SONY KLV-17HR1 Service Manual

SERVICE MANUAL

SPECIFICATIONS

Power requirements

Power consumption (W)

Television system

Colour system

Stereo/Bilingual

system

Channel coverage

VHF

UHF

CATV

HYPER

D/K

L

I

8(Aerial)

Audio output (Speaker)

Number of terminal

i 1/

r 2 (S Video)

t 2 (Video)

o 2 R/D/D/D

L/G/S/I

i (Headphones)

LCD panel

Display resolution

Screen size (cm)

(w/h, diagonal)

Dimensions (w/h/d, mm)

with stand

without stand

Mass (kg)

with stand

without stand

Design and specifications are subject to change without notice.

220 - 240 V AC, 50Hz (Using the supplied AC power adapter, 16.5 V DC input)

Indicated on the rear of the TV.

B/G, I, D/K, L

PAL, SECAM

NTSC3.58, NTSC 4.43 (video input only)

NICAM Stereo/Bilingual D/K, I, B/G, L;

A2 Stereo/Bilingual (German) B/G, D/K

E2 to E12

E21 to E69

S1 to S20, S01 to S03

S21 to S41

R1 to R12, R21 to R69

F2 to F10, B to Q, F21 to F69

UHF B21 to B69

75-ohm external terminal

3 W + 3 W (RMS)

21-pin Scart connector (CENELEC standard)

1

including audio/video input, RGB input, TV audio/video output

S video input (4-pin mini DIN)

Video input (phono jack)

Audio input (phono jacks)

Stereo minijack

a Si TFT active matrix

Y: 1 Vp-p, 75 ohms, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

1 Vp-p, 75 ohms, sync negative

500 mVrms

KLV-17HR1

1280 dots (horizontal)

x 768 lines (vertical)

37.1 x 22.2, 43.2

472 x 405 x 184

472 x 348 x 73

Approx. 5.7

Approx. 4.9

KLV-17HR1

AEP Model

LCD Colour TV

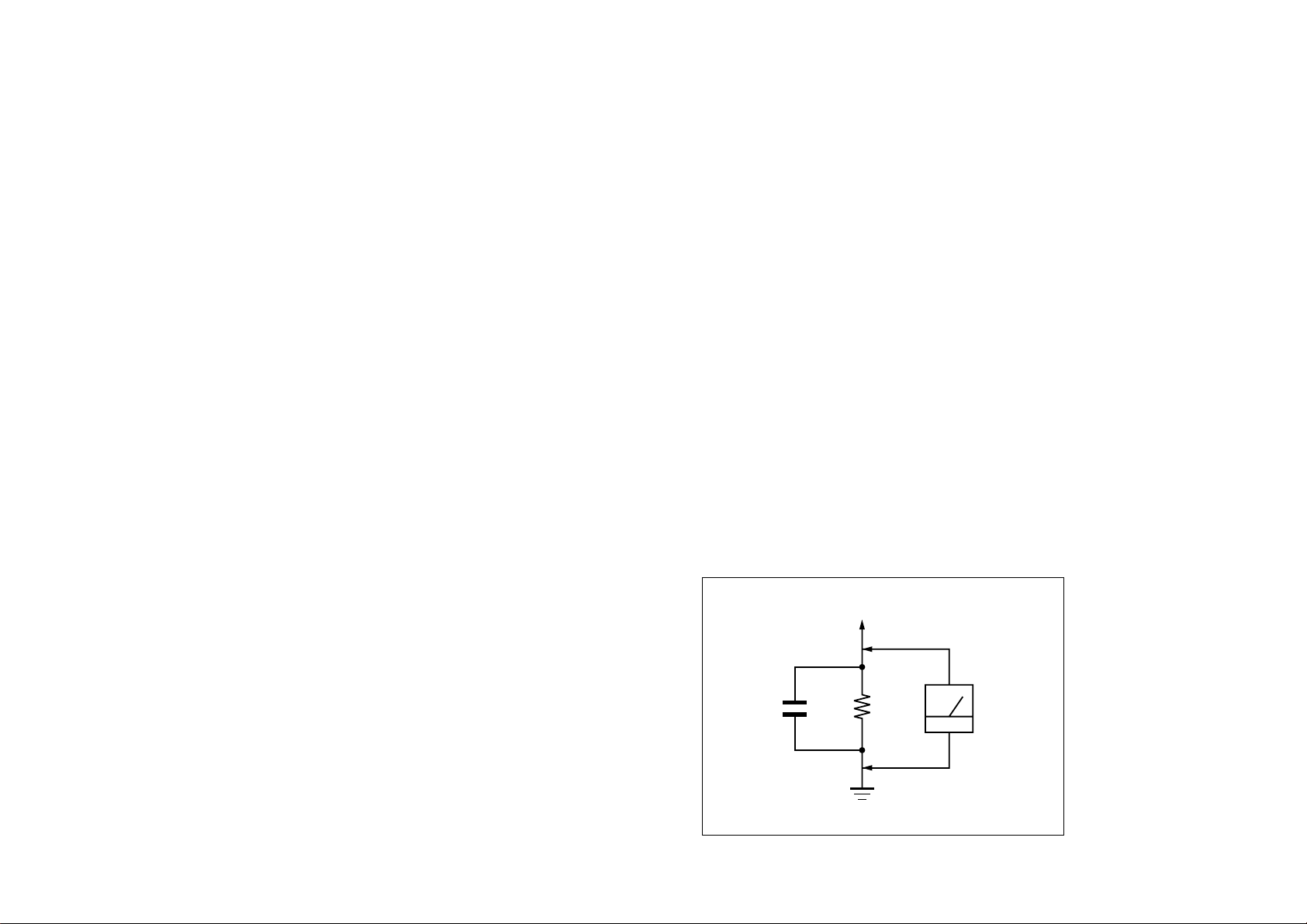

1.5 k

Ω

0.15 µF

AC

Voltmeter

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety

checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that you

have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that

were installed during a previous repair. Point them out to the customer

and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specified values. Make sure your

instruments are accurate; be suspicious of your HV meter if sets always

have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws, and

all other exposed metal parts for AC Leakage. Check leakage as

described right.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and from all

exposed metal parts to any exposed metal part having a return to chassis,

must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA WT540A. Follow the manufacturers’ instructions to use these instruments.

2. A battery-operated AC milliammeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM or

battery-operated AC voltmeter. The “limit” indication is 0.75 V, so

analog meters must have an accurate low-voltage scale. The Simpson 250

and Sanwa SH-63Trd are examples of a passive VOMs that are suitable.

Nearly all battery operated digital multimeters that have a 2 V AC range

are suitable. (See Fig. A)

Fig. A. Using an AC voltmeter to check AC leakage.

KLV-17HR1(AEP) 2

WARNING!!

AVERTISSEMENT!!

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE CRITICAL FOR SAFE OPERATION ARE

IDENTIFIED IN THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

ATTENTION AUX COMPOSANTS RELATIFS À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE TRAME ET UNE

MARQUE ! SONT CRITIQUES POUR LA SÉCURITÉ. NE LES

REMPLACER QUE PAR UNE PIÈCE PORTANT LE NUMÉRO

SPECIFIÉ. LES RÉGLAGES DE CIRCUIT DONT L’IMPORTANCE EST

CRITIQUE POUR LA SÉCURITÉ DU FONCTIONNEMENT SONT

IDENTIFIÉS DANS LE PRÉSENT MANUEL. SUIVRE CES

PROCÉDURES LORS DE CHAQUE REMPLACEMENT DE

COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS

FONCTIONNEMENT EST SUSPECTÉ.

KLV-17HR1(AEP) 3

TABLE OF CONTENTS

Section Title Page Section Title Page

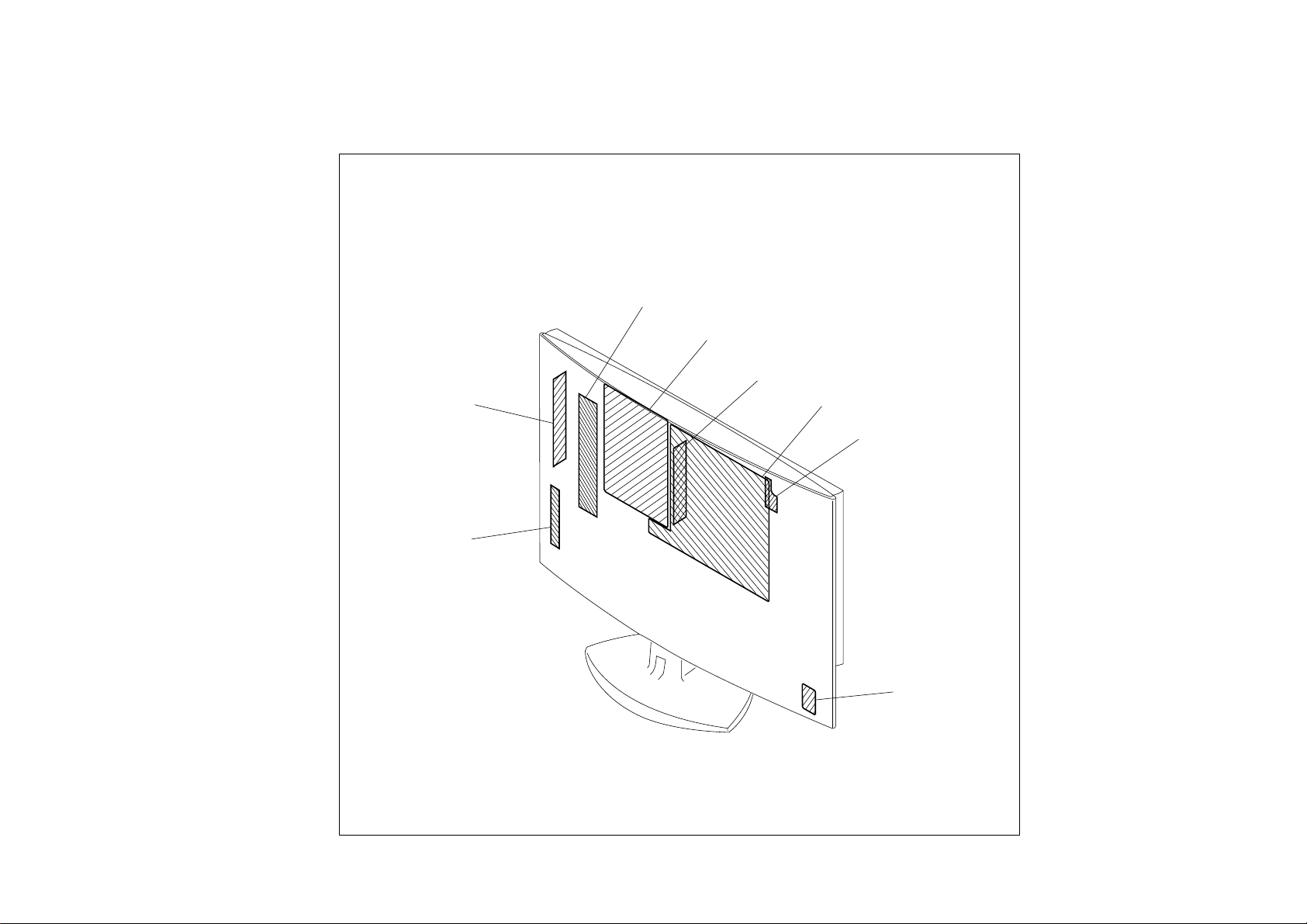

1. DISASSEMBLY

1-1. Rear Panel Removal ............................................. 1-1

1-2. Rear Cover Removal ............................................ 1-2

1-3. H2 Board Removal .............................................. 1-3

1-4. D1 Board Removal .............................................. 1-4

1-5. TU Board Removal............................................... 1-5

1-6. A Board and B Board Removal ............................ 1-6

1-7. LCD Panel Removal ............................................. 1-7

1-8. H3 Board Removal ............................................... 1-8

1-9. H1 Board Removal ............................................... 1-9

2. ADJUSTMENT

2-1. Service Mode ........................................................ 2-1

2-2. White Balance Adjustment (Normal, Warm, Cool)

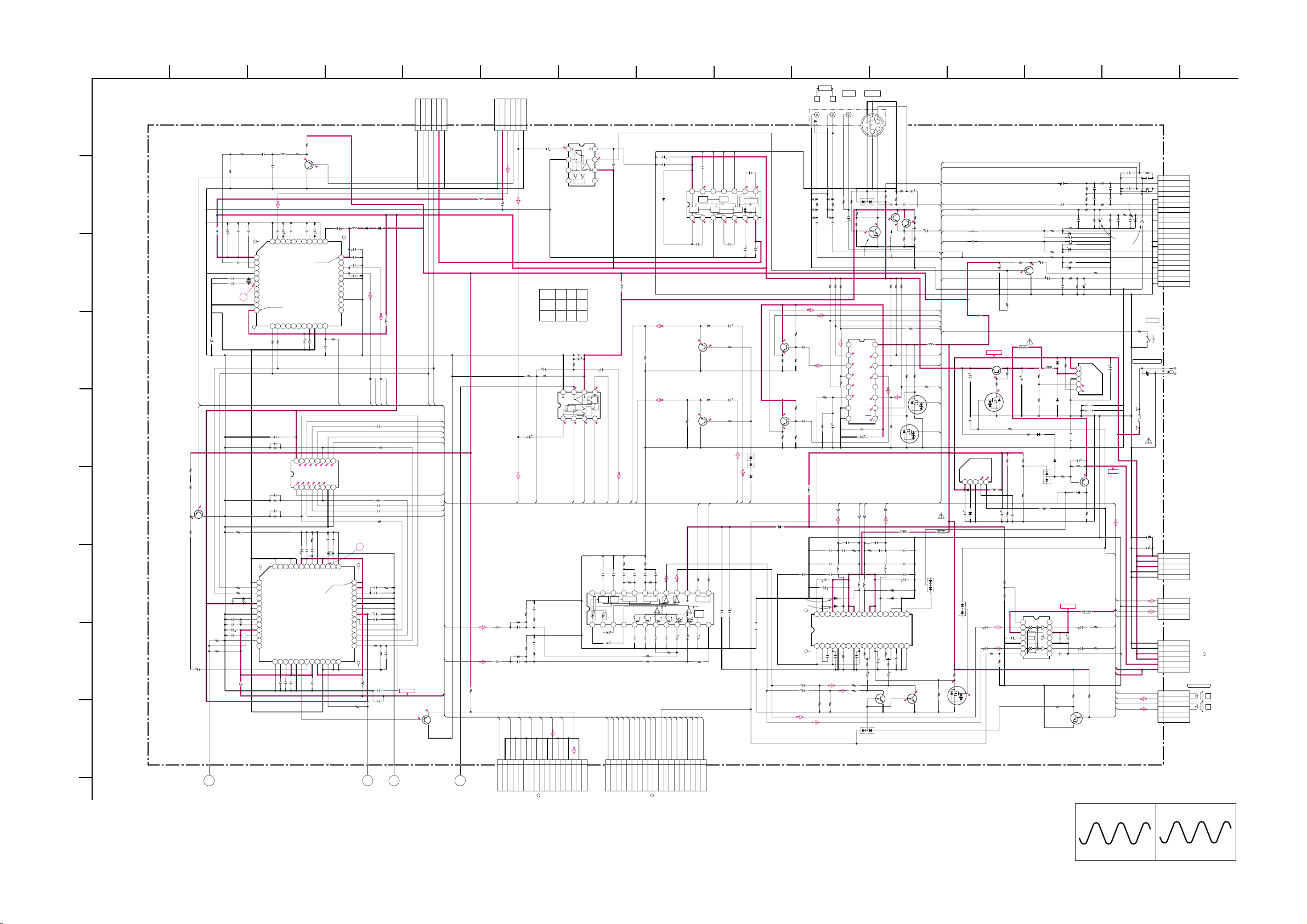

3-3. Schematic Diagrams

and Printed Wiring Boards.................................... 3-3

(1) Schematic Diagrams of A Board ............................ 3-4

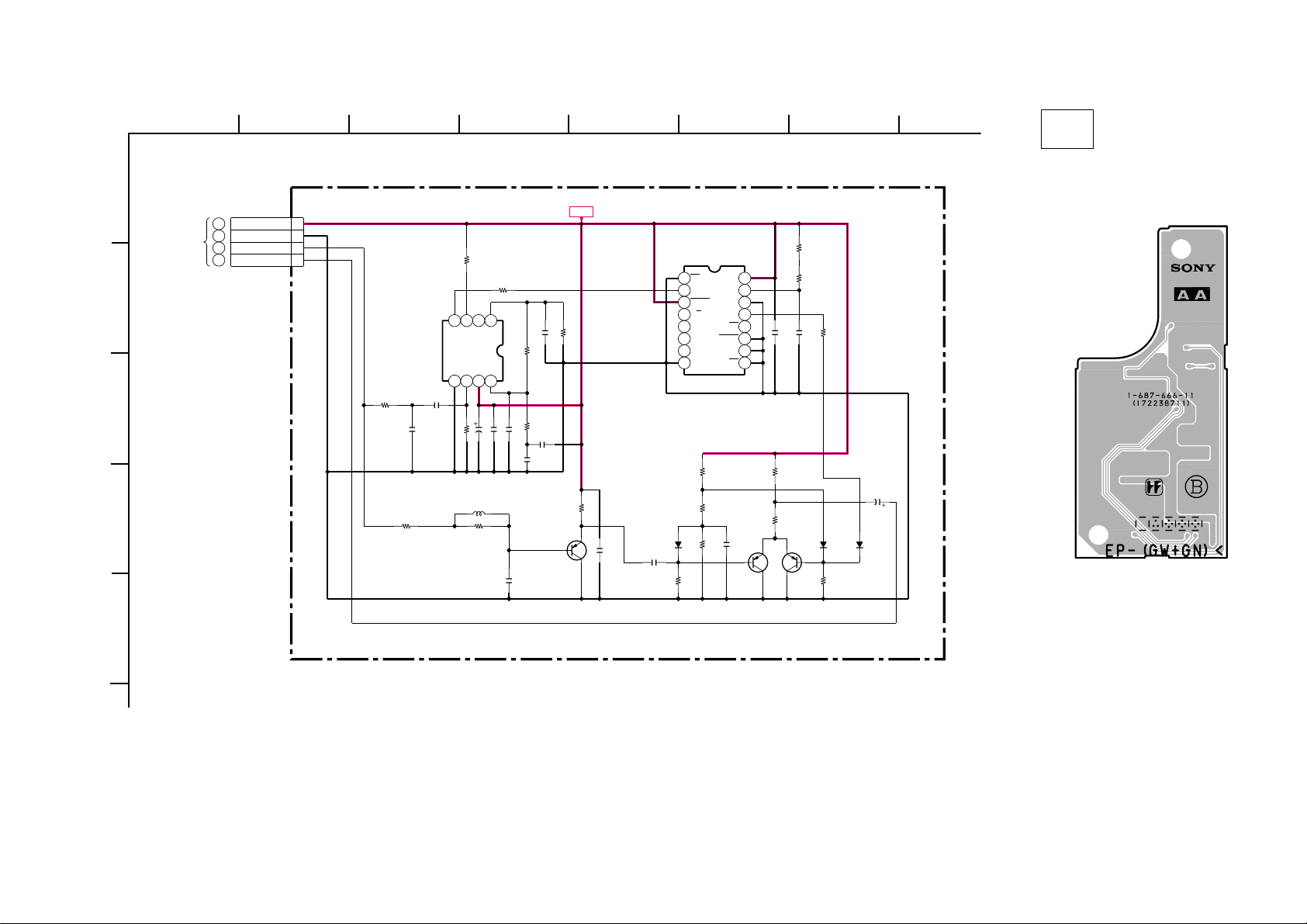

(2) Schematic Diagram of AA Board ........................ 3-6

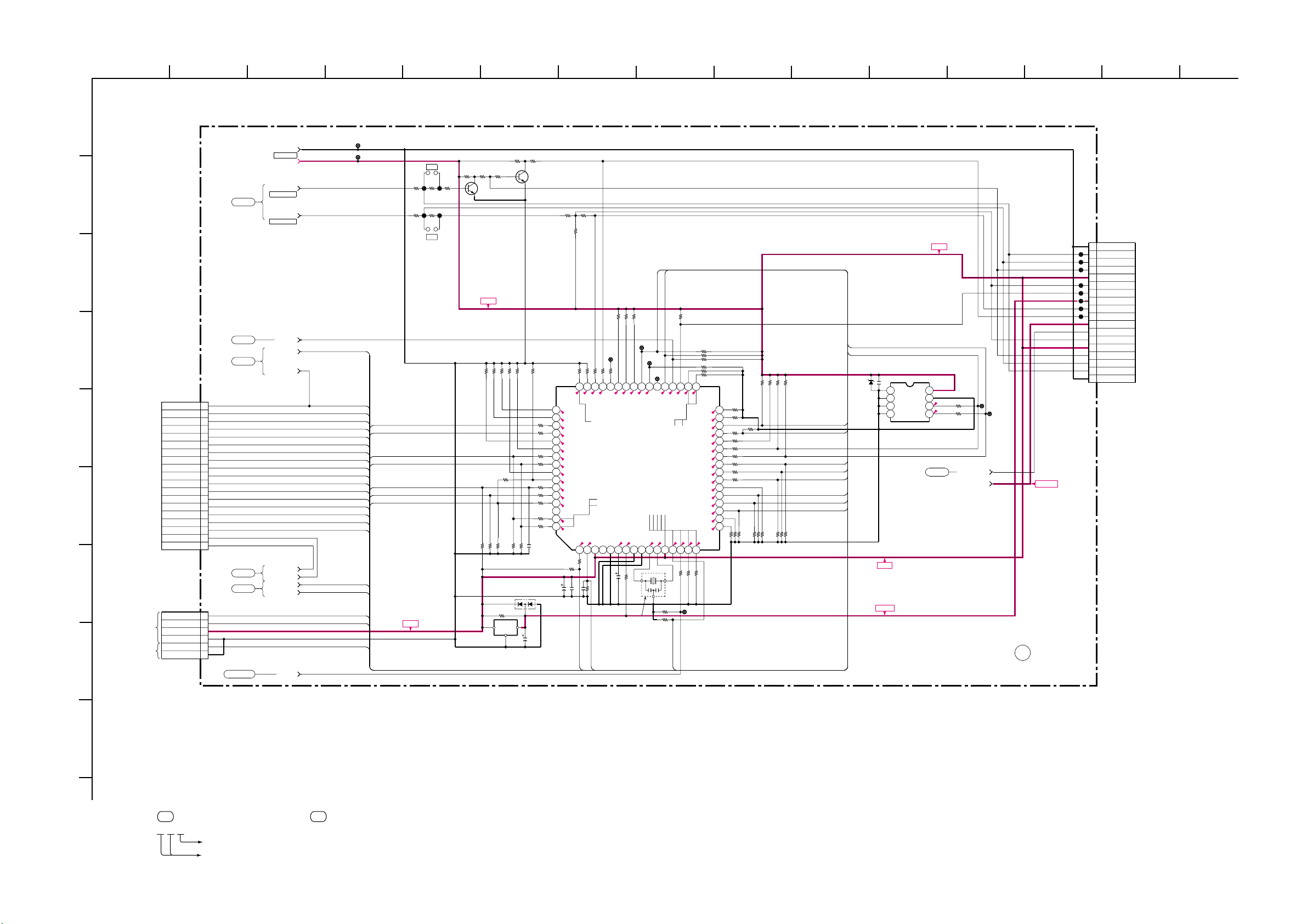

(3) Schematic Diagram of B (a, b, c, d, e) Board

.............................................................................. 3-7

(4) Schematic Diagram of D1 Board ......................... 3-13

(5) Schematic Diagram of H1 Board ......................... 3-15

(6) Schematic Diagram of H2 Board .......................... 3-16

(7) Schematic Diagram of H3 Board .......................... 3-17

(8) Schematic Diagram of TU Board.......................... 3-18

3-4. Semiconductors .................................................... 3-19

4. EXPLODED VIEWS .............................................. 4-1

.............................................................................. 2-1

3. DIAGRAMS

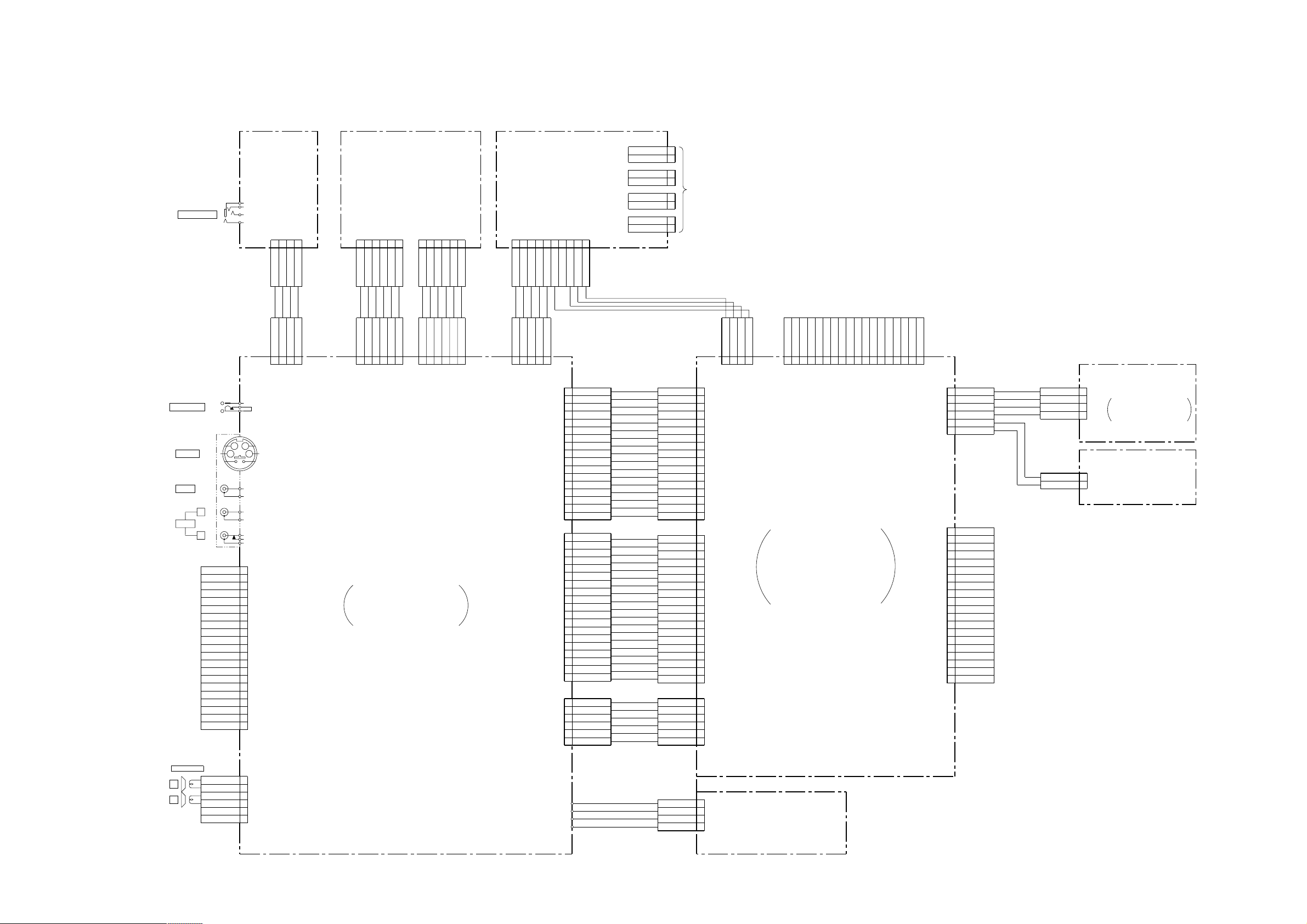

3-1. Frame Diagram ..................................................... 3-1

3-2. Circuit Boards Location........................................ 3-2

(1) Chassis .................................................................. 4-2

(2) Packing Materials ................................................. 4-4

5. ELECTRICAL PARTS LIST ............................... 5-1

KLV-17HR1(AEP) 4

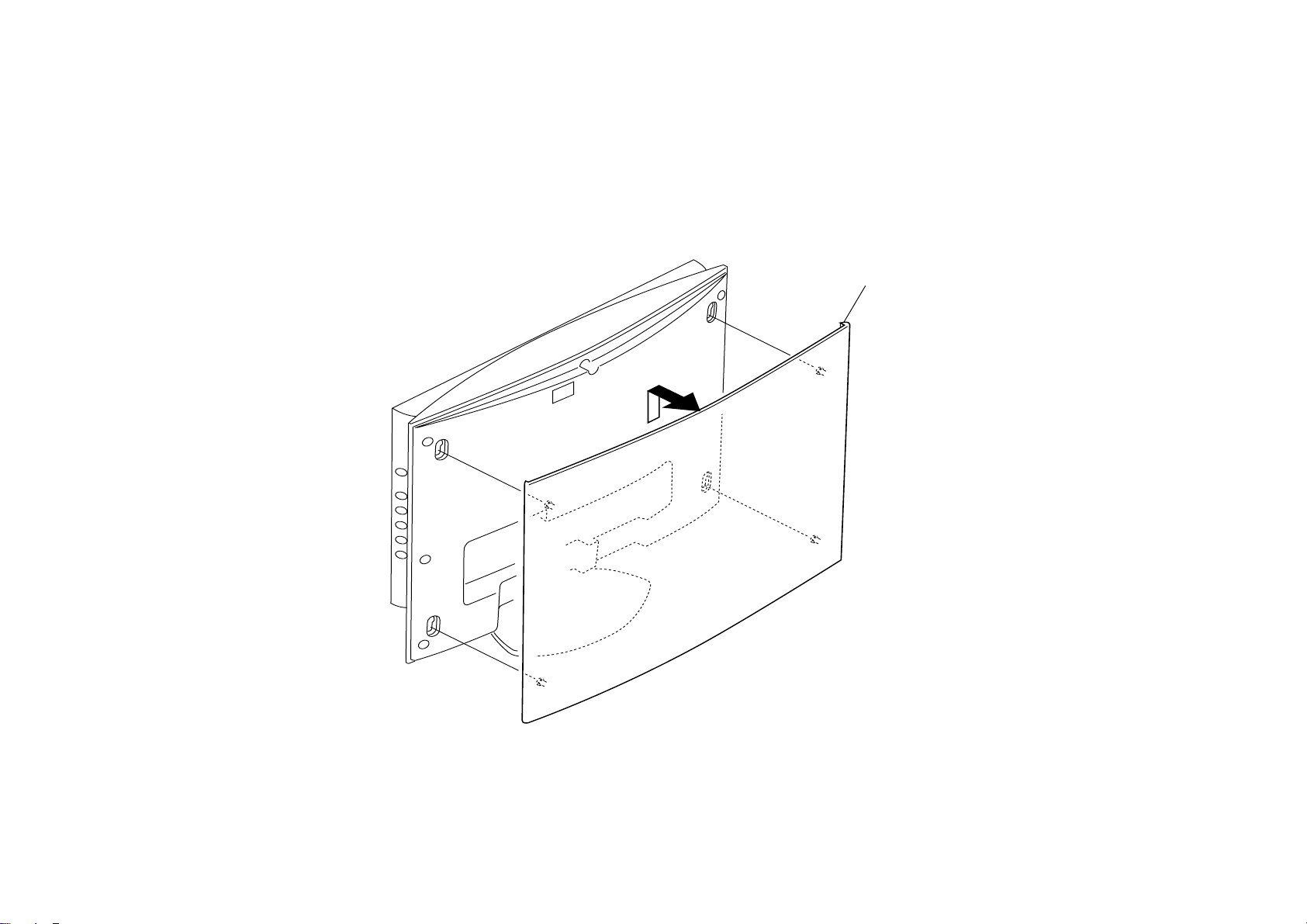

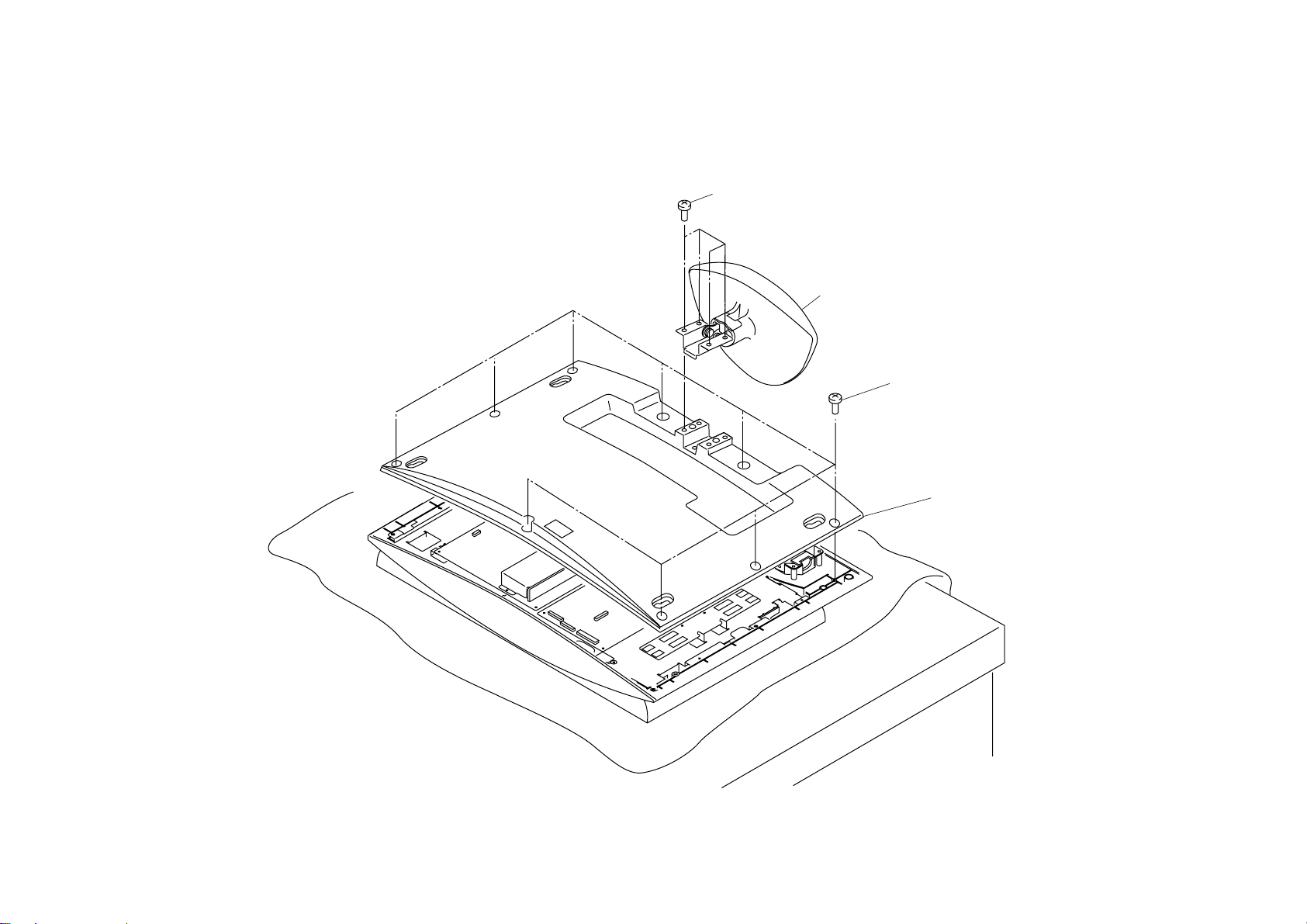

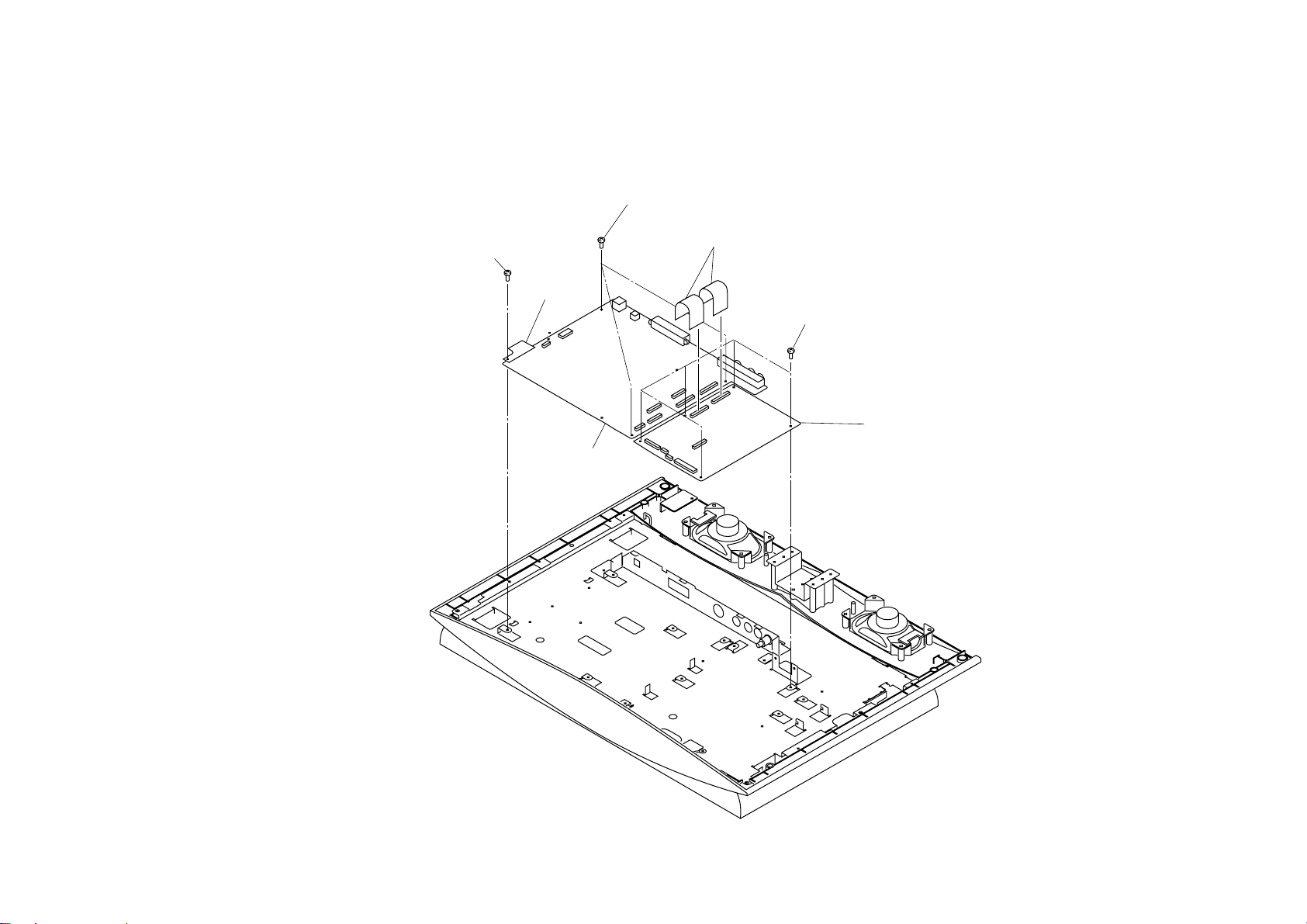

1-1. REAR PANEL REMOVAL

SECTION 1

DISASSEMBLY

1 Rear panel (17)

KLV-17HR1(AEP) 1-1

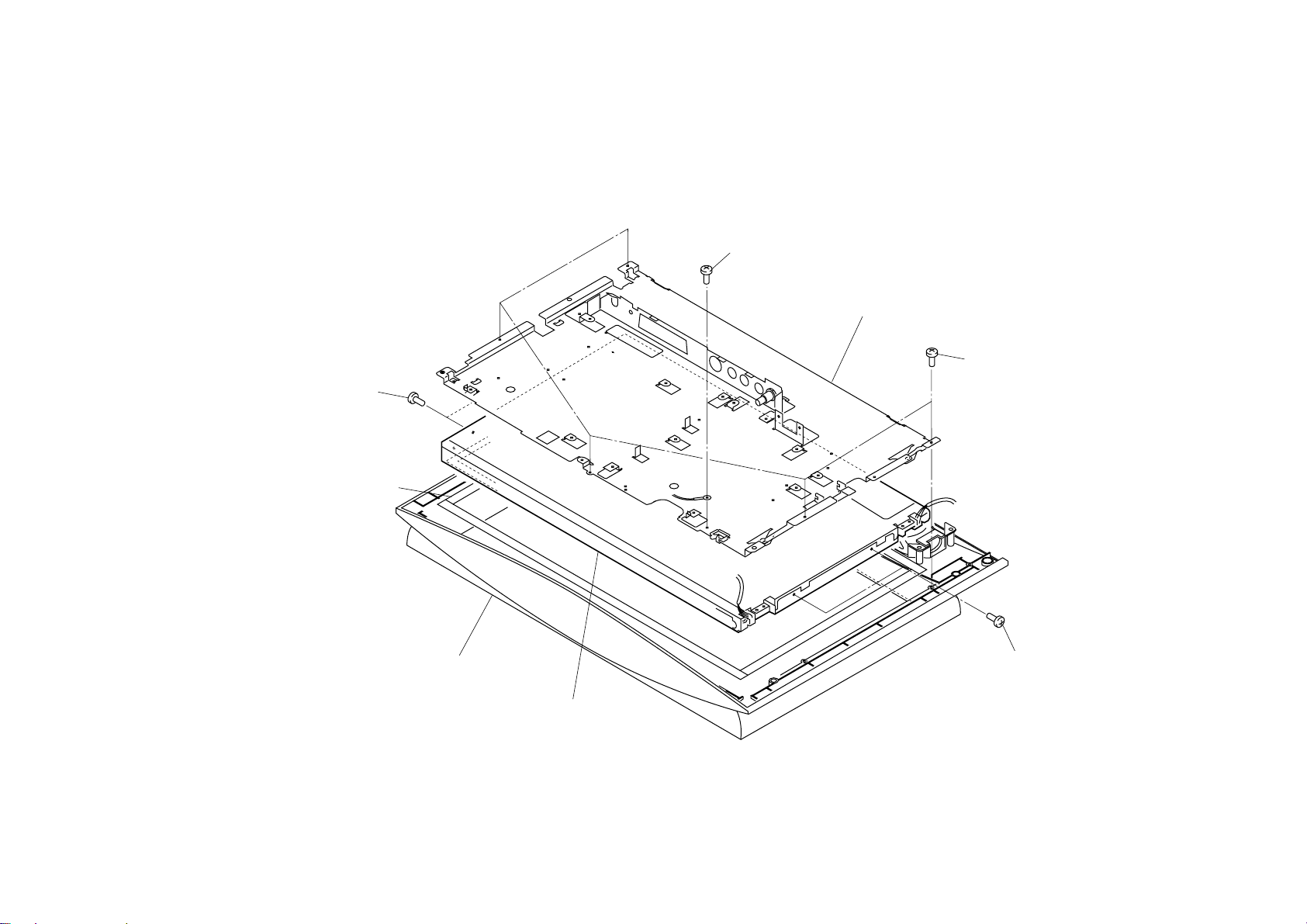

1-2. REAR COVER REMOVAL

1 Four screws

(+M 4x10)

2 Stand block assy

3 Nine screws

(+BVTP 3x10)

4

Rear cover (17)

KLV-17HR1(AEP) 1-2

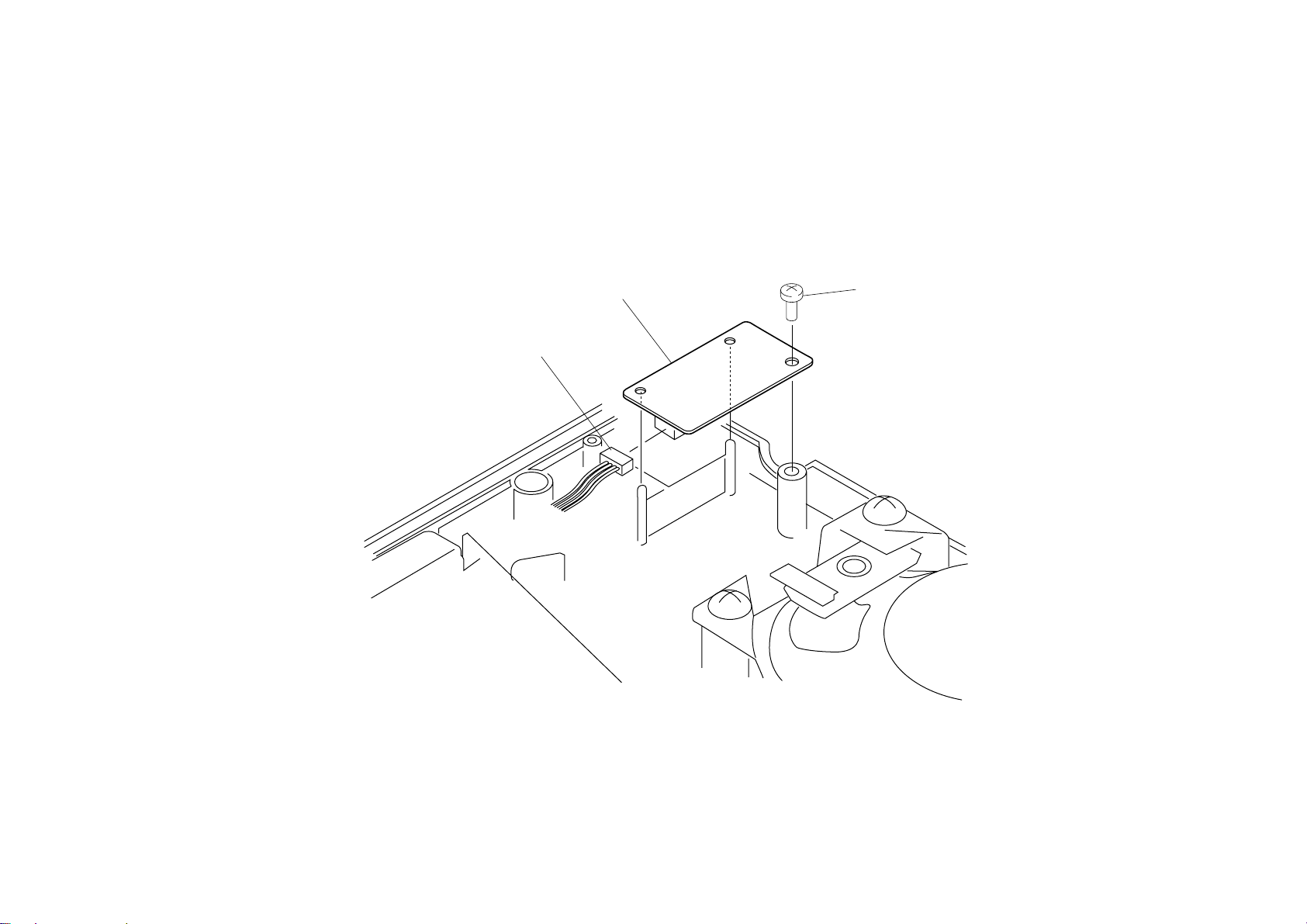

1-3. H2 BOARD REMOVAL

1 Connector

CN1

3 H2 board

2 Screw

(+BVTP 3 x 10)

KLV-17HR1(AEP) 1-3

1-4. D1 BOARD REMOVAL

2 Two screws

(+BVTT 3x6)

1 Connector

CN8001

3 D1 board

Two claws

1 Connector

CN8002, CN8004

1 Connector

CN8003, CN8005

KLV-17HR1(AEP) 1-4

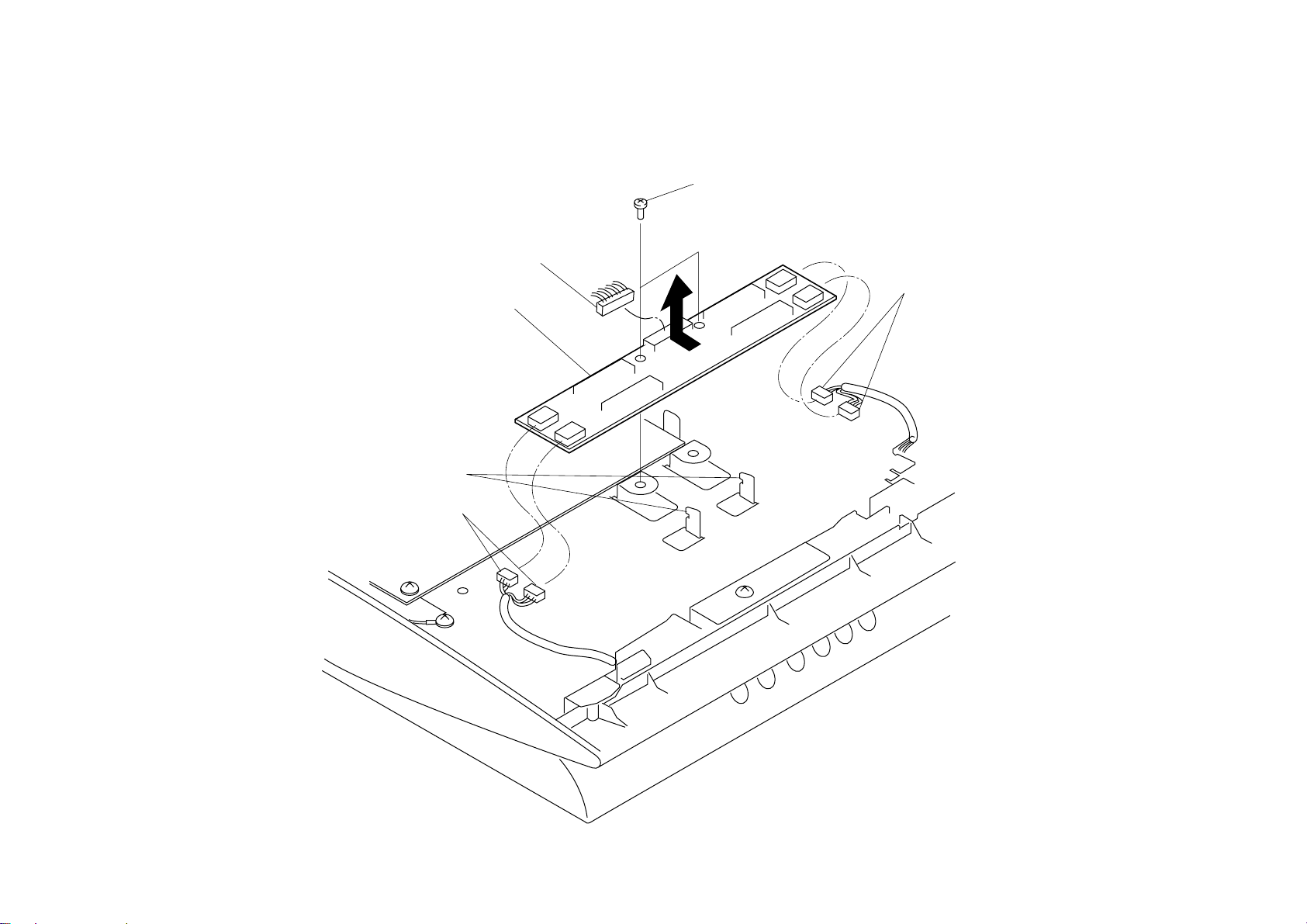

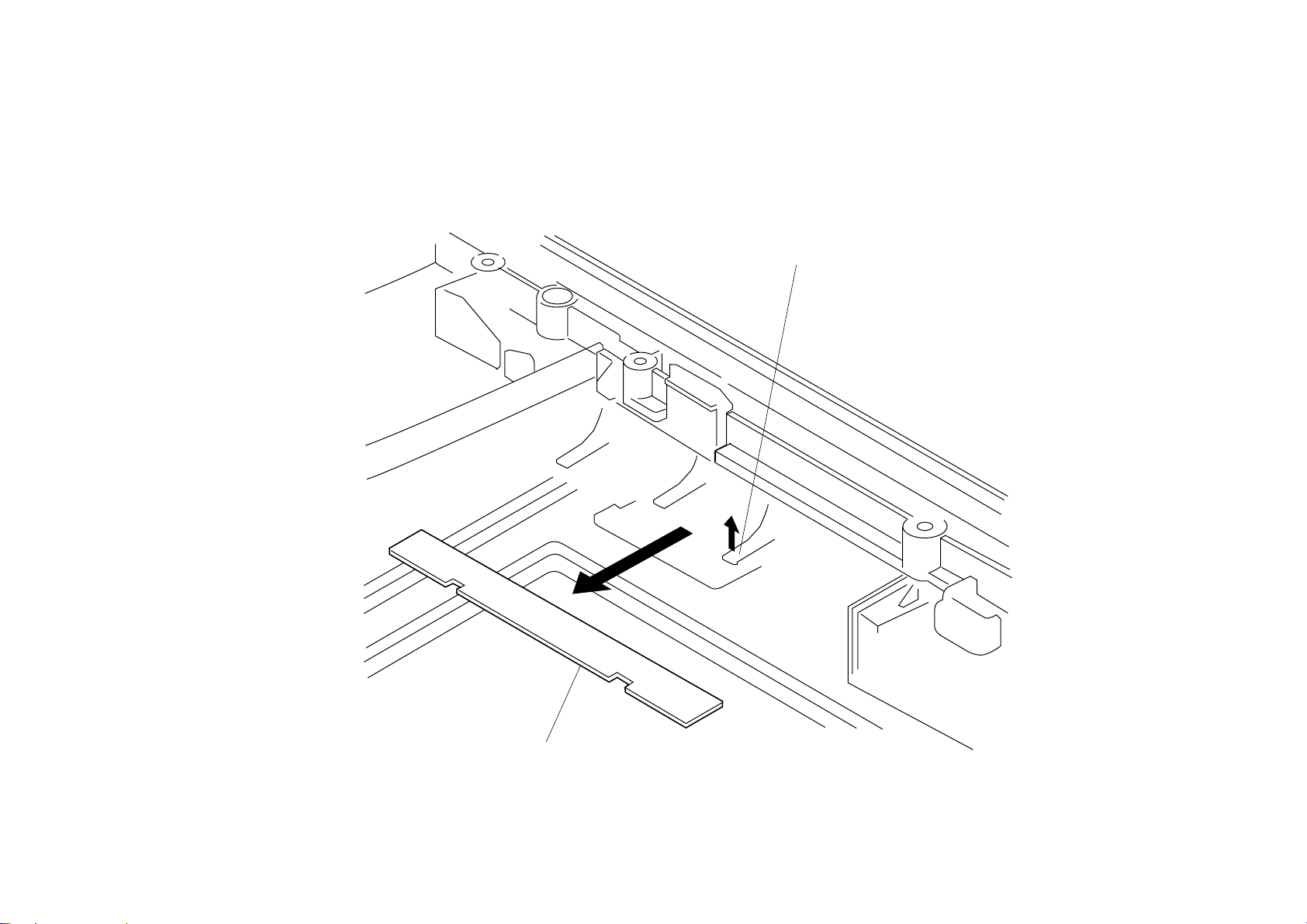

1-5. TU BOARD REMOVAL

2 Two screws

(+BVTT 3 x 6)

1 P-P cable

3 Tuner bracket

4 Tuner board

KLV-17HR1(AEP) 1-5

1-6. A, AA, AND B BOARD REMOVAL

2 Screw

(+BVTT 3 x 8)

AA board

3 Three screws

(+BVTT 3 x 6)

1 Two flexible flat cables

5 Five screws

(+BVTT 3 x 6)

6 B board

4 A board

KLV-17HR1(AEP) 1-6

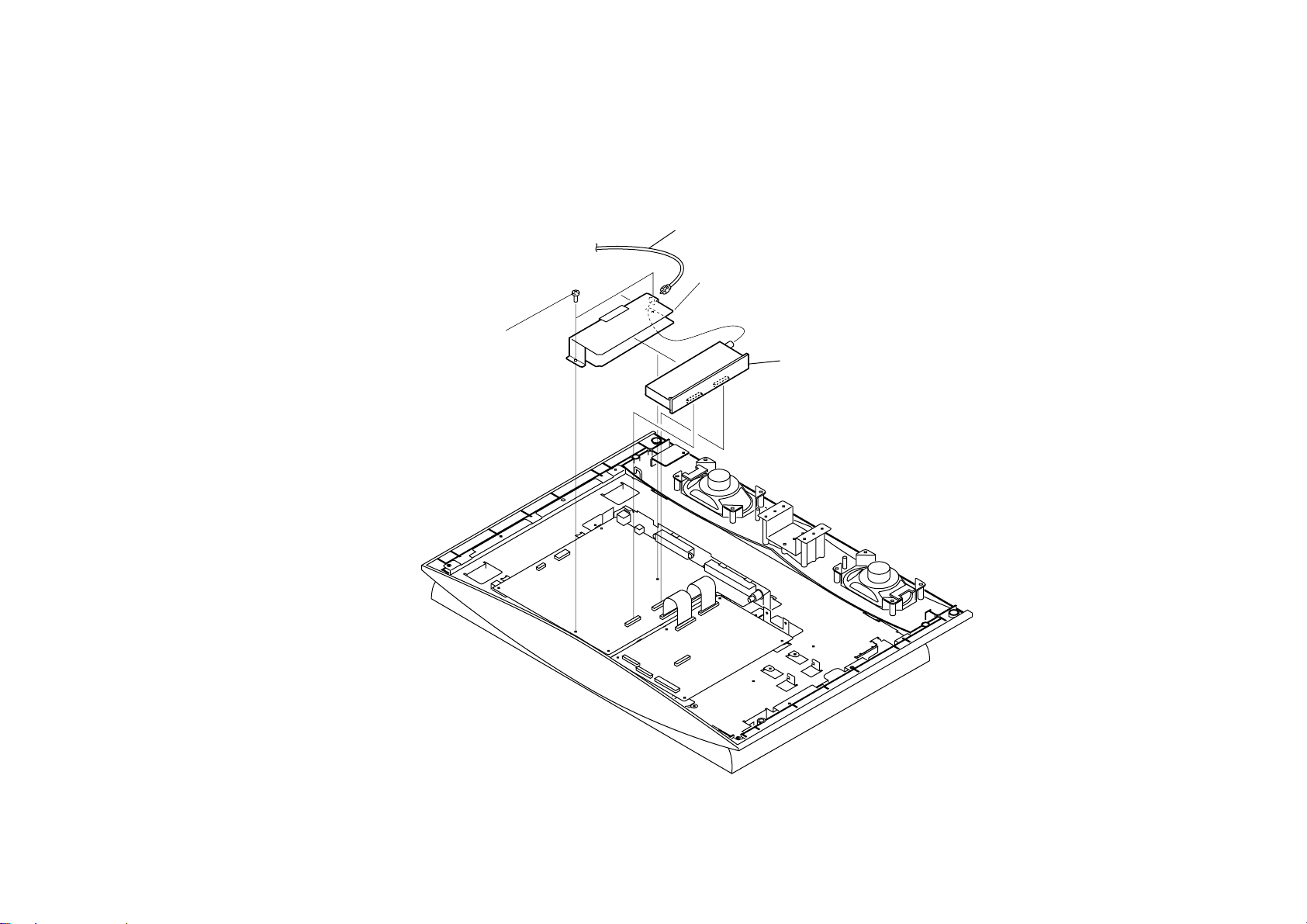

1-7. LCD PANEL REMOVAL

2 Screw

(+BVTT 3 x 6)

3 LCD bracket

4 Two screws

(+PSW 3 x 10)

Dustproof cushion

Front panel

1 Five screws

(+BVTP 3 x 8)

4 Two screws

(+PSW 3 x 10)

5 LCD panel

KLV-17HR1(AEP) 1-7

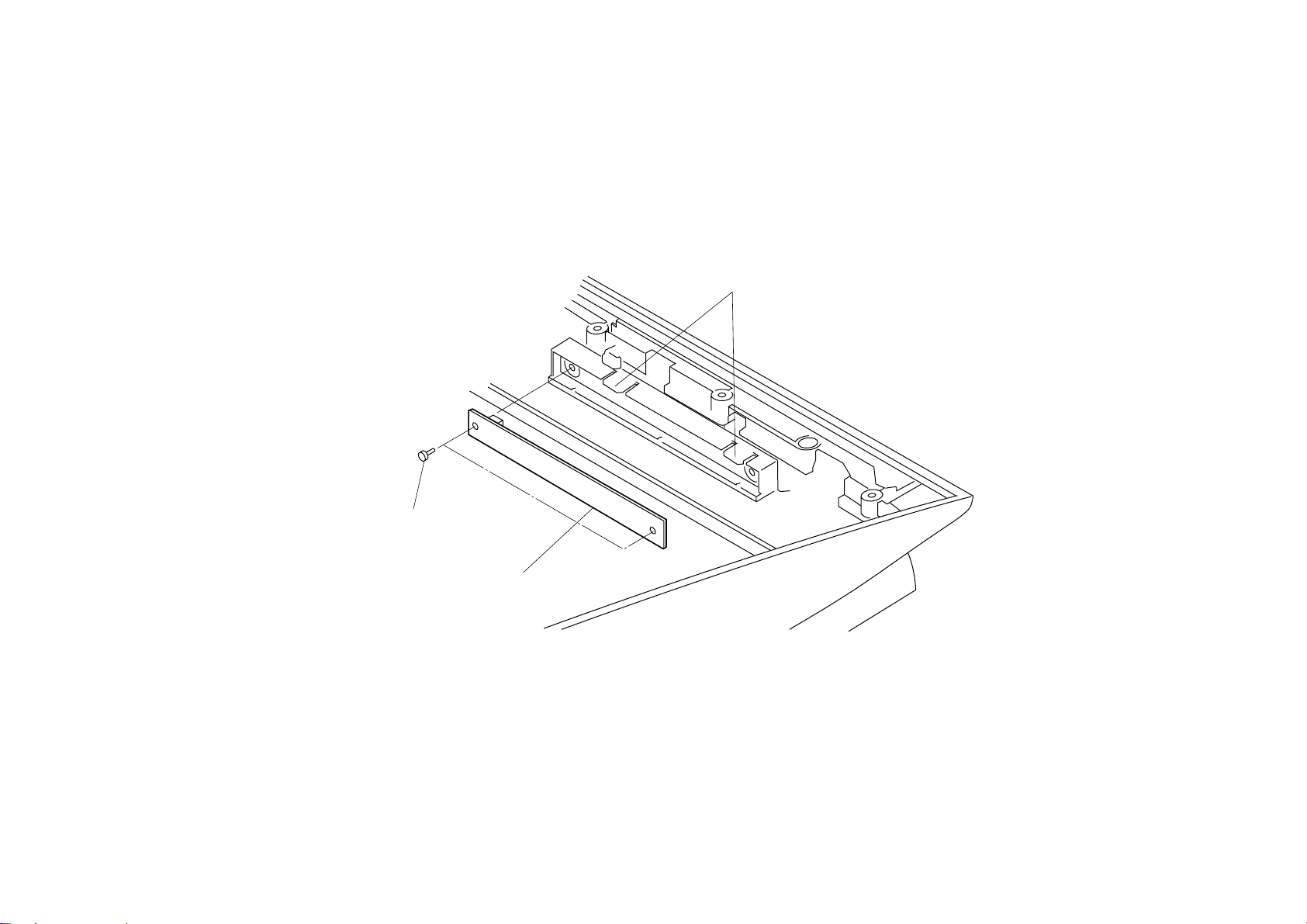

1-8. H3 BOARD REMOVAL

Claw

1 H3 board

KLV-17HR1(AEP) 1-8

1-9. H1 BOARD REMOVAL

1 Two screws

(+BVTP 3x8)

Two claws

2 H1 board

KLV-17HR1(AEP) 1-9

SECTION 2

ADJUSTMENTS

2-1. Service Mode

1. How to enter into ‘Service’ mode

(1) Send “TEST” command by Test Commander.

Or fix the accompanying RC as follows.

(1) Select ‘TV’ by SELECTOR button.

(2) Keep pushing the yellow button on the RC during LED of TV turning on.

(3) Remain pushed till the TV-selected LED blinking get slower (about 10

seconds).

(4) Push “9” key five times and TV, VCR, and DVD all turns on then off.

(5) Press ‘VIDEO I/O’ key toward the object set.

(The procedure above enables RC to always release “TEST” command.)

(To reset, follow the above procedure except (4); “0” instead of “9”)

2. How to get out of ‘Service’ mode

(1) Send “TEST” command by Test Commander.

Or

(2) Select “FACTORY MODE EXIT” in ‘Service’ menu, then press “OK” key.

2-2. White Balance Adjustment (NORMAL, WARM, COOL)

1. Preparation

(1) Measuring point: center of the screen

(2) Measuring directions: earth connection of luminance meter must be vertical

to the screen from right, left, upper and down

(3) Equipment for measure: colorimetric luminance meter MINORUTA CS-1000

or the equivalent

(4) Signal generator: ASTRO DESIGN VG-828D or the equivalent

3. Input all-white signal (70IRE) to AV1 (SCART).

4. Set image quality mode to “LIVE”.

5. Select “PICTURE” on the main menu and “RESET” using UP and DOWN

key, then push OK and the operation starts.

6. On the ‘Service’ mode, adjust RGB gain to the following value.

(Each RGB gain has three adjustments: NORMAL, WARM, and COOL.)

(Only calling the value is not reflected to the screen unless it is increased/

decreased.)

(1) NORMAL adjustment standard

Minimum aging time: 10 minutes

x y luminance (cd/m2)

0.285±0.003 0.293±0.003 Withdrawal Aging below 60 minutes

0.287±0.003 0.296±0.003 Withdrawal Aging 60 minutes or more

(2) WARM adjustment standard

Minimum aging time: 10 minutes

x y luminance (cd/m2)

0.293±0.003 0.302±0.003 Withdrawal Aging below 60 minutes

0.295±0.003 0.305±0.003 Withdrawal Aging 60 minutes or more

(3) COOL adjustment standard

2. Condition of measurement

(1) Set PICTURE MODE to PERSONAL for the input used for the signal, then

execute ‘RESET’ on ‘PICTURE’ menu on OSD.

(2) Input signal: All-white signal (70IRE)

Minimum aging time: 10 minutes

x y luminance (cd/m2)

0.274±0.003 0.279±0.003 Withdrawal Aging below 60 minutes

0.276±0.003 0.282±0.003 Withdrawal Aging 60 minutes or more

KLV-17HR1(AEP) 2-1

B

SYSTEM CONTROL,

VIDEO DECODER,

IP CONVERSION,

SCAN CONVERTER

POWER SUPPLY

INPUT TERMINAL

AUDIO AMP,

VIDEO SWITCH,

A

H1

(KEY INPUT)

LED,

H3

(HP JACK)

H2

TU

(TUNER)

B-SS3666<AEP>-KESSENZU

(DC-DC CONVERTER)

D1

TO LCD

GND

KEY0

1

2

CN901

2P

RMC

LED

EVER5V

GND

1

2

3

4

CN951

4P

6P

V 52808

18P

19P

CN4

CN2

CN1

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

18

17

16

15

14

13

12

11

10

987

65432

1

6

5

4

3

2

1

GND

GND

E5V

#RESET_PW

E5V

UART PWTXD

SW H8RXD HOLD

#NMI HOLD

R3.3V

SW H8RXD HOLD

UART PWTXD

SW H8TXD HOLD

SW H8TXD HOLD

UART H8TXD HOLD

UART H8RXD HOLD

HOLD

#RESET MAIN

UART PWRXD

UART PWRXD

RMC

LED

E5V

GND

KEY0

GND

E_DET

SCL

SDA

#RESET

POWER

SEL0

SEL1

SC

SI

S_IN_DET

MUTE_SP

SC_F

SC_BL

AGC

INITIAL

MUTE_LNA

#TEXT/RGB

V_SEL0

V_SEL1

17P

CN501

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

GND

GND

GND

RGB-FB

GND

INT-V

GND

CVBS

GND

YC-C

GND

TEXT-V

GND

NC

RGB-R/V

RGB-G/Y

RGB-B/U

20P

CN701

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

GAMMA

GND

TXD-

TXD+

GND

TX1-

TX1+

GND

TX2-

TX2+

GND

TXCLK-

TXCLK+

GND

TX3-

TX3+

GND

GND

VCC(R5V)

VCC(R5V)

4P

6P

CN802

CN801

6

5

4

3

2

1

432

1

GND

GND

EVER16.5V

EVER16.5V

EVER5V

REG3.3V

DIMMER

R5V

BACK LIGHT

PANEL DET

6P

6P

5P

CN102

19P

6P6P

V SCART

21P

4P

17P

CN303

CN401

CN301CN14CN13

J702

J701

CN402

CN101

6

5

4

3

2

1

6

5

4

3

2

1

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

5

432

1

432

1

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R

L

V

43

21

65432

1

65432

1

SP L+

SP L-

SP R-

SP R+

TO SPEAKER

NC

NC

5V

L

R

S-VIDEO

VIDEO

AUDIO

R

L

+

-

J301

HEC3900

2

1

3

AC ADAPTER

4P

CN1

432

1

HP-L

A.GND

HP-R

HP_SW

HEAD PHONE

J1

HSJ1637

6P 6P

CN3 CN4

65432

1

65432

1

GND

AGC

SCL

SDA

32V

GND

GND

5V

FM/AM

QSS

VIDEO

GND

10P

2P

2P

2P

2P

CN8001

CN8005

CN8003

CN8002

CN8004

2

1

2

1

2

1

2

1

10

987

65432

1

COOL-3

HOT-3

HOT-4

COOL-4

COOL-1

HOT-1

HOT-2

COOL-2

BACK LIGHT

PANEL DET

GND

D5V

GND

GND

16.5V

16.5V

16.5V

DIMMER

TEXT-V-OUT

TEXT-V-IN

R5V

GND

1

2

3

4

CN701

4P

AA

(SYNC SEPARATOR)

IR RECEIVE

VIDEO-IN/Y-IN

AUDIO-R-OUT

AUDIO-R-IN

AUDIO-L-OUT

AUDIO-GND

GND

AUDIO-L-IN

BLUE/-

FUNCTION-SW

GND

NC

GREEN/-

NC

GND

GND

RED/C

BLANKING/-

GND

GND

VIDEO-OUT

SHILD-GND

SC

SI

S_IN_DET

MUTE_SP

MUTE_LNA

#TEXT/RGB

E_DET

SCL

SDA

#RESET

POWER

SEL0

SEL1

SC_F

SC_BL

AGC

INITIAL

V_SEL0

V_SEL1

GND

GND

GND

GND

GND

GND

GND

GND

RGB-R/V

RGB-G/Y

RGB-B/U

RGB-FB

INT-V

CVBS

YC-C

TEXT-V

N.C.

GND

GND

EVER16.5V

EVER16.5V

EVER5V

REG3.3V

HP-L

A.GND

HP-R

HP_SW

16.5V

16.5V

16.5V

GND

GND

GND

FM/AM

QSS

VIDEO

GND

GND

AGC

SCL

SDA

32V

GND

TO LCD

3-1. FRAME DIAGRAM

SECTION 3

DIAGRAMS

KLV-17HR1(AEP) 3-1

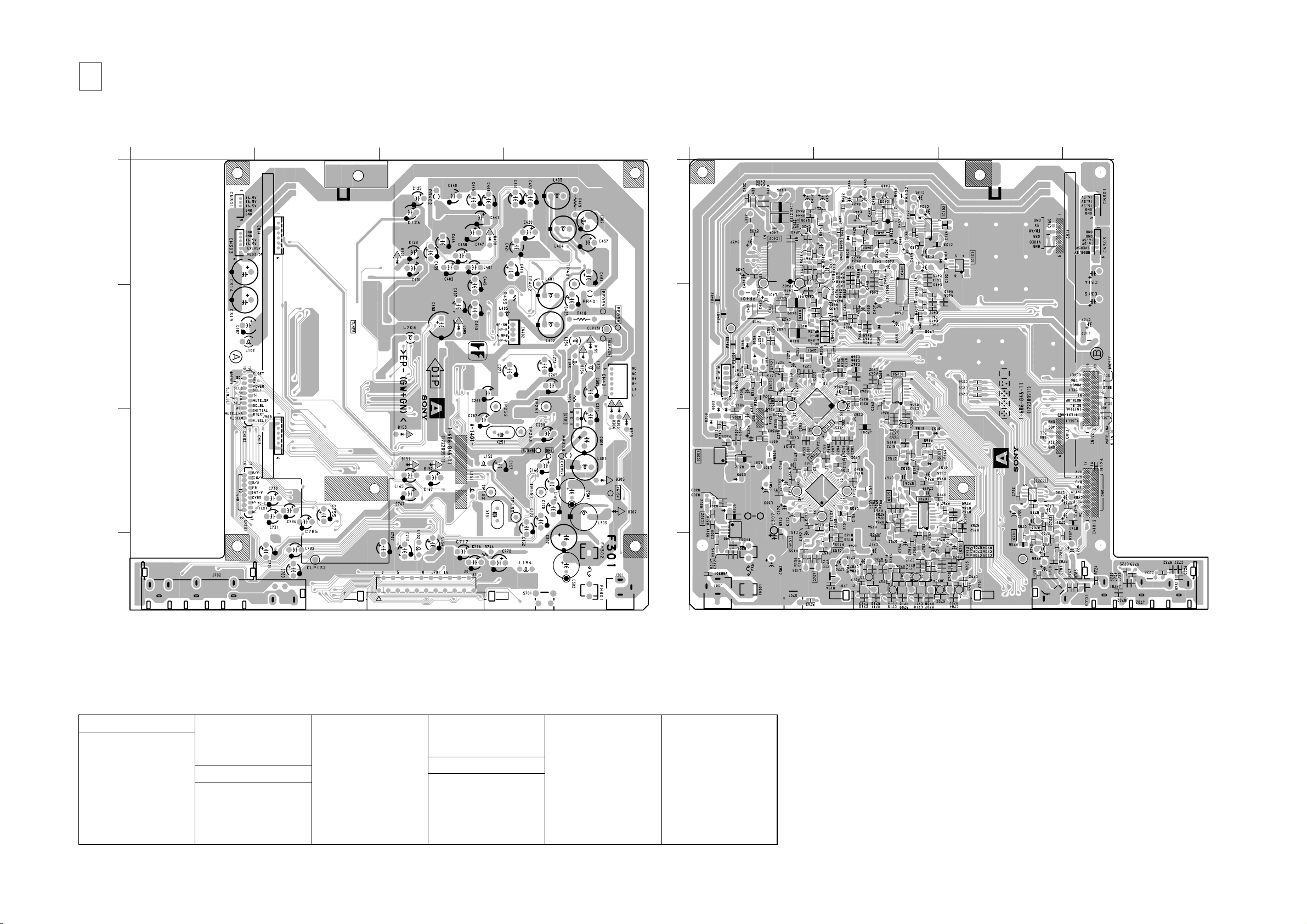

3-2. CIRCUIT BOARDS LOCATION

D1 board

B board

TU board

H1 board

H3 board

A board

AA board

H2 board

KLV-17HR1(AEP) 3-2

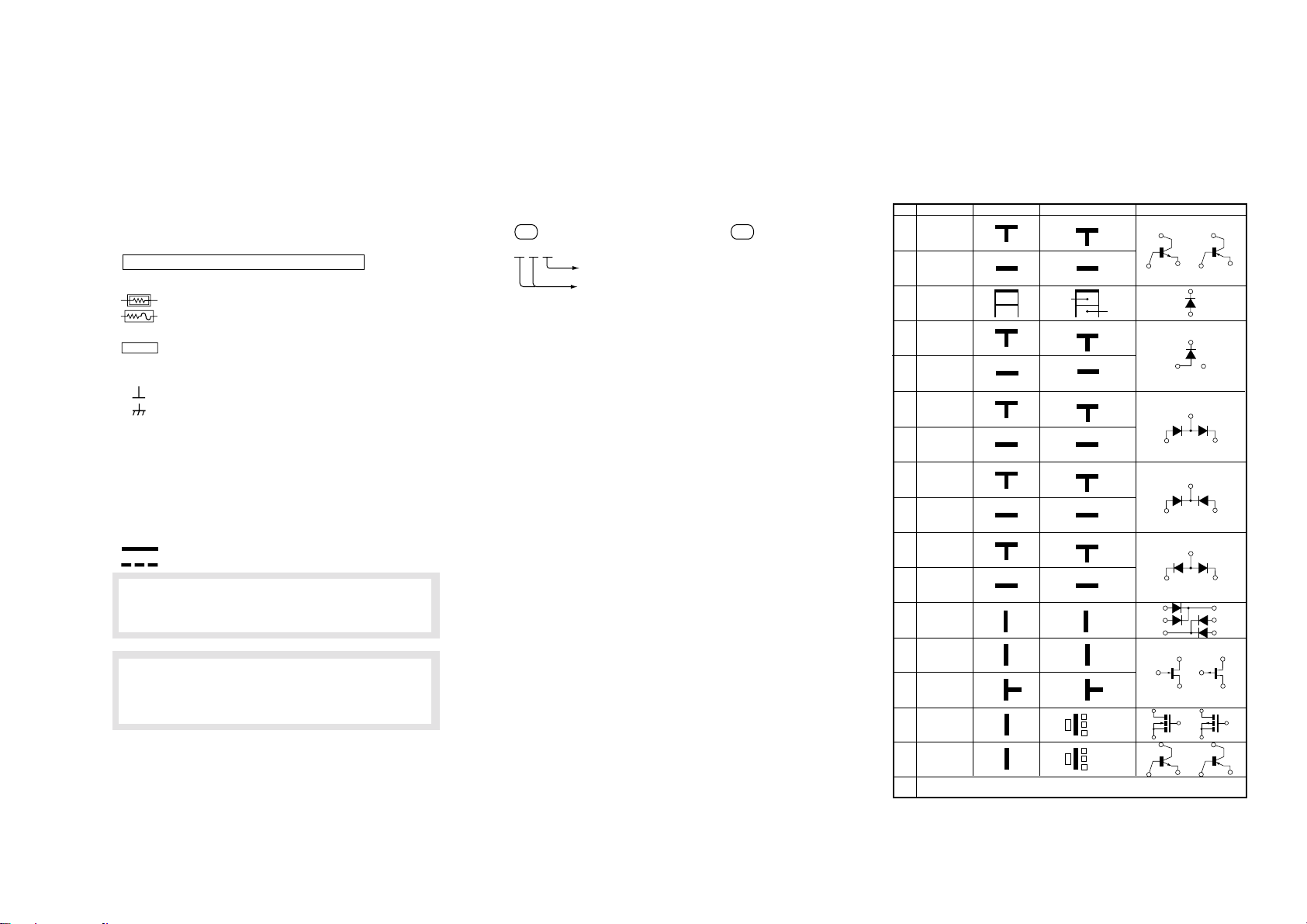

3-3. SCHEMATIC DIAGRAMS AND PRINTED WIRING BOARDS

Note:

• All capacitors are in µF unless otherwise noted. (pF: µµF)

Capacitors without voltage indication are all 50 V.

• Indication of resistance, which does not have one for rating electrical

power, is as follows.

Pitch: 5 mm

Rating electrical power 1/4 W (CHIP : 1/10 W)

• All resistors are in ohms.

• : nonflammable resistor.

• : fusible resistor.

T : internal component.

•

• : panel designation, and adjustment for repair.

• All variable and adjustable resistors have characteristic curve B, unless

otherwise noted.

• : earth-ground.

• : earth-chassis.

• When replacing the part in below table, be sure to perform the related

adjustment.

• All voltages are in V.

• Readings are taken with a 10 M digital multimeter.

• Readings are taken with a color-bar signal input.

• Voltage variations may be noted due to normal production tolerances.

•

• Circled numbers are waveform references.

: Can not be measured.

*

• : B + bus.

• : B – bus.

Note: The components identified by shading and

mark ! are critical for safety. Replace only

with part number specified.

Note: Les composants identifiés par un tramé et

une marque ! sont critiques pour la

sécurité. Ne les remplacer que par une pièce

portant le numéro spécifié.

• Divided circuit diagram

One sheet of B board is circuit diagram is divided into five sheets,

each having the code B-a to B-e. For example, the destination

ab1 on the code B-a sheet is connected to ab1 on the B-b sheet.

a b 1

Ref. No.

Circuit diagram division code

Terminal name of semiconductors in silk screen

printed circuit ( )

Device Printed symbol Terminal name

Transistor

1

Transistor

2

3

Diode

4

Diode

Diode

5

Diode

6

Diode

7

8

Diode

Diode

9

Diode

0

Diode

qa

Diode

qs

Transistor

qd

(FET)

Transistor

qf

(FET)

Transistor

qg

(FET)

Transistor

qh

Discrete semiconductot

–

(Chip semiconductors that are not actually used are included.)

*

Collector

Base

Collector

Base

Cathode

Cathode

Anode

Cathode

Anode

Common

Anode

Common

Anode Cathode

Common

Anode

Common

Anode Anode

Common

Cathode

Common

Cathode

Anode

Anode

Cathode

Drain

Drain

Emitter

Emitter

Anode

(NC)

(NC)

Cathode

Anode

Cathode

Cathode

Cathode

Anode

Anode

Source

Gate

Source

Gate

Source

Drain

Gate

Emitter

Collector

Base

Circuit

D

G

D

S

D

G

S

S

D

G

G

S

Ver.1.6

KLV-17HR1(AEP) 3-3

(1) Schematic Diagrams of A Board

AUDIO L

AUDIO R

AUDIO

AUDIO

VIDEO

VIDEO

AUDIO

AUDIO

VIDEO

AUDIO

AUDIO

AUDIO R

AUDIO L

AUDIO L/R

AUDIO R

AUDIO L

AUDIO L

AUDIO R

AUDIO R

AUDIO L

3.5

2.9

3.4

2.7

0.1

0.1

2.9

31.2

1.9

9.9

2.3

6.5

17.5

1.7

1.3

2.9

2.2

2.7

3.3

1

00000

5.1

0

0

0.100

0

0

5.4

4.8

2

2.1

2.8

0

2.6

0

3.3

2.8

3.7

0

0.8

0

0.8

4.9

5.5

4.9

5.5

3.5

3.5

4.1

3.8

3.9

9.4

9.3

3.5

3.5

4.1

3.8

4.5

5.1

1.3

16.4

5.2

0.1

0.1

4.1

0

7.5

0

VIDEOVIDEO

AUDIO L

AUDIO R

AUDIO L

AUDIO R

AUDIO R

AUDIO L

AUDIO R

AUDIO L

AUDIO R

AUDIO L

AUDIO L

AUDIO R

AUDIO R

AUDIO L

16.5V

E5V

R3.3V

R3.3V

0uH

100uH

L102

D702

UDZSTE-178.2B

D703

UDZSTE-1712B

UDZSTE-178.2BD704

D705 UDZSTE-178.2B

UDZSTE-178.2BD706

UDZSTE-178.2B

D707

100

R784

FB404

0uH

FB401

0uH

FB403

0uH

FB402

1

C313

47k

R317

25V

25V

470

C314

470

C315

+9V REG

+5V SW

5V CONTROL

+5V REG

BUFFER

VIDEO BUFFER

VIDEO BUFFER

VIDEO SW

AUDIO SW

6dB AMP

DC-DC CONVERTER

6dB AMP

SW

DECODER

SOUND

SELECTOR

DECODER

TELE TEXT

SYNC BUFFER

3

TO AA BOARD

4

TO AA BOARD

1

TO AA BOARDTO AA BOARD

2

VC

O_ADJ

COM

VOUT

VIN

COMVCO_ADJ

VOUT

VIN

VSS

VEE

INHI

SC-AR

INT-R

SP-R

AV2R

SEL0

SEL1

VDD

AV2L

SC-AL

SP-L

INT-L

VSS

VEEY0YXX1X0W1

CONT

Y1Z0Z1

Z

W

W0

VDD

BUFFER

TO TU BOARD

CN4CN3

TO TU BOARD

AUDIO CONTROL

MUTE

MUTE

BUFFER

BUFFER

SW

SW

LR

AUDIO

VIDEO S-VIDEO

POWER

TO D1 BOARD

CN8001

CN1

TO H2 BOARD

TO B( e )BOARD

CN801

R

L

AUDIO AMP

HP AMP

HP SW

MUTE SW.

MUTE

MUTE

TO B( b )BOARD

CN501

CN1

TO B( a )BOARD

B-SS3672<AEP>-A..

(VIDEO SW,AUDIO AMP,INPUT TERMINAL)

A

V_SEL1

V_SEL0

INITIAL

AGC

SC_BL

SC_F

SI

SC

SEL1

SEL0

POWER

#RESET

SDA

SCL

E_DET

#TEXT/RGB

MUTE_LNA

MUTE_SP

S_IN_DET

N.C.

GND

TEXT-V

GND

YC-C

GND

CVBS

GND

INT-V

GND

RGB-FB

GND

RGB-B/U

GND

RGB-G/Y

GND

RGB-R/V

GND

32V

SDA

SCL

AGC

GND

GND

VIDEO

QSS

FM/AM

5V

GND

VIDEO-IN/Y-IN

SHILD-GND

VIDEO-OUT

GND

GND

BLANKING/-

RED/C

GND

GND

NC

GREEN/-

NC

GND

FUNCTION-SW

BLUE/-

AUDIO-L-IN

GND

AUDIO-GND

AUDIO-L-OUT

AUDIO-R-IN

AUDIO-R-OUT

CP1 CP2 CP3

ZENER

SWOSC

SC

SI

VCCOUT2OUT1BNF1

1

BOUT

2

BOUT

BNF2TNF2

TNF1

CAP

GND

FILTER

VCC/2

C2C1B2B1A2A1

SEL2SEL1

VIN2VIN1

VCC/2

VCC/2

VCC/2VCC/2

LOGIC

TRABLE2

FC=8KHZ

FC=8KHZ

TRABLE1

F0=80HZ

BASS2

SURROUND

F0=80HZ

BASS1

VREF

A

OUT

C

OUT

B

OUT

DNC

V+

GND

MUTE TCMUTE

INB

BEEP

SW

INA

STBY

VREF

PA-B PA-C PA-A

SW2

IN2

SW1

IN1

IN3

VCCOUT

GND

NC NC

VCC

OUT

GND

IN2

SW

IN1

CLAMP

CLAMP

CLAMP

BIAS

6DB

SW

SW

6DB

SW

CLAMP

CLAMP

BIAS

NC

NC

NC

NC

VDD2

VDD1

NC

NC

VP2

5VGEN CPUMP

PGND1

VDDA

NC

OUTP1

VDD1

OUTM1

OUTM2

VDD2

OUTP2

DGND

PGND2

FAULTSLEEP

LOADB

OVER

AGND3

BIASCAP

IN2

MUTE

IN1

VP1

V5A

AGND2

REF

AGND1

V5D

DCAP1

DCAP2

GND

GND

16.5V

16.5V

16.5V

HLL

LHL

AV2AV1INT

SEL1

SEL0

TO SPEAKER

TO AC ADAPTER

SP R+

SP R-

SP LSP L+

REG3.3V

EVER5V

EVER16.5V

EVER16.5V

GND

GND

HP_SW

HP-R

A.GND

HP-L

CSO

FLAG2

FLAG1

TSTAPP

GND5V1

VDD3V4

VDD3V3

PLLRC2

GND3V3

VDD3V2

OSCOUT

OSCIN

GND2V3

VDD3V1A

VDD3V1B

PLLRC1

GND3V1B

GND3V1A

GND3V5

VDD5V2

RSTB

MUTE

RED

GREEN

BLUE

BLANK

SCEN

TSTIO

STDBY

GND5V2

VDD3V5

VDDA3

VIDEOIN

SYNC

GNDA3

VDDA2

VCM

VBG

GNDA2

NC

GNDA1B

VINP

VDDA1

VREFN

VREFP

GNDA1A

GND3V4

VDD5V1

TDO

SDA

SCL

CS1

AVSS

MONO_IN

VREFTOP

SC_IN_R

SC_IN_L

NCNCNC

AGNDC

AHVSS

CAPL_M

AHVSUP NC

SC_OUT_L

SC_OUT_R

VREF1

NC

DACAM_L

DACAM_R

VREF2

NC

NC

RESETQ

TP

DVSS

DV_SUP

TP_CO

TPTPTP

TP

I2C_DA

I2C_CL

STANDBYQ

ADR_SEL

D_CTR_I/O_0

D_CTR_I/O_1

TP

X_OUT

X_IN

TESTEN

IN-

IN+

AVSUP

123

456

123

456

1 2 3 4 5 6 7

891011121314

12

34

V

L

R

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

12345

1 2 3 4 5

1 2 3 4 5 6 7

8

109 11 12

131415161718192021222324

1 2 3 4

5678

1

2

3

4

12345678

9 10 11 12 13 14 15 16

+

-

1

2

3

4

5

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

192021222324252627282930313233343536

1234567891011

1213141516171819202122

23 24 25 26 27 28 29 30 31 32 33

3435363738394041424344

1234

5 6 7 8

1 2 3 4 5 6 7 8

910111213141516

12345678910111213

14151617181920212223242526

27 28 29 30 31 32 33 34 35 36 37 38 39

404142434445464748

49

505152

123

45678

9

10111213141516

17

1234567

8 9 10 11 12 13 14

123

45678

9

101112131415161718

19

S

S

S

S

1

2

3

4

5

6

1

2

3

4

5

6

C102

C128

C130

C151

C153

C154

C158

C159

C164

C171

C173

C263

C265

C270

C272

C273 C274 C275

C276

C278

C282

C284

C285

C408

C409C410C411C412

C413

C414

C416 C417

C418

C422

C424

C426

C430

C432

C436

C443

C456

C457

C461

C462

C701

C702

C703

C704

C705C706

C708C709

C711

C714

C715

C718

C719

C720

C723

C724

C725

C726

C727

C728

C732

C751

C752

C753

C782

CN101

CN402

D153

D154

D301

D303

D304

D305

D306

D307

D308

IC101

IC301

IC302

IC701

J301

J701

J702

JR703

L301

L302

L401

L402

L403

L404

Q152

Q154

Q404

Q405

Q406

Q705

Q706

Q752

R151

R152

R153

R164

R165

R166

R171

R172

R173

R251

R252

R253

R255

R257

R258

R269

R303

R304

R306

R308

R309

R312

R313

R314

R315

R316

R405R406

R407

R408

R409

R410

R413

R414

R415

R424

R425

R434

R440

R441

R442

R443

R444

R448

R449

R450

R454

R455

R456

R457

R458

R701

R702

R703

R704

R706

R707

R709

R710

R711

R714

R715

R724

R729

R730

R731

R732

R733R734

R751

R752

R754

R755

R757

R758

R759R760

R761

R762 R763R764

R765

R768

R781

R782

R783

S701

C162

C163

C403 C404 C405 C406

C442

IC403

Q702

R302

R735

R737

R418 R419

CN13 CN14

JR702

Q302

JR401

CN102

IC151

C427

C428

C429

C433

C434

C435

C458

C463

IC401

R305

C780

C781

C784

R254

JR701

Q301

Q305

Q410

R259

R743

C440

L303

C267

C266

C268

R301

R155

R160

Q151

C161

R159

R422

R423

R268

R265

R263

R264

R266

R267

FB251

C166

C256

C259

C155

C156

C289

R154

R271

R460R435

R744

CN301

R411

R412

R256

R272

R753

R756

R741

D701

R739

IC402

C304

C307

L154

CN401

R736

R161

D309

IC251

X151

X251

IC702

R738

D155

L254

Q251

Q252

Q707

Q703

Q701

CN303

L703

R461

C123 C124

C127

R156

PR401

IC252

PR303

PR402

D302

D405

D406

D407

R770

R769

R767

R462

R463

R464 R465

C292

C291

C283

R270

C101

C125

C126

C129

C152

C157

C165

C167

C168

C169

C170C172

C264

C287

C305

C311

C401

C402

C407

C419

C420

C421

C425

C438

C439

C441

C444

C445

C449 C450

C451

C452

C453

C707

C710

C716

C717

C721

C730

C731

C754

C755

C767

C785

JR201

C290

D156

R766

C770

FB151

R720

FB701

R717

R716

R712

C712

R705

C107

L151

L152

L153

L405

L702

C787

C301

C302

F301

FH301FH302

TP151

TP152

TP153

TP251

TP252

TP253

TP401

TP402

VDR301

C293

R708

R713

C713

R307

C312

D101

Q751

R742

D411

D412

D409

D410

C281

C280

C279

C269

C286

C262

C160

C437

C431

IC102

0.1

25V

150p

0.1

25V

470p

56p

56p

470p

100p

470p

0.1

25V

0.1

25V

0.1

25V

0.1

25V

0.1

25V

22

0.1

25V

0.1

25V

0.1

25V

0.1

25V 0.1

25V

0.022

25V

18p

0.022

25V

0.1

25V

0.1

25V

0.1

25V

0.1

25V

0.1

25V

2200p

2200p

0.1

25V

0.1

25V

0.1

25V 0.1

25V

0.1

25V

0.1

25V

0.1

25V

0.1

25V

0.1

25V

0.1

25V

0.22

16V

1000p

0.22

16V

1000p

47p

47p

47p

47p

47p47p

100p100p

100p

1000p

100p

0.1

25V

0.1

25V

0.1

25V

100p

100p

1

10V

100p

100p

1

10V

0.1

25V

0.1

25V

1

10V

1

10V

0.1

25V

17P

V 52806

4P

V WHT PH

1SS133

1SS133

M1FM3

1SS133

1SS133

1SS133

M1FM3

1SS133

1SS133

MM1116XFBE

PQ1CZ21H2ZP

PQ1CZ21H27P

CD4052NS

HEC3900

21P

V SCART

PIN 3P+S JXT1057

0

100uH

ELC10E101L

33u

PJ87

10uH

10uH

10uH

10uH

2SC2412KR

2SC2412KR

DTC323TU

DTC323TU

2SK2158

2SK2158

2SK2158

2SC2412KR

100

100

330

1k

100k

100

1k

100k

100

100

100

100

47k

1k

1k

1k

100k

1.2k

10k

12k

15k

220

47k

47k

100

4.7k

1k1k

390k

5.6k

390k

5.6k

8.2k

20k

8.2k

100k

47k

1k

47k

150k

150k

1k

1k

12k

39k

10k

12k

39k

10k

2.2k

2.2k

330

330

330

47k

47k

75

100

75

100

4.7k

100

75

330

47k

330

47k

1k1k

18k

33k

18k

33k

4.7k

4.7k

330k330k

330k

330k 330k330k

270

22k

75

75

10k

KSH0636BTS

0.01

25V

0.01

25V

0.01

25V

0.01

25V

0.01

25V

0.01

25V

0.01

25V

NJM2772

2SC2412KR

1.8k

2.2k

1k

10 10

6P 6P

0

2SK2158

0

19P

V 52806

MSP3417G

0.47

25V

0.47

25V

0.47

25V

0.47

25V

0.47

25V

0.47

25V

6800p

6800p

BD3870FS

0

47

16V

0.1

25V

47 16V

150

0

2SA1585STPR

2SA1037AK-T146QR

DTC114EKA

0

0

47

16V

150uH

LHLIO

0.1 25V

0.1 25V

0.47 25V

5.6k

1k

1k

2SA1037AK-T146QR

120p

0

120

120

1k

1k

1k

120

120

120

BLM18PG600SN1

0

0

0

3p

3p

3p

1k

1k

47k1k

1/4W

470

1/4W

5P ZR

8.2k

20k

220

1k

560

2125

560

2125

560

2125

MC2840

2.2k

TA2024-T

470

16V

ZL

470

16V

ZL

8.2u

LAL02

6P

1.2k

0

1SS133

ET-TVT008B

18.432MHz

13.875MHz

MM1118

2.2k

2125

1SS133

10uH

LAV35

2SA1037AK-T146QR

2SA1037AK-T146QR

2SA1037AK-T146QR

DTC114YKA T-146

2SC2412KR

6P ZR

10uH

LAV35

47k

0.22 0.22

0.22

47

2.0A

MC14551BF

2.5A

315MA

MC2836

MC2838

MC2838

MC2838

18k

18k

1k

10k

10k

10k 10k

390p

390p

33p

220

47

16V

4.7

4.7

47

16V

47

16V

47

16V

2.2

2.2

47

16V

10

3.310

100

100

100

100

2.2

2.2

47

16V

2.2

2.2

1

1

2.2

2.2

100

100

100

2.2 2.2

2.2

2.2

1000

16V

2.2

2.2

47 16V

10

47

16V

47

16V

47

16V

100

100

10

10

0

:3216

390p

MC2840

1k

220

16V

0

BLM18RK121SN1

75

75

75

100p

330

47 35V

22u

LAL02

22u

LAL02

22u

LAL02

100uH

LAL02

100uH

82P

220

25V

330

25V

6.3A

250V

390p

100

6.8k

100p

1.5k

5600p

1SS133

2SC2412KR

100k

RB161L-40TE25

RB161L-40TE25

RB161L-40TE25

RB161L-40TE25

0.1 25V

100

0.1 25V

100

0.1 25V

0

1 10V

220 16V M

220 16VM

LA7995M

2

1

3

SCL

SDA

INT-L0

INT-L1

INT-R0

INT-R1

#RESET

AGC

F_BL

RGB-B/U

SC-B

SC-G

#TEXT/RGB

RGB-G/Y

SC-R/C

REG3.3V0

CVBS1

YC-C

AV2-V

AV2-AL

AV2-AR

SC-AR

SC-AL

SC-B

SC_F

SC-G

SC-V

SC-R/C

SC_BL1

SC_BL0

L-OUT

R-OUT

INITIAL

E_DET

AV2-AL

SC-AL

INT-R1

AV2-AR

SC-AR

SEL0

SEL1

HP-L

HP-R

REG3.3V1

POWER

SP R+

SP R-

SP L-

SP L+

SC

SI

AL

AR

AR

AL

INT-L0

INT-R0

MUTE_LNA

L-OUT

R-OUT

AV2-V

CVBS0

V_SEL1

SC-V

V_SEL0

CVBS1

INT-V

RGB-R/V

F_BL

INT-V

CVBS0

YC-C

E_DET

SCL

SDA

#RESET

POWER

SEL0

SEL1

SC

SI

SDET

SC_F

AGC

INITIAL

MUTE_LNA

#TEXT/RGB

V_SEL0

V_SEL1

HP-L

HP-R

REG3.3V0

REG3.3V1

SP L+

SP L-

SP R-

SP R+

HP_SW

INT-L1

HP_SW

RGB-B/U

RGB-G/Y

RGB-R/V

SC_BL1

SDET

SC_BL0

A

B

C

D

E

F

G

H

I

1

2

10

11

12

13

14

• A BOARD WAVEFORMS

1

0.3V

P-P

(18.432MHz)

KLV-17HR1(AEP) 3-4

2

0.15V

15

P-P

(13.875MHz)

43

98765

A

C782

R782

C728

R460

R271

R270

R305

R767

R265

R159

C259

C102

C457

R784

R454

C465

R448

C461

R269

C456

R462

C463

R262

C154

R444

C162

R442

C309

R441

R443

R706

R258

R154

R172

R316

R272

JR703

C723

JR701

C289

R317

R314

C308

R311

C432

R313

R307

R264

R303

R731

R312

R308

C303

C462

R770

C724

R309

R310

R724

R732

C726

R703

C727

C781

C706

R729

R781

R704

C701

R701

C704

R702

R716

R766

C703

C702

C705

C709

R708

R764

C753

C711

R762

R751

R752

R769

C718

R165

R164

R166

R707

R713

R714

C714

C715

R710 C712

C719R709

R715

R730

C128

C708

C130

R712

R711 C713

C720

R717

R720

C751

C263

R457

R768

R458

R301

R302

R734

R757

R758

R760

R705

R759

R761

R763

R160

R754

R755

C732

R171

R173

R257

JR702

R253

R266

C282

R254

C752

C288

C286

R263

C285

C284

C283

R261

C281

C262

R151

JR704

C279

R252

R251

R267

C278

C277

R268

R255

R315

C276

C275

C274

C273

C270

C267

C265

C426

C406

C403

C404

R450

C160

C405

C442

C408

C409

R449

R455

R406

C411

R405

R456

R409

R410

R408

R407

C410

R425

R424

C414

C413

R422

R423

R765

R426

C412

R428

C443

C416

R427

C417

R411

R412

C418

C422

C424

C415

R413

R414

R415

R440

R733

R256

R157

C436

C430

C163

C171

C458

C156

R434

R461

C173

C448

FB251

R158

C158

R306

R152

C159

C166

R259

C164

C155

R260

C153

C151

C256

C312

C313

R153

R735

C161

JR401

R736

R737

R739

R740

R742

R743

R155

R156

C174

C266

R161

R463

R464

R465

C292

C291

C290

C293

R174

C786

FB151

C787

VD301

C725

Q152

Q305

Q408

Q405

Q701

Q707

Q251

Q154

Q752

Q404

Q252

Q153

Q151

Q410

Q702

Q751

FB402

FB701

FB401

FB404

FB403

R756

R753

R738

R741

C268

C428

C127

C123

C427

C124

C433

C434

C435

C429

IC702

D707

D311

D312

D706

D705

D702

D704D703

IC102

Q406

Q706

Q302

Q703

Q407

Q705

IC701

IC252

IC101

D405

D407

D406

D302

D301

D306

IC302

IC301

IC251

IC401

IC402

D409

D412

D411

D410

IC151

D156

D701

JR201

IC403

1 2 34

A

B

C

D

[

VIDEO SW, AUDIO AMP, INPUT TERMINAL

— A BOARD —

1 2 34

]

CN301

C314

C315

CN102

CN101

C107

L102

C721

C730

C731

CN14 CN13

C755

C784

C785

C783

C780

CL132

Q252 B-1 1

Q301 C-4 C-1 Q302 B-1 !›

Q305 C-1 1

Q404 A-2 1

Q405 A-2 1

Q406 A-2 !›

Q410 B-2 1

Q701 D-3 1

*

Q702 C-3 1

Q703 D-3 1

Q705 C-2 !›

Q706 C-2 !›

C707

J701

A

C303

B

• A BOARD SEMICONDUCTOR LOCATION

IC1 B-1

IC101 A-3

IC101 A-3

IC102 A-2

IC151 C-2

IC251 B-2

IC252 B-2

IC301 C-1

IC302 C-1

IC401 B-2

: Refer to Terminal name of semiconductors in silk screen printed circuit (see page 3-3)

*

C

D

(COMPONENT) (CONDUCTOR)

IC

J702

IC402 A-1

IC403 A-2

IC701 C-2

IC702 C-3

Q151 D-1 1

Q152 C-2 1

Q154 C-2 1

Q251 B-1 1

TRANSISTOR

(COMPONENT) (CONDUCTOR)

D153

D101

D151

L703

C710

C125

C126

C439

C129

C101

D152

C165

C767

L702

C754

PR402

C446

C453

C167

C445

C440

C447

C438

C402 C401

C449

C407

C450

D309

L151

C717

C716

C441

C444

D408

C287

L152

C264

TP152

L405

TP252

C157

X151

C770

X251

C451

C421

C419

R435

CN402

C271

TP253

TP153

Q707 D-2 1

Q751 C-3 1

Q752 D-2 1

DIODE

(COMPONENT) (CONDUCTOR)

D101 A-3 A-3 D153 C-3 C-2 D154 B-4 B-1 D155 B-4 B-1 D156 C-2 6

S701

L401

L402

C272

TP251

L403

C168

C169

C280

C170

L404

C269

C307

C302

C425

PR303

C301

R419

TP401

L254

L153

R304

Q301

L301

L303

PR401

D154

C304

L302

C431

D155

L701

C305

C311

F301 FH301FH302

C152

C452

C420

TP402

TP151

C172

L154

D301 C-1 3

D302 C-1 !‚

D303 B-4 B-1 D304 B-4 B-1 D305 C-4 C-4 D306 C-1 3

D307 C-4 C-1 D308 C-4 C-1 -

*

D309 B-3 B-2 D405 B-1 8

D406 A-2 8

D407 A-2 8

D409 B-1 3

C437

R418

D305

CL131

D307

CN401

D304

D303

J301

D308

D410 B-1 3

D411 A-1 3

D412 A-1 3

D701 D-4 6

<CONDUCTOR SIDE><COMPONENT SIDE>

KLV-17HR1(AEP) 3-5

(2) Schematic Diagram of AA Board

1

2

43

8765

AA

[

SYNC SEPARATOR

]

A

B

C

D

E

TO A BOARD

1

2

3

4

CN701

4P

RSV

GND

TEXT-V-IN

TEXT-V-OUT

— AA BOARD —

C701

R704

100p

130k

R705

10k

C702

0.47

R713

470

Q702

SYNC SEP

R5V

C710

0.01

25V

B

1SS355

1 10V

C719

AA

R715

27k

MF

R716

120k

MF

C711 C712

0.1

0.01

16V

25VB10k

R728

1k

R729

180

R717

C717

100

10V

CHIP

D702 D703

1SS355 1SS355

R730

22k

D701

R727

22k

IC702

TC74HC123AF

(EL)

MULTI VIB.

12345678

1A

VCC

1RX

1B

1CLR

1CX

Q

1Q

1

2Q

2Q

2CLR

2CX

2B

2RX

GND

R726

330

9 10 11 12 13 14 15 16

2A

R724

560

R725

82

C720

1

10V

Q703 Q704

2SA1037AK-T146QR 2SA1037AK-T146QR

BUFFER BUFFER

(SYNC SEPARATOR)

B-SS3666<AEP>-AA.

<CONDUCTOR SIDE>

1

2

3

4

IC701

BA7046F-E2

SYNC SEP

R707

330

C707

C708

1000p

R723

0

1 10V

R701

10k

VD

HD

SYNC

VIDEO

IN

GND

VCC

5 6 7 8

470k

47 16V CHIP

R706

C706

L701

18µH CHIP

R712

1.8k

R702

1k

1234

R703

470k

2200p

0.022 25V

C703

0.47

C704

C705

2SA1037AK-T146QR

C709

39p

KLV-17HR1(AEP) 3-6

(3) Schematic Diagrams of B (a, b, c, d, e) Board

1

2

A

43

98765

10

11

12

13

14

15

B

C

D

E

F

G

H

TO A BOARD

CN102

TO H3 BOARD

CN951

TO H1 BOARD

CN901

CN1

19P

V 52808

E_DET

SCL

SDA

#RESET

POWER

SEL0

SEL1

SC

SI

S_IN_DET

MUTE_SP

SC_F

SC_BL

AGC

INITIAL

MUTE_LNA

#TEXT/RGB

V_SEL0

V_SEL1

CN4

6P

V ZH-SM3

RMC

LED

E5V

GND

KEY0

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

1

2

3

4

5

6

ad-15

ab-4

ac-3

ad-2

ae-5

abcd-6

GNDD

FROM PS

E5V

TXD

TO PW112

RXD

TO PW112

C_SYNC

POWER_AV

E_DET

V_SEL1

V_SEL0

PANEL DET

POWER_LCD

RESET

POWER_AV

A-E_DET

SCL_AV

SDA_AV

#RESET_AV

POWER_AV

SEL0

SEL1

CLK_ATT

DATA_ATT

S_IN_DET

MUTE_SP

A-SCF_D1AS

A-SCBL_D1IP

AGC_CAPDET

INITIAL

MUTE_LNA

#TEXT_RGB_SW

PANEL_DET

POWER_LCD

#REMOCON

LED_POWER

A-KEYO

TL2

TL1

#REMOCON

S_IN_DET

A-SCF_D1AS

A-SCBL_D1IP

A-KEYO

A-E_DET

AGC_CAPDET

E5V

R71

100

TL71

TL70

R70

100

TXD

JR2

JR1

RXD

0

0

TL72

R72

4.7k

TL73

R74

R75

R73

100

100

4.7k

Q1

2SC2412KR

BUFFER

E5V

47k

47k

R50

R48

R86

10k

2.2k

47k

R58

R60

R81

47k

13

IO

G

IC3

M51943BML

3.3V REG

2

47k

R47

R76

10k

47k

R63

47k

R56

R77

1k

2SC2412KR

BUFFER

47k

R51

R49

R64

R52

R54

R57

R59

R61

R65

R66

47k

47k

100p

R55

R53

C6

D2

MC2840

C7

1

Q2

470k

R83

100

100

100

100

100

100

100

100

100

R78 R80

4.7k 4.7k

R79

47k

R39R40R41

2.2k2.2k2.2k

TL8

R42R43R44R45R46

10010010047k47k

2.5

5.1

5.1

5.1

4.9

5.1

1.1

1.1

HRXD_DVD

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

AMUTE_DVD

0.9

HTXD_DVD

#REMOCON

S_IN_DET

AVLINK_IN

NC

A-SCF_D1AS

A-SCBL_D1IP

YRGB_SW_DVD

AVLINK_OUT

A-KEY0

A-E_DET

AGC_CAPDET

A-AFT

R2

2.2k

C1

1

H8TXD_PWRXD

5.1

3.1

2.9

0.9

48PIN_HSCK_DVD

0

0

0

0

4.3

5.1

63PIN A-SCF_D1AS

0.7

64PIN A-SCBL_D1IP

4.4

00

0

5.1

2.1

X2_OPEN

AVCC_E5V

V-DET_DVD

A-KEY1_DVD

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

R1

100

R3

1M

C2

C11

0.01

1000p

PANEL_DET

INITIAL

E10T_P85

E10T_P86

E10T_P87

RESERVED

H8RXD_PWTXD

IC1

HD64F3687H

SYSTEM CONTROL

3.4

5.0

VSS_GND

TEST_VSS

#RESET_MAIN

VCL_BIAS

X1_VSS

0.1

100

C3

R4

X1

16.00MHz

CSTCE V

MUTE_SP

MUTE_LNA

TL11

TL7

TL6

5.1

5.0

4.7

1.0

MUTE_SP

MUTE_LNA

#HSYNC_VOUT

ACA_BKLIGHT

DT_BU2092_DVD

34PIN_CLK_BU2092_DVD

VCC E5V

15PIN_MOTOR-CLOSE_DVD

16PIN_MOTOR-OPEN_DVD

#RESET_VIDEO

#RESET_AV

2.5

2.3

5.1

OSC1

OSC2

R7

22k

R5

22k

#RESET_AV

R35

1k

33343536373839404142434445464748

0

0.8

#FPREQ_DVD

1.0

CS_BU2092_DVD

0

CLK_ATT

0

DATA_ATT

0

V_MUTE

0

SCL_AV

5.1

SDA_AV

5.1

LED_POWER

5.1

SEL1

5.1

SEL0

0

#SYS_M

0

#TEXT_RGB_SW

5.1

POWER_LCD

5.1

POWER_AV

5.1

#OPEN-LID_DVD

0.9

0.9

5.100

47k

47k

10k

R9

R8

R6

TL5

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

#E10T_NMI

33PIN_#FPCS_DVD

#CLOSE-LIN_DVD

R84

47k

R31

47k

R30

47k

R27

R25

R23

R21

R19

R17

R15

CN2

18P

V 52808

1

TL17

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

GND

UART PWTXD

UART PWRXD

SW H8RXD HOLD

E5V

SW H8TXD HOLD

#NMI HOLD

#RESET MAIN

HOLD

UART H8TXD HOLD

UART H8RXD HOLD

R3.3V

#RESET_PW

SW H8TXD HOLD

E5V

SW H8RXD HOLD

UART PWRXD

UART PWTXD

GND

E5V

CLK_ATT

SEL1

SEL0

SDA_AV

SCL_AV

C8

0.01

25V

D1

UDZSTE-176.2B

IC2

M24C08-WMN6T(A)

NVM

1234

VCC

WP

4.9

SCL

4.8

VSS SDA

5 6 7 8

abd-1

R68

100

R69

100

RESET_PW

R3.3V

TL3

TL4

R36R37R38

22k22k47k

R32R33R34

47k47k47k

47k

47k

4.7k

4.7k

R26

R29

R22

R24

100

100

R85

47k

100

100

100

100

100

R28

47k

22k

R11

4.7k

R12

R13

47k

47k

R14

47k

R16

R18

47k

DATA_ATT

LED_POWER

#TEXT_RGB_SW

POWER_LCD

POWER_AV

47k

R20

R3.3V

TL16

TL15

TL18

TL20

TL21

TL22

TL23

E5V

3.3V

B-a

(SYSTEM CONTROL)

B-SS3672<AEP>-B..-P1

I

• Divided circuit diagram

One sheet of B board is circuit diagram is divided into five sheets,

each having the code B-a to B-e. For example, the destination

ab1 on the code B-a sheet is connected to ab1 on the B-b sheet.

a b 1

Ref. No.

Circuit diagram division code

KLV-17HR1(AEP) 3-7

A

1

2

1.8VP-P(H)

3

0.4VP-P(20.25MHz)

•B-(b)BOARD WAVEFORMS

1.7VP-P(H)

1

2

43

98765

10

11

12

13

14

15

B

C

D

E

F

G

H

TO A BOARD

CN101

CN501

17P

V 52808

RGB-R/V

GND

RGB-G/Y

GND

RGB-B/U

GND

RGB-FB

GND

INT-V

GND

CVBS

GND

YC-C

GND

TEXT-V

GND

NC

CN503

3P

GND

GND

GND 3

CN502

#

GND

I2C_SCL_PW

I2C_SDA_PW

#RESET_PW

R3.3V

GNDA1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1

2

1

TL511

2

TL510

3

TL512

4

5

bd-14

bad-1

ba-4

R5V

C_SYNC

TL501

TL502

TL503

TL504

TL505

TL506

TL508

TL509

TL507

I2C_SCL_PW

I2C_SDA_PW

#RESET_PW

R3.3V

R5V

R565

4.7k

5.1 0.3

Q502

2SC2412KR

C594

BUFFER

2200p

R533

1k

C532

1

10V

R531

120k

R534

:1608

75

:1608

2.4

2.0

R532

82k

:1608

Q501

2SA1037AK-

T146-QR

BUFFER

C502

0

C501

560p

R560

330

R535

1k

:1608

C591

C590

1000p

R519

1k

R520

1k

1

VIDEO

R521

2

VIDEO

1k

R522

R3.3V

R564

4.7k

1

R561

470k

C505

27p

C506

27p

1k

R563

10k

1234

IC503

BA7046F-E2

COMP

5 6 7 8

C593

C592

47

0.022

6.3V

JR502

JR503

JR504

JR505

Y DATA

TL554

VID VS

VID HS

VID UV(0..7)

VID Y(0..7)

R3.3V

VID CLK

bc-8

#RESET

bacd-6

SDA

bcd-7

SCL

GNDD

bc-10

bc-9

R562

120k

R-Y/B-Y DATA

FB501

BLM18PG600SN1

FB502

0

75

75

75

C555

0.047

C558

390p

C559

1500p

C560

0.22

C561

6.3V

BLM18PG600SN1

C554 C556

47

6.3V

R551

C513

C514

C516

22

C562

0.047

C551

C550

10

0.01

16V

25V

C553

10

16V

C552

0.01

25V

VIDEO

R511

R510

R509

R508

0

0

0

0

100

4V

0

C563

16V

C522

C521

C520

C564

16V

C557

0.047

1000p

1 10V

1 10V

10

0.22

0.22

0.22

R5V

C565

0.1

10

C566

3p

X501

C567

3p

65

GND(F)

66

VRT

67

I2CSEL

68

ISGND

69

5.0V(F)

70

ANALOG V OUT

71

C IN

72

V IN1

73

V IN2

74

V IN3

75

V IN4

76

5.0V(AI)

77

GND(AI)

78

VREF

79

FB1 IN

80

AIS GND

20.25MHz

3

NC

XTAL1

XTAL2

2.4

2.4

ANALOG

SHILD GND

2.5

1.6

1.5

1.4

1.5

2.5

0

1.3

1.1

1.1

1.1

CB2 IN

CR1 IN

CB1 INNCY1 IN

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

TL550

CP501

22

FPDAT

0.1

CLK5MHZ

5.0V(STBY)

1.3

1.3

ANALOG SHLD GND

CR2 IN

Y2 IN

C582

1500p

C529C530C531

0.10.10.1

TL552

TL551

TL553

C569

1500p

0

2.6

0.1

FSY/HC

MSY/HS

ACTIVE V OUT

V SYNC PULSE

3.3

GND(D)

3.3V(D)

3.3V(CAP)

C580

0.1

C581

390p

C583

0.22

VID UV0

C568

0.047

C0

0

GND(SYNC)

3.3V(SYNC)

INTERLACE OUT

IC501

VPC3230D

(DECODER)

3.5

2.4

3.1

RESET INPUT

GND(CAP)

SDA

SCL

VID UV1

VID UV2

VID UV3

VID UV4

CP502 CP503

C570

0.068

C3C2C1

000

GND(C)

3.3V(C)

VGAV

FFRSTW

FFWE

FFIE

YCOEQ

TEST

C579

10

16V

R540

47

R541

47

C586 C587

100p 100p

VID UV5

VID UV6

VID UV7

414243444546474849505152535455565758596061626364

C7

C6

C5

C4

000

2.3

1.3

1.3

1.3

1.3

3.3V(Y)

GND(Y)

1.3

1.3

1.3

1.4

GND(LLC)

3.3V(LLC)

CLK OUT

1.6

DOUBLE CLK OUT

3.3V(PA)

3.2

GND(PA)

CLK

FFOE

FFRE

20.25MHZ

R542

47

R543

47

00

C571

0.1

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

FB503

BLM18RK121SN1

R3.3V

C572

10

16V

CP504

0

CP505

0

VID Y0

VID Y1

VID Y2

VID Y3

VID Y4

VID Y5

VID Y6

VID Y7

R552

0

C585

33p

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

C573

0.068

C574

0.068

C575 C576

1500p 0.047

C577

10

16V

C578

0.1

B-b

(VIDEO DECODER)

B-SS3672<AEP>-B..-P2

I

• Divided circuit diagram

One sheet of B board is circuit diagram is divided into five sheets,

each having the code B-a to B-e. For example, the destination

ab1 on the code B-a sheet is connected to ab1 on the B-b sheet.

a b 1

Ref. No.

Circuit diagram division code

KLV-17HR1(AEP) 3-8

1

2

43

98765

10

11

12

13

14

15

A

B

C

D

E

F

G

H

MA5

MA4

MA6

MA7

CLK

DQMH

#CAS

#WE

MCAS-

VID UV5

VID UV4

COMP

YQ1

C622

10V

#RAS

#CS

MRAS-

MCS-

VID UV2

VID UV3

VVDD

VA

1

MA8

A9

A11NCCKE

A10

BA1

BA0

MA10

MA9

VID UV0

VID UV1

VGND

YQ0

C623

0.1

F:CHIP

MD29

MD30

MD31

IC603

HY57V641620HGT-H

64MDRAM

C681

0.1

282930313233343536373839404142434445464748495051525354

C682

0.1

A4A5A6A7A8

VSS

C683

0.1

C684

0.1

C685

VDD

A3A2A1

MA0

UQ9

C624

10

16V

BC7

A0

MA1

MA2

VREFOUT

AGND

C625

0.1

C686

0.1

MA3

VID Y6

VID Y7

Y6Y7U0

U1

U2U3U4U5U6U7V0V1V2V3V4V5V6

VDD

IC601

PW1210

-NV320DRC-MF

PVSS

VSS

VREFIN

AVDD

C626 C627 C628 C629 C630

0.1 0.1 0.1 0.1 0.1

0.1

PVDD

UQ6

UQ7

UQ8

BC5

BC3

BC4

BC6

VSS

VSSQ

DQ15

DQ14

DQ1

DQO

VDD

VDDQ

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

C680

47

4V47

VSS

UQ5

VID Y5

VID Y4

Y5

VDD

BC2

VID Y3

UQ4

BC1

VID Y2

UQ2

UQ3

BC0

VID Y0

VID Y1

Y0Y1Y2Y3Y4

PVSS

UQ1

MD16

PVDD

UQ0

MD17

MD18

LLA

HREF0

PVDD

VQ9

RC7

DQ13

DQ2

RC6

MA5

MA4

MA6

MA7

VDDQ

VSSQ

MD28

DQ12

DQ3

MD19

MD27

DQ11

DQ4

MD20

VSSQ

VDDQ

MD26

DQ10

DQ5

MD21

MD25

DQ9

DQ6

MD22

VDDQ

VSSQ

MD24

DQ8

DQ7

MD23

NC

VSS

DQMH

VDD

#WE

DQML

MWE-

CLK

#CAS

MCAS-

#RAS

MRAS-

#CS

MCS-

MA8

282930313233343536373839404142434445464748495051525354

A4A5A6A7A8

A9

A11NCCKE

BA1

BA0

MA10

VSS

VDD

A10

A3A2A1

A0

MA0

MA1

MA2

MA3

MA9

R3.3V

C643

C644

0.1

3.3

R614

C645C646C647C649

330

0.10.10.10.1

PVDD

DVDB

P3GND

PVSS

VQ3

VQ4

100101102 103104

RC1

RC2

P3VDD

P1GND

157158159160161162163164165166167168169170171172173174175176177178179180181182183184185186187188189190191192193194195196197198199200201202203204205206207208

DQ24

DVDLLC

P1VDD

VQ2

RC0

PVSS

DQ25

DQ26

DQ27

PVDD

DQ28

DQ29

DQ30

DQ31

PVSS

DQ16

DQ17

DQ18

PVDD

DQ19

DQ20

DQ21

DQ22

PVSS

DQ23

DQM1

#WE

#CAS

VSS

XTALI

XTALD

VDD

PVDD

#RAS

#CS

A10

PVSS

PVDD

CAS1

CSA0

PVSS

12C3W

SCC

RFROCK

PLLFS

PVDD

OEQ

P60

DVQ

PVSS

TEST

VQ0

VQ1

PVDD

C631

0.1

A8

A0

A1

A2

A3

CLV

PVSS

DVDHS

DVDHS

VQ5

VQ6

VQ7

VQ8

RC5

RC3

RC4

R3.3V

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

C642

C632 C633

3.3 100

4V

100

4V

C641

0.1

C635

0.1

C634

0.1

C640

0.1

C639

0.1

C638

0.1

C637

0.1

C636

0.1

R608

MD24

MD25

MD26

MD27

MD28

MD29

MD30

MD31

MD16

MD17

MD18

MD19

MD20

MD21

MD22

MD23

MWE-

MCAS-

R612

1M

MRAS-

MCS-

MA10

MA8

MA0

MA1

MA2

MA3

R610

0

0

R607

47

X601

10MHz

R613

680

RC0

RC1

RC2

RC3

RC4

RC5

RC6

RC7

BC0

BC1

BC2

BC3

BC4

BC5

BC6

BC7

CP601

47

VGR0

VGR1

VGR2

47

CP603

47

CP604

47

CP605

47

CP606

47

VGR3

VGR4

VGR5

VGR6

VGR7

VGB0

VGB1

VGB2

VGB3

VGB4

VGB5

VGB6

VGB7

CP602

GY0

GY1

GY2

GY3

GY4

GY5

GY6

GY7

VGG0

VGG1

VGG2

VGG3

VGG4

VGG5

VGG6

VGG7

R

B

G

PAL60

VPEN

GNDD

VCLK

VHS

VVS

VGR(0..7)

VGB(0..7)

VGG(0..7)

cd-13

cd-12

cd-12

cd-11

MD8

DQ13

DQ2

VDDQ

VSSQ

P2GND

YANCNC

MD11

MD12

DQ11

DQ12

DQ4

DQ3

MD3

MD4

LLC

HRC

#RESEET

YGND

YVDD

YQ4

GY2

VSSQ

VDDQ

GY1

MD10

DQ10

DQ5

MD5

CREF

YQ3

MD9

MD6

HREF

PVDD

C619

0.1

NC

VSS

DQ8

DQ9

VDDQ

VDD

DQ7

DQ6

VSSQ

DQML

MD7

MWE-

VID UV6

VID UV7

VS

HS

V7

ODD

UGND

YVDD

YQ2

UA

NC

C620

0.1

C621

0.1

GY0

MD15

MD13

MD14

VSS

VSSQ

DQ15

DQ14

DQ1

DQO

VDD

VDDQ

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

MD0

MD1

MD2

16V

C648

100

4V

DQ7

PVDD

P2VDD

DQ6

1

DQ5

2

PVDD

3

DQ4

4

DQ3

5

DQ2

6

PVSS

7

DQ1

8

DQ0

9

DQ15

10

PVDD

11

DQ14

12

DQ13

13

DQ12

14

PVSS

15

DQ11

16

DQ10

17

DQ9

18

PVDD

19

DQ8

20

DQMO

21

CLK

22

PVSS

23

LLAD2

24

VSS

25

A9

26

HRA

27

VDD

28

A7

29

A6

30

PVDD

31

A5

32

A4

33

SDA

34

SCL

35

PVSS

36

PCLK

37

HSQ

38

HBQ

39

PVDD

40

VSQ

41

VBQ

42

RSET

43

PVSS

44

YQ9

45

YQ8

46

YQ7

47

PVDD

48

YQ6

49

ADGND

50

ADVDD

51

YQ5

52

PVSS

53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

C617

100

4V

C618

0.1

R5V

cb-9

ca-6

cb-10

cb-8

cbd-7

R5V

C601

10

16V

C602

10

16V

C603

0.1

R602

22k

R603 R604

4.7k 39k

C605

16V

VID Y(0..7)

VID UV(0..7)

#RESET

VID HS

VID VS

R3.3V

VID CLK

SDA

SCL

IC604

HY57V641620HGT-H

64MDRAM

4.7

R605

750

10

Y DATA

R-Y/B-Y DATA

VDD

ZENR

SIG-IN

PC2OUT

R2

R1

SF-OUT

9 10 11 12 13 14 15 16

VCO-IN

PCP-OUT

PC1OUT

COMP-IN

VCO-OUT

INH

C1A

C1B

GND

12345678

BLM18PG600SN1

BLM18PG600SN1

FB601

FB602

C606

39p

IC602

CD74HCT4046A

R601

R3.3V

GY7

GY6

GY5

GY4

FB603

BLM18PG600SN1

GY3

C614

10

16V

C691

0.1

C692

0.1

C693

0.1

C694

0.1

C695

0.1

C696

0.1

C690

4V

R3.3V

C650 C652

C651 C653

0.1 0.1

3.3 10

MD7

MD6

MD5

C607

0.1

MD4

MD3

MD2

MD1

MD0

MD15

C608

0.1

MD14

MD13

MD12

MD11

MD10

MD9

C609

0.1

MD8

MA9

C610

0.1

MA7

MA6

C611

0.1

MA5

MA4

C612

0.1

R606

100

C613

0.1

C615

0.1

C616

0.1

JR601

0

I

B-c

(DRC)

B-SS3672<AEP>-B..-P3

• Divided circuit diagram

One sheet of B board is circuit diagram is divided into five sheets,

each having the code B-a to B-e. For example, the destination

ab1 on the code B-a sheet is connected to ab1 on the B-b sheet.

a b 1

Ref. No.

Circuit diagram division code

KLV-17HR1(AEP) 3-9

Loading...

Loading...