Sony KF-50SX100/U/K Schematic

LE-3SERVICE MANUAL

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

–––––––– ––––––––––––––– –––––– ––––––––––––––

KF-50SX100 RM-903 AEP SCC-P59A-A

KF-50SX100K RM-903 OIRT SCC-P60A-A

KF-50SX100U RM-903 UK SCC-P61A-A

MODEL COMMANDER DEST. CHASSIS NO.

–––––––– ––––––––––––––– –––––– ––––––––––––––

VIDEO TV

1

2

3

4

5

6

7

8

9

0

OK

PROGR

MENU

RM

903

SONY

TV

RM-903

KF-50SX100/50SX100K/50SX100U

LCD PROJECTION TV

∗ Please file according to model size. .......

50

KF-50SX100/50SX100K/50SX100U

RM-903RM-903 RM-903

SPECIFICATIONS

– 2 –

KF-50SX100/50SX100K/50SX100U

SELF DIAGNOSIS FUNCTION

1-1. LE-3 SELF DIAGNOSTIC SOFTWARE

The identification of errors within the LE-3 chassis is triggered in one of two ways : - 1: Busy or 2: Device failure to respond to IIC. In

the event of one of these situations arising the software will first try to release the bus if busy (Failure to do so will report with

continuous flashing LED) and then communicate with each device in turn to establish if a device is faulty. If a device is found to be

faulty the relevant device number will be displayed through the LED (Series of flashes which must be counted) See table 1., non fatal

errors are reported using this method.

RM-903RM-903 RM-903

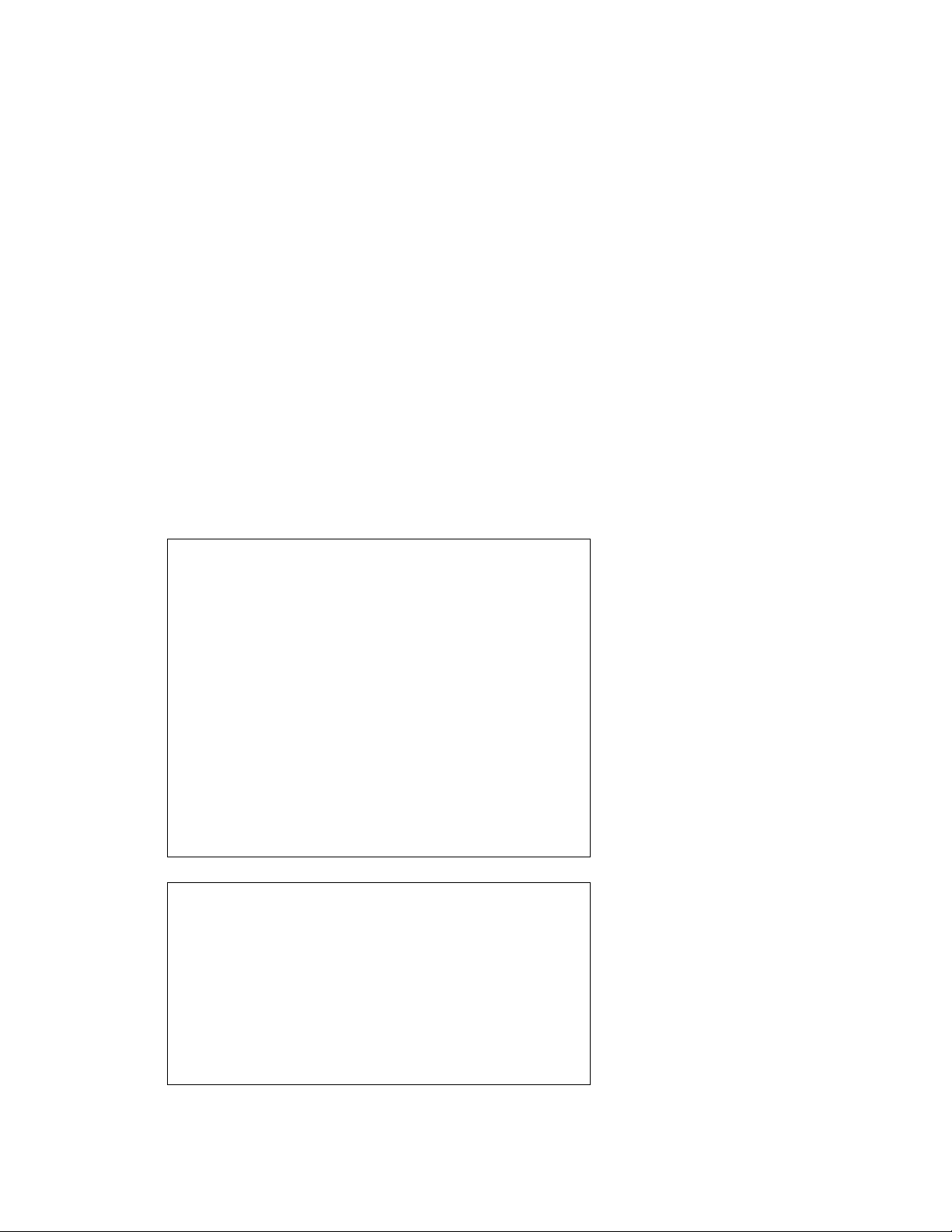

Diagnostic Item

Description

Power does not turn on Does not light

SET 5V Dowin 2 times

No. of times Standby

LED Flashes

ERROR STBY LED ERROR COUNT

No error 00

Not allowed (may be confused with Sircs response flash) 01

SET 5V Down 02

Lamp Cover error 03

Fan error 04

Lamp Driver error 05

Not used 06

Speaker Protection 07

General IIC Line 0 error 08

MEGATEXT (IC9502) 09

NVM (IC9108) 10

Main colour decoder (IC8301) 11

MCP (IC701) 14

Multi sound processor (IC4702) 15

Auto Wide (IC8700) 16

External RAM (IC9107) 17

Lamp error Lamp LED continnously on

Probable cause Location

Power cord is not plugged in

Fuse is Burned out

Q1606, 1607 Power FET is shorted Power does not come on

(G Board) Load on power line has shorted

Detected Symptoms

Power does not come on

No power is supplied to the TV

AC power supply is faulty

Flash Timing Example : e.g. error number 3

ON

OFF OFF

ON ONStandby LED

– 3 –

KF-50SX100/50SX100K/50SX100U

RM-903RM-903 RM-903

1-2. ERROR DETECTION MONITOR

Device acknowledge is used to check IIC errors.

Each device is checked three times, if there is no acknowledge after every attempt, it will be regarded as an error.

There are three step to check errors.

1. IIC line 0

If all devices except the NVM have errors, IIC line 0 error is displayed.

2. Each device check

if IIC line error and board error are not detected then the device with an error is displayed.

The detected errors can be displayed as follows:

1. Error Monitor Menu

2. Error Reader

1-2-1. Error Monitor Menu

The error monitor menu is displayed by selecting Service mode : Monittoring. The following menu will be displayed:

Error Monitor

Ignore Errors OFF

1

Operating Time :

Stored Errors :

1. J-B MSP3410

2. B3-B CXA2101 MCP

3. J-B CXA2123 Main Col Dec

4. Error Code Not Valid

5. Error Code Not Valid

Current Error :

Start Error Sequence

000021 h 40 min

Error Monitor

1 LAMP : 0

5 LAMP DRIVER : 0

4FAM : 0

3 LAMP COVER : 1

WDT-E : 0

ON ON

Error Monittor

LCD-Engine error menu

– 4 –

KF-50SX100/50SX100K/50SX100U

1-2-2. Error Reader Display

The error reader display is connected to the service connector to read actual error codes. The part number for the error reader display is

S-188-900-10.

Once an error has been detected it will then be displayed on the two digit error reader. The errors displayed refer to the following table:

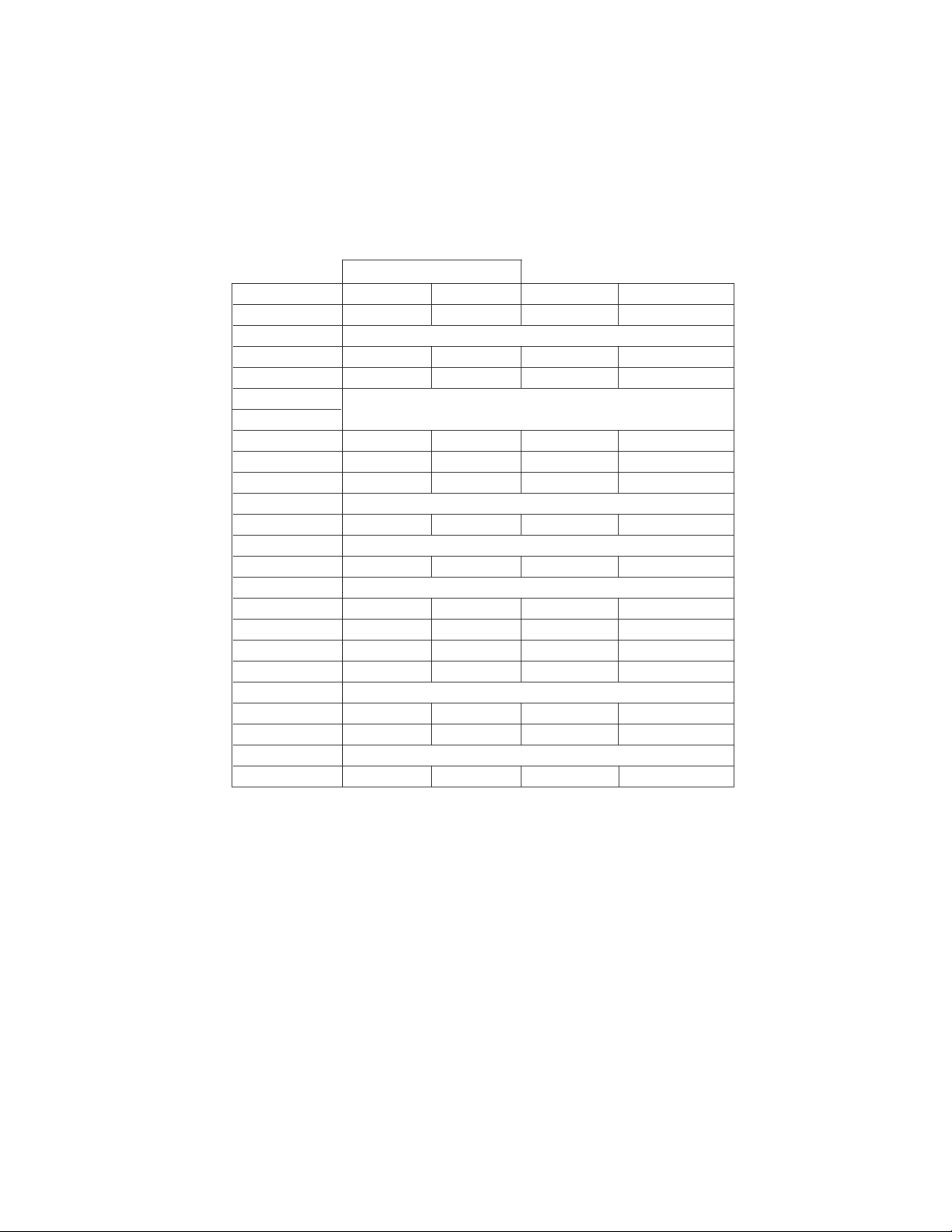

Send Data to Error Reader

Error Code Data High Data Low Error Type Function

00 00h – f0h no device

Gen. IIC Error

00 01h f0h 01h IIC 0 line

00 02h f0h 02h IIC 1 line not used

Device Error

A Board

01 01h f1h 01h CXA1875 Port Expander

01 02h f1h 02h TU1301 Main Tuner

01 03h f1h 03h TU1302 Sub Tuner

BB Board

04 01h f4h 01h CXD9509 MID-X

BB Board

06 01h f6h 01h CXA2101 MCP

J Board

04 04h f4h 04h TDA9178 Picture Booster

07 03h f7h 03h CXA2123 Sub Colour

07 04h f7h 04h CXA2123 Main Colour

07 0Ah f7h 0Ah CXA2149 AV SW

S Board

07 05h f7h 05h CXA1875 Sub Sound

07 08h f7h 08h MSP3410D Sound Proc

M Board

08 01h f8h 01h ST24C32 NVM

RM-903RM-903 RM-903

– 5 –

KF-50SX100/50SX100K/50SX100U

RM-903RM-903 RM-903

TABLE OF CONTENTS

Section Title Page

–––––– –––– ––––

SELF DIAGNOSIS FUNCTION ............................................ 3

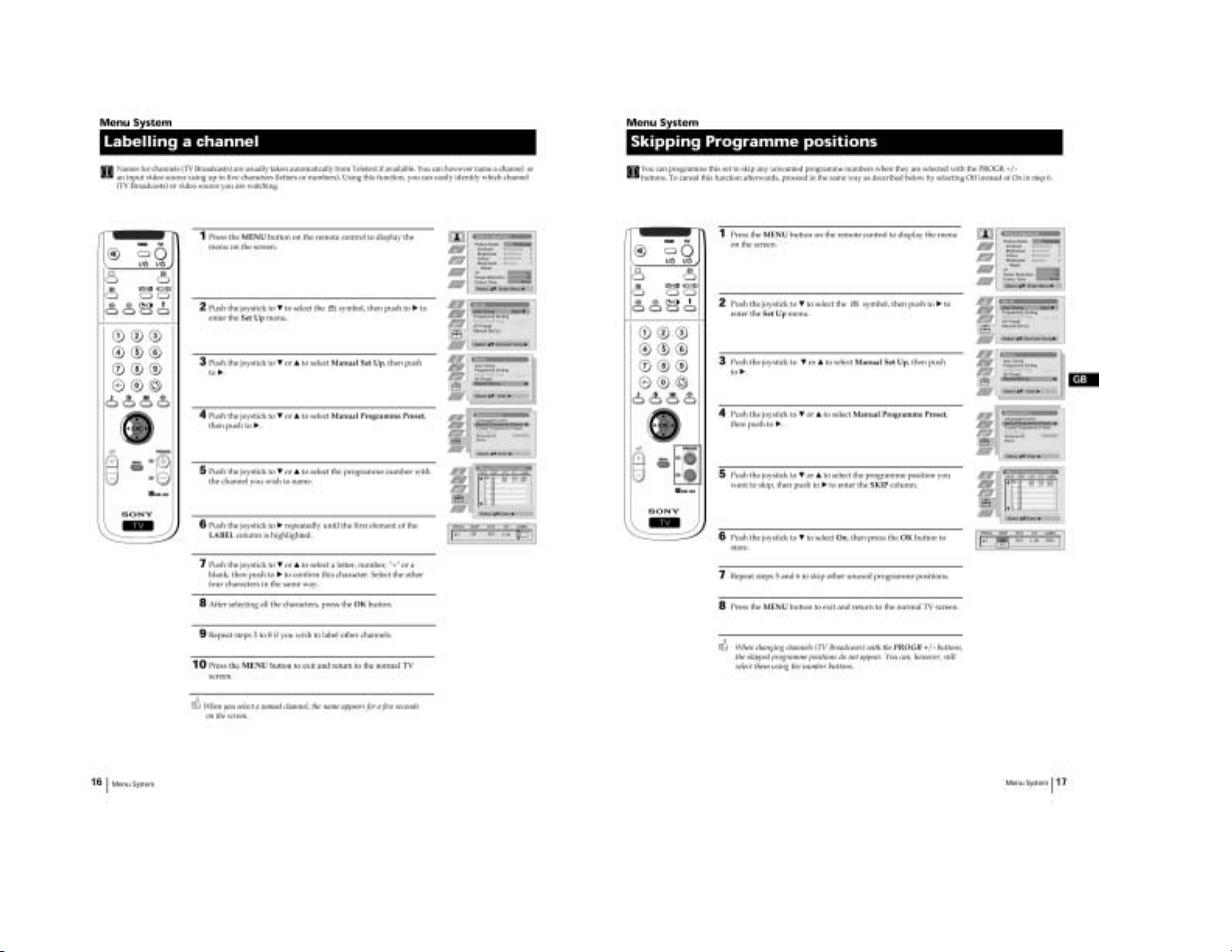

1. GENERAL

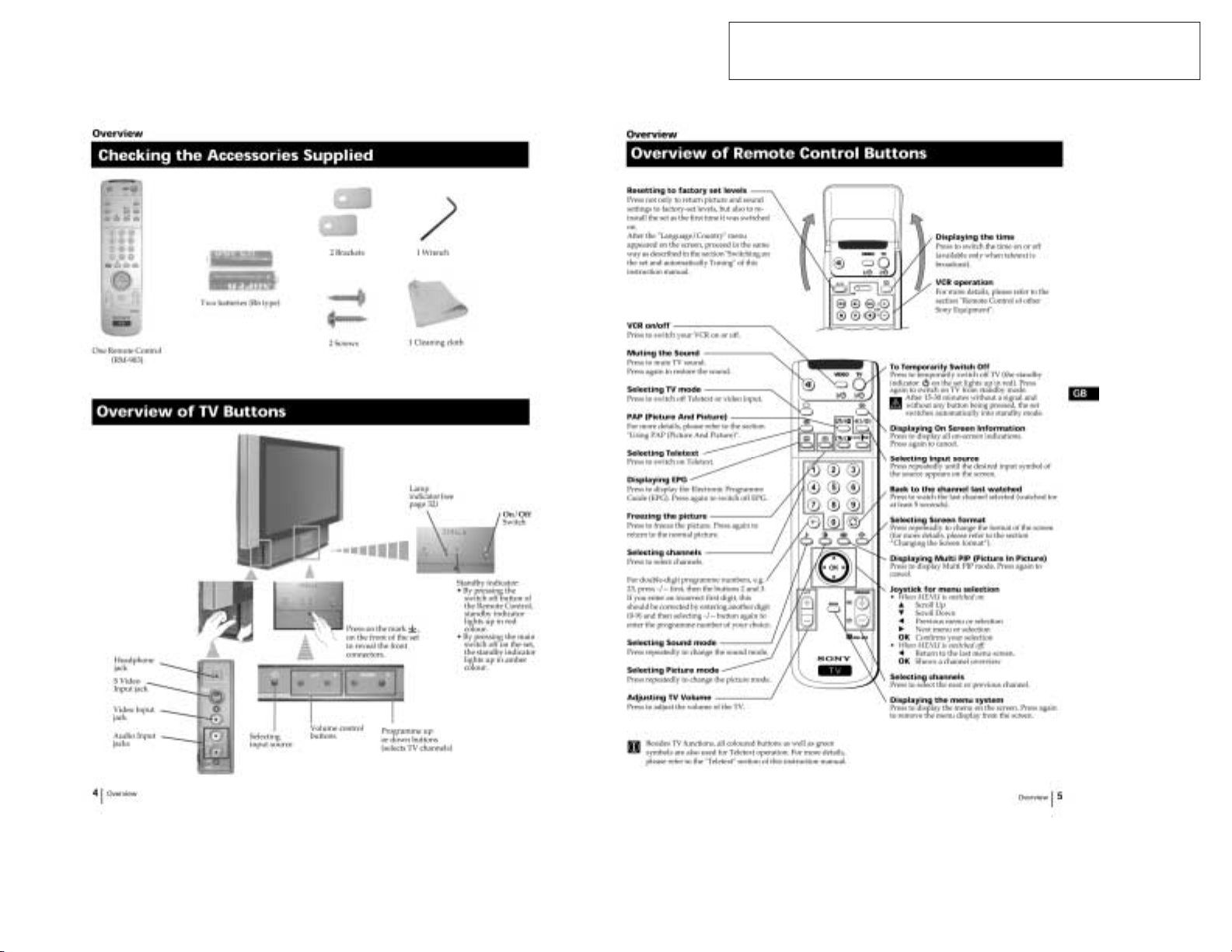

Overview ................................................................................. 8

Installation ............................................................................... 9

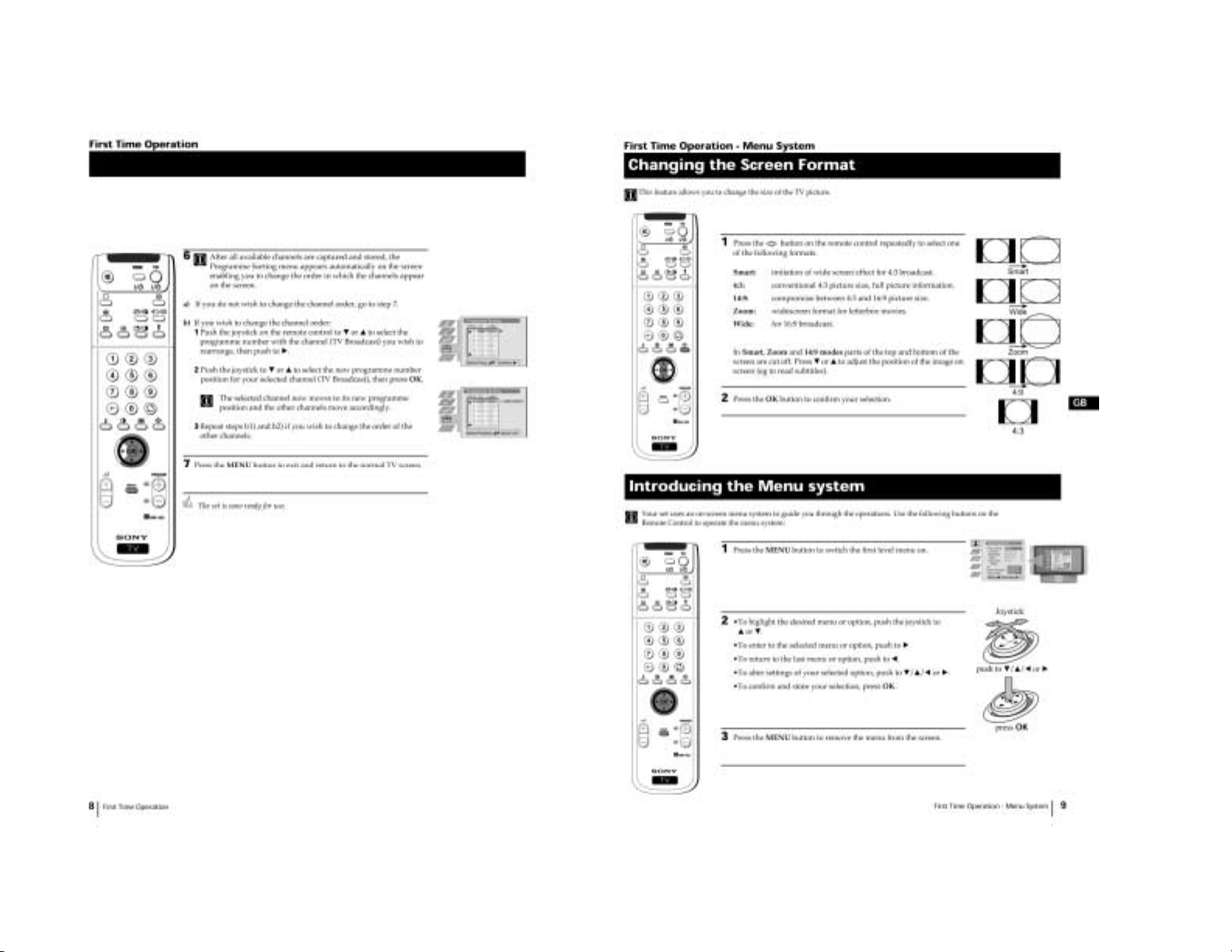

First Time Operation ............................................................... 9

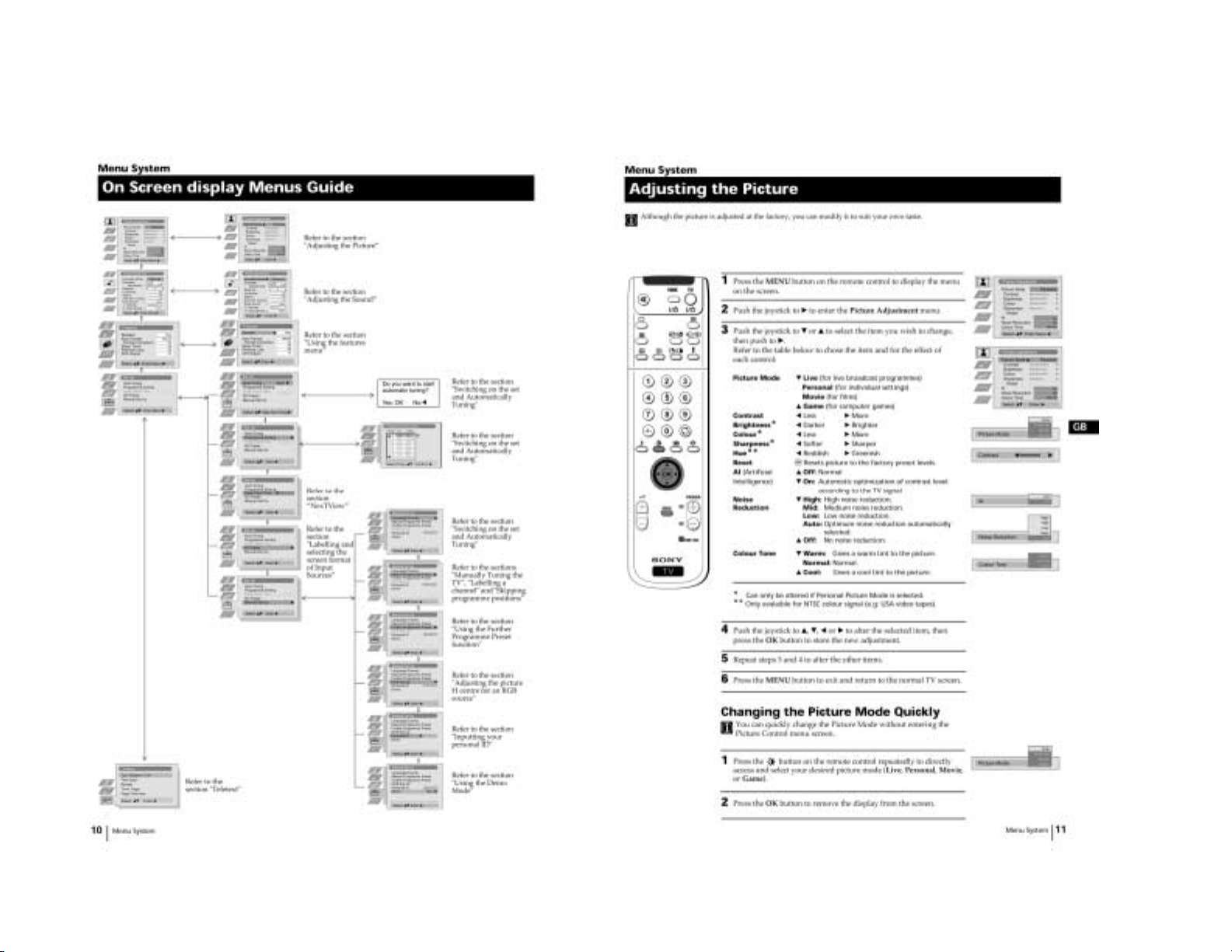

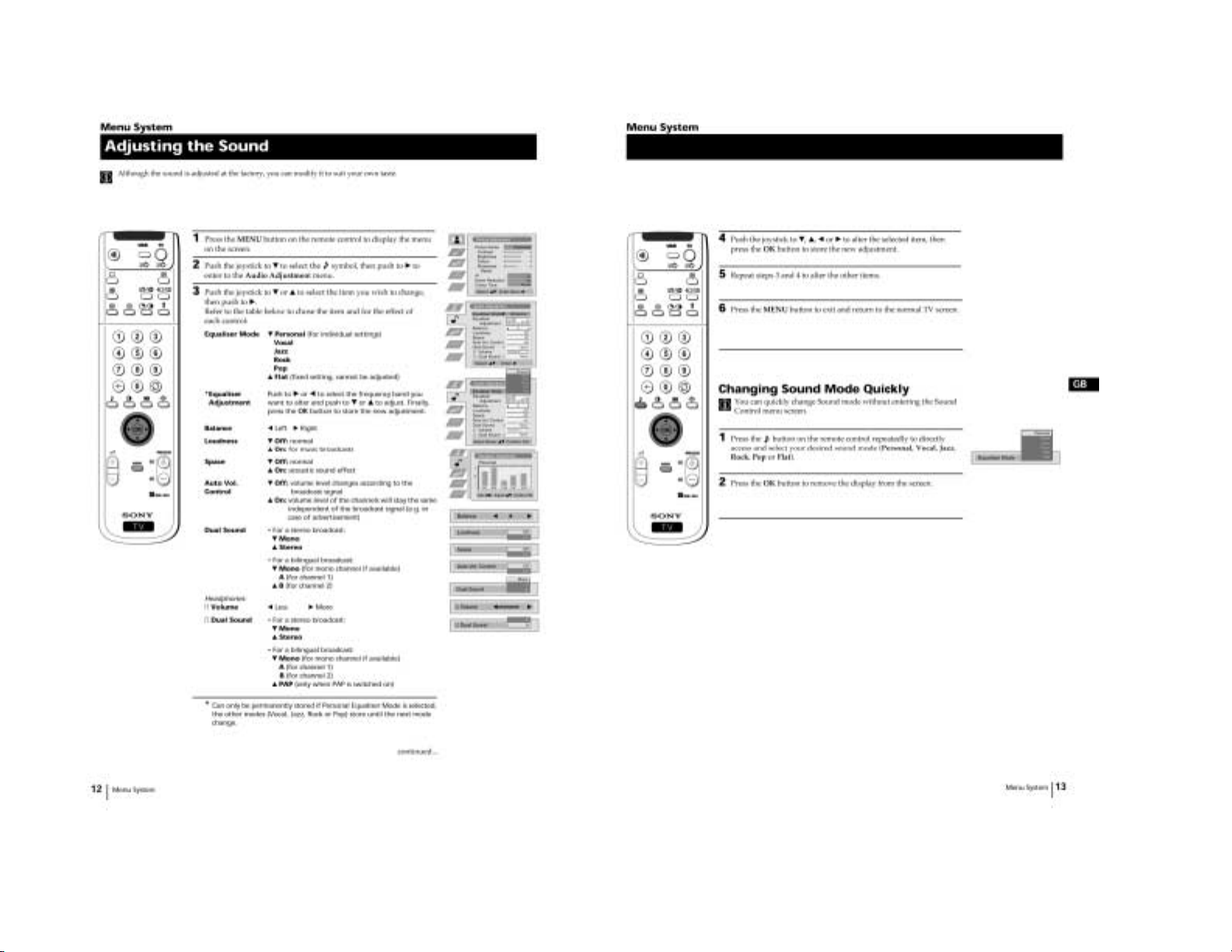

Menu System ......................................................................... 10

Teletext .................................................................................. 18

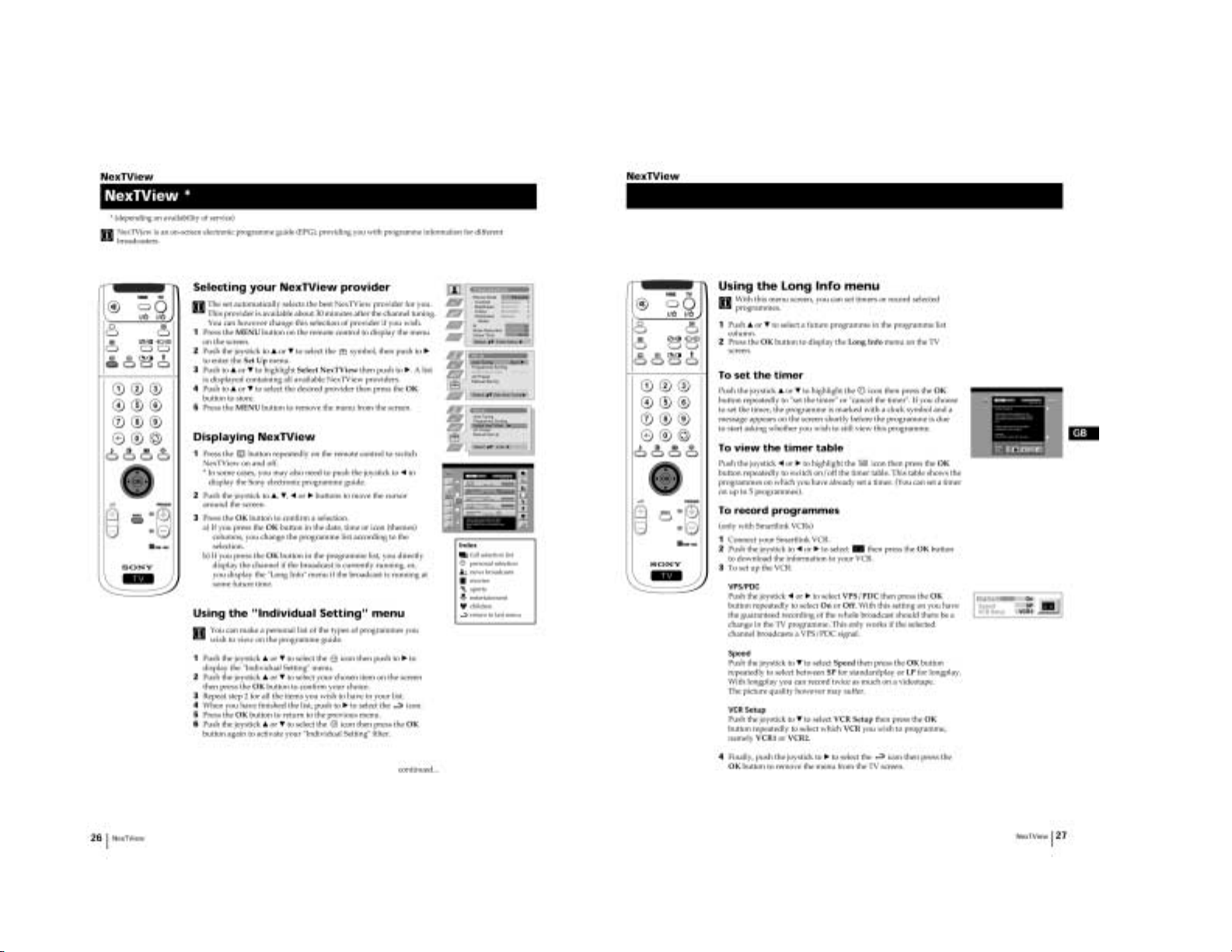

NexTView ............................................................................. 19

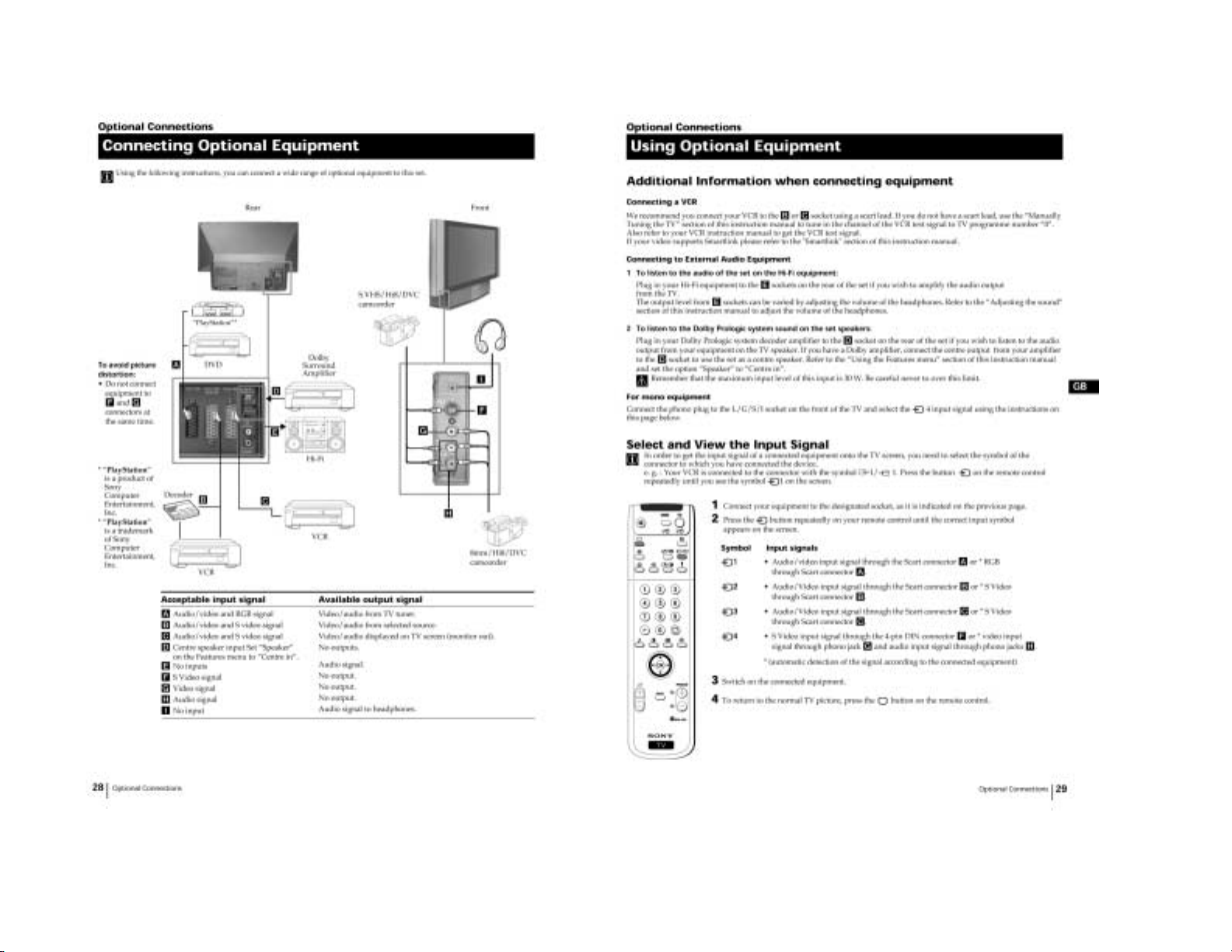

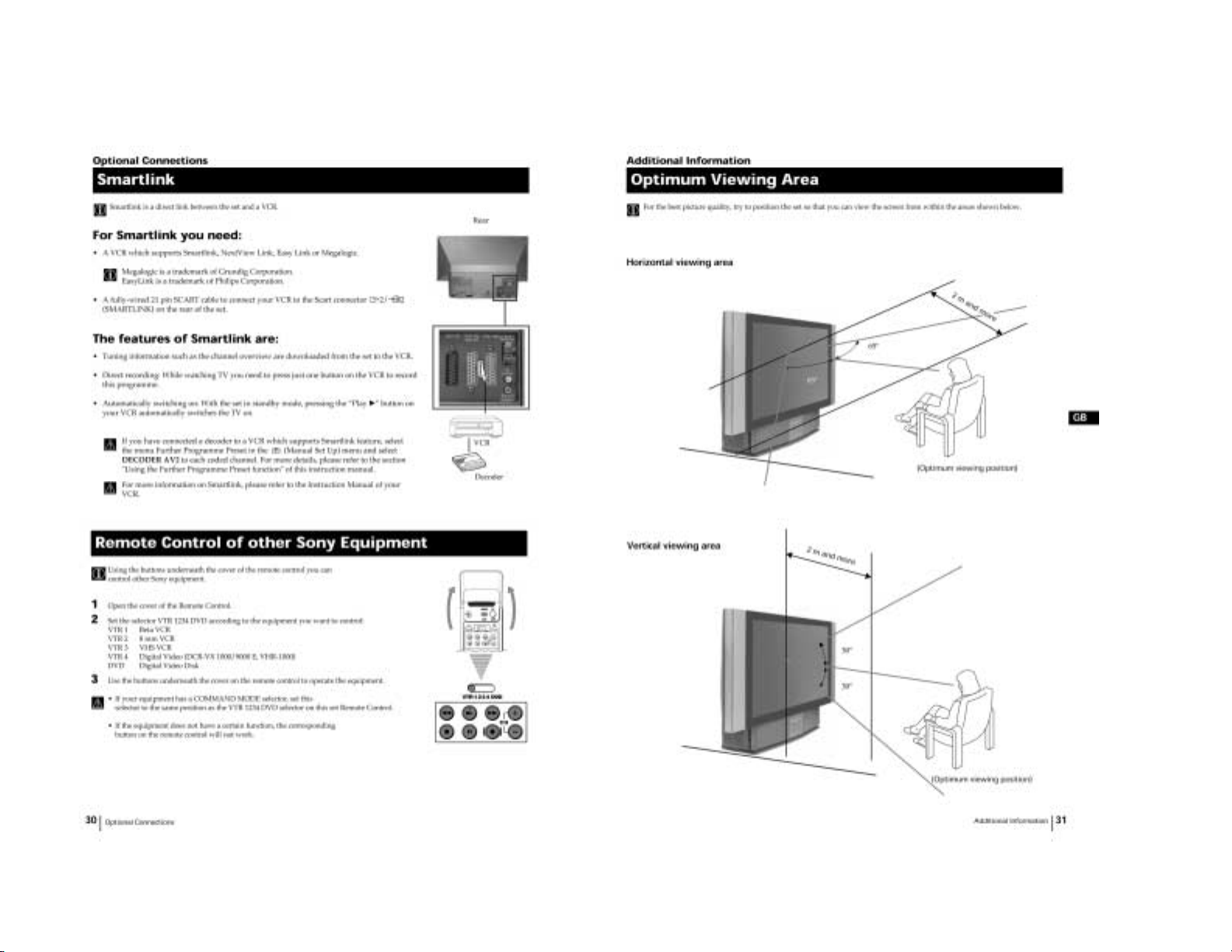

Optional Connections ............................................................ 20

Additional Information .......................................................... 21

2. DISASSEMBLY

2-1. Rear Cover Assembly ................................................ 23

2-2. Service Position ......................................................... 23

2-3. OU Bracket Removal ................................................ 23

2-4. Duct Block Assembly................................................ 23

2-5. Power Block .............................................................. 24

2-6. Optical Unit Block Assembly.................................... 24

2-7. J Board Removal ....................................................... 25

2-8. M, BD, S, N Board Removal .................................... 25

2-9. T Board ...................................................................... 25

2-10. A Board Removal ...................................................... 25

2-11. G Block Assembly Removal ..................................... 26

2-12. G Board Removal ..................................................... 26

2-13. Front Cover Removal ................................................ 26

2-14. Control Panel Block Assembly Removal .................. 26

2-15. H4 Board Removal ................................................... 27

2-16. H2 Board Removal ................................................... 27

2-17. Screen, Mirror Block Assembly ................................ 27

2-18. Mirror Cover Block Assembly Removal ................... 27

2-19. Contrast Screen, Diffusion Plates Removal .............. 28

2-20. Squawker Block Assemblies, Woofer Block

Assembly Removal ................................................... 28

2-21. Speaker Removal ...................................................... 29

2-22. Mirror Removal ......................................................... 29

2-23. H1 Board Removal .................................................... 29

3. ELECTRICAL ADJUSTMENTS

3-1. Adjustment With Commander................................... 30

3-2. LCD Projecter Engine ............................................... 42

3-3. Sub Colour Adjustment ............................................. 42

3-4. RGB Output Level Adjustment................................. 43

3-5. Vertical Stripe Adjustment ........................................ 43

3-6. Sub Bright Adjustment .............................................. 43

3-7. Screen Center Adjustment ......................................... 44

3-8. Test-Test Mode .......................................................... 44

Section Title Page

–––––– –––– ––––

4. DIAGRAMS

4-1. Block Diagram (1) ..................................................... 47

Block Diagram (2) ..................................................... 50

Block Diagram (3) ..................................................... 53

Block Diagram (4) ..................................................... 57

Block Diagram (5) ..................................................... 61

Block Diagram (6) ..................................................... 61

Block Diagram (7) ..................................................... 64

4-2. Frame Schematic Diagrams ...................................... 67

4-3. Circuit Boards Location ............................................ 70

4-4. Printed Wiring Boards and Schematic Diagrams ...... 70

• A Board ................................................................... 71

• BB (1/4) Board ....................................................... 81

• BB (2/4) Board ....................................................... 85

• BB (3/4) Board ....................................................... 89

• BB (4/4) Board ....................................................... 93

• M (1/2) Board ......................................................... 97

• M (2/2) Board ....................................................... 101

• J (1/2) Board ......................................................... 109

• J (2/2) Board ......................................................... 113

• H1 Board ............................................................... 117

• T Board ................................................................. 117

• H2 Board ............................................................... 118

• H4 Board ............................................................... 119

• N Board ................................................................. 120

• S Board ................................................................. 125

• G Board ................................................................. 127

4-5. Semiconductors ....................................................... 132

5. EXPLODED VIEWS

5-1. Mirror Section ......................................................... 134

5-2. Screen Section ......................................................... 135

5-3. Cabinet Section ....................................................... 136

5-4. Optical Unit Section ................................................ 137

5-5. Chassis Section ........................................................ 138

6. ELECTRICAL PARTS LIST ...................................... 139

– 6 –

(CAUTION)

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE

ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR CAR-

BON PAINTED ON THE CRT, AFTER REMOVING THE ANODE.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECElVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESECOMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL TO SAFEOPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

KF-50SX100/50SX100K/50SX100U

RM-903RM-903 RM-903

– 7 –

– 8 –

SECTION 1

GENERAL

The operating instructions mentioned here are partial abstracts from the

Operating Instructions Manual. The page numbers of the Operating

Instruction Manual remain as in the manual. (Part no : 4-078-836-11)

– 9 –

– 10 –

– 11 –

– 12 –

– 13 –

– 14 –

– 15 –

– 16 –

– 17 –

– 18 –

– 19 –

– 20 –

– 21 –

– 22 –

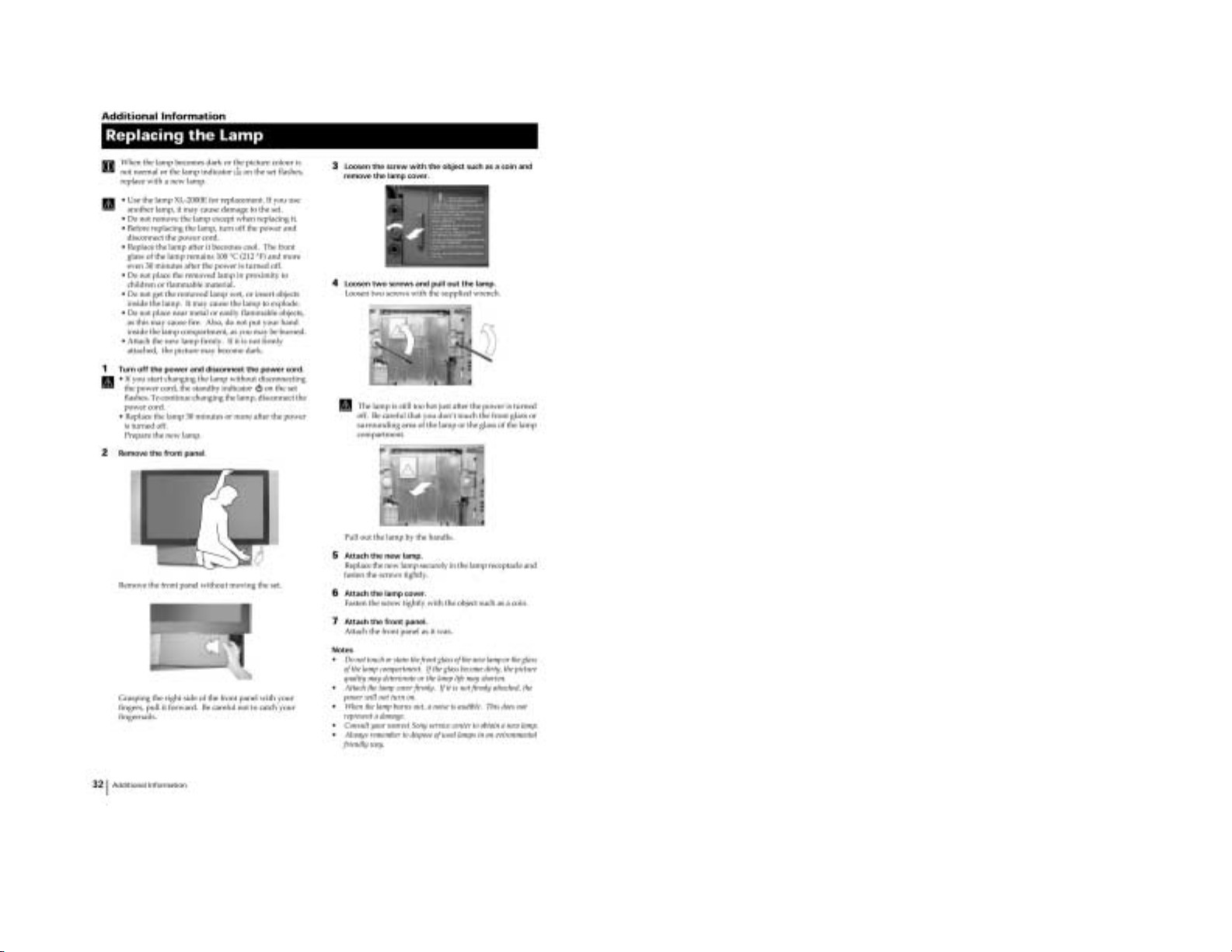

SECTION 2

DISASSEMBLY

KF-50SX100/50SX100K/50SX100U

RM-903RM-903 RM-903

2-1. REAR COVER ASSEMBLY

2 Rear cover assembly

1 Eleven screws

(+BVTP 4 X 16)

2-2. SERVICE POSITION

1

2-3. OU BRACKET REMOVAL

2-4. DUCT BLOCK ASSEMBLY

1 Remove the lamp

2 OU bracket

3 Connector

1 Five screws

(+BVTP 4 X 16)

4 Duct block assembly

2 Screw

(+BVTP 4 X 16)

– 23 –

KF-50SX100/50SX100K/50SX100U

RM-903RM-903 RM-903

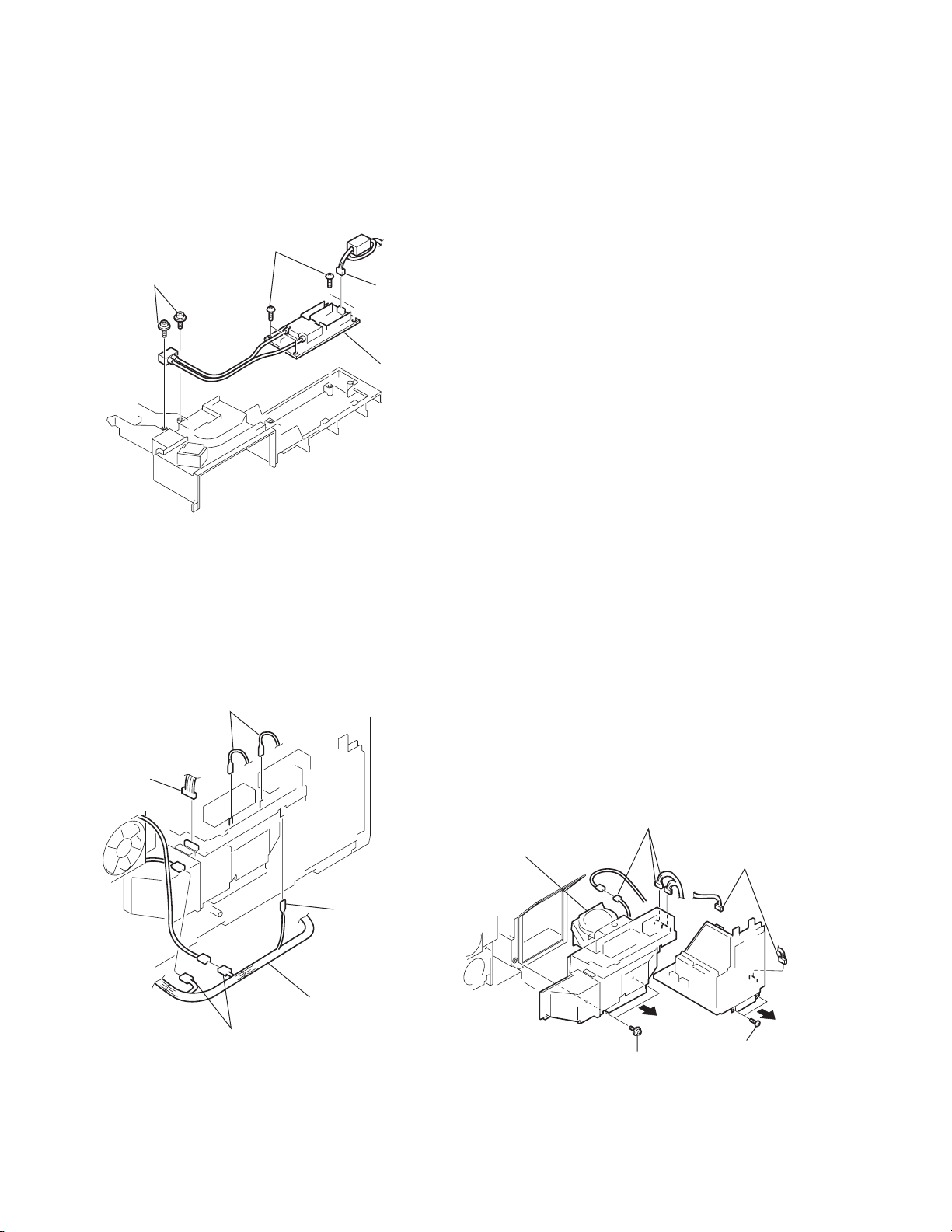

2-5. POWER BLOCK

3 Four screws

(+BVTP 3 X 12)

2 Two screws

(+BVWHTP 3 X 12)

1 Connector

4 Power block

2-6. OPTICAL UNIT BLOCK ASSEMBLY

1 Fasten tags

2 Connector

1 Fasten tag

4 Loosen cables

3 Conectors

Note: Be careful about the no dust or dirt are on the surface

contacts the optical unit block assembly.

• Clean the periphery of the set.

• Clean the periphery of the optical unit block assembly in

the set (the inside of the control panel, the surface contacts

between the optical unit block assembly and the bottom

cabinet and periphery).

q; Optical unit block assembly

9 Connectors

8

7 Two screws

(+P 4 X 35)

6 Connectors

5

4 Two screws

(+BVTP 4 X 16)

– 24 –

KF-50SX100/50SX100K/50SX100U

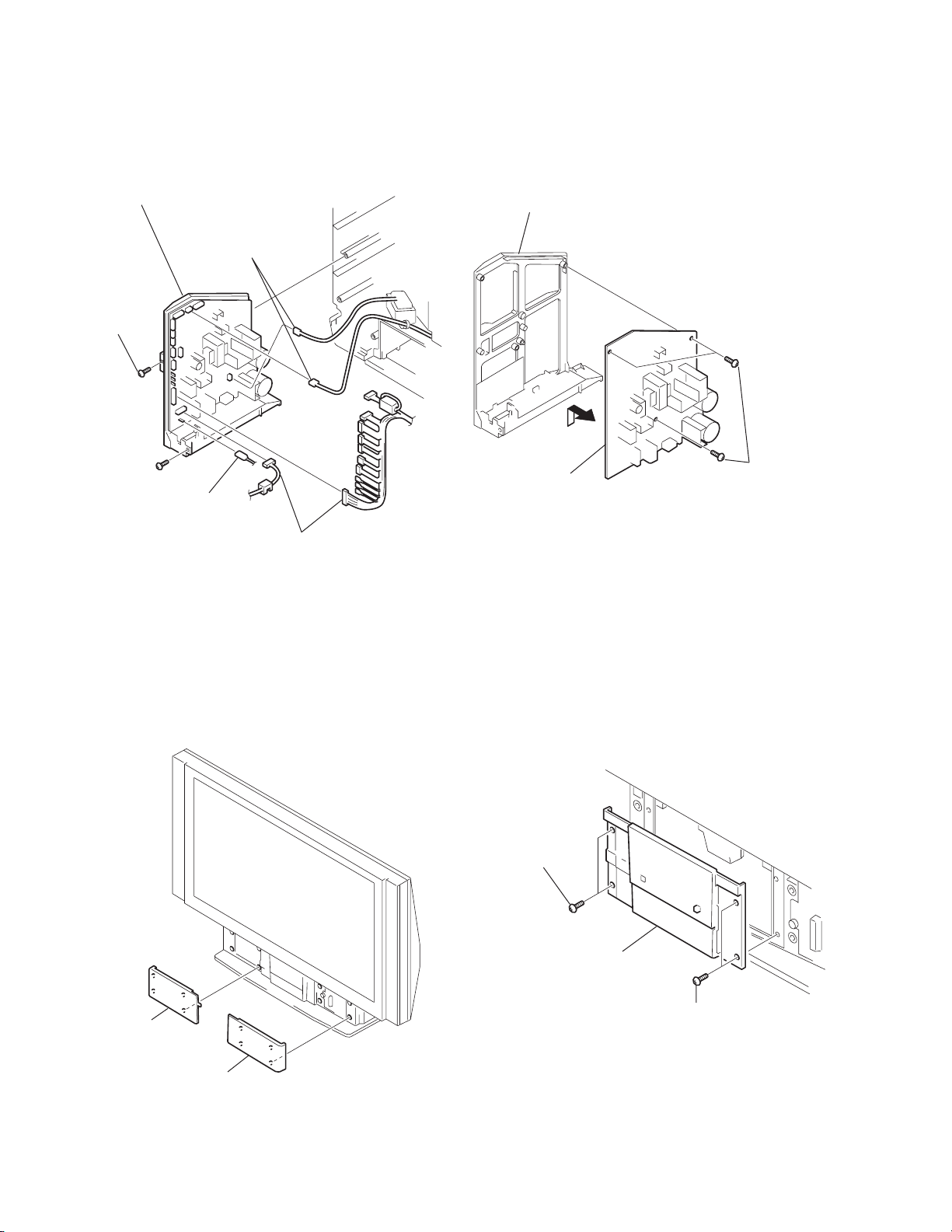

2-7. J BOARD REMOVAL 2-8. M, BD, S, N BOARDS REMOVAL

RM-903RM-903 RM-903

1 Connectors

6 Shield

cover J

5

2 Two screws

(+BVTP 3 X 12)

3 Three screws

(+BVTP 4 X 16)

4 Bracket J

2 BB board

2 M board

A board

3 S board

4 N board

2-9. T BOARD

1 Remove the optical block assembly

4 T board

3 Screw

(+BVTP 3 X 12)

2 Connectors

2-10. A BOARD REMOVAL

1 Fasten tag

2 Connector

2 Connectors

3 Claws

2 RF cable

2 Connectors

4 A board

2 Connectors

– 25 –

KF-50SX100/50SX100K/50SX100U

RM-903RM-903 RM-903

2-12. G BOARD REMOVAL2-11. G BLOCK ASSEMBLY REMOVAL

5 G block assembly

1 Two screws

(+BVTP 4 X 16)

2 Fasten tag

4 Connectors

3 Connectors

G bracket

3 G board

2

1 Three screws

(+BVTP 4 X 16)

2-13. FRONT COVERS REMOVAL

Front cover L

Front cover R

2-14. CONTROL PANEL BLOCK ASSEMBLY

REMOVAL

1 Two screws

(+BVTP 4 X 16)

2 Control panel

block assembly

1 Two screws

(+BVTP 4 X 16)

– 26 –

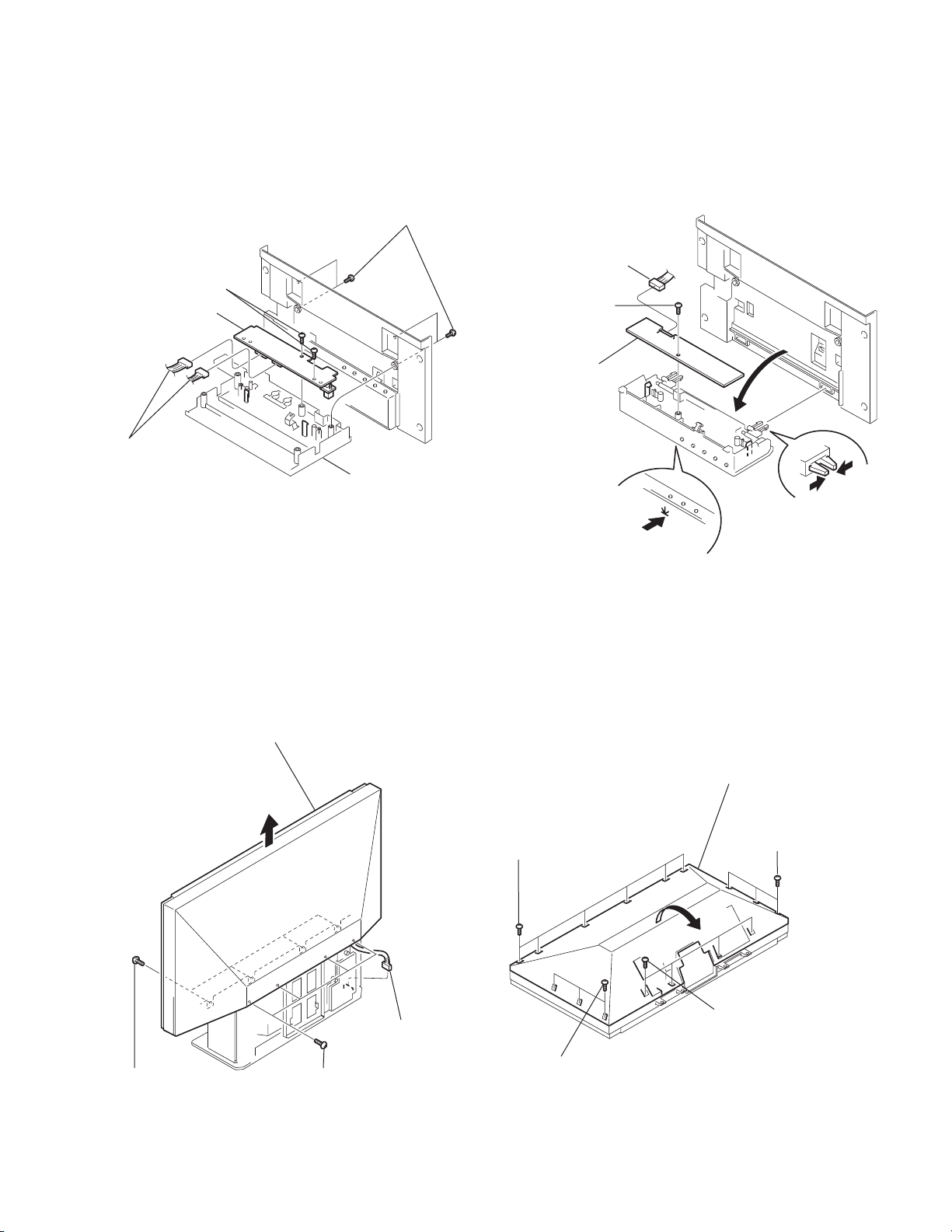

KF-50SX100/50SX100K/50SX100U

4 Screw

(+BVTP 3 X 12)

6 H2 board

5

2

1

3 Connector

2-15. H4 BOARD REMOVAL 2-16. H2 BOARD REMOVAL

1 Four screws

(+BVTP 4 X 16)

3 Two Screws

(+BVTP 3 X 12)

4 H4 board

2 Connector

Indication panel

assembly

RM-903RM-903 RM-903

2-17. SCREEN, MIRROR BLOCK ASSEMBLY

Screen mirror block assenbly

1 Four Screws

(+BVTP 4 X 16)

4

3 Connector

2 Four screws

(+BVTP 4 X 16)

2-18. MIRROR COVER BLOCK ASSEMBLY

REMOVAL

Mirror cover block assembly

1 Six screws

(+BVTP 4 X 16)

2

1 Four screws

(+BVTP 4 X 16)

1 Three screws

(+BVTP 4 X 16)

1 Three screws

(+BVTP 4 X 16)

– 27 –

KF-50SX100/50SX100K/50SX100U

RM-903RM-903 RM-903

2-19. CONTRAST SCREEN, DIFFUSION PLATES REMOVAL

1 Six screws

(+BVTP 4 X 16)

1 Four screws

(+BVTP 4 X 16)

2 Screen holder (S)

3 Diffusion plates

2 Screen holder (L)

1 Four screws

(+BVTP 4 X 16)

2 Screen holder (S)

1 Six screws

(+BVTP 4 X 16)

2 Screen holder (L)

Screen frame assembly

4 Contrast screen

2-20. SQUAWKER BLOCK ASSEMBLIES, WOOFER BLOCK ASSEMBLY REMOVAL

1 Two screws

(+BVTP 4 X 16)

5 Two screws

(+BVTP 4 X 16)

6 Squawker

block (R)

assembly

7 Two screws

(+BVTP 4 X 16)

2 Squawker block (L)

assembly

3 Two screws

(+BVTP 4 X 16)

4 Woofer block (L)

assembly

8 Woofer block

(R) assembly

– 28 –

KF-50SX100/50SX100K/50SX100U

RM-903RM-903 RM-903

2-21. SPEAKERS REMOVAL

1 Two screws (+BVTP 4 X 16)

3 Speaker (13 X 7cm)

5 Fasten tags

1 Two screws

(+BVTP 4 X 16)

4 Two screws

(+BVTP 3 X 12)

6 Speaker

(2cm)

5 Fasten tags

2-22. MIRROR REMOVAL

1 Two screws

(+BVTP 4 X 16)

5 Two screws

(+BVTP 4 X 16)

6 Mirror

holder (R)

2 Mirror

holder (L)

7 Mirror

3 Screw

(+BVTP 4 X 16)

4 Mirror holder (U)

2-23. H1 BOARD REMOVAL

3 Fasten tag

4 Connectors

6 H1 board

1 H1 lid

1 Two screws

(+BVTP 3 X 8)

1 Two screws

(+BVTP 4 X 16)

– 29 –

KF-50SX100/50SX100K/50SX100U

RM-903RM-903 RM-903

ELECTRICAL ADJUSTMENTS

SECTION 3

3-1. ADJUSTMENTS WITH COMMANDER

Service adjustment to this model can performed with the supplied

remote commander RM-903.

MUTE

TV MODE

JOYSTICK

VOLUME +

MENU

1

4

7

2

5

8

0

OK

MENU

SONY

TV

VIDE O TV

3

6

9

PROGR

RM

903

TV STANDBY

ON SCREEN

DISPLAY

SCREEN

FORMAT

4:3/16:9

RM-903

3. Press “-” + “-” on the commander. If “ (TV MODE)”

button is pressed, the set exits from the TT mode and returns to

normal TV mode.

3-1-2. How to Enter Service Menu

1. Select TT mode.

2. Press “MENU” button on the commander once, and normal

menu screen will appear, or press it once more, and the follow-

ing service menu screen will appear.

Service AE5(A)

Initialising

Reset Devices

Monitoring

Device Register Setting

Special Adjustment

Select : v V Next menu : B

3. Following the screen, press v or V key on the joystick to select the desired item, and press B key to enter the selected

item.

4. Press v or V key on the joystick to change data of each item,

and press “

(OK)” button to write changed data.

(Except Projector Engine mode)

5. To return from each item, press b key on the joystick. Or, to

return to the TT mode, press the “MENU” button.

(Except Projector Engine mode)

1. Selection of Mode Between PAL and NTSC

PAL mode : Enter PAL signal with color burst.

NTSC mode: Enter NTSC signal with color burst. (VIDEO

input only)

2. Selection of Screen Format

1) Press “

(BLUE)” button on the commander.

2) Press v or V key on the joystick to select screen format and

press “

(OK)” button. At this time, normal screen comes

back. (In the TT mode, the menu is switched to the Service

menu.)

3-1-1. How to Enter TT Mode

1. Turn on the main power switch to place this set in standby

mode. (LED will light in red.)

2. Press the buttons on commander as follows, and the TT

mode will be selected.

Enter the

“TT MODE”

(

DISPLAY

5

(DIGIT 5) (VOLUME +) (TV MODE)ON SCREEN

)

“TT - -” will appear in the top right corner of the screen.

Other status information will also be displayed.

3-1-3. Screen Display for Service Menu

If each item of service menu is selected, the following screen is

displayed.

• Initialising

Initialising

Model Setting

Destination Setting

Basic Setting

Feature Setting

Select : v V Next menu : B

– 30 –

Loading...

Loading...