Sony KLV-32M300A Schematic

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

000

1.

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION

KLV-32M300A

KLV-37M300A

RM-SA012 CHINA

RM-SA012 CHINA

LAX U

CHASSIS

ORIGINAL MANUAL ISSUE DATE: 4

REVISION DATE SUBJECT

8/2007 Correction of 3-5. Average Value of W/B and update of 6-1., 6-2. REPLACEMENT PARTS

LIST.

LCD Colour TV

9-834-175-02

B

B

B B

SERVICE MANUAL

U

O E S V G

MODEL NAME REMOTE COMMANDER DESTINATION

LAX U

CHASSIS

KLV-32M300A

KLV-37M300A

RM-SA012 CHINA

RM-SA012 CHINA

O E S V G

RETU N

MENU

PROG

KLV-32M300A/KLV-37M300A RM-SA012

LCD Colour TV

9-834-175-02

B

B

B B

TABLE OF CONTENTS :

A

A

Prep

aaa

aaa

tttto

ooooo

st W

h

t aaaaa

a

W

h

ttttt

t

al

a

ace o

aaaa

aaaaaaaaa

a

n

eee

e of

f W

A

/////

SPECIFICATIONS 3

WARNINGS AND CAUTIONS 5

SAFETY-RELATED COMPONENT WARNING 6

SAFETY CHECK-OUT 8

SECTION 1 : DISASSEMBLY 9

SECTION 2 : SERVICE MODE (factory mode) 15

SECTION 3 : ADJUSTMENT 17

3-1. Preparation 17

3-2. Adjust White Balance of "COOL" temperature; 17

3-3. Adjust White Balance of "NEUTRAL" temperature; 17

3-4. Adjust White Balance of "WARM" temperature; 17

3-5. Average Value of W/B 17

SECTION 4 : TIMING CHART 18

SECTION 5 : DIAGRAMS 19

5-1. BOARD Layout/WIRING Layout 19

5-1-1. KLV-32M300A 19

5-1-2. KLV-37M300A 20

5-2. Frame Diagram 21

5-3. BLOCK DIAGRAM 22

5-4. SCHEMATIC 23

5-5. PCB Layout 43

B

B

B B

SECTION 6 : EXPLODED VIEW & REPLACEMENT PARTS LIST 49

6-1. KLV-32M300A 49

6-2. KLV-37M300A 52

KLV-32/37M300A2

SPECIFICATIONS :

2

2

2

Vi

io:ii

T

log

log

log

log

log

g

ue

ue

au

PCPCPCPCPCPCPC

PC

InInInInIn

In

putput

put

putpput(DD(D(D

D

b

0.7

-p,

-p,

-p,

-p,

-

75

75

75

ohoo

m

0.700

Vp

-p,

-p-p75757575ohohohms/mm

H

P

C aaudi

udi

udi

udi

udi

o i

o

t (

t (

t (

t

minmin

ija

ijaija

ija

ija

ijaijck)cck)

)

dpdpdp

one

one

one

s j

ack

50

HzHzHzHz

)

)

0

on

tal

tal

tal

tal

)

)

)

)

)

nes

(v

(v

e

ert

ereica

1414141414

0 W

W

796

796

44

16.

14

.0

Model name KLV-37M300A KLV-32M300A

System

Panel System LCD (Liquid Crystal Display) Panel

TV System D/K, B/G, I, M

Colour System PAL, PAL60 (only Video In), NTSC4.43 (only Video In), NTSC3.58

Channel Coverage D/K: VHF: C1 to C12, R1 to R12/ UHF: C13 to C57, R21 to R60/ CATV: S01 to

S03, S1 to S41, Z1 to Z39

I: UHF: B21 to B69/ CATV: S01 to S03, S1 to S41

B/G: VHF: E2 to E12/ UHF: E21 to E69/ CATV: S01 to S03, S1 to S41

M: VHF: A2 to A13/ UHF: A14 to A79/ CATV: A-8 to A-2, A to W+4, W+6 to W+84

Sound Output 10 W + 10 W (as distortion of 7%)

Input/Output jacks

Antenna 75 ohms external terminal

1, 2 S video input (4-pin mini DIN)

Y: 1.0 Vp-p, 75 ohms unbalanced/C: 0.286 Vp-p (Burst signal), 75 ohms

1, 2 Video input (phono jacks): 1 Vp-p, 75 ohms unbalanced, sync negative

1, 2 Audio input (phono jacks): 500 mVrms, Impedance: 47 kilohms

1, 2 Component input (phone jacks)

Supported formats: 1080p, 1080i, 720p, 576p, 576i, 480p, 480i

Y: 1 Vp-p, 75 ohms, 0.3V sync negative/P

P

R/CR

: 0.7 Vp-p, 75 ohms

1, 2 Audio input (phono jacks): 500 mVrms, Impedance: 47 kilohms

Video output (phono jack): 1 Vp-p, 75 ohms unbalanced, sync negative

Audio output (phono jacks): 500 mVrms (100% modulation)

HDMI IN Video: 1080p, 1080i, 720p, 576p, 576i, 480p, 480i

Audio: Two channel linear PCM 32, 44.1 and 48 kHz, 16, 20 and 24 bits

Analogue audio input (phono jacks): 500 mVrms, Impedance: 47 kilohms

PC IN (RGB) PC Input (D-sub 15-pin)

G: 0.7 Vp-p, 75 ohms, non Sync on Green/B: 0.7 Vp-p, 75 ohms/

R: 0.7 Vp-p, 75 ohms/HD: 1-5 Vp-p/VD: 1-5 Vp-p

PC IN PC audio input (minijack): 500 mVrms, Impedance: 47 kilohms

Headp nes jack

Power and others

Power Requirements 220 V AC, 50 Hz

Viewing Screen Size (diagonal) 94 cm (37 inches) 80 cm (32 inches)

Display Resolution 1,366 pixels (horizontal) × 768 lines (vertical)

li

Power Consumption 155 W 140 W

Dimensions

(w × h × d)*

with stand (mm) 918 × 656 × 264 796 × 591 × 214

without stand (mm) 918 × 609 × 108 796 × 544 × 99

Mass* with stand (kg) 21.0 16.5

without stand (kg) 18.0 14.0

Product usage condition

Environment Temperature 5°C - 35°C

Humidity 20% - 80%

Air Pressure 86 kPa - 106 kPa

* Dimensions and mass are approximate values.

B/PB

: 0.7 Vp-p, 75 ohms/

B

3 KLV-32/37M300A

B B

B

Design and specifications are subject to change without notice.

nc

c

ce

d) in the

abchchchch

cchchart

w

h

a 60 Hz ve

rticicicalal

f

re

qu

e

6

444444888

8

4

44444

4

666

6

0

0

55555

5

76888888

0

666

66666

000000

00

444

0000

0

00000

ntal

ixel

)

andnd

nd

pepepe

p

cicifi

ca

Input Sig

fefefefererere

e

PC Input Signal Reference Chart

Horizontal

Signals

VGA 640 480 31.5 60 VGA

SVGA 800 600 37.9 60 VESA Guidelines

XGA 1024 768 48.4 60 VESA Guidelines

WXGA 1280 768 47.4 60 VESA

rizo

(Pixel)

Vertical (Line)

640 480 37.5 75 VESA

720 400 31.5 70

800 600 46.9 75 VESA

1024 768 56.5 70 VESA

1024 768 60 75 VESA

1280 768 47.8 60 VESA

1360 768 47.7 60 VESA

Horizontal

frequency (kHz)

Vertical

frequency (Hz)

Standard

VGA-T

• This TV’s PC input does not support Sync on Green or Composite Sync.

• This TV’s PC input does not support interlaced signals.

• For the best picture quality, it is recommended to use the signals (boldfaced) in the above chart with a 60 Hz

vertical frequency from a personal computer. In plug and play, signals with a 60 Hz vertical frequency will be

selected automatically.

B

B

B B

4 KLV-32/37M300A

WARNINGS AND CAUTIONS

onen

tsww

ititithh

nynnpony.

CAUTION

These servicing instructions are for use by qualified service personnel only. To reduce the risk of electric shock, do not perform any

servicing other than that contained in the operating instructions unless you are qualified to do so.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis.The chassis of

this receiver is directly connected to the ac power line.

!

SAFETY-RELATED COMPONENT WARNING!!

Replace all components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony.

B

B

5 KLV-32/37M300A

B B

SAFETY-RELATED COMPONENT WARNING

tcho

vevettt

t

t

he

h

h

txposososososososthth

th

cont

ac

t wiwi

thththththwwwwe

on

nect t

heAAAwewwe

we

w

w

we

w

vo

ltage oc

cu

t

t t t t

t tt ththee

e

an the L

CDwwwh

n handling

thehehehehe

wires

o

l from ESD tavoi

d

E

AKAKAKAK

AGAGU

RR

Vololololot-t-t-t

t

dsDUDUDUIDUT

It is essential that all critical parts be replaced only with the part number specified in the electrical parts list to prevent electric shock,

fire, or other hazard.

NOTE: Do not modify the original design without obtaining written permission from the manufacturer or you will void the original parts and

labor guarantee.

USE CAUTION WHEN HANDLING THE LCD PANEL

When repairing the LCD panel, be sure you are grounded by using a wrist band.

To avoid damaging the LCD panel:

do not press on the panel or frame edge to avoid the risk of electric shock.

do not scratch or press on the panel with any sharp objects.

do not leave the module in high temperatures or in areas of high humidity for an extended period of time.

do not expose the LCD panel to direct sunlight.

avoid contact with water. It may cause a short circuit within the module.

disconnect the AC power when replacing the backlight (CCFL) or inverter circuit.

(High voltage occurs at the inverter circuit at 650Vrms.)

always clean the LCD panel with a soft cloth material.

use care when handling the wires or connectors of the inverter circuit. Damaging the wires may cause a short.

protect the panel from ESD to avoid damaging the electronic circuit (C-MOS).

LEAKAGE CURRENT HOT CHECK CIRCUIT

AC Volt-meter

Good Earth Ground

To Instruments

exposed

METALLIC PARTS

1.5 Kohm/10W

Such as WATER PIPE,

CONDUIT etc.

B

B

B B

6 KLV-32/37M300A

The circuit boards used in these models have been processed using

eeeeee

Solthe s

e s

e ssold

le e e

of

of

of

of

of

of

acc

ura

te

tem

at

Sol

Sol

Sol

leaato

tth

Lead Free Solder.

The servicing of these boards requires special precautions to be taken

as outlined below.

It is strongly recommended to use Lead Free Solder material in order to guarantee optimal quality of new solder joints.

Lead Free Solder is available under the following part numbers:

Due to the higher melting point of Lead Free Solder the soldering iron tip temperature needs to be set to 370 degrees centigrade.

This requires soldering equipment capable of accurate temperature control coupled with a good heat recovery characteristics.

For more information on the use of Lead Free Solder, please refer to http://www.sony-training.com

B

7 KLV-32/37M300A

B

B B

SAFETY CHECK-OUT

d

stalalalalalleled

d

mer ananand d d d rrrreco

ar

ts which,

ououou

ghghghghghgh

f

ffffun

u

u

u

ct

on

. Point

themooooutututututtto

th

ce

ment.

or

cracks

anabrasisision. R

lineeccccccoroororod

dtotheh custotototmem

r

alalaltt

ttri

riririririri

mm,mmmm

metalliziz

k

pa

rt

rtrtrtrts s s fo

fofofofor Aeaka

k..ChCCC

e

b

cece

ptpp

ac

cacaca

tetetetetett

tttthe

illicececef

th

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps,

and mounting hardware have been replaced. Be absolutely certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and recommend their replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for C leakage. Check

leakage as described below.

LeakageTest

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75V, so analog meters must have an accurate low voltage scale.

The Simpson’s 250 and Sanwa SH-63TRD are examples of

passive VOMs that are suitable. Nearly all battery-operated

digital multimeters that have a 2 VAC range are suitable (see

Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate

retaining screw on most AC outlet boxes is also at earth ground. If

the retaining screw is to be used as your earth ground, verify that

it is at ground by measuring the resistance between it and a coldwater pipe with an ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt

trou le- light (not a neon lamp) between the hot side of the

receptacle and the retaining screw. Try both slots, if necessary, to

locate the hot side on the line; the lamp should light at normal

brilliance if the screw is at ground potential (see Figure B).

To Exposed Metal

Parts on Set

AC

μ

F

0.15

Earth Ground

Figure A. Usingan AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

Voltmeter

(0.75V)

B

B

8 KLV-32/37M300A

B B

SECTION 1 : DISASSEMBLY

vavava

va

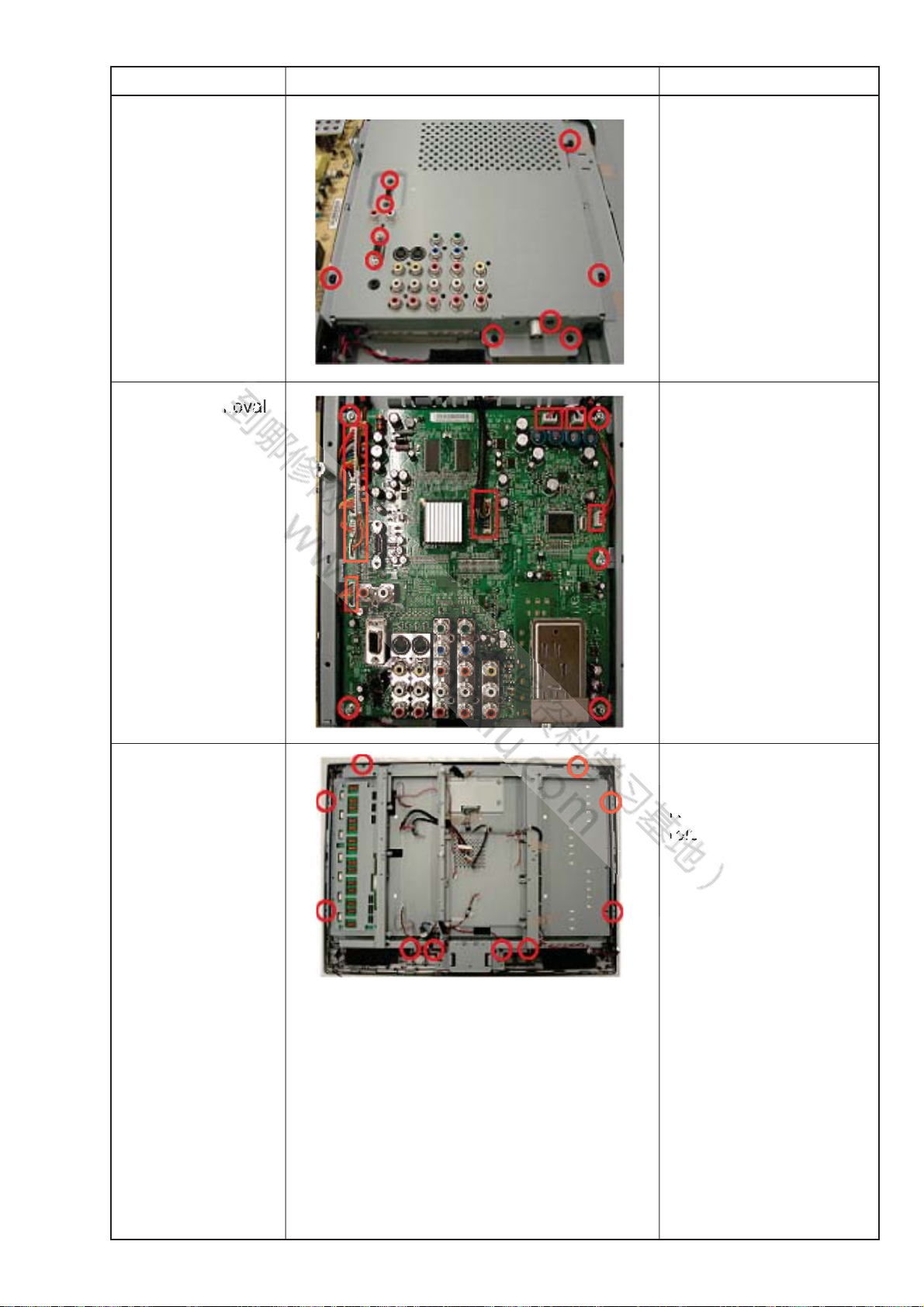

STEP PICTURE DESCRIPTION

Service Position

Stand Removal

Gently place the TV set

face down on the table.

KLV-32M300A:

Remove 3 screws to

release the Tabletop

Stand from the unit.

KLV-37M300A:

Remove 4 screws to

release the Tabletop

Stand from the unit.

B

KLV-32/37M300A9

B

B B

STEP PICTURE DESCRIPTION

Rear Cover

Removal

KLV-32M300A:

Remove 16 screws to

release the rear cover.

KLV-37M300A:

Remove 16 screws to

release the rear cover.

Wall Mount

Bracket

Removal

Remove 6 screws to

release the Wall Mount

Bracket.

KLV-32/37M300A10

B

B

B B

STEP PICTURE DESCRIPTION

s

Cover Sheet

Removal

Botton ASSY

Removal

Remove 1 screw to

release the Cover

Sheet.

Remove function cable

from function board

connector.

H1 Mount

Removal

Key Cover and

Multi Botton

Removal

H2 Mount

Removal

Multi Button

Function Key Cover

Bend key cover hooks

to release function

board.

Dismantle function key

form function key cover.

Remove 2 screws and

1 connector to release

the H2 Mount.

KLV-32/37M300A11

B

B

B B

STEP PICTURE DESCRIPTION

H3 Mount

Removal

AC Inlet Removal

Remove 1 screw and

1 connector to release

the H3 Mount.

Remove 1 screw and

1 connector to release

the AC Inlet.

G Mount Removal

Remove 6 screws and

3 connectors to release

the G Mount.

KLV-32/37M300A12

B

B

B B

STEP PICTURE DESCRIPTION

movavavavava

Shield Case

Removal

A Mount Removal

Remove 10 screws to

release the Shield

Case.

Remove 5 screws and

9 connectors to release

the A Mount.

Bezel Removal

KLV-32M300A/

37M300A:

Remove 10 screws to

release the Bezel.

B

KLV-32/37M300A13

B

B B

STEP PICTURE DESCRIPTION

LCD Panel

Removal

KLV-32M300A:

Remove 10 screws to

release the LCD Panel.

KLV-37M300A:

Remove 14 screws to

release the LCD Panel.

KLV-32/37M300A14

B

B

B B

SECTION 2 : SERVICE MODE (factory mode)

ce

mode",

pr

s s s

ththth

thththe ME

M

tonn

n

n

VVVVVVV]]]]]]

OfOOfOfOf

f

f]]OOOOOO

O

O

ffffffffff

ff

or

y Me

To adjust various set features, use the Remote Commander to put the set into service mode to display the service menu. Input the signal

to monitor, please confirm that there is no OSD before enter the service mode.

1) Press “LEFT”button

2) Press “RIGHT” button

3) Press “MUTE” button

4) Press “ENTER” button

5) Press “MUTE” button

6) Press “MENU” button

To exit "service mode", press the MENU button

Factory Menu

INPUT SOURCE VIDEO1

WHITE BALANCE [ Of ]

INTERNAL PATTER [ Off ]

COLOR TEMP. [

Neutral

R GAIN [ 229 ]

G GAIN [ 230 ]

B GAIN [ 235 ]

R OFFSET [ 124 ]

G OFFSET [ 125 ]

B OFFSET [ 123 ]

AGING MODE [ Off ]

ADC CALIBRATION [ Off ]

FACTORY RESET [ Off ]

VGA EDID Prot. [ Off ]

HDMI EDID Prot. [ Off ]

ALL RESET [ Off ]

Recall Data [ Off ]

PANEL VERSION: AUO_32

FW: A, 1

MODEL: KLV-32M300A

Menu : Save / Exit Menu

]

It differs according to

the model name and inducing.

B

B

B B

15 KLV-32/37M300A

Loading...

Loading...