Sony MZDH-710 Service manual

MZ-DH710

SERVICE MANUAL

Ver. 1.0 2005.04

US and foreign patents licensed from Dolby Laboratories.

• SonicStage and SonicStage logo are trademarks or registered trademarks

of Sony Corporation.

• MD Simple Burner, OpenMG, “Magic Gate”, “MagicGate Memory

Stick”, “Memory Stick”, Hi-MD, Net MD, ATRAC, ATRAC3,

ATRAC3plus and their logos are trademarks of Sony Corporation.

• Microsoft, Windows, Windows NT and Windows Media are trademarks

or registered trademarks of Microsoft Corporation in the United States

and /or other countries.

• IBM and PC/AT are registered trademarks of International Business

Machines Corporation.

• Macintosh is a trademark of Apple Computer, Inc. in the United States

and/or other countries.

•Pentium is a trademark or registered trademark of Intel Corporation.

• All other trademarks and registered trademarks are trademarks or

registered trademarks of their respective holders.

•™ and ® marks are omitted in this manual.

• CD and music-related data from Gracenote, Inc., copyright © 2000-2004

Gracenote. Gracenote CDDB® Client Software, copyright 2000-2004

Gracenote. This product and service may practice one or more of the

following U.S. Patents: #5,987,525; #6,061,680; #6,154,773, #6,161,132,

#6,230,192, #6,230,207, #6,240,459, #6,330,593, and other patents issued

or pending. Services supplied and/or device manufactured under license

for following Open Globe, Inc. United States Patent 6,304,523. Gracenote

is a registered trademarks of Gracenote. The Gracenote logo and logotype,

and the “Powered by Gracenote” logo are trademarks of Gracenote.

US Model

Canadian Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MT-MZNH900-181

Optical Pick-up Name ABX-U

SPECIFICATIONS

Audio playing system

MiniDisc digital audio system

Laser diode properties

Material: GaAlAs

Wave length: λ = 790 nm

Emission duration: continuous

Laser output: less than 44.6 µW

– Continued on next page –

Program © 2001, 2002, 2003, 2004, 2005 Sony Corporation

Documentation © 2005 Sony Corporation

9-879-660-01

2005D05-1

© 2005.04

Sony Corporation

Personal Audio Group

Published by Sony Engineering Corporation

PORTABLE MD PLAYER

MZ-DH710

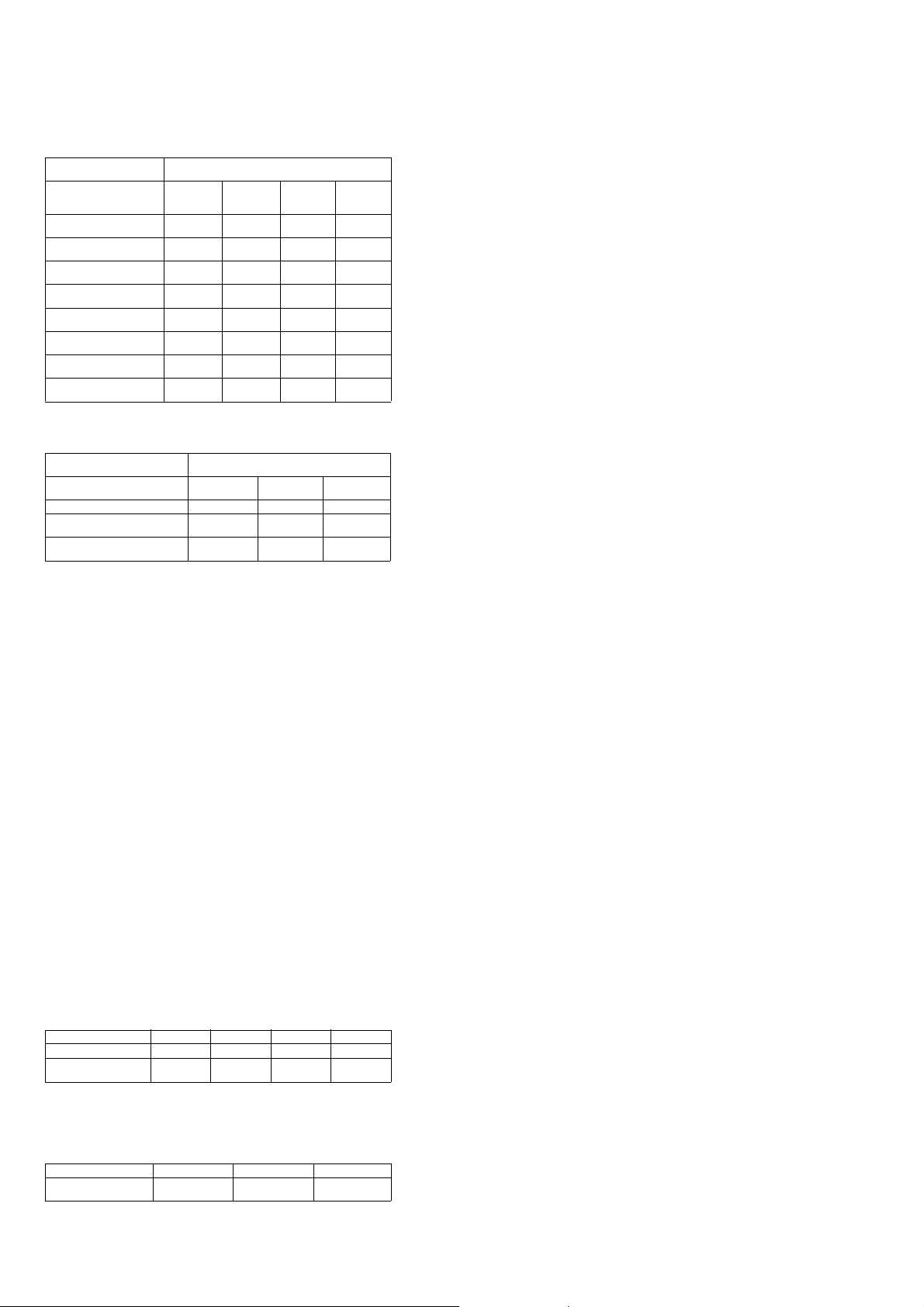

Recording and playback time

List of the recording time for each disc

When using a disc in Hi-MD mode

When transferring from

the computer

Codec/Bit rate 1GB Hi-MD

Linear PCM/1.4Mbps 1 hour and

ATRAC3plus/256kbps 7 hours and

disc

34 minutes

55 minutes

ATR AC3plus/64kbps 34 hours 10 hours and

ATR AC3plus/ 48 kbps 45 hours 13 hours and

ATR AC3/132kbps 16 hours and

ATR AC3/105kbps 20 hours and

ATR AC3/66kbps 32 hours and

30 minutes

40 minutes

40 minutes

Recording time

80-minute

standard

disc

28 minutes 26 minutes 21 minutes

2 hours and

20 minutes

10 minutes

30 minutes

4 hours and

50 minutes

6 hours and

10 minutes

9 hours and

50 minutes

MP3/128kbps 17 hours 5 hours 4 hours and

1)

Approximate time

2)

When transferring 4-minute tracks

1)2)

74-minute

standard

disc

2 hours and

10 minutes

9 hours and

20 minutes

12 hours and

30 minutes

4 hours and

30 minutes

5 hours and

40 minutes

9 hours 7 hours and

30 minutes

60-minute

standard

disc

1 hour and

40 minutes

7 hours and

40 minutes

10 hours

3 hours and

40 minutes

4 hours and

40 minutes

20 minutes

3 hours and

30 minutes

When using a disc in MD mode

When transferring from the

computer

Codec/Bit rate 80-minute

standard disc

Recording time

74-minute

standard disc

1)2)

60-minute

standard disc

ATR AC(stereo)/292kbps 80 minutes 74 minutes 60 minutes

ATRAC3/132, 105kbps 2 hours and

ATR AC3/66kbps 5 hours and

1)

Approximate time

2)

When transferring 4-minute tracks

Revolutions

350 rpm to 3,000 rpm (CLV)

Error correction

Hi-MD:

LDC (Long Distance Code)/BIS (Burst

Indicator Subcode)

MD:

ACIRC (Advanced Cross Interleave Reed

Solomon Code)

Sampling frequency

44.1 kHz

Audio formats supported b y this

player

Linear PCM (44.1 kHz/16 bit)

ATRAC3plus (Adaptive TRansform Acoustic

Coding 3 plus)

AT R A C 3

AT R A C

MP3 (MPEG-1 Audio Layer-3/Sampling

frequency 44.1 kHz/Bit rate 32 - 320 kbps

(constant/variable bit rate))

Modulation system

Hi-MD:

1-7RLL (Run Length Limited)/PRML

(Partial Response Maximum Likelihood)

MD:

EFM (Eight to Fourteen Modulation)

Frequency response

20 to 20,000 Hz ± 3 dB

Outputs

i: stereo mini-jack

Maximum output (DC)

Headphones:

5 mW + 5 mW (16 Ω)

Power requirements

One LR6 (size AA) alkaline battery (not

supplied)

Operating temperature

+5°C (+41°F) to +35°C (+95°F)

Battery operation time

Battery life

1)

40 minutes

20 minutes

When playing continuously in Hi-MD mode

Disc type Linear PCM Hi-SP Hi-LP MP3

2 hours and

28 minutes

4 hours and

56 minutes

2 hours

4 hours

(Unit: approx. hours) (JE ITA2))

3)

1GB Hi-MD disc 9.5 16.5 19.5 19.0

60/74/80-minute

standard disc

1)

When using a new Sony LR6 (size AA) alkaline dry battery (produced in Japan)

2)

Measured in accordance with the JEITA (Japan Electronics and Information Technology Industries

Association) standard.

3)

Tracks transferred at 128 kbps .

When playing continuously in MD mode

Disc type

60/74/80-minute

standard disc

8.5 16.0 19.0 18.5

(Unit: approx. hours) (J EITA)

SP

LP2 LP4

18.0 21.5 23.5

Dimensions

Approx. 83.6 × 29.5 × 77.0 mm (w/h/d)

3

(3

/8 × 13/16 × 31/8 in.)(excluding projecting

parts and controls)

Mass

. 107 g (3.8 oz.) (the player only)

Approx

Supplied accessories

Earphones

Dedicated USB cable

CD-ROM (SonicStage/MD Simple Burner)*

Recordable disc

* Do not play a CD-ROM on an audio CD player.

Design and specifications are subject to change

without notice.

2

MZ-DH710

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

TABLE OF CONTENTS

1. SERVICING NOTES ............................................... 4

2. GENERAL ................................................................... 5

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 6

3-2. Case (Lower) Section ...................................................... 7

3-3. MAIN Board.................................................................... 7

3-4. Case (Upper) Section....................................................... 8

3-5. Mechanism Deck Section (MT-MZNH900-181),

MD Standard Pin ............................................................. 8

3-6. Set Chassis Assy.............................................................. 9

3-7. Gear (BSA), Gear (SB) ................................................... 9

3-8. OP Service Assy .............................................................. 10

3-9. DC Motor SSM18D/C-NP (Spindle) (M701),

DC Motor (Sled) (M702),

DC Motor Unit (Over Write Head Up/Down) (M703) ... 10

3-10. Holder Assy ..................................................................... 11

3-11. Position of Ferrite Core ................................................... 11

4. TEST MODE.............................................................. 12

5. ELECTRICAL ADJUSTMENTS .......................... 16

6. DIAGRAMS

6-1. Block Diagram – MD SERVO Section – ........................ 21

6-2. Block Diagram – POWER SUPPLY Section – ............... 22

6-3. Printed Wiring Board – MAIN Section (1/2) – ............... 24

6-4. Printed Wiring Board – MAIN Section (2/2) – ............... 25

6-5. Schematic Diagram – MAIN Section (1/8) – .................. 26

6-6. Schematic Diagram – MAIN Section (2/8) – .................. 27

6-7. Schematic Diagram – MAIN Section (3/8) – .................. 28

6-8. Schematic Diagram – MAIN Section (4/8) – .................. 29

6-9. Schematic Diagram – MAIN Section (5/8) – .................. 30

6-10. Schematic Diagram – MAIN Section (6/8) – .................. 31

6-11. Schematic Diagram – MAIN Section (7/8) – .................. 32

6-12. Schematic Diagram – MAIN Section (8/8) – .................. 33

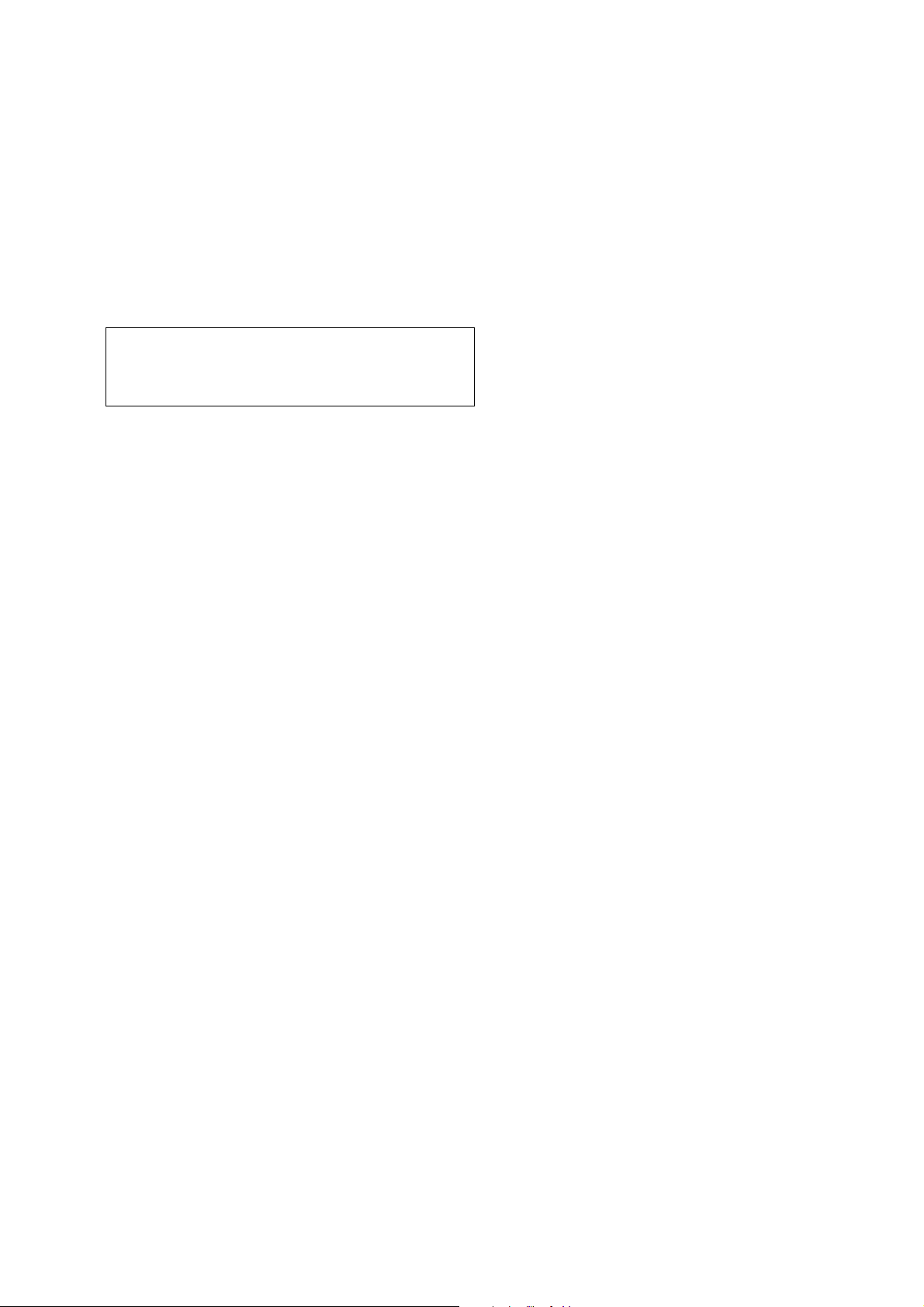

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS

QUE PAR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU D ANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

7. EXPLODED VIEWS

7-1. Case (Lower) Section ...................................................... 44

7-2. Case (Upper) Section....................................................... 45

7-3. Chassis Section................................................................ 46

7-4. Mechanism Deck Section (MT-MZNH900-181) ............ 47

8. ELECTRICAL PARTS LIST................................ 48

3

MZ-DH710

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

NOTES ON REPLACEMENT OF CSP (CHIP SIZE

PACKAGE) IC

Replacement of SN761059AZQLR (IC501), SC901585VAR2

(IC601) and CXD2681-225GG (IC801) used in this set requires a

special tool.

OPERATION CHECK WHEN THE MAIN BOARD IS

REMOVED

In making an operation check with the MAIN board removed from

the set, short the SL894 of the MAIN board with the solder before

starting the operation check.

Note: Be sure to remove the solder used for shortcircuit after the repaire

completed.

– MAIN BOARD (Conductor Side) –

SL894

Providing the required system environment

System requirements

The following system environment is required in order to use the SonicStage Ver. 3.0/MD

Simple Burner Ver. 2.0 software for the MD Walkman.

Computer IBM PC/AT or Compatible

•CPU: Pentium III 450 MHz or higher

•Hard disk drive space: 200 MB or more (1.5 GB or more is

recommended) (The amount space will vary according to Windows

version and the number of music files stored on the hard disk.)

•RAM: 128 MB or more

Others

•CD drive (capable of digital playback by WDM) (A CD-R/RW drive

is necessary for CD writing)

•Sound Board

•USB port

Operating

System

Display High Color (16bit) or higher, 800 u 600 dots or better (1024 u 768 dots

Others • Internet access: for Web registration, EMD services and CDDB

This software is not supported by the following environments:

• OSs other than the indicated above

• Personally constructed PCs or operating systems

• An environment that is an upgrade of the original manufacturer-installed operating system

• Multi-boot environment

• Multi-monitor environment

• Macintosh

Notes

• We do not ensure trouble-free operation on all computers that satisfy the system requirements.

• The NTFS format of Windows XP/Windows 2000 Professional can be used only with the standard

(factory) settings.

• For Windows 2000 Professional users, install Service Pack 3 or later version before using the

software.

• We do not ensure trou bl e-free operation of the system suspend, sleep, or hibernation function on all

computers.

Factory installed:

Windows XP Media Center Edition 2005/Windows XP Media Center

Edition 2004/Windows XP Media Center Edition/Windows XP

Professional/Windows XP Home Edition/Windows 2000 Professional/

Windows Millennium Edition/Windows 98 Second Edition

or better is recommended)

•Windows Media Player (version 7.0 or higher) installed for playing

WMA files

4

SECTION 2

GENERAL

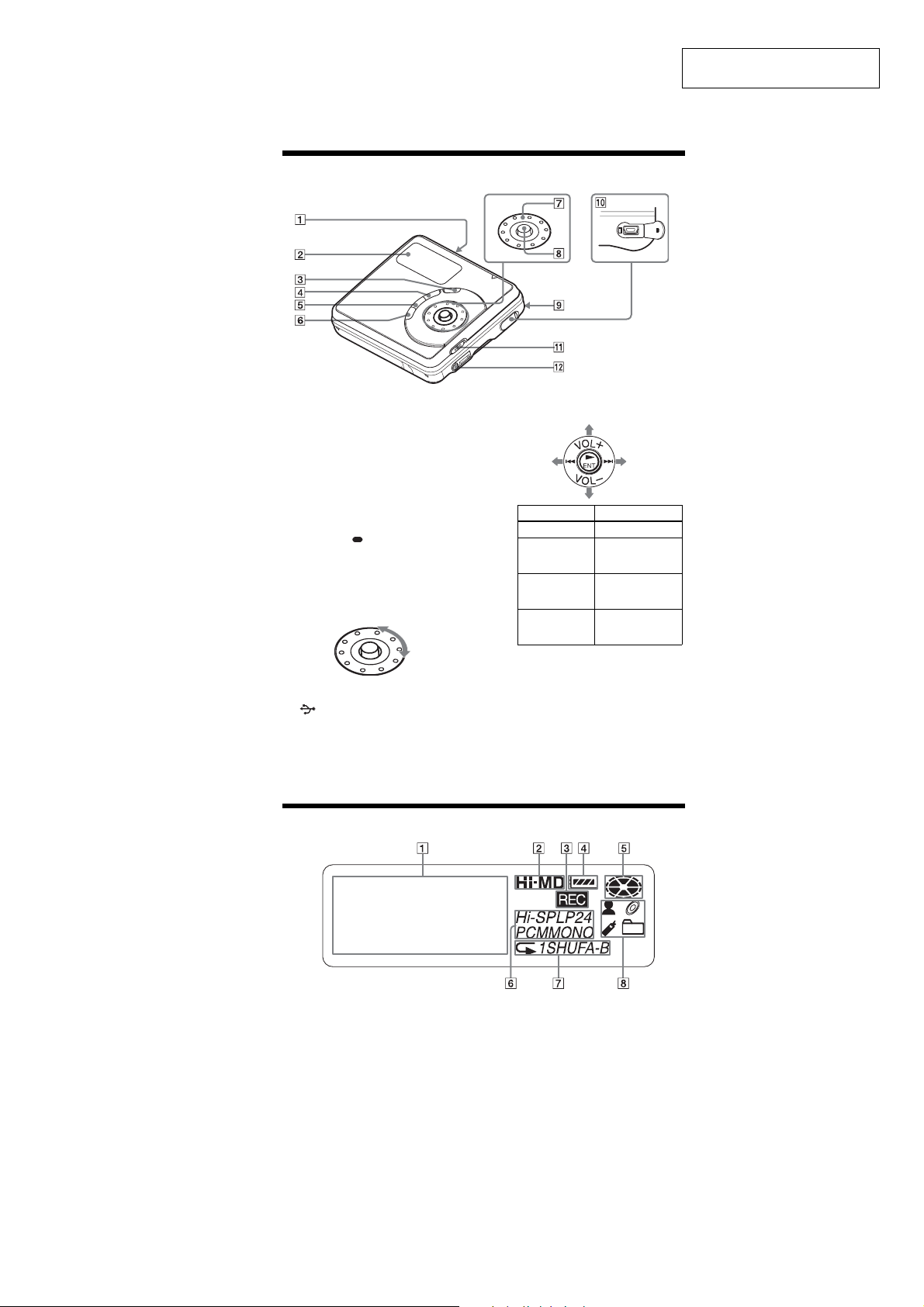

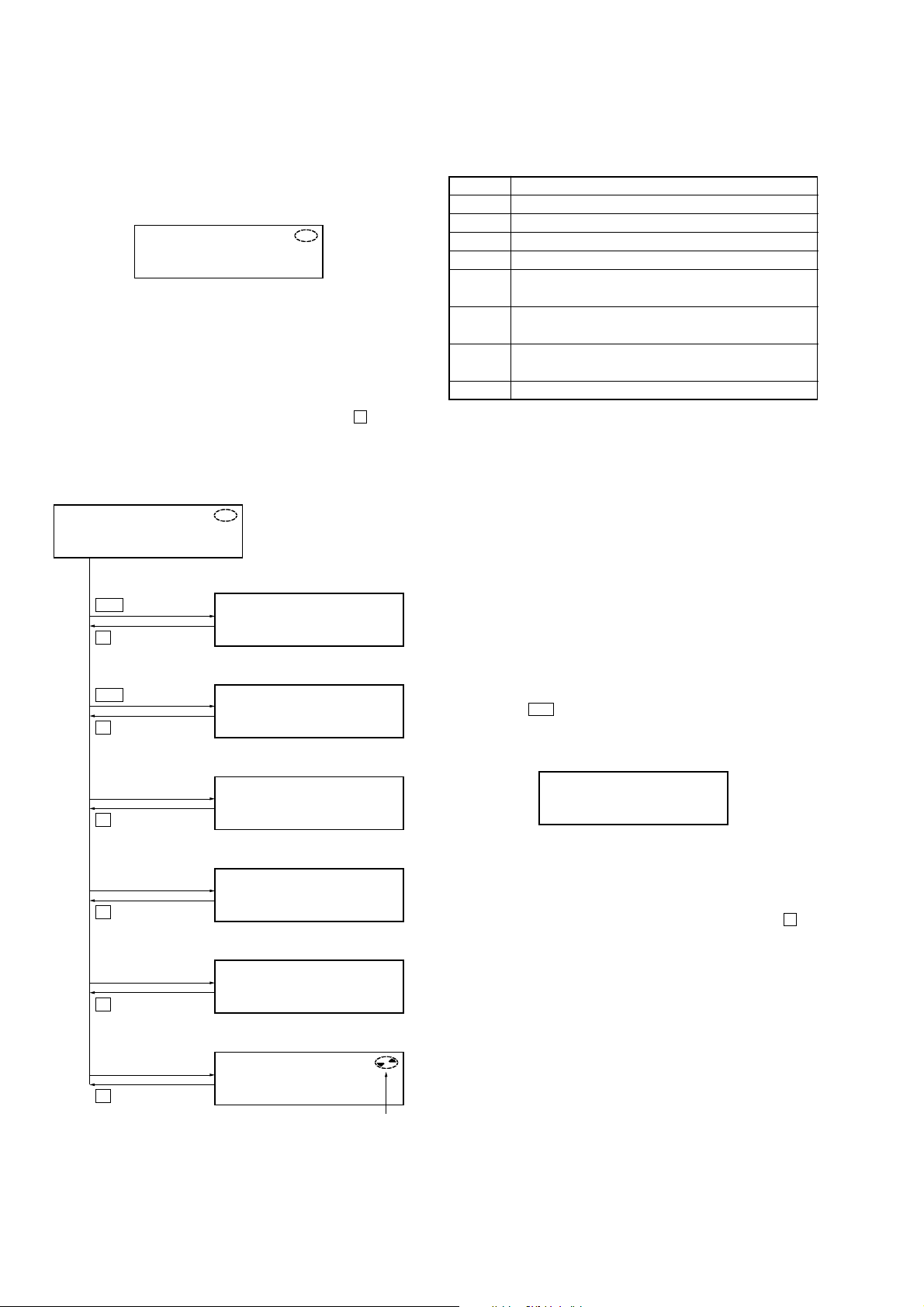

Looking at controls

The player

MZ-DH710

This section is extracted from

instruction manual.

A OPEN switch

B Display window

C DOWNLOAD button

This button allows you to record

music tracks from an audio CD in the

CD drive of your computer to an MD

Walkman using the supplied MD

Simple Burner software.

D X (pause) button

E •SEARCH/ MENU button

Press lightly to go to the SEARCH

setting mode. Press for 2 seconds or

more to go to the MENU setting mode.

F x (stop) • CANCEL button

G Jog dial

I Battery compartment (at the bottom)

J USB cable connecting jack

H 5-way control key

Operation Function

Press NENT

Press towards . find the beginning

Press towards > find the beginning

Press towards

VOL +

VOL –.

1)

There are tactile dots b eside the NENT

and

K HOLD switch

Slide the switch in the direction of the

arrow to disable the buttons on the

player. To prevent the buttons from

being accidentally operated when you

carry the player, use this function.

L i (earphones) jack

The display window of the player

1)

or

VOL +

1)

play, enter

of the previous

track, rewind

of the next track,

fast forward

volume

buttons.

A Character information display

Displays the disc and track names,

date, error messages, track numbers,

etc.

B Hi-MD/MD indication

“Hi-MD” lights up when the

operation mode of the player is in HiMD mode and “MD” lights up when

the operation mode is in MD mode.

C REC indication

Lights up during file transfers from

the computer. When flashing, the

player is in record standby mode.

D Battery indication

Shows the approximate remaining

battery power. If the battery is weak,

the indication becomes empty an d

starts flashing.

E Disc indication

Shows that the disc is rotating for

playing.

F Track mode (PCM, Hi-SP , Hi-LP, SP,

LP2, LP4, MONO) indication

G Sub play mode/Repeat play

indications

Shows the selected Sub play mode

(single-track play, shuffle play , etc.) or

Repeat play.

H Main play mode indications

Shows the selected main play mode

(group play, bookmark play, etc.).

5

MZ-DH710

SECTION 3

DISASSEMBLY

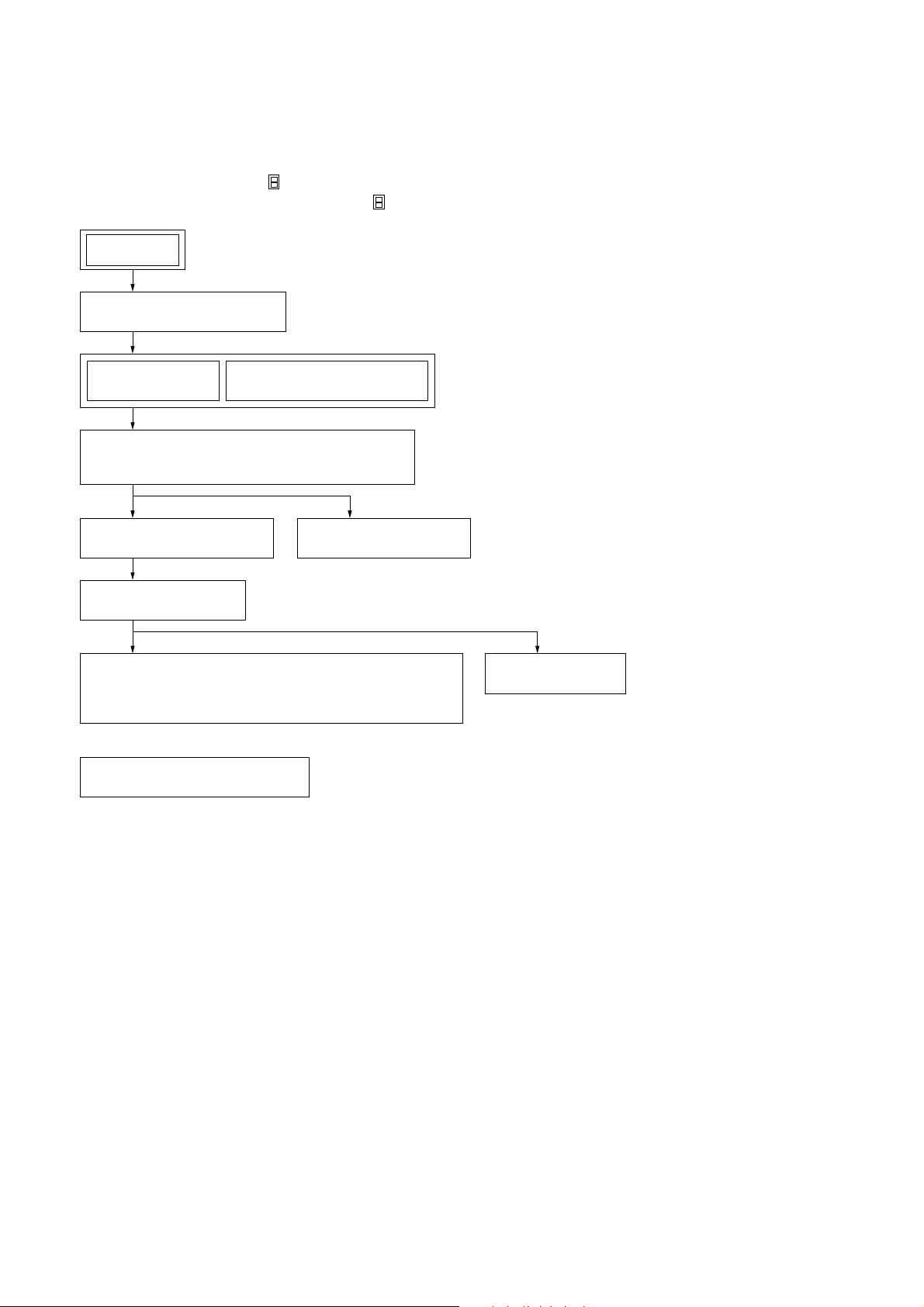

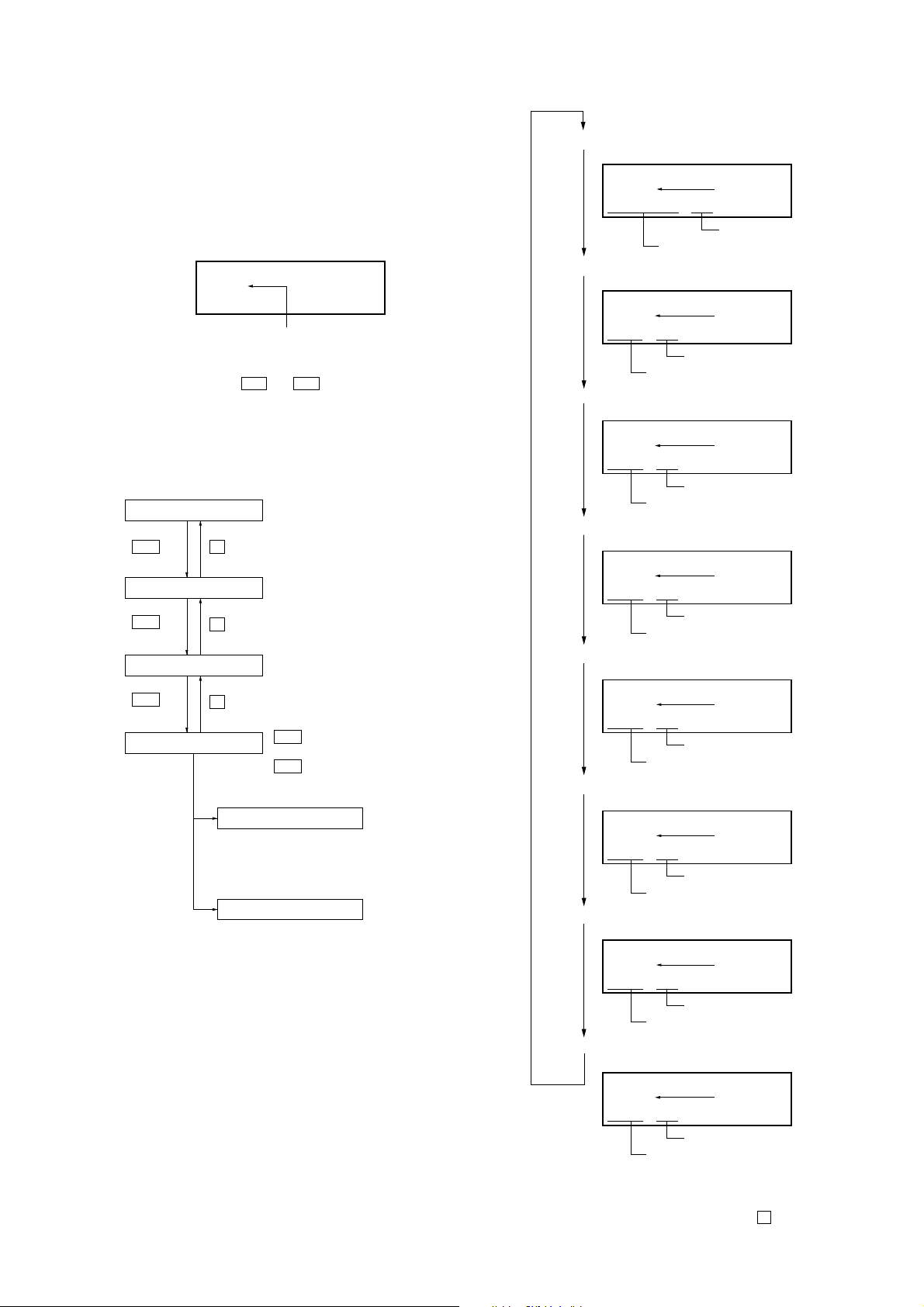

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

Note 1: The process described in can be performed in any order.

Note 2: Without completing the process described in , the next process can not be performed.

SET

3-2. CASE (LOWER) SECTION

(Page 7)

3-3. MAIN BOARD

(Page 7)

3-5. MECHANISM DECK SECTION (MT-MZNH900-181),

MD STANDARD PIN

(Page 8)

3-7. GEAR (BSA), GEAR (SB)

(Page 9)

3-8. OP SERVICE ASSY

(Page 10)

3-9. DC MOTOR SSM18D/C-NP (SPINDLE) (M701),

DC MOTOR (SLED) (M702),

DC MOTOR UNIT (OVER WRITE HEAD UP/DOWN) (M703)

(Page 10)

3-11. POSITION OF FERRITE CORE

(Page 11)

3-4. CASE (UPPER) SECTION

(Page 8)

3-6. SET CHASSIS ASSY

(Page 9)

3-10. HOLDER ASSY

(Page 11)

6

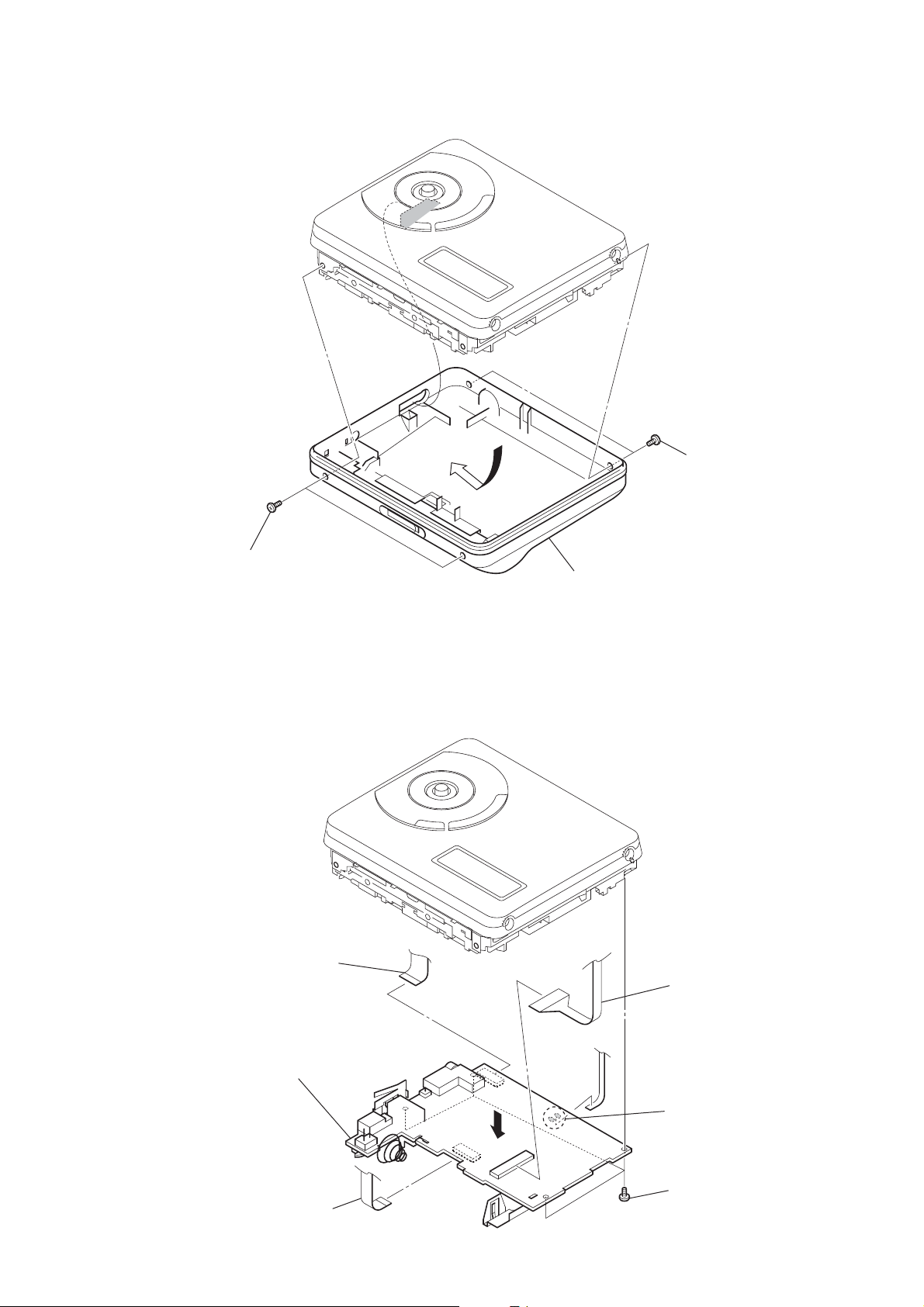

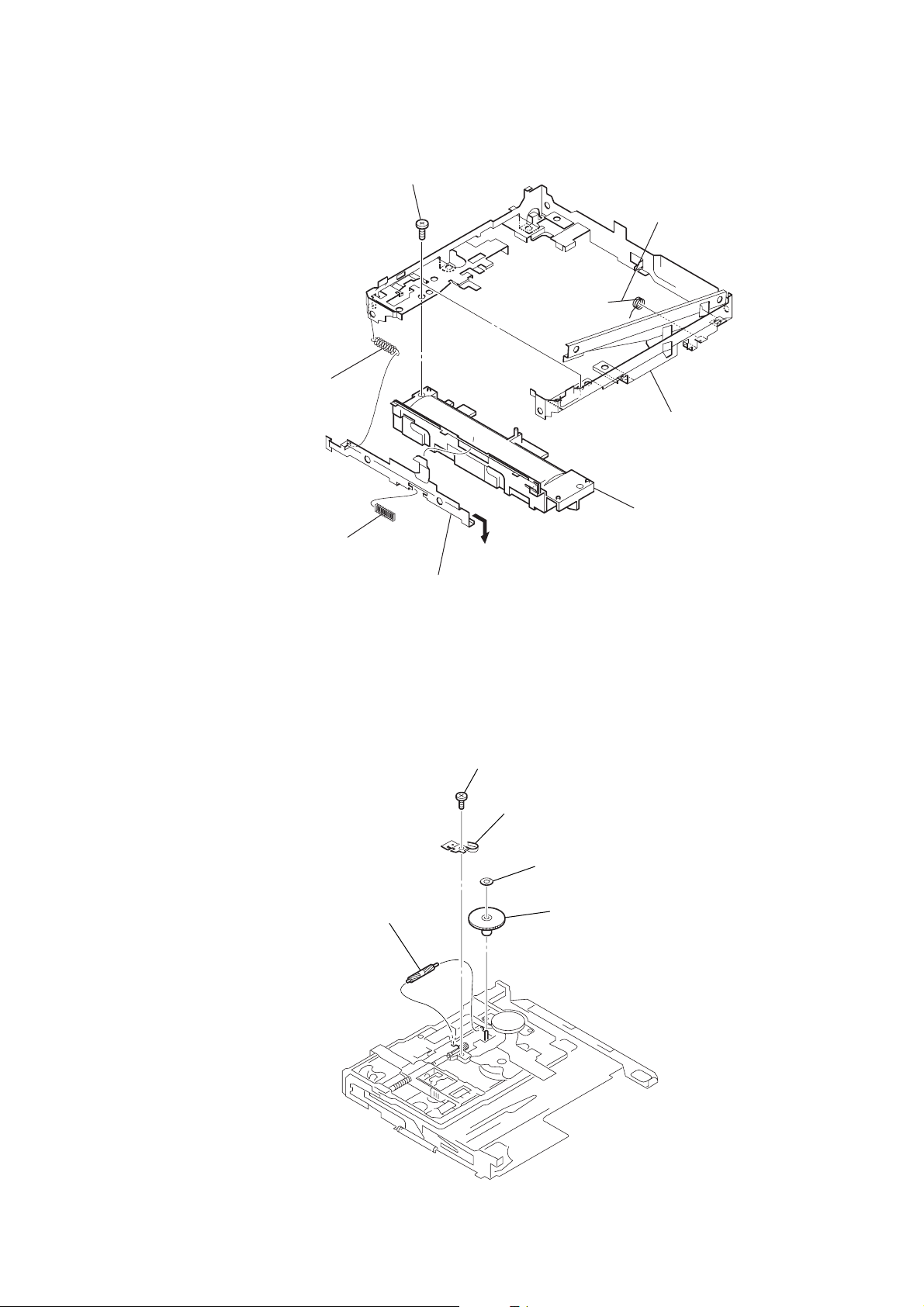

3-2. CASE (LOWER) SECTION

n

1

two screws

(M1.4)

MZ-DH710

1

two screws

(M1.4)

3-3. MAIN BOARD

3

flexible board

(CN471)

2

Remove the case (lower) sectio

in the direction of the arrow.

6

flexible board

(CN501)

7

MAIN board

2

flexible board

(CN701)

5

1

Remove two solders.

4

four screws

(M1.4)

7

MZ-DH710

)

3-4. CASE (UPPER) SECTION

7

case (upper) section

3

torsion spring

(pop up L)

6

boss

5

4

two step screws

1

flexible board (CN471

2

Open the case (upper) section.

3-5. MECHANISM DECK SECTION (MT-MZNH900-181), MD STANDARD PIN

1

two step screws (MD)

2

3

MD standard pin

mechanism deck section

(MT-MZNH900-181)

8

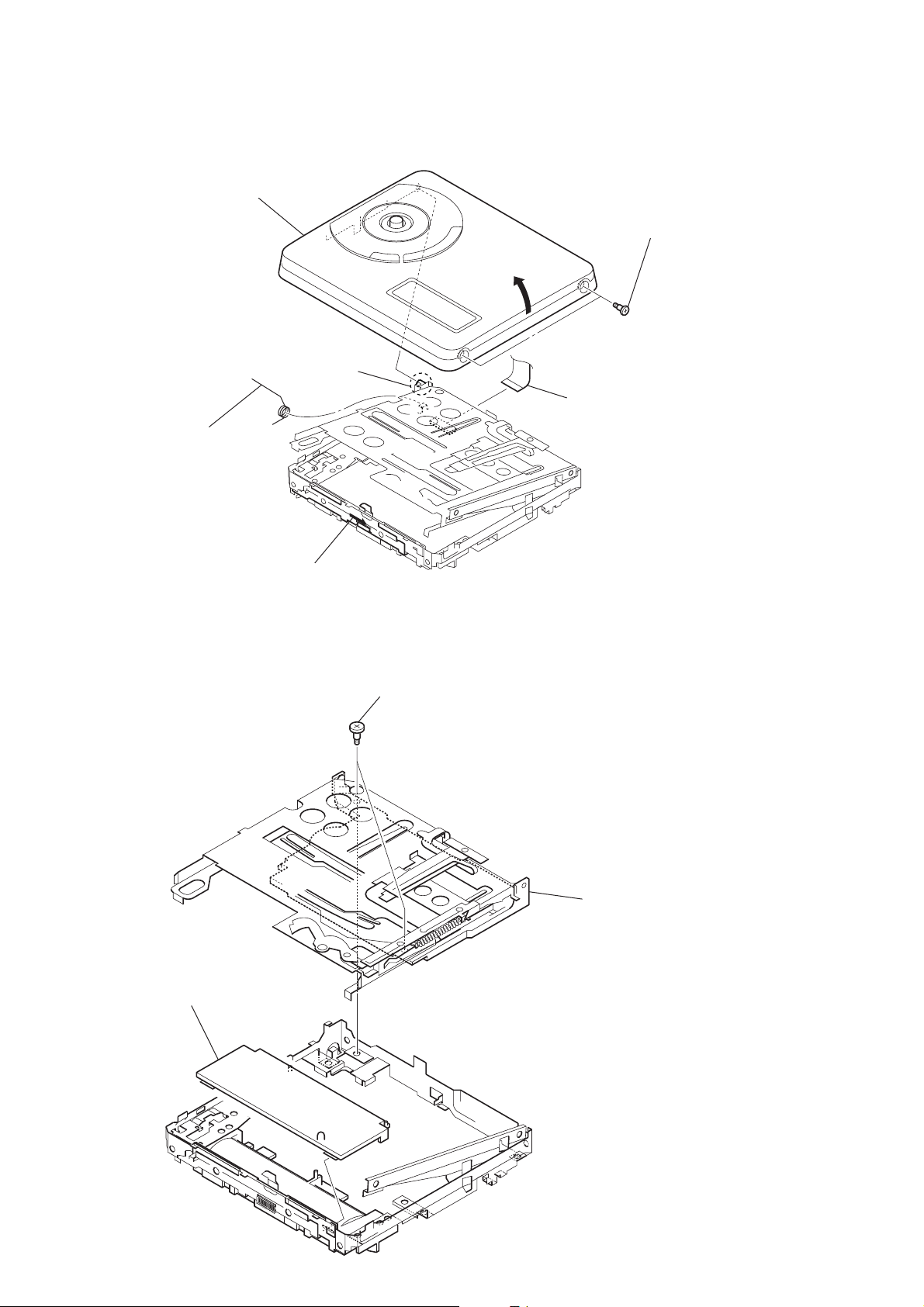

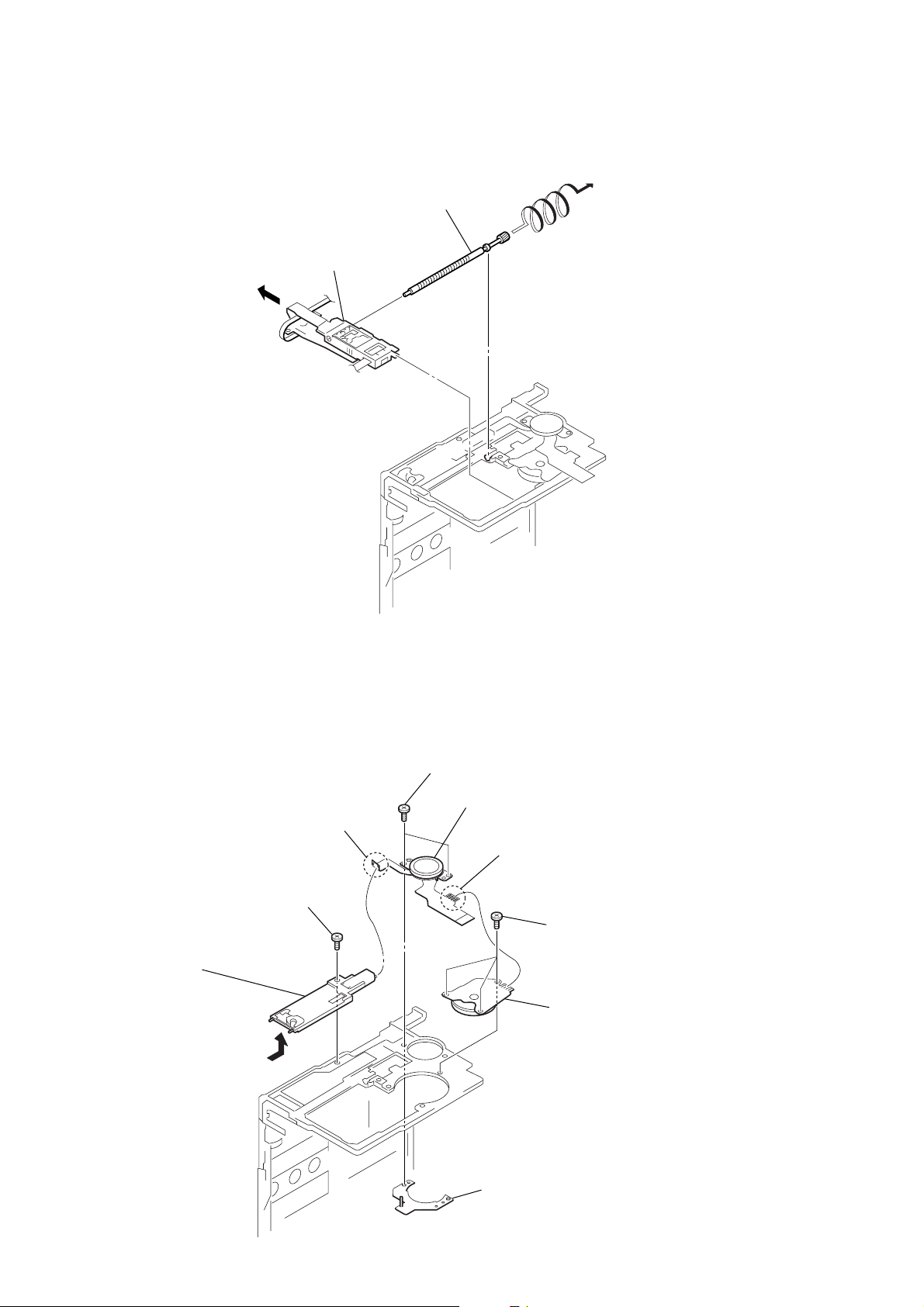

3-6. SET CHASSIS ASSY

2

extension spring (R)

5

two screws

1

torsion coil spring (R)

7

set chassis assy

MZ-DH710

3

compression coil spring (limitter)

3-7. GEAR (BSA), GEAR (SB)

5

gear (SB)

4

open slider

1

self tap screw

2

thrust retainer spring

3

washer (0.8-2.5)

4

gear (BSA)

6

battery case

9

MZ-DH710

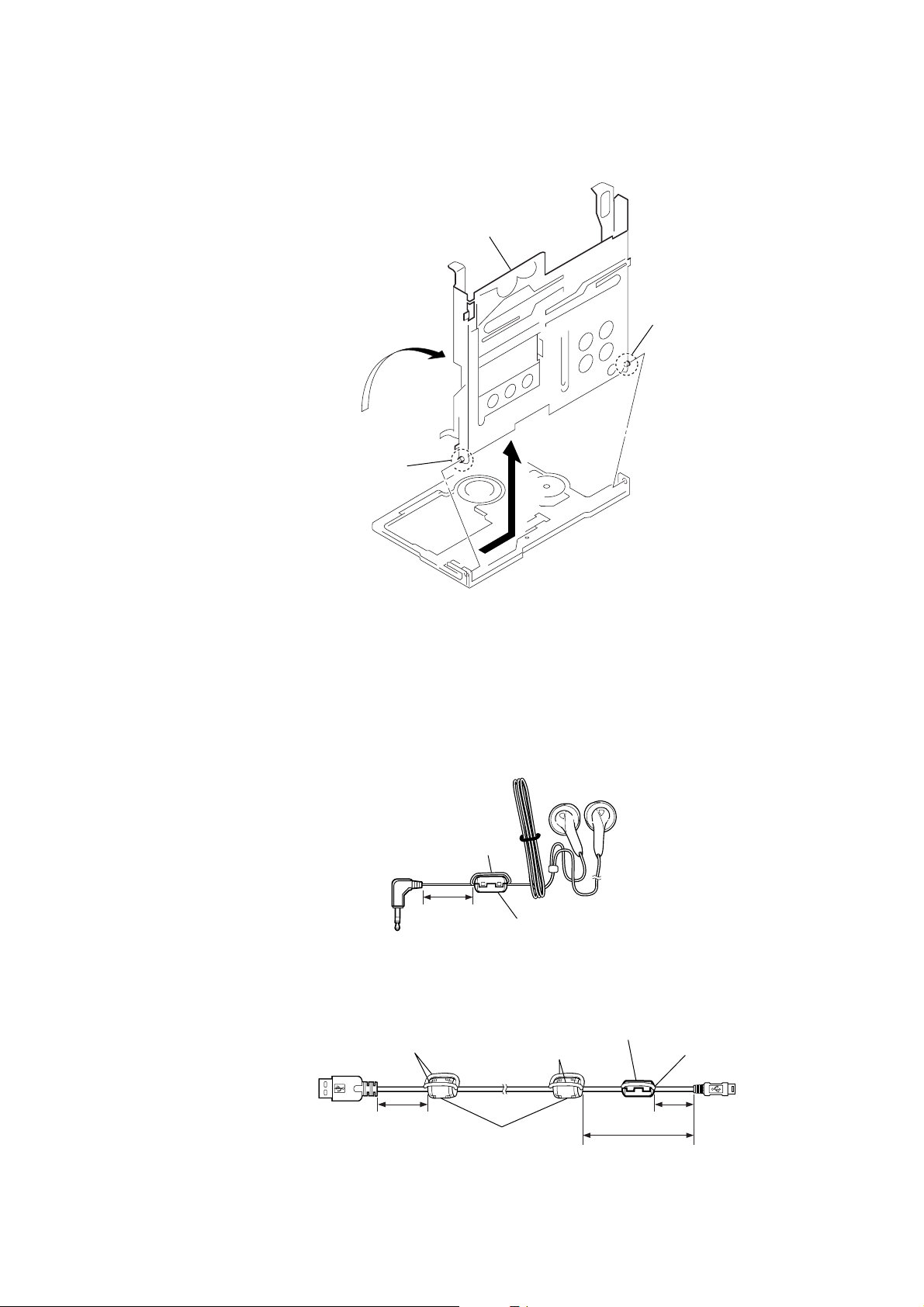

3-8. OP SERVICE ASSY

1

Lead screw block assy is turned

and it removes from OP service assy.

2

OP service assy

3-9. DC MOTOR SSM18D/C-NP (SPINDLE) (M701), DC MOTOR (SLED) (M702),

DC MOTOR UNIT (OVER WRITE HEAD UP/DOWN) (M703)

3

two screws (M1.4)

4

DC motor (sled)

2

Remove two solders of flexible board.

8

self tap screw

9

DC motor unit

(over write head up/down)

(M703)

(M702)

1

Remove four solders of flexible board.

6

three self tap screws

7

DC motor SSM18D/C-NP

(spindle) (M701)

10

5

motor base assy

3-10. HOLDER ASSY

4

Remove the holder assy

to the direction of the arrow

3

Open the holder assy.

1

boss

A

MZ-DH710

.

2

boss

A

3-11. POSITION OF FERRITE CORE

-EARPHONES-

-USB CABLE-

A cable is rolled twice.

USB A type

A cable is rolled once.

4cm

clamp filter (ferrite core)

(Part No. 1-400-877-11)

A cable is rolled twice.

4cm

clamp filter (ferrite core)

(Part No. 1-400-878-11)

clamp filter (ferrite core)

(Part No. 1-400-877-11)

A cable is rolled once.

USB mini B type

1cm

4cm

11

MZ-DH710

SECTION 4

TEST MODE

OUTLINE

Operation in the test mode is performed with the set. A k ey having

no particular description in the text, indicates a set key. Also, For

the LCD display, the LCD on the set is shown.

1. OPERATION IN SETTING THE TEST MODE

• When the test mode becomes active, first the Display Check

mode is selected.

• Other mode can be selected from the Display Check mode.

• When the test mode is set, the LCD repeats the following

display.

• When the x key is pressed and hold down, the display at that

time is held so that display can be checked.

Display check mode:

Set LCD display

Hi-MD

REC

Hi-SPLP

All lit

All off

Microcomputer

version

display

007[80**]

Ver 1.000

BEr******

24

PCMMONO

1SHUFA-B PGM

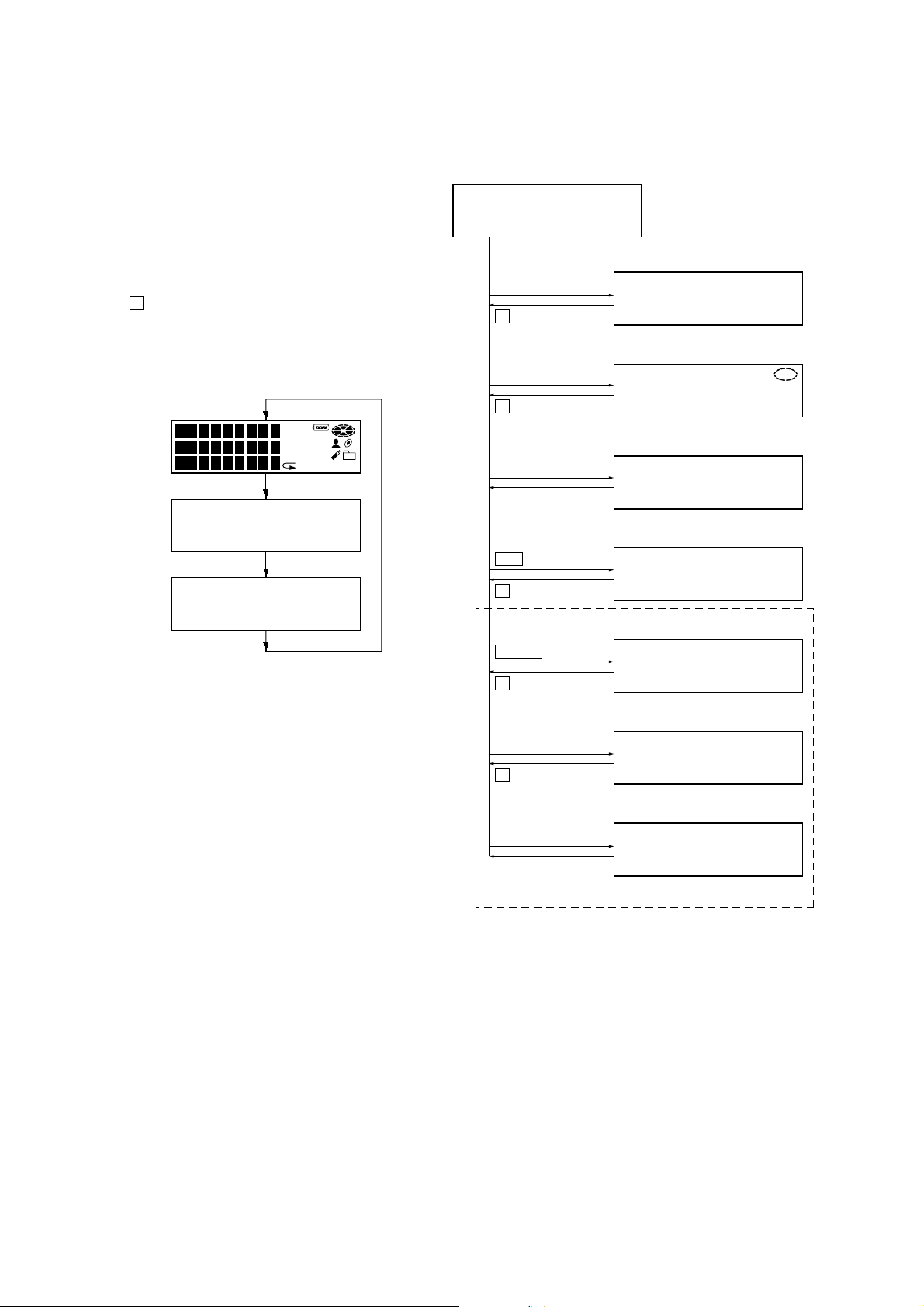

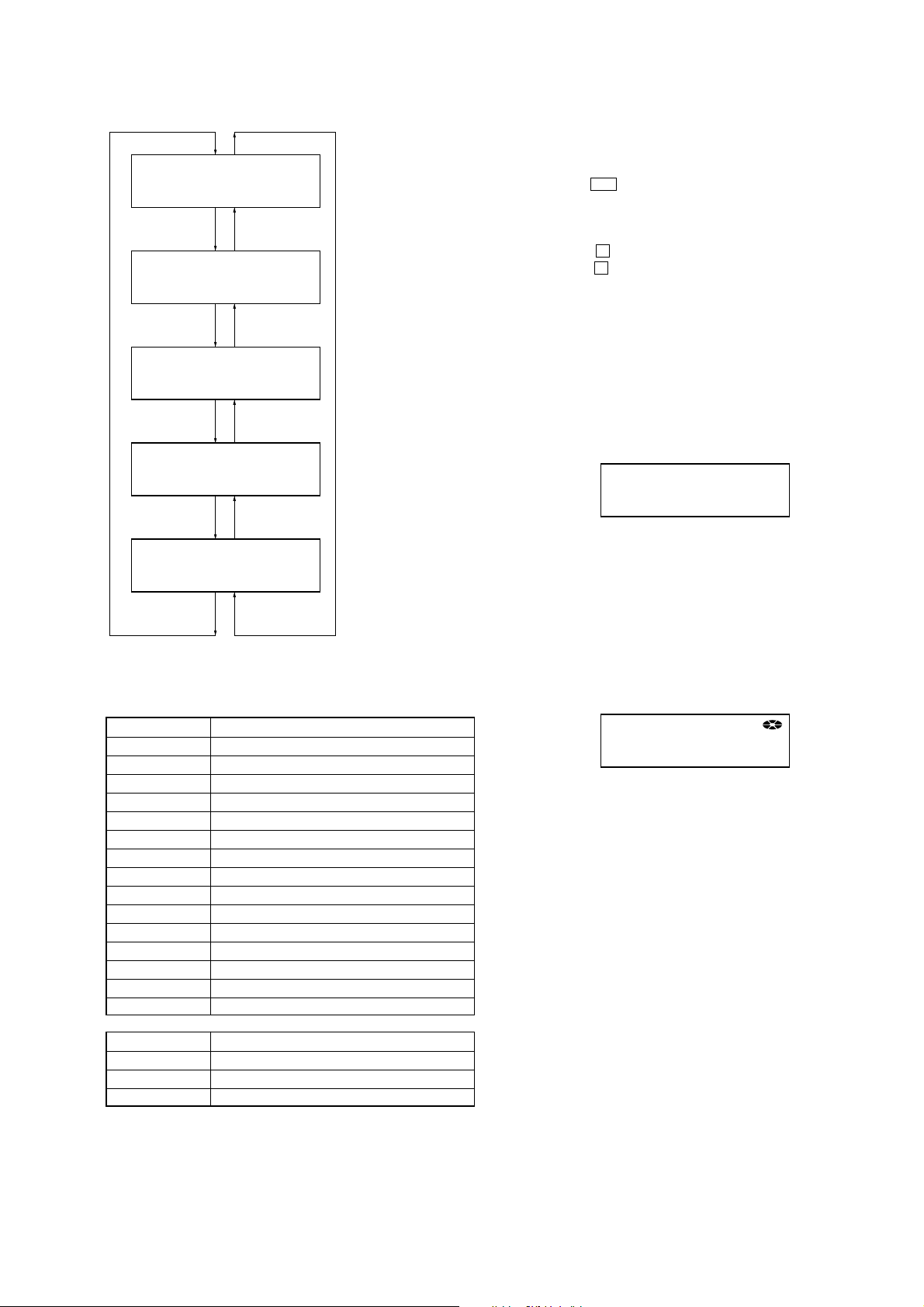

2. CONFIGURATION OF THE TEST MODE

Flow of the test mode:

Display Check Mode

007[80**]

Ver 1.000

BEr******

[VOL +]

key

Version display

→

All off → Version display...

Manual Mode

0000

key

x

[VOL --]

key

Manual

Overall Adjustment Mode

0000

key

x

[SEARCH/MENU]

Open the lid

key

>

AdjF**

Key Check Mode

key

0114

10

Self-Diagnosis Result Display Mode

0000

key

x

N ENT

key

1 0000

Sound Skip Check Result

Display Mode (Play)

0000

key

x

[DOWNLOAD]

key

P00r00

Sound Skip Check Result

Display Mode (REC)

0000

key

x

p00R00

→

All lit

[SEARCH/MENU]

(press a few

seconds)

Remote commander

[DISPLAY]

(press a few seconds)

key

key

Key Count Mode

01

MENU 000

(Not used in servicing)

12

3. MANUAL MODE

This is mode to adjust or check the operation of the set by function.

Operation of The Manual Mode

1. Enter the test mode (Display Check mode).

2. Press the [VOL+] key to activate the Manual mode where the

LCD displays as shown below.

Display

0000

Manual

Number of 1000th place

3. During Manual mode, the optical pick-up moves outward or

inward while the > or . key is pressed for several

seconds respectively.

4. Each test item is assigned with a four-digit item number; 1000th

place is a top item, 100th place is a major item, 10th place is a

medium item, and unit place is a minor item.

Flow of manual mode operation:

[VOL +]

Top item switching

>

key

x

key

key: 1000th place of item

number increase.

[VOL --]

key: 1000th place of item

number decrease.

MZ-DH710

• Item Title Display

• Address & Adjusted Value Display

• Jitter Value & Adjusted Value Display

• Block/Bite Error Value & Adjusted Value Display

Set LCD display

XXXX

****** ##

item title

Set LCD display

XXXX

***S##

adjusted value

address

Set LCD display

XXXX

***J##

adjusted value

jitter value

Set LCD display

item number

adjusted value

item number

item number

[VOL +]

Major item switching

>

key

Medium item switching

>

key

Minor item switching

key

x

key

x

Adjusted value variation

[VOL +]

[VOL --]

Adjusted value write

[ ]

key: Adjusted value is written.

X

key: 100th place of item

number increase.

[VOL --]

key: 100th place of item

number decrease.

[VOL +]

key: 10th place of item

number increase.

[VOL --]

key: 10th place of item

number decrease.

>

key: 1st place of item

number increase.

.

key: 1st place of item

number decrease.

key: Increases the adjusted

value.

key: Decreases the adjusted

value.

5. The display changes a shown below each time the

[SEARCH/MENU] key is pressed.

XXXX

item number

***B##

adjusted value

block/bite error value

• Bite Error LPF Value & Adjusted Value Display

Set LCD display

XXXX

item number

***L##

adjusted value

bite error LPF value

• CEMAX Value & Adjusted Value Display

Set LCD display

XXXX

item number

***C##

adjusted value

CEMAX value

• ADIP Error Value & Adjusted Value Display

Set LCD display

XXXX

item number

***A##

adjusted value

ADIP error value

• Focus Drive Value & Adjusted Value Display

Set LCD display

XXXX

item number

***F##

adjusted value

focus drive voltage value

*1) It is skipped excluding the item number 5000 less than 8000.

6. To release the Manual mode, press the x key to return to the

Display Check mode.

13

MZ-DH710

4. OVERALL ADJUSTMENT MODE

4-1. Operation of The Overall Adjustment Mode

1. Enter the test mode (Display Check mode).

2. Press the [VOL--] key to activate the Ov erall Adjustment mode

where the LCD displays as shown below.

Display

0000

AdjF**

Disc mark:

Lit the inner segments: Completed the power supply adjustment.

Lit the outer segments: Completed the check of charge function.

“**”:

If “DF” or “FF” is displayed, it mean that completed the servo

overall adjustment.

3. To release the Over all Adjustment mode, press the x key and

return to the Display Check mode.

Flow of overall adjustment mode:

Overall Adjustment Mode

0000

AdjF**

CD Overall Adjustment Mode

key

.

****

x

>

key

key

CD Run

MD1 Overall Adjustment Mode

****

key

x

MD1Run

4-2. Error Message in The Overall Adjustment Mode

In the Overall Adjustment mode, if an error occurred, it displays as

following table.

Display Description

Close! Dose not close the lid

DfDis! Unsuitableness disc was inserted

NoChg! Does not finish the check of charge function yet

NoTmp! Does not setting the temperature correction value

NotCD! Does not complete the CD Overall adjustment before the

MD1 Overall adjustment

NotM1! Does not complete the MD1 Overall adjustment before the

Hi-MD3 Overall adjustment

NotH3! Does not complete the Hi-MD3 Overall adjustment before

the Stray Light Offset Overall adjustment

****NG Error of item number “****”

5. SELF-DIAGNOSIS RESULT DISPLAY MODE

This set uses the self-diagnostic function system in which if an error

occurred during the recording or playing, the mechanism control

block and the power supply control block in the microcomputer

detect it and record its cause as history in the nonvolatile memory.

By checking this history in the test mode, you can analyze a fault

and determine its location.

Total recording time is recorded as a guideline of how long the

optical pick-up has been used, and by comparing it with the total

recording time at the time when an error occurred in the selfdiagnosis result display mode, you can determine when the error

occurred.

Clear the total recording time, if the optical pick-up was replaced.

5-1. Operation of The Self-Diagnosis Result Display

Mode

1. Enter the test mode (Display Check mode).

2. Press the

mode where the LCD displays as shown below.

> key to activate the Self-Diagnosis Result Display

[VOL +]

key

key

x

[VOL --]

key

key

x

[SEARCH/MENU]

key

x

[DOWNLOAD]

key

x

key

Hi-MD3 Overall Adjustment Mode

****

HM3Run

Stray Light Offset Overall

Adjustment Mode

****

OfsRun

Optical Pick-up Operation

Check Mode

key

0000

OPChk

Initialize The Adjustment Values

1911

ResOK?

Display

****

$$####

“****”: Error display code

“$$”: Error rivision history code

“####”: Addition information when error occurs

3. To release the Self-Diagnosis Result Display mode, press the x key

and return to the Display Check mode.

(rotation)

14

MZ-DH710

Flow of Self-diagnosis Result Display mode operation:

****

The first error

1 ####

[VOL --]

[VOL +]

****

key

key

The last error

N ####

[VOL --]

[VOL +]

****

key

key

One error before

the last

N1####

[VOL +]

key

****

[VOL --]

key

Two error before

the last

N2####

[VOL +]

key

****

[VOL --]

key

Total recording time

R_####

[VOL +]

key

[VOL --]

key

5-3. Clear The Total Recording Time

After replacing the optical pick-up, clear the total recording time.

1. Enter the test mode (Display Check mode).

2. Press the > key to acti vate the Self-Diagnosis Result Display

mode.

3. Press the [VOL--] key once to display the total recording time

indication.

4. Press the X key and display “ClrOK?”.

5. Press the X key again to display “RecT 0” and clear the total

recording time.

6. KEY CHECK MODE

This mode is used for key check.

Operation of The Key Check Mode

1. Enter the test mode (Display Check mode).

2. Press the [SEARCH/MENU] key to activate the Key Check mode

where the LCD displays as shown below.

Displayr

0114

$$$$$$ ##

“$$$$$$”:Pressed key name.

When the jog dial is turned, it displays “JOG+ X” or “JOG-

X” (“X” is number of 1 to 3). If the jog dial is turned four

click, it displays “JOG+OK” or “JOG-OK”

“##”:Key voltage of remote commander. (He xadecimal number)

5-2. Error Code of The Self-Diagnosis Result Display

Mode

Error display code Description

000 No error

001 Attempt to access an abnormal address

002 High temperature detected

003 Focus error (no change)

004 Abnormal rotation of disc

005 Fault of disc discriminate

006 Error of access loop (no change)

007 Error of access loop (with change)

008 Could not read address

009 Focus error (with change)

012 Could not read data with SYNC

013TOC address data error

032Focus error, ABCD offset error

033Tracking error, offset error

034 X1 tracking error, Tracking error, offset error

Error display code Addition information when error occurs

000 0000

001 Illegal cluster specified when error occurs

002 to 034 Total recording time when erroe occurs

3. When all keys check is OK on the main unit, it displays as

follows.

Display

0888

SET OK ##

4. When all keys check are OK, it display backs to the Display

Check mode automatically.

5. To release the K ey Check mode, open the lid and retur n to the

Display check mode.

15

MZ-DH710

SECTION 5

ELECTRICAL ADJUSTMENTS

1. PRECAUTIONS FOR ADJUSTMENT

1. Adjustment must be done in the test mode only. After adjusting,

release the test mode. A key having no particular description

in the text, indicates a set key. Also, for the LCD display, the

LCD on the set is shown.

2. Use the following tools and measuring instruments.

• Digital multi meter

• Regulated dc power supply (two sets)

• Thermometer

• Laser power meter

• CD adjustment disc TDYS-1 (Part No. : 4-963-646-01)

• MD1/HiMD1 hybrid adjustment disc MDW-74/GA2

(Part No. : J-2503-022-A)

• Hi-MD3 adjustment disc HMD1GSDJ

(Part No. : 8-892-388-38) *1

*1) Hi-MD3 adjustment disc (HMD1GSDJ) is consumable.

Therefore if it is used 400 times, exchange it for a new.

2. ADJUSTMENT SEQUENCE

Adjustment must be done with the following order.

Adjustment order:

1. Entering the test mode

Note: Enter the test mode with a key.

2. Initialize the adjustment value

3. Setting the temperature correction value

4. Power supply voltage adjustment

5. Laser power check

6. Setting the adjustment values

7. Servo Overall adjustment

8. Resume clear

9. Releasing the test mode

3. ADJUSTMENT OF THE EACH ITEM

3-1. Initialize The Adjustment Value

Procedure:

1. In the test mode (Display Check mode), press the [VOL--] key

to enter the Overall adjustment mode.

2. Press the [DOWNLOAD] key and display “911 ResOK?”.

3. Press the

adjustment values.

4. Press the x key and back to Display Check mode.

3-2. Setting The Temperature Correction Value

Procedure:

1. Enter the test mode (Display Check mode).

2. Press the [VOL+] key to enter the Manual mode.

3. Press the > key twice, and press the [VOL+] key twice to

display as follows.

X key to display “911 Reset!” and initialize the

Display

0130

Temp

5. Measure the ambient temperature.

6. Adjust with [VOL+]/[VOL--] keys so that the adjusted value

(hexadecimal value) becomes the ambient temperature.

(example: 25 °C = 19h)

7. Press the X to write the adjusted value.

8. Press the x key four times and back to the Display Check

mode.

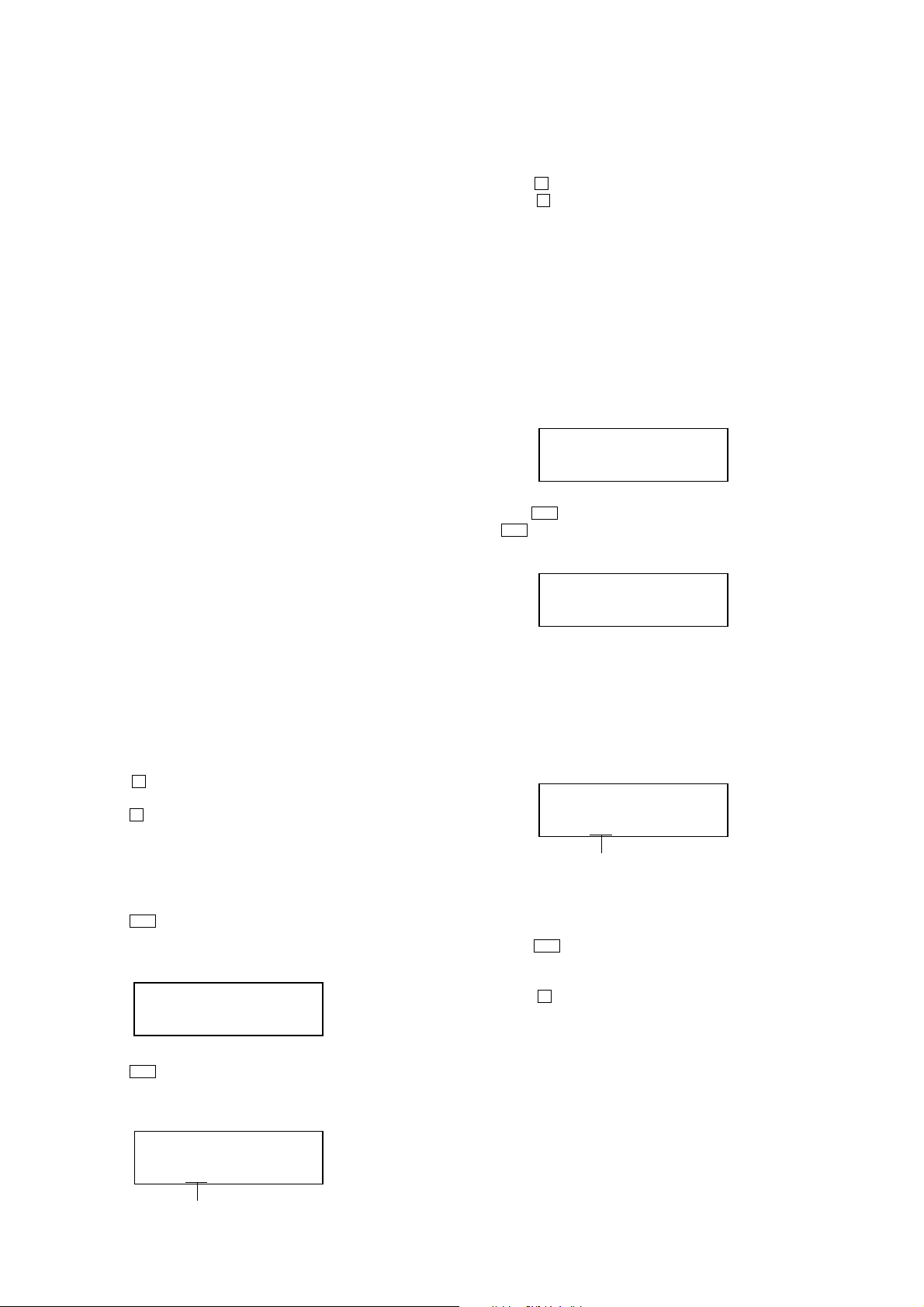

3-3. Power Supply Voltage Adjustment

Adjustment must be done with the following order.

3-3-1. Setting

Procedure:

1. Apply the voltage of 1.2 V to the battery terminals, and enter

the test mode (Display Check mode).

2. Press the [VOL+] key to enter the Manual mode.

3. Press the [VOL+] key twice to display as follows.

Display

2000

POWER

4. Press the > key once, press the [VOL+] key once, and press

the > key once again to display as follows.

Display

2210

PwrAdj

5. Repeat the next procedures (3-3-2. PwrAdj Adjustments), and

adjust all contents of “table 3-3-1. PwrAdj Specifications”.

3-3-2. PwrAdj adjustments

Repeat the following procedures and adjust all contents of “table 33-1. PwrAdj Specifications”.

Example Display (Item No. 2211)

2211

**

adjustment value (hexadecimal)

Procedure:

1. Connect the digital multi meter to measuring point (refer to

the following table) and CL433 (GND).

2. Press the > key to change the item numberr to 2211.

3. Adjust with [VOL+]/[VOL--] keys so that the value of digital

multi meter becomes specification value.

4. Press the X key to write the adjusted value. (Shifts to the

next item automatically)

5. Repeat adjustment from step 3 until item number 2233.

4. Press the > key once to select the item number 0131 and

display as follows.

Display

0131

###S**

adjustment value (hexadecimal)

16

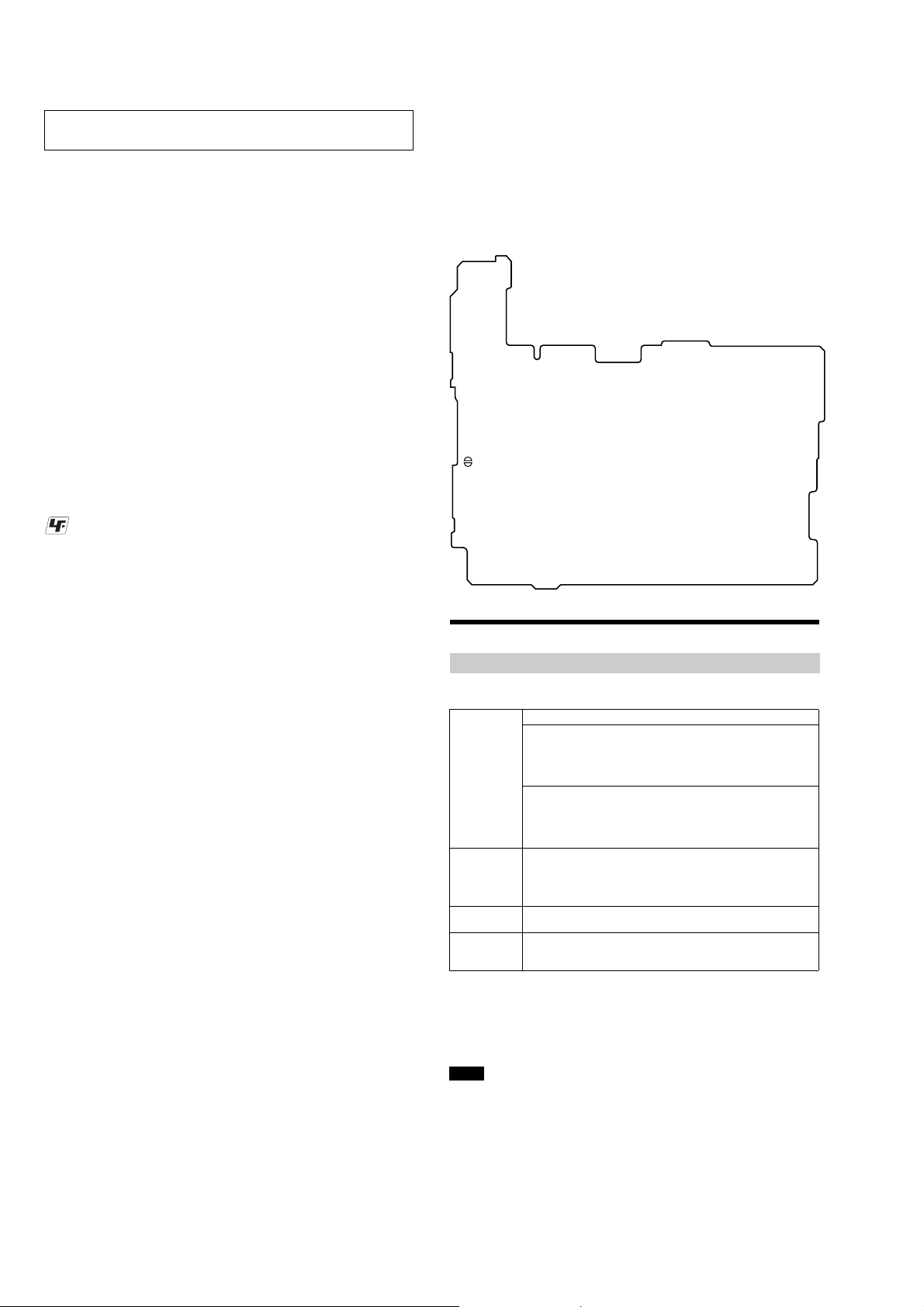

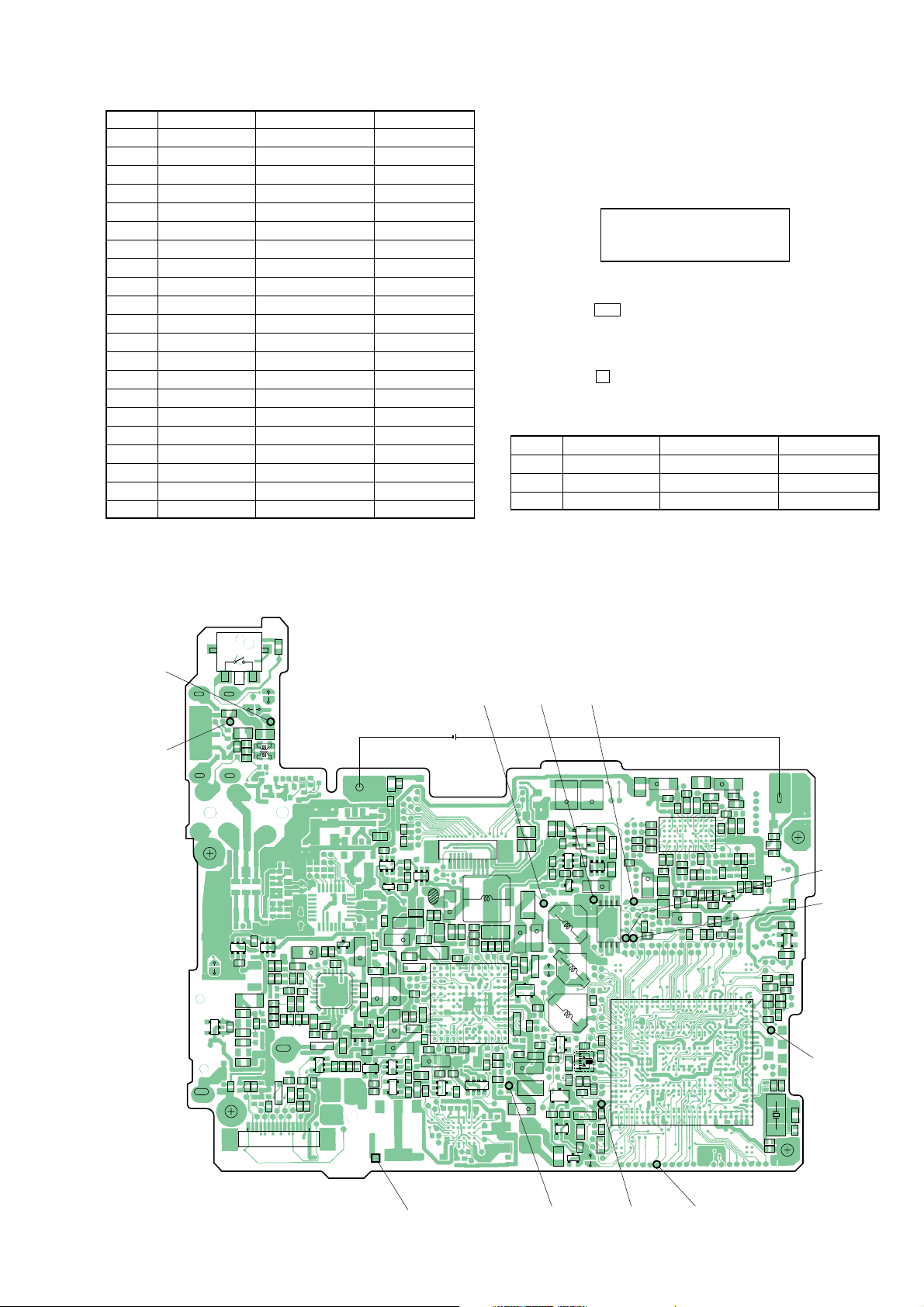

MZ-DH710

9

ItemNo. Display Specification value Measuring point

2211 211 VC1 ** 2.05V + 0.02V CL8027

2212 212 VC1H N ** 2.25V ± 0.01V CL8027

2213 213 VC2 ** 1.20V + 0.01V CL8001

2214 214 DDC3 L ** 3.10V ± 0.015V CL658

2215 215 DDC3 H ** 3.10V ± 0.015V CL658

2216 216 REG1 L ** 3.02V ± 0.02V CL919

2217 217 REG1 H ** 3.02V ± 0.02V CL919

2218 218 REG2 1 ** 2.275V ± 0.01V CL921

2219 219 REG2 2 ** 2.480V ± 0.01V CL921

2221 221 REG2 3 ** 2.740V ± 0.01V CL921

2222 222 REG2 4 ** 2.985V ± 0.01V CL921

2223 223 REG3 ** 2.52V ± 0.02V CL931

2224 224 VREC 1 ** 0.89V ± 0.02V CL604

2225 225 VREC 2 ** 1.08V ± 0.02V CL604

2226 226 VREC 3 ** 1.52V ± 0.02V CL604

2227 227 VREC 4 ** 2.27V ± 0.02V CL604

2228 228 VREC 5 ** 2.97V ± 0.02V CL604

2229 229 VREC 6 ** 0.94V ± 0.02V CL604

2231 231 VREC 7 ** 1.28V ± 0.02V CL604

2232 232 VREC 8 ** 2.57V ± 0.02V CL604

2233 233 VREC 9 ** 2.57V ± 0.02V CL604

Note1: “**” is adjustment value (hexadecimal number).

Note2: Ground point of all measuring points is CL433.

Table 3-3-1. PwrAdj Specifications

Adjustment Location:

– MAIN BOARD (Conductor Side) –

3-3-3. VBsAdj adjustments

Procedure:

1. In the “3-3-2. PwrAdj Adjustments” completed status, display

as follows.

Display

2240

VBsAdj

2. Apply the voltage of 5 V to the CL453 and CL460 (GND).

3. Press the > key to change the item number to 2241.

4. Adjust with [VOL+]/[VOL--] keys so that the value of digital

multi meter becomes specification value. (Refer to “table 33-2. VBsAdj Specifications”)

5. Press the X key to write the adjusted value.

6. Repeat adjustments to item number 2243 at the same manner

as step 4 to step 5.

ItemNo. Display Specification value Measuring point

2241 241 REG4 ** 1.13 V ± 0.01 V CL8001

2242 242 REG5 ** 2.05 V + 0.02 V CL8027

2243 243 REG6 ** 3.30 V ± 0.01 V CL8055

Note1: “**” is adjustment value (hexadecimal number).

Note2: Ground point of all adjustment points is CL433.

Table 3-3-2. VBsAdj Specifications

CL460

(GND)

CL453

S892

(HALF LOCK)

SL891

SL892

R454

FB451

FB452

C455

C456

C459

C458

LF451

DGDD

2C 1B 1E

R358

Q353

Q352

2E 2B 1C

SL894

D352

K

K

DS

R356

R253

R153

F351

C151

C152

FB355

K

A

K

C251

C252

R355

C364

FB354

FB353

FB357

C361

R472

R471

D471

R473

116

CN471

C457

C354

C351

R254

R252

R154

R251

R151

C253

R258

R257

R158

C478

R478

FB471

KA

+

R353

18 13

R152

IC352

24 7

C153

1

R157

C154

R255

R155

C254

KA

D251

1C

1B

E

2C

2B

Q471

C429

C476

R474

R475

CL658

DRY BATTERY

SIZE "AA"

(IEC DESIGNATION R6)

1PC. 1.5V

AK

C425

D435

W404

C430

R455R456

R406

R618

1C 2B 2E

Q608

R619

1E 1B 2C

R609

ECB

R601

Q607

R677

D604

Q351

BCE

R354

R352

R485

C636

+

C658

R643

C356

L608

+

AK

D610

AK

KA

D613

1219

6

IC602

C601

C479

R483

R484

IC606

D609

IC601

C612

C621

C355

C630

+

+

C619

C625

45

C613

R652

+

D601

31

+

C614

C673

Q618

1

2

1E

1C

R683

1B

2B

2C

2E

43

R685C677

1

R682

R684

342

IC607

DGDD

Q611

DS

C653

BP701

+

R628

R665

AK

R649

C643

R664

C672

C644

57 56 54 52 49 4541 37 34 32 30 29

58 59 55 53 50 4642 38 35 33 31 28

∗

60 61 27 26

62 63 64 51 47 43 39 36 25 24

65 66 67 68 48 44 40 23 22 21

69 70 71 72 20 19 18 17

73 74 75 76 16 15 14 13

77 78 79 96 10010412 11 10 9

R608

C604

80 81 92 95 99 103107 8 7 6

82 83 5 4

KA

84 87 89 91 94 98102106 109 111 3 2

85 86 88 90 93 97101 105 108 110 112 1

C602

R645C675R653

+

C616

C671

R647

C607

135

C609

4

R654

R679

IC605

CN701

R675

R648

R616

C641

Q609

CL935 CL931

L701

L702

110

L605

+

C666

C637

C642

C645

R617

R629

R671

C634

C638

D

Q612

G

D602

KA

R670

C620

R605

+

R612

C627

58

C611

L601

41

+

C622

L603

CL658

+

C635

AK

D603

S

C633

R673

R681

C628

IC804

SL901

R867 C856

L503

+

C518

D611

C661

R657

KA

DGDD

R635

+

85

Q901

14

C822

R802

C853

R832

AK

D803

C557

L502

C511

C515

FB501

R860

C520

5451 4845 43 42 4037 34 31

C517

5552 4947 44 41 3836 33 30

5653 5046 39 3532 29

C516

14711 18222528

25810131619212427

C521

36912141517202326

C522

C525

C527

+

C556

L506 L504

C529

C559

C423

C424

+

+

IC603

135

C660

R650

4

R636

2C

2E

1B

2B

R642

Q614

R641R640

1E

1C

Q615

R639

R638

DS

C652

GDS

Q613

CL935

L907

L901

R861

L906

IC902

3

R646

X801

124

C961

FB801

R801

R806

R807

D

R804

R805

Q802

G

S

D801

AK

12

R845

43

R862

GDS

C674

SL801

Q801

IC801

+

C553

C519

C513

C531

C533

C566

+

∗

C554

C524

C530

R525

R526

C523

C528

R505

C537

C536

∗

IC501

C538

C545

R502

R501

Q504

R512

C565

R519

R518

ECB

R511

R517

SL802

C567

C847

R843

R868

R827

R828

R810

R823

W403

C539

C427

KA

D441

C574

C550

C552

C547

C526

R520

C555

R509

R524

IC604

C803

C805

R817

C857

C809

R820

R869

CL921

CL91

C860

C669

431

2

C668

C804

R811

R812

R815

CL8027

C802

R808

X802

FB807

C801

C858

C859

CL433

(GND)

CL604

CL8001CL8055

17

Loading...

Loading...