SONY KV-DX29K9H, KV-DX29K9B, KV-DX29K90B, KV-DX29K90L Service Manual

HISTORY

When clicking an item, it’s detail is displayed.

Model Name: KV-DX29K9H/DX29K9H/B/

DX29K90B/DX29K90L

SERVICE MANUAL

Part No. : 9-965-357-02

Date SUPP./CORR. Description of SUP/COR

2003.02 NEW –

2004.05 Revised KV-DX29K90B/DX29K90L Models Addition. Yes

Change of

main text

SERVICE MANUAL

DX-1J

CHASSIS

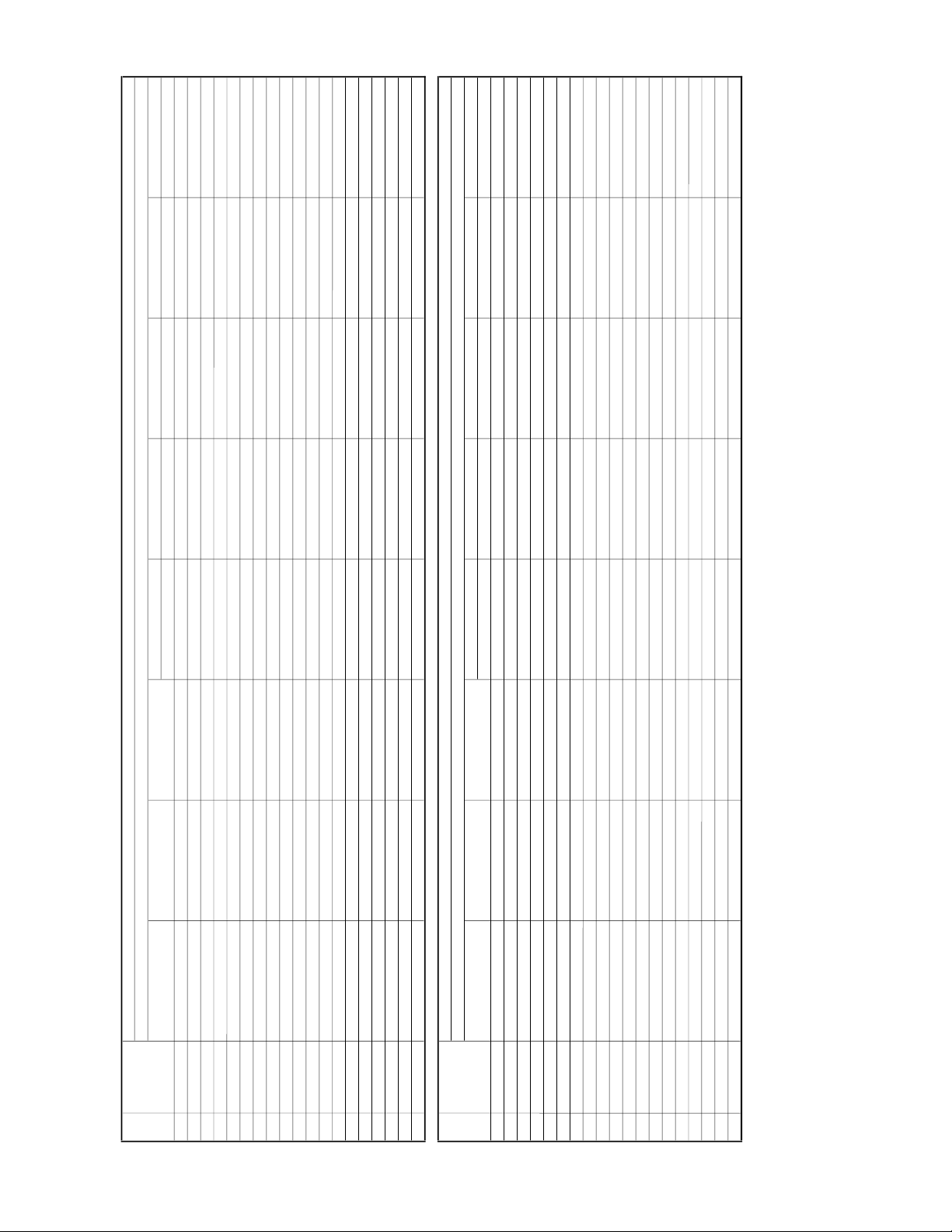

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

KV-DX29K9H RM-1006 Korean SCC-P81E-A

KV-DX29K9H/B

KV-DX29K90B

KV-DX29K90L

RM-1006 Korean SCC-P81E-A

RM-1006 Korean SCC-P81G-A

RM-1006 Korean SCC-P81H-A

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

RM-1006

KV-DX29K9H/KV-DX29K9H/B/

DX29K90B/DX29K90L

TRINITRON COLOR TV

R

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

Specifications

Antenna 75 ohm external terminal for VHF/UHF

Television System NTSC, American TV Standard

Screen Size (measured diagonally) 29 inches

Channel Coverage

VHF 2-13

UHF 14-69

CATV 1-125

Power Requirements

Number of Inputs/Outputs

Vid eo (IN) 4 1 Vp-p, 75 ohms unbalanced, sync negative

S Video (IN) 3 Y: 1 Vp-p, 75 ohms unbalanced, sync negative

Audio (IN) 6 500 mVrms (100% modulation)

TV Out 1 Video: 1 Vp-p 75 ohms unbalanced, Sync

DTV (HD)/DVD Input 2 (Y, P

RF Inputs 1

Converter 1

Speaker Output 7 W x 2

Dimensions (W x H x D) 765 x 578 x 502 mm

Mass 48.5 kg

Power Consumption

Design and specifications are subject to change without notice.

220 V AC, 60 Hz

, PR)Y: 1.0 Vp-p, 75 ohms unbalanced, sync

B

Indicated on the rear of the TV

C: 0.286 Vp-p (Burst signal), 75 ohms

Impedance: 47 kiloohms

negative

Audio: 500 mVrms

negative

P

: 0.7 Vp-p, 75 ohms

B

PR: 0.7 Vp-p, 75 ohms

– 2 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR CARBON PAINTED ON THE CRT, AFTER REMOVING THE ANODE.

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECElVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON

THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PAR TS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESECOMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL TO SAFEOPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

(CAUTION)

WARNING!!

– 3 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

TABLE OF CONTENTS

Section Title Page

–––––– –––– ––––

1. SELF DIAGNOSIS FUNCTION .................................... 5

2. DISASSEMBLY

2-1. REAR COVER ............................................................ 8

2-2. SPEAKER ................................................................... 8

2-3. CHASSIS ASSEMBLY ............................................... 9

2-4. ASSEMBLING CHASSIS ASSEMBLY .................. 10

2-5. SERVICE POSITION ............................................... 11

2-6. U BRACKET ............................................................ 11

2-7. F4 BOARD ................................................................ 12

2-8. U3 BOARD ............................................................... 12

2-9. B1 BOARD ............................................................... 12

2-10. H5 BOARD ............................................................... 13

2-11. REMOVAL OF ANODE-CAP .................................. 14

2-12. CRT ........................................................................... 15

2-13. PARTS LOCATION AND WIRING ......................... 16

3. SERVICE MODE

3-1. METHOD OF SETTING THE SERVICE

ADJUSTMENT MODE ............................................ 17

3-2. SERVICE MODE ADJUSTMENT ........................... 17

3-3. MEMORY WRITE CONFIRMATION METHOD .. 17

3-4. ADJUSTING BUTTONS AND INDICATOR.......... 17

3-5. SERVICE MODE LIST ............................................ 18

Section Title Page

–––––– –––– ––––

5. SAFETY RELATED ADJUSTMENTS

5-1. +B MAX VOLTAGE CONFIRMATION .................. 52

5-2. HV REGULATION CIRCUIT ADJUSTMENT ....... 52

5-3. HV PROTECTOR CIRCUIT ADJUSTMENT ......... 52

5-4. IK PROTECTOR CIRCUIT CHECK (D BOARD).. 52

6. DIAGRAMS

6-1. BLOCK DIAGRAM (1) ............................................ 53

BLOCK DIAGRAM (2) ............................................ 55

BLOCK DIAGRAM (3) ............................................ 57

BLOCK DIAGRAM (4) ............................................ 59

BLOCK DIAGRAM (5) ............................................ 61

BLOCK DIAGRAM (6) ............................................ 63

BLOCK DIAGRAM (7) ............................................ 65

6-2. CIRCUIT BOARDS LOCATION ................................. 71

6-3. PRINTED WIRING BOARDS AND SCHEMATIC

DIAGRAMS................................................................... 71

6-4. SEMICONDUCTORS ................................................. 135

7. EXPLODED VIEWS

7-1. SPEAKER SECTION ............................................. 137

7-2. CHASSIS SECTION .............................................. 138

7-3. BEZNET SECTION ................................................ 139

7-4. CRT SECTION ....................................................... 140

4. SET-UP ADJUSTMENTS

4-1. BEAM LANDING .................................................... 46

4-2. CONVERGENCE ADJUSTMENT .......................... 47

4-3. G2 (SCREEN) ADJUSTMENT ................................ 49

4-4. FOCUS ADJUSTMENT 1 ........................................ 49

4-5. NECK ASSY TWIST AJUSTMENT ........................ 49

4-6. P&P SUB CONTRAST ADJUSTMENT

(VIDEO) (SCON) ..................................................... 50

4-7. P&P SUB CONTRAST ADJUSTMENT

(RF) (SCON) ............................................................. 50

4-8. P&P SUB-HUE AND SUB-COLOR

ADJUSTMENT (VIDEO) (SHUE, SCOL) .............. 50

4-9. P&P SUB-HUE AND SUB-COLOR

ADJUSTMENT (RF) (SHUE, SCOL) ...................... 50

4-10. WHITE BALANCE, SUB BRIGHT

ADJUSTMENT ......................................................... 51

4-11. FOCUS ADJUSTMENT 2 ........................................ 51

4-12. PICTURE DISTORTION ADJUSTMENT .............. 51

8. ELECTRICAL PARTS LIST..................................... 141

– 4 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

SECTION 1

SELF DIAGNOSIS FUNCTION

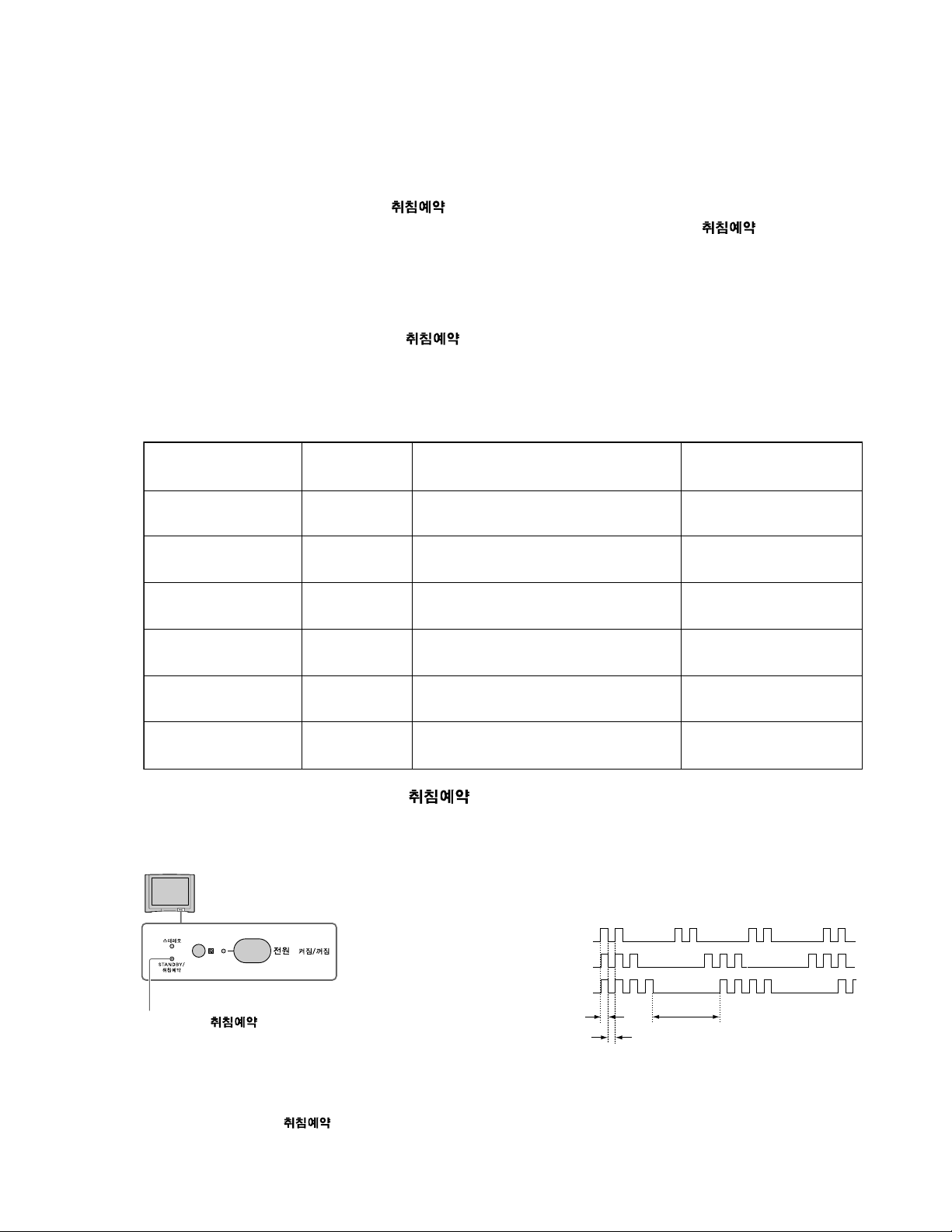

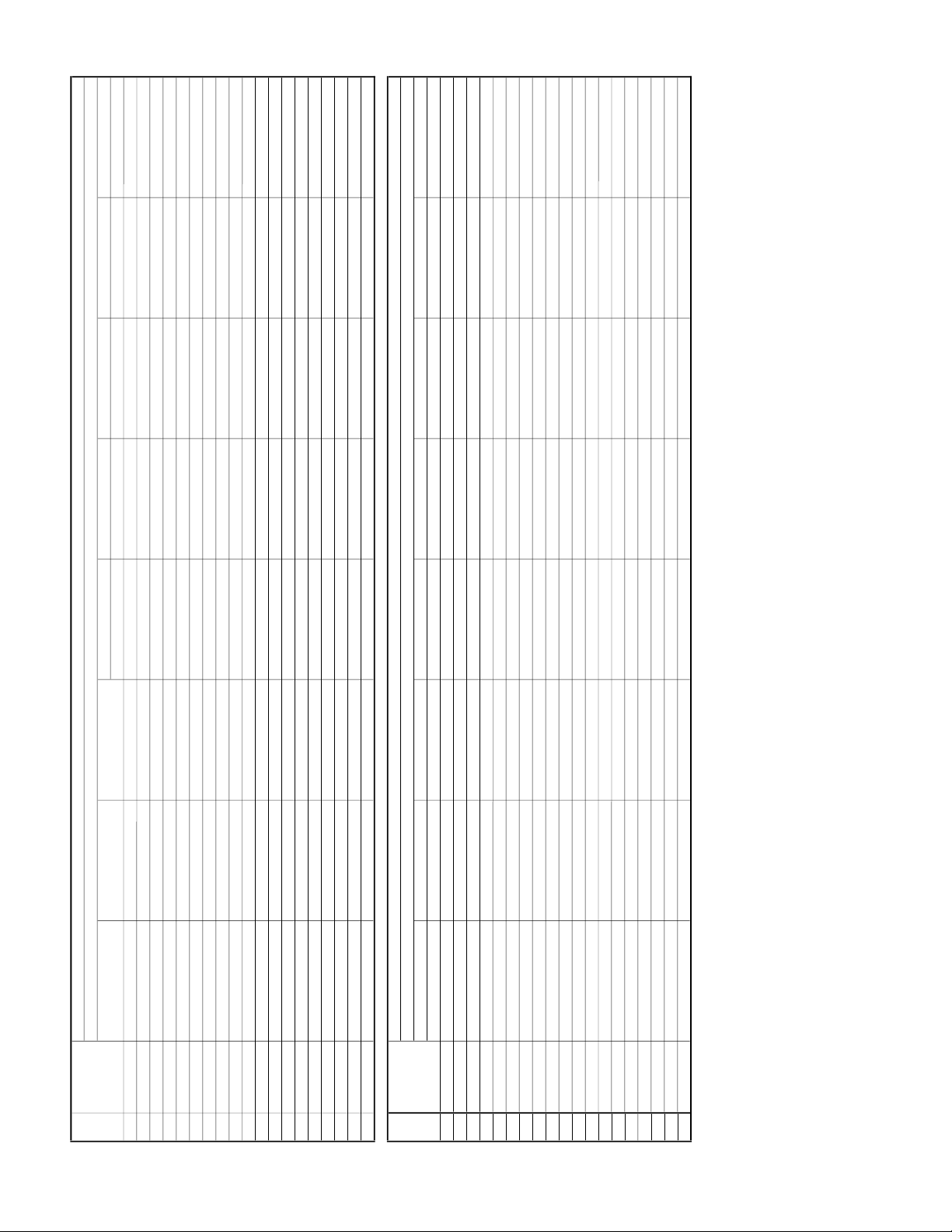

1. Summary of Self-Diagnosis Function

• This device includes a self-diagnosis function.

• In case of abnormalities, the STANDBY/ indicator automatically blinks. It is possible to predict the abnormality

location by the number of blinks. The Instruction Manual describes blinking of the /STANDBY/ indicator.

• If the symptom is not reproduced sometimes in case of a malfunction, there is recording of whether a malfunction was generated

or not. Operate the remote command to confirm the matter on the screen and to predict the location of the abnormality.

2. Diagnosis Items and Prediction of Malfunction Location

• When a malfunction occurs the STANDBY/ indicator only blinks for one of the following diagnosis items. In case of

two or more malfunctions, the item which first occurred blinks. If the malfunctions occurred simultaneously, the item with the

lower blink count blinks first.

• The screen display displays the results regarding all the diagnosis items listed below. The display “ 0 ” means that no malfunctions occurred.

Number of times

Diagnosis Item

+B overcurrent (OCP)

+B overvoltage (OVP)

Vertical deflection stopped

(V-STOP)

IK error (AKB ERROR)

Low-B error

STANDBY/

indicator blinks

2 times

3 times

4 times

5 times

6 times

Probable Cause Location

T8001 (FBT) Rare short-circuit etc. (D6 board)

Q5030 (H-OUT), Q5028 (D6 board)

+B load open (D6 board) R6570 Open

PH6502, control system malfunction L2603

Open

IC5004 (V. OUT) (D6 board) IC201

(CXA2150Q) (A6 board)

VIDEO OUT IC malfunction IC9001, 9002,

9003 (C3 board) IC201 (CXA2150Q)

(A6 board)

Sub power supply system load shorted etc.

(A6 board)

Detected Symptoms

Has entered standby mode.

(Relay is off when the power

turns on.)

Has entered standby mode.

Has entered standby mode.

Has not entered standby mode.

Has entered standby mode.

Horizontal deflection

stopped (H-STOP)

7 times

IC201 (CXA2150Q) (A6 board) Q5031

(S-COR-OUT), Q5030 (H-OUT), Q5028

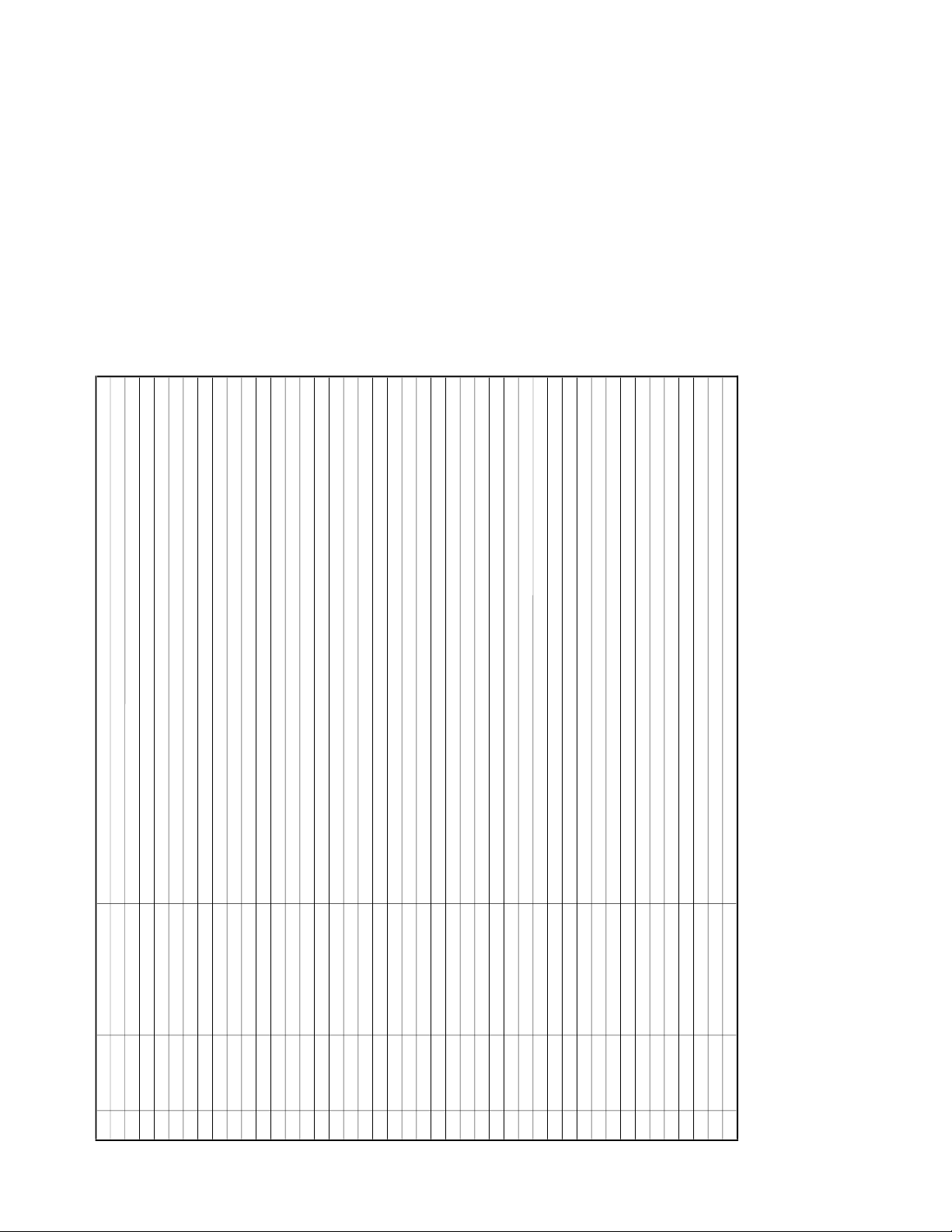

3. Blinking count display of STANDBY/ indicator

< FRONT PANEL >

STANDBY/ indicator

Release of STANDBY/ indicator blinking.

• The STAND BY indicator blinking display is released by turning OFF the power switch

on the TV main unit or removing the plug from the power.

* One blink is not used for self-diagnosis.

•EXAMPLE

<Diagnosis Items> <Number of Blinks>

• +B overcurrent 2 times

• +B overvoltage 3 times

• Vertical deflection stop 4 times

Lamp ON : 0.3 seconds

Lamp OFF : 0.3 seconds

Has entered standby mode.

Lamp OFF :

3.0 seconds

– 5 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

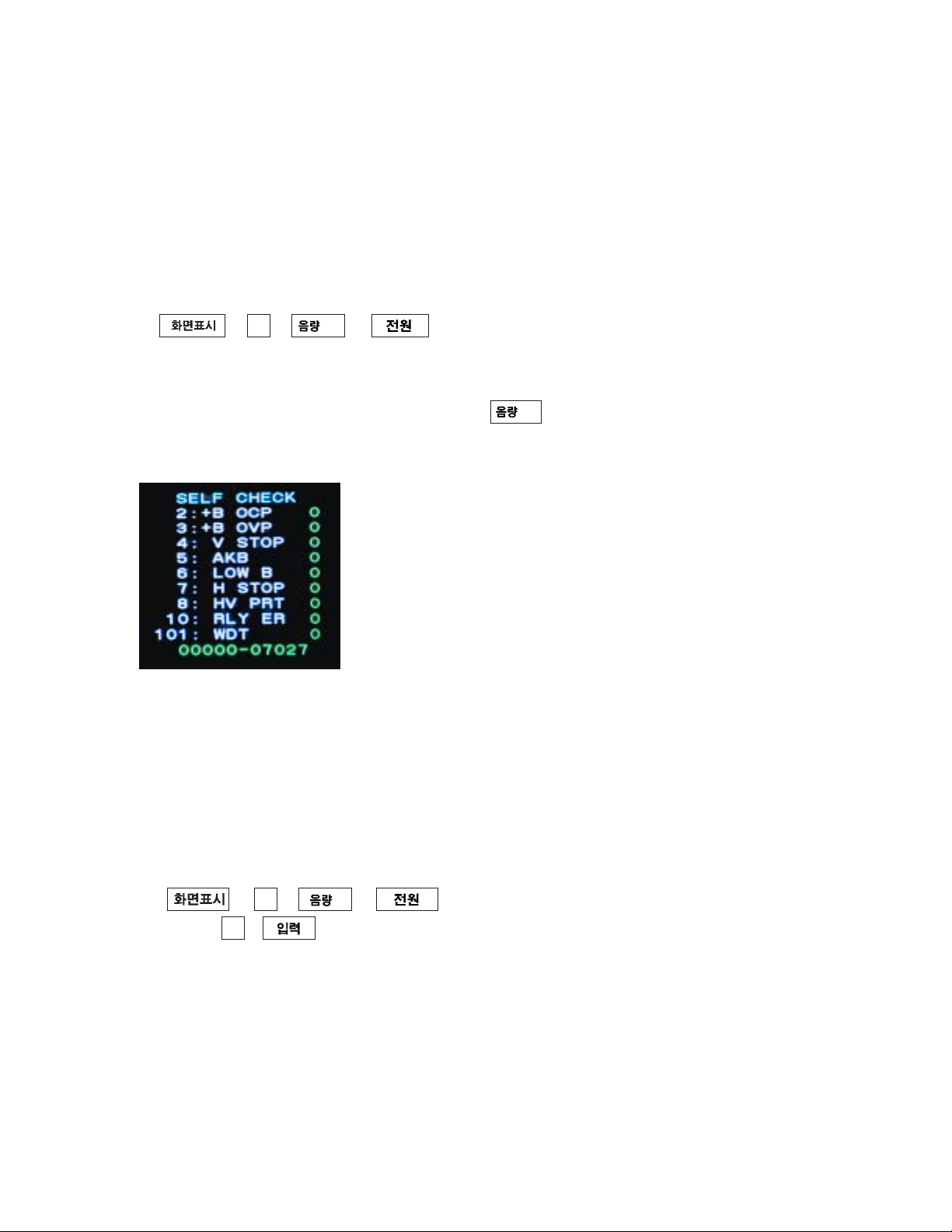

4. Self-diagnosis screen displays

• In cases of malfunctions where it is not possible to determine the symptom such as when the power goes off occasionally or when

the screen disappears occasionally, there is a screen display on whether the malfunction occurred or not in the past (and whether

the detection circuit operated or not) in order to allow confirmation.

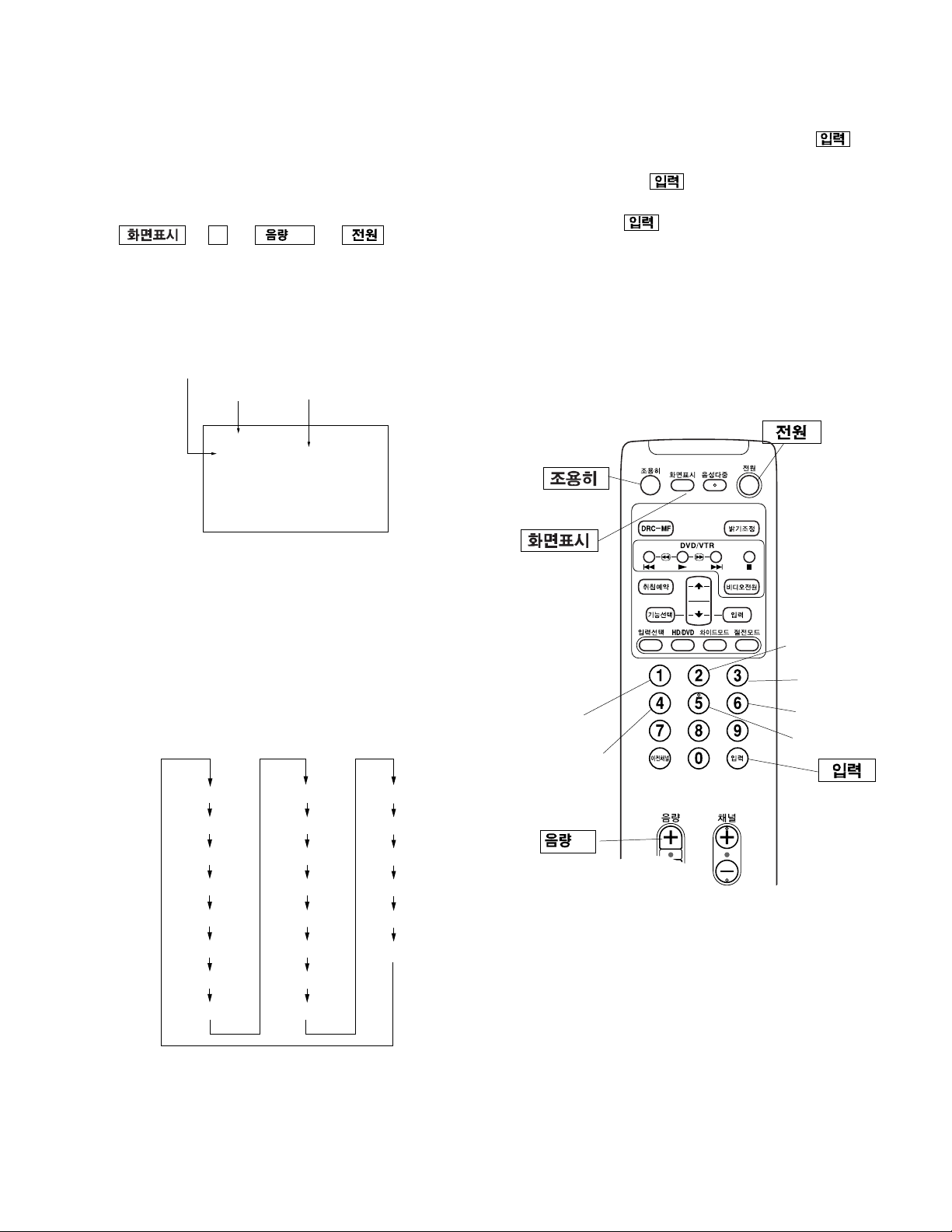

<Screen Display Method>

• Quickly press the remote command button in the following order from the standby state.

5

b b b

–

˘

Be aware that this differs from the method of

entering the service mode ( + ).

Self-diagnosis screen display

• "G" : OK, "NG" : DETECTS ONCE OR MORE

• THE 10 DIGITS OF NUMERALS ARE FOR CHECKING,

NO RELATION TO DIAGNOSIS.

• 101 : NO LED BLINKING FOR WDT.

"0" : NUMBER OF DETECTION.

5. After the self-diagnosis operation

• The results display is not automatically cleared. In case of repairs and after repairs, check the self-diagnosis screen and be sure

to return the results display to “ 0 ”.

• If the results display is not returned to “ 0 ” it will not be possible to judge a new malfunction after completing repairs.

<Method of Clearing Results Display>

1. Power off (Set to the standby mode)

2. b 5 b + b (Service Mode)

3. Channel 8 b (Test reset = Factory preset condition)

<Method of Ending Self Diagnosis Screen>

• When ending the self-diagnosis screen completely, turn the power switch OFF on the remote commander or the main unit.

– 6 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

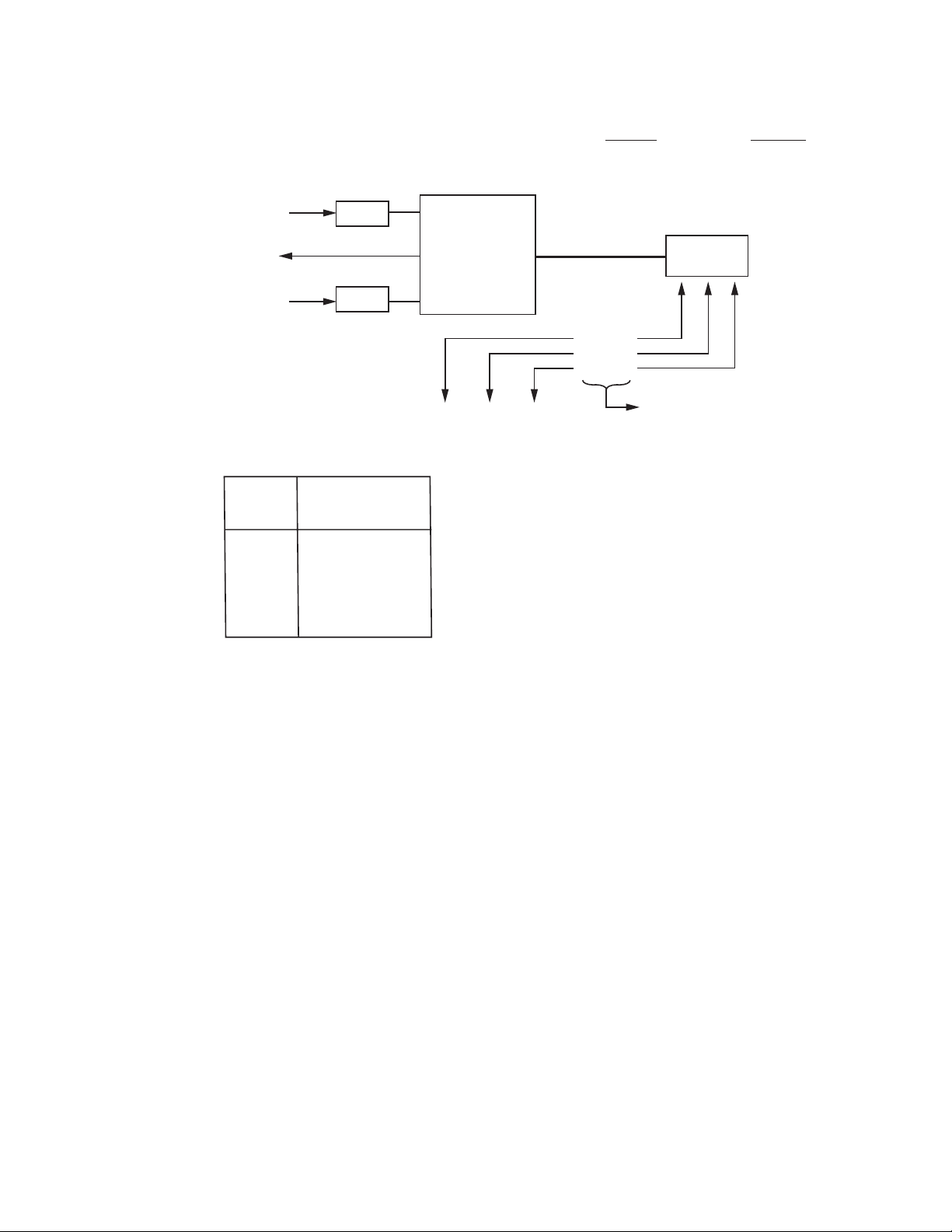

Q727

Q729

OVP

(FROM D BOARD)

AC-RLY

(TO D BOARD)

OCP

(FROM D BOARD)

• I2C YCJ RETURN DATA

11111111

LED

BLINKING

TIMES

2

3

4

5

6

7

LATCH

LATCH

Q726

Q728

SYMPTOM

+B OCP

+B OVP

V-STOP

AKB

LOW-B ERROR

H-STOP

OVP

MAIN

MICROCOMPUTER

IC701

M308V2

OCP

RM-1006 RM-1006 RM-1006 RM-1006

A1 BOARD

12C BUS

A K B

H-STOP

V-STOP

YCJ IC201

CXA-2150Q

WHEN

A K B

H-STOP

V-STOP

ARE ALL 1= LOW B ERROR

+B OCP If the IC701 Pin 44 (+B OCP DET) is high 2 seconds, turn AC-RELAY low (P-OFF) and make STANDBY

LED blinks twice.

+B OVP If the IC701 Pin 45 (+B OVP DET) is high 2 seconds, turn AC-RELAY low (P-OFF) and make STANDBY

LED blinks three times.

V-STOP If the return data Bit0 (VNG) from CXA2150Q is “1” while 2 seconds, turn AC-RELAY low (P-OFF) and

make STANDBY LED blinks four times.

AKB If the return data Bit2 (IKREF) from CXA2150Q is “0” and there is no change for 20 seconds, make

STANDBY LED blinks five times.

At this time, AC-RELAY continues to high.

LOW-B ERROR If the IC701 Pin 69 (AC-RELAY) is high and the Pin 43 (LOW-B ERROR DET) is low while 5 seconds,

turn AC-RELAY low (P-OFF) and make STANDBY LED blinks six times.

H-STOP If the return data Bit1 (HNG) from CXA2150Q is “1” while 2 seconds, turn AC-RELAY low (P-OFF) and

make STANDBY LED blinks seven times.

W. D. T. Observes the watch dock timer (BUS COMMUNICATION ERROR DET) bus communication. If errors are

detected, counts up and reform the bus communication and displays the number of time.

(No LED blinking).

– 7 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

SECTION 2

DISASSEMBLY

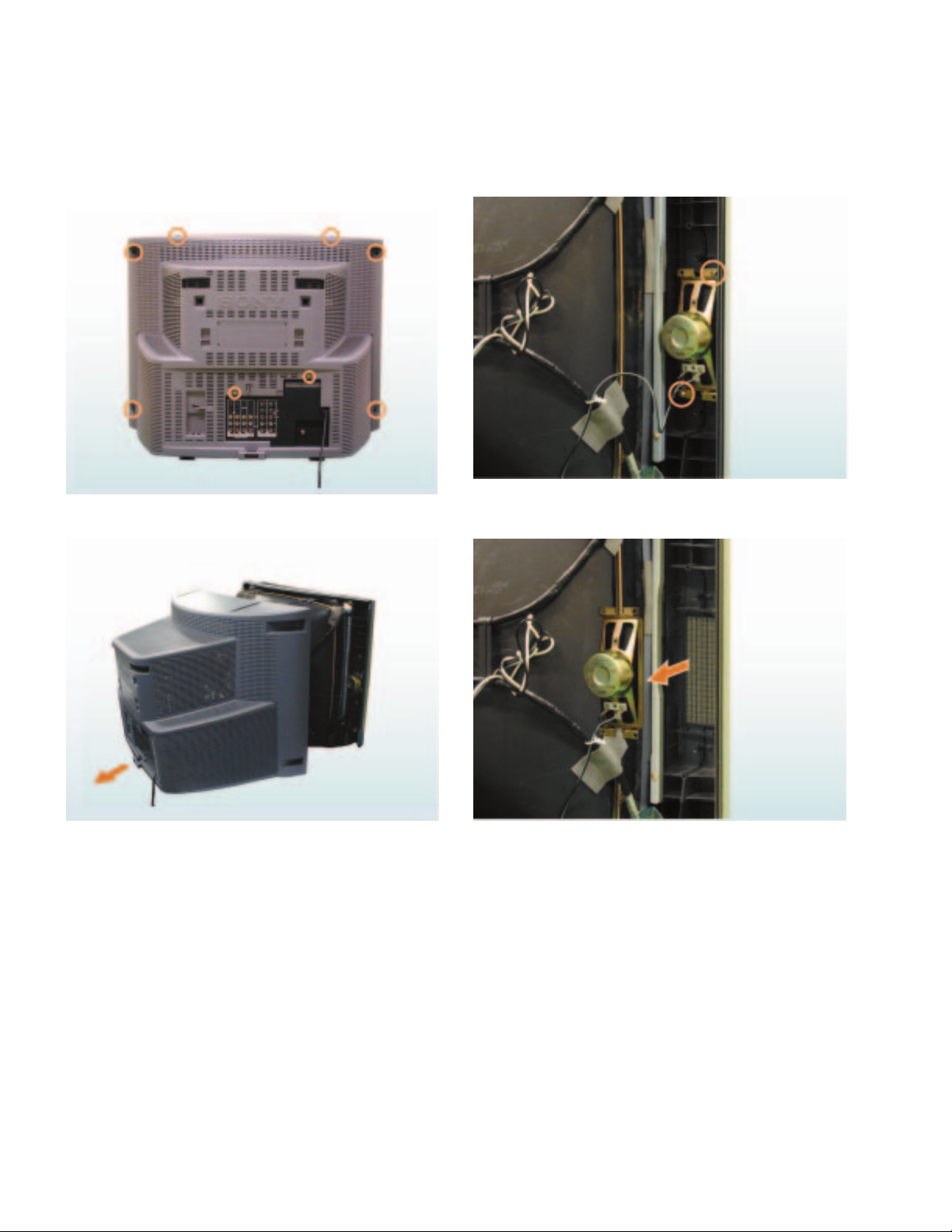

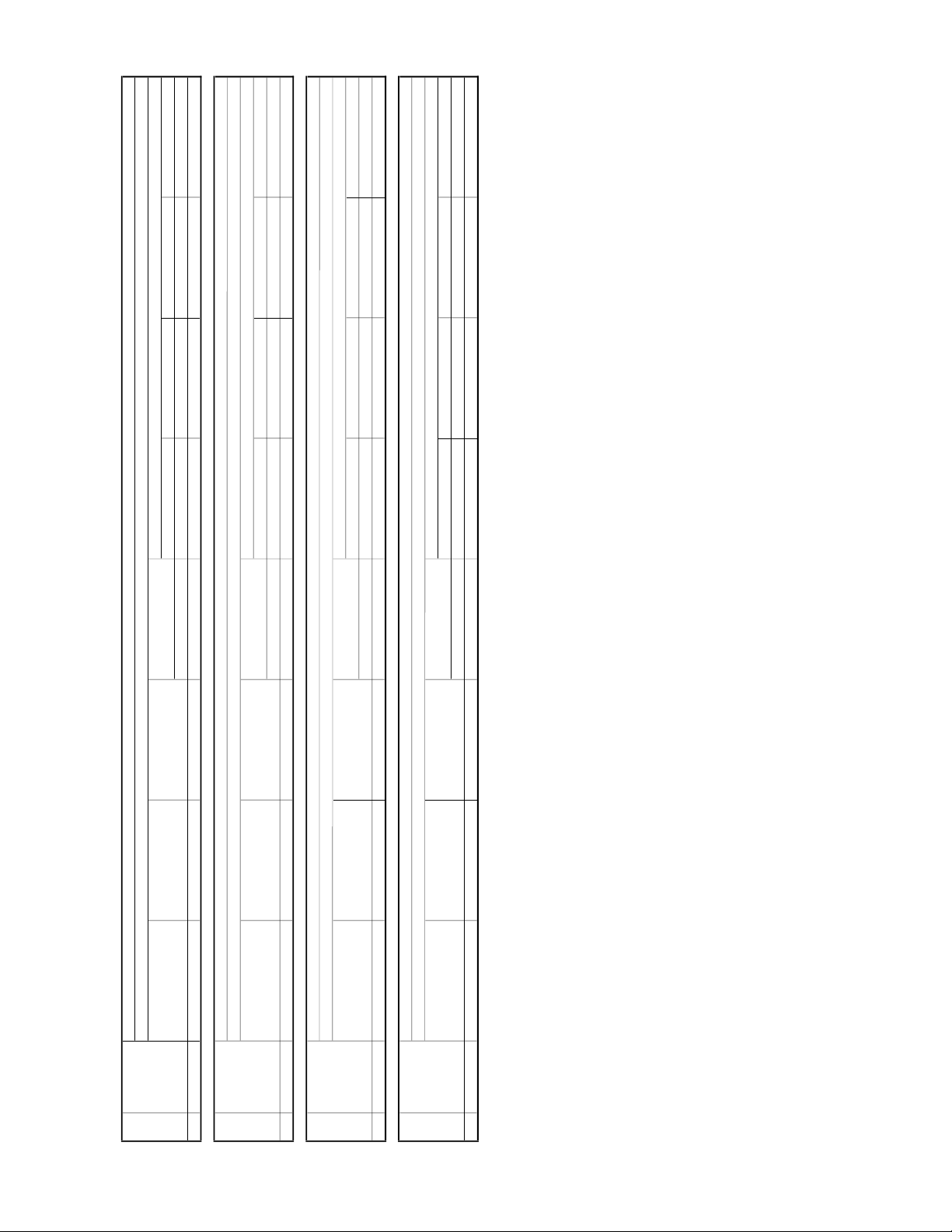

2-1. REAR COVER

1) Remove eight screws secured the rear cover.

2) Remove the rear cover by pulling backward.

2-2. SPEAKER

1) Remove two screws secured the speaker.

2) Remove the speaker backward.

– 8 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

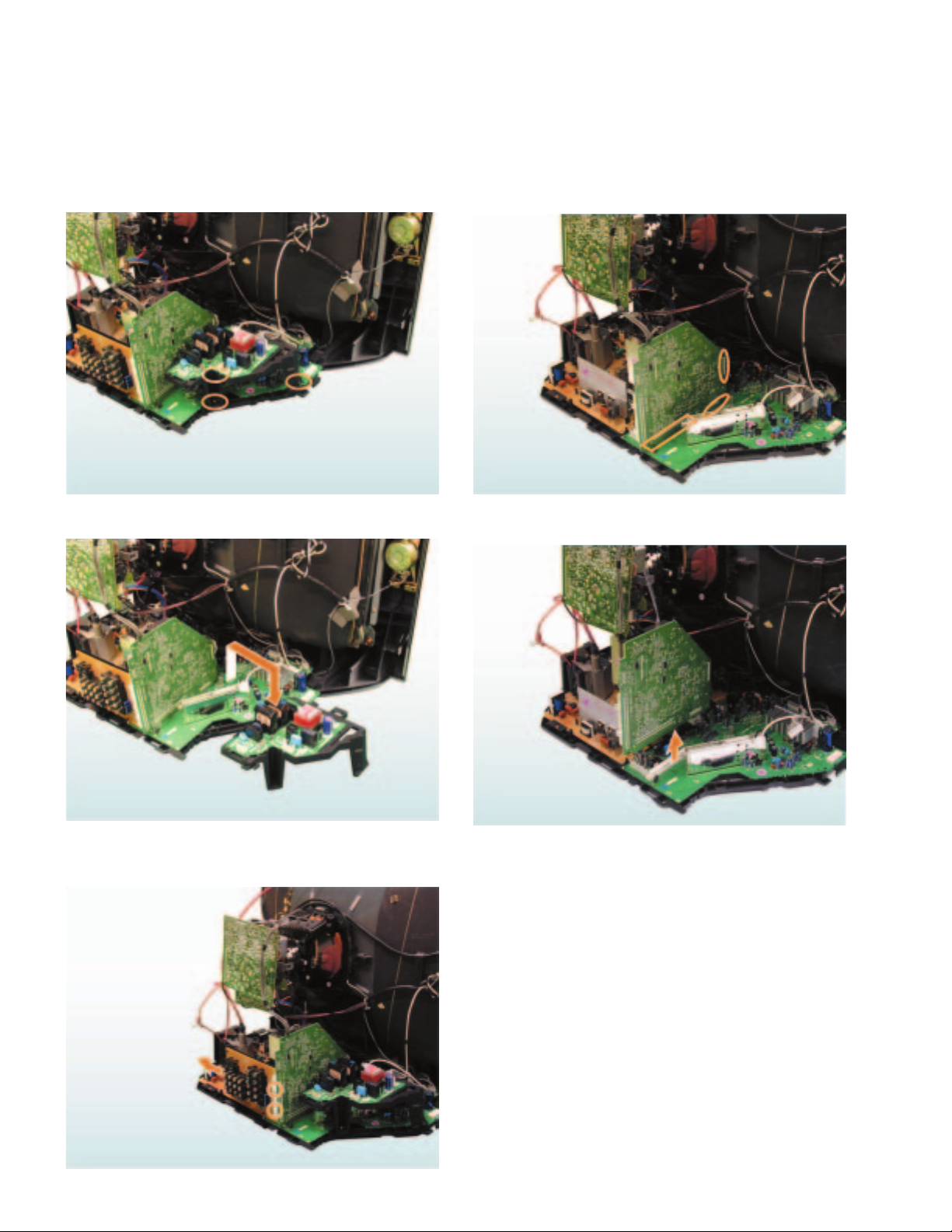

2-3. CHASSIS ASSEMBLY

1) Remove two claws on both sides of the chassis assembly

by pulling up.

Enlarged view (left side)

Enlarged view (right side)

2) Pull out the chassis assembly backward.

– 9 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

2-4. ASSEMBLING CHASSIS ASSEMBLY

1) Hold the both sides of the chassis assembly.

2) Push forward until the claws on both sides of the chassis

assembly fit into the beznet assembly.

Enlarged view (left side)

Enlarged view (right side)

– 10 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

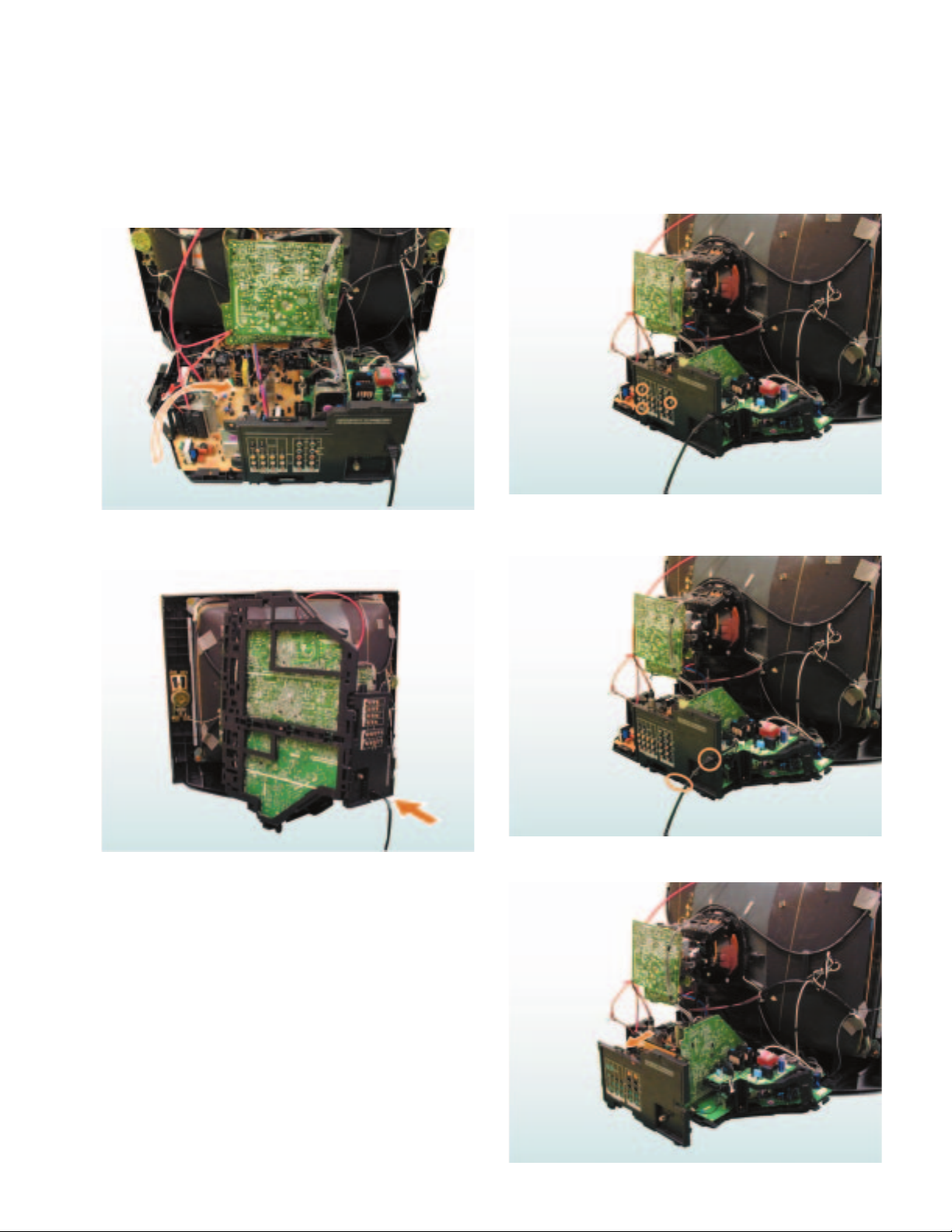

2-5. SERVICE POSITION

1) Hold the chassis assembly in the rear.

2) Turn it clockwise 90 degrees and stand it.

3) Settle it by inserting the chassis assembly holder under

the U bracket.

2-6. U BRACKET

1) Remove three screws secured the U bracket.

2) Pull out the power cord and while pulling up the claw

secured the U bracket,

3) Remove the U bracket.

– 11 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

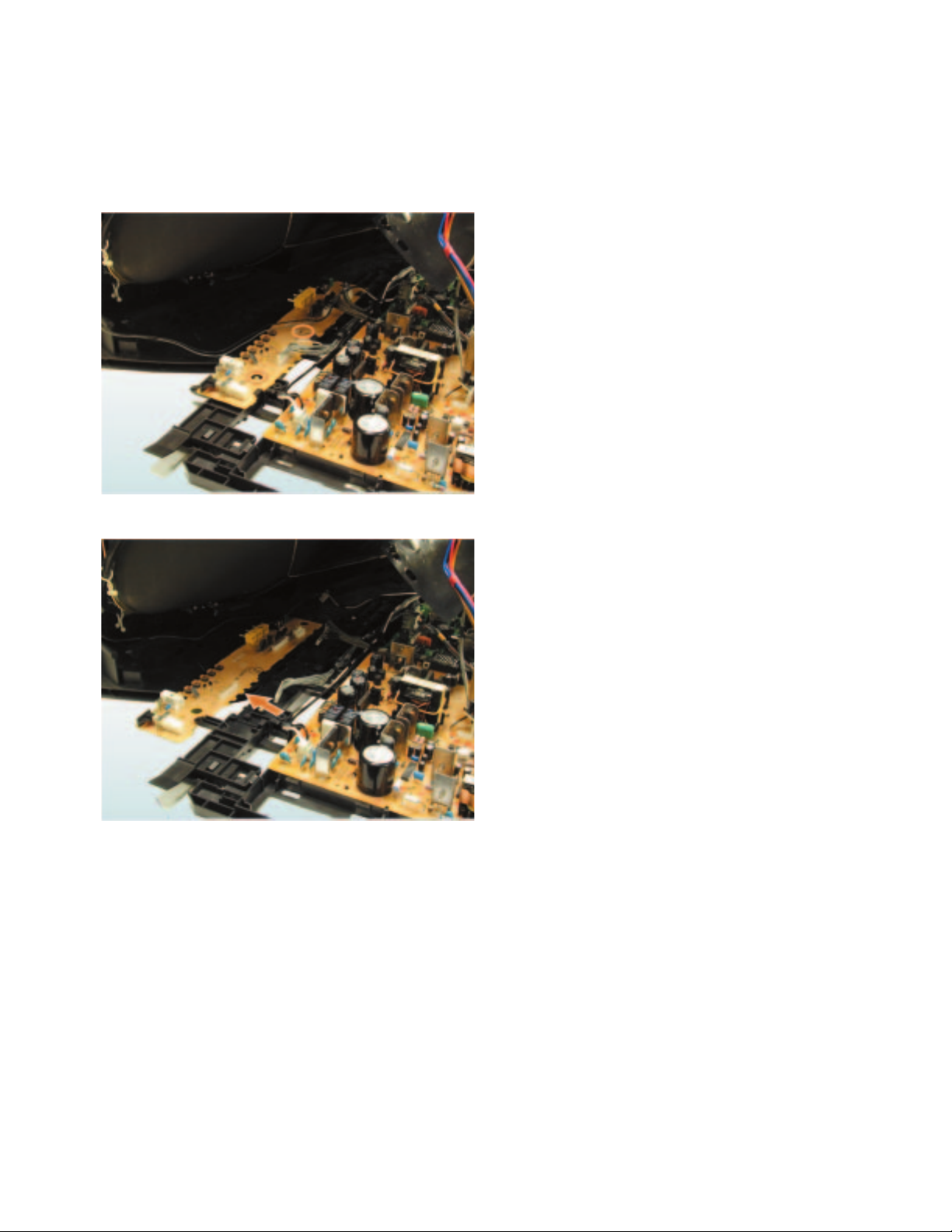

2-7. F4 BOARD

1) Remove three screws secured the F1 bracket.

2) Remove F4 board with the F1 bracket.

2-9. B1 BOARD

1) Remove connector CN3003 on B1 board.

2) Remove B1 board while putting off three claws on two Bto-B connectors.

2-8. U3 BOARD

1) While pulling two claws on the B-to-B connector,

2) Remove U3 board from B1 board.

– 12 –

2-10. H5 BOARD

1) Remove two screws secured H5 board.

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

2) Remove H5 board.

– 13 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

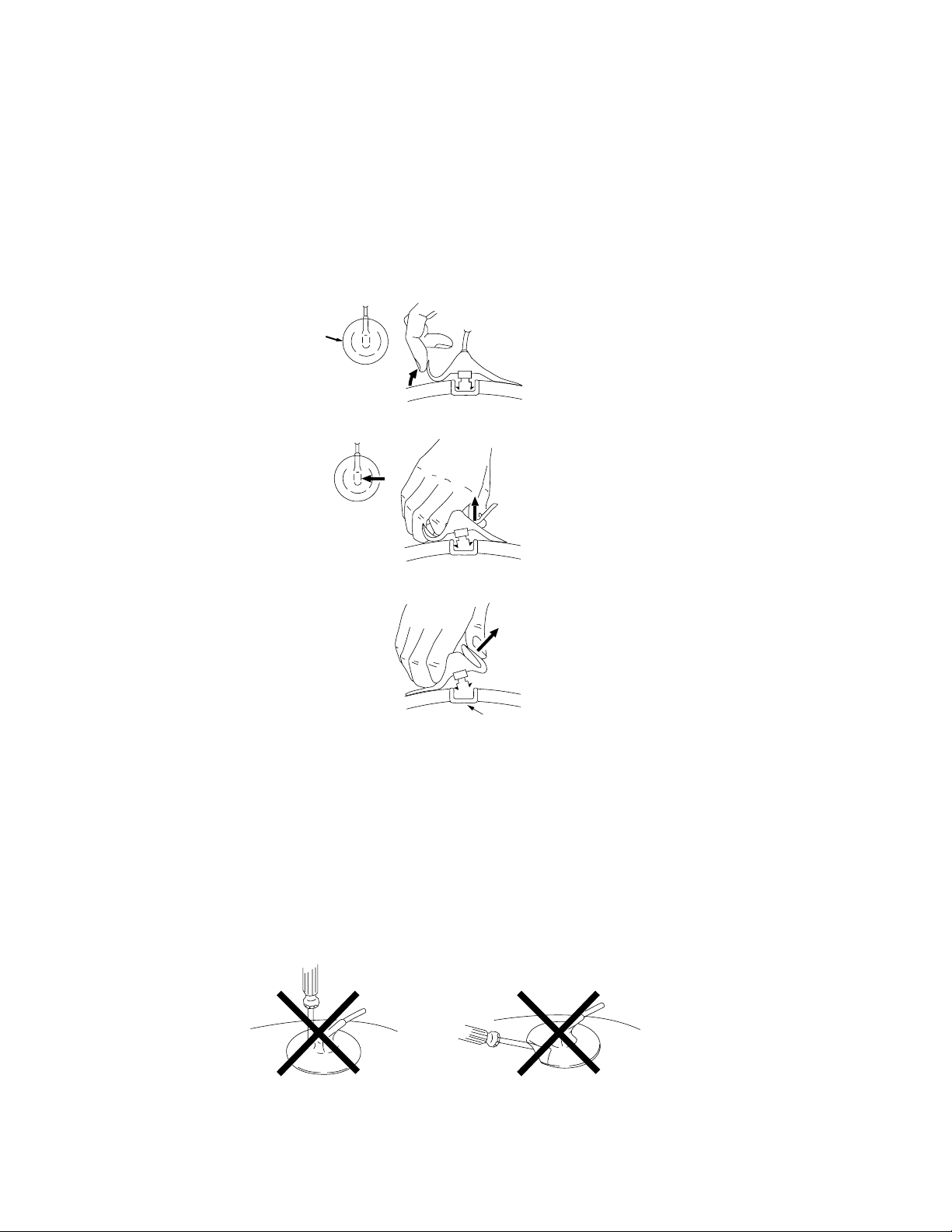

2-11. REMOVAL OF ANODE-CAP

NOTE : After removing the anode, short circuit

the anode cap to the metal chassis, CRT shield or carbon paint on the

CRT.

• REMOVING

1 Turn up one side of the rubber

2 Using a thumb pull up the rubber

PROCEDURES

a

a

cap in the

b

cap firmly in the direction

direction indicated

the anode of the picture tube and

by the arrow a.

b

indicated by the arrow b.

c

3 When one side of the rubber

can be removed by turning up the rubber cap and pulling it up in the direction of the

arrow

c.

cap is separated

from the anode b

utton, the anode-cap

• HOW TO HANDLE AN ANODE-CAP

1 Do not dama

2 Do not press

A metal fitting called

3 Do not turn

The shatter-hook

ge the surface

the rubber too hard

the foot of rubber over too hard.

terminal will stick out

of anode-caps with

so as not to damage the inside of

the shatter-hook terminal is built into

or damage the rubber

sharp shaped objects.

anode-cap.

the rubber.

.

– 14 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

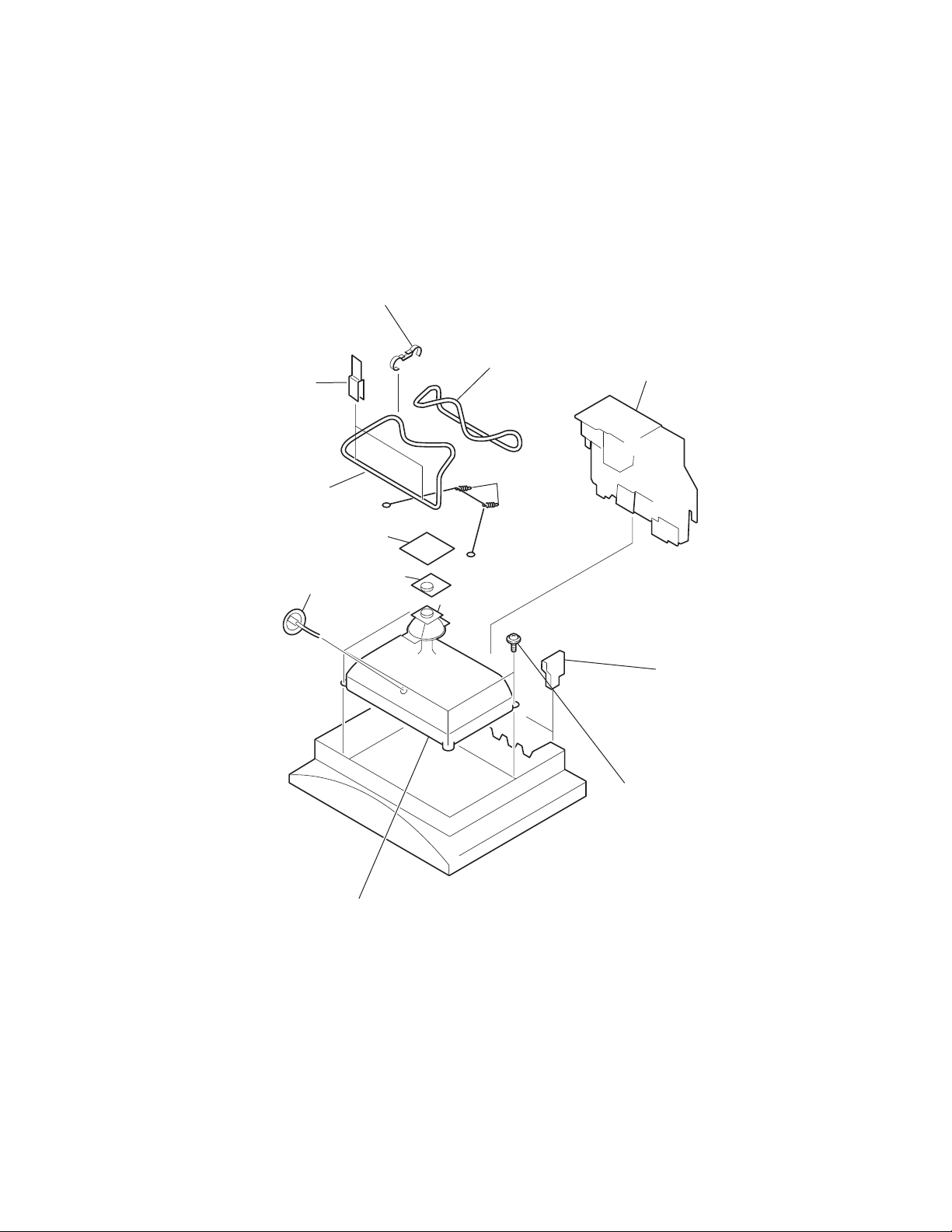

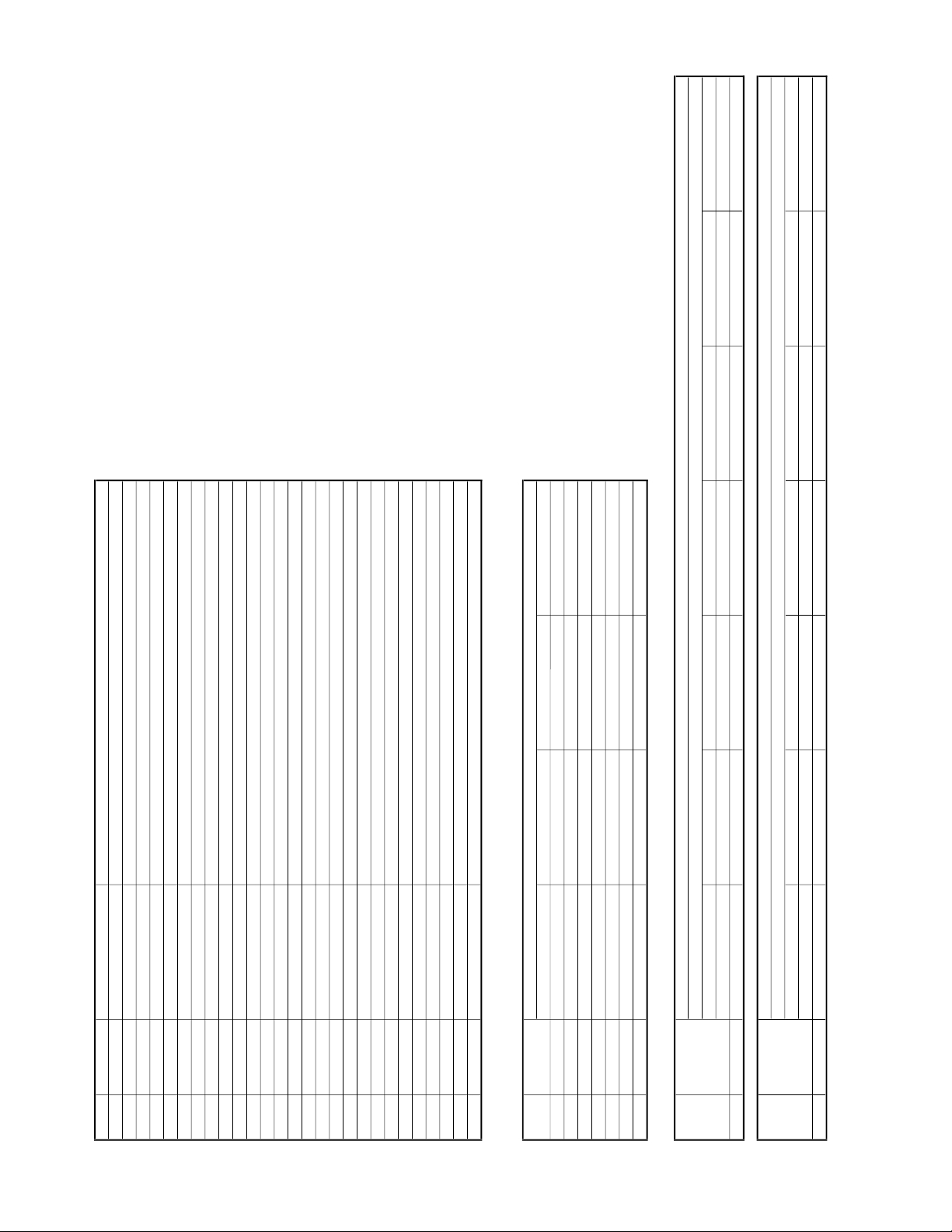

2-12. CRT

NOTE: After removing the anode, short circuit the anode of the picture tube

and the anode cap to the metal chassis, CRT shield or carbon paint

on the CRT.

1 Rear cover assembly

9 DGC holder

8 DGC holders

qa Degauss coil

5 Neck assembly

2 Anode cap

4 C1 board

qa Degauss coil

qs Extension

springs

6 Deflection

yoke

3 Chassis assembly

7 CRT supporter

qd Screws

(Crown washer +TP 7x40)

qf CRT

– 15 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

RM-1006 RM-1006 RM-1006 RM-1006

2-13. PARTS LOCATION AND WIRING

– 16 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

SECTION 3

SERVICE MODE

3-1. METHOD OF SETTING THE SERVICE ADJUSTMENT

MODE

SERVICE MODE PROCEDURE

1. Standby mode. (Power off)

2. n 5 n (+) n

on the Remote Commander.

(Press each button within a second.)

3-2. SERVICE MODE ADJUSTMENT

Item NO.(register name)

Category

Data

RM-1006 RM-1006 RM-1006 RM-1006

7. If you want to recover the latest values press 0 then to

read the memory.

8. Press [MUTING] then to write into memory.

9. Turn power off.

Note: Press 8 then on the Remote Commander to initialize

or turn set off and on to exit.

3-3. MEMORY WRITE CONFIRMATION METHOD

1. After adjustment, turn power off with the remote commander.

2. Turn power on and set to Service Mode.

3. Call the adjusted items again and confirm they were adjusted.

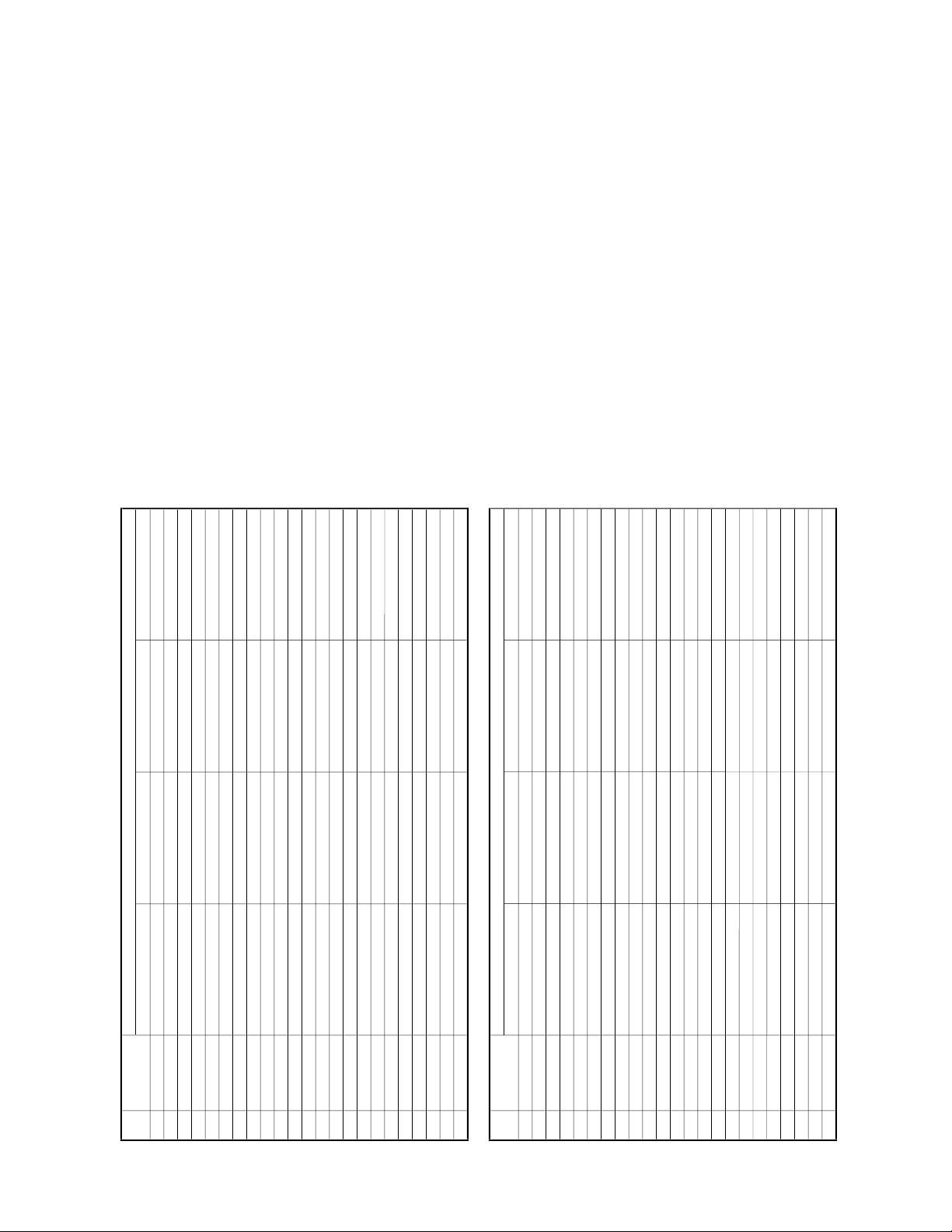

3-4. ADJUSTING BUTTONS AND INDICATOR

3D-COMB

0 NRMD

FH: - - - - - /

FV: - - - - -

0 - - -

000

0

0

3. The SCREEN displays the item being adjusted.

4. Press 1 or 4 on the Remote Commander to select the

adjustment item.

5. Press 3 or 6 on the Remote Commander to change the data.

6. Press 2 or 5 on the Remote Commander to select the

category.

Every time you press 2(Category up), Service mode changes

in the order as shown below.

3D-COMB

2103-1

2150P-1

2150D-3

2151

D-CONV

MIDXE3

OSD

GR

Adjustment item up

Adjustment item down

(+)

Category up

Data up

Data down

Category down

2150P-2

2150P-3

2150P-4

2150D-1

2150D-2

2026

AP

AUTO-WIDE

MIDXE1

MIDXE2

SNNR

TP

OP

RM-1006

– 17 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

3D COMB

No. Name Standards

1 YAPS *1 Y-output correction

2 CLKS *1 System clock setting

3

4

5

6 CDL *1 C-signal phase with respect to the Y-signal

7 DYCO *2 DY detection coring level (Y detection coring)

8 DYGA *2 DY detection gain (Y motion detection gain)

9 DCCO *2 DC detection coring level (C motion detection coring)

10 DCGA *2 DC detection gain ( C motion detection gain)

11 YNRL *1 Frame recursive YNR nonlinear filter limit level

12 CNRL *1 Frame recursive CNR nonlinear filter limit level

13 VTRH *3 Hysteresis for Hsysnc non-standard signal detection

14 VTRR *3 Sensitivity for Hsysnc non-standard signal detection

15 LDSR *3 Sensitivity for frame non-standard signal detection

16 VAPG *4 V-aperture compensation gain

17 VAPI *4 V-aperture compensation convergence point

18 YPFT *5 Y peaking filter (BPF) center frequency

19 YPFG *5 Y peaking filter (BPF) gain

20 YHCO *1 Y output high frequency component coring

21 YHCG *1 Y output high frequency component coring gain

22 HSSL *1 Hsync slice level

23 VSSL *1 Vsync slice level

24 ADCL *1 ADC clock delay

25 D2GA *2 Moving detection gain

26 KILR *1 Killer detection reference

27 OP *1 Option: Selection of comb filter&recursive n.reduction types.

28 NR1 *6 Noise reduction on/off

29 NR2 *1 SNNR control on/off

31 HPLL *1 H-PLL filter

32 BPLL *1 Burst PLL filter

33 FSCF *1 Burst extraction gain

34 PLLF *1 PLL loop gain

35 CC3N *3 Selection if a line-comb filter C separation filter characteristic

36 HDP *1 Fine adjustment of the system H-phase

37 BGPS *1 Internal

38 BGPW *1

39 TEST *1 Test bit (0:Normal mode 1:Test mode) * forbidden setting

40 WSC *1 Amount of noise detection coring

41 LIND *3 DRC-M line-doubling setting for non-standard signals UHF/VHF&Video1-4

42 PFGO *7 (YPFG offset at GR on) * Not used

43 WSS *1

Remarks

RM-1006 RM-1006 RM-1006 RM-1006

3-5.SERVICE MODE LIST

– 18 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

Standards *1

U/V VIDEO1 VIDEO2 VIDEO3

1 YAPS 3 3 3 3

2 CLKS 1 1

6 CDL 2 3

11 YNRL 1 1

12 CNRL 1 1

20 YHCO 0 0

21 YHCG 0 0

22 HSSL 12 12 12 12

23 VSSL 8 8

24 ADCL 1 1

26 KILR 3 3

27 OP 1

29 NR2 0 0 0 0

31 HPLL 1 1

32 BPLL 1 1

33 FSCF 0 0

34 PLLF 1 1

36 HDP 5 5 5 5

37 BGPS 4 4

38 BGPW 10 10 10 10

39 TEST 0 0

40 WSC 1 1 1 1

43 WSS 0 0 0 0

No. Name

Standards

33

33

11

11

11

11

11

111

11

11

00

00

88

00

00

44

VIDEO4/DEC S VIDEO1 S VIDEO2 S VIDEO3

1 YAPS 3 3 3 3

2 CLKS

6 CDL

11 YNRL

12 CNRL

20 YHCO

21 YHCG

22 HSSL 12 12 12 12

23 VSSL

24 ADCL

26 KILR

27 OP

29 NR2 0 0 0 0

31 HPLL

32 BPLL

33 FSCF

34 PLLF

36 HDP 5 5 5 5

37 BGPS

38 BGPW 10 10 10 10

39 TEST

40 WSC 1 1 1 1

43 WSS 0 0 0 0

No. Name

Standards

33 3 3

33 3 3

11 1 1

11 1 1

11 1 1

11 1 1

11 1 1

11 1 1

11 1 1

11 1 1

00 0 0

00 0 0

88 8 8

00 0 0

00 0 0

44 4 4

RM-1006 RM-1006 RM-1006 RM-1006

– 19 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

Standards *2

3DYC 2DYC+YCNR MNNR YCNR

NRMD = 0 NRMD = 1 NRMD = 2 NRMD = 3

7 DYCO 2 2 2 2

8 DYGA 10 10 10 10

9 DCCO 5 5 5 5

10 DCGA 5 5 5 5

25 D2GA 4 4 4 4

Standards *3

UV/BS Video AV multi D component

13 VTRH 1 1 1 1

14 VTRR 1 1 1 1

15 LDSR 2 2 2 2

35 CC3N 0 0 0 0

41 LIND 0 0 2 0

Standards *4

Dynamic Standard Living

16 VAPG 7 0 0

17 VAPI 1 4 4

Standards *5

Dynamic Standard Living

AV Pro VM: Off AV Pro VM: Low,Mid,High

18 YPFT 3 3 3 3 3

19 YPFG 8 8 8 8 8

Dynamic Standard Living

AV Pro VM: Off AV Pro VM: Low,Mid,High

18 YPFT 3 3 3 3 3

19 YPFG 8 8 8 8 8

Dynamic Standard Living

AV Pro VM: Off AV Pro VM: Low,Mid,High

18 YPFT 3 3 3 3 3

19 YPFG 8 8 8 8 8

No. Name Video

Standards

No. Name BS

Standards

Standards

No.

No. Name

Standards

No. Name

Name UV

Name

Standards

Standards

No.

VM: Off VM: Low VM: Mid VM: High

16 VAPG

17 VAPI

No. Name

Standards

AV Pro

0007

4441

RM-1006 RM-1006 RM-1006 RM-1006

– 20 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

Standards *6

UV Video 1 S Video 1 Video 2

28 NR1 0 0 0 0

S Video2 Video 3 S Video 3 Video 4/DEC

28 NR1 0 0 0 0

Standards *7

Standards

GR: On

42 PFGO 3

Name

Standards

Standards

No. Name

No. Name

No.

CXA2103 1

No. Name Standards

0 YLEV *1 Y-Out gain

1 CLEV *1 Cb&Cr-Out gain

2 SCON *2 Sub contrast

3 SCOL *2 Sub color

4 SHUE *2 Sub hue

5 YDLY *2 Y/C delay time

6 SHAP *3 Sharpness

7 SHF0 *3 Sharpness f0 selector

8 PREO *3 Sharpness pre/over-shoot ratio

9 BPF0 *3 Chroma band filter f0 setting

10 BPFQ *3 Chroma band filter Q setting

11 BPSW *3 Chroma bnad filter on/off

12 TRAP *3 Y block chroma trap filter on/off

13 LPF *3 Y Cb Cr-Output LPF on/off

14 AFCG *4 AFC Loop gain (PLL between Hsync & HVCO)

15 CDMD *4 V countdown system mode selector

16 SSMD *4 H&Vsync slide level setting

17 HMSK *4 Masking of macrovision signal on/off

18 HALI *4 H automatic adjustment on/off

19 PPHA *4 H TIM phase adjustment video

20 CBOF *1

21 CROF *1

22 ATPD 0 Auto-pedestal Inflection Point P&P & Favorite UBLK=0

23 DCTR 0 DC Transmission Ratio P&P & Favorite UBLK=0

24 RSCO *5

25 RSCL *5

26 RSHU *5

Standards *1

UV/Video D1,D2 AV Multi RGB AV Multi YUV UV/Video D1,D2

0 YLEV 28 32 36 32 63 63

1 CLEV 21 39 38 39 63 63

20 CBOF 36 41 46 41 63 63

21 CROF 36 41 46416363

No. Name DRC VDO

Remarks

Standards

RM-1006 RM-1006 RM-1006 RM-1006

– 21 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

Standards *2

UV Video

2 SCON 7 7

3 SCOL 6 7

4 SHUE 6 7

5 YDLY 0 0

Standards *3

UV GR: Off UV GR: On

Video D1,D2 AV Multi RGB,YUV S Video

6 SHAP

7 SHF0

8 PREO

9 BPF0

10 BPFQ

11 BPSW

12 TRAP

13 LPF

Standards *4

UV Video D1,D2 AV Multi

14 AFCG

15 CDMD

16 SSMD

17 HMSK

18 HALI

19 PPHA

Standards *5

Standards

GR: On

24 RSCO 3

25 RSCL 3

26 RSHU 4

No. Name

No. Name

No. Name

No. Name

Standards

Standards

Standards

00 00

10 00

33 33

00 00

11 11

00 00

79 38

00

00 00 00

00 0 0 00

33 0 0 00

33 3 0 00

33 3 3 33

66 510105

11 0 0 00

RM-1006 RM-1006 RM-1006 RM-1006

– 22 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

CXA2150P-1

No. Name Standards

0 SBOT *1 Offset for SBRT

1 YOF *1 Y OFFSET: DC-offset for Y signal

2 CBOF *1 CB OFFSET: DC-offset for Cb signal

3 CROF *1 CR OFFSET: DC-offset for Cr signal

4 RDVL 41

5 GDVL 31

6 BDVL 33

7 RCTL 41

8 GCTL 16

9 BCTL 27

10 BRTL 26

11 RDVH 41

12 GDVH 31

13 BDVH 31

14 RCTH 41

15 GCTH 17

16 BCTH 31

17 BRTH 25

18 WBSW -

19 SBOF *2 Offset for SBRT

20 RDOF *2 Offset for RDRV

21 GDOF *2 Offset for GDRV

22 BDOF *2 Offset for BDRV

23 RCOF *2 Offset for RCUT

24 GCOF *2 Offset for GCUT

25 BCOF *2 Offset for BCUT

26 GMLW 0

27 GMHI 2

Standards *1

D480P

D720P/1035i/1080i D1035i/1080i

AVM-RGB

AVM-RGB720P/1080i AVM-RGB1080i D480i

AVM-YUV720P/1080i AVM-YUV1080i

MID ANALOG

)

0 SBOT 7 7 7 7 7 7 7 7

1 YOF 10 0 0 0 0 0 0 0

2 CBOF 31 47 43 36 43 30 33 31

3 CROF 31 43 41 36 44 30 33 31

Standards *2

Color temp.: Mid Color temp.: Low

19 SBOF 64 64

20 RDOF 63 63

21 GDOF 65 67

22 BDOF 64 74

23 RCOF 63 63

24 GCOF 62 66

25 BCOF 55 73

Remarks

UV/Video

AVM-YUV480P

MID

Standards

Standards

ANALOG

AVM-RGB,YUV480i

No. Name

No. Name

480P

RM-1006 RM-1006 RM-1006 RM-1006

– 23 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

CXA2150P-2

No. Name Standards

0

1

2 BLKB 3 BLK BTM: RGB output bottom limit level (Black level)

3LIML 0 PLIMIT LEV: Threshold level for excessively high inputs

4 PABL 15 P ABL: DC-level in RGB output detection for PEAK ABL

5 SABL 0 S ABL: S ABL gain

6 AGNG 0 AGING W/AGING B: AGING W/AGING B modes on/off

7 AKBO 0 AKBOFF: Automatic/Manual = Cut off setting

8 SYPH *1 SYNC PHASE: Hsync delay with respect to Video (100%H-period)

9 CLPH *1 CLP PHASE: Internal clamp pulse phase (100%H-period)

10 CLGA *1 CLP GATE: Switch for the gated internal clamp pulse with Hsync

11 0 JAXIS: color axis switch

12 0 BLKO: Blanking switch

Standards *1

D,AVM-YUV D,AVM-RGB,YUV D,AVM-RGB,YUV AVM-RGB D,AVM-RGB,YUV

480i 1035i/1080i 480i

8 SYPH 0 0 0 0 0 0

9 CLPH 3 3 3333

10 CLGA 000000

Remarks

UV/BS/Video

Standards

No. Name

CXA2150P-3

No. Name Standards

0 SYSM *1 SYSTEM: Signal bandwidth setting

1 UVML *1 VM LEV: VM OUT level

2 VMMO *1 System Micro pin#40

3 VMCR *1 VM COR: VM OUT coring level

4 VMLM *1 VM LMT: VM OUT limit level

5 VMF0 *1 VM F0: VM f0

6 VMDL *1 VM DLY:VM OUT phase (defined by phase difference from R OUT)

7 SHOF *1 Offset for USHP=SHOF x 4

8 SHF0 *1 SHP F0: Sharpness circuit f0

9 PROV *1 PRE/OVER: Y signal pre/over-shoot ratio

10 F1LV *1 SHP F1: Sharpness for higher f0 (4.2/5.6Mhz @NORMAL mode)

11 CDSP *1 SHP CD: Sharpness in part of high color saturation

12 LTLV *1 LTI LEV: Luminance transient improvement (LTI)

13 LTMD *1 LTI MODE: LTI mode setting

14 CTLV *1 CTI LEV: Chrominance transient improvement (CTI)

15 CTMD *1 CTI MODE: CTI mode setting

16 UBOF *1 Offset for UBRT (Picture clarity adjustment)

17 UCOF *1 Offset for UCOL=UCOF x 2 (Picutre clarity adjustment)

18 UHOF *1 Offset for UHUE (Picutre clarity adjustment)

19 MIDE *2 MID enhancement setting

20 VMOF 1

21 VDCG 1

22 POCG 1

23 LTOF 1

Remarks

RM-1006 RM-1006 RM-1006 RM-1006

– 24 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

Standards *1

D,AVM-YUV D,AVM-RGB,YUV D,AVM-RGB,YUV D,AVM-RGB,YUV D,AVM-RGB,YUV

1080i (MID) 1035i/1080i (ANALOG)

0 SYSM

1 UVML

2 VMMO

3 VMCR

4 VMLM

5 VMF0

6 VMDL

7 SHOF

8 SHF0

9 PROV

10 F1LV

11 CDSP

12 LTLV

13 LTMD

14 CTLV

15 CTMD

16 UBOF

17 UCOF

18 UHOF

D,AVM-YUV D,AVM-RGB,YUV D,AVM-RGB,YUV D,AVM-RGB,YUV D,AVM-RGB,YUV

1080i (MID) 1035i/1080i (ANALOG)

0 SYSM

1 UVML

2 VMMO

3 VMCR

4 VMLM

5 VMF0

6 VMDL

7 SHOF

8 SHF0

9 PROV

10 F1LV

11 CDSP

12 LTLV

13 LTMD

14 CTLV

15 CTMD

16 UBOF

17 UCOF

18 UHOF

DEC Video

Standards

No. Name

Standards

AI Mode: Living

AI Mode: Dynamic

UV DEC Video

UV

No. Name

11111232

33333333

00000000

03200000

33333000

11111101

00000000

20000331

11111101

33111313

00033003

33333333

33233223

01000001

33100303

00000000

7777710109

22112000

11111000

11111232

33333333

11111111

00000000

33333000

11111101

00000000

00000130

11111101

32211313

00333002

33333333

22222122

01111111

33100303

00000000

77777777

22111111

22222001

RM-1006 RM-1006 RM-1006 RM-1006

– 25 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

D,AVM-YUV

D

,

AVM- YUV

D,AVM-RGB,YUV D,AVM-RGB,YUV D,AVM-RGB,YUV

1080i (MID) 1035i/1080i (ANALOG)

0 SYSM

1 UVML

2 VMMO

3 VMCR

4 VMLM

5 VMF0

6 VMDL

7 SHOF

8 SHF0

9 PROV

10 F1LV

11 CDSP

12 LTLV

13 LTMD

14 CTLV

15 CTMD

16 UBOF

17 UCOF

18 UHOF

UV

DEC

Video D,AVM-YUV

D

,

AVM- YUV

D,AVM-RGB,YUV D,AVM-RGB,YUV D,AVM-RGB,YUV

1080i (MID) 1035i/1080i (ANALOG)

0 SYSM

1 UVML

2 VMMO

3 VMCR

4 VMLM

5 VMF0

6 VMDL

7 SHOF

8 SHF0

9 PROV

10 F1LV

11 CDSP

12 LTLV

13 LTMD

14 CTLV

15 CTMD

16 UBOF

17 UCOF

18 UHOF

Standards

AI Mode: AV Pro

Video

DEC

No. Name

No. Name

Standards

AI Mode: Standard

UV

11111132

22322232

00000000

00200000

33333300

11111101

00000000

00221130

11111101

32211113

00333302

33333333

22233302

01111111

33100003

00000000

77777777

22112211

22222201

11111233

00000000

00000000

00000000

33333000

11111101

00000000

00000230

11111101

32211313

00333000

00000000

22202111

01111111

33000303

00000000

77777777

00000110

00000000

RM-1006 RM-1006 RM-1006 RM-1006

– 26 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

Standards *2

AVM-YUV AVM-RGB,YUV AVM-RGB,YUV AVM-RGB,YUV

480i 480i 480P 1035i/1080i 720P

19 MIDE 3 3 7 23 23 11 11 27

AVM-YUV AVM-RGB,YUV AVM-RGB,YUV AVM-RGB,YUV

480i 480i 480P 1035i/1080i 720P

19 MIDE 2 2 6 22 22 10 10 26

AVM-YUV AVM-RGB,YUV AVM-RGB,YUV AVM-RGB,YUV

480i 480i 480P 1035i/1080i 720P

19 MIDE 1 1 5 21 21 9 9 25

AVM-YUV AVM-RGB,YUV AVM-RGB,YUV AVM-RGB,YUV

480i 480i 480P 1035i/1080i 720P

19 MIDE 0 0 4 20 20 8 8 24

AVM-RGB

AVM-RGB

UV

DEC

Video

UV

DEC

UV

DEC

Video

AI Mode: Living

D Componemt

AVM-RGB

AI Mode: AV Pro

D Componemt

UV

DEC

Video

AVM-RGB

No. Name

Standards

Standards

Standards

Standards

AI Mode: Dynamic

D Componemt

AI Mode: Standard

D Componemt

No. Name

Video

No. Name

No. Name

RM-1006 RM-1006 RM-1006 RM-1006

– 27 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

CXA2150P-4

No. Name Standards

0 UPIC *1 PICTURE: Picture

1 UBRT *1 BRIGHT: Brightness

2 UCOL *1 COLOR:

3 UHUE *1 HUE:Hu

4 USHP *1 SHARPNESS: Sharpness

5 UTMP *1 Color Temperature (0:Warm 1:Neutral 2:Cool)

6 UDCL *1 DCOL: D

7 AXIS *2 COL AXIS: color matrix setting

8UGAM *3 GAMMA/GAMMA L: RGB output GAMMA correction setting

9 AGAM *4 GAMMA/GAMMA L (AV Pro user control) - Void Data

10 GSBO *5 Offset for SBRT

11 GCOO *5 Offset for UCOL

12 GHUO *5 Offset for UHUE

13 UBLK *3 Item#15-18 pack F1 data controls

14 ABLK *6 (Av Pro user control) - Void Data

15 DCTR *7 DC TRAN: Y signal DC transmission

16 DPIC *7 DPIC LEV: Y signal AUTO PEDESTAL level

17 DSBO *7 Offset for SBRT

18 ABLM *7 ABL MODE: ABL mode

19 ABLT *8 ABL TH: ABL current detection Vth contro

20 ABLC *8

21 EPOF *9 Offset for UPIC=EPOF x (UPIC/63) (for power save) - Void Data

22 SPOF *10 Offset for UPIC=SPOF x (UPIC/64) - Data Not used

23 SCON *11 SUB CONTRAST: SUB PICTURE

24 CLOF *11 Offset for UCOL

25 HUOF *11 Offset for UHUE

26 USOF *12

Standards *1

Dynamic Standard Living AV Pro

0 UPIC 53 47 31 31

1 UBRT 26 31 31 31

2 UCOL 35 33 31 31

3 UHUE 31 31 31 31

4 USHP 31 31 31 31

5 UTMP 2 2 2 1

6 UDCL 3 2 2 0

Standards *2

UV/Video D, AVM-YUV D, AVM-RGB,YUV D D, AVM-RGB,YUV AVM-RGB D, AVM-RGB,YUV

480i 480P 1035i 1080i 480i

7 AXIS 3 3 3 3 3 3 3

UV/Video D, AVM-YUV D, AVM-RGB,YUV D D, AVM-RGB,YUV AVM-RGB D, AVM-RGB,YUV

480i 480P 1035i 1080i 480i

7 AXIS 3 3 3 3 3 3 3

Remarks

Standards

Standards

AI Mode: AV Pro

Standards

AI Mode: Dynamic, Standard, Living

No. Name

No.

No. Name

Name

RM-1006 RM-1006 RM-1006 RM-1006

– 28 –

KV-DX29K9H/KV-DX29K9H/B/DX29K90B/DX29K90L

Standards *3

UV/Video D, AVM-YUV D, AVM-RGB,YUV D, AVM-RGB,YUV AVM-RGB D, AVM-RGB,YUV

480i 480P 1035i/1080i 480i

8UGAM 555444

13 UBLK 7 7 7 7 5 7

UV/Video D, AVM-YUV D, AVM-RGB,YUV D, AVM-RGB,YUV AVM-RGB D, AVM-RGB,YUV

480i 480P 1035i/1080i 480i

8 UGAM 4 44343

13 UBLK 5 5 5 5 5 5

UV/Video D, AVM-YUV D, AVM-RGB,YUV D, AVM-RGB,YUV AVM-RGB D, AVM-RGB,YUV

480i 480P 1035i/1080i 480i

8 UGAM 4 4 4 3 4 3

13 UBLK 5 5 5 5 2 5

UV/Video D, AVM-YUV D, AVM-RGB,YUV D, AVM-RGB,YUV AVM-RGB D, AVM-RGB,YUV

480i 480P 1035i/1080i 480i

8 UGAM 0 0 0 0 0 0

13 UBLK 0 00000

AI Mode: AV Pro

No. Name

Standards

No. Name

Standards

No. Name

Standards

AI Mode: Standard

AI Mode: Living

No. Name

Standards

AI Mode: Dynamic

Standards *4

Gamma: Low Gamma: Mid Gamma: High

9AGAM 2 4 6

Standards *5

UGAM0 UGAM1 UGAM2 UGAM3

10 GSBO 0 0 0 0

11 GCOO 0 0 0 0

12 GHUO 0 0 0 0

Standards *6

Black level: Low Black level: Mid Black level: High

14 ABLK 2 5 7

Standards

Standards

Standards

No. Name

No. Name

No. Name

UGAM4 UGAM5 UGAM6 UGAM7

10 GSBO 0 0 0 0

11 GCOO 0 0 0 0

12 GHUO 0 0 0 0

Standards

No. Name

RM-1006 RM-1006 RM-1006 RM-1006

– 29 –

Loading...

Loading...