Sony KP-57WV600, KP-65WV600, KP-65WV700 Schematic

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL

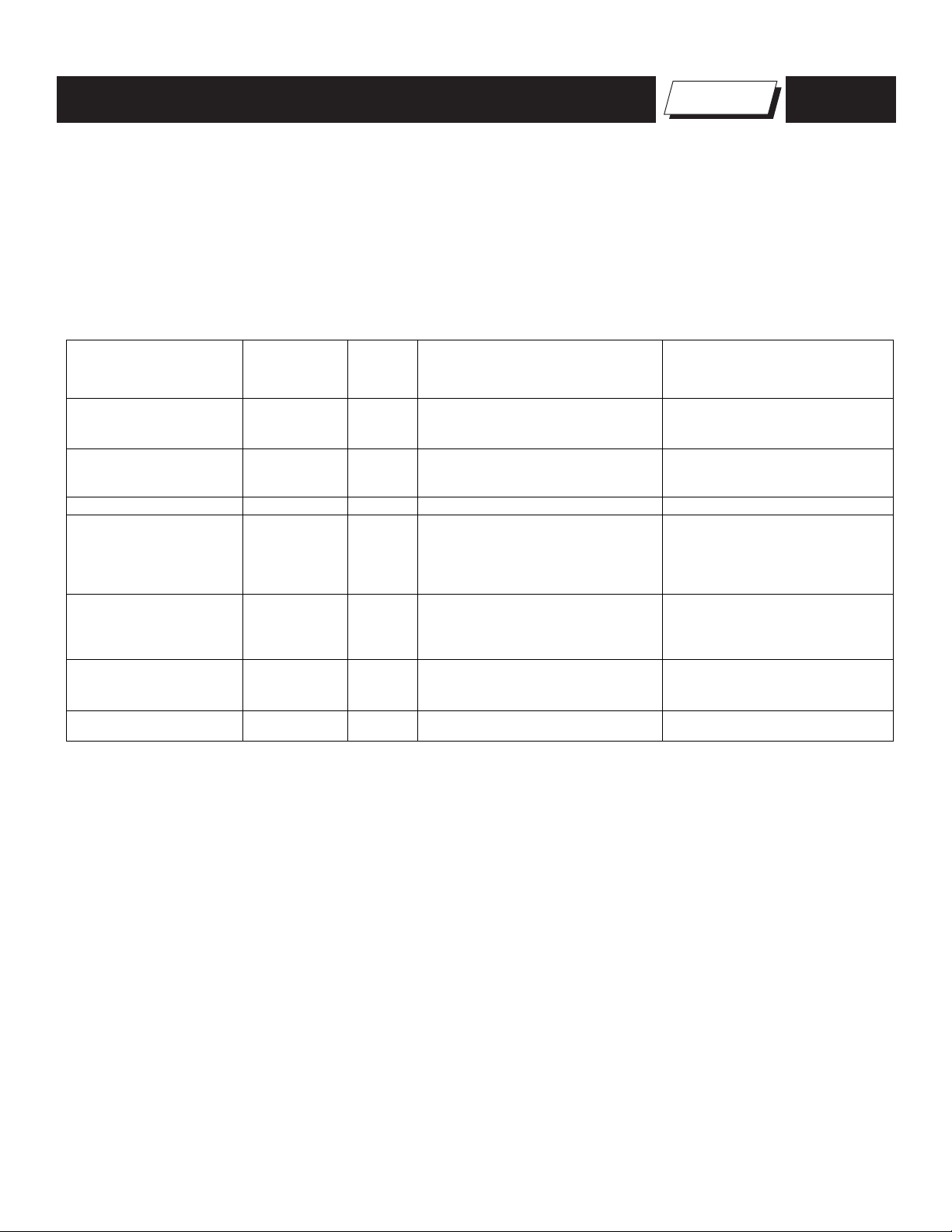

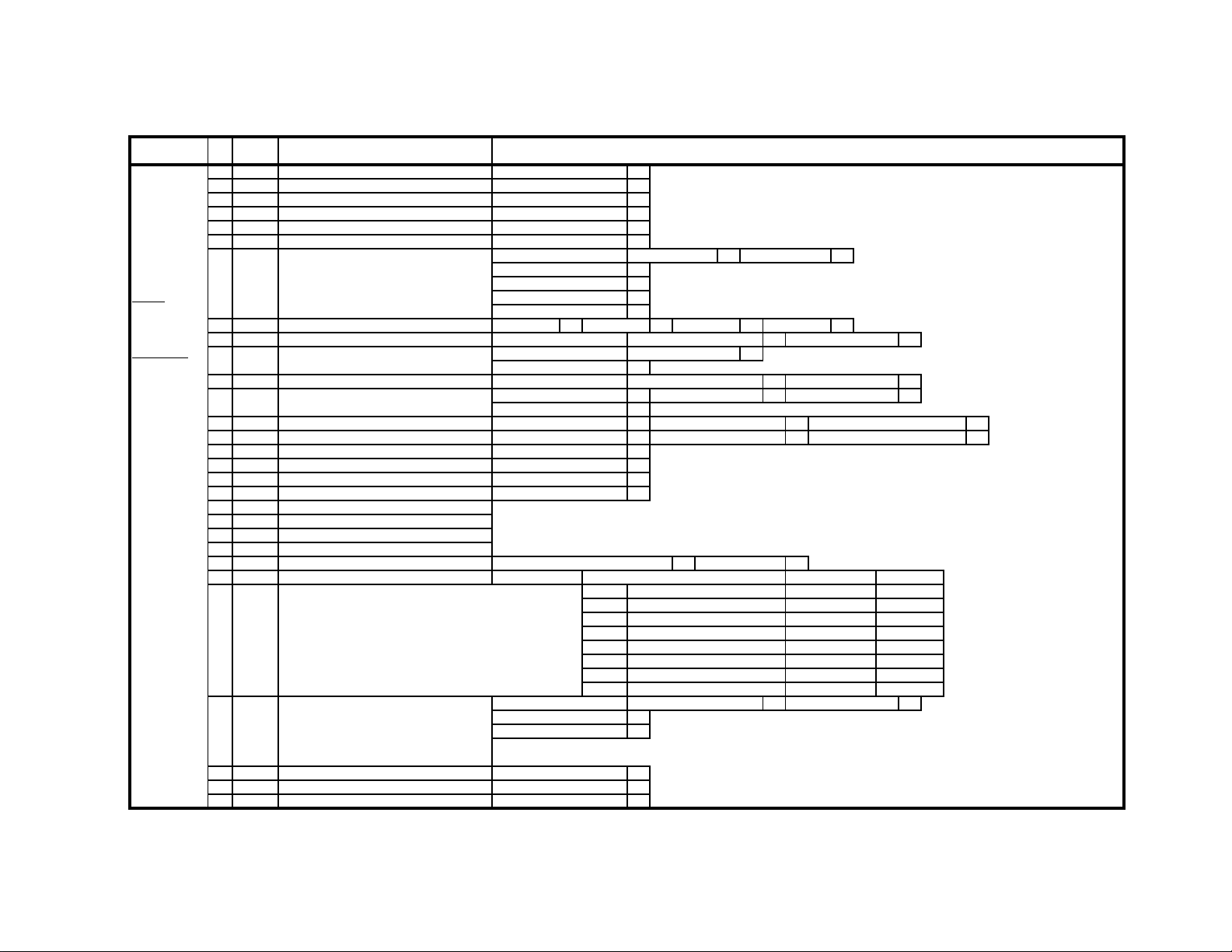

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KP-57WV600

KP-57WV700

KP-65WV600

KP-65WV700

RM-Y188 US/CND SCC-P92D-A

RM-Y188 US/CND SCC-P92B-A

RM-Y188 US/CND SCC-P92C-A

RM-Y188 US/CND SCC-P92A-A

DA-4X

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 6/2002

ALL REVISIONS AND UPDATES TO THE ORIGINAL MANUAL ARE APPENDED TO THE END OF THE PDF FILE.

REVISION DATE REVISION TYPE SUBJECT

6/2002 No revisions or updates are applicable at this time.

7/2002 Re-release Manual Revised Service Data List (pgs. 21, 22, 25, 43, 44, 45)

Revised Circuit Boards Location (pg. 60) to include U Board and UD Board

Removed Shade(B) (pg. 110)

8/2002 Correction-1 Revised Exploded View Cover diagrams to refl ect

accurate position of Contrast Screen Assembly. (pgs.107 & 108)

10/2002 Correction-2 Corrected P/N for Rear Boards on Exploded View Cover parts list, and

added P/N for Mirror Cover. (pg.107)

11/2002 Supplement-1 Replaced MS1 Board with BM1C Board, Updated AD Board and D Board,

Updated Exploded View P/Ns, Updated Parts List

1/2003 Correction-3 Convergence Adjustment Procedure (pgs. 48 & 52)

1/2003 Correction-4 Corrected P/N for Caster on Exploded View Chassis parts list. (pg.109)

9/2003 Correction-5 Corrected A PWB Component and Conductor side (pg. 75 & 76)

COLOR REAR VIDEO PROJECTOR

9-965-926-08

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KP-57WV600

KP-57WV700

KP-65WV600

KP-65WV700

RM-Y188 US/CND SCC-P92D-A

RM-Y188 US/CND SCC-P92B-A

RM-Y188 US/CND SCC-P92C-A

RM-Y188 US/CND SCC-P92A-A

DA-4X

CHASSIS

9-965-926-08

KP-57WV600

RM-Y188

COLOR REAR VIDEO PROJECTOR

KP-57WV600/57WV700/

65WV600/65WV700

TABLE OF CONTENTS

SECTION TITLE PAGE SECTION TITLE PAGE

SpeciÞ cations .................................................................... 4

Warnings and Cautions ..................................................... 5

Safety Check-Out .............................................................. 6

Self-Diagnostic Function.................................................... 7

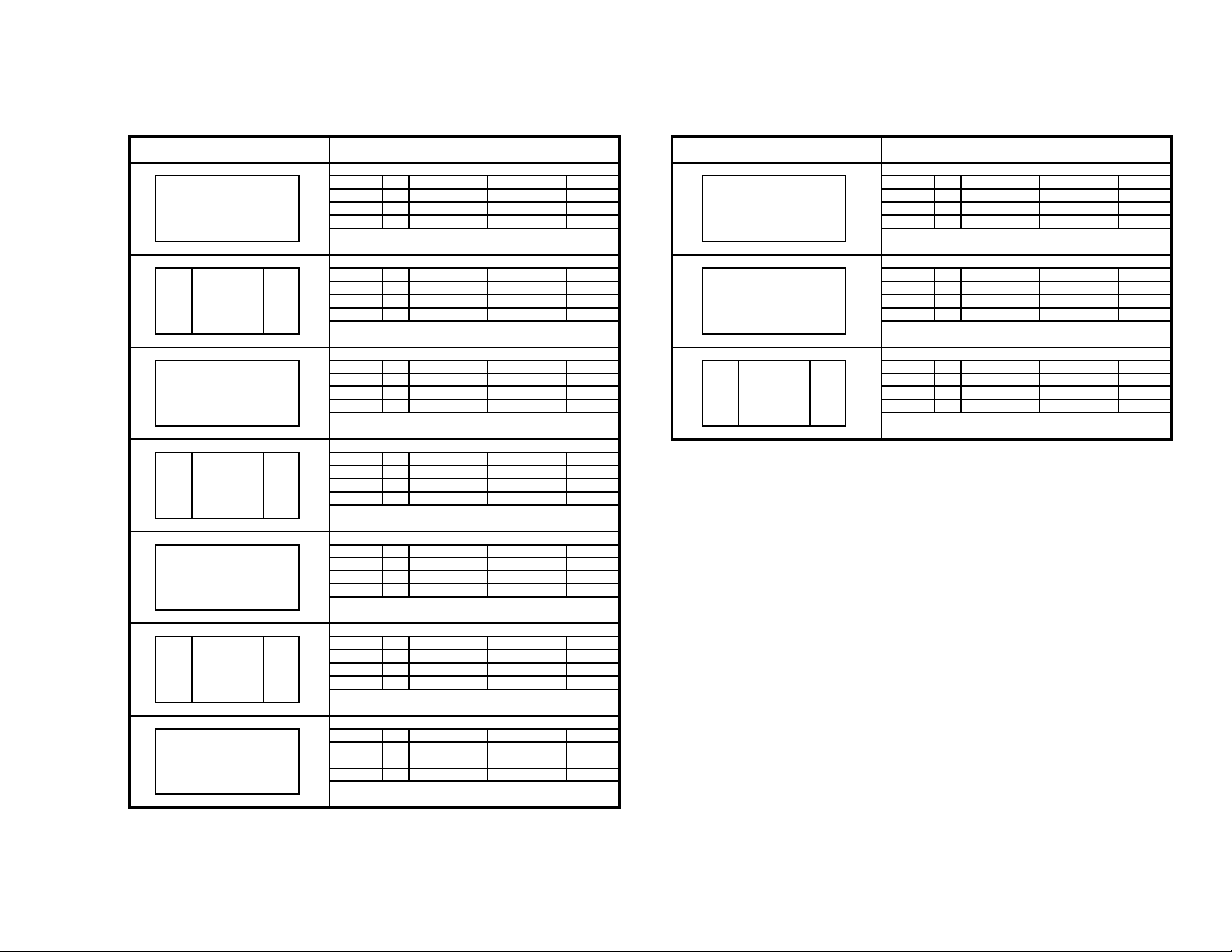

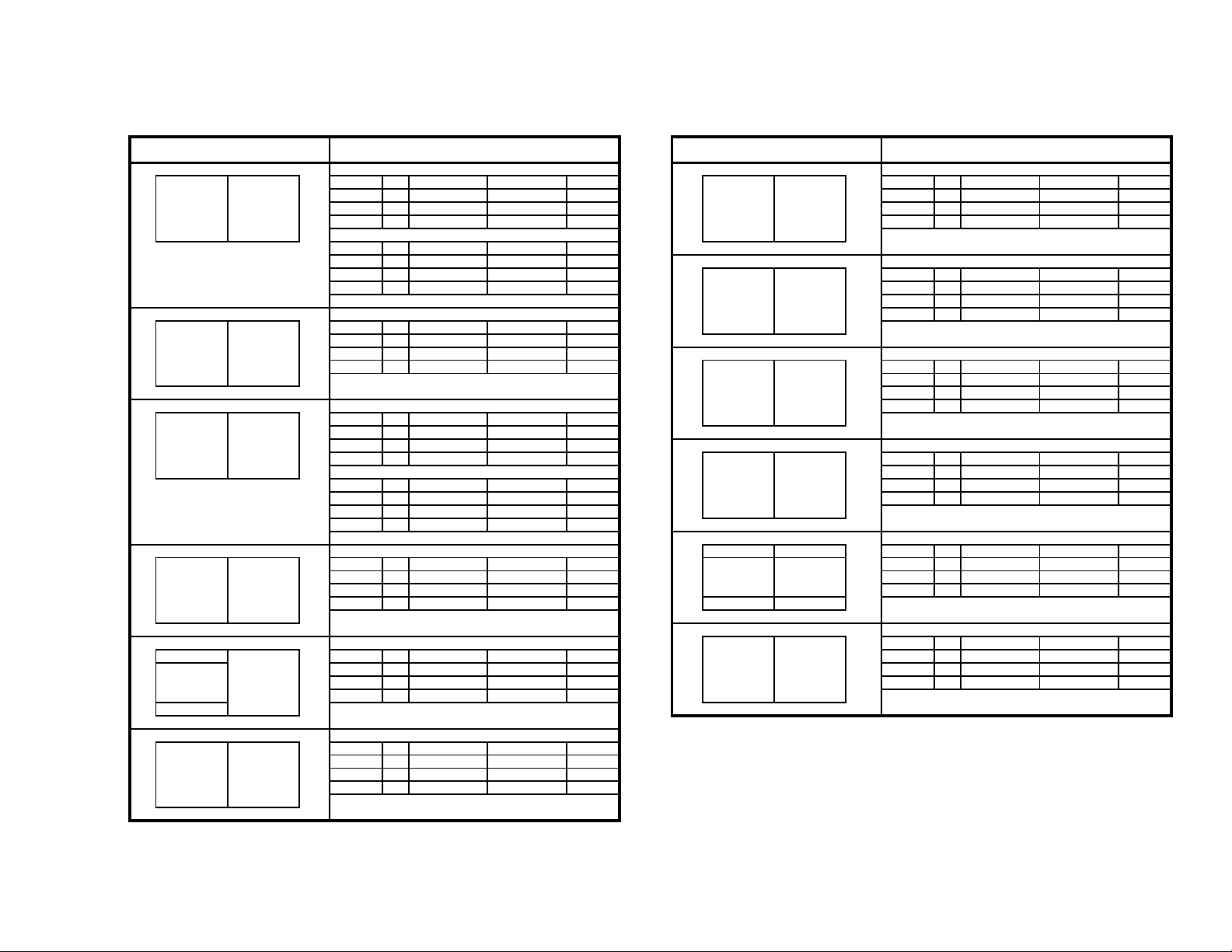

1. Disassembly

1-1. Rear Board Removal....................................................... 10

1-2. Chassis Assembly Removal ............................................ 10

1-3. Service Position............................................................... 10

1-4. Terminal Board and UD Board Removal ......................... 11

1-5. AD Board, B Board, M Board, MS1 Board,

and U Board Removal ..................................................... 11

1-6. D Board, A Board, and G Board Remvoal ....................... 12

1-7. High-Voltage Cable Installation and Removal ................. 12

1-8. Picture Tube Removal ..................................................... 13

1-9. Grille, HA Board, HM Board, and HB Board Removal..... 13

1-10. Beznet Assembly Removal.............................................. 14

1-11. SR Board Removal.......................................................... 14

1-12. Mirror Cover Removal (KP-57WV600/57WV700 Only) ... 15

2. Set-up Adjustments

2-1. Screen Voltage Adjustment (G2) (Coarse Adjustment) ... 16

2-2. Screen (G2) Adjustment (Fine Adjustments) ................... 16

2-3. Deß ection Yoke Tilt Adjustment ....................................... 16

2-4. Focus Lens Adjustment ................................................... 17

2-5. Focus VR Adjustment...................................................... 17

2-6. 2-Pole Magnet Adjustment .............................................. 18

2-7. Centering Magnet Adjustment ........................................ 18

2-8. 4-Pole Magnet Adjustment .............................................. 18

2-9. Defocus Adjustment (Blue) .............................................. 18

2-10. Electrical Adjustments By Remote Commander.............. 19

2-11. Service Data Lists............................................................ 20

2-12. Registration Adjustment (PJE mode only)....................... 48

2-13. PJE Adjustment (Sub Deß ection Adjustment).................. 50

2-14. Auto Registration Offsets................................................. 53

2-15. Auto Registration Error Codes......................................... 54

2-16. Auto Registration Diagnostics ......................................... 55

3. Safety Related Adjustments

D Board

3-1. HV Regulation Circuit Check and Adjustment ................. 56

3-2. HV Hold Down Circuit Operation

Check and Adjustment..................................................... 56

G Board

3-3. +B Max Voltage ConÞ rmation.......................................... 57

3-4. +B OVP ConÞ rmation ...................................................... 57

4. Circuit Adjustments

4-1. P&P Sub Contrast Adjustment (Video) (SCON) .............. 58

4-2. P&P Sub Contrast Adjustment (RF) (SCON)................... 58

4-3. P&P Sub-Hue and Sub-Color Adjustment Video

(SHUE, SCOL) ................................................................ 58

4-4. P&P Sub-Hue and Sub-Color Adjustment (RF)

(SHUE, SCOL) ................................................................ 58

4-5. Blue Offset Adjustment.................................................... 59

5. Diagrams

5-1. Circuit Boards Location ................................................... 60

5-2. Printed Wiring Boards and

Schematic Diagrams Information .................................... 60

5-3. Block Diagrams ............................................................... 62

5-4. Schematics and Supporting Information.......................... 65

VM Board .................................................................... 65

CR Board .................................................................... 67

CG Board .................................................................... 68

CB Board..................................................................... 69

U Board ....................................................................... 70

UD Board .................................................................... 72

A Board ....................................................................... 74

B Board ....................................................................... 77

MS1 Board .................................................................. 85

G Board....................................................................... 89

AD Board..................................................................... 91

D Board ....................................................................... 94

M Board....................................................................... 97

HB Board................................................................... 102

HM Board .................................................................. 103

SR Board................................................................... 104

HA Board................................................................... 105

5-5. Semiconductors............................................................. 106

6. Exploded Views

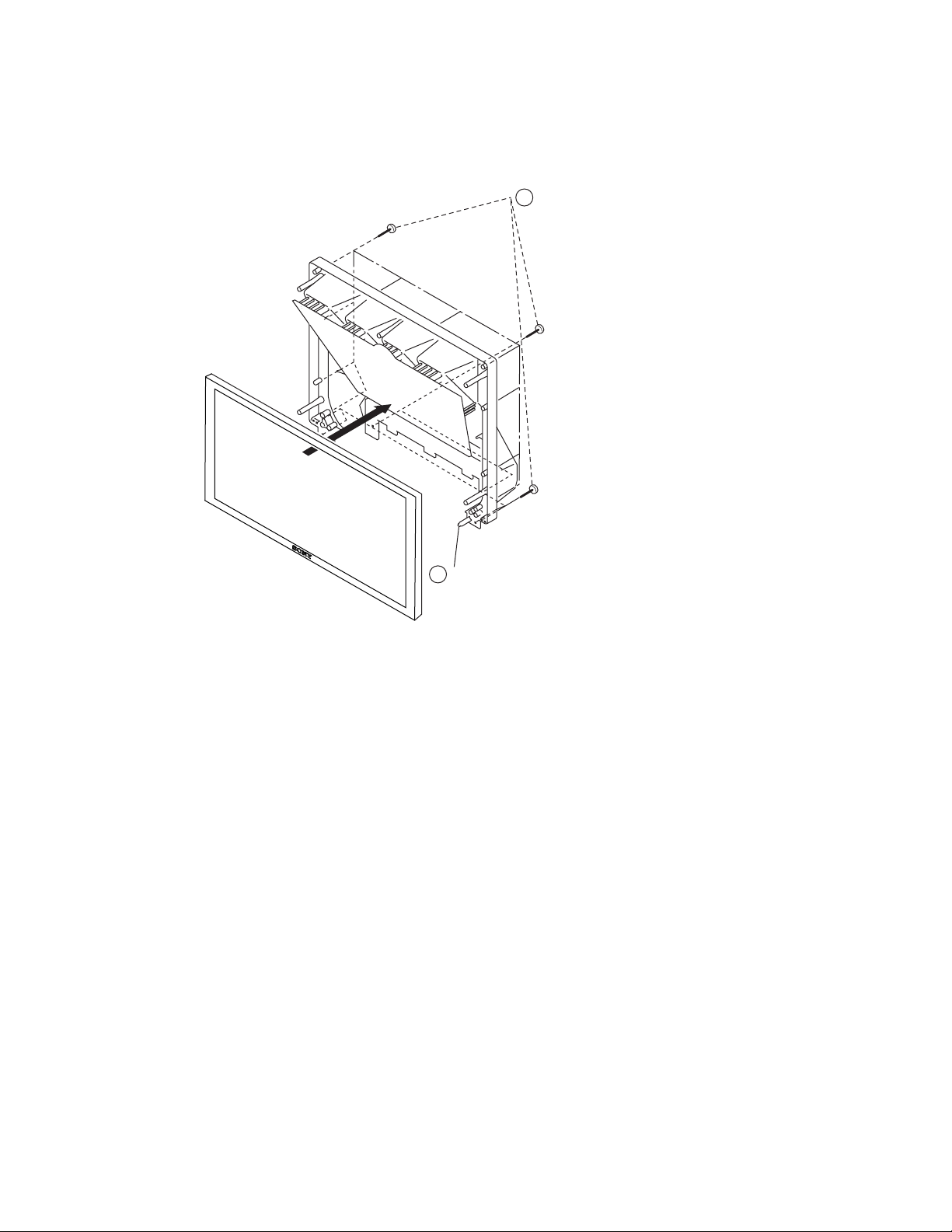

6-1. Cover (KP-57WV600/57WV700 Only) .......................... 107

6-2. Cover (KP-65WV600/65WV700 Only)........................... 108

6-3. Chassis.......................................................................... 109

6-4. Picture Tube ................................................................. 110

7. Electrical Parts List ...................................................................111

— 3 —

SPECIFICATIONS

KP-57WV600/57WV700/

65WV600/65WV700

Power Requirements

120V AC, 60Hz

Power Consumption (W)

In Use (Max)

In Standby

Inputs/Outputs

295W

1 W

DVI-HDTV

1 terminal, 3.3V T.M.D.S., 50 ohms

The DVI-HDTV input terminal is compliant with the EIA-861

standard and is not intended for use with personal computers.

Video (IN)

4 total (1 on front panel)

1Vp-p, 75ohms unbalanced, sync negative

S Video (IN)

3 total (1 on front panel)

Y: 1Vp-p, 75ohms unbalanced, sync negative

C: 0.286Vp-p (Burst signal), 75ohms

Speaker Output (W)

Audio (IN)

7 total (1 on front panel)

500 mVrms (100% modulation)

Impedance:47 kilohm

Component Video Input

2 total

Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative;

PB: 0.7 Vp-p, 75 ohms;

PR: 0.7 Vp-p, 75 ohms

Control S (IN/OUT)

Variable/Fixed Audio (OUT)

More than 408 m Vrms at the maximum volume setting (Variable)

More than 408 m Vrms (Fixed) Impedance (output):2 kilohms

KP-57WV600

KP-57WV700 KP-65WV600 KP-65WV700

20W x 2

Dimensions (W x H x D)

mm

in

1361 x 1394 x 689 mm 1542 x 1516 x 735 mm

5/8

15/16

53

x 54

1/8

x 27

in 60

Mass kg

98 kg 136 kg 134 kg

216 lbs 300 lbs 295 lbs

lbs

Projection System

3 picture tubes, 3 lenses, horizontal in-line system

Picture Tube

7-inch high-brightness monochrome tubes (6.3 raster size), with

optical coupling and liquid cooling system.

Projection Lenses

High performance, large diameter hybrid lens F1.1

Antenna

75 ohm external terminal for VHF/UHF

Television System

NTSC, American TV Standard

Channel Coverage

VHF: 2-13/ VHF: 14-69/ CATV: 1-125

3/4

3/4

x 28

15/16

in

x 59

Screen Size (measured diagonally)

57 inches (KP-57WV600/57WV700)

65 inches (KP-65WV600/65WV700)

Supplied Accessories

Remote Control RM-Y188

Batteries (2) size AA (R6)

Optional Accessories

A/V Cable (VMC-810/820/830 HG)

Audio Cable (RKC-515HG)

Component Video Cable (VMC-10/30 HG)

Control S Cable (RK-G69HG)

Memory Stick media:

8 MB (MSA-8A)

16 MB (MSA-16A)

32 MB (MSA-32A)

64 MB (MSA-64A)

128 MB (MSA-128A)

Design and speciÞ cations are subject to change without notice.

— 4 —

KP-57WV600/57WV700/

65WV600/65WV700

WARNINGS AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield, or carbon painted on the CRT,

after removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the ac power line.

! SAFETY-RELATED COMPONENT WARNING!!

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for

safe operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

ATTENTION!!

Apres avoir deconnecte le cap de l’anode, court-circuiter l’anode du tube cathodique et celui de l’anode du cap au chassis metallique

de l’appareil, ou la couche de carbone peinte sur le tube cathodique ou au blindage du tube cathodique.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout

dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de

pieces sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont

le numero de piece est indique dans le present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont

l’importance est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de

chaque remplacement de composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

— 5 —

SAFETY CHECK-OUT

e

KP-57WV600/57WV700/

65WV600/65WV700

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if sets

always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage

as described below.

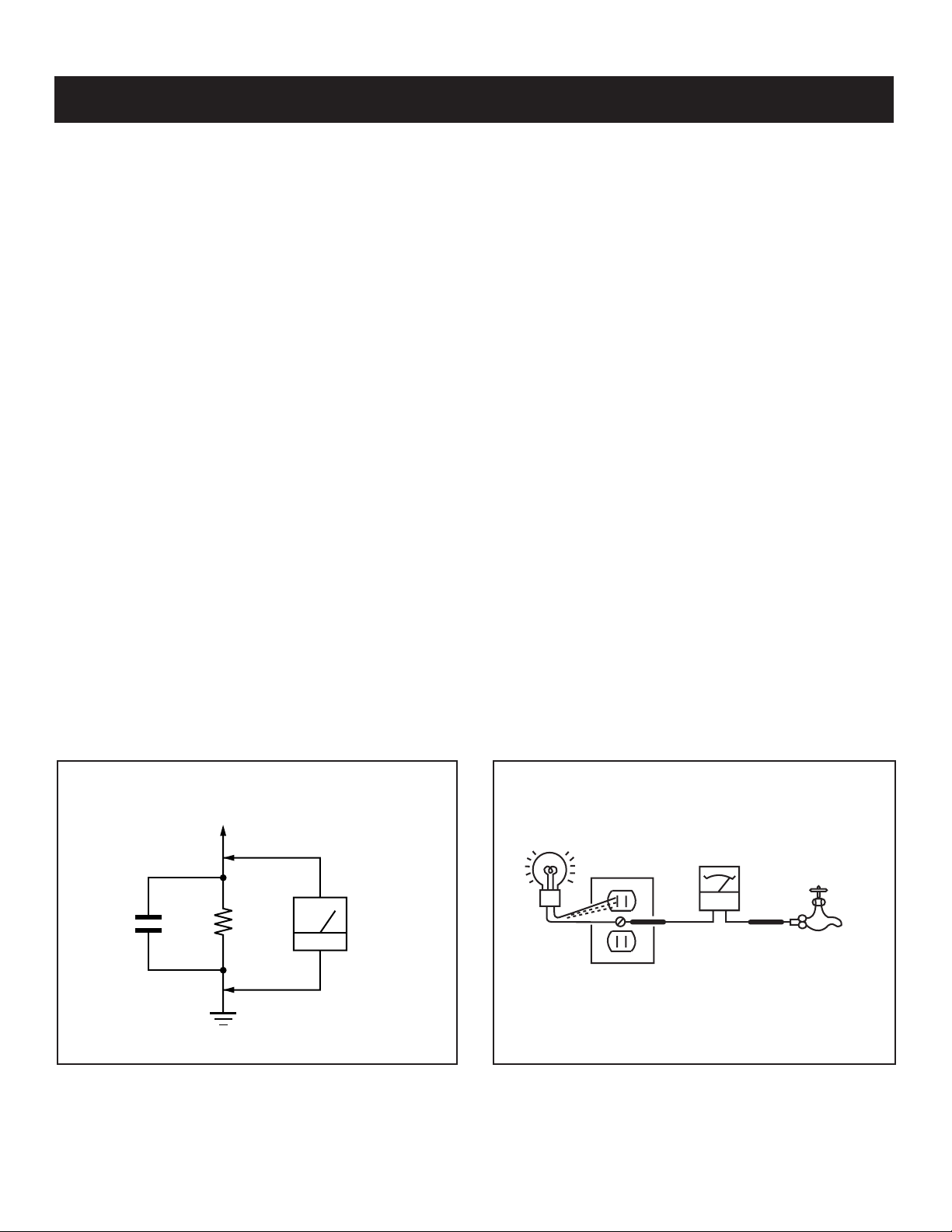

Leakage Test

The AC leakage from any exposed metal part to earth ground and from

all exposed metal parts to any exposed metal part having a return to

chassis, must not exceed 0.5 mA (500 microamperes). Leakage current

can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliammeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75 V,

so analog meters must have an accurate low voltage scale. The

Simpson’s 250 and Sanwa SH-63TRD are examples of passive

VOMs that are suitable. Nearly all battery-operated digital multimeters

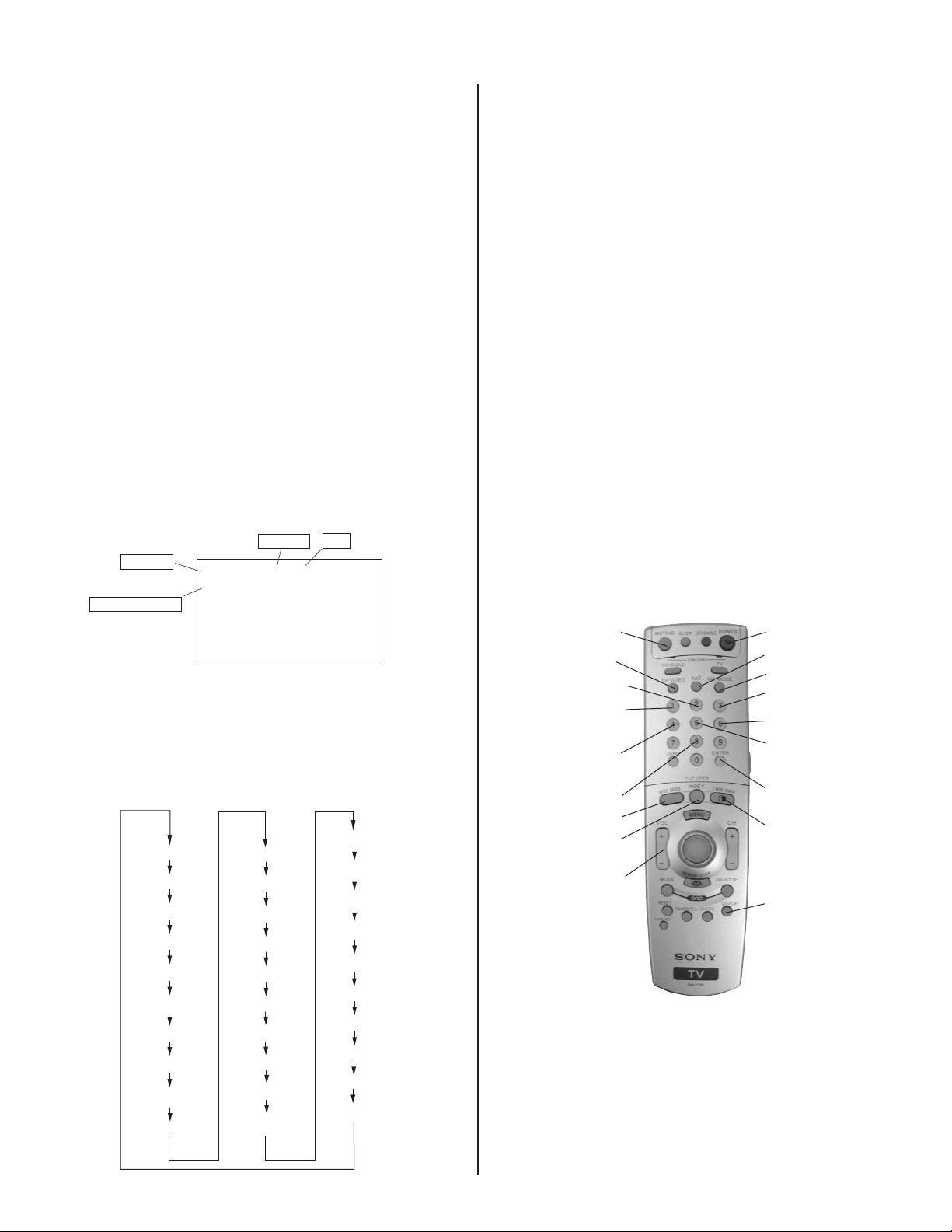

that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining

screw on most AC outlet boxes is also at earth ground. If the retaining

screw is to be used as your earth ground, verify that it is at ground

by measuring the resistance between it and a cold-water pipe with an

ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt troublelight (not a neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot side on the

line; the lamp should light at normal brilliance if the screw is at ground

potential (see Figure B).

To Exposed Metal

Parts on Set

Trouble Light

Ohmmeter

.15 µF

kΩ

1.5

Earth Ground

AC Outlet Box

AC Voltmeter

(0.75 V)

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

— 6 —

Cold-water Pip

KP-57WV600/57WV700/

65WV600/65WV700

SELF-DIAGNOSTIC FUNCTION

Self Diagnosis

Supported model

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/TIMER LED will automatically begin to ß ash. The number

of times the LED ß ashes translates to a probable source of the problem. A deÞ nition of the STANDBY/TIMER LED ß ash indicators is listed in the

instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review

the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

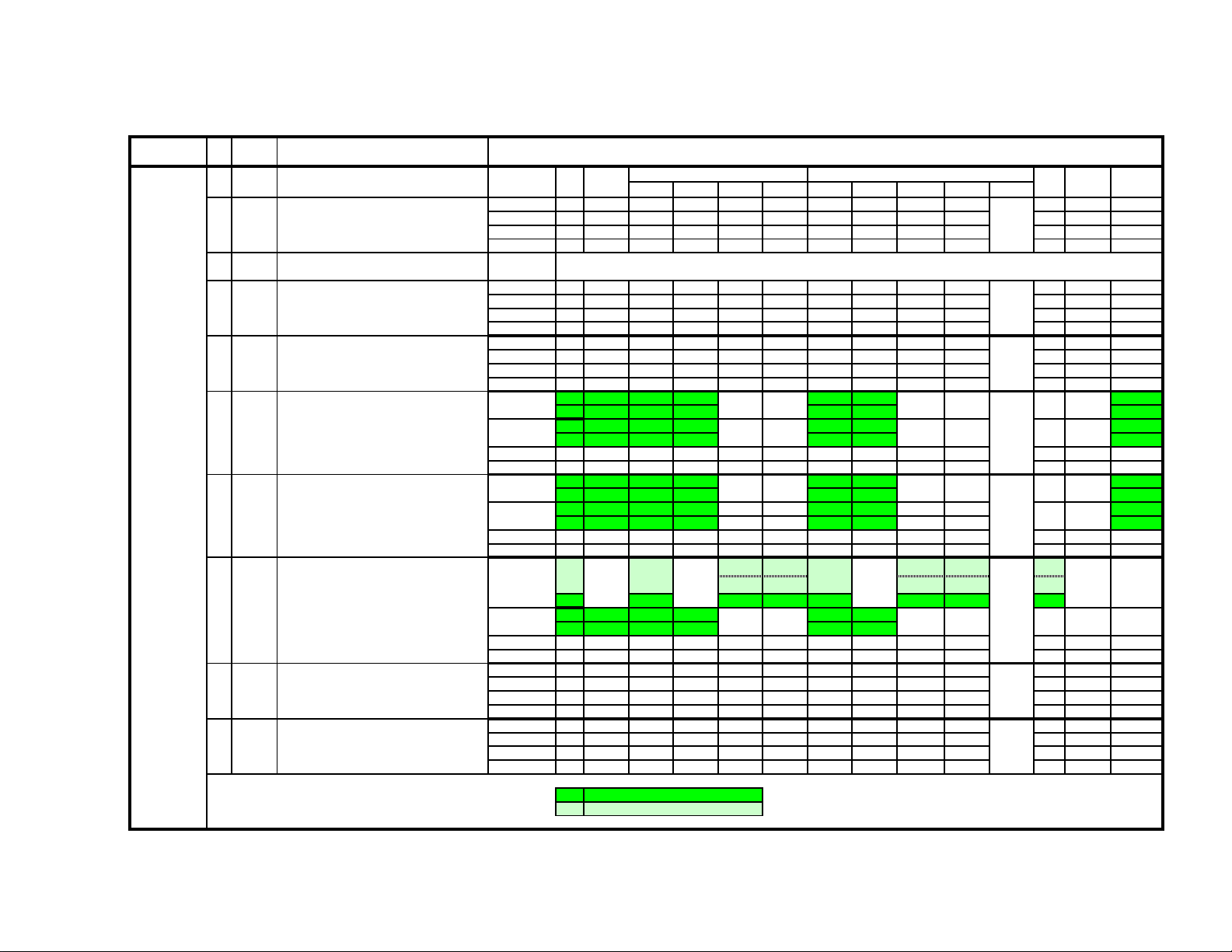

Diagnostic Test Indicators

When an error occurs, the STANDBY/TIMER LED will ß ash a set number of times to indicate the possible cause of the problem. If there is more than

one error, the LED will identify the Þ rst of the problem areas.

Results for all of the following diagnostic items are displayed on screen. If the screen displays a “0”, no error has occurred.

No. of times

Diagnostic Item

Power does not turn on Does not light _______

+B Overcurrent (OCP)* 2 times 2:0 or 2:1

Low +B Overvoltage (OVP) 3 times 3:0 or 3:1

Vertical Deflection Stopped 4 times 4:0 or 4:1

White Balance Failure

(not balanced)

LOW +B OCP/OVP

(overcurrent/overvoltage)***

Horizontal Deflection

Stopped

STANDBY /

TIMER lamp

flashes

5 times 5:0 or 5:1

6 times 6:0 or 6:1

7 times 7:0 or 7:1

Display

Result

Probable Cause Location Detected Symptoms

• Power cord is not plugged in.

• Fuse is burned out (F501). (A Board)

• H.OUT (Q8024) is shorted. (D Board)

• +B PWM (Q8035) is shorted.

(D Board)

• IC6504 is faulty. (D Board) • Has entered standby mode.

• 15V is not supplied. (D Board)

• IC8003 is faulty. (D Board)

• Video OUT (IC9101, IC9201, IC9301)

is faulty. (CR, CG, CB Board)

• CRT drive (IC2801) is faulty. (B Board)

• G2 is improperly adjusted.**

• +5 line is overloaded. (A, B, M Boards)

• +5 line is shorted. (A, B, M Boards)

• IC504 is faulty. (A Board)

• Power does not come on.

• No power is supplied to the TV.

• AC Power supply is faulty.

• Power does not come on.

• Load on power line shorted.

• Has entered standby mode after

Horizontal raster.

• Vertical deflection pulse is stopped.

• Power line is shorted or power

supply is stopped.

• No raster is generated.

• CRT cathode current detection

reference pulse output is small.

• No picture

• No picture

* If a +B overcurrent is detected, stoppage of the vertical deflection is detected simultaneously. The symptom that is diagnosed first by the

microcontroller is displayed on the screen.

** Refer to Screen (G2) Adjustment (Fine Adjustments) in Section 2 of this manual.

*** If STANDBY/STEREO LED flashes six (6) times, unplug the unit and wait 10 seconds before performing the adjustment.

— 7 —

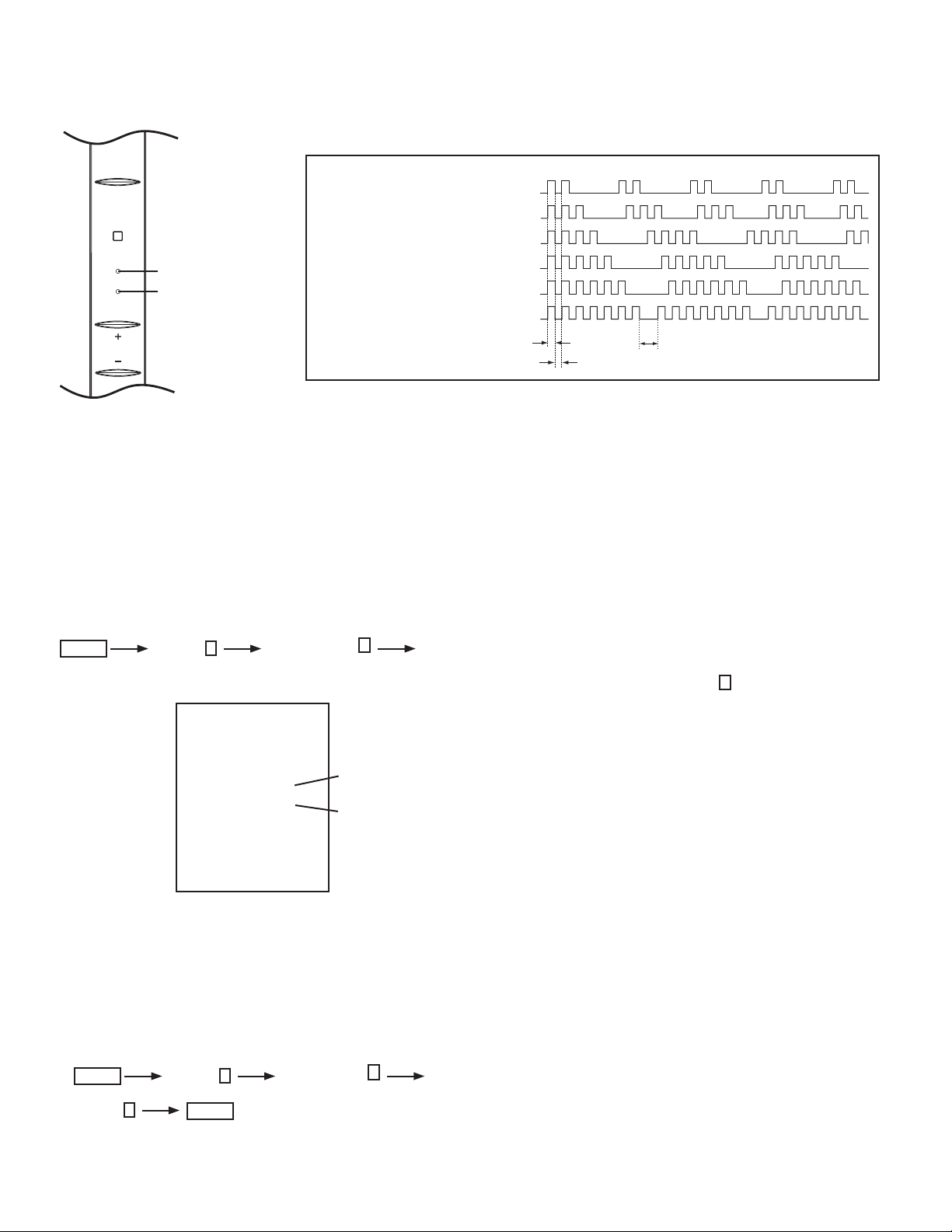

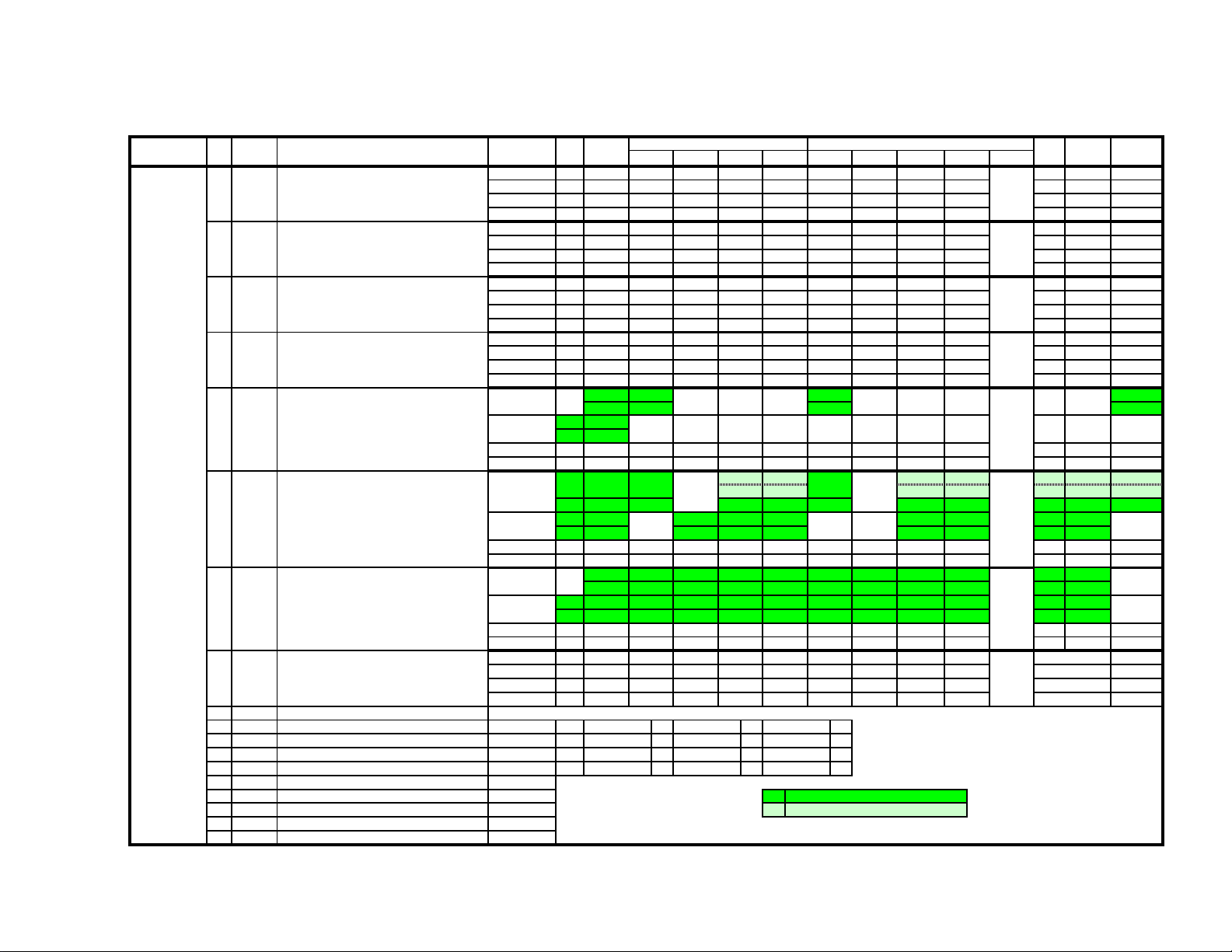

Display of Standby/Timer LED Flash Count

KP-57WV600/57WV700/

65WV600/65WV700

POWER

STAND BY

TIMER

CHANNEL

STAND BY Indicator

TIMER Indicator

Diagnostic items Flash count

+B Overcurrent 2 times

Low +B Overvoltage 3 times

Vert. Deflection Stopped 4 times

White Balance Failure 5 times

Low +B OCP/OVP 6 times

Horiz. Deflection Stopped 7 times

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

Lamp OFF 3 sec.

Release of TIMER STAND BY indicator blinking

The TIMER/STANDBY indicator blinking display is released by turning OFF the power switch on the TV main unit or removing the plug from the

power.

Self-Diagnosis Screen Displays

In cases of malfunctions where it is not possible to determine the symptom such as when the power goes off occasionally or when the screen

disappears occasionally, there is a screen display on whether the malfunction occurred or not in the past (and whether the detection circuit operated

or not) in order to allow conÞ rmation.

Screen Display Method

Quickly press the remote command button in the following order from the standby state.

Display

Channel

Sound Volume*

5

_

Power ON

*Note that this differs from entering the service mode (sound volume

)

+

SELF DIAGNOSIS

2: +B OCP 0

3: +B OVP 0

4: VSTOP 0

5: AKB 1

6: LOWB 0

7: H-STOP 0

Numeral “0”

means that no fault was detected.

Numeral “1”

means a fault was detected one

time only.

101: WDT 24

Self-Diagnosis Screen Display

The results display is not automatically cleared. In case of repairs and after repairs, check the self-diagnosis screen and be sure to return the

results display to “ 0 ”.

If the results display is not returned to “ 0 ” it will not be possible to judge a new malfunction after completing repairs.

Method of Clearing Results Display

1. Power off (Set to the stanby mode.)

2.

Display

3. Channel

8

Channel

ENTER

Sound Volume

5

(Test reset = Factory preset condition)

+

Power ON (Service Mode)

Method of Ending Self Diagnosis Screen

When ending the self-diagnosis screen completely, turn the power switch OFF on the remote commander or the main unit.

— 8 —

KP-57WV600/57WV700/

65WV600/65WV700

Self-Diagnosis Function Operation

+B overcurrent (OCP)

Occurs when excessive current ß ows through R5013. The increase in voltage across R5013 causes the output of Q5004 to go high, and this high

signal goes to the micro.

+B overvoltage (OVP)

IC6505 detects +B OVP condition and turns on Q6522. This sends a high signal to the micro and also shuts down the AC relay.

V-STOP

Occurs when an absence of the vertical deß ection pulse is detected by pin 24 of IC2801 (B Board). Power supply will shut down when waveform

interval exceeds 2 seconds.

White Balance Failure

If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will be detected by IC2801. TV will stay on, but there

will be no picture.

*(Refers to the RGB levels of the AKB detection Ref pulse that detects 1K).

Low B OCP/OVP

Occurs when set 5V is out.

Horizontal Deß ection Stopped

Occurs when either:

1) a +B overcurrent is detected (IC5007), or

2) overheating is detected (Thermistor TH5002).

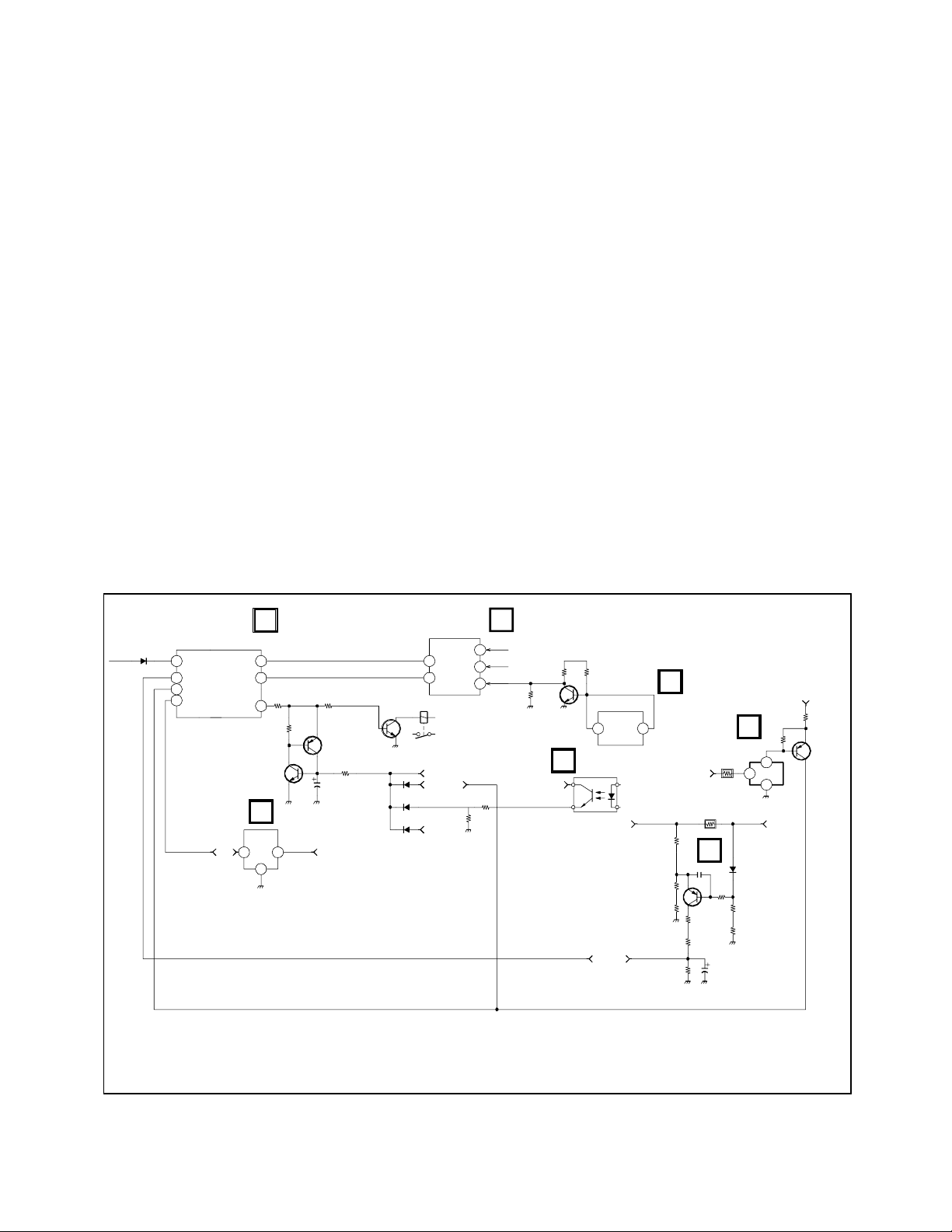

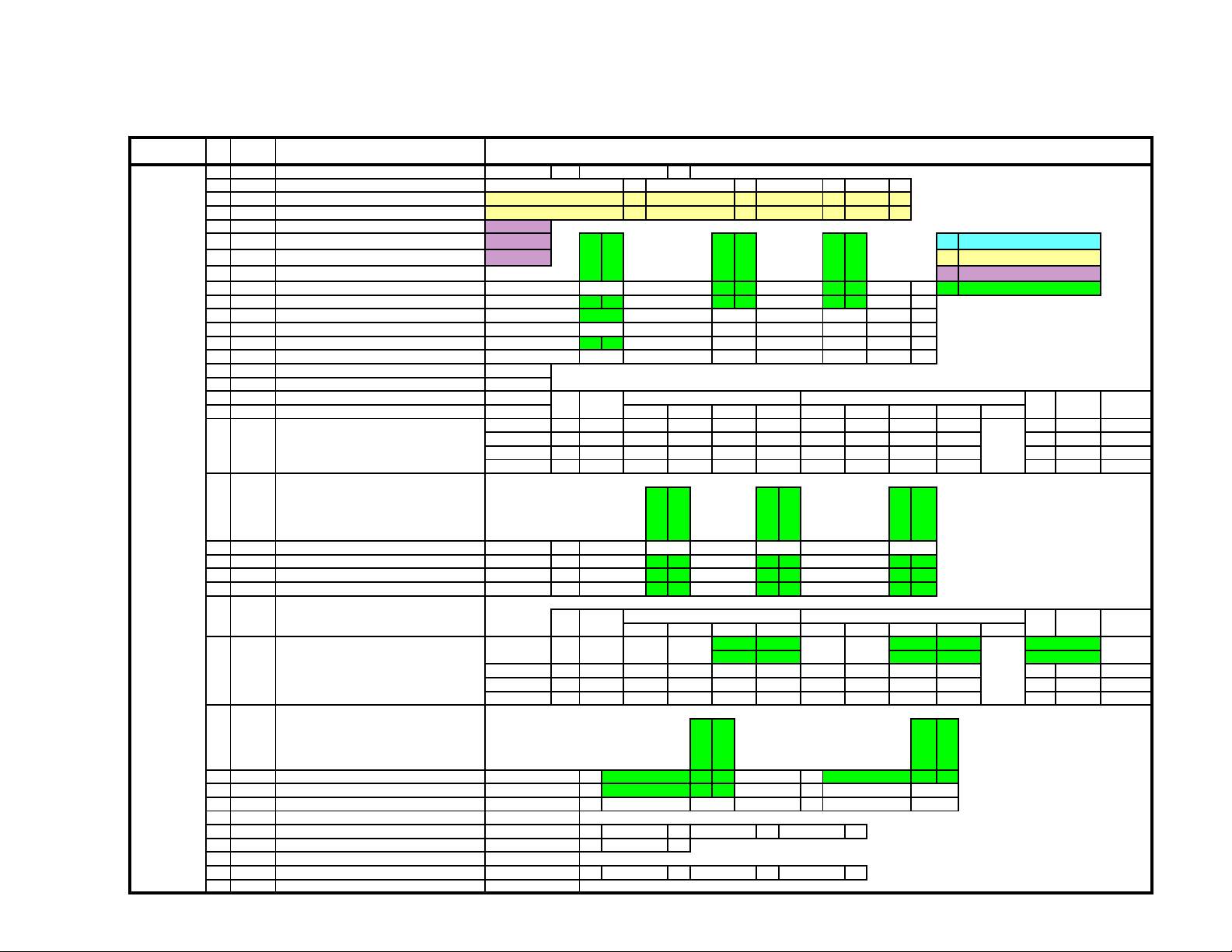

Self-Diagnosis Block Diagram

IC2300

STBY-LED

MAIN MICRO

STR

48

STBY-LED

44

OCP

45

OVP

43

LOW B ERR

AC RLY

5V UNREG 7V

CLKO

DATO

M

29

30

69

Q6527

Q6530

Q6532

A

IC504

IO

O

IC2801

Y/C JUNGLE

SCL

26

25

SDA

RY6501

P_SW(-)

21

34

1K-PROT2

+B OVP

D6537

D6505

HV PROT

D5007

M

AKB

58

CRT

35

VPROT

HPROT

VDY-

34

R5104 R5105

R5125

UNREG 11V

B

Q5018

D

IC5007

2

14

PH6501

1

4

2

3

+B +B

D

IC6505

+B

R5013

1

5V

2

3

Q6522

D

Q5004

+B OCP

D5005

— 9 —

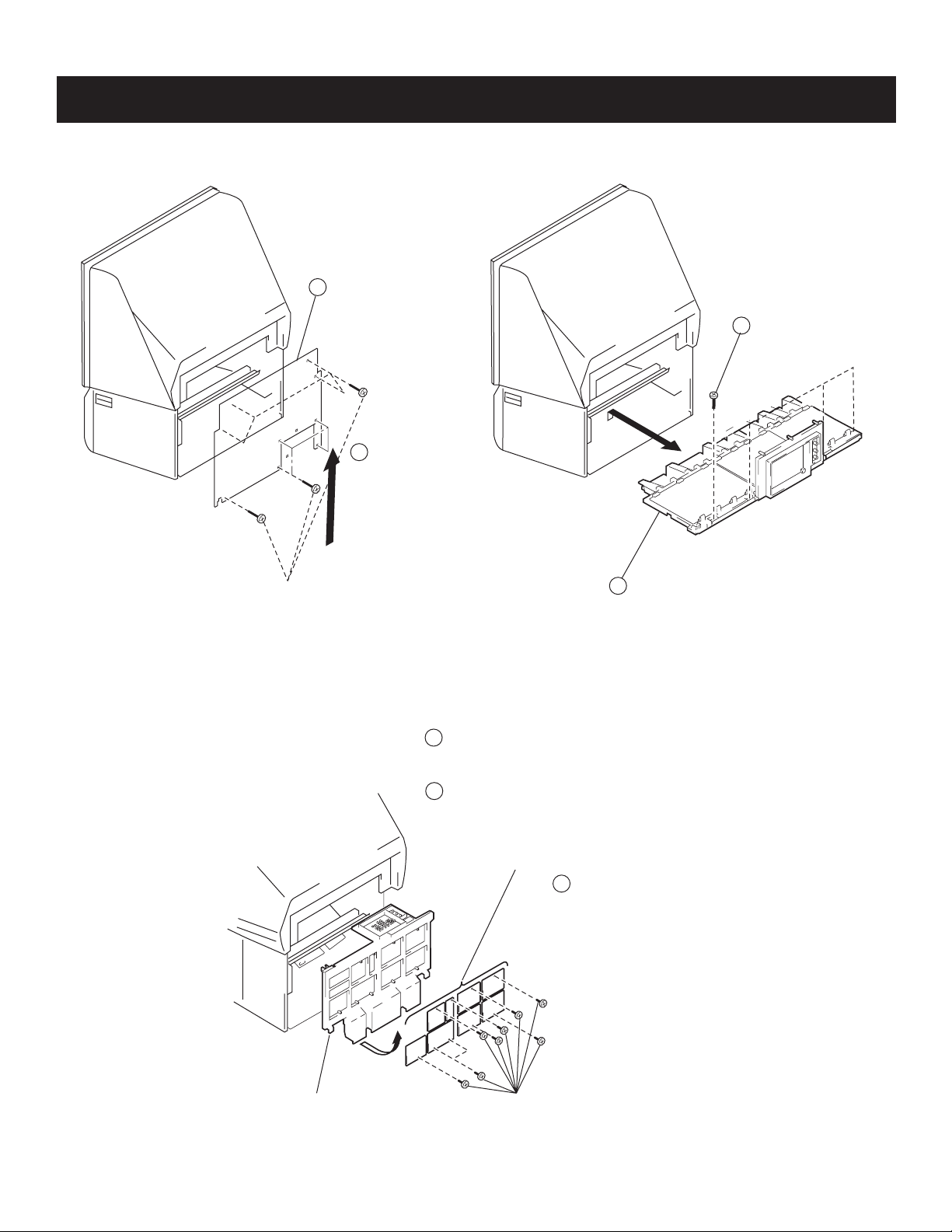

KP-57WV600/57WV700/

SECTION 1: DISASSEMBLY

1-1. REAR BOARD REMOVAL 1-2. CHASSIS ASSEMBLY REMOVAL

Rear board

2

1

Four screws

Dome Washer

(Hex Tap 4 x 20)

Fifteen Screws

1

Dome Washer

(Hex Tap 4 x 20)

65WV600/65WV700

1-3. SERVICE POSITION

2

Chassis assy

Free wiring from purse locks.

1

NOTE: Observe wire dress

and return to original condition.

2

Covers

Remove covers from chassis assembly

with pliers when checking printed circuit boards.

After checking, turn the covers over

and re-secure them with the screws.

When plugging in connector from

3

HM Board to B Board at CN3603

insure two brown wires are facing

upward towards the HV block

assembly.

Chassis assembly

Screws

(+BVTP3x12)

— 10 —

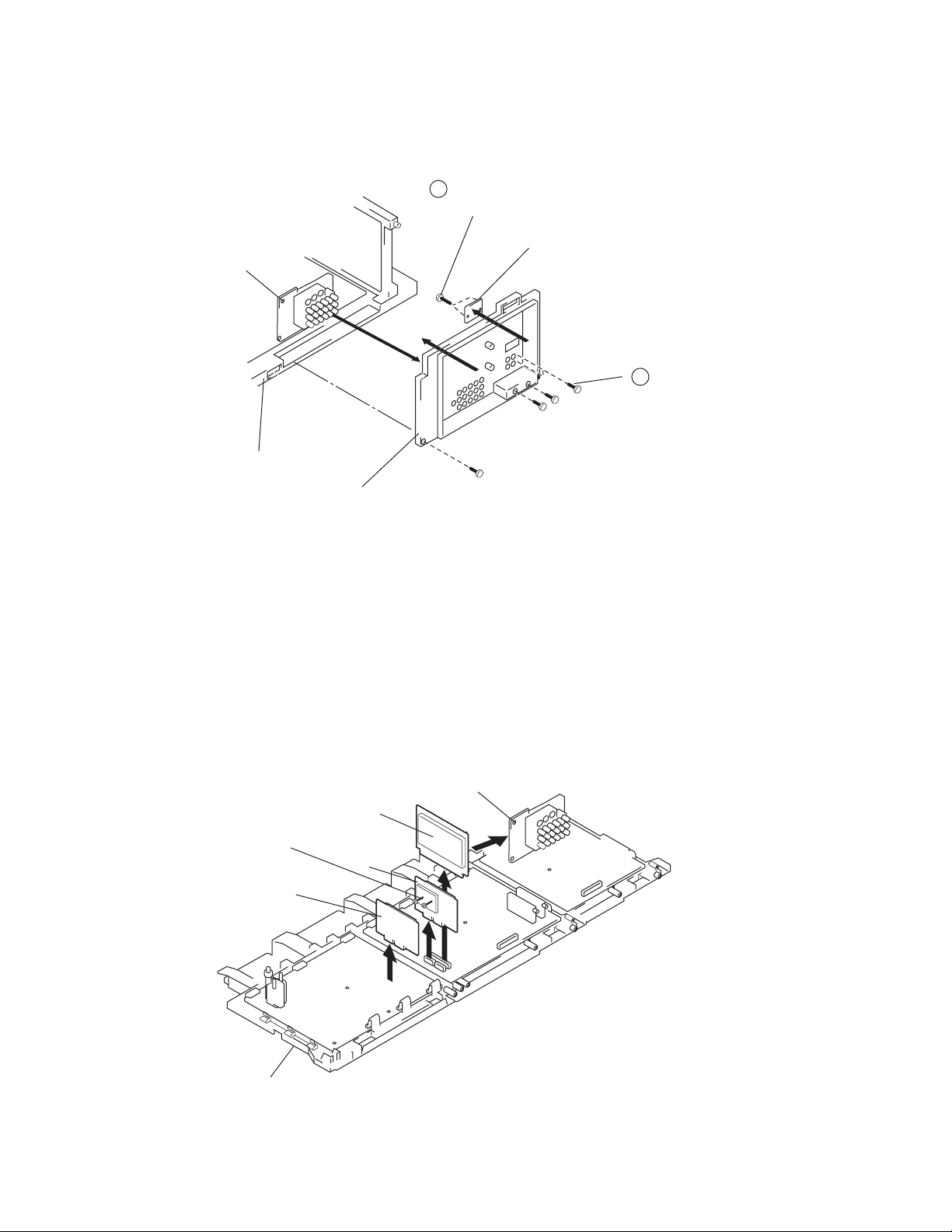

1-4. TERMINAL BOARD AND UD BOARD REMOVAL

2

Two screws

(+BVTP 3x12)

U board

Main bracket

UD board

1

Four screws

(+BVTP 3x12)

KP-57WV600/57WV700/

65WV600/65WV700

Terminal board

1-5. AD BOARD, B BOARD, M BOARD, MS1 BOARD, AND U BOARD REMOVAL

U board

MS1 Board

Two screws

((M3) Tapping)

AD board

M board

B board

Main bracket

— 11 —

e

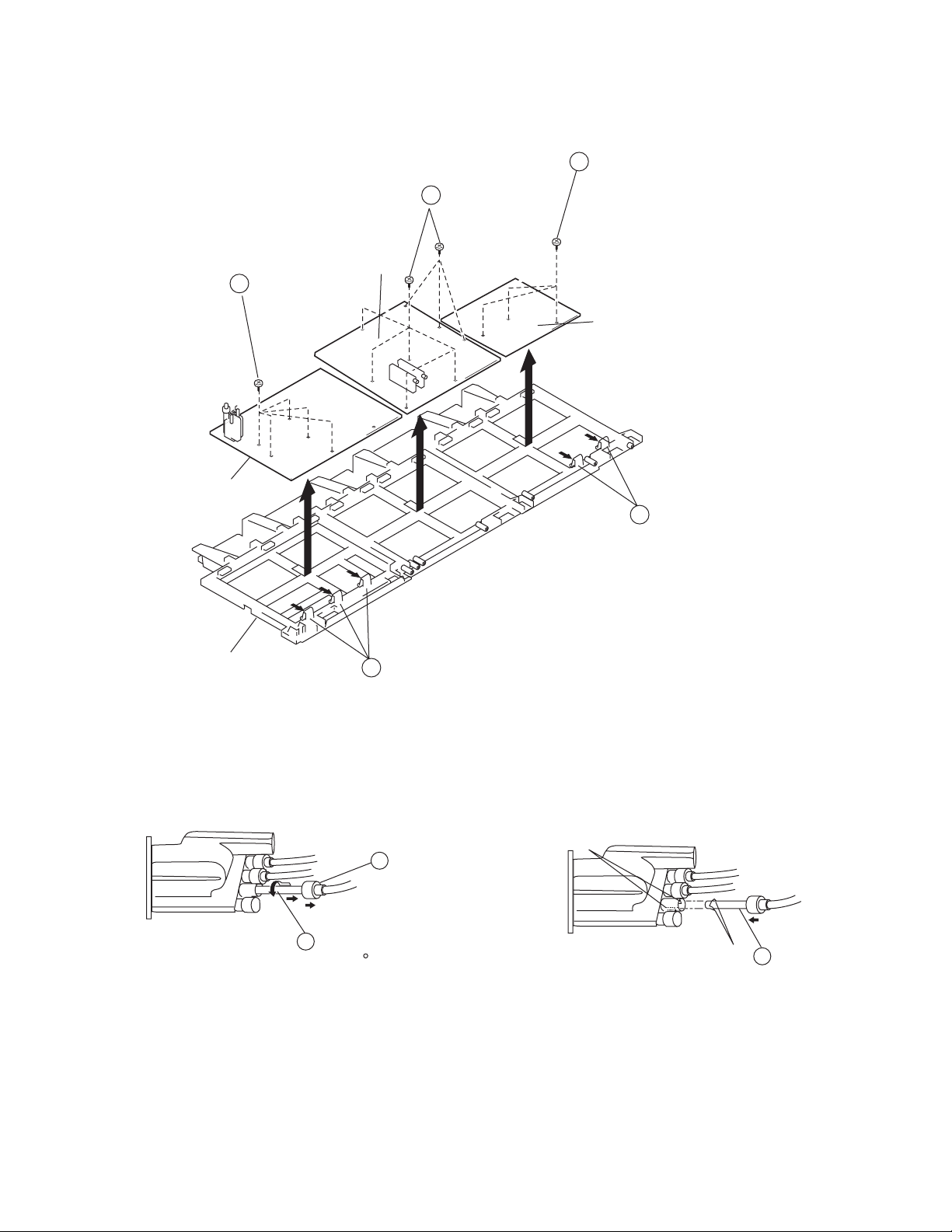

1-6. D BOARD, A BOARD, AND G BOARD REMOVAL

Eight screws

2

(+BVTP 3x12)

A board

1

Five screws

(+BVTP 3x12)

D board

Three screws

3

(+BVTP 3x12)

G board

KP-57WV600/57WV700/

65WV600/65WV700

Main bracket

4

Claws

1-7. HIGH-VOLTAGE CABLE INSTALLATION AND REMOVAL

(1) Removal

2

HV cable

turn 90

1

Rubber cap

(2) Installation

Gutter

4

Claws

Hook

HV cabl

1

— 12 —

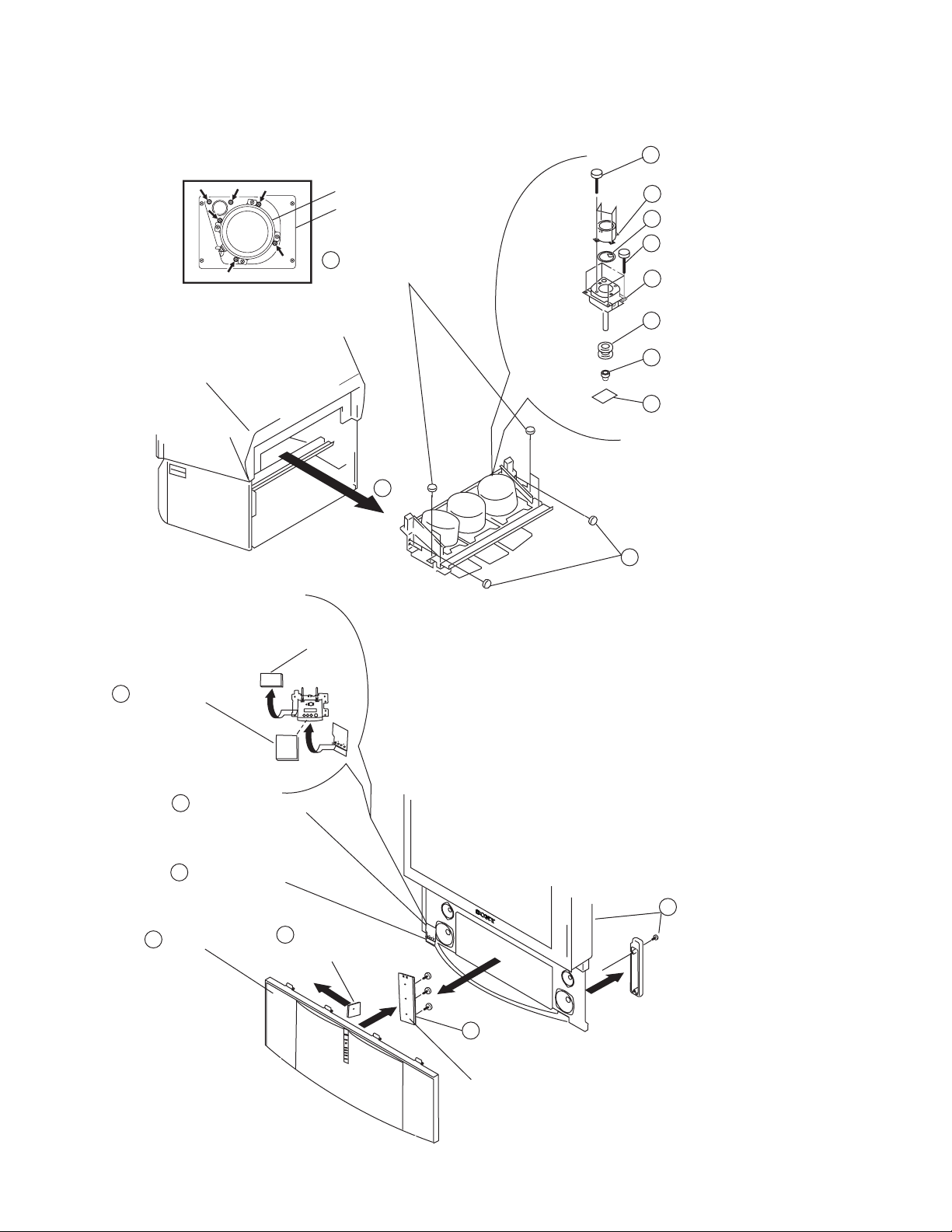

1-8. PICTURE TUBE REMOVAL

CAUTION: Removing the arrow-marked screws is strictly prohibited. If removed, it may cause liquid to spill.

Lens

Picture tube

2

Four screws

(Screw(4x20), tapping)

3

Four screws

4

(Screw(4x20), tapping)

Lens

5

Shade

6

Four screws

10

(+BVTP 4x12)

Picture tube

11

Deflection yoke

9

Neck assy

8

CR board

7

KP-57WV600/57WV700/

65WV600/65WV700

7

Input Terminal Plate

One screw

(+BVTP3x12)

6

Input Terminal Bracket

Four screws

Dome Washer

(Hex Tap 4 x 20)

5

Input Terminal Cover

Two screws

(+BVTP3x12)

Grille Assy

2

HB board

4

Onescrew

(+BVTP3x12)

1

Four screws

(Screw(4x20), tapping)

1-9. GRILLE, HA BOARD, HM BOARD,

AND HB BOARD REMOVAL

Five screws

1

(+BVTP4x16)

KP-57WV600/

57WV700 Only

3

Three screws

(+BVTP3x12)

HA board

— 13 —

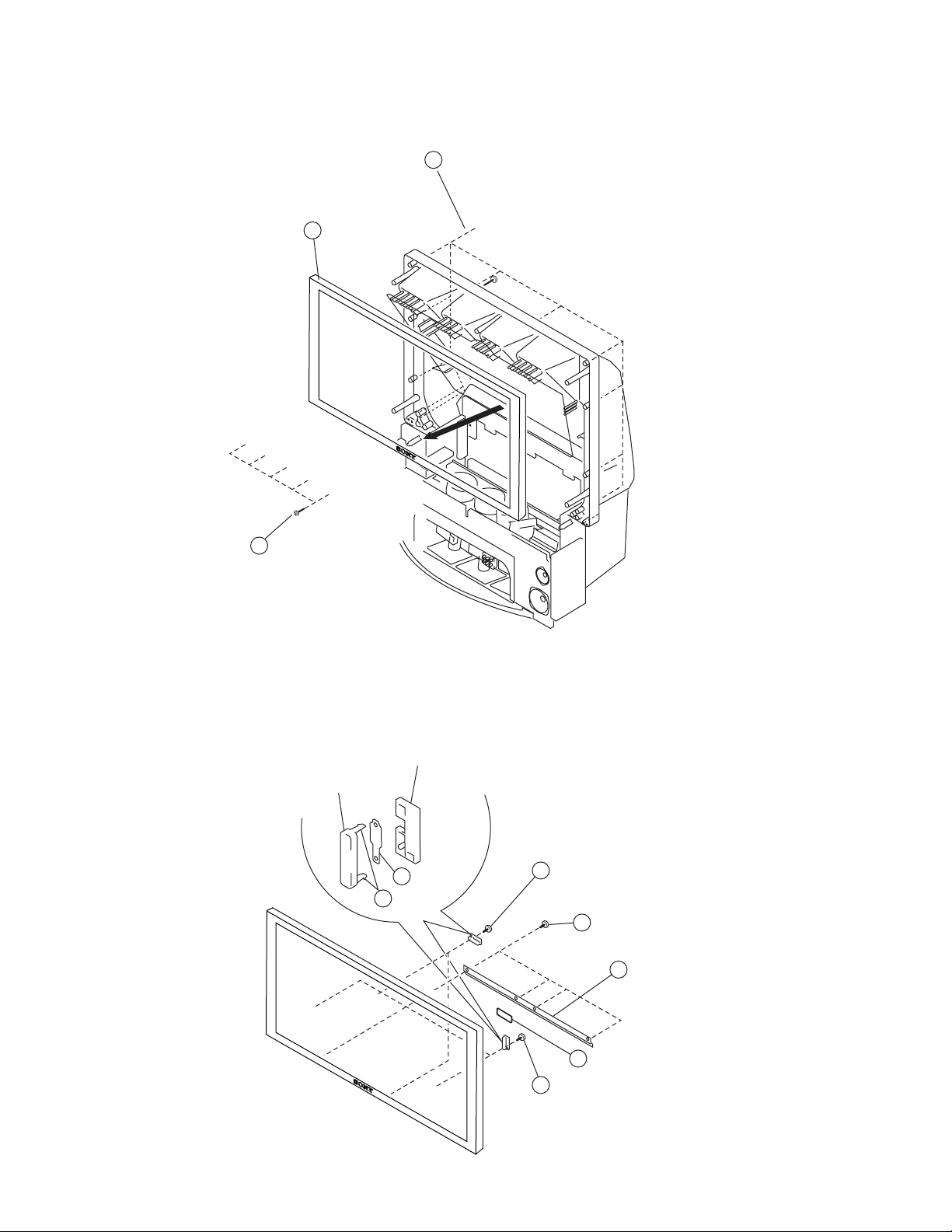

1-10. BEZNET ASSEMBLY REMOVAL

Beznet assy

2

Seventeen screws

1

Dome Washer

(Hex Tap 4x20)

KP-57WV600/57WV700/

65WV600/65WV700

1

Eight screws

(KP-57WV600/

57WV700 Only)

Dome Washer

(Hex Tap 4x20)

1-11. SR BOARD REMOVAL

The Screen Holder does not need

to be removed in order to remove

the SR boards.

Sensor

bracket (B)

Sensor

bracket (A)

7

SR board

6

Claws

One screw

4

(+BVTP 4x12)

1

Four screws

(+BVTP 4x12)

L screen

2

holder

— 14 —

HC board

3

One screw

5

(+BVTP 4x12)

1-12. MIRROR COVER REMOVAL (KP-57WV600/57WV700 ONLY)

1

Twenty-one screws

(Screw (4x20), tapping)

KP-57WV600/57WV700/

65WV600/65WV700

2

Mirror cover

— 15 —

SECTION 2: SET-UP ADJUSTMENTS

KP-57WV600/57WV700/

65WV600/65WV700

2-1. SCREEN VOLTAGE ADJUSTMENT (G2) (COARSE ADJUSTMENT)

1. Receive the Monoscope signal..

2. Set BRIGHTNESS to 50% and PICTURE to minimum.

3. Turn the red VR on the focus block all the way to the left and then

gradually turn it to the right until the retrace line is barely visible.

4. Gradually turn the control to the left until the retrace line disappears.

R G B

SCREEN

R G B

FOCUS

FOCUS Block

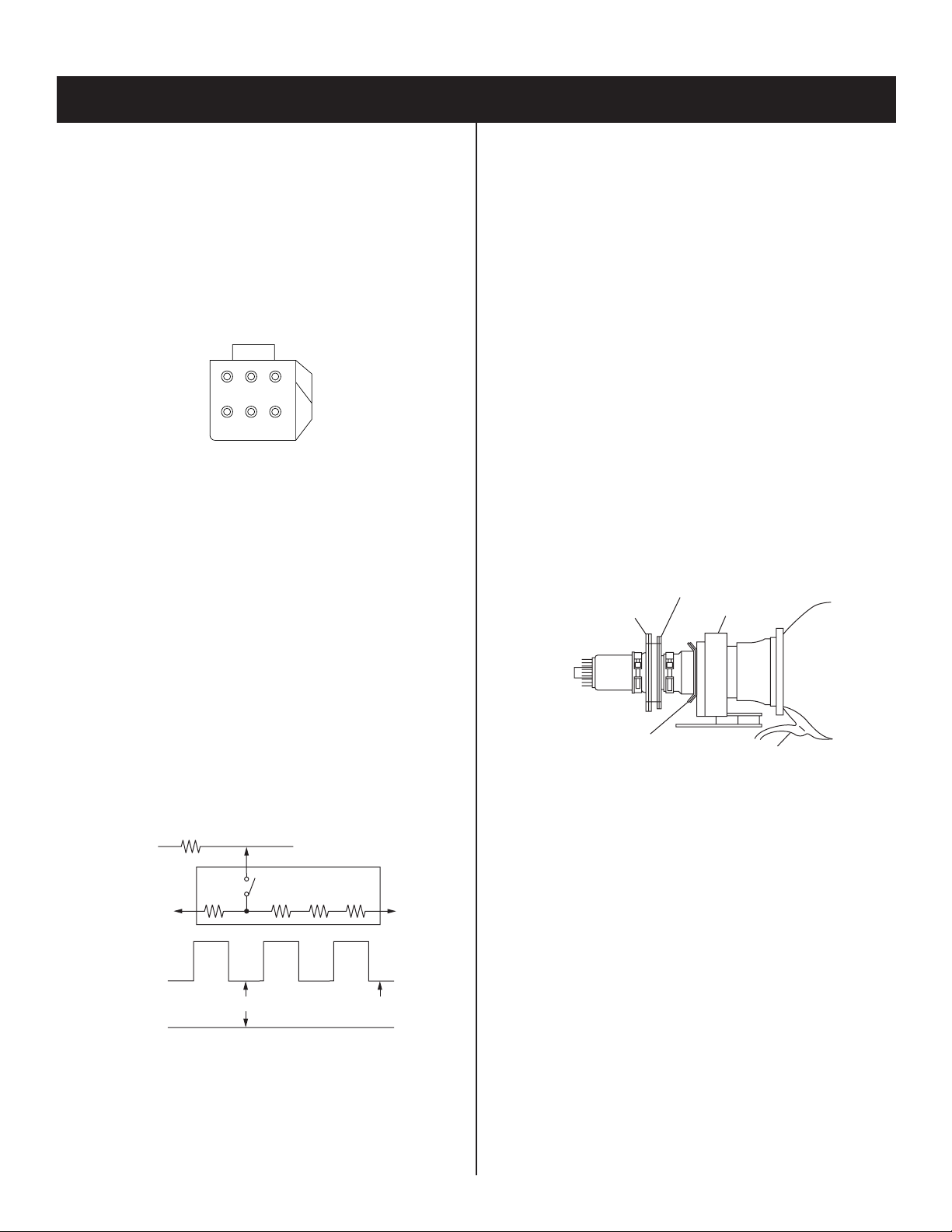

2-2. SCREEN (G2) ADJUSTMENT

(FINE ADJUSTMENT)

If the jig described below is available, it is recommended that the G2

Fine Mode Adjustment be performed to set the screen controls to their

optimal condition. If desired, you can build the jig illustrated below,

using 3-watt resistors. Please note that if the proper voltage is not

obtained with the listed resistor’s values, then increase or decrease one

of the values in the resistor network to obtain the correct voltage.

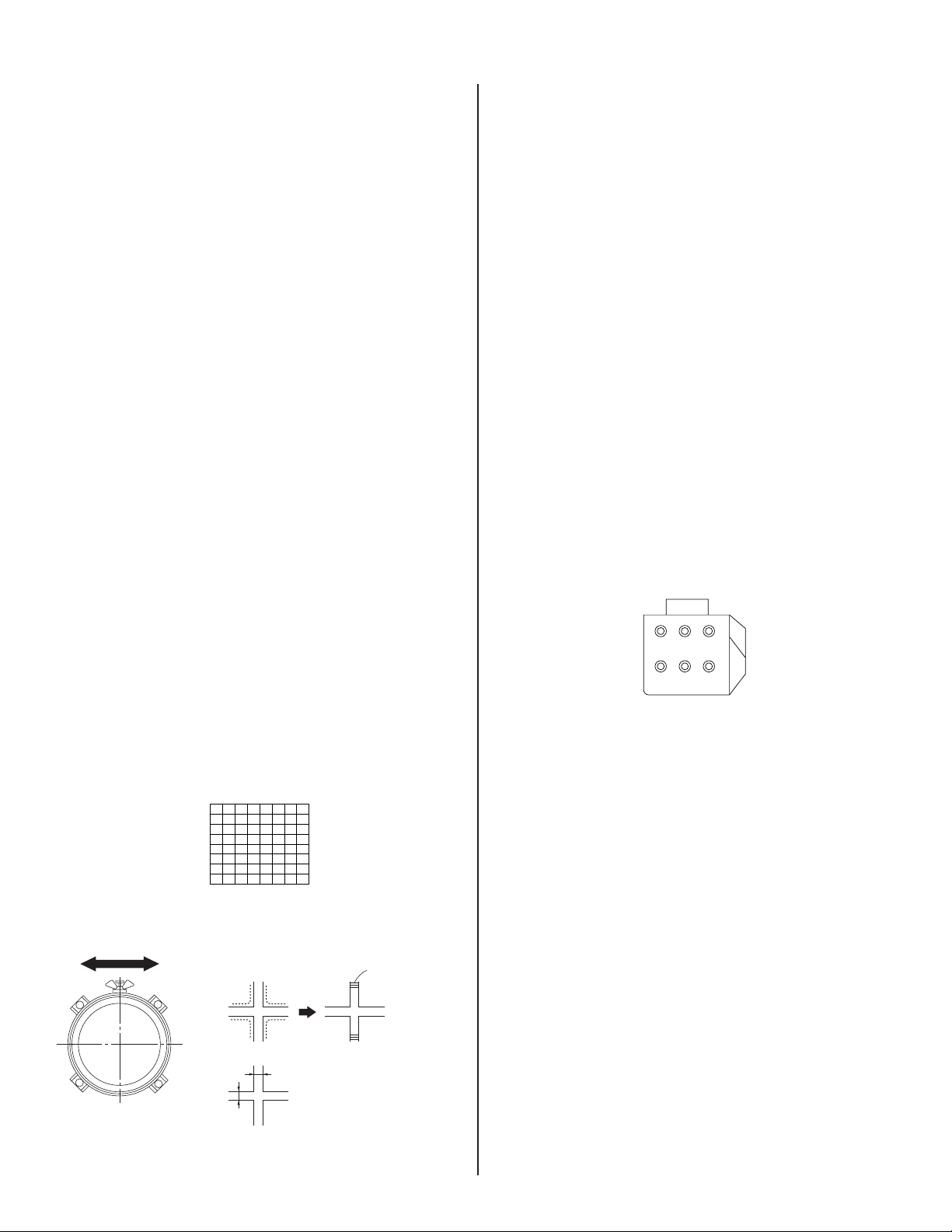

2-3. DEFLECTION YOKE TILT ADJUSTMENT

1. Connect the color bar generator monoscope patter to Video 1 input.

2. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

3. Loosen the CRT’s deß ection yoke set screw and align the tilt of

the deß ection yoke so that the horizontal bars at the center of the

cross-hatch pattern are parallel to the top and bottom edges of the

screen.

4. After aligning the deß ection yoke fasten it securely to the

funnel-shaped portion (neck) of the CRT.

5. Cover the green and blue CRT lenses with lens caps to allow only

green to show (or use the method shown in the note below for turning

off the CRTs individually without using lens caps), then repeat steps

3 and 4 for the red CRT.

Cover the green and red CRT lenses with lens caps o allow only

green to show (or use the method shown in the note below for turning

off the CRTs individually without using lens caps), then repeat steps

3 and 4 for the blue CRT.

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode 2170P-2 RGBS.

4-pole magnet

2-pole magnet

Deflection yoke

1. Select VIDEO-1 mode no signal applied (the screen must be black).

2. Connect the G2 JIG.

3. SW on JIG.

4. Connect an oscilloscope to the TP9101(KR), TP9201(KG) and

TP9301(KB) of CR board, CG board, and CB board.

5. Adjust red, green, and blue screen voltage to 177.5+/-0.5V with screen

VR on the focus block.

K

G2 JIG

TO CG BOARD

TP9202

(210V)

GND

3.3k 5.6k 5.6k 6.8k

177.5V +/- 0.5V

SW

GND

All resistors are 3W type

pedestal level

Centering magnet

Anode cap

— 16 —

KP-57WV600/57WV700/

65WV600/65WV700

2-4. FOCUS LENS ADJUSTMENT

In this adjustment, use the remote commander while in service mode.

For details on the usage of the service mode and the remote

commander, please refer to section

2-10. ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER.

1. Loosen the lens screw.

2. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

3. Turn the green lens to adjust to the optimum focus point with the

crosshatch signal.

4. Tighten the lens screw.

5. Cover the green and blue CRT lenses with the lens caps to allow only

red to show (or use the method shown in the note below for turning off

the CRTs individually without using lens caps).

6. Turn the red lens to adjust to the optimum focus point with the

crosshatch signal.

7. Tighten the lens screw.

8. Cover the green and red CRT lenses with the lens caps to allow only

blue to show (or use the method shown in the note below for turning

off the CRTs individually without using lens caps).

9. Turn the blue lens to adjust to the optimum focus point with the

crosshatch signal.

10. Tighten the lens screw.

11. After adjusting the items:

2-5. FOCUS VR ADJUSTMENT,

2-6. 2-POLE MAGNET ADJUSTMENT,

2-8. 4-POLE MAGNET ADJUSTMENT,

reconÞ rm the optimum focus point and adjust again if necessary.

2-5. FOCUS VR ADJUSTMENT

1. Set generator to crosshatch.

2. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

3. Turn the green focus VR on the focus block to adjust to the optimum

focus point with the crosshatch signal.

4. Cover the green and blue picture lenses with lens caps to allow only

red to show (or use the method shown in the note below for turning off

the CRTs individually without using lens caps).

5. Turn the red focus VR on the focus block to adjust to the optimum

focus point with the crosshatch signal.

6. Cover the green and red picture lenses with lens caps to allow only

blue to show (or use the method shown in the note below for turning

off the CRTs individually without using lens caps).

7. Turn the blue focus VR on the focus block to adjust to the optimum

focus point with the crosshatch signal.

8. After adjusting the items:

2-4. FOCUS LENS ADJUSTMENT,

2-6. 2-POLE MAGNET ADJUSTMENT,

2-8. 4-POLE MAGNET ADJUSTMENT,

reconÞ rm the optimum focus point and adjust again if necessary.

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode 2170P-2 1 RGBS.

R G B

SCREEN

R G B

FOCUS

* In PJE mode, every time 6 is pressed, the test signal changes to:

“crosshatch+video signal” → “crosshatch+borderline(black)” →

”crosshatch(black)” → “dots(black)” → off

Test Signal

Scanning line visible.

A

Minimize both A and B.

Lens

B

Center of crosshatch

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode 2170P-2 1 RGBS.

FOCUS Block

— 17 —

KP-57WV600/57WV700/

65WV600/65WV700

2-6. 2-POLE MAGNET ADJUSTMENT

1. Set the picture mode to PRO and picture to MAX.

2. Receive the Dot signal.

3. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

4. Turn the green focus VR on the focus block to the left (counter

clockwise) and set it to overfocus to enlarge the spot.

5. Adjust the green CRT’s 2-pole magnet so that the small bright spot

is in the center.

6. Align the green focus VR on the focus block and set it for the best

focus.

7. Repeat steps 1 through 6 for the red CRT except now you will

cover the green and blue CRT lenses with lens caps to allow

only red to show (or use the method shown in the note below

for turning off the CRTs individually without using lens caps) and you

will adjust the red focus control on the focus block.

8. Repeat steps 1 through 6 for the blue CRT except now you will

cover the red and green CRT lenses with lens caps to allow

only blue to show (or use the method shown in the note below

for turning off the CRTs individually without using lens caps) and you

will adjust the blue focus control on the focus block.

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode 2170P-2 1 RGBS.

2-8. 4-POLE MAGNET ADJUSTMENT

1. Set the picture mode to PRO and picture to MAX.

2. Receive the Dot signal.

3. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

4. Turn the (green) focus VR on the focus block to the right (clockwise)

and set it to under-focus to reduce the spot.

5. Adjust the 4-pole magnet so that the small spot in the center of the

screen becomes round for green and red.

6. Adjust the blue spot to an oval shape X:Y=1:1.2

7. Repeat steps 1 through 6 for the red CRT except now you will

cover the green and blue CRT lenses with lens caps to allow

only red to show (or use the method shown in the note below

for turning off the CRTs individually without using lens caps) and you

will adjust the red focus control on the focus block.

8. Repeat steps 1 through 6 for the blue CRT except now you will

cover the red and green CRT lenses with lens caps to allow

only blue to show (or use the method shown in the note below

for turning off the CRTs individually without using lens caps) and you

will adjust the blue focus control on the focus block.

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode 2170P-2 1 RGBS.

Use the center dot

x

2-7. CENTERING MAGNET ADJUSTMENT

1. Set the picture mode to PRO.

2. Receive the monoscope signal.

3. Cover the red and blue CRT lenses with lens caps to allow only green

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

4. Adjust the green CRT’s centering magnet to put the center of the

monoscope signal to the center of the screen.

5. Repeat steps 1 through 4 for the red CRT except now you will

cover the green and blue CRT lenses with lens caps to allow

only red to show (or use the method shown in the note below

for turning off the CRTs individually without using lens caps) and you

will adjust the red centering magnet.

6. Repeat steps 1 through 4 for the blue CRT except now you will

cover the red and green CRT lenses with lens caps to allow

only blue to show (or use the method shown in the note below

for turning off the CRTs individually without using lens caps) and you

will adjust the blue centering magnet.

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode 2170P-2 1 RGBS.

y

x : y = 1:1 (Green, Red)

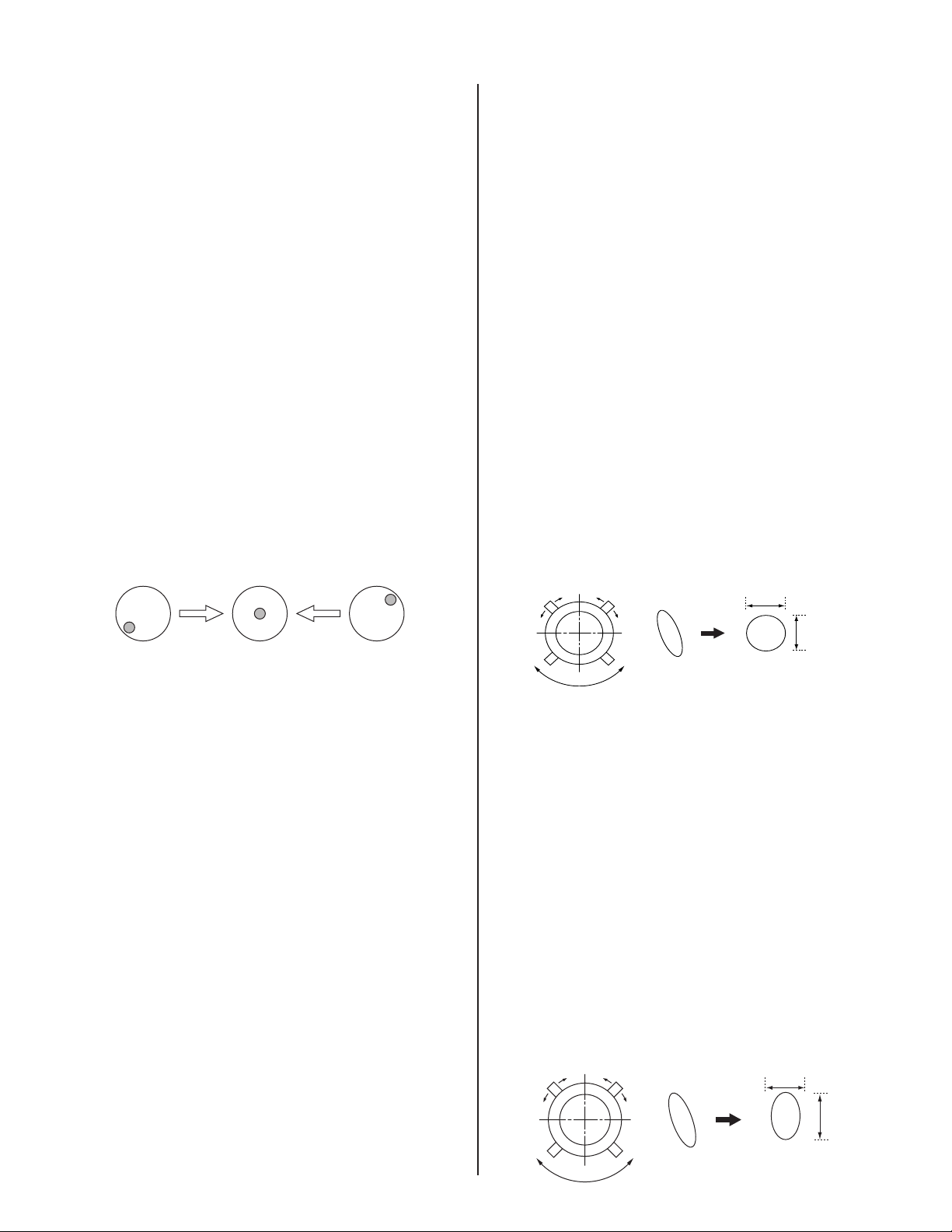

2-9. DEFOCUS ADJUSTMENT (BLUE)

Note: Adjust the blue dot to be slightly larger than red and green dots.

This adjustment provides a more pleasing picture to the customer.

1. Set the picture mode to PRO.

2. Receive the Dot signal.

3. Cover the red and green CRT lenses with lens caps to allow only blue

to show (or use the method shown in the note below for turning off the

CRTs individually without using lens caps).

4. Turn the blue focus VR on the focus block to the right (clockwise) to

make the round dot elliptical.

5. Check the ß are with a high luminance signal to make sure the ß are is

minimal while the dot shape is elliptical.

6. Set the generator to an all white signal and check uniformity.

Note: If lens caps are unavailable, you can cut off the unnecessary color

beams by controlling the service mode 2170P-2 1 RGBS.

Use the center dot

x

— 18 —

y

x : y = 1:1.2 (BIue)

KP-57WV600/57WV700/

65WV600/65WV700

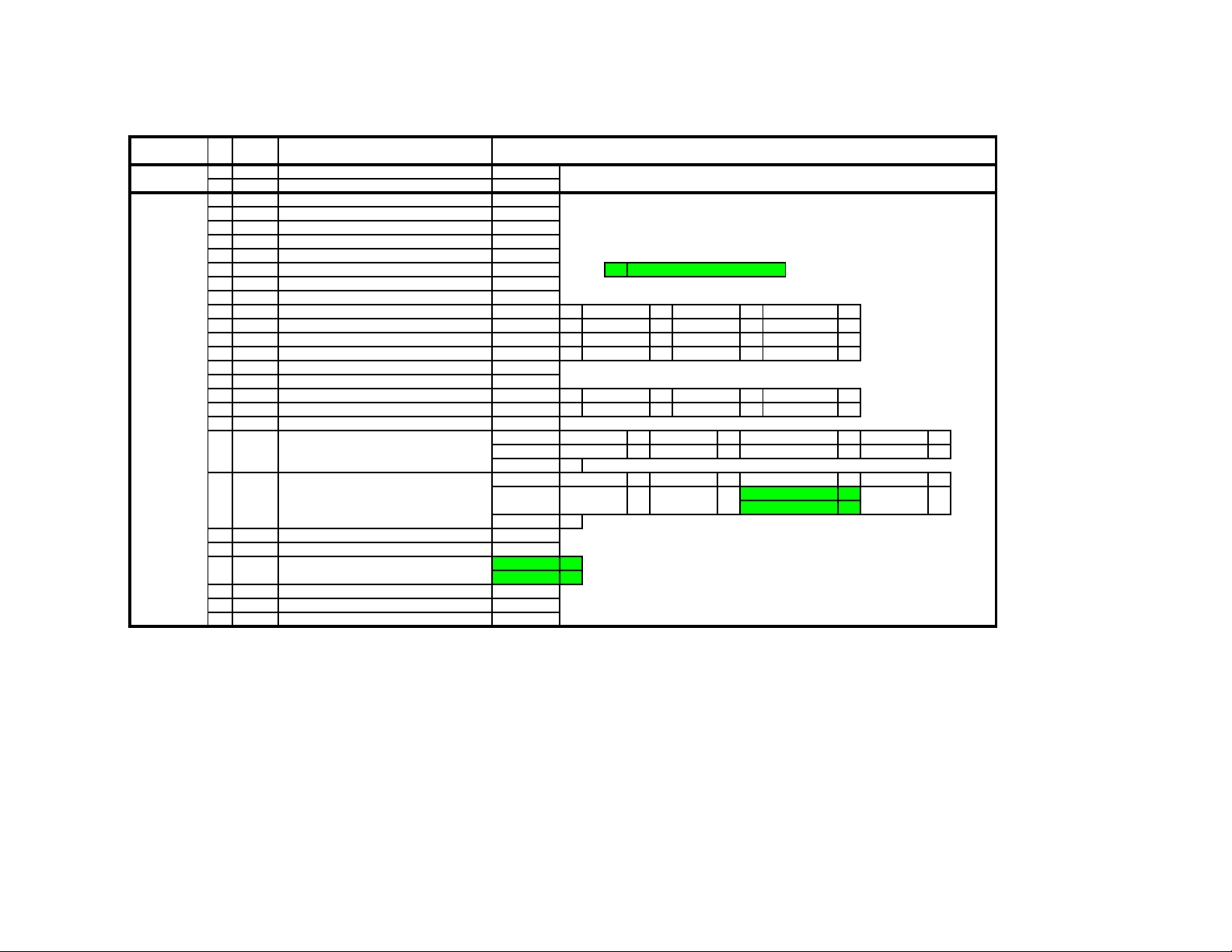

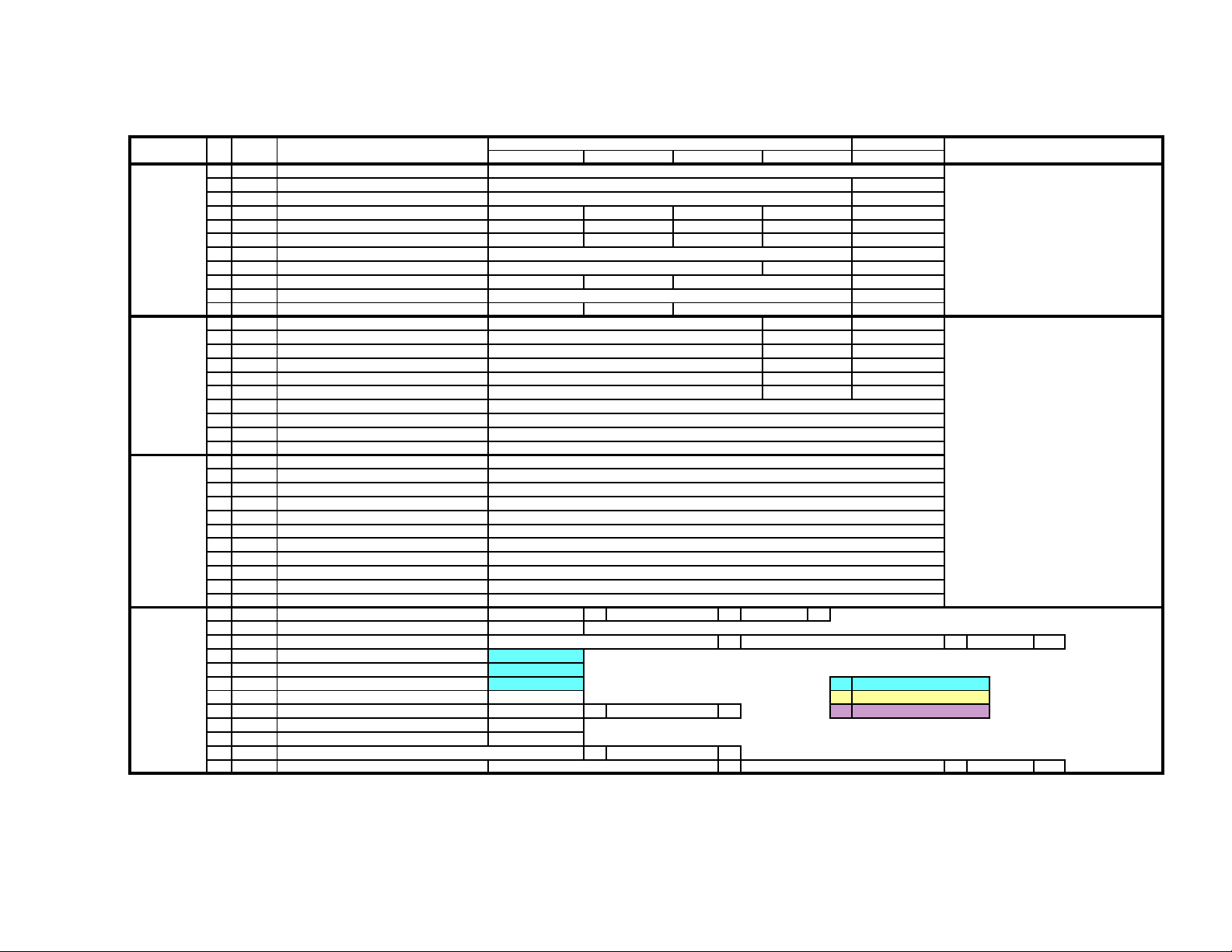

2-10. ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER

All of the circuit adjustments can be made by using the remote

commander (RM-Y188).

NOTE : The following test equipment is required:

1. Pattern Generator (with component outputs)

2. Frequency counter

3. Digital multimeter

4. Audio oscillator

2-10-1.METHOD OF ENTERING THE SERVICE

ADJUSTMENT MODE

SERVICE MODE PROCEDURE

1. TV must be in Standby mode. (Power off)

2. Press “DISPLAY”, “5”, “VOL +”, then “POWER” on the remote

commander.

(Press each button within 1 second of pressing the previous button.)

SERVICE MODE ADJUSTMENT

Data

SERVICE

TV

Category

Adjustment Item

3D-COMB

NRMD

Item NO.

0 0

WSL : XXX

7. If you want to go back to the most recently saved value, press “0”

then “ENTER” to read the memory.

8. Press “MUTING” then “ENTER” to write the new adjustment data into

memory.

9. Turn power off when you want to exit the service mode.

Note: Press “8” then “ENTER” on the remote commander to restore the

factory settings for user controls and channel memories (this will also

turn set off and then on to exit the service mode).

2-10-2.MEMORY WRITE CONFIRMATION

METHOD

1. After adjustment, turn the power off with the remote commander.

2. Turn the power ON and set to service mode.

3. Cycle through the adjusted items again and confi rm that the

adjustments were saved.

2-10-3.ADJUSTING BUTTONS AND

INDICATOR

Note: When the PJE mode (which displays an internally generated

signal) is activated, several buttons on the remote commander will have

different functions than the ones listed below. Therefore, when in the PJE

mode, refer to section 2-12-3 for button functions.

F / A FLAG : XXXXXXXX

CBA FLAG : XXXXXXXX

3. The screen displays the item being adjusted within that category.

4. Press 1 or 4 on the remote commander to select the adjustment item

5. Press 3 or 6 on the remote commander to change the data

6. Press 2 or 5 on the remote commander to select the adjustment

category

Every time you press 2(Category up), service mode changes in the

order shown below:

VERSION

3D-COMB

2103-1

2103-2

2170P-1

2170P-2

2170P-3

2170P-4

2170D-1

2170D-2

2170D-3

2170D-4

2170D-5

D-CONV

2151

MID1

MID2

MID3

MID5

CXA350GR

AUDIO

SNNR

CCP

3DNR

DRCV

PJED FDIS

PJED ROGH

GRN CENT

OP

ID

MUTING

TV/VIDEO

Category up

Adjustment

item up

Adjustment

item down

Test Reset

WIDE MODE

INDEX

VOLUME

POWER

ANT

PIC MODE

Data up

Data down

Category

down

ENTER

TWIN VIEW

DISPLAY

RM-Y188

— 19 —

SERVICE DATA LISTS 2-11

y

e

g

t

y

t

e

t

t

y

)

)

y

g

e

KP-57WV600/57WV700/

65WV600/65WV700

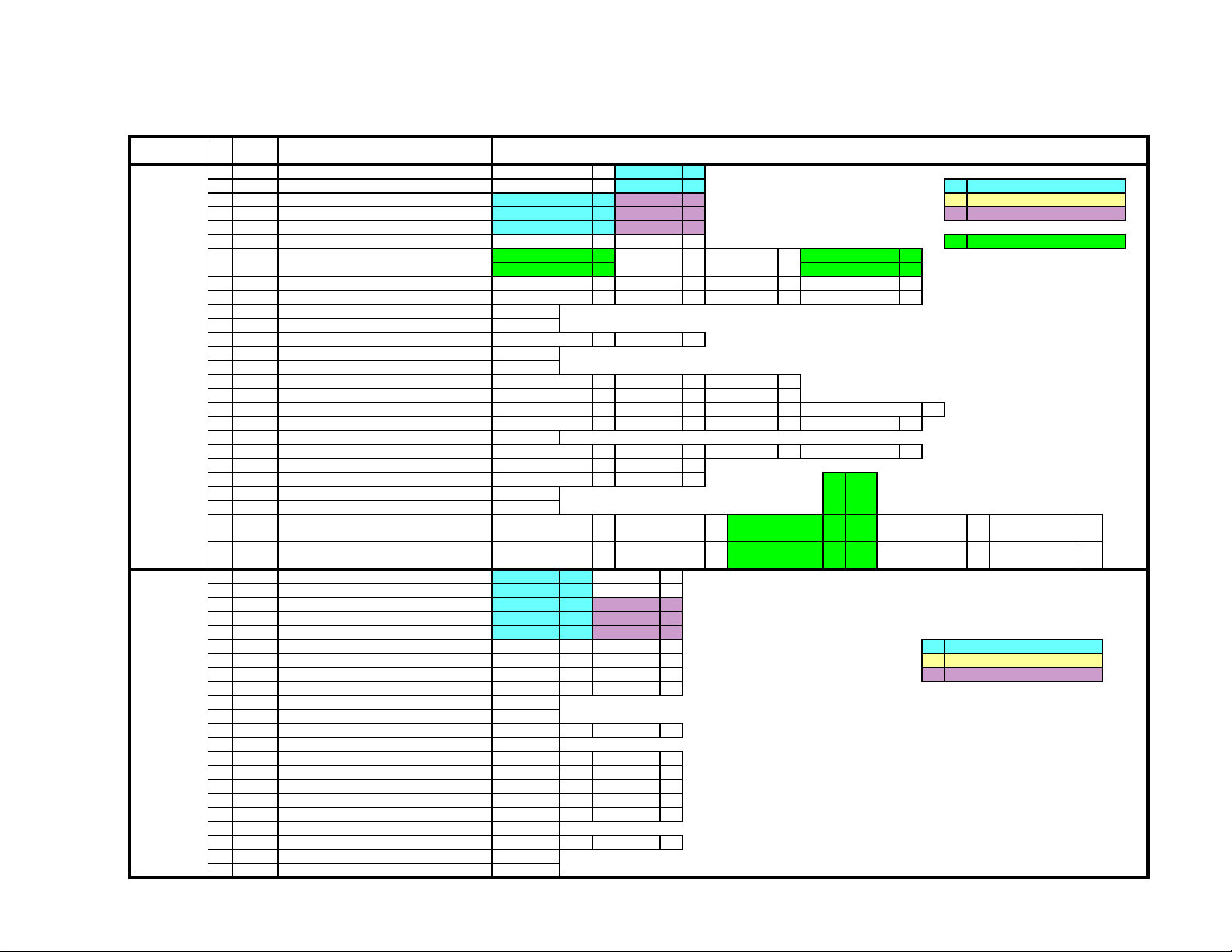

CATEGORY # ITEM DESCRIPTION DATA

VERSION 0 VER Software version displa

1 DMY1

3DCOMB 0 NRMD Noise Reduction Mod

1 CLKS Forced Clock System

2 NSDS Non-Standard/Standard Signal Processin

3 MSS Frame / Line Processing

4 KILS Color Killer Setting

5 FRZE External Memory Test Bi

6 EXCS External C Sync Input (CSI Pin)

7 CDL C Signal Output Dela

8 DYCO Y Motion Detection Coring NRMD = 0 2 NRMD = 1 2 NRMD = 2 2 NRMD = 3 2

9 DYGA Y Motion Detection Gain NRMD = 0 10 NRMD = 1 10 NRMD = 2 10 NRMD = 3 10

10 DCCO C Motion Detection Coring NRMD = 0 5 NRMD = 1 5 NRMD = 2 5 NRMD = 3 5

11 DCGA C Motion Detection Gain NRMD = 0 5 NRMD = 1 5 NRMD = 2 5 NRMD = 3 5

12 WSC Noise Detection Amoun

13 WSS Noise Detection Pre-Filter Typ

14 VAPG Vertical Apperature Gain Vivid 0 Standard 0 Movie 0 Pro 0

15 VAPI Vertical Apperature Convergence Poin

16 TEST Test Bi

17 YPFT Y Peaking BPF Center Frequenc

18 YPFG Y Peaking BPF Gain RF Vivid 7 Standard 7 Movie 5 Pro 5

19 SEDC C Detection High-Freq Sensitivity

20 SEDY Y Detection Low-Freq Sensitivit

21 YHCO Y Output High-Freq Corin

22 YHCG Y Output High-Freq Gain

23 SYSP System Power-down Mod

24 TES2 Test Bits

0

255

0

1

0

0

1

0

1

3

1

0

Vivid 0 Standard 0 Movie 0 Pro 0

0

RF Vivid 3 Standard 3 Movie 3 Pro 3

V1-V4 Vivid 3 Standard 3 Movie 3 Pro 3

Twin 3

V1-V4

Twin 7

0

1

♥

WV700

♥

WV600

0

0

0

♥ WV600 and WV700 are different

Movie (WV600

Movie (WV700

2

3

♥ 6

♥ 5

Pro 55StandardVivid 5

— 20 —

SERVICE DATA LISTS

t

r

0

0

o

g

g

F

F

F

e

t

F

t

t

t

t

t

t

)

o

)

t

t

t

r

w

o

g

g

F

F

F

e

t

F

t

t

t

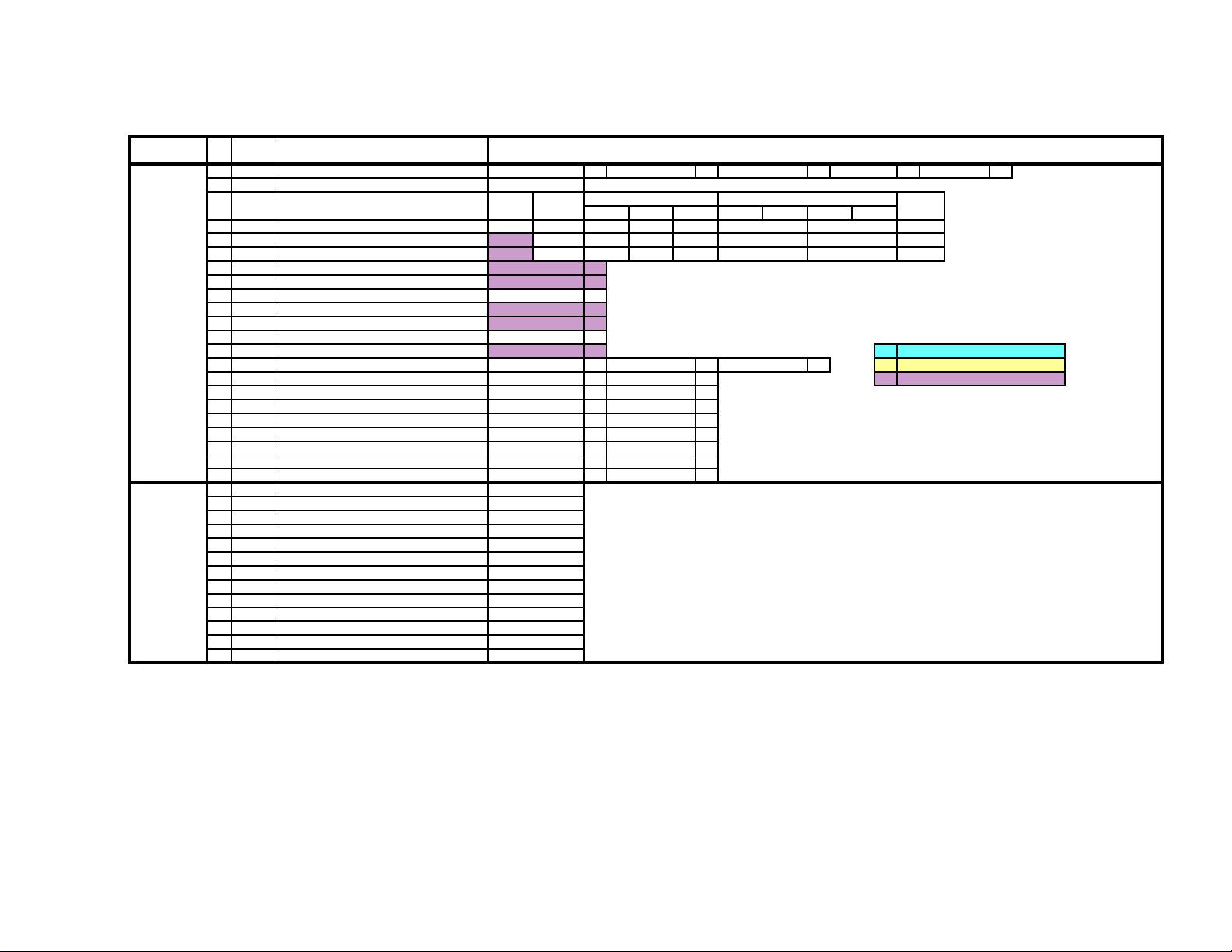

CATEGORY # ITEM DESCRIPTION DATA

CXA2103-1 0 YLEV Y-out input/output gain 17 Others

1 CLEV CbCr input/output gain 15 Others

Main YCT 2 SCON Sub Contras

3 SCOL Sub Colo

4 SHUE Sub Hue 5 Others ♠ 11

5 YDLY Y/C Delay 0 Others 0

6 SHAP Sharpness level 11 V5, V6 (480i) 4 V7 (480i) 4 Others (WV60

7 SHF0 Sharpness f0 0 V5, V6 (480i) 3 V7 (480i) 3 Others 0

8 PREO Sharpness preshoot:overshoot rati

9 BPF0 Chroma band-pass filter f0 settin

10 BPFQ Chroma band-pass filter Q settin

11 BPSW Chroma band-pass filter ON/OF

12 TRAP Y block chroma trap ON/OF

13 LPF YCbCr output low-pass filter ON/OF

14 AFCG H block PLL loop gain 0 RF 1 Others 0

15 CDMD V countdown system mod

16 SSMD Sync separation circui

17 HMSK Macrovision signal masking ON/OF

18 HALI H automatic adjustment function

19 PPHA Video and H TIM phase adjustmen

20 CBO1 Cb offset of Cb IN (pin 34) inpu

21 CRO1 Cr offset of Cr IN (pin 35) inpu

22 CBO2 Cb offset of DVI Cb (Pin 38) inpu

23 CRO2 Cr offset of the DVI Cr (Pin 39) inpu

24 ATPD Auto-Pedestal Poin

(Data is applied to 2103-2 also

25 DCTR DC transmission rati

(Data is applied to 2103-2 also

CXA2103-2 0 YLEV Y-out input/output gain DRC*

1 CLEV CbCr input/output gain DRC*

Sub-YCT 2 SCON Sub Contras

3 SCOL Sub Colo

4 SHUE Sub Hue V1-V4**

5 YDLY Y/C Delay V1-V4** 0 Others** 0 ♣

6 SHAP Sharpness level V1-V4** 6 Others** 6 ♦

7 SHF0 Sharpness f0 V1-V4** 0 Others** 0 ♠

8 PREO Sharpness preshoot:overshoot rati

9 BPF0 Chroma band-pass filter f0 settin

10 BPFQ Chroma band-pass filter Q settin

11 BPSW Chroma band-pass filter ON/OF

12 TRAP Y block chroma trap ON/OF

13 LPF YCbCr output low-pass filter ON/OF

14 AFCG H block PLL loop gain V1-V4** 0 Others** 1

15 CDMD V countdown system mod

16 SSMD Sync separation circui

17 HMSK Macrovision signal masking ON/OF

18 HALI H auto adjustment function

19 PPHA Video and H TIM phase adjustmen

20 CBO1 Cb offset of Cb IN (pin 34) inpu

21 CRO1 Cr offset of Cr IN (pin 35) inpu

RF, V1-V4

RF, V1-V4

V1-V4

♣

V1-V4 ♣

V1-V4

♣

V1-V4

V1-V4 (WV600) ♥

V1-V4 (WV700) ♥

V1-V4

V1-V4

3

0

V1-V4 0 Others 1

0

1

V1-V4

V1-V4

V1-V4

V1-V4

0

V1-V4

V5, V6 (480i)

V5, V6 (480i)

25

27

Single Picture 0 Twin: 0 Twin ♥ 1 3 Twin 0 Twin 0

Single Picture 0 Twin 0 Twin ♥ 2 3 Twin 0 Twin 0

9 Others ♠ 9 ♦

2 Others ♠ 2 ♠

8 Others (WV70

3 V5, V6 (480i) 3 V7 (480i) 3 Others 3

3 RF 3 Others 3

0 RF 0 Others 0 No Signal / Blanking 3

1 V5, V6 (480i) 1 V7 (480i) 0 Others 1

7 V5, V6 7 V7 (480i) 7 Others 7

36 Others 34

38 Others 32

2170P-4:BLK = 0 2170P-4:BLK = 1 2170P-4:BLK = 2 2170P-4:BLK = 3

2170P-4:BLK = 0 2170P-4:BLK = 1 2170P-4:BLK = 2 2170P-4:BLK = 3

♣ 16

♣ 21 ♣

♣ 14 VDO* 45

♣ 7 VDO* 25 * DRC - Left picture of twin view is 480P, 720P, or 1080i inpu

V1-V4** ♣ 9 Others** ♠ 9 * VDO - Left picture of twin view is 480i inpu

V1-V4** ♣ 2 Others** ♠ 2

♣ 5 Others** ♠ 11 ** Refers to the right picture of twin vie

V1-V4** 3 Others** 3

3

0

V1-V4** 0 Others** 0

0

DRC* 0 VDO* 0

V1-V4** 3 Others** 3

V1-V4** 0 Others** 0

V1-V4** 1 Others** 0

0

V1-V4** 7 Others** 7

29

26

WV600

KP-57WV600/57WV700/

65WV600/65WV700

Adjustable - M Board CBA

Adjustable - B Board CBA

Adjustable - On Line (STD LIST)

♥ WV600 and WV700 are different

♥ 11

♥ 6

WV700

Adjustable - M Board CBA

Adjustable - B Board CBA

Adjustable - On Line (STD LIST)

— 21 —

SERVICE DATA LISTS

t

t

t

p

)

p

p

p

f

p

f

p

f

p

t

p

t

t

t

t

s

f

e

f

t

CATEGORY # ITEM DESCRIPTION DATA

CXA2170P-1 0 YOSW Y Offset Switch RF, V1-4 1 480i (V5, V6) 0 HD (V5,V6) 0 MS 0 V7 1

CXA2170P-2 0 PICO Picture+Ref.pulse on/off for G2 adj.

1 TCOF

2 YOF Y offse

3 CBOF Cb offse

4 CROF Cr offse

5 SBRT SUB brightness Neutral Tem

6 RDRV R drive gain Neutral Tem

7 GDRV G drive gain Neutral Tem

8 BDRV B drive gain Neutral Tem

9 RCUT R cut-of

10 GCUT G cut-of

11 BCUT B cut-of

12 WBSW White balance offse

13 SBOF Sub brightness offset-ColorTemp. Warm Temp 7 Cool Temp 7 ♠

14 RDOF RDRV offset Warm Temp 34 Cool Temp 34

15 GDOF GDRV offse

16 BDOF BDRV offset Warm Temp 25 Cool Temp 34

17 RCOF RCUT offse

18 GCOF GCUT offse

19 BCOF BCUT offse

20 DCOL Dynamic Color for Cool Cool Temp 2 Others 0

1 RGBS RGB CRT ON/OFF combination

2 BLKB Bottom limiter level

3 RGBL RGB limmiter level

4 YLMT Y limiter level

5 AGNG Black/White aging

6 AKBO AKB on/of

7 CLPP Clamp pulse phas

8 CLPG Clamp gate on/of

9 CLPS Clamp pulse start timing shif

10 PPAD Picture Position

11 SYNP

12 HVBT 0

0

RF, V7

V1-V4 480i 480P 720P 1080i 480P VGA 720P 1080i MS

44

44 ♠

15

0

♠

44

44

V5/V6V5-7

7

7

47

44

47

7

44

4444

0

40

42 42

41

0

♠ 20 *SBRT is offset from adjust point (57WV700: +4, 65WV700: +6, 57WV600: +6, 65WV600: +4

♠ 45

30 * DRC - any 480i signal

♠ 34 * HD / VDO - any non-480i signal

Neutral Tem

Neutral Tem

Neutral Tem

Warm Temp 0 Cool Temp 0 Neutral Tem

Warm Temp 31 Cool Temp 31

Warm Temp 33 Cool Temp 32

Warm Temp 31 Cool Temp 31

Warm Temp 27 Cool Temp 45

♠ 41

41

♠ 35 ♣

1

7

0

2

2

0

0

3

0

0

3

0

0 ♦

Adjustable - M Board CBA

Adjustable - B Board CBA

Adjustable - On Line (STD LIST)

7

34

34

KP-57WV600/57WV700/

65WV600/65WV700

— 22 —

KP-57WV600/57WV700/

y

0

2

♥

2♥2♥2♥2♥2♥2

♥

0

2

e

1

8

1

8

2

♥

1♥2♥2♥1♥2♥2

♥

2

♥

0

2

y

o

•

65WV600/65WV700

SERVICE DATA LISTS

CATEGORY # ITEM DESCRIPTION DATA

CXA2170P-3 RF MS MS

WV600 Data 0 SYSM Selects the signal bandwidth Vivid 1 11133113 3 33 2

1 VMLV VM output level

[0:NTSC, 1:FF, 2:HD, 3:DTV] Standard 1 11133113 3 33 2

Movie 1 11133113 3 33 2

Pro

7

V1-V4

121133113 3 33 2

V5,V6 V7

1080i

Play Menu

1

Twin480i 480P 1080i 720P 480i 480P 720P VGA

2 VMCR VM output coring level Vivid 1 11100110 0 03 1

3 VMLM VM limiter level Vivid 0 00000000 0 00 0

4 VMF0 VM output center frequenc

5 VMDL VM output phas

6 SHOF Sharpness gain 2

7 SHF0 Sharpness center frequenc

8 PROV Pre-shoot / Over-shoot rati

Standard 1 11100110 0 03 1

Movie 1 11100110 0 03 1

Pro 111100110 0 03 1

Standard 0 00000000 0 00 0

Movie 0 00000000 0 00 0

Pro 000000000 0 00 0

Vivid

Standard

Movie 2 22222222 2 22 2

Pro

Vivid

Standard

Movie

Pro

Vivid

Standard

Movie 1 11111111 1 10 1

Pro 000000000 0 00 0

Vivid 1 11111111 1 11 1

Standard 1 11111111 1 11 1

Movie 1 11111111 1 11 1

Pro 111111111 1 11 1

Vivid 3 33333333 3 33 2

Standard 3 33333333 3 33 2

Movie 3 33333333 3 33 2

Pro 333333333 3 33 2

♥

0 ♥ 1 ♥ 1 ♥ 1 ♥ 1 ♥ 0 ♥

♥

0 ♥ 1 ♥ 1 ♥ 1 ♥ 1 ♥ 0 ♥

♥

2 ♥ 2 ♥ 2 ♥ 2 ♥ 2 ♥ 2 ♥

0

2

5 ♥

♥

5 ♥

♥

8 881010881010

815 10 10

•

0

♥

♥

♥

22

15 ♥ 11 ♥ 11 ♥ 11 ♥ 11 ♥ 15 ♥

8 ♥ 8 ♥ 8 ♥ 8 ♥ 8 ♥ 8 ♥

15 ♥ 11 ♥ 11 ♥ 10 10 11 ♥ 11 ♥ 10 10 15 ♥

8 ♥ 8 ♥ 8 ♥ 8 ♥ 8 ♥ 8 ♥

8

2 •

1

1 ♥ 1 ♥ 1 ♥ 1 ♥ 1 ♥

2 ♥ 2 ♥ 0 ♥ 2 ♥ 0 ♥

WV600 and WV700 are different

65WV600 and 57WV600 different

22

22 2 2 22

22

10 10 10 10 10 10

• 2 • 2 • 2 •

0

3 • 3 • 3 • 3 •

22 2 2 20 0

222

2

•

2

0

0

0

2

2

2

22

8

0

1

3

2

22

10

10

10 10 8

2 •

00

3 •

8810108810108

— 23 —

KP-57WV600/57WV700/

V

e

13

UBOF

U

t

1

14

UCOF

U

t

0

1

0♥0♥0

1♥1

15UHOF

U

t

1♥1

2♥2

1

1♥1♥2

2♥2

e

]

t

t

t

22

23

VGAB

•

25

V

V

V

V

65WV600/65WV700

SERVICE DATA LISTS

CATEGORY # ITEM DESCRIPTION RF

CXA2170P-3 9 F1LVSharpness f1 Vivid 0 00033003 3 300

10 LTL

11 LTMD LTI mod

12 CTLV CTI level Vivid 0 00000000 0 00 0

16 MIDE MID Enhancement setting tabl

LTI level Vivid 3 33333333 3 33 3

[0:for B&W, 1:for Black]

[0:Off, 1:Low, 2:Mid, 3:High]

serbrightness offse

BRIGHT=BRIGHT+UBOF*2

ser color offse

COLOR=COLOR+UCOF*2

serhue offse

[0:HUE+0, 1:HUE+1 ,2:HUE+2, 3:HUE+3]

Standard 0 00033003 3 30 0

Movie 0 00033003 3 30 0

Pro 000033003 3 30 0

Standard 2 23333333 3 33 3

Movie 1 11111111 1 11 1

Pro 000000000 0 00 0

Vivid 1 11111111 1 11 0

Standard 1 11111111 1 11 0

Movie 0 00000000 0 00 0

Pro 111111111 1 11 0

Standard 0 00000000 0 00 0

Movie 0 00000000 0 00 0

Pro 000000000 0 00 0

44

Standard 4 432

Movie 0 03333333 3 33 2

Pro 003333333 3 33 4

Vivid

Standard

Movie 0 00000000 0 00 0

Pro 000000000 0 00 0

Vivid

Standard

Movie 0 00000000 0 00 0

Pro 000000000 0 00 0

Vivid 7 12 17 22 27 32 17 22 27 32 27 27 57

Standard 5 11 16 21 26 31 16 21 26 31 26 26 56

Movie 3 10 15 24 25 30 15 24 25 30 25 25 55

Pro 0 8 13 18 23 28 13 18 23 28 23 23 53

5 ♥

3

♥

♥

♥

♥

♥

♥

♥

480i

1-V4

2 ♥ 4 ♥ 4 ♥ 4 ♥

3 ♥ 3 ♥ 3 ♥ 0 ♥

1 ♥

2

0 ♥

3

3

1 ♥ 1 ♥ 3 ♥ 3 ♥ 1 ♥ 3 ♥ 3 ♥ 33 0 ♥

2 ♥ 1 ♥ 0 ♥ 0 ♥ 0 ♥ 0 ♥

0 ♥ 0 ♥ 1 ♥ 1 ♥ 1 ♥ 1 ♥

0 ♥ 1 ♥ 0 ♥ 1 ♥ 1 ♥ 1 ♥ 0 ♥ 1 ♥ 1 ♥

3 ♥ 3 ♥ 2 ♥ 2 ♥ 2 ♥ 3 ♥ 2 ♥ 2 ♥ 2 ♥

0 ♥ 1 ♥ 0 ♥ 1 ♥ 1 ♥ 1 ♥ 0 ♥ 1 ♥ 1 ♥

3 ♥ 3 ♥ 2 ♥ 2 ♥ 2 ♥ 3 ♥ 2 ♥ 2 ♥ 2 ♥

♥

♥

1

2

2422

3

1

4

1 • 1 • 1 • 1 •

2 • 2 • 2 • 2 •

3

♥

1

11 0

5,V6

480P 1080i 720P 480i 480P 1080i 720P

7

4

MS MS

Play Menu

GA

0

0

0

0

3

1 • 1 •

2 • 2 •

0

Twin

22Vivid

744

1 •

2 •

♥

♥

22

♥

0

1

0

♥

17 VM Initial VM [0:off, 1:Low, 2:Mid, 3:High

18 VM_H VM high level assignmen

19 VM_M VM mid level assignmen

20 VM_L VM low level assignmen

21 VGAP

VGAS ♥

24 VGAC

VGAV

Vivid 3 Standard 3 Movie 2 Pro 0

Vivid 15 Standard 15 Movie 12 Pro 15

Vivid 10 Standard 10 Movie 8 Pro 10

Vivid 5 Standard 5 Movie 4 Pro 5

5

0

0

0

5

WV600 and WV700 are different

65WV600 and 57WV600 different

— 24 —

SERVICE DATA LISTS

t

t

t

r

p

3♥3

2♥2

K

e

.

)

♥

♥

♥

♥

♥

KP-57WV600/57WV700/

65WV600/65WV700

CATEGORY # ITEM DESCRIPTION DATA

CXA2170P-4 0 YCON Y signal gain 0 1

1 SPIC Sub picture RF, V1-4, 480i(V5, V6) 14 HD* (V5,V6) 15 HD (V7) 15 MS 0

2 SCOL Sub color adjustmen

3 SHUE Sub HUE adjustmen

4 SPIO Sub picture offse

5 SCLO Sub color offset ♣ Adjustable - M Board CBA

6 SHUO Sub HUE offset ♦ Adjustable - B Board CBA

7 UPIC User Picture gain Vivid Standard 50 47 Movie 20 18 Pro 31 ♥ WV600 and WV700 are different

8 UBRT User Brightness Vivid 28 19 Standard 36 31 Movie 34 31 Pro 31

9 UCOL User Colo

10 UHUE User Hue Vivid Standard Movie Pro 31

11 USHP User Sharpness Vivid 29 25 Standard Movie Pro 31

12 UTMP User Color Tem

13 R-YR R-Y/R

14 R-YB R-Y/B

15 G-YR G-Y/R RF MS MS

16 G-YB G-Y/B

17 GAMM Initial Gamma 3 33333333 3 33 3

[0:Weak, 3:Strong] 222222222 2 22 2

18 GAMS GAM shape GAMM = 0 0 GAMM =1 GAMM =2 GAMM =3

19 GAMR R output gamma GAMM = 0 0 GAMM =1 6 4 GAMM =2 4 3 GAMM =3 9 7

20 GAMG G output gamma GAMM = 0 0 GAMM =1 6 4 GAMM =2 4 3 GAMM =3 9 7

21 GAMB B output gamma GAMM = 0 0 GAMM =1 6 4 GAMM =2 4 3 GAMM =3 9 7

[0:Low, 1:Mid, 2:High, 3:Inhibit] Vivid Standard Movie Pro 1

MS

RF, V1-4, 480i(V5, V6) ♦ 34 HD* (V5,V6) ♦ 36 HD (V7) ♦ 34 MS ♦ 31 *HD = 480P, 720P, 1080i

RF, V1-4, 480i(V5, V6) ♦ 30 HD* (V5,V6) ♦ 30 HD (V7) ♦ 30 MS ♦ 30

♠

7

7 ♠

7 ♠

Vivid Standard Movie Pro 31

8

15

9

6 V1-V4

Vivid

Standard

Movie

Pro

Others

WV700♥WV600

63

33

31

2

V5,V6

111111111 1 11 1

000000000 0 00 0

♥

♥

WV700

WV600

77 7

WV700

WV600

31

31

29

1

♥

♥

WV600

WV700

WV700

33

31

23

0

WV600

♠ Adjustable - On Line (STD LIST)

V7

♥

WV700

♥

WV600

VGA

0

Play Menu

Twin480i 480P 1080i 720P 480i 480P 1080i 720P

RF MS MS

V1-V4

22 BLK Initial black level 3 ♥ 3 ♥ 3 ♥ 3 ♥

23 DCTR DC tran ratio BLK = 0 0 BLK = 1

24 APED Auto pedestal level BLK = 0 0 BLK = 1

25 DSBO Sub bright offset for UBL

26 IDSW ID Switch

27 ABLM ABL mode BLK = 0 0 BLK = 1 0 BLK = 2 1 BLK = 3 1

28 ABLT ABL threshold voltag

29 SPOF Picture offset for Twin, Freeze, & Norm

30 DPSQ Auto Pedestal black size inflection settingBLK=0 0 BLK=1 0 BLK=2 0 BLK=3 0

31 LRGB Picture gain control for LRGB (OSD RGB

[0:-7step, 15:+8st] BLK=0 7 BLK=1 BLK=2 7 BLK=3

Vivid

Standard

Movie

Pro

Single Picture 8 Others 8

211111111 1 11 1

000000000 0 00 0

000000000 0 00 0

0

0

0

480i 480P 1080i 720P 480i 480P

333

V5,V6 V7

2 ♥ 2 ♥ 2 ♥ 2 ♥

♥

♥ 5 10 BLK = 2 8 BLK = 3 ♥ 815

WV700♥WV600

♥ 1 2 BLK = 2 1 BLK = 3

77

33

♥

WV700♥WV600

3

Play Menu

0

TwinVGA720P1080i

♥

13

♥

— 25 —

SERVICE DATA LISTS

y

r

e

y

y

y

)

)

CATEGORY # ITEM DESCRIPTION

CXA2170D-1 0 VPOS Vertical Position

CXA2170D-2 0 HCNT Shading DC

1 VSIZ Vertical Size

2 VSZO V Size offset (PJ only)

3 VLIN Vertical Linearit

4 VSCO Vertical S-Correction

5 VCEN Vertical Cente

6 VPIN Vertical Pin ♦ Adjustable - B Board CBA

7 MVPN Vertical Middle Pin

8 NSCO Rotation

9 HTPZ Horizontal Trapezoid

10 MHTZ Middle Horizontal Trapezoid * This data resides in th

11 ZOOM Zoom Switch same location in NVM.

12 APSW Aspect Switch

13 ASPT Aspect Ratio

14 SCRL Vertical Scroll

15 UVLN Upper Vertical Linearit

16 LVLN Lower Vertical Linearit

1 HPOS Horizontal Position

2 HSIZ Horizontal Size

3 SLIN Blue Offset DC

4 MPIN Blue Offset Para-Amp

5 PIN Horizontal Pin

6 PINO Pin Off-Set (PJ only)

7 UCP Upper Corner Pin

8 LCP Lower Corner Pin

9 UXCG Upper Extra Corner Pin Gain

10 LXCG Lower Extra Corner Pin Gain

11 UXCP Upper Extra Corner Pin Position

12 LXCP Lower Extra Corner Pin Position

13 XCPP Extra Corner Pin Polarit

14 PPHA Pin Phase

15 VANG AFC Angle

16 LANG Shading Phase

17 VBOW AFC Bow

18 LBOW Shading Para Amp

WideZoom Zoom

5

10

1

1

24

29

4

♠

31

9 ♠

0

10

7

31

31

31 31

480P/960i 540P/1080i

Full (Fav,Scroll

25 ♠

31

0

15* 15*

1

1

49

29

23

77

31

0

31

15

0

29

19

0

0

2

2

0

31

31

31

48

KP-57WV600/57WV700/

65WV600/65WV700

Normal Full (Twin, MS

♠

5

8

15

1

5

31 ♠

9 ♠

10

31

31

0

1

5

29

04

0

0

77

§0

♣ Adjustable - M Board CBA

♠ Adjustable - On Line (STD LIST)

0

3

29

23

— 26 —

SERVICE DATA LISTS

T

T

e

)

y

t

e

g

x

c

o

b

r

Y

t

t

c

)

)

)

)

CATEGORY # ITEM DESCRIPTION

CXA2170D-3 0 HBLK Horizontal Blanking Switch

CXA2170D-4 0 QPAM DQP amplitude LEVEL

CXA2170D-5 0 VFRQ Vertical Frequenc

CXA2171 0 MTRX Matri

1 LBLK Left Blanking

2 RBLK Right Blanking

3 VBLK Vertical Blanking Switch

4 TBLK Top Blanking

5 BBLK Bottom Blanking

6 AFCM AFC Loop Gain

7 JUMP Reference Pulse Jump Switch

8 VDJP Vertical Drive Jump Switch

9 VDST Vertical Drive Start Switch

10 AKBT AKB Timing

1 QPAV DQP amplitude VERTICAL MODULATION

2 QPAP DQP amplitude TIL

3 QPDC DQP DC level

4 QPDV DQP DC level VERTICAL MODULATION

5 QPDP DQP DC level TIL

6 CPY1 COPY FUNCTION (Full to Vcomp/normal

7 DF DF phase

8 DQP DQP phase

9 DHMT DH Board Mute

1 VON Vertical Drive On Switch

2 EWDC Pin DC Level Shif

3 MS15 FH=15K @ MS Mode

4 HFRQ Fh setting @multi-scan

5 HFRX Reciprocal Fh @mult-scan

6 VMPS Vertical Mult-scan Mod

7 INTR Free-run Interlace Settin

8 VLNL Vertical # of Lines (L)

9 VLNH Vertical # of Lines (H)

10 AGCS Vertical AGC Mode

1 GAIN Output gain for Vide

2 FIXS SYNC type 000

3 CBGN Output gain for C

4 CRGN Output gain for C

5 YGN Output gain for

6 VTC V SYNC sep. time constan

7 HTC H SYNC sep. time constan

8 HWID H SYNC width

9 HSEP SYNC sep. type

10 HMSK H SYNC MASK during V SYNC period 1080i 0 Others 1

11 FRGB Matrix=3:RGB 000

480P/960i 540P/1080i

WideZoom

0

7

7

1

9

FRGB = 1

0

V5/V6 (480p, 720p, 1080i, No Sync)

♣

5

5 ♣

5 ♣

0

Tri-level syn

1

1

V5/V6 (480p, 720p, 1080i, No Sync

Zoom Full (Fav,Scroll

0

7

7

1

9

31 31

7

20

60

7

3 V5,V6,V7, no syn

0 Others 1 ♠

KP-57WV600/57WV700/

65WV600/65WV700

1

4

8

0

0

31

31

0

1

1

0

0

80

25

0

0

0

0

0

1 Others 0

V7 (480p, VGA, 720p, 1080i, No Sync) Others

V7 (480p, VGA, 720p, 1080i, No Sync

Normal Full (Twin, MS

11*

4

8

00* 0*

1

9

1717

7

60

7

♣

♦

Adjustable - On Line (STD LIST)

5656

2525

1*

4

6

33

1

0

9

17*

31*

7*

20*20

60

7*

Adjustable - M Board CBA

Adjustable - B Board CBA

* This data resides in th

same location in NVM.

Others

— 27 —

SERVICE DATA LISTS

e

0

e

0

e

0

e

0

0

0

t

o

e

x

t

0

s

e

e

o

e

x

o

e

x

e

e

e

e

e

e

e

e

i

t

y

y

y

z

z

)

f

)

y

s

s

t

x

x

CATEGORY # ITEM DESCRIPTION DATA

MID-1 0 DHPH h active display area phas

Common 2 DHAR h active display area siz

picture 3 DVAR v active display area siz

data 4 DHPW display h pulse width H-resolution = 192

NOTE:

All data listed MID Mode = Scroll / Inde

data unless 7 DYSD display output ys signal delay correc

INITIALIZE:

Display twin Input = Others 0

mode with one 10 MDHS main display picture h siz

the other. 11 MDVS main display picture v siz

Enter service. Input = Others 135

"7" + "JUMP" 12 MLHP multi picture mode h position MID Mode = Twin / Mem

+ "ENTER" 13 MLVP multi picture mode v position MID Mode = Twin / Mem

Wait until pics 14 SDHP sub display picture h position MID Mode = Favorit

become same 15 SDVP sub display picture v position MID Mode = Favorit

size. WRITE. 16 SDHS sub display picture h siz

1 DVPH v active display area phas

5 DVPW display v pulse width H-resolution = 192

6 DYCD display output yc signal delay correc

8 MDHP main display picture h position H-resolution = 192

9 MDVP main display picture v position Input = 480i / 480P / VGA Widemode = Others30

17 SDVS sub display picture v siz

18 PDHP PinP Large mode h position 0

19 PDVP PinP Large mode v position 0

20 PDHS PinP Large mode h siz

21 PDVS PinP Large mode v siz

22 DPSW display pll switch MID Mode = Single, Input = 1080

23 MDLO model selec

24 BCOL Background color

[ 0 = Black, 15 = White] MID Mode = MS 5

H-resolution = 192

H-resolution = 192

H-resolution = 192

H-resolution = 192

MID Mode = Single Analog 480i 0 Analog Others 0

MID Mode = Twin 2

MID Mode = Mem

MID Mode = Favorit

Table 0 7 Table 1 4 Table 2 2 Table 3 1 Table = (2170P-3 SYSM) + (2170P-3 SHFO) - 1

H-resolution = 1920

Input = 480i 120 Widemode = Others120

MID Mode = Favorit

MID Mode = Favorit

0

0

12

MID Mode = Single Widemode = Normal 5 Widemode = Other

MID Mode = Other

106

20

240

135

55

5

2

2

2

Widemode = Normal 160 Widemode = Other

Widemode = Normal 163 Widemode = Others240

43 MID Mode = Favorit

9 MID Mode = Favorit

167

6

115

75

0 Others 0

MDLO Details Ļ 0 Ļ 1 Ļ

Bit7 Not Used

Bit6 Not Used

Bit5 Scroll Sub-Picture (16:9 only) 4:3 Displa

Bit4 Memory-PLL Freguenc

Bit3 ADC-PLL Select Internal External

Bit2 Frame On/Off (Twin

Bit1 Display Type (Scroll) 16:9 Model 4:3 Model

Bit0 Display Type (Twin, Memo

5

35 MID Mode = Scroll / Inde

30 MID Mode = Scroll / Inde

18.54…MH

Of

16:9 Model 4:3 Model

KP-57WV600/57WV700/

65WV600/65WV700

0

40

29

16:9 Displa

17.26…MH

On

5

25 DYSS display output ys signal type selec

26 OSDH Index Sub-Picture OSD H position MID Mode = Scroll / Inde

27 OSDV Index Sub-Picture OSD V position MID Mode = Scroll / Inde

MID Mode = MS 3

32

16

— 28 —

SERVICE DATA LISTS

S

S

KP-57WV600/57WV700/

65WV600/65WV700

MID MODESINGLE PICTURE

RF, V1-4 MID2 0 DRHP H Pos 117 1080i MID3 0 VDHP H Pos 100

Full (Other) MID2 1 DRHS H Size 178 MID3 1 VDHS H Size 240

MID2 MID3

RF, V1-4 MID2 0 DRHP H Pos 154 VGA MID3 0 VDHP H Pos 167

Normal MID2 1 DRHS H Size 162 Full (Other) MID3 1 VDHS H Size 228

MID2 MID3

480i, V5-7 MID2 0 DRHP H Pos 118 VGA MID3 0 VDHP H Pos 213

Full (Other) MID2 1 DRHS H Size 177 Normal MID3 1 VDHS H Size 207

MID2 MID3

480i, V5-7 MID2 0 DRHP H Pos 154

Normal MID2 1 DRHS H Size 161

MID2

480P MID3 0 VDHP H Pos 147

Full (Other) MID3 1 VDHS H Size 240

MID3

ERVICE DATA MID MODESINGLE PICTURE

MID2 2 DRVP V Pos 36 MID3 2 VDVE V Pos 18

MID2 3 DRVS V Size 120 MID3 3 VDVS V Size 135

MID2 2 DRVP V Pos 37 MID3 2 VDVE V Pos 36

MID2 3 DRVS V Size 120 MID3 3 VDVS V Size 119

MID2 2 DRVP V Pos 37 MID3 2 VDVE V Pos 38

MID2 3 DRVS V Size 120 MID3 3 VDVS V Size 118

MID2 2 DRVP V Pos 33

MID2 3 DRVS V Size 122

MID3 2 VDVE V Pos 37

MID3 3 VDVS V Size 120

ERVICE DATA

480P MID3 0 VDHP H Pos 201

Normal MID3 1 VDHS H Size 216

MID3

720P MID3 0 VDHP H Pos 139

MID3

MID3 2 VDVE V Pos 44

MID3 3 VDVS V Size 116

MID3 1 VDHS H Size 158

MID3 2 VDVE V Pos 25

MID3 3 VDVS V Size 179

— 29 —

SERVICE DATA LISTS

S

S

KP-57WV600/57WV700/

65WV600/65WV700

MID MODE TWIN PICTURE

RF, V1-4 RF, V1-4 MID2 0 DRHP H Pos 145 RF, V1-4 FREEZE MID2 0 DRHP H Pos 146

MID2 MID3 MID2

480i (V5-7) MID2 0 DRHP H Pos 144 MID2

MID2 MID3 1 VDHS H Size 219

480P RF, V1-4 MID2 0 DRHP H Pos 153 MID3

MID3 MID2 MID3 1 VDHS H Size 147

720P MID3 0 VDHP H Pos 160 1080i FREEZE MID3 1 VDHS H Size 220

MID3

1080i MID3 1 VDHS H Size 221 MID3 2 VDVE V Pos 60

MID3 MID3 3 VDVS V Size 124 MID3

ERVICE DATA MID MODE FREEZE

MID2 1 DRHS H Size 165 MID2 1 DRHS H Size 164

MID2 2 DRVP V Pos 58 MID2 2 DRVP V Pos 58

MID2 3 DRVS V Size 110 MID2 3 DRVS V Size 110

MID3 0 VDHP H Pos 74

MID3 1 VDHS H Size 165

MID3 2 VDVE V Pos 25 480i (V5-7) FREEZE MID2 0 DRHP H Pos 145

MID3 3 VDVS V Size 56 MID2 1 DRHS H Size 163

MID2 1 DRHS H Size 164

MID2 2 DRVP V Pos 44

MID2 3 DRVS V Size 117 480P FREEZE MID3 0 VDHP H Pos 188

MID2 1 DRHS H Size 165

MID2 2 DRVP V Pos 58

MID2 3 DRVS V Size 110 720P FREEZE MID3 0 VDHP H Pos 161

MID3 0 VDHP H Pos 188 MID3 2 VDVE V Pos 54

MID3 1 VDHS H Size 220 MID3 3 VDVS V Size 165

MID3 2 VDVE V Pos 60 MID3

MID3 3 VDVS V Size 108

MID3 1 VDHS H Size 148 MID3 2 VDVE V Pos 43

MID3 2 VDVE V Pos 55 MID3 MID3 3 VDVS V Size 123

MID3 3 VDVS V Size 165

VGA FREEZE MID3 0 VDHP H Pos 204

MID3 0 VDHP H Pos 141 MID3 1 VDHS H Size 210

MID3 2 VDVE V Pos 41 MID3 3 VDVS V Size 108

ERVICE DATA

MID2 2 DRVP V Pos 44

MID2 3 DRVS V Size 117

MID3 2 VDVE V Pos 62

MID3 3 VDVS V Size 107

MID3 0 VDHP H Pos 142

VGA MID3 0 VDHP H Pos 198

MID3

MID3 1 VDHS H Size 213

MID3 2 VDVE V Pos 54

MID3 3 VDVS V Size 111

— 30 —

Loading...

Loading...