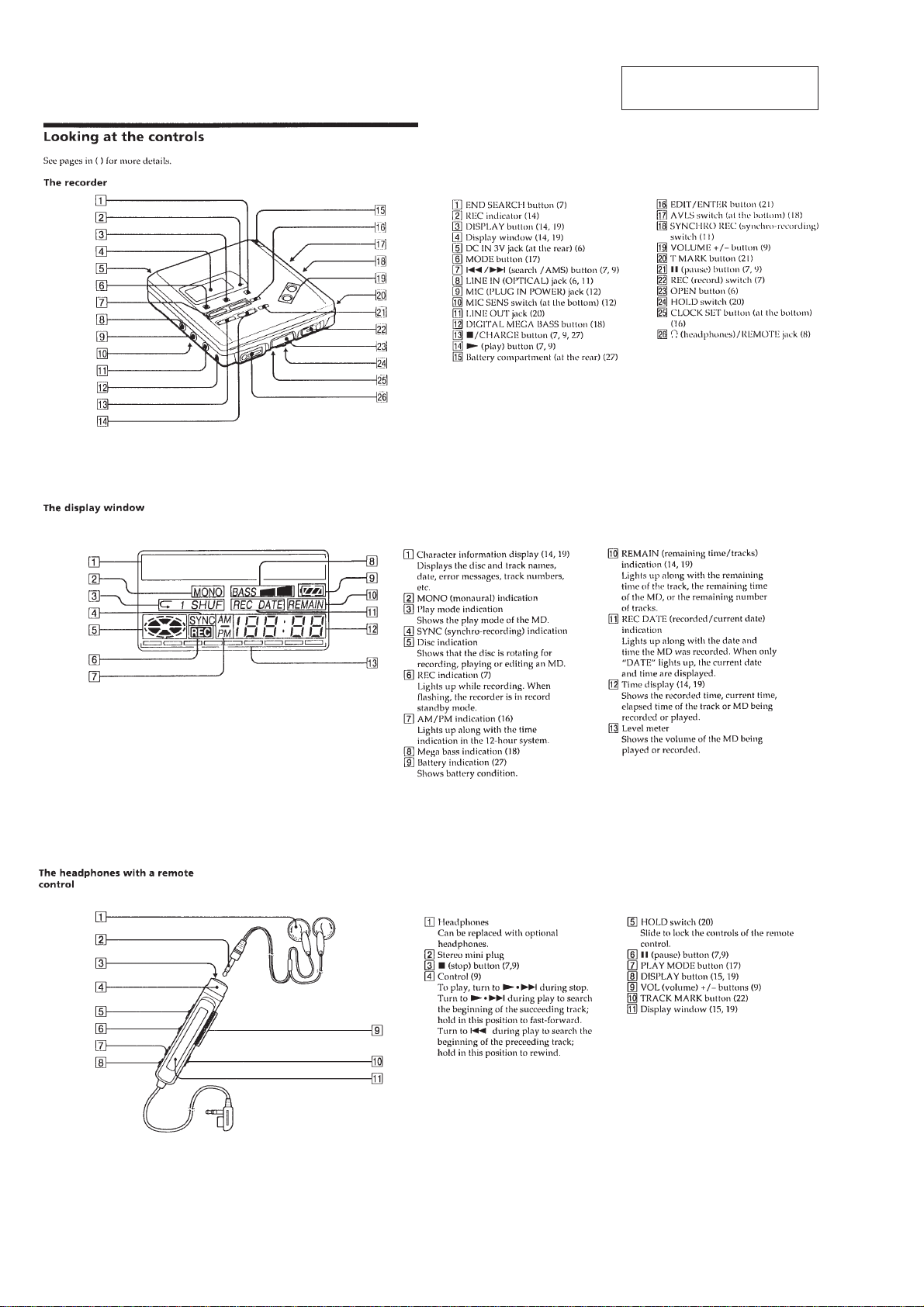

SECTION 1

GENERAL

This section is extracted from

instruction manual.

– 4 –

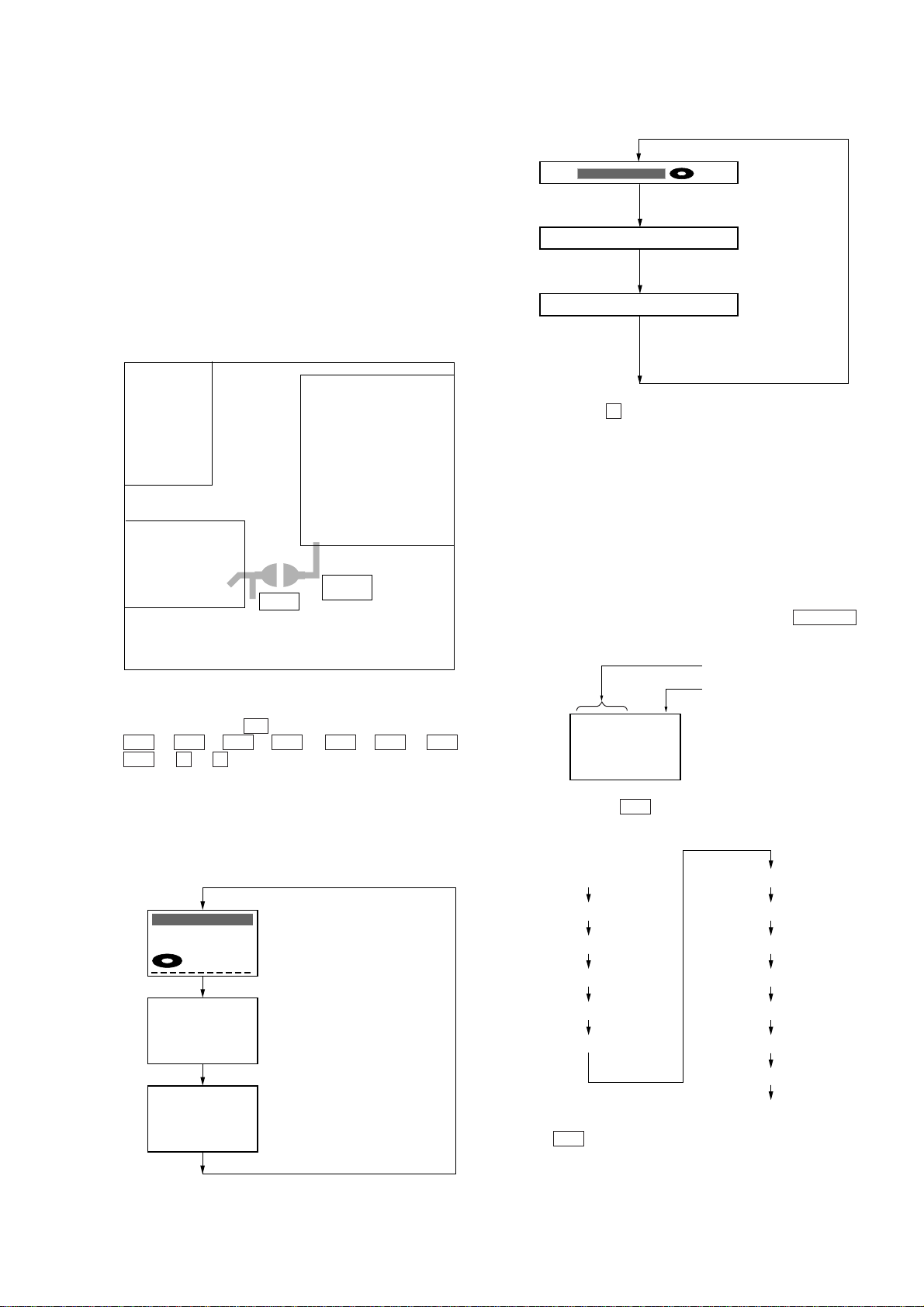

SECTION 2

888

ı

Ver ‚.8‚

All ON

All OFF

Microprocessor

version

display

SELF-DIAGNOSTIC

2-1. GENERAL

This set uses the self-diagnostic system in which if an error occurs

in playback/recording mode, the error is detected by the model

control and power control blocks of the microprocessor and information on the cause is stored as history in EEPROM.

By viewing this history in test mode, it helps you to analyze a fault

and determine its location.

2-2. TEST MODE SETTING

There are two different methods to set the test mode:

1 Short BP801 (TEST) on the main board with a solder bridge

(connect pin @§ of IC801 to the ground). Then, turn on the

power.

–

main board

IC503

IC509

(side B)

–

IC802

BP801

R818

C309

2) Remote controller LCD

• Holding down P allows the current display to be maintained

while it being depressed.

2-4. RELEASING THE TEST MODE

For test mode set with the method 1:

Turn off the power and open the solder bridge on BP801 on the

main board.

For test mode set with the method 2:

Turn off the power.

2-5. SELF-DIAGNOSTIC MODE

1. Go into the test mode.

2. With the unit LCD indicators all flashing, press DISPLA Y key

to go into the self-diagnostic mode.

2 In the normal mode, use the keys on the unit to perform the

following operations:

Press and hold down ( and press the keys below in this turn:

+ n + n =n = n + n = n + n

= n P n P

2-3. OPERATION IN TEST MODE SETTING

When the test mode is set, the LCD shows repeated cycles of the

following display:

1) Unit LCD

ı

All ON

188:88

All OFF

Ver ‚‚.8‚

Microprocessor

version

display

History code

Error indication code

1st ‚ ‚‚

3. Then, eac h time ) ke y is pressed, the reference information

display changes as given below.

1st ‚ XX

1st 1 ‚‚

1st 2 ‚‚

N ‚ XX

N 1 ‚‚

N 2 ‚‚

N-1 ‚ XX

N-1 1 ‚‚

N-1 2 ‚‚

N-2 ‚ XX

N-2 1 ‚‚

N-2 2 ‚‚

REC XXXX

1st ‚ XX

• Press = key to go back to the previous display.

(return)

– 5 –

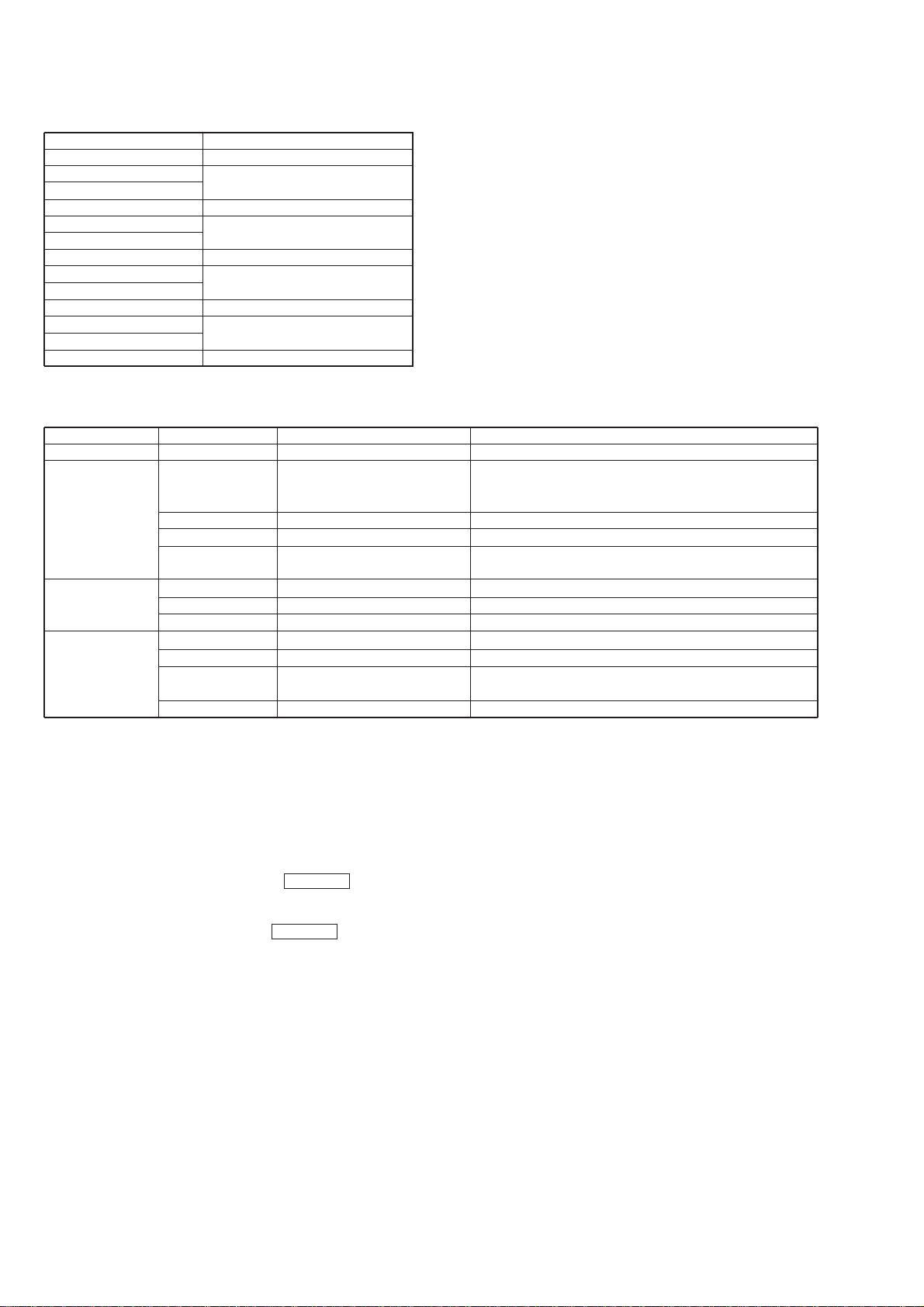

• Description of History Codes

History code number Description

1st 0 The first error

1st 1

1st 2

N 0 The last error

N1

N2

N-1 0 One error before the last.

N-1 1

N-1 2

N-2 0 Two errors before the last.

N-2 1

N-2 2

REC Total recording time *1)

• Description of Error Indication Codes

Problem Indication code Meaning of code Description

No error 00

Abnormal stop

during recording

Abnormal stop

during playback

Abnormal stop of

recording/playback

caused by power

system

00 indicated

00 indicated

00 indicated

00 indicated

01 Servo error Focus out of alignment.

02 ADIP read error Unable to read the ADIP address.

03 Shock detected during write Jumped by 1.5 tracks or more due to shock during write.

04

11 No focus applied Focus could not be applied.

12 CRC error Unable to read the address.

15 FG error Abnormal rotation of disc.

21 Lower voltage due to overload Power voltage reduced due to overload.

22 Momentary interruption Momentary interruption detected.

23

24 Low power voltage in DSP

Shock detected during

laser down

Lower power voltage in motor Power voltage for motor continuously reduced to less than

system 1V.

*1) Total recording time

Total recording time is recorded in minutes as an index for load to

the OP. It is recorded in hexadecimal format and up to 65,535 min.

(about 886 discs of 74-minute disc) can be counted. It returns to

“0000h” when recorder goes beyond this limit.

Example :REC 000A n Approx. 10 min.

REC 00A0 n Approx. 160 min.

REC 0A00 n Approx. 2560 min.

Abnormal disc RPM.

Attempt to access an abnormal address.

Shock detected when laser was moving down.

2-6. CLEARING THE ERROR INDICATION CODE

AND TO TAL RECORDING TIME

After repair, reset the error indication code.

Reset the total recording time when you have replaced the OP.

1. Go into the self-diagnostic mode. (See page 5.)

2. To reset the error indication code, slide REC c key when

the code is displayed.

(All data including 1st, N , N-1 and N-2 are reset.)

3. T o reset the total recording time, slide REC c key when the

time is displayed.

– 6 –

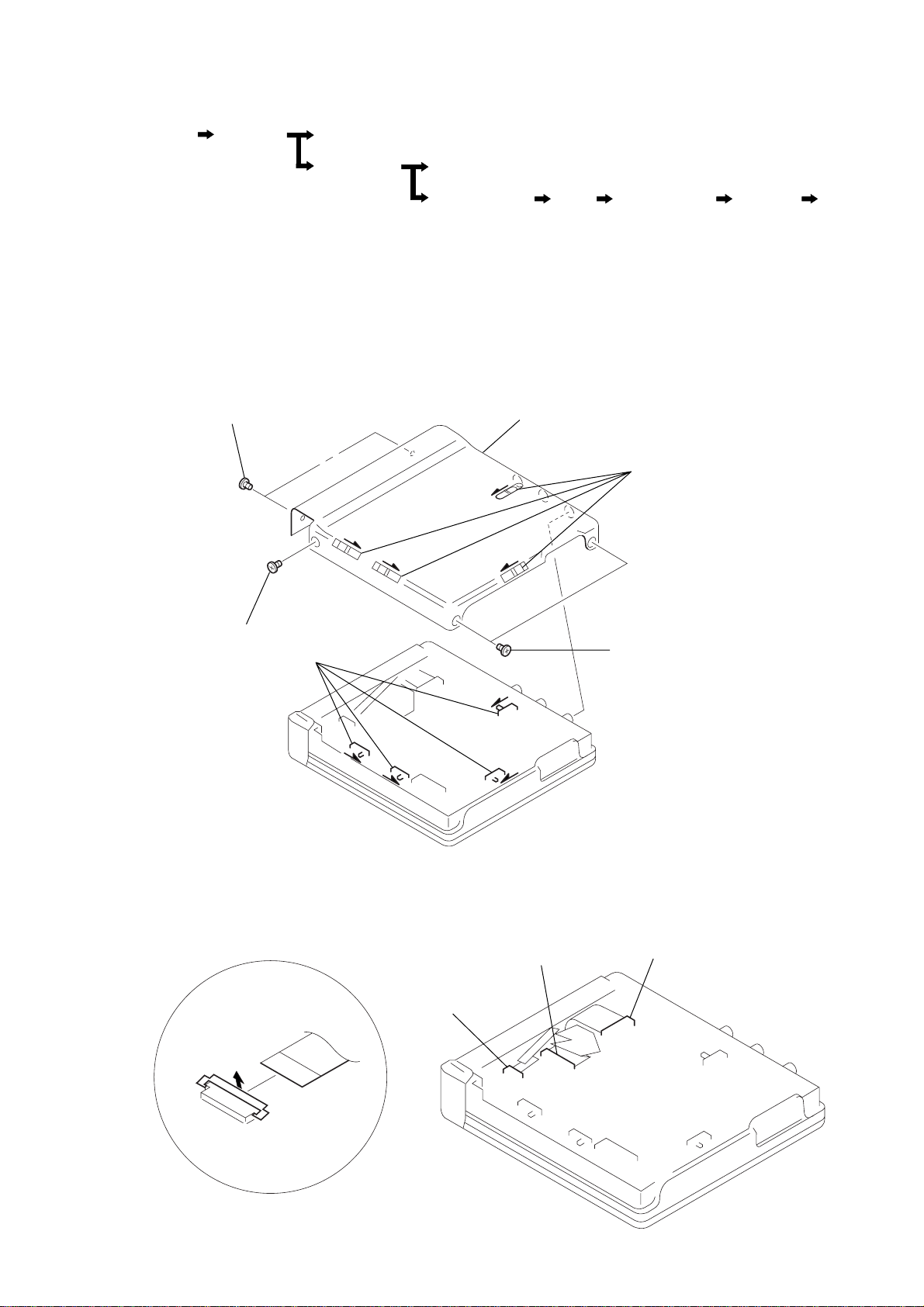

SECTION 3

y

DISASSEMBLY

Note : This set can be disassemble according to the following sequence.

Bottom

Connector

Panel

assy

Note : Follow the disassembly procedure in the n umerical order given.

3-1. BOTTOM PANEL ASSY

Note) When installing, fit the each positions knobs with switches.

2

precision pan screws (M1.4)

Main Board

Upper Panel

Block assy

LCD Block assy

Ornametal Belt

Block assy

4

bottom panel assy

Main

Board

Chassis (Main)

assy

knobs

OP Block

assy

Holder

ass

3-2. CONNECTOR

3

precision pan screw (M1.4)

switches

1

CN601

3

CN502

1

precision pan screws (M1.4)

2

CN801

– 7 –

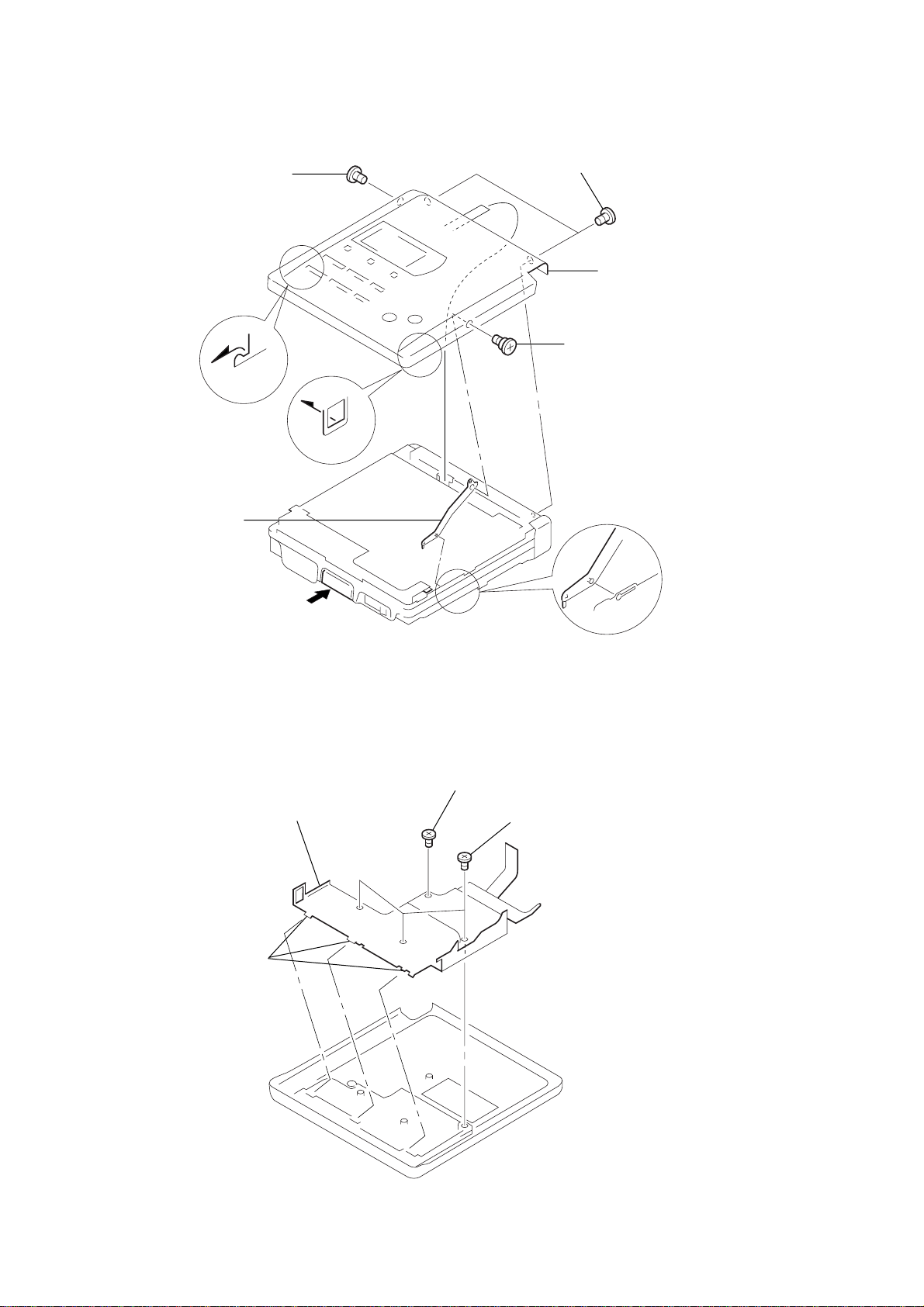

3-3. UPPER PANEL BLOCK ASSY

2

precision pan screw (M1.4)

5

3

precision pan screws (M1.4)

7

upper panel block assy

4

step screw (click arm)

0

click arm assy

3-4. LCD BLOCK ASSY

6

1

4

LCD block assy

8

1

precision pan screw (M1.4)

2

tapping screws (1.7)

9

3

claws

– 8 –

Loading...

Loading...