Page 1

MDR-RF875R

SERVICE MANUAL

Ver 1.0 2000. 08

MDR-RF875R is the component model block one in the MDR-RF875RK.

COMPONENT MODEL NAME FOR MDR-RF875RK

Headphones MDR-RF875R

Transmitter TMR-RF875R

AEP Model

UK Model

SPECIFICATIONS

Headphones

Power source DC 2.4 V: Built-in rechargeable

battery

Mass Approx. 350 g (12.25 oz.) incl.

built-in rechargeable battery

Built-in Ni-MH rechargeable battery

Model name NH-AAC

Voltage 1.2 V

Capacity 1,000 mAh

Design and specifications are subject to change without

notice.

HEADPHONES

Page 2

SECTION 1

GENERAL

This section is extracted

from instruction manual.

5

Turn up the volume to a moderate

level with the VOL control.

Press the TUNING button briefly for

automatic tuning of the headphones.

If you do not receive a clear audio

signal, press it again.

TUNING

VOL control

Try the above steps 3 and 5 until the

receiving performance becomes better.

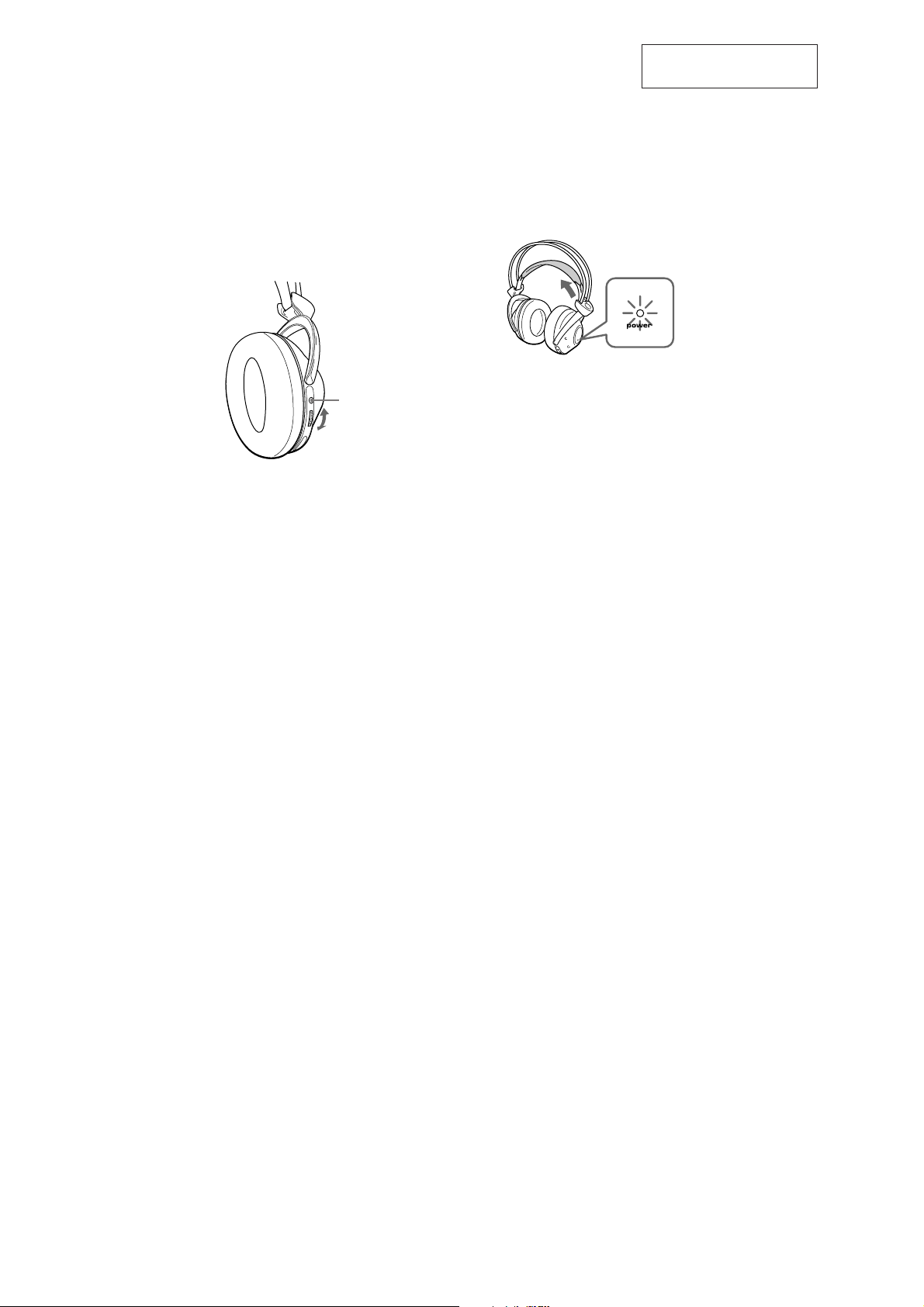

Auto power on/off function

When you remove the headphones from your

head, the power turns off automatically. Do not

allow the self adjusting band to be pulled up,

otherwise the headphones will be switched on.

The power turns on.

Note

If a hissing noise is heard move closer to the transmitter.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

— 2 —

Page 3

SECTION 2

DISASSEMBLY

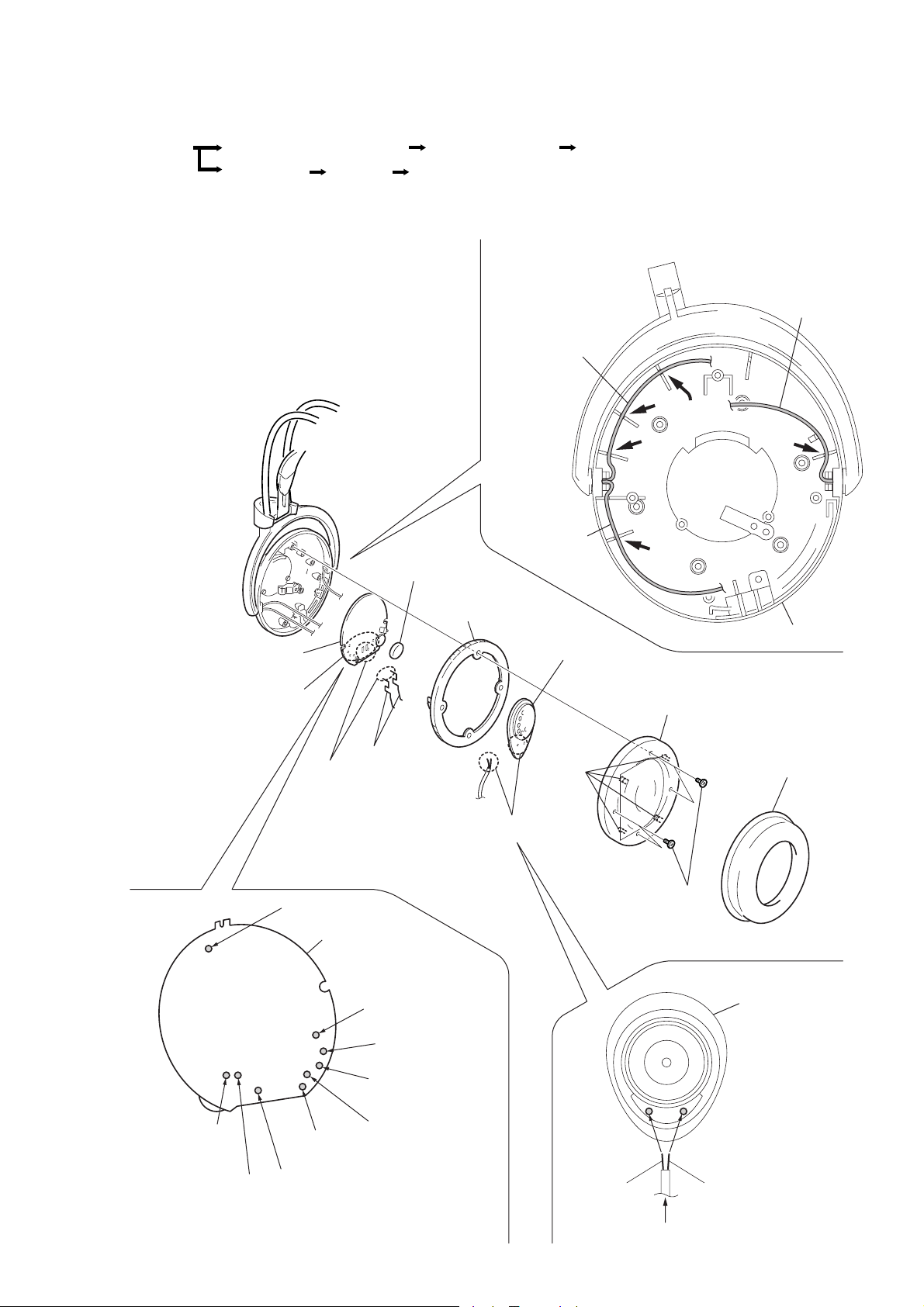

• The equipment can be removed using the following procedure.

Set

Driver (R side), RX-BASE board

Driver (L side), Hanger (L)

SW board, Harger (R)

Holder (L)

Note : Follow the disassembly procedure in the numerical order given.

2-1. DRIVER (R SIDE), RX-BASE BOARD

9

Volume knob

Set the each leads as illustrated below.

From head

band assy (rear).

Holder (R)

From head

band assy (front).

Groove

Groove

Groove

From

SW board.

Groove

qa

RX-BASE board

0

Remove the

eight solderings.

(Housing (R) side)

Head band

assy (front)(natural)

8

Charge terminal

7

Remove the

two solderings.

Precaution for installtion

ANT

RX-BASE board

SW board

Head band

assy (rear)(natural)

Head band

assy (rear)(green)

Driver (natural)

Driver (red)

4

Ear pad holder (R)

5

Remove the

two solderings.

6

Four

claws

Driver

2

Four screws (M 2

Housing (R)

Precaution for installtion

3

Front plate (R) assy

1

Ear pad

× 5)

Precaution for installtion

Driver (R side)

Head band

assy (front)(black)

Solder the each leads directly to the position as shown

while being cautions of colors.

SW board

Red Natural

From RX-BASE board.

— 3 —

Page 4

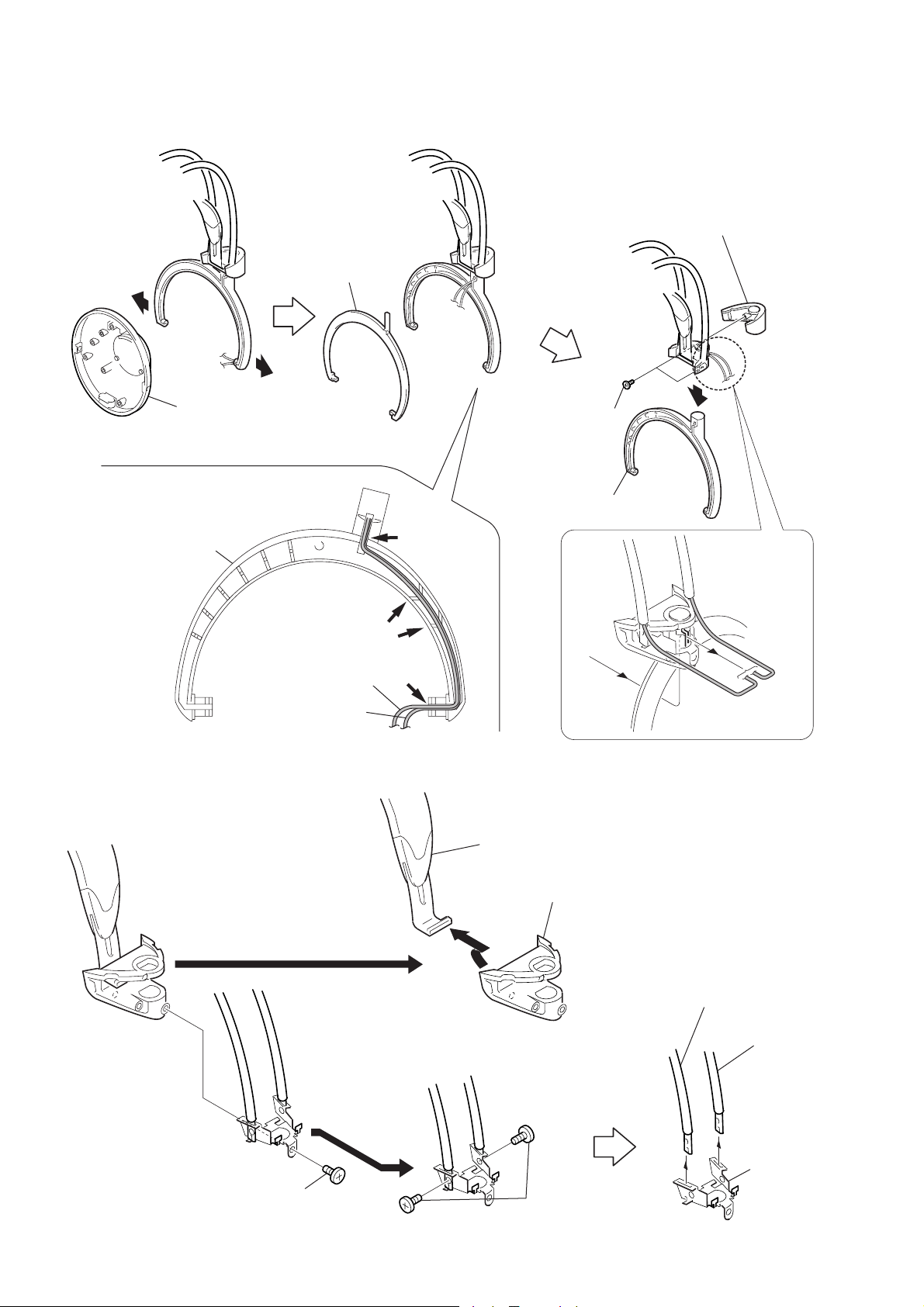

2-2. SW BOARD, HANGER (R)

s

1

1

2

Housing (R)

Precaution for installtion

Set the each leads as illustrated below.

From

SW board.

Groove

Hanger (R)

3

Hanger lid (R)

8

7

Remove the

two solderings.

SW board

5

Holder lid (R)

4

Two screw

(P 2

9

Hanger (R)

× 8)

Groove

2-3. HOLDER (R)

Groove

From head

band assy (front).

From head

band assy (rear).

2

Spring

Groove

Groove

Groove

3

Holder (R)

SW board

6

4

Head cushion assy

8

Head band assy (front)

7

Head band assy (rear)

1

Screw (P 2

× 8)

— 4 —

5

Two screws

(P 2

× 8)

6

Shassis

Page 5

2-4. DRIVER (L SIDE)

Set the each leads as illustrated below.

From head

band assy (front).

Groove

Groove

Housing (L)

Precaution for installtion

3

Front plate (L) assy

1

Ear pad

2

Four screws (M 2

Precaution for installtion

× 5)

Driver (L side)

From head

band assy (rear).

8

Driver

Four

claws

7

Remove the

two solderings.

4

Two nickle

hydrogen batterys

6

Ear pad

holder (L)

Green

Natural

5

Remove the

two solderings.

Green Natural

From head band assy (rear).

— 5 —

Page 6

2-5. HANGER (L)

1

3

Hanger lid (L)

1

2

Housing (L)

Precaution for installtion

4

Two screws

× 5)

(M 2

5

Holder lid (L)

Set the each leads as illustrated below.

2-6. HOLDER (L)

Hanger (L)

Groove

From head

band assy (front).

From head

band assy (rear).

Groove

Groove

7

Hanger (L)

3

Head cushion assy

2

Holder (L)

6

6

Head band assy (front)

7

Head band

assy (rear)

5

Shassis

1

Screw (M 2

× 5)

4

Two screws

(M 1.7

× 3)

— 6 —

Page 7

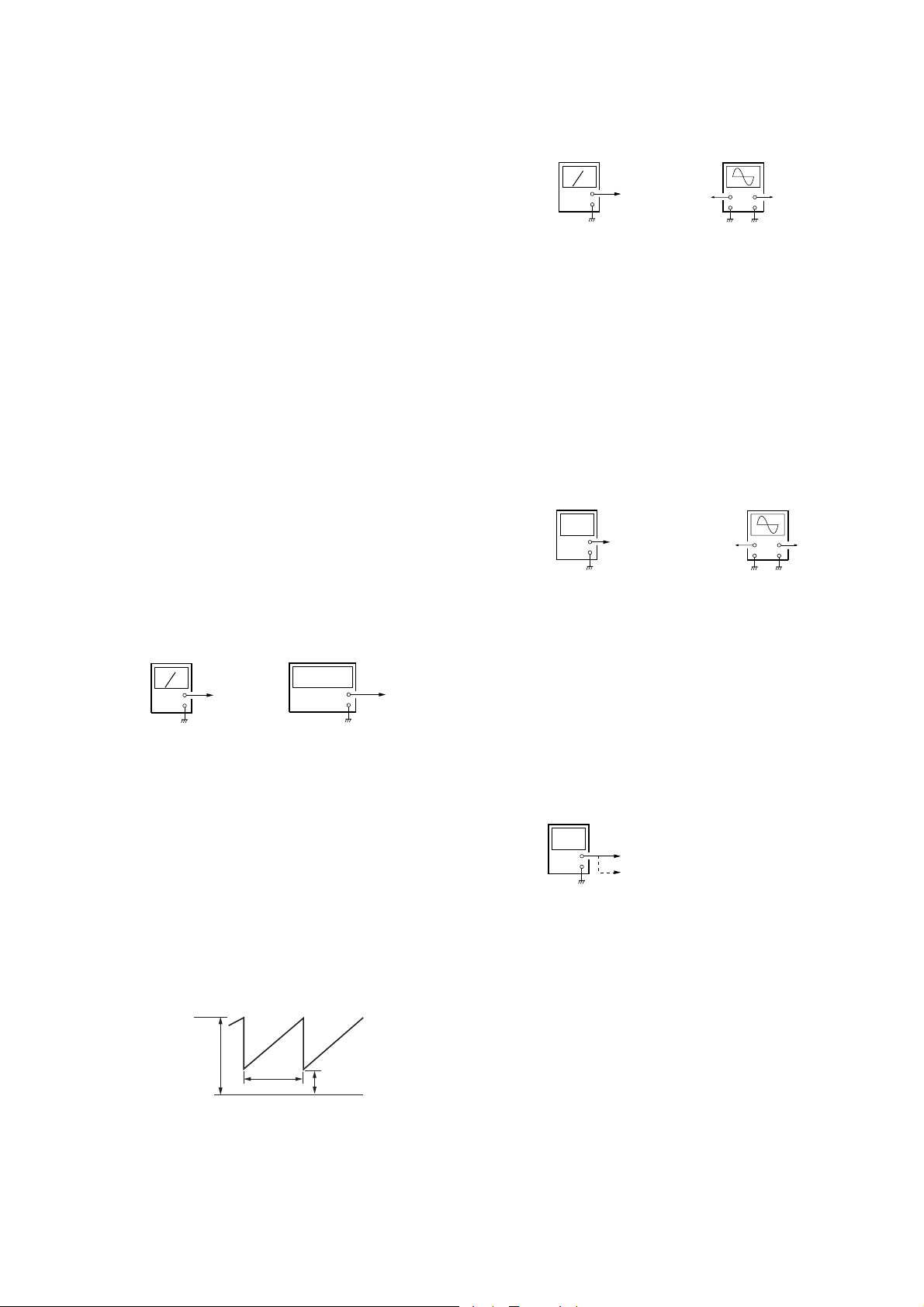

SECTION 3

4

4

+

–

Digital voltmeter

(AC range)

IC301 pin6

+

–+–

IC301 pin6

IC301 pin4

OSCILLOSCPE

CH1 CH2

7

7

ELECTRICAL ADJUSTMENTS

Notes:

1. Use a transmitter to which check and adjustment are already

completed.

2.

On adjusting the headphones section, use the transmitter as a jig.

Headphones:MDR-RF875R

Transmitter:TMR-RF875R

Procedure:

1. Connect an oscillator with attenuator and terminator (600 Ω)

to the transmitter AUDIO IN-A connector (J402).

2. Connect an A C adapter to the transmitter DC IN 9V jack (J404).

3. Short between Q303 collector and GND on the RX board.

4. Connect DC 2.4V to the +B power line externally.

5. Connect lead wires to IC301 pin 4, pin 6, pin 7, IC 307 pin 7,

IC 308 pin 7 and GND on the RX-BASE board.

6. Connect a 33KΩ resistor between IC301 pin 4 and pin 7.

7. Connect lead wires to the speakers’ terminals (L+,L-,R+,R-)

on the RX-BASE board. (See page 9)

3-1. Free Run Frequency Check and Adjustment

1. Set the transmitter AUDIO IN-A connector (J402) to no signal.

Note: In this case, operation time is about 4 or 5 minutes.

2. Check the transmitter power indicator (red) lights.

3. Set the transmitter CHANNEL switch to 1.

4. Connect DC 1.2V across TP and GND.

5. Connect a frequency counter to IC301 pin 4 and GND on the

RX-BASE board.

6. Adjust the value of the frequency counter to specification by

RV301 on the RX-BASE board.

Specified values: 76kHz ± 50Hz.

Setting :

Requlated power supply

(DC 1.2V)

TP

+

–

Frequency counter

+

–

IC301 pin

3-2. Receive Frequency Check and Adjustment

1. Set the transmitter CHANNEL switch to 2.

2. Set the transmitter NOISE FILTER switch to OFF.

3. Input a signal of 1kHz, 316mVrms to transmitter AUDIO INA (L-ch) connector only.

4. Keep distance between transmitter and headphones to 5 meters over.

5. Set the headphones volume (RV302) to minimum.

6. Connect DC 1.2V across TP and GND.

7.

Connect an oscilloscope CH1 and CH2 to IC301 pin 6 and pin 4.

8. Check the waveform of the oscilloscope to CH1 is demodulated

1kHz signal and CH2 is GND.

9. If CH1 and CH2 are not satisfied in step 8, adjust the coil (L301)

on the RX board to satisfied step 8.

10. Open between Q303 corrector and GND on the RX board.

11. When the transmitter off, check the waveform of the

oscilloscope as follows:

1.8V

GND

2–3 sec

12. Set the transmitter CHANNEL switch to 1.

13. Push the headphones tuning switch (S301) to receive radio

frequency.

14. Check same step 8.

15. Set the transmitter CHANNEL switch to 3.

16. Push the headphones tuning switch (S301) to receive radio

frequency.

17. Check same step 8.

0.6V

Setting :

Requlated power supply

(DC 1.2V)

TP

+

–

OSCILLOSCPE

IC301 pin6

CH1 CH2

+

–+–

IC301 pin

3-3. Carrier Modulation Check

1. Set the transmitter CHANNEL switch to 2.

2. Set the transmitter NOISE FILTER switch to OFF.

3. Input a signal of 1kHz, 316mVrms to transmitter AUDIO INA (L-ch) connector only.

4. Set the headphones volume (RV302) to minimum.

5.

Connect an oscilloscope CH1 and CH2 to IC301 pin 6 and pin 4.

6. Push the headphones tuning switch (S301) to receive radio

frequency.

7. Check the waveform of the oscilloscope that the CH1 is

demodulated 1kHz signal and CH2 is GND.

8. Connect an AC voltmeter with LPF to IC301 pin 6 and GND.

9. Check the value of the AC voltmeter to 40mVrms ± 5mV

Setting :

3-4. Expander Output Check

1. Set the transmitter CHANNEL switch to 2.

2. Input a signal of 1kHz, 316mVrms to transmitter AUDIO INA L and R connector.

3. Connect an AC voltmeter to IC307 pin 7 and IC308 pin 7.

4. Measure the value of the AC voltmeter.

5. Input a signal of 1kHz, 31.6mVrms to transmitter AUDIO INA L and R connector.

6. Measure the value of the AC voltmeter.

7. Check the difference of the step 4 and step 6 to more than 20

dB ± 3 dB.

Setting :

Digital voltmeter

(AC range)

+

–

IC307 pin

IC308 pin

3-5. Separation Check

1. Set the transmitter CHANNEL switch to 2.

2. Set the transmitter NOISE FILTER switch to OFF.

3. Input a signal of 1kHz, 316mVrms to transmitter AUDIO INA (L-ch) connector only.

4. Connect an oscilloscope CH1 to speakers terminal (L+,L-) and

CH2 to IC301 pin 4 and GND.

5. Push the headphones tuning switch (S301) to receive radio

frequency.

6. Check the waveform of the oscilloscope that the CH1 is

demodulated 1kHz signal and CH2 is GND.

7.

Connect an AC voltmeter with LPF to speakers terminal (L+,L-).

8. Adjust the value of the AC voltmeter to specification by

headphones volume RV302.

Specified values: 155mVrms

9.

Connect an A C v oltmeter with LPF to speak ers terminal (R+,R-).

10. Measure the value of the AC voltmeter.

11. Check the difference of the L and R to more than 25dB.

12. Input a signal of 1kHz, 316mVrms to transmitter AUDIO INA (R-ch) connector only.

— 7 —

Page 8

13.

4

4

Connect an A C v oltmeter with LPF to speak ers terminal (R+,R-).

14. Adjust the value of the AC voltmeter to specification by

headphones volume RV302.

Specified values: 155mVrms

15.

Connect an AC voltmeter with LPF to speakers terminal (L+,L-).

16. Measure the value of the AC voltmeter.

17. Check the difference of the L and R to more than 25dB.

18. Remove a 33KΩ resistor between IC301 pin 4 and pin7.

Setting :

Digital voltmeter

(AC range)

OSCILLOSCPE

L+ / R+

+

L– / R–

–

L+

L–

CH1 CH2

+

–+–

IC301 pin

3-6. MPX Signal Modulation Check

1. Set the transmitter CHANNEL switch to 2.

2. Set the transmitter NOISE FILTER switch to OFF.

3. Input a signal of 1kHz, 316mVrms to transmitter AUDIO INA (L-ch) connector only.

4. Connect an oscilloscope CH1 to speakers terminal (L+,L-) and

CH2 to IC301 pin 4 and GND.

5. Push the headphones tuning switch (S301) to receive radio

frequency.

6. Check the waveform of the oscilloscope that the CH1 is

demodulated 1kHz signal and CH2 is GND.

7.

Set the headphones volume (RV302) to max.

8.

Connect an AC voltmeter with LPF to speakers terminal (L+,L-).

9.

Check the value of the AC voltmeter to specification.

Specified values: 450mVrms to 650mVrms

Note: When the specification is not satisfied in step 9, adjust

RV402 of the TMR-RF875R until the specification of 450

to 650mVrms is obtained.

Setting :

Digital voltmeter

(AC range)

+

–

L+

L–

OSCILLOSCPE

CH1 CH2

+

L+

–+–

L–

IC301 pin

Adjustment Location : (See page 9)

— 8 —

Page 9

Adjustment Location :

[RX-BASE BOARD]

(Conductor side)

IC301

7

IC301

4

IC301

(Connect a 33 KΩ resistor)

6

GND

TP

GND

RV301

Free Run Frequency

Check and Adjustment

Short

+B

power line

L301

Receive Frequency

Check and Adjustment

L–

L+

R–

R+

RV302

Corrier Modulation/Separation/

MPX Signal Modulation Check

— 9 —

Page 10

SECTION 4

DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

®

•

• b : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from

(Side B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Side A) the parts face are indicated.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF 50 WV or

• All resistors are in Ω and 1/

•

• A : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 2.4 V and fed with regulated dc power supply

• Voltages are dc with respect to ground under no-signal conditions.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: Through hole.

less are not indicated except for electrolytics and tantalums.

4

W or less unless otherwise specified.

¢

: internal component.

from battery terminal.

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

F:FM

L: AUDIO

• IC BLOCK DIAGRAMS

IC302 LA4533M IC305 TC7W74FU

AMP1

AMP2

MUTE

CIRCIUT

10

MT/SW

OUT1

9

8

POWER GND

7

OUT2

6

VCC

P/SW

IN1

PRE GND

IN2

REF

POWER

1

SWITCH

2

BIAS

3

4

5

VCC

1

CK

CLR

6

7PR8

RSQ

QDC

3

2

Q

D

Q

5

4

GND

— 10 —

Page 11

4-1. BLOCK DIAGRAM

FRONT END

FE UNIT

18

20

FM FE

+V

L302

CF301

CF302

10.7MHz

MDR-RF875R

IF AMP/DECODE

IC301

Q306

FM IF/

1316

DISCRI

26

AUTO

BLEND

PD1

PD1

1/2

COUNTER

DECODE

AMP

DETUNE

MUTE

TUNING

IND

6 2

5

10

12

HPF

R-CH

IC304

DETECT

Q305

IC309 IC306

LPF EQ

IC305

Q

FF

D

Q

S301

TUNING

IC307

EXPANDER

AMP

RV302

VOLUME

POWER AMP

IC302

10

MUTE

Q304

9

R-CH

SPEAKER

L-CH

SPEAKER

R-CH

MUTE

REG

22

+V

L301

RECEIVE

FREQ.

D301

16

IC303

D/A

CONV

21

+V

OSC

Q301

SWITCH

Q303

VCO

27

RV301

FREE RUN

FREQ.

MONO/ST

SW

STEREO

IND

S1

ON/OFF SW

B+

D304

(POWER)

+

-

• Signal path.

: FM

• R-ch is omitted due to same as L-ch.

— 11 — — 12 —

Page 12

MDR-RF875R

4-2. SCHEMATIC DIAGRAM

• See page 10 for Note on Schematic Diagrams.

• See page 10 for IC Block Diagrams.

— 13 — — 14 —

Page 13

MDR-RF875R

1234 567

RX SW board

(power)

C

VOL

TUNE

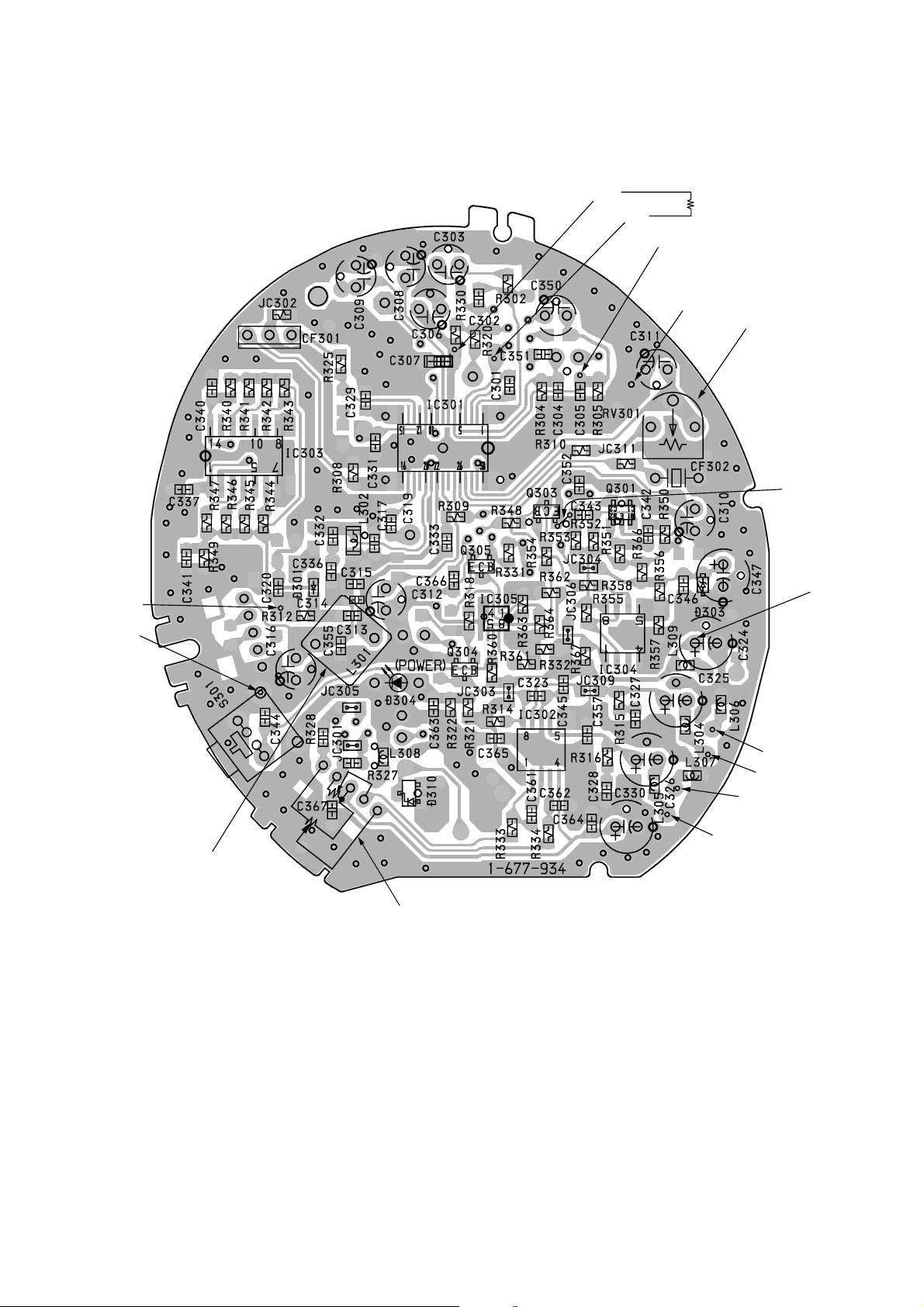

4-3. PRINTED WIRING BOARD

• See page 10 for Note on Printed Wiring Board.

• Semiconductor

Location

Ref. No. Location

D301 B-1

D303 B-3

D304 B-2

D310 C-2

IC301 A-2

IC302 C-2

IC303 A-1

IC304 B-3

IC305 B-2

IC306 C-5

IC307 C-6

IC308 B-6

IC309 B-5

Q301 B-3

Q303 B-2

Q304 B-2

Q305 B-2

Q306 A-5

Q307 B-5

— 15 — — 16 —

Page 14

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

4

#3

20

#3

14

#3

a

b

21

23

24

SECTION 5

EXPLODED VIEWS

• The mechanical parts with no reference number

in the exploded views are not supplied.

• Accessories and packing materials are gi ven in

the last of this parts list.

b

3

6

7

39

10

9

16

not

supplied

e

22

26

#2

8

41

36

5

e

#1

27

a

#1

37

#1

12

1

2

#1

d

c

13

14

d

#2

38

c

#3

11

15

25

37

40

28

#3

33

17

6

18

not

supplied

19

29

#3

32

34

35

23 3-046-706-01 HANGER (R)

24 3-049-954-01 LID(R), HANGER

25 3-046-708-01 HOUSING (R)

26 3-046-710-01 CAP (R), ORNAMENTAL

27 3-224-571-01 FILM (R), HOLOGRAM

* 28 A-4542-639-A RX-BASE BOARD, COMPLETE

29 3-049-797-01 LIGHT, MDR GUIDE

30 3-046-713-01 BUTTON, TUNING

31 3-220-124-01 PLATE (R), HOUSING ORNAMENTAL

32 3-046-715-01 TERMINAL, CHARGE

#3

#3

4

30

31

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 X-3379-300-1 BAND ASSY (REAR), HEAD

2 X-3379-299-1 BAND ASSY (FRONT), HEAD

3 X-3379-301-1 CUSHION ASSY, HEAD

4 3-046-718-01 PAD,EAR

5 X-3379-304-1 PLATE (L) ASSY, FRONT

6 1-542-416-11 DRIVER (030F031)

7 3-046-723-01 HOLDER (L), EAR PAD

8 1-756-109-11 BATTERY, NICKEL HYDROGEN

9 3-046-717-01 TERMINAL (SMALL), BATTERY

10 3-224-570-01 FILM (L), HOLOGRAM

11 3-046-709-01 CAP(L), ORNAMENTAL

12 3-046-716-01 TERMINAL (LARGE), BATTERY

13 3-046-696-01 HOLDER (L)

14 3-046-695-01 CHASSIS

15 3-046-698-01 LID (L), HOLDER

16 3-220-123-01 PLATE (L), HOUSING ORNAMENTAL

17 3-046-707-01 HOUSING (L)

18 3-049-953-01 LID(L), HANGER

19 3-046-705-01 HANGER (L)

20 3-046-699-01 LID(R), HOLDER

* 21 1-678-685-11 RX-SW BOARD

22 3-046-697-01 HOLDER (R)

33 3-049-951-01 KNOB, VOLUME

34 3-046-724-01 HOLDER (R), EAR PAD

35 X-3379-305-1 PLATE (R) ASSY, FRONT

36 3-224-569-01 SPRING (ON/OFF)

37 3-223-909-01 SCREW (B2)

38 3-224-572-01 SHEET, HOLOGRAM (L), ADHESIVE

39 3-224-688-01 SHEET (L), LIGHT PREVENTION

40 3-224-689-01 SHEET (R), LIGHT PREVENTION

41 3-224-573-01 SHEET, HOLOGRAM (R) ADHESIVE

#1 7-621-255-15 SCREW +P 2X3

#2 7-685-103-14 SCREW +P 2X5 TYPE2 NON-SLIT

#3 7-685-104-14 SCREW +P 2X6 TYPE2 NON-SLIT

— 17 — — 18 —

Page 15

SECTION 6

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* A-4542-639-A RX-BASE BOARD, COMPLETE

***********************

* A-4542-642-A FE UNIT (FRONT END)

< CAPACITOR >

C301 1-164-346-11 CERAMIC CHIP 1uF 16V

C302 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C303 1-124-259-11 ELECT 4.7uF 20.00% 16V

C304 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C305 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C306 1-124-234-00 ELECT 22uF 20% 16V

C307 1-163-059-91 CERAMIC CHIP 0.01uF 10.00% 50V

C308 1-124-234-00 ELECT 22uF 20% 16V

C309 1-104-942-11 ELECT 1uF 20.00% 50V

C310 1-104-942-11 ELECT 1uF 20.00% 50V

C311 1-124-233-11 ELECT 10uF 20.00% 16V

C312 1-126-162-11 ELECT 3.3uF 20% 50V

C313 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C314 1-164-441-11 CERAMIC CHIP 68PF 5.00% 50V

C315 1-163-235-11 CERAMIC CHIP 22PF 5.00% 50V

C316 1-124-233-11 ELECT 10uF 20.00% 16V

C317 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C318 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C319 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C320 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C321 1-164-346-11 CERAMIC CHIP 1uF 16V

C322 1-164-346-11 CERAMIC CHIP 1uF 16V

C323 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C324 1-124-635-00 ELECT 220uF 20.00% 6.3V

C325 1-124-635-00 ELECT 220uF 20.00% 6.3V

C326 1-124-635-00 ELECT 220uF 20.00% 6.3V

C327 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C328 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C329 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C330 1-124-242-00 ELECT 33uF 20% 25V

C331 1-164-346-11 CERAMIC CHIP 1uF 16V

C332 1-163-245-11 CERAMIC CHIP 56PF 5.00% 50V

C333 1-163-220-11 CERAMIC CHIP 3PF 0.25PF 50V

C336 1-163-245-11 CERAMIC CHIP 56PF 5.00% 50V

C337 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C340 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C341 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C342 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C343 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C344 1-163-038-11 CERAMIC CHIP 0.1uF 25V

• CAPACITORS:

uF: µF

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• COILS

uH: µH

C345 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C346 1-164-489-11 CERAMIC CHIP 0.22uF 10.00% 16V

C347 1-124-589-11 ELECT 47uF 20% 16V

C352 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C353 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C354 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C355 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C356 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C357 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C359 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C361 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C362 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C363 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C370 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C371 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C372 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C373 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C374 1-163-259-91 CERAMIC CHIP 220PF 5.00% 50V

C375 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C376 1-163-259-91 CERAMIC CHIP 220PF 5.00% 50V

C377 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C378 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C379 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C380 1-124-259-11 ELECT 4.7uF 20.00% 16V

C381 1-124-259-11 ELECT 4.7uF 20.00% 16V

C382 1-164-346-11 CERAMIC CHIP 1uF 16V

C383 1-164-346-11 CERAMIC CHIP 1uF 16V

C384 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C385 1-164-161-11 CERAMIC CHIP 0.0022uF 10% 100V

C386 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C387 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C388 1-163-255-11 CERAMIC CHIP 150PF 5.00% 50V

C389 1-163-255-11 CERAMIC CHIP 150PF 5.00% 50V

C391 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C392 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C393 1-124-233-11 ELECT 10uF 20.00% 16V

C394 1-124-233-11 ELECT 10uF 20.00% 16V

C395 1-164-346-11 CERAMIC CHIP 1uF 16V

C396 1-164-346-11 CERAMIC CHIP 1uF 16V

C397 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C398 1-164-505-11 CERAMIC CHIP 2.2uF 16V

C399 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C400 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C402 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C403 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C404 1-164-346-11 CERAMIC CHIP 1uF 16V

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

When indicating parts by reference number,

please include the board name.

RX-BASE

— 18 —

Page 16

RX-BASE

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

< FILTER >

CF301 1-577-588-11 FILTER, CERAMIC 10.7MHz

CF302 1-577-572-11 FILTER, CERAMIC 10.7MHz

< DIODE >

D301 8-719-002-81 DIODE 1T363

D303 8-719-056-71 DIODE UDZ-TE-17-2.2B

D304 8-719-077-16 LED TLSU124(TPJ52)(power)

D310 8-719-975-40 DIODE RB411D

R318 1-216-089-11 RES-CHIP 47K 5% 1/10W

R320 1-216-001-00 METAL CHIP 10 5% 1/10W

R321 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R322 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R325 1-216-037-00 METAL CHIP 330 5% 1/10W

R330 1-216-001-00 METAL CHIP 10 5% 1/10W

R331 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R332 1-216-049-11 RES-CHIP 1K 5% 1/10W

R333 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R334 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

< IC >

IC301 8-752-072-12 IC CXA1538N

IC302 8-759-802-75 IC LA4533M

IC303 8-759-453-43 IC TC74HC4024AF(EL)

IC304 8-759-510-73 IC BA10393F-E2

IC305 8-759-083-94 IC TC7W74FU

IC306 8-759-344-00 IC NJM2100E(TE2)

IC307 8-759-384-90 IC TK10691M

IC308 8-759-384-90 IC TK10691M

IC309 8-759-344-00 IC NJM2100E(TE2)

< JUMPER >

JC303 1-216-295-11 SHORT 0

JC304 1-216-295-11 SHORT 0

JC306 1-216-295-11 SHORT 0

JC309 1-216-295-11 SHORT 0

JC311 1-216-295-11 SHORT 0

< COIL >

L301 1-422-317-31 COIL, AIR-CORE

L302 1-412-933-11 INDUCTOR 0.33uH

L304 1-414-234-11 INDUCTOR CHIP 0uH

L305 1-414-234-11 INDUCTOR CHIP 0uH

L306 1-414-234-11 INDUCTOR CHIP 0uH

L307 1-414-234-11 INDUCTOR CHIP 0uH

L308 1-414-234-11 INDUCTOR CHIP 0uH

L309 1-414-234-11 INDUCTOR CHIP 0uH

L350 1-414-234-11 INDUCTOR CHIP 0uH

< TRANSISTOR >

R340 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R341 1-216-113-00 METAL CHIP 470K 5% 1/10W

R342 1-216-106-00 METAL CHIP 240K 5% 1/10W

R343 1-216-099-00 METAL CHIP 120K 5% 1/10W

R344 1-216-092-00 RES-CHIP 62K 5% 1/10W

R345 1-216-084-00 METAL CHIP 30K 5% 1/10W

R346 1-216-077-00 RES-CHIP 15K 5% 1/10W

R347 1-216-070-00 METAL CHIP 7.5K 5% 1/10W

R348 1-216-089-11 RES-CHIP 47K 5% 1/10W

R349 1-216-073-00 METAL CHIP 10K 5% 1/10W

R350 1-216-077-00 RES-CHIP 15K 5% 1/10W

R351 1-216-121-11 RES-CHIP 1M 5% 1/10W

R352 1-216-121-11 RES-CHIP 1M 5% 1/10W

R353 1-216-077-00 RES-CHIP 15K 5% 1/10W

R354 1-216-081-00 METAL CHIP 22K 5% 1/10W

R355 1-216-089-11 RES-CHIP 47K 5% 1/10W

R356 1-216-081-00 METAL CHIP 22K 5% 1/10W

R357 1-216-081-00 METAL CHIP 22K 5% 1/10W

R358 1-216-081-00 METAL CHIP 22K 5% 1/10W

R360 1-216-081-00 METAL CHIP 22K 5% 1/10W

R361 1-216-081-00 METAL CHIP 22K 5% 1/10W

R362 1-216-073-00 METAL CHIP 10K 5% 1/10W

R363 1-216-081-00 METAL CHIP 22K 5% 1/10W

R364 1-216-081-00 METAL CHIP 22K 5% 1/10W

R366 1-216-029-00 METAL CHIP 150 5% 1/10W

R367 1-216-089-11 RES-CHIP 47K 5% 1/10W

R370 1-216-071-00 METAL CHIP 8.2K 5% 1/10W

R371 1-216-071-00 METAL CHIP 8.2K 5% 1/10W

R372 1-216-071-00 METAL CHIP 8.2K 5% 1/10W

R373 1-216-071-00 METAL CHIP 8.2K 5% 1/10W

Q301 8-729-903-10 TRANSISTOR FMW1

Q303 8-729-200-72 TRANSISTOR 2SC2712-L

Q304 8-729-200-72 TRANSISTOR 2SC2712-L

Q305 8-729-027-44 TRANSISTOR DTC114TKA-T146

Q306 8-729-200-72 TRANSISTOR 2SC2712L-TE85L

Q307 8-729-200-72 TRANSISTOR 2SC2712L-TE85L

< RESISTOR >

R302 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R304 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R305 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R308 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R309 1-216-097-11 RES-CHIP 100K 5% 1/10W

R310 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R312 1-216-077-00 RES-CHIP 15K 5% 1/10W

R314 1-216-097-11 RES-CHIP 100K 5% 1/10W

R315 1-216-001-00 METAL CHIP 10 5% 1/10W

R316 1-216-001-00 METAL CHIP 10 5% 1/10W

— 19 —

R374 1-216-064-00 METAL CHIP 4.3K 5% 1/10W

R375 1-216-064-00 METAL CHIP 4.3K 5% 1/10W

R376 1-216-097-11 RES-CHIP 100K 5% 1/10W

R377 1-216-097-11 RES-CHIP 100K 5% 1/10W

R378 1-216-063-91 RES-CHIP 3.9K 5% 1/10W

R379 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R380 1-216-049-11 RES-CHIP 1K 5% 1/10W

R381 1-216-049-11 RES-CHIP 1K 5% 1/10W

R382 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R383 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R384 1-216-067-00 METAL CHIP 5.6K 5% 1/10W

R385 1-216-067-00 METAL CHIP 5.6K 5% 1/10W

R386 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R387 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R390 1-216-097-11 RES-CHIP 100K 5% 1/10W

Page 17

MDR-RF875R

RX-BASE

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

R391 1-216-097-11 RES-CHIP 100K 5% 1/10W

R392 1-216-063-91 RES-CHIP 3.9K 5% 1/10W

R393 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R394 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R395 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R396 1-216-083-00 METAL CHIP 27K 5% 1/10W

R397 1-216-083-00 METAL CHIP 27K 5% 1/10W

R398 1-216-073-00 METAL CHIP 10K 5% 1/10W

R399 1-216-073-00 METAL CHIP 10K 5% 1/10W

R400 1-216-025-11 RES-CHIP 100 5% 1/10W

R401 1-216-025-11 RES-CHIP 100 5% 1/10W

R403 1-216-073-00 METAL CHIP 10K 5% 1/10W

R404 1-216-073-00 METAL CHIP 10K 5% 1/10W

RV301 1-241-763-11 RES, ADJ, CARBON 4.7K

RV302 1-227-189-11 RES, VAR CARBON 20K/20K (VOL )

S301 1-771-980-11 SWITCH, TACTILE (TUNE)

**************************************************************

6 1-542-416-11 DRIVER (030F031)

8 1-756-109-11 BATTERY, NICKEL HYDROGEN

* 21 1-678-658-11 RX-SW BOARD

< VARIABLE RESISTOR >

< SWITCH >

MISCELLANEOUS

**************

9-927-967-11

Sony Corporation

Audio Entertainment Group

— 20 —

Printed in Japan © 2000.8

2000H1646-1

Published by PE General Engineering Dept.

Page 18

TMR-RF875R

SERVICE MANUAL

Ver 1.0 2000. 08

TMR-RF875R is the component model block one in the MDR-RF875RK.

COMPONENT MODEL NAME FOR MDR-RF875RK

Headphones MDR-RF875R

Transmitter TMR-RF875R

AEP Model

UK Model

SPECIFICATIONS

General

Carrier frequency

863.5 – 864.5 MHz

Channel Ch1, Ch2, Ch3

Modulation FM stereo

Frequency response

18 – 22,000 Hz

Transmitter

Power source DC 9 V: supplied AC power

adaptor

Audio input phono jacks/stereo mini jack

Dimensions Approx. 130 × 135 × 150 mm

(5 1/4 × 5 3/8 × 6 in.) (w/h/d)

Mass Approx. 200 g (7 oz.)

Design and specifications are subject to change without

notice.

TRANSMITTER

Page 19

Setting up the

transmitter

1

Connect the transmitter to audio/video

equipment. Select one of the hookups

below depending on the jack type:

A To connect to a headphone jack

SECTION 1

GENERAL

This section is extracted

from instruction manual.

Transmitter

OFF ON

FILTERNOISE

Right channel

(red)

Connecting cord

(supplied)

Unimatch plug

adaptor

(supplied)

to headphones

jack (stereo

phone jack)

RBAL

AUDIO IN

CD Walkman,

MD Walkman,

WALKMAN*,

VCR, etc.

to AUDIO IN

A jacks

DC IN 9V

123

CHANNEL

Left channel

(white)

to headphones

jack (stereo

mini jack)

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

— 2 —

Page 20

SECTION 2

)

)

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. HOUSING (UPPER)

2

Housing (upper)

1

Four screws (P 2

× 8)

2-2. TX-BASE BOARD

Housing (upper)

Screw

3

TX-BASE board

2-3. CHG-NR BOARD

Housing (upper

2

2

CHG-NR board

1

Screw (P 2

× 6

— 3 —

1

Four screws (P 2

× 6)

Page 21

SECTION 3

ELECTRICAL ADJUSTMENTS

Setting :

AF signal

generator

set

TMR-RF875R

L-CH / R-CH (J402)

Telescopic

antenna

Frequency counter

8 cm

set

TMR-RF875R

Transmission Frequency Check

1. Set the noise filter SW to OFF.

2. Input a signal of 1 kHz, 40 mVrms to only the L-CH (J402).

3. Connect a telescopic antenna to the frequency counter input

and extend the antenna to a length of approximately 8 cm.

4. Place TX-BASE board close to the frequenc y counter, then measure the frequencies of CH1, CH2 and CH3 and make sure the

values are as follows:

CH1 : 863.5 MHz ± 40 kHz

CH2 : 864.0 MHz ± 40 kHz

CH3 : 864.5 MHz ± 40 kHz

Pilot Signal and MPX Signal Modulation Check and

Adjustment

1. Set the channel to CH2.

2. No signal input (The operating time in this case is limited to 4

or 5 minutes.)

3. See the RV402 and RV403 to max. (clockwise)

4. Connect a digital voltmeter (A C range) to the movable terminal

of RV403 (Fig.2).

5. Adjust the value of the digital voltmeter to minimum b y R V401.

6. See the RV402 to minimum. (counter clock wise)

7. Adjust the value of the digital voltmeter to max by L407.

8. Adjust the value of the digital voltmerter to 1.7 mVrms ± 0.1

mV by RV403.

9. Connect a digital voltmeter (AC range) with LPF to movable

terminal of RV403 (Fig.2).

10. Input a signal of 1 kHz, 316 mVrms to only the L-CH.

11. Adjust the value of the digital voltmeter to 2.5 mVrms ± 0.2

mV by RV402.

Connection points and Adjustment Location :

CH3

L407

←

CH2 ←CH1

S402

RV403RV402

R464

(L-CH) (R-CH)

J402

VCO UNIT

CHG-NR board

When the frequency does not satisfy the specified value, exchange the vco unit. When completed with replacement, recheck

the frequecies of CH1, CH2 and CH3.

Compresser Output Check

1. Set the channel to CH2.

2. Input a signal of 1 kHz, 316 mVrms to L-CH and R-CH of J402.

3. Measure IC 601 pin 7 and IC 602 pin 7 on the CHG-NR board

using a digital voltmeter (AC range) and confirm the value is

100 mVrms ± 5mV (Fig.1).

4. Input a signal of 1 kHz, 31.6 mVtms to L-CH and R-CH of J402.

5. Measure IC 601 pin 7 and IC 602 pin 7 on the CHG-NR board

using a digital voltmeter (AC range) and confirm the value is

31.6 mVrms ± 5 mV (Fig.1).

6. When the frequency is not satisfied the specified v alue, exchange

TX- BASE board or CHG-NR board.

RV401-403,

L407

Modulation

check and

adjustment.

digital

voltmeter

(AC range)

R464

(Fig. 2)

RV401

+

–

digital

voltmeter

(AC range)

+

–

(Fig. 1)

1

4

IC 601

7 pin

IC 602

8

5

8

1

5

4

— 4 —

Page 22

4-1. BLOCK DIAGRAM

SECTION 4

TMR-RF875R

DIAGRAMS

AUDIO IN

16

R-CH

J401

B

J402

L

A

R R-CH

NOISE FILTER

S401

OFF

ON

NOISE

FILTER

|

• R-ch is omitted due to same as L-ch.

• Signal path.

L : AUDIO

IC401

IC601

MODULATION

12 11

TIME

DEVISION

MPX

BUFFER

OSC

AMP

X401

38kHz

BUFFER

RV401

76

Q401

VS

BUFFER

DIVIDER

D404,405

RECT

IC403

STEREO MPX

LPF

72113

R-CH

CH1

14

AMP

CH2

1

AMP

2V

D408

RV402

9

MODULATION

L407

8

MODULATION

IC405(1/2)

INPUT

DET

Q403

SWITCH

RV403

MODULATION

15

MOD IN

VCO UNIT

CE

CE

IC404

VCO CONTROLLER

ANT401

ANT

IC405(2/2)

T-OUT

IC402

S402

CHANNEL

+5V

REG

D401

(power)

5V

DI

DI

B+

CL

13101211

CL

16

5V

679

1

2

3

POWER OFF

DET

SWITCH

Q404

+4V

Q402

SWITCH

Q601

SWITCH

Q602

D402

(chg)

IC604(1/2)

DETECT

SWITCH

Q604

IC603

COMPARATOR

OSC

Q605

IC605

+5V

REG

IC604(2/2)

DETECT

SWITCH

Q603

CHARGE

REF V

J404

DC IN 9V

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• b : Pattern from the side which enables seeing.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF 50 WV or

• All resistors are in Ω and 1/

•

• A : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 9 V and fed with regulated dc power supply

• Voltages are dc with respect to ground under no-signal conditions.

• Voltages are taken with a VOM (Input impedance 10 MΩ).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

— 5 — — 6 —

less are not indicated except for electrolytics and tantalums.

4

W or less unless otherwise specified.

¢

: internal component.

from battery terminal.

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

L: AUDIO

Page 23

TMR-RF875R

4-2. SCHEMATIC DIAGRAM –MAIN SECTION–

• See page 6 for Note on Schematic Diagrams.

RV401-403, L407

MODULATION

VDD

XOUT

HOLD

XIN

R53

RESET

R51

R52

T2

INT2

R42

R43

R50

VSS

R40

R41

— 7 — — 8 —

Page 24

TMR-RF875R

4-3. PRINTED WIRING BOARD –MAIN SECTION–

X

• See page 6 for Note on Printed Wiring Board.

T

• Semiconductor

Location

Ref. No. Location

D401 D-3

D402 D-3

D403 A-4

D404 D-2

D405 D-2

D407 B-3

D408 D-4

D410 B-4

IC401 B-2

IC402 B-4

IC403 D-4

IC404 B-3

IC405 D-2

Q401 D-1

Q402 B-4

Q403 B-4

Q404 B-4

— 9 — — 10 —

Page 25

TMR-RF875R

4-4. SCHEMATIC DIAGRAM –BATTERY CHARGER SECTION–

• See page 6 for Note on Schematic Diagrams.

IC601,IC602 TK10690M

IC603 TB1004AF

1

OSC1

2

OSC2

3

OSC3

4

CMP-

INITIALIZE

5

GND

— 11 — — 12 —

22BIT COUNTER

CK Q22

R

SQ

R

SQ

Q

CK

R

R

Q

CK

R

SQ

RQ

10 VDD

*

9

TIMER OUT1

*

8

TIMER OUT2

7

CMP+

6

RESET

Page 26

TMR-RF875R

4-5. PRINTED WIRING BOARD –BATTERY CHARGER SECTION–

• See page 6 for Note on Printed Wiring Board.

• Semiconductor

Location

Ref. No. Location

D601 B-3

IC601 A-1

IC602 A-1

IC603 4-4

IC604 A-3

IC605 B-3

Q601 A-3

Q602 A-3

3

2

Q603 B-3

Q604 B-4

Q605 A-4

— 13 — — 14 —

Page 27

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

SECTION 5

EXPLODED VIEWS

• The mechanical parts with no reference number

in the exploded views are not supplied.

• Accessories and packing materials are given in

the last of this parts list.

1

2

5

3

4

#1

6

7

#1

#1

#1

8

9

#2

#2

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 3-046-727-01 HOUSING (UPPER)

2 3-049-798-01 CUSHION, ANTENNA

3 3-046-726-01 LIGHT, GUIDE,

* 4 A-4542-634-A TX-BASE BOARD, COMPLETE

* 5 A-4542-635-A CHG-NR BOARD, COMPLETE

6 3-048-485-01 TERMINAL (+), CHARGE

7 3-048-486-01 TERMINAL (-), CHARGE

8 A-4540-630-A CABINET ASSY, LOWER

9 4-984-729-01 FOOT,RUBBER

#1 7-685-104-19 SCREW +P2X6 TYPE2 NON-SLIT

#2 7-685-105-19 SCREW +P2X8 TYPE2 NON-SLIT

— 15 — — 16 —

Page 28

SECTION 6

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* A-4542-634-A TX-BASE BOARD, COMPLETE

***********************

* A-4542-646-A VCO (VCO UNIT)

< ANTENNA >

ANT401 4-213-164-01 TERMINAL, ANTENNA

< CAPACITOR >

C403 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C406 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C407 1-126-961-11 ELECT 2.2uF 20.00% 50V

C413 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C416 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

• CAPACITORS:

uF: µF

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• COILS

uH: µH

C465 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C466 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C468 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C470 1-126-382-11 ELECT 100uF 20.00% 16V

C472 1-163-243-11 CERAMIC CHIP 47PF 5.00% 50V

C474 1-164-346-11 CERAMIC CHIP 1uF 16V

C475 1-124-635-00 ELECT 220uF 20.00% 6.3V

C476 1-126-382-11 ELECT 100uF 20.00% 16V

C478 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C480 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C481 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C483 1-163-224-11 CERAMIC CHIP 7PF 0.25PF 50V

C487 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C488 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

When indicating parts by reference number,

please include the board name.

TX-BASE

C417 1-126-961-11 ELECT 2.2uF 20.00% 50V

C421 1-124-234-00 ELECT 22uF 20% 16V

C422 1-126-382-11 ELECT 100uF 20.00% 16V

C423 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C425 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C426 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C427 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

C428 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C429 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C430 1-124-259-11 ELECT 4.7uF 20.00% 16V

C431 1-126-157-11 ELECT 10uF 20% 16V

C432 1-163-018-00 CERAMIC CHIP 0.0056uF 5% 50V

C433 1-164-346-11 CERAMIC CHIP 1uF 16V

C435 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C436 1-126-157-11 ELECT 10uF 20% 16V

C438 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C441 1-126-157-11 ELECT 10uF 20% 16V

C442 1-163-018-00 CERAMIC CHIP 0.0056uF 5% 50V

C443 1-164-346-11 CERAMIC CHIP 1uF 16V

C444 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C445 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C451 1-124-635-00 ELECT 220uF 20.00% 6.3V

C452 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C453 1-126-157-11 ELECT 10uF 20% 16V

C454 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C455 1-163-227-11 CERAMIC CHIP 10PF 0.50PF 50V

C456 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C457 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C458 1-126-157-11 ELECT 10uF 20% 16V

C459 1-163-134-00 CERAMIC CHIP 510PF 5.00% 50V

C460 1-163-131-00 CERAMIC CHIP 390PF 5% 50V

C461 1-163-011-11 CERAMIC CHIP 0.0015uF 10% 50V

C462 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C463 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C464 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

< CONNECTOR >

CNP401 1-794-572-11 PIN, CONNECTOR

CNP402 1-794-572-21 PIN, CONNECTOR

< DIODE >

D401 8-719-059-98 LED SLR-342VC3F (power)

D402 8-719-048-87 LED SLR-332MGF03 (chg)

D403 8-719-200-82 DIODE 11ES2

D404 8-719-991-33 DIODE 1SS133T-77

D405 8-719-991-33 DIODE 1SS133T-77

D407 8-719-991-33 DIODE 1SS133T-77

D408 8-719-109-54 DIODE RD2.2ES-B2

D410 8-719-982-11 DIODE MTZJ-4.3B

< IC >

IC401 8-759-998-71 IC BA3308F

IC402 8-759-537-90 IC KIA78S05P-TP

IC403 8-759-667-59 IC NJM2035M(TE2)

IC404 8-759-679-76 IC KMP47C101M-1B54

IC405 8-759-510-73 IC BA10393F-E2

< JACK >

J401 1-566-822-51 JACK (AUDIO IN B)

J402 1-580-441-61 JACK, PIN 2P (AUDIO IN A)

J404 1-785-066-11 JACK,DC

JC421 1-216-295-11 SHORT 0

JC422 1-216-296-91 SHORT 0

JC423 1-216-296-91 SHORT 0

JC424 1-216-296-91 SHORT 0

JC425 1-216-296-91 SHORT 0

JC430 1-216-295-11 SHORT 0

JC431 1-216-295-11 SHORT 0

(POLARITY UNIFIED TYPE) (DC IN 9V)

< JUMPER >

— 16 —

Page 29

TX-BASE

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

< COIL >

L401 1-414-234-11 INDUCTOR CHIP 0uH

L402 1-414-234-11 INDUCTOR CHIP 0uH

L404 1-414-234-11 INDUCTOR CHIP 0uH

L405 1-414-234-11 INDUCTOR CHIP 0uH

L406 1-419-637-11 COIL, VARIABLE

L407 1-419-638-11 COIL, VARIABLE

L408 1-419-079-21 COIL (MPX FILTER)

L409 1-419-079-21 COIL (MPX FILTER)

L410 1-419-662-31 COIL, AIR-CORE

L411 1-414-234-11 INDUCTOR CHIP 0uH

L413 1-414-234-11 INDUCTOR CHIP 0uH

L414 1-414-234-11 INDUCTOR CHIP 0uH

L415 1-414-234-11 INDUCTOR CHIP 0uH

R454 1-216-073-00 METAL CHIP 10K 5% 1/10W

R455 1-216-077-00 RES-CHIP 15K 5% 1/10W

R456 1-216-051-00 METAL CHIP 1.2K 5% 1/10W

R457 1-216-214-00 RES-CHIP 4.7K 5% 1/8W

R458 1-216-049-11 RES-CHIP 1K 5% 1/10W

R459 1-216-077-00 RES-CHIP 15K 5% 1/10W

R460 1-216-086-00 RES-CHIP 36K 5% 1/10W

R461 1-216-091-00 METAL CHIP 56K 5% 1/10W

R462 1-216-121-11 RES-CHIP 1M 5% 1/10W

R463 1-216-085-00 METAL CHIP 33K 5% 1/10W

R464 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R466 1-216-081-00 METAL CHIP 22K 5% 1/10W

R467 1-216-081-00 METAL CHIP 22K 5% 1/10W

R468 1-216-055-00 METAL CHIP 1.8K 5% 1/10W

R469 1-216-079-00 METAL CHIP 18K 5% 1/10W

CHG-NR

< TRANSISTOR >

Q401 8-729-200-72 TRANSISTOR 2SC2712-L

Q402 8-729-200-72 TRANSISTOR 2SC2712-L

Q403 8-729-200-72 TRANSISTOR 2SC2712-L

Q404 8-729-045-00 TRANSISTOR KTA1266GR-AT

< RESISTOR >

R401 1-216-085-00 METAL CHIP 33K 5% 1/10W

R403 1-216-018-00 METAL CHIP 51 5% 1/10W

R404 1-216-085-00 METAL CHIP 33K 5% 1/10W

R406 1-216-085-00 METAL CHIP 33K 5% 1/10W

R407 1-216-049-11 RES-CHIP 1K 5% 1/10W

R408 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R411 1-216-085-00 METAL CHIP 33K 5% 1/10W

R413 1-216-018-00 METAL CHIP 51 5% 1/10W

R414 1-216-085-00 METAL CHIP 33K 5% 1/10W

R416 1-216-085-00 METAL CHIP 33K 5% 1/10W

R417 1-216-049-11 RES-CHIP 1K 5% 1/10W

R418 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R421 1-216-097-11 RES-CHIP 100K 5% 1/10W

R422 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R423 1-216-033-00 METAL CHIP 220 5% 1/10W

R424 1-216-133-00 METAL CHIP 3.3M 5% 1/10W

R425 1-216-097-11 RES-CHIP 100K 5% 1/10W

R426 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R427 1-216-033-00 METAL CHIP 220 5% 1/10W

R428 1-216-045-00 METAL CHIP 680 5% 1/10W

R470 1-216-079-00 METAL CHIP 18K 5% 1/10W

R471 1-216-049-11 RES-CHIP 1K 5% 1/10W

R472 1-216-186-00 RES-CHIP 330 5% 1/8W

R473 1-216-049-11 RES-CHIP 1K 5% 1/10W

R474 1-216-047-91 RES-CHIP 820 5% 1/10W

R482 1-216-081-00 METAL CHIP 22K 5% 1/10W

R483 1-216-081-00 METAL CHIP 22K 5% 1/10W

R484 1-216-081-00 METAL CHIP 22K 5% 1/10W

R485 1-216-081-00 METAL CHIP 22K 5% 1/10W

R486 1-216-081-00 METAL CHIP 22K 5% 1/10W

R490 1-216-073-00 METAL CHIP 10K 5% 1/10W

< VARIABLE RESISTOR >

RV401 1-238-602-31 RES, ADJ, CARBON 47K

RV402 1-238-600-31 RES, ADJ, CARBON 10K

RV403 1-241-763-11 RES, ADJ, CARBON 4.7K

< SWITCH >

S401 1-771-961-11 SWITCH, SLIDE (NOISE FILTER)

S402 1-771-962-11 SWITCH, SLIDE (CHANNEL)

< VIBRATOR >

X401 1-781-850-11 VIBRATOR, CRYSTAL 38kHz

**************************************************************

* A-4542-635-A CHG-NR BOARD, COMPLETE

***********************

R429 1-216-073-00 METAL CHIP 10K 5% 1/10W

R430 1-216-073-00 METAL CHIP 10K 5% 1/10W

R431 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R432 1-216-129-00 METAL CHIP 2.2M 5% 1/10W

R433 1-216-081-00 METAL CHIP 22K 5% 1/10W

R438 1-216-105-91 RES-CHIP 220K 5% 1/10W

R440 1-216-049-11 RES-CHIP 1K 5% 1/10W

R441 1-216-033-00 METAL CHIP 220 5% 1/10W

R442 1-216-045-00 METAL CHIP 680 5% 1/10W

R446 1-216-051-00 METAL CHIP 1.2K 5% 1/10W

R447 1-216-214-00 RES-CHIP 4.7K 5% 1/8W

R448 1-216-049-11 RES-CHIP 1K 5% 1/10W

R449 1-216-077-00 RES-CHIP 15K 5% 1/10W

R452 1-216-077-00 RES-CHIP 15K 5% 1/10W

R453 1-216-073-00 METAL CHIP 10K 5% 1/10W

— 17 —

< CAPACITOR >

C601 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C602 1-126-157-11 ELECT 10uF 20% 16V

C603 1-126-157-11 ELECT 10uF 20% 16V

C604 1-164-346-11 CERAMIC CHIP 1uF 16V

C605 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C606 1-126-157-11 ELECT 10uF 20% 16V

C607 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C609 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C611 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C612 1-126-157-11 ELECT 10uF 20% 16V

C613 1-126-157-11 ELECT 10uF 20% 16V

C614 1-164-346-11 CERAMIC CHIP 1uF 16V

C615 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C616 1-126-157-11 ELECT 10uF 20% 16V

C617 1-163-038-11 CERAMIC CHIP 0.1uF 25V

Page 30

TMR-RF875R

CHG-NR

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

C618 1-124-234-00 ELECT 22uF 20% 16V

C619 1-163-251-11 CERAMIC CHIP 100PF 5.00% 50V

C621 1-163-986-00 CERAMIC CHIP 0.027uF 10.00% 25V

C622 1-164-346-11 CERAMIC CHIP 1uF 16V

C623 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C624 1-126-786-11 ELECT 47uF 20.00% 16V

C626 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C627 1-163-038-11 CERAMIC CHIP 0.1uF 25V

C628 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C629 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C630 1-163-021-91 CERAMIC CHIP 0.01uF 10.00% 50V

R601 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R602 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R603 1-216-081-00 METAL CHIP 22K 5% 1/10W

R604 1-216-081-00 METAL CHIP 22K 5% 1/10W

R605 1-216-073-00 METAL CHIP 10K 5% 1/10W

R611 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R612 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R613 1-216-081-00 METAL CHIP 22K 5% 1/10W

R614 1-216-081-00 METAL CHIP 22K 5% 1/10W

R615 1-216-073-00 METAL CHIP 10K 5% 1/10W

< RESISTOR >

< CONNECTOR >

* CN601 1-794-571-11 HOUSING, CONNECTOR

* CN602 1-794-571-21 HOUSING, CONNECTOR

< DIODE >

D601 8-719-069-55 DIODE UDZS-TE17-5.6B

< IC >

IC601 8-759-384-88 IC TK10690M

IC602 8-759-384-88 IC TK10690M

IC603 8-759-678-31 IC TB1004AF

IC604 8-759-510-73 IC BA10393F-E2

IC605 8-759-537-90 IC KIA78S05P-TP

< JUMPER >

JC601 1-216-295-11 SHORT 0

JC602 1-216-295-11 SHORT 0

< TRANSISTOR >

Q601 8-729-025-88 TRANSISTOR 2SB1386-T100-R

Q602 1-801-806-11 TRANSISTOR DTC144EKA-T146

Q603 8-729-027-40 TRANSISTOR DTA144VKA-T146

Q604 1-801-806-11 TRANSISTOR DTC144EKA-T146

Q605 8-729-903-10 TRANSISTOR FMW1

R624 1-216-047-91 RES-CHIP 820 5% 1/10W

R625 1-216-689-11 METAL CHIP 39K 0.5% 1/10W

R626 1-216-089-11 RES-CHIP 47K 5% 1/10W

R627 1-216-093-00 RES-CHIP 68K 5% 1/10W

R628 1-216-079-00 METAL CHIP 18K 5% 1/10W

R629 1-216-073-00 METAL CHIP 10K 5% 1/10W

R630 1-216-121-11 RES-CHIP 1M 5% 1/10W

R631 1-216-077-00 RES-CHIP 15K 5% 1/10W

R632 1-216-121-11 RES-CHIP 1M 5% 1/10W

R633 1-216-121-11 RES-CHIP 1M 5% 1/10W

R634 1-216-077-00 RES-CHIP 15K 5% 1/10W

R635 1-216-081-00 METAL CHIP 22K 5% 1/10W

R636 1-249-411-11 CARBON 330 5% 1/4W

R637 1-249-411-11 CARBON 330 5% 1/4W

R638 1-249-411-11 CARBON 330 5% 1/4W

R639 1-249-411-11 CARBON 330 5% 1/4W

R640 1-249-411-11 CARBON 330 5% 1/4W

**************************************************************

9-927-966-11

Sony Corporation

Audio Entertainment Group

— 18 —

Printed in Japan © 2000.8

2000H1646-1

Published by PE General Engineering Dept.

Loading...

Loading...