Page 1

MZ-R500/R500PC

SERVICE MANUAL

Ver 1.0 2001. 01

Ver 1.0 2001. 06

This service manual contains the

information on the MZ-R500

(9-873-054-11).

Photo: MZ-R500

US and foreign patents licensed from Dolby

Laboratories Licensing Corporation.

SPECIFICATIONS

System

Audio playing system

MiniDisc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength: λ = 790 nm

Emission duration: continuous

Laser output: less than 44.6 µW

(This output is the value measured at a

distance of 200 mm from the lens surface

on the optical pick-up block with 7 mm

aperture.)

Recording and playback time

When using MDW-80

Maximum 160 min. in monaural

Maximum 320 min. in stereo

Revolutions

350 rpm to 2,800 rpm (CLV)

Error correction

ACIRC (Advanced Cross Interleave Reed

Solomon Code)

Sampling frequency

44.1 kHz

Sampling rate converter

Input: 32 kHz/44.1 kHz/48 kHz

Coding

ATRAC (Adaptive TRansform Acoustic

Coding)

ATRAC3-LP2

ATRAC3-LP4

Modulation system

EFM (Eight to Fourteen Modulation)

Number of channels

2 stereo channels

1 monaural channel

Frequency response

20 to 20,000 Hz ± 3 dB

Wow and Flutter

Below measurable limit

Inputs

Line in: stereo mini-jack, minimum input

level 49 mV

Optical (Digital) in: optical (digital) minijack

Outputs

i: stereo mini-jack, maximum output level

5 mW + 5 mW, load impedance 16 ohm

US Model

Canadian Model

MZ-R500/R500PC

AEP Model

UK Model

E Model

Chinese Model

MZ-R500

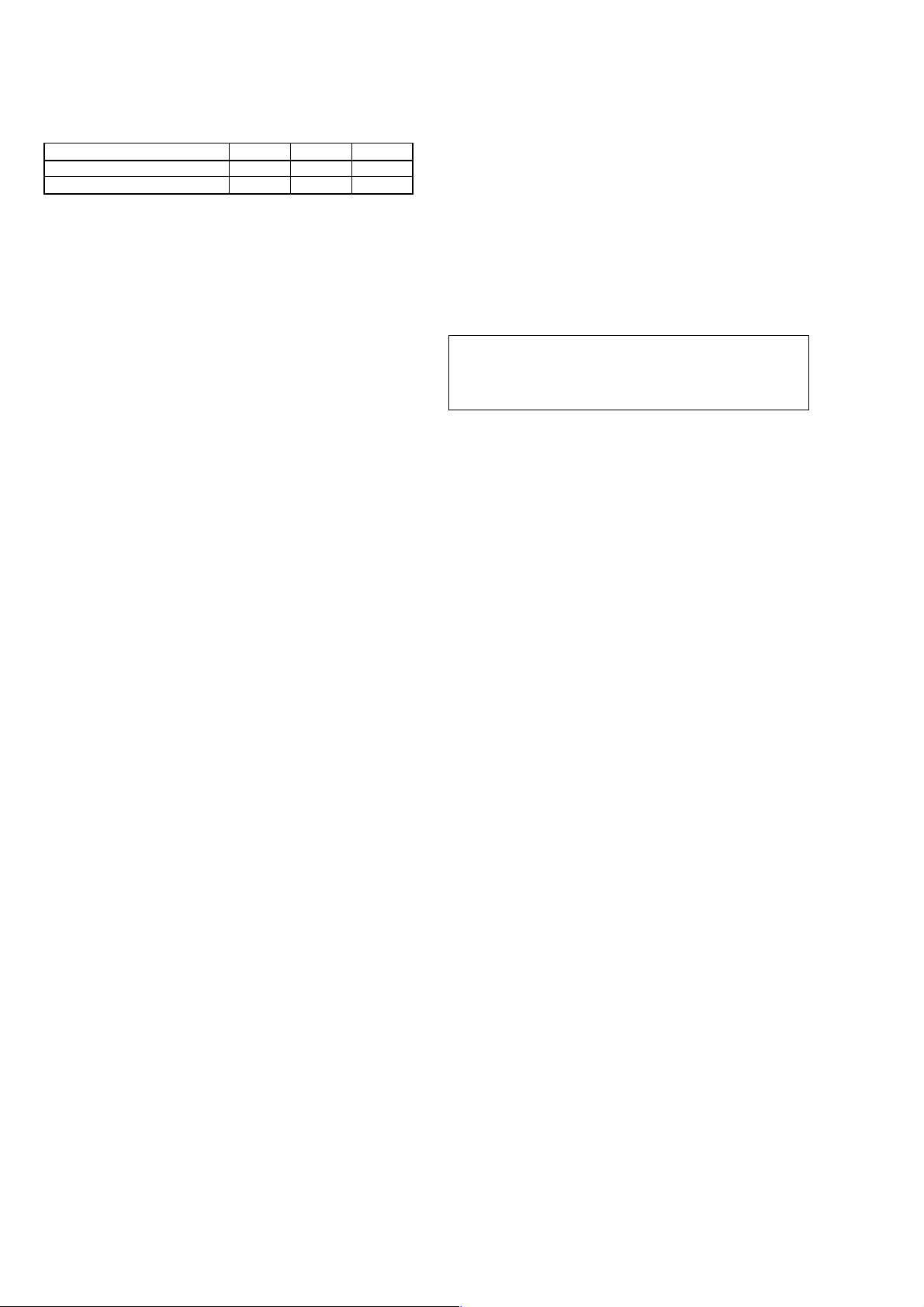

Model Name Using Similar Mechanism NEW

Mechanism Type MT-MZR500-172

Optical Pick-up Name LCX-4R

General

Power requirements

Sony AC Power adaptor connected at the

DC IN 3 V jack (AEP, Chinese and

Argentine models only):

230 V AC, 50/60 Hz (AEP model)

220 V AC, 50 Hz (Chinese model)

220 V AC, 50 Hz (Argentine model)

One LR6 (size AA) alkaline dry battery (not

supplied)

– Continued on next page –

9-873-177-01

2001F0400-1

© 2001. 6

PORTABLE MINIDISC RECORDER

Sony Corporation

Personal Audio Company

Shinagawa Tec Service Manual Production Group

1

Page 2

MZ-R500/R500PC

Battery operation time

Battery life

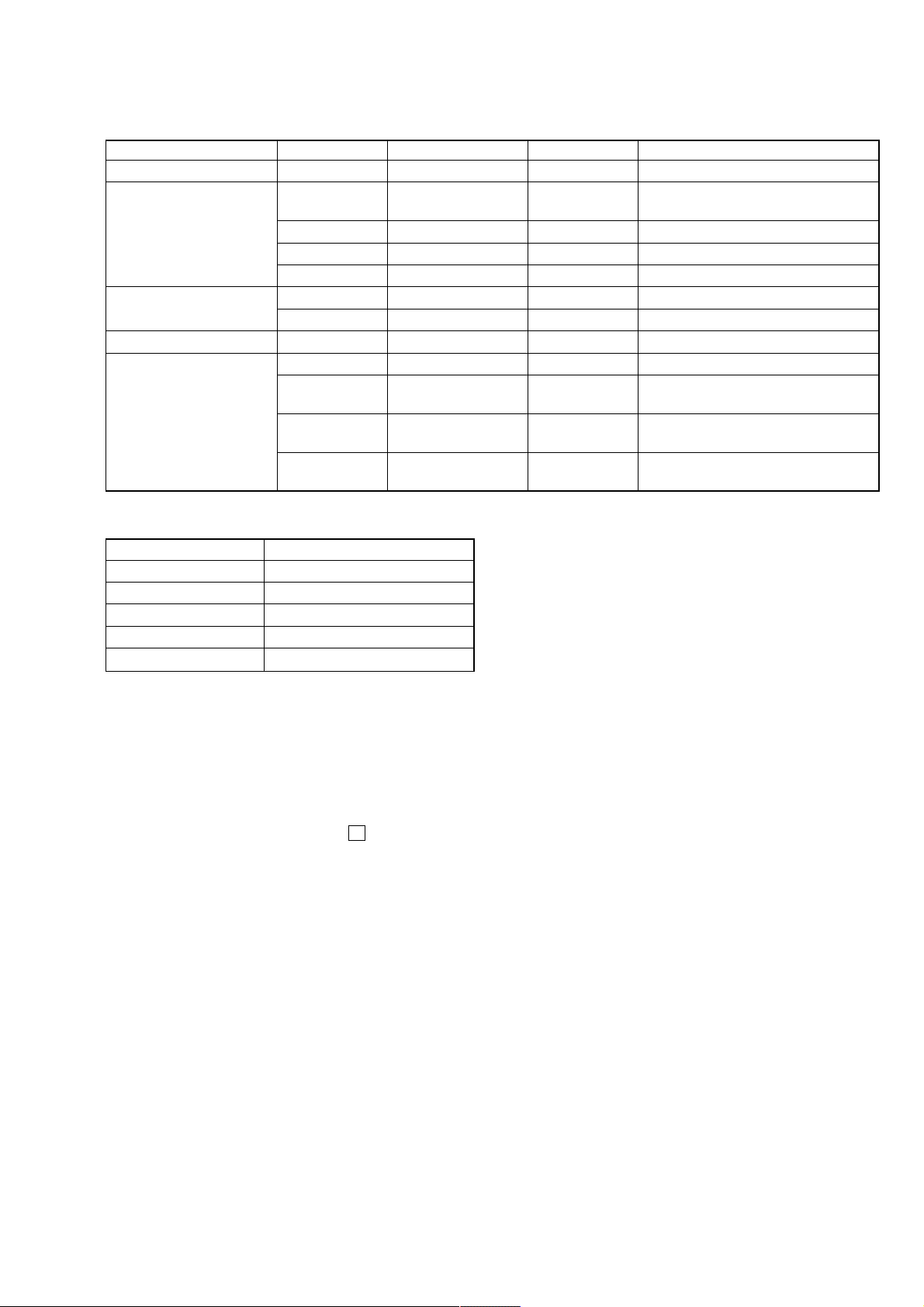

LR6 (SG) alkaline dry battery3)Normal LP2 LP4

Recording

Playback 36 42 48

1)

2)

3)

4)

Dimensions

Approx. 83.0 × 27.8 × 75.8 mm (w/h/d)

(3 3/8 × 1 1/8 × 3 in.) without projections.

Mass

Approx. 113 g (4.0 oz) the recorder only

Supplied accessories

AC power adaptor (AEP, Chinese and Argentine models only) (1)

Headphones/earphones (1)

Optical cable (AEP, Chinese and Argentine models only) (1)

Design and specifications are subject to change

without notice.

1)

4)

The battery life may be shorter due to operating conditions, the

temperature of the location, and varieties of batteries.

Measured in accordance with the EIAJ (Electronic Industries

Association of Japan) standard.

When using a Sony LR6 (SG) “STAMINA” alkaline dry battery

(produced in Japan).

To prevent interrupted recording due to drained battery, use new

battery for recording operations.

(Unit: approx.hours) (EIAJ2))

7.5 10 13.5

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270°C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL

OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

À LA SÉCURITÉ!!

2

Page 3

TABLE OF CONTENTS

MZ-R500/R500PC

1. SERVICING NOTE......................................................... 4

2. GENERAL

Looking at the Controls ...................................................... 5

Record an MD..................................................................... 5

Playing an MD right away ..................................................6

3. DISASSEMBLY

3-1. Case (Lower) Assy .............................................................. 7

3-2. Case (Upper) Assy .............................................................. 7

3-3. LCD Module ....................................................................... 8

3-4. Main Board .........................................................................8

3-5. MD Mechanism Deck ......................................................... 9

3-6. Service Assy, OP.................................................................9

3-7. Holder Assy.......................................................................10

3-8. Motor Flexible Board ........................................................ 10

3-9. Motor, DC (M602) ............................................................ 11

3-10. “Motor, DC (M601)”, “Motor, DC (M603)” .................... 11

4. TEST MODE

4-1. Outline............................................................................... 12

4-2. Setting Method of Test Mode............................................ 12

4-3. Operation in Setting the Test Mode...................................12

4-4. Releasing the Test Mode ...................................................12

4-5. Configuration of Test Mode ..............................................13

4-6. Manual Mode ....................................................................13

4-7. Overall Adjustment Mode ................................................. 14

4-8. Self-Diagnosis Result Display Mode ................................ 14

4-9. Reset the Error Display Code............................................15

4-10. Sound Skip Check Result Display Mode .......................... 16

4-11. Key Check Mode...............................................................16

5. ELECTRICAL ADJUSTMENTS

5-1. Outline............................................................................... 18

5-2. Precautions for Adjustment............................................... 18

5-3. Adjustment Sequence........................................................ 18

5-4. NV Reset ........................................................................... 18

5-5. Power Supply Manual Adjustment.................................... 19

5-6. Temperature Correction..................................................... 20

5-7. Laser Power Check ........................................................... 20

5-8. Overall Adjustment Mode ................................................. 21

5-9. Resume Clear ....................................................................23

5-10. Patch Data Rewriting when Nonvolatile

Memory was Replaced...................................................... 23

6. DIAGRAMS

6-1. IC Pin Function Description ............................................ 30

6-2. Block Diagram – Servo Section – ..................................... 36

6-3. Block Diagram – Audio Section – ....................................37

6-4. Block Diagram – System Control/Power Section – .......... 38

6-5. Printed Wiring Board – Main Section –............................ 40

6-6. Schematic Diagram – Main Section (1/3) – ...................... 42

6-7. Schematic Diagram – Main Section (2/3) – ...................... 43

6-8. Schematic Diagram – Main Section (3/3) – ...................... 44

7. EXPLODED VIEWS

7-1. Case (Lower) Section........................................................ 49

7-2. Case (Upper) Section ........................................................ 50

7-3. Chassis Section .................................................................51

7-4. MD Mechanism Deck Section .......................................... 52

8. ELECTRICAL PARTS LIST...................................... 53

3

Page 4

MZ-R500/R500PC

SECTION 1

SERVICING NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

Never look into the laser diode emission from right above when

checking it for adjustment. It is feared that you will lose your sight.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

(LCX-4R)

The laser diode in the optical pick-up block may suffer electrostatic break-down easily. When handling it, perform soldering

bridge to the laser-tap on the flexible board. Also perform measures against electrostatic break-down sufficiently before the operation. The flexible board is easily damaged and should be handled

with care.

• In performing the repair with the power supplied to the set,

removing the MAIN board causes the set to be disabled.

In such a case, fix a convex part of the open/close detect switch

(S806 on MAIN board) with a tape in advance.

Handle the FLEXIBLE board (overwrite head) with care, as it

has been soldered directly to the MAIN board.

In repairing the component side of MAIN board, connect the

FLEXIBLE board (overwrite head) and the MAIN board with

the lead wires in advance. (See page 8)

FLEXIBLE board

(Over write head)

panel assy, upper

Tape

laser-tap

OPTICAL PICK-UP FLEXIBLE BOARD

S806

MAIN board

• Replacement of CDX2671-204GA (IC801) used in this set

requires a special tool.

• On the set having the microcomputer version 1.000, some

adjusted values were set in the manual mode at the shipment,

but these data will be cleared when the NV is reset. Therefore,

on the set having the microcomputer version 1.000, change the

adjusted values following the Change of Adjusted Values

immediately after the NV was reset. (See page 18)

• If the nonvolatile memory was replaced on the set, the modified

program data must be written to the nonvolatile memory . In such

a case, write the modified data that meets the microcomputer

version following the patch data rewriting procedure at the

replacement of nonvolatile memory. (See page 23)

4

Page 5

SECTION 2

GENERAL

MZ-R500/R500PC

This section is extracted from

instruction manual.

5

Page 6

MZ-R500/R500PC

6

Page 7

SECTION 3

I

DISASSEMBLY

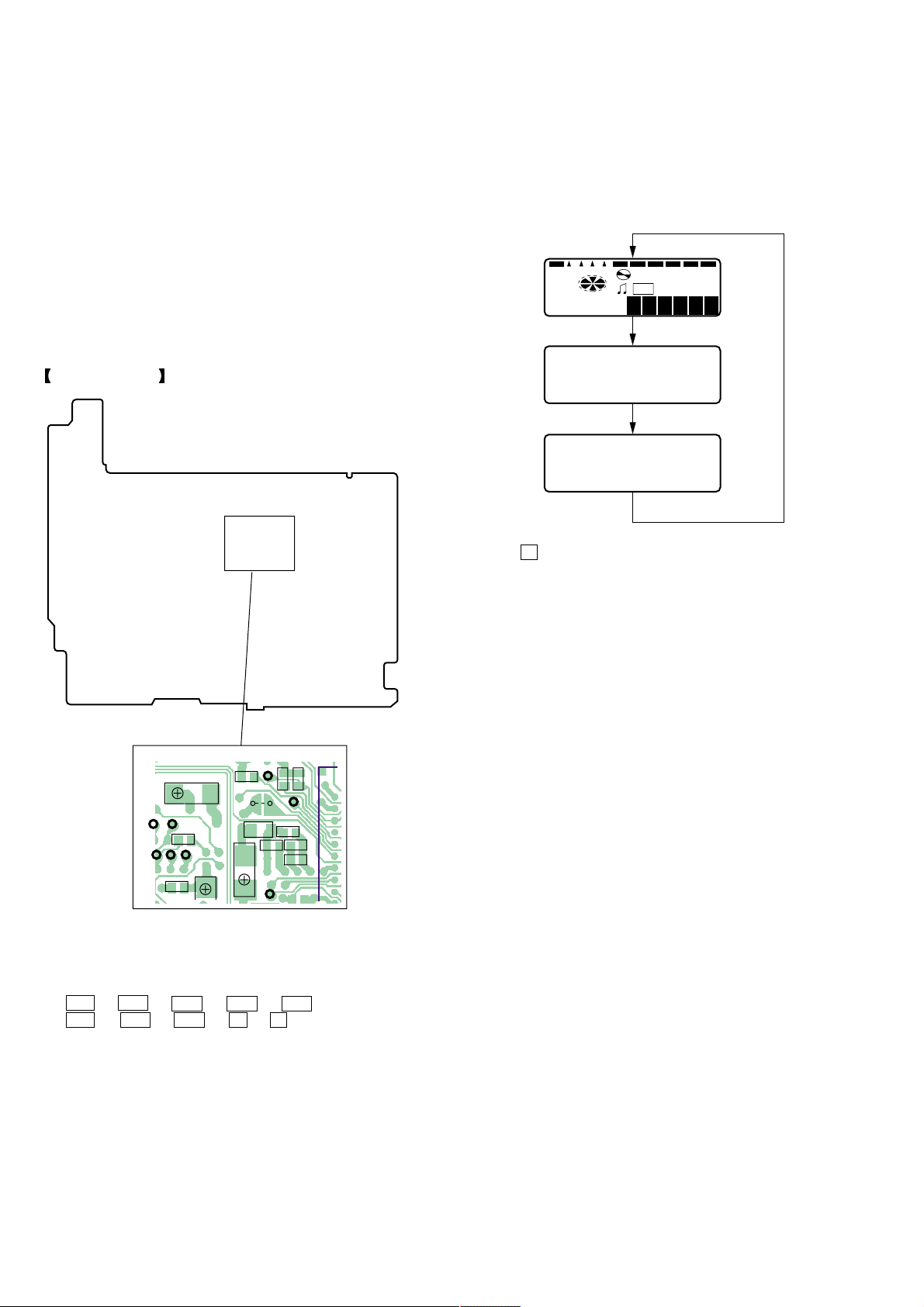

Note : This set can be disassemble according to the following sequence.

Set Case (Lower) Assy Case (Upper) Assy LCD Module

Main Board MD Mechanism Deck

MZ-R500/R500PC

Service Assy, OP

Holder Assy

Motor Flexible Board

Motor, DC (M602)

"Motor, DC (M601)"," Motor, DC (M603)"

Note : Follow the disassembly procedure in the numerical order given.

3-1. CASE (LOWER) ASSY

4

claw

1

screw (1.7), MI

3

screws (1.7), MI

knob (hold)

3-2. CASE (UPPER) ASSY

4

spring (pop-L), torsion

spring (pop-L), torsion

6

case(lower) assy

chassis assy

2

screw (1.7), MI

3

case (upper) assy

5

2

CN801

1

screws (1.7), M

7

Page 8

MZ-R500/R500PC

y

d

3-3. LCD MODULE

2

screws (1.7x3), tapping

3

1

screws (1.7x3), tapping

4

LCD module

3-4. MAIN BOARD

qs

terminal (-), battery

qa

Remove the solder

4

screws (M1.4x2),

toothed lock

7

CN501

6

case (upper) ass

2

Remove the solders

3

toothed lock

screws (M1.4x2),

1

CN701

8

MAIN boar

5

screw (M1.4x2),

toothed lock

9

0

terminal (+), battery

8

Remove the solder

Page 9

3-5. MD MECHANISM DECK

t

e

3

MD mechanism deck

boss

2

MZ-R500/R500PC

chassis assy, se

3-6. SERVICE ASSY, OP

3

precision pan screw

(M1.4)

4

rack spring (S)

1

washer (0.8 - 2.5)

2

gear (SA)

5

precision pan screw

(M1.4)

6

spring, thrust detent

8

Pull off the lead screw.

B

1

screws (1.7), MI

7

Opening the over write head

9

toward the direction

OP Service assy toward

the direction

Note: Do not open the entire assy

forcibly, when opening

the over write head.

B

.

A

, remove th

over write head section

A

9

Page 10

MZ-R500/R500PC

3-7. HOLDER ASSY

4

1

Open the holder assy.

Remove the holder assy to

direction of the arrow

A

B

.

2

B

3-8. MOTOR FLEXIBLE BOARD

1

Remove four solders of

DC motor (sled) (M602).

4

adhesive sheet

Note: Align a circular hole in the stripping paper

with a circular hole in the DC motor (sled),

when mounting the motor

flexible board.

boss

3

5

motor flexible board

2

Remove two solders of

DC motor (over write head up/down) (M603).

3

Remove four solders of

DC motor (spindle) (M601).

10

Page 11

3-9. MOTOR, DC (M602)

1

Remove six solders of

motor flexible board.

4

three precision pan screws

(M1.4)

qs

DC motor (over write head up/down)

(M603)

6

two precision pan screws

(M1.4)

qa

chassis assy, gear

0

screw

(M1.2 × 1.5)

9

gear (HA)

8

gear (HB)

7

washer (0.8 - 2.5)

2

washer (0.8 - 2.5)

3

gear (HC)

5

DC motor

(spindle)

(M601)

DC motor

(over write head up/down)

(M603)

gear chassis assy

gear (HA)

2.65 mm

Note: Press-fit the gear (HA) up to the

position of the DC motor (over write

head up/down) (M603) as shown

below.

5

DC motor (sled) (M602)

4

two precision pan screws

(M1.4)

1

Remove four solders of

motor flexible board.

2

MZ-R500/R500PC

washer (0.8 - 2.5)

3

gear (SA)

3-10. “MOTOR, DC (M601)”, “MOTOR, DC (M603)”

11

Page 12

MZ-R500/R500PC

SECTION 4

TEST MODE

4-1. Outline

• This set provides the Overall adjustment mode that allows CD

and MO discs to be automatically adjusted when in the test mode.

In this overall adjustment mode, the disc is discriminate between

CD and MO, and each adjustment is automatically executed in

order. If a fault is found, the system displays its location. Also,

the manual mode allows each individual adjustment to be automatically adjusted.

4-2. Setting Method of T est Mode

There are two different methods to set the test mode:

1 Short TAP801 (TEST) on the MAIN board with a solder bridge

(connect pin 3 of IC801 to the ground). Then, turn on the

power.

MAIN BOARD (SIDE B)

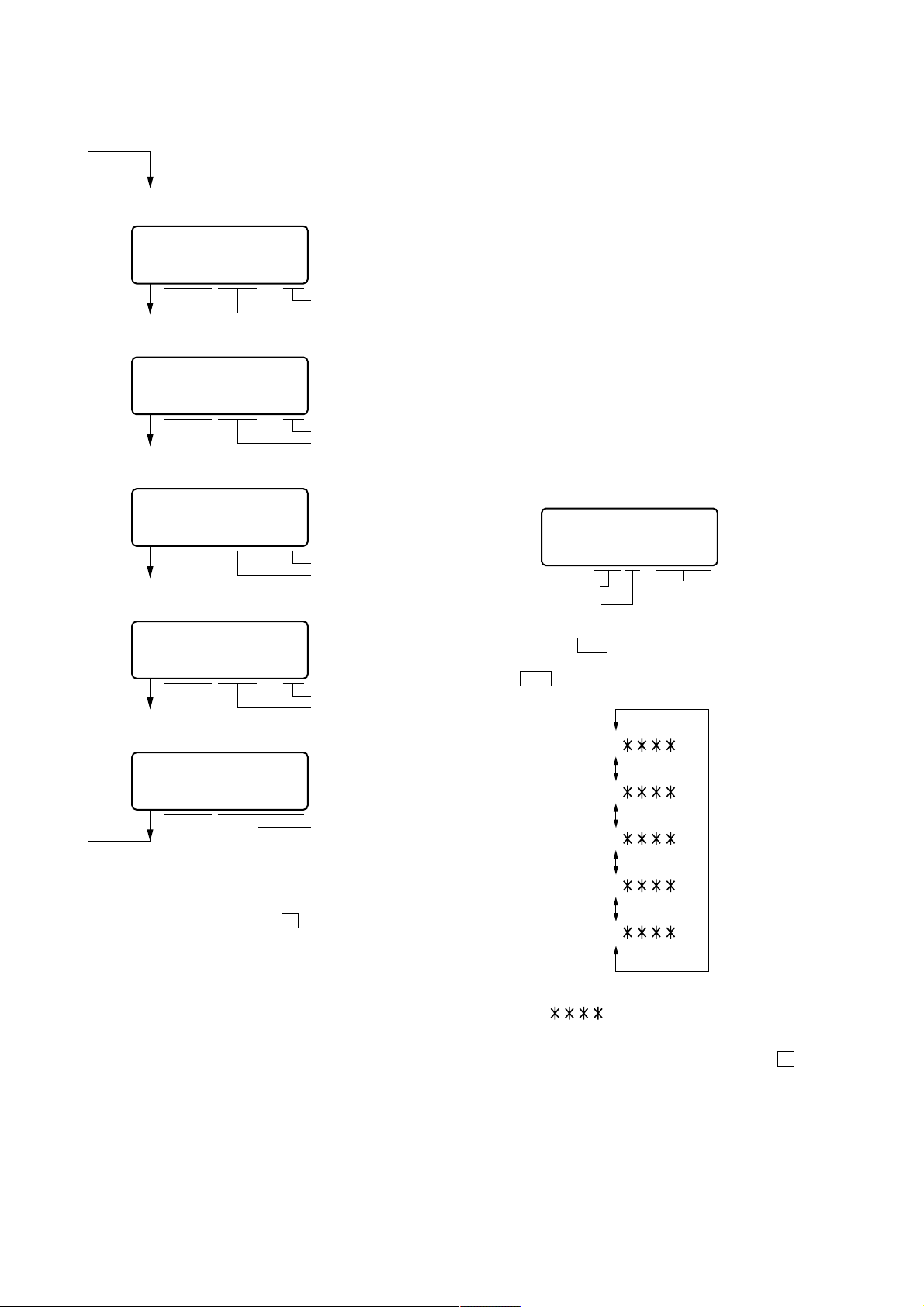

4-3. Operation in Setting the Test Mode

• When the test mode becomes active, first the display check mode

is selected.

• Other mode can be selected from the display check mode.

• When the test mode is set, the LCD repeats the following dis-

play.

This set LCD display

All lit

u

SYNCMONO REC REMAIN

SHUFREC

1F

-a 8 8 : 8 8

All off

Microcomputer

version

display

00 6

• When the

time is held so that display can be checked.

X key is pressed and hold down, the display at that

V1.200

AP856

AP526

AP529

AP530

R811

AP528

C521

C815

AP531

R805

TAP801

(TEST)

FB801

C830

C807

AP802

AP803

C808

R810

R830

R806

R807

2 In the normal mode, turn on the [HOLD] switch. While press-

ing the [VOL --] key press the following order:

> t > t . t . t > t

. t > t . t X t X

Caution: On the set having the microcomputer version 1.000,

some adjusted values were set in the manual mode at

the shipment, but these data will be cleared when the

NV is reset. Therefore, on the set having the microcomputer version 1.000, change the adjusted values

following the Change of Adjusted Values immediately

after the NV was reset (see page 18).

4-4. Releasing the Test Mode

For test mode set with the method 1:

Turn off the power and open the solder bridge on T AP801 (TEST)

on the MAIN board.

Note: Remove the solders completely. Remaining could be shorted

with the chassis, etc.

For test mode set with the method 2:

Turn off the power.

Note: If electrical adjustment (see page 18) has not been finished

completely, always start in the test mode. (The set cannot

start in normal mode)

12

Page 13

4-5. Configuration of T est Mode

x key N key

x key N key

Major item switching

Minor item switching

Medium item switching

. key: Unit Place of item number

decrease.

VOL – key: 10th Place of item number

decrease.

VOL + key: 10th Place of item number

increase.

VOL – key: Decreases the

adjusted value

VOL + key: Increases the

adjusted value

VOL – key: 100th Place of item number

decrease.

VOL + key: 100th Place of item number

increase.

N key: Unit Place of item number

increase.

X key: When adjusted value is

chaged:

Adjusted value is written.

When adjusted value is

not changed:

That item is adjusted

automatically.

Adjusted value variation

Adjusted value write

Test mode (Display Check Mode)

Press the > or VOL+ key

Manual Mode

Press the x key

Press the . or VOL– key

Overall Adjustment Mode

Press the x key

ENTER key

Self-Diagnosis Result Display Mode

Press the x key

Servo Adjustment

Audio Adjustment

Power Supply Adjustment

OP Alignment Adjustment

Electrical Offset Adjustment

Power Supply Adjustment

Auto item Feed

CD Overall Adjustment/

MO Overall Adjustment

MZ-R500/R500PC

4-6. Manual Mode

Mode to adjust or check the operation of the set by function.

Normally, the adjustment in this mode is not executed.

However, the Manual mode is used to clear the memory, power

supply adjustment, and laser power check before performing

automatic adjustments in the Overall Adjustment mode.

• Transition method in Manual Mode

1. Setting the test mode (see page 12).

2. Press the > or[VOL +] key activates the manual mode where

Press the N or T.MARK + N keys.

Sound Skip Check Result Display Mode

Press the x key

Press the T.MARK + X keys.

Key Check Mode

The key check quits,or open the upper panel

the LCD display as shown below.

This set LCD display

0 0 0 Manual

3. During each test, the optical pick-up moves outward or in-

4. Each test item is assigned with a 3-digit item number;

ward while the > or . key is pressed for several seconds respectively.

100th place is a major item, 10th place is a medium item, and

unit place is a minor item.

The values adjusted in the test mode are written to the

nonvolatile memory (for the items where adjustment was

made).

13

Page 14

MZ-R500/R500PC

e

e

e

e

0 XX1

0 XXN

0 XXN1

0 XXN2

0 XXR_

XX

:Error code

:Total recording time

5. The display changes a shown below each time the

[ENTER] key on the set is pressed.

• Address & Adjusted V alue Display

This set LCD display

0 11

item number

• Jitter Value & Adjusted Value Display

This set LCD display

0 11

item number

• Block Error Value & Adjusted Value Display

This set LCD display

0 11

item number

• ADIP Error Value & Adjusted Value Display

This set LCD display

3A4S1D

adjustment valu

address

OFEJ1D

adjustment valu

jitter value

063B1D

adjustment valu

block error value

4-8. Self-Diagnosis Result Display Mode

This set uses the self-diagnostic function system in which if an

error occurred during the recording or playing, the mechanism

control block and the power supply control block in the

microcomputer detect it and record its cause as history in the

nonvolatile memory.

By checking this history in the test mode, you can analyze a fault

and determine its location.

Total recording time is recorded as a guideline of how long the

optical pickup has been used, and by comparing it with the total

recording time at the time when an error occurred in the selfdiagnosis result display mode, you can determine when the error

occurred.

Clear both self-diagnosis history data and total recording time, if

the optical pickup was replaced.

• Self-Diagnosis Result Display Mode Setting Method

1. Setting the test mode (see page 12).

2. In the display check mode, press the [ENTER] key activates the

self-diagnosis result display mode where the LCD display as

shown below.

This set LCD display

0 XX

error

display code

history code

1 0000

Total recording time

when error occurred

0 11

item number

• Item Title Display

This set LCD display

0 11

item number

However in the power mode (item number 700’s), only the

item is displayed.

6. Quit the manual mode, and press the

test mode (display check mode).

072A1D

LrefPw

x key to return to the

4-7. Overall Adjustment Mode

Mode to adjust the servo automatically in all items.

Normally, automatic adjustment is executed in this mode at the

repair.

For further information, refer to “Section 5 Electrical Adjustments”

(see page 18).

adjustment valu

ADIP error value

item title

3. Then, each time the

by one as shown below. Also, the LCD display ascends by one

when the

4. Quit the self-diagnosis result display mode, and press the x key

to return to the test mode (display check mode).

. key is pressed.

> key is pressed, LCD display descends

14

Page 15

MZ-R500/R500PC

• Description of Error Indication Codes

Problem Indication code Meaning of code Simple display Description

No error 00 No error --- No error

01

Servo system error 02 High temperature Temp High temperature

03 Focus error Fcus Disordered focus

04 Spindle error Spdl Abnormal rotation of disc

TOC error

Power supply system error 22 Low battery LBat Momentary interruption detected

Offset system error

11 TOC error TOC Faulty TOC contents

12 Data reading error Data Data could not be read at SYNC

31 Offset error Ofst Offset error

32

33

34

Illegal access target

address was specified

Focus error ABCD

offset error

Tracking error

Offset error

X1 tracking error

Offset error

Adrs Attempt to access an abnormal address

ABCD Focus error ABCD offset error

TE Tracking error Offset error

X1TE X1 tracking error Offset error

• Description of Indication History

History code number Description

1 The first error

N The last error

N1 One error before the last.

N2 Two errors before the last.

R_ Total recording time

4-9. Reset the error display code

After servicing, reset the error display code.

• Setting method of Reset the Error Display Code

1. Setting the test mode (see page 12).

2. Press [ENTER] key activates the self-diagnosis result display

mode.

3. To reset the error display code, press the X key (2 times) when

the code is displayed (except “R_****”).

(All the data on the 1, N, N1, and N2 will be reset)

15

Page 16

MZ-R500/R500PC

g

)

This set LCD display

8 8 8

RMC OK

This set LCD display

8 8 8 FF

4-10. Sound Skip Check Result Display Mode

This set can display the count of errors that occurred during the

recording/playing for checking.

• Setting method of sound skip check result display

mode

1. Set the test mode (see page 12).

2. Press the N key or [T.MARK] + [PLAY] keys, and the play-

ing or recording sound skip result display mode becomes

active respectively where the LCD displays the following.

This set LCD display

0 00

Total count of play

system errors(hex.)

3. When the N key is pressed, total error count is displayed on

the LCD, and each time the > key is pressed, the display

item moves down by one as shown below. Also, if the . key

is pressed, the display item moves up by one, then if the

P R

Total count record

system errors(hex.)

[T.MARK] + N keys is pressed, the display in the record

mode appears.

When the [T.MARK] + N keys is pressed, total error count

is displayed on the LCD, and each time the > key is pressed,

the display item moves down by one as shown below. Also, if

the . key is pressed, the display item moves up by one,

then if the N key is pressed, the display in the play mode

appears.

• Cause of Sound Skip Error

Cause of error Description of error

EIB Sound error correction error

Play

Record

4. To quit the sound skip check result display mode and to return

to the test mode (display check mode), press the

Stat Decoder status error

Adrs Address access error

BEmp Buffer is empty

BOvr

Bful

Rtry Retry times over

Buffer is full, and sounds were

dumped

Buffer capacity becomes less,

and forcible writing occurred

x key.

4-11. Key Check Mode

This set can check if the set function normally.

• Setting Method of Key Check Mode

1. Setting the test mode (see page 12).

2. Press the [T.MARK] + X keys activates the key check mode.

(At the last two digits, AD value of remote commander key

line is displayed in hexadecimal)

Playing sound skip

result display

0 00 P R

0 00 EIB

0 00 Stat

0 00 Adrs

0 00 BEmp

0 00 ######

P R

:Total play/record errors(hex.)

:Counter of sound skip check each item(hex.)

:6-di

######

it address where sound was skipped last(hex.

Recording sound skip

result display

0 00 P R

0 00 BOvr

0 00 Bful

0 00 Rtry

0 00 ######

3. When each key on the set and on remote commander is pressed,

its name is displayed on the LCD. (The operated position is

displayed for 4 seconds after the slide switch is operated. If

any other key is pressed during this display, the remote commander LCD switches to its name display)

Example1: When > key on the set is pressed:

16

Page 17

4. When all the keys on the set and on the remote commander are

considered as OK, the following displays are shown for 4 seconds.

Example1: When the keys on the set are considered as OK:

This set LCD display

8 8 8 RMC OK

5. When all keys were checked or if the upper panel is opened,

the key check mode quits and the test mode (display check

mode) comes back.

MZ-R500/R500PC

17

Page 18

MZ-R500/R500PC

This set LCD display

0 2 1 ResNV

This set LCD display

0 2 1 ResOK?

: Address

E4: Adjusted value

This set LCD display

8 3 2

SE4

SECTION 5

ELECTRICAL ADJUSTMENTS

5-1. Outline

• In this set, automatic adjustment of CD and MO can be performed by entering the test mode (see page 12).

However, before starting automatic adjustment, the memory

clear, power supply adjustment, and laser power check must be

performed in the manual mode.

• A key having no particular description in the text, indicates a

set key.

• For the LCD display, the LCD display on the set is shown.

5-2. Precautions for Adjustment

1. Adjustment must be done in the test mode only.

After adjusting, release the test mode.

2. Use the following tools and measuring instruments.

• Test CD disc TDYS-1

(Part No. : 4-963-646-01)

• SONY MO disc available on the market

• Digital voltmeter

• Laser power meter LPM-8001

(Part No. : J-2501-046-A)

• Thermometer (using the Temperature Correction)

3. Unless specified otherwise, supply DC 3V from the DC IN

3V jack (J601).

4. Switch position

HOLD switch ............................................... OFF

5-3. Adjustment Sequence

• Setting method of NV reset

1. Select the manual mode of the test mode, and set item number

021NV Reset (see page 13).

2. Press the X key.

3. Press the X key once more.

This set LCD display

0 2 1

0 2 1

Res

NV reset(after several seconds)

Reset!

1. NV Reset(Memory clear)

2. Power Supply Manual Adjustment

3. Temperature Correction(item number:014)

4. Laser Power Check

5. Electrical offset Adjustment

Caution: This adjustment must be made with

no disc loaded.

6. CD Overall Adjustment

7. MO Overall Adjustment

8. RESUME Clear

Manual Mode

Overall Mode

Manual Mode

Overall Mode

Manual Mode

5-4. NV Reset

Caution: On the set having the microcomputer version 1.000,

some adjusted values were set in the manual mode at

the shipment, but these data will be cleared when the

NV is reset. Therefore, on the set having the microcomputer version 1.000, change the adjusted values

following the Change of Adjusted Values immediately

after the NV was reset.

4. Press the x key to quit the manual mode, and activate the

test mode (display check mode).

• Change of Adjusted Values

On the set having the microcomputer version 1.000, some adjusted

values were set in the manual mode at the shipment, but these data

will be cleared when the NV is reset. Therefore, on the set having

the microcomputer version 1.000, modify the adjusted values

through the following procedure immediately after the NV was

reset.

1. Item numbers in which the adjusted values are to be modified

Item number 832

Item number 862

Item number 871

Item number 872

2. Adjusted values modifying procedure

1) Select the manual mode of the test mode, and set item number

832 (see page 13).

This set LCD display

8 3 2

2) Adjust with the

key (adjusted value down) so that the adjusted value becomes

E4.

[VOL+] key (adjusted value up) or [VOL--]

Pw-T W

18

Page 19

MZ-R500/R500PC

This set LCD display

0 0 0

Assy11

This set LCD display

7 6 2

Vc1PWM

This set LCD display

7 6 3

VchPWM

3) Press the X key to write the adjusted value.

4) Select the manual mode of the test mode, and set item number

862 (see page 13).

This set LCD display

8 6 2

5) Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

01.

This set LCD display

8 6 2

: Address

01: Adjusted value

6) Press the X key to write the adjusted value.

7) Select the manual mode of the test mode, and set item number

871 (see page 13).

This set LCD display

8 7 1

8) Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

20.

This set LCD display

8 7 1

: Address

20: Adjusted value

9) Press the

10) Select the manual mode of the test mode, and set item number

872 (see page 13).

X key to write the adjusted value.

This set LCD display

V1dat

S01

V5num

S20

• Setting method of power supply manual adjustment

1. Make sure that the power supply voltage is 3V.

2. Set the test mode (see page 12).

3. Press the

mode.

4. Press the

the item number to be switched to 762.)

• Adjustment method of Vc PWM Duty (L)

(item number: 762)

1. Press the [ENTER] key and set the address & adjusted value

display (see page 14).

2. Connect a digital voltmeter to the TP902 (VC) on the MAIN

board, and adjust [VOL +] key (voltage up) or [VOL --] key

(voltage down) so that the voltage becomes 2.40 ± 0.01 V.

3. Press the X key to write the adjusted value.

(The item number changes to 763 when X key is pressed)

. or [VOL--] key to activate the overall adjustment

[END SEARCH] k ey. (the [END SEARCH] key causes

This set LCD display

7 6 2

: Adjusted value

MAIN board

TP902(VC)

TP910(GND)

AD

digital

voltmeter

8 7 2

11) Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

39.

This set LCD display

8 7 2

: Address

39: Adjusted value

12) Press the X key to write the adjusted value.

5-5. Power Supply Manual Adjustment

• Adjustment sequence

Adjustment must be done with the following steps.

1. Vc PWM Duty (L) adjustment (item number 762)

2. Vc PWM Duty (H) adjustment (item number 763)

3. Vl PWM Duty adjustment (item number 764)

V5dat

S39

Adjustment and Connection Location:MAIN board

(see page 21)

• Adjustment method of Vc PWM Duty (H)

(item number: 763)

1. Press the

[ENTER] key and change the LCD display.

This set LCD display

7 6 3

: Adjusted value

AD

19

Page 20

MZ-R500/R500PC

: Address

14: Adjusted value

This set LCD display

0 1 4 S14

r

This set LCD display

0 1 0

Laser

This set LCD display

0 1 1

LrefPw

2. Connect a digital voltmeter to the TP902 (VC) on the MAIN

board, and adjust [VOL +] key (voltage up) or [VOL --] key

(voltage down) so that the voltage becomes 2.75 ± 0.01 V.

digital

voltmeter

MAIN board

TP902(VC)

TP910(GND)

3. Press the X key to write the adjusted value.

(The item number changes to 764 when X key is pressed)

Adjustment and Connection Location:MAIN board

(see page 21)

• Adjustment method of Vl PWM Duty

(item number: 764)

This set LCD display

7 6 4

1. Press the [ENTER] key and change the LCD display.

This set LCD display

V1 PWM

3. Adjust with [VOL +], [VOL --] key so that the adjusted value

(hexadecimal value) becomes the ambient temperature.

(Initial value: 14h = 20 °C, Adjusting range: 80h to 7fh (–128

°C to +127 °C)

4. Press the X key to write the adjusted value.

5-7. Laser Power Check

Connection :

Optical pick-up

objective lens

MAIN board

TP(+)

TP(–)

laser

power meter

digital voltmete

7 6 4

: Adjusted value

2. Connect a digital voltmeter to the TP901 (VL) on the MAIN

board, and adjust [VOL +] key (voltage up) or [VOL --] key

(voltage down) so that the voltage becomes 2.30 ± 0.01 V.

MAIN board

TP901(VL)

TP910(GND)

3. When press the X key to write the adjusted value, LCD displays as follows and power supply manual adjustment has completed.

This set LCD display

0 0 0

Adjustment and Connection Location:MAIN board

AD

digital

voltmeter

ADJ OK

5-6. T emperature Correction

• Adjustment Method of temperature correction

1. Select the manual mode of test mode, and set the mode number 014 (see page 13).

This set LCD display

Checking Method :

1. Select the manual mode of test mode (see page 13), and set the

laser power adjusting mode (item number 010).

2. Press the

moves to the most inward track.

3. Open the cover and set the laser power meter on the objective

lens of the optical pick-up.

4. Press the N key , and set the laser MO read adjustment mode

(item number 011).

5. Press the [ENTER] key and set the address & adjusted value

display (See page 14).

. key continuously until the optical pick-up

This set LCD display

0 1 1

###: Address

: Adjusted value

###S

0 1 4

2. Measure the ambient temperature.

20

SetTmp

6. Check that the laser power meter reading is 0.81 ± 0.08 mW.

7. Check that the voltage both ends (TP (+) and TP (–)) of resistor R501 at this time is below 44 mV.

Page 21

MZ-R500/R500PC

8. Press the N key, and set the laser CD read adjustment

mode (item number 012).

This set LCD display

0 1 2

HrefPw

9. Press the [ENTER] key and set the address & adjusted value

display (see page 14).

This set LCD display

0 1 2 ###S

###: Address

: Adjusted value

10. Check that the laser power meter reading is 0.97 ± 0.10 mW.

11. Check that the voltage both ends (TP (+) and TP (–)) of resistor R501 at this time is below 44 mV.

12. Press the N key , and set the laser MO write adjustment mode

(item number 013).

This set LCD display

0 1 3

WritPw

5-8. Overall Adjustment Mode

• Configuration of overall adjustment

Overall adjustment mode

(Title display)

N key

Protect switch

ON

x key

x key

Protect switch

OFF

> key

. key

CD overall

adjusting

All item

OK

CD overall

adjustment

OK

N key

MO overall

adjusting

NG item exists

or x key

CD overall

adjustment

NG

NG item exists

or x key

13. Press the [ENTER] key and set the address & adjusted value

display (See page 14).

This set LCD display

0 1 3 ###S

###: Address

: Adjusted value

14. Check that the laser power meter reading is 4.95 ± 0.50 mW.

15. Check that the voltage both ends (TP (+) and TP (–)) of resistor R501 at this time is below 80 mV.

16. Press the

test mode (display check mode).

Checking and Connection Location: MAIN board

Adjustment/checking and Connection Location:

x key to quit the manual mode, and activate the

MAIN BOARD (SIDE B)

MO overall

adjustment

x key

x key

ENTER key

x key

END SEARCH key

x key

Test mode (display check mode)

MO overall

adjustment

OK

NG

Electrical

offset

adjustment

Power supply

adjustment

auto item feed

Note: Adjust the CD first, when performing adjustment.

TP901

(VL)

TP910(GND)

TP902(VC)

TP(–

)

R501

(+)

TP

21

Page 22

MZ-R500/R500PC

This set LCD display

0 0 0 Assy

This set LCD display

X X X CD RUN

XXX: Item number for which on

adjustment is being executed.

This set LCD display

0 0 0

CD OK

This set LCD display

X X X MO RUN

XXX: Item number for which on

adjustment is being executed.

This set LCD display

0 0 0

MO OK

• Overall Adjustment Mode (Title Display)

This set LCD display

0 0 0

: (Disc mark) At end power supply adjustment:Outside lit

At end of electrical offset adj.:inside lit

Note:On the set having microcomputer version 1.000,the disc

mark is displayed on the set LCD only.

: Left side = MO overall adjustment information

F : MO overall adjustment completed

1 : Manual adjustment exists(overall adj.not completed)

0 : Not adjusted

Right side = CD overall adjustment information

F : CD overall adjustment completed

1 : Manual adjustment exists(overall adj.not completed)

0 : Not adjusted

• Electrical Offset Adjusting Method

Caution: The electrical offset adjustment must be made with no

disc loaded.

1. Make sure that the power supply voltage is 3V.

2. Set the test mode (see page 12).

3. Press the

mode.

Assy

. or [VOL--] key to activate the overall adjustment

This set LCD display

• Adjustment Method of Overall CD and MO Adjustment

Mode

1. Setting the test mode (see page 12).

2. Press the

ment mode.

3. Insert CD disc in the set, and press the

Overall CD Adjustment mode. Automatic adjustments are made.

4. In case of CD overall adjustment NG, reset the NV (see page

18), then readjust from the temperature correction (see page

20).

. or [VOL --] key activates the overall adjust-

. key to set the

This set LCD display

0 0 0

4. Press the [ENTER] key.

This set LCD display

0 3 5

: Adjusted value

5. Electrical offset adjustment is over, if the following display

appears.

This set LCD display

0 0 0

Assy11

Ofst

OfstOK

0 0 0

: NG item number

5. If OK through the overall CD adjustments, then perform overall MO adjustments.

6. Insert MO disc in the set, and press the > key to set the

Overall MO Adjustment mode. Automatic adjustments are

made.

7. In case of MO overall adjustment NG, reset the NV (see page

18), then readjust from the temperature correction (see page

20).

This set LCD display

NG

22

0 0 0 NG

: NG item number

8. If OK through the overall MO adjustments, press the x key

to return to the test mode and terminate the Overall Adjustment

mode.

Page 23

MZ-R500/R500PC

This set LCD display

0 4 3

Resume

This set LCD display

0 2 2

PatClr

• Overall CD and MO adjustment items

1. Overall CD adjustment items

Item No. Description

312

313 CD electrical offset adjustment

314

321 CD tracking error gain adjustment

328 CD TWPP gain adjustment

324

332

336 CD ABCD gain adjustment

344 CD focus gain adjustment

345 CD tracking gain adjustment

521

522

2. Overall MO adjustment items

Item No. Description

112

113

114

118

221 Low reflective CD tracking error gain adjustment

224

232

236 Low reflective CD ABCD level adjustment

244 Low reflective CD focus gain adjustment

245 Low reflective CD tracking gain adjustment

121 MO tracking error gain adjustment

122 MO TON offset adjustment

134 MO TWPP gain adjustment

131

132

136 MO ABCD gain adjustment

144 MO focus gain adjustment

145 MO tracking gain adjustment

434 MO write TWPP gain adjustment

431 MO write TWPP offset adjustment

432 MO tracking error offset adjustment

436 MO write ABCD gain adjustment

445 MO write tracking gain adjustment

411 MO normal speed read TWPP offset adjustment

412 MO tracking error offset adjustment

448 20 sec full recording

CD tracking error offset adjustment

CD two-axis sensitivity adjustment

MO electrical offset adjustment

Low reflective CD tracking error offset adjustment

MO double speed read TWPP offset adjustment

5-9. Resume Clear

Perform the Resume clear when all adjustments completed.

• Resume Clear Setting Method

1. Select the manual mode of the test mode, and set item number

043 (see page 13).

2. Press the X key.

This set LCD display

0 4 3

0 4 3

3. Press the x key to return to the test mode (display check

mode).

Res

Resume clear complete

ResClr

5-10. Patch Data Rewriting When Nonvolatile

Memory was Replaced

When the microcomputer in this set is replaced with a different

version of microcomputer, it is needed to initialize the modified

program data in the nonvolatile memory and write specific modified data for the new version in the memory.

If the microcomputer is replaced with a different version, the patch

data should be rewritten as performed when the nonvolatile memory

is replaced.

For a version where the method to write patch data is not described,

the modified data should be initialized as specified below:

• Initial set of modified data

1. Select the manual mode of the test mode, and set item number

022 (see page 13).

2. Press the

display (see page 14).

[ENTER] key and set the address & adjusted value

This set LCD display

0 2 2

CC: Adjusted value

3. Press the X key to initialize the patch data.

(The modified data writing is over, if the adjusted value changes

to DD.)

This set LCD display

0 2 2

DD: Adjusted value

SCC

SDD

23

Page 24

MZ-R500/R500PC

This set LCD display

0 2 3 0D581E

1E: Adjusted value

This set LCD display

0 2 3 0D5900

00: Adjusted value

This set LCD display

0 2 3 0D59B2

B2: Adjusted value

This set LCD display

0 2 3 0D5E8B

8B: Adjusted value

This set LCD display

0 2 3 0D5F00

00: Adjusted value

4. Write specific modified data.

For a version where there is no need for writing specific modified data, the power should be turned off once.

• Modified Data Writing Method (version 1.000)

1. Select the manual mode of the test mode, and set item number

022 (see page 13).

This set LCD display

0 2 2

2. Press the

display (see page 14).

[ENTER] key and set the address & adjusted value

This set LCD display

0 2 2

CC: Adjusted value

3. Press the X key to initialize the patch data.

This set LCD display

PatClr

SCC

9. Press the X key.

(0D58 is blinking)

10. Press the [VOL+] key once to change the blinking portion to

0D59.

11. Press the x key.

(00 is blinking)

12. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

B2.

0 2 2

DD: Adjusted value

4. Select the manual mode of the test mode, and set item number

022 (see page 13).

This set LCD display

0 2 3

5. Press the

display (see page 14).

[ENTER] key and set the address & adjusted value

This set LCD display

SDD

Patch

0 2 3 ###S00

###: Address

00: Adjusted value

6. Press the [VOL+] key once to change the adjusted value to 01.

7. Press the [T.MARK] + [PAUSE] keys to activate the patch

data write mode.

(The following display will appear where 00 is blinking)

This set LCD display

13. Press the X key.

(0D59 is blinking)

14. Press the [VOL+] key once to change the blinking portion to

0D5E.

15. Press the

(00 is blinking)

16. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

8B.

17. Press the X key.

(0D5E is blinking)

18. Press the [VOL+] key once to change the blinking portion to

0D5F.

This set LCD display

0 2 3

00: Adjusted value

x key.

0D5E00

0 2 3

00: Adjusted value

8. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

1E.

This set LCD display

24

0 2 3

1E: Adjusted value

0D5800

0D581E

19. Press the x key.

(00 is blinking)

Page 25

MZ-R500/R500PC

This set LCD display

0 2 3 0D6204

04: Adjusted value

This set LCD display

0 2 3 0D6500

00: Adjusted value

This set LCD display

0 2 3 0D6520

20: Adjusted value

This set LCD display

0 2 3

Patch

This set LCD display

0 2 3

01: Adjusted value

S01

This set LCD display

0 2 3

DD: Adjusted value

SDD

20. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

20.

21. Press the X key.

(0D5F is blinking)

22. Press the [VOL+] key once to change the blinking portion to

0D60.

23. Press the x key.

(00 is blinking)

24. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

08.

This set LCD display

0 2 3

20: Adjusted value

This set LCD display

0 2 3

00: Adjusted value

This set LCD display

0D5F20

0D6000

31. Press the

(00 is blinking)

32. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

04.

33. Press the

(0D62 is blinking)

34. Press the [VOL+] key once to change the blinking portion to

0D65.

35. Press the x key.

(00 is blinking)

36. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

20.

x key.

X key.

0 2 3

08: Adjusted value

25. Press the X key.

(0D60 is blinking)

26. Press the

0D61.

[VOL+] key once to change the blinking portion to

This set LCD display

0 2 3

00: Adjusted value

27. Press the x key.

(00 is blinking)

28. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

A1.

This set LCD display

0 2 3

A1: Adjusted value

29. Press the X key.

(0D61 is blinking)

30. Press the [VOL+] key once to change the blinking portion to

0D62.

This set LCD display

0D6008

0D6100

0D61A1

37. Press the

(0D65 is blinking)

38. Press the [T.MARK] key for several seconds (about 3 seconds)

to exit the patch data write mode (to return to the manual mode

display in the test mode).

39. Press the [ENTER] key and set the address & adjusted value

display (see page 14).

40. Press the X key to write the modified data. (The adjusted value

changes to CC)

41. The modified data writing is over, if the adjusted value changes

to DD.

X key.

0 2 3

00: Adjusted value

0D6200

42. Turn the power of f.

25

Page 26

MZ-R500/R500PC

• Modified Data Writing Method (version 1.100)

1. Select the manual mode of the test mode, and set item number

022 (see page 13).

This set LCD display

0 2 2

2. Press the

display (see page 14).

[ENTER] key and set the address & adjusted value

This set LCD display

0 2 2

CC: Adjusted value

3. Press the X key to initialize the patch data.

This set LCD display

0 2 2

DD: Adjusted value

4. Select the manual mode of the test mode, and set item number

023 (see page 13).

This set LCD display

0 2 3

5. Press the

display (see page 14).

[ENTER] key and set the address & adjusted value

This set LCD display

0 2 3

###: Address

00: Adjusted value

6. Press the [VOL+] key once to change the adjusted value to 01.

7. Press the [T.MARK] + [PAUSE] keys to activate the patch

data write mode.

(The following display will appear where 00 is blinking)

This set LCD display

0 2 3

00: Adjusted value

8. Press the X key.

(0D5C is blinking)

9. Press the [VOL+] key once to change the blinking portion to

0D5D.

This set LCD display

0 2 3

00: Adjusted value

10. Press the x key.

(00 is blinking)

PatClr

SCC

SDD

Patch

###S00

0D5C00

0D5D00

11. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

AA.

This set LCD display

0 2 3 0D5DAA

AA: Adjusted value

12. Press the X key.

(0D5D is blinking)

13. Press the [VOL+] key once to change the blinking portion to

0D5E.

This set LCD display

0 2 3 0D5E00

00: Adjusted value

14. Press the x key.

(00 is blinking)

15. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

04.

This set LCD display

0 2 3 0D5E04

04: Adjusted value

16. Press the X key.

(0D5E is blinking)

17. Press the

[VOL+] key to change the blinking portion to 0D61.

This set LCD display

0 2 3 0D6100

00: Adjusted value

18. Press the x key.

(00 is blinking)

19. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

20.

This set LCD display

0 2 3 0D6120

20: Adjusted value

20. Press the X key.

(0D61 is blinking)

21. Press the [VOL+] key to change the blinking portion to 0D64.

This set LCD display

0 2 3 0D6400

00: Adjusted value

22. Press the x key.

(00 is blinking)

26

Page 27

MZ-R500/R500PC

23. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

F4.

This set LCD display

0 2 3 0D64F4

F4: Adjusted value

24. Press the X key.

(0D64 is blinking)

25. Press the [VOL+] key once to change the blinking portion to

0D65.

This set LCD display

0 2 3 0D6500

00: Adjusted value

26. Press the x key.

(00 is blinking)

27. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

1C.

This set LCD display

35. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

80.

36. Press the X key.

(0D68 is blinking)

37. Press the [VOL+] key once to change the blinking portion to

0D69.

38. Press the x key.

(00 is blinking)

39. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

09.

This set LCD display

0 2 3

80: Adjusted value

This set LCD display

0 2 3

00: Adjusted value

This set LCD display

0D6880

0D6900

0 2 3

1C: Adjusted value

28. Press the X key.

(0D65 is blinking)

29. Press the

0D66.

[VOL+] key once to change the blinking portion to

This set LCD display

0D651C

0 2 3 0D6600

00: Adjusted value

30. Press the x key.

(00 is blinking)

31. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

03.

This set LCD display

0 2 3 0D6603

03: Adjusted value

32. Press the X key.

(0D66 is blinking)

33. Press the [VOL+] key to change the blinking portion to 0D68.

This set LCD display

0 2 3

09: Adjusted value

40. Press the X key.

(0D69 is blinking)

41. Press the

[VOL+] key to change the blinking portion to 0D6C.

This set LCD display

0 2 3

00: Adjusted value

42. Press the x key.

(00 is blinking)

43. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

F6.

This set LCD display

0 2 3

F6: Adjusted value

44. Press the X key.

(0D6C is blinking)

45. Press the [VOL+] key once to change the blinking portion to

0D6D.

This set LCD display

0D6909

0D6C00

0D6CF6

0 2 3 0D6800

00: Adjusted value

34. Press the x key.

(00 is blinking)

0 2 3

00: Adjusted value

46. Press the x key.

(00 is blinking)

0D6D00

27

Page 28

MZ-R500/R500PC

47. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

1C.

48. Press the X key.

(0D6D is blinking)

49. Press the [VOL+] key once to change the blinking portion to

0D6E.

50. Press the x key.

(00 is blinking)

51. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

03.

This set LCD display

0 2 3

1C: Adjusted value

This set LCD display

0 2 3

00: Adjusted value

This set LCD display

0D6D1C

0D6E00

59. Adjust with the

key (adjusted value down) so that the adjusted value becomes

D3.

[VOL+] key (adjusted value up) or [VOL--]

This set LCD display

0 2 3 0D73D3

D3: Adjusted value

60. Press the X key.

(0D73 is blinking)

61. Press the [VOL+] key once to change the blinking portion to

0D74.

This set LCD display

0 2 3 0D7400

00: Adjusted value

62. Press the x key.

(00 is blinking)

63. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

F8.

This set LCD display

0 2 3

03: Adjusted value

52. Press the X key.

(0D6E is blinking)

53. Press the

[VOL+] key to change the blinking portion to 0D72.

This set LCD display

0 2 3

00: Adjusted value

54. Press the x key.

(00 is blinking)

55. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

05.

This set LCD display

0 2 3

05: Adjusted value

56. Press the X key.

(0D72 is blinking)

57. Press the [VOL+] key once to change the blinking portion to

0D73.

This set LCD display

0D6E03

0D7200

0D7205

0 2 3 0D74F8

F8: Adjusted value

64. Press the X key.

(0D74 is blinking)

65. Press the

0D75.

[VOL+] key once to change the blinking portion to

This set LCD display

0 2 3 0D7500

00: Adjusted value

66. Press the x key.

(00 is blinking)

67. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

1C.

68. Press the X key.

(0D75 is blinking)

69. Press the [VOL+] key once to change the blinking portion to

0D76.

This set LCD display

0 2 3

1C: Adjusted value

This set LCD display

0D751C

0 2 3

00: Adjusted value

58. Press the x key.

(00 is blinking)

28

0D7300

0 2 3

00: Adjusted value

70. Press the x key.

(00 is blinking)

0D7600

Page 29

MZ-R500/R500PC

This set LCD display

0 2 3

01: Adjusted value

S01

This set LCD display

0 2 3

DD: Adjusted value

SDD

71. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

03.

This set LCD display

0 2 3 0D7603

03: Adjusted value

72. Press the X key.

(0D76 is blinking)

73. Press the [VOL+] key to change the blinking portion to 0D78.

This set LCD display

0 2 3

00: Adjusted value

74. Press the x key.

(00 is blinking)

75. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

01.

This set LCD display

0D7800

82. Press the

display (see page 14).

83. Press the X key to write the modified data. (The adjusted value

changes to CC)

84. The modified data writing is over, if the adjusted value changes

to DD.

85. Turn the power of f.

[ENTER] key and set the address & adjusted value

0 2 3

01: Adjusted value

76. Press the X key.

(0D78 is blinking)

77. Press the

0D79.

[VOL+] key once to change the blinking portion to

This set LCD display

0D7801

0 2 3 0D7900

00: Adjusted value

78. Press the x key.

(00 is blinking)

79. Adjust with the [VOL+] key (adjusted value up) or [VOL--]

key (adjusted value down) so that the adjusted value becomes

E0.

This set LCD display

0 2 3 0D79E0

E0: Adjusted value

80. Press the X key.

(0D79 is blinking)

81. Press the [T.MARK] key for several seconds (about 3 seconds)

to exit the patch data write mode (to return to the manual mode

display in the test mode).

This set LCD display

0 2 3

Patch

29

Page 30

MZ-R500/R500PC

SECTION 6

DIAGRAMS

6-1. IC PIN FUNCTION DESCRIPTION

• IC501 SN761057DBT (RF AMP, FOCUS/TRACKING ERROR AMP)

Pin No. Pin Name I/O Description

1 TE O Tracking error signal output to the system controller (IC801)

2 REXT — Connect terminal to the external resistor for ADIP amp control

3 WPPLPF — Connect terminal to the external capacitor for TPP/WPP low-pass filter

4 VREF O Reference voltage output terminal (+1 V)

5 C I Signal (C) input from the optical pickup detector

6 D I Signal (D) input from the optical pickup detector

7 D-C I Signal (D) input from the optical pickup detector (AC input)

8 IY I I-V converted RF signal (IY) input from the optical pickup detector

9 IX I I-V converted RF signal (IX) input from the optical pickup detector

10 JX I I-V converted RF signal (JX) input from the optical pickup detector

11 JY I I-V converted RF signal (JY) input from the optical pickup detector

12 A I Signal (A) input from the optical pickup detector

13 A-C I Signal (A) input from the optical pickup detector (AC input)

14 B I Signal (B) input from the optical pickup detector

15 TON-C — Connect terminal to the external capacitor for TON hold

16 CIG —

17 CDN —

18 PD-I I Light amount monitor input terminal (invert input)

19 PD-NI I Light amount monitor input terminal (non-invert input)

20 PD-O O Light amount monitor output terminal

21 ADIP O ADIP duplex FM signal (22.05 kHz ± 1 kHz) output to the system controller (IC801)

22 DVDD — Power supply terminal (+2.3 V) (digital system)

23 SBUS I/O SSB serial data input/output with the system controller (IC801)

24 SCK I SSB serial clock signal input from the system controller (IC801)

25 XRST I Reset signal input from the system controller (IC801) “L”: reset

26 OFTRK I Off track signal input from the system controller (IC801)

27 DGND — Ground terminal (digital system)

28 BOTM O

29 PEAK O

30 VREF075 — Connect terminal to the external capacitor for the internal reference voltage

31 VC O Middle point voltage (+1.2 V) generation output terminal

32 CCSL2 — Connect terminal to the external capacitor for TPP/WPP low-pass filter

33 RF OUT O Playback EFM RF signal output to the system controller (IC801)

34 AGND — Ground terminal (analog system)

35 – 37 EQ, LP, PS — Connect terminal to the external capacitor for the RF equalizer

38 AVCC — Power supply terminal (analog system) (+2.3 V)

39, 40 OFC-2, OFC-1 — Connect terminal to the external capacitor for RF AC coupling

41 ABCD O Light amount signal (ABCD) output to the system controller (IC801)

42 FE O Focus error signal output to the system controller (IC801)

43 S-MON O Servo signal monitor output to the system controller (IC801)

44 ADIP-IN I ADIP duplex FM signal (22.05 kHz ± 1 kHz) input terminal

Connect terminal to the external capacitor for the low-pass filter of NPP divider

denominator

Connect terminal to the external capacitor for the low-pass filter of CSL divider

denominator

Bottom hold signal output of the light amount signal (RF/ABCD) to the system

controller (IC801)

Peak hold signal output of the light amount signal (RF/ABCD) to the system

controller (IC801)

30

Page 31

MZ-R500/R500PC

• IC801 CXD2671-204GA (SYSTEM CONTROLLER, DIGITAL SIGNAL PROCESSOR, 16M BIT D-RAM)

Pin No. Pin Name I/O Description

1 PAUSE KEY I Set key input terminal (X key input)

2 (MIC SENSE) O

3 XTEST I Input terminal for the test mode set up “L”: test mode (normally fixed at “H”)

4, 5 NC O Not used (open)

6 MCUVDD0 — Power supply terminal (for microcomputer block) (+1.5 V)

7 MIFVSS3 — Ground terminal (for microcomputer I/F)

8 XRST I System reset signal input terminal from the power control (IC901) “L”: reset

9 S MON I Servo signal monitor input terminal (A/D input) from RF amp (IC501)

10 VB MON I Voltage monitor input terminal of UNREG power supply (A/D input)

11 CHG MON I Charge voltage monitor input terminal (A/D input) Not used (open)

12 VREF MON I Clear reference voltage input terminal (A/D input) from RF amp (IC501)

13, 14

15 VL MON I VL voltage monitor input terminal (A/D input)

16 HIDC MON I HIGH DC voltage monitor input terminal (A/D input)

17 WK DET I Set key start switching detection signal input terminal (A/D input)

18 REC KEY I REC key input terminal (A/D input)

19 HALF LOCK SW I

20 RMC KEY I Key input terminal (A/D input) of the remote commander attached headphone

21 AVDD — Power supply terminal (for the analog circuit block) (+2.8 V)

22 AVSS — Ground terminal (for the analog circuit block)

23 VDIOSC — Power supply terminal (for OSC cell) (+2.4 V)

24 OSCI I System clock (45.1584 MHz) input terminal

25 OSCO O System clock (45.1584 MHz) output terminal

26 VSIOSC — Ground terminal (for OSC cell)

27 DAVDD — Power supply terminal (for the built-in D/A converter) (+2.4 V)

28 VREFL I Reference voltage input terminal (for the internal D/A converter L-CH)

29 AOUTL O Built-in D/A converter (L-CH) output terminal

30 AOUTR O Built-in D/A converter (R-CH) output terminal

31 VREFR I Reference voltage input terminal (for the built-in D/A converter R-CH)

32 DAVSS — Ground terminal (for the built-in D/A converter)

33 ASYO O Playback EFM duplex signal output terminal

34 ASYI I Playback EFM comparison slice level input terminal

35 AVD1 — Ground terminal (for the analog) (+2.4 V)

36 BIAS I Bias input for the playback EFM comparison

37 RFI I Playback EFM RF signal input from RF amp (IC501)

38 AVS1 — Ground terminal (for the analog)

39 PCO O Phase comparison output for the master clock of playback EFM system master PLL

40 PDO O Phase comparison output for the analog PLL Not used (open)

41 FILI I Filter input for the master clock of the playback EFM system master PLL

42 FILO O Filter output for the master clock of the playback EFM system master PLL

43 CLTV I Internal VCO control voltage input for the playback EFM system master PLL

44 PEAK I Peak hold signal input of the light amount signal (RF/ABCD) from RF amp (IC501)

45 BOTM I Bottom hold signal input of the light amount signal (RF/ABCD) from RF amp (IC501)

46 ABCD I Light amount signal (ABCD) input from RF amp (IC501)

47 FE I Focus error signal input from RF amp (IC501)

48 AUX1 I Support signal (I3 signal/temperature signal) input terminal (A/D input)

49 VC I Middle point voltage (+1.2 V) input terminal

50 ADIO O Monitor output of A/D converter input signal Not used (open)

51 ADRT I A/D converter the upper limit voltage input (fixed at “H” in this set)

SET KEY 1,

SET KEY 2

Control signal output to the microphone amp

“H”: HIGH, “L”: LOW, normally: “H” Not used (open)

I Set key input terminal (A/D input)

Open button detection switch (S805) input terminal (A/D input)

“L”: when normal position, “H”: when locked

31

Page 32

MZ-R500/R500PC

Pin No. Pin Name I/O Description

52 AVD2 — Power supply terminal (for the analog) (+2.4 V)

53 AVS2 — Ground terminal (for the analog)

54 ADRB I A/D converter the lower limit voltage input (fixed at “L” in this set)

55 SE I Sled error signal input terminal Not used (fixed at “L”)

56 TE I Tracking error signal input from RF amp (IC501)

57 DCHG — Connecting analog power supply of the low impedance (fixed at “H” in this set)

58 APC I Error signal input for the laser automatic power control Not used (fixed at “H”)

59 DSPVDD0 — Power supply terminal (for DSP block) (+1.5 V)

60 DSPVSS0 — Ground terminal (for DSP block)

61 XTSL I

62 DIN1 I Input terminal of the record system digital audio signal

63 (DOUT) O Output terminal of the playback system digital audio signal Not used (open)

64 (DAPWMLP) O D/A converter PWM output (L-CH right phase) Not used (open)

65 (DAPWMLN) O D/A converter PWM output (L-CH reverse phase) Not used (open)

66 (DAPWMRP) O D/A converter PWM output (R-CH right phase) Not used (open)

67 DADT O Audio data output Not used (open)

68 ADDT I Data signal input from the external A/D converter (IC301)

69 LRCK O L/R sampling block signal (44.1 kHz) output to the external A/D converter (IC301)

70 XBCK O Bit clock signal (2.8224 MHz) output to the external A/D converter (IC301)

71 FS256 O 11.2896 MHz clock signal output to the external A/D converter (IC301)

72 (MVCI) I Vibrate input for the digital in PLL from the external VCO Not used (fixed at “L”)

73 DSPVDD1 — Power supply terminal (for DSP block) (+1.5 V)

74 ADFG I ADIP duplex FM signal (20.05 ± 1 kHz) input from RF amp (IC501)

75 (F0CNT) O Filter cut off control signal output Not used (open)

76 DIFVDD0 — Power supply terminal (for DSP I/F) (+2.3 V)

77 DIFVSS0 — Ground terminal (for DSP I/F)

78 APCREF O

79 (LDDR) O PWM signal output for the laser automatic power control Not used (open)

80 TRDR O Tracking servo drive PWM signal output (–) to the motor driver (IC701)

81 TFDR O T racking servo drive PWM signal output (+) to the motor driver (IC701)

82 FFDR O Focus servo drive PWM signal output (+) to the motor driver (IC701)

83 FRDR O Focus servo drive PWM signal output (–) to the motor driver (IC701)

84 MCUVDD1 — Power supply terminal (for the microcomputer block) (+1.5 V)

85 (FGIN) I FG signal input terminal for the spindle servo Not used (open)

86 FS4 O 176.4 MHz clock signal output to the power control (IC601, IC901)

87 SPRD/SPDU/RTG0 O Spindle servo drive PWM signal output terminal (–) to the motor driver (IC701)

88 SPFD/SPVS/PWM3 O Spindle servo drive PWM signal output (+)

89 SPDV/RTG1 O

90 SPDW/RTG2 O

91 DSPVDD2 — Power supply terminal (for DSP block) (+1.5 V)

92 DSPVSS1 — Ground terminal (for DSP block)

93 SPCU I Spindle motor drive comparison signal input (U) from the motor driver (IC701)

94 SPCV I Spindle motor drive comparison signal input (V) from the motor driver (IC701)

95 SPCW I Spindle motor drive comparison signal input (W) from the motor driver (IC701)

96 SRDR O Sled servo drive PWM signal output (–) to the motor driver (IC701)

97 SFDR O Sled servo drive PWM signal output (+) to the motor driver (IC701)

98 SLDV O

Input terminal for the frequency set up of the system clock

“L”: 45.1584 MHz, “H”: 22.5792 MHz (fixed at “L” in this set)

Control signal output to the reference voltage generation circuit for the laser

automatic power control

Spindle motor drive control signal output (V)/RTG output 1 to the motor

driver (IC701)

Spindle motor drive control signal output (W)/RTG output 2 to the motor

driver (IC701)

Sled motor drive signal output (V) to the motor driver (IC701)/drive control signal

output (1–)

32

Page 33

MZ-R500/R500PC

Pin No. Pin Name I/O Description

99 SLDW O

100 SLCU I Spindle motor drive comparison signal input (U) from the motor driver (IC701)

101 SLCV I Spindle motor drive comparison signal input (V) from the motor driver (IC701)

102 SLCW I Spindle motor drive comparison signal input (W) from the motor driver (IC701)

103 DIFVDD1 — Power supply terminal (for DSP I/F) (+2.3 V)

104 DIFVSS1 — Ground terminal (for DSP I/F)

105 EFMO O EFM encode data output for the record to the over write head drive (IC601)

106 (MNT0) O Internal DSP monitor output (0) terminal Not used (open)

107 (MNT1) O Internal DSP monitor output (1) terminal Not used (open)

108 MNT2 O Internal DSP monitor output (2) terminal Not used (open)

109 (MNT3) O Internal DSP monitor output (3) terminal Not used (open)

110 (SENSE) O Internal DSP (SENS) monitor output terminal Not used (open)

111 (TX) O

112 (RECP) O Laser power changeover signal output monitor terminal Not used (open)

113 DAPVDD3 — Power supply terminal (for DSP block) (+1.5 V)

114 – 117 NC O Output terminal for the external D-RAM Not used (open)

118 DRAMVSS0 — Ground terminal (for the external D-RAM)

119 DRAMVDD0 — Power supply terminal (for the external D-RAM) (+2.4 V)

120 – 138 NC O Output terminal for the external D-RAM Not used (open)

139 DRAMVDD1 — Power supply terminal (for the external D-RAM) (+2.4 V)

140 DRAMVSS1 — Ground terminal (for the external D-RAM)

141 TSB MST VDD — Power supply terminal (for TSB master communication) (+2.8 V)

142 RMC DTCK I/O TSB serial data input/output with the remote commander attached headphone

143 TSB SLV VDD — Power supply terminal (for I/F to TSB slave communication) (+2.3 V)

144 (TSB SLVI) I TSB slave signal input from the remote commander attached headphone (fixed at “L”)

145 (TSB SLVO) O

146 TDI I Data input terminal for JTAG Not used (open)

147 TMS I Test mode control input terminal for JTAG Not used (open)

148 TCK I Clock input terminal for JTAG Not used (open)

149 XTRST I Reset input terminal for JTAG Not used (open)

150 TDO O Data output terminal for JTAG Not used (open)

151 JTAGVDD — Power supply terminal (for JTAG) (+2.4 V)

152 JTAGVSS — Ground terminal (for JTAG)

153 MCUVDD2 — Power supply terminal (for the microcomputer block) (+1.5 V)

154 MIFVDD0 — Power supply terminal (for the microcomputer I/F block) (+2.3 V)

155 MIFVSS0 — Ground terminal (for the microcomputer I/F block)