Sony KV-29FS12K Service manual

SERVICE MANUAL

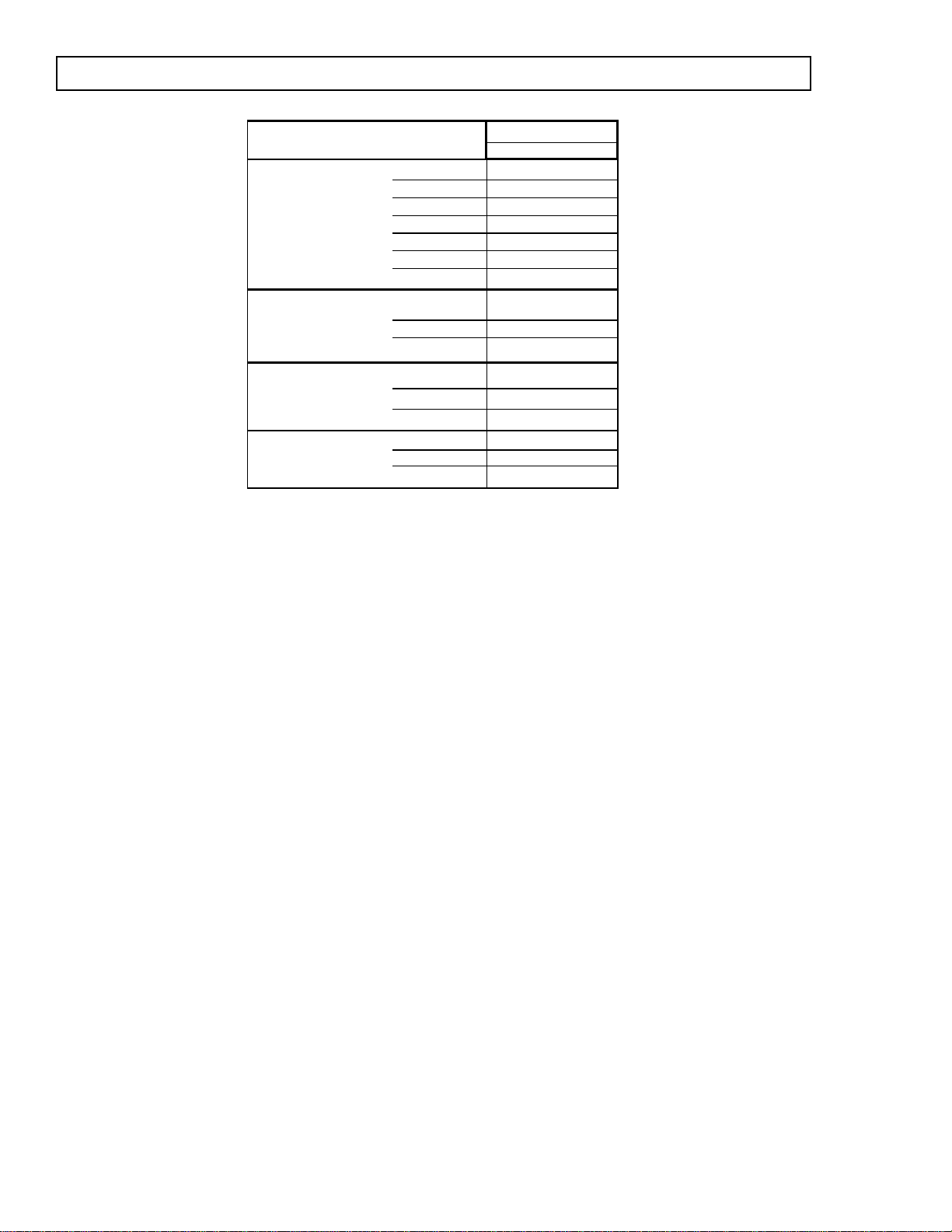

MODEL COMMANDER DEST CHASSIS NO.

BA-5 CHASSIS

KV -29FS12K

RM-Y149A KOREA SCC-S53A-A

RM-Y149AKV-29FS12K

TRINITRON® COLOR TV

KV-29FS12K

KV-29FS12K

Power requirements 120V-220V, 60Hz/50Hz

Number of inputs/outputs

Video

1)

3

S Video

2)

1

Audio

3)

3

Audio Out

4)

1

Y, P

B

, P

R

5)

1

Speaker output(W) 5Wx2

Power Consumption(W)

In use(Max) 185W

In standby 1W

Dimensions(W/H/D)

(mm)

700 x 632 x 512 mm.

(in)

27

1/2

x 24

7/8

x 20

1/6

in.

Mass

(kg) 47kg

(lbs) 103 lbs. 10 oz.

SPECIFICATIONS

1) 1 Vp-p 75 ohms unbalanced, sync negative

2) Y: 1 Vp-p 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

3) 500mVrms (100% modulation), impedance: 47kilohms

4) More than 408 mVrms at the maximum volume setting (variable)

More than 408 mVrms (fix)

5) Y: 1.0 Vp-p, 75 ohms, sync negative; PB: 0.7 Vp-p, 75 ohms;

PR: Vp-p, 75 ohms

Television system

American TV Standard/NTSC

Channel coverage

VHF:2-13/UHF:14-69/CATV:1-125

Visible screen size

27” picture measured diagonally

Actual screen size

29” picture measured diagonally

Antenna

75 ohm external antenna terminal for VHF/UHF

Supplied accessories

Remote Commander RM-Y149A

Size AA (R6) batteries (2)

Optional accessories

Connecting cables: VMC-810S/820S, VMC-720M,

YC-15V/30V , RK74A

U/V mixer EAC-66

Design and specifications are subject to change without notice.

— 2 —

KV-29FS12K

TABLE OF CONTENTS

Section Title Page

Warnings and Cautions ....................................................................................................................................... 4

Self-Diagnostic Function ...................................................................................................................................... 4

Safety Check-Out Instructions.............................................................................................................................. 7

1. DISASSEMBLY

1-1. Rear Cover Removal ................................................................................................................................. 8

1-2. Chassis Assembly Removal....................................................................................................................... 8

1-3. Service Position ........................................................................................................................................ 8

1-4. Picture Tube Removal............................................................................................................................... 9

2. SET-UP ADJUSTMENTS

2-1. Beam Landing......................................................................................................................................... 10

2-2. Convergence ...........................................................................................................................................11

2-3. Focus...................................................................................................................................................... 12

2-4. Screen (G2) ............................................................................................................................................ 13

2-5. Method of Setting the Service Adjustment Mode..................................................................................... 13

2-6. White Balance Adjustments .................................................................................................................... 13

3. SAFETY RELATED ADJUSTMENTS

3-1.

3-2. B+ Volt age Confirmation and Adjustment................................................................................................ 14

R564 Confirmation Method (HV Hold-Down Confirmation) and Readjustments ................................. 14

4. CIRCUIT ADJUSTMENTS

4-1. Setting the Service Adjustment Mode...................................................................................................... 16

4-2. Memory Write Confirmation Method........................................................................................................ 16

4-3. Adjustment Buttons and Indicators.......................................................................................................... 16

4-4. MA Board Adjustments............................................................................................................................ 20

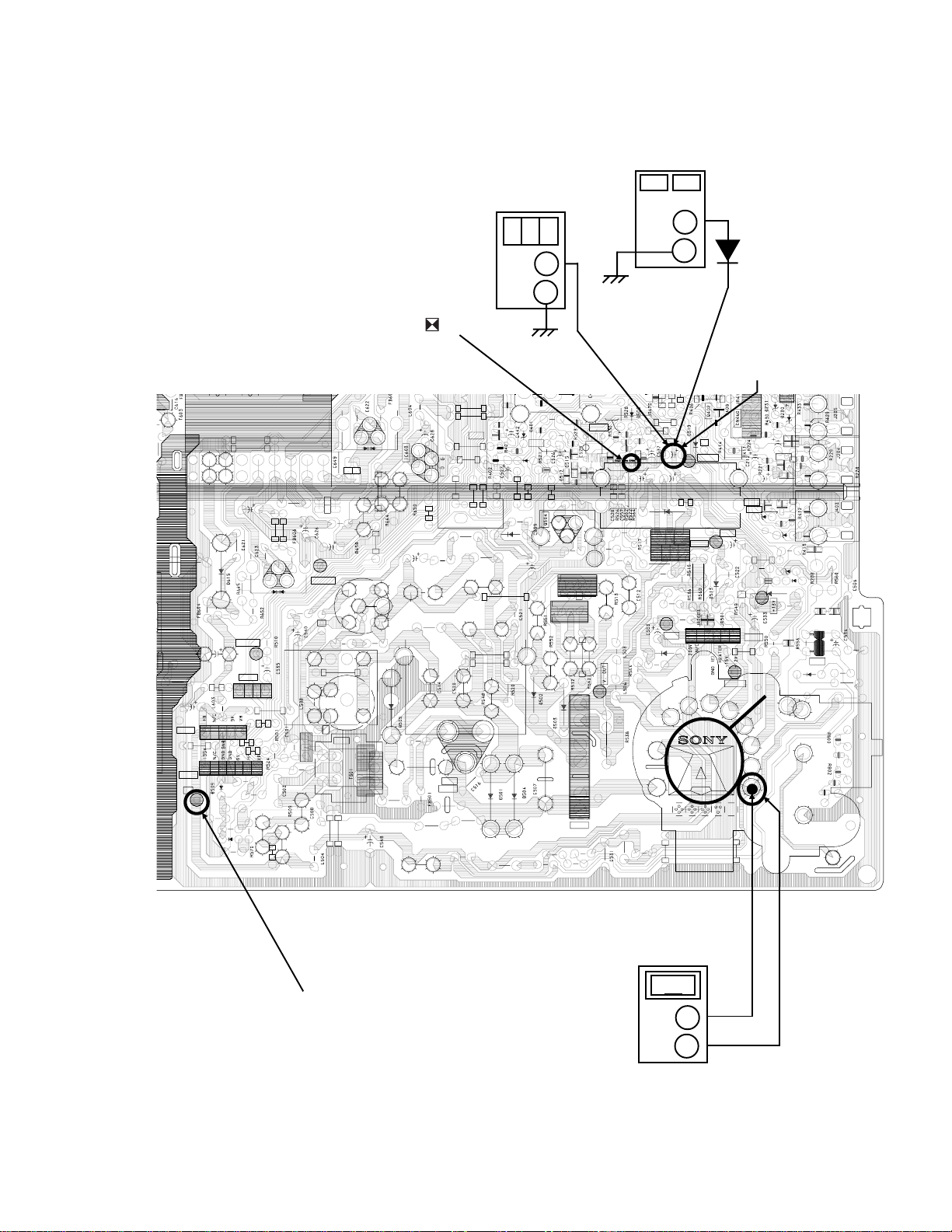

5. DIAGRAMS

5-1. Block Diagram......................................................................................................................................... 22

5-2. Circuit Board Location............................................................................................................................. 28

5-3. Printed Wiring Boards and Schematic Diagrams..................................................................................... 28

• A Board .............................................................................................................................................. 29

• MA Board............................................................................................................................................ 36

• HX Board............................................................................................................................................ 40

• CA Board............................................................................................................................................ 42

• HZ Board............................................................................................................................................ 43

• K Board .............................................................................................................................................. 44

• V A Board ............................................................................................................................................ 45

• D Board .............................................................................................................................................. 46

5-4. Semiconductors ...................................................................................................................................... 48

6. EXPLODED VIEW

6-1. Chassis ................................................................................................................................................... 49

7. ELECTRICAL P ARTS LIST

................................................................................................................................................ 50

— 3 —

KV-29FS12K

WARNINGS AND CAUTIONS

CAUTION

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE

AND THE ANODE CAP TO THE METAL CHASSIS, CRT

SHIELD, OR CARBON PAINTED ON THE CRT, AFTER

REMOVING THE ANODE.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED

DURING ANY SERVICE TO AVOID POSSIBLE SHOCK

HAZARD, BECAUSE OF LIVE CHASSIS. THE CHASSIS

OF THIS RECEIVER IS DIRECTLY CONNECTED TO THE

AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK

ON THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS,

AND IN THE PARTS LIST ARE CRITICAL FOR SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL FOR SAFE OPERA TION ARE IDENTIFIED

IN THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED

OR IMPROPER OPERATION IS SUSPECTED.

ATTENTION!!

APRES AVOIR DECONNECTE LE CAP DE L'ANODE, COURT-CIRCUITER

L'ANODE DU TUBE CATHODIQUE ET CELUI DE L'ANODE DU CAP AU

CHASSIS METALLIQUE DE L'APPAREIL, OU AU COUCHE DE CARBONE

PEINTE SUR LE TUBE CATHODIQUE OU AU BLINDAGE DU TUBE

CATHODIQUE.

ATTENTION!!

AFIN D'EVITER TOUT RESQUE D'ELECTROCUTION PROVENANT D'UN

CHÁSSIS SOUS TENSION, UN TRANSFORMATEUR D'ISOLEMENT DOIT ETRE

UTILISÉ LORS DE TOUT DÉPANNAGE. LE CHÁSSIS DE CE RÉCEPTEUR EST

DIRECTEMENT RACCORDÉ À L'ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

LES COMPOSANTS IDENTIFIES PAR UNE TRAME ET PAR UNE MARQUE

SUR LES SCHEMAS DE PRINCIPE, LES VUES EXPLOSEES ET LES

LISTES DE PIECES SONT D'UNEIMPORTANCE CRITIQUE POUR LA

SECURITE DU FONCTIONNEMENT. NE LES REMPLACER QUE PAR DES

COMPOSANTS SONY DONT LE NUMERO DE PIECE EST INDIQUE DANS

LE PRESENT MANUEL OU DANS DES SUPPLEMENTS PUBLIES P AR SONY.

LES REGLAGES DE CIRCUIT DONT L'IMPORT ANCE EST CRITIQUE POUR

LA SECURITE DU FONCTIONNEMENT SONT IDENTIFIES DANS LE

PRESENT MANUEL. SUIVRE CES PROCEDURES LORS DE CHAQUE

REMPLACEMENT DE COMPOSANTS CRITIQUES, OU LORSQU'UN

MAUVAIS FONTIONNEMENT SUSPECTE.

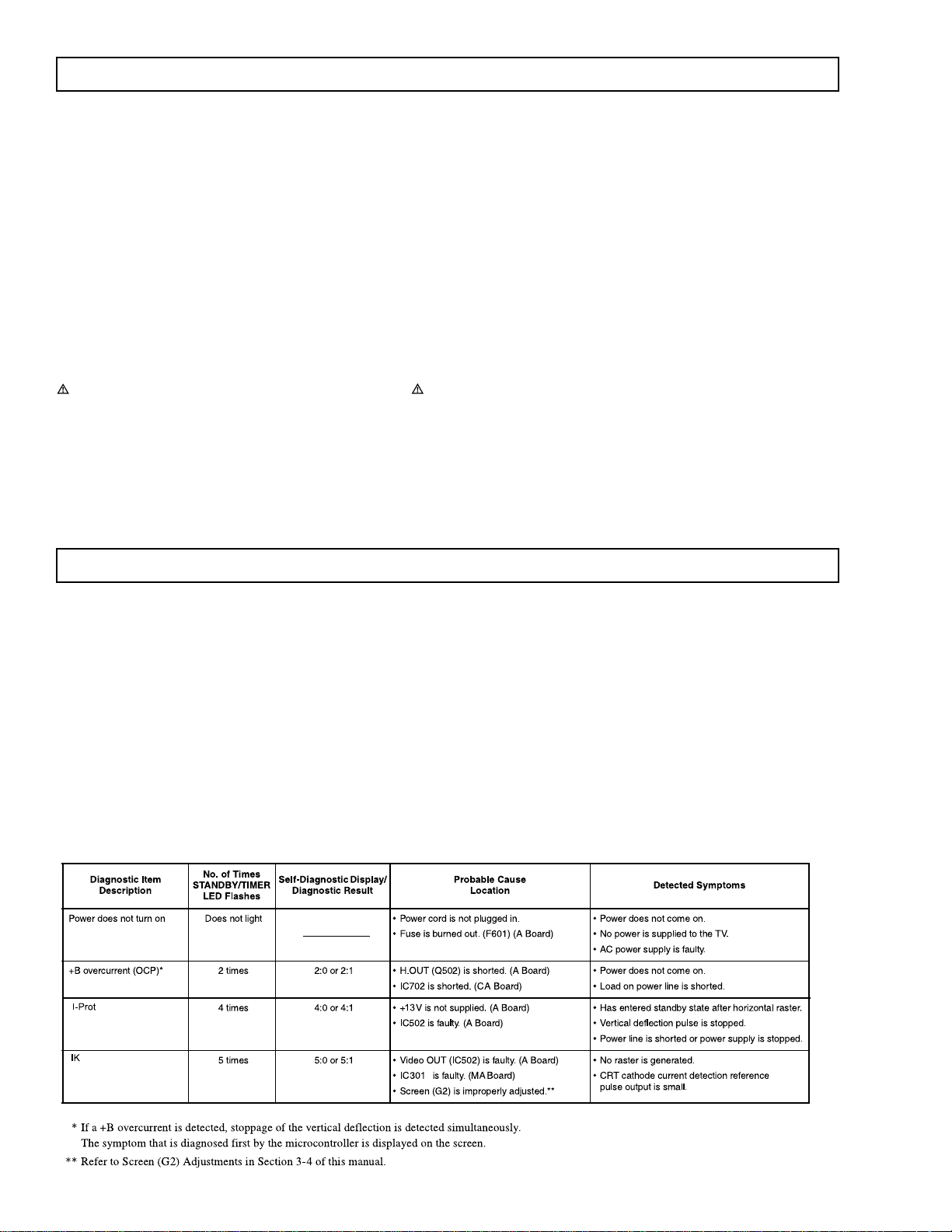

SELF-DIAGNOSTIC FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the ST ANDBY/TIMER LED will automatically begin to flash.

The number of times the LED flashes translates to a probable source of the problem. A definition of the STANDBY/TIMER LED flash

indicators is listed in the instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote

Commander can be used to review the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

Diagnostic Test Indicators

When an error occurs, the STANDBY/TIMER LED will flash a set number of times to indicate the possible cause of the problem. If there is

more than one error, the LED will identify the first of the problem areas.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

— 4 —

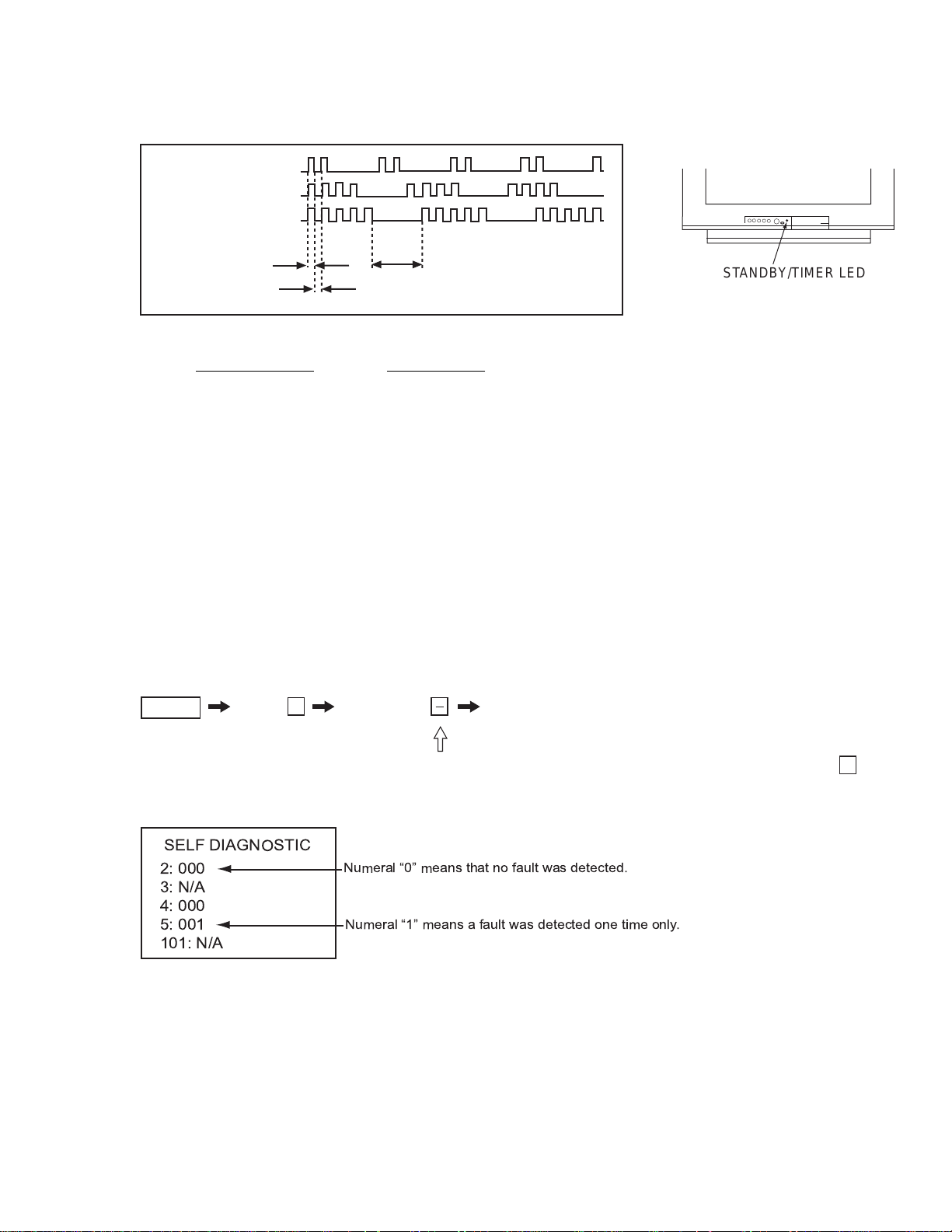

Display of Standby/Timer LED Flash Count

2 times

4 times

5 times

KV-29FS12K

LED ON 0.3 sec.

LED OFF 0.3 sec.

LED OFF

3 sec.

STANDBY/TIMER LED

Diagnostic Item Flash Count*

+B overcurrent 2 times

I-Prot 4 times

IK 5 times

*One flash count is not used for self-diagnostic.

Stopping the Standby/Timer LED Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/TIMER LAMP from flashing.

Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it is possible

to bring up past occurrences of failure on the screen for confirmation.

To Bring Up Screen Test

In standby mode, press buttons on the Remote Commander sequentially, in rapid succession, as shown below:

Display Channel

5

Sound volume

Power ON

Self-Diagnostic Screen Display

SELF DIAGNOSTIC

2: 000

Numeral 0 means that no fault was detected.

3: N/A

4: 000

5: 001

Numeral 1 means a fault was detected one time only.

101: N/A

Note that this differs from entering the service mode (sound volume

— 5 —

+

).

KV-29FS12K

Handling of Self-Diagnostic Screen Display

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs.

When you have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the

repairs.

Clearing the Result Display

To clear the result display to “0”, press buttons on the Remote Commander sequentially when the diagnostic screen is displayed,

as shown below:

8

ENTERChannel

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn of f the power switch on the Remote Commander or the main unit.

Self-Diagnostic Circuit

FROM

CA BOARD

CN705 PIN 1

FROM

A BOARD

IC501 PIN 3

MA BOARD

IC301

Y/CHROMA JUNGLE

IK IN

36

HP/PROTECT

33

SDA

A BOARD

IC502

V. OUT

3

REF

61

5

43

MA BOARD

IC001

SYSTEM

I-PROT

IO-SDAT

IO-BDAT

O-LED

42

22

DISPLAY

MA BOARD

MEMORY

B-DAT

5

IC003

+B overcurrent (OCP) Occurs when an overcurrent on the +B (135V) line is detected by pin 33 of IC301 (MA Board). If

the voltage of pin 33 of IC301 (MA Board) is less than 1V when V.SYNC is more than seven

verticals in a period, the unit will automatically turn off.

I-Prot Occurs when an absence of the vertical deflection pulse is detected by pin 5 of IC001 (MA

Board). Power supply will shut down when waveform interval exceeds 2 seconds.

IK If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will be

detected by IC301 (MA Board). TV will stay on, but there will be no picture.

*(Refers to the RGB levels of the AKB detection Ref pulse that detects 1K).

— 6 —

SAFETY CHECK-OUT

KV-29FS12K

After correcting the original service problem, perform the

following safety checks before releasing the set to the

customer:

1. Check the area of your repair for unsoldered or poorly

soldered connections. Check the entire board surface

for solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground

straps, and mounting hardware have been replaced.

Be absolutely certain that you have replaced all the

insulators.

4. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair .

Point them out to the customer and recommend their

replacement.

5. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer

and recommend their replacement.

6. Check the line cords for cracks and abrasion.

Recommend the replacement of any such line cord

to the customer.

7. Check the B+ and HV to see if they are specified

values. Make sure your instruments are accurate;

be suspicious of your HV meter if sets always have

low HV .

8. Check the antenna terminals, metal trim, “metallized”

knobs, screws, and all other exposed metal parts for AC

leakage. Check leakage as described below.

Leakage Test

The AC leakage from any exposed metal p art to earth

ground and from all exposed metal parts to any exposed

metal part having a return to chassis, must not exceed 0.5

mA (500 microamperes). Leakage current can be

measured by any one of three methods.

1. A commercial leakage tester , such as the Simp son 229

or RCA WT-540A. Follow the manufacturers'

instructions to use these instructions.

2. A battery-operated AC milliammeter . The Data Precision

245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means

of a VOM or battery-operated AC voltmeter. The “limit”

indication is 0.75 V , so analog meters must have an

accurate low voltage scale. The Simpson’s 250 and

Sanwa SH-63TRD are examples of passive VOMs that

are suitable. Nearly all battery-operated digital

multimeters that have a 2 VAC range are suitable

(see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the coverplate retaining screw on most AC outlet boxes is also at earth

ground. If the retaining screw is to be used as your earth

ground, verify that it is at ground by measuring the resistance

between it and a cold-water pipe with an ohmmeter. The

reading should be zero ohms. If a cold-water pipe is not

accessible, connect a 60- to 100-watt trouble- light (not a

neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary , to locate the hot

side on the line; the lamp should light at normal brilliance if the

screw is at ground potential (see Figure B).

— 7 —

Trouble Light

AC Outlet Box

Figure B. Checking for earth ground.Figure A. Using an AC voltmeter to check AC leakage.

Ohmmeter

Cold-water Pipe

KV-29FS12K

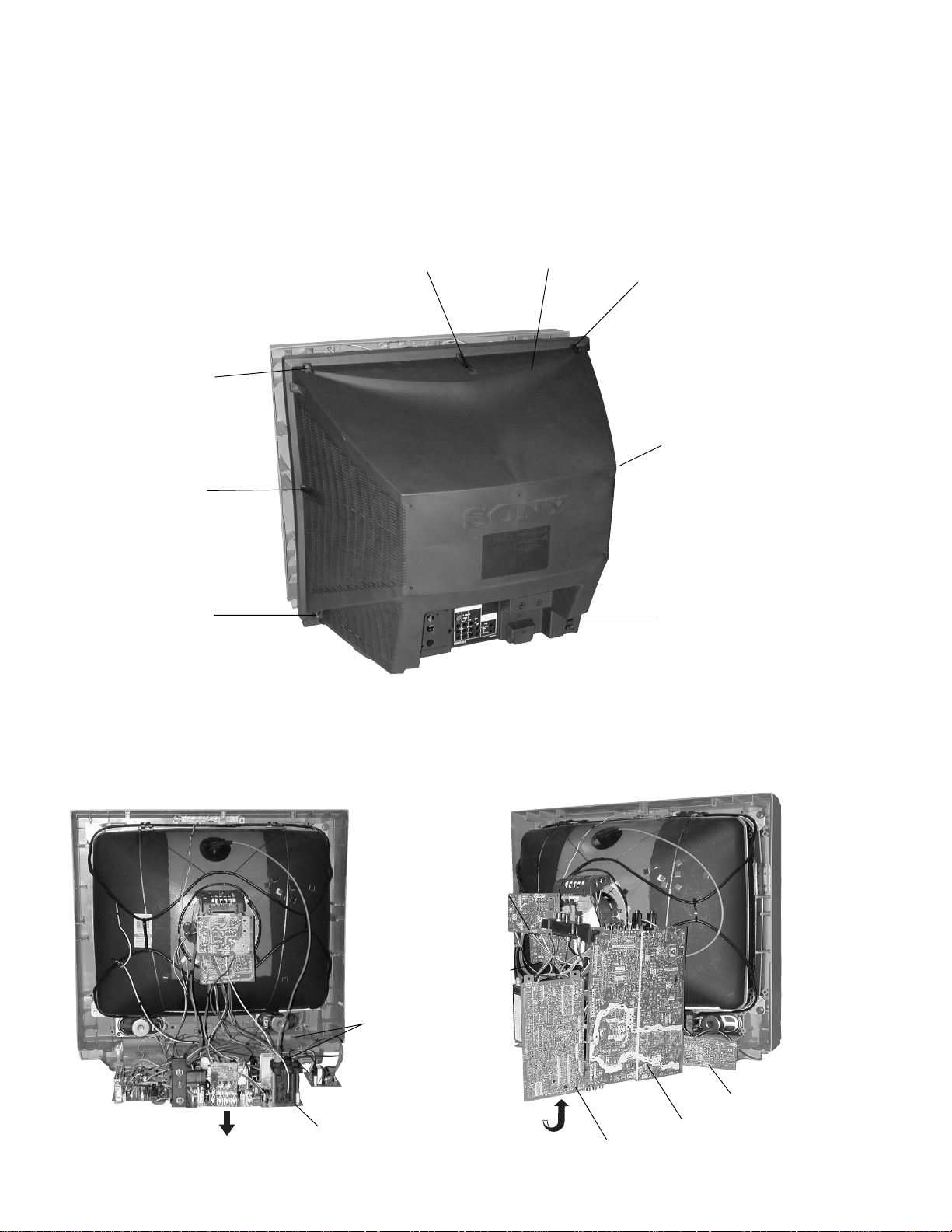

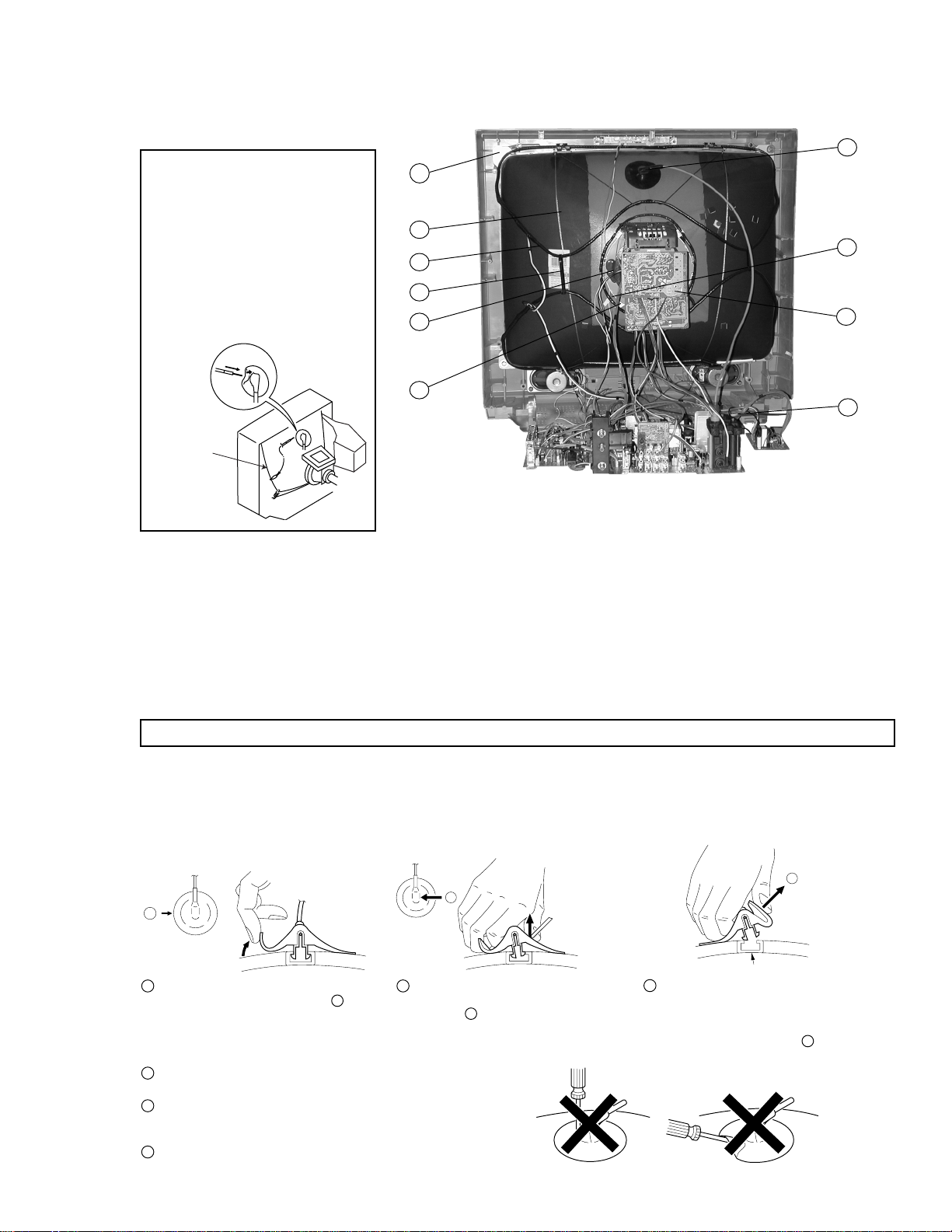

1-1. REAR COVER REMOV AL

SECTION 1

DISASSEMBLY

Screw +BVTP 4x16

Screw +BVTP 4x16

Screw +BVTP 4x16

Screw +BVTP 4x16

Rear Cover

Screw +BVTP 4x16

Screw +BVTP 4x16

Screw +BVTP 4x16

1-2. CHASSIS ASSEMBL Y REMOVAL 1-3. SERVICE POSITION

CA Board

VA Board

Claw

Chassis

Assembly

MA Board

D Board

A Board

— 8 —

1-4. PICTURE TUBE REMOVAL

WARNING:

BEFORE REMOVING

THE ANODE CAP

KV-29FS12K

1

10

High voltage remains in the CRT

even after the power is disconnected.

T o avoid electric shock, discharge

CRT before attempting to remove the

9

8

7

anode cap. Short between anode and

CRT coated earth ground strap.

6

5

Coated

Earth

Ground

Strap

1. Discharge the anode of the CRT and remove the anode cap.

2. Unplug all interconnecting leads from the deflection yoke, neck

assembly, degaussing coils and CR T grounding strap.

3. Remove the CA Board from the CRT.

4. Remove the chassis assembly .

5. Loosen the neck assembly fixing screw and remove.

2

3

4

6. Loosen the deflection yoke fixing screw and remove.

7. Place the set with the CR T face down on a cushion and remove

the degaussing coil holders.

8. Remove the degaussing coils.

9. Remove the CRT grounding strap and spring tentioners.

10. Unscrew the four CRT fixing screws [located on each CRT

corner] and remove the CRT [Take care not to handle the

CRT by the neck].

ANODE CAP REMOV AL

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electrical shock, discharge the CRT before

NOTE: After removing the anode, short circuit the anode of the picture tube and the anode cap to either the metal chassis, CRT shield,

attempting to remove the anode cap. Short between anode and coated earth ground strap of CRT.

or carbon painted on the CRT.

REMOVAL PROCEDURES

c

b

a

Anode Button

1

Turn up one side of the rubber cap in

the direction indicated by arrow

2

a

.

Use your thumb to pull the rubber

cap firmly in the direction indicated

by arrow

b

.

3

When one side of the rubber cap

separates from the anode button,

the anode cap can be removed by

turning the rubber cap and pulling

it in the direction of arrow

c

.

HOW TO HANDLE AN ANODE CAP

1

Do not use sharp objects which may cause damage to the

surface of the anode cap.

2

To avoid damaging the anode cap, do not squeeze the rubber

covering too hard. A material fitting called a shatter-hook terminal

is built into the rubber.

3

Do not force turn the foot of the rubber cover. This may cause

the shatter-hook terminal to protrude and damage the rubber.

— 9 —

KV-29FS12K

SECTION 2

SET -UP ADJUSTMENTS

The following adjustments should be made when

a complete realignment is required or when a new

picture tube is installed.

These adjustments should be performed with rated

power supply voltage unless otherwise noted.

Set the controls as follows unless otherwise noted:

VIDEO MODE: ST ANDARD

PICTURE control: ................ Normal

BRIGHTNESS control: ........ Normal

2-1. BEAM LANDING

Before beginning adjustment procedure:

1. Degauss the entire screen.

2. Feed in the white pattern signal.

Adjustment Procedure

1. Input a raster signal with the pattern generator .

2. Loosen the deflection yoke mounting screw and set the purity

control to the center as shown below.

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)

5. White Balance

Note: T est equipment required:

• Color Bar Pattern Generator

• Degausser

• DC Power Supply

• Digital Multimeter

5. Move the deflection yoke forward and adjust so that the entire

screen becomes green.

6. Switch over the raster signal to red and blue and confirm

the condition.

7. When the position of the deflection yoke is determined,

tighten it with the deflection yoke mounting screw.

8. If landing at the corner is not right, adjust by using the disk

magnets.

Purity Control

3. T urn the raster signal of the pattern generator to green.

4. Move the deflection yoke backward and adjust the purity

control so that green is in the center and red and blue are

at the sides evenly.

Blue Red

Green

Disk magnets

or rotatable disk

magnets correct

these areas (a-d)

b

d

Purity control

corrects this area

ba

cd

Deflection yoke positioning

corrects these areas

a

— 10 —

c

KV-29FS12K

2-2. CONVERGENCE

Before starting convergence adjustments:

1. Perform FOCUS, V.LIN AND V .SIZE adjustments.

2. Set BRIGHTNESS control to minimum.

3. Feed in dot pattern.

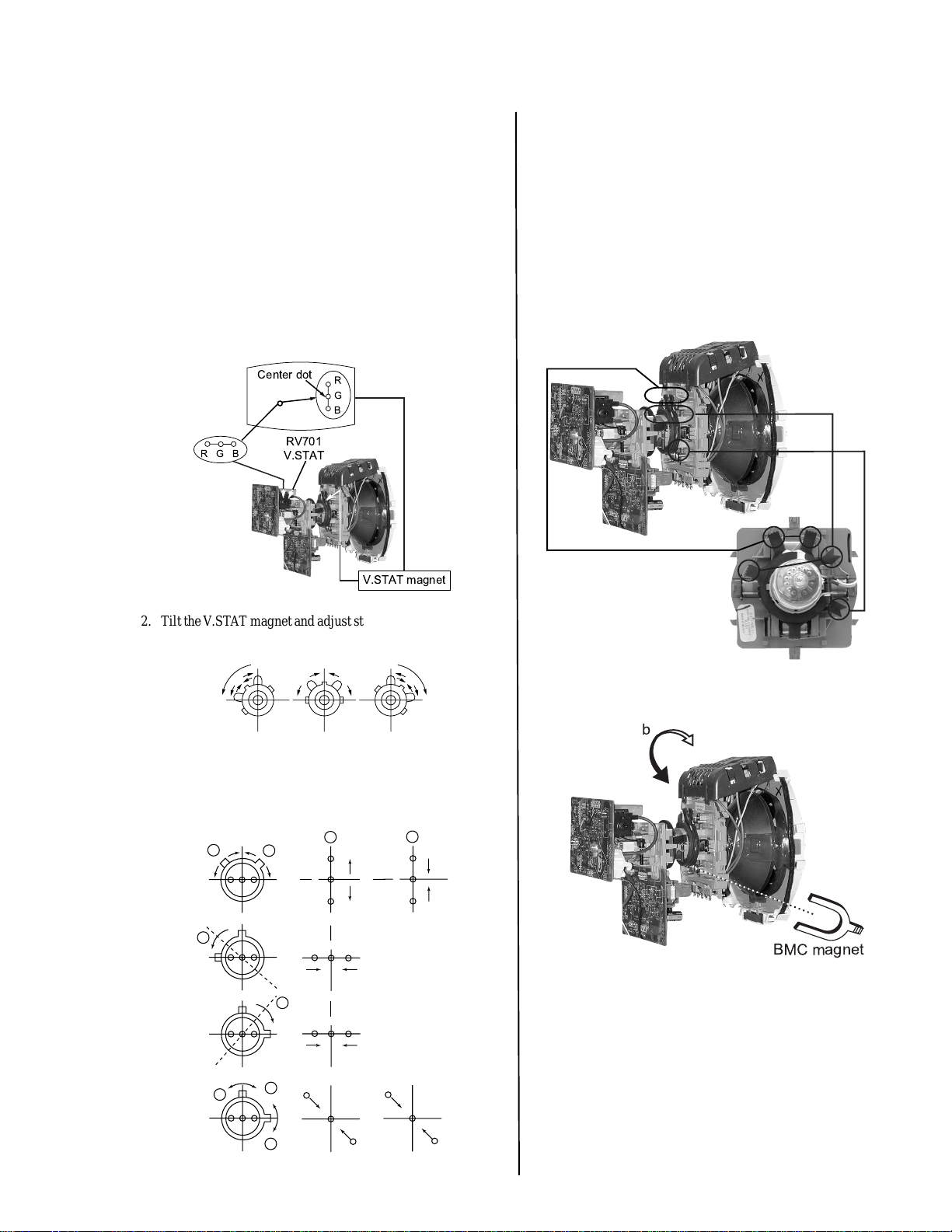

Vertical Static Convergence

1. Adjust V.STAT magnet to converge red, green and blue

dots in the center of the screen (Vertical movement adjust

V .STAT RV701 to converge).

RGB

Center dot

RV701

V.STAT

R

G

B

V.STAT magnet

Horizontal Static Convergence

If the blue dot does not converge with the red and green dots,

perform the following:

1. Move BMC magnet (a) to correct insufficient H. S tatic

convergence.

2. Rotate BMC magnet (b) to correct insufficient V. Static

convergence.

3. After adjusting the BMC magnet, repeat Beam Landing

Adjustment.

V.S TAT

BMC MAGNET

PURITY

2. T ilt the V.STAT magnet and adjust static convergence to open

or close the V.STA T magnet.

When the V.STA T magnet is moved in the direction of arrows

a and b, red, green, and blue dots move as shown below:

(1)

a

b

(2)

a

(3)

b

b

b

a

b

a

B

G

R

BGR

RGB

R

G

B

b

B

G

R

B

G

R

b

BMC magnet

Dynamic Convergence Adjustment

Before performing this adjustment, perform Horizontal

and Vertical Static Convergence Adjustment.

1. Slightly loosen deflection yoke screw .

2. Remove deflection yoke spacers.

3. Move the deflection yoke for best convergence

as shown on the following page.

— 11 —

KV-29FS12K

RGB

BGR

R

G

B

RGB

B

G

R

BGR

RGB

G

B

4. Adjust XCV core to balance X axis.

B

G

R

5. Adjust YCH VR to balance Y axis.

6. Adjust vertical red and blue convergence with V.TIL T

(TLV VR).

Note: Perform adjustments 3-6 while tracking items 1 and 2.

BGR RGB

Screen-Corner Convergence

1. Affix a permalloy assembly corresponding to the

misconverged areas.

R

G

B

R

b

a

4. Tighten the deflection yoke screw.

5. Install the deflection yoke spacers.

TLH Plate Adjustment

1. Input crosshatch pattern.

2. Adjust PICTURE QUALITY to standard, PICTURE and

BRIGHTNESS to 50%, and OTHER to standard.

3. Adjust the Horizontal Convergence of red and blue dots

by tilting the TLH plate on the deflection yoke.

RV701

V.STAT

CA

Board

VA

Board

TLH Plate

XCV

YCH

TLV

a-d: screen-corner

d

c

2-3. FOCUS

1. Adjust FOCUS control for best picture.

ba

misconvergence

cd

B R R B

(R)(B) (B)(R)

TLH+

TLH-

(TLV)

Focus (FV)

Screen (G2)

— 12 —

KV-29FS12K

r

2-4. SCREEN (G2)

1. Input a dots pattern.

2. Set the PICTURE and BRIGHTNESS controls at minimum

and COLOR control at normal.

3. Adjust SBR T , GCUT, BCUT in service mode with an

oscilloscope as shown below so that voltages on the red,

green, and blue cathodes are 170 VDC ± 2V.

Pedestal

Ground

170 VDC – 2V

4. Observe the screen and adjust SCREEN (G2) VR in FBT

to obtain the faintly visible background of dot signal.

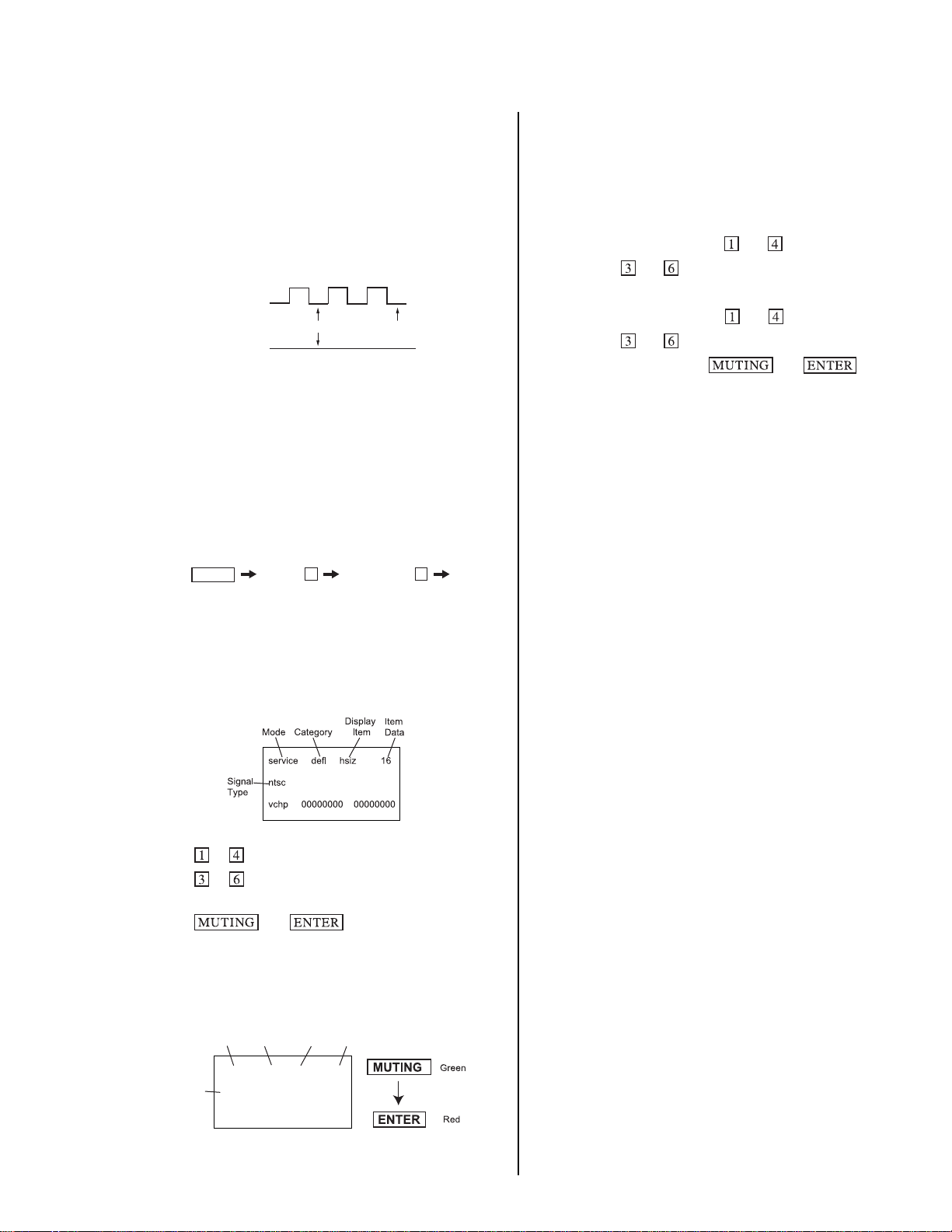

2-5. METHOD OF SETTING THE SERVICE

ADJUSTMENT MODE

Service Mode Procedure

1. Standby mode (power off).

2. Press

Display Channel

5

Sound volume Powe

on the Remote Commander (press each button within a

second).

+

2-6. WHITE BALANCE ADJUSTMENTS

1. Input an entire white signal with burst.

2. Set to Service Adjustment Mode.

3. Set the PICTURE and BRIGHTNESS to minimum.

4. Adjust with SBR T if necessary .

5. Select GCUT and BCUT with

6. Adjust with

and for the best white balance.

7. Set PICTURE and BRIGHTNESS to maximum.

8. Select GDRV and BDRV with

9. Adjust with

and for the best white balance.

10. T o write into memory , press

and .

and .

then .

Service Adjustment Mode In

1. The CR T displays the item being adjusted.

2. Press or on the Remote Commander to select the item.

3. Press

or on the Remote Commander to change the

data.

4. Press

then to save into the memory.

Service Adjustment Mode Memory

Turn set off then on to exit Service Adjustment Mode.

Display

Category

Mode

service defl hsiz 16

Signal

ntsc

Type

vchp 00000000 00000000

Item

write

Item

Data

— 13 —

KV-29FS12K

SECTION 3

SAFETY RELATED ADJUSTMENTS

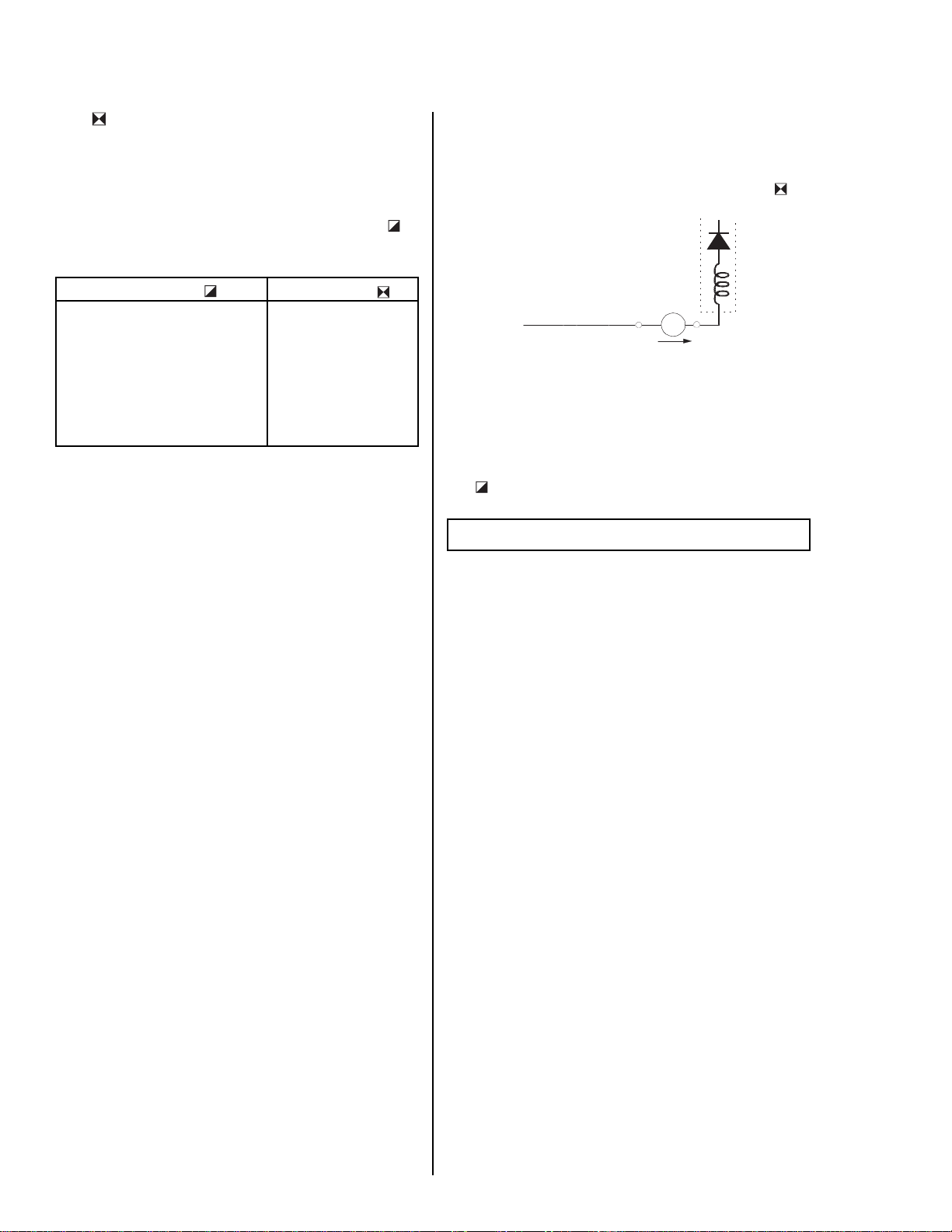

3-1.

R564 CONFIRMATION METHOD

(HV HOLD-DOWN CONFIRMATION) AND

READJUSTMENTS

The following adjustments should always be performed when

replacing the following components which are marked with

on

the schematic diagram:

Part Replaced ( )

DY , T505, CRT , IC501, C507,

C520, C505, C509, C515, T504,

T503, C551, L510, C546, C537,

C547, D517, D518, D519, R560,

R561, R562, R563, R565, R566,

R567, R525 ....................... A Board

IC301.............................. MA Board

Adjustment (

HV HOLD-DOWN

R564

)

Preparation Before Confirmation

1. Using a Variac, apply AC input voltage: 120 ± 2 VAC.

2. T urn the POWER switch ON.

3. Input a white signal and set the PICTURE and

BRIGHTNESS controls to maximum.

4. Confirm that the voltage between C546 (+) or TP503

and ground is more than 21.0 VDC.

Hold-Down Operation Confirmation

1. Connect the current meter between Pin 1 1 of the FBT

(T505) and the PWB land where Pin 11 would normally

attach. (See Figure 1 on the next page.)

2. Input a dot signal and set PICTURE and BRIGHTNESS

to minimum: IABL = 1730 ± 100 µA.

3. Confirm the voltage of A Board TP-600 is 135 ± 1.5 VDC.

4. Connect the digital voltmeter and the DC power supply

via diode 1SS119 to C546 (+) and ground. (See Figure 1

on the next page.)

5. Increase the DC power voltage gradually until the picture

blanks out.

6. T urn DC power source off immediately .

7. Read the digital voltmeter indication

(standard < 24.78+0,-0.1 VDC).

8. Input a white signal and set PICTURE and BRIGHTNESS to

maximum: IABL = 1730 ± 100 µA.

9. Repeat Steps 4 to 7.

Hold-Down Readjustment

If the setting indicated in Step 2 of Hold-Down Operation

Confirmation cannot be met, readjustment should be performed by

altering the resistance value of R564 component marked with

T505

FBT

ammeter

3.0 mA DC

range

ABL

+

IABL

-

A

.

3-2. B+ VOLTAGE CONFIRMATION AND

ADJUSTMENT

Note: The following adjustments should always be performed

when replacing the following components, which are marked

with

on the schematic diagram on the A Board.

A BOARD: IC601, PH601

1. Using a Variac, apply AC input voltage: 130 + 2.0, -0.0 V AC.

2. Input a dot signal.

3. Set the PICTURE and BRIGHTNESS controls to minimum.

4. Confirm that the voltage of A Board TP-600 is <136.5 VDC.

5. If Step 3 is not satisfied, replace the components listed above,

then repeat Steps 1–3.

— 14 —

11119

+

+

+

+

18

1818

9

5

6

C

9

5

6

C

9

5

6

9

5

C

6

C

R601

R601

R601R601

R615

R615

R615R615

D616

D616

D616D616

1

6

0

B

1

F

0

6

B

F

1

6

0

B

1

F

0

6

B

F

C624

C624

C624C624

H.DRIVE

H.DRIVE

H.DRIVEH.DRIVE

CN511

CN511

C611

C611

CN511CN511

C611C611

C654

C654

C654C654

CN506

CN506

CN506CN506

1111

1111

CN515

CN515

CN515CN515

+B

+B

+B+B

R515

R515

R515R515

C536

C536

C536C536

D521

D521

D521D521

4444

1111

5555

7777

R503

R503

R503R503

R516

R516

R516R516

C503

C503

C503C503

C554

C554

C554C554

R502

R502

R502R502

R547

R547R547

9

99

10

1018

1010

5

6

R

5

6

R

9

9

5

6

R

5

6

R

9

9

L602

L602

L602L602

C629

C629

C629C629

H.PULSE

H.PULSE

H.PULSEH.PULSE

FB503

FB503

FB503FB503

R507

R507

R507R507

T503

T503

T503T503

T502

T502

T502T502

Q501

Q501

Q501Q501

C504

C504

C504C504

R547

KV-29FS12K

POWER

SUPPLY

DIGITAL

MUL TIMETER

+

–

1SS119

+

–

R564

C546

R438

R438

R449

R449

R454

R454

R454R454

JR503

JR503

JR503JR503

R445

R445

R445R445

Q411

Q411

Q411Q411

D620

D620

D620D620

C524

C524

C524C524

R506

R506

R506R506

D506

D506

C510

C510

C510C510

L502

L502

T504

T504

T504T504

L509

L509

L509L509

C513

C513

C513C513

R504

R504

R504R504

L502L502

L505

L505

L505L505

C517

C517

C517C517

E

E

E

E

R505

R505

R505R505

C555

C555

C555C555

2

0

5

Q

2

0

5

Q

2

0

2

5

0

Q

5

Q

O

-

H

O

-

H

T

U

T

U

O

-

O

H

-

H

T

U

T

U

C505

C505

C505C505

C515

C515

C515C515

R553

R553

R553R553

D506D506

C550

C550

C550C550

C511

C511

C511C511

L501

L501

L501L501

B

B

B

B

B

B

B

B

C

C

C

C

C509

C509

C509C509

L510

L510

L510L510

R568

R568

R568R568

R449R449

C448

C448

C448C448

R450

R450

R450R450

R567

R567

R567R567

R565

R565

R565R565

IC501

IC501

IC501IC501

R522

R522

R522R522

R525

R525

R525R525

Q503

Q503

Q503Q503

R447

R447

R447R447

D507

D507

D507D507

FB502

FB502FB502

8888

1111

R527

R527

R541

R541

R541R541

R514

R514

R514R514

FB502

R527R527

B

B

E

E

BB

E

E

E

E

E

E

C525

C525

C525C525

5555

4444

3333

2222

1111

5

1

N

0

C

1

5

0

N

C

5

1

N

0

C

1

5

0

N

C

R546

R546

R546R546

R533

R533

R533R533

R534

R534

C551

C551

R534R534

C551C551

R438R438

C530

C530

C530C530

R529

R529

R529R529

5555

R573

R573

R573R573

R531

R531

R531R531

4444

C541

C541

C541C541

D510

D510

D510D510

6

6

6

6

6

6

66

R539

R539

R539R539

R518

R518

R518R518

7

7

77

R540

R540

R540R540

C543

C543

C543C543

C519

C519

C519C519

R537

R537

R537R537

D511

D511

D511D511

C552

C552

C552C552

R403

R403

R403R403

R563

R563

R563R563

C546

C546

C546C546

H.PROT

H.PROT

H.PROTH.PROT

C542

C542

C542C542

2

2

22

4

4

44

2

2

22

C518

C518

C518C518

IC502

IC502

IC502IC502

1

1

11

TH501

TH501

TH501TH501

R543

R543

R543R543

6

6

6

6

200V

200V

200V200V

6666

V DY -

V DY V DY -V DY -

V DY +

V DY +

V DY +V DY +

H DY -

H DY H DY -H DY -

H DY -

H DY H DY -H DY -

H DY +

H DY +

H DY +H DY +

H DY +

H DY +

H DY +H DY +

R545

R545

R545R545

L507

L507

L507L507

R225

R225

R225R225

D235

D235

D235D235

D234

D234

D234D234

C213

C213

C213C213

R218

R218

R218R218

R407

R407

R407R407

-13V

-13V

-13V-13V

HEATER

HEATER

HEATERHEATER

C211

C211

C211C211

Q205

Q205

Q205Q205

1

1

1

1

CN502

CN502

CN502CN502

Q206

Q206

Q206Q206

C523

C523

C523C523

R532

R532

R532R532

Q201

Q201

Q201Q201

D236

D236D236

D232

D232

D232D232

R232

R232R232

R511

R511

R511R511

R561

R561

R561R561

T505

FBT

135V

135V

135V135V

ABL11

R226

R226

R226R226

R227

R227

D236

R231R232

R231R231

D233

D233

D233D233

D514

D514D514

T505

T505

T505T505

R227R227

R231

D520

D520

D520D520

D518

D518

D518D518

D517

D517

D517D517

D514

C532

C532

C532C532

R558

R558

R558R558

R559

R559

JR502

JR502

JR502JR502

R559R559

R557

R557

R557R557

Q505

Q505

Q505Q505

R554

R554

R554R554

D516

D516

D516D516

R555

R555

R555R555

R535

R535

R535R535

JUMPER-ID

JUMPER-ID

JUMPER-IDJUMPER-ID

R801

R801

R801R801

R803

R803

R803R803

R804

R804

R804R804

CN504

CN504

CN504CN504

TP600

AMMETER

3mA dc range

A

+

–

Figure 1

— 15 —

Loading...

Loading...