Page 1

HISTORY INFORMATION FOR THE FOLLOWING MANUAL:

SERVICE MANUAL (COMMON)

Version Date Subject

1 3/2015 1st Issue.

RB2G CHASSIS

Segment: XM-L

LCD TV

9-888-170-01

For SM - Uni q u e , pleas e ref er :

9-888-170-Ax ( America )

9-888-170-Jx ( Japan )

9-888-170-Ex ( Europe )

9-888-170-Px ( Pan Asia )

Page 2

SERVICE MANUAL (COMMON)

RB2G CHASSIS

Segment: XM-L

LCD TV

Page 3

MODEL LIST

THIS SERVICE MANUAL CONTAINS COMMON INFORMA TION FOR BELOW REGIONS AND MODELS:

REGION

ASIA JAPAN AMERICA EUROPE

MODEL

KJ-32W7*C

KDL-32W7*C

KJ-40W7*C KDL-40W7*C

KJ-48W7*C KDL-48W7*C

3

Page 4

Overvie w of C on trol B utton s .......... .. .. ... .. ... .. ... .. ... .. .... . .... . .... .. ... .. ... .. ... .. ..

TABLE O F CON TE NTS

Sect ion T itle Page

1. SAFETY NOTES

1-1. Warnings and Caution……………………………………… ……………… . 5

1-2. Caution Handling of LCD P ane l ......…………….................................... 5

1-3. Caution About the Lithium Batter………………………………… ……….. 6

1-4. Safety Ch e ck Out ........................……………......................................... 6

1-5. Leakage Te st .......................................................................................... 6

1-6. How to Find a Good Earth Ground………………………………………… 7

1-7. Lead Free Information….…………………………………………………… 7

1-8. Handli ng the Flexible Flat Cable (FFC)……………………………………. 7

2. SELF DIAGNOSTIC FUNCTION

2-1.

2-2. LED Display Control ………..................................................................... 9

2-3. LED Pattern………………........................................................................ 9

2-4. Standby LED Error Display…………………………………………………. 9

2-5. Triage Chart ............................................................................................ 10

3. TROU BL E S HOOT ING

3-1. No Power…….……………………………………………………………….. 11

3-2. LED Blinking……………….………………………………………............... 12

3-3. No Sound……………………………......................................................... 20

3-4. No Picture................................................................................................. 21

3-5. Side Buttons Malfunction……………………………………………………. 23

3-6. IR Remote Commander Malfunction……………………………………… 23

3-7. Light Sensor Error……………………………… ……………… ………… . 23

3-8. Network Malfunction: Ethernet (Wired)………………………… …………. 24

3-9. 3D-Glasses (Active) malfunction………… ………… ………… …… …….. 25

3-10. Wireless N etwork Malfunction………………… …………………… ……. 26

3-11. Bluetooth Malfunction……………………………………………………….. 27

8

Sect ion T itle Page

4. SERVICE ADJUSTMENTS

4-1. Accessing Service Mode ..................................................................... 28

4-2. Transition o f Each M icro’s S ervice Mode……….………………… …… 28

4-3. Change Data b y Service Mode 1…………………………… ……..……. 28

4-4. Change Data b y Service Mode 2…………………………… …………... 29

4-5. Restore WB / Gamma Adj. Data to B Board.………………………….. 31

4-6. WB Adjustment by Service Mode…………………………… ………….. 32

4-7. VCOM Adjustment (NFR-AUO/SDC/FXC Pane l) …………………………… 33

4-8. VCOM Adjustment (HFR-AUO /FXC Panel) …………………………………. 33

4-9. REC Setting………………………………………................................... 33

4-10. Reset Panel Operation Time………………………………… ……....... .. 34

4-11. Set to Shipping Condition……………………………………….............. 34

4-12. Summary of Service Control……………………………………….......... 34

4-13. Service Menu Tree……………………………………… ....... ........ ......... 35

4-14. How to Enter Self Diagnosis Display…………………………………… 36

5. DIAGRAMS

5-1. Circuit Board Location ......................................................................... 38

5-2. Block Diagram ………………………………………...................... 38

5-3. Connector Diagram ………………………………………...................... 46

Please refer Service Manual – Unique for below information :

-Safety Warnings

-Wire Dressing

-Circuit Board Location

-Disassembly and Exploded View.

4

Page 5

SECTION 1

SA FETY NOTES

1-1. Warnings and Caution

1) These servicing instructions are for use by qualified service personnel only.

2) To reduce the risk of electric shock, do not perform any servicing other than

that contained in the operating instructions unless you are qualified to do so.

3) An isolation transformer should be used during any service to avoid

Possible shock hazard, because of live chassis. The chassis of this receiver is

directly connected to the ac power line.

4) Be sure to follow these guidelines to protect your property and

avoid causing serious injury :

• Carry the TV with an adequate number of people; larger size TVs require

two or more people.

• Correct hand placement while carrying the TV is very important for

safety and to avoid damages.

5) Components identified by shading and mark on the exploded views,

!

and in the parts list are critical for safe operation. Replace these

components with Sony parts whose part numbers appear as shown in this

manual or in supplements published by Sony. Circuit adjustments that are

critical for safe operation are identified in this manual. Follow these

procedures whenever critical components are replaced or improper

operation is suspected.

1-2. Caution Handling of LCD Panel

When repairi ng the LCD Panel, make sure you are grounded w ith a wrist band.

When repairi ng the LCD Panel on the wall, the panel must be secured using the

4 mounting hol es on the rear cover .

1) Do not press the panel or frame edge to avo id the risk of electr ic shock.

2) Do not scr atch or press on the panel w ith any sharp object s.

3) Do not leave the module in high temperat ure or in areas of high hum idity for

an extended per iod of time.

4) Do not expose the LCD panel to direct sunlight.

5) Avoid contact with water . I t may cause short ci rcu it within the module.

6) Disco nnect the AC power when replaci ng the backl ight ( CCF L) or

inverter cir cuit . (Hi gh voltage occur s at the inver ter ci rcui t at 650Vrms)

7) Always cl ean the LCD panel with a soft cloth mater ial .

8) Use care when handli ng the wir es or connectors of the inver ter ci rcui t.

Damaging the w ir es may cause a short circu it.

9) Protect the panel from ESD to avoid damaging the elect roni c circuit (C-MOS).

10) Dur i ng the r epai r , DO NOT l eave the Pow er On or Burn-i n period for more

than 1 hour w hil e the T V i s face dow n on a cloth.

Figure 1. TV is faced down on a cloth during repair.

5

Page 6

Safety Notes

1-3. Caution About the Lithium Battery

1) Danger of explosion if battery is incorrectl y replaced. Replace only with

the same or equivalent type.

2) Outer case broken battery shoul d not contact to water.

1-4. Safety Check-Out

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:-

1) Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and bridges.

2) Check the inter board wiring to ensure that no wires are pinched or

contact high-wattage resistors.

3)Check all control knobs, shields, covers, ground straps and mounting

hardware have been replaced. Be absolutely certain you have replaced all

the insulators.

4) Look for unauthorized replacement parts, particularly transistors that

were installed during a previous repair. Point them out to the customer and

recommend their replacement.

5) Look for parts which, though functioning show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6) Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7) Check the antenna terminals, metal trim, metalized knobs, screws and all

other exposed metal parts for AC leakage. Check leakage test as described

next.

8. For safety reasons, repairing the Power board and/or Inverter board is

prohibited.

1-5.Leakage Test

The AC leakage from any exposed m etal par t to earth ground and from all

exposed metal par ts to any exposed metal part having a retur n to chassi s must

not exceed 0.5mA (500 micr oamperes) .

Leakage cu rrent can be measur ed by any one of the three m ethods:-

1) A commerci al leakage t ester such as the SI M PSON 229 or RCA WT540A.

Follow the manufacturers instr uctions to use those instruct ions.

2) A battery-operate d AC milliampmeter The DATA PRECISI ON 245 digital

multimeter is suitable for this job.

3) Measu ring the volt age dr op across a resi stor by means of a VOM or battery

operated AC voltmeter. The 'li mi t' indication is 0.75V so analog m eters m ust

have an accurate low volt age scale. T he SIM PSON' S 250 and SANWA SH63TRD are exampl es of passi ve VOM s that are sui table. N early all battery

operated digi tal mul timeter that have a 2 VAC range are sui table.

(see Figur e 2.)

Figure 2. AC voltmeter to check AC leakage

1-6. How to Find a Good Earth Ground

1) A cold-water pi pe is a guaranteed ear th ground; t he cover-pl ate retaini ng

screw on most AC outlet boxes i s also at earth ground.

2) If the retaining scr ew is to be used as your earth ground, veri fy that it is at

ground by measur i ng the r esistance between it and a cold-w ater pi pe with an

ohmmeter. T he readi ng should be zer o ohms.

3) I f a cold-w ater pi pe is not accessi ble, connect a 60- to 100-watt t roublelight (not a neon lamp) between the hot side of the recept acle and the

retaining scr ew. Tr y both slots, if necessa ry, to locate the hot si de on the line;

the l am p shoul d l i ght at normal br i l l i ance i f the screw is at gr ound pot enti al

(see Figur e 3).

Figure 3. Checking for earth

ground.

6

Page 7

Safety Notes

1-7. Lead Free Information

The circui t boards used i n these model s have been pr ocessed using Lead

Free Solder. The boards ar e identified by the LF logo loca ted close to the

board designation.

Pleas e hol d rei nfor ce men t b oard an d

plunge it to depths.

Main Board

Please pull out FFC while pushing the

but ton of both end s at the s ame tim e.

Main Board

The servici ng of these boards r equires special precautions. It is strongly

recommended to use Lead Free Solder mat erial in order to guarantee opt imal

Figure 4: LF Logo

Figure 5: LF logo on circuit board

quality of new solder joi nts.

1-8. Handling the FLEXIBLE FLAT CABLE (FFC)

When you insert / pull out FFC, please grasp a reinforcement board and main

body of FFC.

< Insertion>

Release Button

of Connector

FFC connector broken if pull out FFC

without press and hold both Release

Button of connector. S ymptom 5X blinking

will be appear due to improperly seated .

<Pull out>

7

Page 8

Self Diagnostic Function

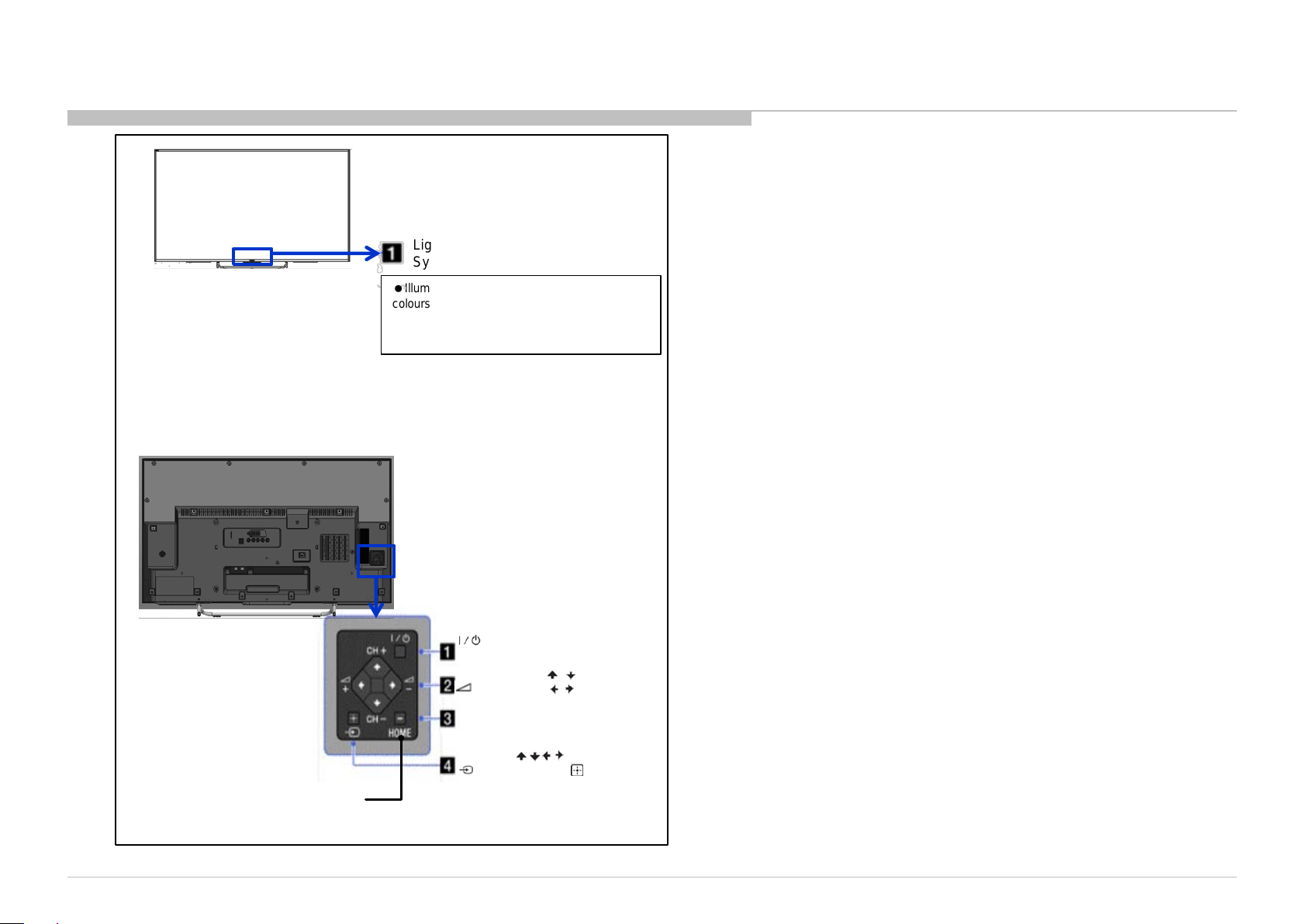

2-1. Overview of Control Buttons

2-1-1.

FRONT

REAR OF TV

SECTION 2

SELF DIAGNOSTIC FUNCTION

TV CONTROLS/ TERMINALS/ INDICATOR

Remote Control Sensor /

Light sensor / * Illumination LED / 3D

Sync Transmitter

Illumination lights up or blinks in different

col ours ac cor di n g t o the s tat us of the T V

( details refer to 2-2. LE D Dis play Control

HOME

Press to display

the TV Home Menu.

Power

Turn the TV on or switch to standby mode

CH+/- (Channel) / / ,

+/- (Volume) / / .

Press to select the next or previous

channel.

Press to adjust the volume.

In TV Home Menu: buttons will

work as , , , .

INPUT SELECT /

SELECT/ CONFIRM

Press to select the next or

previous channel.

In TV Home Menu: buttons will

work as (select/confirm)

8

Page 9

Self Diagnostic Function

2-2. LED Display Control

White Center

Status

Pow er Of f

( by power saving switch off and *1)

Pow er On White Off Off

STBY/i.LINK STBY/PC STBY

( by rem ote c ontrol off onl y )

Sky pe C al l R ec ei ve White White one shot Off

Pi cture Off White looping White one shot Off

Devi ce C onn ect ion White Cyan on e shot Off

Pow er ON A n i mati on White White one shot Off

Sl eep T i mer/ O n

Tim er / Rem in der /R EC Ti m er/ P hot o

Frame

( Power On )

On Timer/ Reminder/REC Tim er

( Deep Standby )

Failure Off

Aging mode White Green Blinking Off Blinking:0.5sec On / 0.5sec Off

End of Aging mode White Green Blinking Off Blinking:3sec On / 3sec Off

Soft war e Updat in g white blinking white blinking off

Software Updating finish White Blue lit off

Test R eset White white blinking

Err or of pan el I D White Green Blinking

REC (SCART REC & HDD

REC/LIVE PAUSE) [AEP/J on l y ]

ePOP/

Shop Illumination

LED

(applicable for

HSC2 only)

Off Off Off

Off Off Off

White

Off Off Amber

White

White Cyan l oop Off

Side RGB LED

Amber

One s hot -> Li t*2

Red

Blinking

Red(Pink)

One s hot -> Li t*2

Side Amber

LED

*1 power switch off (by side

Off *2 One S hot is only user act i on.

The number of LED blinking

Off

Amber

blinking

Amber

Blinking

Blinking:0.5sec O n / 0.5sec Off

Off *2 One S hot is only user act i on.

Remarks

key)

Aft er 5 m i nu t es , si d e amber

LED On

ind i c at es c au se of f ai l u re

( refer to Led Error / Triage

chart)

2-3. LED Pattern

When safety shutdown occurs, Standby LED display reports the cause by using the lightning

patterns as indicated below

.

2-4. Standby LED Error Display

Smart

Core RED

LED

blinking

count

2x

3x

4x

5x

6x Backlight failure [BACKLIGHT] LED driver (LD) board

7x

8x

9x

Main 19.5V failure [MAIN_POWE]

* This failure is not saved

Main 5.0/3.3/1.0 failure [DC_ALERT]

* 5.0/1.0V failures are not saved.

Audio amp. protection [AUD_ERR]

HDMI equalizer/switch I2C NACK [HDMI_EQ]

* There is Temp. sensor on the same I2C bus

Tuner or demodulator I2C NACK [TU_DEMOD]

AFE device I2C NACK [AFE_I2C]

AFE device SPI NACK [AF E_SPI] * o nl y for AEP,C H

LED driver failure [LD_ERR]

LED voltage error [VLED]

Panel ID EEPROM I2C NACK (Also panel power failure is a

suspect) [P_ID_ERR]

(*detect at startup sequence only)

Over temperature protecti on [T EMP_ERR]

Temp. sensor I2C NACK [TEMP_ERR]

Software Error (Also the main board’s memor y or CAM module is a

suspect)

Tuner board error [TU_BOARD]

Detection Items

Power Adapter

BAXL Board

BAXL Board

BAXL Board

Speaker

BAXL Board

BAXL Board

Tuner Board

BAXL Board

Tuner Board

BAXL Board

Tuner Board

LED driver (LD) board

Panel Module

Panel module

Tcon board

G** Board

BAXL Board

BAXL Board

BAXL Board

Tuner Board

Board Error Item

0.5sec

Example: The figure above shows LED display when SHUTDOW N is caused by Audio

Error. It repeats f lashing f or a specified number of t imes in 0.5sec/c ycl e and has a 3 s econds

interval of lighting off. Please note that a 3 seconds interval of lighting off is fixed regardless of abnormal state types.

0.5sec

3.0sec 3.0sec

B** Board Type

Size

32”

40”

48”

H**

BAXL

BAXL

BAXL

G** Board Type

Not applicable HSC3 TUS TUW

Not applicable HSC3 TUS TUW

Not applicable HSC3 TUS TUW

Board

Type

Tuner Board

America/

Asia/Europe

Japan

9

Page 10

response

dots

Self Diagnostic Function

2-5. Tri age C hart

Reference

BAXL Board

2

p

3 4 5 6 7 8 9 10

l p p l l

TU Board p

H* Board

Speaker

p

Skype Module

Wi-fi Module

BT Module

LD Board

LVDS FFC

Tcon

LCD Panel

Symptoms - Shutdown. Power LED

blinking red diagnostics sequences

No

Power

Video

- missing or distorted

Remote Network Audio Skype

No White

Power

LED &

does not

to remote

Stationary

coloured

lines or

No

video

One of

Inputs

No

video

all

Inputs

No

Remote

Wireless

can't

connect

(Dead

Set)

p

l

p p l l p p l p p p

p

l l

l

l

l

p p

p l p

l l l p

p

p

p

l

p

p

p

p

No Audio

Skype

Can't Work

p

l

l

l

p

Smart

Core

Smart

Core no

LED (Set

is still

alive)

l

Bluetooth

(BT)

Bluetooth /

One Step

Remote

(OSR) can 't

connect

l

Problem

Power Power LD

Panel

(Tcon)

Panel

(Backlight) TEMP

Software

Emitter

FAN

Audio

(N/A)

Local

I2C

B** Board Type

Most likely defective part

Secondary possible defective part

Not Applicable

Size

32”

40”

48”

BAXL

BAXL

BAXL

G** Board Type

Not applicable HSC3 TUS TUW

Not applicable HSC3 TUS TUW

Not applicable HSC3 TUS TUW

H**

Board

Type

Tuner Board

America/

Asia/Europe

Japan

10

Page 11

Troubleshooting

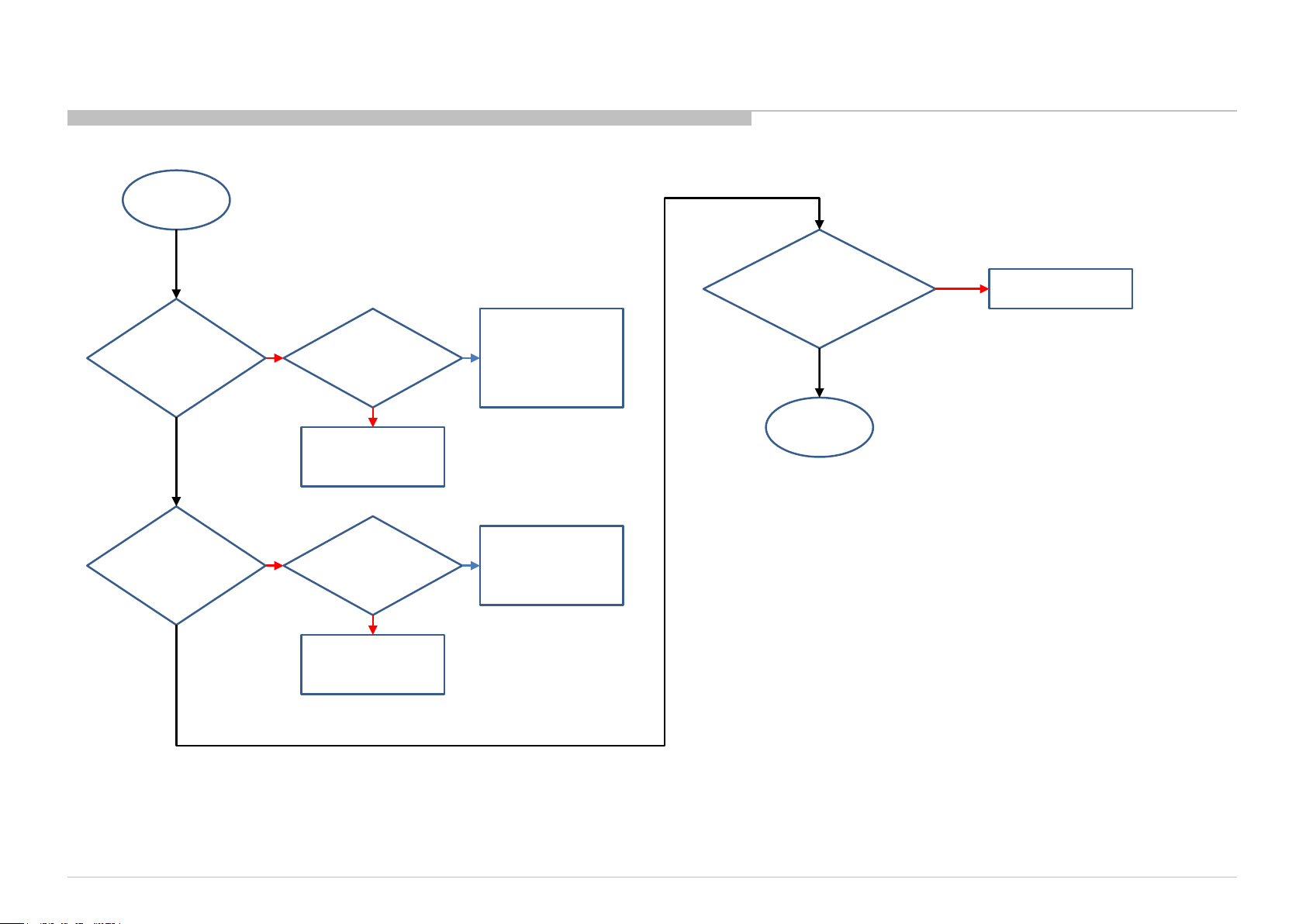

3-1. NO POWER

3-1-1. NO POWER

SECTION 3

TROUBLESHOOTING

3-1-2. NO POWER – LD Board

No P ow er

Check STBY 3.3V

L9107 or C9179

OK

B* Board

NG

Replace

LD-board

to B-board

harness

OK

Harness

broken

DC/DC converter check

NO POWER: Ayu2 control

NG

Replace

LD-board

NG

Board PWB ( A side ) Detail

OK

LD- board

broken

No Power

Check F1002,

Is the voltage > 18V?

Yes

Check D1001,

Is the voltage > 18V?

Yes

Check Q1004,

Is the voltage > 18V?

Yes

Check C1042,

Is the voltage > 3.3V?

Yes

Check connection

Harness CN1001

OK

Check C1024,

Is the voltage > 12V?

Yes

No

No

No

No

NG

No

DC Adaptor

broken

FUSE F1002

broken

MOSFET Q1004

broken

Case 1 :

Check 3.3V DDCON

Harness CN1001

broken

Case 2 :

Check 12V DDCON

B* Board

Symptoms

NO POWER: DC/DC converter check

B** Board Type

Size

32”

C9179

L9179

40”

48”

BAXL

BAXL

BAXL

G** Board Type

Not applicable HSC3 TUS TUW

Not applicable HSC3 TUS TUW

Not applicable HSC3 TUS TUW

H**

Board

Type

Tuner Board

America/

Asia/Europe

Japan

11

Page 12

Troubleshooting

Case 1 : Check 3.3V DDCON

Check 3.3V DDCON

Check F1004,

Is the voltage > 18V?

Yes

Remove Harness CN1001

and Check C1042,

Is the Power line

short to ground?

No

Remove Harness CN1001

and Check C1042,

Is the voltage > 3.3V?

Yes

B* Board

No

Yes

No

FUSE F1004

broken

DDCON IC1002

DDCON IC1002

broken

broken

Case 2 : Check 12V DDCON

Check 12V DDCON

Check F1003,

Is the voltage > 18V?

Yes

Remove Harness CN1001

and Check C1024,

Is the Power line

short to ground?

No

Connect Harness CN1001

and Check Pin 3 IC1001,

Is the voltage > 3V?

No

B* Board

No

Yes

Yes

FUSE F1003

broken

DDCON IC1001

broken

DDCON IC1001

broken

Symptoms

Symptoms

NO POWER: DC/DC converter check

NO POWER: DC/DC converter check

12

Page 13

Troubleshooting

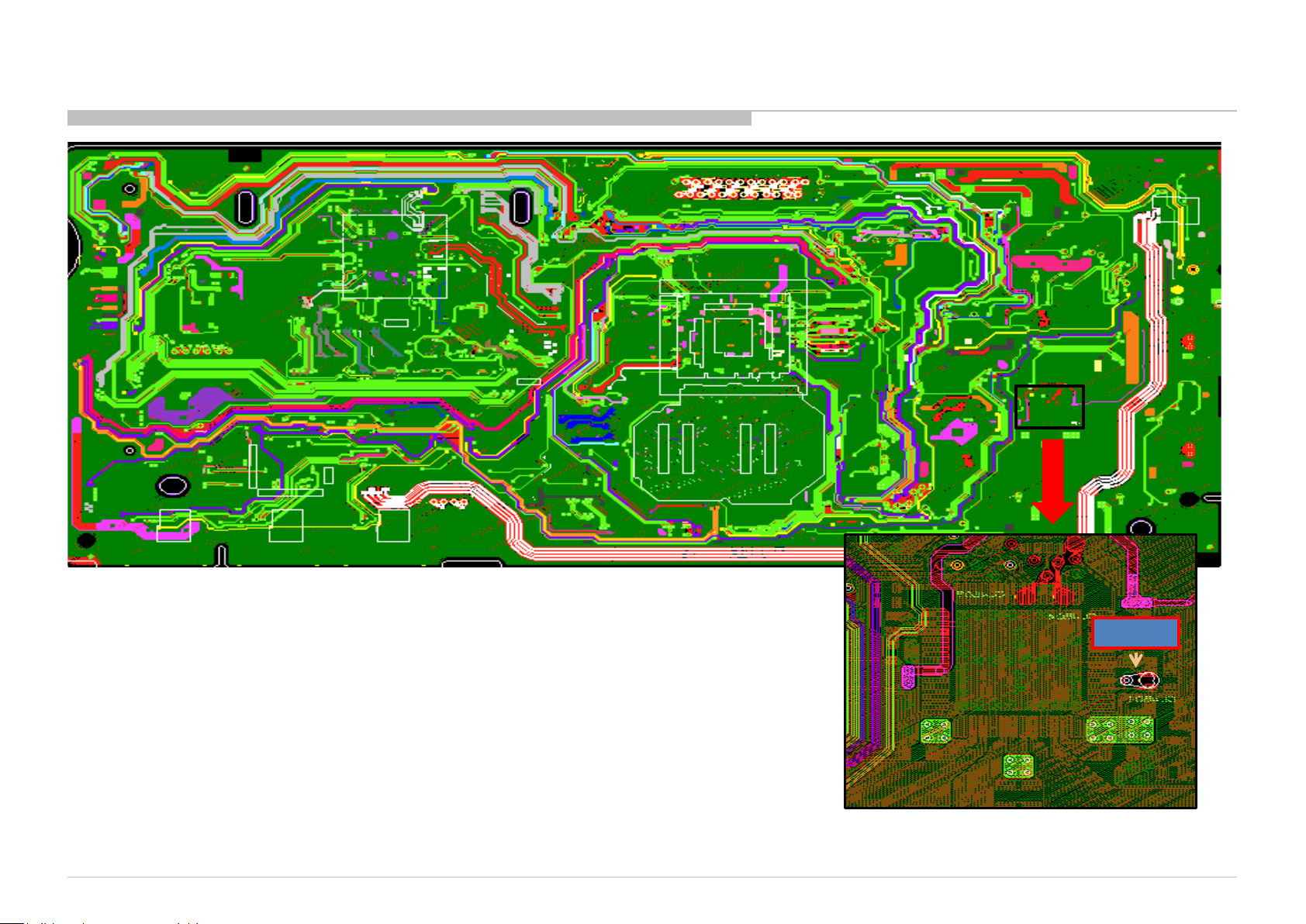

Board Name Board PWB (A side) Detail

LD-XM-L

CN1001

F1002

D1001

Q1004

Detail

F1002

CN1001

Measuring

Point

D1001

Q1004

13

Page 14

Troubleshooting

Board Name Board PWB (A side) Detail

LD-XM-L

IC1002

C1042

Detail

F1004

F1004

IC1002

C1042

Measuring

Point

14

Page 15

Troubleshooting

Board Name Board PWB (A side) Detail

LD-XM-L

F1003

C1024

IC1001

Detail

F1003

C1024

IC1001

Measuring

Point

15

Page 16

Troubleshooting

3-1-3. NO POWER: Ay u2L control

No Power

Check STBY_+3.3V

at AYU2L

(H15, H16, H17 pin

C7376)

OK

Check STBY_+1.8V

at AYU2L

(H19 pin

C7374)

OK

Check STBY_+1.0V

at AYU2L

(J15, J16, J17 pin

C7380)

OK

Che ck X tal o scilla tio n

X7301, 32.768kHz

(A23, B23 pin

R7396)

NG

NG

NG

NG

look for where

STBY_+3.3V is NG.

look for where

STBY_+1.8V is NG.

look for where

STBY_+1.0V is NG.

Replace X7301 or Ayu2L

Check AC_MON

at AYU2

(C11 pin C7334)

OK

Check MAIN_PWR

at AYU2

(C13 pin C7315)

OK

Check +19.5V(Adapter)

Or +12V(G-Board)

at CN9101 pin21

OK

It might be power supply problem

Please refer "DC/DC converter check" sheet.

NG

NG

NG

Look for AC_MON line

at CN9101 pin12/C9131 or

Adapter/ G board failure

Look for MAIN_POWER line

at CN9101 pin11

or replace AYU2

Adapter/

G-board

OK

16

Page 17

Troubleshooting

Board

Name

Board PWB ( A side ) Detail

BAX-L

1. C7376

2. C7374

3. C7380

4. R7396

5. C7334

6. C7315

1, 3, 4

5,6

2

1, 3, 4

5, 6

C7376

C7380

2

C7374

AYU2L

X7301

R7396

C7334

C7315

17

Page 18

Troubleshooting

Board

Name

Board PWB ( A side ) Detail

BAX-L

1. C7376

2. C7374

3. C7380

4. R7396

5. C7334

6. C7315

7. CN9101

1, 3, 4

7. CN9101

5,6

2

1, 3, 4

5, 6

C7376

C7380

2

C7374

AYU2L

X7301

R7396

7. CN9101

C7334

Pin12

C9131

C7315

Pin11

Pin21

18

Page 19

Troubleshooting

3-1-4. NO POWER: DC/DC converter check

START

CONDITION SYMPTOM

19.5V_SS not availa ble. Board will not t u r n O N . N o bli nk ing.

STBY_+3.3V, STBY_+1.8V and STBY_+1.0V not

available.

19.5V_HOLD not available. 2X blinking.

+5.0V_MAIN not available. 2X blinking.

D+1.0V, +5.0V_VBUS, +3.3V_MAIN_1,

DDR3_+1.5V or +1.8V_MAIN not availa ble.

D+1.1V not available.

Board will not t u r n ON . No bl inking.

3X blinking.

Board turn ON. No blinking at first, but after

few minutes (±5min) 8X blinking occur.

IC9106

output or

input short

to GND?

C9302,

C9214

NO

IC9101

output or

input short

to GND?

SL9104,

C9114

NO

Q9108

output or

input short

to GND?

SL9110,

C9158

YES

YES YES

YES YES

Remove

IC9106.

Still short?

NO

IC9106 broken

Remove

IC9101.

Still short?

NO

IC9101 broken

Remove

Q9108. Still

short?

NO

YES

Other part in

+5.0V_VBUS line or

19.5V_SS line

broken.

Other part in

+5.0V_MAIN line or

19.5V_SS line

broken.

Other part in D+1.0V

line or +5.0V_MAIN

line broken. ( AYU2L

maybe broken)

IC9103

output or

input short

to GND?

SL9110,

C9147

NO

IC9104

output or

input short to

GND?

SL9107,

C9155

NO

IC9105

output or

input short

to GND?

SL9108,

C9163

NO

YES YES

YES YES

YES YES

Remove

IC9103.

Still short?

NO

IC9103 broken

Remove

IC9104.

Still

short?

NO

IC9104 broken

Remove

IC9105.

Still short?

NO

IC9105 broken

Other part in D+1.0V

line or +5.0V_MAIN

line broken. ( AYU2L

maybe broken)

Other part in

+3.3V_MAIN_1 line

or +5.0V_MAIN line

broken.

Other part in D+1.1V

line or +5.0V_MAIN

line broken.

NO

Q9108 broken

SHEET 2

19

Page 20

Troubleshooting

3-1-4. NO POWER: DC/DC converter check

SHEET 2

IC9104

output or

input short

to GND?

SL9109,

C9171

NO

Q9107

output or

input short

to GND?

SL9106,

C9148

NO

YES

YES

Remove

IC9104. Stil l

short?

NO

IC9104 broken

Remove

Q9107. Stil l

short?

NO

Q9107 broken

YES

YES

+1.5V_DDR line or

+5.0V_MAIN line

broken. (DDR maybe

+3.3V_MAIN line or

+3.3V_MAIN_1 line

Other part in

broken)

Other part in

broken.

Check fuse

F9101, F9102,

F9104, F9105,

F9106.

OK

SHEET 3

OPEN

High current surge

20

Page 21

Troubleshooting

3-1-4. NO POWER: DC/DC converter check

Sheet 3

19.5V_SS,

19.5V_HOLD

OK?

C9196, C9197

YES

STBY_+3.3V

OK?

L9107

YES

STBY_+1.8V,

STBY_+1.0V

OK?

C7374,C736

9

YES

+5V_VBUS

(IC9106) OK ?

C9214

YES

+5V_MAIN

(IC9101) OK ?

SL9104

YES

Turn ON board

NO

NO

NO

NO

NO

Refer AYU2L manual

MAIN_

PWR

high

NO

service sheet

YES

Check LD Board or

Harness

Check LD Board or

Harness

Check IC7304 ( 1.8V)

or IC7305 (1.0V)

IC9106 broken

IC9101 broken

D+1.0V

(IC9103) OK ?

SL9110

YES

+3.3V_MAIN_1

(IC9104) OK ?

SL9107

YES

D+1.1V

(IC9105) OK ?

SL9108

YES

+1.8V_MAIN

OK?

C9202

YES

+1.5V_DDR

(IC9104) OK ?

SL9109

YES

+3.3V_MAIN

(Q9107) OK ?

SL9106

YES

All

DDCON

OK

NO

NO

NO

NO

NO

NO

SYSTE

M1_P

WR

high

NO

Refer AYU2L manual

service sheet

SYSTE

M2_P

WR

high

NO

Refer AYU2L

manual service

sheet

SYSTE

M3_P

WR

high

NO

Refer AYU2L manual

service sheet

IC9103 broken

YES

IC9104 broken

IC9105 broken

YES

IC9201 broken

IC9104 broken

YES

Q9107 broken

21

Page 22

4

1

2

3

22

Page 23

1

Q9108

MAIN_PW

R

C9158

F9105

L9107

F9101

C9114

19.5V_S

S

F9102

19.5V_HOL

D

C9302

IC9101

SL9104

SL9110

IC9106

C9147

IC9103

SYSTEM1_PWR

C9214

23

Page 24

2

C9202

C9148

IC9201

Q9107

C7369

C7374

IC7305

SL9106

IC7304

24

Page 25

3

C9155

SL9107

F9104

IC9104

C9171

SYSTEM

3_PWR

SL9109

25

Page 26

4

SL910

8

IC9105

F9106

C9163

26

Page 27

Troubleshooting

3-1-5. NO POWER – AYU2L failur e

AYU2L Fail Suspected

eMMC / RawNAND erase

Product SW rewrite

Recover?

No

AYU2L LOG is

displayed

No

(1) Check DDR &

eMMc / RawNAND

interface OK?

No

Replace Board

Yes

Yes

Yes

Product SW

writing issue

Check DDR

using CheckSW

Replace

AYU2L or Board

Find Some

Error message

Yes

DDR device fail

From the error

message, we can

find which device

has failure.

Move to device

analysis phase.

No

Data fails are

esp ecia lly in

environment area.

If this Area has

broken, check soft

cannot run

Check

eMMC / RawNAND

using CheckSW

No

eMMC/ RawNAND

data fail

Find Some

Error message

No

Store SW log,

Check SW

behaviors.

Erase

eMMC/ RawNAND

In this case, corrupted

data are written to

eMMC/ NAND flash in

proper way.

So, we have to check the

logs of exce ption or

errors.

Erase eMMC/

RawNAND is a last

option. If st ill N G afte r

erase, please replace

eMMC/RawNAND

Yes

Check error message

It is unacceptable

error?

Yes

Erase & Replace

eMMC/ RawNAND

Product SW write

If still NG after SW

rewrite, please go to

(1) Check

MMC/RawNAND

interface

27

Page 28

Troubleshooting

3-1-6. NO POWER – AYU2L replacement

AYU2L

replacement flow

eMMC / RawNAND erase

AYU2L replacement

Data on eMMC/NAND need

to be erase first before

changing AYU2L.

Product SW write

Recover?

Yes

AYU2L issue

No

Board Issue

28

Page 29

Troubleshooting

3-2. LED BLINKING

3-2-1. LED Blinking: 2x (Main power Error)

BAX-L board (XM-L)

2-time blinking

Check 19.5V_HOLD

at pin 18 of CN9101

on B* Board

OK

Turn off power

IC9101 output

or input short to GND?

SL9104, C9114

OK

Turn on power

+5V_MAIN

(IC9101) OK?

SL9104

OK

NG

NG

NG

Check

Harness/connection

LD*Board to B*Board

OK

Harness

Remove IC9101.

Still sho rt?

OK

IC9101 broken

MAIN_PWR high?

OK

IC9101 broken

NG

NG

NG

Other part in

+5.0V_MAIN line or

19.5V_SS line broken.

Refer AYU2L

Troubleshooting

Replace

LD* Board

OK

LD* Board

NG

AC Adapter

B* Board

Note: Board Details refer Section 3

main page.

29

Page 30

Troubleshooting

3-2-1. LED Blinking: 2x (Main power Error)

Troubleshooting References

1

30

Page 31

Troubleshooting

3-2-1. LED Blinking: 2x (Main power Error)

Troubleshooting References

1

19.5V_HOLD

C9114

MAIN_PWR

IC9101

SL9104

SYSTEM1_PWR

31

Page 32

Troubleshooting

3-2-2. LED Blinking: 3x (DC Alert & Communication Error)

3-time blin king

Check D+1.0V at

JL9127 on

the B* Board

OK

Check

+3.3V_MAIN_1

at JL9117 on

the B* Board

OK

Check

+1.8V_MAIN on

Pin 2 of IC9201

OK

Check

+5.0V_MAIN

at JL9112 on

the B* Board

DC_ALERT

NG

NG

NG

NG

F9105,IC9103,

Etc (B* Board)

F9104,IC9104,

etc (B* Board)

IC9201,etc

(B* Board)

IC9101

,etc (B* Board)

DMD_TU_I2C

or I2CB bus check:

Probe CL2101, CL2102 /

CL2318, CL2101 on

TU* Board

OK

SPIC check

Probe RB8517

OK

I2C_CCP check

R8546 and R8547

OK

I2CA bus check:

Probe CL5023,

CL5024

OK

NG

Brownie

NG

TUNER

I2C bus dumping or

AYU2L

SPI dumping

resistor

or AYU2L

I2C_CCP Pull

Up

HDMI

I2CA bus

dumping

resistor

or AYU2L

Check

Speaker Impedance

at SP Connector

OK

Check

Audio +12.5V

at pin 18/20 of CN9101

on the B* Board

(except Adapter model)

OK

Check

+12.5V / +19.5V

at Power Amp side

of F4601 on

the B* Board

OK

IC4601,etc

(B* Board)

#3

NG

NG

NG

AUDIO

Speaker

G* Board

F4601, IC4601

,etc

(B* Board)

#2

Note: Board Details refer Section 3

main page.

32

Page 33

Troubleshooting

3-2-2. LED Blinking: 3x (DC Alert & Communication Error)

Troubleshooti ng References

Board Name Board PWB Detail

BAXL

(F9104)

BAXL

(IC9104)

F9104

IC9104

BAXL

(IC9201)

IC9201

33

Page 34

Troubleshooting

3-2-2. LED Blinking: 3x (DC Alert & Communication Error)

Troubleshooti ng References

Board Name Board PWB (A side) Detail

BAXL

(IC9101)

IC9101

BAXL

(JL9112)

TU-S

(CL2101,

CL2102)

JL9112

B-Side

CL2102

CL2101

34

Page 35

Troubleshooting

3-2-2. LED Blinking: 3x (DC Alert & Communication Error)

Troubleshooti ng References

Board Name Board PWB Detail

TU-W

(CL2318,

CL2319)

BAXL

(RB8517)

BAXL

(R8546, R8547)

CL2318

CL2319

RB8517

R8546

R8547

35

Page 36

Troubleshooting

3-2-2. LED Blinking: 3x (DC Alert & Communication Error)

Troubleshooti ng References

Board Name Board PWB (A side) Detail

BAXL

(CL5023, CL5024)

BAXL

(F4601)

CL5024

CL5023

F4601

BAXL

(IC4601)

IC4601

36

Page 37

Troubleshooting

3-2-2. LED Blinking: 3x (DC Alert & Communication Error)

Troubleshooti ng References

Board Name Board PWB (A side) Detail

BAXL

(CN9101)

CN9101

37

Page 38

Troubleshooting

3-2-3. LED BLI N KIN G 3x (Audio Error) BAX-L(HE-L, HM, HE -H, XM-L) board only

(at fuse F4601)

Low impedance

burn or broken ?

#2

F4601,IC4601,etc

(B* Board)

Check 19.5V

to GN D

impedance

IC4601

High

enough

No

Replace F4601

Check broken parts

around IC4601

#3

IC4601,etc

(B* Board)

Check the IC4601

Out pin 37, 41, 44, 46

Switching 0V to 19V

around 300-400kHz

Yes

Check the CN4601

DC level ~9.7V

(at JL4621~JL4624)

Yes

No

No

Check the IC4601

pin 18 (at CL4606)

is HIGH?

Yes

Solder NG

IC4601 or parts around IC4601

NG

L4601-L4604

or C4611-C4614

NG

No

Yes

Replace IC4601

Check the IC4601

I2S line p in

4, 12, 15, 16 (at

CL4601~CL4604)

OK

IC4601 NG

NG

IC9000 NG

38

Page 39

Troubleshooting

3-2-3. LED BLI N KIN G 3x (Audio Error) BAX-L(HE-L, HM, HE -H, XM-L) board only

Troubleshooti ng Reference

CL4604

CL4602

CL4603

2

5

3

6

2

3

4

7

3

1

IC4601

4

1

9

4

1

8

1

4

4

1

6

3

5

1

2

4

F4601

1

4

6

8

BAX-L board Side A

39

39

Page 40

Troubleshooting

3-2-3. LED BLI N KIN G 3x (Audio Error) BAX-L(HE-L, HM, HE -H, XM-L) board only

Troubleshooti ng Reference

JL4624

JL4623

CL4601

JL4621

JL4622

BAX-L board Side B

40

Page 41

Troubleshooting

3-2-4. LED BLINKING 5x (Panel Communi cation Error) – a) 12.5V NG

5-times blinking

Check

PANEL_VCC 12.5V at

CN8001

on the B* Board

OK

Replace the Harness

Between LD board

and B board

NG

Replace

the LVDS Harness

NG

Symptom

improve

Symptom

improve

XM-L : LD Board

*3-1-2. NO POWER – LD

Board

NG

Check 12.5V

LD Board

OK

Harness

LVDS Harness

LD Board

Change

B* Board

Symptom

improvement

B*Board

Refer I2C Error

Checking in next slide

NG

Change

Panel (T-con)

NG

Note: Board Details refer Section 3

main page.

41

Page 42

Troubleshooting

3-2-4. LED BLINKIN G 5x (Panel Communication Error) – b) 12C Error

5-times blinking

PANEL ID Check

Check I2C (Data & CLK)

At CL

NG

I2C Error

Change B-Board

NG

Change FFC

NG

Change FRC

XM-L (BAX-L): CL8027 & CL8028

B-Board NG

OK

OK

OK

FFC NG

FRC NG

42

Page 43

Troubleshooting

BAXL (B-Side)

BAXL Probing Points – 12.5 V Check

JL9132

(PANEL_VCC)

43

Page 44

Troubleshooting

BAXL (B-Side)

BAXL Probing Points – I2C Line Check

CL8027

CL8028

(I2C_S_CLOCK)

(I2C_S_DATA)

44

Page 45

Troubleshooting

3-2-5. LED BLINKING 6x (Backlight Error)

6-times blinking

Check

JL9016

BACKLIGHT_MON

on B*Board

Voltage < 1.8 V

Voltage ≥ 1.9 V

Check

harness/connection

G*board to B*Board

or

LD board to B*Board

Harness /

Connection OK

G* Board

Refer to 1.5

Out1 & Out2 Check (LED_Output)

PSU OK

Harness /

Connection

broken

improvement

Improvement

Change

harness

No

G*Board

or LD?

Visual Check LS Bar

FFC Conductive Copper

Peel Off?

Yes

Change

Panel

No

Change

B* board

Improvement

Symptom

LD

No

Symptom

Improvement

Symptom

Improvement

Harness

Suspect LS

Bar Broken

Panel

B* Board

45

Page 46

Troubleshooting

3-2-5. LED BLINKING 6x (Backlight Error)

BAX-L: B Side

JL9016

46

Page 47

Troubleshooting

3-2-6. LED BLIN K IN G 7x (Temperatu re Erro r)

7-time blin king

Setting

circumstance is OK?

Temperature,

Ventilation, etc.

Yes

Change B* Board,

and Aging a few

hours

Symptom

improvement

B* Board

Troubleshooting Reference

No

NG

Set to another

location, etc.

Panel

I2CA bus check:

HDMI is working?

No

I2CA bus dumping or

Ayu2L check

Board Name Board PWB (A side) Detail

Yes

Temp sensor

IC7001

BAXL

(IC7001)

IC7001

47

Page 48

Troubleshooting

3-3. No Sound

No Sound

“Audio System ”

Check the

“Speakers se tting”

“TV Speakers”

Change the Speaker

Harness

Speaker Harness

NG

Symptom

improvement

Change to

“TV Speaker”

Replace

the B* Board

NG

Speaker

Symptom

improvement

B* Board

No Sound: Audio

No Sound: Tuner

No Sound: HDMI

48

Page 49

Troubleshooting

3-3-1. No Sound : Audio (For all models)

No sound :Audio (for all model) TUS,TU W & BAX-L(HE-L,HM,HE-H,XM-L) board only

#1

Check the

Digital out

(use Video input)

OK

Check the

Speaker Sound

(use Video input)

OK

Check the HP out

(use Video input)

NG

Check the IC4501

VDD 3.3V

(IC4501 pin9)

OK

#1

No signal

NG

OK

NG

No signal

Check the

CN3103 pin1

(SPDIF input)

OK

CN3103 is NG

Power Amp Block (F4601,IC4601,etc)

is NG. See item: LED blinking: 3x

(Audio error)

No Problem

DC/DC converter is NG

See No POWER - DDCON/LDO.

IC9000 is NG

Check the

IC4501 VSS -3.3V

(IC4501 pin6)

OK

Check the

X_AUDIO_MUTE_

SPHPLO

pin5 is HIGH?

OK

Check the

INR+ & INL+ pin1 &14.

(at CL4502 and CL4501)

Signal is coming?

OK

IC4501 NG

NG

NO

No signal

Check the solder

of IC4501 CP & CN

(7&8pin) & C4501

OK

Solder NG

IC4501 NG

This is MUTE situation.

Check IC9000

IC9001 is NG

Note:

(AYU2/Ayu2L) – IC9000

(Brownie)- IC9001

NG

49

Page 50

Troubleshooting

Troubleshooting Reference

TUS board Side B

CN3103

Vin ( p in 1)

Vcc

50

Page 51

Troubleshooting

Troubleshooting Reference

TUW board Side B

CN3103

Vin ( p in 1)

Vcc

51

Page 52

Troubleshooting

Troubleshooting Reference

BAX-L board Side A

(Pin 5)

CN (Pin 7)

X_AUDIO_MUTE_MUTE_SPHLO

Vss (Pin 6)

INR+ (Pin1)

CL4502

C4501

IC4501

CL4501

CP (Pin 8)

VDD (Pin 9)

INL+ (Pin14)

52

Page 53

Troubleshooting

3-3-2. N o Sound : Audio (For AEP models only) TUS (HE-L,HM,HE-H,XM-L)

#1

Check the SCART

(use Digital RF

Tuner input)

NG

Check the IC3101 pin 3

VCC 3.3V

OK

Check the

IC3101 pin 6

VEE-3.3V

#1

OK

NG

NG

No Problem

DC/DC converter is NG

See to section “1.3. No

POWER: - DDCON/LDO.

Check the solder

Of IC3101 CP & CN

(4&5pin) & C4511

NG

Check the

CNT pin7 (IC3101)

is HIGH?

OK

INR & INL

pin10 &1 (IC3101)

(at CL3100 and CL3105)

Signal is coming?

OK

IC3101 NG

NO

No signal

This is MUTE situation.

Check IC9000

IC9001 is NG

OK

OK

IC3101 NG

Solder NG

Note:

(AYU2/Ayu2L) – IC9000

(Brownie)- IC9001

53

Page 54

Troubleshooti ng Reference

TUS board Side A

CP (Pin 4)

CN (Pin5)

C4511

VCC (Pin3)

INR (Pin1)

CL3100

IC3101

INR (Pin10)

VEE (Pin6)

CNT (Pin7)

CL3105

54

Page 55

Troubleshooting

3-3-3. Main Board Power Off Checking (for Main SP Lch & Rch) for BAX-L (HE L,HE H,H M,XM-L) board only

No Checking Item OK NG

1 Check fuse F4601 Fuse short Fuse open

2 Check connectivity audio Vcc to GND

C4606 – GND

C4607 – GND

C4608 – GND

C4609 – GND

3 Check connectivity audio +3.3V_MAIN to GND (only for BAX-

L board)

IC4601 (Pin8) – GND

IC4601 (Pin27) – GND

4 Check connectivity audio output to GND.

CN4601

Pin 1 – GND

Pin 2 – GND

Pin 3 – GND

Pin 4 – GND

5 Check connectivity audio output path

(only for BAX-L board):

L4601 (near to IC side) – CN4601 Pi n4

L4602 (near to IC side) – CN4601 Pi n3

L4603 (near to IC side) – CN4601 Pi n2

L4604 (near to IC side) – CN4601 Pi n1

No short to GND

No short to GND Either 1 short to GND

No short to GND Either 1 of pin short to GND

Must have good connection (~0 Ω) Open circuit.

Either 1 short to GND

55

Page 56

Troubleshooting

Troubles hooting Refere nce

BAX-L board Side A

L4604

L4603 L4602

Pin 1

Pin 2

CN4601

L4601

Pin 3

Pin 4

56

56

Page 57

Troubleshooting

Troubles hooting Refere nce

BAX-L board Side A

C4609

2

2

5

7

3

6

3

IC4601

7

C4608

1

2

8

1

4

8

C4606

C4607

F4601

57

Page 58

Troubleshooting

3-3-4. Main Board Power On Checking (for Main SP Lch & Rch) for BAX-L (HE L ,HE H, HM, X M-L) board only

No Checking Item OK NG If NG If NG

1 Check

IC4601 side-terminal of

L4601,L4602,

L4603,L4604

2 Check F4601 MainSP

(for BAX-L only)

3 Check F4601 MainSP

(BAX-L board only)

4 Check IC4601 (Pin 8) and

C4601 (Pin 27)

(for BAX-L board only)

5 Check CL4605, CL4606,

CL4607

6 Check CL4601, CL4602,

CL4603, CL4604

Switching Freq = 384kHz or

768KHz ±20KHz

Vrms = don’t care

V(before fuse) = 12.5V ± 0.5V

V(after fuse) = 12.5V ± 0.5 V

No switching

frequency at either

one of the CL

No voltage.

Go to next checking.

Check fuse broken?

Check CN9101 Pin 8 &10

got 12.5V?

V(before fuse) = 19.5V ± 0.5V

No voltage. Change fuse (5A).

V(after fuse) = 19.5V ± 0.5V

V(before fuse) = 3.3V ± 0.5V

No voltage. Check +3.3V_MAIN

V(after fuse) = 3.3V ± 0.5V

Vdc = 3.3V ± 0.3V Vdc < 0.8V CL4606 NG,

Check IC4601

CL4601 = 12.288MHz

CL4603 = 3.072MHz

CL4604 = 48KHz

CL4602 = moving CLK

All Vp-p ≈ 3.3V

If no frequency at

CL4601, CL4603,

CL4604, Ayu2 IC

(IC9000) NG.

If no frequency at

If sound source OK, but

CL4602 = NG, Ayu2 IC

(IC9000) NG.

CL4602, make sure

sound source OK.

Change fuse (5A).

Check power supply board

audio VCC.

Check power supply board

audio VCC.

supply.

CL4605,4607 NG, Check

IC9000

Note:

(AYU2/Ayu2L) – IC9000

(Brownie)- IC9001

58

Page 59

Troubleshooting

Troubleshooti ng Reference

BAX-L board Side A

Pin 27

2

5

3

6

2

3

4

IC4601

7

4

1

3

1

2

1

8

Pin 8

F4601

L4604

L4603 L4602

L4601

59

Page 60

Troubleshooting

Troubleshooti ng Reference

BAX-L board Side A

Pin 8

Pin 10

CN9101

60

Page 61

Troubleshooting

Troubleshooti ng Reference

BAX-L board Side B

CL4601

61

Page 62

Troubleshooting

Troubleshooti ng Reference

BAX-L board Side B

CL4601

62

Page 63

Troubleshooting

Troubleshooti ng Reference

BAX-L board Side A

CL4605

CL4604

CL4602

CL4603

CL4607

CL4605

13

15

12

25

16

24

18

IC4601

4

36 1

48

37

41

39

46

44

63

Page 64

Troubleshooting

3-3-5. No Sound: HP / Lineout Only

No Sound

HP / Lineout only

This is for Mai n SP got sound, but HP / Lineout no sound

BAX-LPower On checki ng

GN1 Main Board Power On Checking

No Checking Item OK NG If NG

Note:

(AYU2/Ayu2L) – IC9000

(Brownie)- IC9001

1 Insert HP Jack. Check R4508

2 Check IC4501 Pin 5

(X_AUDIO_MUTE_ SPHPLO)

3 Check CL4505, CL4506.

(with audio signal input)

4 Check IC4501 pin 9 Vdc = 3.3V ± 0.3V No 3.3V supply. Please refer

5 Check CL4501, CL4502

(with audio signal input)

Vdc = 3.3V ± 0.3V Vdc = 0V or < 1V Check HP_DET line

Vdc = 3.3V ± 0.3V Vdc = 0V or < 1V

Can see audio signal waveform Cannot see audio signal

waveform

item 1.3. No POWER DDCON/LDO.

Can see audio signal waveform Cannot see audio signal

waveform

(R7020 – for BAX-L)

got short to GND? If short to GND

replace board.

Check X_AUDIO_ MUTE_ SPHLO (Pin

5) short to GND. If short to GND replace

board.

Go to below item No. 4 for checking

Brownie IC (IC9001) NG

64

Page 65

Troubleshooting

3-3-5. No Sound: HP / Lineout Only

Troubleshooti ng Reference

BAX-L board Side A

X_AUDIO_MUTE_ SPHPLO (Pin 5)

CL4502

IC4501

CL4501

VDD (Pin 9)

65

Page 66

Troubleshooting

3-3-5. No Sound: HP / Lineout Only

Troubleshooti ng Reference

BAX-L board Side A

R7020

CL4506

R4508

CL4505

66

Page 67

Troubleshooting

3-3-6. N o Sound : Scart Out Audio (For AEP model) for BAX-L board only

No Sound

This is for Mai n SP got sound, but SCART out no sound.

Note:

(AYU2/Ayu2L) – IC9000

(Brownie)- IC9001

SCART out only

Please check this condi tion in Di gital RF mode

BAX-L Power On checking

GN1 Main Board Power On Checking

No Checking Item OK NG If NG

1 Check CL3103 ,CL3104.

(with audio signal input – Digital RF

mode)

2 Check IC3101 pin3 Vdc = 3.3V ± 0.3V No 3.3V supply

3 Check CL3100, CL3105

(with audio signal input – Digital RF

mode)

Can see output audio signal

waveform

Can see input audio signal waveform Cannot see audio signal

Cannot see audio signal

waveform

waveform

Go to checking

3.2: No sound: Audio (For AEP

models only)

Brownie IC (IC9001) NG

67

Page 68

Troubleshooting

Troubleshooti ng Reference

TUS board Side A

Vcc (Pin 3)

IC3101

CL3103

CL3100

CL3104

CL3105

68

Page 69

Troubleshooting

3-3-7. NO SOUND: TUNER

This troubleshooting i s only for Analog

No Sound

with norm al picture

Only RF tuner input??

Yes

Check Brownie

NO

Please refer audio

troubleshooting

3-3-8. NO SOUND: MHL

No Sound

NG

Check the picture

OK

Check Sound by other TV set

whic h is sam e m odel

NG

Check Source equipmen t

by Ref er e nce T V set

(For example, Samsung TV(UN 46ES7000)

, Toshiba TV(42WL863))

or VA-1836

Ref er to MHL NO PICTURE

OK

OK

Check R5071, C5071, C5072,

Chan ge B* Boar d

Replace

IC9000

OK

C5059, C5073

NG

Repl ace N G par t

Note:

(AYU2/Ayu2L) – IC9000

(Brownie)- IC9001

NG

Chec k th e s ett in gs of

Source equipment

Note: Board Details refer Section 3

main page.

69

Page 70

Troubleshooting

BAXL-A Sid e

C5073 C5072

C5059

C5071

R5071

70

Page 71

Troubleshooting

3-3-9. NO SOUND : HDMI

No Sound

NG

Check the picture

OK

Chec k th e mod e

of S ourc e eq u ipme n t

HDMI

Does th i s model ha v e

D-sub input ?

NO

Check Sound by other TV set

whic h is sam e m odel

NG

Is Distributor used ?

YES

Conn ect S ourc e

equipment directly

Refer to HDMI NO PICTURE

DVI

Chan ge th e mod e of

Source equipment to HDMI

YE

S

“HDMI/DVI Audio Source”

Auto or HD MI Audio

OK

NO

What is set in

of Sound MEN U ?

PC Audio

Check R5071, C5071, C5072,

Check Source equipmen t

by Reference TV set

(For example, RB1)

NG

Chec k th e s ett in gs of

Source equipment

Change “HDMI/DVI Audio Source”

to Auto

Replace

IC9000

OK

C5059, C5073

OK

Inform the designer

NG

Repl ace N G par t

of it

71

Page 72

Troubleshooting

3-4. NO PICTURE: (XM-L)

No Picture

Got Any Normal

Display?

Yes

Check Other

Portion:

Ext. Video Input -

HDMI - No Picture

Tuner - No Picture

No

No Picture

Check Smart Core

Behavior

(5x Blinking)

Yes

5x Blinking

BL_ON (L or H):

XM-L (BAX-L): JL9105

Check

BL_ON

No

on the B* Board

Backlight

BL_ON:H

BL_ON:L

Replace

the LVDS FFC

Harness

Symptom

improvement

LVDS FFC

Harness

NG

Replace

the B-Board

Symptom

improvement

B-Board NG

NG

LCD Panel

(T-CON)

Note: Board Details refer Section 3

main page.

72

Page 73

Troubleshooting

BAXL (B-Side)

BAXL Probing Points

JL9132

(PANEL_VCC)

73

Page 74

Troubleshooting

BAXL (A-Side)

BAXL Probing Points

F8001

(+12V)

74

Page 75

Troubleshooting

BAXL (A-Side)

BAXL Probing Points

F8001

(+12V)

75

Page 76

3-4-1. Video Analog Signal Path

76

Page 77

Troubleshooting

3-4-2 : No Picture AEP Destination (BAX-L+TUS AEP) (a)

No Picture AEP

SCART RGB

No Picture

Check SCART _FB

IC9001 V15

[FBIN] at R3108

OK [HIGH]

Check wave b etween

C3014/C3015/C3016

and IC9001

OK

Confirm

Analog R F

input

working

OK

NG

NG

[LOW]

Detailed check all parts

at SCART_FB signa l

Path [VD3108/R3108]

Detailed check all parts

CN3101 along signal path at

NG

7: [VD3111, R3004, R3010]

11: [VD3107, R3003, R3009]

15: [VD3104, R3005, R3011]

Check signal

between

IC9001 and

IC9000

[R8570]

SCART CVBS

No Picture

NG

Check CN3101

Connection

OK

OK

CN3101

Connector

Problem

pin No:

OK

NG

OK OK

NG

CN3101

Connectivi ty

Problem

NG

Parts B roken

NG

Detailed SDIF

path

Check between

IC9001 and

IC9000

Check SCART _FB

IC9001 V15

[FBIN] at R3108

OK [HIGH]

Check wave b etween

C3000 and IC9001

OK

Confirm

Analog R F

input

working

OK

[LOW]

NG

NG

Check CN3101

Connection

OK

Detailed check all parts

at SCART_FB signa l

Path [VD3108/R3108]

OK

CN3101

Connector

Problem

Detailed check all parts

CN3101 along signal path at

pin No:

20: [VD3110, R3008, R3000]

Check signal

between

IC9001 and

IC9000

[R8570]

OK

NG

NG

CN3101

Connectivi ty

Problem

NG

Parts B roken

NG

Detailed SDIF

path

Check between

IC9001 and

IC9000

Brownie [IC9001]

Problem

Ayu2 [IC9000]

Problem

Brownie [IC9001]

Problem

Ayu2 [IC9000]

Problem

Page 78

Troubleshooting

3-4-2 : No Picture AEP Destination (BAX-L+TUS AEP) (b)

No Picture AEP

VIDEO 2

No Picture

Check if input

OSD si grey ou t

OK [NOT

GREYED]

Check wave

between C3018 and

IC9001

OK

Confirm

Analog R F

input

working

OK

Brownie

[IC9001]

Problem

NG

[GREY]

NG

J3104 along signal path at pin

NG

Check J3104

Connection

OK

Detailed ch eck parts

at VIDEOB_DET

Path [C7026]

OK

J3104

Connector

Problem

OK

Detailed check all parts

GREEN:

[VD3127, R3014, R3021]

Check signal

between

IC9001 and

IC9000

[R8570]

OK

Ayu2 [IC9000]

Problem

NG

NG

J3104

Connectivi ty

Problem

NG

Parts B roken

NG

Detailed SDIF

path

Check between

IC9001 and

IC9000

Component

No Picture

Check if input OSD

is GREY OUT

OK [HIGH]

Check wave

between

C3018/C3019 and

IC9001

OK

Confirm

HDMI input

working

OK

Confirm

Analog R F

input

working

OK

Brownie

[IC9001]

Problem

NG

NG

NG

[LOW]

NG

Check J3104

Detailed ch eck parts

at VIDEOB_DET path

[C7026] and CR_DET

path [C7025]

Detailed check all parts

J3104 along signal path at pin

[VD3127, R3014, R3021]

HDMI EQ

[IC5009]

Problem

Check signal

between

IC9001 and

IC9000

[R8570]

Ayu2 [IC9000]

Problem

Connection

OK

OK

J3104

Connector

Problem

OK

GREEN:

OK

NG

NG

J3104

Connectivi ty

Problem

NG

Parts B roken

NG

Detailed SDIF

path

Check between

IC9001 and

IC9000

Page 79

Troubleshooting

BAX-L AEP > A-SIDE

RB5008

R8570

C7026

C7025

Page 80

Troubleshooting

BAX-L AEP > A-SIDE

R3000

R3011

R3008

R3009

R3010

R3021

C3000

R3005

C3016

C3014

C3015

R3003

R3004

C3018

C3019

R3014

80

Page 81

Troubleshooting

TUS > A-SIDE

CN3101

J3104

VD3111

VD3107

VD3104

VD3110

VD3127

Page 82

Troubleshooting

3-4-3 : No Picture HOTEL_B2B ( B AX_L + TUS AEP,U C /PA)

No Picture B2B

PC

No Picture

Check if input

OSD is grey out

OK [NOT

GREYED]

Check wave between

R3149/R3150 and

IC9001

OK

NG

[GREY]

NG

Check CN3102

NG

Connection

OK

Detai l ed ch eck part s

at PC_CON_DET

Path [C7018]

OK

CN3102

Connector

Problem

OK

Detai l ed ch eck all p art s

CN3102 along signal path at

pin No:

13: [R3149, R3151]

14: [ R3150, R3152]

LEGEND

BAX-L

TUS/TUW

CN3102

Connectivity

Problem

NG

Parts Broken

NG

Confirm

HDMI input

working

NG

HDMI EQ

[IC5009] Problem

OK

Check wave between

C3030/C3022/C3029

and IC9001

OK

Confir m

Analog RF

input working

OK

Brownie [IC9001]

Problem

NG

OK

Detai l ed ch eck all p art s

CN3102 along signal path

NG

at pi n N o:

1: [R3026]

2: [ R3024]

3: [R3025]

Check signal

between

IC9001 and

IC5009

[RB5008]

Ayu2 [IC9000]

Problem

OK

NG

NG

Detailed TMDS path

Check between

IC9001 and IC5009

Page 83

Troubleshooting

BAX-L AEP B2B > A-SIDE

C7018

C3029

R3025

C3022

R3024

C3030

R3026

Page 84

Troubleshooting

TUS B2B > A-SIDE

CN3102

R3149

R3150

R3151

R3152

Page 85

Troubleshooting

3-4-4 : No Picture UC/GA/CH (BAX_L +TUS UC/GA/CH) (a)

No Picture GA

LEGEND

BAX-L

TUS/TUW

Video 1

No Picture

Check if i nput

OSD is GREY

OUT

OK [HIGH]

Check wave b etween

C3000 and IC9001

OK

Confirm

Analog R F

input

working

OK

Brownie [IC9001]

Problem

NG

NG

[LOW]

Detailed check all parts

at [VD3103,R3116,

Detailed check all parts

NG

CN3101 along signal path at

[VD3110, R3008, R3000]

Check signal

between

IC9001 and

IC9000

[R8570]

Ayu2 [IC9000]

Problem

Check J3101

Connection

OK

at VIDEOA_DET

C7030]

OK

J3101

Connector

Problem

OK

pin YEL:

OK

NG

NG

J3101

Connectivi ty

Problem

NG

Parts B roken

NG

Detailed SDIF

path

Check between

IC9001 and

IC9000

VIDEO 2

No Picture

Check if input

OSD si grey ou t

OK [NOT

GREYED]

Check wave

between C3018 and

IC9001

OK

Confirm

Analog R F

input

working

OK

Brownie

[IC9001]

Problem

[GREY]

NG

NG

Check J3104

Connection

Detailed ch eck parts

at VIDEOB_DET

Path [C7026]

Detailed check all parts

NG

J3104 along signal path at pin

[VD3127, R3014, R3021]

Check signal

between

IC9001 and

IC9000

[R8570]

Ayu2 [IC9000]

Problem

OK

OK

J3104

Connector

Problem

OK

GREEN:

OK

NG

NG

J3104

Connectivi ty

Problem

NG

Parts B roken

NG

Detailed SDIF

path

Check between

IC9001 and

IC9000

85

Page 86

Troubleshooting

3-4-4 : No Picture UC/GA/CH (BAX_L +TUS UC/GA/CH) (b)

No Picture GA

Component No

Picture

Check if input OSD

is GREY OUT

86

Check wave between

C3018/C3019 and

IC9001

Confirm HDMI

input working

Confirm

Analog RF

input working

OK [HIGH]

OK

OK

OK

NG

NG

NG

[LOW]

Detailed check parts

at VIDEOB_DET path

[C7026] and CR_DET

J3104 Connector

NG

Detailed check all parts

J3104 along signal path at pin

[VD3127, R3014, R3021]

HDMI EQ

[IC5009] Problem

Check signal

between IC9001

and

IC9000 [R8570]

Check J3104

Connection

OK

path [C7025]

OK

Problem

OK

GREEN:

OK

NG

NG

J3104

Connectivity

Problem

NG

Parts Broken

NG

Detailed SDIF

path

Check between

IC9001 and

IC9000

Brownie [IC9001]

Problem

Ayu2 [IC9000]

Problem

Page 87

Troubleshooting

BAX-L PA > A-SIDE

R3021

R3014

R3008

C3018

C3019

C3000

R3000

C7026

C7030

C7025

R8570

Page 88

Troubleshooting

TUS PA > A-SIDE

J3101

VD3103

R3116

VD3127

VD3110

Page 89

Troubleshooting

3-4-4 : No Picture Japan Destination (BAX-L + TUW JP)(a)

No Picture JP

ビデオ

No Picture

Check if input

OSD is GREY

OUT

OK [HIGH]

Check wave between

C3000 and IC9001

OK

Confirm

Analog RF

input working

OK

Brownie [IC9001]

Problem

NG

NG

[LOW]

NG

Check J3101

Connection

OK

Detailed check all parts

at VIDEOA_DET

at [R3114, C7030]

OK

J3101 Connector

Problem

Detailed check all parts

CN3101 along signal path at pin

[VD3110, R3008, R3000]

Check signal

between IC9001

and

IC9000 [R8570]

OK

Ayu2 [IC9000]

Problem

YEL:

OK

NG

NG

J3101

Connectivity

Problem

NG

Parts Broken

NG

Detailed SDIF

path

Check between

IC9001 and

IC9000

コンポー ネント

No Picture

Check if input OSD

is GREY OUT

OK [HIGH]

Check wave between

C3018/C3019 and

IC9001

OK

Confirm HDMI

input working

OK

Confirm

Analog RF

input working

OK

Brownie [IC9001]

Problem

NG

NG

NG

[LOW]

Detailed check parts

at VIDEOB_DET path

NG

Detailed check all parts

TB3101 along signal path at

HDMI EQ

[IC5009] Problem

Check signal

between

IC9001 and

IC9000 [R8570]

Ayu2 [IC9000]

Problem

Check TB3101

Connection

OK

[C7026]

OK

TB3101

Connector

Problem

OK

pin :

7[R3014, R3021]

OK

89

NG

NG

TB3101

Connectivity

Problem

NG

Parts Broken

NG

Detailed SDIF

path

Check between

IC9001 and

IC9000

Page 90

Troubleshooting

BAX-L JP > A-SIDE

R3021

R3014

R3008

C3018

C3019

C3000

R3000

C7030

C7026

R8570

Page 91

Troubleshooting

TUW JP > A-SIDE

TB3101

J3101

VD3110

R3114

91

Page 92

Troubleshooting

3-4-6 : Input Skip function – BAX L

Input Signal

AV1

(detect alw ays)

Input Signal

AV2

Component

(Y && Pr/Cr)

"GPIO_12/TIMER_CMPD/SPDIF_SEL"

PC

Non-Detect

ASPECT (IC9000 J3)

"STBY _ADC_IN_9"

SCART FB (IC9001 V15)

VIDEOB_DET(IC9000 AD2)

"GPIO_45/FE_PWMC”

VIDEOB_DET [Y] (IC9000 AD2)

" GPIO_45/FE_PWMC”

CR_DET [Pr/Cr] (IC9000 AA1)

PC_CON_DET(IC9000)

SCART AV1

Always detected

“FBIN "

" GPIO_35"

(Typical)

0/3V 0V V

AEP B2B Models Only

Component/AV2

AV1

Rear Side Rear Side Rear Side

CVBS Detect

(Typical)

0V

0.28 ~ 0.76V

Non-Detect

(Typical)

0V 3.3V

0V 3.3V

0V 3.3V

3.3V 0V

PC

RGB Detect

(Typical)

0.28 ~ 0.76V

Detect

(Typical)

Input Signal

Video1

Video2

Component

(Y && Pr/Cr)

PC

VIDEOA_DET(IC9000 AA3)

"GPIO_47/DAUI_SPDIF_0"

VIDEOB_DET(IC9000 AD2)

" GPIO_45/FE_PWMC”

VIDEOB_DET [Y] (IC9000 AD2)

" GPIO_45/FE_PWMC”

CR_DET [Pr/Cr] (IC9000 AA1)

GPIO_12/TIMER_CMPD/SPDIF_SEL "

PC_CON_DET(IC9000 U25)

Component/Video2

Video1

"

"GPIO22"

Non-Detect

(Typical)

0V 3.3 V

0V 3.3V

0V 3.3V

0V 3.3V

3.3V 0.07V

PC

Detect

(Typical)

Input Signal

ビデオ

コンポーネント

PC

VIDEOA_DET(IC9000 AA3)

" GPIO_47/DAUI_SPDIF_0 "

VIDEOB_DET(IC9000 AD2)

" GPIO_45/FE_PWMC”

PC_CON_DET(IC9000 U25)

コンポーネント

ビデ オ

"GPIO22"

Non-Detect

(Typical)

0V 3.3V

3.3V 0V

3.3V 0.07V

PC

Detect

(Typical)

AEP UC/GA/CH JP

92

92

Page 93

Troubleshooting

3-4-7 : NO PICTURE: @ Tuner UC / KR

No Picture

Noisy Picture

Check Brownie

Check M’t condition

in AGC1 line

RF Level =

High

L

Analog only

OK

Confirm RF Level and AGC

of Analog RF by Servic e mod e

AGC = 0 AGC = 0

Confirm AGC1

(TUS: IC2501 Pin6)

(TUS-A: IC2602 Pin4)

H

Input signal is too big

Insert Attenuator

RF Level = Low RF Level = Low

Which is NG?

Analog RF or Digital RF

Both

Confirm ANT connection

NG

Connect ANT Cable

correctly

Confirm Power s upply

for RF input circuit

A2.5V / LNA_5V

OK

Confirm tuner control line

TU_SCL / TU_SDA

A_RESET

OK

Confirm IF1 line

IFOUTP1 / IFOUTN1

Digital only

NG

NG

NG

Sound is normal ?

Confirm RF Level and AGC

of Digital RF by Service mode

Check Power supply

circuit

Check M’t condition

in tuner control line

Check M’t condition

in IF1 line

No sound

Yes

RF Level = High

Check IC9001(Brownie)/

IC9001(Ayu2)

Check Brownie

OK

Check RF input circ uit

include

TUS: IC2501 Pin6

TUS-A: IC2602 Pin4

93

Page 94

Troubleshooting

BAXL BOARD

IC9001

Page 95

Troubleshooting

Tuner

IC 2501

TUS BOARD

Page 96

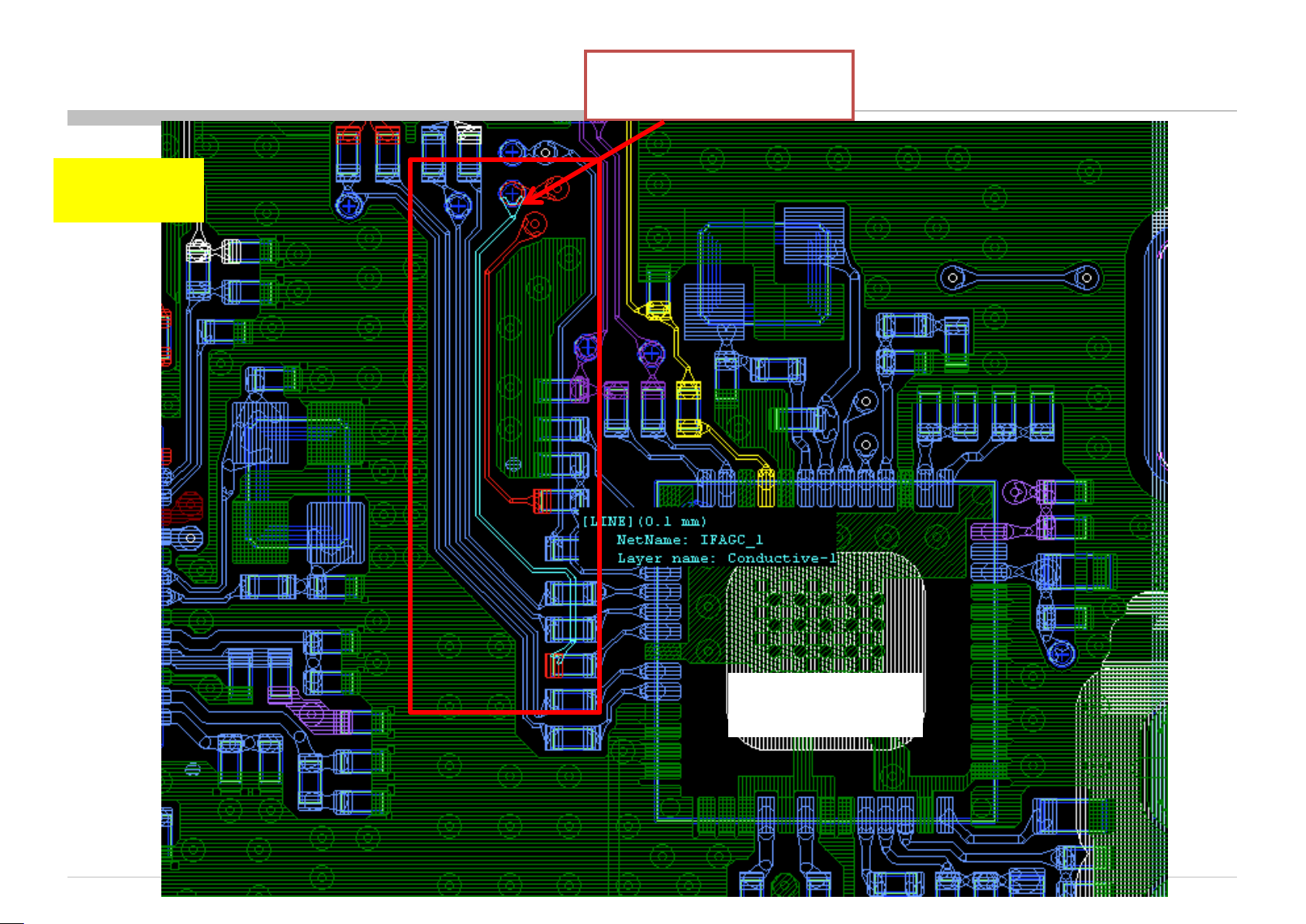

Troubleshooting

TUS BOARD

Tuner

IFAGC_1

IC2501

Page 97

Troubleshooting

TUS BOARD

Tuner

A2.5V

IC2501

Page 98

TUS BOARD

Tuner

A_RESET

TU_SDA

IC2501

TU_SCL

IC2501

Page 99

TUS BOARD

Tuner

IC2501

IFOUTN_1

IFOUTP_1

Page 100

TUS-(A) BOARD

Tuner

IC 2602

Loading...

Loading...