SONY KE-42M1, KE-P42M1 Service Manual

KE-42M1/P42M1

PANEL MODULE SERVICE MANUAL

PDP Module Name

S42SD-YB03

KE-42M1 UC Model

KE-P42M1 AEP Model

FLAT PANEL COLOR TV

CONTENTS

1. OUTLINE································································································································ 3

1-1. Model Name of Plasma Display ······························································································ 3

1-2. External View ·························································································································· 3

1-3. Specifications·························································································································· 4

2. PRECAUTIONS······················································································································ 5

2-1. Handling Precautions for Plasma Display ··············································································· 5

2-2. Safety Precautions for Service

(Handling, prevention of electrical shock, measure against power outage, etc)······················ 5

2-2-1. Safety Precautions ········································································································ 5

2-2-2. Precautions for servicing electrostatic sensitive devices ··············································· 6

3. NAME and FUNCTION·········································································································· 8

3-1. Layout of Assemblies ·············································································································· 8

3-2. Block Diagrams ······················································································································· 10

3-2-1. Block Diagrams for Drive Circuit Operations ································································· 10

3-2-2. Logic Circuit Block Diagram··························································································· 12

3-3. Main Functions of Each Assembly ·························································································· 12

3-3-1. X-Main board ················································································································· 12

3-3-2. Y-Main board ················································································································· 13

3-3-3. Logic Main board ··········································································································· 13

3-3-4. Logic buffer (E, F)·········································································································· 13

3-3-5. Y-buffer board (upper/lower)·························································································· 13

3-3-6. COF (Chip on Flexible)·································································································· 13

3-4. Product/Serial Label Locations································································································ 14

4. OPERATION CHECKING AFTER RECTIFICATION ···························································· 15

4-1. Flow Charts ····························································································································· 15

4-1-1. No voltage output ·········································································································· 15

4-1-2. No video (Each voltage is normal.)················································································ 16

4-1-3. Abnormal display (Abnormal image is displayed.)························································· 18

4-1-4. Sustain Open (No horizontal stripes are displayed.)······················································ 20

4-1-5. Sustain Short (Some horizontal stripes are linked.)······················································· 20

4-1-6. Address Open (No vertical stripes are displayed.)························································· 21

4-1-7. Address Short (Some vertical stripes are linked.)·························································· 22

4-2. Defects, Symptoms, and Defective Parts ·············································································· 23

5. DISASSEMBLING/REASSEMBLING ···················································································· 31

5-1. Tools/Measurements··············································································································· 31

5-2. Exploded View························································································································· 31

5-3. Removal Procedures··············································································································· 32

5-3-1. Removing the Logic PCB Ass'y board from the Chassis Base······································ 32

5-3-2. Removing the Y-Main Ass'y board from the Chassis Base············································ 32

5-3-3. Removing the X-Main Ass'y board from the Chassis Base············································ 32

5-3-4. Removing the Y-BUFFER board from the Chassis Base ·············································· 33

5-3-5. Removing the ADDRESS-BUFFER board from the Chassis Base································ 33

5-4. Installation Procedures············································································································ 34

5-4-1. Installing the TCPs on the Logic Buffer ········································································· 34

5-4-2. Installing the Y-Main Ass'y Board on the Y-Buffer························································· 35

5-4-3. Installing X-Main and Y-Main Ass'y boards on the Chassis Base·································· 35

5-4-4. Installing the Logic PCB Ass'y board on the Chassis Base ··········································· 36

- 1 -

6. Operation Checks After Repair Service·············································································· 38

6-1. Check Items ···························································································································· 38

6-2. Check Procedure····················································································································· 38

7. Adjustment Procedure ········································································································· 39

7-1 Adjustment Spec. and locations ································································································· 39

7-2. Procedure·································································································································· 39

8. DATA······································································································································ 43

• Back Side (TCP type) ···················································································································· 43

• Logic Main Block Diagram ············································································································· 44

• Drive Waveform ····························································································································· 45

• Reset ············································································································································· 46

• Address (Scan) ······························································································································ 47

• Sustain Waveform ························································································································· 48

9. Service Parts ························································································································· 49

- 2 -

1. OUTLINE

1-1. Model Name of Plasma Display

MODEL : S42SD-YB03

1-2. External View

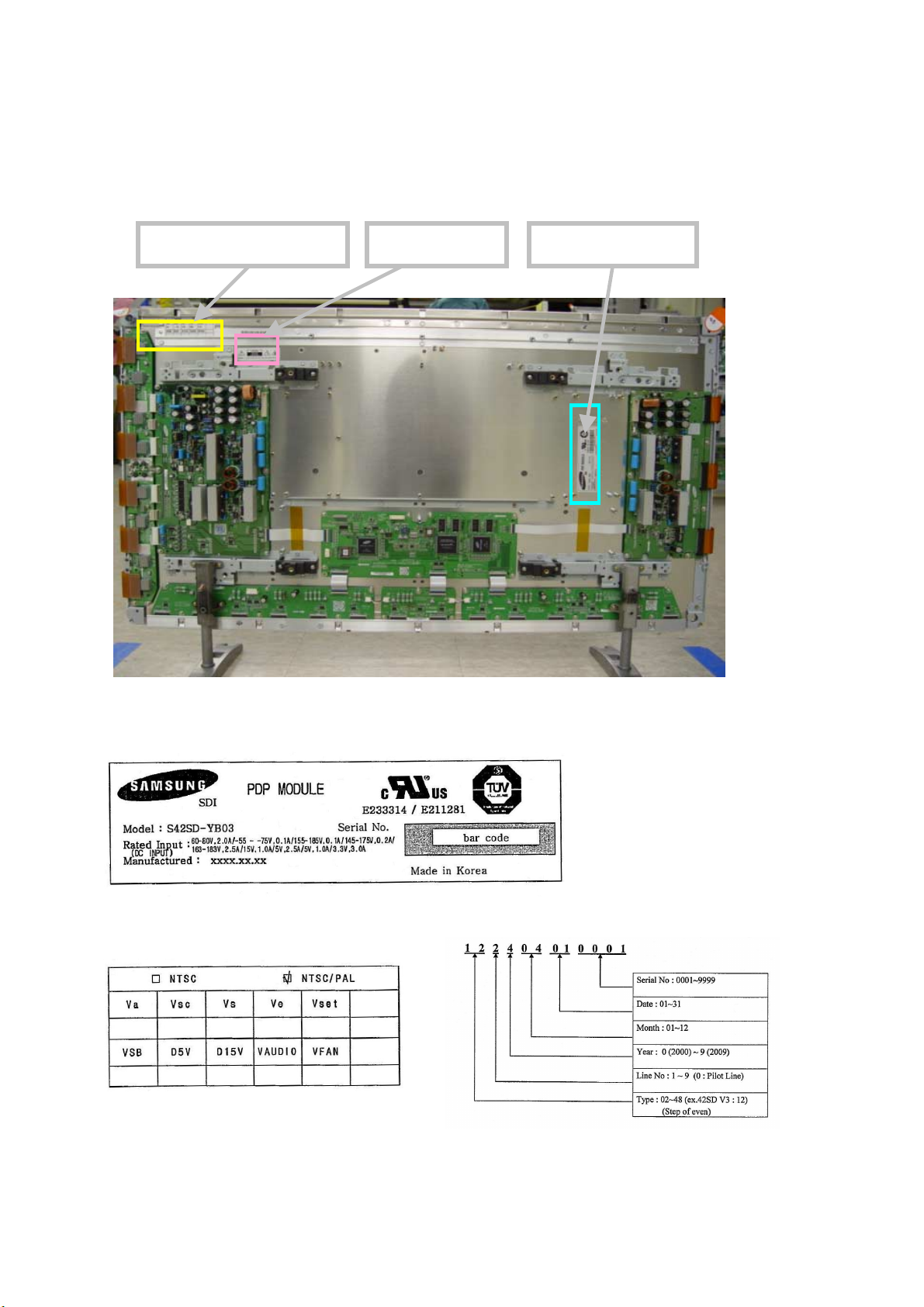

< M1 = X Board + Y Board + Logic Board >

- 3 -

1-3. Specifications

No

1

2

3

4

5

6

7

8

9

Item

Pixel

Number of Cells

Pixel pitch 1095 (H) x 1110 (V) mm

Cell Pitch

Display size

Screen size Diagonal 42" Color Plasma Display Module

Screen aspect 16 : 9

Display color 16.77 million colors

Viewing angle

R 0.365 (H) x 1.110 (V) mm

G 0.365 (H) x 1.110 (V) mm

B 0.365 (H) x 1.110 (V) mm

(Angle with 50% and greater brightness perpendicular to PDP module.)

852 (H) x 480 (V) pixels (1 pixel = 1 R, G, B cells)

932.940 (H) x 532.800 (V) mm

Specification

2556 (H) x 480 (V)

[36.73 x 20.98 inches]

Over 160º

10

11

12

13

Broadcasting reception vertical

14

Dimensions 982 (W) x 582 (H) x 52.9 (D) mm

Weight Module 1 About 16.6 kg

Packing weight Module 1 240 ± 5kg (including modules) / 10pcs/BOX

Packing size L1175 x W1140 x H970 (mm)/10pcs / BOX

frequency

and

video/logic interface

S42SD-YB03 60Hz/50Hz, LVDS

- 4 -

2. PRECAUTIONS

To prevent the risks of unit damage, electrical shock and radiation, take the following safety, service, and ESD

precautions.

2-1. Handling Precautions for Plasma Display

2-2. Safety Precautions for Service (Handling, prevention of electrical shock, measure

against power outage, etc)

2-2-1. Safety Precautions

1) Before replacing a board, discharge forcibly the remaining electricity from the board.

2) When connecting FFC and TCPs to the module, recheck that they are securely

connected.

3) To prevent electrical shock, be careful not to touch leads during circuit operations.

4) To prevent the Logic circuit from being damaged, do not connect/disconnect signal

cables during circuit operations.

5) Follow voltage information when adjust it.

6) Before reinstalling the chassis and the chassis assembly, be sure to use necessary

protective stuffs.

7) Caution for design change: Do not install any additional devices to the module, and do

not change the electrical circuit design.

8) If any parts or wire is overheated or damaged, replace it with a new specified one

immediately, and identify the cause of the problem to resolve it.

- 5 -

9) Check that the wires are correctly arranged and connected. Do not change the

distances between the parts and the printed circuit board. Check that the AC power

cord is not damaged. Keep heating parts away from lead wires and other parts.

10) Product safety indication : Some electrical circuits and devices have specific safety

characteristics. Therefore when replacing parts, use the same parts as originals.

Safety and protective function will be lost even if parts with higher voltage and wattage

capability are used.

11) Be sure to disconnect the AC power cord before servicing.

12) After servicing, check that the screws, parts, and wires are correctly installed. Also

check that the peripheral parts are not damaged.

2-2-2. Precautions for servicing electrostatic sensitive devices

Some semiconductors (such as ICs and FETs) are easily damaged by electrostatic.

These devices are called electrostatic sensitive devices (ESD).

The rate of electrostatic damage to devices can be decreased by observing the

following precautions.

1) Before handling semiconductors and assemblies, discharge electrostatic from your

body with an earth ground, or wear an antistatic band.

(Be sure to discharge electrostatic before turning on the power, to prevent electrical

shock)

2) After removing the ESD assembly, place it on an antistatic mat with aluminum foil to

avoid electrostatic charge.

3) Use only a ground-tip soldering iron to solder and unsolder the ESD.

4) Use only an antistatic soldering removal device for the ESD. General soldering

removal devices are non-antistatic. Using such non-antistatic devices will damage the

ESD.

- 6 -

5) Before removing the protective material from the lead of a new ESD, bring the lead

into contact with the chassis or the circuit assembly that the ESD is to be installed on.

6) When handling an unpacked ESD for replacement, do not move around too much.

Moving (legs on the carpet, for example) generates enough electrostatic to damage

the ESD.

7) Do not take a new ESD from the protective case until the ESD is ready to be installed.

Most ESDs have a lead, which is easily short-circuited by conductive materials (such

as conductive foam and aluminum).

- 7 -

3. NAME and FUNCTION

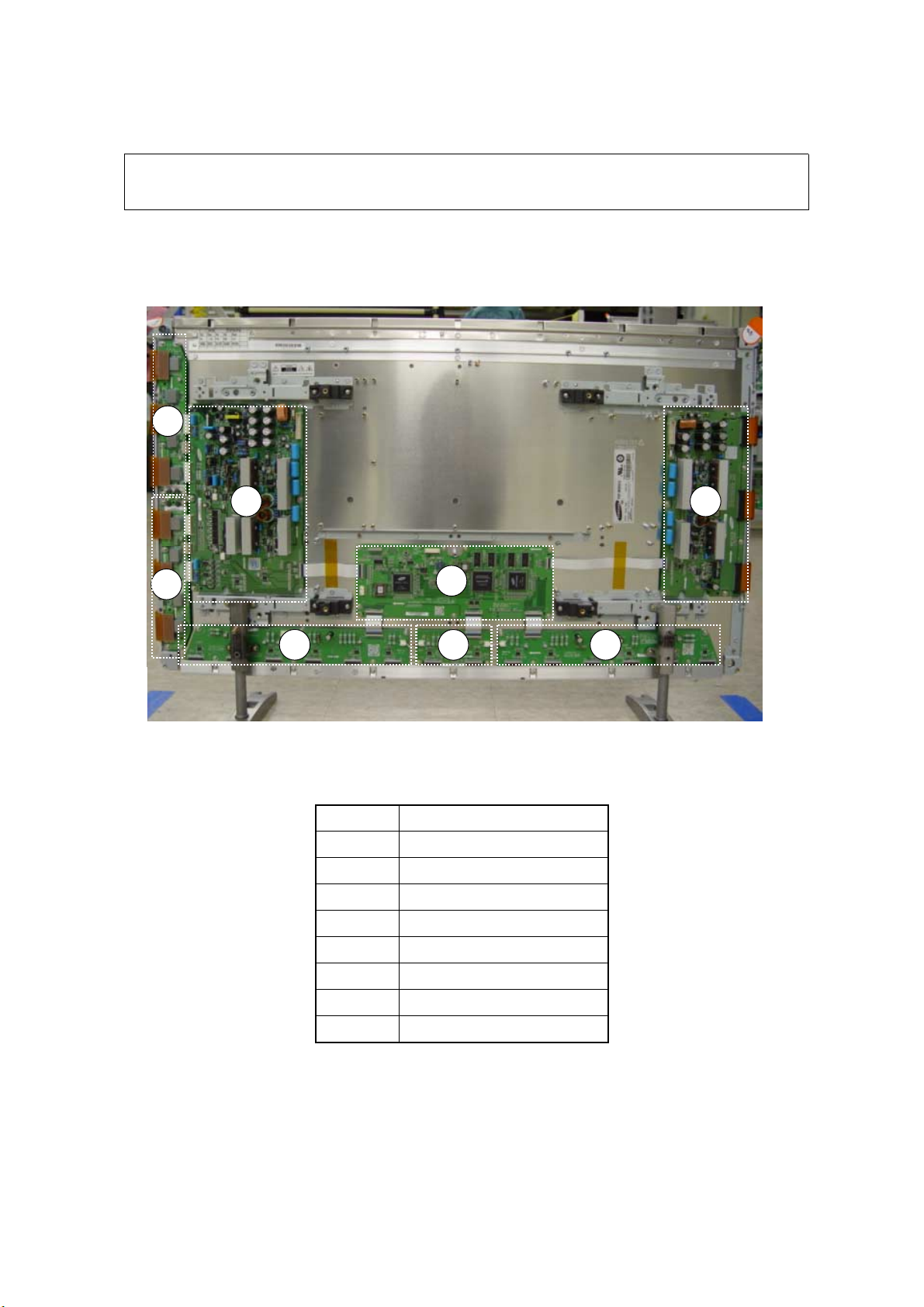

3-1. Layout of Assemblies

4

5

6 7 8

2 3

1

No. Board

1 Logic Main

2 X-Main

3 Y-Main

4 Y-Buffer (upper)

5 Y-Buffer (lower)

6 Logic E Buffer

7 Logic F Buffer

8 Logic G Buffer

- 8 -

1. L-Main 5. Y-Buffer (lower)

2. X-Main 6. E-Buffer

3. Y-Main 7. F-Buffer

4, Y-Buffer (upper) 8. G-Buffer

- 9 -

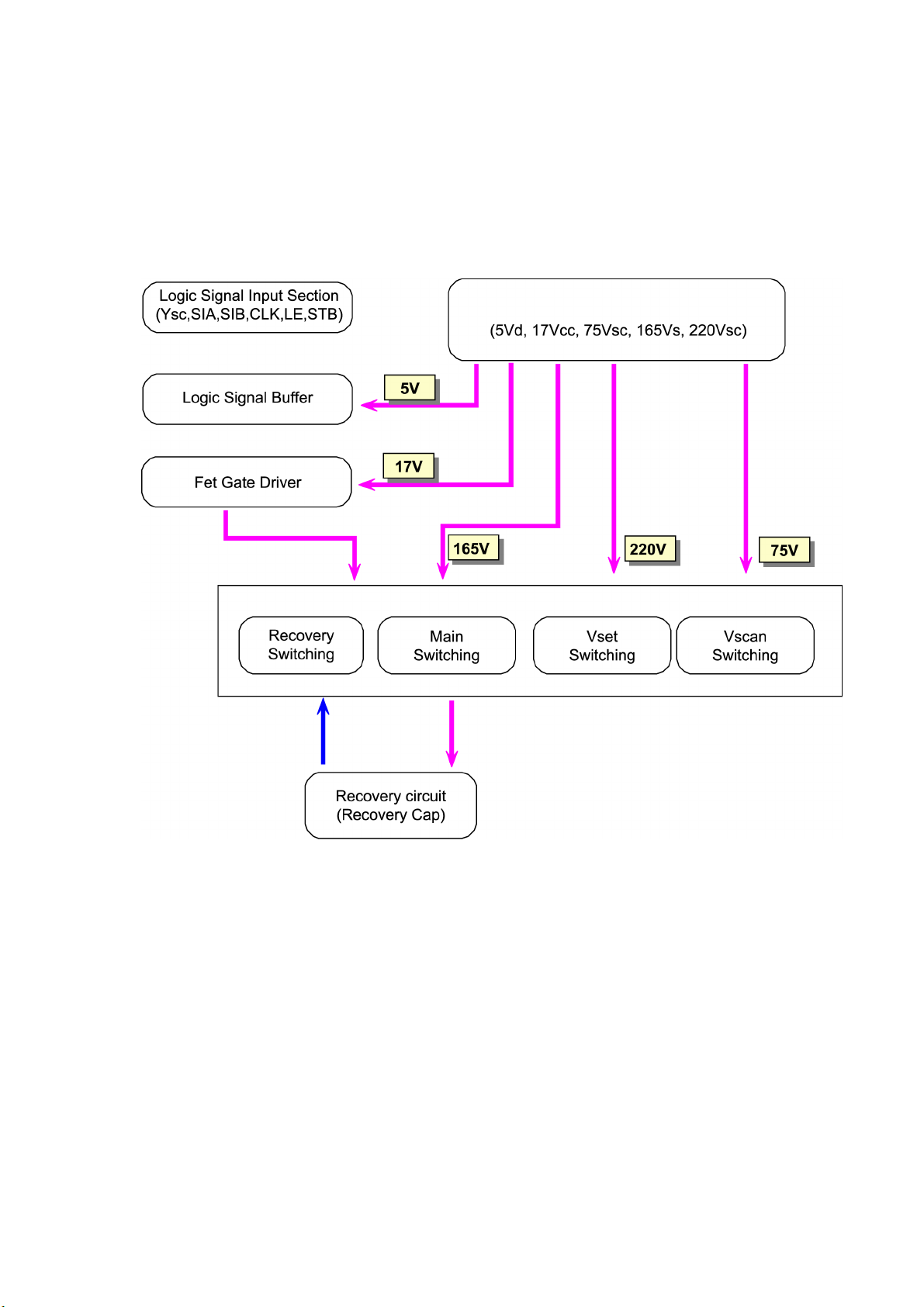

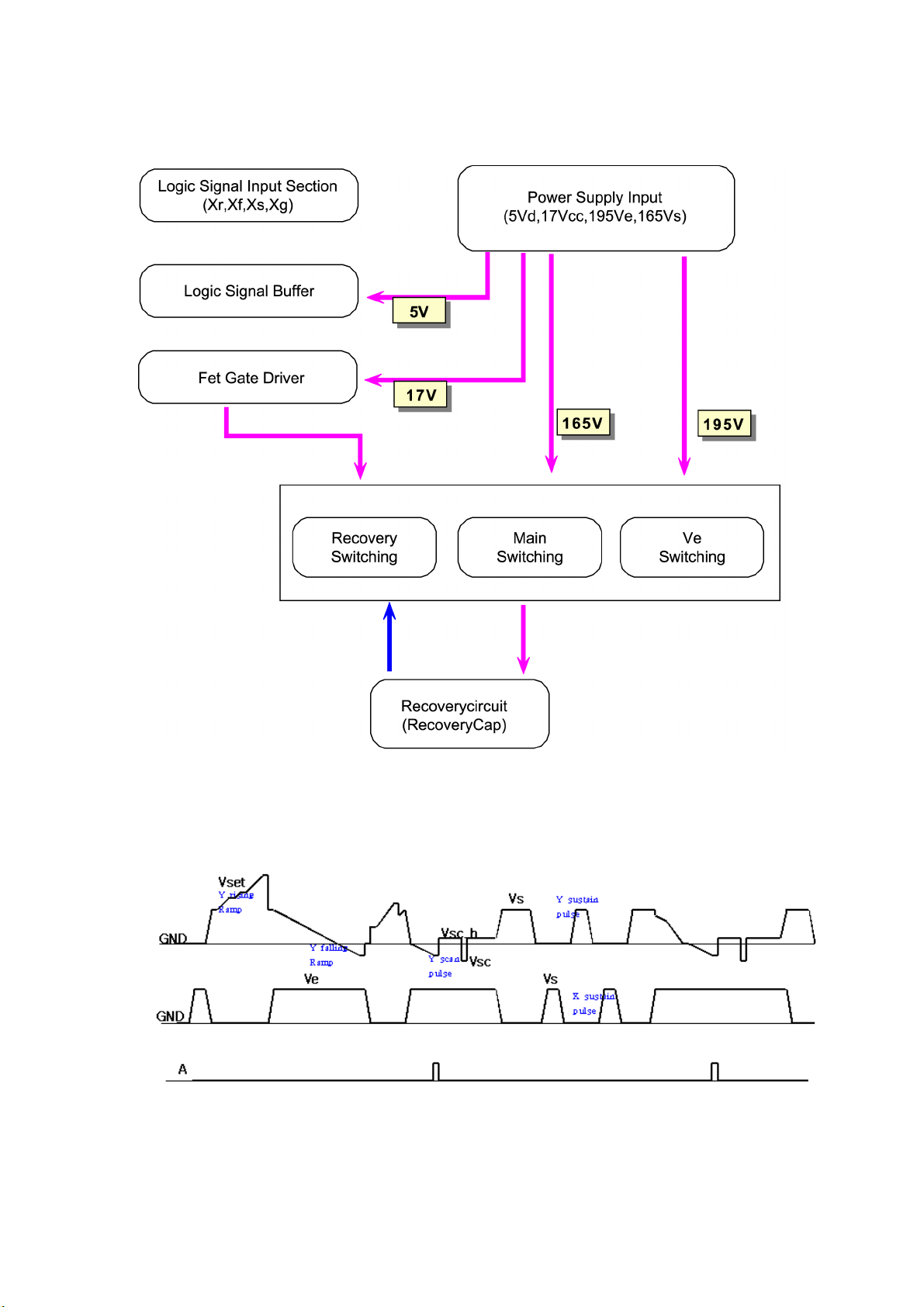

3-2. Block Diagrams

3-2-1. Block Diagrams for Drive Circuit Operations

<Drive Y Board>

- 10 -

<Drive X Board>

<Drive Waveforms>

- 11 -

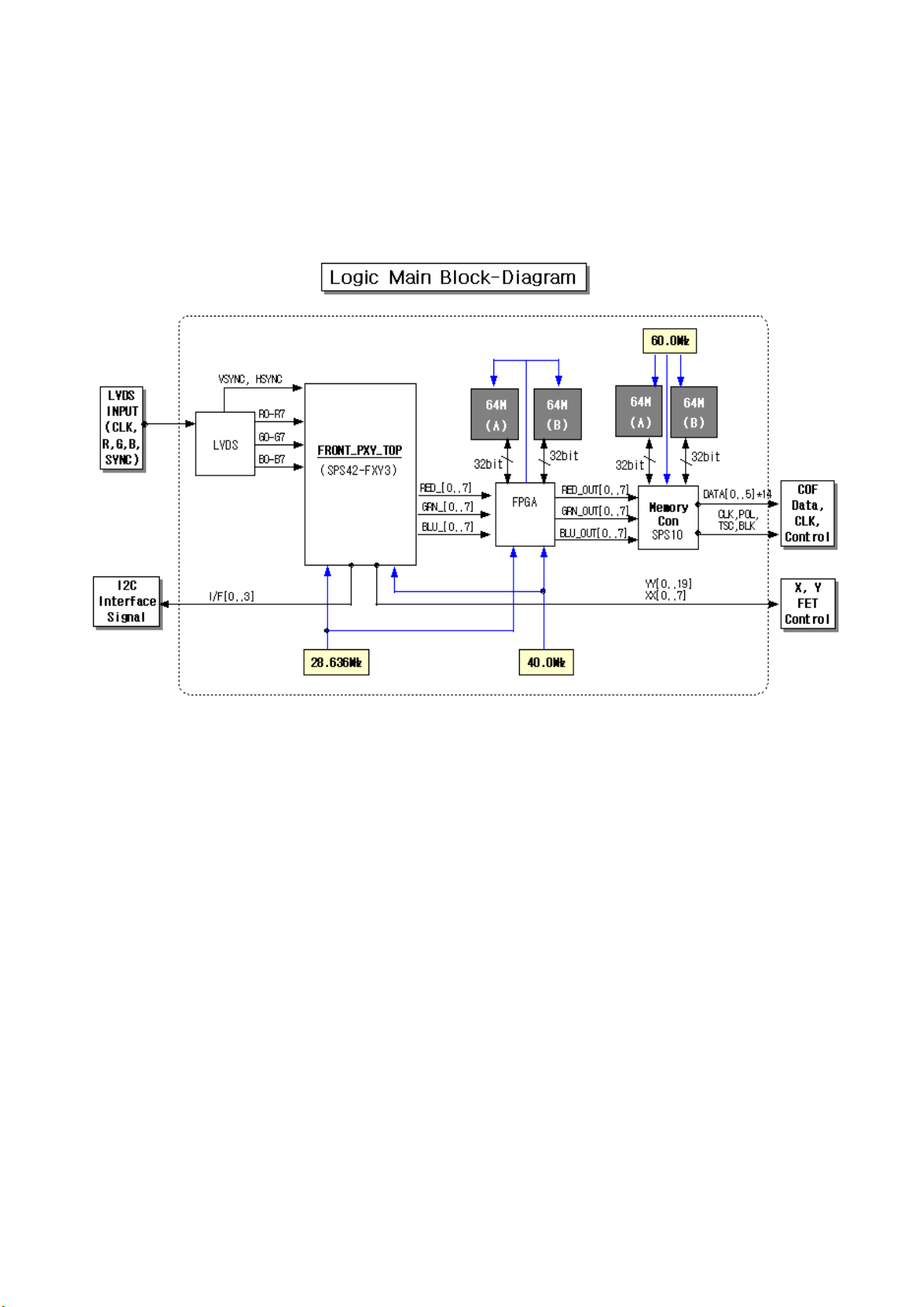

3-2-2. Logic Circuit Block Diagram

3-3. Main Functions of Each Assembly

3-3-1. X-Main board

The X-MAIN board generates a drive signal by switching the FET in synchronization

with the Logic Main board timing, and supplies the X electrode of the panel with the

drive signal through the connector. This board, connected to the panel’s X terminal,

has the following main functions.

1) Maintain voltage waveforms (including ERC).

2) Generate X Rising Ramp signal.

3) Maintain Ve bias between scan intervals.

- 12 -

3-3-2. Y-Main board

The Y-MAIN board generates a drive signal by switching the FET in synchronization

with the Logic Main board timing, and sequentially supplies the Y electrode of the

panel with the drive signal through the scan driver IC on the Y-buffer board. This

board, connected to the panel’s Y terminal, has the following main functions:

1) Maintain voltage waveforms (including ERC).

2) Generate Y Rising Ramp signal.

3) Maintain Vscan bias.

3-3-3. Logic Main board

The Logic Main board generates and outputs the address drive output signal and the

XY drive signal by processing the video signals. This board buffers the address drive

output signal and feeds it to the address driver IC (COF module).

(Video signal processing – XY drive signal generation - frame memory control –

address/data rearrangement – system control)

3-3-4. Logic buffer (E, F)

The logic buffer transmits data signals and control signals using a COF (Chip on

Flexible).

3-3-5. Y-buffer board (upper/lower)

The Y-buffer board consisting of the upper and lower boards supplies the Y terminal

with a scan waveform. The board comprises eight scan driver ICs (STMicroelectronics

STV7617: 64 or 65 output pins), but four ICs for the SD Class.

3-3-6. COF (Chip on Flexible)

The COF applies Va pulse to the address electrode, and constitutes address

discharge by the potential difference between the Va pulse and the pulse applied to

the Y electrode. The COF comprises four data driver ICs (STV7610A: 96 output pins).

Seven COFs are required for single scan.

- 13 -

3-4. Product/Serial Label Locations

Voltage information label Serial No. label Panel module label

Panel Module Label

Voltage information Label Serial No. Label

(Voltage specification)

- 14 -

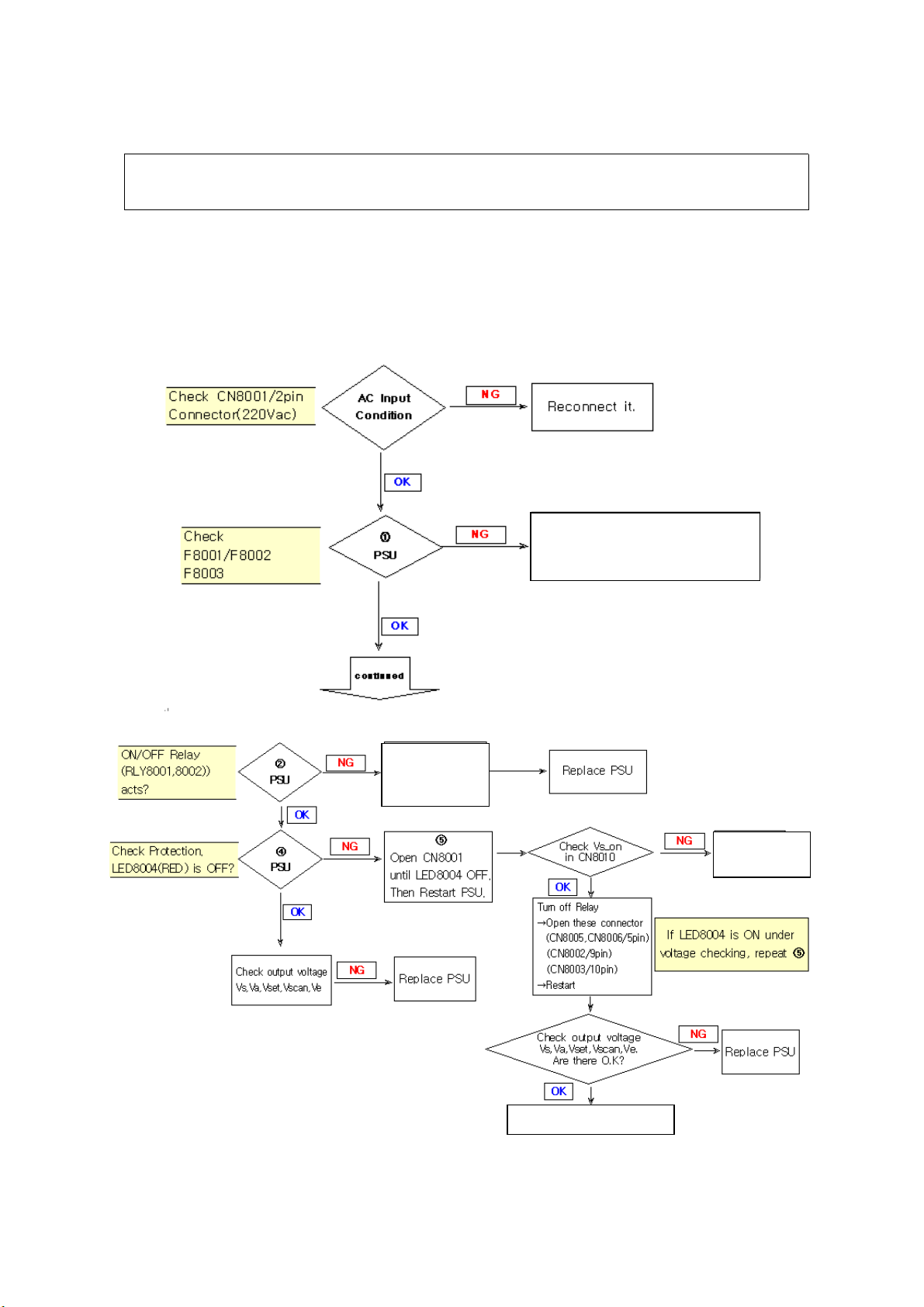

4. OPERATION CHECKING AFTER RECTIFICATION

4-1. Flow Charts

4-1-1. No voltage output

Replace PSU and

check driver B’D in advance

(Refer to ‘4-1-2 No display’)

LED (Green)

RLY8001,8002

off

Go to ‘4-1-2 No Display’

Go to ‘4-1-2

No Display’

- 15 -

Loading...

Loading...