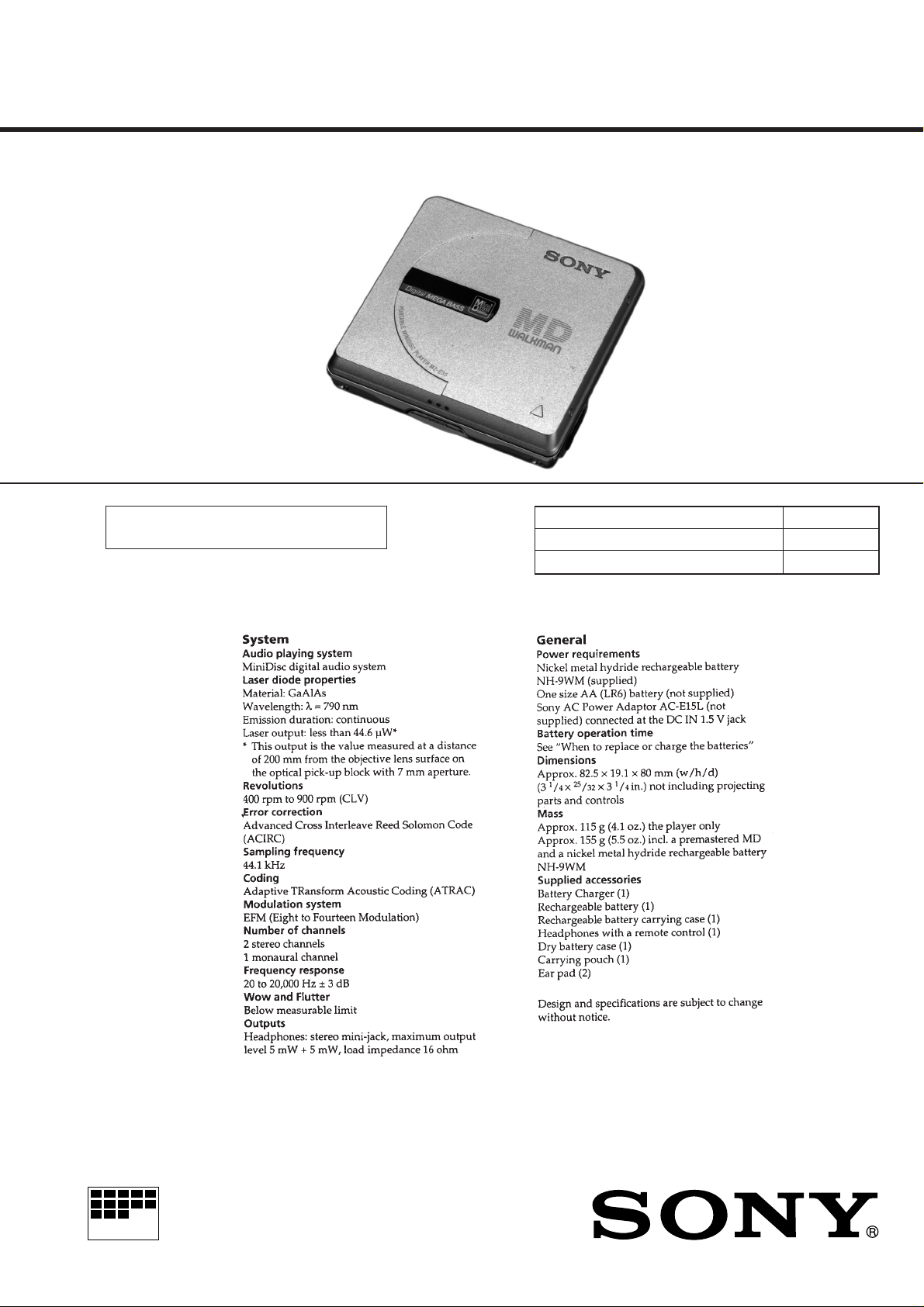

Sony MZE-35 Service manual

MZ-E35

SERVICE MANUAL

US and foreign patents licensed from Dolby

Laboratories Licensing Corporation.

SPECIFICATIONS

US Model

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MT-MZE35-140

Optical Pick-up Type ODX-1B

MICROFILM

PORTABLE MINIDISC PLAYER

TABLE OF CONTENTS

SERVICING NOTES

1. GENERAL ................................................................... 3

2. DISASSEMBLY ......................................................... 5

3. TEST MODE.............................................................. 8

4. ELECTRICAL ADJUSTMENTS......................... 11

5. DIAGRAMS

5-1. Block Diagram ................................................................ 13

5-2. Printed Wiring Board

(US, Hong Kong Model)................................................. 15

5-3. Printed Wiring Board

(AEP, UK, E, French Model) .......................................... 19

5-4. Schematic Diagram ......................................................... 21

5-5. IC Pin Function Description ........................................... 30

6. EXPLODED VIEWS ................................................33

7. ELECTRICAL PARTS LIST ............................... 35

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

This MiniDisc player is classified as a CLASS 1

LASER product.

The CLASS 1 LASER PRODUCT label is located

on the bottom exterior.

– 2 –

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

SECTION 1

GENERAL

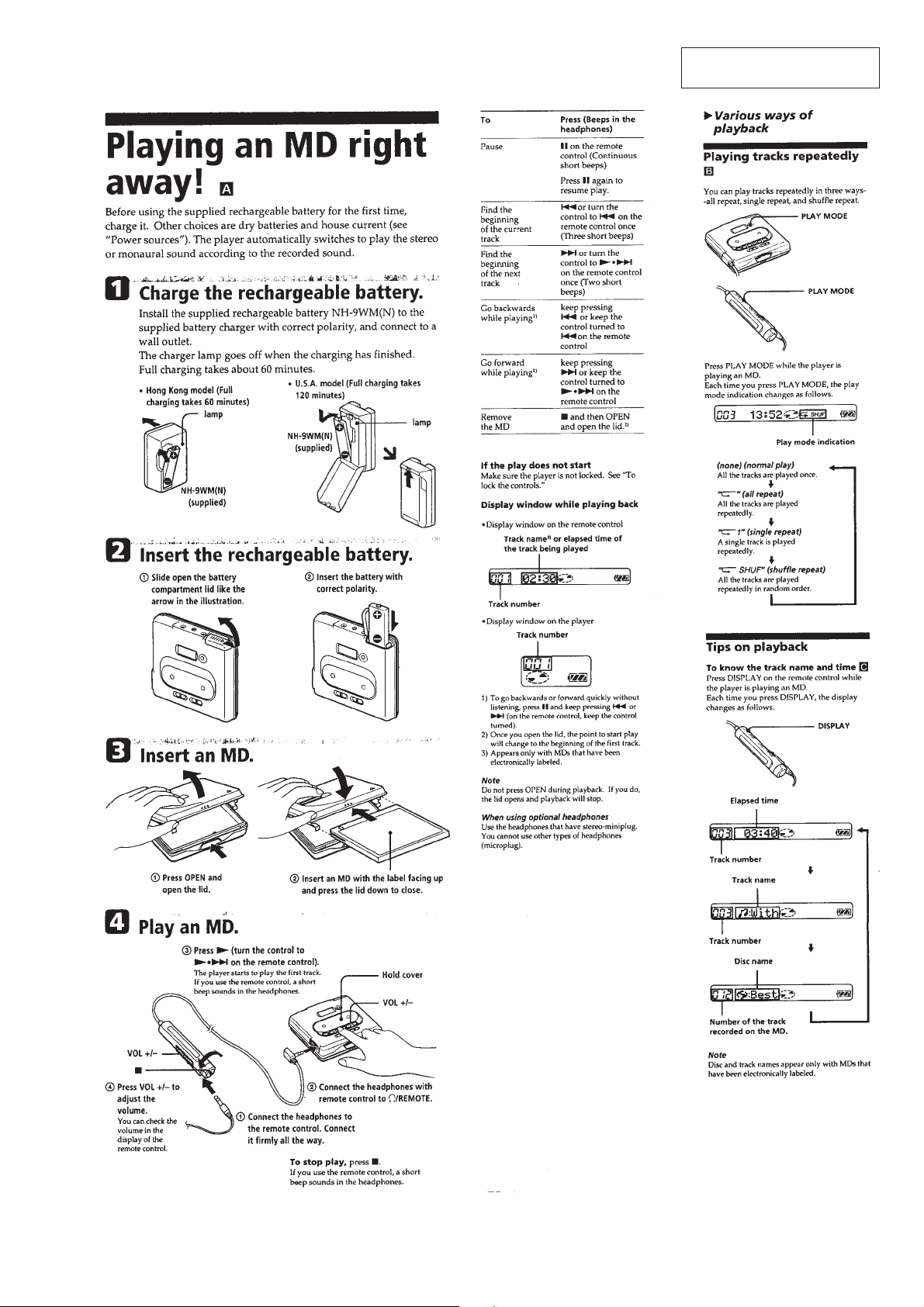

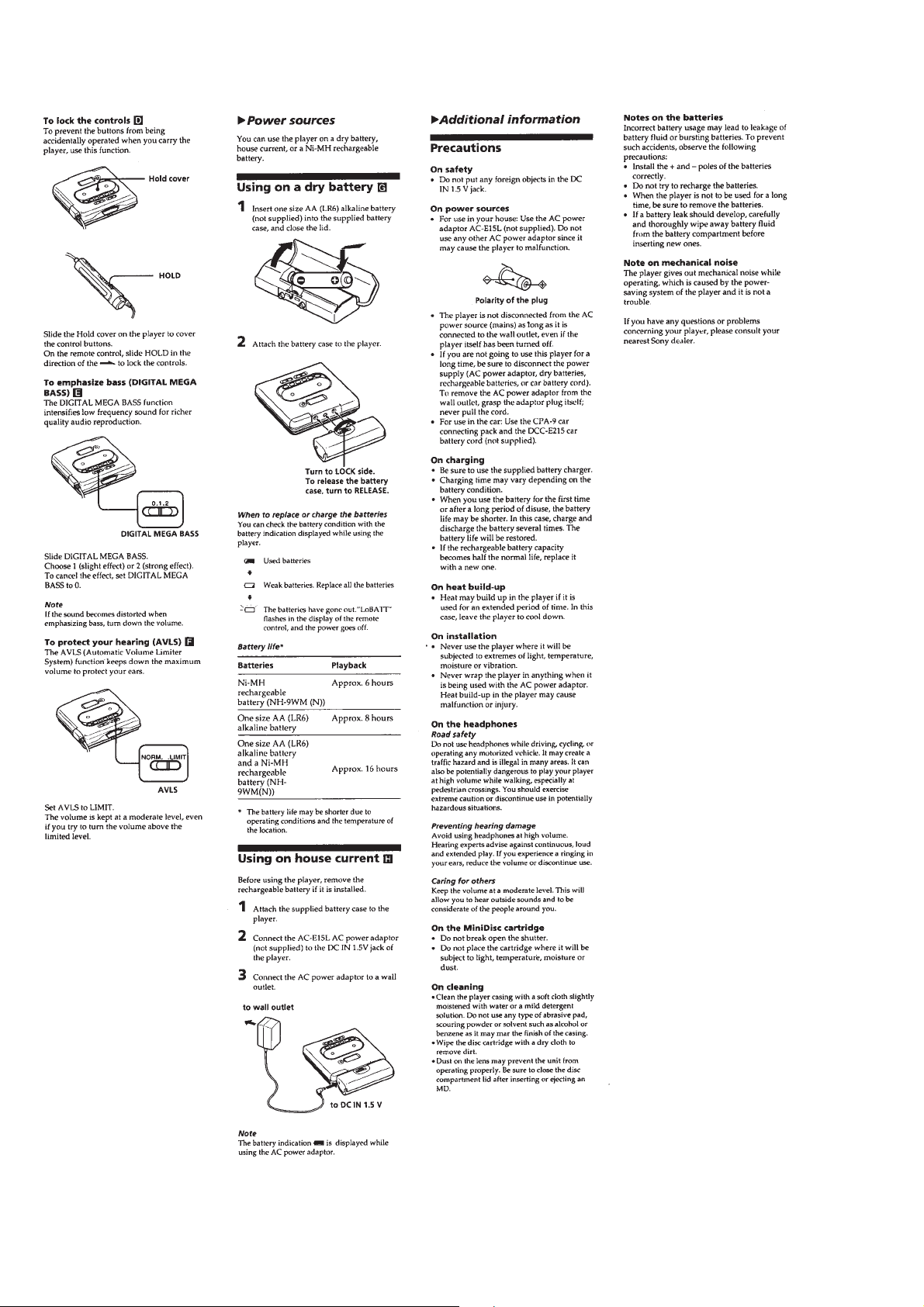

This section is extracted from

instruction manual.

– 3 –

– 4 –

SECTION 3

TEST MODE

General

• In the TEST mode, this set provides the Auto mode in which

both CD and MO are adjusted automatically. In the Auto mode,

whether a disc is CD or MO is discriminated, then each

adjsutment is automatically executed sequentially. If a fault is

found, it is displayed. Also, in the Servo mode, eac h item can be

adjusted automatically.

Entering TEST Mode

Bridge the T AP801 (TEST) on MAIN boar d (connect IC801 #™ to

GND), and turn the power on.

Then, press ( key and the TEST mode is activated.

Releasing TEST Mode

Turn the power off, and remove the bridge from TAP801 (TEST)

on MAIN board.

Operation in TEST Mode

In the TEST mode, the LCD display is as shown below:

300

Main unit LCD

300 V3.000

Remote controller LCD

• ROM version display → All ON → All OFF are repeated.

• To hold the display for confirmation, press the PLAY MODE

key.

ROM version

display (Ver3.00

or Ver3.20)

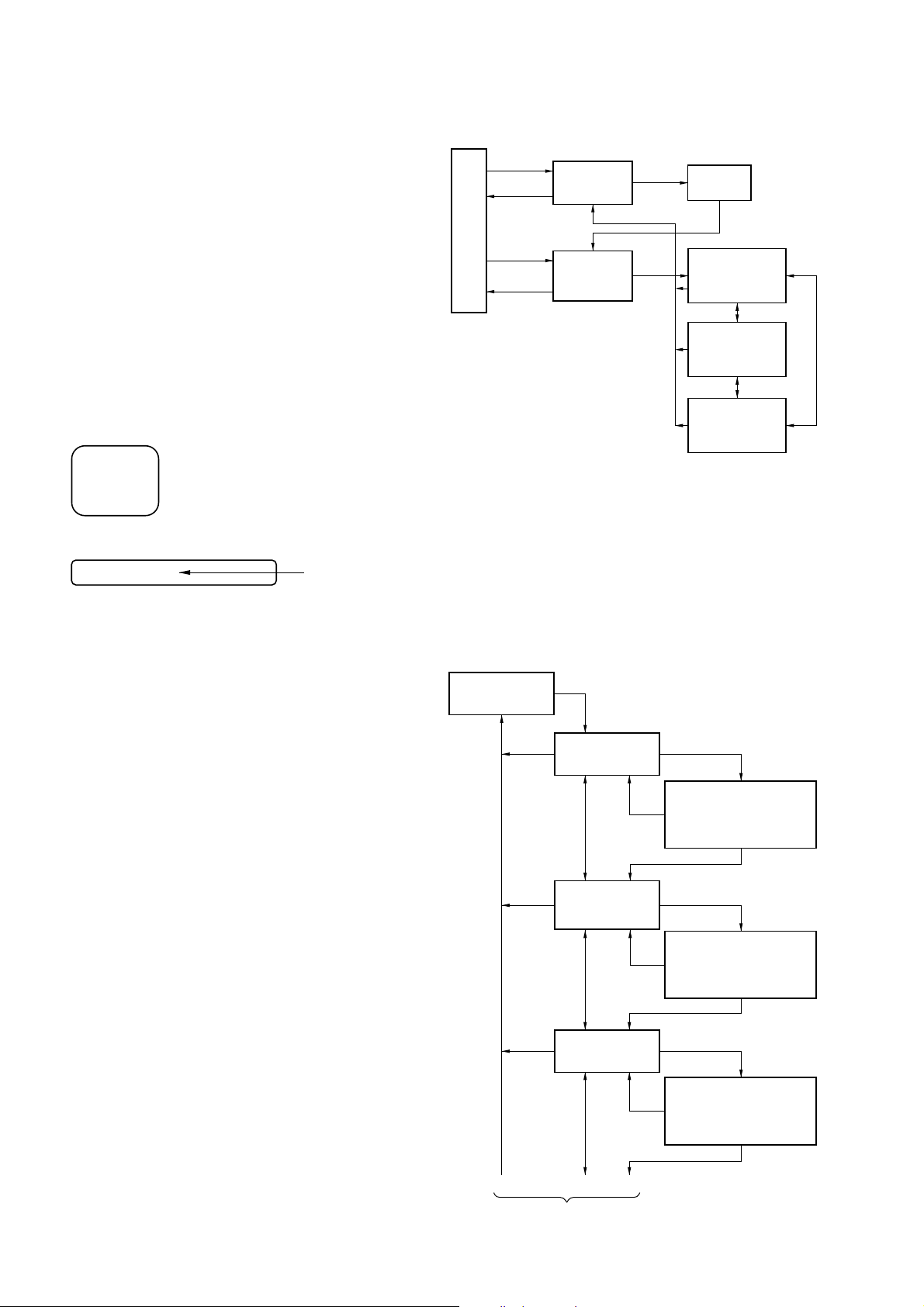

Configuration of TEST Mode

The TEST mode configuration of this set is as follows:

+key

p

key

–key

p

key

Display in TEST Mode

AUTO Mode

(Auto?)

MANUAL

Mode

(Manu?)

(

key

(Start?)

p

key

(

key

p

key

SERVO Mode

0 0 0

+,

–

key

AUDIO Mode

1 0 0

+,

–

key

POWER Mode

( ) for Remote controller LCD display

3 0 0

SERVO Mode

• Enter the TEST mode, press VOL − key and ( key to select

the SERVO mode.

• When the second digit of mode number is not 0 and the first

digit is 0 (010, 020, 030, etc.), the optical pickup moves to outside track or inside track with + key or = key respectively.

• To select other modes, refer to the TEST mode configuration.

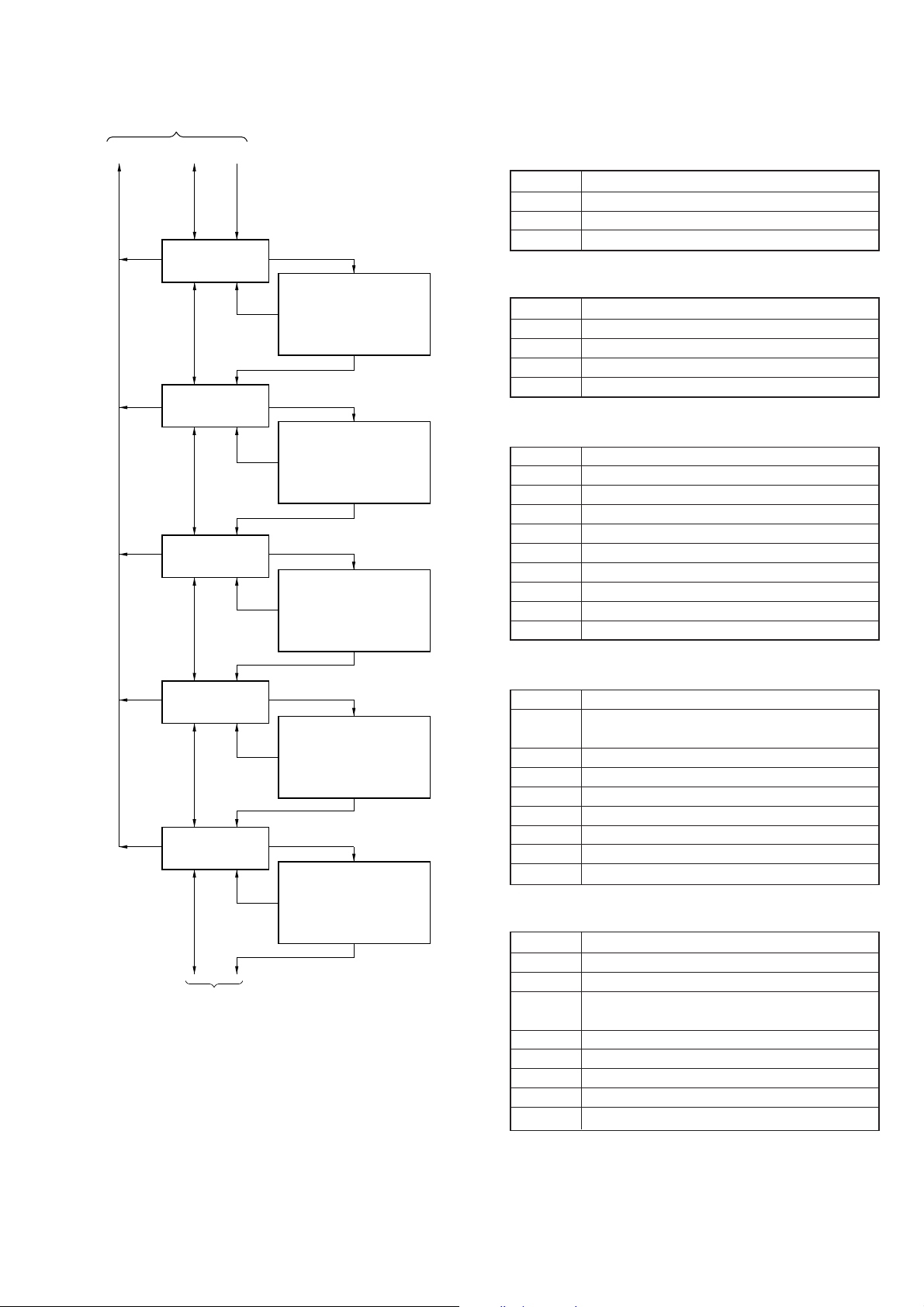

1. Configuration of SERVO Mode

SERVO Mode

(

key

0 0 0

key

–

+,

p

key

OFFSET Adj.

(

0 1 0

Each time (key is pressed,

011-013

are switched. (For each

p

key

mode, see relevant table)

p

key

LASER

POWER Adj.

(

0 2 0

Each time

ed,

p

key

+,–key +,–key

p

key

MO Adj.

021-024

are switched. (For each

mode, see relevant table)

(

0 3 0

Each time

ed,

p

key

031-039

are switched. (For each

mode, see relevant table)

123

key

key

key

modes

(

key

(

key is press-

modes

(

key

(

key is press-

modes

(

key

– 8 –

(To page 9 )

(To page 8 )

2. Description of Each Mode

123

p

key

LOW REF CD Adj.

0 4 0

p

+,–key+,–key+,–key+,–key

p

key

CD Adj.

Each time (key is

pressed,

modes are switched.

key

(For each mode, see

relevant table)

0 5 0

Each time (key is

pressed,

p

p

key

SLED Move

0 6 0

p

p

key

AUTO Adj.

modes are switched.

key

(For each mode, see

relevant table)

Each time (key is

pressed,

modes are switched.

key

(For each mode, see

relevant table)

0 7 0

p

key

p

key

NV

0 9 0

Each time (key is

pressed,

p

+,–key

Return to OFFSET Adj.

modes are switched.

key

(For each mode, see

relevant table)

(

key

041-048

(

key

(

key

051-058

(

key

(

key

061

and

062

(

key

(

key

Each time (key is

pressed,

modes are switched.

(For each mode, see

relevant table)

(

071-074

key

(

key

091-093

(

key

(

010

)

010 Offset Adjustment

Mode Description

011 Focus error offset

012 Tracking error offset

013 All servo ON

020 Laser Power Adjustment

Mode Description

021 MO power A

022 MO power E

023 CDL power

024 CD power

030 MO Adjustment

Mode Description

031 MO EF balance (MO traverse)

032 MO EF gain

033 MO ABCD gain

034 MO focus gain

035 MO tracking gain

036 MO RF gain

037 MO ADIP gain

038 MO focus bias E

039 MO focus bias A

040 Low Reflection CD Adjustment

Mode Description

041

042 Low reflection CD EF gain

043 Low reflection CD ABCD gain

044 Low reflection CD focus gain

045 Low reflection CD tracking gain

046 Low reflection CD RF offset

047 Low reflection CD RF gain

048 Low reflection CD focus bias

Low reflection CD EF balance

(CD traverse)

050 CD Adjustment

Mode Description

051 CD EF balance

052 CD EF gain

053

054 CD focus gain

055 CD tracking gain

056 CD RF offset

057 CD RF gain

058 CD focus bias

CD ABCD gain

(CD RF level check)

– 9 –

Loading...

Loading...