Sony KE-50XBR900 - 50"" Xbr Plasma Wega&trade, Integrated Television Service Manual

MODEL NAME : KE-50XBR900

SERVICE MANUAL

PARTS No. : 9-978-756-02

MODIFICATION

HISTORY

* Blue characters are linking.

No. DATA CONTENTS

1

2003. 2 Addition of Disassembly, Adjustments, Troubleshooting and Diagrams

(P.1-1, P.2-1, P.3-1, P.4-1)

Revised all pages for Exploded Views (P.5-1)

SERVICE MANUAL

SPECIFICATIONS

KE-50XBR900

FLAT PANEL COLOR TV

US Model

Canadian Model

Panel System Plasma Display panel

Display resolution Display resolution:

1365 pixels (horizontal) × 768 pixels (vertical)

Antenna 75 ohm external terminal for VHF/UHF

Television System NTSC, American TV Standard

Channel Coverage VHF 2-13

UHF 14-69

CATV 1-125

Power Requirements 120V, 60 Hz

Inputs/Outputs

DVI-HDTV 1 terminal, 3.3V T.M.D.S., 50 ohms

The DVI-HDTV input terminal is compliant with the EIA-861 standard and is not

intended for use with personal computers.

Video (IN) 3 total (1 on front panel) 1 Vp-p, 75 ohms unbalanced, sync negative

S Video (IN) (1 on front panel) Y: 1 Vp-p, 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

Audio (IN) (1 on front panel) 500 mVrms (100% modulation)

Impedance: 47 k i lohm

Component Video Input 2 (Y, P

B, PR) Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative;

P

B: 0.7 Vp-p, 75 ohms

P

R: 0.7 Vp-p, 75 ohms

CONTROL S (OUT)

Variable/Fixed Audio (OUT) More than 408 m Vrms at the maximum volume

setting (Variable)

More than 408 mVrms (Fixed)

Impedance (output): 2 kilohms

Monitor/Fixed Audio (OUT) ×1

1

1

3 total

6 total

KE-50XBR900(UC) 2

Sub woofer (OUT) 1

2

1

phono jack

RF Input

Converter

Supplied Accessories Remote Control RM-927Y

AAA (LR03) Batteries 2 supplied for remote control

Screen Size (measured diagonally)

KE-50XBR900 50 inches

Speaker Output 15W × 2

Dimensions (W × H × D)

PDM-5000 1573 × 856 × 108 mm

(62

1

/8 × 33 3/4 × 4 3/8 in)

MBT-XBR900 430 × 105 × 360 mm

(17 × 4

1

/4 × 14 1/4 in)

Design and specifications are subject to change without notice.

Mass Display unit

PDM-5000: 53kg (114 lbs)

Media receiver unit

MBT-XBR900: 7.5kg (16 lbs)

Power Consumption

Display unit

PDM-5000: 540 W

Media receiver unit

MBT-XBR900: 36 W

In Standby

In Use

Under 1.5 W

AC power code (2)

Display interface cable (1)

Antenna cable (1)

Cleaning cloth

KE-50XBR900(UC) 3

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and from all

exposed metal parts to any exposed metal part having a return to chassis,

must not exceed 0.5 mA (500 microamperes).

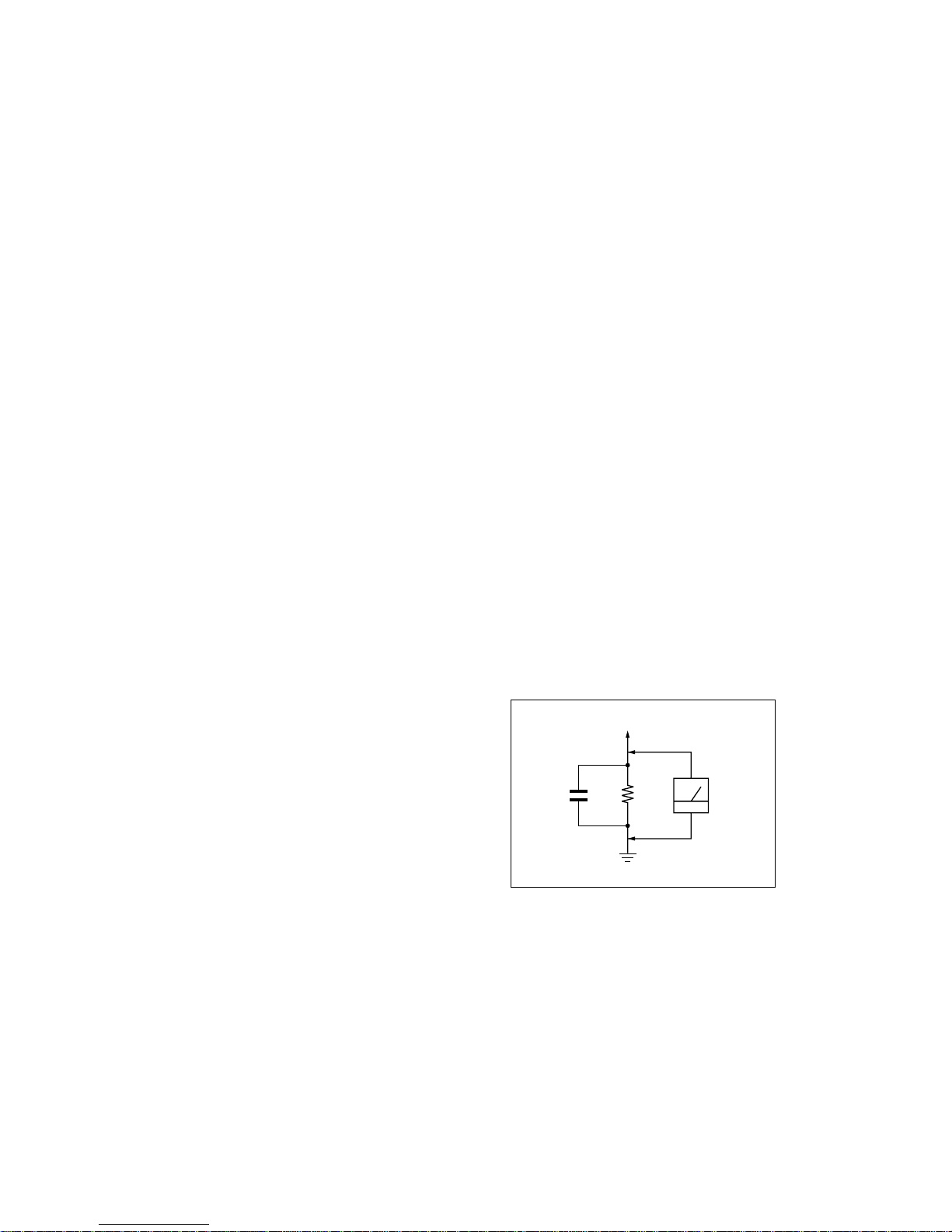

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA WT540A. Follow the manufacturers’ instructions to use these instruments.

2. A battery-operated AC milliammeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM or

battery-operated AC voltmeter. The “limit” indication is 0.75 V, so

analog meters must have an accurate low-voltage scale. The Simpson 250

and Sanwa SH-63Trd are examples of a passive VOMs that are suitable.

Nearly all battery operated digital multimeters that have a 2 V AC range

are suitable. (See Fig. A)

Fig. A. Using an AC voltmeter to check AC leakage.

1.5 k

Ω

0.15 µF

AC

Voltmeter

(0.75 V)

To Exposed Metal

Parts on Set

Earth Ground

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety

checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that you

have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that

were installed during a previous repair. Point them out to the customer

and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the connector shell, metal trim, “metallized” knobs, screws, and

all other exposed metal parts for AC Leakage. Check leakage as described right.

KE-50XBR900(UC) 4

AVERTISSEMENT!!

ATTENTION AUX COMPOSANTS RELATIFS À LA SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE TRAME ET UNE

MARQUE ! SONT CRITIQUES POUR LA SÉCURITÉ. NE LES

REMPLACER QUE PAR UNE PIÈCE PORTANT LE NUMÉRO

SPECIFIÉ. LES RÉGLAGES DE CIRCUIT DONT L’IMPORTANCE EST

CRITIQUE POUR LA SÉCURITÉ DU FONCTIONNEMENT SONT

IDENTIFIÉS DANS LE PRÉSENT MANUEL. SUIVRE CES

PROCÉDURES LORS DE CHAQUE REMPLACEMENT DE

COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS

FONCTIONNEMENT EST SUSPECTÉ.

WARNING!!

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL FOR SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART

NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT ARE CRITICAL FOR SAFE OPERATION ARE

IDENTIFIED IN THIS MANUAL. FOLLOW THESE PROCEDURES

WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

KE-50XBR900(UC) 5

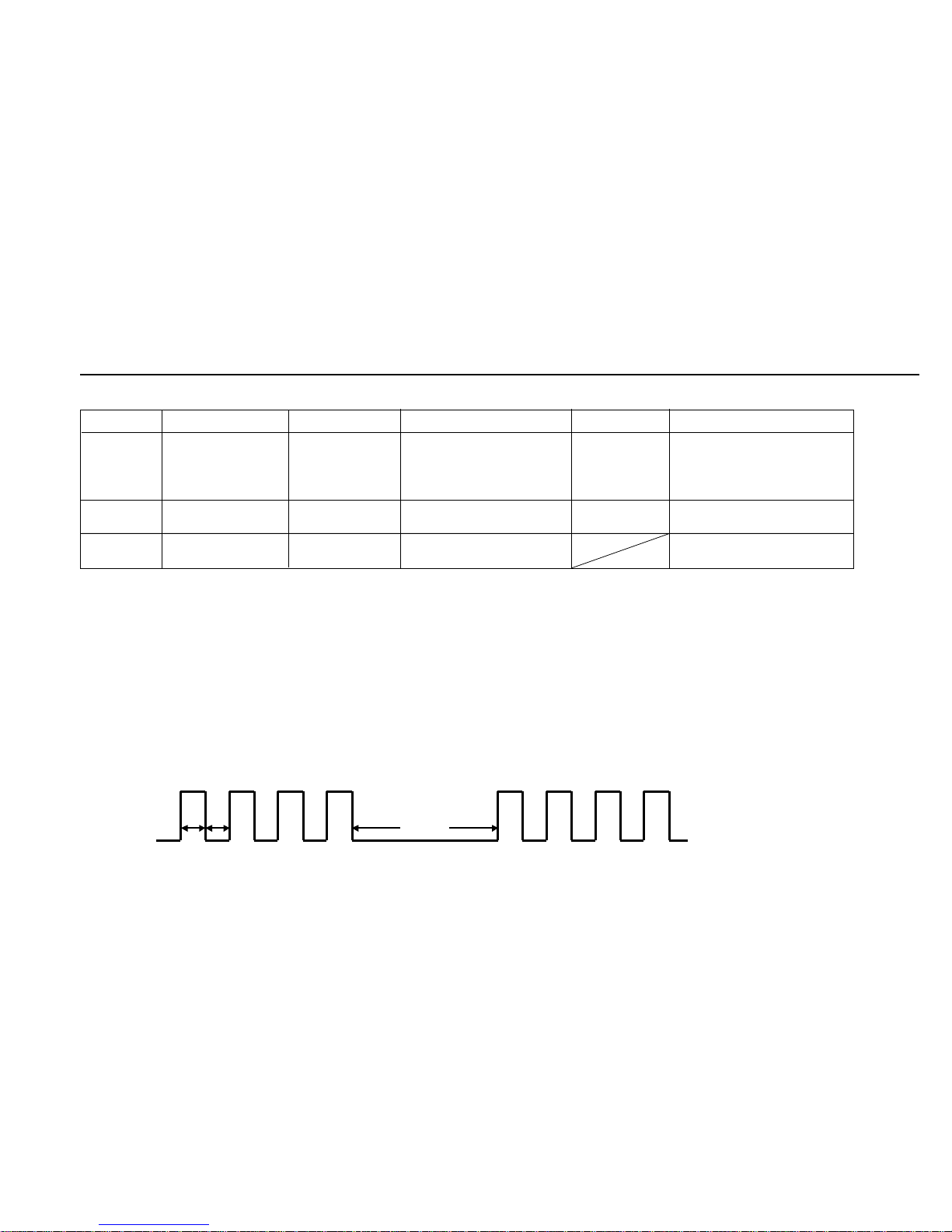

DIAGNOSIS (Reliability Self Diagnostic Display Specifications for MEDIA RECEIVER)

1) *Operation count is based on WDT.

*For flashes, the Power/Standby LED flashes in red.

*The flash period is based on the reliability standard.

Repair part

• FAN

• FAN CONNECTOR

• SET 11V LINE

• SET 5V LINE

DP board

• Q1612, Q1613, Q1614

Panel Display Unit

The abnormal conditions are indicated by the following LED flashes.

Flash Count Error Display Name Error Description Oprating Detection Port

4 Fan Error Error detected for Detects Low when fan IC6200 pin #2

fan in Media function normally.

Receiver box. Detects High when Fan stops

abnormally

8 Digtal OVP OVP for DD Con- Detects High when normal. IC5210 pin #49

verter on DP board Detects Low when abnormal.

9 Panel Error Panel malfunction Detects during communication

detected with panel.

*A failure part can be expected by the number of times of blink of LED.

*When two failures occur, the failure item generated previously is detected.

*When failure occurs simultaneously, an item with little number of times of blink is detected.

*In other than “Fan Error”, the unit is in standby state and blink LED at intervals of regulation.

In “Fan Error”, the unit is in a standby state after display for 1 minute about the message of “Fan problem –

Powering down”

every about 0.3s

about 3s

• Timing of LED blink (example of 4 times blink)

ON

OFF

KE-50XBR900(UC) 6

In the following case, POWER LED of Media Receiver Box blinks at a fixed interval in ORANGE

• When the cable which connects between Media Receiver Box and Panel Display has fallen out.

• When the AC code for Panel Display has fallen out.

In the following case, POWER LED of Panel Display

blinks at a fixed interval in ORANGE

• When the cable which connects between Media Receiver Box and Panel Display has fallen out.

• When the AC code for Media Receiver Box has fallen out.

2)

The example which judges whether it is failure

• POWER LED of Media Receiver Box: Blink 9 times in RED, and of Panel Display blink,

and No picture or Power circuit does not work → Large possibility that Panel Display is out of order.

• When turn on Media Receiver Box, and NO LED of Box shine

•

When NO Blue LED of Box shine → Large possibility that Media Receiver Box is out of order.

Check SET5V or IIC line on H1 board.

• When turn on Media Receiver Box, and Fan does not work

→ Large possibility that Media Receiver Box is out of order

3)

→ Large possibility that Media Receiver Box is out of order.

KE-50XBR900(UC) 7

SAFETY CHECK-OUT ................................................... 3

DIAGNOSIS ...................................................................... 5

1. DISASSEMBLY

1-1. Display Unit (PDM-5000)

1-1-1.Rear Cover Removal ....................................... 1-1

1-1-2.K and F Boards Removal ................................ 1-2

1-1-3.P Board Removal ............................................ 1-3

1-1-4.G and F2 Boards Removal .............................. 1-4

1-1-5.R1 Board Removal .......................................... 1-5

1-1-6.R2 Board Removal .......................................... 1-6

1-2. Media Receiver Unit (MBT-XBR900)

1-2-1.Panel and Covers Removal.............................. 1-7

1-2-2.H1 Board Removal ......................................... 1-8

1-2-3.H4 Board Removal.......................................... 1-9

1-2-4.H3 Board Removal ......................................... 1-10

1-2-5.MS2 Board Removal....................................... 1-11

1-2-6.H2 Board Removal ......................................... 1-12

1-2-7.A Board Removal............................................ 1-13

1-2-8.B Block Assy Removal .................................. 1-14

1-2-9.M, AD, and AU Boards Removal ................... 1-15

TABLE OF CONTENTS

Section Title Page Section Title Page

1-2-10.A and AU Boards Removal........................... 1-16

1-2-11.M Board Removal ........................................ 1-17

1-2-12.IF Boards Removal........................................ 1-18

1-2-13.U1 Boards Removal ...................................... 1-19

1-2-14.U2 Boards Removal ...................................... 1-20

2. ADJUSTMENTS

2-1. VS, VD Voltage Adjustment (PDM-5000)............... 2-1

2-2. White Balance Adjustment (PDM-5000).................. 2-2

3. TROUBLESHOOTING

3-1. Display Unit (PDM-5000) ........................................ 3-1

3-2. Media Receiver Unit (MBT-XBR900) ..................... 3-2

4. DIAGRAMS

4-1. Block Diagrams

4-1-1.Display Unit(PDM-5000)................................ 4-1

4-1-2.Media Receiver Unit (MBT-XBR900) ........... 4-6

4-2. Frame Diagram ......................................................... 4-15

4-3. Circuit Boards Location

4-3-1.Display Unit(PDM-5000)................................ 4-16

KE-50XBR900(UC) 8

Section Title Page

Section Title Page

4-3-2.Media Receiver Unit (MBT-XBR900)............ 4-17

4-4. Schematic Diagrams and Printed WiringBoards....... 4-18

4-4-1.Display Unit(PDM-5000)................................ 4-19

(1)Schematic Diagrams of F Board ......................... 4-19

(2)Schematic Diagram of F2 Board ......................... 4-20

(3)Schematic Diagrams of G Board ......................... 4-21

(4)Schematic Diagram of K Board .......................... 4-25

(5)Schematic Diagrams of P Board ......................... 4-27

(6)Schematic Diagrams of R1 amd R2 Boards ........ 4-32

4-4-2.Media Receiver Unit (MBT-XBR900)................... 4-33

(1)Schematic Diagrams of A Board ......................... 4-33

(2)Schematic Diagram of AD Board ....................... 4-36

(3)Schematic Diagrams of AU Board ...................... 4-41

(4)Schematic Diagram of DP Board ........................ 4-43

(5)Schematic Diagrams of H1 and H5 Boards ......... 4-45

(6)Schematic Diagrams of H2 Board ....................... 4-47

(7)Schematic Diagram of H3 and H4 Board ............ 4-48

(8)Schematic Diagrams of IFA Board ..................... 4-49

(9)Schematic Diagrams of M Board ........................ 4-51

(10)Schematic Diagrams of MS2 Boards ................ 4-57

(11)Schematic Diagrams of U1 Board ..................... 4-59

(12)Schematic Diagram of U2 Board ...................... 4-61

(13)Schematic Diagram of BM1C Board ................ 4-61

(14)Schematic Diagram of DICA Board ................. 4-65

4-5. Semiconductors......................................................... 4-71

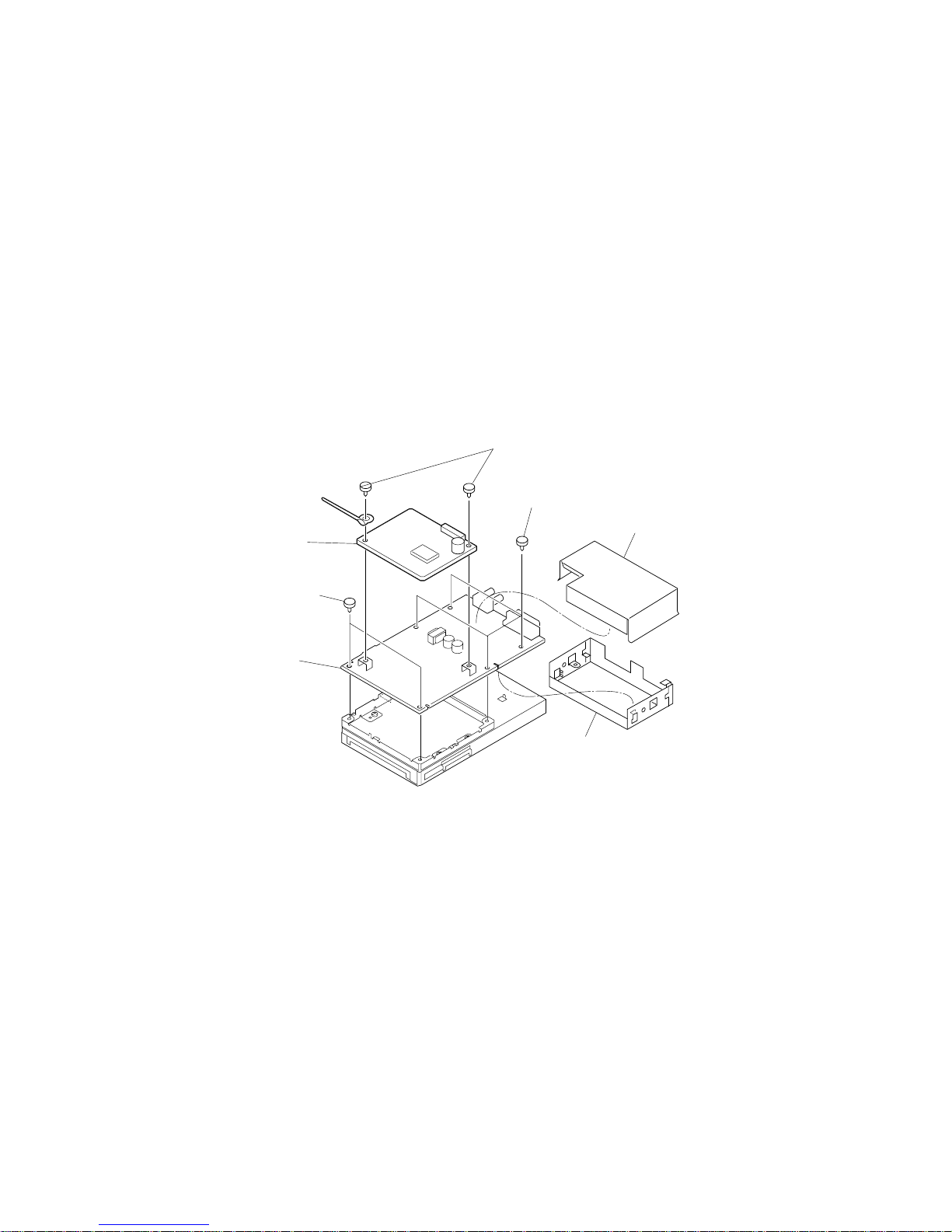

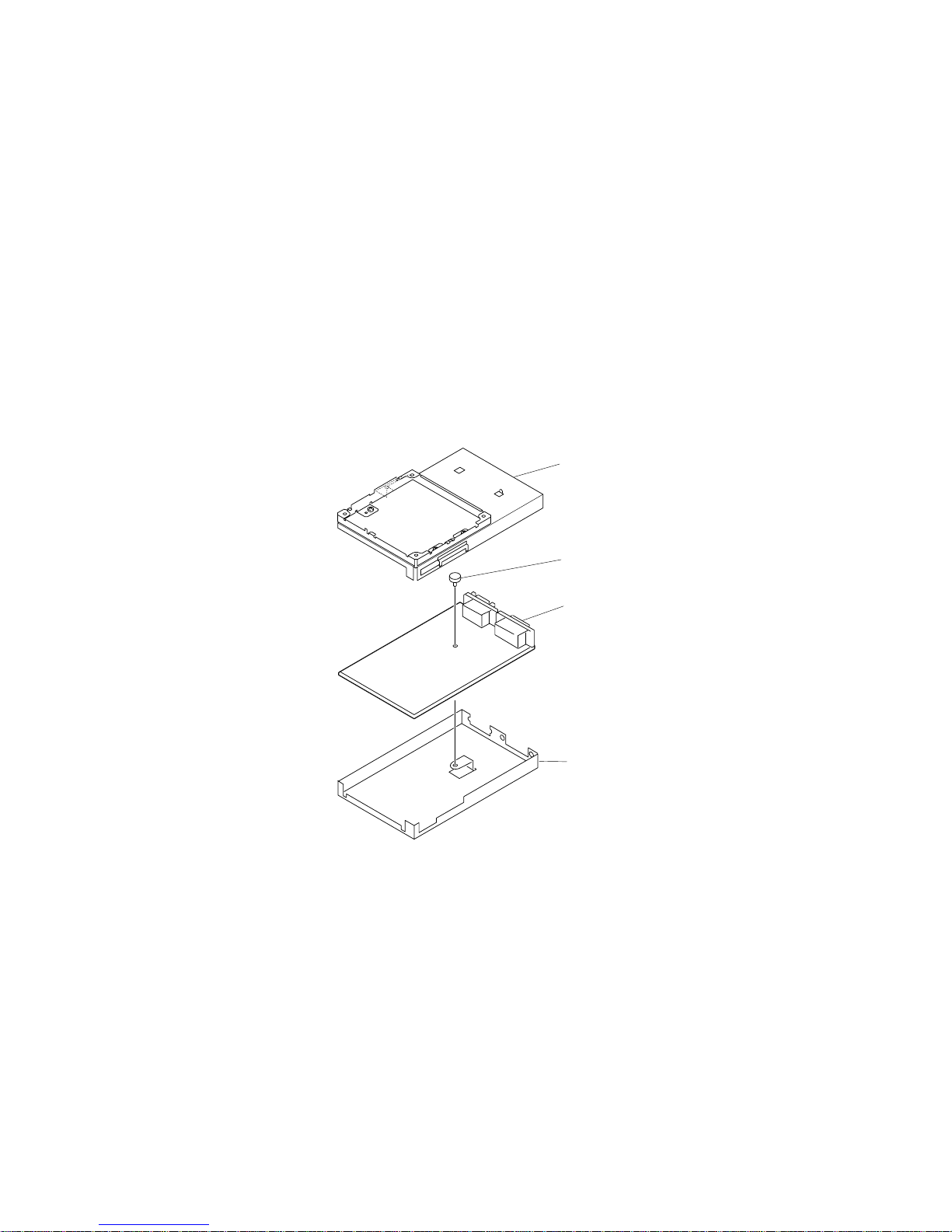

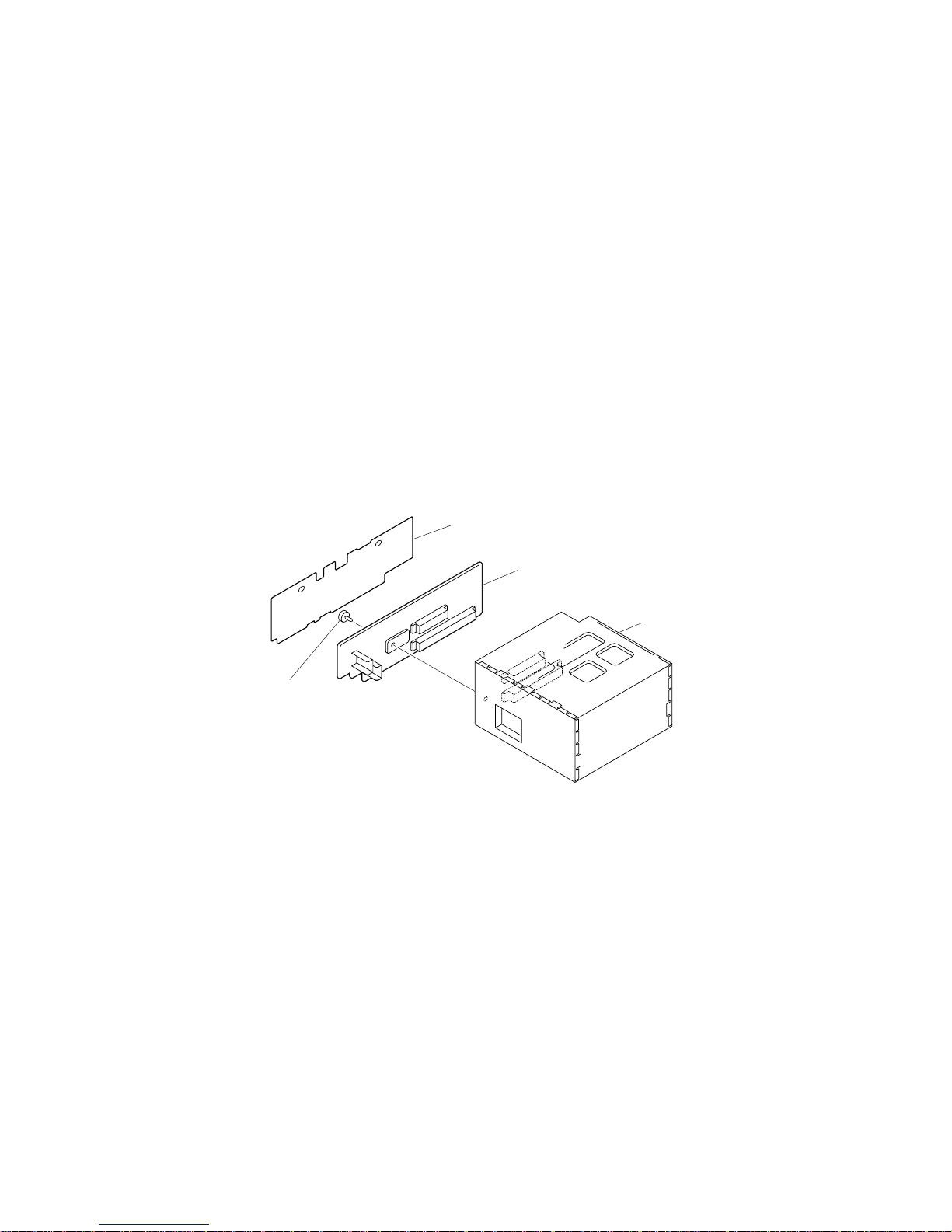

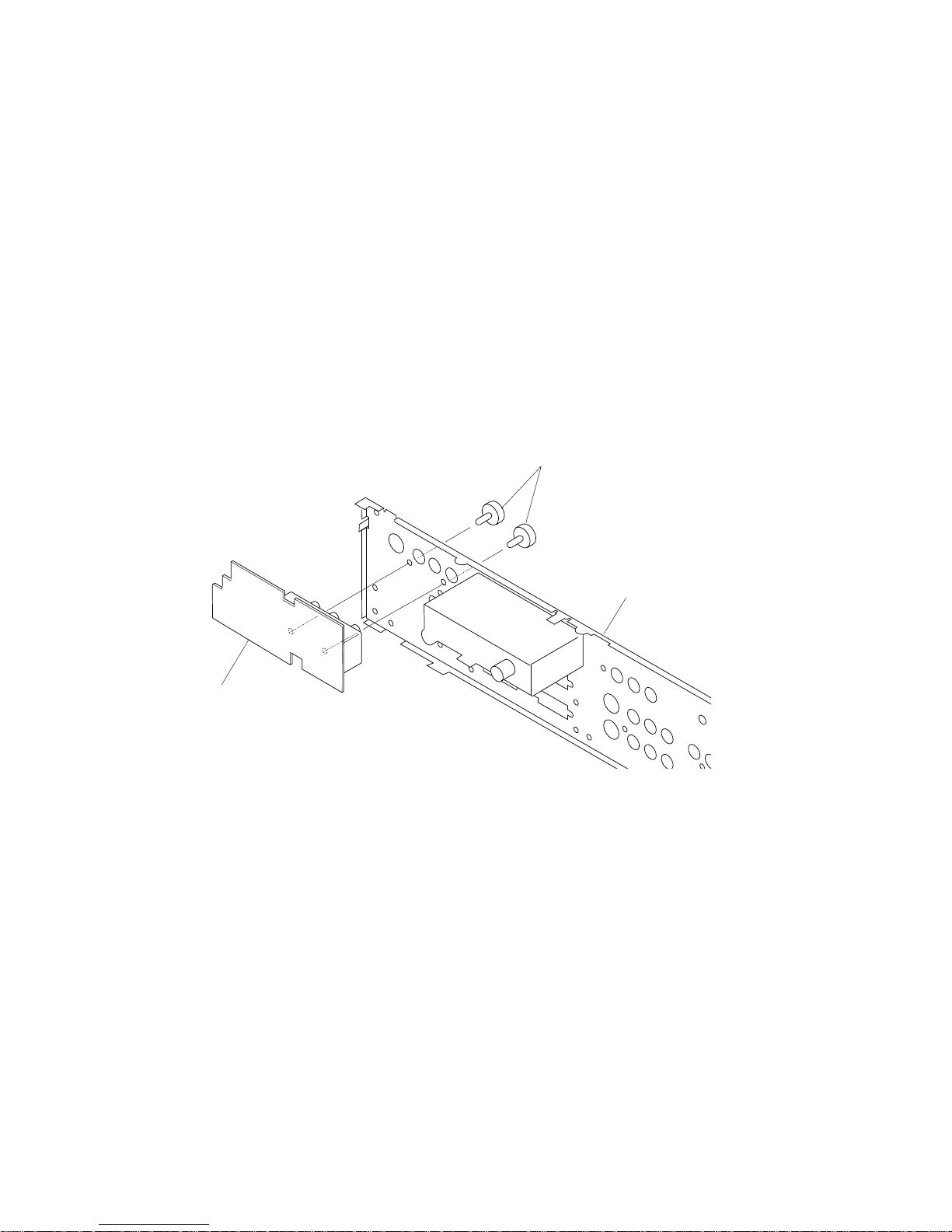

5. EXPLODED VIEWS .................................................. 5-1

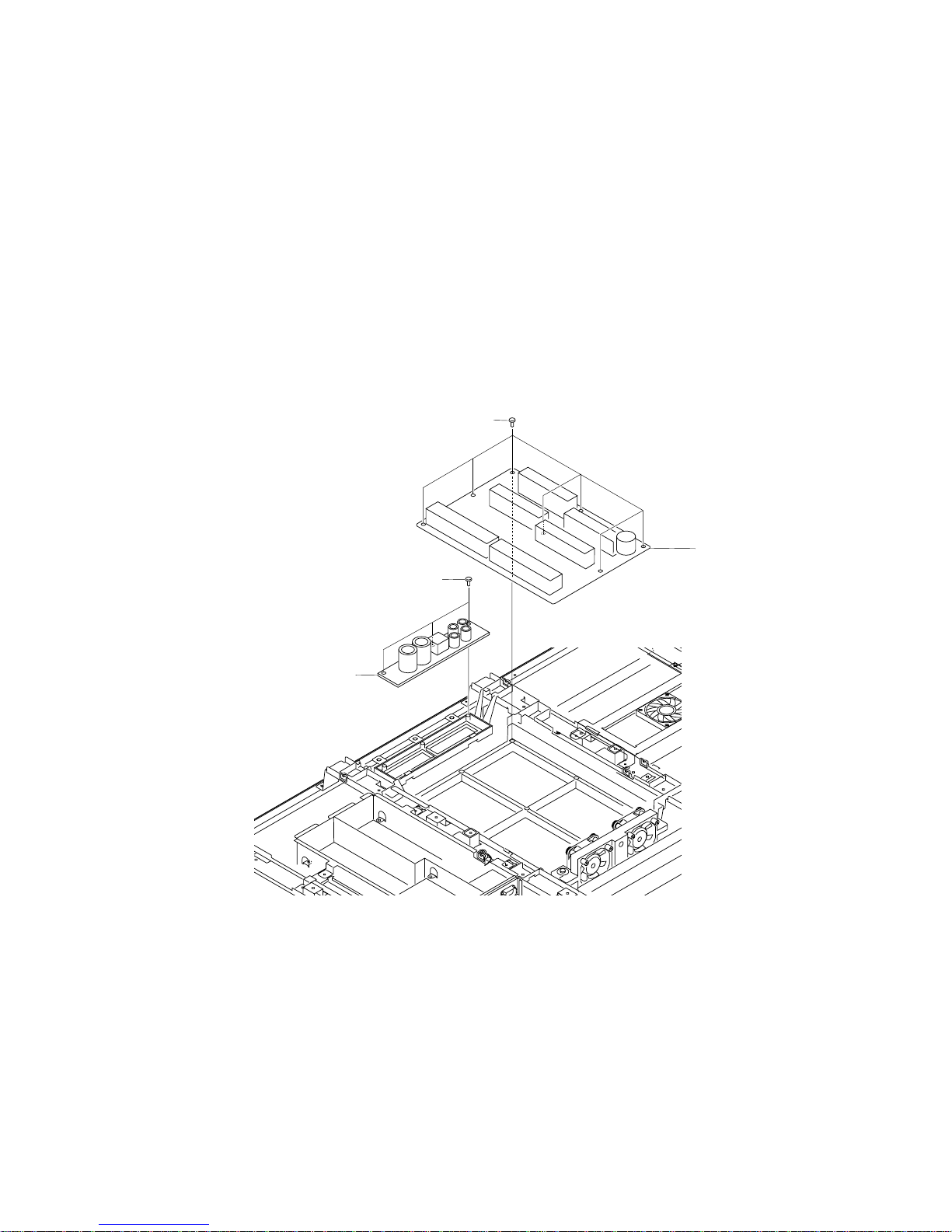

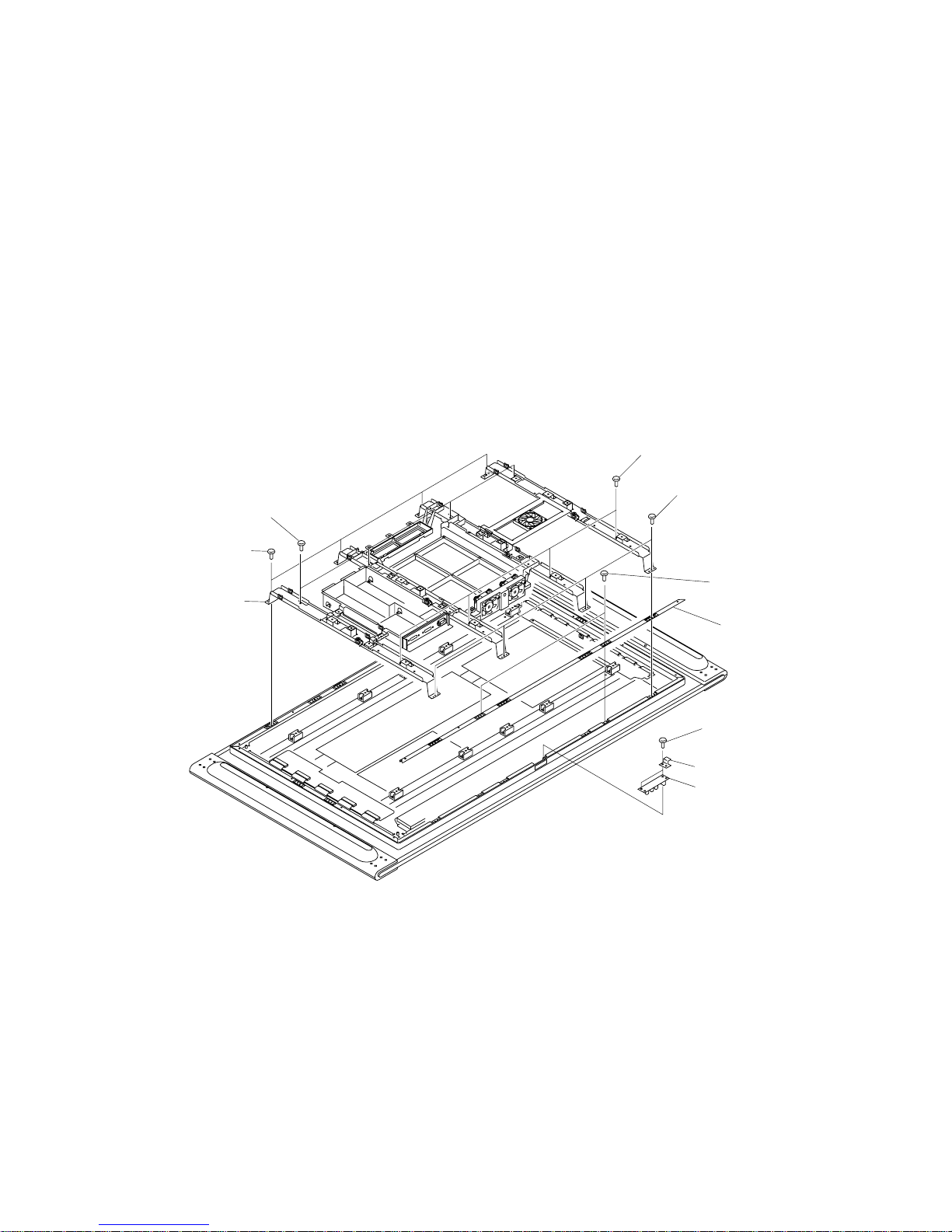

5-1. Display Unit (PDM-5000) ....................................... 5-2

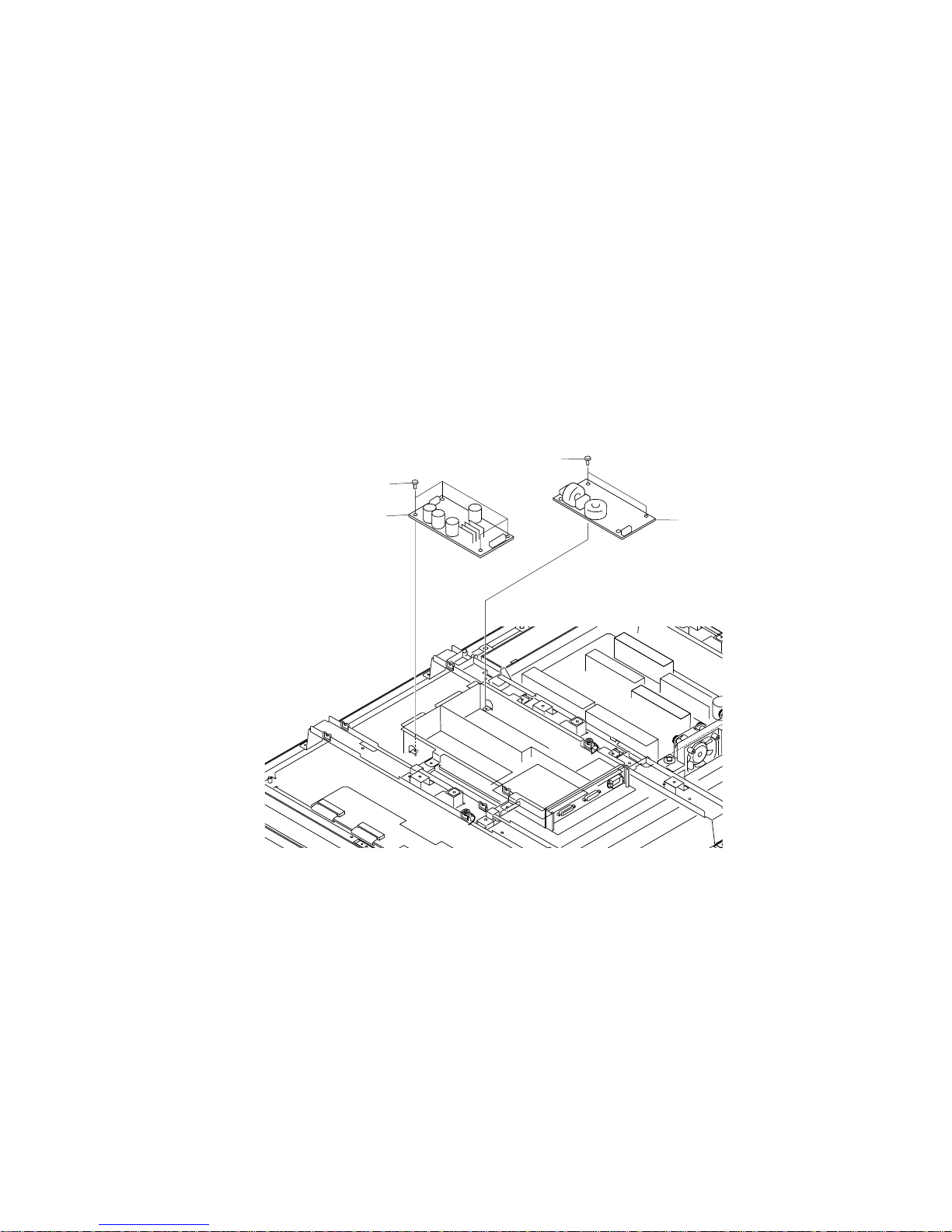

5-2. Media Receiver Unit-1 (MBT-XBR900) ................. 5-4

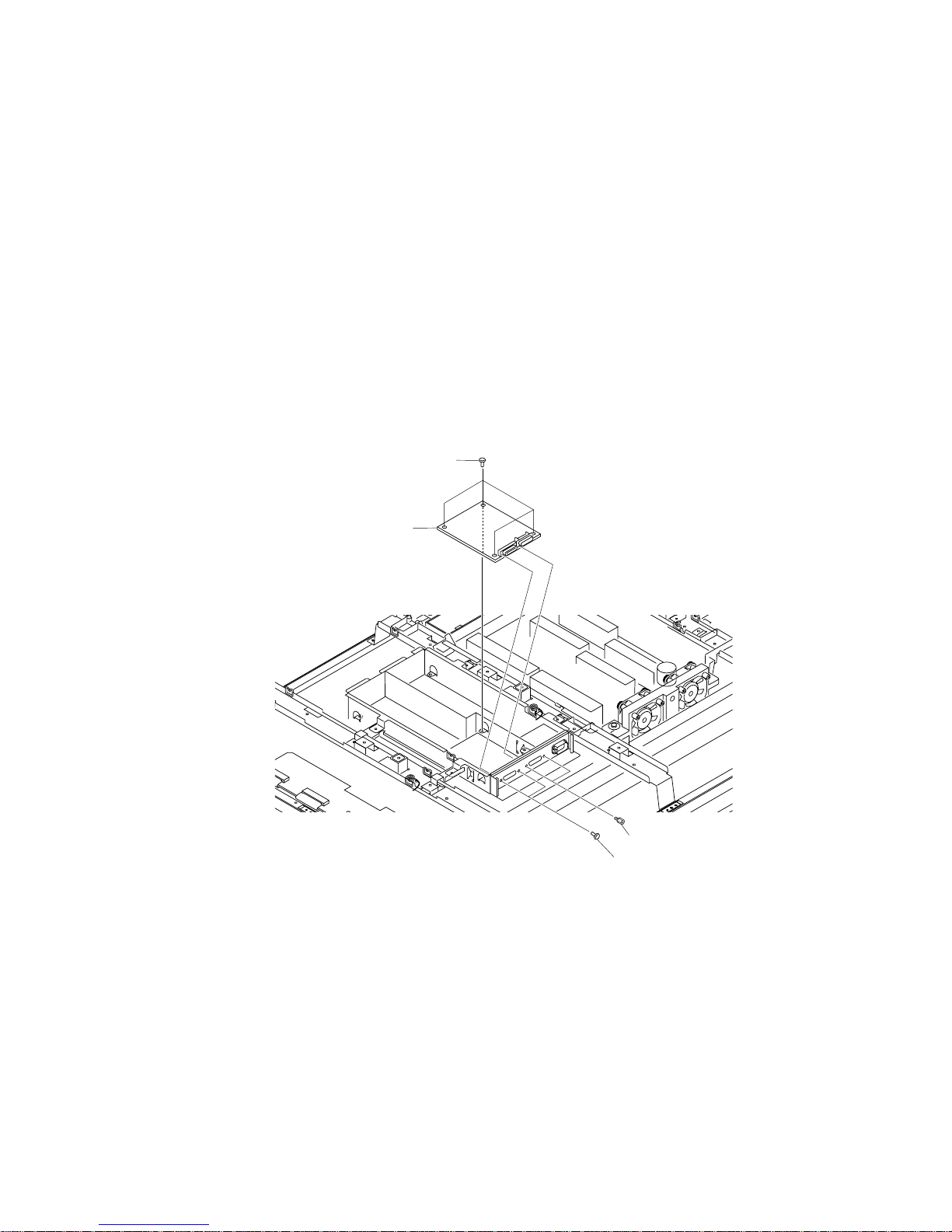

5-3. Media Receiver Unit-2 (MBT-XBR900).................. 5-6

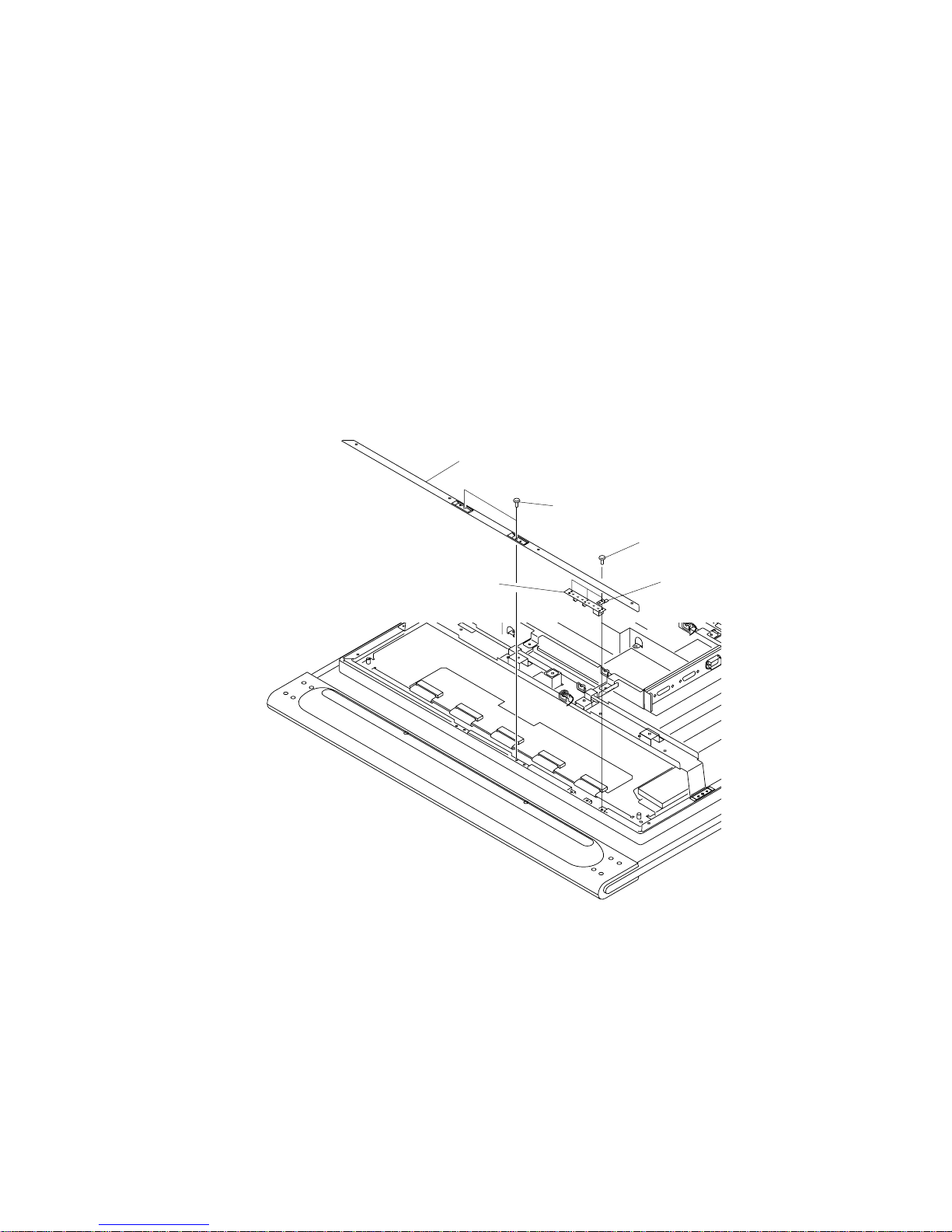

5-4.

Packing Materials for Display Unit (PDM-5000)

........ 5-7

5-5. Packing Materials for Media Receiver Unit

(MBT-XBR900) ...................................................... 5-8

6. ELECTRICAL PARTS LIST ................................... 6-1

KE-50XBR900(UC) 1-1

SECTION 1

DISASSEMBLY

1-1. PANEL UNIT (PDM-5000)

1-1-1. REAR COVER REMOVAL

4 Rear cover assy

1 Eight screws

(+PSW 5X16)

2 Three screws

(+PSW 3X8)

3 T en screws

(+BVTP 4X16)

3 T en screws

(+BVTP 4X16)

1

KE-50XBR900(UC) 1-2

1-1-2. K AND F BOARDS REMOVAL

3 Four screws

(+PSW 3X8)

1 T wo screws

(+PSW 3X8)

2 F Board

4 K Board

KE-50XBR900(UC) 1-3

1-1-3. P BOARD REMOVAL

3 Four screws

(+PSW 3X8)

4 P Board

1 Two Connector screws

2 Two screws

(M2.6 S HEAD)

KE-50XBR900(UC) 1-4

1-1-4. G AND F2 BOARDS REMOVAL

1 Three screws

(+BVTP 3X12)

2 F2 Board

3 Seven screws

(+BVTP 3X12)

4 G Board

KE-50XBR900(UC) 1-5

1-1-5. R1 BOARD REMOVAL

1 Two screws

(+BVTP 4X16)

2 Filter bracket (V) assy

3 Three screws

(+BVTP 3X10)

Earth plate

4 R1 Board

KE-50XBR900(UC) 1-6

1-1-6. R2 BOARD REMOVAL

7 R2 Board

1 Four screws

(+BVTP 4X16)

1 Four screws

(+BVTP 4X16)

2 Four screws

(+PSW 5X16)

2 Four screws

(+PSW 5X16)

3 Panel assy

4 Two screws

(+BVTP 4X16)

5 Filter bracket (H) assy

6 Two screws

(+BVTP 3X10)

Earth plate

KE-50XBR900(UC) 1-7

1-2. MEDIA RECEIVER UNIT (MBT-XBR900)

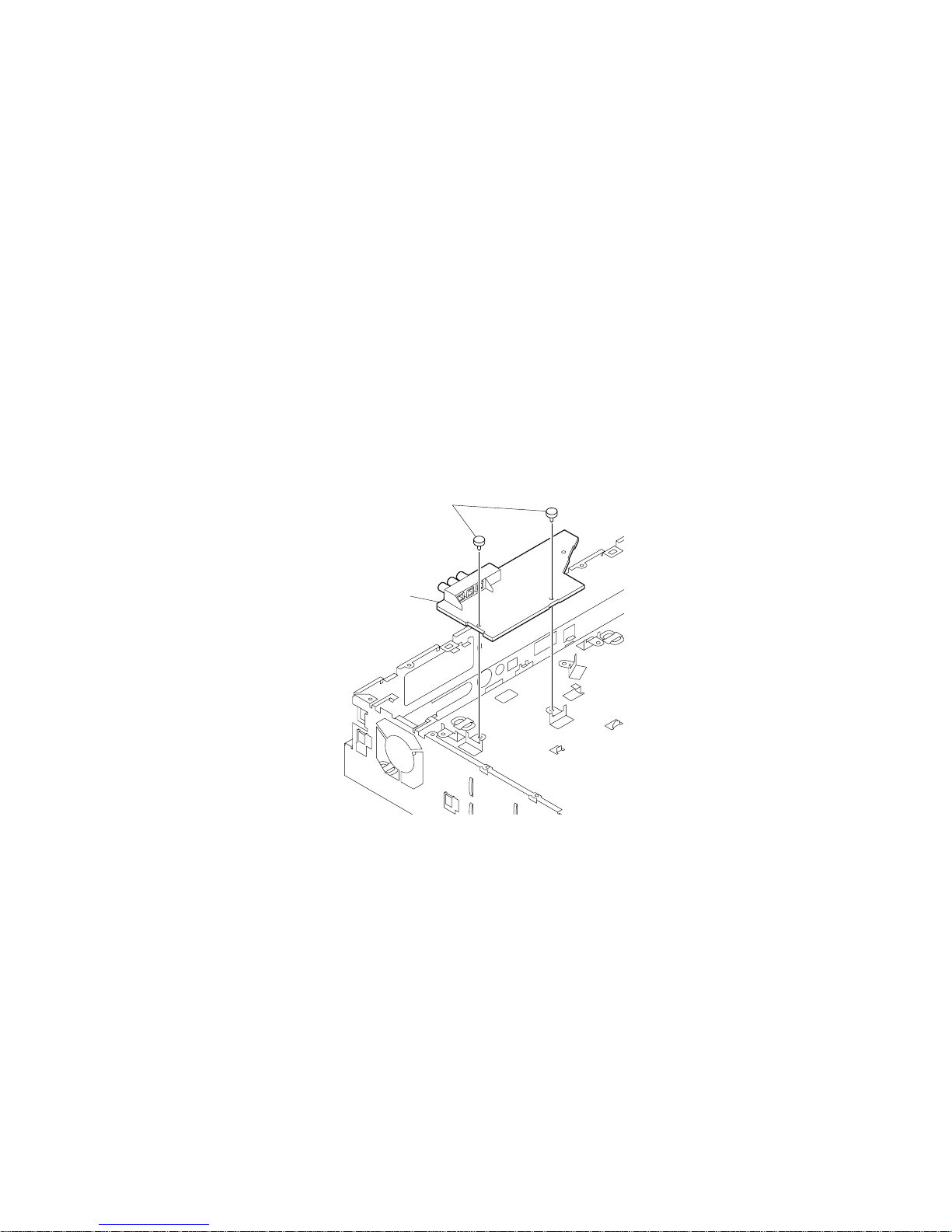

1-2-1. PANEL AND COVERS REMOVAL

!¡Rear panel

6 Bottom cover assy

7Front panel assy

1 T wo screws

(+PSW 3X8)

1 T wo screws

(+PSW 3X8)

!º Two screws (HEX)

!º Two screws (HEX)

8Four screws (+PSW 3X8)

8Two screws (+PSW 3X8)

9 Two screws GRIP, M2.6 S'HEAD(EG)

8 T wo screws

(+PSW 3X8)

3 Eight screws

(precision)

3 Four screws

(precision)

5crew

(+PSW 3X8)

5 Screw

(+PSW 3X8)

2 Top cover assy

4 Top chassis assy

KE-50XBR900(UC) 1-8

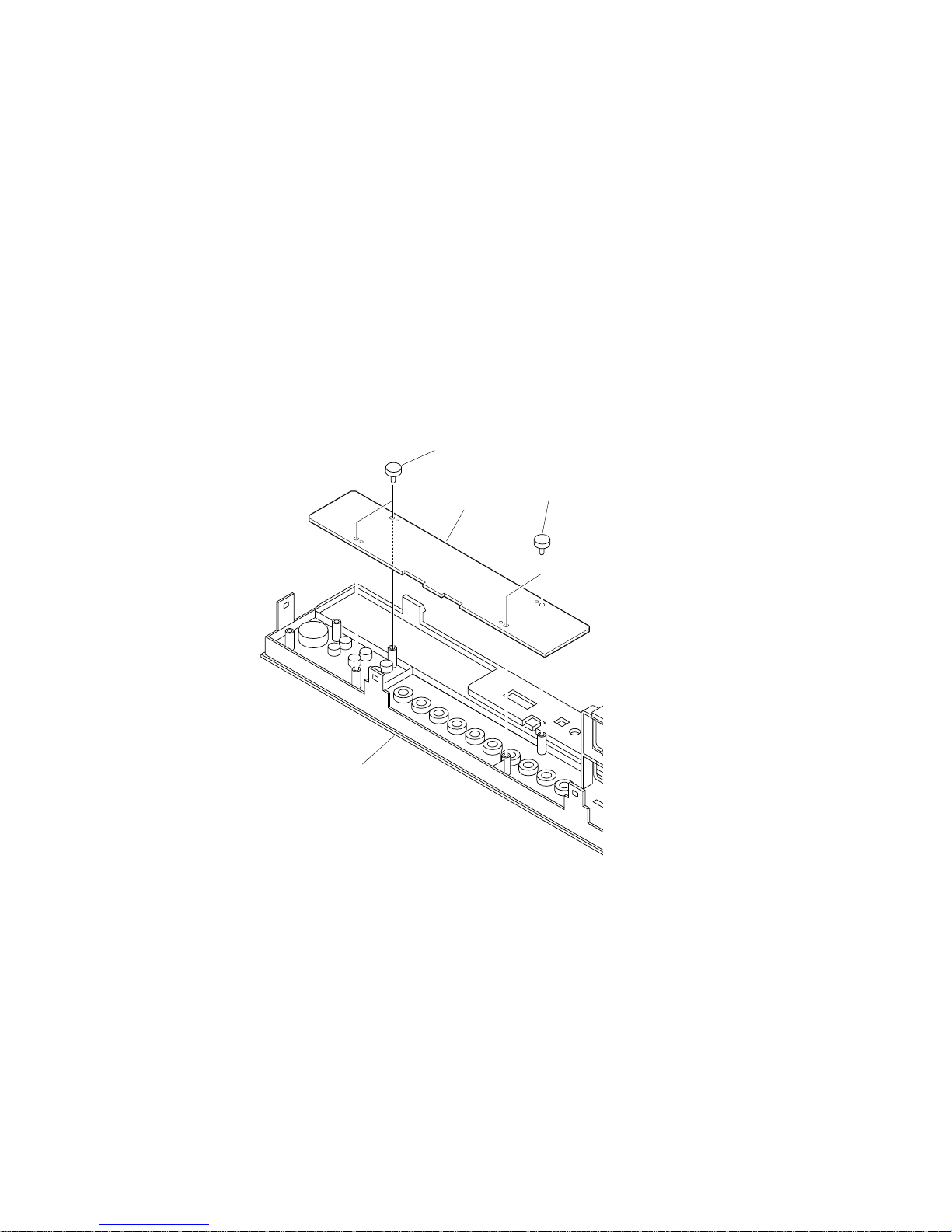

1-2-2. H1 BOARD REMOVAL

1 T wo screws

(+BVTP 3X12)

2 H1 Board

1 T wo screws

(+BVTP 3X12)

Front panel

KE-50XBR900(UC) 1-9

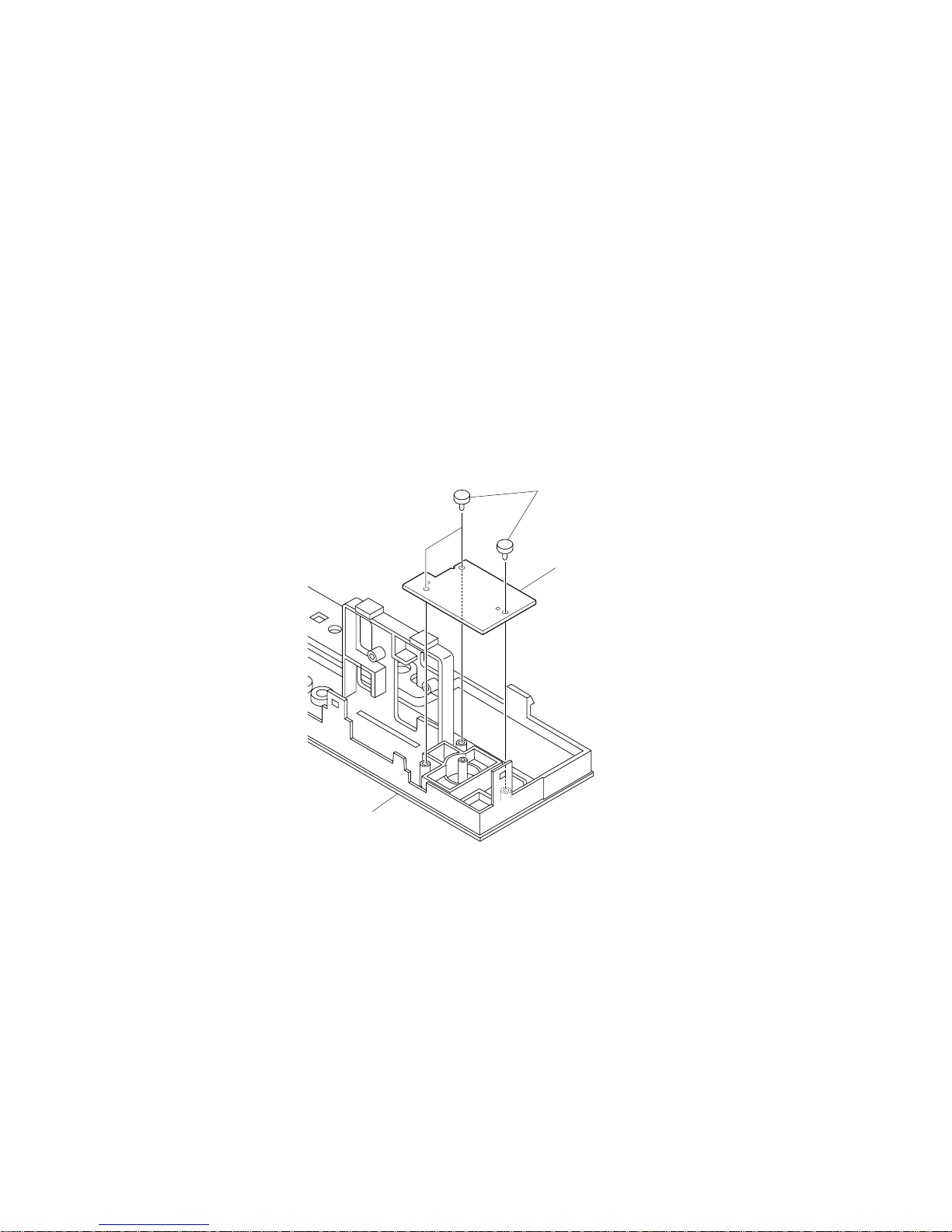

1-2-3. H4 BOARD REMOVAL

1 T wo screws

(+BVTP 3X12)

2 H4 Board

Front panel

KE-50XBR900(UC) 1-10

1-2-4. H3 BOARD REMOVAL

1 Three screws

(+BVTP 3X12)

2 H3 Board

Front panel

KE-50XBR900(UC) 1-11

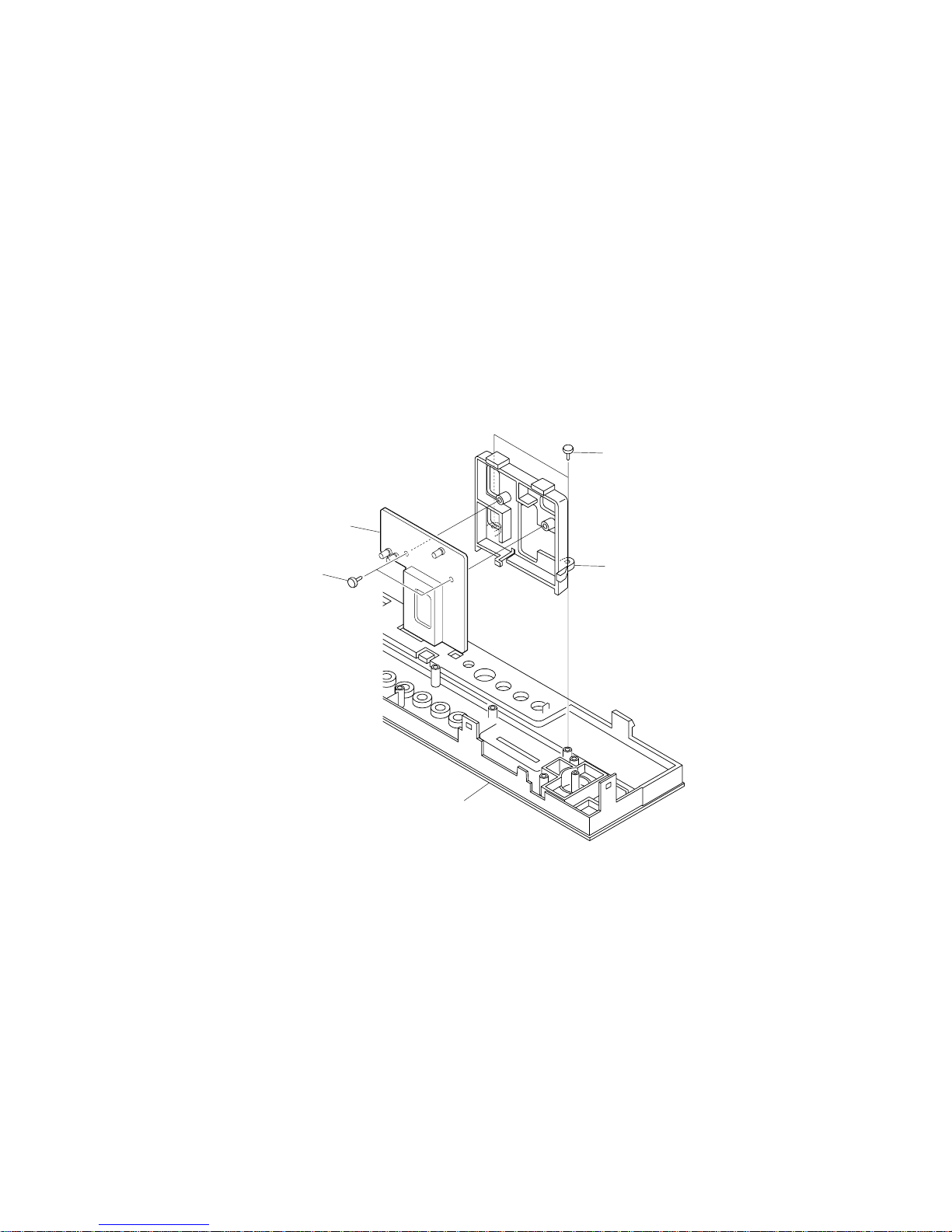

1-2-5. MS2 BOARD REMOVAL

3 T wo screws

(+BVTP 3X12)

4 MS2 Board

1 T wo screws

(+BVTP 3X12)

2 MS bracket

Front panel

KE-50XBR900(UC) 1-12

1-2-6. H2 BOARD REMOVAL

1 T wo screws

(M 3X8),P,SW (+)

2 H2 Board

KE-50XBR900(UC) 1-13

1-2-7. A BOARD REMOVAL

1 Screw

(M 3X8),P,SW (+)

1 T wo screws

(M 3X8),P,SW (+)

1 T wo screws

(M 3X8),P,SW (+)

2 A Board

KE-50XBR900(UC) 1-14

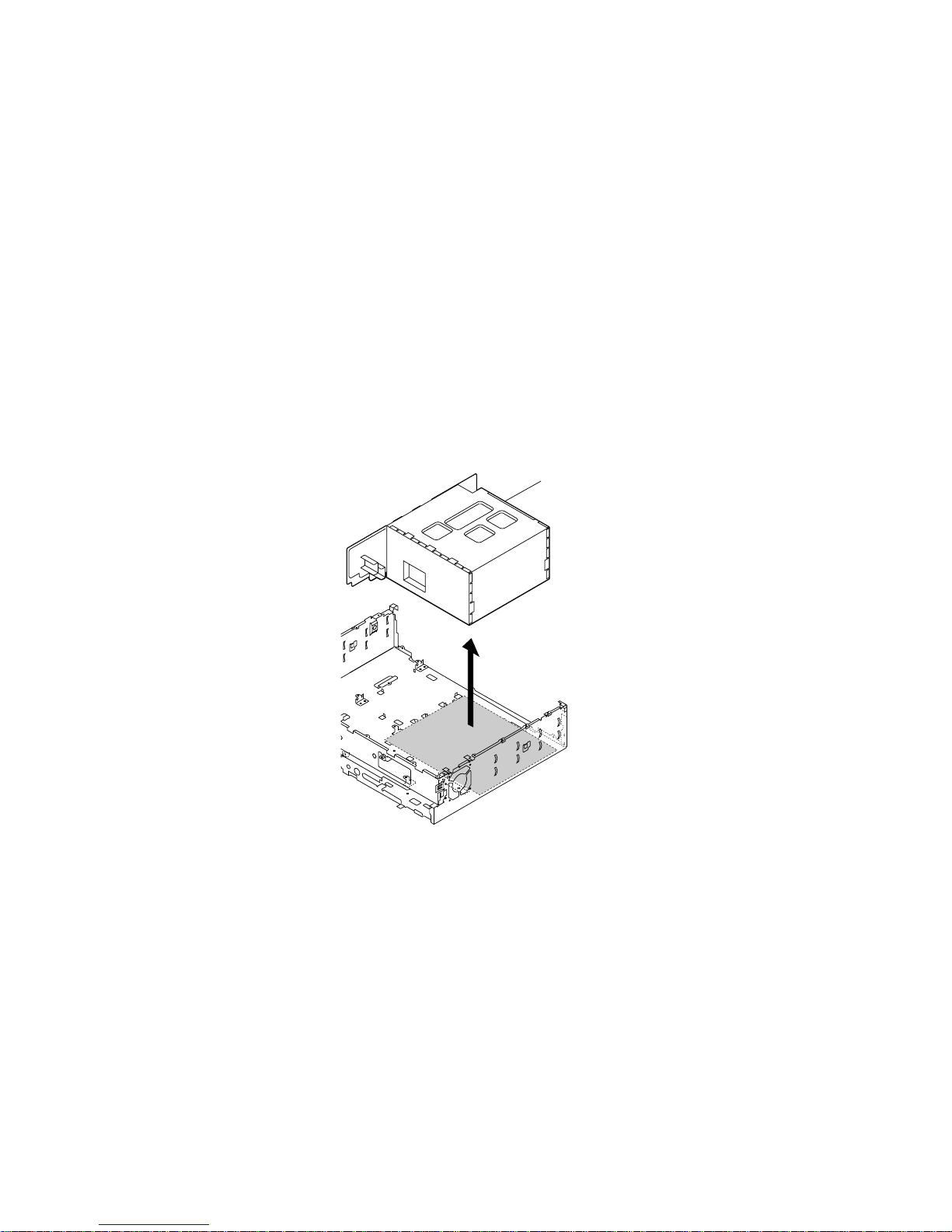

1-2-8. B BLOCK ASSY REMOVAL

1 B Block assy

KE-50XBR900(UC) 1-15

1-2-9. M, AD, AND AU BOARDS REMOVAL

2 Shield case

1 Screw

(+PSW 3x8)

KE-50XBR900(UC) 1-16

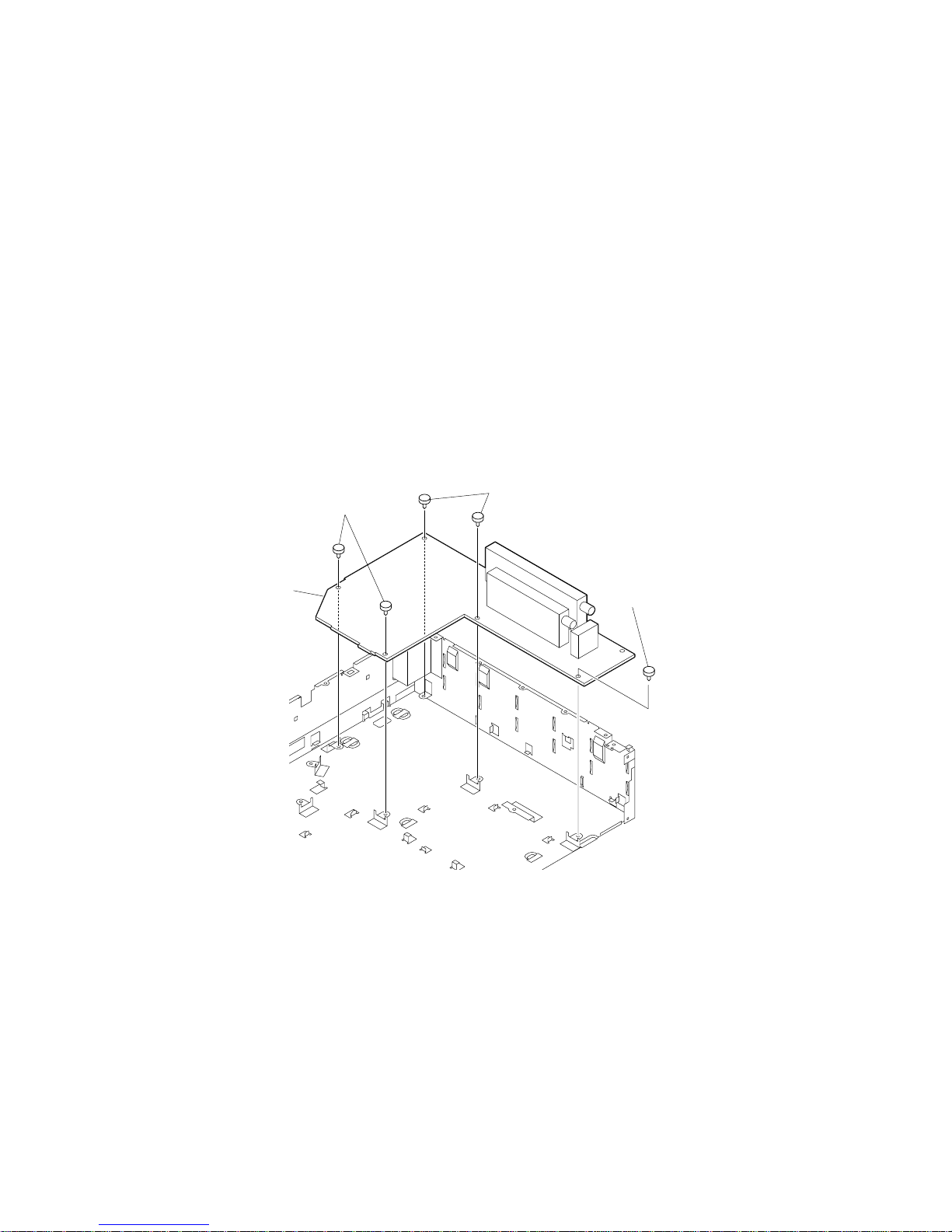

1-2-10.AD AND AU BOARDS REMOVAL

1 Two screws

(PSW 3x8)

3 Four screws

(PSW 3x8)

Shield upper

Shield main

3 Two screws

(PSW 3x8)

3 AD Board

2 AU Board

KE-50XBR900(UC) 1-17

1-2-11.M BOARD REMOVAL

2 Screw

(+PSW 3x8)

3 M Board

1 Shield case (upper)

Shield case (main)

KE-50XBR900(UC) 1-18

1-2-12.IF BOARD REMOVAL

1 IF Shield sheet

3 IF Board

B Block assy

2 Screw

(+PSW 3x8)

KE-50XBR900(UC) 1-19

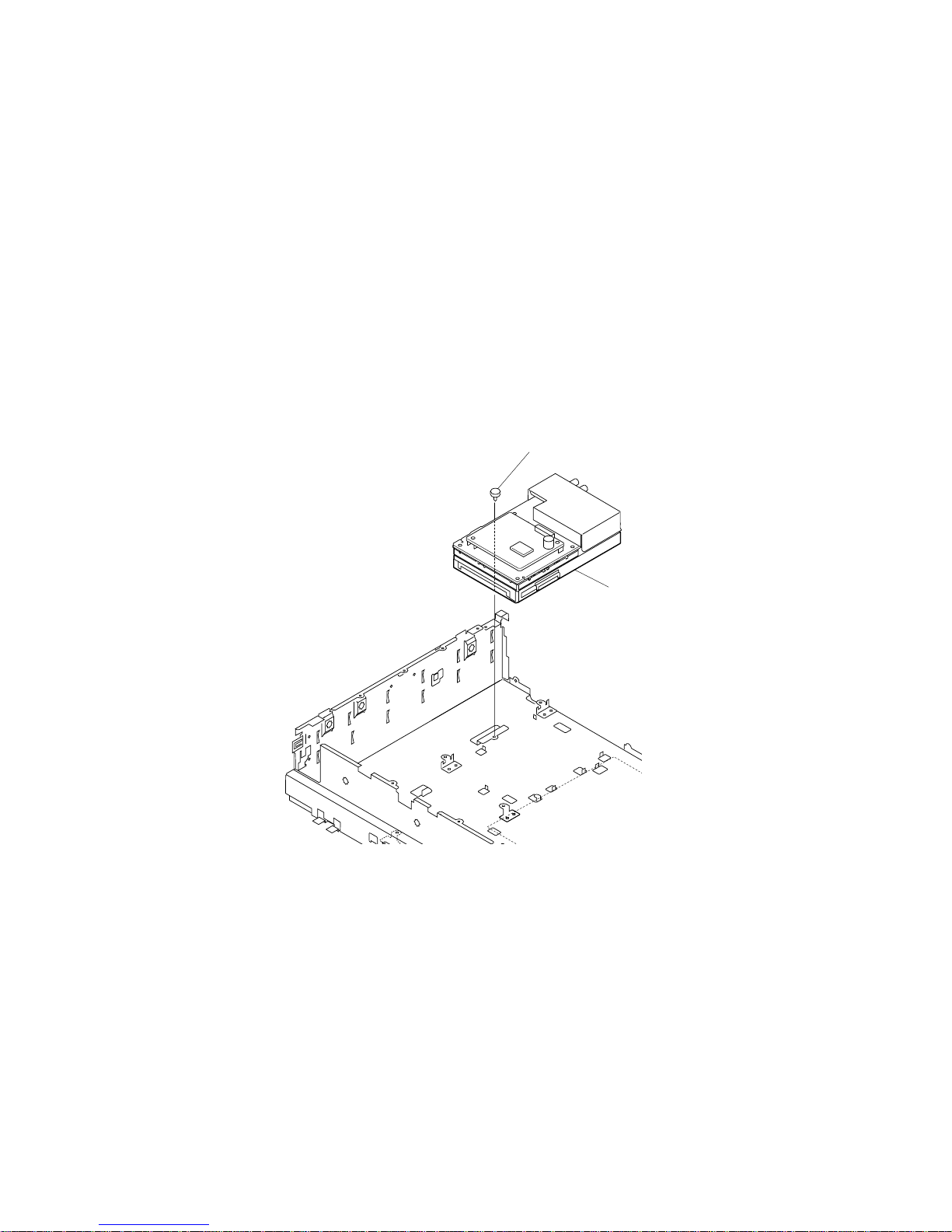

1-2-13.U1 BOARD REMOVAL

1 Four screws

(+BVTP 3x12)

2 U1 Board

3 Core (FPC)

KE-50XBR900(UC) 1-20

1-2-14.U2 BOARD REMOVAL

1 Tow screws

(+BVTP 3x12)

2 U2 Board

Rear panel

KE-50XBR900(UC) 2-1

SECTION 2

ADJUSTMENTS

1

2-1. VS, VD Voltage Adjustment (PDM-5000)

• Preparation for adjustment

1.Slide the DIP switch (S3201) No. 8 of P board to on position with no silkscreen mark r.

2.Connect a digital voltmeter to the following terminals of G board.

VS voltage=G board TP1701 (VS)-TP1502 (GND)

VD voltage=G board TP1501 (VD)-TP1502 (GND)

3.Connect a AC cord in DISPLAY UNIT.

4.Perform the adjustment in 10 seconds after connecting the cord.

• Procedure for adjustment

1. Slide the DIP switch (S3201) No. 7 of P board to on position with no silkscreen mark r.

2. Confirm the lighting of SONY LOGO LED.

3. Adjust the VS voltage to the following voltage value.

VS voltage of proper value for each model.

Ex.) VS proper value=185V thru 185.6V at 185V.

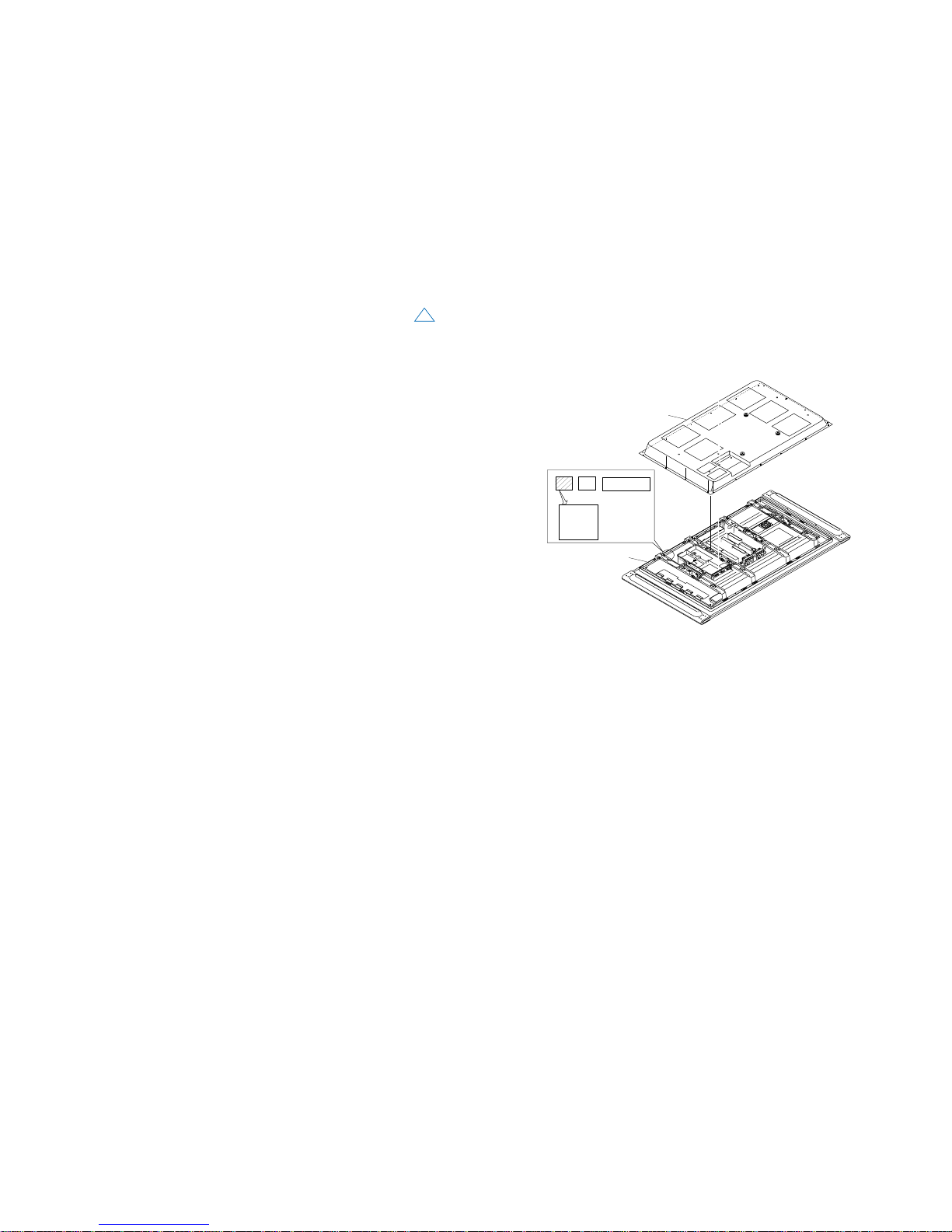

(Check the proper value with a seal on upper left of panel unit. Refer to right Fig.)

4. Adjust the VD voltage to the following voltage value.

VD voltage ±0.3V of proper value for each model.

Ex.) VD proper value=64.7V thru 65.3V at 65.0V.

(Check the proper value with a seal on upper left of panel unit. Refer to right Fig.)

5. Check a Fan rotation.

6. Slide the DIP Switch (S3201) No. 7 of P board to the off position with the silkscreen mark

r.

7. Slide the DIP Switch (S3201) No. 8 of P board to the off position with the silkscreen mark

r.

8. Disconnect an AC cord of DISPLAY UNIT.

9. Reconnect the AC cord in one second.

10. Assure that “POWER ON/STANDBY” LEDs is flashing amber.

+6V

–0V

<SEAL POSITION>

Rear cover assy

SERIAL No.

301201440

Vd=65V

Vs=193.4V

CODE AA-01

BAR CODE SEAL

Panel unit

Loading...

Loading...