Sony KV-21FA350, KV-21FA550 Service Manual

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

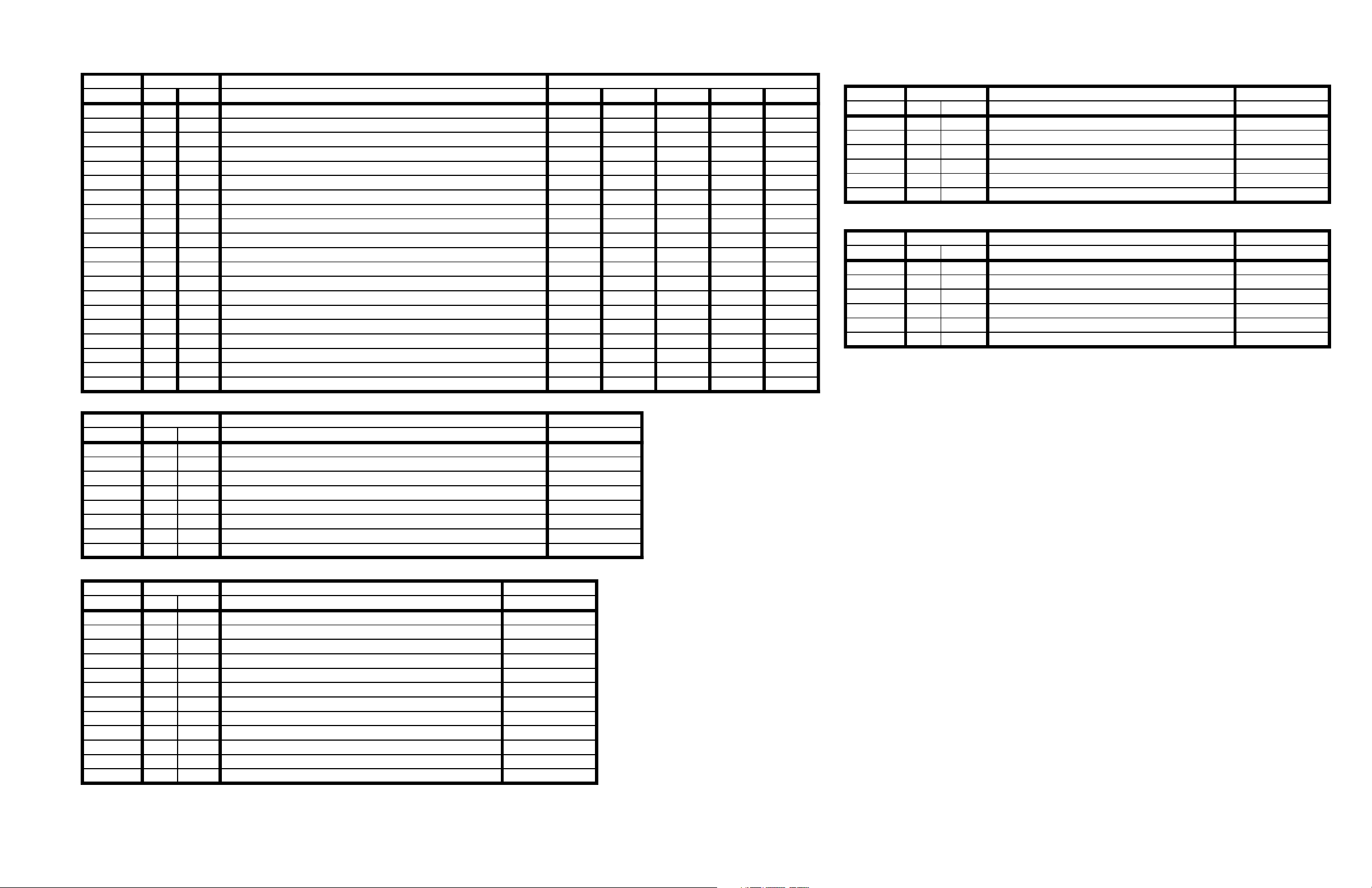

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-21FA350

KV-21FA350

KV-21FA550

KV-21FA550

RM-YA005 LATIN NORTH SCC-S79K-A

RM-YA005 LATIN SOUTH SCC-S79L-A

RM-YA005 LATIN NORTH SCC-S79M-A

RM-YA005 LATIN SOUTH SCC-S79N-A

BX-1S

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 2/2007

REVISION DATE SUBJECT

2/2007 No revisions or updates are applicable at this time.

TRINITRON® COLOR TELEVISION

9-883-736-01

Self Diagnosis

+

TV

P

O

W

E

R

T

V

/

V

ID

E

O

C

H

R

E

T

U

R

N

S

O

U

N

D

M

O

D

E

S

L

E

E

P

1

6

:9

R

E

S

E

T

V

O

L

D

IS

P

L

A

Y

P

IC

T

U

R

E

M

O

D

E

M

T

S

/S

A

P

M

U

T

I

N

G

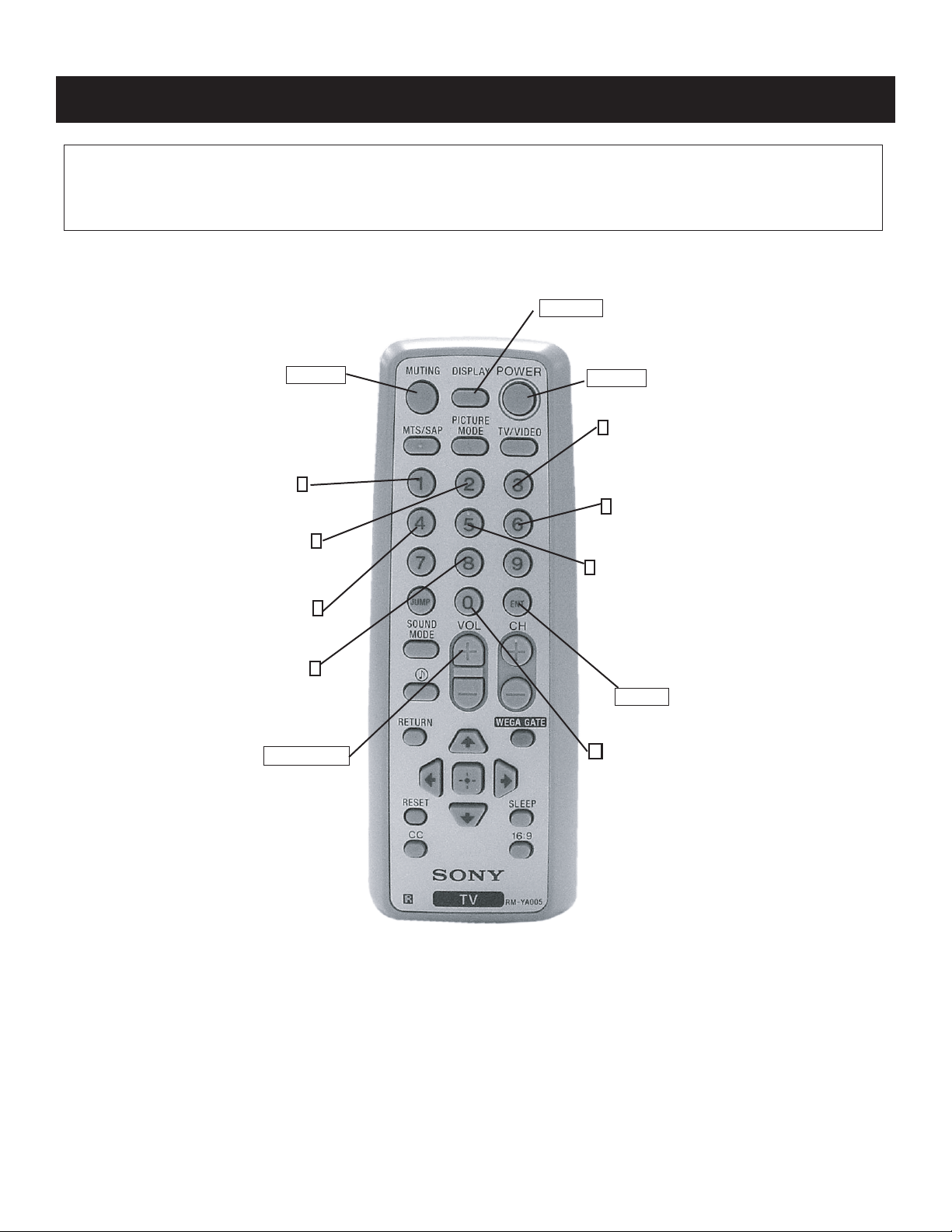

RM-Y

A005

1

2

3

4

6

7

8

9

0

5

EN

T

JU

M

P

W

EG

A G

A

TEWEGAGATE

C

C

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-21FA350

KV-21FA350

KV-21FA550

KV-21FA550

RM-YA005 LATIN NORTH SCC-S79K-A

RM-YA005 LATIN SOUTH SCC-S79L-A

RM-YA005 LATIN NORTH SCC-S79M-A

RM-YA005 LATIN SOUTH SCC-S79N-A

BX-1S

CHASSIS

KV-21FA550 RM-YA005

TRINITRON® COLOR TELEVISION

9-883-736-01

KV-21FA350/21FA550

TABLE OF CONTENTS

SECTION TITLE PAGE

Specifi cations ....................................................................................................................................................................................................... 4

Warnings and Cautions ........................................................................................................................................................................................ 5

Safety Check-Out ................................................................................................................................................................................................. 6

Self-Diagnostic Function ...................................................................................................................................................................................... 7

SECTION 1: DISASSEMBLY ............................................................................................................................................................................................. 9

1-1. Rear Cover Removal .................................................................................................................................................................................... 9

1-2. Chassis Assembly Removal ......................................................................................................................................................................... 9

1-3. Service Position ............................................................................................................................................................................................ 9

1-4. Picture Tube Removal ................................................................................................................................................................................ 10

Anode Cap Removal Procedure ................................................................................................................................................................. 10

SECTION 2: SET-UP ADJUSTMENTS .............................................................................................................................................................................11

2-1. Beam Landing .............................................................................................................................................................................................11

2-2. Convergence .............................................................................................................................................................................................. 12

2-3. Focus .......................................................................................................................................................................................................... 13

2-4. Screen (G2) ................................................................................................................................................................................................ 14

SECTION 3: CIRCUIT ADJUSTMENTS .......................................................................................................................................................................... 15

3-1. Remote Adjustment Buttons and Indicators ............................................................................................................................................... 15

3-2. Accessing the Service Menu Mode ............................................................................................................................................................ 16

3-3. Confi rming Service Adjustment Changes ................................................................................................................................................... 17

3-4. White Balance Adjustments ........................................................................................................................................................................ 17

3-5. Picture Quality Adjustments ....................................................................................................................................................................... 17

3-6. Service Data ............................................................................................................................................................................................... 19

SECTION 4: DIAGRAMS ................................................................................................................................................................................................. 28

4-1. Circuit Boards Location .............................................................................................................................................................................. 28

4-2. Printed Wiring Board and Schematic Diagram Information ........................................................................................................................ 28

4-3. Block Diagram ............................................................................................................................................................................................ 29

Signal Flow Block Diagram ........................................................................................................................................................................ 29

4-4. Schematics and Supporting Information .................................................................................................................................................... 30

A Board Schematic Diagram (1 of 6) ......................................................................................................................................................... 30

A Board Schematic Diagram (2 of 6) ......................................................................................................................................................... 31

A Board Schematic Diagram (3 of 6) ......................................................................................................................................................... 32

A Board Schematic Diagram (4 of 6) ......................................................................................................................................................... 33

A Board Schematic Diagram (5 of 6) ......................................................................................................................................................... 34

A Board Schematic Diagram (6 of 6) ......................................................................................................................................................... 35

CV Board Schematic Diagram ................................................................................................................................................................... 37

H2 Board Schematic Diagram ................................................................................................................................................................... 38

J4 Board Schematic Diagram .................................................................................................................................................................... 39

W Board Schematic Diagram ..................................................................................................................................................................... 40

4-5. Semiconductors .......................................................................................................................................................................................... 41

SECTION 5: EXPLODED VIEWS .................................................................................................................................................................................... 42

5-1. Chassis and Speakers ............................................................................................................................................................................... 42

5-2. Picture Tube ............................................................................................................................................................................................... 43

SECTION 6: ELECTRICAL PARTS LIST ........................................................................................................................................................................ 44

KV-21FA350/21FA550

3

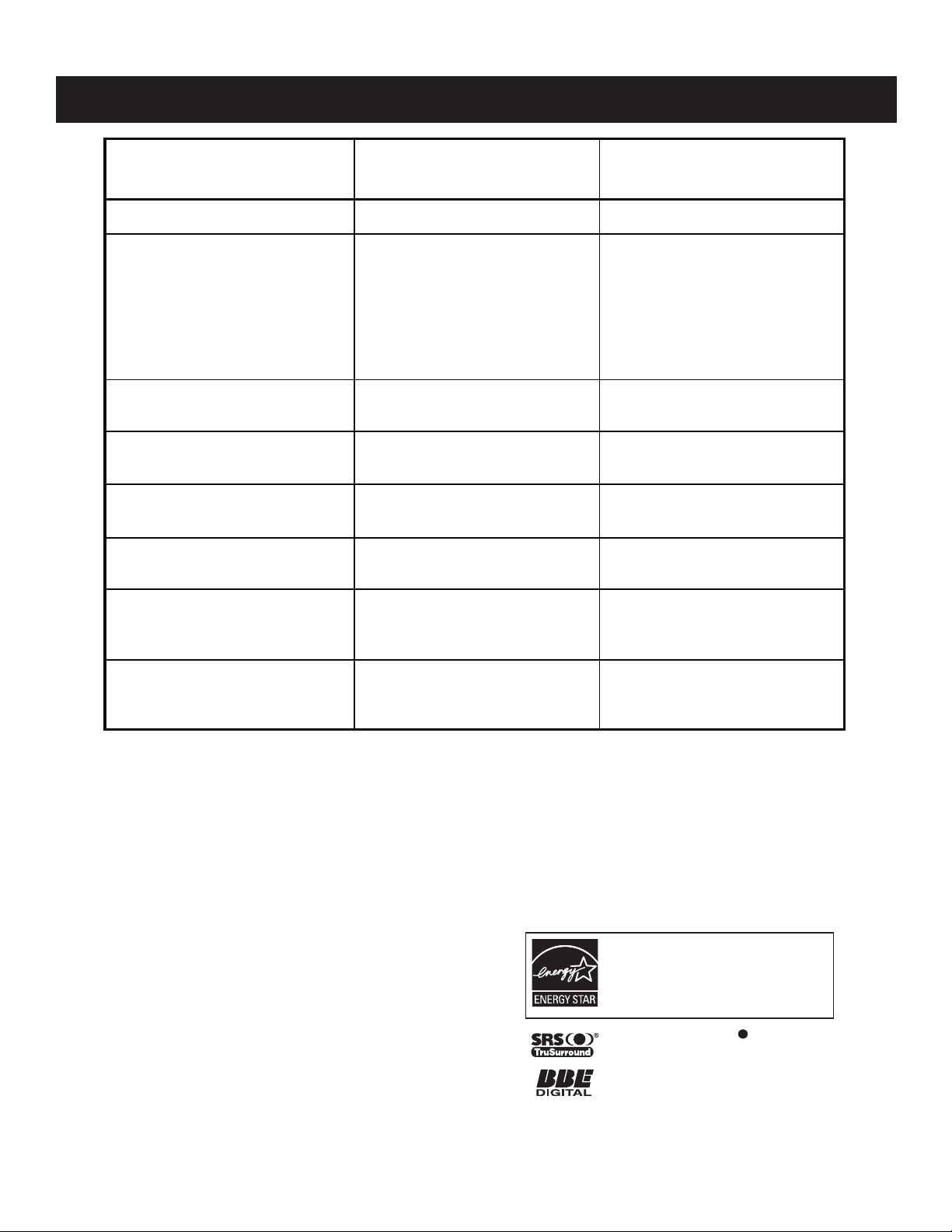

SPECIFICATIONS

KV-21FA350/21FA550

Television system

American TV standard, NTSC

Channel coverage

VHF: 2-13/UHF: 14-69/CATV: 1-125

Antenna

75-ohm external antenna terminal for VHF/UHF

Picture tube

FD Trinitron® tube

Visible screen size

508mm (20-inch) picture measured diagonally

Actual screen size

533.4mm (21-inch) measured diagonally

Supplied Accessories

Remote Commander RM-YA005

Two Size AA (R6) Batteries

Converter EAC-25

Dipolo Antenna

2 - Bocinas Satelite cables (KV-21FA550 Only)

KV-21FA350/21FA550

1)

1 Vp-p 75 ohms unbalanced, sync negative

2) Y: 1Vp-p 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

3) Y: 1.0 Vp-p, 75 ohms, sync negative; PB: 0.7 Vp-p, 75 ohms;

PR Vp-p, 75 ohms.

4)

500 mVrms (100% modulation), Impedance: 47 kilohms

5)

This specifi cation is the maximum wattage.

Trademarks and Copyrights

As an ENERGY STAR® Partner, Sony

Corporation has determined that this

product meets the ENERGY STAR®

guidelines for energy efficiency. ENERGY

STAR® is a U.S. regis tered mark.

TruSurround, SRS and the ( )® symbol are trademarks of

SRS Labs, Inc.

Manufactured under license from BBE Sound,

Inc. Licensed by BBE Sound, Inc. under USP

4638258, 5510752 a nd 5736897. BBE and BBE

symbol are registered trademarks of BBE

Sound, Inc.

Sony, FD Trinitron, WEGA®, Steady Sound and Intelligent Picture

are

registered trademarks of Sony Corporation.

Design and specifi cations are subject to change without notice.

4

KV-21FA350/21FA550

WARNINGS AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield, or carbon painted on the CRT, after

removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of this

receiver is directly connected to the AC power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for safe

operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements published

by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures whenever critical

components are replaced or improper operation is suspected.

KV-21FA350/21FA550

5

SAFETY CHECK-OUT

KV-21FA350/21FA550

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if

sets always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage. Check

leakage as described below.

Leakage Test

The AC leakage from any exposed metal part to earth ground and from

all exposed metal parts to any exposed metal part having a return to

chassis, must not exceed 0.5 mA (500 microamperes). Leakage current

can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75 V,

so analog meters must have an accurate low voltage scale. The

Simpson’s 250 and Sanwa SH-63TRD are examples of passive

VOMs that are suitable. Nearly all battery-operated digital

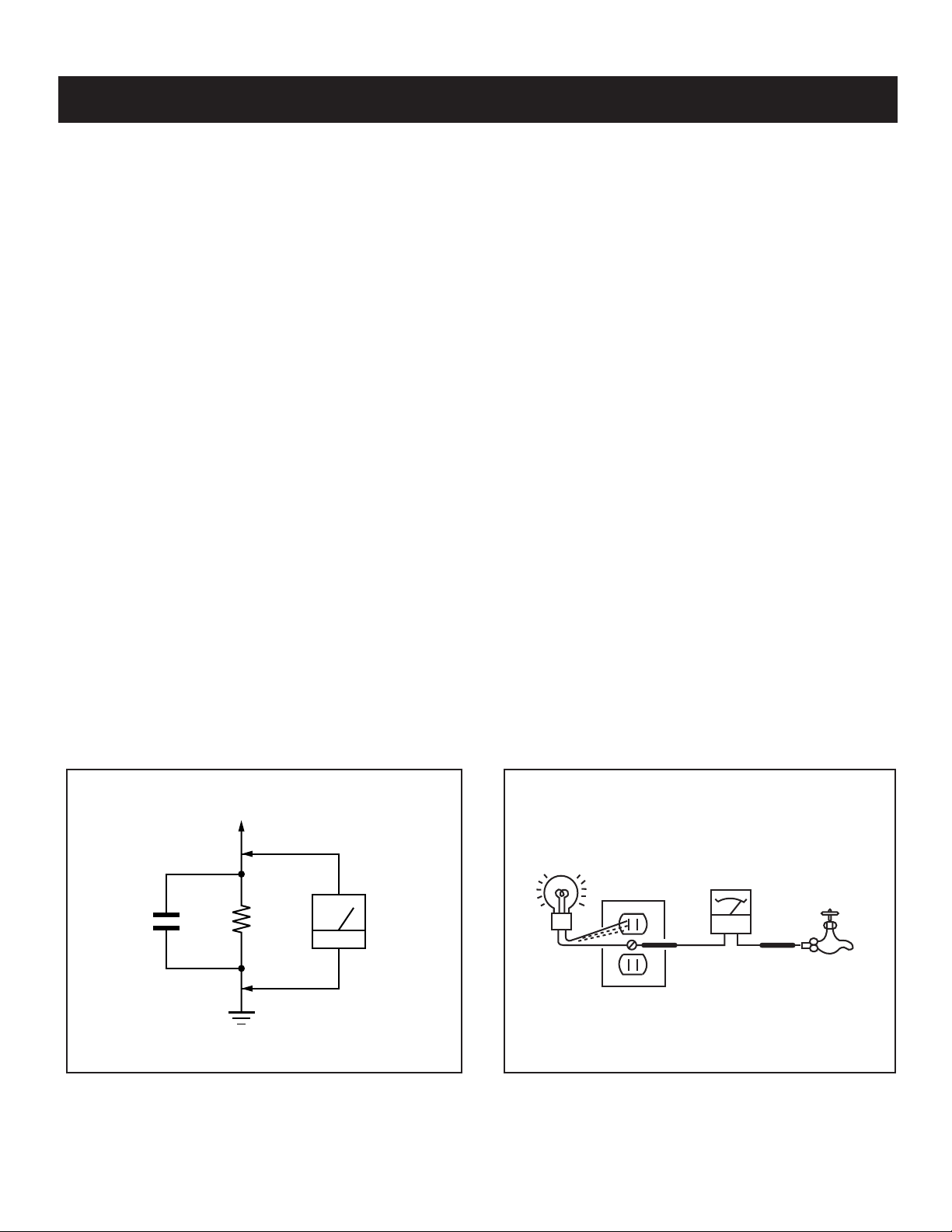

multimeters that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If the

retaining screw is to be used as your earth ground, verify that it is at

ground by measuring the resistance between it and a cold-water pipe

with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt troublelight (not a neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot side on

the line; the lamp should light at normal brilliance if the screw is at

ground potential (see Figure B).

0.15 µF

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

KV-21FA350/21FA550

To Exposed Metal

Parts on Set

1.5 K Ω

Earth Ground

AC

Voltmeter

(0.75 V)

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

6

KV-21FA350/21FA550

SELF-DIAGNOSTIC FUNCTION

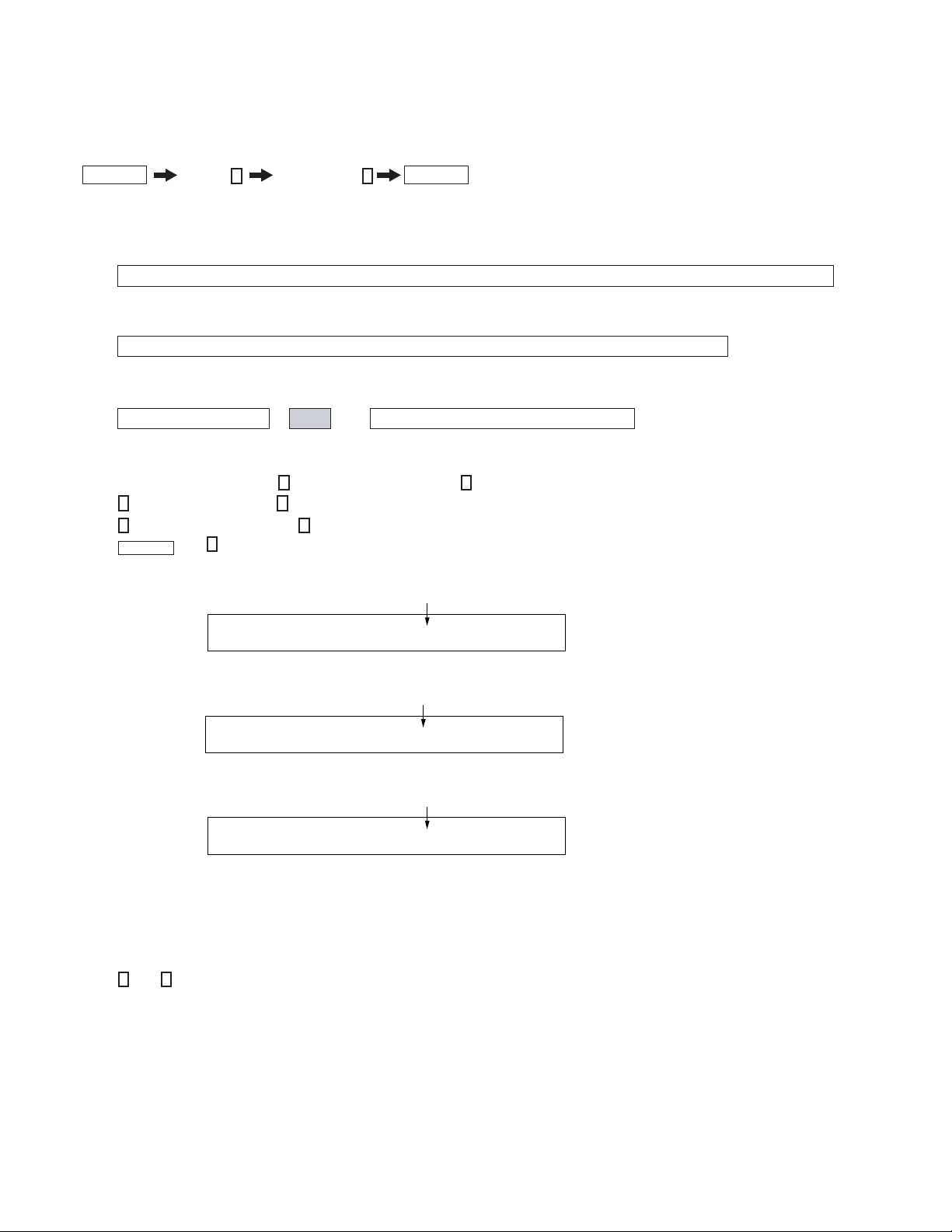

Self Diagnosis

Supported model

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY LED indicator will automatically begin to fl ash. The number of

times the LED fl ashes translates to a probable source of the problem. A defi nition of the STANDBY LED fl ash indicators is listed in the instruction manual

for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review the failure occurrence

data stored in memory to reveal past problems and how often these problems occur.

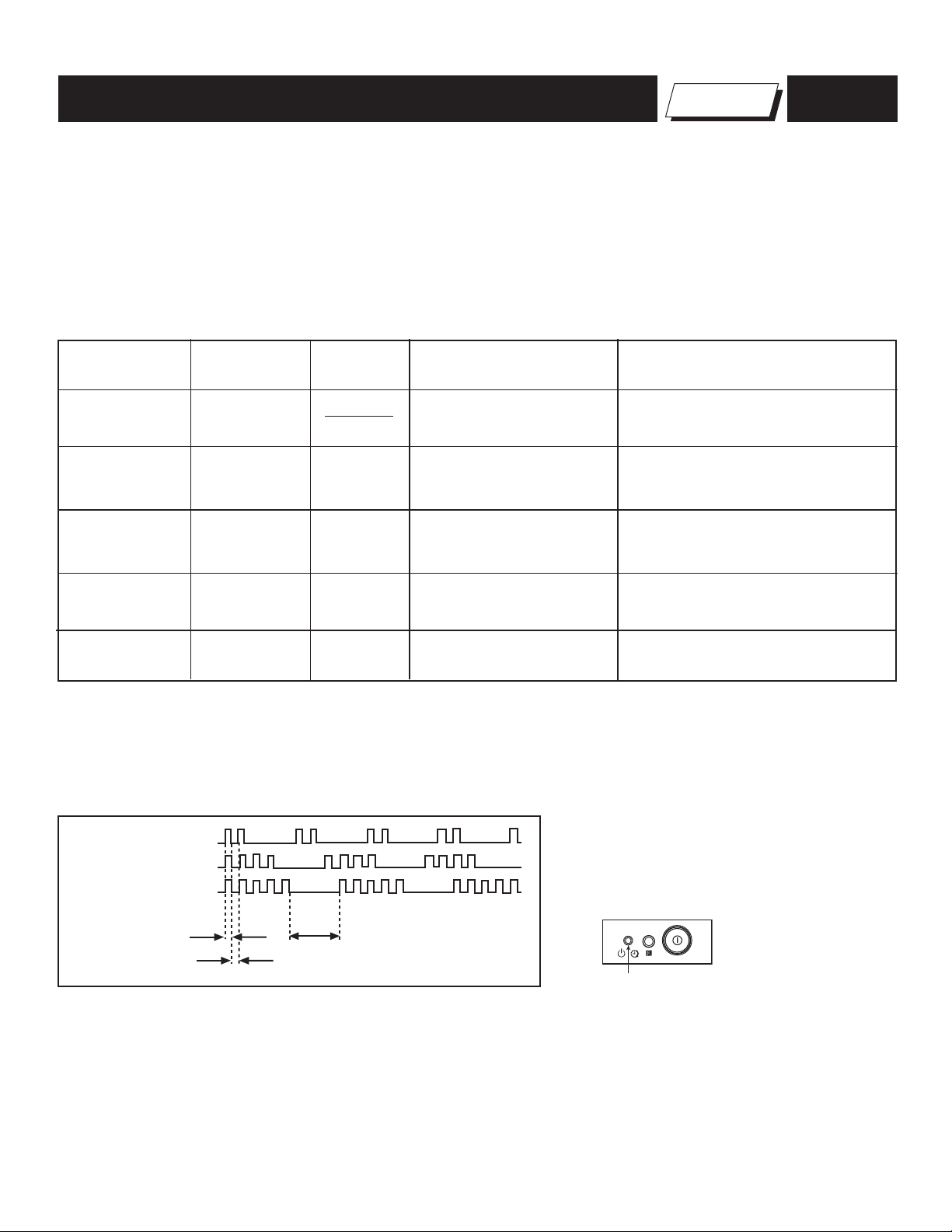

1. Diagnostic Test Indicators

When an error occurs, the STANDBY LED indicator will fl ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the indicator will identify the fi rst of the problem areas.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

Diagnostic Item

Description

Power does not turn on

+B overcurrent (OCP)*

V-Protect (OVP)

IK (AKB)

Power Supply

NG (+5V) for

Video Processor

No. of Times

STANDBY LED

Indicator Flashes

Does not light

2 times *

4 times

5 times

8 times

Self-Diagnositc

Display/

Diagnostic Result

2:0

or

2:1 - 255

4:0

or

4:1 - 255

5:0

or

5:1 - 255

8:0

or

8:1 - 255

Probable Cause Location

• Power cord is not plugged in.

• Fuse is burned out (F600). (A Board)

• H.OUT (Q805) is shorted. (A Board)

• IC751 is shorted. (C Board)

• +13V is not supplied. (A Board)

• IC804 is faulty. (A Board)

• Video OUT (IC1545) is faulty(A Board)

• IC001 is faulty. (A Board)

• Screen (G2) is improperly adjusted.**

• IC604 is faulty.

• IC602 is faulty.

Detected Symptoms

• Power does not come on.

• No power is supplied to the TV.

• AC Power supply is faulty.

• Power does not come on.

• Load on power line is shorted.

• Has entered standby state after horizontal raster.

• Vertical defl ection pulse is stopped.

• Power line is shorted or power supply is stopped.

• No raster is generated.

• CRT Cathode current detection reference pulse

output is small.

• No power supply to CRT Anode.

• No RASTER is generated.

*One fl ash count is not used for self-diagnostic.

*If a +B overcurrent is detected, stoppage of the vertical defl ection is detected simultaneously. The symptom that is diagnosed fi rst by the mircrocontroller

is displayed on the screen.

**Refer to Screen (G2) Adjustments in Section 2-4. of this manual.

2. Display of STANDBY LED Flash Count

2 times

4 times

5 times

LED ON 0.3 sec.

LED OFF 0.3 sec.

LED OFF

3 sec.

Standby indicator

3. Stopping the STANDBY LED Indicator Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY LED Indicator from fl ashing.

4. Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confi rmed, it is possible to bring up past

occurrences of failure on the screen for confi rmation.

KV-21FA350/21FA550

7

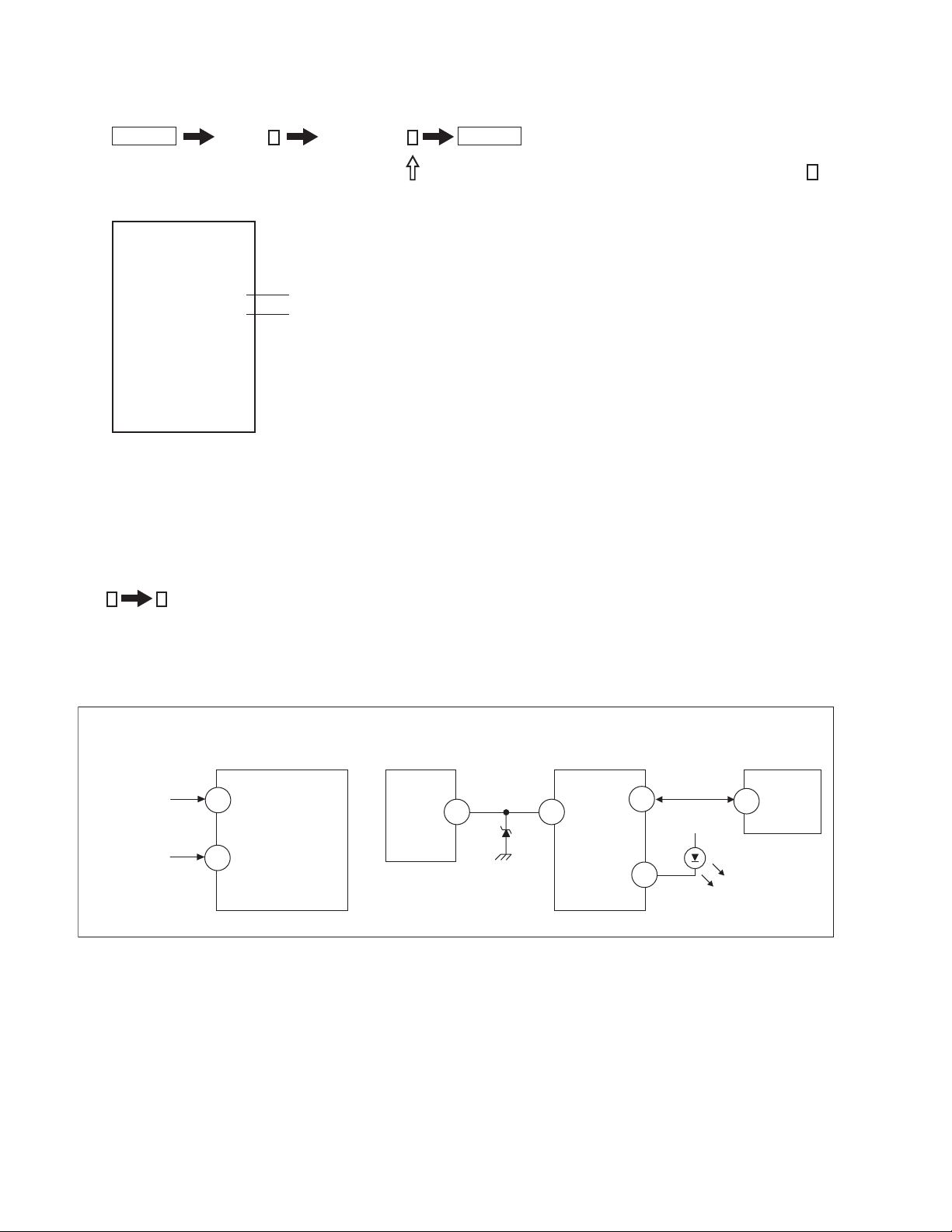

To Bring Up Screen Test

In standby mode, press buttons on the Remote Commander sequentially, in rapid succession, as shown below:

KV-21FA350/21FA550

The following screen will be displayed indicating the error count:

Handling of Self-Diagnostic Screen Display

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs. When you

have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the repairs.

Clearing the Result Display

To clear the result display to “0”, press buttons on the Remote Commander sequentially when the diagnostic screen is displayed, as shown below:

DISPLAY

SELF DIAGNOSTIC

2 OCP : 0

3 OVP : N/A

4 VSTOP : 0

5 AKB : 1

8 SUP : 0

101 WDT : N/A

SERIAL:

MODEL:

Channel

5

Sound Volume -

Number “0” means that no fault was detected.

Number “1” means a fault was detected one time only.

POWER

Note that this differs from entering the Service Mode (Sound Volume + ).

Channel 8

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn off the power switch on the Remote Commander or the main unit.

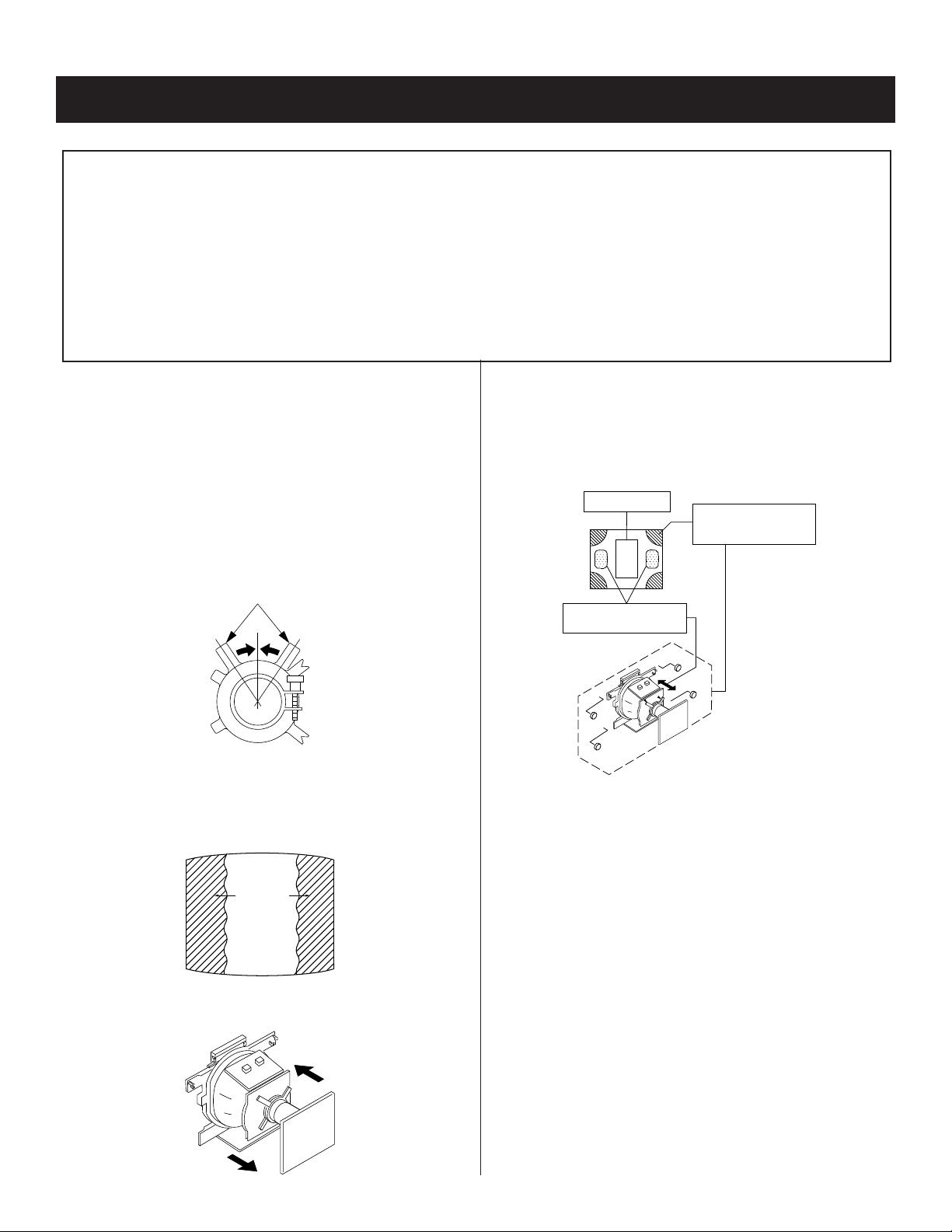

Self-Diagnostic Circuit

FROM

C BOARD

IC751 PIN 5

0

A BOARD

IC001

Y/CHROMA JUNGLE

84

IK

A BOARD

IC804

V. OUT

F.B-PLS

3

A BOARD

IC001

SYSTEM

13

V. GUARD

SDAO

109

A BOARD

IC003

MEMORY

5

SDA

FROM

32

A BOARD

Q816

COLLECTOR

+B overcurrent (OCP)

Occurs when an overcurrent on the +B (135V) line is detected by pin 32 of IC001 (A Board). If the voltage of pin 32 of IC001 (A Board) is more than 4V

when V.SYNC is more than seven verticals in a period, the unit will automatically turn off.

V-Protect

Occurs when an absence of the vertical defl ection pulse is detected by pin 13 of IC001 (a Board). Power supply will shut down when waveform interval

exceeds 2 seconds.

IK (AKB)

If the RGB levels* do not balance within 15 seconds after the power is turned on, this error will be detected by IC001 (A Board). TV will stay on, but there

will be no picture.

Power Supply NG (+5V) for Video Processor

Occurs when IC001 internal HV protect detects an abnormal H-Pulse (frequency) due to improper power supply to IC001. The TV cuts off high voltage

power of anode CRT. No picture will be detected. eg: faulty IC602 or IC604

EHTO

RED-LED

122

DISPLAY

KV-21FA350/21FA550

8

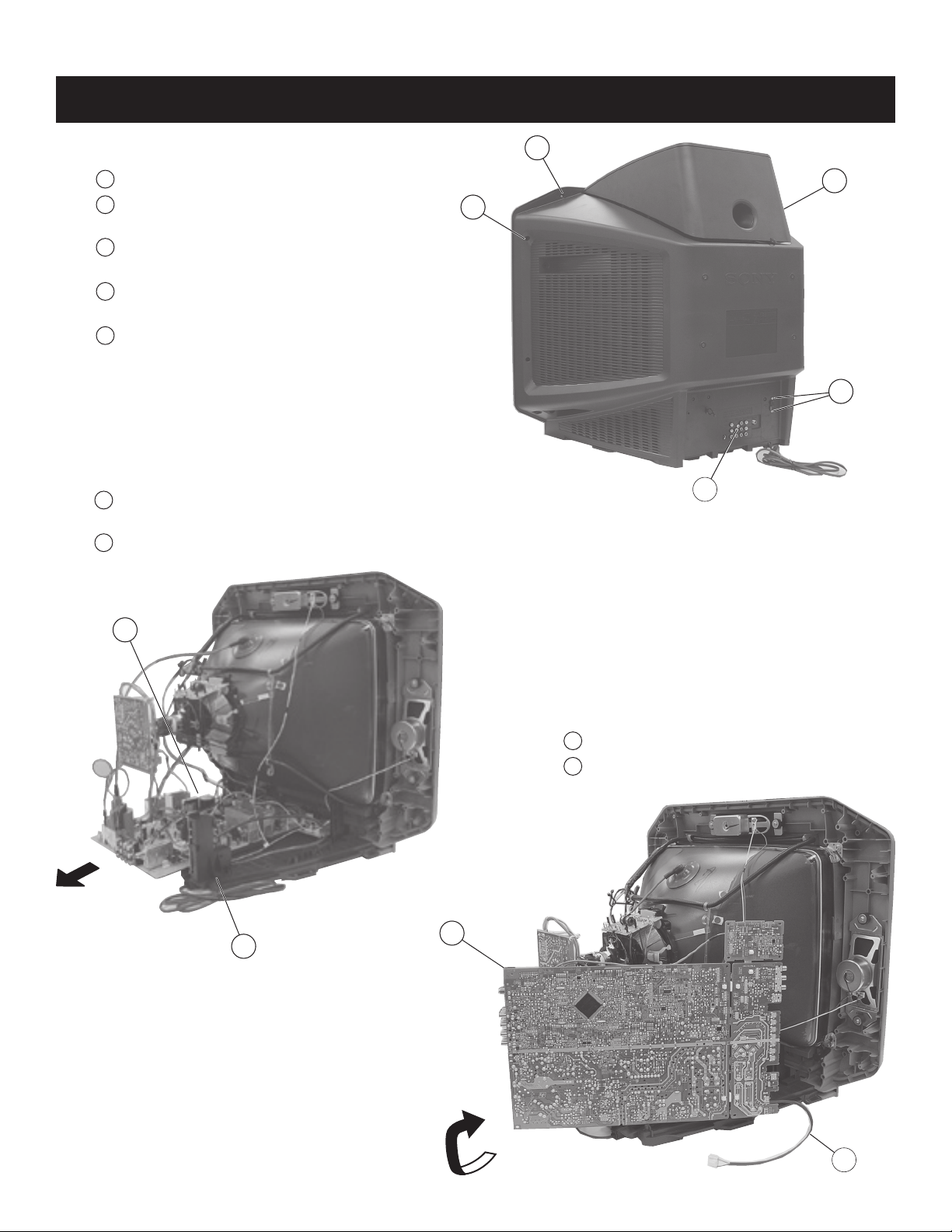

SECTION 1: DISASSEMBLY

KV-21FA350/21FA550

1-1. REAR COVER REMOVAL

1

Lift to remove Subwoofer from top of Rear Cover.

2

Remove screws from top of Rear Cover.

4 Screws +BVTP2 4x16

3

Remove screws from both sides of Rear Cover.

6 Screws +BVTP2 4x16

Remove screw from bottom of Rear Cover.

4

1 Screw +BVTP2 4x16

Remove screws from Speaker Switch and Rear Cover.

5

2 Screws +BVTP 3x12 TYPE2 TT(B)

Slide to remove Rear Cover from Beznet.

1-2. CHASSIS ASSEMBLY REMOVAL

1

Remove J4 Board and Bracket.

One Screw +BVTP 3x12 TYPE2 IT-3

2

Push down claw and slide out A, H2 and W Board.

2

1

3

5

4

2

1-3. SERVICE POSITION

1

Release AC Power cord.

2

Rotate A, H2 and W Boards.

2

1

KV-21FA350/21FA550

1

9

1-4. PICTURE TUBE REMOVAL

WARNING: BEFORE REMOVING THE ANODE CAP

High voltage remains in the CRT even after the power is disconnected. To avoid electric shock,

discharge CRT before attempting to remove the anode cap. Short between anode and CRT

coated earth ground strap.

KV-21FA350/21FA550

1

8

9

10

7

1. Discharge the anode of the CRT and remove

the anode cap.

2. Unplug all interconnecting leads from the

6

2

5

3

4

defl ection yoke, neck assembly, degaussing

coils and CRT grounding strap.

3. Remove the CV Board from the CRT.

4. Remove the chassis assembly.

5. Loosen the neck assembly fi xing screw and

remove.

6. Loosen the defl ection yoke fi xing screw and

remove.

7. Place the set with the CRT face down on

a cushion and remove the degaussing coil

holders.

8. Remove the degaussing coils.

9. Remove the CRT grounding strap and spring

tension devices.

10. Unscrew the four CRT fi xing screws [located on

each CRT corner] and remove the CRT [Take

care not to handle the CRT by the neck].

ANODE CAP REMOVAL PROCEDURE

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electric shock, discharge CRT before attempting to remove

the anode cap. Short between anode and coated earth ground strap of CRT.

NOTE: After removing the anode cap, short circuit the anode of the picture tube and the anode cap to either the metal chassis, CRT shield, or carbon

painted on the CRT.

REMOVAL PROCEDURES

c

b

a

Anode Button

Turn up one side of the rubber cap in

the direction indicated by arrow a .

HOW TO HANDLE AN ANODE CAP

1. Do not use sharp objects which may cause damage to the surface of the

anode cap.

2. To avoid damaging the anode cap, do not squeeze the rubber covering too

hard. A material fi tting called a shatter-hook terminal is built into the rubber.

3. Do not force turn the foot of the rubber cover. This may cause the shatterhook terminal to protrude and damage the rubber.

KV-21FA350/21FA550

Use your thumb to pull the rubber

cap fi rmly in the direction indicated

by arrow b .

When one side of the rubber cap separates from

the anode button, the anode cap can be removed

by turning the rubber cap and pulling it in the

direction of arrow c .

10

SECTION 2: SET-UP ADJUSTMENTS

KV-21FA350/21FA550

The following adjustments should be made when a complete realignment

is required or a new picture tube is installed.

These adjustments should be performed with rated power supply voltage

unless otherwise noted.

Set the controls as follows unless otherwise noted:

Picture control NORMAL

Brightness control NORMAL

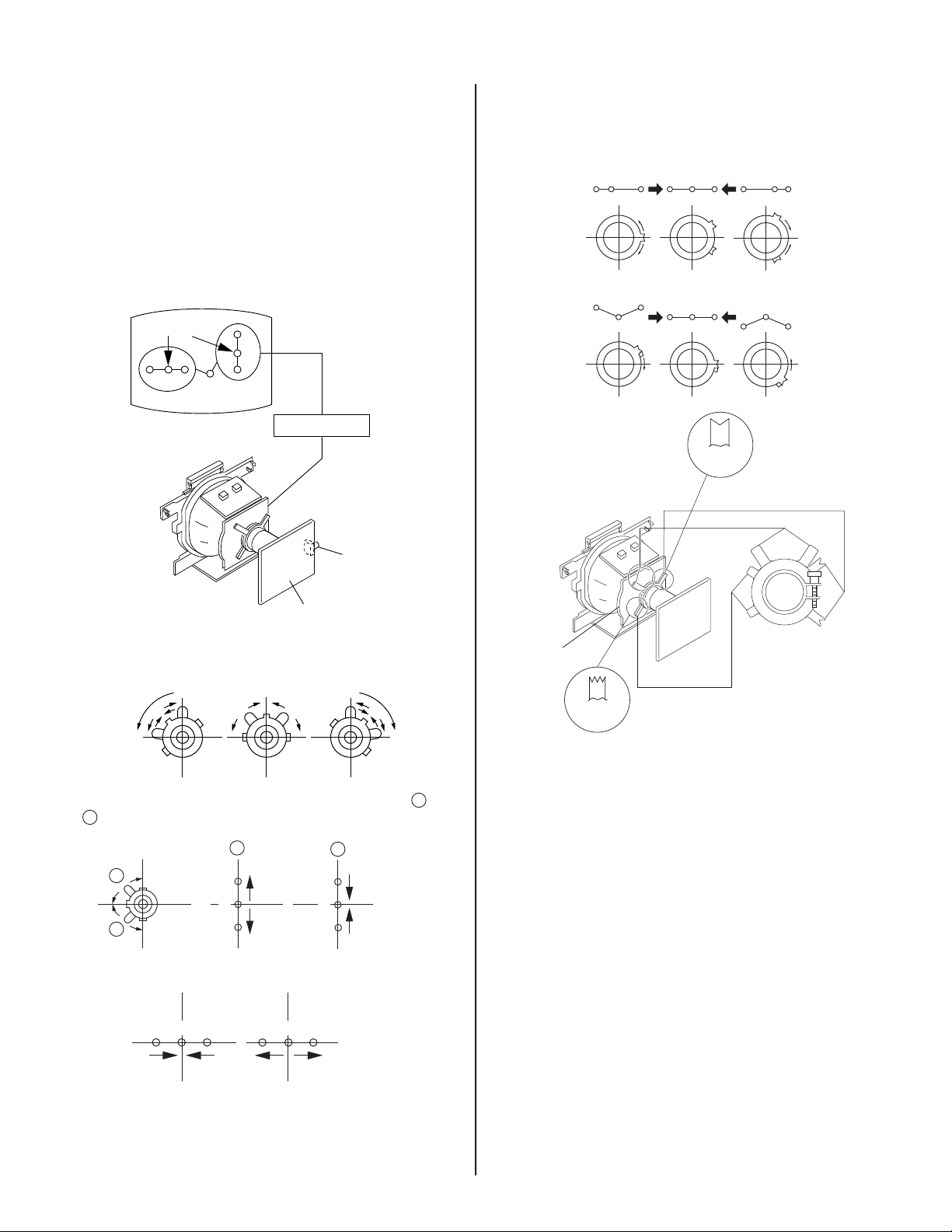

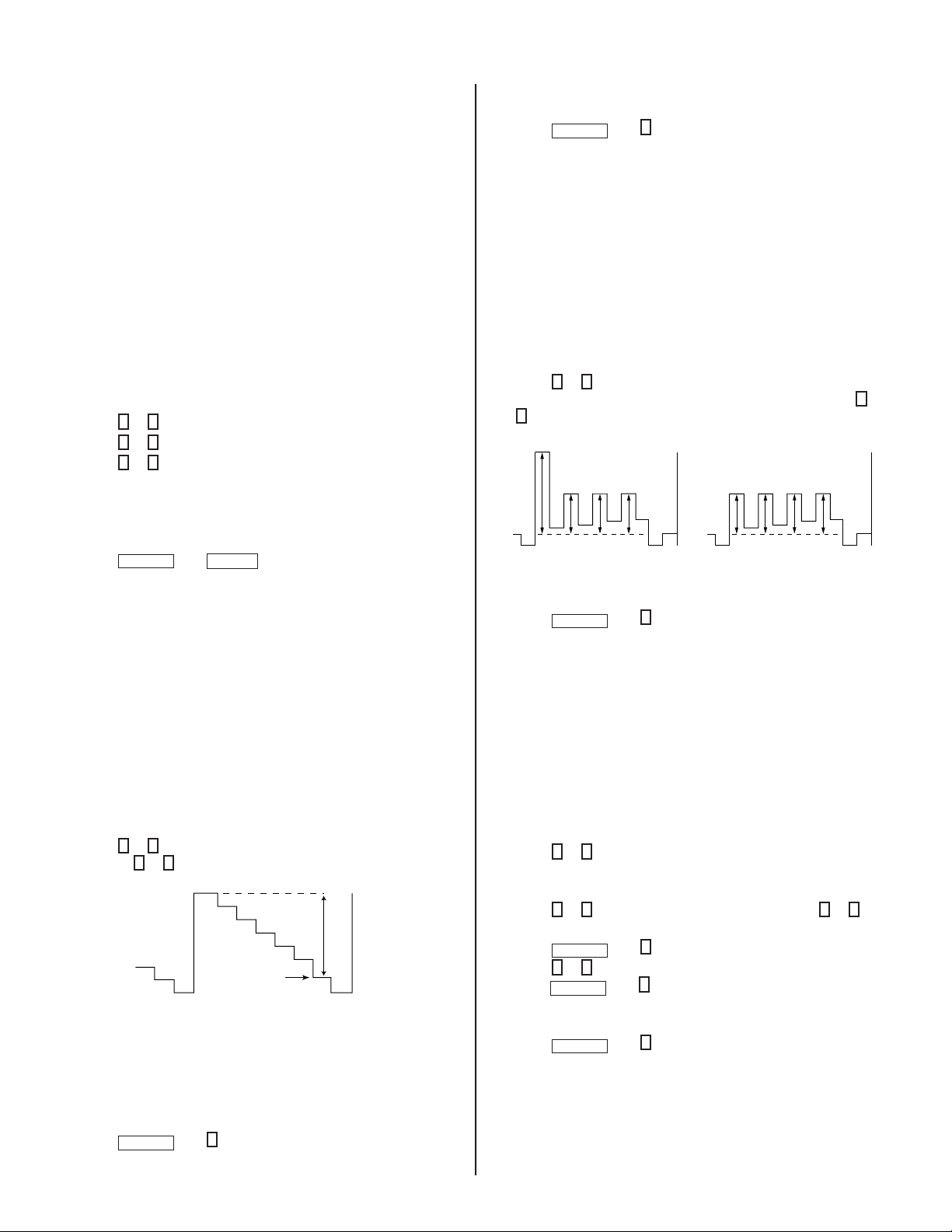

2-1. BEAM LANDING

Before beginning adjustment procedure:

1. Feed in the white pattern signal.

2. In order to reduce the geomagnetism on the set’s picture tube, face

it east or west.

Adjustment Procedure

1. Input a raster signal with the pattern generator.

2. Loosen the defl ection yoke mounting screw, and set the purity

control to the center as shown below:

Purity control

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)

5. White Balance

Note Test Equipment Required:

1. Color Bar Pattern Generator

2. Degausser

3. DC Power Supply

5. Oscilloscope

6. Landing Checker

7. XCV Adjuster

4. Digital Multimeter

6. Switch over the raster signal to red and blue and confi rm the

condition.

7. When the position of the defl ection yoke is determined, tighten it

with the defl ection yoke mounting screw.

8. If landing at the corner is not right, adjust by using the disk

magnets.

Purity control

corrects this area.

a

b

d

c

Deflection yoke positioning

corrects these areas.

Disc magnets or rotatable

disc magnets correct these

areas (a-d).

3. Turn the raster signal of the pattern generator to green.

4. Move the defl ection yoke backward, and adjust with the purity

control so that green is in the center and red and blue are even on

both sides.

Blue

Red

Green

5. Move the defl ection yoke forward, and adjust so that the entire

screen becomes green.

b

c

a

d

KV-21FA350/21FA550

11

KV-21FA350/21FA550

2-2. CONVERGENCE

Before starting convergence adjustments:

1 Perform FOCUS, VLIN and VSIZE adjustments.

2. Set BRIGHTNESS control to minimum.

3. Set Picture mode to STANDARD.

4. Feed in dot pattern.

Vertical Static Convergence

1. Adjust the 4 pole magnet to converge red, green and blue dots in

the center of the screen.

Center dot

R G B

R

G

B

4 pole magnet

Horizontal Static Convergence

If the blue dot does not converge with the red and green dots, use the 6

pole magnet to adjust as shown:

RG B R G B R GB

RB

G

RG

RB

6 Pole

Magnet

6 Pole Magnet

Purity

GB

RV750

H. STAT

C/CV Board

2. Tilt the 4 pole magnet and adjust static convergence to open or

close the 4 pole magnet.

When the 4 pole magnet is moved in the direction of arrow A and

B

, the red, green, and blue dots move as shown below:

A

B

A

B

G

R

B

B

G

R

Moved RV750 (H.STAT)

DY pocket

4 Pole

Magnet

4 Pole Magnet

RGGRB

KV-21FA350/21FA550

B

12

KV-21FA350/21FA550

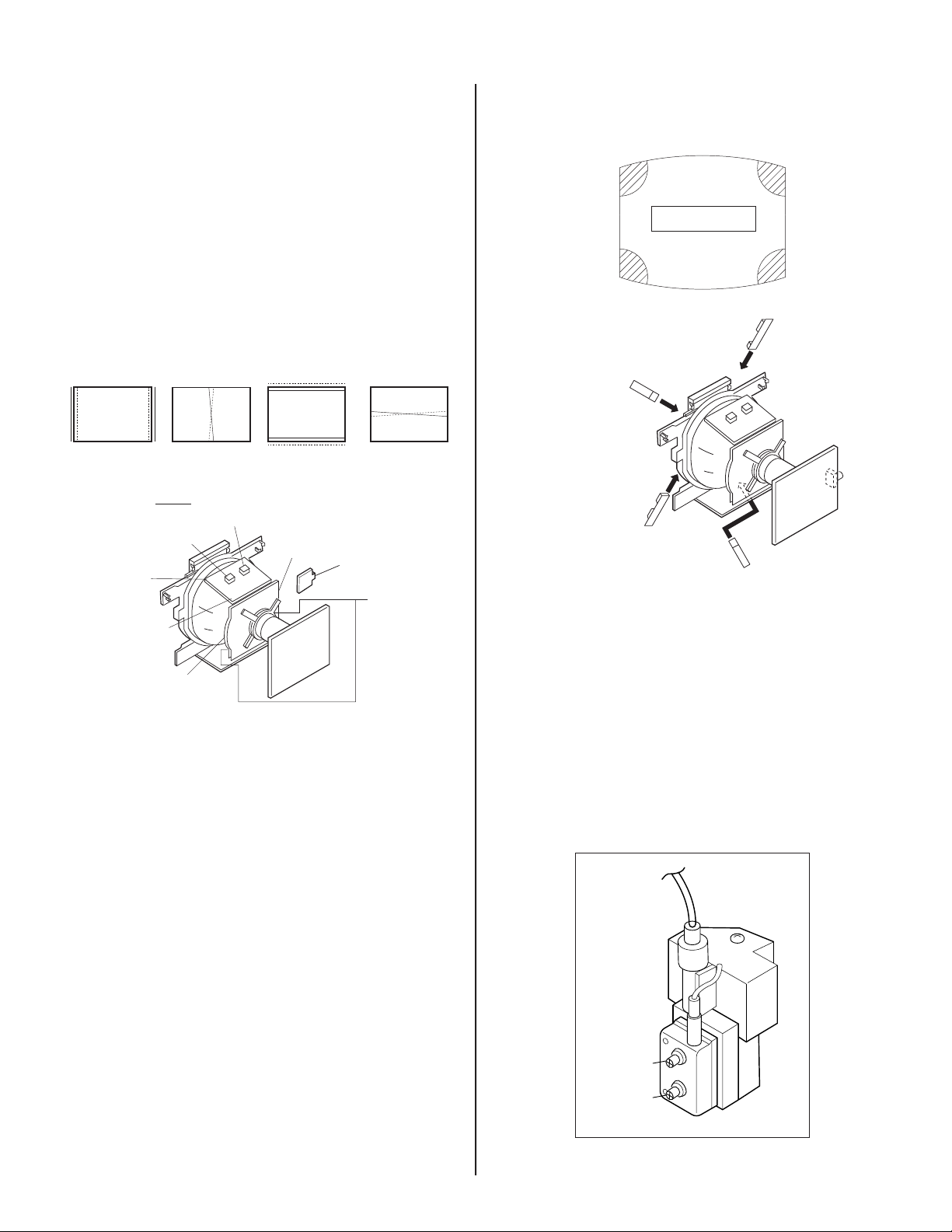

Convergence Rough Adjustment

Before performing this adjustment, perform Horizontal and Vertical Static

Convergence Adjustment.

Input cross hatch pattern.

a) TLH

Adjust the horizontal convergence of red and blue dots by inserting

TLH Correction Plate to the DY pocket (left or right).

b) YCH

Adjust YCH to balance Y axis.

c) TLV

Adjust YCh to balance Y axis.

d) XCV

Adjust XCV to balance X-axis.

YCH

DY pocket

RB

YCH

TLV

B

R

TLV

DY pocket

R

B

TLH Plate

XCV

XCV

B

R

TLH

ON DY:

TLV

XCV

Screen Corner Convergence

Affi x a Piece A (90), Convergence Correct/Permaloy Assy Correction to

the misconverged areas.

ba

a-d : screen-corner

misconvergence

cd

b1

a1

d1

a1~d1:Piece A (90), Convergence Correct

Permaloy Assy Correction

or

c1

2-3. FOCUS

FOCUS adjustment should be completed before White Balance

adjustment. (See 4-4. White Balance Adjustment)

1. Receive digital monoscope pattern.

2. Set Picture Mode to “DYNAMIC”.

3. Adjust focus VR to obtain a just focus at the center of the screen.

4. Change the receiving signal to white pattern and blue back.

5. Confi rm magenta ring is not noticeable. In case magenta ring is

obvious, then adjust FOCUS VR to balance magenta ring and

FOCUS.

KV-21FA350/21FA550

FOCUS

SCREEN

13

2-4. SCREEN (G2)

1. Before beginning adustment procedure:

-Set Picture and Brightness to “STANDARD”.

-Set TV to Video mode.

-Set WHBL 016 “RGBB” to 01

2. Connect R, G, B of the C Board cathode to oscilloscope.

3. Adjust Brightness to obtain the cathode value to the value shown

below:

165 ± 2VDC

4. Adjust SCREEN VR on the FBT until the scanning line disappears.

5. Set WHBL 16 “RGBB” back to 00.

KV-21FA350/21FA550

KV-21FA350/21FA550

14

SECTION 3: CIRCUIT ADJUSTMENTS

Electrical Adjustments by Remote Commander

Use the Remote Commander (RM-YA005) to perform the circuit adjustments in this section.

Test Equipment Required: 1. Pattern generator 2. Frequency counter 3. Digital multimeter 4. Audio oscillator

3-1. REMOTE ADJUSTMENT BUTTONS AND INDICATORS

DISPLAY

(Service Mode)

KV-21FA350/21FA550

MUTING

(Enter into

memory)

1

Display next

Item

2

Display next

Category

4

Display previous

Item

8

(Initialize)

VOLUME (+)

(Service Mode)

POWER

(Service Mode)

3

Increase

Data value

6

Decrease

Data value

5

Display previous

Category

ENTER

(Enter into

memory)

0

(Remove

from memory)

KV-21FA350/21FA550

RM-YA005

15

3-2. ACCESSING THE SERVICE MENU MODE

Use the remote commander to access the service meu mode and perform the following adjusments.

1. Standby mode (Power off).

2. Press the following buttons on the remote commander within a second of each other:

DISPLAY

Channel

5

Sound Volume +

The screen displays the fi rst service data category item.

POWER

KV-21FA350/21FA550

category in decimal item name in decimal NG service command frequency video input name

GEOM 000 HPOZ 055 x SERVICE 60 VIDEO 1

release ID version in binary for factory color system (decimal)

STR31 7.11U 0011 1111 FF FF - - - - - 00084

000 00 00 0000 3E 40 000 004000 0000FF

item no. service data NVM field channel no./

software service data reserved power on time

Status Byte Status Byte

Flash DCXO #1 SSD #2 SSD

1. On the Remote Commander press 2 to select the next category, or 5 to select the previous category.

2. Press 1 to select the next item, or 4 to select the previous item.

3. Press 3 to increase the data value, or 6 to decrease the data value.

4. Press

MUTING

then 0 to write into memory.

GREEN

GEOM 000 HPOS 039 SERVICE 50 VIDEO 1

write with [MUTING].

GREEN

GEOM 000 HPOS 039 WRITE 50 VIDEO 1

Write executed with -.

RED

GEOM 000 HPOS 039 WRITE 50 VIDEO 1

Resetting the User Menus

Use the following procedure to reset the User Menus to the factory default settings.

1. Access Service Adjustment Mode.

2. Press 8 then 0 on the Remote Commander.

“WRITE” displays when

saving changes

“WRITE” becomes red

when saving, then changes

to “SERVICE”

KV-21FA350/21FA550

16

KV-21FA350/21FA550

3-3. CONFIRMING SERVICE ADJUSTMENT

CHANGES

1. After completing adjustments, pull out the plug from the AC outlet,

then replace the plug in the AC outlet again.

2. Access Service Adjustment Mode.

3. Using the buttons on the Remote Commander, locate the adjusted

items again to confi rm they were adjusted.

3-4. WHITE BALANCE ADJUSTMENTS

NOTE: FOCUS adjustment should be completed before White Balance

adjustment. (See 2-3. FOCUS)

1. Access Service Mode.

2. Input white raster signal using signal generator.

3. Set the following condition:

Picture “DYNAMIC”, PICT 006, note value of “WTS”

then change to 00.

4. Press 2 or 5 to select the WHBL category.

5. Press 1 or 4 to display the 03 “GDRV” and 04 “BDRV” items.

6. Press 3 or 6 to adjust for the best white balance.

7. At Cutoff, select WHBL 000 “BKOR” and 001 “BKOG” and adjust

the data.

8. Perform adjustment at Highlight and Cutoff condition until it reaches

its target.

9. Press

10. Set PICT 006 “WTS” back to its original data.

MUTING

then

ENTER

to save into the memory.

10. Set “PWL” and “BLBG” back to initial data.

(“PWL”: 01h and “BLBG”: 00h)

11. Press

Sub Color Adjustment

1. Set TV to Video mode.

2. Set Picture mode to “CUSTOM”.

3. Input PAL 100% Color Bar (CB) to TV set (OTHER MODEL).

4. INPUT NTSC 75% CB to TV set (NTSC MODEL).

5. Set PICT 006 “WTS” to 00h and Intelligent Picture to “OFF”.

6. Set the following condition:

PICTURE 50%, COLOR 50%, BRIGHTNESS 50%, HUE 50%,

7. Connect an oscilloscope to pin

8. Press

MUTING

SHARPNESS 50%

1

or 4 to select SADJ 004 “SCOL”, then adjust

B2=VB3=VB4

V

6

, then write in the data +5 step offset.

VB1

VB2 VB3 VB4 VB1 VB2 VB3 VB4

VB2 = VB3 = VB4 (for PAL) VB1 = VB4 (for NTSC)

then 0 to write into memory.

2

(B Output) of CN004.

(for PAL),

VB1 = VB4 (for NTSC)

(Difference is within 70mV)

by pressing

3

or

3-5. PICTURE QUALITY ADJUSTMENTS

P Max/Contrast Adjustment

1. Set TV to Video mode.

2. Set Picture mode to “CUSTOM”.

3. Input PAL 100% CB to TV set (OTHERS), NTSC 75% CB (NTSC

model).

4. Set PICT 003 “PWL” to 00h WHBL 017 “BLBG” to 01h.

5. Set the following condition:

PICTURE 100%, COLOR 0%, BRIGHTNESS 50%

6. Connect an oscilloscope to pin

1

7. Press

pressing 3 or 6 until the spec below:

or 4 to display SADJ 000 “PMAX”, then adjust VR by

1.46 ± 0.03 Vp-p = For 21" without VM models

1.65 ± 0.03 Vp-p = With VM models except NTSC models

1.23 ± 0.03 Vp-p = NTSC models VM models

1.10 ± 0.03 Vp-p = For 21" NTSC non VM models

4

(R Output) of CN004.

VR

Black

9. Press

10. Set “WTS” back to original data and Intelligent Picture to “ON”.

11. Copy no.9 data to PAL TV & DVD mode.

MUTING

then 0 to write into memory.

Sub Hue Adjustment

1. Set TV to Video mode.

2. Set Picture mode to “CUSTOM”.

3. Input NTSC 3.58 CB to TV set.

4. Set the following condition:

PICTURE 50%, COLOR 50%, BRIGHTNESS 50%, HUE 50%,

SHARPNESS 50%

5. Press 1 or 4 to select service mode and - 5 step offset from SADJ

004 “SCOL”.

6. Connect oscilloscope to pin

7. Press 1 or 4 to select SADJ 001 “SHUE”, then press 3 or 6 to

adjust the data.

8. Press

9. Press 1 or 4 to select SADJ 004 “SCOL” and +5 step offset, then

10. Select TV channel with 3.58 and repeat item (3) to (7) and +1 step

11. Press

MUTING

press

MUTING

data offset.(NTSC model)

MUTING

then 0 to write into memory.

then 0 to write into memory .

then 0 to write into memory.

2

(B output) of CN004.

8. Select Wide Mode to “ON” in TV and Video mode and write “PMAX”

data - 8 steps (for models with V-Compression features only).

9. Press

MUTING

then 0 to write into memory.

KV-21FA350/21FA550

17

KV-21FA350/21FA550

12. For single system model with NTSC 4.43, select TV channel with

NTSC 4.43 and repeat items (3) to (8)

VB3

VB1

VB2

VB4

80mV

The highest level of VB1, VB2, VB3, VB4

must be aligned at the same time.

The ideal difference between

V

B2 and VB3 is within ± 80mV

13. Once adjustment is completed in Video mode, carry out adjustment

in DVD mode. Set TV to DVD mode. Input NTSC 3.58 CB to DVD

set and perform steps 4 to 9 and 11.

Sub Bright Adjustment

1. Set TV to RF mode.

2. Input PAL monoscope to RF mode.

3. Set Brightness 50% and Picture to “MINIMUM”.

4. Press 1 (or 4) to select WHBL 010 “SBRT”.

5. Press 3 to increase the data value, or 6 to decrease the data value

so that the cut-off level is 10 IRE, slightly glimmer: 20 IRE.

6. Press

MUTING

then 0 to write into memory.

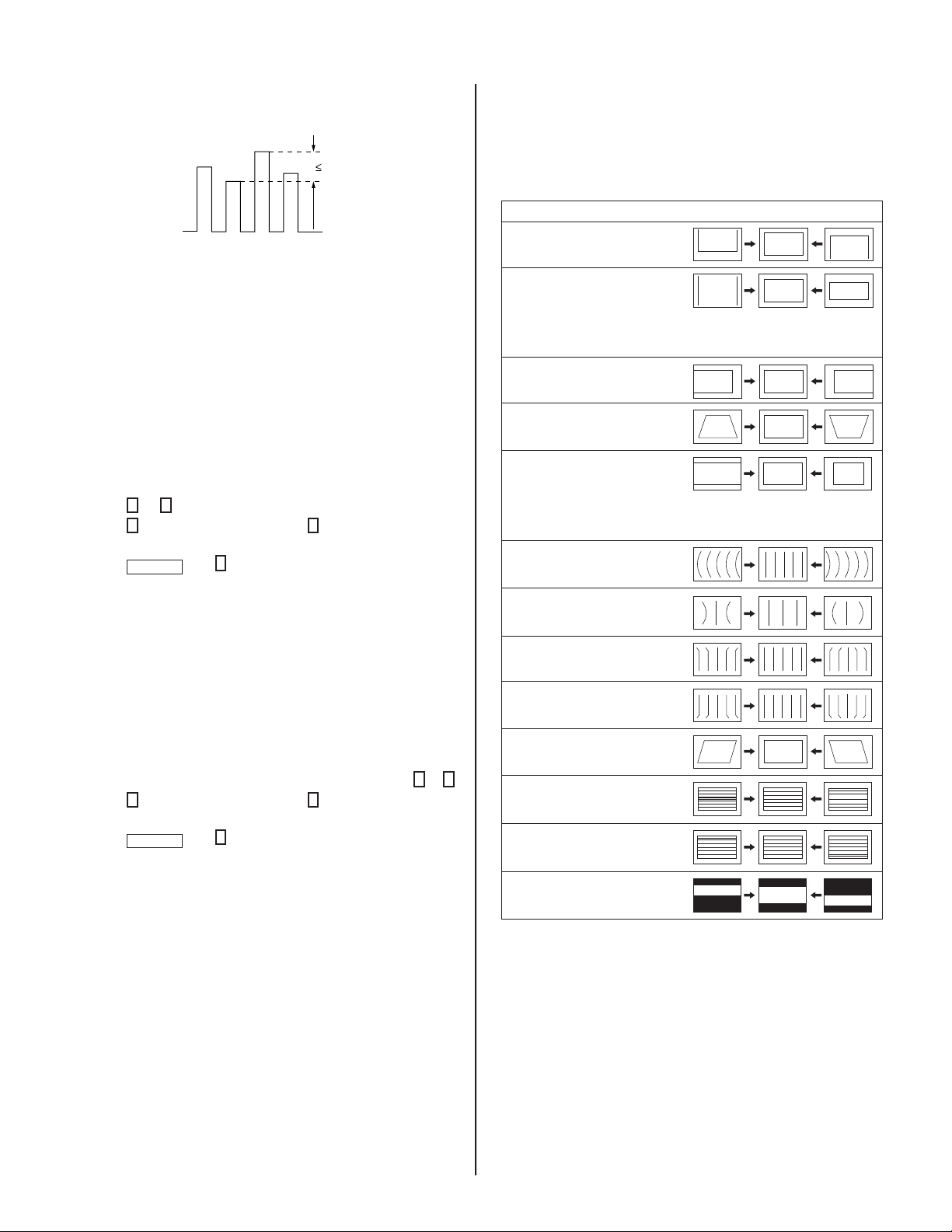

PAL 50Hz Normal Mode

1. Input PAL signal 50Hz in the Service Mode.

2. Set Wide Mode to “OFF”.

3. Perform the below adjustments using the “General Setting”

sequence.

Item No. Function Illustration

GEOM 013 Vertical Shift

(VPOS)

GEOM 011 Vertical Amplitude

(VSIZ)

GEOM 000 Horizontal Shift

(HPOS)

GEOM 009 EW Trapezoid

(EWTZ)

GEOM 005 EW Width (EW)

(HSIZ)

GEOM 002 Horizontal Bow

(HBOW)

Note: Adjust VSIZ to

Note: Adjust HSIZ to

±

(SPCB)

12.4

(PAL Monoscope)

±

11. 3

±

(NTSC Monoscope)

11. 5

±

(SPCB)

16.4

±

(PAL Monoscope)

14.6

±

(NTSC Monoscope)

15.3

Geometry Adjustment

Geometry adjustment must be done for both color systems PAL and

NTSC.

General Setting

1. Input Monoscope or Special Color Bar (SPCB) signal using a

pattern generator.

2. Access Service Mode.

3. Select the category item that needs adjusting by pressing 1 or

4. Press 3 to increase the data value, or 6 to decrease the data

value.

5. Press

MUTING

then 0 to write into memory.

NOTE: Geometry Adjustment must be performed for 4 different modes:

PAL 50Hz NORMAL MODE,

PAL 50Hz WIDE MODE,

NTSC 60Hz NORMAL MODE,

NTSC 60Hz WIDE MODE.

4

GEOM 006 EW Parabola/Width

(EWPW) (PW)

GEOM 007 EW Upper Corner

(UCOP) Parabola

GEOM 008 EW Lower Corner

(LCOP) Parabola

GEOM 001 Horizontal

(HPAR) Parallelogram

GEOM 012 S-Correction(SC)

(SCOR)

GEOM 003 Vertical Linearity

(VLIN)

GEOM 004 Vertical Scroll

(VSCR)

4. After completing the adjustments for PAL 50Hz NORMAL MODE,

set Wide mode to “ON”, and copy all PAL 50Hz NORMAL MODE

adjusted data to PAL 50Hz WIDE MODE except VSCR.

5. Complete the adjustment for NTSC 60Hz NORMAL MODE.

6. Set Wide mode to “OFF”.

7. Complete the adjustment items listed in the above table using the

“General Setting” sequence.

8. After completing the adjustments set Wide mode to “ON” and copy

all NTSC 60Hz NORMAL MODE adjusted data to NTSC 60Hz

WIDE MODE except VSCR.

9. After completing all the adjustments, reconfi rm VSIZ and VPOS.

KV-21FA350/21FA550

18

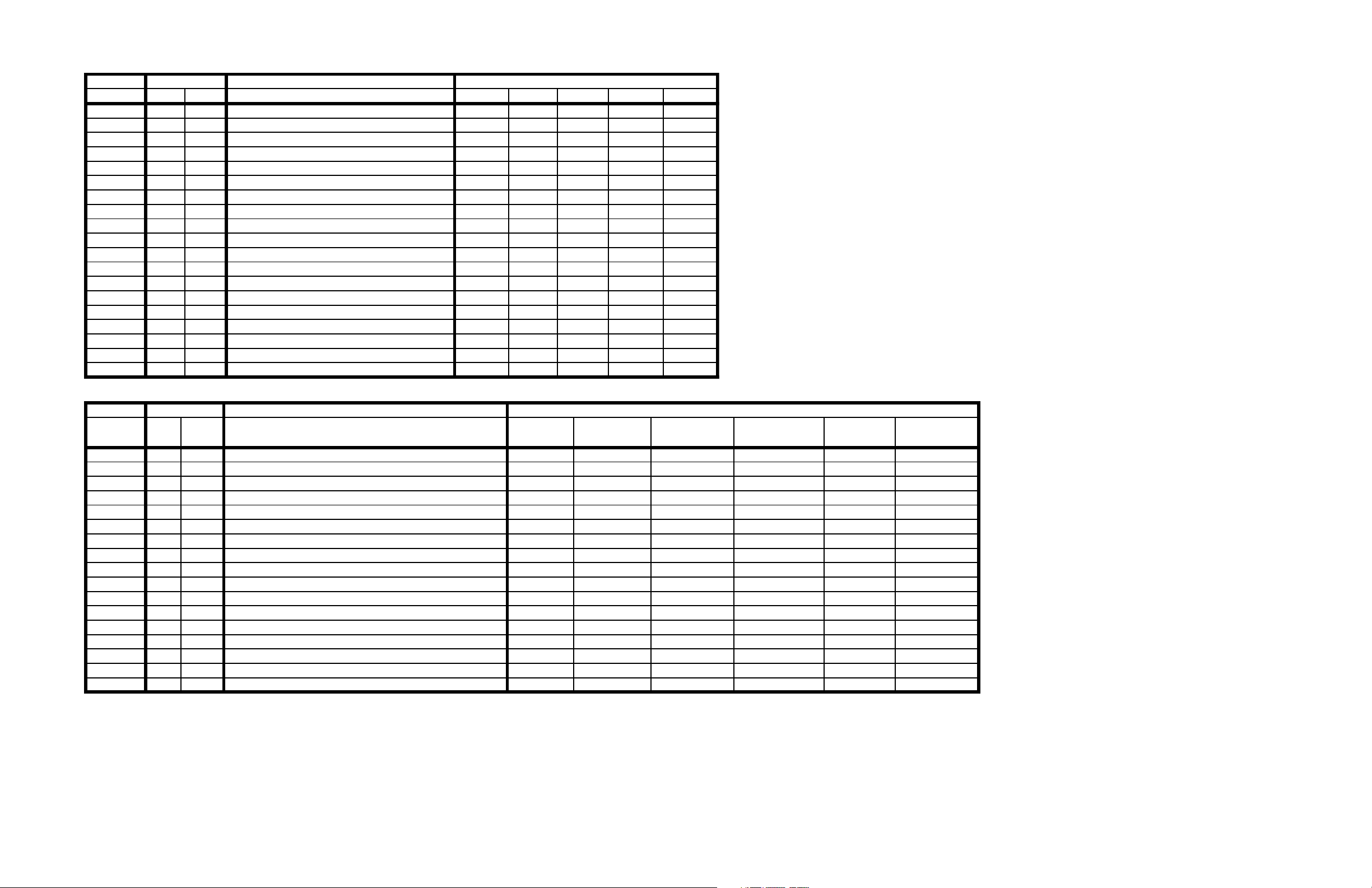

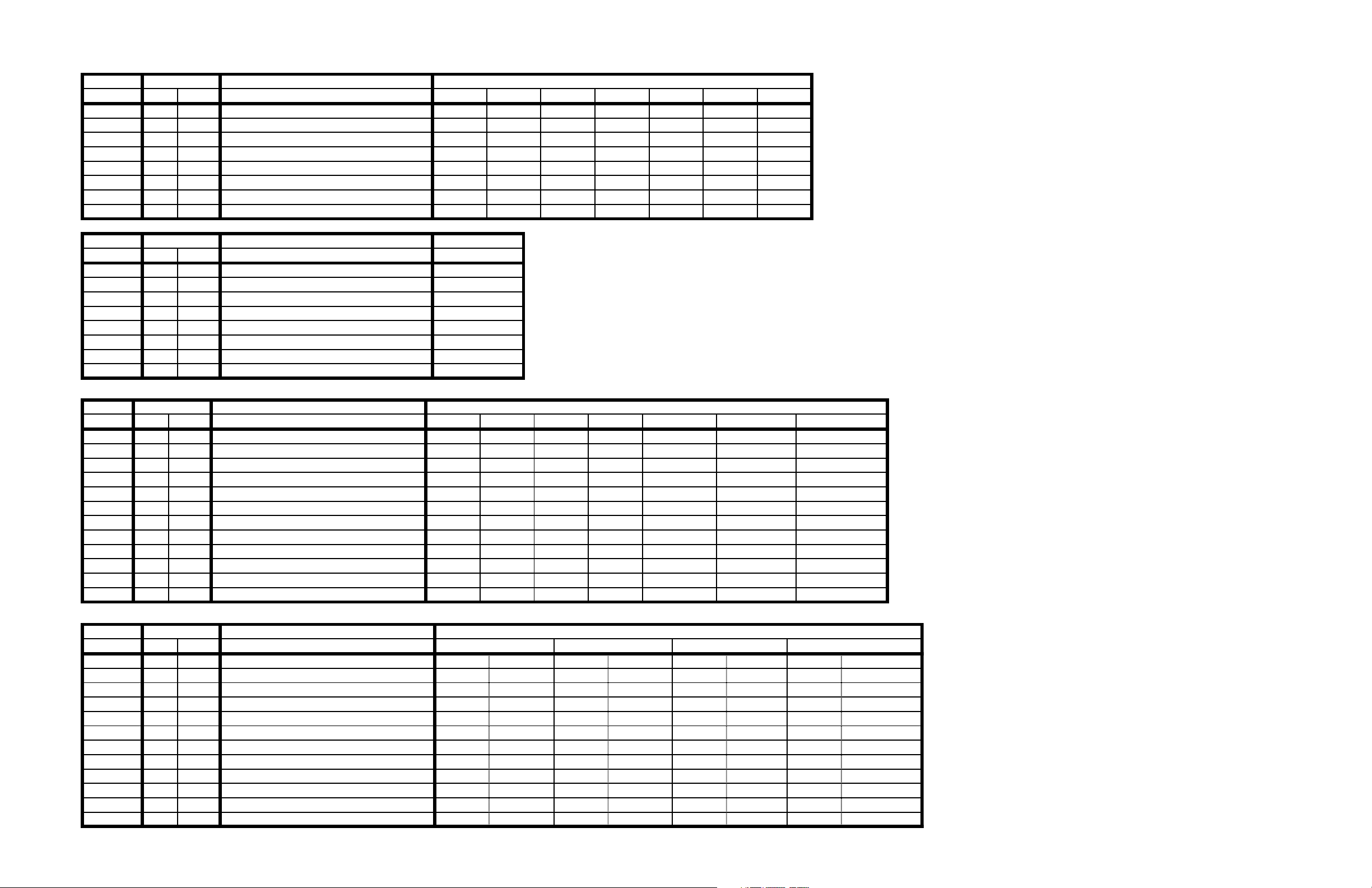

3-6. SERVICE DATA

Initial Value

Initial Value

KV-21FA350/21FA550

TVJ Function

Category No. Name

GEOM 000 HPOS

Functionality

001 HPAR

002 HBOW

003 VLIN

004 VSCR

005 HSIZ

006 EWPW

007 UCOP

008 LCOP

009 EWTZ

010 VSLP

011 VSIZ

012 SCOR

013 VPOS

014 HBL

015 W BF

016 WBR

017 SBL

018 COPY

Horizontal Shift (HS) 31 31 31 31

Horizontal Parallelogram 31 31 31 31

Horizontal Bow 31 31 31 31

Vertical Linearity 31 31 31 31

Vertical Scroll 31 31 31 31

EW Width (EW) 31 31 31 31

EW Parabola/Width (PW) 31 31 31 31

EW Upper Corner Parabola 17 17 17 17

EW Lower Corner Parabola 17 17 17 17

EW Trapezium 31 31 31 31

Vertical Slope (VS) 31 31 31 31

Vertical Amplitude 15 15 15 15

S-Correction (SC) 14 14 14 14

Vertical Shift (VSH) 31 31 31 31

RGB Blanking Mode 01 01 01 01

Timing of Wide Blanking (WBF) 07 07 07 07

Timing of Wide Blanking (WBR) 10 14 10 14

Service Blanking 00

Copy the GEO data to all 50/60Hz NVM area 00

Common

(4:3) 50 (4:3) 60 (4:3) w50 (4:3) w60

TVJ Function

Category No. Name

WHBL 000 BKOR

Functionality

001 BKOG

002 RDRV

003 GDRV

004 BDRV

005 LPG

006 PGR

007 PGG

008 PGB

009 GNOF

010 SBRT

011 SBRO

012 CBS

013 RGBB

014 BLBG

015 OFB

016 WBP

Black Level Offset R (OFB = 00), Offset B (OFB = 01) 31 31 31 31 31

Black Level Offset G 31 31 31 31 31

White Point R 37 37 37 37 37

White Point G 37 37 37 37 37

White Point B 37 37 37 37 37

RGB Gain Preset 01

Preset Gain R (PGR) 50

Preset Gain G (PGG) 50

Preset Gain B (PGB) 50

Preset Gain Offset 15

Sub-Brightness

Sub-Brightness Offset (Intelligent Pic) 02

Control Sequence of Beam Current Limiting 00

RGB Blanking 00

Blanking of Blue & Green Output 00

Black Level Offset Blue 01

Color Temp setting (0:High , 1:Normal , 2,3: Low)

Common

Col Temp

(Cool other)

Col Temp

(Warm other)

Col Temp

(Neutral other)

Col Temp

(Cool YUV)

Col Temp

(Warm YUV)

KV-21FA350/21FA550

19

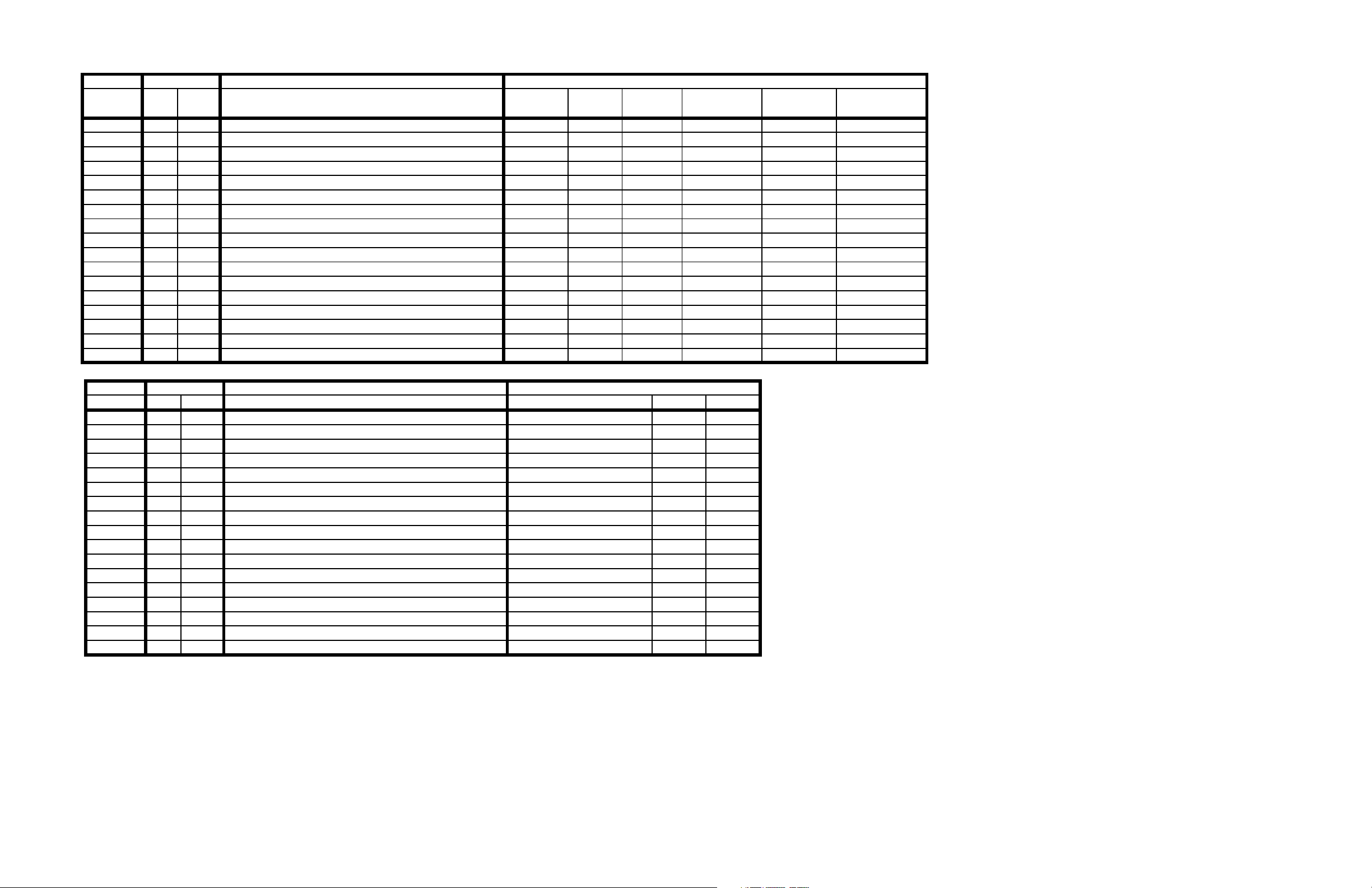

KV-21FA350/21FA550

012

CBS

016

WBP

Initial Value

TVJ Function

Category No. Name

WHBL 000 BKOR

TVJ Function

Category No. Name

WHBL 000 BKOR

Functionality

001 BKOG

002 RDRV

003 GDRV

004 BDRV

005 LPG

006 PGR

007 PGG

008 PGB

009 GNOF

010 SBRT

011 SBRO

013 RGBB

014 BLBG

015 OFB

Functionality

001 BKOG

002 RDRV

003 GDRV

004 BDRV

005 LPG

006 PGR

007 PGG

008 PGB

009 GNOF

010 SBRT

011 SBRO

012 CBS

013 RGBB

014 BLBG

015 OFB

016 WBP

Black Level Offset R (OFB = 00), Offset B (OFB = 01) 31

Black Level Offset G 31

White Point R 37

White Point G 37

White Point B 37

RGB Gain Preset

Preset Gain R (PGR)

Preset Gain G (PGG)

Preset Gain B (PGB)

Preset Gain Offset

Sub-Brightness 31 31 31

Sub-Brightness Offset (Intelligent Pic)

Control Sequence of Beam Current Limiting

RGB Blanking

Blanking of Blue & Green Output

Black Level Offset Blue

Color Temp setting (0:High , 1:Normal , 2,3: Low) 00 01

Black Level Offset R (OFB = 00), Offset B (OFB = 01)

Black Level Offset G

White Point R

White Point G

White Point B

RGB Gain Preset

Preset Gain R (PGR)

Preset Gain G (PGG)

Preset Gain B (PGB)

Preset Gain Offset

Sub-Brightness 31 31

Sub-Brightness Offset (Intelligent Pic)

Control Sequence of Beam Current Limiting

RGB Blanking

Blanking of Blue & Green Output

Black Level Offset Blue

Color Temp setting (0:High , 1:Normal , 2,3: Low) 02

Col Temp

Initial Value

50pal(Video)50pal(TV)YUV

TV VideoPic Mode 2 (CUSTOM)

Pic mode 0

(VIVID)

Pic mode 1

(STANDARD)

KV-21FA350/21FA550

20

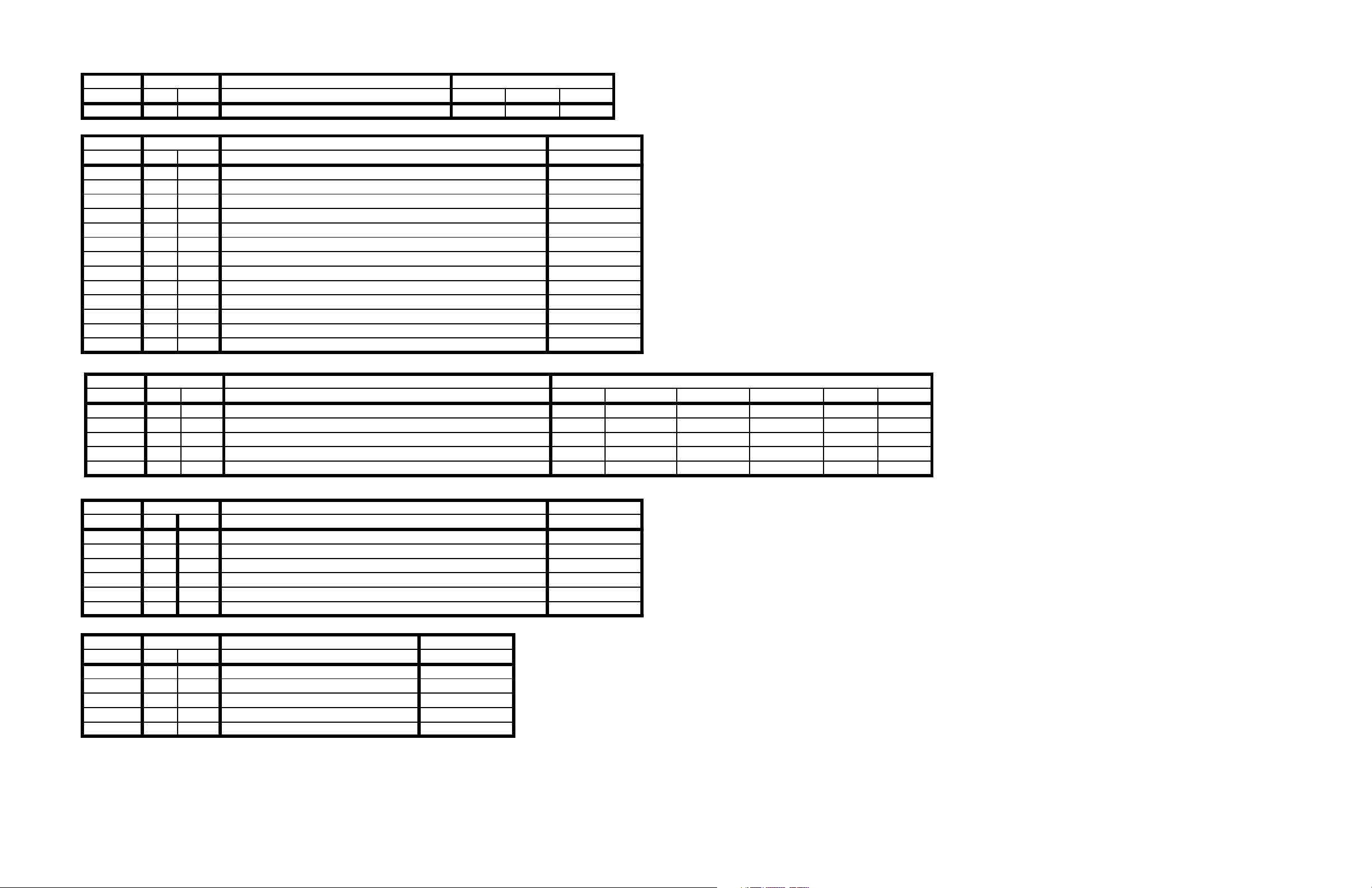

TVJ Function

SADJ

000

PMAX

001

SHUE

Sub-Hue

002

SSHP

Sub-Sharpness

003

SSHO

Sub-Sharpness Offset (Intelligent Pic)

004

SCOL

Sub-Color

005

SCOO

Sub-Color Offset (Intelligent Pic)

006

PIC

Picture Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit 6(invalid)]

007

COL

Color Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit 6(invalid)]

6(invalid)]

send to TINT #1Eh(5-0) with US model)

Functionality

Common

Initial Value

YUV

50secam(TV)

50secam(Video)

TV

Video

50pal(TV)

50pal(Video)

SADJ

000

PMAX

001

SHUE

Sub-Hue

002

SSHP

Sub-Sharpness

003

SSHO

Sub-Sharpness Offset (Intelligent Pic)

004

SCOL

Sub-Color

005

SCOO

Sub-Color Offset (Intelligent Pic)

006

PIC

Picture Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit

007

COL

Color Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit

6(invalid)]

(* send to TINT #1Eh(5-0) with US model)

60YUV

50RGB

60RGB

50YUV

60ntsc(TV)

60ntsc(Video)

60palm(TV)

60palm(Video)

Functionality

Initial Value

SADJ

000

PMAX

001

SHUE

Sub-Hue

002

SSHP

Sub-Sharpness

003

SSHO

Sub-Sharpness Offset (Intelligent Pic)

004

SCOL

Sub-Color

005

SCOO

Sub-Color Offset (Intelligent Pic)

006

PIC

Picture Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit 6(invalid)]

80

007

COL

Color Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit 6(invalid)]

6(invalid)]

send to TINT #1Eh(5-0) with US model)

Functionality

Initial Value

Category No. Name

Picture Maximum

Brightness Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit

008 BRT

Hue Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit 6(invalid)] (*

009 HUE

010 SHP

TVJ Function

Category No. Name

Sharpness Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit

6(invalid)]

Picture Maximum

KV-21FA350/21FA550

42

06

31 31 00 31

02

Brightness Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit

008 BRT

Hue Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit 6(invalid)]

009 HUE

010 SHP

TVJ Function

Category No. Name

008 BRT

009 HUE

010 SHP

Sharpness Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit

6(invalid)]

Picture Maximum 37 37 37 37

Brightness Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit

Hue Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit 6(invalid)] (*

Sharpness Control [GA:0~100(valid); >100(invalid), Others:0~63(valid); ignore bit

6(invalid)]

31 31 31 31 31 31

50RGB 60RGB

Pic mode 0

(VIVID)

100 80

56 50 50

50 50 50

50 50 50

60 50 50

Pic mode 1

(STANDARD)

Pic Mode 2

(CUSTOM)

TV Video

07 07

40 42

TV Wide

(4:3)

Video Wide

(4:3)

KV-21FA350/21FA550

21

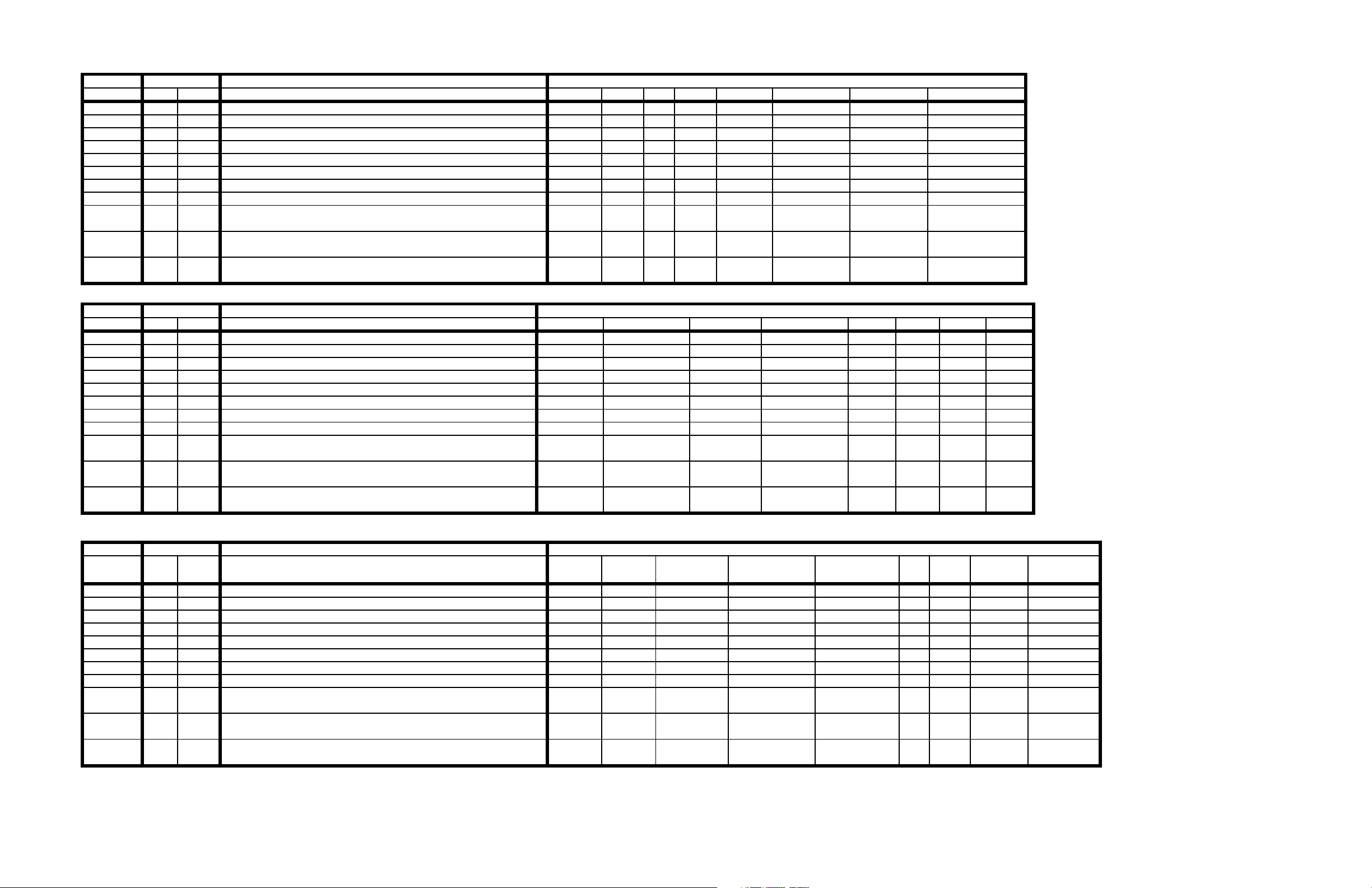

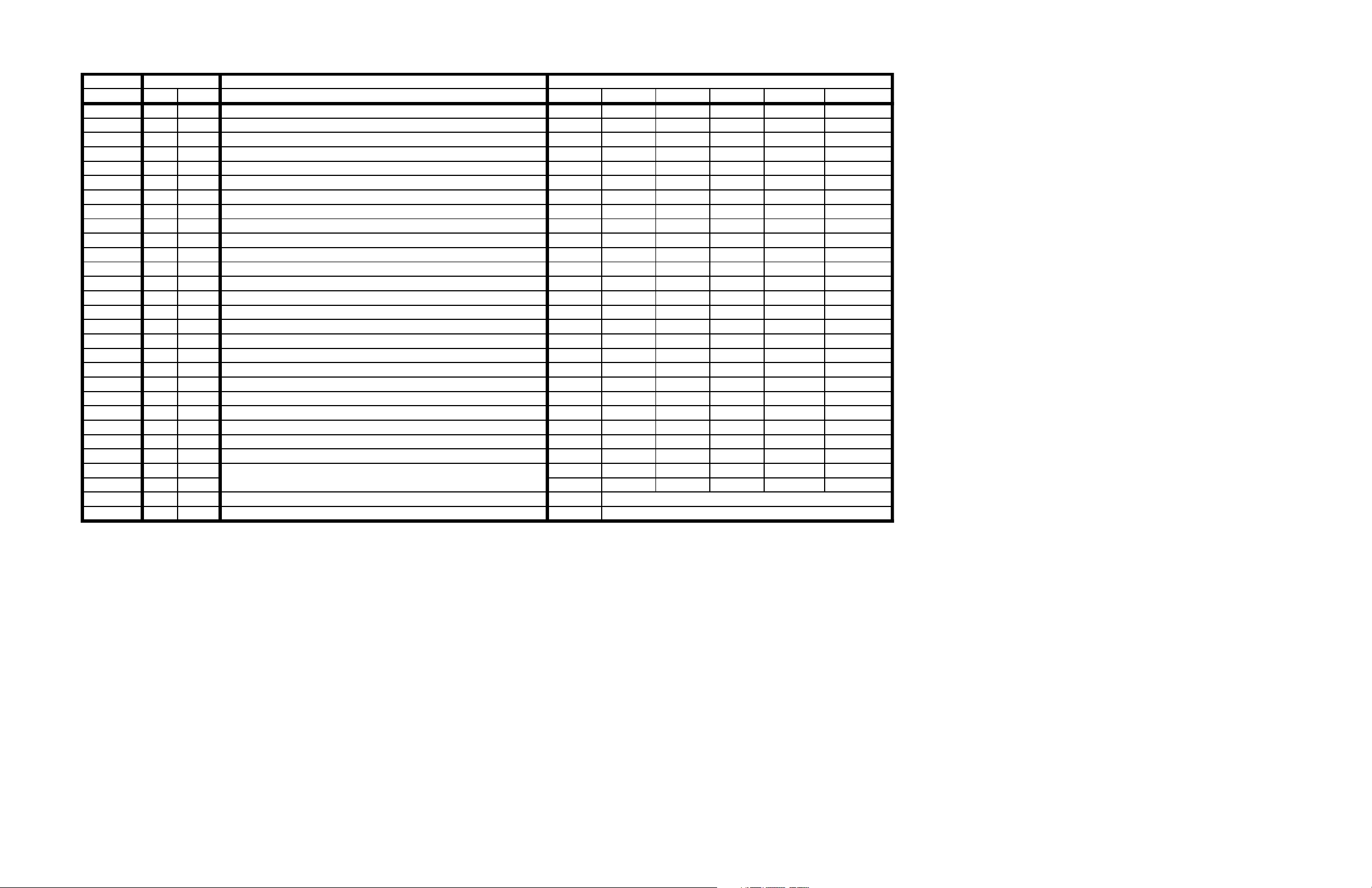

KV-21FA350/21FA550

Initial Value

Initial Value

TVJ Function

Category No. Name

YC 000 PFRQ

TVJ Function

Category No. Name

YC 000 PFRQ

Functionality

001 RPA

002 RPO

003 YDLY

004 CMAT

005 ACL

006 CB

007 SBO

008 CHSE

009 CLO

010 CTRP

011 QDT

012 BPS

013 TINT

014 TUV

015 BWYC

016 OSB

017 BKC

Functionality

001 RPA

002 RPO

003 YDLY

004 CMAT

005 ACL

006 CB

007 SBO

008 CHSE

009 CLO

010 CTRP

011 QDT

012 BPS

013 TINT

014 TUV

015 BWYC

016 OSB

017 BKC

Peaking Center Frequency and Delay 01

Ratio Pre & Over Shoot 02

Ratio of Positive & Negative Peaks 03

Y-Delay 09 8 09 NIL 09

PAL-SECAM or NTSC (Japan/USA) Matrix 01

Automatic Color Limiting 01

Chroma Bandpass Center Frequency 00

SECAM Black Offset 00

PAL/NTSC Ident Sensitivity 02

Center Frequency of Cloche(Bell) Filter 00

Chroma Trap Mode 00

Second Chroma Trap 00

Bypass of Chroma Base-band Delay Line 00

Base-Band Tint Control 31 31

Tint Control on UV Signals 00

Bandwidth at YC mode for 3.58 MHz color system (BWYC) 00

Width of internal burstkey pulse of chroma demodulator (OSB) 00

Burst Key Position 00 00 00

Peaking Center Frequency and Delay 00

Ratio Pre & Over Shoot 03

Ratio of Positive & Negative Peaks 03

Y-Delay 09 02 09

PAL-SECAM or NTSC (Japan/USA) Matrix

Automatic Color Limiting

Chroma Bandpass Center Frequency

SECAM Black Offset

PAL/NTSC Ident Sensitivity

Center Frequency of Cloche(Bell) Filter

Chroma Trap Mode 01

Second Chroma Trap 00

Bypass of Chroma Base-band Delay Line 01

Base-Band Tint Control 31

Tint Control on UV Signals

Bandwidth at YC mode for 3.58 MHz color system (BWYC)

Width of internal burstkey pulse of chroma demodulator (OSB)

Burst Key Position

Common

NTSC(Video) SECAM(Video)

Others PAL(Video)

PAL(TV) NTSC(TV) SECAM(TV)YUV

SECAM NTSC TVS-INPUT

KV-21FA350/21FA550

22

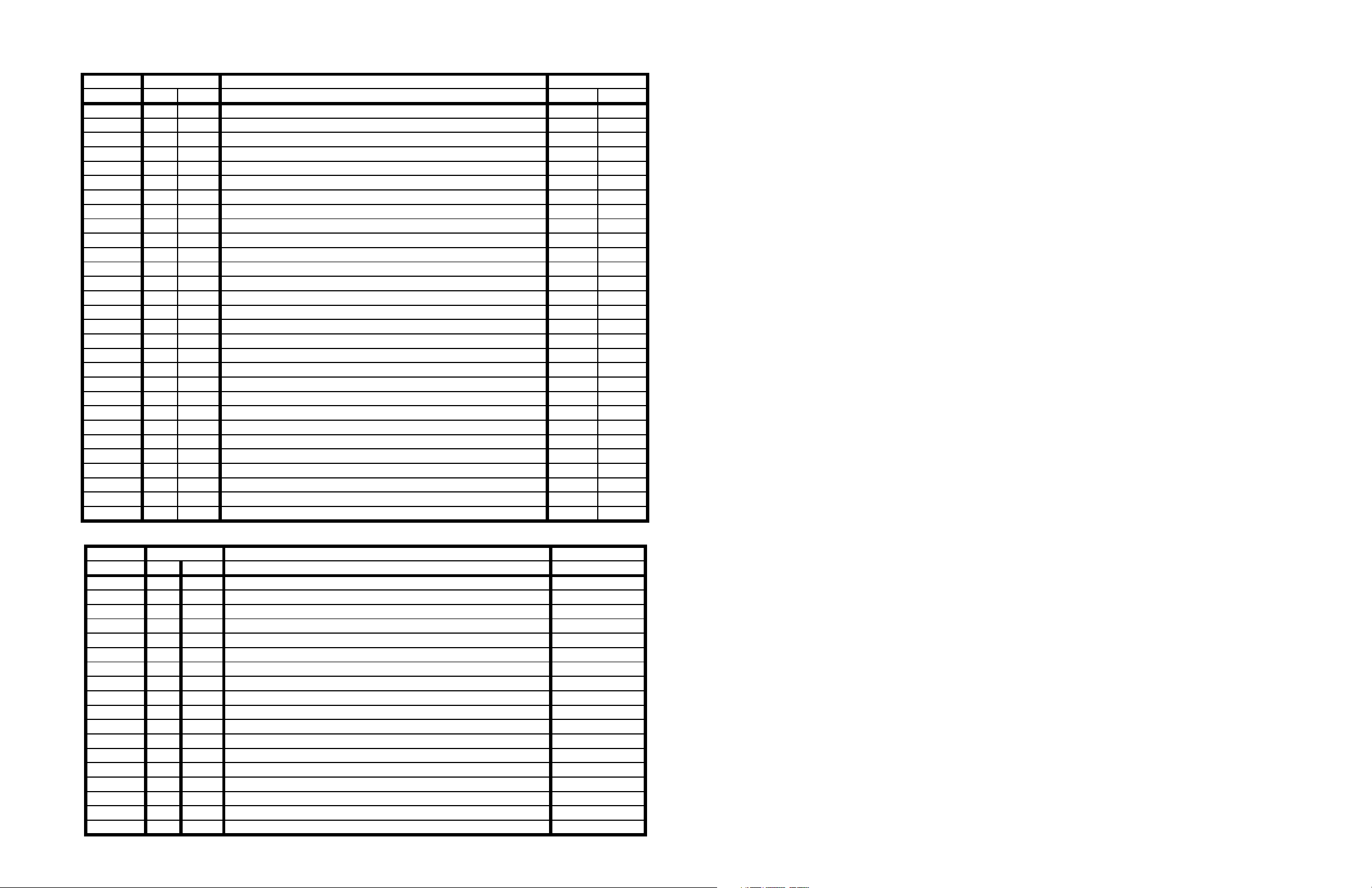

KV-21FA350/21FA550

007

MVK

Initial Value

007

MVK

Initial Value

011

AAS

Initial Value

011

AAS

Initial Value

TVJ Function

Category No. Name

SYNC 000 SYS

TVJ Function

Category No. Name

SYNC 000 SYS

Functionality

001 FO

002 VID

003 FSL

004 SSL

005 SVID

006 FORF

Functionality

001 FO

002 VID

003 FSL

004 SSL

005 SVID

006 FORF

Synchronization on YSYNC Input 00

Phase 1 Time Constant 03 03

Video Ident Mode 00 00

Forced Slicing Level for Vertical Sync 00

Slicing Level Sync Separator 00 00

Source Selection for Video Identification 00 00

Forced Field Frequency 01

Macro Vision Keying 01

Synchronization on YSYNC Input

Phase 1 Time Constant 00

Video Ident Mode

Forced Slicing Level for Vertical Sync

Slicing Level Sync Separator

Source Selection for Video Identification

Forced Field Frequency

Macro Vision Keying

Common

No Signal

(4:3) 50 (4:3) 60 Others TV VideoYUV

TVJ Function

Category No. Name

PICT 000 CADL

TVJ Function

Category No. Name

PICT 000 CADL

Functionality

001 CFA

002 SOC

003 PWL

004 WHTL

005 GAM

006 WTS

007 TFR

008 COR

009 CORO

010 BKS

Functionality

001 CFA

002 SOC

003 PWL

004 WHTL

005 GAM

006 WTS

007 TFR

008 COR

009 CORO

010 BKS

Cathode Drive Level 00

Comb Filter Mode 00

Soft Clipping Level 00

Peak White Limiting Switch 01

Peak White Limiting 00

Gamma 00

Gamma Control and White Stretch 01 01

DC Transfer Ratio of Luminance Signal 01 01

Coring 00 00 00

Coring Offset (Intelligent Pic) 02

Black Stretch 02

Black Area to Switch off the Black Stretch 01

Cathode Drive Level

Comb Filter Mode

Soft Clipping Level

Peak White Limiting Switch

Peak White Limiting

Gamma

Gamma Control and White Stretch

DC Transfer Ratio of Luminance Signal

Coring

Coring Offset (Intelligent Pic)

Black Stretch

Black Area to Switch off the Black Stretch

Common

Others RGB Live

TV(Others) Video(Dyn) Video(Others)

Color Temp (LOW) Color Temp (NORMAL)Color Temp (HIGH) Color Temp (Others)

KV-21FA350/21FA550

23

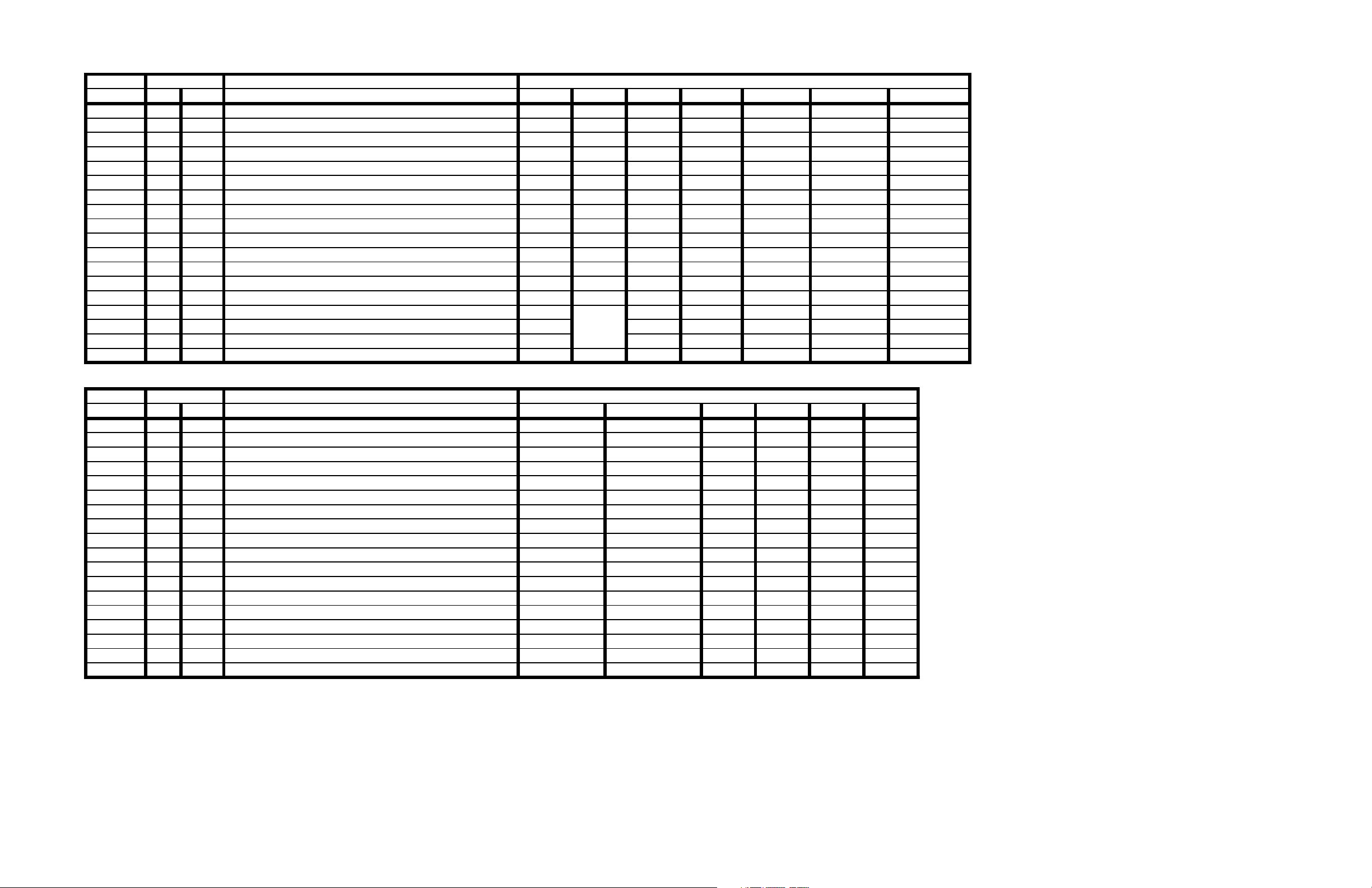

KV-21FA350/21FA550

SW

000

SVO

Initial Value

012

TUSO

Initial Value

005

BPBS

Initial Value

004

Initial Value

TVJ Function

Category No. Name

TVJ Function

Category No. Name

VIF 000 OIFD

TVJ Function

Category No. Name

VM 000 RGBD

Functionality

Functionality

001 AGCT

002 STM

003 GD

004 AGCS

005 FFI

006 LNAI

007 LNAT

008 LNSN

009 LNSD

010 LNEX

011 CHTR

Functionality

001 VMA

002 VMAP

003 VMMO

004 CRAO

Function of IFVO/SVO/CVBSI Pin @ 48 02 01 01

Offset IF Demodulator

AGC Take-over 31

Search Tuning Mode 01

Group Delay on CVBS1 Signal 00

IF AGC Speed

Fast Filter IF PLL 00

RF Amp LNA bit initial value 00

RF Amp Threshold Level

RF Amp SN Level Threshold

RF Amp SN Level Drop Threshold

RF Amp check SN Drop Timing

Channel Threshold after Auto Prg to set RF Amp User Mode 25

Sony Tuner used

Delay of RGB Output to VM Output 04

Amplitude of VM Output 00

VM setting (0:High , 1:Low , 2,3: OFF) 00 01 00

VM Mode 01

Coring on SVM 00

TV VideoYUV

Common

35

00

195

03

01

30

00

Common

Pic mode 0

Initial Value

OTHERS TVPic mode 1 Pic Mode 2

TVJ Function

Category No. Name

SDEM 000 FMWS

TVJ Function

Category No. Name

TXT 000 TXV

Functionality

001 QSS

002 BPB

003 HPVC

004 CMCA

Functionality

001

002

003

THD Teletext H-sync Active Edge Shift 00

TBR Teletext RGB Brightness 00

ACQ Teletext Acquisition (Auto-0, PAL-1) 00

TBRM Teletext Mix Mode Brightness 00

Window Selection for FM Demodulator 02

Quasi Split Sound (QSS) Amplifier Mode(N/A for GA multi M system) 01

Bypass of Sound Bandpass Filter 00

Head Phone Volume Control 00

Activate Mono Channel 00

Bypass of sound bandpass filter at stereo mode (BPBS) 01

Teletext Vertical Position for Philips 00

Common

Common

KV-21FA350/21FA550

24

KV-21FA350/21FA550

028

Initial Value

TVJ Function

Category No. Name

SDSP 000

Functionality

BBL BBE Contour 00

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

021

022

023

024

025

026

027

BBH BBE Process 00

BBLW BBE Contour Offset 06

SVOF Surround /Effect Mode Volume Offset 04 11 04

LAD Decoder Level Adjust 05

LAM Mono Level Adjust 05

LAN Nicam Level Adjust 22

LAS SAP Level Adjust 05

LAA ADC Level Adjust 00 00

SEF Incredible Mono/Stereo Effect

BAS Main Bass Offset 19

TRE Main Treble Offset 19

EQ1 Equalizer Main Channel Band (100 Hz) Offset 18

EQ2 Equalizer Main Channel Band (300 Hz) Offset 18

EQ3 Equalizer Main Channel Band (1000 Hz) Offset 17

EQ4 Equalizer Main Channel Band (3000 Hz) Offset 19

EQ5 Equalizer Main Channel Band (8000 Hz) Offset 21

BFCT DBE, DUB and BBE Control 00

SCEN SRS3D Center Control 04

SSPA SRS3D Space Control 01

BBHW BBE process offset in WOW mode 00

STRE Treble Offset for surround mode 01

BBHT BBE Offset in TV mode 00

TTRE Treble Offset in TV Mode 02

VBAS Bass Offset depend on user volume 01

VTRE Treble Offset depend on user volume 01

TBAS Bass Offset for TV 00

BBLO BBL Offset depend on User Volume 3

BBHO BBH Offset Depend on Use Volume 3

Common

TV Video

SRS/WOWOff Trusurround

KV-21FA350/21FA550

25

KV-21FA350/21FA550

*

028

Initial Value

Initial Value

TVJ Function

Category No. Name

SDSP 000

Functionality

BBL BBE Contour

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

021

022

023

024

025

026

027

BBH BBE Process

BBLW BBE Contour Offset

SVOF Surround /Effect Mode Volume Offset

LAD Decoder Level Adjust

LAM Mono Level Adjust

LAN Nicam Level Adjust

LAS SAP Level Adjust

LAA ADC Level Adjust

SEF Incredible Mono/Stereo Effect 05 03

BAS Main Bass Offset

TRE Main Treble Offset

EQ1 Equalizer Main Channel Band (100 Hz) Offset

EQ2 Equalizer Main Channel Band (300 Hz) Offset

EQ3 Equalizer Main Channel Band (1000 Hz) Offset

EQ4 Equalizer Main Channel Band (3000 Hz) Offset

EQ5 Equalizer Main Channel Band (8000 Hz) Offset

BFCT DBE, DUB and BBE Control

SCEN SRS3D Center Control

SSPA SRS3D Space Control

BBHW BBE process offset in WOW mode

STRE Treble Offset for surround mode

BBHT BBE Offset in TV mode

TTRE Treble Offset in TV Mode

VBAS Bass Offset depend on user volume

VTRE Treble Offset depend on user volume

TBAS Bass Offset for TV

BBLO BBL Offset depend on User Volume

BBHO BBH Offset Depend on Use Volume

ImonoIstereo

04

TVJ Function

Category No. Name

SDEC 000

KV-21FA350/21FA550

Functionality

SPTU Upper Threshold forSAP carrier detection 05

001

002

003

004

005

006

007

008

009

010

011

012

013

014

015

016

017

SPTL Lower Threshold for SAP carrier detection 15

SPTH Noise Threshold for automute of SAP 09

SPHY Hysteresis size for automute of SAP 03

FMTH Noise Threshold for automute of SC2 in FM A2 standard 00

FMHY Hysteresis size for automute of SC2 in FM A2 standard 04

NILE NICAM lower error limit (DDEP) 50

NIUE NICAM upper error limit (DDEP) 200

EPMD DEMDEC Easy Programming (DDEP) 01

STDS Bits multiplexed for ASD and SSS modes 13

OVMA FM overmodulation adaption 00

FLBW FM/AM demodulator filter bandwidth 01

IDMD FM ident speed in SSS mode 01

OVMT Overmodulation level threshold relative to nominal 03

DCXI NICAM DCXO Scaling Control Inverter 00

DCXG NICAM DCXO Scaling Control Gain 00

DCLL NICAM DCXO Scaling Control Limit (L) 00

DCLH NICAM DCXO Scaling Control Limit (H) 00

Common

26

KV-21FA350/21FA550

013

TSYS

019

Initial Value

007

HSYC

009

011

Selectable IF 0:STDSEL(17) 50us deemphasis 1: STDSEL(18) 75us deemph

Initial Value

005

006

005

006

Initial Value

Initial Value

TVJ Function

Category No. Name

OPTM 000

Functionality

ASHT auto shut off timer (data * 5 min) 06

001

002

003

004 MUTE

005

006

007

008 HTXT

009 CMSS

010

011

012 EXBL

014 LNSW

015

016

017

018

OSDB OSD brightness 12

OSDH OSD Horizontal Position 08

OSDV OSD Vertical Position 63 39

RFUL RF Signal Change Counter after Unlocked (Disable when 0fh) 01

RFLK RF Signal Change Counter after Locked (Disable when 0fh) 04

LANG OSD language shipping condition 01

DCXO DCXO Value

DISC target DISCO data for DCXO adjust by color dec

AVUL AV Signal Change Counter after Unlocked (Disable when 0Fh) 04

AVLK AV Signal Change Counter after Locked (Disable when 0Fh) 00

SENH Sound Enhancer Crackling sound c/m (0:Off, 1:On) 01

SPSC SPEED search (0: disable, 1:4times, 2:6times, 3:8times) 01

MULO Audio Mute Port Logic Selection (0:Active High, 1:Active Low) 01

No Signal Mute Switch (1 = enabled) 01

sync separator sw

Sync sw

Extended Blanking Timer to Eliminate White Noise. 06

Memorize TV Sys in NVM at Test Reset [0:B/G, 1:I, 2:D/K, 3:M] (GA Model) 03

Signal Booster Shipping/Test Reset condition (1: Auto, 0:Off) 00

Common

01

47

128

(4:3) 50 (4:3) 60 YUV

Others

00 00

KV-21FA350 ONLY

TVJ Function

Category No. Name

OPTB 001

KV-21FA550 ONLY

TVJ Function

Category No. Name

OPTB 001

Functionality

OPB1 Option 1 (System related) 40

002

003

004

002

003

004

OPB2 Option 2 (Video Signal related) 105

OPB3 Option 3 (Stereo Decoding related) 4

OPB4 Option 4 (Miscellaneous) 24

OPB5 Option 5 (Miscellaneous) 3

OPB6 Option 6 (OSD Language related) 1

Functionality

OPB1 Option 1 (System related) 10

OPB2 Option 2 (Video Signal related) 105

OPB3 Option 3 (Stereo Decoding related) 4

OPB4 Option 4 (Miscellaneous) 28

OPB5 Option 5 (Miscellaneous) 3

OPB6 Option 6 (OSD Language related) 1

Common

Common

TVJ Function

Category No. Name

OPUS 000

TVJ Function

Category No. Name

OPFM 000

Functionality

SOFF stay off (0: follow last memory with AC on, 1: standby with AC on) 01

001

002

003

004

005 OUV

006 CFA2

001

002

003

004

005

006

007

008

010

SPCH Channel Number after Shipping Condition 6

SPCA Cable Selection after Shipping Condition (1 = Cable On) 01

CCBR CC Brightness (only for US) 20

CCHP CC H position (only for US) 13

Functionality

FMCT FM Radio Auto Scan Carrier Threshold 20

RPST Waiting time for each frequency step during radio preset 10

MPTU Upper Threshold for MPX pilot detection (FM_RADIO) 12

DCOU Upper threshold for DC offset from FM demodulator 140

DCOL Lower threshold for DC offset from FM demodulator 114

OVMA FM overmodulation adaption (FM_RADIO) 00

FMBR OSD Brightness during FM Mode 12

RTRE Treble Offset in FM Radio Mode 03

RBAS Bass Offset in FM Radio Mode 02

AGCT ACG takeover in FM Radio Mode 32

FLBW FM/AM demodulator filter bandwidth 01

STDS

Offset Control on UV Input Signals (only for NTSC model)

Forced Comb Filter On (only for NTSC model) 00

H Sync Selection for Tuning (SL, LOCK or SID) only for US 01

Initial Value

Common

Common

01

KV-21FA350/21FA550

27

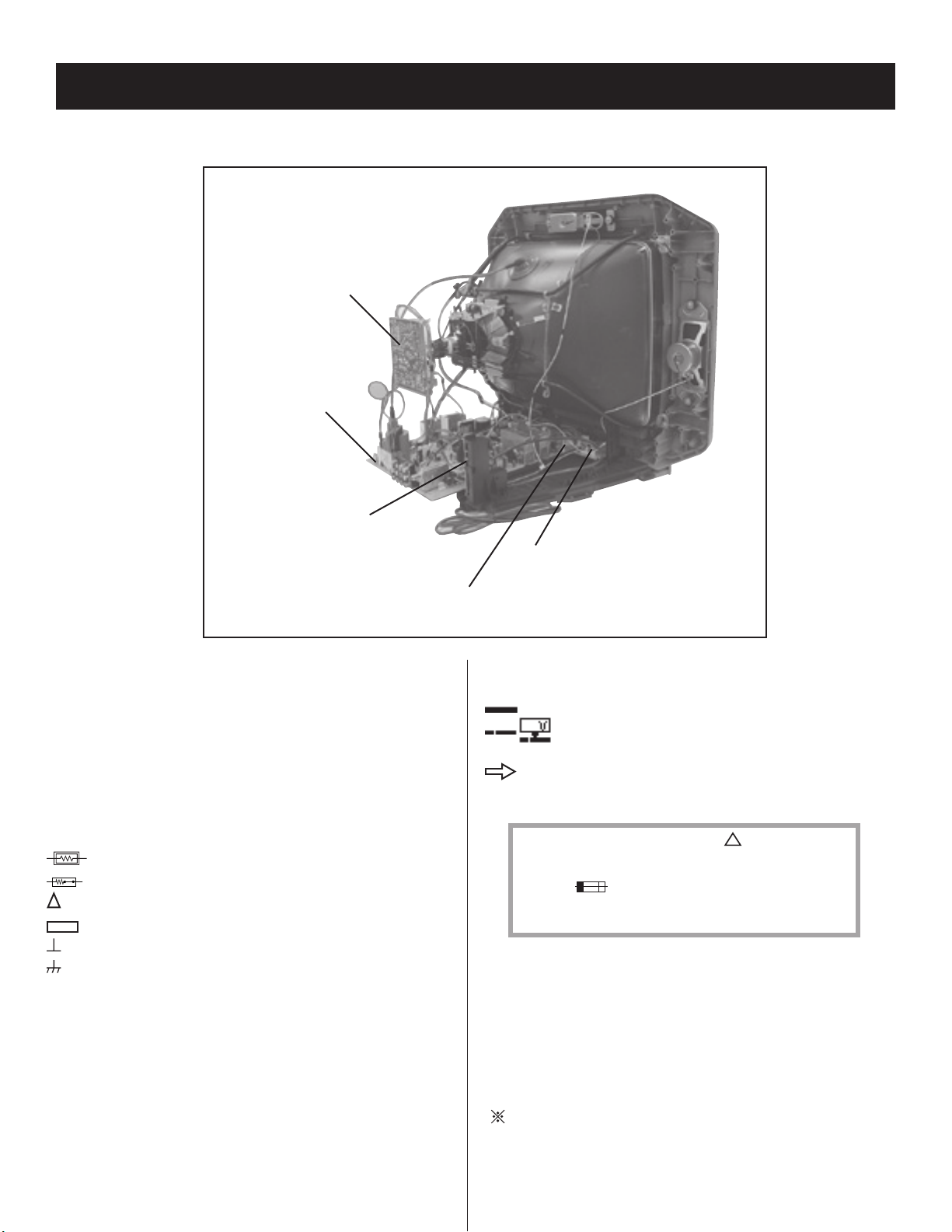

4-1. CIRCUIT BOARDS LOCATION

CV Board

A Board

KV-21FA350/21FA550

SECTION 4: DIAGRAMS

H2 Board

4-2. PRINTED WIRING BOARD AND

J4 Board

SCHEMA

All capacitors are in μF unless otherwise noted. pF : μμF 50WV or less

are not indicated except for electrolytics and tantalums.

All electrolytics are in 50V unless otherwise specifi ed.

All resistors are in ohms. k=1000, M=1000k

Indication of resistance, which does not have one for rating electrical

power, is as follows: Pitch : 5mm Rating electrical power :

1

/

W in resistance, 1/

4

: nonfl ammable resistor.

: fusible resistor.

: internal component.

: panel designation and adjustment for repair.

: earth ground

: earth-chassis

All variable and adjustable resistors have characteristic curve B, unless

otherwise noted.

Readings are taken with a color-bar signal input.

Readings are taken with a 10M digital multimeter.

Voltages are DC with respect to ground unless otherwise noted.

Voltage variations may be noted due to normal production tolerances.

TIC DIAGRAM INFORMATION

W and 1/

10

W in chip resistance.

8

W Board

All voltages are in V.

S : Measurement impossibillity.

: B+line.

: B-line.

(Actual measured value may be different).

: signal path. (RF)

Circled numbers are waveform references.

The components identifi ed by shading and

safety. Replace only with part number specifi ed.

The symbol indicates a fast operating fuse and is displayed on

the component side of the board. Replace only with fuse of the same

rating as marked.

!

symbol are critical for

REFERENCE INFORMATION

RESISTOR

: RN METAL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

: ADJUSTMENT RESISTOR

COIL

: LF-8L MICRO INDUCTOR

CAPACITOR

: TA TANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

KV-21FA350/21FA550

28

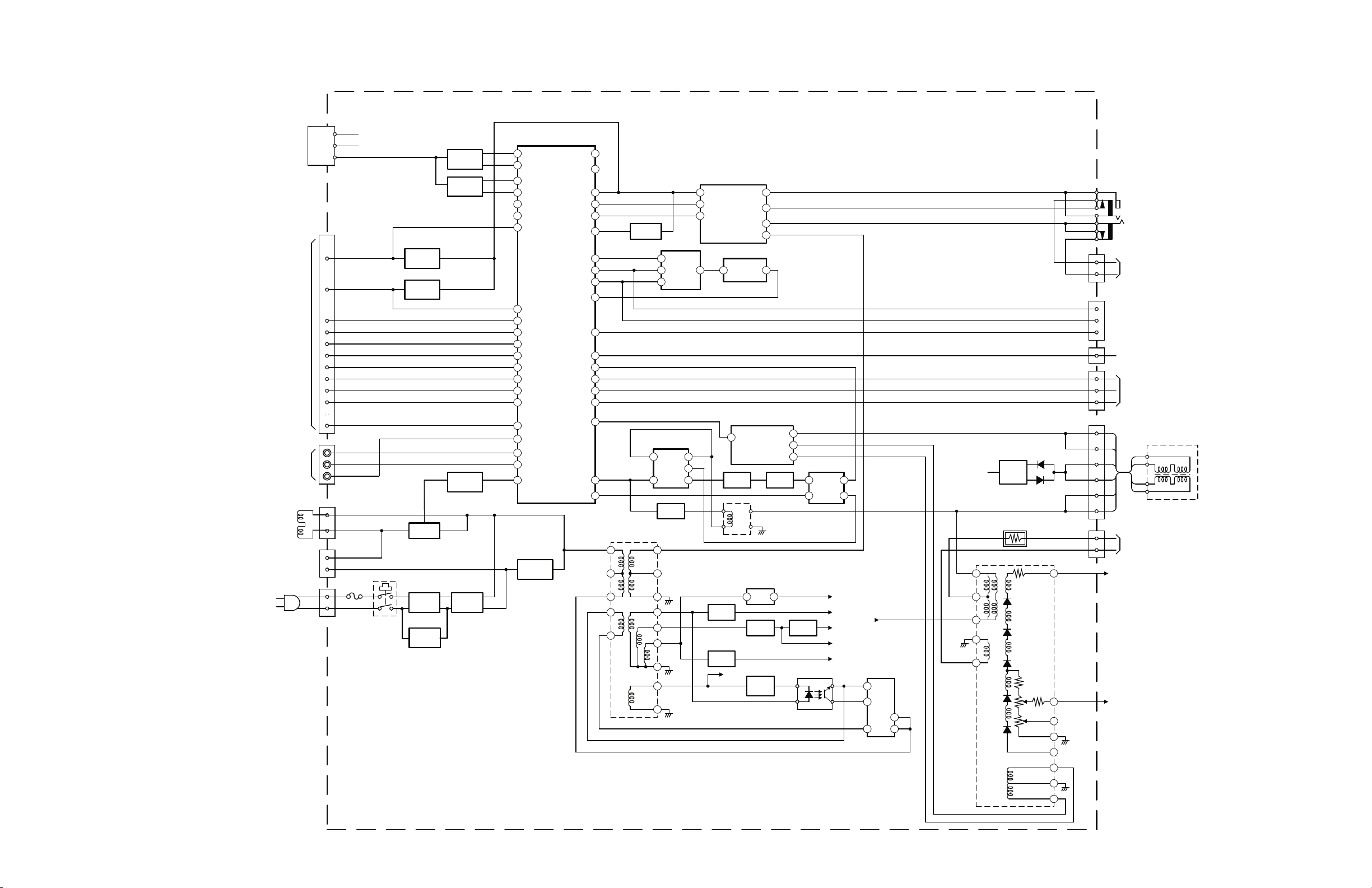

4-3. BLOCK DIAGRAM

SIGNAL FLOW BLOCK DIAGRAM

SCART

FRONT

SOCKETS

AC IN

AC IN

TU101

IF OUT

CN901

J903

CN600

CN601

CN602

SCL

SDA

P16

P15

P7

P9

P3

P5

P11

P10

P12

P14

P1

2

1

2

1

1

2

SCL

SDA

ROUT

LOUT

RIN3

LIN3

RIN1

LIN1

U-OUT

Y-OUT

VOUT

VOUTMON

VIN1

R2

L2

V2

DGC T

DGC T

DGC

DGC

F600

5A

250V

S600

MUTE

SWITCH

Q902

MUTE

SWITCH

Q901

RELAY

RY600

LINE

FILTER

T600

LINE

FILTER

T604

S W F 100

S W F 101

RELAY

SWITCH

Q601

LINE

FILTER

T603

IC001

SY S TE M CONTR OLLE R ,

VIDEO & AUDIO PR OCE SS OR

24

VIF IN 1

25

VIF IN 2

29

SIFIN1

30

SIFIN2

62

SCART HPR

63

SCART HPR

37

OUT R

ROTSW

ROTCTRL

MUTE

LSR

LSL

MO MUTE AUDIO

SDA1

SCR0

SDA0

SIRSC

36

OUT L

54

IN R3

53

57

56

80

79

78

48

58

51

50

49

115

B-Y/BIN

CVBS2/Y2

IN L3

IN R1

IN L1

Y/GIN

R-Y/RIN

MON OU T

CVBS1/-/1

INR 2

INL 2

DGC R E LAY

BINT

KEY

EWD

BOUT

GOUT

ROUT

VD-

HOUT

VD+

MAIN

RECTIFIER

D604

KV-21FA350/21FA550

POWER SUPPLY,

A( )

113

112

IC003

NVM

8

2

5

8

61

5

106

61

60

104

99

108

109

97

102

119

21

87

86

85

22

67

23

SWITCH

Q016

7

6

5

IC801

COMP AR AT O R

3 7

SWITCH

Q803

T602

SRT

1

3

5

7

8

18

17

16

15

14

13

12

11

10

AUDIO 1

AUDIO, DE F LE C TIO N,

IC200

AUDIO AMPLIFIE R

MUTE

PW GND

IN R/NC

IN L

OUT L

OUT R /NC

IC002

IR R E CE IV E R

I O

VERTICAL DEFLECTION

BOOSTER

1

DRV -IN

Q806

Q807

T800

1 4

63

18V R E G ULAT OR

1 2

IC606

3.3V R E G

IC607

2V RE G

+B

TUNER, JACK

9

7

12

10

VCC

OUTVCC

IC804

OUTPUT

VSS

VCC

Q808

IC603

IC602

9V RE G

IC605

ERROR

AMP

5

4

2

IC604

5V RE G

ISO LAT OR

PIN AMP

5

3

PHY600

IC802

1

7

1.8V AUDIO

+3. 3V

+5V

+9V

+1. 8V MA IN

+B

IC601

SWITCHING

REGULATOR

2

5

4 3

J200

HEADP HONE S

CN200

SPL

1

SPR

BINT

BDAT

BCLK

KEY

BOUT

GOUT

ROUT

D821

SWITCH

8V

S800

D819

TO SPE AKERS

4

CN904

2

3

4

CN005

3

TO C ONTROL P ANEL

CN004

2

3

TO C BOARD

4

DY800

6

5

4

3

2

CN701

H.DY

H.DY

V.DY

V.DY

DY

1

CN801

200V

1

4

TO C BOARD

CN703

H1

T801

1

4

2

6

5

1

HV

FV

SV

13

11

9

8

7

TO PICT UR E TUBE

TO C BOARD

FV

J751

KV-21FA350/21FA550

29

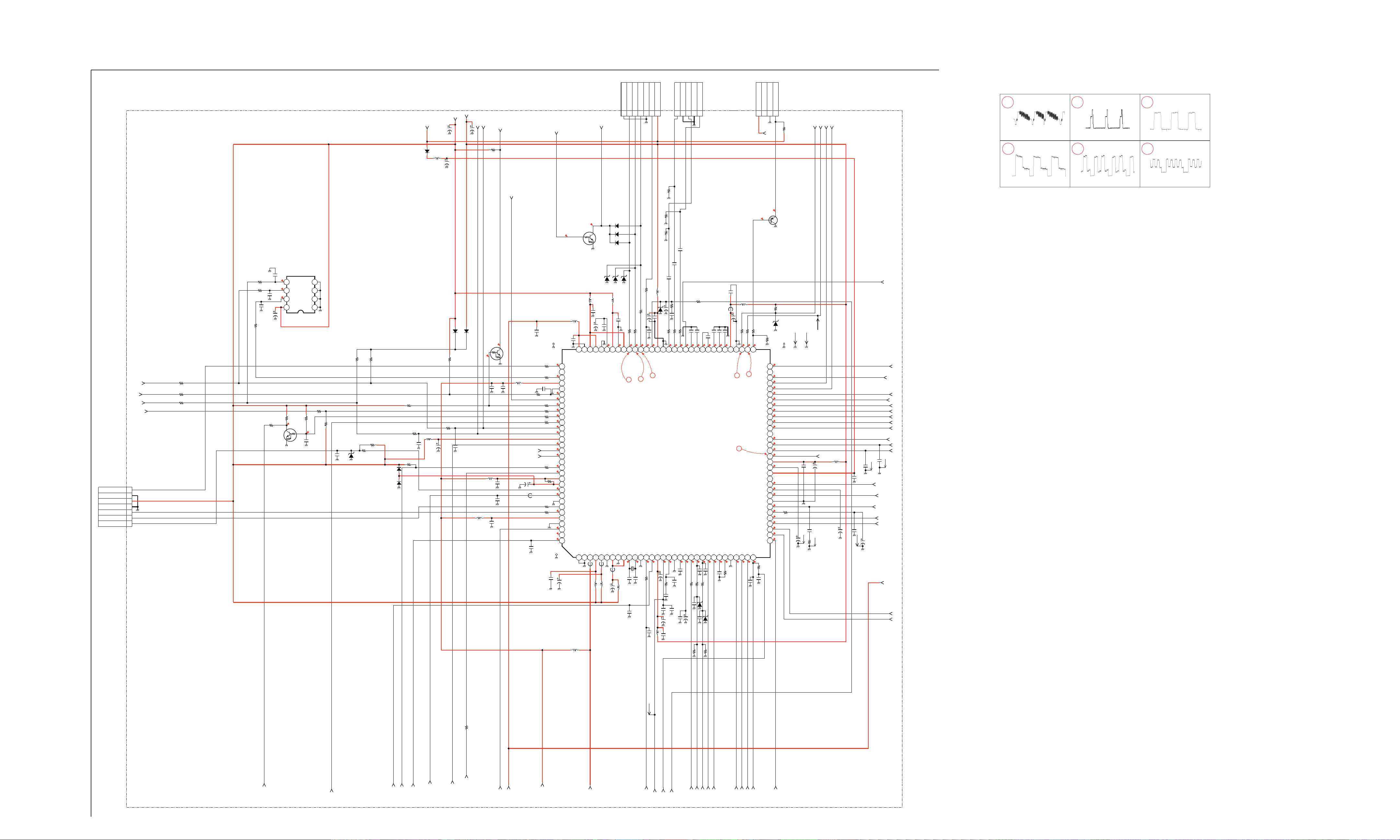

4-4. SCHEMATICS AND SUPPORTING INFORMATION

A BOARD SCHEMATIC DIAGRAM (1 OF 6)

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

A

—

B

—

D066

PG102R

KV-21FA350/21FA550

TO CV BOARD

CN701

TO A BOARD

CN905

TO CV BOARD

CN711

A BOARD WAVEFORMS

GNDIK9V

CN007

5P

YOUT

GND

U OUT / FB

GND

12345

CN003

4P

VOUT

+BNCGND

123

+B

VM OUT

4

LSL-AUDIO

AFC-DEFL

LSR-AUDIO

R377

1.5k

1/10W

RN-CP

HOUT-DEFL

321

2.5 Vp-p (V) 5.4 Vp-p (H) 3.2 Vp-p (H)

4

5 6

CN004

7P

WHT

GND

BOUT

GOUT

ROUT

5V

3.3V

C005

100

16V

SDA-0

9V

C006

470

10V

L003

C004

10uH

100

16V

SCL-0

R394

4.7k

1/10W

RN-CP

MOMUTE-AUDIO

PWR-OFF-MUTE

RGB

1234567

C

—

D

—

E

—

F

—

G

—

H

—

I

—

J

—

K

—

L

—

M

CN006

7P

WHT

TO H2 BOARD

CN4113

SIRCS

GND

GND

LED G

LED R

VCC

KEY

B_CLK

B_INT

B_DAT

AUDIO-STDBY

7

6

5

4

3

2

1

R099

220

1/10W

RN-CP

R096

220

1/10W

RN-CP

R097

1/10W

RN-CP

R388

75

1/10W

D1_JP/MODE2_EU/MONSW-MONO

D025

C028

0.1

16V

47

1608

25V

GNDA

VDDA(1.8)

VDDA3(3.3V)

VREF_POS_LSL

FB006

0uH

L045

10uH

D057

MA111-TX

MA111-TX

MA111-TX

D024

MA8091-M-TX

MA8091-M-TX

L046

10uH

B

0.1

VREFAD

VREFAD_PO

VREF_NEG_LSL+LSR

VREF_POS_LSR+HPL

FB007

0uH

C029

470

10V

D058

D059

D023

R041

100

1/10W

RN-CP

C030

0.22

16V

R039

B

100

1608

1/10W

R038

RN-CP

100

1/10W

RN-CP

0.1

1.6

BOUT

VDDA(3.3V)

VREFAD_NE

6

vREF_NEG_HPL+HPR

VREF_POS_HPR

XTALIN

2.3

C032

10p

50V

CH

1608

C034

10p

&

50V

L047

10uH

CH

1608

C321

0.01

25V

B

1608

1.6

GOUT

5

XTALOUT

2.3

X001

0MHz

R011

470

1/10W

RN-CP

C036

C301

470p

1608

Q001

KRC102S

0.0

C003

100p

50V

CH

1608

R004

100

1/10W

RN-CP

R002

100

1/10W

RN-CP

R393

1/10W

RN-CP

220

3.6

C001

100p

50V

3.6

CH

1608

C318

0.1

16V

B

1608

100

R014

100

1/10W

RN-CP

3.3

8765

C002

470

16V

R342

3.3k

1/10W

RN-CP

CAT24C16WI-GT3

0.0

Q018

RT1N141C-TP-1

MUTE

IC003

NVM

R340

10k

1/10W

RN-CP

2.4

C020

1608

4321

D002

MA111-TX

D003

Q016

KRC102S

MA111-TX

MUTE

0.0

L042

10uH

2.4

C312

1000p

50V

1608

C313

1000p

50V

B

B

1608

L012

C014

10uH

0.22

16V

B

1608

C082

0.22

16V

B

1608

C018

0.01

25V

B

1608

R003

R001

4.7k

4.7k

1/10W

1/10W

RN-CP

RN-CP

R336

4.7k

1/10W

D071

RN-CP

C091

100p

1608

R320

4.7k

1/10W

RN-CP

D072

MA111-TX

R030

100

1/10W

RN-CP

50V

CH

R324

0

CHIP

R338

2.2k

1/10W

RN-CP

R015

R380

100

1/10W

RN-CP

1.5k

1/10W

RN-CP

0.1

16V

B

D068

MA8056-M-TX

C308

0.01

25V

B

1608

MA111-TX

L009

10uH

C311

R010

10k

1/10W

RN-CP

R029

100

1/10W

RN-CP

C090

100p

50V

2.2

50V

1608

CH

L041

10uH

C328

1608

R339

100

1/10W

RN-CP

ROT_CTRL

ROT_SW

C013

100

16V

&

FB021

0uH

2012