Sony KDR60XBR2 Schematic

SERVICE MANUAL

SP-3

CHASSIS

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

KDS-R60XBR2

KDS-R60XBR2

KDS-R70XBR2

KDS-R70XBR2

RM-YD009 USA

RM-YD009

RM-YD009

RM-YD009

CANADA

USA

CANADA

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

KDS-50A2000/50A2010/55A2000/60A2000/60A2010

POWER

LAMP

TIMER

POWER

POWER

LAMP

TIMER

BD/DVD

RM-YD009KDS-R60XBR2/R70XBR2

SXRD PROJECTION TV

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

Specifications

Te le vision system:

NTSC American TV Standard

ATSC (8V SB terrestrial) ATSC compliant 8VSB

QAM on cable ANSI/SCTE 07 2000

Channel coverage:

Ter rest rial (analog) 2-69

Cable TV (analog) 1-125

Ter rest rial (digital) 2-69

Cable TV (digital) 1-135

Antenna:

75-ohm external terminal for VHF/UHF

Screen size (measured diagonally):

KDS-R60XBR2: 60 inches

KDS-R70XBR2: 70 inches

Projection system

3 SXRD panel, 1 lens projection system

SXRD panel

0.61 inch SXRD panel 6,220,800 pixels (2,073,600 × 3)

Projection lens

High performance, large diameter hybrid lens F2.5

Lamp

Ultra High Pressure Lamp, 180 W, XL-X5300

VIDEO IN 1/2/4:

S VIDEO (4-pin mini DIN) (VIDEO 1 only):

VIDEO: 1 Vp-p, 75 ohms unbalanced, sync negative

AUDIO: 500 mVrms (100% modulation)

HD/DVD IN 5/6:

YPBPR (Component Video):

AUDIO: 500 mVrms (100% modulation)

HDMI IN 3/7/8:

HDMI: Video: 480i, 480p, 720p, 1080i, 1080p

AUDIO (for HDMI IN 8 only):

Y: 1.0 Vp-p, 75 ohms unbalanced, sync negative

C: 0.286 Vp-p (Burst signal), 75 ohms

Impedance: 47 kilohms

Y: 1.0 Vp-p, 75 ohms unbalanced,

sync negative

B

: 0.7 Vp-p, 75 ohms

P

R

: 0.7 Vp-p, 75 ohms

P

Signal format: 480i, 480p, 720p, 1080i

Impedance: 47 kilohms

Audio: Two channel linear PCM 32, 44.1 and

48 kHz, 16, 20 and 24 bits

500 mVrms (100% modulation)

Impedance: 47 kilohms

AUDIO OUT:

500 mVrms (100% modulation) (Fixed)

More than 1 Vrms at the maximum volume setting (Variable)

DIGITAL OUT (OPTICAL):

Optical Digital Audio Output (PCM/Dolby digital)

PC IN 9:

D-sub 15-pin, analog RGB, 0.7 Vp-p, 75 ohms, positive

See the PC Input Signal Reference Chart on page 77

PC AUDIO INPUT:

Stereo mini jack, 0.5 Vrms, 47 kilohms

Speaker:

Size:

8cm (

3 1/8 inches)

(2)

Speaker output:

15 W + 15 W

Power requirement:

120 V AC, 60 Hz

Power consumption:

In use: 285 W

In standby: Less than 0.2 W

Dimensions (W/H/D):

KDS-R60XBR2: 1674 × 1016 × 514 mm

×

(66

KDS-R70XBR2: (with speakers) 1885

1

(74

(without speakers) 1714

1

(67

40 × 20

/

4

×

45 1/

/

2

×

45 1/

1

/4 inches)

×

2

×

24 1/8 inches)

2

×

24 1/8 inches)

1154 × 611 mm

×

1154 × 611 mm

Mass:

KDS-R60XBR2: 55 kg (121 lb.)

KDS-R70XBR2: 73 kg (161 lb.)

Supplied accessories:

Remote control RM-YD009 (1)

Size AA batteries (2)

Side cover (2) (KDS-R70XBR2 only)

Operating Instructions (1)

Quick Setup Guide (1)

War rant y Card (1)

Product Registration Card (1)

Replacement Lamp XL-5300 (1)

Optional accessories:

TV Stand: SU-RS51U

Lamp: XL-5300

Design and specifications are subject to change

without notice.

– 2 –

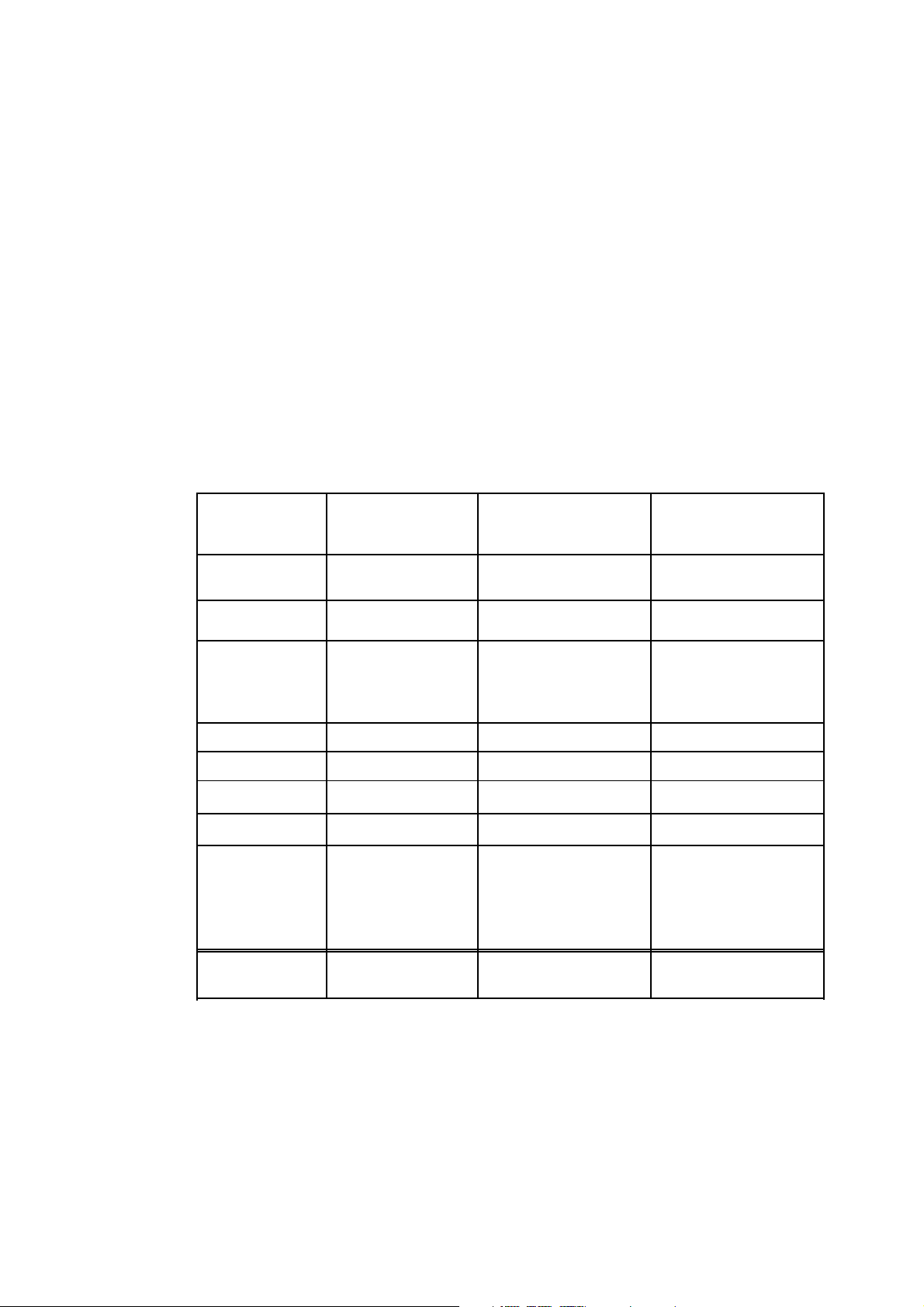

PC Input Signal Reference Chart

Resolution

Horizontal frequency

(kHz)

Ve rt i cal

frequency (Hz)

Standard

Signals Horizontal

(Pixel)

× Ve r tical

(Line)

VGA

640 × 480 31.5 60 VGA

640 × 480 37.5 75 VESA

720 × 400 31.5 70 VGA-T

SVGA

800 × 600 37.9 60 VESA Guidelines

800 × 600 46.9 75 VESA

XGA

1024 × 768 48.4 60 VESA Guidelines

1024 × 768 56.5 70 VESA

1024 × 768 60.0 75 VESA

WXGA

1280 × 768 47.4 60 VESA

1280 × 768 47.8 60 VESA

1280 × 768 60.3 75 VESA

1360 × 768 47.7 60 VESA

SXGA

1280 × 1024 64.0 60 VESA

1280 × 1024 80.0 75 VESA

HDTV

1920 × 1080 67.5 60 EIA

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

– 3 –

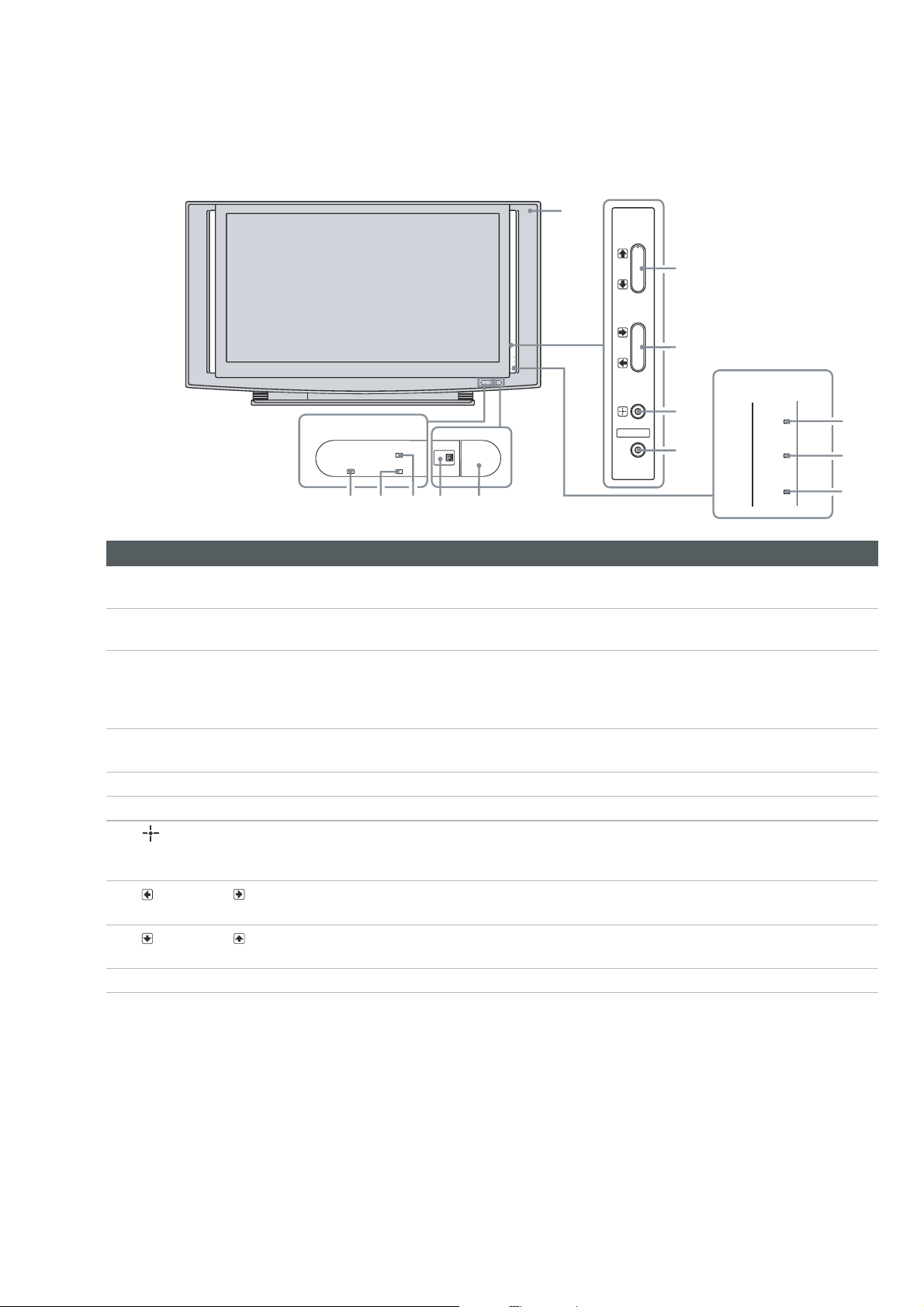

TV Controls

For KDS-R60XBR2

PO WER

TIMER

LAMP

21

354

PO WER

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

0

CHANNEL

3

9

#

VOLUME

3

POWER

LAMP

TIMER

POWER

POWER

LAMP

TIMER

TV/VIDEO

MENU

8

#

For KDS-R70XBR2

7

6

PO WER

LAMP

TIMER

3

2

1

Item Description

TIMER LED When the timer is set, this LED will remain lit even if the TV is turned off. For details, see

1

page 61.

LAMP LED Blinks in red when the lamp for the light source has burned out. For details, see “Replacing the

2

Lamp” on page 66.

POWER LED Lights up in green when the TV is turned on. If the LED blinks in red continuously, this may

3

indicate the display unit needs servicing (see the contacting Sony information on page 2).

When the red LED blinks only three times, the lamp door of the lamp unit or the lamp itself is

not securely attached (see page 68).

(IR) Infrared

4

Receiver

POWER Press to turn on and off the TV.

5

MENU Press to display MENU with TV functions and settings (see “Overview of MENU” on page 47).

6

7

TV/VIDEO

Receives IR signals from the remote control.

Do not put anything near the sensor, as its function may be affected.

Press to cycle through the video inputs. If you set a certain input to Skip in Label Video

Inputs, then the input will not appear. For details, see page 60.

In the MENU screen, this button serves as confirming the selection or setting.

8

Press to adjust the volume. In the MENU screen, these buttons serve as left/right buttons.

VOLUME –/+

9

CHANNEL –/+

Speaker Outputs the audio signal.

q;

Press to scan through channels. To scan quickly through channels, press and hold down either

–/+. In the MENU screen, these buttons serve as up/down buttons.

– 4 –

Replacing the Lamp

The projection lamp, like all lamps, will eventually lose brightness and

functionality, which affects the overall performance of your TV. How long

the lamp maintains its brightness will vary depending upon your usage and

environmental conditions. To maintain the quality of your viewing

experience, Sony recommends that you replace the lamp (1) after

approximately 4,000 hours of use; (2) when the screen becomes dark or the

color looks unusual; (3) when the LAMP LED on the front of the TV blinks;

or (4) when the lamp replacement message appears on the TV screen.

❑

❑

❑

❑

❑

❑

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

WARNING

Electric appliances can cause fire or high temperature, resulting in

injury or death. Be sure to follow the instructions below.

Use the supplied Sony XL-5300 lamp for replacement. Use of any other

lamp may damage the TV.

Do not remove the lamp for any purpose other than replacement. Doing

so may cause injury or fire.

Do not put flammable materials and metal objects inside the lamp

receptacle of the TV after removing the lamp. Doing so may cause fire

or electrical shock. Do not touch the lamp receptacle once the lamp has

been removed.

When the lamp eventually burns out, you may hear a noticeable pop

sound. This is normal and it is inherent to this type of lamp.

In rare instances, the bulb may pop inside the lamp unit, but the lamp

unit is designed to contain all of the broken glass pieces inside the lamp

unit.

This TV’s lamp contains mercury and should be disposed of properly.

Consult your local authorities regarding safe disposal. The material

contained in this lamp are similar to those of a fluorescent lamp, so you

should dispose of it in the same way.

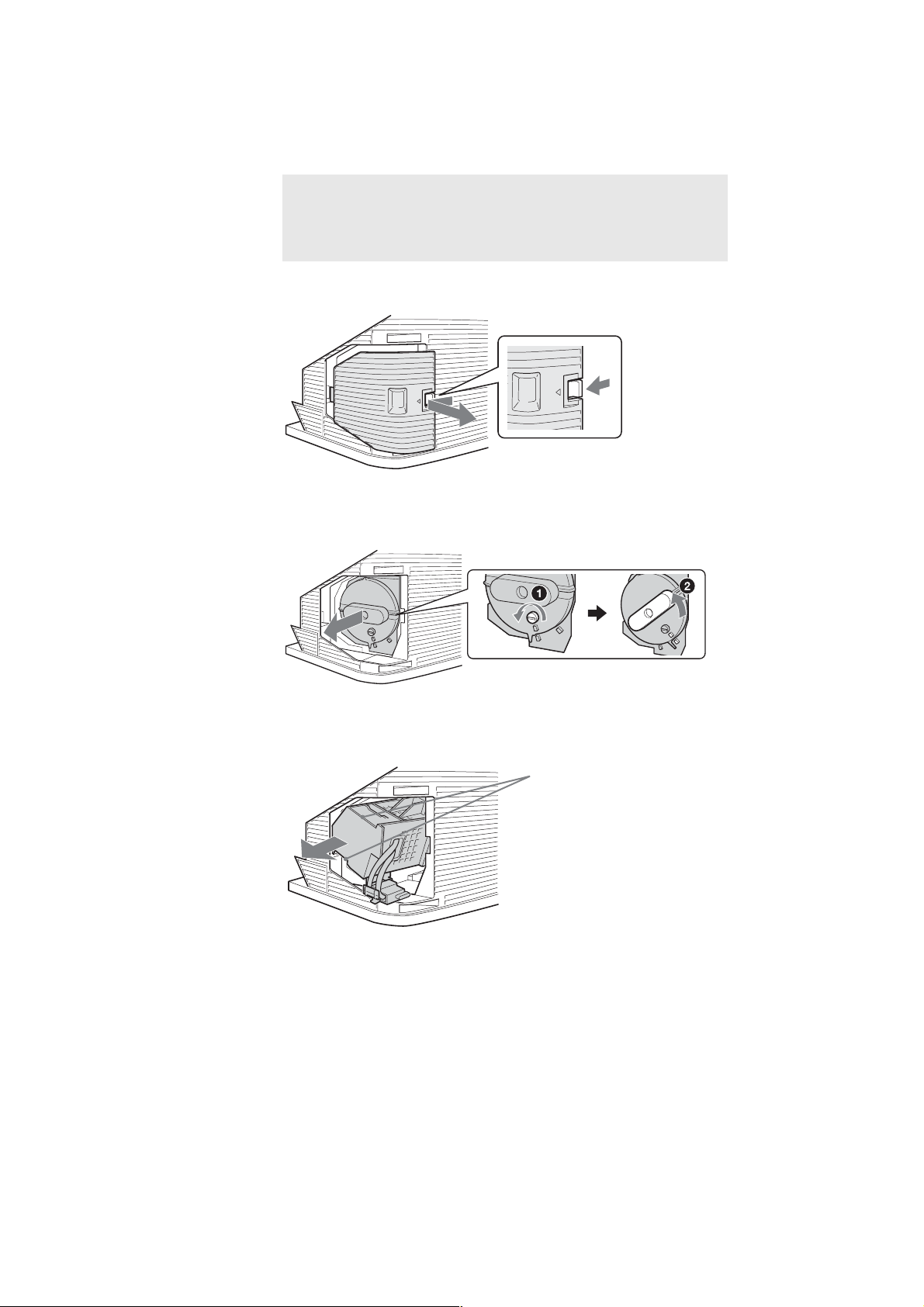

How to Replace the

Lamp

1 Turn off the power on the main unit. Wait several minutes, then unplug

the power cord.

(The cooling fan will continue to operate for about two minutes after

turning the power off.)

2 Wait at least 30 minutes after unplugging the power cord to allow the

lamp to cool down before replacing it. To avoid being burned, do not

touch the lamp receptacle once the lamp has been removed.

– 5 –

3

Take t he new lamp out of the box.

Do not touch the glass portion of the new lamp.

✍

Do not shake the lamp. Vibration can damage the lamp or shorten

its life.

✍

Avoid touching the front glass of a new lamp or the glass of the

lamp receptacle. This may reduce picture quality or lamp life.

4

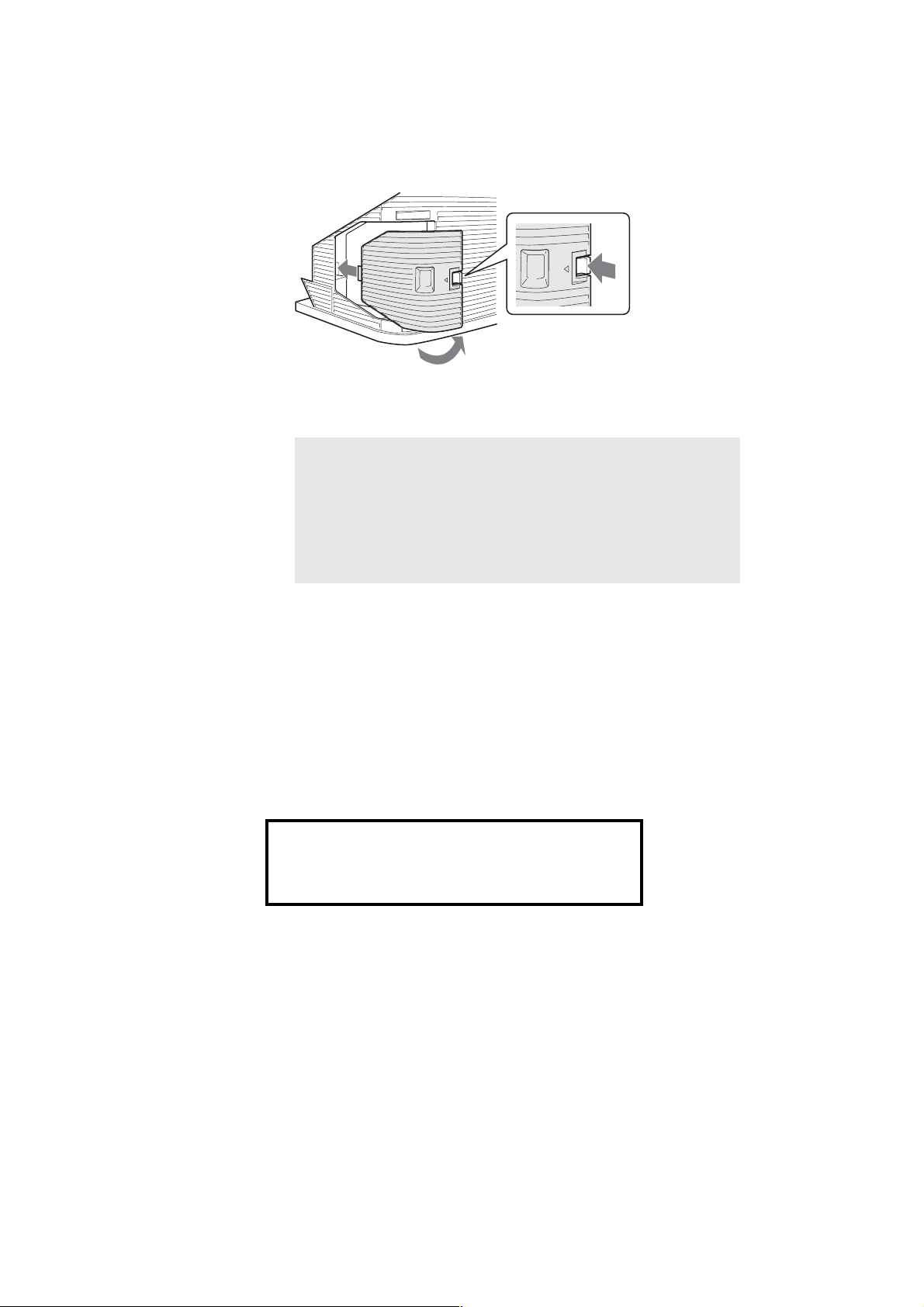

Remove the outside lamp cover.

Release the clamp as shown in the illustration below.

5

Remove the lamp door.

Turn the screw counterclockwise, and then turn the knob to the left until

the marks on the lid and the case line up. Remove the door.

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

6

Pull out the lamp.

Hold the indents on the top and bottom of the lamp, as shown in the

illustration, and pull the lamp straight out.

Hold this part of the lamp

– 6 –

✍ Do not touch the inside of the lamp compartment.

✍ The lamp is very hot immediately after use. Never touch the glass

portion of the lamp or the surrounding parts.

✍ After the used lamp has cooled, place it into the empty box of the

replacement lamp. Never put the used lamp into a plastic bag.

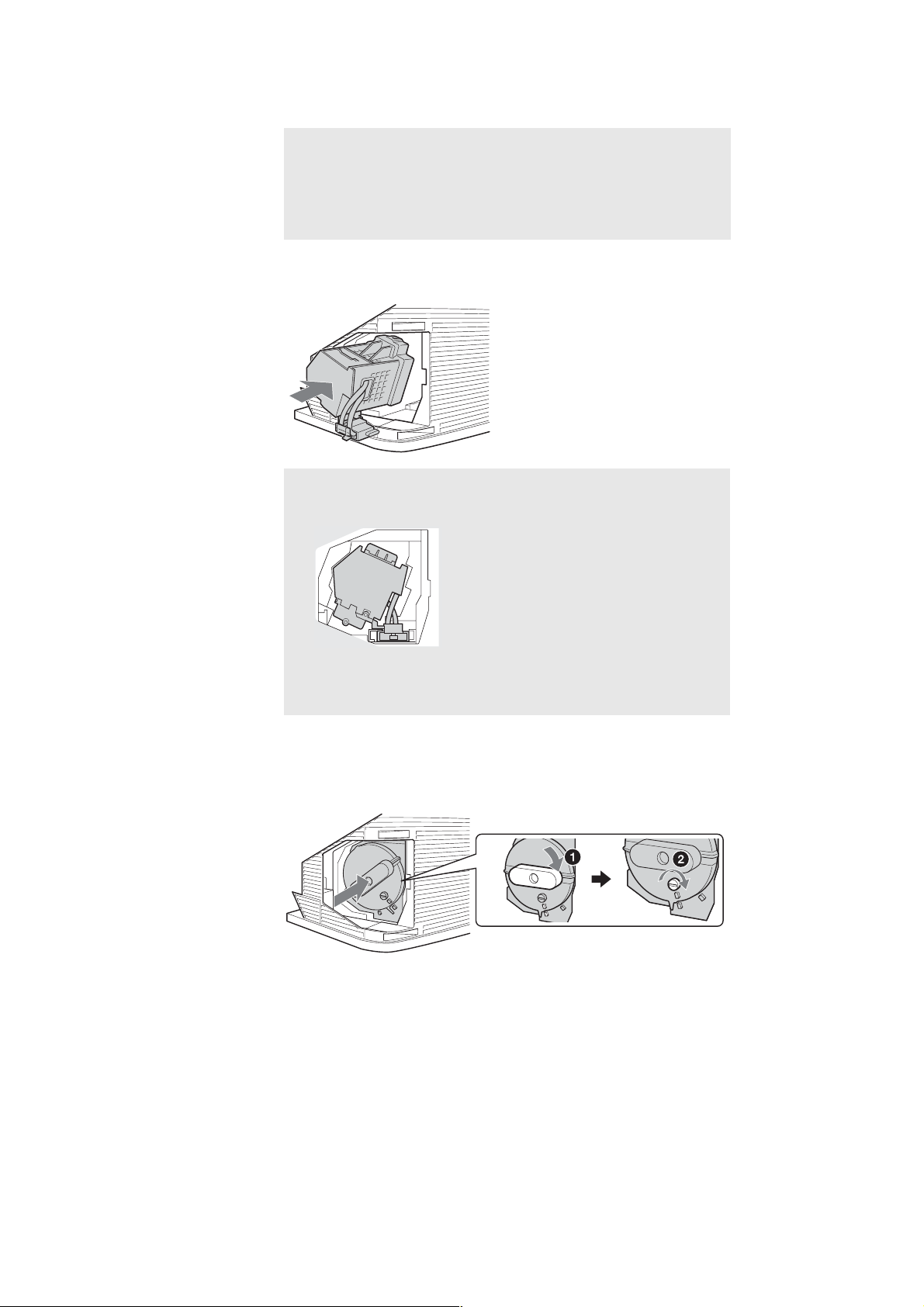

7

Put the new lamp into its place.

Make sure the lamp is securely mounted into the compartment. Failure to

do so may cause a fire or the screen to go dark.

✍ The lamp compartment is tilted, as shown in the following

illustration.

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

✍ If the lamp is not securely reattached, the self-diagnostic function

may be triggered and the POWER LED blinks three times (see

page 37).

8

Reattach the lamp door.

To secure the door, turn the knob to the right while pushing the door in,

until the marks on the lid and the case line up. Then, turn the screw

clockwise to tighten the door.

– 7 –

9

Put the outside lamp cover back in its place.

Replace the cover, inserting it from the left side. Press the clamp on the

right side to secure the cover.

10

Turn on the TV and set the

settings (see page 62). This setting is necessary to inform you when the

next lamp replacement is needed.

Lamp Replacement

option in the

✍ Until you set the Lamp Replacement option, a message

announcing that the lamp is at the end of its life will appear every

time you turn on the TV.

✍ Consult your Sony dealer for a Sony XL-5300 replacement lamp.

✍ Ta ke great care when replacing the lamp or plugging in/unplugging

the connecting cords. Rough handling may cause the TV to fall,

damaging the TV, the TV stand and the floor.

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

Setup

The used lamp

For customers in the United States:

This product contains mercury. Disposal of this product may be regulated if

sold in the United States. For disposal or recycling information, please

contact your local authorities or the Electronics Industries Alliance

(http://www.eiae.org).

❑

Do not leave the used lamp near flammable materials or within the

reach of children.

❑

Do not pour water onto the used lamp or put any object inside the lamp.

Doing so may cause the lamp to burst.

For replacement lamp information visit:

U. S. residents: http://www.sonystyle.com/tv/

Canadian residents: http://www.sonystyle.ca/tv/

– 8 –

SAFETY CHECK-OUT

Fig. B. Checking for earth ground.

Trouble Light

AC Outlet Box

Ohmmeter

Cold-water Pipe

( US model only )

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

After correcting the original service problem, perfom the follow-

ing safety checks before releasing the set to the customer:

l. Check the area of your repair for unsoldered or poorly-sol-

dered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps,

and mounting hardware have been replaced. Be absolutely

certain that you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

5. Look for parts which, through functioning, show obvious

signs of deterioration. Point them out to the customer and

recom mend their replacement.

6. Check the line cords for cracks and abrasion. Recommend

the replacement of any such line cord to the customer.

7. Check the condition of the monopole antenna (if any). Make

sure the end is not broken off, and has the plastic cap on it.

Point out the danger of impalement on a broken antenna to

the customer, and recommend the antenna’s replacement.

8. Check the B+ and HV to see they are at the values specified.

Make sure your instruments are accurate;be suspicious of

your HV meter if sets always have low HV.

9. Check the antenna temminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5mA (500 microampers) . Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to

usc these instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are

examples of a passive VOM that is suitable. NearIy all battery operated digital multimeters that have a 2V AC range

are suitable. (See Fig. A)

HOW TO FIND A GOOD EARTH GROUND

A cold-water pipe is guaranteed earth ground;the cover-plate retaining screw on most AC outlet boxes is also at earth ground. If

the retaining screw is to be used as your earth-ground, verify that it

is at ground by measuring the resistance between it and a coldwater pipe with an ohmmeter. The reading should be zero ohms. If

a cold-water pipe is not accessible, connect a 60-l00 watts trouble

light (not a neon lamp) between the hot side of the receptacle and

the retaining screw. Try both slots, if necessary, to locate the hot

side of the line, the lamp should light at normal brilliance if the

screw is at ground potential. (See Fig. B)

Fig. A. Using an AC voltmeter to check AC leakage.

1.5 µ F

To Exposed Metal

Parts on Set

1.5k Ω

Earth Ground

AC

voltmeter

(0.75V)

– 9 –

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

CAUTION

These servicing instructions are for use by qualified service personnel only.

To reduce the risk of electric shock, do not perform any servicing

other than that contained in the operating instructions unless you

are qualified to do so.

WARNING!!

AN ISOLATION TRANSFORMER SHOULD BE USED DURING

ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECElVER IS DIRECTLY CONNECTED

TO THE AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE

SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION. REPLACE

THESE COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT ADJUSTMENTS THAT

ARE CRITICAL TO SAFE OPERATION ARE IDENTIFIED IN THIS

MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERATION IS SUSPECTED.

ATTENTION!!

AFIN D’EVITER TOUT RISQUE DELECTROCUTION PROVENANT D’UN CHÁSSIS SOUS TENSION, UN TRANSFORMATEUR

D’ISOLEMENT DOIT ETRE UTILISÉ LORS DE TOUT DEPANNAGE.

LE CHÁSSIS DE CE RECEPTEUR EST DIRECTEMENT RACCORDÉ Á L’ALIMENTATION SECTEUR.

ATTENTION AUX COMPOSANTS RELATIFS ÁLA

SÉCURITÉ!!

LES COMPOSANTS IDENTIFIÉS PAR UNE FRAME ET PAR UNE

MAPQUE ! SUR LES SCHÉMAS DE PRINCIPE, LES VUES EXPLOSÉES ET LES LISTES DE PIECES SONT D’UNE IMPORTANCE

CRITIQUE POUR LA SÉCURITÉ DU FONCTIONNEMENT. NE LES

REMPLACER QUE PAR DES COMPOSANTS SONY DONT LE

NUMÉRO DE PIÉCE EST INDIQUÉ DANS LE PRÉSENT MANUEL OU DANS DES SUPPLÉMENTS PUBLIÉS PAR SONY. LES

RÉGLAGES DE CIRCUIT DONT L’IMPORTANCE EST CRITIQUE

POUR LA SÉCURITÉ DU FONCTIONNEMENT SONT IDENTIFIES

DANS LE PRÉSENT MANUEL. SUIVRE CES PROCÉDURES

LORS DE CHAQUE REMPLACEMENT DE COMPOSANTS CRITIQUES, OU LORSQU’UN MAUVAIS FONCTIONNEMENT SUSPECTÉ.

– 10 –

TABLE OF CONTENTS

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

Section Title Page

–––––– –––– ––––

1. SELF DIAGNOSIS FUNCTION ..................... 13

2. DISASSEMBLY

2-1. Rear Cover .......................................................... 17

2-2. Chassis Assembly ............................................... 18

2-3. Terminal Bracket ................................................ 19

2-4. UG Board ............................................................ 19

2-5. S1 Board ............................................................. 19

2-6. QM, QT Boards .................................................. 20

2-7. AU, B2 Boards, GBlock Assembly ................... 21

2-8. G, H3U, PH Board ............................................. 22

2-9. DC Motor SFF21C/C-NP ................................... 22

2-10. Power Supply Block ........................................... 23

2-11. DC Motor SFF25A/C-NP .................................. 23

2-12. DC Motor SFF24A/C-NP .................................. 24

2-13. Cover Unit .......................................................... 24

2-14. Lamp Guide (F) .................................................. 25

2-15. Screen Frame Block Assembly .......................... 25

2-16. H1 Board............................................................. 27

2-17. Optics Block Assembly ...................................... 27

2-18. Mirror Cover Block Assembly ........................... 28

2-19. T1,S2 Board ........................................................ 28

2-20. Notes on Harness Arranemens ........................... 29

3. ELECTRICAL ADJUSTMENTS

3-1. Electrical Adjustment by Remote Commander .... 30

3-1-1. Method of Setting the Service Adjustment

Mode ............................................................... 30

3-1-2. Service Mode Adjustment ............................ 30

3-1-3. Memory Write Confirmation Method .......... 30

3-1-4. Adjusting Buttons and Indicator ................... 31

3-2. Test Reset ........................................................... 31

3-3. H/V Center Confirmation and Adjustment ........ 31

3-3-1. Adjustment ..................................................... 31

3-4. Registration Adjustment .................................... 32

3-5. Picture Distortion Correction Mechanism

(R70XBR2) ......................................................... 32

3-5-1. Preparation .................................................... 32

3-5-2. V-TRAP Correction 1 ................................... 33

3-5-3. V-TRAP Correction 2 ................................... 33

3-5-4. Picture Rotation Correction 1 ....................... 33

3-5-5. Picture Rotation Correction 2 ....................... 33

4. DIAGRAMS

4-1. Block Diagram (1) .............................................. 34

Block Diagram (2) .............................................. 35

Block Diagram (3) .............................................. 36

Block Diagram (4) .............................................. 37

Section Title Page

–––––– –––– ––––

Block Diagram (5) .............................................. 38

Block Diagram (6) .............................................. 39

Block Diagram (7) .............................................. 40

Block Diagram (8) .............................................. 41

Block Diagram (9) .............................................. 42

Block Diagram (10) ............................................ 43

Block Diagram (11) ............................................ 44

Block Diagram (12) ............................................ 45

Block Diagram (13) ............................................ 46

Block Diagram (14) ............................................ 47

Block Diagram (15) ............................................ 48

Block Diagram (16) ............................................ 49

4-2. Frame Schematic Diagram ................................. 50

4-3. Circuit Boards Location ..................................... 51

4-4. Schematic Diagrams ........................................... 51

(1) Schematic Diagram of AU (1/5) Board ............. 52

(2) Schematic Diagram of AU (2/5) Board ............ 53

(3) Schematic Diagram of AU (3/5) Board ............ 54

(4) Schematic Diagram of AU (4/5) Board ............ 55

(5) Schematic Diagram of AU (5/5) Board ............ 56

(6) Schematic Diagram of B2 (1/11) Board ........... 57

(7) Schematic Diagram of B2 (2/11) Board ........... 58

(8) Schematic Diagram of B2 (3/11) Board ........... 59

(9) Schematic Diagram of B2 (4/11) Board ........... 60

(10) Schematic Diagram of B2 (5/11) Board ........... 61

(11) Schematic Diagram of B2 (6/11) Board ............ 62

(12) Schematic Diagram of B2 (7/11) Board ............ 63

(13) Schematic Diagram of B2 (8/11) Board ........... 64

(14) Schematic Diagram of B2 (9/11) Board ........... 65

(15) Schematic Diagram of B2 (10/11) Board .......... 66

(16) Schematic Diagram of B2 (11/11) Board ......... 67

(17) Schematic Diagram of C (1/11) Board ............. 68

(18) Schematic Diagram of C (2/11) Board ............. 69

(19) Schematic Diagram of C (3/11) Board ............. 70

(20) Schematic Diagram of C (4/11) Board ............. 71

(21) Schematic Diagram of C (5/11) Board .............. 72

(22) Schematic Diagram of C (6/11) Board .............. 73

(23) Schematic Diagram of C (7/11) Board ............. 74

(24) Schematic Diagram of C (8/11) Board ............. 75

(25) Schematic Diagram of C (9/11) Board .............. 76

(26) Schematic Diagram of C (10/11) Board ........... 77

(27) Schematic Diagram of C (11/11) Board ........... 78

(28) Schematic Diagram of G (1/2) Board ................ 79

(29) Schematic Diagram of G (2/2) Board ................ 80

(30) Schematic Diagram of H1 Board (R60XBR2) .. 81

(31) Schematic Diagram of H2AU Board

(R60XBR2) ......................................................... 82

(32) Schematic Diagram of H2B Board (R70XBR2) 83

(33) Schematic Diagram of H3U Board .................... 84

(34) Schematic Diagram of H4 Board (R70XBR2) .. 85

(35) Schematic Diagram of PH Board ....................... 86

– 11 –

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

Section Title Page

–––––– –––– ––––

(36) Schematic Diagram of QM (1/6) Board ............ 87

(37) Schematic Diagram of QM (2/6) Board ............ 88

(38) Schematic Diagram of QM (3/6) Board ............ 89

(39) Schematic Diagram of QM (4/6) Board ............ 90

(40) Schematic Diagram of QM (5/6) Board ............ 91

(41) Schematic Diagram of QM (6/6) Board ............ 92

(42) Schematic Diagram of QT Board ...................... 93

(43) Schematic Diagram of QU Board ...................... 94

(44) Schematic Diagram of S1, S2 Boards ................ 95

(45) Schematic Diagram of T1 Board ....................... 96

(46) Schematic Diagram of UU (1/2) Board ............. 97

(47) Schematic Diagram of UU (2/2) Board ............. 98

4-5. Printed Wiring Boards ........................................ 99

(1) AU Board (Side A) ............................................. 99

AU Board (Side B) ............................................. 100

(2) B2 Board (Side A) .............................................. 101

B2 Board (Side B) .............................................. 102

(3) C Board (Side A) ................................................ 103

C Board (Side B) ................................................ 104

(4) G Board (Side A) ................................................ 105

G Board (Side B) ................................................ 106

(5) H1, H2AU, H2B, H4 Boards ............................. 107

(6) H3U Board (Side A) ........................................... 108

H3U Board (Side B) ........................................... 109

(7) PH Boards ........................................................... 110

(8) QM Board ........................................................... 111

(9) QT, S1 Board ...................................................... 112

(10) QU, S2, T1 Boards ............................................. 113

(11) UU Board (Side A) ............................................. 114

UU Board (Side B) ............................................. 115

4-6. Semiconductors .................................................. 116

Section Title Page

–––––– –––– ––––

• S1 Board .................................................................... 174

• S2 Board .................................................................... 174

• T1 Board ................................................................... 174

• UU Board .................................................................. 174

5. EXPLODED VIEWS

5-1. Screen, Covers (R60XBR2) ............................... 118

5-2. Screen, Covers (R70XBR2) ............................... 119

5-3. Bottom block-1 ................................................... 120

5-4. Bottom block-2 ................................................... 121

5-5. Main Chassis Assembly ..................................... 122

6. ELECTRICAL PARTS LIST

• AU Board .................................................................. 123

• B2 Board ................................................................... 134

• C Board ..................................................................... 149

• G Board ..................................................................... 161

• H1 Board (R60XBR2) .............................................. 164

• H2AU Board (R60XBR2) ........................................ 164

• H2B Board (R70XBR2) ........................................... 165

• H3U Board ................................................................ 165

• H4 Board (R70XBR2) .............................................. 165

• PH Board ................................................................... 166

• QM Board ................................................................. 167

• QT Board .................................................................. 172

– 12 –

KDS-R60XBR2/R70XBR2

r

SECTION 1

SELF DIAGNOSIS FUNCTION

1. Summary of Self-Diagnosis Function

-This device includes a self-diagnosis function.

-Incaseofabnormalities, the 1-On/ standby

predict the abnormality location by the number of blinks. The Instruction

describes blinking of indicator.

the 1-On/ standby

-Ifthe symptom is not reproduced sometimes in case of a malfunction, there is recording of

whether a malfunction was generated or not. Operate the remote command to confirm the

matter on the screen and to predict the location of the abnormality.

2. Diagnosis Items and Prediction of Malfunction Location

-When a malfunction occurs the 1-On/ standby indicator only blinks for one of the

following diagnosis items. In case of two or more malfunctions, the item which first

occurred blinks. If the malfunctions occurred simultaneously, the item with the lowe

blink count blinks first.

-The screen display displays the results regarding all the diagnosis items listed below.

Thedisplay "0" means that no malfunctions occurred.

indicator automatically blinks. It is possible to

Manual

RM-YD009 RM-YD009

Number of times

Diagnosis Item

1-On/ standby

indicator blinks

Temp. over

La

mp cover

Fan error

Lamp driver

2 times

3

times

4 times

5 times

Power error 6 times

Audio prot 7 times

Power

OVP

Device error

times

8

9 times

Probable Cause

Location

-The periphery of lamp

heats up abnormally

-L

amp cover is not

attached securely.

power is not

-Fan

supplied.

-Fan connector is not

Defected symptoms

-Nopicture/No sound

-Nopicture/No sound

-Nopicture/No sound

attached securely.

-Lampdriver is faulty. - No picture/No sound

- 11V is low.

- Speaker line is shorted.

over voltage.

is

-11V

-Nopicture/No sound

-Nopicture/No sound

-Nopicture/No sound

Temperature sensors,

Bus decoder ICs

(IC1700, 1800, 1900,

-No picture/No sound

5066, 2305)

IC6402

Lamp error L

AMP-LEDflashes - No picture/No sound

-Lampfor the light

source burns out.

– 13 –

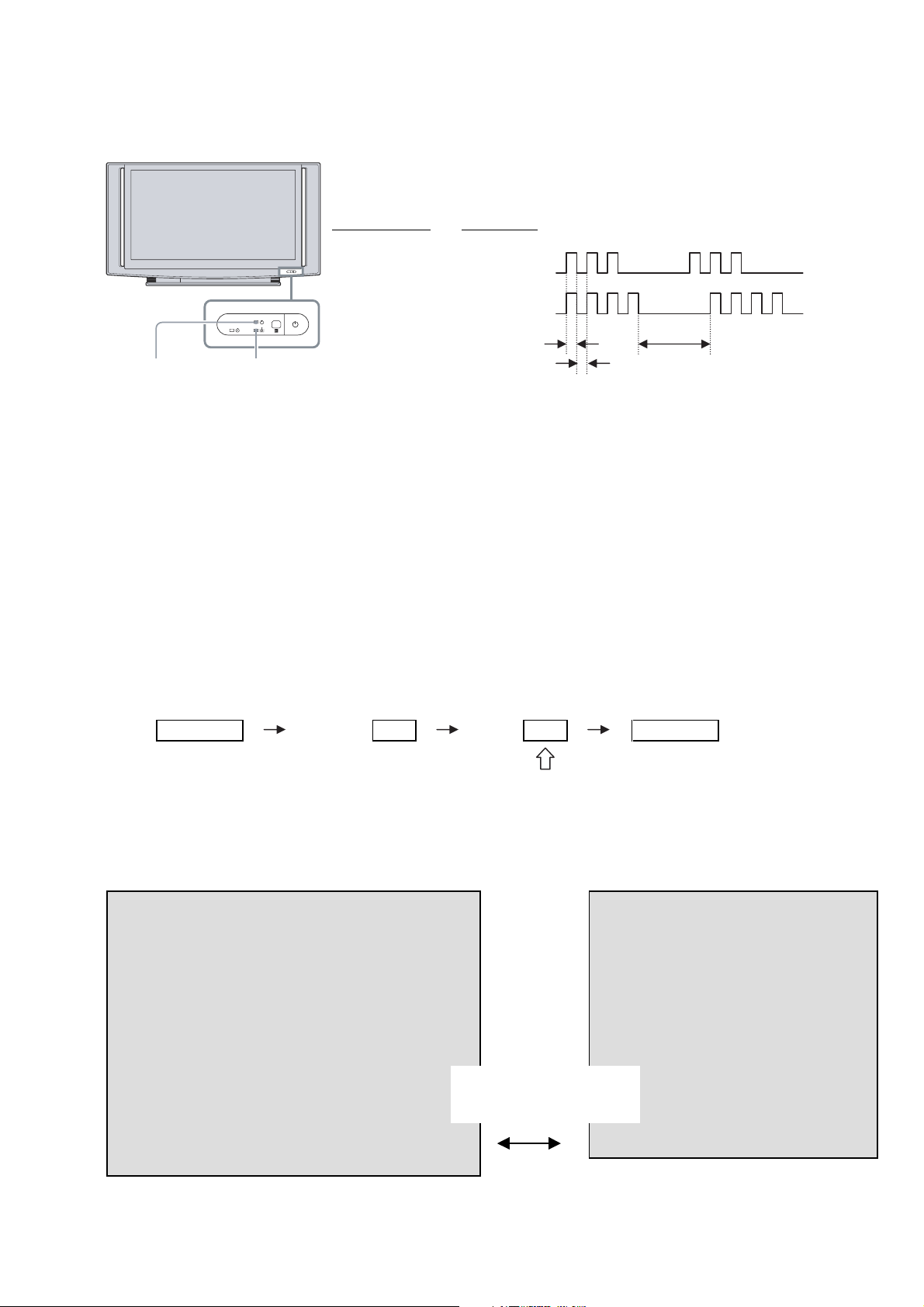

3. Blinking count display of 1-On/ standby indicator

m

r

m

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

KDS-R60XBR2

-One blink is not used for self-diagnosis.

-Example

Diagnosis ite

Lamp cove

LEDblinks

3 times

Fan 4 times

LEDON:0.3sec

1-On/ standby

indicator

LAMP indicator

LEDOFF : 0.3sec

LED OFF

3.0sec

-Releaseof1-On/ standby indicator blinking

The 1-On/ standby indicator blinking display is released by removing the plug from

the power.

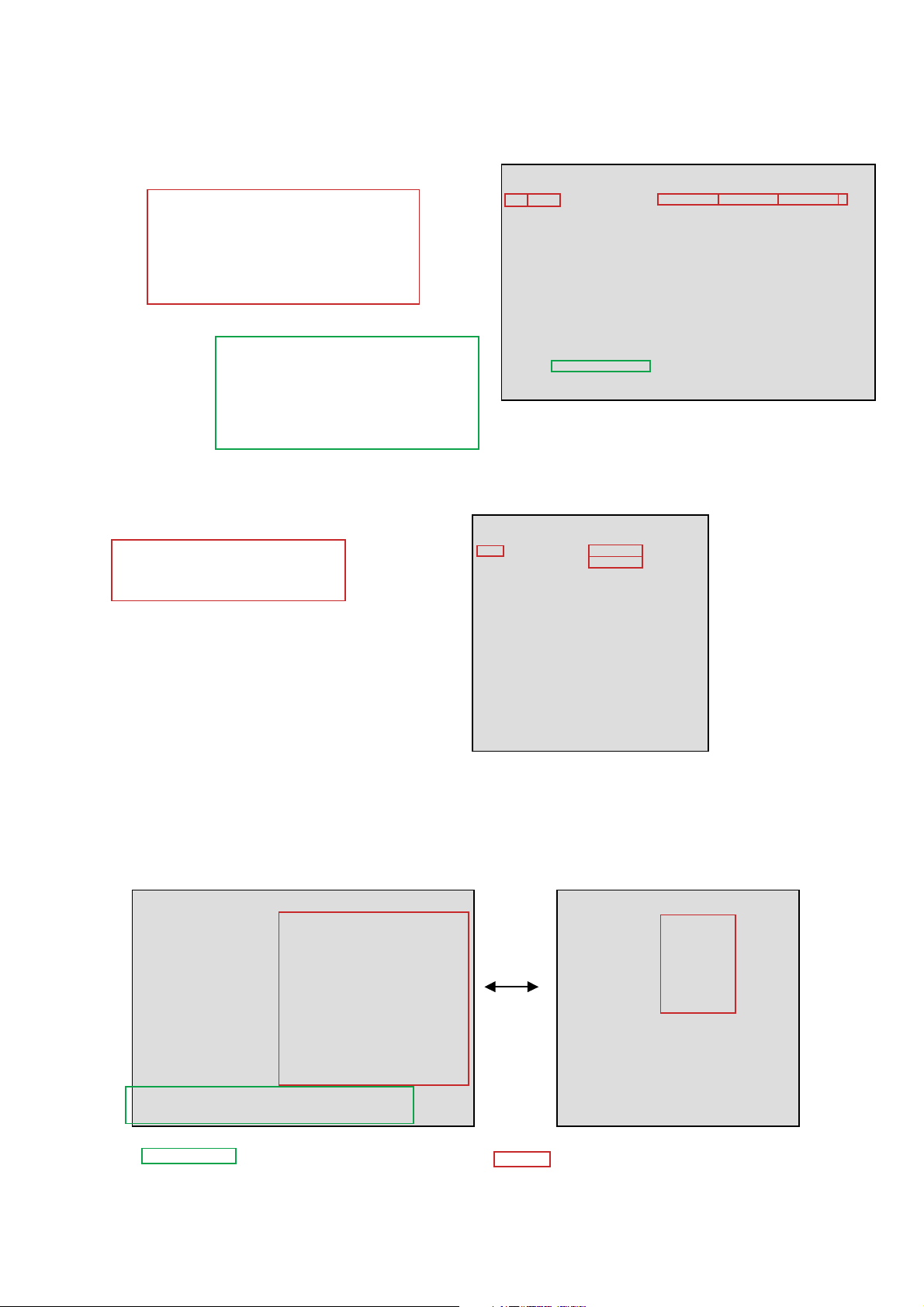

4. Self-diagnosis screen displays

-Incases of malfunctions where it is not possible to determine the symptom such as when

the power goes off occasionally or when the screen disappears occasionally, there is a

screen display on whether the malfunction occurred or not in the past (and whether the

detection circuit operated or not) in order to allow confirmation.

<Screen Display Method>

-Quickly press the remote command button in the following order from the standby state.

DISPLAY 5 - POWER

ChannelVol

Be aware that thisdiffers fro

the method of entering the

service mode (Vol +).

SELF CHECK(1)

002 LTEMP

003 LAMPC

004 FAN

005 LAMPD

006 POWER_ER

007 AUDIO

007 POWER_OV

009 DEMO

<1> Next Page -->

0000000000 0412311234 0501210811 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

SELF CHECK(2)

TVM

WEM

DEM

EMMA

Page movement

TVM 00000-00000

WEM 00000-00000

DEM 00000-00000

EMMA 00000-00000

by <1> and <4>

<-- Prev Page <4>

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

– 14 –

Detail data (diagnosis history screen)

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

Trouble information

002: LED frequency

LTEMP: Item name

0311111825: Last failure time beforehand

0412311234: Failure time before last

0501210811: The last failure time

0 :Error count

Boot count and operation time

TVM: Microcomputer name

24 680

135- 79:

(ex.) Boot Count 13579 times

Operation time 24680 hours

Each max is 99999

An effective value only to DEM is displays

Detail data (device error display)

Trouble information

TVM: Micom name

0001FFFF: Present error information

80000000: Error information history

Anagram display of data

SELF CHECK(1)

002 LTEMP

003 LAMPC

004 FAN

005 LAMPD

006 POWER_ER

007 AUDIO

008 POWER_OV

009 DEMD

SELF CHECK(2)

TVM

WEM

DEM

EMMA

TVM 12345-67890

WEM 00000-00000

DEM 00000-00000

EMMA 00000-00000

<-- Prev Page <4>

0001FFFF

80000000

00000000

00000000

00000000

00000000

00000000

00000000

<1> Next Page -->

0311111825 0412311234 0501210811 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

Deletion object

SELF CHECK(1)

002 TEMP

003 OVP

004 FAN

006 LOWB

007 AUDIO

009 PANEL

101 DTT WDT

102 TVM WDT

103 WEM WDT

104 DEM WDT

TVM 00000-00000

WE 00000-00000

DE 00000-00000

<1> NEXT PAGE->

0000000000 0412311234 0501210811 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

0000000000 0000000000 0000000000 0

Deleted By TEST RESET

– 15 –

SELF CHECK(2)

TVM

WE

DE

<- PREV PAGE <4>

00 00 00 00

00 00 00 00

00 00 00 00

00 00 00 00

00 00 00 00

00 00 00 00

Deleted by <8> -> <0>

-The results display is not automatically cleared. In case of repairs and after repairs, chec

k

the self-diagnosis screen and be sure to return the results display to "0".

-Ifthe results display is not returned to "0" it will not be possible to judge a new malfunction

after completing repairs.

<Method of Clearing Results Display>

1. Power off (Set to the standby mode)

2. Channel Vol

3. Channel

<Method of Ending Self-Diagnosis Screen>

-When ending the self-diagnosis screen completely, turn the power switch OFF on the

remote commander or the main unit.

5. Self-Diagnosis function operation

80

DISPLAY 5 - POWER

2:Temp over When the inside temperature sensed with IC3150, IC3200 and IC2000

mounted on S1 board, S2 board and C board respectively exceed

the threshold, DEM (Display Engine u-com) detects it and makes

turn off the lamp.

3:Lamp cover When the lamp cover is opened or harness from T board is off, DEM detects it

and makes turn off the lamp

4:FAN error When any FAN is stopping or harness is not connected correctly,

DEM detects it and makes turn off the lamp

5:Lamp Driver When the ballast is not working with high voltage, DEM detects it and makes

turn off the lamp

6:Power error When 11V is low, TVM

(TV u-com) detects it and makes turn off the lamp.

7:Audio When DC is appeared by audio amp failure at speaker line, DEM detects it

and makes turn off the lamp.

8:Power-OVP When the output voltage from 11V is abnormally high, TVM detects

it and makes turn off the lamp.

9:Device error When the temperature sensor and bus decoder ICs do not return ACK on IIC

bus to DEM, DEM detects it and makes turn off the lamp.

LAMP : Lamp When the lamp is broken, DEM detects it.

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

– 16 –

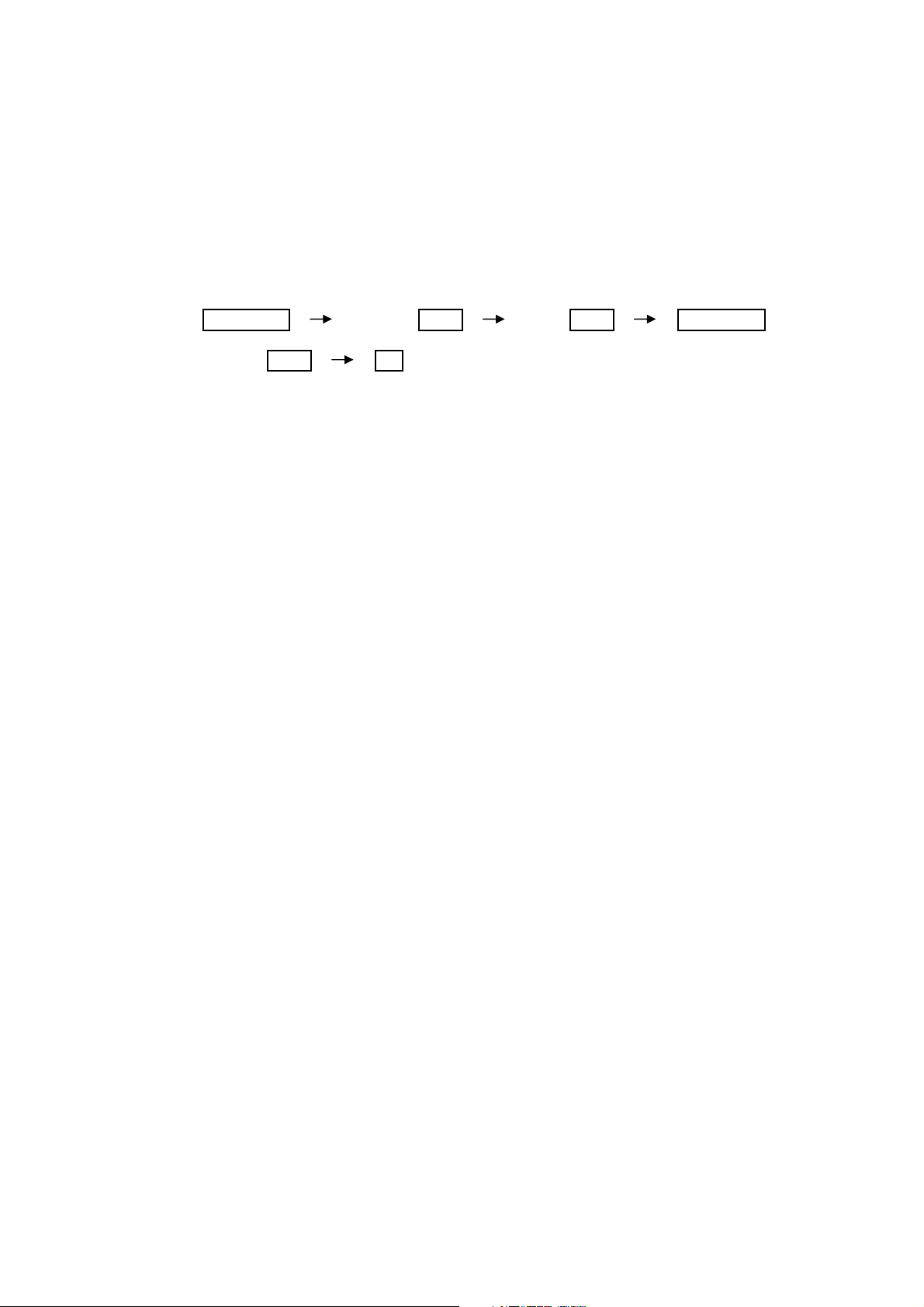

2-1. REAR COVER

SECTION 2

DISASSEMBLY

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

1

Lamp door assembly

2 10 screws (+BVTP 4x16)

3

Rear cover

– 17 –

2-2. CHASSIS ASSEMBLY

1 2 screws(+BVTP2 4x16)

R70XBR2 Model Only

2

5 2 screws(+BVTP2 4x16)

6 2 connectors

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

3 2 screws(+BVTP2 4x16)

9 Disconnect connectors

1 2 screws(+BVTP2 4x16)

R70XBR2 Model Only

8 Wire holder

9 Disconnect connectors

7 Screw (+BVST 3x6)

0 Loosen wire holder

4 Side stay (R)

5 4 screws (+BVTP2 4x16)

qa Disconnect connectors

qs Slide out the chassis block

– 18 –

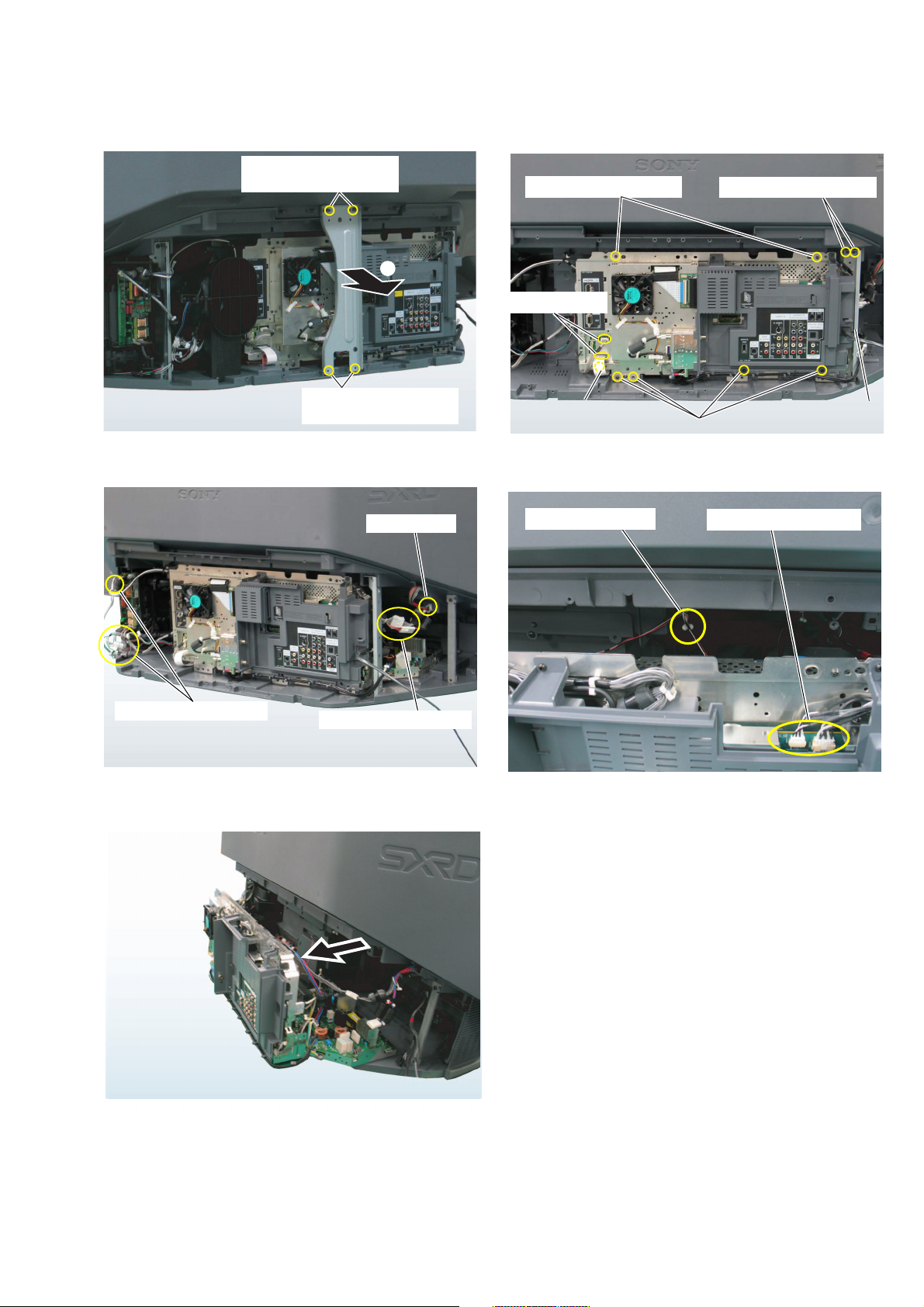

2-3. TERMINAL BRACKET

1 2 screws(+BVST3x6)

3 2 screws(+BV3x12)

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

2 2 nuts

2-4. UU BOARD

1 2 screws(+BVST3x6)

1 2 screws (+BVST3x6)

1 2 screws (+BVST3x6)

4 Terminal bracket

2 2 screws (+BVST3x6)

3 UU board

2 2 screws (+BVST3x6)

S1 board

2-5. S1 BOARD

On removing or attaching UU board,

Be careful about the connector on back.

1 Screw (+BVST3x6)

2 S1 board

– 19 –

2-6 QM, QT BOARDS

1 2 screws (+BVST3x6)

1 2 screws (+BVST3x6)

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

FE shield assembly

2 Connector

3

QT Board

QM board

4 4 screws (+BVST3x6)

On removing or attaching QM board,

Be careful about the connector on back.

5 QM board

6 2 screws (+BVST3x6)

8

7 2 screws (+BVST3x6)

– 20 –

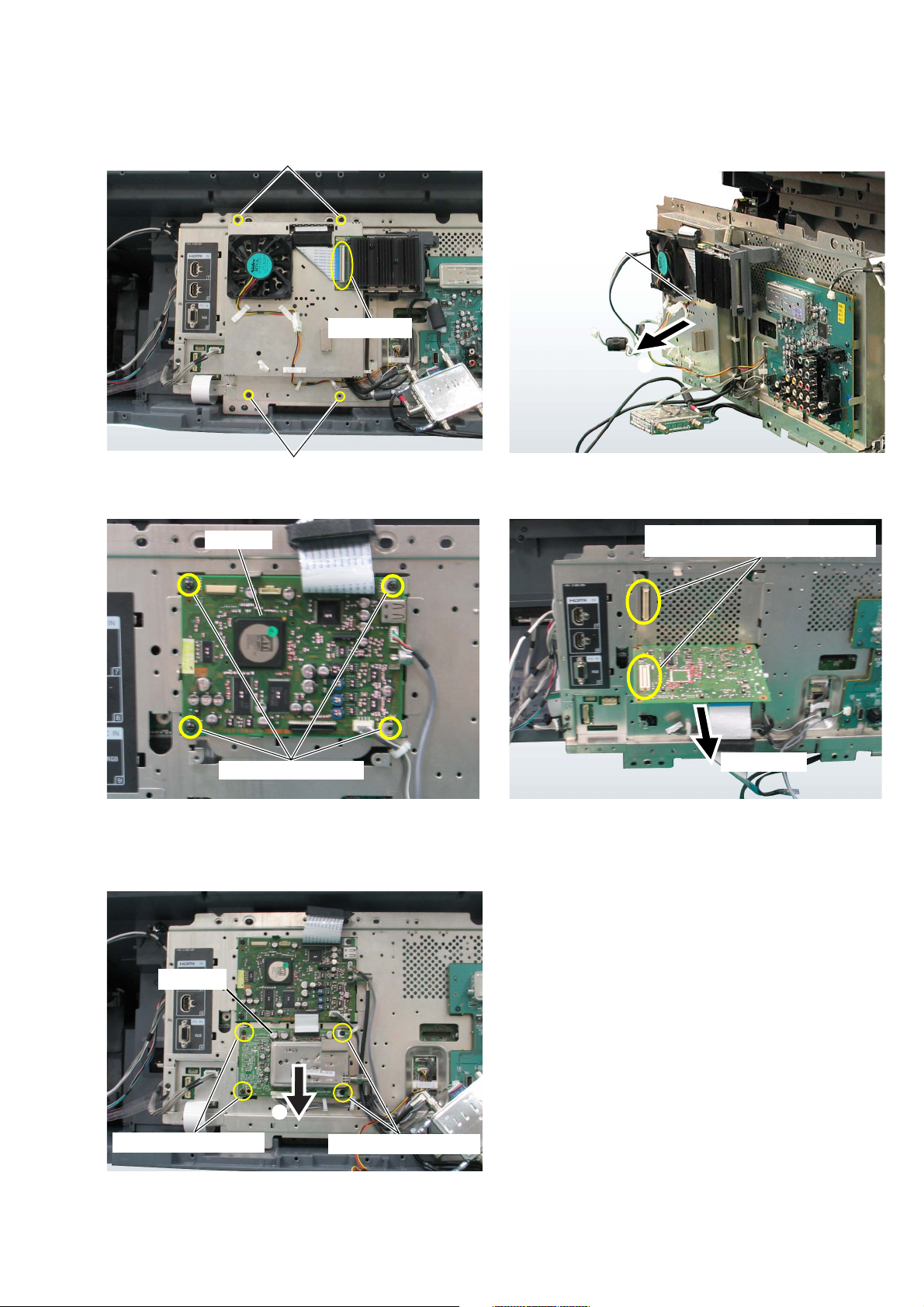

2-7. AU, B2 BOARDS, G BLOCK ASSEMBLY

Main shield

G block

assembly

8

3 2 screws (+PSW M 3x5)

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

2 2 screws

(+BVST3x6)

4 2 screws

(SP 4-40 UNC)

B2 board

1 Screw (+BVST3x6)

2 5 screws (+BVST3x6)

6 4 screws (+BVST3x6)

AU board

5

Main shield (lid)

Be carefull to remove

the main shield (lid).

Because this groove is

caught in G block assembly.

7

6

AU board

Main shield

6 6 screws (+BVST3x6)

9

8 2 screws (+BVST3x6)

B2 board

Disconnect from

G board

These boards are connected in the center.

So, be carefull about it.

– 21 –

2-8. G, H3U, PH BOARDS

2

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

G board

3

PH board

1 2 screws (+BVST3x8)

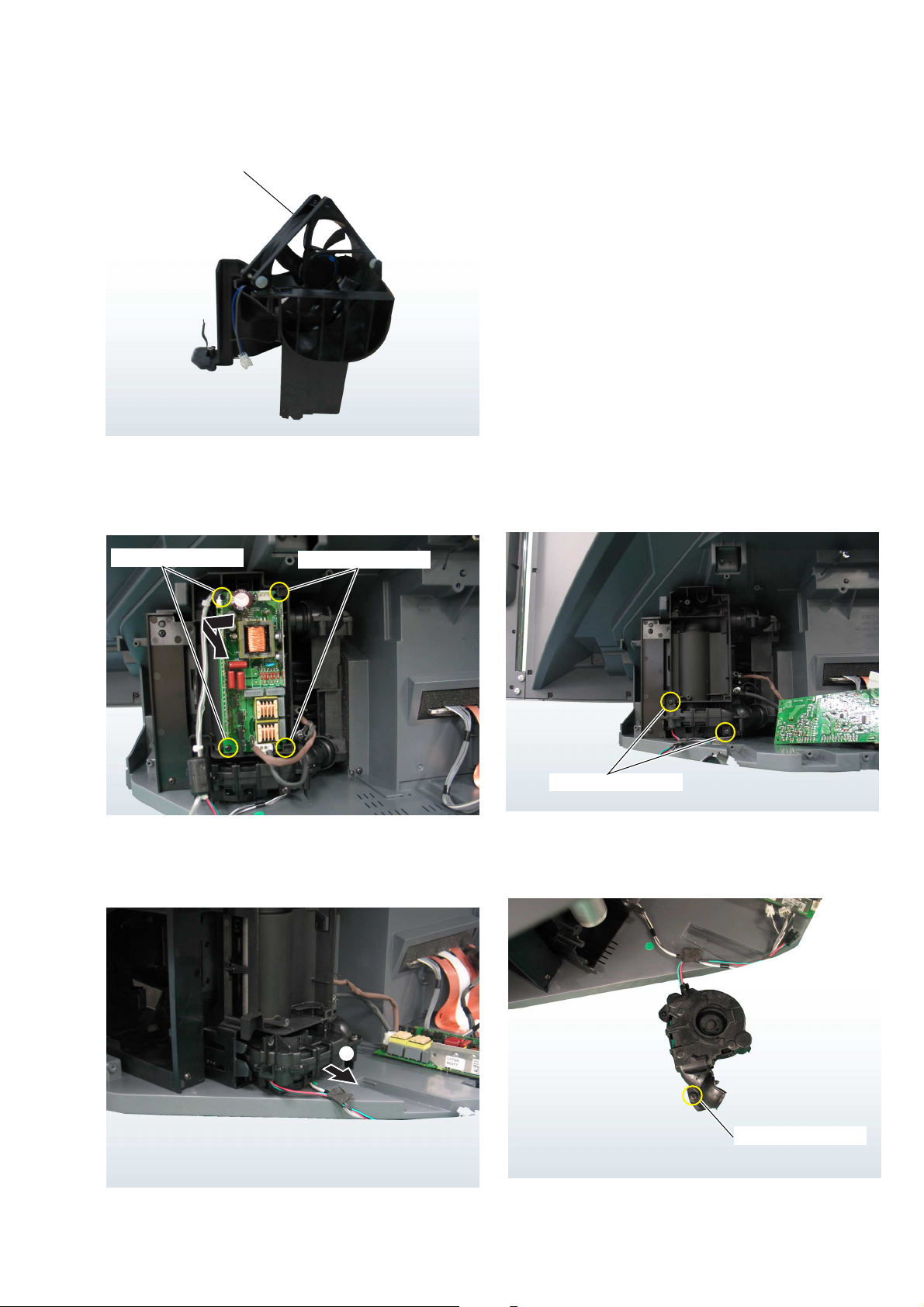

2-9. DC MOTOR SFF21C/C-NP

2 Connector

1 4 screws

(+BVST3x6)

2 2 screws

(+BVST3x6)

3 2 screws

(+BVST3x6)

H3U board

1 Screw(+BVTP4x16)

4 2 Claws

5

3 Screw(+BVTP4x16)

– 22 –

DC motor SFF21C/C-NP

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

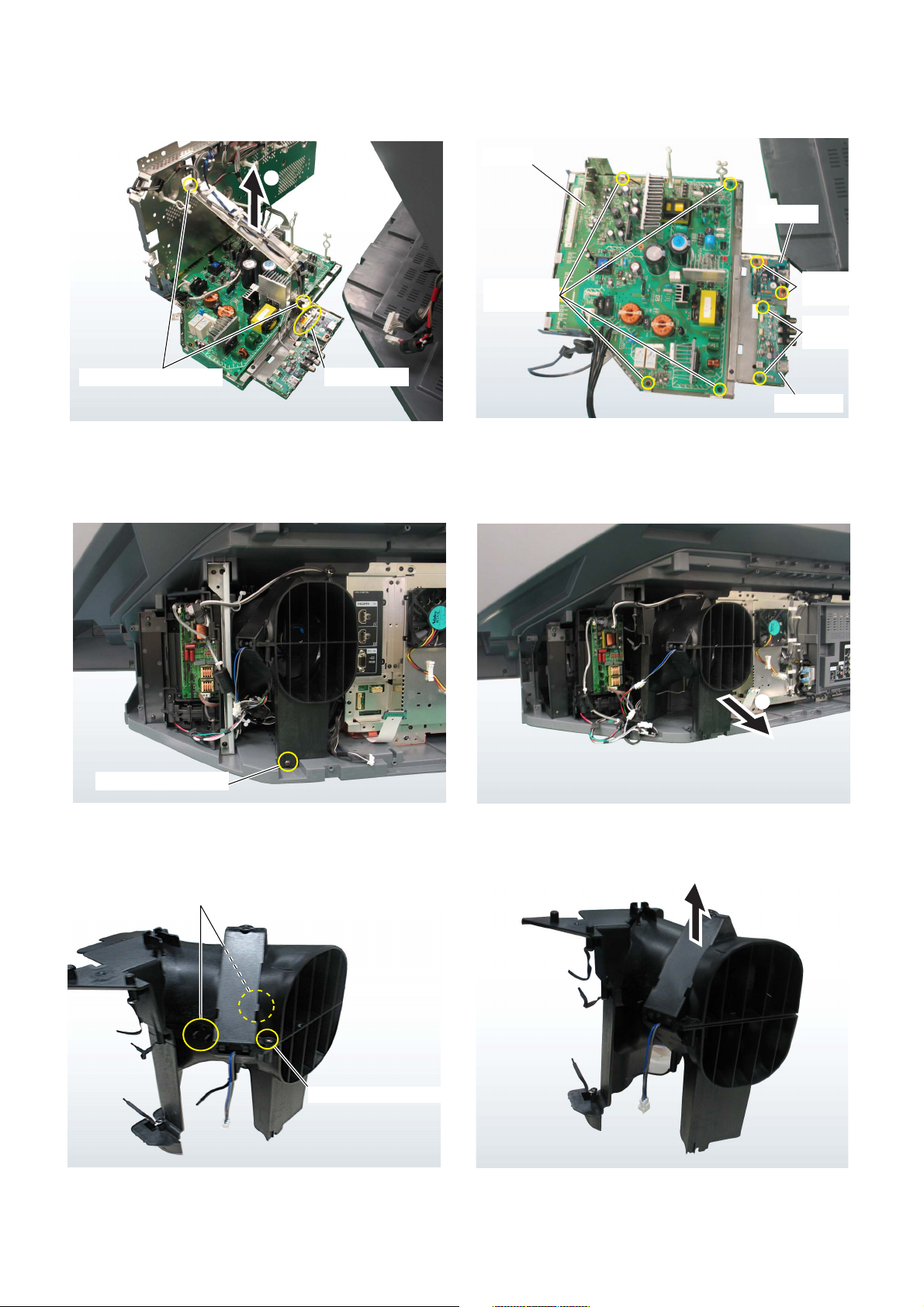

2-10. POWER SUPPLY BLOCK

1 Screw(+BVTP4x16)

2 Screw(+BVTP4x16)

2-11. DC MOTOR SFF25A/C-NP

3 Screw(+BVTP4x12)

4

5 Screw(+BVTP4x16)

– 23 –

2-12. DC MOTOR SFF24A/C-NP

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

7

6 Claw

2-13. COVER UNIT

1 2 screws (+BVTP2 4x16)

3 Scirocco fan

(DC motor SFF24A/C-NP)

2

Scirocco fan cover

Cover unit

1 7 screws

(+BVTP2 4x16)

2 Cover unit

– 24 –

2-14. LAMP GUIDE (F)

1 2 screw(+BVTP4x16)

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

3 2 claws

4

2

5 3 screw(+BVTP4x16)

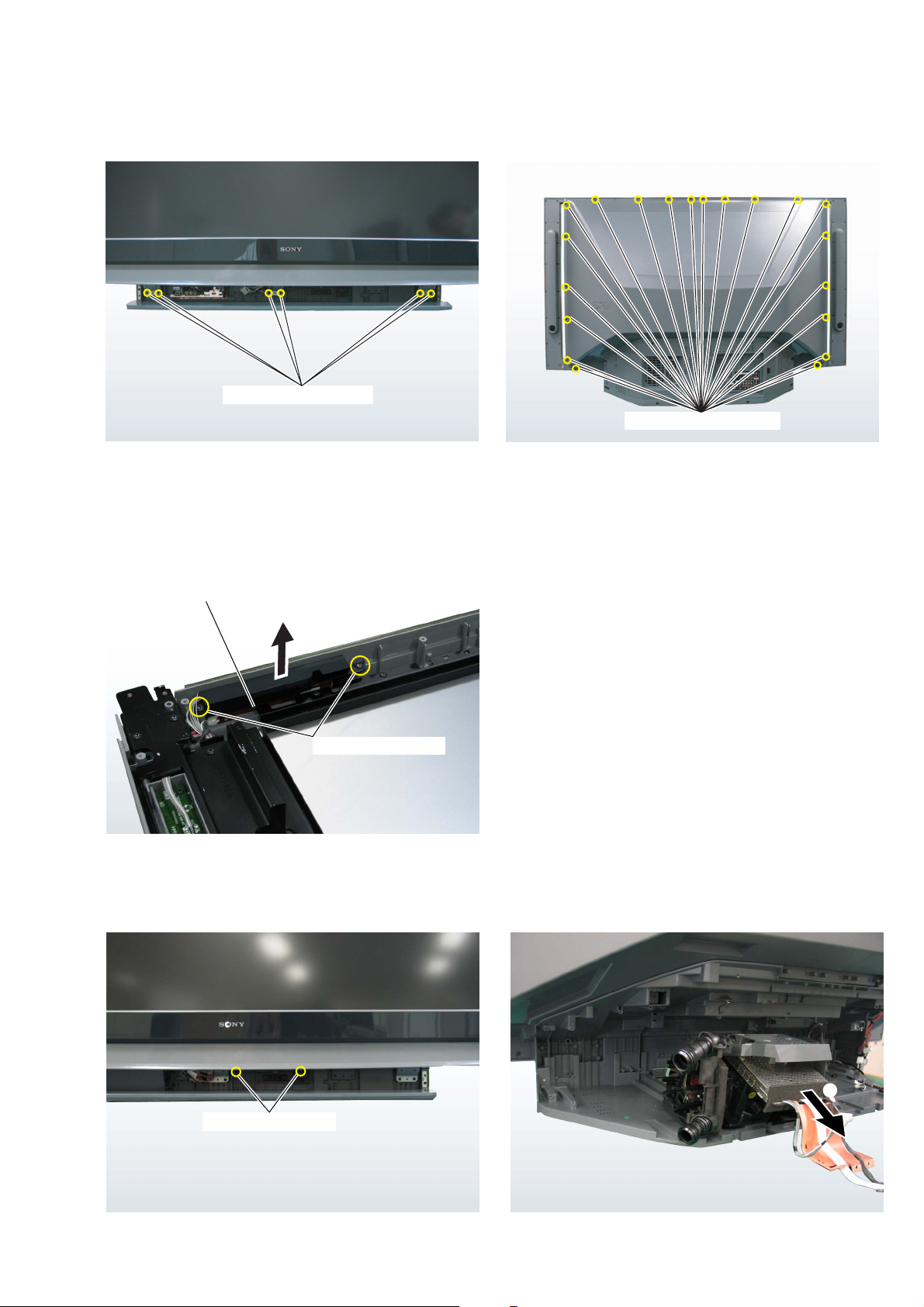

2-15. SCREEN FRAME BLOCK ASSEMBLY

6

2

1 Screw(+BVTP4x16)

– 25 –

3

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

4

Pull it forward picking both

ends of the door.

5 3 connectors

7 Screw(+BVTP4x16)

6 Screw(+BVTP4x16)

8

– 26 –

9 6 screws(+BVTP4x16)

Note:Removethe screw from the under.

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

0 20 screws(+BVTP4x16)

2-16. H1 BOARD

H1 board

2

1 Screw(+BVTP4x16)

2-17. OPTICS BLOCK ASSEMBLY

1 Screw(+BVTP4x16)

2

– 27 –

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

2-18. MIRROR COVER BLOCK ASSEMBLY

R70XBR2 Model Only

1 5 screws(+BVTP4x16) 1 5 screws(+BVTP4x16)

2-19. T1,S2 BOARD

S2 board

1 Screw(+BVTP4x16)

T1 board

S2 board

2

T1 board

– 28 –

2-20. NOTES ON HARNESS ARRANGEMENT

There is no leads to be caught.

Chassis assembly should be atached gradually with managing leads.

Bottom assembly

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

Chassis assembly

The shield and leads from C board come out

from here.

* Be sure not to break the lead.

– 29 –

SECTION 3

ELECTRICAL ADJUSTMENTS

3-1. ELECTRICAL ADJUSTMENT BY REMOTE

COMMANDER

By using remote commander (RM-GA006), all circuit adjust-

ments can be made.

NOTE : Test Equipment Required.

1. Pattern Generator (with component outputs)

2. Oscilloscope

3. Digital multimeter

3-1-1. Method of Setting the Service Adjustment

Mode

1. Standby mode. (Power off)

2. DISPLAY t 5 t VOL (+) t TV POWER

on the remote commander.

(Press each button within a second.)

The following service screen will appear.

Mode

TVM Service Menu SERVICE

XXX VERSION

XXX VERS XXX

<Digital> Program

Boot : X.X.XX

Program : X.XXX

<TV>

Data : X.XXX

Boot : X.XXX

Program : X.XXX

<WE>

Data : X.XXX

Boot : X.XXX

Program : X.XXX

<DE>

Data : X.XXX

Boot : X.XXX

Category Name

Item No.

Sub Item No.

Category Name

Item Name

: X.XX.XXX

Item Name

PANEL SERVICE

0 OP MODE

0T1 5

DIFF 1 50Hz

Data

KDS-R60XBR2/R70XBR2

RM-YD009 RM-YD009

3-1-2. Service Mode Adjustment

1. The SCREEN displays the item being adjusted.

2. Press “1” or “4” on the remote commander to select the

adjustment item.

3. Press “3” or “6” on the remote commander to change the data.

4. Press “2” or “5” on the remote commander to select the category.

Every time you press “2” (Category up), Service mode

changes in the order as shown below.

Key

TVM Service Menu

JUMP

WEM VERSION

JUMP

PANEL SERVICE

0 OPMODE

1 TG

2

2 WB

2

3 CSC

2

4 HUE

2

5 TEST_PAT

: :

: :

34 LUM

2

0 OPMODE

: :

5. If you want to recover the latest values press “-” then

“[ENTER]” to read the memory.

6. Press “[MUTING]” then “[ENTER]” to write into memory.

7. Turn power off.

<Method of setting the shipping condition>

1. Service Adjustment mode.

2. Press “8” then “[ENTER]”

3. Wait until appearing “ Initial Setup” display.

4. Disconnect AC plug and connect again to change factory re-

set condition completely.

Sub Item Name

<DISPLAY ENGINE>

3-1-3. Memory Write Confirmation Method

1. After adjustment, turn power off with the remote commander.

2. Turn power on and set to service mode.

3. Call the adjusted items again and confirm they were adjusted.

– 30 –-

Loading...

Loading...