Sony klv 32w400a, klv 40w400a, klv 46w400a, klv 52w400a schematic

KLV-32W400A/40W400A/46W400A/52W400A

E Model

SERVICE MANUAL

India Model

Indonesia Model

Middle East Model

Thailand Model

Philippines Model

Saudi Arabia Model

South Africa Model

RM-GA011 KLV-32W400A/40W400A/46W400A/52W400A

EX1 CHASSIS

LCD Colour TV

SPECIFICATIONS

KLV-32/40/46/52W400A (GA) 2

KLV-32/40/46/52W400A (GA) 3

WARNINGS AND CAUTIONS SAFETY-RELATED COMPONENT

CAUTION

These servicing instructions are for use by qualified service

personnel only.

To reduce the risk of electric shock, do not perform any servicing

other than that contained in the operating instructions unless you

are qualified to do so.

WARNING!!

WARNING

It is essential that all critical parts be replaced only with the part

number specified in the electrical parts list to prevent electric

shock, fire, or other hazard.

NOTE: Do not modify the original design without obtaining

written permission from the manufacturer or you will

void the original parts and labor guarantee.

An isolation transformer should be used during any service to

avoid possible shock hazard, because of live chassis.

The chassis of this receiver is directly connected to the ac power

line.

! SAFETY-RELATED COMPONENT

WARNING!!

Replace all components with Sony parts whose part numbers

appear as shown in this manual or in supplements

published by Sony.

USE CAUTION WHEN HANDLING THE LCD PANEL

When repairing the LCD panel, be sure you are grounded by

using a wrist band.

When repairing the LCD panel on the wall, the LCD panel must

be secured using the 4 mounting holes on the rear cover.

1) Do not press on the panel or frame edge to avoid the risk of

electric shock.

2) Do not scratch or press on the panel with any sharp objects.

3) Do not leave the module in high temperatures or in areas of

high humidity for an extended period of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water. It may cause a short circuit within

the module.

6) Disconnect the AC power when replacing the backlight (CCFL)

or inverter circuit.

(High voltage occurs at the inverter circuit at 650Vrms.)

7) Always clean the LCD panel with a soft cloth material.

8) Use care when handling the wires or connectors of the inverter

circuit. Damaging the wires may cause a short.

9) Protect the panel from ESD to avoid damaging the electronic

circuit (C-MOS).

KLV-32/40/46/52W400A (GA) 4

SAFETY CHECK-OUT

l

t

µ

d

AC

)

t

Col

pe

.

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly

soldered connections. Check the entire board surface for

solder splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps,

and mounting hardware have been replaced. Be absolutely

certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer and

recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend

the replacement of any such line cord to the customer.

7. Check the antenna terminals, metal trim, “metallized”

knobs, screws, and all other exposed metal parts for AC

leakage. Check leakage as described below.

Leakage Test

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part

having a return to chassis, must not exceed 0.5 mA (500

microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to

use these instructions.

2. A battery-operated AC milliampmeter. The Data Precision

245 digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit”

indication is 0.75 V, so analog meters must have an accurate

low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated

digital multimeters that have a 2 VAC range are suitable (see

Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground.

If the retaining screw is to be used as your earth ground, verify

that it is at ground by measuring the resistance between it and a

cold-water pipe with an ohmmeter. The reading should be zero

ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trouble- light (not a neon lamp) between the hot side of the

receptacle and the retaining screw. Try both slots, if necessary,

to locate the hot side on the line; the lamp should light at normal

brilliance if the screw is at ground potential (see Figure B).

Exposed Meta

Parts on Se

ouble Ligh

AC Outlet Box

.15

0.75V

Earth Groun

Ohmmeter

FigureA. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground

d-water Pi

KLV-32/40/46/52W400A (GA) 5

SELF DIAGNOSIS FUNCTION

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY LED will automatically begin to flash.

The number of times the LED flashes translates to a probable source of the problem.

A definition of the STANDBY LED flash indicators is listed in the instruction manual for the user’s knowledge and reference.

If an error symptom cannot be reproduced, the remote commander can be used to review the failure occurrence data stored in memory to

reveal past problems and how often these problems occur.

1-1. DIAGNOSTIC TEST INDICATORS

When an error occurs, the STANDBY LED will flash a set number of times to indicate the possible cause of the problem.

If there is more than one error, the LED will identify the first of the problem areas.

Result for all of the following diagnostic items are displayed on screen.

If the screen displays a “0”, no error has occurred .

Number of times STANDY LED Monitoring Items

(Red) flashes (Screen Display)

2 times DC_DET Main power supply voltage error (12V, etc)

3 times DC_ALERT1 Malfunction of 3.3V line (Trident circuit, etc)

4 times DC_ALERT2 Malfunction of 5V line

(Voltage Supply to FE, etc)

5 times DC_ALERT3 Malfunction of power supply for screen

6 times BACKLIGHT Malfunction of inverter or overcurrent, etc

7 times TEMPERATURE Abnormal temperature inside unit

8 times AUDIO Audio circuit error (amplifier, etc.)

10 times DEF Digital FE circuit error

11 times B-ENGINE Malfunction of Trident IC or around IC

12 times HFR BH board error

13 times (No item on screen display) Malfunction of balancer

Diagnostic Item Description

1-2. DISPLAY OF STANDBY/TIMER LIGHT FLASH COUNT

[ FLASH COUNT ]

2 times

4 times

5 times

LED ON 0.3 sec.

LED OFF 0.3 sec.

Note: One flash counts is not self-diagnostic.

STANDBY LED

LED OFF

2 sec.

1-3. STOPPING THE STANDBY FLASH

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY LED from flashing.

KLV-32/40/46/52W400A (GA) 6

1-4. SELF-DIAGNOSTIC SCREEN DISPLAY

DC_DET

DC_ALEAT1

DC_ALERT2

DC_ALERT3

BACKLIGHT

TEMPERATURE

AUDIO

DFE

B-ENGINE

HFR

0

0

0

0

0

0

0

0

0

0

TV

Monitoring Items

Error Count Record

For details, refer to "1-1. DIAGNOSTIC TEST INDICATORS"

[ SELF-DIAGNOSTIC SCREEN DISPLAY ]

Number "0": means that no fault detected.

Number "1": means a fault was detected one time only.

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confirmed, it is possible to

bring up past occurrences of failure for confirmation on the screen:

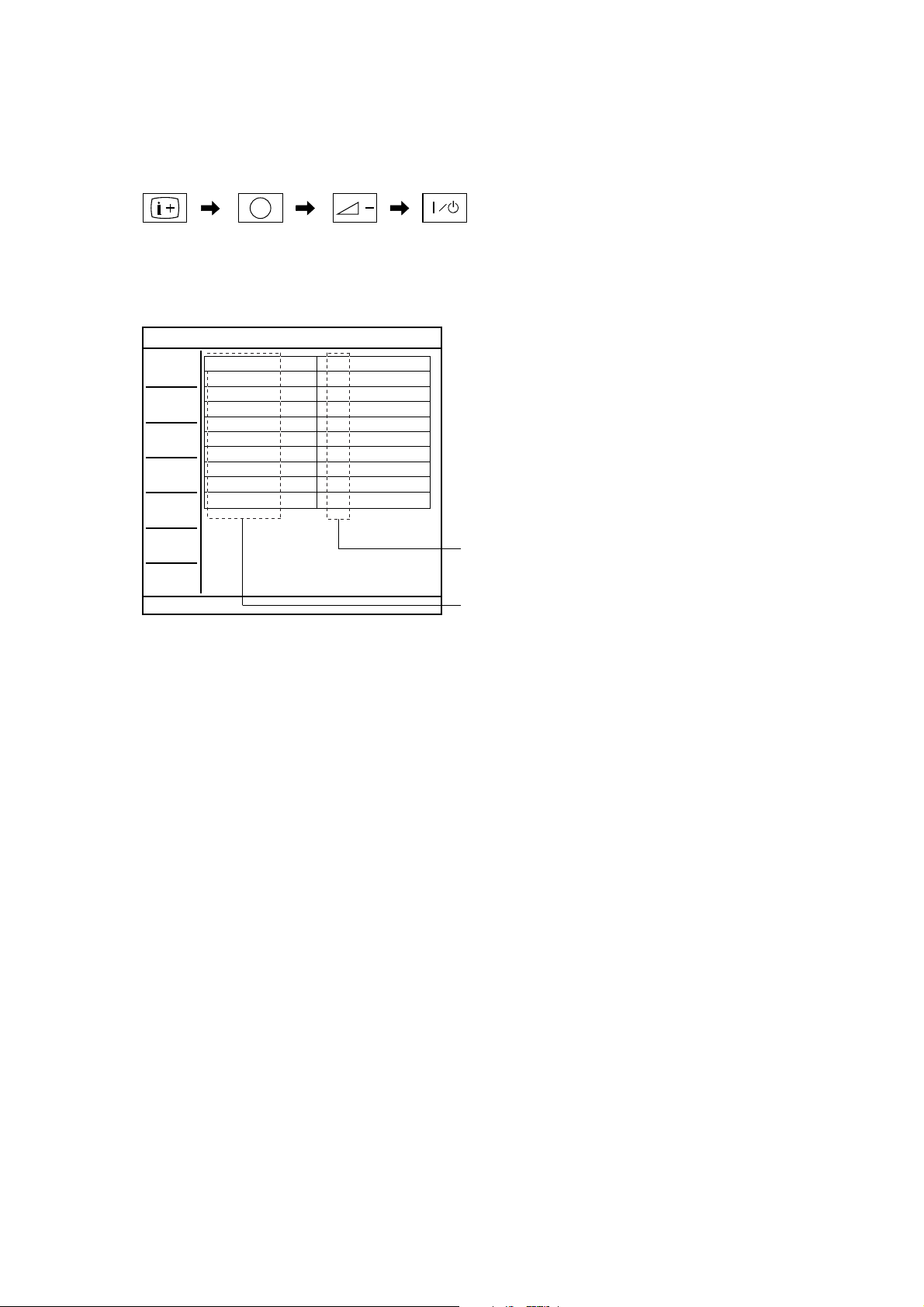

1-4-1. To Bring Up Screen Test

In standby mode, press buttons on the remote commander sequentially in rapid succession as shown below:

5

( Info/Text reveal )

( Number button )

* ( Volume )

( TV standby )

* : Note that this differs from entering the service mode (volume +)

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen

After you have completed the repairs, clear the result display to “0”.

1-5. Quitting Self-diagnostic screen

To quit the entire self-diagnostic screen, turn off the power switch on the remote commander or the main unit.

KLV-32/40/46/52W400A (GA) 7

TABLE OF CONTENTS

SAFETY CHECK-OUT ............................................. 5

SELF DIAGNOSIS FUNCTION ................................ 6

1. DISASSEMBLY ............................................... 1-1

1-1. KLV-32W400A ...................................................... 1-1

1-1-1. REAR COVER AND STAND ASSY

REMOVAL ...................................................... 1-1

1-1-2. SWITCH UNIT AND SIDE JACK BRACKET

REMOVAL ...................................................... 1-2

1-1-3. UNDER COVER AND VESA FRAME (TOP)

REMOVAL ...................................................... 1-3

1-1-4. BG1G BOARD REMOVAL ........................... 1-4

1-1-5. POWER UNIT REMOVAL ............................ 1-5

1-1-6. SPEAKER AND UNDER BAR REMOVAL . 1-6

1-1-7. LCD PANEL, H3E BOARD AND H4 BOARD

REMOVAL ...................................................... 1-7

1-1-8. WIRING LAYOUT ......................................... 1-8

1-2. KLV-40W400A ...................................................... 1-9

1-2-1. REAR COVER AND STAND ASSY

REMOVAL ...................................................... 1-9

1-2-2. AC INLET AND UNDER COVER

REMOVAL .................................................... 1-10

1-2-3. BG1G BOARD AND IP5 BOARD

REMOVAL .................................................... 1-11

1-2-4. FRAME REMOVAL ..................................... 1-12

1-2-5. SPEAKER (L) REMOVAL ........................... 1-13

1-2-6. SPEAKER (R) REMOVAL ........................... 1-13

1-2-7. LCD PANEL, H3E BOARD AND H4 BOARD

REMOVAL .................................................... 1-14

1-2-8. WIRING LAYOUT ....................................... 1-15

1-3. KLV-46W400A .................................................... 1-16

1-3-1. REAR COVER AND STAND ASSY

REMOVAL .................................................... 1-16

1-3-2. AC INLET AND UNDER COVER

REMOVAL .................................................... 1-17

1-3-3. BG1G BOARD AND IP5 BOARD

REMOVAL .................................................... 1-18

1-3-4. FRAME REMOVAL ..................................... 1-19

1-3-5. SPEAKER (L) REMOVAL ........................... 1-20

1-3-6. SPEAKER (R) REMOVAL ........................... 1-20

1-3-7. LCD PANEL, H3E BOARD AND

H4 BOARD REMOVAL ............................... 1-21

1-3-8. WIRING LAYOUT ....................................... 1-22

1-4. KLV-52W400A .................................................... 1-23

1-4-1. REAR COVER AND STAND ASSY

REMOVAL .................................................... 1-23

1-4-2. AC INLET AND UNDER COVER

REMOVAL .................................................... 1-24

1-4-3. D4, D5, G5 AND BG1B BOARDS

REMOVAL .................................................... 1-25

1-4-4. FRAME REMOVAL ..................................... 1-26

1-4-5. SPEAKER (L) REMOVAL ........................... 1-27

1-4-6. SPEAKER (R) ................................................ 1-27

1-4-7. LCD PANEL, H3E BOARD AND H4 BOARD

REMOVAL .................................................... 1-28

1-4-8. WIRING LAYOUT ....................................... 1-29

2. DIAGRAMS ..................................................... 2-1

2-1. CIRCUIT BOARDS LOCATION ......................... 2-1

(1) KLV-32W400A................................................ 2-1

(2) KLV-40W400A................................................ 2-1

(3) KLV-46W400A................................................ 2-1

(4) KLV-52W400A................................................ 2-1

2-2. BLOCK DIAGRAM .............................................. 2-2

(1) BG1G Board ..................................................... 2-2

3. EXPLODED VIEWS ........................................ 3-1

3-1. KLV-32W400A ...................................................... 3-2

3-1-1. REAR COVER AND STAND ASSY ............. 3-2

3-1-2. CHASSIS-1 ...................................................... 3-3

3-1-3. CHASSIS-2 ...................................................... 3-4

3-2. KLV-40W400A ...................................................... 3-5

3-2-1. REAR COVER AND STAND ASSY ............. 3-5

3-2-2. CHASSIS-1 ...................................................... 3-6

3-2-3. CHASSIS-2 ...................................................... 3-7

3-3. KLV-46W400A ...................................................... 3-8

3-3-1. REAR COVER AND STAND ASSY ............. 3-8

3-3-2. CHASSIS-1 ...................................................... 3-9

3-3-3. CHASSIS-2 .................................................... 3-10

3-4. KLV-52W400A .................................................... 3-11

3-4-1. REAR COVER AND STAND ASSY ........... 3-11

3-4-2. CHASSIS-1 .................................................... 3-12

3-4-3. CHASSIS-2 .................................................... 3-13

3-5. PACKING MATERIALS .................................... 3-14

3-5-1. KLV-32W400A.............................................. 3-14

3-5-2. KLV-40W400A.............................................. 3-15

3-5-3. KLV-46W400A.............................................. 3-16

3-5-4. KLV-52W400A.............................................. 3-17

KLV-32/40/46/52W400A (GA) 8

SECTION 1

DISASSEMBLY

1-1. KLV-32W400A

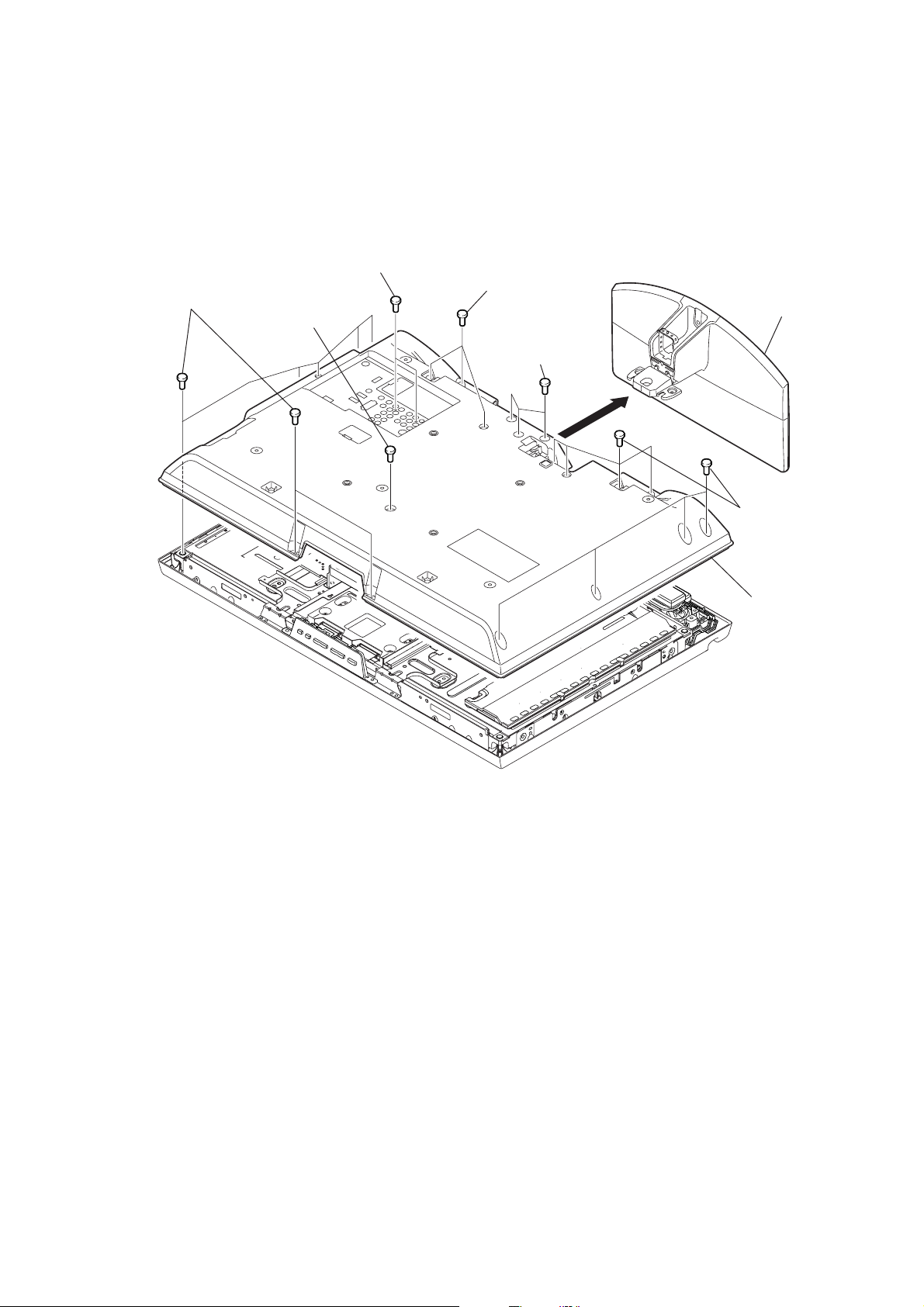

1-1-1. REAR COVER AND STAND ASSY REMOVAL

5 Two screws

(+BV 3X12,

TYPE2, IT-3)

3 Seven screws

(+BVTP2 4X16)

4 One screws

(+PSW M5X8)

3 Three screws

(+BVTP2 4X16)

1 Three screws

(+PSW M5X16)

2 Stand assy

3 Eight screws

(+BVTP2 4X16)

6 Rear cover assy

KLV-32/40/46/52W400A (GA) 1-1

KLV-32W400A

1-1-2. SWITCH UNIT AND SIDE JACK BRACKET REMOVAL

2 Side jack

bracket assy

Claw

Claw

1 Switch unit

KLV-32/40/46/52W400A (GA) 1-2

KLV-32W400A

1-1-3. UNDER COVER AND VESA FRAME (TOP) REMOVAL

5 VESA frame

(TOP)

4 Two screws

(+PSW M4X8)

3 Under cover

2 Two screws

(+BVST 3X8)

1 Power supply

cord

KLV-32/40/46/52W400A (GA) 1-3

KLV-32W400A

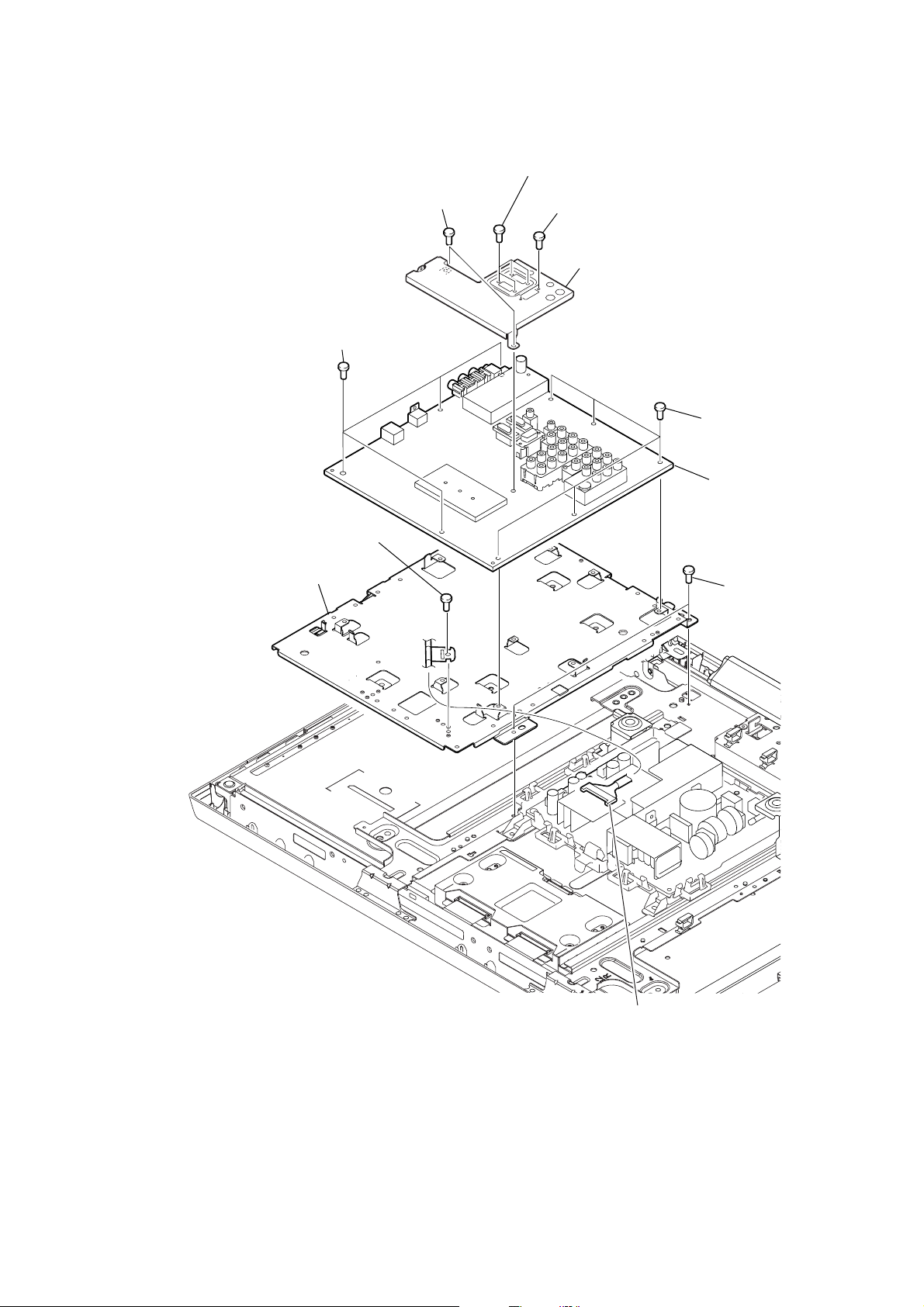

1-1-4. BG1G BOARD REMOVAL

5 Four screws

(+BVST 3X8)

6 One screw

(+BVST 3X8)

q; Main bracket assy

3 One screw

(+BVST 3X8)

1 Four screws

(+PSW M3x5)

2 Two screws

(SP 4-4O UNC)

4 B (J) shield

5 Five screws

(+BVST 3X8)

8 BG1G board

9 Two screws

(+BVST 3X8)

7 Harness with connector

(LVDS)

KLV-32/40/46/52W400A (GA) 1-4

KLV-32W400A

1-1-5. POWER UNIT REMOVAL

1 One screw

(+PSW M4X8)

5 Two screws

(+PSW 3SG)

6 Power unit

7 G1 brackt

Claw

2 VESA frame

(BOTTOM)

5 Two screws

(+PSW 3SG)

3 One screw

(+PSW M4X8)

4 VESA frame

(BOTTOM)

KLV-32/40/46/52W400A (GA) 1-5

KLV-32W400A

1-1-6. SPEAKER AND UNDER BAR REMOVAL

3 Loudspeaker

1 Two screw

(+BVTP2 4X16)

2 Under bar

4 Loudspeaker

KLV-32/40/46/52W400A (GA) 1-6

KLV-32W400A

1-1-7. LCD PANEL, H3E BOARD AND H4 BOARD REMOVAL

1 One screw

(+BVTP2 4X16)

2 Two screws

(+PSW M4X8)

4 One screw

(+BVTP2 4X16)

3 Spine frame (L)assy

7 two screws

(+PSW M4X8)

5 Three screws

(+PSW M4X8)

6 Spine frame (R)assy

8 Two screws

(+BVTP2 4X16)

7 Two screws

(+PSW M4X8)

9 Vesa frame assy

q; One screw

(+BVTP 3X12 TYPE2 IT-3)

qa H4 board

Claw

qs Light guide

qd H3E board

qf Claer panel

qh Two screws

(+BVTP2 4X16)

qj LCD panel

qg Illumination module

qk Bezel assy

KLV-32/40/46/52W400A (GA) 1-7

KLV-32W400A

1-1-8. WIRING LAYOUT

CN001

SWITCH Unit

Inverter

Speaker (L)

CN401

CN301

Power

cord

H4 board

H3E board

Power Unit

CN601

CN602

Illumination

module

CN4001

CN5501

CN5500

CN3004

CN2001

CN4000

CN8001

BG1G board

CN3003

Speaker (R)

KLV-32/40/46/52W400A (GA) 1-8

1-2. KLV-40W400A

1-2-1. REAR COVER AND STAND ASSY REMOVAL

4 Two screws

(+PSW M5X8)

3 Six screws

(+BVTP2 4X16)

4 Two screws

(+PSW M5X8)

6 Two screws

(+BV 3X12,

TYPE2, IT-3)

3 Five screws

(+BVTP2 4X16)

7 Rear cover assy

3 Two screws

(+BVTP2 4X16)

5Two screws

(+PSW M5X12)

3 Four screws

(+BVTP2 4X16)

3 Two screws

(+BVTP2 4X16)

1 Three screws

(+PSW M5X12)

2 Stand assy

8 Switch unit

KLV-32/40/46/52W400A (GA) 1-9

KLV-40W400A

1-2-2. AC INLET AND UNDER COVER REMOVAL

7 Two screws

(+BVST 3X8)

8 AC inlet bracket

6 AC inlet

4 Under cover (L2)

2 Under bar (L)

1 Two screws

(+BVTP2 4X16)

5 Two screws

(+KTT 3X10(S TYPE))

3 One screw

(+BVST 3X8)

KLV-32/40/46/52W400A (GA) 1-10

Loading...

Loading...