Sony kds r50xbr1, kds r60xbr1 schematic

HISTORY

When clicking an item, it’s detail is displayed.

Model Name: KDS-R50XBR1/R60XBR1

SERVICE MANUAL

Part No. : 9-872-762-01

Date SUPP./CORR. Description of SUP/COR

2005.8 – NEW –

Change of

main text

SERVICE MANUAL

SP-1

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

KDS-R50XBR1

KDS-R50XBR1

KDS-R50XBR1

KDS-R60XBR1

KDS-R60XBR1

KDS-R60XBR1

RM-Y914

RM-Y914

RM-Y914

RM-Y914

RM-Y914

RM-Y914

USA

CANADA

MEXICO

USA

CANADA

MEXICO

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

KDS-R50XBR1/R60XBR1

RM-Y914

SXRD PROJECTION TV

KDS-R50XBR1/R60XBR1

Specifications

Projection System 3 SXRD Panel, 1 lens projection system

SXRD Panel 0.61 inch SXRD panel 6,220,800 pixels (2,073,600 × 3)

Projection Lens High Performance, large diameter hybrid lens F2.5

Antenna 75 ohm external terminal for VHF/UHF

Lamp UHP lamp, 120W, XL-5100

Television System NTSC American TV Standard

AT SC (8VSB terrestrial) ATSC compliant 8VSB

QAM on cable ANSI/SCTE 07 2000

Vis ible Screen Size

(picture measured diagonally)

Channel Coverage Terrestrial (analog) 2-69

Power Requirements 120V, 60 Hz

Inputs/Outputs

HDMI IN 2 total Video: 1080i, 720p, 480p, 480i

Vid eo (I N) 3 t ot al (1 on front panel) 1 Vp-p, 75 ohms unbalanced, sync negative

S Video (IN) 3 total (1 on front panel) Y: 1 Vp-p, 75 ohms unbalanced, sync

Audio (IN) 6 total (1 on front panel) 500 mVrms (100% modulation)

Component Video Input 2 (YP

CONTROL S (IN) 1 Mini jack

CONTROL S (OUT) 1 Mini jack

AUDIO OUT (VAR/FIX) 1 500 mVrms at the maximum volume setting

KDS-R50XBR1: 50 inches

KDS-R60XBR1: 60 inches

Cable TV (analog) 1-125

Terrestrial (digital) 2-69

Cable TV (digital) 1-135

Audio: Two channel linear PCM 32, 44.1 and

48 kHz, 16, 20 and 24 bit

negative

C: 0.286 Vp-p (Burst signal), 75 ohms

Impedance: 47 kilohms

BPR

) Y: 1 Vp-p, 75 ohms unbalanced, sync

negative

B

: 0.7 Vp-p, 75 ohms

P

P

R

: 0.7 Vp-p, 75 ohms

(Variable)

500 mVrms (Fixed)

Impedance (output): 2 kilohms

RM-Y914 RM-Y914

– 2 –

Other Information

PC IN D-sub 15-pin, analog RGB, 0.7 Vp-p, 75 ohms, positive

i.LINK 3 total (1 on front panel) 4-pin S400 i.LINK terminal

RF Inputs 2

Digital Audio Optical Output

1Optical Rectangular (1)

(PCM/Dolby Digital)

CableCARD Slot PCMCIA Type I/II

Speaker Output 15 W (L), 15 W (R)

Dimensions (W H D) KDS-R50XBR1 1,453

KDS-R60XBR1 1,674

863

×

1,009 × 514 mm (66 ×39

8 mm (57

1/4 ×

×

47

×

Mass KDS-R50XBR1 43kg (94 lb. 13 oz.)

KDS-R60XBR1 51kg (112 lb. 7 oz.)

Power Consumption

In Use 240 W

In Standby 0.5 W

In i.LINK/CableCARD Standby Less than 30 W

Supplied Accessories

Remote Control RM-Y914

AA (R6) Batteries 2 supplied for remote control

Operating Instructions 1

Quick Setup Guide 1

Warranty 1

Product Registration Card 1

Design and specifications are subject to change without notice.

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

34 × 18

7/

8

3

/4 × 20 1/

inches)

4

inches)

– 3 –

Indicators

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

Screen

POWER/STANDBY

POWER

LAMP TIMER

STD/DUO

Indicators

The indicators show the current status of your TV. If there is a change in the

condition or a problem with the TV, the indicators will flash or light up in

the manner described below to let you know that it requires your attention.

Indicator Flashing because...

POWER/

STANDBY

flashing

LAMP indicator

flashes

TIMER indicator

is lit

Green The lamp for the light source is preparing to turn

on. When it is ready, it turns on.

Red The lamp door or the lamp is not securely attached.

The red indicator will continue to flash in intervals

of three blinks at a time until the lamp door or the

lamp is placed correctly.

The red indicator is on when i.LINK STANDBY is

on or when your TV is in the PC power saving

mode.

The projection lamp has burned out. Replace it with new one

(see page 5 ).

When one of the timers is set the indicator will remain lit (will

not flash) even when the TV is turned off.

Projection Lamp

Your T V uses a projection lamp as its light source. As with any lamp, it has

limited life and needs to be replaced when the Lamp indicator flashes or the

screen becomes darker. Note the following:

After turning on your TV, it may take a while (1 minute or less) before

the picture appears.

When the projection lamp wears out, the screen goes dark. Replace the

lamp with a new Sony XL-5100 replacement lamp (not supplied).

The light em

use. To avoid eye discomfort or injury, do not look into the light

housing when the p

itted from the lamp is quite bright when your TV i s in

ower is on.

– 4 –

Replacing the Lamp

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

The projection lamp, which illuminates the picture, has a limited life.

If the screen becomes dark, the color looks unusual, or the LAMP indicator

on the front of the TV flashes, this indicates the lamp needs to be replaced

with a new one (not supplied).

WARNING

Electric appliances can cause fire or high temperature, resulting in

injury or death. Be sure to follow the instructions below.

Use a Sony XL-5100 replacement lamp (not supplied) for replacement.

Use of any other lamp may damage the TV.

Do not remove the lamp for any purpose other than replacement. Doing

so may cause injury or fire.

Do not put flammable materials and metal objects inside the lamp

receptacle of the TV after removing the lamp. Doing so may cause fire

or electrical shock. Do not touch the lamp receptable once the lamp has

been removed.

When the lamp eventually burns out, you may hear a noticeable “pop”

sound. This is normal and it is inherent to this type of lamp.

In rare instances, the bulb may pop inside the lamp unit, but the lamp

unit is designed to contain all of the broken glass pieces inside the lamp

unit.

The lamps contain mercury. For proper disposal of the used lamps,

follow and observe the local ordinances. See page 107.

– 5 –

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

How to Replace the

Lamp

1

Turn off the power on the main unit. Wait several minutes, then unplug

the power cord.

(The cooling fan will continue to operate for about two minutes after

turning the power off.)

2

Wait at l east 30 minutes after unplugging the power cord to allow the

lamp to cool down before replacing it. To avoid being burned, do not

touch the lamp receptacle once the lamp has been removed.

3

Take th e new lamp out of its package.

Do not touch the glass portion of the new lamp.

Do not shake the lamp. Vibration can damage the lamp or

shorten its life.

Avoid touching the front glass of a new lamp or the glass of the

lamp receptacle. This may reduce picture quality or lamp life.

4

Turn the screw with a screwdriver counterclockwise and remove the

outside lamp cover.

5

Pull out the lamp.

Place your index finger through the hoop of the lamp handle and pull it

upwards, while placing your thumb on the dent on the top. Then pull

the lamp out.

The lamp is very hot after use. Never touch th

lamp or the non-designated surrounding parts (shown in gray).

After the used lamp has cooled, place it into the empty box of the

replacement lamp. Never put the used lamp into a plastic bag.

e glass portion of the

(Continued)

– 6 –

6

Place the lamp halfway in. Follow the gutter in the compartment to

mount the new lamp securely.

Hold this part of the lamp

The lamp compartment is tilted, as shown in the following

illustration.

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

7

Slide it in slowly by pressing the part of the front corners of the

PUSH

lamp until it stops with a firm clicking sound to lock.

PUSH

PUSH

To

ensure the lamp is securely installed, press the area mark

befo

PUSH

If th

e lamp is not securely reattached, the self-diagnostic funct

may be triggered and the POWER/STANDBY indicator flashes in

red three times (see page 4).

re closing the lamp cover.

ed

ion

– 7 –

8

Place the outside lamp cover back in its place. Turn the screw with a

screwdriver clockwise and secure the cover.

Consult your Sony dealer for a Sony XL-5100 replacement

lamp.

Take gr eat care when replacing the lamp or plugging

in/unplugging the connecting cords. Rough handling may

cause the TV to fall, damaging the TV, the TV s tand and the

floor.

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

The used lamp

This product contains mercury. Disposal of this product may be regulated if

sold in the United States. For disposal or recycling information, please

contact your local authorities or the Electronics Industries Alliance

(http://www.eiae.org).

Do not leave the used lamp near flammable materials or within the

reach of children.

Do not pour water onto the used lamp or put any object inside the lamp.

Doing so may cause the lamp to burst.

For replacement lamp information visit:

U. S. residents: http://www.sonystyle.com/tv/

Canadian residents: http://www.sonystyle.ca/tv/

– 8 –

SAFETY CHECK-OUT

Fig. B. Checking for earth ground.

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

( US model only )

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

After correcting the original service problem, perfom the follow-

ing safety checks before releasing the set to the customer:

l. Check the area of your repair for unsoldered or poorly-sol-

dered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps,

and mounting hardware have been replaced. Be absolutely

certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

5. Look for parts which, through functioning, show obvious

signs of deterioration. Point them out to the customer and

recom mend their replacement.

6. Check the line cords for cracks and abrasion. Recommend

the replacement of any such line cord to the customer.

7. Check the condition of the monopole antenna (if any). Make

sure the end is not broken off, and has the plastic cap on it.

Point out the danger of impalement on a broken antenna to

the customer, and recommend the antenna’s replacement.

8. Check the B+ and HV to see they are at the values specified.

Make sure your instruments are accurate;be suspicious of

your HV meter if sets always have low HV.

9. Check the antenna temminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5mA (500 microampers) . Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to

usc these instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are

examples of a passive VOM that is suitable. NearIy all battery operated digital multimeters that have a 2V AC range

are suitable. (See Fig. A)

HOW TO FIND A GOOD EARTH GROUND

A cold-water pipe is guaranteed earth ground;the cover-plate retaining screw on most AC outlet boxes is also at earth ground. If

the retaining screw is to be used as your earth-ground, verify that it

is at ground by measuring the resistance between it and a coldwater pipe with an ohmmeter. The reading should be zero ohms. If

a cold-water pipe is not accessible, connect a 60-l00 watts trouble

light (not a neon lamp) between the hot side of the receptacle and

the retaining screw. Try both slots, if necessary, to locate the hot

side of the line, the lamp should light at normal brilliance if the

screw is at ground potential. (See Fig. B)

Fig. A. Using an AC voltmeter to check AC leakage.

1.5 µ F

To Exposed Metal

Parts on Set

1.5k Ω

Earth Ground

AC

voltmeter

(0.75V)

– 9 –

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

CAUTION

These servicing instructions are for use by qualified service personnel only.

To reduce the risk of electric shock, do not perform any servicing

other than that contained in the operating instructions unless you

are qualified to do so.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECElVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL TO SAFE OPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

ATTENTION!!

AFIN D’EVITER TOUT RISQUE DELECTROCUTION PROVENANT D’UN CHÁSSIS SOUS TENSION, UN TRANSFORMATEUR

D’ISOLEMENT DOIT ETRE UTILISÉ LORS DE TOUT DEPANNAGE.

LE CHÁSSIS DE CE RECEPTEUR EST DIRECTEMENT RACCORDÉ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS ÁLA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE FRAME ET PAR UNE

MAPQUE ! SUR LES SCHÉMAS DE PRINCIPE, LES VUES EXPLOSÉES ET LES LISTES DE PIECES SONT D’UNE IMPORTANCE

CRITIQUE POUR LA SÉCURITÉ DU FONCTIONNEMENT. NE LES

REMPLACER QUE PAR DES COMPOSANTS SONY DONT LE

NUMÉRO DE PIÉCE EST INDIQUÉ DANS LE PRÉSENT MANUEL OU DANS DES SUPPLÉMENTS PUBLIÉS PAR SONY. LES

RÉGLAGES DE CIRCUIT DONT L’IMPORTANCE EST CRITIQUE

POUR LA SÉCURITÉ DU FONCTIONNEMENT SONT IDENTIFIES

DANS LE PRÉSENT MANUEL. SUIVRE CES PROCÉDURES

LORS DE CHAQUE REMPLACEMENT DE COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS FONCTIONNEMENT SUSPECTÉ.

– 10 –

TABLE OF CONTENTS

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

Section Title Page

–––––– –––– ––––

1. SELF DIAGNOSIS FUNCTION ..................... 13

2. DISASSEMBLY

2-1. Rear Cover .......................................................... 16

2-2. Terminal Bracket, D.C Fan ................................ 17

2-3. Service Position .................................................. 17

2-4. Pod Block Assembly, Antenna Switch .............. 18

2-5. Digital Block Assembly ..................................... 18

2-6. DC Motor SFF21C/C-NP ................................... 19

2-7. Power Supply Block ........................................... 19

2-8. Unit Cover Assembly, Lamp (R) Guide

Assembly ............................................................ 20

2-9. DC Motor SFF22A/C-NP .................................. 20

2-10. Optical Block Assembly .................................... 21

2-11. Screen Frame Block Assembly .......................... 21

2-12. Mirror Cover Block Assembly ........................... 22

2-13. H1 Block Assembly ........................................... 22

3. ELECTRICAL ADJUSTMENTS

3-1. Electrical Adjustment by Remote Commander .... 23

3-1-1. Method of Setting the Service Adjustment

Mode ............................................................... 23

3-1-2. Service Mode Adjustment ............................ 23

3-1-3. Memory Write Confirmation Method .......... 23

3-1-4. Adjusting Buttons and Indicator ................... 24

3-2. To read Lamp and Panel time ............................ 24

3-3. Test Reset ........................................................... 24

3-4. H/V Center Confirmation and Adjustment ........ 24

Section Title Page

–––––– –––– ––––

4. DIAGRAMS

4-1. Block Diagram (1) .............................................. 25

Block Diagram (2) .............................................. 26

Block Diagram (3) .............................................. 27

Block Diagram (4) .............................................. 28

Block Diagram (5) .............................................. 29

Block Diagram (6) .............................................. 30

Block Diagram (7) .............................................. 31

Block Diagram (8) .............................................. 32

Block Diagram (9) .............................................. 33

Block Diagram (10) ............................................ 34

Block Diagram (11) ............................................ 35

Block Diagram (12) ............................................ 36

4-2. Frame Schematic Diagram ................................. 37

4-3. Circuit Boards Location ..................................... 39

4-4. Schematic Diagrams ........................................... 39

(1) Schematic Diagram of AK Board ...................... 40

(2) Schematic Diagram of F Board ......................... 41

(3) Schematic Diagram of G (1/3) Board ............... 42

(4) Schematic Diagram of G (2/3) Board ............... 43

(5) Schematic Diagram of G (3/3) Board ............... 44

(6) Schematic Diagram of HM Board ..................... 45

(7) Schematic Diagram of H1 Board ...................... 46

(8) Schematic Diagram of H2 Board ...................... 47

(9) Schematic Diagram of H3 Board ...................... 48

(10) Schematic Diagram of QU Board ..................... 49

(11) Schematic Diagram of S1, S2 Boards ................ 50

(12) Schematic Diagram of T1, T3 Boards ............... 51

4-5. Printed Wiring Boards ........................................ 52

(1) AK Board ............................................................ 52

(2) F Board ............................................................... 53

(3) G Board (Side A) ................................................ 54

(4) G Board (Side B) ................................................ 55

(5) HM, H1 Boards .................................................. 56

(6) H2, H3 Boards .................................................... 57

(7) QU, S1, S2, T1, T3 Boards ................................ 58

4-6. Semiconductors .................................................. 59

– 11 –

Section Title Page

–––––– –––– ––––

5. EXPLODED VIEWS

5-1. Screen, Covers .................................................... 60

5-2. Bottomblock-1 .................................................... 61

5-3. Bottomblock-2 .................................................... 62

5-4. Bottomblock-3 .................................................... 63

6. ELECTRICAL PARTS LIST

• AK Board .................................................................. 64

• F Board ...................................................................... 65

• G Board ..................................................................... 65

• HM Board ................................................................. 69

• H1 Board ................................................................... 70

• H2 Board ................................................................... 70

• H3 Board ................................................................... 70

• QU Board .................................................................. 71

• S1 Board .................................................................... 71

• T1 Board ................................................................... 71

• T3 Board ................................................................... 71

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

– 12 –

KDS-R50XBR1/R60XBR1

r

SECTION 1

SELF DIAGNOSIS FUNCTION

1. Summary of Self-Diagnosis Function

-This device includes a self-diagnosis function.

-Incaseofabnormalities, the POWER/STANDBY indicator automatically blinks. It is

possible to predict the abnormality location by the number of blinks. The Instruction

Manual describes blinking of the POWER/STANDBY indicator.

-Ifthe symptom is not reproduced sometimes in case of a malfunction, there is recording of

whether a malfunction was generated or not. Operate the remote command to confirm the

matter on the screen and to predict the location of the abnormality.

2. Diagnosis Items and Prediction of Malfunction Location

-When a malfunction occurs the POWER/STANDBY indicator only blinks for one of the

following diagnosis items. In case of two or more malfunctions, the item which first

occurred blinks. If the malfunctions occurred simultaneously, the item with the lowe

blink count blinks first.

-The screen display displays the results regarding all the diagnosis items listed below.

Thedisplay "0" means that no malfunctions occurred.

RM-Y914 RM-Y914

Number of times

Diagnosis Item

POWER/STANDBY

indicator blinks

Temp error

La

mp cover error 3 times

2 times

Fanstopped 4 times

Lamp driver error 5 times

Low B error 6 times

Audio error 7 times

Probable Cause

Location

Defected symptoms

- Set temperture is high.

- Temp sensor connector

is not attached securely.

-Nopicture/No sound

(CN7020 on HB board,

CN7180 on S2 board)

-L

amp cover is not

attached securely.

-Nopicture/No sound

-Lamp is not set securely.

-Fan 1-4

power is not

supplied. (AGU board)

-F

an connector is not

-Nopicture/No sound

attached securely.

-Fan caught wires or

harnesses.

-Lampdriver is faulty. - No picture/No sound

- B_12V is not

supplie

(GT board)

- Short-circuit of Audio power

supply line.

-Blow out of fuse.

(PS3001 on K board)

-IC failure.

(IC3005 on K board)

d.

-Nopicture/No sound

-Nopicture/No sound

D-

OVP error 8

ATSC OVP

times

10 times

Lamp error LAMP-LED flashes - No picture/No sound

-B -12V is over voltage.

(B board)

-Q_10.5V is over voltage.

(GT board)

-Lampfor the light

source burns out.

-Nopicture/No sound

-Nopicture/No sound

– 13 –

3. Blinking count display ofPOWER/STANDBY indicator

m

r

m

m

-One blink is not used for self-diagnosis.

-Example

POWER/STANDBY

POWER

LAMP TIMER

STD/DUO

Diagnosis ite

LEDblinks

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

Indicators

Lamp cove

3 times

Fan 4 times

LEDON:0.3sec

LEDOFF : 0.3sec

LED OFF

3.0sec

-Release of POWER/STANDBY indicator blinking

The POWER/STANDBY indicatorblinking display is released by removing the plug fro

the power or leaving for 2 minutes.

4. Self-diagnosis screen displays

-Incases of malfunctions where it is not possible to determine the symptom such as when

the power goes off occasionally or when the screen disappears occasionally, there is a

screen display on whether the malfunction occurred or not in the past (and whether the

detection circuit operated or not) in order to allow confirmation.

<Screen Display Method>

-Quickly press the remote command button in the following order from the standby state.

DISPLAY 5 - POWER

ChannelVol

Be aware that thisdiffers fro

the method of entering the

service mode (Vol +).

SELF CHECK

1:LAMP_ERROR 0

2 : TEMP_ERROR 0

2 : LAMP_TEMP 0

3:LAMP_COVER 0

4:FAN_ERROR 0

5:LAMP_DRIVER 1

6:LOWB_ERROR 0

7:AUDIO_PROT 0

8:D_OVP 0

10 : ATSC_OVP 0

-Numeral "1" means a fault was detected one time

-Numeral "0" means that no fault was detected

– 14 –

KDS-R50XBR1/R60XBR1

k

-The results display is not automatically cleared. In case of repairs and after repairs, chec

the self-diagnosis screen and be sure to return the results display to "0".

-Ifthe results display is not returned to "0" it will not be possible to judge a new malfunction

after completing repairs.

<Method of Clearing Results Display>

1. Power off (Set to the standby mode)

2. Channel Vol

DISPLAY 5 - POWER

RM-Y914 RM-Y914

3. Channel

8ENTER

<Method of Ending Self-Diagnosis Screen>

-When ending the self-diagnosis screen completely, turn the power switch OFF on the

remote commander or the main unit.

5. Self-Diagnosis function operation

2:Temp When the temperature sensor (for Ambient) on the S1 board detects high

temperature or the temperature sensor (for Lamp) on the S2 board detects

high temperature or the temperature sensor (for Panel) on the C board detects

high temperature, the DE-micro (IC5) turns off the lamp.

3:Lamp cover The rib at the back of the lamp cover closes the SW on the T1 board. The lamp

closes the SW on the T2 board.

It is monitored by DE-micro (pin63 of IC5) and turned off the lamp when it is

opened.

4:Fan Fan rotation is detected by ‘‘FAN-PROT” and the DE-micro (pin92 of IC5) turns

off the lamp when it is ‘‘high”.

5:Lamp Driver When the ‘‘LAMP-PROT” (pin83 of IC5) is high, the lamp is not turned on.

If the ‘‘LAMP-HV-DET” (pin94 of IC5) is low at the same time, it classified as

no high voltage of the lamp driver.

6:Low B error When no ‘‘D5V (SW_5V)” is detected, pin 129 of TV-micro (IC7002) is low and

it turns off the main power. (for example, blowout of thermal fuse).

7:Audio When DC voltage is detected at the speaker output, ‘‘SP-PROT” (pin102 of IC5)

is low and it turns off the main power.

8:D-OVP Be not in use.

9 : Panel error When there is not ack from the temperature sensor on the S1, S2 and C board or

IIC line connector (CN2303: ASU board, CN7956: DSU board, CN6901: C board)

is not seated securely. it is monitored by DE-micro.

10 : ATSC-OVP Be not in use.

LAMP : Lamp When the ‘‘LAMP-PROT” (pin83 of IC5) is high, the lamp is not turned on.

If the ‘‘LAMP-HV-DET” (pin94 of IC5) is high at the same time, it classified

as no lamp or a dead lamp.

– 15 –

Photo: KDS-R50XBR1

3

22

1

Loosen screw

Lamp d

bly

2-1. REAR COVER

oor assem

SECTION 2

DISASSEMBLY

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

r cover

– 16 –

2-2. TERMINAL BRACKET, D.C FAN

acket

ets

ecto

ll

bly

y

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

2 3 screws (+BVST 3x6)

rn riv

2-3. SERVICE POSITION

1 2 screws (+BVTP 3x12)

nn

r

D.C fan

rminal br

4 Screw (+BVTP2 4x16)

3 3 screws (+BVST 3x6)

1 2 screws (+BVTP 4x16)

Chassis Assembly

2 Remove side stay (R) by

pulling it down forward

– 17 –

nlock 2 claws and pu

out the chassis assem

carefull

2-4. POD BLOCK ASSEMBLY, ANTENNA SWITCH

itch

ectors

4 2 hexagoral washers

3 3 screws (+BVST 3x6)

3 POD block assembly

1 Connector

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

ntenna sw

2-5. DIGITAL BLOCK ASSEMBLY

1 Loosen cable holders

5 4 screws

(+BVTS 3x6)

2 2 screws (+BVST 3x6)

4 2 screws (right side)

(+BVTS 3x6)

6 Shield case (ATSC)

3 2 screws (+BVTP 3x12)

8 2 connectors

7 Pull out IEEE1394 cable

9 2 screws (+BVST 3x6)

qa PD board

0 2 PWB suppurt

qd 3 screws (+BVST 3x6)

qa

conn

qs Connector

qf 3 screws (+BVST 3x6)

qs Connector

– 18 –

KDS-R50XBR1/R60XBR1

y

)

C/C

with fan dampers

)

)

.

ectors

pply

d.

2-6. DC MOTOR SFF21C/C-NP

RM-Y914 RM-Y914

2-7. POWER SUPPLY BLOCK

box assembl

DC MOTOR SFF21

an guard with cushions

(for bracket

2 PCB spacers

-NP

2 screws (+PWTP2 4x16

2 screws (+BVTP2 4x16

Remove side stay (R) by pulling it down forward

2 Conn

emove the power su

block upwar

6 2 screws (+BVTP2 4x16)

Fan bracket (EX) with fan

– 19 –

KDS-R50XBR1/R60XBR1

)

)

(S)

RM-Y914 RM-Y914

ide stay

crew (+BVTP2 4x16

crew (+BVTP2 4x16

qs Screw (+BVTP 3x12)

qd

a

allast guide

Connector holder

[ In the lamp guide]

2-8. UNIT COVER ASSEMBLY, LAMP (R) GUIDE

ASSEMBLY

1 5 screws (+BVTP2 4x16)

(See below)

3 Release the claw

4 Lamp (R) guide assembly

2 Unit cover assembly

Connector holder with T3 board

2-9. DC MOTOR SFF22A/C-NP

2 holes

2 hooks

Scirocco cover (PN)

1 2 screws (+BVTP2 4x16)

DC motor SFF22A/C-NP

2

<Rear view>

1

– 20 –

2-10. OPTICS BLOCK ASSEMBLY

)

)

)

y

ront cover

crew (+BVTP2 4x16

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

3 4 screws (+PSWM 4x12)

4 Optics block assembly

5 1 screws (+BVTP2 4x16)

2-11. SCREEN FRAME BLOCK ASSEMBLY

Photo: R50XBR1

creen frame block assembl

2 screws (+BVTP2 4x16

screws (+BVTP 4x16

– 21 –

2-12. MIRROR COVER BLOCK ASSEMBLY

)

bly

)

bly

rror cover

block assem

6 screws (+BVTP2 4x16

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

2-13. H1 BLOCK ASSEMBLY

1 block assem

2 screws (+PWTP2 4x16

– 22 –

SECTION 3

ELECTRICAL ADJUSTMENTS

3-1. ELECTRICAL ADJUSTMENT BY REMOTE

COMMANDER

By using remote commander (RM-Y914), all circuit adjust-

ments can be made.

NOTE : Test Equipment Required.

1. Pattern Generator (with component outputs)

2. Oscilloscope

3. Digital multimeter

3-1-1. Method of Setting the Service Adjustment

Mode

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

3-1-2. Service Mode Adjustment

1. The SCREEN displays the item being adjusted.

2. Press “1” or “4” on the remote commander to select the

adjustment item.

3. Press “3” or “6” on the remote commander to change the data.

4. Press “2” or “5” on the remote commander to select the category.

Every time you press “2” (Category up), Service mode

changes in the order as shown below.

VERSION

MSP3714G

CC_T

1. Standby mode. (Power off)

2. DISPLAY t 5 t VOL (+) t TV POWER

on the remote commander.

(Press each button within a second.)

The following service screen will appear.

Category Name

Item Name

Item No.

VERSION 0 0 SERVICE

VER TV

Item Name Input Signal

F/A : xxxxxxxx

CBA : xxxxxxxx

Category Name

Item No.

D9671-1 0 0 G

I2CSCAL

96H 28DEG

9CH 24DEG

LCD PJ ENGINE VER.10.00B

03/10/07 732B

Mode

Data

Data

CXA2209Q

OUT-1

OUT-2

OUT-3

AP

DLBY

BUSSW

CXA2103

CXA2163

2DCOMB

TELETEXT

MSP_SIZE

MSPMD

MSPSEL

MSPFNC

CCPS_1

CCPS_2

CCPS_3

CCPS_4

CCPS_5

CCPS_6

CCPS_7

CCPS_8

CCPS_10

CCPS_11

DELAY_1

DELAY_2

OSD

CC_M

CC_S

HDMI

HDMS

ID

OPB_GA

OP_GA

OP_US

<LCD PROJECTOR ENGINE>

5. If you want to recover the latest values press “-” then

“[ENTER]” to read the memory.

6. Press “[MUTING]” then “[ENTER]” to write into memory.

7. Turn power off.

<Method of setting the shipping condition>

1. Service Adjustment mode.

2. Press “8” then “[ENTER]”

3. Wait until appearing “ Initial Setup” display.

4. Disconnect AC plug and connect again to change factory re-

set condition completely.

3-1-3. Memory Write Confirmation Method

1. After adjustment, turn power off with the remote commander.

2. Turn power on and set to service mode.

3. Call the adjusted items again and confirm they were adjusted.

– 23 –

3-1-4. Adjusting Buttons and Indicator

MUTING

Adjustment item

up

Adjustment item

down

Initialize data

(Not stored)

User control goes

to the standerd state

(Shipping Conditions)

VOL +

POWER

DISPLAY

Adjustment category

up

Data up

Data down

Adjustment category

down

ENTER

Read data from

NVM

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

This screen reads

“Total lamp time is 14 hours” and

“Total lamp ON/OFF cycle is 71 times”

To reset lamp time,

press “3 ” , “MUTE ” and “ENTER ” keys in sequence.

WRI-EXE(Red Character) is momentarily displayed and LampTM

will be reset to “0 ”.

4. Press “ 1 ” key [7 times].

Example

PANEL NVM OK 9 OPTION_E

7 SH SFT1 10 Diff 1

PanelTM 14h

This screen reads

“Total Panel time is 14 hours”

You can’t reset the Panel time with the Service menu .

<To get out of the Service menu>

The Service menu is cleared by turning off the set with a remote com-

mander or the power switch .

RM-Y914

FUNCTION OF KEYS ON COMMANDER

• 1 : Changes adjustment item. (item No. moves up)

• 4 : Changes adjustment item. (item No. moves down)

• 2 : Changes adjustment category.

(category moves up)

• 5 : Changes adjustment category.

(category moves down)

• 3 : Changes data value. (up)

• 6 : Changes data value. (down)

Commander Function

Button Mode Description

[MUTING] + [ENTER] WRITE Writes data to NVM.

- + [ENTER] READ Reads data from NVM.

8 + [ENTER] RESET Set the shipping condition.

3-2. To read Lamp and Panel time

The lamp and panel time of the set are displayed as follows .

<Enter the service mode>

1. Press the keys of the remote commander in rapid sequence as fol-

lows , when the set is in standby mode.

DISPLAY t Channel 5 t Vol + t POWER

3-3. Test Reset

The user settings can be reset to the factory default condition as fol-

lows.

1. Press “TEST “ and “RESET “ key in sequence when the set is ON .

The LAMP,TIMER and POWER/STANDBY LED light and the

picture is muted.

After about 5 seconds the LAMP and TIMER LED go off,

and the color of POWER/STANDBY LED changes from amber

to green.

After another 10 seconds the reset is completed and the initial set-

up display appears.

3-4. H/V Center Confirmation and Adjustment

Please check the picture horizontal/vertical center after the replace-

ment of the following parts .

• Optical block

• Top assembly

1, Check H/V center with 480i monoscope signal in “Full “ mode .

2, If the center is shifted , adjust it with the following service items .

Please record the steps shifted as

CXD9713 DFD 16 (for H center)

DFD 17 (for V center)

DFD 16 and CXD9713 .

DFD17

2. Press the “JUMP ” key [3 times].

You’ll get into DE-micro service menu .

3. Press “2 ” key [9 times] to show the following display .

Example

PANEL NVM OK 9 OPTION_E

0 LAMP 0 Diff 1

LampTM 14 LampCT 71

DFD16

– 24 –

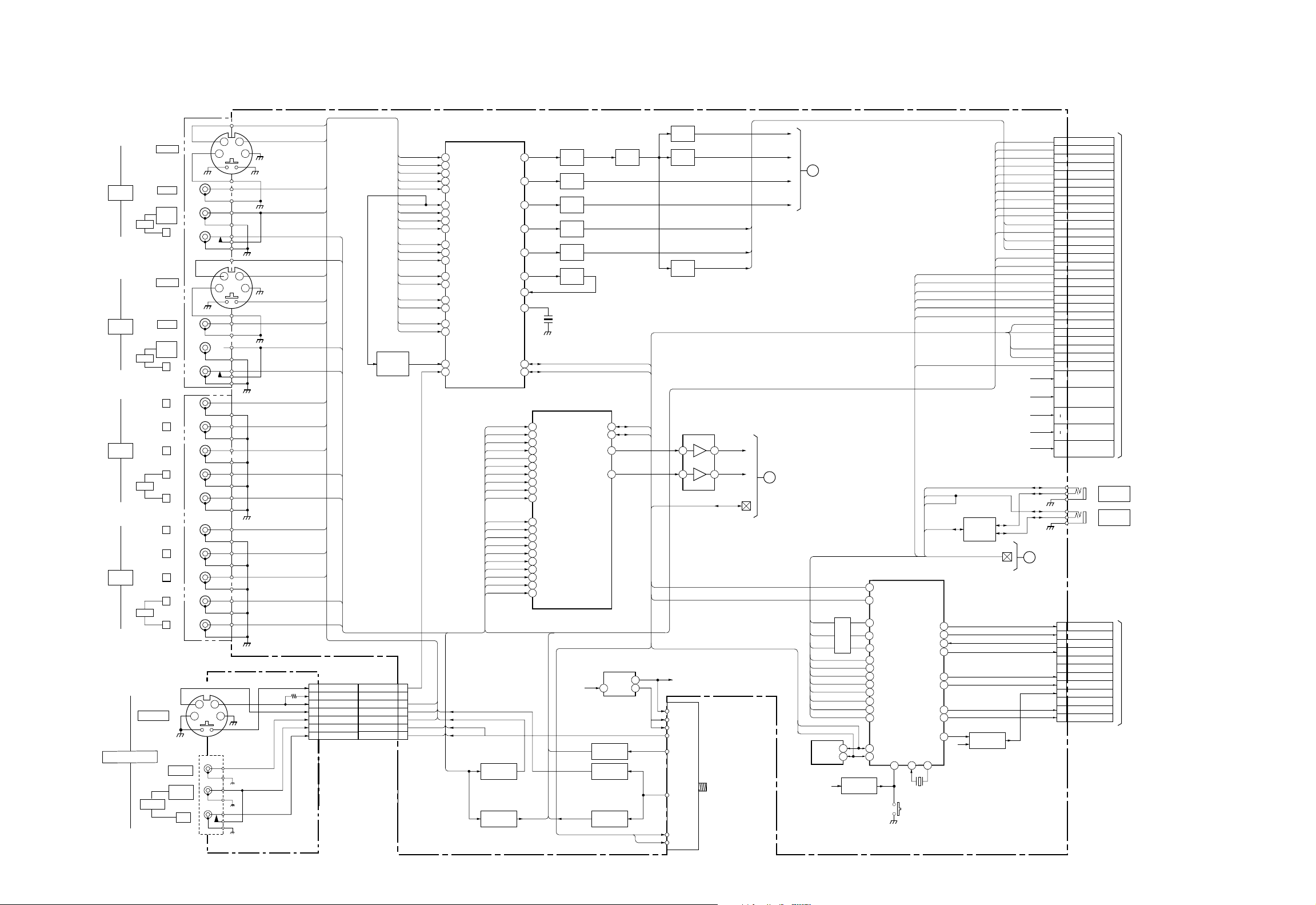

4-1. BLOCK DIAGRAM (1)

SECTION 4

DIAGRAMS

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

VIDEO 1

IN

AUDIO

VIDEO 3

IN

AUDIO

HD/DVD

4 IN

AUDIO

(1080i/720P/480P/480i)

HD/DVD

5 IN

AUDIO

VIDEO 2 INPUT

(MONO)

(MONO)

S VIDEO

AUDIO

S VIDEO

VIDEO

L

R

S VIDEO

VIDEO

L

R

Y

P

P

R

L

R

Y

P

B

P

R

L

R

J309

J304

B

CN7050

VIDEO

(MONO)

43

1 2

Y

L

R

43

1 2

Y

L

R

VG

VB

VR

L

R

VG

VB

VR

L

R

CY

43

1 2

J7050

L

R

(VIDEO 2 INPUT)

CY

CY

H3

V1-Y

V1-C

V1-V

V1-L

V1-R

V3-Y

V3-C

V3_SSW

V3-V

V3-L

V3-R

D4_VG

D4_VB

D4_VR

D4-L

D4-R

D5_VG

D5_VB

D5_VR

D5-L

D5-R

1

2

4

6

8

10

12

CN7051

S_SW2

S2_2

Q301-304

Y SIGNAL

DETECT

V1-V

V2-V

V3-V

A-TU-V

SUB TU V

V1-Y

V2-Y

V3-Y

HDMI-Y

V1-C

V2-C

V3-C

D4_VG

D5_VG

D4_VB

D5_VB

D4_VR

D5 _VR

IC303

VIDEO INPUT SELECT

12

IN5_CV CV/YOUT1

7

IN4_CV

17

IN6_CV

79

IN1_CV

1

IN2_VC

13

IN5_Y

8

IN4_Y

18

IN6_Y

26

IN8_Y

14

IN5_C

9

IN4_C

19

IN6_C

33

IN9_Y

40

34

41

35

42

11

6

IN10_Y

IN9_CB

IN10_CB

IN9_CR

IN10_CR

IN5_S

IN4_S

SYNC_OUT1

EXT_CLK/XTAL

V1-L

V2-L

V3-L

MTU-L

SUB-TU-L

D4-L

D5-L

ATSC-L

HDMI-L

PC-L

V1-R

V2-R

V3-R

MTU-R

SUB-TU-R

D4-R

D5-R

ATSC-R

HDMI-R

PC-R

C/CBOUT1

CROUT1

CV/YOUT2

C/CBOUT2

SEL_OUT1

SDA

SCL

58

59

60

67

68

56

55

51

77

76

1

19

4

22

25

10

13

28

16

7

2

20

5

23

26

11

14

29

17

8

Q316

BUFFER

Q314

BUFFER

Q313

BUFFER

Q230

BUFFER

Q231

BUFFER

Q318

BUFFER

X302

4MHz

IC507

AUDIO INPUT SELECT

IN1_L

IN7_L

IN2_L

IN8_L

IN9_L

IN4_L

IN5_L

IN10_L

IN6_L

IN3_L

IN1_R

IN7_R

IN2_R

IN8_R

IN9_R

IN4_R

IN5_R

IN10_R

IN6_R

IN3_R

Q2004

BUFFER

12C_SDA

12C_SCL

12C_SDA

32

SDA

12C_SCL

31

SCL

39 2 1

LOUT1

37

ROUT1

Q2002

BUFFER

Q2003

BUFFER

Q2001

BUFFER

IC526

6 7

SDAT_IFP

SCLK_IFP

SUB_Y

SUB_C

MAIN_CVY

AMP

12C_S

IC2306

CN004

S_SW2

1

S2_2

2

C2

Y2

V2

L2

R2

C2

Y2

V2

L2

R2

D2-C

4

D2-Y

D2-V

D2-L

D2-R

SUB-TV-V

A-TU-V

SUB-TU-L

SUB-TU-R

MTU_V

Q317,315

BUFFER

Q305

SYNC DETECT

M_HSYNC

6

8

10

12

SUB6.5V

AFT_SUB

SUB_HSYNC

Q323,317,315

SYNC DETECT

+5V

1 3

REG

Q2321

BUFFER

BUFFER

Q324

2

12C_SCL

12C_SDA

A5V

5V (D-D)

5V (TU)

5V (IF)

DE-EM

AFT OUT

DET OUT

CL

DA

TU2100

SUB TUNER

M-L

M-R

MAIN_G

MAIN_Y/CV

MAIN_C/CB

MAIN_CR

2

PC_R

PC_L

ATSC_R

Q305

CTL

MAIN_CVY

SUB_Y

SUB_C

SUB_HSYNC

AFT_SUB

STBY5V

SW3.3V

ATSC_L

HDMI_R

HDMI_L

HDMI_Y

MTU_R

MTU_L

MTU_V

M_HSYNC

I2C_SDA

I2C_SCL

SDA_IFP

SCL_IFP

SW_9V

D5V

ASU (1/2)

TO

ASU (2/2)

1

BOARD

AD_RST

AD_MUTE

LINE_MUTE

SIRCS

USER_RXD

USER_TXD

TO

ASU (2/2)

BOARD

28

I2C_SDA0

I2C_SCL0

27

SDAT_D

SCLK_D

SENB_D

FPC_DET

IRIS_GAIN

FAN PRPT

LAMP_ON

IRIS_CTRL

IRIS_FB

PANEL_ON

PANEL_PD

SDA_E

SCL_E

IC7

EEPROM

SW3.3V

Supplied as the ASU/DSU block ass'y for service.

()

The parts on this board are not supplied individually

IC8

LEVEL SHIFT

5

6

IC4

RESET

PD_SENB

33

SIO_SCK3

34

SIO_SDT3

32

AC_OFF_DET

96

IRIS_GAIN

117

FAN ERR

92

LAMP_ON

86

IRIS_PPG

69

IRIS_FB

41

PANEL_ON

93

PANEL_PD

55

SDA1

65

SCL1

64

90

SP PROT

AU/_MUTE

OF_FLAG_MAIN

K3.3V_SW

M_RST

LATCH_MAIN

SIO_SDT1

SIO_SCK1

AU_RESET_AMP

RESETX1X2

108

107

X1

6MHz

S1

(RESET)

USER_TXD

UARTRX

UARTTX

SIRCS

102

101

8

6

100

9

19

20

103

Q306-312

SIRCS I/F

CONTROL

IC5

SAIPH MICRO

SYNC DETECT

(A/V INPUT,TUNER)

3

TO

ASU (2/2)

BOARD

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A26

A27

A32

A36

A37

A38

B38

A39

A41

B42

A45

B46

A49

A50

7

8

9

10

13

14

15

17

18

CN2006

PC_R

PC_L

ATSC_R

ATSC_L

HDMI_R

HDMI_L

HDMI_Y

MTU_R

MTU_L

MTU_V

CVY_MAIN

TU_H_MAIN

SUB_Y

SUB_C

TU_H_SUB

AFT_SUB

AD_RST

AD_MUTE

LINE_MUTE

SIRCS

USER_RXD

USER_TXD

I2C_SDA

I2C_SCL

SDA1(IFP_SDA)

SCL(IFP_SCL)

AC_RLY

SW_9V

STBY5V

SW3.3V

D5V

ATSC_5VATSC_5V

J301

J303

CN1

SP_PROT

A_MUTE

OVF

3.3V_SW

M_RST

SCLTCH

AMP_RST

SCDT

SCSHIFT

CONTROL

S OUT

CONTROL

S IN

TO

DSU BOARD

CN7003

TO

AK BOARD

CN2603

– 25 –

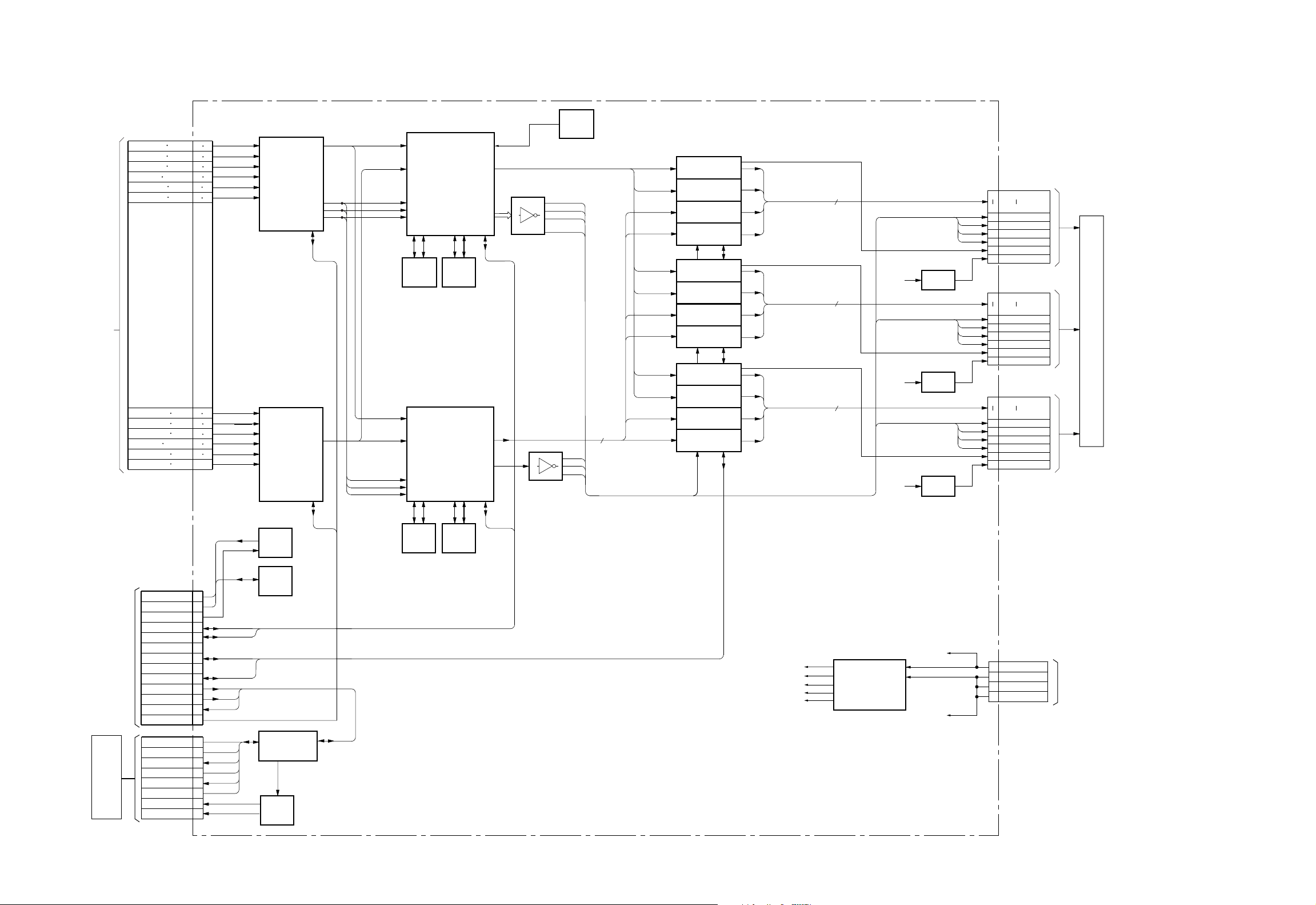

BLOCK DIAGRAM (2)

100P

TO DSU BOARD

CN4000

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

1

TO

AUS (1/2)

BOARD

3

TO

AUS (1/2)

BOARD

2

TO

AUS (1/2)

BOARD

MAIN_G

MAIN_Y/CV

MAIN_C/CB

MAIN_CR

CTL

M-L

M-R

12C_S

12C_SCL

12C_SDA

12C_SDA

12C_SCL

2

3

SCL

I/O0-7

55-50,

47,46

13-15,

17-21

I/O1-8

SDA

IC512

56

57

2

3

IC523

DELAY

27,28,30-32,

35-40,43-45

IC522

AUDIO PROSSESOR

SC1_IN_L

SC1_IN_R

SCL

SDA

AUDIO_

CLOCK_OUT

12S_DEL_IN

12S_DEL_OUT

74 8 9 10 11 21

2

4

11 59 13 8 7 18

11SM_IN

11SM_OUT

A0-16

21,23,24,

12-2,23,

25-28,31

A0-16

IC524

SRAM

CN2010

39

AHVSUP

SPDIF_OUT

76

SC1_OUT_L

37

36 2 1

SC1_OUT_R

71

XTAL_IN

72

XTAL_OUT

12S_DEL_CL

DVSUP

RESET

Q509

RST

LR_CLK

BIT_CLK

6

MUTE

FRD

FWR

29

22

2429

DE

WE

LAMP_ON

I_MAIN_C

B12

A11

LAMP_ON

X501

18.432MHz

I_MAIN_CV

A13

SW_9V

BUFFER

6 7

Q510

PANEL_ON

I_MAIN_R

B15

A15

PANEL_ON

Q511

IC504

AMP

Q502

INITIAL MUTE

Q505

INITIAL MUTE

LVDS_PD

I_MAIN_B

B18

A17

LVDS_PD

3

(IC506,526)

I_MAIN_G

A19

LEVEL SHIFT

1

VS

Q503,504

MUTE

Q512

BUFFER

Q508

BUFFER

Q2322,

2323

BUFFER

STBY5V

D5V

SENS_SCL

A21

IC3

SCLK_D

IC514

REGULATOR

2

SENS_SDA

A22

SDAT_D

SHUNT

Q501

BIAS

5

SCL_E

SDA_E

B25

B27

LINE_MUTE

6

SENB

A28

SENB_D

SW_9V

AC_RLY

AD_RST

AD_MUTE

SCLK

B28

SDAT_D

SCLK_D

SPDIF

IRIS_GAIN

SDAT

A30

A29

IRIS_GAIN

6

5

IRIS_FB

IRIS_CTRL

B31

A31

IRIS_FB

IRIS_CTRL

3

1

SDA_E

SCL_E

LAMP_ON

LAMP_HV

IC2305

DATA DECODER

DAC4

DAC3

14

15

DAC2

DAC1

DAC0

SW3

Q2392,2393,2395

FAN

CONTROL

3

4

5

6

7

10

FAN1-CTL

FAN2-CTL

FAN3-CTL

FAN4-CTL

FAN_CTL

SUB_11V

Q2310,2305

BUFFER

SUB_11V

Q2309,2304

BUFFER

SUB_11V

Q2308,2303

BUFFER

SUB_11V

Q2307,2302

BUFFER

Q2300,2312

IC2300

FAN CONTROL

4 2

IC2301

FAN CONTROL

4 2

IC2302

FAN CONTROL

4 2

IC2303

FAN CONTROL

4 2

ATSA_11V

31

31

31

31

ATSC_9V

D5V

A5V

D5V

SW_3.3V

SW_2.5V

IC2100,2101

IC2103

REGULATOR

FAN_PROT

PFC_DET

AC_RLY

D2301

D2302

D2303

SUB_6.5V

ATSC_5V

SW_9V

Q7

TU32V

STBY_5V

A16.5V

CN2301

1 FAN1-POW

2 FAN1-PROT

4 FAN2-POW

5 FAN2-PROT

7 FAN3-POW

8

FAN3-PROT

9

FAN4-POW

10

FAN4-PROT

CN2100

32 PFC_DET

AC_RLY

31

44

TU32V

41

STBY5V

+B_OVP

40

REC_ON

37

49

16.5V

50

26

SUB6.5V

24

22

15

SUB11VSUB_11V

9

THRU5V

6

2 SW9V

1 SW9V

M

M

M

M

TO

G BOARD

CN6502

FAN

FAN

FAN

FAN

SPDIF+/NC

CN501

TO

AK BOARD

CN7260

SPDIF-

CN2390

GND

GND

LAMP_HV

TO

T1 BOARD

CN7150/

T3 BOARD

CN7155

LAMP COVER

J307

L

AUDIO

AUDIO

OUT

CVAR/FIX

R

Supplied as the ASU/DSU block ass'y for service.

()

The parts on this board are not supplied individually

ASU (2/2) (FAN, POWER CONTROL)

– 26 –

BLOCK DIAGRAM (3)

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

TO

DSU BOARD

CN4202

CN9000

RCLK1-

RCLK2-

RA1-

RB1-

RC1-

RD1-

RE1-

RA2-

RC2-

RD2RE2-

RB2-

38P

RA1+

RB1+

RC1+

RCLK1+

RD1+

RE1+

RA2+

RB2+

RC2+

RCLK2+

RD2+

RE2+

IC9252

IC9101

HS_R

HS_G

HS_B

HCK,VCK,

HST,VST

TEMP.

SENSOR

VS_B

VS_G

VS_B

LRL0-9

LRR0-9

RRL0-9

RRR0-9

LGL0-9

LGR0-9

RGL0-9

RGR0-9

LBL0-9

LBR0-9R

RBL0-9

48

RBR0-9

IC9401

LCD DRIVER L

IC9403

LCD DRIVER R

IC9402

LCD DRIVER L

IC9404

LCD DRIVER R

IC9500

LCD DRIVER L

IC9502

LCD DRIVER R

IC9501

LCD DRIVER L

IC9503

LCD DRIVER R

IC9600

LCD DRIVER L

IC9602

LCD DRIVER R

IC9601

LCD DRIVER L

IC9603

LCD DRIVER R

VS/HS

DIDOUT

SDAT,

SCLK

DIDOUT

SDAT,

SCLK

DIDOUT

SDAT,

SCLK

HCK,VCK,HST,VST

VID_R0-R23

VID_G0-G23

VID_B0-B23

CN9400

29

24

SET3.3V

24

SET3.3V

24

SET3.3V

IC9407

RESET

IC9505

RESET

IC9605

RESET

VID_R0-R23

VID_G0-G23

VID_B0-B23

SIG (0)

6

SIG (23)

43

HCK

42

VCK

41

HST

40

VST

34

VPC

RST

39

CN9500

29

SIG (0)

6

SIG (23)

43

HCK

42

VCK

41

HST

40

VST

34

PID

RST

39

CN9600

29

SIG (0)

6

SIG (23)

43

HCK

42

VCK

41

HST

40

VST

34

PID

RST

39

R

LCD

G

UNIT

B

RRIN0-9

GRIN0-9

BRIN0-9

RLIN0-9

GLIN0-9

BLIN0-9

DOTCLK

HSIN

VSIN

IC9100

NVM

RRIN0-9

GRIN0-9

BRIN0-9

RLIN0-9

GLIN0-9

BLIN0-9

DOTCLK

HSIN

VSIN

IC9102

PAWN

IC9150

DDR SDRAM

IC9253

PAWN

VSOUT

LRL0-9,LGL0-9,LBL0-9

LRR0-9,LGR0-9,LBR0-9

IC 9103

RRL0-9,RGL0-9,RBL0-9

RRR0-9,RGR0-9,RBR0-9

IC9000

LDVS RECEIVER

3

2

6

5

9

8

12

11

15

14

18

17

21

22

25

24

28

27

30

31

34

33

36

37

RA1+/-

RB1+/-

RC1+/RCLK1+/-

RD1+/RE1+/-

IC9001

RA1+/-

RB1+/-

RC1+/RCLK1+/-

RD1+/RE1+/-

IFQE[0-29]

PAWN

IFQO[0-29]

CLKOUT

RC4

RC5

IFQE[0-29]

IFQO[0-29]

IFCLK

IFHSYNC

IFVSYNC

IFQE[0-29]

IFQO[0-29]

IFCLK

IFHSYNC

IFVSYNC

TO

DSU BOARD

CN7956

IRIS

CN6901

SENS_SCL

SENS_SDA

IRIS_CTRL

IRIS_GAIN

CN9050

20P

WP2

SDA_E

SCL_E

SENB

SCLK

SDA1

IRIS_FB

LVDS_PD

8P

DUMP +

DUMP -

HOUT -

HIN -

HOUT +

HIN +

DRIVE -

DRIVE +

WP2

IC6903

EEPROM

IC6901

EEPROM

IC9250

NVM

IC9300

DDR SDRAM

3

5

7

SDADE_400K

8

SCLDE_400K

10

13

14

16

17

18

19

SDAT

SCLK

SET5V

SET3.3V

SET9V

D1 5V

D2 5V

IC6900,6902

IC6904,6905

REGULATOR

20

1

2

IC9050,5052

IRES AMP

A16.5V

D6.5V

1

4

5

6

CN6900

A16.5V

D6.5V

D6.5V

D6.5V

10P

TO

DSU BOARD

CN7954

3

4

5

6

7

8

IC9051

IRIS

DRIVER

Supplied as optics block ass'y for service.

()

The parts on this board are not supplied individually

C (LCD DRIVER)

– 27 –

BLOCK DIAGRAM (4)

CN4000

I_MAIN_C

LAMP_ON

I_MAIN_CV

I_MAIN_R

WP

I_MAIN_B

LVDS_PD

I_MAIN_G

TO

ASU BOARD

CN2010

C BOARD

CN6901

SENS_SCL

SENS_SDA

IRIS_GAIN

IRIS_CTRL

CN7956

SENS_SCL

SENS_SDA

IRIS_CTRL

IRIS_GAIN

LVDS_PD

CN9050

SDA_E

SCL_E

SENB

SCLK

SDAT

IRIS_FB

WP2

SDA_E

SCL_E

SENB

SCLK

SDA1

IRIS_FB

8P

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

IC4300

AIN5

AIN4

AD4_SEL

AIN3

AIN2

AIN1

DQ0–15

ADDR 0–11

BA0

BA1

DQM

XWE

XCAS

XRAS

XCS

CKE

SDCLK

REFCLK_IN

CCPX

OUT1Y2–9

OUT1C2–9

FIFOCLK_IN

DTOCLK_IN

OUT1CLK

OUT1H

OUT1V

AOUT1

AOUT2

D2Y2–9

D2C2–9

D2CLK

D2HTIM

D2VTIM

D1G0–7

D1B0–7

D1R0–7

D1CLK

D1HTIM

D1VTIM

OSDYS

1M_HS

1M_VS

M_D2CLK

M_D2H

M_D2V

M_D1CLK

M_D1H

M_D1V

1MY2–9

1MC2–9

CLOCK1M_CLK

Q4301

BUFFER

Q4300

BUFFER

CCPM_MUTE

I

FL4301

LPF

FL4300

LPF

TO

DSU (2/4)

BOARD

M_D1Y0–7

M_D1C0–7

M_D1R0–7

IC4004

4

Q4308

BUFFER

Q4307

BUFFER

M_D2Y2–9

M_D2C2–9

M_D2CLK

M_D2H

M_D2V

M_D1CLK

M_D1H

M_D1V

1

IC4305

WAVE SHAPER

7

–

+

5

16

–

+

14

IC4200

LVDS RECEIVER

RD3–5,

RB2–6

36–32

15,17,18,

RA1–6,

RB0,

45,46

RD1

20,39–43,

CLKOUT

31

RD0

21

RD6

14

IC4201

LVDS RECEIVER

RD3–5,

RB2–6

36–32

15,17,18,

RA1–6,

RB0,

45,46

RD1

20,39–43,

RD2,

RC0–6

19,22,

24–29

CLKOUT

31

RD0

21

RD6

14

Q4200

RA–

RA+

RB–

RB+

RCLK–

RCLK+

RD–

RD+

RA–

RA+

RB–

RB+

RC–

RC+

RCLK–

RCLK+

RD–

RD+

49

50

51

52

56

57

59

60

PD

3

1

2

4

5

7

8

10

11

13

14

MRXIN0–

MRXIN0+

MRXIN1–

MRXIN1+

MRXIN2–

MRXIN2+

MRXCLK–

MRXCLK+

MRXIN3–

MRXIN3+

TO

QMDV BOARD

CN7313

CN4201

CN4200

49

50

51

52

54

55

56

57

59

60

PD

3

1

2

4

5

7

8

10

11

13

14

MRXIN0–

MRXIN0+

MRXIN1–

MRXIN1+

MRXIN2–

MRXIN2+

MRXCLK–

MRXCLK+

MRXIN3–

MRXIN3+

TO

PD BOARD

CN9502

IC4302

LPF, VIDEO BUFFER

A11

B12

NC

A13

A15

B15

A17

B18

A19

A21

A22

B25

B27

A28

B28

A29

A30

A31

B31

3

5

7

8

10

13

14

16

17

18

19

20

SENS_SCL

SENS_SDA

12C_SCL

12C_SCL

IRIS_GAIN

IRIS_CTRL

SENS_SCL

SENS_SDA

12C_SCL

12C_SCL

IRIS_CTRL

WP

LVDS_PD

SENB

SCLK

SDAT

IRIS_FB

WP2

SENB

SCLK

SDAT

IRIS_FB

LVDS_PD

Q4306, 4317

BUFFER

Q4305, 4316

BUFFER

Q4304,4314

BUFFER

Q4303,4313

BUFFER

Q4302,4312

BUFFER

11 IN2A

8 IN1A

IC4303

LPF, VIDEO BUFFER

13 IN3A

IN2A

11

8

IN1A

IC4002

SCL 12C_SCL

SDA

SCL

SDA

BUS SWITCH

2

6

3

Q4009, 4012

LEVEL

SHIFT

7

OUT2A

OUT2B

OUT3A

OUT3B

OUT2A

OUT1A

OUT1B

21

20

25OUT1A

24OUT1B

SCL

4

SDA

3

17

16

21

20OUT2B

25

24

4

3

1

5

Q4006, 4007

BIAS

12C_SCL_X

12C_SDA_X

12C_SCL

12C_SDA

12C_SCL

12C_SDA

12C_SDA

Q4310

BUFFER

Q4309

BUFFER

IC4304

SDRAM

DQ0–15

A0–11, BA0, BA1

DOML,

DQMH

WE

CAS

PAS

CS

CKE

CLK

M_YS/C

M_CV/Y

M_CLPSW

M_R/V

M_B/U

M_G/Y

DQ0–15

A0–11

BA0, 1

217

MCLK

– 28 –

IC4202

RESET

VCC OUT

3.3V

Supplied as the ASU/DSU block ass'y for service.

()

The parts on this board are not supplied individually

2 1

I2C_I/F

RST/CK

5

6

TO

DSU (4/4)

BOARD

TO

DSU (2/4)

BOARD

DSU (1/4) (HDMI IN, CCPX)

BLOCK DIAGRAM (5)

KDS-R50XBR1/R60XBR1

RM-Y914 RM-Y914

TO

DSU BOARD

(1/4)

CN7650

GRCLK

GRCLK+

I

GRA

GRA+

GRB

GRB+

GRC

GRC+

GRD

GRD+

GRE

GRE+

DRCY1IN0-7

DRCY2IN0-7

DRCC1IN0-7

DRCC2IN0-7

GPIO6

GPIO3

GPIO0

GPIO_INT3

PNCLCLKIN

GPIO10

GPIO09

XTALCLKIN

GPIO11

IC4601

IC4610(1/2)

IFP-2

1

6

42

8

IC4608

GPIO12

ROMDQ0-7

ROMAD0-21

MMDQS0-3

MMDQM0-3

MMDQS4-7

MMDQM4-7

EXTGXHSOUT

EXTGXCKOUT

RESETX

STANDBYX

S_RESETX

IFPR1OUT0

IFPR1OUT9

IFPG1OUT0

IFPG1OUT9

IFPB1OUT0

IFPB1OUT9

IFPR2OUT0

IFPR2OUT9

IFPG2OUT0

IFPG2OUT9

IFPB2OUT0

IFPB2OUT9

ROMCS1

MMD0-31

MMA0-11

MMBA0,1

MWEB

MCASB

MRASB

MCSB0

MCKE0

MCLK0B

MCLK1B

MCLK0

MCLK1

GPIO7

MCLK

IC4203

IFPR1 OUT0-9

IFPG1 OUT0-9

IFPB1 OUT0-9

IFPR2 OUT0-9

IFPG2 OUT0-9

IFPB2 OUT0-9

WP2

LVDS_PD

LVDS TRANSMITTER

TA+/-

TB+/-

TC+/-

TCLK+/-

TD+/-

TE+/-

TA+/-

TB+/-

TC+/-

TCLK+/-

TD+/-

TE+/-

IC4204

LVDS TRANSMITTER

D0-7

A0-21

WE

WE

CS1

OE

OE

MMD0-63 MMD0-31

MMA0-11

MMBA0,1

WE

CAS

RAS

CS

CKE

CLK0

CLK1

CK0

CK1

IC4615

43

61

LVDS_PD

IC4800

DDR

DQ0-31

MMA0-11

MMBA0,1

MMD32-63

MMA0-11

MMBA0,1

IGXHS

IGXCK

Supplied as the ASU/DSU block ass'y for service.

()

The parts on this board are not supplied individually

CAS

RAS

CKE

CLK0

CK0

CAS

RAS

CKE

CLK1

CK1

A0-11

BA0,1

DQS0-3

DM0-3

WE

WE

CAS

RAS

CS

CS

CKE

CK

CK

DQ0-31

A0-11

BA0,1

DQS0-3

DM0-3

WE

WE

CAS

RAS

CS

CS

CKE

CK

CK

IC4802

DDR

LVDS_PD

D0-7

IFP_V

RST/CK

DSU (2/4) IFP

A0-20

CS1

WE

OE

IC4801

DRAM

DQ0-7

A0-20

WE

CE

OE

SUB 6.5V

8

6

TO

DSU BOARD

(3/4)

TO

DSU BOARD

(1/4)

CN4203

36

37

TA1-

TB1-

TC1TCLK1TD1-

TE1-

TA2TB2-

TC2-

TCLK2-

TD2-

TE2-

TA1+

TB1+

TC1+

TCLK1+

TD1+

TE1+

TA2+

TB2+

TC2+

TCLK2+

TD2+

TE2+

TO

C BOARD

CN9000

33

34

30

31

27

28

24

25

21

22

18

17

14

15

11

12

9

8

5

6

1

2

CN7954

1

A16.5V16.5V

4

D6.5V

5

D6.5V

6

D6.5V

TO

C BOARD

CN6900

IC4505

IFP-1

IMY2-9

IMC2-9

CLOCK

IC4503

FLASH RAM

DQ0-31

IC4504

FLASH RAM

DQ0-31

A0-10,

BA0

BA1

WE#

CAS#

RAS#

CS#

CLK

1M_CLK

1M_HS

1M_VS

D0_0-31

A0_0-10

B0_0,1

D1_0-31

DIYD0-7

DICD0-7

CKD1

IHDD

IVDD

DQ000-31

AD000-10,

BA00,BA01

XWE0

XCAS0

XRAS0

XCS0

SDCK0

DQ100-31

DY212-19

DY202-09

DB02-09

DR02-09

CKCI

X4500

79.9918313MHz

DRCY1IN0-7

DRCY2IN0-7

DRCC1IN0-7

DRCC2IN0-7

IC4507

7

SSCLK

IC4508

XIN

4

SSON#

CLKB

8

XIN

3

9

S1

13

12

7S0CLKD

IC4506

GA0-7

GR0-7

GG0-7

GB0-7

GCK

GHS

GVS

LVDS_PD

CKBI

XRST

7

X4600

79.9918313MHz

TO

DSU BOARD

(3/4)

A1_0-10

A0-10,

BA0,

B1_0,1

BA1

WE#

CAS#

RAS#

CS#

CLK

IC7650

MAIN LVDS RECIVER

RA

1

2

3

4

7

8

10

-

11

13

-

14

16

-

17

RA+

RB

RB+

RC

RC+

RCLK

RCLK+

RD

RD+

-

RE

RE+

-

-

-

-

-

PA2-6

PB0-2

RE0-5

RD5,6

RD0-4

RC4,5

RC0-3

RB3-6

CLKOUT

AD100-10,

BA10,BA11

XWE1

XCAS1

XRAS1

XCS1

SDCK1

PA1

PA0

PD

SSCLK

7

IC4502

4

IC4603

CLOCK DRIVE

IC4600

CLOCK SELECT

4

XIN

1

2

SSON#

SSON#

SSCLK

CLKB

XIN

IC4604

XIN

S1

3

8

24

8

7

3

9

13

12

1S0CLKC

7CLKO

3

– 29 –

Loading...

Loading...